Technologies for high-temperature batch annealing of grain-oriented electrical steel: An overview

-

Oula M. H. Fatla

Abstract

The production of grain-oriented, electrical steel consists of a series of processes that lead to a product with superior magnetic properties used in transformers due to the low core loss. The unique properties are gained during the process of secondary recrystallization and abnormal grain growth. The abnormal grain growth occurs during a process of special thermal treatment with careful control over the heating rate, pressure, and type of gas used as atmospheric pressure during the process. The process of thermal treatment is known as high-temperature annealing. Investigating of developing the process hardware is crucially important to sustain energy-efficient processes and to maintain excellent final product properties. This research presents an overview of the technology of high-temperature coil annealing (HTCA) furnaces used at Cogent Power Orb, UK. The research focuses on some specific details of running, managing, and controlling the operation of the HTCA furnaces during the annealing process. The research provides energy analysis of the annealing process at Cogent Power Orb. Different factors were examined to identify the main factors that contribute to the high energy consumption. Actual data were collected from the annealing furnace control system. The raw data were processed and analyzed carefully to examine different factors, namely, steel charge weight, furnace on-time, and furnace heating elements. The study focused then on one specific factor, namely, annealing cycle time, and investigated further the way that this factor affects the process energy consumption. It was found that one of the main reasons for the long cycle duration and the high energy consumption is the failure of the heating elements during the cycle. The research discussed the area of improvements in the process hardware with a particular focus on the furnace design and the potential of introducing convection currents to overcome failure in the heating elements and thus reduce the process on time.

1 Introduction

Grain oriented (GO) is a special type of electrical steel produced by cold-rolling and annealing hot-rolled silicon steel sheets to meet commercial standards for thickness. This process involves subjecting the steel to a series of treatments, resulting in a product with improved magnetic properties and reduced energy loss. The resulting GO steel is commonly used in the production of electrical transformers and motors, where its low energy loss and high magnetic permeability make it an ideal choice for efficient and effective electrical performance. The abnormal grain growth occurs when secondary recrystallization process is applied to the steel sheet of different thickness. This process includes decarburizing annealing in a wet hydrogen atmosphere. Then, the final annealing (high level of temperature) will be applied for the time period of more than 10 h under the level of temperature (greater than 1,100°C). Only a high level of secondary recrystallization can guarantee excellent electrical steel properties such as low core losses [1]. Steel sheets with a high magnetic flux density are those that have reached the right level of secondary recrystallization.

The magnetic properties are developed in the coil annealing at high temperatures. This is a critical stage in GO manufacturing, requiring accurate control over the gas composition and the rate of applied heating. After decarburizing, the high-temperature process of annealing is carried out. Decarburizing is performed to relieve the existing residual stresses due to the reduction in thickness of the steel strip and to enable recovery and recrystallization following changes in crystalline structure after the cold working [2,3].

The production process of GO electrical steel includes many different and multiple processes, starting from obtaining raw materials until reaching the final stages of production of thin steel sheets with abnormal grain growth structures. But one of the most important disadvantages of this process is the high energy use. One of the most general factors affecting the percentage of energy required is annealing, as an increase in the required temperature requires higher energy consumption. In fact, upon extensive and extensive research into the available adapters, it was found that there is very little research on energy analysis in the production of GO steel in Orb Cogent Power. The lack of research in this field creates a large research gap, and this gap requires comprehensive research efforts for studying, analyzing, and addressing the high energy consumption associated with the high-temperature annealing process. The primary objective of this study is to determine and analyze the energy of the high-temperature annealing process in the production of GO and find solutions, based on data collected from Orb Cogent Power, which is part of TATA Steel, based in the United Kingdom. Energy consumption patterns were studied in depth, and practical and fundamental solutions were presented to identify potential energy-saving areas. In addition, this study provided different insights to improve energy efficiency in the GO production cycle. The importance of these research results lies in finding solutions to reduce energy consumption, which will contribute to the development of this process device by identifying the main contributor to energy consumption and proposing some solutions. The results of this study can contribute to the development of devices used in the production of electrical steel.

2 High-temperature-level annealing process

During the high-temperature annealing process, the material undergoes purification, secondary recrystallization, and the formation of forsterite on the surface. The grain size and shape that are affected by temperature adjacent/or around the recrystallization temperature and the holding period at the specified temperature are what allow primary and secondary recrystallization to improve the mechanical properties of the strip. Glass film creation and strip purification are also accomplished during the procedure [4]. An accurate control system was applied to monitor and control the parameters of the process (heating rates, gas composition, and annealing time) according to the used weight.

License holders of high-permeability materials describe accurately the variation of heating rates during the process time. Any deviation above or under the specific value may lead to difficulties in generating an optimal Goss orientation [5]. A crucial factor in assessing the effectiveness of the annealing system is the variation in coil temperatures since it influences the necessary metallurgical modifications and results in uneven mechanical characteristics all the way down the steel strip. It can be considered that the coil temperature difference is the main key parameter when it is required to find the efficiency and performance of an annealing process. The required metallurgical transformations can be affected, and this leads to the steel strip having non-uniform mechanical characteristics. The glass film is formed during the heating phase (cycle), and secondary recrystallization occurs. It should reduce the temperature variation to the minimum level to ensure appearing uniform and optimal changes in the microstructure throughout the coil. In addition, the outer areas of the coil are annealing for a longer period due to the presence of a temperature gradient, which is ideally required. Excessive annealing will occur as a result of remaining for longer periods at the above-mentioned recrystallization temperature. On the other hand, sites that are slower to respond to heat are susceptible to under-annealed.

2.1 Annealing process procedures

The main elements of the batch annealing are the cooling and the heating steel coils in the transportable furnace. The main focus in the development field of batch annealing is on optimizing hardware performance and identifying the optimal cycle periods to obtain the required metallurgical characteristics.

Adopting hydrogen-based high convection batch annealing is one such hardware improvement [6,7] owing to the high magnitude of hydrogen’s thermal conductivity, where the value of hydrogen’s thermal conductivity is equal to seven times the nitrogen’s thermal conductivity under the same temperature [8]. The hydrogen content also exerts an influence on the development of secondary recrystallization through its effect on oxidation processes [9]. Significant progress in the annealing process was observed when applied of 100% hydrogen gas, which, in turn, has reduced effectively the process duration [10].

The lowest/slowest heating and cooling rates occurred when using the ordinary batch annealing furnaces that used an NHx mixture of 90% nitrogen and 10% hydrogen as a shielding gas [10]. In order to penetrate the steel coil layers for the high-level convection batch annealing, a large volume flow rate of recirculating gas is needed. The high-temperature coil annealing (HTCA) furnaces are not like traditional batch annealing facilities in several ways, because they have special specifications such as high-level temperature (extreme level) and processing conditions. In the traditional batch system, during the time when the burner heats the charge, it was used a fan at the furnace base to circulate the ambient gas around. The electrical elements mounted on the walls of the HTCA furnace were used to heat up the steel charge. The main reasons to use a fan are the high level of temperature and large hydrogen gas content to distribute atmospheric gas, which is considered one of the challenges that facing engineers.

The typical steel coil charge consists of eight strip coils, each of which needs a lengthy time to be heated due to its average diameter of about 1,300 mm and weight of about 10 tones. When heating, the coil bore heats more slowly than the exterior [11]. The heating process will be stopped when the two main conditions are met: (1) the coil’s temperature reaches a specified level according to the setup conditions, and (2) when the difference between high and low temperatures is less than 30 C in the coils [12].

3 High-temperature-level coil annealing furnace

Generally, in the HTCA furnaces, when it will be delivered an accurate thermal cycle, this will lead to reaching the product’s mechanical and magnetic properties to the acquiring level. Two main two parts in the furnace are the base (hearth) and bell, in addition to the stacking components (including the separator plates and the inner covers). The bell is a movable part and is lowered over the base once the inner covers and coil charge are properly positioned, while the hearth part is fixed. Thermocouples placed at specified points throughout the bell and base provide temperature readings that are used by a process computer to manage the annealing cycle. During the cycle, the flow rates and the gas compositions are accurately monitored. The heating devices were distributed on the base and bell walls, as shown in Figure 1. Eight coils can normally be charged in the furnace, with a maximum weight of about 70 tons overall.

Schematic diagram of batch annealing furnace.

3.1 Hearth

It was designed the hearth to be around the steel frame and encased by the firebrick. A steel trough encircling the perimeter of the rectangular hearth is divided lengthwise by a steel plate. The inner area is filled with sand and the outer section with water to create an efficient seal when dropped the steel skirts that are connected to the bell into the two hearth troughs. This seal serves as the primary furnace seal, preventing air from entering or furnace gas from escaping, both of which increase the risk of an explosion [13].

Four circular recesses with electrical base heating components are located along the longitudinal axis of the hearth. To make coil loading easier, a steel base plate is set atop the recesses. As illustrated in Figure 2, the hearth is supplied with an emergency nitrogen purge intake and four inlet pipes for gas that are mounted in the four recesses.

Furnace hearth at Orb electrical steel.

3.2 Bell

Figure 3 illustrates a schematic of the suction caused by the bell of the furnace placed on the hearth without the separator plate and the charge. The four vertical walls in the removable furnace (Figure 1) are covered with electrical heating elements. Some coils therefore receive more energy from the furnace than others. The heating element radiation and convection through the process gas heat up the charge. These variations are not controllable because the furnace temperature is used to operate the control system. During cooling, a gas-filled cavity in the bell is removed from the furnace and circulated via a heat exchanger before being reinserted into the furnace. The inner cover is also shown in Figure 3. To prevent oxidation, the inner cover, which also serves as a radiation shield, is essential in keeping the ambient gas at a pressure greater than that of the furnace bell. The bell’s internal geometry is designed to reduce pressure losses and guarantee that the steel charge is heated and cooled uniformly.

Schematic diagram of HTCA furnace bell.

HTCA furnaces and hearths require a high level of maintenance, due to the annealing process that takes place at a high temperature. Electrical failure occasionally happens because of a short circuit or, worse due to open circuit. In the case of an open circuit, the current cannot flow through the heating element, which might be caused by damage to the heating elements during the packing process.

4 Scheduling of the HTCA process

The steel charge is arranged in a specific sequence (started by the steel charge, separated plates, inner covers, and finally with the furnace bell), where the HTCA furnaces operate on a fixed base. A traveling overhead crane is used for every operation in the process. The procedure begins with the sequential stacking of separator plates and steel coils – two coils per stack – atop an empty base. The steel covers are added over the coil-laden stacks and sand-sealed at the base, completing the gas’s protective atmosphere. In the next step, the deoxidizing gas flow is started to remove all of the air from the area beneath the cover. Three primary functions of the protective atmospheric gas are carbon removal, oxidation prevention, and carbon absorption. Therefore, the magnetic properties and the development of the grain structures are affected significantly by the gas composition [14,15]. The gas injection to the steel charge and the steel coil is depicted in Figure 4. After penetrating the sand seal, the gas enters the area beneath the furnace bell, where the furnace bell is moved to be lowered on the base. The pipes for the cooling system, thermocouple devices, and power supply connections are all made.

Coil stacks inside the HTCA furnace.

The initial step in the cycle is started by heating the coils bit-by-bit under the gas of working conditions that consists of a mixture of hydrogen and nitrogen. The charge is held at 750°C in the process of low soak temperature to allow lagging sections of the charge to reach the same temperature as warmer parts before progressing to higher temperatures. Then, the charge is maintained at a precisely regulated heating rate of about 1,200°C in a dry hydrogen atmosphere. According to the correlation between the holding time and the outer coil diameter, it was found that it needs 1 h for each inch in the section [16]. When the annealing conditions are met, the heating process ceases. A mixture of NHx ambient gas is used for cooling. During the cooling stage, the cooling fan is turned on and the furnace is shut off. After removing the furnace, the charge is allowed to cool naturally.

5 HTCA unit topology and monitoring

The battery system of the HTCA unit at Orb Electrical Steel is composed of eight batteries (denoted from A to H). All of these batteries have four bases (hearths), excluding the battery (C) that has two bases. The HTCA monitoring system closely observes the annealing cycle at each base. It assists the HTCA furnace operators by keeping them informed about the status of the process at each battery. The monitoring system provides the operators with detailed information about each charge such as product cycle number, segment type (heating or cooling), soak time, cycle duration, average temperature, gas type, and gas flow rate. Certain information, such as cycle number, soaking time, and cycle duration, is relevant to productivity and particularly important in energy consumption data. For that reason, this information is always noted and preserved in the charge history records.

Power supplies were indexed from each battery according to two terms: supply A and supply B. Every battery has four bases vying for two supplies, except for battery C, which is more productive than the others since it has as many supplies as hearths. The processes are scheduled based on the capacity of the batteries to ensure that all of the batteries in the HTCA unit are as productive as possible.

The HTCA unit uses several furnaces, and various bases can be used with different furnaces. When the cycle is finished and the furnace is lifted, it can be applied if there is any maintenance work is needed; otherwise, it can be applied. In order to heat up the furnace’s structure, the main two factors are the time and energy, including the refractory and internal supports, to the working temperature that could be saved by using the furnace continuously before it cools down [17].

The monitoring system of the bases of an HTCA battery system provides the operators with information such as segment type (heating, cooling, or soaking), gas type, gas flow rate soaking, and cycle duration. All four bases function together; when two run, the other two are discharged from the steel coils or prepared for a new cycle. A new cycle can start as soon as the procedure ceases at one of the bases that are in use because the supply can be reconnected in a very short time to other bases.

6 Energy data collection

Data of the daily energy consumption was collected individually of the eight batteries from the Orb intranet to be the raw data of the present research. The range of date of collected data was started from 2014 to the 22nd week of 2017. This is to collect as many samples of energy consumption of annealing cycles as possible to analyze with a sufficient number of charges. Initially, a time interval during which only one steel coil charge is in process at the designated battery was determined by analyzing the daily energy usage records. The data have some energy overlap, making it difficult to determine the period for the single steel charge; therefore, this step required careful attention (Figure 5). The energy overlapping refers to a situation where multiple energy sources or systems are utilized simultaneously, resulting in an overlap or intersection of their functions or effects. In the case of the annealing furnaces, the energy overlap occurs due to the short time gap between two consecutive cycles on the same battery, as well as the simultaneous use of the same power supply on another base through the same day, as discussed in Section 5.

Daily records of the energy consumption of the steel charges.

The normal annealing cycle duration of 4 to 6 days was the criterion used to verify the samples: records for time intervals longer or shorter than that were deemed to have energy overlap (Figure 5). Following the identification of the steel charge sample from the raw data, more data were gathered to obtain the specifics of each charge, including the number of charge number, number of the cycle, number of the furnace, mass, heating, and soaking times. In the period of collection data (2014–2017), around 300 samples for charges were collected and examined to assess the influence of the energy consumption for each contributor.

7 Energy consumption contributors

The initial step toward energy conservation is examining the various process parameters and determining which ones have the greatest impact on energy consumption. This section explored two potential energy consumers using data from Orb Intranet: (i) the weight of charge and (ii) the time of process. Figure 6 illustrates the consumption of energy (kW h) for HTCA charges from 2014 to 2017. Energy consumption of 24,000–28,000 kW h was excluded from further energy analysis as they were deemed outliers. They exhibit notable variations in values across a variety of samples and account for merely 1% of the charges that were gathered. Additionally, the exclusion of the outliers was predicated on their frequencies across the examined time period, during which comparable values did not appear.

Distribution of energy consumed in HTCA charges.

Two distinct energy-consuming factors – the charge weight and cycle’s on-time – will be examined in the following sections. To learn more about how dependent those contributors’ variations are on energy usage, the coefficient of determination was employed. It can be considered that the correlation coefficient (R 2) is the main key of the regression analysis. It can be defined as the percentage of the variance in the independent variable (contributors) that can be predicted from the dependent variable (consumed energy).

According to the linear regression model that includes one independent variable, the following factor can be determined [18]:

where n is the number of observations of data,

A value between 0 and 1 indicates the extent to which the dependent variable is predictable when R 2 = 0, which means that the energy consumption cannot be predicted from the contributor, and vice versa for R 2 = 1.

7.1 The charge weight

Furnaces’ fuel efficiency is often measured in terms of the amount of fuel or electrical energy used to heat a unit weight of load [19]. During the heat treatment process, the steel coils absorb a large quantity of heating energy to accomplish the necessary chemical changes. The heating energy is directly related to the weight of the charge. So, this useful energy can be determined as follows:

where

Figure 7 illustrates the intricate relationship between consumed energy and charge weight during the steel coil annealing process. Contrary to expectations, the figure reveals that estimating energy requirements solely based on charge weight proves challenging. Notably, certain heavy-weight charges exhibit lower energy consumption than their lighter counterparts. This phenomenon primarily stems from the influence of process parameters and furnace efficiency during the annealing process. The R 2 coefficient value of 0.25 implies that 25% of the energy consumed can be accounted for by the charge weight, highlighting the need to consider other factors such as process parameters and furnace efficiency to accurately estimate energy requirements during the annealing process.

Relationship between energy consumption and charge weight.

7.2 Furnace on-time

The term “on-time” refers to the whole period (interval) of the furnace when it is running during a single cycle, including the heating and soaking phases but not cooling as the furnace during this segment is turned off. According to the process parameters, it will be changed, including the demands of a cycle, the furnace’s temperature, and any disruptive events that may arise. To determine how much of the charges’ energy consumption can be predicted from the process on time, a batch of charges weighing between 70 and 72 tons was chosen.

Any disruptive sources that lead to an increase in the cycle time were omitted. The amount of consumed electrical power (Q el) is a function of the running time, where it can be used in Equation (3) to calculate the total amount of electrical power consumed:

where t total is the on-time, and P is the power load (active).

It is noted that certain charges exhibit illogical discrepancies and disagreement with Equation (3). The cycles with low on-time consumed higher energy compared with cycles with high on-time. The coefficient of determination shows that the energy consumed over the cycle is only predicted to a very low degree (21%) (Figure 8). This again emphasizes the need to consider other factors such as process parameters and furnace efficiency to accurately estimate energy requirements during the annealing process. In the next section, the research examines one of the parameters that have a remarkable influence on the annealing time: the electrical failure of heating elements.

Relationship between energy consumption and furnace on-time.

7.3 Furnace heating elements

Each base plate in the hearth of the furnace has electrical heating elements underneath it, and additional elements are fixed to the interior walls of the furnace. According to HTCA’s manufacturer, Almor Group, the HTCA furnaces installed at Cogent Orb Works provide a connected total thermal input of 770 kW gross. According to a typical electric resistance heating element efficiency of 97%, the total net capacity is 747 kW. However, the furnace hearth beneath each coil stack has a net input of 87 kW. The sole purposes of the base’s heating elements are to keep the refractory material at a certain temperature and slightly heat the product coils. The thermocouples are installed permanently at the furnace’s base and internal walls. They monitor the thermal profile. The thermocouples are used to measure the temperature of the baseplate and furnace atmosphere temperature in four zones.

Since the heating elements operate at the peak of their capabilities, careful observation is necessary to ensure their suitability for use. Throughout the annealing process, the HTCA monitoring system monitors the condition of each heating zone at the furnace walls as well as at the base to identify any sag or failure in the heating elements. The monitoring system identifies the heating element experiencing a sag situation by labeling it as “fault” and as “off” when the heating element is in a short-circuit situation. The charge history records contain a report on every failure that occurs during the process. These records are kept for energy analysis purposes.

The elements occasionally sag or suffer short circuits when the current is unable to flow. Heat loss via the base material refractory makes an electrical failure in the hearth elements more problematic than in the wall components. This produces a zone where there is a lack of heat, which may indicate that the coils are not being properly heat-treated. This can have an impact on the qualities of the finished product, the length of the process, and the amount of energy used.

Figure 9 illustrates the energy consumption for steel charges that were annealed under typical annealing circumstances. The soaking time was 28 h, and the heating time was 67–72 h. HTCA set the weight of each charge at 70–72 tons.

Energy consumption benchmarking of two cycles during a typical annealing process.

Although the charges were handled in various furnaces with varying levels of efficiency, the average energy consumed – roughly 42,000 kW h – is considered to be normal for processing an annealing cycle. An energy benchmarking of the two most generated cycles is shown in Figure 10. The charges’ samples were chosen carefully to highlight the impact of extended process durations on energy consumption and their connection to the events of electrical failure. The chosen charges were all between 70 and 72 tons in weight, had experienced some electrical failure in the wall and base heating elements, and required precisely 36 h to soak at 1,190°C.

Energy consumption benchmarking during electrical failure.

Energy is still used throughout the soaking time to keep the temperature at 1,190°C and to enable some of the coils’ lagging parts – which are near the inactive heating elements – to reach the same level of temperature as during the highly heated soak period. Certain charges utilized less energy than other charges with the same conditions, even with the heating elements failing. The strong possibility is that the charges were treated in a furnace that had low shell losses and exceptionally excellent performance.

8 Thermal efficiency of HTCA furnaces

This section presents an evaluation of the HTCA’s performance based on reports conducted by Orb Works in 2013 regarding energy efficiency [21]. Three main reasons were identified for the high energy consumption by the HTCA unit: shell losses (losses from the outer shell of the furnace), losses due to maintenance, and long thermal cycling losses.

The furnace’s almost 50-year-old design and the lining’s materials caused a considerable amount of heat loss from the casing. As per the reports, the annual losses resulting from radiation and convection from the furnace’s exterior surface during the heating and soaking stages of the annealing cycle were approximated to be more than 7 GW h for all furnaces. This is equivalent to more than £400,000 in monetary terms, a sum that might rise in response to increases in energy prices. When a furnace is removed, its heat is lost since it needs to cool down to perform any required maintenance or inspection. According to reports, this amounts to more than 80 MW h annually for all of the annealing unit’s furnaces.

Long thermal cycles result in losses because of the additional time and energy consumed when the heating cycle is prolonged as a result of open circuits. The annual total of these direct losses is more than £50,000. This results from the cycle being extended by 8 h for base open circuits and 2 h for zone open circuits.

Reducing cycle duration can reduce energy consumption. By reducing the effects of thermal cycling inefficiently and hotspot formation due to huge temperature variations across the furnace, a shorter cycle time can easily be achieved. Fluid recirculation is required to achieve this during the annealing process. Fluid recirculation helps in redistributing the heat within the furnace chamber, preventing hotspots.

9 Discussions

The main objectives of the industrial research activities are to enhance the performance and reduce the costs of manufacturing. This will be accomplished by enhancing processes, conserving energy and materials, maintaining market competitiveness, and adhering to environmental regulations. Considerable research and development work has been done to increase the productivity of GO electrical steel. All efforts were focused on enhancing the performance of hardware and optimizing the production cycle times.

For many years, the GO steel production companies have sought to reduce the cycle time and energy consumption of annealing furnaces during the forging process. To increase safety, lower maintenance costs, and prolong furnace life, manufacturers have also examined contemporary furnace building materials. Nevertheless, the development in the heating sector was not at the expected level. The reasons for this are many: the nature of the industry, the size of the companies that offer industrial heating systems, and the dependence of the whole plant on the heating system.

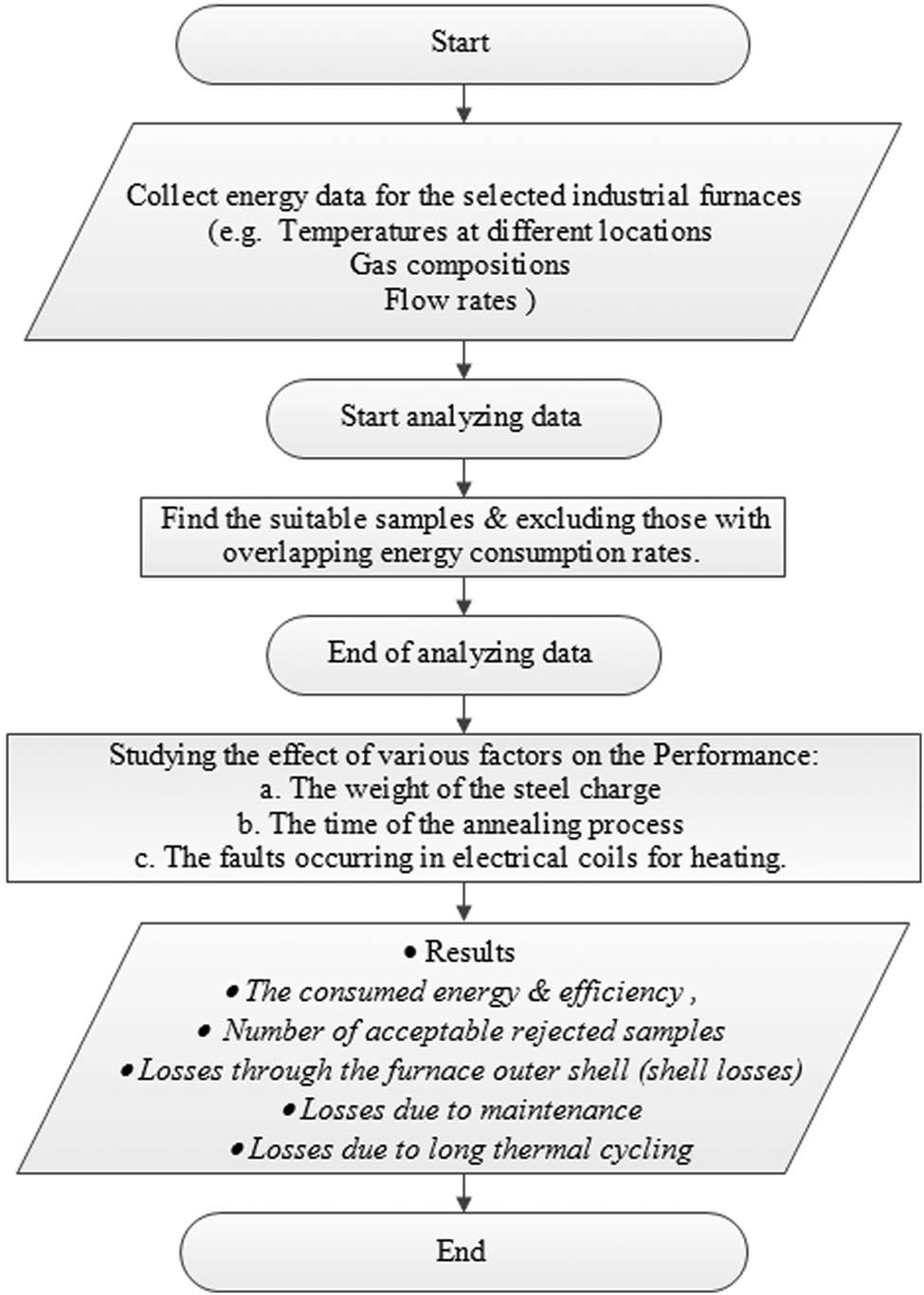

There have been attempts at Orb Steel Works to improve convection and optimize the annealing cycle time by developing the HTCA furnace. A new design was proposed to enhance the heat convection in the HTCA furnace and reduce the time of cycle [22]. Also, there is another suggestion for using rotation to advance turbulence behavior through the atmospheric gas’s process [23]. In the case of electrical steel coils coated with MgO, convection heat transfer is preferable to radiation for materials with low surface emissivity. A proposed redesign of the furnace suggested the use of an impeller to increase convection within the furnace. The impeller circulates the gas around the charge, allowing heat from areas experiencing excessive temperatures to be scrubbed and transported by gas to cooler areas. Super-alloy fan/impellers are expensive and cannot cope with high annealing temperatures. It is also necessary to do engineering work to convert the base so that it can power and seal the fans perfectly. The HTCA furnace works under a hydrogen-based atmosphere. Redesigning and retrofitting existing HTA furnaces may not be a viable option. A radical new design with appropriate technologies installed may be the optimum solution as obsolete HTA assets are replaced. Figure 11 shows the main steps of the energy analysis of the annealing process in the industrial furnace.

Flowchart of the energy analysis of the annealing process in the industrial furnace.

10 Conclusions

This study has covered the energy analysis study of the annealing process of GO electrical steel. There is a lack of research in the literature to address the energy analysis of batch annealing furnaces and to investigate the possible options of optimizing the annealing cycle duration. The results of this study are summarized in the following points:

Based on the energy analysis, it was found that 25% of the consumed energy is predictable from the charge weight. While the coefficient of determination shows a considerable degree of prediction (21%) of the consumed energy over the cycle on time, consider that this percentage is affected by other factors such as the charge weight, the furnace, and base conditions.

The analysis proved that the major energy consumption is due to the long cycle time caused by the failure of some of the heating elements during the annealing process. The cycle is extended for more time to allow the lag parts of the coils to reach the desired temperature.

The study explored the literature review for possible solutions to tackle the problem of long cycle duration and heating element failure. Promoting convection heat transfer mechanisms in an annealing furnace would shorten the annealing cycle and overcome the failure of the heating elements during the cycle. There has been a lack of research to investigate and address this challenge, and more attention should be given to improving the annealing furnace performance toward efficient usage of energy.

Incorporating artificial intelligence (AI) technologies into the monitoring and predictive analysis of heating element failures would offer great improvement. AI algorithms can analyze data from sensors and historical performance records to identify patterns and correlations that may indicate impending failures. AI can predict the likelihood of a heating element failure, enabling proactive maintenance interventions. This predictive capability allows for the scheduling of maintenance activities at optimal times, minimizing downtime and reducing the risk of catastrophic failures. Additionally, AI-powered monitoring systems can provide real-time alerts, enabling operators to respond swiftly to potential issues before they escalate into major disruptions. By investing in AI technologies, manufacturers can enhance the reliability and efficiency of their heating element operations, leading to improved product quality, reduced production costs, and increased customer satisfaction [24].

Acknowledgment

The authors would like to thank Cogent Power Orb Works and Cardiff University for their support while conducting this research.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results and approved the final version of the manuscript. OMHF: supervision, resources, writing – review and editing, formal analysis, funding acquisition. FCJR: methodology, formal analysis, investigation, writing – review and editing. MJJ: formal analysis, writing – review and editing, funding acquisition, resources. NB: validation, funding acquisition, resources. AV-M: investigation, writing – review and editing. HSSA: investigation, project administration, writing – review and editing. MNM: software, resources. OIA: supervision, project administration, writing – review and editing.

-

Conflict of interest: The authors declare no conflict of interest.

-

Data availability statement: The study did not report any data.

References

[1] Matsumura K, Fukuda B. Recent developments of non-oriented electrical steel sheets. IEEE Trans Magnetics. 1984;20(5):1533–8. 10.1109/TMAG.1984.1063223.Search in Google Scholar

[2] Beckley P. Electrical steels for rotating machines. 1st edn. London, UK: Institution of Electrical Engineers; 2002. 10.1049/PBPO037E.Search in Google Scholar

[3] Pawanithiboworn K, Pannachet T, Boonpichetvong M. Investigation of parameters affecting rotational behavior of cold-formed steel connection. Civ Eng J. 2023;9(11):2752–69. 10.28991/CEJ-2023-09-11-08.Search in Google Scholar

[4] Takamiya T, Hanazawa K, Suzuki T. Recent development of grain-oriented electrical steel in JFE steel. JFE Steel Corporation, Japan, JFE Technical Rep. 2016;21:1–6.Search in Google Scholar

[5] Günther K, Abbruzzese G, Fortunati S, Ligi G. Recent technology developments in the production of grain-oriented electrical steel. Steel Res Int. 2016;76(6):413–21. 10.1002/srin.200506030.Search in Google Scholar

[6] Mishra S, Därmann C, Lücke K. On the development of the Goss texture in iron-3% silicon. Acta Metall. 1984;32(12):2185–201. 10.1016/0001-6160(84)90161-5.Search in Google Scholar

[7] Liang YF, Ye F, Lin JP, Wang YL, Chen GL. Effect of annealing temperature on magnetic properties of cold rolled high silicon steel thin sheet. J Alloy Compd. 2010;491(1–2):268–70. 10.1016/j.jallcom.2009.10.118.Search in Google Scholar

[8] Beckley P. Electrical steels: a handbook for producers and users. 1st edn. Newport, Wales: European Electrical Steels; 2000. p. 57.Search in Google Scholar

[9] Stirling DA. Distributed control of batch annealing using coil interior temperature prediction. In Third Conference on Control Engineering 1986: Towards a More Competitive Industry - Preprints of Papers., Sydney, Aust; 1986.Search in Google Scholar

[10] Sakakura A, Takashima H, Taguchi S. Process for producing single-oriented silicon steel sheets having a high magnetic induction. U.S. Patent 3287183A; issued November 22, 1966.Search in Google Scholar

[11] Takahashi N, Suga Y, Kobayashi H. Recent developments in grain-oriented silicon-steel. J Magn Magn Mater. 1996;160(1):98–101. 10.1016/0304-8853(96)00126-6.Search in Google Scholar

[12] Kubota T, Fujikura M, Ushigami Y. Recent progress and future trend on grain oriented silicon steel. J Magn Magn Mater. 2000;215–216(2):69–73. 10.1016/S0304-8853(00)00069-X.Search in Google Scholar

[13] Moghimi M, Saraee M-H, Bagheri A. Modeling of batch annealing process using data mining techniques for cold rolled steel sheets. In Mechatronics (ICM), 2011 IEEE International Conference on Mechatronics; 2011. p. 277–81. 10.1109/ICMECH.2011.5971295.Search in Google Scholar

[14] Zuo Y, Wu WF, Zhang XX, Lin L, Xiang SH, Liu TS, et al. A study of heat transfer in high-performance hydrogen bell-type annealing furnaces. Heat Transf – Asian Res. 2001;30:615–23. 10.1002/htj.10007.Search in Google Scholar

[15] Gur CH, Pan J. Handbook of thermal process modeling steels. 1st edn. Boca Raton: Taylor and Francis; 2009. 10.1201/9781420003581.Search in Google Scholar

[16] Bozorth RM. Ferromagnetism. 2nd edn. Piscataway, New Jersey: Wiley-IEEE Press; 1993.10.1109/9780470544624Search in Google Scholar

[17] Mullinger P, Jenkins B. Industrial and process furnaces: principles, design and operation. 1st edn. Oxford, UK: Elsevier; 2008.10.1016/B978-0-7506-8692-1.00001-6Search in Google Scholar

[18] Al-Zubaidi S, Ghani JA, Haron CHC, Al-Tamimi ANJ, Mohammed MN, Ruggiero A, et al. Investigation of the performance of integrated intelligent models to predict the roughness of Ti6Al4V end-milled surface with uncoated cutting tool. J Mech Behav Mater. 2023;32(1):1–23. 10.1515/jmbm-2022-0300.Search in Google Scholar

[19] Trinks W, Mawhinney MH, Shannon RA, Reed RJ, Garvey JR. Saving energy in industrial furnace systems. In Industrial Furnaces. 6th edn. Hoboken, New Jersey: John Wiley & Sons, Inc; 2004.10.1002/9780470172612Search in Google Scholar

[20] Buckley A. Simulation and redesign of high temperature batch annealing furnaces. PhD, Cardiff University School Of Engineering, CARDIFF; 1999.Search in Google Scholar

[21] Fatla OMH. Development of convection in high-temperature coil annealing furnaces using rotating cylinders technique. PhD, Cardiff University School Of Engineering, CARDIFF; 2019.Search in Google Scholar

[22] Buckley A, Moses AJ, Trollop L. Study and redesign of high temperature batch annealing furnace for production of grain oriented electrical steel. Ironmak Steelmaking. 1999;26:477–82. 10.1179/030192399677338.Search in Google Scholar

[23] Fatla OM, Valera-Medina A, Robinson F, Cichuta M, Beynon N. Development of convection in high-temperature coil annealing furnaces using rotating cylinder technique. Appl Therm Eng. 2018;129:1392–402. 10.1016/j.applthermaleng.2017.10.136.Search in Google Scholar

[24] Mabunda MRD, Mashamba A. Predictive process control framework for online quality control in a hot rolling mill. J Human, Earth, Future. 2022;3(3):263–79.10.28991/HEF-2022-03-03-01Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Methodology of automated quality management

- Influence of vibratory conveyor design parameters on the trough motion and the self-synchronization of inertial vibrators

- Application of finite element method in industrial design, example of an electric motorcycle design project

- Correlative evaluation of the corrosion resilience and passivation properties of zinc and aluminum alloys in neutral chloride and acid-chloride solutions

- Will COVID “encourage” B2B and data exchange engineering in logistic firms?

- Influence of unsupported sleepers on flange climb derailment of two freight wagons

- A hybrid detection algorithm for 5G OTFS waveform for 64 and 256 QAM with Rayleigh and Rician channels

- Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy

- Exploring the potential of ammonia and hydrogen as alternative fuels for transportation

- Impact of insulation on energy consumption and CO2 emissions in high-rise commercial buildings at various climate zones

- Advanced autopilot design with extremum-seeking control for aircraft control

- Adaptive multidimensional trust-based recommendation model for peer to peer applications

- Effects of CFRP sheets on the flexural behavior of high-strength concrete beam

- Enhancing urban sustainability through industrial synergy: A multidisciplinary framework for integrating sustainable industrial practices within urban settings – The case of Hamadan industrial city

- Advanced vibrant controller results of an energetic framework structure

- Application of the Taguchi method and RSM for process parameter optimization in AWSJ machining of CFRP composite-based orthopedic implants

- Improved correlation of soil modulus with SPT N values

- Technologies for high-temperature batch annealing of grain-oriented electrical steel: An overview

- Assessing the need for the adoption of digitalization in Indian small and medium enterprises

- A non-ideal hybridization issue for vertical TFET-based dielectric-modulated biosensor

- Optimizing data retrieval for enhanced data integrity verification in cloud environments

- Performance analysis of nonlinear crosstalk of WDM systems using modulation schemes criteria

- Nonlinear finite-element analysis of RC beams with various opening near supports

- Thermal analysis of Fe3O4–Cu/water over a cone: a fractional Maxwell model

- Radial–axial runner blade design using the coordinate slice technique

- Theoretical and experimental comparison between straight and curved continuous box girders

- Effect of the reinforcement ratio on the mechanical behaviour of textile-reinforced concrete composite: Experiment and numerical modeling

- Experimental and numerical investigation on composite beam–column joint connection behavior using different types of connection schemes

- Enhanced performance and robustness in anti-lock brake systems using barrier function-based integral sliding mode control

- Evaluation of the creep strength of samples produced by fused deposition modeling

- A combined feedforward-feedback controller design for nonlinear systems

- Effect of adjacent structures on footing settlement for different multi-building arrangements

- Analyzing the impact of curved tracks on wheel flange thickness reduction in railway systems

- Review Articles

- Mechanical and smart properties of cement nanocomposites containing nanomaterials: A brief review

- Applications of nanotechnology and nanoproduction techniques

- Relationship between indoor environmental quality and guests’ comfort and satisfaction at green hotels: A comprehensive review

- Communication

- Techniques to mitigate the admission of radon inside buildings

- Erratum

- Erratum to “Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy”

- Special Issue: AESMT-3 - Part II

- Integrated fuzzy logic and multicriteria decision model methods for selecting suitable sites for wastewater treatment plant: A case study in the center of Basrah, Iraq

- Physical and mechanical response of porous metals composites with nano-natural additives

- Special Issue: AESMT-4 - Part II

- New recycling method of lubricant oil and the effect on the viscosity and viscous shear as an environmentally friendly

- Identify the effect of Fe2O3 nanoparticles on mechanical and microstructural characteristics of aluminum matrix composite produced by powder metallurgy technique

- Static behavior of piled raft foundation in clay

- Ultra-low-power CMOS ring oscillator with minimum power consumption of 2.9 pW using low-voltage biasing technique

- Using ANN for well type identifying and increasing production from Sa’di formation of Halfaya oil field – Iraq

- Optimizing the performance of concrete tiles using nano-papyrus and carbon fibers

- Special Issue: AESMT-5 - Part II

- Comparative the effect of distribution transformer coil shape on electromagnetic forces and their distribution using the FEM

- The complex of Weyl module in free characteristic in the event of a partition (7,5,3)

- Restrained captive domination number

- Experimental study of improving hot mix asphalt reinforced with carbon fibers

- Asphalt binder modified with recycled tyre rubber

- Thermal performance of radiant floor cooling with phase change material for energy-efficient buildings

- Surveying the prediction of risks in cryptocurrency investments using recurrent neural networks

- A deep reinforcement learning framework to modify LQR for an active vibration control applied to 2D building models

- Evaluation of mechanically stabilized earth retaining walls for different soil–structure interaction methods: A review

- Assessment of heat transfer in a triangular duct with different configurations of ribs using computational fluid dynamics

- Sulfate removal from wastewater by using waste material as an adsorbent

- Experimental investigation on strengthening lap joints subjected to bending in glulam timber beams using CFRP sheets

- A study of the vibrations of a rotor bearing suspended by a hybrid spring system of shape memory alloys

- Stability analysis of Hub dam under rapid drawdown

- Developing ANFIS-FMEA model for assessment and prioritization of potential trouble factors in Iraqi building projects

- Numerical and experimental comparison study of piled raft foundation

- Effect of asphalt modified with waste engine oil on the durability properties of hot asphalt mixtures with reclaimed asphalt pavement

- Hydraulic model for flood inundation in Diyala River Basin using HEC-RAS, PMP, and neural network

- Numerical study on discharge capacity of piano key side weir with various ratios of the crest length to the width

- The optimal allocation of thyristor-controlled series compensators for enhancement HVAC transmission lines Iraqi super grid by using seeker optimization algorithm

- Numerical and experimental study of the impact on aerodynamic characteristics of the NACA0012 airfoil

- Effect of nano-TiO2 on physical and rheological properties of asphalt cement

- Performance evolution of novel palm leaf powder used for enhancing hot mix asphalt

- Performance analysis, evaluation, and improvement of selected unsignalized intersection using SIDRA software – Case study

- Flexural behavior of RC beams externally reinforced with CFRP composites using various strategies

- Influence of fiber types on the properties of the artificial cold-bonded lightweight aggregates

- Experimental investigation of RC beams strengthened with externally bonded BFRP composites

- Generalized RKM methods for solving fifth-order quasi-linear fractional partial differential equation

- An experimental and numerical study investigating sediment transport position in the bed of sewer pipes in Karbala

- Role of individual component failure in the performance of a 1-out-of-3 cold standby system: A Markov model approach

- Implementation for the cases (5, 4) and (5, 4)/(2, 0)

- Center group actions and related concepts

- Experimental investigation of the effect of horizontal construction joints on the behavior of deep beams

- Deletion of a vertex in even sum domination

- Deep learning techniques in concrete powder mix designing

- Effect of loading type in concrete deep beam with strut reinforcement

- Studying the effect of using CFRP warping on strength of husk rice concrete columns

- Parametric analysis of the influence of climatic factors on the formation of traditional buildings in the city of Al Najaf

- Suitability location for landfill using a fuzzy-GIS model: A case study in Hillah, Iraq

- Hybrid approach for cost estimation of sustainable building projects using artificial neural networks

- Assessment of indirect tensile stress and tensile–strength ratio and creep compliance in HMA mixes with micro-silica and PMB

- Density functional theory to study stopping power of proton in water, lung, bladder, and intestine

- A review of single flow, flow boiling, and coating microchannel studies

- Effect of GFRP bar length on the flexural behavior of hybrid concrete beams strengthened with NSM bars

- Exploring the impact of parameters on flow boiling heat transfer in microchannels and coated microtubes: A comprehensive review

- Crumb rubber modification for enhanced rutting resistance in asphalt mixtures

- Special Issue: AESMT-6

- Design of a new sorting colors system based on PLC, TIA portal, and factory I/O programs

- Forecasting empirical formula for suspended sediment load prediction at upstream of Al-Kufa barrage, Kufa City, Iraq

- Optimization and characterization of sustainable geopolymer mortars based on palygorskite clay, water glass, and sodium hydroxide

- Sediment transport modelling upstream of Al Kufa Barrage

- Study of energy loss, range, and stopping time for proton in germanium and copper materials

- Effect of internal and external recycle ratios on the nutrient removal efficiency of anaerobic/anoxic/oxic (VIP) wastewater treatment plant

- Enhancing structural behaviour of polypropylene fibre concrete columns longitudinally reinforced with fibreglass bars

- Sustainable road paving: Enhancing concrete paver blocks with zeolite-enhanced cement

- Evaluation of the operational performance of Karbala waste water treatment plant under variable flow using GPS-X model

- Design and simulation of photonic crystal fiber for highly sensitive chemical sensing applications

- Optimization and design of a new column sequencing for crude oil distillation at Basrah refinery

- Inductive 3D numerical modelling of the tibia bone using MRI to examine von Mises stress and overall deformation

- An image encryption method based on modified elliptic curve Diffie-Hellman key exchange protocol and Hill Cipher

- Experimental investigation of generating superheated steam using a parabolic dish with a cylindrical cavity receiver: A case study

- Effect of surface roughness on the interface behavior of clayey soils

- Investigated of the optical properties for SiO2 by using Lorentz model

- Measurements of induced vibrations due to steel pipe pile driving in Al-Fao soil: Effect of partial end closure

- Experimental and numerical studies of ballistic resistance of hybrid sandwich composite body armor

- Evaluation of clay layer presence on shallow foundation settlement in dry sand under an earthquake

- Optimal design of mechanical performances of asphalt mixtures comprising nano-clay additives

- Advancing seismic performance: Isolators, TMDs, and multi-level strategies in reinforced concrete buildings

- Predicted evaporation in Basrah using artificial neural networks

- Energy management system for a small town to enhance quality of life

- Numerical study on entropy minimization in pipes with helical airfoil and CuO nanoparticle integration

- Equations and methodologies of inlet drainage system discharge coefficients: A review

- Thermal buckling analysis for hybrid and composite laminated plate by using new displacement function

- Investigation into the mechanical and thermal properties of lightweight mortar using commercial beads or recycled expanded polystyrene

- Experimental and theoretical analysis of single-jet column and concrete column using double-jet grouting technique applied at Al-Rashdia site

- The impact of incorporating waste materials on the mechanical and physical characteristics of tile adhesive materials

- Seismic resilience: Innovations in structural engineering for earthquake-prone areas

- Automatic human identification using fingerprint images based on Gabor filter and SIFT features fusion

- Performance of GRKM-method for solving classes of ordinary and partial differential equations of sixth-orders

- Visible light-boosted photodegradation activity of Ag–AgVO3/Zn0.5Mn0.5Fe2O4 supported heterojunctions for effective degradation of organic contaminates

- Production of sustainable concrete with treated cement kiln dust and iron slag waste aggregate

- Key effects on the structural behavior of fiber-reinforced lightweight concrete-ribbed slabs: A review

- A comparative analysis of the energy dissipation efficiency of various piano key weir types

- Special Issue: Transport 2022 - Part II

- Variability in road surface temperature in urban road network – A case study making use of mobile measurements

- Special Issue: BCEE5-2023

- Evaluation of reclaimed asphalt mixtures rejuvenated with waste engine oil to resist rutting deformation

- Assessment of potential resistance to moisture damage and fatigue cracks of asphalt mixture modified with ground granulated blast furnace slag

- Investigating seismic response in adjacent structures: A study on the impact of buildings’ orientation and distance considering soil–structure interaction

- Improvement of porosity of mortar using polyethylene glycol pre-polymer-impregnated mortar

- Three-dimensional analysis of steel beam-column bolted connections

- Assessment of agricultural drought in Iraq employing Landsat and MODIS imagery

- Performance evaluation of grouted porous asphalt concrete

- Optimization of local modified metakaolin-based geopolymer concrete by Taguchi method

- Effect of waste tire products on some characteristics of roller-compacted concrete

- Studying the lateral displacement of retaining wall supporting sandy soil under dynamic loads

- Seismic performance evaluation of concrete buttress dram (Dynamic linear analysis)

- Behavior of soil reinforced with micropiles

- Possibility of production high strength lightweight concrete containing organic waste aggregate and recycled steel fibers

- An investigation of self-sensing and mechanical properties of smart engineered cementitious composites reinforced with functional materials

- Forecasting changes in precipitation and temperatures of a regional watershed in Northern Iraq using LARS-WG model

- Experimental investigation of dynamic soil properties for modeling energy-absorbing layers

- Numerical investigation of the effect of longitudinal steel reinforcement ratio on the ductility of concrete beams

- An experimental study on the tensile properties of reinforced asphalt pavement

- Self-sensing behavior of hot asphalt mixture with steel fiber-based additive

- Behavior of ultra-high-performance concrete deep beams reinforced by basalt fibers

- Optimizing asphalt binder performance with various PET types

- Investigation of the hydraulic characteristics and homogeneity of the microstructure of the air voids in the sustainable rigid pavement

- Enhanced biogas production from municipal solid waste via digestion with cow manure: A case study

- Special Issue: AESMT-7 - Part I

- Preparation and investigation of cobalt nanoparticles by laser ablation: Structure, linear, and nonlinear optical properties

- Seismic analysis of RC building with plan irregularity in Baghdad/Iraq to obtain the optimal behavior

- The effect of urban environment on large-scale path loss model’s main parameters for mmWave 5G mobile network in Iraq

- Formatting a questionnaire for the quality control of river bank roads

- Vibration suppression of smart composite beam using model predictive controller

- Machine learning-based compressive strength estimation in nanomaterial-modified lightweight concrete

- In-depth analysis of critical factors affecting Iraqi construction projects performance

- Behavior of container berth structure under the influence of environmental and operational loads

- Energy absorption and impact response of ballistic resistance laminate

- Effect of water-absorbent polymer balls in internal curing on punching shear behavior of bubble slabs

- Effect of surface roughness on interface shear strength parameters of sandy soils

- Evaluating the interaction for embedded H-steel section in normal concrete under monotonic and repeated loads

- Estimation of the settlement of pile head using ANN and multivariate linear regression based on the results of load transfer method

- Enhancing communication: Deep learning for Arabic sign language translation

- A review of recent studies of both heat pipe and evaporative cooling in passive heat recovery

- Effect of nano-silica on the mechanical properties of LWC

- An experimental study of some mechanical properties and absorption for polymer-modified cement mortar modified with superplasticizer

- Digital beamforming enhancement with LSTM-based deep learning for millimeter wave transmission

- Developing an efficient planning process for heritage buildings maintenance in Iraq

- Design and optimization of two-stage controller for three-phase multi-converter/multi-machine electric vehicle

- Evaluation of microstructure and mechanical properties of Al1050/Al2O3/Gr composite processed by forming operation ECAP

- Calculations of mass stopping power and range of protons in organic compounds (CH3OH, CH2O, and CO2) at energy range of 0.01–1,000 MeV

- Investigation of in vitro behavior of composite coating hydroxyapatite-nano silver on 316L stainless steel substrate by electrophoretic technic for biomedical tools

- A review: Enhancing tribological properties of journal bearings composite materials

- Improvements in the randomness and security of digital currency using the photon sponge hash function through Maiorana–McFarland S-box replacement

- Design a new scheme for image security using a deep learning technique of hierarchical parameters

- Special Issue: ICES 2023

- Comparative geotechnical analysis for ultimate bearing capacity of precast concrete piles using cone resistance measurements

- Visualizing sustainable rainwater harvesting: A case study of Karbala Province

- Geogrid reinforcement for improving bearing capacity and stability of square foundations

- Evaluation of the effluent concentrations of Karbala wastewater treatment plant using reliability analysis

- Adsorbent made with inexpensive, local resources

- Effect of drain pipes on seepage and slope stability through a zoned earth dam

- Sediment accumulation in an 8 inch sewer pipe for a sample of various particles obtained from the streets of Karbala city, Iraq

- Special Issue: IETAS 2024 - Part I

- Analyzing the impact of transfer learning on explanation accuracy in deep learning-based ECG recognition systems

- Effect of scale factor on the dynamic response of frame foundations

- Improving multi-object detection and tracking with deep learning, DeepSORT, and frame cancellation techniques

- The impact of using prestressed CFRP bars on the development of flexural strength

- Assessment of surface hardness and impact strength of denture base resins reinforced with silver–titanium dioxide and silver–zirconium dioxide nanoparticles: In vitro study

- A data augmentation approach to enhance breast cancer detection using generative adversarial and artificial neural networks

- Modification of the 5D Lorenz chaotic map with fuzzy numbers for video encryption in cloud computing

- Special Issue: 51st KKBN - Part I

- Evaluation of static bending caused damage of glass-fiber composite structure using terahertz inspection

Articles in the same Issue

- Regular Articles

- Methodology of automated quality management

- Influence of vibratory conveyor design parameters on the trough motion and the self-synchronization of inertial vibrators

- Application of finite element method in industrial design, example of an electric motorcycle design project

- Correlative evaluation of the corrosion resilience and passivation properties of zinc and aluminum alloys in neutral chloride and acid-chloride solutions

- Will COVID “encourage” B2B and data exchange engineering in logistic firms?

- Influence of unsupported sleepers on flange climb derailment of two freight wagons

- A hybrid detection algorithm for 5G OTFS waveform for 64 and 256 QAM with Rayleigh and Rician channels

- Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy

- Exploring the potential of ammonia and hydrogen as alternative fuels for transportation

- Impact of insulation on energy consumption and CO2 emissions in high-rise commercial buildings at various climate zones

- Advanced autopilot design with extremum-seeking control for aircraft control

- Adaptive multidimensional trust-based recommendation model for peer to peer applications

- Effects of CFRP sheets on the flexural behavior of high-strength concrete beam

- Enhancing urban sustainability through industrial synergy: A multidisciplinary framework for integrating sustainable industrial practices within urban settings – The case of Hamadan industrial city

- Advanced vibrant controller results of an energetic framework structure

- Application of the Taguchi method and RSM for process parameter optimization in AWSJ machining of CFRP composite-based orthopedic implants

- Improved correlation of soil modulus with SPT N values

- Technologies for high-temperature batch annealing of grain-oriented electrical steel: An overview

- Assessing the need for the adoption of digitalization in Indian small and medium enterprises

- A non-ideal hybridization issue for vertical TFET-based dielectric-modulated biosensor

- Optimizing data retrieval for enhanced data integrity verification in cloud environments

- Performance analysis of nonlinear crosstalk of WDM systems using modulation schemes criteria

- Nonlinear finite-element analysis of RC beams with various opening near supports

- Thermal analysis of Fe3O4–Cu/water over a cone: a fractional Maxwell model

- Radial–axial runner blade design using the coordinate slice technique

- Theoretical and experimental comparison between straight and curved continuous box girders

- Effect of the reinforcement ratio on the mechanical behaviour of textile-reinforced concrete composite: Experiment and numerical modeling

- Experimental and numerical investigation on composite beam–column joint connection behavior using different types of connection schemes

- Enhanced performance and robustness in anti-lock brake systems using barrier function-based integral sliding mode control

- Evaluation of the creep strength of samples produced by fused deposition modeling

- A combined feedforward-feedback controller design for nonlinear systems

- Effect of adjacent structures on footing settlement for different multi-building arrangements

- Analyzing the impact of curved tracks on wheel flange thickness reduction in railway systems

- Review Articles

- Mechanical and smart properties of cement nanocomposites containing nanomaterials: A brief review

- Applications of nanotechnology and nanoproduction techniques

- Relationship between indoor environmental quality and guests’ comfort and satisfaction at green hotels: A comprehensive review

- Communication

- Techniques to mitigate the admission of radon inside buildings

- Erratum

- Erratum to “Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy”

- Special Issue: AESMT-3 - Part II

- Integrated fuzzy logic and multicriteria decision model methods for selecting suitable sites for wastewater treatment plant: A case study in the center of Basrah, Iraq

- Physical and mechanical response of porous metals composites with nano-natural additives

- Special Issue: AESMT-4 - Part II

- New recycling method of lubricant oil and the effect on the viscosity and viscous shear as an environmentally friendly

- Identify the effect of Fe2O3 nanoparticles on mechanical and microstructural characteristics of aluminum matrix composite produced by powder metallurgy technique

- Static behavior of piled raft foundation in clay

- Ultra-low-power CMOS ring oscillator with minimum power consumption of 2.9 pW using low-voltage biasing technique

- Using ANN for well type identifying and increasing production from Sa’di formation of Halfaya oil field – Iraq

- Optimizing the performance of concrete tiles using nano-papyrus and carbon fibers

- Special Issue: AESMT-5 - Part II

- Comparative the effect of distribution transformer coil shape on electromagnetic forces and their distribution using the FEM

- The complex of Weyl module in free characteristic in the event of a partition (7,5,3)

- Restrained captive domination number

- Experimental study of improving hot mix asphalt reinforced with carbon fibers

- Asphalt binder modified with recycled tyre rubber

- Thermal performance of radiant floor cooling with phase change material for energy-efficient buildings

- Surveying the prediction of risks in cryptocurrency investments using recurrent neural networks

- A deep reinforcement learning framework to modify LQR for an active vibration control applied to 2D building models

- Evaluation of mechanically stabilized earth retaining walls for different soil–structure interaction methods: A review

- Assessment of heat transfer in a triangular duct with different configurations of ribs using computational fluid dynamics

- Sulfate removal from wastewater by using waste material as an adsorbent

- Experimental investigation on strengthening lap joints subjected to bending in glulam timber beams using CFRP sheets

- A study of the vibrations of a rotor bearing suspended by a hybrid spring system of shape memory alloys

- Stability analysis of Hub dam under rapid drawdown

- Developing ANFIS-FMEA model for assessment and prioritization of potential trouble factors in Iraqi building projects

- Numerical and experimental comparison study of piled raft foundation

- Effect of asphalt modified with waste engine oil on the durability properties of hot asphalt mixtures with reclaimed asphalt pavement

- Hydraulic model for flood inundation in Diyala River Basin using HEC-RAS, PMP, and neural network

- Numerical study on discharge capacity of piano key side weir with various ratios of the crest length to the width

- The optimal allocation of thyristor-controlled series compensators for enhancement HVAC transmission lines Iraqi super grid by using seeker optimization algorithm

- Numerical and experimental study of the impact on aerodynamic characteristics of the NACA0012 airfoil

- Effect of nano-TiO2 on physical and rheological properties of asphalt cement

- Performance evolution of novel palm leaf powder used for enhancing hot mix asphalt

- Performance analysis, evaluation, and improvement of selected unsignalized intersection using SIDRA software – Case study

- Flexural behavior of RC beams externally reinforced with CFRP composites using various strategies

- Influence of fiber types on the properties of the artificial cold-bonded lightweight aggregates

- Experimental investigation of RC beams strengthened with externally bonded BFRP composites

- Generalized RKM methods for solving fifth-order quasi-linear fractional partial differential equation

- An experimental and numerical study investigating sediment transport position in the bed of sewer pipes in Karbala

- Role of individual component failure in the performance of a 1-out-of-3 cold standby system: A Markov model approach

- Implementation for the cases (5, 4) and (5, 4)/(2, 0)

- Center group actions and related concepts

- Experimental investigation of the effect of horizontal construction joints on the behavior of deep beams

- Deletion of a vertex in even sum domination

- Deep learning techniques in concrete powder mix designing

- Effect of loading type in concrete deep beam with strut reinforcement

- Studying the effect of using CFRP warping on strength of husk rice concrete columns

- Parametric analysis of the influence of climatic factors on the formation of traditional buildings in the city of Al Najaf

- Suitability location for landfill using a fuzzy-GIS model: A case study in Hillah, Iraq

- Hybrid approach for cost estimation of sustainable building projects using artificial neural networks

- Assessment of indirect tensile stress and tensile–strength ratio and creep compliance in HMA mixes with micro-silica and PMB

- Density functional theory to study stopping power of proton in water, lung, bladder, and intestine

- A review of single flow, flow boiling, and coating microchannel studies

- Effect of GFRP bar length on the flexural behavior of hybrid concrete beams strengthened with NSM bars

- Exploring the impact of parameters on flow boiling heat transfer in microchannels and coated microtubes: A comprehensive review

- Crumb rubber modification for enhanced rutting resistance in asphalt mixtures

- Special Issue: AESMT-6

- Design of a new sorting colors system based on PLC, TIA portal, and factory I/O programs

- Forecasting empirical formula for suspended sediment load prediction at upstream of Al-Kufa barrage, Kufa City, Iraq

- Optimization and characterization of sustainable geopolymer mortars based on palygorskite clay, water glass, and sodium hydroxide

- Sediment transport modelling upstream of Al Kufa Barrage

- Study of energy loss, range, and stopping time for proton in germanium and copper materials

- Effect of internal and external recycle ratios on the nutrient removal efficiency of anaerobic/anoxic/oxic (VIP) wastewater treatment plant

- Enhancing structural behaviour of polypropylene fibre concrete columns longitudinally reinforced with fibreglass bars

- Sustainable road paving: Enhancing concrete paver blocks with zeolite-enhanced cement

- Evaluation of the operational performance of Karbala waste water treatment plant under variable flow using GPS-X model

- Design and simulation of photonic crystal fiber for highly sensitive chemical sensing applications

- Optimization and design of a new column sequencing for crude oil distillation at Basrah refinery

- Inductive 3D numerical modelling of the tibia bone using MRI to examine von Mises stress and overall deformation

- An image encryption method based on modified elliptic curve Diffie-Hellman key exchange protocol and Hill Cipher

- Experimental investigation of generating superheated steam using a parabolic dish with a cylindrical cavity receiver: A case study

- Effect of surface roughness on the interface behavior of clayey soils

- Investigated of the optical properties for SiO2 by using Lorentz model

- Measurements of induced vibrations due to steel pipe pile driving in Al-Fao soil: Effect of partial end closure

- Experimental and numerical studies of ballistic resistance of hybrid sandwich composite body armor

- Evaluation of clay layer presence on shallow foundation settlement in dry sand under an earthquake

- Optimal design of mechanical performances of asphalt mixtures comprising nano-clay additives

- Advancing seismic performance: Isolators, TMDs, and multi-level strategies in reinforced concrete buildings

- Predicted evaporation in Basrah using artificial neural networks

- Energy management system for a small town to enhance quality of life

- Numerical study on entropy minimization in pipes with helical airfoil and CuO nanoparticle integration

- Equations and methodologies of inlet drainage system discharge coefficients: A review

- Thermal buckling analysis for hybrid and composite laminated plate by using new displacement function

- Investigation into the mechanical and thermal properties of lightweight mortar using commercial beads or recycled expanded polystyrene

- Experimental and theoretical analysis of single-jet column and concrete column using double-jet grouting technique applied at Al-Rashdia site

- The impact of incorporating waste materials on the mechanical and physical characteristics of tile adhesive materials

- Seismic resilience: Innovations in structural engineering for earthquake-prone areas

- Automatic human identification using fingerprint images based on Gabor filter and SIFT features fusion

- Performance of GRKM-method for solving classes of ordinary and partial differential equations of sixth-orders

- Visible light-boosted photodegradation activity of Ag–AgVO3/Zn0.5Mn0.5Fe2O4 supported heterojunctions for effective degradation of organic contaminates

- Production of sustainable concrete with treated cement kiln dust and iron slag waste aggregate

- Key effects on the structural behavior of fiber-reinforced lightweight concrete-ribbed slabs: A review

- A comparative analysis of the energy dissipation efficiency of various piano key weir types

- Special Issue: Transport 2022 - Part II

- Variability in road surface temperature in urban road network – A case study making use of mobile measurements

- Special Issue: BCEE5-2023

- Evaluation of reclaimed asphalt mixtures rejuvenated with waste engine oil to resist rutting deformation

- Assessment of potential resistance to moisture damage and fatigue cracks of asphalt mixture modified with ground granulated blast furnace slag

- Investigating seismic response in adjacent structures: A study on the impact of buildings’ orientation and distance considering soil–structure interaction

- Improvement of porosity of mortar using polyethylene glycol pre-polymer-impregnated mortar

- Three-dimensional analysis of steel beam-column bolted connections

- Assessment of agricultural drought in Iraq employing Landsat and MODIS imagery

- Performance evaluation of grouted porous asphalt concrete

- Optimization of local modified metakaolin-based geopolymer concrete by Taguchi method

- Effect of waste tire products on some characteristics of roller-compacted concrete

- Studying the lateral displacement of retaining wall supporting sandy soil under dynamic loads

- Seismic performance evaluation of concrete buttress dram (Dynamic linear analysis)

- Behavior of soil reinforced with micropiles

- Possibility of production high strength lightweight concrete containing organic waste aggregate and recycled steel fibers

- An investigation of self-sensing and mechanical properties of smart engineered cementitious composites reinforced with functional materials

- Forecasting changes in precipitation and temperatures of a regional watershed in Northern Iraq using LARS-WG model

- Experimental investigation of dynamic soil properties for modeling energy-absorbing layers

- Numerical investigation of the effect of longitudinal steel reinforcement ratio on the ductility of concrete beams

- An experimental study on the tensile properties of reinforced asphalt pavement

- Self-sensing behavior of hot asphalt mixture with steel fiber-based additive

- Behavior of ultra-high-performance concrete deep beams reinforced by basalt fibers

- Optimizing asphalt binder performance with various PET types

- Investigation of the hydraulic characteristics and homogeneity of the microstructure of the air voids in the sustainable rigid pavement