Recovery of Cr from chrome-containing leather wastes to develop aluminum-based composite material along with Al2O3 ceramic particles: An ingenious approach

-

Shashi Prakash Dwivedi

, Ambuj Saxena

, Madhulika Mishra

Abstract

Leather industries cause soil pollution in terms of leather wastes. Chrome-containing leather wastes (CCLW) also cause various types of pollutions such as air and soil pollution. The utilization of CCLW in the development of aluminum-based composite is the emerging area in the synthesis of materials. In this study, chromium(Cr) in the form of collagen powder was extracted from CCLW. Extracted collagen powder was ball milled with alumina particles for 12.5, 25, 50, 75, and 100 h. The average density of the mixture of ball-milled collagen and alumina particles was reduced by about 1.20% after ball milling for about 100 h. The stir casting technique was employed to develop the aluminum-based composite material. The ball-milled reinforced aluminum-based composite material showed a fair distribution of reinforcement particles as compared without ball-milled reinforced composite material. Tensile strength and hardness of composite material improved by about 35.53 and 46.61%, respectively, after using the mixture of ball-milled 5% collagen powder and 5% alumina particles in the aluminum alloy. However, ductility and toughness were reduced. Corrosion weight loss and thermal expansion of the Al/5% collagen/5% alumina particles with ball-milled composite were found to be 0.022 mg and 5.44 mm3, respectively. X-Ray diffraction of the Al/5% collagen/5% alumina particles with ball-milled composite showed the presence of Al, Al2O3, Cr2O3, and Cr phases. The presence of hard phases such as Al2O3, Cr2O3, and Cr was responsible for enhancing the hardness and tensile strength of the composite. The developed composite material can be utilized in the fabrication of engine blocks, connecting rods, and piston rings.

Abbreviations

- AA6061

-

aluminum alloy 6061

- BPR

-

ball to powder weight ratio

- CCLW

-

chrome-containing leather wastes

- Cr

-

chromium

- HMMCM

-

hybrid metal matrix composite material

- MMC

-

metal matrix composites

- NR

-

natural rubber

- SEM

-

scanning electron microscopy

- UTM

-

universal testing machine

- XRD

-

X-ray diffraction

1 Introduction

Industries are causing lots of pollution in terms of solid wastes in the surrounding. The demolition and dumping of such types of wastes are very costly and difficult. The main disadvantage of such types of wastes comes in the form of degradation of agricultural land. Every year, leather industries have been producing a large amount of such type of waste, which is extremely harmful to the environment. Leather waste containing chrome is a harmful type of waste generated by the leather industry, which is too dangerous for humans and animals. Cr, which is presented in the chrome-containing leather wastes (CCLW), can be taken out in the form of collagen powder from it. According to Gupta et al. [1], the extracted collagen powder can be used as a reinforcement particle in the composite materials. Furthermore, the investigation of Cabeza et al. [2] points out that fertilizers and animal feed additives consist of a large amount of collagen hydrolysates.

Pecha et al. [3] developed a mathematical model that enables technological simulation of the complete process by alkali-enzymatic hydrolysis for chrome shaving utilization. The simulation calculation showed a comparatively thin area between 0.2 and 0.4 wt% of the feedstock dry matter for the enzyme optimal concentration under standard reaction conditions. The results obtained through this engineering approach are valuable for entity waste producers to centralized leather waste processing and the processing plant operation. Zeng et al. [4] presented a facile route for de-crosslinking of chrome-tanned collagen fibers and to realize physically debundling over and above the prepared leather shaving wastes (LSW)/natural rubber (NR) composite by solid-state shear milling (S3M) equipment. The improved interfacial interaction and dispersion allow the merger of 40 wt% LSW to afford the respective NR composites with outstanding stress at 100% strain (S100) and modulus, which are 5.07 and 27.33 MPa, respectively, over and above superior thermal stability and tear strength. Long et al. [5] worked to recover Cr(vi) from tannery sludge and chrome-tanned leather shavings by Na2CO3-segmented calcinations. In this study, thermogravimetric characterization and thermodynamic calculation were used for analyzing chrome tanned leather shavings (CTLs) and the factors affecting recovery of Cr in the calcination process and the theoretical feasibility of calcinating Ts. The results showed that organic compounds in materials and calcination time, temperature, Na2CO3 content, and calcination environment could greatly affect the recovery of Cr(vi) from Ts and CTLs. Zhu et al. [6] fabricated pH-sensitive and chromium(iii)-loaded nanoparticles (Cr-PPAG NPs) as a smart tanning system. Results showed that due to the core–shell structure, these Cr-PPAG NPs exhibit a “Trojan horses” behavior, which can protect Cr3+ from reacting with skin collagen during the penetration process, leading to effective and uniform delivery of Cr3+ to the rawhide’s interior. Cao et al. [7] used collagen-containing solid wastes to prepare biochar. Results showed that the highest surface area of the biochar prepared from wastes reached 967 m2/g. A facile method was reported by Liu et al. [8] by using the S3M process to disengage the cross-linked collagen fibers and developed leather solid waste-based composites which exhibited superior comprehensive properties. The collagen was used by Banerjee et al. [9] for recovering hydrolysate from the leather waste and functioning as a substrate that boosts the growth of hydroxyapatite crystals. With the help of activated carbon which is processed by wet blue leather waste, Luis et al. [10] removed the organic oxidation and hydrogen peroxide from the aqueous medium. Padilha et al. [11] removed phosphorus from thermo-treated footwear leather waste to assemble raw materials for the production of ferrochromium alloys.

The composite material consisting of more than two reinforcement particulates is known as hybrid metal matrix composite. Several problems occur during the mixing of two powders such as SiC, B4C, Al2O3, Si3N4, and graphite before the casting process of hybrid metal matrix composite material (HMMCM). The polymeric and grain structure of hybrid composite material are not uniform and consistent. We can see that for the hybrid composite material, the main reason of losing the mechanical properties is the mismatch densities of reinforcement fragments, which results in the non-uniform microstructure. Aluminum-based alloy is used to develop the composite by using various reinforcement particles for the application in various manufacturing sectors. Mahinroosta and Allahverdi [12] pointed out the number of applications related to lightweight and high strength aluminum such as rotors and some internal parts of brakes, different structural parts, and internal combustion engine piston, and the mechanical testing has been performed to find out the properties of base metal aluminum. Mismatch reinforcement fragments in densities are either float or sink in the melted aluminum alloy. Clustering and agglomeration were observed after the solidification of hybrid composite material. Different techniques must be employed to avoid the agglomeration and clustering of mixed reinforcement fragments. Shaikh et al. [13] reported that the mechanical property of hybrid composite material may be enhanced if reinforcement powders are mixed consistently.

It was noted that not many researchers have used a combination of collagen powder and Al2O3 fragments as a reinforcing particulate with aluminum alloy according to the available literature. Dwivedi et al. [14] and Mandal et al. [15] illustrated collagen-derived composites using collagen as a matrix particulate and Al2O3 as a reinforcing particulate. However, Dwivedi and Srivastava [16] fabricated an aluminum-based composite with collagen powder with Al2O3. Results showed that reinforcement fragments were not distributed uniformly due to density mismatch between collagen powder and Al2O3 ceramic fragment reinforcement. At the surface of the melt matrix material, collagen powder was floating due to the lower density reinforcement fragments compared to aluminum. Also, in the melt matrix material Al2O3 ceramic fragments were settled down due to the higher density compared to aluminum. Finally, a non-uniform microstructure emerged. Also, the mechanical properties were not greatly improved.

From the existing literature, it has been observed that very few researchers used the ball-milled collagen and alumina particles with the aluminum alloy. After the consideration of the above-described facts, in the present investigation, collagen powder and Al2O3 ceramic fragments have been ball milled for certain hours. Furthermore, that mixture is utilized as a reinforcement powder in the aluminum matrix. Finally, a comparison has also been presented between the aluminum-based composites.

2 Materials and methods

2.1 Matrix material

Aluminum alloy 6061 (AA6061) has been taken as the matrix material in the present study. AA6061 is considered one of the most significant materials in both automobile and aerospace industries due to its several desirable characteristics such as good specific strength, light weight, and less corrosion loss. Measured mechanical behavior and chemical properties of AA6061 are shown in Tables 1 and 2, respectively.

Measured properties of AA6061

| S. No. | Properties | Values |

|---|---|---|

| 1 | Tensile strength (MPa) | 132 |

| 2 | Hardness (BHN) | 59 |

| 3 | Toughness (Joule) | 18 |

| 4 | Ductility (% elongation) | 16.5 |

| 5 | Corrosion weight loss (mg) in 3.5 wt% NaCl for 120 h | 0.01 |

| 6 | Thermal expansion (mm3) for 72 h at 450°C | 21.5 |

| 7 | Density (g/cm3) | 2.70 |

Measured chemical properties of AA6061

| Mg | Si | Fe | Cu | Cr | Zn | Ti | Mn | Al |

|---|---|---|---|---|---|---|---|---|

| 0.8 | 0.4 | 0.01 | 0.15 | 0.04 | 0.2 | 0.1 | 0.1 | 98.2 |

2.2 Primary reinforcing particulate

In the current research, Al2O3 or alumina, ceramic fragments are considered for primary reinforcing particulate, which is a mixture of aluminum and oxygen chemical compositions. The main purpose of using alumina particles with aluminum alloy was to increase the wettability of the collagen powder used in this study. However, ceramic particles SiC and B4C are also used in the development of aluminum-based composite material. Detailed comparative studies of silicon carbide (SiC), alumina (Al2O3), and boron carbide (B4C) for the selection of primary reinforcement material in the present study are shown in Table 3.

Comparative studies of SiC, Al2O3, and B4C

| Ref. | Properties | SiC | Al2O3 | B4C |

|---|---|---|---|---|

| [17,18,19] | Bulk modulus (GPa) | 210–260 | 130–340 | 190–230 |

| [19,20] | Compressive (crushing) strength (MPa) | 2,700–3,500 | 1,900–2,930 | 1,700–2,200 |

| [19,21] | Density (g/cm3) | 3.1–3.2 | 3.42–4.2 | 2.5–2.65 |

| [19,22] | Elastic (Young’s modulus, GPa) | 390–460 | 220–460 | 380–460 |

| [19,23] | Vickers hardness (GPa) | 27 | 26 | 32 |

| [24,25,26] | Flexural strength (MOR): typical (MPa) | 460–500 | 300–690 | 250–410 |

| [27,28,29] | Fracture toughness (MPa m1/2) | 6.2 | 3.5–5.5 | 4.2 |

| [19,30] | Shear modulus (GPa) | 190–230 | 110–190 | 190–230 |

| [19,31] | Stiffness-to-weight ratio: bulk (MN m/kg) | 69–82 | 38–87 | 74–92 |

| [32,33,34] | Stiffness-to-weight ratio: shear (MN m/kg) | 62–71 | 32–48 | 71–92 |

| [33,35] | Stiffness-to-weight ratio: tensile (MN m/kg) | 120–140 | 64–110 | 140–180 |

| [34,36] | Strength-to-weight ratio: compressive (kN m/kg) | 870–1,100 | 550–730 | 640–880 |

| [36,37,38,39] | Strength-to-weight ratio: flexural (kN m/kg) | 140–150 | 87–170 | 94–160 |

| [40,41,42] | Thermal conductivity: ambient (W/m K) | 115–150 | 16–31 | 50–90 |

| — | Cost | Cheaper | Costly than SiC | Very costly |

2.3 Secondary reinforcing particulate

Figure 1 depicts the experimental phase of extracting collagen powder from CCLW as Cr. In the present investigation, collagen powder developed from CCLW (a tannery solid biowaste in the leather industry) has been taken as a secondary reinforcing particulate in the casting of aluminum-based composites. Initially, leather waste containing chrome was dechromed using conc. H2SO4. Furthermore, the dechromed samples were treated for 3 days with HCl (pH 8), C2H5OH, and EDTA, a similar type of processing suggested by Mandal et al. [15]. Then the solution was held for 1 day after adding acetic acid in it. The collagen fibrils were then kept aside to settle down for 24 h. Then to obtain the collagen in powder form the solubilized collagen was centrifuged. The average particle size of chrome-containing collagen powder was 55 µm. The percentage of Cr2O3 in collagen powder after extracting from CCLW was found to be 6.58%.

Development of collagen powder from leather waste containing chrome.

2.4 Ball milling of reinforcement particles

Figure 2 shows the ball milling set-up. The ball milling process is used in the reinforcement fragment in a single entity. The ball to powder weight ratio (BPR), ball milling time, grinding medium, ball milling speed, ball milling atmosphere, and milling vial are all crucial factors in the ball milling process. However, ball milling time is the crucial parameter in the ball milling process [43,44]. In accordance with the outcomes of the pilot run, the composition of the composite was determined. In the present investigation, Al2O3 ceramic fragments and collagen powder with the mean constituent size of 50 µm have been alloyed mechanically with the help of the ball milling process. The equal weight percentage of Al2O3 ceramic fragments and collagen powder has been ball milled in a stainless-steel milling container with the help of ceramic balls. The BPR and the pace of ball milling have been taken as 5:1 ratio and 200 rpm at the atmospheric environment throughout the experiments.

Line diagram of ball-milling set-up.

2.5 Development of composite particulates

Figure 3 depicts the fabrication process of an aluminum-based composite reinforced with leather-waste collagen powder and alumina ceramic fragments, with and without ball milling of the reinforcing fragments with the help of a line diagram. The leather industry and a chemical shop provided the collagen powder and alumina ceramic fragments, respectively. In a muffle furnace, fragments of aluminum were melted. In the case of without ball-milled reinforcement fragments, primary reinforcing fragment alumina and secondary reinforcing fragment collagen powder were preheated to achieve great susceptibility to water with matrix content. Before being added to the melt matrix material, the mixture of reinforcing fragments in a single entity obtained from the ball milling phase after 100 h was also preheated. At a temperature of about 670°C, preheated reinforcement fragments (with and without ball milling of reinforcement fragments) were merged into the melted matrix material. Figure 3 shows how the composite material was fused using a stir casting technique. The prepared Al/alumina/collagen powder hybrid composites were moved to a universal testing machine (UTM) in the lumpy zone for pushing hard using the stir casting technique (with and without ball milling of reinforcement fragments). To remove the casting defects such as porosity and shrinkage after solidification, a cylindrical die punch assembly has been used which supplies the high compressed pressure in the spongy and pulpy zone of melt composite material.

Development of hybrid composite material.

The compositions of hybrid composite material which is prepared by stir casting technique are mentioned in Table 4. The composition of the composite was decided based on the pilot run investigation. For the selection of reinforcement percentage (alumina weight percentage and collagen weight percentage), numerous experiments were conducted. In the pilot run, when the weight percentage of alumina and collagen was 1% each, then mechanical properties such as tensile strength and hardness of aluminum alloy were not improved. When the weight percentage of alumina and collagen was 1.25% each, some improvement in the mechanical properties has been observed. However, when mechanical properties of the composite were observed at 7.5% of each alumina and collagen with the aluminum alloy, mechanical properties began to decrease. Therefore, the range of reinforcement weight percentage was from 2.5% (1.25% each of alumina and collagen) to 12.5% (1.25% each of alumina and collagen).

Selection of composition

| Specimen | Composition | Alumina (%) | Collagen (%) |

|---|---|---|---|

| A1 | Al + 0% alumina + 0% collagen | 0 | 0 |

| A2 | Al + 1.25% alumina + 1.25% collagen | 1.25 | 1.25 |

| A3 | Al + 2.5% alumina + 2.5% collagen | 2.5 | 2.5 |

| A4 | Al + 3.75% alumina + 3.75% collagen | 3.75 | 3.75 |

| A5 | Al + 5% alumina + 5% collagen | 5 | 5 |

| A6 | Al + 6.25% alumina + 6.25% collagen | 6.25 | 6.25 |

2.6 Material testing

The developed composite materials have been characterized in terms of microstructure, tensile strength, hardness (10 mm × 10 mm × 25 mm), toughness (10 mm × 10 mm × 55 mm with 45° V notch at the center of 2 mm depth according to ASTM A370 standard), thermal expansion, corrosion loss, and X-ray diffraction (XRD) of composite materials. The tensile, hardness, and toughness of thermal expansion samples (average of two samples) were tested on a UTM, hardness testing machine, impact testing machine, and muffle furnace at GL Bajaj Institute of Technology and Management, Gr. Noida, India. Tensile samples were prepared according to ASTM B557 standard (test methods for tension testing wrought and cast aluminum and magnesium alloy products). Corrosion test was performed in the in-house developed set-up in the laboratory of GL Bajaj Institute of Technology and Management, Gr. Noida, India. The microstructure testing and XRD were performed at the NIRF lab at IIT Delhi. Corrosion test of each sample has been performed in 3.5 wt% NaCl for 120 h. During the thermal expansion experiment, the sample size is taken as 25 mm × 10 mm × 10 mm (2,500 mm3 volume) during the entire test for both cases of ball-milled and without ball-milled reinforcing composites. A thermal expansion test was carried out in a muffle furnace for 72 h at 450 °C.

3 Results and discussion

3.1 Density behavior of hybrid reinforcement particulates

The density behavior of hybrid reinforcement particulates has been observed at different ball-milling times. Al2O3 ceramic fragments and collagen powder with equal weight percentage (25 + 25 g) have been ball milled for 12.5, 25, 50, 75, and 100 h. The density of Al2O3 was 3.95 g/cm3. The collagen powder was found to have a density of 3.5 g/cm3. The mean density of Al2O3 ceramic fragments and collagen powder (about 25 g of each reinforcement fragment was taken) was 3.725 g/cm3. The milling time was chosen to acquire a state among fracturing and cold welding of the supportive reinforcing fragments. Figure 4 depicts the density variation of reinforcing fragments (Al2O3 ceramic fragments and collagen powder) with time. Initially, the density of combined reinforcement fragments (Al2O3 ceramic fragments and collagen powder) at 0 h was 3.725 g/cm3. When milling time was increased up to 25 h, combined reinforcement fragment density was 3.768 g/cm3. Results showed that about 1.20% density increased. However, the combined density of reinforcement fragment powder was decreased up to 3.68 g/cm3 after ball milling time for 100 h. If the milling time will be more than 100 h, this will result in the formation of undesirable phases in the combination powder of reinforcement. Therefore, ball milling of reinforcing fragments is necessary for a given interval of time. Due to the increase in van der Waals interactions between the Al2O3 fragments and collagen powder, the density of mixed reinforcing fragments boosted (to 25 h), and due to the increase in van der Waals interactions of reinforcing fragments, it was observed that the ceramic balls and reinforcing particulates collided with greater intensity. Low van der Waals interaction existing in reinforcing fragments, according to Suryanarayana [45], is another factor that contributes to the reduced density at high temperatures. In addition, a mixture of Al2O3 ceramic fragments and collagen powder was ball milled for 100 h, which was studied by Ghadimi et al. [46] to produce composite reinforcement content. Sharma et al. [47] have also estimated the densities of the ball-milled powder. Their results showed good agreement with the results of the present study.

Density variation of reinforcement particles with time.

3.2 Microstructural analysis

Microstructure images of alumina fragments and collagen powder reinforcing aluminum composites with and without ball milling were taken to determine the allocation of reinforcing fragments in the matrix material. Figure 5 gives the scanning electron microscopy (SEM) images of without ball-milled reinforced Al/Al2O3/collagen powder composite material. Clustering and agglomeration can be easily observed from the microstructure after the solidification without ball-milling samples. Figure 5 shows the element mapping of Al, Si, C, O, Mg, and Cu for the Al/Al2O3/collagen powder composite material without ball milling. Finer grain structure can be observed from the elemental mapping. Elemental mapping of Al and Si shows the presence of fewer reinforcement particles due to the clustering and agglomeration, as shown in Figure 5(a and b).

SEM images of green hybrid composites without ball-milled reinforcement fragments at different magnifications: (a) element mapping of Al, (b) element mapping of Si, (c) element mapping of C, (d) element mapping of O, (e) element mapping of Mg, and (f) element mapping of Cu.

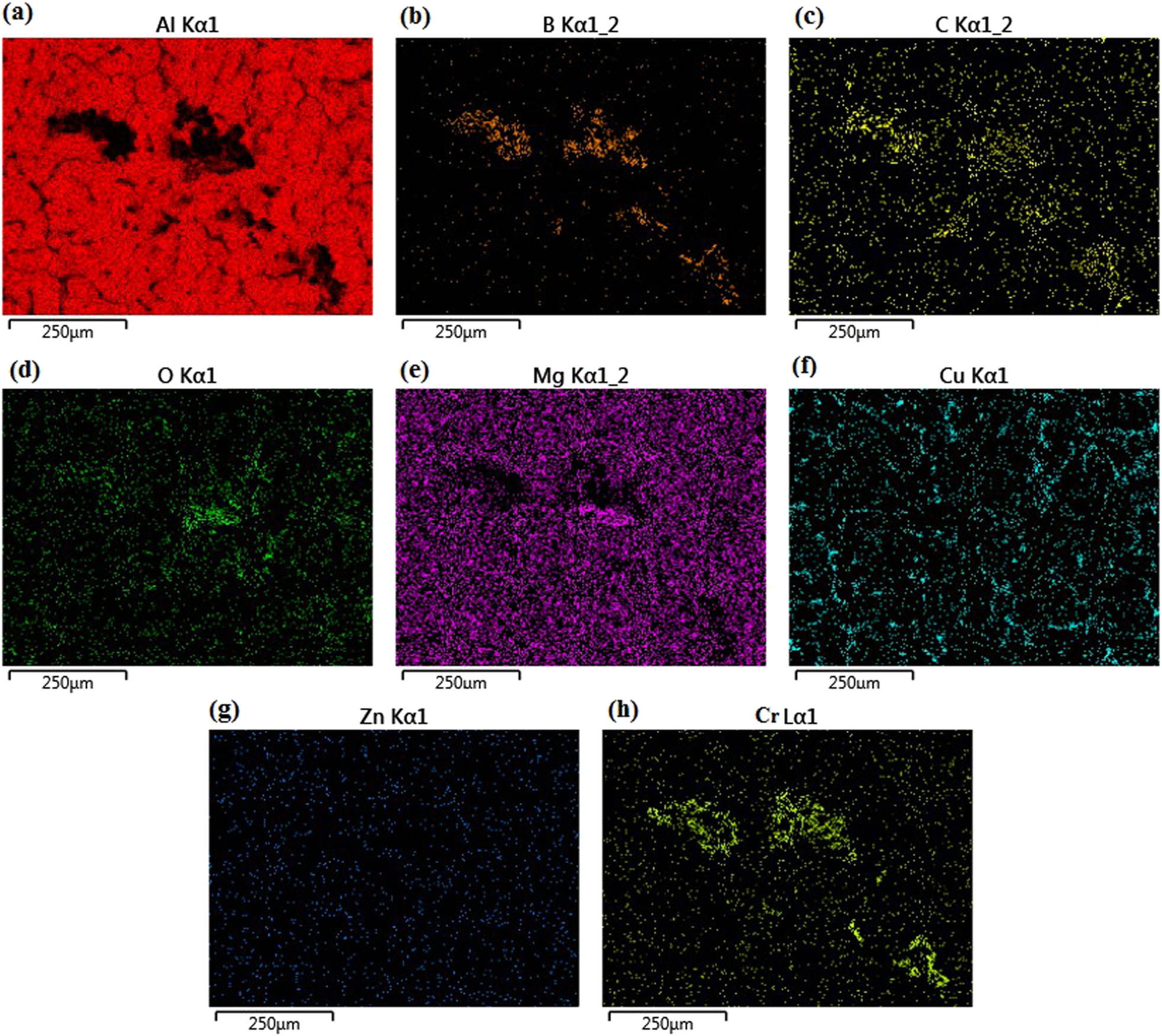

SEM images of composite material with ball-milled reinforcing fragments are shown in Figure 6. The mixture of reinforcing fragments can be seen in a single entity. It was discovered that the distribution of ball-milled reinforcing fragments in a single entity was homogeneous. From the microstructure image, it can be seen that in aluminum-based matrix material there is a homogeneous distribution of alumina-ceramic fragments and collagen powder. The physical characteristics of hybrid composites were diminished due to the non-uniform microstructure of powders that had not been ball milled. It was earlier discussed that a mixture of reinforcement fragments was obtained in a single entity after the ball milling process. Figure 6 shows the element mapping of Al, B, C, O, Mg, Cu, Zn, and Cr for the Al/Al2O3/collagen powder composite material that had been ball milled. Elemental mapping of Al shows the presence of reinforcement particles due to fair distribution, as shown in Figure 6(a). Finer grain structure can be observed from the elemental mapping of C, O, Mg, Cu, Zn, and Cr, as shown in Figure 6(c–h).

SEM images of green hybrid composites with ball-milled reinforcing fragments at different magnification reinforcing fragments: (a) element mapping of Al, (b) element mapping of B, (c) element mapping of C, (d) element mapping of O, (e) element mapping of Mg, (f) element mapping of Cu, (g) element mapping of Zn, and (h) element mapping of Cr.

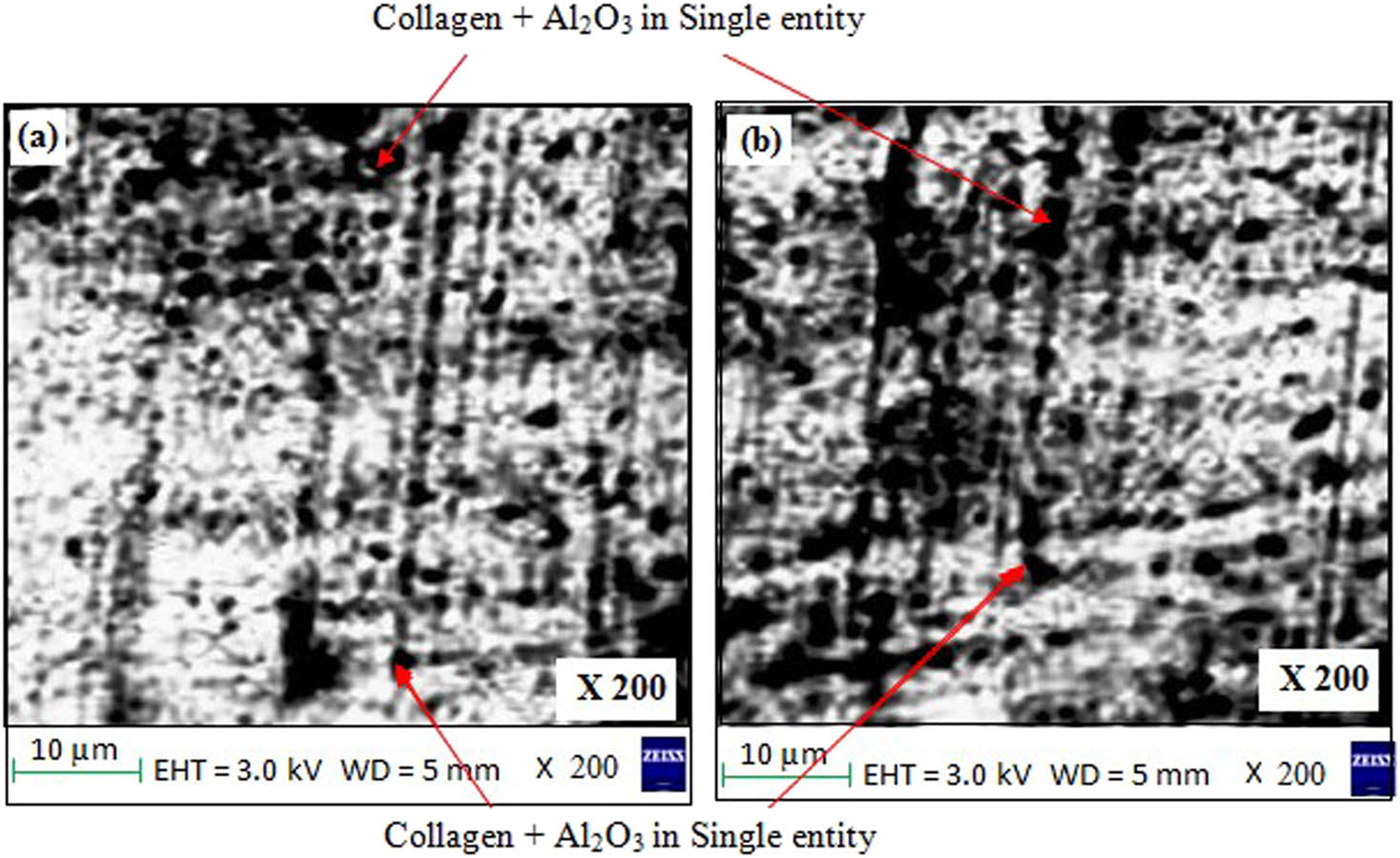

The metallurgical microscopic view of a green hybrid composite material with ball-milled reinforcement fragments is shown in Figure 7. The microstructure of the composite material shows uniform distribution of the mixture of alumina and collagen powder in the aluminum alloy. A proper interfacial reaction layer can also be observed between the reinforcement particles and the matrix material. Shaikh et al. [13] concluded that strong acid and alkali attack has been resisted by Al2O3 ceramic fragments, which also have outstanding dielectric properties with frequency ranges of DC to GHz. As a result, alumina ceramic particles form strong wettability with the matrix material.

(a, b) Metallurgical microscopic view of green hybrid composites with ball-milled reinforcing fragments.

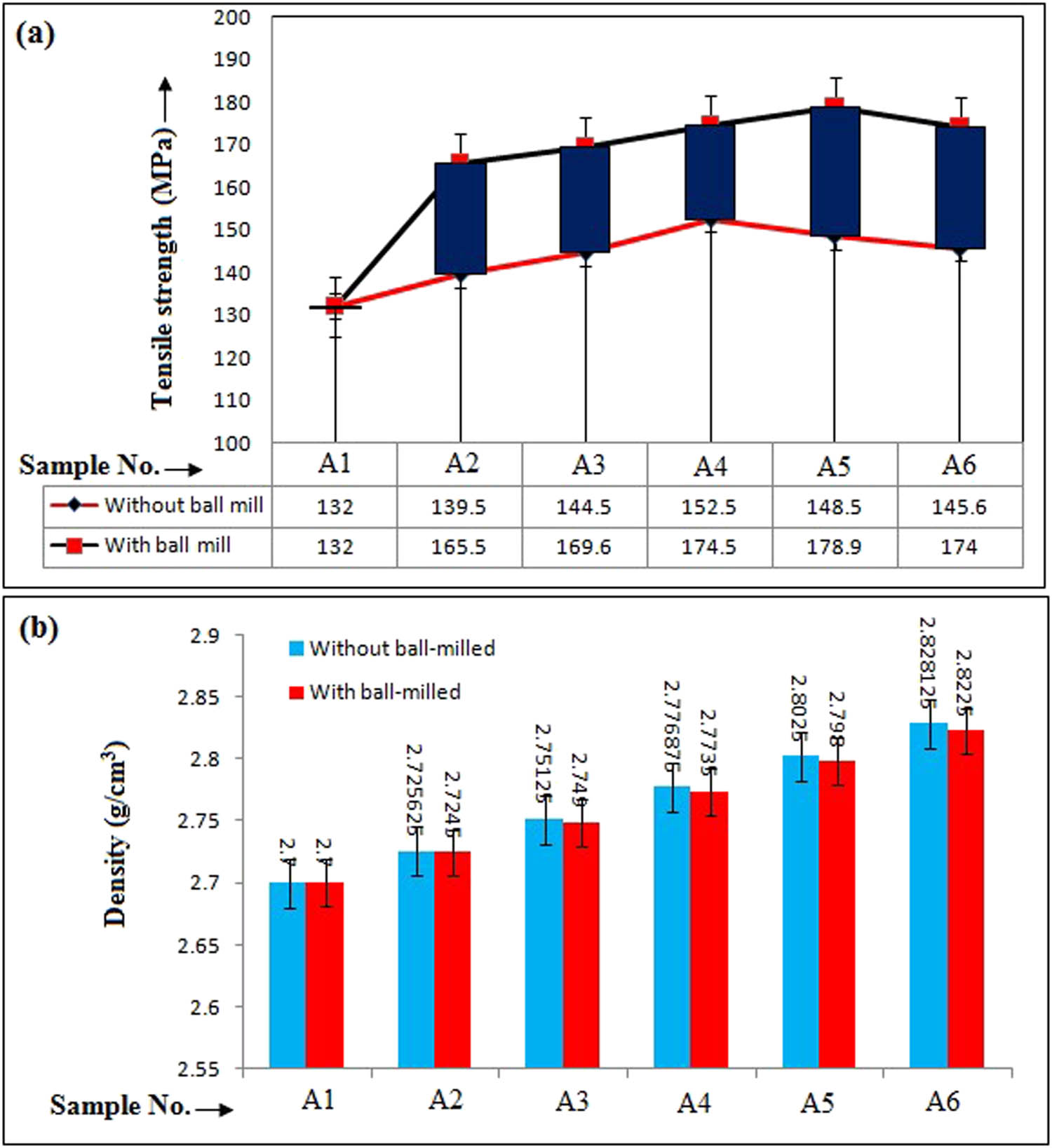

3.3 Tensile strength analysis

Figure 8(a) depicts the durability or firmness of the composites reinforced with ball-milled alumina ceramic fragments and collagen powder compared to the composite material without ball-milled alumina ceramic fragments and collagen powder. It was seen that the firmness of aluminum-based composites is escalating with the increase in the percentage of combined reinforcing fragments (a mixture of alumina ceramic fragments and collagen powder in equal weight percentage without ball milling). Furthermore, this increase in tensile strength trend is followed only up to the percentage of 3.75% Al2O3 + 3.75% collagen powder in the aluminum matrix composites. Nonetheless, tensile strength started to decline after incorporating 3.75% Al2O3 and 3.75% collagen powder that had not been ball milled.

(a) Tensile strength of composite materials and (b) density of the composite.

When a mixture of reinforcing fragments in a single entity after ball milling was added in matrix material, the firmness of composites was enhanced favorably. The maximum tensile strength value is 178.9 MPa for aluminum-based composite material, which is reinforced by the combination of 5% Al2O3 + 5% collagen powder. Mismatch densities of alumina ceramic fragments and collagen powder are the main reason for reducing the mechanical properties of hybrid composite material after adding it without ball milling in melt aluminum. Mismatch reinforcement fragments in densities are either floated or sink in the melted aluminum alloy. Due to this, clustering and agglomeration were seen after the solidification of hybrid composite material, the resulting tensile strength does not enhance properly. After the ball milling process, however, a mixture of Al2O3 ceramic fragments and collagen powder was generated in a single entity. Bauxite which contained aluminum hydroxide is the principal ore of aluminum. It is always easier to make composite material with single reinforcement particulate. After being ball milled, a mixture of alumina ceramic fragments and collagen powder was introduced to aluminum as a single entity. In the matrix content, the single entity of reinforcement particle was uniformly addressed. And this uniform distribution of single entity reinforcement fragments can be accounted for enhancing the tensile strength of composite material. Kumar et al. [48] used alumina and eggshell as reinforcement materials with the aluminum alloy. They also ball milled the reinforcement particles (alumina and eggshell) before mixing with the molten aluminum alloy. Their results showed that by adding the ball-milled Al2O3 and eggshell particles (5% eggshell and 5% alumina) in aluminum alloy about 38.06% tensile strength improved. The results of this study showed that tensile strength was enhanced by about 35.53% after using ball-milled reinforcement fragments for composing Al/5% Al2O3/5% collagen powder composites. The results of this study showed good agreement with those of Kumar et al. [48].

Figure 8(b) shows the density behavior of composite material with and without ball milling of reinforcement particles. The theoretical density of the Al/5% Al2O3 + 5% collagen powder composite without ball-milled reinforcement was found to be 2.8025 g/cm3. The density of the Al/5% Al2O3 + 5% collagen powder composite with ball-milled reinforcement was found to be 2.798 g/cm3. Results showed that about 0.16% density of the Al/5% Al2O3 + 5% collagen powder composite was reduced after using the ball-milled reinforcement particles.

3.4 Hardness analysis

Figure 9 demonstrates the hardness of Al/Al2O3/collagen powder hybrid metal matrix composite with and without ball-milled reinforcement fragments. It was noted that the maximum hardness was 73.5 BHN for without ball milling 3.75% Al2O3 and 3.75% collagen powder-reinforced aluminum-based composite material. The maximum hardness of ball-milled reinforcement fragments was accounted to be 86.5 BHN for Al/5% Al2O3/5% collagen powder metal matrix composite (MMC) material. It was noted that hardness is significantly improved after using the ball-milled reinforcement fragments in a single entity. Leather waste containing chrome contains Cr. Collagen was obtained in the form of Cr. The enhancement in the hardness of composite material can be regarded due to the presence of Al2O3 and Cr. And another reason can be that the reinforcement fragments (a mixture of collagen and Al2O3) are uniformly distributed in a single entity in the matrix material. Kumar et al. [48] identified the hardness of the composite material after adding the mixture of ball-milled eggshell and Al2O3 particles in the aluminum alloy. Their results indicated that after using the mixture of 5% alumina and 5% eggshell reinforcement particles after being ball milled, hardness was improved by about 50.84%. The results of this study showed about 46.61% improvement in the hardness after adding the ball-milled 5% collagen and 5% alumina particles in the aluminum alloy.

Hardness of hybrid composite.

3.5 Toughness (impact strength)

Figure 10 demonstrates the impact strength of Al/Al2O3/collagen powder hybrid metal matrix composite with and without ball-milled reinforcement fragments. From the analysis, it can be observed that on increasing the percentage of alumina ceramic fragments and collagen powder in aluminum for both types of reinforcement particulates (a mixture of with and without ball-milled reinforcement fragments), the toughness is continuously getting reduced. However, for all the compositions, there was an increment in the toughness after using the ball-milled reinforcement fragments. Kumar et al. [48] have also observed the toughness behavior of composite material. Results showed that the addition of hard ceramic particles such as alumina and ceramic particles after ball milling reduced the toughness of the composite material. Reduction in the toughness was observed due to the formation of work-hardened material. The results of this study also showed good agreement with the results of Kumar et al. [48]. The results of this study showed that after adding the mixture of alumina and collagen powder, toughness decreased continuously.

Toughness of hybrid composite.

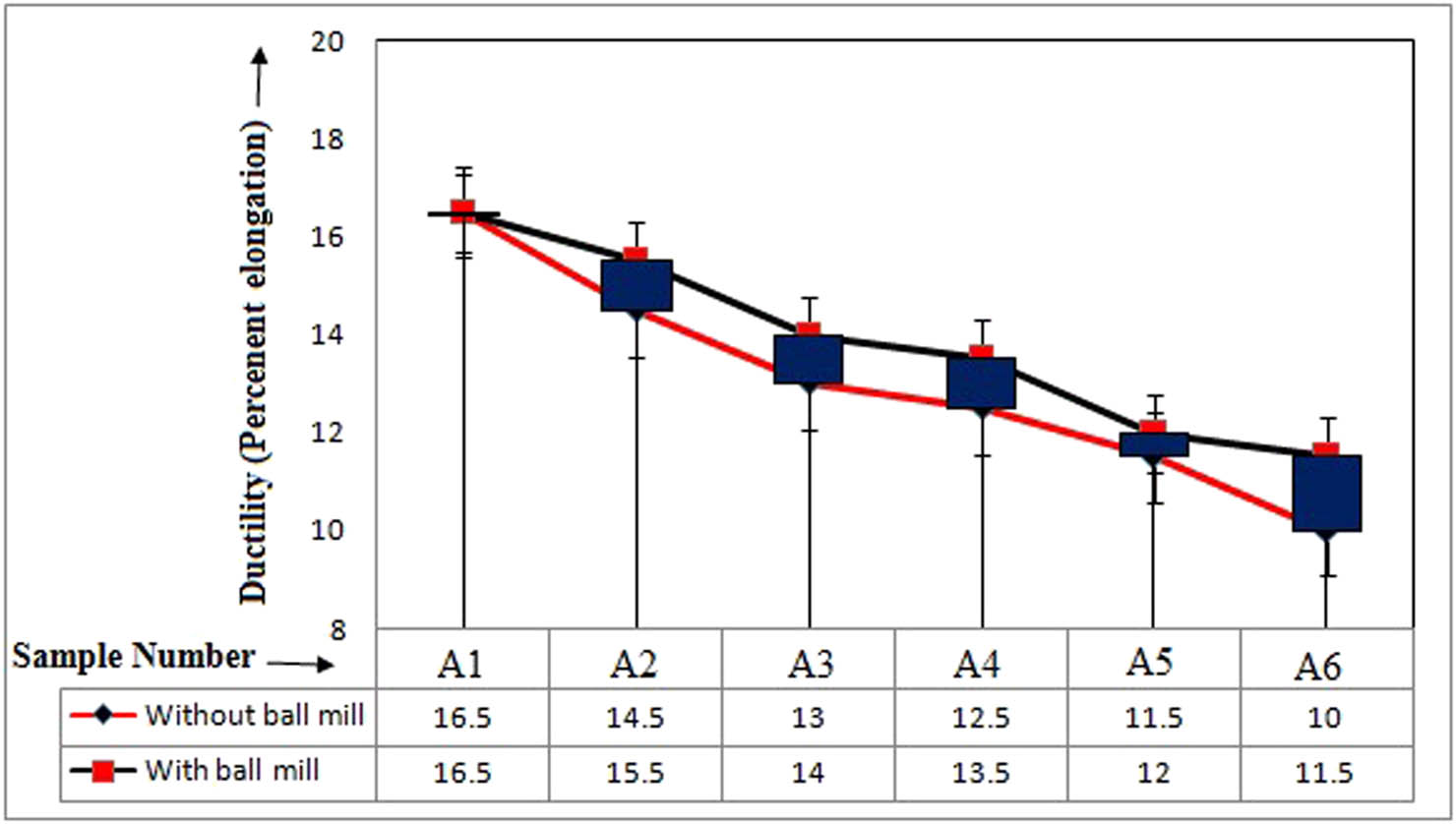

3.6 Ductility

Hybrid aluminum-based-MMC ductility has been evaluated in the form of percentage elongation. The comparison of ductility for Al/Al2O3/collagen powder hybrid aluminum-based MMC with and without ball-milled reinforcement fragments is shown in Figure 11. In the results, a continuous decrease in the ductility of hybrid-aluminum-based-MMC has been noticed with the increase in the percentage of Al2O3 and collagen powder. When the mixture of the reinforcement particles was added to the molten aluminum alloy, it was observed that the plastic flow behavior of the material decreased. Lower plastic flow of the developed composite material increased the brittleness behavior of composite material. As a result, the plastic flow of the material after the elastic point was decreased in the Al/Al2O3/collagen powder hybrid composite material. However, it was discovered that using ball-milled reinforcement fragments strengthened the ductility of the hybrid MMCs. Kumar et al. [48] also showed that the ductility of the composite material reduced after adding the hard ceramic particles in the aluminum alloy.

Ductility of hybrid composite.

3.7 Corrosion behavior

The study of corrosion patterns for hybrid aluminum-based MMC reinforced with alumina ceramic fragments and collagen powder has been carried out. Figure 12 depicts the corrosion weight loss of the investigated products. Hybrid composite samples with a combination of ball-milled 2.5% Al2O3 + 2.5% collagen powder reinforcement show the minimum corrosion loss of 0.011 mg. Furthermore, a direct proportional relationship has been observed between the weight percentage of Al2O3 + collagen powder and corrosion weight loss. The corrosion weight loss continuously increases with an increase in weight percentage of Al2O3 + collagen powder in the aluminum matrix. Figure 13(a) and (b) shows the SEM image of corroded ball-milled reinforced composites and without ball-milled reinforced composite sample. SEM corrosion image of the ball-milled reinforced composite sample shows better corrosion resistance as compared to without ball-milled reinforcing composite sample. Kumar et al. [48] observed the corrosion behavior of Al/eggshell/Al2O3 composite material. It can be observed that by increasing the weight percentage of reinforcement particles (a mixture of eggshell and Al2O3), corrosion resistance of the composite material began to decrease. This decrement was observed due to the formation of Al (OH)3 at the surface of composite in the presence of O2 and OH–. The results of this study also showed that weight loss of the aluminum alloy was increased by increasing the weight percentage of reinforcement particles.

Corrosion weight loss of hybrid composite.

SEM images of corroded: (a) ball-milled reinforcing composites and (b) without ball-milled composite sample.

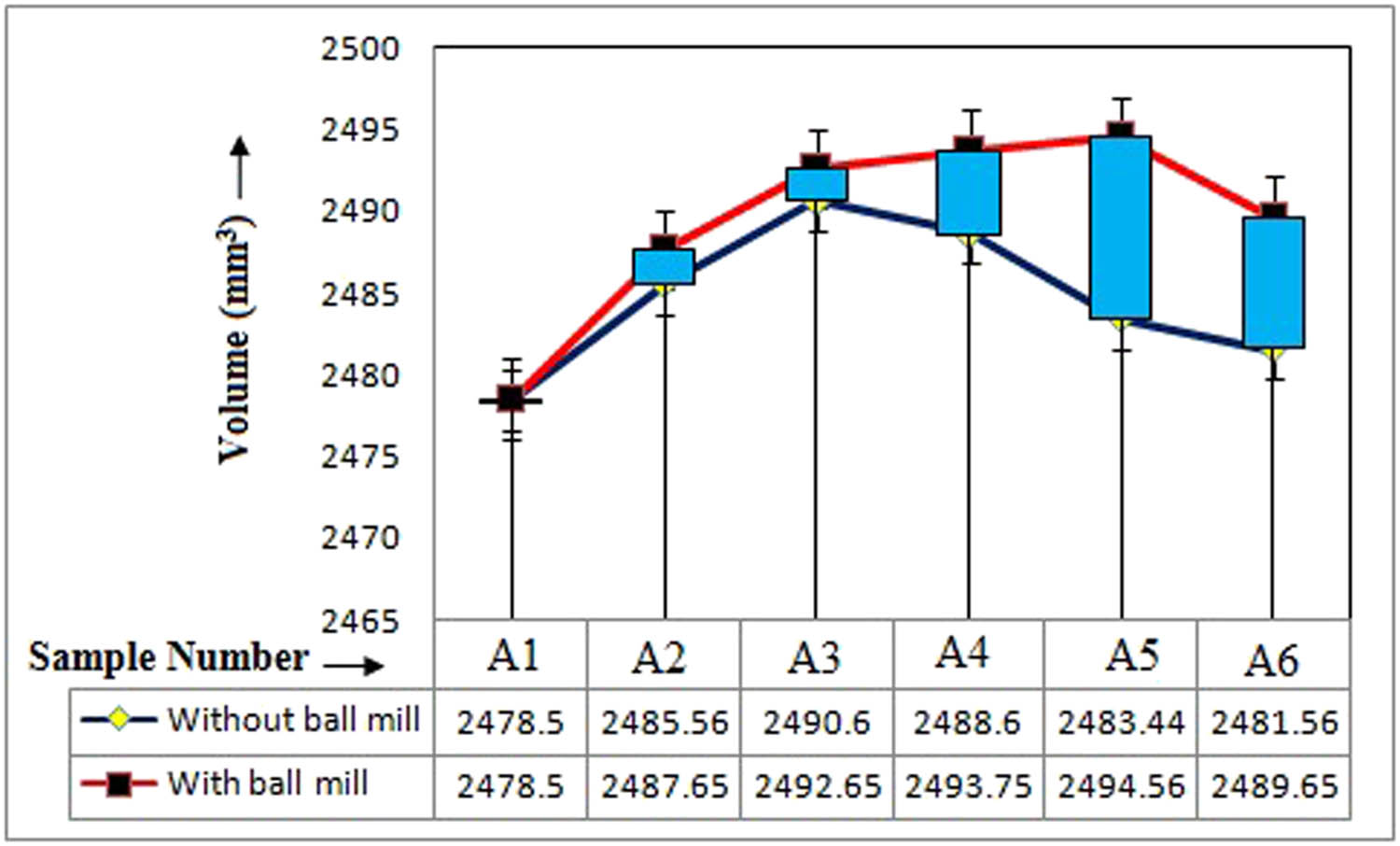

3.8 Thermal expansion behavior

The thermal expansion of an HMMCM is shown in Figure 14. The smallest volume variance was found for Al/5% Al2O3/5% collagen powder ball-milled composites. Figure 15(a) and (b) shows the expansion sample after the thermal expansion test of ball-milled reinforced composite material and without ball-milled composite sample, respectively. It has been observed that collagen powder became coarser in size. As a result, composite material contracted more as compared to the ball-milled reinforced composite material. Kumar et al. [48] showed that after the thermal expansion test of the Al/5 wt% eggshell/5 wt% Al2O3 composite material, change in volume of the composite material at 450°C for 24 h was found to be 3.35 mm3. However, the change in volume in the present study at 450 °C for 72 h after adding the 5% Al2O3 and 5% collagen powder into the aluminum alloy was found to be 5.44 mm3.

Thermal expansion of hybrid composites.

SEM images of thermal expansion sample: (a) ball-milled reinforcing composite material and (b) without ball-milled composite sample.

3.9 XRD of composites

XRD analysis is a kind of non-destructive testing that is used to obtain structural information of materials. In this method, an X-ray is made to fall on the sample and the intensity of scattered radiation is measured as a function of scattered ray direction. The XRD test aims to observe the different phases produced inside the composite after the solidification. The thickness of the sample before conducting XRD test inspection was 2 mm. Figure 16 depicts XRD of ball-milled Al/5% Al2O3/5% collagen powder composites. XRD of generated composite demonstrates the presence of Al, Al2O3, Cr2O3, and Cr phases. These hard phases may be accountable for giving rise to the physical characteristics of composites such as firmness and hardness.

XRD of ball-milled Al/5% Al2O3/5% collagen powder composites.

4 Conclusions

Collagen powder after extracting from the CCLW was used as a primary reinforcement material along with alumina ceramic particles in the fabrication of aluminum-based composite material. Alumina ceramic fragments and collagen powder were obtained in a single entity after ball milling for about 100 h. The density of the ball-milled alumina ceramic fragments and collagen powder was decreased by about 1.20%. According to the microstructure findings, there is a homogeneous allocation of reinforcing fragments within a composite material. Also reinforcing fragments in aluminum matrix material were having an appropriate wettability. Tensile strength and hardness were improved after using the ball-milled alumina ceramic fragments and collagen powder. After the corrosion test, the values for dimension change and weight loss were noted to have a minimum value as for Al/5% Al2O3/5% collagen powder ball-milled composites and ball-milled 2.5%, Al2O3, and 2.5% collagen powder reinforcing composites, respectively. XRD of ball-milled Al/5% Al2O3/5% collagen powder composites has been observed. It was observed that there was noticeable progress in the tensile strength and hardness of composites due to the presence of Al2O3, Cr2O3, and Cr phases.

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Gupta P, Kumar D, Parkash O, Jha AK. Tribo-evaluation of iron-based metal matrix nanocomposites for heavy duty applications. AIP Conf Proc. 1877;2017:030002. 10.1063/1.4999858.Search in Google Scholar

[2] Cabeza LF, Taylor MM, DiMaio GL, Brown EM, Marmer WN, Carrio R, et al. Processing of leather waste: pilot scale studies on chrome shavings. Isolation of potentially valuable protein products and chromium. Waste Manage. 1998;18(3):211–8. 10.1016/s0956-053x(98)00032-4.Search in Google Scholar

[3] Pecha J, Barinova M, Kolomaznik K, Nguyen TN, Dao AT. Technological-economic optimization of enzymatic hydrolysis used for the processing of chrome-tanned leather waste. Processes Saf Environ Prot. 2021;152:220–9. 10.1016/j.psep.2021.06.009.Search in Google Scholar

[4] Zeng S, Ren Y, Liu P, Wang Q, He L, Wang Q. Facile fabrication of chrome-tanned leather wastes/natural rubber composite: Mechanochemical de-crosslinking effect on collagen fibers and chrome complexation enabled in-situ compatibilization. Compos Sci Technol. 2021;214:108998. 10.1016/j.compscitech.2021.108998.Search in Google Scholar

[5] Long H, Huang X, Liao Y, Ding J. Recovery of Cr (vi) from tannery sludge and chrome-tanned leather shavings by Na2CO3 segmented calcination. J Environ Chem Eng. 2021;9(2):105026. 10.1016/j.jece.2021.105026.Search in Google Scholar

[6] Zhu R, Yang C, Li K, Yu R, Liu G, Peng B. A smart high chrome exhaustion and chrome-less tanning system based on chromium (iii)-loaded nanoparticles for cleaner leather processing. J Clean Prod. 2020;277:123278. 10.1016/j.jclepro.2020.123278.Search in Google Scholar

[7] Cao S, Song J, Li H, Wang K, Li Y, Li Y, et al. Improving characteristics of biochar produced from collagen-containing solid wastes based on protease application in leather production. Waste Manage. 2020;105:531–9. 10.1016/j.wasman.2020.02.043.Search in Google Scholar PubMed

[8] Liu B, Li Y, Wang Q, Bai S. Green fabrication of leather solid waste/thermoplastic polyurethanes composite: Physically de-bundling effect of solid-state shear milling on collagen bundles. Compos Sci Technol. 2019;181:107674. 10.1016/J.COMPSCITECH.2019.06.001.Search in Google Scholar

[9] Banerjee P, Madhu S, Babu NC, Shanthi C. Bio-mimetic mineralization potential of collagen hydrolysate obtained from chromium tanned leather waste. Mater Sci Eng C. 2015;49:338–7. 10.1016/j.msec.2015.01.027.Search in Google Scholar PubMed

[10] Luis AMD, Lombrana JI, Menédez A, Sanz J. Analysis of the toxicity of phenol solutions treated with H2O2/UV and H2O2/Fe oxidative systems. Ind Eng Chem Res. 2011;50(4):1928–7. 10.1021/ie101435u.Search in Google Scholar

[11] Padilha D, Wenzel BM, Marcilio NR, Silva ADB, Cavalcanti LP, Godinho M. Dephosphorization of chromium-rich ashes from thermally-treated leather waste for utilization in pyrometallurgical process. Int J Min Processes. 2012;114:63–8. 10.1016/j.minpro.2012.10.006.Search in Google Scholar

[12] Mahinroosta M, Allahverdi A. Hazardous aluminum dross characterization and recycling strategies: A critical review. J Environ Manage. 2018;223:452–8. 10.1016/j.jenvman.2018.06.068.Search in Google Scholar PubMed

[13] Shaikh MB, Arif S, Aziz T, Waseem A, Shaikh MA, Ali M. Microstructural, mechanical and tribological behaviour of powder metallurgy processed SiC and RHA reinforced Al-based composites. Surf Interfaces. 2019;15:166–9. 10.1016/j.surfin.2019.03.002.Search in Google Scholar

[14] Dwivedi SP, Dixit A, Bajaj R. Development of Bio-composite material by utilizing chrome containing leather waste with Al2O3 ceramic fragments. Mater Res Express. 2019;6(10):105105. 10.1088/2053-1591/ab3f8e.Search in Google Scholar

[15] Mandal A, Farhan K, Sastry TP. Effect of reinforced Al2O3 nanofragments on collagen nanobiocomposite from chrome-containing leather waste for biomedical applications. Clean Technol Environ. 2016;18(3):765–3. 10.1007/s10098-015-1045-3.Search in Google Scholar

[16] Dwivedi SP, Srivastava AK. Utilization of chrome containing leather waste in development of aluminium based green composite material. Int J Precis Eng Manuf – Green Technol. 2020;7(3):781–0. 10.1007/s40684-019-00179-1.Search in Google Scholar

[17] Sivasubramanian K, Raju S, Mohandas E. Estimating enthalpy and bulk modulus from thermal expansion data – a case study with α-Al2O3 and SiC. J Eur Ceram Soc. 2001;21(9):1229–5. 10.1016/S0955-2219(00)00323-X.Search in Google Scholar

[18] Pierson HO. Handbook of refractory carbides and nitrides (Properties, characteristics, processing and applications). 1st edn. Westwood, New Jersey: Noyes Publications; 1996.10.1016/B978-081551392-6.50017-9Search in Google Scholar

[19] Paris V, Frage N, Dariel MP, Zaretsky E. Divergent impact study of the compressive failure threshold in SiC and B4C. Int J Impact Eng. 2011;38(4):228–7. 10.1016/j.ijimpeng.2010.10.027.Search in Google Scholar

[20] Nazari A, Riahi S. Improvement compressive strength of concrete in different curing media by Al2O3 nanoparticles. Mater Sci Eng A. 2011;528(3):1183–1. 10.1016/j.msea.2010.09.098.Search in Google Scholar

[21] Cao F, Su S, Xiang J, Sun L, Hu S, Zhao Q, et al. Density functional study of adsorption properties of NO and NH3over CuO/γ-Al2O3 catalyst. Appl Surf Sci. 2012;261:659–4. 10.1016/j.apsusc.2012.08.077.Search in Google Scholar

[22] Souza TM, Luz AP, Brito MA, Pandolfelli VC. In situ elastic modulus evaluation of Al2O3–MgO refractory castables. Ceram Int. 2014;40(1):1699–7. 10.1016/j.ceramint.2013.07.066.Search in Google Scholar

[23] Wan Y, Gong J. Influence of TiC particle size on the load-independent hardness of Al2O3–TiC composites. Mater Lett. 2003;57(22–23):3439–43. 10.1016/S0167-577X(03)00096-X.Search in Google Scholar

[24] Tekeli S. The flexural strength, fracture toughness, hardness and densification behaviour of various amount of Al2O3-doped 8YSCZ/Al2O3 composites used as an electrolyte for solid oxide fuel cell. Mater Des. 2006;27(3):230–5. 10.1016/j.matdes.2004.10.011.Search in Google Scholar

[25] Yang B, Chen N, Hao G, Tian J, Guo K. Novel method to synthesize SiC nanowires and effect of SiC nanowires on flexural strength of Cf/SiC composite. Mater Des. 2013;52:328–31. 10.1016/j.matdes.2013.05.087.Search in Google Scholar

[26] Li J, Lin H, Li J. Factors that influence the flexural strength of SiC-based porous ceramics used for hot gas filter support. J Eur Ceram Soc. 2011;31(5):825–1. 10.1016/j.jeurceramsoc.2010.11.033.Search in Google Scholar

[27] Zhang M, Zhang W, Zhang Y, Gao L. Fabrication, microstructure and mechanical behavior of SiCw-B4C–Si composite. Mater Sci Eng A. 2012;552:410–4. 10.1016/j.msea.2012.05.062.Search in Google Scholar

[28] Maiti K, Sil A. Relationship between fracture toughness characteristics and morphology of sintered Al2O3 ceramics. Ceram Int. 2010;36(8):2337–4. 10.1016/j.ceramint.2010.07.031.Search in Google Scholar

[29] Leon-Patiño CA, Aguilar-Reyes EA, Braulio-Sánchez M, Rodríguez-Ortiz G, Bedolla-Becerril E. Microstructure and shear strength of sintered Cu–Al2O3 composite joined to Cu using Ag–Cu and Cu–Zn filler alloys. Mater Des. 2014;54:845–53. 10.1016/j.matdes.2013.09.011.Search in Google Scholar

[30] Tian H, Liu HT, Cheng HF. Mechanical and microwave dielectric properties of KD-I SiCf/SiC composites fabricated through precursor infiltration and pyrolysis. Ceram Int. 2014;40(7):9009–6. 10.1016/j.ceramint.2014.01.113.Search in Google Scholar

[31] Zhao S, Zhou X, Yu J, Mummery P. Mechanical properties and in situ crack growth observation of SiC/SiC composites. Ceram Int. 2014;40(5):7481–5. 10.1016/j.ceramint.2013.12.098.Search in Google Scholar

[32] Luo Z, Zhou X, Yu J. Mechanical properties of SiC/SiC composites by PIP process with a new precursor at elevated temperature. Mater Sci Eng A. 2014;607:155–61. 10.1016/j.msea.2014.03.011.Search in Google Scholar

[33] Fei YH, Huang CZ, Liu HL, Zou B. Mechanical properties of Al2O3–TiC–TiN ceramic tool materials. Ceram Int. 2014;40(7):10205–9. 10.1016/j.ceramint.2014.03.056.Search in Google Scholar

[34] Wang H, Li Y, Zhu T, Sang S, Wang Q. Microstructures and mechanical properties of Al2O3–C refractories with addition of microcrystalline graphite. Ceram Int. 2014;40(7):11139–48. 10.1016/j.ceramint.2014.03.139.Search in Google Scholar

[35] Mesa MC, Oliete PB, Pastor JY, Martín A, Llorca J. Mechanical properties up to 1900 K of Al2O3/Er3Al5O12/ZrO2eutectic ceramics grown by the laser floating zone method. J Eur Ceram Soc. 2014;34(9):2081–7. 10.1016/j.jeurceramsoc.2013.11.013.Search in Google Scholar

[36] Rehman SS, Ji W, Khan SA, Asif M, Fu Z, Wang W, et al. Microstructure and mechanical properties of B4C based ceramics with Fe3Al as sintering aid by spark plasma sintering. J Eur Ceram Soc. 2014;34(10):2169–75. 10.1016/j.jeurceramsoc.2014.02.014.Search in Google Scholar

[37] Du X, Zhang Z, Wang W, Wang H, Fu Z. Microstructure and properties of B4C-SiC composites prepared by polycarbosilane-coating/B4C powder route. J Eur Ceram Soc. 2014;34(5):1123–9. 10.1016/j.jeurceramsoc.2013.10.039.Search in Google Scholar

[38] Zhang Z, Du X, Li Z, Wang W, Zhang J, Fu Z. Microstructures and mechanical properties of B4C–SiC intergranular/intragranular nanocomposite ceramics fabricated from B4C, Si, and graphite powders. J Eur Ceram Soc. 2014;34(10):2153–1. 10.1016/j.jeurceramsoc.2014.02.032.Search in Google Scholar

[39] Zhang W, Gao L, Li J, Yang B, Yin Y. TiAl/B4C marine material–Fabrication, mechanical and corrosion properties. Ceram Int. 2011;37(3):783–9. 10.1016/j.ceramint.2010.10.019.Search in Google Scholar

[40] Wang L, Li J, Jin Y, Chen M, Luo J, Zhu X, et al. Study on the removal of chromium (iii) from leather waste by a two-step method. J Ind Eng Chem. 2019;79:172–80. 10.1016/j.jiec.2019.06.030.Search in Google Scholar

[41] Oliveira LC, Coura CV, Guimarães IR, Gonçalves M. Removal of organic dyes using Cr-containing activated carbon prepared from leather waste. J Hazard Mater. 2011;192(3):1094–9. 10.1016/j.jhazmat.2011.06.014.Search in Google Scholar PubMed

[42] Saikia P, Goswami T, Dutta D, Dutta NK, Sengupta P, Neog D. Development of a flexible composite from leather industry waste and evaluation of their physico-chemical properties. Clean Technol Environ Policy. 2017;19(8):2171–8. 10.1007/s10098-017-1396-z.Search in Google Scholar

[43] Mu Y, Zhou W, Wang H, Wang C, Qing Y. Mechanical and dielectric properties of 2.5D SiCf/SiC–Al2O3 composites prepared via precursor infiltration and pyrolysis. Mater Sci Eng A. 2014;596:64–0. 10.1016/j.msea.2013.12.040.Search in Google Scholar

[44] Huang S, Zhou W, Luo F, Wei P, Zhu D. Mechanical and dielectric properties of short carbon fiber reinforced Al2O3 composites with MgO additive. Ceram Int. 2014;40(2):2785–91. 10.1016/j.ceramint.2013.10.038.Search in Google Scholar

[45] Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci. 2001;46(1–2):1–4. 10.1016/S0079-6425(99)00010-9.Search in Google Scholar

[46] Ghadimi M, Shokuhfar A, Rostami HR, Ghaffari M. Effect of milling and annealing on formation and structural characterization of nanocrystalline intermetallic compound from Ni– Ti elemental powders. Mater Lett. 2012;80:181–3. 10.1016/j.matlet.2012.04.098.Search in Google Scholar

[47] Sharma P, Sharma S, Khanduja D. On the use of ball milling for the production of ceramic powders. Mater Manuf Processes. 2015;30(11):1370–6. 10.1080/10426914.2015.1037904.Search in Google Scholar

[48] Kumar S, Dwivedi S, Dwivedi VK. Synthesis and characterization of ball-milled eggshell and Al2O3 reinforced hybrid green composite material. J Met Mater Min. 2020;30(2):67–5. 10.14456/jmmm.2020.22.Search in Google Scholar

© 2022 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods

- Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

- Green synthesis of spinel copper ferrite (CuFe2O4) nanoparticles and their toxicity

- The effect of TaC and NbC hybrid and mono-nanoparticles on AA2024 nanocomposites: Microstructure, strengthening, and artificial aging

- Excited-state geometry relaxation of pyrene-modified cellulose nanocrystals under UV-light excitation for detecting Fe3+

- Effect of CNTs and MEA on the creep of face-slab concrete at an early age

- Effect of deformation conditions on compression phase transformation of AZ31

- Application of MXene as a new generation of highly conductive coating materials for electromembrane-surrounded solid-phase microextraction

- A comparative study of the elasto-plastic properties for ceramic nanocomposites filled by graphene or graphene oxide nanoplates

- Encapsulation strategies for improving the biological behavior of CdS@ZIF-8 nanocomposites

- Biosynthesis of ZnO NPs from pumpkin seeds’ extract and elucidation of its anticancer potential against breast cancer

- Preliminary trials of the gold nanoparticles conjugated chrysin: An assessment of anti-oxidant, anti-microbial, and in vitro cytotoxic activities of a nanoformulated flavonoid

- Effect of micron-scale pores increased by nano-SiO2 sol modification on the strength of cement mortar

- Fractional simulations for thermal flow of hybrid nanofluid with aluminum oxide and titanium oxide nanoparticles with water and blood base fluids

- The effect of graphene nano-powder on the viscosity of water: An experimental study and artificial neural network modeling

- Development of a novel heat- and shear-resistant nano-silica gelling agent

- Characterization, biocompatibility and in vivo of nominal MnO2-containing wollastonite glass-ceramic

- Entropy production simulation of second-grade magnetic nanomaterials flowing across an expanding surface with viscidness dissipative flux

- Enhancement in structural, morphological, and optical properties of copper oxide for optoelectronic device applications

- Aptamer-functionalized chitosan-coated gold nanoparticle complex as a suitable targeted drug carrier for improved breast cancer treatment

- Performance and overall evaluation of nano-alumina-modified asphalt mixture

- Analysis of pure nanofluid (GO/engine oil) and hybrid nanofluid (GO–Fe3O4/engine oil): Novel thermal and magnetic features

- Synthesis of Ag@AgCl modified anatase/rutile/brookite mixed phase TiO2 and their photocatalytic property

- Mechanisms and influential variables on the abrasion resistance hydraulic concrete

- Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites

- Achieving excellent oxidation resistance and mechanical properties of TiB2–B4C/carbon aerogel composites by quick-gelation and mechanical mixing

- Microwave-assisted sol–gel template-free synthesis and characterization of silica nanoparticles obtained from South African coal fly ash

- Pulsed laser-assisted synthesis of nano nickel(ii) oxide-anchored graphitic carbon nitride: Characterizations and their potential antibacterial/anti-biofilm applications

- Effects of nano-ZrSi2 on thermal stability of phenolic resin and thermal reusability of quartz–phenolic composites

- Benzaldehyde derivatives on tin electroplating as corrosion resistance for fabricating copper circuit

- Mechanical and heat transfer properties of 4D-printed shape memory graphene oxide/epoxy acrylate composites

- Coupling the vanadium-induced amorphous/crystalline NiFe2O4 with phosphide heterojunction toward active oxygen evolution reaction catalysts

- Graphene-oxide-reinforced cement composites mechanical and microstructural characteristics at elevated temperatures

- Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar

- Preparation of layered gradient Cu–Cr–Ti alloy with excellent mechanical properties, thermal stability, and electrical conductivity

- Recovery of Cr from chrome-containing leather wastes to develop aluminum-based composite material along with Al2O3 ceramic particles: An ingenious approach

- Mechanisms of the improved stiffness of flexible polymers under impact loading

- Anticancer potential of gold nanoparticles (AuNPs) using a battery of in vitro tests

- Review Articles

- Proposed approaches for coronaviruses elimination from wastewater: Membrane techniques and nanotechnology solutions

- Application of Pickering emulsion in oil drilling and production

- The contribution of microfluidics to the fight against tuberculosis

- Graphene-based biosensors for disease theranostics: Development, applications, and recent advancements

- Synthesis and encapsulation of iron oxide nanorods for application in magnetic hyperthermia and photothermal therapy

- Contemporary nano-architectured drugs and leads for ανβ3 integrin-based chemotherapy: Rationale and retrospect

- State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials

- Insights on magnetic spinel ferrites for targeted drug delivery and hyperthermia applications

- A review on heterogeneous oxidation of acetaminophen based on micro and nanoparticles catalyzed by different activators

- Early diagnosis of lung cancer using magnetic nanoparticles-integrated systems

- Advances in ZnO: Manipulation of defects for enhancing their technological potentials

- Efficacious nanomedicine track toward combating COVID-19

- A review of the design, processes, and properties of Mg-based composites

- Green synthesis of nanoparticles for varied applications: Green renewable resources and energy-efficient synthetic routes

- Two-dimensional nanomaterial-based polymer composites: Fundamentals and applications

- Recent progress and challenges in plasmonic nanomaterials

- Apoptotic cell-derived micro/nanosized extracellular vesicles in tissue regeneration

- Electronic noses based on metal oxide nanowires: A review

- Framework materials for supercapacitors

- An overview on the reproductive toxicity of graphene derivatives: Highlighting the importance

- Antibacterial nanomaterials: Upcoming hope to overcome antibiotic resistance crisis

- Research progress of carbon materials in the field of three-dimensional printing polymer nanocomposites

- A review of atomic layer deposition modelling and simulation methodologies: Density functional theory and molecular dynamics

- Recent advances in the preparation of PVDF-based piezoelectric materials

- Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review

- Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2

- Perspectives in biopolymer/graphene-based composite application: Advances, challenges, and recommendations

- Graphene-based nanocomposite using new modeling molecular dynamic simulations for proposed neutralizing mechanism and real-time sensing of COVID-19

- Nanotechnology application on bamboo materials: A review

- Recent developments and future perspectives of biorenewable nanocomposites for advanced applications

- Nanostructured lipid carrier system: A compendium of their formulation development approaches, optimization strategies by quality by design, and recent applications in drug delivery

- 3D printing customized design of human bone tissue implant and its application

- Design, preparation, and functionalization of nanobiomaterials for enhanced efficacy in current and future biomedical applications

- A brief review of nanoparticles-doped PEDOT:PSS nanocomposite for OLED and OPV

- Nanotechnology interventions as a putative tool for the treatment of dental afflictions

- Recent advancements in metal–organic frameworks integrating quantum dots (QDs@MOF) and their potential applications

- A focused review of short electrospun nanofiber preparation techniques for composite reinforcement

- Microstructural characteristics and nano-modification of interfacial transition zone in concrete: A review

- Latest developments in the upconversion nanotechnology for the rapid detection of food safety: A review

- Strategic applications of nano-fertilizers for sustainable agriculture: Benefits and bottlenecks

- Molecular dynamics application of cocrystal energetic materials: A review

- Synthesis and application of nanometer hydroxyapatite in biomedicine

- Cutting-edge development in waste-recycled nanomaterials for energy storage and conversion applications

- Biological applications of ternary quantum dots: A review

- Nanotherapeutics for hydrogen sulfide-involved treatment: An emerging approach for cancer therapy

- Application of antibacterial nanoparticles in orthodontic materials

- Effect of natural-based biological hydrogels combined with growth factors on skin wound healing

- Nanozymes – A route to overcome microbial resistance: A viewpoint

- Recent developments and applications of smart nanoparticles in biomedicine

- Contemporary review on carbon nanotube (CNT) composites and their impact on multifarious applications

- Interfacial interactions and reinforcing mechanisms of cellulose and chitin nanomaterials and starch derivatives for cement and concrete strength and durability enhancement: A review

- Diamond-like carbon films for tribological modification of rubber

- Layered double hydroxides (LDHs) modified cement-based materials: A systematic review

- Recent research progress and advanced applications of silica/polymer nanocomposites

- Modeling of supramolecular biopolymers: Leading the in silico revolution of tissue engineering and nanomedicine

- Recent advances in perovskites-based optoelectronics

- Biogenic synthesis of palladium nanoparticles: New production methods and applications

- A comprehensive review of nanofluids with fractional derivatives: Modeling and application

- Electrospinning of marine polysaccharides: Processing and chemical aspects, challenges, and future prospects

- Electrohydrodynamic printing for demanding devices: A review of processing and applications

- Rapid Communications

- Structural material with designed thermal twist for a simple actuation

- Recent advances in photothermal materials for solar-driven crude oil adsorption

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete