Abstract

Wood and bamboo are the greenest renewable materials used for construction, furniture, and decor from the ancient ages. However, wood and bamboo have intrinsic faults like durability, ductility, physical and mechanical strength, and stability, limiting their applications in the industry. On the other hand, nanotechnology is a popular technology having numerous applications in different fields, resulting in a significant increase in expectations among academics, investors, the government, and industries. In contrast, nanotechnology can protect wood and bamboo from extreme conditions (bacteria, climate, etc.) by improving physicochemical characteristics because of its unique features. Nowadays, the trend of merging nanotechnology and forest industries to overcome the limitations mentioned above and get economically sustainable materials for construction, furniture manufacturing, flexible sensors developments, energy storage, battery manufacturing, and many more is increasing. Presently, several reviews on wood and bamboo modification by nanoparticles and nanomaterials have already been published. But, at this time, this study is essential because it aims to provide a brief guide about the recently developed eco-friendly sustainable materials from wood and bamboo, their uses, and how they can affect people’s daily life and helps to point out the gap of the current knowledge. In addition, we briefly describe the conventional and modern modification methods, including the influence of nanomaterials on wood and bamboo structures. This article is outlined as follows: The first phase of the review deals with wood and bamboo modification methods. The second phase explains how the modification method improves the properties of wood and bamboo materials, and the last step will describe the recent innovation of wood and bamboo materials.

1 Introduction

Wood and bamboo have porous and fibrous structures cells [1,2]. The cells are composites of cellulose, hemicellulose, lignin, and other extractives. Bamboo has higher fibre content [3,4]. According to different research results, nano-cellulose and nano-lignin particles can be extracted from wood and bamboo materials, as cellulose has been considered a matrix compound because it binds fibre and microfibre [2], and lignin is made up of aliphatic and aromatic structures (“glue-like”), which hold and secure the cell walls together and provide rigidity in wood and bamboo [5,6].

Wood and bamboo are the most promising sustainable and renewable materials from the ages as they are biodegradable and renewable and do not cause any pollution to the environment. Recently, the demand for sustainable renewable products is increasing due to environmental pollution and climate change. According to Oliver et al., wood’s carbon footprint is lower than steel and concrete, and increasing the use of wood can reduce CO2 emissions by 14% [7]. Coherently, wood and bamboo base products have been used in building construction and furniture making for a long time. With time, wood and bamboo became unpopular because of their inherent disadvantages of faster decay, high moisture-holding capacity, changing colour quickly, swelling, and shrinking due to sunlight, rain, temperature, and microbial erosion in the external environment [8]. These swelling and shrinking cycles induce stresses in the wood’s cell walls, leading to the wood’s warping and cracking. It also damages the microstructure of the wood and bamboo surface and structure, affecting dimension stability and service life by limiting the application of wood and bamboo materials and their base composites [9,10,11,12]. Therefore, it is necessary to improve the functional quality of wood and bamboo by changing the microstructure of the wood and bamboo surfaces to develop better physical and mechanical properties [13]. In addition, the ancient traditional practice of using wood and bamboo is becoming vogue but in newer ways. Jones and Sandberg demonstrated that the global demand for wood modification is significantly increasing. They claim that the growth of modification of wood will be higher in the next few years due to its eco-friendly approach [14]. Many research studies and reviews claim to modify the properties of wood and bamboo materials through conventional methods but these methods can affect the structure and colour of the materials [15].

But, nowadays, these problems can be solved by using nanomaterials for improving the functional quality of wood and bamboo materials. Nanomaterials can enhance the quality of wood and bamboo, which has widened the usage horizon of such products not only in the construction and furniture industry but also in energy sectors, electronic devices, and many more [16,17,18,19,20,21]. Using nanotechnology in wood and bamboo preservation and application is one of the new topics with enormous promise for the industry [22]. There are many more processes that are discussed in the article later. Yet, it is still important to evaluate any possible risks associated with the use of nanomaterials in wood and bamboo preservation and application in different fields. For example, Sun et al. [23] explained “the mesoscopic characteristics and nanomechanical properties of bamboo” and the benefits of modified bamboo materials and their uses, and Bi et al. [24] analysed and well described different modification methods and the effects of the modification methods on the wood properties in their review article. Rao et al. [25] reviewed the recent advancements in bamboo protection in the outdoor field through the study of photodegradation and photostability. This review article attempts to give an overview of current innovations and product development by nanomaterials from wood and bamboo materials (cellulose and lignin) in different sectors.

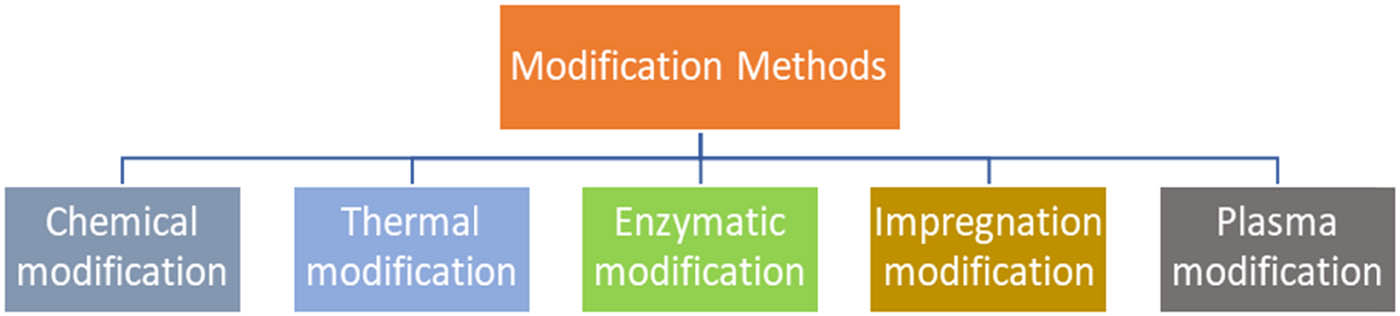

2 Classification of modification methods

Applying chemical, mechanical, physical, or biological techniques to change the qualities of a material is referred to as “wood modification,” which is a broad word. The definition of “wood modification” in this sense encompasses practically everything that occurs to wood after it departs the forest. Different ways of modifying and treating wood/bamboo for more sustainable use exist. The wood modification includes applying a chemical, biological, or physical agent to the material, enhancing the desired quality during the wood’s service life. The modified wood should not emit harmful compounds while in use or at the end of its useful life after being disposed of or recycled. It should also be harmless by itself under service circumstances. The action method should be non-biocidal if the alteration increases resistance to physical assault. It should be emphasized that the above-mentioned does not exclude the use of potentially dangerous chemicals in the production of wood that has been changed, provided that there are no hazardous residues left over after the modification process is completed [26]. It is significant to note that the number of wood modification processes that have been created or are currently being tested have their entire or partial roots in the ground-breaking studies and ground-breaking effort of “Alfred J. Stamm and his colleagues at the Forest Products Laboratory in Madison, Wisconsin, in the 1940s and 1950s” [17] (Figure 1).

Categorization of modification methods.

2.1 Chemical modification

According to Hill’s book, the reaction of a chemical reagent with the polymeric elements of wood, resulting in the development of a covalent link between the reagent and wood substrate, is known as the chemical modification of wood [26]. Wood can be altered by active modifications, which modify the material’s chemical composition, or passive alterations, which change the qualities of the material without changing its chemical composition. Most active modification techniques included a chemical interaction between the –OH group and the reagent in the cell wall of polymers. These –OH groups are the most reactive locations and play a significant role in the wood–water interaction. When wood is wet, water molecules settle between the wood polymers and create hydrogen bonds with hydroxyl groups of specific water molecules. The amount of these water molecules fluctuates, causing the wood to shrink and swell. All possible wood treatments have an impact on how wood and water interact. Multiple wood-treatment interaction mechanisms frequently take place at once. One method of altering cell-wall polymers is heat modification, which can result in cross-linking, a decrease in OH-groups, and the unintended breaking of the polymer chains [27]. According to Teacă and Tanasă, the catalysts, reactor types, and the matter composition of the reactant, and the process have undergone significant development and are still widely employed [28]. Homan et al. described the chemical modification and Plato processes in their review. They found that the shrinkage and swelling were reduced, and the durability and ultraviolet resistance increased. They noticed that mechanical properties are also affected by the modification treatments [29].

2.2 Thermal modification

Heat treatment is a well-known commercial technique for enhancing wood’s dimensional stability and durability. Applying heat to wood to reach the desired improvement in the material performance is referred to as the thermal modification of wood. This discovery was made in the 1920s by Tiemann. There are many great reviews on this subject [30]. The thermally treated timber (TMT) features that change in dry or wet circumstances vary significantly. These variances include variations in weight loss, sorption behaviour, and dimensional stability. A post-treatment water-soaking cycle partially reverses the reduced hygroscopicity of TMT treated under heat treatment-dry circumstances. Still, the dimensional stability of TMT modified under heat treatment-wet settings can be worse than unmodified timber (Figure 2).

![Figure 2

Various moisture conditions of wood after thermal modification [31].](/document/doi/10.1515/ntrev-2022-0528/asset/graphic/j_ntrev-2022-0528_fig_002.jpg)

Various moisture conditions of wood after thermal modification [31].

The method has been much improved since then but the basic idea has not changed: wood is subjected to high temperatures (150–250°C) without oxygen and goes through a chemical transformation. Outside this range, undesirable changes occur below 150°C, water loss typically occurs, and over 250°C, carbonisation begins. Hemicellulose starts to break down and undergoes dehydration as the temperature increases, which causes the hydrophilic OH groups to vanish [32]. Cellulose eventually breaks down, but initially, its amorphous portion. Due to the crystalline nature of cellulose, which makes it more heat-resistant, the sample will become more crystalline and the hydroxyl groups will become less accessible to water and other chemicals [33]. During the degradation of lignin, polycondensation occurs, which creates more cross-links. The removal of the OH groups and the resulting lower attraction for water raises the wood’s lignin content and structural stability. Overall, heat treatment enhances the durability of wood by reducing the amount and availability of hydroxyl groups. However, it also dramatically affects the mechanical characteristics of wood by degrading hemicellulose and amorphous cellulose. Thermal treatments are occasionally coupled with water or outside forces to get better outcomes in terms of characteristics. These techniques are either thermomechanical or thermo-hydromechanical [34,35,36].

2.3 Enzymatic modification

The use of biotechnology in the pulp and paper industry has been extensively studied; over the last few decades, some enzymatic techniques such as bio-pulping and bio-bleaching have already been used as industrial processes. However, the wood or wood-based business still shows little interest in biotechnological treatments [37]. In addition, Kudanga et al. reported a stepwise method to bind functional molecules to an enzymatically modified wood surface with anchor groups. Using the 62 kDa “Trametes hirsute laccase” as an anchor group, phenolic amines were linked to lignin moieties of wood. The coupling reaction to lignin was simulated using the lignin model compounds 4-O-methyl guaiacylglycerol-guaiacyl ether A, guaiacylglycerol-guaiacyl ether E, dehydrodivanillyl alcohol type dibenzodioxins D, and syringylglycerol-guaiacylether. Another use of laccases is the wood veneer treatment process [38]. During a coupling event driven by laccase, a hydrophobic surface was produced. In this study, several hydrophobic molecules were grafted onto the surface of wood, and stable covalent connections between the functional groups on the surface and the compounds were formed, creating a persistent hydrophobic layer on the wood surface.

2.4 Plasma modification

Depending on the thermodynamics involved, plasma, a partly or completely ionised gas, might be considered the fourth state of matter. The presence of neutral and electrically charged particles, including atoms, radicals, free electrons, ions, and photons, especially UV photons, distinguishes it [39].

The Present study demostrates the treatment of wood samples using cold, remote plasma method. Cold plasma therapy is a solvent-free, ecologically friendly alternative to chemical surface treatment procedures that uses relatively little energy and resources. It can also be used to treat materials that are susceptible to heat. Due to these benefits, cold plasma surface modification is becoming more and more common across various sectors, and surface property customisation is a hot research topic. The following two applications were investigated: The first method uses an (N2 + O2) mixture as a plasma gas to treat various wood types (fir, pine, oak, and beech) to prevent them from rotting. It also improves their impregnability as measured by dynamic water contact angles and absorption. The effects of three experimental parameters were evaluated and optimised: O2/N2 ratio, transmitted microwave power, and treatment duration. The second application involves the cold remote (N2 + O2) plasma (CRNOP) polymerising 1,1,3,3 tetramethyldisiloxane to deposit a super-hydrophobic layer over hardwood samples to improve their durability. Under optimal conditions, depositions were carried out on beech wood pre-treated with CRNOP to promote coating penetration inside the wood [40].

There are several uses for atmospheric plasmas. Plasmas are often used in medical procedures involving dangerous or undesired waste or gases. When discharged into the atmosphere, volatile organic compounds (VOCs) or inorganic gases like nitrogen oxides (NO x ) or sulphur dioxide contaminate the ecosystem. These harmful compounds may interact with the plasma’s reactive particles to create free radicals, which may merge into non-toxic molecules. In the industry, plasma can create several gases, including acetylene or the conversion of methane to higher hydrocarbons [41,42].

Consequently, X-ray microtomography was used to examine the coating distribution on the radial surfaces of untreated and plasma-treated spruce and beech wood samples. It was demonstrated that beech samples had a more comprehensive range of coating penetration than spruce samples. Before the coating was applied, the beech specimen’s plasma treatment had no discernible effect on how deeply the coating penetrated. However, the spruce surface undergoing plasma treatment showed a deeper coating penetration. Nevertheless, more thorough research with more samples will be needed for a universal description [20].

Earlier developed low-pressure plasmas are frequently employed in surface preparation and material processing. They differ from atmospheric plasmas in various ways, such as having a higher concentration of ions and radicals and a more uniform glow over a larger gas volume. Still, the need for a vacuum constrains their usage during operation. The entire process is time- and energy-consuming and expensive equipment is needed. As a result, according to some authors, atmospheric equipment is suited for mass production, whereas low-pressure plasma systems are only suitable for the preparation of value-added products [43]. The findings of an exploratory investigation by Blanchard et al. [44] employing various gases and mixes (N2, H2, O2, and Ar) at multiple pressures to apply plasma treatments to sugar maple wood board surfaces are described in that study’s findings (13.3–665 Pa). The wood’s water wettability and adherence to aqueous polyurethane coatings on wood were investigated. The findings reveal a substantial enhancement in coating/wood adhesion, ranging from 30% to 50%, under specific conditions. This improvement can be attributed to the increased wood surface energy resulting from the treatment. Although the methods employed (treatment duration, vacuum process) were not immediately transferrable to the industry, they might be easily modified for an affordable rate [45].

2.5 Impregnation modification

Impregnation is one of the earliest techniques for preserving wood composition, dimensions, or colour [46]. The basic idea behind the methodology is to inject various organic, inorganic, or a combination of such substances into the lumen and cell walls [47]. Intermolecular interactions may emerge between the impregnant and the cell-wall components, such as dipole–dipole or hydrogen bonds. Throughout the process, they produce a dimensionally stable wood with improved resistance to diverse types of degradation. Resins, polymers, oils, and inorganic salts – which may penetrate deeply into the wood structure – are frequently used as impregnation agents. Pressure or vacuum are often utilised to produce an effect close to ideal [48]. There are two different forms of impregnation, each with a different mechanism: either a monomer is injected into the cell wall and is then fixed by the subsequent polymerisation stage or a soluble chemical scatters into the cell walls and is then rendered insoluble [49].

The purpose of impregnation is to permanently swell the cell wall, making the hydroxyl groups physically or chemically inaccessible to water or other substances. Resins (such as phenol, urea, or melamine-formaldehyde resin), polymers, silicon-containing chemicals, or inorganic salts are the most common impregnates. However, it is only used to form a shielding coating on the surface of the wood. The coating agent may be powder, solvent-, or water-based. Traditional painting techniques can apply a volatile substance or a pigment to the surface after being dissolved or dispersed in the solvent. There is also powder coating, which creates a continuous layer of material after the surface has been coated with powder and treated with heat or radiation [50].

To prevent degradation, wood items are treated with wood preservatives. Depending on the end-product usage, pressure or non-pressure preservative treatments can integrate biocide into the wood. In contrast, ZnO/Zn was coated with cold plasma; spraying into a wooden block can improve the UV-blocking properties [23]. Alternative treatments for improving the dimensional qualities of wood and providing natural resistance include thermal and chemical changes. However, there is a contemporary movement in using nanotechnology to preserve wood. Nanotechnology can achieve this goal by impregnating wood with a suspension of metallic nanoparticles or encapsulating biocide in nanocarriers. Various nanomaterials can also be utilised in wood modification, particularly coating treatments, to improve serviceability. Nonetheless, further research is needed to provide standards for the safe deployment of nanomaterials (Table 1).

Summary of different wood/bamboo modification methods

| Methods | Wood structure affected by the modification process | Ref. |

|---|---|---|

| Chemical modification | Cell walls | [24] |

| Enzymatic modification | Surface | [38] |

| Thermal modification | Cell walls | [5,51] |

| Plasma modification | Surface | [19,40] |

| Impregnation modification | Modified substances are filled in lumens. Cell walls are impregnated | [52] |

3 Wood/bamboo modification by nanoparticles/nanomaterials

Nano means exceedingly tiny, a state at the microscopic level; it comes from the Greek word “Nanos,” which means “dwarf.” Combined with technology, it became nanotechnology, first introduced by The American Noble Prize-winning physicist Richard Feynman.

Nanotechnology is considered an interdisciplinary field in sharing knowledge tools and techniques of physics, chemistry, medicine, biology, engineering, and many sub-subjects of science that belong to the nanoscale level. Nanotechnology is not entirely new because chemists have synthesised polymers, large molecules structured by microscopic subunits, in earlier days. In computer chips, nanotechnology has been more than 20 years. On the other hand, Engler and Schweizer proposed some “top-down” and “bottom-up” techniques for synthesising, producing, adjusting, or even manipulating nanoparticles/nanomaterials. The “top-down” approach is based on the cutting and etching of constructing a device, and the” bottom-up” approach is based on the fundamental component of matter (atom) for creating an instrument [26,53]. Nowadays, these two methods combine and pick new hybrid modes of manufacture.

It is essential to describe why nanotechnology is necessary for wood science. Now an attractive science, nanotechnology produces new materials with enhanced properties. The materials that have a dimension of 100 nm are called nanomaterials. Nanomaterials have a high surface/volume ratio that shows more significant attraction in surface-related phenomena than bulky systems with an identical mass [54]. Nanomaterials’ change in the material properties is mainly due to the large interface area that enhances the properties of the original materials, shows excellent compatibility with the conventional materials. and causes a limited modification of their original features [55]. The main advantage of applying nanotechnology in wood science is the unique ability of the nanoparticles to penetrate deeply into wood and bamboo substrates, which mainly focuses on dimensional stability and resistance to attack by microorganisms. Wood and bamboo have well-established cell walls, which show the molecular scale’s porosity. In addition, small-size nanoparticles can easily penetrate and be uniformly distributed into the wood and bamboo. As a result, it alters the surface chemistry of wood and bamboo and improves their properties; therefore, a product’s hyper-performance can be manufactured [56,57].

In the recent trend, three methods have been used to improve the performance of wood and bamboo materials.

Nanosized metals impregnate directly in the substrate.

Polymeric nanocarriers control the release of nanoparticles.

Surface coating treatment by nanoparticles.

3.1 Impregnation of nanosized metals

There are two chemical methods to synthesise nanosized metals: solution-based and vapour-based. Sol–gel, solvothermal, and chemical are solution-based syntheses [57]. Chemical vapour deposition and combustion are vapour-based syntheses. Nanosized materials like metal nanoparticles (silver, gold, and copper) and metal oxides have unique characteristics of a high surface, particles’ equal size distribution, and stability against bacterial growth [58]. These nanomaterials are more active than non-metals because of their physical and chemical properties. The metal oxides used for wood and bamboo treatment are inorganic materials with a higher surface-to-volume ratio. They show a tunnelling effect (related to quantum mechanics) [59].

Nanosized metal nanoparticles have plasmon resonance properties because they show the bright colour of the surface [60]. When the microscopic light interacts with the metal nanoparticles, the conduction of the electrons around metal nanoparticles vibrates at a specific frequency and shows a bright colour [61]. So, the plasmon resonance characteristics are used widely to determine the metal nanoparticles for surface modification [62].

Copper (Cu) is a ductile metal with excellent thermal and electrical conductivity [63]. It is a low cost-effective reagent with good antibacterial and UV resistance properties [64]. According to Ju et al., Cu nanoparticles impregnated with bamboo give a high-voltage electric field and significant antibacterial resistance with ultraviolet resist properties. Wood treated with nano-copper oxide (CuO) in polystyrene improves the wood’s dimensional stability [65]. Akhtari and Nicholas reported that when wood was exposed to a termite attack, the nano-copper formulation could reduce the weight loss from 6.8 to 0.2% [66].

Zinc-based nano-compounds are applied to wood and bamboo to increase their durability. Zinc oxide (ZnO) has good chemical stability, is cost-efficient with antibacterial and fungal ability, and is less harmful to human cells [67]. Because of this reason, it is gaining more attraction in the surface treatment and coating field. US Food and Drug Administration classified ZnO as “generally recognised as safe” [68]. Li et al. also found that ZnO-treated bamboo materials performed better when interacting with Aspergillus niger and penicillium cites [69].

Studies of zinc and copper nano-compounds show that zinc is more active than copper in terms of termite mortality, the inhibition of termite feeding, and white root fungi decay, as shown in Figure 3. Bak and Németh [70] reported the effectiveness of nanoparticles like zinc borate, zinc oxide, copper borate, copper oxide, copper, and silver against the white root fungus. Among the five other nanoparticles, zinc borate was more effective. However, they concluded that the zinc oxide provided complete protection to the wood after leaching [71]. Figure 3 also shows the difference between different nanoparticles.

![Figure 3

The mass loss (%) following termite resistance for leached and unleached pine wood: (i) nano-ZnO; (ii) nano-ZnO plus binder A; (iii) nano-ZnO plus binder B; (iv) nano-zinc borate; (v) nano-zinc borate plus binder A; (vi) nano-CuO; (vii) nano-CuO plus binder A; and (viii) nano-CuO plus binder B [71].](/document/doi/10.1515/ntrev-2022-0528/asset/graphic/j_ntrev-2022-0528_fig_003.jpg)

The mass loss (%) following termite resistance for leached and unleached pine wood: (i) nano-ZnO; (ii) nano-ZnO plus binder A; (iii) nano-ZnO plus binder B; (iv) nano-zinc borate; (v) nano-zinc borate plus binder A; (vi) nano-CuO; (vii) nano-CuO plus binder A; and (viii) nano-CuO plus binder B [71].

Titanium dioxide (TiO2) nanomaterials are photocatalysts activated by UV. Due to the photoreaction range, TiO2 nanoparticles are used for wood and bamboo surface treatment, allowing a thin water film to be formed on the treated substrates that significantly reduce the photocatalytic activity. Its chemical stability and non-toxicity reduce water availability and prevent fungal and bacteria growth [72].

Silicon dioxide (SiO2) is a commonly used nanoparticle. SiO2 has a high surface/weight ratio, and its small size allows it to quickly penetrate the wood and bamboo surface and distribute evenly. It helps to increase the thickness of the cell wall, reduce the moisture absorption of the wood, and improve dimensional stability [73]. The impregnation of SiO2 depends on the deposition time which increases the quality of the composite material, and the thermal and mechanical properties are significantly improved. According to Han et al., impregnation of modified wood with itaconic acid (IA) increases the cell wall thickness significantly, reduces moisture absorption, and improves dramatically the dimensional stability of the wood [74]. Figure 4 shows the process of the reaction.

![Figure 4

The addition of functional groups of –OH with IA is impregnated by in situ polymerisation of nano-SiO2 in the wood cell wall [74].](/document/doi/10.1515/ntrev-2022-0528/asset/graphic/j_ntrev-2022-0528_fig_004.jpg)

The addition of functional groups of –OH with IA is impregnated by in situ polymerisation of nano-SiO2 in the wood cell wall [74].

In the modification process, IA is used to functionalise the –OH groups in the wood cell wall, followed by in situ polymerisation of nano-SiO2.

Ferric oxide (Fe2O3) is one of the primary oxides of iron. It has excellent thermal and chemical stability, non-toxicity, and superparamagnetic performance [75]. It provides superior dimensional strength and mildew resistance to wood and bamboo. Fe2O3 is widely used in the biomedical field of microwave absorption, drug delivery, MRI, and environmental protection [76,77]. In the experiment with bamboo bundles, they impregnate into nano-Fe3O4 at 0.4 mol/L [78].

Based on the above, copper, ZnO, TiO2, and SiO2 offer a broad range of protection features in the wood modification process. For the bamboo, a sample combination of Ag, Cu, and Fe3O4 is used to resist the microorganism and improve its physical properties.

3.2 Polymeric nanocarriers

Polymeric nanoparticles range from 1 to 1,000 nm that can absorb the polymeric core’s surface [79]. It is used for drug delivery. Inwood preservation industry is not popular as nanoparticle impregnation and coating treatment. In the future, technology might rise in the wood preservation industry. Polymeric nanoparticles are made up of poly(lactide) (PLA), epsilon-caprolactone (PCL), poly (lactide-co-glycolide) (PLGA) copolymers and poly (amino acids), and some natural polymers like alginate, gelatine, and albumin [80]. Polymeric nanoparticles facilitate rapid and spontaneous diffusion of polymer solutions into the liquid phase, actively avoiding water molecules. Impregnating wood with these nanoparticles enables the incorporation of organic biocides, followed by water-borne treatments for enhanced performance and protection [81]. In this way, polymeric wood substrates can control the release rate of biocide while acting as a storage reserve and protecting it from exposure to the environment. This process will help shield the material for a long time. Several techniques can be conducted by encapsulating the active ingredient into polymeric nanocarriers [70]. Figure 5 shows different types of nanocarriers for operational ingredient delivery.

![Figure 5

Polymeric nanocarriers. (a and b) The active ingredients in the polymeric nanoparticles are encapsulated in polymers. (c) Polymers and copolymers are arranged in a lipophilic bilayer vesicular system with a hydrophilic inner core [56].](/document/doi/10.1515/ntrev-2022-0528/asset/graphic/j_ntrev-2022-0528_fig_005.jpg)

Polymeric nanocarriers. (a and b) The active ingredients in the polymeric nanoparticles are encapsulated in polymers. (c) Polymers and copolymers are arranged in a lipophilic bilayer vesicular system with a hydrophilic inner core [56].

The polymer capsules were synthesised using amphiphilic gelatine copolymers grafted with methyl methacrylate. The diameters of the polymer capsules ranged from 200 to 400 nm or 10 to 100 nm, depending on the core/polymer shell mass ratio [82].

The polystyrene-soybean copolymer was effectively used by Can et al. to encapsulate nano-silver. They investigated the Scots pine’s resistance to the white-rot fungus by impregnating it with capsules (Trametes Versicolor). The study results show that polystyrene, soybean oil, and nano-silver contributed significantly to the synergistic impact that increased Scots pine’s resistance to decay [83].

3.3 Nano-coating treatment on surfaces

Nanotechnology offers a better surface coating than the traditional coating of wood and bamboo. Standard coating only improves the mechanical properties of materials, while decreasing the flexibility of the hand nano-coating can solve the problems with advanced protection [57]. Due to their high surface volume ratio, coating with nanomaterials can improve physical, mechanical, fire resistance, UV absorption, etc. Also, it maintains the transparency of the coating. Metal inorganic nanoparticles are widely used for nano-coating: (a) solution blend and (b) in situ chemical processes. The surface properties of wood and bamboo are almost similar. The first method is to dissolve the polymer in a suitable solvent before applying pressure to create dispersion. The nano-based coating is sprayed, brushed, or dipped onto a wood surface [84]. The second method entails mixing the nano-compound with monomers, distributing it, and polymerising the resulting mixture. In situ chemical processes such as sol–gel deposition and hydrothermal techniques are used to create nanomaterials on a wood surface [82]. So, the coating process with the nanooxides is also identical. Table 2 gives a summary of coating materials and their advantages.

Nano-coating materials and their advantages

| Coating materials | Advantage of coating | Ref. |

|---|---|---|

| ZnO and its different forms (nanoparticles, nanorods, nanosheets, nano-walls) | Super-hydrophobic, UV protecting, fire resistance, antimicrobial properties, durability, and mechanical properties | [92,93,94] |

| TiO2 (anatase and rutile form) nanoparticles | The photocatalytic effect, water absorption, fire resistance, durability, and antifungal capacity | [95,96,97] |

| TiO2 + ZnO | UV resistance, antifungal capacity, thermal stability, fire resistance capacity | [18,98,99] |

| Ag | Antifungal, durability, and mechanical properties | [100,101] |

| Ag/TiO2 | Antifungal activity, good photocatalytic performance, leaching resistivity, and durability | [102] |

| SiO2 | Water and fire resistance capacity and increased mechanical properties | [73,103,104] |

| GO with nanoparticles | Dimensional stability and mechanical properties | [88] |

|

|

Thermal stability, hydrophobicity, and magnetic microwave absorption | [105] |

| Fe2O3 and TiO2 | Antimicrobial resistance | |

| Nano-clay/ceramic nanoparticles | Improved mechanical properties | [106] |

| CuO/Cu | Water absorption properties, durability, flexibility, and mechanical properties | [98] |

| Al2O3 | Thermal and mechanical properties, decay resistance, and electrical conduction | [52] |

However, it has not been demonstrated to be an efficient agent for increasing water absorption and surface hardness in woods over the fibre saturation limit or in air-dried wood. Inorganic particles mixed into organic polymers are often utilised to improve the mechanical properties of wood treatments. Inorganic materials’ stiffness and hardness are coupled successfully with the polymer’s processability as fillers. When applied in micron size, inorganic particles have drawbacks such as reducing the material’s flexibility and decreasing the coating system’s transparency [85]. Nanocomposite coatings produce a rough hydrophobic surface without compromising the wood’s suppleness or abrasion resistance. Nanomaterial impregnation lowers the pore size and space accessible within the cell wall for water molecule absorption. When wood comes in touch with an ignition source, it is made up of cellulose, hemicelluloses, and lignin, which can cause it to degrade thermally. Wu et al. [86] reported using a water-borne UV (WUV) lacquer product modified with ZnO nanoparticles and stearic acid to create a super-hydrophobic coating with a contact angle of up to 158.4° on the surface of poplar wood. The water resistance of zinc stearate/water-borne UV lacquer super-hydrophobic coating was higher than that of WUV, making it easier and more ecologically friendly to create super-hydrophobic layers. Although numerous fire retardants increase the fire performance of wood, there has been limited efficiency, leaching, and significant environmental and health risk associated with many of these compounds.

Nanoparticles, alone or in combination with other fire-retardant chemicals, can lower the ignitability of wood while also limiting fire-retardant chemical leaching [87]. Graphene also has a high ability to prevent microorganisms from growing. Merging reduced graphene oxide and nano-ZnO to coat bamboo-based outdoor materials via a two-step dip-dry and hydrothermal method has improved mould resistance and antibacterial activity features [88]. To increase the antibacterial properties of wood, water-borne polyurethane (WPU) coatings containing nanocrystalline cellulose and silver nanoparticles were utilised, which is reported by Cheng et al. [89]. In their extraordinary work, a straightforward, one-step solvothermal technique was used by Yao et al. to create a strong, superamphiphobic ZnO nanorod array (ZNA)-treated wood effectively. The superamphiphobic properties were intact in the presence of corrosive substances, mechanical impact, varying temperatures, and water spray. The wood sample in its prepared state also demonstrated higher resilience to UV rays. This research may offer a workable method for creating ZnO/wood hybrid composites that perform well. While constructed, superamphiphobic solid wood treated with ZNA has excellent potential for anti-corrosion, self-cleaning, high-temperature, and humidity functions. The durability of the generated ZnO nanostructures and the dimensional stability of the wood, however, is likely to be the method’s constraints. Due to high temperatures and pressures, using autoclaves with expanded dimensions presents additional issues regarding cost, safety, and the environment [90] (Figure 6).

![Figure 6

SEM image of the surface of (a) wood untreated, (b) wood with ZNAs in low magnification, (c) wood with ZNAs in high magnification, and (d) wood with ZNAs peeled off by the TEM image, HRTEM, and SAED pattern [90].](/document/doi/10.1515/ntrev-2022-0528/asset/graphic/j_ntrev-2022-0528_fig_006.jpg)

SEM image of the surface of (a) wood untreated, (b) wood with ZNAs in low magnification, (c) wood with ZNAs in high magnification, and (d) wood with ZNAs peeled off by the TEM image, HRTEM, and SAED pattern [90].

4 Application of nanotechnology

Nanotechnology integrates technology and science with its multidisciplinary approach, intending to develop new and innovative materials with functional, chemical, and physical qualities [91]. Nowadays, it plays a significant role in the forest and agriculture industries. This part of the literature review will briefly describe the role of nanotechnology in the energy sector, flexible electronics, and green nanotechnology by wood and bamboo materials.

The world is on the verge of a global energy crisis as energy is a valuable resource closely linked to economic growth and development. Though the requirement of altering the source of energy and the usage of technology can secure a reliable quality and safe ecological life, “low carbon life” incorporates all the requirements that should be implemented on a man scale and not just by the individual scale and technical performance. Around 80% of the world’s carbon dioxide (CO2) emissions come from the energy sector. According to IEA “global Energy review: CO2 emissions in 2021,” in 2020, global CO2 emissions increased by almost 2.1 Gt levels. It places 2021 above 2010 as the largest ever “year-on-year” increase in energy related to CO2 emission. In 2021, coal accounted for more than 40% of the overall increase in global CO2 emissions [107]. So, to reduce CO2 emissions, scientists and engineers are working hard to give an effective solution. The literature described some extraordinary research work made in past years. For example, Sun et al. [108] demonstrated a next-generation self-power green building materials by enhancing the elastic compressibility of balsa wood through the sustainable fungal decay pre-treatment. Therefore, the piezoelectric output was increased and a single cube of wood can produce a maximum voltage of 0.87 V and a current of 13.3 nA under 45 kPa stress. Klochko et al. [109] developed the nanocellulose (NC) thin film at near room temperature. They are biodegradable and can be an alternative to petroleum-based polymer substrates for use in flexible electronics due to their renewability, biodegradability, biocompatibility, and extensive capacity for modification. With flexibility and variable shape, nano-cellulose exhibits a strong potential for solar energy. Lithium sulphur batteries are now using NC because of its biodegradability, renewability, flexible chemical tunability, and excellent mechanical and thermal properties. Yiju Li et al. [110] briefly described the structure, properties, and synthesis of NC-based materials, the advantages and disadvantages, and the application of NC into lithium sulphur batteries. Baloch and Labidi [111] reviewed the usage of lignin in different lithium-based conventional and next-generation batteries. According to them, this next-generation sustainable, ecological, and cost-effective material is the new pathway to a sustainable future as lignin has an electroactive redox property with abundant activity. Therefore, it has a high charge-holding capacity, making it a suitable candidate for energy storage. Espinoza-Acosta et al. [112] explained how lignin can be used in batteries, advanced supercapacitors, and solar and fuel cells and described the toxicity and cost effectiveness. Chen et al. [113] fabricated a scalable, high-elastic cellulosic material to improve the natural wood’s tuneable conductivity by the top-down freeze-drying and chemical treatment approach. The experiment was designed to achieve the direction-dependent structure because it provided mechanical robustness and tenable conductivity. It developed into a flexible wood suitable for sensors, nanofluidic systems, oriented tissue engineering, human–machine interface, water filtration, and many more. Figure 7 demonstrates the morphological structure and characterisation of the natural and elastic wood by SEM image and bounce of the end product.

![Figure 7

(a) The growth path of natural wood, (b) the magnification of image (a), (c) the longitudinal section of multiple lattice-like channels of natural wood, (d) the growth path of elastic wood, (e) the magnification of image (d), (f) longitudinal-section view of the channels with an interconnected fibril network of elastic wood, (g and h) large-sized image of natural wood and elastic wood, and (i and j) the image of an excellent bounce of elastic wood balls [113].](/document/doi/10.1515/ntrev-2022-0528/asset/graphic/j_ntrev-2022-0528_fig_007.jpg)

(a) The growth path of natural wood, (b) the magnification of image (a), (c) the longitudinal section of multiple lattice-like channels of natural wood, (d) the growth path of elastic wood, (e) the magnification of image (d), (f) longitudinal-section view of the channels with an interconnected fibril network of elastic wood, (g and h) large-sized image of natural wood and elastic wood, and (i and j) the image of an excellent bounce of elastic wood balls [113].

Similarly, Song et al. [114] developed flexible, breathable wood materials that claim that they can be used as “structure material, flexible electronic, biosensor and flexible 3D conductors.” Moreover, tissue engineering also plays a promising role in bioscaffold material. Figure 8 demonstrates the process of creating ‘supper flexible wood’ by changing the pH.

![Figure 8

Some simple tests showing the final product flexibility after the treatment [114]. (a) Unmodified natural wood tissue, (b) water treatment done on natural wood tissue, (c) wood tissues are modified by HCl treatment, and (d) after NaOH/Na2SO3 treatment, wood tissues become highly flexible.](/document/doi/10.1515/ntrev-2022-0528/asset/graphic/j_ntrev-2022-0528_fig_008.jpg)

Some simple tests showing the final product flexibility after the treatment [114]. (a) Unmodified natural wood tissue, (b) water treatment done on natural wood tissue, (c) wood tissues are modified by HCl treatment, and (d) after NaOH/Na2SO3 treatment, wood tissues become highly flexible.

Through surface machining and chemical treatment, Guan et al. showed a simple method for fabricating a wood-based flexible pressure sensor (FW/rGO) with high performance. The wood-based flexible pressure sensor had a fundamental level of sensitivity of 1.85 kPa−1 over a wide range (0–60 kPa), improved strength over 10,000 cycles, a quick response time (150 ms), and a low detection limit (60 Pa). This innovative and customisable concept for flexible pressure sensors derived from wood will likely bring many new possibilities for improving wearable e-skins, biomedical devices, and electronics [115] (Figure 9).

![Figure 9

A wearable pressure sensor made of natural wood [115].](/document/doi/10.1515/ntrev-2022-0528/asset/graphic/j_ntrev-2022-0528_fig_009.jpg)

A wearable pressure sensor made of natural wood [115].

Li et al. [116] created electrically conductive nano-bamboo charcoal /ultra-high molecular weight polyethene composites by the high-speed mechanical mixing and hot-pressing method. The method used in this study to create the electrically conductive nano-bamboo charcoal was simple, cost-effective, sustainable, and suitable for industrial production.

Gan et al. developed conductive wood, which has a load-bearing capacity and structure of electromagnetic interface of the shielding material. The electrically conductive wood is suitable for flexible electronics, electromagnetic shielding, and energy storage. As per the author’s report, the conductive wood has an EMI shielding effectiveness of 58 dB and a better tensile strain than the traditional carbonised wood, which is approximately 3 and 28.7 times higher. Conductive wood can be used as new generational material as it has advantages like uniform electrical capacity and exceptional compressive strength and is a lightweight, sustainable, renewable, low-cost scalable material [117].

Fu et al. [118] developed a light scattering, polymer matrix-free, and uniformly luminescent 2D flexible wood film with solid mechanical properties using a top-down approach. The authors use organic CdSe/Zn solution for the delignified template, which was modified and designed using a mild chemical treatment process. As a result of being nanostructured and coated with hexadecyltrimethoxysilane (HDTMS), the luminescent wood film became flexible, hydrophobic, and luminous, which scatter light uniformly. To take the experiment one step further, the author’s insert of various QDs is potential, allowing for producing a wide range of colours. They visualise expanding on this concept by creating a crystal transparent wood film with different quantum dots or inorganic nanoparticles. Figure 10 demonstrates the process and uses of the material.

![Figure 10

The schematic diagram for (a) using a top-down approach, luminescent and hydrophobic wood-based functional materials created by chemical vapour deposition with HDTMS. (b) Optical lighting material for interior illumination [118].](/document/doi/10.1515/ntrev-2022-0528/asset/graphic/j_ntrev-2022-0528_fig_010.jpg)

The schematic diagram for (a) using a top-down approach, luminescent and hydrophobic wood-based functional materials created by chemical vapour deposition with HDTMS. (b) Optical lighting material for interior illumination [118].

4.1 Green nanotechnology

Nanomaterials have attracted much attention due to advancements in the material world because of their better chemical, physical, and biological capabilities [119]. The size, surface morphology, form, and composition determine nanomaterial qualities. They have been synthesised and modified for defence, pharmaceuticals, communications, agriculture, and environmental clean-up [120]. However, the increased production of nanomaterials on an industrial scale raises serious concerns about human health and the environment. As a result, developing green pathways for synthesising nanomaterials from bio-based sources employing green nanotechnology with the most negligible waste output has become a significant problem for researchers [121]. Green nanotechnology creates nanomaterials using biological processes such as plants, bacteria, viruses, proteins, and lipids [122]. Green nanotechnology is far more advanced than other physical and chemical processes for synthesising nanoparticles. Green nanotechnology satisfies current demands without risking future generations’ potential. It also minimises waste output by altering garbage generating and disposal procedures. Green routes contain less expensive chemicals, use less energy, and create ecologically acceptable products and decomposition products. Researchers and scientists looking into less hazardous waste creation have used green chemistry concepts as a reference guide [123].

Zahara et al. reported identifying the formulations that performed the best and offered the highest resistance to weathering. The effects of olive leaf extract were combined with the addition of TiO2, ZnO, benzotriazole as UV absorbers and the hindered amine light stabilisers. The same outcomes for complete colour changes were also displayed. Overall, it can be said that polyacrylate with olive leaf extract is an efficient way to shield thermally treated wood from UV radiation and moisture. Further research is needed to produce the finest models [124].

In research, commercial lignin-coated cellulose nanocrystal (L-CNC) particles were used to varied sizes, and irregular surfaces were used to provide a strong base for a superhydrophobic coating. The L-CNC particles are environmentally friendly, biodegradable, and formed by spray-drying the CNC solution containing a small amount of lignin. Spraying an L-CNC/polyvinyl alcohol composite paint and altering it via chemical vapour deposition creates a superhydrophobic covering. As a result, the coating offers excellent abrasion resistance, good superhydrophobicity and self-cleaning qualities. Additionally, neither inorganic nor organic solvents were employed in the production. Consequently, this coating may be used in applications that call for harmless materials [125].

Nair et al. [126] successfully demonstrated for the first time a quasi-solid separating electrolyte for high-energy lithium sulphur batteries designed for ambient temperature use. Thermal polymerisation (curing) was used to create a green polymer electrolyte composed of a methacrylate-based polymer matrix and naturally abundant, natural nanoscale micro-fibrillated cellulose. The overall electrolyte preparation process is water-based and scalable.

4.2 Patents of the wood/bamboo industry

Combining wood science and nanotechnology is a promising research area where sustainable products are manufactured for the betterment of human life. The advancement of these is shown in Table 3.

Patents on wood and bamboo protection and uses

| Patent number | Year | Name of patents | Ref. |

|---|---|---|---|

| US20140363664A1 | 2016 | Use of modified nanoparticles in wood materials for reducing the emission of VOCs | [131] |

| EP2615126B1 | 2013 | ||

| US10843375B2 | |||

| US9056987B2 | 2015 | Super-hydrophobic coating | [132] |

| US8828485B2 | 2014 | Carbon-encased metal nanoparticles and sponges as wood/plant preservatives or strengthening fillers | [133] |

| CN103978532B | 2015 | Timber, bamboo wood modification processing method and improved wood, bamboo wood, and floor | [134] |

| CN108638263A | 2018 | It is to improve the anti-mildew processing method of bamboo wood | [135] |

| US11161271B2 | 2019 | Method for preparing room-temperature cured multifunctional wood modifier and method for wood modification | [136] |

| US6753035B2 | Compositions and methods for wood preservation | [137] | |

| US20190165402A1, US10818952B2 | 2020 | Lignin-based electrolytes and flow battery cells and systems | [138] |

| CN101880508B | 2013 | Preparation method of high abrasion water-borne wood coating | [139] |

| CN1010164314A | 2009 | Nano-antibacterial water woodenware paint and the preparation method thereof | [140] |

| CN102002315B | 2012 | Oily UV white light surface wood lacquer abstract | [141] |

| CN102250537A | 2011 | Water-borne wood paint | [142] |

| CN101974285A | 2011 | Long-acting antibacterial polyurethane water-based wood paint composition | [143] |

| CN105647362A | 2016 | High-durability high-efficiency nano-antimicrobial water-based wood paint and the preparation method thereof | [144] |

| US6675994B2 | 2017 | Superhydrophobic coatings and methods for their preparation | [145] |

| WO2014190515A1 | 2014 | Composition of wood coating | [146] |

| EP3004190B1 | 2020 | ||

| CA2635875C | 2014 | Translucent coating compositions providing improved UV degradation resistance | [147] |

| US7754801B2 | 2010 | ||

| CN102952337B | 2015 | Modified bamboo fibre-reinforced polypropylene composite material and the preparation method thereof | [148] |

| CN105675597B | 2018 | The preparation of a kind of three-dimensional colorimetric and optical electro-chemistry paper substrate equipment and its application in hydrogen peroxide detection | [149] |

| CN103535376B | 2015 | Preparation method of nanometre zinc oxide-bamboo charcoal composite particle with antibacterial and adsorption functions | [150] |

| JP6190356B2 | 2017 | Coating composition and coating film obtained from the composition | [151] |

| US20190185638A1 | 2019 | Oleophilic and hydrophobic NC materials | [152] |

| US10919985B2 | 2021 | NC compositions and processes to produce the same | [153] |

| US10906994B2 | 2021 | Processes and apparatus for producing NC and compositions and products produced therefrom | [154] |

| WO2015153536A1 | 2015 | NC production using lignosulphonic acid | [155] |

| WO2015200584A1 | 2015 | Processes for producing NC-lignin composite materials, and compositions obtained therefrom | [156] |

| EP3872172A1 | 2021 | Conductive cellulose composite materials and uses thereof | [157] |

| US11046858B2 | 2021 | Nano-cellulose compositions, coatings, and uses thereof | [158] |

5 Environmental impact and future prospective

Although many features of wood modification treatments are understood, it is still unclear how the procedure affects the product’s functionality, environment, and end-of-life circumstances. It is crucial to incorporate interactive analyses of process parameters, developed product attributes, and environmental implications to support the low-carbon economy and sustainable development. The life cycle assessments (LCAs) should be used to conduct unbiased environmental impact analyses of commercial modification processes and incorporate environmental impact analyses into wood modification processing and product development, containing recycling and advancement at the end of service life. In addition to the environmental cost of producing wood that has not been treated, there is an additional environmental cost connected with the modification of wood. When there is a long period of time between coats, the potential environmental advantage that may be attained through the usage of modified wood is undeniable. If stored carbon is not considered, the benefits of timber items’ longer lifespans become less noticeable [127]. The standards of ISO 14040 [101] and ISO 14044 [102] outline the same LCA approach. Numerous approaches have been developed since the 1980s, when LCA analysis was first introduced, to categorise, characterise, and normalise environmental consequences. The most prevalent are those that concentrate on the following environmental effect indicators: resource consumption, greenhouse gas emissions, eutrophication, ozone layer depletion, several forms of ecotoxicity, air pollutants, and acidification. In the wood industry, few LCA studies are geographically dispersed, employ a range of databases, and follow effect assessment methodologies. Jones and Hill presented the carbon footprint of 14 main wood products using a cradle-to-gate study. For all items made from sawn wood, removing the wood from the forest is the primary source of emissions; for products made from kiln-dried sawn wood, the drying process comes in second. They addressed the advantages of utilising wood as a building material in connection to the benefits of using wood goods in terms of the environment and compared the carbon footprints, including stored carbon of wood products with various “end-of-life” scenarios and degrading susceptibility. They concluded that there is a crucial need for research into the interactive assessment of the process, product properties, and environmental impact, including recycling and disposal options at the end of the service life, towards upcycling after their service life based on the cradle-to-cradle concept [128].

Werner and Richter studied the environmental effects of the life cycle of wood-based products used in the building industry to functionally similar goods made of other materials, focusing on Central and Northern Europe, North America, and Australia. The study concluded that, compared to competing products, wood products typically consume less fossil fuel, have less potential to contribute to the greenhouse impact and generate less solid waste. Additionally, depending on the preservative, impregnated wood goods are more problematic than comparable items regarding the toxicological effects and photo-generated smog [129].

Despite being one of the most popular building materials, wood has inherent flaws such as dimensional instability and degradation through weathering, fire, and decay that prevent it from being competitive with non-renewable resources in the building and construction sector. By combining intelligent materials with conventional wood modification processes, nanotechnology is one of the most modern and successful wood protection technologies that can open new economic opportunities for using wood in challenging situations. Even if the environmental and physiological risks posed by nanoscale materials are not precisely determined in most research, the potential effect of the technology takes centre stage and calls into question the long-term viability of nano-based treatment [130].

Bi et al. reviewed various wood modification systems’ principles, production processes, benefits and drawbacks, and directions for improvement were compiled and summarised. They thus studied the unique properties of the various wood chemical alteration procedures. They offered suggestions and resources for investigating and creating more affordable and efficient modification methods. Due to their high cost or significant effect on wood strength, thermosetting resin modification, polymer monomer modification, nanotechnology, and paraffin wax modification are still in the research stage [24].

Some companies have achieved Environmental Products Declarations, and manufacturers of modified wood goods have considered the environmental effects of their products. However, the worldwide environmental impact of wood and bamboo modification processing and additional applications of the changed wood products are not yet considered in developing processes and goods, according to a more thorough analysis [159]. Furthermore, the future prospective will be to a large degree, their environmental effects are still unknown, which must alter to satisfy the needs of increasingly environmentally conscious corporate and consumer markets who want to choose the products and services they want to use in an ecologically responsible manner.

6 Conclusion

Wood-based and bamboo-based biomaterials are emerging as desirable answers to various technical problems. These substances – cellulose, hemicellulose, and lignin – are plentiful on Earth and biocompatible and contain intrinsic natural structures that might significantly improve the performance of materials. Although many modern technologies and applications have been established, significant obstacles in fundamental research and understanding must be overcome to accelerate the commercialisation of wood and bamboo materials. There is another big problem with extracting cellulose and lignin. There are gaps to overcome, particularly for innovative technologies like flexible electronics devices, energy storage applications, and green nanotechnology. These include the apparatus’s efficiency with suitable lifetime, durability, and cost-effectiveness, the extraction of biomaterials from wood, system-level integrations with numerous device components, and human health risks. But now, efforts are being made globally to advance novel wood-derived material technologies for a sustainable environment for the next generation. The primary wood modification techniques that use nanomaterials for improving the structure and coatings are reviewed in this article, along with any potential environmental effects of the integrated nanomaterials. An emphasis is placed on the application of lignin, cellulose, and hybrid wood and bamboo applications. The literature review’s in-depth discussion will provide emerging innovations that impact our daily lives.

Acknowledgments

The authors would like to express their heartfelt gratitude to Radek Kovaří for his valuable assistance and to all the individuals for their expertise throughout all aspects of our study and contribution to writing the manuscript. The authors are truly grateful to all of you.

-

Funding information: The authors thank the International Grant Agency (IGA) of the Faculty of Forestry and Wood Technology at Mendel University in Brno (LDF-23-IP-026) for the financial support.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: David Hui, who is the co-author of this article, is a current Editorial Board member of Nanotechnology Reviews. This fact did not affect the peer-review process. The authors declare no other conflict of interest.

References

[1] Rowell R editor. The chemistry of solid wood. Washington, DC: American Chemical Society; 1984 [cited 2022 May 24]. Advances in Chemistry. vol. 207. 10.1021/ba-1984-0207.Search in Google Scholar

[2] Dixon PG, Gibson LJ. The structure and mechanics of Moso bamboo material. J R Soc Interface. 2014;11(99):20140321.10.1098/rsif.2014.0321Search in Google Scholar PubMed PubMed Central

[3] Deschamps P, Haferkamp I, d’Hulst C, Neuhaus HE, Ball SG. The relocation of starch metabolism to chloroplasts: When, why and how. Trends Plant Sci. 2008;13(11):574–82.10.1016/j.tplants.2008.08.009Search in Google Scholar PubMed

[4] Youssefian S, Rahbar N. Molecular origin of strength and stiffness in bamboo fibrils. Sci Rep. 2015;5(1):11116.10.1038/srep11116Search in Google Scholar PubMed PubMed Central

[5] Lin Q, Huang Y, Yu W. An in-depth study of molecular and supramolecular structures of bamboo cellulose upon heat treatment. Carbohydr Polym. 2020;241:116412.10.1016/j.carbpol.2020.116412Search in Google Scholar PubMed

[6] Nilsson T, Rowell R. Historical wood – structure and properties. J Cult Herit. 2012;13(3):S5–9.10.1016/j.culher.2012.03.016Search in Google Scholar

[7] Oliver CD, Nassar NT, Lippke BR, McCarter JB. Carbon, fossil fuel, and biodiversity mitigation with wood and forests. J Sustain Forestry. 2014;33(3):248–75.10.1080/10549811.2013.839386Search in Google Scholar

[8] Žlahtič Zupanc M. Influence of artificial and natural weathering on the moisture dynamic of wood. Bioresources. 2016;12:117–42.10.15376/biores.12.1.117-142Search in Google Scholar

[9] Haiyan T. Damage of bamboo and wooden materials based on linear elastic fracture mechanics in garden design. Frattura ed Integrità Strutturale. 2016;10:472–80.10.3221/IGF-ESIS.35.53Search in Google Scholar

[10] Barkas WW, Golder HQ. Relation of strength of wood to shrinkage. Nature. 1938;141(3576):874–5.10.1038/141874a0Search in Google Scholar

[11] Wiedenhoeft AC. Structure and Function of Wood In: Rowell RM editor. Handbook of wood chemistry and wood composites. United Kingdom: CRC Press; 2005. p. 9–33.10.1201/b12487-4Search in Google Scholar

[12] Depuydt DE, Sweygers N, Appels L, Ivens J, van Vuure AW. Bamboo fibres sourced from three global locations: A microstructural, mechanical and chemical composition study. J Reinforced Plast Compos. 2019;38(9):397–412.10.1177/0731684419828532Search in Google Scholar

[13] Sulaeman A, Dungani R, Nurudin N, Hartati S, Karliati T, Aditiawati P, et al. Review on quality enhancement of bamboo utilization: Preservation, modification and applications. Asian J Plant Sci. 2017;17(1):1–18.10.3923/ajps.2018.1.18Search in Google Scholar

[14] Jones D, Sandberg D. A review of wood modification globally – updated findings from COST FP1407. Interdiscip Perspect Built Environ; 2020 [cited 2022 Dec 12];1. https://ipbe.innorenew.eu/ipbe/article/view/8.10.37947/ipbe.2020.vol1.1Search in Google Scholar

[15] Karami E, Bardet S, Matsuo M, Brémaud I, Gaff M, Gril J. Effects of mild hygrothermal treatment on the physical and vibrational properties of spruce wood. Composite Struct. 2020;253:112736.10.1016/j.compstruct.2020.112736Search in Google Scholar

[16] Jasmani L, Rusli R, Khadiran T, Jalil R, Adnan S. Application of nanotechnology in wood-based products industry: A review. Nanoscale Res Lett. 2020;15(1):207.10.1186/s11671-020-03438-2Search in Google Scholar PubMed PubMed Central

[17] Sandberg D, Kutnar A, Mantanis G. Wood modification technologies - a review. iForest - Biogeosci For. 2017;10(6):895.10.3832/ifor2380-010Search in Google Scholar

[18] Harandi D, Ahmadi H, Mohammadi Achachluei M. Comparison of TiO2 and ZnO nanoparticles for the improvement of consolidated wood with polyvinyl butyral against white rot. Int Biodeterior Biodegrad. 2016;108:142–8.10.1016/j.ibiod.2015.12.017Search in Google Scholar

[19] Wallenhorst L, Gurău L, Gellerich A, Militz H, Ohms G, Viöl W. UV-blocking properties of Zn/ZnO coatings on wood deposited by cold plasma spraying at atmospheric pressure. Appl Surf Sci. 2018;434:1183–92.10.1016/j.apsusc.2017.10.214Search in Google Scholar

[20] Žigon J, Pavlič M, Kibleur P, Bulcke JV, den Petrič M, Acker JV, et al. Treatment of wood with atmospheric plasma discharge: Study of the treatment process, dynamic wettability and interactions with a waterborne coating. Holzforschung. 2021;75(7):603–13.10.1515/hf-2020-0182Search in Google Scholar

[21] Liu SJ, Liao SC. Surface modification of bamboo charcoal by O2 plasma treatment and UV-grafted thermo-sensitive AgNPs hydrogel to improve antibacterial properties in biomedical application. Nanomaterials. 2021;11(10):2697.10.3390/nano11102697Search in Google Scholar PubMed PubMed Central

[22] Evans P, Matsunaga H, Kiguchi M. Large-scale application of nanotechnology for wood protection. Nat Nanotech. 2008;3(10):577.10.1038/nnano.2008.286Search in Google Scholar PubMed

[23] Sun H, Li X, Li H, Hui D, Gaff M, Lorenzo R. Nanotechnology application on bamboo materials: A review. Nanotechnol Rev. 2022;11(1):1670–95.10.1515/ntrev-2022-0101Search in Google Scholar

[24] Bi W, Li H, Hui D, Gaff M, Lorenzo R, Corbi I, et al. Effects of chemical modification and nanotechnology on wood properties. Nanotechnol Rev. 2021;10(1):978–1008.10.1515/ntrev-2021-0065Search in Google Scholar

[25] Rao F, Li X, Li N, Li L, Liu Q, Wang J, et al. Photodegradation and photostability of bamboo: Recent advances. ACS Omega. 2022;7(28):24041–7.10.1021/acsomega.2c02035Search in Google Scholar PubMed PubMed Central

[26] Hill CAS. Wood modification: Chemical, thermal and other processes. Chichester, UK: John Wiley & Sons, Ltd; 2006 [cited 2022 May 26]. 10.1002/0470021748.Search in Google Scholar

[27] Rowell RM. Chemical modification of wood: A short review. Wood Mater Sci Eng. 2006;1(1):29–33.10.1080/17480270600670923Search in Google Scholar

[28] Teacă CA, Tanasă F. Wood surface modification—classic and modern approaches in wood chemical treatment by esterification reactions. Coatings. 2020;10(7):629.10.3390/coatings10070629Search in Google Scholar

[29] Homan W, Tjeerdsma B, Beckers E, Jorissen A. Structural and other properties of modified wood. World Conference on Timber Engineering; 2000.Search in Google Scholar

[30] Hill C, Altgen M, Rautkari L. Thermal modification of wood—a review: Chemical changes and hygroscopicity. J Mater Sci. 2021;56:6581–614.10.1007/s10853-020-05722-zSearch in Google Scholar

[31] Willems W, Altgen M. Hygrothermolytic wood modification process description and treatment level characterisation. Wood Mater Sci Eng. 2020;15(4):213–22.10.1080/17480272.2019.1570970Search in Google Scholar

[32] Kubovský I, Kačíková D, Kačík F. Structural changes of Oak wood main components caused by thermal modification. Polymers. 2020;12(2):485.10.3390/polym12020485Search in Google Scholar PubMed PubMed Central

[33] Sikora A, Kačík F, Gaff M, Vondrová V, Bubeníková T, Kubovský I. Impact of thermal modification on color and chemical changes of spruce and oak wood. J Wood Sci. 2018;64(4):406–16.10.1007/s10086-018-1721-0Search in Google Scholar

[34] Laskowska A, Sobczak JW. Surface chemical composition and roughness as factors affecting the wettability of thermo-mechanically modified oak [Quercus robur L.]. Holzforschung. 2018;72(11):993–1000.10.1515/hf-2018-0022Search in Google Scholar

[35] Khademi Bami L, Mohebby B. Bioresistance of poplar wood compressed by combined hydro-thermo-mechanical wood modification [CHTM]: Soft rot and brown-rot. Int Biodeterior Biodegrad. 2011;65(6):866–70.10.1016/j.ibiod.2011.03.011Search in Google Scholar

[36] Bekhta P, Proszyk S, Krystofiak T, Mamonova M, Pinkowski G, Lis B. Effect of thermomechanical densification on surface roughness of wood veneers. Wood Mater Sci Eng. 2014;9(4):233–45.10.1080/17480272.2014.923042Search in Google Scholar

[37] Mai C, Kües U, Militz H. Biotechnology in the wood industry. Appl Microbiol Biotechnol. 2004;63(5):477–94.10.1007/s00253-003-1411-7Search in Google Scholar PubMed

[38] Kudanga T, Prasetyo EN, Widsten P, Kandelbauer A, Jury S, Heathcote C, et al. Laccase catalyzed covalent coupling of fluorophenols increases lignocellulose surface hydrophobicity. Biores Technol. 2010;101(8):2793–9.10.1016/j.biortech.2009.12.002Search in Google Scholar PubMed

[39] Bárdos L, Baránková H. Cold atmospheric plasma: Sources, processes, and applications. Thin Solid Films. 2010;518(23):6705–13.10.1016/j.tsf.2010.07.044Search in Google Scholar

[40] Bigan M, Mutel B. Cold remote plasma modification of wood: Optimization process using experimental design. Appl Surf Sci. 2018;453:423–35.10.1016/j.apsusc.2018.04.252Search in Google Scholar

[41] Gomez E, Rani DA, Cheeseman CR, Deegan D, Wise M, Boccaccini AR. Thermal plasma technology for the treatment of wastes: A critical review. J Hazard Mater. 2009;161(2):614–26.10.1016/j.jhazmat.2008.04.017Search in Google Scholar PubMed

[42] Okumoto M, Mizuno A. Conversion of methane for higher hydrocarbon fuel synthesis using pulsed discharge plasma method. Catal Today. 2001;71(1):211–7.10.1016/S0920-5861(01)00431-XSearch in Google Scholar

[43] Riedl B, Angel C, Prégent J, Blanchet P, Stafford L. Effect of wood surface modification by atmospheric-pressure plasma on waterborne coating adhesion. BioResources. 2014;9(3):4908–23.10.15376/biores.9.3.4908-4923Search in Google Scholar

[44] Blanchard V, Riedl B, Blanchet P, Evans P. Modification of sugar maple wood board surface by plasma treatments at low pressure In: Mittal KL editor. Contact Angle, Wettability and Adhesion, Volume 6. Netherlands: CRC Press; 2009. p. 311.10.1163/ej.9789004169326.i-400.137Search in Google Scholar

[45] Mittal KL editor. Contact Angle, Wettability and Adhesion, Volume 6 (1st ed.). CRC Press; 2009. 10.1201/b12247.Search in Google Scholar

[46] Özçifçi A, Okçu O. Impacts of some chemicals on combustion properties of impregnated laminated veneer lumber [LVL]. J Mater Process Technol. 2008;199(1):1–9.10.1016/j.jmatprotec.2007.10.003Search in Google Scholar

[47] Ramage MH, Burridge H, Busse-Wicher M, Fereday G, Reynolds T, Shah DU, et al. The wood from the trees: The use of timber in construction. Renew Sustain Energy Rev. 2017;68:333–59.10.1016/j.rser.2016.09.107Search in Google Scholar

[48] Walsh-Korb Z, Avérous L. Recent developments in the conservation of materials properties of historical wood. Prog Mater Sci. 2019;102:167–221.10.1016/j.pmatsci.2018.12.001Search in Google Scholar

[49] Ermeydan MA, Cabane E, Gierlinger N, Koetz J, Burgert I. Improvement of wood material properties via in situ polymerization of styrene into tosylated cell walls. RSC Adv. 2014;4(25):12981–8.10.1039/c4ra00741gSearch in Google Scholar

[50] Mader A, Schirò A, Brischetto M, Pizzo B. Interactions and penetration of polymers and nanolatexes into wood: An overview. Prog Org Coat. 2011;71(2):123–35.10.1016/j.porgcoat.2011.02.007Search in Google Scholar

[51] Wang Q, Wu X, Yuan C, Lou Z, Li Y. Effect of saturated steam heat treatment on physical and chemical properties of bamboo. Molecules. 2020;25(8):E1999.10.3390/molecules25081999Search in Google Scholar PubMed PubMed Central

[52] Gupta A, Kumar A, Sharma KV, Gupta R. Application of high conductive nanoparticles to enhance the thermal and mechanical properties of wood composite. Mater Today: Proc. 2018;5(1):3143–9.10.1016/j.matpr.2018.01.121Search in Google Scholar

[53] Rowell RM. Acetylation of wood – A review. Int J Lignocellul Prod. 2014;1(1):1–27.Search in Google Scholar

[54] Khan I, Saeed K, Khan I. Nanoparticles: Properties, applications and toxicities. Arab J Chem. 2019;12(7):908–31.10.1016/j.arabjc.2017.05.011Search in Google Scholar

[55] Wu Q, Miao WS, Zhang YD, Gao HJ, Hui D. Mechanical properties of nanomaterials: A review. Nanotechnol Rev. 2020;9(1):259–73.10.1515/ntrev-2020-0021Search in Google Scholar

[56] Papadopoulos AN, Bikiaris DN, Mitropoulos AC, Kyzas GZ. Nanomaterials and chemical modifications for enhanced key wood properties: A review. Nanomaterials. 2019;9(4):607.10.3390/nano9040607Search in Google Scholar PubMed PubMed Central

[57] Teng TJ, Arip MNM, Sudesh K, Nemoikina A, Jalaludin Z, Ng EP, et al. Conventional technology and nanotechnology in wood preservation: A Review. BioResources. 2018;13(4):9220–52.10.15376/biores.13.4.TengSearch in Google Scholar

[58] Wu X, Yang F, Gan J, Kong Z, Wu Y. A superhydrophobic, antibacterial, and durable surface of poplar wood. Nanomaterials [Basel]. 2021;11(8):1885.10.3390/nano11081885Search in Google Scholar PubMed PubMed Central

[59] Singh AS, Halder S, Wang J, Imam MA, Chen P. Tannic acid intermediated surface functionalization of bamboo micron fibers to enhance mechanical performance of hybrid GFRP. Compos Part B: Eng. 2019;177:107322.10.1016/j.compositesb.2019.107322Search in Google Scholar

[60] Shajari D, Bahari A, Gill P, Mohseni M. Synthesis and tuning of gold nanorods with surface plasmon resonance. Opt Mater. 2017;64:376–83.10.1016/j.optmat.2017.01.004Search in Google Scholar

[61] Hlaing M, Gebear-Eigzabher B, Roa A, Marcano A, Radu D, Lai CY. Absorption and scattering cross-section extinction values of silver nanoparticles. Opt Mater. 2016;58:439–44.10.1016/j.optmat.2016.06.013Search in Google Scholar

[62] Huang X, El-Sayed MA. Gold nanoparticles: Optical properties and implementations in cancer diagnosis and photothermal therapy. J Advan Res. 2010;1(1):13–28.10.1016/j.jare.2010.02.002Search in Google Scholar

[63] Copper - an overview | ScienceDirect Topics. [cited 2022 May 30]. https://www.sciencedirect.com/topics/nursing-and-health-professions/copper.Search in Google Scholar

[64] Rtimi S, Kiwi J. Recent advances on sputtered films with Cu in ppm concentrations leading to an acceleration of the bacterial inactivation. Catal Today. 2020;340:347–62.10.1016/j.cattod.2018.06.016Search in Google Scholar

[65] Ju Z, Zhan T, Zhang H, He Q, Yuan M, Lu X. Preparation of functional bamboo by combining nano-copper with hemicellulose and lignin under high voltage electric field [HVEF]. Carbohydr Polym. 2020;250:116936.10.1016/j.carbpol.2020.116936Search in Google Scholar PubMed

[66] Akhtari M, Nicholas D. Evaluation of particulate zinc and copper as wood preservatives for termite control. Eur J Wood Wood Prod. 2013;71(3):395–6.10.1007/s00107-013-0690-7Search in Google Scholar

[67] Raghupathi KR, Koodali RT, Manna AC. Size-dependent bacterial growth inhibition and mechanism of antibacterial activity of zinc oxide nanoparticles. Langmuir. 2011;27(7):4020–8.10.1021/la104825uSearch in Google Scholar PubMed

[68] Xie Y, He Y, Irwin PL, Jin T, Shi X. Antibacterial activity and mechanism of action of zinc oxide nanoparticles against Campylobacter jejuni. Appl Environ Microbiol. 2011;77(7):2325–31.10.1128/AEM.02149-10Search in Google Scholar PubMed PubMed Central

[69] Li J, Sun Q, Yao Q, Wang J, Han S, Jin C. Fabrication of robust superhydrophobic bamboo based on ZnO nanosheet networks with improved water-, UV-, and fire-resistant properties. J Nanomater. 2015;2015(1):1.10.1155/2015/431426Search in Google Scholar

[70] Bak M, Németh R. Effect of different nanoparticle treatments on the decay resistance of wood. BioResources. 2018;13(4):7886–99.10.15376/biores.13.4.7886-7899Search in Google Scholar

[71] Mantanis G, Terzi E, Kartal SN, Papadopoulos AN. Evaluation of mold, decay and termite resistance of pine wood treated with zinc- and copper-based nanocompounds. Int Biodeterior Biodegr. 2014;90:140–4.10.1016/j.ibiod.2014.02.010Search in Google Scholar

[72] Parrino F, Pomilla FR, Camera-Roda G, Loddo V, Palmisano L. Properties of titanium dioxide In: Parrino F, Palmisano L, editors. Titanium Dioxide (TiO2) and Its Applications. Elsevier; 2021 [cited 2022 May 30]. p. 13–66. (Metal Oxides). https://www.sciencedirect.com/science/article/pii/B9780128199602000018.10.1016/B978-0-12-819960-2.00001-8Search in Google Scholar

[73] Zhang N, Xu M, Cai L. Improvement of mechanical, humidity resistance and thermal properties of heat-treated rubber wood by impregnation of SiO2 precursor. Sci Rep. 2019;9(1):982.10.1038/s41598-018-37363-3Search in Google Scholar PubMed PubMed Central

[74] Han X, Yin Y, Zhang Q, Li R, Pu J. Improved wood properties via two-step grafting with itaconic acid (IA) and nano-SiO2. Holzforschung. 2018;72(6):499–506.10.1515/hf-2017-0117Search in Google Scholar

[75] Ferric Oxide (Fe2O3) - an overview | ScienceDirect Topics. [cited 2022 May 30]. https://www.sciencedirect.com/topics/engineering/ferric-oxide-fe2o3.Search in Google Scholar