Abstract

In this study, surface treatment, using blended materials of nano-silica (NS) and magnesium potassium phosphate cement (MKPC) slurries containing four dosages of NS, was applied to recycled aggregate (RA) with distinct RA maintenance schemes to enhance the RA concrete (RAC) performance and control NS dosage for economy. The results imply that the NS + MKPC slurry can efficiently bolster the bonding with RA and the new interfacial transition zone (ITZ), contributing to a distinct enhancement of RAC’s macro-properties. Besides, the optimal NS dosage and RA maintenance scheme revealed by the simplified linear weighted sum optimization method were 3% and no pre-curing procedure, respectively. On the basis of the aforementioned optimal conditions, the modified RAC (C-3-N) achieved enhanced compressive strength by 40.75%, split tensile strength by 46.26%, and chloride ion penetration resistance by 65.93% in comparison with the untreated RAC0. Moreover, the advantages observed in C-3-N were attributed to the exceptional microstructural characteristics in both the NS + MKPC slurry and the new ITZ. This study establishes the potential to augment the efficacy of nanomaterials in reinforcing RAC and enhance the economic viability and practicability of RAC applications. Simultaneously, these advancements contribute to fostering sustainable development within the construction industry and yielding environmental benefits.

Abbreviations

- BSE

-

backscattered electron

- CH

-

calcium hydroxide

- C–S–H

-

calcium silicate hydrate

- DM

-

double-mixing method

- EDS

-

energy-dispersive spectrometer

- ITZ

-

interfacial transition zone

- MKPC

-

magnesium potassium phosphate cement

- NA

-

natural aggregate

- NAC

-

natural aggregate concrete

- NS

-

nano-silica

- OPC

-

ordinary Portland cement

- RA

-

recycled aggregate

- RAC

-

recycled aggregate concrete

- RCPTs

-

rapid chloride permeability tests

- SEM

-

scanning electron microscopy

- S-1

-

NS + MKPC slurry with 1% NS dosage

- S-2

-

NS + MKPC slurry with 2% NS dosage

- S-3

-

NS + MKPC slurry with 3% NS dosage

- S-4

-

NS + MKPC slurry with 4% NS dosage

- N0

-

untreated NA

- R0

-

untreated RA

- R-1-P

-

RA treated by the S-1 under the pre-curing scheme

- R-1-N

-

RA treated by the S-1 under the no pre-curing scheme

- R-2-P

-

RA treated by the S-2 under the pre-curing scheme

- R-2-N

-

RA treated by the S-2 under the no pre-curing scheme

- R-3-P

-

RA treated by the S-3 under the pre-curing scheme

- R-3-N

-

RA treated by the S-3 under the no pre-curing scheme

- R-4-P

-

RA treated by the S-4 under the pre-curing scheme

- R-4-N

-

RA treated by the S-4 under the no pre-curing scheme

- NAC0

-

concrete produced using N0

- RAC0

-

concrete produced using R0

- C-1-P

-

concrete produced using R-1-P

- C-1-N

-

concrete produced using R-1-N

- C-2-P

-

concrete produced using R-2-P

- C-2-N

-

concrete produced using R-2-N

- C-3-P

-

concrete produced using R-3-P

- C-3-N

-

concrete produced using R-3-N

- C-4-P

-

concrete produced using R-4-P

- C-4-N

-

concrete produced using R-4-N

- MD-0

-

interface model simulating the interfaces in the RAC0

- MD-1-P

-

interface model simulating the interfaces in the C-1-P

- MD-1-N

-

interface model simulating the interfaces in the C-1-N

- MD-2-P

-

interface model simulating the interfaces in the C-2-P

- MD-2-N

-

interface model simulating the interfaces in the C-2-N

- MD-3-P

-

interface model simulating the interfaces in the C-3-P

- MD-3-N

-

interface model simulating the interfaces in the C-3-N

- MD-4-P

-

interface model simulating the interfaces in the C-4-P

- MD-4-N

-

interface model simulating the interfaces in the C-4-N

1 Introduction

Recycled aggregate (RA) processed from old demolished concrete structures has been adopted as a partial replacement of natural aggregate (NA) in the production of new concrete in numerous countries across the globe [1,2], which has been demonstrated to be an effective strategy for decreasing the quantity of construction and demolition waste [3,4], conserving natural resources [5,6], mitigating environmental impacts [7], as well as saving construction costs [8–10]. Moreover, the residual mortar layer on RA surfaces exhibits high pore and micro-crack contents as a result of the crushing procedure [11]. Consequently, it is generally acknowledged that RA concrete (RAC) made from RA has deteriorated mechanical properties [12–18] and durability [19–25] in comparison with conventional concrete.

Currently, the study of nanomaterials in enhancing RAC properties has garnered considerable attention within the construction sector [26–29] due to their potential function in concrete mixtures, i.e., the ability of nanoparticles to fill extremely small-sized pores as well as to react with calcium hydroxide (CH) facilitating the formation of an additional calcium silicate hydrate (C–S–H) gel within the system, as a result of their amorphous nature and ultra-high surface area. Typically, nanomaterials have been employed in two approaches for RAC’s mechanical properties and durability enhancement [30–36]. Among them, one method is adding nanomaterials (e.g., nano-silica (NS) [30,31]) directly during the RAC mixing process to enhance the properties of the new cement mortar, leveraging the principle that nanomaterials can improve the pore structure of new cement paste. Nevertheless, incorporating nanomaterial as a supplementary cementitious material would deteriorate the workability of fresh concrete [31], which led to extra admixtures including efficient water reducers. Consequently, another modifying treatment has been proposed that can be attained through the pre-coating of RA with a nanomaterial layer [37–39] to enhance the new interfacial transition zone (ITZ) between RA and the new cement mortar, which has been confirmed [40–44] to exhibit a strong correlation with the durability and strength of RAC [45–49].

Notwithstanding, surface treatment of RA by nanomaterials’ pre-coating requires a massive nanoparticle in which porous RA absorbs a certain amount of nanoparticle, resulting in the method not being economical. Thus, if nanomaterials tend to be extensively utilized as surface treatment materials for RAC modification, it is critical to control their dosages or identify a substance that can be utilized in conjunction with the nano-solutions to ensure the economic efficiency of RAC projects [49]. Moreover, Zhang et al. [37] proposed the preparation of surface treatment slurries for RA utilizing NS mixed with ordinary cement. Based on a comparative study with nSi + nCa nano-slurry, it was determined that the cement + nSi slurry enhanced the new ITZ in RAC and had a secured modification effect on RAC’s mechanical properties and durability. Consequently, this hybrid nano-slurry served as a superior substitute for the pure nano-slurry, which contained a greater quantity of nanomaterials, due to its cost-effectiveness and regulated nanomaterial dosage. Nevertheless, as a surface treatment slurry for RA, its bonding performance with RA has not been considered. In accordance with the damage mechanism of RAC, the hypothetical low bond strength of the surface treatment slurry to RA would create weak links in the RAC, enhancing the velocity of crack propagation and corrosive substance ingress when subjected to external loads or erosions. Furthermore, the cement usage in surface-coating materials likewise aids in the increased carbon emissions of RAC projects [50]. Thus, the discovery of an environmentally friendly material with excellent bonding properties to RA that can be employed in conjunction with nanomaterials as a surface treatment slurry is essential in strengthening the performance of RAC composites as well as their practical applications.

Magnesium potassium phosphate cement (MKPC), recognized as an environmentally friendly cementitious substance [51], has found extensive application [52–56] in the strengthening and restoration of civil and road engineering. This is attributed to its superior bonding characteristics, surpassing those of ordinary Portland cement (OPC) [55,57–60]. Typically, MKPC works on two levels for high-strength bonds with cementitious materials including concrete, i.e., excellent mechanical anchorage as a result of the micro-filling effect induced by substrate penetration [61–63], and chemical interactions with the alkali components of the substrate, which was explicitly demonstrated in this work. Accordingly, whether MKPC substitution for OPC to form NS + MKPC slurry can ensure the formation of a strong bond at the interface with RA and repair the RAC weak point-new ITZ, as well as what effects it may have on RAC macro-performance, needs to be further investigated. Moreover, in the case of surface treatment slurry consisting of two materials, it is necessary to examine the optimal proportion as well as reaction mechanism of the two materials, namely, NS and MKPC, for the purpose of obtaining the optimal enhancement of the slurry and the RAC properties.

Thus, the purpose of this study is to explore the innovative application of NS + MKPC in enhancing RAC properties through preparing NS + MKPC slurries with four NS dosing levels to pre-coating RA along with using two RA maintenance schemes to provide an efficient, practical, and cost-effective modification method for RAC. These are the aims of our research:

To assess the efficacy of surface treatment techniques in improving the macro-characteristics of RAC by conducting compressive and split tensile strength tests, as well as rapid chloride permeability tests (RCPTs) of NA concrete (NAC) and different types of RAC.

To comprehend the strengthening mechanism of surface treatment with NS + MKPC on RAC macro-properties and indicate why/how is the optimal reinforcement efficiency generated through micro-characteristic tests of the bonded interfaces, the new ITZ, and NS + MKPC hardened pastes.

Furthermore, regarding micro-testing, mention that interface models for simulating bonding interfaces and new ITZ were prepared to enhance testing accuracy and statistical efficiency, and scanning electron microscopy (SEM) coupled with an energy-dispersive spectrometer (EDS) was applied to characterize the composition, microstructure, as well as porosity evaluation of interfaces and NS + MKPC pastes. Furthermore, a double-mixing method (DM) [25,66] was adopted to further optimize the new ITZ and thus enhance RAC properties.

2 Materials and methods

2.1 Materials and mix design

The coarse aggregates used in this research were RA procured from a supplier in Tianjin, China, and NA obtained from crushed limestone. The RA particle size distribution was essentially identical to that of the NA. Besides, the NA and untreated RA were marked as N0 and R0, respectively, and their particle size distributions, physical properties, and crush values are indicated in Figure 1 and Table 1, respectively. Ordinary river sand was used as the fine aggregate.

Particle size distributions of N0 and R0.

Physical properties and crush values of N0 and R0

| Coarse aggregate | Apparent density (kg/m3) | Water absorption (%) | Crush value (%) |

|---|---|---|---|

| R0 | 2,430 | 5.4 | 17.5 |

| N0 | 2,637 | 1.6 | 10.3 |

The raw materials for the NS + MKPC surface treatment slurries comprised dead burned magnesia (MgO, 1,600°C) powders, industrial-grade potassium dihydrogen phosphate (KH2PO4) particles, as well as NS with purities of 92, 98.7, and 98.5%, respectively. Moreover, the apparent density of MgO was 590 m2/kg, and the mean particle size of NS was 102 nm. Additional 99.8% pure borax granules and the high-efficiency water reducer were incorporated to control the slurry’s setting time and fluidity. In this study, 1, 2, 3, and 4% NS doping of the mass of MgO were investigated. Additionally, the proportions of the distinct raw materials in each series of slurries are illustrated in Table 2 for pre-treatment of 1,000 kg R0. On the condition that the NS ratio was 1, 2, 3, and 4%, and the corresponding NS + MKPC slurries were labeled S-1, S-2, S-3, and S-4, respectively.

Blending ratios for pre-treatment of 1.000 kg R0

| Slurry type | KH2PO4 (kg) | MgO (kg) | NS (kg) | Water (kg) | Borax (kg) | Water reducer (kg) |

|---|---|---|---|---|---|---|

| S-1 | 69.22 | 207.67 | 2.08 | 52.27 | 10.70 | 1.45 |

| S-2 | 68.71 | 206.14 | 4.12 | 52.27 | 10.70 | 2.16 |

| S-3 | 68.21 | 204.62 | 6.14 | 52.27 | 10.70 | 2.86 |

| S-4 | 67.71 | 203.13 | 8.13 | 52.27 | 10.70 | 3.56 |

The subsequent methods were employed to produce four NS + MKPC slurries: first, the NS weighed in proportion, and some water along with surfactant added for the hard-to-disperse nature of the nanoparticles was blended thoroughly utilizing an ultrasonic disperser. Subsequently, in accordance with the ratios in Table 2, the corresponding NS solution was combined with the remaining water and the other raw materials for 120 s. As a result, four enhancing slurries exhibiting desirable dispersibility were produced.

The surface treatment process of the RA consisted of soaking R0 in the corresponding pre-made slurry for 5 min, accordingly, removing the RA from the tank, and adopting a screen to remove the excess slurry adhering to the RA. Besides, the treated RAs were divided into two groups: one group was not pre-cured after slurries initial setting prior to the casting of the corresponding concrete, and the other group was required to dwell in a curing room with a temperature of 20 ± 2°C and a relative humidity of 64 ± 5% for 28 days. Furthermore, the treated RAs were labeled as R-1-P, R-1-N, R-2-P, R-2-N, R-3-P, R-3-P, R-4-N, and R-4-N, respectively, where the front letters “R” imply the modified RA; the numbers “1”, “2”, “3”, and “4” denote the NS proportions in percentage; and “P” or “N” symbolizes the RA maintenance schemes as pre-curing and no pre-curing, which were previously described therein. Except for that, the water absorption rates of R-1-P, R-2-P, R-3-P, and R-4-P were measured to be 5.2, 5.1, 5.3, and 5.4%, respectively.

As illustrated in Table 3, the treated RAs were used for producing eight groups of concrete mixtures, and N0 and R0 were employed to pour concrete NAC0 and RAC0, respectively. The P.O. 42.5 cement with an apparent density of 3,090 kg/m3 was adopted for the concrete mixture preparation in the experimental program, and the tests likewise employed a water reducer to adjust the fresh concrete slump. Each substance was combined in the following proportion of cement: water: aggregate: sand: water reducer = 431:216:1,020:731:1.2. To eliminate the influence of RAs’ high water absorption on the water volume available for the chemical reactions, i.e., the effective “free” water (W ef) [67,68], and, accordingly, the effective water-to-cement (W ef/C) ratio [69] and workability of the RAC, extra mixing water (W ex) was added to RAC mixture [70,71]. Meanwhile, for maintaining a consistent W ef /C, W ex in RAC0 was calculated as 29.88 kg/m3 according to the following equation [72]:

where w Ragg = 1.53% and w Nagg = 0.68%, indicating the rate of moisture content of R0 and N0, respectively; h Rabs = 5.40% and h Nabs = 1.62%, depicting the moisture absorption rate of R0 and N0, respectively; m agg represents the mass of aggregates. As the water absorption and moisture content of R-1-P, R-2-P, R-3-P, and R-4-P demonstrated no significant differences in comparison with those of R0, the same W ex value was used for all of them [28]. For R-1-N, R-2-N, R-3-N, and R-4-N, it is challenging to assess the water absorption of RA in the absence of pre-curing, their W ex was determined to be identical as R-1-P, R-2-P, R-3-P, and R-4-P, respectively, to examine how modified RAC performance is affected by RA maintenance schemes.

Types and slumps of concrete

| Concrete type | Coarse aggregate used | RA maintenance scheme | Strengthening slurry type | Slump (mm) |

|---|---|---|---|---|

| NAC0 | N0 | — | — | 149 |

| RAC0 | R0 | — | — | 144 |

| C-1-P | R-1-P | Pre-curing | S-1 | 141 |

| C-1-N | R-1-N | No pre-curing | S-1 | 137 |

| C-2-P | R-2-P | Pre-curing | S-2 | 140 |

| C-2-N | R-2-N | No pre-curing | S-2 | 135 |

| C-3-P | R-3-P | Pre-curing | S-3 | 136 |

| C-3-N | R-3-N | No pre-curing | S-3 | 131 |

| C-4-P | R-4-P | Pre-curing | S-4 | 136 |

| C-4-N | R-4-N | No pre-curing | S-4 | 129 |

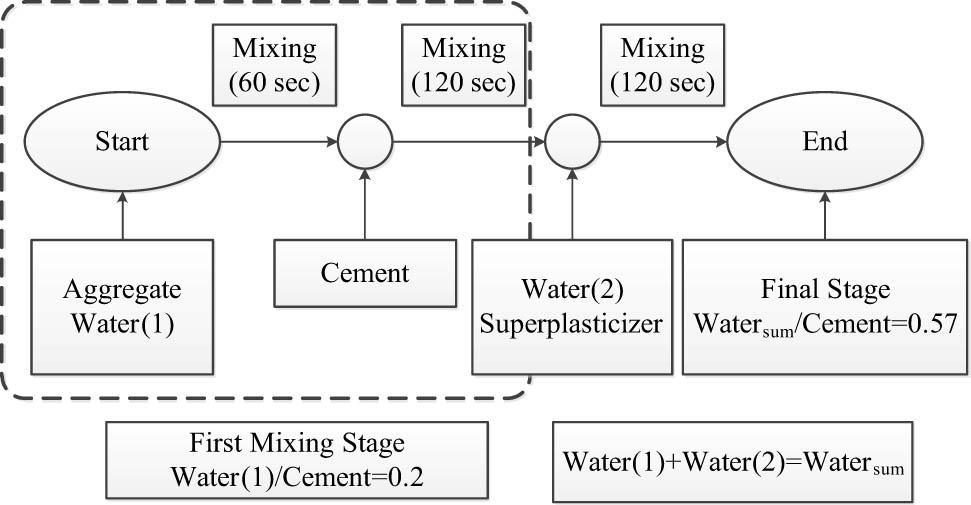

As previously documented, all surface-treated RAs were poured into RAC using DM [66], as illustrated in Figure 2. The slumps of fresh concrete were tested in accordance with GB/T 50080-2016 [73], and the statistical results are given in Table 3. It was evident that the modified RAC had good workability, and yet the slump gradually decreased with the increase in NS content.

DM (Watersum = W ef + W ex).

2.2 Macro-tests

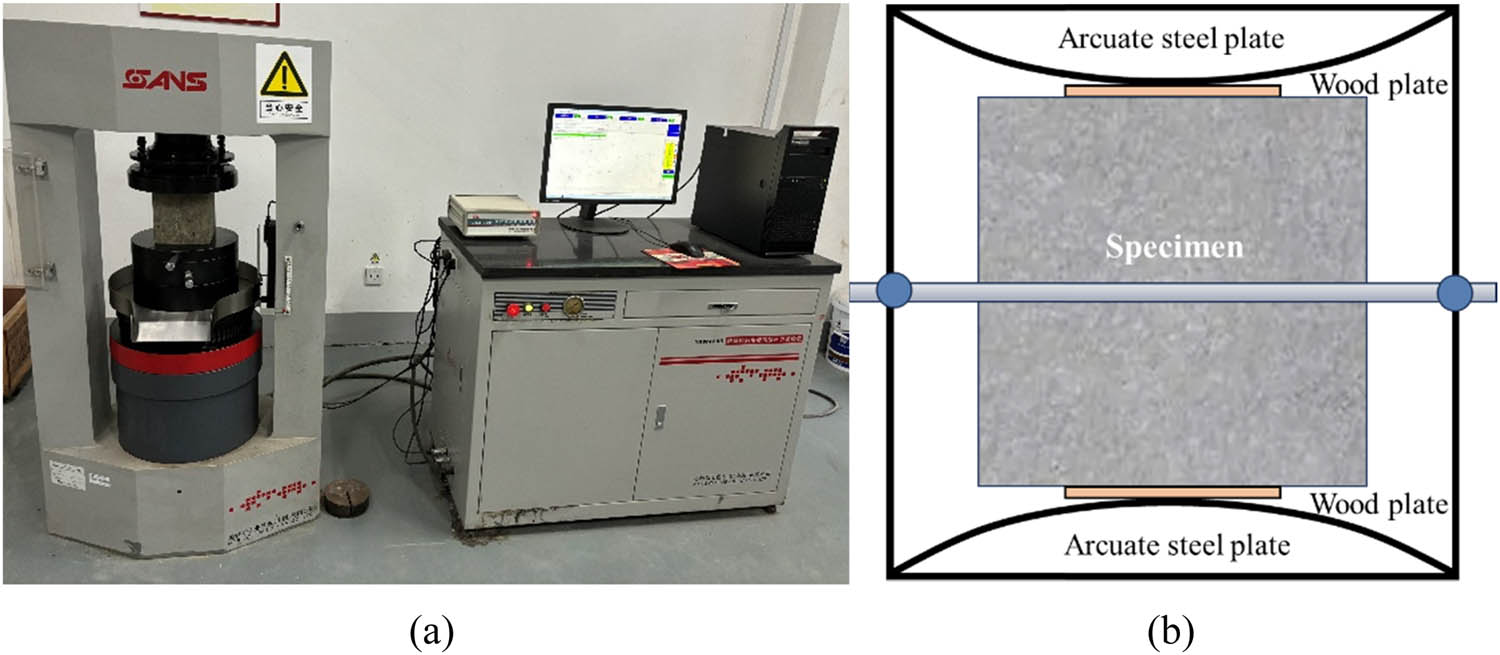

For each concrete group, a series of cylindrical specimens (Φ100 × 50 mm) and cubes (100 × 100 × 100 mm3) were cast and placed with vibration. Besides, all specimens were cured in a laboratory environment (20 ± 2°C, 95 ± 2% relative humidity) for 28 days. Moreover, cylindrical specimens were employed in RCPTs based on the American society for testing and materials C1202 standard [74], and vacuum saturation of the cylindrical specimens was required prior to carrying out RCPTs. Meanwhile, cubic specimens were used to measure the compressive strength and split tensile strength of concrete following GB/T 50081-2019 standard [75]. As illustrated in Figure 3(a), the compressive and split tensile tests were conducted on the 2,000 kN servo-hydraulic compressional testing machine at a loading rate of 0.5 and 0.05 MPa/s, respectively, and the prefabricated mold employed for split tensile tests is demonstrated in Figure 3(b), which could ensure that cubic specimens are subjected to a pure split tensile loading condition [76].

(a) Compressive and split tensile test device and (b) the mold for split tensile strength tests.

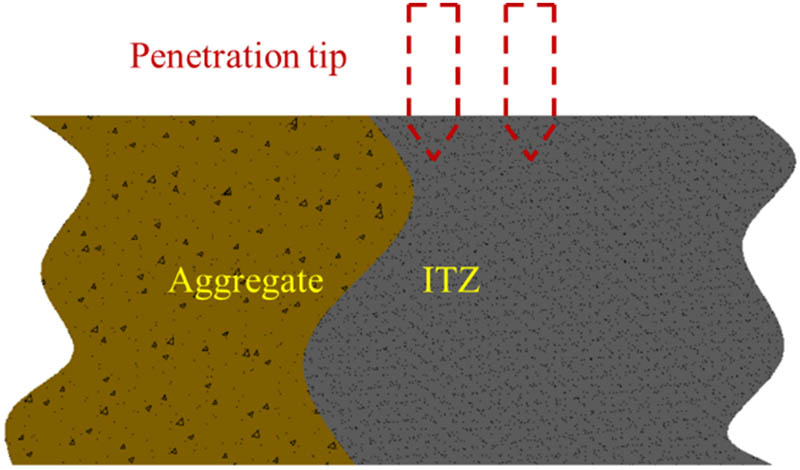

2.3 Innovation of modeled interfaces

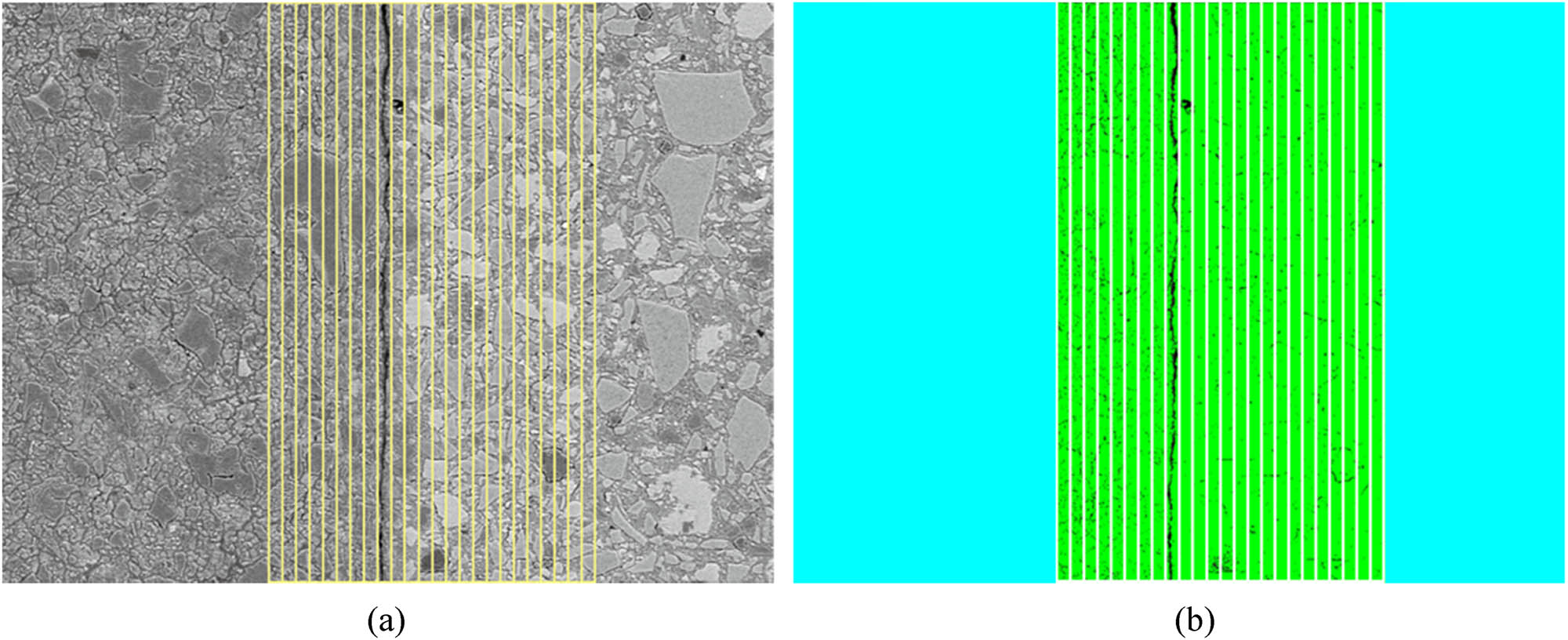

In order to ascertain the efficacy and mechanism by which the surface treatment method strengthens RAC, it is necessary to characterize the microstructures and element distributions at the interface of adhesion between the surface treatment slurry and RA, as well as the new ITZ, across both RA maintenance schemes. Nevertheless, the complex characteristics of RA pose great difficulties for quantitative testing in actual concrete. For example, as revealed in Figure 4, the irregular shape of the aggregate in the direction of penetration will affect the accuracy of micro-tests including EDS. Additionally, with regard to statistical results, attributed to factors including internal leakage around the aggregate, similarly, the microscopic properties of substances surrounding the same aggregate are heterogeneous [77], complicating the acquisition of dependable mean properties while minimizing the testing workload [77,78]. For these reasons, the interface model was employed to simulate the actual interfaces in the RAC referencing previous studies [64], attempting to avoid the variability of attached mortar of RAs [79] and consequently acquiring more reliable interface microstructure testing results within a low statistical effort range. Moreover, the ITZs were predominantly attributed to the wall effect [77], and accordingly, the simulated interfaces were not noticeably distinct from the ones in actual concrete.

Penetration in ITZ.

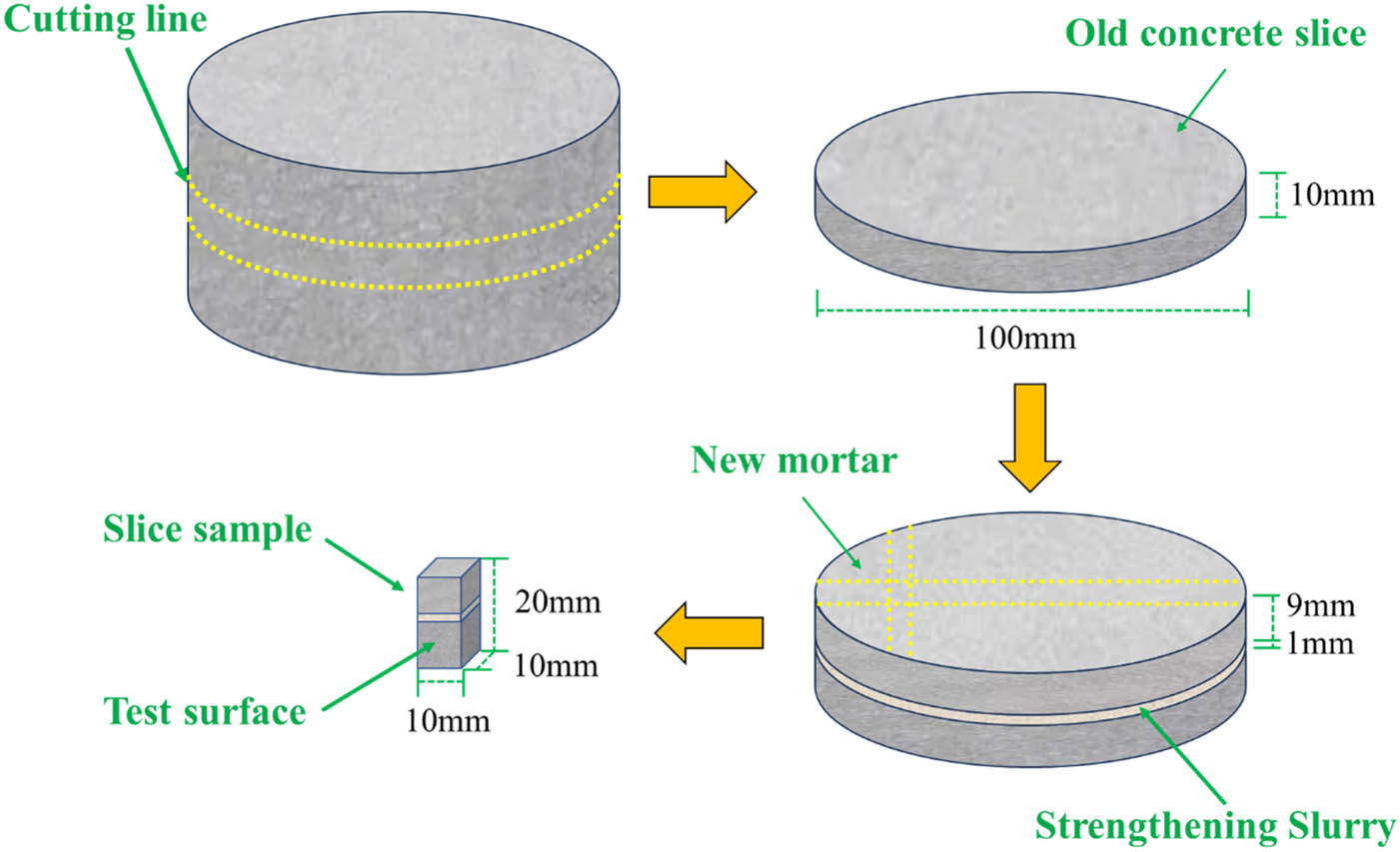

As depicted in Figure 5, the interface models were produced as follows:

A number of Φ100 × 10 mm slices were cut out from old concrete specimens;

Four MKPC + NS slurries with 1 mm thickness were painted on the surface of the old concrete slices, respectively;

A 9 mm thick cement mortar with a 0.2 water-to-cement ratio was poured on the MKPC + NS slurry at setting or 28 day pre-curing. Accordingly, the interface conditions could be created, which were comparable to those of the real RAC using the two RA maintenance schemes and DM.

Procedure for the preparation of interface model samples.

As a point of comparison, an additional set of MD-0 models was cast as a reference group, excluding the surface treatment slurry, in which the water-to-cement ratio of the new mortar was adopted as 0.57 in consistent with RAC0. Besides, the designations of all models and their respective specific meanings are depicted in Table 4. Upon casting, all specimens were cured at 20 ± 2°C and 95 ± 2% relative humidity.

Interface model types

| Model type | Simulated concrete type | Strengthening slurry type |

|---|---|---|

| MD-0 | RAC0 | — |

| MD-1-P | C-1-P | S-1 |

| MD-1-N | C-1-N | S-1 |

| MD-2-P | C-2-P | S-2 |

| MD-2-N | C-2-N | S-2 |

| MD-3-P | C-3-P | S-3 |

| MD-3-N | C-3-P | S-3 |

| MD-4-P | C-4-N | S-4 |

| MD-4-N | C-4-N | S-4 |

2.4 Micro-tests

SEM (TESCAN MIRA LMS, Czech Republic) was employed to apply backscattered electron (BSE) mode to interface models to characterize the microstructures of the bonding interfaces between old concrete slices and NS + MKPC pastes, along with the new ITZ. Besides, elemental distributions in the aforementioned testing regions were investigated by using EDS (Oxford Xplore) equipped in SEM to qualitatively determine the components of the matrices and indicate the chemical interactions between the pastes. The SEM was operated at a 15 mm working distance and 15 kV accelerating voltage. For the purpose of quantitatively analyzing the reinforcement efficiency of NS + MKPC slurries on the new ITZ microstructure, 40 high-magnification BSE images (×500) covering the new ITZ captured by each type of model were used to conduct a statistical analysis of the span and porosity [80] of the new ITZ [81,82] according to the distinct gray values in the images. Sequential calculation regions were partitioned within each BSE image for this objective, and each region was a 10 μm wide strip; moreover, the total span of the calculation regions was 240 μm to cover the new ITZ, as depicted in Figure 6(a), for the specific distribution of the strips. Furthermore, the porosity inside of each strip was derived from the pore area percentage (which is approximately equal to the pore volume percentage [83]) in the gray binary image, and the “overflow method” was used to ascertain the pore gray threshold [84]. On the condition that the boundary of the new ITZ has been determined, the final results were plotted on the basis of the relative distance away from the interface. Except for that, a graphical representation of the BSE image processing and analysis is demonstrated in Figure 6. Detailed descriptions of the method could be found elsewhere [85].

BSE image processing and analysis for porosity statistic: (a) specific distribution of the strips and (b) BSE image binarization process.

The BSE samples were fabricated by taking 10 mm × 10 mm × 20 mm slices from Φ100 × 20 mm interface model specimens, as demonstrated in Figure 5. Then, these slice samples were immersed in anhydrous ethanol to impede cement hydration and dried at 45°C. Successively, following the vacuum impregnation of low-viscosity epoxy resin onto the dried samples, the samples were polished after the epoxy-dried to produce smooth test surfaces.

The micro-morphology, as well as the components of the four hardened NS + MKPC pastes, was characterized and analyzed by using SEM and EDS to expand upon the impact of NS percentage on the operational characteristics of the NS + MKPC composite slurry and the modified RAC. Moreover, the test samples were developed from broken nuggets acquired after RAC strength testing, dehydrated, dried, as well as stored in a vacuum chamber.

The research framework, including methodology, materials used, preparation processes of test specimens, and corresponding measurement equipment in this study, is demonstrated in Figure 7.

Research framework.

3 Results and discussion

3.1 Macro-properties of concrete

3.1.1 Mechanical properties

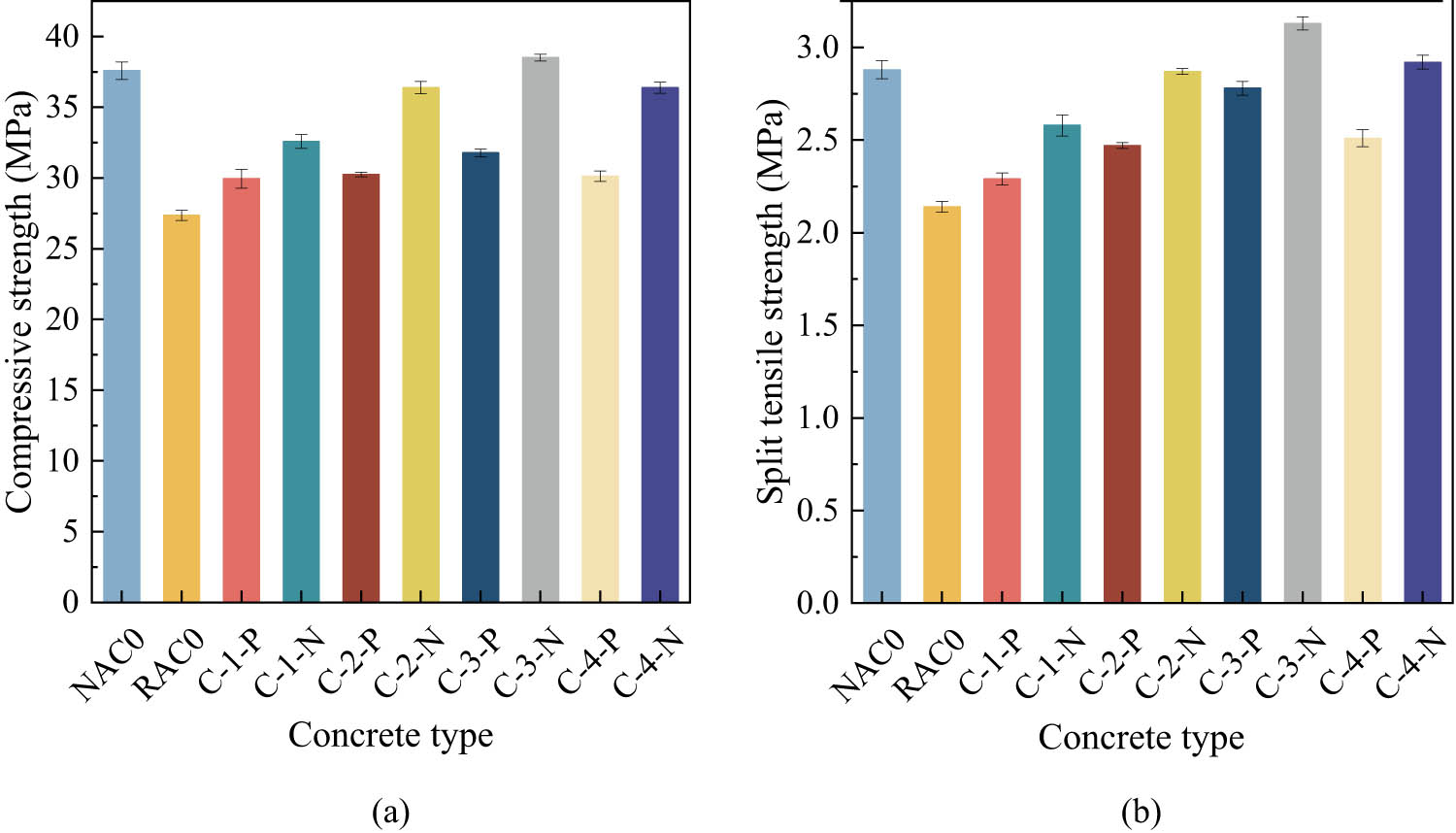

Figure 8(a) and (b) displays the compressive strength and split tensile strength of each type of concrete, respectively. A substantial decrease in either the compressive strength or split tensile strength of RAC0 was observed in comparison with that of NAC0. It was likewise determined that both mechanical strengths of modified RAC were enhanced, and greater strength values were acquired under the RA no pre-curing scenario for each NS + MKPC slurry-modified RAC. Additionally, it was observed that the mechanical strengths of the RAC exhibited a consistent increase as the dosage of NS rose from 1 to 3%, but subsequently decreased as the dosage increased to 4%. Furthermore, the maximum strength improvement was observed at 3% NS dosing in the case of RA no pre-curing, which raised 40.75 and 46.26% in compressive and split tensile strengths, respectively, in comparison with RAC0.

Mechanical strengths of various concrete: (a) compressive strengths and (b) split tensile strengths.

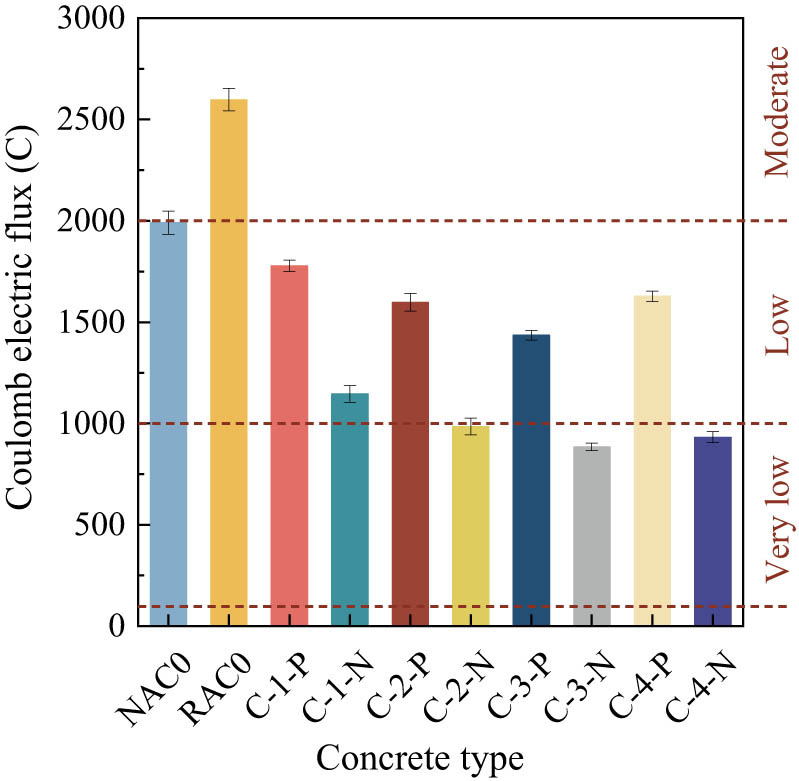

3.1.2 Chloride ion penetration resistance

Figure 9 illustrates the average cumulative electrical flux passed through each set of six concrete samples during 6 h in RCPTs, implying the chloride ion penetration resistance of the concrete. On the condition that using R0 as a substitute for N0, attenuation remained observed regarding resistance to chloride ion permeability. Moreover, the tendency of chloride ion permeation resistance was consistent with the mechanical strengths. The cumulative flux of RAC decreased by 31.57, 38.50, 44.75, and 37.35%, respectively, as NS concentration increased, in comparison with RAC0 under the RA pre-curing regimen, and demonstrated further reductions under the RA no pre-curing regimen. Furthermore, the permeability of each concrete group was qualitatively ranked as specified in the American society for testing and materials C1202 standard. Untreated RAC0 is classified as “moderate,” whereas all modified RAC are classified as “very low” or “low.” The elevated resistance to chloride ion penetration suggests that NS + MKPC modification for RAC enhanced its durability.

Average cumulative electrical fluxes of various concrete types.

Through micro-characterization analyses of the modeled interfaces and the NS + MKPC pastes, the strengthening mechanism of various NS + MKPC slurries for RAC macro-properties under either of the RA maintenance schemes will be interpreted in detail in the following sections.

3.2 Determination of the optimal NS dosage and RA maintenance scheme

The optimal NS dosage and RA maintenance scheme concerning the distinct mechanical properties as well as chloride ion penetration resistance efficiency (η) were determined by employing the linear weighted sum optimization method [65]. η of the various modified RAC specimens were described as the percentage of the electrical flux decline in comparison with RAC0. Additionally, the derived weights displayed in Table 5 were used to multiply the average mechanical properties and η listed in Table 6 using equation (2). The linear weighted sum optimization method used the statistical P-value of each modified RAC compared to the control (RAC0). Moreover, the advantages of this approach are the elimination of bias introduction into the computation, simpler implementation, comprehensive evaluation of mechanical properties and durability, and the ranking of final results to ascertain the optimization result.

where W i is the weighted value for each type of modified RAC properties, and P i for each type of modified RAC = P-value obtained on the condition that each property of modified RAC was referenced to the control value for each respective property. All the experimental data sets were in comparison with the control data set in pairs to determine the respective P-value one following the other at a 5% threshold (α) value. The final weighted outcome and ranking for all modified RAC tested are indicated in Table 7.

Weighted values for mechanical properties and η of each type of modified RAC

| Concrete type | Compressive strength | Split tensile strength | η |

|---|---|---|---|

| C-1-P | 0.1232081 | 0.1241754 | 0.1249785 |

| C-1-N | 0.1252978 | 0.1249460 | 0.1250195 |

| C-2-P | 0.1253300 | 0.1252393 | 0.1250204 |

| C-2-N | 0.1253273 | 0.1252298 | 0.1250198 |

| C-3-P | 0.1253107 | 0.1250969 | 0.1250070 |

| C-3-N | 0.1253243 | 0.1252384 | 0.1249477 |

| C-4-P | 0.1251238 | 0.1249393 | 0.1249963 |

| C-4-N | 0.1253276 | 0.1252367 | 0.1250155 |

Average values of mechanical properties and η

| Concrete type | Compressive strength (MPa) | Split tensile strength (MPa) | η (%) |

|---|---|---|---|

| C-1-P | 29.95 | 2.29 | 31.57 |

| C-1-N | 32.58 | 2.58 | 55.89 |

| C-2-P | 30.24 | 2.47 | 38.49 |

| C-2-N | 36.39 | 2.87 | 62.10 |

| C-3-P | 31.78 | 2.78 | 44.75 |

| C-3-N | 38.51 | 3.13 | 65.93 |

| C-4-P | 30.12 | 2.51 | 37.35 |

| C-4-N | 36.38 | 2.92 | 64.11 |

Optimization result and ranking

| Concrete type | Outcome | Ranking |

|---|---|---|

| C-1-P | 7.920221 | 8 |

| C-1-N | 11.391585 | 4 |

| C-2-P | 8.912398 | 6 |

| C-2-N | 12.683060 | 3 |

| C-3-P | 9.923700 | 5 |

| C-3-N | 13.455744 | 1 |

| C-4-P | 8.751099 | 7 |

| C-4-N | 12.940853 | 2 |

From the optimization result and ranking demonstrated in Table 7, C-3-N and C-3-P possess the maximum performance, ranked number one and five, respectively, under the two RA maintenance schemes. Moreover, C-1-N, C-2-N, C-3-N, and C-4-N without pre-curing recorded higher ranking in comparison with C-1-P, C-2-P, C-3-P, and C-4-P. Based on the mechanical properties and durability of the different modified RAC, this result indicates that the optimal NS dosage and RA maintenance scheme are 3% and no pre-curing scheme, respectively.

3.3 Micro-properties of bonding interfaces

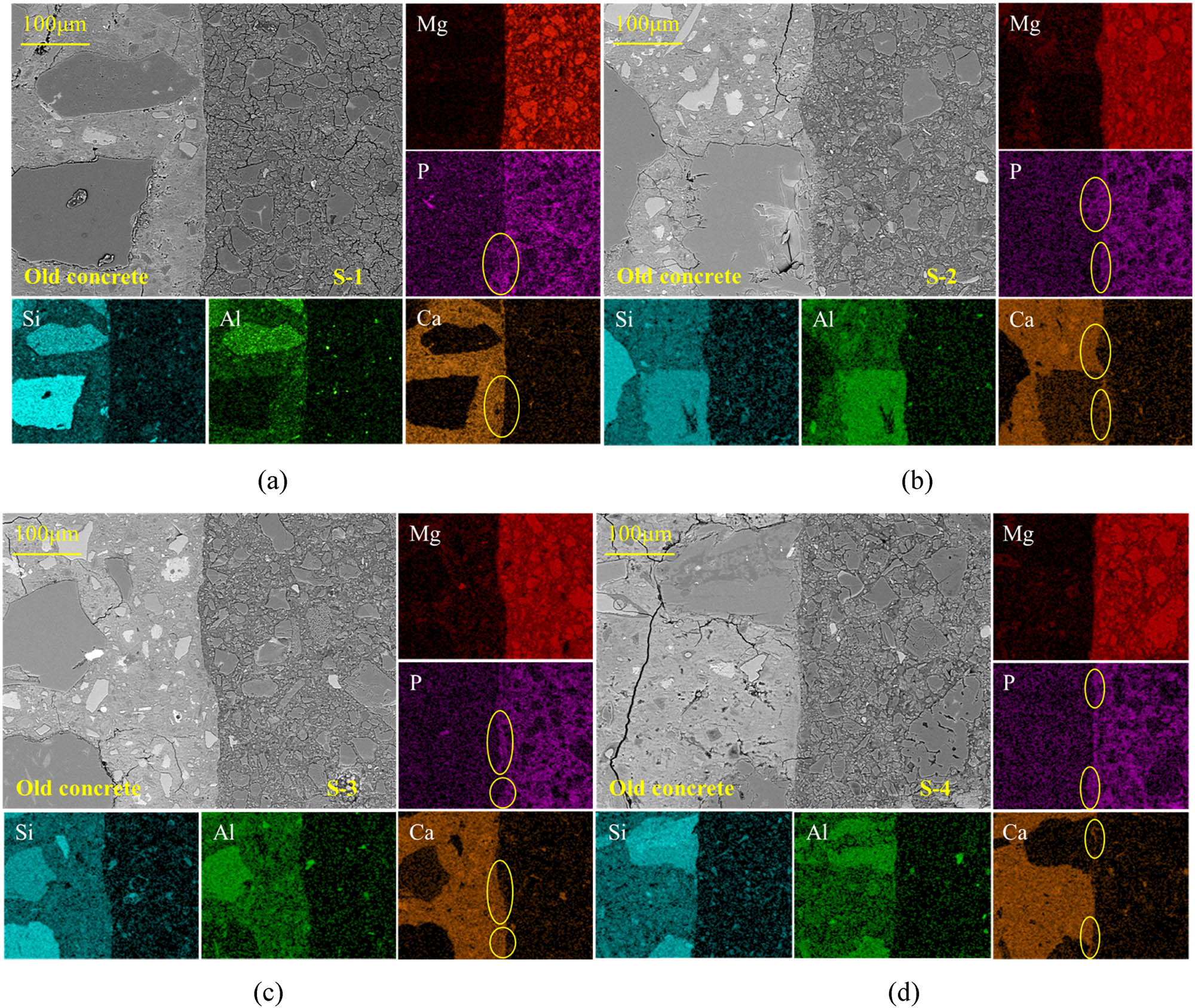

To validate the outstanding bonding performance of NS + MKPC slurry to RA, the typical BSE–EDS test results at a high magnification of a total of four bonding interfaces in models are illustrated in Figure 10. Besides, the bonding interfaces can be identified based on the unique micro-morphologies of the two matrices: the interfaces’ left sides consisted of old concrete matrices, whereas the right sides consisted of various NS + MKPC matrices. From the BSE photographs, certain micro-cracks could be observed in part of the NS + MKPC matrices resulting from polishing throughout the process of sample fabrication, as reported in several works of literature [61,86,87].

Typical BSE photographs and element distributions for the bonding interface in (a) MD-1-N, (b) MD-2-P, (c) MD-3-P, and (d) MD-4-N.

From the figures, it can be determined that all the bonding interface regions were dense, with no apparent micro-cracks or large pores, i.e., the NS + MKPC slurry was firmly bonded to the old concrete. Moreover, BSE–EDS analysis reveals the following two factors as the chief reasons for this: (1) the presence of surface defects on the old concrete, which symbolized RA, provided the NS + MKPC slurries with a strong mechanical anchorage with it, and (2) there was a favorable chemical bonding between the two matrices predicated on the overlap of P and Ca elements manifesting in the vicinity of the interface, i.e., the soluble phosphate in the NS + MKPC slurry penetrated through the micro-defects of the old concrete and reacted with the alkali components, including CH, to produce cementitious substances, which is consistent with findings reported in the prior literature [62]. Furthermore, the NS particles with small particle size and high activity in the slurry would likewise infiltrate into the cracked or loose layers of the old mortar and bonding interface; by functioning as a filler and undergoing a reaction with CH to produce C–S–H gels, it enhanced the chemical bonding at the interface. On the basis of the elemental graphs, a partial overlap of Mg, O, and Si elements are likewise observed, associated with forming the M–S–H gel, further enhancing the nano-slurry’s cementitious properties. Additional findings associated with this will be covered in detail in Section 3.4.

3.4 Micro-properties of the new ITZ and NS + MKPC pastes

Typical BSE photographs and corresponding elemental distribution maps of the interface regions between the NS + MKPC matrices and new mortars in models MD-2-P and MD-2-N are illustrated in Figure 12 to analyze the reinforcing efficiency and mechanism of NS + MKPC slurries on the new ITZ under the two RA maintenance schemes. For comparison purposes, Figure 11 presents a typical BSE image of the new ITZ in an MD-0 sample. It is evident from the image that numerous visible pores and extensive cracks (with a maximum width of approximately 78 μm) are presented within the new ITZ. These features result from the elevated water content and a significant abundance of CH crystals, thereby adversely impacting the macro-properties of RAC0. Nevertheless, no large-sized pores were found within the new ITZ obtained by both RA maintenance schemes following modification by S-2 slurry, and micro-cracks were all substantially reduced, while only a few tiny micro-cracks (with a width of approximately 3–11 μm) were observed under the RA pre-curing scheme. As a result, the formation of a denser microstructure in the new ITZ explains the significant enhancement observed in the mechanical strengths and durability of RAC following slurry strengthening.

Typical BSE photograph of the new ITZ in MD-0.

Examining the elemental distributions in Figure 12 reveals significant overlaps of Ca and P elements in the NS + MKPC slurries near the interface. Additionally, there are limited overlaps of Ca, Mg, and P elements, as well as Ca and Si elements. These observations suggest that Ca ions in the new mortar permeated the NS + MKPC slurries, engaging in reactions with k-struvite, unhydrated phosphate, or NS particles, resulting in the generation of novel gelling substances. It can likewise be noted that the NS + MKPC slurries near the interface increased in compactness due to the penetration of Ca ions and the associated chemical interactions. Upon examination, it was evident that the penetration depth of Ca ions was more extensive in the absence of pre-curing. The same trend was observed under the no pre-curing condition for NS dosages of 1, 3, or 4%, as illustrated in Figure 13, by typical BSE and EDS images of the new ITZ. It can be recognized that the new ITZ modified by NS + MKPC slurries had superior mechanical bonding as well as chemical anchoring, leading to a substantial reduction of defects including de-bonding cracks, while under the no pre-curing method, enhanced chemical bonding resulted in a further reduction of micro-cracks in line with the BSE observations. Additionally, NS particles deposited on the strengthening slurry surface may disintegrate and permeate the new ITZ surrounding it, thus inducing a micro-filling effect and exerting a volcanic ash effect at the same location, which reduced the quantity and size of CH crystals in the new ITZ and generated extra C–S–H gels, contributing to a denser new ITZ. The width and porosity of the new ITZ acquired from the surface treatment with the four slurries under two maintenance methods were rigorously quantified to substantiate this viewpoint.

Typical BSE photographs and element distributions for the new ITZ in (a) MD-2-P and (b) MD-2-N.

Typical BSE photographs and element distributions for the new ITZ in (a) MD-1-N, (b) MD-3-N, and (c) MD-4-N.

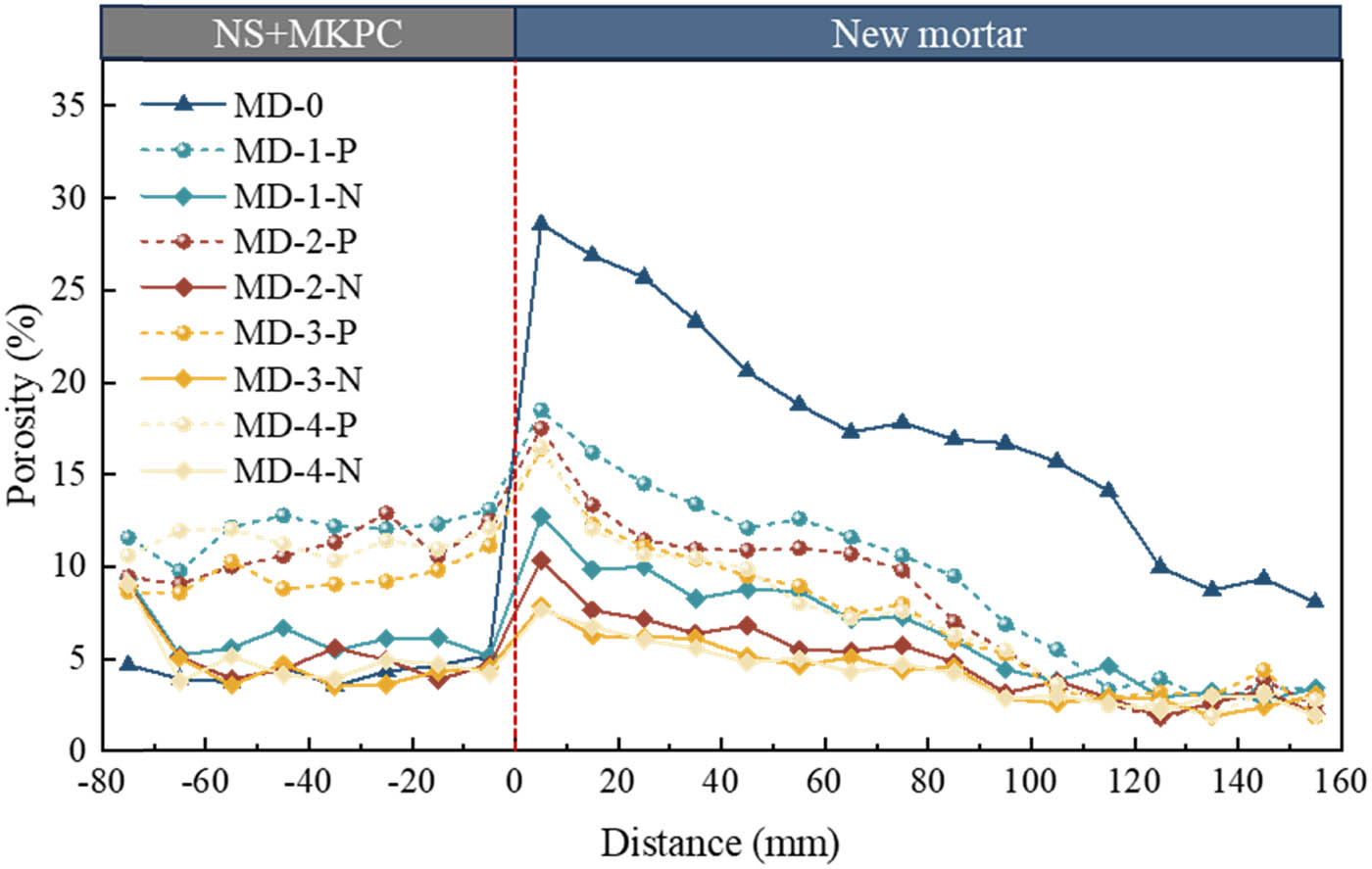

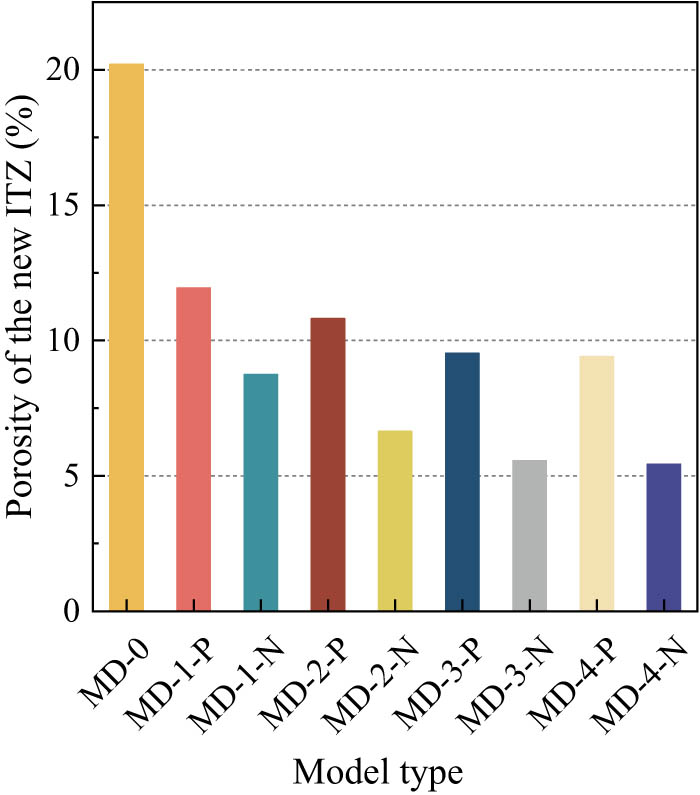

Based on ITZ porosity distribution characteristics, the porosity distribution graphs of the test regions were accomplished by identifying the location where relatively high porosity occurred as the initiating boundary of the new ITZ and setting the origin of the coordinate there. Besides, Figure 14 illustrates the porosity distribution profiles for all modeled new ITZs and their vicinities: positive and negative regions along the x-axis, respectively, represent the NS + MKPC matrix and the new mortar. The figure allows for the determination of the width of the new ITZ, defined as the horizontal distance from the origin of the coordinate to the point of porosity stabilization. This enables the statistical averaging of porosity within the new ITZ, as illustrated in Figure 15. From Figures 14 and 15, it is obvious that the new ITZ in all enhanced treated samples had narrower widths and lower porosities in comparison with MD-0, with the width and porosity progressively diminishing as the NS dosage increased. Additional reductions of widths and porosities achieved through the use of the RA no pre-curing method occurred at approximately 9.52–17.86 and 26.72–42.25% for the four NS doping levels, respectively, as in comparison with the RA pre-curing approach. The chief reason for this is that the RA no pre-curing method facilitated the penetration of NS particles into the new ITZ due to the hydration reaction in the NS + MKPC slurry, which was relatively incomplete. It is evident that with the rise in the total amount of NS infiltration caused by the increased NS doping or easier infiltration, the microstructure of the new ITZ was further enhanced, which demonstrates evidence for the penetration of NS particles in the new ITZ. Additionally, it can likewise be seen in the figure that the NS + MKPC slurry in the vicinity of the new ITZ under the RA no pre-curing scheme had a lower porosity within a certain range with little variation in width at different NS doping levels. Besides, the region had a compact microstructure owing to the cementitious phase produced by Ca ions and NS + MKPC, thus presenting additional evidence of a robust chemical anchorage between the new mortar and the NS + MKPC slurry.

Porosity distributions in the test regions based on the distance to the start boundaries of the new ITZ.

Porosities of the new ITZ in the models.

Synthesizing, outstanding chemical bonding, and NS penetration contributed significantly to the formation of a minute proportion of pores and fissures in the new ITZ that contributed to yielding strengthened mechanical and durability properties for modified RAC.

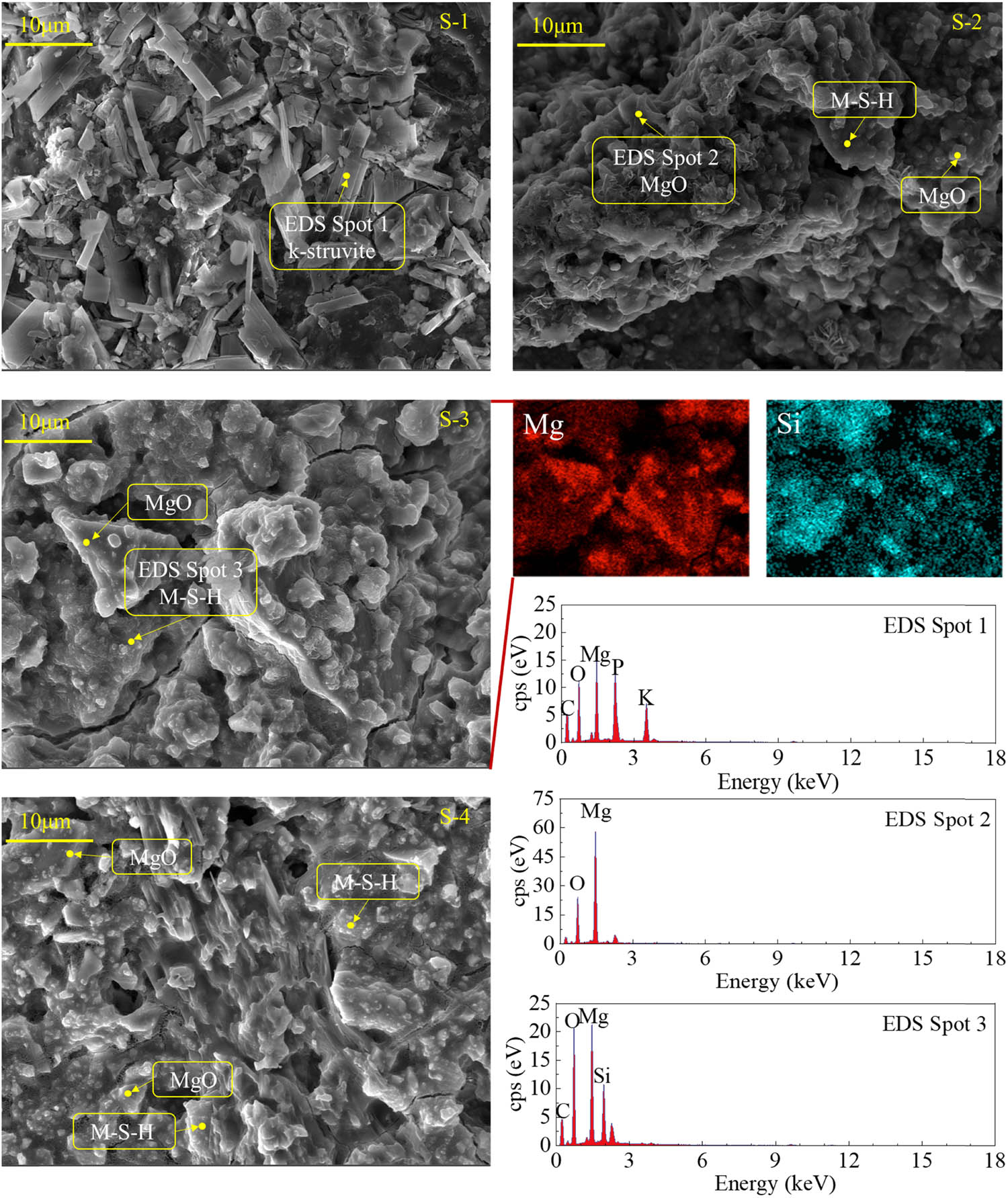

The doping ratio of NS, in addition to influencing the microstructural properties of the new ITZ, would likewise significantly influence the micro-properties of NS + MKPC composite slurries [88] and, thus, the modification efficiency of the slurries for RAC. Figure 16 displays SEM–EDS images of NS + MKPC hardened pastes with varying dosages of NS at a magnification of 5,000. As the NS concentration increased from 1 to 3%, the microstructure of the paste became more compact, as illustrated in the figure. Besides the pore-filling effect of small spherical NS particles in the NS + MKPC paste, the chemical interaction between NS and MKPC generated new gelling substances, which progressively increased in proportion to the NS dosage. Upon analyzing Mg and Si elemental distribution maps and EDS results at the marked point of S-3, it can be identified that the gel was primarily composed of Mg, O, and Si elements and consequently regarded as a newly formed M–S–H phase. Furthermore, in the NS + MKPC system, the M–S–H phase could tightly connect the paste matrix, as well as encapsulate and cement the unreacted MgO better [89], contributing to the NS + MKPC matrix microstructure densification and a further decline in porosity, which contributed benefits to the enhancements of strengths and chloride ion penetration resistance of modified RAC. Nevertheless, on the condition that the NS content increased to 4%, the microstructure of the paste became looser and more porous due to the decreased fluidity of the slurry for the excessive incorporation of nanoparticles. Another reason for the deterioration of microstructure is that the amount of k-struvite playing an important bonding role in the matrix was reduced, as a result of decreased MgO available for reacting with KH2PO4 due to the excessive chemical reaction between NS and MgO. In general, the microstructure of the new ITZ with 4% NS doping is denser, yet not markedly different from that with 3% NS. Conversely, the microstructure of S-4 is notably inferior to that of S-3. Therefore, the optimal level of NS incorporation was determined to be 3%, aligning with the test results of the macro-properties of RAC in the preceding section.

Micro-morphologies and elemental analyses of hardened NS + MKPC pastes with varying NS dosages.

In light of the microstructural characterization of modified RAC and interface models, it can be hypothesized that the reason for the enhancement of modified RAC’s macro-properties could be the superior bonding properties of NS + MKPC to RA, the new ITZ, and NS + MKPC slurry strengthening.

Overall, surface treatment with NS + MKPC enhanced the compressive strength, split tensile strength, and chloride ion penetration resistance of RAC. Nevertheless, the influence of the modification method on the long-term properties of RAC is a primary concern for RAC’s application in structural use [90–96] and possesses a lack of clarity. On this basis, it is recommended to develop studies to monitor the modified RAC’s long-term properties, as well as resistance to the freezing–thawing cycles, carbonation, and sulfate attacks in the future, to furnish crucial guidance for the application of the modified RAC in structures subjected to certain environmental impacts. Likewise, the effect of the surface treatment on particular aspects of RAC’s microstructure has also been examined in this study. Nevertheless, the microhardness variation, which is an essential characterization of the microstructure [64], has not been surveyed. Accordingly, additional research must be undertaken to investigate the microhardness of modified RAC and compare the findings with those of previously published studies in the field. Notably, this study likewise introduced an interface model for microanalysis of interface regions, contributing to enhancing testing accuracy within a low statistical effort range and avoiding the variability of attached mortar of RAs. Yet, this interface model was developed by using old concrete slices obtained by cutting to simulate RA acquired by crushing and was tested under the assumption of no difference between them. Apparently, there are certain differences between concrete cutting and crushing, which can lead to variations in the micro-properties of the bonding interface between NS + MKPC paste and RA, thus affecting RAC’s macro-properties. Likewise, note that straight plain areas not bonded/surrounded from all sides were used on the condition that simulating interfaces, which is distinct from those of the RAC. In future research endeavors, it is recommended to conduct experimental investigations into the variations in porosity, roughness, and other properties of RA surfaces obtained through concrete cutting and crushing. Additionally, the impact of these differences, coupled with the interfacial shape, on the interfacial microstructure should be explored. The aim is to develop a model that facilitates convenient statistical analysis and provides a more accurate representation of the actual scenario. Furthermore, to further prove the financial viability of the modified RAC, enhance its acceptability in the market, and provide a reference for the formulation of relevant policies, it is recommended to quantify the costs and environmental impacts of the aggregates’ treatment and subsequently use that information to conduct a simplified analysis of life cycle costs and life cycle assessment.

4 Conclusions

This study evaluated the feasibility of using NS + MKPC in RAC modification and indicated its function mechanism, controlled dose of NS, and a more effective surface treatment method, and the main conclusions are as follows:

RAC’s compressive strength, splitting tensile strength, and chloride ion penetration resistance were enhanced by RA surface treatment with any NS + MKPC slurries and RA maintenance schemes used in this study. Besides, the optimum dosage of NS in NS + MKPC slurries for improving RAC macro-performances was determined to be 3.0% by the linear weighted sum optimization method. In relation to the pre-curing scheme for surface-treated RA, the no pre-curing approach demonstrated a more pronounced enhancement.

Based on the micro-test results of the interface models, it was determined that the superior bonding interfaces between NS + MKPC slurries and old concrete slices (representing RAs) were responsible for the enhanced macro-properties of the modified RAC. Moreover, another crucial reason is that the new ITZ in interface models containing NS + MKPC slurries was substantially enhanced, with noticeable reductions in width and porosity. Furthermore, the enhanced bonding of the NS + MKPC slurry to new mortar in combination with the micro-filling and volcanic ash effects of NS particles on the new ITZ may be the dominant reason for that result.

For the optimal NS dosage and RA maintenance scheme, the superiority toward enhancing RAC macro-properties was predominantly attributed to the denser new ITZ, as evidenced by the distinctive decrease in porosity. Additionally, the advantages of the NS + MKPC slurry doped with 3% NS were ascribed to the superior microstructure of the slurry.

In particular, the optimal NS dosage of 0.614 wt% of the aggregate in this study was less than the recommended dosages of 1 and 2 wt% of the cement [97,98] for NS and NC [76], and the 3% optimal dosage for NS suspension with a SiO2 content of 34.3%, whereas the optimum compressive strength improvement efficiency of 40.75% is higher than that of 13.9% [28]. Hence, the surface treatment proposed in this study decreased the cost of modification and enhanced the reinforcement efficiency of RAC, thus raising the economic feasibility of RAC application in practice. The low-cost magnesium phosphate cement fabricated from industrial by-product boron muds [99] may be contemplated in the future as a means to further reduce modification expenses. Besides, the proposed RA no pre-curing scenario was more convenient for on-site construction, which simplified the RA surface treatment process and shortened the duration of construction, thus enhancing the operability of RA application in practice. Notably, the additional cement in RAC as one method to enhance its compression strength and durability in considerable studies [100] was avoided precisely owing to the high modification efficiency of this surface treatment method. This resulted in a reduction of cement used in RAC, the production of which emits large amounts of carbon dioxide [101] and is responsible for 5–7% of total global warming impacts [102]. Consequently, the modification of RAC using NS + MKPC is conforming to the policy goals of peaking carbon dioxide emissions and achieving carbon neutrality. In general, the surface treatment with NS and MKPC co-action demonstrates a promising potential for the extensive utilization of RAC in practical engineering applications. This approach also presents prospects for fostering sustainable development within the construction industry, offering environmental advantages.

Acknowledgments

The authors appreciate the financial support from the Natural Science Foundation of Jiangsu Province, China (No. BK20230615).

-

Funding information: The Natural Science Foundation of Jiangsu Province, China (No. BK20230615).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Feng W, Tang Y, Yang Y, Cheng Y, Qiu J, Zhang H, et al. Mechanical behavior and constitutive model of sustainable concrete: Seawater and sea-sand recycled aggregate concrete. Constr Build Mater. 2023;364:130010. 10.1016/j.conbuildmat.2022.130010.Search in Google Scholar

[2] Zhang LW, Sojobi AO, Kodur VKR, Liew KM. Effective utilization and recycling of mixed recycled aggregates for a greener environment. J Clean Prod. 2019;236:117600. 10.1016/j.jclepro.2019.07.075.Search in Google Scholar

[3] Wu J, Jing H, Gao Y, Meng Q, Yin Q, Du Y. Effects of carbon nanotube dosage and aggregate size distribution on mechanical property and microstructure of cemented rockfill. Cem Concr Compos. 2022;127:104408. 10.1016/j.cemconcomp.2022.104408.Search in Google Scholar

[4] Wu J, Wong HS, Zhang H, Yin Q, Jing H, Ma D. Improvement of cemented rockfill by premixing low-alkalinity activator and fly ash for recycling gangue and partially replacing cement. Cem Concr Compos. 2024;145:105345. 10.1016/j.cemconcomp.2023.105345.Search in Google Scholar

[5] Sojobi AO, Liew KM. Multi-objective optimization of high performance concrete columns under compressive loading with potential applications for sustainable earthquake-resilient structures and infrastructures. Compos Struct. 2023;315:117007. 10.1016/j.compstruct.2023.117007.Search in Google Scholar

[6] Sojobi AO, Liew KM. Multi-objective optimization of high performance bio-inspired prefabricated composites for sustainable and resilient construction. Compos Struct. 2022;279:114732. 10.1016/j.compstruct.2021.114732.Search in Google Scholar

[7] Zhang LW, Sojobi AO, Liew KM. Sustainable CFRP-reinforced recycled concrete for cleaner eco-friendly construction. J Clean Prod. 2019;233:56–75. 10.1016/j.jclepro.2019.06.025.Search in Google Scholar

[8] Akhtar A, Sarmah AK. Strength improvement of recycled aggregate concrete through silicon rich char derived from organic waste. J Clean Prod. 2018;196:411–23. 10.1016/j.jclepro.2018.06.044.Search in Google Scholar

[9] Mohammed TU, Hasnat A, Awal MA, Bosunia SZ. Recycling of brick aggregate concrete as coarse aggregate. J Mater Civ Eng. 2015;27(7):B4014005. 10.1061/(ASCE)MT.1943-5533.0001043.Search in Google Scholar

[10] Yang J, Du Q, Bao Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr Build Mater. 2011;25(4):1935–45. 10.1016/j.conbuildmat.2010.11.063.Search in Google Scholar

[11] Kim Y, Hanif A, Kazmi SMS, Munir MJ, Park C. Properties enhancement of recycled aggregate concrete through pretreatment of coarse aggregates – Comparative assessment of assorted techniques. J Clean Prod. 2018;191:339–49. 10.1016/j.jclepro.2018.04.192.Search in Google Scholar

[12] Tayeh BA, Saffar DMAl, Alyousef R. The utilization of recycled aggregate in high performance concrete: A review. J Mater Res Technol. 2020;9(4):8469–81. 10.1016/j.jmrt.2020.05.126.Search in Google Scholar

[13] Gómez-Soberón JM. Porosity of recycled concrete with substitution of recycled concrete aggregate: An experimental study. Cem Concr Res. 2002;32(8):1301–11. 10.1016/S0008-8846(02)00795-0.Search in Google Scholar

[14] Katz A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem Concr Res. 2003;33(5):703–11. 10.1016/S0008-8846(02)01033-5.Search in Google Scholar

[15] Ajdukiewicz A, Kliszczewicz A. Influence of recycled aggregates on mechanical properties of HS/HPC. Cem Concr Compos. 2002;24(2):269–79. 10.1016/S0958-9465(01)00012-9.Search in Google Scholar

[16] Bravo M, de Brito J. Concrete made with used tyre aggregate: durability-related performance. J Clean Prod. 2012;25:42–50. 10.1016/j.jclepro.2011.11.066.Search in Google Scholar

[17] de Juan MS, Gutiérrez PA. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr Build Mater. 2009;23(2):872–7. 10.1016/j.conbuildmat.2008.04.012.Search in Google Scholar

[18] Etxeberria M, Vázquez E, Marí A, Barra M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem Concr Res. 2007;37(5):735–42. 10.1016/j.cemconres.2007.02.002.Search in Google Scholar

[19] Babalola OE, Awoyera PO, Tran MT, Le D-H, Olalusi OB, Viloria A, et al. Mechanical and durability properties of recycled aggregate concrete with ternary binder system and optimized mix proportion. J Mater Res Technol. 2020;9(3):6521–32. 10.1016/j.jmrt.2020.04.038.Search in Google Scholar

[20] Kazmi SMS, Munir MJ, Wu Y-F, Patnaikuni I, Zhou Y, Xing F. Effect of recycled aggregate treatment techniques on the durability of concrete: A comparative evaluation. Constr Build Mater. 2020;264:120284. 10.1016/j.conbuildmat.2020.120284.Search in Google Scholar

[21] Kou S-C, Poon C-S, Etxeberria M. Influence of recycled aggregates on long term mechanical properties and pore size distribution of concrete. Cem Concr Compos. 2011;33(2):286–91. 10.1016/j.cemconcomp.2010.10.003.Search in Google Scholar

[22] Rao A, Jha KN, Misra S. Use of aggregates from recycled construction and demolition waste in concrete. Resour Conserv Recycl. 2007;50(1):71–81. 10.1016/j.resconrec.2006.05.010.Search in Google Scholar

[23] Tam VWY, Tam CM, Le KN. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour Conserv Recycl. 2007;50(1):82–101. 10.1016/j.resconrec.2006.05.012.Search in Google Scholar

[24] Lei B, Li W, Tang Z, Li Z, Tam VWY. Effects of environmental actions, recycled aggregate quality and modification treatments on durability performance of recycled concrete. J Mater Res Technol. 2020;9(6):13375–89. 10.1016/j.jmrt.2020.09.073.Search in Google Scholar

[25] Ryu JS. Improvement on strength and impermeability of recycled concrete made from crushed concrete coarse aggregate. J Mater Sci Lett. 2002;21(20):1565–7.10.1023/A:1020349011716Search in Google Scholar

[26] Liang Z, Hu Z, Zhou Y, Wu Y, Zhou X, Hu B, et al. Improving recycled aggregate concrete by compression casting and nano-silica. Nanotechnol Rev. 2022;11(1):1273–90. 10.1515/ntrev-2022-0065.Search in Google Scholar

[27] Zheng Y, Zhang Y, Zhuo J, Zhang P, Kong W. Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete. Nanotechnol Rev. 2022;11(1):1499–510. 10.1515/ntrev-2022-0077.Search in Google Scholar

[28] Li L, Xuan D, Sojobi AO, Liu S, Chu SH, Poon CS. Development of nano-silica treatment methods to enhance recycled aggregate concrete. Cem Concr Compos. 2021;118:103963. 10.1016/j.cemconcomp.2021.103963.Search in Google Scholar

[29] Li L, Xuan D, Sojobi AO, Liu S, Poon CS. Efficiencies of carbonation and nano silica treatment methods in enhancing the performance of recycled aggregate concrete. Constr Build Mater. 2021;308:125080. 10.1016/j.conbuildmat.2021.125080.Search in Google Scholar

[30] Li W, Long C, Tam VWY, Poon C-S, Hui Duan W. Effects of nano-particles on failure process and microstructural properties of recycled aggregate concrete. Constr Build Mater. 2017;142:42–50. 10.1016/j.conbuildmat.2017.03.051.Search in Google Scholar

[31] Mukharjee BB, Barai SV. Influence of Nano-Silica on the properties of recycled aggregate concrete. Constr Build Mater. 2014;55:29–37. 10.1016/j.conbuildmat.2014.01.003.Search in Google Scholar

[32] Luo Z, Li W, Tam VWY, Xiao J, Shah SP. Current progress on nanotechnology application in recycled aggregate concrete. J Sustain Cem Mater. 2019;8(2):79–96. 10.1080/21650373.2018.1519644.Search in Google Scholar

[33] Mukharjee BB, Barai SV. Development of construction materials using nano-silica and aggregates recycled from construction and demolition waste. Waste Manag Res. 2015;33(6):515–23. 10.1177/0734242X15584840.Search in Google Scholar PubMed

[34] Younis KH, Mustafa SM. Feasibility of using nanoparticles of SiO2 to improve the performance of recycled aggregate concrete. Adv Mater Sci Eng. 2018;2018:1–11. 10.1155/2018/1512830.Search in Google Scholar

[35] Shaikh F, Chavda V, Minhaj N, Arel HS. Effect of mixing methods of nano silica on properties of recycled aggregate concrete. Struct Concr. 2018;19(2):387–99. 10.1002/suco.201700091.Search in Google Scholar

[36] Zheng Y, Zhuo J, Zhang Y, Zhang P. Mechanical properties and microstructure of nano-SiO 2 and basalt-fiber-reinforced recycled aggregate concrete. Nanotechnol Rev. 2022;11(1):2169–89. 10.1515/ntrev-2022-0134.Search in Google Scholar

[37] Zhang H, Zhao Y, Meng T, Shah SP. Surface treatment on recycled coarse aggregates with nanomaterials. J Mater Civ Eng. 2016;28(2):1–11. 10.1061/(ASCE)MT.1943-5533.0001368.Search in Google Scholar

[38] Zeng W, Zhao Y, Zheng H, sun Poon C. Improvement in corrosion resistance of recycled aggregate concrete by nano silica suspension modification on recycled aggregates. Cem Concr Compos. 2020;106:103476. 10.1016/j.cemconcomp.2019.103476.Search in Google Scholar

[39] Meng T, Zhang J, Wei H, Shen J. Effect of nano-strengthening on the properties and microstructure of recycled concrete. Nanotechnol Rev. 2020;9(1):79–92. 10.1515/ntrev-2020-0008.Search in Google Scholar

[40] Casuccio M, Torrijos MC, Giaccio G, Zerbino R. Failure mechanism of recycled aggregate concrete. Constr Build Mater. 2008;22(7):1500–6. 10.1016/j.conbuildmat.2007.03.032.Search in Google Scholar

[41] Xiao J, Li W, Sun Z, Shah SP. Crack propagation in recycled aggregate concrete under uniaxial compressive loading. ACI Mater J. 2012;109(4):451–61.10.14359/51683920Search in Google Scholar

[42] Xiao J, Li W, Corr DJ, Shah SP. Effects of interfacial transition zones on the stress-strain behavior of modeled recycled aggregate concrete. Cem Concr Res. 2013;52:82–99. 10.1016/j.cemconres.2013.05.004.Search in Google Scholar

[43] Xiao J, Li W, Sun Z, Lange DA, Shah SP. Properties of interfacial transition zones in recycled aggregate concrete tested by nanoindentation. Cem Concr Compos. 2013;37:276–92. 10.1016/j.cemconcomp.2013.01.006.Search in Google Scholar

[44] Xu Z, Bai Z, Wu J, Long H, Deng H, Chen Z, et al. Microstructural characteristics and nano-modification of interfacial transition zone in concrete: A review. Nanotechnol Rev. 2022;11(1):2078–100. 10.1515/ntrev-2022-0125.Search in Google Scholar

[45] Sidorova A, Vazquez-Ramonich E, Barra-Bizinotto M, Roa-Rovira JJ, Jimenez-Pique E. Study of the recycled aggregates nature’s influence on the aggregate–cement paste interface and ITZ. Constr Build Mater. 2014;68:677–84. 10.1016/j.conbuildmat.2014.06.076.Search in Google Scholar

[46] Li W, Xiao J, Sun Z, Kawashima S, Shah SP. Interfacial transition zones in recycled aggregate concrete with different mixing approaches. Constr Build Mater. 2012;35:1045–55. 10.1016/j.conbuildmat.2012.06.022.Search in Google Scholar

[47] Poon C, Shui Z, Lam L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr Build Mater. 2004;18(6):461–8. 10.1016/j.conbuildmat.2004.03.005.Search in Google Scholar

[48] Sanchez F, Sobolev K. Nanotechnology in concrete – A review. Constr Build Mater. 2010;24(11):2060–71. 10.1016/j.conbuildmat.2010.03.014.Search in Google Scholar

[49] Zheng Y, Zhang Y, Zhang P. Methods for improving the durability of recycled aggregate concrete: A review. J Mater Res Technol. 2021;15:6367–86. 10.1016/j.jmrt.2021.11.085.Search in Google Scholar

[50] Sojobi AO, Awolusi TF, Aina GB, Oke OL, Oladokun M, Oguntayo DO. Ternary and quaternary blends as partial replacement of cement to produce hollow sandcrete blocks. Heliyon. 2021;7(6):e07227. 10.1016/j.heliyon.2021.e07227.Search in Google Scholar PubMed PubMed Central

[51] Lahalle H, Cau Dit Coumes C, Mesbah A, Lambertin D, Cannes C, Delpech S, et al. Investigation of magnesium phosphate cement hydration in diluted suspension and its retardation by boric acid. Cem Concr Res. 2016;87:77–86. 10.1016/j.cemconres.2016.04.010.Search in Google Scholar

[52] Xing S, Wu C, Xiao H, editors. Preparation of magnesium phosphate cement and application in concrete repair. MATEC Web Conf. 2018;142:02007. 10.1051/matecconf/201714202007.Search in Google Scholar

[53] Du Y, Gao P, Yang J, Shi F. Research on the chloride ion penetration resistance of magnesium phosphate cement (MPC) material as coating for reinforced concrete structures. Coatings. 2020;10(12):1145. 10.3390/coatings10121145.Search in Google Scholar

[54] Yang Q, Zhu B, Wu X. Characteristics and durability test of magnesium phosphate cement-based material for rapid repair of concrete. Mater Struct. 2000;33(4):229–34. 10.1007/BF02479332.Search in Google Scholar

[55] Qiao F, Chau CK, Li Z. Property evaluation of magnesium phosphate cement mortar as patch repair material. Constr Build Mater. 2010;24(5):695–700. 10.1016/j.conbuildmat.2009.10.039.Search in Google Scholar

[56] Seehra SS, Gupta S, Kumar S. Rapid setting magnesium phosphate cement for quick repair of concrete pavements — characterisation and durability aspects. Cem Concr Res. 1993;23(2):254–66. 10.1016/0008-8846(93)90090-V.Search in Google Scholar

[57] Wu J, Lai Z, Deng Q, Liu M, Kou H, editors. Effects of various curing conditions on volume stability of magnesium phosphate cement. Adv Mater Sci Eng. 2021;2021:1–12. 10.1155/2021/6652363.Search in Google Scholar

[58] Abdelrazig BEI, Sharp JH, El-Jazairi B. The microstructure and mechanical properties of mortars made from magnesia-phosphate cement. Cem Concr Res. 1989;19(2):247–58. 10.1016/0008-8846(89)90089-6.Search in Google Scholar

[59] Li J, Zhang W, Cao Y. Laboratory evaluation of magnesium phosphate cement paste and mortar for rapid repair of cement concrete pavement. Constr Build Mater. 2014;58:122–8. 10.1016/j.conbuildmat.2014.02.015.Search in Google Scholar

[60] Qian J, You C, Wang Q, Wang H, Jia X. A method for assessing bond performance of cement-based repair materials. Constr Build Mater. 2014;68:307–13. 10.1016/j.conbuildmat.2014.06.048.Search in Google Scholar

[61] Formosa J, Lacasta AM, Navarro A, del Valle-Zermeño R, Niubó M, Rosell JR, et al. Magnesium Phosphate Cements formulated with a low-grade MgO by-product: Physico-mechanical and durability aspects. Constr Build Mater. 2015;91:150–7. 10.1016/j.conbuildmat.2015.05.071.Search in Google Scholar

[62] Qin J, Qian J, You C, Fan Y, Li Z, Wang H. Bond behavior and interfacial micro-characteristics of magnesium phosphate cement onto old concrete substrate. Constr Build Mater. 2018;167:166–76. 10.1016/j.conbuildmat.2018.02.018.Search in Google Scholar

[63] Li Y, Bai W, Shi T. A study of the bonding performance of magnesium phosphate cement on mortar and concrete. Constr Build Mater. 2017;142:459–68. 10.1016/j.conbuildmat.2017.03.090.Search in Google Scholar

[64] Sojobi AO, Xuan D, Li L, Liu S, Poon CS. Optimization of gas-solid carbonation conditions of recycled aggregates using a linear weighted sum method. Dev Built Environ. 2021;7:100053. 10.1016/j.dibe.2021.100053.Search in Google Scholar

[65] Sojobi AO, Liew KM. Flexural behaviour and efficiency of CFRP-laminate reinforced recycled concrete beams: Optimization using linear weighted sum method. Compos Struct. 2021;260:113259. 10.1016/j.compstruct.2020.113259.Search in Google Scholar

[66] Otsuki N, Miyazato S, Yodsudjai W. Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration and carbonation of concrete. J Mater Civ Eng. 2003;15(5):443–51. 10.1061/(ASCE)0899-1561(2003)15:5(443).Search in Google Scholar

[67] Laserna S, Montero J. Influence of natural aggregates typology on recycled concrete strength properties. Constr Build Mater. 2016;115:78–86. 10.1016/j.conbuildmat.2016.04.037.Search in Google Scholar

[68] Koenders EAB, Pepe M, Martinelli E. Compressive strength and hydration processes of concrete with recycled aggregates. Cem Concr Res. 2014;56:203–12. 10.1016/j.cemconres.2013.11.012.Search in Google Scholar

[69] Lima C, Caggiano A, Faella C, Martinelli E, Pepe M, Realfonzo R. Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr Build Mater. 2013;47:547–59. 10.1016/j.conbuildmat.2013.04.051.Search in Google Scholar

[70] Evangelista L, de Brito J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem Concr Compos. 2007;29(5):397–401. 10.1016/j.cemconcomp.2006.12.004.Search in Google Scholar

[71] Fonseca N, De Brito J, Evangelista L. The influence of curing conditions on the mechanical performance of concrete made with recycled concrete waste. Cem Concr Compos. 2011;33(6):637–43. 10.1016/j.cemconcomp.2011.04.002.Search in Google Scholar

[72] Montero J, Laserna S. Influence of effective mixing water in recycled concrete. Constr Build Mater. 2017;132:343–52. 10.1016/j.conbuildmat.2016.12.006.Search in Google Scholar

[73] Chinese National Standard GB/T 50080- 2016. Standard for test method of performance on ordinary fresh concrete; 2016 (in Chinese).Search in Google Scholar

[74] American Society for Testing and Materials ASTM C1202-19. Standard test method for electrical indication of concrete’s ability to resist chloride ion penetration; 2019.Search in Google Scholar

[75] Chinese National Standard GB/T 50081-2019. Standard for test methods of concrete physical and mechanical properties; 2019 (in Chinese).Search in Google Scholar

[76] Gao C, Huang L, Yan L, Jin R, Chen H. Mechanical properties of recycled aggregate concrete modified by nano-particles. Constr Build Mater. 2020;241:118030. 10.1016/j.conbuildmat.2020.118030.Search in Google Scholar

[77] Scrivener KL, Crumbie AK, Laugesen P. The interfacial transition zone (ITZ) between cement paste and aggregate in concrete. Interface Sci. 2004;12(4):411–21. 10.1023/B:INTS.0000042339.92990.4c.Search in Google Scholar

[78] Scrivener KL. Backscattered electron imaging of cementitious microstructures: understanding and quantification. Cem Concr Compos. 2004;26(8):935–45. 10.1016/j.cemconcomp.2004.02.029.Search in Google Scholar

[79] Jayasuriya A, Adams MP, Bandelt MJ. Understanding variability in recycled aggregate concrete mechanical properties through numerical simulation and statistical evaluation. Constr Build Mater. 2018;178:301–12. 10.1016/j.conbuildmat.2018.05.158.Search in Google Scholar

[80] Scrivener KL. Characterization of the ITZ and its quantification by test methods. In: Alexander MG, Arliguie G, Ballivy G, Bentur A, Marchand J, editors. Engineering and transport properties of the interfacial transition zone in cementitious composites. Torcy, Seine-et-Marne: RILEM Publications; 1999. p. 3–15.Search in Google Scholar

[81] Elsharief A, Cohen MD, Olek J. Influence of aggregate size, water cement ratio and age on the microstructure of the interfacial transition zone. Cem Concr Res. 2003;33(11):1837–49. 10.1016/S0008-8846(03)00205-9.Search in Google Scholar

[82] Gao Y, De Schutter G, Ye G, Tan Z, Wu K. The ITZ microstructure, thickness and porosity in blended cementitious composite: Effects of curing age, water to binder ratio and aggregate content. Compos Part B Eng. 2014;60:1–13. 10.1016/j.compositesb.2013.12.021.Search in Google Scholar

[83] Beushausen H, Höhlig B, Talotti M. The influence of substrate moisture preparation on bond strength of concrete overlays and the microstructure of the OTZ. Cem Concr Res. 2017;92:84–91. 10.1016/j.cemconres.2016.11.017.Search in Google Scholar

[84] Wong HS, Head MK, Buenfeld NR. Pore segmentation of cement-based materials from backscattered electron images. Cem Concr Res. 2006;36(6):1083–90. 10.1016/j.cemconres.2005.10.006.Search in Google Scholar

[85] Gao Y, De Schutter G, Ye G, Huang H, Tan Z, Wu K. Porosity characterization of ITZ in cementitious composites: Concentric expansion and overflow criterion. Constr Build Mater. 2013;38:1051–7. 10.1016/j.conbuildmat.2012.09.047.Search in Google Scholar

[86] Xu B, Ma H, Shao H, Li Z, Lothenbach B. Influence of fly ash on compressive strength and micro-characteristics of magnesium potassium phosphate cement mortars. Cem Concr Res. 2017;99:86–94. 10.1016/j.cemconres.2017.05.008.Search in Google Scholar

[87] Gardner LJ, Bernal SA, Walling SA, Corkhill CL, Provis JL, Hyatt NC. Characterisation of magnesium potassium phosphate cements blended with fly ash and ground granulated blast furnace slag. Cem Concr Res. 2015;74:78–87. 10.1016/j.cemconres.2015.01.015.Search in Google Scholar

[88] Tan H, Yang Z, Deng X, Guo H, Zhang J, Zheng Z, et al. Surface reinforcement of recycled aggregates by multi-diameter recycled powder blended cement paste. J Build Eng. 2023;64:105609. 10.1016/j.jobe.2022.105609.Search in Google Scholar

[89] Sonat C, Unluer C. Investigation of the performance and thermal decomposition of MgO and MgO-SiO2 formulations. Thermochim Acta. 2017;655:251–61. 10.1016/j.tca.2017.07.009.Search in Google Scholar

[90] Chen Z, Yu J, Nong Y, Yang Y, Zhang H, Tang Y. Beyond time: Enhancing corrosion resistance of geopolymer concrete and BFRP bars in seawater. Compos Struct. 2023;322:117439. 10.1016/j.compstruct.2023.117439.Search in Google Scholar

[91] Choi W-C, Yun H-D. Long-term deflection and flexural behavior of reinforced concrete beams with recycled aggregate. Mater Des. 2013;51:742–50. 10.1016/j.matdes.2013.04.044.Search in Google Scholar

[92] Manzi S, Mazzotti C, Bignozzi MC. Short and long-term behavior of structural concrete with recycled concrete aggregate. Cem Concr Compos. 2013;37(1):312–8. 10.1016/j.cemconcomp.2013.01.003.Search in Google Scholar

[93] Zhu C, Liu C, Bai G, Fan J. Study on long-term performance and flexural stiffness of recycled aggregate concrete beams. Constr Build Mater. 2020;262:120503. 10.1016/j.conbuildmat.2020.120503.Search in Google Scholar

[94] Choi HB, Yi CK, Cho HH, Kang KI. Experimental study on the shear strength of recycled aggregate concrete beams. Mag Concr Res. 2010;62(2):103–14. 10.1680/macr.2008.62.2.103.Search in Google Scholar

[95] Zheng Y, Zhuo J, Zhang P, Ma M. Mechanical properties and meso-microscopic mechanism of basalt fiber-reinforced recycled aggregate concrete. J Clean Prod. 2022;370:133555. 10.1016/j.jclepro.2022.133555.Search in Google Scholar

[96] Zheng Y, Zhuo J, Zhang P. A review on durability of nano-SiO2 and basalt fiber modified recycled aggregate concrete. Constr Build Mater. 2021;304(May):124659. 10.1016/j.conbuildmat.2021.124659.Search in Google Scholar

[97] Li W, Huang Z, Cao F, Sun Z, Shah SP. Effects of nano-silica and nano-limestone on flowability and mechanical properties of ultra-high-performance concrete matrix. Constr Build Mater. 2015;95:366–74. 10.1016/j.conbuildmat.2015.05.137.Search in Google Scholar

[98] Li W, Luo Z, Long C, Wu C, Duan WH, Shah SP. Effects of nanoparticle on the dynamic behaviors of recycled aggregate concrete under impact loading. Mater Des. 2016;112:58–66. 10.1016/j.matdes.2016.09.045.Search in Google Scholar

[99] Yu J, Lin L, Qian J, Jia X, Wang F. Preparation and properties of a low-cost magnesium phosphate cement with the industrial by-products boron muds. Constr Build Mater. 2021;302:124400. 10.1016/j.conbuildmat.2021.124400.Search in Google Scholar

[100] Wijayasundara M, Mendis P, Zhang L, Sofi M. Financial assessment of manufacturing recycled aggregate concrete in ready-mix concrete plants. Resour Conserv Recycl. 2016;109:187–201. 10.1016/j.resconrec.2016.02.007.Search in Google Scholar

[101] Wu J, Jing H, Yin Q, Yu L, Meng B, Li S. Strength prediction model considering material, ultrasonic and stress of cemented waste rock backfill for recycling gangue. J Clean Prod. 2020;276:123189. 10.1016/j.jclepro.2020.123189.Search in Google Scholar

[102] Ahmed Shaikh FU, Nath P, Hosan A, John M, Biswas WK. Sustainability assessment of recycled aggregates concrete mixes containing industrial by-products. Mater Today Sustain. 2019;5:100013. 10.1016/j.mtsust.2019.100013.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations