Abstract

The traditional fabric colour matching process has problems such as long cycle, low efficiency, and high cost. To address these limitations and improve the accuracy of fabric brightness prediction, this research combines the theory of light and shadow reconstruction of layered images, multiple regression (MR) prediction, and a neural network to build a fabric brightness regression prediction model. The primary objectives include enhancing the visual representation of fabric colours and establishing a high-precision predictive framework. First, the layering process of the fabric image was determined by the light and shadow reconstruction method, and then a series of factors affecting the brightness value were set as independent variables and the brightness value as the dependent variable on the basis of the layered image by combining the MR model to build the brightness prediction model. Finally, the prediction model was optimised by incorporating a backpropagation neural network. This hybrid method ensures interpretability and nonlinear adaptability through MR prediction and neural networks. Testing the model performance, it is found that the final fabric brightness regression prediction model has better prediction performance, and its error performance is better than that of the traditional multivariate regression model. In practical applications, the proposed model can obtain 95.3 user satisfaction and 97.8 merchant satisfaction, and the difference between its predicted and actual brightness values is within 3°. These results demonstrate the model’s potential for industrial adoption in digital textile design. Future research will extend the model to dynamic lighting conditions and multi-material fabric interactions.

1 Introduction

The look and feel of a fabric is determined by its material, structure, and colour, with brightness being an important component of the fabric’s visual attributes [1,2]. In the digital era, a realistic representation of fabrics requires not only the accurate capture of their colours and textures but also the ability to realistically reproduce their brightness changes under different lighting conditions. This demand is of particular significance in industries such as fashion design, home textiles, and automotive interiors. For example, in clothing design, brightness can affect consumers’ perception of fabric quality. In home textiles, such as curtains and interior decoration, products need to maintain consistent brightness under different indoor lighting conditions. In addition, car interiors also have strict requirements for colour fastness and visual comfort under sunlight exposure. However, due to the complexity of fabrics and their interaction properties with light, realistically capturing and reproducing these properties have been a challenge in computer graphics. The layered image light reconstruction technique is a concept in computer graphics [3,4]. The technique focuses on how to decompose different visual effects in images and complex light and shadow interaction scenarios into multiple layers or parts that are easier to handle. The layered image light and shadow reconstruction technique works by breaking down a complex image or scene into multiple single or simpler layers and processing the light and shadow effects of each layer individually, then combining these effects to obtain a more realistic and detailed overall visual effect [5]. The current fabric colour matching technology has many problems such as long cycle, low efficiency, and high cost, which are difficult to meet the rapidly changing market demand. For example, fast fashion brands require rapid brightness prediction for new fabric designs, while luxury textiles demand high-precision brightness control to maintain brand aesthetics. In addition, most existing methods for predicting fabric brightness are based on simple linear regression or empirical formulas, resulting in low prediction accuracy and applicability. To overcome these problems, this study innovatively introduces a layered image light reconstruction technology, multiple regression (MR) models, and backpropagation (BP) neural networks to build a fabric brightness prediction model. This study is the first to apply layered image light reconstruction technology to fabric brightness prediction. By decomposing complex light and shadow effects into multiple layers, the accuracy and detailed representation of brightness prediction are improved. On the basis of traditional MR models, the model is optimised by combining BP neural networks, which improve the generalisation ability and accuracy of the prediction model.

The article is divided into five parts; the first part is a brief introduction to the full text, the second part is an analysis and summary of related research, the third part is a detailed description of the design method of the article, the fourth part is an analysis of the model performance, and the last part is a summary of the full text.

2 Related works

Regression predictive modelling is a method in statistics commonly used to describe the relationship between two or more predictor variables and a response variable. Many scholars have used this model to estimate and predict the value of the dependent variable for experimental purposes. Dharma et al., in order to predict the future level of pass through inflation and thus help the government to formulate a rational economic policy, proposed a genetic algorithm-based regression model to fulfil the prediction task. The prediction model is constructed by analysing the past historical data of consumer price index of the population, and the genetic algorithm is used to optimise the ability of the regression model to handle non-linear data. The results show that the proposed prediction model has good performance, and its prediction mean square error values are all 0.11, which can make accurate prediction based on the actual consumption data [6]. In order to improve the prediction accuracy of lattice thermal conductivity and optimise the effectiveness of the lattice thermal conductivity prediction model for thermoelectric and semiconductor thermal management, Loftis et al. built a genetic programming symbolic regression model by combining an MR method and a neural network. The performance of this model and other lattice thermal conductivity prediction models is compared using a hybrid cross-validation approach, and the results of the study show that the proposed model has better prediction accuracy [7]. In order to better evaluate the athletic training effect of athletes and to make athletes understand their sports condition more accurately, Wang et al. built a prediction model of athletes’ sports effect by combining the support vector machine and regression prediction model. The results show that compared with the traditional statistical modelling approach, the above modelling method can effectively improve the prediction accuracy of the model, so that it can better predict the training effect of athletes [8].

With the continuous development of deep learning technology, a series of network computations represented by neural networks have not only achieved certain research in the field of image compression but also widely applied in other fields. Bing et al. proposed a collaborative image compression and classification framework based on visual Internet of Things (IoT) applications. Experimental results show that the network structure is able to achieve low bit rate compression and reduce the computational resources required for image transmission [9]. To quickly identify mixed antibiotic residues in water, Yuan used a computational framework combining the convolutional neural network (CNN) and non-negative elastic network methods to qualitatively and quantitatively analyse surface enhanced Raman spectra in water environmental systems. The experimental results showed that the CNN model had a recognition accuracy of 98.68% [10]. Yeoh and others aimed to improve the model in the diagnosis of knee osteoarthritis, 13 different architectures of three-dimensional (3D) CNNs were used, and the two-dimensional (2D) pretraining weights were converted to 3D ones for training through transfer learning. The results showed that the F1 score of this method reached 0.871 [11]. Deng et al. proposed a new hidden network model in order to solve the problem of the existing deep learning algorithms that take too long to train an image domain specifically. The model was tested to have higher detection accuracy and shorter training time [12]. Teoh’s team used an optimised deep learning ensemble model to preprocess mammography images and locate microcalcifications in order to improve the diagnostic accuracy of cancer microcalcification detection, so as to enhance the clinical effect of breast cancer diagnosis. The results indicate that the average confidence level of the integrated model is 0.9305 [13].

In summary, a number of scholars have carried out a series of studies on regression prediction models and image processing methods. As a special class of images, fabric image features are difficult to be accurately identified due to its special texture structure and complex image hierarchy. In this study, a fabric image brightness prediction model is constructed from the theory of light and shadow reconstruction, combined with the MR method and neural network, aiming to provide more references for the actual fabric design and application through the accurate brightness prediction.

3 Construction of a fabric brightness regression prediction model by integrating the principle of light and shadow reconstruction of layered images

Fabric imaging is a presentation method that converts a 3D fabric into a flat image. The converted digitised planar image has a more intuitive visual effect and is also more convenient for mathematical statistics and analysis. In order to accurately predict the brightness of fabric images and check the quality of fabrics according to the brightness difference, this study first designed a light and shadow reconstruction scheme for fabric images, and on the basis of this scheme, a complete prediction model combining the MR model and neural network was built to predict the brightness of fabric images.

3.1 Fabric image light and shadow reconstruction method design

In fabric images, its light and shadow layering phenomenon can reflect the light and shadow information about the fabric more accurately and at the same time provide a technical basis for the subsequent feature extraction of layered images and the regression calculation of the fabric brightness value. The light and shadow layering of fabric images was jointly determined by various types of layering theoretical basis and different layering methods [14,15]. The layering basis of fabric images mainly includes three types of theories: colour mixing principle, optical reflection characteristics, and image processing theory. The layering basis of fabric image is shown in Figure 1.

Principle structure of fabric image layering.

In Figure 1, the fabric image is divided on the basis of layering mainly on the basis of the principle of fabric colour mixing, the influencing factors of fabric colour presentation, and the nature of the fabric image colour. The principle of fabric colour mixing is that yarns of two or more colours are interspersed in the warp and weft of the fabric in a particular order and manner. These yarns are interlaced, overlapped, or partially exposed during the interweaving process, resulting in different colour effects. Colour mixing can be controlled by the density, texture, and arrangement of different yarns to achieve the desired colour effect. Taking jacquard fabric as an example, the final colour of jacquard fabric is formed by interweaving warp and weft yarns of the surface of the colour point and colour line composition [16]. As the human eye at a certain distance cannot distinguish these too small fabric colour point, thus forming a fabric colour space juxtaposition mixing, this juxtaposition mixing of the fabric colour value is in fact the average of the yarn colour of the composition of the fabric. In addition, the final colour of the jacquard fabric is affected by a number of factors, such as yarn colour, fibre, density of arrangement, and fabric material. Finally, in the process of transforming the fabric from a three-dimensional form into a flat image, the original 3D fabric will be transformed into a digital 2D image stored in the form of pixels [17]. By identifying the image and extracting its features, the image layering of different fabrics can be differentiated, which can better restore the original light and shadow composition of the fabric and provide a more accurate range for the colour assignment of the actual yarns. The common digital 2D image expression is shown in Figure 2.

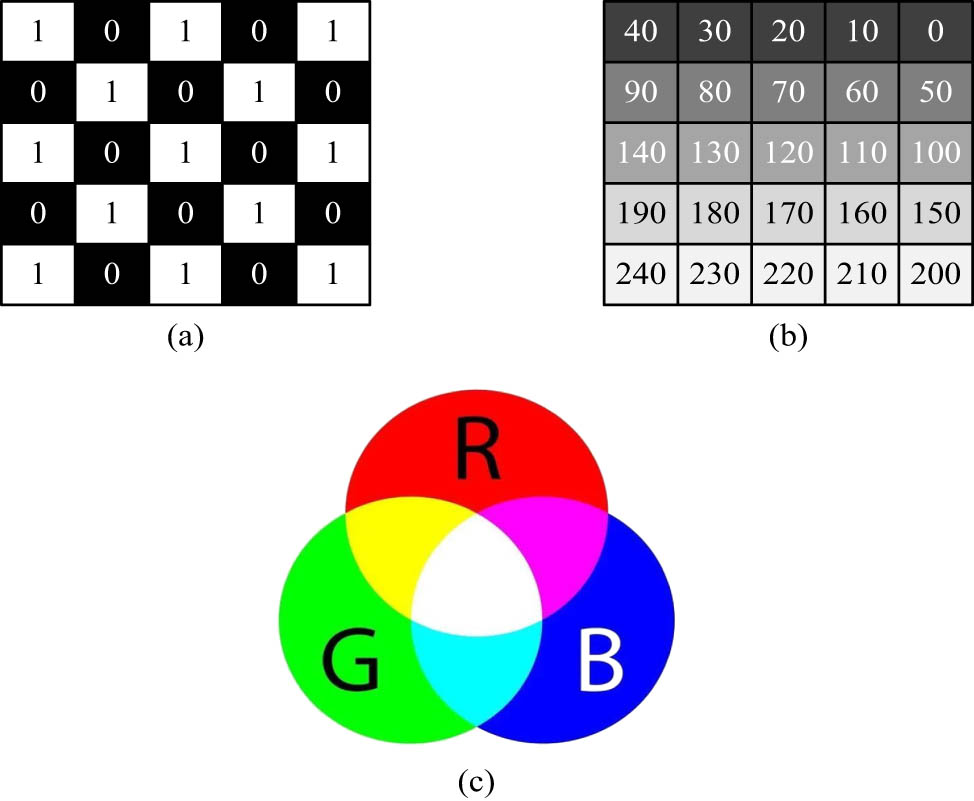

Classification chart of different digital 2D image types. (a) Schematic of a binary image. (b) Schematic of a grey scale image. (c) Colour image.

In Figure 2, there are a total of three different digital 2D image expressions, namely the binary image, grey scale image, and colour image. Among the three digital 2D image expressions, the grey level value of a pixel point in a binary image is represented by 1 and 0, where 1 represents white and 0 represents black. The grey level of a pixel in a grey scale image is represented by 1 to 255, with larger values indicating brighter brightness of the image. The pixel points in a colour image are made up of three colour quantities R, G, and B. When a fabric is converted into a digital 2D image in the form of a 3D fabric, the three different 2D image types mentioned above can be used to represent the grey values of the fabric image. The input value is the 2D image of the fabric collected under a D65 standard light source and the measured brightness data. Each fabric sample was measured randomly at five positions under a D65 standard light source, and the average brightness was recorded with a repeatability of ±0.5%. The luminance value was measured using a Konica Minolta CS-2000 spectrometer. To simulate standard conditions, the lighting was set to 45° and the sensor at 0° to the fabric surface. The specific operations were divided into three layers: graphic layer, shadow layer, and material layer for processing. In the graphic layer, based on the area ratio of yarn colour coverage, as shown in Eqs. (1) to (3), the warp and weft yarn regions were extracted through threshold segmentation, such as white warp/black weft.

In Eq. (1),

In Eq. (2),

In Eq. (3),

In Eq. (4),

In Eq. (5),

Parameters of fabric colour cards

| Parameter | Warp | Weft |

|---|---|---|

| Thread colour | White | Black |

| Wire density | 22.2/24.4 dtex*2 | 22.2/24.4 dtex*2 |

| Wire arrangement specification | 1,100 pcs/10 cm | 1,100 pcs/10 cm |

| Composition | Mulberry silk | Mulberry silk |

| Tissue point transition direction | Weft reinforcement | Weft reinforcement |

| Tissue structure | 15 pcs 3f, 5f, 7f weft satinised | 15 pcs 3f, 5f, 7f weft satinised |

In Table 1, the thread density, colour, alignment density, composition, direction of transition of tissue points, and tissue structure of the radial and weft directions of the fabric swatch weaving yarns are given. Since the material and colour of the warp and weft yarns of the fabric will affect the brightness of the final fabric image, it needs to be strictly controlled according to the parameter specifications in Table 1.

To better predict the brightness values of fabric images, the images need to be layered, thereby better extracting the image features for analysis. Layered image photoreconstruction is a computer graphics and computer vision technique for analysing and reconstructing lighting information of a scene from images. The goal of hierarchical image photoreconstruction is to infer the lighting conditions of a scene from single or multiple images in order to better render or reconstruct a 3D scene. In conventional images, lighting information is mixed in colour and luminance and is difficult to separate out directly. The idea of hierarchical image light reconstruction is to separate the lighting information in an image from other factors such as surface colour and texture in order to better control the lighting conditions, and even to apply this information to other scenes or virtual worlds. The application of layered image light and shadow reconstruction techniques to fabric images can better extract the image layering features to achieve the prediction of fabric colour. The flowchart of the light and shadow reconstruction method for fabric images is shown in Figure 3.

Flowchart of fabric image light and shadow reconstruction method.

In Figure 3, it can be found that the light and shadow reconstruction method of fabric images is mainly composed of three parts: layering, assignment, and reconstruction. Image layering is done to obtain the warp and warp graphic layer, stereo shadow layer, and warp and warp material layer. Taking the warp and weft graphic layer as an example, it is divided into latitudinal area ratio and meridional area ratio, extracted as weft luminance and warp luminance, respectively. The final brightness summation achieves the fabric image. According to the results of fitting the reconstructed luminance value of the fabric image to the actual measured luminance value of the sample fabric, the contribution of the graphical characteristics of the layered image to the luminance of the fabric can be determined. By gradually analysing the brightness of each layer of the image and solving for each parameter value, the final brightness value can be obtained.

3.2 Design of an MR fabric brightness prediction model

MR is an extension of linear regression and is often used to solve situations involving multiple independent variables to more accurately predict the value of the dependent variable [18]. In the problem of fabric brightness prediction, since fabric brightness is related to a variety of factors such as material, fabric colour card, weaving process, image acquisition method, image processing method, etc., the study adopted MR to build a fabric brightness prediction model. The flow chart of the fabric brightness prediction model in MR is shown in Figure 4.

Flowchart for building the MR fabric brightness prediction model.

Figure 4 shows the flowchart of building the MR fabric brightness prediction model. As can be seen from Figure 4, in the process of building the prediction model, it is mainly divided into three parts. The first part is to design the fabric colour card and determine the weaving scheme and colour measurement scheme, so as to provide data for the subsequent prediction model. The second part is further acquisition and processing of data, in which the feature extraction of fabric images and the calculation of relevant parameters are completed. The third part is the construction of the prediction model based on the principle of MR. To control variables during the initial modelling stage and reduce the interference of fibre material differences in brightness prediction, the study chose Mulberry silk as the unified material for warp and weft yarns.

Fly value refers to the number of weft yarns skipped between two adjacent interlacing points in a satin weave structure. This value directly affects the smoothness of the fabric surface and the light reflection pattern [19]. For example, 3-fly (3f) means that the warp yarns float over 3 wefts before interlacing. A lower fly value can lead to more frequent interleaving, resulting in a diffuse matte appearance. A higher fly value will result in longer fluctuations, enhancing specular reflection and perceived brightness. After determining the fabric colour card, it is necessary to carry out the weaving process and collect the corresponding fabric image to extract the image features. The brightness value of the fabric can be obtained through weaving and colour measurement, and the areas of the white warp yarn graphic area, the black weft yarn graphic area, the miscellaneous point graphic area, and the projection graphic area can be obtained through image processing and data acquisition. The above-collected data were taken as independent variables, the fabric brightness was taken as the dependent variable, and the prediction model was established by combining MR. The MR modelling operation establishes a linear relationship through Eqs. (6)–(8). The fabric warp yarn graphic area rate reflects the brightness changes caused by weft yarn reinforcement. There is a linear relationship between the sum of fabric warp yarn graphic area rate, projected area rate, and the proportion of artisan warp yarn area

In Eq. (6),

In Eq. (7),

Here,

To test the performance of the regression prediction model, the coefficient of determination, mean absolute error (MAE), mean relative error (MRE), and root mean squared error (RMSE) were chosen as the testing indexes to test the performance of the model.

In Eq. (9),

In Eq. (10),

In Eq. (11),

In Eq. (12),

3.3 Design of an MR fabric brightness prediction model based on BPNN optimisation

Since the regression prediction model is prone to underfitting after multiple trainings and the BP neural network (BPNN) in machine learning has a better nonlinear fitting performance, the study will combine the BPNN to further optimise the above MR model. The regression model was used to deal with the linear features in the data, the BPNN model was used to deal with the nonlinear features in the data, and finally the two models were combined to obtain the final brightness prediction model.

Since the three-layer BPNN has the advantages of a stable structure that can approximate any functional relationship between the data and achieve multi-dimensional mapping, a three-layer structure was chosen to build the BPNN model. In order to further improve the prediction accuracy of the model, the study uses Eq. (13) to determine the number of neurons in the hidden layer.

In Eq. (13),

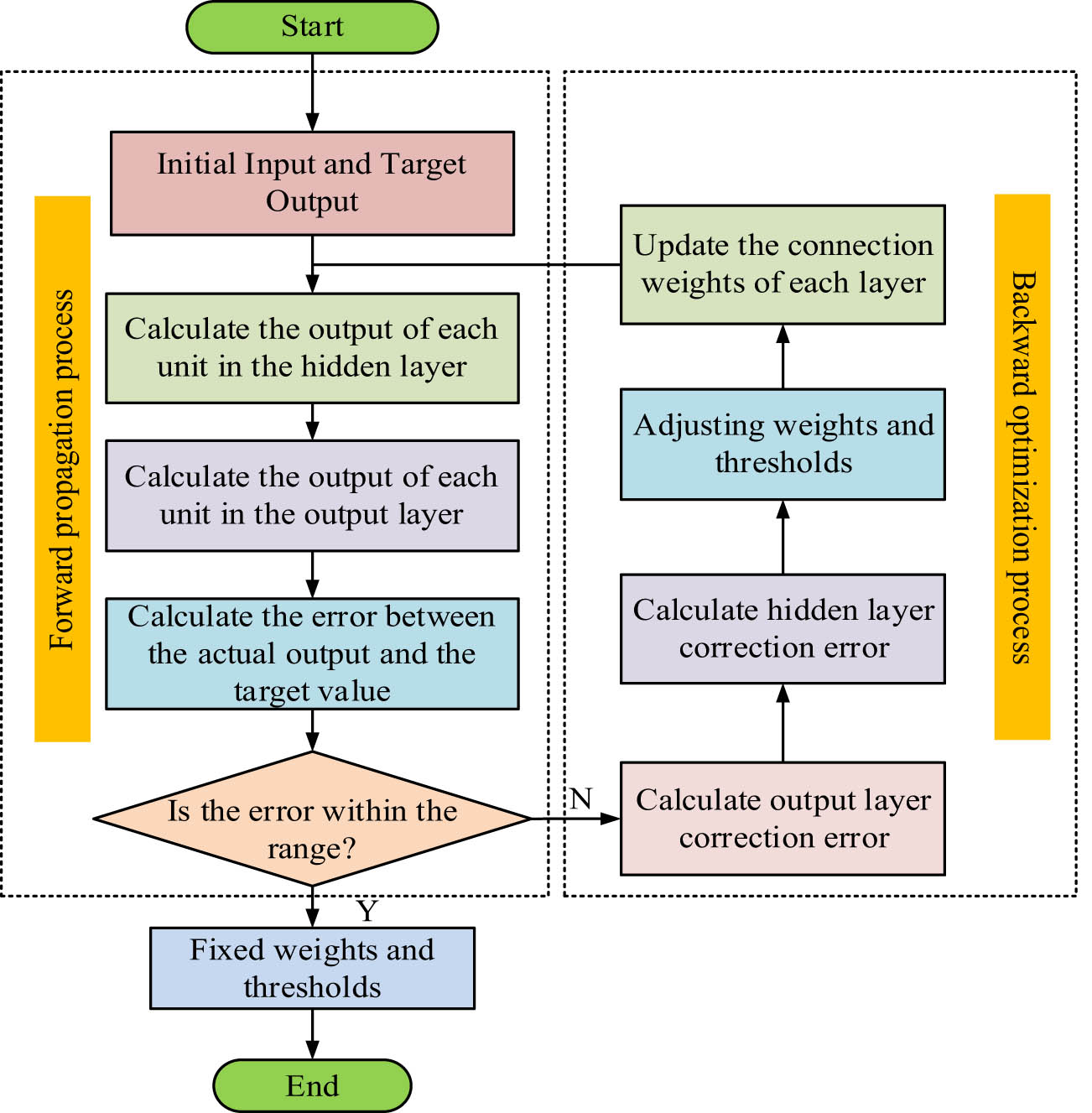

Flow chart of BPNN-MR model prediction.

The flowchart of the operation of the brightness regression prediction model incorporating the BPNN is shown in Figure 5. After the initial input and target output, calculate the output of each unit in the hidden layer and output layer. Then, calculate the error between the actual output and the target value. If the error is within the range, the loop ends with fixed weights and thresholds. If not, calculate the correction error of the hidden layer and output layer. Adjust the weights and thresholds and update the connection weights of each layer. Recalculate the output of each unit in the hidden layer and output layer and loop again. The result after MR prediction was used as the input of the BPNN model for optimisation, and the BPNN learned the implicit mapping relationship between the weave complexity and brightness. The final brightness prediction model was obtained through multiple trainings and is denoted as BPNN-MR. The BPNN part of the BPNN-MR was used to process the nonlinear data in the fabric image, and the MR model was used to process the relationship between the linear data, and finally the hybrid model BPNN-MR was used for the prediction of the fabric brightness value.

4 BPNN-MR fabric brightness prediction model performance testing and application effect analysis

In this study, the coefficient of determination, the MAE, the MRE, and the RMSE were selected as the detection indexes to test the performance of different MR models in the same dataset, so as to verify the performance of BPNN-MR. In addition, two different specifications of fabric upholstery fabrics were selected to test the brightness prediction effect of BPNN-MR in practical applications, and it was found that the predicted brightness values of the model were almost the same as the actual values, which could predict the brightness of fabrics well.

4.1 Performance test of the BPNN-MR fabric brightness prediction model

In order to verify the robustness of the BPNN-MR model for brightness prediction in different fabric structures, the dataset was divided into three parts: the training set contains 3f and 7f colour card samples, accounting for 70% of the total data. The validation set consisted of 15% of the 5f colour card samples and was used for tuning hyperparameters. The test set also consisted of 15% of the 5f colour card samples, which was used to simulate the prediction situation of unknown samples. To further test the performance of the BPNN-MR fabric brightness prediction model, it is first necessary to calculate the mean and standard deviation of the brightness corresponding to different fly values in the colour cards to determine whether different fly values affect the fabric brightness. The mean and standard deviation of 15 cards with 3f, 5f, and 7f values in the colour chart were analysed using one-way ANOVA, as shown in Table 2.

Mean and standard deviation of luminance of fabric swatches with different fly values

| Fabric colour Card fly values | Mean value | Standard deviation | p value (vs 3f) | p value (vs 5f) |

|---|---|---|---|---|

| 3f | 48.56 ± 12.61 | 12.94 ± 8.25 | — | — |

| 5f | 50.21 ± 10.28 | 15.18 ± 10.11 | 0.043 | — |

| 7f | 44.35 ± 11.74 | 13.07 ± 9.69 | 0.021 | 0.003 |

In Table 2, the luminance mean and standard deviation of the fabric swatches with different fly values are given. According to the data in Table 2, it can be seen that the overall luminance mean and standard deviation of the colour cards increased and then decreased with the increase of fabric fly values. The cover factor measured the percentage of fabric area covered by yarn, while the fly value captured the structural periodicity of light scattering points in satin fabrics. Choosing the fly value as the brightness prediction value for satin fabric is more reliable, while cover factor is more suitable for plain weave fabric. There was a significant difference in brightness between 5f and 3f (p = 0.043), and there were significant differences between 7f and both 3f and 5f values (p <0.05). The brightness of the 7f group was significantly lower than the other two groups, which may be related to the long floating line reflection characteristics.

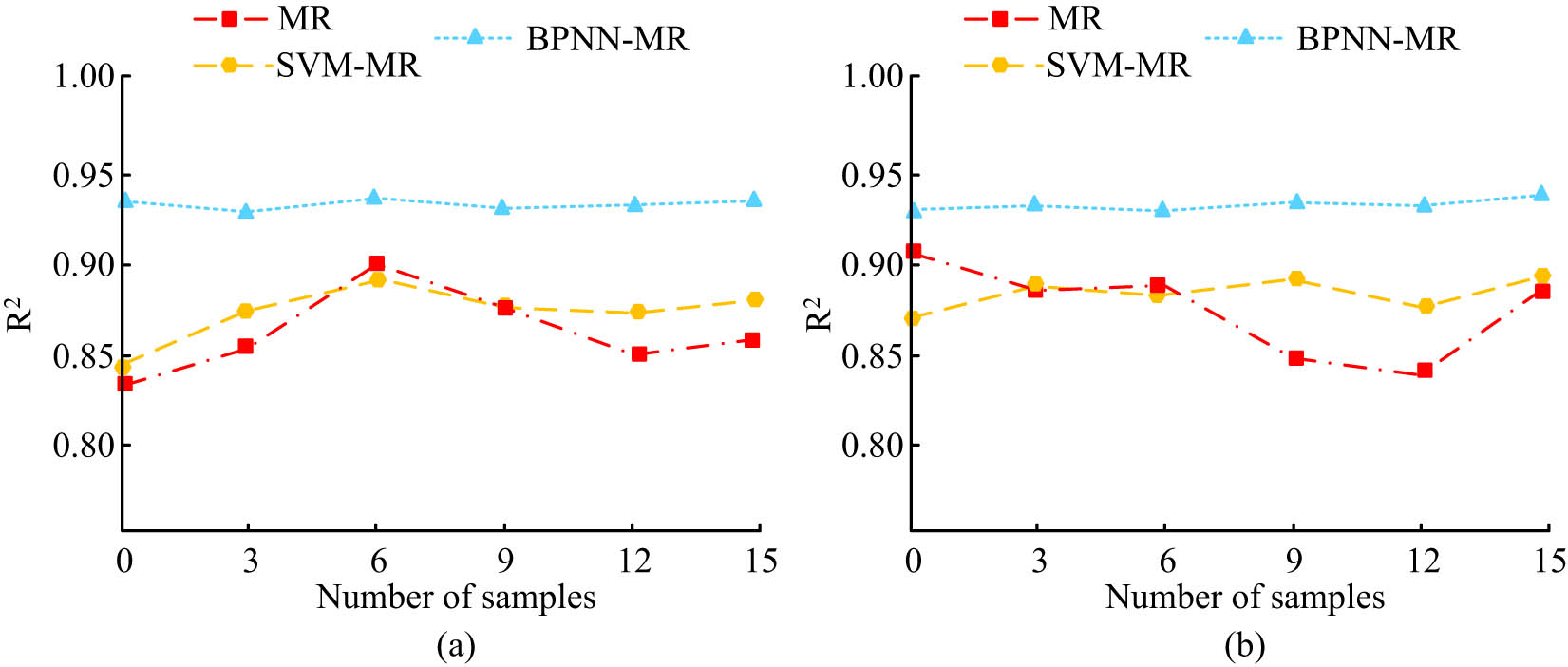

In order to better test the prediction performance of each model for fabric brightness, the study chose the 5f value card in the colour card as the test sample set and 3f and 7f value cards as the training sample sets, and tested the

Values of coefficient of determination for different prediction models. (a) Magnitude of the coefficient of determination values for the three models in the training dataset. (b) Magnitude of coefficient of determination values for the three models in the test dataset.

In Figure 6, the three prediction models are multiple regression (MR), support vector machine-multiple regression (SVM-MR) under optimisation, and the BPNN proposed in this research. Figure 6(a) and (b) presents the

Figure 7(a) and (b) presents the RMSE values of the three prediction models in the training dataset and test dataset, respectively. As can be seen from Figure 7(a), the average RMSE values of the three models BPNN-MR, SVM-MR, and MR in the training dataset are around 3.8, 5.7, and 7.1, respectively. From Figure 7(b), the average RMSE values of the three models BPNN-MR, SVM-MR, and MR in the test dataset are around 3.9, 5.9, and 7.5, respectively. Comparing the RMSE values of the three models, it can be found that the average error value of BPNN-MR is smaller, which indicates that the model has a better prediction effect. In order to further represent the training error situation of the model, the MAE value and MRE value of the two models, BPNN-MR and SVM-MR, are given in Figure 8.

RMSE values for different prediction models. (a) RMSE values of the three models in the training dataset. (b) RMSE values for the three models in the test dataset.

MAE and MRE values for different prediction models. (a) Relative and absolute errors under SVM-MR prediction modelling. (b) Relative and absolute errors under BPNN-MR prediction modelling.

Figure 8(a) and (b) presents the MAE and MRE values of the SVM-MR and BPNN-MR models in the test dataset, respectively. As can be seen from Figure 8(a), the MAE values and MRE values of the SVM-MR model have a large error. Taking sample 1 as an example, the MAE and MRE values of this sample in the SVM-MR model are 4.2 and 11.8, respectively. On the contrary, as can be seen from Figure 8(b), the MAE and MRE values of the BPNN-MR model are closer. Taking sample 1 as an example, the MAE and MRE values of this sample in the BPNN-MR model are 6.1 and 7.9, respectively. In summary, it can be seen that the MAE and MRE values in the BPNN-MR model are much closer to each other, which indicates that the model has a much smaller error during the training process, and its prediction is much closer to the actual situation. In the BPNN-MR model, the estimated coefficient of the intercept term is 2.3, with a standard error of 0.5, and P <0.001, statistically significant. The results of MR prediction have a significant impact on the output of the model, which also verifies the importance of the MR model in predicting brightness values.

4.2 Analysis of the effect of applying the BPNN-MR fabric brightness prediction model

The performance of the above three regression models was tested through the detection indexes of the coefficient of determination

Brightness test results of two upholstery fabrics in BPNN-MR modelling

| Decorative fabric type | Organisation number | Actual luminance value | Tested luminance value |

|---|---|---|---|

| First type of decorative fabric | 1 | 35.45 | 34.25 |

| 2 | 41.26 | 40.16 | |

| 3 | 44.21 | 45.26 | |

| 4 | 38.19 | 37.75 | |

| 5 | 34.82 | 35.09 | |

| 6 | 27.11 | 27.51 | |

| 7 | 48.37 | 50.16 | |

| 8 | 28.15 | 29.34 | |

| 9 | 23.62 | 24.81 | |

| 10 | 39.02 | 40.05 | |

| Second type of decorative fabric | 1 | 68.23 | 70.11 |

| 2 | 73.54 | 72.74 | |

| 3 | 66.15 | 65.54 | |

| 4 | 84.10 | 85.09 | |

| 5 | 67.64 | 67.95 | |

| 6 | 69.21 | 68.08 | |

| 7 | 74.08 | 75.23 | |

| 8 | 77.25 | 75.18 | |

| 9 | 79.63 | 80.17 | |

| 10 | 81.42 | 81.56 |

In Table 3, ten tissue colour blocks were randomly selected from two kinds of decorative fabrics to be labelled in order, and their brightness values were examined. As can be seen from Table 3, the actual luminance values of the first decorative fabric are between 20 and 50, while the actual luminance values of the second decorative fabric are between 60 and 90. The predicted luminance values in the BPNN-MR model are basically the same as the actual luminance values, and the data difference between the predicted values and the actual values is basically within 3°. For the first type of decorative fabric, the BPNN-MR prediction error is only 1.21 ± 0.89 brightness units, which is suitable for heavy fabrics with a high proportion of shadow layers, such as curtain fabrics. For the second type of decorative fabric, the model successfully captures the mirror reflection characteristics of 7f satin pattern, which is suitable for strong light environments such as car interiors.

The predicted brightness values of the two models, BPNN-MR and SVM-MR, for different tissue colour blocks in the two fabric upholstery fabrics are shown in Figure 9. As can be seen from Figure 9(a), the predicted and actual values of each tissue colour block in the BPNN-MR model are basically the same. As the organisation number gradually increases, the trend of luminance value changes is basically similar between the two. From Figure 9(b), it can be seen that in the SVM-MR model, there is a discrepancy between the predicted and actual values of each tissue colour block. The maximum difference between the two is 22. In contrast, BPNN-MR has a better predictive effect on fabric brightness than SVM-MR. This is because the multi-layer structure of BPNN enables it to extract and optimise data features layer by layer, thereby better fitting the changing trend of brightness values. This enables the BPNN-MR model to more accurately reflect the actual brightness of colour blocks in fabric interior organisation.

Predicted and actual values of brightness of each fabric organisation in different prediction models. (a) Predicted and actual brightness values of the BPNN-MR model. (b) Predicted and actual brightness values of the SVM-MR model.

The satisfaction of merchants and users for the three brightness prediction models is shown in Figure 10. From Figure 10, it can be seen that the user and merchant satisfaction values are 79.2 and 82.0 for the MR model, 88.4 and 91.5 for the SVM-MR model, and 95.3 and 97.8 for the BPNN-MR model. In conclusion, the BPNN-MR model is able to obtain higher user satisfaction and merchant satisfaction.

Merchant and user satisfaction with different prediction models.

5 Conclusions

To achieve diversity in fabric design, this study innovatively constructed a BPNN-MR fabric brightness prediction model by combining light and shadow reconstruction theory, MR prediction model, and BPNN. The results indicate that the BPNN-MR model controls the fabric brightness prediction error within 3° through light and shadow layering technology. The

-

Funding information: This study was supported by the 2021 Higher Education Teaching Reform Project of Henan Province “Research and Practice of Personalized Skill Talent Training Mode based on Skills Competition” (Project No.: 2021SJGLX736).

-

Author contributions: The author has accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The author states no conflict of interest.

-

Data availability statement: All data generated or analysed during this study are included in this article and supplementary material.

References

[1] Wang P, Li Q, Shen D, Liu Y. High-dimensional factor regression for heterogeneous subpopulations. Stat Sin. 2023;33(1):27–53. 10.5705/ss.202020.0145.Search in Google Scholar PubMed PubMed Central

[2] Banik A, Dutta S, Bandyopadhyay TK, Biswal SK. Prediction of maximum permeate flux (%) of disc membrane using response surface methodology (RSM). Can J Civ Eng. 2019;46(4):299–307. 10.1139/cjce-2018-0007.Search in Google Scholar

[3] Yoon D, Kim K, Dong HC, Lee M, Im J, Cho D, et al. Development of model output statistics based on the least absolute shrinkage and selection operator regression for forecasting next-day maximum temperature in South Korea. Q J R Meteorol Soc. 2022;148(745):1929–44. 10.1002/qj.4286.Search in Google Scholar

[4] Sun X, Cinar A, Yu X, Rashid M, Liu J. Kernel-regularized latent-variable regression models for dynamic processes. Ind & Eng Chem Res. 2022;61(17):5914–26. 10.1021/acs.iecr.1c04739.Search in Google Scholar

[5] Farias-Basulto GA, Reyes-Figueroa P, Ulbrich C, Szyszka B, Schlatmann R, Klenk R. Validation of a multiple linear regression model for CIGSSe photovoltaic module performance and Pmpp prediction. Sol Energy. 2020;208(9):859–65. 10.1016/j.solener.2020.08.040.Search in Google Scholar

[6] Dharma F, Shabrina S, Noviana A, Tahir M, Hendrastuty N, Wahyono W. Prediction of Indonesian inflation rate using regression model based on genetic algorithms. J Online Inform. 2020;5(1):45–52. 10.15575/JOIN.V5I1.532.Search in Google Scholar

[7] Loftis C, Yuan K, Zhao Y, Hu M, Hu JJ. Lattice thermal conductivity prediction using symbolic regression and machine learning. J Phys Chem A. 2020;125(1):435–50. 10.1021/ACS.JPCA.0C08103.Search in Google Scholar

[8] Wang J, Qu H. Analysis of regression prediction model of competitive sports based on SVM and artificial intelligence. J Intell Fuzzy Syst. 2020;39(4):5859–69.10.3233/JIFS-189061Search in Google Scholar

[9] Bing DU, Duan Y, Zhang H, Tao X, Yue W, Cong RU. Collaborative image compression and classification with multi-task learning for visual Internet of Things. Chin J Aeronaut. 2022;35(5):390–9.10.1016/j.cja.2021.10.003Search in Google Scholar

[10] Yuan Q, Yao LF, Tang JW, Ma ZW, Mou JY, Wen XR, et al. Rapid discrimination and ratio quantification of mixed antibiotics in aqueous solution through integrative analysis of SERS spectra via CNN combined with NN-EN model. J Adv Res. 2025;69:61–74. 10.1016/j.jare.2024.03.016.Search in Google Scholar PubMed PubMed Central

[11] Yeoh PSQ, Lai KW, Goh SL, Hasikin K, Wu X, Li P. Transfer learning-assisted 3D deep learning models for knee osteoarthritis detection: Data from the osteoarthritis initiative. Front Bioeng Biotechnol. 2023;11(1):10. 10.3389/fbioe.2023.1164655.Search in Google Scholar PubMed PubMed Central

[12] Deng XQ, Chen BL, Luo WQ, Luo D. Universal image steganalysis based on convolutional neural network with global covariance pooling. J Computer Sci Technol. 2022;37(5):1134–45. 10.1007/s11390-021-0572-0.Search in Google Scholar

[13] Teoh JR, Hasikin K, Lai KW, Wu X, Li C. Enhancing early breast cancer diagnosis through automated microcalcification detection using an optimized ensemble deep learning framework. PeerJ Computer Sci. 2024;10:e2082. 10.7717/peerj-cs.2082.Search in Google Scholar PubMed PubMed Central

[14] Cao H, Cui R, Liu W, Ma T, Zhang Z, Shen C, et al. Dual mass MEMS gyroscope temperature drift compensation based on TFPF-MEA-BP algorithm. Sens Rev Sens Rev. 2021;41(2):162–75. 10.1108/SR-09-2020-0205.Search in Google Scholar

[15] Guo Y, Mustafaoglu Z, Koundal D. Spam detection using bidirectional transformers and machine learning classifier algorithms. J Comput Cognit Eng. 2022;2(1):5–9.10.47852/bonviewJCCE2202192Search in Google Scholar

[16] Debebe E, Birhan T, Shitahun Y, Belay M, Adelahu N. Effect of jacquard structures on the tensile strength property of weft knitted fabrics. J Des Text. 2024;3(1):30–45.Search in Google Scholar

[17] He W, Song B, Zhang N, Xiang J, Pan R. Modeling and realization of image-based garment texture transfer. Vis Computer. 2024;40(9):6063–79. 10.1007/s00371-023-03153-w.Search in Google Scholar

[18] Xu KL, Guo J. A new test for multiple predictive regression. J Financ Econom. 2024;22(1):119–56.10.1093/jjfinec/nbac030Search in Google Scholar

[19] Wang Q, Xi H, Deng F, Cheng M, Buja G. Design and analysis of genetic algorithm and BP neural network based PID control for boost converter applied in renewable power generations. IET Renew Power Gener. 2022;16(7):1336–44. 10.1049/rpg2.12320.Search in Google Scholar

[20] Meng S, Pan R, Gao W, Yan B, Peng Y. Automatic recognition of woven fabric structural parameters: A review. Artif Intell Rev. 2022;55(8):6345–87. 10.1007/s10462-022-10156-x.Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China

- Nonlinear comprehensive evaluation method based on information entropy and discrimination optimization

- Application of numerical calculation methods in stability analysis of pile foundation under complex foundation conditions

- Research on the contribution of shale gas development and utilization in Sichuan Province to carbon peak based on the PSA process

- Characteristics of tight oil reservoirs and their impact on seepage flow from a nonlinear engineering perspective

- Nonlinear deformation decomposition and mode identification of plane structures via orthogonal theory

- Numerical simulation of damage mechanism in rock with cracks impacted by self-excited pulsed jet based on SPH-FEM coupling method: The perspective of nonlinear engineering and materials science

- Cross-scale modeling and collaborative optimization of ethanol-catalyzed coupling to produce C4 olefins: Nonlinear modeling and collaborative optimization strategies

- Unequal width T-node stress concentration factor analysis of stiffened rectangular steel pipe concrete

- Special Issue: Advances in Nonlinear Dynamics and Control

- Development of a cognitive blood glucose–insulin control strategy design for a nonlinear diabetic patient model

- Big data-based optimized model of building design in the context of rural revitalization

- Multi-UAV assisted air-to-ground data collection for ground sensors with unknown positions

- Design of urban and rural elderly care public areas integrating person-environment fit theory

- Application of lossless signal transmission technology in piano timbre recognition

- Application of improved GA in optimizing rural tourism routes

- Architectural animation generation system based on AL-GAN algorithm

- Advanced sentiment analysis in online shopping: Implementing LSTM models analyzing E-commerce user sentiments

- Intelligent recommendation algorithm for piano tracks based on the CNN model

- Visualization of large-scale user association feature data based on a nonlinear dimensionality reduction method

- Low-carbon economic optimization of microgrid clusters based on an energy interaction operation strategy

- Optimization effect of video data extraction and search based on Faster-RCNN hybrid model on intelligent information systems

- Construction of image segmentation system combining TC and swarm intelligence algorithm

- Particle swarm optimization and fuzzy C-means clustering algorithm for the adhesive layer defect detection

- Optimization of student learning status by instructional intervention decision-making techniques incorporating reinforcement learning

- Fuzzy model-based stabilization control and state estimation of nonlinear systems

- Optimization of distribution network scheduling based on BA and photovoltaic uncertainty

- Tai Chi movement segmentation and recognition on the grounds of multi-sensor data fusion and the DBSCAN algorithm

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part III

- Generalized numerical RKM method for solving sixth-order fractional partial differential equations

Articles in the same Issue

- Research Articles

- Generalized (ψ,φ)-contraction to investigate Volterra integral inclusions and fractal fractional PDEs in super-metric space with numerical experiments

- Solitons in ultrasound imaging: Exploring applications and enhancements via the Westervelt equation

- Stochastic improved Simpson for solving nonlinear fractional-order systems using product integration rules

- Exploring dynamical features like bifurcation assessment, sensitivity visualization, and solitary wave solutions of the integrable Akbota equation

- Research on surface defect detection method and optimization of paper-plastic composite bag based on improved combined segmentation algorithm

- Impact the sulphur content in Iraqi crude oil on the mechanical properties and corrosion behaviour of carbon steel in various types of API 5L pipelines and ASTM 106 grade B

- Unravelling quiescent optical solitons: An exploration of the complex Ginzburg–Landau equation with nonlinear chromatic dispersion and self-phase modulation

- Perturbation-iteration approach for fractional-order logistic differential equations

- Variational formulations for the Euler and Navier–Stokes systems in fluid mechanics and related models

- Rotor response to unbalanced load and system performance considering variable bearing profile

- DeepFowl: Disease prediction from chicken excreta images using deep learning

- Channel flow of Ellis fluid due to cilia motion

- A case study of fractional-order varicella virus model to nonlinear dynamics strategy for control and prevalence

- Multi-point estimation weldment recognition and estimation of pose with data-driven robotics design

- Analysis of Hall current and nonuniform heating effects on magneto-convection between vertically aligned plates under the influence of electric and magnetic fields

- A comparative study on residual power series method and differential transform method through the time-fractional telegraph equation

- Insights from the nonlinear Schrödinger–Hirota equation with chromatic dispersion: Dynamics in fiber–optic communication

- Mathematical analysis of Jeffrey ferrofluid on stretching surface with the Darcy–Forchheimer model

- Exploring the interaction between lump, stripe and double-stripe, and periodic wave solutions of the Konopelchenko–Dubrovsky–Kaup–Kupershmidt system

- Computational investigation of tuberculosis and HIV/AIDS co-infection in fuzzy environment

- Signature verification by geometry and image processing

- Theoretical and numerical approach for quantifying sensitivity to system parameters of nonlinear systems

- Chaotic behaviors, stability, and solitary wave propagations of M-fractional LWE equation in magneto-electro-elastic circular rod

- Dynamic analysis and optimization of syphilis spread: Simulations, integrating treatment and public health interventions

- Visco-thermoelastic rectangular plate under uniform loading: A study of deflection

- Threshold dynamics and optimal control of an epidemiological smoking model

- Numerical computational model for an unsteady hybrid nanofluid flow in a porous medium past an MHD rotating sheet

- Regression prediction model of fabric brightness based on light and shadow reconstruction of layered images

- Dynamics and prevention of gemini virus infection in red chili crops studied with generalized fractional operator: Analysis and modeling

- Qualitative analysis on existence and stability of nonlinear fractional dynamic equations on time scales

- Fractional-order super-twisting sliding mode active disturbance rejection control for electro-hydraulic position servo systems

- Analytical exploration and parametric insights into optical solitons in magneto-optic waveguides: Advances in nonlinear dynamics for applied sciences

- Bifurcation dynamics and optical soliton structures in the nonlinear Schrödinger–Bopp–Podolsky system

- Review Article

- Haar wavelet collocation method for existence and numerical solutions of fourth-order integro-differential equations with bounded coefficients

- Special Issue: Nonlinear Analysis and Design of Communication Networks for IoT Applications - Part II

- Silicon-based all-optical wavelength converter for on-chip optical interconnection

- Research on a path-tracking control system of unmanned rollers based on an optimization algorithm and real-time feedback

- Analysis of the sports action recognition model based on the LSTM recurrent neural network

- Industrial robot trajectory error compensation based on enhanced transfer convolutional neural networks

- Research on IoT network performance prediction model of power grid warehouse based on nonlinear GA-BP neural network

- Interactive recommendation of social network communication between cities based on GNN and user preferences

- Application of improved P-BEM in time varying channel prediction in 5G high-speed mobile communication system

- Construction of a BIM smart building collaborative design model combining the Internet of Things

- Optimizing malicious website prediction: An advanced XGBoost-based machine learning model

- Economic operation analysis of the power grid combining communication network and distributed optimization algorithm

- Sports video temporal action detection technology based on an improved MSST algorithm

- Internet of things data security and privacy protection based on improved federated learning

- Enterprise power emission reduction technology based on the LSTM–SVM model

- Construction of multi-style face models based on artistic image generation algorithms

- Research and application of interactive digital twin monitoring system for photovoltaic power station based on global perception

- Special Issue: Decision and Control in Nonlinear Systems - Part II

- Animation video frame prediction based on ConvGRU fine-grained synthesis flow

- Application of GGNN inference propagation model for martial art intensity evaluation

- Benefit evaluation of building energy-saving renovation projects based on BWM weighting method

- Deep neural network application in real-time economic dispatch and frequency control of microgrids

- Real-time force/position control of soft growing robots: A data-driven model predictive approach

- Mechanical product design and manufacturing system based on CNN and server optimization algorithm

- Application of finite element analysis in the formal analysis of ancient architectural plaque section

- Research on territorial spatial planning based on data mining and geographic information visualization

- Fault diagnosis of agricultural sprinkler irrigation machinery equipment based on machine vision

- Closure technology of large span steel truss arch bridge with temporarily fixed edge supports

- Intelligent accounting question-answering robot based on a large language model and knowledge graph

- Analysis of manufacturing and retailer blockchain decision based on resource recyclability

- Flexible manufacturing workshop mechanical processing and product scheduling algorithm based on MES

- Exploration of indoor environment perception and design model based on virtual reality technology

- Tennis automatic ball-picking robot based on image object detection and positioning technology

- A new CNN deep learning model for computer-intelligent color matching

- Design of AR-based general computer technology experiment demonstration platform

- Indoor environment monitoring method based on the fusion of audio recognition and video patrol features

- Health condition prediction method of the computer numerical control machine tool parts by ensembling digital twins and improved LSTM networks

- Establishment of a green degree evaluation model for wall materials based on lifecycle

- Quantitative evaluation of college music teaching pronunciation based on nonlinear feature extraction

- Multi-index nonlinear robust virtual synchronous generator control method for microgrid inverters

- Manufacturing engineering production line scheduling management technology integrating availability constraints and heuristic rules

- Analysis of digital intelligent financial audit system based on improved BiLSTM neural network

- Attention community discovery model applied to complex network information analysis

- A neural collaborative filtering recommendation algorithm based on attention mechanism and contrastive learning

- Rehabilitation training method for motor dysfunction based on video stream matching

- Research on façade design for cold-region buildings based on artificial neural networks and parametric modeling techniques

- Intelligent implementation of muscle strain identification algorithm in Mi health exercise induced waist muscle strain

- Optimization design of urban rainwater and flood drainage system based on SWMM

- Improved GA for construction progress and cost management in construction projects

- Evaluation and prediction of SVM parameters in engineering cost based on random forest hybrid optimization

- Museum intelligent warning system based on wireless data module

- Optimization design and research of mechatronics based on torque motor control algorithm

- Special Issue: Nonlinear Engineering’s significance in Materials Science

- Experimental research on the degradation of chemical industrial wastewater by combined hydrodynamic cavitation based on nonlinear dynamic model

- Study on low-cycle fatigue life of nickel-based superalloy GH4586 at various temperatures

- Some results of solutions to neutral stochastic functional operator-differential equations

- Ultrasonic cavitation did not occur in high-pressure CO2 liquid

- Research on the performance of a novel type of cemented filler material for coal mine opening and filling

- Testing of recycled fine aggregate concrete’s mechanical properties using recycled fine aggregate concrete and research on technology for highway construction

- A modified fuzzy TOPSIS approach for the condition assessment of existing bridges

- Nonlinear structural and vibration analysis of straddle monorail pantograph under random excitations

- Achieving high efficiency and stability in blue OLEDs: Role of wide-gap hosts and emitter interactions

- Construction of teaching quality evaluation model of online dance teaching course based on improved PSO-BPNN

- Enhanced electrical conductivity and electromagnetic shielding properties of multi-component polymer/graphite nanocomposites prepared by solid-state shear milling

- Optimization of thermal characteristics of buried composite phase-change energy storage walls based on nonlinear engineering methods

- A higher-performance big data-based movie recommendation system

- Nonlinear impact of minimum wage on labor employment in China

- Nonlinear comprehensive evaluation method based on information entropy and discrimination optimization

- Application of numerical calculation methods in stability analysis of pile foundation under complex foundation conditions

- Research on the contribution of shale gas development and utilization in Sichuan Province to carbon peak based on the PSA process

- Characteristics of tight oil reservoirs and their impact on seepage flow from a nonlinear engineering perspective

- Nonlinear deformation decomposition and mode identification of plane structures via orthogonal theory

- Numerical simulation of damage mechanism in rock with cracks impacted by self-excited pulsed jet based on SPH-FEM coupling method: The perspective of nonlinear engineering and materials science

- Cross-scale modeling and collaborative optimization of ethanol-catalyzed coupling to produce C4 olefins: Nonlinear modeling and collaborative optimization strategies

- Unequal width T-node stress concentration factor analysis of stiffened rectangular steel pipe concrete

- Special Issue: Advances in Nonlinear Dynamics and Control

- Development of a cognitive blood glucose–insulin control strategy design for a nonlinear diabetic patient model

- Big data-based optimized model of building design in the context of rural revitalization

- Multi-UAV assisted air-to-ground data collection for ground sensors with unknown positions

- Design of urban and rural elderly care public areas integrating person-environment fit theory

- Application of lossless signal transmission technology in piano timbre recognition

- Application of improved GA in optimizing rural tourism routes

- Architectural animation generation system based on AL-GAN algorithm

- Advanced sentiment analysis in online shopping: Implementing LSTM models analyzing E-commerce user sentiments

- Intelligent recommendation algorithm for piano tracks based on the CNN model

- Visualization of large-scale user association feature data based on a nonlinear dimensionality reduction method

- Low-carbon economic optimization of microgrid clusters based on an energy interaction operation strategy

- Optimization effect of video data extraction and search based on Faster-RCNN hybrid model on intelligent information systems

- Construction of image segmentation system combining TC and swarm intelligence algorithm

- Particle swarm optimization and fuzzy C-means clustering algorithm for the adhesive layer defect detection

- Optimization of student learning status by instructional intervention decision-making techniques incorporating reinforcement learning

- Fuzzy model-based stabilization control and state estimation of nonlinear systems

- Optimization of distribution network scheduling based on BA and photovoltaic uncertainty

- Tai Chi movement segmentation and recognition on the grounds of multi-sensor data fusion and the DBSCAN algorithm

- Special Issue: Dynamic Engineering and Control Methods for the Nonlinear Systems - Part III

- Generalized numerical RKM method for solving sixth-order fractional partial differential equations