Abstract

Triboelectric nanogenerators (TENGs) have been developed as innovative devices for harvesting various forms of mechanical energy generated by our bodies and surroundings, which provide green and sustainable power for increasingly miniaturized and mobile electronics, especially wearables. In this article, the largest possible output energy per cycle of a TENG in the two basic working modes, namely, the vertical contact-separation (CS) mode and the contact-sliding (LS) mode, is analyzed and the energy collected by a capacitor is tested. It is found that more energy output and collected from a vertical CS mode TENG than that from a LS mode TENG with the same size and triboelectric layer materials when the size and displacement range of the TENG are suitable for a wearable energy harvesting device. In order to improve the energy output of a TENG, three methods have been proposed to increase its surface charge density, such as adding a BaTiO3 film or a polydimethylsiloxane (PDMS)-BaTiO3 composite film between the triboelectric layer and the metal electrode, and using a PDMS-BaTiO3 composite film as a negative triboelectric layer, and corresponding TENGs are fabricated for experimental testing. These measures have effectively enhanced the output of the TENGs.

1 Introduction

Mechanical energy is produced by us and the surrounding environments at any time in various forms, such as human movement, tire rolling, wind and rain, etc. If this kind of energy can be effectively harvested, stored, and utilized, it will be of great significance to relieve the current energy pressure. For example, currently widely used wearable electronic devices are still powered by traditional batteries, which have some drawbacks such as short life, needing to be replaced, environmental pollution, and so on [1,2]. One solution is to collect mechanical energy generated by human movement to power wearable electronic devices. In 2012, Professor Zhonglin Wang first proposed Triboelectric Nanogenerators (TENGs), which can generate charges through the contact or friction of two different materials and cause the flow of charges [3], thereby converting mechanical energy into electrical energy. TENGs have the advantages of low cost [4,5], lightweight design [6,7], readily available production materials [8,9], and high output performance [10,11,12], which provide a new way of harvesting mechanical energy for wearable devices [13,14,15,16,17].

TENGs can work in four modes: the vertical contact-separation (CS) mode [18,19], the contact-sliding (LS) mode [20], the single-electrode (SE) mode [21], and the freestanding triboelectric-layer (FT) mode [22]. The basic modes are the CS mode and the LS mode. The structure of a SE mode TENG or a FT mode TENG can also be classified as a CS structure TENG or a sliding structure TENG. In this article, considering the size and displacement range of TENGs used as wearable energy harvesting devices, we analyze whether the CS mode TENG or the LS mode TENG can output larger energy, and then consider how to enhance the energy output performance of this mode TENG.

Regarding enhancing the energy output performance of TENGs, researchers have conducted extensive work, such as increasing the output power density of TENGs by innovative structural design [23,24,25,26], and improving the collected and stored energy by energy management strategies [27,28,29,30] and resistive matching optimization [31,32,33,34]. Since the power density of a TENG is quadratically related to the triboelectric charge density, a lot of studies have been done to improve the surface charge density [35,36,37,38,39,40]. Kim et al. reported a method to increase the contact area between the metal electrode and polydimethylsiloxane (PDMS) triboelectric layer by patterning microstructure on the surface of PDMS through ultrafast laser irradiation [37], thereby improving the triboelectric charge density of the TENG device. Kim et al. adopted the parylene-deposited multi-walled carbon nanotube (MWCNT)-PDMS films to improve the triboelectric performances by inducing interfacial polarization due to the difference in permittivity between the parylene derivatives and MWCNT-PDMS [38]. Chen et al. improved the energy output of a TENG by designing a feasible approach by filling the tribo-material of PDMS with high permittivity nanoparticles (NPs) and pores [39]. Wang et al. proposed a method of coupling surface polarization from triboelectrification and hysteretic dielectric polarization from ferroelectric materials by adding a BaTiO3 sheet between the triboelectric layer and the electrode, so that the output charge density of the TENG is enhanced from 142 μC/m2 in air to 1,003 μC/m2 in high vacuum [40].

The above works have provided inspiration for our study, and some effective methods are proposed in this study to improve the surface charge density and thus enhance the performance of the TENGs. First, since BaTiO3 is a lead-free material and is suitable for wearable devices, we adopted magnetron sputtering to prepare a thinner BaTiO3 film on the electrode compared with the brittle BaTiO3 sheet prepared in literature [40]. This resulted in the addition of a BaTiO3 film between the triboelectric layer and the electrode which is more flexible and suitable for wearable devices. Second, targeting to reduce production costs and considering that PDMS is a viscoelastic organosilicon polymer [41] which is commonly used as a matrix, we propose the method of adding BaTiO3 nanopowders into PDMS to form a flexible PDMS-BaTiO3 composite film and using this composite film to replace the BaTiO3 film in the first method. Moreover, regarding that PDMS is also an electronegative material, we consider using a PDMS-BaTiO3 composite film as a negative triboelectric layer to prepare a TENG with higher surface charge density. Finally, these designed TENGs are fabricated for experimental verification.

2 Energy output by TENGs in different modes

In this article, only the energy output performances of a CS mode TENG and a LS mode TENG are examined. According to the literature [42], the largest possible output energy generated in one reciprocating motion cycle from a TENG is

where V OC,max is the maximum open circuit voltage at Q = 0, Q SC,max is the maximum short-circuit transferred charge, and V’ max is the maximum achievable absolute voltage at Q = Q SC,max [42].

The explicit analytical relationship between E m and the open circuit voltage which is easier to measure is further derived below.

2.1 Largest possible output energy per cycle from a CS mode TENG

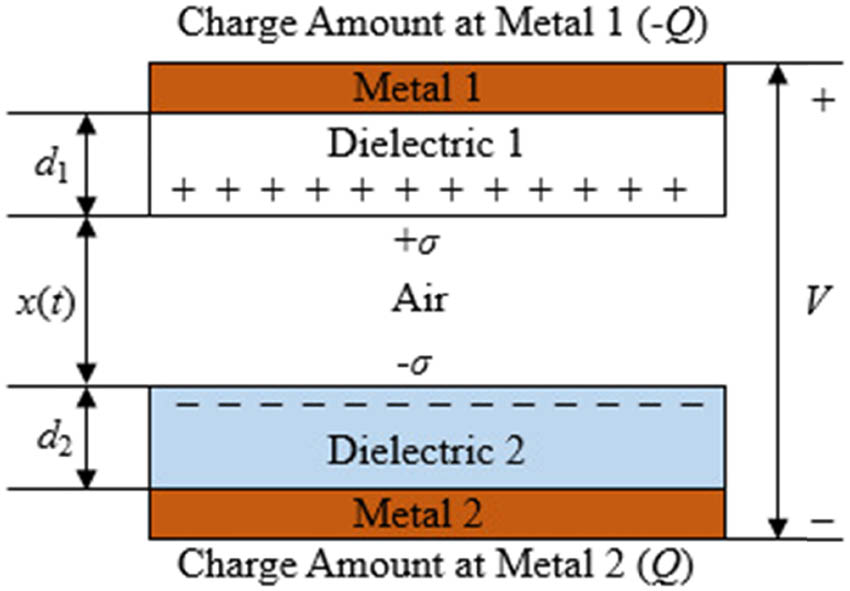

The principle of a CS mode TENG is shown in Figure 1. The sizes of the contact surfaces of the upper and lower triboelectric layers are the same. The thicknesses of the two triboelectric layers are d 1 and d 2. The relative permittivity values of the triboelectric layer materials are ε r1 and ε r2. The distance between the two triboelectric layers is x (t). When the triboelectric layers with different materials come into contact, equal density of positive and negative electrostatic charges, +σ and −σ, will be generated on the surfaces of the two triboelectric layers due to the contact electrification. When the two contact surfaces are separated under the action of external force, an induced potential difference V will be generated between the two electrodes to drive the electrons transfer in the external circuit.

Principle of a CS mode TENG.

When the size of the contact surface of the two triboelectric layers is much larger than d 1 + d 2 + x V,max, (x V,max is the maximum separation distance), the maximum open circuit voltage between the two electrodes is

If the two electrodes are short circuited, the maximum transferred charge value is Q SC,max, and the relationship between Q SC,max and V OC,max is

where

Since V' max = Q SC,max/C, where C is the capacitance value of the TENG when the two triboelectric layers are completely overlapped, V' max is expressed by V OC,max as

Substituting equations (3) and (4) in equation (1), the relationship between E m, that is expressed as E m,V here, and V OC,max of a CS mode TENG is

2.2 Largest possible output energy per cycle of a LS mode TENG

The working principle of a LS mode TENG is illustrated in Figure 2. When one of the triboelectric layers of a LS mode TENG (dielectric 1 in Figure 2) slides along the contact surface with a distance of x, equal amounts of positive and negative charges will be distributed on the non-contact surfaces due to frictional electrification if the triboelectric layer size is much larger than d

1 + d

2. The charge densities in the non-overlapping areas are +σ and −σ, and the charge densities in the overlapping areas are

Principle of a LS mode TENG.

When the sliding distance reaches the maximum value x S,max, the open circuit voltage V OC reaches the maximum value as

If the short-circuit transfer charge amount reaches the maximum value Q SC,max, the relationship between Q SC,max and V OC,max is

V' max can be expressed by V OC,max as

Substituting equations (7) and (8) in equation (1), the relationship between E m, that is expressed as E m,S here, and V OC,max of a LS mode TENG is

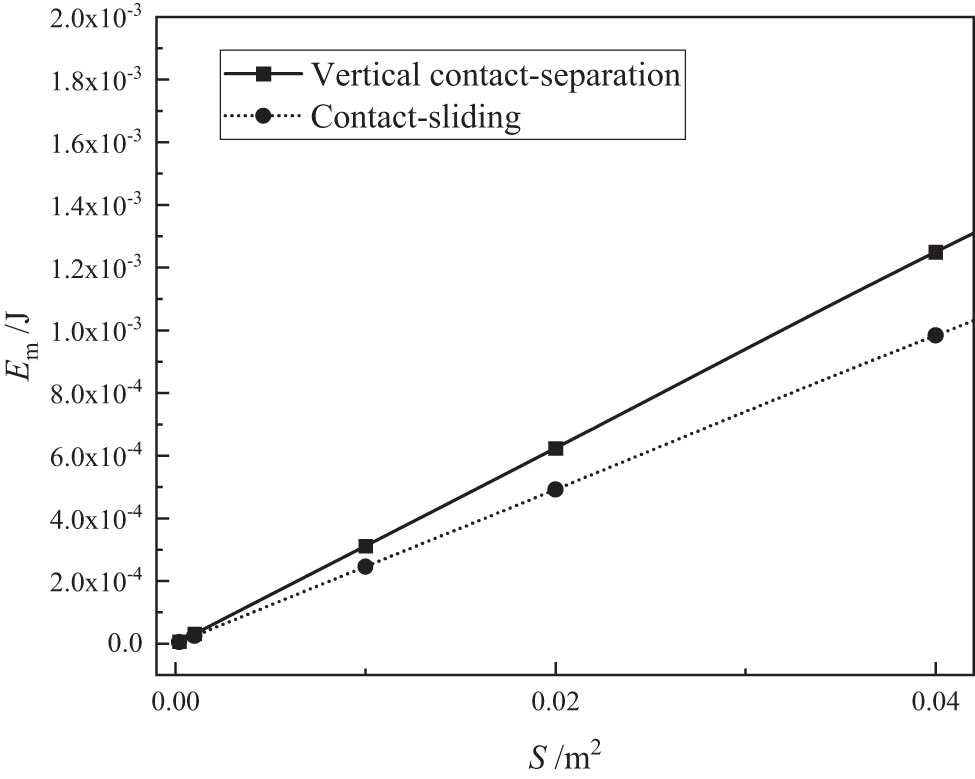

Considering the size of a TENG used as a wearable energy harvesting device is generally in the range of 10 mm × 10 mm to 200 mm × 200 mm (the area S is generally between 100 and 40,000 mm2), which is much larger than the thicknesses of the triboelectric layers, and assuming that the separation distance in a CS mode TENG is 1 mm, the electric field between the TENG triboelectric layers can still be thought to be uniform according to Ahmed et al.’s research on the TENG electric field model that changes with distance [43]. For the LS mode TENG, the sliding distance is set to be 0.95 l. Assuming two TENGs with the same size and the same surface charge density σ, the calculated changes in E m,V and E m,S with S by equations (5) and (9) are shown in Figure 3. It can be seen that the largest possible output energy per cycle of the CS mode TENG is always more than that of the LS mode TENG at this motion scale. It can be inferred that the largest possible output energy per cycle of a vertical CS FT mode TENG or a SE mode TENG is always more than that of an LS FT mode TENG or a SE mode TENG. A similar conclusion is obtained in the study by Yunlong [42], in which the maximum structural figure-of-merit value of TENGs among different maximum displacements is adopted as a standard for quantifying the performance of TENGs, i.e., the maximum structural figure-of-merit value of a CS mode TENG is greater than that of a LS mode TENG. Moreover, the maximum figure-of-merit value of a vertical CS FT mode TENG is also greater than that of the LS FT mode TENG.

Relationships between E m and S of CS mode and LS mode TENGs.

2.3 Harvesting TENG energy using a capacitor

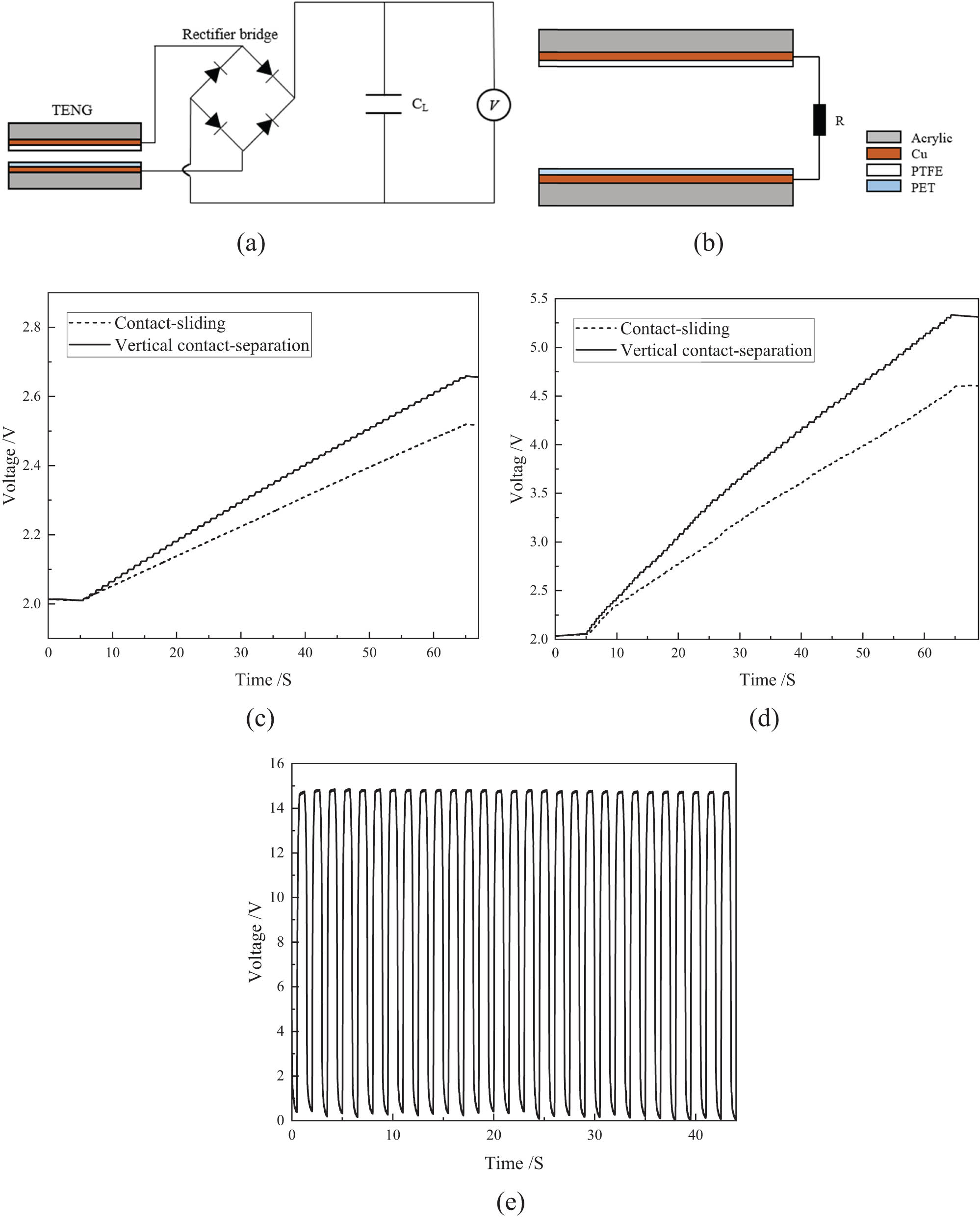

The maximum value of energy per cycle that can be generated by a TENG is obtained under specific load conditions [42]. In an actual operation condition such as the case that a TENG is used as a wearable energy harvesting device, the energy generated per reciprocating motion cycle of a TENG cannot reach this value, and it is also inconvenient to measure. Therefore, the circuit shown in Figure 4(a) is applied to measure the energy collected by a capacitor, which is adopted to investigate the energy output performance of a TENG in this article. In Figure 4(a), the alternating current generated by the TENG is stored in the capacitor after being rectified by the rectifier bridge and filtered by the capacitor. The electric energy collected by the capacitor, E S, is calculated by

where C L is the energy storage capacitor, V 1 is the initial voltage of the energy storage capacitor before the TENG works, and V 2 is the voltage of the capacitor after the TENG works for a period of time.

Collecting energy from a TENG using a capacitor. (a) Electric energy collection circuit. (b) Structure of the TENG. (c) Voltage curves of the capacitor that collects energy from a TENG with the size of 20 mm × 10 mm. (d) Voltage curves of the capacitor that collects energy from a TENG with the size of 60 mm × 30 mm. (e) Voltage measured under the open circuit condition when the TENG with a size of 20 mm × 10 mm performs the CS reciprocating motion with a displacement of 1 mm.

In this study, two TENGs with the sizes of 20 mm × 10 mm and 60 mm × 30 mm are fabricated, in which a 0.1 mm thick polyethylene terephthalate (PET) film is used as the positive triboelectric layer, a 0.08 mm thick polytetrafluoroethylene (PTFE) film is used as the negative triboelectric layer, and two copper films with a thickness of 0.06 mm are used as the two electrodes, as shown in Figure 4(b). A stepper motor is used to drive one triboelectric layer of the TENG to perform a reciprocating CS with a displacement of 1 mm or an LS with a horizontal displacement of 0.95 l relative to the other triboelectric layer at a frequency of 1 Hz (Video S1). According to the research by Niu et al. [44], the optimum load capacitance that matches the TENGs impedance is proportional to the charging cycle numbers and the inherent capacitance of the TENG. Due to the small inherent capacitances of the TENGs fabricated in this study, the capacitance of the energy storage capacitor is 1 μF. In order to avoid the influence of the voltage source in the external environment on the charging of the capacitor, the initial voltage of the capacitor is set as 2 V. The voltage curves of the capacitor adopted to collect the energy from the two TENGs operating for 1 min are shown in Figure 4(c) and (d), respectively. For the TENG with a size of 20 mm × 10 mm working in the CS mode and the SL mode for 60 s, the voltage values of the energy storage capacitor, V 2, are 2.66 and 2.51 V, and the average electrical energy stored by the capacitor in a single working cycle, i.e., the actual collected electrical energy per cycle, is 2.56 × 10−8 J and 1.92 × 10−8 J, respectively. For the TENG with a size of 60 mm × 30 mm working in the CS mode and the LS mode for 60 s, the voltage values of the energy storage capacitor, V 2, are 5.30 and 4.60 V, and the average electrical energy stored by the capacitor in a single working cycle is 2.00 × 10−7 J and 1.43 × 10−7 J, respectively. It can be seen that the TENGs fabricated in this study collect more energy when working in the CS mode than in the LS mode. This is consistent with the conclusion using the largest possible output energy per cycle as an indicator. It can be concluded that for a TENG with the same size and the same triboelectric layer materials used as a wearable energy harvesting device, the energy collected in the CS mode is more than that in the LS mode.

3 Improving surface charge density of TENGs

From the analysis of the largest possible output energy of a TENG in a single cycle in Section 2, it can be seen that increasing the maximum open circuit voltage, which means increasing the surface charge density, is an effective measure to improve the energy output performance of the TENG. The measured voltage of the TENG with the size of 20 mm × 10 mm operating in the CS reciprocating motion with a displacement of 1 mm under the open circuit condition is shown in Figure 4(e) (Video S2), and the corresponding triboelectric charge density is 23.6 μC/m2. In this section, three effective methods are proposed to improve the surface charge density, and corresponding TENGs are fabricated for experimental verification.

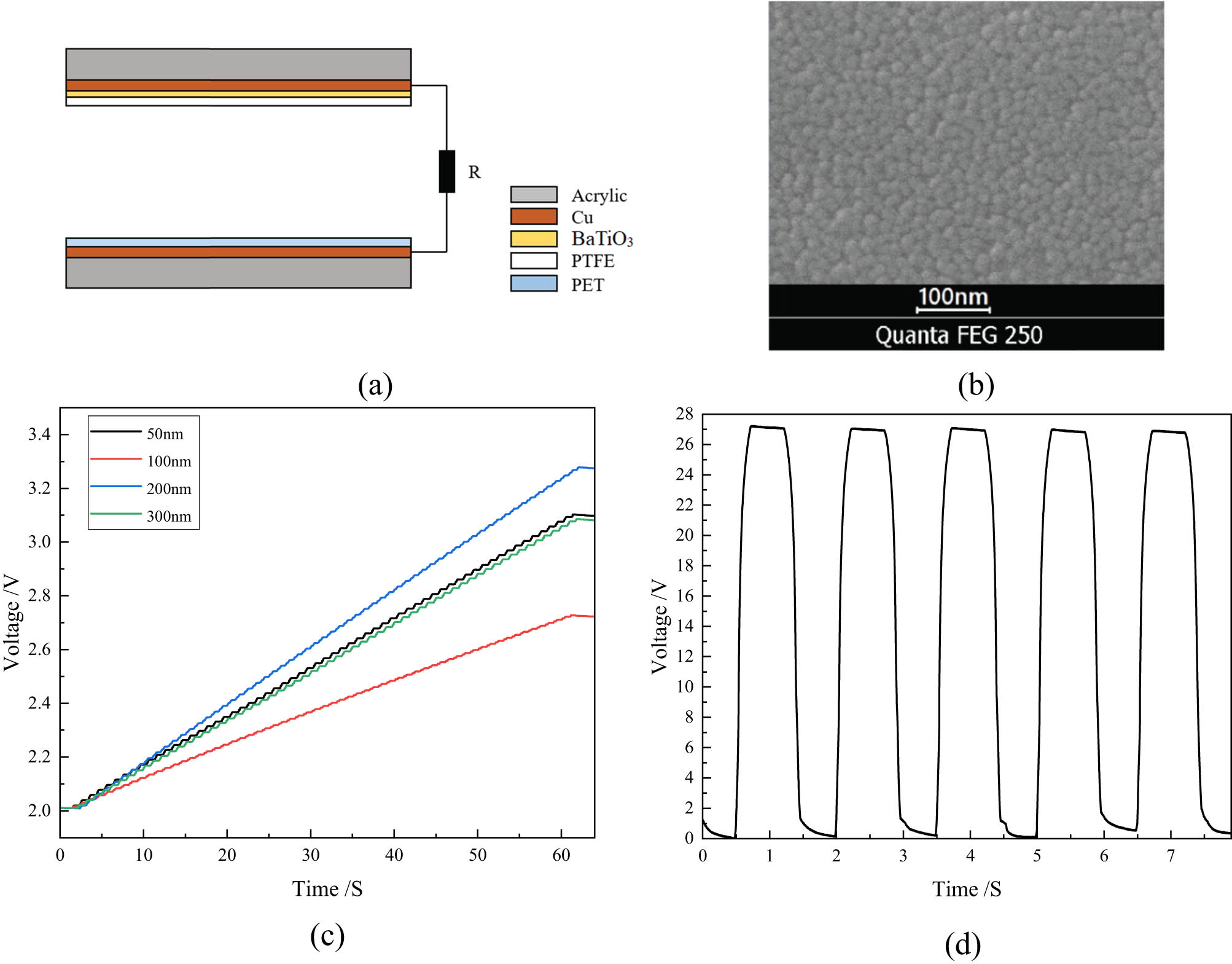

3.1 Adding a BaTiO3 film between the triboelectric layer and the metal electrode

BaTiO3 is a typical ferroelectric material that exhibits dielectric polarization in an electric field, and there will be residual polarization in it after the electric field is withdrawn due to the hysteretic characteristics. When it is adhered to a triboelectric layer, the charge densities on the surfaces of the triboelectric layers will be increased by the coupling effect of the surface polarization from triboelectrification and the hysteretic dielectric polarization [40]. In this study, the radio frequency (RF) magnetron sputtering process is employed to sputter BaTiO3 onto a copper film to form a BaTiO3 film on the copper film electrode, which is adhered to the back of the negative triboelectric layer to produce a TENG with a size of 20 mm × 10 mm. The structure is shown in Figure 5(a), and the SEM image of the BaTiO3 film is shown in Figure 5(b). With the separation movement of triboelectric layer in the TENG, an electric field is generated between the two electrodes, and the BaTiO3 film undergoes dielectric polarization in the electric field. When the triboelectric layers are in contact with each other and the electric field intensity between the two electrodes is zero, there will be residual polarization in the BaTiO3 film due to dielectric hysteresis, which will improve the ability of the negative triboelectric layer to capture electrons and thereby increase the surface charge density.

TENGs with BaTiO3 films. (a) Structure of the TENG. (b) SEM image of the BaTiO3 film. (c) Voltage curves of the energy storage capacitor to collect power output from the TENGs with the BaTiO3 films with different thicknesses. (d) Voltage measured under the open circuit condition when the TENG with a 200 nm thick BaTiO3 film performs the CS reciprocating motion with a displacement of 1 mm.

In this study, the TENGs with the size of 20 mm × 10 mm and the BaTiO3 films with different thicknesses between the PTFE layer and the metal electrode are fabricated which are allowed to perform the CS reciprocating motion with a displacement of 1 mm and a frequency of 1 Hz for 60 s. The same capacitor C L as in Section 2.3 is used to harvest the energy of the TENGs, and the voltage curves of the energy storage capacitor are shown in Figure 5(c). According to equation (10), it can be derived that the energy collected by the capacitor from the TENG with the BaTiO3 film with a thickness of 200 nm is largest. The average electric energy collected by the capacitor from this TENG in a single working cycle is 5.58 × 10−8 J, which is an increase of 118.0% compared to that from the TENG without a BaTiO3 film. The voltage of this TENG measured under the open circuit condition is shown in Figure 5(d) (Video S3). The corresponding surface charge density of the TENG is 42.5 μC/m2, which is 80.1% higher than that of the TENG without a BaTiO3 film.

3.2 Adding a PDMS-BaTiO3 composite film between the triboelectric layer and the metal electrode

The process of producing BaTiO3 films by RF magnetron sputtering is relatively complex and costly. Therefore, it is considered to add BaTiO3 nanopowders (its X-Ray diffraction [XRD] with Reitveld refinement fit is shown in Figure 6(h)) into the PDMS to form a composite ferroelectric film. Moreover, a trace amount of Dy2O3 is added into it because of its superior electrical and dielectric properties [45], and MWCNTs are added as a dispersant and stress enhancer, then a PDMS-BaTiO3 composite film is made to replace the BaTiO3 film. Four composite films with the BaTiO3 mass fractions of 12 and 24% and the Dy2O3 mass fractions of 1 and 2% are prepared, as shown in Figure 6(a). The composite film is adhered to the back of the negative triboelectric layer to fabricate the TENG with the PDMS-BaTiO3 composite film and the size of 20 mm × 10 mm. The structure is shown in Figure 6(b). Then, the TENGs are allowed to perform the CS reciprocating motion with a displacement of 1 mm and a frequency of 1 Hz for 60 s. Using the same energy storage capacitor C L as before, its voltage curves are shown in Figure 6(c). It can be derived that the energy collected by the capacitor from the TENG with a composite film with a mass fraction of BaTiO3 of 24% and a mass fraction of Dy2O3 of 1% is largest. The SEM image, energy dispersive spectrometer (EDS) spectra, and P-E hysteresis loop of this composite film are shown in Figure 6(e)–(g). The average electric energy collected by the capacitor from this TENG in a single working cycle is 3.92 × 10−8 J, which is 53.1% higher than that from the TENG without a composite film. The voltage of this TENG measured under the open circuit condition is shown in Figure 6(d) (Video S4). The corresponding surface charge density of the TENG is 32.3 μC/m2, which is 36.9% higher than that of the TENG without a composite film. Although the collected energy and the surface charge density of the TENG with the composite film are not as large as those of the TENG with the 200 nm thick BaTiO3 film, the composite film is easier to produce, incurs low cost, and thus more practical.

TENGs with PDMS-BaTiO3 composite films. (a) Photograph of the composite film. (b) Structure of the TENG. (c) Voltage curves of the energy storage capacitor to collect power output from the TENGs with the composite films of different compositions. (d) Voltage measured under the open circuit condition when the TENG with composite film with a mass fraction of BaTiO3 of 24% and a mass fraction of Dy2O3 of 1% performs CS reciprocating motion with a displacement of 1 mm. (e) SEM image of the composite film. (f) EDS spectra of the composite film (the gold element is produced by spraying gold on the sample during detection). (g) P-E hysteresis loop of the composite film. (h) XRD with Reitveld refinement fit of BaTiO3 particles.

3.3 Using a PDMS-BaTiO3 composite film as the negative triboelectric layer

Adding BaTiO3 nanopowders to a dielectric material can improve the relative permittivity of the material, thereby increasing the surface charge density of the material [38]. Considering that PDMS is a material with high electronegative properties, it can also be used as the material for the negative triboelectric layer of a TENG. In this study, the PDMS-BaTiO3 composite film containing 24% BaTiO3 mass fraction and 1% Dy2O3 mass fraction in Section 3.2 is directly used as the negative triboelectric layer to fabricate the TENG with the size of 20 mm × 10 mm, and its structure is shown in Figure 7(a). The TENG is allowed to perform the CS reciprocating motion with a displacement of 1 mm and a frequency of 1 Hz for 60 s. Using the same energy storage capacitor C L as before, the voltage curves of the capacitor which is employed to harvest the power from the TENGs with the PDMS negative triboelectric layer and with the PDMS-BaTiO3 composite negative triboelectric layer are shown in Figure 7(b). The average electric energy collected by the capacitor in a single working cycle is calculated to be 2.04 × 10−8 J and 3.72 × 10−8 J, respectively. The energy collected from the TENG using the composite film as the negative triboelectric layer is 82.4% higher than the energy collected from the TENG using the PDMS negative triboelectric layer. The voltage of the TENG with the PDMS-BaTiO3 composite negative triboelectric layer measured under the open circuit condition is shown in Figure 7(c) (Video S5). The corresponding surface charge density of this TENG is 30.9 μC/m2. Compared with the surface charge density of the TENG with the PDMS negative triboelectric layer, i.e., 21.8 μC/m2, the surface charge density of the TENG with the composite negative triboelectric layer is 41.7% higher.

The TENG with a PDMS-BaTiO3 composite film as the negative triboelectric layer. (a) Structural of the TENG with the PDMS negative triboelectric layer (the left) and the TENG with the PDMS-BaTiO3 composite negative triboelectric layer (the right). (b) The voltage curves of the energy storage capacitor employed to harvest the power from the TENGs using PDMS and the composite film as the negative triboelectric layer materials. (c) The voltage measured under the open circuit condition when the TENG with the composite negative triboelectric layer performs the CS reciprocating motion with a displacement of 1 mm.

3.4 Performance evaluation of the TENGs

From the analysis of the largest possible output energy of a TENG in a single cycle in Section 2, it can be concluded that the output energy of a TENG is quadratically related to the surface charge density, so surface charge density is used here to characterize the performance of various generators, and the energy collected by the capacitor is also compared, as shown in Table 1. It can be seen that compared with the PTFE-PET TENG without any improvement measures taken, the performance of the TENG has been improved by adding a BaTiO3 film or a PDMS-BaTiO3 composite film between the triboelectric layer and the metal electrode, and using a PDMS-BaTiO3 composite film as a negative triboelectric layer.

Comparison of surface charge density and collected energy of various designed TENGs

| TENG type | PTFE-PET TENG | PTFE-PET TENG with a BaTiO3 film | PTFE-PET TENG with a PDMS-BaTiO3 film | PDMS-BaTiO3 film-PET TENG |

|---|---|---|---|---|

| Surface charge density/(μC/m2) | 23.6 | 42.5 | 32.3 | 30.9 |

| Collected energy/J | 2.56 × 10−8 | 5.58 × 10−8 | 3.92 × 10−8 | 3.72 × 10−8 |

To evaluate the long-term stability of the TENGs fabricated in this study, the comparison of the average values of voltage under the open circuit condition and surface charge density of the TENGs measured in the dry spring and humid summer environments is shown in Table 2. It can be seen that the voltage and surface charge density values of the three TENGs in the humid environment have decreased compared to those in the dry environment. Among them, the stability of the PTFE-PET TENG with a BaTiO3 film is best, while the stability of the other two TENGs is slightly worse. When used as wearable devices, packaging measures can be taken to reduce the impact of the environment.

Average values of voltage under the open circuit condition and surface charge density of the TENGs measured in the dry spring and humid summer environments

| TENG type | Voltage (V) | Charge density (μC/m2) | ||

|---|---|---|---|---|

| Dry spring | Humid summer | Dry spring | Humid summer | |

| PTFE-PET TENG with a BaTiO3 film | 27.0 | 26.7 | 42.5 | 42.0 |

| PTFE-PET TENG with a PDMS-BaTiO3 film | 20.8 | 19.4 | 32.3 | 30.5 |

| PDMS-BaTiO3 film-PET TENG | 19.8 | 18.1 | 30.9 | 28.5 |

4 Experimental section

4.1 Production of the BaTiO3 film between the triboelectric layer and the electrode

The BaTiO3 thin film is deposited by RF magnetron sputtering on the copper electrode using the MSP 300B magnetron sputtering instrument made in China. The sputtering time is about 2 h for every 100 nm thick

4.2 Production of the PDMS-BaTiO3 composite film with added Dy2O3

First, the BaTiO3 NPs (average diameters: 10 nm, Shenzhen Runyou Chemical Co., Ltd), MWCNTs (average inner diameter: 4.0 nm, average outer diameter: 11.5 nm, average length: 7.5 μm, Shenzhen Suiheng Graphene Technology Co. Ltd), and Dy2O3 powder (average diameter: 20 nm, Shenzhen Runyou Chemical Co., Ltd) are fully stirred and dispersed in the PDMS (Sylgard 184, Dow Corning) liquid. Then, the diffusion oil (the amount is 1% of the mass of PDMS, Kangjin New Materials Technology Co., Ltd) is added to solve the dispersion problem and flocculation phenomenon of BaTiO3 NPs and MWCNTs. Finally, the mixed liquid is placed in a glass Petri dish, and is cured for 45 min at a temperature of 100°C in an oven to obtain the composite film with good flexibility.

4.3 Energy harvesting using a capacitor

A stepper motor is used to drive one triboelectric layer of the TENG to perform a reciprocating CS with a displacement of 1 mm in the CS mode or a LS mode with a horizontal displacement of 0.95 l in the LS mode relative to the other triboelectric layer at a frequency of 1 Hz. A Keithley 6514 electrometer is used to measure the voltage of the TENG under the open circuit condition. A capacitor is adopted to collect the energy output form the TENG, and a Keithley DAQ 6510 multimeter is used to measure its voltage. In order to avoid the influence of the voltage source in the external environment on the charging of the capacitor, the initial voltage of the capacitor is set as 2 V. Then, the electric energy collected by the capacitor can be calculated by equation (10) based on the voltage difference on the capacitor.

5 Conclusion

Considering the size range of TENGs used as wearable energy harvesting devices, assuming that the maximum separation distance of TENGs in the CS mode is 1 mm, and the maximum sliding distance of TENGs in the LS mode is 0.95 l, it can be concluded through calculation and experimental measurement that the electrical energy generated and harvested from the CS TENG in one reciprocating motion is always greater than that from the LS TENG if the size and triboelectric layer materials of the TENGs are the same.

Adding a BaTiO3 film between the triboelectric layer and the electrode can effectively improve the surface charge density of the TENG, thereby increasing its energy output. In this article, the TENG with the size of 20 mm × 10 mm and the 200 nm thick BaTiO3 film between the PTFE layer and the copper electrode and the PET positive triboelectric layer is fabricated. The electrical energy collected by the energy storage capacitor per cycle from this TENG operating in the CS mode is 118.0% higher than that collected from the TENG of the same size without a BaTiO3 film.

Adding a PDMS-BaTiO3 composite film between the triboelectric layer and the electrode is a low-cost method that can improve the surface charge density and thereby increase the energy output of the TENG. In this article, the PDMS-BaTiO3 composite films with different compositions are added between the PTFE layer and the copper electrode. Compared with the TENG of the same size without a composite film, the electric energy collected by the capacitor per cycle from the TENGs with the composite films working in the CS mode is improved. The collected electric energy per cycle from the TENG with the composite film adding 24% BaTiO3 mass fraction and 1% Dy2O3 mass fraction is largest, which is 53.1% higher than that from the TENG without a composite film.

The PDMS-BaTiO3 composite film with added Dy2O3 can also be directly used as a negative triboelectric layer material. Compared with the energy collected from the TENG of the same size with the PDMS negative triboelectric layer, the electrical energy collected by the capacitor per cycle from the TENG with the PDMS-BaTiO3 composite negative triboelectric layer working in the CS mode has increased by 82.4%. Therefore, the PDMS-BaTiO3 composite film with added Dy2O3 can also effectively enhance the energy output of TENGs.

-

Funding information: This work is supported by the Ministry of Industry and Information Technology of China (No. 3030021221910).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Sun YH, Li YZ, Yuan M. Requirements, challenges, and novel ideas for wearables on power supply and energy harvesting. Nano Energy. 2023;115:108715.10.1016/j.nanoen.2023.108715Suche in Google Scholar

[2] Ma X, Jiang Z, Lin Y. Flexible energy storage devices for wearable bioelectronics. J Semiconductors. 2021;42:101602.10.1088/1674-4926/42/10/101602Suche in Google Scholar

[3] Fan FR, Tian ZQ, Wang ZL. Flexible triboelectric generator. Nano Energy. 2012;1:328–34.10.1016/j.nanoen.2012.01.004Suche in Google Scholar

[4] Li Y, Zhao Z, Gao Y, Li S, Zhou L, Wang J, et al. Low-cost, environmentally friendly, and high-performance triboelectric nanogenerator based on a common waste material. Acs Appl Mater Interfaces. 2021;13:30776–84.10.1021/acsami.1c09192Suche in Google Scholar PubMed

[5] Bulathsinghala RL, Ding W, Dharmasena RDIG. Triboelectric nanogenerators for wearable sensing applications: a system level analysis. Nano Energy. 2023;116:108792.10.1016/j.nanoen.2023.108792Suche in Google Scholar

[6] Wang ZL. On Maxwell’s displacement current for energy and sensors: the origin of nanogenerators. Mater Today. 2017;20:74–82.10.1016/j.mattod.2016.12.001Suche in Google Scholar

[7] Wang Z, Tang Q, Shan C, Du Y, He W, Fu S, et al. Giant performance improvement of triboelectric nanogenerator systems achieved by matched inductor design. Energy Environ Sci. 2021;14:6627–37.10.1039/D1EE02852ASuche in Google Scholar

[8] Zhao Z, Zhou L, Li S, Liu D, Li Y, Gao Y, et al. Selection rules of triboelectric materials for direct-current triboelectric nanogenerator. Nat Commun. 2021;12:4686.10.1038/s41467-021-25046-zSuche in Google Scholar PubMed PubMed Central

[9] Zou H, Zhang Y, Guo L, Wang P, He X, Dai G, et al. Quantifying the triboelectric series. Nat Commun. 2019;10:1427.10.1038/s41467-019-09461-xSuche in Google Scholar PubMed PubMed Central

[10] Fu S, Hu C. Achieving ultra-durability and high output performance of triboelectric nanogenerators. Adv Funct Mater. 2024;34:2308138.10.1002/adfm.202308138Suche in Google Scholar

[11] Zhao ZH, Dai YJ, Liu D, Zhou SL, Li SX, Wang ZL, et al. Rationally patterned electrode of direct-current triboelectric nanogenerators for ultrahigh effective surface charge density. Nat Commun. 2020;11:6186.10.1038/s41467-020-20045-ySuche in Google Scholar PubMed PubMed Central

[12] Ruthvik K, Babu A, Supraja P, Navaneeth M, Mahesh V, Kumar KU, et al. High-performance triboelectric nanogenerator based on 2D graphitic carbon nitride for self-powered electronic devices. Mater Lett. 2023;350:134947.10.1016/j.matlet.2023.134947Suche in Google Scholar

[13] Kaur N, Pal K. Triboelectric nanogenerators for mechanical energy harvesting. Energy Technol. 2018;6:958–97.10.1002/ente.201700639Suche in Google Scholar

[14] Zou Y, Libanori A, Xu J, Nashalian A, Chen J. Triboelectric nanogenerator enabled smart shoes for wearable electricity generation. Research. 2020;2020:7158953.10.34133/2020/7158953Suche in Google Scholar PubMed PubMed Central

[15] Xiao X, Chen GR, Libanori A, Chen J. Wearable triboelectric nanogenerators for therapeutics. Trends Chem. 2021;3:279–90.10.1016/j.trechm.2021.01.001Suche in Google Scholar

[16] Doganay D, Demircioglu O, Cugunlular M, Cicek MO, Cakir O, Kayaci HU, et al. Wet spun core-shell fibers for wearable triboelectric nanogenerators. Nano Energy. 2023;116:108823.10.1016/j.nanoen.2023.108823Suche in Google Scholar

[17] Divya S, Panda S, Hajra S, Jeyara R, Paul A, Park SH, et al. Smart data processing for energy harvesting systems using artificial intelligence. Nano Energy. 2023;106:108084.10.1016/j.nanoen.2022.108084Suche in Google Scholar

[18] Wang S, Lin L, Wang ZL. Nanoscale triboelectric-effect-enabled energy conversion for sustainably powering portable electronics. Nano Lett. 2012;12:6339–46.10.1021/nl303573dSuche in Google Scholar PubMed

[19] Niu S, Wang S, Lin L, Liu Y, Zhou YS, Hu Y, et al. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ Sci. 2013;6:3576–83.10.1039/c3ee42571aSuche in Google Scholar

[20] Niu S, Liu Y, Wang S, Lin L, Zhou YS, Hu Y, et al. Theory of sliding-mode triboelectric nanogenerators. Adv Mater. 2013;25:6184–93.10.1002/adma.201302808Suche in Google Scholar PubMed

[21] Yang Y, Zhou YS, Zhang H, Liu Y, Lee S, Wang ZL. A Single-electrode based triboelectric nanogenerator as self-powered tracking system. Adv Mater. 2013;25:6594–601.10.1002/adma.201302453Suche in Google Scholar PubMed

[22] Niu S, Liu Y, Chen X, Wang S, Zhou YS, Lin L, et al. Theory of freestanding triboelectric-layer-based nanogenerators. Nano Energy. 2015;12:760–74.10.1016/j.nanoen.2015.01.013Suche in Google Scholar

[23] Zhu G, Chen J, Zhang T, Jing Q, Wang ZL. Radial-arrayed rotary electrification for high performance triboelectric generator. Nat Commun. 2014;5:3426.10.1038/ncomms4426Suche in Google Scholar PubMed

[24] Chen J, Huang Y, Zhang N, Zou H, Liu R, Tao C, et al. Micro-cable structured textile for simultaneously harvesting solar and mechanical energy. Nat Energy. 2016;1:16138.10.1038/nenergy.2016.138Suche in Google Scholar

[25] Li Q, Fu S, Li X, Chen H, He W, Yang Q, et al. Overall performance improvement of direct-current triboelectric nanogenerators by charge leakage and ternary dielectric evaluation. Energy Environ Sci. 2023;16:3514–25.10.1039/D3EE01408HSuche in Google Scholar

[26] Saritas R, Al-Ghamdi M, Das TM, Rasheed O, Kocer S, Gulsaran A, et al. Nano groove and prism-structured triboelectric nanogenerators. Micromachines. 2023;14:14091707.10.3390/mi14091707Suche in Google Scholar PubMed PubMed Central

[27] Cheng X, Miao L, Song Y, Su Z, Chen H, Chen X, et al. High efficiency power management and charge boosting strategy for a triboelectric nanogenerator. Nano Energy. 2017;38:448–56.10.1016/j.nanoen.2017.05.063Suche in Google Scholar

[28] Liang X, Jiang T, Liu G, Feng Y, Zhang C, Wang ZL. Spherical triboelectric nanogenerator integrated with power management module for harvesting multidirectional water wave energy. Energy Environ Sci. 2020;13:277–85.10.1039/C9EE03258DSuche in Google Scholar

[29] Wen J, Pan X, Fu H, Xu B. Advanced designs for electrochemically storing energy from triboelectric nanogenerators. Matter. 2023;6:2153–81.10.1016/j.matt.2023.04.004Suche in Google Scholar

[30] Xi F, Pang Y, Li W, Jiang T, Zhang L, Guo T, et al. Universal power management strategy for triboelectric nanogenerator. Nano Energy. 2017;37:168–76.10.1016/j.nanoen.2017.05.027Suche in Google Scholar

[31] Dharmasena RDIG, Deane JHB, Silva SRP. Nature of power generation and output optimization criteria for triboelectric nanogenerators. Adv Energy Mater. 2018;8:1802190.10.1002/aenm.201802190Suche in Google Scholar

[32] Zhou H, Liu F, Chen J, Wang J, Wu Y, Chen J, et al. Computer aided design automation for triboelectric nanogenerators. Nano Energy. 2023;118:108963.10.1016/j.nanoen.2023.108963Suche in Google Scholar

[33] Gao F, Zhang Z, Liao Q, Zhang G, Kang Z, Zhao X, et al. A universal strategy for improving the energy transmission efficiency and load power of triboelectric nanogenerators. Adv Energy Mater. 2019;9:201901881.10.1002/aenm.201901881Suche in Google Scholar

[34] Xie X, Zhang Y, Chen C, Chen X, Yao T, Peng M, et al. Frequency-independent self-powered sensing based on capacitive impedance matching effect of triboelectric nanogenerator. Nano Energy. 2019;65:103984.10.1016/j.nanoen.2019.103984Suche in Google Scholar

[35] Wei XY, Zhu G, Wang ZL. Surface-charge engineering for high-performance triboelectric nanogenerator based on identical electrification materials. Nano Energy. 2014;10:83–9.10.1016/j.nanoen.2014.08.007Suche in Google Scholar

[36] Wang H, Xu L, Bai Y, Wang ZL. Pumping up the charge density of a triboelectric nanogenerator by charge-shuttling. Nat Commun. 2020;11:4203.10.1038/s41467-020-17891-1Suche in Google Scholar PubMed PubMed Central

[37] Kim D, Tcho IW, Jin IK, Park SJ, Jeon SB, Kim WG, et al. Direct-laser-patterned friction layer for the output enhancement of a triboelectric nanogenerator. Nano Energy. 2017;35:379–86.10.1016/j.nanoen.2017.04.013Suche in Google Scholar

[38] Kim MP, Lee G, Noh B, Kim J, Kwak MS, Lee KJ, et al. Enhancing energy harvesting performance of bilayered parylene triboelectric nanogenerators through interfacial polarization. Nano Energy. 2024;119:109087.10.1016/j.nanoen.2023.109087Suche in Google Scholar

[39] Chen J, Guo H, He X, Liu G, Xi Y, Shi H, et al. Enhancing performance of triboelectric nanogenerator by filling high dielectric nanoparticles into sponge PDMS film. ACS Appl Mater Interfaces. 2016;8:736–44.10.1021/acsami.5b09907Suche in Google Scholar PubMed

[40] Wang J, Wu C, Dai Y, Zhao Z, Wang A, Zhang T, et al. Achieving ultrahigh triboelectric charge density for efficient energy harvesting. Nat Commun. 2017;8:88.10.1038/s41467-017-00131-4Suche in Google Scholar PubMed PubMed Central

[41] Hajra S, Panda S, Song S, Panigrahi BK, Pakawanit P, Jeong SM, et al. Flexible composite material for self-powered applications via triboelectricity and mechanoluminescence: PDMS/ZnS:Cu composites. Nano Energy. 2023;114:108668.10.1016/j.nanoen.2023.108668Suche in Google Scholar

[42] Yunlong Z, Niu S, Wang J, Wen Z, Tang W, Wang ZL. Standards and figure-of-merits for quantifying the performance of triboelectric nanogenerators. Nat Commun. 2015;6:8376.10.1038/ncomms9376Suche in Google Scholar PubMed PubMed Central

[43] Ahmed AA, Abdullah HM, Qahtan TF, Muthalif AGA, Nafea M, Ali MSM. An enhanced distance-dependent electric field model for contact-separation triboelectric nanogenerator: air-breakdown limit as a case study. Nano Energy. 2023;117:108836.10.1016/j.nanoen.2023.108836Suche in Google Scholar

[44] Niu S, Liu Y, Zhou YS, Wang S, Lin L, Wang ZL. Optimization of triboelectric nanogenerator charging systems for efficient energy harvesting and storage. IEEE Trans Electr Devices. 2015;62(2):641–7.10.1109/TED.2014.2377728Suche in Google Scholar

[45] Cherif A, Jomni S, Mliki N, Beji L. Electrical and dielectric characteristics of Al/Dy2O3/p-Si heterostructure. Phys B. 2013;429:79–84.10.1016/j.physb.2013.07.026Suche in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface

- Potential pharmaceutical applications and molecular docking study for green fabricated ZnO nanoparticles mediated Raphanus sativus: In vitro and in vivo study

- Effect of temperature and nanoparticle size on the interfacial layer thickness of TiO2–water nanofluids using molecular dynamics

- Characteristics of induced magnetic field on the time-dependent MHD nanofluid flow through parallel plates

- Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

- Experimental research on mechanically and thermally activation of nano-kaolin to improve the properties of ultra-high-performance fiber-reinforced concrete

- Analysis of variable fluid properties for three-dimensional flow of ternary hybrid nanofluid on a stretching sheet with MHD effects

- Biodegradability of corn starch films containing nanocellulose fiber and thymol

- Toxicity assessment of copper oxide nanoparticles: In vivo study

- Some measures to enhance the energy output performances of triboelectric nanogenerators

- Reinforcement of graphene nanoplatelets on water uptake and thermomechanical behaviour of epoxy adhesive subjected to water ageing conditions

- Optimization of preparation parameters and testing verification of carbon nanotube suspensions used in concrete

- Max-phase Ti3SiC2 and diverse nanoparticle reinforcements for enhancement of the mechanical, dynamic, and microstructural properties of AA5083 aluminum alloy via FSP

- Advancing drug delivery: Neural network perspectives on nanoparticle-mediated treatments for cancerous tissues

- PEG-PLGA core–shell nanoparticles for the controlled delivery of picoplatin–hydroxypropyl β-cyclodextrin inclusion complex in triple-negative breast cancer: In vitro and in vivo study

- Conduction transportation from graphene to an insulative polymer medium: A novel approach for the conductivity of nanocomposites

- Review Articles

- Developments of terahertz metasurface biosensors: A literature review

- Overview of amorphous carbon memristor device, modeling, and applications for neuromorphic computing

- Advances in the synthesis of gold nanoclusters (AuNCs) of proteins extracted from nature

- A review of ternary polymer nanocomposites containing clay and calcium carbonate and their biomedical applications

- Recent advancements in polyoxometalate-functionalized fiber materials: A review

- Special contribution of atomic force microscopy in cell death research

- A comprehensive review of oral chitosan drug delivery systems: Applications for oral insulin delivery

- Cellular senescence and nanoparticle-based therapies: Current developments and perspectives

- Cyclodextrins-block copolymer drug delivery systems: From design and development to preclinical studies

- Micelle-based nanoparticles with stimuli-responsive properties for drug delivery

- Critical assessment of the thermal stability and degradation of chemically functionalized nanocellulose-based polymer nanocomposites

- Research progress in preparation technology of micro and nano titanium alloy powder

- Nanoformulations for lysozyme-based additives in animal feed: An alternative to fight antibiotic resistance spread

- Incorporation of organic photochromic molecules in mesoporous silica materials: Synthesis and applications

- A review on modeling of graphene and associated nanostructures reinforced concrete

- A review on strengthening mechanisms of carbon quantum dots-reinforced Cu-matrix nanocomposites

- Review on nanocellulose composites and CNFs assembled microfiber toward automotive applications

- Nanomaterial coating for layered lithium rich transition metal oxide cathode for lithium-ion battery

- Application of AgNPs in biomedicine: An overview and current trends

- Nanobiotechnology and microbial influence on cold adaptation in plants

- Hepatotoxicity of nanomaterials: From mechanism to therapeutic strategy

- Applications of micro-nanobubble and its influence on concrete properties: An in-depth review

- A comprehensive systematic literature review of ML in nanotechnology for sustainable development

- Exploiting the nanotechnological approaches for traditional Chinese medicine in childhood rhinitis: A review of future perspectives

- Twisto-photonics in two-dimensional materials: A comprehensive review

- Current advances of anticancer drugs based on solubilization technology

- Recent process of using nanoparticles in the T cell-based immunometabolic therapy

- Future prospects of gold nanoclusters in hydrogen storage systems and sustainable environmental treatment applications

- Preparation, types, and applications of one- and two-dimensional nanochannels and their transport properties for water and ions

- Microstructural, mechanical, and corrosion characteristics of Mg–Gd–x systems: A review of recent advancements

- Functionalized nanostructures and targeted delivery systems with a focus on plant-derived natural agents for COVID-19 therapy: A review and outlook

- Mapping evolution and trends of cell membrane-coated nanoparticles: A bibliometric analysis and scoping review

- Nanoparticles and their application in the diagnosis of hepatocellular carcinoma

- In situ growth of carbon nanotubes on fly ash substrates

- Structural performance of boards through nanoparticle reinforcement: An advance review

- Reinforcing mechanisms review of the graphene oxide on cement composites

- Seed regeneration aided by nanomaterials in a climate change scenario: A comprehensive review

- Surface-engineered quantum dot nanocomposites for neurodegenerative disorder remediation and avenue for neuroimaging

- Graphitic carbon nitride hybrid thin films for energy conversion: A mini-review on defect activation with different materials

- Nanoparticles and the treatment of hepatocellular carcinoma

- Special Issue on Advanced Nanomaterials and Composites for Energy Conversion and Storage - Part II

- Highly safe lithium vanadium oxide anode for fast-charging dendrite-free lithium-ion batteries

- Recent progress in nanomaterials of battery energy storage: A patent landscape analysis, technology updates, and future prospects

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part II

- Calcium-, magnesium-, and yttrium-doped lithium nickel phosphate nanomaterials as high-performance catalysts for electrochemical water oxidation reaction

- Low alkaline vegetation concrete with silica fume and nano-fly ash composites to improve the planting properties and soil ecology

- Mesoporous silica-grafted deep eutectic solvent-based mixed matrix membranes for wastewater treatment: Synthesis and emerging pollutant removal performance

- Electrochemically prepared ultrathin two-dimensional graphitic nanosheets as cathodes for advanced Zn-based energy storage devices

- Enhanced catalytic degradation of amoxicillin by phyto-mediated synthesised ZnO NPs and ZnO-rGO hybrid nanocomposite: Assessment of antioxidant activity, adsorption, and thermodynamic analysis

- Incorporating GO in PI matrix to advance nanocomposite coating: An enhancing strategy to prevent corrosion

- Synthesis, characterization, thermal stability, and application of microporous hyper cross-linked polyphosphazenes with naphthylamine group for CO2 uptake

- Engineering in ceramic albite morphology by the addition of additives: Carbon nanotubes and graphene oxide for energy applications

- Nanoscale synergy: Optimizing energy storage with SnO2 quantum dots on ZnO hexagonal prisms for advanced supercapacitors

- Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation

- Tuning structural and electrical properties of Co-precipitated and Cu-incorporated nickel ferrite for energy applications

- Sodium alginate-supported AgSr nanoparticles for catalytic degradation of malachite green and methyl orange in aqueous medium

- An environmentally greener and reusability approach for bioenergy production using Mallotus philippensis (Kamala) seed oil feedstock via phytonanotechnology

- Micro-/nano-alumina trihydrate and -magnesium hydroxide fillers in RTV-SR composites under electrical and environmental stresses

- Mechanism exploration of ion-implanted epoxy on surface trap distribution: An approach to augment the vacuum flashover voltages

- Nanoscale engineering of semiconductor photocatalysts boosting charge separation for solar-driven H2 production: Recent advances and future perspective

- Excellent catalytic performance over reduced graphene-boosted novel nanoparticles for oxidative desulfurization of fuel oil

- Special Issue on Advances in Nanotechnology for Agriculture

- Deciphering the synergistic potential of mycogenic zinc oxide nanoparticles and bio-slurry formulation on phenology and physiology of Vigna radiata

- Nanomaterials: Cross-disciplinary applications in ornamental plants

- Special Issue on Catechol Based Nano and Microstructures

- Polydopamine films: Versatile but interface-dependent coatings

- In vitro anticancer activity of melanin-like nanoparticles for multimodal therapy of glioblastoma

- Poly-3,4-dihydroxybenzylidenhydrazine, a different analogue of polydopamine

- Chirality and self-assembly of structures derived from optically active 1,2-diaminocyclohexane and catecholamines

- Advancing resource sustainability with green photothermal materials: Insights from organic waste-derived and bioderived sources

- Bioinspired neuromelanin-like Pt(iv) polymeric nanoparticles for cancer treatment

- Special Issue on Implementing Nanotechnology for Smart Healthcare System

- Intelligent explainable optical sensing on Internet of nanorobots for disease detection

- Special Issue on Green Mono, Bi and Tri Metallic Nanoparticles for Biological and Environmental Applications

- Tracking success of interaction of green-synthesized Carbopol nanoemulgel (neomycin-decorated Ag/ZnO nanocomposite) with wound-based MDR bacteria

- Green synthesis of copper oxide nanoparticles using genus Inula and evaluation of biological therapeutics and environmental applications

- Biogenic fabrication and multifunctional therapeutic applications of silver nanoparticles synthesized from rose petal extract

- Metal oxides on the frontlines: Antimicrobial activity in plant-derived biometallic nanoparticles

- Controlling pore size during the synthesis of hydroxyapatite nanoparticles using CTAB by the sol–gel hydrothermal method and their biological activities

- Special Issue on State-of-Art Advanced Nanotechnology for Healthcare

- Applications of nanomedicine-integrated phototherapeutic agents in cancer theranostics: A comprehensive review of the current state of research

- Smart bionanomaterials for treatment and diagnosis of inflammatory bowel disease

- Beyond conventional therapy: Synthesis of multifunctional nanoparticles for rheumatoid arthritis therapy

Artikel in diesem Heft

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface

- Potential pharmaceutical applications and molecular docking study for green fabricated ZnO nanoparticles mediated Raphanus sativus: In vitro and in vivo study

- Effect of temperature and nanoparticle size on the interfacial layer thickness of TiO2–water nanofluids using molecular dynamics

- Characteristics of induced magnetic field on the time-dependent MHD nanofluid flow through parallel plates

- Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

- Experimental research on mechanically and thermally activation of nano-kaolin to improve the properties of ultra-high-performance fiber-reinforced concrete

- Analysis of variable fluid properties for three-dimensional flow of ternary hybrid nanofluid on a stretching sheet with MHD effects

- Biodegradability of corn starch films containing nanocellulose fiber and thymol

- Toxicity assessment of copper oxide nanoparticles: In vivo study

- Some measures to enhance the energy output performances of triboelectric nanogenerators

- Reinforcement of graphene nanoplatelets on water uptake and thermomechanical behaviour of epoxy adhesive subjected to water ageing conditions

- Optimization of preparation parameters and testing verification of carbon nanotube suspensions used in concrete

- Max-phase Ti3SiC2 and diverse nanoparticle reinforcements for enhancement of the mechanical, dynamic, and microstructural properties of AA5083 aluminum alloy via FSP

- Advancing drug delivery: Neural network perspectives on nanoparticle-mediated treatments for cancerous tissues

- PEG-PLGA core–shell nanoparticles for the controlled delivery of picoplatin–hydroxypropyl β-cyclodextrin inclusion complex in triple-negative breast cancer: In vitro and in vivo study

- Conduction transportation from graphene to an insulative polymer medium: A novel approach for the conductivity of nanocomposites

- Review Articles

- Developments of terahertz metasurface biosensors: A literature review

- Overview of amorphous carbon memristor device, modeling, and applications for neuromorphic computing

- Advances in the synthesis of gold nanoclusters (AuNCs) of proteins extracted from nature

- A review of ternary polymer nanocomposites containing clay and calcium carbonate and their biomedical applications

- Recent advancements in polyoxometalate-functionalized fiber materials: A review

- Special contribution of atomic force microscopy in cell death research

- A comprehensive review of oral chitosan drug delivery systems: Applications for oral insulin delivery

- Cellular senescence and nanoparticle-based therapies: Current developments and perspectives

- Cyclodextrins-block copolymer drug delivery systems: From design and development to preclinical studies

- Micelle-based nanoparticles with stimuli-responsive properties for drug delivery

- Critical assessment of the thermal stability and degradation of chemically functionalized nanocellulose-based polymer nanocomposites

- Research progress in preparation technology of micro and nano titanium alloy powder

- Nanoformulations for lysozyme-based additives in animal feed: An alternative to fight antibiotic resistance spread

- Incorporation of organic photochromic molecules in mesoporous silica materials: Synthesis and applications

- A review on modeling of graphene and associated nanostructures reinforced concrete

- A review on strengthening mechanisms of carbon quantum dots-reinforced Cu-matrix nanocomposites

- Review on nanocellulose composites and CNFs assembled microfiber toward automotive applications

- Nanomaterial coating for layered lithium rich transition metal oxide cathode for lithium-ion battery

- Application of AgNPs in biomedicine: An overview and current trends

- Nanobiotechnology and microbial influence on cold adaptation in plants

- Hepatotoxicity of nanomaterials: From mechanism to therapeutic strategy

- Applications of micro-nanobubble and its influence on concrete properties: An in-depth review

- A comprehensive systematic literature review of ML in nanotechnology for sustainable development

- Exploiting the nanotechnological approaches for traditional Chinese medicine in childhood rhinitis: A review of future perspectives

- Twisto-photonics in two-dimensional materials: A comprehensive review

- Current advances of anticancer drugs based on solubilization technology

- Recent process of using nanoparticles in the T cell-based immunometabolic therapy

- Future prospects of gold nanoclusters in hydrogen storage systems and sustainable environmental treatment applications

- Preparation, types, and applications of one- and two-dimensional nanochannels and their transport properties for water and ions

- Microstructural, mechanical, and corrosion characteristics of Mg–Gd–x systems: A review of recent advancements

- Functionalized nanostructures and targeted delivery systems with a focus on plant-derived natural agents for COVID-19 therapy: A review and outlook