An environmentally greener and reusability approach for bioenergy production using Mallotus philippensis (Kamala) seed oil feedstock via phytonanotechnology

-

Bisha Chaudhry

, Awais Bokhari

and Dongwhi Choi

Abstract

Mallotus philippensis, a novel and mostly unexplored feedstock with a significantly greater oil content of 50%, serves as the foundation of a prospective and sustainable supply for biodiesel synthesis. The most notable aspect of this research is the development and application of a bio-based green nanocatalyst with ingenuity and environmental safety via a method employing an autoclave reactor from raw conventional materials such as rotten fungus fruits infused with a nano-WO3 catalyst. The obtained catalyst was then subjected to several analyses, including scanning electron microscopy, energy-dispersive X-ray analysis, X-ray diffraction, and Fourier transform infrared spectroscopy. This research focused on the potential of this unique feedstock within the limits of an industrial setting. The synthesized nanocatalyst showed promising long-term performance and great catalytic efficiency. The biodiesel production reached its peak under optimal conditions, which included a methanol-to-oil ratio of 11:1, a reaction period of 120 min at 110°C, and a catalyst concentration of 0.15% by weight. Under precisely optimized conditions, this investigation rigorously examined the effectiveness, environmental stability, reusability, and economic feasibility of this green catalyst. The findings of this study demonstrate the stability and consistency of nanocatalyst performance, particularly throughout reusability cycles.

Graphical abstract

Nomenclature

- EDX

-

energy-dispersive X-rays

- FAME

-

fatty acid methyl ester

- FT-IR

-

Fourier transform infrared

- GC-MS

-

gas chromatography-mass spectroscopy

- MBD

-

Mallotus philippensis L. biodiesel

- MSO

-

Mallotus philippensis L. seed oil

- NMR

-

nuclear magnetic resonance

- NPs

-

nanoparticles

- SEM

-

scanning electron microscopy

- XRD

-

X-ray diffraction

1 Introduction

The global energy environment has been transformed as a result of multiple interconnected causes [1], including dwindling reserves of nonrenewable fossil fuels, worries about energy security [2], and the urgent need to counteract climate change [3,4]. These difficulties have heightened interest in developing alternative and sustainable energy sources, with biodiesel emerging as a possible answer.

For decades, nonrenewable fossil fuels, principally coal, oil, and natural gas, have formed the foundation of global energy consumption [5]. However, their limited availability and environmental repercussions of combustion, such as greenhouse gas emissions and air pollution, have aroused serious concerns [6]. Many nations have experienced energy insecurity [7] and economic vulnerability [8] as a result of the uneven distribution of fossil fuel deposits across geopolitically sensitive regions [9]. The volatility of fossil fuel costs, which is affected by geopolitical conflicts and market changes, has aggravated global energy issues [10]. The reliance on non-renewable fossil fuels has highlighted the need for shifting to cleaner [11], more sustainable energy sources [12].

Biodiesel, derived from renewable sources such as vegetable oils, animal fats, and waste cooking oils, may be a viable alternative to non-renewable fossil fuels [13]. Because the carbon dioxide emitted during combustion is roughly equivalent to the carbon dioxide absorbed by the plants during their growth [14], biodiesel is considered a carbon-neutral fuel, resulting in a net-zero carbon footprint [15]. This trait addresses the critical issue of greenhouse gas emissions and is consistent with global efforts to mitigate the climate change [16,17].

Furthermore, biodiesel production is scalable and can be integrated into existing infrastructure without requiring any major changes [18,19]. This adaptability reduces the disruption caused by energy transitions [20]. Furthermore, biodiesel can be used as a transitional fuel, reducing immediate reliance on fossil fuels while buying time for the development and implementation of more advanced renewable energy technologies [21,22].

Traditional feedstock sources for biodiesel production include soybean oil, rapeseed oil (canola), palm oil, sunflower oil, and jatropha oil [23]. These oils are widely available, and their fatty acid compositions help to improve biodiesel properties [19,24]. However, in the case of palm oil, competition between food and fuel production has raised concerns about the impact on food security and deforestation [25]. Using waste cooking oils as a feedstock not only reduces waste disposal issues but also reduces concerns about redirecting edible oils for biodiesel production. Algae and animal fats have the potential to generate additional revenue for the industry [26].

Alternative feedstocks are being investigated, including non-edible oils derived from plants such as jatropha, pongamia, and moringa. These oils are environmentally and socially sustainable because they can be produced on marginal lands and do not compete with food production [27,28]. Gasification, pyrolysis, transesterification, and supercritical methods have all been used in the production of biodiesel. The supercritical fluid method provides faster reaction times, higher conversion rates, and requires fewer catalysts. The high pressure and temperature conditions, on the other hand, can pose technical challenges [29]. Pyrolysis is a promising technology for converting biomass into biofuels and value-added products, but it is costly and energy-intensive [30].

Transesterification is the most common method of producing biodiesel. In the presence of a catalyst, triglycerides (fats and oils) are combined with alcohol (usually methanol or ethanol) to produce biodiesel and glycerol. The most common catalysts are alkali (such as sodium or potassium hydroxide) and acids (such as sulfuric or hydrochloric acid) [31]. Because of their close interaction with reactants in the same phase, homogeneous catalysts frequently result in faster reaction rates and higher conversions. Separating the catalyst from the reaction mixture, on the other hand, can be difficult, necessitating additional processes, generating waste, and necessitating purification steps [32,33]. Heterogeneous catalysts are solid and are easily separated from the reaction mixture, making downstream processing easier. It is frequently reusable for multiple reaction cycles, lowering costs and waste. However, the rate of mass transfer of reactants to the catalyst surface can limit the reaction rate of heterogeneous catalysis [34].

Mallotus philippensis, a tropical plant species known for its high oil content, emerges as a promising candidate for biodiesel feedstock due to its widespread availability and cultivation potential in a variety of agroclimatic regions. To the best of authors’ knowledge, no research on the biodiesel synthesis from Mallotus philippensis seed oil has been conducted. It is commonly known as “Kamala,” and it is a medicinal plant in the Euphorbiaceae family. It is native to Asia, including India, Nepal, and Bhutan [35]. Typically, the root system is fibrous, with roots spreading to gather nutrients and water from the soil [36]. Mallotus philippensis stems can be woody at the base and herbaceous above. The bark is usually grayish-brown and has a rough texture. The plant can grow into a small tree or a shrub [37]. The leaves are straightforward, alternate, and specific. They usually have 3–5 leaflets and are palmately lobed or palmately compound. They form an alternative pattern along the stem. Small, unisexual flowers that are typically greenish-yellow or yellow are produced by the plant. Male and female flowers are typically found on separate plants (dioecious), but monoecious plants with both male and female flowers have been observed on occasion [38]. Female flowers mature into capsule-like fruits containing seeds. The fruits are typically three-lobed and spiny in appearance. When the fruits reach maturity, they split open to release the seeds [39].

Researchers have been investigating innovative catalysts derived from unconventional and renewable sources to improve the efficiency of biodiesel synthesis from non-edible feedstocks and to align with green chemistry principles [40]. Among these, the use of nanocatalysts, which have a high surface area and increased catalytic activity, has received special attention [41]. The current study delves into a novel approach involving the use of a green nanocatalyst synthesized from the rotten fungus fruit extract for the synthesis of biodiesel from Mallotus philippensis seed oil. As a precursor, sodium tungstate was used to create the green nanocatalyst. Sodium tungstate was chosen due to its intriguing catalytic properties and potential for nanomaterial synthesis. By combining sodium tungstate with the rotten fungus fruit extract, an environmentally friendly catalyst was created, adhering to the principles of sustainability and green chemistry. This unconventional approach exemplifies not only the versatility of renewable materials in catalysis but also the use of unconventional resources for sustainable energy production [42].

Furthermore, incorporating unconventional catalysts into biodiesel synthesis processes is a critical step toward reducing biodiesel production’s environmental footprint. We hope to improve the efficiency of transesterification reactions, a key step in biodiesel synthesis, by using bio-derived nanocatalysts, while reducing the use of traditional, non-renewable catalysts [43].

The main focus of the following research study is to bridge the gap between biodiesel synthesis, green chemistry principles, and nanotechnology. We investigate the use of a green nanocatalyst made from a rotten fungus fruit extract and sodium tungstate for the synthesis of biodiesel from novel, sustainable, and eco-friendly Mallotus philippensis seed oil. This study aims to advance our understanding of the potential of unconventional catalysts in biodiesel synthesis while contributing to the ever-expanding field of sustainable energy production. The use of non-traditional catalysts in the production of biodiesel is consistent with the primary objective of eco-friendly methodologies. By being aware of their potential, we can investigate more environmentally friendly alternatives, which could lessen the negative effects that traditional catalysts have on the environment. The knowledge acquired from this research provides an important boost to the current attempts for reconciling energy needs with environmental responsibility, as environmental management places an increasing emphasis on sustainable practices. This research essentially acts as a link between the need for environmentally friendly procedures and the exploration of unconventional catalysts. The study creates the foundation for future developments in environmentally friendly practices and sustainable energy by deepening our understanding of biodiesel synthesis through creative catalysts. This promotes an integrated approach to environmental management in the cleaner energy sector.

2 Materials and methodology

The non-edible seeds of Mallotus philippensis were collected from resource-based areas in the country as a raw feedstock. In the process, 99% potassium hydroxide, phenolphthalein indicator, 50% methanol, 99.0% n-hexane, 99.90% ethanol, rotten fungus fruits, and sodium tungstate were all used.

2.1 Extraction of oil

Mallotus philippensis seeds were rinsed with tap water, then distilled water, before being desiccated in an oven at 600°C for 8–10 h. The seeds were then dried further in the oven before being subjected to an electrical expeller to extract the oil. The oil yield from Mallotus philippensis was calculated using equation (1) [44] as follows.

2.2 Determining the oil content of seeds

A Soxhlet apparatus was used to determine the oil content of the seed. Initially, in an oven, 20 g of Mallotus philippensis seeds was dried before being converted into a finely ground powder with a mortar and pestle. This finely ground material was then sieved through a filter paper sieve. A 250 ml round bottom flask with a reflux condenser was assembled for the Soxhlet setup, and the thimble was meticulously adjusted. Subsequently, 85 ml of n-hexane solvent was added to the round bottom flask, and the entire Soxhlet apparatus was set to run at 600°C for 6 h. The process was then completed by using a rotary evaporator to evaporate any excess solvent. The n-hexane solvent recovered in this process was retained for future reuse. The seed powder in the thimble was then subject to another round of oven drying at 65°C for about a day or two (24–48 h). This additional step helped the solvent in the thimble to evaporate. A flask or thimble was used to determine the oil content. Equation (2) was used to determine the weight of an empty thimble [44].

Using round-bottom flasks, the oil content was calculated using equation (3) [44].

The weights in this case are w1 = thimble + sample, w2 = empty thimble, w3 = thimble/flask + sample after Soxhlet extraction, and w4 = sample weight.

Due to the presence of various toxic impurities in the seed oil [45], which could potentially have an adverse impact on the resulting biodiesel, posing a risk or harm to the diesel engine, a prerequisite step involves degumming the oil. This process is essential to get rid of the oil’s moisture content and dangerous contaminants. During the degumming process, the oil was treated for 15–20 min at 60°C with 1% orthophosphoric acid concentration [46].

2.3 Determination of free fatty acids (FFAs)

Titration methods are commonly used to determine FFAs in biodiesel, which is critical for assessing its quality and performance. The FAA contents in Mallotus philippensis were determined using 100 mL of water and 0.14 g of potassium hydroxide through the titration method. In a round-neck flask, N-propyl alcohol and oil were mixed in a 9:1 ratio with a few drops of phenolphthalein indicator. As the color of the oil solution changed from clear to dusky, readings were taken. This procedure was carried out three times in order to achieve accurate findings. Equation (4) was utilized to determine the composition of FAAs [47].

In this case, A stands for the initial KOH volume, B the final KOH volume, C the KOH concentration, and V the oil volume during titration.

2.4 Green nanocatalyst preparation

This environmentally friendly nanocatalyst was created using a biochemical approach and combined with in situ wet impregnation with a few changes [44]. The first step was to clean raw vegetable scraps with pure water to remove harmful chemicals and particulate matter. The leaves were then finely chopped into small fragments. To make a solution, 80 g of vegetable scrap was mixed with 500 ml of distilled water in a large beaker. A solution from vegetable scrap extract was created by heating the mixture to 120°C for 3–4 h. The solution was refrigerated at 4°C overnight after being sieved through filter paper to remove the residual plant material. About 73.45 g of sodium tungstate and 500 ml of distilled water were used to create a 0.5 M sodium tungstate solution, which was stirred for 30 min before use. The potassium iodide aqueous leaf extract was then heated to 250°C for 1–2 h, producing a pale solution. Following impregnation, the catalyst was dried in a controlled oven environment at 65°C for 2–3 days, allowing solvents and volatile elements to be removed. Following that, the material was placed in a petri dish, and scraping tools were used to transfer the material from the petri dishes to Teflon chambers of hydrothermal autoclave reactors of various sizes [48].

2.5 Revolutionizing catalyst processing by harnessing hydrothermal autoclave reactors

The hydrothermal autoclave reactor with a Teflon chamber is a cutting-edge and essential tool for performing hydrothermal synthesis and chemical reactions under precisely controlled conditions. The inner chamber of these reactors is made of Teflon (polytetrafluoroethylene), which has several advantages. The Teflon chamber ensures the reactor’s long-term durability and performance, even when exposed to highly reactive substances [49,50]. The unique conditions provided by hydrothermal autoclave reactors make studying catalytic reactions at high temperatures and pressures possible. This study has important implications for renewable energy production and lowering greenhouse gas emissions. A hydrothermal autoclave reactor was utilized for performing controlled hydrothermal synthesis and chemical reactions. The procedure started with the careful preparation of clean equipment and pure reactants. The reactor was assembled, the dried catalyst was loaded into the Teflon chamber, and airtight seals were ensured. The temperature was increased to 1,300°C for 8 h, followed by a carefully monitored reaction, cooling, and depressurization. Following the experiment, the reactor was opened, and the products were extracted for analysis. Thorough cleaning and maintenance are required, with strict safety precautions always.

The catalyst was then transferred to crucibles for calcination for 4.5 h at a higher temperature of 500°C. The goal of this procedure was to promote precursor compound decomposition and the formation of active catalytic sites. The resulting catalysts were nanopowders or nanocatalysts that can be used directly for transesterification reactions.

2.6 Catalyst characterization

The eco-friendly catalyst was made using the wet impregnation technique, and it was thoroughly characterized in order to assess its structural properties, morphology, and catalytic efficiency. To investigate the catalyst’s inherent properties, analytical methods such as Fourier transform infrared (FT-IR) spectroscopy, energy-dispersive X-ray (EDX) analysis, scanning electron microscopy (SEM), and X-ray diffraction (XRD) analysis were used.

2.7 Transesterification reaction

This study’s novel sodium tungstate nanocatalyst was used in the transesterification process. A 1:15 mixture of methanol and oil with a catalyst concentration of 4.0% w/w was heated for 40–45 min while being continuously stirred to produce the methoxide. Following that, the reactor vessel containing the seed oil was placed on a magnetic stirrer. The oil was stirred slowly to ensure homogeneous mixing before being gradually heated to the desired reaction temperature, which typically ranged from 50 to 70°C, using a heating mantle or hot plate. The temperature may vary depending on the oil type and catalyst. When the desired temperature was reached, the seed oil was carefully introduced into the reactor while stirring was maintained to avoid splashes and spills. The mixture was stirred for a predetermined amount of time, usually 1–2 h, to allow the transesterification reaction to take place. Monitoring the progress of the reaction entailed observing changes in viscosity and appearance. The heat source was turned off after the specified reaction time, and the mixture was allowed to cool to room temperature. A variety of parameters, including the reaction time (60–240 min), oil-to-methanol ratio (1:6–1:18), temperature (55–75°C), and catalyst concentration (0.5–1.5%), were varied during the transesterification reaction in order to maximize the yield.

2.8 Characterization of synthesized biodiesel

Bio-based fuels are extensively characterized to determine their properties, quality, and potential as sustainable energy sources. These characterizations include a variety of techniques for evaluating various fuel attributes. Density, viscosity, flash point, and calorific value are physicochemical properties that provide information about fuel behavior during combustion and transportation. Techniques such as FT-IR and GC-MS were used to determine the elemental composition and molecular structure, revealing fuel components and potential impurities. Characterization also included combustion analysis, which investigates emission profiles and combustion kinetics, both of which are important for understanding environmental impacts [51].

2.9 Application of analytical statistics

Response surface methodology (RSM) is a comprehensive set of statistical and mathematical tools used for complex process analysis and optimization. The Box–Behnken design stands out as a specialized experimental approach within RSM among its methodologies. This method is frequently used to investigate the effect of various factors or variables on a specific response or output. RSM makes it easier to investigate these relationships by fitting mathematical models to experimental data. The Box–Behnken design, in particular, is known for its balanced and efficient nature in experiment design, particularly when approximating a quadratic response surface is the goal. In the context of this study, a total of 29 experiments were carefully conducted in which various variables were manipulated, including (A) the oil to methanol ratio, which ranged from 1:6 to 1:12, (B) catalyst loading, which ranged from 0.5 to 1.5 wt%, (C) reaction temperature, which ranged from 55 to 75°C, and (D) reaction time, which ranged from 60 to 240 min.

2.10 Environmental standardization of fuel properties

Evaluating biodiesel fuel properties is critical for determining its quality, compatibility with existing engines, and environmental implications. The determination of various characteristics is critical to ensuring that biodiesel meets regulatory standards and performs optimally as an alternative fuel. Color, ASTM D-93 for the flash point, ASTM D-1298 for the density at 15°C, ASTM D-445 for the kinetic viscosity, ASTM D-97 for the pour point, ASTM D-2500 for the cloud point, ASTM D-4294 for the sulfur content, and total acid number (ASTM D-974) were among the fuel characteristics that were identified and compared to the Biodiesel International Standards, which include the American (ASTM D-6751), European (EN-14214), and Chinese GB/T 20828 standards. Additionally, a comparison was conducted with previously established biodiesel that was produced from non-food feedstocks like Jatropha and Pongamia.

3 Results and discussion

3.1 Characterization of the catalyst

3.1.1 Na2WO4 biogreen nanocatalyst analysis using XRD

XRD of the prepared material was performed by using a powder X-ray diffractometer of Cu-kα (0.154 nm) having a 2θ span of 10–80°. In the prepared material, significant peaks were observed at 2θ = 18.88, 29.43, 31.16, 49.26, 51.52, 57.49, and 60.36° having d-spacing of 4.69, 3.03, 2.87, 1.85, 1.77, 1.60, and 1.53 Å, respectively. These peaks strongly matched with JCPDS card No. 72-1465 having a monoclinic crystal structure due to the presence of WO3. Moreover, impurity-related peaks have not been found in prepared materials that depicted the loading of the W latticework rather than interstitial sites. The Debye-Scherrer equation (D = (kλ)/(β cos θ)) was used to calculate the average crystallite size. The Scherrer constant (k) is equal to 0.9, λ is the wavelength of Cu-ka (0.154 nm), β is the full width at half-maximum, and θ is Bragg’s angle. The prepared material’s mean crystallite size was 76.34 nm (Figure 1).

XRD analysis of the bio-based green sodium tungstate nanocatalyst.

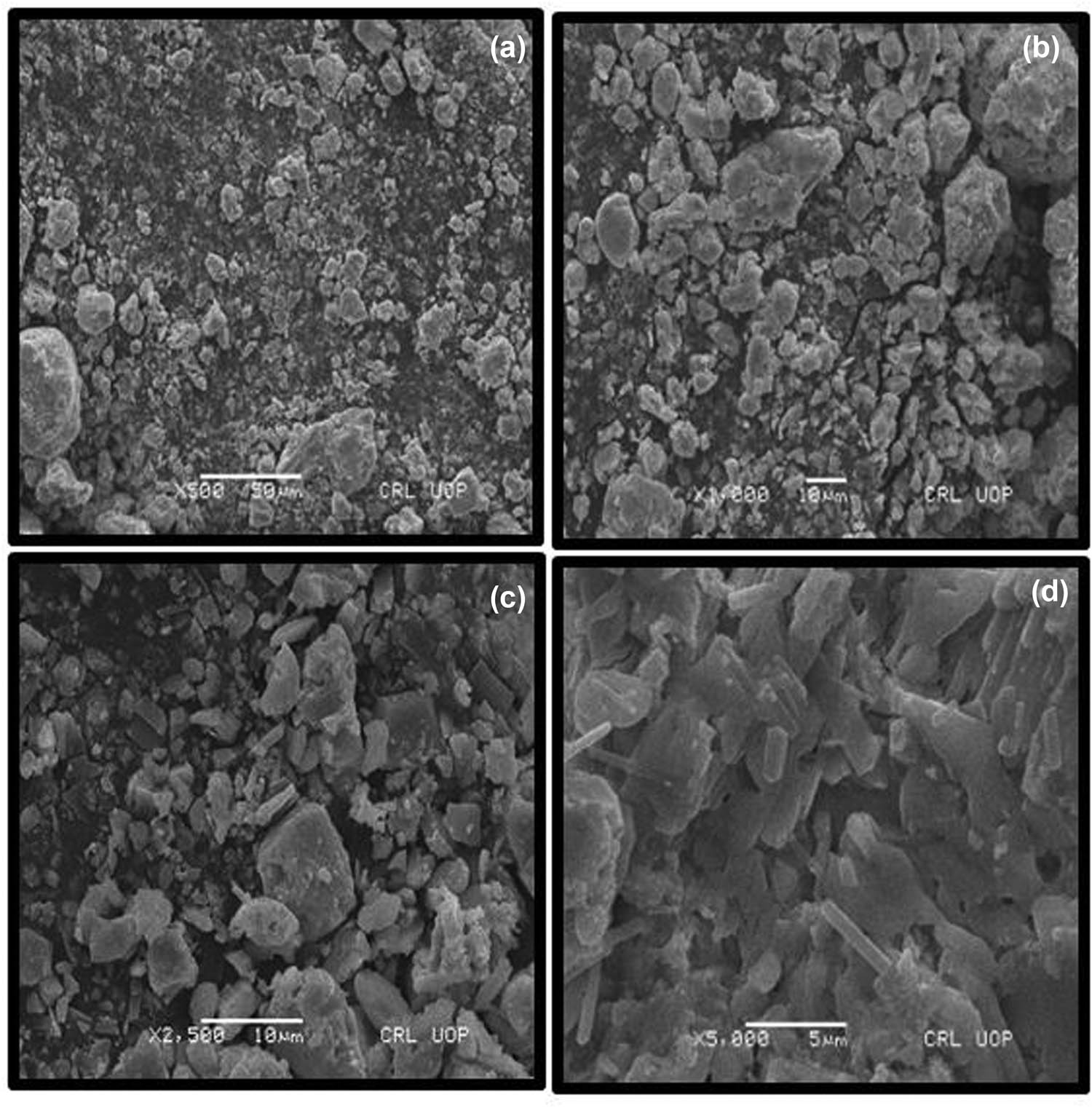

3.1.2 Na2WO4 biogreen nanocatalyst analysis using SEM

The characterization of sodium tungstate nanoparticles (NPs) included the use of SEM to determine their dimensions and surface characteristics. SEM images of sodium tungstate green NPs are shown in Figure 2(a)–(d). SEM analysis revealed a distinct surface morphology of Na2WO4 NPs, which is characterized by irregular, agglomerated, and heterogeneous structures with significant porous aggregates. This intricate morphology suggests that they have the potential to excel in catalytic activities due to the provision of a high surface-to-volume ratio [52]. The particle morphology and size are consistent with previous research findings in this field [53]. The surface of the nanocomposite is distinguished by distinct wrinkles, sharply defined edges, and prominent folds. A spherical and porous, sponge-like arrangement is clearly visible in Figure 2(d), contributing significantly to the enhancement of the catalytic efficacy of the synthesized catalysts [54,55]. The micrographs show a low level of particle aggregation, which can be attributed to electrostatic interactions caused by the NPs’ inherent polarity. The variation in particle size indicates that the NPs have a larger surface area, which provides an increased number of active sites for facilitating transesterification reactions [56].

SEM analysis (a–d) of the bio-based green sodium tungstate nanocatalyst.

3.1.3 Na2WO4 biogreen nanocatalyst analysis using EDX analysis

EDX analysis can be used to determine the elemental composition of a freshly synthesized nanocatalyst [57]. Figure 3 shows distinct peaks corresponding to tungsten (W), sodium (Na), and oxygen (O) with the highest percentage. Tungsten is the most abundant element, accounting for 67.63%, followed by sodium (20.25%) and oxygen (10.50%). Nonetheless, supplementary peaks, specifically sulfur (S) (1.20%) and chlorine (Cl) (0.42%), have been detected, accounting for a minor 1.28%. These extra peaks are attributed to impurities and instrumental variations [44].

EDX spectrum of the bio-based green sodium tungstate nanocatalyst.

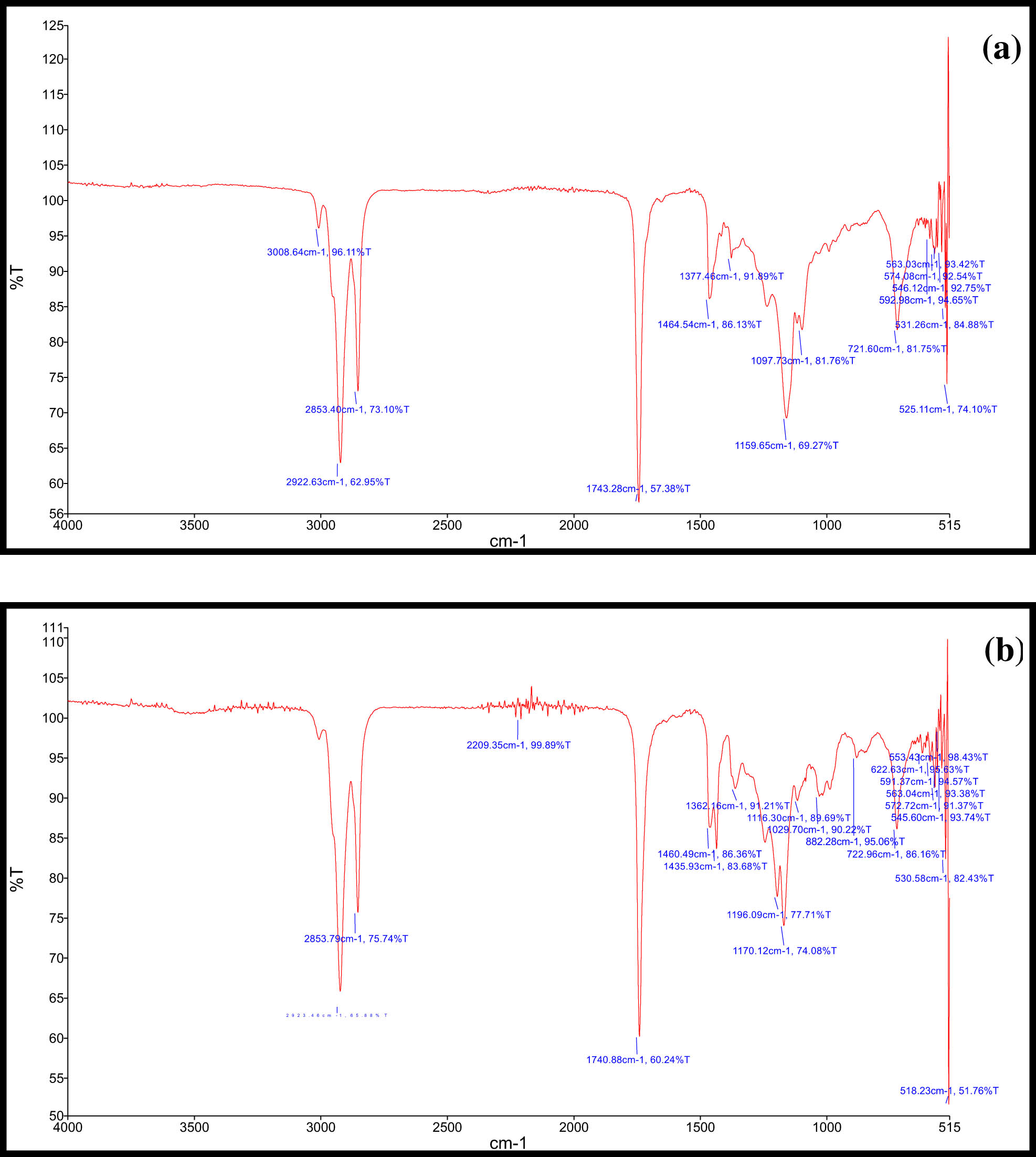

3.1.4 Na2WO4 biogreen nanocatalyst analysis using FT-IR spectroscopy

FT-IR spectroscopy was used to gain valuable insights into the distinct functional groups within sodium tungstate NPs (Figure 4). The stretching of O–H bonds and the bending of H–O–H bonds are attributed to the peak at 3301.49 cm–1 in this spectrum. These bonds are formed by water molecules on the sample’s surface [58,59]. Furthermore, the sharp absorption peaks at 1683.53 cm–1 are attributed to ketone group (C═O) vibrations [60]. Similarly, the absorption bands peaking at 819 cm–1 are likely due to the stretching mode of W–O bonds in conjunction with WO3 tetrahedra [61]. The peak appearing at 587 cm–1 indicates the presence of metal (WO3) [62].

FT-IR spectrum of the bio-based green sodium tungstate nanocatalyst.

3.2 Cleaner biodiesel production

3.2.1 Production of biodiesel through transesterification

The first and most crucial step of our investigation in the present investigation is the use of non-edible Mallotus philippensis L. seed oil (MSO) as a substitute feedstock for the generation of biodiesel. The first and most important task was to determine the oil content and FFAs of this seed oil. We discovered that the total oil content of Mallotus philippensis was quite high, at 50%. This placed it above a number of other inedible feedstocks that are frequently taken into consideration for the production of biodiesel, including Coronopus didymus L. (47%) [44], Silybum marianum L. (46%) [63], Raphnus raphanistrum L. (40.7%) [46], and Azadirachta indica A. Juss. An extensive summary of the percentage of oil of different inedible plants is given in Table 1.

Oil content values for several previously documented seed oil species

| Species | Oil content (wt%) | Ref. |

|---|---|---|

| Mallotus philippensis L. | 50 | Present case |

| Coronopus didymus L. | 47 | [44] |

| Silybum marianum L. | 46 | [63] |

| Raphnus raphanistrum L. | 40.7 | [65] |

| Azadirachta indica A. Juss. (Neem) | 30 | [66] |

| Manilkara zapota L. | 25–30 | [67] |

Furthermore, MSO has an impressively low FAA content, measuring only 1.126%. This low FFA content is especially beneficial for the base-catalyzed transesterification reaction used in biodiesel production. When the FFA content of the oil is higher, a more complex esterification reaction is required, resulting in the production of soap as a byproduct and a subsequent reduction in biodiesel output [64].

The fuel properties of MSO were thoroughly investigated and are detailed in Table 2. As a result, MSO emerges as an exceptional, sustainable, environmentally friendly, and efficient biodiesel feedstock choice, ensuring the highest biodiesel yield while avoiding the formation of unfavorable byproducts.

Physicochemical attributes of raw Mallotus Philippensis seed oil

| S. no. | Seed oil properties | Values |

|---|---|---|

| 1 | Flash point (°C) | 85 |

| 2 | Density at 15°C (kg/L) | 0.8682 |

| 3 | Kinematic viscosity at 40°C (cSt) | 6.52 |

| 4 | Pour point (°C) | −10 |

| 5 | Cloud point (°C) | −12 |

| 6 | Sulfur content (wt%) | 0.0002 |

| 7 | Total acid no. (mg KOH/g) | 0.230 |

The optimized biodiesel yield was achieved through a single-step, base-catalyzed, transesterification approach employing sodium tungstate-impregnated rotten fungus fruit waste extract, and a total of 29 carefully planned experiments were conducted. These experiments investigated a variety of reaction parameters. Notably, Table 3 examines the effects of four distinct uncorrelated factors on the biodiesel yield and contrasts how various salts affect plant-based products. The findings of this study, which achieved a biodiesel yield of 95.5% using a sodium tungstate bio-based green nanocatalyst, are consistent with the findings of Chaudhry et al. [44], who achieved a 97.03% yield using a green nanocatalyst containing KI. Furthermore, as reported by previous studies [51,68], a 95% yield was attained by utilizing green catalysts, namely, calcium oxide (CaO) and iron oxide (Fe2O3), along with oil from Linum usitatissimum L. and Monotheca buxifolia Falc. In order to improve our understanding of the process, this study looked into the effects of a number of independent reaction parameters, including the choice of the catalyst, methanol-to-oil ratio, temperature of the reaction, and reaction time, in addition to the biodiesel yield.

Effects of various green nanocatalysts on biodiesel yield using different feedstocks

| S. no. | Source | Oil content (%) | Bio-based green nanocatalyst | Obtained yield (%) | Ref. |

|---|---|---|---|---|---|

| 1 | Mallotus philippensis L. | 50 | Sodium tungstate (Na2WO4) | 95.5 | (Present case) |

| 2 | Coronopus didymus L. | 47 | Potassium iodide (KI) | 97.03 | [44] |

| 3 | Linum usitatissimum L. | 37.5 | Iron oxide (Fe2O3) | 95 | [69] |

| 4 | Monotheca buxifolia Falc. | _ | Calcium oxide (CaO) | 95 | [68] |

| 5 | Citrus aurantium L. | 38 | Zirconium oxide (ZrO2) | 94 | [70] |

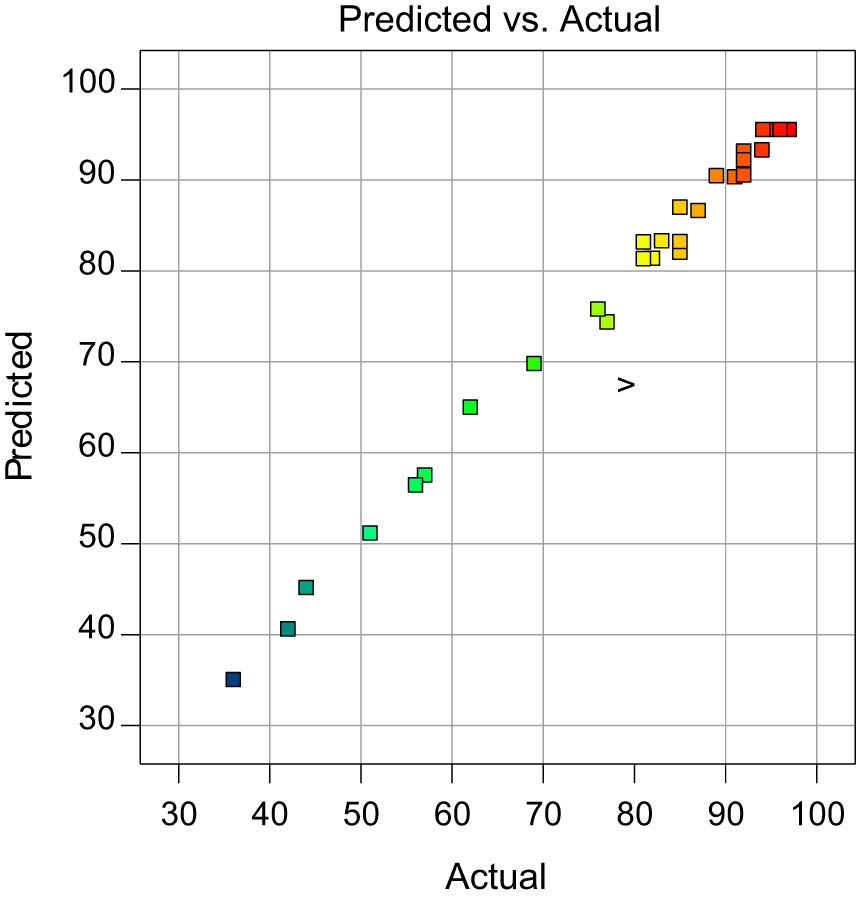

3.2.2 Maximizing the production of biodiesel with RSM

The artificially produced green nanocatalyst that played a key role in the methodical transesterification process that turned seed oil into biodiesel. To optimize the biodiesel yield during this reaction, a thorough investigation of four key variables with a wide range of values was carried out. The oil-to-methanol ratio ranged from 1:10 to 1:12, the catalyst concentration ranged from 0.15 to 0.18 wt%, the reaction temperature ranged from 100 to 120°C, and the reaction time ranged from 60 to 180 min. To determine the connections among the different input and output variables, a model equation was also utilized. This formula clarified the intricate connections between these crucial elements, illuminating how the input variables interact and affect the yield of biodiesel that is produced.

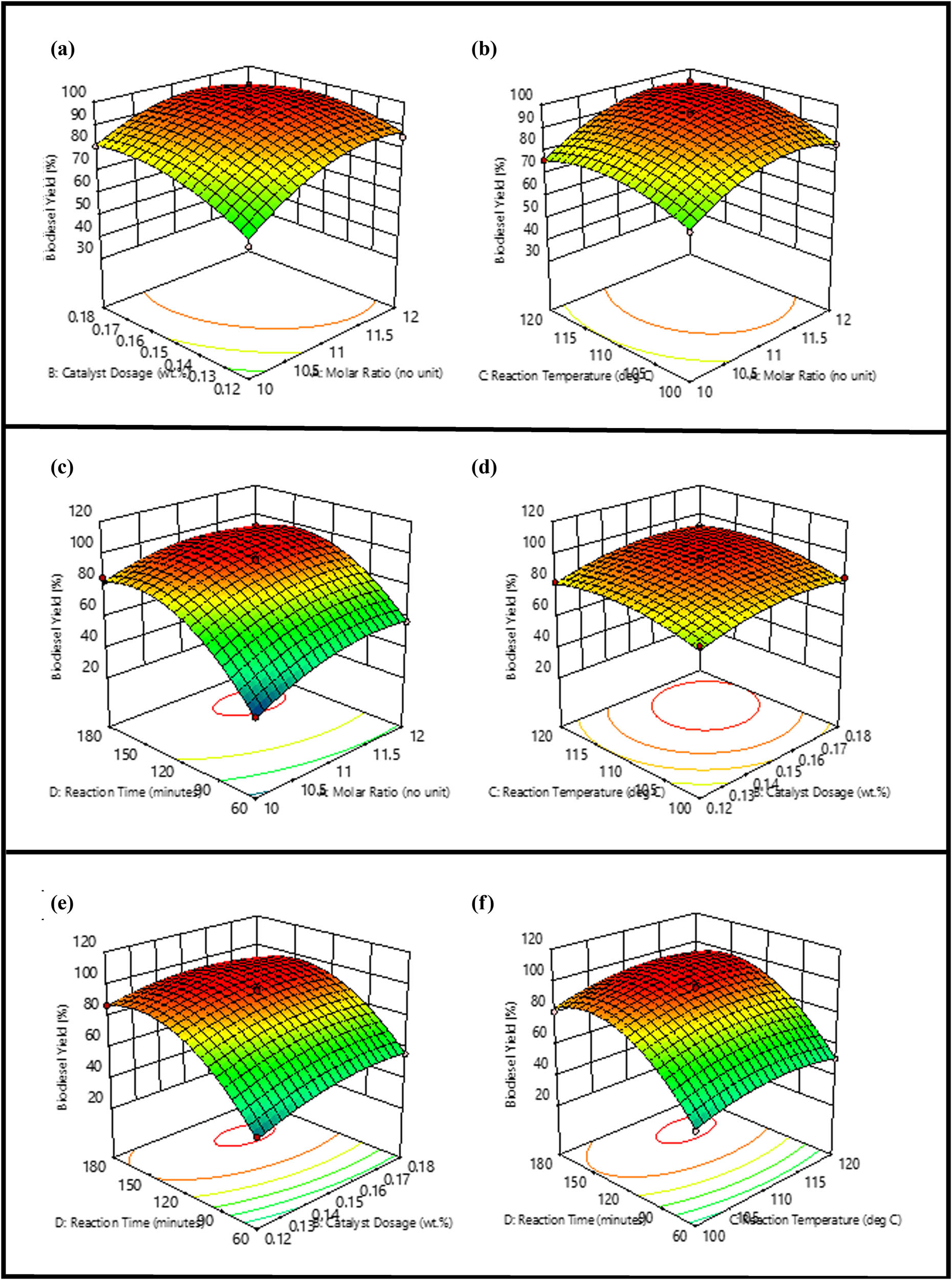

The dynamic interplay of four distinct variables in the transesterification process is vividly illustrated using 3D plots in this comprehensive study. These plots provide a visual representation of how each variable affects the process, assisting in the identification of optimal levels for peak performance. The following subsections explain in detail the interrelated effects of the methanol-to-oil ratio, catalyst concentration, reaction time, and reaction temperature (Figures 5–7).

Predicted versus actual biodiesel yield.

(a–f) Graphical depiction illustrating the interplay and influence of various variables.

FT-IR spectra of (a) Mallotus philippensis seed oil and (b) synthesized biodiesel.

3.2.3 Synergistic effect of oil-to-methanol ratios and catalyst concentration on biodiesel yield

The synergistic effect of oil-to-methanol ratio and catalyst concentration regarding biodiesel yield using Box-experimental design, Figure 8a presents an interactive three-dimensional (3D) surface plot that illustrates how oil-to-methanol ratios and catalyst weights interact to affect biodiesel yields. Notably, during Run 22, which was defined by a 0.15 (wt%) catalyst weight, a 1:11 oil-to-methanol ratio, and an ambient temperature of 110°C for a duration of 120 min, a peak biodiesel yield of 95.5% was attained, as seen in the 3D graph. Keeping the oil-to-methanol ratio constant while increasing the catalyst quantity to 0.18 wt% results in a reduction in the biodiesel yield to 85%, as seen in Run 27. Understanding that higher catalyst concentrations encourage the formation of unfavorable residues, specifically soap compounds, explains this phenomenon [71,72]. Similarly, in Run 20, we attain an 81% biodiesel yield when we decrease the oil-to-methanol ratio to 1:10 and increase the catalyst quantity to 0.18 (wt%). Without a doubt, the most significant factor affecting the yield of biodiesel is the oil-to-methanol ratio. Stoichiometrically, one mole of oil requires three moles of methanol to be converted into biodiesel (three moles) and glycerol (one mole) during the transesterification process. Recognizing that transesterification is a reversible reaction, it is critical to note that additional methanol is required to drive the reaction in the desired direction [73,74]. On the other hand, as illustrated by Run 12, the biodiesel yield dropped to 83% when we used a 0.15 weight percent catalyst and increased the oil-to-methanol ratio to 1:12. The 83% drop in biodiesel production is due to a reversible reaction called glycerolysis, which rivals transesterification. Monoglycerides facilitate the solubility and mixing of glycerol in fatty acid methyl ester (FAME), enabling the FAME to combine again with glycerol and produce monoglycerides yet again. This is a reversible reaction [75]. Additionally, as the current study shows, higher methanol concentrations make glycerol separation more difficult and reduce the FAME yield [76].

GC-MS and library match of synthesized biodiesel.

3.2.4 Synergistic effects of oil-to-methanol ratio and reaction temperature on biodiesel yield

The detailed relationship between the oil-to-methanol ratios, and temperatures of the reaction, and the final biodiesel yields is shown in Figure 8b. Remarkably, Run 22 demonstrated that optimizing the reaction temperature to 110°C and utilizing a 1:11 oil-to-methanol ratio in the reaction medium resulted in the highest biodiesel yield of 95.5%. Similarly, when the temperature exceeded the established threshold level of greater than 70°C, there is a noticeable and significant decrease in the biodiesel yield, as demonstrated by Run 25, where the yield dropped to 51%. Nonetheless, when the temperature exceeded the specified threshold of >70°C, the biodiesel production yield was significantly reduced [77]. For example, in Run 6, the yield fell significantly to 51%. However, due to the immiscibility of oil, methanol, and Na2WO4 NPs, the rate of mass transfer was significantly reduced. However, increasing the temperature to a certain point speeds up the mass transfer process between these three immiscible phases – oil, methanol, and Na2WO4 NPs [78]. This was accomplished by giving the reactant molecules more kinetic energy, resulting in a higher yield of FAME in a shorter reaction timeframe [79]. A lower yield of 81 wt% was obtained if a smaller molar ratio of 1:10 was employed at the same temperature, which was 110°C (Run 20). The yield decreased by 57 wt% when the molar ratio was increased to 1:12, while the reaction temperature remained at 110°C (Run 24). at 1:12, which caused the biodiesel yield to slightly decline to 94 wt%.

3.2.5 Synergistic effect of oil-to-methanol ratio and reaction time on biodiesel yield

Figure 8c shows the effect of oil-to-methanol ratio and reaction time on the biodiesel yield while other variables remained constant. In Run 22, a maximum biodiesel yield of 95.5% was achieved, by using an oil-to-methanol ratio of 1:11 and a reaction time of 120 min. The extended interaction between excess alcohol and the oil is responsible for the high yield [80]. In contrast, a shorter reaction time of only 60 min, combined with a lower oil-to-methanol ratio of 1:10, resulted in a significantly lower biodiesel yield of 36% in Run 4. This result is most likely due to the reactants failing to reach equilibrium within the timeframe specified, resulting in a partial conversion into products. Previous research has provided strong evidence that the reaction time has a significant impact on the biodiesel yield derived from castor oil [81]. With a reaction time of 180 min and an oil-to-methanol ratio of 1:10 (Run 10), a marginal reduction in the biodiesel yield (85%) was observed. This decrease can be attributed to the increased amount of methanol, which shifts the reaction to unfavorable conditions, impeding the achievement of the desired biodiesel yields [82]. These findings are consistent with those reported in another study [83], where a longer reaction duration (50 min) and an iron-doped zinc oxide catalyst were used to produce a higher biodiesel yield (91%) of the product.

3.2.6 Synergistic effect of catalyst loading and reaction temperature on biodiesel yield

Figure 8d shows the combined impact of catalyst concentration and temperature on the biodiesel yield. In Run 22, a maximum yield of biodiesel of 95.5% was obtained with a catalyst weight of 0.15 wt% and a reaction temperature of 110°C. In contrast, Run 8’s biodiesel conversion rate was 77% lower when a catalyst loading of 0.12 wt% and a reaction temperature of 110°C were used. In Run 18, there was very little yield loss (92%) when the catalyst amount and the reaction temperature were increased above 0.18 wt% and 120°C, respectively. The increase in the viscosity of the reaction mixture as the amount of catalyst was increased is what caused this decreased biodiesel yield. [84,85]. Our findings are consistent with previously documented research studies [86].

3.2.7 Synergistic effect of catalyst loading and reaction temperature on biodiesel yield

Figure 8e depicts the combined effect of catalyst concentration and reaction time on the biodiesel yield while the other two variables are held constant. The transesterification reaction achieved equilibrium within the reaction medium by using the newly synthesized catalysts at the optimized ratio of 1:11 and a reaction time of 120 min (0.15 wt%). As a result, as demonstrated in Run 22, this results in the highest Mallotus philippensis L. biodiesel (MBD) yield, with an impressive 95.5% [87]. Deviating from the optimized ranges in Run 6 by increasing the reaction time to 180 min and increasing the catalyst amount to 0.18 wt% resulted in an MBD yield of 89%. This result reflects a consistent pattern of decreased MBD yield, as demonstrated in Run 29, where reducing the catalyst amount and reaction time to 0.12 wt% and 60 min, respectively, resulted in a 42% decrease in the MBD yield. As previously discussed [88], this trend could be attributed to the initiation of a reverse reaction. In Run 11, a 56% MBD yield was obtained by shortening the reaction time to 60 min while increasing the catalyst amount to 0.18 wt%. This result was influenced primarily by the insufficient time available for the reaction to complete [89].

3.2.8 Synergistic effect of reaction time and reaction temperature on biodiesel yield

The 3D surface plots in Figure 9f depict the combined effect of temperature and time on the MBD yield. It is worth noting that a remarkable CBD yield of 95.5% was obtained in Run 22, taking advantage of the optimized time and temperature conditions, specifically 120 min and 110°C, as shown in Table 4. In the field of biodiesel production, it is critical to recognize that the reaction time and temperature are critical factors that have a significant impact on increasing biodiesel yield. They accomplished this by increasing the kinetic energy of molecules, thereby catalyzing the rate of reactant conversion and facilitating the attainment of the highest possible MBD yield [90]. Their relationship is clear: as the reaction time and temperature increased, the biodiesel yield increased, as evidenced by Run 22 results. However, pushing these parameters even higher, as in Run 3 (180 min at 120°C), resulted in a decrease in the MBD yield, which measured 92%. This decrease is due to the negative effects of thermal degradation on the oils, methanol evaporation, and ultimately the formation of unwanted saponification byproducts [91,92]. In Run 5, the reaction time was increased to 180 min, resulting in a lower yield of 81%. This decrease was caused by the facilitation of a reverse reaction in which biodiesel began to react with glycerol, lowering the final yield [93,94]. The findings of this study closely resemble those of previous research (Tables 5 and 6) [95].

NMR spectra of biodiesel H1NMR spectra and C12 NMR spectra.

Actual and predicted biodiesel yields of Mallotus philippensis seed oil via Box–Behnken experimental design

| Run | Oil/ methanol molar ratio | Catalyst concentration (wt%) | Temperature (°C) | Time (min) | Yield (%) |

|---|---|---|---|---|---|

| 1 | 11 | 0.15 | 110 | 120 | 95 |

| 2 | 12 | 0.15 | 120 | 120 | 94 |

| 3 | 11 | 0.15 | 120 | 180 | 92 |

| 4 | 10 | 0.15 | 110 | 60 | 36 |

| 5 | 11 | 0.15 | 100 | 180 | 81 |

| 6 | 11 | 0.18 | 110 | 180 | 89 |

| 7 | 11 | 0.12 | 110 | 180 | 87 |

| 8 | 11 | 0.12 | 100 | 120 | 77 |

| 9 | 10 | 0.12 | 110 | 120 | 62 |

| 10 | 10 | 0.15 | 110 | 180 | 85 |

| 11 | 11 | 0.18 | 110 | 60 | 56 |

| 12 | 12 | 0.15 | 100 | 120 | 83 |

| 13 | 10 | 0.15 | 120 | 120 | 76 |

| 14 | 10 | 0.15 | 100 | 120 | 69 |

| 15 | 11 | 0.12 | 120 | 120 | 82 |

| 16 | 12 | 0.12 | 110 | 120 | 85 |

| 17 | 11 | 0.15 | 100 | 60 | 44 |

| 18 | 11 | 0.18 | 120 | 120 | 92 |

| 19 | 11 | 0.15 | 110 | 120 | 96 |

| 20 | 10 | 0.18 | 110 | 120 | 81 |

| 21 | 11 | 0.15 | 110 | 120 | 97 |

| 22 | 11 | 0.15 | 110 | 120 | 95.5 |

| 23 | 12 | 0.15 | 110 | 180 | 92 |

| 24 | 12 | 0.15 | 110 | 60 | 57 |

| 25 | 11 | 0.15 | 120 | 60 | 51 |

| 26 | 11 | 0.15 | 110 | 120 | 94.1 |

| 27 | 11 | 0.18 | 100 | 120 | 85 |

| 28 | 12 | 0.18 | 110 | 120 | 91 |

| 29 | 11 | 0.12 | 110 | 60 | 42 |

Analysis of variance of obtained results

| Source | Sum of squares | Df | Mean | F-value | p-value | Remarks |

|---|---|---|---|---|---|---|

| Model | 9117.772 | 14 | 651.2694532 | 168.9791 | 4.06 × 10−13 | Significant |

| A – Molar ratio | 720.75 | 1 | 720.75 | 187.0066 | 1.72 × 10−9 | |

| B – Catalyst dosage | 290.0833 | 1 | 290.0833333 | 75.26533 | 5.26 × 10−7 | |

| C – Reaction temperature | 192 | 1 | 192 | 49.81652 | 5.7 × 10−6 | |

| D – Reaction time | 4,800 | 1 | 4,800 | 1245.413 | 4.42 × 10−15 | |

| AB | 42.25 | 1 | 42.25 | 10.96223 | 0.005149 | |

| AC | 4 | 1 | 4 | 1.037844 | 0.325606 | |

| AD | 49 | 1 | 49 | 12.71359 | 0.003103 | |

| BC | 1 | 1 | 1 | 0.259461 | 0.618425 | |

| BD | 36 | 1 | 36 | 9.340598 | 0.008543 | |

| CD | 4 | 1 | 4 | 1.037844 | 0.325606 | |

| A² | 460.597 | 1 | 460.597045 | 119.507 | 3.06 × 10−8 | |

| B² | 247.4673 | 1 | 247.4673153 | 64.20813 | 1.34 × 10−6 | |

| C² | 278.4281 | 1 | 278.4281261 | 72.24126 | 6.72 × 10−7 | |

| D² | 2806.763 | 1 | 2806.763261 | 728.2458 | 1.79 × 10−13 | |

| Residual | 53.958 | 14 | 3.854142857 | |||

| Lack of fit | 49.25 | 10 | 4.925 | 4.184367 | 0.090115 | Not significant |

| Pure error | 4.708 | 4 | 1.177 | |||

| Cor total | 9171.73 | 28 | ||||

| Std. dev. | 1.963197 | R² | 0.994117 | |||

| Mean | 78.15862 | Adjusted R² | 0.988234 | |||

| C.V. % | 2.511811 | Predicted R² | 0.968268 | |||

| Adequate precision | 42.83406 |

Key: Df: Degrees of freedom, C.V.: Coefficient of variance, Std Dev: Standard deviation.

Environmental standardization of fuel properties of Mallotus philippensis biodiesel in comparison with other feedstocks

| Properties | Methods used for biodiesel properties | Mallotus philippensis biodiesel (current study) | Pongamia pinnata biodiesel [99] | Ricinus communis [100] | American (ASTM D-6751) | European EN-14214 | China GB/T 20828-2007 |

|---|---|---|---|---|---|---|---|

| Color | Visual | 2 | 2 | _ | _ | _ | _ |

| Total acid no. (mg KOH/g) | ASTM D-974 | 0.221 | 0.44 | 0.015 | ≤0.5 | ≤0.5 | ≤0.5 |

| Density (kg/m3 at 15°C) | ASTM D-1298 | 0.872 | _ | _ | _ | 0.86–0.89 g/m3 | _ |

| Kinematic viscosity (cSt at 40°C) | ASTM D-445 | 5.32 | 5.44 | 6.48 | 1.9–6.0 | 3.4–5.0 | _ |

| Flash point (°C) | ASTM D-93 | 82 | 158 | 135 | ≥93 | ≥120 | ≥120 |

| Cloud point (°C) | ASTM D-2500 | −11 | 5 | 1 | _ | _ | _ |

| Pour point (°C) | ASTM D-97 | −7 | −2 | 1.5 | _ | _ | _ |

| Sulfur (wt%) | ASTM D-4294 | 0.00041 | <0.005 | <0.005 | ≤0.05 | 0.020 | 0.020 |

3.3 Characterization of biodiesel

3.3.1 FT-IR spectroscopy of Kamala seed oil and biodiesel

Comparing the FT-IR spectra of unprocessed MSO and the resulting MBD in the mid-IR range (400–4,000 cm⁻¹) validates the transformation of triglycerides into FAMEs, as previously observed [96]. Despite minor discrepancies, the spectra exhibited only slight variations, attributed to inherent distinctions in the composition of the initial oil and the ultimate biodiesel product [97]. The fingerprint region, spanning between 500 and 1,500 cm⁻¹ on the right, is renowned for its characteristic spectral traits [98]. The presence of broad stretching vibrations at 1,640 cm⁻¹ serves as conclusive proof that CBD is formed and that C═O carbonyl groups are present, a distinct hallmark of biodiesel. Notably, the characteristic peaks at 1,435 and 1,460 cm⁻¹ signify the presence of methylene group, arising from C–H stretching vibrations, a clear indicator of methyl esters within the CBD. Additionally, the peaks detected at 1,170 and 1,196 cm⁻¹ correspond to conjugated aryl esters C–O stretching vibrations, further affirming the biodiesel’s distinct spectral features. The peak at 2,853 cm⁻¹ indicates vibrations related to methylene stretching, whereas the prominent peak at 2,923 cm⁻¹ indicates the stretching of methyl groups. These peaks provide unequivocal confirmation of the presence of methyl groups within the FAA structure. Conversely, the notable peaks at 1,460 and 1,362 cm⁻¹ emanated from the twisting vibrations of methyl groups.

3.3.2 GC-MS analysis of Mallotus philippensis seed oil biodiesel

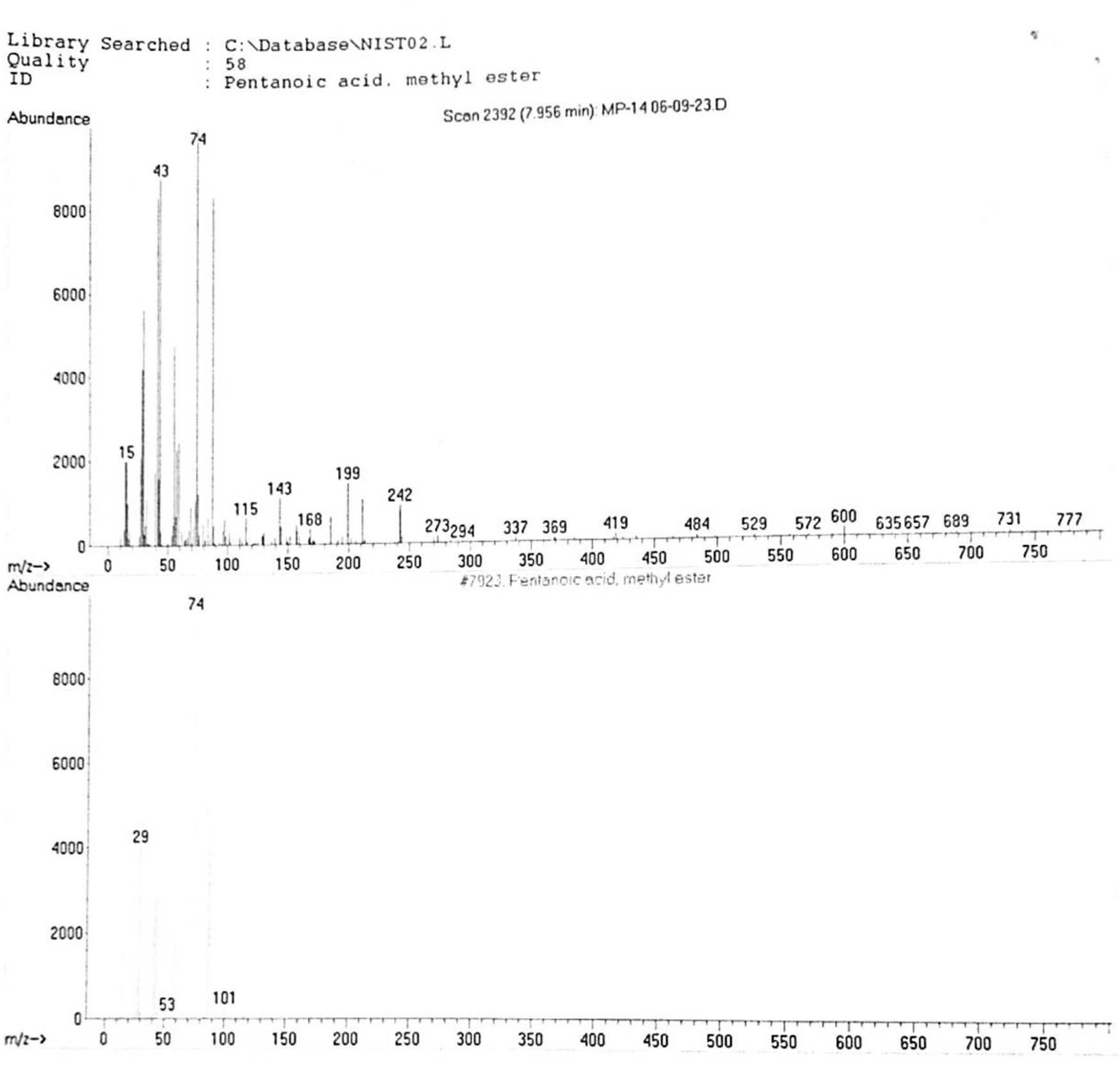

This particular analytical technique is particularly effective in understanding the decomposition of FAME observed in the generated biodiesel and its chemical composition. The synthesized biodiesel was found to have three main peaks, which were identified and further estimated using library matching software (No. NIST02). Figure 8 shows the fragmentation and mass spectra of the methyl ester of pentanoic acid. The fragmentation shown matches with library along with retention times of 2.151 (methyl 6-methyl heptanoate), 4.992 (butanoic acid 3-methyl ester), and 5.798 (dodecanoic acid methyl ester). These peaks attest to the oil’s successful conversion to methyl esters [46]. One of the most notable important fragmentations is the McLafferty rearrangement, which results in base peaks for methyl esters at m/z = 74.

3.3.3 NMR of Kamala seed oil biodiesel

Figure 9a displays the Mallotus biodiesel’s 1H NMR spectrum. The 1H NMR spectrum shows the methoxy group (–OCH3) peak at 3.618 ppm, confirming the effective transformation of oils to biodiesel. A triplet of the α-methylene proton (α-CH2) was observed at 2.27 ppm, whereas a singlet of the β-methylene (β-CH2) was found at 1.220–1.572 ppm. At 0.832 and 0.84 ppm, the peak displaying terminal methyl protons was visible. At 5.28–5.30 ppm, olefinic hydrogen (–CH═CH–) was detected, whereas allylic hydrogen (–CH2–) was detected at 2.27 ppm. The existence of methyl ester compounds in Mallotus oil was verified by all these peaks.

The 13C NMR spectrum, which is shown in Figure 9b, contains information pertaining to the structure of biodiesel. In the spectrum, the typical peak corresponding to methoxy carbon was observed at 51.33 ppm. The signal for the methyl ester’s carbonyl (C–O) group was found at 77.53 ppm, while the signal for the long chains of ethylene carbon (–CH2–) n was found between 29.07 and 29.71 ppm. At 174.25 ppm, a carbonyl group (–COOH) signal was detected. The biodiesel spectrum showed signals for unsaturation (–CH═CH–), which corresponded to the inner non-conjugated carbon at 127.84 ppm. Chemical shifts between δ129.63 and δ129.89 (ppm) indicated the non-conjugated carbon’s outer carbon (–CH═CH–). In the 13C NMR spectrum, aliphatic methylene (–CH2–s) signals were found in the 34–27 ppm range (Figure 10).

Impact of environmental reusability of the green nanocatalyst on the biodiesel yield.

4 Biodiesel’s fuel properties

Prior to using synthesized biodiesel made from non-edible feedstocks in diesel-powered engines, it is critical to measure important fuel characteristics like density, kinematic viscosity, pour point, flash point, and sulfur content. These characteristics act as crucial safety measures to guarantee diesel engines’ compatibility and secure running.

We carried out a thorough examination of the fuel’s properties in this study of Mallotus philippensis (Lam.) Mull. Arg. seed oil and its corresponding biodiesel. We then compared these properties to internationally recognized biodiesel standards, including American (ASTM-6751), European (EN-14214), and Chinese (GB-T) standards. Additionally, we compared our findings with previous research conducted by Sharma et al. [99] and Okechukwu et al. [100] to assess the degree of similarity and alignment with established benchmarks in the field.

One of the most important metrics for evaluating the stability and quality of biodiesel fuel is its acid number. It measures the number of acidic substances – FAAs, in particular – that are present in the biodiesel. The acid number is usually stated as milligrams of potassium hydroxide (KOH) needed to neutralize 1 g of biodiesel [101]. In the current study, the acid number of Mallotus philippensis (Lam.) Mull. Arg. biodiesel is well within the recommended range, measuring at 0.221 mg KOH/g. Notably, this acid number is lower than that observed in previous research for Pongamia pinnata L. seed oil biodiesel (0.44 mg KOH/g) as reported by Sharma et al. [99] and Ricinus communis L. seed oil biodiesel (0.015 mg KOH/g) as reported by Okechukwu et al. [100].

Density is a pivotal parameter in the realm of biodiesel research and application. It signifies the mass of biodiesel per unit volume, usually expressed in kilograms per liter (kg/L). It plays an important role in its energy content. Researchers have delved into tailoring biodiesel’s density to optimize its energy density [102]. Modifying feedstock selection and production processes can lead to variations in density, impacting the energy output per unit volume. Understanding biodiesel density is imperative for efficient storage and transportation. Variations in biodiesel density can influence the weight and volume of stored fuel, affecting storage tank design, logistics, and fuel handling practices [103]. Density also plays a crucial role in biodiesel’s cold weather performance. Higher-density biodiesel may exhibit a higher cloud point or gel point, affecting its flow properties in low temperatures [104]. International biodiesel standards state that the density of biodiesel should be between 860 and 900 kg/m³, which is higher than the density of petroleum diesel, which is 827.2 kg/m³ [105]. In our study, the density of Mallotus philippensis (Lam.) Mull. Arg. biodiesel was found to be 0.8722 kg/m³, well within the prescribed range. This finding suggests that the use of MBD is entirely safe for diesel engines and the environment, as it meets the recommended density standards. It does not pose any detrimental effects on diesel engines or the ecosystem.

Kinematic viscosity is a critical property that characterizes the fluidity or thickness of biodiesel. Lower-viscosity biodiesel tends to atomize better in diesel engines, leading to improved combustion efficiency and reduced particulate matter emissions. Biodiesel’s viscosity is temperature-sensitive [106,107]. Higher-viscosity biodiesel may experience issues like poor cold-flow properties, potentially requiring the use of additives or improved cold-weather blending strategies [108]. Biodiesel viscosity is also indirectly related to its environmental impact. Lower-viscosity biodiesel can lead to reduced engine emissions and improved fuel atomization, contributing to lower greenhouse gas emissions [109]. The biodiesel made from MSO has a kinematic viscosity of 5.32 cSt at 40°C, which is comfortably within the range specified by international biodiesel requirements. Significantly, this viscosity value is in close proximity with the values previously reported for the biodiesel made from Pongamia pinnata L. seed oil (5.44 cSt) and Ricinus communis L. seed oil (6.48 cSt).

The flash point of biodiesel refers to the lowest temperature at which biodiesel vapors can ignite when exposed to an open flame or external heat source. High flash points indicate lower combustibility and a reduced risk of fire hazards. Biodiesel with a higher flash point may have better cold-flow properties, which is advantageous in colder climates. Monitoring and controlling flash points are integral to biodiesel quality assurance [110,111]. Deviations from expected flash point values can signal impurities or issues in the production process [112]. The results of our investigation indicate that the flash point of biodiesel is 82°C, which is comfortably within the range specified by international biodiesel guidelines. Notably, our biodiesel has a flash point that is significantly higher than that of Pongamia pinnata seed oil biodiesel (58°C) and significantly lower than that of Ricinus communis L. seed oil biodiesel (133°C) [100]. It is important to underscore that fuels boasting a flash point exceeding 66°C are particularly advantageous due to their inherently safer characteristics in terms of flammability hazards [113].

The cloud point is the temperature at which solid crystals begin to form in the biodiesel, causing it to become cloudy or hazy [114]. This phenomenon occurs due to the crystallization of saturated methyl esters present in the biodiesel. A lower cloud point is desirable because it indicates improved low-temperature performance, ensuring that biodiesel remains clear and flowable even in cold climates [115]. The pour point is the lowest temperature at which biodiesel can still flow under the force of gravity. It is a critical parameter for assessing biodiesel’s ability to flow and feed into the fuel system, particularly in cold weather conditions [116]. Biodiesel with a lower pour point is preferable, as it remains liquid and flows smoothly at lower temperatures, reducing the risk of clogs or engine start-up problems. In our present research [117], it is worth noting that the cloud point and pour point measurements for Mallotus philippensis seed oil biodiesel exhibit superior performance with values of −11 and −7°C, respectively. Comparatively, Pongamia pinnata seed oil biodiesel showcases slightly elevated cloud and pour points at 5 and −2°C.

The sulfur content in biodiesel is typically very low, often near or below 15 parts per million (ppm). This low sulfur content is a significant advantage of biodiesel compared to traditional petroleum-based diesel fuels, which can have much higher sulfur levels. This low sulfur content is a key factor contributing to biodiesel’s environmental benefits, as it reduces sulfur dioxide emissions upon combustion, which can lead to air pollution and acid rain [118,119]. Researchers in this field have worked on developing biodiesel production methods and feedstock selection strategies that further minimize the sulfur content. They aim to achieve compliance with stringent emissions regulations and to improve the overall environmental sustainability of biodiesel as an alternative to fossil fuels. These efforts have led to the establishment of biodiesel standards that specify maximum sulfur content levels, typically well below 15 ppm, ensuring cleaner and more eco-friendly combustion [120]. The computed value, which is 0.00041%, is well within the ideal range. Amazingly, Pongamia pinnata seed oil biodiesel’s sulfur content matches up quite well, staying at roughly the same level of ≤0.005%.

In conclusion, the most important characteristics to consider when assessing the quality of fuel are its density, kinematic viscosity, pour point, flash point, and sulfur concentration. To assess the compatibility of MSO and biodiesel with global biodiesel standards such as American (ASTM-6751), European (EN-14214), and Chinese (GB-T) benchmarks, an extensive analysis was conducted, focusing on their oil and biodiesel compositions. Viscosity is another essential property of biodiesel. Fuel atomization in diesel engines is greatly aided by the addition of biofuel. Notably, when derived from MSO, biodiesel exhibits a kinematic viscosity of 5.32 cSt at 40°C. Moreover, the study illustrates a flash point of 82°C, which is comfortably within the established parameters specified by global biodiesel standards.

5 Environmental reusability of phytonanocatalysts

Environmental reusability of the catalyst is a pivotal aspect of this research, as it not only impacts the overall cost and environmental sustainability of biodiesel synthesis but also showcases the practicality of the developed green nanocatalyst. As it plays a pivotal role in industrial biodiesel synthesis by reducing the cost and enhancing the production efficiency. In systems where a solid nanocatalyst is employed, the catalyst can be readily separated from the reaction mixture’s two phases once the reaction is completed. It is imperative to acknowledge that the performance and reaction rate of a recycled catalyst are contingent upon the specific catalyst employed and the effectiveness of the separation techniques utilized [65]. The conditions that yielded the optimal results were selected for evaluating the reusability of the sodium tungstate bio-based green nanocatalyst, ultimately leading to the highest biodiesel yield of 95.5%. These conditions encompassed a catalyst loading of 0.15 (wt%), a methanol-to-oil ratio of 11:1, and a reaction temperature of 110°C maintained for 120 min. To achieve the desired outcome, the catalyst was meticulously extracted from the system upon completing the reaction, followed by a recuperation process involving filtration and a thorough methanol wash. Subsequently, the catalyst underwent a controlled baking procedure at 600°C, spanning a duration of 4–5 h, to eliminate any residual moisture from its surface [44]. In the assessment of catalyst reusability, five successive cycles were employed, revealing a notably consistent trend. During the initial three recycling reactions, the biodiesel yield remained consistently high, at approximately 95%. However, a slight decline was observed in the fourth round, with a yield of 93%, which was followed by a marginal decrease to 91.6% in the final cycle. The decline in yield can be attributed to a combination of factors, including the catalyst’s susceptibility to solubility in methanol, which may result in catalyst loss during the recovery process. Additionally, alterations to the catalyst’s active sites due to surface poisoning and pore-filling by triglycerides and glycerol are also contributing factors to this reduction in the biodiesel yield [101]. In conclusion, the reusability of catalysts holds significant importance in biodiesel production. The presence of a solid nanocatalyst in both phases of the reaction mixture streamlines the separation process after the reaction completion. It is worth noting that the choice of catalyst and the efficacy of separation techniques directly influence the catalyst’s performance and reaction kinetics.

6 Anticipated trajectory and crucial commercialization challenges for biodiesel

The globalization of biodiesel production in future holds the promise of diversifying feedstock sources for a cleaner and greener environment and energy security. Researchers are actively exploring various seed oils beyond conventional ones, including non-edible sources. This broadens the scope for sustainable and economically viable biodiesel production. Moreover, the development of green nanocatalysts is expected to progress further, leading to improved catalytic efficiency, enhanced reusability, and cost-effectiveness. Future research will focus on tailoring nanocatalysts to specific feedstocks, thereby optimizing the transesterification process. With increasing environmental awareness, biodiesel’s role in achieving carbon neutrality is set to expand [121]. Future perspectives include advanced sustainability assessments, including life cycle analyses, to ensure the net environmental benefits of biodiesel production. Nowadays, commercialization efforts are poised to introduce biodiesel to a wider market, including industries beyond transportation, such as aviation and maritime sectors. This diversification will require tailored production methods and higher production capacities [122]. Thus, biodiesel production using green nanocatalysts presents opportunities for global integration. Collaboration on research, technology sharing, and knowledge transfer will foster the adoption of sustainable biodiesel production practices worldwide [123].

Nevertheless, in the face of these auspicious opportunities, biodiesel’s path to commercialization is beset with intricate challenges. The economic viability of biodiesel production remains a critical challenge. The costs associated with the preparation of green nanocatalysts, and the scalability of production processes must be addressed to ensure cost-competitive biodiesel production. The commercialization of biodiesel depends on the development of the necessary infrastructure [124]. This includes the establishment of storage, distribution, and retailing facilities to meet the increasing demand for biodiesel. Expanding infrastructure to accommodate biodiesel will require significant investments. Moreover, the biodiesel industry is evolving and often stringent regulations vary from region to region. Navigating the complex regulatory landscape and ensuring compliance with differing standards will continue to be a challenge in commercialization efforts [125,126]. Therefore, ensuring a consistent and sustainable supply of feedstock is crucial for biodiesel production. Balancing feedstock availability with sustainability concerns, including responsible land use and biodiversity preservation, is a complex challenge. To facilitate commercialization, the biodiesel industry must continue to engage in public education and awareness campaigns. Overcoming misconceptions and fostering an informed understanding of biodiesel’s environmental benefits are vital for public acceptance. The transition to new technologies and practices within the biodiesel industry may require adaptation and change management. Ensuring a smooth transition to more sustainable methods while maintaining production efficiency will be a complex challenge [127].

In the current research, a pioneering approach was harnessed to biologically synthesize a nanocatalyst from the rotten fungus fruits using sodium tungstate salt via an in situ wet impregnation technique followed by the reaction in a hydrothermal autoclave reactor. This innovative catalyst stood out for its exceptional catalytic activity in transesterification reactions, distinguished by its eco-friendliness and cost-efficiency. Its remarkable reusability further underscored its efficacy, consistently delivering optimal biodiesel yields. Future research avenues should explore the impact of various salts, employing diverse nanotechnological methodologies. Furthermore, there is an urgent need for continuous exploration of non-edible seed-based biofuel production, harnessing cutting-edge technologies and a diverse array of catalysts produced through various methods. The optimization of biodiesel yields through RSM will play a pivotal role in refining the production process. This study serves as a testament to the potential of biodiesel derived from Mallotus philippensis and underscores the significance of tackling challenges and streamlining processes, ultimately paving the way for the large-scale commercialization of biodiesel. In conclusion, the escalating global energy demands, coupled with mounting environmental apprehensions and the depletion of finite resources, are propelling the exploration of alternative energy sources. Simultaneously, the allure of fossil fuels is diminishing due to their extensive use and associated environmental consequences. Within this shifting energy landscape, biofuels, particularly biodiesel, are emerging as compelling alternatives, offering cleaner and more sustainable energy solutions. Continuous research and innovation in biodiesel production, catalysis, and feedstock utilization hold the promise of ushering in a greener and more sustainable energy future.

7 Conclusions

In the current era, owing to the ongoing energy crisis and the swift exhaustion of fossil fuel reservoirs, the world community is redirecting its focus towards renewable energy sources, and biodiesel is emerging as a cleaner and promising energy source. In this regard, the present study demonstrates using Mallotus philippensis as a prospective solution for cleaner production of renewable fuels via a green innovative sodium tungstate nanocatalyst.

The present investigation has unveiled the following key findings:

Mallotus philippensis seeds boast a substantial oil content, accounting for 50% (w/w), while concurrently the synthesized sodium tungstate bio-based green nanocatalyst exhibits a pronounced aptitude for converting MSO into MBD.

The oil’s FAA profile, quantified at 1.126%, signifies favorable fuel attributes and a marked capacity. It is notably advantageous for the base-catalyzed transesterification reaction involved in biodiesel synthesis.

WO3 bio-based green NPs were generated through a biological approach, involving an in situ wet impregnation process followed by reaction in a hydrothermal autoclave reactor, from unconventional rotten fungus fruits. This catalyst demonstrated exceptional catalytic efficiency in the context of the transesterification reaction.

The epitome of reaction conditions yielded the highest biodiesel yield of 95.5%, characterized by a 11:1 methanol-to-oil ratio, a catalyst concentration of 0.15 (wt%), a reaction duration of 120 min, and a reaction temperature of 110°C.

The presence of methyl esters in the MBD sample was confirmed through comprehensive analytical methods, including NMR, GC-MS, and FT-IR analyses.

A remarkably low sulfur content, measuring merely 0.00041%, has been documented, signifying that the synthesized methyl esters are exceptionally eco-friendly and produce minimal harmful emissions, making them environmentally benign.

In the pursuit of environmental, sustainable, and innovative solutions for the ever-pressing challenges of our time, the exploration of biodiesel synthesis from a novel Mallotus philippensis feedstock, employing an autoclave reactor and a bio-based green nanocatalyst sourced from seemingly unconventional origins, has unveiled a new frontier in renewable energy production. The utilization of Mallotus Philippensis as a biodiesel feedstock has revealed its potential as a sustainable alternative. The hydrothermal autoclave reactor has proven its efficiency and versatility in streamlining the transesterification process, emphasizing its role as a promising technological tool for the biodiesel industry. Furthermore, the economic feasibility of the green nanocatalyst’s regeneration underscores the financial advantages of its incorporation into industrial-scale biodiesel production. This synthesis of sustainable practices with economic and environmental viability brings us closer to a future where energy production and environmental responsibility are intricately intertwined. It is a testament to our capacity for innovation and adaptation in the face of ever-evolving challenges, setting the stage for a greener, more sustainable tomorrow.

Acknowledgments

This work was also supported by the Researchers Supporting Project (RSP2024R405), King Saud University, Saudi Arabia.

-

Funding information: The high-level talent introduction project of Science and Technology Department of Sichuan Province of People’s Republic China (No. 2023JDGD0031) and the special research funding for high level talent teams of Neijiang Normal University (No. RSC202102). This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (No. 2022R1C1C1008831). This research was supported by the “Regional Innovation Strategy (RIS)” through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (MOE)(2023RIS-005). This work was also supported by the Researchers Supporting Project (RSP2024R405), King Saud University, Saudi Arabia.

-

Author contributions: Bisha Chaudhry: investigation and writing – original draft; Shazia Sultana: writing – review and editing; Zhiyong Zhang: review and editing; Mushtaq Ahmad: investigation, writing, and supervision; Mamoona Munir: conceptualization, methodology, and formal analysis; Sameh M. Osman and Muhammad Saeed Akhtar: software, visualization, and funding; Awais Bokhari, Chungyeon Cho, and Dongwhi Choi: supervision, conceptualization, writing – review and editing, and project administration. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Omeiri MH, Khnayzer RS, Yusef HH. Monitoring of pesticide residues in lebanese vegetables and agricultural soils and their impact on soil microbiological properties. Asian J Water Environ Pollut. 2022;19:27–35.10.3233/AJW220085Search in Google Scholar

[2] Ramadan L, Deeb R, Sawaya C, El Khoury C, Wazne M, Harb M. Anaerobic membrane bioreactor-based treatment of poultry slaughterhouse wastewater: Microbial community adaptation and antibiotic resistance gene profiles. Biochem Eng J. 2023;192:108847.10.1016/j.bej.2023.108847Search in Google Scholar

[3] Howell S, Rezgui Y, Hippolyte J-L, Jayan B, Li H. Towards the next generation of smart grids: Semantic and holonic multi-agent management of distributed energy resources. Renew Sustain Energy Rev. 2017;77:193–214.10.1016/j.rser.2017.03.107Search in Google Scholar

[4] Rabbi MF, Popp J, Máté D, Kovács S. Energy security and energy transition to achieve carbon neutrality. Energies. 2022;15:8126.10.3390/en15218126Search in Google Scholar

[5] Elavarasan RM. The motivation for renewable energy and its comparison with other energy sources: a review. Eur J Sustain Dev Res. 2019;3:em0076.10.20897/ejosdr/4005Search in Google Scholar

[6] Kaygusuz K. Energy and environmental issues relating to greenhouse gas emissions for sustainable development in Turkey. Renew Sustain Energy Rev. 2009;13:253–70.10.1016/j.rser.2007.07.009Search in Google Scholar

[7] Sawaya C, Ramadan L, El Khoury C, Al-Alam J, Wazne M, Harb M. Targeted pressure-based development of membrane biofilms improves anaerobic membrane bioreactor effluent quality. Environ Sci: Water Res Technol. 2022;8:1859–73.10.1039/D2EW00386DSearch in Google Scholar

[8] Ghalkhani M, Teymourinia H, Ebrahimi F, Irannejad N, Karimi-Maleh H, Karaman C, et al. Engineering and application of polysaccharides and proteins-based nanobiocatalysts in the recovery of toxic metals, phosphorous, and ammonia from wastewater: A review. Int J Biol Macromol. 2023;242:124585.10.1016/j.ijbiomac.2023.124585Search in Google Scholar PubMed

[9] Munir M, Saeed M, Ahmad M, Waseem A, Alsaady M, Asif S, et al. Cleaner production of biodiesel from novel non-edible seed oil (Carthamus lanatus L.) via highly reactive and recyclable green nano CoWO3@rGO composite in context of green energy adaptation. Fuel. 2023;332:126265.Search in Google Scholar

[10] Karimi F, Zare N, Jahanshahi R, Arabpoor Z, Ayati A, Krivoshapkin P, et al. Natural waste-derived nano photocatalysts for azo dye degradation. Environ Res. 2023;238:117202.10.1016/j.envres.2023.117202Search in Google Scholar PubMed

[11] Karimi-Maleh H, Ghalkhani M, Saberi Dehkordi Z, Mohsenpour Tehran M, Singh J, Wen Y, et al. Mof-enabled pesticides as developing approach for sustainable agriculture and reducing environmental hazards. J Ind Eng Chem. 2024;129:105–23.10.1016/j.jiec.2023.08.044Search in Google Scholar

[12] Berdysheva S, Ikonnikova S. The energy transition and shifts in fossil fuel use: the study of international energy trade and energy security dynamics. Energies. 2021;14:5396.10.3390/en14175396Search in Google Scholar

[13] Mohammad M, Hari TK, Yaakob Z, Sharma YC, Sopian K. Overview on the production of paraffin based-biofuels via catalytic hydrodeoxygenation. Renew Sustain Energy Rev. 2013;22:121–32.10.1016/j.rser.2013.01.026Search in Google Scholar

[14] Saravanan A, Swaminaathan P, Kumar PS, Yaashikaa PR, Kamalesh R, Rangasamy G. A comprehensive review on immobilized microbes - biochar and their environmental remediation: Mechanism, challenges and future perspectives. Environ Res. 2023;236:116723.10.1016/j.envres.2023.116723Search in Google Scholar PubMed

[15] Deivasigamani P, Senthil Kumar P, Sundaraman S, Soosai MR, Renita AA, Bektenov KMN, et al. Deep insights into kinetics, optimization and thermodynamic estimates of methylene blue adsorption from aqueous solution onto coffee husk (Coffee arabica) activated carbon. Environ Res. 2023;236:116735.10.1016/j.envres.2023.116735Search in Google Scholar PubMed

[16] Saleh HM, Hassan AI. Effect of a home-based mobile health app intervention on physical activity levels in patients with heart failure: a randomized controlled trial. Fire. 2023;6:128–39.10.1097/JCN.0000000000000911Search in Google Scholar PubMed

[17] Chen L, Msigwa G, Yang M, Osman AI, Fawzy S, Rooney DW, et al. Strategies to achieve a carbon neutral society: a review. Environ Chem Lett. 2022;20:2277–310.10.1007/s10311-022-01435-8Search in Google Scholar PubMed PubMed Central

[18] Han N, Race M, Zhang W, Marotta R, Zhang C, Bokhari A, et al. Perovskite and related oxide based electrodes for water splitting. J Clean Prod. 2021;318:128544.10.1016/j.jclepro.2021.128544Search in Google Scholar

[19] Maheshwari P, Haider MB, Yusuf M, Klemeš JJ, Bokhari A, Beg M, et al. A review on latest trends in cleaner biodiesel production: Role of feedstock, production methods, and catalysts. J Clean Prod. 2022;355:131588.10.1016/j.jclepro.2022.131588Search in Google Scholar

[20] Taylor B, Xiao N, Sikorski J, Yong M, Harris T, Helme T, et al. Techno-economic assessment of carbon-negative algal biodiesel for transport solutions. Appl Energy. 2013;106:262–74.10.1016/j.apenergy.2013.01.065Search in Google Scholar

[21] Mutezo G, Mulopo J. A review of Africa's transition from fossil fuels to renewable energy using circular economy principles. Renew Sustain Energy Rev. 2021;137:110609.10.1016/j.rser.2020.110609Search in Google Scholar

[22] Barbir F. Transition to renewable energy systems with hydrogen as an energy carrier. Energy. 2009;34:308–12.10.1016/j.energy.2008.07.007Search in Google Scholar

[23] Asif S, Ahmad M, Bokhari A, Chuah LF, Klemeš JJ, Akbar MM, et al. Methyl ester synthesis of Pistacia khinjuk seed oil by ultrasonic-assisted cavitation system. Ind Crop Prod. 2017;108:336–47.10.1016/j.indcrop.2017.06.046Search in Google Scholar

[24] Kim DS, Hanifzadeh M, Kumar A. Trend of biodiesel feedstock and its impact on biodiesel emission characteristics. Environ Prog Sustain Energy. 2018;37:7–19.10.1002/ep.12800Search in Google Scholar

[25] Mukhtar A, Saqib S, Mellon NB, Rafiq S, Babar M, Ullah S, et al. A review on CO2 capture via nitrogen-doped porous polymers and catalytic conversion as a feedstock for fuels. J Clean Prod. 2020;277:123999.10.1016/j.jclepro.2020.123999Search in Google Scholar

[26] Bhatt AK, Bhatia RK, Thakur S, Rana N, Sharma V, Rathour RK. Fuel from waste: a review on scientific solution for waste management and environment conservation. In: Singh A, Agarwal R, Agarwal A, Dhar A, Shukla M, editors. Prospects of alternative transportation fuels. Energy, environment, and sustainability. Singapore: Springer; 2018. p. 205–33.10.1007/978-981-10-7518-6_10Search in Google Scholar

[27] Karmakar A, Karmakar S, Mukherjee S. Properties of various plants and animals feedstocks for biodiesel production. Bioresour Technol. 2010;101:7201–10.10.1016/j.biortech.2010.04.079Search in Google Scholar PubMed

[28] Balat M. Potential alternatives to edible oils for biodiesel production – A review of current work. Energy Convers Manage. 2011;52:1479–92.10.1016/j.enconman.2010.10.011Search in Google Scholar

[29] Ortiz-Martínez V, Salar-García M, Palacios-Nereo F, Olivares-Carrillo P, Quesada-Medina J, De Los Ríos AP, et al. In-depth study of the transesterification reaction of Pongamia pinnata oil for biodiesel production using catalyst-free supercritical methanol process. J Supercrit Fluids. 2016;113:23–30.10.1016/j.supflu.2016.03.009Search in Google Scholar

[30] Prasad B, Padhi R, Ghosh G. A review on key pretreatment approaches for lignocellulosic biomass to produce biofuel and value-added products. Int J Environ Sci Technol. 2023;20:6929–44.10.1007/s13762-022-04252-2Search in Google Scholar

[31] Musa IA. The effects of alcohol to oil molar ratios and the type of alcohol on biodiesel production using transesterification process. Egypt J Pet. 2016;25:21–31.10.1016/j.ejpe.2015.06.007Search in Google Scholar