Abstract

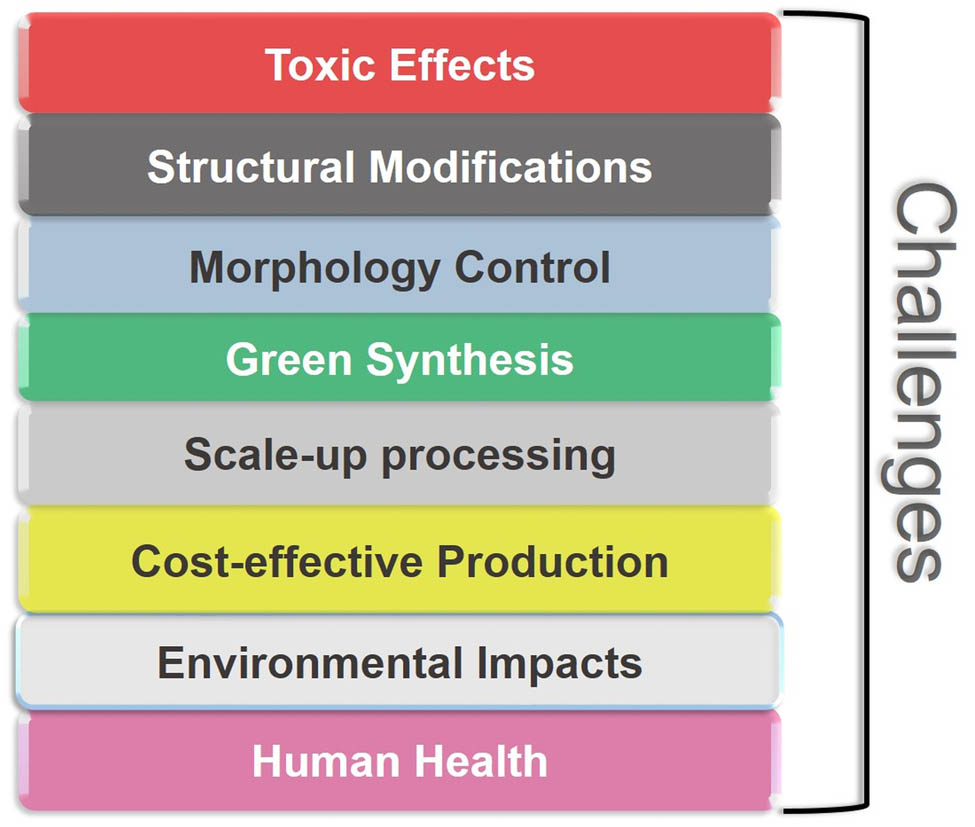

In line with the global recognition of waste-to-wealth concept aiming for circular economy, scientific articles are published in greatly increasing number on the eco-friendly and sustainable utilization of carbon nanocomposites. However, control on the structure and properties of waste-derived carbon nanomaterials still requires substantial future research. In this review, recycling materials into nanocomposites containing graphene are narrated by overviewing all the 120 publications currently available in the literature including their pioneering study in 2012 and their recent developments until 2022, focusing on energy-related aspects of functional graphene-based nanocomposites. Interestingly, almost all currently available sources report on composites in which graphene is a high value-added filler or matrix, and only the other phase originates from wastes. Flexibility of process parameters of pyrolysis methods enables the synthesis of biomass-derived graphene composites for virtually any kind of industrial applications. Biomass often acts both as carbon and SiO2 source, while only a few percentages of graphene material induce significant changes in their physicochemical properties. Utilization of wastes for energetic composites increases abruptly due to their outstanding price-to-value ratio and reusability. Future perspectives and current green chemistry or human health related challenges are also discussed to pave ways for new developments using unexplored waste sources.

1 Introduction

The growing consumption of durable and nondurable consumer goods and the associated production of waste materials is alarming global population for taking urgent steps towards more efficient measures in environmental protection [1]. One of the fastest growing wastes is waste electrical and electronic equipment (WEEE) [2]. According to a recent report by Shittu et al., the global WEEE production was 54 million tons (MT) in 2019 which is a rise of 45 MT since 2016 [3]. This escalation is expected to upsurge to 75 MT by 2030 [4]. The concerns are thoughtful due to human health influences and loss of bio-resources as climate changes. In a recent review about systematic waste management, 366 articles were evaluated according to correlations between country income groups and different issues that indicate possible future trends in the use of municipal solid wastes [5].

Waste materials are used as raw materials in the production of value-added products. Development of perfect industrial symbiosis and cost benefit analysis in meeting the demand of sustainable green energy and eco-friendly recycling of waste materials has been one of the most perplexing waste-related issues in recent decades [6]. Plastic waste, which is the third most abundant waste source on the planet after food and organic waste, has recently emerged to be one of the world’s most serious public health and environmental issues [7]. The total volume of plastic waste is growing in lockstep with the global population and per capita consumption. The amount of waste produced is inextricably linked to consumption and production patterns [8], and may differ substantially even in the same country. For example, Malaysian household waste generation varies by region and economic status, ranging from 0.85 to 1.5 kg per person per day [9].

To deal with the global concerns on waste generation, there is an ongoing demand for the reconsideration and improvement of waste management procedures. One notable example is to introduce economical fabrication methodologies of waste-derived energetic carbon nanomaterials such as graphene, carbon nanotubes (CNTs), and graphene quantum dots (GQDs) for energy storage applications [10]. These energetic substances are classified according to four categories based on their dimensionality features according to the common terminology used in materials science and nanotechnology: zero-dimensional (0D), one-dimensional (1D), two-dimensional (2D), and three-dimensional (3D) nanomaterials. Zero-dimensional energetic nanomaterials [11] include carbon quantum dots and spherical or roughly iso-dimensional carbon nanoparticles (NPs), which show exciting and indispensable prospects in the energy conversion and storage including photo- and electrocatalysis or light-emitting diode and photovoltaic cell fabrication [12]. 1D energetic nanomaterials [13], as the second category, include nanowires, nanorods, nanobelts, and nanotubes. The third category is that of (2D) materials characterized by a typical layered structure [14]: nanosheets and nanomembranes. Finally, 3D energetic nanomaterials [15], constitute structural hierarchies of the previously mentioned nanomaterials as base units. Flower balls made of nanosheets and hollow microspheres made of nanorods are noteworthy examples of such 3D hierarchical structures [16]. Thus, graphene materials are suitable for the synthesis of composite materials with different structural, chemical, and morphological properties and can be produced and used in a wide variety of ways. Figure 1 shows distinctive examples highlighting schematically the four generic types of synthesis methods for the production of waste graphene-based nanocomposites. It is remarkable that most synthesis strategies found in the literature involve two common steps: (i) formulation of a composite liquid dispersion containing both composite counterparts in suspended form and (ii) ultrasonication (either bath or tip sonication). Usually the forthcoming steps differ: the liquid is usually removed (e.g., by spray evaporation, drop casting, or centrifugation/drying) or it is kept during the formation of the composite counterpart (hydrothermal treatment of carbon sources and metal salt precursors).

![Figure 1

Commonly employed synthesis strategies in the current literature for waste-derived graphene nanocomposite fabrication, showing schematic flowcharts of the synthesis steps. (a) Spray pyrolysis derived silicon sludge waste-generated nanocomposite [219]; (b) physically mixed and dispersed MnO2/GO and MnO2/rGO composites from spent battery powder [230]; (c) drop casted waste wool derived keratin/graphene thin films [217]; (d) hydrothermal synthesis of magnetic graphitic carbon nanocomposite using chestnut shell (CS) [224]. All cited display items were reproduced with copyright permission.](/document/doi/10.1515/ntrev-2022-0512/asset/graphic/j_ntrev-2022-0512_fig_001.jpg)

Commonly employed synthesis strategies in the current literature for waste-derived graphene nanocomposite fabrication, showing schematic flowcharts of the synthesis steps. (a) Spray pyrolysis derived silicon sludge waste-generated nanocomposite [219]; (b) physically mixed and dispersed MnO2/GO and MnO2/rGO composites from spent battery powder [230]; (c) drop casted waste wool derived keratin/graphene thin films [217]; (d) hydrothermal synthesis of magnetic graphitic carbon nanocomposite using chestnut shell (CS) [224]. All cited display items were reproduced with copyright permission.

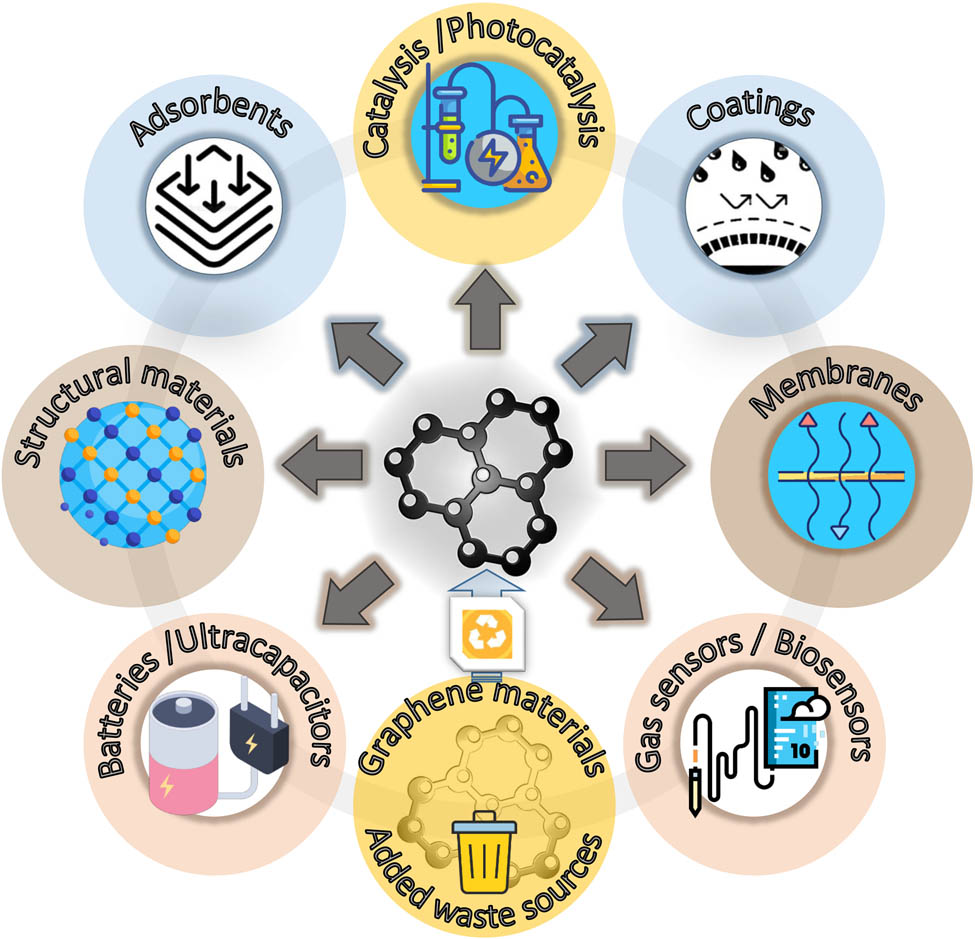

Graphene has an atom’s thickness with a high surface area to volume ratio [17], as well as exceptional mechanical, chemical, thermal, and electrical properties [18]. Recent price checks in the market have revealed the worldwide concerns on the production of commercial graphene. Large-scale production and supply of cost-effective graphene-based nanomaterials with desired properties for specific applications are still an obstacle for its endorsement with high-end consumers and industries [19]. A plentiful of studies have reported on the preparation of nanocomposites of graphene-based materials (chemically derived graphene or graphene oxide, GO) associated with inorganic compounds [20,21,22,23,24,25], or with polymers [26,27,28,29], and demonstrated their utility in extraction processes [30], anode materials for batteries [31], electrochemical supercapacitors [32], bio-based electrocatalytic sensing [33], photocatalysis [34], wastewater treatment [35], energy storage, and other related applications as shown in Figure 2 [36]. In 2021, graphene-based composite materials have been explored across half a dozen review papers, ranging from bio-based graphene nanocomposites [37,38], via magnetic GO nanocomposites [39], to graphene nanocomposites for lithium-ion batteries (LIBs) [40], and biomass-generated graphene like carbons for energy devices [41]. None of these reviews focused on waste-derived graphene nanocomposites.

The most notable applications of waste-generated graphene-based nanocomposite materials.

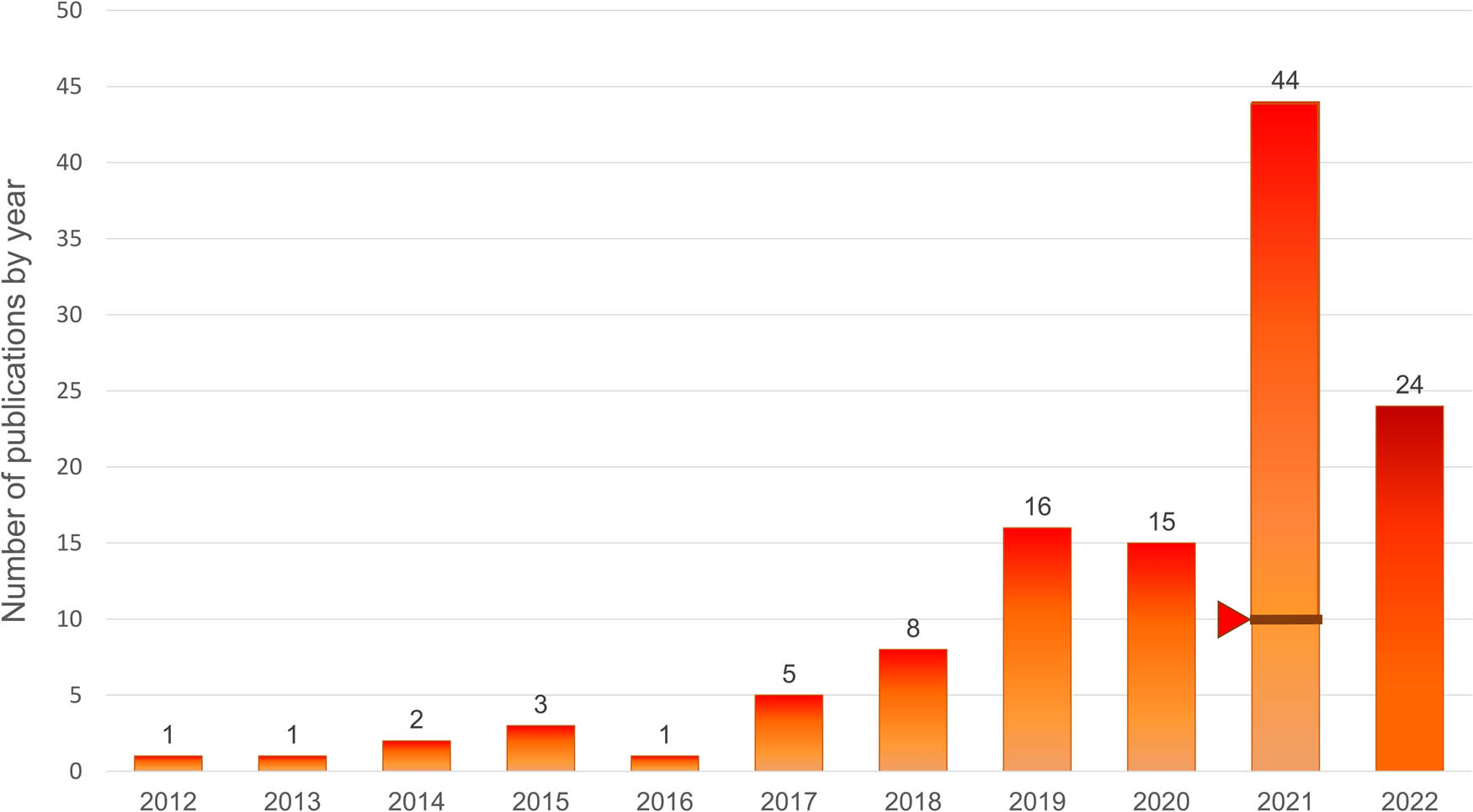

However, the recent publication trend clearly indicates that the incentive towards recycling of waste derivatives into carbonaceous energetic nanomaterials is progressively increasing [42,43,44,45]. Various environmental friendly approaches are required to provide value-added solutions for waste recycling to replace non-biodegradable or toxic conventional practices [46,47]. According to the Web of Science search till July of 2022, a total of 62 papers have been published during 2012–2021 regarding graphene nanocomposites using different waste materials followed by an enormous number (58) of new studies in 2021–2022. This shows a significantly increasing and futuristic attention (as presented in Figure 3) of this hot topic among scientific communities.

Number of publications related to waste-derived graphene nanocomposites in the past decade.

Based on this, a thorough overview is required to compile all the state-of-the-art publications that reported on waste-derived graphene-based nanomaterials. Therefore, in this narrative review, studies on recent improvement of eco-friendly waste-generated graphene nanocomposites are highlighted. To our surprise, this crucially important topic has not been covered earlier.

The comprehensive search strategy employed to locate all related publications relied on the Web of Science database advanced search option. The selective keywords and the derivatives of “waste,” “graphene,” “GO,” “composite,” and “nanocomposite” were used. Peer reviewed research studies in English language were considered for inclusion. Owing to the burgeoning advancement in this field, articles since 2021 are treated separately and they are only involved in statistics without extensive analysis. Instead of providing a critical discussion of the available literature (the full list of which is tabulated as Supporting Information), we aimed to collect papers in the form of a narrative review involving the general discussion of waste-derived graphene nanocomposites in order to give a broad perspective of the current state of the art.

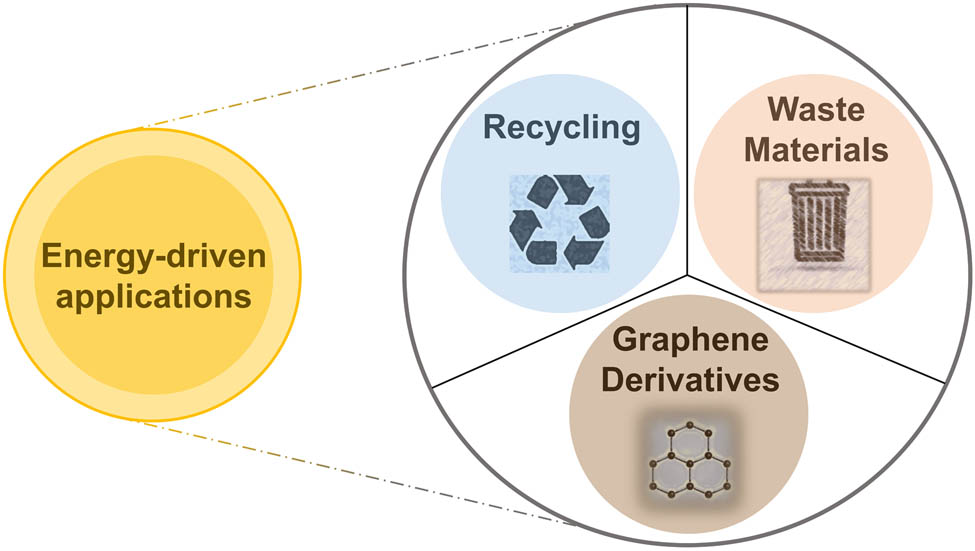

Thus, we begin this review with the discussion of the role of waste materials in the environment and their applicability, followed by a brief overview of graphene-based nanocomposites in industry-related applications, highlighting especially those fields that are associated with energy harvesting and storage as displayed in Figure 4. Then, we combine these two areas into one concept, the main focus will be laid on the comprehensive overview of waste-derived energetic graphene composites. By gathering many different examples of their efficient production and use, we foresee that this review may generate further interest in the discovery and use of new waste-associated precursors and novel methodologies towards the safe and efficient conversion of wastes to valuable energy-related products.

Recycling of waste materials into graphene nanocomposites for energetic applications.

2 Waste materials: their environmental impact and means for possible reuse

Waste materials are generally defined as liquids or solids, which are unwanted, unusable, or at least they lose their basic function after their primary use [48]. The Environmental Quality Act 1974 proclaimed by the Food and Agriculture Organization of the United Nations defines waste as any matter, regardless of solid, liquid, or gaseous form, which are discharged or emitted to the environment resulting in its short-term or long-term change [49,50]. Liquid wastes are, most commonly, residential, commercial, or industrial excess wastewaters released after their use such as cleaning, processing, and cooling [51].

Primarily, waste materials originate from commercial, construction, household, industrial, institutional, imported, and public goods or products [52]. Waste materials have also been categorized into solid and municipal waste, hazardous waste, industrial waste, radioactive waste, and agricultural waste [53,54]. These waste materials are disposed irresponsibly to the surrounding deposits, or even illegally to an adjacent abandoned urban or provincial area, which creates an adverse effect to the environment [55]. Therefore, as per current regulations such as Environmental Quality Act 1974 and Environment Quality (Schedule Waste) Regulations 2005, emerging challenges have been observed which are threatening the environmental and waste management [56,57]. Figure 5 illustrates the continent-based annual waste production categories generated by the World Bank Database.

![Figure 5

Amount of global waste materials generated in megatons (MT) per year as reported for 2016 and projected for 2030 and 2050 [7].](/document/doi/10.1515/ntrev-2022-0512/asset/graphic/j_ntrev-2022-0512_fig_005.jpg)

Amount of global waste materials generated in megatons (MT) per year as reported for 2016 and projected for 2030 and 2050 [7].

It is noteworthy that the projected values of annual waste production for 2030 and 2050 indicate the largest absolute growth for Sub-Saharan Africa, but the growth rate stays minor in four different regions with already different economic development states (Europe and North America vs Middle East and Latin America) [7,58]. This indicates that waste production does not correlate with the current economic development level, but rather with the foreseen rate of development. Hence, the total amount of waste generated is predicted to triple in low-income countries by 2050 [59,60]. In addition, East Asia/Pacific region is expected to generate the world’s largest amount of waste i.e., 23%, on the other hand, North Africa and Middle East are estimated to produce around 6%. The highest projection of waste in South and East Asia/Pacific regions require planned strategies to overcome the consequences to the environment, health, and life [61,62].

2.1 Classification of waste materials

One practical way to classify waste materials is based on the level of detrimental effects they have on the environment. Bertram et al. [63], classified wastes into four categories: (i) eco-friendly, (ii) biodegradable, (iii) non-biodegradable, and (iv) toxic wastes. They suggested the introduction of color codes to indicate these categories. Herein, gray represents category (i), that is, favorable types of wastes which do not pose any harm to the environment [64]. White and blue color codes symbolize waste materials of category (ii) and (iii), respectively, which degrade by more than 20% of their original mass known as biodegradable, or less than 20% called as non-biodegradable. Finally, toxic and harmful types of waste materials are categorized under brown color code. The color classification index which indicates the environmental impact of waste, and its examples are tabulated in Table 1.

Color classification test procedure conducted to group waste materials, adopted by earlier studies [63,64]

| Classification | Color category | Color code based environmental effects | Examples |

|---|---|---|---|

| Eco-friendly waste | Gray | No significant risk to the environment | Food wastes, biomass, etc. |

| Biodegradable waste | White | Biodegradation >20% | Paper wastes, etc. |

| Non-biodegradable waste | Blue | Biodegradation <20% | Plastic, glass, metals, etc. |

| Toxic waste | Brown | Biodegradation <20% and toxicity <10 mg L−1 | Batteries, chemical additives, etc. |

Application of toxic chemicals and additives are widely used in various industries such as oil and gas, electronics, and other energy related sectors [65]. Several authors have reported perilous environmental effects on marine life and humans on using chemical additives such as viscosifiers, lubricants, and surfactants [46,66,67]. Therefore, it is necessary to replace toxic and hazardous chemical additives and use natural and non-toxic materials [68]. In short, the use of eco-friendly and biodegradable materials in the industrial applications reduces the environmental impact and personal safety issues. One of the potential types is biowaste which falls under this category because it is both eco-friendly and biodegradable [69]. Other noteworthy types of waste include hazardous or toxic and non-biodegradable. Thus, biowastes hold great potential as an alternative of expensive and toxic additives in nanomaterials industry [70].

2.2 Recent applicability of waste materials

Accumulation of waste materials is a rising problem that not only threatens the environment but also the public safety. Devadoss et al. reported that Malaysia generated 13.9 MT of municipal solid wastes, heavily relying on landfilling for disposal [71]. According to recent surveys [72,73,74], more than 80% of municipal solid wastes were disposed in the landfills. To reduce the impact of this problem, these waste materials can be recycled and utilized in industries instead of disposing them.

For recycling of dangerous and hazardous wastes, special conditions and measures must be imposed to avoid mass catastrophes [75]. Furthermore, nuclear and radioactive materials must be strictly and completely disregarded from consideration for any types of recycling procedures [76,77]. Besides that, wastes of higher toxicity and complex handling are also unfavorable in any application. This is because waste materials could negatively affect the public health, safety, and the environment [78]. Thus, an increasing demand for the efficient transformation of wastes into benign nanomaterials has emerged to reduce the amount of waste discharged to the environment [79].

Lately, the increase in global concerns towards the sustainability of the Earth has increased public and industrial awareness on the detrimental effects of chemical toxic and non-biodegradable materials [80]. Strong efforts have been exercised to study several non-hazardous waste materials which are applicable in industrial applications such as food, agriculture and construction wastes [81]. Also, recycling of electronic waste has not been extensively adapted though it is a great approach to handle e-waste materials. The most common sources of e-waste include electronic toys, computer chips, circuit boards, batteries, wires, and motherboards [82,83]. Numerous studies have comprehended the recycling of waste materials by differentiating their sources and reutilization, conversion of these waste sources, implementation of disposal treatments, and fabrication into value-added nanomaterials. Finally, energetic applications and energy recovery has been suggested as well [84,85,86].

3 Graphene nanocomposites for industrial applications

There are versatile graphene materials that have been incorporated into industrially relevant composite matrices [87,26]. The two main categories are (i) chemically derived graphene materials and (ii) graphene particles obtained after physical exfoliation or physical deposition procedures [88,89,90]. Figure 6 illustrates a classification of commonly used top-down and bottom-up synthetic routes for graphene derivatives [43]. The chemical routes offer, at present, much cheaper and versatile opportunities to obtain the carbonaceous platelets in large quantities, which can serve a whole section of industry with at least a ton-scale/day production rate [91]. Physical exfoliation (scotch tape method and its developments), chemical vapor deposition or laser irradiation-assisted methods [92] cannot currently compete with this scale of production rate. For the chemical routes, the starting material is almost exclusively graphite oxide [93]. Graphite oxide is usually exfoliated in a liquid phase to produce single layers termed as GO, or at least particles that are dispersed into a few-layered graphene oxide. Graphene-based particles in the final composites are then obtained usually by thermal decomposition of GO (to obtain chemically derived graphene) [94], or by chemical reduction (to obtain reduced graphene oxide, rGO). Other commonly derived forms of graphene include holey graphene, graphene nanoplatelets (GNPs), flower-shaped graphene/GO, graphene nanoribbons (GNRs), and GQDs, etc. [95,96]. The origin of high versatility of chemical properties and structural features is the composition of graphene-based composite materials.

![Figure 6

Classification of synthetic routes for graphene-based materials [43].](/document/doi/10.1515/ntrev-2022-0512/asset/graphic/j_ntrev-2022-0512_fig_006.jpg)

Classification of synthetic routes for graphene-based materials [43].

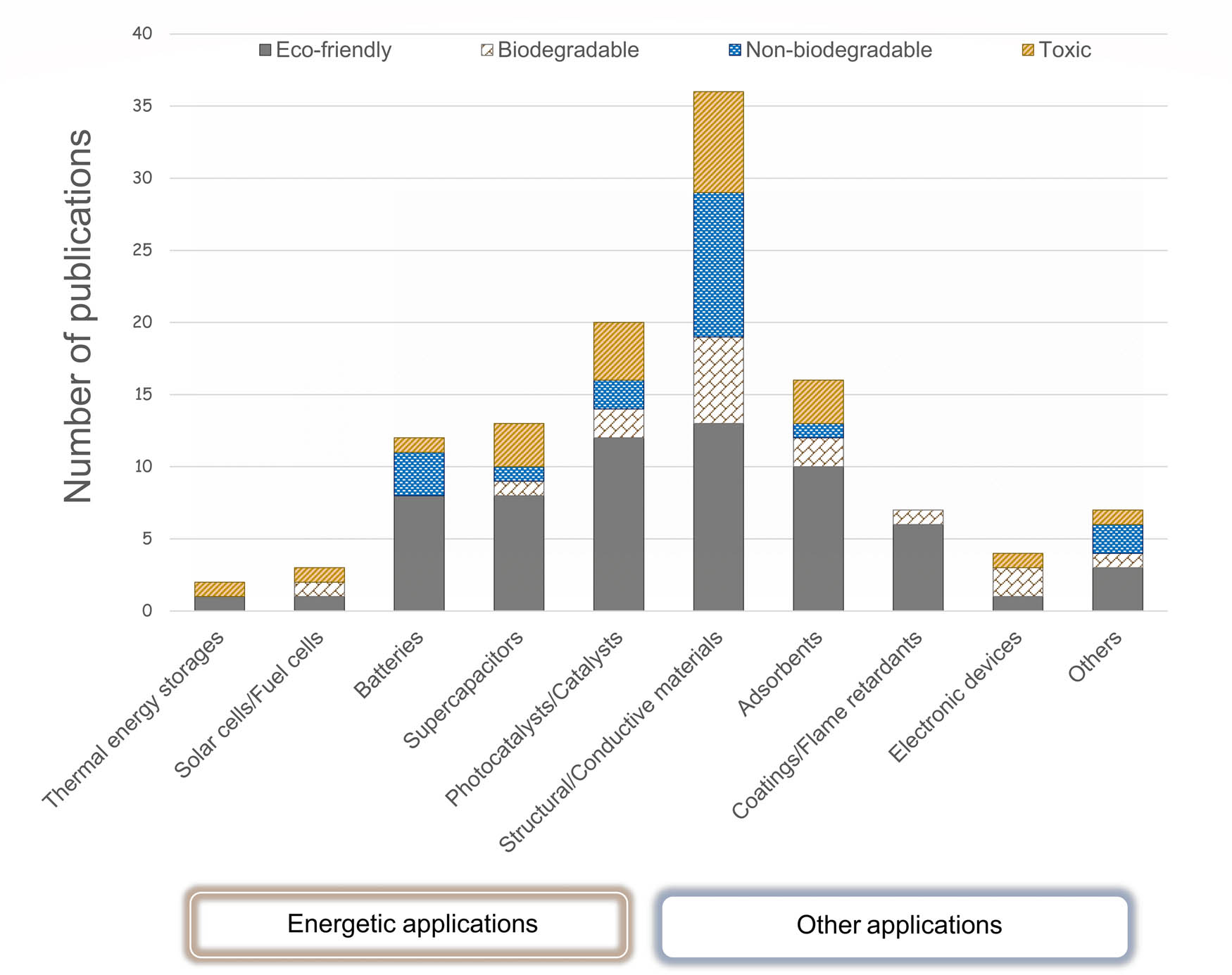

Figure 7 shows the distribution diagram of the application fields of waste-generated graphene-based nanocomposites in which the columns are subdivided by the environmental impact of waste source used according to Bertram s classification [63]. The possible ways of reuse are also tabulated in more details in the Supporting Information. First, one finds that energetic nanocomposites are, at least currently, not among the most frequently studied ones. Supercapacitor and battery-related studies rank 4th and 5th and only a couple of papers focus on solar and fuel cell fabrication or heat storage. The most dominant fields are those which efficiently exploit the low electrical or mechanical percolation thresholds provided by the graphene platelets including studies related to structural materials used in construction (29 papers) and conductive materials (7 papers). Second, it is remarkable that most types of wastes are feasible and usable for the construction of composites to be further used in all sorts of applications.

Waste-derived graphene composites in the current literature classified by their respective field of application.

With regard to the remarkable properties of graphene materials, much research has been done by incorporating graphene and its derivatives into nanocomposites to produce novel materials that make use the best properties and characteristics of each material present in these composites [97,98,99]. The outcomes of these research works have proven that graphene-based nanocomposites significantly improved the performance and functionality of the products, especially in terms of increased electrical conductivity, greater flexibility, thermal resistance, and stability [100,101]. Hence, in Section (3), we discuss the performance of graphene-based nanocomposites in industrial applications. Before this, however, we find it important to make the following remarks on the related terminology:

The term “graphene (based) nanocomposite,” at least within the context of this review, refers to any composite material which contains highly dispersed (single or few-layered) graphene-like carbon platelets, and it is not restricted to systems in which the major counterpart of the composite (matrix) is graphene-based solid. In all cases, nevertheless, the observable properties of the composites are affected by the graphene content.

“Waste-derived” refers to any nanocomposites which include a counterpart obtained from a waste material. Therefore, wastes may be the source of the carbonaceous phase (GO or derived carbons), which is coupled with a regular nanomaterial (e.g., inorganic oxides) as reported in a few studies [224,237,331]. On the other hand, in an overwhelming majority of currently reported cases, the matrix of the nanocomposite originates from a waste source (e.g., plastic) and graphene platelets (from any sources) are employed as high value-added fillers.

3.1 Energy production and storage

3.1.1 LIBs and sodium-ion batteries (SIBs)

The development of LIBs has been triggered by a surge demand in advanced energy storage due to environmental concerns. LIBs are rechargeable and they have high energy density and long cycle life which make them promising to be utilized as power sources for electric vehicles [102]. SIBs displayed similar electrochemical behavior to LIBs, due to the high availability of sodium sources with remarkably low cost [103]. SIBs seem as potential candidates to be fully utilized as energy storage systems. The combination of metal oxides and graphene derivatives are promising anode materials and thus are heavily used in market leader products [104]. In particular, power sources based on 1D, 2D, and 3D graphene nanostructures are the best examples of the frontier devices for serving the new wave of medical devices, flexible screens, or wearable electronics [105]. However, the significant difference between the ionic radii and atomic weights of Li+ and Na+ are also seen in the transfer properties and phase stability which leads to lower energy density of SIBs. The favorable morphology of composite materials contributes greatly to the increase in overall capacity. This is most evident in the case of composites with metals [106]. Characteristics such as high cyclic stability, large surface area, high capacity, and low electrical resistance [107] are still the primary aspects to consider for energy storage performance, but, for e.g., for flexible batteries, the mechanical and structural properties are also of utmost importance. Graphene-based matrices and coatings are able to enhance electrochemical characteristics in different ways. First, the various nanostructures (GQDs, rGO, graphene films etc.,) may lead to increased active surface area, forming greater surface contact with the electrolyte [23]. These materials are also suitable to make electrodes with lower inactive weight and short diffusion path, which also improve the rate of charging/discharging processes. These coatings and composite matrices have improved the electron transfer processes, which also lead to better power density [108].

3.1.2 Supercapacitors

Supercapacitors (also known as ultracapacitors) are electrical energy storage devices that, unlike conventional solid dielectric-based capacitors, rely on electrochemical double layer capacitance and electrochemical pseudo capacitance which contribute to the total capacitance [109,110]. The important difference between conventional LIBs and supercapacitors is in the quantity of energy stored and the quantity of energy obtained per unit time. Batteries can store lot more energy than supercapacitors, but the latter ones can be charged/discharged much faster, so the development of supercapacitors has recently become a cutting-edge challenge. Especially, the automotive industry and the space agencies are trying to build them into the pioneering hybrid energy storage/regeneration technologies. The electrodes of supercapacitors have been typically made of porous carbon, and graphene-based nanomaterials could provide a suitable solution to scale up the capacity of these devices as coatings or main components, because they can both act as matrix or filler in composite materials [111]. For instance, GO materials are versatile en route products to utilize electrode surface with graphene [112], rGO [113], or graphene-based hybrid nanomaterials [114], to improve electrochemical properties [115]. As the maximum energy storage highly depends on the specific surface area of carbonaceous materials hybridized with metal, metal oxide, and metal sulfide composites, they can be utilized as electrode materials of supercapacitors. Nonetheless, they have excellent electron transport features that enhance conductivity. They may also act as structural materials, because of their small weight and may also play the role of a bonding agent between the components in the composites. However, the direct covalent functionalization of graphene is tedious. Even a recent study shed a light for the applicability of GO to improve the energy storage capacity and power handling capability [116].

3.1.3 Solar cells

A solar cell or photovoltaic cell can be defined as a device that converts the sunlight directly into electricity [117]. In next generation, graphene-based solar cell materials attract serious attention of researchers, due to their good conducting properties, low costs, optical transparency, and lack of toxic environmental effects [118]. Perovskite solar cells (PSCs) are one of the widely used types of solar cells [119]. The power conversion efficiency (PCE) of the solar cells is directly dependent on the electrical conductivity of the matrix of the counter electrode. Graphene and rGO can play a crucial role in the improvement of their performance characteristics. Additionally, the presence of rGO in the composite can possibly prevent the aggregation of fillers or dopants helping to keep the electrically active sites intact during the synthesis process [189]. A few studies revealed that graphene-based nanocomposites could act as hole transport layer [120,121]. In some cases, they even outperformed the polymer-based composites in PSCs, which were proved as the best-known materials for hole transport. They also increased the crystallinity of a perovskite film, leading to reduced leakage current (which causes dropped performance) and decreased the so-called J–V hysteresis, thereby allowing more actual determination of PCE. The optical bandgap of the composites is also a direct function of the degree of oxidation in the GO/rGO composites. In addition, graphene-based matrices have also excellent film forming capabilities, which makes them advantageous for the preparation of solar cells containing brittle and unstable semiconductor films [122]. In dye-sensitized solar cells, carbon-based nanostructures and nanocomposites have been used to improve their electrochemical parameters [123,124].

3.2 Chemical sensors

3.2.1 Biosensors

Biosensors with important features such as low price and rapid, highly sensitive, and greatly selective response have been used extensively for clinical diagnostics, metal ion speciation, and formation of batteries [88,125,126]. With today’s technology advancement, the performance of biosensors has been greatly enhanced by graphene-based nanocomposites [127,128]. Graphene-based NPs are capable to act as biomolecule carriers because the selectivity of the device lies on the chemical properties of the immobilized biomolecules [129]. Moreover, their good film-forming properties makes them suitable to be applied for biosensor fabrication. Graphene materials can be a suitable candidate as a precursor of biosensor membranes or probes. Although GO does not conduct electricity because of the presence of the various oxygen containing functionalities, it can be used as a flat-sheet surface to immobilize biomolecules. Moreover, functionalization by reduction is also able to restore the aromatic π electron system and bonds can be formed with carboxylic groups and N-terminal end on amino-acids or proteins, but epoxide or peroxide groups can also be easily functionalized by acid base or redox reactions. In biosensing, a direct connection leading to electron transfer between the active centrum of an enzyme and the carbon atoms plays key role in the process [130]. Biosensors can be grouped into the enzymatic, non-enzymatic and immunosensor categories [131]. According to the literature, various biomolecules, such as micro-RNA [132,133], nucleic acids [134,135], or biomarkers [136], can be detected with good selectivity by graphene-based biosensors. To enhance the electrochemical behavior, reduction of GO can be easily carried out under mild conditions, but even electrochemically reduced GO is widely used for biosensing.

3.2.2 Gas sensors

Gas sensor is an important device for detecting the variation in the concentration of toxic, or chemically active gases, for example to create safe work environment in industry, where precaution needs to be exercised to avoid air poisoning or to monitor the presence of explosive gases. Selective and sensitive gas detection at room temperature and a wide range of ambient humidity is needed for appropriate environmental monitoring [137]. Graphene-based materials have multiple advances in these devices. First, the presence of graphene in metal–graphene sensors can inhibit the oxidation of the metal component. Moreover, the high surface area to volume ratio is also beneficial and the metal–graphene system is also used to establish kinetic or mass transport selectivity [138]. A large number of studies have reported the applicability of graphene-based nanocomposites incorporated in gas sensors, but carbon nanotubes and nanofibers are also frequently examined [139,140,141]. Therefore, the most important class of graphene-based nanocomposite type gas sensors is that of electrochemical sensors [88,142]. The gas adsorption on the carbon-modified surface affects the electrochemical properties such as bandgap and charge transfer processes, that may provide a highly selective sensor membrane with remarkable signal/noise ratio [143]. Additionally, varying the structure, morphology, type, and amount of additives or degree of oxidation makes it possible to influence the selectivity. As it was demonstrated for biosensors, GO can also undergo surface functionalization schemes simply, in one step methods. Moreover, graphene nanocomposites make possible to detect wide range of toxic gases for example NO x [144], CO [145], formaldehyde [146], or CO2 [147]. Metal oxides or conducting polymers such as polyaniline (PANI) are commonly used fillers for the fabrication of graphene nanocomposites, which are found applicable for gas sensing [137,148,149]. The good film forming ability is also relevant, but the probe also can be formed by 3D (i.e., foam-like) composites [150].

3.3 Corrosion protection

Enormous amount of money is spent on repairing the damage caused by corrosion. Therefore, a wealth of research projects is devoted to produce anti corrosion coatings with excellent properties to overcome the problem [151]. Recently, graphene nanocomposites have become potential candidates to deposit anti-corrosion coatings due to their high chemical stability [152,153]. Besides, graphene matrix is composed of sp2 hybridized carbon atoms that are linked to each other in a 2D honeycomb lattice structure with high electron-density in its aromatic rings, which makes it impermeable to all molecules [154]. In the past few years, a lot of cheap and simple methods were developed for the mass production of graphene-based anti-corrosion coatings [155]. However, according to some of the latest reports, graphene materials can have a short-term corrosion protection effect but, conversely, corrosion promotion activity of the coating may occur in the long term. It is clearly stated that this phenomenon is related to the percolation threshold phenomena [154]. Above a certain surface coverage of the graphene particles, they even accelerate the corrosion process either due to the kinetic effects (the uncoated patches act as defects on the coating at which the oxidization becomes faster), or because of thermodynamic effects (decrease in the redox potential) [152,156]. It is also associated with the oxidation degree of GO/rGO, which restores the aromatic structure of graphene. In most cases, however, graphene nanocomposite coatings can prevent the formation of defects on the coating. Nonetheless, after the object was oxidized in the end of the process, the graphene coating helped in keeping the object in one piece, preventing the release of the corroded material to the environment [157]. Furthermore, some researchers stated that the rate of corrosion decreases with the increase in the number of graphene layers on the surface, [158,159] and they did not report the corrosion promoting phenomena, e.g., in the case of plastic/GO coatings. In addition, for monolayer coatings, there is a great importance of the perfect coverage, because structural defects may lead to increased corrosion of the substrate as compared to the bare materials [160]. In summary, the corrosion promotion activity of graphene-based nanocomposites is highly dependent on the quality of the non-carbonaceous component too. Graphene/GO is less suitable to form the matrix in composites, or to be applied only in its pristine state for corrosion protection.

3.4 Membrane processes

Graphene and its derivatives act as a perfect barrier due to high electron density of the aromatic rings that block any atoms or molecules from moving across it. Besides, graphene/GO fillers are the leaders in advanced composite membrane design studies in terms of mechanical properties. In the case of biocomposite membranes, GO loading can also enhance the hydrophilic interactions, dipole interactions, and hydrogen bonding at the same time [161]. In the past decades, water purification became a crucial problem especially for the treatment of municipal sewage or industrial wastewater. Membrane separation is a traditional method to clean the used industrial feed waters and by-product wastewaters [162]. Interestingly, due to their layered structure and special pore system including water permeation channels, pristine GO itself is capable to form membranes with advanced filtering features [163]. However graphene-based nanocomposites are also very competent candidates to beneficially influence the parameters of membranes, but pristine graphene and GO are also suitable to form membranes [164]. Nanocomposite membranes could be applied in a wide range of treatment processes. Among graphene nanocomposites, especially GO has been applied as filler, owing to its ability to keep the structural integrity of the membrane even at high pressures and could be used to form superhydrophilic membranes for increasing the transport rate of the water molecules [165]. For instance, oil-in-water emulsion separation [166] and toxic heavy metal ion removal by adsorption [167] are considerable potential applications of GO composite membranes. It is important to mention that composite membranes can be bestowed by anti-bacterial surface modifiers [168], as GO nanocomposites are extremely capable to immobilize almost any kind of substrates on their surface and the modified carbonaceous lamellae can be easily deposited on the membrane surfaces [169].

It is easily noticeable that polymer/graphene or polymer/GO systems represent the vast majority of carbonaceous composites used for membrane separation applications. The simple reason is that a wide range of polymers (both conducting or non-conducting) can be easily grafted or non-covalently attached to graphene materials in which graphene may act both as the matrix or the filler. Metal-like graphene composite coatings, metal oxide/graphene or GO hybrids, and polymer modified graphene materials and composites containing layered double hydroxides (LDH) and metal organic frameworks were also studied but less frequently [160].

In this part, we summarized the most popular fields of applications of graphene-based nanocomposites, but some of the fields mentioned below are not explained here in detail such as fire retardants or organic catalysts, adsorbent, or photocatalytically active composites. It is due to the minor fraction of literature papers related to waste-derived graphene-based materials in other general applications. Also, the focus of this study is centered towards energy related applications. Nevertheless, we will discuss these from the reusing and valorization point of view.

Without a possibility to give a comprehensive enumeration of all relevant papers in the specific areas, we tabulate representative publications on graphene nanocomposites used in diverse fields of industry, indicating the chemistry of the studied composite counterparts, the objectives of the study, and bullet points of its main findings (Table 2).

Selected publications reporting on the utility of graphene nanocomposites for industrial applications

| Applications | Nanocomposite counterparts | Objectives | Performance outcomes | Ref. |

|---|---|---|---|---|

| LIBs and SIBs | Chitosan/rGO | To enhance the capability rate of LIBs/SIBs | •Support high capacities in Li-ion system (170 mA hg−1) and Na-ion system (80 mA hg−1) | [170] |

| 2D GO/1D LiMn2O4 | To improve the cathodic property of LIBs | •Exhibits high specific charge capacity and Coulombic efficiency (∼98%) after 100 cycles | [171] | |

| •Stable structure after 100 cycles | ||||

| GQDs-doped CuCo2S4 | As a supercapacitor electrode and the role of CuCo2S4 was established to support electrochemical cycling and ion diffusion | •Displayed specific capacitance of 1,725 F g−1 under current density of 0.5 Ag−1 | [172] | |

| •Cycle life of 10,000 cycles while maintaining 90% of energy storage capability | ||||

| SnS2/rGO | Carbon particles in nanocomposite helped to prevent SnS2 agglomeration | •Improved electrochemical performance | [173] | |

| •Excellent rate capacity | ||||

| •Good cyclic stability | ||||

| V2O3/rGO | To investigate Li+ storage behavior of V2O3/rGO | •Achieve high reversible specific capacity of: | [174] | |

| •823.4 mA hg−1 (current density:0.1 Ag−1) | ||||

| •407.3 mA hg−1 (current density: 4.0 Ag−1) | ||||

| 3D sandwiched-shape graphene/MnCo2O4 | As anode material of high-performance LIBs | •Enhanced rate capability | [175] | |

| •Remarkable cycle performance with high capability | ||||

| Nb2O5/rGO | As anode material of LIBs | •Good initial discharge-charge capacity | [176] | |

| •Capacity retention of 195 mA hg−1 at 0.2 Ag−1 after 200 cycles and 98 mA hg−1 at 2 Ag−1 after 1000 cycles | ||||

| CuSi2P3@Graphene | As anode material | •Great electrochemical performance | [177] | |

| •High reversible capability over 500 cycles | ||||

| •Long lasting cycling stability of 1,394 mA hg−1 after 1,500 cycles at 2 A g−1; 1,804 mA hg−1 after 500 cycles at 200 mA g−1 | ||||

| SiOx@Fe3O4@FLG | Excellent electrochemical performance | •Outstanding performance of 1,550 mA h cm−3 at 0.5 Ag−1 after 500 cycles | [178] | |

| Zn2Ti3O8/rGO | An alternative energy storage device to fill the gap between LIBs and supercapacitors | •Specific capacity of 560 mA hg−1 at 0.1 Ag−1 and 300 mA hg−1 at 2.0 Ag−1 with superior rate capability | [179] | |

| Double shell Co3Sn2/SnO2@C@Graphene | Superior electrochemical performance as anode material | •Good sodium storage capacity | [180] | |

| •Reversible charge storage capacity of: | ||||

| •744 mA hg−1 after 100 cycles | ||||

| •605 mA hg−1 after 300 cycles | ||||

| rGO/Zn/polycarbazole | Supercapacitor device performances and electrochemical measurements were enhanced | •Enhanced the capacitance compared to the single NPs | [181] | |

| •High power of 442.5 W kg−1 | ||||

| •Energy storage capabilities (1.66 W h kg−1 | ||||

| Supercapacitors | PANI/sulfonated graphene | As negative electrode of the asymmetric supercapacitor | •Extended potential window | [182] |

| •85% capacitance retention after 5,000 cycles | ||||

| •Satisfactory energy and power density | ||||

| Poly(3,4 ethylenedioxythiophene)polystyrene sulfonate/GO/glucose | As a novel electrode material for flexible supercapacitors | •Specific capacitance of 16 F g−1 | [183] | |

| N-doped graphene | As an electrode material for supercapacitors | •Higher specific capacitance compared to metal oxides | [184] | |

| •Better cyclic stability up to 1,000 cycles | ||||

| W18O49 nanowires-graphene (W18O49 NWs-rGO//rGO) | As an electrode material for supercapacitors | •Showed pseudocapacitive behavior with: | [185] | |

| •High specific capacitance | ||||

| •Good rate capability | ||||

| •Good cyclic stability | ||||

| •W18O49 NWs-rGO/rGO supercapacitor shows energy density of 28.5 W h kg−1 | ||||

| Graphene/Ni3V2O8 | As electrode material for supercapacitors | •Electrochemical performance better than pristine Ni3V2O8 | [186,187] | |

| •Good specific capacitance | ||||

| •Good energy density | ||||

| •Reasonable cyclic stability | ||||

| •Recorded Coulombic efficiency of 83% after 3,000 cycles | ||||

| Multivalent VO x /Graphene | As electrode for high-energy-density symmetric supercapacitors | •Obtained high three-electrode specific capacitance of 1,110 F g−1 | [115] | |

| •High energy density of 54 W h kg−1 with virtually no capacitance loss after 20,000 cycles | ||||

| •Maintaining 92% energy storage capability after 20,000 cycles | ||||

| Solar cells | MoS2/graphene | Fabrication of nanocomposite utilized as a photoanode for dye-sensitized solar cells | •Nanocomposite showed tremendous photo-conversion efficiency of 8.92% | [188] |

| MoS2 and N-doped GQDs anchored rGO | Nanocomposites have been fabricated for dye-sensitized solar cells (DSSCs) due to their superior electrochemical properties and high chemical stability | •The DSSCs assembled with fabricated nanocomposites and their photovoltaic power conversion efficiency (η) was | [189] | |

| •2.01% for | ||||

| •3.92% for MoS2@rGO | ||||

| •3.53% for N-GQDs@MoS2 | ||||

| •4.65% for N-GQDs@MoS2@rGO | ||||

| ZnO/GO | For remediation of MB dye | •33% faster decolorization of 20 mg/L of MB dye | [190] | |

| TiO2–GO | Improved efficacy of solar cells | •The initial band gap of the TiO2 showed a significant decrease to 1.81–1.40 eV after incorporation of GO in various amounts | [191,192] | |

| Electrochemical biosensors | Copper-carboxylated graphene | To determine electrocatalytic activity for glucose oxidation | •Low limit of detection of 7.96 nM | [193] |

| •Rapid response time of 2 s and wide linear response range from 0.1 µM to 5.48 mM | ||||

| •High sensitivity of 1,142 µA mM−1 cm−2 and good selectivity | ||||

| CNTs/rGO/BiVO4 | Non-enzymatic sensor as it proved that CNTs/rGO/BiVO4 electrode is the best photoelectrochemical electrode for non-enzymatic glucose detection | •Excellent electrocatalytic activity for providing maximum sensitivity of 501.5 mA cm−2 mM−1 and good stability with negligible current response | [194] | |

| rGO/functionalized-ordered mesoporous carbon | Selective and sensitive electrochemical genobiosensor | •Long term stability (21 days) with linear range (0.1–3 µM) | [195] | |

| •High sensitivity of 0.0188 mA µM−1 | ||||

| •Limit of detection: 120 nM | ||||

| Nickle NPs-modified graphene-based GCE (NiNPs/Nafion/graphene/GCE) | Biosensor for sensitive nonenzymatic glucose detection | •High sensitivity recorded with a linear range of 1–200 µM | [196] | |

| •Sensitivity of 2,848.6 µA in linear range of 200–10,800 µM | ||||

| •At concentration <200 µM: | ||||

| •Obtained linear range | ||||

| •Limit of detection: 0.6 µM | ||||

| •Response time: 1–1.5 s | ||||

| •Good stability | ||||

| •Excellent electrical properties | ||||

| rGO–CuFe2O4 | High performance H2 gas sensor | •Able to detect H2 at low concentration of ppm at room temperature | [197,198] | |

| Gas sensors | Bi2O3–GO | Ammonia gas sensor imposed superior sensing performance, including quick response and recovery of the Bi2O3–GO nanocomposite sensor | •Bi2O3–GO nanocomposite sensor at 50 ppm NH3 in just 14 s operation duration was ∼81.23, which is improved 25-fold and 13-fold compared to pristine GO sensors | [199] |

| 3D TiO2/graphene-CNT | Highly selective and fast room temperature gas sensing | •Highly selective sensing in VOC mixtures | [200] | |

| •Good selectivity in the range of 50–500 ppm | ||||

| •Excellent response time in 500 ppm and still satisfying in the range of 100 ppm | ||||

| Anti-corrosion coatings | Nickel–graphene | Anti-corrosion for mild steel | •Superior anti-corrosion performance at current density of 9 A m−2 | [151] |

| GO@CSA–PANI | Fabrication of a promising nanomaterial for adsorption and coatings protection | •Good absorption properties of electromagnetic wave | [201] | |

| •High corrosion resistance | ||||

| •Minimum reflection loss of −48.1 dB and 5.3 GHz with a 2.4 mm matching thickness | ||||

| •Excellent corrosion protection capability (97.43%) after 168 h | ||||

| GO/HAP | As anti-corrosion pigment | •Excellent anti-corrosion performance | [202] | |

| •The impedance increased by 754.4% due to synergistic effect of the nanocomposite | ||||

| GO–polymer | Nanocomposite membrane for reverse osmosis | •Good water transport properties | [203] | |

| •An anti-swelling tendency | ||||

| •Stable under severe oxidizing environment | ||||

| Membranes | PMMA-co-MA-PEG/PC/GNRs | Gas separation membrane | •Due to molecular sieving; | [204] |

| •Permselectivity increased by 51.6% | ||||

| •Permeability decreased by 24.7% | ||||

| Functionalized GO/GQDs | Highly efficient reverse osmosis | •Nanocomposite membrane performed remarkably high water permeance up to 5.89 L m−2 h−1 bar−1 | [205] | |

| •Rejection ratio of 97.1% | ||||

| Polyvinylidene fluoride functionalized PANI–GO (PVDF–PANI–GO) | Nano-filtration membrane for textile effluents removal | •Nanocomposites membrane with 0.1%w/v GO established a maximum of 98% dye rejection at 0.1 MPa | [206] | |

| •Recovery ratio reached about 94% |

Note: LIBs, lithium-ion batteries; SIBs, sodium-ion batteries; rGO, reduced graphene oxide; GQDs, graphene quantum dots; FLG, few layered graphene; PANI, polyaniline; GCE, glassy carbon electrode; CSA, camphor sulfonic acid; HAP, hydroxyapatite; PMMA-co-MA-PEG/PC/GNR, poly(methyl methacrylate-co-methacrylic amide)-polyethylene glycol/polycarbonate and graphene-based nanoribbons.

4 Recycling of waste materials into graphene nanocomposites

Despite the global COVID-19 pandemic, graphene industry is expected to grow due to increased demand for mobile devices such as smartphones and tablets, as well as optoelectronics and storage devices. While these electronic devices have numerous advantages, they also contribute to a major problem, which is the growing pile of e-waste. According to the World Economic Forum, 50 MT of e-waste are produced each year, but only 20% is recycled, with the remainder often incinerated or dumped in landfills [2,3,4]. More than just adding to landfill, most e-waste is made of non-biodegradable materials, and it may also contain materials that are potentially hazardous and toxic to our health and the environment if simply discarded. As a result, many problems associated with e-waste management are exacerbated [6,7,15]. To address this issue, agricultural waste could be used to create biodegradable materials, which could then be used to make electronic devices. After their lifetime (sometimes rather limited), these obsolete or unserviceable devices (or at least some of their parts) could then be easily degraded upon their disposal. This lays the groundwork for circular economy systems in the electronics industry, increasing their sustainability [61,71,72]. To ensure the understanding of waste-derived nanocomposites fabrication, Figure 8 highlights the GO assembling of cobalt-based metal framework into GO–Co nanocomposite.

![Figure 8

Schematic diagram of synthesis of magnetic cobalt–graphene (MCG) nanocomposite [208].](/document/doi/10.1515/ntrev-2022-0512/asset/graphic/j_ntrev-2022-0512_fig_008.jpg)

Schematic diagram of synthesis of magnetic cobalt–graphene (MCG) nanocomposite [208].

4.1 Processing factors of graphene nanocomposites

GO is an oxidized form of graphene that has widespread use as a catalyst support, composite filler, or the precursor of high-surface-area carbon materials [26]. Its benefit as a precursor of processable aqueous suspensions of carbon nanoplatelets is also increasingly realized and exploited, leading to various products of electronics and energy conversion. The presence of oxygenated groups and aromatic domains on the GO structure resulted in excellent organic molecule adsorptive capabilities [39]. However, due to the unavoidable van der Waals interaction, GO layers may agglomerate in aqueous medium, especially at higher salinities or in the solutions of other electrolytes, already at fairly low concentrations [207,208]. As a result, adsorption capacity is reduced, making the recovery process more difficult. One way to prevent the aggregation of GO is to formulate a composite with activated carbon (AC) or other materials conjugated with GO by using waste materials as carbon sources. This will significantly improve the adsorption efficiency due to the synergism between the porous structures of the two carbon materials [208,209].

A variety of methods for the processing of graphene nanocomposites have been discussed in earlier studies and are not focus of our work. Examples of dedicated publications for nanocomposite formulation are: covalent or electrostatic functionalization by Dreyer et al. [18], silanization by Zou et al. [99], mechanical mixing by Sun et al. [210], functionalization with NPs or in situ polymerization by Chen et al. [211], utilizing polymers as nanofillers by Ramanathan et al. [90], using few layered graphene materials with polymers by Young et al. [212], combining multi-layered and monolayered graphene materials with various nanofillers by Shahil et al. [213], and utilizing epoxy matrix with graphene nanoplatelets by Monti et al. [214].

Most of these studies have discussed a wide series of matrices, fillers, and NPs based on their suitability and application field [125,167]. For the preparation of the composites, melt processing, solution blending, in situ polymerization, and sol gel procedures are the most commonly used lab-scale methods relying on van der Waals interactions or the creation of covalent bonds between base material matrices and NPs [90]. Based on the process parameters and the particle size and shape of the component phases, different morphologies can be attained [210]. Platelets, isodimensional or elongated particles are largely used types of NPs. Well dispersed, percolating, and agglomerating are typical arrangements for isodimensional and elongated NPs [53,212,215]. However, micro composite formation, intercalation, and exfoliation offer a broad variety of microstructural arrangements to fabricate nanocomposites using platelet-shaped NPs. Here micro composite refers to inefficient matrix affinity and particles distance [170,172]. Also, intercalated and exfoliated nanocomposites are noteworthy for their increased interlayer distance and homogeneous filler dispersion in the polymeric matrices, respectively [216]. Figure 9 displays the synthesis mechanism including dispersion, pyrolysis, and oxidization into cobalt oxide/GO nanocomposite.

![Figure 9

Synthesis of cobalt–graphene nanocomposite (Co/GC) through (1) dispersion of graphite oxide and CoPc using chemical reduction, (2) pyrolysis at the temperature of 800°C, and (3) further oxidation to fabricate nanocomposite at 400°C [208].](/document/doi/10.1515/ntrev-2022-0512/asset/graphic/j_ntrev-2022-0512_fig_009.jpg)

Synthesis of cobalt–graphene nanocomposite (Co/GC) through (1) dispersion of graphite oxide and CoPc using chemical reduction, (2) pyrolysis at the temperature of 800°C, and (3) further oxidation to fabricate nanocomposite at 400°C [208].

To fabricate stable waste-derived graphene nanocomposites, a good dispersion of fillers is critical to maintain their properties [46]. Table 3 entails the role of various waste-derivatives into graphene nanocomposites using a variety of matrix, fillers and excellent outcomes for energy related device transformations.

Summary of waste-generated nanocomposites according to their particle types, sizes, and chemical processing

| Type of particle/waste | Matrix | Fabrication process | Filler % | Particle size | Remarks | Ref. |

|---|---|---|---|---|---|---|

| Keratin/waste wool | PDMS | Ink drop casting (Keratin + GNPs) | GNPs 30% | 100–150 µm thick films | •Novel transformation of waste wool into electronic devices | [217] |

| Coconut coir and coconut shell | rGO electrode | Catalytic synthesis with ferrocene | — | — | •Very stable supercapacitors from biomass with high specific capacitance (111.1 F g−1 and 60.2 F g−1) | [218] |

| •Cyclic stability (99% after 300 cycles) | ||||||

| Si@rGO/silicon waste sludge | Graphene shell | Ultrasonic-assisted atomization and spray pyrolysis | Si spheres with size ∼0.2 µm | 0.6–0.8 µm | •One-step synthesis | [219] |

| •Electrode in LIBs with high specific capacity (1,626 mA h g−1), stability, and Coulombic efficiency (63.89%) | ||||||

| Fe3O4/chitosan/graphene/waste batteries | Fe3O4/chitosan | Simple electrochemical method, co-precipitation | Graphene ∼54% | — | •Simple and direct electrochemical synthesis method | [220] |

| •The form of composite was Fe3O4/chitosan/graphene precipitate | ||||||

| •Efficient adsorbent of MB (q e = 47.35 mg g−1) prepared with co-precipitation method | ||||||

| Lignin@GO/lignin waste | PVA | Solvent casting method | Alkali lignin – GO hybrid (4:1) nanofiller 4% | — | •Enhanced thermal stability | [221] |

| •Synergetic effect on Young’s modulus and tensile strength | ||||||

| BiVO4@cellulose/fruit peels | BiVO4 | Direct hydrothermal synthesis | Cellulose – various | 24–35 nm | •Good photocatalytic activity with high photodegradation efficiency (87%) | [222] |

| Graphene@polypropylene/tire waste | Polypropylene homo- and copolymer | Melt mixing | GNPs 1–5 wt% | 50 nm sized GNPs in the matrix | •Significantly increased mechanical properties: flexural strength, tensile strength, thermal stability, mechanically beneficial crystal structure | [223] |

| Fe3O4@C/coconut shell waste | Carbon material similar to GO | Direct hydrothermal synthesis | Fe3O4 | Nanoporous material with 5–60 nm pore size distribution | •One-step synthesis method | [224] |

| •Magnetic nanocomposite with good magnetic performance | ||||||

| •Enhanced surface area | ||||||

| •Beneficial adsorption properties (removal efficiency on MB > 90%) | ||||||

| Polyethylene@graphene/recycled high density polyethylene | Polyethylene | From recycled PE mixing, sonication, and evaporation of the solvent, injection molding | GNPs (0–8 wt%) | — | •Increased hydrophobicity and enhanced mechanical properties | [225] |

| •Slightly increased thermal and mechanical conductivity | ||||||

| Wood-hydrolysates/mont-morillonite@rGO or GO/forestry waste | Wood-hydrolysates/montmorillonite | Hydrothermal treatment of wood chips, mixing and stirring, reduction with hydroiodic acid | GO or rGO (0.3 –2 wt%) | Few microns thick film | •Peak heat release rate reduced with more than 90% compared to that of neat wood hydrolysate | [226] |

| •In the case of WH–MMT–rGO good hydrophobicity (88° contact angle) | ||||||

| •Superior mechanical properties (∼124 MPa maximum tensile strength) | ||||||

| rGO/MnO x nanocomposite/Manganese waste | rGO | Immobilization of manganese compounds on GO, freeze-drying, anneal treatment | MnO x | MnO x nanospheres with a size of 10–90 nm on rGO from “ultralarge” GO nanosheets 50–90 µm thick film on the electrode | •Coatings of symmetric supercapacitor electrodes | [227] |

| •Extremely good capacitance retention after 20,000 cycles (96,6%) | ||||||

| •Superior energy storage/conversion performance | ||||||

| rGO@Au NPs/peanut peel waste | rGO | Mixing and stirring the precursors, free drying | Gold nanoparticles (Au-NPs) 23.29% | Avg. size ∼660 nm | •Peanut peel waste catalyzed the formation of the nanocomposite | [228] |

| •Efficient removal for MB and MG dyes (∼93%) | ||||||

| •Good catalytic reduction of 4-aminophenol and 4-nitrophenol | ||||||

| Graphene–tin oxide nanocomposite/wood and coconut shell charcoal | Wood derived: graphene nanosheets coconut derived: aggregated carbon nanodots and Sn nanorods | One-step hydrothermal treatment | Wood derived: SnO2 nanodots with uniform distribution | Wood derived GTO: SnO2 < 3 nm nanodots on graphene sheets coconut derived GTO: aggregated network of carbon nanodots (5–11 nm) and Sn nanorods (length 20–34 nm) | •Eco-friendly one-step synthesis without hazardous chemicals | [229] |

| •One of the highest reported antibacterial activities of its kind (wood derived: 27 ± 1.0 mm, coconut derived: 38 ± 0.7 mm inhibition zone) | ||||||

| •Good colloidal stability | ||||||

| MnO2/GO and MnO2/rGO/spent battery powder | GO or rGO | Mixing, sonicating, stirring | Spent battery powder (MnO2): various mass ratios | 20–100 nm | •Excellent cyclic stability (100% after 1,000 cycles) | [230] |

| •Significant improvement in the specific capacitance depending on matrix-filler ratio (best on 1:5) 116 F g−1 SBP/GO and 150 F g−1 SBP/rGO (two times higher than the original batteries) | ||||||

| Twisted graphene coconut husk ash/coconut husk ash | Twisted graphene | Ball milling, washing | Coconut husk ash (100:1,50:1,25:1) CHA: graphene | — | •Simple and mass synthesis | [231] |

| •Excellent yield of Biginelli reaction (best 94%) | ||||||

| •Solvent free synthesis | ||||||

| •Good catalytic stability (80% yield after 6 cycles) | ||||||

| CNTs-HAP/LLDPE and GO/HAP/LLDPE/waste eggshells | LLDPE | Melt mixing | CNTs–HAP or GO–HAP (1–5 wt%) | HAP particles 50–200 nm | •Increased hardness (best 34%) tensile strength, impact strength, lowering flammability (best 31%) related to the amount of filler | [232] |

| Tree gum–GO/Tree gum waste | Gum Arabic, gum karaya, gum kondagugu | Solution casting method | GO (0.5, 1.0 wt%) | — | •Utilized as gas barriers with very low oxygen transmission rate (lowest 13.9 cm3 atm−1 day−1 m−2 | [233] |

| •Increasing Young’s modulus and tensile strength (68 and 47% best, respectively) | ||||||

| •Good thermal stability | ||||||

| •Biodegradable | ||||||

| rGO/TiO2/tea waste | rGO | Hydrothermal method | TiO2 different ratios: 1:4–1:10 | — | •Good photocatalytic activity in degradation of wastewater pollutants (methyl orange) | [234] |

| Lignin–GO–ZnO/palm oil waste | Lignin, GO | Solvothermal method | ZnO (29% Zn(ii) content) | 100–200 nm irregular aggregates (ZnO NPs ∼100 nm) | •Applicability to remove heavy metal ions from wastewater (Cd(ii) 90%) | [235] |

| •Relatively high stability and high thermal stability | ||||||

| •Outstanding current density (135.96 mA m−2) | ||||||

| •Highest voltage (191 ± 4 mV) | ||||||

| •Relatively high mechanical strength | ||||||

| HrGO, SGO, MSG/PET bottle waste | Highly reduced rGO, sulfonated GO, magnetically modified GO | Activation in electric furnace in high T, sulfonating, co-precipitating with Fe3O4 | — | — | •Simple synthesis method using a usual waste (PET) | [236] |

| •High amount of adsorbed material for antibiotics (170–236 mg g−1) | ||||||

| •Outstanding removal efficiency (99.94% ampicillin, SG) | ||||||

| •Easy removal of spent adsorbent caused by the magnetic modification | ||||||

| CEPG–PANI–Ag/coffee waste | CEPG | Simple synthesis with mixing and stirring in acidic media after extraction | PANI and Ag | ∼100 nm avg. pore size with 10–30 nm Ag particles on the surface | •High surface area: 1033.65 m2 g−1, specific capacity: 1,428 C g−1 at 5 mV s−1 | [237] |

| •Good cyclic stability (94.5% after 5,000 cycles) | ||||||

| n-Nonadecane–rGO–AC/palm oil waste | rGO/AC | Simple impregnation process | n-Nonadecane (10–90 wt%) | — | •Efficient thermal stability | [238] |

| •High phase change latent heat values in the 25–40°C range | ||||||

| •High thermal energy storing capability due to encapsulation of n-nonadecane | ||||||

| ZnO–GO/metallurgic waste | GO | Co-precipitation + annealing | ZnO (other metal ion as contaminants) | — | •Excellent photodegradation efficiency of the azo dye AO7 was found which was significantly higher when waste steel leachate derived zinc precursor was used instead of pure zinc oxide | [239] |

| CFA–GO–WO3NR/coal fly ash waste | CFA | Hydrothermal | GO–tungsten nanorods | — | •Efficient removal agent of lead ions (max. adsorption capacity 41.51 mg g−1) | [240] |

| •Outstanding photocatalytic activity spent adsorbent (original composite + Pb2+ in the degradation of acetaminophen 93% | ||||||

| Polyurethane GO–HAP/PET waste | Polyurethane | In situ GO–Hap synthesis + polymerization + SCPL method | GO–HAP (0,1,2,5,10 wt%) | Porous scaffold 0.5–1 µm GO sheets decorated with 10–30 nm HAP platelets of avg. pore size: 236–266 µm | •Remarkable antibacterial activity against Gram-positive and Gram-negative bacteria | [241] |

| •Improved mechanical parameters (Young’s modulus, tensile strength, flexural strength, hardness, compressive modulus, elongation) | ||||||

| •Potential bone tissue engineering applications |

Note: PDMS, polydimethylsiloxane; GNPs, graphene nanoplates; PVA, polyvinylalcohol; rGO, reduced graphene oxide; NPs, nanoparticles; LLDPE, linear low-density polyethylene; CEPG, coffee extracted porous graphene; CFA, coal fly ash waste; SCPL, solvent casting particulate leaching.

Numerous types of waste materials such as agricultural and other biowastes, steel waste, plastic, paper, and other industrial wastes have shown ability to form stable composites with carbon-based materials by changing their structural morphologies [217,222,227,229]. Recycling of these waste precursors into nanomaterials using several methods have been highlighted repeatedly [215,218]. In order to get the desired morphology of graphene nanocomposites, graphene-based NPs play a vital role which enable interaction with the base matrices [220]. Nevertheless, not all groups of graphene family are successful to get the preferred structures [232,233].

When graphene is used as a filling agent in composites, it usually results in an improvement of their electrical, mechanical, and thermal properties. Consequently, the nanocomposite can perform multiple functions when used in any system. To synthesize GO based nanocomposites, appropriate exfoliation of graphene or GO and their restacking/aggregation are issues to be resolved [235,236]. Conclusively, poor dispersion negatively affects the performance in most kinds of applications. However, greater levels of dispersion can be achieved for GO as compared to graphene due to its oxygenated groups which enables its easy incorporation into water-soluble matrices [238]. Based on recent research works, accommodation of graphene and GO fillers into various types of polymers has been done using in situ polymerization, solution intercalation, electrospinning, wet spinning, drop casting, melt intercalation, and freeze-drying procedures [240,241].

A remarkable waste-generated graphene nanocomposite was introduced through keratin wool waste into electronic devices. Energetic nanocomposites were developed by tuning conductivity of nanofillers among GNPs. In order to get homogenous dispersion of GNPs with waste proteins, carbon particles were 100–150 µm thick. By adding 5 wt% of GNPs, the resistance released five folds from 1,010 Ω sq−1 to ∼105 Ω sq−1, and as low as ≈10 Ω sq−1 by adding 30 wt% of GNPs. Moreover, capacitors were fabricated using 1 cm2 waste keratin with excellent impedance, dielectric properties, and capacitance of 50–550 pF from −85 to 87°. Moreover, this keratin-based graphene nanocomposite was successfully used to develop an insulator with soft and flexible texture with no cracks at ambient temperature [217].

In a recent study, coconut waste has been converted into rGO nanocomposites with high surface area and electrochemical properties for supercapacitors. In its fabrication, ferrocene was used as a catalyst under 300°C opposite to the conventional techniques in which it has been crucial to remove carbon basal plane defects as a strong reducing solvent. The effects of temperature on the oxygen content and band gap were evaluated. It was observed that the increase in the temperature decreased the amount of oxygenated groups in rGO with high amount of defects in rGO lattice structure. Thus, successful efforts were made to recycle defect free rGO nanocomposites from coconut waste [218].

Similarly, an economical and facile approach of coffee waste-derived GO nanocomposites has been introduced for lithium-ion capacitors. Parameters such as particle size, matrix loading, and conductivity for battery electrode and pore size and surface area for capacitor electrode were optimized. It was observed that ball milling method induced a prominent reduction in particle size of 2–5 µm. The incorporation of rGO into the carbon matrix led to significant increase in the overall capacitance of lithium ion capacitor (40–70%) on different applied current rates. This state-of-the-art waste-derived energetic graphene nanocomposite enhanced power and capacitance for up to 80% after 3,000 cycles which further heightened to 15,000 cycles [242].

In an interesting study, researchers reported tire waste recycled nanocomposite fabricated using poly (lactic acid) (PLA) and GNPs to accelerate mechanical properties. The energetic nanocomposite was prepared through twin-screw extruder using a die press of 0.5 mm thickness and 25 mm width. It was found that incorporation of GNPs (1, 2, and 3 wt%) in tire waste/PLA blend enhanced the tensile properties. Morphological analysis through scanning electron microscopy (SEM) presented that GNP nanocomposite reduced the formation rate and pore volume. In addition, GNP nanocomposite increased thermal stability and mechanical properties due to heat deformation. Adhesion of PLA with tire waste was not homogenous due to polymeric contents as the surface was heterogeneous and the polar macromolecule of PLA could not interact strongly with the hydrophobic parts of the carbonaceous nanosheets. Thus, functionalization through GNP fillers provided an ideal homogenous dispersion with tire waste (70 wt%) and PLA (30 wt%) nanocomposite. However, the dispersibility of GNPs was limited which paved a way for further research works [243].

Furthermore, sludge waste consisting of Si (40%) has been utilized to convert graphene nanocomposite for LIBs. Recycling of Si from waste was introduced using one-step aerosol method which was also recycled into Si NPs (78%) with SiC mass fraction of 3.2 wt%. Further, ultrasonic atomization spray pyrolysis was deployed to produce Si–graphene nanocomposite as efficient anode material for batteries. As per morphological analysis, the developed Si–graphene nanocomposite turned into a crumpled paper ball with the average size range of 0.6–0.8 µm using different parameters. No variation was found using FESEM technique in the structural analysis. However, XRD showed high peaks of Si and SiC as graphene content was lower compared to Si. By increasing the temperature from 300 to 500°C, the Si–graphene nanocomposite size remained the same (0.66 µm). It was observed that the size distribution of this energetic nanocomposite was homogeneous as it aggregated in the absence of graphene and thus, recovered by aerosol method where the particles were spherical with 0.47 µm diameter. The electrochemical analysis was performed which revealed highly efficient presentation as anode materials in terms of capacity, Coulombic efficiency, and stability for LIBs [219].

The significance of energetic graphene nanocomposites has also been signified by recycling of coffee waste. Coffee waste-derived GO was doped using a polymer (PANI) and silver NPs to fabricate nitrogen doped coffee waste extracted porous graphene (CEPG-PANI-Ag) nanocomposite. Development of this novel nanocomposite improved electrochemical properties by increasing the electrode surface, porosity, and high surface area of 1033 m2 g−1 for electrons mobility due to combined functionality through nitrogen and oxygenated groups on graphene nanostructure. Morphological analysis through XRD, FESEM, and TEM confirmed the crystalline structure of AgNPs, a reflection at 22.6° diffraction angle, characteristic of graphene, broad peaks of PANI chains, and about ∼200 nm size of CEPG-PANI-Ag with homogeneous dispersion. For energetic application, it was demonstrated that developed nanocomposite displayed a very high specific capacity of 1,428 C g−1 at 5 mV s−1 scan rate and 5,000 cycles stability. This study presented an outstanding example of biowaste-derived energetic graphene nanocomposite for high performance rechargeable batteries [237].

Newly, oil palm waste-derived AC doped with rGO has been developed as a nanocomposite for thermal energy storage. It showed advances of surface area of 680 m2 g−1 and an average pore size of 22 Å. A fruitful intrusion of n-nonadecane into the developed nanocomposite was completed and their nitrogen gas adsorption-desorption isotherms were determined. There was no leakage observed during this phase alteration as it was homogeneously dispersed from solid to liquid phase in graphene matrix. This novel, eco-friendly, and thermally stable waste-generated graphene nanocomposite has been introduced for thermal energy storage applications [238].

Likewise, oil palm waste-derived lignin GO (L-GO) was doped with ZnO using 39% carbon and 29% Zn to prepare L-GO-ZnO energetic nanocomposite. In this recent work, biowaste-generated anode material was prepared which was utilized for removal of Cd(ii) substrates from wastewater through microbial fuel cells. Self-assembled L-GO was combined with ZnO NPs which enhanced physicochemical properties such as great energy output of 135.96 mA m−2 which is eight times greater than typical GO anodes. It further evidenced the removal of Cd(ii) from wastewater by using microbial fuel cells via waste-generated anodes. It was reported that by changing the morphological characteristics of the designed graphene nanocomposite, 90% of removal efficiency was achieved [235].

In addition, value-added morphological impacts of other remarkable waste-derivatives, such as human hair [244], sisal fibers [245], Prosopis juliflora shrubs [246,247], orange peels [248], olive pits [249], green tea waste [250], Indian cake husk [251], peanut hull, bagasse, corn stalk, potato waste, defatted soybean, tobacco rods, fermented rice, prawn shells, and onion husks [252], have been thoroughly evaluated for energetic applications and electronic devices. Interestingly, most of these wastes have been converted into AC and graphene flakes, rather than graphene nanocomposites.

4.2 Applications of waste-generated graphene nanocomposites

The production of nanomaterials from biomass has been viewed as a bio-based economy and a green solution to local and global pollution issues. Since graphene-based technology is efficient, cost-effective, simple, and environmentally friendly, it has become the solution to today’s sustainability issues [41,55]. For example, agriculture waste biomass is a low-cost source for nanomaterial synthesis, and because of its abundance as well as various studies on it, mass production of graphene-derived nanocomposites is possible [234,237,253].

Due to graphene’s excellent in-plane properties, new opportunities for tailoring nanocomposites have emerged. Graphene/GO/rGO bio-nanocomposites have a potential to be applied in various fields including adsorption [254], separation of organic and inorganic compounds [255], photocatalytic degradation of organic matters [256], disinfection and antimicrobial compounds [257], hydrogen storage and production [258], and electrochemical biosensors [259]. Therefore, lots of research are now focusing on the strengthening/toughening, electrical conduction, thermal transportation, and photothermal energy conversion of graphene/polymer nanocomposites as well as studying the effect of graphene configuration – layer number, defects, and lateral size, on both intrinsic graphene and graphene/polymer nanocomposites properties [260,261]. A variety of waste sources and their utilization for favorable applications are presented in Figure 10.

![Figure 10

Schematics of waste source incorporation into graphene nanocomposites and their remarkable energetic applications. The structural motif of GO is reproduced with permission from [262].](/document/doi/10.1515/ntrev-2022-0512/asset/graphic/j_ntrev-2022-0512_fig_010.jpg)

Schematics of waste source incorporation into graphene nanocomposites and their remarkable energetic applications. The structural motif of GO is reproduced with permission from [262].

Recent studies have shown significant impact of waste-derived graphene nanocomposites among industrial applications. For instance, Rezania et al. [263] utilized waste frying oil to synthesize biodiesel using magnetic GO doped mixed metal oxide MGO@MMO nanocomposite. They studied the effect of several experimental parameters such as material amount, methanol-to-oil ratio, temperature, and time. They observed that the optimized parameters were as 94% of yield, 8:1 ratio, and 60°C with the reaction time of 90 min, respectively.

Other recent studies include utilization of steel sludge waste in ZnO–GO nanocomposite for improved catalytic efficiency [239], oil palm biomass derived GO nanocomposites as an effective medium for energy transportation through microbial fuel cells [235] or for thermal energy storage [238]. Coffee waste-derived [242], coconut shell and grapes seed derived [218,264] rGO containing composites find use in supercapacitors, while Bengal gram bean husk derived graphene-like porous carbon nanostructure is applicable for improved adsorption of organic dyes [265]. Additionally, the impact of GO nanocomposite has been evaluated on carbon conversion and methane production using anaerobic digestion of waste activated sludge [266]. Table 4 represents the summary of waste-generated graphene nanocomposites for significant industrial applications and their impacts.

Role of waste sources derived graphene nanocomposites for industrial applications

| Waste materials | Nanocomposites | Method of synthesis | Particle size | Graphene concentration | Outcomes | Energetic applications | Ref. |

|---|---|---|---|---|---|---|---|

| Wool waste | Keratin–graphene nanocomposite | Dispersing | — | 5% | Flexible electrodes with remarkable sheet resistance (≈10 Ω sq−1) | Production of sustainable electronic devices | [217] |

| Sludge waste | Si–GR | One-step aerosol process | 532 nm | 0.5% | Improved electrochemical performance was evaluated with Si–GR composites | LIBs | [219] |

| Tire waste | GNPs–PP | Melt mixing | 50 nm | 1% | Fabrication of tire waste-derived GNPs doped PP nanocomposite | Crystallization and mechanical properties | [223] |

| Eggshells waste | GO–HAP/LLDPE | In situ process | 50–200 nm | 1, 2, 3, 4 and 5% | HAP-decorated GO filler were used in LLDPE nanocomposite. | Thermo-mechanical properties analysis | [232] |