A review of the performance of fibre-reinforced composite laminates with carbon nanotubes

-

Mahdi Hosseini

, Milan Gaff

, Haitao Li

, Petr Konvalinka

Abstract

Impact loads lead to the failure of structures and significantly diminish their operational lifespan. The necessity to enhance impact performance has shown gradual progress, resulting in utilising nano-fillers as an additional reinforcement within the matrix. Despite the significant number of studies that have been done on this unique hybrid material, there have only been a few reviews published that discuss the effect of production processes on mechanical properties and performance in these hybrid composites under projectile impact. There have been conflicting results obtained in experimental results from the literature. The disparity is related to the variation in dispersion, bonding states, and inconsistent fabrication processes. This work defines the pros and cons of carbon nanotube (CNT)-based composites along with a systematic representation of the development of CNT-reinforced composites under projectile impact using experimental, analytical, and numerical techniques. The potential of CNT reinforcement on fibre-reinforced polymers (FRPs) and its effect on mechanical properties have been discussed. Furthermore, different impact test setups are explored to determine the effective method to determine the impact performance of CNT-reinforced laminates. Moreover, the impact of surface treatment is discussed using different non-destructive methods, and the influence of CNT reinforcement is determined. In addition, mechanical and impact response with varying configurations of fibres is gathered from the available literature, and optimal design based on the required application is suggested. Also, analytical methods developed to determine the impact response of laminates are discussed to determine the parameters dominating the impact response of the laminate. This review will help researchers find the right combination of FRP materials for a given application.

1 Introduction

Fibre-reinforced polymer (FRP) composites have a high specific strength, modulus, and corrosion resistance properties, making them one of the basic materials in various fields such as aircraft, automotive, naval, medical, energy harvesting, and other industries [1,2,3,4,5]. The structures made of FRP composites are often exposed to impact loads during their service life [6,7,8]. Traditionally, impact scenarios are distinguished as (a) low-velocity impact (LVI), (b) intermediate-velocity impact, and (c) high-velocity impact (HVI) [9]. LVI determines that barely visible damage in the structure may go undetected, leading to a considerable decrease in structural lifespan. The highest limit of velocity for LVI can range from 1 to 10 m/s, depending on the target stiffness, the material’s characteristics, and the mass and stiffness of the impactor [10]. Under LVI, the mass ratio between the impactor and the target determines the target material response [11]. Intermediate-velocity impact velocity falls between LVI and HVI. The literature review does not clearly define the impact velocities under this category [12]. In the case of HVI, the impactor weight is lower, and the impinging velocity is very high, leading to transverse deflection or complete penetration of the projectile. Finally, the ballistic impact can be referred to as an HVI accompanied by high-magnitude forces acting on structures, leading to significant localised deformation in the contact region and, eventually, fracture of the impacting surface.

Impact events being a high-strain rate event, the structural response is dominated by the following parameters: (a) changes in the material strength and stiffness, (b) fracture during impact, (c) inertial forces during contact with the projectile, and (d) wave propagation after the impact [13,14]. Numerous tests and strategies have been developed to consider the behaviour of materials under dynamic conditions, and every experimental method is designated to a particular strain rate effect. The respective experimental test and the following material properties are listed in Table 1.

Experimental methods to determine material properties at various strain rates

| Experimental technique | Application | Strain rate (

|

Velocity | Material properties testing |

|---|---|---|---|---|

| Quasi-static material tests: tension, compression, torsion and flexural tests | FRP-reinforced RC concretes |

|

2 mm/min | Quasi-static material properties |

| Drop specimen tests | 1 m springboard |

|

4.4 m/s | Test susceptibility for damage and assessment of failure type |

| Drop weight tests | 3–10 m springboard |

|

7–14 m/s | Energy absorption of a material/component |

| Pendulum impact tests (Izod or Charpy) | Armoured vehicle/buried explosive |

|

5–15 m/s | Fracture energy of a notched specimen |

| Split Hopkinson pressure bar test | Bird Strike Military aircraft |

|

283 m/s | Dynamic material properties at high strain rates |

| Taylor cylinder impact test | Rifle bullets |

|

750–950 m/s | The dynamic yield strength in compression |

| Flyer plate or ball impact experiments | Warhead fragment speeds |

|

1–2 km/s | Dynamic properties of materials at very high strain rates |

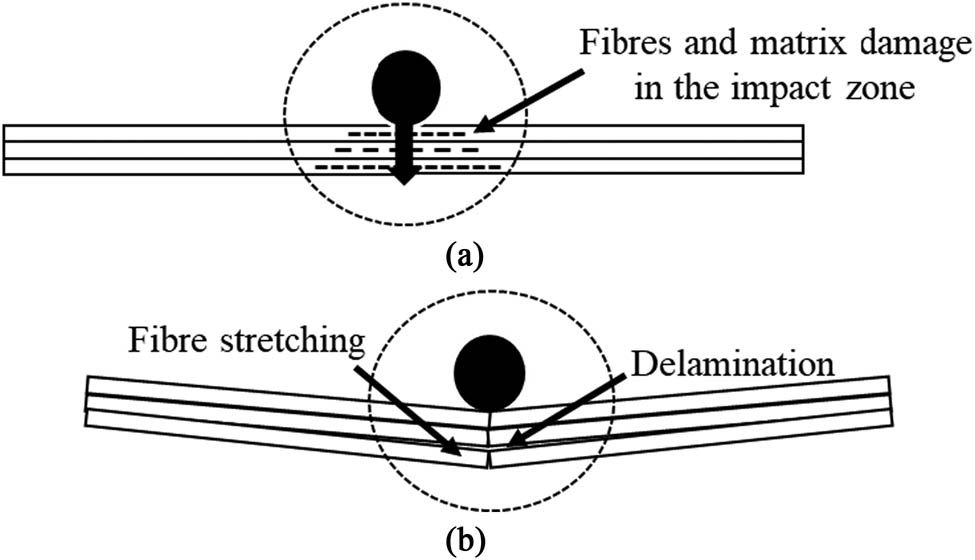

Usually, ballistic impact testing is employed to determine the ballistic limit (V50) of a structure [15], where the V50 ballistic limit is determined by taking the mean of the highest partial penetration projectile velocity and mean of lowest perforation impact velocity of the projectile on the defined structure. The structural material suffers from stretching, shearing, twisting, and compression due to the complex state of stresses generated during projectile penetration events. In FRP composites, the damage due to projectile impact can be segregated into two distinct phases, as shown in Figure 1. First, fibres and the outer layer of the matrix are damaged in the impact zone due to projectile impact. Second, the decelerating projectile energy is absorbed through matrix shearing and fibre stretching, followed by delamination.

Stages of damage due to projectile impact: (a) localised damage due to projectile impact and (b) damage progression leading to fibre stretching and delamination.

Most researchers are directed to focus on developing FRPs modified with carbon nanotubes (CNTs) to withstand impact loading, which is the current trend. A “Science Direct” search using the keywords “impact, composite, and CNT” suggests that at least 5,515 articles were published in the area in 2022. As shown in Figure 2, roughly 80% of the articles were published after 2014.

Publications on composite-reinforced CNTs under impact loads.

1.1 Distinction of nanoparticles

Due to their extraordinary versatility, CNTs have been employed in a variety of industrial products, including antifouling coatings, rechargeable batteries, sporting goods, and water filters [16,17,18]. Recent studies have grafted fibres with nanoparticles or added nanofillers in the matrix to improve FRP laminate’s impact performance and toughness. The nanoparticles can be distinguished into zero-dimensional (0D), one-dimensional (1D), two-dimensional (2D), and three-dimensional (3D) structures where the morphology, size, and shape dominate the properties of the composite laminates. Many researchers have reported using 0D nanoparticles like nano-silica, carbon black, fullerene, and alumina to enhance the mechanical properties of composite laminates [19,20,21,22]. Subsequently, introducing nanoparticles into the matrix influenced the impact properties of the composite laminate; whereas, contradicting the existing research, some authors also reported degradation in impact properties due to the agglomeration of these particles in the matrix [23,24]. 1D nanoparticles, such as CNTs, are frequently favoured over 0D nanoparticles when considering toughening or impact resistance properties of FRP laminates [25,26,27].

1.2 Historical development of CNT

About three decades ago, in 1991, Sumio Iijima discovered tubular-like structures formed of carbon at the nanometre scale, which are popularly known as CNTs [28,29]. Since then, these structures have accounted for considerable research and technical interest, showing extraordinary mechanical and electrical properties [30,31]. CNTs are the most potent known nanomaterials in nature due to covalently bonded carbon atoms, forming an extremely stable configuration resulting in axial Young’s modulus in the range of about 1–1.8 TPa [32]. Consequently, CNTs offer unique opportunities for developing primary CNT-reinforced composite structures, leading to fundamentally new materials with advanced properties. Figure 3 depicts several forms of CNTs where the chiral vector is employed to specify the rollup direction of the graphene sheet. An integer pair (n, m) approximating the chiral vector is used to classify the variety of nanotubes. The armchair configuration has the same value for n and m, whereas m = 0, a zigzag tube is obtained; all other combinations are chiral nanotubes:

where

![Figure 3

Different chiralities of CNTs [33]. (a) Armchair CNT, (b) (5, 0) Zigzag CNT, and (c) (6, 2) chiral CNT.](/document/doi/10.1515/ntrev-2023-0164/asset/graphic/j_ntrev-2023-0164_fig_003.jpg)

Different chiralities of CNTs [33]. (a) Armchair CNT, (b) (5, 0) Zigzag CNT, and (c) (6, 2) chiral CNT.

1.3 Different nanoparticles and their effects

Compared with steel wire, single-walled CNTs (SWCNTs) have approximately 50 times more ultimate strength [34]. Multiwalled CNTs (MWCNTs) have been primarily used in the study of nanoparticle-reinforced FRP composites compared to SWCNTs as they are commercially available at a lower cost and with ease of dispersion into the matrix [35]. Because of their geometric arrangement and higher crystallinity, SWCNTs provide better mechanical properties and efficient load transfer than MWCNTs [36,37]. Yet, they pose severe problems in dispersion and functionalisation without changing the SWCNT structure.

Ajayan et al. [38] were the first to report on CNT-reinforced polymer composite materials in 1994. Single or multiple sheets with dimensions defined in two directions are called 2D nanoparticles. Graphene and nano clay are often used as 2D nanostructures to study the effects of these particles on FRP laminates [39,40]. The study of fibre reinforced with nano-clay composites under ballistic impact loads shows substantial improvements in the ballistic limit and energy absorption mechanism [41,42,43]. Due to the incorporation of 2D nanoparticles, the failure behaviour shifted from interlaminar to intralaminar, leading to enhanced stiffness and ballistic resistance. However, the excessive addition of nanoparticles into the matrix leads to agglomerations in the composite laminates with lower or sometimes degraded mechanical properties [44].

Aerogels are 3D nanomaterials that have superior properties and a large surface area. They are utilised to improve the structural strength of a composite laminate. Due to quantum mechanics effects, the structural dimensions of 3D nanoparticles are not restricted to the nanoscale. Hsieh et al. [45] experimentally studied the impact response of carbon fibres (CFs) reinforced with nanocarbon aerogels (NCAs) and concluded that 0.3 wt% NCAs produced the best results, although they reported the degradation of material properties at 0.5 wt% NCAs. Thus, the optimum wt% of nanofiller can deter crack growth between the fibre and matrix, resulting in efficient energy absorption, while lower filler wt% cannot effectively mitigate the impact energy between the fibre and matrix. In the case of higher nanofiller content, agglomerates of nanofillers would create steric barriers, preventing the resin from flowing into the agglomerates and causing gaps and voids between the fibre and resin, resulting in stress concentration.

1.4 Methods of production of CNTs

CNTs can be reinforced into the FRP structure in a variety of ways, including adding them to the fibre surface, the polymer matrix, and in between the layers of the FRP. Chemical vapour deposition (CVD), electrophoretic deposition (EPD), electrospray deposition (ESD), and chemical functionalisation are the most effective techniques and methodologies utilised to create FRP-reinforced CNT structures. One of the most extensively researched techniques for directly growing CNTs on the fibre surface is CVD. By using catalysts like nickel and cobalt, CVD produces CNTs from carbon vapour. However, the CVD chamber needs to be heated at high temperatures, typically above 500°C, in order to evaporate the carbon sources, since most natural and polymeric fibres begin to break down at such temperatures. Consequently, the optimum materials to use this procedure on are carbon and glass fibres. Figure 4 shows a typical schematic figure illustrating the entire procedure of CNT growth on the fibre surface by CVD. This process exposes the surface of the fibre to a volatile precursor, which reacts and decomposes on the surface of the fibre to create the required CNT deposit. Although the use of CVD represented one of the most efficient ways to create fibre-reinforced CNT, this method is affected by a high processing temperature, which may result in thermal damage to the fibres and degrade the mechanical properties of FRP-reinforced CNT structures. In recent research, there has been a challenge in producing CNTs using CVD at lower temperatures and this needs further investigation.

![Figure 4

Representation of the CVD process [47].](/document/doi/10.1515/ntrev-2023-0164/asset/graphic/j_ntrev-2023-0164_fig_004.jpg)

Representation of the CVD process [47].

The EPD technique is another potential approach that has drawn growing interest from the scientific community. EPD is achieved using coagulated particles as charged particles, which are dispersed in a liquid suspension. Under an applied electric field, the charged particles are deposited towards the oppositely charged electrode surface. The build-up of the charged particle during the EPD process will result in a uniform deposit at the electrode surface due to the charged particle’s electrophoretic motion. There are still a few conditions that must be satisfied for an EPD to be effective, although numerous researchers have offered various techniques for enhancing the EPD process. A post-treatment of the CNT is consequently required to shorten and functionalise it because the CNTs are chemically inert and are frequently aggregated or entangled because of the van der Waals force. In a short duration, the EPD process generates CNTs that are vertically aligned. However, for a more successful CNT grafting process, EPD functions better with conductive fibres like CFs. EPD-deposited CNTs on fibres are more efficient because they produce a more uniform morphology for CNTs.

In recent years, there has been increasing interest in the ESD method among the research community. The ESD method was discovered to make non-agglomerating nano-droplets of consistent sizes by transforming the liquid into fine aerosol by the application of an electric field. It was also determined to be useful for creating spray layers that are micrometre thin or even thinner [46]. ESD is a relatively simple and scalable method that involves the electrostatic deposition of CNTs onto a substrate. The process begins by creating a suspension of CNTs in a suitable solvent or dispersion medium. This suspension may contain CNTs of varying lengths and may be functionalised or modified to enhance dispersion and adhesion. The CNT suspension is then fed into an atomiser, typically a nozzle or an ultrasonic device, which aerosolises the liquid, breaking it into tiny droplets. These droplets carry CNTs and are highly charged due to the electrostatic forces applied within the atomiser. A target substrate, often a flat or 3D surface, is negatively charged or grounded. The charged CNT-laden droplets are electrostatically attracted to the substrate due to the difference in charge polarity. As the charged droplets approach the substrate, the solvent evaporates, leaving behind the CNTs, which adhere to the substrate due to the electrostatic attraction. The CNTs form a thin film or coating on the substrate. After the electrostatic deposition, the coated substrate may undergo post-processing steps like drying, annealing, or additional treatments to improve the adhesion and alignment of CNTs. ESD being one of the simplest processes has multiple advantages over other proposed methods. ESD is a scalable technique that can be applied to coat large surfaces or produce CNT films of varying thicknesses. It also allows for control over the thickness of the CNT film by adjusting the suspension concentration and the deposition time. The horizontal nozzle with a vertically positioned collecting target was found to be the best configuration among all of the alternatives as the resulting coating was homogeneous and even thickness was obtained.

ESD-produced CNT coatings find applications in various fields, including (a) CNT coatings can be used as conductive films, transparent electrodes, and heat-dissipating layers in electronic devices. (b) CNT-coated substrates are employed in chemical and biological sensors due to their high surface area and sensitivity. (c) CNT films are used in supercapacitors and batteries to enhance energy storage and discharge capabilities. (d) ESD can be used to coat fibres or reinforce composite materials with CNTs to improve mechanical and electrical properties. In summary, the ESD method is a versatile and scalable approach for producing CNT coatings on various substrates.

There are numerous methods for enhancing the matrix toughness and the strength of the interface, such as reinforcing the matrix with nanomaterials, chemical grafting, oxidation, plasma treatment, and other surface modifications. There is a significant contradiction in determining the effect of nanofiller concentration. The literature lacks information on defining the reason for the enhancement of degradation in mechanical properties of the composite laminate. This review aims to highlight the enhancement in properties of FRP composites due to the infusion of CNTs in the matrix. In the subsequent sections, the focus will be on the different effects of nanofiller on different mechanical properties, impact test setups used to study the impact behaviour of FRP composites, the effect of impact loading on other composite structures, and finally, the proposed analytical models in the literature to predict the behaviour of the composite structure under impact loading.

1.5 Significance and industrial application

CNTs play a crucial role in enhancing the impact resistance properties of FRP with profound implications for various industries. CNTs are renowned for their extraordinary mechanical properties. They possess a tensile strength several times greater than steel and a high stiffness-to-weight ratio. When incorporated into FRP composites, they reinforce the polymer matrix, resulting in increased strength and stiffness. This enhancement ensures that FRP structures can withstand greater impact forces without deforming or fracturing. Reinforcing CNTs into FRP has a remarkable capacity to absorb and dissipate energy during impact events. This means that when subjected to impact loads, CNT-infused FRP composites effectively absorb the energy in the form of crack bridging, reducing the risk of catastrophic failure. CNTs act as effective barriers to crack propagation. Their high aspect ratio and strong adhesion to the polymer matrix impede the spread of cracks. This enhanced resistance to crack formation and growth makes FRP composites more durable and resilient against impact-induced damage. This is crucial in applications where impact resistance is of paramount importance, such as in automotive and aerospace components.

A significant advantage of using CNTs in FRP composites is that they can enhance impact resistance without adding substantial weight. This is particularly critical in industries like aerospace, where reducing the weight of components and structures is essential for improving fuel efficiency and overall performance. The incorporation of CNTs significantly increases the overall toughness of FRP composites. As a result, FRP structures become more durable and less prone to sudden and catastrophic failure.

2 CF/CNT-reinforced polymer composite mechanical performance

Despite various advancements in the manufacturing techniques of carbon-reinforced composites, their out-of-plane properties are much inferior compared to the mechanical strength and stiffness of these materials in the in-plane direction. Due to this drawback, extensive work on CNT-reinforced FRPs was proposed by Ajayan et al. [38] to develop composites into modified nanocomposites with enhanced properties. The physical factors determining the improved mechanical properties of the nanocomposites are driven by micro-mechanical interlocking, chemical bond formation, and interfacial shear stress (IFSS) mechanisms occurring between fibre–CNT, CNT–matrix, and electrostatic forces, i.e., van der Waals force [48].

2.1 Effect of CNTs on the tensile strength and modulus

In order to improve the mechanical characteristics of FRP composites, CNTs can be used to modify the reinforcements and matrix. The combination of CF-reinforced polymer (CFRP)-reinforced CNTs has created much enthusiasm among scholars because of the critical improvements in the mechanical properties observed by researchers [49]. Shahbaz and Berkalp [50] studied two distinct approaches to integrating CNT in FRP composites. Testing was conducted utilising various combinations of reinforcement stacking sequences and contrasted with the equivalent pristine composites. When CNTs were added to the reinforcements, a 12% improvement in tensile strength was seen in comparison to the corresponding neat composites. Zhao et al. [51] worked on grafting CNTs on unidirectional CF/epoxy composites by the EPD method. An increase in the tensile strength of 24.42% for CF-grafted CNTs and 10.41% for CNT reinforced in an epoxy matrix was achieved. The superior properties obtained are derived due to a gradient interface formed due to CNT grafting on the fibre surface. Zhou et al. [52] used an ultrasonic liquid processor with high intensity to infuse MWCNTs into EPON 862 epoxy and determined that the tensile strength enhancement of about 28.3% was obtained at 0.3 wt% MWCNTs, but the degradation of strength was observed at the addition of 0.4 wt% MWCNTs, although the enhancement in modulus was constant. This was attributed to the agglomeration of MWCNTs due to the inefficient mixing of nanofillers in the matrix. A similar trend was observed in the literature [53].

The catalyst-related processes (catalyst coating and annealing) are primarily responsible for the loss of the tensile strength of CFs during catalytic CNT development. In contrast, the CVD process repairs the damaged CFs during the treatment. It was evident that the choice of catalyst and high vacuum conditions strongly influenced the tensile properties of the CNT-modified CF surface. Thus, growing CNTs on CFs using CVD will most often enhance mechanical properties [54]. Studies examined the reinforcing capability of CNTs at the resin–matrix interface and found that EPD was an efficient approach to increase the reinforcing capability with minimal damage to fibres. The findings indicated that adding CNTs to interfaces increased the tensile strength by 9.86% while treating the reinforcement with nitric acid increased the tensile strength by 35.7% [55]. The physical and chemical modification of fibre surfaces, including the alteration of roughness, functional groups, and wettability of fibre surfaces, were responsible for substantial increases in mechanical characteristics. The high performance of composites was also attributed to improved CNT dispersion following modification. A summary of improvement in FRPs with CNT reinforcement has been reported in Table 2.

Effect on tensile properties on the addition of different CNTs

| Ref. | Type of CNT | Nanofiller wt% | Fibre type | Matrix type | % increase in tensile strength |

|---|---|---|---|---|---|

| Bhowmik et al. [56] | MWCNT | 0.5, 1.0, 1.5 | CFRP | Epoxy | 5.55, 13.00–16.84 |

| Sharma and Lakkad [57] | CNT/CNF (carbon nanofillers) | CNT grown on CF | T-300 CFs | Epoxy | 69% |

| Rahmanian et al. [58] | CNT | 5 | CF | Polypropylene-based polymer matrix | 57% |

| Glass fibre | 40% | ||||

| Kim et al. [54] | CNT | CNT grown on CF | CF | — | 14% |

| Wang et al. [59] | CNT | CNT grown on CF | T-300 CFs | Phenolic | 45% |

| Moaseri et al. [60] | MWCNT | Deposition on CF surface | CF | Epoxy | 120% |

| Lv et al. [61] | MWCNT | CNT grown on CF | CF | Epoxy | −7.8% |

| Parameswarreddy et al. [62] | Short CF and MWCNT | 1 | CF | Epoxy | 24.3% |

| An et al. [63] | CNT | CNT grown on CF | T-300 CFs | Epoxy | −1 to −9% |

2.2 Effect of nanofiller on interlaminar and interfacial bonding performance

Being chemically inert, CF shows poor ballistic impact resistance due to weak adhesion and compatibility between the fibre matrix in FRPs. To overcome this challenge, many researchers worked on modifying the CF surface [64,65]. Thus, using CNTs as reinforcement was considered novel and became an effective method to enhance the mechanical properties of fibre-reinforced composite laminates [66,67]. Also, CF hybridisation with CNTs gained popularity as it improved the binding of fibres with the matrix, leading to better mechanical properties. However, this method has limitations as the maximum bonding strength is restricted to the chemical bonding strength at the interface [68,69,70,71].

It is known that the enhancement in the mechanical properties and efficient load transfer from the fibres to the matrix is determined by interfacial adhesion between the components of the polymer composite. Thus, predicting the acceptable performance of CNT-reinforced polymer composites is critical [72]. Changing the orientation and length of MWCNTs while grafting them on CF immobilised MWCNTs resulted in a remarkable improvement in IFSS of up to 175% [61]. Zhang et al. [73] reported a 36% decrease in IFSS when MWCNTs were grown on CFs due to poor wettability with the matrix leading to stress concentrations at the end of MWCNTs. Meanwhile, An et al. [63] used the single fibre pull-out method to determine an increase of 94% in IFSS with a relative degradation of about 10% in the fibre strength, and this trend of reduction in mechanical properties has been reported in the literature [74]. However, contrary to the previous literature, Maoseri et al. [60] determined a 90% increase in IFSS, and Cai et al. [75] showed an increase of 45.2% in interlaminar shear strength (ILSS) when CF was reinforced with functionalised graphene oxide (GO). Li et al. [76] found that the deposition of carboxylic acid-functionalised CNTs (COOH-CNT) on T700SC and T300B resulted in 43 and 12% enhancements in IFSS, respectively. The findings show that interfacial friction, chemical bonding, and resin toughening account for the improved interfacial properties.

Baek et al. [77] evaluated the properties of CF/polycarbonate composites reinforced with CNTs and determined that IFSS was 25% higher when CNTs were added to the thermoplastic polycarbonate resin. Patnaik et al. [78] examined the effect of graphene-based nanofillers on the interlaminar behaviour of CFRP composites. GO and graphene hydroxyl (GOH) nanofillers were applied via EPD. Modified CFRP laminates improved ILSS by 15.6 and 11.42% for CFRP with GO and GOH, respectively. GO was found to be a better modifying nanofiller than GOH. Due to thermal shock and stresses due to cryo conditioning, ILSS values decreased for the specimens. Using scanning electron microscopy (SEM), multiple failure mechanisms were investigated. Figure 5 shows SEM images of different variants of CNT grown on CF fibres. Gao et al. [79] systematically investigated CF surfaces modified with GO and CNT composites and discovered that the resulting composite structures had a 48.12 and 83.39% increase in ILSS and IFSS, respectively.

![Figure 5

SEM images: (a) uniform CNTs grown on CFs, (b) the length of CNTs on CF, (c) uniform CNTs grown on glass fibres, and (d) CNTs grown vertically on glass fibres at the beginning and then entangled [58].](/document/doi/10.1515/ntrev-2023-0164/asset/graphic/j_ntrev-2023-0164_fig_005.jpg)

SEM images: (a) uniform CNTs grown on CFs, (b) the length of CNTs on CF, (c) uniform CNTs grown on glass fibres, and (d) CNTs grown vertically on glass fibres at the beginning and then entangled [58].

2.3 Effect of nanofillers on the fracture toughness performance

Enhancing the interlaminar fracture toughness in composites with brittle matrices has been a crucial subject of research and study for several decades. Also, due to interlaminar fibre-matrix cracking and delamination, CFRP laminates have a limited fracture toughness. To ascertain the mode I interlaminar fracture toughness of CFRP composites, double cantilever beam tests are performed. By linking the lamina interfaces in the matrix, CNTs can act as a toughening material. Many experimental studies are undertaken to determine the increase in Mode I fracture toughness without assessing the influence of failure modes due to CNT-reinforcement interaction. Kim et al. [80] conducted a comparative study to determine the CNT forest’s effect on the hierarchical composite’s delamination resistance. The interlaminar fracture toughness of the hierarchical composites caused degradation. This was attributed to the weaker adhesion between the CNT forest and CF fibres. A SiO2 thin-film diffusion barrier layer is placed over the CF surface using the low-pressure CVD process to increase adhesion. Shin et al. [81] incorporated 9 wt% COOH-CNT in FRPs using ultrasonication and roll milling and reported an enhancement in Mode II interlaminar fracture toughness. When 1.5 wt% MWCNT was added to CF/silicon carbide composites, fracture toughness and an enhancement of 27.9% were observed. Borowski et al. [82] demonstrated that the inclusion of 0.5, 1.0, and 1.5 wt% MWCNTs increased the fracture toughness of CFRP laminates by 25, 20, and 17%, respectively. Microstructural studies employing Fourier transform infrared and X-ray photoelectron spectroscopy confirm the enhancement in fracture properties due to chemical interactions between COOH-MWCNTs and the epoxy resin. Shin et al. [81] worked on increasing the interlaminar fracture toughness of CFRP composite, and a CNT buckypaper was interspersed. SEM investigation of the fracture revealed that the specimen with the buckypaper interleaving was securely attached. This proves that the CNT matrix in the interlayer caused high interfacial adhesion and delamination.

2.4 Summary

The study reveals that FRP/CNT composites enhanced the mechanical properties substantially. EPD from the literature was determined to be the most adopted technique for the surface modification of CFs due to its benefits such as ease of controlling film thickness, uniformity of surface morphology, high deposition rate, and ease of scaling up. Most studies proposed a significant increase in IFSS by grafting CNT onto the fibre surface. However, resolving the issue of wettability during the vapour deposition method can give a broader scope of improvement [83]. Literature studies have suggested that grafting 3D structures like vertically aligned CNTs on fibres enhances the fibre and matrix bonding [84,85,86]. It can be concluded that without compromising the density and toughness, including nano-particles in small quantities can help in achieving the desired mechanical and thermal characteristics [87]. Microstructural analysis reveals that CNTs are firmly embedded in the matrix resulting in crack bridging to prevent matrix cracking. This suggests that CNTs have a strong interfacial connection with the polymer matrix, which facilitates efficient load transmission. Moreover, a greater load is needed for the beginning and growth of cracks. Thus, CNTs reinforced in CFRP increased the mode II fracture toughness.

3 Impact testing setup

HVI events refer to dynamic events with small masses and high-speed impactors, where the velocities range over 10 m/s and dominate by localised damage [88]. Structures under such impact produce a steep increase in loading oscillation for a short period. Due to high strain rates, the structural response is dominated by changes in the fracture strength and stiffness of the material [89]. The parameters like laminate type, thickness, orientation, projectile mass, and geometry influence the fibre-reinforced composite laminate’s responses against HVIs. At higher strain rate loading, the composite laminates sustain damage modes like spalling, cracking, and pedalling, which drastically reduce the load-carrying ability of the laminates. To study the response of structures under HVI, various experimental setups are used. Ahmadi et al. [90] used a helium gas gun to conduct the impact tests. A pressure vessel with a 50 bar capacity consisting of a 4 m barrel made of stainless steel and a solenoid valve equipped to control the speed units was utilised. The system could fire a blunt projectile with a 20 mm length and a weight of about 12 g at a velocity of 175 m/s, measured using chronograph sensors. Randjbaran et al. [91] used a similar setup with helium gas for propelling the projectile with a length of 13.07 and 8.48 mm in diameter made of mild steel, weighing about 6.75 g, and the maximum working pressure was about 21 MPa. High-speed cameras instead of chronograph sensors were used to determine the velocity and analyse the structural response to projectile impact. Pandya et al. [92] used air as the propelling gas in a single-stage gas gun to carry out the ballistic impact test with a 1.5 m-long barrel to guide and propel the projectile. A compressed gas cylinder was used to drive an impactor of 6.36 mm in diameter to a velocity of about 200 m/s. Velmurugan and Balaganesan [93] used a piston-type gas gun with a projectile of 9.5 mm in diameter, and a 7.6 g mass was propelled using air as the working medium, altering the pressure and resulting in velocity change. Laser diodes were used to measure the initial velocity of the projectile. Interestingly, the residual velocity was measured by using two aluminium foil circuits. Micheli et al. [94] performed the ballistic impact experimentally using railguns or electromagnetic launchers, as shown in Figure 6. The arrangement consisted of two parallel rails to guide the projectile, a moving armature to attain the required velocity, and energy storage and supply regulated by electrodes and capacitors. The equipment had an equivalent capacitance of 12,000 mF when connected by high-voltage capacitors of about 6,000 V, and 80 mF, and had dimensions of 1 m length with 5 mm rail bars having a space of 15 mm. The projectile velocity was regulated using a tuneable power source to charge the capacitors to the desired voltage, where velocity was computed using oscilloscope channels using a breakwire system. The bullet velocity was calculated using the voltage change in the two channels. Haro et al. [95] performed an outdoor ballistic impact test with a 270 Winchester rifle and a 150 g power point projectile with a mass of 9.72 g, as shown in Figure 7. The bullets were fired at 15 m from the target plate to achieve stability and reliability in the impact test. Chronograph precision sensors were utilised to determine the muzzle velocity where the projectile’s energy was around 3,667 J compared to NATO standards.

![Figure 6

Railgun equipment setup [94].](/document/doi/10.1515/ntrev-2023-0164/asset/graphic/j_ntrev-2023-0164_fig_006.jpg)

Railgun equipment setup [94].

![Figure 7

Schematic representation of the Ballistic Impact test setup for open field [95].](/document/doi/10.1515/ntrev-2023-0164/asset/graphic/j_ntrev-2023-0164_fig_007.jpg)

Schematic representation of the Ballistic Impact test setup for open field [95].

4 FRP reinforced with CNTs impact response

Researchers are developing composite materials that are lighter and more durable than traditional metallic materials. This requirement leads to the hybridisation of the composites, utilising the superposition of two or more materials to obtain the desired properties. The use of nanoparticles in these hybrid composites has made it conceivable to achieve the required ballistic protection with improved capability, leading to nanoparticles in the range of 1–100 nm that enhance the material properties like strength and stiffness of the structure. Carbon-based composites are felicitous materials as they have imposing mechanical properties. However, they lack cost efficiency and time-saving manufacturing processes and simultaneously show extremely brittle behaviour. Thus, there is a need to investigate the possibility of more combinations of materials that are cost-effective and reliable as FRP composites. A series of studies deals with the characterisation and modelling CNTs or other nanoparticle-based fibre-reinforced composites without considering the progressive damage mode in the polymer matrix [96,97,98].

4.1 Effect of CNT reinforcement on Kevlar laminate

Most protective equipment in the age of cold weapons is quite hefty and performs poorly in terms of flexibility and comfort. However, during the past few decades, light-weight and extremely durable soft materials, like Kevlar, have increasingly replaced the bulky and inflexible equipment that severely limits the wearer’s movement [99]. Liu et al. [100] used mesoporous silica and CNTs in ionic liquids to create a material with shear thickening capabilities. CNTs/STF/Kevlar composites demonstrated enhanced impact resistance when compared to neat Kevlar composite laminate, whereas an investigation of Kevlar 29 fibre reinforced with 0.5 wt% of amino-functionalised MWCNT showed an increase of 56% in energy absorption [101]. MWCNT characterisation of the laminate was carried out using SEM and Raman spectroscopy. The results showed peak broad displacement signifying fewer agglomerations and evident conversion of sp2 to sp3 connections displaying grafting of CNT on fibre surfaces. Gibson et al. [102] utilised composite panels of Kevlar 29 woven fibre reinforced with MWCNT in an epoxy matrix and studied the ballistic performance of the composite laminates as defined in MIL-STD-662 F and concluded that the addition of 1.65 wt% MWCNT resulted in a 6.5% enhancement in the V50 ballistic limit. SEM imaging was utilised to determine the failure mechanism and efficiency of MWCNT dispersion in the resin matrix. The fibres elongated before failure and the resin failure surface was determined to be rough indicating tearing failure was dominated due to the presence of MWCNT instead of sharp brittle failure. Micheli et al. [94] studied the energy absorption capability of carbon-Kevlar fibre polymeric matrix reinforced with MWCNTs upon metallic bullet impact at about 400 and 1,000 m/s. It was observed that 3.5 mm-thick CFRP-Kevlar laminates reinforced with 1 wt% MWCNTs could resist up to 400 m/s impact velocity. Mathusoothanaperumal Sukanya et al. [103] studied the effect of adding CNT on the impact characteristics of Kevlar epoxy composites. The results showed better impact properties for the laminate with 0.5% CNT addition as compared to 1% CNT filled. The major phenomena that considerably enhanced the characteristics of the composite were the front face’s brittle nature with the addition of nanofiller.

4.2 Effect of CNT reinforcement on GFRP laminate

Domun et al. [15] worked on GFRP with additive nanoparticles like graphene platelets, CNTs, hybrid hexagonal boron nitride nanosheets with CNTs, and boron nitride nanotubes with graphene platelets and determined the effect of different nanoparticles on the strength and damage morphology of the GFRP laminates under ballistic impact. To examine the effect of nanofiller on the damage morphology of GFRP laminate, flash-pulse infrared thermography was utilised. The study revealed that the average increase in ballistic resistance efficiency was about 11.4% due to the addition of nanofillers. Nor et al. [104] found that adding CNTs to natural fibre-based hybrid composites absorbed 9.21% less energy at 35 J impact energy. To investigate the effect on the damaged area, a novel NDT technique was utilised and it was concluded that with a reduction in energy absorption, the damaged area was reduced. Pandya et al. [105] experimentally studied the effect of 1 wt% nano-silica and 0.5 wt% amino-functionalised MWCNT in unidirectional E-glass fibres. The specimen of 125 × 125 × 4.3 mm was impacted by a hardened steel spherical projectile of 6.36 mm diameter. The study determined that adding 1 wt% nano-silica and 0.5 wt% amino-functionalised MWCNT resulted in 7.3 and 15.2% enhancement in ballistic limit and energy absorption. A similar study with 0.3% amino-functionalised MWCNT in E-glass increased the ballistic limit by 15–19 m/s increment in the ballistic limit [106]. On comparing the responses of asymmetrical and symmetrical laminates to HVI, as shown in Figure 8, the average damage area extension on the mid-ply of an asymmetrical laminate was more significant than in a balanced laminate. However, both laminates have identical stiffness characteristics [107]. Khoramishad et al. [108] worked on fibre metal laminates reinforced with MWCNTs under HVI response. The results indicated that adding 0.5 wt% MWCNT resulted in a 29.8% reduction in residual velocity and an 18.9% increase in energy absorption. However, it weakened the interlaminar strength between the glass fibre and metallic laminate, leading to plastic deformation of the metallic laminate.

![Figure 8

Schematic representation of the failure interface [109]: (a) symmetric laminate and (b) asymmetric laminate.](/document/doi/10.1515/ntrev-2023-0164/asset/graphic/j_ntrev-2023-0164_fig_008.jpg)

Schematic representation of the failure interface [109]: (a) symmetric laminate and (b) asymmetric laminate.

4.3 Effect of CNT reinforcement on sandwich panels

Fibre-reinforced composites are often used with sandwich structures where the face sheet is separated by a comparatively lighter and thicker core material, which has extensive utility in marine, aeronautical, or automobile applications. The performance of these structures under ballistic impact loading is essentially determined by the face sheet materials, namely FRPs, metals, wood, etc. [110–112]. In sandwich structures, a high-impact loading for a shorter duration is changed over to a smaller magnitude, and longer duration of load action as the front face sheet undergoes deformation and the core undergoes compression, resulting in minimal load transfer to the rear face sheet. Following this, researchers have attempted to improve the impact response of fibre-reinforced composites and sandwich structures [113–115]. In aerospace industries, honeycomb sandwich structures (HSS) with CFRP composite face sheets are extensively employed due to their ability to carry in-plane loads and enhance bending stiffness while minimising weight [116,117]. Muniraj and Sreehari [118] studied the damage behaviour of 0.2, 0.4, 0.6, and 0.8 wt% CNT-reinforced CFRP composite HSS under HVI. They determined that the optimum proportion of CNTs to enhance damage resistance depends on temperature. The study determined that damage parameters were affected by projectile impact energy, nanofiller content, and resin plasticity. The resin performance was determined to be highly dependent on temperature. The findings of an impact test on a CFRP laminate at 393 K are noteworthy since they show that the matrix’s behaviour changes from brittle to ductile, resulting in global deformation instead of localised damage. Naghizadeh et al. [119] studied the effect of COOH-MWCNTs in sandwich structures with face sheets of E-glass/epoxy and E-glass/nylon 6 when subjected to a conical projectile under HVI. It was determined that COOH-MWCNTs reinforcement enhanced the impact resistance performance of the laminate. The enhancement in the properties was attributed to improvements in failure stress and strain and toughness of the face sheet. The infusion of CNT not only enhances the cohesive strength but also serves as a rigid filler and crack arrester.

4.4 Summary

In mechanics, the need for structures to be resistant to mechanical shocks while being lightweight and ease of manufacturing are indispensable requirements. CNTs are combined with different FRP structures to meet the need, and researchers have reported contradicting results. Although MWCNTs reinforced with Kevlar fibres resulted in ballistic limit enhancement of the laminate, the quantity of MWCNT inclusion was not conclusive. Similar results were obtained when functionalised MWCNTs were reinforced with glass fibres. An average 11.4% increase in specific energy absorption was achieved by strengthening the matrix with nanoparticles in the GFRP laminates. Few studies on the impact performance of CFRP reinforced with MWNCTs show improved impact resistance due to the presence of MWCNTs. The overall performance of CFRP-Kevlar laminates reinforced with an excess of 2 wt% MWCNT leads to inefficient load transfer and in-plane displacement [120]. Thus, it can be concluded that wt% of MWCNTs in FRP laminates plays an important role in determining the impact performance of the laminate.

5 Analytical approaches for the evaluation of ballistic impact responses

The extensive utilisation of composite materials as load-carrying members in primary structures prompts the need to understand their behaviour in critical situations like ballistic impact loading. Looking at the current situation, the response of the composite structures against ballistic impact is highly dependent on experimental methods, which are costly. A cost-effective strategy is always needed, which leads to developing numerical and analytical techniques. With this aim, the available analytical modelling techniques for the ballistic impact of projectiles on FRPs are discussed in the following section.

5.1 Analysis based on the energy of the system

Due to the projectile impact, localised stress waves are generated in the impacting structure. Depending on the boundary conditions and wave propagation direction, stress waves due to ballistic impact can be classified into different categories, leading to the need for a thorough understanding of the stress wave propagation in the structure. When considering the behaviour of an infinitely long flexible filament under impact conditions, the strain produced propagates between elastic and plastic wavefronts, followed by transverse waves in the strain region. This led to the development of a theory of transverse wave propagation, which could be ultimately used for determining the effect of transverse impact [121]. Further, Benloulo et al. [122] developed an analytical model for textiles under impact loading, including an energy-based failure criterion. Thus, considering delamination in the FRP composites, Benloulo et al. proposed a differential equation to determine the projectile velocity:

where

Shaktivesh et al. [123,124] presented an analytical formulation based on energy balance and stress wave propagation between the projectile and a 2D plain weave fabric target, considering tensile failure and shear plugging as failure modes as impact events. Udatha et al. [125] evaluated the same wave propagation and energy balance method to determine the ballistic performance of 3D orthogonal woven composites.

5.2 Analysis based on the constitutive model

An analytical model was developed to evaluate the non-Hookean behaviour of the laminate during projectile penetration based on Mindlin’s thick plate theory using the “structural constitutive model” [126,127]. Chocron Benloulo and Sánchez-Gálvez [128] formulated a simplified 1D analytical model to predict the response of ceramic or composite structures to ballistic impact, neglecting the strain rate effect in the stress–strain behaviour. Feli et al. [129] modified the analytical model proposed by Chocron–Galvez by considering the yarn deformation and the strain rate effects on the stress–strain behaviour. Moreover, a failure model was utilised dependent on the absorbed energy until the failure of woven yarns. Also, Gregori et al. [130] used the modified Bernoulli equation and wave propagation theory to develop an analytical formulation to determine the response of ceramic composites to small-calibre projectiles.

5.3 Ballistic limit prediction

Wen [131,132] determined that the resistance exerted by the monolithic FRP can be defined in two ways: quasi-static cohesive resistant pressure and dynamic resistive pressure. Considering the deformation due to HVI is localised, the penetration and perforation of the projectile with a different nose shape into the target plate were considered. Assuming the mean stress applied by a projectile is normal to the FRP laminate, the stress can be quantified as cohesive quasi-static resistive stress (

If

where

Then, the ballistic limit for the FRP composite laminate for conical or ogival nose projectiles can be predicted as

where D is the projectile diameter, G is the projectile mass, and T is the thickness of monolithic FRP laminates.

During the same period of Wen’s work, Morye et al. [133] developed a simplified relation to predicting the energy absorbed by the composite laminate upon ballistic impact, considering three major factors: (a) tensile failure, (b) elastic deformation, and (c) kinetic energy of the composite laminate due to impact. Also, Gellert et al. [134] explained a simplified model describing the behaviour of FRP composites and how ballistic impact affects bond strength and material parameters. It was also determined that the response of thin composite laminates was independent of the projectile nose shape.

5.4 Analysis based on failure during impact

Naik and Shrirao [135,136] identified different mechanisms occurring during ballistic impact on 2D woven fabric composites, such as tensile failure and deformation of yarns, matrix cracking, delamination, cone formation of the back face or shear plugging, and friction between the composite and projectile during penetration. Based on the following observations, an analytical formulation for each occurring mechanism was presented, and properties like ballistic limit, contact duration, and damage radius were determined. Furthermore, the proposed work was extended to thick composites considering the wave propagation in the thickness direction during the impact event [137,138]. A similar formulation was followed by Gama and Gillespie [139] to develop a correlation between quasi-static and ballistic penetration damage for composites made of S-2 glass fibres by using a sequence of quasi-static punch tests at different support spans to mimic the ballistic impact response. Pandya and Naik [140] presented an analytical formulation to predict the response of MWCNT dispersed in epoxy resin under ballistic impact conditions and determined an improvement of 10% in energy absorption when compared with neat epoxy.

Pasquali et al. [141] worked on an analytical formulation to determine the response of a thin composite target under HVI. Considering the propagation of stress waves in the target plate, the damage and energy transfer from the projectile to the plate were studied, and the ballistic limit and the damage size were obtained using the formulation. Bresciani et al. [142] considered the deforming projectiles’ kinetic energy and energy absorption modes to model the analytical formulation.

Composites based on textiles are often preferred as ballistic shields due to their superior mechanical properties. Scazzosi et al. [143] proposed a predictive model considering deformable projectiles and concluded that the proposed analytical model predicted properties efficiently. In contrast to textile composites, ultra-high molecular weight polyethylene (UHMWPE) fibres possess exceptional strength and stiffness properties with low density, as preferred in multiple ballistic shields but implementing such materials into applications is problematic. Langston [144] conducted a thorough study to understand UHMWPE fibres’ energy absorption and failure mechanisms under ballistic impact to develop an analytical model to predict the ballistic behaviour of these fibres. A similar study was conducted by Chen et al. [145] with thick UHMWPE woven laminated plates and proposed an analytical model based on an energy conservation concept considering deformable projectiles.

5.5 Summary

Several analytical models are available that predict the ballistic impact response of composite structures. The solutions obtained from these methods can be utilised for setting primary inputs for experimental tests, leading to cost efficiency. Literature reveals that analytical formulation developed based on energy balance and stress wave propagation between the projectile and FRP laminate can effectively predict the ballistic limit. Although the frictional losses between the projectile and the plate were ignored in the calculation, the proposed formulations could predict the sequential failure of the layers and the ballistic limit for a given target plate.

6 Conclusion

To the best of the author’s knowledge, there are few studies in the open source dealing with the characterisation and progressive damage behaviour of CNT-reinforced polymer composites under HVI. Damage due to ballistic impact on fibre-reinforced composites is a practical issue in engineering. Modifying these fibre-reinforced structures with CNTs has led to a broad scope of improvement. It was evident from the literature that the composite by direct infusion of the CNT (SWCNT, MWCNT, or functionalised CNT) into the reinforcement or grafting it onto the fibre surface-enhanced mechanical properties. Ballistic impact testing can be an expensive phenomenon, and thus analytical and numerical methods have been adopted by various researchers and validated against the experimental results. Based on the observations from the review of the literature, the following conclusions can be made:

The CNT surface morphology has been attempted to be altered by two primary methods, physical and chemical functionalisation, coupled with a variety of dispersion strategies. Surfactant-assisted ultrasonication is the most popular method out of all the ones available.

The majority of the study has concentrated on the FRP composites reinforced with CNTs and their mechanical characteristics. The authors conclude that crack-bridging/deflection, CNT pull-out, and filling are the three primary CNT reinforcing processes impacting the mechanical characteristics.

Positioning thicker nanocomposite layers near the impact surface resulted in the highest level of resistance.

The FRP laminate’s mechanical characteristics are improved by a homogeneous CNT dispersion. It is important to note that excessive CNT concentrations might cause flaws in the laminate, such as agglomerations of nanofillers, which can reduce the mechanical properties.

The utilisation of analytical formulations that rely on energy balance and stress wave propagation between the projectile and FRP laminate can accurately estimate the ballistic limit.

The performance of CNT-reinforced composite laminates is affected by CNT content in the reinforcement, fibre material properties, uniform dispersion of CNT in the matrix, and many other parameters. Therefore, careful consideration must be made when choosing the method and type of these particles to obtain the desired properties in the FRP composites.

Acknowledgments

The authors extend their appreciation to the Nanjing Forestry University, China, Czech Science Foundation GA CR, Czech Republic, and Mendel University in Brno, Czech Republic for funding this research work and to all the individuals for their expertise throughout all aspects of our study and contribution to writing the manuscript. In addition, they thank the anonymous reviewers for their fruitful suggestions to improve the article. The authors are truly grateful to all of them.

-

Funding information: This work was supported by the Scientific Research Fund of Nanjing Forestry University (No. 163050206), Czech Science Foundation GA CR Project (No. 23-06352 S), Foreign Young Talents Project China (No. QN2021014006L), National Natural Science Foundation of China (No. 51878354), 333 talent high-level projects of Jiangsu Province. Any research results expressed in this article are those of the author(s) and do not necessarily reflect the views of the foundations.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: David Hui, who is the co-author of this article, is a current Editorial Board member of Nanotechnology Reviews. This fact did not affect the peer-review process. The authors declare no other conflict of interest.

-

Data availability statement: All data generated or analysed during this study are included in this published article.

References

[1] Bikash Chandra C. FRP for marine application. In: Alberto MM, editor. Fiber-Reinforced Plastics. Rijeka: IntechOpen; 2021. p. Ch. 9.Search in Google Scholar

[2] Chen CH, Tsai PJ, Wang YF, Pan CH, Hung PC, Ho JJ, et al. Respiratory health effects of the fiber glass-reinforced plastic lamination process in the yacht-building industry. Scand J Work Environ Health. 2021;47(1):62–9.10.5271/sjweh.3924Search in Google Scholar PubMed PubMed Central

[3] Hosseini M, Jian B, Li H, Yang D, Wang Z, Feng Z, et al. A Review of Fibre Reinforced Polymer (FRP) reinforced concrete composite column members modelling and analysis techniques. J Renew Mater. 2022;10(12):3243–62. 10.32604/jrm.2022.022171.Search in Google Scholar

[4] Hosseini M, Jian B, Zhang J, Li H, Lorenzo R, Hosseini A, et al. Numerical Study on the Behaviour of Hybrid FRPs Reinforced RC Slabs Subjected to Blast Loads. J Renew Mater. 2023;11(9):3517–31. 10.32604/jrm.2023.028164.Search in Google Scholar

[5] Hosseini M, Li H, Hosseini A, Ghosh P. Performance of composite shear walls strengthened with FRP and subjected to blast load. Rev Constr J Constr. 2023;22(2):431–54. 10.7764/RDLC.22.2.431.Search in Google Scholar

[6] Liang R, Hota G. Development and evaluation of load-bearing fiber reinforced polymer composite panel systems with tongue and groove joints. Sustain Struct. 2021;1(2):000008. 10.54113/j.sust.2021.000008.Search in Google Scholar

[7] Wilt J, GangaRao H, Liang RF, Mostoller J. Structural responses of FRP sheet piles under cantilever loading. Sustain Struct. 2023;3(1):000021. 10.54113/j.sust.2023.000021.Search in Google Scholar

[8] Elshazli MT, Saras N, Ibrahim A. Structural response of high strength concrete beams using fiber reinforced polymers under reversed cyclic loading. Sustain Struct. 2022;2(2):000018. 10.54113/j.sust.2022.000018.Search in Google Scholar

[9] Phadnis VA, Roy A, Silberschmidt VV. 8 - Dynamic damage in FRPs: From low to high velocity. In: Silberschmidt VV, editor. Dynamic Deformation, Damage and Fracture in Composite Materials and Structures. Sawston, United Kingdom: Woodhead Publishing; 2016. p. 193–222. 10.1016/B978-0-08-100080-9.00008-7.Search in Google Scholar

[10] Smojver I, Brezetić D, Ivančević D. Explicit multi-scale modelling of intrinsic self-healing after low-velocity impact in GFRP composites. Compos Struct. 2022;302:116213. 10.1016/j.compstruct.2022.116213.Search in Google Scholar

[11] Olsson R. Mass criterion for wave controlled impact response of composite plates. Compos Part A: Appl Sci Manuf. 2000;31(8):879–87. 10.1016/S1359-835X(00)00020-8.Search in Google Scholar

[12] Abrate S. Impact engineering of composite structures. CISM Courses and Lectures. Italy: CISM; 2011. 10.1007/978-3-7091-0523-8.Search in Google Scholar

[13] Rao CL, Narayanamurthy V, Simha K. Applied Impact Mechanics. Hoboken, New Jersey, United States: John Wiley & Sons; 2016.10.1002/9781119241829Search in Google Scholar

[14] Stronge WJ. Impact mechanics. Cambridge, United Kingdom: Cambridge University Press; 2018.Search in Google Scholar

[15] Domun N, Kaboglu C, Paton KR, Dear JP, Liu J, Blackman BRK, et al. Ballistic impact behaviour of glass fibre reinforced polymer composite with 1D/2D nanomodified epoxy matrices. Compos Part B: Eng. 2019;167:497–506. 10.1016/j.compositesb.2019.03.024.Search in Google Scholar

[16] Ramezani M, Dehghani A, Sherif MM. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr Build Mater. 2022;315:125100. 10.1016/j.conbuildmat.2021.125100.Search in Google Scholar

[17] Ramezani M, Kim YH, Sun Z, Sherif MM. Influence of carbon nanotubes on properties of cement mortars subjected to alkali-silica reaction. Cem Concr Compos. 2022;131:104596. 10.1016/j.cemconcomp.2022.104596.Search in Google Scholar

[18] Ramezani M, Kim YH, Sun Z. Modeling the mechanical properties of cementitious materials containing CNTs. Cem Concr Compos. 2019;104:103347. 10.1016/j.cemconcomp.2019.103347.Search in Google Scholar

[19] Kamble M, Lakhnot AS, Bartolucci SF, Littlefield AG, Picu CR, Koratkar N. Improvement in fatigue life of carbon fibre reinforced polymer composites via a Nano-Silica Modified Matrix. Carbon. 2020;170:220–4.10.1016/j.carbon.2020.08.029Search in Google Scholar

[20] Ghosh P, Ramajeyathilagam K. Experimental and numerical investigations on the effect of MWCNT-COOH and Al2O3 hybrid nanofillers dispersed CFRP laminates subjected to projectile impact. Processes. 2023;11(5):1435.10.3390/pr11051435Search in Google Scholar

[21] Tang Y, Ye L, Zhang D, Deng S. Characterisation of transverse tensile, interlaminar shear and interlaminate fracture in CF/EP laminates with 10wt% and 20wt% silica nanoparticles in matrix resins. Compos Part A: Appl Sci Manuf. 2011;42(12):1943–50.10.1016/j.compositesa.2011.08.019Search in Google Scholar

[22] Yang T, Lu S, Song D, Zhu X, Almira I, Liu J, et al. Effect of Nanofiller on the mechanical properties of carbon fiber/epoxy composites under different aging conditions. Materials. 2021;2021(14):7810.10.3390/ma14247810Search in Google Scholar PubMed PubMed Central

[23] Shanazari H, Liaghat G, Feli S, Hadavinia H. Analytical and experimental study of high-velocity impact on ceramic/nanocomposite targets. J Compos Mater. 2017;51(27):3743–56.10.1177/0021998317692658Search in Google Scholar

[24] Vashisth A, et al. Ballistic impact response of carbon/epoxy tubes with variable nanosilica content. J Compos Mater. 2018;52(12):1589–604.10.1177/0021998317728461Search in Google Scholar

[25] Godara A, Mezzo L, Luizi F, Warrier A, Lomov SV, van Vuure AW. et al. Influence of carbon nanotube reinforcement on the processing and the mechanical behaviour of carbon fiber/epoxy composites. Carbon. 2009;47(12):2914–23.10.1016/j.carbon.2009.06.039Search in Google Scholar

[26] Warrier A, Godara A, Rochez O, Mezzo L, Luizi F, Gorbatikh L, et al. The effect of adding carbon nanotubes to glass/epoxy composites in the fibre sizing and/or the matrix. Compos Part A: Appl Sci Manuf. 2010;41(4):532–8.10.1016/j.compositesa.2010.01.001Search in Google Scholar

[27] Wichmann MHG, Sumfleth J, Gojny FH, Quaresimin M, Fiedler B, Schulte K. Glass-fibre-reinforced composites with enhanced mechanical and electrical properties – Benefits and limitations of a nanoparticle modified matrix. Eng Fract Mech. 2006;73(16):2346–59.10.1016/j.engfracmech.2006.05.015Search in Google Scholar

[28] Iijima S. Helical microtubules of graphitic carbon. Nature. 1991;354(6348):56–8.10.1038/354056a0Search in Google Scholar

[29] Iijima S, Ichihashi T. Single-shell carbon nanotubes of 1-nm diameter. Nature. 1993;363(6430):603–5.10.1038/363603a0Search in Google Scholar

[30] De Volder MFL, Tawfick SH, Baughman RH, Hart AJ. Carbon nanotubes: Present and future commercial applications. Science. 2013;339(6119):535–9.10.1126/science.1222453Search in Google Scholar PubMed

[31] Tasis D, Tagmatarchis N, Bianco A, Prato M. Chemistry of carbon nanotubes. Chem Rev. 2006;106(3):1105–36.10.1021/cr050569oSearch in Google Scholar PubMed

[32] Radhamani AV, Lau HC, Ramakrishna S. CNT-reinforced metal and steel nanocomposites: A comprehensive assessment of progress and future directions. Compos Part A: Appl Sci Manuf. 2018;114:170–87. 10.1016/j.compositesa.2018.08.010.Search in Google Scholar

[33] Lönnecke K, Eberhardt O, Wallmersperger T. Electrostatic charge distribution in armchair and zigzag carbon nanotubes: A numerical comparison of CNT charge models. Acta Mechanica. 2023;234(1):1–16. 10.1007/s00707-021-03085-3Search in Google Scholar

[34] Yu MF, Files BS, Arepalli S, Ruoff RS. Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys Rev Lett. 2000;84(24):5552–5.10.1103/PhysRevLett.84.5552Search in Google Scholar PubMed

[35] Qian H, Greenhalgh ES, Shaffer MSP, Bismarck A. Carbon nanotube-based hierarchical composites: a review. J Mater Chem. 2010;20(23):4751–62.10.1039/c000041hSearch in Google Scholar

[36] Cui S, Kinloch IA, Young RJ, Noé L, Monthioux M. The effect of stress transfer within double‐walled carbon nanotubes upon their ability to reinforce composites. Adv Mater. 2009;21(35):3591–5.10.1002/adma.200803683Search in Google Scholar

[37] Ma P-C, Siddiqui NA, Marom G, Kim J-K. Dispersion and functionalisation of carbon nanotubes for polymer-based nanocomposites: A review. Compos Part A: Appl Sci Manuf. 2010;41(10):1345–67.10.1016/j.compositesa.2010.07.003Search in Google Scholar

[38] Ajayan PM, Stephan O, Colliex C, Trauth D. Aligned carbon nanotube arrays formed by cutting a polymer resin—nanotube composite. Science. 1994;265(5176):1212–4.10.1126/science.265.5176.1212Search in Google Scholar PubMed

[39] Iqbal K, Khan S-U, Munir A, Kim J-K. Impact damage resistance of CFRP with nanoclay-filled epoxy matrix. Compos Sci Technol. 2009;69(11–12):1949–57.10.1016/j.compscitech.2009.04.016Search in Google Scholar

[40] Xu Y, Van Hoa S. Mechanical properties of carbon fiber reinforced epoxy/clay nanocomposites. Compos Sci Technol. 2008;68(3–4):854–61.10.1016/j.compscitech.2007.08.013Search in Google Scholar

[41] Balaganesan G, Velmurugan R, Srinivasan M, Gupta NK, Kanny K. Energy absorption and ballistic limit of nanocomposite laminates subjected to impact loading. Int J Impact Eng. 2014;74:57–66.10.1016/j.ijimpeng.2014.02.017Search in Google Scholar

[42] Reis PNB, Ferreira JAM, Zhang ZY, Benameur T, Richardson MOW. Impact response of Kevlar composites with nanoclay enhanced epoxy matrix. Compos Part B: Eng. 2013;46:7–14.10.1016/j.compositesb.2012.10.028Search in Google Scholar

[43] Velmurugan R, Balaganesan G. Energy absorption characteristics of glass/epoxy nano composite laminates by impact loading. Int J Crashworthiness. 2013;18(1):82–92.10.1080/13588265.2012.745975Search in Google Scholar

[44] Rafiq A, Merah N, Boukhili R, Al-Qadhi M. Impact resistance of hybrid glass fiber reinforced epoxy/nanoclay composite. Polym Test. 2017;57:1–11.10.1016/j.polymertesting.2016.11.005Search in Google Scholar

[45] Hsieh T-H, Huang Y-S, Wang F-X, Shen M-Y. Impact and after-impact properties of nanocarbon aerogels reinforced epoxy/carbon fiber composite laminates. Compos Struct. 2018;206:828–38.10.1016/j.compstruct.2018.08.057Search in Google Scholar

[46] Sabri FNAM, Zakaria MR, Akil HMD. Enhanced flexural strength of carbon nanotubes-glass fiber epoxy composite laminates using an electrospray deposition technique. Polym Compos. 2021;42:2556–64. 10.1002/pc.26001.Search in Google Scholar

[47] Khan W, Sharma R, Saini P, Khan W, Sharma R, Saini P. Carbon nanotube-based polymer composites: Synthesis, properties and applications. In: Carbon Nanotubes—Current Progress of their Polymer Composites. London, UK: Intech Open; 2016. 10.5772/62497.Search in Google Scholar

[48] Sürücü AM, Subaşı S, Danish A, Gencel O, Subaşı A, Ozbakkaloglu T. Mechanical and radiation shielding properties of SWCNT reinforced polymer/glass fiber fabric-based nanocomposite containing different filler materials: A comparative study. J Appl Polym Sci. 2023;140:e53483. 10.1002/app.53483.Search in Google Scholar

[49] Le AT, Govignon Q, Rivallant S, Cutard T. Mode I and mode II fracture behavior in nano-engineered long fiber reinforced composites. Polym Compos. 2023;44:4016–26. 10.1002/pc.27374.Search in Google Scholar

[50] Shahbaz SR, Berkalp ÖB. Effect of MWCNTs addition, on the mechanical behaviour of FRP composites, by reinforcement grafting and matrix modification. J Ind Text. 2020;50:205–23. 10.1177/1528083718825317.Search in Google Scholar

[51] Zhao Z, Teng K, Li N, Li X, Xu Z, Chen L, et al. Mechanical, thermal and interfacial performances of carbon fiber reinforced composites flavored by carbon nanotube in matrix/interface. Compos Struct. 2017;159:761–72. 10.1016/j.compstruct.2016.10.022.Search in Google Scholar

[52] Zhou Y, Pervin F, Lewis L, Jeelani S. Experimental study on the thermal and mechanical properties of multi-walled carbon nanotube-reinforced epoxy. Mater Sci Eng: A. 2007;452–453:657–64. 10.1016/j.msea.2006.11.066.Search in Google Scholar

[53] Ramezani M, Kim YH, Sun Z. Probabilistic model for flexural strength of carbon nanotube reinforced cement-based materials. Compos Struct. 2020;253:112748. 10.1016/j.compstruct.2020.112748.Search in Google Scholar

[54] Kim KJ, Kim J, Yu W-R, Youk JH, Lee J. Improved tensile strength of carbon fibers undergoing catalytic growth of carbon nanotubes on their surface. Carbon. 2013;54:258–67. 10.1016/j.carbon.2012.11.037.Search in Google Scholar

[55] Mei H, Zhang S, Chen H, Zhou H, Zhai X, Cheng L. Interfacial modification and enhancement of toughening mechanisms in epoxy composites with CNTs grafted on carbon fibers. Compos Sci Technol. 2016;134:89–95. 10.1016/j.compscitech.2016.08.010.Search in Google Scholar

[56] Bhowmik K, Khutia N, Tarfaoui M, Jana M, Das K, Roy T, et al. Influence of multiwalled carbon nanotube on progressive damage of epoxy/carbon fiber reinforced structural composite. Polym Compos. 2022;43:7751–72. 10.1002/pc.26877.Search in Google Scholar

[57] Sharma SP, Lakkad SC. Effect of CNTs growth on carbon fibers on the tensile strength of CNTs grown carbon fiber-reinforced polymer matrix composites. Compos Part A: Appl Sci Manuf. 2011;42:8–15. 10.1016/j.compositesa.2010.09.008.Search in Google Scholar

[58] Rahmanian S, Thean KS, Suraya AR, Shazed MA, Mohd Salleh MA, Yusoff HM. Carbon and glass hierarchical fibers: Influence of carbon nanotubes on tensile, flexural and impact properties of short fiber reinforced composites. Mater Des. 2013;43:10–6. 10.1016/j.matdes.2012.06.025.Search in Google Scholar

[59] Wang B, Fu Q, Yin T, Li H, Qi L, Fu Y. Grafting CNTs on carbon fabrics with enhanced mechanical and thermal properties for tribological applications of carbon fabrics/phenolic composites. Carbon. 2018;139:45–51. 10.1016/j.carbon.2018.06.032.Search in Google Scholar

[60] Moaseri E, Karimi M, Maghrebi M, Baniadam M. Fabrication of multi-walled carbon nanotube–carbon fiber hybrid material via electrophoretic deposition followed by pyrolysis process. Compos Part A: Appl Sci Manuf. 2014;60:8–14. 10.1016/j.compositesa.2014.01.009.Search in Google Scholar

[61] Lv P, Feng Y, Zhang P, Chen H, Zhao N, Feng W. Increasing the interfacial strength in carbon fiber/epoxy composites by controlling the orientation and length of carbon nanotubes grown on the fibers. Carbon. 2011;49:4665–73. 10.1016/j.carbon.2011.06.064.Search in Google Scholar

[62] Parameswarreddy G, Yadam YR, Arunachalam K, Sarathi R, Suematsu H. Investigation on the enhancement of electromagnetic shielding with efficient use of short carbon fiber in MWCNT-epoxy nanocomposites. Polym Compos. 2023;44:1522–33. 10.1002/pc.27185.Search in Google Scholar

[63] An F, Lu C, Li Y, Guo J, Lu X, Lu H, et al. Preparation and characterisation of carbon nanotube-hybridised carbon fiber to reinforce epoxy composite. Mater Des. 2012;33:197–202. 10.1016/j.matdes.2011.07.027.Search in Google Scholar

[64] Jiang S, Li Q, Zhao Y, Wang J, Kang M. Effect of surface silanisation of carbon fiber on mechanical properties of carbon fiber reinforced polyurethane composites. Compos Sci Technol. 2015;110:87–94. 10.1016/j.compscitech.2015.01.022.Search in Google Scholar

[65] Sharma SP, Lakkad SC. Impact behavior and fractographic study of carbon nanotubes grafted carbon fiber-reinforced epoxy matrix multi-scale hybrid composites. Compos Part A: Appl Sci Manuf. 2015;69:124–31. 10.1016/j.compositesa.2014.11.005.Search in Google Scholar

[66] Siddiqui NA, Khan SU, Ma PC, Li CY, Kim J-K. Manufacturing and characterisation of carbon fibre/epoxy composite prepregs containing carbon nanotubes. Compos Part A: Appl Sci Manuf. 2011;42:1412–20. 10.1016/j.compositesa.2011.06.005.Search in Google Scholar

[67] Sun X, Liu X, Shen X, Wu Y, Wang Z, Kim J-K. Graphene foam/carbon nanotube/poly(dimethyl siloxane) composites for exceptional microwave shielding. Compos Part A: Appl Sci Manuf. 2016;85:199–206. 10.1016/j.compositesa.2016.03.009.Search in Google Scholar

[68] Anthony DB, Sui X, Kellersztein I, De Luca HG, White ER, Wagner HD, et al. Continuous carbon nanotube synthesis on charged carbon fibers. Compos Part A: Appl Sci Manuf. 2018;112:525–38. 10.1016/j.compositesa.2018.05.027.Search in Google Scholar

[69] Hassanzadeh-Aghdam MK, Ansari R, Darvizeh A. Micromechanical analysis of carbon nanotube-coated fiber-reinforced hybrid composites. Int J Eng Sci. 2018;130:215–29. 10.1016/j.ijengsci.2018.06.001.Search in Google Scholar

[70] Guignier C, Bueno M-A, Camillieri B, Durand B. Influence of composite processing on the properties of CNT grown on carbon surfaces. Appl Surf Sci. 2018;428:835–43. 10.1016/j.apsusc.2017.09.221.Search in Google Scholar

[71] Hassanzadeh-Aghdam MK, Mahmoodi MJ, Jamali J. Effect of CNT coating on the overall thermal conductivity of unidirectional polymer hybrid nanocomposites. Int J Heat Mass Transf. 2018;124:190–200. 10.1016/j.ijheatmasstransfer.2018.03.065.Search in Google Scholar

[72] Lachman N, Carey BJ, Hashim DP, Ajayan PM, Wagner HD. Application of continuously-monitored single fiber fragmentation tests to carbon nanotube/carbon microfiber hybrid composites. Compos Sci Technol. 2012;72:1711–7. 10.1016/j.compscitech.2012.06.004.Search in Google Scholar

[73] Zhang L, De Greef N, Kalinka G, Van Bilzen B, Locquet J-P, Verpoest I, et al. Carbon nanotube-grafted carbon fiber polymer composites: Damage characterisation on the micro-scale. Compos Part B: Eng. 2017;126:202–10. 10.1016/j.compositesb.2017.06.004.Search in Google Scholar

[74] Taha I, Abdin YF. Modeling of strength and stiffness of short randomly oriented glass fiber—polypropylene composites. J Compos Mater. 2011;45:1805–21. 10.1177/0021998310389089.Search in Google Scholar

[75] Cai G, Yan C, Liu D, Xu H, Lu J, Chen G, et al. Effects of functionalised graphene oxide modified sizing agent on the interfacial and mechanical properties of carbon fiber reinforced polyamide 6 composites. Polym Compos. 2022;43:8483–98. 10.1002/pc.27018.Search in Google Scholar

[76] Li M, Gu Y, Liu Y, Li Y, Zhang Z. Interfacial improvement of carbon fiber/epoxy composites using a simple process for depositing commercially functionalised carbon nanotubes on the fibers. Carbon. 2013;52:109–21. 10.1016/j.carbon.2012.09.011.Search in Google Scholar

[77] Baek Y-M, Shin P-S, Kim J-H, Park H-S, DeVries KL, Park J-M. Thermal transfer, interfacial, and mechanical properties of carbon fiber/polycarbonate-CNT composites using infrared thermography. Polym Test. 2020;81:106247. 10.1016/j.polymertesting.2019.106247.Search in Google Scholar

[78] Patnaik S, Gangineni PK, Ray BC, Prusty RK. Effect of graphene-based nanofillers addition on the interlaminar performance of CFRP composites: An assessment of cryo-conditioning. Materials Today: Proceedings, 2nd International Conference on Processing and Characterization of Materials. Vol. 33. 2020. p. 5070–5. 10.1016/j.matpr.2020.02.846.Search in Google Scholar

[79] Gao B, Zhang R, He M, Sun L, Wang C, Liu L, et al. Effect of a multiscale reinforcement by carbon fiber surface treatment with graphene oxide/carbon nanotubes on the mechanical properties of reinforced carbon/carbon composites. Compos Part A: Appl Sci Manuf. 2016;90:433–40. 10.1016/j.compositesa.2016.08.012.Search in Google Scholar

[80] Kim H, Oh E, Hahn HT, Lee K-H. Enhancement of fracture toughness of hierarchical carbon fiber composites via improved adhesion between carbon nanotubes and carbon fibers. Compos Part A: Appl Sci Manuf. 2015;71:72–83. 10.1016/j.compositesa.2014.12.014.Search in Google Scholar

[81] Shin YC, Lee WI, Kim HS. Mode II interlaminar fracture toughness of carbon nanotubes/epoxy film-interleaved carbon fiber composites. Compos Struct. 2020;236:111808. 10.1016/j.compstruct.2019.111808.Search in Google Scholar

[82] Borowski E, Soliman E, Kandil UF, Taha MR. Interlaminar fracture toughness of CFRP laminates incorporating multi-walled carbon nanotubes. Polymers. 2015;7:1020–45. 10.3390/polym7061020.Search in Google Scholar

[83] Wang C, Li Y, Tong L, Song Q, Li K, Li J, et al. The role of grafting force and surface wettability in interfacial enhancement of carbon nanotube/carbon fiber hierarchical composites. Carbon. 2014;69:239–46. 10.1016/j.carbon.2013.12.020.Search in Google Scholar

[84] Ou Y, Wu L, Yi X, Mao D. Understanding Mode I interlaminar toughening of unidirectional CFRP laminates interleaved with aligned ultrathin CNT fiber veils: Thickness and orientation effects. Compos Part B: Eng. 2023;254:110578. 10.1016/j.compositesb.2023.110578.Search in Google Scholar

[85] He Y, Zhang J, Yao L, Tang J, Che B, Ju S, et al. A multi-layer resin film infusion process to control CNTs distribution and alignment for improving CFRP interlaminar fracture toughness. ComposStruct. 2021;260:113510. 10.1016/j.compstruct.2020.113510.Search in Google Scholar

[86] Liu Y, Zou A, Wang G, Han C, Blackie E. Enhancing interlaminar fracture toughness of CFRP laminates with hybrid carbon nanotube/graphene oxide fillers. Diam Relat Mater. 2022;128:109285. 10.1016/j.diamond.2022.109285.Search in Google Scholar