Abstract

Progress in jet grouting technology has been focused on the cutting-edge observer of jets, which aims to generate large columns of jet grouting and increase the activity of construction sites. Since jet grouting techniques vary from conventional grouting methods to modern techniques, they can be used in a variety of soil types and their application areas are expanding quickly. So, grouting methods have become very popular methods for subsoil strengthening. This article includes finding the physical and mechanical properties of the soil of the AL-Rashdia site, using a single-jet grouting machine and a steel model to test concrete piles and jet piles, and a double-jet grouting machine to compare the results obtained from laboratory model of one-dimensional jet grouting column pile with those of a one-dimensional concrete pile. The comparison showed that the settlement of the jet pile was smaller than that of the concrete pile and the bearing load was higher with jet columns giving a high bearing capacity comparable with the concrete pile. Shen’s method is more adequate to find the ultimate bearing load and the settlement for this load. Also, the ultimate pile ratio was 115.63% for the jet column, and the ultimate pile ratio for the concrete column was 123.49%. The compressive strength of the core sample of jet columns was large which improved the bearing capacity of the foundation.

1 Introduction

Engineering construction sites have been restricted due to large and rapid urbanization. So, different construction operations have been shifted to problematic soil sites such as excavation casting areas, filler ground, marine soils, and swamp areas. Loss and very loss soils, soft soils, soils near beaches, loess soils, and dune soils are considered problematic soils. As is well known in foundation engineering, the load coming from superstructures is transferred to the ground by shallow or deep foundations. If all solutions cannot support the soil or do not possess the desired capacity, the soil must be improved to be suitable to support the structure.

The improvement of soils by different methods was one of the solutions. The improvement may be done by mixing the soil with a suitable material like cement, bentonite, or nanomaterial; Choobbasti et al. [1] studied the effect of different ratios of cement and nanomaterial added to the sand to improve the engineering properties of sandy soils including compaction, soil dry density, and shear strength. Materials like Palm Oil Fuel Ash and Ground Granulated Blast Furnace Slag [2] are used to improve beat soil, especially physicochemical, physical, and mechanical properties. To improve the shear strength of peat soils and stabilize them [3] sodium hydroxide was added by using different percentages. Also, Ali and Yousuf [4] used deep compaction, preloading, deep mixing, and grouting with three ratios of cement grout (0.1:0.9, 0.8:0.2, and 0.7:0.3) water–cement ratio and fly ash as replacement material with percentages (10, 25, and 40%). The shear strength parameter and the volume of the routed zone increased.

With the development of improvement techniques and technology, grouting techniques may be divided into different types. One of these techniques is a jet grouting technique, which entails injecting a grout material with pressure into an otherwise inaccessible but interconnected pore or empty area of which neither the configuration nor the volume is known. The grout can be cementitious, resinous, or a solution of chemical combination. In the 1960s, this technique was used by Farmer and Attewell with a high-speed jet to cut the rocks [5]. This idea inspired a Japanese group to use it to improve soil and after that began to spread in the United States of America, Canada, Europe, Italy, United Kingdom, Germany, and worldwide [6,7]. This technique began to develop until now. Lunardi [8] gave details about using the jet grout technique as a retaining structure of buildings in Milan and using the technique in tunnel construction. Durgunoglu et al. [9] investigated the use of jet grouting technology to limit the possibility of liquefaction due to an earthquake that happened in Turkey. Onyelowe et al. [10] in his research studied different criteria to determine the optimum stabilization technique for soft clay soil; one of those criteria was the jet grouting technique. Hamidi et al. [11] studied the use of three types of jet grouting to build impermeable barriers to block water flow while working in different boreholes and compared the results with finite element analysis to verify stresses and deformation. Debost et al. [12] in Sydney used a single jet plus monitor, jet grout, and moderate energy, with sand and gravel soil within a site heavily polluted with dangerous compounds caused by old gas. Moayed et al. [13] detailed the usage of the jet technique at a site in the southern part of Iran. They listed the variables that determine how jet grouting works, including the elastic modulus of the jet grouting column, the model of soil behavior, specific gravity, and compressive strength of the jet grouting column. The column’s diameter was determined by quality control, and the numerical solution using the Plaxis software and Mohr–Coulomb model was compared to the diameter obtained by using shear wave testing and pile integrity tests. Skutnik et al. [14] in this research combined deep mixing with jet grouting techniques to solve the complex geotechnical problems especially building barriers to reduce the hydraulic conductivity of subsoil. Al-Khadaar and Ahmed [15] discussed research studies around the world related to different types of jet grouting techniques. For the double-jet grouting technique, Chuaqui et al. [16] used double fluid jet grouting machine to improve sites sensitive to environmental and cohesionless soil to construct a sewer system with a tunnel 5 km long in Canada. The unconfined compressive strength of grouted soil ranged from 4.6 to 9.7 MPa after 28 days, the permeability was reduced, and the diameter of the grouted column increased. In Bangkok, Iwakubo et al. [17] successfully used large diameter jet grouted piles in Blue Line Extension Project to reduce uplift and piping due to the second stiff layer, increase the hydraulic conductivity, and optimize the time and cost of the constructed site. Zhao et al. [18] proposed a new explicit model to predict column diameter suitable for three types of jet grouting techniques by using a huge database from around the world. They compared the results of the model with those obtained from an empirical method by using cross-validation method.

2 Experimental study

The soil in this study was taken from the Al-Rashdia site North East of Baghdad near the Tigris River as shown in Figure 1. The soil was poorly graded sand where the classification of SP ranged from 2.38 to 0.075 mm, as shown in Figure 2 depending upon grain size analysis [19]. Tables 1 and 2 show the physical, chemical, and mechanical properties obtained from laboratory tests carried out according to ASTM standards.

Al-Rashdia site North east of Baghdad, Iraq.

Grain size distribution of the soil used in the tests.

Physical and mechanical properties of the soil used in the present model

| [21] Index properties and test name | Value | Specification |

|---|---|---|

| Grain size analysis | ASTM D422-2007 | |

| D 10 (m) | 0.158 × 10−3 | |

| D 30 (m) | 0.192 × 10−3 | |

| D 50 (m) | 0.238 × 10−3 | |

| D 60 (m) | 0.265 × 10−3 | |

| Coefficient of uniformity (C u) | 1.678 | |

| Coefficient of curvature (C c) | 0.876 | |

| Soil classification | SP | USCS |

| Specific gravity (G s) [22] | 2.67 | ASTM D854-2000 |

| Dry unit weights | ||

| Maximum dry unit weight (kN/m3) [23] | 14.88 | ASTM D4253-2006 |

| Minimum dry unit weight (kN/m3) [23] | 13.77 | ASTM D4254-2006 [24] |

| Dry unit weight used (kN/m3) | 14.32 | |

| Relative density (% Dr) | 51.49 | |

| Maximum void ratio | 0.939 | |

| Minimum void ratio | 0.794 | |

| Mechanical test [25] | ||

| Apparent cohesion (kN/m2) | 8 | ASTM D3080-2004 |

| φ° | 34.56 | ASTM D3080-2004 |

Chemical properties of the soil used in the present model

| Index properties and test name | Value | Specification |

|---|---|---|

| Chemical tests | BS 1377-3 or ASTM | |

| % So4 | 0.328 | ASTM C1580-14 |

| % So3 | 0.273 | BS 1377-3 [26] |

| % Cl | 0.032 | BS 1377-3 |

| % Organic | 0.144 | ASTM D2974-20 [27] |

| PH | 9.71 | ASTM D4972-19 [28] |

2.1 Geotechnical limitation

The development of geotechnical understanding returns to the physical model. The need for a full-scale model is less because of the time required to construct the model and the increase in cost. So, the use of a small scale is preferred because it allows for conducting more tests and investigating more variables, yet it requires less cost and saves time [20].

The small-scale model has the ability to reduce or eliminate the errors, give much more rapid results, and limit boundary effects.

Scaling factors that were used are listed in Table 3 which shows the general expressions for various modeling variables and also indicates the ratio of model to prototype values which is equal to (1/20). In this study, the diameter of the pile was found to depend upon the diameter of the drilling and routing rod that is used in the grouting device. That means the steel rod affects the diameter of the jet column, and since the diameter of the jet pile injected was found to be 0.0572 m, the scale factor was (1/20). The length of the jet column was found to depend upon the length of the steel rod and the length or thickness of the soil layer. During the penetration of the rod to the desired depth and after raising it the formation of the jet column is completed and the column is cured for 28 days. Drilling the soil and extracting the jet column for different trials and measuring the length indicated that the average length is equal to 0.45 m.

Scaling factors [29]

| Quantity | Laboratory |

|---|---|

| Length | 1/n |

| Mass density | 1 |

| Stiffness | 1/n α |

| Stress | 1/n |

| Strain | 1/n 1−α |

| Displacement | 1/n 2−α |

| Permeability | 1 |

| Time | n 2−α |

n = scaling factor.

From experiments, it was found that (α) can be set to 0.5 for sandy soils while equal to 1.0 for clayey soil. In all models, it was assumed that the same material has been used in the prototype and model so the scale factor for density is equal to unity (1.0).

2.2 Setup test

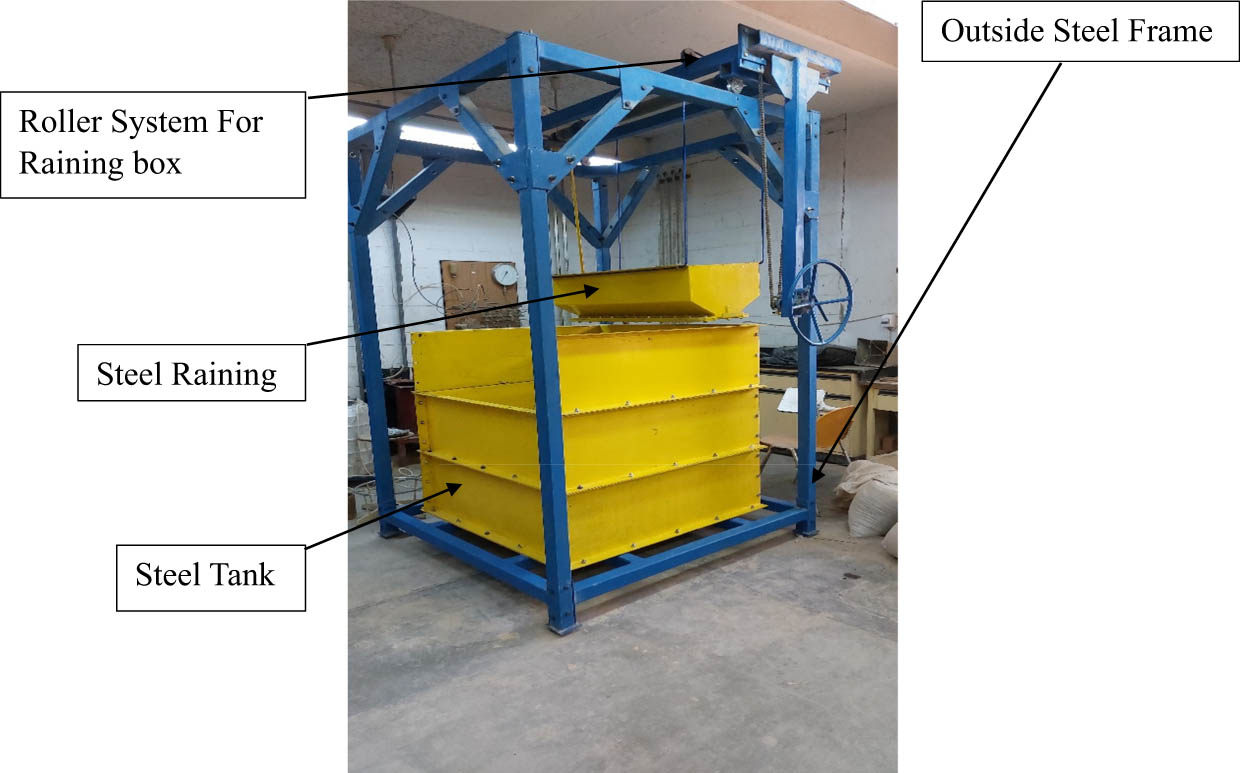

The model setup used in the research consisted of a container made of steel plates 0.005 m. The steel tank consisted of three parts the dimensions of each one of them are 1.2 m × 1.2 m × 0.4 m, and the dimensions of the outer frame are 1.66 m × 1.66 m × 2.60 m.

The apparatus utilized to fill the tank with soil consists of two parts, a shaft gear and a raining box; the apparatus is made of steel 0.850 m × 0.205 m × 1.100 m in dimensions and ended with an inclined funnel used as a hopper above the tank to dispense the substance at various heights. Two rollers were provided to improve the horizontal movement of the raining system box as shown in Figure 3.

Model and raining tank.

2.3 Manufactured jet grouting machine

A small number of researchers have the skills to create a jet grouting physical model in the laboratory over the past 30 years. Ji [30] utilized a single jet grout with low pressure and flow rate while Nikbakhtan [31] utilized a triple jet grout with low pressure and flow rate. Also, few researchers studied the physical, mechanical, and thermal properties of jet grouting processes; instead, most research studies dealt with numerical methods such as neural networks or other programs.

Due to the fast growth of technology, industrialization, and urbanization in different sections, the availability of good sites and soil conditions are decreasing with time. The primary goal of jet grouting is to enhance the soil’s mechanical, thermal, and physical qualities, which consequently reduce settlement, deformation, and permeability of the ground. Besides that, jet grout may be considered inexpensive and requires low cost in comparison with other techniques. Furthermore, jet grout can be used for small projects as well as large ones. The researchers developed a laboratory jet grouting device and necessary parts to work as a double jet grout because the device manufactured by (Al-Tamimi, 2023) was for single jet grout only. Figure 4 shows the parts of the Jet Grouting Machine Manufactured by the researchers.

The developed jet grouting machine.

The grouting device was made by a steel frame composed of a hollow square tube section to hold the parts of the machine. The device was provided with four steel wheels about 0.10 m in diameter as shown in Figure 5. The parts of the device are divided into:

Rotation and drilling motor: consists of two components; the first one is a three-phase motor attached to a gearbox, a screw thread diameter steel shaft with square thread, and a big steel nut welded to a small box that was inserted into a larger box installed on the setup frame. The interior box slipped at 0.2 mpm speed. The second one includes a one-horsepower three-phase variable speed gearbox that rotates clockwise and counterclockwise.

A 1.5 m platform (like a cantilever) to support the rotation motor and grouting rode.

Grouting system consists of the following:

A rod to inject grout and drilling, a hollow 0.025 m diameter steel pipe 0.6 m long;

A 0.003 m diameter nozzle to inject grout;

A 0.003 m diameter air nozzle; and

A Steel drill kit.

A motor for lifting and lowering the platform.

An electric control board which includes all the accessories such as conductors, overloads switches, selectors, emergency switches, and all necessary fittings to control and operate the motors and grouting pumps.

A 2 bar compressor with a control gage to pump air through the nozzle of the injection rod.

A grout system consists of an external cylindrical tank 0.475 m in diameter and a mixing motor to prevent the slurry from separation and falling into the bottom of the tank. A steel cylindrical tube was used to connect the tank with the grouting pump and the injection and drilling rod. All these connections were controlled by gate valves. At the bottom of the tank, there a gate valve with a steel tube was provided to clean the system from slurry after finishing the injection.

A 20–25 kPa pressure gauge to control the injection pressure.

A water pump to help in drilling the soil before injection.

Jet grouting machine with modulation from single to double grout.

2.4 Jet grouting column procedure and properties

The steps followed to perform grouting injection are as follows:

activating the drilling rod by rotating clockwise and downwards,

starting the grouted drill by activating the compressor to drill the soil in the model at the specific place and drill down to the desired point,

activating the pump from the control board to start the injection operation by drilling counterclockwise and begin to drill, inject the slurry, and move upward until reaching the surface of the hole,

during the grouting process, the spoil of grout that exists on the surface is removed to avoid heaving the surface.

carrying on the process of drilling and injecting until the whole grouting columns needed in the model are cast, and

curing the columns by covering the grouted space with wetted canvas cover.

When curing time was over, the jet machine was used to make a number of jet pile trails as shown in Figure 6 to be used in mechanical testing to determine the properties of jet piles. Laboratory testing was then conducted by using the hydraulic jake and pile load test to check the ability of the jet pile to resist the vertical force and know the bearing capacity and the value of settlement of the jet pile. Mechanical and physical characteristics of jet grouting columns are shown in Tables 4 and 5 (Figure 7).

Jet grout column from trial tests.

Tensile strength of jet grouting columns using a theoretical approach [36]

| Sample No. | Uniaxial compressive strength (kN/m2) [37] | Spilt tensile strength | ||||||

|---|---|---|---|---|---|---|---|---|

| ACI committee 318 [38] | CEB-FIB (1991) [39] | [40] | [41] | [42] | [43] | Average tensile strength (kN/m2) | ||

| T = 0.56 × q 0.5 | T = 0.3 × q 0.66 | T = 0.272 × q 0.71 | T = 0.294 × q 0.69 | T = 0.387 × q 0.63 | T = 0.249 × q 0.772 | |||

| 1 | 14,900 | 2.167 | 1.785 | 1.852 | 1.613 | 2.123 | 2.004 | 1,923 |

| 2 | 11,200 | 1.874 | 1.478 | 1.512 | 1.347 | 1.774 | 1.608 | 1,599 |

| 3 | 12,700 | 1.996 | 1.606 | 1.653 | 1.458 | 1.920 | 1.772 | 1,734 |

| 4 | 1,411,000 | 21.036 | 35.960 | 46.853 | 28.350 | 37.318 | 67.242 | 39,460 |

| 5 | 16,000 | 2.24 | 1.870 | 1.948 | 1.687 | 2.220 | 2.118 | 2014 |

| 293,160 | ||||||||

Physical properties of the grouting column [36]

| No. | W/C | UCS (kN/m2) | Ts (kN/m2) | Cohesion (kN/m2) | Angle of friction | Density (kN/m3) | Elasticity modulus (kN/m2) |

|---|---|---|---|---|---|---|---|

| 1 | 1:1 | 14,900 | 1,923 | 2,680 | 50 | 22.814 | 539,049 |

| 2 | 1:1 | 11,200 | 1,599 | 2,090 | 49 | 16.264 | 412,062 |

| 3 | 1:1 | 12,700 | 1,734 | 2,346 | 49 | 19.837 | 1,049,205 |

| 4 | 1:1 | 1,411,000 | 39,460 | 117,981 | 71 | 21.863 | 15,490,250 |

| 5 | 1:1 | 1,600 | 2,014 | 2,838 | 51 | 16.867 | 992,879 |

| 293,160 | 9,346 | 25,587 | 54 | 19.529 | 3,696,689 |

Uniaxial compression test for the jet column parts.

2.5 Concrete pile model

A traditional pipe pile model 0.5 m long was used in this research with an outside diameter of 0.059 m and an inside diameter of 0.0572 m, as shown in Figures 8 and 9. The pile was made of concrete.

Pile concrete mold.

Concrete pile.

The mixes were prepared and tested according to PRC A.211.1-91 [32]; the mixture consisted of cement, sand, gravel, water, superplasticizer, and polyvinyl alcohol (PVA). The percentage of So3 was not more than 0.5% according to IQS No. 45 [33]. Tap water was used, 2% of superplasticizer was added, and 1% of PVA solution was added. PVA is a synthetic polymer that is soluble in water and biodegradable which is found in granular and powdered form.

The cement used in the mix was sulfate-resisting cement C3A which is recommended for foundation works, pilling works, and coastal protective works such as sea walls, buildings near seacoast, and bridge piers. This type of cement provides maximum resistance to chloride and increases the workability and pumpability.

The compressive test was performed according to ASTM [34], after mixing and casting the concrete in cylindrical molds using the shaking table. After curing the average strength was 33,700 kN/m2 as shown in Table 6.

Compressive strength of concrete

| Sample No. | Compressive strength (kN/m2) | Average compressive strength (kN/m2) |

|---|---|---|

| No. 1 | 35,395 | 33,700 |

| No. 2 | 31,455 | |

| No. 3 | 34,250 |

3 Finite element model

Dassault Systems SIMULIA’s finite element analysis program, called ABAQUS, [35] is considered complicated in comparison with other available finite element programs because it can be used to model different materials like metals, rubbers, polymers, composites, reinforced concrete, rocks, and soils. For linear and nonlinear simulations, ABAQUS supplies a wide range of capabilities. In this research, ABAQUS software 2019–2021 was used to simulate the experimental work data with the theoretical data generated by the software. The element used was a brick element of type C8D8R, hexagonal linear, reduced integration or eight-node linear brick, reduced integration, hourglass control with surface-to-surface interaction between soil and pile, and this choice was utilized for all parts of pile, soil, and cap pile. Figure 10 shows the assembly of parts (soil and pile), and Figure 11 shows the failure that happened in the model after the application of load. The comparison in this article depends upon using a single jet grout column injected in the laboratory model box whose dimensions were 1.2 m × 1.2 m × 0.8 m. A double-jet grouting machine with a model of a concrete pile was used as a board pile in the model. The properties of the jet pile and concrete pile are shown in Table 7. The model was subjected to axial loading by mechanical jack and using a load cell and LVDT to measure the load applied and the change in displacement in order to draw the load settlement curve for laboratory tests. The results were compared with those obtained from the finite element program, ABAQUS. Figure 12 shows the results of the first test for the jet grout column in the model as compared with those obtained from program one while Figure 13 shows the results of the concrete column.

Finite element assembly of single pile in ABAQUS program.

Finite element sample after applying the load to failure.

Properties of the material needed for the program

| Property | Jet column | Concrete column | Soil |

|---|---|---|---|

| Unit weight (kN/m3) | 19.529 | 24 | 14.32 |

| Diameter (m) | 0.0572 | 0.0572 | — |

| Length (m) | 0.45 | 0.45 | — |

| Modulus of elasticity (kN/m2) | 70 × 106 | 30 × 106 | 30,000 |

| Poisson’s ratio ν | 0.2 | 0.2 | 0.3 |

| Angle of internal friction φ | — | — | 34.56 |

| Cohesion (kN/m2) | — | — | 8 |

Comparison between jet pile laboratory and jet pile from program.

Comparison between concrete pile from laboratory test and concrete pile from the program.

4 Results and discussion

The results of this research were divided into two parts namely experimental results to find the mechanical and physical properties of the jet column from trial column and concrete pile, and the physical and mechanical properties of core samples. The second part deals with the theoretical results obtained by using ABAQUS program to compare the injected jet column in the model with the concrete board pile.

The experimental properties of the jet column were obtained by using uniaxial compressive strength from Table 4. The strength varied from 11,200 to 1,411,000 kN/m2; tensile strength varied from 1,599 to 39,460 kN/m2; modulus of elasticity varied from 412,000 to15,490,250 kN/m2; while the compressive strength of concrete pile varied from 31,460 to 35,395 MPa. The cohesion, which is better-called adhesion since it is between different materials (cement and soil), increased in grouted soil from 2,090 to 117,980 kN/m2.

In this research, when using a single jet grouting column subjected to axial load by mechanical jack till failure, the values of the load applied were taken from a load cell and LVDT (Linear Variable Differential Transformer), and the value of linear movement as displacement at the surface of the pile top was found by using Shen’s method [44] which utilizes a relationship between load and settlement. After using different methods to find settlement and the ultimate load applied, it was found that Shen’s method is more appropriate for sandy soils and gives results close to actual values. Figure 12 shows the variation of settlement with the load applied on jet grouting columns both from laboratory tests and from the program. Figure 13 shows the variation of settlement with the load applied on concrete columns both from laboratory tests and from the program. The difference between the two values is small, as shown in Table 8, thus using ABAQUS program to analyze other groups of piles is recommended. The results proved that the water–cement ratio binding solution reacts better with sand, and at the end of curing time gave higher strength of the column grout piles in comparison with concrete piles, thus tending to reduce the settlement of jet grout column as approved by AKSOY Eİ [45]. Figures 14 and 15 show the displacement along the interaction point between soil and jet pile, and soil and concrete pile. Figures 16 and 17 show the effect of stresses along the interaction between soil and jet pile and soil and concrete pile. These figures agree with the situation that jet piles may be treated like board piles, and the stresses and displacement appear near the end of the pile. Due to jet pressure the stress at the end is high because of the disturbance that happened due to the compressor. The effect of double grout causes an increase in the diameter of the jet pile in comparison with a single jet [46].

Detail of Settlement and bearing capacity from curves due to Shen’s method

| Type of pile | Settlement (m) | Ultimate pile capacity (kN) | Ultimate pile ratio % (P laboratory/P program) |

|---|---|---|---|

| Jet pile from laboratory | 0.0000093 | 1.85 | 115.63 |

| Jet pile from program | 0.000007 | 1.6 | |

| Concrete Pile from laboratory | 0.0325 | 1.63 | 123.49 |

| Concrete Pile from program | 0.035 | 1.32 |

Relationship between displacement along the interaction between soil and jet pile.

Relation between soil displacement and concrete pile along the interaction.

Stress along the interaction between soil and jet pile.

Stress along the interaction between soil and concrete pile.

Table 8 shows the values of the final settlement and the bearing load for the jet pile and concrete pile as obtained from laboratory tests and the program. Therefore, a good agreement between the results obtained from the program and the laboratory can be obtained by using Shen’s method [44], which is an accurate method to find the bearing capacity in sand.

5 Conclusions

The present research focused on the development of a grouting machine to work as a double grout or fluid system. The machine was then used to conduct laboratory experiments on both concrete piles and jet piles. The settlement and bearing load from both laboratory tests and the results from ABAQUS program were compared for both concrete pile and jet pile on the same scale. The compressive strength of different samples of jet columns and the values of cohesion and angle of internal friction from the samples were found. It was concluded that:

Jet grouting columns increased uniaxial compressive strength from 11,200 to 1,411,000 kN/m2, which is considered high in sand.

The value of settlement of the jet column is so small or negligible as compared to the value of settlement of the concrete pile which was 0.0000093 m for the jet pile while in the concrete pile was 0.0325 m. This means the jet pile columns are more effective in supporting soil.

The adhesion of treated soil by jet grouting increased as compared to the normal soil without grout.

The value of the modulus of elasticity increased in the jet pile column core from 412,000 to 154,902,500 kN/m2 in comparison with the soil without treatment.

The diameter of the jet grout column may be controlled by the diameter of the steel jet rod of the grouting machine.

Shen’s method is considered the best method to find the load from load–settlement curve especially for jet grouting columns.

Generated stress under the pile due to jetting action was 11% greater than the stresses generated under the concrete pile.

The ultimate pile ratio for the jet column was 115.63% while the ratio for the concrete pile was 123.49%.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: Most data sets were generated and analyzed in this study are comprised in this submitted manuscript. The other data sets are available upon reasonable request from the corresponding author with the attached information.

References

[1] Choobbasti AJ, Vafaei A, Kutanaei SS. Mechanical properties of sandy soil improved with cement and nanosilica. Open Eng. 2015;5(1). 10.1515/eng-2015-0011.Suche in Google Scholar

[2] Amaludin AE, Asrah H, Mohamad HM, bin Amaludin HZ, bin Amaludin NA. Physicochemical and microstructural characterization of Klias Peat, Lumadan POFA, and GGBFS for geopolymer based soil stabilization. HighTech Innov J. 2023;4(2):327–48. 10.28991/HIJ-2023-04-02-07.Suche in Google Scholar

[3] Mohamad HM, Sharudin MFI, Amaludin AE, Zakaria SNF. Characteristic and physicochemical properties of peat soil stabilized with sodium hydroxide (NaOH). Civ Eng J. 2023;9(9):2221–32. 10.28991/CEJ-2023-09-09-09.Suche in Google Scholar

[4] Ali HA, Yousuf YM. Improvement of shear strength of sandy soil by cement grout with fly ash. J Eng. 2016;22(12):16–34. 10.31026/j.eng.2016.12.02.Suche in Google Scholar

[5] Farmer I, Attewell P, editors. Rock penetration by high velocity water jet: A review of the general problem and an experimental study. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts. UK: Elsevier; 1965. 10.1016/0148-9062(65)90010-0.Suche in Google Scholar

[6] Guatteri G, Kauschinger JL, Doria AC, Perry EB. Advances in the construction and design of jet grouting methods in South America. USA: International Conference on Case Histories in Geotechnical Engineering; 1988.Suche in Google Scholar

[7] Fang Y-S, Liao J-J, Lin T-K. Mechanical properties of jet grouted soilcrete. Q J Eng Geol. 1994;27(3):257–65. 10.1144/GSL.QJEGH.1994.027.P3.06.Suche in Google Scholar

[8] Lunardi P. Ground improvement by means of jet-grouting. Proc Inst Civ Eng-Ground Improvement. 1997;1(2):65–85. 10.1680/gi.1997.010201.Suche in Google Scholar

[9] Durgunoglu HT, Chinchelli M, Ikiz S, Emrem C, Hurley T, Catalbas F. Soil improvement with jet-grout columns: A case study from the 1999 Kocaeli earthquake. USA: International Conference on Case Histories in Geotechnical Engineering; 2004.Suche in Google Scholar

[10] Onyelowe KC, Ebid AM, Mahdi HA, Baldovino JA. Selecting the safety and cost optimized geo-stabilization technique for soft clay slopes. Civ Eng J. 2023;9(2):453–64. 10.28991/CEJ-2023-09-02-015.Suche in Google Scholar

[11] Hamidi B, Krzeminski M, Berthier D, Vincent P, Yates M. The application of jet grouting for the construction of Sydney International Airport runway end safety area. Aust Geomech. 2010;45(4):21.Suche in Google Scholar

[12] Debost C, Mathieu F, Yates M. Jet grouting within contaminated land fill. Grouting. 2017;2017:135–44.10.1061/9780784480809.014Suche in Google Scholar

[13] Moayed RZ, Azini E. Evaluation of numerical modeling of jet grouting design using in situ loading test. Int J Geotech Geol Eng. 2020;14(6):125–30.Suche in Google Scholar

[14] Skutnik Z, Bajda M, Lech M. The selection of sealing technologies of the subsoil and hydrotechnical structures and quality assurance. Open Eng. 2019;9(1):420–7. 10.1515/eng-2019-0050.Suche in Google Scholar

[15] Al-Khadaar RM, Ahmed MD. Review of jet grouting practice around the world. J Eng. 2023;29(7):48–70. 10.31026/j.eng.2023.07.04.Suche in Google Scholar

[16] Chuaqui M, Hu F, Gurpersaud N, Lees D. A case study: Two-fluid jet grouting for tunneling application-soil stabilization and permeability reduction. Grouting Deep Mixing. 2012;2012:868–79.10.1061/9780784412350.0070Suche in Google Scholar

[17] Iwakubo T, Takeshima H, Venture CJ. Evaluation of large diameter jet grouting technique used for tunnel construction in Bangkok. Tokyo, Japan: International Symposium; 2020.Suche in Google Scholar

[18] Zhao L-S, Qi X, Tan F, Chen Y. A new prediction model of the jet grouting column diameter for three jet grouting systems. Comput Geotech. 2023;163:105753. 10.1016/j.compgeo.2023.105753.Suche in Google Scholar

[19] ASTM D. Standard test method for particle-size analysis of soils. USA:; 2007.Suche in Google Scholar

[20] Wood DM. Geotechnical modelling. Tokyo: CRC Press; 2017.Suche in Google Scholar

[21] ASTM. C1580-15: Standard Test Method for Water-Soluble Sulfate in Soil. American Society for Testing and Materials International (ASTM) West …; 2014.Suche in Google Scholar

[22] Soil, A. C. D.-o. and Rock. Standard test methods for specific gravity of soil solids by water pycnometer. USA: ASTM international; 2006.Suche in Google Scholar

[23] Soil, A. C. D.-o. and Rock. Standard test methods for maximum index density and unit weight of soils using a vibratory table. USA: ASTM international; 2006.Suche in Google Scholar

[24] Soil ACD-o, Rock. Standard test methods for minimum index density and unit weight of soils and calculation of relative density. USA: ASTM international; 2006.Suche in Google Scholar

[25] ASTM, D. “Standard test method for direct shear test of soils under consolidated drained conditions”; 2011 D3080/D3080M 3(9).Suche in Google Scholar

[26] BSI. Methods of test for soils for civil engineering purposes Part 3: Chemical and electro-chemical tests. BS1377-3: 1990. UK: British Standards Institution London; 1975.Suche in Google Scholar

[27] ASTM D, editor. Standard test methods for determining the water (moisture) content, ash content, and organic material of peat and other organic soils. USA: ASTM West Conshohocken, PA: 2020.Suche in Google Scholar

[28] International A. ASTM D4972-19, Standard Test Methods for pH of Soils Internet. USA: ASTM International West Conshohocken, PA: 2019.Suche in Google Scholar

[29] Wood DM. Geotechnical modelling. Tokyo: CRC Press; 2003.10.4324/9780203477977Suche in Google Scholar

[30] Ji H. Physical modelling of jet grouting process. UK: University of Cambridge; 2008.Suche in Google Scholar

[31] Nikbakhtan B. Development of Thermal-Insulating Soilcrete using Laboratory Jet Grouting Setup. Canada; 2015.Suche in Google Scholar

[32] PRC A. 211.1-91. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. Farmington Hills, MI, USA: American Concrete Institute; 2009. p. 1–38.Suche in Google Scholar

[33] I.S.N. 45 “Iraqi Specification No. (45) at 1984 for aggregates from natural sources for concrete and building construction”; 1984.Suche in Google Scholar

[34] ASTM A. C39/C39M-21. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. West ConshohockenPA, USA: ASTM International; 2021.Suche in Google Scholar

[35] Simulia DS. ABAQUS 6.13 User’s manual. Dassault Syst Providence RI. 2013;305:306.Suche in Google Scholar

[36] ASTM, I. “Standard practices for preparing rock core specimens and determining dimensional and shape tolerances.” Designation; 2001. D 4543.Suche in Google Scholar

[37] Tolerances S. Standard Test Method for Unconfined Compressive Strength of Intact Rock Core. USA; 2021.Suche in Google Scholar

[38] Standard A, editor. Building code requirements for structural concrete (ACI 318-11). American Concrete Institute; 2011.Suche in Google Scholar

[39] CEB-FIB Model Code for Concrete Structures Evaluation of the Time Dependent Behaviour of Concrete, Bulletin d’Information No. 199, Comite European du Be´ton/Fe´de´ration Internationale de la Precontrainte, Lausanne; 1991. p. 201.Suche in Google Scholar

[40] Carino NJ, Lew H, editors. Re-examination of the relation between splitting tensile and compressive strength of normal weight concrete. Journal Proceedings; 1982.Suche in Google Scholar

[41] Oluokun FA, Burdette EG, Deatherage JH. Splitting tensile strength and compressive strength relationships at early ages. Mater J. 1991;88(2):115–21. 10.14359/1859.Suche in Google Scholar

[42] Arιoglu N, Girgin ZC, Arιoglu E. Evaluation of ratio between splitting tensile strength and compressive strength for concretes up to 120 MPa and its application in strength criterion. ACI Mater J. 2006;103(1):18–24. 10.14359/15123.Suche in Google Scholar

[43] Lavanya G, Jegan J. Evaluation of relationship between split tensile strength and compressive strength for geopolymer concrete of varying grades and molarity. Int J Appl Eng Res. 2015;10(15):35523–7.Suche in Google Scholar

[44] Mishra A, Sawant V, Deshmukh V. Prediction of pile capacity of socketed piles using different approaches. Geotech Geol Eng. 2019;37:5219–30. 10.1007/s10706-019-00976-0.Suche in Google Scholar

[45] AKSOY Eİ. Mechanical Properties of Jet Grouting For Two Different Soil Types And Different Pressures. Turkey: Hasan Kalyoncu University; 2020.Suche in Google Scholar

[46] Al-Tamimi SH. Mitigation of Seismic Effects in Layered Sandy Soil under Raft Foundation using Jet Grouted Columns. Iraq: Baghdad; 2023.Suche in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Methodology of automated quality management

- Influence of vibratory conveyor design parameters on the trough motion and the self-synchronization of inertial vibrators

- Application of finite element method in industrial design, example of an electric motorcycle design project

- Correlative evaluation of the corrosion resilience and passivation properties of zinc and aluminum alloys in neutral chloride and acid-chloride solutions

- Will COVID “encourage” B2B and data exchange engineering in logistic firms?

- Influence of unsupported sleepers on flange climb derailment of two freight wagons

- A hybrid detection algorithm for 5G OTFS waveform for 64 and 256 QAM with Rayleigh and Rician channels

- Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy

- Exploring the potential of ammonia and hydrogen as alternative fuels for transportation

- Impact of insulation on energy consumption and CO2 emissions in high-rise commercial buildings at various climate zones

- Advanced autopilot design with extremum-seeking control for aircraft control

- Adaptive multidimensional trust-based recommendation model for peer to peer applications

- Effects of CFRP sheets on the flexural behavior of high-strength concrete beam

- Enhancing urban sustainability through industrial synergy: A multidisciplinary framework for integrating sustainable industrial practices within urban settings – The case of Hamadan industrial city

- Advanced vibrant controller results of an energetic framework structure

- Application of the Taguchi method and RSM for process parameter optimization in AWSJ machining of CFRP composite-based orthopedic implants

- Improved correlation of soil modulus with SPT N values

- Technologies for high-temperature batch annealing of grain-oriented electrical steel: An overview

- Assessing the need for the adoption of digitalization in Indian small and medium enterprises

- A non-ideal hybridization issue for vertical TFET-based dielectric-modulated biosensor

- Optimizing data retrieval for enhanced data integrity verification in cloud environments

- Performance analysis of nonlinear crosstalk of WDM systems using modulation schemes criteria

- Nonlinear finite-element analysis of RC beams with various opening near supports

- Thermal analysis of Fe3O4–Cu/water over a cone: a fractional Maxwell model

- Radial–axial runner blade design using the coordinate slice technique

- Theoretical and experimental comparison between straight and curved continuous box girders

- Effect of the reinforcement ratio on the mechanical behaviour of textile-reinforced concrete composite: Experiment and numerical modeling

- Experimental and numerical investigation on composite beam–column joint connection behavior using different types of connection schemes

- Enhanced performance and robustness in anti-lock brake systems using barrier function-based integral sliding mode control

- Evaluation of the creep strength of samples produced by fused deposition modeling

- A combined feedforward-feedback controller design for nonlinear systems

- Effect of adjacent structures on footing settlement for different multi-building arrangements

- Analyzing the impact of curved tracks on wheel flange thickness reduction in railway systems

- Review Articles

- Mechanical and smart properties of cement nanocomposites containing nanomaterials: A brief review

- Applications of nanotechnology and nanoproduction techniques

- Relationship between indoor environmental quality and guests’ comfort and satisfaction at green hotels: A comprehensive review

- Communication

- Techniques to mitigate the admission of radon inside buildings

- Erratum

- Erratum to “Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy”

- Special Issue: AESMT-3 - Part II

- Integrated fuzzy logic and multicriteria decision model methods for selecting suitable sites for wastewater treatment plant: A case study in the center of Basrah, Iraq

- Physical and mechanical response of porous metals composites with nano-natural additives

- Special Issue: AESMT-4 - Part II

- New recycling method of lubricant oil and the effect on the viscosity and viscous shear as an environmentally friendly

- Identify the effect of Fe2O3 nanoparticles on mechanical and microstructural characteristics of aluminum matrix composite produced by powder metallurgy technique

- Static behavior of piled raft foundation in clay

- Ultra-low-power CMOS ring oscillator with minimum power consumption of 2.9 pW using low-voltage biasing technique

- Using ANN for well type identifying and increasing production from Sa’di formation of Halfaya oil field – Iraq

- Optimizing the performance of concrete tiles using nano-papyrus and carbon fibers

- Special Issue: AESMT-5 - Part II

- Comparative the effect of distribution transformer coil shape on electromagnetic forces and their distribution using the FEM

- The complex of Weyl module in free characteristic in the event of a partition (7,5,3)

- Restrained captive domination number

- Experimental study of improving hot mix asphalt reinforced with carbon fibers

- Asphalt binder modified with recycled tyre rubber

- Thermal performance of radiant floor cooling with phase change material for energy-efficient buildings

- Surveying the prediction of risks in cryptocurrency investments using recurrent neural networks

- A deep reinforcement learning framework to modify LQR for an active vibration control applied to 2D building models

- Evaluation of mechanically stabilized earth retaining walls for different soil–structure interaction methods: A review

- Assessment of heat transfer in a triangular duct with different configurations of ribs using computational fluid dynamics

- Sulfate removal from wastewater by using waste material as an adsorbent

- Experimental investigation on strengthening lap joints subjected to bending in glulam timber beams using CFRP sheets

- A study of the vibrations of a rotor bearing suspended by a hybrid spring system of shape memory alloys

- Stability analysis of Hub dam under rapid drawdown

- Developing ANFIS-FMEA model for assessment and prioritization of potential trouble factors in Iraqi building projects

- Numerical and experimental comparison study of piled raft foundation

- Effect of asphalt modified with waste engine oil on the durability properties of hot asphalt mixtures with reclaimed asphalt pavement

- Hydraulic model for flood inundation in Diyala River Basin using HEC-RAS, PMP, and neural network

- Numerical study on discharge capacity of piano key side weir with various ratios of the crest length to the width

- The optimal allocation of thyristor-controlled series compensators for enhancement HVAC transmission lines Iraqi super grid by using seeker optimization algorithm

- Numerical and experimental study of the impact on aerodynamic characteristics of the NACA0012 airfoil

- Effect of nano-TiO2 on physical and rheological properties of asphalt cement

- Performance evolution of novel palm leaf powder used for enhancing hot mix asphalt

- Performance analysis, evaluation, and improvement of selected unsignalized intersection using SIDRA software – Case study

- Flexural behavior of RC beams externally reinforced with CFRP composites using various strategies

- Influence of fiber types on the properties of the artificial cold-bonded lightweight aggregates

- Experimental investigation of RC beams strengthened with externally bonded BFRP composites

- Generalized RKM methods for solving fifth-order quasi-linear fractional partial differential equation

- An experimental and numerical study investigating sediment transport position in the bed of sewer pipes in Karbala

- Role of individual component failure in the performance of a 1-out-of-3 cold standby system: A Markov model approach

- Implementation for the cases (5, 4) and (5, 4)/(2, 0)

- Center group actions and related concepts

- Experimental investigation of the effect of horizontal construction joints on the behavior of deep beams

- Deletion of a vertex in even sum domination

- Deep learning techniques in concrete powder mix designing

- Effect of loading type in concrete deep beam with strut reinforcement

- Studying the effect of using CFRP warping on strength of husk rice concrete columns

- Parametric analysis of the influence of climatic factors on the formation of traditional buildings in the city of Al Najaf

- Suitability location for landfill using a fuzzy-GIS model: A case study in Hillah, Iraq

- Hybrid approach for cost estimation of sustainable building projects using artificial neural networks

- Assessment of indirect tensile stress and tensile–strength ratio and creep compliance in HMA mixes with micro-silica and PMB

- Density functional theory to study stopping power of proton in water, lung, bladder, and intestine

- A review of single flow, flow boiling, and coating microchannel studies

- Effect of GFRP bar length on the flexural behavior of hybrid concrete beams strengthened with NSM bars

- Exploring the impact of parameters on flow boiling heat transfer in microchannels and coated microtubes: A comprehensive review

- Crumb rubber modification for enhanced rutting resistance in asphalt mixtures

- Special Issue: AESMT-6

- Design of a new sorting colors system based on PLC, TIA portal, and factory I/O programs

- Forecasting empirical formula for suspended sediment load prediction at upstream of Al-Kufa barrage, Kufa City, Iraq

- Optimization and characterization of sustainable geopolymer mortars based on palygorskite clay, water glass, and sodium hydroxide

- Sediment transport modelling upstream of Al Kufa Barrage

- Study of energy loss, range, and stopping time for proton in germanium and copper materials

- Effect of internal and external recycle ratios on the nutrient removal efficiency of anaerobic/anoxic/oxic (VIP) wastewater treatment plant

- Enhancing structural behaviour of polypropylene fibre concrete columns longitudinally reinforced with fibreglass bars

- Sustainable road paving: Enhancing concrete paver blocks with zeolite-enhanced cement

- Evaluation of the operational performance of Karbala waste water treatment plant under variable flow using GPS-X model

- Design and simulation of photonic crystal fiber for highly sensitive chemical sensing applications

- Optimization and design of a new column sequencing for crude oil distillation at Basrah refinery

- Inductive 3D numerical modelling of the tibia bone using MRI to examine von Mises stress and overall deformation

- An image encryption method based on modified elliptic curve Diffie-Hellman key exchange protocol and Hill Cipher

- Experimental investigation of generating superheated steam using a parabolic dish with a cylindrical cavity receiver: A case study

- Effect of surface roughness on the interface behavior of clayey soils

- Investigated of the optical properties for SiO2 by using Lorentz model

- Measurements of induced vibrations due to steel pipe pile driving in Al-Fao soil: Effect of partial end closure

- Experimental and numerical studies of ballistic resistance of hybrid sandwich composite body armor

- Evaluation of clay layer presence on shallow foundation settlement in dry sand under an earthquake

- Optimal design of mechanical performances of asphalt mixtures comprising nano-clay additives

- Advancing seismic performance: Isolators, TMDs, and multi-level strategies in reinforced concrete buildings

- Predicted evaporation in Basrah using artificial neural networks

- Energy management system for a small town to enhance quality of life

- Numerical study on entropy minimization in pipes with helical airfoil and CuO nanoparticle integration

- Equations and methodologies of inlet drainage system discharge coefficients: A review

- Thermal buckling analysis for hybrid and composite laminated plate by using new displacement function

- Investigation into the mechanical and thermal properties of lightweight mortar using commercial beads or recycled expanded polystyrene

- Experimental and theoretical analysis of single-jet column and concrete column using double-jet grouting technique applied at Al-Rashdia site

- The impact of incorporating waste materials on the mechanical and physical characteristics of tile adhesive materials

- Seismic resilience: Innovations in structural engineering for earthquake-prone areas

- Automatic human identification using fingerprint images based on Gabor filter and SIFT features fusion

- Performance of GRKM-method for solving classes of ordinary and partial differential equations of sixth-orders

- Visible light-boosted photodegradation activity of Ag–AgVO3/Zn0.5Mn0.5Fe2O4 supported heterojunctions for effective degradation of organic contaminates

- Production of sustainable concrete with treated cement kiln dust and iron slag waste aggregate

- Key effects on the structural behavior of fiber-reinforced lightweight concrete-ribbed slabs: A review

- A comparative analysis of the energy dissipation efficiency of various piano key weir types

- Special Issue: Transport 2022 - Part II

- Variability in road surface temperature in urban road network – A case study making use of mobile measurements

- Special Issue: BCEE5-2023

- Evaluation of reclaimed asphalt mixtures rejuvenated with waste engine oil to resist rutting deformation

- Assessment of potential resistance to moisture damage and fatigue cracks of asphalt mixture modified with ground granulated blast furnace slag

- Investigating seismic response in adjacent structures: A study on the impact of buildings’ orientation and distance considering soil–structure interaction

- Improvement of porosity of mortar using polyethylene glycol pre-polymer-impregnated mortar

- Three-dimensional analysis of steel beam-column bolted connections

- Assessment of agricultural drought in Iraq employing Landsat and MODIS imagery

- Performance evaluation of grouted porous asphalt concrete

- Optimization of local modified metakaolin-based geopolymer concrete by Taguchi method

- Effect of waste tire products on some characteristics of roller-compacted concrete

- Studying the lateral displacement of retaining wall supporting sandy soil under dynamic loads

- Seismic performance evaluation of concrete buttress dram (Dynamic linear analysis)

- Behavior of soil reinforced with micropiles

- Possibility of production high strength lightweight concrete containing organic waste aggregate and recycled steel fibers

- An investigation of self-sensing and mechanical properties of smart engineered cementitious composites reinforced with functional materials

- Forecasting changes in precipitation and temperatures of a regional watershed in Northern Iraq using LARS-WG model

- Experimental investigation of dynamic soil properties for modeling energy-absorbing layers

- Numerical investigation of the effect of longitudinal steel reinforcement ratio on the ductility of concrete beams

- An experimental study on the tensile properties of reinforced asphalt pavement

- Self-sensing behavior of hot asphalt mixture with steel fiber-based additive

- Behavior of ultra-high-performance concrete deep beams reinforced by basalt fibers

- Optimizing asphalt binder performance with various PET types

- Investigation of the hydraulic characteristics and homogeneity of the microstructure of the air voids in the sustainable rigid pavement

- Enhanced biogas production from municipal solid waste via digestion with cow manure: A case study

- Special Issue: AESMT-7 - Part I

- Preparation and investigation of cobalt nanoparticles by laser ablation: Structure, linear, and nonlinear optical properties

- Seismic analysis of RC building with plan irregularity in Baghdad/Iraq to obtain the optimal behavior

- The effect of urban environment on large-scale path loss model’s main parameters for mmWave 5G mobile network in Iraq

- Formatting a questionnaire for the quality control of river bank roads

- Vibration suppression of smart composite beam using model predictive controller

- Machine learning-based compressive strength estimation in nanomaterial-modified lightweight concrete

- In-depth analysis of critical factors affecting Iraqi construction projects performance

- Behavior of container berth structure under the influence of environmental and operational loads

- Energy absorption and impact response of ballistic resistance laminate

- Effect of water-absorbent polymer balls in internal curing on punching shear behavior of bubble slabs

- Effect of surface roughness on interface shear strength parameters of sandy soils

- Evaluating the interaction for embedded H-steel section in normal concrete under monotonic and repeated loads

- Estimation of the settlement of pile head using ANN and multivariate linear regression based on the results of load transfer method

- Enhancing communication: Deep learning for Arabic sign language translation

- A review of recent studies of both heat pipe and evaporative cooling in passive heat recovery

- Effect of nano-silica on the mechanical properties of LWC

- An experimental study of some mechanical properties and absorption for polymer-modified cement mortar modified with superplasticizer

- Digital beamforming enhancement with LSTM-based deep learning for millimeter wave transmission

- Developing an efficient planning process for heritage buildings maintenance in Iraq

- Design and optimization of two-stage controller for three-phase multi-converter/multi-machine electric vehicle

- Evaluation of microstructure and mechanical properties of Al1050/Al2O3/Gr composite processed by forming operation ECAP

- Calculations of mass stopping power and range of protons in organic compounds (CH3OH, CH2O, and CO2) at energy range of 0.01–1,000 MeV

- Investigation of in vitro behavior of composite coating hydroxyapatite-nano silver on 316L stainless steel substrate by electrophoretic technic for biomedical tools

- A review: Enhancing tribological properties of journal bearings composite materials

- Improvements in the randomness and security of digital currency using the photon sponge hash function through Maiorana–McFarland S-box replacement

- Design a new scheme for image security using a deep learning technique of hierarchical parameters

- Special Issue: ICES 2023

- Comparative geotechnical analysis for ultimate bearing capacity of precast concrete piles using cone resistance measurements

- Visualizing sustainable rainwater harvesting: A case study of Karbala Province

- Geogrid reinforcement for improving bearing capacity and stability of square foundations

- Evaluation of the effluent concentrations of Karbala wastewater treatment plant using reliability analysis

- Adsorbent made with inexpensive, local resources

- Effect of drain pipes on seepage and slope stability through a zoned earth dam

- Sediment accumulation in an 8 inch sewer pipe for a sample of various particles obtained from the streets of Karbala city, Iraq

- Special Issue: IETAS 2024 - Part I

- Analyzing the impact of transfer learning on explanation accuracy in deep learning-based ECG recognition systems

- Effect of scale factor on the dynamic response of frame foundations

- Improving multi-object detection and tracking with deep learning, DeepSORT, and frame cancellation techniques

- The impact of using prestressed CFRP bars on the development of flexural strength

- Assessment of surface hardness and impact strength of denture base resins reinforced with silver–titanium dioxide and silver–zirconium dioxide nanoparticles: In vitro study

- A data augmentation approach to enhance breast cancer detection using generative adversarial and artificial neural networks

- Modification of the 5D Lorenz chaotic map with fuzzy numbers for video encryption in cloud computing

- Special Issue: 51st KKBN - Part I

- Evaluation of static bending caused damage of glass-fiber composite structure using terahertz inspection

Artikel in diesem Heft

- Regular Articles

- Methodology of automated quality management

- Influence of vibratory conveyor design parameters on the trough motion and the self-synchronization of inertial vibrators

- Application of finite element method in industrial design, example of an electric motorcycle design project

- Correlative evaluation of the corrosion resilience and passivation properties of zinc and aluminum alloys in neutral chloride and acid-chloride solutions

- Will COVID “encourage” B2B and data exchange engineering in logistic firms?

- Influence of unsupported sleepers on flange climb derailment of two freight wagons

- A hybrid detection algorithm for 5G OTFS waveform for 64 and 256 QAM with Rayleigh and Rician channels

- Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy

- Exploring the potential of ammonia and hydrogen as alternative fuels for transportation

- Impact of insulation on energy consumption and CO2 emissions in high-rise commercial buildings at various climate zones

- Advanced autopilot design with extremum-seeking control for aircraft control

- Adaptive multidimensional trust-based recommendation model for peer to peer applications

- Effects of CFRP sheets on the flexural behavior of high-strength concrete beam

- Enhancing urban sustainability through industrial synergy: A multidisciplinary framework for integrating sustainable industrial practices within urban settings – The case of Hamadan industrial city

- Advanced vibrant controller results of an energetic framework structure

- Application of the Taguchi method and RSM for process parameter optimization in AWSJ machining of CFRP composite-based orthopedic implants

- Improved correlation of soil modulus with SPT N values

- Technologies for high-temperature batch annealing of grain-oriented electrical steel: An overview

- Assessing the need for the adoption of digitalization in Indian small and medium enterprises

- A non-ideal hybridization issue for vertical TFET-based dielectric-modulated biosensor

- Optimizing data retrieval for enhanced data integrity verification in cloud environments

- Performance analysis of nonlinear crosstalk of WDM systems using modulation schemes criteria

- Nonlinear finite-element analysis of RC beams with various opening near supports

- Thermal analysis of Fe3O4–Cu/water over a cone: a fractional Maxwell model

- Radial–axial runner blade design using the coordinate slice technique

- Theoretical and experimental comparison between straight and curved continuous box girders

- Effect of the reinforcement ratio on the mechanical behaviour of textile-reinforced concrete composite: Experiment and numerical modeling

- Experimental and numerical investigation on composite beam–column joint connection behavior using different types of connection schemes

- Enhanced performance and robustness in anti-lock brake systems using barrier function-based integral sliding mode control

- Evaluation of the creep strength of samples produced by fused deposition modeling

- A combined feedforward-feedback controller design for nonlinear systems

- Effect of adjacent structures on footing settlement for different multi-building arrangements

- Analyzing the impact of curved tracks on wheel flange thickness reduction in railway systems

- Review Articles

- Mechanical and smart properties of cement nanocomposites containing nanomaterials: A brief review

- Applications of nanotechnology and nanoproduction techniques

- Relationship between indoor environmental quality and guests’ comfort and satisfaction at green hotels: A comprehensive review

- Communication

- Techniques to mitigate the admission of radon inside buildings

- Erratum

- Erratum to “Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy”

- Special Issue: AESMT-3 - Part II

- Integrated fuzzy logic and multicriteria decision model methods for selecting suitable sites for wastewater treatment plant: A case study in the center of Basrah, Iraq

- Physical and mechanical response of porous metals composites with nano-natural additives

- Special Issue: AESMT-4 - Part II

- New recycling method of lubricant oil and the effect on the viscosity and viscous shear as an environmentally friendly

- Identify the effect of Fe2O3 nanoparticles on mechanical and microstructural characteristics of aluminum matrix composite produced by powder metallurgy technique

- Static behavior of piled raft foundation in clay

- Ultra-low-power CMOS ring oscillator with minimum power consumption of 2.9 pW using low-voltage biasing technique

- Using ANN for well type identifying and increasing production from Sa’di formation of Halfaya oil field – Iraq

- Optimizing the performance of concrete tiles using nano-papyrus and carbon fibers

- Special Issue: AESMT-5 - Part II

- Comparative the effect of distribution transformer coil shape on electromagnetic forces and their distribution using the FEM

- The complex of Weyl module in free characteristic in the event of a partition (7,5,3)

- Restrained captive domination number

- Experimental study of improving hot mix asphalt reinforced with carbon fibers

- Asphalt binder modified with recycled tyre rubber

- Thermal performance of radiant floor cooling with phase change material for energy-efficient buildings

- Surveying the prediction of risks in cryptocurrency investments using recurrent neural networks

- A deep reinforcement learning framework to modify LQR for an active vibration control applied to 2D building models

- Evaluation of mechanically stabilized earth retaining walls for different soil–structure interaction methods: A review

- Assessment of heat transfer in a triangular duct with different configurations of ribs using computational fluid dynamics

- Sulfate removal from wastewater by using waste material as an adsorbent

- Experimental investigation on strengthening lap joints subjected to bending in glulam timber beams using CFRP sheets

- A study of the vibrations of a rotor bearing suspended by a hybrid spring system of shape memory alloys

- Stability analysis of Hub dam under rapid drawdown

- Developing ANFIS-FMEA model for assessment and prioritization of potential trouble factors in Iraqi building projects

- Numerical and experimental comparison study of piled raft foundation

- Effect of asphalt modified with waste engine oil on the durability properties of hot asphalt mixtures with reclaimed asphalt pavement

- Hydraulic model for flood inundation in Diyala River Basin using HEC-RAS, PMP, and neural network

- Numerical study on discharge capacity of piano key side weir with various ratios of the crest length to the width

- The optimal allocation of thyristor-controlled series compensators for enhancement HVAC transmission lines Iraqi super grid by using seeker optimization algorithm

- Numerical and experimental study of the impact on aerodynamic characteristics of the NACA0012 airfoil

- Effect of nano-TiO2 on physical and rheological properties of asphalt cement

- Performance evolution of novel palm leaf powder used for enhancing hot mix asphalt

- Performance analysis, evaluation, and improvement of selected unsignalized intersection using SIDRA software – Case study

- Flexural behavior of RC beams externally reinforced with CFRP composites using various strategies

- Influence of fiber types on the properties of the artificial cold-bonded lightweight aggregates

- Experimental investigation of RC beams strengthened with externally bonded BFRP composites

- Generalized RKM methods for solving fifth-order quasi-linear fractional partial differential equation

- An experimental and numerical study investigating sediment transport position in the bed of sewer pipes in Karbala

- Role of individual component failure in the performance of a 1-out-of-3 cold standby system: A Markov model approach

- Implementation for the cases (5, 4) and (5, 4)/(2, 0)

- Center group actions and related concepts

- Experimental investigation of the effect of horizontal construction joints on the behavior of deep beams

- Deletion of a vertex in even sum domination

- Deep learning techniques in concrete powder mix designing

- Effect of loading type in concrete deep beam with strut reinforcement

- Studying the effect of using CFRP warping on strength of husk rice concrete columns

- Parametric analysis of the influence of climatic factors on the formation of traditional buildings in the city of Al Najaf

- Suitability location for landfill using a fuzzy-GIS model: A case study in Hillah, Iraq

- Hybrid approach for cost estimation of sustainable building projects using artificial neural networks

- Assessment of indirect tensile stress and tensile–strength ratio and creep compliance in HMA mixes with micro-silica and PMB

- Density functional theory to study stopping power of proton in water, lung, bladder, and intestine

- A review of single flow, flow boiling, and coating microchannel studies

- Effect of GFRP bar length on the flexural behavior of hybrid concrete beams strengthened with NSM bars

- Exploring the impact of parameters on flow boiling heat transfer in microchannels and coated microtubes: A comprehensive review

- Crumb rubber modification for enhanced rutting resistance in asphalt mixtures

- Special Issue: AESMT-6

- Design of a new sorting colors system based on PLC, TIA portal, and factory I/O programs

- Forecasting empirical formula for suspended sediment load prediction at upstream of Al-Kufa barrage, Kufa City, Iraq

- Optimization and characterization of sustainable geopolymer mortars based on palygorskite clay, water glass, and sodium hydroxide

- Sediment transport modelling upstream of Al Kufa Barrage

- Study of energy loss, range, and stopping time for proton in germanium and copper materials

- Effect of internal and external recycle ratios on the nutrient removal efficiency of anaerobic/anoxic/oxic (VIP) wastewater treatment plant

- Enhancing structural behaviour of polypropylene fibre concrete columns longitudinally reinforced with fibreglass bars

- Sustainable road paving: Enhancing concrete paver blocks with zeolite-enhanced cement

- Evaluation of the operational performance of Karbala waste water treatment plant under variable flow using GPS-X model

- Design and simulation of photonic crystal fiber for highly sensitive chemical sensing applications

- Optimization and design of a new column sequencing for crude oil distillation at Basrah refinery

- Inductive 3D numerical modelling of the tibia bone using MRI to examine von Mises stress and overall deformation

- An image encryption method based on modified elliptic curve Diffie-Hellman key exchange protocol and Hill Cipher

- Experimental investigation of generating superheated steam using a parabolic dish with a cylindrical cavity receiver: A case study

- Effect of surface roughness on the interface behavior of clayey soils

- Investigated of the optical properties for SiO2 by using Lorentz model

- Measurements of induced vibrations due to steel pipe pile driving in Al-Fao soil: Effect of partial end closure

- Experimental and numerical studies of ballistic resistance of hybrid sandwich composite body armor

- Evaluation of clay layer presence on shallow foundation settlement in dry sand under an earthquake

- Optimal design of mechanical performances of asphalt mixtures comprising nano-clay additives

- Advancing seismic performance: Isolators, TMDs, and multi-level strategies in reinforced concrete buildings

- Predicted evaporation in Basrah using artificial neural networks

- Energy management system for a small town to enhance quality of life

- Numerical study on entropy minimization in pipes with helical airfoil and CuO nanoparticle integration

- Equations and methodologies of inlet drainage system discharge coefficients: A review

- Thermal buckling analysis for hybrid and composite laminated plate by using new displacement function

- Investigation into the mechanical and thermal properties of lightweight mortar using commercial beads or recycled expanded polystyrene

- Experimental and theoretical analysis of single-jet column and concrete column using double-jet grouting technique applied at Al-Rashdia site

- The impact of incorporating waste materials on the mechanical and physical characteristics of tile adhesive materials

- Seismic resilience: Innovations in structural engineering for earthquake-prone areas

- Automatic human identification using fingerprint images based on Gabor filter and SIFT features fusion

- Performance of GRKM-method for solving classes of ordinary and partial differential equations of sixth-orders

- Visible light-boosted photodegradation activity of Ag–AgVO3/Zn0.5Mn0.5Fe2O4 supported heterojunctions for effective degradation of organic contaminates

- Production of sustainable concrete with treated cement kiln dust and iron slag waste aggregate

- Key effects on the structural behavior of fiber-reinforced lightweight concrete-ribbed slabs: A review

- A comparative analysis of the energy dissipation efficiency of various piano key weir types

- Special Issue: Transport 2022 - Part II

- Variability in road surface temperature in urban road network – A case study making use of mobile measurements

- Special Issue: BCEE5-2023

- Evaluation of reclaimed asphalt mixtures rejuvenated with waste engine oil to resist rutting deformation

- Assessment of potential resistance to moisture damage and fatigue cracks of asphalt mixture modified with ground granulated blast furnace slag

- Investigating seismic response in adjacent structures: A study on the impact of buildings’ orientation and distance considering soil–structure interaction

- Improvement of porosity of mortar using polyethylene glycol pre-polymer-impregnated mortar

- Three-dimensional analysis of steel beam-column bolted connections

- Assessment of agricultural drought in Iraq employing Landsat and MODIS imagery

- Performance evaluation of grouted porous asphalt concrete

- Optimization of local modified metakaolin-based geopolymer concrete by Taguchi method

- Effect of waste tire products on some characteristics of roller-compacted concrete

- Studying the lateral displacement of retaining wall supporting sandy soil under dynamic loads

- Seismic performance evaluation of concrete buttress dram (Dynamic linear analysis)

- Behavior of soil reinforced with micropiles

- Possibility of production high strength lightweight concrete containing organic waste aggregate and recycled steel fibers

- An investigation of self-sensing and mechanical properties of smart engineered cementitious composites reinforced with functional materials

- Forecasting changes in precipitation and temperatures of a regional watershed in Northern Iraq using LARS-WG model

- Experimental investigation of dynamic soil properties for modeling energy-absorbing layers

- Numerical investigation of the effect of longitudinal steel reinforcement ratio on the ductility of concrete beams

- An experimental study on the tensile properties of reinforced asphalt pavement

- Self-sensing behavior of hot asphalt mixture with steel fiber-based additive

- Behavior of ultra-high-performance concrete deep beams reinforced by basalt fibers

- Optimizing asphalt binder performance with various PET types

- Investigation of the hydraulic characteristics and homogeneity of the microstructure of the air voids in the sustainable rigid pavement

- Enhanced biogas production from municipal solid waste via digestion with cow manure: A case study

- Special Issue: AESMT-7 - Part I

- Preparation and investigation of cobalt nanoparticles by laser ablation: Structure, linear, and nonlinear optical properties

- Seismic analysis of RC building with plan irregularity in Baghdad/Iraq to obtain the optimal behavior

- The effect of urban environment on large-scale path loss model’s main parameters for mmWave 5G mobile network in Iraq

- Formatting a questionnaire for the quality control of river bank roads

- Vibration suppression of smart composite beam using model predictive controller

- Machine learning-based compressive strength estimation in nanomaterial-modified lightweight concrete

- In-depth analysis of critical factors affecting Iraqi construction projects performance

- Behavior of container berth structure under the influence of environmental and operational loads

- Energy absorption and impact response of ballistic resistance laminate

- Effect of water-absorbent polymer balls in internal curing on punching shear behavior of bubble slabs

- Effect of surface roughness on interface shear strength parameters of sandy soils

- Evaluating the interaction for embedded H-steel section in normal concrete under monotonic and repeated loads

- Estimation of the settlement of pile head using ANN and multivariate linear regression based on the results of load transfer method

- Enhancing communication: Deep learning for Arabic sign language translation

- A review of recent studies of both heat pipe and evaporative cooling in passive heat recovery

- Effect of nano-silica on the mechanical properties of LWC

- An experimental study of some mechanical properties and absorption for polymer-modified cement mortar modified with superplasticizer

- Digital beamforming enhancement with LSTM-based deep learning for millimeter wave transmission

- Developing an efficient planning process for heritage buildings maintenance in Iraq

- Design and optimization of two-stage controller for three-phase multi-converter/multi-machine electric vehicle

- Evaluation of microstructure and mechanical properties of Al1050/Al2O3/Gr composite processed by forming operation ECAP

- Calculations of mass stopping power and range of protons in organic compounds (CH3OH, CH2O, and CO2) at energy range of 0.01–1,000 MeV

- Investigation of in vitro behavior of composite coating hydroxyapatite-nano silver on 316L stainless steel substrate by electrophoretic technic for biomedical tools

- A review: Enhancing tribological properties of journal bearings composite materials

- Improvements in the randomness and security of digital currency using the photon sponge hash function through Maiorana–McFarland S-box replacement

- Design a new scheme for image security using a deep learning technique of hierarchical parameters

- Special Issue: ICES 2023

- Comparative geotechnical analysis for ultimate bearing capacity of precast concrete piles using cone resistance measurements

- Visualizing sustainable rainwater harvesting: A case study of Karbala Province

- Geogrid reinforcement for improving bearing capacity and stability of square foundations

- Evaluation of the effluent concentrations of Karbala wastewater treatment plant using reliability analysis

- Adsorbent made with inexpensive, local resources

- Effect of drain pipes on seepage and slope stability through a zoned earth dam

- Sediment accumulation in an 8 inch sewer pipe for a sample of various particles obtained from the streets of Karbala city, Iraq

- Special Issue: IETAS 2024 - Part I

- Analyzing the impact of transfer learning on explanation accuracy in deep learning-based ECG recognition systems

- Effect of scale factor on the dynamic response of frame foundations

- Improving multi-object detection and tracking with deep learning, DeepSORT, and frame cancellation techniques

- The impact of using prestressed CFRP bars on the development of flexural strength

- Assessment of surface hardness and impact strength of denture base resins reinforced with silver–titanium dioxide and silver–zirconium dioxide nanoparticles: In vitro study

- A data augmentation approach to enhance breast cancer detection using generative adversarial and artificial neural networks

- Modification of the 5D Lorenz chaotic map with fuzzy numbers for video encryption in cloud computing

- Special Issue: 51st KKBN - Part I

- Evaluation of static bending caused damage of glass-fiber composite structure using terahertz inspection