Abstract

Two-dimensional (2D) nanomaterial-reinforced polymer composites exhibit superior properties and multifunctional applications. Compared to lower dimensional nanomaterials such as nanotubes and nanoparticles, 2D nanomaterials show a larger surface area. The large surface area makes 2D nanomaterials more effectively restrict the mobility of polymer chains and yields better reinforcing efficiency than the lower-dimensional nanomaterials. To gain an in-depth understanding and extend the applications of polymer composites reinforced with 2D nanomaterials, this paper reviews the progress in the fundamentals of synthesis and applications of such composites. The motivation and improvement of adding 2D nanomaterials to polymer materials are introduced first, followed by the synthesis approaches and the properties of typical 2D nanomaterials, including graphene, boron nitride nanosheet, and molybdenum disulfide nanosheet. Based on the properties of 2D nanomaterials, polymer composites reinforced with different types of 2D nanomaterials are designed for structural application, thermal dissipation application, tribological application, three-dimensional printing composite structures, and strain sensing application. Afterwards, the significance of reinforcement–matrix interaction and its improving approach are reviewed. The current progress envisions that polymer composites reinforced with 2D nanomaterials can be used in the fields of aviation and aerospace for improving radiation shielding capacity and nanomedical engineering.

Abbreviations

- 2D

-

two-dimensional

- 3D

-

three-dimensional

- BNNS

-

boron nitride nanosheet

- GO

-

graphene oxide

- HPAM

-

hydrolyzed polyacrylamide

- PEO

-

poly(ethylene oxide)

- PET

-

polyethylene terephthalate

- PLA

-

Polylactic acid

- PMMA

-

polymethyl methacrylate

- PS

-

polystyrene

- PUB

-

polyurethane binder

- PVA

-

polyvinyl alcohol

- PVDF

-

poly(vinylidene fluoride)

- rGO

-

reduced graphene oxide

- SU-8

-

epoxy-based photoresist

- UHMWPE

-

ultra-high molecular weight polyethylene

1 Introduction

Various types of nanomaterials have been used to modify the properties of polymer materials in previous research because pristine polymer materials lack high mechanical properties [1,2], thermal conductivity [3], and thermal stability [4]. Compared with conventional fibers, adding nanomaterials to polymer materials gives polymer composites better mechanical properties [5,6,7] and thermal and electrical conductivity [8,9]. Hence, polymer composites reinforced with nanomaterials have broad applications in practice such as military equipment [10,11], safety [12], protective clothing [12,13], automotive [14,15], aerospace [14,15,16], electronics [14,15,17], optical devices [14,16], medical devices [14], and constructions and buildings [18]. For a detailed discussion of the application of 2D nanomaterials for military equipment and protective clothing, the reader is advised to refer to a recent review article [19]. It is reported that the lower dimensional nanomaterials (i.e. nanotubes [20,21,22,23,24] and nanoparticles [25,26,27,28]) can improve the properties of the polymer. However, two-dimensional (2D) nanomaterials (i.e. nanosheets) exhibit a larger surface area than lower dimensional nanomaterials. The larger surface area provides more robust interfacial properties between 2D nanomaterials and polymer materials than those between lower dimensional nanomaterials and polymer materials. Therefore, 2D nanomaterials show a better reinforcing efficiency in properties of polymer materials than that of lower dimensional nanomaterials. For example, the thermal conductivity of pristine epoxy is increased by 133, 217, and 339% with the addition of 3 vol% (a volume fraction of 3%) boron nitride nanoparticles, boron nitride nanotubes, and boron nitride nanosheets (BNNS), respectively [29]. With the addition of 2D nanomaterials to polymer materials, the polymer composites show excellent performance and broad applications in practice.

The polymer composites exhibit advanced properties after curing owing to the admixture of 2D nanomaterials with polymer materials [30,31,32,33,34]. The mechanical properties [35,36,37], optical properties [38,39,40], thermal conductivity [41,42,43], electrical conductivity [37,44,45], and corrosion resistance [46,47] of polymer materials can be boosted by adding proper 2D nanomaterials. For example, with the addition of 0.3 wt% BNNS to polymethyl methacrylate (PMMA), the elastic modulus and the strength of PMMA are increased by 22 and 11%, respectively [35]. Besides, the transition temperature of PMMA is increased from 69 to 72°C [35]. The improvement made by 2D nanomaterials in the properties of polymer composites is dependent on the advanced physical properties of the 2D nanomaterials. 2D nanomaterials such as graphene and BNNS possess higher mechanical properties, thermal conductivity, and thermal stability than pristine polymer materials. Hence, it is expected that adding these 2D nanomaterials to polymer materials will improve the properties of polymer composites. However, the reinforcing efficiency of 2D nanomaterials in the properties of polymer composites is significantly dependent on the interfacial interaction between 2D nanomaterials and polymer materials. For example, the interface between BNNS and polymer materials accounts for the thermal conductivity of polymer composite [48]. Defects (e.g. voids and pores) at the reinforcement–matrix interface lead to ineffective thermal conduction in polymer composites [49,50]. To improve the interfacial interaction between 2D nanomaterials and polymer materials, the functionalization of 2D nanomaterials is adopted. The functionalized 2D nanomaterials present significant improvements in the properties of the polymer composites [34,51,52,53,54,55,56,57]. With the development of nanotechnology, various types of 2D nanomaterial-reinforced polymer composites are being designed and manufactured. These multifunctional polymer composites can be used in different fields. To utilize these polymer composites efficiently to meet the practical demands, it is of interest to specify their properties and applications.

This article aims to review the properties and applications of polymer composites reinforced with 2D nanomaterials. The applications of different types of 2D nanomaterial-reinforced polymer composites are summarized. We selected widely used 2D nanomaterials, such as graphene, BNNS, and molybdenum disulfide (MoS2) nanosheet, as the typical materials. For these typical 2D nanomaterials, scalable synthesis is of great interest for practical application. Two types of synthesis approaches (i.e. the bottom-up approach and the top-down approach) were developed to produce the 2D nanomaterials. Based on these two approaches, different exfoliation techniques were used to prepare the nanomaterials on a large scale. Due to the development of synthesis techniques and the superior properties of 2D nanomaterials, 2D nanomaterials are widely used in practice for structural engineering, thermal dissipation, three-dimensional (3D) printing techniques, and strain sensing. In view of the fact that the interface between the reinforcement and matrix influences the properties of polymer composite reinforced with 2D nanomaterials, the significance of the reinforcement–matrix interaction is discussed. The effect of the functionalization of 2D nanomaterials on the improvement of the properties of the polymer composites is evaluated. The comprehensive knowledge of the fundamentals and the application of 2D nanomaterials in reinforcing polymer materials accelerates the development of reinforced composites. This development is of interest in terms of overcoming the shortcomings of the existing materials in engineering.

2 Fundamentals of the synthesis and physical properties of 2D nanomaterials

2.1 Synthesis of 2D nanomaterials

The synthesis of 2D nanomaterials can be divided into the bottom-up approach [58,59,60,61] and the top-down approach [62,63,64,65]. The bottom-up approach involves chemical/physical vapor deposition, molecular beam/atomic layer epitaxy, and chemical synthesis. This approach requires harsh reaction conditions and shows a low production rate in the fabrication of 2D nanomaterials [66,67,68]. The top-down approach involves chemical exfoliation and physical exfoliation. This approach is capable of producing scalable 2D nanomaterials in ambient conditions [67]. To have a comprehensive understanding of the synthesis approaches of 2D nanomaterials, a summary of different synthesis approaches is presented in Table 1. As the top-down approach is straightforward, cost-effective, and productive, this approach is widely used to fabricate 2D nanomaterials [69,70,71], which involves mechanical exfoliation, liquid-phase exfoliation, and electromechanical exfoliation.

A summary of the bottom-up approach and top-down approach for synthesizing 2D nanomaterials

| Synthesis approaches | Bottom-up approach | Top-down approach | |||

|---|---|---|---|---|---|

| Chemical/physical vapor deposition | Molecular beam/atomic layer epitaxy | Chemical synthesis | Chemical exfoliation | Physical exfoliation | |

| Advantages | (a) The resolution of nanosheets can be controlled to distinguish the angstrom-level difference [72] | (a) The top-down approach is able to address the precise locations and sizes of nanosheets [74] | |||

| (b) The stacking number of nanosheets can be controlled by the bottom-up approach [73] | (b) The top-down approach is simple, straightforward, and cost-effective [69,70,71] | ||||

| Limitations | (a) The bottom-up approach is slow, laborious, and expensive owing to the requirements of aggressive reaction conditions (e.g. high energy, reduced atmosphere, and long reaction period) [74,75] | (a) The sizes of nanosheets prepared by the top-down approach are limited by the size of the starting materials [75] | |||

| (b) It is less precise to place nanosheets prepared by the top-down approach in the expected location [76] | (b) The stabilization of nanosheets prepared by the top-down approach is low, resulting in restacking of nanosheets [73,77] | ||||

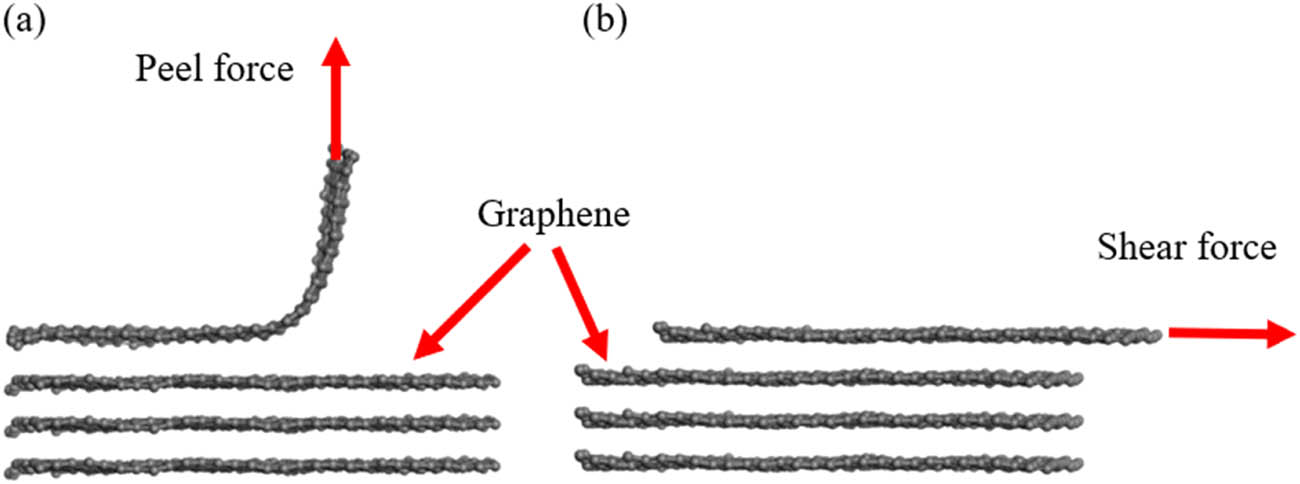

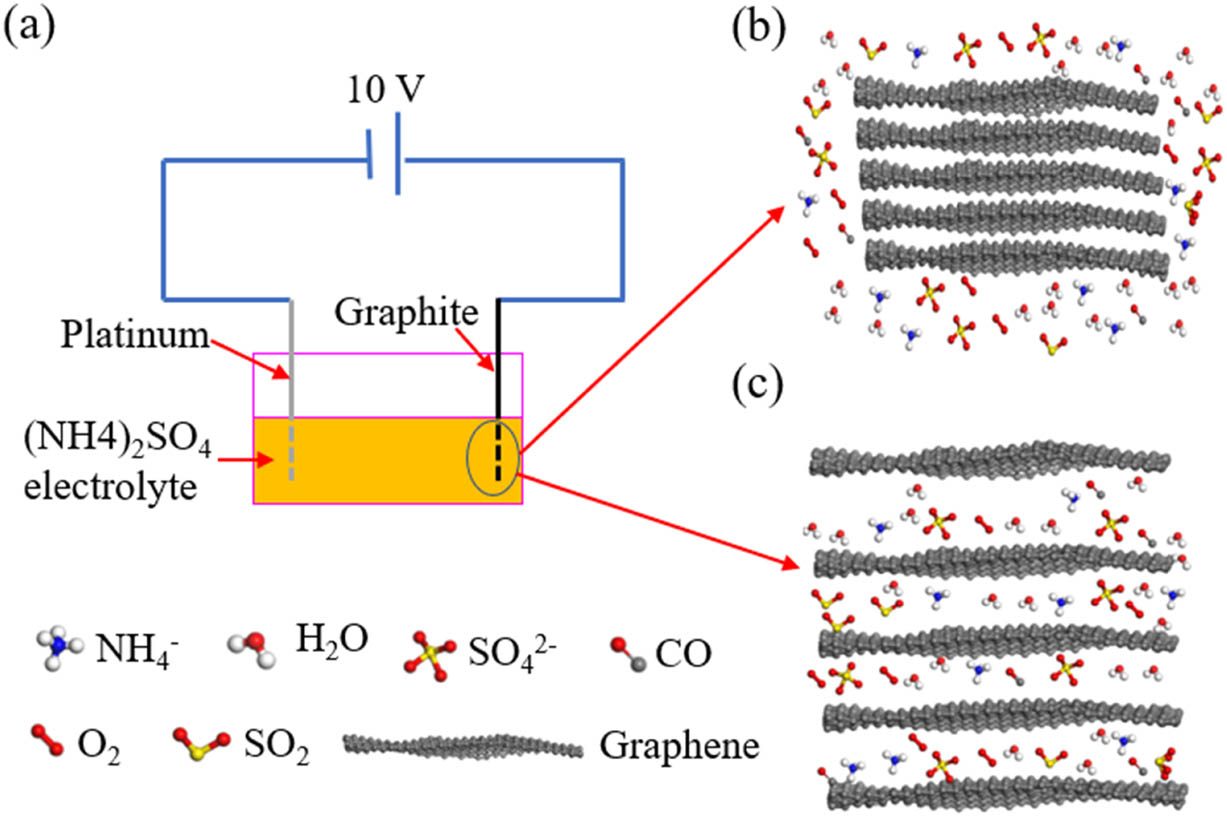

Graphene is one of the most prevailing 2D nanomaterials; it was first synthesized by exfoliating oriented pyrolytic graphite in 2004 [78]. As exfoliation methods are productive and low cost, various types of exfoliation methods such as mechanical exfoliation [79,80], liquid-phase exfoliation [81,82], and electrochemical exfoliation [83,84,85] have been proposed to prepare graphene. The schematics of mechanical exfoliation are shown in Figure 1. The peel force in Figure 1(a) and shear force in Figure 1(b) are applied to the layer of graphene to overcome the van der Waals interaction between adjacent graphene [80,86]. As a result, the single layer of graphene is obtained by micromechanical cleavage [78,87,88] and balling milling methods [89,90]. The liquid-phase exfoliation is also an efficient way to synthesize 2D nanomaterials. For example, after the dispersion of graphite in organic solvents, the ultrasonication process is performed. The shear force induced by ultrasonication is applied to the bulk graphite. Due to the existence of cavitation in the bulk graphite, some voids in the bulk graphite are expanded under external shear force. As a result, graphene is exfoliated from bulk graphite [81,82]. Figure 2 shows the mechanism of electrochemical exfoliation for preparing graphene in the (NH4)2SO4 aqueous solution [91]. By applying a constant bias voltage to the graphite electrodes, the water is reduced, creating hydroxyl ions in the electrolytes at the edge and the boundary of graphite, as shown in Figure 2(a) and (b). As a result, oxidation resulting from the attack of hydroxyl ions leads to expansion of the edge and boundaries of the graphite. This expansion allows

Schematics of mechanical exfoliation to obtain a single layer of graphene by applying (a) peel force and (b) shear force.

Electrochemical exfoliation of graphene in (NH4)2SO4 aqueous solution. (a) The bias voltage is applied on the graphite electrodes in the (NH4)2SO4 aqueous solution. (b) The attack of ions results in the expansion of graphite on the edge and boundary, which allows

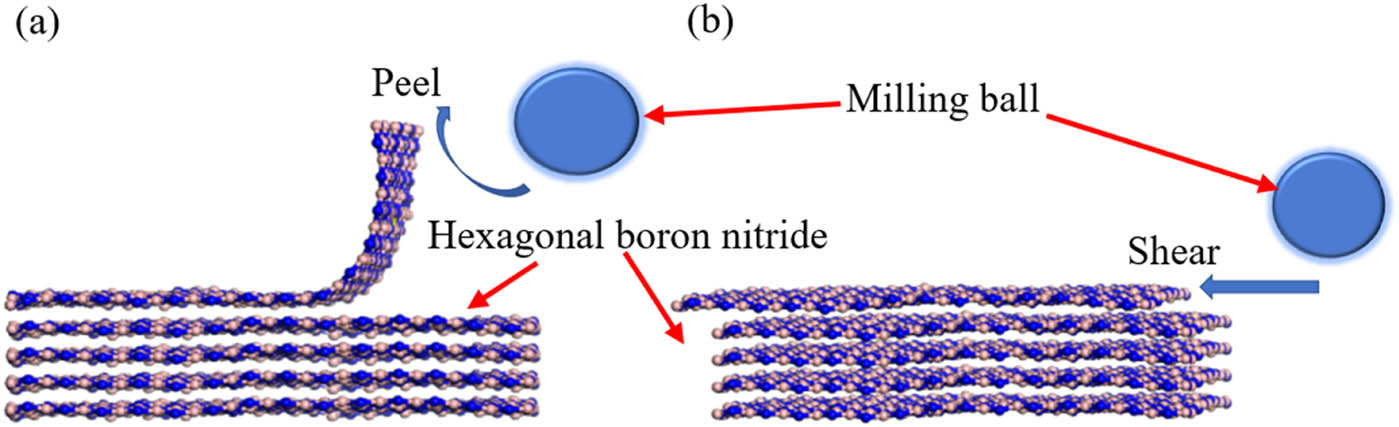

BNNS, as an analog of graphene, is termed “white graphene” because of its white appearance [94]. The available exfoliation methods for preparing BNNS are mechanical exfoliation, liquid-phase exfoliation, and electrochemical exfoliation. The first isolation of BNNS was exfoliated by mechanical cleavage in 2008 [95]. Following this, different types of mechanical exfoliation techniques were developed. Figure 3 shows the mechanisms of exfoliating BNNS by ball milling [96]. Ball milling is a shear force-dominant process used to exfoliate BNNS from bulk boron nitride materials. When the metallic balls, grinding media, and bulk boron nitride materials are placed in the rotating shell, the bulk boron nitride materials are splintered by the shear force and peel force created by the metallic rotating balls [97,98]. As a result, the van der Waals interaction between adjacent BNNS in bulk boron nitride materials is overcome, which yields one-atom-thick BNNS. To avoid damage to the structure of BNNS, the exfoliation method is improved by adopting controllable balling, small milling media, and appropriate milling media types as lubrication during the milling process [99]. In addition, atomic force microscope tips are employed to delaminate the multilayers of boron nitride flakes based on mechanical exfoliation. Furthermore, a mechanochemically delaminated method and ion intercalation–assisted electrochemical exfoliation are used to prepare BNNS.

Schematics of exfoliating BNNS from hexagonal boron nitride under (a) peel force and (b) shear force created by the metallic balls in the rotating shell.

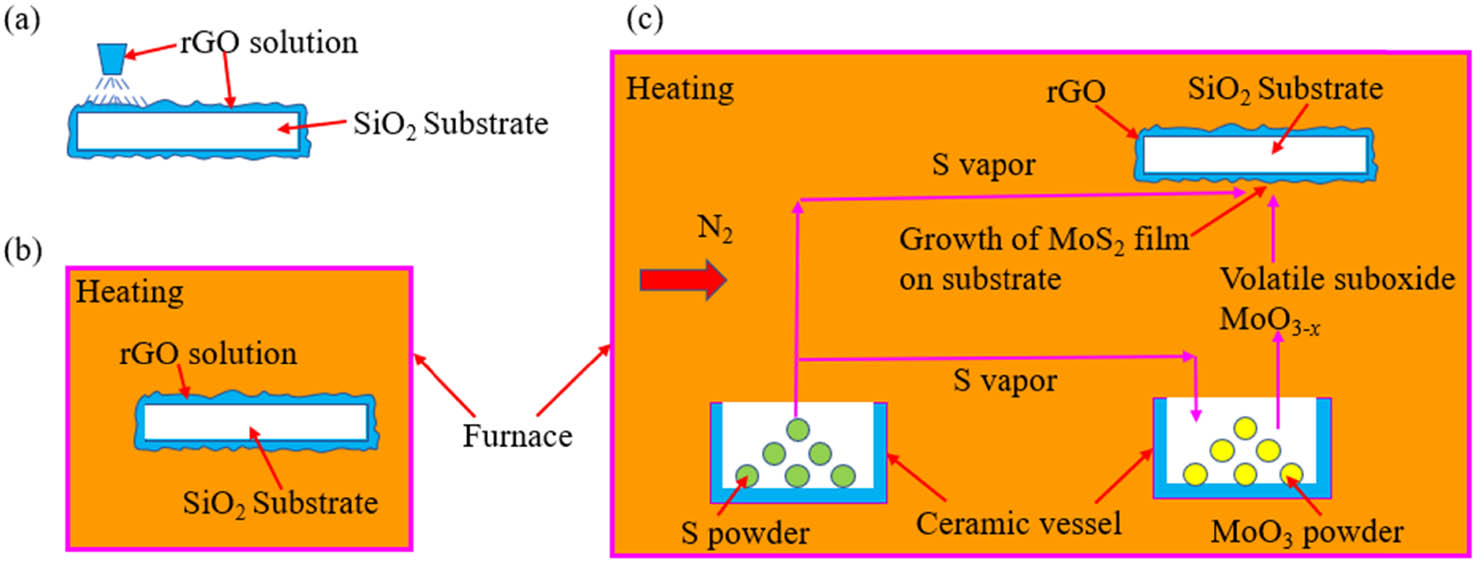

Transition metal dichalcogenide nanosheets, including MoS2 nanosheet and tungsten disulfide nanosheet, can also be synthesized by mechanical exfoliation. However, as mechanical exfoliation uses a decent microscope and adhesive tape to prepare nanosheets, it cannot produce 2D nanomaterials on a large scale [100]. The liquid-phase exfoliation method, in contrast, can be used to produce 2D nanomaterials on a large scale; however, this exfoliation method shows a significant overlap in the transition metal dichalcogenide flakes and the in-plane resistance of transition metal dichalcogenide film [100,101]. Hence, neither mechanical exfoliation nor liquid-phase exfoliation is widely used for the synthesis of transition metal dichalcogenide nanosheets. Instead, the molecular beam epitaxy, chemical vapor deposition, and chemical vapor deposition-related methods are used to prepare transition metal dichalcogenide nanosheets. Chemical vapor deposition is one of the most practical methods for synthesizing transition metal dichalcogenide nanosheets such as molybdenum disulfide (MoS2) nanosheets [100,102]. In contrast to molecular beam epitaxy, the ultrahigh vacuum chamber is not required in chemical vapor deposition. Hence, the chemical vapor deposition is cheap and compatible with the existing synthesis process [100,103]. The first report on synthesis based on chemical vapor deposition yielded multilayers of MoS2 nanosheet [104]. To control the thickness of the MoS2 nanosheet, chemical vapor deposition using sulfur and molybdenum oxide powders is used to yield the growth of the MoS2 nanosheet on the SiO2 substrate [105,106]. The principle for synthesizing MoS2 nanosheet using chemical vapor deposition is presented in Figure 4. Before the synthesis of the MoS2 nanosheet, the reduced graphene oxide (rGO) solution is spined on the surface of the SiO2 substrate, as shown in Figure 4(a). Subsequently, the SiO2 substrate with rGO solution is dried in a furnace at 50°C, as shown in Figure 4(b). The SiO2 substrate is then placed in a furnace with sulfur (S) powder and molybdenum oxide (MoO3) powder at 650°C in a nitrogen environment, as shown in Figure 4(c). In Figure 4(c), the S powder and MoO3 powder are placed in two separate ceramic vessels. At the temperature of 650°C, the S vapor is carried by the nitrogen gas to react with the MoO3 powder, yielding volatile suboxide MoO3−x compound. SiO2 substrate is placed on top of the ceramic vessel with the MoO3 powder and faced with the MoO3 powder. Hence, the volatile suboxide MoO3−x compound can react with the S vapor on the surface of the SiO2 substrate. As a result, the reaction product (i.e. MoS2 film) grows on the surface of the SiO2 substrate.

The principle of chemical vapor deposition for synthesizing MoS2 nanosheet based on the reaction between sulfur (S) and molybdenum oxide (MoO3) at elevated temperature. (a) The rGO solution is spun on the surface of the SiO2 substrate. (b) The rGO solution is dried in a furnace at 50°C. (c) The sulfur (S) powder and molybdenum oxide (MoO3) powder are put in a furnace at 650°C in a nitrogen environment.

2.2 Structures and properties of 2D nanomaterials

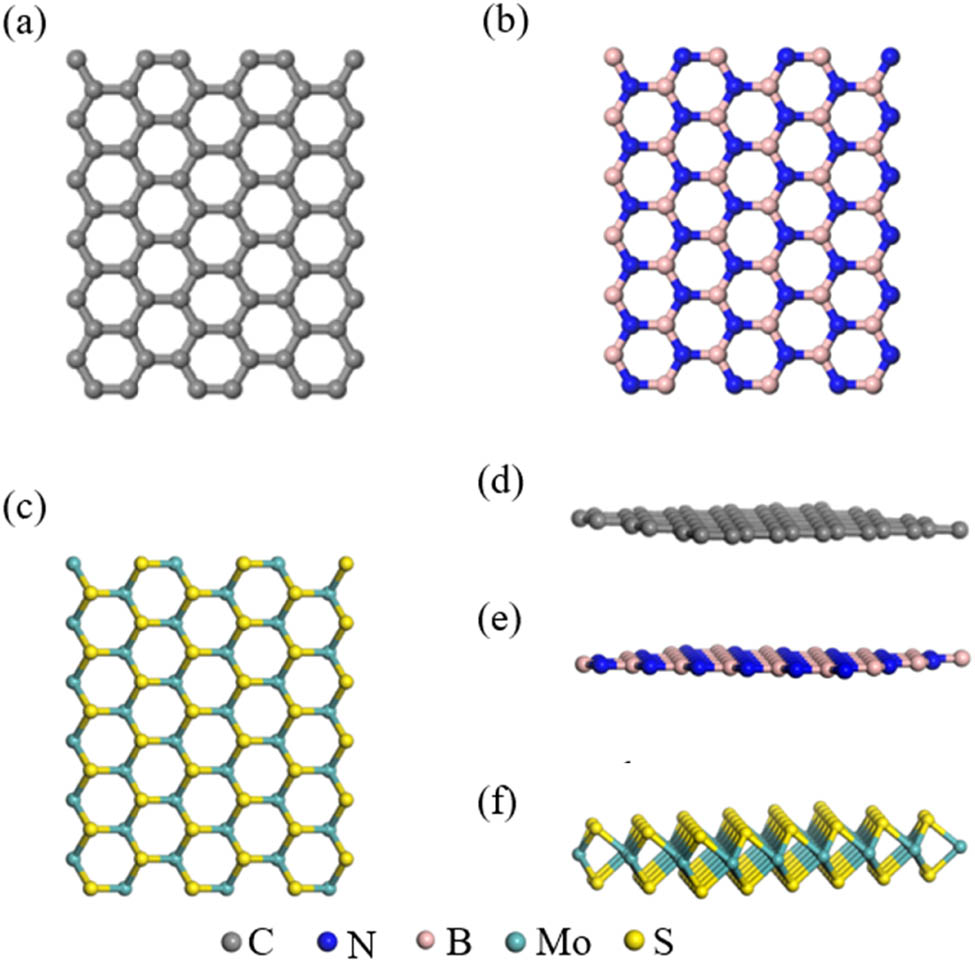

The structures and properties of typical 2D nanomaterials are significantly different, which results in different applications of polymer composites reinforced with 2D nanomaterials. Figure 5 shows the in-plane structure and lateral structure of graphene, BNNS, and MoS2 nanosheet. Graphene is structurally similar to BNNS, as shown in Figure 5(a)–(d), and the boron–nitrogen bonds in BNNS are polarized, offering a partial ionicity [107]. Hence, the boron atoms and nitrogen atoms are partially charged. The partially charged atoms in BNNS exhibit electrostatic interaction with polymer materials, while the carbon atoms in graphene exhibit no partial ionicity. The presence of van der Waals interaction and electrostatic interaction between BNNS and polymer materials is advantageous as it allows the BNNS to form robust interfacial interaction with the polymer materials [33]. As a result, BNNS shows more robust interaction with polymer materials than graphene [108]. Besides, for the multilayered BNNSs, the interlayer interaction between adjacent BNNSs differs from graphene. It is reported that the interlayer shear modulus and bending rigidity of multilayered BNNSs are approximately three times as large as those of graphene, which is attributed to the robust interlayer interaction between polarized boron and nitrogen atoms restricting the interlayer shear sliding of multilayered BNNSs [109,110]. For MoS2 nanosheet, its in-plane structure is similar to that of BNNS and graphene. However, the lateral structure of MoS2 nanosheet is totally different from BNNS and graphene. BNNS and graphene possess flat planes in the lateral view, while MoS2 nanosheet presents a sandwich structure in the lateral view, as shown in Figure 5(d)–(f). The Mo-atom layer is sandwiched by two S-atom layers forming the weak sandwich structure [111]. The S–Mo–S sandwich structure is assembled due to van der Waals interaction. The weak interlayer interaction between sandwich structures results in relative sliding between the layers [111,112].

The in-plane structures of (a) graphene, (b) BNNS, and (c) MoS2 nanosheet, and the lateral structure of (d) graphene, (e) BNNS, and (f) MoS2 nanosheet.

The physical properties of graphene, BNNS, and MoS2 nanosheets are different, as presented in Table 2. These three types of 2D nanomaterials show excellent thermal stability, as indicated by the oxidation resistance in Table 2. Young’s modulus of graphene and BNNS are comparable; they are larger than that of MoS2 nanosheet. However, Young’s modulus and tensile strength of MoS2 nanosheet are still much higher than those of conventional materials (e.g. steel). The thermal conductivity of graphene is superior, as presented in Table 2. Hence, graphene is a good candidate for improving the thermal dissipation of polymer materials. However, the bandgap of graphene is close to zero, indicating that it is electrically conductive. Hence, graphene cannot be used in the thermal dissipation of electronics, where dielectricity of reinforcement is required. Instead, BNNS with a high value of bandgap indicates its insulating characteristic. In addition, the bandgap of MoS2 is tunable under mechanical strain. Hence, the electrical conductivity of MoS2 nanosheet can be modulated due to the changing strain of the nanosheet [113]. MoS2 nanosheet’s coupling of electrical conductivity with mechanical properties provides the potential for developing a polymer composite sensor reinforced with this nanosheet.

3 Applications of polymer composites reinforced by 2D nanomaterials

3.1 Structural application

2D nanomaterials (e.g. graphene [119,120], BNNS [121], and MoS2 nanosheet [122,123]) exhibit excellent tensile strength and Young’s modulus. With the addition of BNNS to polymer materials, it is expected that the tensile strength and Young’s modulus of polymer materials can be significantly improved. The simple estimation of Young’s modulus of 2D nanomaterial-reinforced polymer composites is shown in equation (1).

where E C is Young’s modulus of the polymer composite, E m is Young’s modulus of the matrix, E f is Young’s modulus of reinforcement, V m is the volume fraction of the matrix, and V R = 1 − V M is the volume fraction of the nanofiller. This simple model for estimating Young’s modulus can be used to determine the upper bound of Young’s modulus of a polymer composite reinforced with 2D nanomaterials. The lower bound of Young’s modulus of a polymer composite reinforced with 2D nanomaterials is calculated by equation (2).

The excellent reinforcing efficiency of 2D nanomaterials in the static mechanical properties of polymer materials, as shown in Table 3. Specifically, with the addition of 2D nanomaterials, the improvement of Young’s modulus and tensile strength of polymer materials are in the range of 14–71 and 11–130%, respectively. For PVA, the addition of graphene shows better reinforcing efficiency in Young’s modulus than that of BNNS and MoS2 nanosheet, while the addition of MoS2 nanosheet to polymers shows better reinforcing efficiency in tensile strength than that of graphene and BNNS. The improvement of Young’s modulus of the polymer composites is attributed to the intrinsic superior Young’s modulus of these 2D nanomaterials. With the addition of a reinforcement that has a higher Young’s modulus than that of the matrix, the polymer composites gain a higher Young’s modulus than that of the matrix materials. The tensile strength of polymer composites reinforced with 2D nanomaterials is attributed to the efficient stress transfer at the reinforcement–matrix interface [129]. Specifically, nanosheet adsorbs polymer chains and restricts the motion of polymer chains due to the interfacial interaction between nanosheets and polymer materials [130]. Therefore, the tensile strength of polymer composite reinforced with 2D nanomaterials is significantly improved. Furthermore, adding nanosheets to polymer materials reduces the formation of microscale voids in polymer materials. Voids in polymer materials evolve into defects under tension, which weakens the tensile strength of pristine polymer materials [131]. However, adding 2D nanomaterials to polymer materials yields densified structures. It is reported that there are microscale voids in pristine poly(ethylene oxide) (PEO), whereas there is no visible microscale void in PEO reinforced with MoS2 nanosheet under the same magnification. The experimental observation indicates that adding MoS2 nanosheet to PEO refines the microstructure and reduces the defects in PEO composites [132]. The scanning electron microscope figures are provided in ref. [132]. As a result, the tensile strength of the polymer composite is significantly improved. While the reinforcing efficiency of 2D nanomaterials in static mechanical properties of polymer composites is very good, the reinforcing efficiency of 2D nanomaterials in the dynamic properties of polymer composites is not studied in the aforementioned research. The dynamic properties of polymer composite are very important because the resistance of polymer composite to dynamic loads exhibits good durability and impact protection in case of a car crash, bird striking of the plane, ship collision, etc. Hence, the dynamic properties of 2D nanomaterial-reinforced polymer composites are reviewed.

Mechanical improvement of polymer materials reinforced by typical 2D nanomaterials

| Polymer materials | 2D nanomaterials (weight fraction) | Young’s modulus (improvement) | Tensile strength (improvement) |

|---|---|---|---|

| Epoxy [124] | Graphene (2%) | 2 GPa (58%) | 55 MPa (130%) |

| UHMWPE [125] | Graphene (1%) | 1.24 GPa (44%) | 22.2 MPa (76%) |

| PMMA [35] | BNNS (0.3%) | 2.13 GPa (22%) | ∼42 MPa (11%) |

| PVA [126] | Graphene (0.4%) | 8.2 GPa (71%) | 110 MPa (16%) |

| PVA [127] | BNNS (0.8%) | 2.69 GPa (17%) | 91 MPa (18%) |

| PVA [128] | MoS2 nanosheet (0.25%) | 3.2 GPa (14%) | 127 MPa (18%) |

2D nanomaterials are added to fiber-reinforced polymer composites for improving the dynamics properties of polymer composites [133,134]. The fiber-reinforced polymer composite is widely used in automobiles, planes, ship structures, etc., due to its lightweight characteristic and high mechanical performance [135,136]. However, the fiber-reinforced polymer composites (e.g. carbon fiber-reinforced epoxy composite) show brittle nature. As a result, the carbon fiber-reinforced epoxy composite, for example, shows a sharp drop in stress–strain curves with low-energy absorption capacity [137]. This brittleness of polymer composite decreases impact protection of polymer composite structures in case of the aforementioned car crash, bird striking of the plane, ship collision, etc. 2D nanomaterial-reinforced polymer composite exhibits excellent fracture toughness [137,138], which makes 2D nanomaterials attractive candidates for improving the impact resistance of fiber-reinforced polymer composites. It is reported that the mode II interlaminar fracture toughness of carbon fiber-reinforced epoxy composite is increased by 46.7% with the addition of 2% (weight fraction) nanosheets owing to the crack deflection when the cracks encounter the nanosheets [139]. With the improvement of 2D nanomaterials in the fracture toughness of polymer composite, the impact protection of composite structures made of carbon fiber-reinforced polymer composites can be significantly increased. The picture of 2D nanomaterial-reinforced polymer composite structures is shown in Figure 17 in ref. [140].

3.2 Thermal dissipation

The development of miniaturization has required high thermal dissipation of various products (e.g. the battery units in electric vehicles and central processing units in smartphones and tablets) in the pursuit of high performance, reliability, longevity, and safety [141,142,143]. However, the materials used for thermal transport in electric vehicles and smartphones exhibit low thermal conductivity. The thermal conductivity of most polymer materials ranges from 0.1 to 0.5 W m−1 K−1 [144]. Various types of 2D nanomaterials show the potential to improve the thermal transport of polymer materials, owing to their superior thermal conductivity and thermal stability [145,146,147]. Furthermore, 2D nanomaterials form efficient heat-conducting paths across polymer materials at low volume fractions due to the large surface area of the 2D nanomaterials [148]. One typical example is graphene, which has superior thermal conductivity and thermal stability, as presented in Table 2. It is worth noting that graphene presents a zero value at the bandgap, indicating that it is an excellent electric conductor. Adding excellent electric conductors such as graphene to polymer materials can increase the electrical conductivity of polymer composites. Hence, graphene-reinforced polymer composites are unsuitable to be used in electronics, as it is necessary to avoid short circuits. However, BNNS displays electrical insulation, thermal stability, and good thermal conductivity [149]. Hence, it is a perfect candidate for improving thermal transport in electronics and electric vehicles.

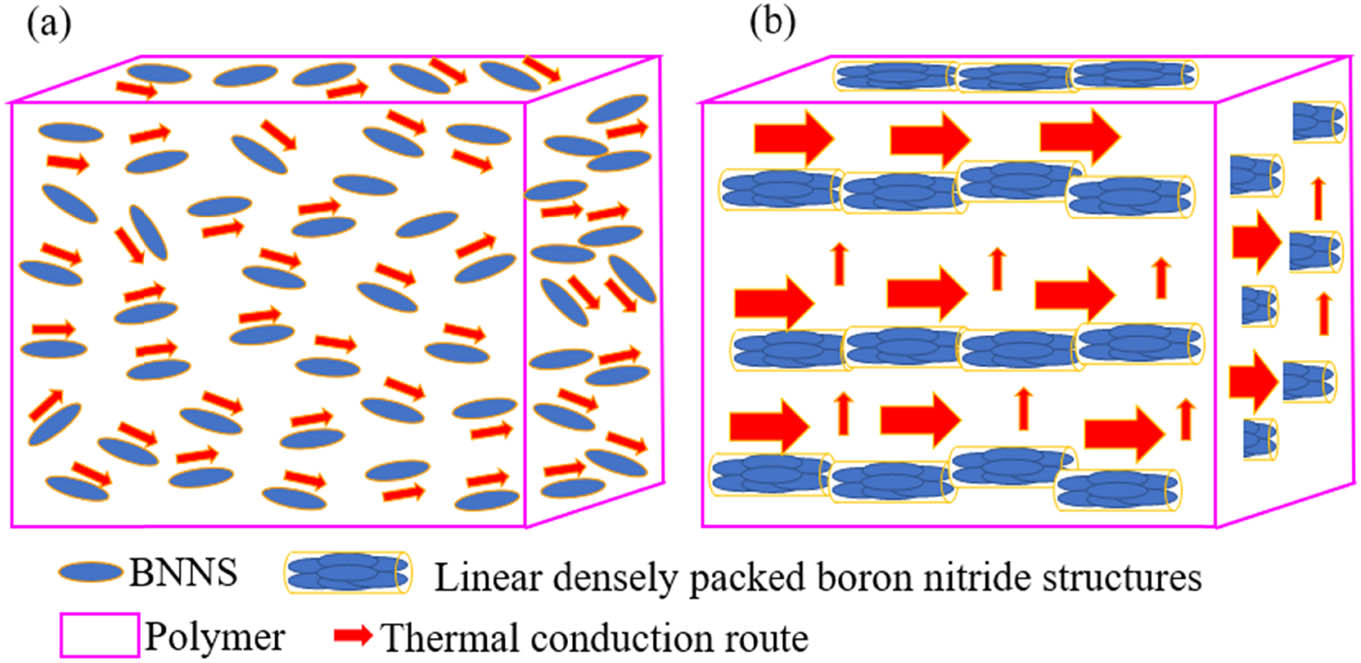

The thermal transport of polymer composites reinforced with 2D nanomaterials has been studied in previous studies [150,151]. The picture of 2D nanomaterial-reinforced polymer composite products for thermal management is shown in Figure 5 in ref. [152]. It is reported that the conductivity of epoxy is increased from ∼0.2 to ∼1.5 W m−1 K−1 by adding graphene at a proportion of 2.8 vol% [150]. The thermal conductivity of these polymer composites is significantly dependent on the polymer materials due to the high content of these polymer materials in the composites. As a result, the thermal conductivity of epoxy composite reinforced with graphene is still much lower than that of graphene with thermal conductivity of 2,600 W m−1 K−1. To take advantage of the thermal conductivity of 2D nanomaterials, the proportion of 2D nanomaterials should be increased. By increasing the amount of 2D nanomaterials in polymer composites, the thermal conductivity of polymer composites will be significantly increased. For example, the in-plane thermal conductivity of BNNS-reinforced poly(diallyl dimethyl ammonium chloride) is increased from ∼0 to 220 W m−1 K−1 when the proportion of BNNS content is increased from 0 to 90% [152]. In the existing literature, it is reported that the ordered alignments of reinforcement in polymer significantly optimize the heat transfer from the 2D nanopaper to shape memory polymer resin [153]. For further improvement of the thermal conductivity of polymer composites, BNNSs, for example, are aligned to form linear densely packed boron nitride structures in polymer materials, as shown in Figure 6. The linear densely packed boron nitride structure–reinforced polymer composite transports the heat in the polymer materials through the thermal conduction routes. However, the thermal dissipation of 2D nanomaterial-reinforced polymer composites has some limitations. The limitations of two-dimensional nanomaterials in thermal dissipation include the anisotropic thermal conductivity, the interfacial thermal resistance, and the interfacial phonon scattering induced by defects and mismatches at the reinforcement–matrix interface. While the linear densely packed boron nitride structures in the polymer can effectively increase the thermal transport along the thermal conduction routes, as shown in Figure 6, the thermal conductivity in the direction of perpendicular to the thermal conduction routes is still very low. It is expected that a network structure can be inserted into polymer composite so that the thermal conductivity of polymer composite is significantly increased in different directions. Besides, the efficient thermal conduction at the interface between two-dimensional nanomaterials and polymer restricts the improvement of two-dimensional nanomaterials in the thermal conductivity of polymer composite. It is reported that an abrupt temperature drop occurs across the interface between graphene and PMMA [154], indicating inefficient thermal transport across the reinforcement–matrix interface. This inefficient thermal transport is mainly due to the interfacial thermal resistance between graphene and PMMA, which significantly decreases the improvement in the thermal conductivity of polymer composites reinforced with 2D nanomaterials. Furthermore, the weak interfacial interaction between 2D nanomaterials and polymer materials leads to defects and mismatches at the reinforcement–matrix interface. The defects and mismatch act as the phonon scattering decrease the thermal conductivity of polymer composites [33,155,156]. This limitation can be solved by improving the interfacial interaction between two-dimensional nanomaterials and polymer through the functionalization of 2D nanomaterials.

Schematic illustrations of thermal conduction routes in polymer composites reinforced by (a) randomly distributed BNNS and (b) oriented linear densely packed BN structure. The larger arrows indicate that the thermal conduction is more efficient than that of the smaller arrows.

3.3 Tribological application

Polymer materials such as epoxy are widely used in automobile, aerospace, marine, etc. [157]. It is not uncommon that the contact between two moving surfaces of structures in engineering leads to friction and wear of polymer materials, which results in friction heat build-up due to the high sliding between contacted surfaces and structural damage in the structures [158,159]. To reduce the friction heat and avoid structural damage, it is necessary to mitigate the coefficient of friction and improve the thermal conductivity and the mechanical properties of polymer composites [160,161]. 2D nanomaterials exhibit high mechanical properties, thermal conductivity, and low friction, making 2D nanomaterials an attractive solid lubricant. The picture of 2D nanomaterial working as a lubricant for machine element is provided in Figure 1 in ref. [162]. In the existing literature, it is reported that the addition of 2 wt% BNNS to polyimide and the addition of 0.5 wt% BNNS to epoxy reduce the wear rate of polymer composites by 83 and 33%, respectively [163,164]. The addition of 0.5 wt% BNNS to epoxy shows a 17% reduction in the coefficient of friction [163]. Compared to the fiber reinforcement (e.g. glass fiber) and particle reinforcement (e.g. silicon carbide particles), 2D nanosheets possess lower density than the fiber reinforcement and particle reinforcement [165]. As a result, 2D nanosheets can be well dispersed in polymer composites. Besides, 2D nanomaterials show better compatibility with polymer materials than that of fiber reinforcement and particle reinforcement [159]. Hence, the stress transfer and thermal conduction at the interface between 2D nanomaterials and polymer materials are efficient, which significantly improves the mechanical properties and thermal conductivity of polymer composites. Unlike one-dimensional nanomaterials (e.g. carbon nanotubes (CNTs) and boron nitride nanotubes), multilayered 2D nanomaterials due to agglomeration show weak van der Waals interaction between adjacent layers. As a result, the shear sliding between interlayers of 2D nanomaterials occurs easily. The easy shear sliding between the large smooth surfaces of multilayered 2D nanomaterials exhibits the self-lubricant characteristic, which is beneficial to reduce the coefficient of friction of polymer composites [166,167]. The low coefficient of friction of polymer composites can reduce the build-up of the friction heat and the frictional force, which is of interest to avoid structural damage. Hence, 2D nanomaterials are very attractive to improve the tribological performance of polymer composites.

2D nanomaterials working as solid lubricants for improving the tribological performance of polymer materials are desirable to be highly durable, easy to deliver to the contact interfaces, and environmentally insensitive [166]. Graphene, BNNS, and MoS2 nanosheets are highly durable 2D nanomaterials under thermal conditions and loadings because of their high thermal stability and mechanical properties, as shown in Table 2, and chemical inertness. The durability of 2D nanomaterials is helpful to maintain the tribological performance of 2D nanomaterial-reinforced polymer composites. Due to the good dispersion and ultrathin shape of 2D nanomaterials in polymer composites, 2D nanomaterials can easily enter the contact area of sliding surfaces [168]. However, the friction and wear of graphene, BNNS, and MoS2 nanosheet are influenced by environmental humidity. It is reported that the friction and wear of graphene decrease when the environmental humidity increases [169,170]. The reduction of friction and wear of graphene in high environmental humidity is attributed to the repair of the bond broken area. Specifically, water molecules disassociate and yield hydrogen radicals and hydroxyl radicals. These radicals react with the carbon dangling bonds and repair the damaged graphene [170]. As a result, graphene maintains its function as a lubricant. BNNS shows similar dependence on the environmental humidity to graphene [171]. However, the friction and wear of MoS2 nanosheet increases when the environmental humidity increases. The rising of friction and wear of MoS2 nanosheet is due to the accelerated oxidation on the surface of MoS2 nanosheet in water molecules. Besides, the occupation of the wedge-shaped cavities of MoS2 nanosheet increases the adhesion force on the sliding surfaces [171]. Hence, graphene and BNNS are proper candidates for improving the tribological performance of polymer composites in humid environments, while MoS2 nanosheet is a proper candidate for improving the tribological performance of polymer composites as a dry lubricant.

3.4 Three-dimensional printed composites

The 3D printing technique is a promising method for preparing composite structures owing to its reliability, automated construction, simple fabrication, and low cost [172,173,174,175]. To maintain the shape stability of 3D-printed polymer composites and avoid their collapse, 2D nanomaterials (e.g. graphene) are added to improve the viscosity of polymer composites. When 2D nanomaterials are added to polymer materials, a robust interfacial interaction between 2D nanomaterials and polymer materials forms. The motion of polymer chains is restricted by 2D nanomaterials. As a result, the viscosity of polymer materials is increased by adding 2D nanomaterials [176]. Concurrently, these composites show a shear-thinning behavior. The shear-shinning behavior means that the viscosity of composites decreases with the increasing shear rate. It is reported that hydrolyzed polyacrylamide (HPAM) reinforced by graphene-based nanosheet shows a lower viscosity than the initial viscosity of pristine HPAM when the shear rate is increased [176]. Due to the reduced viscosity of polymer composites at a high shear rate, the polymer composites reinforced with 2D nanomaterials assure a smooth printing process during its flow in the extrusion nozzle. Furthermore, the viscosity of polymer composites can be reduced by heating the print head and the nozzle plate [176,177]. In addition to the printability and shape stability of 3D-printed polymer composites, adding 2D nanomaterials to polymer materials can also improve the mechanical and thermal conductivity of 3D-printed composite structures, as mentioned in Secs. 3.1 and 3.2, respectively. The picture of 3D-printed mechanical gear with 2D nanomaterial-reinforced PLA is provided in Figure 1 in ref. [178].

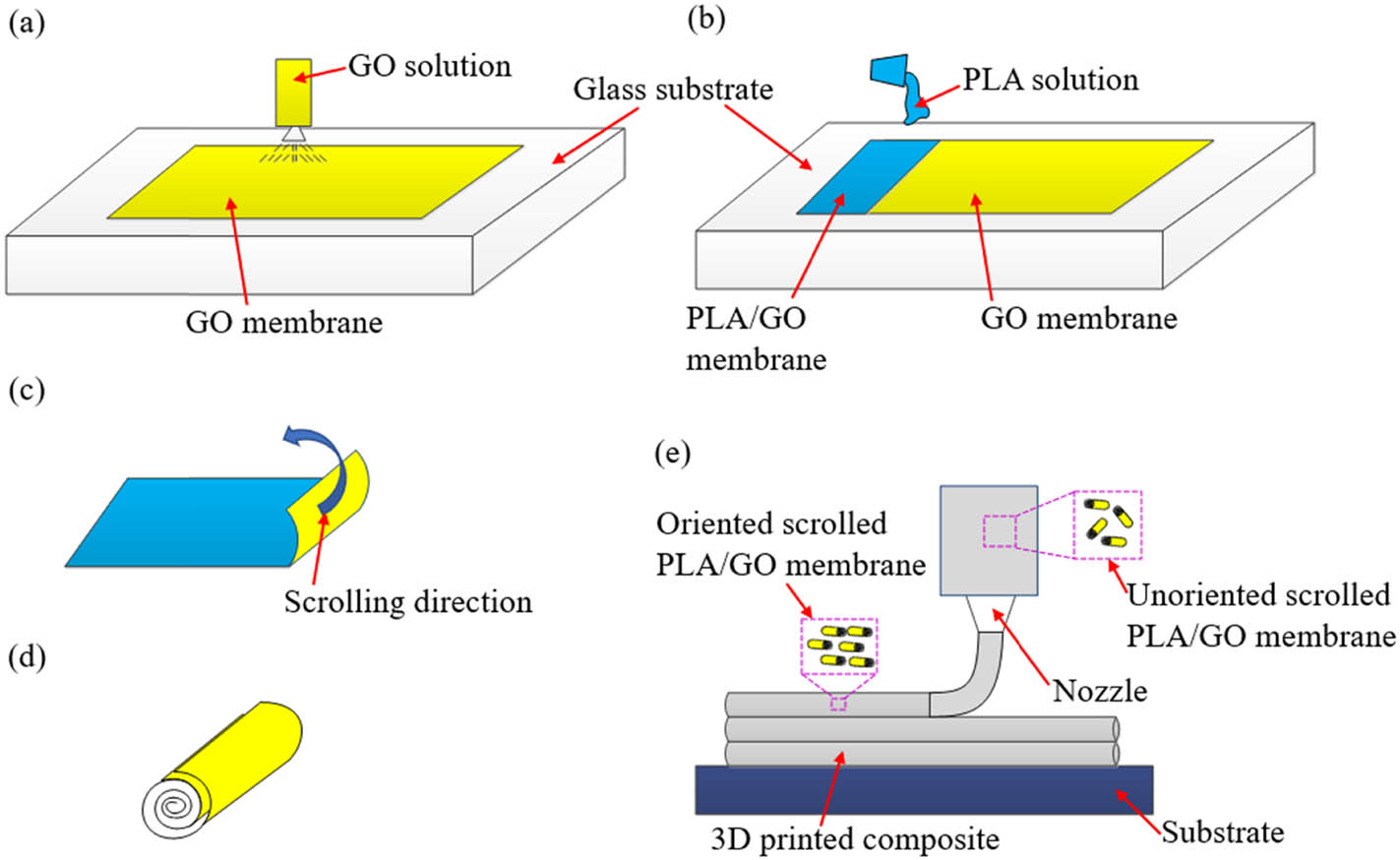

3D-printed polymer composite can prepare oriented 2D nanomaterials in polymer materials [178,179]. The oriented 2D nanomaterials create a thermal conduction route for thermal dissipation in polymer composite. Based on the extrusion method, the 2D nanomaterials are aligned along the printing direction [180]. The 2D nanomaterials are oriented due to the shear force in the printing process, which aligns the 2D nanomaterials along the same direction, as presented in Figure 7 [178]. First, GO solution is sprayed on the surface of the glass substrate to form a GO membrane, as shown in Figure 7(a). Subsequently, PLA solution is cast onto the GO membrane to obtain PLA/GO membrane, as shown in Figure 7(b). Following this, the PLA/GO membrane is peeled off from the glass substrate and scrolled to obtain the scrolled PLA/GO membrane, as shown in Figure 7(c) and (d). The interface between GO and PLA membranes is strong due to the hydrogen bond interaction between them, which ensures that the GO/PLA membrane can be peeled off from the glass substrate smoothly without deteriorating the GO/PLA interface. Finally, the scrolled PLA/GO membrane is added to the PLA to be printed using the 3D printing technique, which yields the oriented PLA/GO membrane in 3D-printed composite.

Schematic diagram of making highly oriented 2D nanomaterials for 3D printed composites. (a) Graphene oxide (GO) solution is sprayed on the surface of the glass substrate to form a GO membrane. (b) Polylactic acid (PLA) solution is cast on the surface of GO solution to form PLA/GO membrane. (c) PLA/GO membrane is scrolled. (d) Unoriented scrolled PLA/GO membrane is transferred to oriented scrolled PLA/GO membrane in 3D printed composite. (e) 2D nanomaterials are oriented in the 3D printed structures.

3.5 Strain sensor application

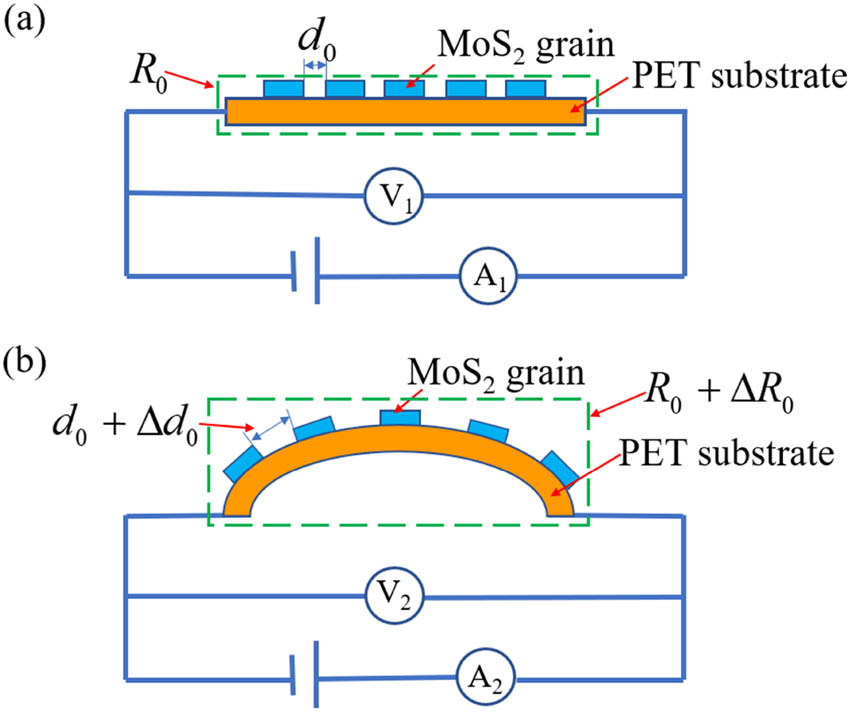

A strain sensor is a widely used sensor that identifies and responds to mechanical motion, exchanging this motion with an electrical signal based on the electrical resistance of polymer materials [181]. However, the low sensitivity of polymer materials to small mechanical strain restricts the applications of strain sensors [182,183]. 2D nanomaterials are attractive candidates for improving the sensitivity to applied strain and the functionality of polymer sensors. The sensitivity of the strain sensor is defined as the gauge factor. It is reported that the graphene-based thermoplastic polyurethane shows a gauge factor of 35.7 at the applied strain higher than 60% [184]. This value is much higher than that of carbon nanotube-based thermoplastic polyurethane. It is reported that carbon nanotube-based thermoplastic polyurethane shows a gauge factor of 7.08 at the applied strain of 100% [185]. Figure 8 shows the process of making MoS2 nanosheet-reinforced polymer composite sensor and the electrical response of the composite strain sensor to the mechanical deformation. First, the gold electrodes are deposited on the flexible substrate, which is made of polyethylene terephthalate (PET). The MoS2 nanosheet is then encapsulated by SU-8 (epoxy-based photoresist) polymer to obtain the composite sensor. The composite sensor is stressed due to bending deformation, which increases the tunneling gap in the MoS2 grain (made of nanosheet-reinforced polymer) from d 0 to d 0 + Δd 0, as shown in Figure 7(a) and (b). As a result, the potential barrier for electrons passing through the tunneling gap is increased, which suppresses the current, indicating that the resistance of the composite sensor is increased from R 0 to R 0 + ΔR 0. The relationship between the average tunneling gap and the resistance is determined by the tunneling and destruction model [186,187], which is calculated by equations (3) and (4).

where R is the resistance between grains, h is the plank’s constant, L is the grain number, A is the effective area of the grain, d is the average tunneling gap between grains, D is the number of the current path through the grains, m is the mass of an electron passing through the tunneling gap, and ϕ is the potential barrier between adjacent grains [188]. The resistance of the composite sensor can be quantified based on the measurements of the current and voltage at different levels of stress. The results indicate that composite reinforced with MoS2 nanosheet exhibits outstanding piezoresistive properties, which couple electrical properties with mechanical properties. Moreover, when 2D nanomaterials are added to polymer materials, the composite sensor shows better durability due to improved mechanical properties. It is reported that the polymer composite remains intact even under a high-stress level beyond 14 MPa due to the improvement of the 2D nanomaterial in the mechanical properties of MoS2-reinforced SU-8 polymer composite [188].

Schematics of measuring the current–voltage curves of MoS2 film/PET composite sensor at (a) relaxed state and (b) stressed state. d 0 and d 0 + Δd 0 are the tunneling gap between MoS2 films at the relaxed and stressed states, respectively. R 0 and R 0 + ΔR 0 are the resistance of the MoS2 film/PET composite at relaxed and stressed states, respectively.

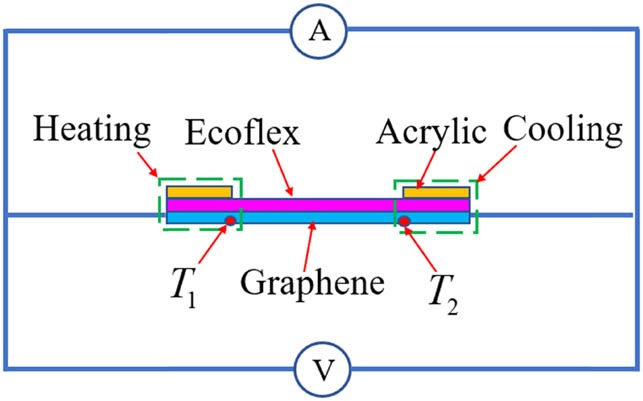

In addition to the strain sensor made of MoS2-based polymer composite, there are strain sensors made by BNNS-based polymer composites [184] and graphene-based polymer composites [189,190]. For example, it is reported that a self-powered strain sensor made of graphene-based ecoflex composite film is obtained due to the thermal gradient between human skin and the ambient environment, which can bear 1,000 cycles of repetitive strains and show a strain resolution of 0.125% with response time in 0.6 s [191]. Figure 9 shows the schematic of the self-powered thermoelectric device made of graphene-based ecoflex composite. When the heater and cooler are applied on the heating side and cooling side, respectively, the thermal gradient (ΔT = T 1 − T 2) across graphene-based ecoflex composite film is obtained. As a result, the graphene-based ecoflex composite film yields voltage and current due to the thermal gradient between human skin and the ambient environment. Specifically, under the thermal gradient of ΔT = 14.5 K, the graphene-based ecoflex composite film yields direct current output with the voltage of ∼0.48 mV and the current of ∼130 nA [191]. In view that the voltage yielded by the self-powered thermoelectric device is dependent on the thermal gradients between human skin and the ambient environment and is independent of the level of the strain of the graphene-based ecoflex composite film, the level of the strain of the graphene-based ecoflex composite film can be related to the current yielded by the self-powered thermoelectric device under a certain thermal gradient. The measurements show that the current yielded by the thermoelectric device is decreased as the strain of the composite film is increased under external loading because the electrical resistance of the composite film is increased with the stretching of the composite film. Compared to carbon nanotube-based ecoflex elastomer composite film, the graphene-based ecoflex composite film yields a large current–voltage signal owing to the excellent thermoelectric performance of graphene. The large current–voltage signal indicates that the thermal gradient between human skin and the ambient environment can be efficiently used for the self-powered strain sensor. The picture of 2D nanomaterial-reinforced polymer composite for the ultrasensitive self-powered strain sensor system is provided in Figure 5 in ref. [191].

Schematic of the self-powered thermoelectric device made of graphene-based ecoflex composite film for measuring the output voltage and current under the thermal gradient (ΔT = T 1 − T 2). T 1 denotes the temperature at the point of the heating side; T 2 denotes the temperature at the point of the cooling side.

A strain sensor made of 2D nanomaterial-based polymer composite is promising for use in different fields [181,192–196]. For example, structural health monitoring is a very important application of strain sensors. Infrastructures (e.g. dams, bridges, and buildings) are vulnerable to external loads and environmental conditions such as humidity, wind loads, and temperature variations [181]. These harsh conditions cause unpredictable and invisible structural defects in the infrastructures. As these defects develop, the infrastructures are endangered. A composite sensor can help to detect the invisible structural deterioration more efficiently and repair the structure.

4 Reinforcement–matrix interface

4.1 Influence of reinforcement–matrix interface on properties of composites

The interfacial interaction between the reinforcement and matrix has a significant influence on the mechanical properties [197–199], thermal conductivity [154], thermal stability [200], and other aspects of composites [201,202]. It is reported that an abrupt temperature drop occurs across the interface between graphene and PMMA [154], indicating inefficient thermal transport across the reinforcement–matrix interface. This is mainly due to the interfacial thermal resistance between graphene and PMMA. Furthermore, the weak interfacial interaction between 2D nanomaterials and polymer materials leads to defects and mismatches at the reinforcement–matrix interface. The defects and mismatches act as the phonon scattering [33]. As a result, the thermal conductivity of polymer composites is significantly decreased [155,156]. In addition to defects at the interface, graphene could contain Stone-Wales defects that are similar to those found in CNTs. In a previous study, it was shown that any two defects could interact between them when the CNT is loaded in tension or torsion, although the significance of the interaction diminishes with separation distance [203,204]. How the defects in graphene interact among themselves when the graphene is loaded in tension or torsion and how these interaction mechanisms affect the interaction of the graphene with the polymer matrix at the interface are still not well understood. It is reported that stress transfer between graphene and polymer materials under tension is reduced due to the deterioration of the reinforcement–matrix interface [205]. As a result, the load-carrying capacity of reinforcement (i.e. graphene) with high mechanical properties cannot be used fully.

The interfacial interaction between reinforcement and polymer materials also has a significant influence on the glass transition temperature of polymer composites. Due to the weak interfacial interaction between BNNS and polymer materials, the motion of polymer chains in the polymer composites cannot be effectively restricted. The loosened polymer chains lead to a reduction in the glass transition temperature of the polymer composites. As a result, the thermal stability of the composites is reduced [200]. While BNNS shows excellent thermal stability, the interface between BNNS and polymer composite can be deteriorated due to thermal-induced deformation. It is reported that the thermal-induced deformation of BNNS is irreversible at elevated temperatures [206]. This irreversible deformation of BNNS is due to the mismatch of thermal expansion between BNNS and substrate materials. As a result, the irreversible deformation of BNNS in interfacial sliding at the interface between BNNS and substrate materials. The interfacial sliding at the interface between BNNS and substrate materials inevitably reduces the reinforcing efficiency of BNNS in the mechanical properties of BNNS-based polymer composite.

4.2 Improvement of the reinforcement–matrix interface

As the reinforcement–matrix interface governs the mechanical, thermal, and electrical properties of polymer composites, it is necessary to enhance the interfacial matching and strength between 2D nanomaterials and polymer materials [207]. This interfacial interaction is closely related to the adhesion energy between the materials [150], which is contributed by weak nonbonded interactions such as the van der Waals interaction and electrostatic interaction. To improve the interfacial adhesion energy between 2D nanomaterials and polymer materials, one approach is to add functional groups onto the surface of 2D nanomaterials. Due to the functionalization of 2D nanomaterials, there are robust hydrogen bonds forming between 2D nanomaterials and polymer materials. Functionalization on the surface of 2D nanomaterials can be divided into two types, which are physical functionalization and chemical functionalization. The physical functionalization on the surface graphene and BNNS is not very common because the foreign materials have a weak nonbonded interaction with graphene and BNNS [208]. However, the foreign materials have a robust covalently bonded interaction with nanomaterials (e.g. nanotubes and nanosheets). These surface modification on nanotubes and nanosheets yields significant improvement in the physical properties of polymer composites [107,209,210]. Table 4 presents the improvement of functionalized 2D nanomaterials in the properties of polymer composites. For example, functionalized graphene causes a large restriction on the mobility of PMMA chains. As a result, the glass transition temperature of PMMA is increased. In addition, Young’s modulus and tensile strength of functionalized graphene-reinforced PMMA are increased by 80 and 20%, respectively [54]. Furthermore, the functionalization of graphene shows significant improvement in viscosity [176], thermal conductivity [211], and sensitivity to mechanical motion of polymer composites [56]. These improvements are beneficial for the application of polymer composites reinforced with graphene in practice. The functionalization on the surface of BNNS is different from that on the surface of graphene because of the partial charges on the boron and nitrogen atoms. Specifically, the positively charged boron sites are reactive to nucleophilic groups (e.g. hydroxyl groups and amino groups), while the negatively charged nitrogen sites are attractable by electrophilic ones (e.g. hydrogen) [107]. With the functionalization on the surface of BNNS, the mechanical properties of the composite can be significantly increased. It is reported that an addition of 0.1% weight fraction of BNNS functionalized by hydroxyl groups increases the elastic modulus of the composite by 186% [212]. In contrast, an addition of the same amount of pristine BNNS increases the elastic modulus of the composite by 20% [212]. While the surfaces of graphene and BNNS are covalently functionalized by hydroxyl, carboxyl, etc., to improve the interface between graphene (or BNNS) and polymer, it is hard to modify the surface of MoS2 nanosheet by chemical functionalization. To modify the surface of MoS2 nanosheet, the physical functionalization can be adopted. The physical functionalization on the surface of MoS2 nanosheet makes MoS2 nanosheet dispersed well in organic solvents and aqueous solution. Hence, the functionalization of MoS2 nanosheet shows excellent reinforcing efficiency in thermal stability and fire resistance of MoS2 nanosheet-reinforced polymer composites [213]. Specifically, the addition of 3% weight fraction of MoS2 nanosheet functionalized by cetrimonium bromide in polymer reduces the flammability of polymer by 20% compared with the pure polymer. Besides, the storage modulus of polymer material is increased by 84% with the addition of 3 wt% cetrimonium bromide functionalized MoS2 nanosheet. The functional groups on the surface of 2D nanomaterials form robust hydrogen bonds with polymer chains. Thus, the adhesion energy between 2D nanomaterials and polymer materials is increased. In addition, these functional groups give a wrinkled structure to 2D nanomaterials, which allows mechanical interlocking with the polymer chains and improves the interfacial interaction between the reinforcement and the matrix [56,214].

Improvement of functionalized 2D nanomaterials in the properties of polymer composites

| Reinforcement | Content (wt%) | Matrix | Improvement in properties of composites |

|---|---|---|---|

| GO | 0.05 | PMMA | Glass temperature is increased by 30°C [54] |

| Young’s modulus is increased by 80% [54] | |||

| Tensile strength is increased by 20% [54] | |||

| 0.5 | PUB | Thermal conductivity is increased by 62% [211] | |

| Oleylamine-BNNS | 0.1 | PVDF | Young’s modulus is increased by 823% [57] |

| Tensile strength is increased by 343% [57] | |||

| 4 | PVDF | The sensitivity of the sensor is increased by 10% [57] | |

| Cetrimonium bromide-MoS2 nanosheet | 3 | PS | Flammability is reduced by 20% [114] |

| Storage modulus is increased by 84% [213] |

5 Prospects

5.1 Hybridization of 2D nanomaterials

The application of 2D nanomaterials overcomes a lot of challenges in engineering. 2D nanomaterials show diverse characteristics and have diverse applications in engineering, as discussed in Section 3. However, one of the characteristics of the 2D nanomaterial contradicts another characteristic. For example, graphene is one of the widely used 2D nanomaterials with high thermal conductivity [114]. Hence, graphene is an attractive additive to thermal management materials. However, the nature of the electrical conductivity of graphene restricts the application of thermal manage materials containing graphene in electronics because the electronics are required to be electrically insulating to avoid short circuits. Besides, BNNS exhibits high thermal conductivity and good electrical insulation [114]. However, BNNS is hard to be dispersed in polymer materials due to its hydrophobicity and agglomeration, which reduces the thermal conductivity of BNNS-reinforced polymer composites. To make the perfect 2D nanomaterials for fulfilling the demand of thermal management materials in electronics, it is proposed to hybridize different types of 2D nanomaterials so that the shorting comings of the individual 2D nanomaterial can be overcome and the advantage of the individual 2D nanomaterial can be maintained. Specifically, the hybridized graphene/BNNS shows good solubility and dispersion, and high thermal conductivity [215]. Concurrently, the presence of BNNS hinders the electron transmission between graphene [216]. As a result, the hybridized graphene/BNNS exhibit high electrical insulation and thermal conductivity.

5.2 Flash synthesis of 2D nanomaterials

2D nanomaterials synthesized by top-down approach consume a large amount of solvents and energy to exfoliate from bulk materials (e.g. bulk graphite and hexagonal boron nitride), while the bottom-down approach yields a small amount of 2D nanomaterials and takes a lot of time [153]. Flash Joule heating is a promising method to synthesize 2D nanomaterials. This method can turn the solid waste containing prerequisite elements (e.g. carbon and silicon) to flash 2D nanomaterials [218–220]. For example, the solid waste containing the carbon element like rubber tires is compressed between two electrodes in a ceramic tube without requiring the furnace or solvent. The carbon source in the solid waste is turned to flash graphene by heating to 3,000 K in 100 ms during the high voltage electric discharge from a capacitor [217]. This synthesis needs no furnace, no solvent, or no purification process, which is a sustainable, environmentally friendly, and straightforward approach. Currently, this flash synthesis is widely used in producing graphene. With the development of the flash synthesis, it envisions to be used to synthesize other types of 2D nanomaterials in the future.

5.3 Integration of exfoliation and functionalization of 2D nanomaterials

It is discussed in Section 4 that the functionalization (i.e. modification) of 2D nanomaterials improves the interfacial interaction between 2D nanomaterials and polymer materials, which significantly improves the mechanical properties, thermal conductivity, viscosity, and fire retardance of 2D nanomaterial-reinforced polymer composites. In the existing literature, the exfoliation and functionalization of 2D nanomaterials are performed individually, as discussed in Secs. 2 and 4. To simplify the preparation of functionalized 2D nanomaterials, the exfoliation and functionalization of 2D nanomaterials can be performed simultaneously [107]. It is reported that the ultrasonication-based exfoliation method is used to prepare BNNS. The boron–nitrogen bonds are broken under ultrasonication. As a result, the hydroxyl group is formed on the boron sites in water [221]. Besides, in the electrochemical exfoliation, the degree of functionalization of graphene can be controlled by tuning the electrochemical exfoliation of graphene, which can control the number of defects on the surface of graphene [222].

5.4 Promising applications

With the development of technologies in aviation and aerospace, interplanetary travel can be realized in the future. However, space radiation (e.g. thermal neutron radiation) is certain to cause damage to spacecraft made of lightweight polymer composites [223]. It will be necessary to integrate radiation shielding material into polymer composites to improve the radiological tolerance of spacecraft. Polymer composites will be required to have superior load-carrying capacity and resistance to thermal and radiation attacks [224]. However, polymer materials possess low glass transmission temperature and radiation shielding capacity, indicating that spacecraft made of ordinary polymer composite will not be able to resist thermal and radiation attacks. 2D nanomaterials that exhibit multifunctional properties (e.g. high mechanical properties and thermal resistance) are promising in terms of improving the performance of polymer composites in the space environment. For example, the mechanical properties [55,223,225], thermal resistance [55], and shielding capacity [223,225] of polymer materials can be improved by adding BNNS. With the addition of BNNS to polymer materials, neutron radiation can be effectively shielded against, owing to the existence of 10B atoms in BNNS. 10B means boron-10, which is a stable isotope of boron with a mass number of 10. The 10B atoms have a high thermal neutron capture cross section. As a result, the neutrons can be absorbed by and react with the 10B atoms, producing free electrons [226]. This reaction transforms thermal neutron radiation into free electrons. Hence, the attack of thermal neutron radiation on spacecraft is expected to be reduced by 2D nanomaterial-reinforced polymer composites.

2D nanomaterials can also be used in nanomedical engineering (e.g. wound dressings, tissue engineering materials, and bioelectronic devices) [227]. With the development of nanobiotechnology, polymeric nanosheets with tens-of-nanometer thickness are fabricated. The polymeric nanosheets exhibit tunable flexibility, molecular permeability, and free-standing characteristic without being restricted by the substrates. These features make polymeric nanosheets attractive to be used to regenerate and maintain tissues and organs. It is reported that polymeric nanosheets are used to repair tissue defects, which reduces the inflammatory response or postsurgical tissue adhesion [228]. Besides, 2D nanomaterial-based polymer composite is used in bone tissue engineering. These types of artificial tissues lead to fast tissue regeneration [229]. The incorporation of 2D nanomaterials in biocomposites significantly improves the mechanical supporting capacity and biocompatibility of bone tissue and promotes cell adhesion and osteoblast differentiation [229,230]. Using the artificial tissues made of 2D nanomaterial-based biocomposite overcomes the problems in traditional bone grafting techniques (including autograft, allograft, and xenograft [231]), such as donor site pain, inflammation, graft rejection, hematoma formation, and pathogen transmission [232]. In the future, it is expected that 2D nanomaterial-based biocomposites can be used to fabricate implantable electronic devices and to connect to the living tissues for monitoring health status or providing health care.

6 Conclusion

The synthesis and properties of typical 2D nanomaterials, applications of polymer composites reinforced with 2D nanomaterials, and the prospects of 2D nanomaterials and polymer composites have been reviewed in this article, which is summarized as follows:

1) The mature synthesis strategies, including top-down and bottom-up strategies, yield high-quality and scalable-production 2D nanomaterials. The typical three types of 2D nanomaterials (i.e. graphene, BNNS, and MoS2 nanosheet) exhibit higher tensile strength and Young’s modulus than the traditional materials such as fibers. At the same time, these three types of 2D nanomaterials show unique characteristics. Graphene shows larger tensile strength and Young’s modulus than BNNS and MoS2 nanosheet, but BNNS has large thermal conductivity and low electrical conductivity. Hence, BNNS is a good candidate for improving the thermal dissipation of electronic systems. While MoS2 nanosheet shows lower mechanical properties and thermal conductivity than graphene and BNNS, MoS2 nanosheet is a good additive for developing strain sensors because its tunable bandgap value can effectively couple the electrical conductivity and mechanical properties.

2) Due to the properties and uniqueness of typical 2D nanomaterials, including graphene, BNNS, and MoS2 nanosheet, it has been shown to be beneficial to adapt 2D nanomaterials to develop advanced polymer composites with improved structural performance, thermal dissipation of electronic systems, capability for 3D printing, and sensitivity of strain sensor.

3) The reinforcement–matrix interaction in polymer composites is of interest in terms of stress transfer and thermal transport, which significantly influences the performance and application of polymer composites reinforced with 2D nanomaterials. In terms of improving the interfacial interaction between 2D nanomaterials and polymer materials, the functionalization of 2D nanomaterials is effective in increasing the adhesion energy between the reinforcement and matrix owing to the formation of hydrogen bonds at the reinforcement–matrix interface.

4) With the development of 2D nanomaterials, it is expected that different types of 2D nanomaterials will be used to enhance the radiation shielding capacity of polymer materials in the fields of aviation and aerospace. Besides, it is expected that 2D nanomaterials can be used to repair tissue defects, promote bone tissue regeneration, and fabricate implantable electronic devices for providing health monitoring and health care in nanomedical engineering.

-

Funding information: The authors are grateful for the support from the Research Grants Council (RGC) of the Hong Kong Special Administrative Region, China (Project No. CityU 11207617), and the support from Shenzhen Science and Technology Innovation Committee under the grant JCYJ20170818103206501.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: David Hui, who is the co-author of this article, is a current Editorial Board member of Nanotechnology Reviews. This fact did not affect the peer-review process. The authors declare no other conflict of interest.

References

[1] Domun N, Hadavinia H, Zhang T, Sainsbury T, Liaghat GH, Vahid S. Improving the fracture toughness and the strength of epoxy using nanomaterials-a review of the current status. Nanoscale. 2015;7(23):10294–329.10.1039/C5NR01354BSearch in Google Scholar PubMed

[2] Lau D, Jian W, Yu Z, Hui D. Nano-engineering of construction materials using molecular dynamics simulations: prospects and challenges. Compos Pt B-Eng. 2018;143:282–91.10.1016/j.compositesb.2018.01.014Search in Google Scholar

[3] Huang C, Qian X, Yang R. Thermal conductivity of polymers and polymer nanocomposites. Mat Sci Eng R. 2018;132:1–22.10.1016/j.mser.2018.06.002Search in Google Scholar

[4] Hu K, Kulkarni DD, Choi I, Tsukruk VV. Graphene-polymer nanocomposites for structural and functional applications. Prog Polym Sci. 2014;39(11):1934–72.10.1016/j.progpolymsci.2014.03.001Search in Google Scholar

[5] Srivastava VK, Gries T, Veit D, Quadflieg T, Mohr B, Kolloch M. Effect of nanomaterial on mode I and mode II interlaminar fracture toughness of woven carbon fabric reinforced polymer composites. Eng Fract Mech. 2017;180:73–86.10.1016/j.engfracmech.2017.05.030Search in Google Scholar

[6] Qin R, Zhou A, Yu Z, Wang Q, Lau D. Role of carbon nanotube in reinforcing cementitious materials: an experimental and coarse-grained molecular dynamics study. Cem Concr Res. 2021;147:106517.10.1016/j.cemconres.2021.106517Search in Google Scholar

[7] Bhat A, Budholiya S, Aravind Raj S, Sultan MTH, Hui D, Md Shah AU, et al. Review on nanocomposites based on aerospace applications. Nanotechnol Rev. 2021;10(1):237–53.10.1515/ntrev-2021-0018Search in Google Scholar

[8] Wang J, Cheng Q, Lin L, Chen L, Jiang L. Understanding the relationship of performance with nanofiller content in the biomimetic layered nanocomposites. Nanoscale. 2013;5(14):6356–62.10.1039/c3nr00801kSearch in Google Scholar PubMed

[9] Wang D, Zhang X, Zha J-W, Zhao J, Dang Z-M, Hu G-H. Dielectric properties of reduced graphene oxide/polypropylene composites with ultralow percolation threshold. Polymer. 2013;54(7):1916–22.10.1016/j.polymer.2013.02.012Search in Google Scholar

[10] Ramdani N, editor. Polymer nanocomposites for advanced engineering and military applications. Hershey: IGI Global; 2019.10.4018/978-1-5225-7838-3Search in Google Scholar

[11] Abreu I, Ferreira DP, Fangueiro R. Versatile graphene-based fibrous systems for military applications. AVT-304. 2019.Search in Google Scholar

[12] Bhattacharjee S, Joshi R, Chughtai AA, Macintyre CR. Graphene modified multifunctional personal protective clothing. Adv Mater Interfaces. 2019;6(21):1900622.10.1002/admi.201900622Search in Google Scholar PubMed PubMed Central

[13] Robbins JR, Ding JL, Gupta YM. Load spreading and penetration resistance of layered structures-a numerical study. Int J Impact Eng. 2004;30(6):593–615.10.1016/j.ijimpeng.2003.08.001Search in Google Scholar

[14] Stankovich S, Dikin DA, Dommett GHB, Kohlhaas KM, Zimney EJ, Stach EA, et al. Graphene-based composite materials. Nature. 2006;442(7100):282–6.10.1038/nature04969Search in Google Scholar PubMed

[15] Wu S, Peng S, Wang CH. Multifunctional polymer nanocomposites reinforced by aligned carbon nanomaterials. Polymers. 2018;10(5):542.10.3390/polym10050542Search in Google Scholar PubMed PubMed Central

[16] Kuilla T, Bhadra S, Yao D, Kim NH, Bose S, Lee JH. Recent advances in graphene based polymer composites. Prog Polym Sci. 2010;35(11):1350–75.10.1016/j.progpolymsci.2010.07.005Search in Google Scholar

[17] Sun X, Sun H, Li H, Peng H. Developing polymer composite materials: carbon nanotubes or graphene? Adv Mater. 2013;25(37):5153–76.10.1002/adma.201301926Search in Google Scholar PubMed

[18] Nie F, Jian W, Lau D. An atomistic study on the thermomechanical properties of graphene and functionalized graphene sheets modified asphalt. Carbon. 2021;182:615–27.10.1016/j.carbon.2021.06.055Search in Google Scholar

[19] Naveen J, Jawaid M, Goh KL, Reddy DM, Muthukumar C, Loganathan TM, et al. Advancement in graphene-based materials and their nacre inspired composites for armour applications-a review. Nanomaterials. 2021;11(5):1239.10.3390/nano11051239Search in Google Scholar PubMed PubMed Central

[20] Zhang Y, Ma J, Wei N, Yang J, Pei Q-X. Recent progress in the development of thermal interface materials: a review. Phys Chem Chem Phys. 2021;23(2):753–76.10.1039/D0CP05514JSearch in Google Scholar PubMed

[21] Li Y, Wang S, Wang Q, Xing M. A comparison study on mechanical properties of polymer composites reinforced by carbon nanotubes and graphene sheet. Compos Pt B-Eng. 2018;133:35–41.10.1016/j.compositesb.2017.09.024Search in Google Scholar

[22] Jing C, Liu W, Hao H, Wang H, Meng F, Lau D. Regenerated and rotation-induced cellulose-wrapped oriented CNT fibers for wearable multifunctional sensors. Nanoscale. 2020;12(30):16305–14.10.1039/D0NR03684FSearch in Google Scholar PubMed

[23] Jian W, Lau D. Understanding the effect of functionalization in CNT-epoxy nanocomposite from molecular level. Compos Sci Technol. 2020;191:108076.10.1016/j.compscitech.2020.108076Search in Google Scholar

[24] Jian W, Lau D. Creep performance of CNT-based nanocomposites: a parametric study. Carbon. 2019;153:745–56.10.1016/j.carbon.2019.07.069Search in Google Scholar

[25] Gao Z, Zhang P, Guo J, Wang K. Bonding behavior of concrete matrix and alkali-activated mortar incorporating nano-SiO2 and polyvinyl alcohol fiber: theoretical analysis and prediction model. Ceram Int. 2021;47(22):31638–49.10.1016/j.ceramint.2021.08.044Search in Google Scholar

[26] Wang K, Zhang P, Guo J, Gao Z. Single and synergistic enhancement on durability of geopolymer mortar by polyvinyl alcohol fiber and nano-SiO2. J Mater Res Technol. 2021;15:1801–14.10.1016/j.jmrt.2021.09.036Search in Google Scholar

[27] Zhang P, Gao Z, Wang J, Wang K. Numerical modeling of rebar-matrix bond behaviors of nano-SiO2 and PVA fiber reinforced geopolymer composites. Ceram Int. 2021;47(8):11727–37.10.1016/j.ceramint.2021.01.012Search in Google Scholar

[28] Scotti R, Conzatti L, D’Arienzo M, Di Credico B, Giannini L, Hanel T, et al. Shape controlled spherical (0D) and rod-like (1D) silica nanoparticles in silica/styrene butadiene rubber nanocomposites: role of the particle morphology on the filler reinforcing effect. Polymer. 2014;55(6):1497–506.10.1016/j.polymer.2014.01.025Search in Google Scholar

[29] Zhu M, Li J, Chen J, Song H, Zhang H. Improving thermal conductivity of epoxy resin by filling boron nitride nanomaterials: a molecular dynamics investigation. Comput Mater Sci. 2019;164:108–15.10.1016/j.commatsci.2019.04.012Search in Google Scholar

[30] Chen C, Xie Y, Wang J, Lan Y, Wei X, Zhang Z. Enhancing high field dielectric properties of polymer films by wrapping a thin layer of self-assembled boron nitride film. Appl Surf Sci. 2021;535:147737.10.1016/j.apsusc.2020.147737Search in Google Scholar

[31] Guerra V, Wan C, McNally T. Thermal conductivity of 2D nano-structured boron nitride (BN) and its composites with polymers. Prog Mater Sci. 2019;100:170–86.10.1016/j.pmatsci.2018.10.002Search in Google Scholar

[32] Hu J, Huang Y, Zeng X, Li Q, Ren L, Sun R, et al. Polymer composite with enhanced thermal conductivity and mechanical strength through orientation manipulating of BN. Compos Sci Technol. 2018;160:127–37.10.1016/j.compscitech.2018.01.045Search in Google Scholar

[33] Rasul MG, Kiziltas A, Arfaei B, Shahbazian-Yassar R. 2D boron nitride nanosheets for polymer composite materials. npj 2D Mater Appl. 2021;5(1):56.10.1038/s41699-021-00231-2Search in Google Scholar

[34] Veca LM, Lu F, Meziani MJ, Cao L, Zhang P, Qi G, et al. Polymer functionalization and solubilization of carbon nanosheets. Chem Commun (Cambridge, U K). 2009;18:2565–7.10.1039/b900590kSearch in Google Scholar PubMed

[35] Zhi C, Bando Y, Tang C, Kuwahara H, Golberg D. Large-scale fabrication of boron nitride nanosheets and their utilization in polymeric composites with improved thermal and mechanical properties. Adv Mater. 2009;21(28):2889–93.10.1002/adma.200900323Search in Google Scholar

[36] Pang Y, Yang J, Curtis TE, Luo S, Huang D, Feng Z, et al. Exfoliated graphene leads to exceptional mechanical properties of polymer composite films. ACS Nano. 2019;13(2):1097–106.10.1021/acsnano.8b04734Search in Google Scholar PubMed

[37] Wang X, Pakdel A, Zhang J, Weng Q, Zhai T, Zhi C, et al. Large-surface-area BN nanosheets and their utilization in polymeric composites with improved thermal and dielectric properties. Nanoscale Res Lett. 2012;7(1):662.10.1186/1556-276X-7-662Search in Google Scholar PubMed PubMed Central

[38] Yu S, Wu X, Wang Y, Guo X, Tong L. 2D materials for optical modulation: challenges and opportunities. Adv Mater. 2017;29(14):1606128.10.1002/adma.201606128Search in Google Scholar PubMed

[39] Popa D, Sun Z, Torrisi F, Hasan T, Wang F, Ferrari AC. Sub 200 fs pulse generation from a graphene mode-locked fiber laser. Appl Phys Lett. 2010;97(20):203106.10.1063/1.3517251Search in Google Scholar

[40] Koo J, Park J, Lee J, Jhon YM, Lee JH. Femtosecond harmonic mode-locking of a fiber laser at 3.27 GHz using a bulk-like, MoSe2-based saturable absorber. Opt Express. 2016;24(10):10575–89.10.1364/OE.24.010575Search in Google Scholar PubMed

[41] Cui X, Ding P, Zhuang N, Shi L, Song N, Tang S. Thermal conductive and mechanical properties of polymeric composites based on solution-exfoliated boron nitride and graphene nanosheets: a morphology-promoted synergistic effect. ACS Appl Mater Interfaces. 2015;7(34):19068–75.10.1021/acsami.5b04444Search in Google Scholar PubMed

[42] Wang F, Zeng X, Yao Y, Sun R, Xu J, Wong C-P. Silver nanoparticle-deposited boron nitride nanosheets as fillers for polymeric composites with high thermal conductivity. Sci Rep. 2016;6(1):19394.10.1038/srep19394Search in Google Scholar PubMed PubMed Central

[43] Shao L, Shi L, Li X, Song N, Ding P. Synergistic effect of BN and graphene nanosheets in 3D framework on the enhancement of thermal conductive properties of polymeric composites. Compos Sci Technol. 2016;135:83–91.10.1016/j.compscitech.2016.09.013Search in Google Scholar

[44] Jia Q, Huang X, Wang G, Diao J, Jiang P. MoS2 nanosheet superstructures based polymer composites for high-dielectric and electrical energy storage applications. J Phys Chem C. 2016;120(19):10206–14.10.1021/acs.jpcc.6b02968Search in Google Scholar

[45] Qin H, Deng C, Lu S, Yang Y, Guan G, Liu Z, et al. Enhanced mechanical property, thermal and electrical conductivity of natural rubber/graphene nanosheets nanocomposites. Polym Compos. 2020;41(4):1299–309.10.1002/pc.25455Search in Google Scholar

[46] Li J, Gan L, Liu Y, Mateti S, Lei W, Chen Y, et al. Boron nitride nanosheets reinforced waterborne polyurethane coatings for improving corrosion resistance and antifriction properties. Eur Polym J. 2018;104:57–63.10.1016/j.eurpolymj.2018.04.042Search in Google Scholar

[47] Rajabi M, Rashed GR, Zaarei D. Assessment of graphene oxide/epoxy nanocomposite as corrosion resistance coating on carbon steel. Corros Eng, Sci Technol. 2015;50(7):509–16.10.1179/1743278214Y.0000000232Search in Google Scholar

[48] He J, Liu S, Li Y, Zeng S, Qi Y, Cui L, et al. Fabrication of boron nitride nanosheet/polymer composites with tunable thermal insulating properties. New J Chem. 2019;43(12):4878–85.10.1039/C8NJ06236FSearch in Google Scholar

[49] Sato K, Ijuin A, Hotta Y. Thermal conductivity enhancement of alumina/polyamide composites via interfacial modification. Ceram Int. 2015;41(8):10314–8.10.1016/j.ceramint.2015.04.088Search in Google Scholar

[50] Gowda A, Esler D, Tonapi S, Nagarkar K, Srihari K. Voids in thermal interface material layers and their effect on thermal performance. Proceedings of 6th Electronics Packaging Technology Conference (EPTC 2004) (IEEE Cat. No.04EX971); 2004. p. 41–610.1109/EPTC.2004.1396574Search in Google Scholar

[51] Morishita T, Okamoto H. Facile exfoliation and noncovalent superacid functionalization of boron nitride nanosheets and their use for highly thermally conductive and electrically insulating polymer nanocomposites. ACS Appl Mater Interfaces. 2016;8(40):27064–73.10.1021/acsami.6b08404Search in Google Scholar PubMed

[52] Fang M, Wang K, Lu H, Yang Y, Nutt S. Covalent polymer functionalization of graphene nanosheets and mechanical properties of composites. J Mater Chem. 2009;19(38):7098–105.10.1039/b908220dSearch in Google Scholar

[53] Romasanta LJ, Hernández M, López-Manchado MA, Verdejo R. Functionalised graphene sheets as effective high dielectric constant fillers. Nanoscale Res Lett. 2011;6(1):508.10.1186/1556-276X-6-508Search in Google Scholar PubMed PubMed Central