Abstract

Under the turbulence of global change, the production of boards has been influenced by the rising demand and price of wood-based materials. To improve the structural performance of boards, reinforcement materials have been added, such as nanoparticles. The purpose of this review is to explore the application of nanomaterials, including nano-SiO2, nano-Al2O3, nano-ZnO, nano-Fe2O3, nano-cellulose, nano-lignin, and nano-chitosan, to evaluate the physical and mechanical properties of particleboards. These nanoparticles have demonstrated their ability to reduce formaldehyde emissions, enhance the dimensional stability, bending strength, bending stiffness, fire resistance, and resistance to thermal conductivity in board production. For example, the addition of nano-SiO2, known for its hydrophilicity, attracts and holds water molecules and acts as a thermal barrier due to its high melting point and low thermal conductivity. In contrast, nano-Al2O3 is known for its high compressive strength (up to 3 GPa), hardness strength (9 Mohs scale), and high thermal conductivity, which helps to dissipate heat more effectively. This comprehensive evaluation brings together recent advances in producing particleboards and medium density fiberboard reinforced with nanoparticles, which are essential for future research and industry applications. The study emphasizes how innovative nanoparticles can contribute to sustainable urban development and construction practices, reduce deforestation, preserve natural habitats, and provide affordable housing. The research indicates that nanoparticle boards meet (e.g., nanoclay and nanoalumina panels) and in some cases exceed the minimum requirement for general-purpose panels set standards such as the ANSI/A208.1-1999, including water absorption of 8%, thickness swelling of 3% and EN 312 for the bending strength (15–16 MPa) and bending stiffness (2.2–2.4 GPa) for P4 and P6 boards, respectively. These results support the transformative power of nanomaterials in promoting a more sustainable and future solution for boards in the building construction industry.

1 Introduction

Population growth, climate change, energy crisis, deforestation, and forest degradation are significant factors contributing to the rise in global greenhouse gas emissions [1,2,3,4]. A study in the New England’s Forest highlights that the demand for wood products exacerbates these issues, especially when it comes to timber harvesting, which can result in forests shifting from net carbon sinks to net carbon sources, potentially emitting up to 909 million metric tons of CO2 equivalent by 2060 [5]. Demand for wood products often exceeds the available supply, driving up prices. Moreover, this demand, particularly for construction purposes, contributes to changes in land use [6]. The projected growth of the construction industry, driven by future population trends, is expected to further fuel the demand for wood products [7]. However, if managed sustainably, this increased demand can help store CO2 and reduce greenhouse gas emissions, as wood products sequester carbon and require less energy to produce compared to materials such as concrete and steel.

On the other hand, in the construction industry, concerns have arisen due to formaldehyde emissions from conventional particleboards and medium density fiberboard (MDF), which are mostly made of wood fibers and urea-formaldehyde (UF) resin and have been reported to have negative effects on human health [8,9]. Indeed, traditional particleboards made with UF and wood fibers, when installed in kitchen or bathroom countertops, have a very little moisture resistance because water comes into permanent contact with boards. Over time, they swell, break apart, and release formaldehyde, which is negative for human health and leads to cancer in the human body, causes eye irritation and nausea, and affects upper respiratory system and nervous system [10,11]. Indeed, Hosseini and Fadaei [12] demonstrated that particleboards made from chips of mixed wood species and UF at a thickness swelling (TS) of 30% after 24 h can have formaldehyde emissions up to 0.3 mg/L when tested using the desiccator method according to the American Society for Testing and Materials (ASTM) D5582 [13]. Also, according to the United States Department of Housing and Urban Development, particleboards, MDF, and hardwood plywood made with a veneer core or composite core typically have formaldehyde emissions below 0.09, 0.13, 0.11, and 0.05 ppm, respectively [14].

MDF and particleboards differ in appearance, density, strength, durability, and moisture absorption. In contrast to particleboard, which is made with coarsely ground recycled, generally wood shavings, sawdust, and chips, is less strong and has less water resistance, MDF, known for its good water resistance, consists of wood fibers of the same size with a smooth finish [15]. Integrating nanomaterial reinforcement such as nano-SiO2, nano-Al2O3, nano-ZnO, nano-CaSiCO3, and nanocellulose in particleboard production for structural purposes is important for sustainable alternatives in board manufacturing leading to affordable housing. Nanoparticles exist in various chemical compositions, such as micelles, metal oxides, synthetic polymers, and large biomolecules. Each of these materials possesses distinct chemical compositions, which can be examined using various techniques such as X-ray fluorescence and scanning electron microscopy (SEM) [16]. The use of these nanoparticles, which typically range in size from 1 to 100 nm, has shown promise in reducing formaldehyde emissions, improving bending strength and stiffness, and reducing the TS percentage. Wen et al. [17] demonstrated that adding 3% (mass fraction) of nano-SiO2 particles improves the mechanical properties of gypsum particleboard production. Similarly, Karkoodi et al. [18] discovered that incorporating various concentrations of nano-Al2O3 in the production of MDF leads to the creation of high-performance particleboards.

This research focuses on investigating the use of nanomaterial reinforcement in addressing three main issues. The first is the insufficient mechanical strength and bonding performance of particleboards that can be addressed by the resin’s interaction with nanoparticles during board production, which significantly improves in properties. The second, nanoparticle technology, shows promise for enhancing the durability of particleboards and MDF by improving their dimensional stability. Finally, the absence of guidance for structural applications can be addressed by analyzing the connections between nanoparticle characteristics (density, electrical conductivity, melting point, etc.) with the bonding resin, facilitating the classification, use, and grade of nanoparticle board in building construction. This research provides valuable reference data for producing high-performance boards to meet the growing demand for engineered wood products in construction.

2 Nanoparticle boards

2.1 Metal oxide-based nanoparticle board

Metal oxide nanoparticles, such as nano- zinc oxide (ZnO) [19], nano-aluminum oxide (Al2O3) [20], nano-iron oxide (Fe2O3) [21], nano-silver (Ag) [22,23], nano-titanium oxide (TiO2), and nano-copper oxide (CuO) [22,23], are increasingly being utilized to enhance boards’ physical and mechanical properties. Furthermore, Ag has the highest density compared to ZnO, FeO3, Al2O3, and CuO with 5.9, 5.25, 3.987, and 6.31 g/cm3 as densities, respectively [24,25], while it has the lowest melting point with 1,974, 1,539, 2,072, and 1,201°C, respectively. Also, nanoparticles including ZnO, Al2O3, and CuO have thermal conductivity and electricity conductivity of 30 W/m K with high electron mobility and 401 W/m K and can be used as an electrical insulator, respectively. These properties have the potential to increase the boards’ quality in building production. Indeed, researchers have demonstrated that nanoparticles can be used as reinforcement in panel production. For instance, the interaction between nano-ZnO and UF resin primarily occurs through hydrogen bonding and acid-base interactions. The chemical structure of UF can be formed in the reaction below [26,27]:

NH2CONHCH2OH has key functional groups: Carbonyl (C═O), amino (−NH₂), and hydroxyl (−OH). Indeed, the hydroxyl groups (−OH) on the surface of nano-ZnO can interact with the carbonyl (C═O) and amino (−NH2) groups of the UF resin, forming hydrogen bonds. The hydroxyl groups (−OH) on the surface of nano-ZnO can form hydrogen bonds with the carbonyl (C═O) and amino (−NH2) groups of the UF resin. Hydrogen bonding occurs when a hydrogen atom (H) bonded to an electronegative atom (X), such as oxygen (O) or nitrogen (N), interacts with another electronegative atom (Y) nearby. In this case, the hydrogen atoms (H) of the surface hydroxyl groups (−OH) on nano-ZnO can form hydrogen bonds (X–H···Y) with the oxygen atom (O) of the carbonyl group (C═O) and the nitrogen atom (N) of the amino group (−NH2) in the UF resin. This interaction improves the dispersion of nanoparticles within the resin matrix, leading to enhanced strength of the boards and reduced formaldehyde emissions [28,29,30].

Fourier-transform infrared spectroscopy provides insights into these interactions, with shifts in characteristic bands indicating interactions between ZnO nanoparticles and UF resin. These shifts suggest that ZnO acts as a Lewis acid, while the NH groups in the UF resin act as Lewis bases. This acid-base interaction increases cross-linkage density, providing stability to the zinc oxide nanoparticles within the UF resin matrix and enhancing mechanical strength and water resistance [31].

When added to particleboards or MDF, they have demonstrated the potential to improve not only mechanical but also heat transfer properties due to the high thermal conductivity of metal oxide nanoparticles, in particular nano-ZnO and nano-Al2O3, contributing to the boards’ durability and longevity [19,20]. They catalyze condensation reactions, ensure uniform curing, and increase cross-linking density. The catalyzing effect of metal oxide nanoparticles in panel production is primarily a chemical effect, with the physical effect of quicker warming playing a secondary role. The high thermal conductivity of nano-ZnO (49 W/m·K at 300 K and 10 W/m·K at 1,000 K) [32] and nano-Al2O3 (20–30 W/m·K with a pH level ranging between 8 and 10 at 25°C) [33] can contribute to faster warming of the mat during hot pressing in board production. Incorporating these nanoparticles into the UF resin can enhance heat transfer throughout the mat, resulting in more efficient and uniform curing of the resin. This faster heat distribution can lead to improved mechanical properties and reduced pressing time.

Because of their chemical properties, they create a compact, less porous structure, acting as a barrier to moisture penetration and reducing water absorption (WA) and TS. Additionally, nano-Al₂O₃ forms a protective layer, enhancing fire resistance in board production. On the other hand, nano-Ag particles have also been employed in particleboard production. They possess unique properties due to their high surface area-to-volume ratio, which imparts antimicrobial characteristics to the particleboards and MDF. The high surface area-to-volume ratio of nanoparticles (e.g., a particle of size 3 nm has 50% of its atoms on the surface) [34] such as nano-Ag enhances their antimicrobial efficacy by increasing the contact area and reactivity with bacterial cell membranes. This, in turn, facilitates the release of antimicrobial ions (Ag+) that interact with cellular components, disrupt metabolic processes, and cause oxidative stress, ultimately leading to cell death [35,36].

The incorporation of nano-Ag effectively inhibits the growth of microorganisms, thereby enhancing the particleboards’ resistance to biological degradation [22,23,37]. This is particularly advantageous in environments that demand high levels of hygiene, including healthcare facilities or food processing areas. Finally, nano-Cu has been used to fabricate panels. Indeed, the copper ions (Cu+/Cu2+) may form coordination complexes with the nitrogen atoms present in the UF resin during the fabrication process to bond together [38,39].

2.2 Calcium-based nanoparticle board

Calcium-based nanoparticles are used to fabricate particleboards and MDF to improve their physical and mechanical properties. These nanoparticles have unique characteristics that can positively impact the performance of particleboards. Studies have shown that incorporating nano-calcium carbonate (CaCO3) [40,41] and nano-calcium silicate (CaSiO3) [42] can increase the bending stiffness, bending strength, and internal bond (IB) strength, as well as improve the dimensional stability of particleboard and MDF. The physical and mechanical basis for the improvement in board properties when incorporating nano-CaCO₃ and nano-CaSiO₃ can be attributed to their high surface area-to-volume ratio, density, and thermal stability. For example, CaCO3 has a density of 2.71 g/cm³ and a melting point of 1,339°C, while CaSiO₃ has a density of 2.9 g/cm³ and a melting point of 1,540°C. By adding 1% nano-CaCO₃, it increases the bending strength and stiffness by 3% and 2%, respectively, while adding 3% increases the tensile strength by 30% [43]. Additionally, nano-CaCO3 and CaSiO3 can potentially enhance the fire resistance of boards. They can be used as insulators and have been reported to have a thermal conductivity of 3.14 and 1.5 W/m·K, respectively, improving fire resistance [44,45]. The basis for this improvement lies in the thermal decomposition of CaCO₃ at 1,339°C, which produces CaO and CO₂ [46,47]. This reaction is given in the equation below [46,47]:

CaCO3 → CaO + CO2

The above reaction leads to the formation of a protective CaO-layer on the surface of the panel. The char layer acts as a thermal barrier, slowing down heat transfer and combustion [45]. Similarly, with a melting point of 1,540°C, CaSiO3 undergoes thermal decomposition at high temperatures, releasing CO2 and forming a protective layer of CaO and SiO2 which provides an effective thermal shield, improving the overall fire resistance of the particleboard [48,49].

2.3 Silica-based nanoparticle board

Nano-SiO2, also known as nano-silica or silica nanoparticles, an inorganic nanoparticle, refers to silicon dioxide particles with sizes in the nanometer range, typically less than 100 nm in diameter, exhibiting unique properties due to their small size. Adding nano-SiO₂ leads to improvements in the modulus of rupture (MOR), modulus of elasticity (MOE), and IB strength of both particleboards and MDF, as well as reduced WA and TS percentage.

The incorporation of nano-SiO2 can be attributed to the strong interfacial interactions between the nano-SiO2 particles, wood fibers, and polymer matrix (Si–O–Si). The high surface area-to-volume ratio of nano-SiO2 particles improves their reactivity up to 300 m2/g. These hydrogen bonding (Si–OH···O–C) interactions improve stress transfer and mechanical properties of the panels.

Indeed, the physical properties of nano-SiO2 such as its density (2.65 g/cm3), high melting point (1,713°C), and low thermal conductivity (1.4 W/m·K), contribute to the improvement in dimensional stability of the panels [50]. The well-dispersed nano-SiO2 particles fill voids and micropores within the wood fibers and at the fiber-matrix interface, creating a more compact and less porous structure.

Furthermore, nano-SiO₂ has been associated with improved fire retardancy, making it suitable for applications where fire safety is a concern [42,51]. The presence of nano-SiO2 in panels leads to stronger fire retardancy compared to panels without nanomaterials. The protective layer formed during combustion acts as a thermal barrier and slows down heat transfer more effectively when nano-SiO2 is incorporated. For example, when exposed to high temperatures, nano-SiO2 undergoes a reaction with hydrofluoric acid to form silicon tetrafluoride (SiF4) and water (H2O). This reaction contributes to the release of non-combustible gases, further enhancing the fire resistance of the panels. Additionally, studies have shown that the incorporation of nano-SiO2 into intumescent fire-retardant coatings improves their flame retardancy and smoke suppression properties. Nano-SiO2 coatings on regenerated cellulose fibers have been found to increase the temperature at which the fiber starts to decompose by 20°C and hinder the flow of oxygen to the generated volatiles during thermal decomposition.

Nano-SiO₂ enhances the wood-adhesive interaction through various mechanisms, despite the size discrepancy between the nanoparticles (typically less than 100 nm) and the larger wood voids such as lumens (up to 30 μm). While nano-SiO2 particles are too small to directly fill these larger voids, they can fill nanoscale crevices and surface roughness on the wood cell walls, creating a more uniform and smoother surface for the adhesive to interact with. This improves the contact area and adhesion between the wood and the adhesive. The high surface area and reactivity of nano-SiO2 particles allow them to form strong interfacial bonds with both the wood surface and the adhesive, enhancing the adhesion and durability of the wood-adhesive interface. These interactions contribute to improved bonding strength and reduced formaldehyde emissions in wood composites. For instance, using the desiccator method and mixing 12% UF resin with nanoclay at three different levels (1.5, 2, and 2.5%), Khorramabadi et al. [52] found that it reduced 5, 15, and 22% of formaldehyde emissions, respectively. The decrease in formaldehyde emission of the MDF with nanoclay can be attributed to the strong absorbability of SiO2 and the barrier property (shielding effect) of nanoparticles. The SiO2 can react with the active group of the pure UF resin and absorb free formaldehyde. Also, after adding nanoclay to UF resin, UF molecules penetrate between clay layers and exfoliate the clay. Exfoliated clay layers create a barrier to gases and water, forcing them to follow a tortuous path.

2.4 Cellulose-based nanoparticle board

Nanocellulose, a nanomaterial derived from natural cellulose, is obtained from cellulose and typically has dimensions ranging from a few to tens of nanometers in width. They can be classified into various forms, including cellulose nanocrystals (CNCs) and cellulose nanofibrils (CNFs), each with their own unique properties and potential applications in particleboard and MDF production (Figure 1). In addition to these two nanomorphologies, bacterial nanocellulose (BCN) also exists [53]. BCN has shown promise for enhancing the mechanical properties of boards due to its high purity, three-dimensional nanofibril network structure composed of ribbon-like nanofibers around 100 nm in diameter and 100 μm in length, and a high bending stiffness ranging from 16 to 18 GPa and ultimate strength up to 260 MPa.

![Figure 1

Schematic illustration of cellulosic fibers (nanocrystals and nanofibrils) hierarchical structure [71].](/document/doi/10.1515/ntrev-2024-0119/asset/graphic/j_ntrev-2024-0119_fig_001.jpg)

Schematic illustration of cellulosic fibers (nanocrystals and nanofibrils) hierarchical structure [71].

CNCs consist of cylindrical, elongated, and rod-like nanoparticles with a high aspect ratio (length-to-diameter ratio) ranging from 3–5 nm in width and 50–500 nm in length [54]. They are known for their high strength, with a theoretical tensile strength of 7.5–7.7 GPa [55], the bending stiffness ranging between 110 and 220 GPa [56], and a density of 1.6 g/cm3 as well as improved dimensional stability, making them suitable for reinforcing composite materials such as particleboards and MDF [57].

On the other hand, CNFs are long and thin fibrillar nanoparticles that have high aspect ratios, typically ranging from 5 to 50 nm in diameter and several micrometers in length, and a large surface area [58] with a density of 1.25–1.5 g/cm3, the bending stiffness ranges between 50 and 160 GPa, while the tensile strength is between 0.8 and 1 GPa [59].

Several articles support the use of nanocellulose in particleboard production. For instance, Amini et al. [60] demonstrated the utilization of CNFs as a binder for particleboard manufacture, where the CNFs formed a three-dimensional network that held the wood particles together upon drying. A variation of 5% CNFs content increases slightly the MOR from 7.9 to 9.9 MPa and MOE from 1,200 to 1,250 MPa, approximately at 0.60–0.79 g/cm3 density for low-density panels as specified by the ASTM D1037 standard [61]. Additionally, recent advances in nanocellulose-based biomaterials have been reviewed, emphasizing the advantageous features of nanocellulose, such as its nanoscale effect, nontoxicity, biocompatibility, biodegradability, high specific surface area, and high mechanical strength [62].

The integration of nanocellulose in board production offers a promising avenue for enhancing board performance and sustainability. The unique characteristics of CNCs and CNFs, such as their high strength (especially for CNCs), stiffness (Young’s modulus up to 150 GPa for CNCs and CNFs), aspect ratio (10–70 for CNCs and 5–50 for CNFs), and surface area (several hundred m²/g for CNFs), make them valuable reinforcements for composite materials, contributing to the development of advanced nanocellulose-based particleboards with improved strength, stiffness, and dimensional stability [60,63,64,65]. The high surface area (>200 m²/g) and abundant hydroxyl groups (−OH) of nanocellulose form extensive hydrogen bonds (O–H···O) with wood fibers and adhesives, creating a robust 3D network [66]. The high aspect ratio (10–100) of nanocellulose fibrils enables mechanical interlocking and micro-void penetration, improving load transfer [62]. Nanocellulose acts as a coupling agent, enhancing interfacial adhesion and stress distribution. Its nanoscale dimensions (1–100 nm) create a path for water molecules, improving dimensional stability [67]. Nanocellulose can also catalyze cross-linking reactions (R−OH + R′−NCO → R−O−CO−NH−R′) within the adhesive matrix [68]. These mechanisms significantly improve the mechanical properties (e.g., 30–50% increase in MOE) and moisture resistance (20–40% reduction in TS) of nanocellulose-reinforced panels [64]. Additionally, CNCs and CNFs exhibit low thermal conductivity (0.1–0.5 W/m K) and electrical insulation properties, which can be beneficial for applications requiring thermal management and electrical insulation [64,69]. For example, a study by Koga et al. [70] showed that CNFs have a high electrical resistance (>1014 Ω) due to the presence of sp3-hybridized carbons in cellulose molecules.

2.5 Nanolignin reinforcement

Nanolignin particles are lignin components from plant biomass that have been reduced to dimensions below 100 nm. Decreasing the size of lignin to the nanoscale increases its surface area, which can enhance properties such as reactivity and interactions when used in composites [72]. The 3D structure of lignin consists of three monomer units (p-coumaryl alcohol, sinapyl alcohol, and coniferyl alcohol) (Figure 2) linked by ether and carbon–carbon bonds, containing aliphatic, aromatic, and hydroxyl functional groups. Isolating cellulose, hemicellulose, and lignin from biomass is crucial for effective biomass utilization. Nanolignin exhibits antioxidant, UV-absorption, thermal stability, and biocompatibility, suiting applications such as nanocomposites, packaging, biomedicine, and environmental remediation by acting as a reinforcing agent and improving mechanical strength when incorporated into polymer matrices [73,74,75]. For instance, nanolignin, with a concentration ranging between 1 and 5 wt%, has been used as a reinforcement to improve the adhesion between wood flour and polypropylene matrix in wood-plastic composites [76]. The nanolignin panels’ superior results compared to control with the MOR, MOE, IB, and impact strength vary from 22 to 35 MPa, 1.8 to 2.8 GPa, 15 to 22 MPa, and 0.8 to 1.4 MJ/m2, respectively.

![Figure 2

3D structure of lignin [72].](/document/doi/10.1515/ntrev-2024-0119/asset/graphic/j_ntrev-2024-0119_fig_002.jpg)

3D structure of lignin [72].

2.6 Nano-chitosan reinforcement

Chitosan nanoparticles are biodegradable, nontoxic carriers for nucleotides and drugs with potential broad applications in human disease. They are derived from chitin, a natural biopolymer found in the exoskeletons of crustaceans such as shrimp, crab, and lobster. As shown in Figure 3, seafood waste from these marine sources serves as the raw material for chemical extraction processes to obtain chitin [77]. The chitin then undergoes deacetylation to produce chitosan, which is the starting material for synthesizing chitosan nanoparticles. Chitosan is a natural cationic polysaccharide composed of randomly distributed N-acetyld-glucosamine and b-(1,4)-linked d-glucosamine (Figure 4) [77,78]. Further, the chitosan molecules can form crosslinks with epoxidized linseed oil through ring-opening reactions, creating a stronger network structure to enhance the mechanical and physical properties of the composite material [79].

![Figure 3

A summary of chitosan nanoparticle extraction [77].](/document/doi/10.1515/ntrev-2024-0119/asset/graphic/j_ntrev-2024-0119_fig_003.jpg)

A summary of chitosan nanoparticle extraction [77].

![Figure 4

Chitosan, epoxy, and wood fibers molecular reaction [78].](/document/doi/10.1515/ntrev-2024-0119/asset/graphic/j_ntrev-2024-0119_fig_004.jpg)

Chitosan, epoxy, and wood fibers molecular reaction [78].

Due to its chemical composition, nano-chitosan reinforcement has shown promising results in improving the properties of boards and other wood-based composites. Studies have demonstrated that producing MDF panels from hardwood fibers using nano-chitosan can significantly improve the panel properties. For example, mixing nano-chitosan with UF decreases the TS and WA from 25% to 5% and 47% to 17%, respectively [78]. Indeed, chitosan nanoparticles are known to enhance bonding through their reactive amino (–NH2) and hydroxyl (–OH) groups, improve water resistance by reacting with formaldehyde, fill micro-voids, and increase crosslinking in the adhesive network. Their nanoscale size (up to 100 nm) allows for uniform distribution and intimate interaction with wood fibers and adhesives, leading to significant improvements in board properties.

3 Material and methods

Nanoparticle boards can be manufactured by mixing nanoparticles such as Al2O3, ZnO, and Fe2O3 with a binder, typically UF, and raw materials including pine wood fibers, rice husk, sawdust, etc. (Figure 5.i). In the study by Gul [80], the next step, after collecting materials, involves SEM (Figure 5.iii) and X-ray diffraction (XRD) (Figure 5.iv), which are used to determine the void content and chemical composition of the various nanoparticles, binder, and raw materials, respectively. Also, in the same study, MDF panels measuring 450 × 450 × 16 mm and having densities between 700 and 750 kg/m³ were made with Al₂O3-UF nanofiller. The Al₂O3-UF nanofillers were sprayed on Populus deltoides (Poplar) and Euamericana fibers via spray gun, followed by hot pressing at 185°C and 150 bar for 4 min using a hydraulic hot press of Burkle fabricated in Germany. The panels then underwent horizontal cooling for 72 h. For Fe₂O₃-UF nanofillers, panels of identical dimensions and comparable densities were produced. The nanofillers were combined with poplar wood fibers in a rotary drum mixer, hot-pressed at 168°C and 162 bar for 4.2 min using a hydraulic hot press of Burkle manufactured in Germany, and subsequently cooled for 3 days. In preparing ZnO-UF nanofiller MDF, Populus caspica fibers were blended with the nanofillers in a rotary mechanical drum. The final nano-MDF underwent hot pressing at 175°C and 165 bar for 4.1 min. The resulting panels were subjected to cooling for 72 h in a forced convection cooling wheel. These nanoparticle boards were then subjected to physical and mechanical tests according to different standards (e.g., European Standards (EN), ASTM) using a universal testing machine (UTM) (Figure 5.vi), as well as a thermal conductivity test (Figure 5.viii) before the thermogravimetric analysis (TGA) and dynamic mechanical analysis (Figure 5.v). The results obtained from these tests determine the suitability of the nanoparticle boards for various construction applications, ensuring that they meet standards. To ascertain the dimensional stability of the panel in accordance with ASTM D 1037-06a [81], equations (1) and (2) are employed:

where w f and w i symbolize the final and initial weights, respectively, and t f and t i signify the corresponding final and initial thicknesses.

![Figure 5

(i) Mixing process: (a) Alumina nanoparticles, (b) UF resin, and (c) natural fibers; (ii) Gold sputtering; (iii) SEM analysis with energy-dispersive X-ray spectroscopy (EDS) system; (iv) XRD apparatus; (v) TGA/DSC apparatus; (vi) UTM; (vii) Schematic representation of MOE and MOR; (viii) thermal conductivity measuring apparatus, own elaboration based on [80].](/document/doi/10.1515/ntrev-2024-0119/asset/graphic/j_ntrev-2024-0119_fig_005.jpg)

(i) Mixing process: (a) Alumina nanoparticles, (b) UF resin, and (c) natural fibers; (ii) Gold sputtering; (iii) SEM analysis with energy-dispersive X-ray spectroscopy (EDS) system; (iv) XRD apparatus; (v) TGA/DSC apparatus; (vi) UTM; (vii) Schematic representation of MOE and MOR; (viii) thermal conductivity measuring apparatus, own elaboration based on [80].

The mechanical properties, encompassing the bending strength or MOR and bending stiffness or Young’s modulus or MOE, are determined by conducting a three-point bending test utilizing a UTM. Equations (3) and (4) are employed to calculate the MOR and MOE, considering the sample’s width (b), thickness (d), span length (L), maximum load (P), load at the proportional limit (P 1), and center deflection at the proportional limit load (y 1). Figure 5.vii provides a schematic representation of the bending stiffness and bending strength test [82]. The appendix depicts a standardized sample cut-up pattern used for testing various properties of particleboard and similar wood-based panel products according to ASTM test procedures (Figure A1).

4 Results and discussion

This study reviews the performance of nanoparticle-based MDF and particleboards. Results showed that adding nanoparticle elements in MDF production increases the energy peak and the heat content and decreases the curing temperature. For instance, a study conducted by Gul et al. [31] shows that by analyzing pure UF resin and UF resin containing 3% of alumina nanoparticles, as the SEM in Figure 6, the weight% of oxygen (O) along with potassium (K) and aluminum (Al) increases their energies peaks from 29.69–0.13% to 32.39–1.87% by weight, respectively. The term energy peak here refers to the peak intensities observed in the EDS analysis, indicating the presence and concentration of these elements. Additionally, as depicted in Figure 7, the presence of 4.5% concentration Al–O nanoparticles in the UF resin shows a peak intensity at 21.25, 61.25, and 66.5°C (a) with a heat flow peak at 120°C in 1.5% alumina is formed due to the creation of bonding in UF at the interface (b). This increased intensity (counts/s) suggests a more ordered structure, which can improve the mechanical properties of the composite. The alumina nanoparticles exhibit Lewis acidity, acting as a catalytic agent due to the presence of hydroxyl groups, which polymerize the UF resin, as reported by Kumar et al. [83]. The differential scanning calorimetry (DSC) curves reveal that adding alumina nanoparticles does not significantly change the curing peak temperature but increases the total heat flow (w/g). The higher heat flow indicates an exothermic reaction during curing, suggesting that the nanoparticles act as catalysts, enhancing the cross-linking density and thermal stability of the resin and leading to improved performance of the panels.

![Figure 6

(a) EDS analysis of pure UF resin and (b) EDS analysis of UF resin containing 3% alumina nanoparticles [80].](/document/doi/10.1515/ntrev-2024-0119/asset/graphic/j_ntrev-2024-0119_fig_006.jpg)

(a) EDS analysis of pure UF resin and (b) EDS analysis of UF resin containing 3% alumina nanoparticles [80].

![Figure 7

(a) XRD of different concentrations of alumina nanoparticles in urea formaldehyde resin and (b) differential scan calorimetry of UF resin with different concentrations of alumina nanoparticles [80].](/document/doi/10.1515/ntrev-2024-0119/asset/graphic/j_ntrev-2024-0119_fig_007.jpg)

(a) XRD of different concentrations of alumina nanoparticles in urea formaldehyde resin and (b) differential scan calorimetry of UF resin with different concentrations of alumina nanoparticles [80].

After this initial stage, nanoparticle boards are fabricated with a specific timeline, curing temperature, and pressure, followed by physical and mechanical tests to determine their use and grade according to different board standards [31].

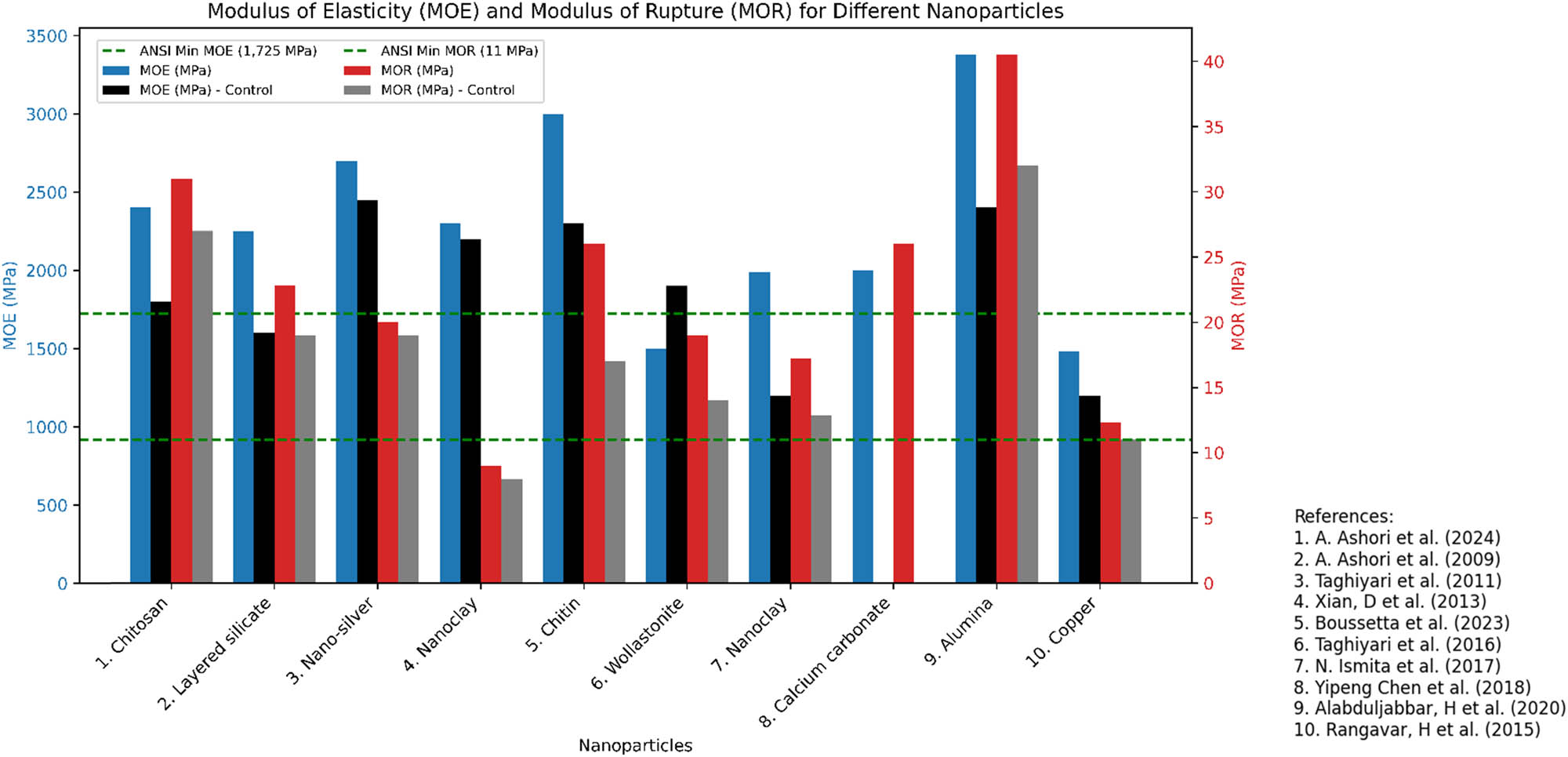

In fact, this research summarizes ten studies highlighting different nanoparticles used to improve the boards’ physical and mechanical properties, including the TS, WA, MOR, and MOE. These nanoparticles are derived from different molecules such as nano-clay (4–7) [84,85], nano-silver (3) [37], nano-silicate (2) [86], nano-wollastonite (5–6) [23,87], calcium carbonate nanoparticle (8) [88], nano-alumina (9) [89], and copper (10) [90]. Figure 8 and Table 1 show the variation in the effect of nanoparticles on the dimensional stability of the particleboards with the maximum requirement of TS of 8% specified by the American National Standard Institute (ANSI A208.1-1999) [91]. However, according to ANSI A208.1, panels for commercialization may exhibit a TS of up to 35% after being immersed in water for 24 h (Figure 8), while the EN 312-2005 standard states that panels should not exceed a TS of 8 and 15% after being immersed in water for 2 and 24 h, respectively [92]. While Figure 9 highlights the minimum requirement of grade M1 for the MOR and MOE with 11.5 and 1,725 MPa, respectively. In addition, the European Standards EN 312 (2003) establish a minimum MOR of 14 MPa for P4 applications, which is raised to 15 MPa for P6 for structural purposes. These standards also specify a needed MOE of 1,600 MPa. Conversely, the Brazilian Standard, ABNT BNR 14810-2 [93], sets the maximum acceptable TS to be 19% minimum required value for MOR at 16 MPa and MOE at 2,300 MPa (Table 1) for P4 boards [94].

WA and TS of panels (own elaboration).

Typical TS, MOR, and MOE

| Standard | Board type | TS (%) | MOR (MPa) | MOE (MPa) |

|---|---|---|---|---|

| EN 312 | P4 | 15 | 15 | 2,200 |

| P6 | 14 | 16 | 2,400 | |

| ABNT | P4 | 19 | 16 | 2,300 |

| ANSI | M1 | 8 | 11 | 1,725 |

| M2 | 14.5 | 2,250 | ||

| Min. | 3 (min) | 550 (min) |

MOR, and MOE of panels (own elaboration).

5 Performance of nanoparticle-modified panels

The performance of nanoparticle-modified particleboards and MDF was evaluated through an analysis of the physical and mechanical properties of board samples. Experimental values of TS and WA for MDF samples incorporating clay, calcium carbonate, silver nanoparticles, and wollastonite exhibited varying ranges, with the highest values recorded for wollastonite at 85% for WA [87] and for silver at 62% for TS [37].

However, according to ANSI A208.1, the superior performance of nanoclay [95], alumina [89], and calcium carbonate [40] nanoparticles in reducing TS up to 6% compared to the control can be attributed to several factors. Their high aspect ratio and platelet structure (especially for nanoclay) create a path for water molecules. The strong interactions with the wood matrix and adhesive reduce void spaces where water can accumulate. Additionally, they may contribute to a more tightly crosslinked network within the composite. However, the other nanoparticles (e.g., nano-silver [37], chitosan [78], chitin [96], silicate [86], nano-wollastonite [87], nano-copper [97]) show much higher TS values, sometimes exceeding 25%. This poor performance could be due to the incompatibility with the wood matrix or adhesive system, the agglomeration of nanoparticles, creating weak points in the composite structure, the insufficient dispersion or concentration to effectively improve moisture resistance, and the potential interference with the curing process of the adhesive.

Furthermore, the results demonstrated that lower TS and WA percentages were associated with higher bending strength and stiffness, with values reaching up to 28 MPa and 2.4 GPa, respectively. This suggests that the overall quality of the board, influenced by various parameters including the adhesive system and nanoparticle addition, leads to better mechanical properties. Furthermore, the incorporation of nanoparticles such as alumina was found to enhance the structural performance, resulting in MOR and MOE values of 41 MPa and 3.4 GPa, respectively [89]. This is because alumina as a molecule has a high strength-to-weight ratio, superior hardness (9 on the Mohs scale), compressive strength (it can reach 3 GPa), excellent thermal resistance (high conductivity and a melting point that exceeds 2,000°C) and chemical stability [98] (Table 2). Its small particle size (typically 20–50 nm [99]) allows for uniform dispersion and strong interfacial bonding with the matrix, effectively transferring loads and restricting crack propagation. Compared to copper or calcium carbonate, with MOE board values of 2 and 1.4 GPa (Figure 9), alumina’s covalent bonding and crystalline structure contribute to its superior mechanical properties.

Physical and mechanical properties of selected inorganic nanoparticles (own elaboration based on [98,99,100,101,102,103])

| Inorganic nanoparticle | Particle size (nm) | Compressive strength (MPa) | Hardness (Mohs scale) | Thermal resistance (°C) at melting point | Density (kg/m3) |

|---|---|---|---|---|---|

| Silver | 2–100 | 200–250 | 2.5–3 | 961 | 10,490 |

| Clay | 1–100 | Varies widely | 1–2.5 | Varies widely | 1,800–2,600 |

| Wollastonite | 20–100 | 300–400 | 4.5–5 | 1,540 | 2,900 |

| Calcium carbonate | 20–50 | 30–250 (as limestone) | 3 | 825 | 2,710 |

| Alumina | 20–50 | 3,000 | 9 | 2,072 | 3,950–4,100 |

| Copper | 20–100 | 220 | 2.5–3 | 1,084 | 8,960 |

These results surpassed the minimum requirements for M1 and M2 particleboards according to ANSI A208.1-1999 and P4 and P6 specified by EN 312, indicating their suitability and sustainability for building construction. The improved mechanical properties and dimensional stability make these nanoparticle-modified boards a viable option for various construction applications, particularly in dry conditions.

6 Conclusion

The investigation into nanoparticle-modified panels has demonstrated their potential to meet or exceed industry standards, particularly in terms of their MOE, MOR, IB, WA, and TS. The formaldehyde emission levels are a crucial property that has also shown improvement with the incorporation of nanoparticles. For instance, adding alumina nanoparticles has been shown to reduce formaldehyde emissions, contributing to the overall performance and safety of the panels. Furthermore, some nanoparticle panels have exhibited reduced electrical resistance, which can help avoid static charge buildup. For example, CNCs and CNFs exhibit low thermal conductivity (0.1–0.5 W/m·K) and electrical insulation properties. This property, combined with the inherent fire resistance and protection against biological degradation provided by certain nanoparticles, enhances the safety and durability of the boards. This research demonstrates the potential of these nanoparticle-modified panels in manufacturing environmentally eco-friendly and versatile materials for structural applications such as partition walls, bathroom countertops, and floors. The eco-friendly nature of these panels is attributed to the reduced formaldehyde emissions and the use of sustainable raw materials, aligning with sustainable development goals. To further advance this field, future research should focus on diversifying the use of nanoparticles (nano-SiO2, nano-Al2O3, CNCs, etc.), such as exploring the use of CNC or combining two or more types of nanoparticles and investigating more eco-friendly adhesive alternatives to UF, such as protein-based, tannin-based, starch-based, or lignin-based adhesives. Additionally, exploring three-layers by combining nanoparticles to manufacture panels should be conducted to understand the impact on dimensional stability and strength. Furthermore, investigating the potential of incorporating Machine Learning and Deep Learning algorithms, such as convolutional neural networks for defect detection and random forest models for property prediction, could provide valuable insights and optimization opportunities. Finally, conducting comprehensive lifecycle analyses and market studies will help understand the environmental impact and consumer preferences, ensuring the development of truly sustainable products. Promoting the benefits of these sustainable nanoparticle panels makes it possible to drive demand and contribute to a more sustainable and environmentally conscious future. However, it is essential to consider the potential health risks associated with nano-chemicals. The impact of nanoparticles on health, especially during mechanical processing such as sanding, cutting, and drilling, needs to be thoroughly investigated. Nanoparticles are under strong surveillance due to their possible health impacts, and this aspect should be discussed and addressed in future research to ensure the safe use of nanoparticle-modified panels.

Acknowledgments

We gratefully acknowledge the reviewers who contributed to the improvement of the quality of the manuscript.

-

Funding information: The authors state no funding involved.

-

Author contributions: Derrick Mirindi: writing – review and editing, writing – original draft, visualization, validation, software, methodology, investigation, formal analysis, data curation, and conceptualization. James Hunter: writing – review and editing, writing – original draft, supervision, resources, project administration, and conceptualization. David Sinkhonde: writing – review and editing and writing – original draft. Frederic Mirindi: writing – review and editing and writing – original draft. Fatemeh Yazdandoust: Conceptualization, Writing – review & editing, Writing – original draft. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

Appendix

Test Sections based on the ASTMD 1037-96a: the sample is divided into the following labeled sections (ANSI A-208 1999):

Hardness (H):

H1, H2: Used to determine the hardness or resistance to indentation of the particleboard surface.

IB (I):

I1, I2: These specimens are used to measure the IB or tensile strength perpendicular to the board surface.

Linear Expansion (L):

L1: Evaluates the linear expansion or dimensional stability of the material.

MOR/MOE (M):

M1, M2, M3, M4, M5, M6: These sections are used to determine the MOR (bending strength) and MOE (stiffness) of the particleboard.

TS (T):

T1, T2: Measure the thickness swell or expansion of the board after exposure to moisture.

Concentrated Load (C):

C: Required only for certain higher grades like D-2 and D-3, this section tests the board’s resistance to concentrated loads or point loads.

![Figure A1

ANSI A208.1-1999 Test Sections based [91].](/document/doi/10.1515/ntrev-2024-0119/asset/graphic/j_ntrev-2024-0119_fig_010.jpg)

ANSI A208.1-1999 Test Sections based [91].

References

[1] Datta A, Krishnamoorti R. Understanding the greenhouse gas impact of deforestation fires in Indonesia and Brazil in 2019 and 2020. Front Clim. 2022;4:799632.10.3389/fclim.2022.799632Search in Google Scholar

[2] Kruid S, Macedo MN, Gorelik SR, Walker W, Moutinho P, Brando PM, et al. Beyond deforestation: carbon emissions from land grabbing and forest degradation in the Brazilian Amazon. Front For Glob Change. 2021;4:645282.10.3389/ffgc.2021.645282Search in Google Scholar

[3] Timothy R, Pearson H, Brown S, Murray L, Sidman G. Greenhouse gas emissions from tropical forest degradation: An underestimated source. Carbon Balance Manag. 2017;12(1):1.10.1186/s13021-017-0072-2Search in Google Scholar PubMed PubMed Central

[4] Yazdandoust F. Decision support for the design of a building form coupling daylight and natural ventilation consideration in a dense urban context. Iowa, USA: Iowa State University; 2023.Search in Google Scholar

[5] MacLean MG, Duveneck MJ, Plisinski J, Morreale LL, Laflower D, Thompson JR. Forest carbon trajectories: Consequences of alternative land-use scenarios in New England. Glob Environ Change. 2021;69:102310.10.1016/j.gloenvcha.2021.102310Search in Google Scholar

[6] Mishra A, Humpenöder F, Churkina G, Reyer CP, Beier F, Bodirsky BL, et al. Land use change and carbon emissions of a transformation to timber cities. Nat Commun. 2022;13(1):4889.10.1038/s41467-022-32244-wSearch in Google Scholar PubMed PubMed Central

[7] Mirindi D, Panthi K, Thach TNS, Hunter J. A review of the evolution and performance of particleboard from different types of organic waste and adhesives. Proc 60th Annu Associated Sch. 2024;5:740–9.Search in Google Scholar

[8] Bekhta P, Noshchenko G, Réh R, Kristak L, Sedliačik J, Antov P, et al. Properties of eco-friendly particleboards bonded with lignosulfonate-urea-formaldehyde adhesives and PMDI as a crosslinker. Materials. 2021;14(17):4875.10.3390/ma14174875Search in Google Scholar PubMed PubMed Central

[9] Song W, Cao Y, Wang D, Hou G, Shen Z, Zhang S. An investigation on formaldehyde emission characteristics of wood building materials in Chinese standard tests: Product emission levels, measurement uncertainties, and data correlations between various tests. PLoS One. 2015;10(12):e0144374.10.1371/journal.pone.0144374Search in Google Scholar PubMed PubMed Central

[10] Mirindi D, Onchiri RO, Thuo J. Physico-mechanical properties of particleboards produced from macadamia nutshell and gum arabic. Appl Sci. 2021;11(23):11138.10.3390/app112311138Search in Google Scholar

[11] Raj-Reichert G. Safeguarding labour in distant factories: Health and safety governance in an electronics global production network. Geoforum. 2013;44:23–31.10.1016/j.geoforum.2012.05.007Search in Google Scholar

[12] Hosseini SM, Fadaei M. Properties of particleboard made from UF with Low-formaldehyde (E1). Int J Eng. 2013;26(1):45–50.10.5829/idosi.ije.2013.26.01a.07Search in Google Scholar

[13] Astm. 2024.Search in Google Scholar

[14] Cornell. 2024. https://www.law.cornell.edu/cfr/text/24/3280.308.Search in Google Scholar

[15] Lumi. 2024. https://www.lumi.cn/en/news%26blog-detail/10-differences-you-must-know-about-particleboard-and-mdf.Search in Google Scholar

[16] Hashim MS, Shafiq RF, Mohammed SI, Bakr AN. X-ray fluorescence computed tomography imaging of nanoparticles and recent advances in biomedical X-ray fluorescence imaging. Clin Images Case Rep. 2024;2(6):52–62.Search in Google Scholar

[17] Wen L, Deng YH, Mei Z, Ling X, Qian F. Mechanical properties of nano SiO2 filled gypsum particleboard. Trans Nonferrous Met Soc China. 2006;16:s361–4.10.1016/S1003-6326(06)60210-0Search in Google Scholar

[18] Karkoodi S, Liaghat G, Hosseinabadi HZ, Ahmadi H. Characterization of MDF reinforced with Al2O3 nano particles considering physical, mechanical and quasi-static properties. Wood Mater Sci Eng. 2021;16(6):380–90.10.1080/17480272.2020.1768436Search in Google Scholar

[19] Marzbani P, Afrouzi YM, Omidvar A. The effect of nano-zinc oxide on particleboard decay resistance. Maderas Cienc y Tecnología. 2015;17(1):63–8.10.4067/S0718-221X2015005000007Search in Google Scholar

[20] Lopes Junior WE, Cabral MR, Christoforo AL, de Campos CI, Fiorelli J. Investigating the effects of Al2O3 microparticles on wood waste OSBs: a Study on physical, mechanical, and durability performance. Polymers. 2023;15(12):2652.10.3390/polym15122652Search in Google Scholar PubMed PubMed Central

[21] Gul W, Alrobei H, Shah SRA, Khan A. Effect of iron oxide nanoparticles on the physical properties of medium density fiberboard. Polymers. 2020;12(12):2911.10.3390/polym12122911Search in Google Scholar PubMed PubMed Central

[22] Pour MF, Mehdinia M, Kiamahalleh MV, Hoseini KD, Hatefnia H, Dorieh A. Biological durability of particleboard: fungicidal properties of Ag and Cu nanoparticles against Trametes versicolor white-rot fungus. Wood Mater Sci Eng. 2022;17(6):929–36.10.1080/17480272.2021.1977996Search in Google Scholar

[23] Taghiyari HR, Moradi-Malek B, Kookandeh MG, Bibalan OF. Effects of silver and copper nanoparticles in particleboard to control Trametes versicolor fungus. Int Biodeterior & Biodegrad. 2014;94:69–72.10.1016/j.ibiod.2014.05.029Search in Google Scholar

[24] Angstromsciences. 2024. https://angstromsciences.com/density-elements-chart.Search in Google Scholar

[25] Chemicalbook. 2024. https://www.chemicalbook.com/ChemicalProductProperty_EN_CB3853034.htm.Search in Google Scholar

[26] Akinterinwa A, Ismaila A, Aliyu B. Concise chemistry of urea formaldehyde resins and formaldehyde emission. Ins Org Inorg. 2020;1:1–6.10.33552/ICBC.2020.02.000507Search in Google Scholar

[27] Rammon RM, Johns WE, Magnuson J, Dunker AK. The chemical structure of UF resins. J Adhes. 1986;19(2):115–35.10.1080/00218468608071217Search in Google Scholar

[28] Noei H, Qiu H, Wang Y, Löffler E, Wöll C, Muhler M. The identification of hydroxyl groups on ZnO nanoparticles by infrared spectroscopy. Phys Chem Chem Phys. 2008;10(47):7092–7.10.1039/b811029hSearch in Google Scholar PubMed

[29] Anuj Kumar AK, Arun Gupta AG, Sharma K, Suriati Binti Gazali SBG. Influence of aluminum oxide nanoparticles on the physical and mechanical properties of wood composites. North Carolina, USA: BioResources; 2013.Search in Google Scholar

[30] Song J, Chen S, Yi X, Zhao X, Zhang J, Liu X, et al. Preparation and properties of the urea-formaldehyde res-in/reactive halloysite nanocomposites adhesive with low-formaldehyde emission and good water resistance. Polymers. 2021;13(14):2224.10.3390/polym13142224Search in Google Scholar PubMed PubMed Central

[31] Gul W, Shah SRA, Khan A, Pruncu CI. Characterization of zinc oxide-urea formaldehyde nano resin and its impact on the physical performance of medium-density fiberboard. Polymers. 2021;13(3):371.10.3390/polym13030371Search in Google Scholar PubMed PubMed Central

[32] Wu X, Lee J, Varshney V, Wohlwend JL, Roy AK, Luo T. Thermal conductivity of wurtzite zinc-oxide from first-principles lattice dynamics–a comparative study with gallium nitride. Sci Rep. 2016;6(1):1–10.10.1038/srep22504Search in Google Scholar PubMed PubMed Central

[33] Techinstro. 2024. https://www.techinstro.com/aluminium-oxide-nanoparticles/.Search in Google Scholar

[34] Royalsociety. 2024. https://www.rsc.org/cpd/teachers/content/filerepository/frg/pdf/Nanoparticles.pdf.Search in Google Scholar

[35] Navya P, Daima HK. Rational engineering of physicochemical properties of nanomaterials for biomedical applications with nanotoxicological perspectives. Nano Convergence. 2016;3:1–14.10.1186/s40580-016-0064-zSearch in Google Scholar PubMed PubMed Central

[36] Bruna T, Maldonado-Bravo F, Jara P, Caro N. Silver nanoparticles and their antibacterial applications. Int J Mol Sci. 2021;22(13):7202.10.3390/ijms22137202Search in Google Scholar PubMed PubMed Central

[37] Taghiyari HR, Rangavar H, Bibalan OF. Effect of nano-silver on reduction of hot-pressing time and improvement in physical and mechanical properties of particleboard. BioResources. 2011;6(4):4067–75.10.15376/biores.6.4.4067-4075Search in Google Scholar

[38] Wang X, Zhao H, Zhang B, Wen X, Huang S, Gan W. The removal of formaldehyde from urea formaldehyde adhesive by sodium borohydride treatment and its application in plywood. Polymers. 2024;16(7):969.10.3390/polym16070969Search in Google Scholar PubMed PubMed Central

[39] Yang S, Galih NM, Kim J, Lee H, Kang S. Physical and mechanical properties of particleboard mixed with waste ACQ-treated wood. J Mater Cycles Waste Manag. 2024;26(1):410–20.10.1007/s10163-023-01837-ySearch in Google Scholar

[40] Chen Y, Cai T, Dang B, Wang H, Xiong Y, Yao Q, et al. The properties of fibreboard based on nanolignocelluloses/CaCO3/PMMA composite synthesized through mechano-chemical method. Sci Rep. 2018;8(1):5121.10.1038/s41598-018-23497-xSearch in Google Scholar PubMed PubMed Central

[41] Srivabut C, Ratanawilai T, Hiziroglu S. Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubberwood fiber. Constr Build Mater. 2018;162:450–8.10.1016/j.conbuildmat.2017.12.048Search in Google Scholar

[42] Nazerian M, Nanaii HA, Gargarii RM. Silica (SiO2) content on mechanical properties of cement-bonded particleboard manufactured from lignocellulosic materials. Drvna Industrija. 2018;69(4):317–28.10.5552/drind.2018.1758Search in Google Scholar

[43] Albagli S, Iwama AY. Citizen science and the right to research: building local knowledge of climate change impacts. Humanit Soc Sci Commun. 2022;9(1):1–13.10.1057/s41599-022-01040-8Search in Google Scholar

[44] Thermtest. 2024. https://thermtest.com/application/thermal-conductivity-of-calcium-carbonate.Search in Google Scholar

[45] Özdemir F, Tutuş A. Effects of coating with calcite together with various fire retardants on the fire properties of particleboard. BioResources. 2016;11(3):6407–15.10.15376/biores.11.3.6407-6415Search in Google Scholar

[46] Knowt. 2024. https://knowt.com/note/5813a8c1-6295-4594-8c0b-8b2018372189/17-Carbonates.Search in Google Scholar

[47] Edu. 2024. https://edu.rsc.org/experiments/thermal-decomposition-of-calcium-carbonate/704.article.Search in Google Scholar

[48] Zhang Z, Zhang DB, Onga K, Hasegawa A, Ohta K, Hirose K, et al. Thermal conductivity of CaSiO3 perovskite at lower mantle conditions. Phys Rev B. 2021;104(18):184101.10.1103/PhysRevB.104.184101Search in Google Scholar

[49] Pham ST, Tieu AK, Sencadas V, Joseph P, Arun M, Cortie D. Thermoresponsive hybrid colloidal capsules as an inorganic additive for fire-resistant silicone-based coatings. Ind Eng Chem Res. 2022;61(35):13104–16.10.1021/acs.iecr.2c01967Search in Google Scholar

[50] Funcmater. 2024. https://www.funcmater.com/silicon-dioxide-crystal.html.Search in Google Scholar

[51] Yadav R. Development of low formaldehyde emitting particle board by nano particle reinforcement. J Appl Nat Sci. 2021;13(4):1187–97.Search in Google Scholar

[52] Khorramabadi LA, Behrooz R, Najafi SK. Reduction of formaldehyde emission from medium density fiberboard using nanoclay modified with 3-aminopropyltriethoxysilane and l-Lysine as additives to urea-formaldehyde adhesive. Int J Adhes Adhes. 2023;125:103426.10.1016/j.ijadhadh.2023.103426Search in Google Scholar

[53] Fernandes A, Cruz-Lopes L, Esteves B, Evtuguin D. Nanotechnology applied to cellulosic materials. Materials. 2023;16(8):3104.10.3390/ma16083104Search in Google Scholar PubMed PubMed Central

[54] Kim HJ, Lee WJ. The influence of cellulose nanocrystal characteristics on regenerative silk composite fiber properties. Materials. 2023;16(6):2323.10.3390/ma16062323Search in Google Scholar PubMed PubMed Central

[55] George J, Sabapathi S. Cellulose nanocrystals: synthesis, functional properties, and applications. Nanotechnol Sci Appl. 2015;8:45–54.10.2147/NSA.S64386Search in Google Scholar PubMed PubMed Central

[56] Yadav C, Saini A, Zhang W, You X, Chauhan I, Mohanty P, et al. Plant-based nanocellulose: A review of routine and recent preparation methods with current progress in its applications as rheology modifier and 3D bioprinting. Int J Biol Macromolecules. 2021;166:1586–616.10.1016/j.ijbiomac.2020.11.038Search in Google Scholar PubMed

[57] Missale E, Maniglio D, Speranza G, Frasconi M, Pantano MF. Cellulose nanocrystal composites with enhanced mechanical properties for robust transparent thin films. ACS Appl Nano Mater. 2023;7:18167–76.10.1021/acsanm.3c02946Search in Google Scholar

[58] Gupta P, Singh B, Agrawal AK, Maji PK. Low density and high strength nanofibrillated cellulose aerogel for thermal insulation application. Mater Des. 2018;158:224–36.10.1016/j.matdes.2018.08.031Search in Google Scholar

[59] Huo Y, Liu Y, Xia M, Du H, Lin Z, Li B, et al. Nanocellulose-based composite materials used in drug delivery systems. Polymers. 2022;14(13):2648.10.3390/polym14132648Search in Google Scholar PubMed PubMed Central

[60] Amini E, Tajvidi M, Gardner DJ, Bousfield DW. Utilization of cellulose nanofibrils as a binder for particleboard manufacture. BioResources. 2017;12(2):4093–110.10.15376/biores.12.2.4093-4110Search in Google Scholar

[61] McNatt JD, Link CL. Analysis of ASTM D 1037 accelerated-aging test. Prod J. 1989;39(10):51–7.Search in Google Scholar

[62] Trache D, Tarchoun AF, Derradji M, Hamidon TS, Masruchin N, Brosse N, et al. Nanocellulose: from fundamentals to advanced applications. Front Chem. 2020;8:392.10.3389/fchem.2020.00392Search in Google Scholar PubMed PubMed Central

[63] Veigel S, Rathke J, Weigl M, Gindl-Altmutter W. Particle board and oriented strand board prepared with nanocellulose-reinforced adhesive. J Nanomater. 2012;2012:158503.10.1155/2012/158503Search in Google Scholar

[64] Kaur P, Sharma N, Munagala M, Rajkhowa R, Aallardyce B, Shastri Y, et al. Nanocellulose: Resources, physio-chemical properties, current uses and future applications. Front Nanotechnol. 2021;3:747329.10.3389/fnano.2021.747329Search in Google Scholar

[65] Xu X, Liu F, Jiang L, Zhu J, Haagenson D, Wiesenborn DP. Cellulose nanocrystals vs cellulose nanofibrils: a comparative study on their microstructures and effects as polymer reinforcing agents. ACS Appl Mater Interfaces. 2013;5(8):2999–3009.10.1021/am302624tSearch in Google Scholar PubMed

[66] Heise K, Koso T, King AW, Nypelö T, Penttilä P, Tardy BL, et al. Spatioselective surface chemistry for the production of functional and chemically anisotropic nanocellulose colloids. J Mater Chem A. 2022;10(44):23413–32.10.1039/D2TA05277FSearch in Google Scholar

[67] Rana AK, Frollini E, Thakur VK. Cellulose nanocrystals: Pretreatments, preparation strategies, and surface functionalization. Int J Biol Macromol. 2021;182:1554–81.10.1016/j.ijbiomac.2021.05.119Search in Google Scholar PubMed

[68] Ghasemlou M, Daver F, Ivanova EP, Habibi Y, Adhikari B. Surface modifications of nanocellulose: From synthesis to high-performance nanocomposites. Prog Polym Sci. 2021;119:101418.10.1016/j.progpolymsci.2021.101418Search in Google Scholar

[69] Patil TV, Patel DK, Dutta SD, Ganguly K, Santra TS, Lim KT. Nanocellulose, a versatile platform: From the delivery of active molecules to tissue engineering applications. Bioact Mater. 2022;9:566–89.10.1016/j.bioactmat.2021.07.006Search in Google Scholar PubMed PubMed Central

[70] Koga H, Nagashima K, Suematsu K, Takahashi T, Zhu L, Fukushima D, et al. Nanocellulose paper semiconductor with a 3D network structure and its nano–micro–macro trans-scale design. ACS Nano. 2022;16(6):8630–40.10.1021/acsnano.1c10728Search in Google Scholar PubMed PubMed Central

[71] Rol F, Vergne B, El Kissi N, Bras J, eds. New high solid content cellulose nanofibrils production by twin screw extrusion optimization. International Conference on Nanotechnology for Renewable Materials; 2019.Search in Google Scholar

[72] Zhang Z, Terrasson V, Guénin E. Lignin nanoparticles and their nanocomposites. Nanomaterials. 2021;11(5):1336.10.3390/nano11051336Search in Google Scholar PubMed PubMed Central

[73] Kirar S, Mohne D, Singh M, Sagar V, Bhise A, Goswami S, et al. Eco-friendly lignin nanocomposite films as advanced UV protective and antimicrobial sustainable packaging materials. Sustain Mater Technol. 2024;40:e00864.10.1016/j.susmat.2024.e00864Search in Google Scholar

[74] Prasad V, Siddiqui L, Mishra PK, Ekielski A, Talegaonkar S. Recent advancements in lignin valorization and biomedical applications: a patent review. Recent Pat Nanotechnol. 2022;16(2):107–27.10.2174/1872210515666210216085831Search in Google Scholar PubMed

[75] Makri SP, Xanthopoulou E, Klonos PA, Grigoropoulos A, Kyritsis A, Tsachouridis K, et al. Effect of micro-and nano-lignin on the thermal, mechanical, and antioxidant properties of biobased PLA–lignin composite films. Polymers. 2022;14(23):5274.10.3390/polym14235274Search in Google Scholar PubMed PubMed Central

[76] Younesi-Kordkheili H, Pizzi A. Nanolignin, a coupling bio-agent for wood-plastic composites. J Renew Mater. 2023;11:2075–83.10.32604/jrm.2023.026706Search in Google Scholar

[77] Teixeira-Costa BE, Andrade CT. Chitosan as a valuable biomolecule from seafood industry waste in the design of green food packaging. Biomolecules. 2021;11(11):1599.10.3390/biom11111599Search in Google Scholar PubMed PubMed Central

[78] Ashori A, Kuzmin A. Effect of chitosan-epoxy ratio in bio-based adhesive on physical and mechanical properties of medium density fiberboards from mixed hardwood fibers. Sci Rep. 2024;14(1):5057.10.1038/s41598-024-55796-xSearch in Google Scholar PubMed PubMed Central

[79] Fusteș-Dămoc I, Dinu R, Măluțan T, Mija A. Valorisation of chitosan natural building block as a primary strategy for the development of sustainable fully bio-based epoxy resins. Polymers. 2023;15(24):4627.10.3390/polym15244627Search in Google Scholar PubMed PubMed Central

[80] Gul W. Effect of the embedment of nano particles on the manufacturing process parameters and the mechanical properties of medium density fiberboard (MDF). Ann Arbor, USA: University of Engineering & Technology Peshawar (Pakistan); 2021.Search in Google Scholar

[81] ASTM. 2024. https://www.astm.org/d1037-06a.html.Search in Google Scholar

[82] Mirindi D. A review of particleboard development and performance using non-toxic and biodegradable adhesives. Int J Eng Trends Technol. 2024;72(5):252–60.10.14445/22315381/IJETT-V72I5P126Search in Google Scholar

[83] Kumar A, Gupta A, Sharma KV, Gazali SB. Influence of aluminum oxide nanoparticles on the physical and mechanical properties of wood composites. BioResources. 2013;8(4):6231–41.10.15376/biores.8.4.6231-6241Search in Google Scholar

[84] Faruk O, Mutuana LM. Nanoclay reinforced HDPE as a matrix for wood-plastic composites. Compos Sci Technol. 2008;68(9):2073–7.10.1016/j.compscitech.2008.03.004Search in Google Scholar

[85] Ismita N, Lokesh C. Effects of different nanoclay loadings on the physical and mechanical properties of Melia composita particle board. Bois For des Tropiques. 2017;334:7–12.10.19182/bft2017.334.a31487Search in Google Scholar

[86] Ashori A, Nourbakhsh A. Effects of nanoclay as a reinforcement filler on the physical and mechanical properties of wood-based composite. J Compos Mater. 2009;43(18):1869–75.10.1177/0021998309340936Search in Google Scholar

[87] Taghiyari HR, Mohammad-Panah B, Morrell JJ. Effects of wollastonite on the properties of medium-density fiberboard (MDF) made from wood fibers and camel-thorn. Maderas Cienc y tecnología. 2016;18(1):157–66.10.4067/S0718-221X2016005000016Search in Google Scholar

[88] da Silva APS, Ferreira BS, Favarim HR, Silva MFF, Silva JVF, dos Anjos Azambuja M, et al. Physical properties of medium density fiberboard produced with the addition of ZnO nanoparticles. BioResources. 2019;14(1):1618–25.10.15376/biores.14.1.1618-1625Search in Google Scholar

[89] Alabduljabbar H, Alyousef R, Gul W, Shah SRA, Khan A, Khan R, et al. Effect of alumina nano-particles on physical and mechanical properties of medium density fiberboard. Materials. 2020;13(18):4207.10.3390/ma13184207Search in Google Scholar PubMed PubMed Central

[90] Rangavar H, Hoseiny F. The effect of nanocopper additions in a urea-formaldehyde adhesive on the physical and mechanical properties of particleboard manufactured from date palm waste. Mech Compos Mater. 2015;51(51):119–26.Search in Google Scholar

[91] Dokumen. 2024. https://dokumen.tips/documents/ansi-a2081-1999-pb-56743ca23d906.html?page=13.Search in Google Scholar

[92] Mitchual SJ, Prosper M, Kwasi FM, Emmanuel A-K. Characterization of particleboard produced from residues of plantain pseudostem, cacao pod and stem and ceiba. Mater Sci Appl. 2020;11:817.10.4236/msa.2020.1112054Search in Google Scholar

[93] Herradon MP. Resíduos de movelaria com polietileno tereftalato para produção de painéis aglomerados aglutinados com poliuretano derivado de mamona. Brazil: Paulista State University; 2023.Search in Google Scholar

[94] Sugahara ES, da Silva SA, Buzo AL, de Campos CI, Morales EA, Ferreira BS, et al. High-density particleboard made from agro-industrial waste and different adhesives. BioResources. 2019;14(3):5162–70.10.15376/biores.14.3.5162-5170Search in Google Scholar

[95] Xian D, Semple K, Haghdan S, Smith G. Properties and wood bonding capacity of nanoclay-modified urea and melamine formaldehyde resins. Wood Fiber Sci. 2013;45:383–95.Search in Google Scholar

[96] Boussetta A, Benhamou AA, Charii H, Ablouh E-H, Mennani M, Kasbaji M, et al. Formulation and characterization of chitin-starch bio-based wood adhesive for the manufacturing of formaldehyde-free composite particleboards. Waste Biomass Valoriz. 2023;14(11):3671–87.10.1007/s12649-023-02091-xSearch in Google Scholar

[97] Rangavar H, Hoseiny Fard M. The effect of nanocopper additions in a urea-formaldehyde adhesive on the physical and mechanical properties of particleboard manufactured from date palm waste. Mech Compos Mater. 2015;51:119–26.10.1007/s11029-015-9482-ySearch in Google Scholar

[98] Steelceram. 2024. https://www.steelceram.com/en/alumina-and-its-mechanical-properties/.Search in Google Scholar

[99] Yildirim M, Candan Z. Performance properties of particleboard panels modified with nanocellulose/boric acid. BioResources. 2021;16(1):1875–90.10.15376/biores.16.1.1875-1890Search in Google Scholar

[100] ASMHandbook. 2001. http://sme.vimaru.edu.vn/sites/sme.vimaru.edu.vn/files/volume_2_-_properties_and_selection_nonf.pdf.Search in Google Scholar

[101] Murray HH. Applied clay mineralogy: occurrences, processing and applications of kaolins, bentonites, palygorskitesepiolite, and common clays. Amsterdam, The Netherlands: Elsevier; 2006.10.1016/S1572-4352(06)02008-3Search in Google Scholar

[102] Maxim LD, Niebo R, Utell MJ, McConnell E, LaRosa S, Segrave AM. Wollastonite toxicity: an update. Inhalation Toxicol. 2014;26(2):95–112.10.3109/08958378.2013.857372Search in Google Scholar PubMed

[103] Oates JA. Lime and limestone: chemistry and technology, production and uses. Darmstadt, Germany: John Wiley & Sons; 2008.Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface

- Potential pharmaceutical applications and molecular docking study for green fabricated ZnO nanoparticles mediated Raphanus sativus: In vitro and in vivo study

- Effect of temperature and nanoparticle size on the interfacial layer thickness of TiO2–water nanofluids using molecular dynamics

- Characteristics of induced magnetic field on the time-dependent MHD nanofluid flow through parallel plates

- Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

- Experimental research on mechanically and thermally activation of nano-kaolin to improve the properties of ultra-high-performance fiber-reinforced concrete

- Analysis of variable fluid properties for three-dimensional flow of ternary hybrid nanofluid on a stretching sheet with MHD effects

- Biodegradability of corn starch films containing nanocellulose fiber and thymol