Abstract

Roller-compacted concrete pavement (RCCP) is a brittle material with low tensile strength that does not contain steel or dowel bars. This, in addition to the rigidity of the RCCP, causes degradation or cracking before the RCCP reaches its service life. To improve the performance of the RCCP, crumb rubber (CR) can be used as an aggregate. Hence, in this study, CR was used to replace 0, 10, 20, and 30% of the fine aggregate in the RCCP. To mitigate the adverse effect of the CR on the properties of the RCCP, nano-silica (NS) was added by weight of cement in proportions of 0, 1, 2, and 3%. To select an optimal mix based on various performance criteria, multicriteria-based optimization was carried out using techniques such as order of preference by similarity to ideal solution, evaluation based on distance from average solution, weighted sum model, and weighted product model techniques. During experimentation, CR improved the consistency and reduced the mechanical and durability properties of the RCCP, while NS reduced the consistency and improved the mechanical and durability performance of the RCCP. The M2 mix (mix containing 0% CR and 1% NS) is consistently ranked as the best choice for multi-criteria decision-making techniques and sensitivity analyses due to its exceptional physical, mechanical, and durability attributes, ensuring reliability across various decision-making scenarios. This study provides insights into the decision-making process for the choice of appropriate RCCP mix produced with CR and NS for improved performance in pavement applications and the importance of utilizing waste tire rubber in concrete pavements to promote sustainability.

1 Introduction

Roller-compacted concrete pavement (RCCP) has several advantages over conventional rigid pavement, including faster construction and lower cost, making the RCCP emerge as the next choice for pavement concrete pavement construction [1,2]. Other benefits of RCCP over conventional and rigid pavement concrete are the low cement content required to achieve similar strength as conventional concrete, decreased shrinkage, lower life-cycle cost, and the ability to quickly open vehicles [2]. In comparison to asphaltic pavements, RCCP has long-term durability performance, which includes high resistance to temperature, low deformation under wheel loading, and modest compressive strength [3,4]. Traditionally, RCCP is utilized in low-speed zones for pavements driven by heavy vehicles. Some known facilities constructed using RCC pavement include the intermodal yard at the Port of Tacoma, Washington, and the railroad at the intermodal hub at Burlington Northern in Houston, Texas [5,6]. One of the main properties of RCCP is its low consistency, which is caused by the increased aggregate, low water, and cement paste contents, resulting in a zero slump [4]. RCCP construction is similar to asphaltic pavement in that it is placed with the aid of asphaltic paving machines and compacted using vibratory rollers [2,7]. Due to the drier nature and the way RCCP is compacted, it does not require the use of forms, steel reinforcements, or dowers. This gives the RCCP construction the benefit of lower cost and faster construction. Therefore, in RCCP, the vehicular and other loads are transferred through aggregate interlocking created by the compaction process [1]. For any RCCP mix, it must have adequate stiffness for stability under vibratory roller compaction and still be wet enough to allow for proper mixing and paste distribution without segregating. Hence, it is necessary to achieve a maximum compacted density for any RCCP mixture. Due to this, consistency (workability) and compatibility are very crucial in determining a good RCCP mix proportion [8]. Because of these properties of RCCP, well proportioning of the constituent materials is a key to achieving a good quality RCCP mix both during mixing, placement, compaction, adequate strength, and long-term durability performance. Therefore, RCCP mix proportioning should be done using trial-and-error methods, and it should be carried out following a systematic and scientific approach that takes into consideration the economy, engineering properties, and construction requirements [9]. There are different methods of proportioning RCCP mixtures, but the soil compaction method using the modified Proctor test in accordance with ASTM D1557 [10] is more commonly used. The method requires deriving the moisture content–dry density correlation to obtain the optimum water content required to achieve maximum density and strength [8,9,11]. With the growing interest in sustainability, the highway industry has also developed an interest in environmental and materials sustainability by lowering the use of non-renewable and natural resources [2,12]. Some ways of promoting sustainability on the pavement are through a reduction in the use of virgin materials, especially aggregates, mix design optimization, and implementing innovative paving methods [2,13]. Among the listed, the most significant way to improve sustainability in pavement technology is by fully or partly substituting natural aggregates with alternative materials such as furnace steel slag, recycled concrete aggregates, reclaimed asphalt pavement, plastic wastes, and waste tire aggregates (crumb rubber (CR)) [2,3,14,15,16,17,18,19]. The use of these alternative aggregates has a series of benefits, which includes cost reduction, solid waste disposal, and carbon footprint reduction [2]. Throughout its service life RCCP is subjected to fatigue and flexural loads from vehicles. With time cyclic fatigue causes deterioration, reduces the performance, and reduces the service life of the RCCP. Additionally, as steel reinforcement or dowel bars are not used in RCCP, the fatigue loads have more effect on it compared to conventional rigid pavement. The cyclic loads increase the cost of maintenance of the RCCP. Hence, it is vital to develop some ways to improve the fatigue resistance of the RCCP, which will delay the deterioration and prolong the service life of the RCCP. Some of the methods include the addition of additives such as polymers including plastic wastes and CR, or fibers into the RCCP mixes, such that the additive will strain energy and deformations due to traffic loads [20,21]. The lower flexibility or higher stiffness of concrete pavement in comparison to asphaltic pavement limit their acceptability for use in highway industries [22].

Circular economy has become a major key performance indicator for sustainable development in the 2twenty-first century, as applied by several nations globally [23,24]. Annually, more than 1.5 billion tires are generated globally after reaching their end-of-life. This number is forecasted to exceed 5 billion by 2030 [25]. Most of these waste tires end up in landfills without proper recycling or reusing. These disposed waste tires become shelters for rodents such as rats and cats. They also become an incubation centre for mosquitoes and other insects, which end up transmitting diseases like Malaria. Furthermore, the dumped waste tires ruin the aesthetic appearance of the environment [26,27]. Another common practice of discarding scrap tires is by burning them. Even though burning reduces the volume of tire waste, it causes air pollution and increases CO2 emission to the environment by releasing toxic and poisonous smoke/gases into the air. Additionally, the toxic compounds from the tire ash leach into the soil, contaminate the groundwater and soil, and affect the life of animals and other organisms [27,28,29]. Some of the ways of addressing the problems of waste tire disposal are by cutting it and reducing it to small sizes in the form of CR and used as a partial substitute for natural aggregates. This will also address the problems related to the use of natural aggregate and hence improve materials’ sustainability. Additionally, the use of CR as aggregate in concrete will benefit in the reduction of the brittleness of concrete, due to the CR’s high ductility, as its composition contains more than 50% rubber [30,31]. CR has been used as a partial substitute for fine and coarse aggregates in concrete and has been reported to decrease the durability and mechanical properties of concrete, as reported by several studies [22,26,29,31,32,33]. The reduction in the performance of concrete with adding CR as aggregate is due to the following reasons as reported by previous studies: Hydrophobicity of the CR deters its bonding with the cement paste, creating a weak path for premature failure. CR increases the pore volume in the concrete matrix by entrapping air on its surface and repelling water during mixing. CR has lower strength and stiffness than natural aggregates; this leads to a decline in the maximum load capacity of the concrete produced with CR [22,32].

However, there are a series of advantages when CR is incorporated into concrete as an aggregate. Concrete produced using CR as a partial substitute to aggregates shows enhancement in the following properties in comparison to conventional concrete. The properties include ductile behaviour, impact resistance, energy absorption capacity, fracture toughness, damping ratio, electrical conductivity, and acoustic properties [25,34,35].

To reduce or mitigate the undesirable effect of CR on the properties of concrete, some researchers performed different treatment methods on the CR before adding to the concrete and they reported some improvement. Li et al. [36] treated the CR using NaOH solution and obtained 14% increment in strength compared to using untreated CR. Emam and Yehia [37] used carbon disulfide treatment to the CR and reported a 28% increment in strength compared to using untreated CR. Treating the CR with chemicals such as HCl, KOH, KMnO4, H2SO4 ethanol, methanol, and acetone enhanced the surface roughness of the CR and improved bonding between the CR and cement matrix, thus mitigating the loss of strength due to the CR addition in the concrete [27,31]. Other researchers added different pozzolanic materials either as additives or partial substitutes to cement in the concrete containing CR to lessen the loss in the performance of concrete due to the negative effects of CR. Supplementary cementitious materials (SCM) such as fly ash, silica fume, metakaolin, slag, and nano-silica (NS) have been used in rubberized concrete. Fakhri [38] replaced 10% cement with silica fume in RCCP containing CR as a fractional replacement to fine aggregate; he observed an increase in compressive strength by 37% compared to the RCCP with 100% cement and 10% CR. Gupta et al. [39] found that by substituting 10% cement with silica fume in rubberized concrete produced with 25% fine aggregate replaced with CR, the compressive strength was enhanced by 33.3% compared to concrete containing 25% CR without silica fume. Gupta et al. [40] also reported significant mitigation in the reduction in the strengths of concrete due to the negative effect of CR, when silica fume was added as an SCM in the concrete. Findings by many researchers had shown that when metakaolin was added as an SCM to concrete containing CR as an aggregate replacement, the metakaolin significantly mitigated the reduction in the durability and mechanical performance of the concrete due to the negative effect of CR [28,41,42].

NS due to its extremely finer sizes and high pozzolanic reaction has been used as additives to cementitious materials in rubberized concrete to alleviate the undesirable impact of the CR on the mechanical properties and durability of the concrete. Mohammed et al. [43] reported a substantial enhancement in the mechanical properties of rubberized concrete with the addition of NS for up to 3% by weight of cement, where they attributed to the densification of ITZ between the cement paste and rubber particles, and filling the pores created by the CR in the cement matrix. Mohammed and Adamu [16] also reported similar findings, where they found that adding up to 2% NS to RCCP containing CR totally diminished the loss in mechanical performance due to the undesirable effects caused by up to 20% CR. Adamu et al. [44] also added up to 3% NS by weight of cement to RCCP containing 10, 20, and 30% CR. They found that up to 2% NS totally mitigated the loss in durability performance of the RCCP due to the undesirable effects of CR.

In the domain of decision-making, the challenge often lies in selecting the optimal solution from a pool of options, each characterized by conflicting parameters. This complexity can pose a formidable hurdle for designers and decision-makers. To address this, multi-criteria decision making (MCDM) techniques have gained prominence, offering a powerful means to enhance analysis and provide robust decision support through mathematical models [45,46,47]. MCDM methods employ decision algorithms and mathematical models for analytically assessing and ranking various alternatives, considering multiple criteria. These approaches enable decision-makers to navigate the intricate web of trade-offs among diverse factors, such as technical, social, and economic considerations, ultimately facilitating a more balanced and informed choice. Extensive research has illustrated the effectiveness of MCDM techniques in the realm of concrete materials [48,49,50,51,52,53,54]. For example, an innovative MCDM method was utilized by Kurda et al. [48] to assess the overall sustainability of cementitious materials. This method explored numerous facets, including mechanical properties, cost, environmental impact, and service life, in addition to demonstrating its efficacy in analysing non-traditional materials. In addition, standardized MCDM techniques, including the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS), have been employed in other research endeavours to determine the most advantageous alternatives within the domain of building construction. These endeavours have demonstrated the precision of MCDM in identifying the most suitable options [52,53]. However, it is essential to acknowledge that the outcomes of MCDM analyses are significantly influenced by the chosen weighting scenarios, underscoring the importance of judicious weight selection [54].

RCCP is a brittle material with low tensile strength, and because of its construction and compaction methods, it cannot be reinforced with steel or dowel bars. As such, all the vehicular loads are transmitted to the lower layers via the aggregate interlocking system. The flexural and fatigue loads are the main loads acting on RCCP. This, in addition to the high rigidity of the RCCP, causes deterioration or cracking in the RCCP before reaching its service life. To address this challenge, the thickness of the RCCP is increased, which seems not economical [21]. Alternatively, the brittleness of the RCCP could be decreased, and its fatigue resistance was increased. As such CR due to its high elastic and deformation properties can be incorporated as aggregate into the RCCP. In addition to resolving the problems related to waste tire disposal, this measure will enhance the concrete’s flexural and fatigue performance. However, CR has been reported to negatively affect the strengths and durability of concrete.

To address these drawbacks of CR in concrete, NS was incorporated as an additive to cement in the RCCP. Hence, the objective of this research was to determine the impact of CR and NS on the properties of RCCP. Different RCCPs were produced by varying the replacement ratio of CR from 0 to 30% by volume of fine aggregate and the addition ratio of NS from 0 to 3% by weight of cement. The MCDM technique was employed to select the optimized RCCP mixes considering the factors related to fresh properties, mechanical and durability performances.

2 Experimental methodology

2.1 Materials

Type I cement conforming with ASTM C150 [55] specifications was used in this research. The cement’s properties are summarized in Table 1. For the fine aggregate, natural river sand with particle gradation presented in Figure 1 was used. To achieve the recommended combined aggregate gradation limits, two nominal sizes of crushed gravels were blended in the proportion of 50% each as coarse aggregate. Their specific gravities are 2.55 and 2.67 for the 6.35 and 19 mm sized aggregates, respectively. The 6.35 and 19 mm sized aggregates have water absorptions of 0.76 and 0.54%, respectively. CR was used to partly substitute fine aggregate. The CR was thoroughly washed with clean water severally and air dried before using it to remove dirt, dust, and impurities from its surface. To obtain a relatively similar gradation to fine aggregate, three particle sizes of CR, i.e., mesh 30 (0.6 mm), 1–3 mm, and 3–5 mm size, were blended in a definite proportion. After a series of trials of sieve analysis were carried out using the methods outlined in ASTM D5644 [56], a gradation curve for the CR similar to the fine aggregate, as shown in Figure 1, was achieved by blending the mesh 30, 1–3 mm and 3–5 mm sized CR in the ratio of 1:2:2, respectively.

| Oxide composition (%) | Cement | Fly ash |

|---|---|---|

| SiO2 | 20.76 | 57.06 |

| Al2O3 | 5.54 | 20.96 |

| Fe2O3 | 3.35 | 4.15 |

| MnO | — | 0.033 |

| CaO | 61.4 | 9.79 |

| MgO | 2.48 | 1.74 |

| Na2O | 0.19 | 2.23 |

| K2O | 0.78 | 1.53 |

| TiO2 | — | 0.68 |

| Loss of ignition | 2.2 | 1.25 |

| Specific gravity | 3.15 | 2.3 |

| Blaine fineness (m2/kg) | 325 | 290 |

Aggregate gradations curve.

Due to the dry nature of the RCCP mix, it is recommended that 2–8% of the total aggregate contents should be fine materials with sizes less than 75 µm to obtain a cohesive paste and reduce voids in the cement matrix. The materials used as fillers in RCC pavement includes natural fine sand, non-plastic silt, fly ash, or natural pozzolans [58,59]. In this study, Class F fly ash with the properties shown in Table 1 was utilized as the filler material. Fly ash was selected as a filler material due to its dual advantages of acting as a filler material and pozzolanic material. Hence, the fly ash can react with cement and NS through hydration reaction to improve the strength development in the concrete. NS used in this study was obtained commercially in the form of whitish powder, which is highly dispersive and amorphous in nature. The NS has particle sizes ranging between 10 and 25 nm and is hydrophobic in nature. The NS has a SiO2 content of more than 99%, average sizes of 10–25 nm, specific surface area of 100 ± 25 (m2/g). The properties of the NS are summarized in Table 2.

Properties of NS [16]

| Item | Quality |

|---|---|

| SiO2 content | ≥99.8 (%) |

| Average particle size | 10–25 nm |

| Appearance | High-dispersive white powder |

| Hydrophobicity | Strong |

| Surface density | ≤0.15 (g/ml) |

| Specific surface area | 100 ± 25 (m2/g) |

| Heat reduction (105°C 2 h) | ≤3 (%) |

| Loss of ignition | ≤6 (%) |

| Dispensability (%) (CCl4) | ≥80 (%) |

| Oil-absorbed value | ≥250 (ml/100 g) |

| pH value | 6.5–7.5 |

2.2 Mix design and proportioning

2.2.1 Mix design

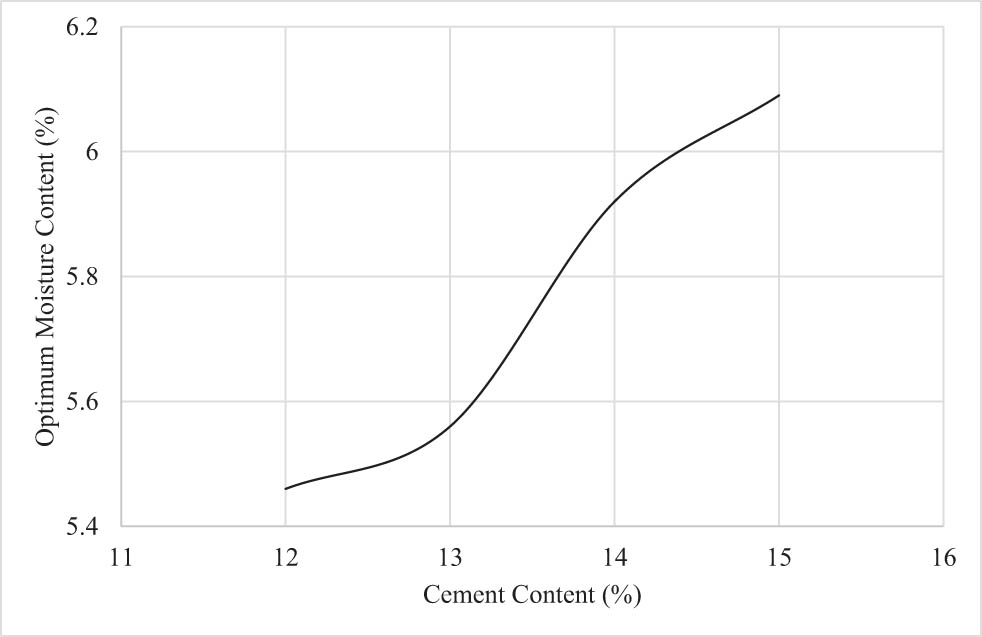

The mix design RCCP for the RCCP was carried out using the methods explained in ACI 211.3R-02 [59], which is based on the geotechnical approach. The combined aggregate sieve analysis was first carried out to obtain the percentages of each of the aggregates and fillers required to acquire the combined aggregate gradation as specified by ACI 211.3R-02 [59]. The gradation curve is presented in Figure 2 and was obtained by blending the following proportions by weight of the total aggregate materials: 55% fine aggregates, 40% coarse aggregates, and 5% filler. Next, four RCC mixes were prepared using the proportions of the aggregates from the combined aggregate gradations and different proportions of cements between 12 and 15% by dry mass of the aggregates. The optimum moisture contents (OMC) and maximum dry densities of the RCC pavement mixes were determined using the specifications outlined in ASTM D1557 [10]. The relationship between the OMC and cement content for the different RCC mixes is presented in Figure 3. After obtaining the OMC, RCCP mixes were produced by varying the cement contents between 12 and 15% by mass of dry aggregates using their equivalent OMCs as the water contents. From the relationship between the flexural strengths and cement contents of the RCCP in Figure 4, based on a target flexural strength of 4.8 MPa at 28 days, a 13% cement content was selected and used for the control RCCP mix.

Combined gradation of aggregates.

Cement content–OMC relationship.

Flexural strength–cement content relationship.

2.2.2 Mix proportions

After designing the control RCC mix, other mixes were generated by varying the proportions of the variables. The variables used were CR as a partial substitute to fine aggregate and NS as an additive by cement weight. The CR was varied between 0 and 30% by aggregate’s volume. In contrast, the NS was varied between 0 and 3% by mass of cement. The NS was limited to only 3% to avoid dispersion and agglomeration-related problems, which can cause a reduction in the strengths of the RCCP [16,60]. Sixteen mixes were generated using combinations of the CR and NS, as shown in Table 3. The mixes were categorized into four generations, in each generation, the NS is constant while the proportion of CR varied.

Mix proportions

| Mix | Variables (%) | Cement (kg/m3) | NS (kg/m3) | Filler (kg/m3) | Fine aggregate (kg/m3) | Coarse aggregate (kg/m3) | Water (kg/m3) | CR (kg/m3) | |

|---|---|---|---|---|---|---|---|---|---|

| CR | NS | ||||||||

| M1 | 0 | 0 | 268.69 | 0 | 103.76 | 1148.05 | 831.88 | 98.24 | 0 |

| M2 | 0 | 1 | 268.69 | 2.69 | 103.76 | 1148.05 | 831.88 | 98.24 | 0 |

| M3 | 0 | 2 | 268.69 | 5.37 | 103.76 | 1148.05 | 831.88 | 98.24 | 0 |

| M4 | 0 | 3 | 268.69 | 8.06 | 103.76 | 1148.05 | 831.88 | 98.24 | 0 |

| M5 | 10 | 0 | 268.69 | 0 | 103.76 | 1033.25 | 831.88 | 98.24 | 114.89 |

| M6 | 10 | 1 | 268.69 | 2.69 | 103.76 | 1033.25 | 831.88 | 98.24 | 114.89 |

| M7 | 10 | 2 | 268.69 | 5.37 | 103.76 | 1033.25 | 831.88 | 98.24 | 114.89 |

| M8 | 10 | 3 | 268.69 | 8.06 | 103.76 | 1033.25 | 831.88 | 98.24 | 114.89 |

| M9 | 20 | 0 | 268.69 | 0 | 103.76 | 918.44 | 831.88 | 98.24 | 229.78 |

| M10 | 20 | 1 | 268.69 | 2.69 | 103.76 | 918.44 | 831.88 | 98.24 | 229.78 |

| M11 | 20 | 2 | 268.69 | 5.37 | 103.76 | 918.44 | 831.88 | 98.24 | 229.78 |

| M12 | 20 | 3 | 268.69 | 8.06 | 103.76 | 918.44 | 831.88 | 98.24 | 229.78 |

| M13 | 30 | 0 | 268.69 | 0 | 103.76 | 803.64 | 831.88 | 98.24 | 344.67 |

| M14 | 30 | 1 | 268.69 | 2.69 | 103.76 | 803.64 | 831.88 | 98.24 | 344.67 |

| M15 | 30 | 2 | 268.69 | 5.37 | 103.76 | 803.64 | 831.88 | 98.24 | 344.67 |

| M16 | 30 | 3 | 268.69 | 8.06 | 103.76 | 803.64 | 831.88 | 98.24 | 344.67 |

First-generation mixes

M1 is the control RCCP mix produced by adding 0% CR and 0% NS as additives to cement.

M2 is an RCC mix produced by adding 0% CR and 1% NS as additives to cement.

M3 is an RCC mix produced by adding 0% CR and 2% NS as additives to cement.

M3 is an RCC mix produced by adding 0% CR and 3% NS as additives to cement.

Second-generation mixes

M5 is an RCCP mix produced by adding 10% CR and 0% NS as additives to cement.

M6 is an RCC mix produced by adding 10% CR and 1% NS as additives to cement.

M7 is an RCC mix produced by adding 10% CR and 2% NS as additives to cement.

M8 is an RCC mix produced by adding 10% CR and 3% NS as additives to cement.

Third-generation mixes

M9 is an RCCP mix produced by adding 20% CR and 0% NS as additives to cement.

M10 is an RCC mix produced by adding 20% CR and 1% NS as additives to cement.

M11 is an RCC mix produced by adding 20% CR and 2% NS as additives to cement.

M12 is an RCC mix produced by adding 20% CR and 3% NS as additives to cement.

Fourth-generation mixes

M13 is an RCCP mix produced by adding 30% CR and 0% NS as additives to cement.

M14 is an RCC mix produced by adding 30% CR and 1% NS as additives to cement.

M15 is an RCC mix produced by adding 30% CR and 2% NS as additives to cement.

M16 is an RCC mix produced by adding 30% CR and 3% NS as additives to cement.

2.3 Test methods

The batching, weighing, mixing, and curing of the RCC mixes were executed by adopting the methods explained in ASTM C192 [61]. The mixing was done using a pan-type concrete mixer. The aggregates were in saturated surface dried conditions during mixing, while the cement and NS were free from any lump or agglomeration. The mixing was carried out until homogeneity was achieved in the freshly mixed concrete. To mimic the real roller compaction, the RCCP samples were compacted using a 50 Hz Bosch vibration hammer. The placement, compaction, and consolidation of the RCC mixes were done based on the standard specifications of ASTM C1435 [62]. Each sample was compacted in three layers, and full compaction was achieved after a ring of mortar paste was formed across the circumference of the base plates. After mixing, the fresh concrete was cast into the designated moulds and kept in the laboratory under a normal temperature of 23 ± 2°C for 24 h to harden. After hardening, the concrete samples were removed from the moulds and cured in clean water. The curing method was done in accordance with ASTM C192/C192M [63] under normal conditions at a temperature of 23°C for a period of 28 days before testing.

The compressive strength test was conducted in adherence to the guidelines outlined in BS EN 12390-3 [64] using cubic samples of 100 mm dimensions. The tensile strength test was conducted using cylinder samples measuring 200 mm in height and 100 mm in diameter, in compliance with the specifications outlined in BS EN 12390-6 [65].

The flexural strength of the RCC mixes was measured using the standard specifications in ASTM C293/C293M [66] using beam samples of 100 mm by 100 mm by 500 mm dimensions. For each strength test, a universal testing equipment with a 3,000 kN capacity was utilized, and all samples were cured in water for a period of 28 days prior to the testing process. The modulus of elasticity (MoE) of the RCCP was evaluated utilizing cylindrical samples measuring 150 mm in diameter and 300 mm in height in accordance with the ASTM C469/C469M [67] guidelines.

The water absorption was evaluated in accordance with the guidelines of ASTM C642 [68], using cylinders measuring 100 mm in diameter that were cured for 28 days prior to testing. The Cantabro abrasion loss (CAL) test was done in accordance with ASTM C1747/C1747M [69] specifications. Before testing, concrete cylinders measuring 100 mm in height and 150 mm in diameter were fabricated and cured for a period of 28 days. For the CAL test, a Los Angeles abrasion machine without the steel balls was used. The samples were initially weighed, and after subjecting them to 300 cycles of revolutions, they were removed and cleaned before weighing again. The CAL was then measured using equation (1).

CAL denotes Cantabro abrasion loss in %, III1 and III2 are the initial and final weights of the samples before and after 300 revolutions, respectively, in kg.

The pore volume of the RCCP mixes was measured using mercury intrusion Porosimetry (MIP) using the methods outlined in ASTM D4284 [70]. A Thermofisher scientific Porosimeter was used for the MIP test. The rebound hammer test was conducted in accordance with the specifications of ASTM C805/C805M [71], using the Schmidt rebound hammer. The ultrasonic pulse velocity (UPV) test was accomplished with reference to the specifications of ASTM C597 [72] using the PUNDIT equipment attached with two 54 KHz transducers. Cube samples of 150 mm sizes were used for the testing after curing for 28 days.

2.4 MCDM methodology

Automating the selection process for RCC mixtures is achievable through the application of analytical techniques. This entails the evaluation and measurement of parameters focusing on physio-mechanical and durability considerations. As these criteria determine the material’s overall performance for the specific application. Each criterion comprises multiple properties that require assessment. To determine the best possible mix for 16 designed compositions, it becomes crucial to adopt MCDM methodology. In this research, to assess the compositions based on their properties, four distinct methodologies are commonly employed in material analysis and screening. These methods were selected based on insights from prior literature.

2.4.1 Technique for order of preference by similarity to ideal solution (TOPSIS) method

The TOPSIS method stands out as an effective approach for appraising and classifying choices by considering their closeness to predefined reference points. The basic concept underlying TOPSIS involves the selection of a substitute that aligns closely with the favourable reference point while minimizing its divergence from the unfavourable reference point. When applying the TOPSIS method, the initial step entails the construction of a decision matrix, which is then transformed into a normalized matrix characterized by non-dimensional attributes that amalgamate the choices and criterion. After establishing the optimal (A +) and least favourable (A−) reference solutions according to these criteria, the alternatives are prioritized by assessing their proximity to these reference points [48]. To derive the relative closeness coefficient (RCC) for every choice, the computation of positive (D+) and negative (D−) disjointing matrices using a distinct method was adopted. The top-performing alternative is determined by selecting the maximum RCC score, while the least favourable choice is determined by identifying the minimum RCC score, as illustrated in Figure 5. The effectiveness of the TOPSIS technique has been showcased across various fields. For instance, Rashid et al. [73] applied it to devise a method for producing eco-friendly concrete blends. Additionally, Ahmed et al. [74] employed this approach in their study, concentrating on the selection of the most environmentally friendly recycled concrete. Figure 5 illustrates the procedural workflow of the TOPSIS method.

Flowchart for TOPSIS methodology.

2.4.2 Evaluation based on distance from average solution (EDAS) method

The EDAS method is designed to enhance efficiency and reduce time requirements in contrast to alternative approaches for evaluating choices by considering their deviation from a typical solution. Within the domain of cement-based materials, the EDAS method has been put to use in establishing the optimal blend of cement substitution by incorporating a mixture of fly ash and pozzolans into M40-grade concrete, as demonstrated by Naik et al. [75], based on their experimental findings. The effectiveness of EDAS as an MCDM method was showcased through its comparison with frequently employed methodologies. This method evaluates options by gauging their divergence from the mean performance considering specific parameters, utilizing both favourable and unfavourable disparities to appraise advantageous and disadvantageous criteria. The steps involved in identifying the best alternative, as depicted in Figure 6, encompass generating an average decision matrix, establishing a matrix of mean solutions, computing positive and negative disparities, determining weighted sums, calculating normalized metrics, evaluating appraisal scores, and ultimately ranking the options considering the assessment scores, as delineated by the work of Ghorabaee et al. [76].

Flowchart for EDAS methodology.

2.4.3 Weighted sum model (WSM) method

The WSM method, as highlighted by Chourabi et al. [77], stands as one of the oldest and most extensively used models, particularly in situations where actual criterion values necessitate calculation, specifically in single-dimensional scenarios. In scenarios involving X options and Y factors, the first stage includes the creation of a decision matrix, which is then followed by the calculation of a normalized matrix with assigned weights considering the decision matrix in its normalized format. The last phase involves the summation of values within the weighted normalized matrix to identify the optimal composition of material by ranking and choosing the maximum score. The flow process of using the WSM technique is shown in Figure 7.

Flowchart for WSM methodology.

2.4.4 Weighted product model (WPM) method

The WPM, as described by Chourabi et al. [77], shares similarities with the WSM, but it deviates in the computation of the weighted normalized matrix. Instead of using multiplication, the WPM method involves exponentiating the base (which is the normalized decision matrix) to a power equal to the relative weight assigned to the respective factor. Individual option is then evaluated in comparison to others through a series of multiplication operations, with individual factors corresponding to a criterion and raised to the power that corresponds to that criterion’s weight. Importantly, this approach presents a distinct benefit when compared to the WSM in its applicability to both single and multi-dimensional decision scenarios. Figure 8 provides a workflow diagram for adopting the WPM method. Although these techniques share common procedures, an extensive investigation carried out by Panda et al. [78] analysed it collectively as a part of the MCDM method, aiming to ascertain the optimal concrete blend by substituting different proportions of waste materials.

Flowchart for WPM methodology.

3 Results and discussions

3.1 Experimental results

The results of the fresh density, Vebe time, mechanical strengths, MoE, CAL, water absorption, and pore volume of the RCC mixes are elaborated in Mohammed and Adamu [16]. Similarly, the results of unit weight, rebound number, and UPV of the RCC pavement mixes containing CR and NS are demonstrated by Mohammed and Adamu [57]. The results are summarized in Table 4 and are used for the MCDM analysis. The Vebe time, fresh density, and unit weight of the RCC pavement mixes are reduced with an increase in the percentage replacement of fine aggregate with CR. For mix M5, i.e., mix containing 10% CR and 0%, its Vebe time, fresh density, and unit weight values were lower than that of the control mix (M1) by 9.09, 0.96, and 2.49%, respectively. Likewise, for mix M9 containing 20% CR and 0% NS, its Vebe time, fresh density, and unit weight were less than that of the control mix (M1) by 24.24, 6.66, and 5.78%, respectively. Similar result trends can be observed fir mix M13 (containing 30% CR and 0% NS. The reduction in Vebe time is ascribed to the repulsion of water by the CR during mixing due to its hydrophobicity. While the reduction in fresh and hardened densities is ascribed to the lower bulk density of the CR in comparison to the fine aggregate it partially replaced [16,57]. NS addition slightly increased the Vebe time, fresh density, and unit weight of the RCC pavement, as shown in Table 4. In comparison to the control mix (M1), the Vebe time, fresh density, and unit weight of M2 (0% CR and 1% NS) were higher by 0, 1.72, and 1.1%, respectively. For mix M3 (0% CR and 2% NS), its Vebe time and unit weight were higher by 3.03 and 0.72% respectively. Likewise for mix M4 (0% CR and 3% NS), its Vebe time and fresh density were higher by 6.06 and 1.01%, respectively. The increment in Vebe consistency was attributed to the higher water absorption of the NS due to its finer sizes, making it absorb part of the mixing water and reduce the consistency. While the increase in density is ascribed to the filler effect of the NS, making it densify the cement paste in the fresh and hardened state [16,57].

Experimental results

| Mix | CR (%) | NS (%) | FD (kg/m3) | UW (kg/m3) | VT (s) | Fc (MPa) | STS (MPa) | FF (MPa) | UPV (m/s) | RN | MOE (Gpa) | WA (%) | CAL (%) | PV (mm3/g) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 0 | 0 | 2386 | 2372 | 33 | 52.58 | 4.76 | 5.61 | 5094 | 41 | 29.17 | 1.53 | 6.57 | 3.85 |

| M2 | 0 | 1 | 2427 | 2398 | 33 | 80.87 | 6.13 | 8.85 | 5238 | 52 | 37.79 | 1.31 | 4.95 | 1.95 |

| M3 | 0 | 2 | 2376 | 2389 | 34 | 58.86 | 5.13 | 6.54 | 5047 | 44 | 33.11 | 1.37 | 5.97 | 4.67 |

| M4 | 0 | 3 | 2410 | 2359 | 35 | 53.90 | 5.46 | 4.86 | 5006 | 36 | 28.53 | 1.44 | 7.08 | 3.73 |

| M5 | 10 | 0 | 2363 | 2313 | 30 | 60.11 | 5.65 | 7.81 | 5153 | 45 | 29.51 | 1.72 | 6.89 | 4.20 |

| M6 | 10 | 1 | 2333 | 2326 | 31 | 75.11 | 6.13 | 8.18 | 5178 | 49 | 36.81 | 1.34 | 6.49 | 2.90 |

| M7 | 10 | 2 | 2355 | 2317 | 32 | 67.01 | 5.87 | 7.33 | 5022 | 47 | 30.24 | 1.61 | 6.39 | 3.26 |

| M8 | 10 | 3 | 2333 | 2308 | 32 | 50.05 | 4.72 | 4.55 | 4758 | 33 | 34.18 | 1.56 | 6.63 | 5.02 |

| M9 | 20 | 0 | 2227 | 2235 | 25 | 44.02 | 4.05 | 6.13 | 4769 | 28 | 16.95 | 1.85 | 7.23 | 9.91 |

| M10 | 20 | 1 | 2261 | 2259 | 27 | 52.37 | 4.74 | 6.50 | 4923 | 38 | 19.67 | 1.60 | 7.04 | 4.76 |

| M11 | 20 | 2 | 2265 | 2272 | 28 | 49.85 | 4.19 | 5.88 | 4700 | 31 | 17.97 | 1.74 | 6.92 | 5.20 |

| M12 | 20 | 3 | 2304 | 2263 | 30 | 51.30 | 4.81 | 5.03 | 4744 | 26 | 16.88 | 1.48 | 6.94 | 6.33 |

| M13 | 30 | 0 | 2232 | 2196 | 24 | 40.41 | 3.36 | 5.67 | 4155 | 23 | 15.95 | 2.01 | 8.31 | 16.09 |

| M14 | 30 | 1 | 2223 | 2199 | 25 | 44.95 | 4.08 | 5.96 | 4305 | 27 | 20.50 | 1.91 | 8.04 | 10.43 |

| M15 | 30 | 2 | 2244 | 2184 | 27 | 41.57 | 3.99 | 5.89 | 3814 | 20 | 17.35 | 1.88 | 8.19 | 13.41 |

| M16 | 30 | 3 | 2232 | 2165 | 27 | 28.52 | 3.17 | 4.60 | 3511 | 22 | 17.27 | 1.78 | 8.48 | 17.60 |

*CR = Crumb rubber, NS = Nano-silica, FD = Fresh density, UW = Unit weight, VT = Vebe time, Fc = Compressive strength, STS = Split tensile strength, FF = Flexural strength, UPV = Ultrasonic pulse velocity, RN = Rebound number, MoE = Modulus of elasticity, WA = Water absorption, CAL = Cantabro abrasion loss, PV = Pore volume.

The partial substitution of 10% fine aggregate with CR led to an increment in the compressive strength, tensile strength, and MoE of the RCC mixes. For instance, from Table 4, by comparing the strengths values of the control mix (M1) with that of mix M5 (10% CR with 0% NS), the latter has higher compressive strength, split tensile strength, flexural strength and MoE values by 14.32, 18.7, 39.22 and 1.17% respectively in comparison to the latter (M1). The enhancement in strengths and MoE with replacement of fine aggregate with CR is ascribed to the fibrous nature and high flexibility and deformability of the CR, this gives the concrete the ability to resist compressive and tensile forces even after first failure (cracking) before ultimate failure occurrence [79]. Similar findings have been reported by Thomas and Gupta [79] and Mohammed and Adamu [16]. While substitution of up to 20% fine aggregate with CR increased the flexural strength of the RCC pavement. Above these substitution values, the strengths and MoE of the RCC declined. On the other hand, the reduction in strengths and MoE with addition of CR to the RCC is due to the poor adhesion between the rubber particles and cement paste, thereby creating a weak path for premature failure to occur. Another reason is that due to the hydrophobic nature of CR, it increases the thickness of the ITZ between the rubber particles/aggregates with the cement paste, thus causing an additional premature failure path in the matrix [16]. Similar results findings have been reported by Samingthong et al. [80] when they partially replaced natural aggregates with CR in rigid pavement. The addition of up to 2% NS to the RCC mixes containing different proportions of CR enhanced its mechanical strengths and MoE as shown in Table 4. This increment was ascribed to the high pozzolanic reactivity of the NS where it reacts with the Ca(OH)2 from cement hydration and produces more C–S–H gel structures in the cement matrix which is accountable for strength development and filling the pores in the cement matrix. Furthermore, NS due to its large surface area act as a filler material in the concrete and densifies the concrete’s microstructure, hence enhancing the strengths [16,57]. The addition of 3% NS to the RCC mixes containing different proportions of NS causes reduction in the mechanical properties of the concrete. For example, the compressive strength of mix M5 (10% CR and 0% NS) is 60.11 MPa, while mix M8 (10% CR and 3% NS) its compressive strength is 50.05 MPa. Similarly, mix M13 containing 30% CR and 0% NS has a compressive strength of 40.41 MPa, while for mix M16 containing 30% CR and 3% NS has a compressive strength of 28.52. The reduction in compressive strength with addition of 3% NS is caused by the agglomeration of the nanoparticles due to its larger surface area. This in addition to the drier nature of the RCC mixes causes poor consistency and agglomeration of the NS, thus resulting in a reduction in the mechanical strengths of the concrete. Similar findings have been reported by Norhasri et al. [81] and Mohammed and Adamu [16].

In terms of durability performance, CR as a partial substitute to fine aggregate in RCC mixes increases the water absorption, CAL, and pore volume of the concrete. This increase is ascribed to the ability of the CR to entrap air on its surface and repel water during mixing. After the concrete is hardened, this increases the pore volume in the cement matrix thereby negatively affecting the durability of the RCC. On the contrary, the addition of NS reduced the water absorption, CAL, and pore volume due to its high pozzolanic reaction and pore filler effect [54].

The rebound number (RN) and UPV values of the RCC mixes decrease with an increase in the percentage replacement of fine aggregate with CR, as already reported by Mohammed and Adamu [57]. This is because the UPV and RN of concrete are directly proportional to its compressive strength, and CR reduced the strength of the concrete; therefore, it led to lower RN and UPV. Additionally, CR escalates the porosity in the cement paste; this increases the travel duration for the ultrasonic pulse through the concrete, hence reducing the UPV [57]. The addition of 1% NS increased the UPV and RN of the RCC, as seen in Table 4. This is due to the increased pozzolanic reaction in the cement matrix by the NS, and pore filling ability of the NS. This led to an increment in strength and, hence, higher UPV and RN.

3.2 Multicriteria optimization

In the previous section, the discussion was around the technical aspect of roller compacted concrete using CR. Nevertheless, the task of selecting an appropriate mix design proves challenging due to the multitude of criteria under investigation. Hence, employing the Multiple Criteria Decision Making (MCDM) technique becomes paramount in determining the optimal alternative among the 12 performance parameters. The adoption of diverse MCDM methods brings forth numerous benefits, such as improved resilience, heightened precision, deeper understanding, and added flexibility when it comes to choosing the most appropriate option.

Initiating the MCDM technique entails establishing the weight for each criterion. The determination of weights for MCDM methods was facilitated through the entropy method. The steps involved in the MCDM method can be seen in Figure 9. For a comprehensive view of the weighted decision matrix and the calculated entropy weight, refer to Tables 5 and 6.

Flowchart representing the process of decision-making.

Weighted decision matrix

| Mix designation | Fresh density (kg/m3) | Vebe time (s) | Unit density (kg/m3) | Compressive strength (MPa) | Split tensile strength (Mpa) | Flexural strength (Mpa) | UPV (m/s) | Rebound no | MOE (Gpa) | Water abs (%) | CAL (%) | Pore volume (mm3/g) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 0.932 | 0.727 | 0.913 | 0.650 | 0.776 | 0.634 | 0.973 | 0.788 | 0.772 | 0.856 | 0.753 | 0.506 |

| M2 | 0.916 | 0.727 | 0.903 | 1.000 | 0.999 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 |

| M3 | 0.936 | 0.706 | 0.906 | 0.728 | 0.836 | 0.739 | 0.964 | 0.846 | 0.876 | 0.956 | 0.829 | 0.418 |

| M4 | 0.923 | 0.686 | 0.918 | 0.666 | 0.890 | 0.549 | 0.956 | 0.692 | 0.755 | 0.910 | 0.699 | 0.523 |

| M5 | 0.941 | 0.800 | 0.936 | 0.743 | 0.921 | 0.883 | 0.984 | 0.865 | 0.781 | 0.762 | 0.718 | 0.464 |

| M | 0.953 | 0.774 | 0.931 | 0.929 | 1.000 | 0.924 | 0.989 | 0.942 | 0.974 | 0.978 | 0.763 | 0.672 |

| M7 | 0.944 | 0.750 | 0.934 | 0.829 | 0.958 | 0.829 | 0.959 | 0.904 | 0.800 | 0.814 | 0.774 | 0.598 |

| M8 | 0.953 | 0.750 | 0.938 | 0.619 | 0.769 | 0.515 | 0.908 | 0.635 | 0.904 | 0.840 | 0.746 | 0.388 |

| M9 | 0.998 | 0.960 | 0.969 | 0.544 | 0.660 | 0.692 | 0.910 | 0.538 | 0.449 | 0.708 | 0.685 | 0.197 |

| M10 | 0.983 | 0.889 | 0.958 | 0.648 | 0.772 | 0.735 | 0.940 | 0.731 | 0.521 | 0.819 | 0.703 | 0.410 |

| M11 | 0.981 | 0.857 | 0.953 | 0.616 | 0.683 | 0.665 | 0.897 | 0.596 | 0.476 | 0.753 | 0.715 | 0.375 |

| M12 | 0.965 | 0.800 | 0.957 | 0.634 | 0.784 | 0.569 | 0.906 | 0.500 | 0.447 | 0.885 | 0.714 | 0.308 |

| M13 | 0.996 | 1.000 | 0.986 | 0.500 | 0.548 | 0.641 | 0.793 | 0.442 | 0.422 | 0.652 | 0.595 | 0.121 |

| M14 | 1.000 | 0.960 | 0.985 | 0.556 | 0.666 | 0.673 | 0.822 | 0.519 | 0.542 | 0.686 | 0.616 | 0.187 |

| M15 | 0.991 | 0.889 | 0.991 | 0.514 | 0.650 | 0.666 | 0.728 | 0.385 | 0.459 | 0.697 | 0.604 | 0.145 |

| M16 | 0.996 | 0.889 | 1.000 | 0.353 | 0.517 | 0.520 | 0.670 | 0.423 | 0.457 | 0.736 | 0.584 | 0.111 |

Entropy weights

| Fresh density (kg/m3) | Vebe time (sec) | Unit density (kg/m3) | Compressive strength (MPa) | Split tensile strength (Mpa) | Flexural strength (Mpa) | UPV (m/s) | Rebound no | MOE (Gpa) | Water abs (%) | CAL (%) | Pore volume (mm3/g) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Entropy Weights | 0.001 | 0.020 | 0.001 | 0.083 | 0.052 | 0.056 | 0.017 | 0.121 | 0.139 | 0.024 | 0.027 | 0.458 |

Hence, through the adoption of the MCDM technique, decision-makers can assess numerous alternatives considering multiple criteria, facilitating well-informed decision-making. Utilizing the entropy method to establish criterion weights empowers decision-makers to appropriately assign significance to each criterion. This approach provides a comprehensive view of the decision challenge, empowering decision-makers to comprehend the trade-offs and consequences linked to their decisions. The equations used to calculate the entropy weight (

where n = number of alternatives.

Further, the entropy reduction

where H is the entropy of the entire decision matrix (considering all criteria)

The weight (

Weighting criteria are pivotal in MCDM as they directly impacts decision outcomes. In this study, the entropy method was adopted to objectively determine criteria weights, aiming to mitigate biases and subjectivity. The entropy method is widely recognized for weight determination in MCDM, particularly in the absence of explicit information or prior knowledge about criteria importance. It operates on the principle of maximizing the information content of criteria, ensuring a balanced weight distribution based on available data. Criteria weights were determined through rigorous analysis and validation. Initially, we assessed the relevance and significance of each criterion in our research context. Subsequently, sensitivity analyses were conducted to evaluate weight robustness and their impact on decision outcomes.

As discussed in the previous section, the TOPSIS method serves as a comprehensive tool for facilitating decision-making processes by evaluating and ranking alternative solutions based on a multitude of criteria. It employs a range of metrics and computations to discern the most favourable options from the least favourable ones, ultimately offering a clear preference for decision-makers. A critical aspect of TOPSIS lies in the utilization of RCC scores, which play a pivotal role in guiding the decision-making process. These values act as crucial indicators, allowing for the distinction of the ideal choice from other alternatives. The maximum RCC score serves as a clear marker for the preferred option, simplifying intricate decision scenarios by providing an unambiguous ranking rooted in the assessment of diverse criteria.

Within the framework of TOPSIS, the Si value is a significant component, symbolizing the Euclidean distance between an alternative solution and the ideal solution. In essence, it quantifies how closely an alternative aligns with the best achievable outcome. Conversely, the Si− value, another vital component, is computed as the Euclidean distance between the alternative solution and the negative-ideal solution, offering a measure of how far an alternative deviates from the worst-case scenario.

Enhancing the decision-making process further, the Ci value plays a pivotal role by indicating the relative proximity of each alternative solution to the ideal solution. Calculated as the ratio of the distance from the negative-ideal solution to the alternative solution, divided by the sum of the distances from both the ideal and negative-ideal solutions, this ratio provides a comprehensive perspective on how each alternative compares to both the best and worst-case scenarios, facilitating a balanced and insightful evaluation.

To derive a final ranking, TOPSIS integrates the Si+, Si−, and Ci values in a synergistic manner. This integrated approach offers a holistic assessment of each alternative’s performance across the chosen criteria. The outcomes of this ranking process are presented in Table 7. In the specific context of your study, the results of the TOPSIS rankings reveal that among all the compositions under consideration, the M2 blend emerges as the top choice, signifying its superior performance across the evaluated criteria.

Calculations of Si+, Si−, Ci, NsPi, NsNi, AsI. TOPSIS & EDAS Ranks

| TOPSIS | EDAS | |||||||

|---|---|---|---|---|---|---|---|---|

| Mix No | Si+ | Si− | Ci | Rank of TOPSIS | NsPi | NsNi | AsI | Rank of EDAS |

| M1 | 0.032 | 0.187 | 0.852 | 4 | 0.460 | 0.990 | 0.725 | 6 |

| M2 | 0.001 | 0.215 | 0.993 | 1 | 1.000 | 0.997 | 0.999 | 1 |

| M3 | 0.039 | 0.177 | 0.819 | 7 | 0.459 | 0.996 | 0.728 | 5 |

| M4 | 0.033 | 0.188 | 0.851 | 5 | 0.452 | 0.981 | 0.716 | 7 |

| M5 | 0.034 | 0.183 | 0.844 | 6 | 0.506 | 0.998 | 0.752 | 4 |

| M6 | 0.013 | 0.202 | 0.938 | 2 | 0.823 | 0.999 | 0.911 | 2 |

| M7 | 0.022 | 0.196 | 0.900 | 3 | 0.654 | 0.998 | 0.826 | 3 |

| M8 | 0.047 | 0.171 | 0.784 | 8 | 0.334 | 0.965 | 0.650 | 8 |

| M9 | 0.113 | 0.104 | 0.478 | 12 | 0.006 | 0.672 | 0.339 | 12 |

| M10 | 0.048 | 0.174 | 0.784 | 9 | 0.298 | 0.963 | 0.630 | 9 |

| M11 | 0.056 | 0.167 | 0.750 | 10 | 0.221 | 0.918 | 0.570 | 10 |

| M12 | 0.070 | 0.152 | 0.685 | 11 | 0.093 | 0.893 | 0.493 | 11 |

| M13 | 0.195 | 0.021 | 0.098 | 15 | 0.007 | 0.145 | 0.076 | 15 |

| M14 | 0.119 | 0.097 | 0.449 | 13 | 0.006 | 0.645 | 0.325 | 13 |

| M15 | 0.160 | 0.057 | 0.262 | 14 | 0.003 | 0.360 | 0.182 | 14 |

| M16 | 0.215 | 0.003 | 0.013 | 16 | 0.003 | 0.000 | 0.002 | 16 |

Moreover, the EDAS approach was utilized to assess and rank the various compositions. EDAS functions by calculating the disparity between each option and the mean solution within a MCDM context. The EDAS ranking is displayed in Table 7, established through a structured procedure illustrated in Figure 10. The calculation encompasses both favourable and unfavourable disparities, the weighted accumulation, normalized metrics (NSPi and NSNi), and the evaluation score (ASi) for each individual option, as exhibited in Table 8. Based on the findings from EDAS, it was deduced that the M2 blend was the most favorable option, consistent with the outcome derived from the TOPSIS approach. Nevertheless, some minor disparities in rankings were noted for certain blends when comparing the results of the TOPSIS and EDAS methods.

Ranking for all techniques.

Calculations of S WSM and S WPM

| WSM | WPM | |||

|---|---|---|---|---|

| Mix no | S WSM | Rank of WSM | S WPM | Rank of WPM |

| M1 | 0.639 | 6 | 0.625 | 5 |

| M2 | 0.994 | 1 | 0.993 | 1 |

| M3 | 0.639 | 5 | 0.603 | 7 |

| M4 | 0.634 | 7 | 0.622 | 6 |

| M5 | 0.658 | 4 | 0.631 | 4 |

| M6 | 0.817 | 2 | 0.805 | 2 |

| M7 | 0.734 | 3 | 0.722 | 3 |

| M8 | 0.574 | 8 | 0.542 | 8 |

| M9 | 0.409 | 13 | 0.352 | 12 |

| M10 | 0.559 | 9 | 0.537 | 9 |

| M11 | 0.506 | 10 | 0.487 | 10 |

| M12 | 0.464 | 11 | 0.434 | 11 |

| M13 | 0.341 | 15 | 0.265 | 15 |

| M14 | 0.411 | 12 | 0.350 | 13 |

| M15 | 0.357 | 14 | 0.290 | 14 |

| M16 | 0.316 | 16 | 0.244 | 16 |

3.3 WSM and WPM ranks

Figure 10 represents the rankings obtained using both the WSM and WPM approaches. These two methods follow similar procedures up to the calculation of the weight-normalized matrix, as explained in the earlier section. Table 8 introduces S WSM as a variation of the WSM technique used in the MCDM approach, where alternative performance values are weighted by a straightforward summation of weights. On the other hand, S WPM, which stands for the simple WPM, is an alternative technique applied in MCDM methodology.

Figure 10 presents a comparative ranking of all four methods. Based on the outcomes derived from the results obtained through these MCDM methodologies, it can be inferred that the M2 blend represents the most favourable selection, taking into account a range of criteria including workability, physico-mechanical, and durability criteria. Uniformly, in the TOPSIS, EDAS, and WPM approaches, the M2 blend consistently emerges as the top choice. A comprehensive comparative ranking for all four methods is visually presented in Figure 10.

3.4 Scenario analysis

The adoption of MCDM methods underscores the substantial influence that assigned criteria weights exert on the ranking of alternatives. Consequently, modifying these weights can result in alterations to the ranking order. To explore the relationship between criterion weights and rankings, the sensitivity analysis was conducted, examining various weight scenarios. In Scenario 1, each dimension is accorded the same level of importance. In Scenarios 2–13, specific critical dimensions receive heightened importance, with one alternative’s weight consistently set at 0.5, the remaining weights are distributed uniformly among the remaining dimensions. This method involves determining the weight of individual criteria by distributing the weight of each dimension proportionally among all the criteria being evaluated. The radar graphs presented in Figure 11 offer a clear visual representation of the rankings of RCC mixes, highlighting variations when assessed through different MCDM approaches in distinct scenarios. Each radar chart comprises 16 levels, with the outermost ones representing the highest scores and the innermost ones signifying the lowest scores.

Sensitivity analysis of various scenarios.

In Scenario 1, equal weight is assigned to all criteria, resulting in M2 being the top choice, followed by M6. Transitioning to Scenario 2, M2 becomes the preferred mix, with M6 closely following. Scenario 3 sees M2 claiming the top spot, with M6 and M10 as the second choice, primarily due to the higher weight assigned to be time. Scenario 4 highlights M2 as the optimal mix, followed by M6, considering the greater importance of unit density. In Scenario 5, M2 emerges as the most suitable mix, followed by M6, with a primary focus on CS. Scenario 6 reinforces M2’s dominance, followed by M16, with a weighted emphasis on FS. Scenario 7 showcases M2 as the optimal choice, followed by M6, given the higher significance of Split tensile strength. Shifting to Scenario 8, M2 takes the lead, followed by M6, aligning with the prioritized FS criterion. In Scenario 9, M2 is the preferred mix, followed by M6, with UPV as the chief consideration. In Scenario 10, M2 emerges as the best mix, followed by M6, with Rebound No taking precedence. Scenario 11 Favors M2 as the top choice, with M6 as the second option, primarily focusing on WA. Scenario 12 identifies M2 as the most suitable mix, followed by M6, acknowledging the higher weightage of Abrasion Loss. In Scenario 13, M2 secures the top position, followed by M6, taking pore volume into account with more significance. Overall, across the 13 radar scenarios, there is a noticeable bias towards M2 in the first position, while M6 consistently holds the second position. In conclusion, despite minor variations in rankings in the 13 scenarios, the overarching results closely align with those obtained using MCDM approaches.

4 Conclusions

RCCP is a brittle material with low tensile strength and rigidity, causing cracking before its service life. To improve its performance and flexibility, CR was used as a fine aggregate replacement in the RCCP. NS was added to mitigate the negative effect of CR on RCCP properties. Multicriteria-based optimization was used to select an optimal mix based on performance criteria for the RCCP containing CR and NS. The following conclusions were derived based on the experimental results and analysis.

Incorporation of CR into RCC mixes as fine aggregate replacement resulted in improvement in consistency and reduction in density. NS addition on the other hand reduced the consistency of the RCC mixes in a fresh state.

The partial replacement of fine aggregate with CR in the RCC pavement resulted in a reduction in mechanical strengths, MoE and durability performance of the concrete.

The incorporation of NS as an additive to cement in the RCC pavement containing CR improved its mechanical strengths and durability performance, where NS filled the pores in the matrix and densified the concrete’s microstructure.

The research consistently identifies the M2 mix as the optimal choice across various MCDM techniques and sensitivity analyses. Its remarkable performance remains unwavering, showcasing its excellence in terms of physical, mechanical, and durability attributes.

The mix M2 ability to maintain its top-ranking position regardless of changes in criterion weights or the use of different MCDM methodologies underscores its robust suitability. This adaptability makes it a reliable choice across a wide range of decision-making scenarios.

Acknowledgments

The authors wish to thank the Structures and Materials Research Laboratory, Prince Sultan University for their viable support.

-

Funding information: The support of Prince Sultan University for paying the Article Processing Charges (APC).

-

Author contributions: Musa Adamu: conceptualization, methodology, investigation, formal analysis, writing – original draft; Ashwin Narendra Raut: Software, formal analysis, writing – original draft, Yasser E. Ibrahim: resources, supervision, writing – review and editing; Supriya Janga: Software, formal analysis, writing – original draft; Veerendrakumar C Khed: methodology, investigation, analysis, writing – review and editing. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Aghaeipour A, Madhkhan M. Mechanical properties and durability of roller compacted concrete pavement (RCCP)–A review. Road Mater Pavement Des. 2020;21(7):1775–98.10.1080/14680629.2019.1579754Suche in Google Scholar

[2] Selvam M, Debbarma S, Singh S, Shi X. Utilization of alternative aggregates for roller compacted concrete pavements–A state-of-the-art review. Constr Build Mater. 2022;317:125838.10.1016/j.conbuildmat.2021.125838Suche in Google Scholar

[3] Lam MN-T, Jaritngam S, Le D-H. Roller-compacted concrete pavement made of Electric Arc Furnace slag aggregate: Mix design and mechanical properties. Constr Build Mater. 2017;154:482–95.10.1016/j.conbuildmat.2017.07.240Suche in Google Scholar

[4] Ashrafian A, Gandomi AH, Rezaie-Balf M, Emadi M. An evolutionary approach to formulate the compressive strength of roller compacted concrete pavement. Measurement. 2020;152:107309.10.1016/j.measurement.2019.107309Suche in Google Scholar

[5] Larson J. Roller-compacted concrete pavement design practices for intermodal freight terminals at the port of Tacoma. State-of-the-art Report. 1986. p. 4.Suche in Google Scholar

[6] Logie CV, Oliverson JE. Burlington northern railroad intermodal hub facility. Concr Int. 1987;9(2):37–41.Suche in Google Scholar

[7] Lee SW, Cho Y-H, Park C. Mechanical performance and field application of low cement based concrete under compaction energy. KSCE J Civ Eng. 2014;18:1053–62.10.1007/s12205-014-0353-1Suche in Google Scholar

[8] Chhorn C, Kim YK, Hong SJ, Lee SW. Evaluation on compactibility and workability of roller-compacted concrete for pavement. Int J Pavement Eng. 2019;20(8):905–10.10.1080/10298436.2017.1366762Suche in Google Scholar

[9] Chhorn C, Hong SJ, Lee S-W. A study on performance of roller-compacted concrete for pavement. Constr Build Mater. 2017;153:535–43.10.1016/j.conbuildmat.2017.07.135Suche in Google Scholar

[10] Standard test methods for laboratory compaction characteristics of soil using modified effort (56,000 ft-lbf/ft3 (2,700 kN-m/m3)), ASTM D1557. West Conshohocken, PA, USA, 2021.Suche in Google Scholar

[11] Harrington D, Abdo F, Ceylan H, Adaska W, Hazaree C, Bektas F. Guide for roller-compacted concrete pavements. National Concrete Pavement Technology Center, Institute for Transportation, Iowa State University, USA, 2010.Suche in Google Scholar

[12] Chan S, Lane B, Kazmierowski T, Lee W. Pavement preservation: A solution for sustainability. Transp Res Rec. 2011;2235(1):36–42.10.3141/2235-05Suche in Google Scholar

[13] Sobhan K, Mashnad M. Roller-compacted fiber concrete pavement foundation with recycled aggregate and waste plastics. Transp Res Rec. 2001;1775(1):53–63.10.3141/1775-08Suche in Google Scholar

[14] Fardin HE, Santos AGd. Roller compacted concrete with recycled concrete aggregate for paving bases. Sustainability. 2020;12(8):3154.10.3390/su12083154Suche in Google Scholar

[15] Aghayan I, Khafajeh R, Shamsaei M. Life cycle assessment, mechanical properties, and durability of roller compacted concrete pavement containing recycled waste materials. Int J Pavement Res Technol. 2021;14:595–606.10.1007/s42947-020-0217-7Suche in Google Scholar

[16] Mohammed BS, Adamu M. Mechanical performance of roller compacted concrete pavement containing crumb rubber and nano silica. Constr Build Mater. 2018;159:234–51.10.1016/j.conbuildmat.2017.10.098Suche in Google Scholar

[17] Haruna S, et al. Multiscale investigation of the impact of recycled plastic aggregate as a fine aggregate replacement on one-part alkali-activated mortar performance. J Build Eng. 2024;86:108768.10.1016/j.jobe.2024.108768Suche in Google Scholar

[18] Adamu M, Trabanpruek P, Limwibul V, Jongvivatsakul P, Iwanami M, Likitlersuang S. Compressive behavior and durability performance of high-volume fly-ash concrete with plastic waste and graphene nanoplatelets by using response-surface methodology. J Mater Civ Eng. 2022;34(9):04022222.10.1061/(ASCE)MT.1943-5533.0004377Suche in Google Scholar

[19] Adamu M, Trabanpruek P, Jongvivatsakul P, Likitlersuang S, Iwanami M. Mechanical performance and optimization of high-volume fly ash concrete containing plastic wastes and graphene nanoplatelets using response surface methodology. Constr Build Mater. 2021;308:125085.10.1016/j.conbuildmat.2021.125085Suche in Google Scholar

[20] Moghaddam TB, Karim MR, Abdelaziz M. A review on fatigue and rutting performance of asphalt mixes. Sci Res Essays. 2011;6(4):670–82.Suche in Google Scholar

[21] Adamu M. Development of nanosilica modified high volume fly ash roller compacted rubbercrete for pavement application. Universiti Teknologi PETRONAS; 2018.Suche in Google Scholar

[22] Aghamohammadi O, Mostofinejad D, Mostafaei H, Abtahi SM. Mechanical properties and impact resistance of concrete pavement containing crumb rubber. Int J Geomech. 2024;24(1):04023242.10.1061/IJGNAI.GMENG-7620Suche in Google Scholar

[23] Siddika A, Al Mamun MA, Alyousef R, Amran YM, Aslani F, Alabduljabbar H. Properties and utilizations of waste tire rubber in concrete: A review. Constr Build Mater. 2019;224:711–31.10.1016/j.conbuildmat.2019.07.108Suche in Google Scholar

[24] Han Y, Lv Z, Bai Y, Han G, Li D. Experimental study on the mechanical properties of crumb rubber concrete after elevated temperature. Polymers. 2023;15(14):3102.10.3390/polym15143102Suche in Google Scholar PubMed PubMed Central

[25] Moasas AM, et al. A worldwide development in the accumulation of waste tires and its utilization in concrete as a sustainable construction material: A review. Case Stud Constr Mater. 2022;17:e01677.10.1016/j.cscm.2022.e01677Suche in Google Scholar

[26] Assaggaf R, Maslehuddin M, Al-Osta MA, Al-Dulaijan SU, Ahmad S. Properties and sustainability of treated crumb rubber concrete. J Build Eng. 2022;51:104250.10.1016/j.jobe.2022.104250Suche in Google Scholar

[27] Assaggaf RA, Ali MR, Al-Dulaijan SU, Maslehuddin M. Properties of concrete with untreated and treated crumb rubber–A review. J Mater Res Technol. 2021;11:1753–98.10.1016/j.jmrt.2021.02.019Suche in Google Scholar

[28] Ismail MK, Hassan AA. Use of metakaolin on enhancing the mechanical properties of self-consolidating concrete containing high percentages of crumb rubber. J Clean Prod. 2016;125:282–95.10.1016/j.jclepro.2016.03.044Suche in Google Scholar

[29] Thomas BS, Gupta RC, Panicker VJ. Recycling of waste tire rubber as aggregate in concrete: durability-related performance. J Clean Prod. 2016;112:504–13.10.1016/j.jclepro.2015.08.046Suche in Google Scholar

[30] Nematzadeh M, Mousavimehr M. Residual compressive stress–strain relationship for hybrid recycled PET–crumb rubber aggregate concrete after exposure to elevated temperatures. J Mater Civ Eng. 2019;31(8):04019136.10.1061/(ASCE)MT.1943-5533.0002749Suche in Google Scholar

[31] Assaggaf RA, Al-Dulaijan SU, Maslehuddin M, Al-Amoudi OSB, Ahmad S, Ibrahim M. Effect of different treatments of crumb rubber on the durability characteristics of rubberized concrete. Constr Build Mater. 2022;318:126030.10.1016/j.conbuildmat.2021.126030Suche in Google Scholar

[32] Ren F, Mo J, Wang Q, Ho JCM. Crumb rubber as partial replacement for fine aggregate in concrete: An overview. Constr Build Mater. 2022;343:128049.10.1016/j.conbuildmat.2022.128049Suche in Google Scholar

[33] Iqbal HW, et al. Effect of graphene nanoplatelets on engineering properties of fly ash-based geopolymer concrete containing crumb rubber and its optimization using response surface methodology. J Build Eng. 2023;75:107024.10.1016/j.jobe.2023.107024Suche in Google Scholar

[34] Youssf O, Swilam A, Tahwia AM. Performance of crumb rubber concrete made with high contents of heat pre-treated rubber and magnetized water. J Mater Res Technol. 2023;23:2160–76.10.1016/j.jmrt.2023.01.146Suche in Google Scholar

[35] Qaidi SM, Dinkha YZ, Haido JH, Ali MH, Tayeh BA. Engineering properties of sustainable green concrete incorporating eco-friendly aggregate of crumb rubber: A review. J Clean Prod. 2021;324:129251.10.1016/j.jclepro.2021.129251Suche in Google Scholar

[36] Li Y, Yang X, Lou P, Wang R, Li Y, Si Z. Sulfate attack resistance of recycled aggregate concrete with NaOH-solution-treated crumb rubber. Constr Build Mater. 2021;287:123044.10.1016/j.conbuildmat.2021.123044Suche in Google Scholar

[37] Emam E, Yehia S. Experimental study on enhanced crumb rubber concrete. Int J Sci Eng Res. 2018;9(2):1240–7.Suche in Google Scholar

[38] Fakhri M. The effect of waste rubber particles and silica fume on the mechanical properties of roller compacted concrete pavement. J Clean Prod. 2016;129:521–30.10.1016/j.jclepro.2016.04.017Suche in Google Scholar

[39] Gupta T, Chaudhary S, Sharma RK. Mechanical and durability properties of waste rubber fiber concrete with and without silica fume. J Clean Prod. 2016;112:702–11.10.1016/j.jclepro.2015.07.081Suche in Google Scholar

[40] Gupta T, Sharma RK, Chaudhary S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int J Impact Eng. 2015;83:76–87.10.1016/j.ijimpeng.2015.05.002Suche in Google Scholar

[41] Sidhu AS, Siddique R. Utilisation of crumb tire rubber in development of sustainable metakaolin based high strength concrete. Constr Build Mater. 2022;345:128412.10.1016/j.conbuildmat.2022.128412Suche in Google Scholar

[42] Sidhu AS, Siddique R. Durability assessment of sustainable metakaolin based high strength concrete incorporating crumb tire rubber. J Build Eng. 2023;72:106660.10.1016/j.jobe.2023.106660Suche in Google Scholar

[43] Mohammed BS, Awang AB, San Wong S, Nhavene CP. Properties of nano silica modified rubbercrete. J Clean Prod. 2016;119:66–75.10.1016/j.jclepro.2016.02.007Suche in Google Scholar

[44] Adamu M, Mohammed BS, Shafiq N, Liew MS. Durability performance of high volume fly ash roller compacted concrete pavement containing crumb rubber and nano silica. Int J Pavement Eng. 2020;21(12):1437–44.10.1080/10298436.2018.1547825Suche in Google Scholar

[45] Alenezi M, Agrawal A, Kumar R, Khan RA. Evaluating performance of Web application security through a fuzzy based hybrid multi-criteria decision-making approach: Design tactics perspective. IEEE Access. 2020;8:25543–56.10.1109/ACCESS.2020.2970784Suche in Google Scholar

[46] Haseeb K, Rehman A, Saba T, Bahaj SA, Lloret J. Device-to-device (D2D) multi-criteria learning algorithm using secured sensors. Sensors. 2022;22(6):2115.10.3390/s22062115Suche in Google Scholar PubMed PubMed Central

[47] Agrawal A, Alenezi M, Kumar R, Khan RA. A unified fuzzy-based symmetrical multi-criteria decision-making method for evaluating sustainable-security of web applications. Symmetry. 2020;12(3):448.10.3390/sym12030448Suche in Google Scholar

[48] Kurda R, de Brito J, Silvestre JD. CONCRETop-A multi-criteria decision method for concrete optimization. Environ Impact Assess Rev. 2019;74:73–85.10.1016/j.eiar.2018.10.006Suche in Google Scholar

[49] Soni A, Chakraborty S, Das PK, Saha AK. Materials selection of reinforced sustainable composites by recycling waste plastics and agro-waste: An integrated multi-criteria decision making approach. Constr Build Mater. 2022;348:128608.10.1016/j.conbuildmat.2022.128608Suche in Google Scholar

[50] Yoris-Nobile AI, et al. Life cycle assessment (LCA) and multi-criteria decision-making (MCDM) analysis to determine the performance of 3D printed cement mortars and geopolymers. J Sustain Cement-Based Mater. 2023;12(5):609–26.10.1080/21650373.2022.2099479Suche in Google Scholar

[51] Shmlls M, Abed M, Fořt J, Horvath T, Bozsaky D. Towards closed-loop concrete recycling: Life cycle assessment and multi-criteria analysis. J Clean Prod. 2023;410:137179.10.1016/j.jclepro.2023.137179Suche in Google Scholar

[52] Chen C-H. A novel multi-criteria decision-making model for building material supplier selection based on entropy-AHP weighted TOPSIS. Entropy. 2020;22(2):259.10.3390/e22020259Suche in Google Scholar PubMed PubMed Central

[53] Navarro IJ, Martí JV, Yepes V. Analytic network process-based sustainability life cycle assessment of concrete bridges in coastal regions. Sustainability. 2022;14(17):10688.10.3390/su141710688Suche in Google Scholar

[54] Revilla-Cuesta V, Skaf M, Espinosa AB, Ortega-López V. Multi-criteria feasibility of real use of self-compacting concrete with sustainable aggregate, binder and powder. J Clean Prod. 2021;325:129327.10.1016/j.jclepro.2021.129327Suche in Google Scholar

[55] Standard specification for portland cement, ASTM C150. West Conshohocken, PA, USA, 2019.Suche in Google Scholar

[56] Standard Test Method for Rubber Compounding Materials—Determination of Particle Size Distribution of Recycled Vulcanizate Particulate Rubber, ASTM D5644. West Conshohocken, PA, USA, 2018.Suche in Google Scholar

[57] Mohammed BS, Adamu M. Non-destructive evaluation of nano silica-modified roller-compacted rubbercrete using combined SonReb and response surface methodology. Road Mater Pavement Des. 2019;20(4):815–35.10.1080/14680629.2017.1417891Suche in Google Scholar

[58] Standard Practice for Selecting Proportions for Roller Compacted Concrete (RCC) Pavement Mixtures Using Soil Compaction Concepts, CRD-C 162. Washington, DC, USA, 1992.Suche in Google Scholar

[59] Guide for Selecting Proportions for No-Slump Concrete, ACI 211.3R-02. Michigan, USA, 2009.Suche in Google Scholar

[60] Adamu M, Mohammed BS, Liew MS. Mechanical properties and performance of high volume fly ash roller compacted concrete containing crumb rubber and nano silica. Constr Build Mater. 2018;171:521–38.10.1016/j.conbuildmat.2018.03.138Suche in Google Scholar

[61] Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory, ASTM C192. West Conshohocken, PA, USA, 2018.Suche in Google Scholar

[62] Standard Practice for Molding Roller-Compacted Concrete in Cylinder Molds Using a Vibrating Hammer, ASTM C1435. West Conshohocken, PA, USA, 2020.Suche in Google Scholar

[63] Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory, ASTM C192/C192M. West Conshohocken, PA, United States, 2015.Suche in Google Scholar

[64] Testing hardened concrete - Compressive strength of test specimens, BS EN 12390-3. London, United Kingdom, 2019.Suche in Google Scholar

[65] Testing hardened concrete. Tensile splitting strength of test specimens, BS EN 12390-6. London, United Kingdom, 2023.Suche in Google Scholar

[66] Standard Test Method for Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading), ASTM C293/C293M. West Conshohocken, PA, USA, 2016.Suche in Google Scholar

[67] Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression, ASTM C469/C469M. West Conshohocken, PA, USA, 2014.Suche in Google Scholar

[68] Standard Test Method for Density, Absorption, and Voids in Hardened Concrete, ASTM C642. West Conshohocken, PA, USA, 2021.Suche in Google Scholar

[69] Standard Test Method for Determining Potential Resistance to Degradation of Pervious Concrete by Impact and Abrasion, ASTM C1747/C1747M. West Conshohocken, PA, USA, 2012.Suche in Google Scholar

[70] Standard Test Method for Determining Pore Volume Distribution of Catalysts and Catalyst Carriers by Mercury Intrusion Porosimetry, ASTM D4284. West Conshohocken, PA, USA, 2012.Suche in Google Scholar

[71] Standard Test Method for Rebound Number of Hardened Concrete, ASTM C805/C805M. West Conshohocken, PA, USA, 2018.Suche in Google Scholar

[72] Standard Test Method for Pulse Velocity Through Concrete, ASTM C597. West Conshohocken, PA, USA, 2016.Suche in Google Scholar

[73] Rashid K, Razzaq A, Ahmad M, Rashid T, Tariq S. Experimental and analytical selection of sustainable recycled concrete with ceramic waste aggregate. Constr Build Mater. 2017;154:829–40.10.1016/j.conbuildmat.2017.07.219Suche in Google Scholar

[74] Ahmed M, Mallick J, AlQadhi S, Ben Kahla N. Development of concrete mixture design process using MCDM approach for sustainable concrete quality management. Sustainability. 2020;12(19):8110.10.3390/su12198110Suche in Google Scholar

[75] Naik B, Paul S, Mishra SP, Rout SP, Barua A, Bagal DK. Performance analysis of M40 grade concrete by partial replacement of Portland Pozzolana Cement with Marble Powder and Fly Ash Using Taguchi-EDAS method. J Appl Sci Comput VI (VI). 2019;6(6):733–43.Suche in Google Scholar

[76] Ghorabaee MK, Zavadskas EK, Amiri M, Turskis Z. Extended EDAS method for fuzzy multi-criteria decision-making: an application to supplier selection. Int J Computers Commun Control. 2016;11(3):358–71.10.15837/ijccc.2016.3.2557Suche in Google Scholar

[77] Chourabi Z, Khedher F, Babay A, Cheikhrouhou M. Multi-criteria decision making in workforce choice using AHP, WSM and WPM. J Text Inst. 2019;110(7):1092–101.10.1080/00405000.2018.1541434Suche in Google Scholar

[78] Panda S, Behera GC, Bagal DK, Dash P. Performance exploration of M25 grade concrete by fractional replacement of ordinary Portland cement by means of glass fiber using WASPAS method. Int J Recent Technol Eng. 2020;9(1):2588–91.10.35940/ijrte.E6695.059120Suche in Google Scholar

[79] Thomas BS, Gupta RC. Properties of high strength concrete containing scrap tire rubber. J Clean Prod. 2016;113:86–92.10.1016/j.jclepro.2015.11.019Suche in Google Scholar

[80] Samingthong W, Hoy M, Ro B, Horpibulsuk S, Yosthasaen T, Suddeepong A, et al. Natural rubber latex-modified concrete with PET and crumb rubber aggregate replacements for sustainable rigid pavements. Sustainability. 2023;15(19):14147.10.3390/su151914147Suche in Google Scholar

[81] Norhasri MM, Hamidah M, Fadzil AM. Applications of using nano material in concrete: A review. Constr Build Mater. 2017;133:91–7.10.1016/j.conbuildmat.2016.12.005Suche in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder