Abstract

In order to clarify the characteristics of tight oil reservoirs and their impact on seepage, we conducted a comprehensive analysis of the reservoir characteristics of the Chang-7 tight sandstone using advanced equipment such as X-ray diffractometers and high-pressure mercury injection devices from the perspective of nonlinear engineering. We studied the effect of reservoir characteristics on oil and water seepage. The results show that tight cores are mainly quartz arenite and feldspar arenite with high clay mineral content. They have abundant irregular, disconnected pore spaces and micro-fractures, leading to low permeability and poor physical properties. Tight cores are stress-sensitive, with core permeability decreasing as effective pressure increases. An exponential fitting function can effectively reflect the relationship between permeability and effective stress of tight sandstone cores in this area. As the air-measured permeability of the core increases, the start-up pressure gradient first decreases sharply and then gradually stabilizes. The oil–water two-phase start-up pressure gradient and permeability have a power relationship: G = 5.66 × 10−4 K−1.42. For tight cores, a slight increase in permeability can significantly reduce the start-up pressure gradient. This study provides a theoretical basis and technical support for the efficient development of tight oil reservoirs from a nonlinear engineering perspective, which helps to optimize development strategies and provide ideas to enhance tight oil reservoir recovery.

1 Introduction

Unconventional oil and gas resources account for about 80% of newly explored and developed resources and have become an important part of oil and gas production. China has abundant unconventional oil and gas resources, including shale gas, tight oil, and tight gas, with broad development prospects.

Tight oil is a type of unconventional oil and gas resource, generally referring to sandstone, limestone, and other oil-bearing layers with matrix permeability less than or equal to 0.1 mD, usually with light oil quality [1]. Due to the complex pore structure and nano-scale pores in tight oil reservoirs, the fluid migration in these reservoirs differs significantly from that in conventional sandstone reservoirs, making existing seepage theories inadequate for accurate characterization and description.

X-ray diffraction (XRD) analysis shows that tight reservoirs contain various rock-forming minerals, such as quartz, calcite, dolomite, feldspar, and clay minerals [2]. With the introduction of advanced testing technologies, our understanding of tight reservoirs’ microscopic pore-throat structures has deepened. Pore connectivity is a key indicator for revealing pore-throat network and connectivity structure characteristics [3]. Scholars both domestically and internationally have studied the microscopic pore-throat structure characteristics of reservoirs, focusing on pore-throat size, shape, distribution, and connectivity [4]. Tan classified pores into large and small categories using high-pressure mercury injection data [5]. Mu et al. used cast thin sections, scanning electron microscopy, and high-pressure mercury injection technology with fractal theory to quantitatively characterize tight sandstone pore-throat structures [6]. Tight oil reservoirs are highly heterogeneous, with poor porosity and permeability. Conventional oil reservoir technologies for improving oil-displacement efficiency are less effective in tight oil reservoirs and cannot mobilize crude oil in nano-pore-dominated tight oil reservoirs [7]. Kang et al. pointed out that a key reason for the difficulty in developing tight oil reservoirs is their low reservoir rock permeability, small porosity, high capillary pressure, and poor reservoir fluid movability [8].

China has a large volume of tight oil resources, but their exploration and development are challenging and require special technologies. To enhance oil well productivity, it is crucial to study the physical property distribution and fluid seepage characteristics of tight oil reservoirs. This article explores the pore-throat characteristics and seepage features of tight oil reservoirs through lab experiments, studies seepage laws of tight reservoirs, offers data for development strategies, and helps enhance tight oil recovery.

2 Experimental methods

2.1 Material selection

Cores from the Chang-7 tight sandstone were prepared into Φ2.5 cm × H5 cm standards and cleaned with toluene, petroleum ether, and ethylene glycol, then dried [9]. Their lithological, pore-throat, and porosity–permeability characteristics were analyzed using X-ray diffraction, scanning electron microscopy, high-pressure mercury injection, permeability measurement, and porosity measurement [10].

2.2 Experimental scheme

2.2.1 Lithological characteristics

X-ray diffraction experiments were conducted to analyze the mineral composition of the Chang-7 tight sandstone. A powder sample of less than 100 mesh was prepared by crushing and sieving rock blocks, then tested with an X-ray diffractometer equipped with array detectors and scintillation counters.

Standard experimental cores of Φ2.5 cm × H5 cm were prepared from the Chang-7 tight sandstone. Rock blocks corresponding to the core were cut and crushed into 10–30-mesh particles using a geological hammer. A press was then used to further crush the particles, after which a 100-mesh sieve was employed to collect powders larger than 100 mesh for XRD testing.

2.2.2 Pore-throat characteristics

A Quanta 200 F field-emission environmental scanning electron microscope was used to observe pore-throat types and fracture shapes in rock samples. With a resolution of 1.2 nm and a magnification range of 25–200 K, it can analyze pore structures and measure pore sizes. Following the instrument’s requirements, tight-reservoir cores were processed into thin sections for analysis.

One main way to study reservoir pore-throat structures in the lab is mercury injection porosimetry [11]. The capillary pressure curves from mercury injection experiments on cores can offer lots of information on the pore structures of porous media. Using relevant capillary pressure formulas, each capillary pressure value can be converted into a pore-throat radius value. The shape of the capillary pressure curve is affected by sorting and skewness, so it can also be used to analyze the pore-throat characteristics of rock samples. An automatic high-pressure mercury porosimeter was used for mercury injection experiments on several core samples from the tight reservoir to study the pore-throat distribution in the area.

2.2.3 Porosity–permeability characteristics

Porosity and permeability of sandstone samples were tested according to SY/T 5336-2006. The PDP-200 gas permeability meter was used to measure core permeability via the non-steady-state pulse decay method in line with the API standard. This instrument, with a measuring range of 0.00001–10 mD, ensures short experimental duration and high numerical accuracy. The KXD-3 porosity meter, based on Boyle’s law and using helium as the working medium, was employed to measure the porosity of experimental cores. This method is simple to operate and offers high numerical precision. An indoor displacement device was used to measure the start-up pressure gradient of Chang-7 tight sandstone standard cores.

3 Pore-throat characteristics of tight oil reservoirs

3.1 Lithological characteristics

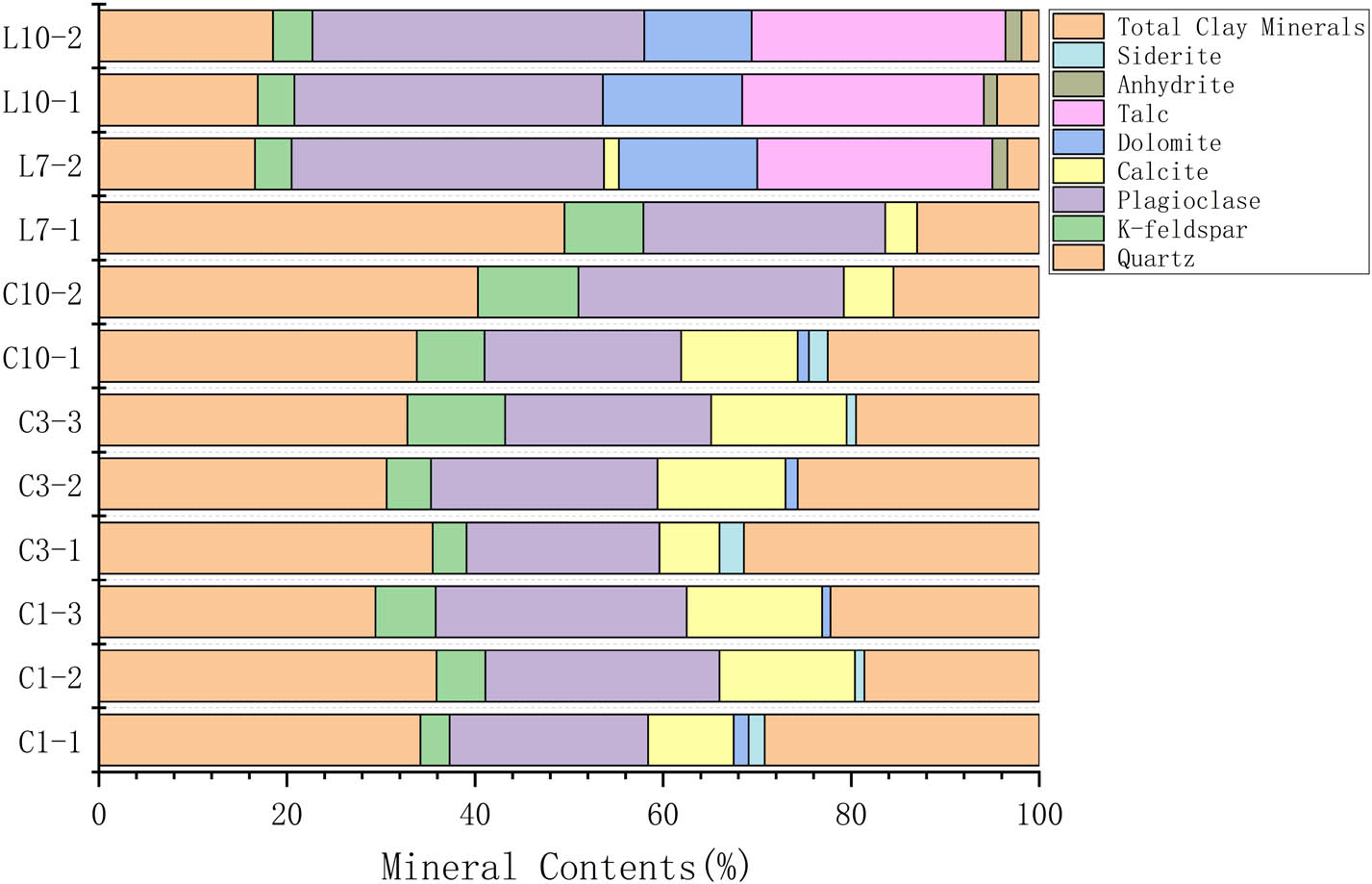

X-ray diffraction results showed that the Chang-7 tight sandstone has high clay mineral content, with small amounts of anhydrite and iron dolomite. The main mineral is quartz (29.4–35.8%), followed by plagioclase (20.5–26.7%), clay minerals (18.5–31.4%), and calcite (6.4–14.4%) (Table 1 and Figure 1).

Mineral composition analysis

| Sample no. | Mineral types and contents (%) | Total clay minerals (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Quartz | K-feldspar | Plagioclase | Calcite | Dolomite | Talc | Anhydrite | Siderite | ||

| C1-1 | 34.2 | 3.1 | 21.1 | 9.1 | 1.6 | — | — | 1.6 | 29.2 |

| C1-2 | 35.8 | 5.2 | 24.9 | 14.4 | — | — | — | 1 | 18.5 |

| C1-3 | 29.4 | 6.4 | 26.7 | 14.4 | 0.9 | — | — | — | 22.2 |

| C3-1 | 35.5 | 3.5 | 20.5 | 6.4 | — | — | — | 2.6 | 31.4 |

| C3-2 | 30.6 | 4.7 | 24.1 | 13.6 | 1.3 | — | — | — | 25.7 |

| C3-3 | 32.8 | 10.2 | 21.9 | 14.4 | — | — | — | 1 | 19.5 |

| C10-1 | 33.8 | 7.2 | 20.9 | 12.4 | 1.2 | — | — | 2 | 22.5 |

| C10-2 | 40.3 | 10.7 | 28.2 | 5.3 | — | — | — | — | 15.5 |

| L7-1 | 49.5 | 8.4 | 25.7 | 3.4 | — | — | — | — | 13 |

| L7-2 | 16.6 | 3.9 | 33.2 | 1.6 | 14.7 | 25 | 1.6 | — | 3.4 |

| L10-1 | 16.9 | 3.9 | 32.8 | — | 14.8 | 25.7 | 1.4 | — | 4.5 |

| L10-2 | 18.5 | 4.2 | 35.3 | — | 11.4 | 27 | 1.7 | — | 1.9 |

Composition chart of minerals.

As shown in Table 2 and Figure 2, the clay minerals in the Chang-7 tight cores are mainly illite–montmorillonite mixed-layers and illite, with small amounts of chlorite and kaolinite.

Clay minerals composition analysis

| Sample no. | Relative content of clay minerals (%) | |||||

|---|---|---|---|---|---|---|

| Saponite group minerals | Illite–montmorillonite mixed-layer | Illite | Kaolinite | Chlorite | Chlorite–montmorillonite mixed layers | |

| C1-1 | — | 60 | 24 | 12 | 4 | — |

| C3-1 | — | 38 | 42 | 10 | 10 | — |

| C10-1 | — | 75 | 20 | 3 | 2 | — |

| L7-1 | — | 20 | 80 | — | — | — |

| L10-1 | — | 7 | 93 | — | — | — |

Composition chart of clay minerals.

3.2 Pore-throat characteristics

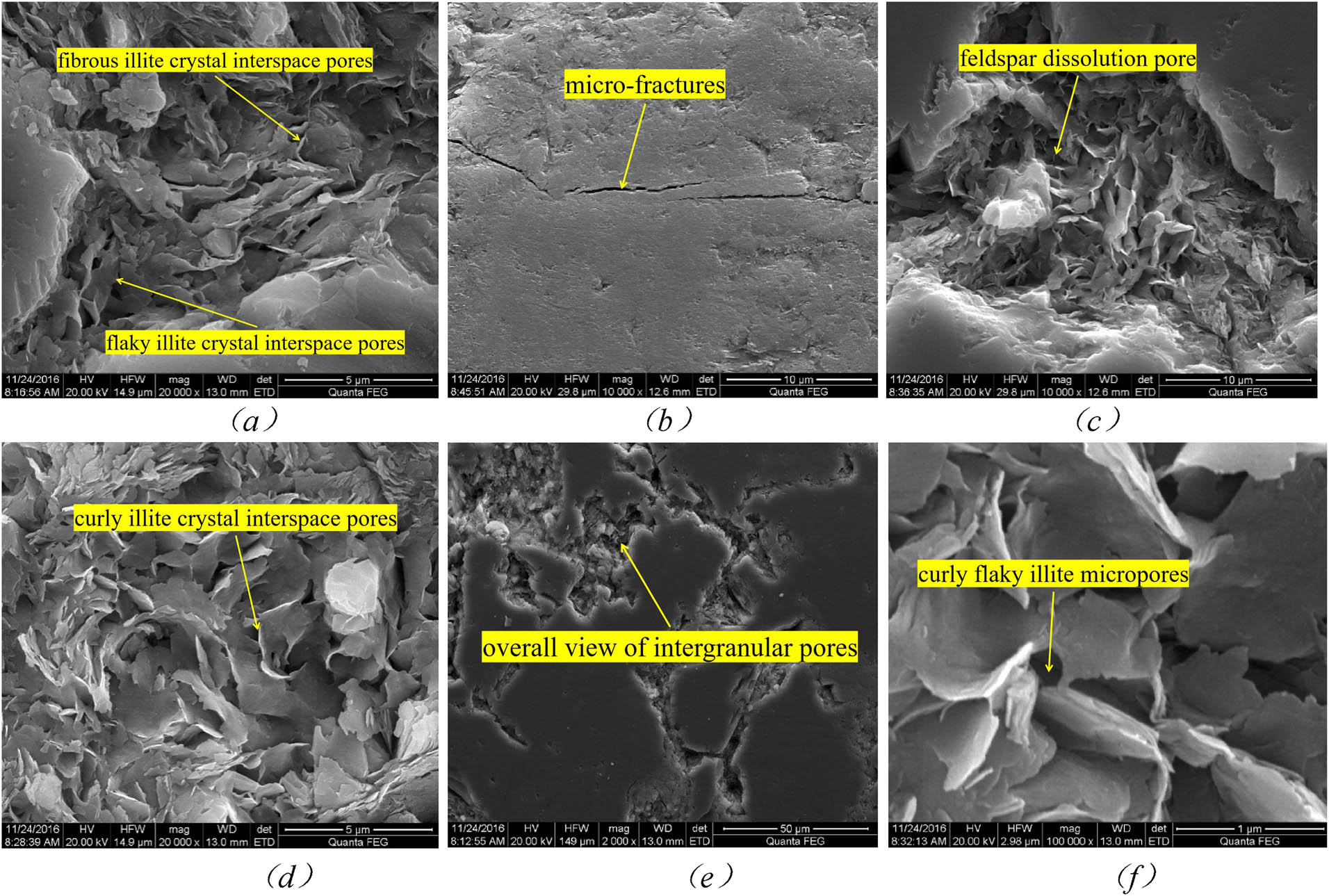

Analysis of scanning electron microscope images indicates that the reservoir space in this area is predominantly porous with a small number of fractures. As shown in Figure 1, the pore types in the tight sandstone samples are mainly intergranular pores, intracrystalline pores, and dissolution pores. Intergranular pores, which are the primary reservoir space, have straight edges and diverse shapes (Figure 3(e)). Clay mineral intracrystalline pores, commonly formed by filamentous and flaky illite, are also prevalent and have complex shapes (Figure 3(a) and (d)). Additionally, there are dissolution micro-pores, mostly formed by feldspar dissolution, which have a honeycomb shape (Figure 3(c)). Micro-fractures, which are mostly discontinuous, are also present in the rock samples (Figure 3(b)). The presence of these irregular pore spaces and discontinuous micro-fractures significantly increases the fluid flow resistance in the reservoir, resulting in the extremely low permeability of the tight sandstone.

Pore types in tight sandstone: (a) Interspace pores of flaky and fibrous illite, C1-4; (b) micro-fractures, C1-5; (c) feldspar dissolution pore, C3-4; (d) curly illite crystal interspace pores, C3-5; (e) overall view of intergranular pores, C3-6; and (f) curly flaky illite micropores, C10 -5.

The capillary pressure curves from mercury injection experiments on cores can offer lots of information on the pore structures of porous media. Using relevant capillary pressure formulas, each capillary pressure value can be converted into a pore-throat radius value. The shape of the capillary pressure curve is affected by sorting and skewness, so it can also be used to analyze the pore-throat characteristics of rock samples. For a particular core, if the capillary pressure curve shows good sorting and coarse skewness, it is beneficial for fluid flow. An automatic high-pressure mercury porosimeter was used for mercury injection and withdrawal experiments on each tight core to obtain the capillary pressure curves. Then, data processing was carried out to get the parameters of pore-throat size, distribution, etc., as shown in Table 3 and Figures 4–6.

Mercury injection parameter of core

| Core sample | Permeability (mD) | Porosity (%) | Displacement pressure (MPa) | Largest pore throat radius (µm) | Average pore throat radius (µm) | Median pressure (MPa) | Median radius (µm) | Sorting coefficient | Kurtosis | Skewness | Highest mercury injection saturation (%) | Residual mercury saturation (%) | Mercury withdrawal efficiency (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0.032 | 3.51 | 2.099 | 0.352 | 0.238 | 67.095 | 0.011 | 1.147 | 0.998 | −0.364 | 69.57 | 48.71 | 29.99 |

| C3 | 0.046 | 3.54 | 2.985 | 0.248 | 0.226 | 49.263 | 0.015 | 1.048 | 0.938 | −0.175 | 88.74 | 56.69 | 36.13 |

| C10 | 0.034 | 3.5 | 2.986 | 0.248 | 0.227 | 65.008 | 0.011 | 1.159 | 0.962 | −0.334 | 68.99 | 45.81 | 33.61 |

| L7 | 0.0028 | 0.35 | 2.989 | 0.248 | 0.155 | 67.736 | 0.011 | 1.606 | 0.582 | −0.018 | 61.6 | 21.51 | 65.08 |

| L10 | 0.003 | 0.34 | 2.993 | 0.247 | 0.186 | 56.103 | 0.013 | 1.548 | 0.635 | 0.285 | 63.07 | 30.46 | 51.7 |

Mercury injection curve of core.

Pore-throat distribution frequency chart of core.

Permeability contribution chart of core.

Analysis of the pore structure characteristics of reservoir rocks from the above charts shows that the capillary pressure curves from mercury injection indicate that the core’s pore throats have average sorting and are fine-grained with small radii [12]. The median radius of the tested core samples is 0.011–0.015 μm, the maximum pore-throat radius is 0.247–0.352 μm, and the average pore-throat radius is 0.155–0.238 μm. In other words, the pore-throat radii of the cores are relatively small. The maximum mercury injection saturation of the experimental core samples is 61.6–88.74%, the displacement pressure is 2.089–2.973 MPa, and the mercury withdrawal efficiency is 29.99–65.08%, indicating that the core’s throats are fine and poorly connected.

In summary, the maximum pore-throat radius of the core is 0.3 μm, and the average is 0.2065 μm, with fine-grained throats. The capillary pressure curves from mercury injection of the cores show fine skewness and average sorting. The pore-throat distribution frequency and permeability contribution charts indicate that the distribution frequency and permeability contribution of pore throats do not match. There are many small throats in the cores, but they contribute little to permeability. As a result, the core’s permeability is generally low, and the physical properties are poor [13].

3.3 Porosity–permeability characteristics

The porosity and permeability data of the tight cores are shown in Figure 7. Generally, porosity and permeability are positively correlated. The porosity of the cores ranges from 6 to 11% (average 8%), and permeability ranges from 0.02 to 0.08 mD (average 0.05 mD), indicating low porosity and low permeability characteristics.

Relationship between porosity and permeability of tight sandstone.

An indoor displacement device was used to measure the relative permeability of tight cores, with results shown in Figure 8 and Table 4. Analysis of the Chang-7 tight core relative permeability curves shows that as water saturation increases, the relative permeability of the simulated oil declines rapidly, while that of water rises slowly. The average water saturation at the isopermeability point of the oil–water relative permeability curve is 54.5%, with an average oil–water relative permeability of 0.035 mD. The average bound water saturation of the core is 24.4%, the average residual oil saturation is 59.3%, and the average oil–water two-phase permeability interval is 34.9%. These results indicate a low amount of mobile fluid and difficult fluid flow within the experimental cores.

Relative permeability curve.

Relative permeability analysis table

| Formation | Permeability (mD) | Porosity (%) | Bound water | Intersection | Residual oil | |||

|---|---|---|---|---|---|---|---|---|

| Water saturation (%) | Oil effective permeability (mD) | Water saturation (%) | Oil–water relative permeability (mD) | Water saturation (%) | Water relative permeability (mD) | |||

| C10-5 | 0.19 | 8.7 | 21.6 | 0.0025 | 52.1 | 0.02 | 56.9 | 0.27 |

| C10-6 | 0.25 | 9.2 | 25.3 | 0.0116 | 58.1 | 0.027 | 59.7 | 0.26 |

| C10-7 | 0.29 | 10.3 | 26.3 | 0.0205 | 53.4 | 0.06 | 61.4 | 0.14 |

4 Impact of tight oil reservoir characteristics on seepage

4.1 Stress sensitivity of tight oil reservoirs

Stress sensitivity refers to the variation of reservoir rock properties with effective stress. Following the SY/T 5358-2002 standard for reservoir sensitivity flow experiment evaluation, this manuscript analyzes core stress sensitivity by changing confining pressure to measure permeability under different pressures, as shown in Table 5.

Core stress sensitivity test data

| Core sample | C3-1-1 | C3-1-4 | C3-1-19 | C3-1-35 | |

|---|---|---|---|---|---|

| Effective stress (MPa) | Permeability (mD) | Permeability (mD) | Permeability (mD) | Permeability (mD) | |

| Pressure increase process | 4 | 0.021416 | 0.023068 | 0.050919 | 0.032051 |

| 10 | 0.014869 | 0.016778 | 0.025556 | 0.013504 | |

| 15 | 0.011877 | 0.013413 | 0.014772 | 0.006368 | |

| 20 | 0.009806 | 0.011332 | 0.008947 | 0.003333 | |

| 25 | 0.007999 | 0.009228 | 0.006262 | 0.002146 | |

| 30 | 0.00667 | 0.007799 | 0.003252 | 0.001282 | |

| 40 | 0.004691 | 0.005712 | 0.001623 | — | |

| Pressure decrease process | 30 | 0.005525 | 0.006757 | 0.002344 | — |

| 25 | 0.006075 | 0.007519 | 0.003065 | 0.001535 | |

| 20 | 0.006998 | 0.008561 | 0.004553 | 0.002051 | |

| 15 | 0.008038 | 0.010082 | 0.007046 | 0.003156 | |

| 10 | 0.009751 | 0.012306 | 0.013905 | 0.005514 | |

| 4 | 0.013116 | 0.016906 | 0.027781 | 0.013838 | |

As shown in Table 5, core permeability decreases with increasing effective stress [14,15]. During pressure increase, permeability drops rapidly at low stress and then slows down. This is because throats are compressed first and then pores as stress increases. During pressure decrease, permeability increases with reducing effective stress but remains lower than the initial value, indicating permeability damage.

To better illustrate the relationship between core permeability and effective stress, exponential, binomial, and power-law fitting were applied to the pressure-increase data of four cores, as displayed in Figure 9(a)–(d) and Table 6. Results show that the exponential fitting has the highest correlation coefficient for all four cores, indicating it can effectively reflect the stress sensitivity of permeability in tight cores in this area [16]. Thus, the exponential fitting relationship can be used in practice to represent the stress sensitivity of permeability in tight cores.

Fitting of stress-sensitivity data for cores during pressure increase: (a) C3-1-1, (b) C3-1-4, (c) C3-1-19, and (d) C3-1-35.

Fitting of stress–permeability relationship during pressure increase for tight cores

| Core | Fitting method | Regression equation | Correlation coefficient | Fitting relevance |

|---|---|---|---|---|

| C3-1-1 | Exponential fitting | y = 0.0248 × 10−0.04575x | R² = 0.98561 | Maximum |

| Polynomial fitting | y = 1.26598 × 10−5 x 2 − 9.90252 × 10−4 x + 0.02443 | R² = 0.98177 | General | |

| Power-law fitting | y = 0.04689x −0.54091 | R² = 0.95475 | Minimum | |

| C3-1-4 | Exponential fitting | y = 0.02646 × 10−0.04197x | R² = 0.98849 | Maximum |

| Polynomial fitting | y = 1.25623 × 10−5 x 2 − 0.00101x + 0.0263 | R² = 0.98849 | Maximum | |

| Power-law fitting | y = 0.04814x −0.50319 | R² = 0.94663 | Minimum | |

| C3-1-19 | Exponential fitting | y = 0.07829 × 10−0.10919x | R² = 0.99825 | Maximum |

| Polynomial fitting | y = 5.85988 × 10−5 x 2 − 0.00379x + 0.06158 | R² = 0.95256 | Minimum | |

| Power-law fitting | y = 0.21666x −1.0276 | R² = 0.96307 | General | |

| C3-1-35 | Exponential fitting | y = 0.05654 × 10−0.14242x | R² = 0.99883 | Maximum |

| Polynomial fitting | y = 7.13416 × 10−5 x 2 − 0.00351x + 0.04366 | R² = 0.96854 | Minimum | |

| Power-law fitting | y = 0.17547x −1.21634 | R² = 0.97474 | General |

4.2 Start-up pressure gradient of tight oil reservoirs

The start-up pressure gradient of tight cores was measured using a high-precision ISCO pump, as shown in Figure 10. During the experiment, the displacement pressure difference was gradually increased at a low flow rate. Once the fluid flow stabilized, the pressure difference and flow rate data were recorded. A flow-rate versus pressure-gradient curve was then plotted to determine the start-up pressure gradient. In real-world oil reservoir production, during the early stage of oil well production, formation water exists as bound water. Therefore, the oil–water two-phase start-up pressure gradient is a key indicator of the reservoir’s actual mobilization status [17]. To determine this, we conduct indoor experiments to measure the oil–water two-phase start-up pressure gradient. In the experiment, simulated oil is used to displace formation water in the core, determining the bound water saturation. Then, simulated formation water is slowly injected into the core. Once the flow stabilizes, pressure and flow rate data are recorded to plot the seepage curve. The resulting start-up pressure gradient from this curve represents the core’s oil–water two-phase start-up pressure gradient [18].

Schematic diagram of start-up pressure gradient measurement device.

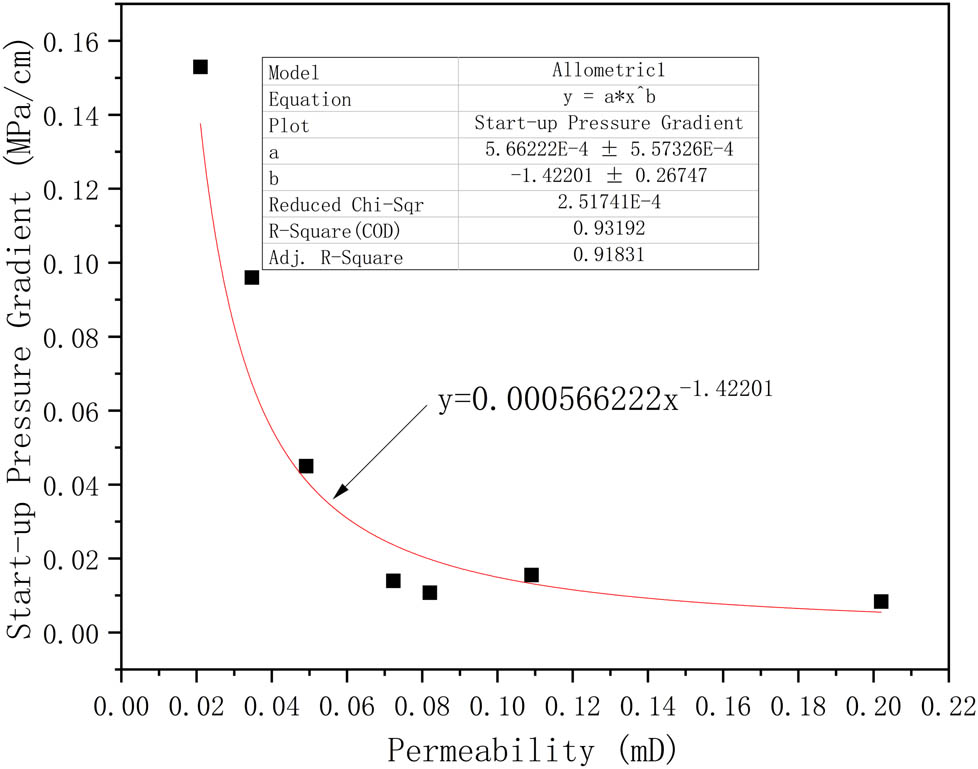

As shown in Figure 11, which illustrates the oil–water two-phase start-up pressure gradient for tight cores, the gradient initially rises slowly with decreasing core permeability. Once the permeability drops below a certain threshold, the gradient escalates sharply. This occurs because tighter cores, with finer pore throats, intensify the Jamin effect and other phenomena, requiring greater pressure for fluid flow. Analysis reveals a power-law relationship between the start-up pressure gradient and permeability: G = 5.66 × 10−4 K−1.42. For instance, when the permeability of a tight core is 0.02 mD, the oil–water two-phase start-up pressure gradient is approximately 0.153 MPa/cm. However, when the core’s permeability increases to 0.2 mD, this gradient drops to 0.0084 MPa/cm, highlighting the significant impact of permeability changes on reservoir development [19].

Fitting curve of oil–water two-phase start-up pressure gradient for tight cores.

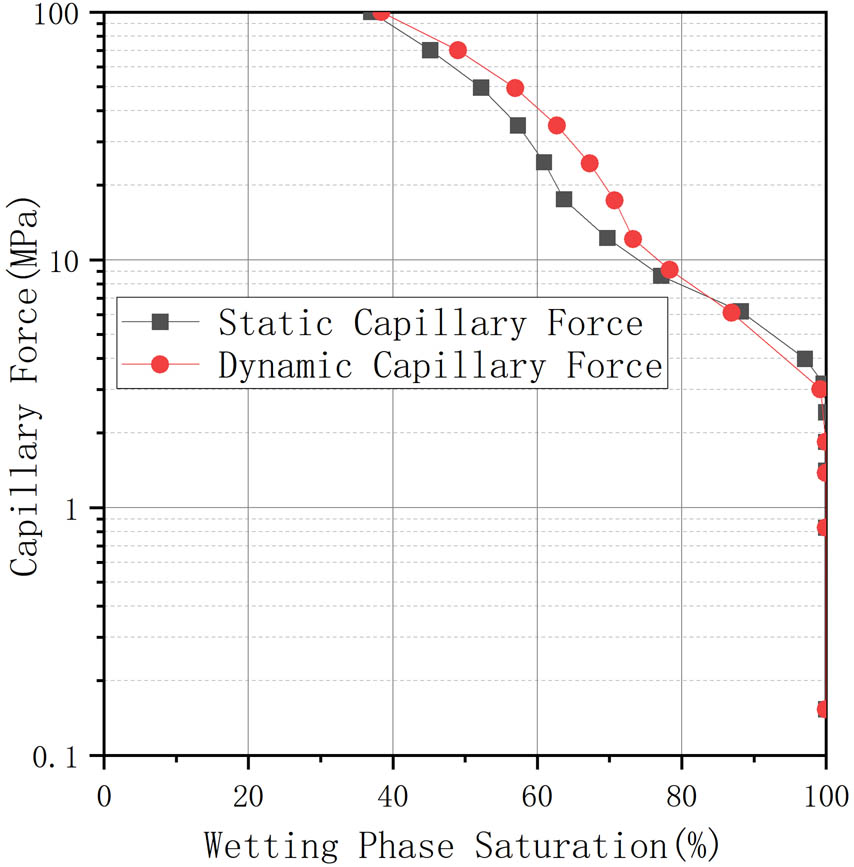

4.3 Dynamic capillary force in tight oil reservoirs

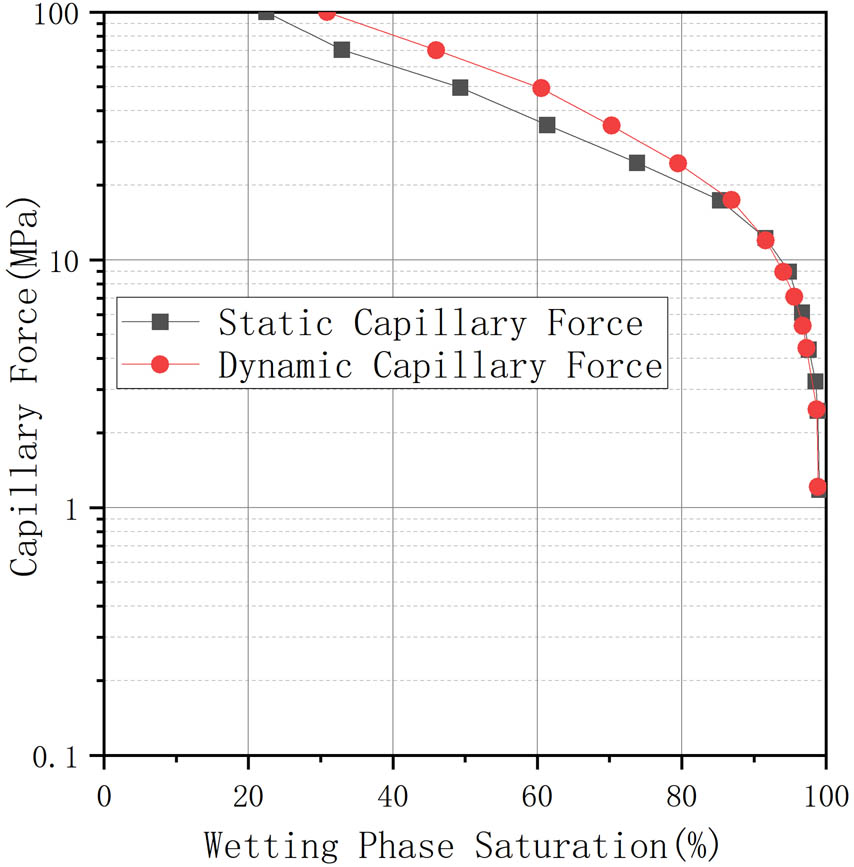

In tight sandstone reservoirs, poor rock properties and small pore throats result in high oil–water capillary forces. During development, fluids in the reservoir are usually in an unstable state, leading to differences between the interfacial capillary forces of oil–water two-phase flow and conventional static capillary forces. This is known as the dynamic capillary force effect, which can impact fluid seepage and, consequently, oil well productivity [20,21].

The most commonly used formula for dynamic capillary force in oil–water two-phase seepage was derived by Hassanizadeh and Gray [22]. The formula is as follows:

where P dyn and P equ are the dynamic and static capillary forces (in MPa), S w is the wetting phase fluid saturation (a decimal), and τ is the non-equilibrium capillary force coefficient, typically obtained through experimental measurement.

An automatic mercury porosimeter was used to measure the capillary force of tight cores. When the equilibrium time for fast mercury injection was 10–50 s, the two-phase interface did not reach equilibrium, resulting in strong dynamic effects and a dynamic capillary force curve. For an equilibrium time of 300–600 s, a static capillary force curve was obtained.

As shown in Figures 12 and 13, the dynamic and static capillary forces for two cores at the same saturation level differed by up to 27.3 and 45.1%. This indicates a significant difference between dynamic and static capillary forces, which must be considered in tight oil reservoir development.

Dynamic and static capillary force curves of Core C10.

Dynamic and static capillary force curves of Core L10.

5 Conclusions

This manuscript presented an experimental study on Chang-7 tight sandstone. The following conclusions can be drawn from this study:

The Chang-7 tight sandstone cores consist mainly of quartz arenite and feldspar arenite with high clay mineral content. The pore types are predominantly intergranular pores, clay mineral intercrystalline pores, dissolved pores, and micro-fractures. The average porosity is 8%, and average permeability is 0.05 mD, with a general positive correlation between porosity and permeability. The small oil–water two-phase permeability interval indicates difficult fluid flow in the cores.

The tight cores exhibit stress sensitivity, with permeability decreasing as effective pressure increases. During initial pressure increase, permeability drops rapidly and then slows down. Exponential fitting best describes the relationship between permeability and effective stress.

The start-up pressure gradients of tight cores with different permeabilities were measured experimentally. The start-up pressure gradient decreases sharply with increasing core permeability and then stabilizes. The oil–water two-phase start-up pressure gradient and permeability follow a power relationship: G = 5.66 × 10−4 K−1.42. Even a slight increase in permeability can significantly reduce the start-up pressure gradient in tight cores.

Dynamic capillary force measurements show significant differences from static capillary force, indicating the need to consider dynamic capillary force effects in tight oil reservoir development.

Next, an oil-well productivity prediction model for tight oil reservoirs will be established using this study’s experimental data and results. The model will incorporate stress sensitivity, start-up pressure gradient, and dynamic capillary force of tight oil reservoirs to provide accurate productivity prediction and help enhance tight oil recovery.

-

Funding information: Authors state no funding involved.

-

Author contributions: Conceptualization: Guodong Zeng, Xinfang Ma, and Yuehao Liu; methodology: Guodong Zeng; conduct experiments: Guodong Zeng and Yuehao Liu; analyze experimental data: Guodong Zeng, Xinfang Ma, and Yuehao Liu; writing – original draft preparation: Guodong Zeng and Yuehao Liu; writing – review and editing: Xinfang Ma; supervision: Yuehao Liu; project administration: Xinfang Ma. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Nilsson C, Raun K, Yan F, Larsen MO, Tang-Christensen M. Types, characteristics, genesis and prospects of conventional and unconventional hydrocarbon accumulations: taking tight oil and tight gas in China as an instance. Acta Petrol Sin. 2012;33(2):173–87.10.1038/aps.2011.203Search in Google Scholar PubMed PubMed Central

[2] Wu S, Zhu R, Yang Z, Mao Z, Cui J, Zhang X. Distribution and characteristics of lacustrine tight oil reservoirs in China. J Asian Earth Sci. 2019;178:20–36.10.1016/j.jseaes.2018.05.013Search in Google Scholar

[3] Zhao J, Hu Q, Liu K, Jin Z, Dultz S, Kaufmann J, et al. Pore connectivity characterization of shale using integrated wood’s metal impregnation, microscopy, tomography, tracer mapping and porosimetry. Fuel. 2020;259:116248.10.1016/j.fuel.2019.116248Search in Google Scholar

[4] Qu HJ, Yang B, Tian XH, Liu XS, Yang H, Dong WW, et al. The primary controlling parameters of porosity, permeability, and seepage capability of tight gas reservoirs: a case study on Upper Paleozoic Formation in the eastern Ordos Basin, Northern China. Pet Sci. 2019;16:1270–84.10.1007/s12182-019-00373-5Search in Google Scholar

[5] Tan Q, Kang Y, You L, Xu F, Meng S. A comprehensive insight into the multiscale pore structure characterization of saline-lacustrine tight carbonate reservoir. J Pet Sci Eng. 2020;187:106744.10.1016/j.petrol.2019.106744Search in Google Scholar

[6] Mu C, Hua H, Wang X. Characterization of pore structure and reservoir properties of tight sandstone with CTS, SEM, and HPMI: a case study of the tight oil reservoir in fuyu oil layers of Sanzhao Sag, Songliao basin, NE China. Front Energy Res. 2023;10:1053919.10.3389/fenrg.2022.1053919Search in Google Scholar

[7] Van Wagener D, Aloulou F. Tight oil development will continue to drive future US crude oil production. United States: US Energy information administration. Vol. 28, 2019.Search in Google Scholar

[8] Kang Y, Tian J, Luo P, You L, Liu. X. Technical bottlenecks and development strategies of enhancing recovery for tight oil reservoirs. Acta Petrol Sin. 2020;41(4):467–77.Search in Google Scholar

[9] Chao Z, Xiaohan Q, Aifang Z, Shinian C, Haibin G, Jin W, et al. Microscopic pore structure of tight sandstone reservoirs and its influence on oil–water seepage. J Xi’an Shiyou Univ. 2024;39:65–73+84.Search in Google Scholar

[10] Jie C, Ying ZG, Liang ZX, Cheng H. Overview of study methods of reservoir rock pore structure. Spec Oil Gas Reservoirs. 2005;12(4):11–4.Search in Google Scholar

[11] He S, Jiao C, Wang J, Luo F, Zou L. Discussion on the differences between constant-speed mercury injection and conventional mercury injection techniques. Fault-Block Oil Gas Field. 2011;18(2):235–7.Search in Google Scholar

[12] Jiyong Z, Zhenwang L, Qichao X, Jingping Z. Micro pore throat structural classification of Chang 7 tight oil reservoir of Jiyuan Oilfield in Ordos Basin. China Pet Exploration. 2014;19(5):73–9.Search in Google Scholar

[13] Li ZQ, Fan YR. Pore-throat distribution of carbonate reservoir in Tahe oilfield. West-China Explor Eng. 2010;22(11):138–40.Search in Google Scholar

[14] Rong NX, Long WC, Jiao L. Experimental study on stress sensitivity for tight reservoirs based on time scale. Unconv Oil Gas. 2016;3(4):21–4.Search in Google Scholar

[15] Wei SY, Fang CY, Fang ZW, Xia SF, Ming YS. Analysis of stress sensitivity and optimization of fracturing parameter for tight reservoirs. Fault-Block Oil Gas Field. 2018;25(4):493–7.Search in Google Scholar

[16] Xi Z, YuMing S, ChengYun H, Jingmei G. Experimental research and analysis on stress-sensitive of low permeability reservoir sandstone. Xinjiang Oil Gas. 2011;07(1):76–80.Search in Google Scholar

[17] Zhu WY, Tian W, Zhu HY, Zhang XL, He YQ, Li Y, et al. Study on experiment of threshold pressure gradient for tight sandstone. Sci Technol Eng. 2015;15(3):79–83.Search in Google Scholar

[18] Zheng MQ, Lai YS, Ping LD, Gen K, Hao L, Can C. Study on the physical properties of tight reservoir and the regularity of the threshold pressure gradident—taking the Xinjiang Jimsar Basin Lucaogou Group as an example. Sci Technol Eng. 2016;16(24):42–7.Search in Google Scholar

[19] Yongchao X, Xiaofeng T. Characteristics of Chang-7 tight oil, Ordos basin. Spec Oil Gas Reservoirs. 2014;21(3):111–5.Search in Google Scholar

[20] Wang JC, Zhang WY, Zhong Z, Wei AB, Bao QH, Zhang Y, et al. Dynamic effect of capillary pressure in low permeability reservoirs. Pet Explor Dev. 2012;39(3):378–84.10.1016/S1876-3804(12)60057-3Search in Google Scholar

[21] Yong ZH, Li HS, Yan JC, Quan MC, Hua LG, Yuan MS, et al. Study of dynamic capillary pressure in ultra-low permeability reservoir. Sci Technol Eng. 2013;13(12):3261–6.Search in Google Scholar

[22] Hassanizadeh SM, Gray WG. Mechanics and thermodynamics of multiphase flow in porous media including interphase boundaries. Adv Water Resour. 1990;13(4):169–86.10.1016/0309-1708(90)90040-BSearch in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- User profiling in university libraries by combining multi-perspective clustering algorithm and reader behavior analysis

- Exploring bifurcation and chaos control in a discrete-time Lotka–Volterra model framework for COVID-19 modeling

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China

- Nonlinear comprehensive evaluation method based on information entropy and discrimination optimization

- Application of numerical calculation methods in stability analysis of pile foundation under complex foundation conditions

- Research on the contribution of shale gas development and utilization in Sichuan Province to carbon peak based on the PSA process

- Characteristics of tight oil reservoirs and their impact on seepage flow from a nonlinear engineering perspective

- Nonlinear deformation decomposition and mode identification of plane structures via orthogonal theory

- Numerical simulation of damage mechanism in rock with cracks impacted by self-excited pulsed jet based on SPH-FEM coupling method: The perspective of nonlinear engineering and materials science

- Cross-scale modeling and collaborative optimization of ethanol-catalyzed coupling to produce C4 olefins: Nonlinear modeling and collaborative optimization strategies

- Unequal width T-node stress concentration factor analysis of stiffened rectangular steel pipe concrete

- Special Issue: Advances in Nonlinear Dynamics and Control

- Development of a cognitive blood glucose–insulin control strategy design for a nonlinear diabetic patient model

- Big data-based optimized model of building design in the context of rural revitalization

- Multi-UAV assisted air-to-ground data collection for ground sensors with unknown positions

- Design of urban and rural elderly care public areas integrating person-environment fit theory

- Application of lossless signal transmission technology in piano timbre recognition

- Application of improved GA in optimizing rural tourism routes

- Architectural animation generation system based on AL-GAN algorithm

- Advanced sentiment analysis in online shopping: Implementing LSTM models analyzing E-commerce user sentiments

- Intelligent recommendation algorithm for piano tracks based on the CNN model

- Visualization of large-scale user association feature data based on a nonlinear dimensionality reduction method

- Low-carbon economic optimization of microgrid clusters based on an energy interaction operation strategy

- Optimization effect of video data extraction and search based on Faster-RCNN hybrid model on intelligent information systems

- Construction of image segmentation system combining TC and swarm intelligence algorithm

- Particle swarm optimization and fuzzy C-means clustering algorithm for the adhesive layer defect detection

- Optimization of student learning status by instructional intervention decision-making techniques incorporating reinforcement learning

- Fuzzy model-based stabilization control and state estimation of nonlinear systems

- Optimization of distribution network scheduling based on BA and photovoltaic uncertainty

- Tai Chi movement segmentation and recognition on the grounds of multi-sensor data fusion and the DBSCAN algorithm

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part III

- Generalized numerical RKM method for solving sixth-order fractional partial differential equations

Articles in the same Issue

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- User profiling in university libraries by combining multi-perspective clustering algorithm and reader behavior analysis

- Exploring bifurcation and chaos control in a discrete-time Lotka–Volterra model framework for COVID-19 modeling

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China

- Nonlinear comprehensive evaluation method based on information entropy and discrimination optimization

- Application of numerical calculation methods in stability analysis of pile foundation under complex foundation conditions

- Research on the contribution of shale gas development and utilization in Sichuan Province to carbon peak based on the PSA process

- Characteristics of tight oil reservoirs and their impact on seepage flow from a nonlinear engineering perspective

- Nonlinear deformation decomposition and mode identification of plane structures via orthogonal theory

- Numerical simulation of damage mechanism in rock with cracks impacted by self-excited pulsed jet based on SPH-FEM coupling method: The perspective of nonlinear engineering and materials science

- Cross-scale modeling and collaborative optimization of ethanol-catalyzed coupling to produce C4 olefins: Nonlinear modeling and collaborative optimization strategies

- Unequal width T-node stress concentration factor analysis of stiffened rectangular steel pipe concrete

- Special Issue: Advances in Nonlinear Dynamics and Control

- Development of a cognitive blood glucose–insulin control strategy design for a nonlinear diabetic patient model

- Big data-based optimized model of building design in the context of rural revitalization

- Multi-UAV assisted air-to-ground data collection for ground sensors with unknown positions

- Design of urban and rural elderly care public areas integrating person-environment fit theory

- Application of lossless signal transmission technology in piano timbre recognition

- Application of improved GA in optimizing rural tourism routes

- Architectural animation generation system based on AL-GAN algorithm

- Advanced sentiment analysis in online shopping: Implementing LSTM models analyzing E-commerce user sentiments

- Intelligent recommendation algorithm for piano tracks based on the CNN model

- Visualization of large-scale user association feature data based on a nonlinear dimensionality reduction method

- Low-carbon economic optimization of microgrid clusters based on an energy interaction operation strategy

- Optimization effect of video data extraction and search based on Faster-RCNN hybrid model on intelligent information systems

- Construction of image segmentation system combining TC and swarm intelligence algorithm

- Particle swarm optimization and fuzzy C-means clustering algorithm for the adhesive layer defect detection

- Optimization of student learning status by instructional intervention decision-making techniques incorporating reinforcement learning

- Fuzzy model-based stabilization control and state estimation of nonlinear systems

- Optimization of distribution network scheduling based on BA and photovoltaic uncertainty

- Tai Chi movement segmentation and recognition on the grounds of multi-sensor data fusion and the DBSCAN algorithm

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part III

- Generalized numerical RKM method for solving sixth-order fractional partial differential equations