Advancements in aluminum matrix composites reinforced with carbides and graphene: A comprehensive review

-

Mohammad Azad Alam

, Hamdan B. Ya

, Mohammad Azeem

Abstract

Automotive and aircraft industries are advancing swiftly, creating a constant need for innovative and trustworthy materials. Aluminum composites (aluminum matrix composites [AMCs]) exhibit enhanced mechanical and tribological behaviors when contrasted to their conventional equivalents and as a result have superior potential to be widely accepted for automotive and aircraft engineering and other component applications. This study aims to provide a thorough and critical analysis of the most recent research initiatives concerning the processing, characteristics, and applications of AMCs. It covers the recent advancements in the aluminum-based composites reinforced with SiC, TiC, and graphene, fabrication methods, and mechanical properties of AMCs. Graphene nanoplatelets are many times stronger and yet lighter than steel and other metals, and thus a good contender for reinforcing them. However, the homogeneous distribution of graphene into the metal or aluminum is a challenging aspect for material researchers. The fabrication techniques for AMCs for achieving homogeneous distribution of graphene are critically reviewed. The mechanical properties, specifically microhardness, wear behavior, and tensile strength of aluminum-based composites, are reviewed and analyzed. Finally, a way forward for fostering further development in this area has been discussed.

1 Introduction

Competition to boost fuel efficiency and reduce CO2 emissions has intensified in the automotive and aerospace sectors as a result of new fuel economy requirements being adopted by governments throughout the world and increasing consumer demand for more fuel-efficient cars. As an illustration, according to a report from the Environmental Protection Agency (EPA) in April 2020, the transportation industry in the United States (US) generated around 28% of all US GHG emissions in 2018. To increase the fuel efficiency of vehicles (passenger cars and light trucks) and reduce CO2 emissions, CAFE (Corporate Average Fuel Economy) requirements have been devised in the United States. The CAFE criterion for passenger cars has increased from 18 mpg (miles per gallon) in 1978 to 42 mpg currently, and it is expected to increase to 54.5 mpg by 2025. For the model years 2021–2026, the National Highway Traffic Safety Administration and the EPA amended the CAFE criteria and proposed a new value of 43.7 mpg. Every nation has its fuel economy regulations, and many of them are stricter than American regulations. The combined objectives of lowering CO2 emissions and enhancing fuel efficiency, however, are shared by all countries. For most nations and regions, achieving the average fuel efficiency target for passenger vehicles is difficult in terms of CO2 emissions per kilometer of driving (g/km) as depicted in Figure 1(a) [1]. In particular, the United States set the 2025 target for average CO2 emissions to be 89 g/km, down nearly 40% from the 2015 level. Beyond increased fuel efficiency and emission reduction, higher performance and simpler recycling also help to advance the development of lighter, stronger, and more environmentally friendly cars.

![Figure 1

Pushing demand for lighter materials of automotives. (a) Various countries have different fuel economy goals (passenger vehicles). (b) Production of light vehicles in the main market, in million units [1].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_001.jpg)

Pushing demand for lighter materials of automotives. (a) Various countries have different fuel economy goals (passenger vehicles). (b) Production of light vehicles in the main market, in million units [1].

Vehicle weight reduction is one of the many strategies that manufacturers have tried to meet fuel efficiency criteria and satisfy customer demands. Either the vehicle’s size can be reduced, or lightweight materials can be used [2]. The safety and comfort of the passengers may be jeopardized if the size of the vehicle is reduced. As a result, it is common to try to reduce vehicle weight by using lighter materials while maintaining performance. Light vehicle production has increased steadily during the past few years in all the major markets (Figure 1(b)) [1]. According to reports, a 10% weight reduction in a car can increase fuel efficiency by 8–10%, and a 100 kg weight reduction can reduce CO2 emissions by 12.5 g/km [3,4]. Additionally, the lighter vehicle offers better performance without compromising occupant safety.

1.1 Demand for aluminum in engineering sectors

There is an urgent need to produce high-performance, lightweight materials for the following generation of transportation sectors given the increasing demand for CO2 control, fuel economy, and lightweight in other industries (such as maritime transportation). Low-carbon steel and cast iron were the two materials that the automotive industry used the most until the 1970s. A passenger car’s engine block and cylinder head are among its two most important parts. Cast iron has traditionally been used for both parts due to its superior wear resistance, high-temperature strength, and castability. However, because cast iron has a very high specific gravity (7.87 g/cm3), the engine block is the heaviest part of the car, comprising up to 3–4% of its overall weight [4]. The materials landscape for engine blocks is shifting toward adopting alternative, lightweight materials with a focus on lowering vehicle weight and CO2 emissions. Aluminum and its alloys have increasingly risen to the top of the list of lightweight materials used in automobiles in recent years from the perspective of automotive engineering (Figure 2(a)). Additionally, the market is aiming for light vehicle aluminum content to reach 570 net pounds per vehicle by 2030, with cast aluminum alloy potentially making up more than 50% of that total (Figure 2(b)). Mercedes Benz used a sophisticated material composition with a high aluminum content to create the bodyshell architecture of the new AMG SL in order to guarantee low weight while maximizing stiffness (Figure 2(c)).

![Figure 2

(a) Yearly change of aluminum content in the light vehicle from 1975 to 2030 (North American market. (b) Predicted proportion of different types of aluminum alloy in 2030. (c) New Mercedes AMG SL with high aluminum content in the bodyshell architecture to lower weight while achieving maximum rigidity (from Mercedes Benz [1]).](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_002.jpg)

(a) Yearly change of aluminum content in the light vehicle from 1975 to 2030 (North American market. (b) Predicted proportion of different types of aluminum alloy in 2030. (c) New Mercedes AMG SL with high aluminum content in the bodyshell architecture to lower weight while achieving maximum rigidity (from Mercedes Benz [1]).

Due to their lightweight (2.7 g/cm3), which is around 65% lower than that of cast iron, aluminum alloys were thought to be an immediate replacement for cast irons and steels. Engine blocks with Al alloys instead of cast iron had a fair chance of losing up to 45% of their weight. Al alloy engine blocks have been produced since the late 1970s, and over the past 10 years, Al alloy cylinder heads have completely replaced cast iron ones [4]. Figure 3 depicts the trend in the weight percentages of aluminum, steel, and cast iron in light-duty American automobiles. As a result of the enormous demand from the automotive and aerospace industries, market observers anticipate a significant increase in Al production over the next years.

![Figure 3

A trend in the proportion of steel, cast iron, and aluminum in the weight of automobiles [3].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_003.jpg)

A trend in the proportion of steel, cast iron, and aluminum in the weight of automobiles [3].

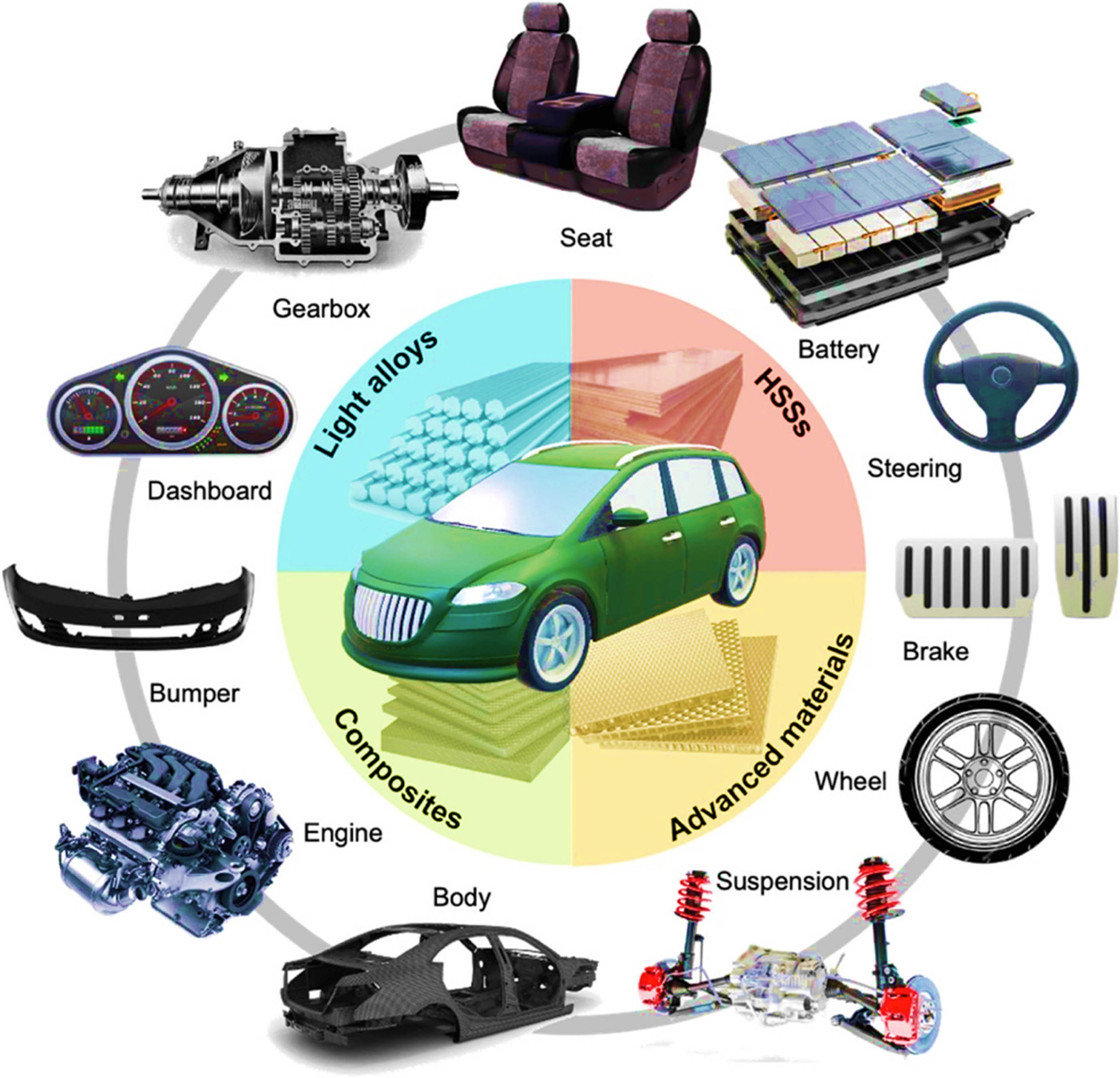

1.2 Need of aluminum alloys and composites

Lightweight materials for automobiles can be broadly categorized into four groups as potential replacements for traditional engineering materials (such as steel and cast iron), including light alloys (such as aluminum, magnesium, and titanium alloys), the high-speed steel (HSS) family (such as conventional HSSs and advanced high-strength steels), composites (such as Al-based composites or carbon-fiber-reinforced plastics), and advanced materials (e.g., mechanical metamaterials). These lightweight materials have been used extensively in the automotive industry since the turn of the century for a variety of parts including the dashboard, bumper, engine, body shell, wheel, suspension system, brake, steering system, battery, seat, and gearbox (Figure 4).

Typical lightweight materials for use in vehicle components include light alloys (such as aluminum, magnesium, and titanium alloys), HSSs, composites, and innovative materials.

1.3 Composites

Composites can save weight by 15–40% depending on the type of reinforcement used, and they also have other desirable qualities for the automotive sector, including high specific strength, strong corrosion resistance, design flexibility, and low thermal conductivity [5]. Hard ceramic materials are utilized as reinforcement particles, while ductile metal alloys are the preferred matrix materials. In metal matrix composites (MMCs), a second phase serves as reinforcement for the metal matrix. Ceramic particles and fibers made of different materials, such as other metals, ceramics, and carbon, are two common types of reinforcing phases. There are various matrix materials available, including copper, magnesium, titanium, and aluminum (Al, Mg) (Cu). Al is the most favored matrix material accessible due to its remarkable qualities, including high strength-to-weight ratio, good corrosion resistance, better toughness, lower melting point, and affordability [6].

Aluminum matrix composites (AMCs) have drawn the attention of numerous researchers for the past 30 years to investigate their physical, tribological, mechanical, thermal, and electrical properties. When utilized in the production of composite materials, aluminum is preferred over other matrices due to its advantageous qualities, which can be adjusted by paying attention to the matrix, reinforcements, and processing techniques [7,8,9,10,11,12,13,14,15,16]. AMCs are a type of lightweight material that are frequently used in the automotive, aerospace, and defense industries [17,18] due to their wide range of characteristics, including low density, high strength, large elastic modulus, and excellent corrosion resistance [19,20]. Today’s applications for aluminum alloys also include novel ones, such as 3D printing, the composite material industry, and aircraft. Because of aluminum’s superior qualities, low cost, high scrap value, and expanding recycling market, the aluminum industries are predicted to expand throughout the twenty-first century, and metal will likely continue to play a key role in our culture and daily lives [21]. To get even more desirable results, researchers need to have a better understanding of the many series of aluminum alloys when creating composite materials. Table 1 provides details about the matrix elements, along with their key characteristics and areas of use.

Frequently utilized Al alloy as a matrix material

| Matrix material | Main alloying element | Characteristics | Applications | Ref. |

|---|---|---|---|---|

| Pure Al | Aluminum 98.8–99.99 wt% | Recyclability, ductility, and workability | Automobiles, aerospace, and structural applications | [22] |

| AA 2024 | Copper | High machinability, surface finish, and fatigue strength | Wheels for cars, sheets for labs, biomedical applications, and aircraft parts | [23] |

| AA 3003 | Manganese | Good machinability, formability, and weldability | Heat exchangers, pressure vessels, and storage tanks | [24] |

| AA 4043 | Silicon | Excellent resistance against corrosion | Filler material | [25] |

| AA 5083 | Magnesium | Excellent corrosion resistance, medium-to-high wear resistance, good weldability | Appropriate for marine applications, hydraulic tubes for aviation, and various sheet metal operations | [26] |

| AA 6061 | Magnesium and silicon (heat-treatable) | Enhanced strength, strong heat-treatment-induced corrosion resistance, excellent machinability, and weldability | Pipelines, storage tanks, truck parts, multipurpose alloy, and railroad cars | [27] |

| AA 7075 | Zinc (heat-treatable) | Good machinability and fatigue strength, medium-to-high corrosion resistance, low toughness, excellent strength for structural applications | Aircraft wings, airframes, gears and shafts for cars, and bicycle components | [28] |

| A356 (cast alloy) | Silicon | Superior machinability, resistance to wear, and exceptional fatigue strength | Pistons, castings for aircraft, and car chassis, pump impeller | [29] |

1.4 Necessity of reinforcements

The mechanical and tribological behavior of AMCs has recently been improved, thanks to the ongoing efforts of material scientists and engineers to develop novel and cutting-edge techniques. The performance of composites as a whole is determined by the reinforcement materials, hence efforts were made to choose the best ones. The most popular technique for enhancing mechanical and tribological behavior involves embedding hard ceramic particles. In a metal matrix, a wide range of ceramic particles are reinforced. However, TiC, SiC, and B4C are the most popular ceramics in usage. The mechanical characteristics of MMCs are noticeably improved by their inclusion. Additionally, their inclusion improves the composites’ wear resistance and frictional coefficient [30,31,32]. The key reinforcement-related variables influencing the tribological performance of AMCs are as follows: volume/weight ratio, reinforcement size, and reinforcement shape, in that order. The right choice of reinforcement and its quantity enhances the physical, thermal, and mechanical properties of AMCs in addition to their tribological features. Since these materials determine the overall performance of the composites, studies were carried out to select the best-suited reinforcement materials. Particulate reinforcements were heavily utilized among the various types since they are readily available and have greater dispersive qualities. Additionally, the distribution of reinforcement is a significant factor when analyzing the mechanical and wear characteristics of aluminum composites [33,34,35,36,37,38,39,40].

If adequate reinforcements are not chosen and combined with aluminum alloy with care, it might be challenging to obtain the necessary qualities of the composite. Therefore, learning about different reinforcements and how they are used is crucial. Table 2 lists the characteristics of various types of reinforcements utilized in the creation of aluminum composites. Many researchers have studied the microstructural characterization of aluminum composites with improvements to their structural characteristics. Table 3 highlights the results of MMCs after taking into account various types and forms of reinforcements.

| Characteristics | SiC | TiC | TiB2 | Al2O3 | GNP |

|---|---|---|---|---|---|

| Density (g/cm3) | 3.16 | 4.93 | 4.52 | 3.99 | 1.8–2.2 |

| Melting point (°C) | 1,955 | 3,067 | 3,225 | 2,043 | 3,600 |

| Thermal conductivity (W/m/K) | 16–120 | 17–32 | 60–120 | 30 | 4,840–5,300 |

| Modulus of elasticity (GPa) | 448 | 400 | 560 | 400 | 1,000 |

| Hardness, Vickers (GPa) | 35–45 | 24–32 | 25–35 | 18–21 | — |

Frequently used reinforcements in AMCs and the study’s findings

| Reinforcement | Relevant properties | Applications | Ref. |

|---|---|---|---|

| TiC | High wear resistance and good strength | Automotive applications, brake disc, rotor, and cutting tools | [44,45,46] |

| SiC | High thermal conductivity, stiffness, hardness, and refractoriness | Rotors, braking discs, shafts, connecting rods, rubber tires, etc. | [47,48] |

| GNP | High strength-to-weight ratio | Tribological applications, nanofluids, memory devices, and energy storage | [49,50,51] |

| CNT | Ductility, corrosion resistance, excellent strength-to-weight ratio, and low density | Cylinder liners, sports utilities, and gears | [52] |

| TiB2 | High strength and resistance to abrasion | Aerospace and automotive structural applications | [53] |

To further improve the microstructure and mechanical properties of AMCs, several reinforcements are being developed [5,6]. When selecting reinforcements, three common issues are encountered: low density, high strength, and strong contact bonding with the matrix [7]. Currently, particle reinforcements (such as SiC, TiC, and GNP) clearly outperform fiber reinforcements in terms of pricing [8,9,10]. Additionally, it has been demonstrated that mixing the particle reinforcements with the matrix is simpler [11]. Ceramics are frequently chosen as the primary raw material for particle reinforcements [12]. Ceramic particles, however, frequently render poor microstructure in AMCs (such as aggregation and voids) [13). Because the thermal expansion coefficients of ceramic particles and the matrix are different, the agglomeration of ceramic particles frequently results in the early failure of AMCs [14]. Researchers have been searching for novel particle reinforcements to help solve this issue. Due to the extensive use of ceramic-reinforced composites with magnesium matrix for orthopedic implants, an emphasis on fabrication techniques, in vitro corrosion, and in vitro biocompatibility have been studied recently by Khorashadizade et al. [54].

1.4.1 Silicon carbide (SiC)-reinforced Al composites

SiC is one of the most often utilized ceramic particles that belong to the carbide nature category. It has exceptional resilience to wear and thermal shock. It behaves mechanically well at high temperatures. Mechanical seals frequently use SiC due to their chemical and wear resistance [55]. SiC is a synthetic (man-made) mineral distinguished by extremely high hardness and resistance to abrasion. Pump seals, valve parts, and wear-intensive applications like rollers and retainers for the paper industry are examples of common applications. Numerous scholars have studied how the homogeneous distribution of SiC microns or nanoparticles in the matrix of aluminum improves the interfacial, physical, and mechanical properties [5,56,57,58,59]. The fabrication process used as well as the quantity, size, and distribution of ceramic inclusions all affect the mechanical properties of Al/SiC composites. Al-based composite materials have a limited range of applications due to rapid strain softening at high temperatures [60].

Due to their unusual combination of low density and high strength, aluminum–SiC (Al–SiC) composites have been regarded as promising materials for lightweight structural applications. Several SiC-reinforced aluminum composites have been reported to improve the mechanical properties of the aluminum matrix by adding SiC [61,62,63,64,65]. SiC is a well-known reinforcing element and a classic essential component in the creation of composite materials based on aluminum [66,67,68,69]. Roy et al. [70] reported that the grain refinement effect greatly lowers the wear rate when SiC and CB are added to AA 7075 alloys. Bathula et al. [71] produced Al 5083/SiC nanocomposite powders via high-energy ball milling and by spark plasma sintering (SPS) at 500°C at a heating rate of 300°C/min and a cycle of 8 min. The mechanical properties were found to substantially increase after sintering employing SPS. By combining AA 6061 powders with varied SiC volume fractions in a WC vial using a planetary mill, Li et al. [72] produced the combinations. Then, using the SPS method, the composites were produced using a compaction pressure of 50 MPa and a heating rate of 50°C/min. The sintering temperature and duration were maintained at 560°C for 3 min. As the proportion of SiC particles increased, the AA 6061-SiC composites became stronger. When the volume percentage of SiC was 20%, the composites’ yield strength, ultimate tensile strength (UTS), and elasticity modulus were 373, 414 MPa, and 95 GPa, respectively. Dislocation, grain boundary, and secondary phase strengthening were all present in the composites. The effect of sintering temperature on the microstructure and selected properties of spark plasma sintered Al–SiC composites were investigated by Leszczyńska-madej et al. [73]. It was established that composites sintered at 600°C have higher bending strengths. The best degree of mechanical qualities was discovered to be present in composites sintered at 600°C with a 20 wt% SiC strengthening phase. These composites have a hardness of 55 HB and a transverse rupture strength of 331 MPa for flexural strength. The effect of SiC wt% and sintering duration on the microstructural and mechanical behavior of Al 6061/SiC composites manufactured by powder metallurgy (PM) route were investigated by Surya [74]. The key factor for increasing the physical and mechanical properties of the composites was discovered to be a high interfacial bonding between Al and SiC in 15 wt% SiC. The finer microstructure is produced by reinforcing at its ideal proportion. The grain growth is slowed down by the hard ceramic particles, which function as a barrier to the grain boundaries. When the sintering time is increased from 1 to 3 h, Al 6061/SiC contacts are improved; however, when the sintering time was prolonged from 1 to 3 h, the hardness value of the 15 wt% SiC composite increased from 70 to 81 HRB. Reddy et al. [75] studied the performance of nanosized SiC-reinforced (0, 0.3, 0.5, 1.0, and 1.5 vol%) Al metal matrix nanocomposites that were created using hot extrusion and microwave sintering processes. With the addition of SiC, a discernible improvement in the strength (compressive and tensile) of the Al–SiC nanocomposites was observed. However, it has been found that as the volume proportion of SiC is increased, the ductility of Al–SiC nanocomposites diminishes. According to the thermal analysis, the coefficient of thermal expansion (CTE) of Al–SiC nanocomposites reduces as harder SiC nanoparticles are gradually added. In comparison to other produced Al–SiC nanocomposites, hot extruded Al 1.5 vol% SiC nanocomposites showed the best mechanical and thermal performance. Rahman and Al Rashed [76] studied the wear characteristics, microstructure, and mechanical properties of SiC-reinforced AMCs. An AMC reinforced with 7 wt% SiC showed maximum wear resistance, tensile strength, and compressive strength. The addition of SiC significantly improves the mechanical and wear characteristics of the base metal. Devaganesh et al. [77] examined the mechanical and tribological characteristics of hybrid SiC–Al 7075 MMCs. The results show that Al 7075 with 5% SiC and 5% graphite composite outperforms all other hybrid composites by demonstrating superior mechanical and tribological properties; this may be because graphite and Al 7075–SiC work synergistically.

1.4.2 Titanium carbide (TiC)-reinforced Al composites

TiC is incredibly interesting due to its exceptional physical and mechanical qualities and, most importantly, its adequate wettability with aluminum [7]. It is also a very fascinating material due to its low density (4.93 g/cm3), high Young’s modulus (400 GPa), and high hardness. As a result, it is possible to considerably improve the mechanical behavior of aluminum alloys, particularly by adding micron-sized reinforcement to the TiC hard particles. To improve the desired mechanical properties of the produced composites, many researchers reinforced TiC in the Al matrix [59,60,61,62,63]. By using the hot consolidation approach, Mohapatra et al. [45] examined the microstructure and mechanical characteristics of Al–TiC composites. The composites showed improved Young’s modulus and mechanical characteristics with notable ductility, demonstrating the importance of using TiC reinforcement. The scientists concluded that, like other aluminum-based MMCs, Al–TiC aluminum composites made using this approach are appropriate for structural and industrial usage. Ramkumar et al. [78] prepared AA 7075/(0, 2.5, 5, and 7.5 wt%) TiC MMCs via the stir-casting route. They concluded that, compared to monolithic AA 7075 alloy, the bending strength of AA 7075–7.5 wt% TiC composites had significantly increased by 5.8 times with the addition of ceramic, which was attributed to the matrix’s embedding of reinforcement particles and improved grain refinement. The increasing reinforcement in the matrix exhibited improved wear resistance due to an increase in the strength in the matrix, dispersion strengthening, and effective bonding. Saravanan et al. [79] synthesized aluminum 7075 matrix composites reinforced with TiC at different weight percentages (0, 8, and 16 wt%) through PM. A significant improvement in wear loss was observed. Baskaran et al. [80] investigated the dry sliding wear behavior of high-strength 7075 AMCs with 4 and 8 wt% of TiC particulate reinforcement, synthesized using the reactive in situ casting technique. The optimal level combination for minimum wear rate was identified as 4 wt% TiC reinforcement, 9.81 N load, 3 m/s sliding velocity, and 1,500 m sliding distance. The microhardness and wear behavior of Al–4.5 wt% Cu–TiC nanocomposites produced by the PM route were investigated by Nemati et al. [81]. A planetary ball mill was used to combine the particles. The process of consolidation involved uniaxial pressing at 650 MPa. The sintering process was conducted for 90 min at 400°C. The findings showed that while relative density, grain size, and distribution uniformity drop as the TiC particle size is decreased to the nanoscale range and the TiC concentration is increased to optimal levels, the composite gains much more hardness and wear resistance. Composites reinforced with nanoparticles had a harder surface than those with TiC reinforcement in the micron range. The hardness of the composites increased steadily as the volume fraction of nano-size TiC was increased up to 5 wt%; however, after that point, particle agglomeration decreased the amount of useful particulate that was available, and the particle strengthening effect decreased.

The mechanical characteristics and microstructure of Al–15 wt% TiC composite synthesized using spark plasma, microwave, and traditional sintering were examined by Ghasali et al. [82]. The SPS, microwave, and conventional furnaces were used to sinter the material at temperatures of 400, 600, and 700°C, respectively. The findings revealed that the maximum relative density (99% of theoretical density), bending strength (291 ± 12 MPa), and hardness (253 ± 23 HV) were all found in sintered samples produced using SPS. An investigation on the Al 7075–TiC nanocomposite synthesized by mechanical alloying (MA) followed by hot pressing was performed by Azimi et al. [83]. In contrast, increasing the temperature over 400°C resulted in lower hardness due to significant grain development during hot pressing. Increasing hot pressing temperature and pressure improved sintering and mechanical properties. More intriguingly, the hot-pressing pressure value had a significant impact on how the milling time affected the mechanical properties. Furthermore, consolidation under ideal conditions produced a tensile strength of 725 MPa. The nano-sized TiC (5 wt%) particle-reinforced AA 7075 Al alloy composites made by ball milling and hot pressing were the subject of research by Salur et al. [84]. In terms of grain formation behavior, hardness, tensile strength, and relative density findings, the impact of milling duration on the microstructural and mechanical characteristics of the bulk TiCn/AA 7075 composites was assessed. The findings showed that a sample of AA 7075 alloy that had been hot-pressed and milled for 10 h had a hardness value that was three times higher than the initial value (94.43 HB). This was due to the homogeneous distribution of hardened nanoparticles within the matrix and the longer milling time. Tensile tests revealed that the UTS (284.46 MPa) of the 1 h-milled TiCn/AA 7075 composite was 40% higher than that of the original AA 7075 alloy (210.24 MPa). According to the findings, TiCn gradually dissolved into the matrix as ball-milling time increased and scattered evenly after 2 h of milling. The milled powders were heat-pressed for 30 min at 400 MPa and 430°C to consolidate them. Kar et al. [85] used TiC as the reinforcement for Al 7075 in their study. They found that the coefficient of friction is lowered by 20% due to the improved strength and hardness with the optimal amount of TiC. Using an electric stir-casting process, Rao et al. [86] fabricated AMMCs using TiC (2–10%) as a reinforcing material and the Al 7075 alloy as the metal matrix. A pin-on-disc device was utilized as a wear mechanism. Weight loss, friction coefficient, and wear rates for both reinforced and non-reinforced composites were measured. The findings show superior wear resistance to basic metal. The most important factor affecting the hardness of composites created by stir-casting treatment was the weight percentage of ceramic particles. As a result, Al 7075, which contains 8% TiC pieces, demonstrated the best hardness. The wear resistance increases as the weight percent of TiC increases. The wear resistance does not greatly improve with the addition of 10% TiC. As the weight proportion of TiC particles increased in comparison to the base alloy, the wear cost of the composites decreased. According to a research study, Al 7075/TiC exhibits superior mechanical and tribological capabilities. Devaneyan et al. [87] studied the mechanical behavior of aluminum 7075 reinforced with SiC (SiC) and TiC via the PM route. They found the highest value of microhardness (52.12 HV) with 90% of Al 7075, 4% of SiC, and 8% of TiC.

The experimental studies for the enhanced dry sliding properties of the AA 6063/TiC composite were carried out by Moorthy et al. [46]. According to the study, composite materials with higher fractions of TiC particles have much greater wear resistance, which is further improved by heat treatment. The effect of reinforcement on composite wear resistance is greatest when 9 wt% of TiC reinforcement is used for solutionized and aged conditions. Different volume fractions, ranging from 1.5, 3, and 6 vol%, of 20–30 nm diameter nano-sized TiC particles were used to strengthen the AA 6005 by Cabeza et al. [88]. By lengthening the milling duration, the microhardness of the unreinforced and reinforced matrix powder continuously increases. After 10 h of milling, the nanocomposite with 1.5 vol% of n-TiC particles has a hardness that is almost 1.3 times that of the Al alloy matrix, and it has a hardness that is nearly 1.55 times that of the nanocomposite with 3 and 6 vol% of n-TiC particles. Sujith et al. [44] investigated the abrasive wear behavior of Al 7079/TiC in situ MMCs produced by the in situ melt reaction method. It explored how in situ Al-7079 would be affected by the sliding distance applied force and the weight percent (5, 7, and 9) of TiC. According to experimental findings, the weight percent of TiC and the sliding distance had a greater impact on the coefficient of friction, and the applied force had a significant impact on the weight loss. There was a reduction of almost 40% loss in the weight at 9 wt% of TiC reinforcement addition as compared to that of the base Al-7079 matrix. Ravi Kumar et al. [20] studied the TiC particles (2,4,6, 8, and 10 wt%) reinforced in aluminum alloy (AA 6063) composites fabricated by the stir-casting method. The density, hardness, and tensile strength of composites increased to a maximum of 7.8, 20, and 19.55%, respectively, while adding TiC particles. Gopalakrishnan and Murugan [89] produced and investigated specific strength and wear resistance. They concluded that the specific strength of the material improved appreciably with the increased addition of TiC. Percentage elongation was also maintained at an appreciable level even though the specific strength was increased. Hence, this method is the most economical and effective way of producing the Al–TiC composite. The wear rate increased marginally with increased TiC addition.

1.4.3 Graphene nanoplatelet (GNP)-reinforced aluminum composites

Graphene has attracted considerable attention in the last several years because of superior properties such as high mechanical strength and modulus, electrical and thermal conductivity, and optical transmittance [90,91,92]. A two-dimensional hexagonal lattice of carbon atoms, graphene serves as the fundamental building block of other allotropic forms of carbon, such as fullerenes, diamonds, carbon nanotubes, and graphite [93]. Graphene is the thinnest material made of just a single layer of carbon atoms bound together by a backbone of overlapping sp2 hybrid bonds. The unusual characteristics of graphene originate from the 2p orbitals, which form the p-state bands that delocalize over the sheet of carbons that create graphene. Table 4 summarizes the unique properties of graphene with exceptional mechanical strength, high Young’s modulus, low density, excellent electrical and thermal conductivity, as well as large theoretical specific surface area with unique geometry, making them perfect reinforcement for the composites [94,95]. In comparison to diamond (1.2 TPa), steel (200 GPa), and copper, Young’s modulus measured by various simulations in the graphene plane can be as high as 1–1.8 TPa (100 GPa). Both have tensile strengths that are equal to annealed steel (700 MPa) and annealed copper (800 MPa), are half as dense as aluminum, and range from 100 to 200 GPa (20 times that of high-strength alloys) (200 MPa) [96,97]. Graphene’s exceptional electrical characteristics, which include outstanding carrier mobility and capacity, are also well recognized and make it a desirable material for use in future high-speed electronics [98]. Exfoliated semiconducting graphene demonstrated carrier mobility ranging from 230,000 cm2/V/s in suspended structures to 100,000 cm2/V/s on insulating surfaces. Additionally, both have current carrying capacities that are 1,000 times greater than those of the copper wire (109 A/cm2) and above [99]. In a similar vein, graphene’s in-plane thermal conductivity can range from 3,000 to 7,000 W/mK, which is far higher than that of copper (400 W/mK), carbon fiber (1,950 W/mK), diamond (2,000 W/mK), and carbon fiber [100]. Due to these properties, graphene has found a wide range of potential applications in medicine, paper, electronics, and composite materials.

Physical and mechanical properties of graphene [101]

| Characteristics | Values |

|---|---|

| Density | 1.06–2.2 |

| Tensile strength (GPa) | 130 |

| Young’s modulus (TPa) | 1.02 |

| Thermal conductivity (W/mK) | 5,300 |

| CTE | (−8 ± 0.7) × 10−4 |

The physical, mechanical, and wear behavior of the matrix material is improved by the addition of hard ceramic particles. Ductility and fracture toughness are sacrificed in order to obtain this gain in characteristics. Additionally, the use of hard ceramic reinforcement increases the hardness, making machining challenging and expensive. Balancing hardness, wear resistance, and machining of the ceramic-reinforced composites is challenging. One of the most popular combinations is an aluminum metal matrix supplemented with GNP because GNP improves the composites’ wear resistance and machinability. A thin coating of graphite is formed under sliding conditions to prevent direct metal-to-metal contact, hence minimizing wear loss [102,103].

In comparison to aluminum composites reinforced with other ceramic particles like Al2O3 and SiC, adding GNP particles to an aluminum matrix improves tribological characteristics. Due to the addition of GNP particles, self-lubricating composites exhibit significantly lower friction and wear rates than unreinforced matrix metals [101,104]. In addition, the intrinsic lubricating action of the GNP particles reduces the frictional heat produced at the interface. As a result of the decreased friction force, wear resistance will consequently increase [105,106]. Due to the exceptional capabilities of GNPs, aluminum MMCs with GNP reinforcement have been researched recently [107,108,109,110,111]. Wang et al. [112] produced graphene-reinforced aluminum composites by the PM technique. Aluminum composites with only 0.3 wt% GNPs inclusion have tensile characteristics that are 62% higher than pure aluminum. According to Rashad et al. [113], graphene has an impact on the hardness, tensile strength, and compressive strength of aluminum composites. The tensile strength (+11.1%) and Vickers hardness (+11.8%) for 0.3 wt% of pure aluminum are both higher. The compressive strength decreased by 7.8%, but the addition of GNPs increased it. Bastwros et al. [114] published a study on the flexural strength of PM-produced graphene-reinforced aluminum nanocomposites. When compared to the Al 6061 alloy, a strength improvement of 47% was found. Gürbüz et al. investigated the impact of process variables on the hardness and microstructure of aluminum composites, including sintering time, temperature, and graphene content. According to their findings, the ideal sintering conditions were 180 min, 630°C, and 0.1 wt% of graphene. Graphene-reinforced aluminum composites’ hardness increased from 28 2 to 57 2.5 HV [115]. Table 5 illustrates a summary of the reported studies along with key observations for the fabrication of Gr-AMMCs by MA. A summarized overview of the studies utilizing the solution mixing technique with major observations and key findings is presented in Table 6. Recent investigations on Mg-based matrix composites incorporating GNPs have been summarized by Abazari et al. with regard to their mechanical, corrosion, and biological properties. Their findings indicate the advantages of GNPs over other reinforcing phases like ceramic particles, such as their synergistic ability to increase ductility while strengthening and decreasing weight, are quite compelling [116].

Reported Al/GNPs synthesized by MA

| Matrix | Composition | Dispersion strategy | Consolidation treatment | Key observations | Ref. |

|---|---|---|---|---|---|

| Al | 0.25–1.0 wt% GNP | Ball milling | Compaction and sintering | Longer milling times may promote graphene distribution in the matrix and lead to smaller particle sizes. However, it can also cause the structure of GNPs to amorphized | [111] |

| Al | 0.5–1.0 wt% GNF | Cryomilling | Extrusion and annealing | Low milling temperatures make it possible to prevent the formation of intermetallic compounds. However, 1.0 wt% of GNPs were observed to aggregate. A maximum of 4.0 wt% graphene concentration was suggested | [134] |

| Al | 0.3–0.7 vol% few-layer graphene (FLG) | Planetary ball milling, high-energy ball milling | Compaction and hot rolling | Graphene sheets that are rolled along the rolling axis may become partially aligned and wrinkled. FLG has a substantially wider contact area with the matrix than multiwalled carbon nanotubes (MWCNTs), which have a 2.6 times smaller surface area. When compared to MWCNTs, graphene has a higher strengthening efficiency | [135] |

| Al | 1.0 wt% reduced graphene oxide (RGO) | Mechanical mixing and ball milling | Hot extrusion, annealing, and shot peening treatment | Shot peening can significantly improve dislocation pile-up by reducing the domain size, boosting dislocation density, and even causing the creation of nanocrystalline layers | [136] |

Reported Al/GNPs synthesized by solution-assisted mixing (semi-PM)

| Matrix | Reinforcement | Dispersion strategy | Consolidation treatment | Key observations | Ref. |

|---|---|---|---|---|---|

| Al | 0.3 wt% Gr | Ball milling, ultrasonication, mixing, and dispersing agent | Compaction, sintering, and hot extrusion | Due to shape compatibility, the flake-like morphology of the Al powder improves interaction with graphene oxide (GO) sheets. PVA can also improve the wettability of GO and Al powder. The qualities of the composite can be compromised by incomplete GO reduction | [137] |

| Al | 0.3 wt% RGO | Ball milling, ultrasonication, and mixing | Compaction and hot pressing | Milled Al powder with a flaky shape improves interaction with graphene by electrostatic interaction, which can be passivated by the formation of oxide film on the flake surface | [138] |

| Al | 0.75–1.50 vol% RGO | Ultrasonication, ball milling and stir mixing | Uniaxial compaction, hot pressing, and hot rolling | Dispersion is aided by the electrostatic contact between GO and Al. Because of the composite’s nanolaminated structure, graphene sheet may prevent dislocations and produce high strength. Microcracks appeared when the content was more than 2.5 vol%. During processing, a layer of amorphous alumina was also formed | [139] |

| Al | 0.1–0.5 wt% Gr | Ultrasonication, stirring, and surfactant | Press sintering | Due to the electrostatic interaction facilitated by the surfactant, the oppositely charged surfaces of GO and Al powder can bind and disperse well. However, agglomeration accelerates as loading content exceeds 0.3 wt% | [140] |

| Al | 0.07–0.3 wt% RGO | Ultrasonication and mixing | Cold compaction and sintering | When consolidating the composite powder, a higher compaction pressure, particularly in the core, can generate parts with a high density and therefore improved mechanical performance | [141] |

| Al | 0.5–1.0 wt% GNP | Ultrasonication and mixing | Cold compaction and sintering | Al and graphene did not interface well. Carbide production and GNP aggregation can successfully improve characteristics up to 0.5 wt% | [142] |

| Al | 0.5–5.0 wt% | Ultrasonication | SPS | Poor mechanical performance was the outcome of GNP aggregation above 1.0 wt% | [143] |

| Al | 0.1 wt% FLG, and few-layer graphene oxide | Ball milling, ultrasonication, and mixing | Compaction and sintering | Al and GO powders interacted more readily with one another when functional groups were present on the GO surface, improving the mechanical performance. However, FLG had a poor interaction with the Al matrix, and the composite’s underlying strength was caused by inhomogeneous dispersion | [144] |

| Al | 0–1.5 wt% GNP | Solution ball milling, ultrasonication, and surfactant | Cold compaction, and sintering | Density is affected by increased pressure and the presence of graphene. Al matrix and graphene’s interfacial interaction are not investigated | [145] |

1.4.3.1 Fabrication methods for GNP-reinforced AMCs

Over the past 10 years, researchers have produced AGNPs using a variety of processing methods, including PM, friction stir processing (FSP), casting, selective laser melting (SLM), mechanical impregnation, etc. Casting and FSP are the next most popular techniques after PM (Figure 5). In addition to these methods, researchers have also experimented with 3D printing, high-pressure torsion, mechanical impregnation, and other methods to manufacture AGNPs.

![Figure 5

The percentage contribution of different processing techniques employed by researchers to produce AGNPs [3].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_005.jpg)

The percentage contribution of different processing techniques employed by researchers to produce AGNPs [3].

Soon after the graphene discovery, many research investigations started using graphene as reinforcement. The interest in using graphene as reinforcement in metallic matrices is spurred by the successful incorporation of graphene into polymers to fabricate high-performance polymer composites with tremendous increment in the mechanical and thermal properties [117]. In comparison to polymers, metal matrix graphene is clearly superior due to its stability at higher temperatures, increased strength, rigidity, and greater electrical and thermal conductivity. However, it is quite challenging to introduce graphene into the metals successfully due to some critical issues such as difficulty in obtaining a uniform dispersion and structural retention during processing. These challenges are caused by graphene’s larger surface area, which results in agglomeration clusters and twists as a result of strong van der Waal forces (surface tension) between carbon atoms in the graphitic structure [118]. This tension produces enormous surface energy that makes it difficult to wet metal and makes separation easier [119]. Thus, with such concerns, it is very important to embrace processing techniques that would ensure the successful incorporation of graphene in metal matrices by addressing these issues simultaneously. The proper processing technique plays a vital role in the final properties of composites. As per published reports, a variety of processing techniques have been followed to develop graphene-reinforced aluminum matrix nanocomposites (AMNCs). However, the most adopted methods for CNT and graphene-AMNC fabrication are PM [120,121,122,123,124,125,126,127], melting and solidification, and electrochemical deposition [128,129]. Recently, some novel processing techniques such as molecular level mixing, thermal spray, melt integration, and FSP [130,131,132] were also introduced to address the main challenges of graphene AMNCs. Graphene dispersion (porosity formed by agglomeration) is the core problem encountered during processing; therefore, for high-quality development of graphene-reinforced AMNCs, achievement of the uniform dispersion is a critical concern. Among the above techniques, PM is the most common and widely accepted applied technique to fabricate graphene-reinforced AMNCs. Most of the studies carried out on carbon nanofiller (carbon nanotube and graphene) incorporation into various metallic matrices mainly with Al, Cu, and Mg using PM techniques. In the last decades, PM emerged as the most efficient method and has great potential to address issues connected with carbon nanofiller specifically graphene materials, i.e., successful uniform distribution through processing parameter optimization. Due to its widespread industrial-scale adoption, PM is regarded as the superior processing method for graphene-AMNCs. Due to several reasons such as simplicity, flexibility, and near net shape capability, any composition can be formed due to less involvement of thermodynamics and the phase diagram as in the case of ingot metallurgy. Finally, parts produced from the PM process were far better in mechanical properties due to the better capability to generate uniformly distributed particles. As in ingot metallurgy, low-density graphene gets separated due to buoyancy forces and is not fully integrated. The incorporation of graphene as reinforcement in light metals like Al matrices is majorly dependent on the PM processing steps and their parameters as they dictate the final microstructure and ultimately final properties of the AMNCs.

Developing AMNCs with the PM technique starts with the process of mixing and blending with the initial raw metal like Al metal and nanofiller (graphene) powders using high-energy ball milling (planetary ball mill) or low-energy ball milling (horizontal tumbling milling). This kind of PM processing is also termed MA, which is then followed by consolidation of the mixed nanocomposite powder [133]. The most widely adopted consolidation techniques are cold compaction and pressure sintering, cold isostatic pressing, deformation-assisted sintering, hot isostatic pressing (HIP), and SPS.

1.4.3.2 Influence of aluminum carbide (Al4C3) formed at the Al–GNP interface

The interaction between graphene and aluminum leads to the formation of aluminum carbide (Al4C3) due to its low Gibbs free energy of −196 kJ/mol at 298 K. The reaction between carbon and aluminum is thermodynamically favorable, making it challenging to control the interface reaction in graphene-reinforced MMCs. It is worth noting that the effects of the Al4C3 phase on the mechanical properties of AMCs reinforced with graphene are currently a topic of ongoing discussion. It has been explained by numerous recent studies with microstructural observations of graphene-reinforced Al composites.

Recently, Yu et al. [146] investigated the microstructural evolution of graphene-reinforced aluminum composites. Figure 6 presents transmission electron microscopy (TEM) images illustrating the microstructure of an extruded composite consisting of aluminum (Al) and 0.5 wt% GNPs. As shown in Figure 6(a), the Al matrix exhibits equiaxed grains with a relatively uniform grain size of approximately 450 nm, which aligns closely with the calculated value obtained from X-ray diffraction (XRD) results. Figure 6(b) displays the SAED pattern for the region highlighted by a white ellipse in Figure 6(a). This SAED pattern confirms the presence of both Al and GNPs, with the GNPs specifically marked by blue dotted lines in Figure 6(a). Furthermore, the two-dimensional TEM images in Figure 6(c) and (d) demonstrate that the GNPs are linearly distributed, indicating successful dispersion within the Al matrix. The high-resolution TEM (HRTEM) micrograph in Figure 6(d) reveals the interface between the Al matrix and GNPs. The blue box highlights a well-defined GNPs/Al interface, suggesting the absence of any interfacial reaction. Conversely, the green box indicates the presence of an Al4C3/Al interface, where layers with a d-spacing of approximately 0.2897 nm, corresponding to the (101) orientation of the Al4C3 phase, are identified in the inset of Figure 6(d). Additionally, an orientation relationship of (200)GNPs //(101)Al4C3 is observed, indicating that Al4C3 nucleated at the GNPs/Al interface and grew toward the GNPs. Consequently, it is confirmed that some of the GNPs reacted with the Al matrix, which could explain the absence of GNP peaks in the XRD patterns obtained after the extrusion process.

![Figure 6

TEM images for the composite of Al–0.5 wt% GNPs, depicting the following: (a) the shape of Al grains and the dispersion of GNPs, (b) the SAED pattern illustrating the presence of Al and GNPs, (c) the characteristic morphology of GNPs, and (d) the condition of the interface [146].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_006.jpg)

TEM images for the composite of Al–0.5 wt% GNPs, depicting the following: (a) the shape of Al grains and the dispersion of GNPs, (b) the SAED pattern illustrating the presence of Al and GNPs, (c) the characteristic morphology of GNPs, and (d) the condition of the interface [146].

In another investigation, Zhou et al. [147] demonstrated the improvement in the interfacial load transfer and strength of FLG/Al composites through interfacial reaction. By manipulating the sintering temperature, monocrystalline Al4C3 nanorods were formed, tightly connecting the FLG platelets with the Al matrix. By TEM analysis and a shear lag model, it was observed that the Al4C3 nanorods effectively facilitated load transfer at the FLG–Al interface, resulting in a significant enhancement of composite strength. It was observed that upon increasing the sintering temperature to 883 K, it was confirmed through X-ray photoelectron spectroscopy (XPS) analysis that an interfacial reaction occurred at the interfaces between FLG and Al. The presence of the Al4C3 phase with a rhombohedral crystal structure, characterized by lattice parameters a = 0.334 nm and c = 2.50 nm, was identified by the SAED patterns (insets in Figure 7(a) and (c)) and lattice images (Figure 7(d)). The Al4C3 phase exhibited a rod-like morphology, distinct from the initial sheet-like GO. Based on statistical analysis of 50 TEM images, the Al4C3 rods were found to have an average length of approximately 90 nm and a diameter of approximately 25 nm. Notably, one end of the Al4C3 rod was tightly bonded to the FLG platelet, while the other end was embedded in the Al matrix (Figure 7(a)–(c)). The formation of this unique structure can be explained as follows: during the high-temperature SPS, the liquid Al momentarily infiltrated the boundaries of Al particles through the partially fractured side of the Al2O3 layer (Figure 7(b)) at the sandwiched Al2O3–FLG–Al2O3 interface, facilitated by the surface-cleaning effect of the SPS process. This infiltrated liquid Al directly contacted the FLG platelets, allowing for a possible reaction of carbon with aluminum, leading to the formation of Al4C3 (C + Al → Al4C3). While pristine graphene surfaces are chemically stable and do not react with molten Al, reduced graphene oxide (r-GO) contains intrinsic defects such as vacancies or topological defects that can serve as preferred reaction sites for aluminum atoms. Due to the higher free energy of the graphitic prism planes compared to the basal planes, Al4C3 preferentially grew along the 〈110〉 direction (Figure 7(b) and (d)). Some edge defects were observed in the Al4C3 crystals (Figure 7(d)), attributed to their rapid growth rate. Assuming a lateral size of approximately 700 nm and a thickness of approximately 2 nm for FLG, it can be concluded that certain graphene sheets within the FLG acted as carbon sources, contributing to the formation of Al4C3 rods. In this scenario, the Al4C3 phase strongly connected the Al matrix and the unreacted FLG sheets through a locking effect (Figure 7(b)). The interface linking Al4C3 and Al exhibits a highly clean and tightly bound structure (Figure 7(d)–(e)). Within the Al4C3 phase, a twinned structure was observed (Figure 7(d)), with a mirror plane of (001) and a twinning direction of [110] (Figure 7(a), inset). This twinning phenomenon is attributed to the compressive stress generated by the disparate CTEs between Al (2.5 × 10−5/K) and Al4C3 (3.6 × 10−6/K) [30]. The formation of twins signifies a robust Al4C3/Al interface capable of transferring loads. This suggests that a small amount of Al4C3 was formed, enhancing the strength of the FLG–Al interface through covalent bonding, while simultaneously maintaining the inherent strength of FLG for reinforcing the composite.

![Figure 7

The morphologies of FLG/Al composites in the transversal cross-section at 883 K are depicted as follows: (a–c) a TEM image illustrating the formation of Al4C3 at the FLG–Al interface, and (d–e) high-resolution TEM (HRTEM) images displaying the Al4C3–Al interface. In (b), the white square area in (a) is magnified. The insets in (a) showcase the diffraction patterns of Al4C3 obtained from the green spot and Al obtained from the yellow spot. The inset in (b) exhibits the energy-dispersive spectroscopy analysis taken from the red spot. The inset in (c) reveals the diffraction pattern of Al4C3 acquired from the green spot. Lastly, the insets in (e) display the fast Fourier transform patterns of Al from the red square and Al4C3 from the yellow square [147].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_007.jpg)

The morphologies of FLG/Al composites in the transversal cross-section at 883 K are depicted as follows: (a–c) a TEM image illustrating the formation of Al4C3 at the FLG–Al interface, and (d–e) high-resolution TEM (HRTEM) images displaying the Al4C3–Al interface. In (b), the white square area in (a) is magnified. The insets in (a) showcase the diffraction patterns of Al4C3 obtained from the green spot and Al obtained from the yellow spot. The inset in (b) exhibits the energy-dispersive spectroscopy analysis taken from the red spot. The inset in (c) reveals the diffraction pattern of Al4C3 acquired from the green spot. Lastly, the insets in (e) display the fast Fourier transform patterns of Al from the red square and Al4C3 from the yellow square [147].

Additional reports have supported that Al4C3 formation could reduce mechanical characteristics due to the induction of microcracks, leading to the early failure of Al/graphene composites [120,148,149].

In conclusion, it is still debatable whether the presence of Al4C3 strengthens the interfacial interaction between aluminum and graphene. According to some reports, Al4C3 increased graphene’s ability to transfer loads and offered a strengthening impact that helped the material’s strength. The integrity of graphene also influences the creation of Al4C3, with the possibility of Al4C3 formation increasing with decreasing graphene integrity. According to some reports, Al4C3 serves as a harmful interfacial phase and causes early failure as a result of the formation of microcracks. Nevertheless, the parameter affecting Al4C3 formation is well worth addressing and optimizing in future studies to attain enhanced properties because they may have positive or negative consequences on the strength.

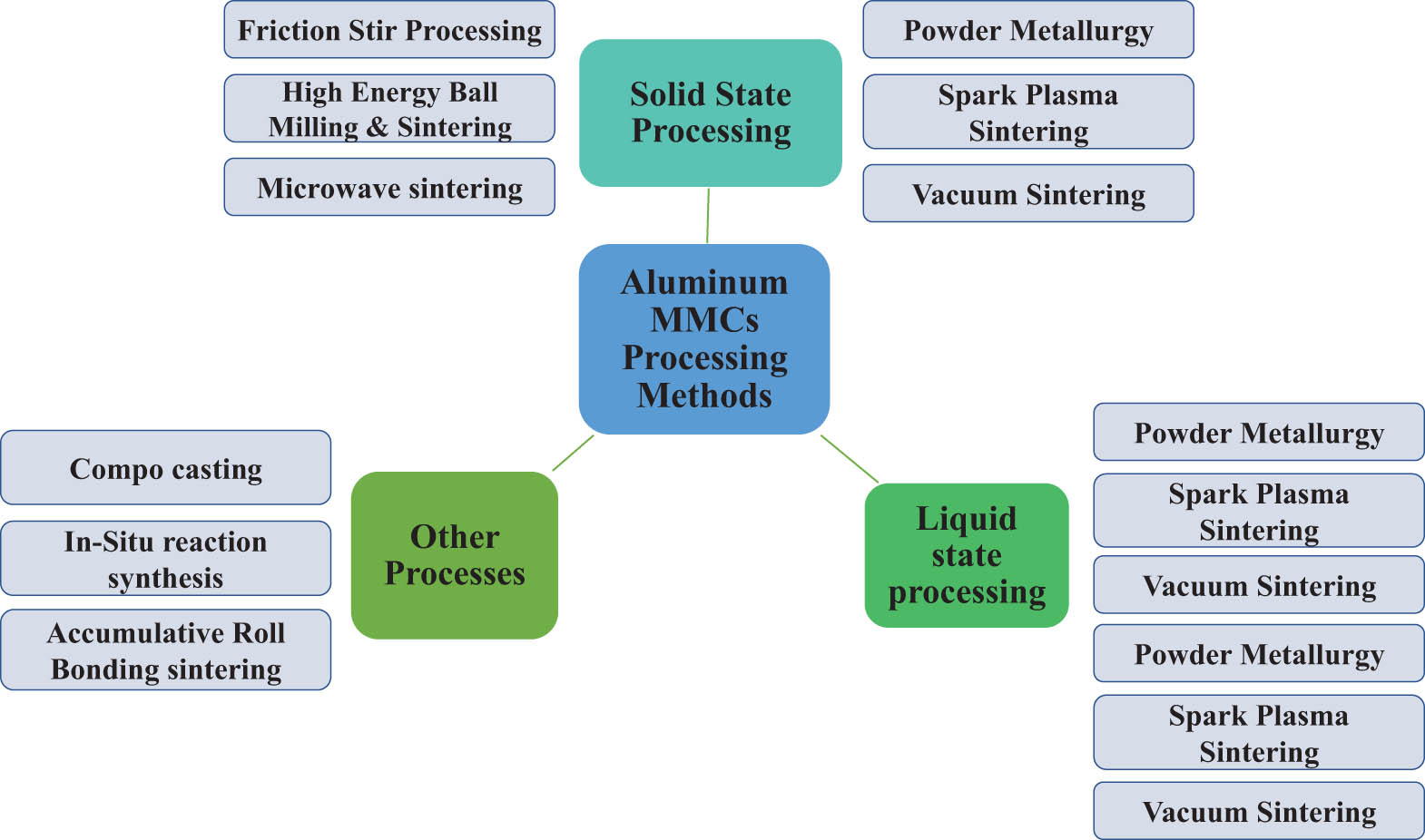

2 Processing techniques of aluminum-based composites

Composites for the aluminum matrix can be produced using a variety of techniques. Mechanical performance, including tensile strength, impact strength, hardness, fatigue, and cost-effectiveness, is significantly impacted by the fabrication procedures. The fabrication procedures are divided into different categories, as shown in Figure 8, based on how the matrix is handled, whether it is in a solid, liquid, or other form (such as semi-liquid, compo-casting, etc.). An overview of the processes available for producing aluminum MMCs is given in this section.

Process classification for manufacturing aluminum MMCs.

2.1 Solid-state processing

Metal is processed in a solid or semi-solid state using the solid-state method. The issue of metal and reinforcement materials oxidizing is solved by processing at a lower temperature. High pressure is used in solid state operations at temperatures above ambient but below the melting point of the metal in order to produce a bonding or interacting interaction. Al-MMCs were produced using a variety of solid-state methods, including PM and diffusion bonding.

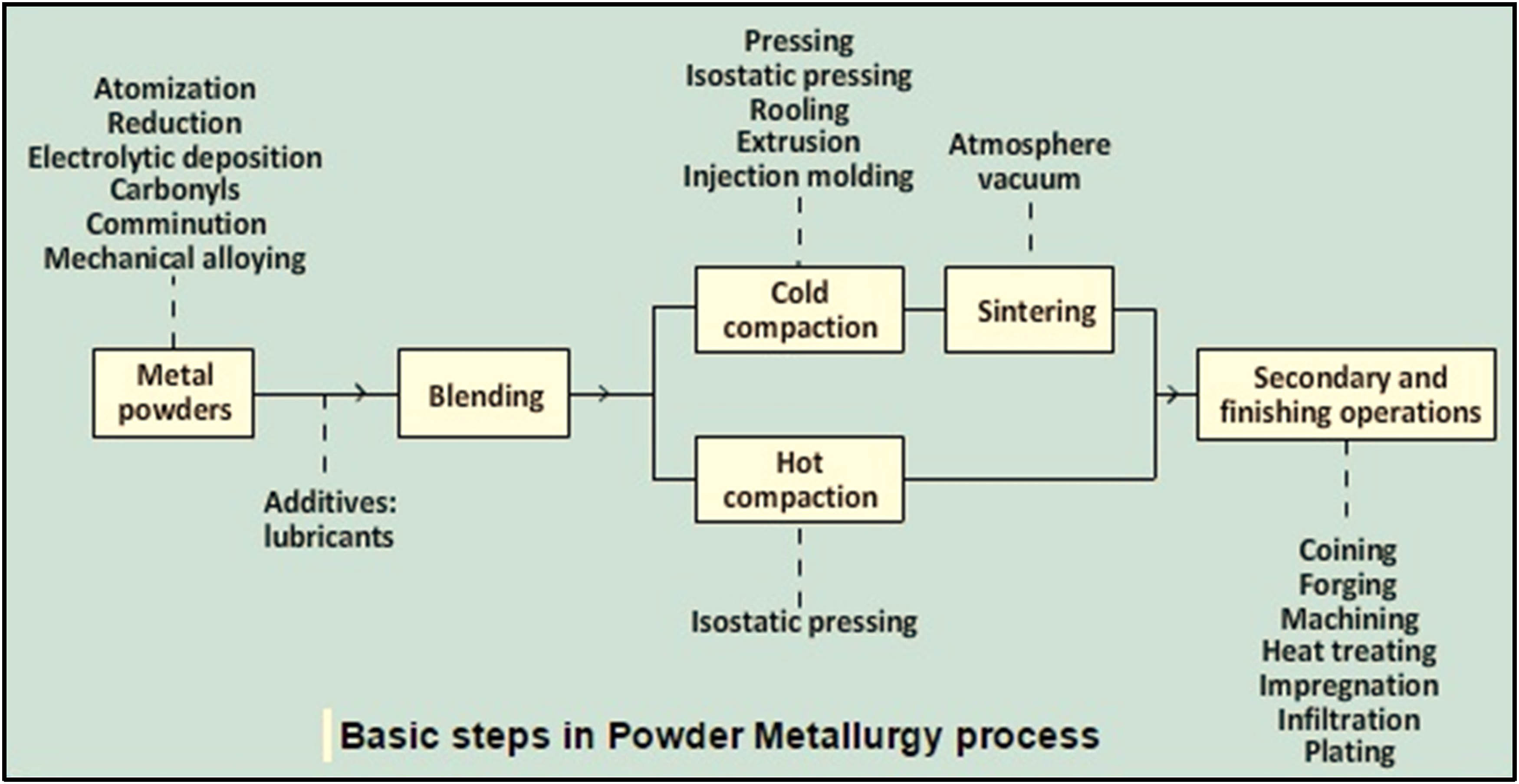

2.1.1 Powder metallurgy

The mass manufacturing of porous bronze bushes for bearings and the production of tungsten carbides in the 1920s marked the beginning of modern PM technology. The production of a wide range of ferrous and nonferrous materials, including various composites, advanced throughout the Second World War, and from the years following the war until the early 1960s, there was a sustained growth period. Since then, the increase in PM has accelerated due to three possible causes: cost-effective processing, distinctive features, and captive processes. The PM process is primarily a quick, affordable, and high-volume manufacturing technique for producing precise components from powders. It is possible to roll powders into sheets, extrude them into bars, etc., or condense them isostatically into components with more complex geometries using a variety of related consolidation techniques. The technology of powder forging has become well-established over the past 10 years for creating precision engineering parts with qualities similar to those of traditional forgings from powders. The general flow diagram for processing PM is shown in Figure 9.

Processing steps for PM.

PM is a method of processing metals in which metallic powders are used to create parts. The powders are compressed into the proper shape as part of the standard PM production process, and then they are heated to cause the bonding of the particles into a hard, rigid mass. The process of pressing, also known as compression, is carried out in a press-type machine with tools made, especially for the component being produced. PM and tooling are therefore best suited for medium and high production levels. Tooling typically comprises a die and one or more punches. Sintering, a type of heating procedure, is carried out below the metal’s melting point. Mass production of PM parts in net or nearly net shape can eliminate or minimize the requirement for further processing. Only a small amount of raw materials is wasted during the PM process itself; roughly 97% of the initial powders are transformed into finished goods. This contrasts positively with casting procedures where the production cycle wastes material in the form of sprues, runners, and risers. Three steps make up the traditional PM process: blending and mixing the powders; compaction, which involves pressing the powders into the desired part shape; and sintering, which entails heating to a temperature below the melting point in order to strengthen the part and causing the particles to form solid-state bonds. Figure 10 depicts the three phases, which are also known as primary operations in PM.

![Figure 10

The conventional PM production sequence: (1) blending, (2) compacting, and (3) sintering; (a) the condition of the particles; (b) the operation and/or work part during the sequence [150].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_010.jpg)

The conventional PM production sequence: (1) blending, (2) compacting, and (3) sintering; (a) the condition of the particles; (b) the operation and/or work part during the sequence [150].

2.1.1.1 Blending and mixing of powders

When using materials processing techniques with powders as the initial material, powder mixing is a crucial procedure. No matter if these metals are to form an alloy with certain desired attributes or to remain in the compact as independent constituents while preserving their unique properties, thorough and consistent mixing is always necessary. The metallic powders must first be completely homogenized in order to obtain good compaction and sintering results. Both the words “blending” and “mixing” are appropriate here. When powders with the same chemical make-up but potentially varying particle sizes are mixed, the process is known as blending. To lessen porosity, different particle sizes are frequently combined. Powders of various chemistries are blended when something is mixed. The ability to combine different metals into alloys that would be challenging or impossible to create through conventional methods is one benefit of PM technology. In industrial practice, the line between blending and mixing is not always clear. Convection, diffusion, and shear are the three mechanisms that influence powder mixing. Usually, when blending and/or combining metallic powders, other substances are used. These additives consist of (1) lubricants, such as zinc and aluminum stearates, which are used sparingly to lessen friction between particles and at the die wall during compaction; (2) binders, which are occasionally needed to achieve adequate strength in the pressed but unsintered parts; and (3) deflocculants, which prevent powder agglomeration for better flow characteristics during subsequent processing.

2.1.1.1.1 Turbula mixing and MA

Mixing of the nanoparticles and micron particles is also done by Turbula mixing. A laboratory-scale mixer called the Turbula is frequently used in the process of making or test powder formulations [151]. The rotation, translation, and inversion actions that are applied to the powders in this mixer are intense and pulsating on a regular basis [152,153]. MA is a dry powder processing method that has been utilized to create equilibrium and metastable phases of useful and intriguing materials for both business and science. The method was first developed by Benjamin [11,12] in 1966 to create a superalloy based on nickel that combines oxide dispersion strengthening with precipitation hardening for use in gas turbine applications. A method of processing in the solid state was required because the oxides cannot be disseminated in a liquid form. Thus, an industrial necessity is responsible for MA’s inception. MA is a straightforward and adaptable method that is also economically viable and has significant technical advantages. One of MA’s major benefits is the ability to synthesize unique alloys that are impossible to make using any other method, such as alloying of ordinarily immiscible elements. This is because MA is an entirely solid-state processing method, hence any restrictions imposed by phase diagrams do not apply. Dry, elemental, or simple alloy powders are attired at high speeds in modified, high-energy ball mills as part of the process. Figure 11 depicts a typical flow diagram for the high-energy ball milling and sintering process. Ball–powder–ball and ball–powder–container collisions that take place during milling cause the powder particles to repeatedly deform, cold weld, and shatter (Figure 12). The interplay between welding and particle breakage, along with strain-enhanced diffusion, gradually homogenizes the powders, leading to alloy formation in the end. About 1 μm or smaller particle sizes are possible, and solid solubilities can be increased past their equilibrium ranges.

![Figure 11

High-energy ball milling and sintering [154].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_011.jpg)

High-energy ball milling and sintering [154].

![Figure 12

Ball–powder–ball collision of powder mixture in MA [133].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_012.jpg)

Ball–powder–ball collision of powder mixture in MA [133].

In MA, the individual elemental powders or prealloyed powders are loaded into a high-energy ball mill together with the grinding medium (usually hardened steel or tungsten carbide balls), typically maintaining a ball-to-powder weight ratio of 10:1 or greater. The MA procedure is carried out in a stainless-steel container sealed under a protective argon environment for the required amount of time to avoid/minimize oxidation and nitridation during milling. Powder particles are repeatedly cold-welded, fractured, and re-welded in this process. By balancing the fracturing and welding events during the process, the size of the resultant powder can be managed. When milling powders of ductile metals, in particular, a process control agent (often stearic acid) is typically added in amounts of around 1–2 wt% to prevent excessive cold welding among the powder particles. Figure 13 summarizes the many sectors in which the MA products are used.

![Figure 13

An overview of applications of the mechanically alloying process [133].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_013.jpg)

An overview of applications of the mechanically alloying process [133].

2.1.1.2 Powder compaction

The compaction of the metal powders is done to consolidate the powder into the desired shape, to impart the desired final dimensions with due consideration to any dimensional changes resulting from sintering, to impart the desired level of porosity, and to impart adequate strength for subsequent handling. When powders are compacted, enough pressure is applied to give them the desired shape. The pressing method, in which powders contained in a die are squeezed by opposing punches, is the traditional method of compaction. Figure 14 depicts the pressing cycle’s steps. After pressing, the work component is referred to as a “green compact,” with “green” denoting incomplete processing. The part’s density after pressing, known as the green density, is significantly higher than the initial bulk density. When pressed, the part’s green strength is sufficient for handling but significantly less than that attained following sintering. The powders are initially repacked into a more effective configuration as a result of the applied pressure during compaction, which also reduces pore space and increases the number of contacting points between particles while removing “bridges” created during filling. The particles are plastically deformed as pressure increases, expanding the interparticle contact area and bringing more particles into contact. Additionally, the pore volume is reduced as a result. Figure 15(a) shows the evolution of starting particles with a spherical shape in three different perspectives. Three perspectives as a function of applied pressure are frequently used to depict the associated density.

![Figure 14

Pressing the common method of compacting powders in PM: (1) filling the die with the powder, (2) initial, and (3) final positions of upper and lower punches during compaction, and (4) ejection of the part [150].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_014.jpg)

Pressing the common method of compacting powders in PM: (1) filling the die with the powder, (2) initial, and (3) final positions of upper and lower punches during compaction, and (4) ejection of the part [150].

![Figure 15

Influence of pressure during compaction: (1) loose particles at first after filling, (2) refilling, and (3) particle deformation; and (b) particles’ density in relation to pressure. Here, the order is step-based 1, 2, and 3 in Figure 2.8 [150].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_015.jpg)

Influence of pressure during compaction: (1) loose particles at first after filling, (2) refilling, and (3) particle deformation; and (b) particles’ density in relation to pressure. Here, the order is step-based 1, 2, and 3 in Figure 2.8 [150].

The presses used in conventional PM compaction are hydraulic, mechanical, or a combination of the two. For producing PM, a press’s capacity is typically expressed in tons, kN, or MN. The predicted size of the PM component (area in the horizontal plane for a vertical press) multiplied by the pressure necessary to compact the supplied metal powders determines the required force for pressing. Expressing it in an equation form,

where F is the force, N; A is the area of the part, mm2; and P is the compaction pressure required to give up powder material. Compaction pressure typically ranges from 70 to 500 MPa. The effect of applied pressure during compaction is shown in Figure 15(b).

2.1.1.3 Sintering of compacts

The green compact is weak and brittle after pressing, thus it crumbles rapidly under light strains. The compact is put through a heat-treatment process called sintering to bind the metallic particles, which boosts the strength and hardness. Usually, the treatment is performed between 0.7 and 0.9 of the metal’s melting point (absolute scale). Because the metal does not melt at these treatment temperatures, the names solid-state sintering or solid-phase sintering are occasionally used to describe this traditional sintering. Researchers generally concur that the fundamental driving mechanism for sintering is a decrease in surface energy [155,156]. The green compact has a relatively large total surface area since it is made up of numerous unique particles, each with its unique surface. The development and growth of bonds between the particles causes the surface area to decrease under the impact of heat, which also results in a decrease in surface energy. The overall surface area is higher and the pushing force behind the process is greater the finer the initial powder size.

The illustrations in Figure 16 depict the changes that take place during the sintering of metallic particles on a microscopic level. To produce the necks and transform them into grain boundaries during sintering, mass transfer is required. Diffusion is the main process that takes place here; however, plastic flow is another potential one. Pore size reduction during sintering causes shrinkage. This heavily depends on the density of the green compact, which is dependent on the compaction pressure. In general, shrinkage may be predicted when processing conditions are strictly monitored.

![Figure 16

Sintering on a microscopic scale: (1) particle bonding is initiated at contact points; (2) contact points grow into “necks”; (3) the pores between particles are reduced in size; and (4) grain boundaries develop between particles in place of the necked regions [150].](/document/doi/10.1515/ntrev-2023-0111/asset/graphic/j_ntrev-2023-0111_fig_016.jpg)

Sintering on a microscopic scale: (1) particle bonding is initiated at contact points; (2) contact points grow into “necks”; (3) the pores between particles are reduced in size; and (4) grain boundaries develop between particles in place of the necked regions [150].

Even at room temperature, almost all technical metals react with the gas in their surrounding atmosphere, but this reaction is amplified when the metal is heated. The primary goal of employing special sintering atmospheres is to protect sintered metal powders against oxidation and re-oxidation. The fundamental sintering process can be affected by a sintering environment in various ways. The environment may produce highly mobile metal atoms by lowering the oxides. The environment in the furnace is regulated by current sintering procedures. A regulated environment serves four functions: (1) protecting against oxidation, (2) providing a reducing atmosphere to eliminate any existing oxides, (3) supplying a carburizing atmosphere, and (4) helping to remove any lubricants and binders used during pressing. An inert gas, nitrogen-based, dissociated ammonia, hydrogen, and natural gas are common sintering furnace atmospheres [156,157]. For some metals, such as stainless steel and tungsten, vacuum environments are employed. The majority of common metals and alloys are inert to nitrogen. It is also utilized as a safety purge for flammable atmospheres because it is nonflammable. Molecular nitrogen is the primary component of the nitrogen-based system. Air, which contains about 78% N2, 21% O2, 0.93% argon, 0.03% carbon dioxide, and a minor quantity of rare gases like neon and helium, is the source of molecular nitrogen. Air separation is the primary method of producing nitrogen.

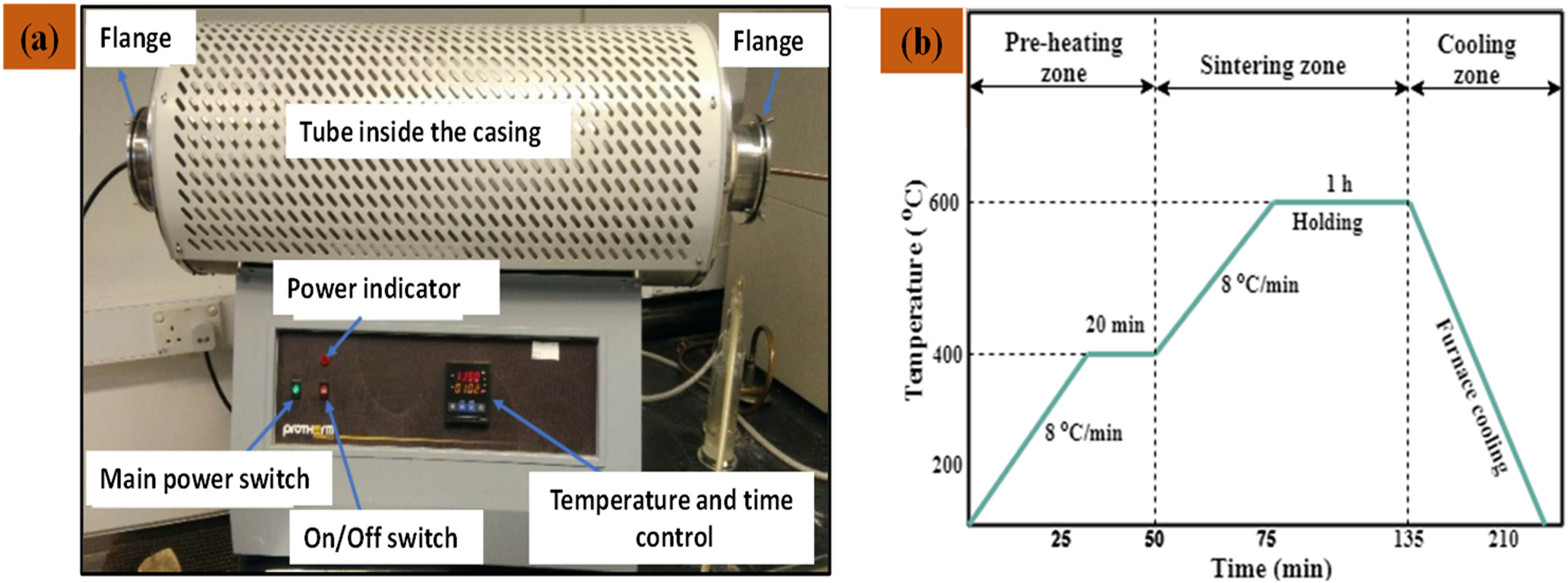

2.1.1.4 Sintering zones

Three separate zones can be seen in a typical sintering furnace: the burn-off or pre-heating zone, the entrance zone, and the high-temperature sintering zone. The green compacts are intended to be heated gradually to a moderate temperature of around 450°C in the burn-off zone of the furnace. The volatilization and removal of the admixed lubricant are the primary purposes of this burn-off zone. Figure 17(a) and (b) illustrates the tube furnace and sintering zones for aluminum alloy-based powder.

(a) Tube furnace for sintering of the green compacts. (b) Schematic illustrations of the sintering cycle in a controlled nitrogen atmosphere of the tube furnace.

To prevent high pressures inside the compact and potential expansion and fracture, a modest heating rate is required. Before the compacts enter the high-temperature zone, this zone must be long enough to allow for the complete removal of the lubricant. The lubricating vapors must be expelled, and this depends on the atmosphere’s flow. To do this, there must be enough atmosphere gas available, and the flow must be positioned so that the vapors are evacuated toward the furnace entrance rather than into the high-heat zone.

The actual sintering of the compacts occurs at the high-temperature sintering zone. It must be adequately heated in order to obtain the desired temperature and heated for a long enough period to develop the required final qualities in the sintered pieces. The burn-off and high-temperature zones typically have similar lengths. A gastight muffle is used because a reducing environment must be present during the sintering process. In order to prevent thermal shock in the compacts and the furnace, the cooling zone gradually lowers the components’ temperature from a high sintering temperature to a lower one. It also maintains a low temperature to stop the material from oxidizing when exposed to the air.

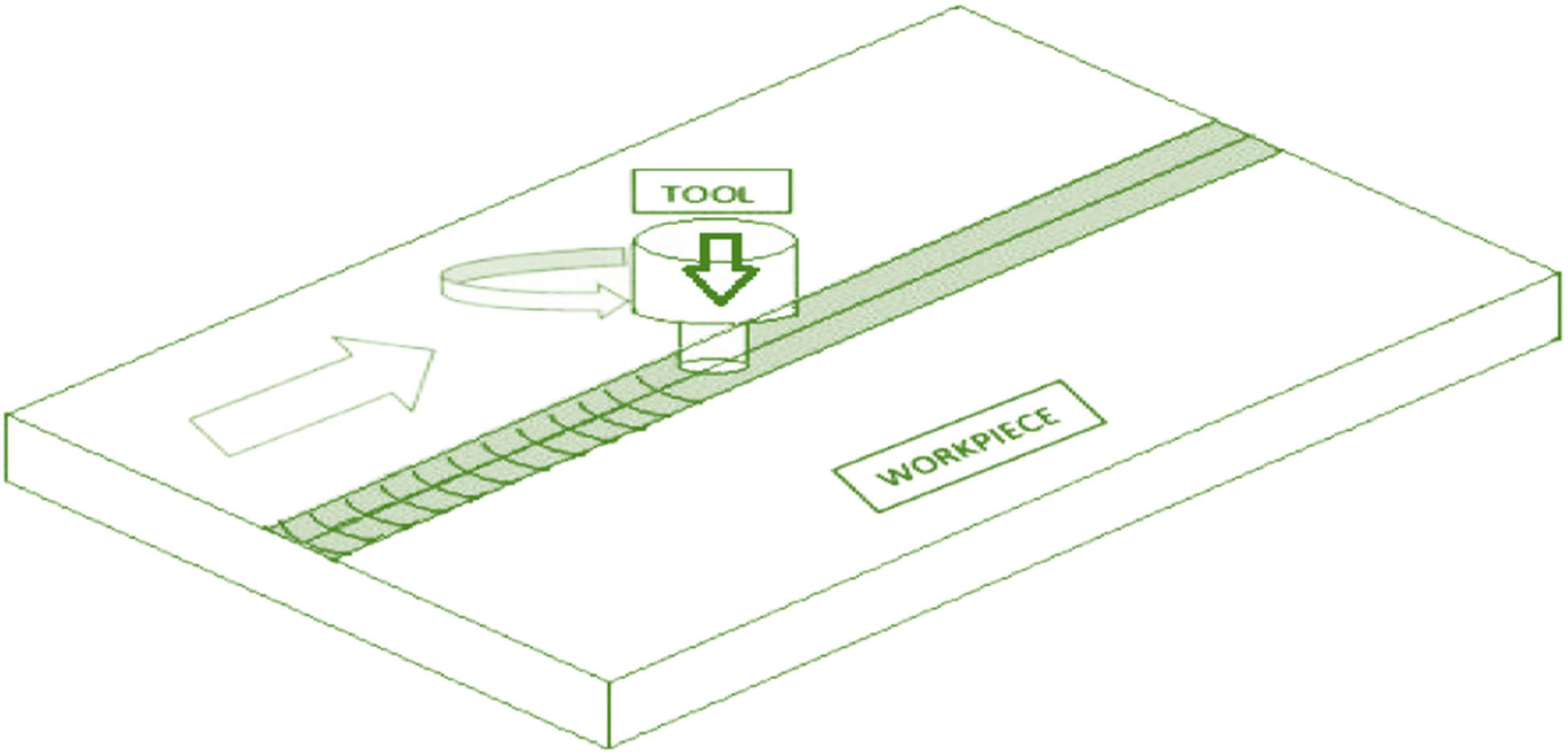

2.1.2 Use friction stir processing

Friction stir welding was adapted to allow for the formation of fine-grained microstructures close to the surface of metallic materials via dynamic recrystallization, and this resulted in the development of FSP. A revolving tool pin is placed into the substrate during the procedure, which causes the workpiece to become heated and pliable due to friction and plastic deformation caused by the tool. The tool pin thus encourages material mixing in the immediate area. For joining the metals, FSP uses the theory of extreme plastic deformation. This technique, which falls under the domain of solid-state joining processes [158,159], is derived from friction stir welding (invented at the TWI, UK). The procedure's potential benefit is that it does not alter the basic matrix characteristics and aids in creating AMCs with superior surface qualities. As shown in Figure 18, the FSP operating principle is displayed. During the procedure, a non-consumable tool that rotates at a rapid rate is used. Large amounts of heat are generated by friction when this revolving tool comes into contact with aluminum. The reinforced material is combined in this high heat that transforms the intended contact metal part into a plastic zone. In recent years, several research articles reported the synthesis of AMCs through FSP.

Schematic representation of the FSP process.

To provide the product with the appropriate shape, extrusion was used on Al-graphene MMCs. The structure of graphene was seen to stay intact following extrusion, albeit with some bending and wrinkling [160]. A fascinating finding was that the extrusion technique improved the interfacial adhesion between GNFs and the Al matrix, which was essential for enhancing the mechanical characteristics of MMCs. To enhance the GNP particle distribution, the FSP has also been investigated [161]. Multi-pass friction stirring was shown to further improve GNP dispersion and bonding in the Al matrix (Figure 19).

2.2 Liquid-state processing

In liquid-state techniques, molten metal is used to perform the dispersion of reinforcement. The Al-MMCs are produced via a variety of liquid-state methods, such as in situ processing, spray deposition, stir-casting, and compo-casting [162,163,164,165].

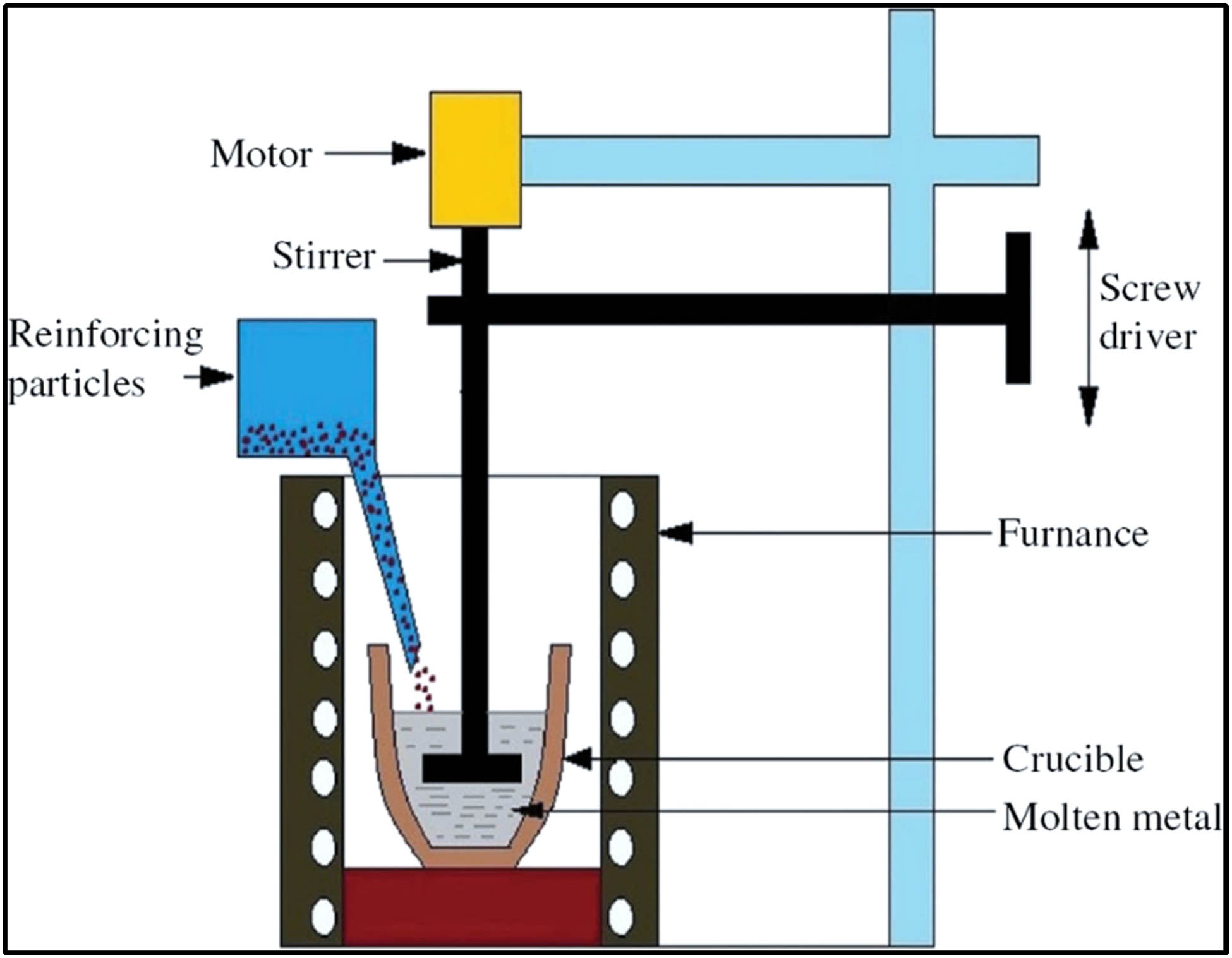

2.2.1 Stir-casting method

In the stir-casting process, the liquid matrix melt receives reinforcement, and the MMCs subsequently solidify. After the matrix has melted, it is vigorously stirred for a while to create a vortex in the melt; next, reinforcement particles are added to the vortex’s side, as shown in Figure 20. It is easy to use, affordable, and suitable for mass manufacturing. Wettability, poor interfacial bonding, and uneven reinforcement distribution have all been reported [8].

Schematic representation of the casting process.

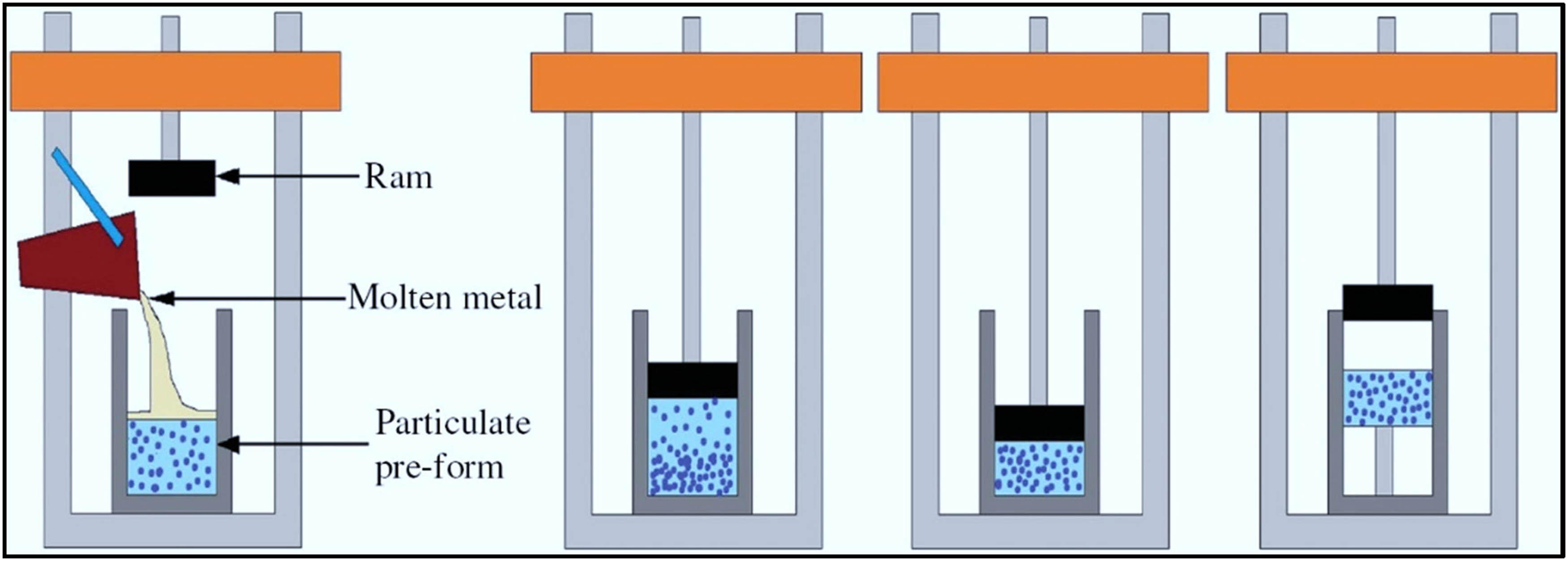

2.2.2 Squeeze-casting method

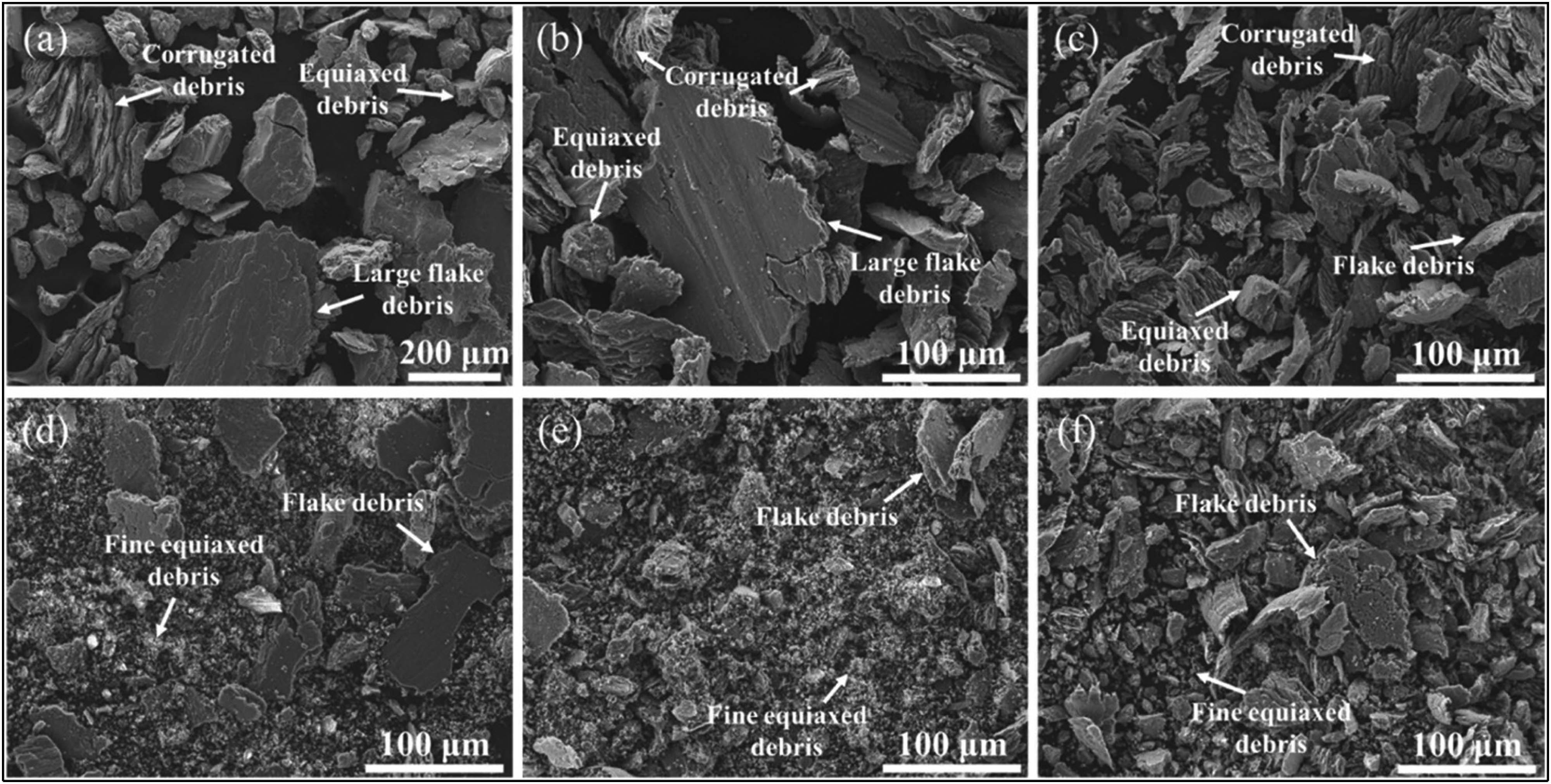

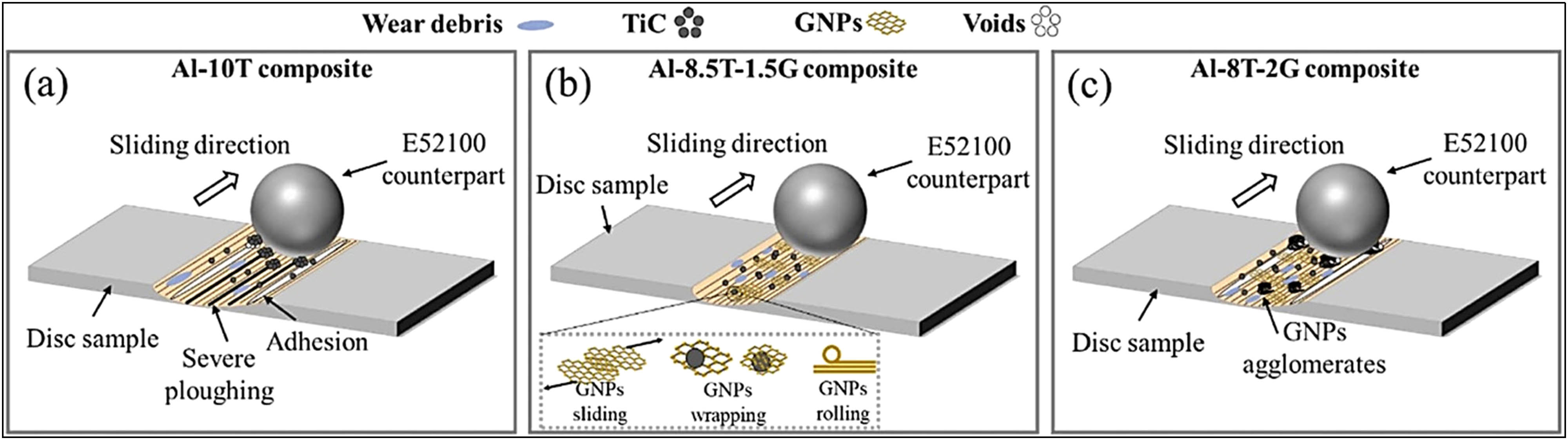

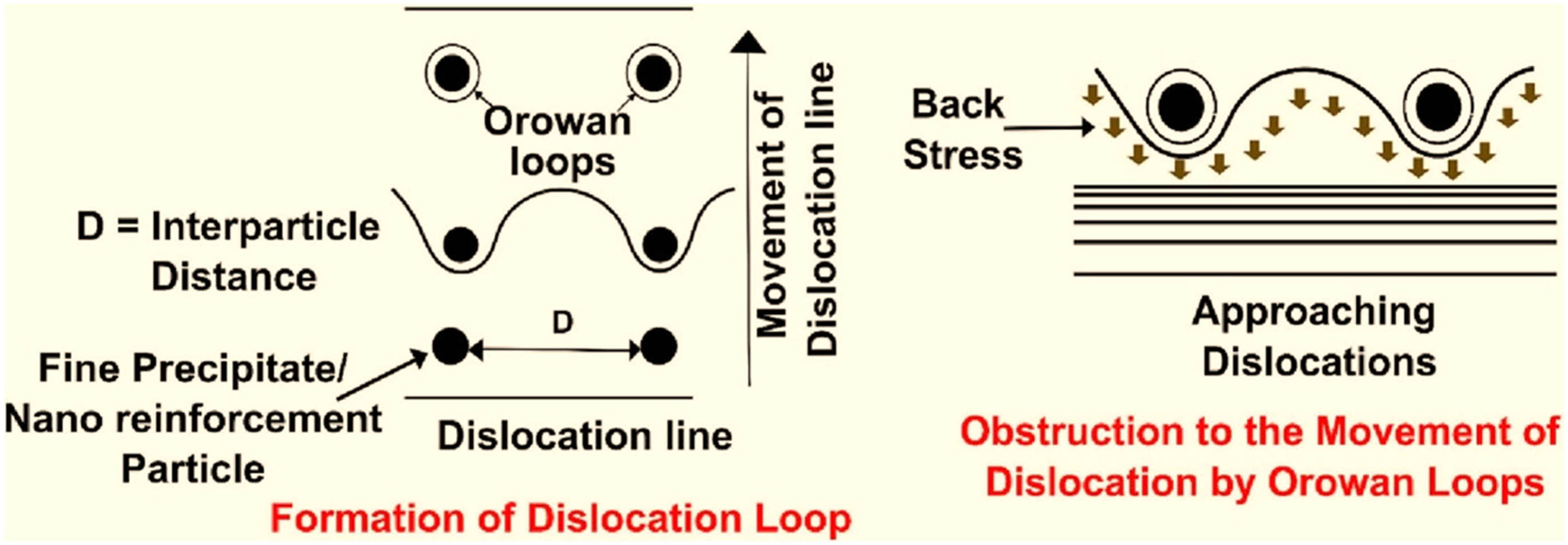

MMCs are established by pressing the molten metal onto a particulate pre-form. The matrix material is melted in a crucible along with the necessary additives, and the reinforcing element is preheated separately [166]. Finally, as shown in Figure 21, pressure is applied through a ram while the molten metal is poured on top of the reinforcement. The key advantages of this approach are low shrinkage, the capacity to create complicated shapes, and the least interfacial reactivity of the matrix with reinforcement [167].