Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

-

Natesan Karthikeyan

, Murugan Rajesh

and Victor Feizal Knight

Abstract

Co-curing bonding is more efficient than co-bonding and secondary bonding for structural component assembly. This work used novel covered laminas with co-cured joining techniques (CL-CCT) to create carbon fibre-reinforced polymer (CFRP) composite adhesive-bonded joints. Additionally, the researchers evaluated how multi-walled carbon nanotubes (MWCNTs) affect the bending and dynamic properties of CFRP composite joints. The researchers added various weights of MWCNTs to the covered laminas along with co-cured CFRP adhesive-bonded joints. The study revealed that epoxy and 0.25 wt% MWCNT adhesive produced the strongest and most flexible joints. These joints were 118 and 15% stronger than joints made from pure epoxy CL-CC CFRP, respectively. Compared to pure epoxy CC-CFRP composite joints, the strength of CL-CC CFRP composite joints with 0.25 wt% MWCNTs increased by 374 and 109%, respectively. Interestingly, MWCNTs with a wt% of 1.25 had the greatest natural frequency in all three vibration modes, which are 19, 19, and 13% higher than that of the pure epoxy CL-CC CFRP composite joint. There are 28, 30, and 24% more natural frequencies in 1.25 wt% MWCNT-based CL-CC CFRP composite joints than those in pure epoxy-based joints in all three modes. Analysis of variance was employed for statistical investigation. Optimization and prediction were done using an artificial neural network and the Levenberg–Marquardt technique.

Acronyms

- ANN

-

artificial neural network

- ANOVA

-

analysis of variance

- CC-CFRP

-

co-cured carbon fibre-reinforced polymer

- CFRP

-

carbon fibre-reinforced polymer

- CL-CC-CFRP

-

covered lamina with co-cured carbon fibre-reinforced polymer

- CL-CCT

-

covered lamina with co-cured joining techniques

- FESEM

-

field emission scanning electron microscopy

- FRP

-

fibre-reinforced polymer

- GFRP

-

glass fibre-reinforced polymer

- GNPs

-

graphene nanoplatelets

- MWCNTs

-

multiwalled carbon nanotubes

- SLJ

-

single lap joint

1 Introduction

Lightweight applications like aerospace, marine, and automobiles have greatly benefited from fibre-reinforced polymer (FRP) composite structures [1,2,3,4]. For large-scale manufacturing, joining techniques are unavoidable. Various traditional joining techniques such as bolted, riveted, and welded joints have more drawbacks such as localized stress, higher fatigue life, weight addition, and delamination while using mechanical fasteners. The adhesive-bonded joints have overcome the problems of traditional bonding techniques [5,6,7,8]. In aerospace applications, this bonding method is used in various composite parts in wings, fuselages, and frames [9]. The mechanical performance of the adhesive-bonded joints considered the following factors such as the joining method [2,3,10,11,12,13], surface treatment [14,15,16,17,18,19,20,21,22,23], type of the matrix used [9,21,24], matrix modification by nanofillers [3,10,12,23,24,25,26,27,28,29,30], and additional reinforcement with adhesives [1,2,10,12,13,31,32,33]. The development of adhesive-bonded techniques and adhesions was driven by the need to manufacture components on a large scale.

There are various types of adhesive-bonded joining methods such as secondary bonding, co-bonding, co-curing, and multi-material bonding [2,3,4,11,12]. Secondary bonding techniques joined two cured laminates. The co-bonding technique joined one cured laminate to another uncured laminate. Co-cured composite joints were one of the joining methods for FRP adhesively bonded joints, which involved joining both uncured laminates. Co-cured composite joints have higher strength and durability than secondary bonding methods. This method enables seamless integration of the two laminates, resulting in a stronger overall bond. In addition, co-cured composite joints are a more efficient and cost-effective way to join laminates than secondary bonding methods. Furthermore, this technique reduces the likelihood of delamination or separation of the two materials over time. Furthermore, in co-curing joining methods, there is no need for additional surface treatment methods. The multi-material bonding process is used to join cured dissimilar composites and metals.

The composite material consists of a combination of the glass fibre-reinforced polymer (GFRP) and carbon nanotubes (CNTs), which together make up approximately 0.25% of the material’s weight. The composite joint exhibits a resonance frequency of 53.1 Hz and a shear strength of 16.73 MPa in Mode 1 [11,12]. Similarly, 0.75 wt% of GNP and 2.5 vol% of 90°/Z-pins + 0.75 wt% GNP-based adhesives in GFRP composite joints have attained the shear strength of 13.10 and 17.83 MPa, respectively [34]. Research has shown that incorporating steel Z-pins into the matrix significantly enhances the fracture resistance of co-cured carbon fibre-reinforced polymer (CFRP) composite joints [31]. Quan et al. used surface-treated CF/PEEK tape-based adhesive to create the co-cured CFRP composite joints, which had shear strengths of 27 and 25 MPa at 22 and 130°C, respectively [35]. The effects of adherends modified on the surface and adhesives modified with a nanofiller on the shear behaviour of secondary-bonded and co-bonded single-lap joints were reviewed by Karthikeyan and Naveen [4]. Additionally, they talked about how different nanofiller adhesives in the FRP composite and dissimilar composite single-lap joints are affected by different mechanical properties [1]. Incorporating multi-walled carbon nanotubes (MWCNTs) can enhance various properties, including tensile modulus, tensile strength, flexural strength, interlaminar shear strength (ILSS), toughness, damping behaviour, and glass transition temperature. At specified stirring times, the flexural strength of the treated MWCNTs–CFRP laminates is 948 MPa, while the ILSS is 66.7 MPa [36]. The incorporation of glass powder into a co-cured glass fibre-reinforced polymer composite resulted in a substantial improvement in its mechanical properties. Specifically, there was a substantial rise in both the flexural and shear strengths, increasing from 19.31 to 208.92 MPa. In addition, the natural frequency of the composite in Mode-3 increased to 881.3 Hz [37]. The statistical analysis utilized the one-way analysis of variance (ANOVA) method to evaluate the error rate and the impact of different inputs on the output parameters of the composites [22,38,39]. The genetic algorithm, artificial neural network (ANN), and Levenberg–Marquardt algorithm were collectively employed to optimize and forecast the outcomes of the joints and composites [22,33,38,39,40,41]. A thorough examination of the composite materials was conducted using advanced optimization techniques, resulting in substantial enhancements to their mechanical properties.

After carefully examining the literature, several significant findings were uncovered. Numerous studies have been conducted to analyse the shear, flexural, and vibrational properties of co-cured GFRP composite joints that incorporate an adhesive enhanced with MWCNTs. There is currently a limited amount of research available on the flexural and vibration properties of co-cured CFRP composite joints that use adhesives enhanced with MWCNTs. This study examined the impact of MWCNTs on the dynamic and flexural characteristics of novel covered laminas with co-cured carbon fibre-reinforced polymer (CL-CC CFRP) composite joints. In addition, the JMP Pro 17 software will be used to perform a one-way ANOVA to investigate any significant differences in the results. Utilizing an ANN and MATLAB software, the performance and prediction model for forecasting future outcomes is finely tuned.

2 Materials and methods

2.1 Materials

SM Composites in Chennai, India, provided the bi-directional woven carbon fabric with an area weight and thickness of 220 g/m2 and 0.40 mm, respectively. MWCNTs were acquired from BTCORP Generique Nano Pvt Ltd in Bangalore. The properties of MWCNTs are 20 nm in diameter, 20 µm in length, >99% purity, 220 m2/g specific surface area, and 0.16 g/cm3 bulk density. SM Composites in Chennai, India, supplied the epoxy resin [LY556] and the triethylenetetramine araldite epoxy hardener [HY951].

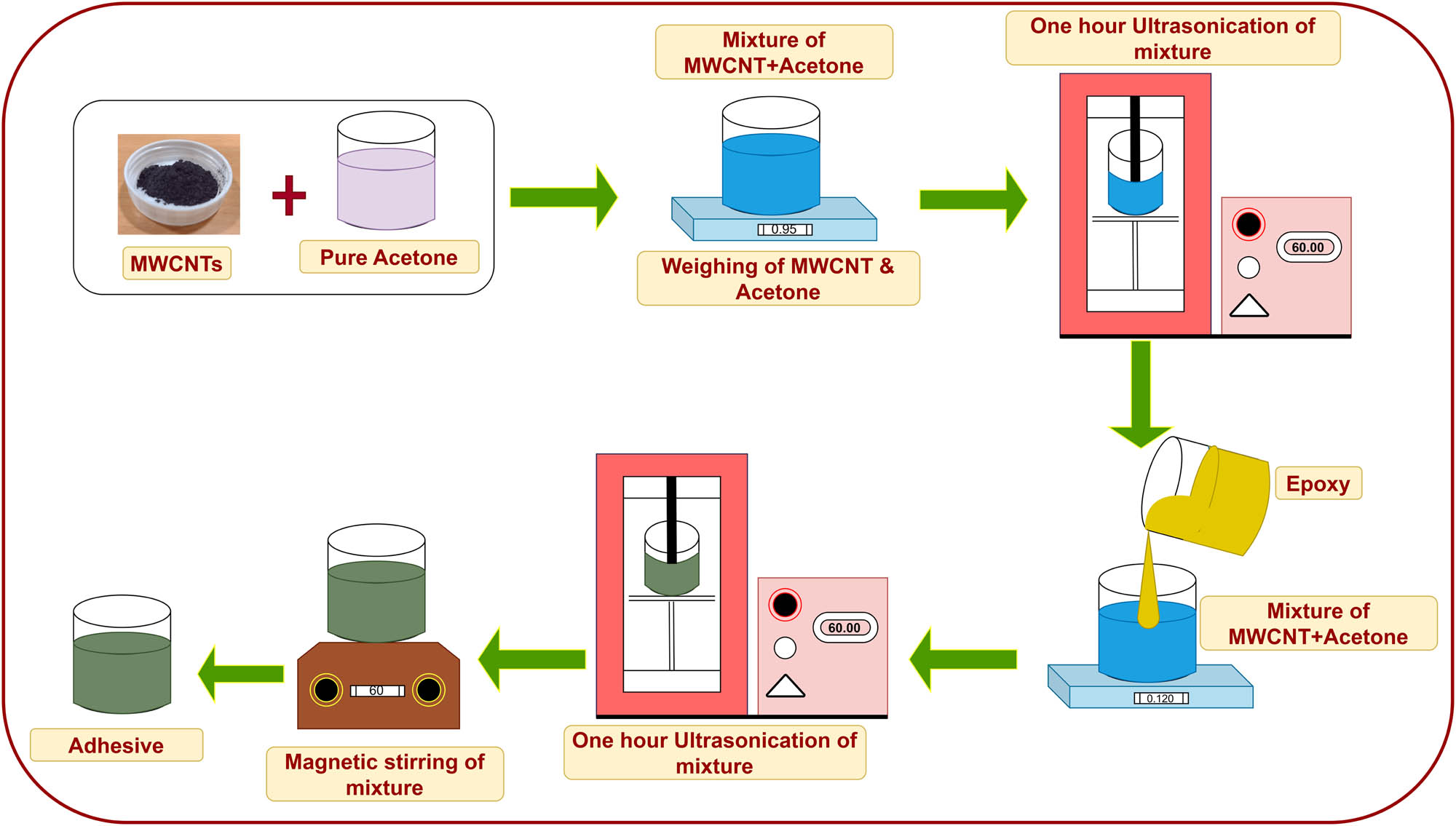

2.2 MWCNT dispersion method

The process of spreading MWCNTs in epoxy is shown in Figure 1, which describes the technique. In the beginning, a precise weighing device was used to ascertain the various weight proportions of MWCNT particles. The weight percentages of 0.25, 0.5, 0.25, 0.75, 1.0, 1.25, and 1.5 were given attention, and observations were made about them. After that, the MWCNTs were combined in a beaker that previously had 100 g of acetone that was in its purest form. The beaker was subjected to ultrasonication for 1 h in an ultrasonicator, with the frequency ranging from 30 to 40 kHz. A mixture that contained approximately 50% acetone was obtained as a consequence of the sonication process, which resulted in the vaporization of approximately 50% of the acetone. The mixture was then subjected to an extra round of sonication after a required quantity of epoxy was added to the MWCNT/acetone mixture and mixed well. After that, acetone is present in the epoxy/MWCNT composite mixture in proportions that have been accurately calculated. During the process of extracting the acetone from the liquid, a magnetic stirrer was used to swirl the liquid at a speed of 900 revolutions per minute, while the temperature was maintained at 60°C. In the end, the adhesive formed a uniform combination of MWCNTs and epoxy, resulting in improved bonding of single-lap joints [1,2,3,4,12,13,26,27,42].

MWCNT/epoxy adhesive preparation using the MWCNT dispersion process.

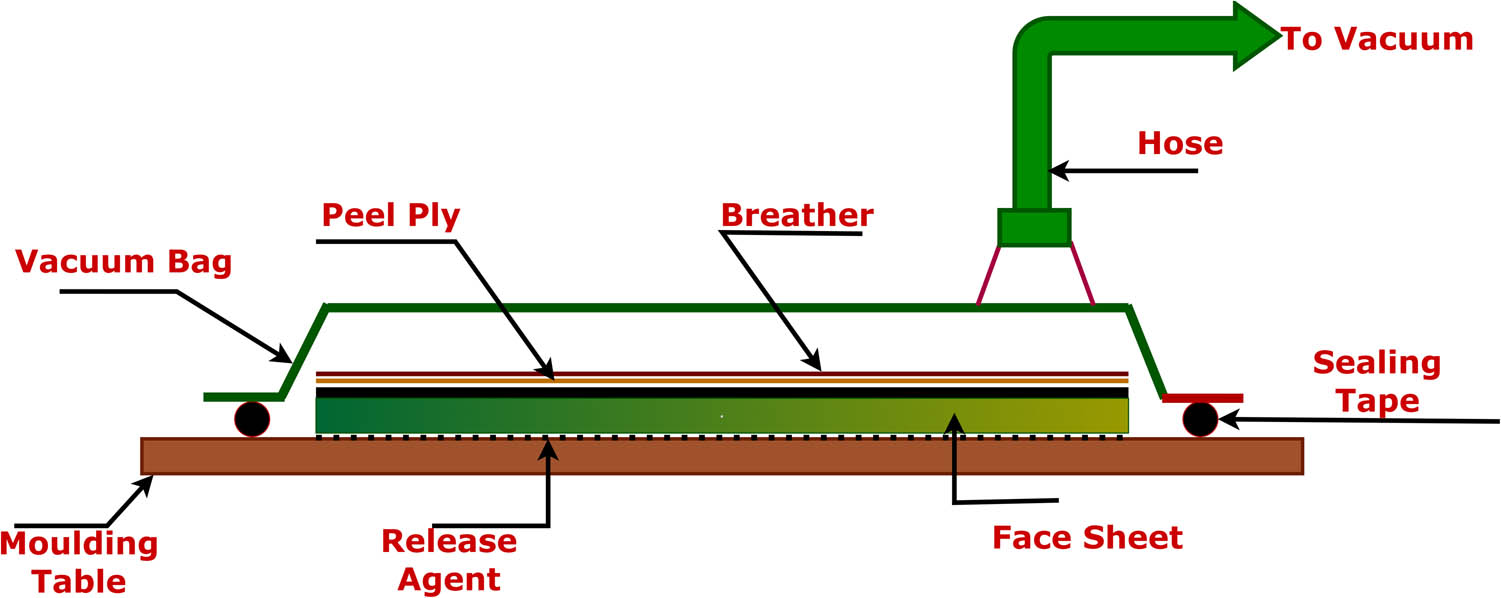

2.3 Uncured laminate preparation

An uncured CFRP composite was fabricated by combining the epoxy resin and hardener in a weight ratio of 10:1. First, manufacturing of the four-ply CFRP laminates was carried out using the manual process of hand layup, which is the recommended method. The CFRP laminates have a matrix and fibre weight ratio of 50/50. To remove any excess resin, the laminates that had not yet solidified were subjected to vacuum sealing and crushed at a pressure of 1 bar for 30 min [2,3,11,12,13,27]. Figure 2 depicts a diagrammatic representation of the vacuum bag moulding process.

Schematic diagram of the vacuum bag moulding process.

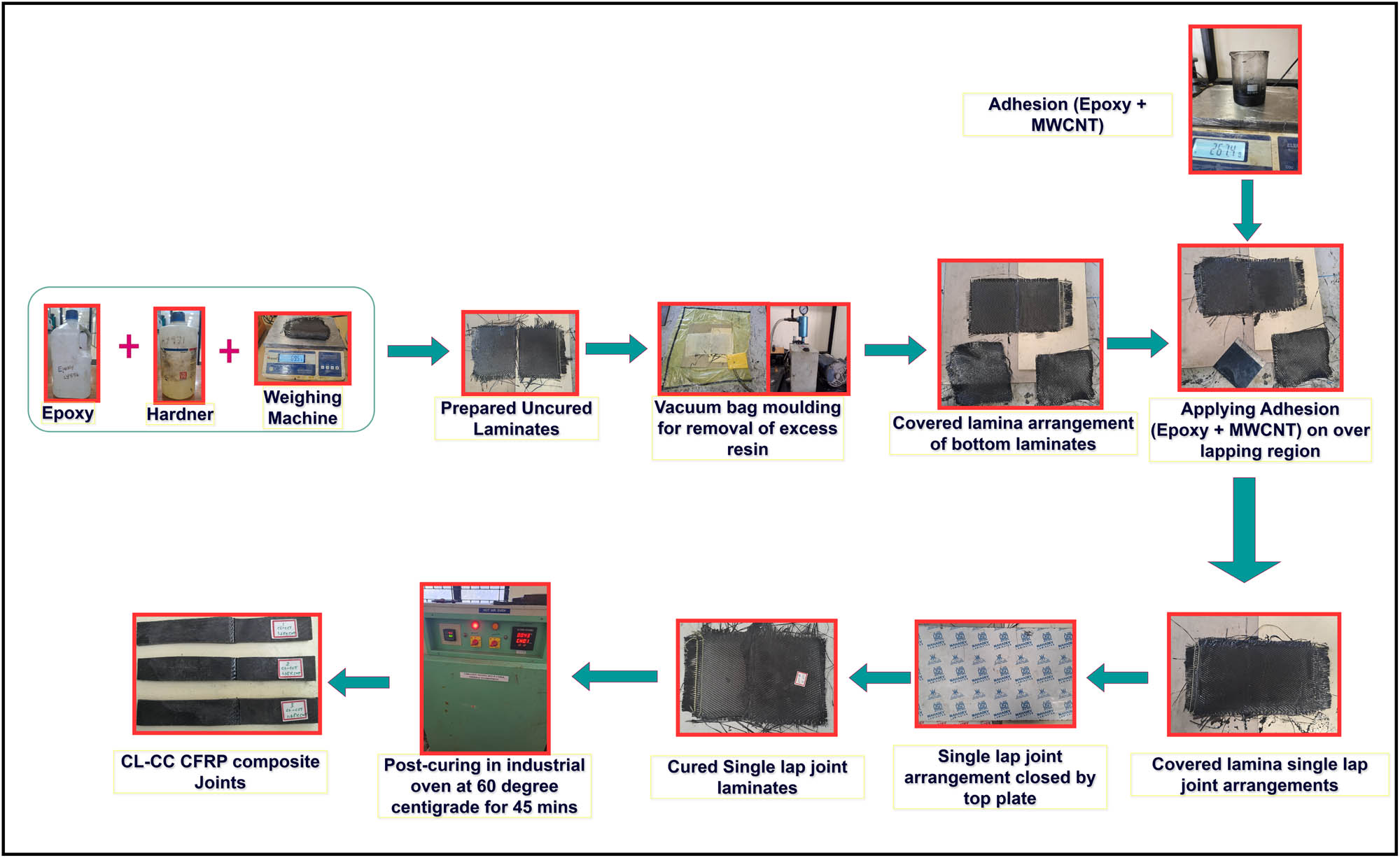

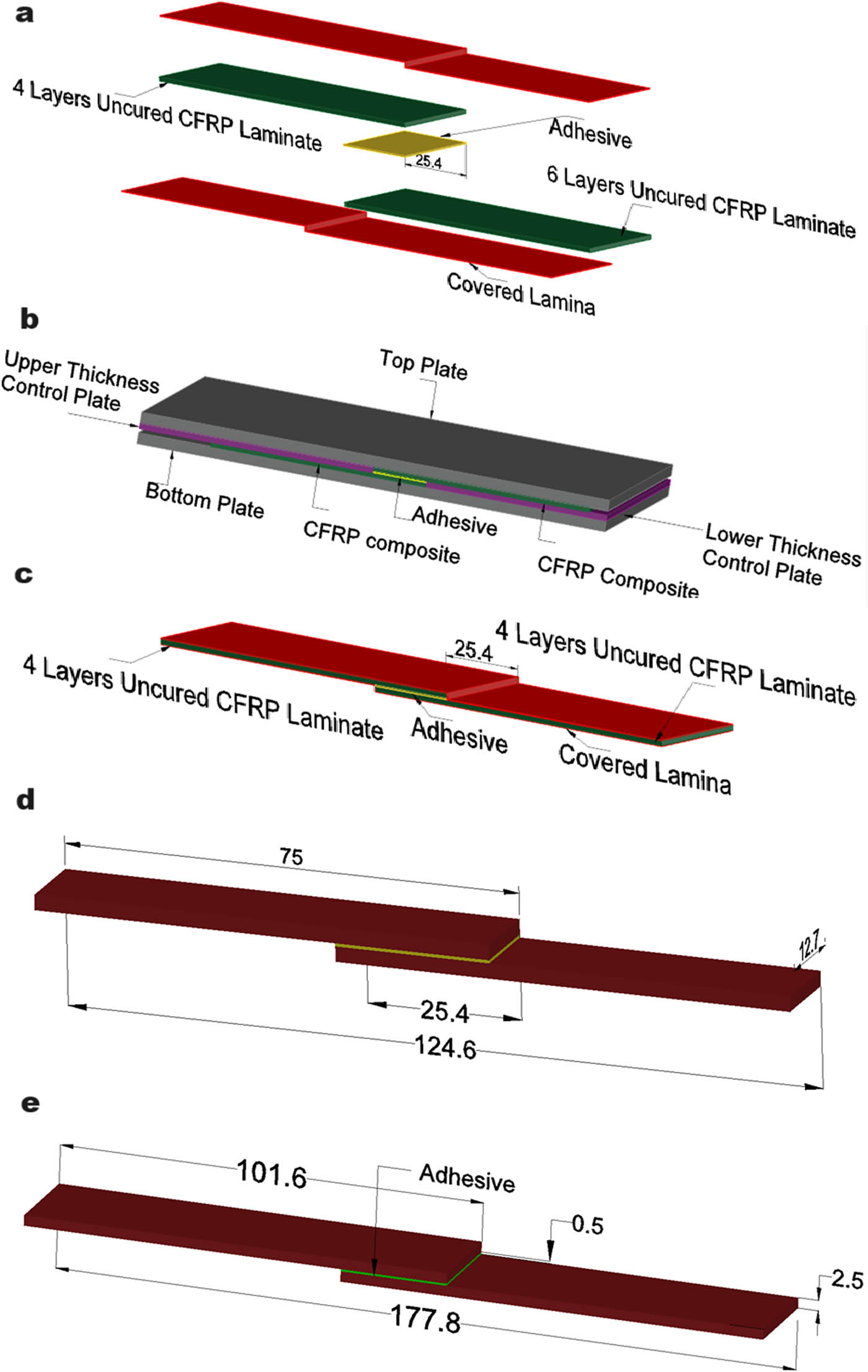

2.4 CL-CC-CFRP composite joint preparation

The study involved fabricating adhesive-bonded CFRP single-lap joint samples using co-curing adhesive-bonding methods. Figure 3 displays an accomplished single-lap connection made with CFRP composites using the co-curing bonding technique. A specially designed mould maintained the adhesive thickness in the CFRP single-lap joint at 0.5 mm. The top and bottom wood control plates and support plates, each measuring 3 mm in thickness, comprised the custom mould. The four-layer uncured CFRP composite specimens were arranged with overlapping gaps of 25.4 mm. There is a fifth and sixth lamina covered on both sides of the single lap joints. Figure 4(a)–(c) presents a custom-made mould, highlighting the covered lamina with CFRP single lap joint configuration. The adhesive, made up of MWCNTs and pure epoxy, was combined with a hardener using a weight ratio of 10:1. The adhesive was applied to both the regions of overlap and the covered lamina of the joints. With precision, the thickness control plate measures the adhesive thickness in the overlap zone at a precise value of 0.5 mm. Following their preparation, the composite joints underwent a two-step curing process. Initially, they were placed in a controlled environment for an entire day. Following that, they were transferred to an industrial oven set at a temperature of 60°C and left for 45 min. The flexural and vibration test sample dimensions were set following the specifications provided by ASTM D 790 and ASTM D 5868, respectively, which are illustrated in Figure 4(d) and (e).

CFRP single lap joint fabrication process.

Fabrication technique: (a) arrangement of adherends, (b) a specially designed mould, (c) single lap joint, (d) flexural test sample dimensions, and (e) vibration test sample dimensions.

2.5 Testing procedures

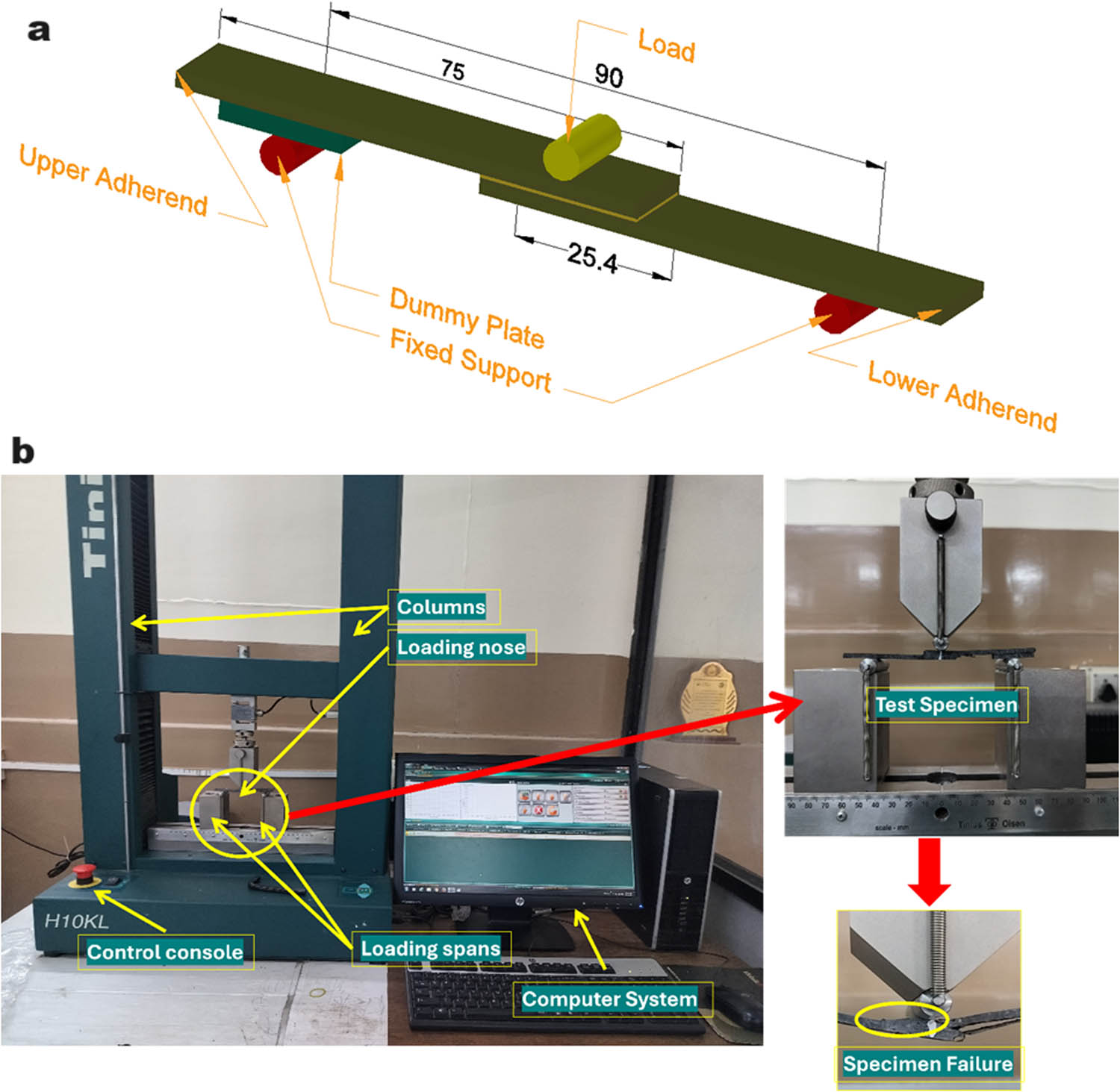

2.5.1 Flexural testing

The H10KL universal testing equipment, manufactured by Tinius Olsen, was employed to perform a flexural test under normal room temperature conditions. Figure 5(a) illustrates a schematic representation of a flexural test specimen for covered laminas with co-cured joining techniques (CL-CCT) CFRP composite single lap joints that is attached to the UTM machine fixture. This joint was produced in compliance with the specifications established by ASTM D 790. Three specimens were used for the flexural test, with each specimen representing a different weight percentage. The loading rate in this experiment was consistently maintained at 2 mm/min. In Figure 5(b), a specimen is loaded and then subjected to a flexural test.

(a) Flexural test specimen and (b) flexural test setup under loading conditions.

To examine the values of flexural stress and flexural strain on the adhesive joints, equations (1) and (2) were used.

where σ f is the flexural stress at the midpoint in MPa, W is the load at the midpoint, L is the span of support in mm, b is the joint’s width (mm), and d is the joint’s depth in mm.

where ε f represents the midpoint flexural strain in mm/mm and D is the displacement measured in mm at the joint’s centre.

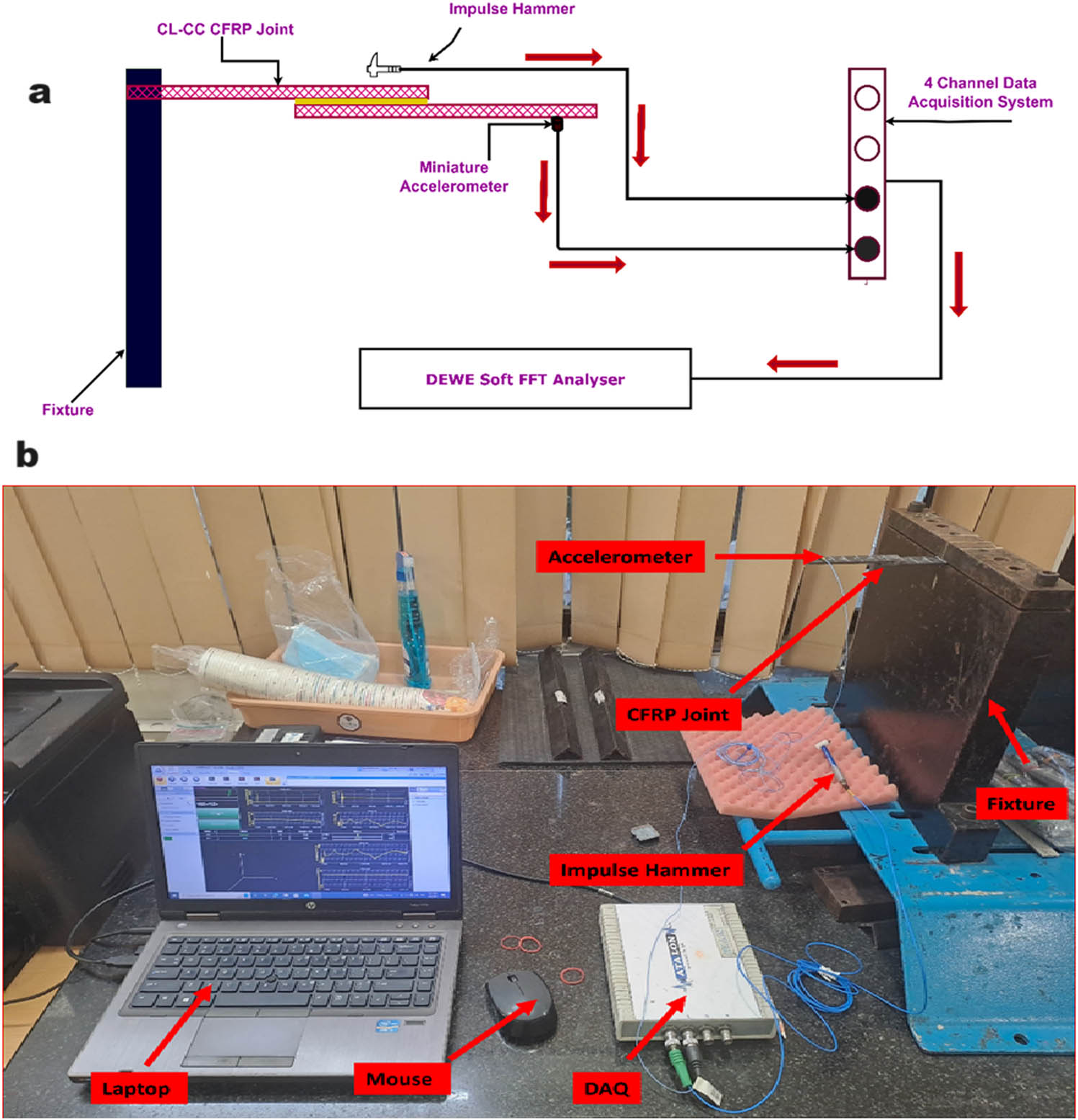

2.5.2 Free vibration testing

This study investigates the impact of varying weight percentages of MWCNTs on the inherent vibration characteristics of CL-CCT CFRP composite single-lap joints. The joints were created using a co-curing bonding process. A study was conducted to investigate the occurrence of free vibrations with fixed-free boundary conditions, utilizing three replicates of samples. An analysis was performed on the first three mode shapes to calculate the natural frequency of the CL-CCT CFRP single-lap joint samples. The CFRP composite junction was firmly attached to a stationary support at one end. Figure 6(a and b) illustrates the procedure of applying excitations using a Dytran (5800SL) impulse hammer, which has a sensitivity of 23.493 mV/N. Having been attached to the composite joint, a highly sensitive accelerometer (352C22/NC) with a sensitivity of 10.54 mV per g was utilized to gather the impact signal. The time–domain data were analysed using a fast Fourier transform with a data-collecting device that has four channels and a sampling rate of 52.13 kg samples per second. It accurately determined the natural frequency of composite joints using the DEWE software.

(a) Schematic diagram of the vibration test and (b) experimental vibration test setup with the CFRP joint specimen.

A Nyquist plot was generated using the circle fit technique to determine the damping ratio of the mode. The primary benefit of this method was a diminished impact on the ultimate result, achieved by decreasing the number of locations around the primary point of response and its intensity. A benefit of the half-power band approach is its ability to precisely compute the damping ratio, regardless of the proximity of the mode frequencies. Upon using the circle fit technique on the resonance peak data, it became evident that the data points were arranged circularly [43]. The damping value can be determined by using the circle fit method and applying the following formula:

where ω 0 implies the angular frequency at resonance, α 1 and α 2 denote the angle between angular frequencies, respectively, and ω 1 and ω 2 denote the angular frequencies, respectively [44].

2.5.3 Morphology testing

An FEI Quanta 250 FEG, a Thermo Fisher field emission scanning electron microscopy (FE-SEM) apparatus, was employed to examine the morphological characteristics of the fractured surface of single lap joints. The device obtains its principal electron supply from a Schottky field emission electron cannon. The features of this instrument are truly unique and unparalleled. The device operates within a voltage range of 5–30 kV and attains a magnification of 100,000× when employed in a high vacuum environment at 30 kV. Following the failure of flexural surface samples, the fractography of those samples was performed using a field emission scanning electron microscope. The primary aim was to ascertain the exact mechanism by which the fracture occurred. Prior to analysis, the specimens underwent resizing using a specialized cutting instrument to achieve dimensions of 10 mm × 10 mm × 2.5 mm. In order to enhance the electrical conductivity of the surfaces, a preparatory layer of gold was folio-coated.

3 Results and discussion

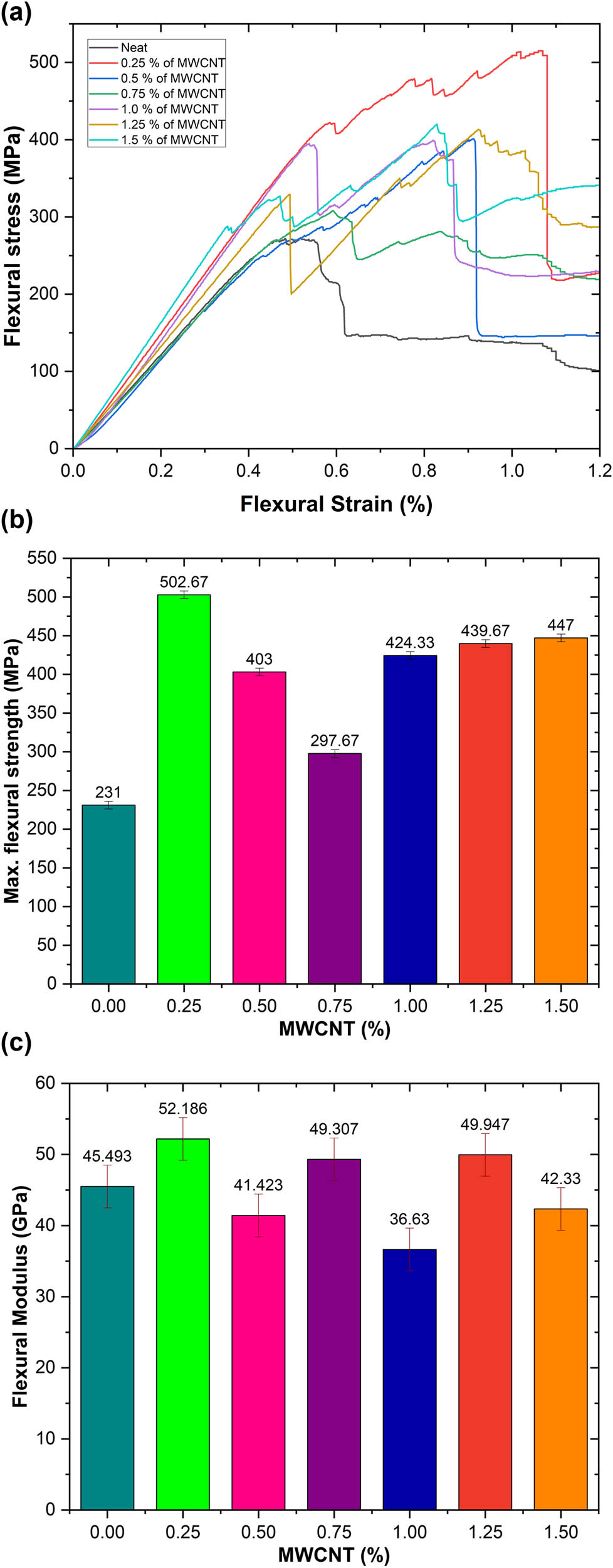

3.1 Flexural analysis

The flexural performance of adhesive-bonded joints in CL-CC CFRP composites has been improved by adding different weight percentages (0.25, 0.5, 0.75, 1.0, 1.25, and 1.5) of MWCNTs. The experimental data demonstrate the impact of MWCNTs on stress–strain, as shown in Figure 7(a). The addition of MWCNTs to the epoxy adhesive significantly enhances the energy-absorbing capabilities of composite joints, as shown in Figure 7(b). The outcome is a catastrophic collapse of a CL-CC CFRP junction with only epoxy as a bond, experimentation of which is proven to be true. MWCNTs have been included in epoxy adhesives to enhance their linear elasticity. The material’s capacity is enhanced to inhibit the initiation and propagation of matrix fractures. The addition of MWCNTs to the adhesive helps reduce the formation of concentrated stress when subjected to bending loads. It is well recognized that tension in fibres is less prone to debonding or failure when it is uniformly distributed. The research demonstrated that the adhesive containing MWCNTs exhibited significantly enhanced adhesion compared to the pure adhesive. The flexural strength of a composite joint made only of adhesive-based CL-CC CFRP is 231 MPa. The pure epoxy adhesive was modified with different concentrations of MWCNTs, namely, 0.25, 0.5, 0.75, 1.00, 1.25, and 1.5%. The flexural strength values for each concentration were found under the flexural loading. The findings indicated that the inclusion of 0.25% by weight of MWCNT resulted in a substantial enhancement in the flexural strength of the epoxy. The greatest value achieved was 502 MPa, representing a 118% increase compared to the pure epoxy adhesive.

(a) Flexural stress versus flexural strain, (b) flexural strength versus wt% of MWCNT content, and (c) flexural modulus versus wt% of MWCNT content.

Composite joints’ flexural modulus is substantially enhanced when MWCNTs are added to epoxy adhesive, as shown in Figure 7(c). The research showed that adding 0.25% MWCNTs by weight significantly increased the epoxy’s flexural modulus, reaching a maximum of 52.19 GPa. On the other hand, the strength of this material is 15% more than that of pure epoxy. The adhesive’s spreading and adhesion capabilities are diminished, and its viscosity increases with larger nanoparticle concentrations, both of which degrade the adherence. Additionally, due to their enormous surface area, nanoparticles have a tendency to aggregate, which causes tension to accumulate at the aggregated particles and a subsequent weakening of the material. A coarse surface developed on the adhesive layer, which increased its strength. Because of this layer, the glue was able to cling to the substrate much better. As a result, the usual joint’s resistance to bending stress was much improved [27]. Compared with the previous research work by the same author, the flexural strength and modulus of pure epoxy-based CL-CC CFRP composite joints exhibit a significant increase compared to those of pure epoxy CC-CFRP composite joints which is 118 and 91%, respectively. In comparison, the CL-CC CFRP composite joints with 0.25 wt% of MWCNTs show a significant increase of 374 and 109% compared to the pure epoxy CC-CFRP composite joints. Based on these findings, it has been observed that the covered lamina effectively functions as a load-bearing reinforcement when subjected to flexural load in the CFRP composite joints.

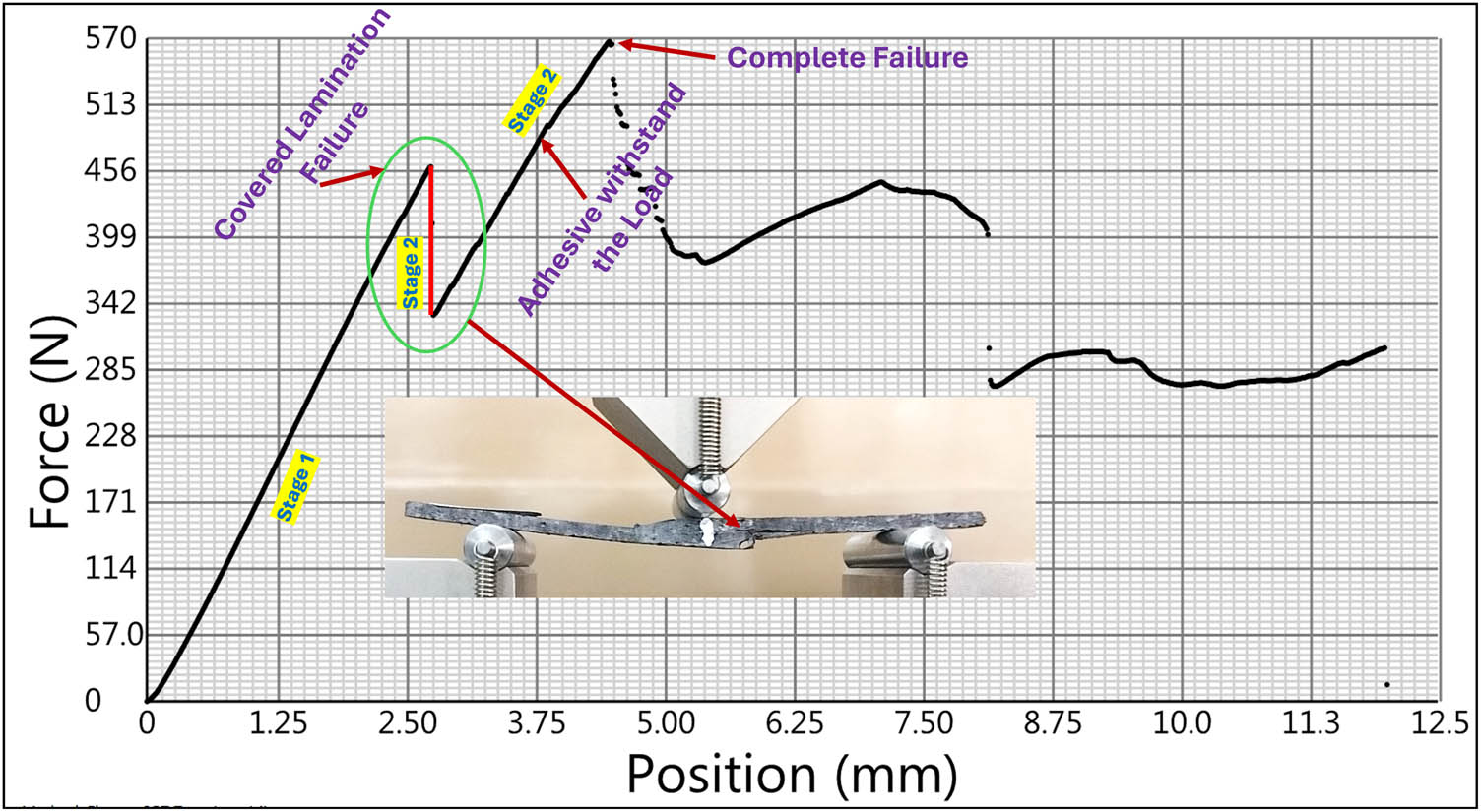

The load–displacement curves depict the bending load that leads to the failure of these joints made of CFRP composites, which is illustrated in Figure 8. When a flexural load is applied to the CL-CC CFRP composite joints, both the covered lamina and adhesive initially resist the load. Subsequent loading results in the initial failure occurring on both sides of the covered lamina in the overlapped region. At that moment, the load abruptly dropped without any deformation. Furthermore, the adhesive has the ability to endure further stress until it eventually breaks. The hand layup technique is used to construct joints to accommodate changing flexural stress and modulus, leading to varying composite thickness. Excessive quantities of adhesive containing MWCNTs lead to specimen slippage during testing, which in turn affects the point where the load is applied. To reduce the occurrence of specimen slips, it is advised to exercise meticulous control over the quantity of MWCNT-based glue used during the manufacturing process. In addition, maintaining a constant load application point throughout testing will aid in correctly evaluating the performance of the joints at varying levels of bending stress and modulus.

Failure mode of the CL-CC CFRP composite joint under flexural loading.

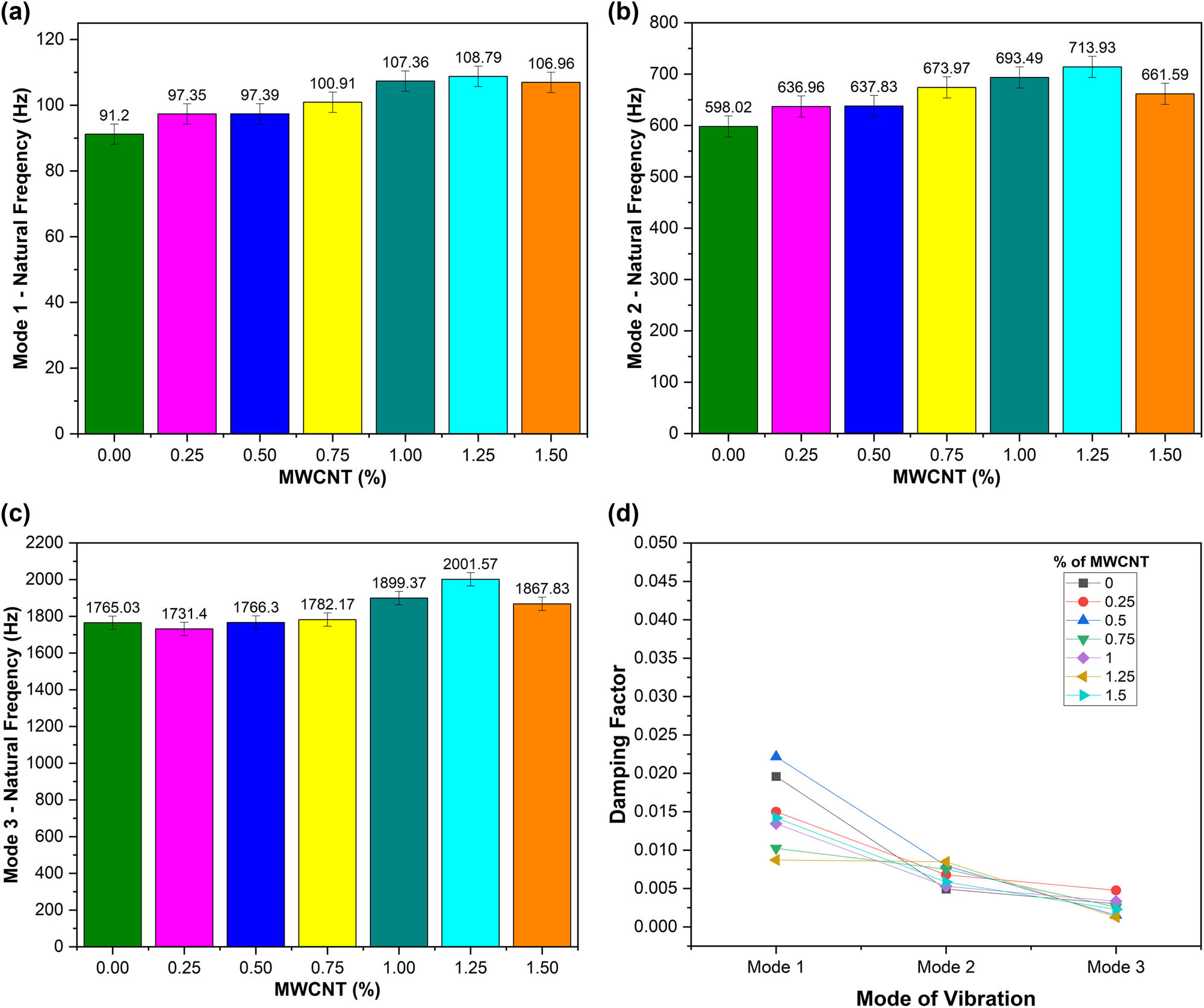

3.2 Vibrational behaviour analysis

Figure 9(a)–(c) displays the experimental examination of the natural frequencies of Mode-1, Mode-2, and Mode-3 in MWCNTs reinforced with adhesive-based CFRP composite joints, conducted by a free vibration test. The damping factor of the tested samples in three modes is shown in Figure 9(d). The CFRP composite joint specimen, bonded with pure epoxy adhesive, demonstrates natural frequencies of 91.20, 598.02, and 1765.03 Hz for Mode 1, Mode 2, and Mode 3, respectively. The pure epoxy-based CL-CC CFRP composite joint showed enhancements of 7, 9, and 9%, as compared to the joint made only from epoxy-based CC-CFRP composite joints. These results indicate that the CL-CC CFRP composite joint constructed with 1.25 wt% of MWCNTs combined with epoxy has achieved its maximum natural frequency. The frequencies corresponding to Mode 1, Mode 2, and Mode 3 are 108.79, 713.93, and 2001.57 Hz, respectively. These values exceed those of pure epoxy by 19, 19, and 13%, respectively. The natural frequencies of 1.25 wt% MWCNT-based CL-CC CFRP composite joints are 28, 30, and 24% greater than the natural frequencies of pure epoxy-based CC-CFRP composite joints in the three modes, respectively. The increase in natural frequency is attributed to the addition of MWCNTs, which enhances the stiffness and strength of the composite joint. These results demonstrate the potential for improved performance and durability in structural applications. Furthermore, the enhanced natural frequencies also suggest that the composite joint with MWCNTs is more resistant to vibrations and dynamic loads compared to pure epoxy joints. This indicates a promising direction for future research on advanced materials for structural engineering.

(a) Mode 1 – natural frequency versus wt% of MWCNT content, (b) Mode 2 – natural frequency versus wt% of MWCNT content, (c) Mode 3 – natural frequency versus wt% of MWCNT content, and (d) plot for damping factor versus mode of vibration corresponding to wt% of MWCNT content.

A considerable improvement in the natural frequency was achieved with the use of 1.25 wt% of MWCNT reinforcements with adhesive. The effective incorporation of MWCNTs led to an improvement in the bonding between the adherent and the adhesive. Therefore, it functioned as a precise mechanism to ensure the trustworthy bonding of the adhesive substance and the laminate plies that had been co-cured and cured together. It is possible to reduce the natural frequency of the CFRP composite junction by clumping, which is caused by the addition of an excessive amount of MWCNTs to the adhesive. In comparison to other specimens, the damping values of the lap joints that were reinforced with 1.25 wt% of MWCNTs and that were subjected to co-curing were found to be lower. The increased adhesion between the adherend and the adhesive leads to a decrease in the energy dissipation behaviour of the composite joints that have been co-cured. Therefore, it is possible to conclude that the drop in energy dissipation behaviour resulted in a fall in the inherent damping value of composite materials [13]. This suggests that there is an optimal amount of MWCNTs that can be added to the adhesive to maintain desired damping values in composite joints. Further research could explore different reinforcement methods or materials to improve the energy dissipation behaviour without sacrificing damping values.

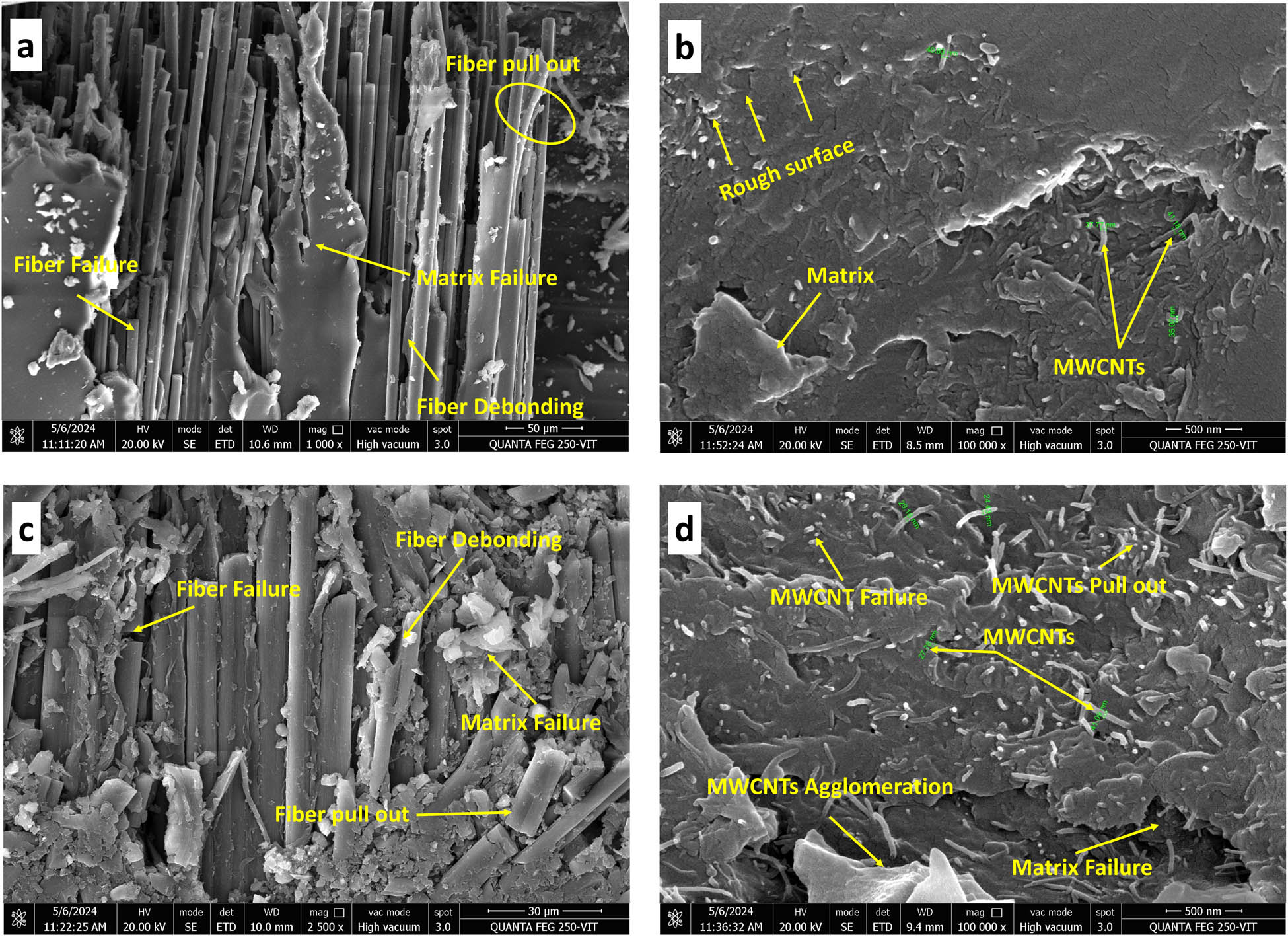

3.3 Microstructural analysis

An FE-SEM instrument developed by Thermo Fisher, FEI Quanta 250 FEG, was used to examine the surface morphology of fracture tested samples. This device relies on a Schottky field-emitting electron cannon as its main electron source. There are a number of unique aspects to this instrument. With a voltage of 30 kV and a high vacuum environment, the apparatus is capable of magnifying objects up to 100,000 times. Its operational voltage range is 5–30 kV. FESEM analysis of fractography followed previous efforts to comprehend flexural surface cracking. A precise cutting instrument was used to carefully trim the specimens to dimensions of 10 mm × 10 mm before analysis. To improve the surfaces’ electrical conductivity, they were gilded before scanning.

The presence of uniform and smooth failure surfaces reduced the adhesive’s ability to bond with the adherend in specimens without MWCNTs, as shown in Figure 10(a). Because of this, the joint’s strength and stability were diminished, and it became more easily damaged. The presence of MWCNTs in the adhesive zone caused the crack propagation trajectory to change to a longer one, as shown in Figure 10(b). Prolonging the failure process made it easier to reinforce the joint, which in turn enhanced the cohesive force. Through co-curing bonding techniques, a rough surface was formed on both adherends in an overlapping zone. As a result, the flexural strengths between the matrix and the fibre strengthened, and the bond between the two was further solidified. This resulted in improved cohesive and adhesive qualities. The capacity of layers to adhere to one another or interlayer adhesion is essential for bending force resistance because it stops layers from peeling apart and fibres from coming loose. By creating a rough area in the bonding zone and evenly dispersing MWCNTs, the flexural strength of the CL-CC CFRP composite joint was enhanced. Additionally, MWCNTs introduced additional nano-scale toughening mechanisms to adhesives, increasing their fracture resistance. This made adhesive-bonded joints more prone to fracture [45,46].

FESEM images of the fractured surfaces under a flexural load. (a) Neat CL-CCT, (b) 0.25% of MWCNT CL-CCT, (c) 0.5% of MWCNT CL-CCT, and (d) 0.75% of MWCNT CL-CCT.

Figure 10(c) shows that the probability of crack formation and propagation is reduced when there are uneven surfaces close to the bonding region. Increased flexural strength and delayed joint failure were the end outcomes. Due to its emphasis on uniform MWCNT dispersion and strong matrix–MWCNT bonding, the described procedure is effective for co-cured joints. The co-cured joint showed more clusters of nanoparticles as the percentage of MWCNTs increased. This is because MWCNTs increased the joint’s strength. Compared to joints devoid of MWCNTs, those reinforced with these nanoparticles showed lower flexural strength and higher stress concentration. Nanoparticle aggregation in the adhesive layer substantially increased the weight percentage, as shown in Figure 10(d). An increase in stress concentration was noted when MWCNTs were present. The co-cured composite joints could only support a certain amount of weight and were thus less likely to fail. From these results, in CL-CC CFRP composite joints, the flexural strength improved by three techniques – co-curing, covered lamina, and matrix modification.

4 Statistical analysis

A statistical method was used to analyse the relationships among the means of input and output variables. There are various statistical testing techniques, such as hypothesis testing, confidence intervals, regression analysis, and ANOVA. Based on the categories of independent and dependent variables, the testing techniques were selected. In this research, statistical analyses were performed on every parameter assessed using JMP Pro 17. The first step of this analysis was to ensure a normal distribution of the data, such as natural frequency across all three modes, flexural strength, and modulus. A normal quantile plot was used. After confirmation of data that were normally distributed, the data were applied to statistical analysis. In this research, independent variables were considered categorical and dependent variables were considered continuous. Due to both dependent and independent variable groups, ANOVA was conducted to examine the flexural strength, flexural modulus, and natural frequency of different modes in CL-CC CFRP composite single-lap joints with varying weight percentages of MWCNT additives. According to the findings presented in Table 1, this analysis indicates that the data conform to a normal distribution. The primary objective of this study was to determine if there were any significant variations in the properties of CFRP single-lap joints with the addition of MWCNTs, specifically in terms of their weights. All attributes examined yielded a P-value below 0.05, as indicated in Table 2. When combined with CL-CC CFRP composite single-lap joints, there is a notable variation in the average weights of the MWCNTs (0, 0.25, 0.75, 1.0, 1.25, and 1.5). This discrepancy is indicated by the 95% confidence level. According to the results, the amount of MWCNTs in the material’s weight has a notable impact on its flexural strength, flexural modulus, and natural frequency.

Normal quantile plot and one-way ANOVA

| Parameters | Normal quantile plot for experimental results | One-way ANOVA for experimental results |

|---|---|---|

| Flexural stress (MPa) |

|

|

| Flexural modulus (MPa) |

|

|

| Mode 1 – natural frequency |

|

|

| Mode 2 – natural frequency |

|

|

| Mode 3 – natural frequency |

|

|

ANOVA of various wt% of MWCNTs of CL-CC CFRP joint specimens

| Parameters | Source | Degree of freedom | Sum of squares | Mean square | F | P-value |

|---|---|---|---|---|---|---|

| Flexural stress (MPa) | % of MWCNTs | 6 | 204566.00 | 34094.3 | 8.7965 | 0.0004* |

| Error | 14 | 54262.67 | 3875.9 | |||

| C. Total | 20 | 258828.67 | ||||

| Flexural modulus (MPa) | % of MWCNTs | 6 | 718,496,834 | 119,749,472 | 5.0464 | 0.0060* |

| Error | 14 | 332,214,507 | 23,729,608 | |||

| C. Total | 20 | 1,050,711,341 | ||||

| Mode 1 – natural frequency (Hz) | % of MWCNTs | 6 | 773.2106 | 128.868 | 4.5147 | 0.0095* |

| Error | 14 | 399.6186 | 28.544 | |||

| C. Total | 20 | 1172.8292 | ||||

| Mode 2 – natural frequency (Hz) | % of MWCNTs | 6 | 27267.704 | 4544.62 | 3.5749 | 0.0232* |

| Error | 14 | 17797.821 | 1271.27 | |||

| C. Total | 20 | 45065.524 | ||||

| Mode 3 – natural frequency (Hz) | % of MWCNTs | 6 | 167893.92 | 27982.3 | 7.0262 | 0.0013* |

| Error | 14 | 55755.79 | 3982.6 | |||

| C. Total | 20 | 223649.72 |

Bold values denote statistical significance at the p < 0.05 level.

*A p-value less than 0.05 is typically considered to be statistically significant, in which case the null hypothesis should be rejected.

*P-Value greater than 0.05 is not considered to be statistically significant, meaning the null hypothesis should not be rejected.

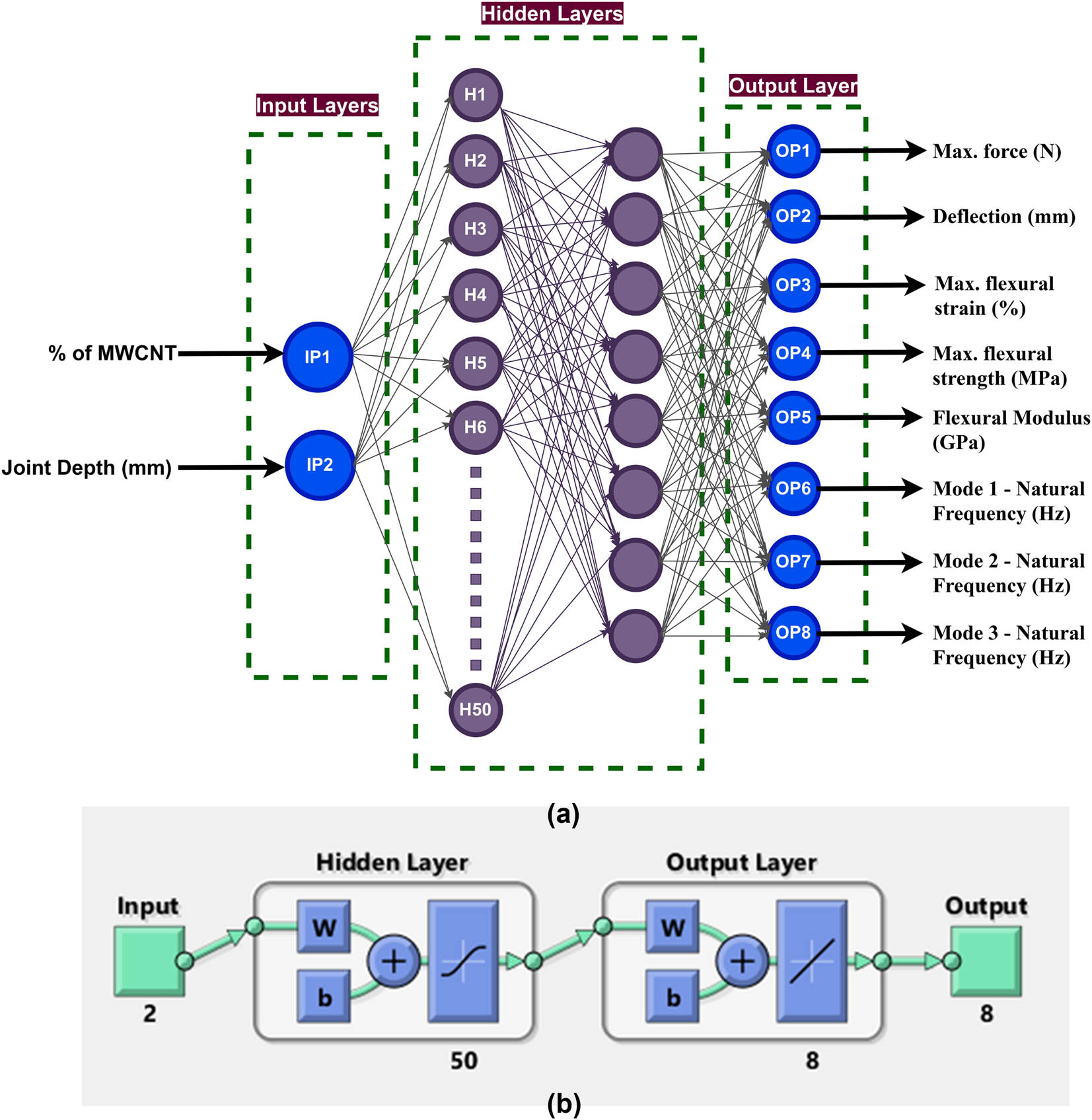

5 Prediction using the ANN

The ANN model faithfully mimics the anatomical and functional features of the real neurological system. For processes that require a high degree of rigidity, like the bending and oscillation properties of CFRP composite joints made of CL-CCT, this performance boost can be quite useful. We must think about how the parameters might affect the material’s properties when we choose them. A system of interconnected systems, or neurons, was used to find the best combination of joint depth and reinforcement filler. An input, an output, and a hidden component made up the scheme. As shown in Figure 11(a), a careful analysis of various critical parameters is required to ascertain the number of hidden layers in an ANN. The generated ANN model using the MATLAB ANN tool is shown in Figure 11(b). The intricacies of the subject under examination are of utmost significance. This study highlights the use of complex networks and specialized numerical layers in analysing intricate data patterns and issues. Fifty hidden layers were discovered during this investigation. After conducting numerous tests and evaluations, including training the network on one dataset and confirming its functionality on another, this condition was ultimately chosen.

(a) Input and output parameters in the ANN model. (b) Generated ANN model.

The main consideration behind this decision was the network’s capacity to effectively adjust to new information while upholding a well-balanced model complexity. Both the joint depth and weight percentage of MWCNTs are among the four input factors considered in this study. Every parameter on the input layer is controlled by a neuron. Empirical measurements are utilized to train the neural network model and establish the correlation between the input and output data. The input data consist of variables that range from 0 to 1. The eight neurons comprising the output layer are specifically tailored to represent various characteristics of the CL-CCT CFRP composite joints. In addition, these parameters encompass the maximum flexural strain, maximum flexural strength, flexural modulus, maximum force, deflection, and natural frequencies of the first, second, and third modes.

It randomly divides experimental data to 70% for training, 15% for testing, and 15% for validation. A significant portion of the data is allocated for training purposes, while a smaller portion is reserved for testing and validating the experimental outcomes. Choosing an appropriate cycle number is essential for ensuring reliable training in neural network algorithms. The research utilized a feed-forward back-propagation methodology to predict the vibration behaviour and flexural properties of CL-CCT CFRP composites with adhesively bonded joints. The MATLAB software was employed to achieve this objective.

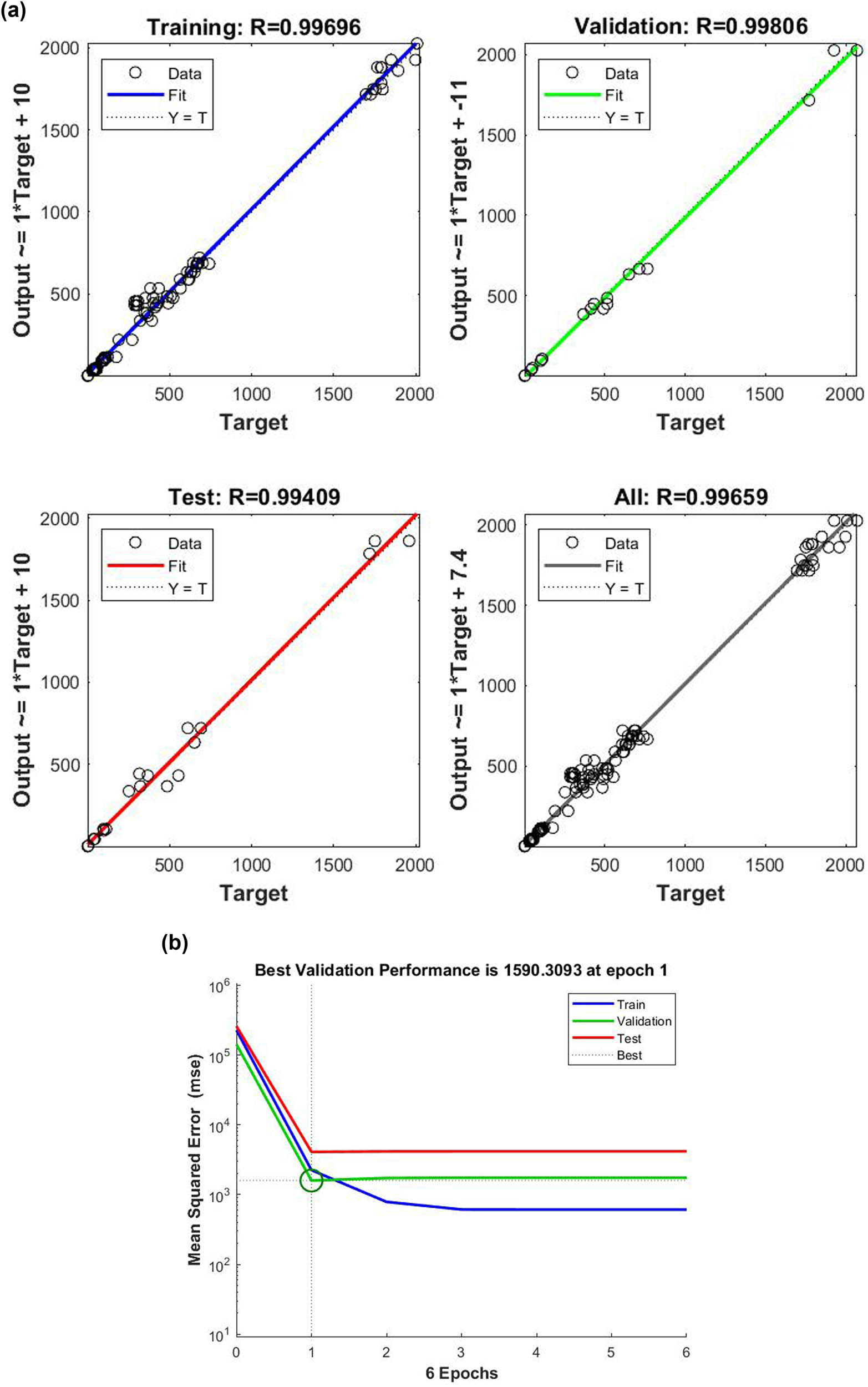

Using the Levenberg–Marquardt ANN, linear regression predictions were made, and the percentage error between the network’s output and the experimental data was calculated. In Figure 12(a), it is evident that the neural network Levenberg–Marquardt model outperformed the experimental results in the training set. Based on prior research, the model demonstrates a slight improvement compared to other models when considering the validation set. Based on the performance of the validation set, it appears that the developed model has a higher prediction accuracy. The ANN model outperformed other models in this regard. It tested the models’ predictive capabilities involved using unseen data. The results indicate that the ANN model demonstrates strong generalization capabilities. Scatter plots in Figure 12(b) showcase the correlation between the identified output characteristics and the predicted results of the ANN models. Once the coefficient of determination reaches high values for training, validation, testing, and overall, the network is selected for forecasting. These values are R = 0.99696, 0.99806, 0.98409, and 0.99659, respectively. Figure 12(b) demonstrates the impressive accuracy of predictions made by models trained using ANNs for the vibration and flexural properties of CL-CCT CFRP composite joints. In addition, the ANN model demonstrates significantly lower error values compared to the existing literature. Table 3 shows that the confirmation of experimental results with ANN predicted results with minimal error.

(a) Performance curves of the ANN for predicting the best wt% of MWCNTs and joint depth for their targeted properties and (b) regression analysis of the ANN for predicting the best wt% of MWCNTs and joint depth for their targeted properties.

Confirmation of experimental results with ANN predicted results

| Factors | Analysis | Output responses | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| % of MWCNT | Joint depth (mm) | Max. force (N) | Deflection (mm) | Max. flexural strain (%) | Max. flexural strength (MPa) | Flexural modulus (GPa) | Mode 1 – natural frequency (Hz) | Mode 2 – natural frequency (Hz) | Mode 3 – natural frequency (Hz) | |

| 0 | 2.63 | Experiment | 149.50 | 2.65 | 0.52 | 231.00 | 45.493 | 91.20 | 598.02 | 1765.03 |

| ANN prediction | 140.67 | 2.703 | 0.53 | 217.33 | 41.886 | 91.20 | 598.02 | 1765.03 | ||

| % of error | 5.91 | 2.11 | 2.10 | 5.92 | 7.93 | 0.00 | 0.00 | 0.00 | ||

| 0.25 | 2.75 | Experiment | 358.00 | 4.75 | 0.97 | 502.67 | 52.186 | 97.35 | 636.96 | 1731.40 |

| ANN prediction | 358.00 | 4.750 | 0.97 | 502.67 | 52.186 | 97.35 | 636.96 | 1731.40 | ||

| % of error | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 0.5 | 2.91 | Experiment | 321.33 | 4.50 | 0.97 | 403.00 | 41.423 | 97.39 | 637.83 | 1766.30 |

| ANN prediction | 320.00 | 4.910 | 1.06 | 401.00 | 37.830 | 94.26 | 633.21 | 1789.70 | ||

| % of error | 0.41 | 9.11 | 9.24 | 0.50 | 8.67 | 3.21 | 0.72 | 1.32 | ||

| 0.75 | 3.25 | Experiment | 296.00 | 2.52 | 0.61 | 297.67 | 49.308 | 100.91 | 673.97 | 1782.17 |

| ANN prediction | 296.00 | 2.515 | 0.61 | 297.67 | 49.308 | 100.91 | 673.97 | 1782.17 | ||

| % of error | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 1 | 3.4 | Experiment | 461.33 | 4.64 | 1.17 | 424.33 | 36.631 | 107.36 | 693.49 | 1899.37 |

| ANN prediction | 434.00 | 4.510 | 1.13 | 399.00 | 35.310 | 109.07 | 666.19 | 1850.40 | ||

| % of error | 5.92 | 2.73 | 3.14 | 5.97 | 3.61 | 1.59 | 3.94 | 2.58 | ||

| 1.25 | 3.34 | Experiment | 460.00 | 4.35 | 1.07 | 439.67 | 40.947 | 108.79 | 713.93 | 2001.57 |

| ANN prediction | 473.50 | 4.495 | 1.11 | 452.50 | 40.721 | 107.53 | 688.15 | 1967.60 | ||

| % of error | 2.93 | 3.33 | 3.42 | 2.92 | 0.55 | 1.16 | 3.61 | 1.70 | ||

| 1.5 | 3.05 | Experiment | 391.67 | 4.65 | 1.05 | 447.00 | 42.334 | 106.96 | 661.59 | 1867.83 |

| ANN prediction | 403.50 | 4.835 | 1.09 | 460.50 | 41.807 | 105.24 | 650.92 | 1855.40 | ||

| % of error | 3.02 | 3.90 | 3.93 | 3.02 | 1.25 | 1.60 | 1.61 | 0.67 | ||

The bold font indicates the minimum error percentage.

6 Conclusions

The purpose of this study is to investigate the effects of adhesive-bonded joints in CL-CC CFRP by employing MWCNTs as a reinforcing agent in a pure epoxy adhesive. To fabricate the joints, a combination of vacuum bag hand layup and covered lamina with co-curing bonding techniques was selected as the method of choice. In addition, the flexural properties were evaluated using a three-point bending test. Furthermore, the vibration characteristics were investigated using a free vibration test that made use of a cantilever beam boundary condition. Based on the investigation, the following assertion can be derived as the inference:

The flexural strength and modulus of the MWCNT-mixed epoxy adhesive at a weight percentage of 0.25% are significantly higher than those of pure epoxy. Specifically, the flexural strength has increased by 118%, while the modulus has increased by 15%. The addition of MWCNTs enhances the mechanical properties of the epoxy adhesive, making it a promising option for applications requiring high strength and stiffness.

By incorporating 1.25 wt% of MWCNTs into the epoxy, the vibration characteristics of CL-CC CFRP composite joints were effectively improved. The natural frequencies of Modes 1, 2, and 3 were found to exhibit improvements of 19, 19, and 13%, respectively, when compared to the value of pure epoxy. The addition of MWCNTs also increased the damping ratio of the composite joints, indicating enhanced energy dissipation capabilities. These improvements are crucial for enhancing the overall performance and durability of CL-CC CFRP composite joints in various applications.

According to the findings of morphological analysis, the bonding that occurred at the interface resulted in an improvement in the flexural properties of the CL-CC CFRP composite joints. Many distinguishable characteristics play a part in determining the bonding property at the interface, as shown in the images obtained from FE-SEM. Several phenomena fall under this category, including crack generation, crack propagation, fibre pullout, and matrix pullout. These phenomena can be influenced by factors such as the surface roughness of materials, the presence of contaminants, and the curing process. Understanding these interactions is crucial for optimizing the performance of composite joints in various applications.

A level of confidence of 95% was reached regarding the findings, which demonstrated statistical significance. In situations where the F-value is higher than the critical F-values and the p-value is lower than 0.05, the conclusion can be stated without any reservations. This level of confidence indicates that the results are unlikely to have occurred by chance. Therefore, the findings can be considered reliable and valid for concluding this study.

The mean squared error values that the ANN produced during the training, validation, and testing phases were R = 0.99696, R = 0.99806, and R = 0.98409, respectively. These values were obtained throughout the program. The overall MSE was achieved at R = 0.99659. Based on the findings of the analytical study, it is hypothesized that the application of the ANN methodology could be an exceptionally effective method for predicting outcomes. The consistently high R-values obtained during the training, validation, and testing phases indicate a strong performance of the ANN model. This suggests that the ANN methodology has great potential for accurate outcome predictions in future applications.

Acknowledgments

The authors thank the Advanced Vibrations Lab and Composite Lab in the School of Mechanical Engineering, VIT Vellore, for providing access to their facilities. We would also like to acknowledge and thank Universiti Pertahanan Nasional Malaysia (UPNM) for their collaboration and support.

-

Funding information: The authors would like to express gratitude for the financial support from the Universiti Pertahanan Nasional Malaysia (UPNM).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Karthikeyan N, Naveen J. Progress in adhesive-bonded composite joints: A comprehensive review. J Reinf Plast Compos. 2024. 10.1177/07316844241248236.Search in Google Scholar

[2] Dhilipkumar T, Rajesh M. Influence of manufacturing process and GFRP pin loading on shear and dynamic behaviour of composite joints. J Adhes. 2023;99:538–57. 10.1080/00218464.2022.2025782.Search in Google Scholar

[3] Dhilipkumar T, Rajesh M. Enhancing shear strength and structural stiffness of composite joint with carbon nanotube reinforced adhesive through co-bonding technique. J Adhes Sci Technol. 2022;36:2143–57. 10.1080/01694243.2021.2002066.Search in Google Scholar

[4] Karthikeyan N, Naveen J. Effect of surface modified adherend and nanofiller modified adhesives on the shear behaviour of single lap joints: a mini review. J Adhes Sci Technol. 2024;1–20. 10.1080/01694243.2024.2362297.Search in Google Scholar

[5] Gualberto HR, do Carmo Amorim F, Costa HRM. A review of the relationship between design factors and environmental agents regarding adhesive bonded joints. J Braz Soc Mech Sci Eng. 2021;43:389. 10.1007/s40430-021-03105-2.Search in Google Scholar

[6] Kaybal HB, Ulus H. Comparative analysis of thermoplastic and thermoset adhesives performance and the influence on failure analysis in jointed elium ‐based composite structures. Polym Compos. 2024;45:3474–92. 10.1002/pc.28003.Search in Google Scholar

[7] Tınastepe MT, Kaybal HB, Ulus H, Erdal MO, Çetin ME, Avcı A. Quasi-Static tensile loading performance of Bonded, Bolted, and hybrid Bonded-Bolted Carbon-to-Carbon composite Joints: Effect of recycled polystyrene nanofiber interleaving. Compos Struct. 2023;323:117445. 10.1016/j.compstruct.2023.117445.Search in Google Scholar

[8] Yildirim C, Ulus H, Beylergil B, Al-Nadhari A, Topal S, Yildiz M. Tailoring adherend surfaces for enhanced bonding in CF/PEKK composites: Comparative analysis of atmospheric plasma activation and conventional treatments. Compos Part A Appl Sci Manuf. 2024;180:108101. 10.1016/j.compositesa.2024.108101.Search in Google Scholar

[9] Budhe S, Banea MD, de Barros S, da Silva LFM. An updated review of adhesively bonded joints in composite materials. Int J Adhes Adhes. 2017;72:30–42. 10.1016/j.ijadhadh.2016.10.010.Search in Google Scholar

[10] Venugopal A, Sudhagar PE. Enhancing shear strength of single lap composite adhesive joint with graphene nano-particles and Z-pins reinforcement through co-curing technique. Tribol Int. 2024;195:109636. 10.1016/j.triboint.2024.109636.Search in Google Scholar

[11] Dhilipkumar T, Rajesh M. Enhancing strength and stiffness of composite joint through co-cure technique. Compos Commun. 2021;27:100878. 10.1016/j.coco.2021.100878.Search in Google Scholar

[12] Dhilipkumar T, Rajesh M. Multi-scale strengthening of co-cure joints through multiwall carbon nanotube modified adhesive and GFRP pins. Compos Commun. 2022;29:101056. 10.1016/j.coco.2022.101056.Search in Google Scholar

[13] Dhilipkumar T, Rajesh M. Influence of glass fibre reinforced polymer composite pin reinforcement on shear and dynamic behaviour of composite joint manufactured through co-cure technique. J Compos Mater. 2022;56:1799–809. 10.1177/00219983221088900.Search in Google Scholar

[14] Layec J, Ansart F, Duluard S, Turq V, Aufray M, Labeau MP. Development of new surface treatments for the adhesive bonding of aluminum surfaces. Int J Adhes Adhes. 2022;117:103006. 10.1016/j.ijadhadh.2021.103006.Search in Google Scholar

[15] Yudhanto A, Alfano M, Lubineau G. Surface preparation strategies in secondary bonded thermoset-based composite materials: A review. Compos Part A Appl Sci Manuf. 2021;147:106443. 10.1016/j.compositesa.2021.106443.Search in Google Scholar

[16] Ejaz H, Saboor D, Bin Sohail MS, Mansoor AH. Effect of various surface treatments on lap shear strength of aluminum adhesive joints. Proceedings of 2022 19th International Bhurban Conference on Applied Sciences and Technology, IBCAST 2022. Institute of Electrical and Electronics Engineers Inc. 2022. p. 76–81. 10.1109/IBCAST54850.2022.9990536.Search in Google Scholar

[17] Liu J, Xue Y, Dong X, Fan Y, Hao H, Wang X. Review of the surface treatment process for the adhesive matrix of composite materials. Int J Adhes Adhes. 2023;126:103446. 10.1016/j.ijadhadh.2023.103446.Search in Google Scholar

[18] Xu LY, Lu JR, Li KM, Hu J. Experimental study of CFRP laser surface modification and bonding characteristics of CFRP/Al6061 heterogeneous joints. Compos Struct. 2022;283:115030. 10.1016/j.compstruct.2021.115030.Search in Google Scholar

[19] Guo L, Liu J, Xia H, Li X, Zhang X, Yang H. Effect of surface morphology characteristic parameters on the shear strength of aluminum bonded joints. Int J Solids Struct. 2022;238:111420. 10.1016/j.ijsolstr.2022.111420.Search in Google Scholar

[20] Ou J, Shao Y, Huang C, Bi X. Bond behavior of CFRP sheets-to-steel shear joints with different steel surface treatments. Compos Struct. 2023;322:117376. 10.1016/j.compstruct.2023.117376.Search in Google Scholar

[21] Safari A, Farahani M, Ghabezi P. Experimental study on the influences of different surface treatment processes and adhesive type on the aluminum adhesive-bonded joint strength. Mech Based Des Struct Mach. 2022;50:2400–13. 10.1080/15397734.2020.1777876.Search in Google Scholar

[22] Arpitha GR, Mohit H, Madhu P, Verma A. Effect of sugarcane bagasse and alumina reinforcements on physical, mechanical, and thermal characteristics of epoxy composites using artificial neural networks and response surface methodology. Biomass Convers Biorefin. 2023;14:12539–57. 10.1007/s13399-023-03886-7.Search in Google Scholar

[23] Wang W, Wang Z, Guo R, Xian G. A novel treatment: effects of nano-sized and micro-sized Al2O3 on steel surface for the shear strength of epoxy–steel single-lap joints. Polymers (Basel). 2022;14(17):3438. 10.3390/polym14173438.Search in Google Scholar PubMed PubMed Central

[24] Yadollahi M, Barkhordari S, Gholamali I, Farhoudian S. Effect of nanofillers on adhesion strength of steel joints bonded with acrylic adhesives. Sci Technol Weld Join. 2015;20:443–50. 10.1179/1362171815Y.0000000037.Search in Google Scholar

[25] Trivedi DN, Rachchh NV. Graphene and its application in thermoplastic polymers as nano-filler – A review. Polym (Guildf). 2022;240:124486. 10.1016/j.polymer.2021.124486.Search in Google Scholar

[26] Ayatollahi MR, Nemati Giv A, Razavi SMJ, Khoramishad H. Mechanical properties of adhesively single lap-bonded joints reinforced with multi-walled carbon nanotubes and silica nanoparticles. J Adhes. 2017;93:896–913. 10.1080/00218464.2016.1187069.Search in Google Scholar

[27] Venugopal A, Sudhagar PE. Enhancing shear and flexural strength of single lap composite joints with a graphene nanoparticle‐reinforced adhesive through a co‐curing technique. Polym Compos. 2023;45(5):4202–20. 10.1002/pc.28053.Search in Google Scholar

[28] Kumar M, Saini JS, Bhunia H. Investigations on the strength of mechanical joints prepared from carbon fiber laminates with addition of carbon nanotubes. J Mech Sci Technol. 2020;34:1059–70. 10.1007/s12206-020-0208-2.Search in Google Scholar

[29] Khoramishad H, Ashofteh RS, Mobasheri M, Berto F. Temperature dependence of the shear strength in adhesively bonded joints reinforced with multi-walled carbon nanotubes. Eng Fract Mech. 2018;199:179–87. 10.1016/j.engfracmech.2018.05.032.Search in Google Scholar

[30] Srivastava VK, Gries T, Quadflieg T, Mohr B, Kolloch M, Kumar P. Fracture behavior of adhesively bonded carbon fabric composite plates with nano materials filled polymer matrix under DCB, ENF and SLS tests. Eng Fract Mech. 2018;202:275–87. 10.1016/j.engfracmech.2018.09.030.Search in Google Scholar

[31] Ravindran AR, Ladani RB, Wang CH, Mouritz AP. Design considerations in the strengthening of composite lap joints using metal z-pins. Compos Part A Appl Sci Manuf. 2022;160:107031. 10.1016/j.compositesa.2022.107031.Search in Google Scholar

[32] Campilho RDSG, Pinto AMG, Banea MD, Silva RF, da Silva LFM. Strength improvement of adhesively-bonded joints using a reverse-bent geometry. J Adhes Sci Technol. 2011;25:2351–68. 10.1163/016942411X580081.Search in Google Scholar

[33] Hiremath VS, Reddy MD, Reddy RM, Naveen J, Chand RP. Enhancing shear strength in 3D printed single lap composite joints: A multi-faceted exploration of GNP integration, print orientation, utilizing artificial neural networks, and dynamic analysis. J Appl Polym Sci. 2024;141(23):e55469. 10.1002/app.55469.Search in Google Scholar

[34] Venugopal A, Sudhagar PE. Dual-scale reinforcement of co-cure single lap joints through graphene nanoparticles and CFRP Z-pin. Mater Lett. 2024;370:136833. 10.1016/j.matlet.2024.136833.Search in Google Scholar

[35] Quan D, Zhao G, Scarselli G, Alderliesten R. Co-curing bonding of carbon fibre/epoxy composite joints with excellent structure integrity using carbon fibre/PEEK tapes. Compos Sci Technol. 2022;227:109567. 10.1016/j.compscitech.2022.109567.Search in Google Scholar

[36] Tefera G, Bright G, Adali S. Flexural and shear properties of CFRP laminates reinforced with functionalized multiwalled CNTs. Nanocomposites. 2021;7:141–53. 10.1080/20550324.2021.1961507.Search in Google Scholar

[37] Vijaya Rajan V, Gnanavel BK. An experimental investigation on enhancing the strength and stiffness of GFRP co-cured composite joint: effect of glass powder addition. Mater Res Express. 2022;9:085301. 10.1088/2053-1591/ac8396.Search in Google Scholar

[38] Mohit H, Sanjay MR, Siengchin S, Kanaan B, Ali V, Alarifi IM, et al. Predicting physico-mechanical and thermal properties of loofa cylindrica fibers and Al2O3/Al-SiC reinforced polymer hybrid composites using artificial neural network techniques. Constr Build Mater. 2023;409:133901. 10.1016/j.conbuildmat.2023.133901.Search in Google Scholar

[39] Mohit H, Sanjay MR, Siengchin S, Kanaan B, Ali V, Alarifi IM, et al. Machine learning-based prediction of mechanical and thermal properties of nickel/cobalt/ferrous and dried leaves fiber-reinforced polymer hybrid composites. Polym Compos. 2024;45:489–506. 10.1002/pc.27793.Search in Google Scholar

[40] Kradinov V, Madenci E, Ambur DR. Application of genetic algorithm for optimum design of bolted composite lap joints. Compos Struct. 2007;77:148–59. 10.1016/j.compstruct.2005.06.009.Search in Google Scholar

[41] Gowid S, Mahdi E, Alabtah F. Modeling and optimization of the crushing behavior and energy absorption of plain weave composite hexagonal quadruple ring systems using artificial neural network. Compos Struct. 2019;229:111473. 10.1016/j.compstruct.2019.111473.Search in Google Scholar

[42] Ulus H, Burak Kaybal H. Out-of-plane static loading performance of lightweight aluminum/composite FML structures for retrofitting applications: Effectiveness of bonded, bolted and hybrid bonded/bolted joining techniques under hydrothermal aging environment. Constr Build Mater. 2023;403:133124. 10.1016/j.conbuildmat.2023.133124.Search in Google Scholar

[43] Rajesh M, Pitchaimani J. Dynamic mechanical analysis and free vibration behavior of intra-ply woven natural fiber hybrid polymer composite. J Reinf Plast Compos. 2016;35:228–42. 10.1177/0731684415611973.Search in Google Scholar

[44] Rajesh M, Pitchaimani J. Experimental investigation on buckling and free vibration behavior of woven natural fiber fabric composite under axial compression. Compos Struct. 2017;163:302–11. 10.1016/j.compstruct.2016.12.046.Search in Google Scholar

[45] Ulus H, Kaybal HB, Cacık F, Eskizeybek V, Avcı A. Effect of long‐term stress aging on aluminum‐BFRP hybrid adhesive joint’s mechanical performance: Static and dynamic loading scenarios. Polym Compos. 2022;43:5301–18. 10.1002/pc.26828.Search in Google Scholar

[46] Ulus H, Kaybal HB, Cacık F, Eskizeybek V, Avcı A. Fracture and dynamic mechanical analysis of seawater aged aluminum-BFRP hybrid adhesive joints. Eng Fract Mech. 2022;268:108507. 10.1016/j.engfracmech.2022.108507.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface

- Potential pharmaceutical applications and molecular docking study for green fabricated ZnO nanoparticles mediated Raphanus sativus: In vitro and in vivo study

- Effect of temperature and nanoparticle size on the interfacial layer thickness of TiO2–water nanofluids using molecular dynamics

- Characteristics of induced magnetic field on the time-dependent MHD nanofluid flow through parallel plates

- Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

- Experimental research on mechanically and thermally activation of nano-kaolin to improve the properties of ultra-high-performance fiber-reinforced concrete

- Analysis of variable fluid properties for three-dimensional flow of ternary hybrid nanofluid on a stretching sheet with MHD effects

- Biodegradability of corn starch films containing nanocellulose fiber and thymol

- Toxicity assessment of copper oxide nanoparticles: In vivo study

- Some measures to enhance the energy output performances of triboelectric nanogenerators

- Reinforcement of graphene nanoplatelets on water uptake and thermomechanical behaviour of epoxy adhesive subjected to water ageing conditions

- Optimization of preparation parameters and testing verification of carbon nanotube suspensions used in concrete

- Max-phase Ti3SiC2 and diverse nanoparticle reinforcements for enhancement of the mechanical, dynamic, and microstructural properties of AA5083 aluminum alloy via FSP

- Advancing drug delivery: Neural network perspectives on nanoparticle-mediated treatments for cancerous tissues

- PEG-PLGA core–shell nanoparticles for the controlled delivery of picoplatin–hydroxypropyl β-cyclodextrin inclusion complex in triple-negative breast cancer: In vitro and in vivo study

- Conduction transportation from graphene to an insulative polymer medium: A novel approach for the conductivity of nanocomposites

- Review Articles

- Developments of terahertz metasurface biosensors: A literature review

- Overview of amorphous carbon memristor device, modeling, and applications for neuromorphic computing

- Advances in the synthesis of gold nanoclusters (AuNCs) of proteins extracted from nature

- A review of ternary polymer nanocomposites containing clay and calcium carbonate and their biomedical applications

- Recent advancements in polyoxometalate-functionalized fiber materials: A review

- Special contribution of atomic force microscopy in cell death research

- A comprehensive review of oral chitosan drug delivery systems: Applications for oral insulin delivery

- Cellular senescence and nanoparticle-based therapies: Current developments and perspectives

- Cyclodextrins-block copolymer drug delivery systems: From design and development to preclinical studies

- Micelle-based nanoparticles with stimuli-responsive properties for drug delivery

- Critical assessment of the thermal stability and degradation of chemically functionalized nanocellulose-based polymer nanocomposites

- Research progress in preparation technology of micro and nano titanium alloy powder

- Nanoformulations for lysozyme-based additives in animal feed: An alternative to fight antibiotic resistance spread

- Incorporation of organic photochromic molecules in mesoporous silica materials: Synthesis and applications

- A review on modeling of graphene and associated nanostructures reinforced concrete

- A review on strengthening mechanisms of carbon quantum dots-reinforced Cu-matrix nanocomposites

- Review on nanocellulose composites and CNFs assembled microfiber toward automotive applications

- Nanomaterial coating for layered lithium rich transition metal oxide cathode for lithium-ion battery

- Application of AgNPs in biomedicine: An overview and current trends

- Nanobiotechnology and microbial influence on cold adaptation in plants

- Hepatotoxicity of nanomaterials: From mechanism to therapeutic strategy

- Applications of micro-nanobubble and its influence on concrete properties: An in-depth review

- A comprehensive systematic literature review of ML in nanotechnology for sustainable development

- Exploiting the nanotechnological approaches for traditional Chinese medicine in childhood rhinitis: A review of future perspectives

- Twisto-photonics in two-dimensional materials: A comprehensive review

- Current advances of anticancer drugs based on solubilization technology

- Recent process of using nanoparticles in the T cell-based immunometabolic therapy

- Future prospects of gold nanoclusters in hydrogen storage systems and sustainable environmental treatment applications

- Preparation, types, and applications of one- and two-dimensional nanochannels and their transport properties for water and ions

- Microstructural, mechanical, and corrosion characteristics of Mg–Gd–x systems: A review of recent advancements

- Functionalized nanostructures and targeted delivery systems with a focus on plant-derived natural agents for COVID-19 therapy: A review and outlook

- Mapping evolution and trends of cell membrane-coated nanoparticles: A bibliometric analysis and scoping review

- Nanoparticles and their application in the diagnosis of hepatocellular carcinoma

- In situ growth of carbon nanotubes on fly ash substrates

- Structural performance of boards through nanoparticle reinforcement: An advance review

- Reinforcing mechanisms review of the graphene oxide on cement composites

- Seed regeneration aided by nanomaterials in a climate change scenario: A comprehensive review

- Surface-engineered quantum dot nanocomposites for neurodegenerative disorder remediation and avenue for neuroimaging

- Graphitic carbon nitride hybrid thin films for energy conversion: A mini-review on defect activation with different materials

- Nanoparticles and the treatment of hepatocellular carcinoma

- Special Issue on Advanced Nanomaterials and Composites for Energy Conversion and Storage - Part II

- Highly safe lithium vanadium oxide anode for fast-charging dendrite-free lithium-ion batteries

- Recent progress in nanomaterials of battery energy storage: A patent landscape analysis, technology updates, and future prospects

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part II

- Calcium-, magnesium-, and yttrium-doped lithium nickel phosphate nanomaterials as high-performance catalysts for electrochemical water oxidation reaction

- Low alkaline vegetation concrete with silica fume and nano-fly ash composites to improve the planting properties and soil ecology

- Mesoporous silica-grafted deep eutectic solvent-based mixed matrix membranes for wastewater treatment: Synthesis and emerging pollutant removal performance

- Electrochemically prepared ultrathin two-dimensional graphitic nanosheets as cathodes for advanced Zn-based energy storage devices

- Enhanced catalytic degradation of amoxicillin by phyto-mediated synthesised ZnO NPs and ZnO-rGO hybrid nanocomposite: Assessment of antioxidant activity, adsorption, and thermodynamic analysis

- Incorporating GO in PI matrix to advance nanocomposite coating: An enhancing strategy to prevent corrosion

- Synthesis, characterization, thermal stability, and application of microporous hyper cross-linked polyphosphazenes with naphthylamine group for CO2 uptake

- Engineering in ceramic albite morphology by the addition of additives: Carbon nanotubes and graphene oxide for energy applications

- Nanoscale synergy: Optimizing energy storage with SnO2 quantum dots on ZnO hexagonal prisms for advanced supercapacitors

- Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation

- Tuning structural and electrical properties of Co-precipitated and Cu-incorporated nickel ferrite for energy applications

- Sodium alginate-supported AgSr nanoparticles for catalytic degradation of malachite green and methyl orange in aqueous medium

- An environmentally greener and reusability approach for bioenergy production using Mallotus philippensis (Kamala) seed oil feedstock via phytonanotechnology

- Micro-/nano-alumina trihydrate and -magnesium hydroxide fillers in RTV-SR composites under electrical and environmental stresses

- Mechanism exploration of ion-implanted epoxy on surface trap distribution: An approach to augment the vacuum flashover voltages

- Nanoscale engineering of semiconductor photocatalysts boosting charge separation for solar-driven H2 production: Recent advances and future perspective

- Excellent catalytic performance over reduced graphene-boosted novel nanoparticles for oxidative desulfurization of fuel oil

- Special Issue on Advances in Nanotechnology for Agriculture

- Deciphering the synergistic potential of mycogenic zinc oxide nanoparticles and bio-slurry formulation on phenology and physiology of Vigna radiata

- Nanomaterials: Cross-disciplinary applications in ornamental plants

- Special Issue on Catechol Based Nano and Microstructures

- Polydopamine films: Versatile but interface-dependent coatings

- In vitro anticancer activity of melanin-like nanoparticles for multimodal therapy of glioblastoma

- Poly-3,4-dihydroxybenzylidenhydrazine, a different analogue of polydopamine

- Chirality and self-assembly of structures derived from optically active 1,2-diaminocyclohexane and catecholamines

- Advancing resource sustainability with green photothermal materials: Insights from organic waste-derived and bioderived sources

- Bioinspired neuromelanin-like Pt(iv) polymeric nanoparticles for cancer treatment

- Special Issue on Implementing Nanotechnology for Smart Healthcare System

- Intelligent explainable optical sensing on Internet of nanorobots for disease detection

- Special Issue on Green Mono, Bi and Tri Metallic Nanoparticles for Biological and Environmental Applications

- Tracking success of interaction of green-synthesized Carbopol nanoemulgel (neomycin-decorated Ag/ZnO nanocomposite) with wound-based MDR bacteria

- Green synthesis of copper oxide nanoparticles using genus Inula and evaluation of biological therapeutics and environmental applications

- Biogenic fabrication and multifunctional therapeutic applications of silver nanoparticles synthesized from rose petal extract

- Metal oxides on the frontlines: Antimicrobial activity in plant-derived biometallic nanoparticles

- Controlling pore size during the synthesis of hydroxyapatite nanoparticles using CTAB by the sol–gel hydrothermal method and their biological activities

- Special Issue on State-of-Art Advanced Nanotechnology for Healthcare

- Applications of nanomedicine-integrated phototherapeutic agents in cancer theranostics: A comprehensive review of the current state of research

- Smart bionanomaterials for treatment and diagnosis of inflammatory bowel disease

- Beyond conventional therapy: Synthesis of multifunctional nanoparticles for rheumatoid arthritis therapy

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features