Abstract

The advent of digital twin technology has precipitated a surge of interest in its implementation within the manufacturing sector, particularly with respect to enhancing productivity and mitigating the risk of equipment failure. However, due to the incomplete maturity of the technology, the manufacturing industry is prone to failures and reduced production efficiency in the production process. To reduce the frequency of failure and improve production efficiency, the optimized digital twin technology is combined with the long and short-term memory network to predict the health condition of the improved computer numerical control (CNC) machine tool. The proposed model is predicated on a convolutional neural network and a long and short-term memory network, the purpose of which is to extract the feature data of CNC machine tool parts. Second, the attention mechanism is introduced to enhance the importance weight of the model to the time feature. Finally, the Kalman filtering is employed to denoise the data and generate the final prediction result. The experimental findings of the model demonstrated that the maximum error between the predicted and true value of the convolution-long short-term memory (LSTM) model in the machine tool part health monitoring data was 0.06, and the minimum error was 0.035. The convolution-LSTM model in the anomalous point inspection displacement of the amount of positive displacement did not exceed 25 mm, and the negative displacement did not exceed −23 mm. The Kalman wave-LSTM model demonstrated an accuracy of 90.5% in monitoring the health status of the part at the minimum. The results show that the proposed method has good fitting effect and high accuracy in different monitoring cycles. This research provides a new method for monitoring and predicting the health condition of parts of CNC machine tools, which has important practical significance for optimizing and improving the production efficiency of manufacturing industries.

1 Introduction

The rapid and steady development of China’s economy promotes the rapid development of infrastructure, and the requirements for infrastructure in manufacturing have become higher. Computer numerical control (CNC) machine tools are important production equipment for modern manufacturing. Its normal operation is essential to ensure product quality and productivity [1,2]. The mechanism of the CNC machine (CNCM) tool has grown more sophisticated in order to meet the demands of the rapidly increasing productivity, and it is also necessary to continuously increase the CNCM tool’s automation level. By monitoring the health of CNCM tools in real time it is possible to detect machine failures in advance and to predict and maintain them [3]. This is because once a malfunction occurs and causes the manufacturing line to come to a standstill, it will result in huge economic losses and even have an impact on the personal safety of the production line workers. Relying solely on manual maintenance within the enterprise is clearly inadequate to effectively address these existing issues. Therefore, the study reconstructs the long short-term memory (LSTM) model based on digital twins in order to realize the timely and accurate prevention and diagnosis of CNC equipment health condition monitoring and evaluation system, to realize the high-precision manufacturing and processing of CNCM tools, and to improve the productivity rate [4,5]. Convolutional neural networks (CNNs) and digital twins share the same principles for data feature extraction; hence, CNN and LSTM are combined to create the CNN-LSTM model. The deep learning algorithm of CNN network neural model is used to provide deeper statistics on the monitoring data of CNCM tools. Then, the KF-LSTM model is constructed by fusing Kalman filtering (KF). The noise generated in the algorithm in the process of monitoring data is filtered by KF to exclude more data interference factors. The integrated model that the research team has created is expected to make it easier to monitor and assess the condition of CNCM parts. Furthermore, it is expected to contribute to the optimization and updating of production infrastructure equipment and the improvement of production rate.

The study is divided into four sections. The first section is a discussion of domestic and international research on CNNs, LSTMs, and predictive modeling for monitoring aspects of production equipment. The second section is the reconstruction of LSTM based on digital twins. The application analysis of the rebuilt model is covered in the third section. A description of the research’s limitations and application is included in the fourth section.

2 Related works

The maintenance and updating of production equipment is becoming more and more important in today’s world where productivity is growing vigorously. Many researchers are monitoring and collecting equipment data by combining it with digitalization. Aiming at the problem of liquid rocket engine (LRE) fault detection, Wang et al. proposed a comprehensive investigation of the development of LRE diagnostic systems and methods and related strategies. Through a thorough review of the historical development of LRE diagnostic systems, this study classified existing fault detection methods into three categories, including signal processing methods, model-driven methods, and artificial intelligence (AI) methods. According to the classification characteristics of the algorithm, the specific algorithm was discussed, and the future development of fault detection method was predicted [6]. To address the issue of not being able to track tool wear and forecast tool life in real time during the machining process, Worapong and Pakanun suggested a progressive tool wear prediction modeling approach based on machine vision. The technique took pictures of tool wear using a CCD camera and processed them using machine vision. The results proved that the proposed method was able to predict tool wear [7]. For conventional monitoring platforms, Vignesh et al. presented a smart energy monitoring technique that called for thorough data analysis utilizing a variety of sensors and controller data. The method obtained data information through a multi-intelligence networking structure. The results proved that the proposed method was able to optimize the problems in the data analysis process [8]. In response to the issue that the CNC shakes occasionally during the milling process carried out by CNCM tools, resulting in cracks or damage, Peng et al. suggested the use of an LSTM model to monitor the CNC. Then, spectral data were used to examine the process using the fast Fourier Transform (FFT). The results proved that the model was able to monitor the risk [9]. Martinova et al. proposed a subsystem component model in order to assess and monitor CNC health. It allowed determining the moments when the technical indicators of the machine mechanism approached or exceeded the permissible deviations. The simulation experiments revealed the feasibility of the proposed model for the assessment of the CNC health condition [10].

Huang et al. proposed a technique based on CNNs for the problem of fault diagnosis in power grids. In their approach, this study applied a sliding window method to the data, sampled features and delays from multivariate time series, and used LSTM networks to capture temporal information. Experimental results showed that the proposed method achieved good fault prediction accuracy [11]. Xiong et al. addressed the problem of segment diagnosis in power system fault diagnosis by proposing a binary gain shared knowledge-based algorithm. In their approach, the researchers utilized a binary encoding for the individuals to broaden the search space. They employed a binary division technique to tackle the frame planning challenge and conducted logical operations to continuously refine and update the individuals within the algorithm. Experimental results showed that the proposed method maintained a high level of diagnostic success rate [12]. Mukherjee et al. focused on the power state problem in power system fault diagnosis and introduced a combined machine learning approach. They estimated the operating state of the power system based on previous measurements and compensated for measurement losses using state prediction results. Experimental results showed that the proposed method provided faster diagnosis speed [13]. Wu et al. tackled the open-circuit fault diagnosis problem in power system fault diagnosis by proposing a fault hypothesis-based technique. This process involved estimating the extreme voltage and diagnosing variables by averaging and summing calculations, while adaptive thresholds were designed by considering voltage parameters. Experimental results showed that the proposed method had good diagnostic effectiveness [14]. In response to the issue that the manufacturing process’s operating conditions greatly impacted the workpiece’s ultimate size and shape accuracy, Sarvas et al. suggested a geometric accuracy control approach. The technique used an intelligent control system to govern the proper geometric configuration parameters. The results illustrated the reasonableness of the proposed intelligent control method for geometric setup of machine tools [15].

In summary, many domestic and foreign researchers have proposed many CNN-based and intelligent control methods for CNC monitoring. However, there are fewer studies on combining models and combining filtering for noise reduction in CNC monitoring applications. Therefore, the study of CNN-LSTM model reconstructed based on digital twins and KF-LSTM model fused with KF is very valuable for the prediction of CNC part health status.

3 Reconstruction of LSTM network models based on digital twins

The study is divided into two sections to reconstruct the network model of LSTM. First, CNN-LSTM prediction model is constructed by combining LSTM network with CNN network based on the characteristics of digital twins. Then, the LSTM model is fused with wavelet/KF model to construct KF-LSTM model.

3.1 Adaptation-based CNN-LSTM prediction model construction

This section describes the construction method of CNN-LSTM prediction model based on digital twin characteristics, which combines the advantages of CNN and LSTM network to improve the monitoring ability of CNCM health.

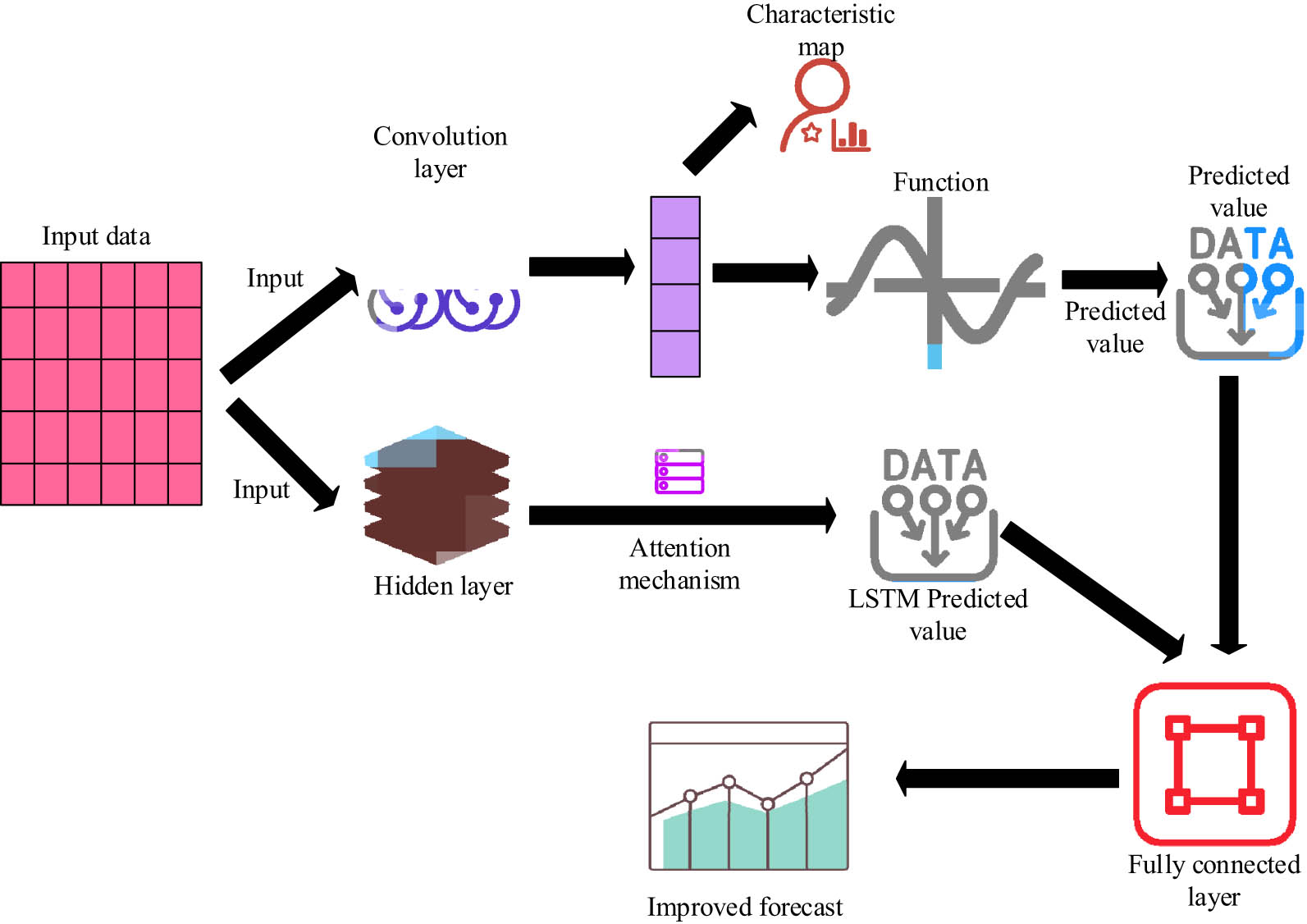

Utilizing data from physical models, sensor updates, and operation histories, digital twins enable the integration of interdisciplinary and multiscale feature sets through feature mapping in virtual space. The unique convolutionalization operation of CNN is to utilize the feature mapping characteristics of digital twins for feature extraction. LSTM neural network has strong memory and better effect on serialized data processing. Therefore, based on the consideration of the advantages of the two neural network models, the two models are combined to construct the CNN-LSTM model. Its structure is shown in Figure 1.

Structure diagram of reconstructed CNN-LSTM model.

In Figure 1, at the beginning, the convolutional layer as well as the LSTM implicit layer receives the input data for transmission to the convolutional layer. The CNN convolutional layer gets the feature result map by convolution. The resultant map is parsed through the fully connected layers (FCLs) of the Reshape function to obtain the CNN’s predicted values of part health. The LSTM implicit layer similarly gets the temporal features (TFs) of the data through functions in the network structure [16]. Then, the attention mechanism is introduced in the model. The TFs are weighted and averaged by the attention mechanism to obtain the predicted values of the LSTN. The overall network combines the advantages of two different networks through divergent branching, respectively. The input data are processed differently from both temporal and global perspectives for prediction. Finally, the two different predictions are fused. A fully connected network is used to connect the two divergent branches for the final output. The final computational result can be expressed in Eq. (1).

where

where

Overall architecture of CNN-LSTM model.

In the model architecture of Figure 2, the inspection data of CNC parts after preprocessing is input to construct the CNC part database. The types of data in the database include the initial input data for monitoring the deformation of CNC parts, the data for spatial feature (SF) extraction by CNN and the sequence prediction for temporal extraction by LSTM [17,18]. The optimized model also needs to be tested through the algorithmic process before the final results can be obtained. The algorithmic process starts with initialization of the population and then individual fitness is evaluated by fitness function. Then, selection and mutation are performed. If the conditions are satisfied, then output the optimal solution to obtain the weights and bias output the sequence of time prediction and the data information of the FCL. If the condition is not satisfied, then return to re-do the evaluation of fitness. Finally, output the prediction model’s results if the conditions are satisfied. The cross variance in the fitness function can be expressed as Eq. (3).

where

Eq. (4) can enhance the adaptability of the model to different data distributions and improve its generalization ability by adjusting the variation rate. The fitness function screening process has an optimal value for the evolved data. The calculation formula can be expressed in Eq. (5).

where

where

where

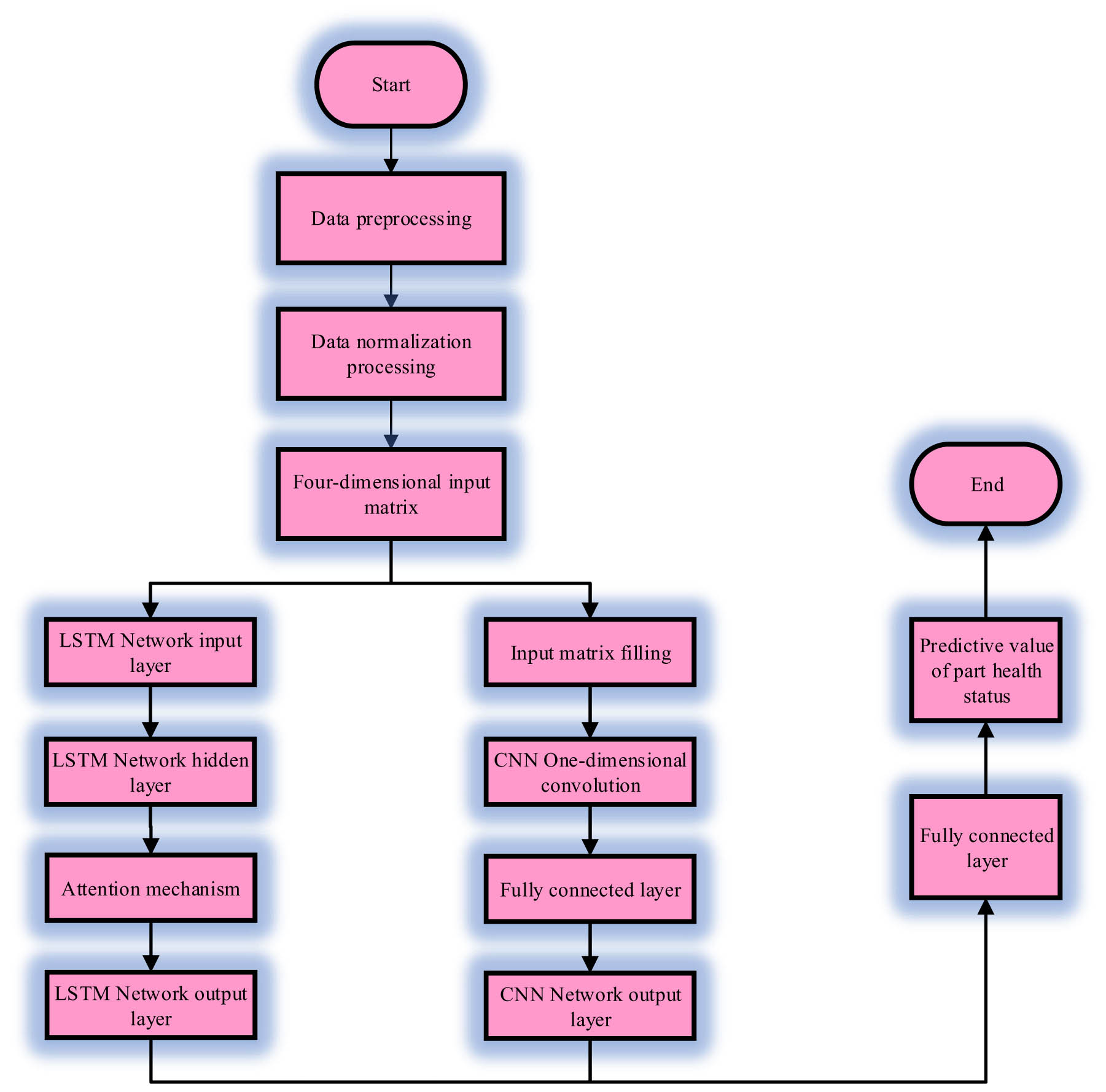

CNN-LSTM prediction model flow chart.

In the model flowchart of Figure 3, the data are first normalized after inputting the preprocessed data of the digitized automated machine part. Then, the four-dimensional input matrix of the data is obtained through the function. Through the LSTM’s network input layer, the matrix’s data are sent to the implicit layer. They are then transferred to another level of the LSTM network output layer after the computation of the attention mechanism. After the filling of the input matrix, it is transmitted to the CNN one-dimensional convolution after which it is transmitted to the CNN network output layer after the computation of the FCL. The LSTM and CNN output layers undergo the FCL of the model for the prediction of the part data of the digitized fully automated machine tool and then the prediction modeling process is concluded.

3.2 LSTM model construction with wavelet/KF fusion

In this section, the construction scheme of the LSTM model combining the wavelet denoising algorithm and the KF will be discussed. The purpose of this combination is to enhance the performance and reduce the noise effect in the monitoring data. The result of this combination is an improvement in the prediction accuracy of the model.

LSTM model is able to learn long- and short-term dependencies and has LSTM capability. However, the LSTM model requires high sample quality. Moreover, the acquisition of time series data in range monitoring often inevitably acquires noisy monitoring information due to instruments and complex environments. The study combines the wavelet threshold denoising algorithm to design an LSTM displacement prediction model that integrates wavelet/KF. The KF is chosen as the noise reduction method in the research mainly because of its superiority and flexibility in dynamic system state estimation. The KF is a recursive estimation algorithm that can dynamically update and optimally estimate the system state in the presence of random noise and measurement errors. This feature makes the KF very suitable for processing time-varying data related to the operation of CNCM tools, which can not only effectively remove process noise, but also track the change in system state in real time. In addition, KF can synthesize past measurements by using information from previous steps to improve current state estimates, thereby increasing the stability and accuracy of predictions. Compared to other noise reduction methods, such as wavelet denoising or mean filtering, KF is superior in processing dynamic and nonstationary signals, especially in high-frequency noisy environments, by dynamically adjusting the weight of prediction and measurement values, the signal characteristics can be better preserved. The CNC monitoring data collection process is shown in Figure 4.

Structure diagram of data machine parts collection process.

In Figure 4, the source of data is the basic equipment, such as CNC, robot, injection molding machine, metal baler, balancing machine, and so on. The data collected from the basic equipment are transmitted to the equipment number mining and analysis system, and then the equipment template and equipment center in the system analyze the parameter information of the basic production equipment [19]. The operation center and analysis center are responsible for data integration, statistics, and classification to obtain the final data analysis results and trend direction. Part of the derived data results is transferred to the enterprise information system and cloud for storage. Another part is sent back to the production equipment level for parameter reset and equipment update. The big data analysis platform reprocesses the data and sends it to the equipment data mining and analysis system. The wavelet threshold denoising flow chart is shown in Figure 5. The change characteristics of sequence data in data processing can be expressed as Eq. (8).

where

where

where

Denoising flow chart of wavelet threshold.

In Figure 5, the noisy data are filtered by feature extraction and then by low-pass filtering for signal reconstruction and finally the data are output after denoising. A common method in signal and image processing is wavelet threshold denoising. The fundamental principle is to divide the signal into its frequency components using the wavelet transform, and then apply the threshold to eliminate noise. Ultimately, the denoised signal is obtained by applying a wavelet inverse transform on it. When realizing wavelet threshold denoising, the signal first needs to be decomposed into different frequency components by wavelet decomposition. Then, according to the characteristics of the noise, a suitable threshold is selected for the wavelet coefficients. For wavelet coefficients larger than the threshold, their true values are retained. For wavelet coefficients smaller than the threshold are set to zero. To produce the denoised signal, the processed wavelet coefficients are next subjected to wavelet inversion. Figure 6 depicts the KF-LSTM model’s denoising procedure.

Denoising flow chart of KF-LSTM model.

In the flowchart of the modeling algorithm in Figure 6, the data input are first subjected to wavelet decomposition to determine the number of layered layers. Thresholding is performed after selecting a suitable wavelet to decompose the preprocessed data. The appropriate thresholding principle is selected to threshold the high-frequency part obtained from the decomposition to obtain the useful signal [20]. Then, the threshold data are subjected to wavelet reconstruction to obtain the de-noised displacement trend term. Finally, the LSTM prediction model of the displacement trend term is established. The LSTM network structure, the number of iterations, and the appropriate optimization algorithm as well as the learning tuning strategy are determined. The displacement of the observation is calculated, and the displacement increment is calculated by substituting the observation as shown in Eq. (11).

where

where

where

where

The linear functional relationship of the fusion function can be expressed as Eq. (16).

where

4 Effectiveness of the application of predictive modeling and KF-LSTM modeling

This section is split into two parts to evaluate the effectiveness of the updated model. First, a test is conducted on the reconstruction prediction model that is created by fusing the CNN and LSTM network models. Then, the constructed KF-LSTM model is tested for its ability and performance in processing the data information generated from CNC parts. The traditional LSTM model, the CNN-LSTM model, the KF-LSTM model, and the single feature model are investigated and compared. LSTM is a recursive neural network that deals with time series data and can capture long-term dependencies in the data. The CNN-LSTM model combines the advantages of CNN and LSTM. First, CNN-LSTM is used to extract SFs, and then the extracted features are input to LSTM for time series prediction. The KF-LSTM model fuses KF and LSTM, preprocesses the monitoring data by wavelet denoising algorithm to reduce noise, and then uses LSTM for displacement prediction. A single feature input is predicted based on a monitoring indicator.

4.1 Performance effects of the model

This section evaluates the performance of different models in CNC part health monitoring, focusing on the comparison between the CNN-LSTM model and the traditional LSTM model.

In the research, the steps of data preprocessing are very important, including data cleaning, feature engineering, and normalization. Initially, data cleaning is employed to eliminate noise and outliers that may be generated during the detection process. This process is integral for ensuring the accuracy and validity of the data utilized. In the subsequent feature engineering stage, the features directly related to the health state of CNCM tools are selected, including vibration, temperature, load, and other monitoring indicators. The dimensions of the dataset are enriched by extracting features in the time domain and the frequency domain. In addition, to make the input data comparable at different scales, the study normalized the features and adopted the z-score standardization method, so that the mean value of each feature is 0 and the standard deviation is 1. These preprocessing steps lay the foundation for the subsequent KF and LSTM network input, enhance the model’s adaptability to the data, and thus improve the prediction accuracy and stability. By elucidating these steps, it is possible to ensure the transparency and repeatability of research methods, thereby providing substantial support for subsequent research.

The combined CNN-LSTM model has the advantages of both CNN networks being able to identify the SFs of the data in depth and LSTM networks being able to analyze the TFs of the data and having long-term memory. The CNN-LSTM model is used to analyze the performance of CNC part data processing. Table 1 displays the experimental software configuration.

Experimental software configuration

| Designation | Versions |

|---|---|

| TensorFlow | 2.40 |

| NumPy | 1.23.6 |

| Keras | 2.7.0 |

| Pandas | 1.3.6 |

| Sklearn | 0.26.1 |

| Matplotlib | 3.4.3 |

| System | Windows 1,164 bits |

In the software configuration given in Table 1, the version requirement bit for the symbolic number system is version 2.4.0, and the version requirement for the array object-based computational library is version 1.23.6. The required version for advanced neural networks is version 2.7.0, and the standard data provision tool in the computational library requires version 1.3.6. The required version of the software ML library is version 0.26.1, and the required version of the library for generating publication-quality graphs is version 3.4.3. The experiments are performed in a computer with system Windows section 1,164b. The datasets used in the study are derived from real-time monitoring systems for multiple CNCM tools, specifically designed to assess the health of machine parts. The dataset contains more than 10,000 data records covering a variety of monitoring indicators under different operating conditions, including key parameters such as vibration, temperature, pressure, and load. These machines include many types of CNC equipment such as milling machines, lathes, and EDM machines, ensuring a diverse and representative dataset. At the same time, the monitoring records in the dataset are divided into normal operating state and fault state for fault detection and prediction. Each record contains a time stamp, sensor measurements, and a corresponding health state label, which allow the study to analyze differences in machine performance under different operating conditions, thereby improving the accuracy and robustness of the health monitoring model. Figure 7 compares the error between the CNN-LSTM model’s actual and predicted values with those of other data detection procedures in the CNC parts inspection dataset.

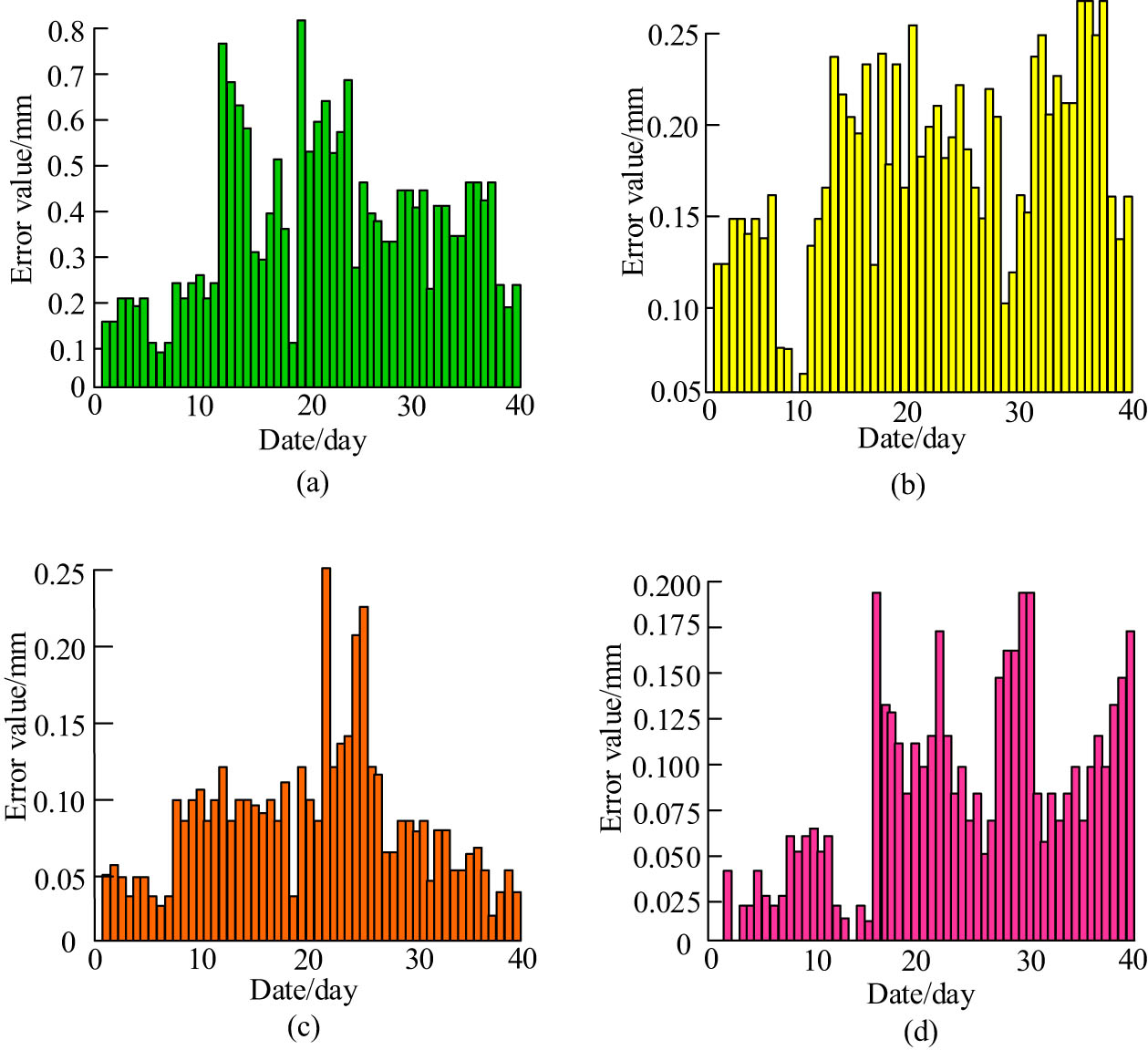

The error comparison diagram of the true value and the predicted value in the testing process of CNN-LSTM model part data. (a) LSTM network model predicted and true error values. (b) CNN network model predicted and true error values. (c) M-LSTM network model predicted and true error values. (d) CNN-LSTM network model predicted and true error values.

In Figure 7(a), the LSTM network models have error values less than 0.3 during the first 10 days of part monitoring. During the period of 10–40 days, the error values are mostly concentrated above 0.2, with a difference of 0.7 between the maximum and the minimum. In Figure 7(b), the maximum error is at 0.25 and the minimum is at 0 during the 40 days of performing the fault diagnosis, which is a very obvious difference. In Figure 7(c), the single-feature LSTM network models have errors above 0.025 during the part failure monitoring. The CNN-LSTM network model and the LSTM model for machine tool part health monitoring data have a coarse difference, and the distribution of the anomalies is expressed in terms of displacements. A comparison of the two models is shown in Figure 8.

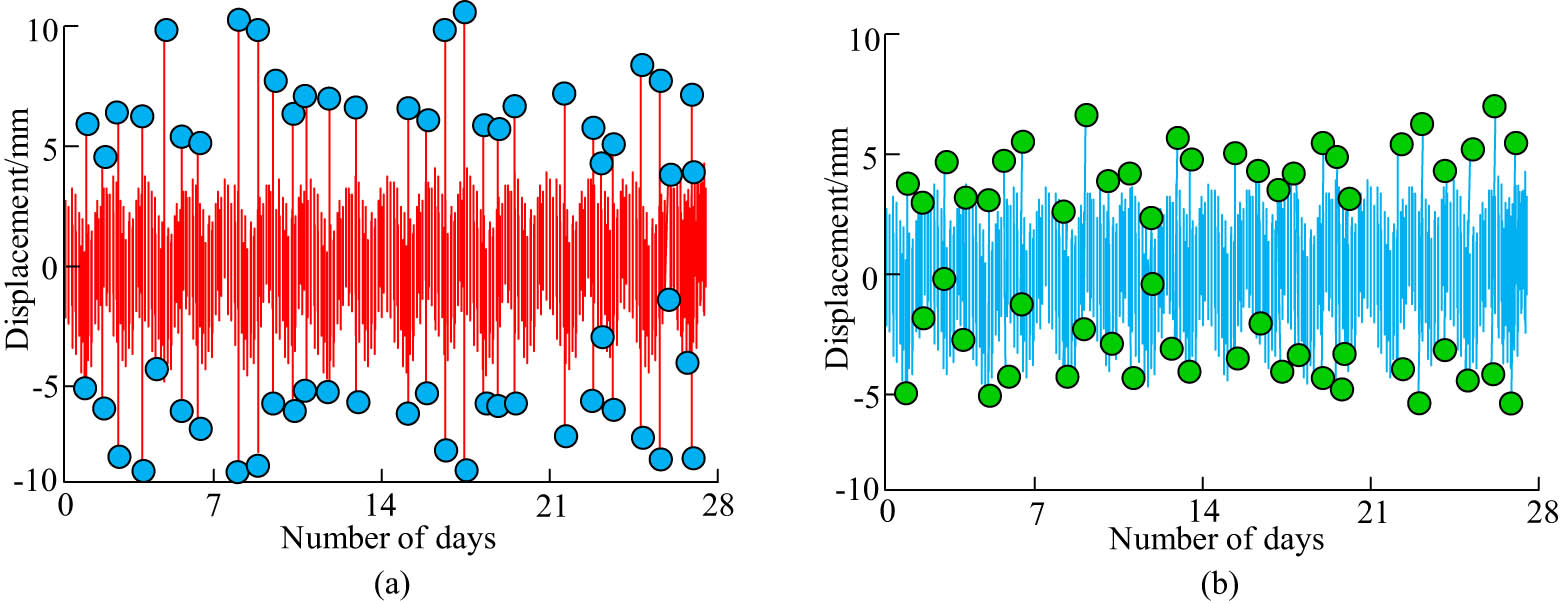

Abnormal point distribution of NN-LSTM network model and LSTM model in machine tool parts health monitoring data. (a) Monitoring displacement of LSTM model over time. (b) Monitoring displacement of CNN-LSTM model over time.

In Figure 8(a), when the LSTM model monitors the health status of the parts in the first week, the positive and negative displacements of the abnormal point distributions of the parts are almost always more than 5. The maximum displacement even reaches 10. In the second week, the positive and negative displacements of the abnormal point distributions are more than 5, and the number of points close to 10 becomes more. The situation in the third week is similar to that in the second week, and the distribution does not get better. In the fourth week, there are a small number of points where the displacement decreases, but most of the points are closer to 10. In Figure 8(b), the displacement of the distribution of part anomalies in the first week of part health monitoring by CNN-LSTM reaches up to 5. In the second week, the displacement of anomalies is almost less than 5, and there exists only 1 day with a displacement greater than 7. The displacement in the third week is similar to that in the first 2 weeks, and there is no large fluctuation. In the fourth week, there is a little fluctuation in the displacement, with a few days with anomalies of 5 or more. However, the fluctuation has little effect on the monitoring situation, and the overall stability of the model is good.

4.2 Application analysis of the simulation effect of the model

This section will discuss the simulation effect of the KF-LSTM model when processing actual CNC part monitoring data, and analyze its performance and accuracy in different monitoring time periods.

By choosing the wavelet basis function, the original signal is transformed from the time domain to the wavelet domain in the wavelet filtering principle. The wavelet coefficients are processed and then the processed wavelet coefficients are converted from the wavelet domain back to the time domain to get the denoised signal. Thus, KF-LSTM is able to process the noise values of the monitoring data in a better way. Table 2 displays the KF-LSTM model’s primary parameter settings.

Important parameters of LSTM prediction model

| Argument | Parameter value |

|---|---|

| Optimizer | Adam |

| LSTM number of layers | 1 |

| LSTM number of nodes | 32 |

| Number of FCLs | 2 |

| Activation function | ReLU function |

| Training rounds | 200 |

| Batch size | 8 |

The parameter value for the number of layers in the KF and CNN is ideally set to 1 in KF-LSTM model’s parameter settings listed in Table 2. The best optimization algorithm is the Adam algorithm and the activation function is the ReLU function. It is necessary for each layer of the LST to have 32 neurons, and the batch size parameter value must be 8. The parameter value of the number of training rounds is 200 and the byte size is 8. The function performs continuous scaling and translation-based wavelet transforms in such a setup, and the signals are computed as an inner product with the wavelet function in the non-stop transforms to obtain a series of wavelet coefficients on successive scales and translational positions. The continuous wavelet transform can provide richer time-frequency information. Figure 9 illustrates the accuracy of several detection methods in determining the condition of machine tool parts.

The accuracy of different detection models in detecting the health state of machine parts. (a) Monitor the change in accuracy during the first month. (b) Monitor the changes in accuracy in the second month.

Figure 9 shows the monitoring accuracy of the model for the health status of the parts. At the fifth day of monitoring, the traditional LSTM model has the lowest monitoring accuracy of 50.3%. Neither of the two improved models of LSTM had a better monitoring accuracy than the KF-LSTM model. The KF-LSTM model has the highest accuracy of 90.5%. On day 10 of monitoring, the KF-LSTM model has the highest accuracy of 92.5%. On the 20th day of monitoring, the accuracy of monitoring is 56.5% for the traditional LSTM model and 93.9% for the KF-LSTM model. During the later month, the accuracy of the models does not change particularly significantly, based on maintaining a high accuracy rate. As the monitoring time increased, the monitoring accuracy does not change, the fusion model accuracy remained at the highest level. The fit of each model to the original values (OVs) for different periods of time while monitoring the parts is shown in Figure 10.

The fitting of each model to the OV in different periods of part monitoring. (a) Displacement during deformation acceleration. (b) Displacement in gradient phase. (c) The displacement of each model in the convergence period.

Figure 10 shows the fitting of each model to the OV in different monitoring cycles, reflecting its error distribution in the prediction process. While the KF-LSTM model demonstrates superior performance in terms of displacement at most time nodes, with a maximum difference of −0.2, indicating a high degree of fit, the model’s prediction accuracy can be compromised under certain conditions, such as when the machine operates under high loads or in extreme environmental conditions. This phenomenon can be attributed to abnormal fluctuations in the data or dynamic changes in the characteristics, leading to increased bias in the results. In addition, the single feature model shows a large error in the monitoring process, especially in the deformation acceleration period, the maximum deviation reaches −10, indicating that the model is not sensitive enough to deal with variable working conditions. Therefore, the comprehensive error analysis not only reveals the limitations of the model under certain conditions but also provides an important improvement direction for improving the applicability and stability of the model in the future. To further verify the advanced nature of the proposed method, more real-world datasets are used for comparative analysis of the model, including Case Western Reserve bearing dataset, self-collected bearing dataset, and IMS bearing dataset, and are denoted as A, B, and C, respectively. In the research, several domain adaptive methods and several machine learning methods are selected for comparison with the proposed methods. These include the domain discriminative component (DCC), domain-adversarial neural network (DANN), and the deep convolutional transformation learning network (DCTLN). DCC is to find the feature transformation that can maximize the difference between two different domains, so that the transformed features are more discriminative, thus improving the accuracy of cross-domain classification. DANN reduces the difference between the source and target domains by introducing a domain classifier. DCTLN maps the source and target domain data by designing a transformation layer within the network, so that the model can extract a more general feature representation and perform effective transfer learning based on it. The model comparison results are shown in Table 3.

Comparison results of model advancement

| Model | A → B/% | B → A/% | A → C/% | C → A/% | B → C/% | C → B/% | Average value/% |

|---|---|---|---|---|---|---|---|

| DCC | 74.78 | 72.93 | 75.67 | 74.09 | 70.13 | 58.83 | 71.07 |

| DANN | 79.02 | 85.49 | 82.02 | 78.98 | 73.94 | 64.92 | 77.40 |

| DCTLN | 88.21 | 85.26 | 90.12 | 89.92 | 82.58 | 80.82 | 86.15 |

| Research method | 95.11 | 94.02 | 98.18 | 88.28 | 88.86 | 99.18 | 93.94 |

In Table 3, A → B indicates that training is conducted by combining labeled data from dataset A with unlabeled data from dataset B, and testing is performed on dataset B. The results show that the proposed method performs particularly well in the A → C scenario, achieving a prediction accuracy of 98.18%. It indicates that the algorithm demonstrates excellent performance when migrating from dataset A to dataset C. The performance of migrating from the same source dataset to different target datasets reflects the ability of each algorithm to adapt to changing environments. The average across all test scenarios reflects the overall performance of each algorithm. According to Table 3, the proposed method ranks first in terms of average accuracy, reaching 93.94%, demonstrating significant stability and efficiency in the cross-dataset migration process.

5 Conclusion

This study proposed an innovative health state prediction model based on digital twin technology, which combined CNN and LSTM and utilizes wavelet denoising and KF. Compared with the traditional LSTM model, the CNN-LSTM improved the feature extraction capability of CNCM health data through deep learning, which significantly improved the prediction accuracy. The KF-LSTM model improved the signal-to-noise ratio of data by effectively removing noise, which made the model superior in dynamic monitoring and fault prediction. The experimental results showed that the maximum prediction error of the CNN-LSTM model was 0.06, and the minimum error was 0.035, which showed its excellent performance in short-term prediction. In contrast, the traditional LSTM model showed a larger error under the same conditions, demonstrating the obvious advantages of the new model in terms of accuracy and robustness. In addition, the accuracy of KF-LSTM in different monitoring cycles was more than 90%, and it also showed good predictive ability in the case of multi-feature input, showing stronger adaptability. The research not only promoted the development of CNCM tool health monitoring technology, but also provided a new perspective and methodology for the field of intelligent manufacturing. Overall, this research contributed an important theoretical and practical basis for the automation and intelligence process in the manufacturing industry, which helped to improve the efficiency of equipment management and reduce operating costs. Although the proposed model shows good performance in predicting the condition of CNCM parts, there are still some limitations that deserve attention. First, the validity of the model has not been verified in other engineering application scenarios, so there is no detailed data support for its scalability and application effect in different industries. In addition, the design process of the model is based on a number of assumptions, such as the quality of the monitoring data, the selection of features, and their correlation, which can affect the accuracy of its predicted results. If the data quality is not high or the feature selection is not appropriate, the performance of the model may be significantly reduced. Therefore, future research should focus on comprehensive verification in different application areas, explore the applicability of the model in more realistic scenarios, and rigorously test and revise the assumptions of the model to improve its robustness and generalization ability in complex environments.

-

Funding information: The research is supported by School Grants platform for Scientific Research of Shandong Huayu University of Technology in 2025: CNC tool manufacturing process research and development center.

-

Author contributions: Guo Chen: study design, data collection, statistical analysis, visualization, formal analysis, funding acquisition, writing, and revision of the original draft. Haifang Yin: data collection, statistical analysis, and revision of the manuscript. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The data used to support the findings of the research are available from the corresponding author upon reasonable request.

References

[1] Ouyang X, Matt A, Wang F. Attention LSTM U-net model for Drosophila melanogaster heart tube segmentation in optical coherence microscopy images. Biomed Opt Express. 2024;15(6):3639–53.10.1364/BOE.523364Search in Google Scholar PubMed PubMed Central

[2] Wang H, Sun W, Sun W. A novel tool condition monitoring based on Gramian angular field and comparative learning. Int J Hydromechatronics. 2023;6(2):93–107.10.1504/IJHM.2023.130510Search in Google Scholar

[3] Hossein G, Ayman M, Mahmoud H. Hybrid offline-online optimization, monitoring and control of milling processes. CIRP Ann Manuf Technol. 2023;72(1):85–8.10.1016/j.cirp.2023.04.017Search in Google Scholar

[4] Alek, Iskandar I. Analyzing the internal part condition on the planetary gear unit with conditioning monitoring method at cement factory horizontal milling station. J Mech Civ Ind Eng. 2022;3(3):71–8.10.32996/jmcie.2022.3.3.9Search in Google Scholar

[5] Maryam J, François JC, Xavier R. Tool condition monitoring based on the fractal analysis of current and cutting force signals during CFRP trimming. Int J Adv Manuf Technol. 2022;121(11–12):8127–42.10.1007/s00170-022-09860-3Search in Google Scholar

[6] Tambake N, Deshmukh B, Pardeshi S, Haitham A. Particle swarm optimized fuzzy proportional-integral-derivative controller-based transverse leaf spring active suspension for vibration control. J Low Freq Noise Vib Active Control. 2024;43(2):979–6.10.1177/14613484231221953Search in Google Scholar

[7] Worapong S, Pakanun W. A model approach for in-process tool condition monitoring in CNC turning using machine vision. Int J Interact Des Manuf. 2022;16(4):1439–56.10.1007/s12008-022-01010-zSearch in Google Scholar

[8] Vignesh S, Zhicheng X, Sangkee M. Intelligent operation monitoring of an ultra-precision CNC machine tool using energy data. Int J Precis Eng Manuf Green Technol. 2022;10(1):59–69.10.1007/s40684-022-00449-5Search in Google Scholar

[9] Peng CY, Ully R, Kuo SW, Chen YZ. Sound detection monitoring tool in CNC milling sounds by K-Means clustering algorithm. Sensors (Basel). 2021;21(13):4288–95.10.3390/s21134288Search in Google Scholar PubMed PubMed Central

[10] Martinova LI, Kozak NV, Kovalev IA, Aleksandr B. Creation of CNC system’s components for monitoring machine tool health. Int J Adv Manuf Technol. 2021;117(7–8):1–8.10.1007/s00170-021-07107-1Search in Google Scholar

[11] Huang T, Zhang Q, Tang X, Zhao S, Lu X. A novel fault diagnosis method based on CNN and LSTM and its application in fault diagnosis for complex systems. Artif Intell Rev. 2022;55(2):1289–315.10.1007/s10462-021-09993-zSearch in Google Scholar

[12] Xiong G, Yuan X, Mohamed AW, Zhang J. Fault section diagnosis of power systems with logical operation binary gaining-sharing knowledge-based algorithm. Int J Intell Syst. 2022;37(2):1057–80.10.1002/int.22659Search in Google Scholar

[13] Li D, Zhao Y, Zhao Y. A dynamic-model-based fault diagnosis method for a wind turbine planetary gearbox using a deep learning network. Prot Control Mod Power Syst. 2022;7(2):1–14.10.1186/s41601-022-00244-zSearch in Google Scholar

[14] Wu C, Sehab R, Akrad A, Morel C. Fault diagnosis methods and fault-tolerant control strategies for the electric vehicle powertrains. Energies. 2022;15(13):4840–6.10.3390/en15134840Search in Google Scholar

[15] Sarvas M, Holub M, Marek T, Prochazka J, Bradac F, Blechal P. Influence of machine tool operating conditions on the resulting circularity and positioning accuracy. Machines. 2024;12(5):352–65.10.3390/machines12050352Search in Google Scholar

[16] Dhote ND, Khond MP. Condition monitoring approach for wear recognition in gear pump. J Fail Anal Prev. 2022;22(4):1558–65.10.1007/s11668-022-01448-zSearch in Google Scholar

[17] Netzer M, Palenga Y, Fleischer J. Machine tool process monitoring by segmented time-series anomaly detection using subprocess-specific thresholds. Prod Eng. 2022;16(5):1–10.10.1007/s11740-022-01120-3Search in Google Scholar

[18] Amin SN, Shivakumara P, Jun TX, Chong KY, Zan DLL, Rahavendra R. An augmented reality-based approach for designing interactive food menus of restaurants using Android artificial intelligence and applications. Artif Intell Appl. 2023;1(1):26–34.10.47852/bonviewAIA2202354Search in Google Scholar

[19] Nsugbe E. Toward a self-supervised architecture for semen quality prediction using environmental and lifestyle factors. Artif Intell Appl. 2023;1(1):35–42.10.47852/bonviewAIA2202303Search in Google Scholar

[20] Choudhuri S, Adeniye S, Sen A. Distribution alignment using complement entropy objective and adaptive consensus-based label refinement for partial domain adaptation. Artif Intell Appl. 2023;1(1):43–51.10.47852/bonviewAIA2202524Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- User profiling in university libraries by combining multi-perspective clustering algorithm and reader behavior analysis

- Exploring bifurcation and chaos control in a discrete-time Lotka–Volterra model framework for COVID-19 modeling

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China

- Nonlinear comprehensive evaluation method based on information entropy and discrimination optimization

- Application of numerical calculation methods in stability analysis of pile foundation under complex foundation conditions

- Research on the contribution of shale gas development and utilization in Sichuan Province to carbon peak based on the PSA process

- Characteristics of tight oil reservoirs and their impact on seepage flow from a nonlinear engineering perspective

- Nonlinear deformation decomposition and mode identification of plane structures via orthogonal theory

- Numerical simulation of damage mechanism in rock with cracks impacted by self-excited pulsed jet based on SPH-FEM coupling method: The perspective of nonlinear engineering and materials science

- Cross-scale modeling and collaborative optimization of ethanol-catalyzed coupling to produce C4 olefins: Nonlinear modeling and collaborative optimization strategies

- Unequal width T-node stress concentration factor analysis of stiffened rectangular steel pipe concrete

- Special Issue: Advances in Nonlinear Dynamics and Control

- Development of a cognitive blood glucose–insulin control strategy design for a nonlinear diabetic patient model

- Big data-based optimized model of building design in the context of rural revitalization

- Multi-UAV assisted air-to-ground data collection for ground sensors with unknown positions

- Design of urban and rural elderly care public areas integrating person-environment fit theory

- Application of lossless signal transmission technology in piano timbre recognition

- Application of improved GA in optimizing rural tourism routes

- Architectural animation generation system based on AL-GAN algorithm

- Advanced sentiment analysis in online shopping: Implementing LSTM models analyzing E-commerce user sentiments

- Intelligent recommendation algorithm for piano tracks based on the CNN model

- Visualization of large-scale user association feature data based on a nonlinear dimensionality reduction method

- Low-carbon economic optimization of microgrid clusters based on an energy interaction operation strategy

- Optimization effect of video data extraction and search based on Faster-RCNN hybrid model on intelligent information systems

- Construction of image segmentation system combining TC and swarm intelligence algorithm

- Particle swarm optimization and fuzzy C-means clustering algorithm for the adhesive layer defect detection

- Optimization of student learning status by instructional intervention decision-making techniques incorporating reinforcement learning

- Fuzzy model-based stabilization control and state estimation of nonlinear systems

- Optimization of distribution network scheduling based on BA and photovoltaic uncertainty

- Tai Chi movement segmentation and recognition on the grounds of multi-sensor data fusion and the DBSCAN algorithm

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part III

- Generalized numerical RKM method for solving sixth-order fractional partial differential equations

Articles in the same Issue

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- User profiling in university libraries by combining multi-perspective clustering algorithm and reader behavior analysis

- Exploring bifurcation and chaos control in a discrete-time Lotka–Volterra model framework for COVID-19 modeling

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China

- Nonlinear comprehensive evaluation method based on information entropy and discrimination optimization

- Application of numerical calculation methods in stability analysis of pile foundation under complex foundation conditions

- Research on the contribution of shale gas development and utilization in Sichuan Province to carbon peak based on the PSA process

- Characteristics of tight oil reservoirs and their impact on seepage flow from a nonlinear engineering perspective

- Nonlinear deformation decomposition and mode identification of plane structures via orthogonal theory

- Numerical simulation of damage mechanism in rock with cracks impacted by self-excited pulsed jet based on SPH-FEM coupling method: The perspective of nonlinear engineering and materials science

- Cross-scale modeling and collaborative optimization of ethanol-catalyzed coupling to produce C4 olefins: Nonlinear modeling and collaborative optimization strategies

- Unequal width T-node stress concentration factor analysis of stiffened rectangular steel pipe concrete

- Special Issue: Advances in Nonlinear Dynamics and Control

- Development of a cognitive blood glucose–insulin control strategy design for a nonlinear diabetic patient model

- Big data-based optimized model of building design in the context of rural revitalization

- Multi-UAV assisted air-to-ground data collection for ground sensors with unknown positions

- Design of urban and rural elderly care public areas integrating person-environment fit theory

- Application of lossless signal transmission technology in piano timbre recognition

- Application of improved GA in optimizing rural tourism routes

- Architectural animation generation system based on AL-GAN algorithm

- Advanced sentiment analysis in online shopping: Implementing LSTM models analyzing E-commerce user sentiments

- Intelligent recommendation algorithm for piano tracks based on the CNN model

- Visualization of large-scale user association feature data based on a nonlinear dimensionality reduction method

- Low-carbon economic optimization of microgrid clusters based on an energy interaction operation strategy

- Optimization effect of video data extraction and search based on Faster-RCNN hybrid model on intelligent information systems

- Construction of image segmentation system combining TC and swarm intelligence algorithm

- Particle swarm optimization and fuzzy C-means clustering algorithm for the adhesive layer defect detection

- Optimization of student learning status by instructional intervention decision-making techniques incorporating reinforcement learning

- Fuzzy model-based stabilization control and state estimation of nonlinear systems

- Optimization of distribution network scheduling based on BA and photovoltaic uncertainty

- Tai Chi movement segmentation and recognition on the grounds of multi-sensor data fusion and the DBSCAN algorithm

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part III

- Generalized numerical RKM method for solving sixth-order fractional partial differential equations