Abstract

In this study, we investigated the mechanical properties and chloride ion permeation resistance of geopolymer mortars based on fly ash modified with nano-SiO2 (NS) and polyvinyl alcohol (PVA) fiber and metakaolin (MK) at dose levels of 0–1.2% for PVA fiber and 0–2.5% for NS. The Levenberg–Marquardt (L–M) back propagation (BP) neural network, as well as the radial-based function (RBF) neural network, was used to predict the compressive strength and chloride ion permeation resistance of the geopolymer mortar with different admixtures of nanoparticles and PVA fiber, wherein the electric flux value was used as the index for chloride ion permeation performance. The RBF–BP composite neural network was constructed to study the compressive strength and chloride ion permeation resistance of nanoparticle-doped and PVA fiber ground geopolymer mortars. According to the experimental results of the RBF–BP composite neural network model, the mean square error (MSE) was observed to be 0.00071943, root mean square error (RMSE) was 0.026822, and mean absolute error (MAE) was 0.026822, thereby showing higher prediction accuracy, faster convergence, and better fitting effect compared with the single BP neural network and RBF neural network models. In this study, we combined the RBF–BP composite artificial neural network, providing a new method for the future assessment of the compressive strength and chloride ion penetration resistance of geopolymer mortar merging PVA fibers and NS in experiments and engineering studies.

1 Introduction

With rapid population growth and damaged infrastructure, increasing attention is being focused on the construction industry. Cement-based materials are one of the most widely used materials in the construction industry globally [1]. Most cement-based materials use silicate cement (OPC) as a binder [2], and cement is produced from two different sources of carbon dioxide, with rotary kilns operated via fossil fuel combustion being the largest source and the chemical process of calcining limestone into lime, which is also produced by cement kilns [3]. The OPC releases almost equal amounts of carbon dioxide during its production. Data from the US Geological Survey show that since 2013, approximately 4 billion tons of polyester cement have been produced annually, accounting for 8% of the total global carbon dioxide emissions. With the rapid growth of the global economy, it is estimated that in the next 30 years, cement output will increase to approximately 5 billion tons globally [4]. Such massive emissions of carbon dioxide have caused serious environmental pollution and has brought about huge social pressure. Many researchers are beginning to look for materials that save energy and are environmentally friendly, for example, Golewski discovered plain concretes prepared based on a quaternary binder to reduce carbon dioxide emissions [5]. In addition, cement-based materials have serious dissolution problems that affect the strength and durability of buildings [6]. Therefore, there is an urgent need for an energy-saving and environmentally friendly alternative material to fundamentally solve this problem [7,8]. As a potential alternative to cement, geopolymers have demonstrated many advantages such as excellent mechanical properties, high temperature resistance, corrosion resistance, and low energy consumption in production owing to their unique three-dimensional mesh structure [9,10].

Chithambaram et al. [11] explored the thermodynamic phenomena of geopolymer mortar and showed that it exhibited a change from crystalline to amorphous state above 600°C. Bingol et al. [12] explored the thermodynamic phenomena of geopolymer mortars and compared the durability of slag geopolymer mortars with cement mortars and observed that the durability of slag geopolymer mortars was considerably higher than that of cement mortars. Elyamany et al. [13] showed that geopolymer mortars were more resistant to magnesium sulfate attacks than ordinary silicate cement mortars. Owing to the defects of slow curing, high porosity, and slow strength development of geopolymers, in recent years, domestic and foreign scholars have added nano-SiO2 (NS) to geopolymers to improve the densification of geopolymers and concrete, which in turn improves the mechanical properties [14,15,16], durability [17,18], rheological properties [19], and post-high-temperature mechanical properties [20]. Zidi et al. [21] synthesized NS partially based geopolymers and discovered that the mechanical strength of the geopolymer was improved by adding a moderate amount of NS. Phoo-ngernkham et al. [22] improved the bond strength between the concrete matrix and the geopolymer. NS not only improves the properties of geopolymer mortar but also exhibits superiority of low cost and excellent performance. Therefore, adding NS to geopolymer mortar is in line with the scientific basis.

Owing to the low flexural and tensile strengths of geopolymer mortars, the addition of certain fibers such as steel fibers [23], polyvinyl alcohol (PVA) fibers, and polypropylene fibers [24] to geopolymer mortars can improve the toughness and enhance their durability performance as shown in relevant domestic and international studies. Among them, PVA fiber demonstrates excellent qualities such as high strength, high modulus of elasticity, wear resistance, acid and alkali resistance, good weather resistance, among others, and are non-toxic, non-polluting, and non-damaging to human skin and harmless to human body, which is one of the new generation of high-tech green building materials [25]. Xu et al. [26] showed that PVA fibers can enhance the toughness and denseness of fly ash geopolymer composites and improve their bonding, and Malik et al. [27] observed that PVA fibers could enhance the strength and durability of geopolymers; simultaneously, it was observed that PVA fiber and NS materials could significantly reduce the explosion spalling of geopolymers. The properties of geopolymer mortar can be effectively improved by adding NS and PVA fibers [28,29].

China is a vast country, and materials such as concrete face a variety of service environments, of which saline environments are one of the most common. China has a large number of marine and offshore projects, where structures are susceptible to damage owing to the harsh marine environment with complex multi-field coupling effects such as waves, tides, dry and wet cycles, and salt [30,31,32]. In coastal, marine, and offshore areas, the presence of chlorides can easily lead to severe deterioration of reinforced concrete structures and high maintenance costs [33]. Geopolymer mortars are more resistant to chloride ion penetration and have greater corrosion protection than cement mortars [33,34]. The use of geopolymer mortar for engineering construction can not only save costs, save energy, and protect the environment but also enhance the durability of the building [35]. Therefore, studying the chloride ion permeability resistance of geopolymer mortars with NS and PVA fibers is necessary.

With developments in artificial intelligence, various properties of construction materials have been predicted using machine learning. Golewski [36,37] proposed digital image correlation technology to test the fracture performance of fly ash concrete and achieved good results. Owing to the diverse composition of building materials, conducting experiments on each of them is not possible, so the prediction of unknown data is often made using artificial neural network models based on existing data. Nagajothi and Elavenil [38] used an artificial neural network (ANN) model to predict the mechanical properties of aluminum silicate on geopolymer concrete, and the results showed that the prediction results of the ANN were in good agreement with the experimental results. Rahman and Al-Ameri [39] proposed an ANN model to assess the bond behavior of self-compacting geopolymer concrete with basaltic fiber reinforced plastics (FRP) bars. The ANN predicted all properties of cement mortar [40,41,42], geopolymer concrete [43,44,45,46], and geopolymer mortar [47,48]. Li et al. [49] explored that radial-based function–back propagation (RBF–BP) neural network that can identify the membership of six common basic patterns of shape defects. Liu [50] realized fault attribute classification and fault diagnosis of building electrical system by using RBF–BP neural network. However, there are few studies on the properties of geopolymer mortars merging PVA fibers and NS at home and abroad, and there are no suitable prediction methods and models for the prediction of compressive strength and chloride ion permeability of geopolymer mortars merging PVA fibers and NS. Therefore, in this study, the proposed RBF–BP composite neural network model is crucial for the prediction of the compressive strength and chloride ion permeability of geopolymer mortar merging PVA fibers and NS. The RBF–BP composite neural network can provide guidance for further experiments and engineering studies on the mechanical properties and chloride ion permeation resistance of geopolymer mortars merging PVA fibers and NS.

2 Experiment program

The objective of this investigation is to explore the effect of different amounts of SiO2 nanoparticles and PVA fibers on the compressive strength and chloride ion penetration resistance of geopolymer mortars. When designing the proportion of geopolymer mortar with NS and PVA fibers, the control variable method was used, that is, fixing the water–binder ratio, cement–sand ratio, water–glass modulus, and excitation ratio (the ratio of alkaline exciter to cementitious material), while varying the amount of NS or PVA fibers.

The NS, a loose white powder, has a content of 99.7%, with an average particle size of 30 nm produced by Hangzhou Wanjing New Materials Co. The PVA fiber, with the compressive strength of 1,560 MPa, has a diameter of 40 µm, standard length of 12 mm, and elongation of 6.5%. The metakaolin concludes 54% SiO2 and 43% Al2O3, and the margin of error is 2%. Besides, the metakaolin contains less than 1.3% Fe2O3, 0.8% CaO and MgO, and 0.7% K2O and Na2O. The fly ash whose water absorbing capacity is 105% has the bulk density of 0.77 g/cm3, standard consistency of 47.1%, and specific gravity of 2.16 g/cm3. The test mix design was carried out with reference to the literature [51,52], and the parameters of the mix were finally determined through trial mixing as follows: water–binder ratio (the ratio of water contained in the added water and alkali exciter to cementitious material) of 0.65, cement–sand ratio of 1:1, 30% fly ash, and 70% metakaolin as raw material for silica-aluminate, and alkali exciter solution comprising solid sodium hydroxide, sodium silicate solution, and water. The modulus of water glass was decreased from 3.2 to 1.3 by adding sodium hydroxide and then an appropriate amount of water was added to adjust the mass fraction of sodium oxide to 15%, referring to the water–glass modulus adjustment and calculation proposed by other researcher [53]. NS and PVA fibers were incorporated in two forms: single and compound. The NS and PVA fibers were incorporated into the compounded geopolymer mortar, where the NS dose was fixed at 1.0% and the PVA fiber dose was 0.2, 0.4, 0.6, 0.8, 1.0, or 1.2% when the PVA fiber dose was changed [54]; when the NS dose was changed, the PVA fiber dose was fixed at 0.6% and the NS dose was 0.5, 1.0, 1.5, 2.0, or 2.5%.

To assess the resistance to chloride ion permeation of geopolymer mortars with SiO2 and PVA fibers, we herein use the electrical flux method for the chloride ion permeation test that visually and accurately assesses the chloride ion resistance of geopolymer mortars by testing the electrical flux values. Conversely, the lower the measured flux value, the better is the resistance of the mortar to chloride ions. The specific dosage and mix of each material are listed in Table 1.

Mix proportions of geopolymer mortar for train set [32]

| Mix no. | Water | Metakaolin | Fly ash | Quartz sand | Water glass | NaOH | PVA fiber | NS | Water-reducing agents | Compressive strength | Electric flux values |

|---|---|---|---|---|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | % | % | kg/m3 | MPa | C | |

| 1 | 106.2 | 429.5 | 184.1 | 613.6 | 445.4 | 71 | 0 | 0 | 3.07 | 44.2 | 1426.31 |

| 2 | 106.2 | 429.5 | 184.1 | 613.6 | 445.4 | 71 | 0.2 | 0 | 3.07 | 50.8 | 1294.38 |

| 3 | 106.2 | 429.5 | 184.1 | 613.6 | 445.4 | 71 | 0.4 | 0 | 3.07 | 55.3 | 1216.08 |

| 4 | 106.2 | 429.5 | 184.1 | 613.6 | 445.4 | 71 | 0.6 | 0 | 3.07 | 58.5 | 1185.84 |

| 5 | 106.2 | 429.5 | 184.1 | 613.6 | 445.4 | 71 | 0.8 | 0 | 3.07 | 60.3 | 1150.24 |

| 6 | 106.2 | 429.5 | 184.1 | 613.6 | 445.4 | 71 | 1.0 | 0 | 3.07 | 50.5 | 1158.52 |

| 7 | 106.2 | 429.5 | 184.1 | 613.6 | 445.4 | 71 | 1.2 | 0 | 3.07 | 48.1 | 1195.41 |

| 8 | 106.2 | 427.2 | 183.1 | 613.6 | 445.4 | 71 | 0 | 0.5 | 3.07 | 45.0 | 1220.82 |

| 9 | 106.2 | 425.0 | 182.2 | 613.6 | 445.4 | 71 | 0 | 1.0 | 3.07 | 47.3 | 1185.06 |

| 10 | 106.2 | 422.7 | 181.2 | 613.6 | 445.4 | 71 | 0 | 1.5 | 3.07 | 50.1 | 1121.13 |

| 11 | 106.2 | 420.4 | 180.2 | 613.6 | 445.4 | 71 | 0 | 2.0 | 3.07 | 48.8 | 1164.84 |

| 12 | 106.2 | 418.1 | 179.2 | 613.6 | 445.4 | 71 | 0 | 2.5 | 3.07 | 46.4 | 1190.52 |

| 13 | 106.2 | 429.5 | 182.2 | 613.6 | 445.4 | 71 | 0.2 | 1.0 | 3.07 | 53.9 | 1147.62 |

| 14 | 106.2 | 429.5 | 182.2 | 613.6 | 445.4 | 71 | 0.4 | 1.0 | 3.07 | 57.4 | 1107.48 |

| 15 | 106.2 | 429.5 | 182.2 | 613.6 | 445.4 | 71 | 0.8 | 1.0 | 3.07 | 62.4 | 1071.78 |

| 16 | 106.2 | 429.5 | 182.2 | 613.6 | 445.4 | 71 | 1.0 | 1.0 | 3.07 | 55.7 | 1076.94 |

3 Model establishment

An RBF–BP composite neural network with a BP neural network and RBF neural network was used to predict the compressive strength and resistance to chloride ion penetration of geopolymer mortar merging PVA fiber and NS by combining fly ash, water, alkali exciter, metakaolin, quartz sand, water-reducing agent, NS, and PVA fiber dosing parameters.

Herein the NS and PVA fibers are the main objects of our study; however, because NS will replace fly ash with equal mass and simultaneously affect the amount of kaolinite added, four material parameters affecting the compressive strength and chloride ion penetration resistance of the geopolymer mortar, namely, NS admixture, PVA fiber admixture, kaolinite admixture, and fly ash admixture, are finally chosen as input parameters, so each neural network of the input layer has four neurons. In the compressive strength experiment, the compressive strength value was chosen as the output parameter. As the electric flux method is used as the experimental method in the chloride ion penetration resistance experiment, the processed electric flux value was chosen as the output parameter. Therefore, for each experiment, the output layer was 1. In the training process, 70% of the sample data were set as the training set data, and the remaining 30% was the prediction set data.

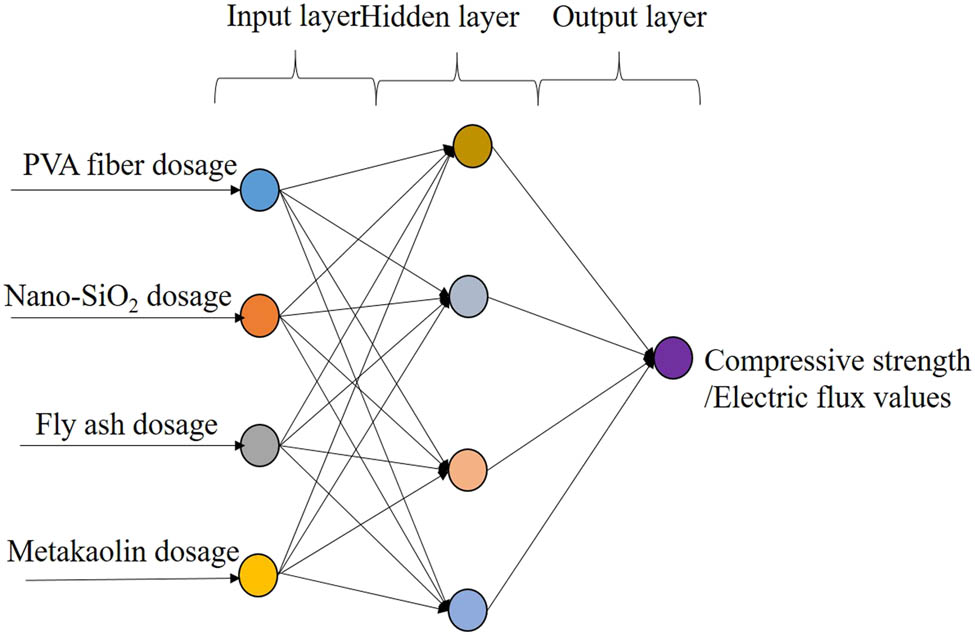

3.1 BP neural network

On the basis of the error back propagation algorithm, the BP neural network is a multi-layer feed-forward neural network composed of an import layer, one or more intermediate layers, and an export layer. In each layer, the number of neurons relies on a specific analysis of the problem.

Owing to slow convergence, low learning efficiency, and difficulty in deciding the number of intermediate layers and their neurons, as well as easily falling into local minima of the traditional BP neural network, we herein adopt the improved Levenberg–Marquardt BP neural network. As a three-layer BP neural network was proven to theoretically achieve any complex nonlinear mapping, a BP neural network whose hidden layer is one which can meet most prediction requirements. The number of neurons in the implicit layer can be derived from the following equation [55]:

where

The above equation can calculate the range of the number of neurons in the implicit layer, but a specific and precise value cannot be obtained, and several experiments are needed to combine the prediction accuracy and convergence; finally, the number of neurons is set to eight.

In this study, the excitation function of the implicit layer selects the tansig function, the output layer transfer function uses the purelin function, and the reverse training uses the trainlm gradient descent method. Suppose that the

where

However, when using the weight adjustment formula, assigning initial values to the weight matrix is necessary; in this study, the weight matrix is initialized using a random number generation method. As the BP neural network is trained and learned, the error between the output and the real result becomes increasingly small. For the purpose of making the BP neural network model training effect more accurate, the mean square error was selected as 10−7, and to avoid too slow convergence, the upper limit of the iterations number was set as 10,000. Generally speaking, the larger the learning rate, the faster is the convergence speed; however, a larger learning rate is likely to cause oscillations in the convergence process, resulting in an increase in the number of iterations, whereas a smaller learning rate will extend the training time and cannot guarantee that the error value of the network jumps out of the minima and eventually converges to the minimum error. After several training sessions, it was observed that when set to 0.5, the learning rate was optimal. The BP neural network structure can be displayed in Figure 1, and the set of parameters for the final constructed BP neural network are listed in Table 2.

Structure of BP neural network.

BP neural network parameters

| Parameters | Hidden layer neurons | Hidden layer transfer function | Output layer transfer function | Target error | Iteration limit | Learning rate | |

|---|---|---|---|---|---|---|---|

| Value | 8 | Tansig | Purelin | 10−7 | 10,000 | 0.5 | |

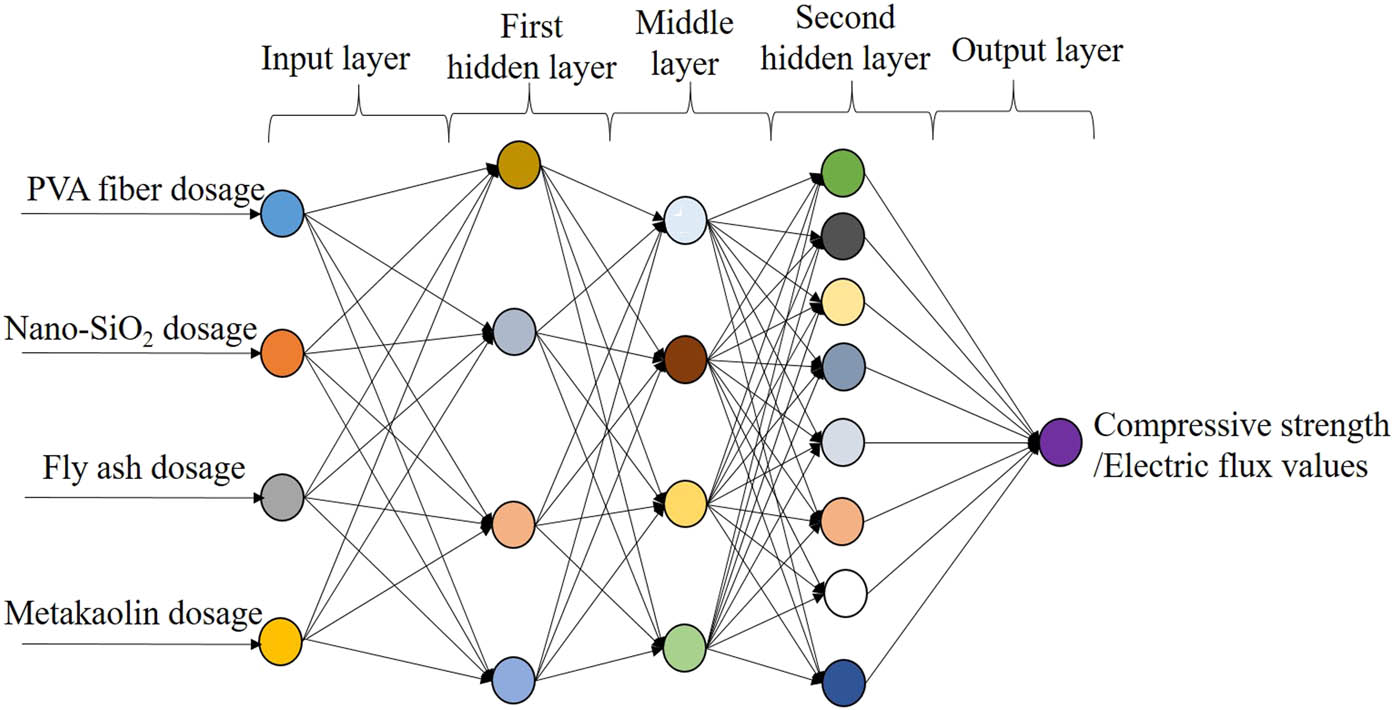

3.2 RBF neural network

The RBF neutral network is a feed-forward neural network that includes a single implicit layer, and the topology of the RBF neural network is similar to that of BP, which comprises three layers. The input layer only transmits the input signal without transforming the input information and maps the input data directly to the hidden layer. The radial basis function, including inverse multi-quadratic functions, Gaussian functions, multi-quadratic functions, among others, is the excitation function in the hidden layer, which responds to the local signal and produces a larger output [56]. The output layer then acts in response to the action of the input pattern. The mapping from the input to output of the RBF neural network structure is nonlinear, while the mapping from the implicit layer to the output layer is linear [57]. Hartman et al. [58] observed that there are enough neurons in the implicit layer, and RBF neural networks can approximate any continuous function with arbitrary accuracy.

Owing to its simple form, the excitation function for neurons in the implicit layer chooses a Gaussian function, and its formula is shown in equation (6).

where

The learning algorithm of RBF neural network needs to solve three types of problems: first, determination of the neuron numbers for the implicit layer and RBF centers; second, selection of the expansion constants; and third, the weight matrix adjustment from the implicit layer space to the output space. The neurons in the implicit layer of regularized neural networks are sample inputs; in this study, this number was 4. Radial basis function centers are determined by self-organized learning, supervised selection, least squares, and random selection methods [59]. The extension constant selection is calculated using equation (7). The weights of the implied layer space and the output space are calculated using the least-squares method and are given in equation (8).

where

To increase the comparability of the BP and RBF neural networks, the upper iteration limit, target error, and learning rate were kept the same as those of the BP neural network. The RBF neural network structure can be displayed in Figure 2, and the set of parameters of the final constructed RBF neural network are listed in Table 3.

Structure of RBF neural network.

RBF neural network parameters

| Parameters | Hidden layer neurons | Hidden layer transfer function | Output layer transfer function | Target error | Iteration limit | Learning rate |

|---|---|---|---|---|---|---|

| Value | 4 | Gauss | Linear | 10−7 | 10,000 | 0.5 |

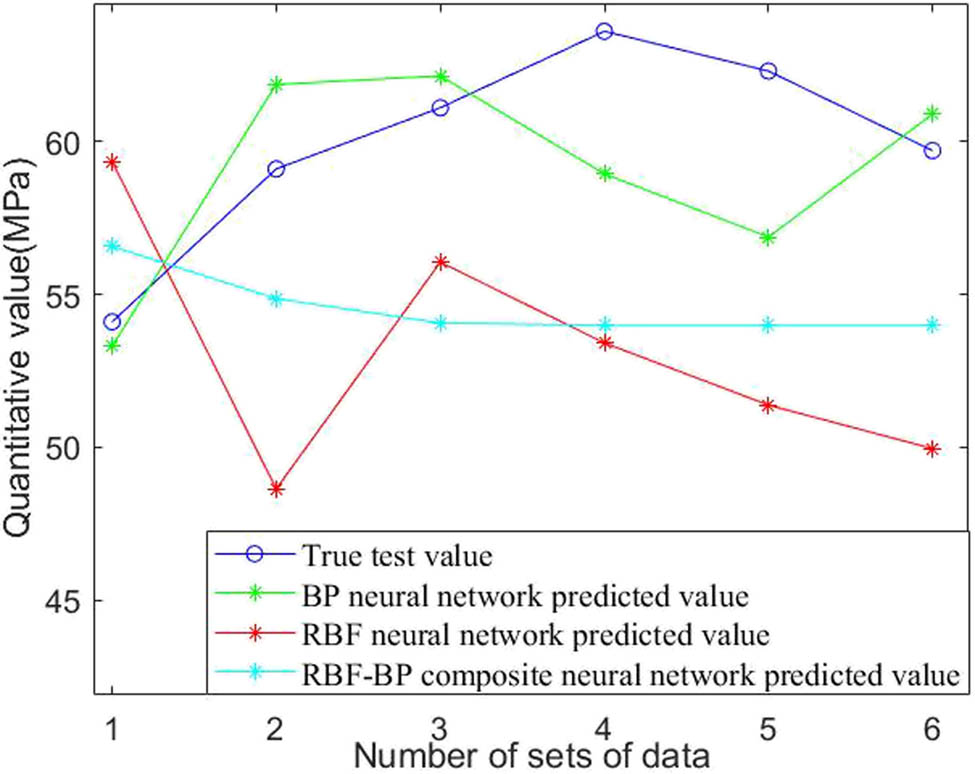

3.3 RBF–BP composite neural network

Both the RBF and BP neural network have their own characteristics. Complex nonlinear mapping can be realized by a BP neural network, whose disadvantages are low learning efficiency, slow convergence speed, and susceptibility to local minima in the learning process, and the determination of the neural network structure is extremely blind. The RBF neural network compensates for the defects in the BP neural network, but the mapping from the implicit layer to the output layer can only be linear. Under nonlinear conditions, the prediction results are more biased and the network generalization ability is poor [60]. Therefore, combining these two types of neural network structures can promote the respective defects of the BP and RBF neural network. Based on the above, an RBF–BP composite neural network has been proposed, wherein the two networks are organically combined to form a composite neural network with two hidden layers comprising a BP subnet and an RBF subnet. The excitation function of the first implicit layer, which is a Gaussian function, is consistent with that of the RBF neural network, and the excitation function of the second implicit layer, using a sigmoid-type function, is consistent with that of the BP neural network. The RBF–BP composite neural network not only solves the shortcomings of slow convergence and low learning efficiency of the BP neural network model but also improves the performance of the RBF neural network. The RBF–BP composite neural network not only solves the problems of low learning efficiency and slow convergence of the BP neural network but also improves the problem that the RBF neural network cannot make like nonlinear predictions and enhances the nonlinear fitting ability, and the final obtained RBF–BP composite neural network has more network generalization ability and higher prediction accuracy.

The parameters of the RBF–BP composite neural network model, including the learning rate, upper limit of iteration number, and target error, are consistent with those of the other two types of neural network models. The RBF–BP composite neural network structure is displayed in Figure 3, and the set of parameters of the final RBF–BP composite neural network are listed in Table 4.

Structure of RBF–BP composite neural network.

RBF–BP composite neural network parameters

| Parameters | First layer of hidden layer neurons | Second layer of hidden layer neurons | First hidden layer excitation function | Second hidden layer excitation function | Output layer transfer function | Target error | Iteration limit | Learning rate |

|---|---|---|---|---|---|---|---|---|

| Value | 4 | 8 | Gauss function | Tansig | Purelin | 10−7 | 10,000 | 0.5 |

4 Model training and result analysis

On the basis of determining the research method and training model, 70% of the sample data used the model to train, and after the model was trained, the remaining 30% of the sample data was used for testing and the test results were analyzed and evaluated, and the test set data are shown in Table 5.

Mix proportions of geopolymer mortar for test set

| Mix no. | Water | Metakaolin | Fly ash | Quartz sand | Water glass | NaOH | PVA fiber | Nano -SiO2 | Water-reducing agents | Compressive strength | Electric flux values |

|---|---|---|---|---|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | % | % | kg/m3 | MPa | C | |

| 1 | 106.2 | 429.5 | 182.2 | 613.6 | 445.4 | 71 | 1.2 | 1.0 | 3.07 | 54.1 | 1102.36 |

| 2 | 106.2 | 429.5 | 183.1 | 613.6 | 445.4 | 71 | 0.6 | 0.5 | 3.07 | 59.1 | 1157.88 |

| 3 | 106.2 | 429.5 | 182.2 | 613.6 | 445.4 | 71 | 0.6 | 1.0 | 3.07 | 61.1 | 1096.02 |

| 4 | 106.2 | 429.5 | 181.2 | 613.6 | 445.4 | 71 | 0.6 | 1.5 | 3.07 | 63.6 | 1055.16 |

| 5 | 106.2 | 429.5 | 180.2 | 613.6 | 445.4 | 71 | 0.6 | 2.0 | 3.07 | 62.3 | 1107.06 |

| 6 | 106.2 | 429.5 | 179.2 | 613.6 | 445.4 | 71 | 0.6 | 2.5 | 3.07 | 59.7 | 11566.98 |

4.1 Network training and testing methods

The six sets of data above were learned and trained by training the three types of neural network models to predict the compressive strength and chloride ion penetration resistance of the nanoparticle-doped PVA fiber in the geopolymer mortar.

To avoid the influence of the absolute size and units of the sample data of the training results and facilitate subsequent data processing, the sample data were normalized before applying the sample data, and the data were mapped to between [−1,1] [61]. Simultaneously, before the model is trained and the training results are output, the output data are normalized back to the original value interval. The inverse normalization formula for the input and output data can be calculated using equation (9).

where

First, the neural network model was applied to train 16 sets of experimental data. Subsequently, the trained neural network was used to predict the remaining six sets of data. Finally, the training results were compared and analyzed with real results.

4.2 Experimental results and analysis

Developing a set of practical evaluation indicators to comprehensively measure the performance of the three types of neural networks is necessary. According to the evaluation principles and practices, we herein selected mean square error (MSE), root mean square error (RMSE), and mean absolute error (MAE) as the evaluation indicators.

MSE:

RMSE:

MAE:

In the above three equations,

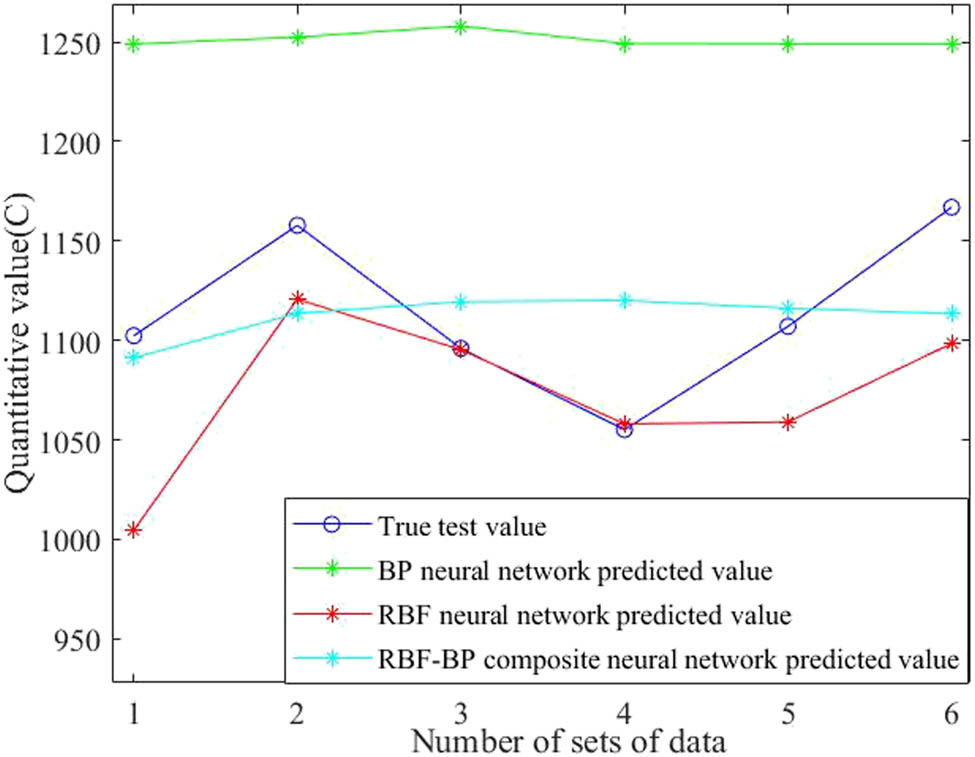

The compressive strength and resistance to chloride ion permeability predicted from the three types of neural networks were compared with the experimental values, and the comparison results are shown in Figures 4 and 5.

Compressive strength predicted results of three neural networks.

Predicted results of three neural networks against chloride ion penetration.

The predicted results in Figures 4 and 5 show the effect of SiO2 nanoparticles and PVA fibers on the compressive strength and chloride ion penetration resistance of the geopolymer mortar. When the NS content was 1.5%, the compressive strength of the geopolymer mortar was the highest, which is generally consistent with previous studies where the optimum NS content in geopolymer mortars was predicted to be between 1.0% and 2.0% [22,62]. However, unlike the optimum SiO2 content in cement mortar and concrete [63,64], the geopolymer mortar showed optimum resistance to chloride ion penetration as the dosage of PVA fiber was 0.6% and the NS content was 1.0%. NS increases its hydration and makes the geopolymer mortar denser owing to its high reactivity [65,66], reducing the porosity of the material during geopolymer hardening and increasing its density, which in turn leads to a denser structure and reduced micro-cracking [67,68,69]. These results are in general agreement with those of previous studies [70,71].

The predictions obtained from three neural network models were all close to the experimental values. However, from the fitting effect, the RBF–BP neural network outperforms the other two types of neural networks, and the BP neural network fits the worst, indicating that the RBF–BP neural network has better generalization ability and approximates the true results more accurately. In terms of errors, all three neural networks had small errors and met the prediction requirements. By comparing the evaluation indices of three types of neural networks, the results are presented in Table 6.

Comparison of evaluation indices of each neural network model

| Neural network models | MSE | RMSE | MAE |

|---|---|---|---|

| BP neural network | 0.014563 | 0.12068 | 0.12068 |

| RBF neural network | 0.0023757 | 0.048741 | 0.037715 |

| RBF–BP composite neural network | 0.00071943 | 0.026822 | 0.026822 |

In general, MSE, RMSE, and MAE have a positive correlation, and the smaller the MSE, RMSE, and MAE, the better is the prediction effect, the higher is the prediction accuracy, and the more stable is the prediction data. Among the above three neural network models, compared with the errors of the RBF neural network, the RBF–BP composite neural network model is significantly smaller, and the errors of BP neural network model are largest. In terms of fitting ability, the RBF–BP composite neural network fits best, and the BP neural network has the worst effect. Furthermore, the RBF–BP neural network has a better learning ability and faster convergence speed. In summary, combined with two single neural network models, the RBF–BP composite neural network model has a greater prediction effect than before, and the performance of the RBF–BP composite neural network is considerably better than that of the other two types of neural networks. All three types of neural networks have small error and good predicted effect. The above conclusions are similar to those obtained from previous studies on BP network, RBF network, and RBF–BP network [72,73,74], and the three types of neural networks are compared and supplemented by previous studies. Meanwhile, this study applies the three kinds of neural networks to geopolymer mortar merging PVA fiber and NS.

Comparative analysis of the predicted values revealed that the predicted values of the compressive strength and chloride ion permeation resistance of geopolymer mortar merging PVA fiber and NS by the above three neural networks are in line with the actual situation and meet the requirements for the prediction of compressive strength and chloride ion permeation resistance index electric flux values, thereby possibly providing guidance for the study of the mechanical properties and chloride ion permeation resistance of geopolymer mortar merging PVA fiber and NS. The results of the aforementioned three neural network models can provide guidance for further experiments and engineering studies on the mechanical properties and chloride ion permeation resistance of geopolymer mortars merging PVA fibers and NS.

5 Conclusion

BP neural networks use the gradient descent method to reduce errors and correct the weight matrix during the training process, requiring several iterations, a slow convergence speed, and a long convergence time. Simultaneously, the BP neural network requires many experiments when selecting neurons in the hidden layer, which is a tedious process. However, the MSE is only 0.014563, which is small and meets the accuracy requirements, and the predicted results are close to the experimental results, with good network generalization ability.

The RBF–BP composite neural network couples the advantages of the other two types of neural networks and adopts a double hidden layer structure, having features wherein the BP neural network can solve nonlinear problems and the RBF neural network has a fast convergence rate. Among the three neural networks, the RBF–BP composite neural network fits the best and makes the most accurate prediction.

According to the comparison analysis of the assessment results of the three types of neural networks with the real values, the RBF–BP composite neural network model can accurately and effectively predict the compressive strength and chloride ion permeability resistance index electric flux values, and the prediction results fit the real results to a high degree, and the dispersion degree was small. The RBF–BP composite neural network can provide effective guidance for the prediction of the compressive strength and chloride ion permeation resistance of geopolymer mortars merging PVA fibers and NS.

-

Funding information: The authors would like to acknowledge the financial support received from National Natural Science Foundation of China (Grant No. 51979251, U2040224), Natural Science Foundation of Henan (Grant No. 212300410018), Program for Innovative Research Team (in Science and Technology) in University of Henan Province of China (Grant No. 20IRTSTHN009), and National Innovation and Entrepreneurship Training Program for College Students (Grant No. 202110459175).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Zhang P, Zhang H, Cui G, Yue X, Guo J, Hui D. Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2. Nanotechnol Rev. 2021;10(1):504–17.10.1515/ntrev-2021-0040Suche in Google Scholar

[2] Ling Y, Zhang P, Wang J, Taylor P, Hu S. Effects of nanoparticles on engineering performance of cementitious composites reinforced with PVA fibers. Nanotechnol Rev. 2020;9(1):504–14.10.1515/ntrev-2020-0038Suche in Google Scholar

[3] Shahmansouri AA, Akbarzadeh B, Ghanbari S. Compressive strength prediction of eco-efficient GGBS-based geopolymer concrete using GEP method. J Build Eng. 2020;31:101326.10.1016/j.jobe.2020.101326Suche in Google Scholar

[4] Hu W, Ma Y, Koehler M, Gong H, Huang B. Mix design optimization and early strength prediction of unary and binary geopolymer from multiple waste streams. J Hazard Mater. 2021;403:123632.10.1016/j.jhazmat.2020.123632Suche in Google Scholar PubMed

[5] Golewski GL. Green concrete based on quaternary binders with significant reduction in CO2 emissions. Energies. 2021;14(15):4558.10.3390/en14154558Suche in Google Scholar

[6] Wang L, Lu X, Liu L, Xiao J, Zhang G, Guo F, Li L. Influence of MgO on the hydration and shrinkage behavior of low heat Portland cement-based materials via pore structural and fractal analysis. Fractal Fract 2022;6:247.10.3390/fractalfract6010040Suche in Google Scholar

[7] Zhang P, Wang KX, Wang J, Guo JJ, Ling YF. Macroscopic and microscopic analyses on mechanical performance of metakaolin/fly ash based geopolymer mortar. J Clean Prod. 2021;294:126193.10.1016/j.jclepro.2021.126193Suche in Google Scholar

[8] Darvish P, Alengaram UJ, Alnahhal AM, Poh YS, Ibrahim S. Enunciation of size effect of sustainable palm oil clinker sand on the characteristics of cement and geopolymer mortars. J Build Eng. 2021;44:103335.10.1016/j.jobe.2021.103335Suche in Google Scholar

[9] Zhang P, Wang KX, Wang J, Guo JJ, Hu SW, Ling YF. Mechanical properties and prediction of fracture parameters of geopolymer/alkali-activated mortar modified with PVA fiber and nano-SiO2. Ceram Int. 2020;46(12):20027–37.10.1016/j.ceramint.2020.05.074Suche in Google Scholar

[10] Zhang P, Gao Z, Wang J, Guo JJ, Hu SW, Ling YF. Properties of fresh and hardened fly ash/slag based geopolymer concrete: a review. J Clean Prod. 2020;270:122389.10.1016/j.jclepro.2020.122389Suche in Google Scholar

[11] Chithambaram SJ, Kumar S, Prasad MM. Thermo-mechanical characteristics of geopolymer mortar. Constr Build Mater. 2019;213:100–8.10.1016/j.conbuildmat.2019.04.051Suche in Google Scholar

[12] Bingol S, Bilim C, Atis CD, Durak U. Durability properties of geopolymer mortars containing slag. IJST-T Civ Eng. 2020;44(1):561–9.10.1007/s40996-019-00337-0Suche in Google Scholar

[13] Elyamany HE, Abd EAM, Elshaboury AM. Magnesium sulfate resistance of geopolymer mortar. Constr Build Mater. 2018;184:111–27.10.1016/j.conbuildmat.2018.06.212Suche in Google Scholar

[14] Liu X, Peng ZC, Pan CH, Hu X, Wan CJ, Yang HY. Mechanical properties and microscopic analysis of nano-silica modified fly ash geopolymer. Mater Rev. 2020;34(11B):22078–82.Suche in Google Scholar

[15] Szostak B, Golewski GL. Improvement of strength parameters of cement matrix with the addition of siliceous fly ash by using nanometric C-S-H seeds. Energies. 2020;13(24):6734.10.3390/en13246734Suche in Google Scholar

[16] Szostak B, Golewski GL. Effect of nano admixture of CSH on selected strength parameters of concrete including fly ash. IOP Conf Ser: Mater Sci Eng. 2019;416:012105.10.1088/1757-899X/416/1/012105Suche in Google Scholar

[17] Zhang P, Sha DH, Li QF, Zhao SK, Ling YF. Effect of nano silica particles on impact resistance and durability of concrete containing coal fly ash. Nanomater Basel. 2021;11(5):1296.10.3390/nano11051296Suche in Google Scholar PubMed PubMed Central

[18] Wang L, Guo FX, Yang HM, Wang Y. Comparison of fly ash, PVA fiber, MgO and shrinkage-reducing admixture on the frost resistance of face slab concrete via pore structural and fractal analysis. Fractals. 2021;29(2):2140002.10.1142/S0218348X21400028Suche in Google Scholar

[19] Szostak B, Golewski GL. Rheology of cement pastes with siliceous fly ash and the CSH nano-admixture. Mater. 2021;14(13):3640.10.3390/ma14133640Suche in Google Scholar PubMed PubMed Central

[20] Wu LS, Lu ZH, Zhuang CL, Chen Y, Hu RH. Mechanical properties of nano SiO2 and carbon fiber reinforced concrete after exposure to high temperatures. Mater. 2019;12(22):3373.10.3390/ma12223773Suche in Google Scholar PubMed PubMed Central

[21] Zidi Z, Ltifi M, Zafar I. Synthesis and attributes of nano-SiO2 local metakaolin-based geopolymer. J Build Eng. 2021;33:101586.10.1016/j.jobe.2020.101586Suche in Google Scholar

[22] Phoo-ngernkham T, Chindaprasirt P, Sata V, Hanjitsuwan S, Hatanaka S. The effect of adding nano-SiO2 and nano-Al2O3 on properties of high calcium fly ash geopolymer cured at ambient temperature. Mater Des. 2014;55:58–65.10.1016/j.matdes.2013.09.049Suche in Google Scholar

[23] Zhang P, Wang J, Li QF, Wan JY, Ling YF. Mechanical and fracture properties of steel fiber-reinforced geopolymer concrete. Sci Eng Compos Mater. 2021;28(1):299–313.10.1515/secm-2021-0030Suche in Google Scholar

[24] Ali S, Sheikh MN, Hadi MNS. Behavior of axially loaded plain and fiber-reinforced geopolymer concrete columns with glass fiber-reinforced polymer cages. Struct Conceret. 2021;22(3):1800–16.10.1002/suco.202000231Suche in Google Scholar

[25] Gao Z, Zhang P, Wang J, Wang K. Interfacial properties of geopolymer mortar and concrete substrate: effect of polyvinyl alcohol fiber and nano-SiO2 contents. Constr Build Mater. 2022;315:125735.10.1016/j.conbuildmat.2021.125735Suche in Google Scholar

[26] Xu F, Deng X, Peng C, Zhu J, Chen JP. Mix design and flexural toughness of PVA fiber reinforced fly ash-geopolymer composites. Constr Build Mater. 2017;150:179–89.10.1016/j.conbuildmat.2017.05.172Suche in Google Scholar

[27] Malik MA, Sarkar M, Xu SL, Li QH. Effect of PVA/SiO2 NPs additive on the structural, durability, and fire resistance properties of geopolymers. Appl Sci Basel. 2019;9(9):1953.10.3390/app9091953Suche in Google Scholar

[28] Gao Z, Zhang P, Guo J, Wang K. Bonding behavior of concrete matrix and alkali-activated mortar incorporating nano-SiO2 and polyvinyl alcohol fiber: theoretical analysis and prediction model. Ceram Int. 2021;47(22):31638–49.10.1016/j.ceramint.2021.08.044Suche in Google Scholar

[29] Zhang P, Gao Z, Wang J, Wang KX. Numerical modeling of rebar-matrix bond behaviors of nano-SiO2 and PVA fiber reinforced geopolymer composites. Ceram Int. 2021;47(8):11727–37.10.1016/j.ceramint.2021.01.012Suche in Google Scholar

[30] Hu C, Chen P, Zhang XP, Xiang WH, Liu RJ, Tian Y. Investigating on chloride ion and sulfate corrosion resistance of different steel phase cements. Concrete. 2020;10:98–101.Suche in Google Scholar

[31] Wang L, Luo R, Zhang W, Jin M, Tang S. Effects of fineness and content of phosphorus slag on cement hydration, permeability, pore structure and fractal dimension of concrete. Fractals. 2021;29(2):2140004.10.1142/S0218348X21400041Suche in Google Scholar

[32] Wang WC. Study on durability of nano-particles and fiber reinforced geopolymer mortar. Dissertation. Zhengzhou: Zhengzhou University; 2020.Suche in Google Scholar

[33] Liu QF, Iqbal MF, Yang J, Lu XY, Zhang P, Rauf M. Prediction of chloride diffusivity in concrete using artificial neural network: Modelling and performance evaluation. Constru Build Mater. 2021;268:121082.10.1016/j.conbuildmat.2020.121082Suche in Google Scholar

[34] Yang T, Yao X, Zhang ZH. Quantification of chloride diffusion in fly ash-slag-based geopolymers by X-ray fluorescence (XRF). Construct Build Mater. 2014;69:109–15.10.1016/j.conbuildmat.2014.07.031Suche in Google Scholar

[35] Wang KX, Zhang P, Guo JJ, Gao Z. Single and synergistic enhancement on durability of geopolymer mortar by polyvinyl alcohol fiber and nano-SiO2. J Mater Res Technol. 2021;15:1801–14.10.1016/j.jmrt.2021.09.036Suche in Google Scholar

[36] Golewski GL. Validation of the favorable quantity of fly ash in concrete and analysis of crack propagation and its length - Using the crack tip tracking (CTT) method - In the fracture toughness examinations under Mode II, through digital image correlation. Construct Build Mater. 2021;296:122362.10.1016/j.conbuildmat.2021.122362Suche in Google Scholar

[37] Golewski GL. Evaluation of fracture processes under shear with the use of DIC technique in fly ash concrete and accurate measurement of crack paths lengths with the use of a new crack tip tracking method. Measurement. 2021;181:109632.10.1016/j.measurement.2021.109632Suche in Google Scholar

[38] Nagajothi S, Elavenil S. Influence of aluminosilicate for the prediction of mechanical properties of geopolymer concrete - artificial neural network. Silicon-neth. 2020;12(5):1011–21.10.1007/s12633-019-00203-8Suche in Google Scholar

[39] Rahman SK, Al-Ameri R. Experimental investigation and artificial neural network based prediction of bond strength in self-compacting geopolymer concrete reinforced with basalt FRP bars. Appl Sci-Basel. 2021;11(11):4889.10.3390/app11114889Suche in Google Scholar

[40] Asteris PG, Apostolopoulou M, Skentou AD, Moropoulou A. Application of artificial neural networks for the prediction of the compressive strength of cement-based mortars. Comput Concrete. 2019;24(4):329–45.Suche in Google Scholar

[41] Onal O, Ozturk AU. Artificial neural network application on microstructure-compressive strength relationship of cement mortar. Adv Eng Softw. 2010;41(2):165–9.10.1016/j.advengsoft.2009.09.004Suche in Google Scholar

[42] Abdelhedi M, Jabbar R, Mnif T, Abbes C. Prediction of uniaxial compressive strength of carbonate rocks and cement mortar using artificial network and multiple linear regressions. Acta Geodyn Geomater. 2020;17(3):367–77.10.13168/AGG.2020.0027Suche in Google Scholar

[43] Ling YF, Wang KJ, Wang XH, Li WG. Prediction of engineering properties of fly ash-based geopolymer using artificial neural networks. Neural Comput Appl. 2021;33(1):85–105.10.1007/s00521-019-04662-3Suche in Google Scholar

[44] Bhogayata A, Kakadiya S, Makwana R. Neural network for mixture design optimization of geopolymer concrete. Aci Mater J. 2021;118(4):91–6.10.14359/51732711Suche in Google Scholar

[45] Aneja S, Sharma A, Gupta R, Yoo DY. Bayesian regularized artificial neural network model to predict strength characteristics of fly-ash and bottom-ash based geopolymer concrete. Mater. 2021;14(7):1729.10.3390/ma14071729Suche in Google Scholar PubMed PubMed Central

[46] Gunasekara C, Atzarakis P, Lokuge W, Law DW, Setunge S. Novel analytical method for mix design and performance prediction of high calcium fly ash geopolymer concrete. Polymers Basel. 2021;13(6):900.10.3390/polym13060900Suche in Google Scholar PubMed PubMed Central

[47] John SK, Cascardi A, Nadir Y, Aiello MA, Girija K. A new artificial neural network model for the prediction of the effect of molar ratios on compressive strength of fly ash-slag geopolymer mortar. Adv Civ Eng. 2021;2021:6662347.10.1155/2021/6662347Suche in Google Scholar

[48] Nazari A, Sanjayan JG. Modelling of compressive strength of geopolymer paste, mortar and concrete by optimized support vector machine. Ceram Int. 2015;41(9):12164–77.10.1016/j.ceramint.2015.06.037Suche in Google Scholar

[49] Li XH, Zhang T, Deng Z, Wang J. Preparation and mechanical properties of a base polymer of metakaolin: A recognition method of plate shape defect based on RBF–BP neural network optimized by genetic algorithm. 26th Chinese Control and Decision Conference; 2014: p. 3992–6.10.1109/CCDC.2014.6852879Suche in Google Scholar

[50] Liu GH. A new method for fault diagnosis of building electrical system based on RBF–BP neural network. ICICAS; 2019: p. 470–4.10.1109/ICICAS48597.2019.00104Suche in Google Scholar

[51] Han D, Che YX, Song P, Wang Q. Preparation and mechanical properties of a base polymer of metakaolin. Sichuan Cement. 2009;168(1):44–50.Suche in Google Scholar

[52] Apha S, Prinya C, Kedsarin P. Workability and strength of lignite bottom ash geopolymer mortar. J Hazard Mater. 2009;168(1):44–50.10.1016/j.jhazmat.2009.01.120Suche in Google Scholar PubMed

[53] Sun S. Adjustment and calculation of water glass modulus. Mine Construct Technol. 1984;2:26–9.Suche in Google Scholar

[54] Zhang P, Han X, Zheng YX, Wan JY, Hui D. Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete. Rev Adv Mater Sci. 2021;60(1):418–37.10.1515/rams-2021-0039Suche in Google Scholar

[55] Shen H, Wang ZX, Gao CY, Qin J, Yao FB, Xu W. Determining the number of BP neural network hidden layer units. J Tianjin Univ Technol. 2008;05:13–5.Suche in Google Scholar

[56] Hu X. Prediction of high performance concrete strength based on artificial neural network. Changsha, China: Hunan University; 2014.Suche in Google Scholar

[57] Drioli C, Rocchesso D. Orthogonal least squares algorithm for the approximation of a map and its derivatives with a RBF network. Signal Progress. 2003;83(2):283–96.10.1016/S0165-1684(02)00397-3Suche in Google Scholar

[58] Hartman EJ, Keeler JD, Kowalski JM. Layered neural networks with Gaussian hidden units as universal approximations. Neural Comput. 1990;2:210–25.10.1162/neco.1990.2.2.210Suche in Google Scholar

[59] Yi ZM, Deng ZD, Qin JZ, Liu Q, Du D, Zhang DS. NOx prediction of sintering flue gas based on RBF–BP hybrid neural network. J Iron Steel Res. 2020;32(7):639–46.Suche in Google Scholar

[60] Wen H, Xie WX, Pei JH. A structure-adaptive hybrid RBF–BP classifier with an optimized learning strategy. PLoS One. 2016;11(10):164719.10.1371/journal.pone.0164719Suche in Google Scholar PubMed PubMed Central

[61] Yi Z, Qin J, Deng Z, Liu Q. Prediction NOx emission from sintering plant with a radial basis function and back propagation hybrid neural network. Int J Environ Sci Technol. 2021. 10.1007/s13762-021-03379-y.https://doi.org/10.1007/s13762-021-03379-ySuche in Google Scholar

[62] Assaedi H, Alomayri T, Siddika A, Shaikh F, Alamri H, Subaer S, et al. Effect of nanosilica on mechanical properties and microstructure of PVA fiber-reinforced geopolymer composite (PVA-FRGC). Mater. 2019;12(21):3624–35.10.3390/ma12213624Suche in Google Scholar

[63] Tavakoli D, Dehkordi RS, Divandari H, De BJ. Properties of roller-compacted concrete pavement containing waste aggregates and nano SiO2. Construct Build Mater. 2020;249:118747.10.1016/j.conbuildmat.2020.118747Suche in Google Scholar

[64] Li G, Zhou JC, Yue J, Gao X, Wang KJ. Effects of nano-SiO2 and secondary water curing on the carbonation and chloride resistance of autoclaved concrete. Construct Build Mater. 2020;235:117465.10.1016/j.conbuildmat.2019.117465Suche in Google Scholar

[65] Sun JF, Shen XD, Tan G, Tanner JE. Modification effects of Nano-SiO2 on early compressive strength and hydration characteristics of high-volume fly ash concrete. J Mater Civ Eng. 2019;31(6):04019057.10.1061/(ASCE)MT.1943-5533.0002665Suche in Google Scholar

[66] Sun HF, Li ZSS, Memon SA, Zhang QW, Wang YC, Liu B, et al. Influence of ultrafine 2CaO·SiO2 powder on hydration properties of reactive powder concrete. Mater. 2015;8(9):6195–207.10.3390/ma8095300Suche in Google Scholar PubMed PubMed Central

[67] Liu FY, Xu K, Ding WQ, Qiao YF, Wang LB. Microstructural characteristics and their impact on mechanical properties of steel-PVA fiber reinforced concrete. Cement Concrete Compos. 2021;123:104196.10.1016/j.cemconcomp.2021.104196Suche in Google Scholar

[68] Guo L, Wu YY, Xu F, Song XT, Ye JY, Duan P, et al. Sulfate resistance of hybrid fiber reinforced metakaolin geopolymer composites. Compos Part B-Eng. 2020;183:107689.10.1016/j.compositesb.2019.107689Suche in Google Scholar

[69] Batista RP, Trindade ACC, Borges PHR, Silva FD. Silica fume as precursor in the development of sustainable and high-performance MK-based alkali-activated materials reinforced with short PVA fibers. Front Mater. 2019;6:77.10.3389/fmats.2019.00077Suche in Google Scholar

[70] Xu SL, Malik MA, Qi Z, Huang BT, Li QH, Sarkar M. Influence of the PVA fibers and SiO2 NPs on the structural properties of fly ash based sustainable geopolymer. Construct Build Mater. 2018;164:238–45.10.1016/j.conbuildmat.2017.12.227Suche in Google Scholar

[71] Xiao SH, Liao SJ, Zhong GQ, Guo YC, Lin JX, Xie ZH, et al. Dynamic properties of PVA short fiber reinforced low-calcium fly ash-slag geopolymer under an SHPB impact load. J Build Eng. 2021;44:103220.10.1016/j.jobe.2021.103220Suche in Google Scholar

[72] Li H, Peng T. Prediction of concrete compression strength based on BP and PBF neural network theories. J Wuhan Univ Technol. 2009;31(8):33–6.Suche in Google Scholar

[73] Li N, Zhao JH, Wang J, Zhu Q. Prediction of hybrid fiber reinforced concrete strength on base of RBF & BP. Adv Mater Res. 2014;1035:180–5.10.4028/www.scientific.net/AMR.1035.180Suche in Google Scholar

[74] Zou H, Zhou YH, Wang L, Zhang ZY. Maximum temperature prediction of concrete pouring storehouse of high arch dam based on RBF–BP neural network model. Water Res Pwr. 2016;34(3):67–9.Suche in Google Scholar

© 2022 Xuemei Zhang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods

- Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

- Green synthesis of spinel copper ferrite (CuFe2O4) nanoparticles and their toxicity

- The effect of TaC and NbC hybrid and mono-nanoparticles on AA2024 nanocomposites: Microstructure, strengthening, and artificial aging

- Excited-state geometry relaxation of pyrene-modified cellulose nanocrystals under UV-light excitation for detecting Fe3+

- Effect of CNTs and MEA on the creep of face-slab concrete at an early age

- Effect of deformation conditions on compression phase transformation of AZ31

- Application of MXene as a new generation of highly conductive coating materials for electromembrane-surrounded solid-phase microextraction

- A comparative study of the elasto-plastic properties for ceramic nanocomposites filled by graphene or graphene oxide nanoplates

- Encapsulation strategies for improving the biological behavior of CdS@ZIF-8 nanocomposites

- Biosynthesis of ZnO NPs from pumpkin seeds’ extract and elucidation of its anticancer potential against breast cancer

- Preliminary trials of the gold nanoparticles conjugated chrysin: An assessment of anti-oxidant, anti-microbial, and in vitro cytotoxic activities of a nanoformulated flavonoid

- Effect of micron-scale pores increased by nano-SiO2 sol modification on the strength of cement mortar

- Fractional simulations for thermal flow of hybrid nanofluid with aluminum oxide and titanium oxide nanoparticles with water and blood base fluids

- The effect of graphene nano-powder on the viscosity of water: An experimental study and artificial neural network modeling

- Development of a novel heat- and shear-resistant nano-silica gelling agent

- Characterization, biocompatibility and in vivo of nominal MnO2-containing wollastonite glass-ceramic

- Entropy production simulation of second-grade magnetic nanomaterials flowing across an expanding surface with viscidness dissipative flux

- Enhancement in structural, morphological, and optical properties of copper oxide for optoelectronic device applications

- Aptamer-functionalized chitosan-coated gold nanoparticle complex as a suitable targeted drug carrier for improved breast cancer treatment

- Performance and overall evaluation of nano-alumina-modified asphalt mixture

- Analysis of pure nanofluid (GO/engine oil) and hybrid nanofluid (GO–Fe3O4/engine oil): Novel thermal and magnetic features

- Synthesis of Ag@AgCl modified anatase/rutile/brookite mixed phase TiO2 and their photocatalytic property

- Mechanisms and influential variables on the abrasion resistance hydraulic concrete

- Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites

- Achieving excellent oxidation resistance and mechanical properties of TiB2–B4C/carbon aerogel composites by quick-gelation and mechanical mixing

- Microwave-assisted sol–gel template-free synthesis and characterization of silica nanoparticles obtained from South African coal fly ash

- Pulsed laser-assisted synthesis of nano nickel(ii) oxide-anchored graphitic carbon nitride: Characterizations and their potential antibacterial/anti-biofilm applications

- Effects of nano-ZrSi2 on thermal stability of phenolic resin and thermal reusability of quartz–phenolic composites

- Benzaldehyde derivatives on tin electroplating as corrosion resistance for fabricating copper circuit

- Mechanical and heat transfer properties of 4D-printed shape memory graphene oxide/epoxy acrylate composites

- Coupling the vanadium-induced amorphous/crystalline NiFe2O4 with phosphide heterojunction toward active oxygen evolution reaction catalysts

- Graphene-oxide-reinforced cement composites mechanical and microstructural characteristics at elevated temperatures

- Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar

- Preparation of layered gradient Cu–Cr–Ti alloy with excellent mechanical properties, thermal stability, and electrical conductivity

- Recovery of Cr from chrome-containing leather wastes to develop aluminum-based composite material along with Al2O3 ceramic particles: An ingenious approach

- Mechanisms of the improved stiffness of flexible polymers under impact loading

- Anticancer potential of gold nanoparticles (AuNPs) using a battery of in vitro tests

- Review Articles

- Proposed approaches for coronaviruses elimination from wastewater: Membrane techniques and nanotechnology solutions

- Application of Pickering emulsion in oil drilling and production

- The contribution of microfluidics to the fight against tuberculosis

- Graphene-based biosensors for disease theranostics: Development, applications, and recent advancements

- Synthesis and encapsulation of iron oxide nanorods for application in magnetic hyperthermia and photothermal therapy

- Contemporary nano-architectured drugs and leads for ανβ3 integrin-based chemotherapy: Rationale and retrospect

- State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials

- Insights on magnetic spinel ferrites for targeted drug delivery and hyperthermia applications

- A review on heterogeneous oxidation of acetaminophen based on micro and nanoparticles catalyzed by different activators

- Early diagnosis of lung cancer using magnetic nanoparticles-integrated systems

- Advances in ZnO: Manipulation of defects for enhancing their technological potentials

- Efficacious nanomedicine track toward combating COVID-19

- A review of the design, processes, and properties of Mg-based composites

- Green synthesis of nanoparticles for varied applications: Green renewable resources and energy-efficient synthetic routes

- Two-dimensional nanomaterial-based polymer composites: Fundamentals and applications

- Recent progress and challenges in plasmonic nanomaterials

- Apoptotic cell-derived micro/nanosized extracellular vesicles in tissue regeneration

- Electronic noses based on metal oxide nanowires: A review

- Framework materials for supercapacitors

- An overview on the reproductive toxicity of graphene derivatives: Highlighting the importance

- Antibacterial nanomaterials: Upcoming hope to overcome antibiotic resistance crisis

- Research progress of carbon materials in the field of three-dimensional printing polymer nanocomposites

- A review of atomic layer deposition modelling and simulation methodologies: Density functional theory and molecular dynamics

- Recent advances in the preparation of PVDF-based piezoelectric materials

- Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review

- Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2

- Perspectives in biopolymer/graphene-based composite application: Advances, challenges, and recommendations

- Graphene-based nanocomposite using new modeling molecular dynamic simulations for proposed neutralizing mechanism and real-time sensing of COVID-19

- Nanotechnology application on bamboo materials: A review

- Recent developments and future perspectives of biorenewable nanocomposites for advanced applications

- Nanostructured lipid carrier system: A compendium of their formulation development approaches, optimization strategies by quality by design, and recent applications in drug delivery

- 3D printing customized design of human bone tissue implant and its application

- Design, preparation, and functionalization of nanobiomaterials for enhanced efficacy in current and future biomedical applications

- A brief review of nanoparticles-doped PEDOT:PSS nanocomposite for OLED and OPV

- Nanotechnology interventions as a putative tool for the treatment of dental afflictions

- Recent advancements in metal–organic frameworks integrating quantum dots (QDs@MOF) and their potential applications

- A focused review of short electrospun nanofiber preparation techniques for composite reinforcement

- Microstructural characteristics and nano-modification of interfacial transition zone in concrete: A review

- Latest developments in the upconversion nanotechnology for the rapid detection of food safety: A review

- Strategic applications of nano-fertilizers for sustainable agriculture: Benefits and bottlenecks

- Molecular dynamics application of cocrystal energetic materials: A review

- Synthesis and application of nanometer hydroxyapatite in biomedicine

- Cutting-edge development in waste-recycled nanomaterials for energy storage and conversion applications

- Biological applications of ternary quantum dots: A review

- Nanotherapeutics for hydrogen sulfide-involved treatment: An emerging approach for cancer therapy

- Application of antibacterial nanoparticles in orthodontic materials

- Effect of natural-based biological hydrogels combined with growth factors on skin wound healing

- Nanozymes – A route to overcome microbial resistance: A viewpoint

- Recent developments and applications of smart nanoparticles in biomedicine

- Contemporary review on carbon nanotube (CNT) composites and their impact on multifarious applications

- Interfacial interactions and reinforcing mechanisms of cellulose and chitin nanomaterials and starch derivatives for cement and concrete strength and durability enhancement: A review

- Diamond-like carbon films for tribological modification of rubber

- Layered double hydroxides (LDHs) modified cement-based materials: A systematic review

- Recent research progress and advanced applications of silica/polymer nanocomposites

- Modeling of supramolecular biopolymers: Leading the in silico revolution of tissue engineering and nanomedicine

- Recent advances in perovskites-based optoelectronics

- Biogenic synthesis of palladium nanoparticles: New production methods and applications

- A comprehensive review of nanofluids with fractional derivatives: Modeling and application

- Electrospinning of marine polysaccharides: Processing and chemical aspects, challenges, and future prospects

- Electrohydrodynamic printing for demanding devices: A review of processing and applications

- Rapid Communications

- Structural material with designed thermal twist for a simple actuation

- Recent advances in photothermal materials for solar-driven crude oil adsorption

Artikel in diesem Heft

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets