Abstract

Nanosilica (NS) may be obtained as a by-product in several industrial processes and is associated with high availability and affordability among other nanoadditives. NS has been used for asphalt modification, and improvement in high-temperature performance and several other physical properties has been reported. However, due to the wide varieties and intrinsic variability of asphalt materials, concerns have been raised about the reproducibility of some conclusions, and therefore, a review was conducted. According to the results, NS additives with a purity of over 99% were usually used for modification and the specific surface area was over 100 m2/g, leading to the superior absorption of asphalt and thus improvement in rutting resistance of the mixtures. Due to a lack of guidance for the blending procedures, inconsistency exists among studies in the shear speed, blending duration, and temperature, leading to possible excessive blending and unnecessary energy and time consumption. Rises in NS concentration would cause higher softening point and rotational viscosity, and therefore elevated temperatures for mixing and paving, but penetration would be reduced. According to rheological evaluations, with the rise of NS concentration, the rutting parameter would increase, indicating an improvement in the high-temperature performance, but the low-temperature performance may deteriorate.

1 Introduction

Asphalt concrete plays a dominant role in pavement construction. The applications in wide territorial ranges require adaptability to different thermal and moisture conditions, and the increasing traffic loads require better mechanical properties and fatigue resistance [1]. To satisfy the requirements for asphalt binders and mixtures, additives have been used for modification [2], including nanomaterials, e.g., nanocarbon [3], nanoclay [4], nano-TiO2 [5], nanographene oxide [6], nano-Al2O3 [7,8], and nanosilica (NS) [2]. Nanomaterials have a particle size ranging from 1 to 100 nm [9]. With small particle sizes and large specific surface areas, proper nanoparticles can adsorb asphalt and reduce liquidity [10]. NS has advantages among nanomaterials in stability and affordability, for example, the NS used by Shi et al. [11] in 2018 was 50 CNY (about 7 USD) per kilogram. NS used for asphalt modification is usually white or off-white spherical inorganic non-metallic particles with sizes of about 30 nm [12]. The main component is silica oxide and therefore NS has stable chemical properties and is non-toxic [13]. NS has a long history of applications in cement concrete to improve the strength, wear resistance, and durability and reduce material segregation [14].

In recent years, NS additives have been used for asphalt modification [15], where the particles usually have a high purity of over 99%, a small dimension within 30 nm, and a large specific area of over 100 m2/g [16,17,18,19]. In the modification processes, NS is first blended with asphalt binders by high-shear mixers, but due to a lack of guiding standards, the blending procedures vary among studies in terms of the shear speed of mixers, the duration, and the temperature. For example, they were blended at 145℃ and 1,500 rpm for 60 min in the study of Saltan et al. [20] and 150–160℃ and 4,000 rpm for 120 min in the study of Sukhija et al. [21]. Most studies claimed that their blending procedures were sufficient to guarantee proper dispersion of NS particles in binders with evidence from scanning electron microscope (SEM) photos, but excessive blending may exist, leading to the aging of binders and unnecessary consumption of time and energy, hindering the economical effectiveness of NS additives. In addition, investigated NS-concentration ranges vary among studies, for example, the maximum tested NS concentration was 7% in the study of Ezzat et al. [22], but it was only 0.5% in the study of Saltan et al. [20]. Apart from the mixing approach by high-speed mixers, a recent research manufactured microcapsules from NS and vegetable oil by in situ polymerization for further use in asphalt, but associated research is limited [23].

To evaluate the modification effects of NS additives on asphalt binders, experiments have been conducted on aged and unaged binder samples before and after modification, where conventional and rheological properties of the samples have been examined [12,16,17,18,19]. Standards for evaluations of asphalt binders have been well established and usually followed in studies about NS modification. Conventionally, several empirical parameters have been used to characterize the binders, including penetration, softening points, ductility, viscosity, and other parameters obtained from associated tests [24,25]. More rheological parameters (e.g., complex modulus and phase angle [26,27]) and associated tests (e.g., dynamic shear rheometer [DSR] test and bending beam rheometer [BBR] tests) have been introduced in Superpave specifications as a result of Strategic Highway Research Program (SHRP) [28,29]. Several other advanced technologies have also been used, for example, Fourier transform infrared spectrum (FTIR) tests were used to examine the dispersion and possible chemical reactions of NS particles in binders, and special functional groups were identified by FTIR to evaluate the aging status of binders [30,31]. Several conclusions have been obtained from the results, for example, NS additives would bring a reduction in penetration and an increase in softening point and viscosity, and therefore, higher stiffness and rutting resistance [18,32,33], and experiments have also shown that they improve the self-healing behavior of asphalt mixtures [34]. The molecular dynamic method has also been used to simulate NS-modified asphalt [35] and explain the self-healing mechanism [36], but associated studies are limited, possibly due to the difficulties brought by complex components of asphalt materials.

However, asphalt materials are associated with wide varieties and intrinsic variability [37,38]. Properties of asphalt may vary with, for example, additives, manufacturing, construction processes, and environmental conditions [39]. In studies about the effects of NS, binder samples with different grades, grading systems, additives, and manufacturers were used and inconsistency existed among some of the results [40]. Different evaluating systems have been applied to describe a single behavior of asphalt binders, for example, low-temperature cracking of mixtures may be predicted by ductility, DSR tests, frequency sweep tests, etc. For the aforementioned reasons, different, even contrary conclusions have been drawn about the effects of NS on asphalt binders. Therefore, concerns have been raised about the reproducibility of some conclusions and especially the quantitative ones. It hinders the commercialization and further applications of NS additives [14,33]. A systematic literature review is, therefore, necessary to describe and compare the properties of NS additives, asphalt types, and blending procedures used for the modification. Test procedures and parameters used for the characterization of NS-modified binders also require investigations in terms of their effectiveness and consistency among different studies.

In this review, the NS additives for modification in existing literature were first described, including the morphology, purity, density, and concentration. Second, the blending procedures by high-shear mixers for NS additives and binders were described and compared in terms of the shear speed, the blending durations, and the temperatures. Technical approaches to identify the dispersion of NS particles in binders were also introduced, e.g., SEM and FTIR tests. Third, conventional empirical tests and parameters used for evaluating NS-modified binders (e.g., penetration, softening point, and ductility) and associated results were presented with extensive comparisons. In the end, tests conducted as per Superpave specifications on rheological properties of NS-modified binders before and after aging were reviewed and the conclusions were compared with those obtained from the conventional tests.

2 Properties of NS for asphalt modification

Porous amorphous NS powders were used in existing studies for asphalt modification due to their superior morphology and physical and chemical properties [41]. First, NS is physically and chemically stable in a wide temperature range, with a melting point exceeding 1,600℃ [20,42], and therefore, would not be affected by the temperature of up to about 180℃ in the modification and mixing process of asphalt. According to the infrared spectrum test, the modification would not produce new chemical groups and the process is therefore physically dominated [18] due to the high chemical stability of NS [12].

Second, NS is highly dispersive due to the nanodimension and strong hydrophobicity [12]. It may be distributed better than several other alternative nanomodifiers (e.g., nanomontmorillonite) in the asphalt binders and no obvious agglomeration formed in existing research after proper blending [22]. Properties of NS used in the related literature are shown in Table 1. It may be noticed that the bulk density (also referred to as surface density in the literature) of NS is about 0.1 g/cm3, while the true density is 2.4 g/cm3, suggesting that NS has a fluffy status with a large proportion of void.

Properties of NS used for asphalt modification

| Diameter (nm) | Surface area (m2/g) | Bulk density (g/cm3) | True density (g/cm3) | Purity (%) | Ref. |

|---|---|---|---|---|---|

| 15 ± 3 | 160 ± 12 | <0.14 | — | >99.9 | Ghasemi et al. [15] |

| 20–30 | 130–600 | — | 2.1 | >99.0 | Shafabakhsh and Ani [48] |

| 11–13 | 200 | <0.1 | 2.4 | 99 | Taherkhani et al. [43] |

| 80 | 20–45 | — | — | — | Han et al. [31] |

| — | 140 | 0.2 | 2.4 | >99.0 | Enieb and Diab [17] |

| 20–30 | 180–600 | <0.10 | 2.4 | 99.5 | Nazari et al. [42] |

| 10–25 | 100 ± 25 | 0.15 | — | >99.9 | Bala et al. [12] |

| 30 | 225 | 0.04 | — | 99.8 | Shi et al. [11] |

| 20–30 | 180–600 | <0.10 | — | >99.0 | Shafabakhsh et al. [49] |

| 20–30 | 180–600 | <0.10 | 2.4 | >99.0 | Motamedi et al. [30] |

| 30–50 | 200–250 | 0.10 | 2.5 | 99.5 | Bhat and Mir [16] |

| 10–25 | 100 ± 25 | 0.15 | — | >99.9 | Al-Sabaeei et al. [50] |

| 14 | 80–120 | 0.04 | — | ≥99.8 | Lushinga et al. [51] |

| 30 | 200 ± 34 | 0.032–0.058 | — | 99.82 | Babagoli et al. [52] |

Third, the large specific surface area of NS is beneficial for absorbing asphalt. The specific surface area of a particle generally increases with the decrease in the particle size; therefore, a large specific surface area is one of the main characteristics of nanomaterials. NS particles used in the relevant studies have porous structures, which further increase the specific surface area. The NS particle sizes used in related studies generally range from 10 to 30 nm, and the maximum one is 80 nm, leading to a large surface area of 100–600 m2/g (Table 1).

The specific surface areas of spherical and fibrous NS have been compared in a recent study, where fibrous NS was synthesized in laboratory conditions [33]; the specific surface area of fibrous nanosilica (FNS) was 702 m2/g, and it was only 195 m2/g for the spherical control group. This specific surface area of FNS is also higher than the other spherical NS used in studies listed in Table 1. In asphalt modification, FNS showed more positive effects on asphalt stiffness and rutting resistance than spherical ones [33]. Despite these advantages, FNS was not used in other research possibly due to considerations of affordability and commercial availability.

As listed in Table 1, the used NS additives have over 99% purity and are from commercial products [11] or synthesis methods in laboratories [33]. Other element compositions in NS include Fe (<200 ppm), Ti (<120 ppm), Na (<50 ppm), and Ca (<20 ppm) [30], and the major impurities are consistent with the study by Taherkhani et al. [43]. In another study it includes Mg (<1,000 ppm), Ca (<800 ppm), Fe (<500 ppm), and Al (<200 ppm) [16]. The element compositions of NS additives, therefore, vary among studies, and it may depend on the raw materials and manufacturing processes. NS powders may also be obtained as the by-product in the production of elemental silica or alloys containing silica in electric arc furnaces, but some of them have large sizes (0.1–0.3 µm) and lower purity and are referred to as silica fume in literature [44,45]. Silica fume has also been used for asphalt modification, but they have different properties from NS and are not further discussed in this review [46,47].

As a core indicator, the specific surface areas are obtained by the N2 adsorption experiment, which is demanding and time-consuming [33]. According to the data listed in Table 1, a negative relation between the specific surface areas and the bulk density has been noticed as shown in Figure 1 [11,12,15,16,17,43,50,52] and may be used to roughly estimate the specific surface areas. NS in literature [51] was modified by polydimethylsiloxane; therefore, the data were not included in Figure 1.

3 Blending of NS and asphalt

3.1 Asphalt type

Practical applications require proper dispersion of NS particles in asphalt binders. Due to the high viscosity of binders and small sizes of NS particles, high-shear mixers were used for blending and the procedures from 19 existing studies have been summarized in Table 2, where the asphalt types, NS concentrations, blending temperatures, shear speeds, and durations are listed. The NS concentration refers to the percentage of NS to asphalt by weight.

Blending procedures for NS and asphalt binders

| Asphalt | NS (%) | T (℃) | Blending rpm × time | Comment | Country | Ref. |

|---|---|---|---|---|---|---|

| PG58-34 | 4, 6 | 130 | 4,000 rpm × 120 min | ABS-modified asphalt was used. | US and China | Yao et al. [32] |

| Pen 60/70 | 2, 4 | 130, 165 | 4,000 rpm × 10 min + 6,100 rpm × 50 min | Effects were compared with TiO2 (2–4%) and CaCO3 (2–4%). | Iran | Nazari et al. [42] |

| Pen 60/70 | 2, 4, 6 | 140 | 2,500 rpm × 80 min | Blending was as per ASTM C1738. | Iran | Ghanoon and Tanzadeh [19] |

| PG52 | 3, 5, 7 | 145 | 1,500 rpm × 60 min | Effects were compared with nano-MMT. | Egypt | Ezzat et al. [22] |

| Pen 80/100 | 1, 2, 3, 4 | 150 | 4,000 rpm × 45 min | Asphalt was pre-treated with 5% PP. | Malaysia and Nigeria | Bala et al. [12] |

| VG10 | 0.5, 1, 3 | 150 | 3,500 rpm × 120 min | Blending duration was optimized. | India | Bhat and Mir [16] |

| Pen 60/70 | 1.2 | 150 | 5,000 rpm × 30 min | Freeze-thaw cycles were applied | Iran | Zarei et al. [63] |

| VG10 and VG30 | 2, 4 | 150–160 | 4,000 rpm × 120 min | Control groups were also blended. | India | Sukhija et al. [21] |

| Pen 60/70 | 0.4, 1.2, 2.0, 2.8 | 155 | 4,000 rpm × 15 min | NS was added with TiO2 (1–7%). | Iran | Shafabakhsh and Ani [48] |

| Pen 60/70 | 0.5, 1, 1.5, 2 | 160 | 3,000 rpm × 60 min | NS was milled with SBS before blending; storage stability was studied. | Iran | Ghasemi et al. [15] |

| PG76 | 2, 4 | 160 | 1,500 rpm × 60 min | Polymer-modified asphalt was used. | Malaysia | Yusoff et al. [61] |

| PG64-22 | 0.1, 0.3, 0.5 | 160 | 4,000 rpm × 120 min | No other additives were used. | Turkey | Saltan et al. [20] |

| Pen 60/70 | 1, 3, 5 | 160 | 3,000 rpm × 60 min | Effects were compared with Zyco-Soil. | Iran | Taherkhani et al. [43] |

| Pen 60/70 | 2, 4, 6 | 160 | 2,000 rpm × 60 min | No other additives were used. | Egypt | Enieb and Diab [17] |

| Pen 85/100 | 3, 5, 7 | 160 | 4,000 rpm × 80 min | Effects were compared with PU polymer. | Iran | Motamedi et al. [30] |

| PG64-16 | 2, 4, 6 | 160 | 1,200 rpm × 15 min + 5,000 rpm × 45 min | Fibrous and spherical NS particles were compared. | Iran | Moeini et al. [33] |

| PG64 | 2, 4, 6 | 160 | 4,000 rpm × 120 min | NS was added with TPO (0–15%). | Malaysia | Al-Sabaeei et al. [50] |

| PG76 | 2, 4, 6 | 163 | 3,000 rpm × 60 min | Polymer-modified asphalt was used; storage stability was studied. | Malaysia and China | Alhamali et al. [62] |

| Pen 60/70 | 1, 2, 3 | 170 | 5,000 rpm × 30 min | NS was added with rock asphalt (0–6%). | China | Shi et al. [11] |

| Pen 60/70 | 2, 4, 6 | 170 | 6,000 rpm × 30 min | NS was added with gilsonite (0–7%) | Iran and US | Babagoli et al. [52] |

| Pen 60/70 | 2, 4, 6 | 180 | 4,000 rpm × 120 min | Mesoporous NS was used; storage stability was studied. | US and Iran | Fini et al. [18] |

| Pen 80/100 | 0.5, 1.5, 3 | 180–190 | 4,000 rpm × 120 min | Asphalt was pre-treated with 8% crumb rubber. | China and Zambia | Lushinga et al. [51] |

| PG64-22 | 2, 4, 6 | ∼185 | ∼4,000 rpm × ∼55 min | Crumb-rubber-modified asphalt was used. | China | Han et al. [31] |

Three grading systems for asphalt have been used in studies in Table 2, where PG refers to the performance grade (PG), Pen indicates the penetration, and VG stands for the viscosity grade [21]. Pen 60/70 asphalt is used by most studies due to frequent use in practice. All studies listed in Table 2 have included a control group without NS, and control groups were usually not subjected to blending procedures. A study suggested that the control groups also require blending to eliminate the differences brought by the aging of asphalt binders during blending [17,21], but in practice neat asphalt would not be blended before mixing with aggregates. Neat asphalt and several types of polymer-modified asphalt have been investigated, and the polymers include polypropylene [12], crumb rubber [31,51], styrene butadiene styrene (SBS) [15], acrylonitrile-butadiene-styrene terpolymer (ABS) [32], and polyurethane (PU) [30]. Modification effects of NS have also been compared or incorporated with TiO2 (2–4%), CaCO3 (2–4%) [42], nanomontmorillonite (nano-MMT, 3%) [22], tyre pyrolysis oil (TPO) [50], and waste denim fiber [53]. Reclaimed asphalt pavement materials have also been used as additives together with NS in existing literature [54,55]. Therefore, a research mode is evaluating the effect of NS on asphalt binders with different modifiers, and a wide range of studies has been conducted due to the rich types of existing and potential modifiers. However, the applicability of a particular study may be limited since the results depend significantly on the base asphalt and modifiers. Several other additives have also been conventionally used for asphalt modification, but research on their synergic effect with NS is still limited, indicating opportunities for further research, and these additives include styrene-ethylene-butadiene-styrene copolymer [56], polyethylene terephthalate [57], styrene-butadiene rubber [58], polyphosphoric acid [58], etc. It should be noted that these additives can be used for asphalt modification alone or in concert.

3.2 NS concentrations

To determine the optimal NS concentration, binder samples with various NS concentrations were subjected to existing evaluation systems after proper blending to quantify their performance variation with NS concentrations. Two main evaluation systems have been involved, where the first one is more conventional and based on empirical indicators [16], including penetration, softening point, ductility, etc. This evaluation is still widely used in practical projects and associated studies are discussed in Section 4. Another evaluation system focuses more on rheological properties of asphalt [18], and it involves DSR test, BBR test, BBR test, multiple stress creep and recovery (MSCR) tests, etc. Associated studies are discussed in Section 5. In practice, requirements on asphalt properties would be determined based on environmental conditions, traffic loads, and affordability, and optimal NS concentrations are determined accordingly. Therefore, the optimal NS concentration depends on practical requirements.

The NS concentrations listed in Table 2 range from 0.1 to 7%, and the maximum concentrations reach at least 6% in 11 out of 23 studies. Divergence in the tested ranges of NS concentrations is also noticed. In several studies, the maximum NS concentrations go up to 7% [22,30], while they are no more than 0.5% in some other research [20].

3.3 Blending procedures

The blending temperatures are between 150 and 170℃ in 17 out of 23 studies and are similar to the mixing temperatures for asphalt binders and aggregates [59]. Such a temperature range may balance the aging effects and the fluidity of asphalt. Requirements of special additives also affect the blending temperature, for example, a low blending temperature of 130℃ was used in the study of Yao et al. [32], because the additives included ABS with a boiling point of 145℃. A relatively high blending temperature of 180℃ was applied when incorporating mesoporous NS, which requires higher fluidity for asphalt to fill the microvoids [18].

Revolutions per minute (rpm) and blending durations of high-shear mixers are the main parameters to be determined in the blending procedures. A standard (ASTM C1738/C1738M-18) for hydraulic cement pastes was followed in an existing study [19], since special standards for blending asphalt and NS are still not available. References or reasons for blending procedures were not mentioned in most studies in Table 2. Investigations and optimizations for the blending procedures are meaningful, since insufficient blending may cause agglomeration and segregation in materials as could be observed in SEM photos, while excessive blending may cause aging of asphalt and additives and unnecessary energy consumption and therefore deteriorate the competitiveness of NS.

Different procedures, i.e., blending rpm and time, are used among the studies listed in Table 2. The rpm ranges from 1,200 to 6,100, while the duration ranges from 15 to 120 min. The total revolutions, i.e., the product of rpm and duration, range from 60,000 to 480,000 rpm. After blending, SEM photos are taken for the modified asphalt specimens, and all blending procedures have been claimed to guarantee proper dispersion of NS in asphalt in existing studies. Similarly, X-ray diffraction (XRD) [33] and FTIR tests [30] have been used to evaluate the dispersion of NS in asphalt binders.

The sensitivity of NS dispersion to the blending rpm and durations is seldom investigated in these studies, and excessive blending probably exists. A quantitative sensitivity analysis was conducted by [16], where samples were taken from the mixer every 15 min and the complex modules were measured; the modules kept rising until 120 min; therefore, the blending duration was determined as 120 min. Another research blended polymer-modified asphalt binders with NS at 4,000 rpm and concluded that increasing the blending duration from 60 to 90 min would not significantly affect the properties of asphalt binders in terms of penetration, softening point, viscosity at 135°C, recovery, and non-recoverable creep compliance [60], and thus suggested a blending duration of 60 min.

Therefore, inconsistencies exist among studies on proper blending procedures, including the blending speeds, durations, and temperature, possibly due to the use of different asphalt binders and additives, as well as a lack of adequate research. Meanwhile, different approaches (e.g., SEM, XRD and FTIR) and criteria have been used to evaluate the dispersion of NS in asphalt binders [61,62,63], but their effectiveness and cost efficiency have not been evaluated. These approaches are mainly empirical and lack quantitative evaluation on uniformity of NS dispersion, which may lead to insufficient or excessive blending. Insufficient blending causes partially inferior material performance, while excessive blending wastes time and energy and causes asphalt aging, which hinders the industrial application of NS. This implies research opportunities to propose reasonable approaches and criteria for determining proper blending procedures in practice.

Despite the inconsistencies, conventional blending procedures in literature could be summarized. First, the blending temperature usually ranges from 150 to 170°C, while it may be about 180°C for asphalt with crumb rubber. Second, binders with higher viscosity require more blending revolutions, and the total revolutions should be over 180,000 for polymer-modified asphalt and over 90,000 for other binders, but the maximum revolution is 480,000. The criterion of proper blending is adequate dispersion of NS in binders.

Since existing studies suggest that NS mainly improves the high-temperature performance of asphalt binders, relevant research was conducted by countries constructing asphalt pavement in high-temperature scenarios, e.g., Iran, Egypt, and Malaysia, as shown in Table 2.

4 Conventional physical properties

4.1 Penetration

The penetration reflects the shearing resistance, stiffness, and viscosity [64] and was therefore used by existing studies to evaluate the modification effects of NS. The penetration test is usually conducted as per ASTM D5, although several other standards have also been used, e.g., AASHTO T 49 and IS: 1203 [16]. The standard penetration needle and test temperature (i.e., 25℃) among different standards are identical.

Variations in penetration with NS concentration for neat asphalt and polymer-modified asphalt based on results from existing studies have been presented in Figure 2 [15,16,17,18,30,31,33,62]. The unit for penetration is 0.1 mm, i.e., decimillimeter (dmm), but was written as “mm” in several studies and led to unusual results [16,18], and it has been amended before the results were adapted to Figure 2. Types of asphalt, blending procedures, and additives used in these studies have been listed in Table 2.

As shown in Figure 2, for all tested asphalt samples, the penetration decreases as NS concentration rises, indicating a rise in the stiffness, viscosity, and shearing resistance. Existing literature suggested that absorption of the maltene phase in asphalt and high stiffness of NS contributed to an overall high stiffness of modified asphalt [48]. Generally consistent results are witnessed in Figure 2a, but an unusual rapid decrease in penetration is reported at 0.5 and 1% NS by Bhat and Mir [16], possibly because a different test testing standard (i.e., IS 1203) and special asphalt were used. A maximum of 6% NS was used in the other four studies, and according to average results, when 6% NS was added to neat asphalt, the penetration decreases from 64 to 49 dmm. In Figure 2a, FNS stands for fibrous NS, while SNS is the spherical one. According to the results from Moeini et al. [33], spherical and fibrous NS particles have almost identical effects on the penetration of neat asphalt, and the maximum difference is smaller than 5%. Similarly, when the NS rises from 0 to 6%, the penetration of polymer-modified binders decreases from 72 to 48 dmm on average as shown in Figure 2b, and the decrease is more obvious than that of the neat asphalt.

4.2 Softening point

The softening point is also an empirical parameter and is obtained from the ring and ball tests as per ASTM D36 and IS: 1205 [16]. It characterizes the susceptibility of asphalt to temperature. As shown in Figure 3, the softening point generally increases with the rise in NS concentration, although slight decreases are witnessed when the NS rises from 0 to 2% and 4 to 6% in a study [17]. Based on average results, by adding 6% NS, the softening point increases from 49.2 to 56.7℃ for neat asphalt (Figure 3a) and from 56.3 to 68.3℃ for polymer-modified asphalt (Figure 3b).

An improved softening point is favorable since it indicates less susceptibility to temperature, and the asphalt mixtures would have better resistance to rutting and permanent deformation at high temperatures [48,65]. Effects of NS morphology are not obvious according to results from Moeini et al. [33]. An unusual sharp increase is reported by Bhat and Mir as shown in Figure 3a [16], possibly because a different test testing standard (i.e., IS 1203) and special asphalt were used.

4.3 Storage stability

Asphalt would be heated to a high temperature during processing and becomes more flowable, then segregation may happen in asphalt binders with insoluble additives due to density differences. Storage stability may also affect the transporting, mixing, and paving process of asphalt. ASTM standards have been available for evaluating the storage stability of asphalt binders modified with SBS and ethylene-vinyl-acetate polymers, i.e., ASTM D 5976 and ASTM D 5841. Ghasemi et al. [15] reported an evaluation of the storage stability of 5%-SBS-modified asphalt with NS, where the samples were cast into aluminum foil tubes with a diameter of 32 mm and a height of 160 mm. The tubes were then sealed and placed vertically in an oven at 163℃ for 48 h before being cooled and cut evenly into three sections. Softening points of samples from the top and bottom sections were measured and the difference is required to be within 2.5℃. The samples with NS (0.5–2%) passed the tests with the maximum temperature differences of 1.2℃, while the control group without NS failed [15]. In a similar test on polymer-modified asphalt with 2–6% NS, an aluminum foil tube with a different dimension was used, and the temperature differences decreased with NS concentration, and only the sample with 6% NS passed the test [62]. Results from the two studies suggest that adding NS can enhance the storage stability of polymer-modified asphalt, and the effect would increase with the rise in the concentration of NS.

The storage stability of neat asphalt with 2–6% NS has also been investigated by similar tests as per BS EN 13399, where the samples were stored at 180℃ for 72 h. All samples passed the test, and the maximum difference in softening points between the top and bottom sections was only 0.6℃, much smaller than the requirement of 5℃ [18]. However, the temperature differences would increase as NS concentration rises, which is in contrast to the situation of polymer-modified asphalt; therefore, NS is negative for the storage stability of neat asphalt. Neat asphalt with up to 6% added NS still satisfies the requirement in the storage stability. Standards for polymer-modified asphalt have been used in existing studies for evaluating the storage stability of NS-modified binders, but the polymer additives have different working mechanism with NS. Polymer additives are melted when blending with asphalt, while NS is intact during blending due to its high melting point exceeding 1,600℃ [20,42]; therefore, the feasibility of standards for polymer additives on NS requires further justification.

It can be seen that NS has a two-sided effect on the storage stability of asphalt binders. First, due to the stable chemical and physical properties, NS exists as particles in asphalt binders. NS particles have a density of 2.1–2.5 g/cm3, which is higher than the densities of the SARA components of asphalt, i.e., saturates, aromatics, resins, and asphaltenes [66], ranging 0.90–1.15 g/cm3; therefore, NS in asphalt would precipitate due to natural density differences. Second, for SBS-modified asphalt, NS would absorb the saturates and aromatics and reduce the fluidity of asphalt and segregation of SBS. Since SBS and asphalt are thermodynamically incompatible, SBS exists in the form of micelles in asphalt after proper blending. Density differences and SBS coalescence would lead to segregation especially at elevated temperatures where asphalt presents high followability. In the mixing and storage temperature of about 180°C, saturates and aromatics exist as liquid and mainly contribute to the fluidity of asphalt, whereas asphaltenes do not show any thermal transition up to 200°C and mainly build the viscosity of asphalt. The added NS would absorb the saturates and aromatics with a small molecular weight, while the asphaltenes and resins are almost unaffected. As a result, the overall viscosity of asphalt increases, the SBS micelles become more stable, and the storage stability of SBS-modified asphalt would increase.

4.4 Ductility

Ductility is an empirical parameter to characterize the plasticity of asphalt and is associated with low-temperature performance. Asphalt mixtures made with low-ductility asphalt binders are more likely to crack at low temperatures. The ductility of NS-modified asphalt was not evaluated in most relevant studies, possibly because NS additives are usually used to improve the high-temperature performance of asphalt and therefore applied in hot regions (Table 2). Results from studies are summarized in Figure 4, and all the tests are performed at 25℃, although different standards have been referred to, e.g., ASTM D113 [18,62] and IS 1208 [16]. As shown in Figure 4, NS usually causes a reduction in ductility, and according to Fini et al. [18], when the NS rises from 0 to 6%, the ductility decreases almost linearly from over 150 to 27 cm by 82%. Therefore, NS may have negative effects on the low-temperature performance of asphalt mixtures, and the ductility of NS-modified binders should be evaluated before applications in cold regions. The influence of NS on the ductility of asphalt mainly attributes to the absorption of saturates and aromatics by NS. The two components have higher fluidity, contributing to lubrication and softening of asphalt, but they are easily adsorbed by NS. After their adsorption by NS, the effects of asphaltene and resins are more obvious and the asphalt get hardened and brittle. In the study by Alhamali et al. [62], an unusual increase in the ductility was witnessed when NS concentration increased from 2 to 6%, possibly because a special asphalt, i.e., PG-76 (Dorotech Hr-Super) polymer-modified bitumen, was used, but more information about the polymer modifier was unavailable.

4.5 Penetration index (PI)

The PI is calculated based on the results of penetration and softening point to evaluate the sensitivity of asphalt to temperature. Figure 5 shows evaluations on PI in existing studies, where PI is calculated by equation (1) [16,62] and background information of type of asphalt, blending procedures, and additives has been provided in Table 2.

where Pen is the penetration, in dmm, and SP is the softening point, in ℃.

Other formulations for calculating PI are available in the literature and the relationships between different formulas are available in the study of Ehinola et al. [67]. It theoretically ranges from −3 to 7, and a higher PI indicates less temperature sensitivity, thus more resistance against rutting and low-temperature cracking. Inconsistency among different studies is witnessed about the effects of NS on PI as shown in Figure 5. In two studies by Alhamali et al. [62] and Enieb and Diab [17], PI just fluctuates among the original value after adding NS, and therefore, the effects are not obvious, while in the other two studies, PI is increased from 0.9 to 3.0 in the study of Bhat and Mir [16] and from −0.3 to 1.4 by adding 2% NS [48]. Such inconsistency among different studies suggests that the modification effects of NS on PI may depend on the properties of asphalt binders and additives used in practice as shown in Figure 5 and Table 2.

4.6 Rotational viscosity

The viscosity reflects the blending, mixing, and working properties of asphalt. The rotational viscosity at 135℃ obtained by Brookfield viscometer as per ASTM D 4402 and AASHTO T 316 has become a major parameter in evaluating the viscosity of asphalt after being put forward by SHRP. The rotational viscosity at 135℃ of polymer-modified asphalt binders is required to be smaller than 3 Pa s, i.e., 3,000 cP, as per Superpave specification (AASHTO M 320).

The variation of viscosity at 135℃ with NS concentration from existing studies is presented in Figure 6. An unusual rapid increase in viscosity with NS concentration was reported by Motamedi et al. [30], where a neat asphalt binder with a low softening point (i.e., 46.6℃ as shown in Figure 3b) and viscosity (250 cP as shown in Figure 5) and high penetration (i.e., 88 dmm as shown in Figure 2b) was used; the viscosity rises from 250 to 510 cP at 3% NS and to 2810 cP at 7% NS, approaching the upper limit of Superpave specification. In the other studies presented in Figure 6, the rise in viscosity is more smooth, and based on an average value on the results, when adding 6% NS to asphalt, the viscosity rises from 425 to 593 cP by 40%. A higher viscosity means better resistance to deformation but would make blending more difficult; therefore, procedures for blending NS and asphalt and producing asphalt mixtures should consider the effects of NS on viscosity and be altered based on NS concentration. In addition, the effect of the morphology of NS on the viscosity is not obvious [33].

4.7 Mixing and paving temperature

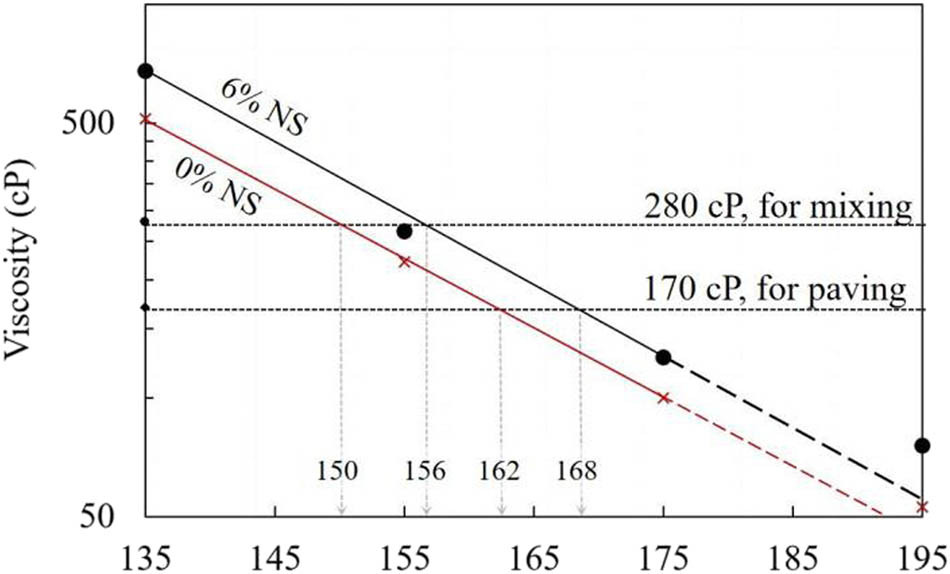

The rotational viscosity at other temperatures has also been experimentally determined in existing studies since the physical properties of asphalt binders are sensitive to temperature. An example has been provided in Figure 7, where the rotational viscosity at 135, 155, 175, and 195℃ is determined for asphalt binder samples with 0 and 6% NS. When a logarithmic longitudinal axis is used, the viscosity of both samples decreases almost linearly with the temperature rise, and in the involved scale of temperature, the NS additive is always able to provide a stable increase in viscosity.

Temperature-viscosity behavior and determination of proper mixing and paving temperatures.

In pavement construction, the mixing and paving temperatures are determined based on the rotational viscosity of asphalt binders as a balance between the workability and aging of asphalt. For unmodified asphalt binders, the temperature corresponding to a viscosity of 170 ± 20 cP is suggested for mixing and 280 ± 30 cP for paving (Figure 7) [20]. It means that the rise in viscosity brought by NS would also require higher temperatures in mixing and paving.

As shown in Figure 7 and Table 3, proper mixing and paving temperatures rise from 162 to 168℃ and from 150 to 156℃, respectively, when 6% NS was added to neat asphalt [17], and a more obvious rise was observed in another study [22]. The additional energy consumption and CO2 emission should be included in the feasibility analysis of NS modification, but associated studies are limited. The blending temperature for NS and asphalt binders may also refer to this approach and vary with the viscosity and NS concentration.

5 Rheological properties before and after aging

5.1 DSR test

The DSR tests are used to evaluate the rheological properties of aged and unchanged asphalt binders at different temperatures as per AASHTO T 315 or ASTM D 7175 [68]. In related studies, a loading rate of 10 rad/s is usually applied, and the testing temperature ranges from 58 to 82℃ with an interval of 6℃ following the requirements of the PG system. Low temperature is usually not applied in these tests since the low-temperature performance of binders focuses on cracking susceptibility and is usually evaluated by BBR tests. Temperature sweep and frequency sweep tests have also been conducted in several studies to obtain more valid and precise results. For example, DSR tests have been conducted at 25 levels of temperature ranging from 30 to 90℃ [18]. The main parameters from the DSR test are complex shared modulus (G*) and phase angle (δ). G* is obtained as the maximum shear stress divided by the maximum shear loading, indicating the resistance of asphalt binders to repeated share deformation. δ is the lag between the strain and the stress during the shear test, indicating the ratio between recoverable and non-recoverable deformation. A phase angle of 0° represents an elastic solid and 90° is a viscous liquid [32]. G*/sinδ is used in the PG system to characterize the high-temperature performance and rutting resistance of asphalt binders. G*/sinδ less than 1.0 kPa indicates the failure of unaged binders. G*sinδ is usually used to evaluate the fatigue performance of pressure aging vessel (PAV)-aged binders [30].

A typical result of variation in G*/sinδ with temperature for neat and NS-modified binders adapted from the literature [18] is presented in Figure 8, and when the temperature rises, G* decreases, but δ increases. 6% NS improves G*/sinδ at all tested temperatures, and such improvement is more obvious in elevated temperatures.

![Figure 8

Variation of G*/sinδ with temperature for neat and NS modified binders (adapted from [18]).](/document/doi/10.1515/ntrev-2023-0138/asset/graphic/j_ntrev-2023-0138_fig_008.jpg)

Variation of G*/sinδ with temperature for neat and NS modified binders (adapted from [18]).

Trends in variations of G*, δ, and G*/sinδ with NS concentration from literature are shown in Table 4, where “↗” indicates a rising trend, “→” means no obvious trend, and “↘” denotes a decreasing trend. The results from Table 4 show general consistency that G* would increase and δ would decrease with the rise in NS concentration, resulting in an increase in G*/sinδ and better high-temperature performance. This result is supported by statistical analysis by the analysis of variance test [11] and is also valid at different loading frequencies from 0.1 to 100 rad/s according to frequency sweep tests [16]. A different result was reported in the study of Saltan et al. [20], possibly because a low NS concentration within only 0.5% was used and the effects of NS were not obvious. It should be mentioned that master curves from frequency sweep tests have also been used to obtain the Glover-Rowe parameter and ΔT c as indicators for cracking [69]; ΔT c is the temperature difference between the stiffness (S) meets 300 MPa and the m value meets 0.3, but such factors have not been used to evaluate the effects of NS on asphalt binders.

Results of unaged neat and NS-modified asphalt binders

| Ref. | G* | δ | G*/sinδ | Details |

|---|---|---|---|---|

| Shafabakhsh and Ani [48] | ↗ | ↘ | ↗ | NS worked with different dosages of TiO2. |

| Fini et al. [18] | ↗ | ↘ | ↗ | Rise in G* was obvious at high temperatures. |

| Saltan et al. [20] | → | → | ↘ | Maximum NS concentration was 0.5%. |

| Han et al. [31] | ↗ | ↘ | ↗ | Only 4% NS concentration was studied. |

| Shi et al. [11] | ↗ | → | ↗ | Conclusions were based on statistical results. |

| Moeini et al. [33] | ↗ | ↘ | ↗ | FNS was more effective than SNS. |

| Bhat and Mir [16] | ↗ | ↘ | ↗ | Frequencies ranged from 0.1–100 rad/s. |

The approach to determine the failure temperature, i.e., the temperature corresponding to G*/sinδ equaling 1,000 Pa, is also shown in Figure 8, and it is 65℃ for neat asphalt and 73℃ for 6%-NS-modified asphalt. Similarly, the failure temperature and its variation with NS concentration obtained from literature directly or by interpolation are presented in Figure 9 [11,18,31,33]. Higher failure temperature indicates better high-temperature performance and rutting resistance. Consistent results in Figure 9 evidenced positive effects of NS, and when NS rises from 0 to 4%, the average increase in failure temperature is 4.2℃. PG of binders may be enhanced by such an increase and would be discussed in Section 5.4.

5.2 DSR test after short-term aging

The DSR tests have also been used to evaluate the rheological properties of aged binders. Two aging procedures are usually used, where rolling thin film oven test (RTFOT) is performed for short-term aging as per ASTM D2872 and AASHTO T 240, and PAV is performed after RTFOT for long-term aging as per ASTM D 6521 and AASHTO R 28. According to Superpave specification and PG system, G*/sinδ of binders after RTFOT is required to stay over 2.2 kPa at the high pavement temperature of PG [70,71]. Similar to the approach for unaged samples presented in Figure 8, the failure temperature of RTFOT-aged binder samples corresponding to a G*/sinδ of 2.2 kPa is presented in Figure 10 based on results from associated studies [11,18,33]. As shown in Figure 10, the failure temperature increases as the NS concentration rises. Based on average results, the failure temperature rises 5.6℃ by adding 6% NS, and FNS shows superiority over SNS. Therefore, NS may improve the high pavement temperature in PG of binders.

5.3 BBR tests after long-term aging

The BBR tests are conducted on the residuals of binder samples after RTFOT and PAV to characterize the crack susceptibility of asphalt at low temperatures [72]. The creep stiffness (S) and the material relaxation constant (m-valve) are obtained from BBR. S reflects the resistance to load and m-valve indicates the crack resistance at low temperatures. At the low pavement temperature, S should be less than 300 MPa and the m-value should be more than 0.3 in the 60-s loading process in the BBR test as per ASTM D6648 [11,31,32,33]. It is a common conclusion that S will increase at a lower temperature, but the m-value is in contrast, and it also applies to NS-modified binders. Consistent results from the literature indicate that the addition of NS would cause an increase in S and a decrease in m-value, and the effects are more obvious at higher NS concentrations [11,31,32,33], indicating that NS additives would deteriorate the low-temperature performance.

5.4 PG

In existing literature, the PG of a binder is determined based on results from a range of tests including DSR, RTFOT, PAV, and BBR as per the AASHTO MP 1 specification. The nomenclature of the PG grade includes two temperatures. The first one is the high pavement temperature (in °C) in which the binder should resist rutting, and it is determined as the maximum temperature level at which G*/sinδ stays over 1.0 kPa before aging and 2.2 kPa after RTFOT aging. The second one (a negative number in °C) is the low pavement temperature in which the binder should resist cracking, and it is usually determined as the lowest temperature level with creep stiffness (S) smaller than 300 MPa and an m-valve over 0.3. Therefore, the PG reflects the high- and low-temperature performance of binders at the same time directly and, therefore, can reflect the changes in properties brought by NS.

By adding NS into asphalt binders, the PG grade may be changed and the variation of PG with NS concentration in literature is presented in Table 5. Consistent results indicate that NS can improve the high pavement temperature in PG by one or two levels, e.g., from PG 58 to PG 70. It indicates the practical and economic value of NS additives. However, the low pavement temperature may deteriorate for one level, e.g., from −22 to −16°C. Therefore, the positive modification effects of NS are limited to high pavement temperatures [21,22].

Effects of NS concentration on PG grades

| Motamedi et al. [30] | NS (%) | 0 | 3 | 5 | 7 |

| PG | PG58-22 | PG58-16 | PG64-16 | PG70-16 | |

| Shi et al. [11] | NS (%) | 0 | 1 | 2 | 3 |

| PG | PG64-22 | PG64-22 | PG70-22 | PG70-16 | |

| Moeini et al. [33] | NS (%) | 0 | 2 | 4 | 6 |

| PG (FNS) | PG64-16 | PG64-16 | PG70-16 | PG70-10 | |

| PG (SNS) | PG64-16 | PG64-16 | PG64-10 | PG70-10 | |

| Sukhija et al. [21] | NS (%) | 0 | 4 | 6 | |

| PG (VG10) | PG58 | PG70 | PG70 | ||

| PG (VG30) | PG64 | PG76 | PG76 | ||

| Ezzat et al. [22] | NS (%) | 0 | 7 | ||

| PG | PG58 | PG70 |

A more updated standard (AASHTO M 322) has been available for PG grading of asphalt since 2020, where traffic loading has been taken into consideration. Parameters from MSCR tests for samples after RTFOT aging, and those from dynamic shear, creep stiffness, and direct tension for samples after PAV aging are used for asphalt grading. However, research on effects of NS on PG grade of asphalt binders under the updated grading criterions is still limited and requires further investigations.

5.5 MSCR tests

The MSCR tests have been used to characterize the rutting resistance of neat and NS-modified asphalt as per ASTM D7405 and AASHTO TP70 in literature [73,74], and updated standards have been available (i.e., AASHTO T 350 for MSCR tests and AASHTO M 322 for asphalt grading). MSCR tests have shown effectiveness in predicting the rutting performance of asphalt mixtures practically according to existing studies [73,74]. In the tests, dynamic load cycles were applied to samples and each cycle included a 1-s creeping and a 9-s recovery. The standard stress levels are 0.1 and 3.2 kPa and the corresponding accumulated non-recoverable creep compliances were measured and referred to as J nr0.1 for 0.1-kPa loads and J nr3.2 for 3.2-kPa loads. A lower value of J nr0.1 and J nr3.2 indicates a better resistance to rutting.

In evaluations on NS-modified binders, a wide range of test scenarios with combinations of different load levels (e.g., 5 and 10 kPa in the study of Sukhija et al. [21]) and temperatures (e.g., 58, 64, and 70℃ in the study of Ghanoon and Tanzadeh [19] and 50℃ in the study of Fini et al. [18]) has been included in literature. Both unaged and RTFOT-aged samples have been investigated [18,21]. Consistent results were reported from these studies that J nr0.1 and J nr3.2 would be decreased by NS additives and would be further reduced with the rise of NS concentration. Therefore, NS additives are effective in improving the rutting resistance of asphalt binders, and the results are consistent with those obtained from the DSR tests.

5.6 FTIR test

When light passes through a sample, a certain amount of light is absorbed by molecules, indicating the chemical groups in the sample. The FTIR results are recorded as the transmitted or absorbed radiation versus the wavenumber, i.e., the frequency of light radiation. Details of the FTIR method have been described in the literature [75]. FTIR tests have been used to identify characteristic functional groups in modified asphalt. Since a functional group may be associated with a specific property of asphalt, by detecting formations of new functional groups in modification processes, FTIR provides a solution to understand the modification mechanism of different additives, e.g., SBS [76], PU [77], TiO2 [78], and also NS [18].

FTIR tests have been conducted on samples of NS, neat asphalt, and NS-modified asphalt, and the wavenumbers ranged from 4,000 to 400 cm−1 [17,18,30,31,32]. The concerned peaks in wavenumbers and the associated chemical groups are presented in Table 6. It should be mentioned that the characteristic absorption peak for a specific bond may show differences among studies, for example, the absorption peak for the C═C bond was witnessed at 1,604 cm−1 in the study of Han et al. [31] and 1,602 cm−1 in the study of Enieb and Diab [17]. According to the results from FTIR tests, neat and NS-modified asphalt shows almost identical chemical groups, indicating that no new chemical groups were produced in the modification process, and the modification effects are physically dominated [31].

Wavenumber and associated chemical groups

| Wavenumber (cm−1) | Chemical group | Component | Ref. |

|---|---|---|---|

| 470, 804 and 1,114 | Si–O–Si bond | NS | [30,31] |

| 723–870 | CH and CH2 bonds | Polyaromatics | [30] |

| 1,384 and 1,458 | Bending vibration of C–H bond | Alkanes | [31] |

| 1,600–1,700 | C═O bond | Aging | [18] |

| 1,604 | Stretching vibration of C═C bond | Aromatics | [31] |

| 1,635 and 3,410 | Hydroxyl | NS | [31] |

| 2,922 and 2,852 | Stretching vibration of C–H bond | Alkanes | [30] |

FTIR tests have also been used to evaluate the aging resistance of binders [18], since the aging process is associated with oxidation characterized by the formation of the carbonyl functional group, and the appearance of the group can be indicated by the C═O bond. It has been evidenced that the C═O infrared signal would increase with the oxidation process of asphalt binder [79]. The superiority of C═O over C═C or S═O as an indicator for asphalt aging has been evidenced in the literature [32]. Based on this theory, asphalt samples with 0–6% of NS after aging have been subjected to FTIR tests. The rolling thin film oven was used for short-term aging [18] and the PAV was for long-term aging [32]. The results showed that the samples with 6% NS had the lowest peak intensity and hence best resistance to aging. Apart from the large surface area, the presence of hydroxyl groups in NS as shown in Table 6 was suggested to be responsible for the improvement, since they would interact with polar aromatic and asphaltene molecules and reduce their susceptibility to oxidation [18].

6 Future research directions

6.1 Effects of variations in material properties

In existing research, one study usually focuses on a single type of asphalt and NS, where NS concentrations are investigated but effects of variations in material properties are neglected, which hinders practical applications. In these studies, similar NS was used with particle dimension of smaller than 30 nm and the purity over 99%, where effects of morphology, purity, and particle size are ignored. Therefore, an opportunity for further research is effects of variations in properties of asphalt binders and NS on the modification process. Since high-quality NS is not always affordable, such research is meaningful to reduce the cost of NS-modified asphalt and achieve industrialization.

6.2 Optimization of blending procedures by quantitative approaches

Insufficient blending causes partially inferior material performance, while excessive blending wastes time and energy and causes asphalt aging. In existing research, blending status is empirically evaluated by SEM or FTIR tests, where quantitative approaches are still unavailable. Quantitative approaches are necessary to objectively evaluate the distribution of NS in asphalt binders and hence to determine reasonable blending temperature, shearing speed, and blending duration. After that, standards may be established to guide industrial production.

6.3 Comparison among conventional and rheological indicators

Different evaluating systems have been applied to describe a single behavior of asphalt binders, for example, low-temperature cracking of mixtures may be predicted by ductility, DSR tests, frequency sweep tests, etc. Different, even contrary conclusions have been drawn about the effects of NS on asphalt binders. Therefore, an opportunity for further research is evaluating the effectiveness of conventional and rheological indicators by laboratorial and field tests on asphalt mixtures.

6.4 Evaluation on NS-modified asphalt under updated standards and techniques

With the development of research and techniques, the specifications for asphalt testing and characterization have been constantly updated, and these updated standards and techniques should be applied to NS-modified asphalt binders. For example, in existing studies, the MSCR tests have been conducted as per ASTM D7405 and AASHTO TP70, while updated standards have been available (i.e., AASHTO T 350 for MSCR tests and AASHTO M 322 for asphalt grading). An updated standard (AASHTO M 322) has also been available for the PG grading of asphalt since 2020. However, such updated standards have seldom been used in the characterization of NS-modified asphalt. Several new indicators, e.g., Glover-Rowe parameter and ΔT c, have seldom been used in studies about NS-modified asphalt, leaving an opportunity for future research.

7 Conclusion

In this study, a literature review was conducted on the modification effects of NS additives on asphalt binders, where basic morphological and physical properties of NS particles were first introduced. Blending procedures for NS and binders were presented and compared. The modification effects were evaluated by conventional test methods and rheological ones in the literature and the results were extensively reviewed and compared. According to the results, the following conclusions may be drawn:

A large specific surface area is the base for the modification effects of NS on asphalt binders. The particle dimension is usually smaller than 30 nm and the purity over 99%, leading to a specific surface area of over 100 m2/g.

The blending procedure varies among studies due to a lack of specific standards. It ranges from 130 to 185℃ in temperature, 1,500–6,100 rpm in the shear speed, and 15–120 min in the blending duration. Quantitative methods require further investigation to optimize the blending procedure.

Consistent results suggest that the penetration and the ductility would decrease as NS concentration rises, but the softening point presents a contrasting trend. It indicates the positive effects on high-temperature performance and possible negative effects on low-temperature performance. The storage stability of polymer-modified asphalt binders may be improved by NS.

Viscosity of binders at 135℃ rises with NS concentration according to DSR tests and would cause an obvious rise in proper mixing and paving temperatures. The complex modulus (G*) and rutting parameters (G*/sinδ) rise with increasing NS concentration. Results from DSR tests on aged samples and MSCR tests also support the improvement in high-temperature performance. It may cause a possible rise in the high pavement temperature of PG grade.

Results from BBR tests suggest that NS would deteriorate the cracking resistance and low-temperature performance of asphalt binders, and the low pavement temperature in PG may also be negatively affected. Therefore, NS may be improper for low-temperature conditions.

-

Funding information: The support from the IUR Project of Science and Technology Bureau of Ningde (2021C008), the Key S&T Project of Ministry of Transport of China (2021-ZD1-004), the Scientific Research Program Project of Shanghai Municipal Transportation Commission (JT2021-KY-016), the Qishan Scholar Project (511062) of Fuzhou University, and the Fuzhou University Testing Fund of Precious Apparatus (2023T024) are gratefully acknowledged.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Alae M, Xu L, Cao Z, Xu X, Xiao F. Fatigue and intermediate-temperature cracking performance of rejuvenated recycled asphalt binders and mixtures: A review. J Clean Prod. 2023;384:135587.10.1016/j.jclepro.2022.135587Search in Google Scholar

[2] Li R, Xiao F, Amirkhanian S, You Z, Huang J. Developments of nano materials and technologies on asphalt materials – A review. Constr Build Mater. 2017;143:633–48.10.1016/j.conbuildmat.2017.03.158Search in Google Scholar

[3] Ziari H, Amini A, Goli A, Mirzaiyan D. Predicting rutting performance of carbon nano tube (CNT) asphalt binders using regression models and neural networks. Constr Build Mater. 2018;160:415–26.10.1016/j.conbuildmat.2017.11.071Search in Google Scholar

[4] Amini A, Ziari H, Saadatjoo SA, Hashemifar NS, Goli A. Rutting resistance, fatigue properties and temperature susceptibility of nano clay modified asphalt rubber binder. Constr Build Mater. 2021;267:120946.10.1016/j.conbuildmat.2020.120946Search in Google Scholar

[5] Lima O, Afonso C, Rocha Segundo I, Landi S, Homem NC, Freitas E, et al. Asphalt binder “Skincare”? aging evaluation of an asphalt binder modified by nano-TiO2. Nanomaterials (Basel, Switz). 2022;12(10):1678.10.3390/nano12101678Search in Google Scholar PubMed PubMed Central

[6] Wang D, Zhang F, Huang K, Zhang L. Study on preparation and performance of advanced nano‐modified epoxy asphalt. J Appl Polym Sci. 2023;140(14):n/a.10.1002/app.53688Search in Google Scholar

[7] Bhat FS, Mir MS. Study investigating the influence of warm-mix asphalt additives on rutting and fatigue performance of nano-modified asphalt binders. Transp Res Rec. 2022;2676(4):719–31.10.1177/03611981211064995Search in Google Scholar

[8] Ji Z, Sun L, Chen L, Gu W, Tian Y, Zhang X. Pavement performance and modification mechanisms of asphalt binder with nano-Al2O3. Int J Pavement Eng. 2022;ahead-of-print (ahead-of-print) 1–11.10.1080/10298436.2022.2136373Search in Google Scholar

[9] Barot T, Rawtani D, Kulkarni P. Nanotechnology-based materials as emerging trends for dental applications. Rev Adv Mater Sci. 2021;60(1):173–89.10.1515/rams-2020-0052Search in Google Scholar

[10] Debbarma K, Debnath B, Sarkar PP. A comprehensive review on the usage of nanomaterials in asphalt mixes. Constr Build Mater. 2022;361:129634.10.1016/j.conbuildmat.2022.129634Search in Google Scholar

[11] Shi X, Cai L, Xu W, Fan J, Wang X. Effects of nano-silica and rock asphalt on rheological properties of modified bitumen. Constr Build Mater. 2018;161:705–14.10.1016/j.conbuildmat.2017.11.162Search in Google Scholar

[12] Bala N, Napiah M, Kamaruddin I. Effect of nanosilica particles on polypropylene polymer modified asphalt mixture performance. Case Stud Constr Mater. 2018;8:447–54.10.1016/j.cscm.2018.03.011Search in Google Scholar

[13] Liu C, Su X, Wu Y, Zheng Z, Yang B, Luo Y, et al. Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete. Nanotechnol Rev. 2021;10(1):1395–409.10.1515/ntrev-2021-0097Search in Google Scholar

[14] Yunchao T, Zheng C, Wanhui F, Yumei N, Cong L, Jieming C. Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete. Nanotechnol Rev. 2021;10(1):819–38.10.1515/ntrev-2021-0058Search in Google Scholar

[15] Ghasemi M, Marandi SM, Tahmooresi M, Jalalkamali R, Taherzadeh R. Mousavian, Modification of Stone Matrix Asphalt with Nano-SiO2. J Basic Appl Sci Res. 2012;2:1338–44.Search in Google Scholar

[16] Bhat FS, Mir MS. Rheological investigation of asphalt binder modified with nanosilica. Int J Pavement Res Technol. 2021;14(3):276–87.10.1007/s42947-020-0327-2Search in Google Scholar

[17] Enieb M, Diab A. Characteristics of asphalt binder and mixture containing nanosilica. Int J Pavement Res Technol. 2017;10(2):148.10.1016/j.ijprt.2016.11.009Search in Google Scholar

[18] Fini EH, Hajikarimi P, Rahi M, Moghadas Nejad F. Physiochemical, rheological, and oxidative aging characteristics of asphalt binder in the presence of mesoporous silica nanoparticles. J Mater Civ Eng. 2016;28(2):4015133.10.1061/(ASCE)MT.1943-5533.0001423Search in Google Scholar

[19] Ghanoon SA, Tanzadeh J. Laboratory evaluation of nano-silica modification on rutting resistance of asphalt Binder. Constr Build Mater. 2019;223:1074–82.10.1016/j.conbuildmat.2019.07.295Search in Google Scholar

[20] Saltan M, Terzi S, Karahancer S. Examination of hot mix asphalt and binder performance modified with nano silica. Constr Build Mater. 2017;156:976–84.10.1016/j.conbuildmat.2017.09.069Search in Google Scholar

[21] Sukhija M, Saboo N, Yadav AK, Rath C. Laboratory study on the suitability of nano-silica as a modifier for asphalt binders. Constr Build Mater. 2021;302:124406.10.1016/j.conbuildmat.2021.124406Search in Google Scholar

[22] Ezzat H, El-Badawy S, Gabr A, Zaki S, Breakah T. Predicted performance of hot mix asphalt modified with nano-montmorillonite and nano-silicon dioxide based on Egyptian conditions. Int J Pavement Eng. 2020;21(5):642–52.10.1080/10298436.2018.1502437Search in Google Scholar

[23] Ji X, Wang S, Yao B, Si W, Wang C, Wu T, et al. Preparation and properties of nano-SiO2 modified microcapsules for asphalt pavement. Mater Des. 2023;229:111871.10.1016/j.matdes.2023.111871Search in Google Scholar

[24] Dai Y, Jiang J, Gu X, Zhao Y, Ni F. Sustainable urban street comprising permeable pavement and bioretention facilities: a practice. Sustainability. 2020;12(19):8288.10.3390/su12198288Search in Google Scholar

[25] Jiang J, Leng Z, Yang B, Lu G, Tan Z, Han M, et al. Penetration mechanism of the emulsion-based rejuvenator in damaged porous asphalt mixture: Microstructure characterization and 3D reconstruction. Mater Des. 2022;221:111014.10.1016/j.matdes.2022.111014Search in Google Scholar

[26] Luo H, Huang X, Rongyan T, Ding H, Huang J, Wang D, et al. Advanced method for measuring asphalt viscosity: Rotational plate viscosity method and its application to asphalt construction temperature prediction. Constr Build Mater. 2021;301:124129.10.1016/j.conbuildmat.2021.124129Search in Google Scholar

[27] Tan Z, Leng Z, Jiang J, Cao P, Jelagin D, Li G, et al. Numerical study of the aggregate contact effect on the complex modulus of asphalt concrete. Mater Des. 2022;213:110342.10.1016/j.matdes.2021.110342Search in Google Scholar

[28] Zhao Y, Jiang J, Dai Y, Zhou L, Ni F. Thermal property evaluation of porous asphalt concrete based on heterogeneous meso-structure finite element simulation. Appl Sci. 2020;10(5):1671.10.3390/app10051671Search in Google Scholar

[29] Zhao Y, Jiang J, Zhou L, Dai Y, Ni F. Meso-structure image pre-selection method for two-dimensional finite element modeling in beam bending simulation of asphalt mixture. Constr Build Mater. 2021;268:121129.10.1016/j.conbuildmat.2020.121129Search in Google Scholar

[30] Motamedi M, Shafabakhsh G, Azadi M. Evaluating fatigue-damage of asphalt binder and mastic modified with nano-silica and synthesized polyurethane using VECD method. J Mater Civ Eng. 2020;32(8):04017054.10.1061/(ASCE)MT.1943-5533.0003280Search in Google Scholar

[31] Han L, Zheng M, Li J, Li Y, Zhu Y, Ma Q. Effect of nano silica and pretreated rubber on the properties of terminal blend crumb rubber modified asphalt. Constr Build Mater. 2017;157:277–91.10.1016/j.conbuildmat.2017.08.187Search in Google Scholar

[32] Yao H, You Z, Li L, Lee CH, Wingard D, Yap YK, et al. Rheological properties and chemical bonding of asphalt modified with nanosilica. J Mater Civ Eng. 2013;25(11):1619–30.10.1061/(ASCE)MT.1943-5533.0000690Search in Google Scholar

[33] Moeini AR, Badiei A, Rashidi AM. Effect of nanosilica morphology on modification of asphalt binder. Road Mater Pavement Des. 2020;21(8):2230–46.10.1080/14680629.2019.1602072Search in Google Scholar

[34] Kie Badroodi S, Reza Keymanesh M, Shafabakhsh G. Experimental investigation of the fatigue phenomenon in nano silica-modified warm mix asphalt containing recycled asphalt considering self-healing behavior. Constr Build Mater. 2020;246:117558.10.1016/j.conbuildmat.2019.117558Search in Google Scholar

[35] Long Z, You L, Tang X, Ma W, Ding Y, Xu F. Analysis of interfacial adhesion properties of nano-silica modified asphalt mixtures using molecular dynamics simulation. Constr Build Mater. 2020;255:119354.10.1016/j.conbuildmat.2020.119354Search in Google Scholar

[36] Long Z, Tang X, Guo N, Ding Y, Ma W, You L, et al. Atomistic-scale investigation of self-healing mechanism in Nano-silica modified asphalt through molecular dynamics simulation. J Infrastruct Preserv Resil. 2022;3(1):1–24.10.1186/s43065-022-00049-2Search in Google Scholar

[37] Alvarez AE, Espinosa LV, Caro S, Rueda EJ, Aguiar JP, Loria LG. Differences in asphalt binder variability quantified through traditional and advanced laboratory testing. Constr Build Mater. 2018;176:500–8.10.1016/j.conbuildmat.2018.05.046Search in Google Scholar

[38] Mohammad LN, Elseifi MA, Cooper SB, Raghavendra A. Evaluating effects of volumetric and mechanistic test variability on predicted performance of asphalt pavement: Applying the mechanistic–empirical pavement design guide. Transp Res Rec. 2012;2268(1):43–9.10.3141/2268-06Search in Google Scholar

[39] Chen M, Geng J, Xia C, He L, Liu Z. A review of phase structure of SBS modified asphalt: Affecting factors, analytical methods, phase models and improvements. Constr Build Mater. 2021;294:123610.10.1016/j.conbuildmat.2021.123610Search in Google Scholar

[40] Zhou X, Huang Q, Xu S. Multi-scale analysis of moisture diffusion and distribution in different types of asphalt mixtures. Int J Pavement Eng. 2022;23(2):187–96.10.1080/10298436.2020.1736295Search in Google Scholar

[41] Ortiz-Islas E, Sosa-Arróniz A, Manríquez-Ramírez ME, Rodríguez-Pérez CE, Tzompantzi F, Padilla JM. Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells. Rev Adv Mater Sci. 2021;60(1):25–37.10.1515/rams-2021-0009Search in Google Scholar

[42] Nazari H, Naderi K, Moghadas Nejad F., Improving aging resistance and fatigue performance of asphalt binders using inorganic nanoparticles. Constr Build Mater. 2018;170:591–602.10.1016/j.conbuildmat.2018.03.107Search in Google Scholar

[43] Taherkhani H, Afroozi S, Javanmard S. Comparative Study of the Effects of Nanosilica and Zyco-Soil Nanomaterials on the Properties of Asphalt Concrete. J Mater Civ Eng. 2017;29(8):04017054.10.1061/(ASCE)MT.1943-5533.0001889Search in Google Scholar

[44] Guo Y, Zhang YX, Soe K, Wuhrer R, Hutchison WD, Timmers H. Development of magnesium oxychloride cement with enhanced water resistance by adding silica fume and hybrid fly ash-silica fume. J Clean Prod. 2021;313:127682.10.1016/j.jclepro.2021.127682Search in Google Scholar

[45] Tiwari N, Satyam N. Evaluation of strength and water susceptibility performance of polypropylene fiber-reinforced and silica fume-modified hot mix asphalt. Adv Civ Eng Mater. 2021;10(1):380–95.10.1520/ACEM20210029Search in Google Scholar

[46] Zheng X, Xu W, Feng H, Cao K. High and low temperature performance and fatigue properties of silica fume/SBS compound modified asphalt. Materials. 2020;13(19):4446.10.3390/ma13194446Search in Google Scholar PubMed PubMed Central

[47] Zhu J, Xu W. Aging resistance of silica fume/styrene-butadiene-styrene composite-modified asphalt. Materials. 2021;14(21):6536.10.3390/ma14216536Search in Google Scholar PubMed PubMed Central

[48] Shafabakhsh GH, Ani OJ. Experimental investigation of effect of Nano TiO2/SiO2 modified bitumen on the rutting and fatigue performance of asphalt mixtures containing steel slag aggregates. Constr Build Mater. 2015;98:692–702.10.1016/j.conbuildmat.2015.08.083Search in Google Scholar

[49] Shafabakhsh G, Motamedi M, Firouznia M, Isazadeh M. Experimental investigation of the effect of asphalt binder modified with nanosilica on the rutting, fatigue and performance grade. Pet Sci Technol. 2019;37(13):1495–500.10.1080/10916466.2018.1476534Search in Google Scholar

[50] Al-Sabaeei A, Napiah M, Sutanto M, Habib NZ, Bala N, Kumalasari I, et al. Application of nano silica particles to improve high-temperature rheological performance of tyre pyrolysis oil-modified bitumen. Road Mater Pavement Des. 2022;23(9):1999–2017.10.1080/14680629.2021.1945483Search in Google Scholar

[51] Lushinga N, Dong Z, Cao L. Evaluating the high-temperature properties and reaction mechanism of terminal blend rubber/nano silica composite modified asphalt using activated rubber. Nanomaterials (Basel). 2022;12(24):4388.10.3390/nano12244388Search in Google Scholar PubMed PubMed Central

[52] Babagoli R, Ameli A, Salari S, Hosseinian SM, Ebrahimi Moghaddam A. Investigation of the effect of combined nanosilica and iranian natural binder on the rheological behavior of mastics and performance of asphalt mixtures. J Mater Civ Eng. 2023;35(4):04023041.10.1061/(ASCE)MT.1943-5533.0004695Search in Google Scholar

[53] Al-Sabaeei AM, Napiah MB, Sutanto MH, Alaloul WS, Zoorob SE, Usman A. Influence of nanosilica particles on the high-temperature performance of waste denim fibre-modified bitumen. Int J Pavement Eng. 2022;23(2):207–20.10.1080/10298436.2020.1737060Search in Google Scholar

[54] Kamboozia N, Saed SA, Rad SM. Rheological behavior of asphalt binders and fatigue resistance of SMA mixtures modified with nano-silica containing RAP materials under the effect of mixture conditioning. Constr Build Mater. 2021;303:124433.10.1016/j.conbuildmat.2021.124433Search in Google Scholar

[55] Saed SA, Kamboozia N, Mousavi Rad S. Performance evaluation of stone matrix asphalt mixtures and low-temperature properties of asphalt binders containing reclaimed asphalt pavement materials modified with nanosilica. J Mater Civ Eng. 2022;34(1):0004016.10.1061/(ASCE)MT.1943-5533.0004016Search in Google Scholar

[56] Ke Y, Cao J, Xu S, Bian C, Zhang C, Jia X. Storage stability and anti-aging performance of SEBS/organ-montmorillonite modified asphalt. Constr Build Mater. 2022;341:127875.10.1016/j.conbuildmat.2022.127875Search in Google Scholar

[57] Yao L, Leng Z, Lan J, Chen R, Jiang J. Environmental and economic assessment of collective recycling waste plastic and reclaimed asphalt pavement into pavement construction: A case study in Hong Kong. J Clean Prod. 2022;336:130405.10.1016/j.jclepro.2022.130405Search in Google Scholar

[58] Han Y, Cui B, Tian J, Ding J, Ni F, Lu D. Evaluating the effects of styrene-butadiene rubber (SBR) and polyphosphoric acid (PPA) on asphalt adhesion performance. Constr Build Mater. 2022;321:126028.10.1016/j.conbuildmat.2021.126028Search in Google Scholar

[59] Qasim ZI, Abed AH, Almomen KA. Evaluation of Mixing and Compaction Temperatures (MCT) for modified asphalt binders using zero shear viscosity and Cross-Williamson model. Case Stud Constr Mater. 2019;11:e00302.10.1016/j.cscm.2019.e00302Search in Google Scholar

[60] Gražulytė J, Vaitkus A, Bitarytė S. Optimisation of nano-ZnO And nano-SiO2 mixing time for bitumen modification. IOP Conf Ser: Mater Sci Eng. 2021:1202:1.10.1088/1757-899X/1202/1/012017Search in Google Scholar

[61] Yusoff NIM, Breem AAS, Alattug HNM, Hamim A, Ahmad J. The effects of moisture susceptibility and ageing conditions on nano-silica/polymer-modified asphalt mixtures. Constr Build Mater. 2014;72:139–47.10.1016/j.conbuildmat.2014.09.014Search in Google Scholar

[62] Alhamali DI, Yusoff NIM, Wu J-T, Liu Q, Albrka SI. The effects of nano silica particles on the physical properties and storage stability of polymer-modified bitumen. J Civ Eng Res. 2015;5:11–6.Search in Google Scholar

[63] Zarei M, Salehikalam A, Tabasi E, Naseri A, Worya Khordehbinan M, Negahban M. Pure mode I fracture resistance of hot mix asphalt (HMA) containing nano-SiO2 under freeze–thaw damage (FTD). Constr Build Mater. 2022;351:128757.10.1016/j.conbuildmat.2022.128757Search in Google Scholar

[64] Ye Z, Ren W, Yang H, Miao Y, Sun F, Wang L. An improved asphalt penetration test method. Materials (Basel). 2021;14(1):147.10.3390/ma14010147Search in Google Scholar PubMed PubMed Central

[65] Wang H-P, Guo Y-X, Wu M-Y, Xiang K, Sun S-R. Review on structural damage rehabilitation and performance assessment of asphalt pavements. Rev Adv Mater Sci. 2021;60(1):438–49.10.1515/rams-2021-0030Search in Google Scholar

[66] Lesueur D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv Colloid Interface Sci. 2009;145(1):42–82.10.1016/j.cis.2008.08.011Search in Google Scholar PubMed

[67] Ehinola O, Falode O, Jonathan G. Softening point and Penetration Index of bitumen from parts of Southwestern Nigeria. Nafta Zagreb. 2017;63:319–23.Search in Google Scholar

[68] Sun X, Zhang Y, Peng Q, Yuan J, Cang Z, Lv J. Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate. Nanotechnol Rev. 2021;10(1):1801–11.10.1515/ntrev-2021-0106Search in Google Scholar

[69] Zhang R, Sias JE, Dave EV. Evaluation of the cracking and aging susceptibility of asphalt mixtures using viscoelastic properties and master curve parameters. J Traffic Transp Eng. 2022;9(1):106–19.10.1016/j.jtte.2020.09.002Search in Google Scholar

[70] Xu S, Liu L, Jia X, Tighe S, Zhang C, Ma H, et al. Investigation of aging resistance of organic layered double hydroxide/antioxidant composite-modified asphalt. ACS Sustain Chem Eng. 2023;11(1):267–77.10.1021/acssuschemeng.2c05344Search in Google Scholar

[71] Xu S, Jia X, Huang R, Fang L, Ma Z, Zhang C, et al. Preparation and performance evaluation of different bitumens modified by antioxidant/PABA-LDHs composites. Constr Build Mater. 2023;367:130286.10.1016/j.conbuildmat.2022.130286Search in Google Scholar

[72] Walubita LF, Fuentes L, Tanvir H, Chunduri HR, Dessouky S. Correlating the Asphalt-Binder BBR Test Data to the HMA (ML-OT) Fracture Properties. J Mater Civ Eng. 2021;33(9):04021230.10.1061/(ASCE)MT.1943-5533.0003866Search in Google Scholar

[73] Zhang J, Walubita LF, Faruk ANM, Karki P, Simate GS. Use of the MSCR test to characterize the asphalt binder properties relative to HMA rutting performance – A laboratory study. Constr Build Mater. 2015;94:218–27.10.1016/j.conbuildmat.2015.06.044Search in Google Scholar

[74] Yang X, You Z. High temperature performance evaluation of bio-oil modified asphalt binders using the DSR and MSCR tests. Constr Build Mater. 2015;76:380–7.10.1016/j.conbuildmat.2014.11.063Search in Google Scholar

[75] Karahancer SS, Kiristi M, Terzi S, Saltan M, Oksuz AU, Oksuz L. Performance evaluation of nano-modified asphalt concrete. Constr Build Mater. 2014;71:283–8.10.1016/j.conbuildmat.2014.08.072Search in Google Scholar

[76] Yan C, Huang W, Ma J, Xu J, Lv Q, Lin P. Characterizing the SBS polymer degradation within high content polymer modified asphalt using ATR-FTIR. Constr Build Mater. 2020;233:117708.10.1016/j.conbuildmat.2019.117708Search in Google Scholar

[77] Jin X, Guo N, You Z, Wang L, Wen Y, Tan Y. Rheological properties and micro-characteristics of polyurethane composite modified asphalt. Constr Build Mater. 2020;234:117395.10.1016/j.conbuildmat.2019.117395Search in Google Scholar

[78] Zhang S, Hong H, Zhang H, Chen Z. Investigation of anti-aging mechanism of multi-dimensional nanomaterials modified asphalt by FTIR, NMR GPC. Constr Build Mater. 2021;305:124809.10.1016/j.conbuildmat.2021.124809Search in Google Scholar

[79] Ge D, Chen S, You Z, Yang X, Yao H, Ye M, et al. Correlation of DSR results and FTIR’s carbonyl and sulfoxide indexes: effect of aging temperature on asphalt rheology. J Mater Civ Eng. 2019;31(7):04019115.10.1061/(ASCE)MT.1943-5533.0002781Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Preparation of CdS–Ag2S nanocomposites by ultrasound-assisted UV photolysis treatment and its visible light photocatalysis activity

- Significance of nanoparticle radius and inter-particle spacing toward the radiative water-based alumina nanofluid flow over a rotating disk

- Aptamer-based detection of serotonin based on the rapid in situ synthesis of colorimetric gold nanoparticles

- Investigation of the nucleation and growth behavior of Ti2AlC and Ti3AlC nano-precipitates in TiAl alloys