Abstract

The manufacturing of ballistic impact-resistant (BIR) body armours has evolved over the years with the aim of reducing their weight and enhancing their energy-absorbing capacity upon ballistic impacts. The incorporation of nanoparticles into advanced BIR body armour systems is considered one of the promising techniques. The methods employed in incorporating various nanoparticles in the manufacturing of textile-based body armour systems face a research gap in the optimisation of the associated parameters. This article discusses the mechanism involved in the energy absorption of composites and nanocomposites upon ballistic impact. The current review article highlights the chemical, physical, and mechanical properties of various nanoparticles incorporated into BIR body armour systems. BIR nanocomposites consisting of carbon nanotubes, graphene nanoplatelets, nano-silica, nanoclays, nano-alumina, etc., have been discussed herein. In addition, the significance of various techniques for the dispersion of these nanoparticles was also highlighted. Various methods, such as sol–gel, PVD, CVD, thermal spray, and electroless methods for coating the nanoparticles on the surface of the fibre/fabric were also discussed.

1 Introduction

A body armour system is essential for safeguarding the human body against various levels of threats ranging from combat projectiles to sharp objects. Materials employed in manufacturing these body armours have evolved consistently along with human civilisation, from stones to advanced nanomaterials. In the past, people used to safeguard their bodies from different levels of threat by using primitive materials like stone, wood, leather, steel, and copper [1]. In time, people started to employ fibres like nylon, cotton, linen, and silk to produce textile-based protective clothing [1,2]. The revolution of advanced body armours began in 1960 with the evolution of modern synthetic fibres having excellent ballistic impact-resistant (BIR) properties [3]. Due to the advanced technologies, ever-increasing precision in military operations is pushing the need to enhance the performance of body armours without compromising their weight.

Traditionally, body armours employed in ballistic applications were manufactured using heavier inserts, which increase the overall weight of the body armour and eventually reduce the mobility of the wearer [4]. To overcome these shortcomings, textile-based polymer composites have been explored to produce lighter and BIR body armours [5]. Recently, research on nanocomposites for various applications has increased. In particular, the incorporation of nanoparticles into textile fabrics as coatings for high-velocity ballistic impact applications has attracted the attention of researchers [6,7]. To reduce the weight and enhance the mobility of the wearer, researchers have started to produce textile-based soft body armours. This approach helped to reduce the body armour weight to a certain extent. Generally, to improve the BIR capacity of the composite, more layers are employed, which again increases the weight of the body armour [8]. With the emergence of nanotechnology, researchers have started to incorporate nanoparticles into the manufacturing of soft body armour to further reduce its weight. To obtain suitable ballistic impact properties, nanoparticles can be coated on the surface of textiles, which will eventually help in reducing the number of layers employed in making soft body armours [9].

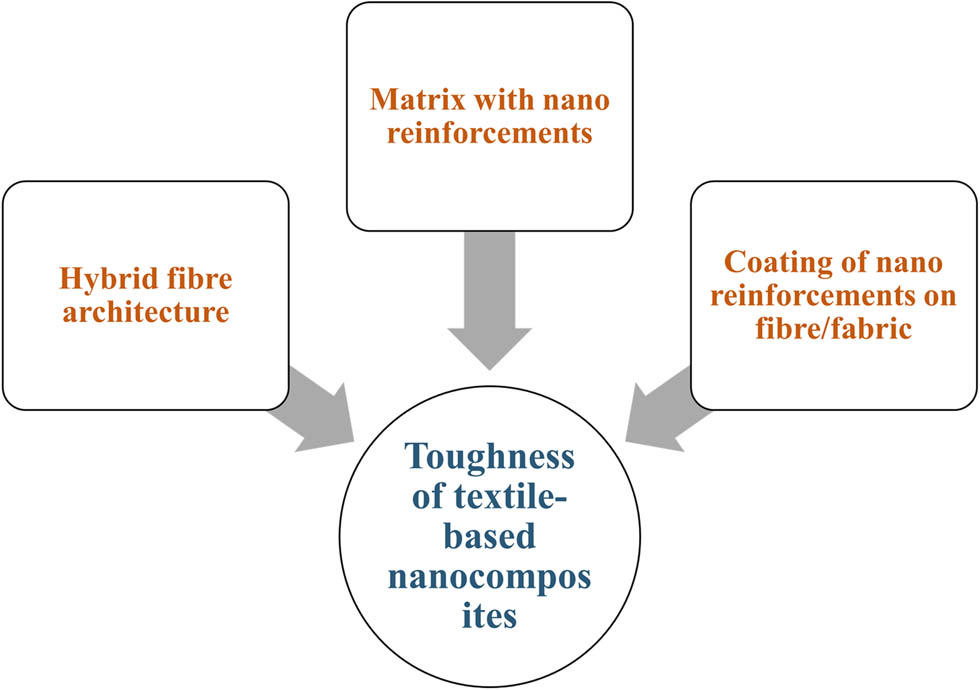

For ballistic applications, the timeframe within which the ballistic impact mechanism occurs is very small (0–200 µs) [10]. Hence, for ballistic impact applications, it is important to have the correct material that performs precisely within this short period. It is a well-known fact that ballistic-resistant material should possess a higher value of toughness to have enhanced energy absorption and resistance to delamination. To obtain higher toughness for composites, various methods like matrix modification, hybridisation [11,12,13], optimisation of fibre architecture [4,14], and addition of nanoparticles [15,16,17] have been explored as depicted in Figure 1. Nanomaterials exhibit outstanding properties and are considered an excellent option for ballistic impact applications [6,18]. This has resulted in the development of advanced nanocomposites with lower density, remarkable strength and stiffness, greater fracture resistance, and outstanding absorption of impact energy [19,20]. In recent times, nanoparticles like carbon nanotubes (CNTs) [21,22,23,24], nano-silica [25,26,27,28], nano-clay [6,29,30], graphene nano-platelets [18,31,32], milled nanofibres [6], buckypaper [33], and nano-alumina [4,18,34] have been employed to enhance the ballistic impact behaviour of nanocomposites.

Factors influencing the toughness of textile-based nanocomposites.

High-performance fibres, such as ultra-high molecular weight polyethylene (UHMWPE), Kevlar, Twaron, PBO, and PIPD, are employed in ballistic impact applications. These fibres exhibit a smooth surface, lower surface energy, chemical inertness, and lower functional groups, which hampers their ability to adhere properly to the matrix material and eventually produces a fragile bond between the fibre and matrix at the interface, which is not ideal for the absorption of energy [35]. For ballistic impact applications, moderate interfacial properties are desirable to enhance energy absorption by mechanisms like friction slippage, cracks, and matrix debonding [36]. The introduction of suitable nanoparticles like nano-silica [37], graphene [38], CNTs (SWCNT and MWCNT) [39], zinc oxide [37], nano-clay [40], and other ceramic nanoparticles on the surface of these high-performance fibres helps to overcome their limitations and further enhances the BIR properties. Generally, the ability of nanocomposites to absorb impact energy depends mainly on the type of fibres, matrix, and incorporated nanoparticles. In addition, the dispersion of nanoparticles, methods used for the dispersion, weight fraction of the nanoparticles, and interfacial properties between various constituents of the nanocomposites determine its energy-absorbing capacity [41]. Similarly, natural fibre-based nanocomposites are gaining momentum for use in ballistic impact applications because of their biodegradability, good strength, low density, and low cost. These composites are typically composed of natural fibres, such as jute [42], curaua [43], sisal [44], and kenaf [45], as well as a polymer matrix, such as epoxy, polyethylene glycol (PEG), and polyester resin, reinforced with nanoparticles, such as graphene oxide [46], CNTs [47], and metal oxide nanoparticles [48]. One advantage of natural fibre-based composites is their ability to absorb impact energy through their viscoelastic deformation behaviour, which can effectively mitigate the damage caused by ballistic impacts [49]. The addition of nanoparticles can further enhance this behaviour by improving the interfacial bonding between the natural fibres and polymer matrix, which can lead to increased stiffness and strength [46].

We begin with a discussion of how technologies have evolved over the years in the development of body armour systems. This study addresses the significance of nanoparticles in the absorption of ballistic impact energy. In particular, the influence of nanoparticle coating on the enhancement of BIR properties of high-performance and natural fabrics is discussed. This study explores the suitability of various nanoparticles for incorporation in the manufacturing of BIR materials. This also highlights the importance of the homogeneous dispersion of nanoparticles in exploiting their full potential. Finally, various techniques available for coating the nanoparticles on the surface of conductive as well as non-conductive fibres and challenges in fabricating BIR nanocomposites were addressed.

2 Technology development

The technology involved in the development of body armour systems is constantly evolving. Figure 2 provides information about technology development over the years. The use of textile-based body armour systems began during World war I and II by utilising silk and nylon fabric. Body armours produced from silk and nylon were able to resist projectiles at considerably lower velocities [54]. To further enhance the energy absorbing capacity of textile-based armours, high-performance fibres such as Aramids (Kevlar, Technora Twaron, etc.) and UHMWPE (Dyneema and spectra) were invented during 1970–1980 [54,55]. The ever-increasing requirements to produce lighter, high-performing, and cost-effective body armours pushed researchers towards hybridisation in the 1990s [51]. Structural hybridisation of the body armour system is an evolving research area. With the emergence of nanotechnology, researchers have begun to incorporate nanoparticles in the development of nanocomposites for various applications. However, the incorporation of nanoparticles in the development of body armour systems took place around 2005 [52,56]. Most of the researchers have incorporated the nanoparticles by mixing them with a matrix material, but there are only a few studies on the coating of nanoparticles on the surface of the fibres [57,58].

3 Energy absorption and failure mechanism in ballistic impact

In the ballistic impact, the absorption of projectiles’ kinetic energy occurs via four important mechanisms: (a) absorption of energy during shearing of yarns, (b) absorption of energy during the formation of a cone at the back side, (c) absorption of energy in the compression and fabric movement, and (d) absorption of energy in the form of heat. In particular, the yarn pull-out, yarn rupture, yarn fibrillation, friction, cone formation, and bowing are the modes of energy absorption [59].

The failure mechanism of textile-based body armours varies with respect to impact velocity (low, medium, and high) as well as with the energy absorption capacity of the constituent materials of the target (fibre, resin, and nano-reinforcement). The mechanism of failure involved in ballistic impacts is quite different in comparison with low-velocity impacts [60]. This mechanism can be attributed to the multiple layers of laminates employed in ballistic applications. As the thickness of the panel increases, the time available for the target to respond against a high-velocity projectile also increases [60]. When the bullet hits the panel, the bullet will perforate if its kinetic energy is beyond the energy-absorbing capacity of the panel. On the other hand, a panel can catch the bullet if its energy-absorbing capacity is beyond the bullet’s kinetic energy [61].

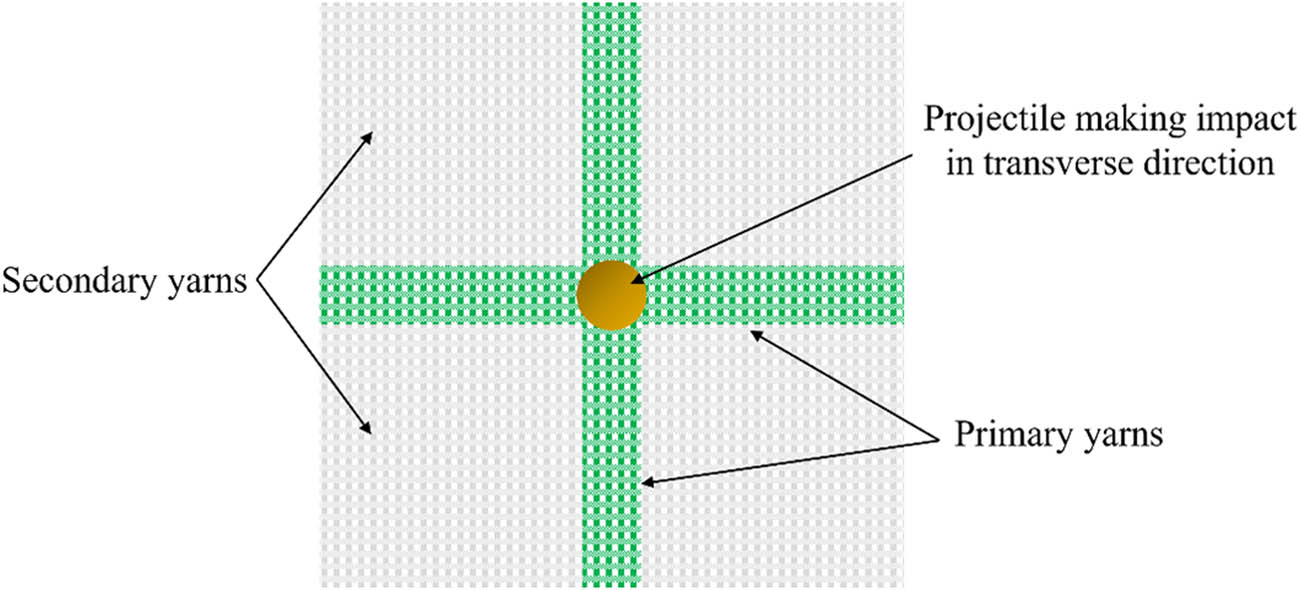

When the projectile hits the fabric, yarns that come under contact with the projectile directly are labelled as primary yarns, and yarns that do not come under direct contact with the projectile are termed secondary yarns, as depicted in Figure 3 [31,62].

Primary and secondary yarns of the fabric upon projectile impact.

In general, different failure mechanisms like compression of the panel under projectile, compression in the vicinity of the point of impact, primary yarns undergoing tensile failure, deformation in the secondary yarns, shear plugging, matrix cracking, and delamination can take place at different stages in the thickness direction of the panel. In addition, back-face deformation, inter-yarn friction, and friction between fabric and projectile in the thickness direction occur [25].

3.1 Energy absorption mechanism in the nanocomposites under a ballistic impact

The mechanical performance of polymer composites tends to increase with the reinforcement of nanoparticles. This nano-reinforcement is generally recognised as the third phase. However, the mechanism involved in the performance of nanocomposites can be completely different compared to composites having reinforcements at the micron level [63]. This situation is due to the higher surface area of the nanoparticles. For example, upon ballistic impact, polymer resins without nanoparticles will undergo failure mechanisms like radial cracks, shear yielding, and shear plugging. However, if nanoparticles are incorporated into polymer resins, the failure mechanism takes place through crack bridging, crack deflection, debonding of nanoparticles, and plastic void growth [17]. In this direction, it is essential to understand the mechanism involved in the absorption of impact energy for nanocomposites. Eq. (1) helps in understanding how the total energy of the projectile is absorbed by the nanocomposites. It provides the energy lost (E L) by the projectile in the process of perforating the target:

where m denotes the projectile’s mass, V denotes the projectile’s incident velocity, and V r denotes the projectile’s residual velocity. Eq. (2) describes the energy the laminate has absorbed overall (E Total):

where

3.2 Pinning of cracks

The incorporation of nanoparticles in the composites helps in the stoppage of crack propagation. It is commonly recognised as a mechanism of crack pinning. From Figure 4, it can be seen that the addition of nano-silica resulted in the pinning of cracks [64]. This is one of the dominant mechanisms when it comes to energy absorption [65].

![Figure 4

SEM images of crack pinning in epoxy resin (a) without nano-silica, (b) with 2.5 vol% nano-silica, and (c) with 13.4 vol% nano-silica [64].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_004.jpg)

SEM images of crack pinning in epoxy resin (a) without nano-silica, (b) with 2.5 vol% nano-silica, and (c) with 13.4 vol% nano-silica [64].

3.2.1 Deflection of crack

Composites consisting of stiffer nanoparticles make the crack deviate by tilting or twisting, which results in the alteration of the plane of crack propagation, thereby eventually enhancing the overall surface area associated with the crack. As the surface area of the crack increases, the absorption of energy also increases [66]. Generally, to deflect the crack propagation to another plane, well-bonded and hard particles are incorporated.

3.2.2 Immobilised polymer

Polymeric chain mobility is restricted when the nanoparticles are dispersed in it, necessitating significantly more energy to move the chains [18,67]. In addition, these nanoparticles also have the potential to change the glass transition temperature as well as the chemical behaviour of the composites.

3.2.3 Bridging of cracks

The incorporation of nanoparticles into the fibre-reinforced composites helps the bridging of cracks through the toughening mechanism. Among the nanoparticles, CNT helps significantly in crack bridging due to higher elongation at break [68]. This crack-bridging phenomenon tends to slow down the growth of the crack and simultaneously increases energy absorption.

3.2.4 Debonding and voids

Debonding is another mechanism by which toughness is induced into nanocomposites. When a projectile hits the target, debonding slippage takes place between the matrix and nanoparticles, which results in the enhancement of interface friction, which eventually helps in the dissipation of energy [47]. However, the dissipation of energy is quite lower in the case of debonding in comparison with other mechanisms.

4 Nanoparticles incorporated in developing body armour systems

Nanomaterials consist of nanoparticles with dimensions in the range of 1–100 nm, unlike bulk materials (above 100 nm). Nanocomposites are obtained by incorporating these nanoparticles in the continuous phase of the material. These nanocomposites (combined form) exhibit enhanced properties in comparison with their constituents (uncombined form). One of the key characteristics of nanomaterials is the surface area/volume ratio, which decides the material’s unique properties and usability [69]. In general, nanoparticles are categorised based on their size, morphology, and chemical properties. Depending on the chemical and physical characteristics, some important classes of nanoparticles are classified as carbon-, ceramic-, metal-, and polymeric-based [70,71]. In this section, important nanomaterials which have been employed frequently in the development of body armour systems are discussed.

4.1 Nano-silica-based shear thickening fluid (STF)

STF is a smart anti-ballistic material that tends to change from liquid to solid phase upon ballistic impact to resist the impact caused by high-speed projectiles [42]. Upon the disappearance of the impact, the solid phase returns to its initial state (liquid phase) reversibly. STF is a non-Newtonian fluid in which shear stress increases non-linearly with an increase in the shear rate. The viscosity of the STF increases suddenly as the shear rate crosses the critical value called the critical shear rate. It is generally known as shear thickening behaviour, and this process is reversible, i.e. upon release of impact force, STF tends to come back to its initial flow state. Figure 5 shows the shear thickening phenomenon. STF is generally made up of two phases: the dispersed phase and the dispersion medium. The dispersed phase is made up of sub-micron or nanoscale particles of silica, poly-methyl methacrylate (PMMA) or calcium carbonate, etc. On the other hand, the dispersion medium consists of water, polyethylene glycol (PEG), silicon oils, and polypropylene glycol (PPG) [72,73]. The key to attaining the shear thickening behaviour is the proper interaction between the dispersed phase and the dispersion medium. For dispersed phase, fumed silica or colloidal silica nanoparticles, and for dispersion medium, PEG is extensively used by most researchers. The main reason behind choosing PEG as a dispersion medium is due to its non-toxic nature, thermal stability, and ease of handling [74,75,76]. To achieve the optimal distribution of particles throughout the STF, breaking of intermolecular interaction among nanoparticles is essential [77]; this can be accomplished by the use of techniques like sonochemical, magnetic stirrer, high-speed homogenisation, ultrasound sonication, etc. [78,79].

![Figure 5

Mechanism of shear thickening [25].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_005.jpg)

Mechanism of shear thickening [25].

Different theories have been suggested by researchers to describe the behaviour of shear thickenings, such as order–disorder theory, dilation theory, hydrocluster theory, and contact-rheology theory [77,80,81]. The behaviour of STF depends upon crucial parameters such as the presence of solid content, particle shape, particle aspect ratio, size of the particles and their distribution, interaction among particles, particle hardness and temperature, pH, and nanofillers [4]. Generally, to prepare STF, first nano-silica particles are dispersed in ethanol with the help of ultrasonication; then, a known amount of PEG is added to this solution with subsequent ultrasonication, and finally, the prepared STF is dried in an oven to evaporate excess ethanol. To perform the impregnation of fabric, STF is again diluted with ethanol and ultrasonicated; then, the fabric is soaked in the STF solution and dried in an oven to evaporate the excess ethanol, as depicted in Figure 6.

![Figure 6

The preparation process of STF-impregnated fabrics: (a) SEM images of silica particles, (b and c) impregnation process, and (d) drying treatment [82].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_006.jpg)

The preparation process of STF-impregnated fabrics: (a) SEM images of silica particles, (b and c) impregnation process, and (d) drying treatment [82].

In the case of neat panels, when a fabric is hit by a bullet, angular orientations act as a facilitator in the propagation of stress waves through primary yarns in different directions. This beneficial effect (facilitated by angular orientation) is insignificant due to the smaller number of primary yarns and relatively insufficient contribution from secondary yarns in energy absorption. The involvement of secondary yarns can be enhanced by impregnating the fabric in STF. Thus, the use of STF further enhances the advantage of angular orientation by increasing the dome formation area (Figure 7) [83].

![Figure 7

Propagation of stress waves in neat and STF-treated fabrics [83].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_007.jpg)

Propagation of stress waves in neat and STF-treated fabrics [83].

SEM images of the Kevlar fabric impregnated in STF (35 wt%) have indicated good dispersion of silica nanoparticles on the surface of Kevlar fabric(Figure 8) at different magnifications. Deposition of STF in the inter-yarn gaps at the yarn crossover region was also observed. The specific energy absorption (SEA) capacity of the Kevlar/STF composite was 2.3 times higher compared to the neat Kevlar fabric.

![Figure 8

SEM images of Kevlar fabric impregnated with STF (35 wt%) [84].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_008.jpg)

SEM images of Kevlar fabric impregnated with STF (35 wt%) [84].

A rheometer is generally used to understand the rheological response of the developed STF. Figure 9(a) and (b) depicts the influence of nano-silica wt% on the rheological response of the developed STF, and Figure 9(c) and (d) presents the rheological response of the developed STF at different operating temperatures. From the figure, it is evident that the viscosity of all the developed STFs varies non-linearly with respect to the applied shear rate. Upon application of the shear rate, STF experienced both shear thinning as well as shear thickening. At lower shear rates, a shear-thinning response was observed and at higher shear rates, a shear-thickening response was observed [42,79,85,86]. From Figure 9(a) and (b), it can be observed that with the increase in the nano-silica wt%, critical shear rate values have decreased, and once the shear rate exceeds its critical value, a sudden jump in the viscosity of the STF can be observed. When the effect of the temperature was investigated on the rheological response of the STF, it was found that with the increase in the temperature, the shear rate required for attaining the highest viscosity and critical value of the shear rate also increases and decreases in peak viscosity values, as depicted in Figure 9(c) and (d). Also, results of the rheological study have revealed that, with the increase in the particle size (from 100 to 500 nm), the critical shear rate values decrease. Along with the many advantages in ballistic impact applications, STF exhibits certain limitations like temperature sensitivity, limited durability, and complex manufacturing processes [87].

4.2 Graphene nanoparticle coating

As graphene is a rigid and high-strength material, the potential future of graphene in ballistic applications has been investigated [90,91,92]. Previously, graphene layers were employed in manufacturing body armours to reduce blunt trauma and dissipate the projectile’s kinetic energy away from the strike zone. However, the manufacturing of graphene-layered body armour is quite expensive. With the development of nanotechnology, graphene nanoparticles have been used in the manufacturing of body armours.

The application of graphene nanoplates on the high-performance fabric surface results in the increase of tensile strength, tenacity, and Young’s modulus of the nanocomposites [93]. Reinforcement of Aramid fabric (Twaron®) was performed with graphene oxide (GO) solution; subsequently, heat treatment was carried out at 120°C. The ballistic behaviour of the fabric was improved by increasing the coefficient of friction of the fibres. A comparison between neat and GO-coated fabrics with one and two filtrations was carried out; GO-coated fabric with two filtrations has shown better resistive force (50% increase) in comparison with neat fabrics [31]. All the samples were compared using optical microscopy (OM) and scanning electron microscopy (SEM). As shown in Figure 10, smooth surfaces were observed on OM (a) and SEM (b) for neat aramid fabric. Figure 10(c) and (d) shows the partial covering of GO flakes from the first filtration. Moreover, Figures 10(e) and 26(f) show almost complete covering of small GO flakes on aramid from the second filtration [31]. The uniform distribution of GO flakes during coating helps in obtaining a superior ballistic performance of the aramid [90].

![Figure 10

(a) OM of neat aramid, (b) SEM of neat aramid, (c) OM of aramid+ GO (1), (d) SEM of aramid+ GO(1), (e) OM of aramid + GO(2), and (f) SEM of aramid + GO(2) [31].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_010.jpg)

(a) OM of neat aramid, (b) SEM of neat aramid, (c) OM of aramid+ GO (1), (d) SEM of aramid+ GO(1), (e) OM of aramid + GO(2), and (f) SEM of aramid + GO(2) [31].

A molecular dynamic test was carried out on graphene-coated polyethylene samples, and it was found that graphene has the potential to transform polyethylene into a BIR high-performance material. Over an eight-fold increase in the ballistic impact, the resistant capacity of the polyethylene can be achieved by coating a layer of graphene on it. The impact of graphene was more pronounced when graphene was added in the form of a coating on the surface rather than as reinforcement. In the multi-layered body armour system, graphene at the topmost layers only contributed to the absorption of ballistic impact energy, as depicted in Figure 11 [94].

![Figure 11

Velocity profile of the projectile: (a) coated sample and (b) multi-layered reinforced sample [94].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_011.jpg)

Velocity profile of the projectile: (a) coated sample and (b) multi-layered reinforced sample [94].

To understand the significance of the incorporation of graphene nanopowder in its ballistic properties, experiments were conducted on a glass fibre-based composite. Two types of composites with 2 and 3 mm thicknesses were developed using the vacuum-assisted resin transfer moulding technique. Upon the addition of 0.1 wt% of graphene nanoplatelet to the composite, the energy absorption capacities of the 2 and 3 mm thick samples improved by 9.2 and 8.2%, respectively. An increase in the energy absorption capacity was attributed to the enhanced ductile properties of the composite [95].

To evaluate ballistic performance, an investigation was carried out on curaua fibres (CFs) coated with graphene oxide. The coating was done by immersing the CF in the graphene oxide solution (0.1 wt% with respect to the fibre), and then the coated fibres were dried in an oven for 24 h at 80°C. The presence of graphene oxide was confirmed by the Raman and Fourier transform infrared spectroscopy. From the FTIR analysis, it was evident that graphene oxide exhibited changes in the characteristic bands of the CFs [96]. Changes in the surface morphologies of the CFs after the deposition of graphene oxide can be observed in SEM images, as presented in Figure 12. At higher magnifications, cracks have opened up on the CF surface due to the intensity of the electron beams, as presented in Figure 12(a), with a white arrow indicating the crack location. However, graphene oxide-coated CF was more stable, and the surface was more intact without any visible cracks, as shown in Figure 12(b).

![Figure 12

SEM images of the surface of the fibres: (a) CFs and (b) graphene oxide-coated CFs [96].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_012.jpg)

SEM images of the surface of the fibres: (a) CFs and (b) graphene oxide-coated CFs [96].

4.3 CNT coating

CNTs have been extensively employed in various applications owing to their excellent chemical, electrical, magnetic, and mechanical properties. CNTs are used in the making of useful articles like bulletproof vests, artificial muscles, expansion-proof blankets, and reinforced materials [97]. To explore the capability of CNTs in ballistic behaviour, it is essential to understand the mechanism of bullet impact involving how the velocity, momentum, force, and energy vary in the time horizon when the bullet strikes. CNTs with a larger area can withstand projectiles with higher velocity. Body armours from CNTs exhibit sustained resistance, even when multiple bullets are shot at the same location [98]. The performance of polymer composites at cryogenic temperatures can be enhanced with the inclusion of an appropriate amount of CNTs. CNTs are categorised into two types: single-walled and multi-walled CNTs. From an economical perspective, MWCNTs are comparatively less expensive than SWCNTs [99].

Though fibres like UHMWPE are used significantly in ballistic and aerospace applications, it possesses poor adhesion properties with the polymers due to their non-polarity and chemical inertness [100,101,102,103]. To overcome this limitation, two approaches are generally employed: (i) the use of surface treatment of the fibre to enhance the surface energy and (ii) the inclusion of nano-reinforcements in the matrix to decrease the surface energy [104,105,106]. The introduction of polar functional groups onto the polymer matrix can be achieved by incorporating various nano-reinforcements, like multi-walled CNTs, carbon nanofibres (CNFs), nano-clay, and graphene nanoplatelets (GnPs) [107,108,109]. CNTs are known for possessing outstanding Young’s modulus (greater than 1 TPa) and tensile strength (100 times greater than that of the strongest steel). An investigation was carried out on the UHMWPE/epoxy composite by incorporating MWCNT as a secondary reinforcement. To enhance the compatibility with the epoxy matrix, chemical treatment is carried out on UHMWPE and MWCNTs by using glycidyl methacrylate and amino-thiol. Results showed that chemical treatment increases the wettability, adhesion, tensile properties, and inter-laminar shear stress [110]. The study conducted on carbon fibre/MWCNT/epoxy nanocomposites found that the inclusion of MWCNT results in an increase in conductivity. thermogravimetric analysis has shown that with the increase in MWCNT content, the thermal stability of the nanocomposites is also enhanced [111]. As the army bases are located in various climate conditions, soft body armours must possess good thermal stability.

An investigation was carried out by growing CNT on the E-glass fabric using the CVD method. The introduction of CNT in the composite resulted in the reduction of ILSS and bending properties. However, when the ballistic impact test (V50) was carried out, the composite consisting of CNT exhibited an inflated V50 value (up by 11.1%) due to the enhanced energy absorption properties [15]. An evaluation of the BIR capacity of the newly developed composite was carried out. The composite was made up of CNT/polystyrene ethyl acrylate (PSt-EA)/C-STF/Kevlar. The rheological behaviour of the STF developed from PSt-EA was found to increase significantly upon the addition of CNT. The study also highlighted the importance of adding an optimum amount of CNT (1.0%) into the STF. In the current work, when the amount of CNT addition exceeded 1%, it reduced its significance. Figure 13(a–d) depicts the results of the yarn pull-out tests. From the results, it can be observed that for the neat Kevlar fabric, highest pull-out force recorded was around 2.5 N, and it increased to 9 N for the Kevlar/STF sample. Upon the addition of CNT, the pull-out force reached nearly 15 N, which was the highest among all the samples. An increase in the pull-out force was attributed to the enhanced inter-yarn friction (from 0.50 to 0.80) upon the addition of CNTs. Figure 14(a–c) depicts the SEM images of neat Kevlar, Kevlar/STF, and Kevlar/STF/CNT. Figure 14(d) presents the deposition pattern of PSt-EA and CNT nanoparticles [22].

![Figure 13

Yarn pull-out test: (a) neat Kevlar, (b) Kevlar/STF, (c) Kevlar/STF/CNT, and (d) pull-out forces at 20 mm/min for all the samples [22].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_013.jpg)

Yarn pull-out test: (a) neat Kevlar, (b) Kevlar/STF, (c) Kevlar/STF/CNT, and (d) pull-out forces at 20 mm/min for all the samples [22].

![Figure 14

SEM images of (a) neat Kevlar, (b) Kevlar/STF, (c) Kevlar/STF/CNT, and (d) deposition patterns of PSt-EA and CNT nanoparticles [22].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_014.jpg)

SEM images of (a) neat Kevlar, (b) Kevlar/STF, (c) Kevlar/STF/CNT, and (d) deposition patterns of PSt-EA and CNT nanoparticles [22].

4.4 Nano-clay

Nano-clays are made up of layered silicates having octahedrally shared Al(OH)3/Mg(OH)3 edge and Si atom bound tetrahedrally as structural elements. Nano-clays are obtained from organic sources [112]. In comparison with other nanoparticles, nano-clays are less expensive from an economical perspective and are pro-environment. These advantages have encouraged researchers to further explore the utilisation of nano-clays in nanocomposites for various applications. An investigation was carried out by Pol et al. [41] to identify the influence of nano-clays on the ballistic behaviour of the E-glass/epoxy composite panel. Nano-clays are loaded into the epoxy system by varying their weight percentage (0–7 wt%) with respect to the resin. With the incorporation of 3 wt% of nano-clays, 16% enhancement in the Young’s modulus was achieved. On the other hand, for 5 wt% of nano-clays, enhancement of Young’s modulus was restricted to 8%. Upon the addition of 5 wt% of nano-clays, energy absorption and damaged area of the panel increased significantly at 142 m/s. Another experimental work was carried out on Kevlar fibre, and nano-clay-reinforced epoxy composite. Graphene and nano-clay (up to 10 wt%) were added to the Kevlar/epoxy (70/30 vol%) composite as nanofillers. Results from the flow velocity and drop-down tests indicated that the addition of nano-clay had a more significant effect in terms of absorption of energy and impact resistance capability in comparison with graphene. In the penetration behaviour study, nano-clays outperformed graphene [38].

Assessment of ballistic performance of E-glass/nano-clays/polyester composite was carried out at various pre-load conditions like without preload, and preload in both uniaxial and biaxial directions for tension and compression. Results indicated that the application of preload would result in a decrease in energy absorption and ballistic behaviour of the composites. For comparison, two types of samples were developed, one without nano-clays and another one with nano-clays (1.5 wt%). Upon the addition of nano-clays, the surface morphology of the composite changed significantly, as shown in Figure 15 [113]. Ballistic test results revealed that the incorporation of nano-clays in the composite results in an increase in energy absorption for both no-preload and preload conditions [113].

![Figure 15

SEM images of the composite (a) without nano-clay and (b) with nano-clays (1.5 wt%) [113].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_015.jpg)

SEM images of the composite (a) without nano-clay and (b) with nano-clays (1.5 wt%) [113].

4.5 Other nanoparticles

Apart from nano-silica, graphene, CNTS, and nano-clays, other nanoparticles like silica carbide (SiC), titanium boride (TiB2), boron carbide (B4C), graphite, ZnO nanowires, and aluminium oxide (Al2O3) were also employed as reinforcement in the development of BIR composites. An examination was conducted to understand the effect of silane-treated alumina nanoparticles on the ballistic performance of the UHMWPE/epoxy composites. The addition of silane-treated alumina nanofillers was done at different weight percentages like 0, 1, 3, and 5 wt%. Among all the samples, energy absorbed by the composite consisting of 5 wt% of alumina was the highest (183.2 J), and the minimum number of plies required for stopping the bullet was also the least. When the ballistics test was carried out at an initial projectile velocity of 373 m/s, the residual velocity recorded for the sample having 5 wt% of alumina was also the least among all [114].

To improve the inter-yarn fraction of aramid fabrics, ZnO nanowires were grown on the surface of aramid fabric [115]. The increase in the inter-yarn friction was attributed to the interlocking mechanism between the grown ZnO nanowires and fibres. In addition to the inter-yarn friction, ZnO nanowire growth improved the tensile strength (13%) and Young’s modulus (10%) of the fabric. In another work, to improve the fracture toughness of fibre-reinforced composites (glass/carbon/epoxy), alumina nanofillers (Al2O3) and graphene nanoplatelets (GNPs) were added as hybrid nano-reinforcements [116]. Upon the addition of nanoparticles, nanobubbles observed for the neat samples are filled with nanoparticles (Figure 16), which resulted in the improvement of fracture toughness of the composite.

![Figure 16

(a) Glass fibres, (b) carbon fibres, (c) hybrid glass and carbon fibres, (d) hybrid glass and carbon fibres at 1.5 wt% GNPs and1.5 wt% Al2O3. (e) Hybrid glass and carbon fibres at 3 wt% Al2O3. (f) Higher magnification of hybrid glass and carbon fibres at 1.5 wt% GNPs and 1.5 wt% Al2O3 [116].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_016.jpg)

(a) Glass fibres, (b) carbon fibres, (c) hybrid glass and carbon fibres, (d) hybrid glass and carbon fibres at 1.5 wt% GNPs and1.5 wt% Al2O3. (e) Hybrid glass and carbon fibres at 3 wt% Al2O3. (f) Higher magnification of hybrid glass and carbon fibres at 1.5 wt% GNPs and 1.5 wt% Al2O3 [116].

The influence of various nanofillers like GNPs, CNTs, and hexagonal boron nitride sheets (BNNS) on the ballistic performance of the glass/epoxy composite was studied. Five variants of nanocomposites, namely (i) glass/epoxy, (ii) glass/epoxy + GNPs, (iii) glass/epoxy + CNTs, (iv) glass/epoxy + BNNS + GNPs, and (v) glass/epoxy + BNNS + CNTs, were developed for carrying out a comparative study. Ballistic impact test results show that an increase in impact resistance was observed for all the samples consisting of nanofillers compared to samples without nanofillers (glass/epoxy). Among all the samples, glass/epoxy + BNNS + GNPs recorded the lowest exit velocity when tested at the impact velocity of 134 m/s, as depicted in Figure 17(a). Across samples, SEA was highest for glass/epoxy + BNNS + CNTs (16.3% higher compared to neat samples as shown in Figure 17(b)). SEA of all the nanocomposites was higher than that of the neat sample [47].

![Figure 17

Influence of nanomaterials on the (a) exit velocity of the projectile and (b) upon ballistic impact (134 m/s) SEA by all the samples [47].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_017.jpg)

Influence of nanomaterials on the (a) exit velocity of the projectile and (b) upon ballistic impact (134 m/s) SEA by all the samples [47].

4.6 Dispersion of nanoparticles

The incorporation of nanoparticles in the development of soft body armour systems is considered one of the prominent methods to enhance its ballistic impact performance without compromising on the weight aspects. However, the dispersion of nanoparticles in the composites in a homogeneous manner is a very challenging task. Non-homogenous dispersion of nanoparticles can restrict the exploitation of their advantages [117]. Agglomeration of nanoparticles results in the reduction of their overall effectiveness [118]. During the synthesis of nanoparticles, two types of clusters are generally formed, known as aggregates and agglomerates. Aggregate clusters are formed by the covalent bond between the primary particles, whereas agglomerate clusters are formed by weak bonding forces, which can be separated into primary particles [119,120]. To obtain proper homogenous dispersion of nanofillers in a suitable liquid medium, researchers have used mechanical stirring and ultrasonication with high intensity [121,122]. Similarly, GnPs were dispersed in epoxy resin with acetone, ultrasonication, and magnetic stirring (hot plate), as depicted in Figure 18 [19].

![Figure 18

Steps involved in the dispersion of GnPs in the epoxy resins [19].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_018.jpg)

Steps involved in the dispersion of GnPs in the epoxy resins [19].

To improve the dispersion of CNTs and break the agglomerates, plasma functionalisation was carried out on the surface of CNTs [113]. After functionalisation, CNTs were able to gel with the matrix material and form a good homogenous solution. Plasma functionalisation brought changes to the surface morphology by developing small defects and functional groups [123]. The hydrothermal reaction is another effective method for the dispersion of nanoparticles, in which a solution consisting of nanoparticles and solvent undergoes a heterogeneous reaction at high temperature and pressure. In an earlier study, MWCNTs were dispersed in various organic media like ethanol, dichloromethane, hexane, and isopropyl alcohol by employing a hydrothermal reaction. Raman spectroscopy characterisation revealed that, among all the dispersion media, the dispersion and debundling ability of MWCNTs increased significantly for dichloromethane. Results obtained from other characterisation techniques like UV-Vis spectroscopy and transmission electron microscopy were also in agreement with the Raman spectroscopy results [124].

In another study, the dispersion of MWCNs was assessed in different media like sodium hydroxide, sodium silicate, and combined sodium hydroxide and sodium silicate. Among them, the dispersion of MWCNTs was found to be excellent in the sodium silicate medium. The dispersion process was carried out with naphthalene sulfonate and ultrasonication, as shown in Figure 19. The effect of ultrasonication in the dispersion of MWCNT is evident in Figure 19. The MWCNT bundle had the smallest size, and its behaviour was most stable in sodium silicate in comparison with other media. Control over crack propagation and spatial distribution is best for MWCNTs dispersed in sodium silicate [125].

![Figure 19

Effect of ultrasonication in the dispersion of MWCNTs [125].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_019.jpg)

Effect of ultrasonication in the dispersion of MWCNTs [125].

The summary of the influence of various nanofillers on the ballistic behaviour of the composites in terms of absorption of energy and the ballistic limit is presented in Table 1.

Influence of nanofillers on the ballistic behaviour of the composites

| Fibre/fabric | Matrix | Nanophase reinforcement | Energy absorption | Ballistic limit | Ref. |

|---|---|---|---|---|---|

| Jute | PEG | 40 wt% of nano-silica | 34 J | 75 m/s | [42] |

| Luffa fibre | Epoxy | Graphene nanofiller | 80.15 J | 120 m/s | [126] |

| Basalt fibre | Epoxy | 2 wt% nano-zirconium oxide + 0.1 wt% graphene oxide | Increased by 67% | Increased by 30% | [127] |

| Flax fibres | Epoxy | 0.2 wt% of TiO2 | Increased energy absorption after TiO2 deposition | — | [128] |

| Curaua | Epoxy | Graphene oxide coating | Higher energy absorption for GO-coated CFs | — | [96] |

| Heracron | PEG | 65 wt% of nano-silica | Increased by 13% | 206 m/s | [87] |

| Kevlar (12 layers) | Epoxy | Graphene nanoplatelets (0.25 wt%) | 150–160 J | 250–260 m/s | [19] |

| Kevlar 29 | Epoxy | 1.65 wt% MWCNTs | 6.5% improvement (V 50) | [129] | |

| E-glass | Epoxy | Amino-functionalised MWCNTs (0.3 wt%) | 109.56 J | Increased by 5–6.5% | [130] |

| E-glass | Unsaturated polyester E15-8082 resin | MWCNTs were grown on E-glass using CVD | SEA increased by 106% | V 50 values increased by 11.1% | [15] |

| E-glass | Epoxy | 0.5 wt% nano-silica | 56.3 J | 110 m/s | [131] |

| Kevlar | PEG | 35 wt% of nano-silica | 70 J (increased by 600%) | 115 m/s (increased by 187.5%) | [84] |

| UHMWPE | PEG | 65 wt% of nano-silica | Increased by 90% | 430 m/s | [89] |

| Kevlar | PEG400 | Aluminium powder | 693 J | [132] | |

| Colloidal silica | 679 J | ||||

| Silica carbide | 663 J | ||||

| E glass | Epoxy | Nano-clay (5 wt%) | 100 J (increased by 5%) | 130 m/s | [41] |

| UHMWPE | Epoxy | Silane-treated alumina (Al2O3) 5 wt% | 183.2 J increased by 18.04% | [114] |

5 Methods employed in the coating of nanoparticles on the fibre/fabric surface

Over the years, techniques available for the coating of various materials on fibre surfaces have evolved, as depicted in Figure 20. Some of the important coating methods employed during 1990–2000 were sol–gel, physical vapour deposition (PVD), chemical vapour deposition (CVD), thermal spray, and electroless [57]. Each coating method has its scope, limitation, and significance. For instance, dip coating and electroless deposition can be accomplished at lower operating temperatures, unlike CVD and PVD, in which the minimum operating temperature required for the initiation of the coating process itself is 250°C. Such higher operating temperatures can restrict the utilisation of CVD and PVD methods for the fibres having lower melting points like polymers. Along with these coating techniques, advanced methods like the EPD technique [133], atmospheric plasma spraying [134], spray coating [135], radio frequency plasma- enhanced CVD [136], and flame synthesis methods [137] are also available for the coating of nanoparticles to enhance the flexural, tensile, and thermal properties of the fibre/fabric.

![Figure 20

Technology development in the coating of fibres by various methods [57].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_020.jpg)

Technology development in the coating of fibres by various methods [57].

Fibres employed in the development of textile-based body armour systems are mostly non-conductive. Hence, it is important to understand the coating techniques suitable for non-conductive materials. Generally, sol–gel, the failure mechanism of textile-based body, PVD, thermal spray, and electroless techniques are employed for the coating of nanoparticles on the non-conductive high-performance fibres, as depicted in Figure 21.

5.1 Sol–gel

It is an economical chemical process in which sol is a suspension of solid particles in a phase consisting of liquid and gel is solid particles submerged in the liquid solvent [138]. In this process, a chemical solution acts as a precursor to form an integrated system from discrete particles. Sol–gel coating can be done in various forms like spraying, dip coating, and spinning. As the sol–gel coating process is considerably slow, it is not considered a cost-effective option for industrial applications where a high rate of production is required [142]. However, sol–gel coating is significant when substrate has to be protected against decreasing ion release and corrosion. Inter-yarn friction of a given fabric material plays a significant role in determining its BIR capacity. The sol–gel method can be employed to introduce nanoparticles on the surface of high-performance fabrics (Figure 22), which improves inter-yarn friction and eventually helps in absorbing the projectile energy during the ballistic impacts [138].

![Figure 22

Schematic representation of the sol–gel method [7].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_022.jpg)

Schematic representation of the sol–gel method [7].

5.2 PVD coating

PVD-coated materials are employed in a wide range of applications, from industrial parts to decorative objects where corrosion and wear-resistant slim films are required [140]. The main benefit of this method is that customised corrosion, mechanical, and aesthetic properties can be obtained. Generally, the PVD process is carried out in a high-vacuum chamber where solid or liquid materials get vaporised, and subsequently, vapour condensation takes place, which in turn produces a dense and solid film [143]. Evaporation and spluttering are the two commonly employed PVD types. Coating layers obtained from the PVD process are quite thin; hence multi-layered coating and careful selection of material become even more important. To summarise, PVD coating has the potential to be employed in various applications like aerospace, automotive, biomedical, and defence [144]. The PVD process offers flexibility in the usage of organic as well as an inorganic coating material for obtaining the hard and corrosive resistant layer. The utilisation of the PVD process for the deposition of polymer material is considered a challenging option due to polymer degradation. Owing to its higher coating initiation temperatures of PVD, it is not preferred to develop polymer-based nanocomposites for ballistic impact applications. In this direction, further research is required to overcome these challenges.

5.3 CVD coating

CVD is another vapour deposition method to produce a coating on the substrate. Like the PVD process, this process is carried out in a high-vacuum chamber. However, the coating material in CVD is in the form of gas [145]. In this process, chemical gases are fed into the high-vacuum chamber, and chemical reactions among these gases produce a layer of coating [46]. A wide range of materials in different forms and compositions can be used to coat the substrate using the CVD process, including nitrides, oxynitrides, carbides, a composition consisting of Si with Ge and O, carbon in different forms like a diamond, fluorocarbons, graphene, polymers, nanotubes/nanofibres/fibres W and Ti. The CVD process can be performed in various categories like an ultra-high vacuum, low pressure, and atmospheric pressure. Ultra-high vacuum and low-pressure processes are frequently used. Further classification of the CVD process is done based on material properties, substrate heating, and the kind of plasma employed in the vaporisation of the materials. In the case of the CVD process, heating of the substrate at 900° is required, which means it cannot be employed for the materials sensitive to the temperatures. On the other hand, PVD is considered a potential option for temperature-sensitive materials.

The growth of CNTs occurs on top of the full 30 cm × 30 cm region on the de-sized GF2 sample. The density of the grown CNT particles was slightly non-uniform across the substrate area. The de-sizing process was responsible for the slightly uneven growth of CNTs [146]. The SEM images of the grown CNTs at different magnifications are shown in Figure 23(b–g). The CNT forest was composed of MWCNTs and the growth of these MWCNTs around the exposed cylindrical surfaces of the glass fibres (Figure 23(c–g)). The presence of CNT forest on the upper and lower surfaces of the fibre was visible, as shown in Figure 23(f). It indicates the good coverage of MWCNTs around the fibre surface. Penetration of the grown MWCNTs in the thickness direction of the fabric was also observed.

![Figure 23

Growth of MWCNTs on the de-sized GF2 samples: (a) optical microscopic image of GF1, GF2, and CNT-GF2 fabrics and (b–g) SEM images presenting the growth of MWCNTs at various magnifications [15].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_023.jpg)

Growth of MWCNTs on the de-sized GF2 samples: (a) optical microscopic image of GF1, GF2, and CNT-GF2 fabrics and (b–g) SEM images presenting the growth of MWCNTs at various magnifications [15].

Although the use of the CVD technique for coating the nanoparticles on the fibre surfaces has been done in the past, they are very less in number, particularly in the development of BIR nanocomposites. The primary reason for limited usage is due to the higher coating initiation temperature associated with CVD, which restricts its application on low melting point materials like polymers. In this direction, further research is required.

5.4 Thermal and other spray coatings

The thermal spray coating process is known to use the heat source generated from the combustion of chemical, electric, and plasma to melt the assigned material and eventually spray the molten material on the substrate to obtain the protective coating. The coatings obtained from this type are reliable from a wear and corrosion resistance point of view. The thickness obtained from this technique varies from 20 µm to some millimetres, which is quite higher in comparison with the thickness obtained from PVD, CVD, or electroplating. The categorisation of thermal spray coating into different types is done based on their process specification and characteristics. Frequently used categories are detonation, plasma, high-velocity oxyfuel, high-velocity air fuel, and warm/cold and wire arc spraying. Although thermal spray coatings are carried out on fibres for different applications [57,147], it is yet to be explored for ballistic impact applications. In addition to thermal spray coating, other spray coating techniques like ultrasonic spray and hand spray coating techniques have been employed [135,148]. To enhance the surface properties of carbon fibres, CNTs were spray coated on them (Figure 24) and then the coated carbons fibres were reinforced with high-density polyethylene to produce composites. A significant change in the morphology of the CNT-coated carbon fibres was observed compared to uncoated carbon fibres as depicted in Figure 25. The composites prepared from CNT-coated fibres exhibited enhanced mechanical properties [135]. Similarly, this method has the potential to be employed for developing BIR materials.

![Figure 24

Ultrasonic spray coating of MWCNTs on carbon fibres [135].](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_024.jpg)

Ultrasonic spray coating of MWCNTs on carbon fibres [135].

![Figure 25

SEM images of CNTs spray-coated carbon fibres [135]. (a) raw CFs, (b) CNTs, (c) and (d) CFs with CNT spray coatings.](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_025.jpg)

SEM images of CNTs spray-coated carbon fibres [135]. (a) raw CFs, (b) CNTs, (c) and (d) CFs with CNT spray coatings.

5.5 Electroless coating

The electroless coating, also called auto-catalytic coating, is a non-galvanic kind of coating technique in which several reactions take place simultaneously in a water-based solution without the aid of electricity [149,150]. The electroless coating process is carried out in four steps, namely, surface treatment, surface sensitisation, surface activation, and deposition of material on the substrate, as depicted in Figure 26 [149,151]. Generally, electroless coating bath consists of a metal ion source, complexing agents, reducing agents, buffering agents, wetting agents, and a stabiliser [151]. Temperature and pH are the two controllable parameters in the electroless coating [152]. Electroless coating on different fibres was performed in the past to improve the conductivity, strength, and EMI shielding capability [149,153]. However, the potential of electroless coating on fibres for ballistic impact applications is yet to be explored. The electroless NiP-coated fibres exhibit the island-shaped protuberances (below 70°) and tree-shaped protuberances (80°), as depicted in Figure 27.

![Figure 27

SEM images of electroless NiP-coated carbon fibres [149]. (a) Island-shaped protuberance and (b) Tree-shaped protuberance.](/document/doi/10.1515/ntrev-2023-0574/asset/graphic/j_ntrev-2023-0574_fig_027.jpg)

SEM images of electroless NiP-coated carbon fibres [149]. (a) Island-shaped protuberance and (b) Tree-shaped protuberance.

Electroless coating technique is considered one of the effective options, owing to its cost-effectiveness, higher throwing power, higher potential to coat conductive as well as non-conductive surfaces, and potential to coat the substrate continuously and uniformly [154,155].

The selection of techniques in the development of nanocomposites depends on the type of fibres, nano-reinforcements, the thickness of the deposition, and operating conditions. To date, most of the researchers have developed nanocomposites for ballistic impact applications by modifying the matrix with nano-reinforcements and by dip-coating methods. Significant scope lies ahead in exploring the potential of sol–gel, CVD, PVD, spray, and electroless-coating techniques in the development of BIR nanocomposites.

6 Conclusion

The ballistic impact mechanism is a fast and complex process that takes place within 0–200 µs. In composites, the absorption of ballistic impact energy takes place via major mechanisms like the tensile failure of yarns that come under direct contact with the projectile, pull-up of other yarns that do not come in direct contact with the projectile, toughness at the interface, and toughness possessed by the matrix. On the other hand, nanocomposites absorb the ballistic impact energy via the mechanisms like pinning cracks, deflection of cracks, immobilisation of polymer chains, bridging of cracks, and debonding. These mechanisms also help in enhancing resistance to delamination. From the literature, it can be stated that effective results from the incorporation of nanoparticles can be achieved only when they are used in optimum quantity.

The significance of impregnation of fabrics in the nano-silica-based STF for the enhancement of BIR is realised herein. The incorporation of other nanoparticles along with nano-silica in the development of STF has the potential to produce smart and multifunctional body armour systems. Similarly, the significance of graphene nanoparticles, CNTs, nano-clays, alumina, zinc oxide nanorods, and other nanoparticles is highlighted from the BIR point of view. In the future, research on the incorporation of hybrid nanofillers for ballistic impact applications needs to be carried out to realise their combined potential.

Techniques employed in the incorporation of the nanoparticles also significantly influence the BIR properties of the nanocomposites. Among the various coating techniques, sol–gel, PVD, CVD, thermal spray, and electroless are suitable for both conductive and non-conductive surfaces. Most of the fibres employed in the making of body armour systems are non-conductive. Among the coating methods available for non-conductive surfaces, the electroless method was found to be more economical and user-friendly. As the operating temperature in the electroless coating is around 80–90°, it can be a promising option for materials having low melting points like polymers. Another big challenge in the incorporation of nanoparticles is agglomeration. If nanoparticles are not dispersed properly, then their impact becomes less significant. To achieve better dispersion of nanoparticles, ultrasonication is carried out for the desired period in various media. The medium used for the dispersion depends on the type of nanoparticle employed in the work.

Acknowledgments

The authors thank the Vellore Institute of Technology, Vellore, for funding this research. The authors would like to thank Universiti Putra Malaysia for the financial support through Geran Inisiatif Putra Siswazah (GP-IPS) with grant number 9739200. The authors would also like to thank the Department of Aerospace Engineering, Faculty of Engineering, University Putra Malaysia, and the Laboratory of Bio-composite Technology, Institute of Tropical Forestry and Forest Product (INTROP), University Putra Malaysia, for the close collaboration in this research.

-

Funding information: This research was funded by the Vellore Institute of Technology, Vellore. The authors would like to thank Universiti Putra Malaysia for the financial support through Geran Inisiatif Putra Siswazah (GP-IPS) with grant number 9739200.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: David Hui, who is the co-author of this article, is a current Editorial Board member of Nanotechnology Reviews. This fact did not affect the peer-review process. The authors declare no other conflict of interest.

References

[1] Sunitha K, Vasudev H. A short note on the various thermal spray coating processes and effect of post-treatment on Ni-based coatings. Mater Today Proc. 2022;50:1452–7. 10.1016/j.matpr.2021.09.017.Search in Google Scholar

[2] Fotovvati B, Namdari N, Dehghanghadikolaei A. On coating techniques for surface protection: A review. J Manuf Mater Process. 2019;3(1):28.10.3390/jmmp3010028Search in Google Scholar

[3] Mawkhlieng U, Majumdar A, Laha A. A review of fibrous materials for soft body armour applications. RSC Advances. London, UK: Royal Society of Chemistry; 2019. Vol. 10. p. 1066–86.10.1039/C9RA06447HSearch in Google Scholar

[4] Mawkhlieng U, Majumdar A. Soft body armour. Text Prog. 2019 Apr 3;51(2):139–224.10.1080/00405167.2019.1692583Search in Google Scholar

[5] Abtew MA, Boussu F, Bruniaux P, Loghin C, Cristian I. Ballistic impact mechanisms – A review on textiles and fibre-reinforced composites impact responses. Compos Struct. 2019;223(March):110966. 10.1016/j.compstruct.2019.110966.Search in Google Scholar

[6] Clifton S, Thimmappa BHS, Selvam R, Shivamurthy B. Polymer nanocomposites for high-velocity impact applications-A review. Compos Commun. 2020;17(August 2019):72–86. 10.1016/j.coco.2019.11.013.Search in Google Scholar

[7] Mandal L, Verma B, Patel PK. Review on polymer nanocomposite for ballistic & aerospace applications. Mater Today Proc. 2019;26:3161–6. 10.1016/j.matpr.2020.02.652.Search in Google Scholar

[8] Abtew MA, Boussu F, Bruniaux P. Dynamic impact protective body armour: A comprehensive appraisal on panel engineering design and its prospective materials. Def Technol. 2021;17(6):2027–49. 10.1016/j.dt.2021.03.016.Search in Google Scholar

[9] Sadiku ER, Agboola O, Mochane MJ, Fasiku VO, Owonubi SJ, Ibrahim ID, et al. The use of polymer nanocomposites in the aerospace and the military/defence industries. Florida, United States of America: Embry-Riddle Aeronautical University; 2019. Vol. i. p. 316–49.10.4018/978-1-5225-7838-3.ch011Search in Google Scholar

[10] Crouch IG. Body armour – New materials, new systems. Def Technol. 2019;15(3):241–53. 10.1016/j.dt.2019.02.002.Search in Google Scholar

[11] Bandaru AK, Vetiyatil L, Ahmad S. The effect of hybridization on the ballistic impact behavior of hybrid composite armors. Compos Part B Eng. 2015;76:300–19.10.1016/j.compositesb.2015.03.012Search in Google Scholar

[12] Rajesh M, Jayakrishna K, Sultan MTH, Manikandan M, Mugeshkannan V, Shah AUM, et al. The hydroscopic effect on dynamic and thermal properties of woven jute, banana, and intra-ply hybrid natural fiber composites. J Mater Res Technol. 2020;9(5):10305–15.10.1016/j.jmrt.2020.07.033Search in Google Scholar

[13] Mousavi MV, Khoramishad H. The effect of hybridization on high-velocity impact response of carbon fiber-reinforced polymer composites using finite element modeling, Taguchi method and artificial neural network. Aerosp Sci Technol. 2019 Nov 1;94:105393.10.1016/j.ast.2019.105393Search in Google Scholar

[14] Syed Abdullah SIB, Iannucci L, Greenhalgh ES, Ahmad Z. The impact performance of Vectran/Epoxy composite laminates with a novel non-crimp fabric architecture. Compos Struct. 2021;265(September 2020):113784. 10.1016/j.compstruct.2021.113784.Search in Google Scholar

[15] Boddu VM, Brenner MW, Patel JS, Kumar A, Mantena PR, Tadepalli T, et al. Energy dissipation and high-strain rate dynamic response of E-glass fiber composites with anchored carbon nanotubes. Compos Part B Eng. 2016;88:44–54. 10.1016/j.compositesb.2015.10.028.Search in Google Scholar

[16] Nurazzi NM, Asyraf MRM, Khalina A, Abdullah N, Sabaruddin FA, Kamarudin SH, et al. Fabrication, functionalization, and application of carbon nanotube-reinforced polymer composite: An overview. Polymers (Basel). 2021;13(7):13.10.3390/polym13071047Search in Google Scholar PubMed PubMed Central

[17] Pandya KS, Akella K, Joshi M, Naik NK. Ballistic impact behavior of carbon nanotube and nanosilica dispersed resin and composites. J Appl Phys. 2012;112(11):0–8.10.1063/1.4769750Search in Google Scholar

[18] Shakil UA, Abu Hassan SBin, Yahya MY, Mujiyono, Nurhadiyanto D. A review of properties and fabrication techniques of fiber reinforced polymer nanocomposites subjected to simulated accidental ballistic impact. Thin-Walled Struct. 2021;158(September 2020):107150. 10.1016/j.tws.2020.107150.Search in Google Scholar

[19] Naveen J, Jawaid M, Zainudin ES, Sultan MTH, Yahaya R. Effect of graphene nanoplatelets on the ballistic performance of hybrid Kevlar/Cocos nucifera sheath-reinforced epoxy composites. Text Res J. 2019 Nov 1;89(21–22):4349–62.10.1177/0040517519833970Search in Google Scholar

[20] Jensin Joshua J, Venkatanarayanan PS, Singh D. A literature review on composite materials filled with and without nanoparticles subjected to high/low velocity impact loads. Mater Today Proc. 2020;33:4635–41. 10.1016/j.matpr.2020.08.294.Search in Google Scholar

[21] Liu M, Zhang S, Liu S, Cao S, Wang S, Bai L, et al. CNT/STF/Kevlar-based wearable electronic textile with excellent anti-impact and sensing performance. Compos Part A Appl Sci Manuf. 2019;126(August):105612. 10.1016/j.compositesa.2019.105612.Search in Google Scholar

[22] Cao S, Pang H, Zhao C, Xuan S, Gong X. The CNT/PSt-EA/Kevlar composite with excellent ballistic performance. Compos Part B Eng. 2020;185(January):107793. 10.1016/j.compositesb.2020.107793.Search in Google Scholar

[23] Seifoori S, Abbaspour F, Zamani E. Molecular dynamics simulation of impact behavior in multi-walled carbon nanotubes. Superlattices Microstruct. 2020;140(February):106447. 10.1016/j.spmi.2020.106447.Search in Google Scholar

[24] Taş H, Soykok IF. Puncture resistance of STF impregnated MWCNTs-grafted carbon fabrics. Mater Today Commun. 2021;28:102692.10.1016/j.mtcomm.2021.102692Search in Google Scholar

[25] Khodadadi A, Liaghat G, Taherzadeh-Fard A, Shahgholian-Ghahfarokhi D. Impact characteristics of soft composites using shear thickening fluid and natural rubber–A review of current status. Compos Struct. 2021;271(January):114092. 10.1016/j.compstruct.2021.114092.Search in Google Scholar

[26] Ávila AF, de Oliveira AM, Leão SG, Martins MG. Aramid fabric/nano-size dual phase shear thickening fluid composites response to ballistic impact. Compos Part A Appl Sci Manuf. 2018;112(January):468–74. 10.1016/j.compositesa.2018.07.006.Search in Google Scholar

[27] Wang X, Zhang J, Bao L, Yang W, Zhou F, Liu W. Enhancement of the ballistic performance of aramid fabric with polyurethane and shear thickening fluid. Mater Des. 2020;196:109015. 10.1016/j.matdes.2020.109015.Search in Google Scholar

[28] Majumdar A, Butola BS, Srivastava A. Development of soft composite materials with improved impact resistance using Kevlar fabric and nano-silica based shear thickening fluid. Mater Des. 2014;54:295–300. 10.1016/j.matdes.2013.07.086.Search in Google Scholar

[29] Balali E, Kordani N, Sadough Vanini A. Response of glass fiber-reinforced hybrid shear thickening fluid (STF) under low-velocity impact. J Text Inst. 2017;108(3):376–84.10.1080/00405000.2016.1166853Search in Google Scholar

[30] Akella K, Naik NK. Composite armour - A review. J Indian Inst Sci. 2015;95(3):297–312.Search in Google Scholar

[31] da Silva AO, Weber RP, Monteiro SN, Lima AM, Faria GS, Silva WO, Da, et al. Effect of graphene oxide coating on the ballistic performance of aramid fabric. J Mater Res Technol. 2020;9(2):2267–78. 10.1016/j.jmrt.2019.12.058.Search in Google Scholar

[32] Martínez-Morlanes MJ, Pascual FJ, Guerin G, Puértolas JA. Influence of processing conditions on microstructural, mechanical and tribological properties of graphene nanoplatelet reinforced UHMWPE. J Mech Behav Biomed Mater. 2021;115(October 2020):104248.10.1016/j.jmbbm.2020.104248Search in Google Scholar PubMed

[33] Wang S, Gao E, Xu Z. Interfacial failure boosts mechanical energy dissipation in carbon nanotube films under ballistic impact. Carbon N Y. 2019;146:139–46. 10.1016/j.carbon.2019.01.110.Search in Google Scholar

[34] Gore PM, Kandasubramanian B. Functionalized aramid fibers and composites for protective applications: a review. Ind Eng Chem Res. 2018;57(49):16537–63.10.1021/acs.iecr.8b04903Search in Google Scholar

[35] Shanmugam L, Feng X, Yang J. Enhanced interphase between thermoplastic matrix and UHMWPE fiber sized with CNT-modified polydopamine coating. Compos Sci Technol. 2019;174(July 2018):212–20. 10.1016/j.compscitech.2019.03.001.Search in Google Scholar

[36] Benzait Z, Trabzon L. A review of recent research on materials used in polymer–matrix composites for body armor application. J Compos Mater. 2018;52(23):3241–63.10.1177/0021998318764002Search in Google Scholar

[37] Dixit P, Ghosh A, Majumdar A. Hybrid approach for augmenting the impact resistance of p-aramid fabrics: grafting of ZnO nanorods and impregnation of shear thickening fluid. J Mater Sci. 2019;54(20):13106–17. 10.1007/s10853-019-03830-z.Search in Google Scholar

[38] Rahman AS, Mathur V, Asmatulu R. Effect of nanoclay and graphene inclusions on the low-velocity impact resistance of Kevlar-epoxy laminated composites. Compos Struct. 2018;187:481–8. 10.1016/j.compstruct.2017.12.054.Search in Google Scholar

[39] Hanif WYW, Risby MS, Noor MM. Influence of carbon nanotube inclusion on the fracture toughness and ballistic resistance of twaron/epoxy composite panels. Procedia Eng. 2015;114:118–23. 10.1016/j.proeng.2015.08.049.Search in Google Scholar

[40] Pol MH, Liaghat G, Zamani E, Ordys A. Investigation of the ballistic impact behavior of 2D woven glass/epoxy/nanoclay nanocomposites. J Compos Mater. 2015;49(12):1449–60.10.1177/0021998314535010Search in Google Scholar

[41] Pol MH, Liaghat GH, Hajiarazi F. Effect of nanoclay on ballistic behavior of woven fabric composites: Experimental investigation. J Compos Mater. 2013;47(13):1563–73.10.1177/0021998312449768Search in Google Scholar

[42] Mahesh V, Harursampath D, Mahesh V. An experimental study on ballistic impact response of jute reinforced polyethylene glycol and nano silica based shear thickening fluid composite. Def Technol. 2022;18(3):401–9. 10.1016/j.dt.2021.03.013.Search in Google Scholar

[43] da Silva AO, Monsores KGDC, Oliveira SD, Weber RP, Monteiro SN. Ballistic behavior of a hybrid composite reinforced with curaua and aramid fabric subjected to ultraviolet radiation. J Mater Res Technol. 2018;7(4):584–91. 10.1016/j.jmrt.2018.09.004.Search in Google Scholar

[44] Rohen LA, Margem FM, Monteiro SN, Vieira CMF, De Araujo BM, Lima ES. Ballistic efficiency of an individual epoxy composite reinforced with sisal fibers in multilayered armor. Mater Res. 2015;18(December):55–62.10.1590/1516-1439.346314Search in Google Scholar

[45] Loganathan TM, Sultan MTH, Gobalakrishnan MK, Muthaiyah G. Ballistic impact response of laminated hybrid composite materials. Mechanical and physical testing of biocomposites, fibre-reinforced composites and hybrid composites. Sawston, Cambridge: Elsevier Ltd; 2018. p. 171191. 10.1016/B978-0-08-102292-4.00010-2.Search in Google Scholar

[46] Galan U, Lin Y, Ehlert GJ, Sodano HA. Effect of ZnO nanowire morphology on the interfacial strength of nanowire coated carbon fibers. Compos Sci Technol. 2011;71(7):946–54. 10.1016/j.compscitech.2011.02.010.Search in Google Scholar

[47] Domun N, Kaboglu C, Paton KR, Dear JP, Liu J, Blackman BRK, et al. Ballistic impact behaviour of glass fibre reinforced polymer composite with 1D/2D nanomodified epoxy matrices. Compos Part B Eng. 2019;167(March):497–506. 10.1016/j.compositesb.2019.03.024.Search in Google Scholar

[48] Attia NF, Moussa M, Sheta AMF, Taha R, Gamal H. Effect of different nanoparticles based coating on the performance of textile properties. Prog Org Coatings. 2017;104:72–80. 10.1016/j.porgcoat.2016.12.007.Search in Google Scholar

[49] Monteiro SN, de Assis FS, Ferreira CL, Simonassi NT, Weber RP, Oliveira MS, et al. Fique fabric: A promising reinforcement for polymer composites. Polymers (Basel). 2018 Feb 28;10(3):246.10.3390/polym10030246Search in Google Scholar PubMed PubMed Central

[50] Vinson JR, Zukas JA. On the ballistic impact of textile body armor. Am Soc Mech Eng. 1975;42(2):263–8.10.1115/1.3423564Search in Google Scholar

[51] Peijs AAJM, Venderbosch RW, Lemstra PJ. Hybrid composites based on polyethylene and carbon fibres Part 3: Impact resistant structural composites through damage management. Composites. 1990;21(6):522–30.10.1016/0010-4361(90)90425-VSearch in Google Scholar

[52] Wisniewski A. Nanotechnology for body protection. Issues Armament Technol. 2007;102(1):7–17.Search in Google Scholar

[53] Kurahatti RV, Surendranathan AO, Kori SA, Singh N, Kumar AVR, Srivastava S. Defence applications of polymer nanocomposites. Def Sci J. 2010;60(5):551–63.10.14429/dsj.60.578Search in Google Scholar

[54] Bajaj P. Sriram. Ballistic protective clothing: An overview. Indian J Fibre Text Res. 1997;22(4):274–91.Search in Google Scholar

[55] van Dingenen J. High performance dyneema fibres in composites. Mater Des. 1989;10(2):101–4.10.1016/S0261-3069(89)80021-4Search in Google Scholar

[56] Thilagavathi G, Raja ASM, Kannaian T. Nanotechnology and protective clothing for defence personnel. Def Sci J. 2008;58(4):451–9.10.14429/dsj.58.1667Search in Google Scholar

[57] Arulvel S, Mallikarjuna Reddy D, Dsilva Winfred Rufuss D, Akinaga T. A comprehensive review on mechanical and surface characteristics of composites reinforced with coated fibres. Surfaces and Interfaces. 2021;27(April):101449. 10.1016/j.surfin.2021.101449.Search in Google Scholar

[58] Wu S, Sikdar P, Bhat GS. Recent progress in developing ballistic and anti-impact materials: Nanotechnology and main approaches. Def Technol. 2022;21:33–61. 10.1016/j.dt.2022.06.007.Search in Google Scholar

[59] Sadegh AM, Cavallaro PV. Mechanics of energy absorbability in plain-woven fabrics: An analytical approach. J Eng Fiber Fabr. 2012;7(1):10–25.10.1177/155892501200700102Search in Google Scholar

[60] Karthick P, Ramajeyathilagam K. Numerical study of influence of target thickness and projectile incidence angle on ballistic resistance of the GFRP composites. Mater Today Proc. 2021;47:992–9. 10.1016/j.matpr.2021.05.459.Search in Google Scholar

[61] Nilakantan G, Merrill RL, Keefe M, Gillespie JW, Wetzel ED. Experimental investigation of the role of frictional yarn pull-out and windowing on the probabilistic impact response of kevlar fabrics. Compos Part B Eng. 2015;68:215–29. 10.1016/j.compositesb.2014.08.033.Search in Google Scholar

[62] Chen X, Zhu F, Wells G. An analytical model for ballistic impact on textile based body armour. Compos Part B Eng. 2013;45(1):1508–14. 10.1016/j.compositesb.2012.08.005.Search in Google Scholar

[63] Sun L, Gibson RF, Gordaninejad F, Suhr J. Energy absorption capability of nanocomposites: A review. Compos Sci Technol. 2009;69(14):2392–409. 10.1016/j.compscitech.2009.06.020.Search in Google Scholar

[64] Johnsen BB, Kinloch AJ, Mohammed RD, Taylor AC, Sprenger S. Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer (Guildf). 2007;48(2):530–41.10.1016/j.polymer.2006.11.038Search in Google Scholar

[65] Bashar M, Mertiny P, Sundararaj U. Effect of nanocomposite structures on fracture behavior of epoxy-clay nanocomposites prepared by different dispersion methods. J Nanomater. 2014;2014:312813.10.1155/2014/312813Search in Google Scholar

[66] Quaresimin M, Schulte K, Zappalorto M, Chandrasekaran S. Toughening mechanisms in polymer nanocomposites: From experiments to modelling. Compos Sci Technol. 2016;123(December):187–204.10.1016/j.compscitech.2015.11.027Search in Google Scholar

[67] Zhang H, Zhang Z, Friedrich K, Eger C. Property improvements of in situ epoxy nanocomposites with reduced interparticle distance at high nanosilica content. Acta Mater. 2006;54(7):1833–42.10.1016/j.actamat.2005.12.009Search in Google Scholar

[68] Sheth D, Maiti S, Patel S, Kandasamy J, Chandan MR, Rahaman A. Enhancement of mechanical properties of carbon fiber reinforced epoxy matrix laminated composites with multiwalled carbon nanotubes. Fullerenes Nanotub Carbon Nanostructures; 2020;29(4):288–94.10.1080/1536383X.2020.1839424Search in Google Scholar

[69] Vinyas M, Athul SJ, Harursampath D, Loja M, Thoi TN. A comprehensive review on analysis of nanocomposites: from manufacturing to properties characterization. Mater Res Express. 2019 Jul 19 [cited 2021 Jul 12];6(9):092002. 10.1088/2053-1591/ab3175.Search in Google Scholar

[70] Khan I, Saeed K, Khan I. Nanoparticles: Properties, applications and toxicities. Arab J Chem. 2019;12(7):908–31. 10.1016/j.arabjc.2017.05.011.Search in Google Scholar

[71] Ealias AM, Saravanakumar MP. A review on the classification, characterisation, synthesis of nanoparticles and their application. IOP Conf Ser Mater Sci Eng. 2017;263(3):032019.10.1088/1757-899X/263/3/032019Search in Google Scholar

[72] Wagner NJ, Brady JF. Shear thickening in colloidal dispersions. Phys Today. 2009;62(10):27–32.10.1063/1.3248476Search in Google Scholar

[73] Qin J, Zhang G, Shi X. Study of a shear thickening fluid: the suspensions of monodisperse polystyrene microspheres in polyethylene glycol. J Dispers Sci Technol. 2017;38(7):935–42. 10.1080/01932691.2016.1216435.Search in Google Scholar

[74] Zhang XZ, Li WH, Gong XL. The rheology of shear thickening fluid (STF) and the dynamic performance of anSTF-filled damper. Smart Mater Struct. 2008;17(3):035027.10.1088/0964-1726/17/3/035027Search in Google Scholar

[75] Hasanzadeh M, Mottaghitalab V. The role of shear-thickening fluids (STFs) in ballistic and stab-resistance improvement of flexible armor. J Mater Eng Perform. 2014;23(4):1182–96.10.1007/s11665-014-0870-6Search in Google Scholar

[76] Hasanzadeh M, Mottaghitalab V, Rezaei M. Rheological and viscoelastic behavior of concentrated colloidal suspensions of silica nanoparticles: A response surface methodology approach. Adv Powder Technol. 2015;26(6):1570–7. 10.1016/j.apt.2015.08.011.Search in Google Scholar

[77] Ghosh A, Majumdar A, Butola BS. Rheometry of novel shear thickening fluid and its application for improving the impact energy absorption of p-aramid fabric. Thin-Walled Struct. 2020;155(June):106954. 10.1016/j.tws.2020.106954.Search in Google Scholar

[78] Hassan TA, Rangari VK, Jeelani S. Synthesis, processing and characterization of shear thickening fluid (STF) impregnated fabric composites. Mater Sci Eng A. 2010;527(12):2892–9. 10.1016/j.msea.2010.01.018.Search in Google Scholar