A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

-

Humaira Yasmin

, Laila A. AL-Essa

Abstract

This study presents a numerical investigation of a viscous and incompressible three-dimensional flow of hybrid nanofluid composed of Ag and Al2O3 nanoparticles over a convectively heated bi-directional extending sheet with a porous medium. The main equations are converted into dimensionless form by using appropriate variables. The effects of magnetic field, porosity, Brownian motion, thermophoresis, and chemical reaction are investigated. Furthermore, the mass flux and zero-mass flux constraints are used to study heat and mass transfer rates. The obtained data show that the growing magnetic factor has reduced the velocity profiles while increasing the thermal profile. The increased porosity factor has decreased the velocity profiles. The increased thermal Biot number has increased the concentration and thermal profiles. When compared to passive control of nanoparticles, the hybrid nanofluid flow profiles are strongly influenced by the embedded factor in the active control of nanoparticles.

1 Introduction

Nanofluids, colloidal suspensions of nanoparticles in pure fluid, have gained considerable interest due to their remarkable thermal properties and potential to improve heat transfer. The addition of nanoparticles, typically ranging from a few to hundreds of nanometers in size, significantly enhances the thermal conductivity of pure fluid, leading to improved heat transfer rates as perceived initially by Sus [1]. This improvement is particularly noticeable in convective heat transfer, where nanofluids have shown higher convective heat transfer coefficients compared to conventional fluids. Shoaib et al. [2] investigated the effects of thermal transportation on Maxwell nanofluid flow on a movable surface with magnetohydrodynamic (MHD) effects and analyzed the main equations using an artificial neural network (ANN) approach. Khan et al. [3] examined thermal flow analysis for nanofluid flow between two permeable sheets using thermophoresis and Brownian motion effects. Nanofluids in microchannel heat exchangers show potential for improving heat transfer due to their improved thermal properties, making them appropriate for applications such as electronics cooling and micro reactors. Khan et al. [4] studied carbon nanotube nanofluid flow with thermally radiated performance and heat sink/source through a microchannel. With the passage of time, it was discovered that suspending two different varieties of nanoparticles in pure fluid can further broaden the thermal behavior of pure fluids [5]. Hybrid nanofluids represent a sophisticated advancement in thermal engineering, combining the benefits of traditional nanofluids with additional additives or nanostructures to further improve heat transfer processes [6]. Abas et al. [7] studied the passive control strategy for blood-based hybrid nanofluid flow over a bi-directional, convectively heated elongating surface. Mumtaz et al. [8] discussed the thermal flow behavior of trihybrid nanofluid flow on an elongating curved sheet using chemical reaction. The hybrid nature of these fluids allows for fine-tuning of properties such as viscosity, stability, and heat transfer performance, making them highly adaptable to specific application requirements [9]. In practice, hybrid nanofluids have demonstrated superior heat transfer performance in various heat exchange systems, including cooling applications in electronics, solar thermal collectors, and automotive radiators [10]. However, challenges such as optimizing the composition and dispersion of hybrid nanoparticles, as well as ensuring long-term stability, remain active research areas to fully unlock the potential of hybrid nanofluids for effective heat transfer processes.

MHD fluid flow is the study of fluid motion using the effects of magnetic fields. When a conductive fluid interacts with a magnetic field, it experiences Lorentz forces that influence its flow behavior. In terms of heat transfer phenomena, MHD fluid flow can have significant impacts due to its ability to alter fluid motion and thermal conductivity [11]. The Lorentz forces induced by the magnetic field can change the velocity profile of the fluid, leading to modifications in heat transfer rates and temperature distributions. Ullah et al. [12] used ANN approach to treat computationally squeezed fluid flow through a circular sheet and have found that fluid velocity decreased as the magnetic factor increased. Jawad et al. [13] studied three-dimensional (3D) MHD thin film nanofluid, mass, and thermal transportation on a permeable gyrating disk. MHD fluid flow has implications for various engineering applications, including nuclear reactors, metallurgical processes, and geophysical fluid dynamics [14]. MHD fluid flow is crucial for optimizing heat transfer processes in these applications, as magnetic fields can be harnessed to manipulate fluid behavior and improve thermal performance [15]. Fiza et al. [16] studied 3D gyrating Jeffery fluid flow through two sheets with effects of Hall current and concluded that the mass flux decreased at the bottom surface. Khan et al. [17] examined dual diffusive Jeffery MHD fluid flow through the cone and disk zones using the effects of different geometries' rotations.

Porous media describe the materials that contain interconnected void spaces. These voids can be filled with air, water, or other fluids, and they play a crucial role in various natural and engineered systems [18]. Examples of porous media include soil, rocks, sponges, and filters. Fluid flow through porous media is a complex process with significant implications for heat transfer velocity. Porous media, such as soil, rocks, and packed beds, contain a network of interconnected voids that alter fluid flow behavior compared to non-porous materials. When a fluid flows through porous media, it encounters resistance due to interactions with the solid matrix, leading to pressure gradients and changes in flow velocity [19]. Darcy’s law governs this flow, relating the fluid velocity to the pressure gradient. In terms of heat transfer, porous media play a crucial role in redistributing thermal energy [20]. The presence of pores provides a large surface area for heat exchange between the fluid and the solid matrix, enhancing heat transfer rates compared to non-porous materials [21]. Convection is the dominant heat transfer mechanism in fluid-saturated porous media, where the flowing fluid carries heat with it, influencing temperature distributions within the porous medium. Additionally, the thermal conductance and diffusivity of the porous medium impact heat transfer velocity, with variations in pore size, shape, and connectivity affecting thermal transport properties [22]. These interactions are essential for optimizing heat transfer processes in various applications, including geothermal energy extraction, groundwater flow, and the heat exchanger design [23]. Modeling simulation and experimental studies are key tools used to investigate fluid flow in permeable media and its impacts on heat transfer velocity, supporting the expansion of efficient and maintainable engineering solutions. Megahed et al. [24] discussed the cross flow of fluid in a permeable medium using chemical reactivity and thermally radiative effects.

Brownian motion, a fundamental phenomenon, refers to the unpredictable, haphazard movement of particles suspended in a fluid medium due to collisions with surrounding molecules. In the framework of heat and mass transfer, Brownian motion significantly influences the behavior of colloidal suspensions and nanofluids [25]. For heat transfer phenomena, Brownian motion enhances thermal mixing and increases the effective contact area between particles and the surrounding fluid, facilitating more efficient heat dissipation [26]. This effect is particularly prominent at small length scales, like in microfluidic devices or nanoporous materials, where thermal fluctuations play a significant role. In mass transfer phenomena, Brownian motion administers the dispersion and diffusion of solute particles, impacting concentration gradients and mass transfer rates [27]. Accurately modeling Brownian motion is crucial for optimizing heat and mass transfer processes in various applications, including pharmaceuticals, biotechnology, and environmental engineering. Thermophoresis, in contrast, refers to the directed motion of particles in a fluid medium in response to a temperature gradient [28]. In heat transfer phenomena, thermophoresis effects arise when temperature gradients induce particle migration, leading to concentration variations within the fluid [29]. This occurrence is mostly pertinent in systems where temperature gradients exist like in combustion processes, microfluidic devices, or industrial furnaces. Thermophoresis impacts heat transfer by influencing particle deposition, aggregation, or dispersion, which in turn can alter convective heat transfer rates and heat distribution within the system [29]. Additionally, in mass transfer processes, thermophoresis affects the transport of particles and solutes, leading to non-uniform concentration profiles and modifying overall mass transfer rates [30,31]. The relationship between thermophoresis and other transport mechanisms is essential for accurately predicting heat and mass transfer phenomena in complex systems and optimizing engineering processes for various applications [32]. Brownian motion and thermophoresis are essential for controlling mass and heat transmission in fluid flow systems [33,34]. Brownian motion enhances thermal mixing and mass dispersion, while thermophoresis influences particle migration and concentration gradients [35]. These two phenomena optimize heat and mass transfer efficiency in various applications.

In many scientific and engineering fields, the study of hybrid nanofluid flow across a three-dimensional extending sheet has great potential. Through the use of advanced control mechanisms, this study seeks to maximize fluid dynamics and heat transfer, improving energy efficiency in a variety of applications comprising renewable energy systems, cooling systems, and aeronautical engineering. The knowledge gathered from this research can also be applied to the biomedical engineering field to improve medication delivery systems and the material processing sectors to improve production processes. Furthermore, this finding has significant environmental consequences since it may lead to improvements in pollution control and wastewater treatment systems. Additionally, the investigation of nanofluid flow behavior in microfluidic devices creates new avenues for applications in medical diagnostics, lab-on-a-chip technologies, and analytical chemistry. Fundamentally, research into the active and passive regulation of nanofluid flow over expanding sheets is a multidisciplinary approach that has broad ramifications for many other sectors. This method encourages creativity and advances the development of effective and sustainable solutions. Therefore, in this work, we have scrutinized the viscous and incompressible 3D flow of a hybrid nanofluid composed of Ag and Al2O3 nanoparticles over a convectively heated bi-directional extending sheet using a porous medium. Furthermore, both the mass flux and zero-mass flux conditions are imposed to examine the heat and mass transfer rates.

2 Problem formulation

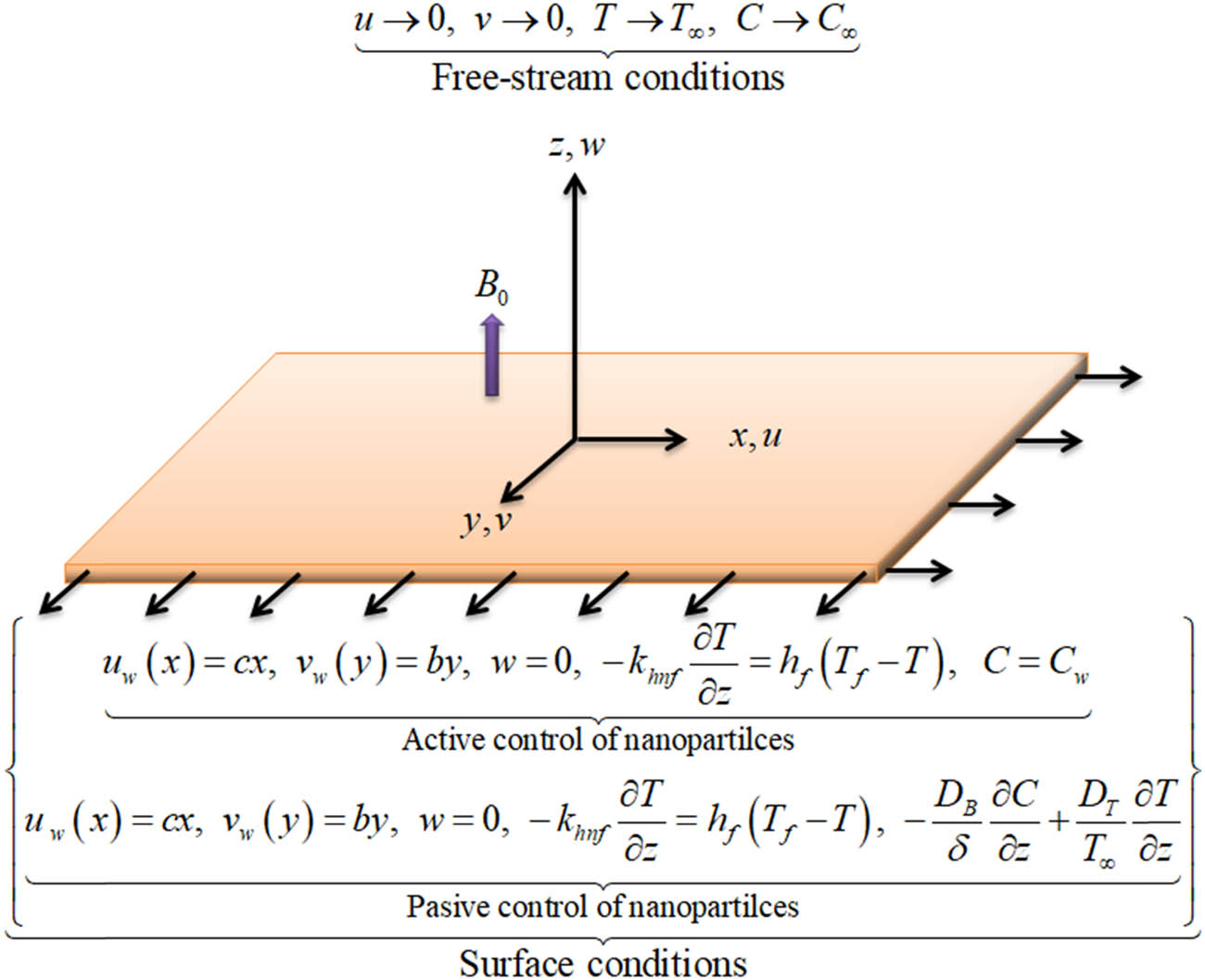

Assume the viscous and incompressible 3D flow of hybrid nanofluid composed of Ag and Al2O3 nanoparticles on a bi-directional extending sheet using a porous medium. The sheet stretches with velocities

with boundary conditions [38–40]:

Flow problem geometrical view.

The dynamic viscosity (

The subscripts f,

Thermophysical properties of

| Thermophysical properties | Base fluid and nanoparticles | ||

|---|---|---|---|

|

|

|

|

|

|

|

997.1 | 10,500 | 3,970 |

|

|

0.613 | 429 | 40 |

|

|

4,179 | 235 | 765 |

|

|

5.5 × 10−6 | 3.6 × 107 | 3.5 × 107 |

The similarity variables are defined as [44,45]

By employing the above similarity variables, we obtained the following dimensionless equations:

with boundary conditions:

In equations (11)–(16),

The skin friction coefficients, local Nusselt number, and Sherwood number are defined as

where

Since we have considered the mass flux and zero-mass flux conditions, for the case of zero-mass flux condition, there is no mass flow at the sheet surface (i.e.,

where

3 Numerical solution

Bvp4c is a potent numerical methodology used extensively in many scientific and engineering domains. Due to its adaptability, it is extremely helpful in solving differential equations with boundary conditions, especially when obtaining analytical solutions is challenging or impossible. One well-known application is in mechanical engineering, where complicated structural systems like beams, plates, and shells are modeled using bvp4c. Engineers can improve designs, strengthen structural integrity, and guarantee safety requirements in projects ranging from bridges to aerospace components by precisely forecasting stress distributions and deformation behaviors. Bvp4c is also widely used in mathematical biology and epidemiology, where it helps with simulating ecological interactions, disease propagation, and population dynamics. The error tolerance of 10−6 is defined to show the higher accuracy of the modeled problem. To apply this method, we have converted the higher-order model equations (11)–(14) with boundary conditions (15) and (16) into first-order differential equations; we assume that

then, the final equations are reduced as

with boundary conditions:

4 Validation

In Table 2, the validation of present results with published results by Eswaramoorthi and Bhuvaneswari [36] and Qayyum et al. [37] for

Validation of the present results of

|

|

|

|

||||

|---|---|---|---|---|---|---|

| Eswaramoorthi and Bhuvaneswari [36] | Qayyum et al. [37] | Present results | Eswaramoorthi and Bhuvaneswari [36] | Qayyum et al. [37] | Present results | |

| 0.0 | 1.00000 | 1.000000 | 1.000062 | 0.00000 | 0.000000 | 0.000000 |

| 0.1 | 1.02026 | 1.020259 | 1.020300 | 0.06685 | 0.066847 | 0.066859 |

| 0.2 | 1.03950 | 1.039495 | 1.039523 | 0.14874 | 0.148736 | 0.14875 |

| 0.3 | 1.05795 | 1.057954 | 1.057974 | 0.24336 | 0.243359 | 0.243372 |

| 0.4 | 1.07479 | 1.075788 | 1.075802 | 0.34921 | 0.349208 | 0.349219 |

| 0.5 | 1.09309 | 1.093095 | 1.093105 | 0.46521 | 0.465204 | 0.465213 |

| 0.6 | 1.10995 | 1.109946 | 1.109955 | 0.59063 | 0.590528 | 0.590535 |

| 0.7 | 1.12640 | 1.126397 | 1.126403 | 0.72453 | 0.724531 | 0.724537 |

| 0.8 | 1.14249 | 1.142428 | 1.142493 | 0.86668 | 0.866682 | 0.866687 |

| 0.9 | 1.15826 | 1.158253 | 1.158257 | 1.01654 | 1.016538 | 1.016542 |

| 1.0 | 1.17331 | 1.173720 | 1.173723 | 1.17371 | 1.173720 | 1.173723 |

| 1.2 | — | — | 1.203849 | — | — | 1.508794 |

| 1.4 | — | — | 1.233019 | — | — | 1.869722 |

| 1.6 | — | — | 1.261347 | — | — | 2.254771 |

| 1.8 | — | — | 1.288916 | — | — | 2.662509 |

| 2.0 | — | — | 1.315799 | — | — | 3.091739 |

5 Results and discussion

5.1 Analysis of results

5.2 Discussion of results

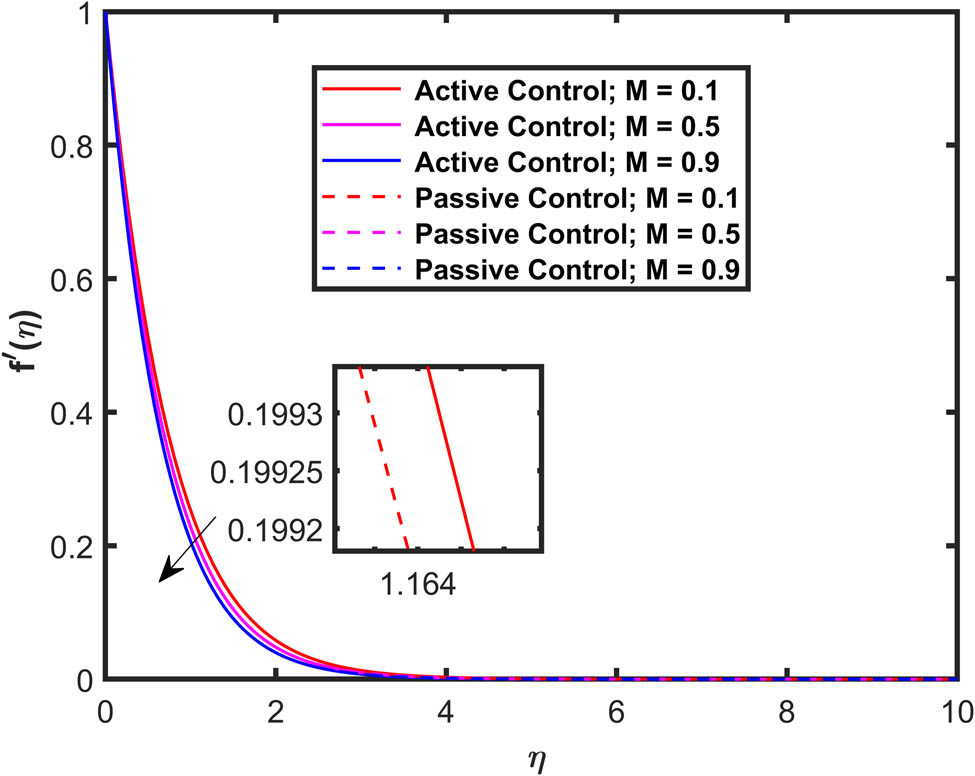

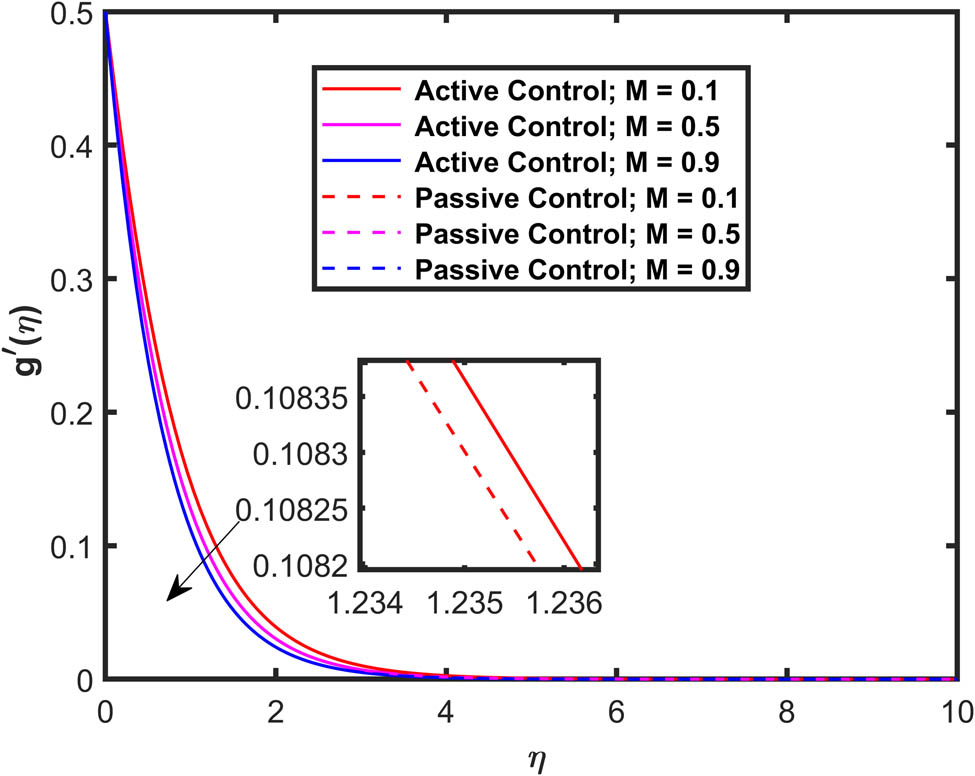

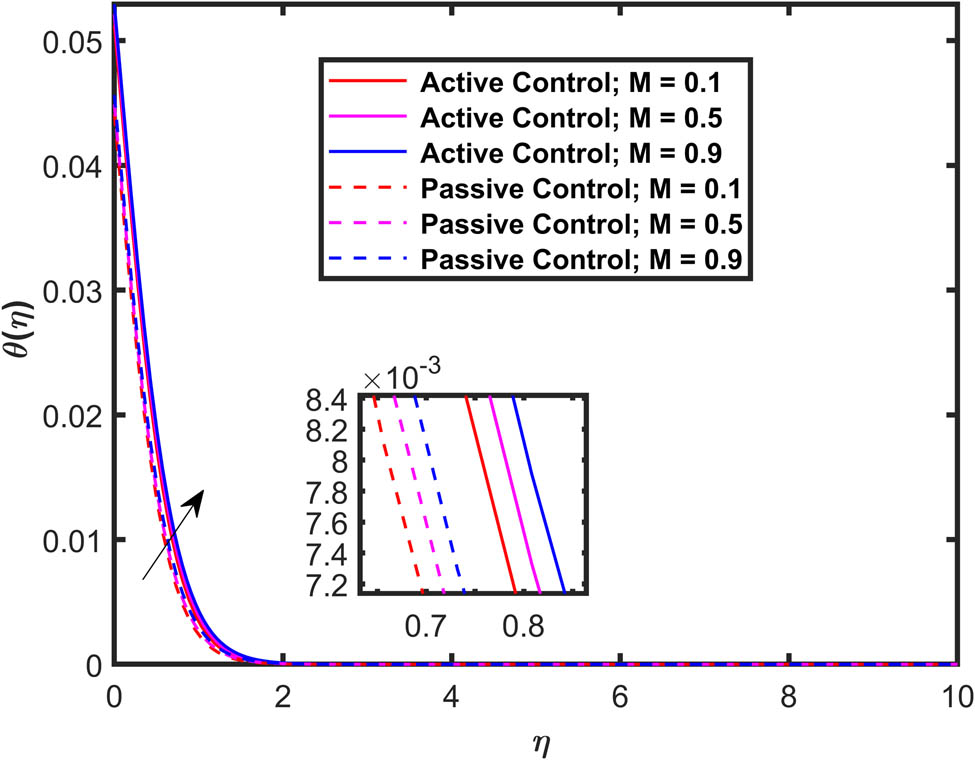

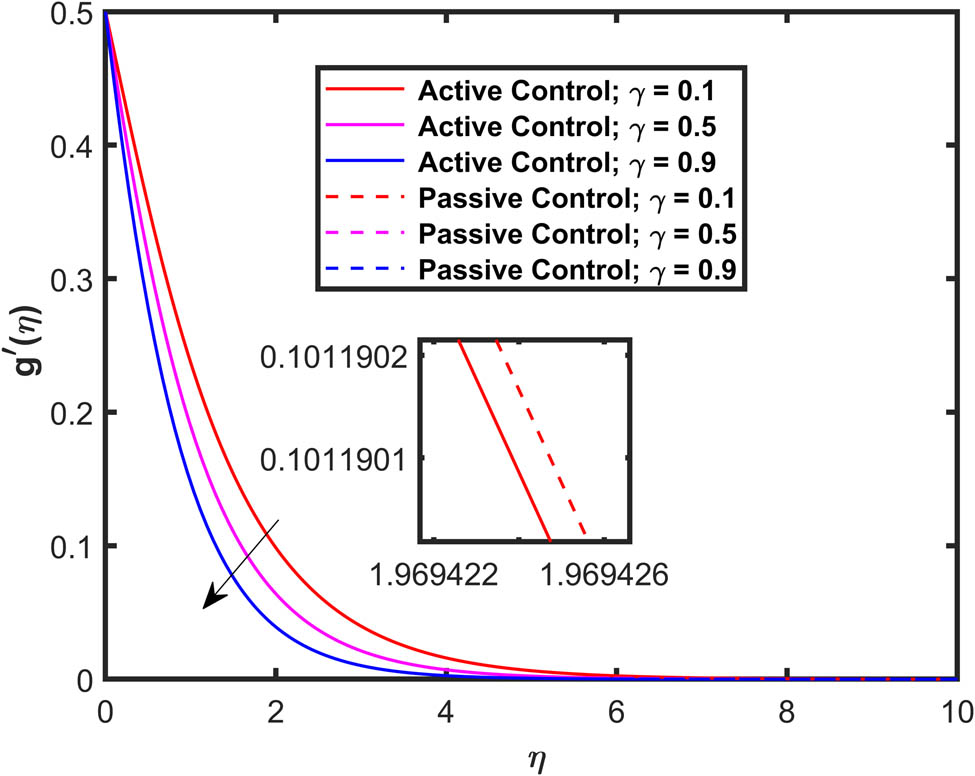

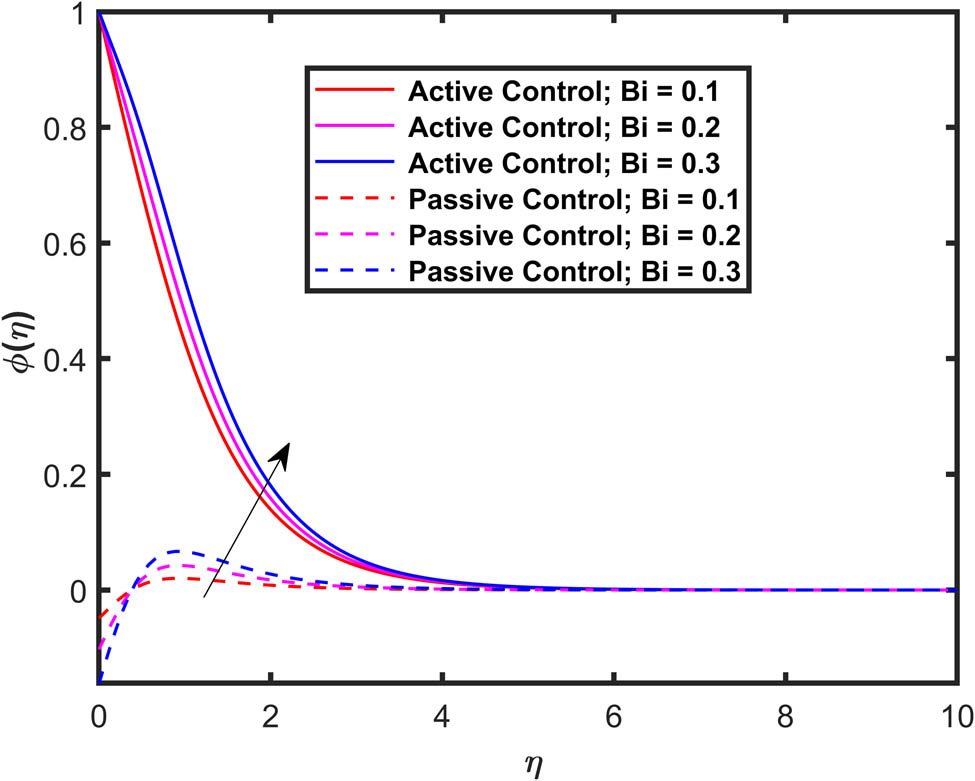

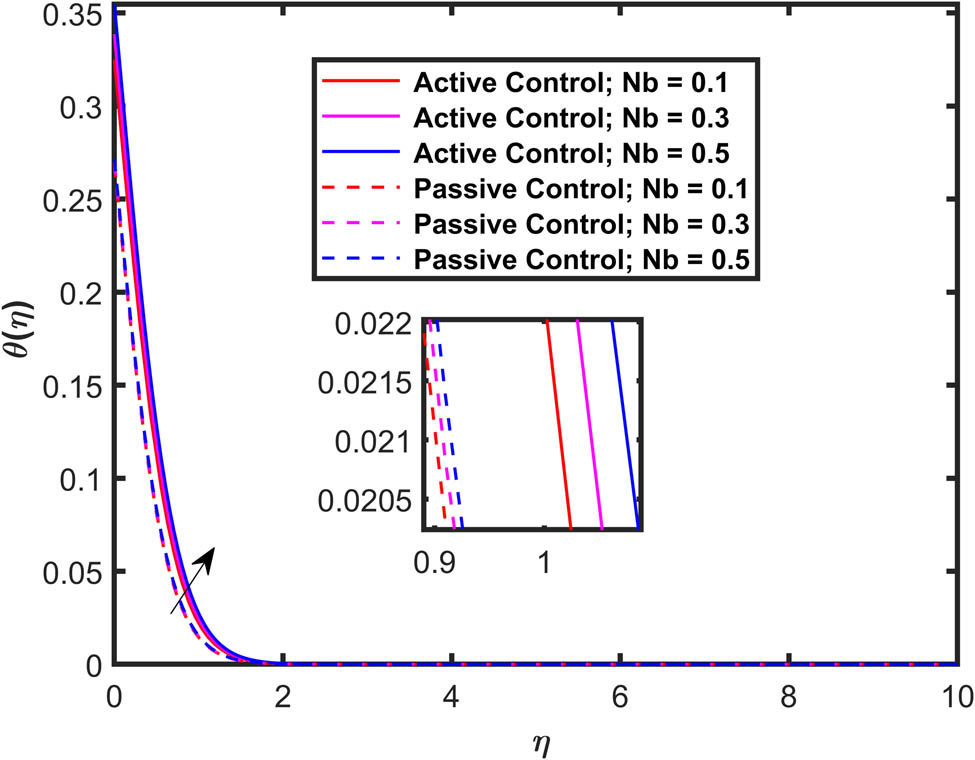

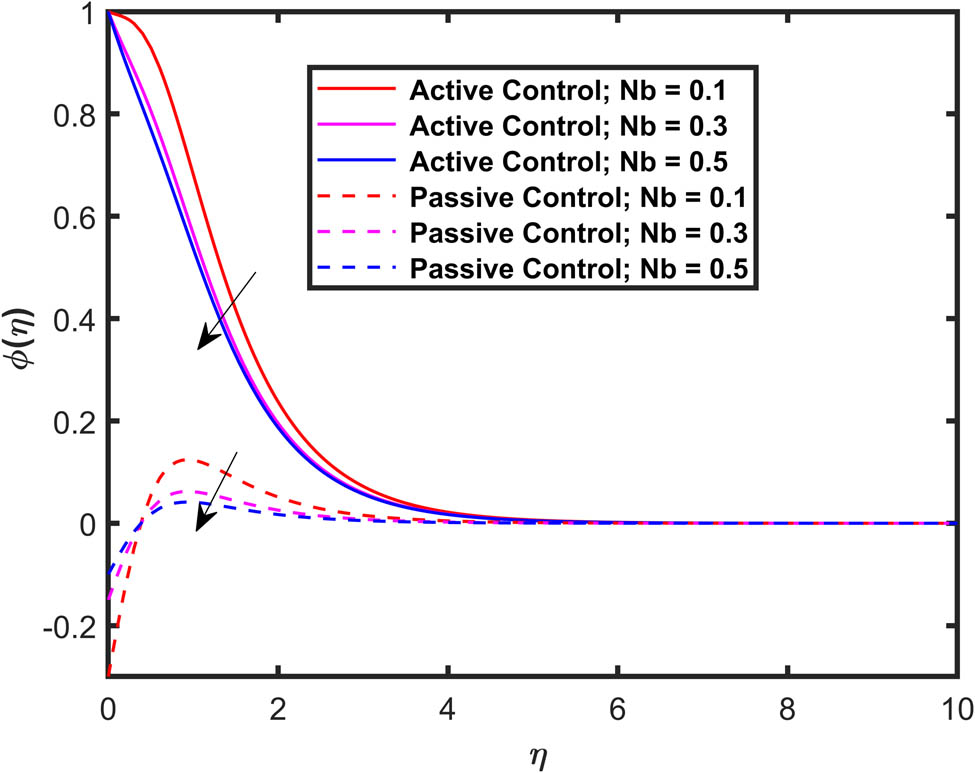

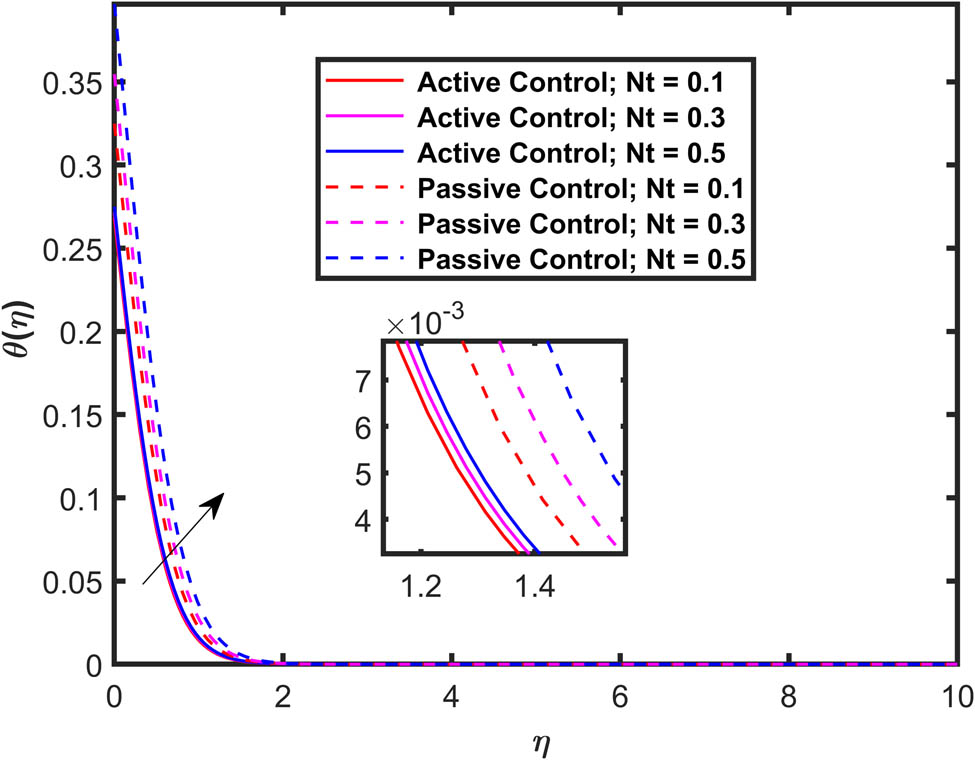

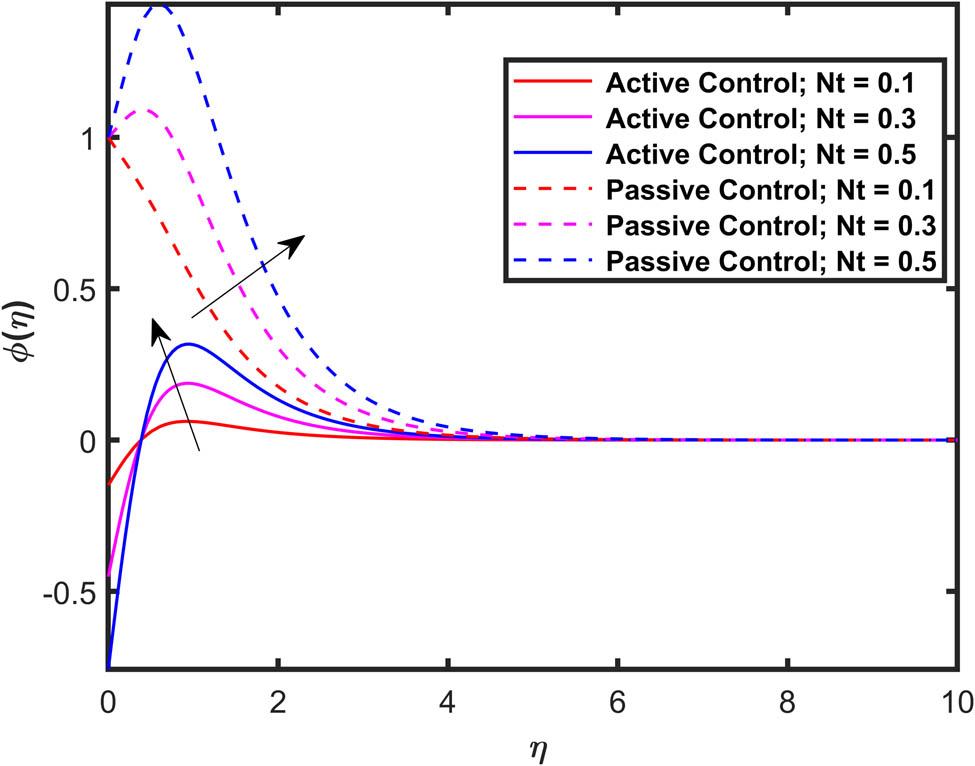

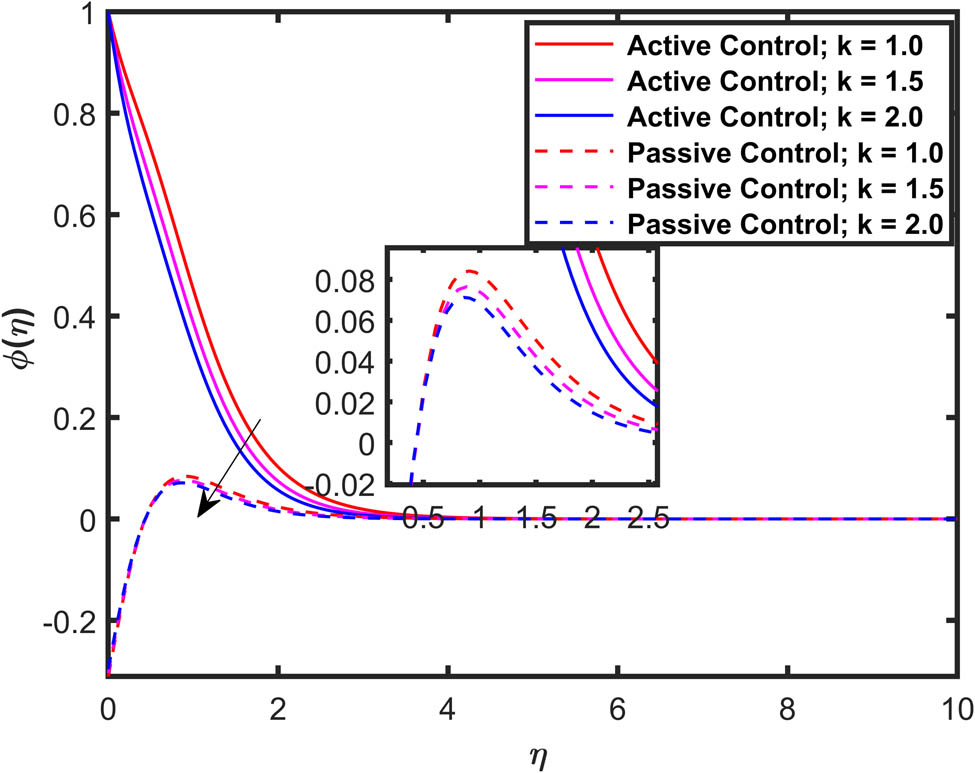

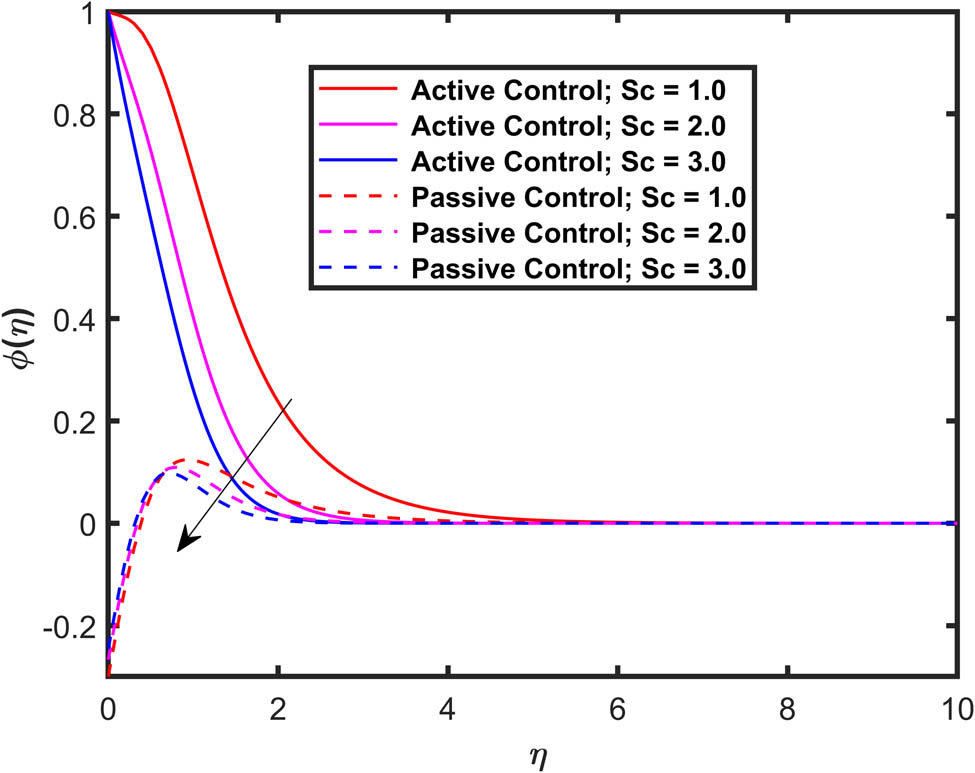

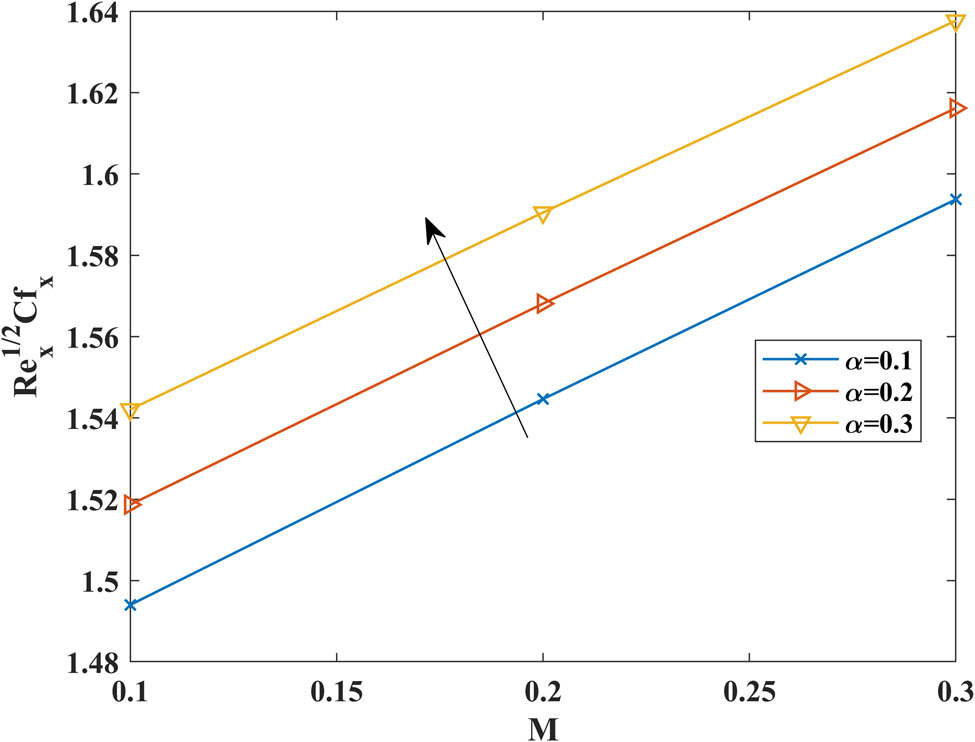

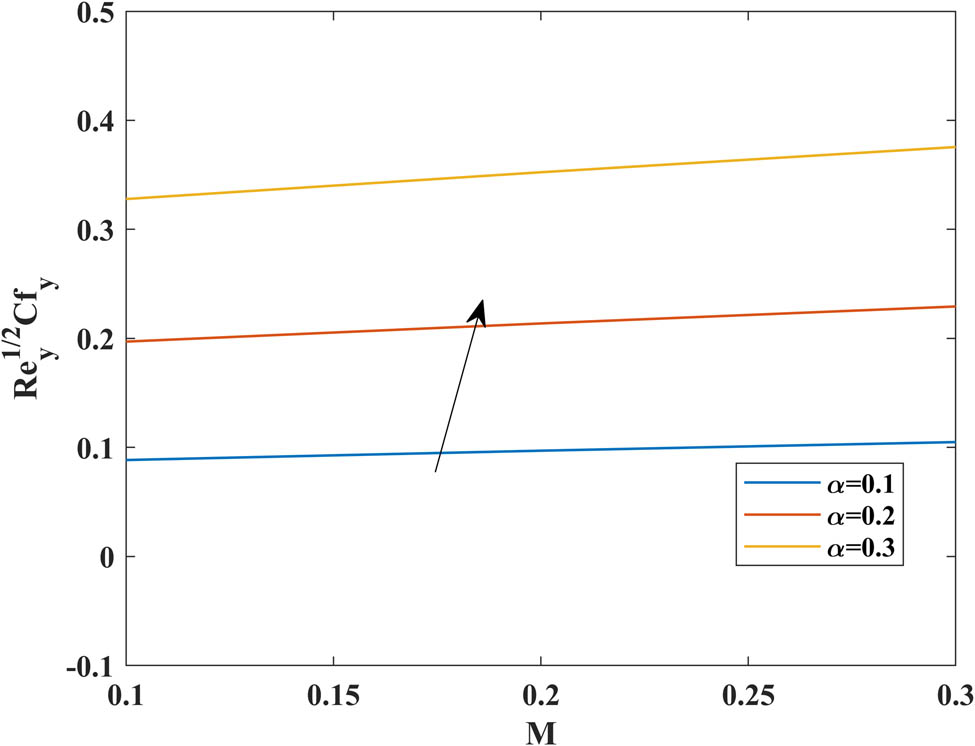

This section represents the debate on results obtained for viscous and incompressible 3D flow of hybrid nanofluid composed of Ag and Al2O3 nanoparticles over a bi-directional extending sheet using porous medium. The outcomes are displayed in Figures 2–16 and Tables 3 and 4. Figure 2 shows the distinction in velocity profile (

Effect of

Effect of

Effect of

Effect of

Effect of

Effect of

Effect of

Effect of

Effect of

Effect of

Effect of

Effect of

Effect of

Effects of

Effects of

Effects of

|

|

|

|

|

|

|---|---|---|---|---|

| Active control | Passive control | |||

| 0.1 | 0.105476 | 0.104761 | ||

| 0.2 | 0.223467 | 0.220038 | ||

| 0.3 | 0.356961 | 0.347578 | ||

| 0.1 | 0.658281 | 0.680756 | ||

| 0.2 | 0.675423 | 0.689774 | ||

| 0.3 | 1.083114 | 0.700570 | ||

| 0.1 | 0.648743 | 0.689774 | ||

| 0.2 | 0.648743 | 0.735752 | ||

| 0.3 | 0.648743 | 0.806770 | ||

Effects of

|

|

|

|

|

|

|---|---|---|---|---|

| Active control | ||||

| 0.1 | 0.015993 | |||

| 0.2 | 0.365269 | |||

| 0.3 | 0.478633 | |||

| 0.1 | 0.372568 | |||

| 0.2 | 0.015993 | |||

| 0.3 | −0.34412 | |||

| 1.0 | 0.015993 | |||

| 2.0 | 0.512234 | |||

| 3.0 | 0.891084 | |||

| 0.1 | 0.015993 | |||

| 0.2 | 0.124563 | |||

| 0.3 | 0.221747 |

6 Conclusions

A numerical investigation of a viscous and incompressible 3D flow of hybrid nanofluid composed of Ag and Al2O3 nanoparticles over a bi-directional extending sheet using porous medium has been presented here. The impacts of magnetic field, porosity, Brownian motion, thermophoresis, and chemical reaction are investigated. The flow is considered to be convectively heated with a hot working fluid. Furthermore, both the mass flux and zero-mass flux conditions are imposed to investigate the heat and mass transfer rates. Based on the above assumptions, the following key points are obtained:

The increased magnetic factor has decreased the velocity profiles while increasing the temperature profile.

The increased porosity factor has reduced the velocity profiles.

The increased thermal Bi has led to intensification in temperature and concentration distributions.

The increased Brownian motion factor has led to an increase in the temperature profile and a decrease in the concentration profile.

The increased thermophoresis factor has led to an increase in temperature and concentration profiles.

The increased chemical reaction factor and Sc have led to a decrease in the concentration profiles.

The greater magnetic and ration factors have increased the friction forces at the surface of the sheet.

The greater thermal Bi, thermophoresis, and Brownian motion factors have increased the heat transfer rates.

The hybrid nanofluid flow profiles are strongly influenced by the embedded factor in the case of active control of nanoparticles when compared to the case of passive control of nanoparticles.

-

Funding information: This research was funded by Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP2024R443), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia. This work was supported by the Deanship of Scientific Research, the Vice Presidency for Graduate Studies and Scientific Research, King Faisal University, Saudi Arabia (GrantA264).

-

Author contributions: Conceptualization, A.S. and H.Y.; methodology, L.A.E; software, A.S.; R.B.; validation, H.A., and S.A.L.; formal analysis, H.Y.; investigation, S.A.L and A.S.; writing original draft preparation, L.A.E. and S.A.L.; writing review and editing, H.Y. R.B., and S.A.L.; visualization, H.Y. and H.A. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Sus C. Enhancing thermal conductivity of fluids with nanoparticles, developments and applications of non-Newtonian flows. 231, ASME; 1995. p. 99–105.Search in Google Scholar

[2] Shoaib M, Khan RA, Ullah H, Nisar KS, Raja MAZ, Islam S, et al. Heat transfer impacts on maxwell nanofluid flow over a vertical moving surface with MHD using stochastic numerical technique via artificial neural networks. Coatings. 2021;11:1483.10.3390/coatings11121483Search in Google Scholar

[3] Khan RA, Ullah H, Raja MAZ, Khan MAR, Islam S, Shoaib M. Heat transfer between two porous parallel plates of steady nano fludis with Brownian and Thermophoretic effects: a new stochastic numerical approach. Int Commun Heat Mass Transf. 2021;126:105436.10.1016/j.icheatmasstransfer.2021.105436Search in Google Scholar

[4] Khan A, Shah Z, Islam S, Dawar A, Bonyah E, Ullah H, et al. Darcy-Forchheimer flow of MHD CNTs nanofluid radiative thermal behaviour and convective non uniform heat source/sink in the rotating frame with microstructure and inertial characteristics. AIP Adv. 2018;8:125024.10.1063/1.5066223Search in Google Scholar

[5] Abbasi A, Farooq W, Tag-ElDin ESM, Khan SU, Khan MI, Guedri K, et al. Heat transport exploration for hybrid nanoparticle (Cu, Fe3O4) – Based blood flow via tapered complex wavy curved channel with slip features. Micromachines. 2022;13:1415.10.3390/mi13091415Search in Google Scholar PubMed PubMed Central

[6] Elattar S, Helmi MM, Elkotb MA, El-Shorbagy MA, Abdelrahman A, Bilal M, et al. Computational assessment of hybrid nanofluid flow with the influence of hall current and chemical reaction over a slender stretching surface. Alex Eng J. 2022;61:10319–31.10.1016/j.aej.2022.03.054Search in Google Scholar

[7] Abas SA, Ullah H, Islam S, Fiza M. A passive control of magnetohydrodynamic flow of a blood‐based Casson hybrid nanofluid over a convectively heated bi‐directional stretching surface. ZAMM‐J Appl Math Mech für Angew Math und Mech. 2024;104:e202200576.10.1002/zamm.202200576Search in Google Scholar

[8] Mumtaz M, Islam S, Ullah H, Shah Z. Chemically reactive MHD convective flow and heat transfer performance of ternary hybrid nanofluid past a curved stretching sheet. J Mol Liq. 2023;390:123179.10.1016/j.molliq.2023.123179Search in Google Scholar

[9] Rehman A, Saeed A, Bilal M. Analytical study of three-dimensional MHD hybrid nanofluid flow along with thermal characteristics and radiative solar energy. Waves Random Complex Media. 2022;1–15.10.1080/17455030.2022.2077472Search in Google Scholar

[10] Rauf A, Faisal, Shah NA, Botmart T. Hall current and morphological effects on MHD micropolar non-Newtonian tri-hybrid nanofluid flow between two parallel surfaces. Sci Rep. 2022;12:16608.10.1038/s41598-022-19625-3Search in Google Scholar PubMed PubMed Central

[11] Majeed AH, Mahmood R, Shahzad H, Pasha AA, Raizah ZA, Hosham HA, et al. Heat and mass transfer characteristics in MHD Casson fluid flow over a cylinder in a wavy channel: Higher-order FEM computations. Case Stud Therm Eng. 2023;42:102730.10.1016/j.csite.2023.102730Search in Google Scholar

[12] Ullah H, Fiza M, Zahoor Raja MA, Khan I, Shoaib M, Al-Mekhlafi SM. Intelligent computing of levenberg-marquard technique backpropagation neural networks for numerical treatment of squeezing nanofluid flow between two circular plates. Math Probl Eng. 2022;2022:2022–11.10.1155/2022/9451091Search in Google Scholar

[13] Jawad M, Shah Z, Khan A, Islam S, Ullah H. Three-dimensional magnetohydrodynamic nanofluid thin-film flow with heat and mass transfer over an inclined porous rotating disk. Adv Mech Eng. 2019;11:1687814019869757.10.1177/1687814019869757Search in Google Scholar

[14] Ashraf MB, Tanveer A, Ulhaq S. Effects of Cattaneo-Christov heat flux on MHD Jeffery nano fluid flow past a stretching cylinder. J Magn Magn Mater. 2023;565:170154.10.1016/j.jmmm.2022.170154Search in Google Scholar

[15] Goud BS, Srilatha P, Mahendar D, Srinivasulu T, Dharmendar Reddy Y. Thermal radiation effect on thermostatically stratified MHD fluid flow through an accelerated vertical porous plate with viscous dissipation impact. Partial Differ Equ Appl Math. 2023;7:100488.10.1016/j.padiff.2023.100488Search in Google Scholar

[16] Fiza M, Alsubie A, Ullah H, Hamadneh NN, Islam S, Khan I. Three-dimensional rotating flow of MHD Jeffrey fluid flow between two parallel plates with impact of hall current. Math Probl Eng. 2021;2021:1–9.10.1155/2021/6626411Search in Google Scholar

[17] Khan A, Gul T, Ali I, Abd El-Wahed Khalifa H, Muhammad T, Alghamdi W, et al. Thermal examination for double diffusive MHD Jeffrey fluid flow through the space of disc and cone apparatus subject to impact of multiple rotations. Int J Heat Fluid Flow. 2024;106:109295.10.1016/j.ijheatfluidflow.2024.109295Search in Google Scholar

[18] Nabizadeh A, Abbasi M, Siavashi J, Sharifi M, Movaghar MRK. Fluid flow modeling through pressure-dependent porous media: An analytical solution and a computational fluid dynamics approach. Groundw Sustainability Dev. 2022;18:100776.10.1016/j.gsd.2022.100776Search in Google Scholar

[19] Alnahdi AS, Khan A, Gul T, Ahmad H. Stagnation point nanofluid flow in a variable darcy space subject to thermal convection using artificial neural network technique. Arab J Sci Eng. 2024;1–18.10.1007/s13369-023-08697-6Search in Google Scholar

[20] Bafakeeh OT, Raghunath K, Ali F, Khalid M, Tag-ElDin ESM, Oreijah M, et al. Hall current and Soret effects on unsteady MHD rotating flow of second-grade fluid through porous media under the influences of thermal radiation and chemical reactions. Catalysts. 2022;12(10):1233. 10.3390/catal12101233Search in Google Scholar

[21] Kazemi E, Luo M. A comparative study on the accuracy and conservation properties of the SPH method for fluid flow interaction with porous media. Adv Water Resour. 2022;165:104220.10.1016/j.advwatres.2022.104220Search in Google Scholar

[22] Nhunduru RAE, Jahanbakhsh A, Shahrokhi O, Wlodarczyk KL, Garcia S, Maroto-Valer MM. The impact of wettability on dynamic fluid connectivity and flow transport kinetics in porous media. Water Resour Res. 2022;58:e2021WR030729.10.1029/2021WR030729Search in Google Scholar PubMed PubMed Central

[23] Elbashbeshy EMA, Asker HG. Fluid flow over a vertical stretching surface within a porous medium filled by a nanofluid containing gyrotactic microorganisms. Eur Phys J Plus. 2022;137:541.10.1140/epjp/s13360-022-02682-ySearch in Google Scholar

[24] Megahed AM, Abbas W. Non-newtonian cross fluid flow through a porous medium with regard to the effect of chemical reaction and thermal stratification phenomenon. Case Stud Therm Eng. 2022;29:101715.10.1016/j.csite.2021.101715Search in Google Scholar

[25] Sharma BK, Khanduri U, Mishra NK, Mekheimer KS. Combined effect of thermophoresis and Brownian motion on MHD mixed convective flow over an inclined stretching surface with radiation and chemical reaction. Int J Mod Phys B. 2023;37:2350095.10.1142/S0217979223500959Search in Google Scholar

[26] Maheswari C, Ravuri MR, Prakash GB, Ramesh D, Kumar DV. Influence of thermophoresis and brownian motion on MHD hybrid nanofluid MgO-Ag/H2O flow along moving slim needle. J Adv Res Appl Sci Eng Technol. 2023;36:67–90.10.37934/araset.36.2.6790Search in Google Scholar

[27] Waqas H, Khan SA, Ali B, Liu D, Muhammad T, Hou E. Numerical computation of Brownian motion and thermophoresis effects on rotational micropolar nanomaterials with activation energy. Propuls Power Res. 2023;12:397–409.10.1016/j.jppr.2023.05.005Search in Google Scholar

[28] Shahzad A, Imran M, Tahir M, Ali Khan S, Akgül A, Abdullaev S, et al. Brownian motion and thermophoretic diffusion impact on Darcy-Forchheimer flow of bioconvective micropolar nanofluid between double disks with Cattaneo-Christov heat flux. Alex Eng J. 2023;62:1–15.10.1016/j.aej.2022.07.023Search in Google Scholar

[29] Almeida F, Gireesha BJ, Venkatesh P. Magnetohydrodynamic flow of a micropolar nanofluid in association with Brownian motion and thermophoresis: Irreversibility analysis. Heat Transf. 2023;[cited 2024 Feb 14]52:2032–55. 10.1002/htj.22773 Search in Google Scholar

[30] EL-Dabe NTM, Attia HA, Essawy MAI, Ramadan AA, Abdel-Hamid AH. Two-phase nanofluid flow exhibiting Brownian motion and thermophoretic diffusion via a horizontal circular pipe: numerical simulation. JMST Adv. 2024;6:1–18.10.1007/s42791-024-00063-3Search in Google Scholar

[31] Agunbiade SA, Ayoade AA, Oyekunle TL, Akolade MT. Brownian motion and thermophoresis influence in magnetized Maxwell upper-convected stagnation point fluid flow via a stretching porous surface. J Taibah Univ Sci. 2024;18:2301130.10.1080/16583655.2023.2301130Search in Google Scholar

[32] Anandika R, Puneeth V, Manjunatha S, Shehzad SA, Arshad M. Exploration of Thermophoresis and Brownian motion effect on the bio-convective flow of Newtonian fluid conveying tiny particles: aspects of multi-layer model. Proc Inst Mech Eng part C J Mech Eng Sci. 2022;236:10185–99.10.1177/09544062221098537Search in Google Scholar

[33] Thabet EN, Khan Z, Abd-Alla AM, Bayones FS. Thermal enhancement, thermophoretic diffusion, and Brownian motion impacts on MHD micropolar nanofluid over an inclined surface: numerical simulation. Numer Heat Transf Part A Appl. 2023;1–20.10.1080/10407782.2023.2276319Search in Google Scholar

[34] Sudarmozhi K, Iranian D, Alessa N. Investigation of melting heat effect on fluid flow with brownian motion/thermophoresis effects in the occurrence of energy on a stretching sheet. Alex Eng J. 2024;94:366–76.10.1016/j.aej.2024.03.065Search in Google Scholar

[35] Ahmad S, Ahmad A, Ali K, Bashir H, Iqbal MF. Effect of non-Newtonian flow due to thermally-dependent properties over an inclined surface in the presence of chemical reaction, Brownian motion and thermophoresis. Alex Eng J. 2021;60:4931–45.10.1016/j.aej.2021.03.014Search in Google Scholar

[36] Eswaramoorthi S, Bhuvaneswari M. Passive and active control on 3D convective flow of viscoelastic nanofluid with heat generation and convective heating. Front Mech Eng. 2019;5:36.10.3389/fmech.2019.00036Search in Google Scholar

[37] Qayyum A, Hayat T, Alhuthali MS, Malaikah HM. Newtonian heating effects in three-dimensional flow of viscoelastic fluid. Chin Phys B. 2014;23:54703.10.1088/1674-1056/23/5/054703Search in Google Scholar

[38] Sarkar A, Kundu PK. Active and passive controls of nanoparticles in bioconvection nanofluid flow containing gyrotactic microorganisms. J Nanofluids. 2022;11:227–36.10.1166/jon.2022.1832Search in Google Scholar

[39] Dawar A, Islam S, Shah Z, Mahmuod SR, Lone SA. Dynamics of inter-particle spacing, nanoparticle radius, inclined magnetic field and nonlinear thermal radiation on the water-based copper nanofluid flow past a convectively heated stretching surface with mass flux condition: A strong suction case. Int Commun Heat Mass Transf. 2022;137:106286.10.1016/j.icheatmasstransfer.2022.106286Search in Google Scholar

[40] Dawar A, Islam S, Shah Z, Mahmuod SR. A passive control of casson hybrid nanofluid flow over a curved surface with alumina and copper nanomaterials: a study on sodium alginate-based fluid. J Mol Liq. 2023;382:122018.10.1016/j.molliq.2023.122018Search in Google Scholar

[41] Wakif A, Boulahia Z, Amine A, Animasaun IL, Afridi MI, Qasimd M, et al. Magneto-convection of alumina – water nanofluid within thin horizontal layers using the revised generalized Buongiorno’s model. Front Heat Mass Transf. 2019;12.10.5098/hmt.12.3Search in Google Scholar

[42] Acharya N, Maity S, Kundu PK. Framing the hydrothermal features of magnetized TiO2–CoFe2O4 water-based steady hybrid nanofluid flow over a radiative revolving disk. Multidiscip Model Mater Struct. 2020;16:765–90.10.1108/MMMS-08-2019-0151Search in Google Scholar

[43] Das S, Ali A, Jana RN, Makinde OD. EDL impact on mixed magneto-convection in a vertical channel using ternary hybrid nanofluid. Chem Eng J Adv. 2022;12:100412.10.1016/j.ceja.2022.100412Search in Google Scholar

[44] Waqas H, Farooq U, Alqarni MS, Muhammad T. Numerical investigation for 3D bioconvection flow of Carreau nanofluid with heat source/sink and motile microorganisms. Alex Eng J. 2022;61:2366–75.10.1016/j.aej.2021.06.089Search in Google Scholar

[45] Dawar A, Wakif A, Saeed A, Shah Z, Muhammad T, Kumam P. Significance of Lorentz forces on Jeffrey nanofluid flows over a convectively heated flat surface featured by multiple velocity slips and dual stretching constraint: a homotopy analysis approach. J Comput Des Eng. 2022;9:564–82.10.1093/jcde/qwac019Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface

- Potential pharmaceutical applications and molecular docking study for green fabricated ZnO nanoparticles mediated Raphanus sativus: In vitro and in vivo study

- Effect of temperature and nanoparticle size on the interfacial layer thickness of TiO2–water nanofluids using molecular dynamics

- Characteristics of induced magnetic field on the time-dependent MHD nanofluid flow through parallel plates

- Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

- Experimental research on mechanically and thermally activation of nano-kaolin to improve the properties of ultra-high-performance fiber-reinforced concrete

- Analysis of variable fluid properties for three-dimensional flow of ternary hybrid nanofluid on a stretching sheet with MHD effects

- Biodegradability of corn starch films containing nanocellulose fiber and thymol

- Toxicity assessment of copper oxide nanoparticles: In vivo study

- Some measures to enhance the energy output performances of triboelectric nanogenerators

- Reinforcement of graphene nanoplatelets on water uptake and thermomechanical behaviour of epoxy adhesive subjected to water ageing conditions

- Optimization of preparation parameters and testing verification of carbon nanotube suspensions used in concrete

- Max-phase Ti3SiC2 and diverse nanoparticle reinforcements for enhancement of the mechanical, dynamic, and microstructural properties of AA5083 aluminum alloy via FSP

- Advancing drug delivery: Neural network perspectives on nanoparticle-mediated treatments for cancerous tissues

- PEG-PLGA core–shell nanoparticles for the controlled delivery of picoplatin–hydroxypropyl β-cyclodextrin inclusion complex in triple-negative breast cancer: In vitro and in vivo study

- Conduction transportation from graphene to an insulative polymer medium: A novel approach for the conductivity of nanocomposites

- Review Articles

- Developments of terahertz metasurface biosensors: A literature review

- Overview of amorphous carbon memristor device, modeling, and applications for neuromorphic computing

- Advances in the synthesis of gold nanoclusters (AuNCs) of proteins extracted from nature

- A review of ternary polymer nanocomposites containing clay and calcium carbonate and their biomedical applications

- Recent advancements in polyoxometalate-functionalized fiber materials: A review

- Special contribution of atomic force microscopy in cell death research

- A comprehensive review of oral chitosan drug delivery systems: Applications for oral insulin delivery

- Cellular senescence and nanoparticle-based therapies: Current developments and perspectives

- Cyclodextrins-block copolymer drug delivery systems: From design and development to preclinical studies

- Micelle-based nanoparticles with stimuli-responsive properties for drug delivery

- Critical assessment of the thermal stability and degradation of chemically functionalized nanocellulose-based polymer nanocomposites

- Research progress in preparation technology of micro and nano titanium alloy powder

- Nanoformulations for lysozyme-based additives in animal feed: An alternative to fight antibiotic resistance spread

- Incorporation of organic photochromic molecules in mesoporous silica materials: Synthesis and applications

- A review on modeling of graphene and associated nanostructures reinforced concrete

- A review on strengthening mechanisms of carbon quantum dots-reinforced Cu-matrix nanocomposites

- Review on nanocellulose composites and CNFs assembled microfiber toward automotive applications

- Nanomaterial coating for layered lithium rich transition metal oxide cathode for lithium-ion battery

- Application of AgNPs in biomedicine: An overview and current trends

- Nanobiotechnology and microbial influence on cold adaptation in plants

- Hepatotoxicity of nanomaterials: From mechanism to therapeutic strategy

- Applications of micro-nanobubble and its influence on concrete properties: An in-depth review

- A comprehensive systematic literature review of ML in nanotechnology for sustainable development

- Exploiting the nanotechnological approaches for traditional Chinese medicine in childhood rhinitis: A review of future perspectives

- Twisto-photonics in two-dimensional materials: A comprehensive review

- Current advances of anticancer drugs based on solubilization technology

- Recent process of using nanoparticles in the T cell-based immunometabolic therapy

- Future prospects of gold nanoclusters in hydrogen storage systems and sustainable environmental treatment applications

- Preparation, types, and applications of one- and two-dimensional nanochannels and their transport properties for water and ions

- Microstructural, mechanical, and corrosion characteristics of Mg–Gd–x systems: A review of recent advancements

- Functionalized nanostructures and targeted delivery systems with a focus on plant-derived natural agents for COVID-19 therapy: A review and outlook

- Mapping evolution and trends of cell membrane-coated nanoparticles: A bibliometric analysis and scoping review

- Nanoparticles and their application in the diagnosis of hepatocellular carcinoma

- In situ growth of carbon nanotubes on fly ash substrates

- Structural performance of boards through nanoparticle reinforcement: An advance review

- Reinforcing mechanisms review of the graphene oxide on cement composites

- Seed regeneration aided by nanomaterials in a climate change scenario: A comprehensive review

- Surface-engineered quantum dot nanocomposites for neurodegenerative disorder remediation and avenue for neuroimaging

- Graphitic carbon nitride hybrid thin films for energy conversion: A mini-review on defect activation with different materials

- Nanoparticles and the treatment of hepatocellular carcinoma

- Special Issue on Advanced Nanomaterials and Composites for Energy Conversion and Storage - Part II

- Highly safe lithium vanadium oxide anode for fast-charging dendrite-free lithium-ion batteries

- Recent progress in nanomaterials of battery energy storage: A patent landscape analysis, technology updates, and future prospects

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part II

- Calcium-, magnesium-, and yttrium-doped lithium nickel phosphate nanomaterials as high-performance catalysts for electrochemical water oxidation reaction

- Low alkaline vegetation concrete with silica fume and nano-fly ash composites to improve the planting properties and soil ecology

- Mesoporous silica-grafted deep eutectic solvent-based mixed matrix membranes for wastewater treatment: Synthesis and emerging pollutant removal performance

- Electrochemically prepared ultrathin two-dimensional graphitic nanosheets as cathodes for advanced Zn-based energy storage devices

- Enhanced catalytic degradation of amoxicillin by phyto-mediated synthesised ZnO NPs and ZnO-rGO hybrid nanocomposite: Assessment of antioxidant activity, adsorption, and thermodynamic analysis

- Incorporating GO in PI matrix to advance nanocomposite coating: An enhancing strategy to prevent corrosion

- Synthesis, characterization, thermal stability, and application of microporous hyper cross-linked polyphosphazenes with naphthylamine group for CO2 uptake

- Engineering in ceramic albite morphology by the addition of additives: Carbon nanotubes and graphene oxide for energy applications

- Nanoscale synergy: Optimizing energy storage with SnO2 quantum dots on ZnO hexagonal prisms for advanced supercapacitors

- Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation

- Tuning structural and electrical properties of Co-precipitated and Cu-incorporated nickel ferrite for energy applications

- Sodium alginate-supported AgSr nanoparticles for catalytic degradation of malachite green and methyl orange in aqueous medium

- An environmentally greener and reusability approach for bioenergy production using Mallotus philippensis (Kamala) seed oil feedstock via phytonanotechnology

- Micro-/nano-alumina trihydrate and -magnesium hydroxide fillers in RTV-SR composites under electrical and environmental stresses

- Mechanism exploration of ion-implanted epoxy on surface trap distribution: An approach to augment the vacuum flashover voltages

- Nanoscale engineering of semiconductor photocatalysts boosting charge separation for solar-driven H2 production: Recent advances and future perspective

- Excellent catalytic performance over reduced graphene-boosted novel nanoparticles for oxidative desulfurization of fuel oil

- Special Issue on Advances in Nanotechnology for Agriculture

- Deciphering the synergistic potential of mycogenic zinc oxide nanoparticles and bio-slurry formulation on phenology and physiology of Vigna radiata

- Nanomaterials: Cross-disciplinary applications in ornamental plants

- Special Issue on Catechol Based Nano and Microstructures

- Polydopamine films: Versatile but interface-dependent coatings

- In vitro anticancer activity of melanin-like nanoparticles for multimodal therapy of glioblastoma

- Poly-3,4-dihydroxybenzylidenhydrazine, a different analogue of polydopamine

- Chirality and self-assembly of structures derived from optically active 1,2-diaminocyclohexane and catecholamines

- Advancing resource sustainability with green photothermal materials: Insights from organic waste-derived and bioderived sources

- Bioinspired neuromelanin-like Pt(iv) polymeric nanoparticles for cancer treatment

- Special Issue on Implementing Nanotechnology for Smart Healthcare System

- Intelligent explainable optical sensing on Internet of nanorobots for disease detection

- Special Issue on Green Mono, Bi and Tri Metallic Nanoparticles for Biological and Environmental Applications

- Tracking success of interaction of green-synthesized Carbopol nanoemulgel (neomycin-decorated Ag/ZnO nanocomposite) with wound-based MDR bacteria

- Green synthesis of copper oxide nanoparticles using genus Inula and evaluation of biological therapeutics and environmental applications

- Biogenic fabrication and multifunctional therapeutic applications of silver nanoparticles synthesized from rose petal extract

- Metal oxides on the frontlines: Antimicrobial activity in plant-derived biometallic nanoparticles

- Controlling pore size during the synthesis of hydroxyapatite nanoparticles using CTAB by the sol–gel hydrothermal method and their biological activities

- Special Issue on State-of-Art Advanced Nanotechnology for Healthcare

- Applications of nanomedicine-integrated phototherapeutic agents in cancer theranostics: A comprehensive review of the current state of research

- Smart bionanomaterials for treatment and diagnosis of inflammatory bowel disease

- Beyond conventional therapy: Synthesis of multifunctional nanoparticles for rheumatoid arthritis therapy

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface

- Potential pharmaceutical applications and molecular docking study for green fabricated ZnO nanoparticles mediated Raphanus sativus: In vitro and in vivo study

- Effect of temperature and nanoparticle size on the interfacial layer thickness of TiO2–water nanofluids using molecular dynamics

- Characteristics of induced magnetic field on the time-dependent MHD nanofluid flow through parallel plates

- Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

- Experimental research on mechanically and thermally activation of nano-kaolin to improve the properties of ultra-high-performance fiber-reinforced concrete

- Analysis of variable fluid properties for three-dimensional flow of ternary hybrid nanofluid on a stretching sheet with MHD effects

- Biodegradability of corn starch films containing nanocellulose fiber and thymol

- Toxicity assessment of copper oxide nanoparticles: In vivo study

- Some measures to enhance the energy output performances of triboelectric nanogenerators

- Reinforcement of graphene nanoplatelets on water uptake and thermomechanical behaviour of epoxy adhesive subjected to water ageing conditions

- Optimization of preparation parameters and testing verification of carbon nanotube suspensions used in concrete

- Max-phase Ti3SiC2 and diverse nanoparticle reinforcements for enhancement of the mechanical, dynamic, and microstructural properties of AA5083 aluminum alloy via FSP

- Advancing drug delivery: Neural network perspectives on nanoparticle-mediated treatments for cancerous tissues

- PEG-PLGA core–shell nanoparticles for the controlled delivery of picoplatin–hydroxypropyl β-cyclodextrin inclusion complex in triple-negative breast cancer: In vitro and in vivo study

- Conduction transportation from graphene to an insulative polymer medium: A novel approach for the conductivity of nanocomposites

- Review Articles

- Developments of terahertz metasurface biosensors: A literature review

- Overview of amorphous carbon memristor device, modeling, and applications for neuromorphic computing

- Advances in the synthesis of gold nanoclusters (AuNCs) of proteins extracted from nature

- A review of ternary polymer nanocomposites containing clay and calcium carbonate and their biomedical applications

- Recent advancements in polyoxometalate-functionalized fiber materials: A review

- Special contribution of atomic force microscopy in cell death research

- A comprehensive review of oral chitosan drug delivery systems: Applications for oral insulin delivery

- Cellular senescence and nanoparticle-based therapies: Current developments and perspectives

- Cyclodextrins-block copolymer drug delivery systems: From design and development to preclinical studies

- Micelle-based nanoparticles with stimuli-responsive properties for drug delivery

- Critical assessment of the thermal stability and degradation of chemically functionalized nanocellulose-based polymer nanocomposites

- Research progress in preparation technology of micro and nano titanium alloy powder

- Nanoformulations for lysozyme-based additives in animal feed: An alternative to fight antibiotic resistance spread

- Incorporation of organic photochromic molecules in mesoporous silica materials: Synthesis and applications

- A review on modeling of graphene and associated nanostructures reinforced concrete

- A review on strengthening mechanisms of carbon quantum dots-reinforced Cu-matrix nanocomposites

- Review on nanocellulose composites and CNFs assembled microfiber toward automotive applications

- Nanomaterial coating for layered lithium rich transition metal oxide cathode for lithium-ion battery

- Application of AgNPs in biomedicine: An overview and current trends

- Nanobiotechnology and microbial influence on cold adaptation in plants

- Hepatotoxicity of nanomaterials: From mechanism to therapeutic strategy

- Applications of micro-nanobubble and its influence on concrete properties: An in-depth review

- A comprehensive systematic literature review of ML in nanotechnology for sustainable development

- Exploiting the nanotechnological approaches for traditional Chinese medicine in childhood rhinitis: A review of future perspectives

- Twisto-photonics in two-dimensional materials: A comprehensive review

- Current advances of anticancer drugs based on solubilization technology

- Recent process of using nanoparticles in the T cell-based immunometabolic therapy

- Future prospects of gold nanoclusters in hydrogen storage systems and sustainable environmental treatment applications

- Preparation, types, and applications of one- and two-dimensional nanochannels and their transport properties for water and ions

- Microstructural, mechanical, and corrosion characteristics of Mg–Gd–x systems: A review of recent advancements

- Functionalized nanostructures and targeted delivery systems with a focus on plant-derived natural agents for COVID-19 therapy: A review and outlook

- Mapping evolution and trends of cell membrane-coated nanoparticles: A bibliometric analysis and scoping review

- Nanoparticles and their application in the diagnosis of hepatocellular carcinoma

- In situ growth of carbon nanotubes on fly ash substrates

- Structural performance of boards through nanoparticle reinforcement: An advance review

- Reinforcing mechanisms review of the graphene oxide on cement composites

- Seed regeneration aided by nanomaterials in a climate change scenario: A comprehensive review

- Surface-engineered quantum dot nanocomposites for neurodegenerative disorder remediation and avenue for neuroimaging

- Graphitic carbon nitride hybrid thin films for energy conversion: A mini-review on defect activation with different materials

- Nanoparticles and the treatment of hepatocellular carcinoma

- Special Issue on Advanced Nanomaterials and Composites for Energy Conversion and Storage - Part II

- Highly safe lithium vanadium oxide anode for fast-charging dendrite-free lithium-ion batteries

- Recent progress in nanomaterials of battery energy storage: A patent landscape analysis, technology updates, and future prospects

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part II

- Calcium-, magnesium-, and yttrium-doped lithium nickel phosphate nanomaterials as high-performance catalysts for electrochemical water oxidation reaction

- Low alkaline vegetation concrete with silica fume and nano-fly ash composites to improve the planting properties and soil ecology

- Mesoporous silica-grafted deep eutectic solvent-based mixed matrix membranes for wastewater treatment: Synthesis and emerging pollutant removal performance

- Electrochemically prepared ultrathin two-dimensional graphitic nanosheets as cathodes for advanced Zn-based energy storage devices

- Enhanced catalytic degradation of amoxicillin by phyto-mediated synthesised ZnO NPs and ZnO-rGO hybrid nanocomposite: Assessment of antioxidant activity, adsorption, and thermodynamic analysis

- Incorporating GO in PI matrix to advance nanocomposite coating: An enhancing strategy to prevent corrosion

- Synthesis, characterization, thermal stability, and application of microporous hyper cross-linked polyphosphazenes with naphthylamine group for CO2 uptake

- Engineering in ceramic albite morphology by the addition of additives: Carbon nanotubes and graphene oxide for energy applications

- Nanoscale synergy: Optimizing energy storage with SnO2 quantum dots on ZnO hexagonal prisms for advanced supercapacitors

- Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation

- Tuning structural and electrical properties of Co-precipitated and Cu-incorporated nickel ferrite for energy applications

- Sodium alginate-supported AgSr nanoparticles for catalytic degradation of malachite green and methyl orange in aqueous medium

- An environmentally greener and reusability approach for bioenergy production using Mallotus philippensis (Kamala) seed oil feedstock via phytonanotechnology

- Micro-/nano-alumina trihydrate and -magnesium hydroxide fillers in RTV-SR composites under electrical and environmental stresses

- Mechanism exploration of ion-implanted epoxy on surface trap distribution: An approach to augment the vacuum flashover voltages

- Nanoscale engineering of semiconductor photocatalysts boosting charge separation for solar-driven H2 production: Recent advances and future perspective

- Excellent catalytic performance over reduced graphene-boosted novel nanoparticles for oxidative desulfurization of fuel oil

- Special Issue on Advances in Nanotechnology for Agriculture

- Deciphering the synergistic potential of mycogenic zinc oxide nanoparticles and bio-slurry formulation on phenology and physiology of Vigna radiata

- Nanomaterials: Cross-disciplinary applications in ornamental plants

- Special Issue on Catechol Based Nano and Microstructures

- Polydopamine films: Versatile but interface-dependent coatings

- In vitro anticancer activity of melanin-like nanoparticles for multimodal therapy of glioblastoma

- Poly-3,4-dihydroxybenzylidenhydrazine, a different analogue of polydopamine

- Chirality and self-assembly of structures derived from optically active 1,2-diaminocyclohexane and catecholamines

- Advancing resource sustainability with green photothermal materials: Insights from organic waste-derived and bioderived sources

- Bioinspired neuromelanin-like Pt(iv) polymeric nanoparticles for cancer treatment

- Special Issue on Implementing Nanotechnology for Smart Healthcare System

- Intelligent explainable optical sensing on Internet of nanorobots for disease detection

- Special Issue on Green Mono, Bi and Tri Metallic Nanoparticles for Biological and Environmental Applications

- Tracking success of interaction of green-synthesized Carbopol nanoemulgel (neomycin-decorated Ag/ZnO nanocomposite) with wound-based MDR bacteria

- Green synthesis of copper oxide nanoparticles using genus Inula and evaluation of biological therapeutics and environmental applications

- Biogenic fabrication and multifunctional therapeutic applications of silver nanoparticles synthesized from rose petal extract

- Metal oxides on the frontlines: Antimicrobial activity in plant-derived biometallic nanoparticles

- Controlling pore size during the synthesis of hydroxyapatite nanoparticles using CTAB by the sol–gel hydrothermal method and their biological activities

- Special Issue on State-of-Art Advanced Nanotechnology for Healthcare

- Applications of nanomedicine-integrated phototherapeutic agents in cancer theranostics: A comprehensive review of the current state of research

- Smart bionanomaterials for treatment and diagnosis of inflammatory bowel disease

- Beyond conventional therapy: Synthesis of multifunctional nanoparticles for rheumatoid arthritis therapy