Abstract

The unmanned double steel wheel vibration roller enhances high-quality unmanned compaction operations by ensuring precise walking control, thus avoiding human error-related issues like under- and over-compaction. However, its complex construction technology, cooperative operation challenges, and high construction quality demands present significant difficulties for unmanned operation. This study addresses the challenges associated with compaction mechanisms and construction technology. It analyzes the interaction between the vibrating roller and the compacted material using the U-K equation to develop a dynamic force model, which leads to a method for determining optimal compaction parameters. Simulations reveal that the compaction speed of the three rollers is approximately 0.3 m/s, and the parameter optimization module performs as anticipated. The simulated pilot roller effectively executes motion planning under various compaction conditions, with an overlap distance of about 0.2 m between adjacent rolling belts after lane changes. This overlap, which is 0.5 times the width of the 0.4 m steel wheel, successfully prevents both under-compaction and over-compaction. A cluster motion planning strategy, based on a pilot-following structure, is proposed for the roller cluster in the compaction area. The strategy includes designing the following roller formation based on the compaction operation range and roller group configuration parameters.

1 Introduction

Compared with the car, the roller has a closed or half closed work scene, a fixed vehicle route, no traffic rules, no or less traffic participants, advantages, and roller using unmanned technology, not only can let the driver get rid of the bad working environment, avoid health problems, but also can improve the overall work efficiency and reduce the construction cost [1,2]. Therefore, roller is one of the best applications of unmanned driving, and unmanned driving is also the mainstream development direction of roller in the future. The double steel wheel vibration roller has specific requirements for compaction speed stability during the compaction process. This includes maintaining a consistent speed to ensure uniform compaction and meet the quality standards of the pavement, such as achieving a compaction degree of 98% and a maximum pavement clearance of 5 mm [3]. After the compaction operation, the pavement quality is measured by the compaction degree and flatness. The compaction degree of the highway pavement should reach 98% of the test section density [4]. When the pavement flatness is accepted, the maximum pavement clearance shall not exceed 5 mm. In addition, in the process of large-scale engineering construction, in order to ensure timely road compaction, multiple rollers often need to work together [5]. Compared with the movement planning and control of a single roller, the control of roller group construction is more complex, and the rollers need to realize the functions of mutual cooperation, information interaction, and resource allocation [6]. To sum up, the roller group has the characteristics of cooperative operation, complex compaction process, and strict operation quality requirements. Compared with the unmanned driving of traditional vehicles, the motion planning and control of the unmanned roller group should not only realize the automatic walking control of the machine group but also dynamically plan the compaction path and compaction parameters according to the compaction quality requirements to ensure the overall compaction quality of the construction area [7,8].

At present, the application of the unmanned roller is developing rapidly, but there is a lack of theoretical research on the group planning and cooperative control of unmanned roller groups related to compaction quality [9]. In this article, a complex dynamic model of a double steel wheel vibrating roller coupled with the compaction material is established by the U-K equation, and a method of determining the compaction degree model and the optimal compaction parameters is proposed according to the compaction specifications and the optimal compaction parameters. Due to the double hinge structure of the unmanned double steel wheel vibration roller, its motion and control are more complex. This structure affects the roller’s ability to maneuver and requires careful consideration in the design of the path-tracking control system to ensure accurate compaction and movement. Vibration compaction refers to the compaction method that uses the vibration load to rearrange the compacted material particles in the high-frequency vibration state, so as to make the density of the compacted material increase [10,11]. The compaction effect mainly depends on the vibration frequency, vibration amplitude, and the physical characteristics of the compacted material. Therefore, in order to analyze the influence of the working parameters of the roller and the physical characteristics of the compacted material on the compaction quality and deeply discuss the nature of vibration compaction, scholars at home and abroad have continuously explored and carried out a large number of theoretical and experimental studies [12,13]. Intelligent compaction technology is based on continuous compaction technology, using the roller response information in materials and controlling the compaction quality of road surfaces. It can be divided into two aspects: auxiliary compaction technology and compaction parameter feedback regulation technology. The auxiliary compaction technology collects the working parameter information, construction information, and compaction quality information of the compacted material in real time through the acceleration sensor, temperature sensor, GPS, and other sensors. Compaction parameter feedback regulation technology, the compacted material information collected in real time, such as material temperature, compaction degree, material stiffness, and damping, automatically adjusts the vibration frequency, amplitude, and compaction speed of the roller to reach the optimal working parameters, so as to improve the compaction efficiency and compaction quality [14,15].

The auxiliary compaction technology focuses on the real-time detection technology of the compaction degree [16]. In 1976, the Dutch company and Dana Parker took the lead in developing the compaction instrument and proposed to use the ratio of the second harmonic and the base wave collected by the acceleration sensor to reflect the compaction degree of the compacted material. In 2000, BMW proposed the soil dynamic stiffness index E vb as the measurement value of intelligent compaction, which excluded the influence of roller vibration parameters on the measurement results [17]. In 1994, the stiffness coefficient k s of the roller was taken as the compaction quality evaluation index, and it was verified in the actual products. In 2004, Sakai proposed a dimensionless compaction measurement CCV considering both the fundamental and subharmonic frequencies. Compared with the auxiliary compaction technology, the research of compaction parameter feedback regulation technology started late, and the related technologies are less applied, and most of them are in the theoretical research part [18]. A method based on the boundary element method and material characteristics is proposed to determine the amplitude and frequency of the compaction equipment. This involves establishing a discrete mathematical model of the aggregate particle migration, considering parameters and the determination of the rolling mode. The rolling speed is related to vibration impact distance and frequency, and the relationship between them under specific impact distance is obtained to optimize the compaction process [19,20].

2 Study on the operation parameters of a double steel wheel vibrating roller

2.1 System dynamics model of “vibratory roller-compacted material”

Analyzing the influence of the working parameters of the roller on the compaction effect and establishing the vibration dynamic model describing the compaction process, as shown in Eqs. (1) and (2), this article mainly studies the ground compaction and avoids the late compaction jump by selecting reasonable working parameters:

Under the grounding compaction condition, the displacement of the vibration wheel is equal to the displacement of the compacted material, the “vibrating roller-compacted material” system is subject to a complete constraint, and the actual force between the vibration roller and the compacted material is bound by the system. As shown in Eqs. (3) and (4), U-K equation, as a new method to establish mechanical system dynamics model, can embed complete and non-complete constraints into the system dynamics model to obtain explicit dynamic equations and analytical solution of system binding:

Therefore, the U-K equation is used to model the vibration dynamics of “vibrating roller-compacted material.” As shown in Eqs. (5) and (6), compared with the track control of a single roller, the theoretical research of the roller group control is still in the initial stage, and most of the related research focuses on the machine group scheduling and construction process monitoring:

This article studies the requirements of intelligent construction of machine group, and an intelligent roller with stepless variable amplitude and wireless communication function is designed. For the compaction process of bridge deck pavement, as shown in Eqs. (7) and (8), a roller group configuration method is proposed from the perspective of paving material and the required compaction work

Based on the multi-agent theory and technology, a set of comprehensive supervision and scheduling system of roller cluster information is developed, which helps the roller operators grasp the road compaction condition in real time and stores and manages the data in a unified way, providing information for post-construction analysis and fault diagnosis. Based on the theory of multi-agent, the genetic algorithm, as shown in Eqs. (9) and (10), is used to study the dynamic configuration and construction process management of the cluster, which lays a foundation for the intelligent control of the cluster:

2.2 Study on the optimal working parameters of double steel wheel vibration roller based on the compaction model

Because most of the relevant theoretical studies focus on machine cluster configuration, cluster scheduling, and cluster status monitoring, the control theory of machine cluster is less studied. Therefore, this article studies the multi-machine formation control technology of mobile robots. As shown in Eqs. (11) and (12), the robot formation control method mainly includes the pilot-follow method, based on the behavior method and the virtual structure method. The front and rear racks of the double steel wheel vibrating roller are equipped with one vibrating steel wheel. The shock absorber is connected between the steel wheel and the rack, and the front and rear racks are connected by a Hin gated oil cylinder

As shown in (13) and (14), the vibration force of the roller in the horizontal direction can offset each other, so the system of “double steel wheel vibration roller-compacted material” can be simplified to the dynamics of the plane only considering the vibration force of the vibration wheel in the vertical direction

When the roller works, the vibration wheel and the frame can be approximated as the rigid body motion, so the frame and the vibration wheel can be simplified to the concentrated mass blocks m1 and m2. Because of the obvious elastic deformation, as shown in Eqs. (15) and (16), and the mass of the shock block is far less than the quality of the vibration wheel, the shock absorber can be simplified to the grading of different types of compaction materials, the arrangement of particles and the size of interaction force are different, the compaction energy to achieve the target compaction degree is different, so the same type of roller compaction with the same compaction process compaction effect

According to the indoor standard Marshall experiment, the internal factors affecting soil compaction mainly include soil water content, soil particle composition, and gradation. In this article, through indoor experiments such as the standard Marshall compaction experiment, the internal factors affecting soil compaction, including soil water content, particle composition, and gradation, are studied. The energy model of the compacted material is established based on these experiments to analyze the compaction process and determine the optimal working parameters for the unmanned double steel wheel vibration roller. In the standard Marshall experiment, the strike sufficiently proof with the specified mass was allowed to compact the compacted material in the lower strike cylinder freely from the set height along the guide cylinder, and the single hit energy was considered to be the potential energy reduced by the strike sufficiently proof

The compaction model of the compacted material is established from the perspective of energy equivalence. By considering factors such as the force exerted on the material and its displacement, as shown in Eqs. (19) and (20), the model can quantitatively analyze the effect of working parameters on compaction under different external conditions. This helps in understanding the compaction process and optimizing the operation of the unmanned roller. In this paper, through the indoor Marshall experiment, the energy required to achieve the target compaction degree for a unit volume of compaction material is determined. In actual compaction operations, the unmanned double steel wheel vibration roller takes into account that the material often has a certain initial compaction degree, such as the asphalt mixture spread by the paver with an initial compaction degree of about 90%. This information is used to optimize the compaction process and ensure the final quality of the pavement.

3 Study on the motion planning method of an unmanned double steel wheel vibrating roller group

3.1 Construction technology analysis of a double steel wheel vibrating roller

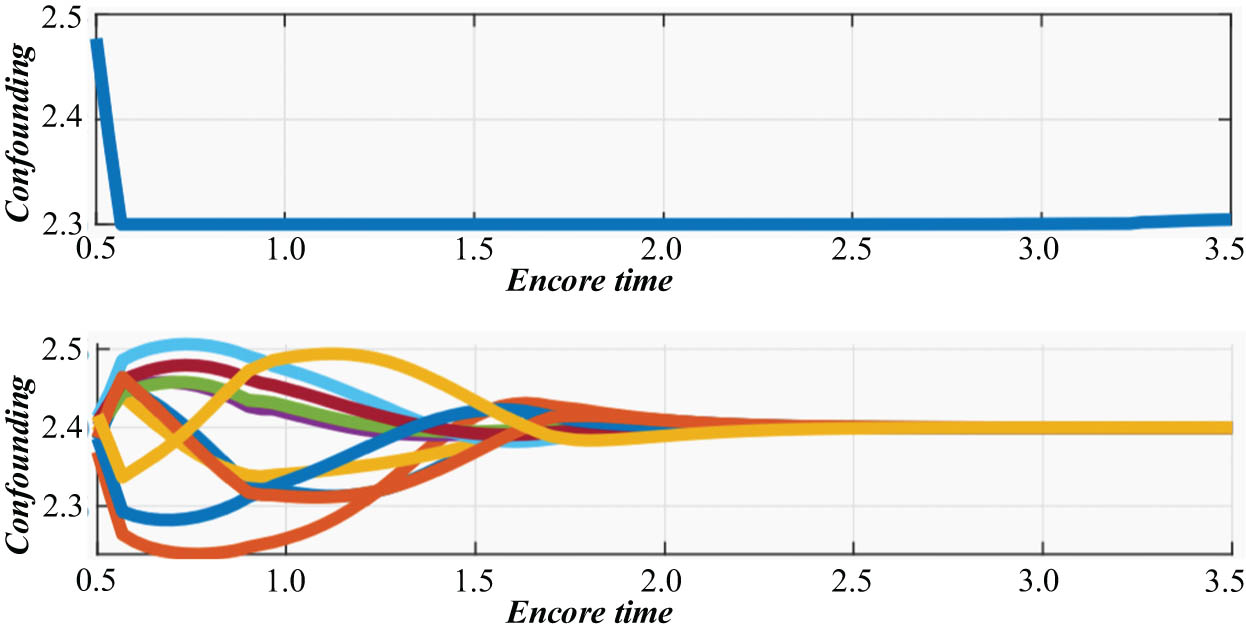

The effect of the working frequency and amplitude of a double steel wheel vibration roller on compaction quality can be regarded as the dynamic response study of double steel wheel vibration rollers at different working frequencies [21,22]. When selecting the basic parameters of a set of double steel rollers and the basic parameters of the compacted material, the speed of the double steel roller vibration roller includes the compacted speed during the compaction operation and the transfer speed when replacing the rolling belt and the compacted area. From the perspective of compaction efficiency, improving the compaction speed of the double steel wheel vibrating roller can reduce the construction time and cost [23,24]. However, from the perspective of energy transfer, with the structural parameters and vibration parameters of the roller being unchanged, the higher the compaction speed, the lower the compaction energy affected by the compacted material per unit volume, and the lower the compaction degree of the compacted material, resulting in the final compaction quality is not up to standard. Therefore, the optimal compaction speed should be selected according to the current state of the compacted material and the vibration parameters of the roller, and compaction efficiency should be improved as far as possible when the compaction quality is guaranteed [25,26]. The relationship between compaction speed and compaction efficiency can be expressed by vibration impact spacing, which refers to the distance when the vibration wheel travels in the eccentric block for a week. When the impact spacing is too small, overpressure occurs, which reduces the compaction efficiency, and the compacted material particles may be crushed; when the impact spacing is too large, the leakage pressure will occur, which reduces the flatness and uniformity of the compaction surface [27,28]. When the grounding width of the vibration wheel equals the impact spacing, the corresponding compaction speed is the optimal compaction speed. While the impact spacing is related to the diameter of the vibration wheel, which is 3 cm in maximum engineering. Then, the compaction speed expression is as follows with the compaction process: The stiffness of the compacted material increases with increasing compaction, the damping of the compacted material decreases with increasing compaction, increasing vibration frequency throughout the compaction process, while the natural frequency ratio of the operating frequency to the compacted material remains within the range of 22, while ensuring highly efficient compaction, avoid reducing the working life and reliability of the machine parts due to resonance. As for the compaction rate, in the initial pressure stage, low-speed compaction can avoid the generation of the compacted material to ensure compaction quality. After the stable performance of the material after the initial pressure, the compaction speed gradually improves to ensure the compaction efficiency, which is in line with the actual engineering situation. Unit motion planning is one of the key contents of the unmanned double steel wheel vibration roller. Reasonable planning can not only ensure the final compaction quality, but also shorten the construction time and reduce the construction cost. In this article, fully considering the construction process requirements, we adopt the pilot-following method to complete the motion planning of the unmanned double steel wheel vibration roller group, ensure the overlap of the roller formation design, take the compaction index as the basis of the compaction motion planning, complete the changing path planning in line with the motion constraints of the pilot roller by a five-order polynomial curve, according to the working parameter optimization algorithm, and obtain the pilot roller speed planning by the S-shaped speed planning method.

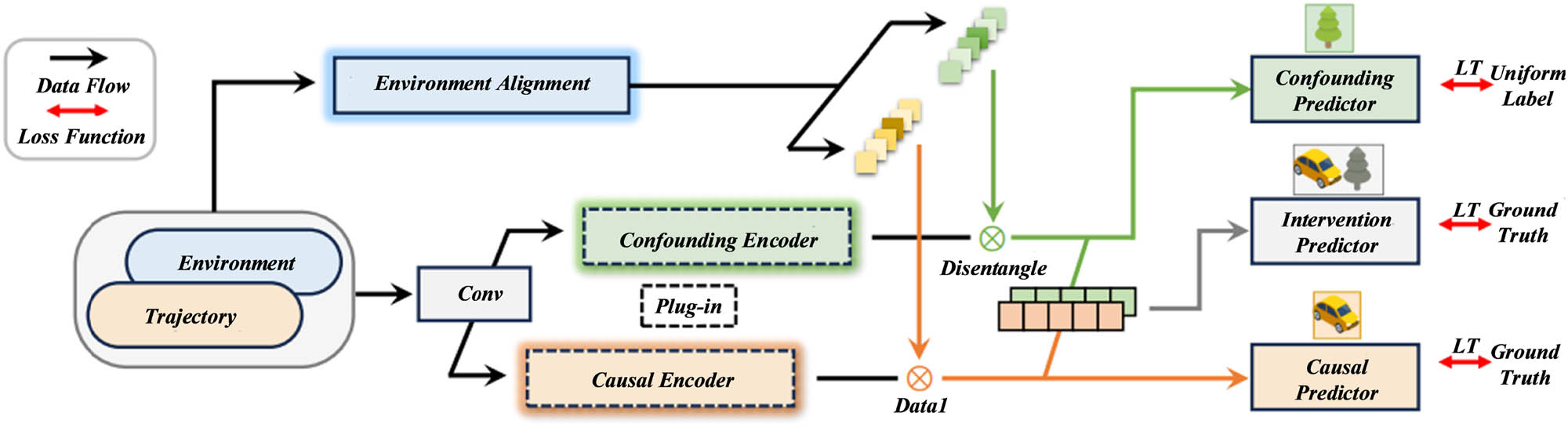

The double steel wheel vibrating roller is mostly used for the compaction of road bases, asphalt pavement layer, and various small and medium-sized filling projects, among which the compaction process of the asphalt pavement layer is the most complex, and the process is the most complicated. Figure 1 shows the adaptive path planning and tracking control framework of the unmanned roller. Taking the compaction of the asphalt surface as an example, a process-based motion planning method of a double steel wheel vibration roller is proposed. In the process of asphalt pavement compaction work, the double steel wheel vibrating roller often works together with the paver. Later the paver completes the paving and the recompacting work of the asphalt mixture. During the operation of the unmanned double steel wheel vibration roller, it must strictly follow the process specifications. This includes starting, uniform compaction, parking, and lane changing operations. The roller should start and park smoothly with a stable speed to ensure uniform compaction of the road. Lane changes should be executed precisely to meet the requirements of overlapping distances between adjacent rolling belts and lap distances at the ends of the same roller belt, thereby preventing leakage pressure and under pressure phenomena and ensuring the final quality of the road in terms of compaction, flatness, and uniformity. The specific process requirements for the unmanned double steel wheel vibration roller operation are as follows: the roller should not stop at inappropriate positions during compaction, and the length of the compaction section should be minimized, generally not exceeding 60 m. It is advisable to complete the first pavement compaction when the asphalt temperature is high. To prevent issues such as pavement material passage and package, the roller should operate with a first low frequency and then high frequency, and a first slow and then fast speed. Additionally, the roller must comply with the compaction index and motion constraints, ensuring that the driving route is stable and that there is no shift during compaction. The return position of the roller at both ends should be adjusted according to the position of the paver, and different rolling belts should have different return positions. To prevent the compaction speed from being too fast and causing pavement material passage or package, the unmanned double steel wheel vibration roller should operate in accordance with specific speed and frequency regulations. It should start with a lower frequency and speed and gradually increase them as the compaction progresses, ensuring that the compaction quality is maintained while also improving efficiency. This approach helps to avoid potential damage to the pavement material and ensures that the final compaction result meets the required standards. In the process of compaction, the driving route of the double steel wheel vibrating roller cannot be shifted, and the return position of both ends is gradually promoted with the position of the paver, and the return position of different rolling belts can no longer be the same section. In order to prevent leakage pressure and under pressure phenomenon, the double steel wheel vibration roller at the two ends of the same roller belt should have a certain lap distance and a certain width overlaps between the adjacent rolling belts each time. When the thickness of the paver is large, it is necessary to adopt high vibration frequency and large amplitude compaction, and when the thickness of the paver is thin, in order to prevent aggregate crushing due to overpressure, high frequency and low amplitude compaction should be given priority. The quantity configuration of rollers should comprehensively consider the paving power of the pavers, the compaction capacity of the rollers, and the material compaction characteristics.

Adaptive path planning and tracking control framework of the unmanned roller.

3.2 Formation method of unmanned double steel wheel vibration roller group

During the unmanned double steel wheel vibration roller construction, the movement needs to meet all the construction process constraints. Different from the movement planning of traditional driverless vehicles, the movement planning of the roller group not only needs to meet the needs of the machine group. Therefore, the movement planning of the roller group should meet the following conditions: no leakage pressure, no pressure in the whole compaction area to ensure the pavement compaction; during the whole compaction process, the roller speed fluctuation is small to ensure the flatness and uniformity of the road surface and optimize the dynamic operation parameters according to the state of the compacted material, and improve the compaction efficiency. Based on the pilot-following method, this article proposes the motion planning strategy of the roller group. This strategy designates an unmanned double steel wheel vibrating roller as the pilot and makes the rest of the roller the follower. Since the following roller maintains the same movement mode as the pilot roller, when the pilot roller completes the motion planning, the movement planning of the following roller can be guaranteed through the formation design.

Considering the requirements of compaction quality and compaction efficiency, the pilot roller plans the optimal working parameters of the current compaction and changes the track according to the established compaction model after each compaction and the specific steps are as follows: the asphalt material information of the compacted pavement is collected by the receiving sensor of the pilot roller, and the optimal working parameters of the current system are obtained by the working parameter optimization algorithm. The double steel wheel vibrating roller carries out the compaction operation of the current rolling belt with the optimal working parameters, and after a long distance, it stops at a safe distance after the paver. Table 1 shows the room parameter. The roller obtains the compacted asphalt material information in real time according to the sensor and determines whether the compaction degree requirements are met by the compaction prediction model. If the standard, the lane will be changed. When the compaction degree of the current rolling belt is required to meet the standard, the pilot roller changes the path from the current rolling belt to the adjacent rolling belt, and the transverse changing distance is the width of the vibrating wheel of the roller minus the overlapping distance, and the double steel wheel vibration roller body after the changing is parallel to the next rolling belt. Since the following roller maintains the same movement mode as the pilot roller, the compaction status of the whole group can be defined through the formation information when the motion planning of the pilot roller is completed.

Room parameter

| Parameter name | Numeric value | Unit |

|---|---|---|

| Chassis diameter | 348.5 | Mm |

| Left and right wheel diameter | 72.0 | Mm |

| Left and right wheel wheelbase | 235.0 | Mm |

| Line speed range | −0.5 to 0.5 | m/s |

| The angular velocity range | −4.25 to 4.25 | Rad/s |

In order to achieve the non-collision cooperative compaction operation of each roller in the roller group and realize the uniform compaction of the whole construction area without omission, the formation between each roller should be set. First of all, the operation range of the roller group is obtained through the GPS positioning module on both sides of the paver fuselage, and the compaction area is divided according to the configuration information of the roller group. An unmanned double steel wheel vibrating roller corresponds to a compaction area. Figure 2 shows the cooperative operation control system of an unmanned roller under multi-objective optimization. Then, each area is divided into rolling zones according to the requirements of the roller vibration roller width, the overlapping distance between the boundary information and the adjacent rolling belt, and the formation information of the unmanned double steel wheel vibration roller group is determined through the zoning situation. According to the motion planning strategy of the roller group proposed above, the motion planning of the roller group can be realized by planning the motion of the pilot roller. When the path and speed information of the pilot roller are given, the path and speed of following the roller can be determined by the formation information of the pilot roller. Based on the construction technology and process of the roller, it can be known that the movement of a single roller in the compaction operation includes two parts: linear compaction and lane change. Therefore, this article plans the two movement modes of the pilot roller, respectively. In motion planning, the kinematic model parameters, such as the path, speed, and heading angle, need to be planned, so the kinematic model of the roller is analyzed first.

Unmanned roller cooperative operation control system under multi-objective optimization.

The unmanned double steel wheel vibration roller has five plane degrees of freedom due to its double articulated structure, so it needs five parameters to fully determine its posture. After collecting the information on the compacted material, the aerial roller judges the compaction degree of the current rolling road. When the compaction degree reaches the standard, the roller closes the vibration and opens the lane change mode. Because the roller immediately carries out a new round of compaction after the lane change, it is required to adjust the body and the articulated steering angle of the roller after the lane change is zero, and the whole lane change path needs to be continuous and smooth to meet the kinematic and dynamic constraints of the roller. At present, the common S-type curve planning methods include double circular arc tangent curve, polynomial curve, Bessel curve, etc., and the curvature of the two circular arc tangents will change, which does not meet the requirements of double steel wheel vibrating roller lane change. The polynomial curve meets the requirements of zero curvature at the beginning and the end, and the curvature of the whole curve, which is simpler and smaller than the Bessel curve. Therefore, this article plans the path change based on the five-time polynomial curve. At the start and end of the change, the double steel wheel vibrating roller is straight compacted, and the corresponding starting point and end point curvature should be 0. Due to the limited steering angle of the double steel wheel vibration roller, the turning radius of the roller should be greater than the minimum turning radius of the roller.

4 Research on a path-tracking control system of unmanned rollers based on a optimization algorithm and real-time feedback

The path of the pilot roller is divided into linear compaction path and switching path, and its speed planning can therefore be divided into compaction speed planning and switching speed planning. Since the lane change is completed on the compacted pavement, the selection of the compaction speed has no significant influence on the compaction quality of the pavement, so a certain fixed value can be selected for each lane change. And double steel wheel vibration roller compaction speed, as the key compaction parameters, is very important to compaction quality; if the compaction speed is too fast, the pavement asphalt material rolling is not sufficient, which may lead to the final compaction quality being below standard; if the compaction speed is too slow, not only it can reduce the compaction efficiency, but it can also cause overpressure, which can lead to aggregate crushing. Therefore, before each compaction, it is necessary to obtain the optimal vibration frequency and compaction speed of a single compaction trip using the working parameter optimization algorithm based on compacted material information and then complete the target speed as the speed planning of starting and stopping, so as to achieve the purpose of smooth compaction. At present, the common speed planning methods in engineering include trapezoidal speed planning, five polynomial S-shaped speed planning, seven polynomial S-shaped speed planning, and so on. Table 2 shows the main parameters of D300-GNSS difference GPS. The trapezoidal speed planning is the simplest. The whole process includes three stages: uniform acceleration stage, uniform speed stage, and uniform deceleration stage. The speed curve is continuous but not smooth, the acceleration curve has mutations, seven polynomial S-shaped speed planning is adopted. A complete S-shaped velocity planning process consists of seven stages: the acceleration phase from 0 to t 1, the uniform acceleration phase from t 1 to t 2, the reduced acceleration phase from t 2 to t 3, the uniform phase from t 3 to t 4, and the reduction and deceleration phase from t 6 to t 7. The S-shaped velocity curve of the whole process is continuous and smooth, the acceleration is controllable and continuous, the acceleration is controllable, the whole movement process is smooth, and the control effect is good. The model prediction control algorithm, also known as rolling time domain control (RHC), is an important branch of optimization control, which is applicable to state quantity constraints, control quantity constraints and uncertainty. As a closed-loop optimization control method, the model predictive control consists of three key parts, namely, the prediction model, rolling optimization, and feedback correction. The prediction model can predict the system output in the future based on the current system state and future control amount. Rolling optimization refers to the future control amount obtained through repeated online optimization of system performance indicators, while feedback correction aims to improve the system’s resistance to interference and uncertainty through closed-loop control.

D300-GNSS difference GPS main parameters

| Parameter name | Numeric value | Unit |

|---|---|---|

| Data update rate | 20 | Hz |

| Positioning update rate | 20 | Hz |

| Positioning accuracy (dynamic) | 50 | Mm |

| Speed accuracy | 0.03 | m/s |

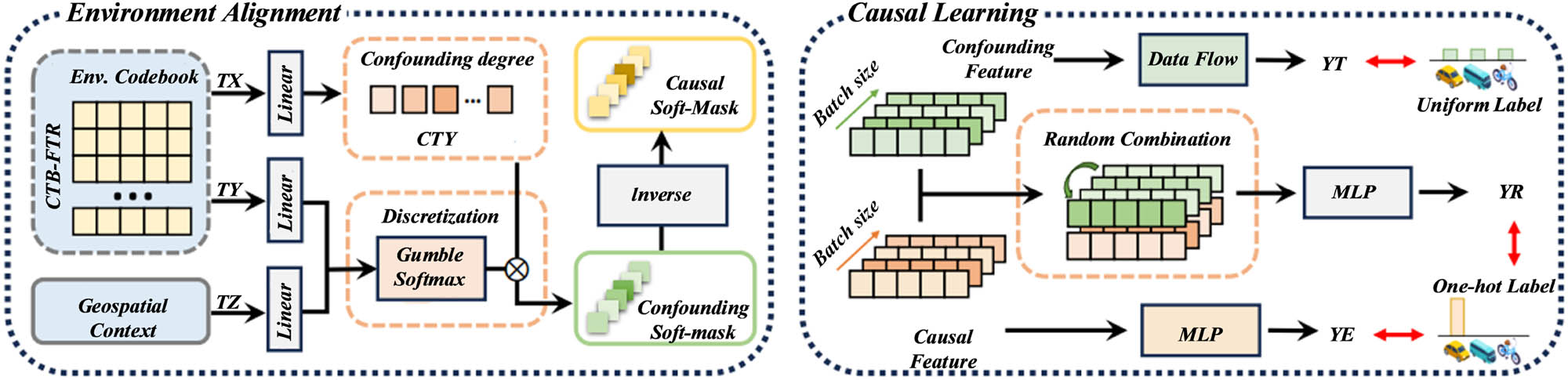

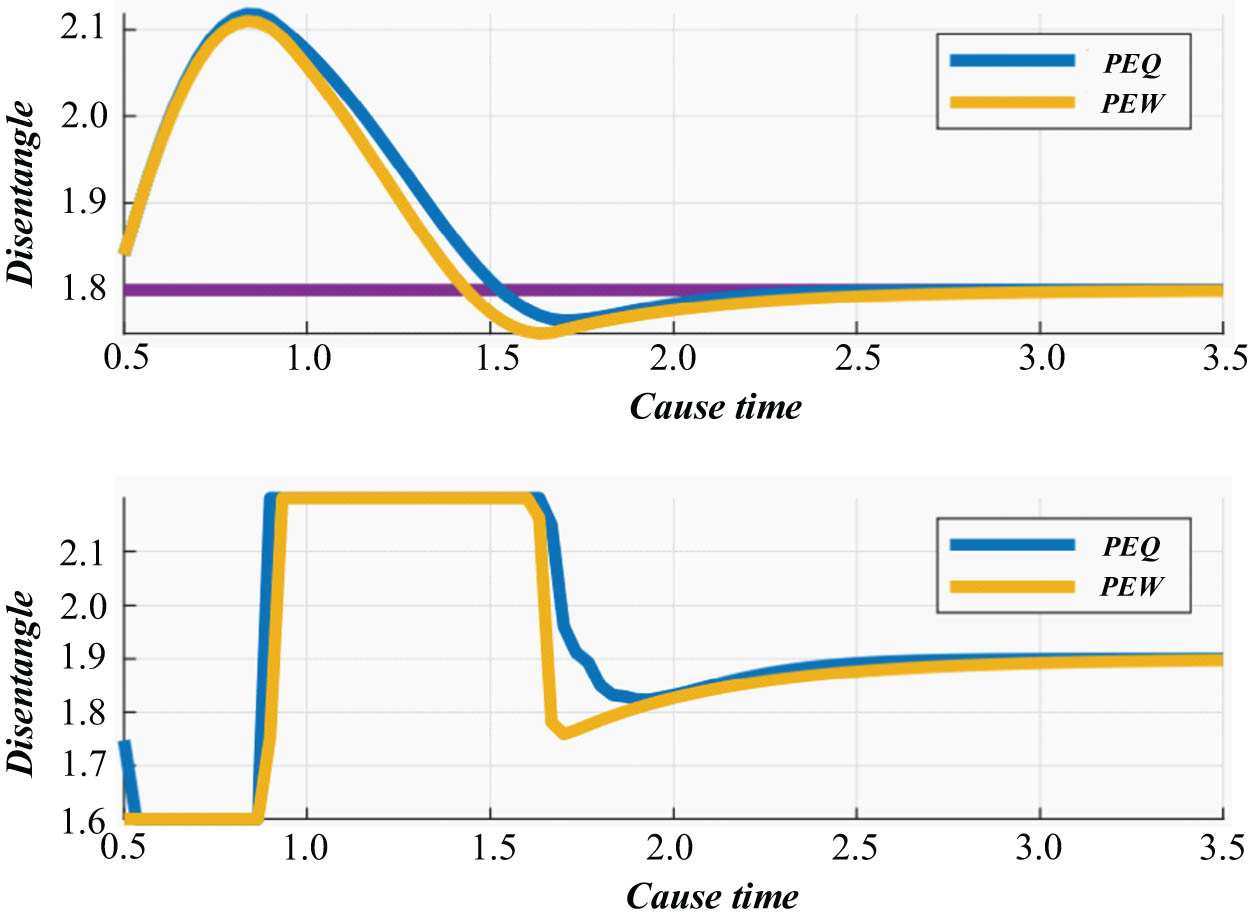

The MPC principle for the future [k, k + Np] system state, with constraint multi-objective function optimization, obtains the future finite time [k, k + Np] optimal control sequence, the first optimal control of the optimal control sequence as the next moment of the system control, and then the k + 1 moment system state back to the MPC controller, again optimization solution, repeated rolling optimization solution, until the whole control process is completed. Model prediction control is based on whether the controlled system is continuous, and the linear model prediction and nonlinear model prediction according to whether the controlled system is a linear system. Because the kinematic model of single double steel wheel vibrating roller and the formation kinematic model of double steel wheel vibrating roller are continuous nonlinear systems. Figure 3 shows the relationship curve between path-tracking accuracy and speed using a linear discrete prediction model derived from a continuous nonlinear system. This transforms the optimal control problem with constraints into a standard quadratic type problem. The common pilot-follow model can be divided into two types: distance–angle pilot follow model and distance–distance pilot follow model. The SBC model follow roller requires at least two pilot double steel wheel vibration roller position information, and only the two pilot roller distance determines their position. The SSC model follow the roller only requires a pilot double steel wheel vibration roller position information, and by maintaining a certain distance and angle can only determine their position. Because the SBC model is controlled by two pilot rollers simultaneously, and the controller design is too complicated. Therefore, the SBC model is used to model the formation of the unmanned double steel wheel vibrating roller group.

Path-tracking accuracy and speed relationship curve.

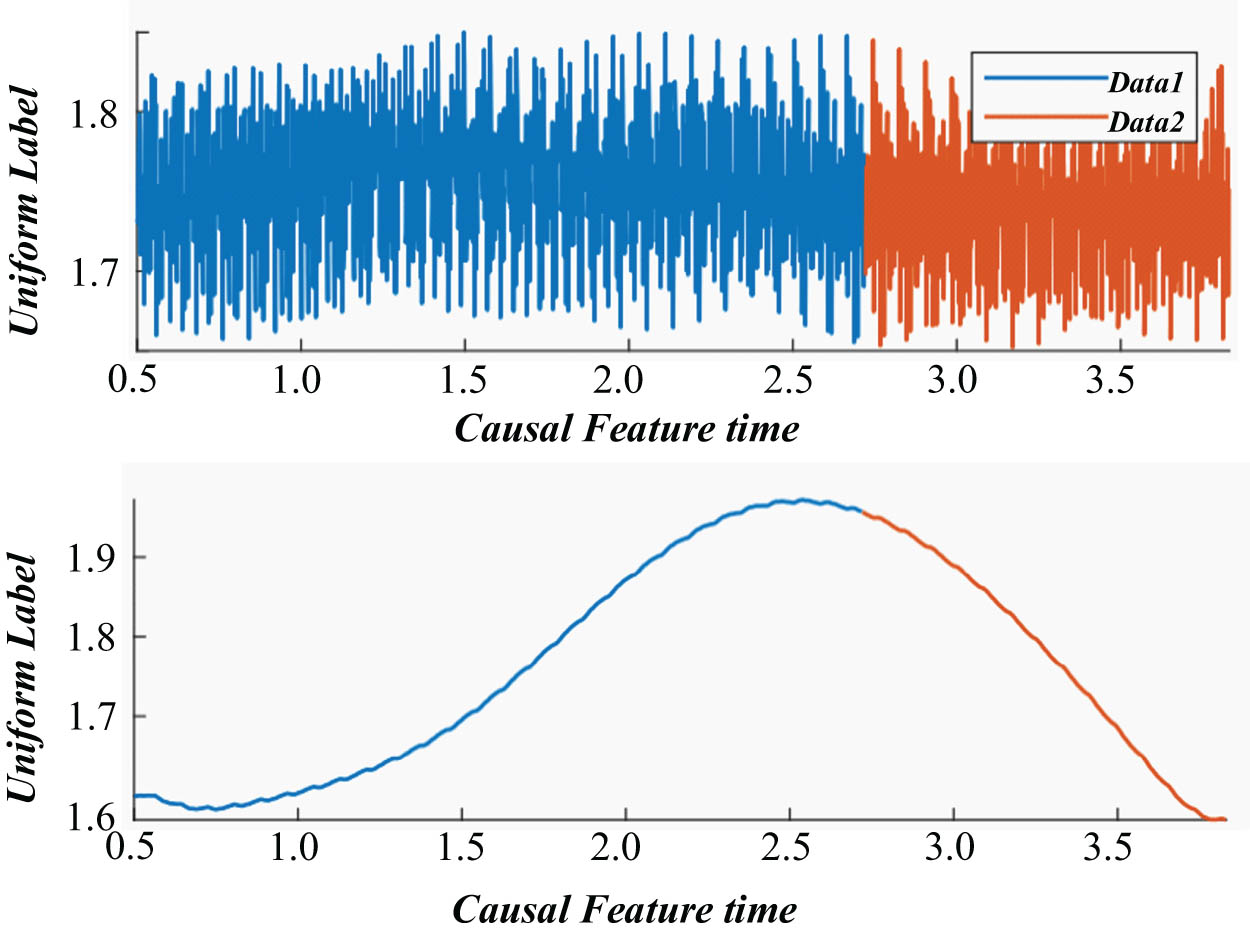

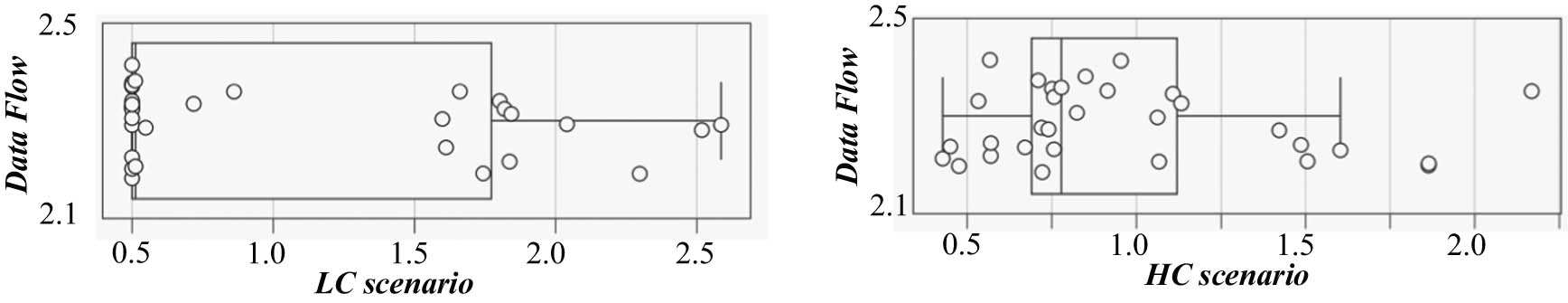

In the entire formation model, the pilot roller is responsible for tracking the expected trajectory based on the compaction process planning and following the roller to maintain the formation of the entire roller group by maintaining a certain distance and angle with the pilot roller. The distance and angle between each following the roller and the pilot roller are determined by the construction technique and the environment in which they are rolled. The formation holding controller based on the SBC pilot-following structure is designed to enable each follower roller Ri with the pilot roller and maintain the expected formation based on the process, so as to complete the pressure implementation work of the unmanned double steel wheel vibration roller group. This article also completes the formation holding controller design using model prediction control. In the roller cluster control system, an independent controller is configured as the main computing unit to realize the main functions of the system, which optimizes the operating parameters, cluster movement planning and the track tracking and control functions of the pilot roller, and follows the roller to realize the formation keeping function. For the purpose of comparing different aspects related to the unmanned double steel wheel vibration roller, such as the optimization algorithm iteration and path planning efficiency, various methods and parameters are considered. The comparison is made to evaluate the performance of the roller in different scenarios and to determine the most suitable strategies for compaction operations. This includes analyzing the relationship between the roller’s path-tracking accuracy and speed, as well as the effects of different factors on the overall compaction process. WIFI communication between the controller and the PC, the controller and GPS, IMU, and the controller and the roller can communicate through CAN. The front and rear vibration wheels of the unmanned double steel wheel vibration roller are connected to the middle hinge frame through the cross shaft. The rotation angle of the front and rear vibration wheels relative to the middle hinge frame, known as the hinge angle, and the angle between the driving direction of the front vibration wheel and the X-axis, referred to as the heading angle of the roller, are important parameters. These angles are crucial for accurately determining the position and orientation of the roller during the compaction process and are used in the control system to ensure precise path-tracking and formation keeping. In the process of the pilot roller’s track tracking control and the following roller’s formation keeping control, it is essential to collect information about the roller’s heading angle, the corner information of the front and rear vibration wheels relative to the middle-hinged frame. This information is used to accurately determine the actual position of the roller in real-time. By using sensors such as the IMU (Inertial Measurement Unit), the attitude and angles of the roller can be precisely measured, enabling the control system to make appropriate adjustments to ensure that the pilot roller follows the desired trajectory and the following rollers maintain the correct formation, thereby achieving efficient and accurate compaction operations. The IMU (Inertial Measurement Unit) is used as a crucial sensor in the unmanned double steel wheel vibration roller system. It measures the inertial forces acting on the roller and provides information about its attitude and angles. Specifically, it helps in determining the two hinge angles and the heading angle of the roller. This data is essential for the accurate control of the roller’s movement, as it allows the system to understand the roller’s orientation and position in real-time. By integrating the IMU data with other control algorithms, the roller can perform precise path-tracking and formation keeping during the compaction process. Figure 4 shows a comparison of the iteration times of the optimization algorithm and the efficiency of the path planning. Based on the characteristics of distributed computing of robot operating system (ROS) and topic communication between nodes, this article realizes the functions of the system into different modules and deploys them to their respective computing units. Different functional modules communicate information between different modules and different machines through topics.

Comparison of the iteration times of the optimization algorithm and the efficiency of the path planning.

5 Experimental analyses

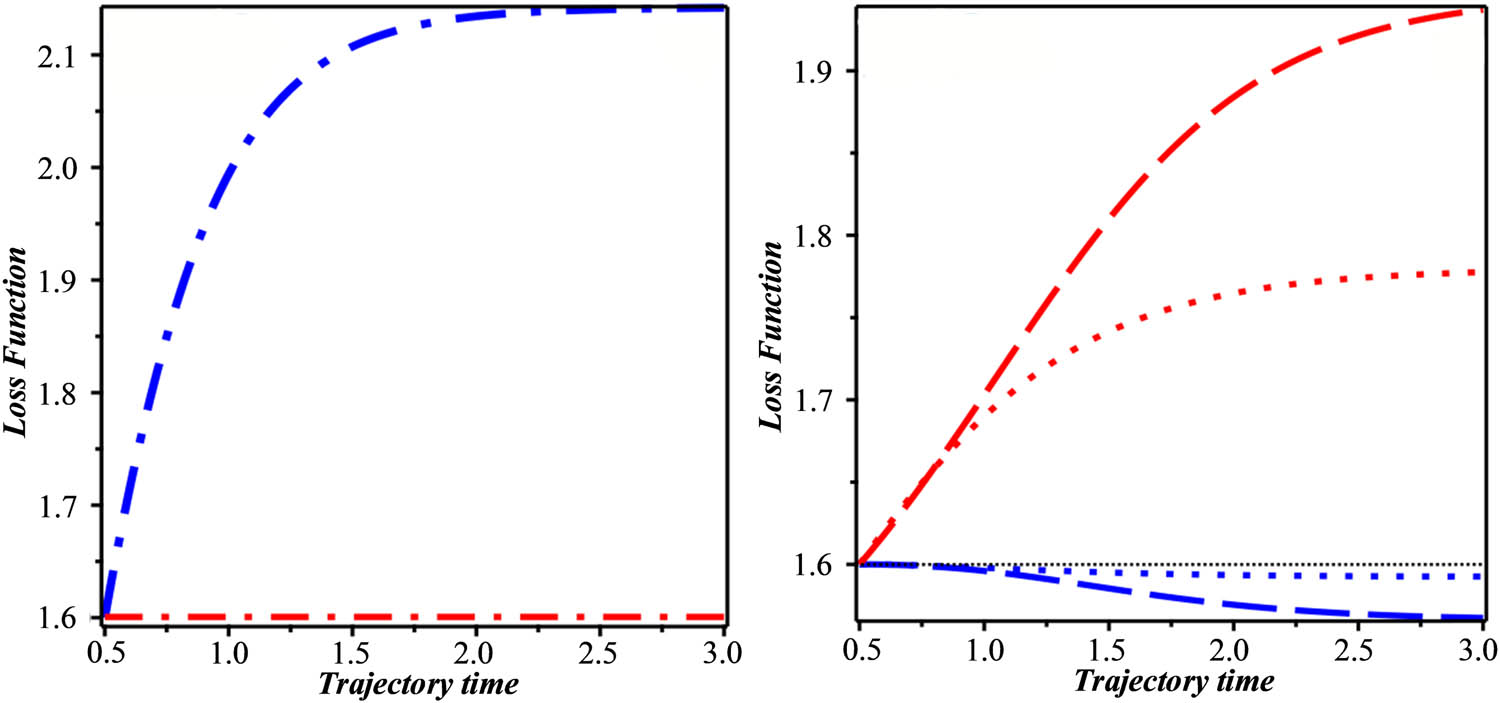

During unmanned compaction operations, the pilot roller and the following rollers initially operate based on preset working parameters. The acceleration amplitude measured by the vibration sensor installed on the double steel wheel vibration roller is related to the energy consumption and the stiffness and damping of the pavement material (Figure 5). Before the next compaction trip, the compacted material’s current stiffness is used to determine the optimal operating parameters. This process ensures that the rollers adapt to the changing conditions of the compacted material and perform efficient and high-quality compaction. Before the next trip of compaction, the compacted material has the current stiffness for the optimal operating parameters.

Relationship between energy consumption and working area.

This article assumes that all the rollers in the roller group are the same model, and the working parameters of each roller are the same as those of the pilot roller. Therefore, the optimization of the working parameters of the roller is only completed on the host machine, and the corresponding topic is broadcast. Figure 6 shows comparison of multi-machine cooperative operation efficiency with the number of machines. The optimal working parameters can be learned after the subscription to the topic with the roller.

Comparison of multi-machine cooperative operation efficiency with the number of machines.

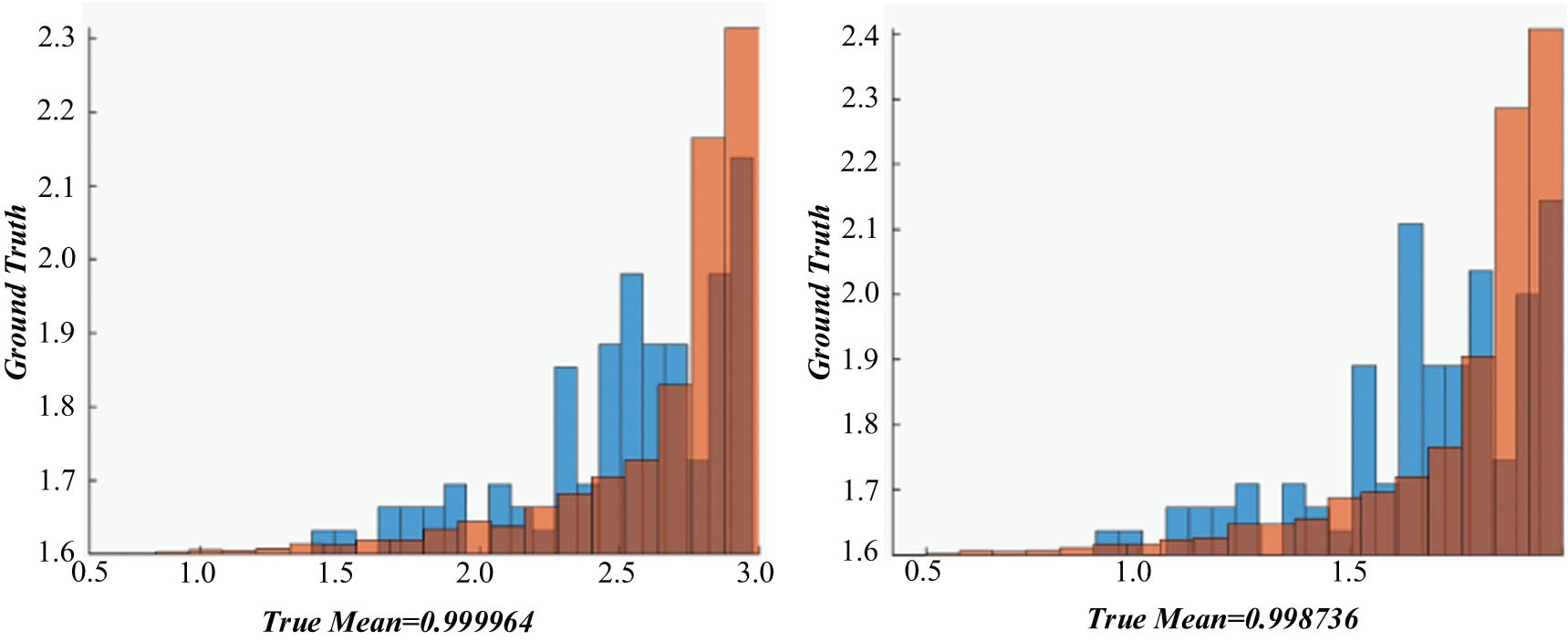

The movement planning module, specifically the cluster movement planning module, is situated in the pilot roller’s raspberry pie. This module can be divided into two parts: pilot roller trajectory planning and following roller formation generation. The initial information for this module includes compaction area boundary information, specific parameters of the unmanned double steel wheel vibration roller, and the configuration number of the unmanned roller unit. This information can be obtained through PC remote manual input and is used to plan the movement of the roller cluster, ensuring efficient and coordinated compaction operations. Figure 7 shows the effects of real-time feedback frequency on control stability, the left and right rolling belt overlap range, before and after rolling the lap distance, and other information; the initial information can be obtained through the PC remote manual input.

Effects of real-time feedback frequency on control stability.

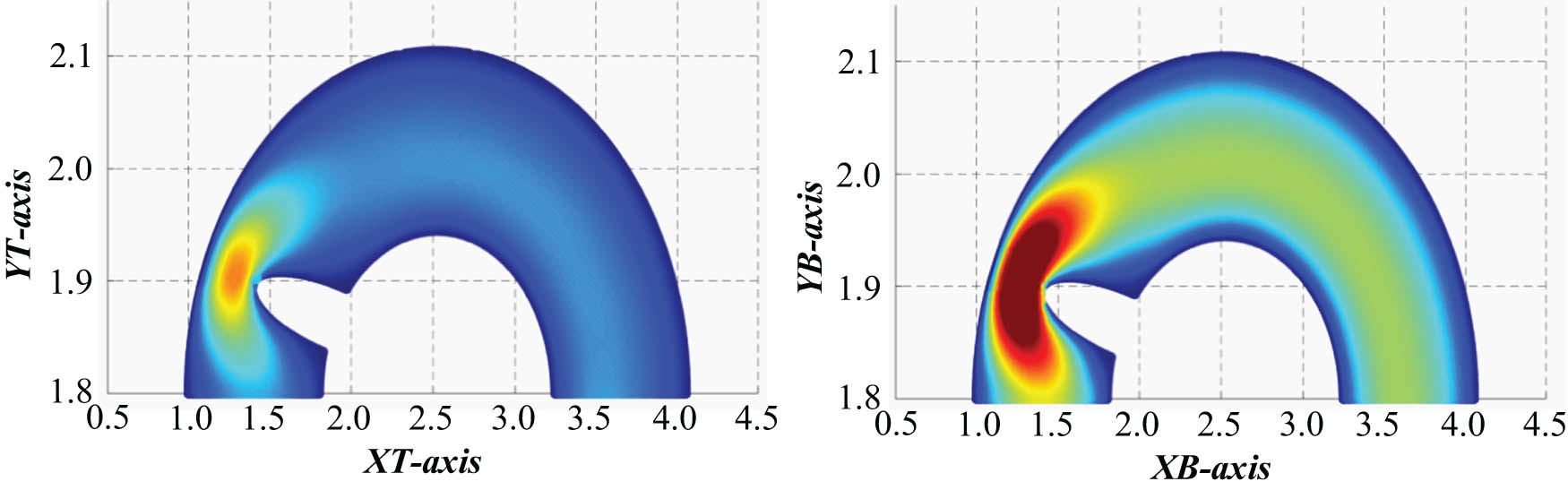

The trajectory planning of the pilot roller is divided into two sub-modules: linear compaction trajectory planning and lane trajectory planning. Figure 8 shows the path-tracking error distribution under environmental interference. According to the number of roller clusters and the width of the compaction area of the parameter optimization module, the trajectory of the pilot roller compaction and lane trajectory planning method is obtained.

Path-tracking error distribution under environmental interference.

The formation generation part of the following roller can be calculated according to the number of unmanned double steel wheel vibration rollers. Figure 9 shows controlling of the relationship between the response time and the pavement quality score. The real-time positioning and track display module realizes the high-precision positioning of the roller based on RTK, dynamically displays the crushed area of the roller through the ROS plug-in RVIZ, and keeps the construction process, so as to facilitate the real-time monitoring and backtracking of the construction personnel.

Controlling of the relationship between the response time and the pavement quality score.

RVIZ is a 3D visualization software that can display sensor information, machine status, and the surrounding environment in real time. Its supported sensor types include torque sensors, LiDAR, odometer, sonar sensors, and infrared sensors. Figure 10 shows parameter sensitivity analysis of the optimization algorithm. The navigation bar at the upper part of the RVIZ operation interface is a toolbar, including functions such as perspective adjustment and target setting; the left side is the display format; the middle part is the 3D message display area for displaying the subscribed information; the right side is the observation perspective control area, which can flexibly adjust the observation perspective; the lower part is the data display area for displaying the current ROS time and system time.

Parameter sensitivity analysis of the optimization algorithm.

6 Conclusion

A motion planning strategy based on a pilot-following structure, with full consideration of the process requirements, completes the fleet formation design. By analyzing the structural characteristics and the kinematic model of the unmanned double steel wheel vibration roller, on this basis, the compaction path planning and the switching path planning of the pilot roller are completed. Considering the impact of the compaction speed of the double steel wheel vibration roller on operational quality, the rolling section is 40 m long, with an expected compaction speed of 1.21 m/s². The initial conditions include a longitudinal error of −0.1 m in the x-axis, a transverse error of 0.1 m in the y-axis, and an initial heading error of −0.1 radians. During the simulation, the longitudinal error converges to zero in about 4 s. The transverse error, direction angle error, and steering hinge angle error all converge to zero within approximately 7 s, demonstrating that the pilot roller can quickly align with the desired compaction path. The formation error of the roller cluster, including formation distance error and formation angle error, also converges to zero after 7 s and remains stable throughout subsequent compaction operations. This indicates that the following rollers maintain the desired formation relative to the pilot roller, ensuring complete compaction of the entire area. Initially, the compaction speed of the roller group shows slight fluctuations but stabilizes at 1.21 m/s2 after about 7 s. The rollers decelerate smoothly as they approach the end of the rolling belt.

Throughout the entire compaction process, the acceleration and deceleration stage of the unit lasts approximately 3 seconds. The combined time for starting and parking accounts for about one-sixth of the total compaction operation time. This is in line with the typical starting and stopping characteristics of the double steel wheel vibration roller and the roller cluster planning and control method. The roller group control system is designed to manage these processes effectively, and corresponding modules such as parameter optimization, motion planning, real-time positioning, trajectory display, and cluster control are implemented to ensure the smooth and efficient operation of the compaction process. In the experiment, the double steel wheel vibrating roller, supporting the method in practical application.

-

Funding information: The author states no funding involved.

-

Author contribution: Haosen Ma wrote this paper, revised it, and reviewed. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The author states no conflict of interest.

-

Data availability statement: The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

[1] Abu-Bakr M, Mahmood HF, Mohammed AA. Investigation of metakaolin and steel fiber addition on some mechanical and durability properties of roller compacted concrete. Case Stud Constr Mater. 2022;16:13.10.1016/j.cscm.2022.e01136Suche in Google Scholar

[2] Algin Z, Gerginci S. Freeze-thaw resistance and water permeability properties of roller compacted concrete produced with macro synthetic fibre. Constr Build Mater. 2020;234:9.10.1016/j.conbuildmat.2019.117382Suche in Google Scholar

[3] Ashrafian A, Gandomi AH, Rezaie-Balf M, Emadi M. An evolutionary approach to Equationte the compressive strength of roller compacted concrete pavement. Measurement. 2020;152:14.10.1016/j.measurement.2019.107309Suche in Google Scholar

[4] Bao K, Zhang Q, Liu Y, Dai J. Fatigue life of the welding seam of a tracked vehicle body structure evaluated using the structural stress method. Eng Fail Anal. 2021;120:15.10.1016/j.engfailanal.2020.105102Suche in Google Scholar

[5] Bratu P, Tonciu O, Nitu MC. Modeling the vibratory compaction process for roads. Buildings. 2023;13(11):12.10.3390/buildings13112837Suche in Google Scholar

[6] Calis G, Yildizel SA, Keskin US. Investigation of color pigment incorporated roller compacted high performance concrete as a mitigation tool against urban heat island. Case Stud Constr Mater. 2022;17:18.10.1016/j.cscm.2022.e01479Suche in Google Scholar

[7] Colpo LR, de Souza CE. Assessment of adjustable damping in the ride comfort of a baja SAE vehicle. J Braz Soc Mech Sci Eng. 2020;42(11):12.10.1007/s40430-020-02660-4Suche in Google Scholar

[8] Elipse C, Kim JW, Ohm BS. Performance evaluation on the application of MAST and RCC on a cambodian rural road: A case study. Buildings. 2023;13(12):17.10.3390/buildings13122993Suche in Google Scholar

[9] Gungor AG, Sengun E, Yilmaz Y, Yaman IO. Enhancing bonding performance in two-layer roller-compacted concrete pavements: Bridging laboratory insights with field performance. Constr Build Mater. 2024;418:16.10.1016/j.conbuildmat.2024.135469Suche in Google Scholar

[10] Hamla W, Benamara D, Noui A. Statistical modeling of physical and mechanical responses of roller-compacted sand concrete made with ternary sand using the experimental design method. Constr Build Mater. 2022;345:21.10.1016/j.conbuildmat.2022.128354Suche in Google Scholar

[11] Huang H, Hu YB, Wang XB. A fusion positioning system based on camera and LiDAR for unmanned rollers in tunnel construction. Sensors. 2024;24(13):20.10.3390/s24134408Suche in Google Scholar PubMed PubMed Central

[12] Huang H, Wang XB, Hu YB, Tan P. Accuracy analysis of visual odometer for unmanned rollers in tunnels. Electronics. 2023;12(20):13.10.3390/electronics12204202Suche in Google Scholar

[13] Jia J, Wan YP, Liu HH, Qi KL, Zhang JG. Evaluation of compaction uniformity of the paving layer based on transverse and longitudinal measurements. Int J Pavement Eng. 2021;22(2):257–69.10.1080/10298436.2019.1600692Suche in Google Scholar

[14] Kessal O, Achour Y, Noui A, Belkadi AA, Benouadah A, Belagraa L, et al. Bio-fiber reinforced roller compacted concrete designed for road construction: feasibility of date palm fibers in pavements. Eur J Environ Civ Eng. 2023;27(3):1224–46.10.1080/19648189.2022.2077838Suche in Google Scholar

[15] Kilic I, Gok SG. Strength and durability of roller compacted concrete with different types and addition rates of polypropylene fibers. Rev De La Constr. 2021;20(2):205–14.10.7764/RDLC.20.2.205Suche in Google Scholar

[16] Kim HJ, Kim JY, Kim JW, Kim SK, Na WS. Unmanned aerial vehicle-based automated path generation of rollers for smart construction. Electronics. 2024;13(1):13.10.3390/electronics13010138Suche in Google Scholar

[17] Kim J, Lee SY, Cho JW. A study on the analysis of the ground compaction effect according to the roller operation method through CMV analysis using IC rollers. Adv Civ Eng. 2023;2023:10.10.1155/2023/6589652Suche in Google Scholar

[18] Kolase PK, Desai AK. Experimental study on monotonic and fatigue behaviour of polypropylene fibre-reinforced roller-compacted concrete with fly ash. Road Mater Pavement Des. 2019;20(5):1096–113.10.1080/14680629.2018.1436466Suche in Google Scholar

[19] Levin J, Fan Y, Keenan S, Koppi KA, Nickless B, Pressler J, et al. Role of additives in compacted concrete pavements. Transp Res Rec. 2024;2678(6):27–39.10.1177/03611981231193403Suche in Google Scholar

[20] Liao ZC, Bai XX, Li Y, Deng XC, Sun J. Design, modeling, and verification of a test bench for braking simulation of 1/4 vehicle. Proc Inst Mech Eng Part D-J Automob Eng. 2020;234(5):1425–41.10.1177/0954407019874961Suche in Google Scholar

[21] Lopez-Uceda A, Agrela F, Cabrera M, Ayuso J, López M. Mechanical performance of roller compacted concrete with recycled concrete aggregates. Road Mater Pavement Des. 2018;19(1):36–55.10.1080/14680629.2016.1232659Suche in Google Scholar

[22] Lopez-Uceda A, Ayuso J, Jiménez JR, Galvín AP, Del Rey I. Feasibility study of roller compacted concrete with recycled aggregates as base layer for light-traffic roads. Road Mater Pavement Des. 2020;21(1):276–88.10.1080/14680629.2018.1483257Suche in Google Scholar

[23] Lv K, Mu XH, Li LS, Xue WB, Wang ZY, Xu L. Design and test methods of rubber-track conversion system. Proc Inst Mech Eng Part D-J Automob Eng. 2019;233(7):1903–29.10.1177/0954407018794101Suche in Google Scholar

[24] McHale MJ, Gordon M, Ferguson A. Use of digital technology to improve the way asphalt roads are constructed. Proc Inst Civ Eng-Munic Eng. 2023;176(4):189–95.10.1680/jmuen.23.00005Suche in Google Scholar

[25] Nedoma J, Stolarik M, Kepak S, Pinka M, Martinek R, Frnda J, et al. Alternative approaches to measurement of ground vibrations due to the vibratory roller: A pilot study. Sensors. 2019;19(24):17.10.3390/s19245420Suche in Google Scholar PubMed PubMed Central

[26] Nguyen V, Zhang JR, Le V, Jiao RQ. Vibration analysis and modeling of an off-road vibratory roller equipped with three different cab’s isolation mounts. Shock Vib. 2018;2018:17.10.1155/2018/8527574Suche in Google Scholar

[27] Nguyen V, Zhang JR, Yang XZ. Low-frequency performance analysis of semi-active cab’s hydraulic mounts of an off-road vibratory roller. Shock Vib. 2019;2019:15.10.1155/2019/8725382Suche in Google Scholar

[28] Ni DK, Jiao RQ, Nguyen V, Zhang JN. Enhancing the ride comfort of off-road vibratory rollers with seat suspension using optimal quasi-zero stiffness. Proc Inst Mech Eng Part C-J Mech Eng Sci. 2023;237(2):482–96.10.1177/09544062221119929Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- User profiling in university libraries by combining multi-perspective clustering algorithm and reader behavior analysis

- Exploring bifurcation and chaos control in a discrete-time Lotka–Volterra model framework for COVID-19 modeling

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China

- Nonlinear comprehensive evaluation method based on information entropy and discrimination optimization

- Application of numerical calculation methods in stability analysis of pile foundation under complex foundation conditions

- Research on the contribution of shale gas development and utilization in Sichuan Province to carbon peak based on the PSA process

- Characteristics of tight oil reservoirs and their impact on seepage flow from a nonlinear engineering perspective

- Nonlinear deformation decomposition and mode identification of plane structures via orthogonal theory

- Numerical simulation of damage mechanism in rock with cracks impacted by self-excited pulsed jet based on SPH-FEM coupling method: The perspective of nonlinear engineering and materials science

- Cross-scale modeling and collaborative optimization of ethanol-catalyzed coupling to produce C4 olefins: Nonlinear modeling and collaborative optimization strategies

- Unequal width T-node stress concentration factor analysis of stiffened rectangular steel pipe concrete

- Special Issue: Advances in Nonlinear Dynamics and Control

- Development of a cognitive blood glucose–insulin control strategy design for a nonlinear diabetic patient model

- Big data-based optimized model of building design in the context of rural revitalization

- Multi-UAV assisted air-to-ground data collection for ground sensors with unknown positions

- Design of urban and rural elderly care public areas integrating person-environment fit theory

- Application of lossless signal transmission technology in piano timbre recognition

- Application of improved GA in optimizing rural tourism routes

- Architectural animation generation system based on AL-GAN algorithm

- Advanced sentiment analysis in online shopping: Implementing LSTM models analyzing E-commerce user sentiments

- Intelligent recommendation algorithm for piano tracks based on the CNN model

- Visualization of large-scale user association feature data based on a nonlinear dimensionality reduction method

- Low-carbon economic optimization of microgrid clusters based on an energy interaction operation strategy

- Optimization effect of video data extraction and search based on Faster-RCNN hybrid model on intelligent information systems

- Construction of image segmentation system combining TC and swarm intelligence algorithm

- Particle swarm optimization and fuzzy C-means clustering algorithm for the adhesive layer defect detection

- Optimization of student learning status by instructional intervention decision-making techniques incorporating reinforcement learning

- Fuzzy model-based stabilization control and state estimation of nonlinear systems

- Optimization of distribution network scheduling based on BA and photovoltaic uncertainty

- Tai Chi movement segmentation and recognition on the grounds of multi-sensor data fusion and the DBSCAN algorithm

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part III

- Generalized numerical RKM method for solving sixth-order fractional partial differential equations

Artikel in diesem Heft

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- User profiling in university libraries by combining multi-perspective clustering algorithm and reader behavior analysis

- Exploring bifurcation and chaos control in a discrete-time Lotka–Volterra model framework for COVID-19 modeling

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China