Abstract

The structural integrity of a reinforced concrete (RC) beam could be compromised by the need for web holes for utilities like air conditioning and electricity. In places with high shear loads, these voids may appear near the columns supporting the structure. The impact of web openings close to the supports on the behavior of RC beams is inspected numerically in this article. Four-point loads were applied to the supports of seven RC beams with holes of varied sizes and locations. The crack patterns and deflections of the seven beams were analyzed in comparison to those of a solid RC beam without an aperture. The goal of the experiment was to verify that all simulation procedures were accurate and complete. The numerical analysis results showed that the experimentally tested failure load was in excellent consent with the numerical results. Therefore, the finite-element approach is a particularly reliable technique for exploring the nonlinear behavior of beams with multiple apertures, both from the perspectives of difficulty and time savings. Analytical and code equations were used to compare the measured load–deflection magnitude and shear strength of the examined RC beams to their prophesied values. The test findings demonstrated that the shear load capacity of RC beams was reduced by as much as 24.9% as compared to a solid beam, as shown by testing results. The shear load capacity for small-size openings was less than the solid beam by 12.8, 21.1, and 21.6%, while for the biggest openings by 34.6, 29.5, and 34.2% when taking the distance from the support 0, 100, and 200 mm.

1 Introduction

To allow for the routing of wires, tubes, and vents for mechanical and electrical systems, it is usual practice for structures to use reinforced concrete (RC) beams with prefabricated openings. Incorporating these apertures into structures helps maximize space use and prevents the loss of clear height [1]. However, stress accumulation at the corners of openings in RC beams can significantly reduce the beams’ flexural and shear capacities; hence, their use should be avoided if at all possible [2]. There has been a plethora of experimental and numerical research into the behavior of RC beams with holes. Some studies looked at shallow beams, and there were studies that looked at deep beams [3].

Aykac et al. [4] tested nine RC beams to see how their flexural behavior changed when we introduced various web apertures. Premature failure might be avoided if diagonal reinforcement was applied around the openings, as demonstrated by the results. They performed a literature search on studies that compared the performance of RC beams with different shape apertures. Both different deeps of beams of varying aperture sizes and positions were considered in the analyses. To better understand the conduct of RC concrete beams with openings and to create sufficient analytical methods for the design of such beams, the article concluded that further research is required. It was also suggested that experimental and numerical exploration of the behavior of these rays were put through to varied loading arranges to be pursued in the future.

Mansur et al. [5] conducted research on pure torsion effects on RC beams including big rectangular holes. The eccentricity of a beam appears to have only a minor impact on its torsional strength and stiffness, which are observed to decrease with increasing opening length or depth. The beams break because a technique with four hinges forms at the opening’s four corners. Naik et al. [6] investigated the best beam opening forms where bending alone was the loading condition. Cutting openings in a beam near its neutral axis is an efficient way to lighten it for use in pure bending. It is crucial in engineering design that the stress concentration around these openings is kept to a minimum. It is possible to reduce the stress concentration by optimizing the opening form so that, within a given set of geometric limitations and loading conditions, the stress concentration factor is minimized. Mansur et al. [7] conducted a laboratory study of huge transversely opening continuous beams of RC. Considerations include the total spans, the dimensions of each opening, and their placement along each span. The openings at either end of the beam are particularly susceptible to the production of plastic hinges, which ultimately lead to the beam’s failure. When the opening size of a beam is either longer or deeper, the beam’s strength and rigidity are compromised. Thevendran and Shanmugam [8] looked into what happened when we cut holes in the webs of narrow beams. Beams’ ultimate strength and lateral buckling capacity are both diminished by web holes. To determine the critical lateral-buckling loads of thin, doubly symmetric beams with unreinforced web holes, a computational method was devised based on the energy approach. The experimental critical loads are compared with the numerical evaluations. Both numerical and experimental values accord well, as demonstrated by this investigation.

For this study, we used the strut-and-tie model to analyze a RC beam having a transverse circular opening in the web [9]. Ultimate strength, mode of failure, and the fraction of applied shear borne by the chord members above and below the aperture all accord well with theoretical predictions and actual evidence. To reduce concrete discomfort at the throat section, the truss model demonstrates how diagonal reinforcement may carry a considerable amount of applied shear over the discontinuity. Ref. [10] conducted tests on both unreinforced and FRP-sheet-reinforced RC beams with apertures. Deflection, strain, cracking, and ultimate load were all studied to see how they changed after this strengthening method was applied. The conduct and strength of RC beams with shear holes were studied experimentally. The ultimate load-carrying capacity of a RC beam is drastically reduced if it has an unstrengthened aperture in the shear zone. Beam capacity may be reduced by as much as 75% if an opening is present whose height is only 0.6 the beam depth and is not reinforced. Beam deflection, fractures surrounding the opening, and ultimate load-carrying capability are all in a way that is likely to have a strong or far-reaching effect. Miniature when CFRP sheets are applied. For somewhat slight apertures, the full capacity of the beam may be recovered by FRP sheets used to reinforce the zone around the hole.

El-Maaddawy and El-Ariss [11] studied the consequence of externally bonded CFRP compounded sheets on the shear strength of web-open RC beams. The consignment of CFRP sheets utilized for shear strengthening, as well as the opening’s width and depth, were used as a test point of reference. According to the findings of the tests, the beam’s shear capacity and stiffness were greatly diminished by the presence of web holes. It was discovered that adding CFRP sheets around the opening outstandingly increased the beam’s shear resistance and stiffness from the outside. The increase in shear capacity was lessened as the opening size was made wider or deeper. The shear capacity was improved by magnifying the number of vertical CFRP sheets from one to two layers; nevertheless, this improvement was not equivalent to the increase in CFRP thickness.

Mansur [12] presented several helpful pieces of information on the optimal size and disposition of the aperture in RC beams. Their advocacy, for instance, was that the opening depth should not be increased above 50% of the overall beam depth (D) to put a stop to an undue loss in the beam’s capacity. Further, the opening needs to be positioned at a distance of at least half a stage from the support, the concentrated load, or the openings that are near it. To avoid the critical zone, which is where the reinforcement is most likely to be crowded and where shear failure is the predominant kind of failure, this is the primary rationale for doing so. Additionally, they suggested breaking the one long aperture into numerous openings that had the same total size as the original opening. It is possible that this will assist in achieving acceptable serviceability limitations and will assure the stability of the top and bottom chord members. In addition to this, they said that the optimal position for the aperture in T-beams is just below the flange, which makes the process of construction much simpler. Alternatively, the opening point for rectangular beams is often near the section’s mid-depth. This is the case in most cases. However, it is strongly advised to make a little adjustment to the opening along the beam depth in order to guarantee that there is adequate concrete cover for the reinforcement in the lower chord member. At the same time, it is essential to have a sufficient concrete portion in compression in order to prevent the upper chord member from experiencing brittle concrete failure from occurring.

Given the dearth of studies on the behavior of RC beams with web apertures that are near supports and surrounded by additional stirrups, the present work has two primary goals. First and foremost, the purpose of this study is to evaluate the impact that using a near-support web opening of varying widths has on the behavior of RC beams. The second goal is to find the best possible locations for open positions that are close to support. The importance of this research includes that it gives designers an idea about the best location for openings near the supports when designing, as well as the sizes of the openings and their effect.

Daniel’s research [13] suggested that structures with floors that were supported by beams in two orthogonal orientations would become more substantial over time. While this is going on, mechanical engineers need apertures inside the beam so that they may pass through their facilities. Therefore, Daniel conducted an experiment to study the behavior of five RC beams that had elongated apertures attached to them. When the author increased the length of the aperture, they came to the conclusion that the shear and flexural modulus were both decreased. Observations were made on the Vierendeel action mechanism for beams that had significant holes. To be more specific, the collapse of the beam was caused by the formation of four plastic hinges at the opening corners. As a point of reference, some beams that had shorter opening lengths exhibited failure as a result of diagonal shear fractures.

2 Research significance

We set out to accomplish three goals with this work to make up for the dearth of literature on the topic of RC shallow beams with web apertures adjacent to supports and encircled by extra stirrups near supports. The primary objective is to use numerical techniques to investigate the effect of the opening with varied widths close to the support it is meant to sustain on the behavior of RC beams. The other objective is to calculate the expected impact of various separations from the support face. The third ABAQUS goal is to ensure precise simulations. Beginning with a detailed explanation of the numerical program, this article goes on to describe the specimen’s construction, the relative amounts of each material used, and the four-point testing arrangement. The performance of RC beams with web holes is then compared to that of a reference without hole RC beam in the following results section. The load–deflection relationships and crack patterns for both longitudinal and transverse reinforcement are compared.

3 Finite-element (FE) simulation

This section presents the methods and material models of concrete and reinforcement used in the simulation of the suggested numerical model. Validation is performed using test data gathered from the published literature. Deflections, strengths, and crack patterns are compared between the computational and experimental data.

3.1 Model validation using historical test data

The experimental work performed is essential to the suggested numerical model [14]. There were three RC beams subjected to the usual four-point load test. A desired 40.0 MPa cube concrete compressive strength was specified. Each of the beams used in the tests had overall and pure span lengths of 2,200 and 2,000 mm respectively, and a rectangular cross-section measuring 150 by 300 mm. All beams were reinforced in the same manner over their lengths and widths. Each beam has three 16 mm water-filled longitudinal bars at its base and two 10 mm water-filled bars at its top. The whole length of the beams was lined with closed stirrups, each measuring 8 mm in diameter and spaced 200 mm apart, with an additional closed stirrup on either side of the aperture. All beams that have been put through their paces have a pure span of 2,000 mm, a shear span of 667 mm, and a shear span-to-depth ratio of 2.5. The millimeter measurements and the reinforcing pattern of the specimen are shown in Figures 1 and 2, respectively.

Specimen dimension in mm.

Specimen reinforcement arrangement.

3.2 Methodology

3.2.1 Simulation technique

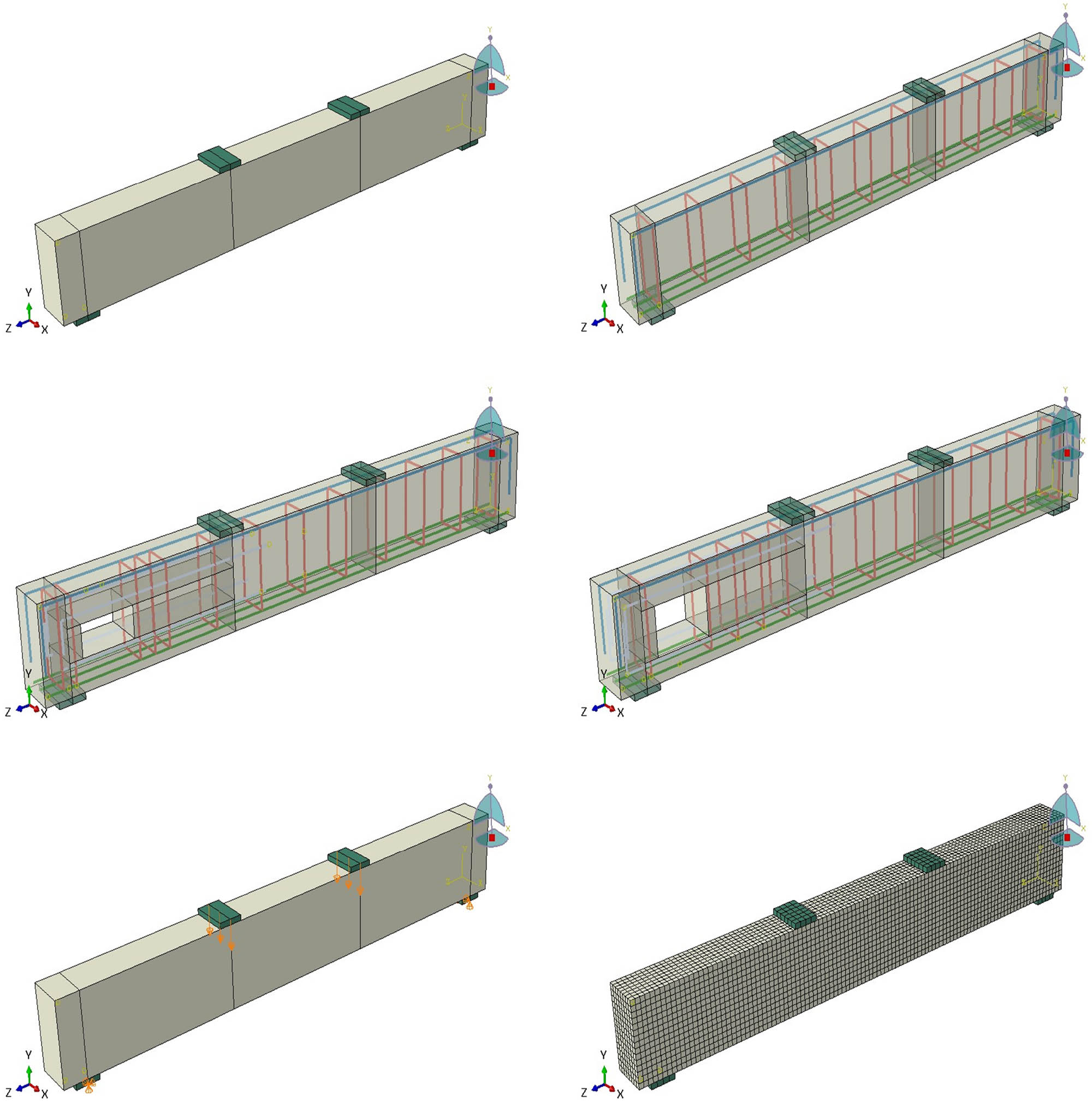

A total of 13,561 pieces were used in the ABAQUS simulation of the beams. To prevent the shear locking effect, concrete with reduced integration employed hexahedral (brick) elements with eight nodes (C3D8R). Modeling reinforcements required 385 two-node linear truss elements (T3D2). Assuming a complete bond between the concrete and the reinforcement, the latter was inserted into the former [15].

Modeling information, such as geometry, boundary conditions, and meshing of specimens, employed in the simulation are shown in Figure 3. Beams in both the vertical and horizontal planes were analyzed using a mesh size of 20 mm. Therefore, six brick pieces were employed, and all concrete elements had the same size of 20 mm to span the 300 mm thickness of the beams [16]. The reference samples were analyzed using a static analysis implemented in ABAQUS/Explicit. The beams were subjected to a surface load that gradually grew from zero to the point of failure. Reactions equal to shear loads were calculated by factoring in the responses at the margins where the boundary constraints were imposed [17].

Simulation RC beams using ABAQUS.

3.2.2 Material models

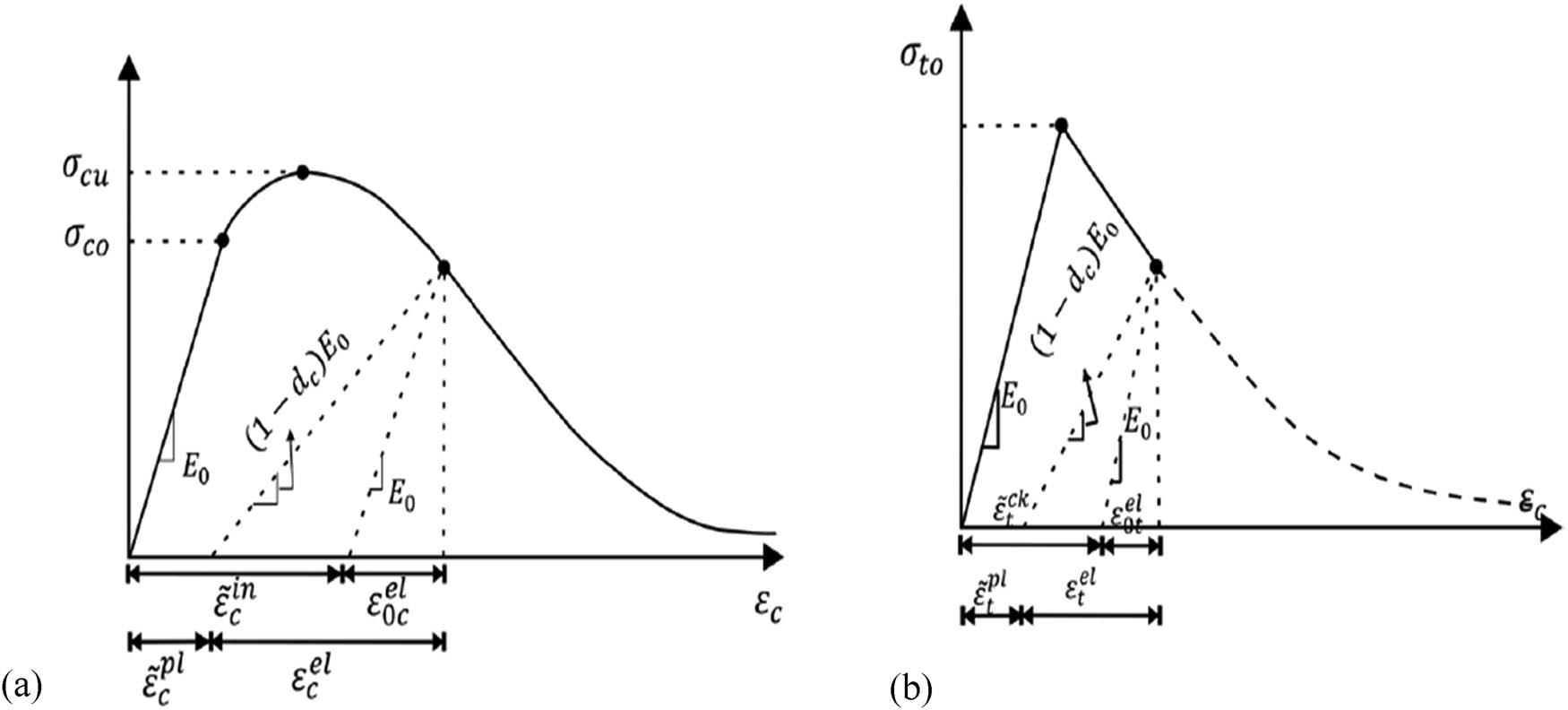

The concrete model using damaged plasticity (CDP) developed in ABAQUS was selected as the constitutive model to use in this study, and a summary of this model is provided here [18]. Figure 4 depicts the stress–strain response. The CDP model uses a stress-fracture energy method to define tension in concrete. Using theories of brittle fracture, Kytinou et al. established the energy needed to open a crack per unit area, Gf, as a material property [19].

Modeling concrete damage plasticity (CDP): (a) models of compression and (b) models of tension.

To include this idea in a FE model, a characteristic length connected to an integration point must be defined. The element geometry and formulation inform this lc, the characteristic crack length. Since the direction in which cracking may develop cannot be predicted, this method is employed. For these simulations, the critical length lc is set to 20 mm, the same as the mesh size. Different sizes were tried the mesh size 20 mm results gave realistic and accurate results.

To describe concrete’s compressive behavior, the Hognestad-type parabola is used. A bilinear strain hardening yield stress–plastic strain curve is used to simulate the uniaxial stress–strain relationship in reinforcement. Young’s modulus of 200,000 MPa and Poisson’s ratio of 0.3 are used to characterize the reinforcement’s elastic behavior.

When the stiffness of the steel is maintained at low strain magnitudes by Young’s or elastic modulus, the reinforcing bars’ steel exhibits nearly linear elastic behavior. Plasticity is the nonlinear, inelastic behavior that appears at large enough strains. Steel’s yield point and post-yield hardening characterize its plastic behavior [20].

At some point on the stress–strain curve, a material will go from behaving elastically to plastically. If the load is removed before the steel reaches its yield point, only elastic strains will have been created, and these will be completely recovered. However, permanent (plastic) deformation starts to occur after the tension in the steel surpasses the yield stress. As the metal continues to deform past the yield point, elastic and plastic strains build up simultaneously. Once the steel gives, its rigidity will decrease. Steel’s yield stress is raised by plastic deformation so that it can withstand greater loads in the future.

4 Results and discussion

4.1 Model validation

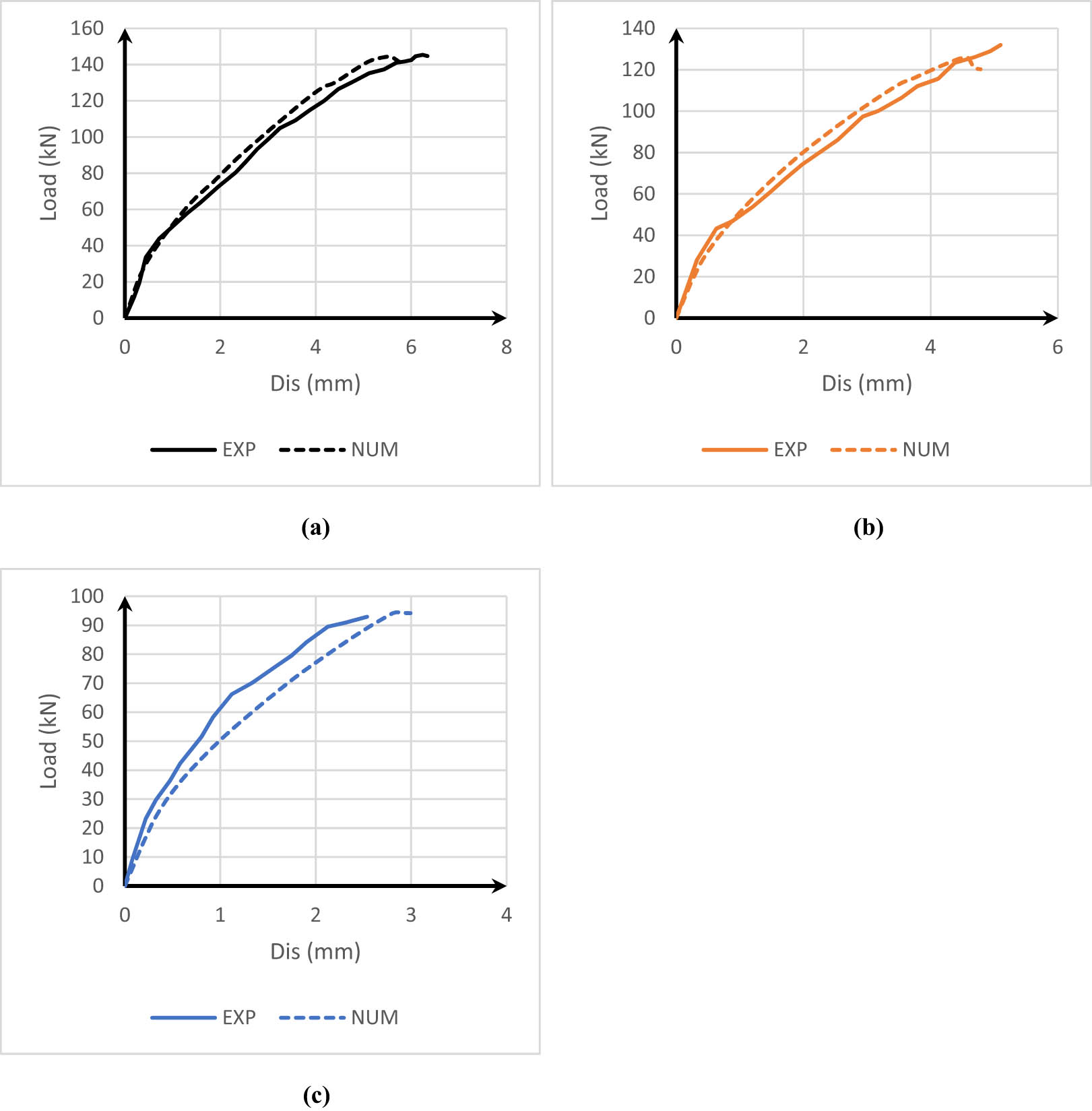

Figure 5 displays the results of a contraction between computational and experimental load–deflection curves for a control RC beam with no apertures and an RC beam with openings near the support. For all beams, the results of the FE analysis and the experimental data correspond quite well. The correlation coefficient typically ranges within reasonable thresholds of (0.003–0.045). Because the FE analysis assumes a perfect connection between the concrete and the steel reinforcement, the beam is usually seen as stronger and somewhat stiffer than it is. Additionally, the results demonstrate that a cohesive zone material constitutive model yields high agreement when compared to experimental data. The comparison’s goal is to verify the accuracy and sufficiency of all simulation procedures, such as element type, material properties, and convergence criteria.

Load–deflection curves: an experimental versus numerical comparison of validation study beams: (a) load versus deflection of B0, (b) load versus deflection of B1, and (c) load versus deflection of B2.

ABAQUS may produce results that are roughly in agreement with those from actual experiments, while there are also discrepancies between the analyzed values and those obtained experimentally. It is illustrated with pictures. However, the actual concrete’s constitution is quite complex, containing cement, sand, gravel, and so on, and these assumptions are not met in FE simulations. Their complex interaction is not simply duplicated by a single form. While the embedded technology used in FE analysis’ processing of the connection between concrete and steel greatly simplifies modeling, this impact is not replicated with an increase in the load of RC or a shift in the nature of the friction moment, especially in the context of reinforced slip simulation. This has the potential to produce skewed findings. Convergence of the FE analysis, appropriateness of simulation parameter values, shape and number of FE division, casting quality, and loading circumstances of the beam in the test all play a role in influencing the final conclusions of the analysis.

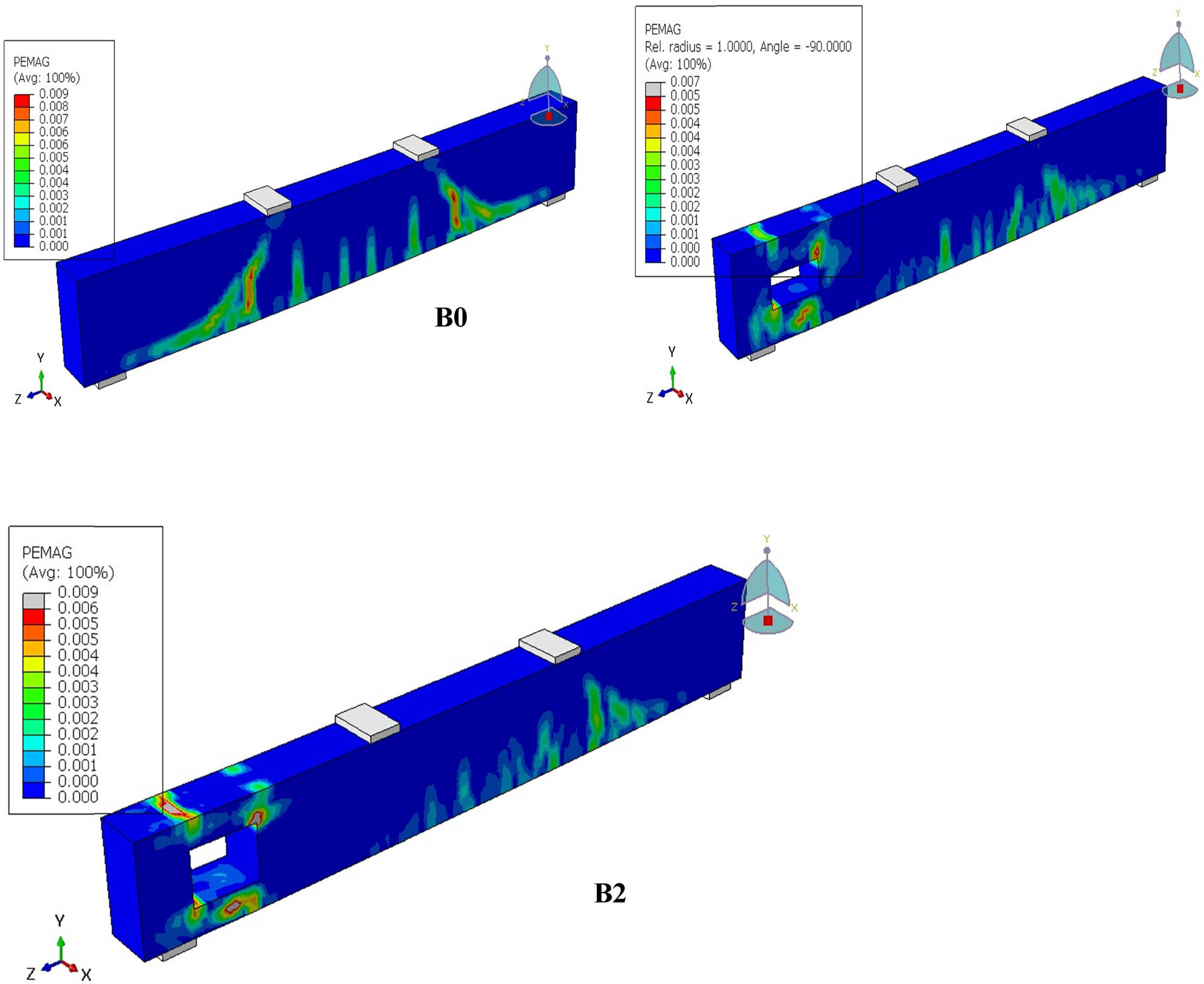

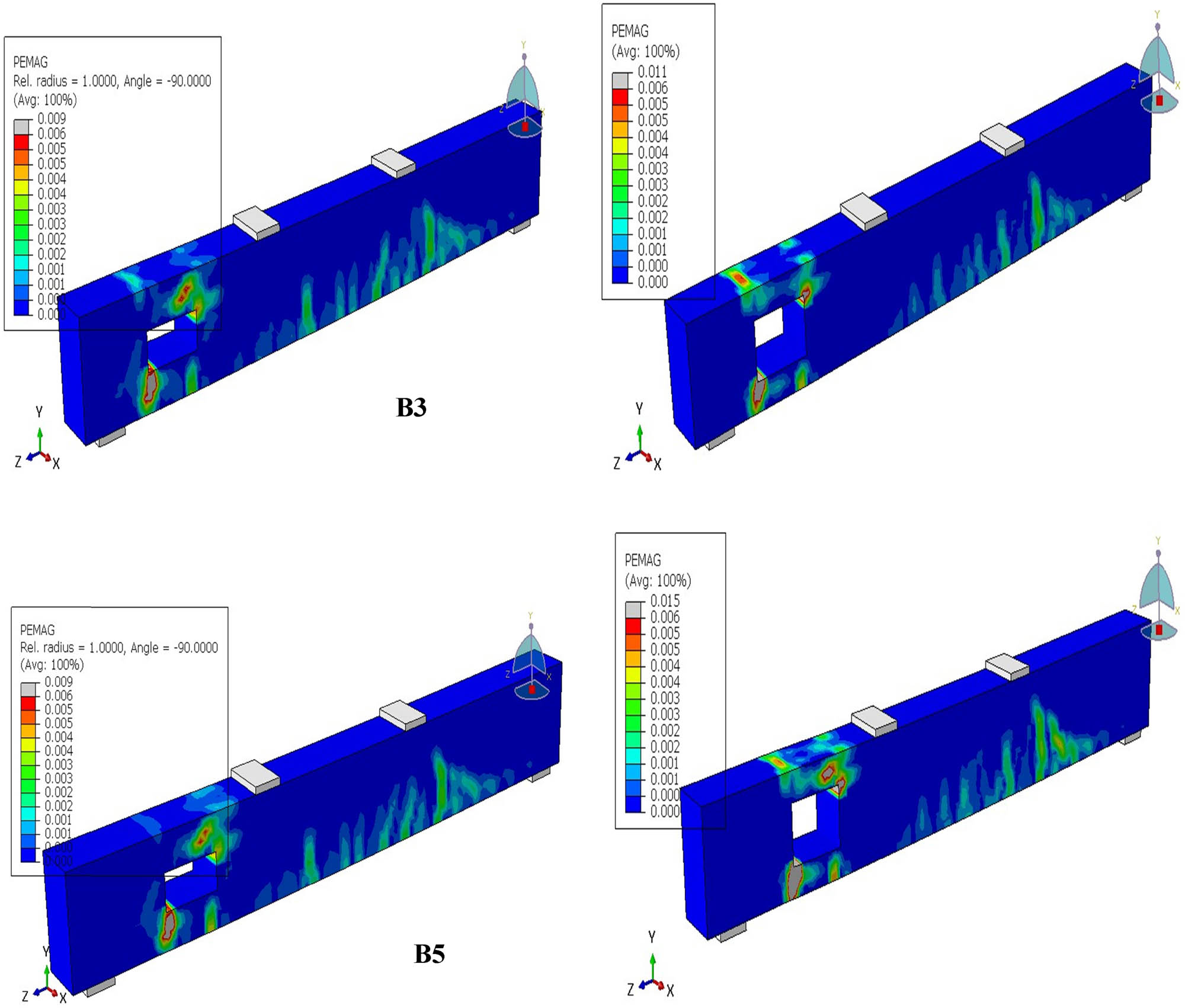

In conclusion, the FE method for nonlinear analysis of beam tests is practical, and the simulation test of RC using FEs is quite close to the real thing. It is a no-brainer crack development simulated using FEs (Figure 6) (Table 1).

FE validation models crack propagation.

Comparison load and deflection of the failure

| Beam | Opening size | Distance from support in mm | Experimental ultimate load kN (P ex) | Numerical ultimate load kN (P num) | Experimental deflection (Defex) | Numerical deflection (Defnum) | P num/P ex | Defnum/Defex |

|---|---|---|---|---|---|---|---|---|

| B0 | — | — | 144 | 144.469 | 6.341 | 5.540 | 1.003 | 0.873 |

| B1 | 200 × 100 | 0 | 132 | 125.952 | 5.100 | 4.561 | 0.954 | 0.894 |

| B2 | 200 × 150 | 0 | 93 | 94.508 | 2.539 | 2.874 | 1.016 | 1.132 |

4.2 Effect of the distance of openings from supports

As was noted, the experimental sample from a prior work has been successfully simulated within the FE model. However, more research into the effect of varying opening distances from the support is warranted. This is achieved in practice by varying the distance from the support, as illustrated in Table 2. The effect of two different aperture widths and two different distances from support on the structural behavior of the considered RC beam is investigated. The models have also been compared to the first numerical model. Figure 7 compares the proposed numerical four models’ mid-span deflection to that of the original model.

FE analysis results and experimental results are compared

| Name | Size | Distance from support (mm) | Ultimate load (kN) | Decrease of load (%) |

|---|---|---|---|---|

| B1 | 200 × 100 | 0 | 125.952 | — |

| B2 | 200 × 150 | 0 | 94.508 | 24.965 |

| B3 | 200 × 100 | 100 | 113.957 | 9.523 |

| B4 | 200 × 150 | 100 | 101.890 | 19.104 |

| B5 | 200 × 100 | 200 | 113.177 | 10.142 |

| B6 | 200 × 150 | 200 | 95.032 | 24.549 |

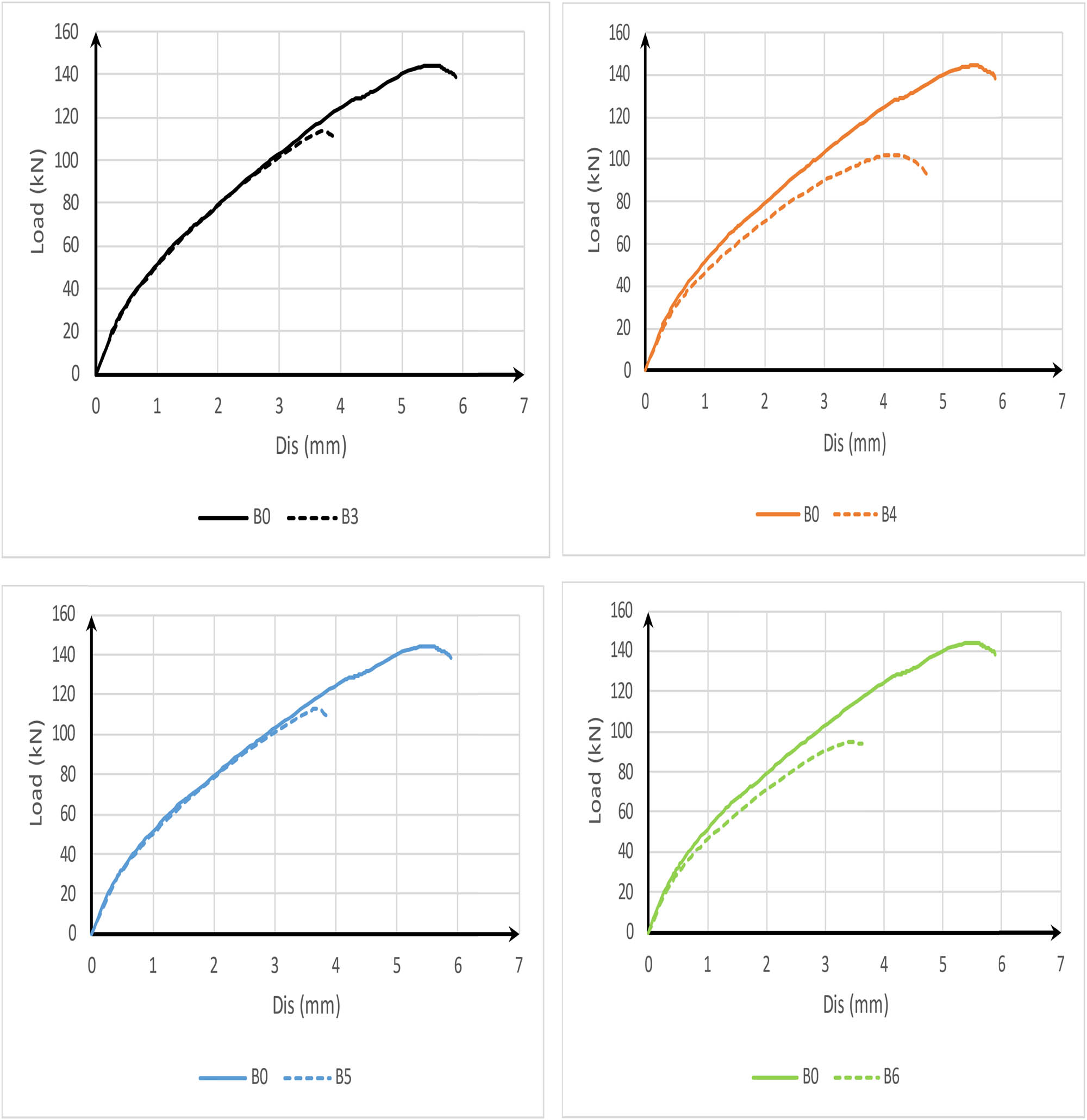

Load–deflection curves: an experimental versus numerical comparison of parametric study beams.

The fracture geometry of the failed beams tested is depicted in the elevation view in Figure 8. Spacious cracks at the openings zone and tiny flexural cracks at the mid-span are visible in beams B1 and B2. There was no discernible difference in the mode of failure between a solid beam and one with an aperture. These beams, as well as the standard beam B0, failed in a shear failure due to diagonal tension in the shear span zone. However, diagonal cracking occurred quickly once the openings were introduced, and the load at the first crack decreased as opening dimensions grew larger. Since there was no additional reinforcing at the opening’s corners, the fissures there were likewise much larger. The hole also diminished the beams’ maximum load-bearing capacity. As the applied stresses were increased, fractures in the shear direction of tension appeared in the shear span surrounding the hole. These fissures extended throughout the shear span, creating a connection between a combination of a loading point and a support. Beams B3, B4, B5, and B6 also broke under shear due to diagonal stress in the shear span zone. The shear fractures propagated along the shear span that was closed off, precisely as they did in the reference beam B0.

FE model crack propagation.

The tested beams’ load-to-midspan deflection relationship up to failure is depicted in Figure 7. All load–deflection curves have a roughly bilinear form, revealing that concrete behavior precracks and steel behavior post cracks. For the tested beams one slope transitions into another may be observed to be smooth due to the nonlinearity of the curves. When compared with the reference beam, we notice a decrease in the load by 12.8% when the opening size (200 × 100), and the decrease in bearing the applied loads increase by 21.1% when the opening is 100 mm away from the bracket and by 21.6% when the opening is 200 mm away. As for the opening measuring 150 × 200, the loads decreased by 34.6% when the opening was adjacent to the support, while it was 29.5% when it was 100 mm away and 34.2% when the opening was 200 mm away. We conclude from this that the change in force decreases with increasing distance from the support.

Beams having holes in them had failure deflections between 2.8 and 4.5 mm. Compared to the other beams with apertures, the reference beam failed at a heavier load; therefore, it had a little larger mid-span deflection of 5.5 mm. When contrasting how different beams behave, the influence of the opening size becomes apparent. B1, B2, B3, B4, B5, and B6 with the reference beam B0. Beams B2, B4, and B6 have a similar depth of opening as beams B1, B3, and B5 with a wider width. When compared with the reference sample, we notice a decrease in deflection by 17.7% when the opening is farther from the support for the opening (200 × 100), and the decrease in deflection increases by 32.7% when the opening is 100 mm away from the support and by 32.9% when the opening is 200 mm away as for the opening measuring (150 × 200), the deflection decreased by 48.1% when the opening was adjacent to the support, while it was 22.3 when it was 100 mm away and 34.2% when the opening was 200 mm away.

Figure 7 demonstrates that the load–deflection relationships of beams B1, B2, B3, B4, B5, and B6 were all quite comparable, indicating that the opening width did not have as much of an influence on load–deflection conduct as the opening depth. However, there is no discernible bilinear behavior. The magnitude of the deflection at the opening position to the mid-span deflection remains relatively constant at roughly 0.28 for both the B0 beam and whole beams that have openings.

5 Conclusions

There appears to be a pattern in the reactions of the few beams that have been examined; without additional numerical analysis, this may not be enough to demonstrate the repeatability of this study. To simulate the shear behavior of the specimens of RC beams, FE analysis was performed using the ABAQUS program, and the most important findings are shown here.

When compared to experimental data for the same geometrical parameters of RC beams, such as dimensions, boundary conditions: loading and supporting conditions, and mechanical features of materials, the results of the FE analysis demonstrated an acceptable level of agreement in general behavior, failure technique, load–deformation, and load capacity. On average, the ultimate load capacity measured in experiments was 0.8% less than what the ABAQUS computer program had estimated it would be. Although the experimental and numerical results differed in terms of deflection at ultimate loads by an average of 3.3%, the difference was not statistically significant.

Every single one of the tested beams failed due to shear, exhibiting a distinct and large crack close to one of the supports as well as tiny flexure cracks close to the midspan.

A decrease in shear capacity of up to 24.9% was incurred as a consequence of the insertion of apertures with bigger diameters.

As a result of the pre-cracking tendency of concrete being so prominent, and steel behavior after cracking, all RC beams exhibited almost similar load–deflection characteristics. These relationships were observed for all beams.

The beams that had apertures in them had failure deflections that varied from 2.8 to 4.5 mm, which were lower than the failure deflections of solid beams.

Beams with tiny aperture sizes exhibited load–deflection behavior that was comparable to that of the solid beam that served as the reference.

-

Funding information: The author states no funding involved.

-

Author contribution: The author confirms the sole responsibility for the conception of the study, presented results, and manuscript preparation.

-

Conflict of interest: The author states no conflict of interest.

-

Data availability statement: Data sharing does not apply to this article as no datasets were generated or analyzed during the current study.

References

[1] Taher HMAM, Dawood MB. Shear strengthening of continuous prestressed concrete beams with precast SIFCON laminates subjected to monotonic and repeated loads. Mater Today Proc. 2022;60:2004–9. 10.1016/j.matpr.2022.01.250.Search in Google Scholar

[2] Dawood MB, Taher HMAM. Various methods for retrofitting prestressed concrete members: A critical review. Periodicals Eng Nat Sci (PEN). Apr. 2021;9(2):657. 10.21533/pen.v9i2.1849.Search in Google Scholar

[3] Dawood MB, Taher HMAM. Experimental investigations of flexural and shear behavior of continuous prestressed HSC beams under repeated loads. Meas: Sens. Feb. 2023;25:100682. 10.1016/j.measen.2023.100682.Search in Google Scholar

[4] Aykac B, Kalkan I, Aykac S, Egriboz YE. Flexural behavior of RC beams with regular square or circular web openings. Eng Struct. Nov. 2013;56:2165–74. 10.1016/j.engstruct.2013.08.043.Search in Google Scholar

[5] Mansur MA, Ting SK, Lee S. Torsion tests of R/C beams with large openings. J Struct Eng. Aug. 1983;109(8):1780–91. 10.1061/(ASCE)0733-9445(1983)109:8(1780).Search in Google Scholar

[6] Naik NK, Kumar RR, Rajaiah K. Optimum hole shapes in beams under pure bending. J Eng Mech. Apr. 1986;112(4):407–11. 10.1061/(ASCE)0733-9399(1986)112:4(407).Search in Google Scholar

[7] Mansur MA, Tan KH, Lee YF, Lee SL. Piecewise linear behavior of RC beams with openings. J Struct Eng. Jun. 1991;117(6):1607–21. 10.1061/(ASCE)0733-9445(1991)117:6(1607).Search in Google Scholar

[8] Thevendran V, Shanmugam NE. Lateral buckling of doubly symmetric beams containing openings. J Eng Mech. Jul. 1991;117(7):1427–41. 10.1061/(ASCE)0733-9399(1991)117:7(1427).Search in Google Scholar

[9] Mansur MA, Tan K-H, Weng W. Analysis of reinforced concrete beams with circular openings using strut-and-tie model. In: Structural engineering, mechanics and computation. Cape Town: Elsevier; 2001. p. 311–8. 10.1016/B978-008043948-8/50030-8.Search in Google Scholar

[10] Abdalla HA, Torkey AM, Haggag HA, Abu-Amira AF. Design against cracking at openings in reinforced concrete beams strengthened with composite sheets. Compos Struct. May 2003;60(2):197–204. 10.1016/S0263-8223(02)00305-7.Search in Google Scholar

[11] El-Maaddawy T, El-Ariss B. Behavior of concrete beams with short shear span and web opening strengthened in shear with CFRP composites. J Compos Constr. Feb. 2012;16(1):47–59. 10.1061/(ASCE)CC.1943-5614.0000237.Search in Google Scholar

[12] Mansur MA. Effect of openings on the behaviour and strength of R/C beams in shear. Cem Concr Compos. 1998;20(6):477–86.10.1016/S0958-9465(98)00030-4Search in Google Scholar

[13] Daniel JJ. Experimental and numerical study on the cracking behavior and flexural strength of RC shallow beams with rectangular opening and varying length. Structures. 2022;40:460–8.10.1016/j.istruc.2022.04.040Search in Google Scholar

[14] Elansary AA, Abdel Aty AA, Abdalla HA, Zawam M. Shear behavior of reinforced concrete beams with web opening near supports. Structures. Mar. 2022;37:1033–41. 10.1016/j.istruc.2022.01.040.Search in Google Scholar

[15] Turkyilmazoglu M. Three dimensional viscous flow due to a squeezing porous slider. Eur J Mechanics-B/Fluids. 2023;98:253–9.10.1016/j.euromechflu.2022.12.015Search in Google Scholar

[16] Kazaz I. Finite element analysis of shear-critical reinforced concrete walls. Comput Concr. 2011;8(3):143–62.10.12989/cac.2011.8.2.143Search in Google Scholar

[17] Demir A, Caglar N, Ozturk H, Sumer Y. Nonlinear finite element study on the improvement of shear capacity in reinforced concrete T-Section beams by an alternative diagonal shear reinforcement. Eng Struct. 2016;120:158–65.10.1016/j.engstruct.2016.04.029Search in Google Scholar

[18] Huang Z, Lü Z, Song S, Tu Y, Blanksvärd T, Sas G, et al. Finite element analysis of shear deformation in reinforced concrete shear-critical beams. Struct Infrastruct Eng. 2018;14(6):791–806.10.1080/15732479.2017.1360915Search in Google Scholar

[19] Kytinou VK, Chalioris CE, Karayannis CG. Analysis of residual flexural stiffness of steel fiber-reinforced concrete beams with steel reinforcement. Materials. 2020;13(12):2698.10.3390/ma13122698Search in Google Scholar PubMed PubMed Central

[20] Chalioris CE, Kytinou VK, Voutetaki ME, Karayannis CG. Flexural damage diagnosis in reinforced concrete beams using a wireless admittance monitoring system – Tests and finite element analysis. Sensors. 2021;21(3):679.10.3390/s21030679Search in Google Scholar PubMed PubMed Central

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Articles

- Methodology of automated quality management

- Influence of vibratory conveyor design parameters on the trough motion and the self-synchronization of inertial vibrators

- Application of finite element method in industrial design, example of an electric motorcycle design project

- Correlative evaluation of the corrosion resilience and passivation properties of zinc and aluminum alloys in neutral chloride and acid-chloride solutions

- Will COVID “encourage” B2B and data exchange engineering in logistic firms?

- Influence of unsupported sleepers on flange climb derailment of two freight wagons

- A hybrid detection algorithm for 5G OTFS waveform for 64 and 256 QAM with Rayleigh and Rician channels

- Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy

- Exploring the potential of ammonia and hydrogen as alternative fuels for transportation

- Impact of insulation on energy consumption and CO2 emissions in high-rise commercial buildings at various climate zones

- Advanced autopilot design with extremum-seeking control for aircraft control

- Adaptive multidimensional trust-based recommendation model for peer to peer applications

- Effects of CFRP sheets on the flexural behavior of high-strength concrete beam

- Enhancing urban sustainability through industrial synergy: A multidisciplinary framework for integrating sustainable industrial practices within urban settings – The case of Hamadan industrial city

- Advanced vibrant controller results of an energetic framework structure

- Application of the Taguchi method and RSM for process parameter optimization in AWSJ machining of CFRP composite-based orthopedic implants

- Improved correlation of soil modulus with SPT N values

- Technologies for high-temperature batch annealing of grain-oriented electrical steel: An overview

- Assessing the need for the adoption of digitalization in Indian small and medium enterprises

- A non-ideal hybridization issue for vertical TFET-based dielectric-modulated biosensor

- Optimizing data retrieval for enhanced data integrity verification in cloud environments

- Performance analysis of nonlinear crosstalk of WDM systems using modulation schemes criteria

- Nonlinear finite-element analysis of RC beams with various opening near supports

- Thermal analysis of Fe3O4–Cu/water over a cone: a fractional Maxwell model

- Radial–axial runner blade design using the coordinate slice technique

- Theoretical and experimental comparison between straight and curved continuous box girders

- Effect of the reinforcement ratio on the mechanical behaviour of textile-reinforced concrete composite: Experiment and numerical modeling

- Experimental and numerical investigation on composite beam–column joint connection behavior using different types of connection schemes

- Enhanced performance and robustness in anti-lock brake systems using barrier function-based integral sliding mode control

- Evaluation of the creep strength of samples produced by fused deposition modeling

- A combined feedforward-feedback controller design for nonlinear systems

- Effect of adjacent structures on footing settlement for different multi-building arrangements

- Analyzing the impact of curved tracks on wheel flange thickness reduction in railway systems

- Review Articles

- Mechanical and smart properties of cement nanocomposites containing nanomaterials: A brief review

- Applications of nanotechnology and nanoproduction techniques

- Relationship between indoor environmental quality and guests’ comfort and satisfaction at green hotels: A comprehensive review

- Communication

- Techniques to mitigate the admission of radon inside buildings

- Erratum

- Erratum to “Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy”

- Special Issue: AESMT-3 - Part II

- Integrated fuzzy logic and multicriteria decision model methods for selecting suitable sites for wastewater treatment plant: A case study in the center of Basrah, Iraq

- Physical and mechanical response of porous metals composites with nano-natural additives

- Special Issue: AESMT-4 - Part II

- New recycling method of lubricant oil and the effect on the viscosity and viscous shear as an environmentally friendly

- Identify the effect of Fe2O3 nanoparticles on mechanical and microstructural characteristics of aluminum matrix composite produced by powder metallurgy technique

- Static behavior of piled raft foundation in clay

- Ultra-low-power CMOS ring oscillator with minimum power consumption of 2.9 pW using low-voltage biasing technique

- Using ANN for well type identifying and increasing production from Sa’di formation of Halfaya oil field – Iraq

- Optimizing the performance of concrete tiles using nano-papyrus and carbon fibers

- Special Issue: AESMT-5 - Part II

- Comparative the effect of distribution transformer coil shape on electromagnetic forces and their distribution using the FEM

- The complex of Weyl module in free characteristic in the event of a partition (7,5,3)

- Restrained captive domination number

- Experimental study of improving hot mix asphalt reinforced with carbon fibers

- Asphalt binder modified with recycled tyre rubber

- Thermal performance of radiant floor cooling with phase change material for energy-efficient buildings

- Surveying the prediction of risks in cryptocurrency investments using recurrent neural networks

- A deep reinforcement learning framework to modify LQR for an active vibration control applied to 2D building models

- Evaluation of mechanically stabilized earth retaining walls for different soil–structure interaction methods: A review

- Assessment of heat transfer in a triangular duct with different configurations of ribs using computational fluid dynamics

- Sulfate removal from wastewater by using waste material as an adsorbent

- Experimental investigation on strengthening lap joints subjected to bending in glulam timber beams using CFRP sheets

- A study of the vibrations of a rotor bearing suspended by a hybrid spring system of shape memory alloys

- Stability analysis of Hub dam under rapid drawdown

- Developing ANFIS-FMEA model for assessment and prioritization of potential trouble factors in Iraqi building projects

- Numerical and experimental comparison study of piled raft foundation

- Effect of asphalt modified with waste engine oil on the durability properties of hot asphalt mixtures with reclaimed asphalt pavement

- Hydraulic model for flood inundation in Diyala River Basin using HEC-RAS, PMP, and neural network

- Numerical study on discharge capacity of piano key side weir with various ratios of the crest length to the width

- The optimal allocation of thyristor-controlled series compensators for enhancement HVAC transmission lines Iraqi super grid by using seeker optimization algorithm

- Numerical and experimental study of the impact on aerodynamic characteristics of the NACA0012 airfoil

- Effect of nano-TiO2 on physical and rheological properties of asphalt cement

- Performance evolution of novel palm leaf powder used for enhancing hot mix asphalt

- Performance analysis, evaluation, and improvement of selected unsignalized intersection using SIDRA software – Case study

- Flexural behavior of RC beams externally reinforced with CFRP composites using various strategies

- Influence of fiber types on the properties of the artificial cold-bonded lightweight aggregates

- Experimental investigation of RC beams strengthened with externally bonded BFRP composites

- Generalized RKM methods for solving fifth-order quasi-linear fractional partial differential equation

- An experimental and numerical study investigating sediment transport position in the bed of sewer pipes in Karbala

- Role of individual component failure in the performance of a 1-out-of-3 cold standby system: A Markov model approach

- Implementation for the cases (5, 4) and (5, 4)/(2, 0)

- Center group actions and related concepts

- Experimental investigation of the effect of horizontal construction joints on the behavior of deep beams

- Deletion of a vertex in even sum domination

- Deep learning techniques in concrete powder mix designing

- Effect of loading type in concrete deep beam with strut reinforcement

- Studying the effect of using CFRP warping on strength of husk rice concrete columns

- Parametric analysis of the influence of climatic factors on the formation of traditional buildings in the city of Al Najaf

- Suitability location for landfill using a fuzzy-GIS model: A case study in Hillah, Iraq

- Hybrid approach for cost estimation of sustainable building projects using artificial neural networks

- Assessment of indirect tensile stress and tensile–strength ratio and creep compliance in HMA mixes with micro-silica and PMB

- Density functional theory to study stopping power of proton in water, lung, bladder, and intestine

- A review of single flow, flow boiling, and coating microchannel studies

- Effect of GFRP bar length on the flexural behavior of hybrid concrete beams strengthened with NSM bars

- Exploring the impact of parameters on flow boiling heat transfer in microchannels and coated microtubes: A comprehensive review

- Crumb rubber modification for enhanced rutting resistance in asphalt mixtures

- Special Issue: AESMT-6

- Design of a new sorting colors system based on PLC, TIA portal, and factory I/O programs

- Forecasting empirical formula for suspended sediment load prediction at upstream of Al-Kufa barrage, Kufa City, Iraq

- Optimization and characterization of sustainable geopolymer mortars based on palygorskite clay, water glass, and sodium hydroxide

- Sediment transport modelling upstream of Al Kufa Barrage

- Study of energy loss, range, and stopping time for proton in germanium and copper materials

- Effect of internal and external recycle ratios on the nutrient removal efficiency of anaerobic/anoxic/oxic (VIP) wastewater treatment plant

- Enhancing structural behaviour of polypropylene fibre concrete columns longitudinally reinforced with fibreglass bars

- Sustainable road paving: Enhancing concrete paver blocks with zeolite-enhanced cement

- Evaluation of the operational performance of Karbala waste water treatment plant under variable flow using GPS-X model

- Design and simulation of photonic crystal fiber for highly sensitive chemical sensing applications

- Optimization and design of a new column sequencing for crude oil distillation at Basrah refinery

- Inductive 3D numerical modelling of the tibia bone using MRI to examine von Mises stress and overall deformation

- An image encryption method based on modified elliptic curve Diffie-Hellman key exchange protocol and Hill Cipher

- Experimental investigation of generating superheated steam using a parabolic dish with a cylindrical cavity receiver: A case study

- Effect of surface roughness on the interface behavior of clayey soils

- Investigated of the optical properties for SiO2 by using Lorentz model

- Measurements of induced vibrations due to steel pipe pile driving in Al-Fao soil: Effect of partial end closure

- Experimental and numerical studies of ballistic resistance of hybrid sandwich composite body armor

- Evaluation of clay layer presence on shallow foundation settlement in dry sand under an earthquake

- Optimal design of mechanical performances of asphalt mixtures comprising nano-clay additives

- Advancing seismic performance: Isolators, TMDs, and multi-level strategies in reinforced concrete buildings

- Predicted evaporation in Basrah using artificial neural networks

- Energy management system for a small town to enhance quality of life

- Numerical study on entropy minimization in pipes with helical airfoil and CuO nanoparticle integration

- Equations and methodologies of inlet drainage system discharge coefficients: A review

- Thermal buckling analysis for hybrid and composite laminated plate by using new displacement function

- Investigation into the mechanical and thermal properties of lightweight mortar using commercial beads or recycled expanded polystyrene

- Experimental and theoretical analysis of single-jet column and concrete column using double-jet grouting technique applied at Al-Rashdia site

- The impact of incorporating waste materials on the mechanical and physical characteristics of tile adhesive materials

- Seismic resilience: Innovations in structural engineering for earthquake-prone areas

- Automatic human identification using fingerprint images based on Gabor filter and SIFT features fusion

- Performance of GRKM-method for solving classes of ordinary and partial differential equations of sixth-orders

- Visible light-boosted photodegradation activity of Ag–AgVO3/Zn0.5Mn0.5Fe2O4 supported heterojunctions for effective degradation of organic contaminates

- Production of sustainable concrete with treated cement kiln dust and iron slag waste aggregate

- Key effects on the structural behavior of fiber-reinforced lightweight concrete-ribbed slabs: A review

- A comparative analysis of the energy dissipation efficiency of various piano key weir types

- Special Issue: Transport 2022 - Part II

- Variability in road surface temperature in urban road network – A case study making use of mobile measurements

- Special Issue: BCEE5-2023

- Evaluation of reclaimed asphalt mixtures rejuvenated with waste engine oil to resist rutting deformation

- Assessment of potential resistance to moisture damage and fatigue cracks of asphalt mixture modified with ground granulated blast furnace slag

- Investigating seismic response in adjacent structures: A study on the impact of buildings’ orientation and distance considering soil–structure interaction

- Improvement of porosity of mortar using polyethylene glycol pre-polymer-impregnated mortar

- Three-dimensional analysis of steel beam-column bolted connections

- Assessment of agricultural drought in Iraq employing Landsat and MODIS imagery

- Performance evaluation of grouted porous asphalt concrete

- Optimization of local modified metakaolin-based geopolymer concrete by Taguchi method

- Effect of waste tire products on some characteristics of roller-compacted concrete

- Studying the lateral displacement of retaining wall supporting sandy soil under dynamic loads

- Seismic performance evaluation of concrete buttress dram (Dynamic linear analysis)

- Behavior of soil reinforced with micropiles

- Possibility of production high strength lightweight concrete containing organic waste aggregate and recycled steel fibers

- An investigation of self-sensing and mechanical properties of smart engineered cementitious composites reinforced with functional materials

- Forecasting changes in precipitation and temperatures of a regional watershed in Northern Iraq using LARS-WG model

- Experimental investigation of dynamic soil properties for modeling energy-absorbing layers

- Numerical investigation of the effect of longitudinal steel reinforcement ratio on the ductility of concrete beams

- An experimental study on the tensile properties of reinforced asphalt pavement

- Self-sensing behavior of hot asphalt mixture with steel fiber-based additive

- Behavior of ultra-high-performance concrete deep beams reinforced by basalt fibers

- Optimizing asphalt binder performance with various PET types

- Investigation of the hydraulic characteristics and homogeneity of the microstructure of the air voids in the sustainable rigid pavement

- Enhanced biogas production from municipal solid waste via digestion with cow manure: A case study

- Special Issue: AESMT-7 - Part I

- Preparation and investigation of cobalt nanoparticles by laser ablation: Structure, linear, and nonlinear optical properties

- Seismic analysis of RC building with plan irregularity in Baghdad/Iraq to obtain the optimal behavior

- The effect of urban environment on large-scale path loss model’s main parameters for mmWave 5G mobile network in Iraq

- Formatting a questionnaire for the quality control of river bank roads

- Vibration suppression of smart composite beam using model predictive controller

- Machine learning-based compressive strength estimation in nanomaterial-modified lightweight concrete

- In-depth analysis of critical factors affecting Iraqi construction projects performance

- Behavior of container berth structure under the influence of environmental and operational loads

- Energy absorption and impact response of ballistic resistance laminate

- Effect of water-absorbent polymer balls in internal curing on punching shear behavior of bubble slabs

- Effect of surface roughness on interface shear strength parameters of sandy soils

- Evaluating the interaction for embedded H-steel section in normal concrete under monotonic and repeated loads

- Estimation of the settlement of pile head using ANN and multivariate linear regression based on the results of load transfer method

- Enhancing communication: Deep learning for Arabic sign language translation

- A review of recent studies of both heat pipe and evaporative cooling in passive heat recovery

- Effect of nano-silica on the mechanical properties of LWC

- An experimental study of some mechanical properties and absorption for polymer-modified cement mortar modified with superplasticizer

- Digital beamforming enhancement with LSTM-based deep learning for millimeter wave transmission

- Developing an efficient planning process for heritage buildings maintenance in Iraq

- Design and optimization of two-stage controller for three-phase multi-converter/multi-machine electric vehicle

- Evaluation of microstructure and mechanical properties of Al1050/Al2O3/Gr composite processed by forming operation ECAP

- Calculations of mass stopping power and range of protons in organic compounds (CH3OH, CH2O, and CO2) at energy range of 0.01–1,000 MeV

- Investigation of in vitro behavior of composite coating hydroxyapatite-nano silver on 316L stainless steel substrate by electrophoretic technic for biomedical tools

- A review: Enhancing tribological properties of journal bearings composite materials

- Improvements in the randomness and security of digital currency using the photon sponge hash function through Maiorana–McFarland S-box replacement

- Design a new scheme for image security using a deep learning technique of hierarchical parameters

- Special Issue: ICES 2023

- Comparative geotechnical analysis for ultimate bearing capacity of precast concrete piles using cone resistance measurements

- Visualizing sustainable rainwater harvesting: A case study of Karbala Province

- Geogrid reinforcement for improving bearing capacity and stability of square foundations

- Evaluation of the effluent concentrations of Karbala wastewater treatment plant using reliability analysis

- Adsorbent made with inexpensive, local resources

- Effect of drain pipes on seepage and slope stability through a zoned earth dam

- Sediment accumulation in an 8 inch sewer pipe for a sample of various particles obtained from the streets of Karbala city, Iraq

- Special Issue: IETAS 2024 - Part I

- Analyzing the impact of transfer learning on explanation accuracy in deep learning-based ECG recognition systems

- Effect of scale factor on the dynamic response of frame foundations

- Improving multi-object detection and tracking with deep learning, DeepSORT, and frame cancellation techniques

- The impact of using prestressed CFRP bars on the development of flexural strength

- Assessment of surface hardness and impact strength of denture base resins reinforced with silver–titanium dioxide and silver–zirconium dioxide nanoparticles: In vitro study

- A data augmentation approach to enhance breast cancer detection using generative adversarial and artificial neural networks

- Modification of the 5D Lorenz chaotic map with fuzzy numbers for video encryption in cloud computing

- Special Issue: 51st KKBN - Part I

- Evaluation of static bending caused damage of glass-fiber composite structure using terahertz inspection

Articles in the same Issue

- Regular Articles

- Methodology of automated quality management

- Influence of vibratory conveyor design parameters on the trough motion and the self-synchronization of inertial vibrators

- Application of finite element method in industrial design, example of an electric motorcycle design project

- Correlative evaluation of the corrosion resilience and passivation properties of zinc and aluminum alloys in neutral chloride and acid-chloride solutions

- Will COVID “encourage” B2B and data exchange engineering in logistic firms?

- Influence of unsupported sleepers on flange climb derailment of two freight wagons

- A hybrid detection algorithm for 5G OTFS waveform for 64 and 256 QAM with Rayleigh and Rician channels

- Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy

- Exploring the potential of ammonia and hydrogen as alternative fuels for transportation

- Impact of insulation on energy consumption and CO2 emissions in high-rise commercial buildings at various climate zones

- Advanced autopilot design with extremum-seeking control for aircraft control

- Adaptive multidimensional trust-based recommendation model for peer to peer applications

- Effects of CFRP sheets on the flexural behavior of high-strength concrete beam

- Enhancing urban sustainability through industrial synergy: A multidisciplinary framework for integrating sustainable industrial practices within urban settings – The case of Hamadan industrial city

- Advanced vibrant controller results of an energetic framework structure

- Application of the Taguchi method and RSM for process parameter optimization in AWSJ machining of CFRP composite-based orthopedic implants

- Improved correlation of soil modulus with SPT N values

- Technologies for high-temperature batch annealing of grain-oriented electrical steel: An overview

- Assessing the need for the adoption of digitalization in Indian small and medium enterprises

- A non-ideal hybridization issue for vertical TFET-based dielectric-modulated biosensor

- Optimizing data retrieval for enhanced data integrity verification in cloud environments

- Performance analysis of nonlinear crosstalk of WDM systems using modulation schemes criteria

- Nonlinear finite-element analysis of RC beams with various opening near supports

- Thermal analysis of Fe3O4–Cu/water over a cone: a fractional Maxwell model

- Radial–axial runner blade design using the coordinate slice technique

- Theoretical and experimental comparison between straight and curved continuous box girders

- Effect of the reinforcement ratio on the mechanical behaviour of textile-reinforced concrete composite: Experiment and numerical modeling

- Experimental and numerical investigation on composite beam–column joint connection behavior using different types of connection schemes

- Enhanced performance and robustness in anti-lock brake systems using barrier function-based integral sliding mode control

- Evaluation of the creep strength of samples produced by fused deposition modeling

- A combined feedforward-feedback controller design for nonlinear systems

- Effect of adjacent structures on footing settlement for different multi-building arrangements

- Analyzing the impact of curved tracks on wheel flange thickness reduction in railway systems

- Review Articles

- Mechanical and smart properties of cement nanocomposites containing nanomaterials: A brief review

- Applications of nanotechnology and nanoproduction techniques

- Relationship between indoor environmental quality and guests’ comfort and satisfaction at green hotels: A comprehensive review

- Communication

- Techniques to mitigate the admission of radon inside buildings

- Erratum

- Erratum to “Effect of short heat treatment on mechanical properties and shape memory properties of Cu–Al–Ni shape memory alloy”

- Special Issue: AESMT-3 - Part II

- Integrated fuzzy logic and multicriteria decision model methods for selecting suitable sites for wastewater treatment plant: A case study in the center of Basrah, Iraq

- Physical and mechanical response of porous metals composites with nano-natural additives

- Special Issue: AESMT-4 - Part II

- New recycling method of lubricant oil and the effect on the viscosity and viscous shear as an environmentally friendly

- Identify the effect of Fe2O3 nanoparticles on mechanical and microstructural characteristics of aluminum matrix composite produced by powder metallurgy technique

- Static behavior of piled raft foundation in clay

- Ultra-low-power CMOS ring oscillator with minimum power consumption of 2.9 pW using low-voltage biasing technique

- Using ANN for well type identifying and increasing production from Sa’di formation of Halfaya oil field – Iraq

- Optimizing the performance of concrete tiles using nano-papyrus and carbon fibers

- Special Issue: AESMT-5 - Part II

- Comparative the effect of distribution transformer coil shape on electromagnetic forces and their distribution using the FEM

- The complex of Weyl module in free characteristic in the event of a partition (7,5,3)

- Restrained captive domination number

- Experimental study of improving hot mix asphalt reinforced with carbon fibers

- Asphalt binder modified with recycled tyre rubber

- Thermal performance of radiant floor cooling with phase change material for energy-efficient buildings

- Surveying the prediction of risks in cryptocurrency investments using recurrent neural networks

- A deep reinforcement learning framework to modify LQR for an active vibration control applied to 2D building models

- Evaluation of mechanically stabilized earth retaining walls for different soil–structure interaction methods: A review

- Assessment of heat transfer in a triangular duct with different configurations of ribs using computational fluid dynamics

- Sulfate removal from wastewater by using waste material as an adsorbent

- Experimental investigation on strengthening lap joints subjected to bending in glulam timber beams using CFRP sheets

- A study of the vibrations of a rotor bearing suspended by a hybrid spring system of shape memory alloys

- Stability analysis of Hub dam under rapid drawdown

- Developing ANFIS-FMEA model for assessment and prioritization of potential trouble factors in Iraqi building projects

- Numerical and experimental comparison study of piled raft foundation

- Effect of asphalt modified with waste engine oil on the durability properties of hot asphalt mixtures with reclaimed asphalt pavement

- Hydraulic model for flood inundation in Diyala River Basin using HEC-RAS, PMP, and neural network

- Numerical study on discharge capacity of piano key side weir with various ratios of the crest length to the width

- The optimal allocation of thyristor-controlled series compensators for enhancement HVAC transmission lines Iraqi super grid by using seeker optimization algorithm

- Numerical and experimental study of the impact on aerodynamic characteristics of the NACA0012 airfoil

- Effect of nano-TiO2 on physical and rheological properties of asphalt cement

- Performance evolution of novel palm leaf powder used for enhancing hot mix asphalt

- Performance analysis, evaluation, and improvement of selected unsignalized intersection using SIDRA software – Case study

- Flexural behavior of RC beams externally reinforced with CFRP composites using various strategies

- Influence of fiber types on the properties of the artificial cold-bonded lightweight aggregates

- Experimental investigation of RC beams strengthened with externally bonded BFRP composites

- Generalized RKM methods for solving fifth-order quasi-linear fractional partial differential equation

- An experimental and numerical study investigating sediment transport position in the bed of sewer pipes in Karbala

- Role of individual component failure in the performance of a 1-out-of-3 cold standby system: A Markov model approach

- Implementation for the cases (5, 4) and (5, 4)/(2, 0)

- Center group actions and related concepts

- Experimental investigation of the effect of horizontal construction joints on the behavior of deep beams

- Deletion of a vertex in even sum domination

- Deep learning techniques in concrete powder mix designing

- Effect of loading type in concrete deep beam with strut reinforcement

- Studying the effect of using CFRP warping on strength of husk rice concrete columns

- Parametric analysis of the influence of climatic factors on the formation of traditional buildings in the city of Al Najaf

- Suitability location for landfill using a fuzzy-GIS model: A case study in Hillah, Iraq

- Hybrid approach for cost estimation of sustainable building projects using artificial neural networks

- Assessment of indirect tensile stress and tensile–strength ratio and creep compliance in HMA mixes with micro-silica and PMB

- Density functional theory to study stopping power of proton in water, lung, bladder, and intestine

- A review of single flow, flow boiling, and coating microchannel studies

- Effect of GFRP bar length on the flexural behavior of hybrid concrete beams strengthened with NSM bars

- Exploring the impact of parameters on flow boiling heat transfer in microchannels and coated microtubes: A comprehensive review

- Crumb rubber modification for enhanced rutting resistance in asphalt mixtures

- Special Issue: AESMT-6

- Design of a new sorting colors system based on PLC, TIA portal, and factory I/O programs

- Forecasting empirical formula for suspended sediment load prediction at upstream of Al-Kufa barrage, Kufa City, Iraq

- Optimization and characterization of sustainable geopolymer mortars based on palygorskite clay, water glass, and sodium hydroxide

- Sediment transport modelling upstream of Al Kufa Barrage

- Study of energy loss, range, and stopping time for proton in germanium and copper materials

- Effect of internal and external recycle ratios on the nutrient removal efficiency of anaerobic/anoxic/oxic (VIP) wastewater treatment plant

- Enhancing structural behaviour of polypropylene fibre concrete columns longitudinally reinforced with fibreglass bars

- Sustainable road paving: Enhancing concrete paver blocks with zeolite-enhanced cement

- Evaluation of the operational performance of Karbala waste water treatment plant under variable flow using GPS-X model

- Design and simulation of photonic crystal fiber for highly sensitive chemical sensing applications

- Optimization and design of a new column sequencing for crude oil distillation at Basrah refinery

- Inductive 3D numerical modelling of the tibia bone using MRI to examine von Mises stress and overall deformation

- An image encryption method based on modified elliptic curve Diffie-Hellman key exchange protocol and Hill Cipher

- Experimental investigation of generating superheated steam using a parabolic dish with a cylindrical cavity receiver: A case study

- Effect of surface roughness on the interface behavior of clayey soils

- Investigated of the optical properties for SiO2 by using Lorentz model

- Measurements of induced vibrations due to steel pipe pile driving in Al-Fao soil: Effect of partial end closure

- Experimental and numerical studies of ballistic resistance of hybrid sandwich composite body armor

- Evaluation of clay layer presence on shallow foundation settlement in dry sand under an earthquake

- Optimal design of mechanical performances of asphalt mixtures comprising nano-clay additives

- Advancing seismic performance: Isolators, TMDs, and multi-level strategies in reinforced concrete buildings

- Predicted evaporation in Basrah using artificial neural networks

- Energy management system for a small town to enhance quality of life

- Numerical study on entropy minimization in pipes with helical airfoil and CuO nanoparticle integration

- Equations and methodologies of inlet drainage system discharge coefficients: A review

- Thermal buckling analysis for hybrid and composite laminated plate by using new displacement function

- Investigation into the mechanical and thermal properties of lightweight mortar using commercial beads or recycled expanded polystyrene

- Experimental and theoretical analysis of single-jet column and concrete column using double-jet grouting technique applied at Al-Rashdia site

- The impact of incorporating waste materials on the mechanical and physical characteristics of tile adhesive materials

- Seismic resilience: Innovations in structural engineering for earthquake-prone areas

- Automatic human identification using fingerprint images based on Gabor filter and SIFT features fusion

- Performance of GRKM-method for solving classes of ordinary and partial differential equations of sixth-orders

- Visible light-boosted photodegradation activity of Ag–AgVO3/Zn0.5Mn0.5Fe2O4 supported heterojunctions for effective degradation of organic contaminates

- Production of sustainable concrete with treated cement kiln dust and iron slag waste aggregate

- Key effects on the structural behavior of fiber-reinforced lightweight concrete-ribbed slabs: A review

- A comparative analysis of the energy dissipation efficiency of various piano key weir types

- Special Issue: Transport 2022 - Part II

- Variability in road surface temperature in urban road network – A case study making use of mobile measurements

- Special Issue: BCEE5-2023

- Evaluation of reclaimed asphalt mixtures rejuvenated with waste engine oil to resist rutting deformation

- Assessment of potential resistance to moisture damage and fatigue cracks of asphalt mixture modified with ground granulated blast furnace slag

- Investigating seismic response in adjacent structures: A study on the impact of buildings’ orientation and distance considering soil–structure interaction

- Improvement of porosity of mortar using polyethylene glycol pre-polymer-impregnated mortar

- Three-dimensional analysis of steel beam-column bolted connections

- Assessment of agricultural drought in Iraq employing Landsat and MODIS imagery

- Performance evaluation of grouted porous asphalt concrete

- Optimization of local modified metakaolin-based geopolymer concrete by Taguchi method

- Effect of waste tire products on some characteristics of roller-compacted concrete

- Studying the lateral displacement of retaining wall supporting sandy soil under dynamic loads

- Seismic performance evaluation of concrete buttress dram (Dynamic linear analysis)

- Behavior of soil reinforced with micropiles

- Possibility of production high strength lightweight concrete containing organic waste aggregate and recycled steel fibers

- An investigation of self-sensing and mechanical properties of smart engineered cementitious composites reinforced with functional materials

- Forecasting changes in precipitation and temperatures of a regional watershed in Northern Iraq using LARS-WG model

- Experimental investigation of dynamic soil properties for modeling energy-absorbing layers

- Numerical investigation of the effect of longitudinal steel reinforcement ratio on the ductility of concrete beams

- An experimental study on the tensile properties of reinforced asphalt pavement

- Self-sensing behavior of hot asphalt mixture with steel fiber-based additive

- Behavior of ultra-high-performance concrete deep beams reinforced by basalt fibers

- Optimizing asphalt binder performance with various PET types

- Investigation of the hydraulic characteristics and homogeneity of the microstructure of the air voids in the sustainable rigid pavement

- Enhanced biogas production from municipal solid waste via digestion with cow manure: A case study

- Special Issue: AESMT-7 - Part I

- Preparation and investigation of cobalt nanoparticles by laser ablation: Structure, linear, and nonlinear optical properties

- Seismic analysis of RC building with plan irregularity in Baghdad/Iraq to obtain the optimal behavior

- The effect of urban environment on large-scale path loss model’s main parameters for mmWave 5G mobile network in Iraq

- Formatting a questionnaire for the quality control of river bank roads

- Vibration suppression of smart composite beam using model predictive controller

- Machine learning-based compressive strength estimation in nanomaterial-modified lightweight concrete

- In-depth analysis of critical factors affecting Iraqi construction projects performance

- Behavior of container berth structure under the influence of environmental and operational loads

- Energy absorption and impact response of ballistic resistance laminate

- Effect of water-absorbent polymer balls in internal curing on punching shear behavior of bubble slabs

- Effect of surface roughness on interface shear strength parameters of sandy soils

- Evaluating the interaction for embedded H-steel section in normal concrete under monotonic and repeated loads

- Estimation of the settlement of pile head using ANN and multivariate linear regression based on the results of load transfer method

- Enhancing communication: Deep learning for Arabic sign language translation

- A review of recent studies of both heat pipe and evaporative cooling in passive heat recovery

- Effect of nano-silica on the mechanical properties of LWC

- An experimental study of some mechanical properties and absorption for polymer-modified cement mortar modified with superplasticizer

- Digital beamforming enhancement with LSTM-based deep learning for millimeter wave transmission

- Developing an efficient planning process for heritage buildings maintenance in Iraq

- Design and optimization of two-stage controller for three-phase multi-converter/multi-machine electric vehicle

- Evaluation of microstructure and mechanical properties of Al1050/Al2O3/Gr composite processed by forming operation ECAP

- Calculations of mass stopping power and range of protons in organic compounds (CH3OH, CH2O, and CO2) at energy range of 0.01–1,000 MeV

- Investigation of in vitro behavior of composite coating hydroxyapatite-nano silver on 316L stainless steel substrate by electrophoretic technic for biomedical tools

- A review: Enhancing tribological properties of journal bearings composite materials

- Improvements in the randomness and security of digital currency using the photon sponge hash function through Maiorana–McFarland S-box replacement

- Design a new scheme for image security using a deep learning technique of hierarchical parameters

- Special Issue: ICES 2023

- Comparative geotechnical analysis for ultimate bearing capacity of precast concrete piles using cone resistance measurements

- Visualizing sustainable rainwater harvesting: A case study of Karbala Province

- Geogrid reinforcement for improving bearing capacity and stability of square foundations

- Evaluation of the effluent concentrations of Karbala wastewater treatment plant using reliability analysis

- Adsorbent made with inexpensive, local resources

- Effect of drain pipes on seepage and slope stability through a zoned earth dam

- Sediment accumulation in an 8 inch sewer pipe for a sample of various particles obtained from the streets of Karbala city, Iraq

- Special Issue: IETAS 2024 - Part I

- Analyzing the impact of transfer learning on explanation accuracy in deep learning-based ECG recognition systems

- Effect of scale factor on the dynamic response of frame foundations

- Improving multi-object detection and tracking with deep learning, DeepSORT, and frame cancellation techniques

- The impact of using prestressed CFRP bars on the development of flexural strength

- Assessment of surface hardness and impact strength of denture base resins reinforced with silver–titanium dioxide and silver–zirconium dioxide nanoparticles: In vitro study

- A data augmentation approach to enhance breast cancer detection using generative adversarial and artificial neural networks

- Modification of the 5D Lorenz chaotic map with fuzzy numbers for video encryption in cloud computing

- Special Issue: 51st KKBN - Part I

- Evaluation of static bending caused damage of glass-fiber composite structure using terahertz inspection