Abstract

Photocatalysis is a new type of renewable energy technology used in environmental treatment and hydrogen energy production. In this regard, a new class of photocatalysts, TiO2 aerogels, are attractive for having the chemical characteristics of TiO2 nanomaterials such as high catalytic activity, good stability, non-toxic, and non-polluting, and the structural characteristics of aerogels such as large specific surface area, high porosity, the 3-dimensional interconnected network structure composed of relatively uniform nanoparticles, and high light transmittance. Here we review the recent progress in TiO2 aerogels for photocatalysis, focusing on preparation techniques, the crystalline phases’ influence on photocatalytic properties, the modification of photocatalytic properties, and the analysis and discussion of future development. In particular, we first summarize various preparation techniques, including sol–gel method, nanoparticles self-assembly synthesis, and high-temperature aerosol technique, then detail the structure and composition of TiO2 crystalline phases that affect the photocatalytic properties. Subsequently, we discuss strategies to further enhance the photocatalytic properties of TiO2 aerogels by the composite of SiO2 aerogel semiconductors, the doping of metal dopants, and the doping or composite of non-metallic substances, and elaborate the modification mechanism and the modification effect achieved. Finally, combined with the research status of TiO2 aerogels and the development experience of other aerogels, we conduct a reasonable analysis and discussion on their further research directions and industrialization roads.

1 Introduction

Environmental pollution and energy shortage have become two major problems hindering the progress of human society [1,2]. With the deepening of understanding, countries all over the world are striving to control environmental pollution and develop new energy sources, and the exploitation of solar energy is in full swing [3,4,5]. Since Fujishima and Honda [6] discovered the photocatalytic decomposition of water on the N-type semiconductor TiO2 in 1972 and opened up a new field of photocatalysis, the technology has received widespread attention. According to the current application requirements, photocatalysis can be divided into environmental photocatalysis and energy photocatalysis [7,8]. The environmental photocatalysis refers to the decomposition of environmental pollutants, viruses, and bacteria through chemical reactions driven by sunlight to achieve the purpose of environmental protection [9,10], and the energy photocatalysis refers to the conversion of low-energy-density solar energy into high-energy-density hydrogen energy to realize the production of new energy [11]. From the perspective of cost, safety, and sustainability of technological development, photocatalytic technique is obviously very promising.

At the end of the twentieth century, the advent of TiO2 aerogels successfully promoted the further development of TiO2 nanomaterials in the field of photocatalysis [12]. Nowadays, three relatively mature technologies for preparing TiO2 aerogels have been formed: 1) the most commonly used sol–gel method for the preparation of TiO2 aerogels with amorphous structure [13]; 2) the nanoparticles self-assembly synthesis for the preparation of TiO2 aerogels with controllable crystalline phase composition [14]; 3) the high-temperature aerosol engineering technique for the preparation of highly crystalline and highly pure structured TiO2 aerogels [15]. These methods can construct a highly porous 3-dimensional TiO2 aerogels’ framework structure. It is precisely because of the aerogels’ framework structure that the photocatalytic properties of TiO2 aerogels are far superior to other types of TiO2 nanomaterials. Their high specific surface area can provide a larger reaction area, resulting in more reaction occasions [16], high porosity is beneficial to ensure the adsorption and accommodation of reactants to form a synergistic effect of reaction and adsorption [17], 3-dimensional interconnected network structure is conducive to the mass transfer process [18], and translucent structure can be simultaneously excited by light on the inner and outer surfaces to form more active electron–hole pairs, thereby generating more reactive centers [19], and these structural advantages all help to accelerate the progress of the photocatalytic reaction. In addition, the TiO2 aerogels in block form are very easy to realize the process of recycle and reuse, which effectively avoids the drawbacks of the secondary pollution caused by partial TiO2 nanomaterials such as powders and fibers that cannot be recycled, it is also one of the structural advantages of aerogels [20].

But even so, TiO2 aerogels have some limitations in structures and photocatalytic properties. In terms of structures, the adsorption properties of TiO2 aerogels are generally weak, and it is difficult to achieve the synergistic effect of photocatalysis and adsorption at low concentrations of reactants [21], and the poor mechanical properties of pulverization and fragility also limit their practical application [22]. Moreover, the most important characteristic of high-efficiency photocatalysts is the effectiveness of solar energy conversion, which depends on four factors: light absorption, charge separation, charge migration, and charge recombination [23]. Considering these factors, the shortcoming of TiO2 aerogels in terms of photocatalytic properties is that the relatively large bandgap energy of 3.0–3.2 eV needs UV-excitation, which comprises only 5% of solar radiation, and the short lifetime of the active electron–hole pairs obtained by light excitation can also reduce the quantum efficiency of the photocatalytic reaction.

In order to overcome the intrinsic limitations of TiO2 aerogels, modification methods of doping and compositing have been widely used [24,25]. According to different modification mechanisms, we reasonably divide the substances used for modification into three categories: SiO2 aerogels, metal dopants, and non-metallic substances. Compared with TiO2 aerogels, SiO2 aerogels have more excellent structural characteristics of aerogels [26,27]. Therefore, TiO2 aerogels can rely on the structure of SiO2 aerogels to exert better photocatalytic properties, and the formation of two aerogels’ composite structure is also conducive in prolonging the lifetime of active electron–hole pairs and controlling the stability of the crystallized TiO2 to a certain extent [28]. The doping of metal dopants mainly reduces the bandgap width of TiO2 aerogels to improve the utilization of sunlight, accelerates the formation of electron–hole pairs, and prolongs their lifetime, and promotes the formation of the crystallized TiO2 to speed up the quantum efficiency of the photocatalysis [29]. The modification mechanism of non-metallic substances is generally more complicated. Some of them can produce a modification effect similar to that of metal dopants [30], and others can enhance the photocatalytic properties of TiO2 aerogels through intrinsic properties [31]. For instance, the TiO2–C composite aerogel realizes the electrochemical adsorption process enhanced by photocatalysis [32], the TiO2–sodium alginate composite aerogel realizes an underwater oleophobic function [31], and the TiO2–graphene composite aerogel realizes the synergistic effect of photocatalysis and high-efficiency adsorption [33].

Up to now, a total of more than 100 research have conducted relatively systematic studies on TiO2 aerogels, partially solving the problems in the preparation and properties improvement. But meanwhile, many challenges that urgently need to be broken have also been left behind. For instance, most of the reported studies focus on the improvement of the photocatalytic properties of TiO2 aerogels, and there are few reports specifically aimed at the improvement of mechanical properties. Although a variety of techniques have been developed to prepare TiO2 aerogels with different structural characteristics, the industrialization process of TiO2 aerogels is still very slow. These all have left us a lot of space for thinking and studying.

On the basis of the above contents, we first introduce three techniques that can prepare TiO2 aerogels with different structures and properties, and systematically analyze the influence of TiO2 crystalline phases on photocatalytic properties. Subsequently, we summarize the modification methods of TiO2 aerogels for environmental treatment and hydrogen energy production, and elaborate the modification mechanism and the modification effect achieved. Finally, combined with the research status of TiO2 aerogels and the development experience of other aerogels, we put forward our own insights on the future development directions and industrialization roads of TiO2 aerogels (Figure 1).

![Figure 1

General overview of the preparation, modification, and application of TiO2 aerogel composites. Modified with permission from ref. [34]. Copyright 2019, American Chemical Society.](/document/doi/10.1515/ntrev-2022-0490/asset/graphic/j_ntrev-2022-0490_fig_001.jpg)

General overview of the preparation, modification, and application of TiO2 aerogel composites. Modified with permission from ref. [34]. Copyright 2019, American Chemical Society.

2 Preparation techniques

2.1 Sol–gel method

Among the relevant research reports currently available, most of them have used the sol–gel method to prepare TiO2 aerogels. The sol–gel method has obvious advantages from others techniques due to the mixing of reaction components at the atomic scale, simplicity of operation, and low cost [25,35]. The process includes two reaction steps: hydrolysis and polycondensation, as shown in Figure 2(a). The Ti-containing precursor first undergoes a hydrolysis reaction to form primary particles-Ti(OH)4, and then the primary particles undergo dehydration and condensation reactions to form the basic components of the TiO2 aerogels’ skeleton network-secondary particles [36]. Subsequently, infinite number of secondary particles are randomly cross-linked in 3-dimensional space to initially build the skeleton structure of TiO2 wet gel. It is worth mentioning that the above reaction steps have no obvious boundaries in the sol–gel reaction process, and they almost exist and proceed simultaneously [16]. After the sol–gel reaction, an aging process is usually needed to strengthen the neck areas between the secondary particles to improve the mechanical properties of the resulting TiO2 wet gel (Figure 2(b)) [37].

(a) Illustration of the sol–gel synthesis process of TiO2 aerogels and (b) illustration of the aging process enhancing the neck areas of secondary particles.

Finally, what needs to be done is the drying process of the TiO2 wet gel. Generally, the liquid surface curvature formed when the solvents in the wet gel volatilize is in the same order of magnitude as the pore size of the wet gel, thereby the surface tension formed between the solid–liquid interface can easily cause the shrinkage and structural collapse of the wet gel, which makes the drying of the wet gel require some special drying methods [35,38]. For the TiO2 wet gel, supercritical drying and ambient pressure drying are mainly used. The supercritical drying refers to the use of supercritical fluid extraction to eliminate the surface tension of the solvents to complete the drying process and transform wet gel to aerogel while maintaining the structure of the gel skeleton [39], which requires not only expensive and complex supercritical drying equipment, but also usually high-temperature and high-pressure operating conditions. Therefore, the technique can only be applied on a laboratory scale and is difficult to be extended to industrial production. Since then, in order to avoid the complicated and harsh drying environment and for the sake of safety, the ambient pressure drying for the TiO2 wet gel is proposed, which mainly includes the following steps: 1) the surface modification, 2) the low surface tension solvent replacement, and (3) the drying under ambient pressure [40]. Thereinto, siloxane-based surfactants are the most widely used in the modification of the TiO2 wet gel in step (1) because they can react incompletely reacted –OH to –OSi(C n H2n+1)3, which not only avoids the structural collapse of the TiO2 wet gel caused by the continuous condensation reaction of −OH during the drying process, but also improves its hydrophobic properties [41,42]. N-hexane is the most frequently used replacement solvent for the TiO2 wet gel in step (2) due to its low surface tension of 17.89 dyne/cm [43]. Although the quality of TiO2 aerogels obtained by the ambient pressure drying is slightly inferior to that obtained by the supercritical drying, from the perspective of large-scale production of TiO2 aerogels, the ambient pressure drying is obviously a better choice.

2.2 Nanoparticles self-assembly synthesis

The photocatalytic properties of TiO2 aerogels can only be displayed in the crystalline state, while the TiO2 aerogels prepared by the sol–gel method are usually amorphous and need to be crystallized at a high temperature before they can be used [37]. However, high-temperature treatment usually leads to the destruction of the TiO2 aerogels’ structure, and the low-porosity crystalline aggregates formed during the process often further weaken the structural characteristics of the aerogel [44]. Undoubtedly, for the TiO2 aerogels prepared by the sol–gel method, it is difficult to find a balance between the structural characteristics of aerogels and the formation of crystalline phases. Based on this problem, the second method of preparing TiO2 aerogels-nanoparticles self-assembly synthesis is proposed [14], which mainly completes the oriental attachment process in the 3-dimensional direction through the surface polymerization of specially treated crystalline TiO2 nanoparticles, thereby constructing a highly porous TiO2 wet gel’s skeleton network, and then the desired TiO2 aerogels are obtained by the supercritical drying or the ambient pressure drying (Figure 3(a)).

![Figure 3

(a) Assembly of TiO2 nanoparticles using either trizma-functionalized nanoparticles or non-functionalized nanoparticles; (b) photographs of the self-assembled TiO2 aerogel and the trizma-functionalized TiO2 nanoparticles; and (c) detailed HRTEM image of a part of the self-assembled TiO2 aerogel, showing the linear subunits and the misoriented junctions. (b) and (c) Modified with permission from ref. [14]. Copyright 2011, Royal Society of Chemistry.](/document/doi/10.1515/ntrev-2022-0490/asset/graphic/j_ntrev-2022-0490_fig_003.jpg)

(a) Assembly of TiO2 nanoparticles using either trizma-functionalized nanoparticles or non-functionalized nanoparticles; (b) photographs of the self-assembled TiO2 aerogel and the trizma-functionalized TiO2 nanoparticles; and (c) detailed HRTEM image of a part of the self-assembled TiO2 aerogel, showing the linear subunits and the misoriented junctions. (b) and (c) Modified with permission from ref. [14]. Copyright 2011, Royal Society of Chemistry.

Generally, the nanoparticles self-assembly synthetic TiO2 aerogels have the structural characteristics of macroporous aerogels, a super-high proportion of crystalline phase composition, and multiple crystalline phases that can exist simultaneously, which successfully overcomes the limitations of the sol–gel preparation of TiO2 aerogels [18]. However, it should be emphasized that the main problem of the self-assembly of nanoparticles to synthesize TiO2 aerogels is the short-range order of the assembly of TiO2 nanoparticles. Generally, the spontaneous assembly size of crystalline TiO2 nanoparticles is less than 1 μm, and the assembly direction is mostly 1-dimensional, so it is difficult to obtain nano-structured 3-dimensional porous materials. The core idea to solve this problem is to modify the crystalline TiO2 nanoparticles to achieve an anisotropic polymerization, thereby constructing a 3-dimensional aerogels’ skeleton network structure. Thereinto, the polymerization process is maintained by directional adsorption, in which adjacent nanoparticles coalesce spontaneously in such a way to share a common crystallographic orientation, and only in this case the size of the self-assembled product can be extended to the cm range (Figure 3(b)). In the reports on the synthesis of TiO2 aerogels by the self-assembly of nanoparticles, trizma is the most widely used for the surface functional modification of crystalline TiO2 nanoparticles [14]. These treated nanoparticles can self-assemble into macroporous TiO2 aerogels with irregular block shapes, which is the result of the directional attachment process experienced by the nanoparticles after the trizma stabilizer is selectively removed from the {001} crystalline plane, as exhibited in Figure 3(c).

2.3 High-temperature aerosol technique

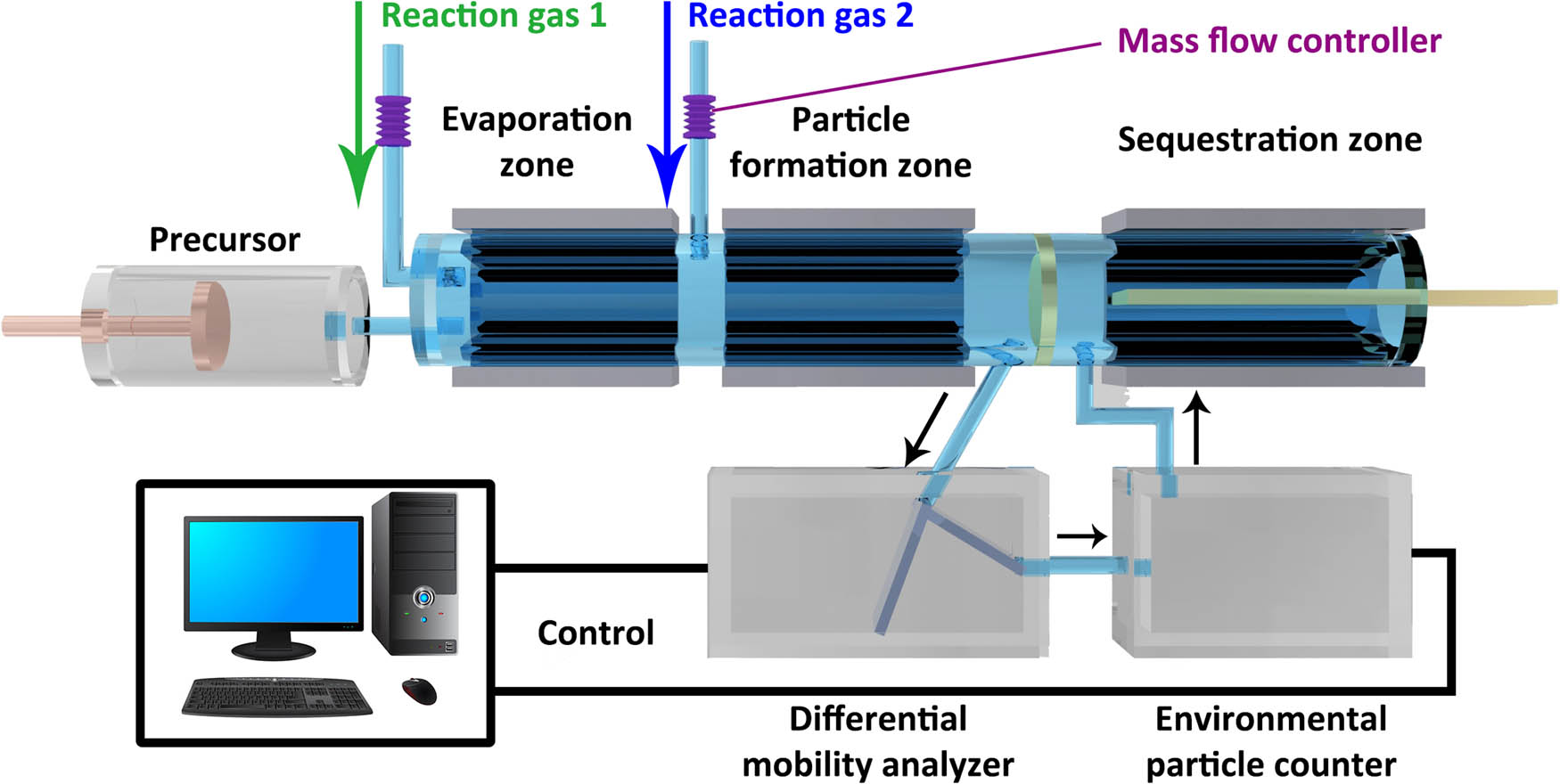

Different from the two techniques mentioned above, the high temperature aerosol technique uses the idea of gas-phase synthesis to prepare TiO2 aerogels. The method first forms TiO2 nanoparticles by evaporating and decomposing the Ti-containing aerosol obtained from the Ti-containing precursor under the accompaniment of selected reaction gases, then adjusts the conditions in the reaction device through a computer program so that the nanoparticles are assembled in 3-dimensional directions under control, and TiO2 aerogels with a highly porous structure are successfully prepared, the detailed process is shown in Figure 4 [15]. During this process, the structural characteristics of the obtained TiO2 aerogels such as particle size, porosity, specific surface area, crystallinity, composition of crystalline phases, etc., are determined by the interaction of preset temperature gradient, precursor concentration, the amount of reactant gases, residence time, etc. To understand the relevance of these conditions, the preparation of TiO2 aerogels with different structures and properties can be realized.

The flow chart of the device for synthesizing TiO2 aerogels by the high-temperature aerosol engineering.

In addition, the nanoparticles in the TiO2 aerogels prepared by the high-temperature aerosol technique are highly pure, highly crystalline, and their surface does not contain any additives. But the two methods mentioned above belong to the liquid phase synthesis, a variety of solvents and chemical additives used to adjust the structure of the wet gel are more or less used, which makes the obtained TiO2 aerogels impossible to be highly pure [18,45]. It can be concluded that the high temperature aerosol technique has some significant advantages in the preparation of highly crystalline and highly pure structured TiO2 aerogels. However, the controllability of the technique is far less than the previous two methods, and it is difficult to understand the influence of the diversity of influencing factors and the complexity of these related factors on the structures and properties of the prepared TiO2 aerogels. Thus, the sol–gel method and the nanoparticles self-assembly synthesis belonging to liquid-phase synthesis and the high temperature aerosol technique belonging to gas-phase synthesis can be complementary to a certain extent in the specific aspects of preparing TiO2 aerogels. For instance, the use of sol–gel method and high-temperature aerosol engineering can make the amorphous TiO2 and crystalline TiO2 distributed in different regions of TiO2 aerogels. In the inner region, the sol–gel method forms an amorphous TiO2 aerogel skeleton structure, maintaining the remarkable aerogel structural properties. In the outer region, high-temperature aerosols form highly crystalline TiO2 aerogels to perform photocatalytic reactions. In this way, the inner regions where light cannot penetrate are composed of amorphous TiO2 aerogels to provide structural support, and the regions where light can shine are composed of crystalline TiO2 aerogels for photocatalytic reactions, and the photocatalytic properties of the resulting TiO2 aerogels can be effectively enhanced [46]. It may also be one of the directions to be explored in the preparation of TiO2 aerogels in the future.

3 Influence of crystalline phases on the photocatalytic properties of TiO2 aerogels

The crystalline phases of TiO2 aerogels greatly affect the progress rate of the photocatalytic reaction. Among the different crystalline phases, it is generally accepted that anatase TiO2 has the strongest catalytic activity, followed by rutile TiO2, and brookite TiO2 and amorphous TiO2 are the weakest [44]. In terms of crystalline structures, both anatase TiO2 and rutile TiO2 have a tetragonal crystalline structure formed by TiO6 octahedral chains, that is, every Ti atom in the unit cell is surrounded by six oxygen atoms, but their assembly mode of the octahedral chain and distortion method of the octahedron are completely different [2,47]. In anatase TiO2, the orthogonality of TiO6 octahedrons is higher than that of the symmetry, and each octahedron is connected to eight adjacent octahedrons. Thereinto, every four unit cells share an edge, and every four unit cells share an angle (Figure 5(a)). And in rutile TiO2, TiO6 octahedrons exhibit irregular orthogonal distortions, and each octahedron is connected to 10 adjacent octahedrons. Thereinto, every two octahedrons share an edge oxygen atom pairs and every eight octahedrons share corner oxygen atoms (Figure 5(b)). In addition, the Ti–O bond length in rutile TiO2 is longer than that of anatase TiO2, while the Ti–Ti bond length is shorter [48]. It is precisely because of the abovementioned difference in the crystalline structures wherein the electronic band structure and mass density of anatase TiO2 and rutile TiO2 are completely different, which causes their photocatalytic intrinsic properties to be completely different [49].

![Figure 5

(a) Tetragonal structures and unit cell structures of anatase TiO2 described by using two cell edge parameters – a and c, and one internal parameter – d; (b) tetragonal structures and unit cell structures of rutile TiO2 described by using two cell edge parameters – a and c, and one internal parameter – d; (c) kinetic curves of the photocatalytic degradation of Cr6+ by the TiO2-EAG-PB (the Prussian blue modified TiO2 aerogel containing appropriate ratio of anatase TiO2 and rutile TiO2) and the TiO2-A-PB (the Prussian blue modified TiO2 aerogel containing only anatase TiO2); and (d) illustration of the mechanism of the mixed crystal effect of anatase TiO2 and rutile TiO2. (a) and (b) Modified with permission from ref. [2]. Copyright 2019, Springer. (c) and (d) Modified with permission from ref. [50]. Copyright 2021, Royal Society of Chemistry.](/document/doi/10.1515/ntrev-2022-0490/asset/graphic/j_ntrev-2022-0490_fig_005.jpg)

(a) Tetragonal structures and unit cell structures of anatase TiO2 described by using two cell edge parameters – a and c, and one internal parameter – d; (b) tetragonal structures and unit cell structures of rutile TiO2 described by using two cell edge parameters – a and c, and one internal parameter – d; (c) kinetic curves of the photocatalytic degradation of Cr6+ by the TiO2-EAG-PB (the Prussian blue modified TiO2 aerogel containing appropriate ratio of anatase TiO2 and rutile TiO2) and the TiO2-A-PB (the Prussian blue modified TiO2 aerogel containing only anatase TiO2); and (d) illustration of the mechanism of the mixed crystal effect of anatase TiO2 and rutile TiO2. (a) and (b) Modified with permission from ref. [2]. Copyright 2019, Springer. (c) and (d) Modified with permission from ref. [50]. Copyright 2021, Royal Society of Chemistry.

In terms of photocatalytic properties, the content and ratio of anatase TiO2 and rutile TiO2 are one of the main factors affecting the properties of TiO2 aerogels [50]. The valence band positions of these 2 crystalline phases are the same, and the formed photo-generated holes have the same oxidation properties. However, the bandgap of anatase TiO2 is 3.2 eV, which is higher than the 3.0 eV of rutile TiO2, indicating that the conduction band potential of anatase TiO2 is more negative, and the photogenerated electrons formed have stronger reducing ability. Also, the lower bandgap of rutile TiO2 easily causes the recombination of photoexcited electron–hole pairs, resulting in a decrease in catalytic activity, so the formation of anatase TiO2 is very beneficial to improve the photocatalytic properties of TiO2 aerogels. However, it has been proven that the photocatalytic properties of TiO2 aerogels containing an appropriate ratio of anatase TiO2 and rutile TiO2 are stronger than that of TiO2 aerogels containing only anatase TiO2 (Figure 5(c)), which is mainly related to the mixed crystal effect achieved by these two crystalline phases [51]. Different crystal types of TiO2 have more defects during the connection of structural elements, and more traps to capture photogenerated electrons and holes, thereby increasing the photocatalytic efficiency. Also, due to the difference in the energy levels of the conduction band and valence band of anatase TiO2 and rutile TiO2, photogenerated electrons formed by light excitation tend to diffuse from rutile TiO2 to anatase TiO2, while photogenerated holes are just the opposite, thereby reducing the recombination probability of electron–hole pairs, and realizing the effective separation of photogenerated carriers, which macroscopically shows that the photocatalytic properties of TiO2 aerogels are improved, as displayed in Figure 5(d).

In addition, the other factor that determines the photocatalytic properties of TiO2 aerogels is the particle size of anatase TiO2 nanoparticles and rutile TiO2 nanoparticles as basic building blocks or secondary particles. As a typical N-type semiconductor, the particle size of TiO2 nanoparticles is generally smaller than the thickness of the space charge layer, so all the effects of the space charge layer can be ignored [52,53]. For instance, the diffusion rate of electrons from within the particle to the surface in 10 nm TiO2 nanoparticles is four orders of magnitude higher than that of the same type of 1 μm TiO2 nanoparticles. Therefore, the smaller the particle size, the shorter the time for photogenerated electrons to diffuse from within the particle to the surface, and the smaller the recombination probability of electrons and holes, which is helpful to improve the photocatalytic efficiency. Also, when the particle size of TiO2 nanoparticles is smaller than a certain value, they can produce size quantum effects that have different properties from crystalline TiO2 macroscopic materials [54]. As a result, electrons and holes are respectively confined in small-sized potential wells, so that the energy levels of the conduction band and the valence band are changed from continuous to separated, resulting in a wider bandgap between the two. In this case, the potential of the conduction band becomes more negative, and the potential of the valence band becomes more positive, which increases the energy of photogenerated electrons and holes. Thus, the redox capacity of TiO2 aerogels is enhanced, and their photocatalytic properties are significantly improved.

In addition, the smaller the particle size of anatase TiO2 nanoparticles and rutile TiO2 nanoparticles in TiO2 aerogels, the larger the specific surface area of TiO2 aerogels [55,56]. On the one hand, the increase in the specific surface area can rapidly increase the number of surface atoms in TiO2 aerogels, thereby improving the light absorption efficiency, increasing the concentration of surface photogenerated electron–hole pairs, and also accelerating the progress of the photocatalytic reaction. On the other hand, the increase in the specific surface area causes the surface bond state and electronic state to be different from the inside, and the uneven coordination of surface atoms increases the number of surface active sites, which enhance the adsorption capacity of TiO2 aerogels for reactants, and also increase the probability of the photocatalytic reaction.

4 TiO2 aerogel composite photocatalysts for environmental treatment

4.1 Mechanism of photocatalysis

Photocatalytic reaction refers to the photochemical redox process that occurs between photocatalysts and their surface adsorbents, such as H2O, organic matters, high-valent metal salts, etc., with the participation of light, which is essentially a free radical reaction [27,57]. As a typical N-type semiconductor, TiO2 contains a full valence band, an empty conduction band, and a bandgap between the two in its electronic structure [29]. When the photon energy absorbed by the TiO2 reaches or exceeds the bandgap energy, the electrons in the valence band are excited to the conduction band, and holes are formed in the original position, that is, electron–hole pairs are formed. Generally, the holes in the valence band and the electrons in the conduction band are very easy to recombine and lose energy in the form of light energy or heat – equations (1) and (2) [58]. When trapping agents or surface states exist, the effective separation of electron–hole pairs can be achieved. Thereinto, holes are excellent oxidants with extremely high reactivity and are the main part of light quantum energy. They generally react with H2O and OH− on the surface of the TiO2 to form active hydroxyl group (˙OH) with strong oxidizing properties – equations (3) and (4) [59]. As a free radical containing unpaired electrons, the ˙OH has a reaction energy of 402,800 kJ/mol, which is much higher than the bond energy of chemical bonds in various substances, such as 607.0 kJ/mol of the C–C bond, 338.32 kJ/mol of the C–H bond, 347.1 J/mol of the H–S bond, 1071.1 kJ/mol of the C≡O bond, and 339.0 kJ/mol of the N–H bond, etc., so it can react with almost all organic pollutants and most inorganic pollutants (Figure 6(a)) [37].

![Figure 6

(a) Schematic diagram of the photocatalytic reaction process of nano-TiO2; (b) photocatalytic degradation, photolysis, and adsorption curves of methylene blue by the TiO2–SiO2 aerogel; (c) linear relationship between CO/C and time for photocatalysis and photolysis of the TiO2–SiO2 aerogel; (d) schematic representation of the photocatalytic decomposition mechanism of methylene blue by the pure TiO2 aerogel and the TiO2–SiO2 composite aerogel; (e) FTIR spectra of the pure TiO2 aerogel and the TiO2/SiO2 aerogel composite calcined at 500°C; and (f) XRD patterns of pure TiO2 aerogels and TiO2/SiO2 aerogel composites calcined at different temperatures. (b) and (c) Modified with permission from ref. [64]. Copyright 2009, Elsevier. (e) and (f) Modified with permission from ref. [74]. Copyright 2011, Elsevier.](/document/doi/10.1515/ntrev-2022-0490/asset/graphic/j_ntrev-2022-0490_fig_006.jpg)

(a) Schematic diagram of the photocatalytic reaction process of nano-TiO2; (b) photocatalytic degradation, photolysis, and adsorption curves of methylene blue by the TiO2–SiO2 aerogel; (c) linear relationship between CO/C and time for photocatalysis and photolysis of the TiO2–SiO2 aerogel; (d) schematic representation of the photocatalytic decomposition mechanism of methylene blue by the pure TiO2 aerogel and the TiO2–SiO2 composite aerogel; (e) FTIR spectra of the pure TiO2 aerogel and the TiO2/SiO2 aerogel composite calcined at 500°C; and (f) XRD patterns of pure TiO2 aerogels and TiO2/SiO2 aerogel composites calcined at different temperatures. (b) and (c) Modified with permission from ref. [64]. Copyright 2009, Elsevier. (e) and (f) Modified with permission from ref. [74]. Copyright 2011, Elsevier.

The reaction speed of the ˙OH is very high, only depends on its diffusion speed in the reaction system, and the reaction mechanism involved is mainly the addition reaction on the unsaturated double bonds and triple bonds, the substitution of H atoms, the transfer of electrons, etc. Studies have shown that the ˙OH plays a leading role in the photocatalytic degradation [60,61].

Generally, the electrons first react with the O2 adsorbed on the surface of the TiO2 photocatalysts to generate superoxide radical (

4.2 Kinetic principles of photocatalysis

The study of the photocatalytic reaction kinetics of TiO2 aerogels is not only a basic requirement for rational design of material components and structures, but also a way to better understand the abovementioned reaction mechanism. Based on the same basis of the photocatalytic reaction of TiO2 aerogels and their composites, Luo et al. [64], Sadrieyeh and Malekfar [23], and Shi et al. [65] have conducted in-depth studies on the photocatalytic kinetics of the TiO2/SiO2 composite aerogel, the Au/Ag nanoparticles doped TiO2 aerogel, and the biomass-derived TiO2/carbonaceous aerogel composite, respectively, and reached a consistent conclusion: the photocatalytic reaction of TiO2 aerogels follows the Langmuir–Hinshelwood (L–H) kinetic model. Take the study of Luo et al. as an example. Under the condition of homogeneous mixed transportation, they made the following assumptions in consideration of the possible mass transmission effects involved: (1) the O2 in the solution is always saturated and (2) the concentration of the reactant at the interface is no different from that in the solution. Based on this, the reaction rate formula shown in equation (10) can be obtained.

where C is the concentration of the reactant, k is the apparent reaction rate constant, and K is the equilibrium adsorption constant of the reactant. By taking the reciprocal of both sides of equation (10), the kinetic constants k and K can be calculated to form linear equation (11).

When the reactant is at a low concentration, the final quasi-first-order kinetic equation (12) is obtained by integrating equation (11).

where k′ is the apparent quasi-first-order reaction rate constant.

In the research of Luo et al. [64], the pseudo-first-order L–H kinetic model is assumed to be consistent with the kinetic model of the photocatalytic degradation of methylene blue by the TiO2/SiO2 composite aerogel. If this assumption is true,

4.3 TiO2/SiO2 composite aerogels

Since Kistler [66] used the supercritical drying process to prepare SiO2 aerogels for the first time in 1931 and opened up a new field of aerogels, SiO2 aerogels have experienced a total of more than 80 years of development from the vigorous development period of the last century to the stable development period of this century [67,68]. There is no doubt that the advanced technology formed during the development of SiO2 aerogels has driven the development of TiO2 aerogels in this century. Especially in recent years, the design and preparation of TiO2/SiO2 composite aerogels has become one of the main research directions to overcome the limitations of TiO2 aerogels.

Compared with TiO2 aerogels, SiO2 aerogels have more significant structural characteristics of aerogels, such as larger specific surface area, higher porosity, finer nanoparticles, higher light transmittance, etc. [40,69,70]. As mentioned earlier, the larger specific surface area can increase the light absorption efficiency of TiO2 aerogels and the number of active sites formed due to the uneven coordination of surface atoms. The higher porosity means that TiO2 aerogels have stronger adsorption and holding capacity for reactants, which is conducive to increasing the concentration of reactants in the active centers and improving the probability of reactions. The finer nanoparticles can effectively increase the specific surface area and form quantum size effects required for photocatalysis, etc. The higher light transmittance represents a wider light excitation space, so the total area of TiO2 aerogels excited by light increases and the number of active centers formed increases (Figure 6(d)).

It is for the above reasons that SiO2 aerogels have great potential to be applied as a kind of nano-catalyst carrier with superior performance, and TiO2 nanomaterials including TiO2 aerogels can rely on the structural characteristics to maximize the photocatalytic properties, which is the first design form of TiO2/SiO2 aerogel composites with SiO2 aerogels as the main body and TiO2 nanomaterials as the guest. Generally, there are two ways to realize this type of TiO2/SiO2 composite aerogels. One is to introduce crystallized TiO2 nanoparticles into the SiO2 aerogels at the formation stage [71], and the other is to immerse the selected Ti-containing precursors into the already formed SiO2 aerogels’ framework network to combine the two to form composite aerogels [72]. Although the content of TiO2 crystalline phases in this type of TiO2/SiO2 composite aerogels is lower than that of pure TiO2 aerogels, their photocatalytic properties are more excellent. As the content of TiO2 crystalline phases increases within a certain range, their photocatalytic properties can be continuously strengthened [72].

For instance, under the irradiation of 250 W UV light source, the TiO2/SiO2 composite aerogels (10 mg) prepared by immersing the formed SiO2 wet gel in the partially hydrolyzed titanium n-butoxide precursor for 5, 10, and 15 times, respectively, achieved 55, 78, and 92% degradation rates (100 min) for methylene blue solution (20 mg/L, 40 mL) [73]. Under the irradiation of UV light source (254 nm), the TiO2/SiO2 composite aerogels (0.277 g) prepared by adding SiO2 aerogels into the TiO2 sol with concentrations of 0.43, 0.75, and 1.20 mol/L by ultrasonic vibration produced about 53, 80, and 54% degradation rates (200 min) for rhodamine B solution (1.0 × 10−4 mol/L, 30 mL), respectively. In the research, the photocatalytic properties of the composite aerogel with the highest TiO2 content decreased, which was mainly related to the weakening of the structural characteristics of the SiO2 aerogel caused by the excessive loading of TiO2 aerogels [72]. Wang et al. [74] prepared a TiO2/SiO2 composite aerogel by adding the SiO2 aerogel to the hydrolysate of Ti-containing precursor, and systematically studied the effect of experimental conditions on the photocatalytic properties. The results showed that the photocatalytic properties of the composite aerogel were the best when the pH value was 4.82, the dosage was 8.0 g/L and the temperature was 20℃, and the degradation rate of 2-sec-butyl-4,6-dinitrophenol (DNBP) (41.90 mg/L, 75 mL) reached 95% (240 min) under sunlight irradiation (0.562 kW/m2). Under the irradiation of a sunlight simulator (132.7 mW/cm2) with a height of 10.16 cm, an inner diameter of 7.62 cm, and an outer diameter of 5.08 cm, the TiO2/SiO2 composite aerogel obtained by immersing the anatase TiO2 aerogel (10 mg/cm2) into the about-to-gel SiO2 sol on a 1 cm × 1 cm glass substrate for nano-gluing reaction achieved the highest degradation rate of 94.3% (60 min) for methylene blue solution (4 mg/L) [64].

In addition, in order to adjust the content and ratio of TiO2 and SiO2 in TiO2/SiO2 composite aerogels more conveniently and flexibly, and try to make the two composites in the form of chemical bonding, researchers are inclined to use co–sol–gel to make Ti-containing precursors and Si-containing precursors react synchronously to construct the structural framework of TiO2/SiO2 composite aerogels, so as to achieve the structural uniformity of the two on the atomic scale, which is another type of TiO2/SiO2 composite aerogels [75,76]. Thereinto, in addition to the advantages of structural characteristics, SiO2 aerogels can also affect the photocatalytic process and structural stability of TiO2 aerogels to a certain extent. SiO2, as a charge transfer catalyst, can affect the transfer process of photogenerated electrons and holes to the surface, thereby inhibiting their recombination. Because anatase TiO2 has an octahedral coordination structure, the existence of SiO2 can lead to the unbalanced distribution of charge, resulting in the formation of Brønsted acid sites. As a result, more OH−s are adsorbed on the surface to achieve charge balance, which not only can further capture holes and improve the separation efficiency of electron–hole pairs, but also promote the generation of ˙OHs, thereby enhancing the photocatalytic properties of TiO2 aerogels [64]. Also, the composite of SiO2 aerogels can effectively inhibit the transformation of anatase TiO2 to rutile TiO2, which is mainly due to the formation of Ti–O–Si bonds which stabilize nearby anatase TiO2 (Figure 6(e) and (f)) [74]. The SiO2 crystal lattice locks the Ti-O species on the interface of the TiO2 region, preventing the nucleation process necessary for the transformation of anatase TiO2 to rutile TiO2, which not only ensures the composition of a high proportion of anatase TiO2, but also ensures the realization of the mixed crystal effect. However, in the former type of TiO2/SiO2 composite aerogels, SiO2 aerogels and TiO2 nanomaterials including TiO2 aerogels are mostly combined by physical means such as impregnation, coating, embedding, etc., thereinto the influence of SiO2 aerogels on the photocatalytic process and the structural stability of TiO2 crystalline phases is very weak. Comparing the research history of the two types of TiO2/SiO2 composite aerogels, it can be found that the design of the second type of composite form is more concerned.

For instance, under the irradiation of 3 W × 10 W OVA lamp sources, the degradation rate of the TiO2/SiO2 composite aerogel (0.5 g, mass ratio of TiO2/SiO2 is 1.8) to gas phase acetaldehyde (2,000 ppmv) in a cuboid reactor (220 mm × 125 mm × 80 mm) reached 82% (20 min), while the Degussa-P25 used in the control group produced only 52% degradation rate under the same conditions [77]. Under the irradiation of a high-pressure mercury lamp (350–450 nm), the adsorption rate of the TiO2/SiO2 composite aerogel (0.1 g, molar ratio of Ti/Si is 4) prepared by sol pre-modification to rhodamine B solution (9.8 × 10−6 mol/L, 20 mL) reached 89.4% within 1 h, and the total photocatalytic/adsorption removal rate reached 96.5% within 10 h [41]. The superhydrophobic TiO2/SiO2 composite aerogel (0.1 g, hydrophobic angle is 165°, and molar ratio of Ti/Si is 1:1) produced a 35% removal rate for rhodamine B solution (10 mg/L, 100 mL) when it was not exposed to light, and a 74.5% (100 min) removal rate was obtained when it was irradiated by an iodine tungsten lamp (125 W) through the synergistic effect of photocatalysis and adsorption, while the Degussa-25 selected in the control group only produced a removal rate of 22% under the same conditions with light irradiation [43]. Under the irradiation of 8 W ultraviolet light source, the mineralization rates of TiO2/SiO2 nanocomposite aerogel catalysts (0.2 g, molar ratio of Ti/Si is 1:1 and 1:4, respectively) for trinitrotoluene reached 99 and 93% (3.5 h), respectively [78]. In addition, the photocatalytic application effects of TiO2/SiO2 composite aerogels used in environmental treatment are shown in Table 1.

Summary of degradation effects of TiO2–SiO2 aerogel composites on various environmental pollutants

| Catalysts | Usage amount | Condition | Target | Time | Removal efficiency (%) | Ref. |

|---|---|---|---|---|---|---|

| TiSi-1 | 10 mg | 250 W UV light | Methylene blue (40 mL, 20 mg/L) | 100 min | 92 | [73] |

| TiSi-1 | 0.277 g | 254 nm UV light | Rhodamine B (30 mL, 1.0 × 10−4 mol/L) | 200 min | 80 | [72] |

| TiSi-1 | 0.6 g | 0.562 kW/m2 sunlight | DNBP (75 mL, 41.90 mg/L) | 240 min | 95 | [74] |

| TiSi-1 | 10 mg | 132.7 mW/cm2 sunlight simulator | Methylene blue (4 mg/L) | 60 min | 94.3 | [64] |

| TiSi-2 | / | 16 W UV light | Glyphosate (500 mL, 20 mg/L) | 180 min | 100 | [28] |

| TiSi-2 | 10 mg | 765 W/m2 visible light | Methylene blue (10 mL, 10 μM) | 12 h | >95 | [71] |

| TiSi-2 | 0.142 g | 5 nm × 365 nm fluorescent black lamps | Gas trichloroethylene (113 ppm) | / | 19.3 | [76] |

| TiSi-2 | 0.2 g | 8 W UV light | TNT (700 mL, 100 ppm) | 3.5 h | 99 | [78] |

| TiSi-2 | 125 μg/mL | 150 W mercury vapor lamp | Methylene blue (50 μM) | 3 h | 82 | [79] |

| TiSi-2 | 125 μg/mL | 150 W mercury vapor lamp | Salicylic acid (500 μM) | 3 h | 30 | [79] |

| TiSi-2 | 0.12 g | 100 W mercury lamp | Methylene blue (200 mL, 48 mg/L) | 70 min | 96 | [75] |

| TiSi-2 | 0.5 g | 3 × 10 W UVA lamps | Acetaldehyde (2.2 L, 2,000 ppmv) | 120 min | 100 | [77] |

| TiSi-2 | 5 g | 2 × 10 W UVA lamps | NOx (0.075 L, 1 ppmv) | 180 min | 91 | [77] |

| TiSi-2 | 0.1 g | 125 W iodine tungsten lamp | Rhodamine B (100 mL, 10 mg/L) | 100 min | 74.5 | [43] |

| TiSi-2 | 0.1 g | 350–450 nm mercury lamp | Rhodamine B (20 mL, 9.8 × 10−6 mol/L) | 10 h | 96.5 | [41] |

| TiSi-2 | 1 mg/mL | 40 W UV lamp | Methylene blue (5 mg/L) | 120 min | 89 | [80] |

Note: TiSi-1 represents the first type of TiO2/SiO2 composite aerogels, TiSi-2 represents the second type of TiO2/SiO2 composite aerogels, and DNBP is 2-sec-butyl-4,6-dinitrophenol.

4.4 Metal dopants modified TiO2 aerogels

Metal dopants are commonly used means to improve the photocatalytic properties of TiO2 aerogels. According to the differences in process methods and modification effects, they can be divided into doping modification of metal ions and local surface plasmon resonance modification of metal nanoparticles [25,56]. Generally, the modification effects of metal ions on TiO2 aerogels are mainly reflected in the following three aspects: (1) inhibit the recombination of photogenerated electron–hole pairs [81], (2) appropriately reduce the bandgap and broaden the response range to visible light [82], and (3) promote the formation of crystalline TiO2 and inhibit the transformation of anatase TiO2 [83]. Up to now, representative transition metal ions such as Zn2+, Fe3+, etc., and rare earth metal ions such as La3+, Nd3+, Eu3+, etc., have been widely used in the modification of TiO2 aerogels. For instance, the doping of Zn2+ effectively promotes the formation of crystalline TiO2 in TiO2 aerogels, and as the Zn/Ti molar ratio increases in the range of 0–7%, the promotion effect is more obvious (Figure 7(a)) [82]. The doping of Fe3+ can reduce the lattice constant c of anatase TiO2 in the TiO2 aerogel while maintaining a unchanged, which inhibits the growth process of crystalline phases when external conditions change, such as temperature rise (Figure 7(b)) [83].

![Figure 7

(a) XRD patterns of heat-treated Zn2+ doped TiO2 aerogels at 800°C for 2h with different mole fractions of Zn; (b) effects of the Fe3+ doping with different molar fractions on lattice parameters a and c of anatase TiO2 in TiO2 aerogels; (c) diffuse reflectance spectra of the Zn0-800°C-2h and the Zn3-800°C-2h; (d) the schematic diagram of synergistic effect between TiO2 and Zn photocatalytic system in the Zn doped TiO2 aerogels under visible light irradiation; (e) graphical illustration of the difference in modification of TiO2 aerogels by Au nanoparticles with different particle sizes; (f) XRD patterns of TiO2 aerogels before and after calcination and the Pt/TiO2 aerogel after calcination; (g) variation curve of turnover frequency with temperature of the catalytic activity for CO oxidation of the Pt nanoparticles surface-modified TiO2 aerogel; (h) competitive effect of the favorable plasma enhancement of Au nanoparticles and the unfavorable photo-induced EMSI on the catalytic activity of TiO2 aerogels for CO in dark and broadband environments; and (i) schematic diagram of the effect of TiO2 aerogels on Cu nanoparticles and changing relationship of temperature on the conversion rate of CO by the Cu nanoparticles surface-modified TiO2 aerogel. (a) and (c) Modified with permission from ref. [82]. Copyright 2018, IOP. (b) Modified with permission from ref. [83]. Copyright 2009, Springer. (e) Reproduced with permission from ref. [57]. Copyright 2013, Elsevier. (f) and (g) Modified with permission from ref. [56]. Copyright 2018, Springer. (h) Reproduced with permission from ref. [96]. Copyright 2020, American Chemical Society. (i) Reproduced with permission from ref. [98]. Copyright 2019, Elsevier.](/document/doi/10.1515/ntrev-2022-0490/asset/graphic/j_ntrev-2022-0490_fig_007.jpg)

(a) XRD patterns of heat-treated Zn2+ doped TiO2 aerogels at 800°C for 2h with different mole fractions of Zn; (b) effects of the Fe3+ doping with different molar fractions on lattice parameters a and c of anatase TiO2 in TiO2 aerogels; (c) diffuse reflectance spectra of the Zn0-800°C-2h and the Zn3-800°C-2h; (d) the schematic diagram of synergistic effect between TiO2 and Zn photocatalytic system in the Zn doped TiO2 aerogels under visible light irradiation; (e) graphical illustration of the difference in modification of TiO2 aerogels by Au nanoparticles with different particle sizes; (f) XRD patterns of TiO2 aerogels before and after calcination and the Pt/TiO2 aerogel after calcination; (g) variation curve of turnover frequency with temperature of the catalytic activity for CO oxidation of the Pt nanoparticles surface-modified TiO2 aerogel; (h) competitive effect of the favorable plasma enhancement of Au nanoparticles and the unfavorable photo-induced EMSI on the catalytic activity of TiO2 aerogels for CO in dark and broadband environments; and (i) schematic diagram of the effect of TiO2 aerogels on Cu nanoparticles and changing relationship of temperature on the conversion rate of CO by the Cu nanoparticles surface-modified TiO2 aerogel. (a) and (c) Modified with permission from ref. [82]. Copyright 2018, IOP. (b) Modified with permission from ref. [83]. Copyright 2009, Springer. (e) Reproduced with permission from ref. [57]. Copyright 2013, Elsevier. (f) and (g) Modified with permission from ref. [56]. Copyright 2018, Springer. (h) Reproduced with permission from ref. [96]. Copyright 2020, American Chemical Society. (i) Reproduced with permission from ref. [98]. Copyright 2019, Elsevier.

Based on the theory established by Rodriguez et al. [84], when the radius of doped metal ions is different from that of Ti4+ (0.068 nm), lattice distortion will be caused, and the resulting stress field will definitely inhibit the movement of grain boundaries, thereby preventing the occurrence of phase transition. Zn2+ has a large ionic radius (0.088 nm) and is difficult to enter the lattice of TiO2. Therefore, low-concentration Zn2+ doping is easy to precipitate ZnO clusters on the surface of TiO2 aerogels and become the nucleation center of rutile TiO2, thereby reducing the temperature of crystalline phase transition. The ionic radius of Fe3+ (0.069 nm) is relatively close to that of Ti4+, which can easily replace Ti4+ in the TiO2 lattice or enter the lattice gap to form a uniform distribution in TiO2 aerogels, and thus become the center of preferential nucleation of rutile TiO2, which also helps to reduce the temperature of crystalline phase transition. Meanwhile, Guidi et al. [85] found that there are fractures of Ti–O bonds in the transformation from anatase TiO2 to rutile TiO2, which causes the increase in mobility and promotes the growth of crystalline grains, and the doping of metal ions can just affect the formation mechanism of rutile TiO2, which makes the nucleation site of rutile TiO2 in TiO2 aerogels transfer from the junction of anatase TiO2 to the surface, resulting in excessive accumulation of rutile TiO2 nucleation centers on the surface, which reduces the growth rate and delays the formation process. As a result, the particle size of TiO2 is reduced, which in turn maintains the stability of anatase TiO2. Also, the growth of a small amount of rutile TiO2 on the surface of anatase TiO2 is also conducive to the realization of the mixed crystal effect.

Furthermore, transition metal ions replace Ti4+ in the TiO2 lattice, enter the lattice gap, precipitate with metal oxides, etc., which can lead to the generation of point defects, and the resulting Coulomb effect increases their separation efficiency by trapping electrons or holes. Meanwhile, the charged metal ions themselves can become trapping potential wells for electrons or holes. Taking Fe3+ doping as an example [86], although its energy level is above the conduction band energy level of rutile TiO2, it is closer to the conduction band of TiO2. Therefore, a deep potential capture well for trapping holes can be formed to reduce the recombination probability of electron–hole pairs. Under the irradiation of 8 W/cm2 UV light, the Fe3+ (3% mole fraction) doped TiO2 aerogel (16.6 g/L) achieved a 85.1% degradation efficiency (120 min) for salicylic acid (5 × 10−4 mol/L), and the photocatalytic effect produced was 1.2 times that of the pure TiO2 aerogel and 6 times that of the Degussa-P25 under the same conditions [83]. Under the sunlight, the Fe3+ (3% mole fraction) doped TiO2 aerogel (0.25 g/L) synthesized with ionic liquid as a template achieved about 95% degradation rate (120 min) for reactive blue dye (40 mg/L, 200 mL), which was higher than 88% of the pure TiO2 aerogel and 35% of the Degussa-P25 under the same conditions [87].

Regarding the regulation of energy band structure, the doping of metal ions can introduce impurity state energy levels in the bandgap of TiO2 to narrow the bandgap, which causes the red shift of the light absorption sideband caused by electrons from the valence band to the conduction band, and broadens the light absorption range of TiO2 aerogels. Take Zn2+ doping as an example [82], the adsorption edge wavenumber of the pure TiO2 aerogel treated at 800℃ for 2 h (Zn-0–800℃) was 378 nm. After doping with 3% mole fraction of Zn2+ (Zn-3–800℃), its adsorption edge wavenumber was increased to 415 nm, indicating that the doping of Zn2+ lead to the occurrence of red shift (Figure 7(c)). This is mainly due to the substitution of Zn2+ for Ti4+ which introduces impurities and defect levels into the bandgap of TiO2, and the resulting sub-forbidden band reduces the bandgap energy and improves the photocatalytic efficiency (Figure 7(d)). In the 2 h non-light adsorption reaction, the adsorption efficiency of the Zn-3–800℃ (0.1 g) on rhodamine B solution (10 mg/L, 50 mL) was 84.28%, and the adsorption efficiency of the Zn-0–800℃ and Degussa-P25 were 83.98 and 2.66% under the same conditions, respectively, which was mainly due to the specific surface area of Degussa-P25 (about 50 m2/g) was much lower than that of the Zn-3–800℃ (614.7 m2/g) and the Zn-0–800℃ (522.0 m2/g). Subsequently, under the irradiation of 300 W tritium lamp, the photocatalytic efficiency of the Zn-3–800℃ reached 98.77% (2 h), which was higher than 95.41% of the Zn-0–800℃ and 91.87% of the Degussa-P25.

In addition to the above modification mechanism, rare earth metal elements have unique incompletely filled 4f orbitals and empty 5d orbitals, and the 4f electrons of their ions can undergo energy level transitions between the f–f configuration or between the f–d configuration, causing the distortion of the TiO2 lattice, thereby making the lattice O atoms easy to fall off to form O vacancies, which improves the adsorption capacity of TiO2 aerogels to the reactants and increases the number of OH−s on the surface to form more ˙OHs [88]. Therefore, the photocatalytic properties of TiO2 aerogels are also improved. For instance, in the 6 h adsorption study, the adsorption capacities of salicylic acid (2 × 10−4 M, 3 mL) on the 0, 0.72, 14.8, 2.71, and 5.30 wt% Eu2O3 doped TiO2 aerogels (7 ± 0.5 mg) were <1, 33.5, 35.3, 33.2, and 31.8 μmol/L, respectively. After 60 min irradiation of 1,000 W Xe-Hg lamp, their photocatalytic degradation efficiency for the salicylic acid reached 4.4 ± 2, 84.8 ± 4, 78.1 ± 4, 79.6 ± 4, and 100%, respectively. In the research, the strong adsorption effect of Eu2O3 doping on TiO2 aerogels has become a key factor in determining the photocatalytic properties [89].

The rapid development of the localized surface plasmon resonance (LSPR) provides a new and effective method for improving the catalytic properties of photocatalysts [90,91,92]. Generally speaking, there are two mechanisms for the influence of plasma metals on the photocatalytic properties of TiO2 aerogels: (1) hot electron transfer mechanism and (2) near-field electromagnetic mechanism. In the mechanism (1), plasma-induced electrons in metal nanoparticles are transferred to the conduction band of TiO2. Thus, reduction and oxidation reactions occur on the surface of TiO2 and plasma metal nanoparticles, respectively [93]. In the mechanism (2), plasma metal nanoparticles act as a light concentrator to amplify the intensity of light irradiation, and ultimately promote the generation of electron–hole pairs near the metal nanoparticles, which usually requires an overlap between the light radiation source, the LSPR of metal nanoparticles and the absorption spectrum of TiO2 [94]. In addition, metal nanoparticles can also have a certain effect on the crystalline structure of TiO2, which is similar to the doping effect of metal ions.

The modification effect of metal nanoparticles largely depends on their type, size, concentration, and doping methods (surface modification or uniform doping) [57]. Meanwhile, the structural characteristics of TiO2 aerogels, such as large specific surface area, high porosity, the 3-dimensional connected nanoporous structure, etc., also provide the structural basis for the loading of metal nanoparticles, which can prevent the aggregation of entrained metal nanoparticles and make them more stable in different environments.

Under the irradiation of 6 × 6 W radiation sources, 5 nm (0.12, 0.19, and 0.22 wt%) and 16 nm (0.14, 0.24, and 0.34 wt.%) Au nanoparticles surface-modified TiO2 aerogels produced reaction rates (7,000 s) of 9.1, 12.6, 46.4 μmol/(L s) and 6.5, 6.5, 23.2 μmol/(L s) for salicylic acid (0.5 mmol/L), respectively, indicating that Au nanoparticles with smaller particle size and higher concentration produced stronger LSPR. Thus, the bandgap of TiO2 was reduced, and the contact area with TiO2 aerogels was increased, resulting in the increase in crystalline region and the formation of more extensive crystallization, as shown in Figure 7(e) [57]. The doping of Ag nanoparticles can produce impurity levels less than 3.3 eV in TiO2 aerogels to reduce their Fermi energy level. As the Ag/Ti molar ratio increased from 1:50 to 1:10, the bandgap energy of the resulting Ag uniformly doped TiO2 aerogel also decreased from 3.26 to 3.15 eV, their photocatalytic antibacterial rates against E. coli and S. aureus have also been improved, and even the TiO2 aerogel with the lowest concentration of Ag nanoparticles also produced more than 90% antibacterial rates against the two bacteria [95]. When Au and Ag nanoparticles were used for the modification of TiO2 aerogels simultaneously, their photocatalytic effect on salicylic acid was stronger than that achieved when they were modified separately, which was mainly due to the combination of the different plasma characteristics of Au and Ag nanoparticles to further enhance the photocatalytic properties of TiO2 aerogels, as demonstrated by Sadrieyeh and Malekfar [23].

In addition to the research on water treatment, TiO2 aerogels modified by metal nanoparticles have also been studied in the catalytic oxidation of industrial CO, which not only depends on the active photochemical properties of TiO2 aerogels, but also on the high activation energy of precious metal nanoparticles. The conversion rate of the 2.95 ± 0.83 nm Pt nanoparticles (3.8% mole fraction) surface-modified TiO2 aerogel (0.1 g) to CO in the test gas (4% CO, 10% O2, and balanced with He) with an hourly space velocity of 6,000 h−1 in a quartz reactor reached 100% (125℃), which was much higher than 30% of the untreated TiO2 aerogel [56]. Pt nanoparticles not only played an important role in promoting the formation of crystalline phases, and the miscible composition of 90.2% anatase TiO2 and 9.8% rutile TiO2 was formed by heat treatment of the TiO2 aerogel only at 500℃, but also showed a high activation energy of 13.4 kcal/mol in the catalytic oxidation of CO (Figure 7(f) and (g)). Pennington et al. [96] systematically studied the effect of the particle size, loading capacity, and interface intimacy of Au nanoparticles with TiO2 aerogels on the activity of CO catalytic oxidation under dark and broadband irradiations, and came to the following conclusions: (1) compared with the surface modification, TiO2 aerogels uniformly doped by Au nanoparticles limited the dispersion and agglomeration of Au nanoparticles to form a more intimate interface contact; (2) the excessive amount of Au nanoparticles increased the average particle size due to the occurrence of agglomeration, and also weakened the Au||TiO2 intimacy; (3) in a dark environment, the conversion rate of the TiO2 aerogel uniformly doped by Au nanoparticles to CO was higher than that of the surface-modified TiO2 aerogel, and the smaller Au nanoparticles produced higher Au||TiO2 intimacy to form a higher CO conversion rate; (4) under broadband irradiation, the catalytic activity of Au-TiO2 aerogels with high Au||TiO2 intimacy was weakened, which was mainly due to the harmful light-induced electronic metal-support interaction exceeding the beneficial LSPR effect (Figure 7(h)), and the increase in the size of Au nanoparticles and the weakening of the Au||TiO2 intimacy could alleviate this harmful effect. In the dark, the TiO2 aerogel uniformly doped by Au nanoparticles (10 mg) produced the highest CO conversion rate for the test gas (1% CO, 20% O2, and 79% He) with a flow rate of 80 mL/min in a glass tube (3/8” OD, 0.22” ID), which was 94.4 ± 0.7% (150℃).

The doping modification of TiO2 aerogels by Cu nanoparticles is a relatively special study. The low-valent Cu0/1+ has an activation energy equivalent to the abovementioned noble metals such as Au, Pt, etc., and it also has the advantages of wide sources and low cost. However, nano-scale Cu is easily oxidized to Cu2+ and is difficult to stabilize at Cu0/1+, and this problem can be solved by the structural characteristics and active photochemical properties of TiO2 aerogels. The transfer of electrons generated by TiO2 aerogels to CuO with high work function is energetically favorable, and the formation of defects such as oxygen vacancies can form Ti3+ in TiO2, which also helps to provide electrons to the loaded Cu nanoparticles. This charge transfer is highly concentrated at Cu||TiO2 interfaces, effectively suppressing the formation of CuO [97]. In addition, the TiCuO x mixed phases formed on the interface area between Cu2O <111> film and TiO2 can stabilize the highly reactive Cu1+ sites and limit the oxidation of Cu2O. Conversely, the presence of Cu nanoparticles can improve the photocatalytic properties of TiO2 aerogels through the LSPR, and the coexistence of the two achieves a synergistic effect of complementary advantages. The Cu nanoparticles (10 wt%) surface-modified TiO2 aerogel (12.5 mg) achieved above 95% CO conversion efficiency for the mixed gas (8 vol% CO) with a flow rate of 50 mL/min (150℃) in a glass tube (3/8”OD, 0.22”ID), and also achieved a high ratio of Cu0/1+/Cu2+ of 1.7 and a high activation energy of 63.7 ± 3.2 kJ/mol (Figure 7(i)) [98]. In addition, the summary of the photocatalytic effects achieved by metal dopants modified TiO2 aerogels is shown in Table 2.

Summary of degradation effects of metal dopants doped TiO2 aerogels on various environmental pollutants

| Catalysts | Usage amount | Condition | Target | Time | Removal efficiency (%) | Ref. |

|---|---|---|---|---|---|---|

| Zn2+-TA | 100 mg | 300 W xenon lamp | Rhodamine B (50 mL, 10 mg/L) | 4 h | 98.77 | [82] |

| Fe3+-TA | 16.6 g/L | 250 W Hg lamp | Salicylic acid (5 × 10−4 M) | 120 min | ≈85.1 | [83] |

| Fe3+-TA | 0.25 g/L | Sunlight | Reactive blue (200 mL, 40 mg/L) | 120 min | 95 | [87] |

| Eu2O3-TA | 7 ± 0.5 mg | 1,000 W Xe-Hg lamp | Salicylic acid (3 mL, 2 × 10−4 M) | 60 min | 100 | [89] |

| AuNPs@TA | / | 6 × 6 W lamps | Salicylic acid (0.5 mM) | 7,000 s | 30 | [57] |

| AgNPs-TA | 100 ppm | Sunlight | Diluted bacteria – E. coli (1 mL) | 24 h | 99.86 | [95] |

| AgNPs-TA | 100 ppm | Sunlight | Diluted bacteria – S. aureus (1 mL) | 24 h | 99.85 | [95] |

| Au/AgNPs@TA | 4 mg | 300 W xenon lamp | Salicylic acid (3 mL, 0.5 mM) | 120 min | ≈65 | [23] |

| Au/AgNPs-TA | 4 mg | 300 W xenon lamp | Salicylic acid (3 mL, 0.5 mM) | 120 min | ≈62 | [23] |

| PtNPs@TA | 100 mg | 125℃ | 6,000 h−1 mixed gas (4 vol% CO) | — | 100 | [56] |

| AuNPs-TA | 35 mg | 300 W xenon lamp | Rhodamine B (100 mL, 2.32 × 10−5 M) | 30 min | 100 | [14] |

| CuNPs@TA | 12.5 mg | 150℃ | 50 mL/min mixed gas (8 vol% CO) | — | >95 | [98] |

| Pdi2NPs-TA | 10 mg | 15 W Osram lamp | p-nitrophenol (40 mL, 0.088 mM) | 200 min | 98 | [60] |

| Au-modified TA | 10 mg | 150 W white light, 150℃ | 0.8 mL/min CO | — | 94.4 ± 0.7 | [96] |

Note: – represents the uniformly doped and @ represents the surface decorated.

4.5 Non-metallic substance doped/composite TiO2 aerogels

The atomic radius of non-metallic elements used for the doping modification of TiO2 aerogels usually needs to be close to that of O atoms [99]. Also, in order to produce a better modification effect, the doped non-metallic elements also need to meet the following conditions: (1) a new energy level that fully overlaps the energy level of TiO2 is generated in the bandgap of TiO2 [100], (2) generation of charged defects such as O vacancies for the efficient separation of electron–hole pairs [30], and (3) reduce the conduction band energy level to achieve the improvement of photocatalytic properties [101]. Nowadays, C and N atoms have attracted much attention due to their similar atomic size as O atoms, smaller ionization energy, and higher stability, so they can be easily incorporated into the TiO2 crystal lattice. Under the irradiation of 500 W UV light, the TiO2–C hybrid aerogel (50 mg) synthesized by sol–gel and high-temperature calcination achieved a 99.6% degradation efficiency (180 min) for methylene blue solution (20 ppm, 50 mL), and produced a rate constant of 0.06 min−1 which was 4.23 times that of the Degussa-P25 in the control group. In addition to the modification effects mentioned above, the high reactivity is also related to the formation of oxygen vacancies in the TiO2 aerogel doped by C atoms, resulting in macropore scattering and high light absorption [30].

The doping modification of N atoms mainly depends on the substitution ratios of internal O atoms and surface O atoms in the TiO2 lattice. Under the irradiation of 250 W high pressure mercury lamp, the N atoms doped TiO2 aerogels (1.66 g) synthesized with urea and ammonia as nitrogen sources produced photon efficiencies ξ of 1.26 × 10−4 and 1.32 × 10−4 for salicylic acid solutions (5 × 10−4 mol/L, 100 mL), respectively – equation (13). Meanwhile, the modification of urea and ammonia produced 15.9 and 6.6% of internal O atom substitutions and 0 and 6.3% of surface O atom substitutions, respectively, which reduced the bandgap of the TiO2 aerogels from 3.04 and 2.97 eV to 2.80 and 2.86 eV, respectively [101].

In addition to the doping modification, the compounding of non-metallic substances is a more commonly used modification method, and the composite form adopted is similar to the first type of TiO2/SiO2 composite aerogels introduced earlier, which is achieved by immersing or depositing TiO2 nanomaterials including TiO2 aerogels in other non-metallic nanomaterials to take advantage of their structural properties and intrinsic properties to maximize the photocatalytic properties.

At present, a variety of C nanomaterials have been widely used in the preparation of TiO2–C composite aerogels. Under simulated sunlight of 100 mW/m2, the TiO2 aerogel/C foam composite (1 g/L) prepared by vacuum infiltration produced a 100% degradation rate (40 min) for rhodamine B solution (1 × 10−5 mol/L). The existence of C foam not only becomes the skeleton support to overcome the weak mechanical properties of TiO2 aerogels and make them suitable for long-term application (Figure 8(a)) but also becomes the electron storage pool for the separation of electron–hole pairs, and also expands the light response range and improves the light utilization efficiency of TiO2 aerogels [102,103]. The active functional groups and defects on the surface of C aerogels synthesized from biomass raw material, wintermelon, are very beneficial to the fixation and growth of TiO2 nanoparticles (Figure 8(b)). Under the irradiation of 500 W tungsten lamp, the as-prepared biomass-derived multifunctional TiO2/C aerogel composite (10 mg) achieved the highest degradation rate of 82% (210 min) for methylene blue solution (40 mg/L, 40 mL), which was higher than 40% of the pure TiO2 aerogel and 20% of the Degussa-P25 under the same conditions [65].

![Figure 8

(a) SEM images and photocatalytic degradation curve of rhodamine B solution of the C foam, the TiO2 aerogel, and the TiO2 aerogel/C foam composite; (b) active functional groups in the framework of C aerogels synthesized from wintermelon, which are beneficial to the fixation and growth of TiO2 nanoparticles, and the demonstration of the ultra-low density of the composite aerogel; (c) schematic diagram of the photocatalysis-enhanced electrosorption reactor (1-electrochemical workstation, 2-TiO2/C aerogel, 3-saturated calomel electrode, 4-counter electrode, 5-quartz tubular, 6-UV lamp, 7-magnetic stirring, and 8-circulating water), and the mechanism of the photocatalysis-enhanced electrosorption process on the TiO2/C aerogel; (d) schematic illustration of the selective adsorption and photodegradation mechanism of TiO2–RGO aerogels; (e) adsorption and photocatalytic degradation curves of the P25, the TiO2–RGO powder and the TiO2–RGO aerogel on rhodamine B solution, and relationship between the catalytic efficiency of the TiO2–RGO aerogel and the number of times of use; and (f) schematic illustration of the immobilization of TiO2 nanoparticles in the regenerated cellulose matrix. (a) Modified with permission from ref. [102]. Copyright 2019, Elsevier. (b) Modified with permission from ref. [65]. Copyright 2016, Royal Society of Chemistry. (d) and (e) Reproduced with permission from ref. [105]. Copyright 2020, Elsevier.](/document/doi/10.1515/ntrev-2022-0490/asset/graphic/j_ntrev-2022-0490_fig_008.jpg)

(a) SEM images and photocatalytic degradation curve of rhodamine B solution of the C foam, the TiO2 aerogel, and the TiO2 aerogel/C foam composite; (b) active functional groups in the framework of C aerogels synthesized from wintermelon, which are beneficial to the fixation and growth of TiO2 nanoparticles, and the demonstration of the ultra-low density of the composite aerogel; (c) schematic diagram of the photocatalysis-enhanced electrosorption reactor (1-electrochemical workstation, 2-TiO2/C aerogel, 3-saturated calomel electrode, 4-counter electrode, 5-quartz tubular, 6-UV lamp, 7-magnetic stirring, and 8-circulating water), and the mechanism of the photocatalysis-enhanced electrosorption process on the TiO2/C aerogel; (d) schematic illustration of the selective adsorption and photodegradation mechanism of TiO2–RGO aerogels; (e) adsorption and photocatalytic degradation curves of the P25, the TiO2–RGO powder and the TiO2–RGO aerogel on rhodamine B solution, and relationship between the catalytic efficiency of the TiO2–RGO aerogel and the number of times of use; and (f) schematic illustration of the immobilization of TiO2 nanoparticles in the regenerated cellulose matrix. (a) Modified with permission from ref. [102]. Copyright 2019, Elsevier. (b) Modified with permission from ref. [65]. Copyright 2016, Royal Society of Chemistry. (d) and (e) Reproduced with permission from ref. [105]. Copyright 2020, Elsevier.

Generally, in high-concentration dye sewage, photocatalysts are prone to deactivation due to the adsorption of dye molecules, which makes the surface unable to accept light excitation, while the photocatalysis-enhanced electrosorption process that can be achieved by TiO2/C composite aerogels can solve this problem well [32]. Under the action of electrochemical polarization, the dye molecules can be enriched on the C electrode, and TiO2 aerogels on the C electrode can degrade the dye molecules, thereby releasing the adsorption sites to carry out the process continuously. Meanwhile, the adsorption makes the dye molecules on the surface of TiO2 aerogels always in a suitable concentration, which ensures the high efficiency of the photocatalytic reaction. Also, generating a positive voltage on TiO2 aerogels can effectively separate photogenerated electrons into an external circuit, improving the separation efficiency of electron–hole pairs. Under 0.6 V external voltage and 80 W UV light irradiation, the TiO2/C composite aerogel electrode (effective working area 3.6 cm2) produced a maximum degradation efficiency of 97.3% (240 min) for 3,4-dihydroxy-9,10-dioxo-2-anthracenesulfonic acid sodium salt solution (400 mg/L, 80 mL), which was 3.1 times that of the electrochemical adsorption process, and successfully realized the efficient treatment of high-concentration dye sewage (Figure 8(c)).

In addition, the composite of graphene and TiO2 aerogels has also become one of the research hotspots in recent years. Graphene has a specific surface area (up to 4,000 m2/g) far exceeding that of TiO2 aerogels and a huge potential adsorption capacity for pollutants, and the formation of the TiO2–graphene aerogel composites’ structure can better utilize this property, especially for the pollutants with aromatic structures, such as methylene blue, rhodamine B, etc., which can form a π–π stacking effect with the aromatic regions of graphene sheets, so that they can be adsorbed on graphene sheets very efficiently and selectively [104]. Also, graphene is an excellent electron acceptor due to its π-conjugation structure, which can effectively inhibit the recombination of electron–hole pairs. The 2-dimensional planar structure of the graphene also has ultra-high electrical conductivity, so that photogenerated electrons can be easily transferred to the reaction sites (Figure 8(d)) [105]. Therefore, the graphene, especially the graphene aerogel, has become an ideal material to form composite aerogels with TiO2. In a dark environment, the one-pot self-assembled TiO2–graphene aerogel composite (5 mg) achieved the highest adsorption rate of 95.1% (180 min) for rhodamine B solution (20 mg/L, 50 mL), and under the irradiation of 300 W pulsed tritium lamp, it achieved the highest photocatalytic degradation rate of 98.7% (180 min) [33]. In a dark environment, the hydrothermally synthesized TiO2–RGO hybrid aerogel (40 mg) yielded a 65.3% adsorption efficiency for high-concentration rhodamine B solution (1 g/L, 100 mL). Under the subsequent 180 min irradiation of 150 W tritium lamp, it achieved the highest degradation rate of 84.6%. Meanwhile, the composite aerogel also exhibited excellent recyclability, still yielding a high efficient photocatalytic degradation rate of up to 79.7% at the fifth use (Figure 8(e)) [105].

In addition, cellulose aerogels not only possess the excellent properties of high tensile strength, high crystallinity, and good biocompatibility of cellulose fibers, but also form a 3-dimensional and uniformly sized nanoporous structure, so they have been studied as a catalyst carrier for TiO2 nanomaterials (Figure 8(f)) [106]. Under the irradiation of 254 nm UV lamp, the degradation rate of methyl orange dye (10 mg/L, 150 mL) by the spherical TiO2 aerogel composite (50 mg) synthesized by cellulose alcohol-gel method was as high as 92.9% (90 min) [107]. Under the irradiation of ultraviolet light, the TiO2-cellulose composite aerogel regenerated by dissolving cellulose with ionic liquid produced about 85% degradation rate for rhodamine B solution [108].

Organic photosensitization is another important means to improve the photocatalytic properties of TiO2 aerogels [109]. Most organic sensitizers have a large π-ring conjugated delocalized system, a wide visible light response range, and super electron donating ability, which can be effectively controlled by modifying their molecular structure. In addition, due to the special nanoporous structure of TiO2 aerogels, the different modes of action of the organic sensitizers will also lead to different improvements achieved. Under the irradiation of 350 W tritium lamp and the acidic atmosphere created by 40 μmol/L formic acid, the red cabbage anthocyanins as structure-directing agents embedded TiO2 aerogel composite (50 mg) achieved a maximum degradation rate of 98% (30 min) for Cr6+ (15 ppm, 50 mL) that could not react with pure TiO2 aerogels, and the effect achieved was more than twice that of the TiO2 aerogel obtained by the surface adsorption of red cabbage anthocyanins [110].

In order to realize the multifunctional application of TiO2 aerogels, environmentally friendly sodium alginate has also been studied as their catalyst carrier. The multifunctional TiO2-alginic acid composite aerogel synthesized by ion-crosslinking and freeze-drying has abundant -OHs and nanoscale rough skeleton surface, which ensures the realization of underwater oil-water separation function. The composite aerogel exhibited the highest oil-water separation efficiency of 99.7%, and had good oil-fouling resistance (the oleophobic angles for kerosene and pump oil were as high as 140.2° and 145.7°, respectively), and its repeated use rate in water was at least 60 times (99.2%). Under the irradiation of 300 W tritium lamp, it (35 mg) produced a maximum degradation rate of 97.6% (150 min) for methylene blue solution (10 ppm, 100 mL), and still reached 87.0% (150 min) in the sixth use, thus also showing good reusability in terms of photocatalytic properties [31]. In addition, the photocatalytic effects achieved by TiO2 aerogels doped or composited with non-metallic substances are shown in Table 3.

Summary of degradation effects of TiO2 aerogels doped or compounded by non-metallic substances on various environmental pollutants

| Catalysts | Usage amount | Condition | Target | Time (min) | Removal efficiency (%) | Ref. |

|---|---|---|---|---|---|---|

| TiO2-C hybrid aerogel | 50 mg | 500 W UV light | Methylene blue (20 ppm, 50 mL) | 180 | 99.6 | [30] |

| TA/C foam composite | 1.0 g/L | 100 mW/m2 sunlight | Rhodamine B (1 × 10−5 mol/L) | 40 | 100 | [102] |

| TiO2/C aerogel composite | 10 mg | 500 W tungsten lamp | Methylene blue (40 mL, 40 mg/L) | 210 | 82 | [65] |

| TiO2/C composite aerogel electrode | Working area 3.6 cm2 | 0.6 V external voltage and 80 W UV light | AR (80 mL, 400 mg/L) | 240 | 97.3 | [32] |

| TiO2-graphene aerogel composite | 5 mg | 300 W tritium lamp | Rhodamine B (50 mL, 20 mg/L) | 180 | 98.7 | [33] |

| TiO2–RGO hybrid aerogel | 40 mg | 150 W tritium lamp | Rhodamine B (100 mL, 1,000 mg/L) | 180 | 84.6 | [105] |

| Spherical TiO2 aerogel | 50 mg | 254 nm UV lamp | Methyl orange (150 mL, 10 mg/L) | 90 | 92.9 | [107] |