Abstract

This article aimed to compare various mechanical properties of epoxy/graphene and epoxy/halloysite nanocomposites. Graphene nanoplatelets (GnPs) and halloysite nanotubes (HNTs) were used as fillers at different concentrations. The studied fillers were dispersed in the epoxy resin matrices. Elastic–plastic mechanical behavior modulation was observed utilizing the fillers’ nanoparticles and carboxyl-terminated butadiene–acrylonitrile copolymer rubber-modified epoxy resin. The hypothesis of the possible preceding inter-particle gliding of the individual GnPs in the complex resin nanocomposite matrix during mechanical testings was also confirmed. Increased ductility (elongation at break increased from 0.33 mm [neat matrix] to 0.46 mm [1 wt% GnPs] [39% increase]) and plasticity of the GnP nanocomposite samples were observed. In contrast, the decreasing mechanical stiffness as reflected in the decreased Young’s modulus of elasticity (from 3.4 to 2.7 GPa [20% decrease]) was found for the epoxy/HNT nanocomposites. The obtained dynamic stiffness of the investigated nanocomposites confirmed the complexity of the mechanical response of the studied material systems as a combination of the ductile and brittle phenomena.

1 Introduction

Polymeric and resin-based nanocomposites are widely used in material engineering research owing to their capacity to modulate plastic–elastic mechanical performance at static and dynamic mechanical loadings [1]. These nanocomposites are characterized by high mechanical toughness and wear resistance, improved self-lubrication properties, and low friction coefficient [2,3]. Therefore, they have a wide range of application potential in the aerospace [4], automotive [5], chemical, and electronic industries as well as high-voltage outdoor insulation materials [6,7,8].

The ability of a material to absorb mechanical impact, i.e., its toughness, requires high force resistance and the existence of the deformation mechanisms that absorb and dissipate the applied mechanical energy over a large path, in a large volume, and for a sufficiently long time. Such mechanisms may be inherent in the material due to its specific microstructure but can also be deliberately incorporated into the structure of polymer/epoxy resin composites and blends [9,10]. Such synergistic effect can be obtained by proper selection of the combination of the nanofiller particles’ type (graphene nanoplatelets [GnPs], halloysite nanotubes [HNTs], etc.), shape, and surface chemistry, by modulating the physicochemical characteristics of the matrix, etc., for example, by adding rubbery plastic components [11,12]. However, literature indicates that relatively few studies have focused on carboxyl-terminated butadiene–acrylonitrile (CTBN) copolymer rubber-modified epoxy resins filled with GnPs exhibiting the improved fracture toughness [13,14,15,16].

Several polymer composites have been reported in recent years, including polyester, polyurethane, epoxy, and phenolics [17,18]. Among these, epoxy polymer composites have gained tremendous attention due to their high mechanical toughness and moisture absorption properties [19]. Additionally, these resins show less shrinkage and less toxic emissions during the curing process [20]. Therefore, epoxy resins are considered high-quality materials on an industrial scale, despite their high cost [21].

In general, the plastic or viscoelastic deformation of materials in front of the crack apex removes part of the crack energy and thus controls its progress within the matrix. Therefore, the difference between brittle and ductile fractures is in their spatial localization and their temporal progression. Most polymer composite materials can break down by either brittle or ductile fractures depending on the external conditions or processes taking place in the material. The transition between ductile and brittle fractures can be temperature dependent, with the temperature regions of the two distinct mechanisms separated by the embrittlement temperature. The latter always lies below the glass-transition temperature. In the same sense, with a drop in temperature, an increase in loading rate can have an effect – although the difference in loading rate must be an order of magnitude greater to have an effect on the nature of the fracture. However, long-term static loading below the yield stress for many polymers also leads to brittle fracture. In this case, the “material self-defence” mechanisms cannot develop sufficiently by creating a plastic zone in front of the crack tip [9].

Tribological properties of resins often indirectly influence their mechanical strength, whereas epoxy resins exhibit limited tribological properties [22]. For example, the service life of pipes made of polymeric composites depends on the effectivity of the energy dissipation during fluid flow, the character of which is dependent on the wall friction of the transported medium. Such pipes are exposed under service conditions to long-term stresses, usually under relatively low temperatures, but sometimes also at the interaction of an active environment. Under these conditions, they cannot properly develop the “self-defense” mechanisms of crack blunting by local plastic deformation, and from the exposed surface small cracks propagate inside the material or even sharp cracks, which eventually lead to brittle fracture [9].

Several methods have been reported to improve these properties, i.e., adding micro- and nano-sized particles as fillers in the resin matrix [23,24]. A large variety of nanofillers, such as SiO2, MnO2, TiO2, Al2O3, SiC, Si3N4, ZnO, MoS2, nanoclay, and carbon nanotubes, have been reported in different types of polymeric resins [25,26,27,28]. These fillers have demonstrated varying efficiencies with certain limitations, which hinder their practical applications [29].

GnPs, consisting of 30–40 layers of graphene, are widely used nanomaterials due to their high thermal stability and conductivity, high Young’s modulus of elasticity, high optical transmittance, high fracture strength, and improved lubrication properties [17,30]. Due to their inherent, intrinsic energy-dissipating mechanisms (sheet bending and sliding), GnPs belong to highly advanced materials used in composite manufacturing [17,31]. However, it is necessary to optimize the content of graphene nanofillers in epoxy resins because higher content leads to nonuniform distribution of graphene in the polymer network [32]. Another challenge is the observed high aggregation rates of graphene arising from the acting Van der Waals interaction forces [33,34,35]. For this reason, it is necessary to optimize a proper mass ratio of graphene nanofillers to epoxy resin in order to obtain the desired mechanical properties.

Halloysite, an aluminosilicate clay material [36], is another filler commonly used in polymer resins owing to its cylindrical structure, improved mechanical performance, and low cost [37,38]. HNTs exhibit higher dispersion ratio and have surface hydroxyl groups with low density, which results in their smooth diffusion into the polymer matrix, leading to less aggregation [39]. Moreover, due to small basal spacing of crystal planes, the intercalation of HNTs with polymers and additives is difficult [40,41]. However, HNT nanofillers belong to potential functional fillers used in industrial practice [42,43].

Published results confirmed synergistic combination of the plastification effect of the rigid epoxy matrix assigned to the gliding of the individual GnP nanofillers and the stiffening effect of the HNT nanofillers when fracture toughness increased. The latter plastification was also enhanced by the addition of the CTBN polymeric rubber component of the composite epoxy matrix, thus improving material’s fracture toughness. A similar effect was also confirmed by molecular dynamics simulations of mono helical soft segments based on Newtonian mechanics theory [44].

In this study, GnPs and HNTs were used separately as fillers to improve the mechanical performance, dispersion, thermal stability, and opto-electronic properties of the epoxy resin composite. A varying mass ratio of both fillers was used in prepared composites, and the effect of the applied nanofillers was evaluated by uniaxial tensile testing, fracture toughness measurements, uniaxial bending testing, indentation micro-hardness measurements, and nondestructive vibration testing.

2 Materials

2.1 Materials

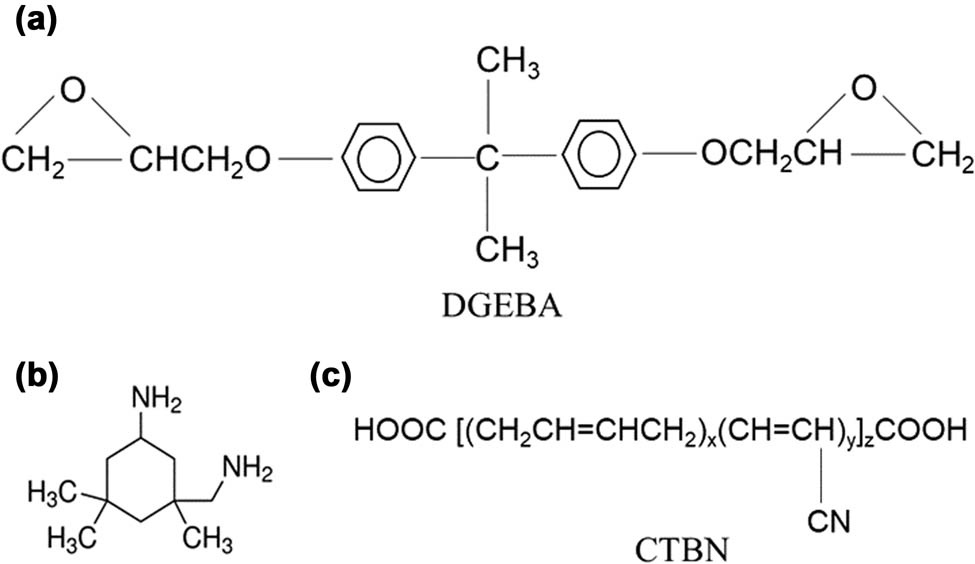

The resin and hardener used in this study were diglycidyl ether of bisphenol A resin (DGEBA) with low viscosity (trade name: laminating resin MGS L285) (Figure 1a) and 3-aminomethyl-3,5,5 trimethylcyclohexylamine (trade name: L285), respectively (both materials were provided from Hexion, USA) (Figure 1b). The liquid rubber used was CTBN copolymer (purchased from Zibo Qilong, China) with an average of 0.58–0.65 carboxyl groups per molecule; its number average molecular weight was about 3,800 Da, and the content of acrylonitrile was of 8–12% (Figure 1c). The technical data of the CTBN are given in Table 1. The chemical structures of epoxy, hardener, and CTBN are shown in Figure 1. Nanofillers used in this study were nonfunctionalized planar-shaped GnPs of 800 m2/g specific surface area, layer thickness of 3–7 nm with an average layer width of 1.5 μm, and 99.9% purity (purchased from Nanografi, Ankara, Turkey). The HNTs (Al2Si2O5(OH)4) used had two layers of nanocylindrical structure (Esan Eczacıbası (Istanbul, Turkey)), whose inner diameter, outer diameter, and length were in the range of 1–20, 30–50, and 100–800 nm, respectively.

The chemical structure of components (a) DGEBA, (b) 3-aminomethyl-3,5,5-trimethylcyclohexylamine, and (c) CTBN.

Properties of the applied CTBN liquid rubber

| Parameter | Value |

|---|---|

| Viscosity (40°C) (Pa s) | 7−12 |

| Carboxyl content (mmol/g) | 0.58−0.65 |

| Nitrile group content (%) | 8.0−12.0 |

| Water content (%) | ≤0.05 |

| Volatile content (%) | ≤2.0 |

2.2 Preparation of nanocomposites and epoxy blends

2.2.1 CTBN–epoxy blends

The chemical formulas of the used epoxy blends are shown in Figure 1. For preparing the epoxy blends with CTBN liquid rubber, 10 wt% CTBN was mechanically mixed with epoxy resin in a glass beaker placed on a preheated plate. The blends in the beaker were then stirred by ultrasonication for 15–20 min to obtain homogeneous blends, followed by 1 h of degassing in the vacuum oven at 60°C. The amine-based curing agent was subsequently added at a stoichiometric ratio of 80:20 (epoxy:hardener) by weight at slow stirring. Blends were subsequently cast into molds and cured for 1 h at 90°C, followed by 3 h post-curing at 120°C.

2.2.2 CTBN– GnPs–epoxy and CTBN–halloysite–epoxy composites

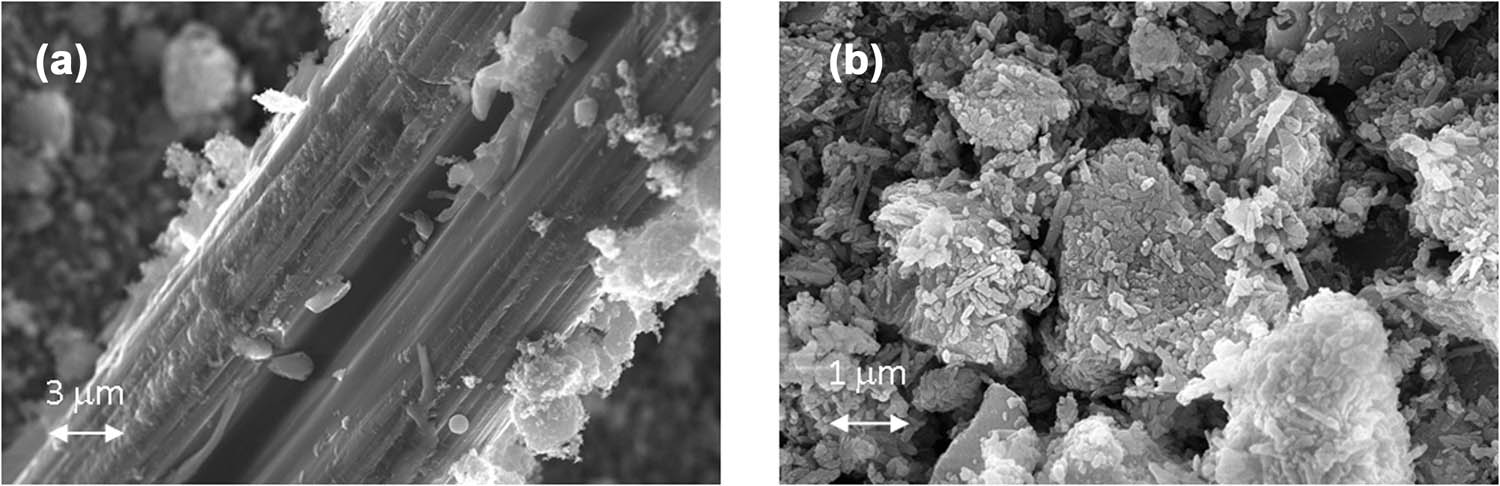

The nano-reinforcement ratios of the epoxy mixtures were created based on the literature. Many authors [43,45–49] have experimentally studied the concentration of GnP and HNTs in the epoxy matrix to be in the range of (0–1) and (0–5) wt%, respectively, and reported the effect of these concentrations on tensile, fracture, and flexural properties of the neat matrix. For preparing the epoxy mixtures with GnPs and HNTs (see Figure 2 for scanning electron microscopy [SEM]), 0, 0.125, 0.25, 0.5, 0.75, and 1 wt% GnPs and 0, 1, 2, 3, 4, and 5 wt% HNTs were added to the epoxy resin, and the obtained mixtures were transferred into a RETSCH-PM 100 planetary mill for mixing at a rotation rate of 200 rpm for 25 h. The epoxy composite mixtures were prepared using 10 mm diameter balls and a bowl made of tungsten carbide as mixing media. The mixing bowls were loaded with the epoxy mixtures and balls, resulting in a ball-to-powder mass ratio of 30:1. First, the mixtures were mixed for 30 min, then rested for 10 min to avoid overheating, then mixed again, and the cycle was continued until the decided mixing time was completed. Subsequently, 10 wt% CTBN was added to each epoxy mixture containing the GnP and HNT reinforcements for preparing the CTBN–GnPs–epoxy and CTBN–HNTs–epoxy composites. The prepared mixtures were stirred using ultrasonication for 25–30 min to obtain the homogeneous mixtures, followed by degassing in a vacuum oven at 60°C for about 1 h. Finally, the curing procedure of CTBN–epoxy blends described in Section 2.2.1 was followed to cure the CTBN–GnPs–epoxy and the CTBN–HNTs–epoxy composites. The same CTBN liquid rubber concentration of 10 wt% was used in all of the investigated epoxy/graphene and epoxy/halloysite nanocomposites; the virgin epoxy matrix prepared was without CTBN liquid rubber.

SEM images of the studied fillers: (a) GnPs, (b) HNT.

3 Methods

3.1 SEM analysis

Zeiss EvoLS10 equipped with an energy-dispersive X-ray detector (Germany) was used for SEM analysis. SEM images were taken by depositing nanofiller samples on a standard 400-grid copper mesh. Fillers’ acetone dispersions were ultrasonicated for 15 min, cast on the copper mesh, and air dried. SEM measurements were performed at an accelerating voltage of 2 kV.

3.2 Uniaxial tensile testing

Universal Testing Machine Autograph AGS-100 Shimadzu (Japan) and Zwick 1456 multipurpose tester (Zwick Roell, Ulm, Germany) equipped with Compact Thermostatic Chamber TCE Series were used for tensile testing of injection-molded specimens. All data were recorded as per ČSN EN ISO 527-1 and ČSN EN ISO 527-2 standards for the tested gauge length of 80 mm. All experiments were performed at room temperature up to break with a 50 mm/min deformation rate. Young’s modulus of elasticity and elongation at break were obtained from the stress–strain dependency plots. Each experiment was repeated 10×, and mean values and standard deviations of the measured quantities were subsequently calculated. All experiments were performed at the ambient laboratory temperature of 25°C.

3.3 Charpy impact testing

Impact tests were carried out using Zwick 513 Pendulum Impact Tester (Zwick Roell, Ulm, Germany) according to the ČSN EN ISO 179-2 standard, allowing a 25 J energy drop. Each experiment was repeated 10× and mean values and standard deviations of the fracture toughness were calculated. All experiments were performed at the ambient laboratory temperature of 25°C.

3.4 Micro-hardness

Micro-indentation tests were performed on a micro-indentation tester (Micro Combi Tester, Anton Paar, Austria), according to the ČSN EN ISO 14577 standard. The applied diamond tip was cube-corner shaped (Vickers, Anton Paar, Austria). Measurement parameters were set as follows: the maximum load of 3 N, loading rate (unloading rate) of 6 N/min, and holding time of 90 s. All experiments were performed according to the depth-sensing indentation method, allowing simultaneous measurement of the acting force on the indenter and the displacement of the indenter’s tip. The indentation modulus (E IT) was calculated from the plane strain modulus of elasticity (E*) using an estimated Poisson’s ratio (ν) of the samples (0.3–0.4 [50,51]):

Each measurement was repeated 10×, and mean values and standard deviations of the indentation modulus were calculated. All experiments were performed at the ambient laboratory temperature of 25°C.

3.5 Uniaxial three-point bending tests

The uniaxial three-point bending test was carried out on a Zwick 1456 testing machine (Zwick Roell GmbH &Co. KG, Ulm, Germany) according to the ČSN EN ISO 14125 standard. The results were evaluated using the TestXpert software. The distance between the supports was set to 64 mm, and the roundness of the supports and the load mandrel was 5 mm. The deformation rate during the three-point bending test was 1 mm/min, and the loading velocity was 50 mm/min.

3.6 Displacement transmissibility measurements

Displacement transmissibility T d is expressed by the following equation [52]:

where y 1 is the displacement amplitude on the input side of the tested sample, y 2 is the displacement amplitude on the output side of the tested sample, a 1 is the acceleration amplitude on the input side of the tested sample, and a 2 is the acceleration amplitude on the output side of the tested sample. The displacement transmissibility of a spring–mass–damper system, which is described by spring (stiffness k), damper (damping coefficient c), and mass m, is given by the following equation [53]:

Under the condition dT d/dr = 0 in equation (3), it is possible to obtain the frequency ratio r 0 at which the displacement transmissibility reaches its maximum value [54,55]:

It is evident from equation (4) that the local extreme of the displacement transmissibility is generally shifted to lower values of the frequency ratio r with increasing damping ratio ζ (or with decreasing material mechanical stiffness k). The local extrema (i.e., the maximum value of the displacement transmissibility T dmax) is found at the frequency ratio r 0 from equation (4). The mechanical vibration tests were performed by forced oscillation method. The displacement transmissibility T d was experimentally measured using the BK 4810 vibrator in combination with a BK 3560-B-030 signal pulse multi-analyzer and a BK 2706 power amplifier at the frequency range from 2 to 3,200 Hz. The acceleration amplitudes a 1 and a 2 on the input and output sides of the investigated samples were recorded by BK 4393 accelerometers (Brüel & Kjær, Nærum, Denmark). Measurements of the displacement transmissibility were done for three different inertial masses m (for 0, 90, and 500 g), which were placed on the top side of the tested samples. The dimensions of the tested specimen were 60 mm × 60 mm × 3 mm (length × width × thickness). Each measurement was repeated 5× at an ambient temperature of 22°C.

4 Results and discussion

A typical shape of the used nanofillers, as observed by SEM analysis, is shown in Figure 2. Here the GnP lamellar structure was clearly visible in Figure 2a with a layer thickness of about 3–7 nm and an average layer width of 1.5–2.0 μm. In contrast, the HNT nanotubes exhibited a compact coagulated structure composed of individual nanotubes of approximately 30–50 nm diameter and 100–800 nm length (Figure 2b).

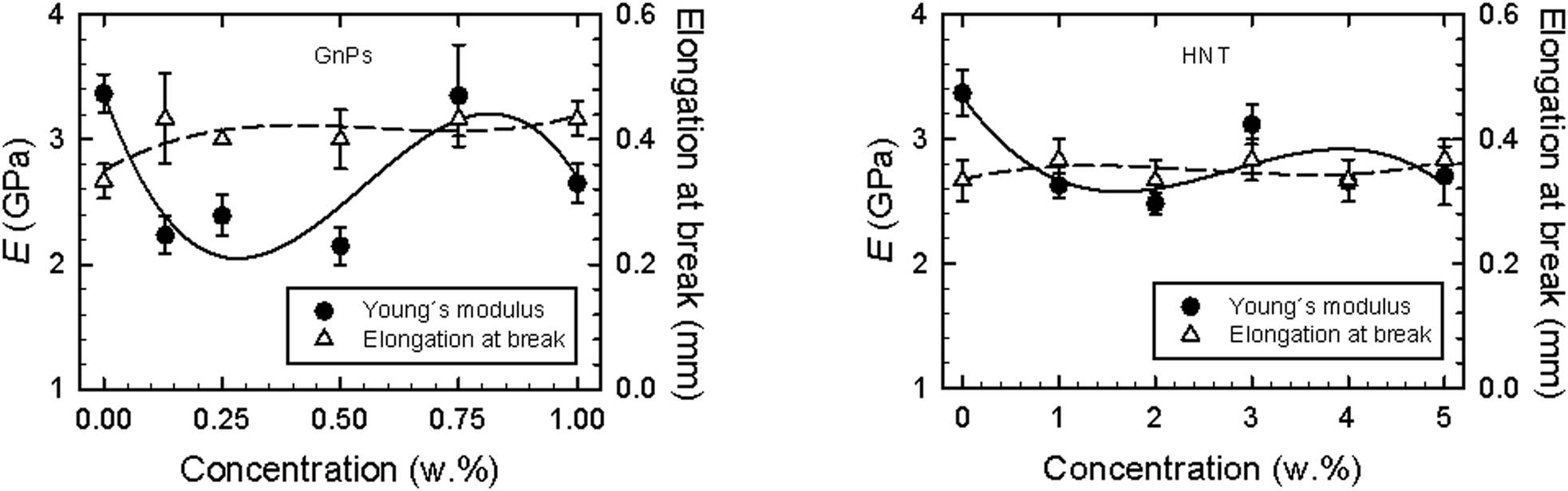

Results of the tensile-testing experiments of the studied nanocomposites are shown in Figure 3. There was a decrease of the Young’s modulus of elasticity (E) during uniaxial testing from 3.4 GPa (neat matrix) to 2.7 GPa (for 1 wt% epoxy/GnP nanocomposite) with increasing GnP filler concentration [56]. This effect was accompanied by the increasing nonlinear trend of the obtained magnitudes of the elongation at break, indicating increasing ductility and plasticizing effect of the GnP nanofiller on the mechanical behavior of the prepared epoxy/GnP nanocomposites. Based on the literature [11], it was assumed that this behavior was ascribed to the gliding of the individual nanoplatelet sheets within complex epoxy/GnP nanocomposite matrix accompanied by the crack deflection, layer breakage, and separation/delamination of GnP layers [13]. However, the opposite effect was found in the case of the epoxy/HNT nanocomposites, where the E decreased from 3.4 GPa (neat matrix) to 2.7 GPa (for 5 wt% epoxy/HNT nanocomposite), thus indicating the decreasing mechanical stiffness of the studied materials. Simultaneously, in contrast to the epoxy/GnP nanocomposites, a more brittle behavior with increasing HNT filler concentration was observed. These observations were demonstrated by constant elongation at break (about 0.36 mm) dependency as shown in Figure 3. Based on the aforementioned facts, it was assumed that the HNT nanofiller increased the brittleness of the composite due to the limited movement of the stiffened HNT nanotubes resulting in the hindered gliding of the HNT nanofillers within the composite matrix.

Nanofiller concentration dependencies of the Young’s modulus of elasticity and the elongation at break of the studied GnPs and HNT nanocomposites. Applied deformation rate was of 50 mm/min. Continuous line – Young’s modulus of elasticity, dashed line – elongation at break.

The above-mentioned results of the uniaxial tensile tests were in excellent agreement with the observed fracture toughness measurements (Figure 4), where higher fracture toughness of 8.2 kJ/m2 of epoxy/HNT nanocomposites was found compared to the 6.0 kJ/m2 of epoxy/GnP nanocomposites (both at 1 wt% filler concentration). At higher HNT filler concentrations (in the concentration range of 1–5 w%) nonlinear decreasing trend of fracture toughness was observed (Figure 4).

Nanofiller concentration dependencies of the unnotched fracture toughness of the studied GnPs and HNT nanocomposites.

In addition, the presence of CTBN (Figure 1c) acted on the continuous composite matrix as a kind of accelerator, which forces it to develop local deformations. The deformation mechanisms in the matrix then dissipate the external mechanical energy over a large volume, thus preventing the development of a single brittle crack. Optimal performance of rubber modification requires several conditions to be met, namely the establishment of a two-phase morphology, the provision of satisfactory interfacial adhesion, and the establishment of a certain critical distance between adjacent rubber domains [9]. Analogous behavior was observed for multi-phase hard and soft segmental flexible polymers, where hard phases served as stiffening element and the soft phases provided elasticity [44].

Results of the micro-hardness vs filler concentration measurements of both the studied epoxy nanocomposites are shown in Figure 5. A nonlinear decreasing trend of the indentation modulus E IT with increasing filler concentration was observed. In the case of the epoxy/GnP nanocomposites, E IT decreased from 4.3 GPa (neat matrix) to 3.4 GPa (for 1 wt% GnP nanocomposite). Similarly, in the case of the epoxy/HNT nanocomposites, E IT decreased from 4.3 GPa (neat matrix) to 3.8 GPa (for 5 wt% HNT nanocomposite). The plasticizing effect of the applied nanofillers was assumed as the most probable cause of this decrease of surface hardness.

Nanofiller concentration dependencies of the indentation modulus of the studied GnPs and HNT nanocomposites.

Results of the uniaxial three-point bending tests of the studied nanocomposites are shown in Figure 6. Here, nonlinear decreasing patterns were found for both the studied nanocomposites. Such behavior is typical for brittle materials. A nonlinear decrease of the bending modulus (E B) from 4.3 GPa (neat matrix) to 2.8 GPa (for 1 wt% GnP nanocomposite) with increasing GnP filler concentration was found. This effect was accompanied by the increasing gradual nonlinear trend of the obtained magnitudes of the elongation at break (from 5.0 mm [neat matrix]) to 6.0 mm (for 1 wt% epoxy/GnP nanocomposite), indicating increasing composite ductility due to the plasticizing effect of the nanofiller of the prepared epoxy/GnP nanocomposites. In the case of the epoxy/HNT nanocomposites, E B nonlinearly decreased from 4.3 GPa (neat matrix) to 3.0 GPa (for 5 wt% epoxy/HNT nanocomposites), indicating decreasing mechanical stiffness of the studied materials. However, the opposite, a minor decreasing nonlinear trend of the elongation at break vs HNT filler concentration, was found, where the elongation at break decreased from 5.0 mm (neat matrix) to 4.1 mm (for 5 wt% epoxy/HNT nanocomposites). These results indicated higher brittleness of the epoxy/HNT nanocomposites compared to the epoxy/GnP nanocomposites.

Nanofiller concentration dependencies of the bending modulus and the elongation at break of the studied GnPs and HNT nanocomposites. Applied deformation rate was of 50 mm/min. Continuous line – bending modulus, dashed line – elongation at break.

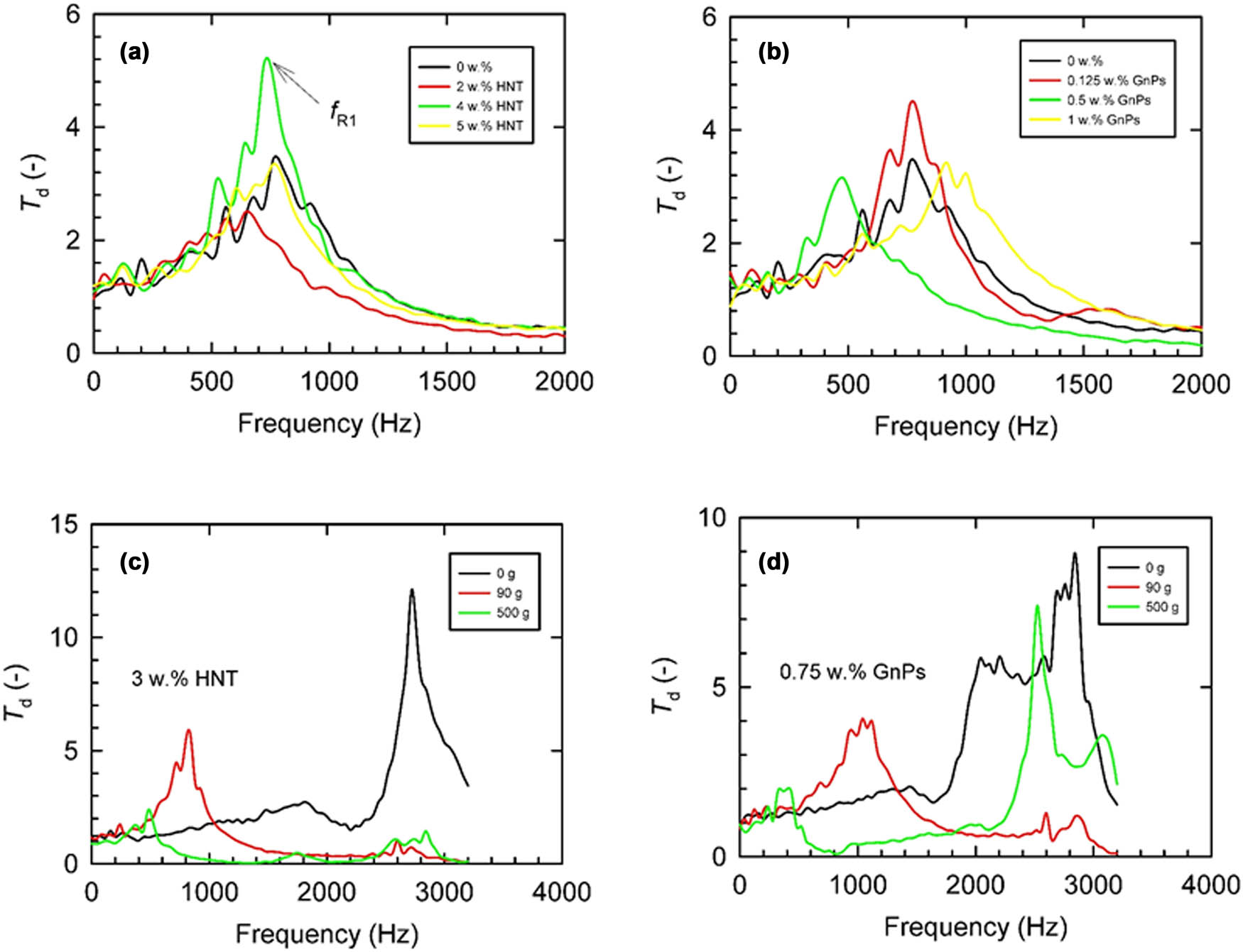

Results of the dynamic mechanical tests of the studied nanocomposites are shown in Figures 7 and 8. Typical frequency dependencies of displacement transmissibility are depicted in Figure 7. The obtained results were in excellent agreement with the uniaxial tensile measurements, indicating increased material stiffness based on the f R1 peak position shift to the higher excitation frequencies according to equation (4). However, a minor decrease of the latter stiffness was found for low filler concentrations, as indicated by the negligible shift of the f R1 to the lower magnitudes (Figure 7a and b). The effect of the inertial mass magnitudes on the frequency dependencies of the displacement transmissibility is demonstrated in Figure 7c and d. It was found that the increasing inertial mass led to the decrease of the first resonance frequency peak position, thereby resulting in the improved materials’ mechanical vibration-damping properties [53]. In addition, the obtained increasing f R1 with GnP concentration again confirmed materials’ increasing stiffness, similar to the case of the previous tensile and fracture toughness measurements (Figures 3 and 4). The latter findings fit very well with the epoxy/GnP nanocomposite results shown in Figure 8, where the linear increase of the f R1 with the filler concentration was observed. In contrast, obtained results for the epoxy/HNT nanocomposites exhibited decreased mechanical stiffness as indicated by decreasing f R1 with increasing filler concentration for the applied inertial masses.

Frequency dependencies of the displacement transmissibility of the tested GnPs and HNT nanocomposites (Inset in a and b: nanofillers concentrations) with applied inertial mass of 90 g (inset in c and d: applied inertial masses).

Concentration dependencies of the first resonance frequencies of the studied GnPs and HNT nanocomposites. Inset legend: inertial mass used.

5 Conclusions

The possibility of elastic–plastic mechanical behavior modulation by means of the application of nanosized GnPs and HNT fillers in the complex epoxy resin-based nanocomposites was confirmed in this study. A complex nonlinear pattern of Young’s modulus of elasticity with increasing GnP filler concentration was found. Simultaneously, in the concentration range of 0–1 wt% GnP nanofiller concentration, an increasing ductility of the studied nanocomposites was found, as reflected in the samples’ increased elongation at break. This kind of behavior was interpreted by the inter-particle gliding effect of the individual GnP nanoparticles dispersed in the complex epoxy resin matrix. A relatively constant trend of Young’s modulus of elasticity (approximately of about 2.8 GPa) accompanied by the similar nonlinear pattern of elongation at break (approximately of 0.35 mm) for the studied epoxy/HNT nanocomposites in the concentration range of 1–5 wt% was also found. It was attributed to the hindered local movement of the HNT nanofillers in the matrix during mechanical tests. Fracture mechanical tests confirmed that the fracture toughness obtained at low filler concentrations was higher in the case of the stiff epoxy/HNT nanocomposites compared to the epoxy/GnP nanocomposites due to the GnP filler’s gliding-dissipative effect. As obtained by the uniaxial three-point bending tests, the elongation at break measurements confirmed the enhanced plasticity and ductility with increasing GnP filler concentration of the complex epoxy/GnP nanocomposites. This was reflected in the exceeding magnitude of the elongation at break of 6 mm compared to 5.3 mm of the epoxy/HNT nanocomposites (both at 1 wt% nanofiller concentration). A similar effect was also confirmed by micro-hardness tests, where the observed indentation modulus of 3.4 GPa of epoxy/GnP nanocomposites was lower compared to 4.0 GPa of epoxy/HNT nanocomposites (both at 1 wt% nanofiller concentration), thus indicating more dissipative mechanical behavior of the epoxy/GnP nanocomposites. The latter we ascribed to the above-mentioned GnP nanofiller gliding friction. As a novel approach, the nondestructive mechanical vibration damping method of forced oscillations was applied in the low-frequency region of 2–3,200 Hz for the comparison of mechanical properties based on the first resonance frequency peak position. The plastification effect of the epoxy/GnP nanocomposites was confirmed by the lower magnitude of the first resonance frequency peak position of 2.6 kHz compared to the observed magnitude of the f R1 of 2.8 kHz for epoxy/HNT nanocomposites (both results obtained at 1 wt% nanofiller concentration and zero inertial mass).

-

Funding information: This study was supported by the European Regional Development Fund in the Research Centre of Advanced Mechatronic Systems project, project number CZ.02.1.01/0.0/0.0/16_019/0000867. LL and YM would like to express their gratitude for financing this research by the internal grants of Palacky University in Olomouc IGA_PrF_2022_020, IGA_PrF_2023_024 and to Tomas Bata University in Zlin (project nos IGA/FT/2022/005 and IGA/FT/2023/007). Financial support to YM by Fischer scholarship of the Faculty of Science, Palacky University in Olomouc, in the year 2022/2023, is also gratefully acknowledged.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Lapcik L, Jindrova P, Lapcikova B, Tamblyn R, Greenwood R, Rowson N. Effect of the talc filler content on the mechanical properties of polypropylene composites. J Appl Polym Sci. 2008 Dec 5;110(5):2742–7.10.1002/app.28797Search in Google Scholar

[2] Bheemappa S, Gurumurthy H. Recent advances in fabrication and characterization of nanofiller filled epoxy nanocomposites. Trends Fabr Polym Polym Compos. 2022;2022:1–40.10.1063/9780735423916_007Search in Google Scholar

[3] Ogbonna VE, Popoola A, Popoola OM, Adeosun SO. A review on the recent advances on improving the properties of epoxy nanocomposites for thermal, mechanical, and tribological applications: challenges and recommendations. Polym Technol Mater. 2022;61(2):176–95.10.1080/25740881.2021.1967391Search in Google Scholar

[4] Krasny I, Lapcik L, Lapcikova B, Greenwood RW, Safarova K, Rowson NA. The effect of low temperature air plasma treatment on physico-chemical properties of kaolinite/polyethylene composites. Compos Part B Eng. 2014 Mar;59:293–9.10.1016/j.compositesb.2013.12.019Search in Google Scholar

[5] Lapcik L, Jindrova P, Lapcikova B. Effect of talc filler content on poly(propylene) composite mechanical properties. Eng Fract. 2009;1:73–80.10.1007/978-1-4020-9402-6_6Search in Google Scholar

[6] Chen X, Li Y, Wang Y, Song D, Zhou Z, Hui D. An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs. Nanotechnol Rev. 2021;10(1):282–91.10.1515/ntrev-2021-0025Search in Google Scholar

[7] Gouda K, Bhowmik S, Das B. A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite. Rev Adv Mater Sci. 2021 jan;60(1):237–75.10.1515/rams-2021-0024Search in Google Scholar

[8] Amin M, Ali M. Polymer nanocomposites for high voltage outdoor insulation applications. Rev Adv Mater Sci. 2015 jun;40(3):276–94.Search in Google Scholar

[9] Lapcik L, Raab M. Materials Science II. Textbook. 2nd edn. Zlin: Tomas Bata University in Zlin; 2004.Search in Google Scholar

[10] Lapcik L’, Jancar J, Stasko A, Sáha P. Electron paramagnetic resonance study of free-radical kinetics in ultraviolet-light cured dimethacrylate copolymers. J Mater Sci Mater Med. 1998;9(5):257–62.10.1023/A:1008800626750Search in Google Scholar PubMed

[11] Vijayan PP, George JS, Thomas S. The effect of polymeric inclusions and nanofillers on cure kinetics of epoxy resin: A review. Polym Sci Ser A. 2021 Nov;63(6):637–51.10.1134/S0965545X21350145Search in Google Scholar

[12] Ouyang CF, Geo Q, Shi YT, Li WT. Effect of CTBN on properties of oxide graphene/epoxy resin composites. Chin Ceram Commun II. 2012;412:393.10.4028/www.scientific.net/AMR.412.393Search in Google Scholar

[13] Wang FZ, Drzal LT, Qin Y, Huang ZX. Enhancement of fracture toughness, mechanical and thermal properties of rubber/epoxy composites by incorporation of graphene nanoplatelets. Compos Part A Appl Sci Manuf. 2016 August;87:10–22.10.1016/j.compositesa.2016.04.009Search in Google Scholar

[14] Lim YJ, Carolan D, Taylor AC. Simultaneously tough and conductive rubber-graphene-epoxy nanocomposites. J Mater Sci. 2016 Sep;51(18):8631–44.10.1007/s10853-016-0122-2Search in Google Scholar

[15] Xie C, Li Y, Han Y. Fabrication and properties of CTBN/Si3N4/Cyanate ester nanocomposites. Polym Compos. 2016 August;37(8):2522–6.10.1002/pc.23439Search in Google Scholar

[16] Konnola R, Joji J, Parameswaranpillai J, Joseph K. Structure and thermo-mechanical properties of CTBN-grafted-GO modified epoxy/DDS composites. RSC Adv. 2015;5(76):61775–86.10.1039/C5RA10599DSearch in Google Scholar

[17] Hashim UR, Jumahat A, Jawaid M. Mechanical properties of hybrid graphene nanoplatelet-nanosilica filled unidirectional basalt fibre composites. Nanomaterials. 2021;11(6):1468.10.3390/nano11061468Search in Google Scholar PubMed PubMed Central

[18] Lapcik L, Manas D, Vasina M, Lapcikova B, Reznicek M, Zadrapa P. High density poly(ethylene)/CaCO3 hollow spheres composites for technical applications. Compos Part B Eng. 2017 Mar 15;113:218–24.10.1016/j.compositesb.2017.01.025Search in Google Scholar

[19] Fiore V, Scalici T, Di Bella G, Valenza A. A review on basalt fibre and its composites. Compos Part B Eng. 2015;74:74–94.10.1016/j.compositesb.2014.12.034Search in Google Scholar

[20] Tarawneh MA, Saraireh SA, Chen RS, Ahmad SH, Al-Tarawni M, Yu LJ, et al. Mechanical reinforcement with enhanced electrical and heat conduction of epoxy resin by polyaniline and graphene nanoplatelets. Nanotechnol Rev. 2020 Jan;9(1):1550–61.10.1515/ntrev-2020-0118Search in Google Scholar

[21] Ma X, Peng C, Zhou D, Wu Z, Li S, Wang J, et al. Synthesis and mechanical properties of the epoxy resin composites filled with sol− gel derived ZrO2 nanoparticles. J Sol Gel Sci Technol. 2018;88(2):442–53.10.1007/s10971-018-4827-3Search in Google Scholar

[22] Sui G, Zhong WH, Liu MC, Wu PH. Enhancing mechanical properties of an epoxy resin using “liquid nano-reinforcements”. Mater Sci Eng A. 2009;512(1–2):139–42.10.1016/j.msea.2009.01.023Search in Google Scholar

[23] Nath S, Jena H, Sahini D. Analysis of mechanical properties of jute epoxy composite with cenosphere filler. Silicon. 2019;11(2):659–71.10.1007/s12633-018-9941-xSearch in Google Scholar

[24] Sim J, Kang Y, Kim BJ, Park YH, Lee YC. Preparation of fly ash/epoxy composites and its effects on mechanical properties. Polymers. 2020;12(1):79.10.3390/polym12010079Search in Google Scholar PubMed PubMed Central

[25] Kiran MD, Govindaraju HK, Jayaraju T, Kumar N. effect of fillers on mechanical properties of polymer matrix composites. Mater Today Proc. 2018;5(10):22421–4.10.1016/j.matpr.2018.06.611Search in Google Scholar

[26] Prasob PA, Sasikumar M. Static and dynamic behavior of jute/epoxy composites with ZnO and TiO2 fillers at different temperature conditions. Polym Test. 2018;69:52–62.10.1016/j.polymertesting.2018.04.040Search in Google Scholar

[27] Savotchenko S, Kovaleva E, Cherniakov A. The improvement of mechanical properties of repair and construction compositions based on epoxy resin with mineral fillers. J Polym Res. 2022;29(7):1–10.10.1007/s10965-022-03138-8Search in Google Scholar

[28] Zhang HY, Li X, Qian WJ, Zhu JG, Chen BB, Yang J, et al. Characterization of mechanical properties of epoxy/nanohybrid composites by nanoindentation. Nanotechnol Rev. 2020 Jan;9(1):28–40.10.1515/ntrev-2020-0003Search in Google Scholar

[29] Tang L, Wan Y, Yan D, Pei Y, Zhao L, Li Y, et al. The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon. 2013;60:16–27.10.1016/j.carbon.2013.03.050Search in Google Scholar

[30] Ioniţă M, Vlăsceanu GM, Watzlawek AA, Voicu SI, Burns JS, Iovu H. Graphene and functionalized graphene: Extraordinary prospects for nanobiocomposite materials. Compos Part B: Eng. 2017;121:34–57.10.1016/j.compositesb.2017.03.031Search in Google Scholar

[31] Sukur EF, Onal G. Graphene nanoplatelet modified basalt/epoxy multi-scale composites with improved tribological performance. Wear. 2020;460:203481.10.1016/j.wear.2020.203481Search in Google Scholar

[32] Kilic U, Sherif MM, Ozbulut OE. Tensile properties of graphene nanoplatelets/epoxy composites fabricated by various dispersion techniques. Polym Test. 2019;76:181–91.10.1016/j.polymertesting.2019.03.028Search in Google Scholar

[33] Wang P, Hsieh T, Chiang C, Shen M. Synergetic effects of mechanical properties on graphene nanoplatelet and multiwalled carbon nanotube hybrids reinforced epoxy/carbon fiber composites. J Nanomater. 2015;2015:1–9.10.1155/2015/838032Search in Google Scholar

[34] Mishra BP, Mishra D, Panda P. An experimental investigation of the effects of reinforcement of graphene fillers on mechanical properties of bi-directional glass/epoxy composite. Mater Today Proc. 2020;33:5429–41.10.1016/j.matpr.2020.03.154Search in Google Scholar

[35] Georgakilas V, Otyepka M, Bourlinos AB, Chandra V, Kim N, Kemp KC, et al. Functionalization of graphene: Covalent and non-covalent approaches, derivatives and applications. Chem Rev. 2012 NOV;112(11):6156–214.10.1021/cr3000412Search in Google Scholar PubMed

[36] Joussein E, Petit S, Churchman J, Theng B, Righi D, Delvaux B. Halloysite clay minerals - A review. Clay Min. 2005 DEC;40(4):383–426.10.1180/0009855054040180Search in Google Scholar

[37] Yuan P, Tan D, Annabi-Bergaya F. Properties and applications of halloysite nanotubes: Recent research advances and future prospects. Appl Clay Sci. 2015;112:75–93.10.1016/j.clay.2015.05.001Search in Google Scholar

[38] Gaaz TS, Sulong AB, Kadhum AAH, Al-Amiery AA, Nassir MH, Jaaz AH. The impact of halloysite on the thermo-mechanical properties of polymer composites. Molecules. 2017;22(5):838.10.3390/molecules22050838Search in Google Scholar PubMed PubMed Central

[39] Tierrablanca E, Romero-García J, Roman P, Cruz-Silva R. Biomimetic polymerization of aniline using hematin supported on halloysite nanotubes. Appl Catal A: Gen. 2010;381(1–2):267–73.10.1016/j.apcata.2010.04.021Search in Google Scholar

[40] Kausar A. Review on polymer/halloysite nanotube nanocomposite. Polym Plast Technol Eng. 2018;57(6):548–64.10.1080/03602559.2017.1329436Search in Google Scholar

[41] Kausar A. Polymer coating technology for high performance applications: Fundamentals and advances. J Macromol Sci Part A Pure Appl Chem. 2018;55(5):440–8.10.1080/10601325.2018.1453266Search in Google Scholar

[42] Ghadikolaee MR, Korayem AH, Sharif A, Liu YM. The halloysite nanotube effects on workability, mechanical properties, permeability and microstructure of cementitious mortar. Constr Build Mater. 2021;267:120873.10.1016/j.conbuildmat.2020.120873Search in Google Scholar

[43] Hashmi MA. Enhancement of mechanical properties of epoxy/halloysite nanotube (HNT) nanocomposites. SN Appl Sci. 2019;1(4):1–8.10.1007/s42452-019-0323-9Search in Google Scholar

[44] Chen FX, Fan JT, Hui DV, Wang C, Yuan FP, Wu XL. Mechanisms of the improved stiffness of flexible polymers under impact loading. Nanotechnol Rev. 2022 Dec 16;11(1):3281–91.10.1515/ntrev-2022-0437Search in Google Scholar

[45] Srivastava S, Pandey A. Mechanical behavior and thermal stability of ultrasonically synthesized halloysite-epoxy composite. Compos Commun. 2019 Feb;11:39–44.10.1016/j.coco.2018.11.003Search in Google Scholar

[46] Alexopoulos ND, Paragkamian Z, Poulin P, Kourkoulis SK. Fracture related mechanical properties of low and high graphene reinforcement of epoxy nanocomposites. Compos Sci Technol. 2017 Sep 29;150:194–204.10.1016/j.compscitech.2017.07.030Search in Google Scholar

[47] Wei JC, Atif R, Vo T, Inam F. Graphene nanoplatelets in epoxy system: Dispersion, reaggregation, and mechanical properties of nanocomposites. J Nanomater. 2015;2015:(3):1–12.10.1155/2015/561742Search in Google Scholar

[48] Chatterjee S, Nafezarefi F, Tai NH, Schlagenhauf L, Nuesch FA, Chu B. Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon. 2012 Dec;50(15):5380–6.10.1016/j.carbon.2012.07.021Search in Google Scholar

[49] Alamri H, Low IM. Microstructural, mechanical, and thermal characteristics of recycled cellulose fiber-halloysite-epoxy hybrid nanocomposites. Polym Compos. 2012 Apr;33(4):589–600.10.1002/pc.22163Search in Google Scholar

[50] Oliver WC, Pharr GM. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J Mater Res. 2004 Jan;19(1):3–20.10.1557/jmr.2004.19.1.3Search in Google Scholar

[51] Manas D, Mizera A, Manas M, Ovsik M, Hylova L, Sehnalek S, et al. Mechanical properties changes of irradiated thermoplastic elastomer. Polymers. 2018 Jan;10(1):87.10.3390/polym10010087Search in Google Scholar PubMed PubMed Central

[52] Rao SS. Mechanical vibrations. 5th edn. Upper Saddle River, USA: Prentice Hall; 2010.Search in Google Scholar

[53] Lapcik L, Vasina M, Lapcikova B, Stanek M, Ovsik M, Murtaja Y. Study of the material engineering properties of high-density poly(ethylene)/perlite nanocomposite materials. Nanotechnol Rev. 2020 Jan;9(1):1491–9.10.1515/ntrev-2020-0113Search in Google Scholar

[54] Carrella A, Brennan MJ, Waters TP, Lopes V, Jr. Force and displacement transmissibility of a nonlinear isolator with high-static-low-dynamic-stiffness. Int J Mech Sci. 2012;55(1):22–9.10.1016/j.ijmecsci.2011.11.012Search in Google Scholar

[55] Ab Latif N, Rus AZM. Vibration transmissibility study of high density solid waste biopolymer foam. J Mech Eng Sci. 2014;6:772–81.10.15282/jmes.6.2014.5.0075Search in Google Scholar

[56] Murtaja Y, Lapcik L, Sepetcioglu H, Vlcek J, Lapcikova B, Ovsik M, et al. Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior. Nanotechnol Rev. 2022 Jan 5;11(1):312–20.10.1515/ntrev-2022-0023Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Preparation of CdS–Ag2S nanocomposites by ultrasound-assisted UV photolysis treatment and its visible light photocatalysis activity

- Significance of nanoparticle radius and inter-particle spacing toward the radiative water-based alumina nanofluid flow over a rotating disk

- Aptamer-based detection of serotonin based on the rapid in situ synthesis of colorimetric gold nanoparticles

- Investigation of the nucleation and growth behavior of Ti2AlC and Ti3AlC nano-precipitates in TiAl alloys

- Dynamic recrystallization behavior and nucleation mechanism of dual-scale SiCp/A356 composites processed by P/M method

- High mechanical performance of 3-aminopropyl triethoxy silane/epoxy cured in a sandwich construction of 3D carbon felts foam and woven basalt fibers

- Applying solution of spray polyurea elastomer in asphalt binder: Feasibility analysis and DSR study based on the MSCR and LAS tests

- Study on the chronic toxicity and carcinogenicity of iron-based bioabsorbable stents

- Influence of microalloying with B on the microstructure and properties of brazed joints with Ag–Cu–Zn–Sn filler metal

- Thermohydraulic performance of thermal system integrated with twisted turbulator inserts using ternary hybrid nanofluids

- Study of mechanical properties of epoxy/graphene and epoxy/halloysite nanocomposites

- Effects of CaO addition on the CuW composite containing micro- and nano-sized tungsten particles synthesized via aluminothermic coupling with silicothermic reduction

- Cu and Al2O3-based hybrid nanofluid flow through a porous cavity

- Design of functional vancomycin-embedded bio-derived extracellular matrix hydrogels for repairing infectious bone defects

- Study on nanocrystalline coating prepared by electro-spraying 316L metal wire and its corrosion performance

- Axial compression performance of CFST columns reinforced by ultra-high-performance nano-concrete under long-term loading

- Tungsten trioxide nanocomposite for conventional soliton and noise-like pulse generation in anomalous dispersion laser cavity

- Microstructure and electrical contact behavior of the nano-yttria-modified Cu-Al2O3/30Mo/3SiC composite

- Melting rheology in thermally stratified graphene-mineral oil reservoir (third-grade nanofluid) with slip condition

- Re-examination of nonlinear vibration and nonlinear bending of porous sandwich cylindrical panels reinforced by graphene platelets

- Parametric simulation of hybrid nanofluid flow consisting of cobalt ferrite nanoparticles with second-order slip and variable viscosity over an extending surface

- Chitosan-capped silver nanoparticles with potent and selective intrinsic activity against the breast cancer cells

- Multi-core/shell SiO2@Al2O3 nanostructures deposited on Ti3AlC2 to enhance high-temperature stability and microwave absorption properties

- Solution-processed Bi2S3/BiVO4/TiO2 ternary heterojunction photoanode with enhanced photoelectrochemical performance

- Electroporation effect of ZnO nanoarrays under low voltage for water disinfection

- NIR-II window absorbing graphene oxide-coated gold nanorods and graphene quantum dot-coupled gold nanorods for photothermal cancer therapy

- Nonlinear three-dimensional stability characteristics of geometrically imperfect nanoshells under axial compression and surface residual stress

- Investigation of different nanoparticles properties on the thermal conductivity and viscosity of nanofluids by molecular dynamics simulation

- Optimized Cu2O-{100} facet for generation of different reactive oxidative species via peroxymonosulfate activation at specific pH values to efficient acetaminophen removal

- Brownian and thermal diffusivity impact due to the Maxwell nanofluid (graphene/engine oil) flow with motile microorganisms and Joule heating

- Appraising the dielectric properties and the effectiveness of electromagnetic shielding of graphene reinforced silicone rubber nanocomposite

- Synthesis of Ag and Cu nanoparticles by plasma discharge in inorganic salt solutions

- Low-cost and large-scale preparation of ultrafine TiO2@C hybrids for high-performance degradation of methyl orange and formaldehyde under visible light

- Utilization of waste glass with natural pozzolan in the production of self-glazed glass-ceramic materials

- Mechanical performance of date palm fiber-reinforced concrete modified with nano-activated carbon

- Melting point of dried gold nanoparticles prepared with ultrasonic spray pyrolysis and lyophilisation

- Graphene nanofibers: A modern approach towards tailored gypsum composites

- Role of localized magnetic field in vortex generation in tri-hybrid nanofluid flow: A numerical approach

- Intelligent computing for the double-diffusive peristaltic rheology of magneto couple stress nanomaterials

- Bioconvection transport of upper convected Maxwell nanoliquid with gyrotactic microorganism, nonlinear thermal radiation, and chemical reaction

- 3D printing of porous Ti6Al4V bone tissue engineering scaffold and surface anodization preparation of nanotubes to enhance its biological property

- Bioinspired ferromagnetic CoFe2O4 nanoparticles: Potential pharmaceutical and medical applications

- Significance of gyrotactic microorganisms on the MHD tangent hyperbolic nanofluid flow across an elastic slender surface: Numerical analysis

- Performance of polycarboxylate superplasticisers in seawater-blended cement: Effect from chemical structure and nano modification

- Entropy minimization of GO–Ag/KO cross-hybrid nanofluid over a convectively heated surface

- Oxygen plasma assisted room temperature bonding for manufacturing SU-8 polymer micro/nanoscale nozzle

- Performance and mechanism of CO2 reduction by DBD-coupled mesoporous SiO2

- Polyarylene ether nitrile dielectric films modified by HNTs@PDA hybrids for high-temperature resistant organic electronics field

- Exploration of generalized two-phase free convection magnetohydrodynamic flow of dusty tetra-hybrid Casson nanofluid between parallel microplates

- Hygrothermal bending analysis of sandwich nanoplates with FG porous core and piezomagnetic faces via nonlocal strain gradient theory

- Design and optimization of a TiO2/RGO-supported epoxy multilayer microwave absorber by the modified local best particle swarm optimization algorithm

- Mechanical properties and frost resistance of recycled brick aggregate concrete modified by nano-SiO2

- Self-template synthesis of hollow flower-like NiCo2O4 nanoparticles as an efficient bifunctional catalyst for oxygen reduction and oxygen evolution in alkaline media

- High-performance wearable flexible strain sensors based on an AgNWs/rGO/TPU electrospun nanofiber film for monitoring human activities

- High-performance lithium–selenium batteries enabled by nitrogen-doped porous carbon from peanut meal

- Investigating effects of Lorentz forces and convective heating on ternary hybrid nanofluid flow over a curved surface using homotopy analysis method

- Exploring the potential of biogenic magnesium oxide nanoparticles for cytotoxicity: In vitro and in silico studies on HCT116 and HT29 cells and DPPH radical scavenging

- Enhanced visible-light-driven photocatalytic degradation of azo dyes by heteroatom-doped nickel tungstate nanoparticles

- A facile method to synthesize nZVI-doped polypyrrole-based carbon nanotube for Ag(i) removal

- Improved osseointegration of dental titanium implants by TiO2 nanotube arrays with self-assembled recombinant IGF-1 in type 2 diabetes mellitus rat model

- Functionalized SWCNTs@Ag–TiO2 nanocomposites induce ROS-mediated apoptosis and autophagy in liver cancer cells

- Triboelectric nanogenerator based on a water droplet spring with a concave spherical surface for harvesting wave energy and detecting pressure

- A mathematical approach for modeling the blood flow containing nanoparticles by employing the Buongiorno’s model

- Molecular dynamics study on dynamic interlayer friction of graphene and its strain effect

- Induction of apoptosis and autophagy via regulation of AKT and JNK mitogen-activated protein kinase pathways in breast cancer cell lines exposed to gold nanoparticles loaded with TNF-α and combined with doxorubicin

- Effect of PVA fibers on durability of nano-SiO2-reinforced cement-based composites subjected to wet-thermal and chloride salt-coupled environment

- Effect of polyvinyl alcohol fibers on mechanical properties of nano-SiO2-reinforced geopolymer composites under a complex environment

- In vitro studies of titanium dioxide nanoparticles modified with glutathione as a potential drug delivery system

- Comparative investigations of Ag/H2O nanofluid and Ag-CuO/H2O hybrid nanofluid with Darcy-Forchheimer flow over a curved surface

- Study on deformation characteristics of multi-pass continuous drawing of micro copper wire based on crystal plasticity finite element method

- Properties of ultra-high-performance self-compacting fiber-reinforced concrete modified with nanomaterials

- Prediction of lap shear strength of GNP and TiO2/epoxy nanocomposite adhesives

- A novel exploration of how localized magnetic field affects vortex generation of trihybrid nanofluids

- Fabrication and physicochemical characterization of copper oxide–pyrrhotite nanocomposites for the cytotoxic effects on HepG2 cells and the mechanism

- Thermal radiative flow of cross nanofluid due to a stretched cylinder containing microorganisms

- In vitro study of the biphasic calcium phosphate/chitosan hybrid biomaterial scaffold fabricated via solvent casting and evaporation technique for bone regeneration

- Insights into the thermal characteristics and dynamics of stagnant blood conveying titanium oxide, alumina, and silver nanoparticles subject to Lorentz force and internal heating over a curved surface

- Effects of nano-SiO2 additives on carbon fiber-reinforced fly ash–slag geopolymer composites performance: Workability, mechanical properties, and microstructure

- Energy bandgap and thermal characteristics of non-Darcian MHD rotating hybridity nanofluid thin film flow: Nanotechnology application

- Green synthesis and characterization of ginger-extract-based oxali-palladium nanoparticles for colorectal cancer: Downregulation of REG4 and apoptosis induction

- Abnormal evolution of resistivity and microstructure of annealed Ag nanoparticles/Ag–Mo films

- Preparation of water-based dextran-coated Fe3O4 magnetic fluid for magnetic hyperthermia

- Statistical investigations and morphological aspects of cross-rheological material suspended in transportation of alumina, silica, titanium, and ethylene glycol via the Galerkin algorithm

- Effect of CNT film interleaves on the flexural properties and strength after impact of CFRP composites

- Self-assembled nanoscale entities: Preparative process optimization, payload release, and enhanced bioavailability of thymoquinone natural product

- Structure–mechanical property relationships of 3D-printed porous polydimethylsiloxane films

- Nonlinear thermal radiation and the slip effect on a 3D bioconvection flow of the Casson nanofluid in a rotating frame via a homotopy analysis mechanism

- Residual mechanical properties of concrete incorporated with nano supplementary cementitious materials exposed to elevated temperature

- Time-independent three-dimensional flow of a water-based hybrid nanofluid past a Riga plate with slips and convective conditions: A homotopic solution

- Lightweight and high-strength polyarylene ether nitrile-based composites for efficient electromagnetic interference shielding

- Review Articles

- Recycling waste sources into nanocomposites of graphene materials: Overview from an energy-focused perspective

- Hybrid nanofiller reinforcement in thermoset and biothermoset applications: A review

- Current state-of-the-art review of nanotechnology-based therapeutics for viral pandemics: Special attention to COVID-19

- Solid lipid nanoparticles for targeted natural and synthetic drugs delivery in high-incidence cancers, and other diseases: Roles of preparation methods, lipid composition, transitional stability, and release profiles in nanocarriers’ development

- Critical review on experimental and theoretical studies of elastic properties of wurtzite-structured ZnO nanowires

- Polyurea micro-/nano-capsule applications in construction industry: A review

- A comprehensive review and clinical guide to molecular and serological diagnostic tests and future development: In vitro diagnostic testing for COVID-19

- Recent advances in electrocatalytic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid: Mechanism, catalyst, coupling system

- Research progress and prospect of silica-based polymer nanofluids in enhanced oil recovery

- Review of the pharmacokinetics of nanodrugs

- Engineered nanoflowers, nanotrees, nanostars, nanodendrites, and nanoleaves for biomedical applications

- Research progress of biopolymers combined with stem cells in the repair of intrauterine adhesions

- Progress in FEM modeling on mechanical and electromechanical properties of carbon nanotube cement-based composites

- Antifouling induced by surface wettability of poly(dimethyl siloxane) and its nanocomposites

- TiO2 aerogel composite high-efficiency photocatalysts for environmental treatment and hydrogen energy production

- Structural properties of alumina surfaces and their roles in the synthesis of environmentally persistent free radicals (EPFRs)

- Nanoparticles for the potential treatment of Alzheimer’s disease: A physiopathological approach

- Current status of synthesis and consolidation strategies for thermo-resistant nanoalloys and their general applications

- Recent research progress on the stimuli-responsive smart membrane: A review

- Dispersion of carbon nanotubes in aqueous cementitious materials: A review

- Applications of DNA tetrahedron nanostructure in cancer diagnosis and anticancer drugs delivery

- Magnetic nanoparticles in 3D-printed scaffolds for biomedical applications

- An overview of the synthesis of silicon carbide–boron carbide composite powders

- Organolead halide perovskites: Synthetic routes, structural features, and their potential in the development of photovoltaic

- Recent advancements in nanotechnology application on wood and bamboo materials: A review

- Application of aptamer-functionalized nanomaterials in molecular imaging of tumors

- Recent progress on corrosion mechanisms of graphene-reinforced metal matrix composites

- Research progress on preparation, modification, and application of phenolic aerogel

- Application of nanomaterials in early diagnosis of cancer

- Plant mediated-green synthesis of zinc oxide nanoparticles: An insight into biomedical applications

- Recent developments in terahertz quantum cascade lasers for practical applications

- Recent progress in dielectric/metal/dielectric electrodes for foldable light-emitting devices

- Nanocoatings for ballistic applications: A review

- A mini-review on MoS2 membrane for water desalination: Recent development and challenges

- Recent updates in nanotechnological advances for wound healing: A narrative review

- Recent advances in DNA nanomaterials for cancer diagnosis and treatment

- Electrochemical micro- and nanobiosensors for in vivo reactive oxygen/nitrogen species measurement in the brain

- Advances in organic–inorganic nanocomposites for cancer imaging and therapy

- Advancements in aluminum matrix composites reinforced with carbides and graphene: A comprehensive review

- Modification effects of nanosilica on asphalt binders: A review

- Decellularized extracellular matrix as a promising biomaterial for musculoskeletal tissue regeneration

- Review of the sol–gel method in preparing nano TiO2 for advanced oxidation process

- Micro/nano manufacturing aircraft surface with anti-icing and deicing performances: An overview

- Cell type-targeting nanoparticles in treating central nervous system diseases: Challenges and hopes

- An overview of hydrogen production from Al-based materials

- A review of application, modification, and prospect of melamine foam

- A review of the performance of fibre-reinforced composite laminates with carbon nanotubes

- Research on AFM tip-related nanofabrication of two-dimensional materials

- Advances in phase change building materials: An overview

- Development of graphene and graphene quantum dots toward biomedical engineering applications: A review

- Nanoremediation approaches for the mitigation of heavy metal contamination in vegetables: An overview

- Photodynamic therapy empowered by nanotechnology for oral and dental science: Progress and perspectives

- Biosynthesis of metal nanoparticles: Bioreduction and biomineralization

- Current diagnostic and therapeutic approaches for severe acute respiratory syndrome coronavirus-2 (SARS-COV-2) and the role of nanomaterial-based theragnosis in combating the pandemic

- Application of two-dimensional black phosphorus material in wound healing

- Special Issue on Advanced Nanomaterials and Composites for Energy Conversion and Storage - Part I

- Helical fluorinated carbon nanotubes/iron(iii) fluoride hybrid with multilevel transportation channels and rich active sites for lithium/fluorinated carbon primary battery

- The progress of cathode materials in aqueous zinc-ion batteries

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part I

- Effect of polypropylene fiber and nano-silica on the compressive strength and frost resistance of recycled brick aggregate concrete

- Mechanochemical design of nanomaterials for catalytic applications with a benign-by-design focus

Articles in the same Issue

- Research Articles

- Preparation of CdS–Ag2S nanocomposites by ultrasound-assisted UV photolysis treatment and its visible light photocatalysis activity

- Significance of nanoparticle radius and inter-particle spacing toward the radiative water-based alumina nanofluid flow over a rotating disk

- Aptamer-based detection of serotonin based on the rapid in situ synthesis of colorimetric gold nanoparticles

- Investigation of the nucleation and growth behavior of Ti2AlC and Ti3AlC nano-precipitates in TiAl alloys

- Dynamic recrystallization behavior and nucleation mechanism of dual-scale SiCp/A356 composites processed by P/M method

- High mechanical performance of 3-aminopropyl triethoxy silane/epoxy cured in a sandwich construction of 3D carbon felts foam and woven basalt fibers

- Applying solution of spray polyurea elastomer in asphalt binder: Feasibility analysis and DSR study based on the MSCR and LAS tests

- Study on the chronic toxicity and carcinogenicity of iron-based bioabsorbable stents

- Influence of microalloying with B on the microstructure and properties of brazed joints with Ag–Cu–Zn–Sn filler metal

- Thermohydraulic performance of thermal system integrated with twisted turbulator inserts using ternary hybrid nanofluids

- Study of mechanical properties of epoxy/graphene and epoxy/halloysite nanocomposites

- Effects of CaO addition on the CuW composite containing micro- and nano-sized tungsten particles synthesized via aluminothermic coupling with silicothermic reduction

- Cu and Al2O3-based hybrid nanofluid flow through a porous cavity

- Design of functional vancomycin-embedded bio-derived extracellular matrix hydrogels for repairing infectious bone defects

- Study on nanocrystalline coating prepared by electro-spraying 316L metal wire and its corrosion performance

- Axial compression performance of CFST columns reinforced by ultra-high-performance nano-concrete under long-term loading

- Tungsten trioxide nanocomposite for conventional soliton and noise-like pulse generation in anomalous dispersion laser cavity

- Microstructure and electrical contact behavior of the nano-yttria-modified Cu-Al2O3/30Mo/3SiC composite

- Melting rheology in thermally stratified graphene-mineral oil reservoir (third-grade nanofluid) with slip condition

- Re-examination of nonlinear vibration and nonlinear bending of porous sandwich cylindrical panels reinforced by graphene platelets

- Parametric simulation of hybrid nanofluid flow consisting of cobalt ferrite nanoparticles with second-order slip and variable viscosity over an extending surface

- Chitosan-capped silver nanoparticles with potent and selective intrinsic activity against the breast cancer cells

- Multi-core/shell SiO2@Al2O3 nanostructures deposited on Ti3AlC2 to enhance high-temperature stability and microwave absorption properties

- Solution-processed Bi2S3/BiVO4/TiO2 ternary heterojunction photoanode with enhanced photoelectrochemical performance

- Electroporation effect of ZnO nanoarrays under low voltage for water disinfection

- NIR-II window absorbing graphene oxide-coated gold nanorods and graphene quantum dot-coupled gold nanorods for photothermal cancer therapy

- Nonlinear three-dimensional stability characteristics of geometrically imperfect nanoshells under axial compression and surface residual stress

- Investigation of different nanoparticles properties on the thermal conductivity and viscosity of nanofluids by molecular dynamics simulation

- Optimized Cu2O-{100} facet for generation of different reactive oxidative species via peroxymonosulfate activation at specific pH values to efficient acetaminophen removal

- Brownian and thermal diffusivity impact due to the Maxwell nanofluid (graphene/engine oil) flow with motile microorganisms and Joule heating

- Appraising the dielectric properties and the effectiveness of electromagnetic shielding of graphene reinforced silicone rubber nanocomposite

- Synthesis of Ag and Cu nanoparticles by plasma discharge in inorganic salt solutions

- Low-cost and large-scale preparation of ultrafine TiO2@C hybrids for high-performance degradation of methyl orange and formaldehyde under visible light

- Utilization of waste glass with natural pozzolan in the production of self-glazed glass-ceramic materials

- Mechanical performance of date palm fiber-reinforced concrete modified with nano-activated carbon

- Melting point of dried gold nanoparticles prepared with ultrasonic spray pyrolysis and lyophilisation

- Graphene nanofibers: A modern approach towards tailored gypsum composites

- Role of localized magnetic field in vortex generation in tri-hybrid nanofluid flow: A numerical approach

- Intelligent computing for the double-diffusive peristaltic rheology of magneto couple stress nanomaterials

- Bioconvection transport of upper convected Maxwell nanoliquid with gyrotactic microorganism, nonlinear thermal radiation, and chemical reaction

- 3D printing of porous Ti6Al4V bone tissue engineering scaffold and surface anodization preparation of nanotubes to enhance its biological property

- Bioinspired ferromagnetic CoFe2O4 nanoparticles: Potential pharmaceutical and medical applications

- Significance of gyrotactic microorganisms on the MHD tangent hyperbolic nanofluid flow across an elastic slender surface: Numerical analysis

- Performance of polycarboxylate superplasticisers in seawater-blended cement: Effect from chemical structure and nano modification

- Entropy minimization of GO–Ag/KO cross-hybrid nanofluid over a convectively heated surface

- Oxygen plasma assisted room temperature bonding for manufacturing SU-8 polymer micro/nanoscale nozzle

- Performance and mechanism of CO2 reduction by DBD-coupled mesoporous SiO2

- Polyarylene ether nitrile dielectric films modified by HNTs@PDA hybrids for high-temperature resistant organic electronics field

- Exploration of generalized two-phase free convection magnetohydrodynamic flow of dusty tetra-hybrid Casson nanofluid between parallel microplates

- Hygrothermal bending analysis of sandwich nanoplates with FG porous core and piezomagnetic faces via nonlocal strain gradient theory

- Design and optimization of a TiO2/RGO-supported epoxy multilayer microwave absorber by the modified local best particle swarm optimization algorithm

- Mechanical properties and frost resistance of recycled brick aggregate concrete modified by nano-SiO2

- Self-template synthesis of hollow flower-like NiCo2O4 nanoparticles as an efficient bifunctional catalyst for oxygen reduction and oxygen evolution in alkaline media

- High-performance wearable flexible strain sensors based on an AgNWs/rGO/TPU electrospun nanofiber film for monitoring human activities

- High-performance lithium–selenium batteries enabled by nitrogen-doped porous carbon from peanut meal

- Investigating effects of Lorentz forces and convective heating on ternary hybrid nanofluid flow over a curved surface using homotopy analysis method

- Exploring the potential of biogenic magnesium oxide nanoparticles for cytotoxicity: In vitro and in silico studies on HCT116 and HT29 cells and DPPH radical scavenging

- Enhanced visible-light-driven photocatalytic degradation of azo dyes by heteroatom-doped nickel tungstate nanoparticles

- A facile method to synthesize nZVI-doped polypyrrole-based carbon nanotube for Ag(i) removal

- Improved osseointegration of dental titanium implants by TiO2 nanotube arrays with self-assembled recombinant IGF-1 in type 2 diabetes mellitus rat model

- Functionalized SWCNTs@Ag–TiO2 nanocomposites induce ROS-mediated apoptosis and autophagy in liver cancer cells

- Triboelectric nanogenerator based on a water droplet spring with a concave spherical surface for harvesting wave energy and detecting pressure

- A mathematical approach for modeling the blood flow containing nanoparticles by employing the Buongiorno’s model

- Molecular dynamics study on dynamic interlayer friction of graphene and its strain effect

- Induction of apoptosis and autophagy via regulation of AKT and JNK mitogen-activated protein kinase pathways in breast cancer cell lines exposed to gold nanoparticles loaded with TNF-α and combined with doxorubicin

- Effect of PVA fibers on durability of nano-SiO2-reinforced cement-based composites subjected to wet-thermal and chloride salt-coupled environment

- Effect of polyvinyl alcohol fibers on mechanical properties of nano-SiO2-reinforced geopolymer composites under a complex environment

- In vitro studies of titanium dioxide nanoparticles modified with glutathione as a potential drug delivery system

- Comparative investigations of Ag/H2O nanofluid and Ag-CuO/H2O hybrid nanofluid with Darcy-Forchheimer flow over a curved surface

- Study on deformation characteristics of multi-pass continuous drawing of micro copper wire based on crystal plasticity finite element method

- Properties of ultra-high-performance self-compacting fiber-reinforced concrete modified with nanomaterials

- Prediction of lap shear strength of GNP and TiO2/epoxy nanocomposite adhesives

- A novel exploration of how localized magnetic field affects vortex generation of trihybrid nanofluids

- Fabrication and physicochemical characterization of copper oxide–pyrrhotite nanocomposites for the cytotoxic effects on HepG2 cells and the mechanism

- Thermal radiative flow of cross nanofluid due to a stretched cylinder containing microorganisms

- In vitro study of the biphasic calcium phosphate/chitosan hybrid biomaterial scaffold fabricated via solvent casting and evaporation technique for bone regeneration

- Insights into the thermal characteristics and dynamics of stagnant blood conveying titanium oxide, alumina, and silver nanoparticles subject to Lorentz force and internal heating over a curved surface

- Effects of nano-SiO2 additives on carbon fiber-reinforced fly ash–slag geopolymer composites performance: Workability, mechanical properties, and microstructure

- Energy bandgap and thermal characteristics of non-Darcian MHD rotating hybridity nanofluid thin film flow: Nanotechnology application

- Green synthesis and characterization of ginger-extract-based oxali-palladium nanoparticles for colorectal cancer: Downregulation of REG4 and apoptosis induction

- Abnormal evolution of resistivity and microstructure of annealed Ag nanoparticles/Ag–Mo films

- Preparation of water-based dextran-coated Fe3O4 magnetic fluid for magnetic hyperthermia

- Statistical investigations and morphological aspects of cross-rheological material suspended in transportation of alumina, silica, titanium, and ethylene glycol via the Galerkin algorithm

- Effect of CNT film interleaves on the flexural properties and strength after impact of CFRP composites

- Self-assembled nanoscale entities: Preparative process optimization, payload release, and enhanced bioavailability of thymoquinone natural product

- Structure–mechanical property relationships of 3D-printed porous polydimethylsiloxane films

- Nonlinear thermal radiation and the slip effect on a 3D bioconvection flow of the Casson nanofluid in a rotating frame via a homotopy analysis mechanism

- Residual mechanical properties of concrete incorporated with nano supplementary cementitious materials exposed to elevated temperature

- Time-independent three-dimensional flow of a water-based hybrid nanofluid past a Riga plate with slips and convective conditions: A homotopic solution

- Lightweight and high-strength polyarylene ether nitrile-based composites for efficient electromagnetic interference shielding

- Review Articles

- Recycling waste sources into nanocomposites of graphene materials: Overview from an energy-focused perspective

- Hybrid nanofiller reinforcement in thermoset and biothermoset applications: A review

- Current state-of-the-art review of nanotechnology-based therapeutics for viral pandemics: Special attention to COVID-19

- Solid lipid nanoparticles for targeted natural and synthetic drugs delivery in high-incidence cancers, and other diseases: Roles of preparation methods, lipid composition, transitional stability, and release profiles in nanocarriers’ development

- Critical review on experimental and theoretical studies of elastic properties of wurtzite-structured ZnO nanowires

- Polyurea micro-/nano-capsule applications in construction industry: A review

- A comprehensive review and clinical guide to molecular and serological diagnostic tests and future development: In vitro diagnostic testing for COVID-19

- Recent advances in electrocatalytic oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid: Mechanism, catalyst, coupling system

- Research progress and prospect of silica-based polymer nanofluids in enhanced oil recovery

- Review of the pharmacokinetics of nanodrugs

- Engineered nanoflowers, nanotrees, nanostars, nanodendrites, and nanoleaves for biomedical applications

- Research progress of biopolymers combined with stem cells in the repair of intrauterine adhesions

- Progress in FEM modeling on mechanical and electromechanical properties of carbon nanotube cement-based composites

- Antifouling induced by surface wettability of poly(dimethyl siloxane) and its nanocomposites

- TiO2 aerogel composite high-efficiency photocatalysts for environmental treatment and hydrogen energy production

- Structural properties of alumina surfaces and their roles in the synthesis of environmentally persistent free radicals (EPFRs)

- Nanoparticles for the potential treatment of Alzheimer’s disease: A physiopathological approach

- Current status of synthesis and consolidation strategies for thermo-resistant nanoalloys and their general applications

- Recent research progress on the stimuli-responsive smart membrane: A review

- Dispersion of carbon nanotubes in aqueous cementitious materials: A review

- Applications of DNA tetrahedron nanostructure in cancer diagnosis and anticancer drugs delivery

- Magnetic nanoparticles in 3D-printed scaffolds for biomedical applications

- An overview of the synthesis of silicon carbide–boron carbide composite powders

- Organolead halide perovskites: Synthetic routes, structural features, and their potential in the development of photovoltaic

- Recent advancements in nanotechnology application on wood and bamboo materials: A review

- Application of aptamer-functionalized nanomaterials in molecular imaging of tumors

- Recent progress on corrosion mechanisms of graphene-reinforced metal matrix composites

- Research progress on preparation, modification, and application of phenolic aerogel

- Application of nanomaterials in early diagnosis of cancer

- Plant mediated-green synthesis of zinc oxide nanoparticles: An insight into biomedical applications

- Recent developments in terahertz quantum cascade lasers for practical applications

- Recent progress in dielectric/metal/dielectric electrodes for foldable light-emitting devices

- Nanocoatings for ballistic applications: A review

- A mini-review on MoS2 membrane for water desalination: Recent development and challenges

- Recent updates in nanotechnological advances for wound healing: A narrative review

- Recent advances in DNA nanomaterials for cancer diagnosis and treatment

- Electrochemical micro- and nanobiosensors for in vivo reactive oxygen/nitrogen species measurement in the brain

- Advances in organic–inorganic nanocomposites for cancer imaging and therapy

- Advancements in aluminum matrix composites reinforced with carbides and graphene: A comprehensive review

- Modification effects of nanosilica on asphalt binders: A review

- Decellularized extracellular matrix as a promising biomaterial for musculoskeletal tissue regeneration

- Review of the sol–gel method in preparing nano TiO2 for advanced oxidation process

- Micro/nano manufacturing aircraft surface with anti-icing and deicing performances: An overview

- Cell type-targeting nanoparticles in treating central nervous system diseases: Challenges and hopes

- An overview of hydrogen production from Al-based materials

- A review of application, modification, and prospect of melamine foam

- A review of the performance of fibre-reinforced composite laminates with carbon nanotubes

- Research on AFM tip-related nanofabrication of two-dimensional materials

- Advances in phase change building materials: An overview

- Development of graphene and graphene quantum dots toward biomedical engineering applications: A review

- Nanoremediation approaches for the mitigation of heavy metal contamination in vegetables: An overview

- Photodynamic therapy empowered by nanotechnology for oral and dental science: Progress and perspectives

- Biosynthesis of metal nanoparticles: Bioreduction and biomineralization

- Current diagnostic and therapeutic approaches for severe acute respiratory syndrome coronavirus-2 (SARS-COV-2) and the role of nanomaterial-based theragnosis in combating the pandemic

- Application of two-dimensional black phosphorus material in wound healing

- Special Issue on Advanced Nanomaterials and Composites for Energy Conversion and Storage - Part I

- Helical fluorinated carbon nanotubes/iron(iii) fluoride hybrid with multilevel transportation channels and rich active sites for lithium/fluorinated carbon primary battery

- The progress of cathode materials in aqueous zinc-ion batteries

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part I

- Effect of polypropylene fiber and nano-silica on the compressive strength and frost resistance of recycled brick aggregate concrete

- Mechanochemical design of nanomaterials for catalytic applications with a benign-by-design focus