Abstract

Nanocellulose derived from plant cell wall, due to its unlimited sources, is regarded as a next-generation green material for the automotive industry because of its high tensile strength (≥3 GPa), high elasticity modulus (110–220 GPa), and low density (1.6 g/cm3). This study first introduces the structural characteristics, preparation techniques, and mechanical properties of nanocellulose. Then, three types of nanocellulose composites, including nanocellulose directly reinforced polymers, hybrid fiber-cellulose composites, and all cellulose composites (ACCs), are reviewed. The corresponding preparation techniques, material properties, reinforcement mechanisms of nanocellulose, and application limitations are discussed in detail. To overcome the insufficient mechanical properties of nanocellulose directly reinforced polymers and ACCs toward the manufacture of automobile structural components, self-assembly techniques prove to be effective to prepare macroscopic fibers by first aligning nanocellulose and then assembling them into continuous micro-size fibers. We reviewed different self-assembly techniques and multiscale modeling techniques of cellulose nanofibers (CNFs) assembled microfibers. Furthermore, we proposed a finite element or finite volume technique-based micromechanics framework to predict the homogenized responses of CNFs assembled microfibers, which serve as a fundamental layer to construct a multiscale modeling strategy toward CNFs assembled microfiber-based composite structures. The proposed multiscale modeling strategy is expected to greatly facilitate the development of CNFs assembled microfiber-based composite structures and significantly advance the application of nanocellulose in automotive structural applications.

1 Introduction

In line with the global trend of achieving carbon neutrality, the automotive industry is striving to reduce carbon emission throughout the entire life cycle of an automobile, from raw materials and manufacturing process to disposal [1]. In particular, high-performance natural materials play a significant role in the car industry, because they make automotive more eco-friendly, lightweight, energy efficient, and low in carbon emission. In recent years, cellulose nanofibers (CNFs), extracted from plant cell wall [2,3], have emerged as very promising green materials due to their high tensile strength (≥3 GPa), high elasticity modulus (110–220 GPa), low density (1.6 g/cm3) [4], high surface area, abundant hydroxyl groups, low toxicity, and biodegradability [5,6,7]. These characteristics facilitate the development of a new generation of high-performance, environmentally friendly lightweight materials for automotive applications.

There are various sources to manufacture nanocellulose materials, including wood, plants, algae, and even bacteria [8]. High-performance green composites may be created by designing multiscale structures from the nanoscale to the macroscale, thanks to the self-polymerization propensity of CNFs [4]. At nanoscale, CNFs exhibit low density, high specific surface area, high aspect ratio, low coefficient of expansion, excellent mechanical strength, and biocompatibility. Particularly, nanocellulose possesses high specific strength [9], making it very attractive for automotive lightweighting. CNFs with some non-crystalline regions removed by chemical means generally exhibit high crystallinity. However, the source, separation, and pretreatment of nanocellulose directly affect the morphology, size, mechanical properties, and the surface molecular groups of the CNFs [10,11]. These factors have a big effect on the mechanical properties, thermal properties, interfacial properties, and dispersion of CNFs in application situations [12,13,14], and the current mass production of nanocellulose with stable mechanical properties is limited.

Due to the appealing mechanical characteristics of CNFs, they have been directly mixed with various polymers that have been widely utilized for automotive non-structural components to reduce the consumption and enhance the mechanical performance of polymers [15,16]. For example, Yano and his team have investigated the preparation methods, and mechanical and thermal properties of nanocellulose directly reinforced polymers. Those composites have been utilized to replace automotive components such as door panels, hoods, and roof panels in a protype automotive [17]. However, due to the hydrophilicity and hydrogen bonding formed by surface functional groups, nanocellulose materials as reinforcements dispersed directly in polymers exhibit agglomeration and porosity in the microstructure and cannot be autonomously and uniformly dispersed in the polymer matrix [18]. Additionally, owing to the differences in preparation process and surface modification of the current nanocellulose, the interface types of the nanocellulose in the polymer matrix are distinct, and the interface performance is inadequate [19,20]. Therefore, a major barrier to enhance the performance of nanocellulose composites is the dispersion and interfacial compatibility of nanocellulose in polymer matrix. Besides, the nanocellulose directly reinforced polymers, hybrid fiber-cellulose composites, and fully degradable all cellulose composites (ACCs) may also find application in automotive non-structural components.

To fully exploit the potential of CNFs with extraordinary mechanical performance, various self-assembly techniques have been developed to produce micro-scale fibers [21], which possess the potential to make lightweight automotive structural components with the assistance of multiscale design strategy. In general, the direction of CNFs is first aligned along fiber direction and then CNFs are assembled to form micro-size and continuous fibers through hydrogen bonds with interfacial ionic bonds [22] and van der Waals forces along the surface of CNFs [23]. Due to the high surface area of CNFs, an extensive distribution of hydrogen bonds on the surface of CNFs, and fracture recombination characteristics of hydrogen bonds the mechanical properties of the assembled fibers are comparable to or even higher than the glass fibers (GFs) [24], which are widely utilized in manufacturing automotive structural components. To produce lightweight automotive structural components in terms of CNFs fiber, it is necessary to adopt a multiscale design and optimization strategy, which can maximize the mechanical performance of automotive structural components at both micro and macro levels.

The remainder of the review study is organized as follows: Section 2 reviews different types of nanocellulose, summarizing their corresponding molecular structures, properties, and preparation techniques. Section 3 reviews various types of nanocellulose composites, including nanocellulose directly reinforced polymers, hybrid fiber-cellulose composites, and ACCs. It also discusses different reinforcement mechanisms for each composite. Section 4 provides a comprehensive review of an important type of ACCs, namely, CNFs assembled microfiber. This section covers the corresponding assembly techniques, microstructure characteristics, and mechanical properties. Additionally, a full-scale multiscale modeling strategy is proposed toward high-performance lightweight automotive structural applications. Section 5 examines the current status of nanocellulose composites in automotive applications and Section 6 concludes the review work.

2 Nanocellulose

2.1 Nanocellulose structure

Cellulose is a highly abundant green substance on our Earth and possesses a hierarchical structure. Figure 1 illustrates the hierarchical structure of cellulose in plant-based biomass. In terms of various retraction strategies, a diverse range of nanocellulosic materials can be obtained with at least one dimension in the nanometer scale. The molecular structure depicts that nanocellulose is mostly made up of repeating D-glucopyranosyl units (also known as dehydrated glucose units, AGUs), arranged in a 4C1 chain arrangement with each monomeric unit helixed at an angle of 180° from its neighboring units [25]. This molecular chain structure enables the nanocellulose surface to contain a large number of hydroxyl functional groups, resulting in the crystalline regions having a much higher number and strength of intermolecular and intermolecular hydrogen bonds than the amorphous regions. Therefore, the crystalline form of nanocellulose cannot be disrupted easily, while the amorphous regions can be disrupted relatively easily.

In general, these nanocellulosic materials can be categorized into three main groups: Cellulose nanocrystals (CNCs), Cellulose nanofibers or nanofibrils (CNFs), and Bacterial nanocellulose (BC). Figure 1(a)–(c) demonstrates the SEM images of CNFs, CNCs, and BC. CNFs consist of highly entangled networks of nanofibrils made of alternating crystalline and amorphous domains. CNFs have the characteristics of high mechanical qualities, high surface area, high aspect ratio, and a profusion of surface functional groups. Contrarily, CNCs are mostly made up of rod-like crystalline regions because the majority of amorphous regions of cellulose have been removed using strong acids (Figure 1). As a result, CNCs have stronger mechanical properties than CNFs but is smaller, more spherical in shape, and has a lower aspect ratio [26]. Unlike CNFs and CNCs, BC is a cellulose nanomaterial processed by various species of the Acetobacteriaceae family.

BC can be distinguished from plant-derived CNFs and CNCs by its high purity and distinct crystal structure. These characteristics make it more suitable for applications in the biomedical field [27,28]. Meanwhile, BC is processed by bacteria instead of direct chemical or mechanical processes. The process to produce BC is less efficient and more expensive in comparison with the process to make CNCs and CNFs. Since the cost of nanocellulose-based automotive components and the efficiency to make them are essential for automotive companies, CNFs and CNCs are more preferred. BC-based composites for automotive applications are also extremely rare, and this study only covers contents related to CNFs and CNCs.

2.2 Preparation technology

In 1974, nanocellulose was first chemically extracted from cellulose by the acid hydrolysis process [33]. Since then, various methods have been developed by numerous researchers to obtain nanocellulosic materials, including CNCs and CNFs. Generally, these methods can be divided into three categories, including chemical treatment technique, physical treatment technique, and combined physical and chemical treatment technique. Table 1 summarizes the commonly used preparation techniques of nanocellulose.

Preparation techniques of nanocellulose

| Technique | Extraction method | Type | Properties | Pros and cons | Ref. |

|---|---|---|---|---|---|

| Chemistry | HCl acid hydrolysis | CNFs | Length: 1,185(±492) nm |

Advantages

|

[34] |

| Diameter: 56(±20) nm | |||||

| Crystallinity: 87% | |||||

| High dispersibility | |||||

| H2SO4 acid hydrolysis and inorganic salts solution | CNCs | Particle size: 66–600 nm | [35] | ||

| Crystallinity: 84.2% | |||||

| High yield and high efficiency | |||||

| TEMPO-mediated oxidation | CNFs | Length: 870 nm | [36] | ||

| Diameter: 3–4 nm | |||||

| Crystallinity: ∼73% | |||||

| Carboxylate groups improve dispersion | |||||

| NaOH alkali treatment | CNFs | Length: 658 ± 290 nm | [37] | ||

| Diameter: 27 ± 13 nm | |||||

| Acetic acid and NaClO2 treatment | Crystallinity: ∼85% | ||||

| Acetylation modification improves dispersion | |||||

| Combined NaOH and enzymatic treatment | CNFs | Length: 150–350 nm | [38] | ||

| Diameter: 10 ± 30 nm | |||||

| Crystallinity: ∼45% | |||||

| Physics | High pressure homogenization and ultrasound | CNFs/CNCs | Particle size: 68 nm |

Advantages

|

[39] |

| Length: 88–1,100 nm | |||||

| Crystallinity: ∼60% | |||||

| High yield and high efficiency | |||||

| High pressure microfluidization | CNFs/CNCs | Diameter: 5–10 nm | [40] | ||

| Crystallinity: 33∼57% | |||||

| Ball milling and ultrasound | Length: 3 μm | [41] | |||

| Diameter: ∼25 nm | |||||

| Crystallinity: 50–70% | |||||

| Combined physics and chemistry | TEMPO oxidation and homogenization | CNFs | Diameter: ∼41 nm |

Advantages

|

[42] |

| High specific surface area and carboxyl distribution. | |||||

| Acid and alkali pretreatment and ultrasound | CNFs | Diameter: 30–70 nm | [43] | ||

| Crystallinity: 66–71% | |||||

| Good mechanical properties and thermal stability | |||||

| Acid pretreatment and microfluidization | CNFs/CNCs | Length: 600–1,000 nm | [44] | ||

| Diameter: 10–40 nm | |||||

| Crystallinity: 71–74% | |||||

| High yield and aspect ratio |

With the assistance of chemical treatment technique, Kishimoto et al. [35] effectively prepared CNCs and enhanced its crystallinity by acid hydrolysis of micron-sized cellulose using various ionic solutions (FeSO4, Fe2(SO4)3, and FeCl3) as catalysts in conjunction with sulfuric acid solutions. Although high crystallinity nanocellulose materials can be prepared chemically, the inorganic strong acid hydrolysis method is highly corrosive to equipment and difficult to recycle, leaving a large amount of strong acid to be treated at the end of the preparation and causing severe environmental pollution. In enzymatic hydrolysis, enzymes are more expensive, the reaction time is lengthier and less efficient, and the comprehensive chemical reaction results in a significantly lower yield compared to the majority of chemical treatment methods.

The physical treatment technique relies on mechanical process. Initially, 2% wood pulp was treated with a high-pressure homogenizer to produce CNFs with diameters below 100 nm [46], and subsequently, microfluidic injection [31], grinding [47], ultrasonic [48], emulsification [49], steam blasting [50], and ball milling [51] were developed. Figure 2 depicts the most widely used methods for the preparation of nanocellulose based on physical treatment techniques, including homogenization (100-KF3-8BS Manton Gaulin homogenizer, USA and M-110Y Microfluidizer, USA), grinding (Masuko Sangyo Co. Ltd, Japan) and other non-conventional processes. The purely mechanical methods are currently regarded as having significant limitations, such as high energy consumption, severe damage to the cellulose structure, uneven particle size and crystallinity [52], and poor dispersion during application process [53].

![Figure 2

Mechanical processes for CNFs production. Reproduced with permission from ref. [45].](/document/doi/10.1515/ntrev-2024-0006/asset/graphic/j_ntrev-2024-0006_fig_002.jpg)

Mechanical processes for CNFs production. Reproduced with permission from ref. [45].

To address the drawbacks of the pure chemical and mechanical methods, combined chemical treatments and physical techniques are developed. For instance, the typical process to process wood residues involves two steps. First, wood residues are pre-treated with chemicals, such as acids and certain enzymes, to remove lignin and hemicellulose and then cellulose is isolated and oxidized by a TEMPO-mediated oxidation system under alkaline conditions. The second step is to conduct a mild homogenization process as a physical treatment to obtain nanocellulose. Vallejos et al. [42] successfully obtained nanocellulose from wood chips by using sodium hydroxide to remove lignin, fractionation, TEMPO oxidation, washing, neutralization, and defibrillation of the resulting cellulose suspension using a homogenization in a five-step sequence, resulting in the CNFs with high surface area. In addition to physical homogenization combined with chemical methods, ultrasonic methods coupled with chemical treatments are also recommended. Xiao et al. [43] created pine needle nanofibers by acidifying sodium chlorite treatment (75°C for 1 h), followed by alkali treatment (KOH), acid hydrolysis (HCl, 80°C for 2 h), and finally coupled with ultrasonic treatment (60 kHz for 30 min). The resulting CNFs had a width between 30 and 70 nm, a crystallinity of 66.19%, which shows great promise of usage in thermoplastic composites.

Therefore, chemical pretreatment can be initially used to dissociate the nanocellulose raw material and to remove some of the indeterminate regions. Then, physical treatment can be used to further stabilize the dimensional stability of the prepared nanocellulose and disperse it. Compared to the pure chemical and physical treatment methods, the combination of chemical and physical treatment methods not only significantly reduces energy consumption (pure physical treatment, 3,000–30,000 kW h/t [54]) and the usage of strong acids and alkalis (much lower concentrations than usual), contributing to the environmental sustainability, but also obtains high-quality CNFs with excellent mechanical performance (high crystallinity, dimensionally stable, and thermal stability). The combined chemical and physical treatment method has provided a realistic technique of nanocellulose mass-production for the automotive industry.

2.3 Mechanical properties

As a polymeric and dense nanomaterial, nanocellulose has impressive mechanical properties, which are further enhanced by the presence of intermolecular and intramolecular hydrogen bonds [55]. The key factors such as size, morphological structure, and cross-linking of nanocellulose vary due to inconsistent sources and different preparation processes, which also bring about significant differences in mechanical properties between the nanocellulose materials. The rod-like CNCs have the best mechanical properties and their overall theoretical modulus is about 100–200 GPa (approximately 63–125 GPa cm3/g), with tensile strengths around 4.9–7.5 GPa (approximately 3.0–4.7 GPa cm3/g) [4]. CNFs also possess exceptional mechanical properties such as outstanding tensile strength (0.3–22 GPa) and Young’s modulus (58–180 GPa). The extraordinary mechanical features of nanocellulose naturally offer a great promise for designing and manufacturing green and lightweight composite materials in the automotive industry.

Table 2 summarizes the mechanical properties of nanocellulose materials and the reinforcement fibers of commonly used automotive composites. While carbon fibers (CF) still have a significant advantage over weaker fibers like glass and aramid, nanocellulose even has a higher specific strength than CF.

Comparison of material properties of cellulose

| Material | Density (g/cm3) | Strength (GPa) | Elastic modulus (GPa) | Strain to failure (%) | Ref. |

|---|---|---|---|---|---|

| CNCs | 1.6 | 7.5–7.7 | 124–155 | 1.6 | [56] |

| CNFs | 1.5–1.6 | 6–7.5 | 106–121 | 1.2 | [57] |

| Natural fiber | 0.9–1.3 | 0.3–0.9 | 18–32 | 1.5–10 | [58] |

| GF | 2.6 | 2.0–4.8 | 69–86 | 4.5–5.5 | [11] |

| Aramid fiber | 1.4 | 2.5–2.8 | 100–134 | 2.5–2.9 | [59,60] |

| CF | 1.8 | 3.5–4.0 | 221–234 | 1.5–2.1 | [61,62] |

3 Nanocellulose composites

The prospect of creating green, lightweight, and high-performance nanocellulose composites toward automotive applications is made possible by the exceptional features of nanocellulose, including outstanding mechanical and thermal properties, biodegradability, low density [63], and rich surface functional groups [64,65]. Researchers have developed various types of composites with nanocellulose, including nanocellulose directly reinforced polymers, hybrid fiber-cellulose composites, and ACCs.

3.1 Nanocellulose directly reinforced polymers

Nanocellulose directly reinforced polymer is one of the most well-studied nanocellulose composites. In this type of composite, CNCs or CNFs are dispersed directly as fillers in various polymers such as polypropylene (PP), high-density polyethylene (HDPE), Acrylonitrile butadiene styrene (ABS), epoxy (EP), and even in polylactic acid (PLA) and thermo-plastic starch (TPS), which are very promising biodegradable polymers. CNCs and CNFs can not only reinforce polymers and directly improve their mechanical properties, but also reduce the consumption of fossil fuel-based polymers. This type of composite possesses a broad potential in making automotive interior and exterior non-structural components, such as door panels, trim components in dashboards, parcel shelves, etc. [66,67,68].

3.1.1 Surface modification of nanocellulose in nanocellulose directly reinforced polymers

In contrast with synthetic inorganic fibers such as GF or CF, nanocellulose possesses a large number of hydroxyl functional groups on its surface, allowing for the formation of a large number of hydrogen bonds. On the one hand, this feature provides great potential to form strong interfacial bonding between nanocellulose and its adjacent matrix. On the other hand, hydrophilic nanocellulose is extremely susceptible to agglomeration [69], which causes poor interfacial compatibility between nanocellulose and matrix, voids inside the composites, and in sequel, the poor mechanical properties of the composites. Therefore, it is critically important to modify the nanocellulose and/or the polymer matrix to improve their interfacial compatibility.

Saba et al. [70] used the hand-paste technique to fabricate CNFs/EP composites with different filler levels (0.5, 7.5, and 10%). They characterized the micro-morphology of the material by scanning electron microscopy (SEM) and transmission electron microscopy (TEM), combined with tensile, impact, and flexural mechanical properties tests, and then discovered that 7.5% of CNFs filler had the best mechanical and structural properties. However, agglomerations and voids continued to be visible in the SEM images. Figure 3 depicts significant voids and agglomerations in the CNFs/EP composites as well as the large fracture of the material during tensile testing, which may be the primary cause of the degradation of the composite properties at high content. This is further emphasized in Palange et al.’s study [71], who created CNFs/PPPE (PP-polyethylene copolymer) composites with various volume fractions, tested their mechanical properties like tensile strength and impact properties, and characterized the fiber distribution. They discovered that the effect of CNFs agglomeration at high content on the mechanical properties of the composites, particularly the impact properties, was very significant. According to the research conducted by Chu et al. [13], the dispersibility and interfacial compatibility of CNFs are greatly influenced by the surface hydrophilicity/hydrophobicity, charge repulsion, and spatial site resistance. In order to create high performance green lightweight structural materials, it is imperative to address the issue of poor interfacial compatibility and aggregation of nanocellulose caused by hydroxyl groups.

![Figure 3

SEM images of the CNFs/EP composites showing (a) agglomerations, (b) void, and (c) deep fracture in 1% CNFs filler loading. Reproduced with permission from ref. [70].](/document/doi/10.1515/ntrev-2024-0006/asset/graphic/j_ntrev-2024-0006_fig_003.jpg)

SEM images of the CNFs/EP composites showing (a) agglomerations, (b) void, and (c) deep fracture in 1% CNFs filler loading. Reproduced with permission from ref. [70].

To enhance the mechanical characteristics of the composites by adding nanocellulose, several research works have been conducted to obtain good dispersion and compatibility of nanocellulose/polymer composites using various methods. One method for enhancing the mechanical characteristics of composites and improving dispersion is to reduce the hydrophilicity of nanocellulose by surface modification. Satio et al. [36] carried out TEMPO-mediated systematic oxidation of natural CNFs to enhance the dispersion and transparency of CNFs in dispersions and water. This method is currently used to improve the dispersion of CNFs by oxidizing hydroxyl groups to carboxyl groups and reducing the formation of hydrogen bonds to improve negative charge rejection. In the research conducted by Noguchi et al. [72], TEMPO-CNFs/PE demonstrated good dispersion and enhancement of the processed CNFs.

In addition to carboxylation, there are some other effective hydrophobic modification methods, such as asesterification [73], silylation [74], and graft copolymerization [75] to introduce a variety of hydrophobic surface functional groups to enhance the electrostatic repulsion between nanocellulose, as shown in Figure 4. Yano et al. [76] accomplished diverse esterification modifications of the hydroxyl groups on the surface of CNFs filaments by adding six aliphatic ester groups with linear, cyclic, and branched chains. The modified CNFs were compounded with HDPE, a hydrophobic polymer commonly used in automobiles, by melt extrusion and injection molding, and X-ray CT analysis revealed that the esterified hydrophobic surface modification of CNFs was effective in enhancing the dispersion of CNFs in hydrophobic materials such as HDPE. In terms of tensile modulus (3.32 GPa), tensile strength (51.2 MPa), and linear swelling of CNFs composites, the incorporation of branched chains such as pentane-oil groups exhibited the highest enhancement efficacy. Figure 5 demonstrates that the incorporation of branched chains, such as pentane-oil groups, enhances both the dispersion of CNFs in HDPE materials and the interfacial compatibility of CNFs/HDPE, thereby enhancing their interfacial properties. Kahawita et al. [77] surface modified CNFs and CNCs with a methylsilane coupling agent (Si-69) and compounded it with PP material. They discovered that the methylsilylated CNFs had good dispersion in the PP material, and compared to the pure PP material, the mechanical properties were enhanced.

![Figure 4

Common surface modification reactions of nanocellulose (CNC as an example). Reproduced with permission from ref. [55].](/document/doi/10.1515/ntrev-2024-0006/asset/graphic/j_ntrev-2024-0006_fig_004.jpg)

Common surface modification reactions of nanocellulose (CNC as an example). Reproduced with permission from ref. [55].

![Figure 5

Enhancement of CNFs in injection-molded HDPE: (a) and (c) the X-ray CT and TEM images of neat HPDE, (b) and (d) the X-ray CT and TEM images of CNFs/HPDE. Reproduced with permission from ref. [76].](/document/doi/10.1515/ntrev-2024-0006/asset/graphic/j_ntrev-2024-0006_fig_005.jpg)

Enhancement of CNFs in injection-molded HDPE: (a) and (c) the X-ray CT and TEM images of neat HPDE, (b) and (d) the X-ray CT and TEM images of CNFs/HPDE. Reproduced with permission from ref. [76].

The addition of nanocellulose improves the mechanical properties of a variety of polymers, but the dispersion of nanocellulose as a reinforcement in the matrix greatly affects the stress transfer within the composite. Therefore, surface modification to improve hydrophobicity to reduce agglomeration is the key to resolving this issue and enhancing the use of nanocellulose materials in automotive applications.

3.1.2 Properties of nanocellulose directly reinforced polymers

Table 3 summarizes the mechanical and thermal properties, and preparation techniques of CNFs or CNCs reinforced polymers. As the most widely used polymer (approximately 45%) in automobiles, PP has been widely studied to examine the effect of nanocellulose on its mechanical and thermal properties. Suzuki et al. [91] utilized a twin-screw extruder to blend various ratios of CNFs materials with PP, commonly found in automotive applications. Cationic polymer having a primary amino group (CPPA) was used as a coupling agent to enhance the interfacial qualities. It was found that 30 wt% CNFs/PP composite had a tensile modulus of 4.6 GPa (70.3% improvement) and a tensile strength of 71.8 MPa (62.4% improvement). The HDT of the material system was also found to be higher, suggesting it could serve as an alternative to PP materials for automotive applications. Peng et al. [79] prepared CNFs/PP composites using a melt lamination process, and MAPP treatment was used to achieve well-dispersed CNFs and improve the interfacial adhesion between CNFs/PP. The highest mechanical properties of the final composites were 1.94 GPa (tensile modulus), 32.8 MPa (tensile strength), 1.63 GPa (flexural modulus), 50.1 MPa (bending strength), and 3.8 kJ/m2 (impact strength), which were approximately 36, 11, 21, 7, and 23% greater than pure PP. Cui et al. [80] recently prepared nanocellulose/PP composite utilizing melt blending and molding techniques, and then conducted three-point bending experiments on standard material specimens, demonstrating that nanocellulose also substantially contributed to the bending properties of the composite.

Preparation techniques and mechanical and thermal properties of CNFs or CNCs directly reinforced polymers

| Material | V f (%) | Surface modification | Preparation technique | Mechanical and thermal properties (compared to pure polymer) | Ref. | |

|---|---|---|---|---|---|---|

| PP | CNFs | 40 | Hydrophobic graft copolymerization using CPPA and MAPP | Twin-screw extrusion and injection molding |

|

[78] |

|

||||||

| CNFs | 30 | Maleic anhydride PP graft modification | Twin-screw extrusion and injection molding |

|

[79] | |

| CNC/CNFs | 10 | Citric acid esterification | Compression molding |

|

[80] | |

| CNFs | 5 | TEMPO-oxidized modification | Compression molding |

|

[81] | |

|

||||||

| PE | CNFs | 40 | Hydrous Zr oxide modification | Hot compression forming process |

|

[82] |

|

||||||

| CNFs | 50 | Use CPAM and MAPE as compatibilizers | Twin-screw extrusion (dry blending method) |

|

[83] | |

|

||||||

| Polyamide 6 (PA6) | CNCs | 5 | None | Injection molding |

|

[84] |

| CNFs | 10 | Acetylated (Ac) modification | Twin-screw extrusion and injection molding |

|

[85] | |

|

||||||

| ABS | CNCs | 20 | None | Compression molding |

|

[86] |

|

||||||

| EP | CNFs | 0.5 | TEMPO-oxidized hydrophobic modification | Low temperature curing |

|

[87] |

|

||||||

| PLA | CNFs | 5 | None | Melt blending and twin-screw extrusion |

|

[88] |

|

||||||

| CNFs | 20 | Esterification modification | Injection molding |

|

[89] | |

|

||||||

| CNCs | 3 | TDI grafting modification | Injection molding |

|

[90] | |

In addition to the positive reinforcement effect on PP, the mechanical properties of other polymers for automotive applications were also significantly enhanced. Mulinari et al. [82] investigated the effect of CNFs on the thermal and mechanical properties of HDPE at different volume fractions and discovered that CNFs at a 40 wt% content improved the material’s Young’s modulus by 122.4% compared to pure HDPE material. Peng et al. [84] also investigated various amounts of CNFs/CNCs-reinforced PA6 and the mechanical test results demonstrated that the addition of CNFs could enhance the composites’ tensile modulus and tensile strength. In addition, researchers have compounded nanocellulose with thermoplastic materials such as PE [92], ABS [86], and EP [70] to obtain improved mechanical and thermal properties, all of which are commonly used as thermoplastic materials in automobiles.

For more environmentally friendly material properties, nanocellulose is also incorporated into biodegradable thermoplastic polymers. Ghasemi et al. [88] prepared composites with varying volume fractions using CNFs as the reinforcement and using maleated PLA (PLA-g-MA) as the matrix through melt blending and twin-screw extrusion processes. Compared to unadulterated PLA, the PLA/CNFs5/PLA-g-MA5 nanocomposites demonstrated a 138% and 40% increase in tensile strength and Young’s modulus, respectively, as well as a 131% increase in maximal impact strength. Zhang et al. [89] prepared LCNFs (Lignin in esterified lignocellulose nanofibers)/PLA composites with up to 20% content by directly merging esterified CNFs with PLA. These composites possessed exceptional flexural resistance (204.5 MPa), which was 120.6% higher than pure PLA. Olonisakin et al. [90] modified CNFs hydrophobically (TDI grafting) to promote its dispersion in PLA, obtaining maximum tensile strength and elongation of the composite at 3% fiber content, an increase of 80.67 and 79.44%, respectively, compared to pure PLA.

As we can see, most of the nanocellulose directly reinforced polymers exhibit better mechanical and thermal properties than the corresponding polymers. Therefore, nanocellulose-reinforced polymers can not only reduce the usage of chemical-based plastics, but also reduce the weight of the corresponding automotive components.

3.2 Hybrid fiber-cellulose composites with nanocellulose-enhanced interface

CF and GF reinforced polymers exhibit high strength, high stiffness, excellent fatigue performance, and corrosion resistance, making them widely utilized in automotive structures. However, CF or GF are inorganic and lack chemical functional groups, often, resulting in weak interfacial properties leading to fiber/matrix debonding and delamination. As a high-performance nanoscale filler, nanocellulose can enhance the interfacial properties between the filaments and matrix, thereby improving the composite’s mechanical properties [93].

Azhary et al. [94] added 1% CNFs to a GF/EP composite and hand-glued and vacuum-bagged standard specimens. Mechanical and thermal property experiments revealed that the addition of CNFs increased the tensile strength and modulus by 9 and 10%, respectively, while the flexural strength and modulus are increased by 16 and 6%, respectively. Moreover, the interlaminar tensile strength of the composite increased by 11% due to the uniform distribution of CNFs at the GF/EP interfacial layer. FT-IR analysis also revealed that the CNFs formed a local strengthening of the matrix around the GF, improving stress transfer and enhancing fracture resistance to delamination. A consistent conclusion was reached in a study by Kumar et al. [95]. They used the preparation method shown in Figure 6(a)–(c) to enable the uniform distribution of CNCs around the GF and then utilized vacuum-assisted resin transfer molding to prepare composite laminates. The addition of CNCs increased the interlaminar shear strength (ILSS) by approximately 30%, the flexural strength by 43%, and the flexural modulus by 40%. The enhancement mechanisms of CNCs in the CNCs/GF/EP composite to resist fracture failure are illustrated in Figure 6(d–f). The strong nanoscale interactions and high modulus of the interfacial layer at the GF/EP interface caused by the CNCs significantly improves the energy absorption of interlaminar fracture (Figure 6(d–f)), as evidenced by the SEM images of the interlaminar fracture (Figure 6(g) and (h)).

![Figure 6

Reinforcement mechanism of hybrid fiber-cellulose composites: (a)–(c) the preparation process of CNCs/GF/EP composites; (d)–(f) CNCs enhancement mechanisms in fracture failure; (g) and (h) SEM images of the GF/EP composites and CNCs/GF/EP composites. Reproduced with permission from ref. [95].](/document/doi/10.1515/ntrev-2024-0006/asset/graphic/j_ntrev-2024-0006_fig_006.jpg)

Reinforcement mechanism of hybrid fiber-cellulose composites: (a)–(c) the preparation process of CNCs/GF/EP composites; (d)–(f) CNCs enhancement mechanisms in fracture failure; (g) and (h) SEM images of the GF/EP composites and CNCs/GF/EP composites. Reproduced with permission from ref. [95].

In addition to CF, nanocellulose has also been utilized in composites containing CF and natural fibers. Wang et al. [96] incorporated CNCs in CF/EP laminates and significantly enhanced the fracture energy, resulting in mode I and II interlayer fracture energies of 310.0 kJ/m2 and 2.843 kJ/m2, respectively, which are highly desirable for the design of high strength, high fracture toughness composites. Qiu et al. [97] even added two nanomaterials, graphene (GO), and CNFs to CF/EP composites to improve the mechanical interlocking and chemical bonding between the fibers and the matrix. These two nanofillers improved the surface roughness and wettability of the CF and increased the interfacial bonding strength.

3.3 ACCs

In contrast with nanocellulose-reinforced polymers and nanocellulose-enhanced fiber reinforced polymers (FRP), ACCs use a single nanocellulose as both reinforcement and matrix. This material type is anticipated to address the problem of fiber/matrix adhesion by employing chemically similar or identical cellulose in both the matrix and reinforcement [98] and enable a desirable green material with full biodegradability.

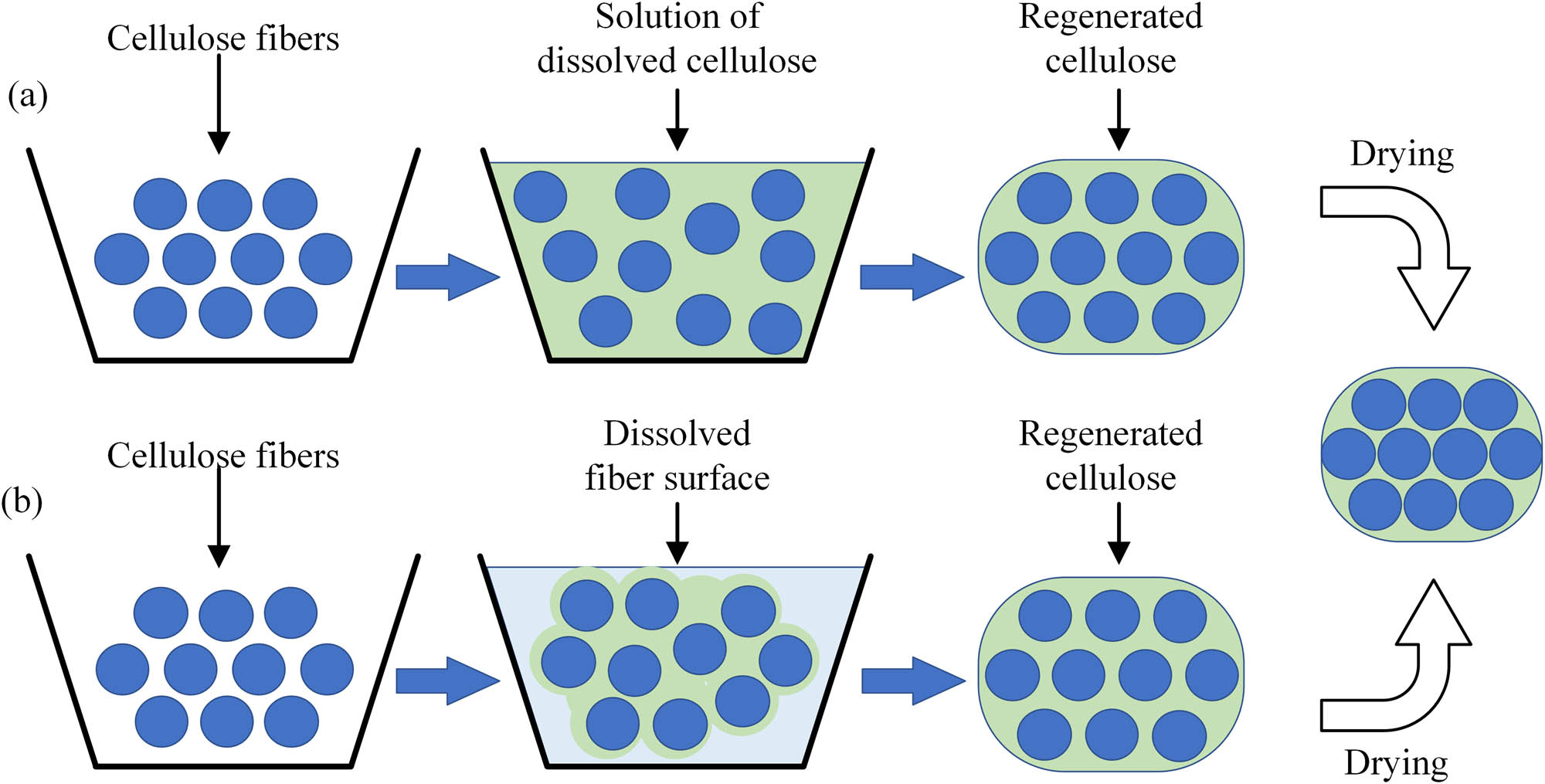

As depicted in Figure 7, the primary methods to prepare ACCs are the CIM, (dissolve nanocellulose completely) and the PDM (dissolve the surface of nanocellulose) [99]. Nishino et al. [100] created the first all-cellulose-composites with tensile strengths of 480 MPa at 25°C and dynamic energy storage moduli of up to 20 GPa at 300°C by partially dissolving different sizes of CNFs/CNCs in solvents (CIM). The mechanical and thermal properties of these materials are comparable or even superior to those of conventional composites reinforced with GF. Gindl et al. [101] also prepared ACCs films by PDM, and depending on the controlled CNFs/CNCs ratio, the final material exhibited excellent strength and resilience with a tensile strength of up to 240 MPa, an elastic modulus of 13.1 GPa, and an elongation at break of 8.6%. Due to the lower solubility, dimensional instability, and residual stress, PDM seems to be more suitable for industrial production than CIM.

Schematic of processing approaches of ACCs: (a) the conventional impregnation method (CIM) and (b) the partial dissolution method (PDM).

In recent years, the self-assembly technique (assembled into one macroscopic material by self-bonding in the non-dissolved state) has emerged as an effective method to prepare high-performance macro or micro-scale material with nanocellulose. Nanopaper, a typical material prepared via the self-assembly technique, is produced using only nanocellulose through processes such as thermosetting or filtration. Henriksson et al. [102] fabricated nanopaper by filtration of uniformly distributed nanocellulose in suspension. The resulting nanopaper exhibited porous properties in microscopic images, but still exhibited excellent mechanical properties, with a Young’s modulus and tensile strength of 13.2 GPa and 214 MPa, respectively, and excellent fracture toughness, which may be caused by fiber breaks and hydrogen bonds slippage. Mittal et al. [22] also assembled nanocellulose by flow-assisted wet spinning based on the concept of multiscale design, and the assembled micro-size fibers exhibited dense, ordered, and interlinked properties, which led to a Young’s modulus and tensile strength of 86 and 1.57 GPa, achieving a microscopic-to-macroscopic transformation of nanocellulose with high performance. Meng and Wang [103] and Rosén et al. [104] used simulation to disclose the nanocellulose strengthening mechanism. The results demonstrated that the increase in intermolecular interactions such as van der Waals forces and hydrogen bonds between chemical functional groups on the surface of nanocellulose improved the mechanical properties of the material, and that properties such as fracture recombination of surface hydrogen bonds also made the assembled CNFs material more ductile, which is the foundation to realize the design and assembly of nanosphere cellulose materials into the next layer.

4 CNFs assembled microfiber and multiscale modeling strategies toward automotive structural application

Nanocellulose is a high-strength and effective reinforcers in traditional polymer matrix composites, interfacial reinforcement, and ACCs. However, compared with current automotive composite reinforcements (GF and CF), its enhancement effect and composite mechanical properties are not attractive. The mechanical properties reported in some studies on nanocellulose composites can only replace the weaker components of the car, such as the instrument panel, door interior components, air intake grille, and other interior components. With the development of nanocellulose assembly processes in recent years, CNFs assembled continuous microfibers, similar to the reinforced continuous fibers commonly used in automobiles, exhibit amazing mechanical properties, which provide the possibility to further improve the application of nanocellulose materials in the automotive sector. Therefore, this section reviews recent research on CNF-assembled continuous microfibers, aiming to provide analysis and design strategies for the manufacture of high-performance green lightweight automotive structural components in the future.

4.1 CNFs assembled continuous microfiber

The primary challenge in fabricating structural materials is to translate the exceptional mechanical properties (such as tensile strength and Young’s modulus, etc.) of nanoscale building blocks into macroscopic blocks. Aligning nanocellulose and assembling them to form continuous macroscopic fibers through bottom-up synthesis strategies is an effective method to fully exploit the properties of nanomaterials. Nanocellulose alignment is a highly effective material design strategy to reduce defects such as pores and improve interfacial bonding between nanocellulose. The size and the mechanical properties of assembled macroscopic fibers are comparable to conventional GF and CF, which are widely utilized in the automotive industry. Since CNFs have a 3D network morphology and are much longer than CNCs, these features facilitate a better interfacial bonding for assembled microfibers and the majority of current research is focused on macroscopic fibers made with CNFs. In our review, CNFs assembled microfiber is utilized to refer to this type of assembled fiber. Various techniques have been developed to prepare CNFs assembled microfiber and Figure 8 depicts the major assembly techniques for nanocellulose assembled microfibers, which include moist wet spinning, self-assembly, surface molecule or group induced assembly, flow-assisted assembly, interfacial complexation, and other techniques. The preparation of dense, highly oriented, and high connection strength assembled fibers is the key to successfully prepare high performance assembled fibers, as determined by microstructure and assembly mechanisms.

![Figure 8

Preparation process of nanocellulose assembled fibers: (a) Wet spinning, (b) self-assembly, (c) and (d) flow assistance, (e) flow assistance and interfacial complexation, (f) and (g) microscopic images of assembled fibers, (h) interaction between enhanced interfacing properties by introducing chitosan. Reproduced with permission from ref. [22,105–107].](/document/doi/10.1515/ntrev-2024-0006/asset/graphic/j_ntrev-2024-0006_fig_008.jpg)

Preparation process of nanocellulose assembled fibers: (a) Wet spinning, (b) self-assembly, (c) and (d) flow assistance, (e) flow assistance and interfacial complexation, (f) and (g) microscopic images of assembled fibers, (h) interaction between enhanced interfacing properties by introducing chitosan. Reproduced with permission from ref. [22,105–107].

Initially, Iwamoto et al. [108] spun a CNFs suspension into an acetone coagulation bath by a wet spinning process, and obtained nanocellulose assembled microfibers with an attractive Young’s modulus of 23.6 GPa, a tensile strength of 321 MPa, and an elongation at break of 2%. In comparison to other plant fibers, the outcomes are very appealing. According to the findings of the present study, wet spinning is one of the most appropriate procedures for the preparation of high-performance nanocellulose assembled fibers, and the resulting fibers are dense, highly oriented, and aligned. In addition to wet spinning, processes such as dry spinning [109] and electrostatic spinning [110] have been utilized in the fabrication of CNF assembled filaments, but these methods continue to be plagued by nanoscale defects and porosity issues. However, this does not fully exploit the full potential of nanocellulose, and it is known that in many high-performance nanocellulose assembled fibers, controlling the degree of orientation is important for the mechanical properties of microfibrils and functionalized materials [111]. For example, nanocellulose exhibits high tensile strength and fracture toughness following highly uniform orientation. Current methods for obtaining highly oriented assembled microfibers rely on external forces, such as shear forces and focused flow channels, to enhance the orientation of microfibers [112]. Table 4 lists the main assembly methods of high-performance nanocellulose microfibers, external forces during preparation, interactions in microfibers, and fiber diameters and properties.

Summary of the assembly methods, interactions in microfibers, and their properties

| Assembly methods | Force during preparation | Interactions in microfibers | Diameter | Properties | Ref. |

|---|---|---|---|---|---|

| Wet spinning | Stretch and shear forces from filament extrusion and pulling |

|

100–500 μm |

|

[113–115] |

|

|||||

|

|

||||

| Dry spinning | Shear and stretch forces during preparation |

|

100–500 μm |

|

[116] |

|

|||||

|

|

||||

| Electric field assistance | Electrostatic fields and shear forces |

|

100 nm to 10 μm |

|

[117,118] |

|

|||||

|

|

||||

| Microfluidic spinning | Flow stretch and shear forces |

|

50–1,000 μm |

|

[22,119] |

|

|||||

|

|||||

| Self-assembly (interfacial complexation) | Intermolecular forces |

|

<30 μm |

|

[120] |

|

|||||

|

|||||

| Interfacial complexation and flow-assisted | Flow stretch and shear forces intermolecular forces |

|

50 nm to 10 μm |

|

[105,121] |

|

|

In a recent study, Mao et al. [114] used a simple wet spinning process with a syringe combined with a stretch drying process to prepare assembled filaments with different concentrations of CNFs spinning suspensions. The final dried CNFs filaments had excellent mechanical properties, including a Young’s modulus of 35 GPa and a tensile strength of 567 MPa. Kim et al. [115] also investigated the stretch drying process following wet spinning and discovered that the alignment of the stretched CNFs assembled fibers was more consistent, which increased the number of hydrogen bonds between the CNFs and consequently enhanced the mechanical properties of the CNFs assembled fibers. Flow-assisted techniques have also been applied to the preparation of CNFs assembled microfiber in an effort to enhance their mechanical properties. Wang et al. [31] designed a self-twisting microfluidic chip to achieve shear forces applied to CNCs assembled fibers during the preparation process, yielding assembled fibers with an orientation of 0.77, a torsion angle of 5.5° on the fiber surface, a tensile strength of 400 MPa, and a Young’s modulus of 37.3 GPa. Mittal et al. [22] used a dual-flow focusing method to put together CNFs. The fibers were arranged in a near-perfect unidirectional dense arrangement, which was also linked to the effect of fiber size. This gave the macroscopically assembled fibers a Young’s modulus of 86 GPa and a tensile strength of 1.57 GPa, which is higher than the known mechanical properties of natural or synthetic biopolymer [122]. During the preparation process, they first introduced deionized water and then low pH acid to reduce the electrostatic repulsion between the fibers caused by the carboxyl group. This has a very positive effect on the dense and isotropic fibers, as there is no significant build-up of defects or pores in the fiber cross-section, and the highly oriented and dense fiber structure results in very high mechanical properties. Electrostatic forces are also used as an important aid in the preparation of dense, highly oriented fibers. Panicker et al. [117] even used AC electric field assisted wet spinning to create nanocellulose assembled fibers, and they discovered that under AC assistance, the fibers’ Young’s modulus, tensile strength, yield strength, strain at break, and toughness all increased because the nanocellulose’s orientation increased with voltage and the fibers were densely stacked.

Another assembly method is to encourage self-assembly and cross-linking of nano fibers. By altering the nanocellulose before spinning it or by adding suitable reinforcement materials, nanocellulose interactions can be enhanced. In reference to the structure of natural spider silk, Zhao et al. [120] assembled protein-nanocellulose fibers with increased mechanical strength and resilience. In the protein-nanocellulose system, it was discovered that the covalent bond bridging fibers, such as the dynamic imine bonds and acetal bonds, required more energy than hydrogen bond bridged fibers to break, achieving higher tensile strength, stretchability, and toughness. This was done by adjusting the interactions between the nanocelluloses. By spinning CNFs/CNCs with different anions and cations, Zhang and Liimatainen [123] successfully created nanocellulose assembled fibers, but the fibers’ poor Young’s modulus and tensile strength were largely attributable to the interfacial complexation’s use of opposite charges, which had a greater influence on the microstructure. Compared to densely aligned fibers prepared by other methods, this fiber has a lower number of hydrogen bonds and weaker mechanical properties.

Currently, the best way to manufacture CNFs assembled fibers is probably to employ interfacial complexation to enhance the interfacial characteristics and flow-assisted control to orient CNFs. In the study by Cai et al. [105], they used a convergent microfluidic spinning technique to apply external forces to the CNFs to improve the orientation of the fibers, as well as to improve the interfacial interaction between the CNFs through chitosan molecules. Finally, through Ca+ synergistic cross-linking of the filaments, the tensile strength was further improved, and the tensile strength was increased to 1,627 MPa, which is already higher than the current mechanical properties of GFs for automotive applications. They also revealed that the mechanism of the high toughness of CNF-assembled fibers is due to the breaking and recombination of hydrogen and interfacial ionic bonds during CNFs slippage through molecular dynamics analysis.

In addition to the above preparation processes, the mechanical properties of assembled microfiber can be improved by adding superior nanomaterials such as graphene [124] or carbon nanotubes [125]. However, in the automotive industry, the automotive parts are cost sensitive. The addition of superior nanomaterials will significantly increase the cost of the corresponding automotive components and hinder their mass production. Therefore, the use of flow-assisted preparation processes and improved interactions between nanocellulose hold promise for the production of green, low-cost, high-performance assembled microfiber in the automotive industry.

4.2 Multiscale modeling of CNFs assembled continuous microfiber

In contrast with conventional CF and GF, CNFs assembled microfiber possesses a distinctive hierarchical microstructure, adding a new layer to the multiscale modeling of CNFs assembled microfiber-based composite structures. Current research is mainly focused on the micromechanics study of CNFs assembled microfiber. These investigations are largely split into two categories: molecular dynamics and theoretical methods. In the study of CNFs assembled fiber by Cai et al. [105], a molecular dynamics model was used to simulate the tensile fracture mechanism of CNFs assembled microfiber. It was discovered that the toughness of the assembled microfiber was primarily due to the energy dissipated by the fracture and reorganization of the ionic and hydrogen bonds at the interface between CNFs. Wan et al. [126] also carried out molecular dynamics simulations on CNFs/single-walled carbon nanotubes (SWNT) wet-spun filaments and discovered that the high mechanical characteristics were due to the high number of hydrogen bonds inside the macroscopic structure of the one-dimensional constructed fiber. However, the molecular dynamics method can only predict the molecular behavior of ionic and hydrogen bonds and it is very time consuming to generate the homogenized responses of CNFs assembled microfiber, which contains numerous CNFs. In contrast to the molecular approach, Meng and Shi [127] developed a multiscale tension-shear model for nanopaper and CNFs assembled microfiber. The theoretical multiscale model not only can consider the nanoscale parameters such as self-healing of hydrogen bonds, but also can predict the macroscopic anisotropic nonlinear behavior of bulk materials. However, the microstructure of CNFs in the theoretical method is simplified to be parallel with each other and the typical curviness of CNFs and entanglement between CNFs, as well as van der Waals force interaction are ignored in their model.

From our perspective, the finite element [128] or finite volume-based micromechanics approach [129–132] could be effective to consider the real CNFs spatial distributions and their interaction inside CNFs. In contrast with the molecular dynamics method, the finite element or finite volume-based approach will be much more efficient since it deals with a limited number of CNFs in a representative volume element (RVE) at the nanoscale instead of coping with numerous molecules directly. To create a high-fidelity RVE of CNFs assembled microfiber, there are two key aspects that need to be considered. First, the 3D spatial distribution of CNFs needs to be characterized and the distribution can be obtained by integrating the SEM images of CNFs assembled microfiber sections processed at different depths via focused ion beam [133]. Second, the current multiscale cohesive law describing the interactions between CNFs, developed by Meng et al. [134], needs to be expanded to consider van der Waals force interaction and the variable distance between adjacent CNFs, as shown in Figure 9.

![Figure 9

Multiscale modeling of cellulose nanopaper: (a) and (b) schematic of the interfacial stretch and shear interaction due to hydrogen bonds, and the cohesive law of the interface; (c) schematic of the crack-bridging model for cellulose nanopaper. Reproduced with permission from ref. [134].](/document/doi/10.1515/ntrev-2024-0006/asset/graphic/j_ntrev-2024-0006_fig_009.jpg)

Multiscale modeling of cellulose nanopaper: (a) and (b) schematic of the interfacial stretch and shear interaction due to hydrogen bonds, and the cohesive law of the interface; (c) schematic of the crack-bridging model for cellulose nanopaper. Reproduced with permission from ref. [134].

4.3 Multiscale modeling and design of CNFs assembled continuous microfiber-based composite structures

Molecular dynamics and finite element method-based homogenization theory have been substantially utilized for the multiscale modeling [135–138] of nanocellulose directly reinforced polymers. Uetsuji et al. [135] conducted a multiscale analysis in terms of a finite element-based asymptotic homogenization theory toward polymers reinforced by randomly distributed nanocellulose. The effects of fiber aspect ratio, aggregation, and fiber volume fraction on the homogenized properties were quantitated. In their recent research [136], a two-step multiscale homogenization scheme is proposed to homogenize PP/Talc/CNFs three-phase composites. The method facilitates the design of new PP composites by finding a combination of the fillers and CNFs contents to tailor the mechanical properties of the composites. Mishnaevsky et al. [137] also developed a code to generate a 3D RVE model of nanocellulose composites reinforced with “snake”-shaped nanocellulose fibrils and conducted a study toward the structure-mechanical properties relationships of composites. Ren et al. [138] conducted a molecular dynamics study on cellulose composites and discussed the bonding mechanism between cellulose and PLA at the molecular level. However, those multiscale methods are focused on the homogenization of nanocellulose randomly reinforced polymers and there is a lack of a modeling strategy toward the nanocellulose assembled microfiber and the relevant structures.

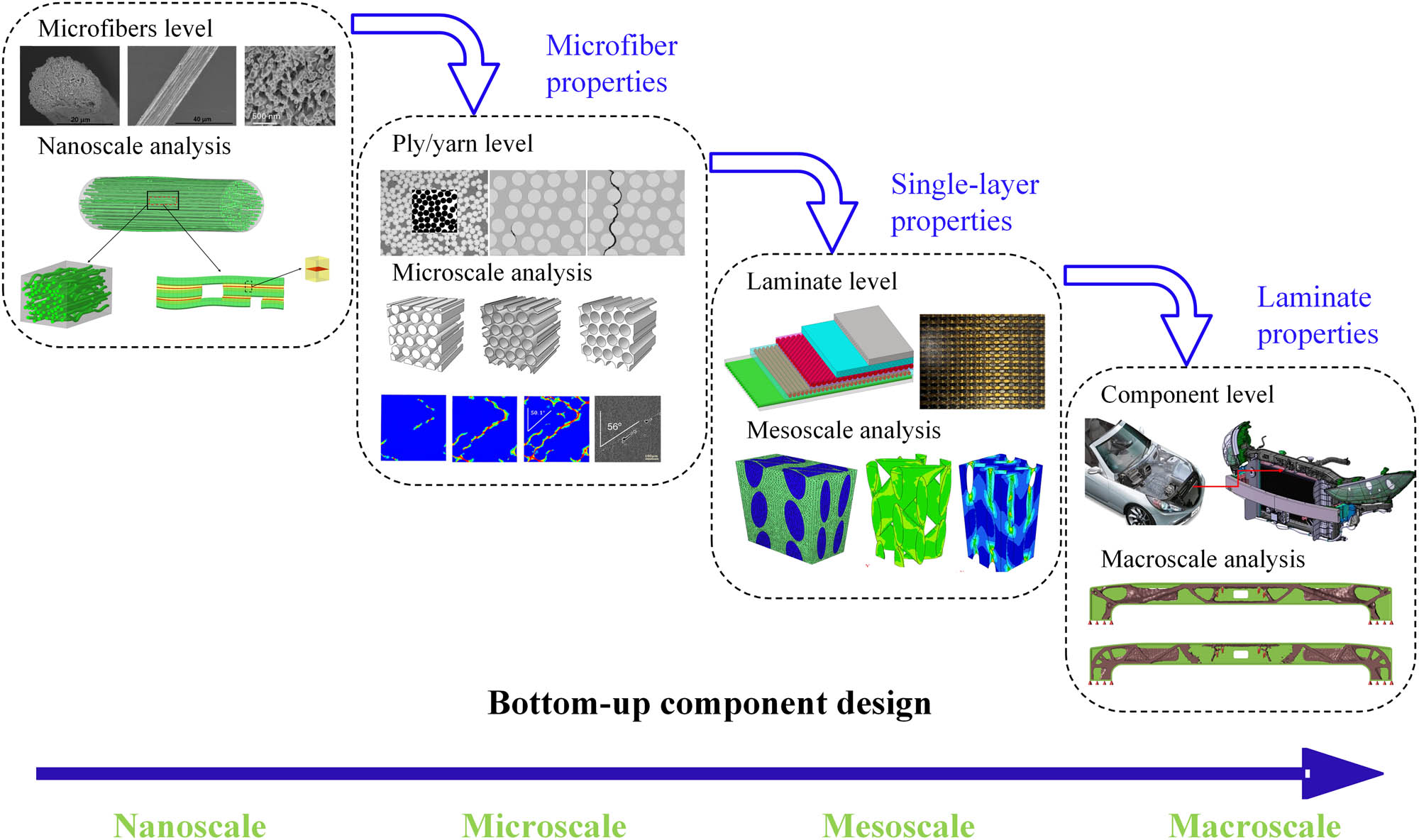

Carbon/glass FRPs have been extensively used in transportation instruments, such as airplanes, and automobiles. The bottom-up multiscale modeling strategy [139–141] has proven to be a highly effective tool to analyze composite materials and structures and facilitate their design. Homogenization techniques are utilized to establish the link between different length scales. The homogenized stress-strain responses are generated and are fed into a constitutive model at the upper scale. To apply the bottom-up multiscale modeling technique to CNFs assembled microfiber composite structures, the conventional bottom-up multiscale modeling strategy needs to be expanded to the nanoscale by incorporating the micromechanics model. As illustrated in Figure 10, from nanoscale to microscale, the anisotropic macroscopic responses of the CNFs assembled microfiber can be predicted via a finite element or finite volume-based micromechanics model and the corresponding RVE contains the real microstructures of CNFs assembled microfibers and the interfacial behaviors between CNFs. Next from microscale to ply level (mm), computational micromechanics are utilized to predict the ply properties from the properties of constituents and geometric information of the microstructure including fiber volume fraction and spatial distribution. With the homogenized ply properties and laminate lay-up information, as well as interplay properties, computational mesomechanics is then used to determine the homogenized relations of laminates. These results are finally utilized within the framework of computational mechanics to obtain the overall response of the composite structures. The detailed process to conduct multiscale modeling is presented in previous studies [139,140].

The bottom-up multiscale modeling strategy of nanocellulose assembled continuous microfiber-based automotive structures.

With the establishment of a multiscale modeling method for CNFs assembled microfiber composite structures, the structural performance can be optimized by adjusting the design parameters at different scales. For instance, at the nanoscale, the diameter and length of CNFs can affect the macroscopic properties of CNFs assembled microfiber. At the microscale, given the CNFs properties, the ply properties are affected by the volume fraction of CNFs, interfacial properties between the fiber and matrix and matrix properties. At the laminate level, the laminate properties are affected by the lamination sequence, and ply thickness. At the structural level, the automotive structures are strongly affected by the type and thickness of the cross-section of automotive components. The CNFs assembled microfiber-based automotive composite structures possess a very large design space from the nanometer scale to the meter scale. This allows for effective utilization of the exceptional properties of CNFs and opens the door to the development of green, high-performance, lightweight structural materials made of nanocellulose.

5 Discussion of nanocellulose composites in automotive applications

Green materials have become increasingly important for the automotive industry due to the demands for environmental protection and sustainable development from society [142]. Nanocellulose, recognized for its high strength, stiffness, and biodegradability, is considered a promising green material for automotive lightweight design with the potential to replace a wide range of automotive components from plastic to steel [143,144]. Nanocellulose directly reinforced polymers have been widely studied by various researchers and have been utilized to manufacture vehicle interior and exterior components. Yano and his team studied the preparation process, mechanical properties, and thermal properties of nanocellulose directly reinforced composites, including HDPE [76,133,145], PP [146], and PA6 [85]. These materials were successfully utilized to replace some automotive components (such as door panels, hoods, roof panels, etc.), resulting in the creation of a Nanocellulose vehicle [17] showcased at the 2019 Tokyo Motor Show. Rwawiire et al. [147] developed a biodegradable composite using natural cellulose fabric (bark cloth) to reinforce epoxy for car instrument or dashboard panels. Amini et al. [148] used CNCs-reinforced Acrodur® to prepare high flexural modulus composites, promoting the use of lighter green materials in automotive interiors. However, nanocellulose directly reinforced composites are mainly utilized to make vehicle interior (such as door trim panels, seat foam, storage bin and inner lid, and lower door panels) and exterior components (such as spare tire wheel covers, back rests, and spoilers), because the composites have limited stiffness and strength and are not strong enough to make automotive structural components.

The interface plays an important role in transferring loading between different phases inside composites [149]. Although CF or GF reinforced composites have been widely utilized to make various automotive structural or non-structural components, interfacial debonding is still a challenging issue due to the smoothness and lack of chemical functional groups of their fiber surface. Nanocellulose has been utilized by various researchers [94–97] to improve the interfacial behaviors of CF or GF reinforced composites by dispersing them into the polymer matrix.

CNFs assembled microfiber is a highly important all cellulose composite for the automobile industry. The CNFs assembled microfiber has comparable mechanical properties with GF and is much lighter. In contrast with the nanocellulose directly reinforced composites, CNFs assembled microfiber has much higher stiffness and strength [22,105]. Meanwhile, with the combination of the proposed full-scale multiscale modeling strategy, it is highly likely to design automotive components at nano, micro, meso, and macro scales, respectively, as shown in Figure 10. This will enable the manufacture of high-performance automotive structural components and stimulate a larger scale adoption of this type of green material, overcoming the current status of only manufacturing non-structural components with nanocellulose directly reinforced polymers.

6 Summary and outlook

Nanocellulose has emerged as a next-generation, high-performance, environmental-friendly material and possess a very promising application prospect in the automotive industry. The combined chemical and physical preparation techniques have proved to be realistic for producing high-quality nanocellulose with limited energy consumption and environmental concerns. A variety of nanocellulose composites, including nanocellulose directly reinforcement composites, hybrid fiber-cellulose composites, ACCs, and CNFs assembled microfiber reinforced composites, have been developed toward different types of automotive components. Nanocellulose directly reinforced polymer is one of the most well-studied nanocellulose composites, primarily utilized for manufacturing automotive interior and exterior components and reducing the application of traditional fossil-fuel based polymers. The current challenge in producing high-quality nanocellulose is to conduct an effective surface modification toward nanocellulose and therefore, to improve its dispersion inside polymer and the compatibility between nanocellulose and polymer. Because the surface of nanocellulose contains rich chemical function groups, nanocellulose is utilized to improve the interfacial properties between fiber and matrix in the FRPs with nanocellulose-enhanced interface.

In contrast to nanocellulose directly reinforced polymers and ACCs which are utilized for automotive non-structural components, CNFs assembled microfiber reinforced polymer has the potential to manufacture automotive structural components. This opens a new horizon for enhancing the application of green materials utilized in automotive applications. The key to prepare a high-quality CNFs assembled microfiber is to align CNFs and form strong bonding between CNFs. Currently, the best strategy is to employ flow-assisted control of fiber orientation and interfacial complexation to enhance interfacial bonding. Furthermore, it is necessary and feasible to develop a sophisticated finite element or finite volume technique-based micromechanics model for CNFs assembled microfiber. The micromechanics model at the nanoscale enables the bottom-up multiscale modeling strategy from the nanoscale to automotive structure. The multiscale modeling strategy will also facilitate the optimization of CNFs assembled microfiber composite structure from the nano level to the meter level and will greatly advance the basic understanding of CNFs assembled microfiber-based composites and its engineering applications.

Acknowledgments

Figures 1 in this paper are reprinted from Refs. [29–32], with permission from Elsevier. Figures 2 in this paper are reprinted from Ref. [45], with permission from Elsevier. Figures 3 in this paper are reprinted from Ref. [70], with permission from Elsevier. Figures 4 in this paper are reprinted from Ref. [55], with permission from Elsevier. Figures 5 in this paper are reprinted from Ref. [76], with permission from Elsevier. Figures 6 in this paper are reprinted from Ref. [95], with permission from Elsevier. Figures 8 in this paper are reprinted from Refs. [22,105–107], with permission from American Chemical Society (2020, 2022), Wiley, and Elsevier. Figures 9 in this paper are reprinted from Ref. [134], with permission from Elsevier.

-

Funding information: W. Tu acknowledges the support of Jiangsu University Faculty Startup Fund (5501120014) and Jiangsu Shuangchuang Doctor Program (1711120022). Y. Zhang acknowledges the support from the National Natural Science Foundation of China (No. 12372163). Q. Wang acknowledges the support from the National Natural Science Foundation of China (No. 22278195).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Zhao F, Liu X, Zhang H, Liu Z. Automobile industry under China’s carbon peaking and carbon neutrality goals: challenges, opportunities, and coping strategies. J Adv Transp. 2022;2022:1–13.10.1155/2022/5834707Suche in Google Scholar

[2] Kargarzadeh H, Ioelovich M, Ahmad I, Thomas S, Dufresne A. Methods for extraction of nanocellulose from various sources. Handb Nanocellul Cellul Nanocompos. 2017;1:1–49.10.1002/9783527689972.ch1Suche in Google Scholar

[3] Kim J-H, Shim BS, Kim HS, Lee Y-J, Min S-K, Jang D, et al. Review of nanocellulose for sustainable future materials. Int J Precis Eng Manuf-Green Technol. 2015;2:197–213.10.1007/s40684-015-0024-9Suche in Google Scholar

[4] Li T, Chen C, Brozena AH, Zhu J, Xu L, Driemeier C, et al. Developing fibrillated cellulose as a sustainable technological material. Nature. 2021;590(7844):47–56.10.1038/s41586-020-03167-7Suche in Google Scholar PubMed

[5] Dufresne A. Nanocellulose: a new ageless bionanomaterial. Mater today. 2013;16(6):220–7.10.1016/j.mattod.2013.06.004Suche in Google Scholar

[6] Heinze T. Cellulose: structure and properties. Cellul Chem Prop. 2016;271:1–52.10.1007/12_2015_319Suche in Google Scholar

[7] Reshmy R, Philip E, Paul SA, Madhavan A, Sindhu R, Binod P, et al. Nanocellulose-based products for sustainable applications-recent trends and possibilities. Rev Environ Sci Bio/Technol. 2020;19:779–806.10.1007/s11157-020-09551-zSuche in Google Scholar

[8] Heise K, Kontturi E, Allahverdiyeva Y, Tammelin T, Linder MB, Nonappa, et al. Nanocellulose: recent fundamental advances and emerging biological and biomimicking applications. Adv Mater. 2021;33(3):2004349.10.1002/adma.202004349Suche in Google Scholar PubMed

[9] Gopakumar DA, Thomas S, Owolabi F, Thomas S, Nzihou A, Rizal S, et al. Nanocellulose based aerogels for varying engineering applications. Encycl Renew Sustain Mater. 2020;2:155–65.10.1016/B978-0-12-803581-8.10549-1Suche in Google Scholar

[10] Dufresne A. Nanocellulose processing properties and potential applications. Curr Forestry. 2019;5:76–89.10.1007/s40725-019-00088-1Suche in Google Scholar

[11] Naik V, Kumar M. A review on natural fiber composite material in automotive applications. Eng Sci. 2021;18:1–10.10.30919/es8d589Suche in Google Scholar

[12] Börjesson M, Westman G. Crystalline nanocellulose preparation, modification, and properties. Cellul-Fundam Asp Curr Trends. 2015;7:1–284.10.5772/61899Suche in Google Scholar

[13] Chu Y, Sun Y, Wu W, Xiao H. Dispersion properties of nanocellulose: A review. Carbohydr Polym. 2020;250:116892.10.1016/j.carbpol.2020.116892Suche in Google Scholar PubMed

[14] Haniffa MACM, Ching YC, Chuah CH, Ching KY, Nazri N, Abdullah LC, et al. Effect of TEMPO-oxidization and rapid cooling on thermo-structural properties of nanocellulose. Carbohydr Polym. 2017;173:91–9.10.1016/j.carbpol.2017.05.084Suche in Google Scholar PubMed

[15] Nurazzi NM, Jenol MA, Kamarudin S, Aisyah H, Hao L, Yusuff SM et al. Nanocellulose composites in the automotive industry. Industrial Applications of Nanocellulose and Its Nanocomposites. Sawston, Cambridge: Woodhead Publishing; 2022. p. 439–67.10.1016/B978-0-323-89909-3.00011-0Suche in Google Scholar

[16] Ferreira FV, Pinheiro IF, de Souza SF, Mei LH, Lona LM. Polymer composites reinforced with natural fibers and nanocellulose in the automotive industry: A short review. J Compos Sci. 2019;3(2):51.10.3390/jcs3020051Suche in Google Scholar

[17] NCV Cellulose Nano Fiber Vehicle; 2019. https://www.rish.kyoto-u.ac.jp/ncv/[Internet].Suche in Google Scholar

[18] Niu F, Li M, Huang Q, Zhang X, Pan W, Yang J, et al. The characteristic and dispersion stability of nanocellulose produced by mixed acid hydrolysis and ultrasonic assistance. Carbohydr Polym. 2017;165:197–204.10.1016/j.carbpol.2017.02.048Suche in Google Scholar PubMed

[19] Ghasemlou M, Daver F, Ivanova EP, Habibi Y, Adhikari B. Surface modifications of nanocellulose: From synthesis to high-performance nanocomposites. Prog Polym Sci. 2021;119:101418.10.1016/j.progpolymsci.2021.101418Suche in Google Scholar

[20] Shen R, Xue S, Xu Y, Liu Q, Feng Z, Ren H, et al. Research progress and development demand of nanocellulose reinforced polymer composites. Polymers. 2020;12(9):2113.10.3390/polym12092113Suche in Google Scholar PubMed PubMed Central

[21] Kontturi E, Laaksonen P, Linder MB, Nonappa, Gröschel AH, Rojas OJ, et al. Advanced materials through assembly of nanocelluloses. Adv Mater. 2018;30(24):1703779.10.1002/adma.201703779Suche in Google Scholar PubMed

[22] Mittal N, Ansari F, Gowda VK, Brouzet C, Chen P, Larsson PT, et al. Multiscale control of nanocellulose assembly: transferring remarkable nanoscale fibril mechanics to macroscale fibers. ACS nano. 2018;12(7):6378–88.10.1021/acsnano.8b01084Suche in Google Scholar PubMed

[23] Yang H, van de Ven TG. A bottom-up route to a chemically end-to-end assembly of nanocellulose fibers. Biomacromolecules. 2016;17(6):2240–7.10.1021/acs.biomac.6b00480Suche in Google Scholar PubMed

[24] Li K, Clarkson CM, Wang L, Liu Y, Lamm M, Pang Z, et al. Alignment of cellulose nanofibers: harnessing nanoscale properties to macroscale benefits. ACS Nano. 2021;15(3):3646–73.10.1021/acsnano.0c07613Suche in Google Scholar PubMed

[25] Gopi S, Balakrishnan P, Chandradhara D, Poovathankandy D, Thomas S. General scenarios of cellulose and its use in the biomedical field. Mater Today Chem. 2019;13:59–78.10.1016/j.mtchem.2019.04.012Suche in Google Scholar

[26] Lu P, Hsieh Y-L. Preparation and properties of cellulose nanocrystals: rods, spheres, and network. Carbohydr Polym. 2010;82(2):329–36.10.1016/j.carbpol.2010.04.073Suche in Google Scholar

[27] Arola S, Malho JM, Laaksonen P, Lille M, Linder MB. The role of hemicellulose in nanofibrillated cellulose networks. Soft Matter. 2013;9(4):1319–26.10.1039/C2SM26932ESuche in Google Scholar

[28] Sionkowska A, Mężykowska O, Piątek J. Bacterial nanocelullose in biomedical applications: A review. Polym Int. 2019;68(11):1841–7.10.1002/pi.5882Suche in Google Scholar

[29] Liu X, Wang Y, Cheng Z, Sheng J, Yang R. Nano-sized fibrils dispersed from bacterial cellulose grafted with chitosan. Carbohydr Polym. 2019;214:311–6.10.1016/j.carbpol.2019.03.055Suche in Google Scholar PubMed

[30] Marakana PG, Dey A, Saini B. Isolation of nanocellulose from lignocellulosic biomass: Synthesis, characterization, modification, and potential applications. J Environ Chem Eng. 2021;9(6):106606.10.1016/j.jece.2021.106606Suche in Google Scholar

[31] Wang S, Zeng J, Cheng Z, Yuan Z, Wang X, Wang B. Precisely controlled preparation of uniform nanocrystalline cellulose via microfluidic technology. J Ind Eng Chem. 2022;106:77–85.10.1016/j.jiec.2021.06.037Suche in Google Scholar

[32] Xu S, Huo D, Wang K, Yang Q, Hou Q, Zhang F. Facile preparation of cellulose nanofibrils (CNFs) with a high yield and excellent dispersibility via succinic acid hydrolysis and NaClO2 oxidation. Carbohydr Polym. 2021;266:118118.10.1016/j.carbpol.2021.118118Suche in Google Scholar PubMed

[33] Mandels M, Hontz L, Nystrom J. Enzymatic hydrolysis of waste cellulose. Biotechnol Bioeng. 1974;16(11):1471–93.10.1002/bit.260161105Suche in Google Scholar

[34] Pawcenis D, Leśniak M, Szumera M, Sitarz M, Profic-Paczkowska J. Effect of hydrolysis time, pH and surfactant type on stability of hydrochloric acid hydrolyzed nanocellulose. Int J Biol Macromol. 2022;222:1996–2005.10.1016/j.ijbiomac.2022.09.289Suche in Google Scholar PubMed

[35] Kishimoto CTM, Moerschbacher L, Prestes RA, Hoepfner JC, Pinheiro LA. Preparation of nanocellulose by hydrolysis catalysedusing salts with different Fe valency. J Nanopart Res. 2020;22(7):200.10.1007/s11051-020-04928-1Suche in Google Scholar

[36] Saito T, Kimura S, Nishiyama Y, Isogai A. Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules. 2007;8(8):2485–91.10.1021/bm0703970Suche in Google Scholar PubMed

[37] Trifol J, Sillard C, Plackett D, Szabo P, Bras J, Daugaard A. Chemically extracted nanocellulose from sisal fibres by a simple and industrially relevant process. Cellulose. 2017;24:107–18.10.1007/s10570-016-1097-5Suche in Google Scholar

[38] Banvillet G, Depres G, Belgacem N, Bras J. Alkaline treatment combined with enzymatic hydrolysis for efficient cellulose nanofibrils production. Carbohydr Polym. 2021;255:117383.10.1016/j.carbpol.2020.117383Suche in Google Scholar PubMed

[39] Mahardika M, Abral H, Kasim A, Arief S, Asrofi M. Production of nanocellulose from pineapple leaf fibers via high-shear homogenization and ultrasonication. Fibers. 2018;6(2):28.10.3390/fib6020028Suche in Google Scholar

[40] Li J, Wang Y, Wei X, Wang F, Han D, Wang Q, et al. Homogeneous isolation of nanocelluloses by controlling the shearing force and pressure in microenvironment. Carbohydr Polym. 2014;113:388–93.10.1016/j.carbpol.2014.06.085Suche in Google Scholar PubMed

[41] Ferreira RR, Souza AG, Nunes LL, Shahi N, Rangari VK, dos Santos Rosa D. Use of ball mill to prepare nanocellulose from eucalyptus biomass: challenges and process optimization by combined method. Mater Today Commun. 2020;22:100755.10.1016/j.mtcomm.2019.100755Suche in Google Scholar

[42] Vallejos ME, Felissia FE, Area MC, Ehman NV, Tarrés Q, Mutjé P. Nanofibrillated cellulose (CNF) from eucalyptus sawdust as a dry strength agent of unrefined eucalyptus handsheets. Carbohydr Polym. 2016;139:99–105.10.1016/j.carbpol.2015.12.004Suche in Google Scholar PubMed

[43] Xiao S, Gao R, Lu Y, Li J, Sun Q. Fabrication and characterization of nanofibrillated cellulose and its aerogels from natural pine needles. Carbohydr Polym. 2015;119:202–9.10.1016/j.carbpol.2014.11.041Suche in Google Scholar PubMed

[44] Wang J, Xu J, Zhu S, Wu Q, Li J, Gao Y, et al. Preparation of nanocellulose in high yield via chemi-mechanical synergy. Carbohydr Polym. 2021;251:117094.10.1016/j.carbpol.2020.117094Suche in Google Scholar PubMed

[45] Nechyporchuk O, Belgacem MN, Bras J. Production of cellulose nanofibrils: A review of recent advances. Ind Crop Products. 2016;93:2–25.10.1016/j.indcrop.2016.02.016Suche in Google Scholar

[46] Li J, Wei X, Wang Q, Chen J, Chang G, Kong L, et al. Homogeneous isolation of nanocellulose from sugarcane bagasse by high pressure homogenization. Carbohydr Polym. 2012;90(4):1609–13.10.1016/j.carbpol.2012.07.038Suche in Google Scholar PubMed

[47] Ghasemi S, Behrooz R, Ghasemi I. Extraction and characterization of nanocellulose structures from linter dissolving pulp using ultrafine grinder. J Nanosci Nanotechnol. 2016;16(6):5791–7.10.1166/jnn.2016.12416Suche in Google Scholar PubMed

[48] Lu Z, Fan L, Zheng H, Lu Q, Liao Y, Huang B. Preparation, characterization and optimization of nanocellulose whiskers by simultaneously ultrasonic wave and microwave assisted. Bioresour Technol. 2013;146:82–8.10.1016/j.biortech.2013.07.047Suche in Google Scholar PubMed

[49] Mabrouk AB, Salon MB, Magnin A, Belgacem M, Boufi S. Cellulose-based nanocomposites prepared via mini-emulsion polymerization: Understanding the chemistry of the nanocellulose/matrix interface. Colloids Surf A: Physicochem Eng Asp. 2014;448:1–8.10.1016/j.colsurfa.2014.01.077Suche in Google Scholar

[50] Zhang Y, Chen J, Zhang L, Zhan P, Liu N, Wu Z. Preparation of nanocellulose from steam exploded poplar wood by enzymolysis assisted sonication. Mater Res Express. 2020;7(3):035010.10.1088/2053-1591/ab7b28Suche in Google Scholar

[51] Piras CC, Fernández-Prieto S, De Borggraeve WM. Ball milling: a green technology for the preparation and functionalisation of nanocellulose derivatives. Nanoscale Adv. 2019;1(3):937–47.10.1039/C8NA00238JSuche in Google Scholar PubMed PubMed Central

[52] Yang X, Han F, Xu C, Jiang S, Huang L, Liu L, et al. Effects of preparation methods on the morphology and properties of nanocellulose (NC) extracted from corn husk. Ind Crop Products. 2017;109:241–7.10.1016/j.indcrop.2017.08.032Suche in Google Scholar