Abstract

For components serving in high temperature, humidity, and salinity marine corrosive environment, it is vital to analyze the causes of corrosion behavior and corrosion mechanisms. Metal matrix composites (MMCs) are commonly used materials for offshore equipment. In this work, the corrosion factors of MMCs in marine environments are analyzed from the characteristics of high temperature, humidity, and salinity service environment, and the corrosion mechanisms are summarized. Graphene (Gr) has excellent comprehensive properties and great potential for applications in metal protection materials. In recent years, research into Gr anti-corrosive applications encompasses two aspects: pure Gr coatings and Gr composite coatings. Gr applied in MMCs is yet to be extensively studied. Therefore, this study analyzes the corrosion resistance of Gr–metal composites and discusses the corrosion resistance mechanisms of Gr-reinforced MMCs, which provides a reference for the design of Gr-reinforced metal composites and the optimization of corrosion resistance performance. Finally, future development directions for Gr–metal composites are proposed, and the critical factors such as defects, dispersion, content, size, arrangement, interface, and conductivity of Gr in the composites affecting their anti-corrosion properties are discussed.

Graphical abstract

1 Introduction

Metals have been widely used in marine environments because of their excellent mechanical properties. Still, high humidity, high temperature, and high salt marine environment will cause significant harm to engineering equipment and facilities. Many inorganic salt ions (Cl−, Br−, S2−, and SO4 2−) in seawater will deliquescence on the metal surface to form water films in high humidity. Han et al. [1] reported that Cl− could accelerate the corrosion rate of composites. The oxide film will be destroyed by Cl−, thus promoting corrosion. Francis and Hebdon [2] also pointed out that as a highly conductive medium, the high galvanic current of seawater may accelerate the local dissolution of metals, thus leading to stress corrosion, pitting corrosion, crevice corrosion, and hydrogen embrittlement [3]. Metals are usually directly exposed to sunlight. The high temperature and light can accelerate the corrosion rate of metals, causing premature failure of metals. The economic loss caused by corrosion is approximately $2.5 trillion (3.4% of the world’s gross domestic product) annually reported by the National Society of Corrosion Engineers [4]. The annual loss of metals due to corrosion in various industries and service fields exceeds 10% of their yearly output [5]. Therefore, it is essential to study the corrosion mechanisms and choose appropriate ways to ameliorate the corrosion properties of metals according to the specific situation. To reduce the corrosion of metal materials, methods such as metal matrix improvement, cathodic protection, coating protection, and corrosion inhibitors can be adopted [13,15,17].

Due to their excellent performance, metal matrix composites (MMCs) are increasingly used in marine environments. The addition of reinforcements will not only improve the mechanical properties of MMCs, but also affect their microstructure, grains, precipitates, and internal defects, thus affecting the corrosion performance of the composites [1,6,7]. Li et al. [6] investigated the corrosion mechanisms of B4C/6061Al composites and reported that the corrosion pits on the surface mainly occurred at the interface of reinforcement/metal and the Si-rich precipitated phase. Winkler and Flower [7] summarized the effects of reinforcements on the corrosion behavior of MMCs, mainly through the following: 1) Galvanic corrosion caused by the potential difference between matrix and reinforcements. 2) The selective corrosion of the interface of reinforcements/metal. 3) The corrosion of defects affecting the formation of intermetallic compounds. 4) There is almost no electrical reaction if the reinforcements are electrical insulators such as Al2O3, B4C, and SiC [7]. However, the interfacial reaction products bind the two materials together, and preferential corrosion may occur if the interfacial phase is a substantial anode or cathode. Shimizu et al. [8] studied the corrosion mechanisms of aluminum matrix composites, the corrosion potential E corr of MMC is more susceptible to pitting due to the galvanic corrosion of the more potential reinforcement with the matrix. Although Al2O3 and SiC fibers are non-conductive, their cathodic current is also more extensive than the matrix. Some phases would form at the reinforcement/matrix interface. Small pits were produced in all samples when the base metal and MMCs were immersed in 3.5% NaCl solution at room temperature for about a week. The pit growth on MMCs is faster than the alloy due to the dissolution of the matrix at the pit, forming a crack between the reinforcement and the matrix.

Among many reinforcements, graphene (Gr) has received attention due to its unique structure and excellent comprehensive properties [9]. Gr can act as a physical barrier layer to effectively block the passage of gas atoms such as water and oxygen [10,11]. Using Gr as a metal protective coating can prevent it from coming in contact with corrosive or oxidizing media and play a role in protecting the substrate material. However, galvanic corrosion tends to occur at the defect and interface [12]. Therefore, how to fully use the barrier effect to prepare defect-free Gr, insulating materials to encapsulate Gr, and Gr packaging strategies have attracted much attention. Sun et al. [13] proposed encapsulating rGO with APTES, which eliminated random connections in the matrix, thus inhibiting the corrosion activity of Gr. Gr can also play a passivation role in coating metal to improve its corrosion resistance [14,15]. Wang et al. [16] studied the influence of Gr addition on the corrosion behavior of Al/Al2O3 composite coating and found that the small size effect of Gr could reduce the porosity. Due to the unique 2-dimensional structure, Gr can effectively isolate electrons and prevent the erosion of Cl− in NaCl solution. In addition, the polymer coating commonly used in metal materials is easy to scratch, while the excellent tribological properties of Gr can improve the anti-wear and anti-friction properties of the material. Gr has been widely studied not only in composite coatings but also in enhancing the corrosion of metal substrates. Xie et al. [17] embedded exposed and semi-exposed graphene nanoplatelets (GNPs) into the oxide film and directly combined well with the oxide film with interface defects. Therefore, GNPs can act as corrosion inhibitors, reducing chloride entry and thus improving corrosion resistance. It is observed that GNPs and oxide film work together to form anticorrosive protective film through diffusion and chemical reaction. The doping of carbon atoms results in higher vacancy formation energy, Cl− entry energy barrier, and charge transfer work function.

This work reviews and summarizes the research progress on the corrosion mechanisms and protection of Gr-reinforced MMCs based on the influence of complex factors. First, the characteristics and influencing factors of environmental corrosion caused by high humidity, high temperature, and high salt service environment were summarized. Second, the corrosion types and mechanisms of high humidity, high temperature, and high salt are summarized in the service environment. Third, the anti-corrosion mechanisms of Gr composite designed according to the characteristics of Gr composite are summarized. On this basis, prospects of Gr-reinforced composites based on the influence of complex factors in the field of corrosion protection in metal materials are presented to improve their corrosion protection effect further and prolong their service life.

2 MMCs marine environment corrosion factors and corrosion mechanisms

Seawater has various gases dissolved in it and contains a lot of salts, which is a very harsh corrosive environment for various metal structures of marine engineering equipment. In the marine environment, the main factor for the accelerated corrosion rate of MMCs is the high Cl− content in the environment. Due to the harsh conditions of high humidity, temperature, and salinity in the marine environment, chloride salt will form on the metal surface after continuous moisture absorption and evaporation [18]. In high humidity and temperature, an electrolyte solution layer containing a high concentration of Cl− is formed on the surface. The solution contacts the substrate through the porous surface oxide layer and includes an oxygen concentration difference cell due to the difference in concentration of Cl− distribution, causing electrochemical corrosion [41,42].

There are many influencing factors in seawater with different characteristics from other environments:

Seawater solution is close to neutral, shallow areas with more dissolved oxygen and oxygen depolarization process controls the corrosion of most metal materials in seawater, high concentration of Cl− in seawater, even stainless steel (SS), can cause corrosion damage;

The resistance of seawater is minimal, it is a fine conductive medium, and the contact between different kinds of materials could lead to galvanic corrosion, which may cause significant damage [18].

Metal structures often suffer localized corrosion damage, such as crevice and pitting corrosion. There are differences in the composition and concentration of seawater in different seas, and the effect of geographical factors is not essential [3]. However, water temperature, currents, and wind and waves vary greatly from sea to sea and influence the corrosion behavior of equipment and protection methods [2].

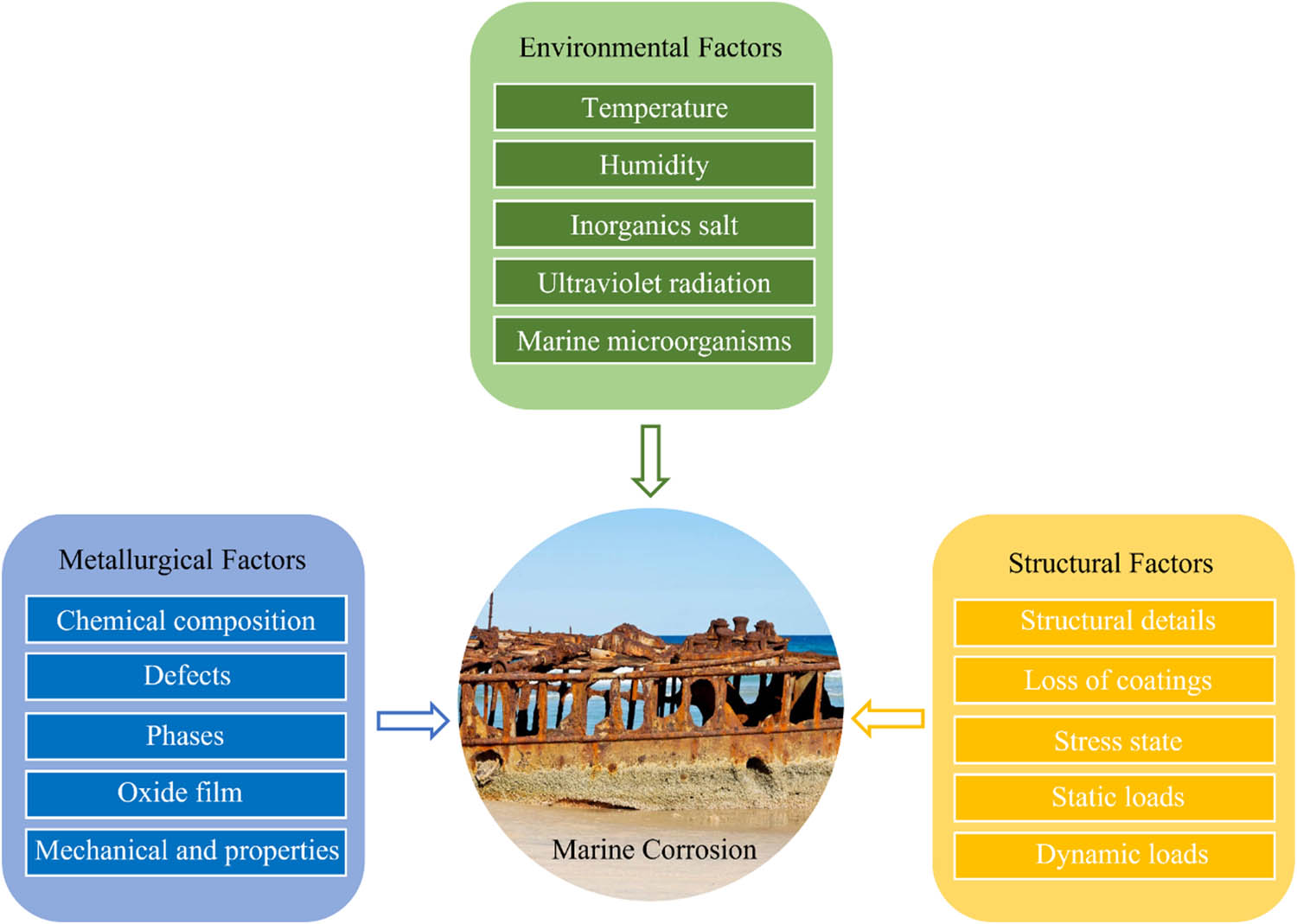

As shown in Figure 1, three main factors affect the corrosion of MMCs used in marine environments. Offshore engineering equipment has a complex structure and needs to withstand long-term use in harsh marine environments. Equipment under the marine environment’s influence makes it easy to bring stress corrosion and other material safety issues [19]. Corrosion fatigue and wear significantly impact the safety of the structure in use [20,21,22]. In most cases, offshore construction equipment will be affected by multiple factors simultaneously, which can easily cause safety hazards and even disasters.

Factors affecting marine corrosion.

2.1 Influencing factors of seawater corrosion

2.1.1 High temperature factor induced material corrosion analysis

The temperature variation of seawater corrodes various materials to different degrees. In addition, temperature changes will lead to changes in other factors. For example, an elevated temperature increases the rate of oxygen diffusion, which in turn leads to an increment in the conductivity of seawater and an accelerated rate of corrosion. The temperature and its changes affect the marine atmospheric corrosion of metal materials by influencing the solubility of corrosive salts and gases in the water film, the condensation of water vapor on MMCs, the corrosion rate of the anode and cathode processes in the corrosion cell, and the resistance of the water film. In the marine atmosphere corrosion environment, the relative humidity (RH) is often higher than the critical RH of MMCs, temperature increases, and corrosion significantly accelerates. Neville and Hodgkiess [23] studied the effect of high-speed impingement flow and high temperature (60°C) on the corrosion behavior of SS and related nickel- and cobalt-based alloys in marine environments. He pointed out that the temperature increases significantly promoted the premature breakdown of the passivation of all materials. The effect of high-speed impingement flow was to further shift the breakdown potential of passivation to more positive values. With the increase in the temperature, the oxidation passivation film became thin and porous, and the protection was diminished due to the dissolution of the film [24]. In Zakaria’s study [25], the corrosion performance of Al/SiC composites is positively correlated with temperature. The effect of temperature depends on the activation energy of corrosion. For MMCs, the corrosion rate increases with the activation energy and temperature increase. In the marine atmosphere, the temperature rise will promote the diffusion of corrosive chloride ions and oxygen, changing the relative content of main corrosion products and accelerating corrosion [44].

However, the influence of temperature is not a simple linear relationship [26]. The solubility of oxygen decreases with the increase in temperature, thus inhibiting metal corrosion [27]. Zhang studied the corrosion behavior of Cu–Al composites at 35, 45, and 55°C. The corrosion rate was the highest at 45℃. The Arrhenius formula analyzed the corrosion rate of Cu–Al composites at different temperatures.

where K is the anodic reaction rate, E R is the activation energy, T is the thermodynamic temperature, R is the molar gas constant, and B is the frequency factor. According to the formula, the increase in temperature leads to an increase in the K value, which accelerates the anode reaction. When the temperature increases to a certain extent, the oxygen content in the solution gradually decreases, leading to a decrease in the cathode reaction rate, thus inhibiting the reduction reaction. Flores et al. [28] evaluated the effect of temperature on the corrosion process of MMCs using Arrhenius diagrams. As shown in Figure 2, the corrosion rate of MMCs varies with temperature, and there is a critical transition temperature T c for the corrosion rate. When the temperature is higher than T c, the range of priority attack zone of MMCs increases, and the number of voids and “microcrack like” sites increase.

![Figure 2

Current density (i) as a function of temperature for the MMCs: (a) WC-FeCrC and WC-FeCr MMCs and (b) WC-NiCrBSi and WC-NiCrMoWB MMCs; Arrhenius plot of the potentiostatic tests of the MMCs: (c) WC-FeCrC and WC-FeCr MMCs, and (d) WC-NiCrBSi and WC-NiCrMoWB MMC [28].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_002.jpg)

Current density (i) as a function of temperature for the MMCs: (a) WC-FeCrC and WC-FeCr MMCs and (b) WC-NiCrBSi and WC-NiCrMoWB MMCs; Arrhenius plot of the potentiostatic tests of the MMCs: (c) WC-FeCrC and WC-FeCr MMCs, and (d) WC-NiCrBSi and WC-NiCrMoWB MMC [28].

2.1.2 High humidity induced material corrosion analysis

Corrosion in atmospheric environments is a discontinuous process that depends on the availability of electrolytes to provide ionic conduction between the cathode and anode. Pitting occurs when an aerosol of salt particles is deposited on MMCs, and the RH reaches the deliquescence point of salt [29]. The deliquescence RH (DRH) of NaCl, the main corrosion medium in the marine environment, is 76%. When the humidity exceeds DRH, solid NaCl will absorb water and deliquescence to form a solution. Schindelholz et al. [30] studied the influence of RH on steel corrosion. The deliquescence point of NaCl does not represent a critical RH value, and corrosion can continue even at 33% RH, as shown in Figure 2. The corrosion rate significantly increased when RH reached 53%, which was 20% lower than the DRH of NaCl. However, the considerable variation in attack between 33 and 53% is due to the chemical hygroscopic behavior formed at the anode and cathode. NaCl deliquescence point corrosion is caused by several physical phenomena under or maintained. These physical phenomena allow the existence of electrolytes, including:

The existence of the adsorbed water related to steel surface salt;

Crystallizing point inhibition caused by the existence of the supersaturated salt water;

The hygroscopicity of chemical corrosion.

Due to the relatively high RH in the ocean atmosphere, the RH of the air is higher than its critical value [31,32], so a thick corrosive water film will be formed. Steel’s corrosion behavior and corrosion mechanism are directly affected by the thickness of the water film on the surface. The corrosion rate increases with the increase in water film thickness. The marine atmosphere corrosion process of corrosive water film on composite material is consistent with the law of electrochemical corrosion in electrolytes. In this process, it is especially easy for oxygen to reach the surface of composite materials, and the corrosion rate of composite materials is controlled by oxygen polarization. The critical RH for pit reactivation 304 is 70–75% and 56–70%. Thus, stable pits grown under invasive conditions will be blunted when RH changes to high values greater than 75%. When the RH of the metal is greater than 70%, the corrosion is severe [33]. Although NaCl is the main component of sea salts, which has a tidal RH of about 76%, the presence of highly hygroscopic salts such as MgCl2 (33% tidal RH) means that sea salt particles begin to wet much earlier [34]. In Cheng et al.’s study [35], the corrosion rate of zinc metal increased with the increase in humidity, with the highest corrosion rate at 97%. Anodic and cathodic processes determine the corrosion rate, and RH mainly affects the cathodic process. The polarization curves of different humidity (75, 85, and 95%) in Huang et al.’s study [36] showed that the initial corrosion process was controlled by oxygen reduction, and the corrosion rate increased with humidity. However, when exposed for a long time, the corrosion products increased with higher RH, which inhibited the anode’s dissolution and decreased the corrosion rate. Wang et al. [37] used an electrolytic method to prepare superhydrophobic zinc–dodecane complex film on a zinc surface, and the obtained film can maintain superhydrophobic properties in the solution system and effectively inhibit corrosion. However, in the simulated marine environment, salt water penetrates the superhydrophobic film during the deliquescence process of NaCl particles, which weakens the advantage of the superhydrophobic film as a corrosion barrier of the marine atmosphere (Figure 3).

![Figure 3

Optical micrographs of crystal-loaded coupons immediately after 7 days of exposure below the DRH of NaCl. The RH was controlled at the indicated value during the imaging. The black regions are rust formation and electrolyte pools are readily visible in the 64 and 71% images [30].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_003.jpg)

Optical micrographs of crystal-loaded coupons immediately after 7 days of exposure below the DRH of NaCl. The RH was controlled at the indicated value during the imaging. The black regions are rust formation and electrolyte pools are readily visible in the 64 and 71% images [30].

2.1.3 High salt induced material corrosion analysis

The marine environment is highly corrosive due to large amounts of salt substances. Among these salts, chlorine salts and sulfates are prone to corrosion, while chlorine salts account for a considerable proportion of seawater and mainly cause changes in the conductivity of seawater [38]. The salt particle impurities dissolve in the water film, becoming a highly corrosive electrolyte and accelerating corrosion. In addition, due to the good hygroscopic property of Cl− and the relatively high humidity of the ocean atmosphere, other Cl− droplets are easy to form in the interface between dry and wet sea water and adhere to the metal surface [39]. Ambler and Bain proved that when the thickness of Cl− containing droplets deposited on the metal surface exceeds 10 μm, corrosion will be caused [40]. In marine environments, chloride deposit on the metal surface to form a thin layer of liquid electrolyte and become the critical factor influencing the marine structures metal. Frankel’s [41] polarization test method proves that the metal corrosion rate increases with the increased concentration of Cl−, and the pitting potential of metal is a linear function of the logarithm of Cl− concentration.

The salinity of seawater will directly affect the content of oxygen and electrical conductivity of seawater, which will change with the increase in the salinity of seawater, affecting the corrosion of materials. Moreover, the corrosion rate of seawater will reach a maximum value with different salinity. The higher the chloride concentration, the more severe the corrosion. When NaCl concentration was lower than 3 wt%, the increasing weight loss trend was more obvious than when NaCl concentration was higher than 3 wt% [26]. The higher the chloride concentration, the higher the corrosion current density. The chloride solution quickly reaches the anode limit current density in the anode region. In the cathode region, the self-corrosion current density of the solution containing chloride ions decreases, and chloride ions have a certain inhibitory effect on the cathodic reaction. Among the many factors of marine corrosion, chloride concentration has the greatest impact on the corrosion rate of metal materials. However, the chloride concentration changes due to the ocean’s different regions and the water film’s evaporation. Li et al. [42] investigated the corrosion behavior of Cu–4Ti alloys in simulated contaminated seawater (3.5 wt% NaCl solution containing S2−. The S2− and Cl− have competing adsorption effects on the corrosion of Cu–Ti alloy, and the strong adsorption of S2− causes severe corrosion of Cu–Ti alloy.

2.1.4 Complex factor induced MMCs corrosion analysis

Actual seawater corrosion is often multi-factor coupled, which has a certain difference compared to the existing corrosion behavior of materials under single-factor conditions and the corrosion mechanism.

2.1.4.1 Dry and wet alternation

Few researchers studied the corrosion behavior and mechanism of MMCs under alternating wetting and drying. Still, it is an unavoidable problem to explore the corrosion mechanism of MMCs in the alternating wetting and drying environment. This study summarizes metal materials’ related mechanisms and research progress in wet and dry alternations. The surface of metal materials is often in a state of alternating wetting and drying under the oceanic atmosphere, which will lead to a high concentration of salt on MMCs and thus affect the corrosion rate of metal materials [43]. The air’s RH affects the wetting and drying frequency by affecting the water film’s thickness. If the sunshine time is too long, the water film will disappear, reducing the wetting time of the surface and the total amount of corrosion. In addition, rain and wind speeds also affect the alternating frequency of wet and dry film on metal surfaces. Some scholars measured the instantaneous corrosion rate of nickel-containing steel by continuous measurement of polarization resistance and found that the wet period of the metal surface was determined by high-frequency impedance. The oceanic and atmospheric environment contains a large amount of Cl−, and the changes after the second stage of atmospheric corrosion are influenced by Cl−, forming aqueous hydrous hydroxide [44].

Various forms of corrosion failure of MMCs occur in marine environments. Liang et al. [45] investigated the corrosion behavior of 6060 aluminum alloys in the ocean tidal, splash, and immersion zones, respectively. The results show that the most intense and dense pitting corrosion occurred in the submerged area. The corrosion forms include shallow pit and deep pit, intergranular corrosion (IGC), and crystal corrosion. This is the result of accumulated corrosion products under local hypoxia conditions. However, corrosion in the tidal and splash zones was less severe. Bailey and Li [46] simulated the wetting process of splashing and the subsequent drying process of exposure to weather. In the study of the dry–wet cycle, it was found that samples under the dry–wet cycle had significant pitting erosion compared with samples under continuous immersion.

2.1.4.2 Light conditions

Light condition is an essential factor affecting marine atmospheric corrosion of materials. Light can promote the photosensitive corrosion reaction of iron metal surfaces and the biological activity of fungi, which provides a greater possibility for moisture and dust to be stored and corroded on metal surfaces [47]. Lin and Frankel’s study [48] proved that ultraviolet light can accelerate the corrosion of copper. The effect of light is manifested in two aspects: first, corrosion products formed on the surface, such as Cu2O, CuO, ZnO, FeO, FeOOH, and Fe2O3, mostly have the properties of semiconductors. Under light radiation, a photovoltaic effect will be generated, and electrons and holes will be formed, changing the charge distribution state. To accelerate or inhibit the corrosion process [49]. Electrons are excited from the valence band (VB) into the conduction band (CB), leaving holes when illuminated by external light of the appropriate wavelength. Photogenerated electrons can reduce, and photogenerated holes can oxidize. The photogenerated electrons can participate in the chemical reaction and affect the corrosion process. Second, light can affect the cathodic and anodic process of corrosion reaction by affecting the thickness of electrolytic thin liquid film on metal surfaces [50]. Song and Chen [51] reported that UV illumination significantly increased the rate of NaCl-induced atmospheric corrosion of zinc.

The positive photovoltage after exposure to corroded zinc was observed under illumination, indicating that the influence of ultraviolet irradiation on the atmospheric corrosion of zinc is mainly through the photovoltaic effect of corrosion products with semiconductor properties. Chen et al. [52] found that ultraviolet irradiation decomposed molecular oxygen into atomic oxygen. Atomic oxygen can participate in the oxidation of silver. Li and Li [53] studied the photoelectric chemical anticorrosion effect of the corrosion product layer of electro-galvanized steel in simulated seawater and concluded that the oxide and corrosion product layer could not only withstand the erosion of harsh environment but also provide additional photocathodic protection for electro-galvanized steel under simulated sunlight. The steel corrosion product layer’s corrosion protection effect under light conditions is 30% better than that under dark conditions. Photoelectrons generated by the ZnO layer can transfer to the substrate to provide cathodic protection for electro-galvanized steel under sunlight. UV illumination affects the formation, morphology, and properties of corrosion products. In Song et al.’s study [54], the electrical conductivity of corrosion products of weathering steel under UV light was much higher than that after exposure to the dark. The increase in electrical conductivity will enhance the carrier strength of the corrosion product layer, increasing chemical reactivity. The formation of Fe3O4 and reduction of γ-FeOOH were promoted by UV irradiation. The corrosion product layer formed under ultraviolet irradiation has photoelectric rectification characteristics similar to N-type semiconductors. Reduction of γ-FeOOH occurs mainly in ultraviolet light, where the photovoltaic effect excites electrons in the VB into the CB, thus leaving holes in VB. Γ-FeOOH quickly captures photogenerated electrons. γ-FeOOH is present in the corrosion product layer and can be used as an effective oxidant in the subsequent reduction reaction.

2.1.4.3 Marine microorganisms

The corrosion of materials by marine organisms has two sides. The effect of slowing down the corrosion of materials can be effectively prevented by the diffusion of dissolved oxygen to the material surface if the attached marine organisms are continuous and tightly packed. Conversely, for SS and other easily passivated metals, the corrosion will be aggravated if the attached marine organisms are intermittent or uneven, resulting in local anoxia forming oxygen concentration differences and local corrosion of the occluded cell type. Various types of carbon steel and SS widely used on the hull of ships are subject to corrosion by several types of microorganisms to varying degrees and failure [55,56]. Xu et al. [57] investigated the influence of marine aerobic biofilm on the corrosion of 316L SS in aeration and deaeration seawater. The aerobic biofilm inhibited the corrosion of 316L SS during the test period. A comparison of the results under aeration and deaeration conditions indicated that the aerobic biofilm inhibited the corrosion of 316L SS requiring live cells, and the polarization curves indicated that the biofilm mainly inhibited the anodic effect. The current–potential curves under deoxygenation conditions showed an electron transfer process between the microorganism and the electrode, as shown in Figure 4.

![Figure 4

(a) Polarization plots of 316L SS after 6 days of immersion in natural and sterile seawater and (b) current–potential curves of 316L SS after 6 days of immersion in sterile and naturally deoxygenated seawater [56].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_004.jpg)

(a) Polarization plots of 316L SS after 6 days of immersion in natural and sterile seawater and (b) current–potential curves of 316L SS after 6 days of immersion in sterile and naturally deoxygenated seawater [56].

2.2 MMCs corrosion mechanisms in the marine environment

After long-term research, the corrosion process of MMCs is complex, but in essence, they go through two completely different processes: pure chemical and electrochemical. No matter how the corrosion reaction process is, electron transfer will occur when corrosion occurs, and the electron transfer will inevitably lead to the fracture of old bonds and the generation of new bonds. The corrosion of MMCs in the marine environment is mainly electrochemical corrosion. Under the influence of many factors in the marine environment, a protective layer composed of oxides and hydroxides is formed on the surface of the MMCs in the initial stage. In a high salt and humidity marine environment, the electrolyte is formed on the surface owing to water adsorption and precipitation of corrosive gases and solid salt particles. For MMCs, the pores and other defects on the surface will form a water film due to the capillary effect. Schindelholz et al.’s [30] research shows that water first adsorbs on metal surface defects to form electrolytic cells. In different MMCs, pitting always occurs at the surface defects. Due to the addition of reinforcement in MMCs, there will be defects at the reinforcement/metal interface. When the electrolyte is formed at the defect of the interface, galvanic corrosion will be formed because of the potential difference between the reinforcement and the metal matrix. The potential of the reinforcement may be higher or lower than that of the matrix, or it may change in corrosion. When the corrosion potential of reinforcement is higher than that of the matrix, the reinforcement will act as an anode and cause the dissolution of the metal.

The thickness of the water film on the metal surface will also increase in a higher RH environment. The corrosion rate increases sharply because of the increase in the conductivity of the electrolyte, then decreases slightly because of a decrease in the rate of oxygen diffusion to the metal surface. For MMCs with different substrates, the properties of the oxide film are also different. The introduction of reinforcement will inevitably affect the corrosion performance of composites while improving their mechanical properties and other properties. The corrosion resistance of MMCs depends on their corrosion potential and the properties of the oxide film. The corrosion behavior of Al composites and Mg matrix composites showed that Gr would reduce the corrosion resistance of the matrix. Rashad et al. [58] investigated the corrosion mechanisms of Mg/GNP composites in NaCl solution. An oxide film is formed after a reaction with an aqueous solution, and the film is composed of Mg, MgO, and Mg(OH)2. The corrosion first occurs in the matrix near the GNPs region, forming local pits and deepening with time. The fracture attack caused by the dislocation density at the composite interface leads to a higher corrosion rate than that of the non-reinforced alloy. The pits are formed by anodic reactions that produce Mg2+ that diffuse outward from the surface. Chloride ions migrate inward the pit to maintain electrical neutrality. With the progress of corrosion, the pit became larger and broader, which destroyed part of the protective film on the Mg matrix.

The locations near Gr that do not have GNP regions are also prone to pitting because of the interface’s discontinuity of the protective oxidation-hydroxide layer. For Fe matrix composites, it is found that hydrogen is concentrated in the iron grain boundary, which makes Fe–Fe bonds parallel to the grain interface stronger than those perpendicular to the grain interface, so it is easy to produce intergranular fracture [59,60]. Hydrogen will change the state of α-Fe atoms, resulting in severe anisotropy of the strength of different cleavage planes in the crystal and significantly reduce the number of lattice electrons in the crystal, which may make α-Fe easy to fracture. The presence of Cr will accelerate the development of corrosion products to the thermodynamic steady state, namely, the transformation process of Fe x H y O z → γ-FeOOH → α-FeOOH → α-Fe2O3. In Fe/(TiB2-CNT) composite coating, Liu et al. [61] confirmed that the presence of Cr could make the α-FeOOH rust layer have cation selectivity, that is, preventing Cl− and SO4 2− from penetrating the matrix surface, thus making the rust layer have a protective effect [62]. Chromium improves the solid solution’s stainless iron base electrode potential and the absorption of electronic iron passivation to impel the contradiction movement of SS internal development to improve corrosion resistance. Therefore, with the increase in chromium content, the corrosion rate of steel decreases continuously. When the chromium mass fraction exceeds 12%, the steel is difficult to corrode and rust. Molybdenum promotes the passivation of Fe-Cr SS and enhances its corrosion resistance, especially the local corrosion resistance in chloride solution [63,64]. The interface between the reinforcements and Fe matrix will become the main starting point of pitting corrosion, and the galvanic corrosion also accelerates the corrosion of the composite because of the potential difference.

2.2.1 Pitting mechanisms

Pitting corrosion is the main corrosion form of MMCs. Passivation film forms on the MMCs surface in a neutral aqueous solution without corrosive ions. However, the pitting of MMCs is enhanced when exposed to corrosive anions such as Cl− in high temperatures. Pitting corrosion occurs when isolated sites of MMCs suffer from rapid attack due to the local breakdown of protective passivity. At the same time, most of the adjacent surfaces remain virtually unaffected, as shown in Table 1.

Different types of realistic morphologies of pitting corrosion

| Type of pitting | Morphologies of pitting |

|---|---|

| Narrow, deep |

|

| Shallow, wide |

|

| Subsurface |

|

| Undercutting |

|

| Vertical grain attack |

|

| Horizontal grain attack |

|

| Elliptical |

|

Sea water will priority adsorb at defects in MMCs. Aggressive anion could passivate the membrane on the surface to be delivered to the interface, where the formation of an electrolytic cell to start the role of the specific mechanism (through) [41], or adsorbed on the surface oxide, reinforced metal cations from oxide to transfer of the electrolyte. The film-breaking mechanism requires that the fracture be carried out within the membrane to allow the anion to directly enter the unprotected metal surface [65]. Once the pit begins to grow, the cathode reactants in the pit, for example, O2, are depleted, which transfers most of the cathodic reactions to the exposed surface outside the pit, while the anodic reactions take place inside the pit. The anodic reaction products, metal cations, are enriched in the pit, and Cl− migrates to the pit to remain electrically neutral. The growth of the pit was facilitated by the hydrolysis of metal cations and the lower pH inside the pit than outside the pit. Ao et al. [66] studied the corrosion mechanisms of 6061Al/(TiC–Al2O3) composites. They found that the introduction of TiC–Al2O3 of fine grain size, and the number of intermetallic compounds AlSiFe and AlMgSiCu increased at the grain boundary. Galvanic corrosion can be formed due to the potential difference between reinforcement, intermetallic compounds, and aluminum matrix. Al2O3 does not participate in galvanic corrosion due to its insulation. The surface energy of the low exponential Miller plane shows that Cl− is readily adsorbed on the AlSiFe phase, which increases the concentration of Cl− and leads to the breakdown of the AlSiFe phase indicating the passivation film. Therefore, pitting occurs preferentially in AlSiFe.

In Ao et al.’s study [66], the electrical conductivity and insulation of the reinforcements are important influencing factors. Simultaneously, the intermetallic compounds produced by the reaction between the matrix and reinforcement will also affect the corrosion performance. The coupling between the metal matrix and reinforcement or the second phase causes the pitting of MMCs. Boag et al. [67] reported that the stable pit of AA2024-T3 aluminum alloy is usually located at intermetallic particles (IMPs). The formation of a stable pit in the alloy requires three steps: (1) Coupling: Al2CuMg (S phase) and Al matrix are coupled with Al–Cu–Fe–Mn IMPs. The Al–Cu–Fe–Mn IMPs act as the cathode to support the anodic dissolution of the Al matrix and S phase; (2) Pitting: Pitting occurs around imp, increasing the susceptibility to local corrosion. (3) Dealloying: after the S-phase is unalloyed owing to corrosion, it becomes a cathode, and Cu is re-deposited on the nearby Al–Cu–Fe–Mn IMPs, which improves its cathodic activity. Pitting occurs preferentially in these grains due to the high electrochemical activity of the T1 phase. Since the T1 phase tends to precipitate on the {111} plane, these sites are more susceptible to corrosion [68]. Pitting corrosion in aluminum alloys correlates with the second phase’s quantity and distribution [69].

Pardo et al. [70] found two corrosion mechanisms in the research of the effect of SiC content and Al matrix composition of reinforcement on the corrosion behavior of the composites. At the beginning of corrosion, chloride ions lead to nucleation and growth of pits. Nucleation pits start at the SiCp/matrix and intermetallic/matrix interfaces. Dissolution is rapid in the pit, whereas aerobic reduction occurs on the adjacent surface. High concentrations of H+ and Al3+ are produced in the pit due to cationic hydrolysis (Al3+ + 3H2O → Al(OH)3 + 3H+). At the later stage of corrosion, there is a significant hydration-induced growth of the Al2O3·3H2O porous layer, which reduces the corrosion rate. Longer immersion time or alternating cycles of low and high humidity are conducive to cracking the protective layer of corrosion products, thus promoting the penetration of oxygen, chlorine, and water. This facilitates the formation of an Al2O3·3H2O layer grown inside the material, resulting in a corrosion loss of Al because of the dissolution of metal and SiC/matrix interface pitting. The Cu–Al galvanic couple accelerated the degradation process. The intermetallic compound Al–Cu has a strong cathodic effect on the metal matrix and, as the cathodic site, promotes the dissolution of Al2O3 and enhances the pitting corrosion. The existence of SiCp and Cu–Al galvanic couple is beneficial to the nucleation and growth of the corrosion layer.

Hu et al. [71] studied the corrosion mechanisms of Zr–Cu–Ni–Al metallic glass (MG) composite coatings and found that MG has high chemical activity, which makes the surface oxidize rapidly, leading to the increase in i corr. The porosity can improve the self-corrosion current density in the coatings. In the polarization process [72], the metal elements are oxidized to Al2O3, NiO, ZrO2, and Cu2O. It is well known that Al2O3, NiO, and ZrO2 are dense and usually exhibit stable chemical activity, while Cu2O is loose because of volume expansion in oxidation [73,74]. In the process of polarization, aggressive chloride ions preferentially adsorb on the interface and porous structure [75]. Therefore, porous Cu2O will become the preferred adsorption site for Cl−, and part of Cu2O will be converted to CuCl. Owing to the thin passivation layer, local adsorption of Cl− will promote the dissolution of Cu2O, leading to the pitting and thinning of the oxide film [76]. Cl− can migrate through the surface film when pitting occurs and react with the metal, forming metal chloride on the metal/film surface [77]. The solubility of CuCl is low, but the formed CuCl will precipitate on the corroded surface, resulting in copper enrichment at the pitting site. Kinetically, CuCl is converted into Cu2O. The dissolution and chlorination of porous Cu2O may mainly cause the passivation damage of the Zr–Cu–Ni–Al coating. MG promotes the formation of a passivation layer with its high chemical activity and inhibits the formation of pitting by reducing the segregation of Cu. The corrosion performance can be improved by increasing MG content and designing new MG with low Cu content.

2.2.2 IGC mechanism

IGC is a locally selective corrosion occurring along a specific grain boundary displacement related to the chemical and physical states of adjacent grains and the influence of environmental factors at grain boundaries [78]. IGC usually begins with the irregular arrangement of atoms at grain boundaries, which are usually corrosive regions in which atoms are loosely and disorderly arranged. Therefore, it has a large activity at the grain boundary. The influence of electrochemistry on the corrosion behavior of grain boundaries is mainly manifested by alloying elements in grain boundaries. Currently, the accepted mechanisms of IGC of SS are mainly divided into grain boundary dilution theory, intergranular σ phase precipitation theory, and grain boundary adsorption theory [79]. IGC and pitting are the main causes of failure of MMCs in Marine environment corrosion. IGC usually occurs because of the inhomogeneity of matrix and grain boundaries. There are alloying elements precipitation regions in grain boundaries of MMCs with alloy matrix. Owing to the potential difference between the precipitated area and the matrix, corrosion will occur at the grain boundary and form the IGC pathway. The precipitation of the second phase at the grain boundary is the main factor of IGC. The heating aging treatment of aluminum alloy can change the precipitate at grain boundaries from continuous to discontinuous, thus improving the corrosion performance [80]. These precipitates include grain boundary precipitates (GBPs), matrix precipitates, and precipitate free zone adjacent to GBPs.

It has been reported that grain size (i.e., grain boundary density) is an essential factor affecting the corrosion behavior of MMCs [81,82]. The addition of reinforcement can effectively refine the grain and has a positive effect on the corrosion performance. Ralston et al. [83] determined a similar Hal–Petch relationship between grain size (d) and corrosion rate (i corr) under different corrosion environments.

where a is the material constant and b is the environment-related constant. In a passive environment (b is negative), the corrosion rate of the aluminum alloy decreases with grain refinement, and a dense protective oxide film is formed on the surface. Therefore, the composites have stronger corrosion resistance. Smaller intermetallic compounds help to improve pitting resistance by reducing microcurrents and forming a continuous passive film. Ralston et al. [84] speculated that the matrix oxide might bridge the small precipitated phase, while the large precipitated phase could not be bridged, which would destroy the stability of the passivation film. Compared with 7050 alloys, TiC addition can refine the grain of aluminum alloy and the aging precipitates in the composite. The decrease in nucleation and growth driving forces caused by the large consumption of interface holes and solute atoms should cause precipitate refinement. However, adding TiC particles can induce IGC and thus reduce the corrosion performance of the composites. The effect of TiC particles on the initiation and propagation of IGC in composites is mainly realized through the influence of the precipitate phase. TiC particles are mainly distributed along GBs. Preferential dissolution of interfacial sediments provides a continuous IGC channel and accelerates the IGC rate of GBPs. The corrosion propagation path is interrupted due to TiC particles in the composite, although the interfacial sediment is also dissolved in the corrosive environment. Therefore, these TiC particles have localized corrosion pits around them and do not affect IGC. The continuous distribution of TiC particles determines the initiation and propagation path of corrosion cracks. The relatively dispersed TiC particles (perpendicular to the ED) had the best corrosion resistance due to the corrosion channel disruption, whereas the particle chains parallel to the ED and with the best continuity were shown to have the most severe IGC.

2.2.3 Stress corrosion mechanism

Stress corrosion cracking (SCC) is the degradation of the mechanical performance of materials because of physical stress and corrosive environments. SCC is a degradation or cracking process in corrosion-prone alloys (such as aluminum and steel). It occurs when three conditions exist simultaneously. Namely, the elements of the material alloy must be corrosion-prone, the tensile stress should be above a certain threshold, and a specific environment promotes cracking. Such failures occur with potentially susceptible metals and under conditions of use and often fail without any warning and lead to catastrophic failure. There are three mechanisms of SCC in Al alloy: 1) Anodic dissolution, preferential corrosion along grain boundaries, resulting in cracking. 2) Hydrogen-induced cracking – corrosion cracks are caused by local corrosion or concentrated stress; atomic hydrogen adsorbed on crack tip weakens grain boundary and leads to crack formation and propagation. 3) Rupture and cracking of passive film along grain boundaries [85]. Winkler and Flower [7] found in the study of 7XXX aluminum matrix composite SCC that the composite has a longer life under the same SCC condition. Compared with the metal matrix, the Ti-rich and Fe-rich phases have more negative polarity, which can generate local galvanic cells between the bulk aluminum and the fiber/matrix interface, leading to pitting corrosion. In addition, it is observed that cracks in the non-corrosive products along the GBs of the metal matrix originate from the bottom of the resulting pits. SCC of MMCs is initiated by pitting or dissolution mechanisms, followed by hydrogen embrittlement crack propagation resulting from hydrolysis and acidification of the solution in the pit. Holroyd et al. [86] suggested that Mg can promote hydrogen embittering in aluminum by promoting hydrogen entry and formation of magnesium hydride at GBs, where SCC cracks could be nucleated. This theory also applies to the boundary between the reinforcement material and the metal matrix in aluminum composites. GBPs mainly control SCC sensitivity because the potential difference between GBPs and surrounding areas is greatest [87]. Coarsened GBPs have two advantages for SCC: 1) Reduce the preferential corrosion interface between GBPs and their adjacent areas. 2) Reduce the potential difference between GBPs and their adjacent periphery.

3 Analysis of anti-corrosion properties of Gr–metal composites

Gr has high thermal and chemical stability and excellent resistance to permeation and can effectively block the passage of gaseous atoms such as oxygen and water. Thus, it has excellent potential for application as a metal protective material [88,89]. Gr has made remarkable research progress in the field of metal corrosion protection as scientists have successfully achieved the preparation of large-area Gr.

3.1 Preparation mechanism of Gr–metal corrosion resistant composites

Pure graphene coatings, namely surface Gr systems, are deeply dependent on the interfacial structure to exploit the corrosion resistance of Gr [90] fully. Pure Gr coatings are typically made by assembling molecular building blocks into single/multi-layer Gr using “bottom-up” methods such as organic synthesis, thermal deposition, or chemical vapor deposition (CVD) [91,92]. The corrosion performance of copper in chlorine-containing environments can be significantly improved by only one or two layers of Gr [93]. Pingale [94] prepared Cu–Ni/Gr composite coatings by embedding graphene nanosheets (GNS) into a Cu–Ni matrix by electric co-deposition, as shown in Figure 5(a). Copper and nickel ions are adsorbed on the GNS surface, and GNS surrounded by Cu and Ni ions diffuse toward the cathode through the diffusion layer. Weak adsorption of GNS occurs on the cathode surface, and Cu and Ni ions are encapsulated and integrated into the Cu–Ni matrix at the cathode and GNS. Figure 5(b) shows a schematic of the CVD apparatus used for Gr growth. The system consists of a quartz tube furnace connected to a mechanical pump and a gas manifold. Gr is grown mainly by introducing a mixed gas stream containing H2 and CH4. Gr was exfoliated from graphite rods, and then Gr-reinforced Cu matrix composites were prepared by electrodeposition, as shown in Figure 5(c).

![Figure 5

(a) Preparation of Gr–metal composites by CVD; (b) Schematic illustration of the home-built CVD equipment for graphene growth; (c) Schematic representation of electrochemical exfoliation of graphene, copper-graphene composite synthesis and flowchart of characterization techniques involved [77,78,85].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_005.jpg)

(a) Preparation of Gr–metal composites by CVD; (b) Schematic illustration of the home-built CVD equipment for graphene growth; (c) Schematic representation of electrochemical exfoliation of graphene, copper-graphene composite synthesis and flowchart of characterization techniques involved [77,78,85].

Behera et al. [95] used mode atomic force microscopy (AFM) and observed the morphology of Cu and Cu–Gr composite films prepared on Ti substrates by electrodeposition. The three-dimensional AFM images of the synthesized coatings over the scanned region are shown in Figure 6(a–d). The figure shows continuous films, but the films are aggregated in a localized manner. The degree of agglomeration may affect the roughness of the film. The pure copper coating surface is less rough than other coatings. However, the agglomerate size is smaller with the addition of more Gr particles. This result may be because the addition of Gr inhibits the grain growth during the deposition process.

![Figure 6

AFM surface topography of copper film and Cu–Gr composite films: (a) 0Gr; (b) 0.1Gr; (c) 0.3Gr; (d) 0.5Gr [95].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_006.jpg)

AFM surface topography of copper film and Cu–Gr composite films: (a) 0Gr; (b) 0.1Gr; (c) 0.3Gr; (d) 0.5Gr [95].

However, the application of CVD is limited by the high cost of precursor gases, sophisticated equipment, the high processing temperatures required, and the wear resistance of ultrathin films [96,97]. Therefore, the preparation of Gr/polymer nanocomposite coatings has been proposed. For example, Gr/resin polymer composites were prepared directly by in situ polymerization by mixing Gr with resin monomers [98]. Gr is more flexible in composite coatings, and the content is usually in the range of 0.05–1.0%, which can significantly reduce the total cost of enhanced organic coatings [99]. Huh et al. [100] synthesized Gr/Cu composites were easily synthesized by growing monolayer graphene uniformly on the Cu surface by dropping acetone through the RTA method. Not only the corrosion properties of Cu will be significantly enhanced, but also the corrosion resistance of various metals and alloys will have potential offshore applications.

3.2 Optimization of anti-corrosion properties of Gr–metal composites

Incorporation of GNS into a metal matrix can improve strength, corrosion resistance, and hardness because of the structure and properties of Gr. The application of Gr coatings as a long-term corrosion protection technology on metal surfaces (mainly Cu, Ni, or Fe) is very promising in the near future [101]. Figure 7(a) shows the polarization curves of Cu–Ni/Gr composite plating fabricated by GNS with different concentrations in the plating solution [77]. As the concentration of GNS in the plating solution increased, E corr of the coatings increased from −0.382 to −0.224 V. The i corr was significantly lower than the pure Cu–Ni coatings, indicating a better corrosion resistance of the composites. Zhu et al. [102] grew different thicknesses of Gr layers on the Cu substrate surface. Figure 7(b) shows that the i corr of the Gr-coated Cu samples were all reduced than those of the bare Cu substrate. The corrosion potentials (E corr) are shifted towards positive potentials of 15, 20, 50, and 70 mV, implying that the Gr layer protects the underlying metal substrate.

![Figure 7

Electrochemical experimental results. (a) Polarization curves of Cu–Ni/Gr nanocomposite plating prepared with different concentrations of GNS in the plating solution. (b) Tafel plots of copper substrates coated and uncoated with different masses of Gr layers [102].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_007.jpg)

Electrochemical experimental results. (a) Polarization curves of Cu–Ni/Gr nanocomposite plating prepared with different concentrations of GNS in the plating solution. (b) Tafel plots of copper substrates coated and uncoated with different masses of Gr layers [102].

Apart from electrochemical experiments, salt spray tests are also important methods to evaluate the corrosion performance of materials. The corrosion resistance of Gr–metal composites is related to factors such as the thickness and defects of the Gr layer. Wu et al. [103] put Cu and Gr-coated Cu in a 48 h salt spray and tested the corrosion morphology. The results showed that the corrosion of the Gr-coated Cu substrate was lower than that of the treated Cu substrate. In addition, Zhu [102] concluded that the corrosion rate decreases with the thickening of Gr layers through a 12 h salt spray test, which confirms the superior corrosion resistance of multilayer Gr. A Cu substrate covered by a single layer of Gr with corrosion spreading throughout the substrate and surrounding intact Gr islands, indicating that the corrosion started at the grain boundaries of the in situ grown Gr. With the stacking of the grown Gr layers, the corrosion of the wrapped copper is retarded. This is because the grain boundaries of different Gr layers are located differently. The upper Gr layer may cover the grain boundaries of the lower Gr layer and the diffusion of the corrosion product Gr grain boundaries is significantly inhibited.

3.3 Optimization of anti-corrosion properties of Gr-derived metal composites

In addition to Gr, polycrystalline graphene, graphene oxide (GO), reduced GO (rGO), and graphene quantum dots (GQDs) have become common Gr-based materials [104,105]. GO, with a relatively low cost, is considered promising for corrosion protection [105]. The oxygen-containing functional groups are highly processable and thus can be used as active sites for further modification or functionalization [106]. In addition to their intrinsic properties, these modifications can lead to versatility in surface chemistry and significantly alter and improve the properties of Gr.

He et al. [107] prepared silver-modified rGO reinforced Cu-based composites via hot-press sintering and tested the polarization curves, as shown in Figure 8. The polarization curves of the composites show a significant positive shift in corrosion potential compared to pure copper, indicating that the corrosion performance of the composites is much better than pure copper. The samples with silver-modified rGO content of 1.6 vol% had the highest corrosion potential, passivation interval, and best corrosion performance. Moreover, the i corr of the composite is much smaller, indicating that the coating forms a very strong protection. This improves the corrosion properties of copper even under very harsh conditions. From the overall results of the Tafel diagram, the rGO uniformly distributed in the Cu matrix acts as a strong passivation layer for ion diffusion and corrosion.

![Figure 8

(a) Tafel polarization curves of pure Cu and composites. (b) Electrochemical corrosion parameters of pure Cu and composites [107].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_008.jpg)

(a) Tafel polarization curves of pure Cu and composites. (b) Electrochemical corrosion parameters of pure Cu and composites [107].

Many Gr films, Gr, and its functionalized composite coatings, and other Gr-like substances, such as GQDs and two-dimensional nanomaterials of GO, have been utilized as building blocks for corrosion protection, as shown in Table 2. This research on Gr-modified organic anticorrosive coatings can be divided into four aspects. First, the ultrathin 2D structure of Gr forms a shielding and barrier effect against corrosive media, retarding the penetration and diffusion of the coating [108]. The effect of shielding against corrosive solution requires a uniform dispersion of Gr and an orientation of Gr parallel to the metal surface. Furthermore, the anticorrosive properties of the coating are related to the shielding properties and depend on the bonding strength [109]. Therefore, enhancing the adhesion of coatings by bonding Gr-modified groups to metal surfaces is also the focus of research. Third, functional groups were modified on the active sites of GO to promote the formation of protective films, thus achieving self-healing defects and damages [110]. Eventually, the superior electrical conductivity of Gr was utilized to improve the cathodic protection effect of zinc-rich coatings on metals. Common MMC coatings and MMC properties are shown in Tables 3 and 4.

Common coating material properties

| Materials | Coating structure | Substrates | Characterization | Coating properties | Ref. |

|---|---|---|---|---|---|

| Gr films | CVD growth of Gr films | Cu | Electrochemical test in NaCl solution | The impedance of the Cu substrate was significantly increased, and the corrosion currents of both anode and cathode were reduced by 1–2 orders of magnitude, demonstrating the superb corrosion resistance of Gr films | [93] |

| Gr | Gr/epoxy nanocomposite coating | — | Local electrochemistry and scanning vibrating electrode technology | Compared to pure epoxy coatings, coatings with Gr content of 0.1% (volume fraction) showed better corrosion resistance | [111] |

| Epoxy primer and polyurethane topcoat, curing agent and thinner are mixed with different proportions of Gr after the coating is finished | 7075-T6 aluminum alloy sheet | Polarization curve and AC impedance of coatings | When the Gr addition is 0.2%, its self-corrosion current density is the smallest. Its impedance modulus and capacitive arc radius are the largest, and the corrosion resistance is the best | [112] | |

| Hexagonal boron nitride (h-BN) | h-BN reinforced polyimide (PI) coating | SS | Water vapor impermeability test | The water vapor transport rate of PI/5 wt% h-BN composite coating was reduced by 84% compared to that of pure PI | [113] |

| CVD growth of monolayer h-BN films | Cu | Density functional theory (DFT) calculation and experimental tools | The impermeability of h-BN to O2 is comparable to that of graphene, and tests conducted after 160 days of aging in ambient environments confirm the long-term corrosion resistance of h-BN | [114] | |

| Monolayer CVD-grown h-BN films | Cu | Electrochemical test in sodium hydroxide solution | CVD-grown h-BN films reduce the corrosion rate by an order of magnitude compared to pure copper | [115] | |

| Boron nitride quantum dot modified h-BN reinforced waterborne epoxy resin (WEP) coating | Carbon steel | Electrochemical tests in 3.5 wt% NaCl solution | WEP/0.5 wt% BNQDs h-BN composite coating reduces corrosion rate by an order of magnitude compared to pure WEP | [116] | |

| GO | Alternate coating of GO/epoxy self-assembled coatings prepared by spin coating method | — | Kinetic potential polarization test in 3.5% NaCl solution | Steel specimens protected by 5 layers of GO-6 epoxy coatings with 17 µm thickness corrode 20 times slower than pure epoxy coated specimens | [117] |

| Resorbed GO | Uniform crack-free rGO-PVPBM composite coating obtained by CVD deposition on copper foil | Cu | Corrosion resistance test in 3.5% mass fraction NaCl solution | Compared to PVPBM coating, rGO-PVPBM composite coating has 3.7 times higher crack expansion resistance and 2 times higher bond strength | [118] |

| GQDs | Silane-functionalized GQDs (f-GQDs) reinforced epoxy composite coatings | Low carbon steel | Electrochemical tests in 3.5 wt% NaCl solution | Epoxy resin/0.5 wt% f-GQDs composite coating reduces corrosion rate by an order of magnitude compared to pure epoxy resin | [119] |

Common MMCs coating properties

| Materials | Coating structure | Substrates | Characterization | Coating properties | Ref. |

|---|---|---|---|---|---|

| Gr | Gr/Ni composite coating | Mild steel | Electrochemical test in 3.5 wt% NaCl solution | The surface morphology of Gr in Ni coating changes to fine grain coating, the grain size decreases, and the hardness increases. The corrosion resistance of the composite coating is better than that of the pure Ni coating | [120] |

| Gr | Gr/Ni composite coating | Cu | Electrochemical test in 0.5 M NaCl solution | The corrosion rate of the coating is seven times slower than that of the nickel coating without these additives, and the corrosion rate of the coating is 85.84% lower than that of the Ni coating | [121] |

| Gr | Novel functional gradient Gr/Ni composite coating | Mild steel | Electrochemical workstation was used to measure the electrochemical behavior of the coating in CO2 saturated seawater | The Gr content and grain size increase with the gradient of coating thickness. The corrosion current densities of FG Ni-Gr coatings are one and three orders of magnitude smaller than those of uniform Ni–Gr composite coatings and mild steel coatings, respectively | [122] |

| Gr | Sandwich Gr/Ni composite coating | AZ91D magnesium alloy | Electrochemical test in 3.5 wt% NaCl solution | Compared with single Gr/Ni composite coatings, sandwich Gr/Ni composite coatings have better long-term corrosion resistance. It comes from the multi-interface passivation film mechanism brought by the multi-layer design, which greatly delays the time of corrosive media invading the substrate | [123] |

| GO | GO/Al2O3/Al composite coating | AZ91D magnesium alloy | Electrochemical test in 3.5 wt% NaCl solution | The mechanical properties of the composite coatings were significantly improved by the addition of GO (about 600%). Due to its high surface area, GO acts as a bridge between alumina nanoparticles. The corrosion resistance is almost twice that of the matrix alloy. This is attributed to GO’s role in preventing crack formation in the coating microstructure | [124] |

| Gr | Al/(Al2O3-G) composite coating | Cu | The cyclic polarization curve and impedance behavior of the coating were tested in 3.5 wt% NaCl static solution | The cold-sprayed Al/Gr coating has good corrosion resistance and strong repassivation ability, because Gr transforms its longitudinal accelerated pitting corrosion mechanism into tangential surface corrosion | [16] |

| Gr | Gr/NiP | Cu | Electrochemical test in 3.5 wt% NaCl solution | The Cu-Gr-NiP coating showed good resistance to electrochemical degradation. The enhanced corrosion is attributed to the uniform dispersion and grain refinement of Gr | [14] |

| Gr | Cu–Ni/Gr nanocomposite coatings were prepared by electrocodeposition | Carbon steel | Electrochemical tests in 3.5 wt% NaCl solution | The addition of GNS stabilized the corrosion potential and improved the corrosion resistance | [94] |

| GO | Electrodeposition of Zn–GO composite coating | Low carbon steel | Electrochemical tests in 3.5 wt% NaCl solution | The permeability resistance of GO hinders the penetration of electroactive media and reduces the oxidation degree of zinc layer, thus slowing the corrosion rate | [125] |

Common MMC properties

| Materials | Structure | Characterization | Properties | Ref. |

|---|---|---|---|---|

| Gr/graphite | Al/Gr and Al/graphite composites | Electrochemical test in 3% NaCl solution | The corrosion resistance of Al in NaCl solution is 3 (corrosion resistance), and the corrosion resistance of aluminum composites is 4 (fairly corrosion resistance). At the same carbon content, the corrosion rate of Al-graphite composites is about three times that of Al-graphite composites | [126] |

| Gr | Gr/Mg composite | Electrochemical test in different salt electrolytes (NaCl, KCl, and Na2SO4) | Electrochemical tests showed that the corrosion rate decreased sharply in three different aqueous solutions, NaCl, KCl, and Na2SO4 | [127] |

| Gr | Gr (0.1, 0.25, and 0.5 wt%)/Mg composite | Electrochemical test in 3.5% NaCl solution | Due to Gr agglomeration, the corrosion performance of the composites decreases. The microelectric reaction occurs because magnesium behaves as an anode while graphene behaves as a cathode | [128] |

| Functionalized few layered graphene nano-sheets (FLGNs) | FLGNs/Cu composites | Electrochemical test in borate buffer and 3.5 wt% NaCl solution | The corrosion resistance of the composites in borate buffer and NaCl solution was improved | [95] |

| Gr | Gr/Cu | Electrochemical test in 3.5% NaCl solution | The addition of Gr reduces the potential difference between the two poles of the corrosion unit, slows down the corrosion rate, reduces the diffusion rate of copper ions in the oxide film, increases the resistance of the composite material, and improves the corrosion resistance of Gr/Cu composite material | [129] |

| Gr | Dispersed Gr-reinforced Al composites | Electrochemical test in 3.5% NaCl solution. IGC test and first principles calculations | The addition of GNPs as long-term corrosion inhibitors in Al matrix composites can simultaneously enhance the energy barrier of vacancy formation, Cl entry, and charge transfer. | [17] |

| Gr | Gr/Cu laminated composites | Electrochemical test in 3.5% NaCl solution | Gr is arranged in parallel to isolate solutions and ions. The layered structure changes the corrosion path | [154] |

| Gr | Gr/2024Al composite | Electrochemical tests in 3.5 wt% NaCl solution | The corrosion rates of 2024Al and Gr/2024Al composite samples at 560°C and 24 h exposure were 7.51 and 5.34 MPY, respectively | [130] |

4 Analysis of the corrosion protection mechanism of Gr composites in metallic materials

4.1 Small size effect of Gr

The small size of Gr can fill the pores and defects in the coating, which prevents and retards the infiltration of small molecule corrosive media into the metal substrate to a certain extent. It also enhances the physical isolation and the anticorrosive properties of the coating. Wang et al. [16] cold sprayed Al/Gr coatings using Gr-coated Al powder having lower porosity than non-Gr-modified coatings. As the Gr content increases, it affects the formation of metallic bonds between metals in contact with each other. The agglomeration of Gr will also decrease the densities. Therefore, appropriate content and homogeneous dispersion of Gr can give full play to its small size effect. To improve the Gr dispersion, Cui et al. [131] used polydopamine (PDA) to modify Gr and fabricated a PDA-modified Gr/epoxy resin composite coating. The well-dispersed PDA-modified GNS filled the pores of the epoxy resin. It makes the coating denser, inhibits corrosive media penetration, and improves epoxy resin adhesion. Meanwhile, the modification of Gr by PDA makes the Gr less prone to curling, has a more effective aspect ratio, and extends the diffusion path of electrolytes. Um et al. [155] investigated the effect of Gr size on the anticorrosion performance of polyurea (PU) composite-coated Cu substrates using electrochemical techniques. The EIS results indicated that the Gr-incorporated PU composites with Gr sizes less than 2 µm provided better corrosion protection for the Cu substrate. This is because the small-sized GNS could be uniformly dispersed in PU, thus generating an extended diffusion pathway to inhibit the penetration of the corrosive medium.

4.2 Gr flake structure role

Gr is an extremely thin sheet structure that can be layered to form a dense physical barrier in the coating. Small molecules of corrosive media can hardly pass through this dense insulation layer, so the anti-corrosion coating mixed with Gr has a solid physical insulation effect. The premise of the shielding property of Gr/GO materials is that their planes are distributed in a direction parallel to the substrate. This is because the intrusion of corrosive media is spread from the coating surface to the substrate. Only a shielding effect parallel to the direction of the substrate can effectively block the intrusion of corrosive agents. Gr/GO-modified materials with vertical or haphazardly oriented distribution cannot meet the structural denseness of the coating and are contrary to the shielding concept [132]. Figure 9 demonstrates the mechanism of action of the titanate-modified graphene oxide (TGO) electrolyte in PU coating with three-dimensional random distribution and parallel arrangement. It shows a zigzag penetration path when the TGO in the composite coating is randomly distributed in three dimensions. And when the TGO layer is self-aligned parallel to the substrate surface, a layer protection network is formed, which gives full play to the surface barrier effect of the modified GO and blocks the electrolyte from penetrating the coating [133]. It is obvious that the ordered arrangement of GO composites can solve the problem of defects in coatings and improve the corrosion properties of coatings. However, the ordered arrangement of Gr/GO composites in coating applications needs more systematic studies. Moreover, the currently used methods have certain limitations, and achieving the ordered arrangement in practical applications is more difficult.

![Figure 9

Schematic diagram of TGO/PU coating [133].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_009.jpg)

Schematic diagram of TGO/PU coating [133].

To further enhance the shielding property of the coating, the ordered arrangement of Gr can be achieved by improving the dispersion. There are mainly ordered alignment methods such as applied electric field induction, magnetic field induction, and layer-by-layer self-assembly [134]. Magnetic field-induced ordered alignment is mainly solved by preparing magnetic Gr materials or loading magnetic substances (Fe2O3 or Fe3O4) onto the surface of the Gr. However, this method requires the presence of a uniform horizontal magnetic field and is costly to operate. Pang et al. [135] investigated the orientation of GNS in polystyrene coatings under the effect of electric field induction. The results show that under an electric field, the conductive particles can cross the polymer’s hindrance and adjust the curling degree. The distribution tends to be parallel to the direction of the electric field, forming multiple conductive channels. The orientation in the electric field-induced ordered arrangement is mainly due to the dipole moment of water molecules in the first hydrated layer on the Gr surface that appears to respond to the orientation under the electric field, tending to be parallel to the direction of the Gr plane and the electric field. Zhao et al. [136] successfully prepared ultrathin multilayer anticorrosion coatings (PVA/GO) of polyvinyl alcohol (PVA) and GO using exfoliated GO as substrates by a bottom-up layer-layer assembly method. The ordered arrangement of organic and inorganic layers was found to result in significantly improved mechanical properties, which was attributed to the well-layered structure of GO in the polymer matrix, as well as the high degree of planar orientation and nanoscale pore filling.

The Gr layer number also affects the corrosion performance. The corrosion resistance of the composites was found to increase and then decrease with the increase in the number of Gr layers [103]. The metal substrate under the Gr boundary is directly exposed to a severely corrosive environment for monolayer Gr, as shown in Figure 10(a). Corrosive media can easily penetrate the defects of Gr and cause severe corrosion to the metal. The anti-corrosion effect of bilayer Gr is effective, as shown in Figure 10(b). In the overlapping structure of bilayer Gr, it is difficult for chloride ions to reach another defect in the lower Gr layer by lateral diffusion, and the path of chloride ions to get the interface between Gr and metal matrix is prolonged. For multilayer Gr coatings (Figure 10(c)), defects in adjacent Gr layers are joined together, creating a lot of corrosion paths from the top Gr layer to the interface between the Gr and the metal substrate. In addition, Cl− is difficult to transfer between the two Gr layers by lateral diffusion. The high-density defect leads to a shortened corrosion pathway and easier penetration of the corrosive medium into the Gr coating. When Cl− reaches the Gr/metal interface, galvanic coupling corrosion begins, further accelerating the corrosion of the metal substrate.

![Figure 10

Schematic diagram of corrosion protection mechanism of Gr coating with different number of layers: (a) Single layer; (b) Double layers; (c) Multi layers [103].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_010.jpg)

Schematic diagram of corrosion protection mechanism of Gr coating with different number of layers: (a) Single layer; (b) Double layers; (c) Multi layers [103].

4.3 Impermeability of Gr

The high impermeability of Gr can be attributed to two factors: the narrow six-membered ring of carbon in GNPs and the dense delocalized cloud of π-orbitals of Gr that can repel any atom or molecule at room temperature. Sun et al. [156] used graphite or h-BN monocrystals to prepare a novel micrometer-sized well encapsulated by Gr, as shown in Figure 11(a). The result showed that the Gr membrane was impermeable to several gases, including He, N2, O2, Ne, Ar, Kr, and Xe. Jiang et al. [157] investigated the selectivity and permeability of Gr with designed sub-nanometer-sized pores using DFT calculations (Figure 11b). Gr with a hydrogen-passivated pore (2.5 Å × 3.8 Å) exhibited a high barrier for CH4 (1.6 eV), whereas it was easy to permeate H2 (0.22 eV), affording an extremely high selectivity for CH4/H2. As a result, perfect Gr sheets are impermeable to most species, but the defects and openings in Gr provide diffusion channels for these species. It is generally believed that the impermeability of Gr is highly related to its quality, temperature, molecular properties, and other external factors. Theoretical results indicate that the barrier energy decreases exponentially with an increase in the defect size of Gr [158]. The energy barrier of different atoms and molecules is shown in Table 5. Perfect Gr sheets are impermeable to most species, but the defects and openings in Gr provide diffusion channels for these species.

![Figure 11

(a) Schematic of monocrystalline containers sealed with Gr [156]; (b) electron-density isosurface of a hydrogen-passivated pore in Gr [157]; (c and d) schematic of the corrosion mechanism occurring on uncoated Cu (top) and Gr coated Cu (bottom) specimens; (e) potentiodynamic polarization of the Gr coated and uncoated Cu [93].](/document/doi/10.1515/ntrev-2022-0566/asset/graphic/j_ntrev-2022-0566_fig_011.jpg)

(a) Schematic of monocrystalline containers sealed with Gr [156]; (b) electron-density isosurface of a hydrogen-passivated pore in Gr [157]; (c and d) schematic of the corrosion mechanism occurring on uncoated Cu (top) and Gr coated Cu (bottom) specimens; (e) potentiodynamic polarization of the Gr coated and uncoated Cu [93].

Energy barrier of different atoms and molecules

| Atom/molecule | Gr | Energy barrier (eV) | Ref. |

|---|---|---|---|

| CH4 | All-hydrogen passivated porous Gr | 1.6 | [157] |

| H2 | 0.22 | [157] | |

| Oxygen atom | Pristine Gr | 16.34 | [89] |

| O2 | Pristine Gr | 10.12 | [89] |

| Cu | Pristine Gr | 30.62 | [159] |

| Oxygen atom | The center of eight-ring defects | 8.014 | [160] |

| The center of seven-ring defects | 10.36 | [160] | |

| The center of six-ring defects | 21.81 | [160] | |

| The center of five-ring defects | 21.36 | [160] | |

| Li+ | Pristine Gr | 7.92 | [161] |

| Gr with single vacancy | 3.6 | [161] | |

| Gr with double vacancy | 1.31 | [161] | |

| Gr with Stone–Thrower–Wales defects | 2.98 | [161] |