Abstract

Examining the deflection properties while designing and analyzing structural elements offers important information about working of visco-thermoelastic plates in microelectromechanical systems, sensors, and flexible electronic systems. The aim of the current study is to increase the stability and durability in heat-sensitive situations. This study focuses on the transverse deflection in a homogeneous, isotropic, visco-thermoelastic rectangular plate under the influence of uniform loading. The edges of plate are considered at different boundary conditions. Boundary conditions can either involve all edges being simply supported or keeping them simply supported and clamped alternatively. The deflection analysis utilizes the Laplace transform and Finite Fourier sine transform. Inverse Laplace transform is resolved using residue method. MATLAB software aids numerical computation of deflection expression post-Inverse Laplace Transform. Graphical analysis explores the diverse boundary conditions across different modes. The variation in deflection has been studied in the plate under varied circumstances. The findings provide useful insights for engineering applications involving thermal and mechanical stability and advance theoretical and computational understanding of deflection dynamics in visco-thermoelastic rectangular plates under uniform loads.

1 Introduction

The applications of visco-thermoelastic rectangular plate resonators in precision engineering, microelectromechanical systems (MEMS), and nanoelectromechanical systems (NEMS) have drawn a lot of attention to their study. The combined effects of viscosity, thermal relaxation, and elastic deformation cause these resonators to behave complexly under external loading. The deflection response, damping properties, and stability of these structures are influenced by the interplay of mechanical vibrations, thermal conduction, and material viscosity.

Lord and Shulman [1] developed a comprehensive theory of thermoelasticity that integrated the interplay between temperature and strain rate, leading to the emergence of finite-speed propagation for heat waves. Bauchau and Craig [2] developed the theory of analysis of plates having one dimension much smaller than the other two and derived the expressions for all strain, stress, displacement components, bending moments, and transverse forces. Sharma and Grover [3] studied thermoelastic damping in MEMS/NEMS thin plates with voids to derive the expressions for deflection, frequency shift, under different boundary conditions. Grover [4] explored the impact of viscosity, thermal relaxation, and geometric variation on damping characteristics. The author investigated the influence of material properties and geometric parameters on deflection, frequency shift, and stability. Li et al. [5] presented an analytical model for the thermoelastic damping in the fully clamped and simply supported rectangular and circular microplates and derived the expression for quality factor using the energy dissipated over the volume of microplate per cycle of vibration. Lal and Kumar [6] studied the free transverse vibration of thin rectangular plates of linearly varying thickness using two-dimensional characteristic orthogonal polynomial. Lal and Saini [7] analyzed the transverse vibration in thin rectangular plates of linearly varying thickness using generalized differential quadrature method. Rana and Robin [8] analyzed the effect on damping due to non-homogeneity in a rectangular plate of parabolically varying thickness resting on elastic foundation. Grover [9] studied the effect of fixed aspect ratio, fixed radius, and fixed thickness on thermoelastic damping of out of plane vibrations in visco-thermoelastic circular plate resonator. Partap and Chugh [10] investigated the expressions for thermoelastic damping temperature distribution, deflection in micro-scale microstretch, micropolar, generalized thermoelastic thin plate. Grover and Seth [11] analyzed the effect of time delay and mechanical relaxation time on thermoelastic damping using generalized dual-phase-lagging model. Liu et al. [12] studied the effect of size and shape on thermoelastic damping and out-of-plane vibration of the laminated rectangular plate. Zuo et al. [13] derived the expressions for thermoelastic damping in trilayered microplate under the boundary conditions of fully clamped. The authors discussed the magnitude of fluctuate temperature, thermoelastic damping and energy dissipation among the three layers. Khan et al. [14] analyzed the dusty viscoelastic fluids under shear stress and heat absorption by considering inclined vertical plates. The study was mainly concerned with fluid flow, but it also demonstrated the wider applicability of boundary-driven thermal effects, which theoretically facilitate the modeling of heat-influenced deflection in visco-thermoelastic solids. Chopra and Singh [15] investigated the transverse deflection in a visco-thermoelastic beam under harmonic loading for different boundary conditions. Gohar et al. [16] examined the effect of periodic magnetic fields and thermal radiation between parallel plates in viscoelastic fluids with dusty nanoparticles. The study provided a better understanding of thermomechanical coupling under detailed boundary conditions. The study played significant role in understanding the study of deflection behavior in visco-thermoelastic plates, where structural response is greatly influenced by heat transfer and external field effects.

Several researchers have previously examined the bending and transverse vibrations in rectangular plates using thermoelasticity theories. Nevertheless, few studies have combined thermal and viscoelastic effects to analyze deflection behavior under external loading. A more realistic framework for comprehending heat conduction and its effect on mechanical deformation is offered by the Lord–Shulman (LS) thermoelastic model, which incorporates thermal relaxation time. Previous research has examined the transverse vibrations of thermoelastic rectangular plates, both with and without external loading. The present study focuses on determining deflection in visco-thermoelastic rectangular plate under uniform loading.

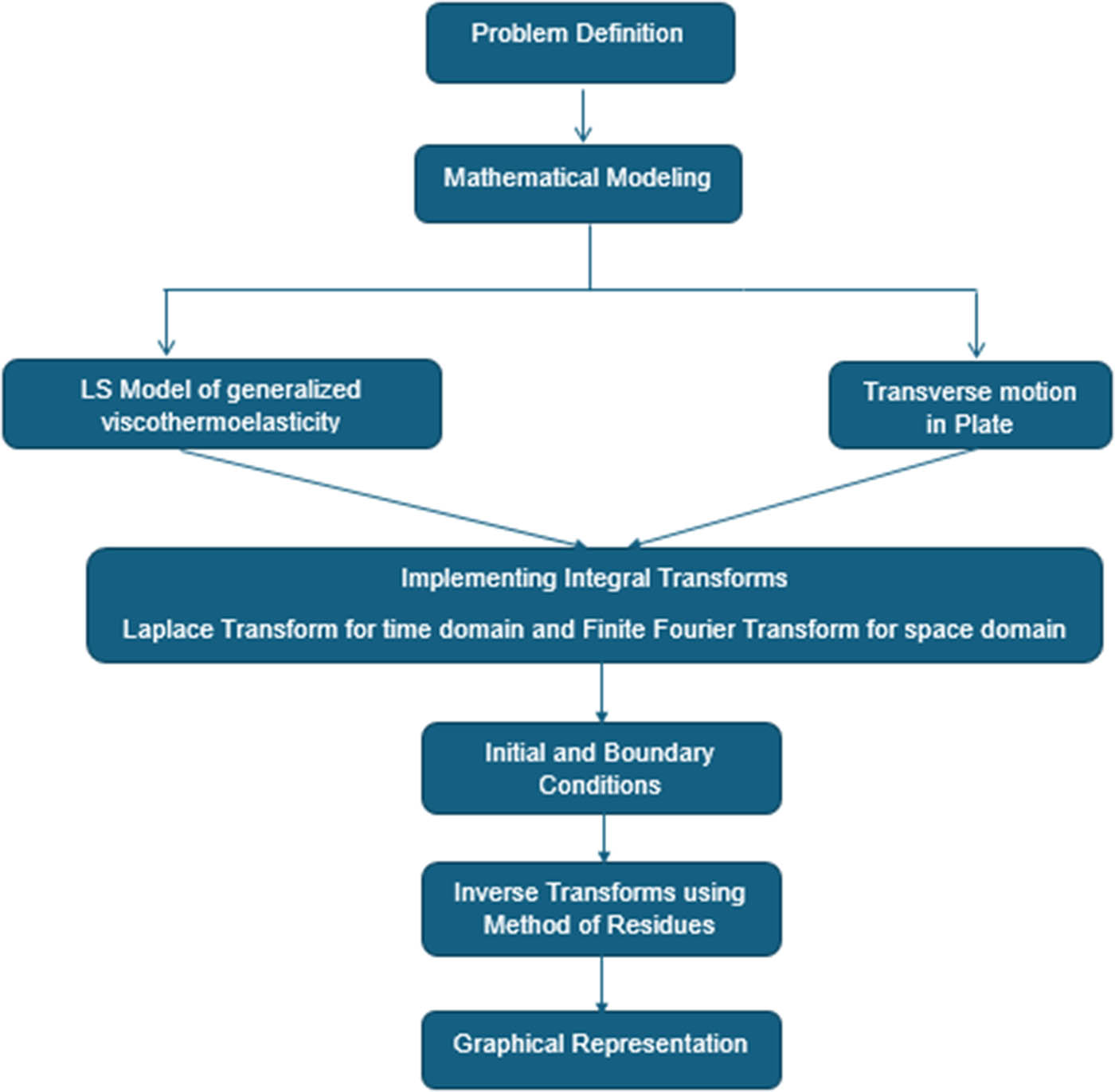

The LS model serves as the basis for the formulation of the governing equations, which include viscoelastic damping and thermal relaxation effects. The governing equations for rectangular plate under the specified initial circumstances are solved using the Laplace transform with respect to time domain. Under the specified clamped-simply supported plate (CSCS) and simply supported plate (SSSS) boundary conditions, a partial differential equation (PDE) that was produced by applying the Finite Fourier sine transform (FFST) with respect to the space domain has been resolved. Further time-domain solutions are extracted by computing the inverse Laplace transform using the method of residues. A thorough foundation for comprehending the dynamic behavior of visco-thermoelastic beam resonators under recurring external excitations is offered by the suggested methodology. The effects of viscosity and boundary conditions on plate deflection are investigated through a variety of graphical investigations. Numerical simulations using MATLAB are performed to validate the theoretical model and illustrate the deflection patterns over time.

2 Primary equations

The present problem considers a homogeneous, isotropic, thermally conductive visco-thermoelastic rectangular plate, which is initially undeformed and at temperature

In view of the Lord and Shulman [1] model of generalized thermoelasticity, the equation of heat conduction along with the constitutive relations, in the absence of heat sources and body forces, which govern the displacement vector

where

Symbols used in the study are defined in Table 1.

LS model derivation The fundamental heat equation, based on Fourier’s law and energy conservation, is

To account for thermal relaxation, we can modify Fourier’s law by introducing a relaxation time

where

In thermoelasticity, temperature changes can induce strains, and conversely, strains can affect the temperature field. This coupling is often represented by a term proportional to the divergence of the displacement or velocity field

Considering further generalization of the Cattaneo–Vernotte equation, including characteristic time, coupling parameter of temperature and velocity field and also, introducing a heat source term (

This form suggests that the heat source is not only influenced by the rate of deformation

Nomenclature

|

|

Components of stress tensor |

|

|

Components of strain tensor |

|

|

Lames parameters |

|

|

Density of medium |

|

|

Viscoelastic relaxation times |

|

|

Thermal relaxation time |

|

|

Linear thermal expansion coefficient |

|

|

Specific heat |

|

|

Kronecker delta function |

|

|

Thermal conductivity |

|

|

Heat source term |

|

|

Coupling coefficient linking the temperature field to the velocity field |

3 Modeling of rectangular plate structure

A homogeneous isotropic, visco-thermoelastic rectangular plate with dimensions as length

Flowchart for the modeling of the visco-thermoelastic rectangular plate.

Using the above displacement vector values, Eqs (1)–(3) reduce to

where

The bending moments per unit length

Using the stress components from (4), we obtain

where

Now, taking up the equation of transverse motion in plate (Figure 1)

where

Taking uniform loading under consideration, i.e.,

Using Eq. (7) in (8), we obtain

Considering non-dimensional quantities

Using the non-dimensional quantities in Eqs (6) and (9), we obtain

(Ignoring the primes for the sake of convenience.)

4 Initial and boundary conditions

A rectangular plate, whose either all the edges are subjected to simply supported conditions (SSSS) or horizontal edges are subjected to simply supported and vertical edges as clamped (CSCS), is considered. The initial conditions in rectangular plate [3] are considered as:

The first condition on the deflection ensures that the plate is in undeformed position initially and the other two conditions signify that no external momentum or force is acting initially. The first condition on

Case I: For SSSS

Case II: For CSCS

With all the edges under simply supported conditions, state that the plate is rigid at the edges and is not allowing the vertical movement but is free to rotate with zero resistance to bending at the boundaries when an external load is applied, while the boundary conditions of CSCS signify that all the edges are restricting the vertical movement, but rotation is restricted only at vertical edges.

Also, there is no flow of heat through the lower and upper surface of visco-thermoelastic rectangular plate, i.e.,

5 Solution along thickness direction

5.1 Laplace transfrom technique

The differential equations given in (10) are analyzed using the Laplace transform technique. Laplace transform converts time-domain problems into complex frequency-domain. The transform converts the time derivatives into algebraic equations, which makes it easier to solve. We apply Laplace transform to the equations w.r.t the time domain, defined as

On applying Laplace transform, under the initial conditions given by (11), we obtain

Using the above expressions, the set of equations in (10) reduce to

where

Under the conditions that no heat flows through upper and lower surfaces of rectangular plate and considerig the fact that thermal gradients are much larger along thickness direction than in the plane of cross section, i.e.,

Using Eq. (16) to find

Using the above expression, Eq. (14) reduces to

where

Re-writing the above expression, we obtain

where

5.2 Fourier transform technique

The FFST method is used to investigate the differential equations mentioned in (20). In general, the Fourier transform makes it easier to analyze wave-like behavior by converting functions from the spatial domain to the wavenumber domain. In particular, PDE can be simplified by converting them into ordinary differential equations using the FFST. This transformation is especially helpful when the function is zero at the domain boundaries and fulfills homogeneous Dirichlet boundary constraints. The FFST greatly reduces computer complexity by breaking down the differential equation into a sequence of sine components by eliminating spatial derivatives. This method is useful for studying wave propagation, thermal conduction, and structural vibrations since it also sheds light on the system’s inherent frequencies and mode shapes.

We apply FFST to the equation w.r.t

Using the boundary conditions from Eqs (12) and (13) along

Using the above expressions, Eq. (20) reduces to non-homogeneous differential equation with constant coefficients as follows:

where

Solving the above differential equation, we obtain

where

Using the boundary conditions along

Case I: For SSSS

Case II: For CSCS

where

Taking inverse FFST of (25) and (26) w.r.t.

Using method of residues for finding inverse Laplace transform defined as

Case I: For SSSS

Residue at

Singularities w.r.t

Using

Residue at

Residue at

Case II: For CSCS

Residue at

Singularities w.r.t

Residue at

Residue at

where

6 Numerical results and graphical discussion

Consider visco-thermoelastic solid-like magnesium with the physical specifications by Sharma and Grover [3] as given below:

Dimensions of the rectangular plate are taken as:

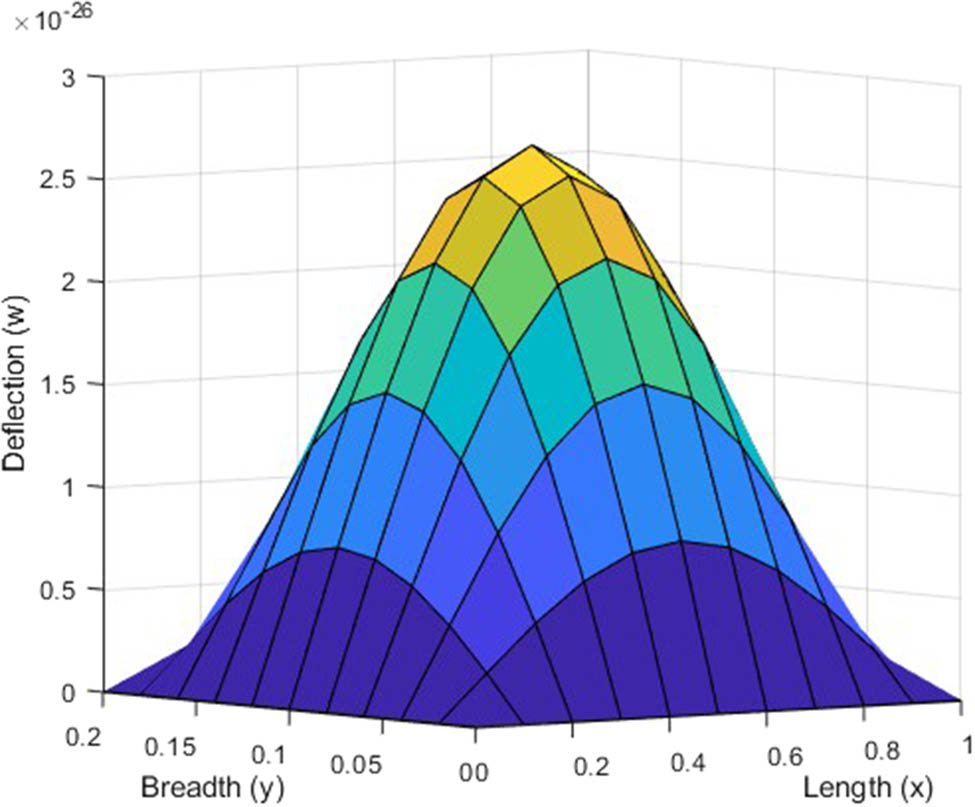

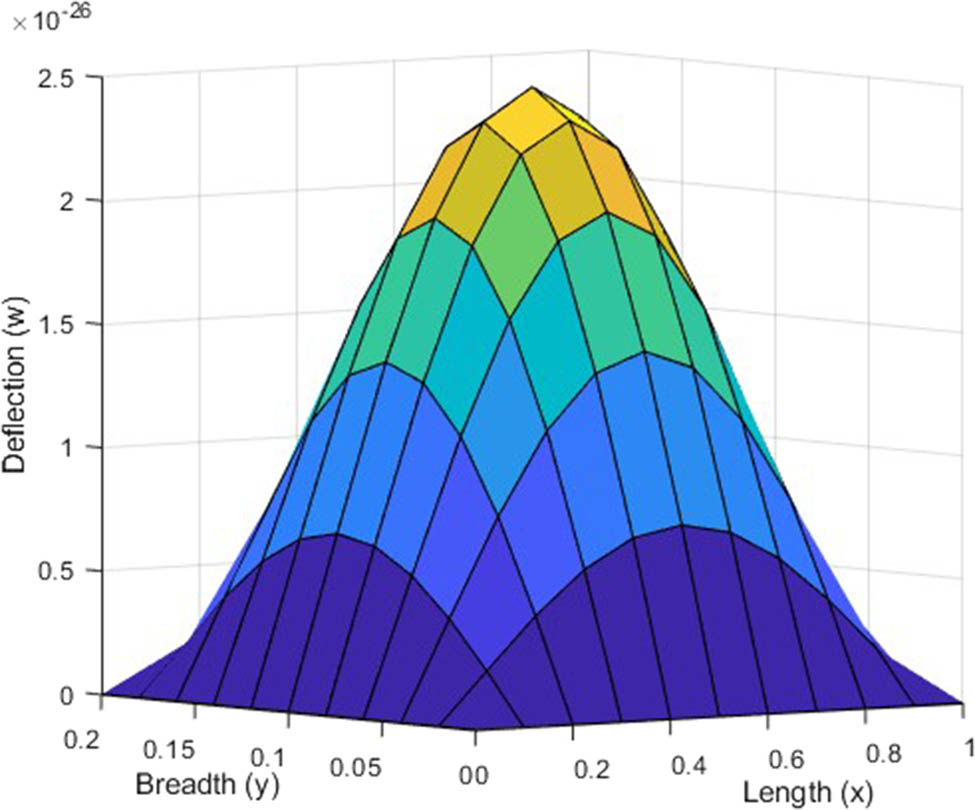

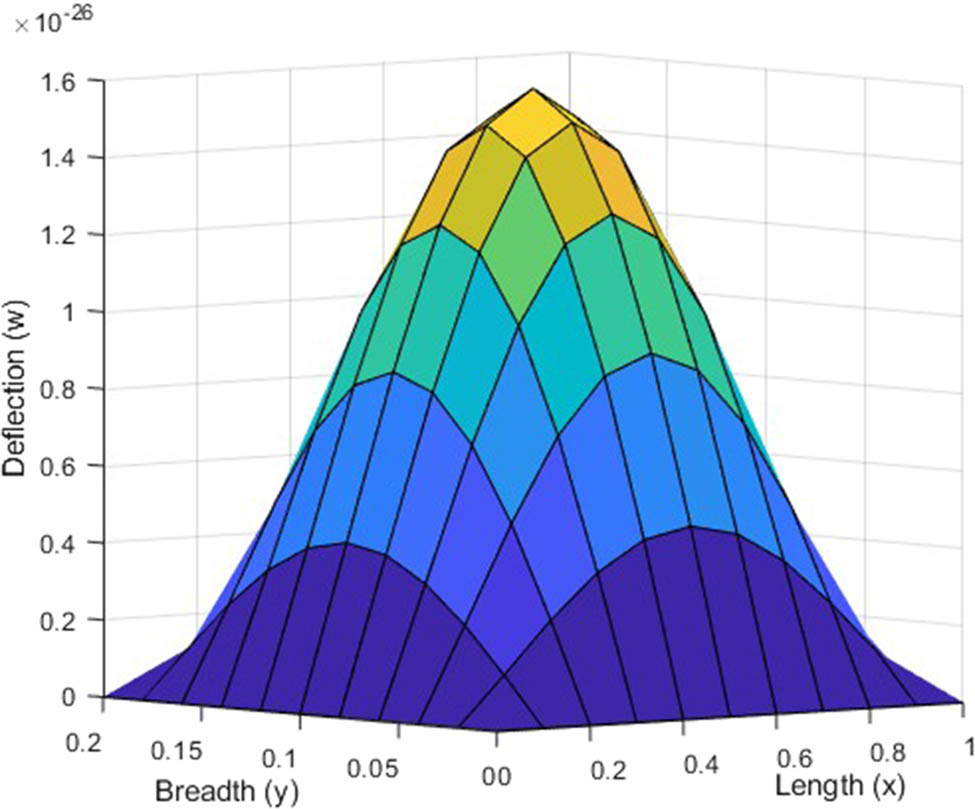

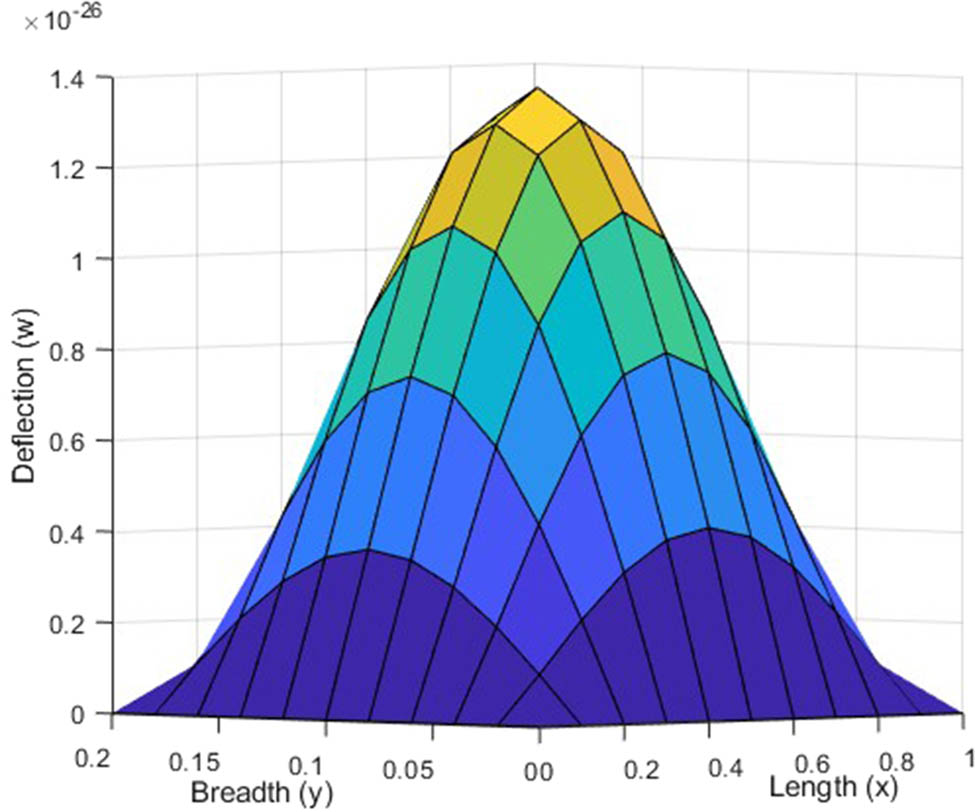

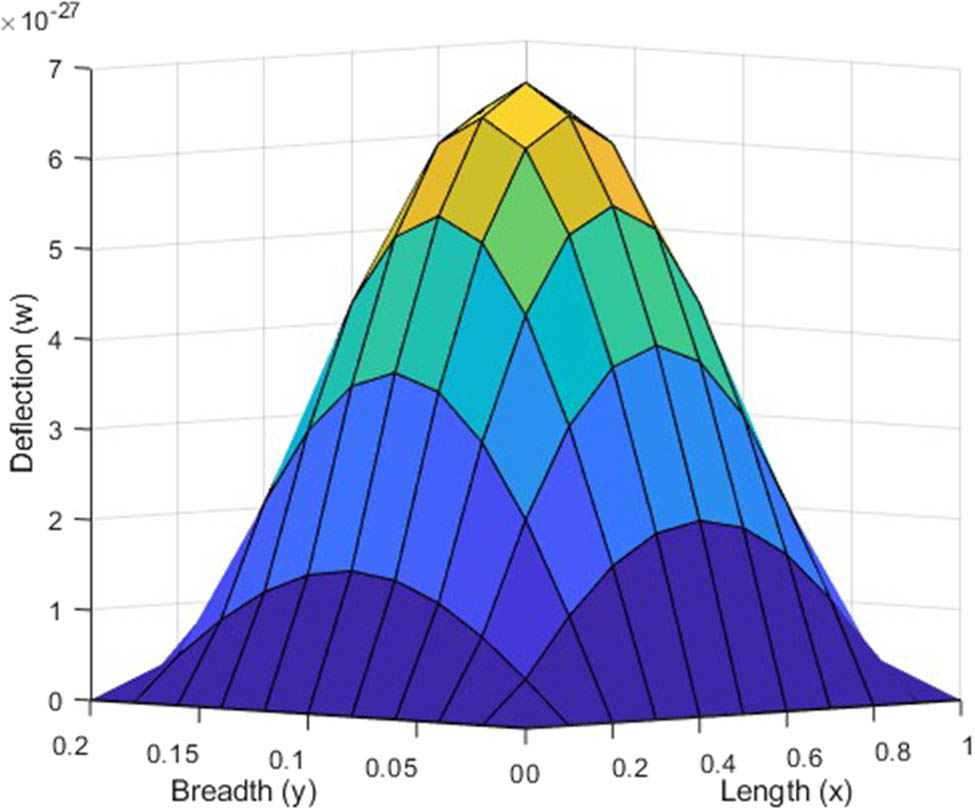

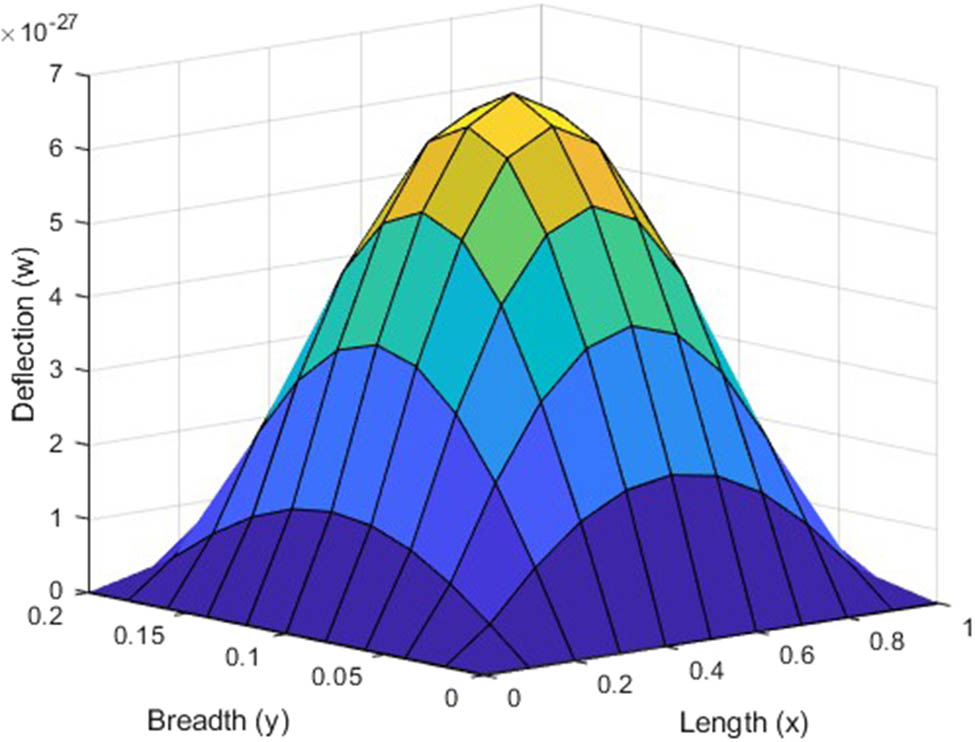

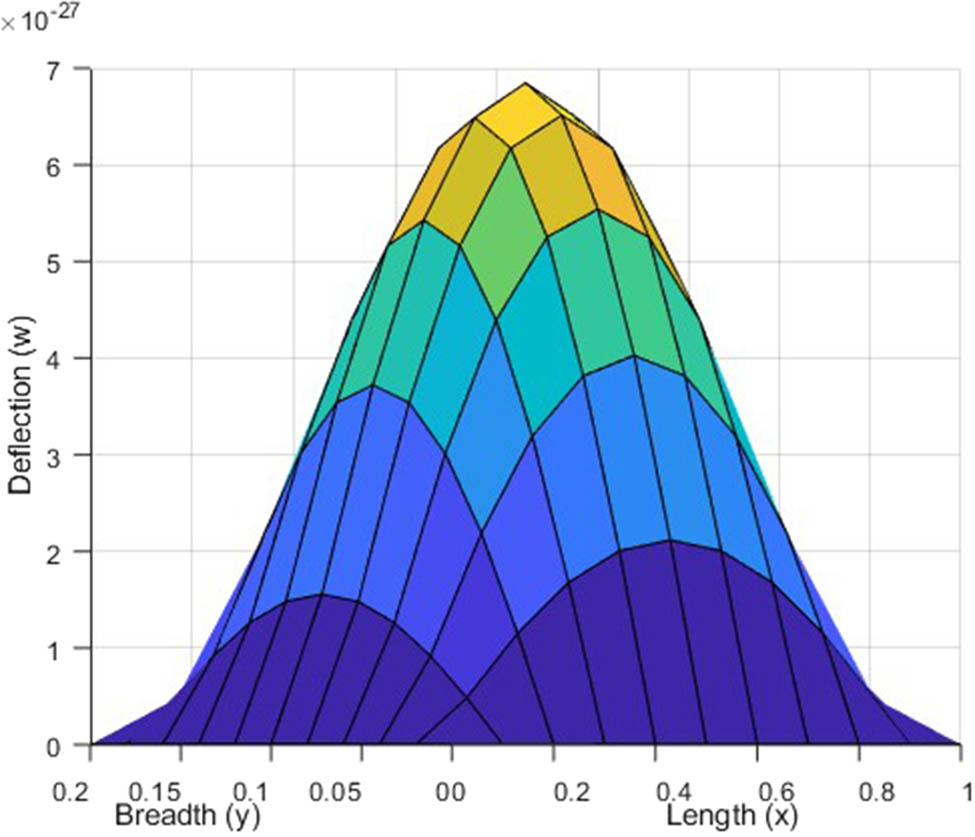

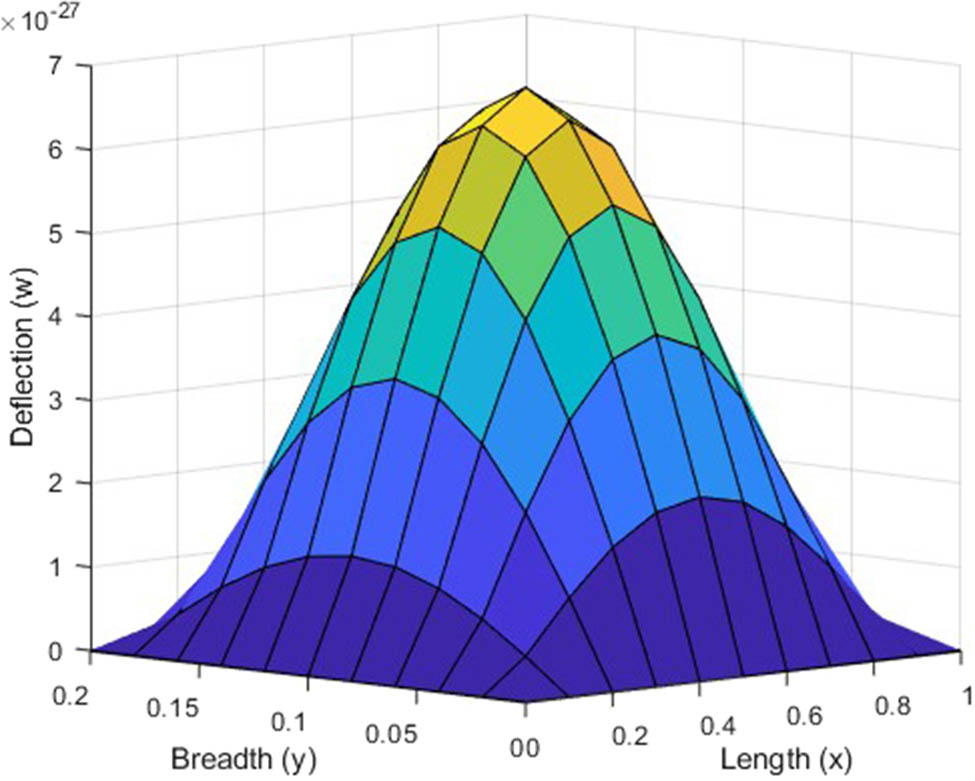

Non-dimensional deflection has been computed for different modes in view of Eq. (27). Figures 2, 3, 4, 5, 6, 7, 8, 9 represent variation in deflection along the dimensions of plate for different modes (1, 1), (1, 2), (2, 1), and (2, 2) for SSSS and CSCS plate under the uniform load. Numerical simulations utilizing MATLAB software programming were conducted for a material analogous to magnesium. Graphical representations of the computer-simulated outcomes were provided, depicting diverse boundary conditions.

Variation in deflection for (1,1) mode in visco-thermoelastic SSSS plate under uniform load along the

Variation in deflection for (1,2) mode in visco-thermoelastic SSSS plate under uniform load along the

Variation in deflection for (2,1) mode in visco-thermoelastic SSSS plate under uniform load along the

Variation in deflection for (2,2) mode in visco-thermoelastic SSSS plate under uniform load along the

Variation in deflection for (1,1) mode in visco-thermoelastic CSCS plate under uniform load along the

Variation in deflection for (1,2) mode in visco-thermoelastic CSCS plate under uniform load along the

Variation in deflection for (2,1) mode in visco-thermoelastic CSCS plate under uniform load along the

Variation in deflection for (2,2) mode in visco-thermoelastic CSCS plate under uniform load along the

The deflection plot clearly signifies the zero deflection at all the four edges. In case of Figures 6–9, the clamped edges are observed to be flat, which signifies that rotation is restricted around these edges. While, in case of Figures 2–5, the absence of flatness in simply supported edges signify that bending of edges is allowed here. It has been remarked that the magnitude of deflection is maximum at the center of the plate and it decreases as we deviate from center in either direction. The symmetric deflection profile depicts the uniform loading on the plate.

Also, it is observed that

7 Conclusion

An investigation was conducted into the dynamic, behavior of a uniform, isotropic visco-thermoelastic rectangular plate subjected to uniform loading. The Laplace transform FFST has been used w.r.t. time and space domain, respectively. It is infered that

The magnitude of deflection is more in SSSS as compared to CSCS.

The deflection curve is symmetrical about the center of plate. The deflection is found to be more symmetrical along both the dimensions in case of SSSS as compared to CSCS.

Maxima of deflection occurs at the center of plate and its magnitude diminishes progressively as it moves further away in either direction.

The change in deflection due to different modes is found to be more pronounced in SSSS plate than CSCS plate.

8 Future Work

The present study provides a comprehensive analysis of the deflection behavior of a rectangular plate under uniform loading. However, several aspects remain open for further exploration. Future research can focus on extending the analysis of deflection on circular plate resonators. Additionally, the impact of loading can be studied by incorporating anisotropic properties and variable thickness to better represent real-world materials.

-

Funding information: The authors state no funding involved.

-

Author contributions: Deepti Chopra: writing – original draft and visualization; Prince Singh: writing – review and editing, and supervision.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Data sharing is not applicable to this article as no datasets were generated or analyzed during the current study.

References

[1] Lord HW, Shulman Y. A generalized dynamical theory of thermoelasticity. J Mech Phys Solids. 1967;15(5):299–309. 10.1016/0022-5096(67)90024-5Suche in Google Scholar

[2] Bauchau O, Craig J. Kirchhoff plate theory. In: Structural analysis. Dordrecht: Springer Netherlands; 2009. p. 819–914. 10.1007/978-90-481-2516-6_16Suche in Google Scholar

[3] Sharma J, Grover D. Thermoelastic vibration analysis of MEMS/NEMS plate resonators with voids. Acta Mech. 2012;223(1):167–87. 10.1007/s00707-011-0557-0Suche in Google Scholar

[4] Grover D. Viscothermoelastic vibrations in micro-scale beam resonators with linearly varying thickness. Can J Phys. 2012;90(5):487–96. 10.1139/p2012-044Suche in Google Scholar

[5] Li P, Fang Y, Hu R. Thermoelastic damping in rectangular and circular microplate resonators. J Sound Vibrat. 2012;331(3):721–33. 10.1016/j.jsv.2011.10.005Suche in Google Scholar

[6] Lal R, Kumar Y. Transverse vibrations of nonhomogeneous rectangular plates with variable thickness. Mech Adv Mater Struct. 2013;20(4):264–75. 10.1080/15376494.2011.584273Suche in Google Scholar

[7] Lal R, Saini R. Transverse vibrations of nonhomogeneous rectangular Kirchhoff plates of variable thickness. In: Mathematical analysis and its applications: Roorkee, India, December 2014. New Delhi: Springer India; 2015. p. 609–18. 10.1007/978-81-322-2485-3_50Suche in Google Scholar

[8] Rana U, Robin R. Study of damped vibration of non homogeneous rectangular plate of variable thickness. Int J Eng Appl Sci. 3(8):257605. Suche in Google Scholar

[9] Grover D. Damping in thin circular visco-thermoelastic plate resonators. Can J Phys. 2015;93(12):1597–605. 10.1139/cjp-2014-0575Suche in Google Scholar

[10] Partap G, Chugh N. Thermoelastic damping in microstretch thermoelastic rectangular plate. Microsyst Tech. 2017;23:5875–86. 10.1007/s00542-017-3350-8Suche in Google Scholar

[11] Grover D, Seth R. Generalized visco-thermoelasticity theory of dual-phase-lagging model for damping analysis in circular micro-plate resonators. Mech Time-Dependent Materials. 2019;23:119–32. 10.1007/s11043-018-9388-xSuche in Google Scholar

[12] Liu S, Ma J, Yang X, Sun Y, Yang J, Wang X. Theoretical 3D model of thermoelastic damping in laminated rectangular plate resonators. Int J Struct Stability Dyn. 2018;18(12):1850158. 10.1142/S0219455418501584Suche in Google Scholar

[13] Zuo W, Li P, Du J, Huang J. Thermoelastic damping in trilayered microplate resonators. Int J Mech Sci. 2019;151:595–608. 10.1016/j.ijmecsci.2018.12.015Suche in Google Scholar

[14] Khan D, Ali G, Kumam P, ur Rahman A. A scientific outcome of wall shear stress on dusty viscoelastic fluid along heat absorbing in an inclined channel. Case Stud Thermal Eng. 2022;30:101764. 10.1016/j.csite.2022.101764Suche in Google Scholar

[15] Chopra D, Singh P. Analysis of deflection in visco-thermoelastic beam resonators subjected to harmonic loading. Int J Appl Mech Eng. 2022;27(2):35–52. 10.2478/ijame-2022-0018Suche in Google Scholar

[16] Ali G, Mahariq I, Abdelmohimen MA, Ahammad NA, Ali MR, Khan D. Enhanced heat transfer in viscoelastic fluids with periodic magnetic fields and dusty nanoparticles between two parallel plates under thermal radiation. Case Stud Thermal Eng. 2024;60:104686. 10.1016/j.csite.2024.104686Suche in Google Scholar

[17] Rao SS. Vibration of continuous systems. Hoboken, NJ: John Wiley & Sons; 2019. Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China

- Nonlinear comprehensive evaluation method based on information entropy and discrimination optimization

- Application of numerical calculation methods in stability analysis of pile foundation under complex foundation conditions

- Research on the contribution of shale gas development and utilization in Sichuan Province to carbon peak based on the PSA process

- Characteristics of tight oil reservoirs and their impact on seepage flow from a nonlinear engineering perspective

- Nonlinear deformation decomposition and mode identification of plane structures via orthogonal theory

- Numerical simulation of damage mechanism in rock with cracks impacted by self-excited pulsed jet based on SPH-FEM coupling method: The perspective of nonlinear engineering and materials science

- Cross-scale modeling and collaborative optimization of ethanol-catalyzed coupling to produce C4 olefins: Nonlinear modeling and collaborative optimization strategies

- Unequal width T-node stress concentration factor analysis of stiffened rectangular steel pipe concrete

- Special Issue: Advances in Nonlinear Dynamics and Control

- Development of a cognitive blood glucose–insulin control strategy design for a nonlinear diabetic patient model

- Big data-based optimized model of building design in the context of rural revitalization

- Multi-UAV assisted air-to-ground data collection for ground sensors with unknown positions

- Design of urban and rural elderly care public areas integrating person-environment fit theory

- Application of lossless signal transmission technology in piano timbre recognition

- Application of improved GA in optimizing rural tourism routes

- Architectural animation generation system based on AL-GAN algorithm

- Advanced sentiment analysis in online shopping: Implementing LSTM models analyzing E-commerce user sentiments

- Intelligent recommendation algorithm for piano tracks based on the CNN model

- Visualization of large-scale user association feature data based on a nonlinear dimensionality reduction method

- Low-carbon economic optimization of microgrid clusters based on an energy interaction operation strategy

- Optimization effect of video data extraction and search based on Faster-RCNN hybrid model on intelligent information systems

- Construction of image segmentation system combining TC and swarm intelligence algorithm

- Particle swarm optimization and fuzzy C-means clustering algorithm for the adhesive layer defect detection

- Optimization of student learning status by instructional intervention decision-making techniques incorporating reinforcement learning

- Fuzzy model-based stabilization control and state estimation of nonlinear systems

- Optimization of distribution network scheduling based on BA and photovoltaic uncertainty

- Tai Chi movement segmentation and recognition on the grounds of multi-sensor data fusion and the DBSCAN algorithm

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part III

- Generalized numerical RKM method for solving sixth-order fractional partial differential equations

Artikel in diesem Heft

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China

- Nonlinear comprehensive evaluation method based on information entropy and discrimination optimization

- Application of numerical calculation methods in stability analysis of pile foundation under complex foundation conditions

- Research on the contribution of shale gas development and utilization in Sichuan Province to carbon peak based on the PSA process

- Characteristics of tight oil reservoirs and their impact on seepage flow from a nonlinear engineering perspective

- Nonlinear deformation decomposition and mode identification of plane structures via orthogonal theory

- Numerical simulation of damage mechanism in rock with cracks impacted by self-excited pulsed jet based on SPH-FEM coupling method: The perspective of nonlinear engineering and materials science

- Cross-scale modeling and collaborative optimization of ethanol-catalyzed coupling to produce C4 olefins: Nonlinear modeling and collaborative optimization strategies

- Unequal width T-node stress concentration factor analysis of stiffened rectangular steel pipe concrete

- Special Issue: Advances in Nonlinear Dynamics and Control

- Development of a cognitive blood glucose–insulin control strategy design for a nonlinear diabetic patient model

- Big data-based optimized model of building design in the context of rural revitalization

- Multi-UAV assisted air-to-ground data collection for ground sensors with unknown positions

- Design of urban and rural elderly care public areas integrating person-environment fit theory

- Application of lossless signal transmission technology in piano timbre recognition

- Application of improved GA in optimizing rural tourism routes

- Architectural animation generation system based on AL-GAN algorithm

- Advanced sentiment analysis in online shopping: Implementing LSTM models analyzing E-commerce user sentiments

- Intelligent recommendation algorithm for piano tracks based on the CNN model

- Visualization of large-scale user association feature data based on a nonlinear dimensionality reduction method

- Low-carbon economic optimization of microgrid clusters based on an energy interaction operation strategy

- Optimization effect of video data extraction and search based on Faster-RCNN hybrid model on intelligent information systems

- Construction of image segmentation system combining TC and swarm intelligence algorithm

- Particle swarm optimization and fuzzy C-means clustering algorithm for the adhesive layer defect detection

- Optimization of student learning status by instructional intervention decision-making techniques incorporating reinforcement learning

- Fuzzy model-based stabilization control and state estimation of nonlinear systems

- Optimization of distribution network scheduling based on BA and photovoltaic uncertainty

- Tai Chi movement segmentation and recognition on the grounds of multi-sensor data fusion and the DBSCAN algorithm

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part III

- Generalized numerical RKM method for solving sixth-order fractional partial differential equations