Abstract

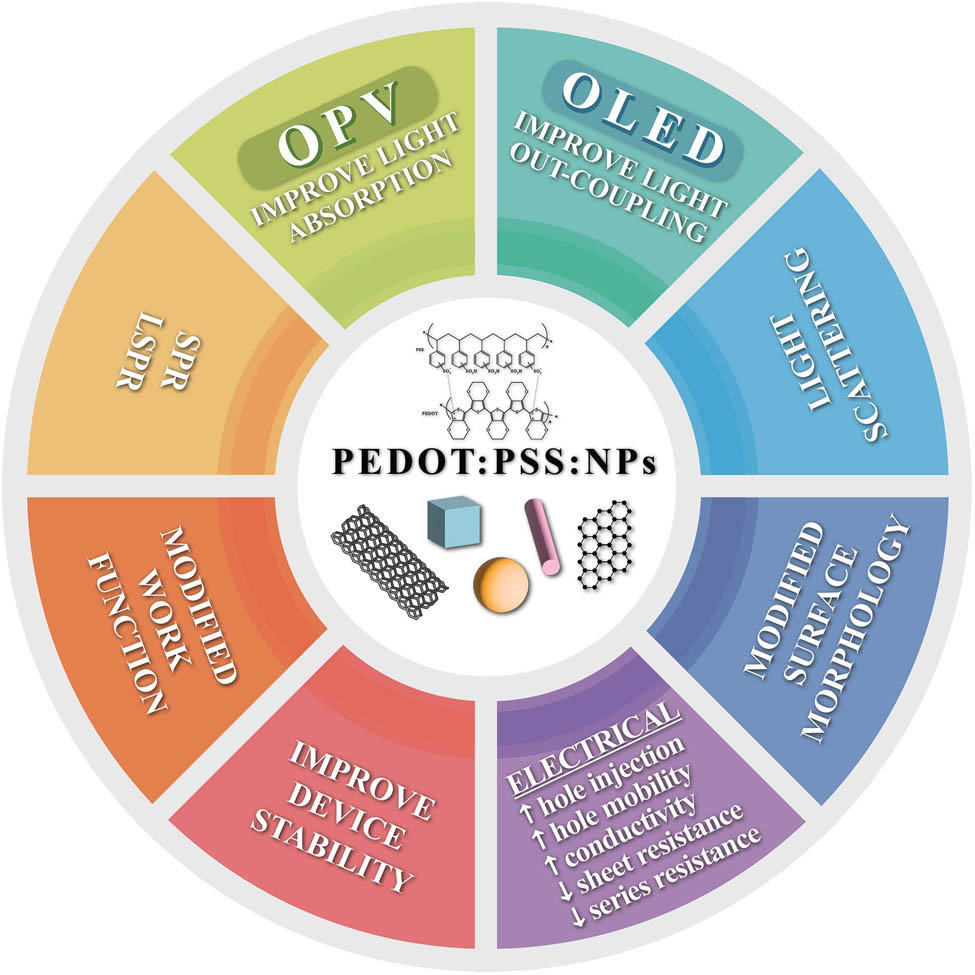

In recent years, several strategies have been proposed and demonstrated to enhance the efficiency of organic light-emitting diodes (OLEDs) and organic photovoltaics (OPVs). In both types of devices, poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) is commonly used to enhance hole injection. The layer is further designed by incorporating metallic-based, carbon-based, organic, inorganic, and hybrid nanoparticles with the aim of improving the performance and hence the efficiency through the improvement of light out-coupling in OLEDs and enhancement in light absorption generation of hole-charge carriers in OPVs. This review elucidates the use of different types of nanoparticles that are doped into PEDOT:PSS and their effects on OLEDs or OPVs. The effects include surface plasmon resonance (SPR), scattering, better charge transport, improvement in surface morphology and electrical properties of PEDOT:PSS. Promising results have been obtained and can potentially lead to low cost, large-area manufacturing process.

1 Introduction

Organic optoelectronic devices, particularly organic light-emitting diodes (OLED) and organic photovoltaic (OPV) solar cells, have attracted attention in recent decades due to various advantages such as low cost, thinness, lightness, semi-transparency, and ability to be fabricated onto flexible substrates [1,2,3,4,5,6]. However, the efficiencies and long-term stability need to be improved. The improvement strategies include the use of new active layer materials [7,8,9,10], new functional layer materials (hole transport layer – HTL or electron transport layer – ETL) [3,11], doping of nanoparticles [12,13], and optimising the device structure [14].

In OLEDs, the injection of charge carriers from the contacting electrodes are required for emitting light. Holes are injected from the anode, and electrons are injected from top metallic cathode; hole-electron pairs are then recombined at the emissive layer where emission occurs [15]. OPVs work in the opposite way where light is absorbed, for example, in bulk heterojunction (BHJ), which consists of the blend of two semiconductors, a donor, and an acceptor. Due to the opposite charges of the hole and electron, they are attracted together to form electron-hole pair known as exciton. The electron-hole pair then separated into cathode and anode in a process known as exciton dissociation. In order to generate electric current, the photons must be continuously absorbed and converted into free charge carriers (electrons and holes) effectively [15].

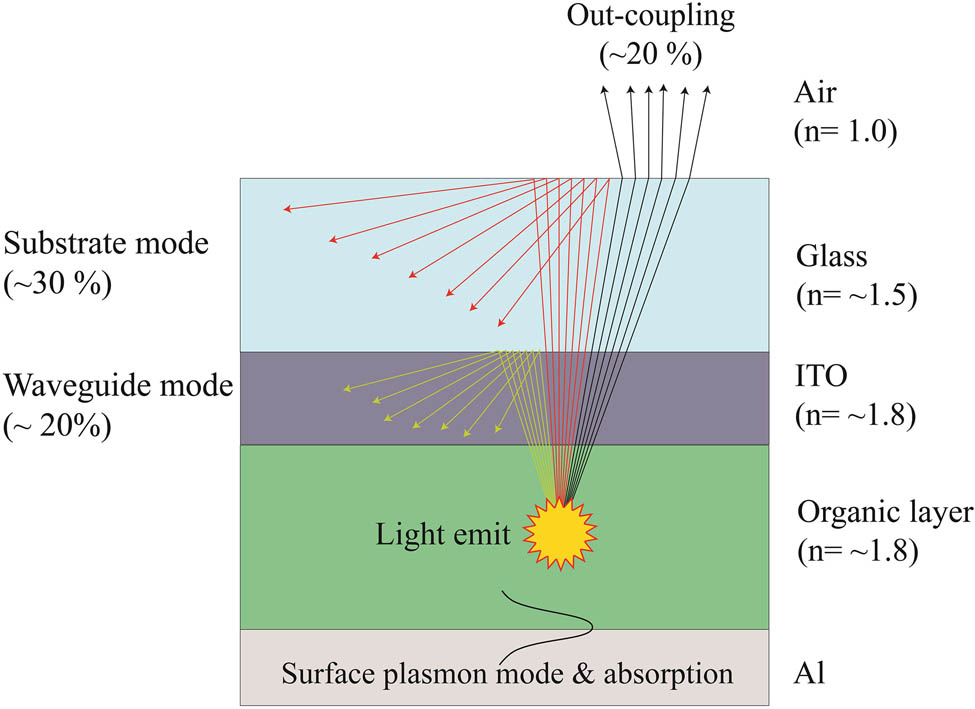

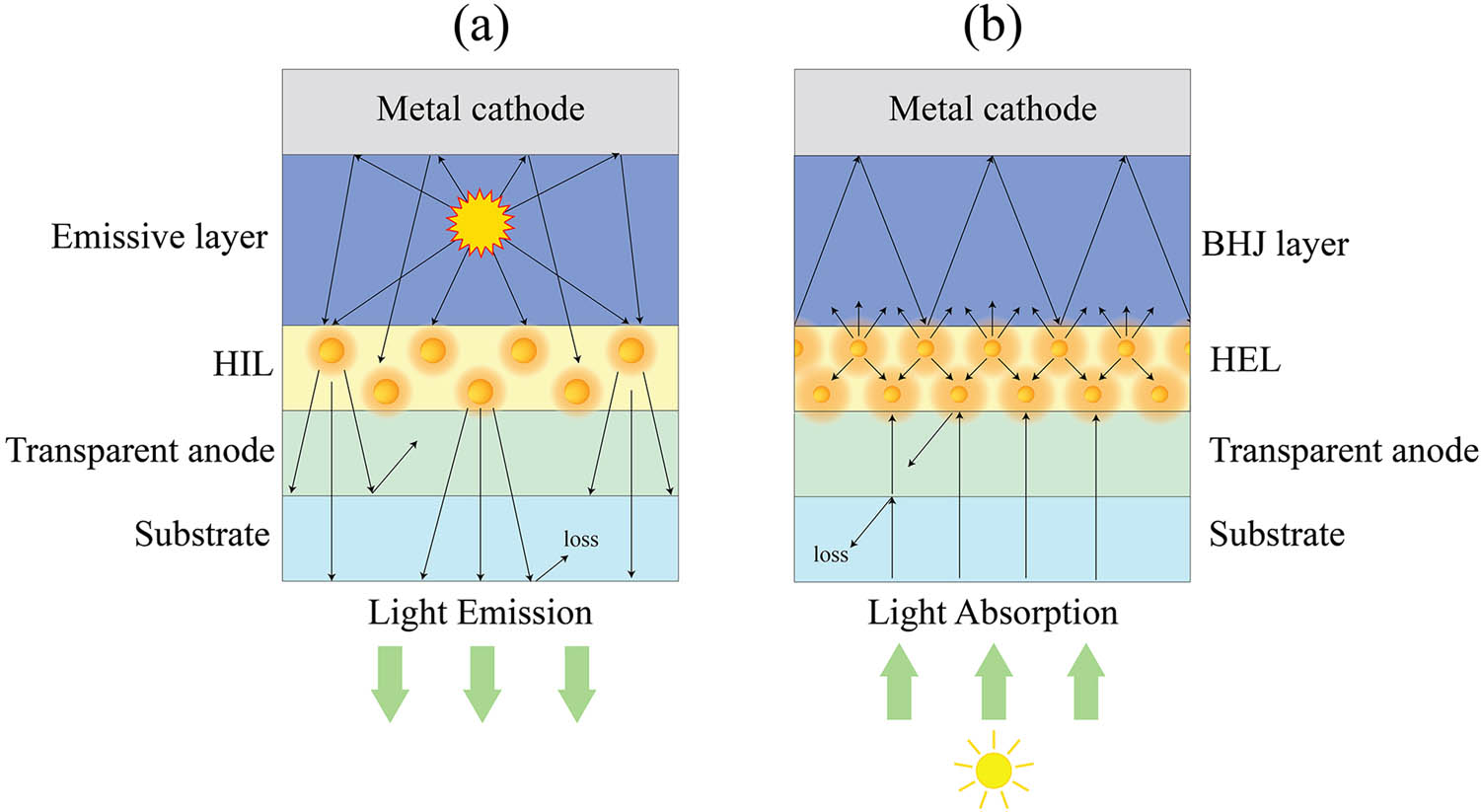

The optical loss for OLEDs is about 80%, where most of the emitted light is trapped inside the OLED devices, and only the remaining ∼20% is able to be extracted out of the substrate [16], as shown in Figure 1. Therefore, various approaches have been investigated to improve optical loss, including the use of silica microspheres [17], microlens arrays [18], and photonic crystal structure [19] for OLEDs. Another promising approach is by applying nano-structures into OLEDs as a scattering layer using nanoparticles (NPs) [20,21]. Compared to the other methods, embedding NPs into OLED is a relatively simple method suitable for large-area manufacturing.

Various optical loss modes such as substrate mode, waveguided mode, and surface plasmon mode in an OLED.

In the case of OPV, one of the significant constraints that limit the performance is the effective absorption of incident light and photogeneration of current. However, a large portion of the incident light tends to be reflected at the surface of air and glass, absorbed in electrode, buffer layers, or escape into the air [22]. Therefore, to acquire high-efficiency OPVs, it is important to reduce the optical losses and increase light absorption in the active layer. Optical losses can be reduced by designing a structured back reflector, a structured substrate, and NPs to induce plasmonic effects, scattering, or near-field enhancement [23].

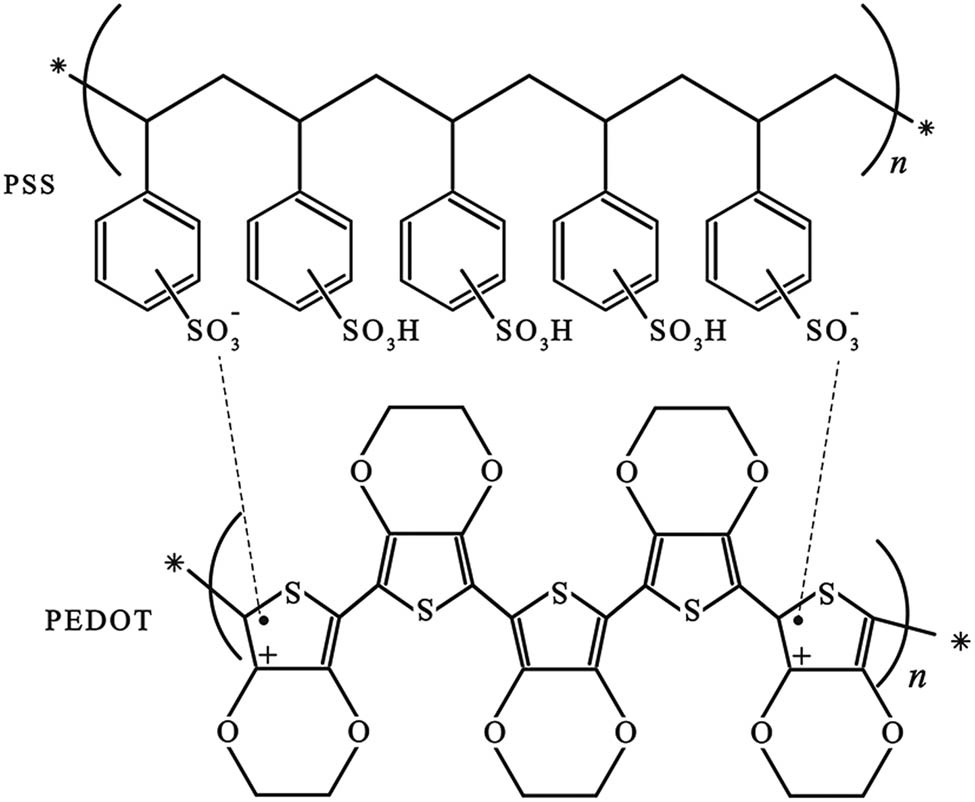

In both the OLED and OPV, a layer between the active layer and the indium tin oxide (ITO) anode layer is added to improve the charge transfer. The layer is known as hole injection layer (HIL) for OLED and the hole extraction layer (HEL) for OPV. Poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) (Figure 2) is the most commonly used HIL or HEL layer for both the devices. PEDOT:PSS is a polyelectrolyte with the combination of electrically conducting conjugated PEDOT (positively charged) and insulating PSS (negatively charged) steadily dispersed in water [24]. Oxidised PEDOT is highly conductive, but it is insoluble in water. The insulated PSS is a polymer surfactant that facilitates PEDOT to disperse in water [25]. PEDOT:PSS is commercialised under the trade name CleviosTM formerly known as Baytron P [25]. The PEDOT:PSS aqueous solutions (Clevios) are widely used for preparing highly conductive and flexible electrodes such as Clevios PH500 [25,26] and Clevios PH1000 [27,28,29,30]; whereas the less conductive PEDOT:PSS (Clevios P VP Al 4083 [31,32,33]) is used as hole injection/extraction layers. The antistatic coating, solid electrolyte capacitor, and printed circuit board were the first practical applications of PEDOT:PSS [34]. The importance of PEDOT:PSS as a hole injection layer has been documented by many groups [35,36]. Until now, PEDOT:PSS has been extensively reported as being used as a buffer layer in organic optoelectronics [25]. The commercially available PEDOT:PSS is a widely used material for organic optoelectronic owing to its high transparency in the visible range, easy to process, excellent surface morphology, great mechanical flexibility, adjustable conductivity, high work function, and excellent thermal stability [20,37,38]. Nevertheless, higher hole injection and conductivity are beneficial. However, pure PEDOT:PSS having low conductivity, is sensitive to air, and adhere weakly to hydrophobic substrates [37]. One strategy is to incorporate NPs such as gold (Au) NPs [39], silver (Ag) NPs [40], or carbon nanotube [41] into the PEDOT:PSS layer for applications in flexible or even stretchable devices [24]. A few effects improve device efficiencies when NPs are doped into PEDOT:PSS, such as better hole injection, higher conductivity, plasmonic effect, scattering, etc. [39,40,41].

The chemical structure of PEDOT:PSS.

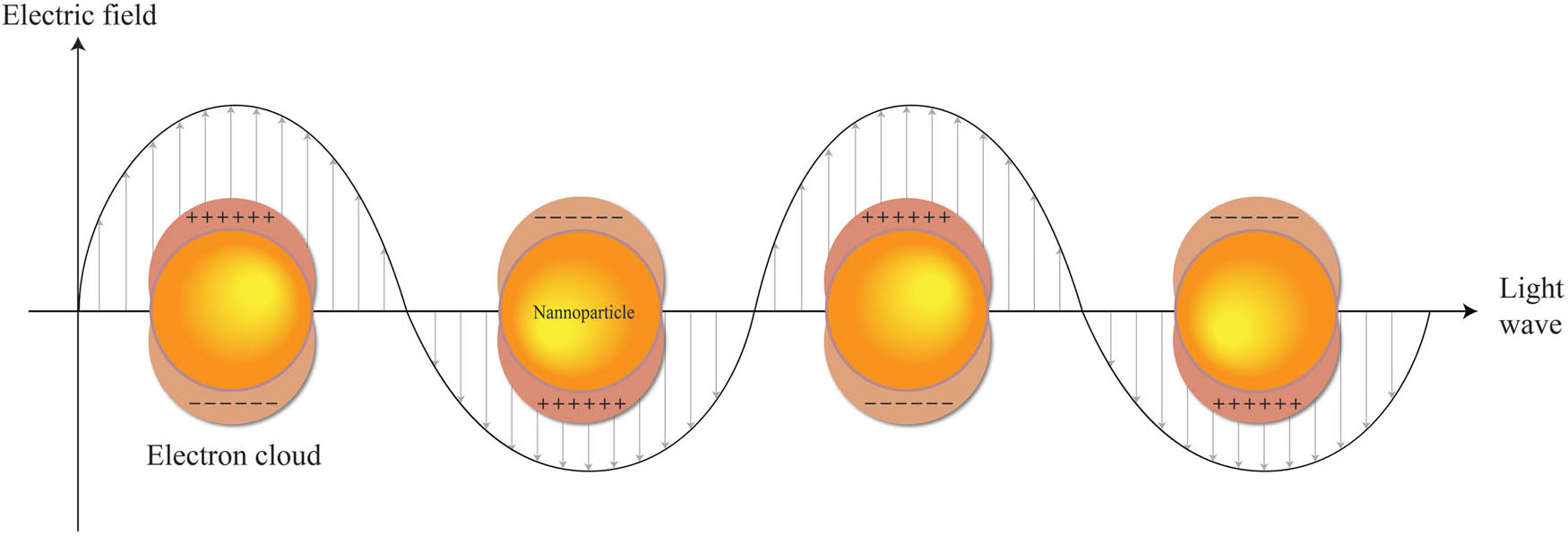

There are varieties of NPs or nanomaterials available, such as metal-based [13], metal oxides [42], organic-based [27], carbon-based [43], 2D materials [44,45], and hybrid-based NPs [46]. They exhibit unique physical and chemical properties and are used in wide range of fields such as water treatment [47], agriculture [48], biological [49,50,51], optoelectronics [52], sensors [53], construction materials (cement) [54,55], photocatalyst [56,57], etc. Furthermore, NPs can be synthesised into different shapes, sizes, and structures. It can be spherical, triangle, square, or irregular form. The combination of NPs such as metal-metal, metal-metal oxide, carbon-metal, and organic-metal forms hybrid NPs, which possess synergetic properties of each type of NP [58,59]. Metallic NPs are widely used in organic optoelectronics due to the surface plasmon resonance effect (SPR) or localised surface plasmon resonance (LSPR). At the same time, they also enhanced the transport layer conductivity to improve the overall device performance [4,60,61]. SPR is defined as the resonant oscillation of conduction electrons that occurs between materials with negative and positive permittivity. At the same time, LSPR is light-induced and matches the frequency of the metallic surface, causing free surface electrons to oscillate collectively.

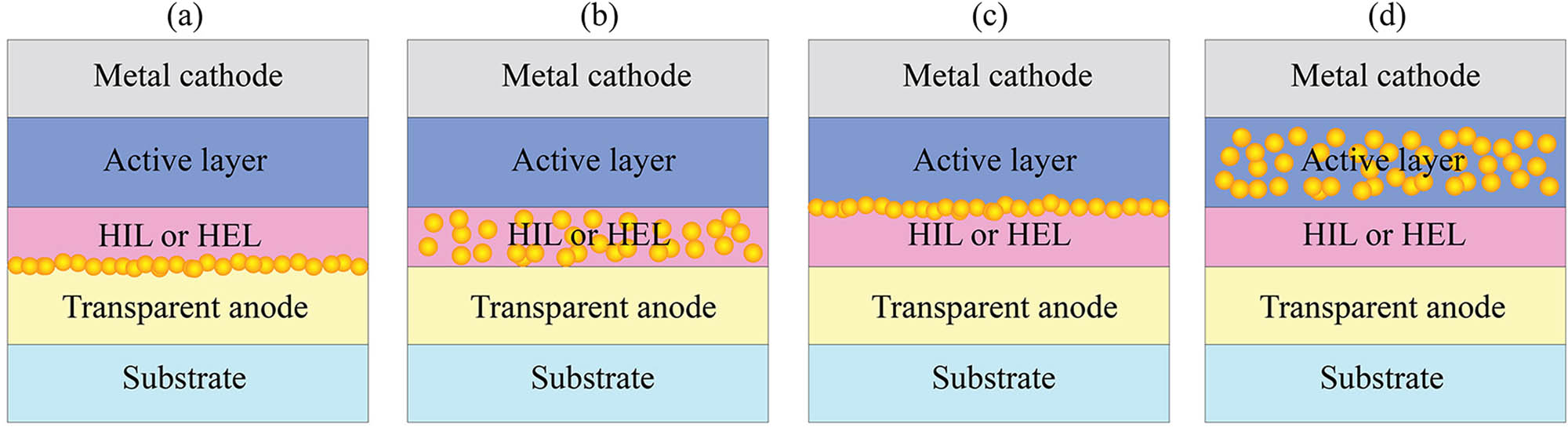

There are few strategies of using NPs on organic optoelectronic devices in terms of the position, which included: (i) between anode and hole injection or extraction layer (ITO/HIL or HEL) [62,63,64] (Figure 3(a)), (ii) in HIL or HEL [21,40,65,66] (Figure 3(b)), (iii) between active layer and HIL or HEL [67] (Figure 3(c)), and (iv) in active layer [68,69,70] (Figure 3(d)). In this review, we will be focusing on the NPs embedded into the HIL for OLEDs or HEL for OPVs (Figure 3(b)). The use of NPs at this position has been proposed for light trapping, absorption, re-scattering of light, and a near-field enhancement [71]. The easiest way is to dope the NPs into a hole injection material such as PEDOT:PSS or deposit them at the top of the anode layer.

Schematic diagram of device structure with NP in OLEDs and OPVs, (a) between anode and hole injection or extraction layer (ITO/HIL or HEL), (b) in HIL or HEL (main focus in this review), (c) between active layer and HIL or HEL, and (d) in active layer.

This review article presents a brief technical summary of the types of NPs embedded into PEDOT:PSS nanocomposite for OLEDs and OPVs. The performances are listed and reviewed. The effects of the NPs in PEDOT:PSS for organic are discussed and summarised. Finally, outlooks and conclusions on nanoparticles-doped PEDOT:PSS for OLEDs and OPVs are drawn.

2 NPs-doped PEDOT:PSS for OLED

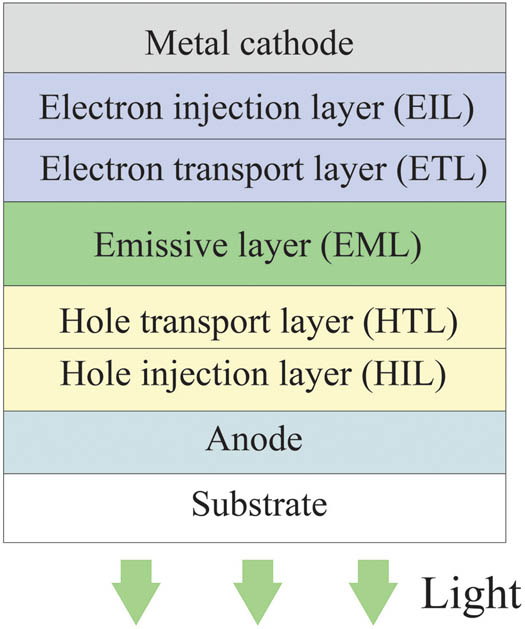

Incorporation of NPs into PEDOT:PSS has evolved into one of the most common ways to improve OLED performance irrespective of the spectral range. It has been used for blue, red, and green-emitting OLEDs. The typical device configuration has been reported are mostly in ITO(anode)/NPs:PEDOT:PSS(HIL)/HTL/EML/ETL/EIL/aluminium (Al) (cathode), (Figure 4).

Device structure of a typical OLED with NPs-doped PEDOT:PSS.

2.1 Metallic-based NPs

The most commonly used metallic NPs are Ag and gold Au with the size of 5–80 nm; the size and concentration are optimised to achieve the best improvement in current efficiency (CE), as shown in Table 1.

Device characteristics of OLEDs with metallic-based NPs-doped PEDOT:PSS

| NPs | Size of NP (nm) | Thickness (nm)(a) | Function | CE (cd/A) | PE (lm/W) | EQE (%) | Enhance in CE (%)(b) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Ag | 6 | 70 | HIL | 0.64 | — | — | 28.90 | Improved hole injection | [13] |

| Ag | 30 | 30 | HIL | — | — | 0.94 | 13.25 (EQE) | Improved hole injection | [72] |

| Ag | 60 | 55 | HIL | 1.46 | — | — | 18.70 | Improved hole injection and LSPR | [12] |

| Ag | 55 | 40 | HIL | 31.00 | 6.80 | 8.20 | 72.20 | LSPR | [73] |

| Cu | 21 | 40 | HIL | 26.60 | 6.20 | 6.30 | 47.80 | LSPR | [73] |

| Au | 20 | 40 | HIL | 27.00 | 7.20 | 8.00 | 50.00 | LSPR | [73] |

| Cu and Ag | 21 and 55 | 40 | HIL | 32.10 | 7.50 | 8.30 | 78.30 | LSPR | [73] |

| Au and Ag | 20 and 55 | 40 | HIL | 35.30 | 8.20 | 9.80 | 96.10 | LSPR | [73] |

| Au | 5 | 75–80 | HIL | 15.10 | — | — | 14.40 | SPR | [21] |

| Au | 10 | 75–80 | HIL | 16.40 | — | — | 24.20 | SPR | [21] |

| Au | 20 | 75–80 | HIL | 17.10 | — | — | 29.50 | SPR | [21] |

| Au Nanorod | — | 75–80 | HIL | 17.50 | — | — | 32.60 | SPR | [21] |

| Bio-Au | 10.4 | 50 | HIL | 1.58 | — | 1.09 | 85.90 | SPR and scattering | [74] |

CE: current efficiency, PE: power efficiency, EQE: external quantum efficiency, HIL: hole injection layer, (—): no data provided.

(a): thickness of PEDOT:PSS:NPs composite layer, (b): compared with pristine PEDOT:PSS.

In 2012, Mucur et al. synthesised Ag NPs with particles size of around 6 nm diameter and mixed them into PEDOT:PSS. 12.5 wt% Ag NPs exhibited the highest performance and the increase in CEs by 28.90% is mainly due to more efficient charge injection without affecting the emission colour [13]. In another work, the CE was also improved (∼13%) using larger Ag NPs (30 nm) with the concentration of 0.025 wt% Ag NPs doped into PEDOT:PSS, it is attributed to the enhanced hole injection [72]. However, larger size ∼60 nm Ag NPs into PEDOT:PSS as HTL was found to exhibit a negligible effect on the hole injection efficiency due to the excitation of LSPR around Ag NPs [12].

The investigation by the same group using copper (Cu), Ag, and Au NPs and also dual metal NPs imbedded into PEDOT:PSS with the device architecture of ITO/NPs-PEDOT:PSS/CBP:Ir(MMPIPA)2(acac)/LiF/Al further confirm the LSPR effects [73]. The optimum particle size and concentration used were Ag (55 nm, 40%), Au (20 nm, 24%), Cu (21 nm, 50%), Cu-Ag (21–55 nm, 62%), and Au-Ag (20–55 nm, 80%), respectively. After doped metal NPs into PEDOT:PSS, all the devices are exhibited better stability due to the alleviated acidic and the hygroscopic nature of PEDOT:PSS. The results also showed that co-doped Au and Ag or Cu and Ag for green OLEDs exhibited higher efficiency due to the synergistic effect of stronger near-field resonance of Au NPs and broadband resonance of Ag NPs. In another work, Au NPs of different sizes and shapes were used in PEDOT:PSS composite. At the same time, Au nanorods showed the highest efficiencies compared to the other spherical-shaped Au NPs with the size of 5, 10, and 20 nm. The results suggest that Au NPs with larger size and higher surface area have more obvious “far-field” surface plasmon resonance (FSPR) effects that acquire higher reflectivity [21].

Biologically synthesised gold nanoparticles (Bio-Au NPs) have been introduced into polymer OLEDs. They used microorganisms to grow at high metal ion concentrations. It can eliminate the toxic effect of metals by adjusting the redox state and metal NPs were formed intracellularly from the metal ions. They optimised the bio-Au NPs’ concentration with 0.125 wt%, which is improved by 85.90% of the current efficiency compared to the non-doped PEDOT:PSS layer [74].

2.2 Inorganic NPs

The investigation of inorganic NPs in PEDOT:PSS for OLED is listed in Table 2. The enhancement of efficiency is mainly attributed to better hole injection. Molybdenum trioxide (MoO3) NPs with the optimal volume ratio of PEDOT:PSS to MoO3 of 3:1 were studied for OLEDs [20]. The composite solution coated as HIL results in a smooth and pin-hole-free morphology compared to the solution-processed pure MoO3. Another advantage of adding MoO3 to PEDOT:PSS as HIL possesses a high work function (5.54 eV) compared to the PEDOT:PSS pristine film. The work function is increased by 0.3 eV, which reduced the energy barrier and improved hole injection. In another work, molybdenum disulphide (MoS2) was added into PEDOT:PSS as HIL and effectively promoted hole injection. MoS2 incorporation in the PEDOT:PSS matrix contributed to promoting conductivity and improved the device durability for the UV OLEDs. At the same time, the current efficiency of the OLED was improved by 68.75% [75].

Device characteristics of OLEDs with inorganic NPs-doped PEDOT:PSS

| NPs | Size of NP (nm) | Thickness (nm)(a) | Function | CE (cd/A) | PE (lm/W) | EQE (%) | Enhance in CE (%)(b) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| MoO3 | 3:1(c) | 30 | HIL | — | 89.2 | 23.9 | ∼84.00 (EQE) | Reduced energy barrier and improved hole injection | [20] |

| MoS2 | 2:1(c) | — | HIL | 8.10 | 5.70 | 4.14 | 68.75 | Promotes conductivity and device durability | [75] |

| WO x | 20:1(c) | — | HIL | — | — | 2.30 | 42.86 (EQE) | Promotes conductivity and device durability | [76] |

| TiO2 | 25 | — | HIL | 7.30 | 3.15 | — | 760.50 | Improved light out-coupling | [79] |

| ZnO | 200 (length) | — | HIL | 11.03 | 4.34 | — | 138.70 | Improved charge mobility and conductivity | [80] |

CE: current efficiency, PE: power efficiency, EQE: external quantum efficiency, HIL: hole injection layer, (—): no data provided.

(a): thickness of PEDOT:PSS:NPs composite layer, (b): compared with pristine PEDOT:PSS, (c): ratio of PEDOT:PSS with NPs (PEDOT:PSS:NPs).

In addition, tungsten oxide (WO x ) doped into PEDOT:PSS also showed a similar effect that improved hole injection and device durability for the UV OLED devices [76]. The improvement is due to the non-stoichiometry in WO x and WO x :PEDOT:PSS accompanied by slight oxygen deficiency [77,78], which provides a hole transport channel to promote hole injection or transport in organic electronic devices [76].

Furthermore, commonly used inorganic NPs, titanium dioxide (TiO2) NPs (20 wt%, 25 nm), was doped into PEDOT:PSS as HIL, and an impressive improvement in the CE of around 760.5% was found and it was due to the improvement in light out-coupling from light scattering layer [79]. Meanwhile, the same group tested the incorporation of zinc oxide (ZnO) nanorod in PEDOT:PSS [80], a lower improvement (138.7%) was achieved compared to TiO2. The ZnO nanocomposite results in strong interaction between ZnO and thiophene rings of PEDOT:PSS and polymer chains changes from coiled to linear [81]. π-electrons are more delocalised in linear PEDOT:PSS; hence, charge mobility and conductivity increase. In addition, it is also possible for nanostructured ZnO to enhance light out-coupling [80].

2.3 Carbon-based NPs

Recently, carbon-based NPs or nanomaterials have been widely used as transparent conducting films (TCFs) [82] in optoelectronic devices [29,37]. Carbon nanomaterials such as nanotubes, graphene, and graphene oxide (GO) have been investigated as substitutes for ITO (Table 3). For example, graphene possesses high transmittance and conductivity, and exhibits optical transmittance comparable to ITO at visible wavelengths [82]. A highly efficient ITO-free OLEDs were obtained by using PEDOT:PSS:GO as an anode with the device configuration of anode/NPB/Alq3/LiF/Al [83]. The highest CE of the device (PEDOT:PSS:GO with the ratio of 15:1) is 5.71 cd/A, while for pristine PEDOT:PSS layer is only 3.47 cd/A; thus, a 55% enhancement was obtained. This improvement indicates that PEDOT:PSS:GO composite possibly reduces the energy level difference, hence better hole injection [84]. Graphene oxide sheets are vigorously oxidised by hydroxyl and epoxide groups, and it helps assemble other materials through π–π stacking and hydrogen bonding [85]. Therefore, GO-doped PEDOT:PSS is able to promote the interaction between GO and PEDOT but not PSS due to the electronegativity of GO.

Device characteristics of OLEDs with carbon-based NPs-doped PEDOT:PSS

| NPs | Concentration | Thickness (nm)(a) | Function | CE (cd/A) | PE (lm/W) | EQE (%) | Enhance in CE (%)(b) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| GO | 15:1 PEDOT:PSS/GO | 57 | Anode | 5.71 | — | — | 55.00 | Improved hole injection | [83] |

| PRPOHA-GO | (2 mg/mL; in EG) 15:1 v/v | 44 | Anode | ∼0.11 | ∼0.06 | ∼0.10 | ∼1.60(c) | Lower resistivity | [28] |

CE: current efficiency, PE: power efficiency, EQE: external quantum efficiency, (—): no data provided.

(a) thickness of PEDOT:PSS:NPs composite layer, (b) compared with pristine PEDOT:PSS, and (c) compared to ITO.

On the other hand, several amines such as n-propylamine (nPRYLA), dipropylamine (DPRYLA), and propanolamine (PRPOHA) have been used to modify GO and doped into PEDOT:PSS (PH1000) with additional ethylene glycol (15:1) used as anode [28]. The device structure is anode/PEDOT:PSS(Al4083)/ADS231BE/Cs2CO3/Al. All the devices show enhancement in CE, PE, and EQE (1.6-, 1.5-, and 1.9-fold enhancement, respectively) compared to the device with ITO anode. PRPOHA-GO was the best device among the amine-modified GO devices due to lower surface resistivity.

2.4 Hybrid NPs

Hybrid NPs are defined as when two or more distinct NPs are assembled but still in nanoscale dimensions. Hybrid NP systems can be obtained by combining two different materials such as organic-inorganic, decorated-metal oxide NPs, metal-metal oxide, and core-shell to obtain unique or synergetic properties [58,59].

When PdCo alloy NPs supported on polypropylenimine dendrimer-grafted graphene (PdCo/PPI-g-G) with 0.02 wt% was doped into PEDOT:PSS, the highest luminous efficiency (2.36 cd/A) and luminous PE (0.11 lm/W) were obtained for poly(9,9-di-n-octylfluorenyl-2,7-diyl) (PFO)-based blue OLED. When PdCo/PPI-g-G is doped in PEDOT:PSS, the energy barrier between the ITO anode and the PEDOT:PSS is around 0.5 eV. At low doping concentrations of 0.02 wt% PdCo/PPI-g-G, the luminance improvement was related to an increase in hole injection, which led to a better balance of electron/hole in the PFO layer. However, further increase in the concentration of PdCo/PPI-g-G (>0.02 wt%) shifted the recombination zone toward to cathode; thus, the luminescence efficiency was decreased [86].

Several studies have been carried out using a combination of a metal core with organic material outer shell doped PEDOT:PSS. Polystyrene (PS)-coated gold core-shell NPs (Au@PS NPs) were studied in green phosphorescent OLEDs with the device configuration of glass/ITO/Au@PS NPs-PEDOT:PSS/PVK:PBD:Ir(PPy)3/LiF/Al. It improved the current efficiency by 42.36% compared to the device with a bare PEDOT:PSS layer. At ambient conditions, the cross-linked PS shell for Au@PS NPs provided hydrophobic and structural stability by ensuring their structural stability against oxidation and minimising the adverse effect of the hygroscopic and acidic PEDOT:PSS film on the organic electronic devices. By using emulsion polymerisation, Au NPs were encapsulated in PS shells. The thickness of PS shell is tunable to optimise plasmonic coupling efficiency between the Au NPs and the emitting or active layers [1]. In another similar work, smaller Ag NPs (3–6 nm) were encapsulated with organic material (o-phenylenediamine [o-PDA]). o-PDA@Ag NPs displayed a surface plasmon absorption band cantered at 448 nm. The improvement is due to the insulating NPs attributed to the film morphology change and enhanced balance of injected electrons and holes. The device consisting of o-PDA@Ag NPs exhibited ∼20% improvement in current efficiency compared to pristine PEDOT:PSS as HIL [87].

Magnetic NPs have recently been reported as a hole-transport layer for OLEDs. Magnetic NPs induce tuning the ratio of singlet to triplet excitons in the emissive layer [88]. In addition, the combination of magnetic NPs Iron(II,III) oxide – Fe3O4) with other materials Fe3O4@G, Fe3O4@SiO2, and Fe3O4@Au have also been studied [89]. Fe3O4 are modified by graphene (G), silicon dioxide (SiO2), and Au nanoclusters, respectively, then mixed with the PEDOT:PSS as HIL. The nanocomposite serves as a light-out coupling layer that contributes to EQE enhancement by combining magnetic, localised surface plasmon resonance, and scattering effects. Compared to bare PEDOT:PSS, the current efficiency enhancement for Fe3O4@G, Fe3O4@SiO2, and Fe3O4@Au are 8.2, 27.1, and 35%, respectively. This enhancement has also been observed in carbon-coated magnetic alloy NPs (CoPt and FePt) [90]. Introducing GO-silver nanowire (AgNWs) [69] and also Ti3C2T x (MXene)-nanosheet-AgNW [91] doped into PEDOT:PPS as anode can lower the sheet resistance, smoothen the surface roughness as compared to AgNWs:PEDOT:PSS or pristine AgNWs layer [69,91]. The enhanced luminescence intensity is also attributed to the SPR effect from the AGNW, thereby reducing the waveguide loss by light scattering [69]. A summary of the data is presented in Table 4.

Device characteristics of OLEDs with hybrid NPs-doped PEDOT:PSS

| NPs | Size of NP (nm) | Thickness (nm)(a) | Function | CE (cd/A) | PE (lm/W) | EQE (%) | Enhance in CE (%)(b) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| PdCo/PPI-g-G | 0.02 wt%(e) | 5 | HIL | 2.36 | 0.11 | — | 223.29 | High hole injection | [86] |

| Au@PS | 34 (core) 100 (outer) | — | HIL | 28.90 | 6.50 | 7.80 | 42.36 | SPR | [1] |

| o-PDA@Ag | 3–6 | 40 | HIL | ∼2.10 | — | — | ∼20.00 | Improved hole injection | [87] |

| Fe3O4@G | 8.6 | — | HIL | 4.11 | 3.16 | 1.35 | 8.20 | Magnetic, LSPR, and scattering | [89] |

| Fe3O4@SiO2 | 15.8 | — | HIL | 4.83 | 4.27 | 1.59 | 27.10 | Magnetic, LSPR, and scattering | [89] |

| Fe3O4@Au | 19.7 | — | HIL | 5.13 | 3.5 | 1.73 | 35.00 | Magnetic, LSPR, and scattering | [89] |

| C-FePt | 11.5 | 40 | HIL | 5.40 | 2.20 | 1.83 | 47.10 | Magnetic, LSPR, and scattering | [90] |

| C-CoPt | 3.4 | 40 | HIL | 5.45 | 3.15 | 1.84 | 21.30 | Magnetic, LSPR, and scattering | [90] |

| GO-AgNW | AgNW 5 μm (length) and 50 nm (dia.) | — | Anode | 6.20 | — | — | 47.62(c) | Lower sheet resistance, smoothened surface roughness, and scattering | [69] |

| AgNW-MXene | AgNW 22 nm (dia.) | — | Anode | 21.0 | — | 25.9 | 766.70(d) | Lower sheet resistance, smoothened surface roughness, and scattering | [91] |

CE: current efficiency, PE: power efficiency, EQE: external quantum efficiency, HIL: hole injection layer, (—): no data provided, dia.: diameter.

(a): thickness of PEDOT:PSS:NPs composite layer, (b): compared with pristine PEDOT:PSS, (c): compared with ITO, (d): compared with bare AgNW, and (e): concentration.

3 NPs-doped PEDOT:PSS for OPVs

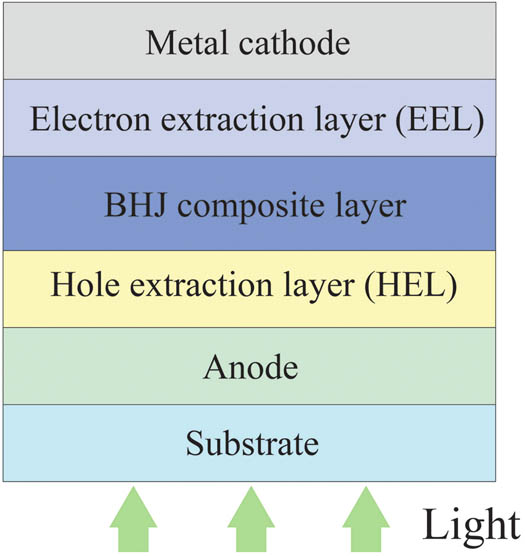

Many groups have reported incorporating NPs into OPV to improve the performance of OPVs by inducing plasmonic effects, increasing light absorption, enhancing the rate of exciton generation, or increasing multiple scattering events, thereby enhancing light absorption efficiency [39,92]. Most of the reported device configuration for OPVs is based on ITO(anode)/PEDOT:PSS(HIL)/BHJ(active layer)/EIL/Al(cathode). P3HT:PCBM blends are commonly used as the active layer for OPV, (Figure 5).

Device structure of a typical OPV with NPs doped into PEDOT:PSS.

3.1 Metal NPs

Metal NPs, especially Ag NPs and Au NPs, are most commonly embedded into PEDOT:PSS to enhance efficiency [4,60,61] (Table 5). Ag NPs usually have an absorption peak between 400 and 450 nm, and Au NPs have an SPR peak between 500 and 600 nm, which relies on the thickness, shape, and distance of the nano-structures [93]. When decahedral and icosahedron of Ag NPs are doped into PEDOT:PSS as hole extraction layer [94], the absorption peaks for decahedral Ag NPs (50–65 nm) are at 407 and 502 nm, while the absorption peak of icosahedron Ag NPs (30–40 nm) is at 412 nm, indicating that the decahedral Ag NPs have a wider light-harvesting range than icosahedron Ag NPs. The AFM measurements revealed that the PEDOT:PSS:Ag-decahedral NPs composite film had a higher roughness, improving the cell’s hole collection efficiency because larger particles lead to a stronger plasmonic scattering effect. It results in an improvement of 12.10% as compared to PEDOT:PSS layer. Meanwhile, improvements in the efficiency of CuPc/C60 solar cells with various AgNP sizes (43, 45, 51, 54, and 57 nm) have been observed [40]. Among the particle sizes tested, 57 nm had the highest power conversion efficiency (PCE) at ∼0.93%, owing to the SPR effect, which can decompose the excitons electron-hole pair into e− and h+ that have moved to the cathode and anode of the cell, which is affecting the efficiency.

Device characteristics of OPVs with metallic-based-NPs doped PEDOT:PSS

| NPs | Active layer | Size of NP (nm) | Thickness (nm)(a) | Function | FF (%) | PCE (%) | Enhance in PCE (%)(b) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Ag | PTB7:PC71BM | 50–65 | 40 | HEL | 63.20 | 6.50 | 12.10 | Better hole collection | [94] |

| Ag | CuPc:C60 | 57 | — | HEL | 39.70 | 0.93 | — | SPR | [40] |

| Ag | P3HT:PCBM | 80 | 55 | HEL | 38.80 | 2.65 | 16.20 | Higher conductivity | [32] |

| Ag | P3HT:PCBM | 20–40 | 40 | HEL | 51.20 | 3.20 | 8.50 | SPR and improved hole collection | [26] |

| Au | P3HT:PCBM | — | 40 | HEL | 51.50 | 3.19 | 8.50 | SPR and improved hole collection | [26] |

| Ag | rrP3HT: PC61BM | 10 | 40 | HEL | 62.00 | 4.94 | 5.55 | SPR, increases absorption length and scattering | [95] |

| Au | rrP3HT: PC61BM | 20 | 40 | HEL | 62.00 | 4.99 | 6.62 | SPR, increases absorption length and scattering | [95] |

| Ag | rrP3HT: PC71BM | 10 | 40 | HEL | 61.00 | 5.29 | 6.65 | SPR, increases absorption length, scattering | [95] |

| Au | rrP3HT: PC71BM | 20 | 40 | HEL | 61.00 | 5.65 | 13.91 | SPR, increases absorption length and scattering | [95] |

| Au | P3HT:PCBM | 11 ± 3 | 30 | HEL | 53.30 | 3.23 | 32.40 | enhanced extraction of charge in hole transport layer | [99] |

| Au | CuPc/C60 | 12–23 | — | HEL | 49.00 | 1.02 | 30.80 | SPR and improved hole collection | [96] |

| Au | P3HT:PC70BM | 18 | 40 | HEL | 69.21 | 3.51 | 18.50 | SPR and improved hole collection | [97] |

| Au | P3HT:PCBM | 45 ± 5 | 50 | HEL | 70.32 | 4.24 | 18.80 | SPR and improved hole collection | [4] |

| Au | P3HT:PCBM | 14 ± 4 | — | HEL | 30.02 | 1.00 | 66.67 | SPR and improved hole collection | [98] |

| Au | P3HT:PC60BM | 50 | 30 | HEL | 66.10 | 4.14 | 15.00 | Stronger near-field enhancement, thus higher photocurrent output | [101] |

| Au | PBDT-TS1:PC70BM | 50 | 30 | HEL | 67.34 | 10.29 | 27.98 | Stronger near-field enhancement, thus higher photocurrent output | [101] |

| Au and Ag | PTB7:PC70BM | 40 and 50 | 60 | HEL | 69.00 | 8.67 | 19.60 | Absorption enhancement and broadens the wavelength range | [102] |

| Au and Ag | rrP3HT:PC61BM | 10 and 20 | 40 | HEL | 62.00 | 5.31 | — | SPR and absorption enhancement | [103] |

| Au and Ag | rrP3HT:PC71BM | 10 and 20 | 40 | HEL | 50.00 | 5.71 | — | SPR and absorption enhancement | [103] |

FF: field factor, PCE: power conversion efficiency, HEL: hole extraction layer, (—): no data provided.

(a): thickness of PEDOT:PSS:NPs composite layer, (b): compared with pristine PEDOT:PSS.

In another report, 80 nm Ag NPs with a spherical shape dispersed in PEDOT:PSS were then fabricated into P3HT:PCBM-based organic solar cells [32]. The Ag NPs are nearly spherical and distributed uniformly on the glass surface; no apparent aggregation is observed. Compared to pure PEDOT:PSS, PEDOT:PSS incorporated with Ag NPs exhibit an increase in PCE up to 16.20%. The author clarified that LSPR is not the origin of efficiency; the concentration of Ag NPs (80 nm) (0, 0.1, and 1 wt%) with PEDOT:PSS composite films show almost similar transmittance ∼90% at the wavelength 300–800 nm, which means the concentration of Ag NPs has no apparent impact on the optical effects. The PEDOT:PSS layer incorporated with Ag NPs exhibited higher conductivity that contributed to PSC improvement. Besides, another study reported the effect of Ag Nps- or Au Nps doped PEDOT:PSS composite as hole extraction layer compared with pristine PEDOT:PSS with the device configuration of ITO/Composite layer/P3HT:PCBM/LiF/Al [26]. PCE was improved by 8.5% for both Ag NPs and Au NPs in the 20–40 nm size range, which was attributed primarily to the SPR effect and improved hole extraction by increasing surface roughness at the buffer layer [26].

Furthermore, a detailed comparison of PEDOT:PSS + Au NPs and PEDOT:PSS + Ag NPs with the average particle size for Ag NPs (∼10 nm) and Au NPs (∼20 nm) was reported [95]. The absorption peaks of Au NPs and Ag NPs were observed at 521 and 431 nm. The optimised OPV device structure for both metal NPs is fabricated with a configuration of ITO/PEDOT:PSS + metal NPs/rrP3HT:PC61BM/BCP/LiF/Al and ITO/PEDOT:PSS + Metal NPs/rrP3HT:PC71BM/BCP/LiF/Al. The surface roughness of the bare pristine PEDOT:PSS layer was around 2.61 nm, whereas the PEDOT:PSS + Au NPs composite and the PEDOT:PSS + Ag NPs composite was 2.69 and 3.56 nm, respectively. Ag NPs and Au NPs have better performance for both BHJ structures than the bare PEDOT:PSS. The PCE improvement in PEDOT:PSS + Ag NPs and Au NPs with rrP3HT:PC61BM were 5.55 and 6.62%, respectively, whereas 6.65 and 13.91% for PEDOT:PSS + Ag NPs and Au NPs with rrP3HT:PC71BM. The surface plasmon effect for metal NPs increases photo absorption length, scattering, and trapping of incident light passing through the HIL. Compared to the device’s performance for both PEDOT:PSS + Ag NPs and PEDOT:PSS + Au NPs, the devices with PEDOT:PSS + Au NPs showed better results due to the absorption range of Au NPs, which absorbed more in visible range [95].

In recent years, incorporating Au NPs with PEDOT:PSS in different OPV device configurations and different Au NPs sizes have resulted in performance enhancement with optimised Au-NPs concentration in PEDOT:PSS [4,95,96,97,98,99]. They shared a similar outcome where Au NPs enhanced charge extraction in the hole transport layer; thus, the energy barrier was lowered and promoted carrier transport [99,100]. Besides that, Au NPs have unique optical properties of the LSPR that enhance the light absorption efficiency to improve the performance of the OPVs [4,96,97]. Optimising the concentration of Au NPs in PEDOT:PSS is important as above a concentration threshold, the additional leakage current was detected resulting from increased defects in the hole transport layer that act as a recombination centre [99]. A fairly high increment of PCE efficiency can be achieved when Au NPs are doped into PEDOT:PSS as hole extraction layer and compared to control devices (bare PEDOT:PSS); 32.4% [99], 30.8% [96], 18.5% [97], 18.8% [4], 66.67% [98], 15.00% [101], and 27.98% [101], respectively. Furthermore, by taking advantage of both Ag NPs and Au NPs with different absorption regions, a mixture of AgNps and Au NPs showed even better solar cell performance than only a single type of metal NPs. EQE spectra and UV-vis absorption spectra for dual NPs showed absorption enhancement compared with single NPs and without NPs with a broader absorption spectrum [102]. The highest PCE value is 5.71% with J sc = 16.44 mA/cm2 for an optimised ratio of Au NPs (10 nm):Ag NPs (20 nm) (25:75) in PEDOT:PSS which consisted of devices architecture of ITO/PEDOT:PSS + Au NPs:Ag NPs(25:75)/rr-P3HT:PC71BM/BCP:LiF:Al, whereas, for ITO/PEDOT:PSS + Au NPs:Ag NPs(25:75)/rr-P3HT:PC61BM/BCP:LiF:Al the best PCE was 5.31% with J sc = 14.77 mA/cm2 [103].

3.2 Organic NPs

Another strategy to further improve the performance of OPV is using organic NPs as listed in Table 6. Cross-linked PS NPs are able to enhance the mechanical durability of flexible electronics [27]. A flexible organic solar cell was investigated using the stamping process of the PEDOT:PSS layer with PSNPs. The PSNPs with a particle size of 68 nm are doped into PEDOT:PSS and diluted by IPA, then spin-coated onto the polyurethane acrylate (PUA)/PC stamp and stamped onto the PH1000/PEN substrate. The complete device structure is PEN/PEDOT:PSS/PEDOT:PSS:PS NPs/PTB7:PC71BM/TiO x /Al; the processes are illustrated in Figure 6. The stamped PEDOT:PSS:PS NPs exhibited significant mechanical stability enhancement when undergoing a bending test. At the same time, the work function of the PEDOT:PSS:PS NPs provided by stamping is 5.09 eV which is lower than the usual spin-coated process for PEDOT:PSS at 5.20 eV. The PEDOT:PSS:PSNP samples possess the highest occupied molecular orbital (HOMO) energy level of 5.15 eV; thus, it has a slightly better hole transport than that of spin-coated PEDOT:PSS. The transferred PEDOT:PSS:PS NPs have the best PCE at 5.71% for PTB7:PC71BM based flexible solar cells and the spin-coated device is only 5.37%. Furthermore, the transferred PEDOT:PSS:PS NPs layer of the flexible organic solar cell device with 1,000 cycles of bending test and retained 65% of its initial efficiency, outperforming the spin-coated PEDOT:PSS device without PS NPs, which retained only 42% of its initial efficiency [27].

Device characteristics of OPVs with organic NPs-doped PEDOT:PSS

| NPs | Active layer | Size of NP (nm) | Thickness (nm)(a) | Function | FF (%) | PCE (%) | Enhance in PCE (%)(b) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| PS | PTB7:PC71BM | 68 | 30 | HEL | 0.52 | 5.71 | 0.70 | Lowered work function and better device mechanical stability | [27] |

| PPy | PTB7:PC61BM | 30 | 40 | HEL | 67.93 | 3.35 | 15.12 | Changes in pH value, increase in conductivity, and morphological changes | [104] |

| PPy | PTB7:PC71BM | 30 | 40 | HEL | 71.06 | 9.44 | 17.90 | Changes in pH value, increase in conductivity, and morphological changes | [104] |

FF: Field factor, PCE: power conversion efficiency, HEL: hole extraction layer, (—): no data provided.

(a): thickness of PEDOT:PSS:NPs composite layer, (b): compared with pristine PEDOT:PSS.

![Figure 6

The stamping transfer process of the PPy NPs:PEDOT:PSS layer for PTB7/PC71BM based flexible solar cell [27]; Copyright (2018) Royal Society of Chemistry.](/document/doi/10.1515/ntrev-2022-0104/asset/graphic/j_ntrev-2022-0104_fig_006.jpg)

The stamping transfer process of the PPy NPs:PEDOT:PSS layer for PTB7/PC71BM based flexible solar cell [27]; Copyright (2018) Royal Society of Chemistry.

Besides that, an impressive PCE of 9.48% was obtained for PTB7:PC71BM based solar cells when water-soluble polypyrrole NPs (PPy NPs) doped PEDOT:PSS was used as buffer layer [104]. PTB7:PC71BM based solar cell was coated a 20% PPy NPs doped PEDOT:PSS layer and obtained a PCE of 9.44%. Comparing this to the pristine PEDOT:PSS and without PEDOT:PSS layer, an improvement of 18 and 152% was achieved. Besides, PTB7:PC61BM based solar cells also improved by 15 and 154% compared to the pristine PEDOT:PSS and without the PEDOT:PSS layer, respectively. Notably, the conductivity of 20% PPy NPs:PEDOT:PSS film with 2.22 × 10−4 ± 0.2 × 10−4 S/cm is 4 times higher than pristine PEDOT:PSS. The pH value of 2.2 for pure PEDOT:PSS is modified to pH value of 7.4, when 20% PPy NPs doped into PEDOT:PSS. The composite is neutralised, while the conductivity and its long-term stability are improved, where hole extraction is much better, and the damage to the ITO surface is lower than the device with pure PEDOT:PSS. Aside from that, the PPy NPs:PEDOT:PSS composite film exhibits phase separation and a bicontinuous interpenetrating network, which are useful for hole transport [104].

3.3 Inorganic NPs

Inorganic semiconductors have shown excellent electronic properties, for example, high dielectric constant, high charge mobility, and thermal stability, while the NPs also exhibit enhanced electronic, photo-conducting, and luminescent properties [105]. The reported work for devices using inorganic NPs doped into PEDOT:PSS is presented in Table 7. An increase in efficiency is observed in small molecule OPVs by incorporating TiO2 NPs with PEDOT:PSS as transparent electrode [106]. With 0.5 wt% TiO2 mixed with PEDOT:PSS, higher transmittance is obtained as compared to the bare PEDOT:PSS layer. The device with the optimised concentration of TiO2 in PEDOT:PSS showed the best PCE of 7.92%, improved by a factor of 1.08 compared to bare PEDOT:PSS devices. TiO2 NPs act as a scattering volume for increased light coupling for OPV devices and the composite layer also enhances mechanical flexibility. Next commonly used vanadium pentoxide (V2O5) NPs have been studied for the effect of carrier mobility, hole-only devices with different HTLs [107]. In this study, for the embedded V2O5NPs in PEDOT:PSS layer, the hole mobility (μ h) was calculated according to the Mott-Gurney law. The value of μ h increases from 2.54 × 10−4 cm2 v−1 s−1 for V2O5 and 3.19 × 10−4 cm2 v−1 s−1 for PEDOT:PSS to 4.19 × 10−4 cm2 v−1 s−1 for V2O5 NPs:PEDOT:PSS. The larger hole mobility can promote charge transfer to enhance photocurrent J SC and fill factor (FF). Notably, wide-angle X-ray scattering (GIWAXS) revealed a stronger lamellar intensity and π-π peaks in the active layer for V2O5 NPs:PEDOT:PSS compared to the pristine PEDOT:PSS layer, further proof that the crystallinity of the active layer (PTB7-Th:PC71BM) coated on the V2O5 NPs:PEDOT:PSS is enhanced. Therefore, V2O5 NPs:PEDOT:PSS acquired a PCE of 9.44% (improved by 14.70%).

Device characteristics of OPVs with inorganic NPs doped into PEDOT:PSS

| NPs | Active layer | Size of NP (nm) | Thickness (nm)(a) | Function | FF (%) | PCE (%) | Enhance in PCE (%)(b) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| TiO2 | DCV5T-Me:C60 | 100 | — | Anode | 60.0 | 7.92 | 8.60 | Scattering and better mechanical flexibility | [106] |

| V2O5 | PTB7-Th:PC71BM | 0.5% v/v(c) | — | HEL | 70.14 | 9.44 | 14.70 | Promotes hole mobility | [107] |

| FMoS2 | P3HT:PCBM | ∼6.7 nm(d) | — | HEL | 62.24 | 3.74 | 15.10 | Lower series resistance | [108] |

| MoO3 | P3HT:PC61BM | 5 | 30 | HEL | 63.00 | 3.29 | 7.87(f) | Improved wettability and film-forming ability on the polymer surface | [109] |

| WO x | PBDB-TF:IT-4F | 1:1(e) | 42 | HEL | 80.79 | 14.57 | 9.63 | Increased surface free energy | [110] |

| WS2 | PM6:Y6 | 3%(g) | 40 | HEL | 73.50 | 15.67 | 9.20 | Increased WF and increased hole mobility | [112] |

FF: field factor, PCE: power conversion efficiency, HEL: hole extraction layer, (—): no data provided.

(a): thickness of PEDOT:PSS:NPs composite layer, (b): compared with pristine PEDOT:PSS, (c): volume ratio of NPs, (d): FMoS2 film thickness, (e): ratio of PEDOT:PSS with NPs (PEDOT:PSS:NPs), (f) compared with only e-MoO3 layer, and (g): volume ratio of WS2 nanosheet.

Another paper used inorganic oleylamine-functionalised molybdenum disulphide (FMoS2) nanosheets doped into PEDOT:PSS as hole extraction layer for P3HT:PCBM based organic solar cell [108]. Introducing a 2D sheet-like FMoS2 into PEDOT:PSS would increase surface hydrophobicity and facilitate the subsequent deposition of the hydrophobic active layer. The device with FMoS2:PEDOT:PSS as HTL has lower sheet resistance (R S) and higher shunt resistance (R SH) than PEDOT:PSS. Therefore, FMoS2:PEDOT:PSS films exhibited a PCE of 3.74%, which is 15.1% higher than the reference device with only PEDOT:PSS layer. In another work, the author demonstrated MoO3 mixed with PEDOT:PSS as hybrid ink resulted in better wettability and forming a smoother surface. The film-forming ability of the MoO3:PEDOT:PSS hybrid ink was improved due to the stronger bonding between the MoO3 NPs and the photoactive layer. The PCE for MoO3:PEDOT:PSS is improved by 7.87% as compared to only MoO3 layer [109].

Furthermore, WO x NPs blended with PEDOT:PSS as HTL can improve device efficiency and surface free energy (γS) [110]. The morphology of BHJ films depends highly on the surface free energy of the underlying interfacial layer [111]. Surface free energies of WO x , WO x :PEDOT:PSS, and PEDOT:PSS HTLs were calculated to be 73.98, 62.09, and 59.30 mN/m, respectively. The introduction of WO x NPs to PEDOT:PSS affected the work function and surface roughness and increased the surface free energy. Based on the optimised WO x :PEDOT:PSS composite layer, an impressive PCE of 14.57% with FF near 81% is achieved, mainly due to efficient carrier extraction, leading to reduced nonradiative recombination [110]. In addition, tungsten disulphide nanosheet (WS2NS) was produced using a low-cost liquid-phase exfoliation method [112]. Incorporating WS2NS into PEDOT:PSS improved the work function to form an Ohmic contact between the photoactive layer and the anode. At the same time, WS2NS increased the hole mobility and lower charge carrier-recombination in PM6:Y6 based OPV.

3.4 Carbon-based NPs

Carbon-related nanomaterials usually possess high conductivity; thus, the series resistance can be improved when doped into PEDOT:PSS layer. The related works are summarised in Table 8. When multi-walled carbon nanotube (MWCNT) with an optimum concentration of 0.04 wt% was doped into PEDOT:PSS, the PCE improvement of 12.7% was achieved as compared to bare PEDOT:PSS as a result of enhanced conductivity that led to a lower series resistance of the device [43]. However, at higher MWCNTs concentration (>0.2 wt%), the transmittance of the composite film was dropped from 93.2 to 86.2%. The MWCNTs-doped PEDOT:PSS OPV device showed an improvement in overall performance, including short-circuit current density, fill factor, and power conversion efficiency from 8.82 to 9.03 mA/cm2, 0.43 to 0.474, and 2.12 to 2.39% as compared to the device with a bare PEDOT:PSS layer. Besides, CNT-related materials, ultra-large GO-PEDOT:PSS was tested as a hole extraction layer with the device configuration ITO/PEDOT:PSS:GO/P3HT:PCBM/LiF/Al [113]. Optimised power conversion efficiencies of PEDOT:PSS:GO (0.04 wt%) with 6 wt% dimethyl sulfoxide (DMSO) is improved by 13.6%. When DMSO is added to the PEDOT:PSS solution, the PEDOT and PSS chains separate. The coulombic attraction of the PEDOT and PSS chains is weakened; thus, the coulombic repulsions among the positive or negative charges in the PEDOT or PSS chain become the dominant factor for the chain conformation and shift to the linear and extended-coil conformations. At the same time, GO functional groups (–COOH and –OH) also effectively separate PSS and PEDOT chains, which helps the PEDOT and PSS chains to form linear and extended-coil conformations. The linear PEDOT chains have stronger inter-chain interactions, which facilitate charge transport between the chains. Therefore, the conductivity of PEDOT:PSS doped with GO increases. In another report with PEDOT:PSS:GO composite, pre-annealing of GO sheets significantly improves the hole collection ability of the PEDOT:PSS buffer layer, and PCE achieved was 3.8% [114]. The value is 1.8 times better than a pristine PEDOT:PSS buffer layer.

Device characteristics of OPVs with carbon-based NPs doped PEDOT:PSS

| NPs | Active layer | Concentration | Thickness (nm)(a) | Function | FF (%) | PCE (%) | Enhance in PCE (%)(b) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| MWCNT | P3HT:PCBM | 0.04 wt% | 90–100 | HEL | 47.40 | 2.39 | 12.70 | Enhanced conductivity | [43] |

| GO | P3HT:PCBM | 0.04 wt% | — | HEL | 62.80 | 3.39 | 13.60 | Enhanced conductivity | [113] |

| GO | P3HT:PCBM | — | 40 | HEL | 43.00 | 3.80 | 81.00 | Enhanced hole collection | [114] |

| SWCNTs + HClO4 | PTB7:PC71BM | (10:1) + (0.1 M) | 100 | Cathode | 54.00 | 8.60 | 15.40(c) | Improved interfacial layer contact and conductivity | [29] |

FF: field factor, PCE: power conversion efficiency, HEL: hole extraction layer, (—): no data provided.

(a): thickness of PEDOT:PSS:NPs composite layer, (b): compared with pristine PEDOT:PSS, (c) compared with ITO.

Apart from using carbon-based nanomaterials-PEDOT:PSS as a hole extraction layer, the composite layer has also been studied as an anode. A stable flexible inverted organic solar cell with HClO4 (0.1 M) doped printed PEDOT-SWCNT films on a PET substrate with the device configuration of PET/PEDOT-SWNTs + (0.1 M) HClO4/PTB7:PC71BM/VO x -PEDOT-PSS/Ag structure has been studied [29]. The bottom electrode (PEDOT:PSS-SWNTs + (0.1 M) HClO4) and VO x -PEDOT:PSS film interface layers were printed with digital materials deposition (DMD), while the PTB7:PC71BM active layer is deposited by spin coating and the Ag electrode by thermal evaporation. Using PEDOT-SWCNTs + (0.1 M) HClO4 as a cathode, better performance and stability are obtained compared to the device based on ITO as an anode. SWNTs increased conductivity by adding a small percentage of HClO4 to improve further the interfacial contact with the electron transporting layer and enhance adhesion to PET substrate. PEDOT:PSS:SWNTs:HClO4 as transparent electrode and VOx-PEDOT:PSS as hole transport layer showed the best PCE of 8.6%, which is about 15.4% improvement as compared to ITO.

3.5 Hybrid NPs

A wide variety of hybrid NPs, such as bimetallic noble metal or metal/metal oxide hybrid nanoparticles, or organic capped metal NPs have been explored for OPV. These special class NPs are gaining interest since the hybrid NPs possess the properties of both the materials (Table 9). The hybridisation of the two distinct NPs can lead to remarkable properties for nanomaterial applications. Poly(ethylene glycol) (PEG)-capped Au NPs with a diameter of ∼18 nm were doped into the PEDOT:PSS for OPV [115]. A PCE of 3.51% was obtained at the optimised concentration (0.32 wt%) of PEG-capped Au NPs in PEDOT:PSS with the device structure of ITO/PEG-capped Au NPs:PEDOT:PSS/P3HT:PCBM/LiF/Al. There was a 13% improvement as compared to the bare PEDOT:PSS, possibly because PEG-Au NPs reduce the resistance of the PEDOT:PSS layer. Upon increasing the PEG-capped AuNP concentration, the surface morphology of the PEG-capped Au NP:PEDOT:PSS film also increases in roughness by 5% (0.32 wt%) and 40% (0.64 wt%), respectively. Higher anode surface roughness led to a higher interface area between the anode and the active layer and enhanced the device’s hole collection. Performance is achieved with no discernible difference in the transmission of PEDOT:PSS with or without Au NPs, so the performance enhancement was concluded to not be due to the optical effects.

Device characteristics of OPVs with hybrid NPs doped PEDOT:PSS

| NPs | Active layer | Size of NP (nm) | Thickness (nm)(a) | Function | FF (%) | PCE (%) | Enhance in PCE (%)(b) | Remarks | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| PEG-capped Au | P3HT:PCBM | 18 | 30 | HEL | 62.0 | 3.51 | 13.20 | Higher roughness and better hole collection | [115] |

| Cu-Au | P3HT:PC61BM | 50 | 40 | HEL | 52.3 | 3.63 | 13.10 | LSPR and better hole collection | [116] |

| Cu-Au | PTB7-th:PC61BM | 50 | 40 | HEL | 57.9 | 7.13 | 9.50 | LSPR and better hole collection | [116] |

| Cu-Au | PTB7-th:PC71BM | 50 | 40 | HEL | 60.1 | 8.48 | 12.60 | LSPR and better hole collection | [116] |

FF: field factor, PCE: power conversion efficiency, HEL: hole extraction layer, (—): no data provided.

(a): thickness of PEDOT:PSS:NPs composite layer, (b): compared with pristine PEDOT:PSS.

Cu-Au bimetallic NPs with core-shell nanostructures with highly stable and broad LSPR has been reported [116]. In particular, LSPR bands for Au NPs and CuNPs are at 530 nm [117] and 590 nm [118], respectively, while Cu-Au NPs exhibit a wide absorption peak at wavelengths 650–700 nm. The PCEs of the P3HT:PC61BM, PTB7-th:PC61BM, and PTB7-th:PC71BM based organic solar cells were 3.63, 7.13, and 8.48%, respectively. After incorporating 0.88 wt% Cu-Au NPs into the PEDOT:PSS, the improvements are 13.1, 9.5, and 12.6%, respectively. The reason for improvement is the increase in the J sc or the plasmonic effect from the Cu-Au NPs, IPCE; this is confirmed by the optical absorption measurements [116].

4 Outlook and challenges

Overall, the best consistent improvement in efficiency is obtained for devices with metallic NPs doped with PEDOT:PSS for OLEDs (up to 96%) and OPVs (up to 67%), which involve the effects of SPR. OLEDs with the best performance is obtained from the devices with co-doped Au NPs and Ag NPs in PEDOT:PSS, where the CE, PE, and EQE are 35.30 cd/m2, 8.20 lm/A, and 9.80%, respectively. The efficiency was improved by 96% with the co-doped NPs, the huge enhancement is mainly attributed to SPR and the synergistic effect from the stronger near-field resonance of Au NPs and the relative broadband resonance of Ag NPs. The co-doped devices showed better electrical properties and long-term stability of OLED devices [73]. For OPV, the most significant improvement of 67% was obtained when Au NPs (14 ± 4 nm) were doped in PEDOT:PSS. The improvement is due to the SPR effect and better hole collection [98]. On the other hand, the device with co-doped Au and Ag in PEDOT:PSS resulted in PCE of 8.67%, which was improved by 19.6% [102]. The improvement was ascribed to the broad wavelength range of the two distinct metal particles.

In SPR, resonant oscillation of conduction electrons occurs between the negative and positive permittivity materials. LSPR occurs when the incident light matches the frequency of the metallic surface and causes free surface electrons to oscillate collectively, this has been seen in the case of using gold or silver NPs. The schematic of LSPR is illustrated in Figure 7. The enhanced near-field amplitude of these electrons thus occurs at the resonance wavelength. The extinction wavelength and improvement of emission for LSPR are determined by the shape and size of the NPs [1,39]. Different sizes, shapes, and structures of NPs that match the photoluminescence (PL) of the emissive layer will be significantly enhanced [21].

Schematic of LSPR where incident light caused the free conduction electrons in the metal NPs to collective oscillation.

The size of plasmonic NPs that exhibit forward scattering is typically between 30 and 70 nm [119,120] (Figure 8a). As the particle size increases, more light is scattered, thus improving the light-out coupling for OLED devices. However, large NPs embedded in the layer are bad for the device because of the inferior layer morphology and strong metallic absorption [121]. The optimum size of plasmonic NPs for OLEDs is in the region of 50–70 nm to achieve the optimum device efficiency [120]. Furthermore, for plasmonic NPs less than 30 nm, the enhancement is dominantly from the LSPR effect instead of scattering [122]. The plasmonic near-field induced in the buffer layer (Figure 8b) is able to enhance the absorption and electric field of OPVs [122]. NPs with different shapes and sizes trigger surface plasmonic effects in organic optoelectronic [123,124,125]. NPs size in the range of 20–60 nm in PEDOT:PSS exhibited a more significant enhancement in OLED devices (30–100%), while minor enhancement was obtained when the size is less than 20 nm. Whereas, in the case of OPVs, smaller NPs (10–20 nm) in PEDOT:PSS is preferable for more extensive PCE enhancement (20–70%). The enhancement is lower when the size is larger than 20 nm.

Schematic diagram of OLEDs and OPVs with plasmonic NPs, (a) NPs in HIL for OLEDs with scattering effect and (b) NPs in HEL for OPVs with LSPR effect.

In addition, metal oxide NPs also show significant enhancement for OLEDs and OPVs. The highest enhancement in current efficiency for OLEDs is 760.5% for the device with TiO2 NPs (20 wt%, 25 nm) doped PEDOT:PSS compared to a bare PEDOT:PSS layer [79]. The current efficiency is 7.30 cd/m2, and the power efficiency is 3.15 lm/A. The impressive improvement was achieved due to improved light out-coupling from light scattering from the modified layer. The best enhancement in power conversion efficiency (81%) are obtained for the OPV devices with GO:PEDOT:PSS. GO sheets were first pre-heated and then mixed with the PEDOT:PSS solution. Pre-annealing of GO sheets significantly improves hole collection ability, with 1.8 times improvement over pristine PEDOT:PSS as a buffer layer [114]. The addition of NPs to PEDOT:PSS improves hole injection and conductivity by lowering the sheet resistance of the film after mixing GO with PEDOT:PSS [83]. Films with low sheet resistance, high transparency, and high conductivity are critical for ITO-free OLEDs. Incorporating GO into PEDOT:PSS improves surface morphology and higher work function, which is advantageous for hole injection. The overview effects of NPs:PEDOT:PSS in OLEDs and OPVs are shown in Figure 9.

Overview effect of NPs-doped PEDOT:PSS for OLED and OPV.

Although promising results have been obtained with the reviewed strategies for doping NPs in PEDOT:PSS, the quest to find a universal solution to improve the efficiency of OLEDs and OPVs continues. NPs synthesis and the properties of NPs are active research areas with new and rapid development. Thus, there are still a lot of new, possible approaches that are yet to be explored extensively. For example, the size of NPs, shape, and concentrations of NPs are also crucial for OLED and OPV as they affect light out-coupling for OLEDs, light trapping for OPVs, and the electrical properties of the PEDOT:PSS layer. However, in most of the reports, the NPs used are spherical and rod in shape [21]. To our best knowledge, an extensive study into the effects of particle shape has not been reported in nanoparticles doped PEDOT:PSS for OLEDs and OPVs specifically. Shape-dependent metal NPs in the active layer were studied in depth. The various polyhedral gold (Au) NPs are included; cubic, rhombic dodecahedral (RD), edge and corner truncated octahedra (ECTO), and triangular shape are used in the device ITO/ZnO/P3HT:PC61BM:NPs/MoO x /Ag [126] (Figure 10). LSPR peaks were detected at 590 nm (cubes and RD), 558 nm (ECTO), and 564 nm (triangular) for each shape. Au NPs with a RD shape have the greatest increase in PCE from 3.4 to 4.4%, followed by ECTO, cube, and triangle (RD > ECTO > cube > triangle). In addition, to further verify the electromagnetic field around the particle surface, 3-dimensional FDTD using transverse electric polarisation with an excitation wavelength of 550 nm was also performed. The result showed that LSPRs around the edges or corners of the RD was significantly enhanced and presented the most potent electric-field responses, followed by ECTO and cube (RD > ETCO > cube). The FDTD results are shown in Figure 11. For Au triangular plates, no electric resonance was induced; thus, the enhancement is mainly caused by scattering. Meanwhile, both simulation and experimental results showed that Au RD NPs demonstrate the most significant enhancement [126].

![Figure 10

SEM images of: (a) cubes, (b) RD, (c) ECTO, and (d) triangular plates of AuNPs. (e) Absorption spectra of cubes, RD, ECTO, and triangular plates of AuNPs solutions [126]; Copyright (2015) American Chemical Society.](/document/doi/10.1515/ntrev-2022-0104/asset/graphic/j_ntrev-2022-0104_fig_010.jpg)

SEM images of: (a) cubes, (b) RD, (c) ECTO, and (d) triangular plates of AuNPs. (e) Absorption spectra of cubes, RD, ECTO, and triangular plates of AuNPs solutions [126]; Copyright (2015) American Chemical Society.

![Figure 11

FDTD simulation analysis of time-averaged and normalised transverse electric field distribution with different polyhedral AuNPs: (a) cube, (b) RD, (c) ECTO, and (d) triangle plate. [126]; Copyright (2015) American Chemical Society.](/document/doi/10.1515/ntrev-2022-0104/asset/graphic/j_ntrev-2022-0104_fig_011.jpg)

FDTD simulation analysis of time-averaged and normalised transverse electric field distribution with different polyhedral AuNPs: (a) cube, (b) RD, (c) ECTO, and (d) triangle plate. [126]; Copyright (2015) American Chemical Society.

It has also been challenging to study the individual effects of NP doped PEDOT:PSS, such as SPR, scattering, carrier transport, etc. The complex optical and electrical processes are difficult to be modelled in numerical simulation alone; thus, extensive experimental work is needed. The combination of both experimental results and numerical analysis can contribute to a better understanding of the carrier behaviour caused by the NP doped PEDOT:PSS layer. On the other hand, non-conducting or non-metallic-based NPs can be used to study pristine optical effects such as scattering, reflectivity, and excluding the plasmonic effect.

Furthermore, ITO-free TCF have recently received much attention because of the scarcity of indium and the process cost. The estimated ITO cost range of organic solar cells is around 40–150 € per m2, PET/ITO accounting for the largest share of total costs, around 38–51% of the total cost of the device [127]. Therefore, alternative materials like PEDOT:PSS are able to lower the cost by using the roll-to-roll process. PEDOT:PSS has a higher HOMO level than ITO, making it more suitable for hole injection, but the low conductivity of PEDOT:PSS limits its application. Thus, NPs doped with PEDOT:PSS have also been explored [124]. PEDOT:PSS with AgNW, GO, etc., have been used to improve the conductivity, but the best conductivity is still in the range of 800–1,500 S/cm [128,129,130]. The performance remains poor and needs to be improved, and the physical mechanism of the composite electrode remains unclear [60].

5 Conclusion

Despite advancements, organic optoelectronics continues to face significant challenges in device stability, including degradation, efficient charge transport, light absorption (OPV), and light out-coupling (OLEDs). NPs doped PEDOT:PSS hole transport layer is one of the promising solutions for both devices because of its capability to improve photo absorption or light out-coupling by either increasing the light scattering process or plasmonic resonance effect without increasing the active layer thickness. At the same time, the morphology of the doped PEDOT:PSS layer can also be optimised. Although the optical properties of NPs, such as plasmonic effects, have received the most attention to date, the effects on the electrical properties of organic optoelectronics, such as charge carrier extraction after exciton dissociation, are not entirely understood and remain a major challenge.

This review highlights the recent effort of NP incorporation in PEDOT:PSS for OLEDs and OPVs. It is clear that the presence of NPs in PEDOT:PSS affords a straightforward yet promising solution to increase the light out-coupling from OLEDs and also better light trapping in OPVs. A few typical effects of the NPs enhance the optical and electrical properties. Optical effects include the surface plasmon effect due to NPs, enhanced scattering, and better absorption of photons. In addition, the SPR effects also improved the hole injection, hence electrical conduction by increasing the hole mobility for organic optoelectronics. Although most of these published works focused on the SPR effects of metallic NPs, other factors that contributed to the device improvement, such as the charge carrier extraction after dissociation and the effects of the shape of the NPs are still not fully understood for plasmonic-based OPVs. In addition, the electrical and morphological properties of the composite are also crucial in nanoscale devices. Further understanding and development will undoubtedly accelerate the implementation of low-cost, large-scale manufacturing.

-

Funding information: The authors acknowledge the support from the Ministry of Education, Malaysia (FRGS/1/2019/STG07/MMU/02/1). S.S. Yap acknowledges the support from the Sandisk/Western Digital Malaysia and the Penang State Government.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Kim T, Kang H, Jeong S, Kang DJ, Lee C, Lee CH, et al. Au@Polymer core-shell nanoparticles for simultaneously enhancing efficiency and ambient stability of organic optoelectronic devices. ACS Appl Mater Interfaces. 2014;6(19):16956–65.10.1021/am504503qSuche in Google Scholar PubMed

[2] Burroughes JH, Bradley DDC, Brown AR, Marks RN, Mackay K, Friend RH, et al. Light-emitting diodes based on conjugated polymers. Nature. 1990;347(6293):539–41.10.1038/347539a0Suche in Google Scholar

[3] Ong GL, Zhang Q, Ong TS, Kek R, Nee CH, Tou TY, et al. Enhanced performance of blue OLED with water/alcohol soluble conjugated polymer as electron injection layer. Synth Met. 2021;272:116658.10.1016/j.synthmet.2020.116658Suche in Google Scholar

[4] Wu JL, Chen FC, Hsiao YS, Chien FC, Chen P, Kuo CH, et al. Surface plasmonic effects of metallic nanoparticles on the performance of polymer bulk heterojunction solar cells. ACS Nano. 2011;5(2):959–67.10.1021/nn102295pSuche in Google Scholar PubMed

[5] Cui M, Rui H, Wu X, Sun Z, Qu W, Qin W, et al. Coexistent integer charge transfer and charge transfer complex in F4-TCNQ-doped PTAA for efficient flexible organic light-emitting diodes. J Phys Chem Lett. 2021;12:8533–40.10.1021/acs.jpclett.1c02281Suche in Google Scholar PubMed

[6] Zhang N, Tian G, Wu X, Qin W, Liu M, Li Y, et al. Low driving voltage and enhanced performance of solution-processed blue flexible organic light-emitting diode with PTAA/AgNWs/PTAA composite hole injection layers. J Phys D Appl Phys. 2019;52(31):8.10.1088/1361-6463/ab1f53Suche in Google Scholar

[7] Peng CC, Yang SY, Li HC, Xie GH, Cui LS, Zou SN, et al. Highly efficient thermally activated delayed fluorescence via an unconjugated donor–acceptor system realizing EQE of over 30%. Adv Mater. 2020;32(48):1–7.10.1002/adma.202003885Suche in Google Scholar PubMed

[8] Su R, Zhao Y, Yang F, Duan L, Lan J, Bin Z, et al. Triazolotriazine-based thermally activated delayed fluorescence materials for highly efficient fluorescent organic light-emitting diodes (TSF-OLEDs). Sci Bull. 2021;66(5):441–8.10.1016/j.scib.2020.08.023Suche in Google Scholar

[9] Fan B, Li M, Zhang D, Zhong W, Ying L, Zeng Z, et al. Tailoring regioisomeric structures of π-conjugated polymers containing monofluorinated π-bridges for highly efficient polymer solar cells. ACS Energy Lett. 2020;5(6):2087–94.10.1021/acsenergylett.0c00939Suche in Google Scholar

[10] You YJ, Song CE, Hoang QV, Kang Y, Goo JS, Ko DH, et al. Highly efficient indoor organic photovoltaics with spectrally matched fluorinated phenylene-alkoxybenzothiadiazole-based wide bandgap polymers. Adv Funct Mater. 2019;29(27):1–11.10.1002/adfm.201901171Suche in Google Scholar

[11] Shi M, He Y, Sun Y, Fang D, Miao J, Ali MU, et al. Bis(diphenylamino)-benzo[4,5]thieno[3,2-b]benzofuran as hole transport material for highly efficient RGB organic light-emitting diodes with low efficiency roll-off and long lifetime. Org Electron. 2020;84:105793.10.1016/j.orgel.2020.105793Suche in Google Scholar

[12] Nam M, Chung NK, Shim S, Yun JY, Kim JT, Pyo SG. Efficiency enhancement of fluorescence blue organic light-emitting diodes by incorporating Ag nanoparticles layers due to a localized surface plasmon. J Korean Phys Soc. 2017;71(5):299–303.10.3938/jkps.71.299Suche in Google Scholar

[13] Mucur SP, Tumay TA, San SE, Tekin E. Enhancing effects of nanoparticles on polymer-OLED performances. J Nanoparticle Res. 2012;14:10.10.1007/s11051-012-1214-9Suche in Google Scholar

[14] Ong TS, Ong GL, Kee YY, Yap SS, Tou TY. Optimisation of graded-mixed transport organic light emitting diode via mixed-source thermal evaporation technique. Microelectron Eng. 2019;213:62–8.10.1016/j.mee.2019.04.021Suche in Google Scholar

[15] Luscombe CK, Maitra U, Walter M, Wiedmer SK. Theoretical background on semiconducting polymers and their applications to OSCs and OLEDs. Chem Teach Int. 2021;3(2):169–83.10.1515/cti-2020-0020Suche in Google Scholar

[16] Park CY, Choi B. Enhanced light extraction from bottom emission OLEDs by high refractive index nanoparticle scattering layer. Nanomaterials. 2019;9:9.10.3390/nano9091241Suche in Google Scholar PubMed PubMed Central

[17] Yamasaki T, Sumioka K, Tsutsui T. Organic light-emitting device with an ordered monolayer of silica microspheres as a scattering medium. Appl Phys Lett. 2000;76(10):1243–5.10.1063/1.125997Suche in Google Scholar

[18] Möller S, Forrest SR. Improved light out-coupling in organic light emitting diodes employing ordered microlens arrays. J Appl Phys. 2002;91(5):3324–7.10.1063/1.1435422Suche in Google Scholar

[19] Do YR, Kim YC, Song YW, Lee YH. Enhanced light extraction efficiency from organic light emitting diodes by insertion of a two-dimensional photonic crystal structure. J Appl Phys. 2004;96(12):7629–36.10.1063/1.1815049Suche in Google Scholar

[20] Lee MH, Choi WH, Zhu F. Solution-processable organic-inorganic hybrid hole injection layer for high efficiency phosphorescent organic light-emitting diodes. Opt Express. 2016;24(6):A592.10.1364/OE.24.00A592Suche in Google Scholar PubMed

[21] Zhuang Y, Liu L, Wu X, Tian Y, Zhou X, Xu S, et al. Size and shape effect of gold nanoparticles in “far-field” surface plasmon resonance. Part Part Syst Charact. 2019;36(1):1–8.10.1002/ppsc.201800077Suche in Google Scholar

[22] Yang C, Zhao C, Sun Y, Li Q, Islam MR, Liu K, et al. Optical management in organic photovoltaic devices. Carbon Energy. 2021;3(1):4–23.10.1002/cey2.97Suche in Google Scholar

[23] Tang Z, Tress W, Inganäs O. Light trapping in thin film organic solar cells. Mater Today. 2014;17(8):389–96.10.1016/j.mattod.2014.05.008Suche in Google Scholar

[24] Yang Y, Deng H, Fu Q. Recent progress on PEDOT:PSS based polymer blends and composites for flexible electronics and thermoelectric devices. Mater Chem Front. 2020;4(11):3130–52.10.1039/D0QM00308ESuche in Google Scholar

[25] Wen Y, Xu J. Scientific importance of water-processable PEDOT–PSS and preparation, challenge and new application in sensors of its film electrode: a review. J Polym Sci Part A Polym Chem. 2017;55(7):1121–50.10.1002/pola.28482Suche in Google Scholar

[26] Woo S, Jeong JH, Lyu HK, Han YS, Kim Y. In situ-prepared composite materials of PEDOT:PSS buffer layer-metal nanoparticles and their application to organic solar cells. Nanoscale Res Lett. 2014;9(1):2–7.10.1186/1556-276X-9-506Suche in Google Scholar PubMed PubMed Central

[27] Lee JH, Kim YY, Park OO. Enhanced performance and mechanical durability of a flexible solar cell from the dry transfer of PEDOT:PSS with polymer nanoparticles. J Mater Chem C. 2018;6(15):4106–13.10.1039/C8TC00502HSuche in Google Scholar

[28] Diker H, Yesil F, Varlikli C. Contribution of O2 plasma treatment and amine modified GOs on film properties of conductive PEDOT:PSS application in indium tin oxide free solution processed blue OLED. Curr Appl Phys. 2019;19(8):910–6.10.1016/j.cap.2019.04.018Suche in Google Scholar

[29] Wageh S, Raïssi M, Berthelot T, Laurent M, Rousseau D, Abusorrah AM, et al. Digital printing of a novel electrode for stable flexible organic solar cells with a power conversion efficiency of 8.5%. Sci Rep. 2021;11(1):1–16.10.1038/s41598-021-93365-8Suche in Google Scholar

[30] Cho EC, Li CP, Huang JH, Lee KC, Huang JH. Three-dimensional conductive nanocomposites based on multiwalled carbon nanotube networks and PEDOT:PSS as a flexible transparent electrode for optoelectronics. ACS Appl Mater Interfaces. 2015;7(21):11668–76.10.1021/acsami.5b03159Suche in Google Scholar PubMed

[31] Prosa M, Tessarolo M, Bolognesi M, Cramer T, Chen Z, Facchetti A, et al. Efficient and versatile interconnection layer by solvent treatment of PEDOT:PSS interlayer for air-processed organic tandem solar cells. Adv Mater Interfaces. 2016;3(23):1–8.10.1002/admi.201600770Suche in Google Scholar

[32] Li X, Deng Z, Yin Y, Zhu L, Xu D, Wang Y, et al. Efficiency enhancement of polymer solar cells with Ag nanoparticles incorporated into PEDOT:PSS layer. J Mater Sci Mater Electron. 2014;25(1):140–5.10.1007/s10854-013-1563-xSuche in Google Scholar

[33] Xie Y, Zhang SH, Jiang HY, Zeng H, Wu RM, Chen H, et al. Properties of carbon black-PEDOT composite prepared via in-situ chemical oxidative polymerization. E-Polymers. 2019;19(1):61–9.10.1515/epoly-2019-0008Suche in Google Scholar

[34] Jonas F, Morrison JT. 3,4-Polyethylenedioxythiophene (PEDT): conductive coatings technical applications and properties. Synth Met. 1997;85(1–3):1397–8.10.1016/S0379-6779(97)80290-1Suche in Google Scholar

[35] Scott JC, Carter SA, Karg S, Angelopoulos M. Polymeric anodes for organic light-emitting diodes. Synth Met. 1997;85(1–3):1197–200.10.1016/S0379-6779(97)80207-XSuche in Google Scholar

[36] Cao Y, Yu G, Zhang C, Menon R, Heeger AJ. Polymer light-emitting diodes with polyethylene dioxythiophene-polystyrene sulfonate as the transparent anode. Synth Met. 1997;87(2):171–4.10.1016/S0379-6779(97)03823-XSuche in Google Scholar

[37] Tian Y, Wang T, Zhu Q, Zhang X, Ethiraj AS, Geng WM, et al. High-performance transparent PEDOT:Pss/CNT films for OLEDs. Nanomaterials. 2021;11:8.10.3390/nano11082067Suche in Google Scholar PubMed PubMed Central

[38] Hu L, Song J, Yin X, Su Z, Li Z. Research progress on polymer solar cells based on PEDOT:PSS electrodes. Polymers. 2020;12(145):1–19.10.3390/polym12010145Suche in Google Scholar PubMed PubMed Central

[39] Lim EL, Yap CC, Teridi MA, Teh CH, Jumali MH. A review of recent plasmonic nanoparticles incorporated P3HT:PCBM organic thin film solar cells. Org Electron. 2016;36:12–28.10.1016/j.orgel.2016.05.029Suche in Google Scholar

[40] Ali AM, Said DA, Khayyat M, Boustimi M, Seoudi R. Improving the efficiency of the organic solar cell (CuPc/C60) via PEDOT:PSS as a photoconductor layer doped by silver nanoparticles. Results Phys. 2020;16:102819.10.1016/j.rinp.2019.102819Suche in Google Scholar

[41] Lee W, Kang YH, Lee JY, Jang KS, Cho SY. Improving the thermoelectric power factor of CNT/PEDOT:PSS nanocomposite films by ethylene glycol treatment. RSC Adv. 2016;6(58):53339–44.10.1039/C6RA08599GSuche in Google Scholar

[42] Zhuo MP, Liang F, Shi YL, Hu Y, Wang RB, Chen WF, et al. WO3 nanobelt doped PEDOT:PSS layers for efficient hole-injection in quantum dot light-emitting diodes. J Mater Chem C. 2017;5(47):12343–8.10.1039/C7TC04575ASuche in Google Scholar

[43] Liu J, Li J, Gao C, Chen G. Nanocomposite hole-extraction layers for organic solar cells. Int J Photoenergy. 2011;2011:1–5.10.1155/2011/392832Suche in Google Scholar

[44] Wang J, Wang J, Yu H, Yu H, Yu H, Hou C, et al. Solution-processable PEDOT:PSS:α-In2Se3 with enhanced conductivity as a hole transport layer for high-performance polymer solar cells. ACS Appl Mater Interfaces. 2020;12(23):26543–54.10.1021/acsami.0c02489Suche in Google Scholar PubMed

[45] Yang Q, Yu S, Fu P, Yu W, Liu Y, Liu X, et al. Boosting performance of non-fullerene organic solar cells by 2D g-C3N4 doped PEDOT:PSS. Adv Funct Mater. 2020;30(15):2–9.10.1002/adfm.201910205Suche in Google Scholar

[46] Ealias AM, Saravanakumar MP. A review on the classification, characterisation, synthesis of nanoparticles and their application. IOP Conf Ser Mater Sci Eng. 2017;263:3.10.1088/1757-899X/263/3/032019Suche in Google Scholar

[47] You J, Wang L, Zhao Y, Bao W. A review of amino-functionalized magnetic nanoparticles for water treatment: features and prospects. J Clean Product. 2021;281:124668.10.1016/j.jclepro.2020.124668Suche in Google Scholar

[48] Singh RP, Handa R, Manchanda G. Nanoparticles in sustainable agriculture: an emerging opportunity. J Control Release. 2021;329:1234–48.10.1016/j.jconrel.2020.10.051Suche in Google Scholar PubMed

[49] El-Megharbel SM, Alsawat M, Al-Salmi FA, Hamza RZ. Utilizing of (Zinc oxide nano-spray) for disinfection against “SARS-COV-2” and testing its biological effectiveness on some biochemical parameters during (covid-19 pandemic) – “ZnO nanoparticles have antiviral activity against (SARS-COV-2)”. Coatings. 2021;11:4.10.3390/coatings11040388Suche in Google Scholar

[50] Dasari S, Yedjou CG, Brodell RT, Cruse AR, Tchounwou PB. Therapeutic strategies and potential implications of silver nanoparticles in the management of skin cancer. Nanotechnol Rev. 2020;9(1):1500–21.10.1515/ntrev-2020-0117Suche in Google Scholar PubMed PubMed Central

[51] Ye P, Ye Y, Chen X, Zou H, Zhou Y, Zhao X, et al. Ultrasmall Fe3O4 nanoparticles induce S-phase arrest and inhibit cancer cells proliferation. Nanotechnol Rev. 2020;9(1):61–9.10.1515/ntrev-2020-0006Suche in Google Scholar

[52] Zhang DD, Xu JL, Sun HB. Toward high efficiency organic light-emitting diodes: role of nanoparticles. Adv Opt Mater. 2021;9(6):1–19.10.1002/adom.202001710Suche in Google Scholar

[53] Jaji ND, Lee HL, Hussin MH, Akil HM, Zakaria MR, Othman MBH. Advanced nickel nanoparticles technology: from synthesis to applications. Nanotechnol Rev. 2020;9(1):1456–80.10.1515/ntrev-2020-0109Suche in Google Scholar

[54] Liu Y, Jia M, Song C, Lu S, Wang H, Zhang G, et al. Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide. Nanotechnol Rev. 2020;9(1):17–27.10.1515/ntrev-2020-0002Suche in Google Scholar

[55] Du M, Jing H, Gao Y, Su H, Fang H. Carbon nanomaterials enhanced cement-based composites: advances and challenges. Nanotechnol Rev. 2020;9(1):115–35.10.1515/ntrev-2020-0011Suche in Google Scholar

[56] Li X, Wang W, Dong F, Zhang Z, Han L, Luo X, et al. Recent advances in noncontact external-field-assisted photocatalysis: from fundamentals to applications. ACS Catal. 2021;11(8):4739–69.10.1021/acscatal.0c05354Suche in Google Scholar

[57] Li X, Xiong J, Gao X, Huang J, Feng Z, Chen Z, et al. Recent advances in 3D g-C3N4 composite photocatalysts for photocatalytic water splitting, degradation of pollutants and CO2 reduction. J Alloys Compd. 2019;802:196–209.10.1016/j.jallcom.2019.06.185Suche in Google Scholar

[58] Banin U, Ben-Shahar Y, Vinokurov K. Hybrid semiconductor-metal nanoparticles: from architecture to function. Chem Mater. 2014;26(1):97–110.10.1021/cm402131nSuche in Google Scholar

[59] Sanchez LM, Alvarez VA. Advances in magnetic noble metal/iron-based oxide hybrid nanoparticles as biomedical devices. Bioengineering. 2019;6:3.10.3390/bioengineering6030075Suche in Google Scholar PubMed PubMed Central

[60] Chen FC, Wu JL, Lee CL, Hong Y, Kuo CH, Huang MH. Plasmonic-enhanced polymer photovoltaic devices incorporating solution-processable metal nanoparticles. Appl Phys Lett. 2009;95(1):1–4.10.1063/1.3174914Suche in Google Scholar

[61] Morfa AJ, Rowlen KL, Reilly TH, Romero MJ, Van De Lagemaat J. Plasmon-enhanced solar energy conversion in organic bulk heterojunction photovoltaics. Appl Phys Lett. 2008;92(1):4–7.10.1063/1.2823578Suche in Google Scholar

[62] Chen X, Yang X, Fu W, Xu M, Chen H. Enhanced performance of polymer solar cells with a monolayer of assembled gold nanoparticle films fabricated by Langmuir-Blodgett technique. Mater Sci Eng B Solid-State Mater Adv Technol. 2013;178(1):53–9.10.1016/j.mseb.2012.10.024Suche in Google Scholar

[63] Heo M, Cho H, Jung JW, Jeong JR, Park S, Kim JY. High-performance organic optoelectronic devices enhanced by surface plasmon resonance. Adv Mater. 2011;23(47):5689–93.10.1002/adma.201103753Suche in Google Scholar PubMed

[64] Lian H, Pan M, Han J, Cheng X, Liang J, Hua W, et al. A MoSe2 quantum dot modified hole extraction layer enables binary organic solar cells with improved efficiency and stability. J Mater Chem A. 2021;9(30):16500–9.10.1039/D1TA04030HSuche in Google Scholar

[65] Feng J, Sun D, Mei S, Shi W, Mei F, Zhou Y, et al. Plasmonic-enhanced organic light-emitting diodes based on a graphene oxide/Au nanoparticles composite hole injection layer. Front Mater. 2018;5:1–8.10.3389/fmats.2018.00075Suche in Google Scholar

[66] Xiao Y, Yang JP, Cheng PP, Zhu JJ, Xu ZQ, Deng YH, et al. Surface plasmon-enhanced electroluminescence in organic light-emitting diodes incorporating Au nanoparticles. Appl Phys Lett. 2012;100(1):2010–4.10.1063/1.3675970Suche in Google Scholar

[67] Pan J, Chen J, Zhao D, Huang Q, Khan Q, Liu X, et al. Surface plasmon-enhanced quantum dot light-emitting diodes by incorporating gold nanoparticles. Opt Express. 2016;24(2):A33.10.1364/OE.24.000A33Suche in Google Scholar PubMed

[68] Chuang MK, Lin CH, Chen FC. Accumulated plasmonic effects of gold nanoparticle−decorated PEGylated graphene oxides in organic light-emitting diodes. Dye Pigment. 2020;180:108412.10.1016/j.dyepig.2020.108412Suche in Google Scholar

[69] Du H, Guo Y, Cui D, Li S, Wang W, Liu Y, et al. Solution-processed PEDOT:PSS:GO/AgNWs composite electrode for flexible organic light-emitting diodes. Spectrochim Acta – Part A Mol Biomol Spectrosc. 2021;248:119267.10.1016/j.saa.2020.119267Suche in Google Scholar PubMed