Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

Abstract

Carbon nanotubes (CNTs) are gaining popularity due to their expanding uses in industrial and technical processes, such as geothermal reservoirs, water and air filters, coatings, solar collection, ceramic material reinforcement, electrostatic dissipation, etc. In addition, the CNTs have superior electrical conductivity and biocompatibility. Based on the aforementioned applications, the current work examines the time-dependent and Darcy–Forchheimer flow of water/glycerin-based Casson hybrid nanofluid formed by single-walled CNTs and multi-walled CNTs over a Riga plate under velocity slip. The energy expression is modeled through nonlinear thermal radiation and viscous dissipation impacts. The incorporation of convective boundary condition into the current model improves its realism. By employing suitable variables, the governing models are re-framed into ordinary differential equations. The bvp4c and the homotopy analysis method are used to find the computational results of the re-framed equations and boundary conditions. The novel characteristics of a variety of physical parameters on velocity, temperature, skin friction coefficient (SFC), and local Nusselt number (LNN) are discussed via graphs, charts, and tables. It is found that the fluid velocity decays when enriching the Forchheimer number, unsteady and porosity parameters. The radiation parameter plays an opposite role in convective heating and cooling cases. The modified Hartmann number enhances the surface drag force, and the Forchheimer number declines the SFC. The unsteady parameter develops the heat transfer rate, and the Forchheimer number suppresses the LNN. The simulated flow problem has many applications in engineering sectors, including ceramic manufacture, heating and cooling systems, energy storage units, thermodynamic processes, and other fields.

Nomenclature

|

|

positive constants |

|

|

capacity of specific heat |

|

|

drag force coefficient |

|

|

permeability of the porous medium |

| Ec | Eckert number |

|

|

Stefan–Boltzmann constant |

|

|

heat transfer coefficient |

|

|

skin friction coefficient |

|

|

local Nusselt number |

| Bi | Biot number |

|

|

slip parameter |

|

|

heat capacity |

|

|

current density applied to the electrodes |

|

|

thermal conductivity |

|

|

magnetic property of the permanent magnets |

| that are organized on top of the plate surface | |

|

|

kinematic viscosity |

|

|

dimensionless variable |

| Q | heat generation or absorption coefficient |

|

|

density |

|

|

temperature of the fluid |

|

|

surface temperature |

|

|

ambient temperature |

|

|

non-dimensional temperature |

|

|

velocity factors |

|

|

space coordinates |

|

|

unsteady parameter |

|

|

porosity parameter |

|

|

temperature ratio parameter |

| Fr | Forchheimer number |

|

|

Casson parameter |

|

|

dimensionless parameter |

| Ha | modified Hartmann number |

| Pr | Prandtl number |

|

|

radiation parameter |

| Re | Reynolds number |

| Hg | heat consumption/generation parameter |

1 Introduction

Many scientists have been interested in nanofluids in recent decades because of their significant heat transfer properties. The heat transmission characteristics of diverse fluids have a significant influence on the performance of many equipment, including air conditioning, the food industry, power generation, transportation, microelectronics, and the thinning and annealing of copper wires. The heat transfer capabilities in many of these applications have been constrained by the use of standard heat transit fluids such as water, ethylene glycol, mineral oils, and they have poor thermal characteristics. Scientists from a variety of disciplines are working to address this shortcoming in several ways. One of the easiest ways to address this shortcoming is by adding solid nanometer-scaled particles like metals

Carbon nanotubes (CNTs) are cylinder-shaped materials made of coils of graphite. The CNTs are measured in micrometers and have a diameter of approximately 0.4–2.0 nm. Based on their carbon molecular count, CNTs are divided into two distinct types: SWCNTs (single-walled carbon nanotubes) and MWCNTs (multi-walled carbon nanotubes). The dusty liquid’s thermal and flow characteristics past an SS (stretching sheet) with viscous dissipation immersed by SWCNTs were investigated by Srilatha et al. [6]. They used methanol as a base fluid. Also, they found that the heat transmission rate in the dust phase improves more quickly than in the fluid phase when the Eckert number rises. The flow of ethylene glycol-based CNTs on a stretchable rotating disk with CCHF (Cattaneo–Christov heat flux) theory was mathematically modeled by Tulu and Ibrahim [7]. Their results clearly show that the MWCNTs have higher radial velocity than the SWCNTs when varying the NPVF values. Khan et al. [8] made an effort that addresses the influence of 3D DFF (Darcy–Forchheimer flow) of micropolar nanofluid suspended with CNTs in

Due to its applicability in several technical and physical processes, the study of nonlinear thermal radiative flow over a plate is an area of prospective interest for scientists and engineers. Some areas that might benefit from such techniques include atomic power, space technology, combustion, furnace design, photochemical reactors, propulsion devices, etc. Jawad et al. [12] employed a homotopy analysis method (HAM) approach to address a 3D CNT flow in a permeable medium with nonlinear thermal radiation. It should be noted that larger radiation values improve the heat transfer rate. The nonlinear thermal radiation impact of 3D Jeffrey nanofluid with viscous dissipation and Joule heating was inspected by Kumar et al. [13]. They deduced that the temperature ratio parameter minimizes the mass transport rate. Some of the rheological aspects of the flow of CNTs in ethylene glycol with nonlinear thermal radiation were looked at by Ramzan et al. [14]. Their results clearly show that the SWCNTs have a higher heat transfer rate compared to the MWCNTs for changing the radiation values. The mathematical model of nonlinear radiative flow of hybrid nanofluid on a wedge was developed by Rana et al. [15]. They made the discovery that the rate of heat transfer for nonlinear thermal radiation is larger in comparison to linear thermal radiation. Mahabaleshwar et al. [16] looked into the radiative characteristics of CNT flow subject to the heat source/sink past a stretching/shrinking sheet. They achieved that the water-SWCNTs have a momentum profile that is noticeably greater than that of the water-MWCNTs. The nonlinear radiative flow of Casson nanofluid past an SS was investigated by Satya Narayana et al. [17]. Mabood et al. [18] investigated how the motion of a water-based hybrid nanofluid (WBHNF) (

The study of boundary layer flow with convective heating plays a necessary role in many industrial processes, such as heat exchangers, drying metal, atomic power, etc. The EMHD flow of nanofluid via a heated Riga plate according to the passive control approach was theoretically explored by Rasool et al. [21]. The authors observed that a large improvement in the wall heat transit rate may be effectively obtained by modifying the convective heating process appropriately. Shah et al. [22] look at how thermophoresis particle deposition affects the flow characteristics of a second-grade fluid with a convective boundary condition. The consequences of MHD NFF past a heated spinning disc were explored by Wakif and Shah [23]. They declared that the convective heating accelerates the thermophoresis process. Dawar et al. [24] performed the theoretical analysis of the 3D MHD flow of Jeffrey nanofluid on a dual SS with velocity slip circumstances. The authors found that the Biot number leads to the development of the thermal profile. The hydrothermal features of non-Darcian flow of water-based alumina nanofluid past a Riga plate were quantitatively assessed by Rasool et al. [25]. Their results clearly explain that the loading of nanoparticles and convection heating speed up the rate of surface heat transfer. Rashid et al. [26] looked into the thermal energy transfer of a WBHNF flow on a heated SS with activation energy. They also mentioned that the fluid temperature enhances when increasing the Biot number.

Prior to conducting the aforementioned literature research, the authors are confident that no study of a WBHNF containing SWCNTs and MWCNTs across a Riga plate under convective condition has been conducted. Therefore, the authors have looked into the nonlinear radiative DFF of a WBHNF containing both SWCNTs and MWCNTs past the heated Riga plate. The combination of two nanoparticles with a base fluid is referred to as a hybrid nanofluid. The exceptional efficiency in transferring heat and the enhanced ability to transmit thermal energy of these fluids have attracted several researchers in the area of nanotechnology. Hybrid nanofluids are a modern kind of nanofluid that have a wide range of uses in heat transfer in several sectors, including vehicle radiators, cooling electronic devices, energy generation, drug delivery, and biomedicine. Also, the DFF plays an important role in tissue transformation, thermal insulation, geothermal reservoirs, and petroleum reservoirs, see Chamkha [27,28].

After we have finished our investigation, we provide the responses to the following inquiries for further research:

What are the impacts of embedded variables on flow profile such as modified Hartmann–Forchheimer numbers, Casson, porosity, unsteady, and slip parameters?

Which of the two base fluids (water and glycerin) forecasts a higher temperature and a lower temperature?

How does convective heating affect the temperature of CNTs flowing over a Riga plate?

Which of the two fluids (viscous and Casson) predicts a greater and smaller skin friction coefficient (SFC), and heat transfer gradient (HTG)?

2 Mathematical formulation

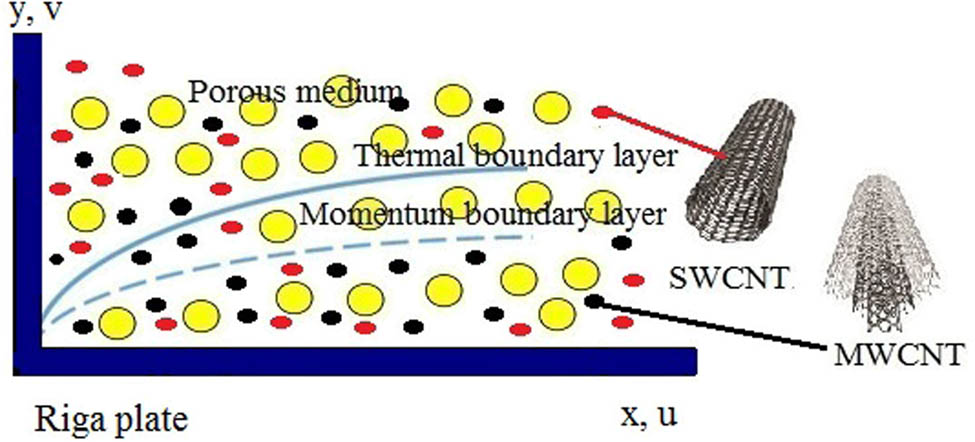

Consider the time-varying DFF of hybrid CNTs (HCNTs) through a Riga plate. The notations

Physical sketch of the model.

The boundary conditions are as follows:

Define, see Mahmood et al. [31] and Madhu et al. [32],

Boundary condition are as follows:

Here

3 Quantities of physical interest

3.1 Skin friction coefficient (SFC)

The mathematical expression of skin friction can be defined as

The wall shear stress (

The dimensionless form of SFC is defined as

3.2 Local Nusselt number (LNN)

The mathematical expression of the LNN can be defined as

The wall heat flux

The dimensionless form of LNN is defined as

4 Methodology

4.1 Analytical method

The analytical computation of the reduced mathematical expressions (7)–(8) and their boundary constraints (9) is made by using the HAM scheme. This method is a semi-analytical one, and it is a quite helpful tool for effectively solving nonlinear ordinary differential equations (ODEs) and partial differential equations. The technique provides a considerable deal of freedom in the representation of series-form solutions in terms of a wide variety of base functions and linear operators for the purpose of constructing solutions, see Loganathan et al. [33].

Initial approximations:

Linear operators:

Linear properties:

where

Zeroth-order deformation problems:

Here

The

n

th order problems:

Here

The HAM parameters (

4.2 Numerical method

The numerical computation of transferred nonlinear ODEs (7)–(8) with boundary restrictions (9) is made possible by using the MATLAB bvp4c solution technique. In the current situation, the first thing that we do is transform the system of higher ODEs into a system of first-order differential equations, see Eswaramoorthi et al. [36] and see Sahu et al. [37]. The convergence criteria were decided to be a difference of

Let us take

with the conditions

5 Result and discussions

This section illustrates the physical interference of results after the problem is successfully computed using an analytical and numerical approaches. The physical characteristics of SWCNTs, MWCNTs, glycerin, and water are provided in Table 1. Table 2 gives the HAM order of approximations and numerical solution. It is clear from this table that 15th order is enough for all computations, and it is also seen that our HAM and numerical solution are almost the same. Comparison of

Physical properties

| Physical characteristics | SWCNTs | MWCNTs | Glycerin | Water |

|---|---|---|---|---|

|

|

6,600 | 3,000 | 0.286 | 0.613 |

|

|

2,600 | 1,600 | 1259.9 | 997.1 |

|

|

425 | 796 | 2,427 | 4,179 |

| Pr | — | — | 6.78 | 6.2 |

HAM order of approximations and numerical solution

| W-CHCNTs | G-CHCNTs | W-VHCNTs | G-VHCNTs | |||||

|---|---|---|---|---|---|---|---|---|

| Order |

|

|

|

|

|

|

|

|

| HAM | ||||||||

| 1 | 0.304376 | 0.235875 | 0.312055 | 0.227445 | 0.552727 | 0.241729 | 0.555362 | 0.232897 |

| 5 | 0.293273 | 0.241622 | 0.291654 | 0.233159 | 0.527721 | 0.242044 | 0.524919 | 0.233406 |

| 10 | 0.293201 | 0.241823 | 0.291830 | 0.233258 | 0.527796 | 0.242058 | 0.524718 | 0.233437 |

| 15 | 0.293203 | 0.241823 | 0.291827 | 0.233259 | 0.527795 | 0.242058 | 0.524722 | 0.233437 |

| 20 | 0.293203 | 0.241823 | 0.291827 | 0.233259 | 0.527795 | 0.242058 | 0.524722 | 0.233437 |

| 25 | 0.293203 | 0.241823 | 0.291827 | 0.233259 | 0.527795 | 0.242058 | 0.524722 | 0.233437 |

| 30 | 0.293203 | 0.241823 | 0.291827 | 0.233259 | 0.527795 | 0.242058 | 0.524722 | 0.233437 |

| Numerical solution | ||||||||

| — | 0.293202 | 0.241823 | 0.291826 | 0.233259 | 0.527794 | 0.242058 | 0.524721 | 0.233438 |

Comparison of

|

|

Present study | Ref. [38] |

|---|---|---|

| 0 | 1.000000 | 1.0000 |

| 1 | 1.414214 | 1.4132 |

| 5 | 2.449490 | 2.4485 |

| 10 | 3.316625 | 3.3165 |

| 100 | 10.049876 | 10.0498 |

| 500 | 22.383029 | 22.3831 |

| 1,000 | 31.638584 | 31.6385 |

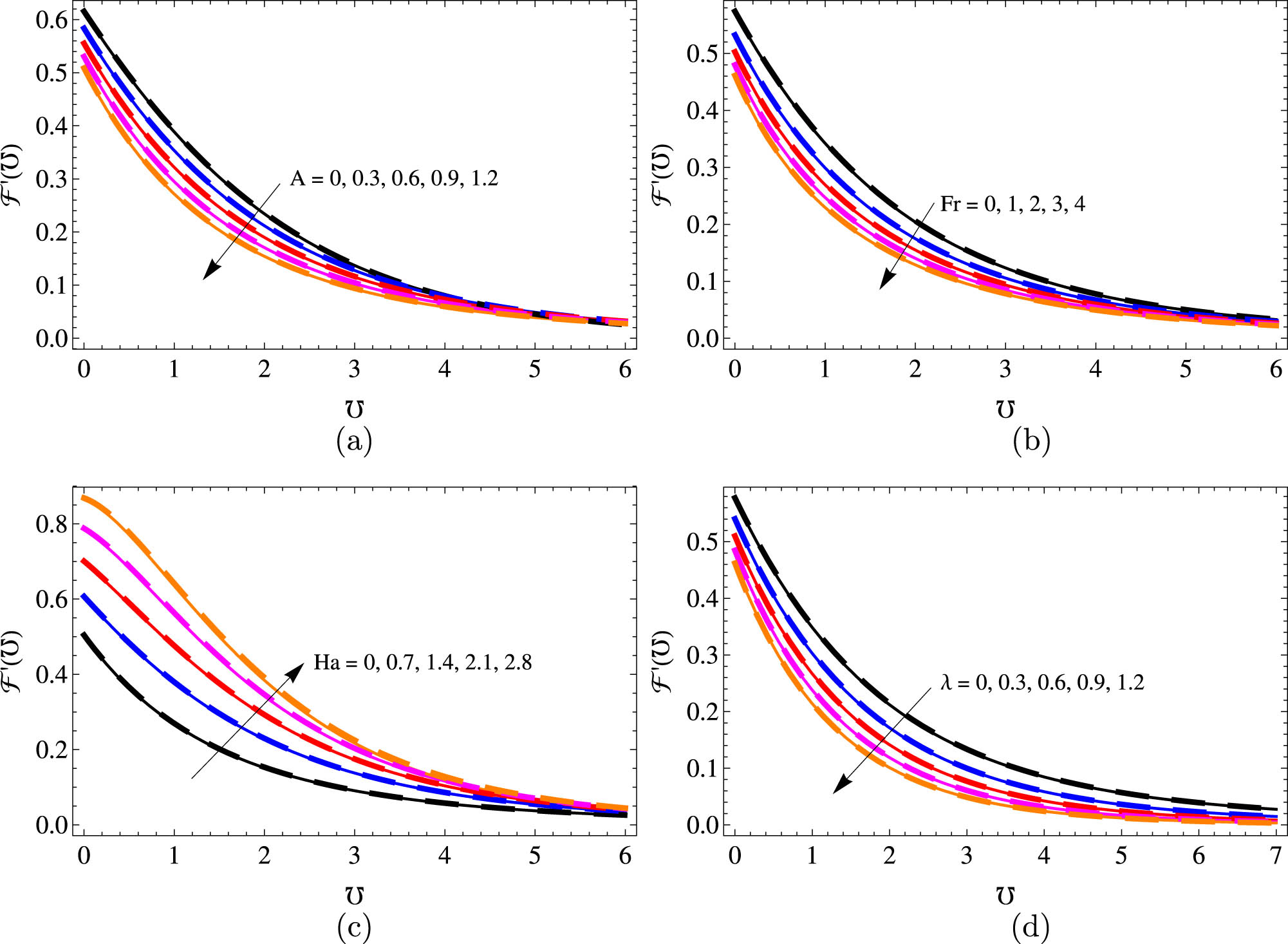

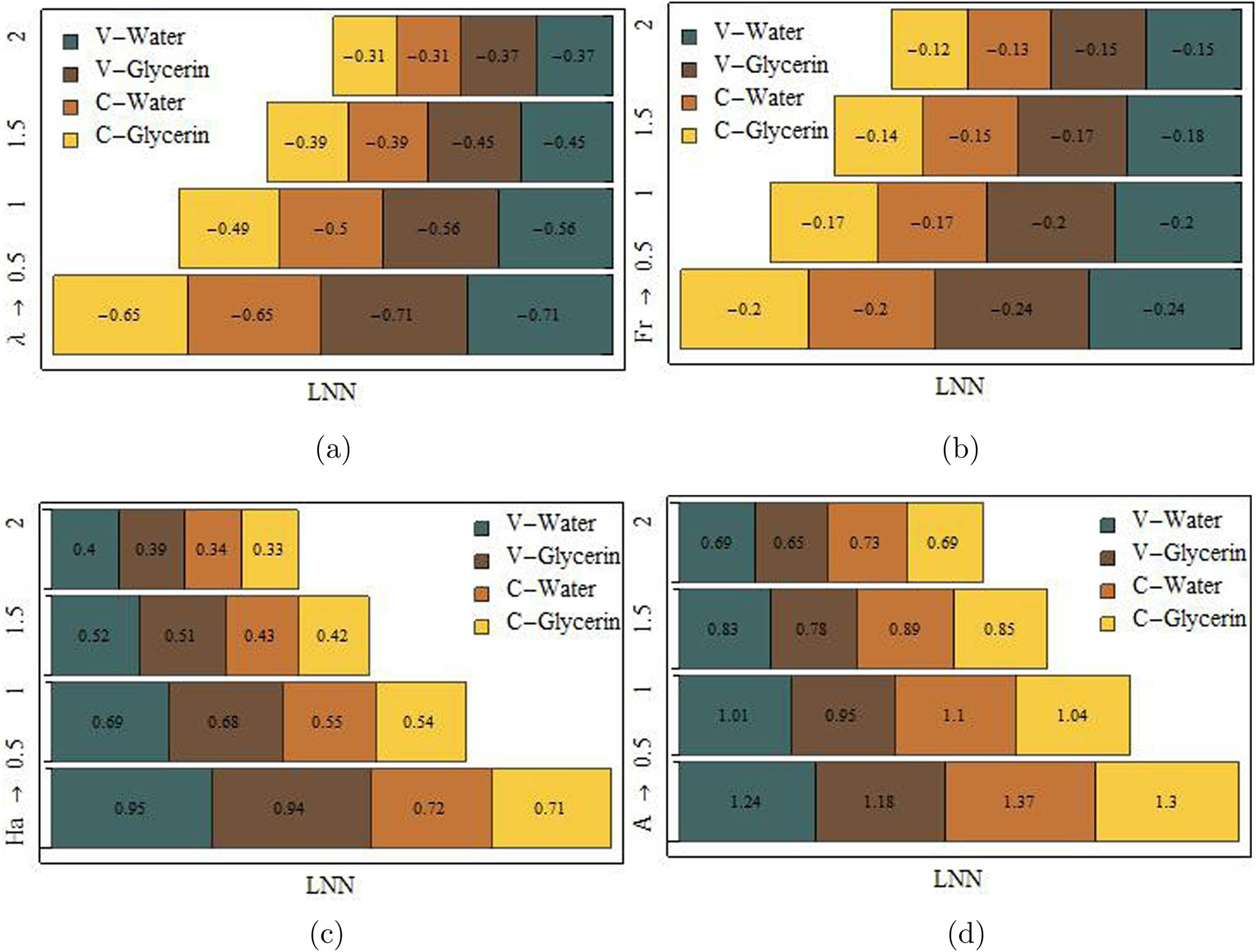

Figure 3(a)–(d) is constructed to analyze the consequences of

The velocity profile for distinct quantities of

The thermal profile for distinct quantities of

The thermal profile for distinct quantities of

The thermal profile for distinct quantities of

The thermal profile for distinct quantities of

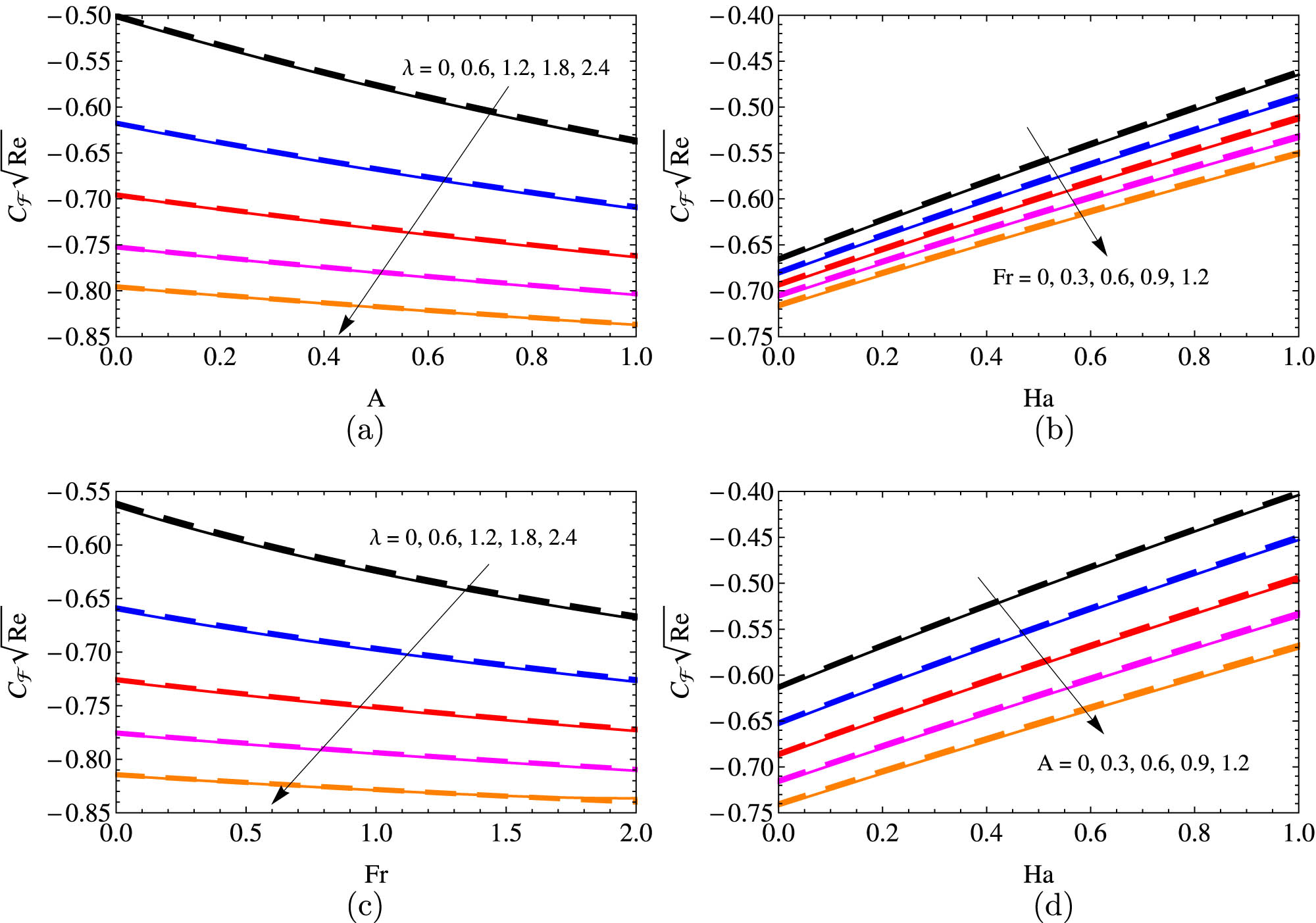

The SFC for distinct quantities of (A and

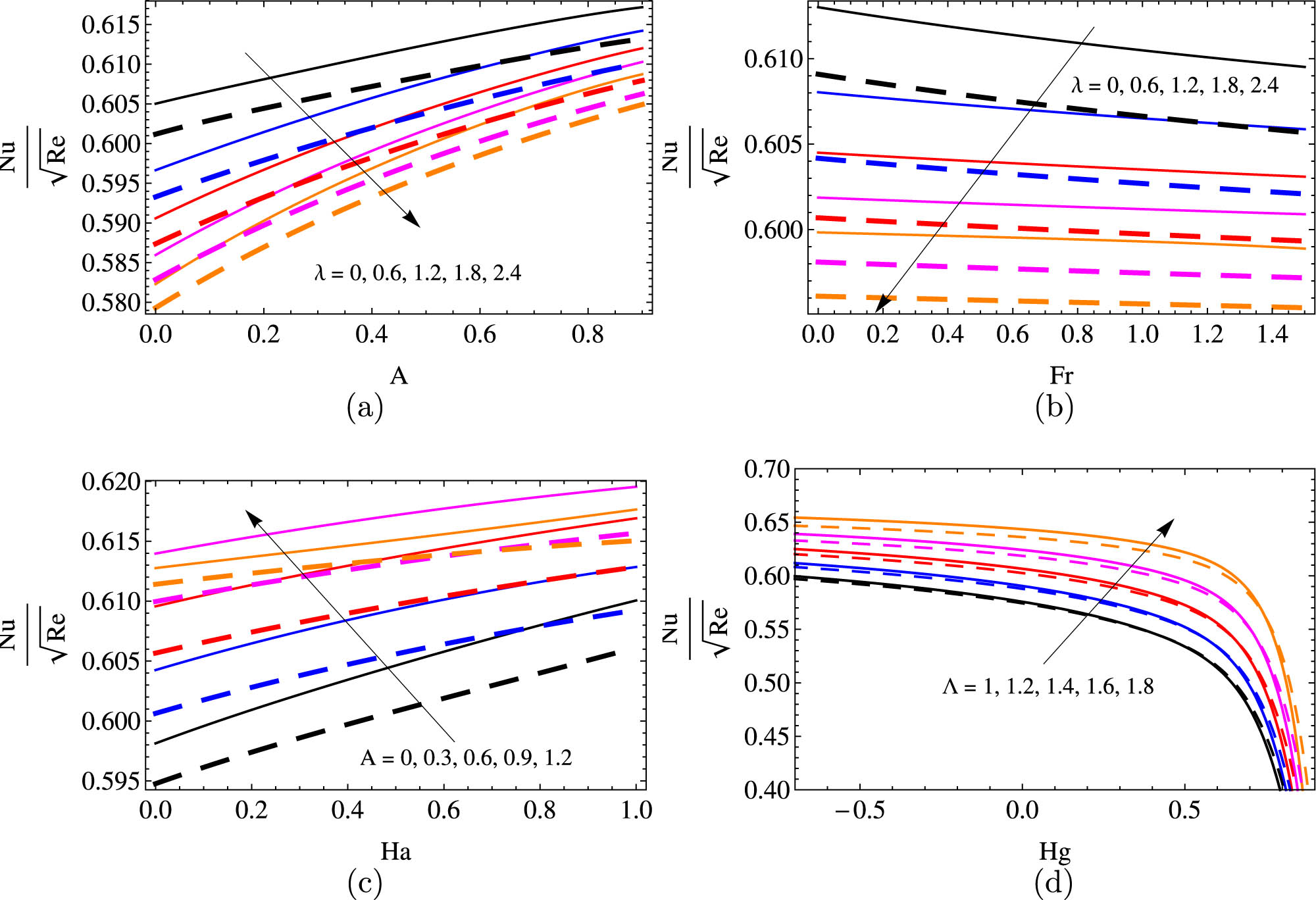

The LNN for distinct quantities of (A and

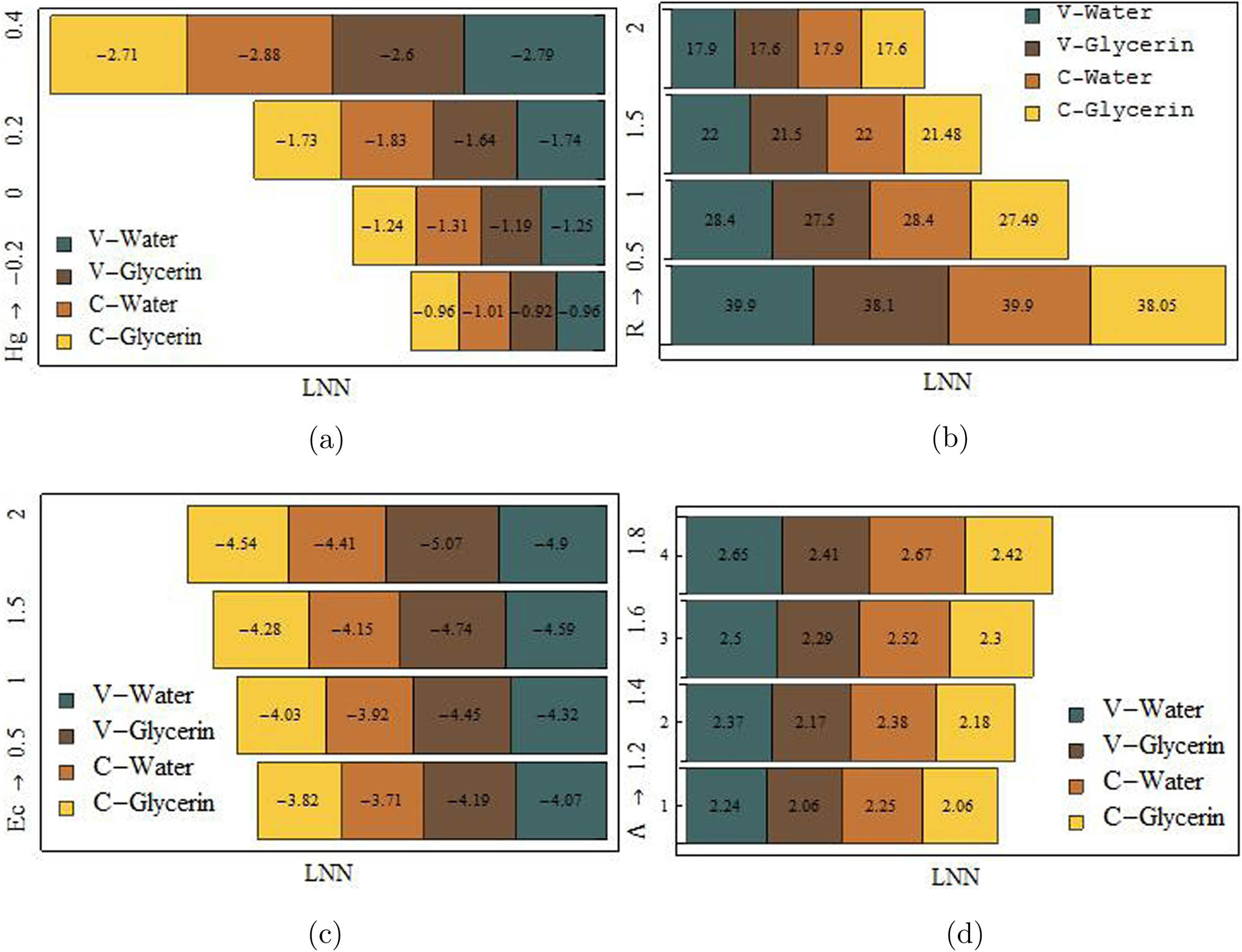

The LNN for distinct quantities of (Hg and R) in water-based HCNTs (a), and glycerin-based HCNTs (b), and (R and

Figure 10(a)–(d) is taken to analyze the fluctuating percentage of

The increment/decrement percentage of SFC for variations of

The fluctuating percentage of LNN for various values of

The increment/decrement percentage of LNN for variations of

The increment/decrement percentage of LNN for variations of Hg (a), R (b), Ec (c), and

6 Conclusions

The current endeavor focuses on the time-dependent and DFF of Casson hybrid nanofluids made of SWCNTs and MWCNTs running over a heated Riga plate with a velocity slip condition. By implementing the necessary transformations, the controlling equations are converted into ODEs. The bvp4c technique is applied to determine the numerical results of the converted equations and boundary conditions. The current flow model has applications in engineering and industrial areas, such as ceramic manufacture, the food industry, energy storage units, power generation, etc. Our findings are stated as follows:

The fluid velocity diminished when enhancing the size of the unsteady and porosity parameters.

Convective heating and cooling exhibit the opposite nature when changing the radiation parameter.

The thermal profile grows when intensifying the Eckert number.

The least decrement percent of SFC is obtained in water-based Casson HCNTs when the Forchheimer number goes from 1.5 to 2, and the largest decrement percent of SFC is obtained in glycerin-based viscous HCNTs when the porosity parameter goes from 0 to 0.5.

The least ascent percentage of LNN obtained in glycerin-based viscous HCNTs occurs when the unsteady parameter goes from 1.5 to 2, and the largest ascent percentage of LNN occurs in water-based viscous HCNTs when the radiation parameter goes from 0 to 0.5.

In the future, it is anticipated that a number of scientific and practical applications will be based on the dynamics of the stream throughout a Riga plate. The outcomes of the current study might be applied to a variety of model investigations. In many areas of science and technology, including microchips, electronic cooling systems, heat exchangers, etc., the findings of the current issue are also highly exciting. Also, we will extend our work with ion slip and Hall effect in the future.

Acknowledgments

The authors extend their appreciation to the Ministry of Education in KSA for funding this research work through the project number KKU- IFP2-DA-6.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Choi SUS. Enhancing thermal conductivity of fluids with nanoparticles. Proc ASME Int Mech Eng Congress Expo. 1995;66:99–105. Search in Google Scholar

[2] Ali R, Shahzad A, Saher KU, Elahi Z, Abbas T. The thin film flow of Al2O3 nanofluid particle over an unsteady stretching surface. Case Stud Therm Eng. 2022;29:101695:13pages. 10.1016/j.csite.2021.101695Search in Google Scholar

[3] Iqbal A, Abbas T. A study on heat transfer enhancement of Copper (Cu)-Ethylene glycol based nanoparticle on radial stretching sheet. Alex Eng J. 2023;71:13–20. 10.1016/j.aej.2023.03.025Search in Google Scholar

[4] Fakour M, Rahbari A, Khodabandeh E, Ganji DD. Nanofluid thin film flow and heat transfer over an unsteady stretching elastic sheet by LSM. J Mech Sci Technol. 2018;32(1):177–83. 10.1007/s12206-017-1219-5Search in Google Scholar

[5] Sadiq MA. Heat transfer of a nanoliquid thin film over a stretching sheet with surface temperature and internal heat generation. J Therm Anal Calorim. 2021;143(3):2075–83. 10.1007/s10973-020-09614-xSearch in Google Scholar

[6] Srilatha P, Gamaoun F, Marouani H, Kumar R, Prasanna Rani S, Yogeesha KM, et al. Melting phenomenon in the flow of dusty nanofluid over a stretching sheet in the presence of single walled carbon nanotubes. Case Stud Therm Eng. 2022;40:102585:10pages. 10.1016/j.csite.2022.102585Search in Google Scholar

[7] Tulu A, Ibrahim W. MHD slip flow of CNT-ethylene glycol nanofluid due to a stretchable rotating disk with Cattaneo–Christov heat flux model. Math Probl Eng. 2020;1374658:13pages. 10.1155/2020/1374658Search in Google Scholar

[8] Khan A, Shah Z, Islam S, Dawar A, Bonyah E, Ullah H, et al. Darcy–Forchheimer flow of MHD CNTs nanofluid radiative thermal behaviour and convective non uniform heat source/sink in the rotating frame with microstructure and inertial characteristics. AIP Adv. 2018;28(12):125024:18pages. 10.1063/1.5066223Search in Google Scholar

[9] Alsagri AS, Nasir S, Gul T, Islam S, Nisar KS, Shah Z, et al. MHD thin film flow and thermal analysis of blood with CNTs nanofluid. Coat. 2019;9(3):175:16pages. 10.3390/coatings9030175Search in Google Scholar

[10] Wang Y, Mansir IB, Al-Khaled K, Raza A, Khan SU, Khan MI, et al. Thermal outcomes for blood-based carbon nanotubes (SWCNTs and MWCNTs) with Newtonian heating by using new Prabhakar fractional derivative simulations. Case Stud Therm Eng. 2022;32:101904:10pages. 10.1016/j.csite.2022.101904Search in Google Scholar

[11] Alzahrani EO, Shah Z, Alghamdi W, Ullah MZ. Darcy–Forchheimer radiative flow of micropoler CNT nanofluid in rotating frame with convective heat generation/consumption. Processes. 2019;7(10):16pages. 10.3390/pr7100666Search in Google Scholar

[12] Jawad M, Shah Z, Islam S, Majdoubi J, Tlili I, Khan W, et al. Impact of nonlinear thermal radiation and the viscous dissipation effect on the unsteady three-dimensional rotating flow of single-wall carbon nanotubes with aqueous suspensions. Symmetry. 2019;11(12):207:18pages. 10.3390/sym11020207Search in Google Scholar

[13] Kumar KG, Rudraswamy NG, Gireesha BJ, Krishnamurthy MR. Influence of nonlinear thermal radiation and viscous dissipation on three-dimensional flow of Jeffrey nanofluid over a stretching sheet in the presence of Joule heating. Nonlinear Eng. 2017;6:207–19. 10.1515/nleng-2017-0014Search in Google Scholar

[14] Ramzan M, Riasat S, Shah Z, Kumam P, Thounthong P. Unsteady MHD carbon nanotubes suspended nanofluid flow with thermal stratification and nonlinear thermal radiation. Alex Eng J. 2020;59(3):1557–66. 10.1016/j.aej.2020.04.004Search in Google Scholar

[15] Rana P, Gupta S, Gupta G, FEM computations and Taguchi optimization in nonlinear radiative MHD MWCNT-MgO/EG hybrid nanoliquid flow and heat transfer over a 3D wedge surface. Case Stud Therm Eng. 2023;41:102639:15pages. 10.1016/j.csite.2022.102639Search in Google Scholar

[16] Mahabaleshwar US, Sneha KN, Chan A, Zeidan D. An effect of MHD fluid flow heat transfer using CNTs with thermal radiation and heat source/sink across a stretching/shrinking sheet. Int Commun Heat Mass Transf. 2022;135:106080. 10.1016/j.icheatmasstransfer.2022.106080Search in Google Scholar

[17] Satya Narayana PV, Tarakaramu N, Sarojamma G, Animasaun IL, Numerical simulation of nonlinear thermal radiation on the 3D flow of a couple stress Casson nanofluid due to a stretching sheet. J Therm Sci Eng Appl. 2021;13(2):021028:10pages. 10.1115/1.4049425Search in Google Scholar

[18] Mabood F, Yusuf TA, Khan WA. Cu−Al2O3−H2O hybrid nanofluid flow with melting heat transfer, irreversibility analysis and nonlinear thermal radiation. J Therm Anal Calorim. 2021;143(2):973–84. 10.1007/s10973-020-09720-wSearch in Google Scholar

[19] Mohanty D, Mahanta G, Shaw S. Analysis of irreversibility for 3-D MHD convective Darcy–Forchheimer Casson hybrid nanofluid flow due to a rotating disk with Cattaneo–Christov heat flux, Joule heating, and nonlinear thermal radiation. Numer Heat Transf B Fund. 2023;84(2):115–42. 10.1080/10407790.2023.2189644Search in Google Scholar

[20] Nayak MK, Mahanta G, Das M, Shaw S. Entropy analysis of a 3D nonlinear radiative hybrid nanofluid flow between two parallel stretching permeable sheets with slip velocities. Int J Ambient Energy. 2022;43(1):8710–21. 10.1080/01430750.2022.2101523Search in Google Scholar

[21] Rasool G, Shah NA, El-Zahar ER, Wakif A. Numerical investigation of EMHD nanofluid flows over a convectively heated Riga pattern positioned horizontally in a Darcy–Forchheimer porous medium: Application of passive control strategy and generalized transfer laws. Waves Random Complex Media. 2022:1–20. 10.1080/17455030.2022.2074571. Search in Google Scholar

[22] Shah NA, Yook SJ, Tosin O. Analytic simulation of thermophoretic second grade fluid flow past a vertical surface with variable fluid characteristics and convective heating. Sci Rep. 2022;12:5445:17pages. 10.1038/s41598-022-09301-xSearch in Google Scholar PubMed PubMed Central

[23] Wakif A, Shah NA. Hydrothermal and mass impacts of azimuthal and transverse components of Lorentz forces on reacting Von Kármán nanofluid flows considering zero mass flux and convective heating conditions. Waves Random Complex Media. 2022:1–22. 10.1080/17455030.2022.2136413. Search in Google Scholar

[24] Dawar A, Wakif A, Saeed A, Shah Z, Muhammad T, Kumam P. Significance of Lorentz forces on Jeffrey nanofluid flows over a convectively heated flat surface featured by multiple velocity slips and dual stretching constraint: a homotopy analysis approach. J Comput Des Eng. 2022;9:564–82. 10.1093/jcde/qwac019Search in Google Scholar

[25] Rasool G, Wakif A, Wang X, Shafiq A, Chamkha Ali J. Numerical passive control of alumina nanoparticles in purely aquatic medium featuring EMHD driven non-Darcian nanofluid flow over convective Riga surface. Alex Eng J. 2023;68:747–62. 10.1016/j.aej.2022.12.032Search in Google Scholar

[26] Rashid A, Ayaz M, Islam S, Saeed A, Kumam P, Suttiarporn P. Theoretical analysis of the MHD flow of a tangent hyperbolic hybrid nanofluid over a stretching sheet with convective conditions: A nonlinear thermal radiation case. S Afr J Chem Eng. 2022;42:255–69. 10.1016/j.sajce.2022.09.005Search in Google Scholar

[27] Chamkha Ali J. Non-Darcy hydromagnetic free convection from a cone and a wedge in porous media. Int Comm Heat Mass Transf. 1996;23(6):875–87. 10.1016/0735-1933(96)00070-XSearch in Google Scholar

[28] Chamkha Ali J. Non-Darcy fully developed mixed convection in a porous medium channel with heat generation/absorption and hydromagnetic effects. Numer Heat Transf A. 1997;32:653–75. 10.1080/10407789708913911Search in Google Scholar

[29] Hayat T, Khan MI, Khan TA, Khan MI, Ahmad S, Alsaedi A. Entropy generation in Darcy–Forchheimer bidirectional flow of water-based carbon nanotubes with convective boundary conditions. J Mol Liq. 2018;265:629–38. 10.1016/j.molliq.2018.06.017Search in Google Scholar

[30] Jamshed W, Suriya Uma Devi S, Goodarzi M, Prakash M, Nisar KS, Zakarya M, et al. Evaluating the unsteady Casson nanofluid over a stretching sheet with solar thermal radiation: An optimal case study. Case Stud Therm Eng. 2021;26:101160:15pages. 10.1016/j.csite.2021.101160Search in Google Scholar

[31] Mahmood A, Jamshed W, Aziz A. Entropy and heat transfer analysis using Cattaneo–Christov heat flux model for a boundary layer flow of Casson nanofluid. Results Phys. 2018;10:640–9. 10.1016/j.rinp.2018.07.005Search in Google Scholar

[32] Madhu M, Kishana N, Chamkha Ali J. Unsteady flow of a Maxwell nanofluid over a stretching surface in the presence of magnetohydrodynamic and thermal radiation effects. Propuls Power Res. 2017;6(1):31–40. 10.1016/j.jppr.2017.01.002Search in Google Scholar

[33] Loganathan K, Eswaramoorthi S, Chinnasamy P, Jain R, Sivasakthivel R, Ali R, et al. Heat and mass transport in Casson nanofluid flow over a 3-D Riga plate with Cattaneo–Christov double flux: A computational modeling through analytical method. Symmetry. 2023;15:725:15pages. 10.3390/sym15030725Search in Google Scholar

[34] Prabakaran R, Eswaramoorthi S, Loganathan K, Sarris IE. Investigation on thermally radiative mixed convective flow of carbon nanotubes/Al2O3 nanofluid in water past a stretching plate with Joule heating and viscous dissipation. Micromachines. 2022;13:1424:19pages. 10.3390/mi13091424Search in Google Scholar PubMed PubMed Central

[35] Naresh Kumar N, Sastry DRVSRK, Shaw S. Irreversibility analysis of an unsteady micropolar CNT-blood nanofluid flow through a squeezing channel with activation energy-Application in drug delivery. Comput Methods Programs Biomed. 2022;226:107156. 10.1016/j.cmpb.2022.107156Search in Google Scholar PubMed

[36] Eswaramoorthi S, Alessa N, Sangeethavaanee M, Kayikci S, Namgyel N. Mixed convection and thermally radiative flow of MHD Williamson nanofluid with Arrhenius activation energy and Cattaneo–Christov heat-mass flux. J Math. 2021;2021:16. 10.1155/2021/2490524Search in Google Scholar

[37] Sahu SK, Rout S, Shaw S, Dash N, Thatoi DN, Nayak MK. Hydrothermal stagnation point flow of Carreau nanofluid over a moving thin needle with non-linear Navier’s slip and cubic autocatalytic chemical reactions in Darcy–Forchheimer medium. J Indian Chem Soc. 2002;99(11):100741. 10.1016/j.jics.2022.100741. Search in Google Scholar

[38] Akbara NS, Tripathib D, Khanc ZH. Numerical investigation of Cattanneo-Christov heat flux in CNT suspended nanofluid flow over a stretching porous surface with suction and injection. Discrete Contin Dyn Syst S. 2018;11(4):1–12. 10.3934/dcdss.2018033Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface

- Potential pharmaceutical applications and molecular docking study for green fabricated ZnO nanoparticles mediated Raphanus sativus: In vitro and in vivo study

- Effect of temperature and nanoparticle size on the interfacial layer thickness of TiO2–water nanofluids using molecular dynamics

- Characteristics of induced magnetic field on the time-dependent MHD nanofluid flow through parallel plates

- Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

- Experimental research on mechanically and thermally activation of nano-kaolin to improve the properties of ultra-high-performance fiber-reinforced concrete

- Analysis of variable fluid properties for three-dimensional flow of ternary hybrid nanofluid on a stretching sheet with MHD effects

- Biodegradability of corn starch films containing nanocellulose fiber and thymol

- Toxicity assessment of copper oxide nanoparticles: In vivo study

- Some measures to enhance the energy output performances of triboelectric nanogenerators

- Reinforcement of graphene nanoplatelets on water uptake and thermomechanical behaviour of epoxy adhesive subjected to water ageing conditions

- Optimization of preparation parameters and testing verification of carbon nanotube suspensions used in concrete

- Max-phase Ti3SiC2 and diverse nanoparticle reinforcements for enhancement of the mechanical, dynamic, and microstructural properties of AA5083 aluminum alloy via FSP

- Advancing drug delivery: Neural network perspectives on nanoparticle-mediated treatments for cancerous tissues

- PEG-PLGA core–shell nanoparticles for the controlled delivery of picoplatin–hydroxypropyl β-cyclodextrin inclusion complex in triple-negative breast cancer: In vitro and in vivo study

- Conduction transportation from graphene to an insulative polymer medium: A novel approach for the conductivity of nanocomposites

- Review Articles

- Developments of terahertz metasurface biosensors: A literature review

- Overview of amorphous carbon memristor device, modeling, and applications for neuromorphic computing

- Advances in the synthesis of gold nanoclusters (AuNCs) of proteins extracted from nature

- A review of ternary polymer nanocomposites containing clay and calcium carbonate and their biomedical applications

- Recent advancements in polyoxometalate-functionalized fiber materials: A review

- Special contribution of atomic force microscopy in cell death research

- A comprehensive review of oral chitosan drug delivery systems: Applications for oral insulin delivery

- Cellular senescence and nanoparticle-based therapies: Current developments and perspectives

- Cyclodextrins-block copolymer drug delivery systems: From design and development to preclinical studies

- Micelle-based nanoparticles with stimuli-responsive properties for drug delivery

- Critical assessment of the thermal stability and degradation of chemically functionalized nanocellulose-based polymer nanocomposites

- Research progress in preparation technology of micro and nano titanium alloy powder

- Nanoformulations for lysozyme-based additives in animal feed: An alternative to fight antibiotic resistance spread

- Incorporation of organic photochromic molecules in mesoporous silica materials: Synthesis and applications

- A review on modeling of graphene and associated nanostructures reinforced concrete

- A review on strengthening mechanisms of carbon quantum dots-reinforced Cu-matrix nanocomposites

- Review on nanocellulose composites and CNFs assembled microfiber toward automotive applications

- Nanomaterial coating for layered lithium rich transition metal oxide cathode for lithium-ion battery

- Application of AgNPs in biomedicine: An overview and current trends

- Nanobiotechnology and microbial influence on cold adaptation in plants

- Hepatotoxicity of nanomaterials: From mechanism to therapeutic strategy

- Applications of micro-nanobubble and its influence on concrete properties: An in-depth review

- A comprehensive systematic literature review of ML in nanotechnology for sustainable development

- Exploiting the nanotechnological approaches for traditional Chinese medicine in childhood rhinitis: A review of future perspectives

- Twisto-photonics in two-dimensional materials: A comprehensive review

- Current advances of anticancer drugs based on solubilization technology

- Recent process of using nanoparticles in the T cell-based immunometabolic therapy

- Future prospects of gold nanoclusters in hydrogen storage systems and sustainable environmental treatment applications

- Preparation, types, and applications of one- and two-dimensional nanochannels and their transport properties for water and ions

- Microstructural, mechanical, and corrosion characteristics of Mg–Gd–x systems: A review of recent advancements

- Functionalized nanostructures and targeted delivery systems with a focus on plant-derived natural agents for COVID-19 therapy: A review and outlook

- Mapping evolution and trends of cell membrane-coated nanoparticles: A bibliometric analysis and scoping review

- Nanoparticles and their application in the diagnosis of hepatocellular carcinoma

- In situ growth of carbon nanotubes on fly ash substrates

- Structural performance of boards through nanoparticle reinforcement: An advance review

- Reinforcing mechanisms review of the graphene oxide on cement composites

- Seed regeneration aided by nanomaterials in a climate change scenario: A comprehensive review

- Surface-engineered quantum dot nanocomposites for neurodegenerative disorder remediation and avenue for neuroimaging

- Graphitic carbon nitride hybrid thin films for energy conversion: A mini-review on defect activation with different materials

- Nanoparticles and the treatment of hepatocellular carcinoma

- Special Issue on Advanced Nanomaterials and Composites for Energy Conversion and Storage - Part II

- Highly safe lithium vanadium oxide anode for fast-charging dendrite-free lithium-ion batteries

- Recent progress in nanomaterials of battery energy storage: A patent landscape analysis, technology updates, and future prospects

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part II

- Calcium-, magnesium-, and yttrium-doped lithium nickel phosphate nanomaterials as high-performance catalysts for electrochemical water oxidation reaction

- Low alkaline vegetation concrete with silica fume and nano-fly ash composites to improve the planting properties and soil ecology

- Mesoporous silica-grafted deep eutectic solvent-based mixed matrix membranes for wastewater treatment: Synthesis and emerging pollutant removal performance

- Electrochemically prepared ultrathin two-dimensional graphitic nanosheets as cathodes for advanced Zn-based energy storage devices

- Enhanced catalytic degradation of amoxicillin by phyto-mediated synthesised ZnO NPs and ZnO-rGO hybrid nanocomposite: Assessment of antioxidant activity, adsorption, and thermodynamic analysis

- Incorporating GO in PI matrix to advance nanocomposite coating: An enhancing strategy to prevent corrosion

- Synthesis, characterization, thermal stability, and application of microporous hyper cross-linked polyphosphazenes with naphthylamine group for CO2 uptake

- Engineering in ceramic albite morphology by the addition of additives: Carbon nanotubes and graphene oxide for energy applications

- Nanoscale synergy: Optimizing energy storage with SnO2 quantum dots on ZnO hexagonal prisms for advanced supercapacitors

- Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation

- Tuning structural and electrical properties of Co-precipitated and Cu-incorporated nickel ferrite for energy applications

- Sodium alginate-supported AgSr nanoparticles for catalytic degradation of malachite green and methyl orange in aqueous medium

- An environmentally greener and reusability approach for bioenergy production using Mallotus philippensis (Kamala) seed oil feedstock via phytonanotechnology

- Micro-/nano-alumina trihydrate and -magnesium hydroxide fillers in RTV-SR composites under electrical and environmental stresses

- Mechanism exploration of ion-implanted epoxy on surface trap distribution: An approach to augment the vacuum flashover voltages

- Nanoscale engineering of semiconductor photocatalysts boosting charge separation for solar-driven H2 production: Recent advances and future perspective

- Excellent catalytic performance over reduced graphene-boosted novel nanoparticles for oxidative desulfurization of fuel oil

- Special Issue on Advances in Nanotechnology for Agriculture

- Deciphering the synergistic potential of mycogenic zinc oxide nanoparticles and bio-slurry formulation on phenology and physiology of Vigna radiata

- Nanomaterials: Cross-disciplinary applications in ornamental plants

- Special Issue on Catechol Based Nano and Microstructures

- Polydopamine films: Versatile but interface-dependent coatings

- In vitro anticancer activity of melanin-like nanoparticles for multimodal therapy of glioblastoma

- Poly-3,4-dihydroxybenzylidenhydrazine, a different analogue of polydopamine

- Chirality and self-assembly of structures derived from optically active 1,2-diaminocyclohexane and catecholamines

- Advancing resource sustainability with green photothermal materials: Insights from organic waste-derived and bioderived sources

- Bioinspired neuromelanin-like Pt(iv) polymeric nanoparticles for cancer treatment

- Special Issue on Implementing Nanotechnology for Smart Healthcare System

- Intelligent explainable optical sensing on Internet of nanorobots for disease detection

- Special Issue on Green Mono, Bi and Tri Metallic Nanoparticles for Biological and Environmental Applications

- Tracking success of interaction of green-synthesized Carbopol nanoemulgel (neomycin-decorated Ag/ZnO nanocomposite) with wound-based MDR bacteria

- Green synthesis of copper oxide nanoparticles using genus Inula and evaluation of biological therapeutics and environmental applications

- Biogenic fabrication and multifunctional therapeutic applications of silver nanoparticles synthesized from rose petal extract

- Metal oxides on the frontlines: Antimicrobial activity in plant-derived biometallic nanoparticles

- Controlling pore size during the synthesis of hydroxyapatite nanoparticles using CTAB by the sol–gel hydrothermal method and their biological activities

- Special Issue on State-of-Art Advanced Nanotechnology for Healthcare

- Applications of nanomedicine-integrated phototherapeutic agents in cancer theranostics: A comprehensive review of the current state of research

- Smart bionanomaterials for treatment and diagnosis of inflammatory bowel disease

- Beyond conventional therapy: Synthesis of multifunctional nanoparticles for rheumatoid arthritis therapy

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface

- Potential pharmaceutical applications and molecular docking study for green fabricated ZnO nanoparticles mediated Raphanus sativus: In vitro and in vivo study

- Effect of temperature and nanoparticle size on the interfacial layer thickness of TiO2–water nanofluids using molecular dynamics

- Characteristics of induced magnetic field on the time-dependent MHD nanofluid flow through parallel plates

- Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

- Experimental research on mechanically and thermally activation of nano-kaolin to improve the properties of ultra-high-performance fiber-reinforced concrete

- Analysis of variable fluid properties for three-dimensional flow of ternary hybrid nanofluid on a stretching sheet with MHD effects

- Biodegradability of corn starch films containing nanocellulose fiber and thymol

- Toxicity assessment of copper oxide nanoparticles: In vivo study

- Some measures to enhance the energy output performances of triboelectric nanogenerators

- Reinforcement of graphene nanoplatelets on water uptake and thermomechanical behaviour of epoxy adhesive subjected to water ageing conditions

- Optimization of preparation parameters and testing verification of carbon nanotube suspensions used in concrete

- Max-phase Ti3SiC2 and diverse nanoparticle reinforcements for enhancement of the mechanical, dynamic, and microstructural properties of AA5083 aluminum alloy via FSP

- Advancing drug delivery: Neural network perspectives on nanoparticle-mediated treatments for cancerous tissues

- PEG-PLGA core–shell nanoparticles for the controlled delivery of picoplatin–hydroxypropyl β-cyclodextrin inclusion complex in triple-negative breast cancer: In vitro and in vivo study

- Conduction transportation from graphene to an insulative polymer medium: A novel approach for the conductivity of nanocomposites

- Review Articles

- Developments of terahertz metasurface biosensors: A literature review

- Overview of amorphous carbon memristor device, modeling, and applications for neuromorphic computing

- Advances in the synthesis of gold nanoclusters (AuNCs) of proteins extracted from nature

- A review of ternary polymer nanocomposites containing clay and calcium carbonate and their biomedical applications

- Recent advancements in polyoxometalate-functionalized fiber materials: A review

- Special contribution of atomic force microscopy in cell death research

- A comprehensive review of oral chitosan drug delivery systems: Applications for oral insulin delivery

- Cellular senescence and nanoparticle-based therapies: Current developments and perspectives

- Cyclodextrins-block copolymer drug delivery systems: From design and development to preclinical studies

- Micelle-based nanoparticles with stimuli-responsive properties for drug delivery

- Critical assessment of the thermal stability and degradation of chemically functionalized nanocellulose-based polymer nanocomposites

- Research progress in preparation technology of micro and nano titanium alloy powder

- Nanoformulations for lysozyme-based additives in animal feed: An alternative to fight antibiotic resistance spread

- Incorporation of organic photochromic molecules in mesoporous silica materials: Synthesis and applications

- A review on modeling of graphene and associated nanostructures reinforced concrete

- A review on strengthening mechanisms of carbon quantum dots-reinforced Cu-matrix nanocomposites

- Review on nanocellulose composites and CNFs assembled microfiber toward automotive applications

- Nanomaterial coating for layered lithium rich transition metal oxide cathode for lithium-ion battery

- Application of AgNPs in biomedicine: An overview and current trends

- Nanobiotechnology and microbial influence on cold adaptation in plants

- Hepatotoxicity of nanomaterials: From mechanism to therapeutic strategy

- Applications of micro-nanobubble and its influence on concrete properties: An in-depth review

- A comprehensive systematic literature review of ML in nanotechnology for sustainable development

- Exploiting the nanotechnological approaches for traditional Chinese medicine in childhood rhinitis: A review of future perspectives

- Twisto-photonics in two-dimensional materials: A comprehensive review

- Current advances of anticancer drugs based on solubilization technology

- Recent process of using nanoparticles in the T cell-based immunometabolic therapy

- Future prospects of gold nanoclusters in hydrogen storage systems and sustainable environmental treatment applications

- Preparation, types, and applications of one- and two-dimensional nanochannels and their transport properties for water and ions

- Microstructural, mechanical, and corrosion characteristics of Mg–Gd–x systems: A review of recent advancements

- Functionalized nanostructures and targeted delivery systems with a focus on plant-derived natural agents for COVID-19 therapy: A review and outlook

- Mapping evolution and trends of cell membrane-coated nanoparticles: A bibliometric analysis and scoping review

- Nanoparticles and their application in the diagnosis of hepatocellular carcinoma

- In situ growth of carbon nanotubes on fly ash substrates

- Structural performance of boards through nanoparticle reinforcement: An advance review

- Reinforcing mechanisms review of the graphene oxide on cement composites

- Seed regeneration aided by nanomaterials in a climate change scenario: A comprehensive review

- Surface-engineered quantum dot nanocomposites for neurodegenerative disorder remediation and avenue for neuroimaging

- Graphitic carbon nitride hybrid thin films for energy conversion: A mini-review on defect activation with different materials

- Nanoparticles and the treatment of hepatocellular carcinoma

- Special Issue on Advanced Nanomaterials and Composites for Energy Conversion and Storage - Part II

- Highly safe lithium vanadium oxide anode for fast-charging dendrite-free lithium-ion batteries

- Recent progress in nanomaterials of battery energy storage: A patent landscape analysis, technology updates, and future prospects

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part II

- Calcium-, magnesium-, and yttrium-doped lithium nickel phosphate nanomaterials as high-performance catalysts for electrochemical water oxidation reaction

- Low alkaline vegetation concrete with silica fume and nano-fly ash composites to improve the planting properties and soil ecology

- Mesoporous silica-grafted deep eutectic solvent-based mixed matrix membranes for wastewater treatment: Synthesis and emerging pollutant removal performance

- Electrochemically prepared ultrathin two-dimensional graphitic nanosheets as cathodes for advanced Zn-based energy storage devices

- Enhanced catalytic degradation of amoxicillin by phyto-mediated synthesised ZnO NPs and ZnO-rGO hybrid nanocomposite: Assessment of antioxidant activity, adsorption, and thermodynamic analysis

- Incorporating GO in PI matrix to advance nanocomposite coating: An enhancing strategy to prevent corrosion

- Synthesis, characterization, thermal stability, and application of microporous hyper cross-linked polyphosphazenes with naphthylamine group for CO2 uptake

- Engineering in ceramic albite morphology by the addition of additives: Carbon nanotubes and graphene oxide for energy applications

- Nanoscale synergy: Optimizing energy storage with SnO2 quantum dots on ZnO hexagonal prisms for advanced supercapacitors

- Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation

- Tuning structural and electrical properties of Co-precipitated and Cu-incorporated nickel ferrite for energy applications

- Sodium alginate-supported AgSr nanoparticles for catalytic degradation of malachite green and methyl orange in aqueous medium

- An environmentally greener and reusability approach for bioenergy production using Mallotus philippensis (Kamala) seed oil feedstock via phytonanotechnology

- Micro-/nano-alumina trihydrate and -magnesium hydroxide fillers in RTV-SR composites under electrical and environmental stresses

- Mechanism exploration of ion-implanted epoxy on surface trap distribution: An approach to augment the vacuum flashover voltages

- Nanoscale engineering of semiconductor photocatalysts boosting charge separation for solar-driven H2 production: Recent advances and future perspective

- Excellent catalytic performance over reduced graphene-boosted novel nanoparticles for oxidative desulfurization of fuel oil

- Special Issue on Advances in Nanotechnology for Agriculture

- Deciphering the synergistic potential of mycogenic zinc oxide nanoparticles and bio-slurry formulation on phenology and physiology of Vigna radiata

- Nanomaterials: Cross-disciplinary applications in ornamental plants

- Special Issue on Catechol Based Nano and Microstructures

- Polydopamine films: Versatile but interface-dependent coatings

- In vitro anticancer activity of melanin-like nanoparticles for multimodal therapy of glioblastoma

- Poly-3,4-dihydroxybenzylidenhydrazine, a different analogue of polydopamine

- Chirality and self-assembly of structures derived from optically active 1,2-diaminocyclohexane and catecholamines

- Advancing resource sustainability with green photothermal materials: Insights from organic waste-derived and bioderived sources

- Bioinspired neuromelanin-like Pt(iv) polymeric nanoparticles for cancer treatment

- Special Issue on Implementing Nanotechnology for Smart Healthcare System

- Intelligent explainable optical sensing on Internet of nanorobots for disease detection

- Special Issue on Green Mono, Bi and Tri Metallic Nanoparticles for Biological and Environmental Applications

- Tracking success of interaction of green-synthesized Carbopol nanoemulgel (neomycin-decorated Ag/ZnO nanocomposite) with wound-based MDR bacteria

- Green synthesis of copper oxide nanoparticles using genus Inula and evaluation of biological therapeutics and environmental applications

- Biogenic fabrication and multifunctional therapeutic applications of silver nanoparticles synthesized from rose petal extract

- Metal oxides on the frontlines: Antimicrobial activity in plant-derived biometallic nanoparticles

- Controlling pore size during the synthesis of hydroxyapatite nanoparticles using CTAB by the sol–gel hydrothermal method and their biological activities

- Special Issue on State-of-Art Advanced Nanotechnology for Healthcare

- Applications of nanomedicine-integrated phototherapeutic agents in cancer theranostics: A comprehensive review of the current state of research

- Smart bionanomaterials for treatment and diagnosis of inflammatory bowel disease

- Beyond conventional therapy: Synthesis of multifunctional nanoparticles for rheumatoid arthritis therapy