Interfacial interactions and reinforcing mechanisms of cellulose and chitin nanomaterials and starch derivatives for cement and concrete strength and durability enhancement: A review

Abstract

Nanomaterials have been widely researched for use in construction materials. Numerous studies demonstrate that nanomaterials in small quantities can significantly improve the macroscopic properties of cement paste, mortar, or concrete through various mechanisms. Nanomaterials retrieved from biomass sources have recently gained particular research interest due to remarkable structural properties and the source material’s abundance and renewability. Cellulose and chitin are the most abundant polysaccharides in nature; thus, they are candidates for nanomaterials extraction as multifunctional additives in cementitious systems. In recent years, cellulose nanomaterials in cementitious composites have been extensively investigated, but chitin nanomaterials and starch derivatives for cement and concrete are still emerging research areas. This review article starts with an overview of polysaccharide nanomaterials’ (PNMs) physicochemical properties as a result of different chemical and mechanical extraction processes. Next a brief overview of cement hydration chemistry and microstructure and the interfacial interactions between the cement and the various surface chemical functionalities of PNMs are discussed. Then, the key mechanisms governing the cement strength enhancement by PNMs, such as bridging, nucleating and filling effect, and internal curing, are described. Finally, the impacts of PNMs on other properties of the cement are discussed.

1 Introduction

Concrete is the most widely used construction material [1]. Increased demand from China, India, the Middle East, Northern Africa, and North America drove the annual global production of cement (the major binder component of concrete) to 4.08 billion metric tons in 2019, with about 86 million tons produced in the U.S. [2]. Concrete is easy to manufacture by proportioning by weight and mechanically mixing the components. Furthermore, it can be made into any desired shape in its fresh state, while some of the cured products gain attractive mechanical properties as early as a few hours [3]. However, CO2 emissions associated with Portland cement production are estimated to be around 5% of the global anthropogenic carbon dioxide [4,5,6,7]. Frequent repairs and infrastructure rebuilding are the main drivers of the high demand for concrete to address cracking. The high susceptibility of current concrete to early cracking is a major concern for the long-term sustainability of infrastructures worldwide.

In the last century, Portland cement has been widely used for different infrastructures, but it results in early cracking [8,9] due to large thermal and drying shrinkage deformations, reduced creep, and increased elastic modulus [8]. Cracks allow water/gas/ions to penetrate the structure faster, leading to steel reinforcement corrosion and subsequent concrete spalling [10]. Therefore, concrete infrastructure requires frequent repairs or replacements, increasing CO2 emissions, and energy usage associated with concrete production. To overcome the burden of recurrent failing infrastructure and reduce concrete-associated CO2 emissions, strategies to enhance the durability of concrete, extend infrastructure life cycle, and delay structural repair and replacement while meeting rapid construction requirements are urgently needed.

In recent years, nanotechnology innovations have enabled improving macroscopic properties of concrete by altering the atomic structure of the calcium–silicate–hydrate (C–S–H) gel [11]. C–S–H is the key cement hydration product (50–70 wt%) and is responsible for the strength development, physical properties, and durability of concrete [12]. However, shrinkage, creep, restructuring, and microcracking can also develop within the C–S–H gel. Therefore, there is a great interest in modifying the structure and properties of C–S–H to achieve desired performance from the concrete composite. Nanomaterials can offer multiple unique advantages such as densification and reinforcement of the C–S–H gel, altering its degree of polymerization (DP) [13] and silica mean chain length of C–S–H [14], and increasing the stiffness of C–S–H [15]. Other effects from nanomaterials on the cement properties have been speculated from the creation of additional nucleation sites to facilitate extra hydration reactions, reduced porosity, and refinement of the cement pore structure [16]. Consequently, improvements in performance, such as subsequent reduction in chloride permeability, have been reported [17,18]. Furthermore, it has been shown that nanomaterials can greatly enhance current ultra-high-performance concrete by reducing cement usage and mitigating their excessive shrinkage and cracking issues [19].

The most researched nanomaterial for cement composites is carbon nanotubes (CNTs), which have demonstrated tremendous abilities in boosting cementitious systems’ mechanical and durability properties. However, wide stream use of CNTs in concrete-based construction is not possible until many challenges associated with CNT manufacturing are overcome to significantly reduce their cost and increase their availability in larger amounts. In addition, due to their inert surface chemistry, CNTs require surface functionalization for good dispersion and interfacial chemical compatibility and reactivity with cement [20,21,22]. Additional treatments and dispersion processes could add to the complexity of concrete production with nanomaterials, concrete cost, and the overall CO2 footprint of concrete production. In order to develop the cost-effective and scalable nanomaterials which can be globally adopted to reduce energy consumption and CO2 emissions of concrete, the nanomaterials should have the following characteristics:

Abundant feedstock resources;

Scalable and low-energy extraction/manufacturing methods,

Convenient dispersion, placement, finishing, and cleanup to maintain construction efficiency and promote implementation by concrete suppliers, builders, and project owners.

Biobased additives from abundant biopolymers in the nanoscale have received significant attention from researchers in recent years. Nanomaterials derived from cellulose (the most abundant biopolymer) have shown great potential for use in the cement industry [23,24,25]. However, less focus has been on chitin as a source for nanomaterials, though chitin is the second most abundant polysaccharide biopolymer [26,27] after cellulose. Other polysaccharides, e.g., starch and its derivatives, are only reported in a few studies [28,29]. Derivatives and nanostructures from these environmentally friendly biopolymers could offer cost-effective and low-energy alternatives to CNTs if sufficient study is carried out for cement and concrete use, providing their manufacturing processes are streamlined. Therefore, this review article aims to turn on the spotlight on these underused biopolymers for nanomaterials extraction for cementitious systems. Furthermore, the effects of polysaccharide nanomaterials (PNMs) on the properties of cement and concrete greatly vary depending on the nature of polysaccharides and the characteristics of PNMs, including surface chemistry, size, morphology, surface charge, etc. The impact of these properties on interfacial interactions with cement and consequential effects on concrete performance has been overlooked in current cement and concrete literature. Therefore, this manuscript aims to give readers an overview of the applications and the ensuing effects and probable reinforcing mechanisms of different types of polysaccharides and their nanomaterials in cement and concrete. This review also aims to draw the attention of researchers to knowledge gaps and areas of future research needed to expand the use of PNMs in cementitious systems.

To do so, this article first presents a comprehensive review of PNMs, including cellulose, chitin, starch (and its derivatives), and their application in cement and concrete. Recent advances in preparation methods and surface modification for making PNMs are reviewed, and their interfacial interactions with cement, and effects on the mechanical properties of cement and concrete are summarized. The mechanisms for nanomaterial-cement interactions and the factors affecting cement and concrete mechanical properties, such as size, morphology, concentration, and dispersion of nanomaterials, are also discussed.

2 Literature review methodology

The literature review methodology used the following search engines; Google scholar, Google patent, SciFinder, Patentsout, and Baidu. The searched keywords included cellulose cement (concrete), cellulose nanocrystal cement, cellulose nanofiber cement (concrete), chitin cement (concrete), chitosan cement (concrete), chitin nanocrystal cement (concrete), chitin nanofiber cement (concrete), starch cement (concrete), polysaccharide cement, among others. The authors reviewed publications and patents reported over the past 30 years.

3 Production methods of PNMs

Emerging biobased PNM additives, particularly cellulose nanomaterials, have been applied in cement and concrete for different end outcomes, e.g., strength enhancement, hydration booster, internal curing, rheological modification, and others. The properties of the PNM-reinforced or modified cement and concrete are usually governed by the characteristics of PNMs, such as their size, morphology, aspect ratio, surface chemistry, charge, etc. PNMs’ characteristics are determined by the nature of the polysaccharides and the extraction methods. Therefore, the following sections provide an overview of different types and production methods of PNMs.

3.1 Sulfated cellulose nanocrystals

Cellulose is a polydisperse linear polymer of poly-β-(1,4)-d-glucose residues and has a flat ribbon-like conformation [30]. The repeating unit (Figure 1a) is comprised of anhydro-glucose rings (C6H10O5) n . Cellulose chains have a degree polymerization of approximately 10,000 glucopyranose units in wood cellulose and 15,000 in native cellulose cotton [31,32]. Nanocellulose can be produced in different ways, leading to different properties and dimensions. Two main forms of cellulose nanomaterials can be obtained: cellulose nanocrystals (CNCs) and cellulose nanofibers (CNFs). Tables 1 and 2 summarize the different methods for producing CNFs or CNCs, such as mechanical fibrillation or sulfuric acid hydrolysis using wood pulp for producing CNFs [33,34,35,36,37]; 2,2,6,6-tetramethylpiperidine-1-oxyl radical ((TEMPO)-mediated oxidation and followed with mild disintegration in water) using wood pulp [38,39,40,41] for producing CNFs; and sulfuric acid hydrolysis with wood pulp, cotton fibers, algae, wood chips, pulp sludge, among other precursors for producing CNCs [42,43,44,45,46].

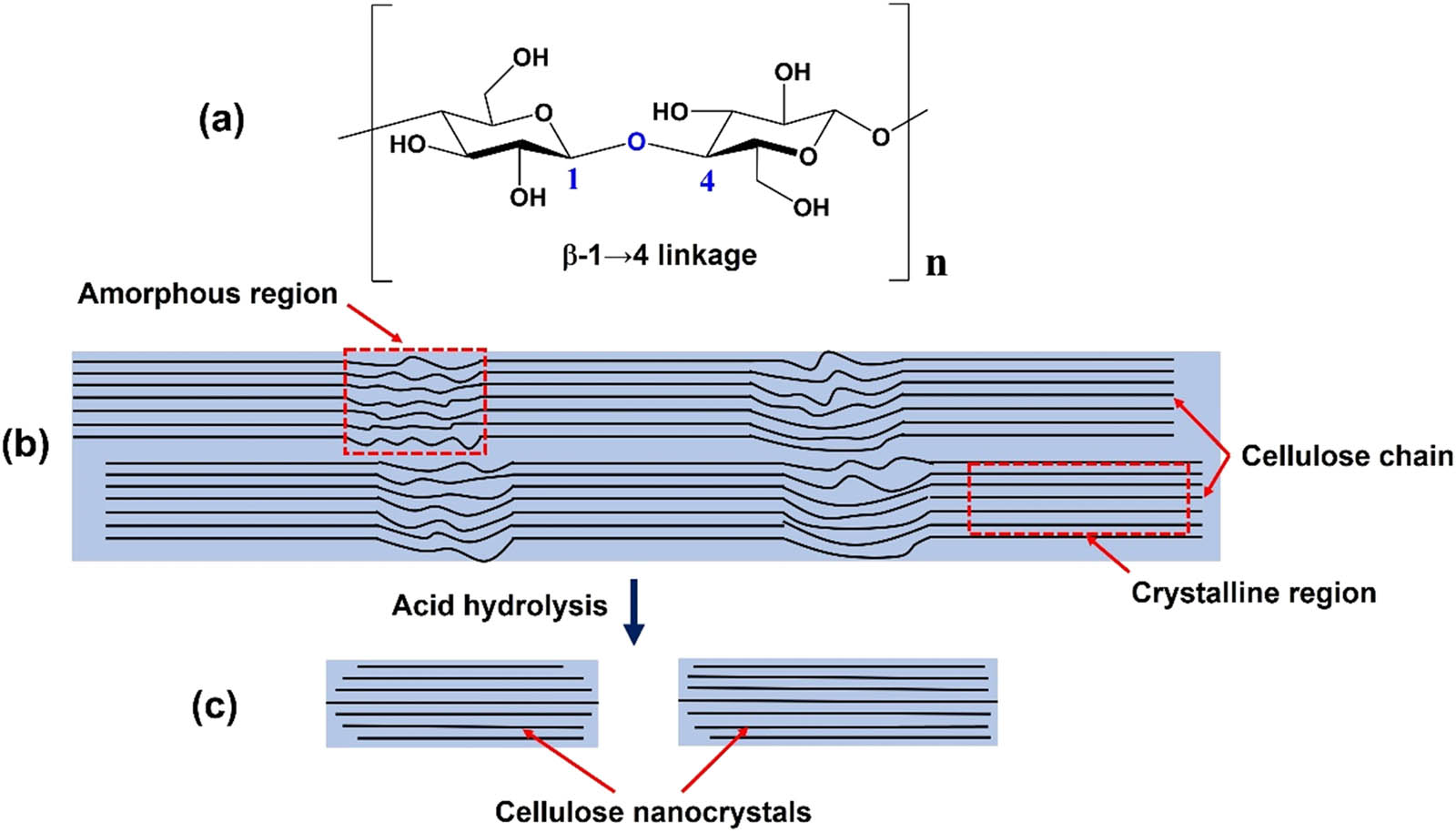

Schematics of (a) repeating unit of cellulose chain with the directionality of the 1 → 4 linkage, (b) idealized cellulose microfibril with one of the suggested configurations of the crystalline and amorphous regions, and (c) cellulose nanocrystals after acid hydrolysis dissolved the disordered regions.

Cellulose nanofibril-reinforced cementitious materials

| PNM type/source/production/size | Nanocellulose dose | Cementitious material | Effects on mechanical properties | Ref. | |

|---|---|---|---|---|---|

| CNF; Source: wood pulp; Production method: mechanical; Diameter: 20–200 nm; Length: 1–2.5

|

0–0.4 wt% of cement | General use limestone cement | ✓ | 106% improvement in fs | [33] |

| ✓ | 184% improvement in energy absorption | ||||

| ✓ | 10% increase in the hardness | ||||

| CNF; Source: wood pulp; Production: TEMPO oxidation; Diameter: 50–90 nm; Length: 400–800 nm | 0–0.4 wt% of cement | Ordinary Portland cement (OPC) (PII 42.5R) | ✓ | 20% increase in Cs | [40] |

| ✓ | 15% increase in fs | ||||

| ✓ | Initial setting time increases from 170 min to 272 min and final setting time increases from 219 min to 310 min | ||||

| CNF; Source: wood pulp; Production: 48% sulfuric acid hydrolysis; Diameter: 20 nm; Length: several microns | 0.04 wt% of cement | Oil well cement (OWC) | ✓ | 23.9% increase in fs | [34] |

| CNF; Source/method: wood pulp with 48% sulfuric acid hydrolysis followed by homogenization; Diameter: 20–30 nm; Length: several hundreds of microns; Aspect ratio: over 1,000 | 0.04 wt% of cement | OWC | ✓ | fs was increased from 11.24 to 13.63 MPa | [35] |

| ✓ | Cs was increased from 39.57 to 39.64 MPa after the addition of 0.04 wt% CNF | ||||

| Nanofibrillated cellulose (NFC); Source: eucalyptus pulp; Production method: bleaching process and deproteination and demineralization; Diameter: 5–10 nm; Length: several microns; Carboxylate content: 0.5 mmol/g fiber | 0.3 wt% of cement | Type I cement 32.5 N EN197-1:2,000 w/c = 0.26 | ✓ | 36% reduction in porosity | [41] |

| ✓ | 43% increase in Cs | ||||

| ✓ | 36% improvement in thermal conductivity | ||||

| ✓ | Both the initial and the final setting times have decreased as NFC contents increase | ||||

| Cellulose filament; Source: wood pulp; Production: mechanical method; Diameter: 10–400 nm; Length: 100–2,000 microns | 0.05, 0.1, 0.15, and 0.2 wt% | Type I cement (ASTM C494 + class F-fly ash | ✓ | Decreased Cs while increased fs | [36] |

| Bleached Chemi-Thermo-Mechanical Pulp (Aspen, grade 325/85/100 H T) was used as the source for the CNF generation by TEMPO method; Diameter:10–20 nm; Length: a few microns | 0–1.18% CNF (kg/m3 paste) | Portland cement type II | ✓ | Addition of CNF increased the yield stress from 11.36 to 22.09 Pa at 0.2% CNF and to 71.06 Pa at 0.8% CNF | [38] |

| ✓ | The viscosity increased only from 0.54 to 0.68 Pa s and to 1.26 Pa s by addition of 0.2 and 0.8% CNF, respectively | ||||

| CNF by InnoTech Alberta; Source: bleached chemo-thermomechanical wood pulp; Production method: TEMPO oxidation followed by Supermass Colloider; Diameter: 5–20 nm; Length: a few microns; Carboxylate content: 0.13 mmol/g fiber | 0–0.185 wt% of cement | Portland cement type GU | ✓ | Significantly alleviated bleeding and shrinkage at early stages of hydration | [39] |

| ✓ | Retarded hydration upon adding CNF | ||||

| ✓ | Reduced ingress of deleterious agents into cement | ||||

| ✓ | Increased degree of hydration (DOH) | ||||

| CNF; Source: wood pulp; Production method: mechanical fibrillation; Diameter: 20–50 nm; Length: typically, less than 0.2 mm; Zeta potential: −34 mV at pH = 7 | 0.015, 0.03, 0.06, 0.09, and 0.15 wt% of cement | Portland cement type I/II | ✓ | 3–31% improvement in 7 days Cs | [37] |

| ✓ | 39–116% improvement in fs | ||||

| ✓ | 49 and 26% reduction in autogenous shrinkage for 0.06 and 0.09 wt% CNF cement, respectively | ||||

| CNF; Source: wood pulp; Production method: mechanical fibrillation; Diameter: 25 and 500 nm; Length: several microns | 0.1–0.8 wt% of cement | OPC | ✓ | Addition of CNF between 0.1 and 0.2 wt% led to a general increase in the modulus of rupture and modulus of elasticity values | [73] |

| CNF; Source: wheat straw; Production method: prepared by HCl, NaOH, peracetic acid pretreatments of wheat straw followed by sonication (30 min) treatment; Diameter: 150–400 nm; Length: several microns | 0.5, 1, 1.5, and 10 wt% of cement mortar | Not provided | ✓ | Improved Cs by 27% at an optimum dosage of 0.5 wt% | [74] |

| CNF; Source: N/A; Production method: N/A. | 0.025, 0.05, 0.1, 0.3, and 0.5% (solids) by weight of cement | OPC type I/II | ✓ | At 90 days, 0.05% CNF in cement paste resulted in 24 and 15% increase in the Cs of cement paste with 0.35 and 0.45 w/c, respectively | [75] |

| ✓ | fs of cement paste increased up to 75 and 55% due to the addition of 0.5% of PCNF and nano silica-CNF, respectively | ||||

| CNF; Production method: mechanically fibrillated cellulose from University of Maine; Diameter: 28.2 ± 20.8 nm; Length: several hundreds of microns | 0.065 wt% by weight of cement | Type I/II OPC | ✓ | Max% increase in 7 days and 28 days Cs 17 and 18%, with 0.065 wt% CNF | [76] |

| ✓ | 0.065 wt% CNF enhanced E by 40% | ||||

| ✓ | Concentrations of CNF resulted in 0 to a maximum of 21 min delay in the initial set time of the control | ||||

| ✓ | 0.075 wt% CNF cement showed a faster initial setting than the control | ||||

| ✓ | Three concentrations of 0.045, 0.05, and 0.055 wt% delayed final setting times by 15, 39, and 56 min | ||||

| ✓ | In the first 90 min period, all CNF-cements showed similar or slightly higher consistency than the control and much higher values than the control + superplasticizer | ||||

| CNF; Production method: N/A; Diameter: 5–20 nm; Length: from 50 to >2,000 nm in length | 0.15 kg/m3 of concrete | Type I cement | ✓ | Slight improvements of Cs and fs were observed for curing times longer than 28 days | [77] |

Cellulose nanocrystal-reinforced cementitious materials

| PNM type/source/production/size | Optimal nanocellulose dose | Cementitious material | Effects on mechanical properties | Ref. | |

|---|---|---|---|---|---|

| CNCs; Source: wood pulp; Production method: sulfuric acid hydrolysis; Width: 3–5 nm; Length: 0.05–0.5

|

0.2 vol% of cement | Type V cement | ✓ | 20–30% improvement in fs | [42] |

| CNCs; Source: wood pulp; Production method: sulfuric acid hydrolysis; Width: 3–5 nm; Length: 0.05–0.5 µm; Zeta potential: –64 mV at pH = 7 | 1.5 vol% of cement | Type V cement | ✓ | 50% improvement in reduced modulus | [43] |

| CNCs; Source: N/A; Production method: Blue Goose Biorefineries Inc.; Width: 90 nm; Length: 500 nm; Zeta potential: –33.4 mV | 0.8 wt% of cement | Type I/II Portland cement | ✓ | Increased fraction of high-density of C–S–H | [78] |

| CNCs Production: Kraft pulp sourced from Alberta’s pulp and paper mill; Width: 5–10 nm; Aspect ratio: 10–60; Zeta potential: N/A | 0–0.44 wt% of OWC | Type G cement | ✓ | Improved Cs and fs by 60% | [45] |

| ✓ | Reduced porosity by 30% | ||||

| CNCs; Source: wood pulp; Production method: mechanical fibrillation; Width: 13–335 nm; Length: 100–400 nm | 0.1–0.8 wt% of cement | OPC | ✓ | Addition of CNC between 0.1 and 0.2 wt% led to a general increase in E and fs | [73] |

| CNCs; Source: wood pulp, cotton fibers, algae, wood chips, and pulp sludge; Production method: sulfuric acid hydrolysis; Width: 3–5 nm; Length: 0.05–0.5

|

0.023–3.311 vol% of cement | Type I/II and type V cement | ✓ | Reduced yield stress by up to 54% at low dosage (<0.2%) | [44] |

| ✓ | Increased yield stress by 10 times at high dosage (1%) | ||||

| CNCs; Source: Oil Palm Empty Fruit Bunch; Production method: 0.2 N HCl at 105°C/15 min, microcrystalline cellulose powder mixed with 64 wt% H2SO4 at 45°C/60 min and constantly stirred to produce CNCs; Zeta potential: –50.4 mV | 0.4 vol% of cement | Portland cement type I | ✓ | Increased Cs by 43–46% | [46] |

| ✓ | Substantial increase in fs | ||||

| Source: any material which comprises a substantial proportion of cellulose; Production method: redox reaction (NaClO with iron sulfate or copper sulfate as a catalyst with buffer) → alkaline extraction → 2nd redox reaction (NaClO with copper sulfate as a catalyst with buffer) → washing and concentrate-CNC; Width: 3–5 nm; Height: 3–20 nm; Length: 50–500 nm | 1–5 g/kg of cement | Cement type GU | ✓ | Marked increase on 3 days, and 30 days, Cs and fs | [79] |

| ✓ | Initial set time: 289 min without CNC and 409 min with 1 g CNC/1 kg cement with superplasticizer and air entrainer | ||||

| Bacterial nanocellulose; Source: derived from cellulose obtained from the aerobic fermentation of bacteria of the genus Gluconacetobacter | 0.05, 0.1, 0.15, and 0.2 wt% of cement | Class G Portland cement | ✓ | Increased Cs at 28 days but decrease Cs at 7 days for 0.15% bacterial nanocellulose-cement samples | [80] |

| CNCs by CelluForce; Production method: sulfuric acid hydrolysis; Width: 6 ± 3 nm; Length: 127 ± 59 nm; Zeta potential: –47.5 ± 2.31 mV at pH = 7.4 | 0.40wt% of cement | Type I/II OPC | ✓ | Max increase in 7 days and 28 days Cs was 9 and 17% at 0.4 wt% CNC, respectively | [76] |

| ✓ | 0.4 wt% CNC increased E by 20% | ||||

| CNCs; Production method: N/A; Width: ∼5 nm; Length: 50–500 nm | 0.15 kg/m3 of concrete | Cement type I | ✓ | Slight improvements in Cs and fs for curing times longer than 28 days | [77] |

CNCs and CNFs, as shown in Figure 1, have distinct physical and chemical properties. For instance, CNCs have a higher degree of crystallinity than CNFs. In addition, CNCs exhibit rod- or whisker-like structures, while CNFs are typically fibrous and include amorphous regions [47].

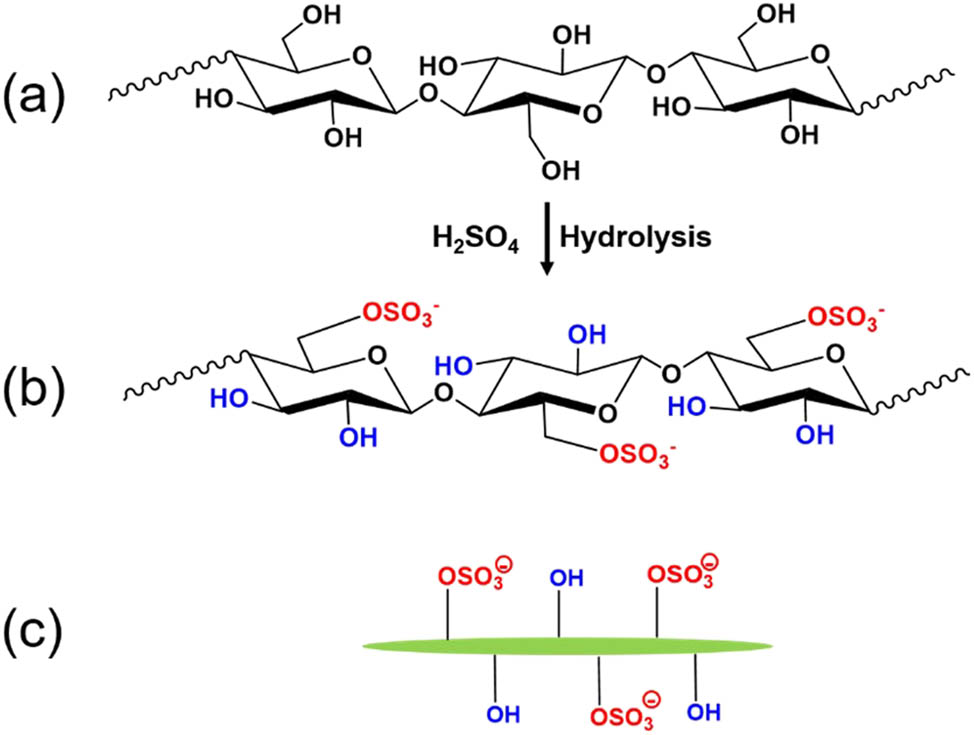

CNCs are usually isolated from semi-crystalline cellulose fibers using a strong sulfuric acid hydrolysis process in which the amorphous region is digested and the crystalline region is intact. Thus, individual crystallites with a little amorphous phase remaining (CNC has high crystallinity of ∼80%) are released with the assistance of mechanical disintegration processes (e.g., ultrasonication), as represented in Figure 2b and c [48]. Sulfuric acid is one of the widely used inorganic acids for the hydrolysis process because of its low cost and its reactivity with the hydroxyl groups on the surface of crystallites; thus, it can introduce anionic sulfate groups. The resulting cellulose nanocrystals are often referred to as sulfated cellulose nanocrystals. These negatively charged sulfate groups play an important role in stabilizing CNCs in water due to interfibrillar electrostatic repulsion forces [48]. Sulfate cellulose nanocrystals are mainly prepared from wood pulp due to abundant resources and low cost. The resulting cellulose nanocrystals exhibited rod-like or spindle-like shapes and have a diameter of 3–5 nm and a length of 50–500 nm [30,48]. Strong acid hydrolysis treatment results in hydrolysis of the glycosidic bonds of cellulose, especially in the amorphous region, thus reducing the DP. It was reported that the DP of cellulose from bleached wood pulp ranges from 140 to 200 [49]. The number of sulfate groups depends on the hydrolysis time and sulfuric acid concentrations. The sulfate content of the resulting sulfated cellulose nanocrystals was about 0.2–0.3 mmol/g CNCs [50,51,52]. Therefore, there are still a certain number of hydroxyl groups co-existing with sulfate groups on the surface of the sulfated cellulose nanocrystals, as shown in Figure 2(b) and (c).

(a) Chemical structure of unmodified cellulose; (b) chemical structure of sulfated cellulose; (c) scheme of rod-shaped sulfated cellulose nanocrystals with hydroxyl and negatively charged sulfate groups on the surface.

3.2 Carboxylated CNFs

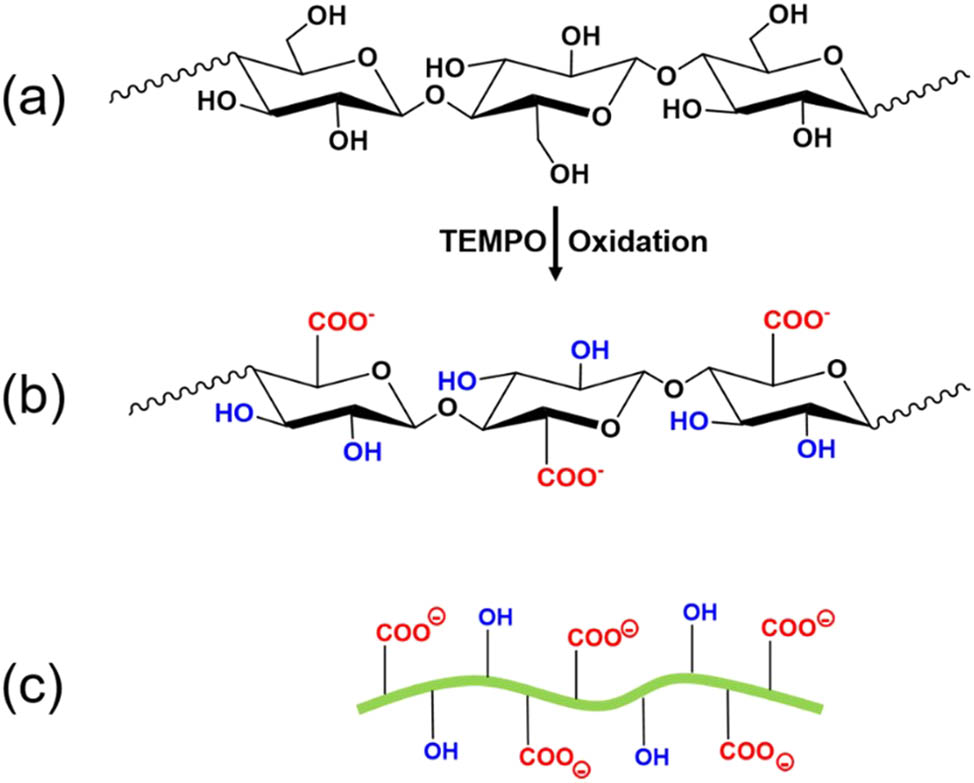

The TEMPO-mediated oxidation is regarded as one of the most effective pretreatment processes of cellulose fibers because it can selectively oxidize primary C-6 hydroxyl groups into anionic carboxylate groups (–COO−) under alkaline conditions [53]. This TEMPO-mediated oxidation reaction occurs on the surface of cellulose fibers and in their amorphous regions. As the carboxylate content increases to a certain amount, cellulose begins to disperse in an aqueous solution [53]. The negative charges can induce interfibrillar electrostatic repulsion forces and thereby facilitate nano-fibrillation in the subsequent mechanical separation process resulting in the production of fine and individualized CNFs with a diameter of 3–4 nm, a length of microns, and an aspect ratio greater than 100 [54,55]. The resulting carboxylated CNFs are often referred to as TEMPO-oxidized CNFs (TOCNFs). Compared to the acid-hydrolyzed cellulose nanocrystals, TOCNFs have much higher shear stress and viscosity due to the relatively higher aspect ratio, higher dispersibility, and fewer bundles in water [53]. The carboxylate content on the cellulose surface is highly dependent on the concentration of the oxidant sodium hypochlorite (NaClO). When the NaClO concentration in the TEMPO-mediated oxidation process increases from 2 to 5 mmol/g-pulp, the carboxylate content increases from 1 mmol/g-CNF to about 1.3 mmol/g-CNF. However, the DP decreases from 1,000 to 520 [55]. As mentioned earlier, TEMPO-mediated oxidation only takes place on the surface of CNFs. In the amorphous region of CNFs, most of the hydroxyl groups on the C2 and C3 remain intact. Thus, there is a high density of hydroxyl groups co-existing with carboxylate groups on the surface of TOCNFs, as shown in Figure 3.

(a) Chemical structure of unmodified cellulose; (b) chemical structure of carboxylated cellulose; (c) scheme of carboxylated CNFs with different groups including hydroxyl and negatively charged carboxylated groups on the surface.

3.3 Mechanically fibrillated CNFs

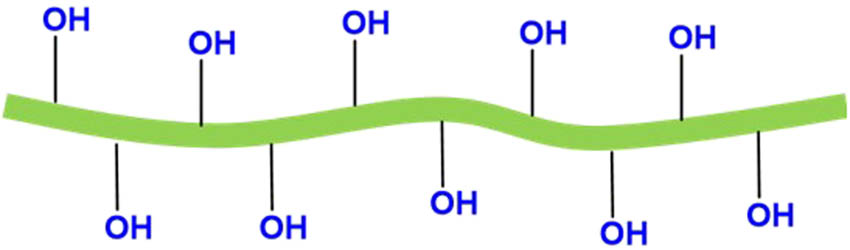

The mechanical fibrillation method does not involve any chemical treatment; it is less effective in de-fibrillation of cellulose fibers into nanofibers than chemical processes (i.e., strong acid hydrolysis and TEMPO-mediated oxidation). However, it may benefit from lower manufacturing costs and no chemical usage to alleviate the environmental burdens compared to the TEMPO-mediated oxidation method for CNFs and the strong sulfuric acid hydrolysis method for CNCs. A friction grinding process is usually applied for the mechanical pretreatment of cellulose fibers [53]. The grinder often consists of two nonporous ceramic grinding discs with adjustable clearance between the upper and lower discs. While the upper grinding disc is static, the lower one is rotated at high speed. The cellulose fiber slurries are subject to massive compression, shearing, and rolling friction forces when fed into a hopper and dispersed by centrifugal forces into the clearance between the two grinding discs. When the shearing forces are applied to the longitudinal fiber axis of the fibrous materials, cellulose fibers are ground into micro- and nanofibers [53]. Due to the complicated, multilayered structure of plant fibers and interfibrillar hydrogen bonding, the resulting mechanically fibrillated CNFs often include aggregated nanofibers with a wide distribution in width [56]. Thus, mechanically fibrillated CNFs are coarser and larger than TOCNFs [53,56]. Mechanically fibrillated CNFs maintain crystalline and amorphous regions of cellulose chains. CNFs are reported to have a diameter smaller than 100 nm and lengths from 500 nm to several microns [57]. The mechanical fibrillation process by grinding discs will result in a decrease in the DP of the resulting CNFs. The number of the pass of dissolved pulp fibers in the grinder (supermass colloider) increased from 0 to 30. The DP decreased from 750 to about 450 [58]. CNFs produced by the mechanical method show relatively simpler surface chemistry as compared to CNFs obtained by the TEMPO-mediated oxidation method. That means that hydroxyl groups were only functional groups on the cellulose surface, as shown in Figure 4. However, it was reported that a negative charge was sometimes found on the surface of mechanically fibrillated CNFs. This is likely due to the presence of carboxylic groups in the glucuronic acid of hemicellulose left from the pulping process [53,59].

Scheme of mechanically fibrillated CNFs.

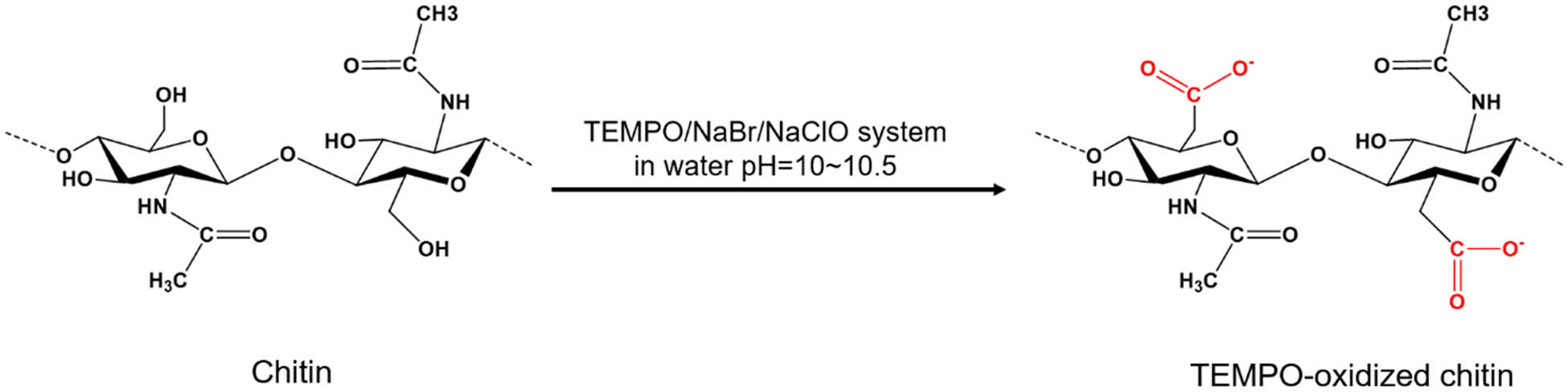

3.4 Carboxylated chitin nanofibers and nanocrystals

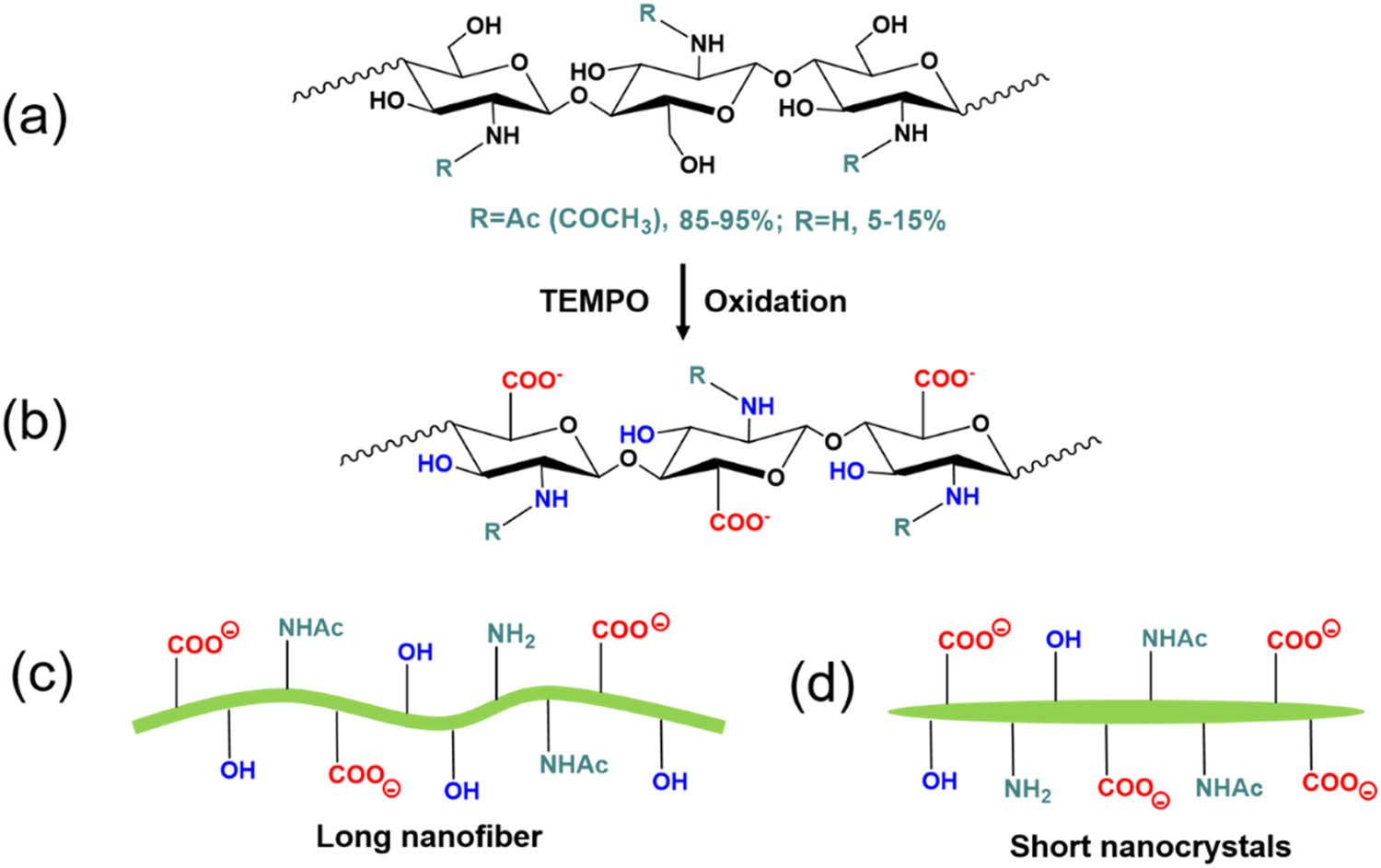

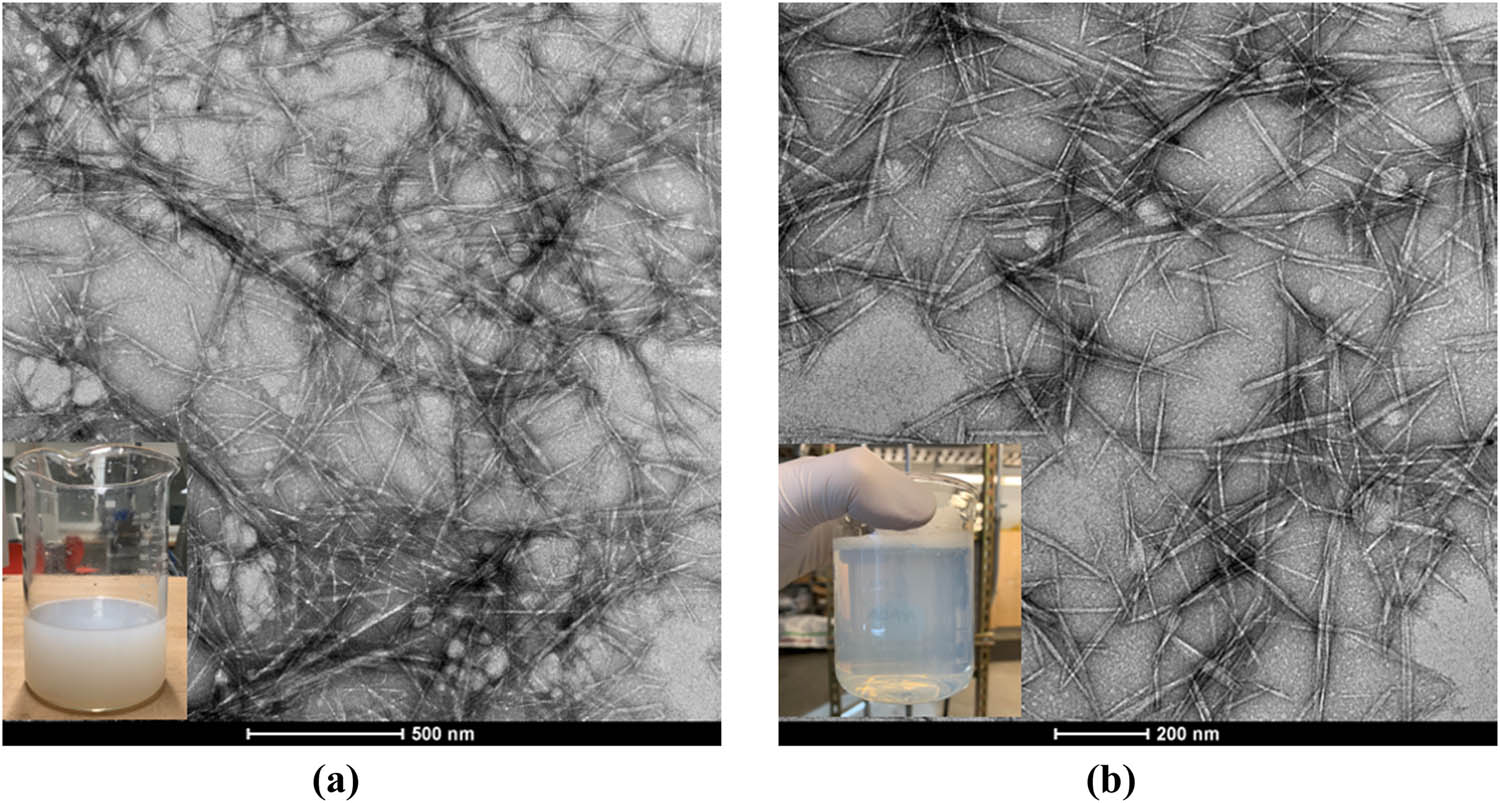

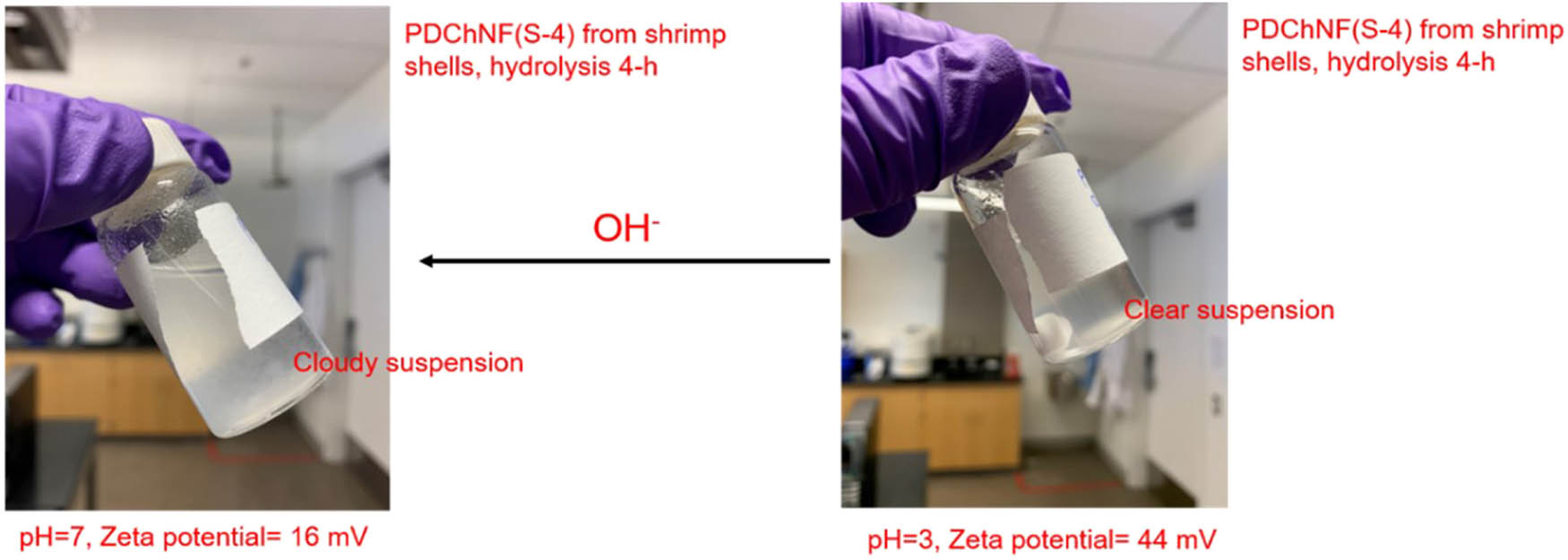

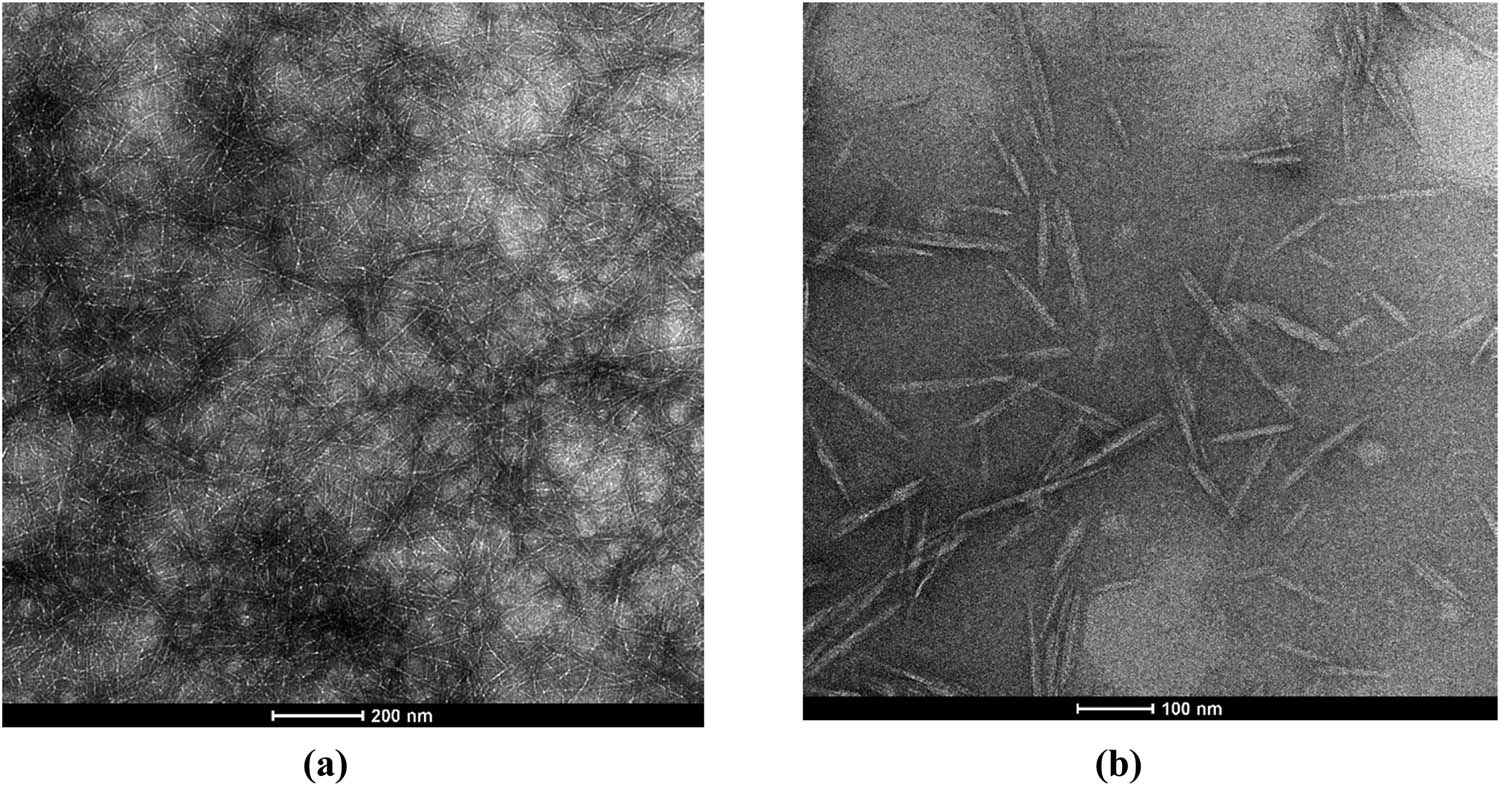

Chitin is a polymer of poly(b-(1–4)-N-acetyl-d-glucosamine), which is structurally similar to cellulose, but has acetamide groups at the C-2 positions, as shown in Figure 5a [60,61]. The degree of acetylation (DA) of chitin is typically around 0.90 with additional 5–15% amino groups due to deacetylation during extraction [62,63]. Due to chemical structural similarity, the extraction methodologies of nanofibers from cellulose are similar to that from chitin. In our current study, the TEMPO-mediated oxidation process has been applied to chitins. During the TEMPO-mediated oxidation process, the primary C-6 hydroxyl groups on the chitin surface or in amorphous regions can be selectively oxidized to carboxylate groups [64]. Most of the TEMPO-oxidized cellulose nanomaterials derived from bleached wood pulp exhibit a length of several microns and an aspect ratio of greater than 100, although the length and DP decreased with the increasing addition of oxidant NaClO in the TEMPO-mediated oxidation process [55,65]. The amount of oxidant NaClO plays a key role in changing the morphology of the chitin nanofibers derived from shrimp shells. We found that when NaClO increased from 3 to 9.5 mmol NaClO/g-chitin, the chitin nanofiber suspensions changed from opaque to transparent suspensions, as shown in Figure 6. The surface chemistry of carboxylated chitin nanofibers or carboxylated chitin nanocrystals is more complex than that of carboxylated CNFs due to the existence and distribution of the acetamido groups or amine groups at the C-2 position, as shown in Figures 5b and 7b. In our experiments, long and aggregated chitin nanofibers were obtained for a low dosage of NaClO, while short and rod-like chitin nanocrystals were obtained for a high dosage of NaClO (as schematically depicted in Figure 6c).

(a) Chemical structure of unmodified chitin; (b) chemical structure of carboxylated chitin; (c) scheme of carboxylated chitin nanofibers with a low degree of oxidation; (d) scheme of carboxylated chitin nanocrystals with a high degree of oxidation.

(a) TEMPO-oxidized chitin nanofibers (3 mmol NaClO/g chitin); (b) TEMPO-oxidized chitin nanocrystals (9.5 mmol NaClO/g chitin).

(a) Chemical structure of unmodified chitin; (b) chemical structure of partially deacetylated chitin; (c) scheme of partially deacetylated chitin nanofibers with protonated amino groups at pH 3–4.

3.5 Partially deacetylated chitin nanofibers

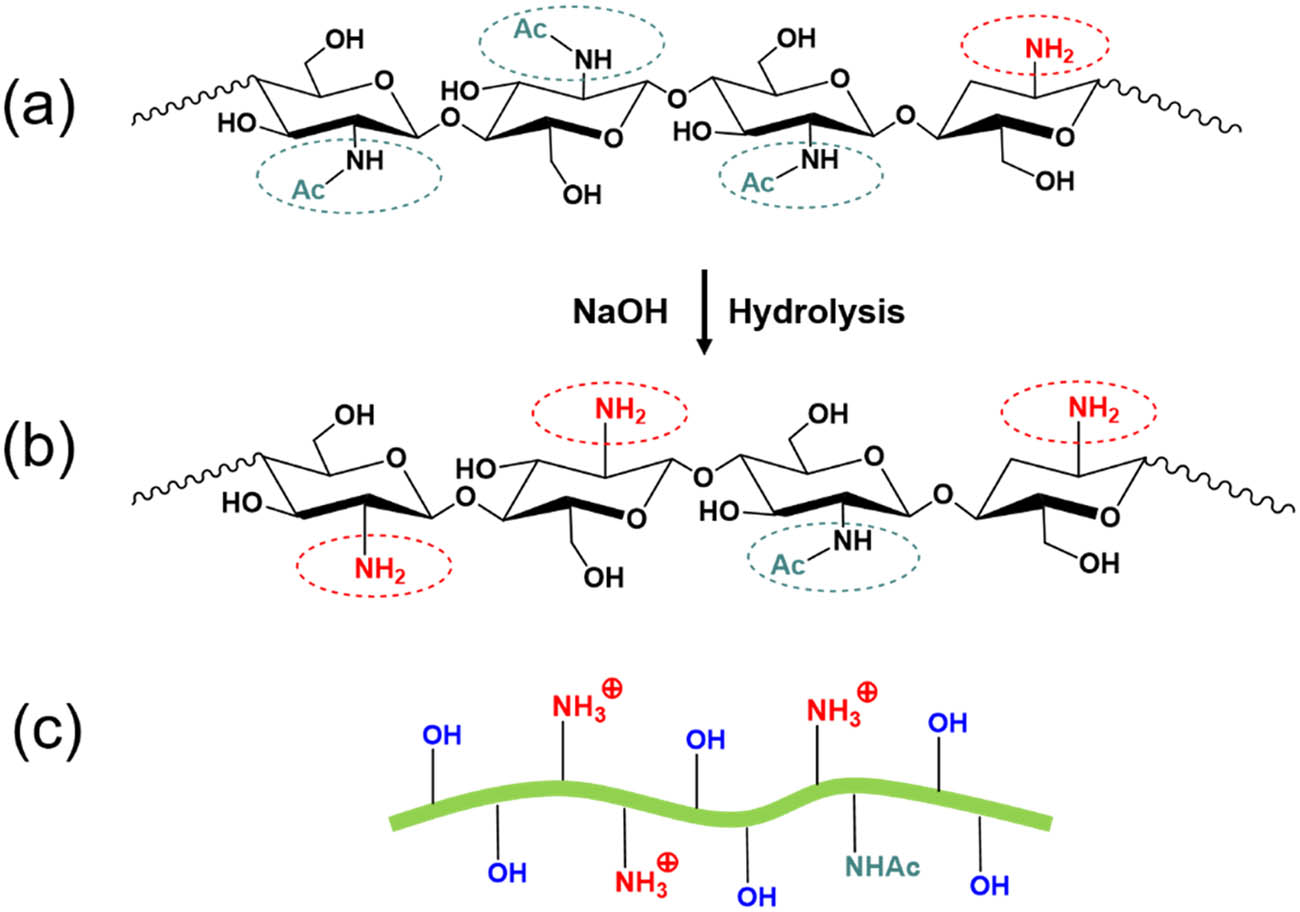

Alkali hydrolysis is a conventional method for producing chitin with positively charged surfaces, as displayed in Figure 7. The variables (e.g., reaction temperature, reaction time, alkali concentration, etc.) during a typical process can be tuned to control the degree of deacetylation to prevent severe degradation of the crystalline structure. Fan et al. [66] reported that α-chitin was partially deacetylated with a degree of N-acetylation (DNAc) around 0.74–0.70 in the presence of 33% sodium hydroxide (90°C for 2–4 h). The yields of the products are around 85–90%. There is no change in the crystallinity index and crystal size of the α-chitin, indicating that most of the deacetylation occurred on the α-chitin crystallite surfaces. After partial alkali deacetylation, acetamido groups in chitin molecules can be converted into amino groups, which can be further protonated under mildly acidic conditions [66], as shown in Figure 7. Positively charged surfaces can facilitate the stable dispersion of chitin nanofibers in acidic water by interfibrillar electrostatic repulsion. It should be noted that pH 3–4 of the dispersing medium was required to ensure protonation of the C2–NH2 groups in partially deacetylated chitin [66]. It is not unclear whether these partially deacetylated chitin nanofibers can be used in alkali cement systems since the pH of pore solution for cement is often 12 or higher. In such alkaline conditions, the C2–NH2 groups in the deacetylated chitin nanofibers may not change; however, the surface charge of chitin nanofibers will drop significantly, which ultimately can lead to the agglomeration of the chitin nanofibers.

3.6 Mechanically fibrillated chitin nanofibers

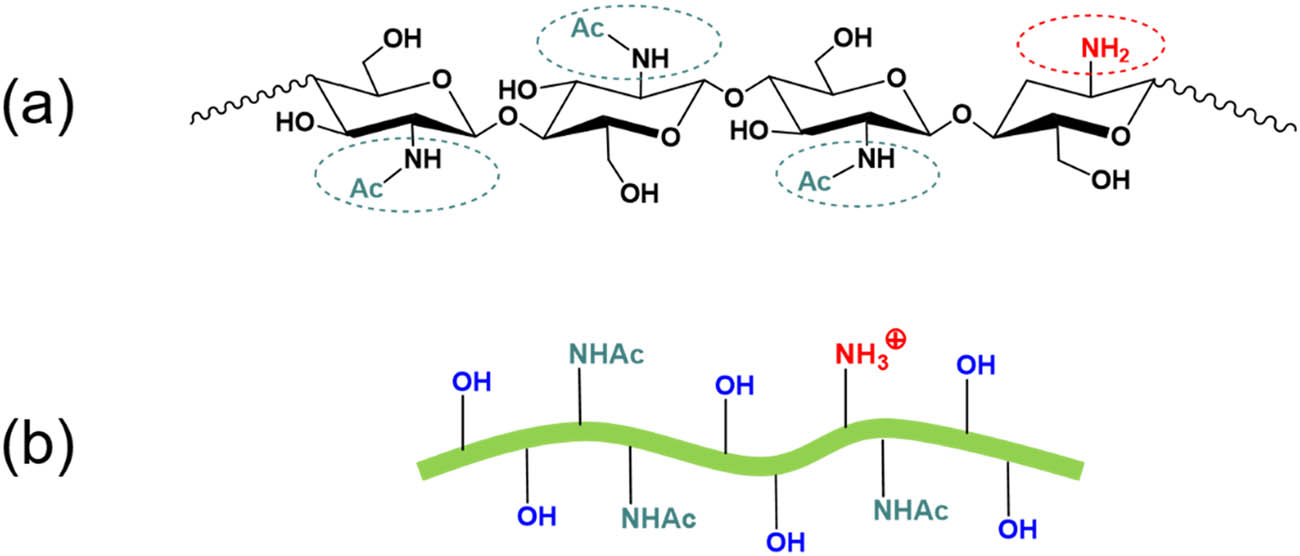

The fully mechanical fibrillation process using grinding discs has been applied to generate nanofibers without changing the chemical structure of chitin. However, the density of hydroxyl groups and amine groups are increased due to the significant increase in the surface areas of chitin nanofibers after ultra-fine grinding. As shown in Figure 8b, the amino groups within mechanically fibrillated chitin nanofibers can be protonated with the addition of acid at a pH of 3–4. This process makes chitin nanofibers positively charged in an acidic aqueous medium. There is no doubt that the positive surface charges of mechanically fibrillated chitin nanofibers are lower than those of partially deacetylated chitin nanofibers because partial deacetylation via NaOH hydrolysis yields more amino groups (–NH2). In our previous research [67], we successfully produced mechanically fibrillated chitin nanofibers with an average diameter of 12 nm using planetary ball milling as pretreatment and further high-pressure homogenization. These mechanically fibrillated chitin nanofibers also exhibited a positive charge in solution, as evidenced by the zeta potential of about 39 mV at a pH of 3.

(a) Chemical structure of unmodified chitin; (b) scheme of mechanically fibrillated CNFs with protonated amino groups at pH 3–4.

3.7 Starch and starch derivatives

Amylose and amylopectin are the two main components of starch. Starch has a similar structure to cellulose and chitin. Natural starch consists of 10–30% amylose and 70–90% amylopectin. Amylose is a linear polysaccharide with d-glucose units and the α-1,4-glycosidic linkages. Amylopectin is a branched-chain polysaccharide with glucose units linked primarily by α-1,4-glycosidic bonds or occasionally by α-1,6-glycosidic bonds, which are responsible for the branching. Amylose is similar to cellulose, but glucose units in cellulose are joined by β-1,4-glycosidic linkages, producing a more extended structure than amylose. This high linearity allows multiple hydrogen bonding formations between hydroxyl (–OH) groups which helps dense packing of nanofibers.

There are several publications describing the use of starch in cement [28,68,69,70,71,72]. Dewacker [28] used unmodified starch as a substitute for cellulose to increase water retention in cement and found adding low-cost starch is beneficial for water retention, rheology improvement, and shear bond strength increase. Peschard et al. [69] found the retardation effect was enhanced with the increase in starch-to-cement ratio. This is particularly true for low molecular weight starch. In their study, five admixtures were chosen to add to conventional cement, including cellulose ether (CE), starch ether (SE), native starch (NS), white dextrin (WD), and yellow dextrin (YD). WD and YD are obtained by dextrinization (break down of starch into dextrin’s) of NS by heat and acid treatment. They found that the cement setting was retarded by measuring a reduction in the heat flow of hydration of admixture-modified cement compared to unmodified cement. For cement with YD, the heat of hydration in the first 24 h was reduced from 99 J/g (plain cement) to 9 J/g. Infrared spectroscopy also demonstrated that C–S–H was formed in the first 8 h of hydration for cement modified with CE, while no C–S–H was identified after 8 hs in SE- and YD-modified cement. Vieira et al. [70] investigated the dispersing effect of anionic starch and cellulose on mortar. The starch was processed with a sulfoethylation or a sulfation process. Slump and mortar spread tests showed that sulfoethylation starch (SES) derivatives and starch sulfate (SS) derivatives perform better as dispersants than commercial polycarboxylate (PCE) ethers. The results were explained by the fact that commercial PCE ether has a lower charge density. In addition, due to their high retardation effect, the 24 h compressive strength (Cs) of SES- and SS-modified concrete was only a fraction (0.15 and 0.13 MPa) of that of commercial Glenium 51- and Melment SL-modified cement (26.6 MPa and 27.7 MPa, respectively).

Zhang et al. [71] studied the effect of starch sulfonate as a water-reducing additive. The fluidity of cement paste significantly increases, particularly with low doses of starch sulfonate compared to commercial product naphthalene sulfonated formaldehyde condensates (FDN). According to the authors, this effect is from the thickness of the adsorption layer of the SS (∼5.3 nm) on the cement particle surface being larger than FDN (0.58 nm). Patural et al. [68] studied seven SEs, including four types of hydroxypropyl starch derivatives and two carboxymethyl-hydroxypropyl derivatives, showing an increase in consistency coefficient and a decrease in water retention values. In Tables 1–3, fs stands for the flexural strength, and Cs is the compressive strength. The letter d is the abbreviation of day. E is Young’s modulus.

Chitin, chitosan, starch, and their derivatives reinforced cementitious materials

| PNM type/source/production/size | Dosage of chitin, chitosan, starch and their derivatives | Cementitious material | Effects on mechanical properties | Ref. | |

|---|---|---|---|---|---|

| Hemicellulose, sulfopropylate, starch sulfopropylate, water-soluble starch sulfoethylate | 0.8–1.3 wt% of cement | ASTM specifications C270 and C125 | ✓ | Increased Cs from 2.7 to 6.9 MPa | [81] |

| A mixture of cold-water-soluble (>90 wt%), unmodified starch and a cellulose | 0.25–0.5 wt% of mortar | Portland type 1 cement | ✓ | N/A | [28] |

| New polysaccharide derivative (NPD) which has a cellulose principal chain and two functional groups (ionic and hydrophobic) | 1–4 wt% of cement | Normal Portland cement | ✓ | Shear stress increased from 28 to 174.5 Pa/s | [82] |

| ✓ | Increased the viscosity significantly with a small amount NPD | ||||

| ✓ | Caused less setting retardation than conventional viscosity agents | ||||

| ✓ | Initial setting is 9 h 33 min for 0.03% NPD, while 12 h 21 min for 0.06% hydroxyethyl cellulose | ||||

| Phosphorylated chitin; M w = 2.6–3.9 ×104 Da | 0–14 wt% of cement | Monocalcium phosphate monohydrate and calcium oxide (CaO) or dicalcium phosphate dihydrate and calcium hydroxide [Ca(OH)2] | ✓ | Increased Cs | [83] |

| ✓ | Retarded setting time from 7 up to 60 min | ||||

| NS, WD, and YD; M w = 85,000–25,200,000 Da | 0.5 wt% of cement | White Portland cement (C1), CPA CEM I 52.5, and gray cement (C2), PMES 42.5 | ✓ | Retarding ability is: NS < WD < YD | [69] |

| Sulfoethylation of starch, sulfation of starch, carboxymethylation of limit-dextrin, carboxymethylation of LODP-cellulose, hydroxyethylation, and subsequent carboxymethylation of cellulose; Degree of polymerization (DPw): 56–2,600, which is calculated from the molecular weight M w, of the peracetylated limit-dextrins | 0.9–20 wt% solution | Kiefersfelden 42.5R | ✓ | N/A | [70] |

| Five hydroxypropylmethyl cellulose (HPMC) and four hydroxyethylmethyl cellulose (HEMC); M w = 210 k–1,010 kDa | 0.27 wt% of dry mix | CEM I-52.5R | ✓ | Molecular weight and the hydroxypropyl content seem to have a lower impact on admixed cement hydration process | [84] |

| Chitin and chitosan were used as additives with protein, aliphatic polyester, a poly(lactide), a poly(glycolide), a poly(e-caprolactone), a poly(hydroxy butyrate), a poly(anhydride), an aliphatic polycarbonate, an orthoester, a poly(orthoesters), a poly(amino acid), a poly(ethylene oxide), or a polyphosphazene; Sizes: microcapsules (several microns to tens of microns) | N/A | N/A | ✓ | N/A | [85] |

| SS using corn starch with 83% amylopectin | 0–3% in water | OPC 32.5R | ✓ | Cement paste with SS can reach maximal fluidity at a lower adsorption amount (5 mg/g) | [71] |

| Chitosans with different molecular weights [low molecular weight (LMW), 50–190 kDa; medium molecular weight (MMW), 190–310 kDa; and high molecular weight (HMW), 310–375 kDa, and different deacetylation degrees (92, 80, and 76%, respectively) | 0.1 wt% of dried mortar | OPC (CEM II 32.5N) | ✓ | Increased viscosity in fresh mortars while retaining more water than plain cement | [86] |

| ✓ | HMW chitosan is the polymer with the greatest retarding ability for heavy metals | ||||

| Three panels of HEMC (named as C and TV), two panels of HPMC (named as J and P), two panels of hydroxyethyl cellulose (HEC, named as H and N). M w (HEMC) = 90–410 kDa; M w (HPMC) = 225–910 kDa; M w (HEC) = 40–2,900 kDa | 0.27 wt% of dry mix | Portland cement CEM I 52.5R | ✓ | Decreased yield stress as HEMC molecular weight increased | [68] |

| ✓ | Increased consistency coefficient and water retention with higher HEMC, HEC, and HPMC molecular weight | ||||

| Chitosan powder | N/A | Class A special for oil well cementation | ✓ | Epoxy/chitosan-modified cement slurry for use in environmental-friendly acidizing procedures of oil wells | [88] |

| Two non-ionic chitosan derivatives (hydroxypropyl and hydroxyethyl chitosans) and one ionic derivative (carboxymethylchitosan, CMCH); CMCH with sizes of tens of microns; Negative values of zeta-potential of CMCH | 0–0.5 wt% of cement | OPC (CEM II 32.5N) | ✓ | Non-ionic derivatives had a weak dosage-related influence on the fresh-state properties | [87] |

| ✓ | Ionic CMCH showed a more marked effect: acted as a powerful thickener and reduced the workable life of the fresh mixtures, whereas it caused a delay in the hydration of cement. CMCH reduced the slump by 50% | ||||

| Carboxylated, sulfonated polysaccharide with molecular weight from about 500–1,000,000 Da, and a ratio of carboxylate functionalities to sulfonate functionalities from about 0.1–4 | 0.1–4 wt% of cement | Class H cement | ✓ | N/A | [89] |

| Commercial chitosan powder (84% of deacetylation degree) | A/F-chitosan aqueous suspension (5 wt% of cement) | Class G cement | ✓ | Significantly improved chemical stability of cement slurries in the presence of acidizing fluids | [90] |

| Water-soluble oligochitosan (CO). M w = 30,183 Da | 0.4 wt% of cement | OPC, Shengwei 42.5R and Jidong 42.5 | ✓ | Increased Cs | [91] |

| ✓ | Strong retarding effect on cement hydration | ||||

| ✓ | Max water-reducing ratio was 43% | ||||

| A PCE-based superplasticizer (SP) and three types of polysaccharide-based viscosity modifying agent (VMA) | 0–0.025 wt% of binder (cement + fly ash) | Normal Portland cement (CEM I 42.5N, EN 197) | ✓ | The 7 days C s decreased from 40 MPa to as low as 22 MPa and 28 days C s decreased from 50 MPa to as low as 32 MPa | [92] |

| ✓ | The addition of VMAs reduced the segregation tendency for all concrete mixtures tested | ||||

| Chitosans with different molecular weights (LMW, 8–15 kDa; and HMW, 150–200 kDa) and 90–92% deacetylation degree; commercial products from the Naijin industry (Shanghai, China) | 0.25, 0.5, and 1 wt% of the cement weight | Class G OWC | ✓ | LMW and HMW chitosan reduced fs of cement paste | [93] |

| ✓ | Chitosan has retarding effect. However, after pre-chelating, retarding effect of chitosan will become weaker | ||||

| Chitosan with a size of 74–297 microns | 0.1– 4 wt% of cement | N/A | ✓ | Retarded setting time significantly | [94] |

| Processing chitin with a 40–49% sodium hydroxide aqueous solution under the temperature of 110–140°C for 4–6 h | 0.2–2 wt% of cement | N/A | ✓ | No obvious change in Cs | [95] |

| Modified LMW chitin polymer | 0–0.6% in water | PII 52.5 cement | ✓ | Increased Cs from 20 MPa using 0.6% CG-M-chitin | [96] |

| ✓ | Used as SP, reduced the water significantly with the same slump | ||||

| Modification of chitosan with methacrylic anhydride and crosslinked to ChiMOD hydrogels | 0.5, 1, and 2 wt% of cement | OPC (CEM I 52.5N) | ✓ | 0.5 and 2 wt% of chiMOD hydrogels decreased fs by 9.6 and 16.7%, and Cs decreased by 17 and 22%, respectively | [97] |

| Oxidation (carboxylic acid converted to hydroxyls) via TEMPO of chitin nanocrystal derivatives and hydrocarbon chitin nanocrystal derivatives and combinations thereof. Amine functional groups are substituted by amide groups. Chitin deacetylation followed by amine functionalities and by acylation; Length: 5–50 nm | 1–25 wt% in dry cement | N/A | ✓ | Hydrocarbon chitin nanocrystal derivative serves as a rheology modifier, emulsion stabilizer, and fluid loss additive | [98] |

| Chitosan-g-POEGMA (Chitosan-g-poly[oligo (ethyleneglycol) methyl ether methacrylate]) graft copolymers | N/A | CEM I 42.5R | ✓ | 28 days Cs is determined as 30 MPa for the reference concrete, 35 MPa for sulphonated graft, and 34 MPa for sulfonated chitosan within the reference concrete series | [99] |

| ✓ | Maintained better consistencies than those with chemical admixtures during 45 min (sulfonated graft and chitosan) | ||||

| LMW chitosan polymer | Polylactic acid M w = 6,000–8,000 Da, used as alkali silicic acid inhibitor | N/A | ✓ | Increased Cs and reduced fs | [100] |

| Chitin-acrylic acid copolymerized multifunctional organic anti-dispersant; M w: 2,170,000–2,480,000 Da | 0.5–2.0% in water | N/A | ✓ | Cs decreases but with better anti-dispersion behavior | [101] |

| Commercially available chitosan with a low M w (number-average M w = 529, weight-average M w = 722) | 0–0.9 wt% of the paste | γ-C2S | ✓ | Cs and fs increased by 66% and 299% at 0.6% chitosan content, respectively | [102] |

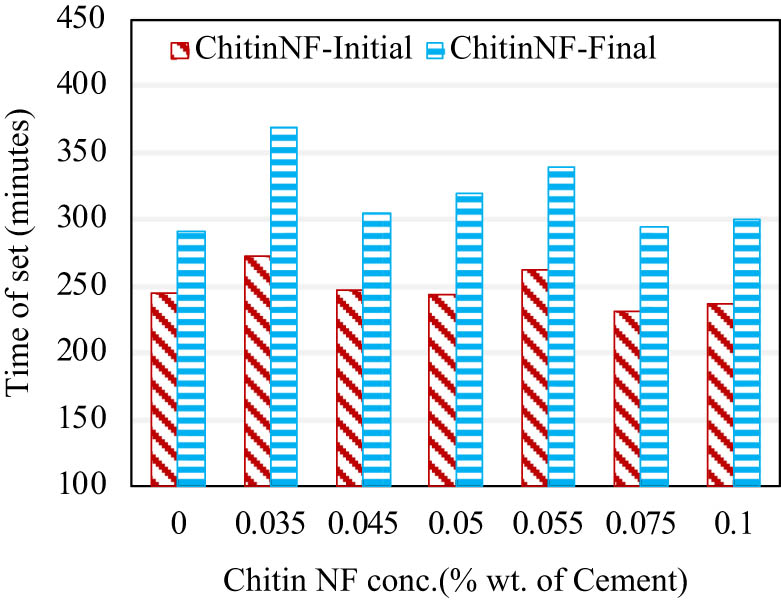

| Chitin nanofibers and chitin nanocrystals; Source: chitin from shrimp shells; Production method: TEMPO-oxidation and mechanical fibrillation chitin nanofibers width: 16 ± 10 nm, length: 1,068 ± 765 nm | 0.035–0.1 wt% of cement | Type I/II OPC | ✓ | Chitin nanofibers significantly increased the 28 days fs by approximately 40% at optimum concentrations of 0.05 wt% | [103] |

| ✓ | Chitin nanocrystals delayed initial and final set times by up to 56 and 106 min, respectively, which are greater than the delays of 35 and 78 min by chitin nanofibers | ||||

| ✓ | Chitin nanofibers increased the viscosity and yield stress of fresh cement paste, but chitin nanocrystals did not impart a notable effect on rheological properties | ||||

4 Overview of cement hydration and cement hydration products

Cement hydration is a complex reaction process during which multiple phases are formed. PNMs can disperse in the cement slurry system, adsorb on the cement particles and to each other depending on surface charges, create additional nucleation sites for reaction products growth, affect the kinetics of hydration reactions and accelerate or decelerate on various stages of hydration. Therefore, incorporation of PNMs in cementitious systems depends on the composition and nature of the cement and in determining the ultimate performance of the PNM–cementitious material. Thus, it is important to understand the main factors that influence cement hydration kinetics, cementitious systems’ structures, and the properties of cementitious materials. This section provides a brief discussion of cement in terms of composition, cement hydration, pore structure, etc., to help understand the potential interaction of PNMs and cement in the following sections.

4.1 Hydration of clinker

A typical OPC clinker has a composition of 67% CaO, 22% SiO2, 5% A12O3, 3% Fe2O3, and 3% other components, and normally contains 4 major phases, alite (tricalcium silicate: C3S), belite (dicalcium silicate: C2S), aluminate (tricalcium aluminate: C3A), and ferrite (tetracalcium aluminoferrite: C4AF). Several other phases, such as alkalis, sulfates, and calcium oxide, are usually present in trace amounts. The hardening of cement results from reactions between the major clinker phases and water. When the cement is mixed with water, various ions are released such as Ca2+,

Initial hydration (minutes): the dissolution of mainly aluminum-rich clinker phases and precipitation of calcium aluminate sulfate hydrates.

Dormant period (minutes to several hours): hydration rates decrease significantly.

Main hydration (hours to days): acceleration of dissolution of dominated silicate-rich phases and precipitation of calcium silicate hydrates and calcium hydroxide lead to setting and early strength development.

Continuous hydration (days to years): further strength development.

C3S is the primary component of Portland cement, controlling hardening and strength development and the durability of cementitious materials [105]. As a result, C–S–H, which mainly results from C3S hydration, is the primary hydration product (comprising about 50–70 wt% by mass) and binding phases in hydrated Portland cement [106]. The growth and densification may be highly affected by the dissolution and diffusion of C3S [107]. C2S is another component that contributes to the C–S–H hydration products [108].

Despite decades of studies of C–S–H, the relationship between its chemical position and structure remains not fully understood due to its complex structure [109,110]. It is widely reported that C–S–H has layered calcium-silicate crystal structures with linear silicate-“dreierketten” and different amounts of bound water [110]. Once the calcium-to-silicate (C/S) ratio is described correctly, a number of characteristic structural features and physical properties can be correlated through atomistic simulations [109]. Therefore, the C/S ratio plays a critical role in constructing the chemical structure of C–S–H. There are two widely agreed molecular models for C–S–H gel depending on the C/S ratio: (1) 14 Å tobermorite (C/S ratio = 0.83, interlayer distance 14

![Figure 9

Schematic molecular model of 14 Å tobermorite, reprinted with permission from ref. [111]; Copyright 2020, MDPI.](/document/doi/10.1515/ntrev-2022-0149/asset/graphic/j_ntrev-2022-0149_fig_009.jpg)

Schematic molecular model of 14 Å tobermorite, reprinted with permission from ref. [111]; Copyright 2020, MDPI.

4.2 Hydration products and pore structure

Cementitious materials are complex multi-component inorganics with multiscale pore systems. The multiphase microstructure of the hydration products in cement mixtures consists primarily of C–S–H, calcium hydroxide (Ca(OH)2), and a porous phase [78]. The formation of the major hydration product C–S–H often induces a significant volume of internal and nanometer-scale pores, such as small capillary pores and gel pores, as schematically shown in Figure 10 [112]. When dry Portland cement powder mixes with water, hydration reactions are initiated and produce solid hydration products with a greater volume than the initial dry solids. As the hydration continues, the water-filled space is gradually replaced with solids during the reaction. Space not filled by solid hydration products is referred to as the capillary pore space [113]. It has been found that the primary C–S–H gel particles have a lamellar or sheet-like shape with a thickness of 5 nm and up to 60 nm in width, which is confirmed by transmission electron microscopy (TEM) and atomic force microscopy (AFM) [114,115]. The gel pores are specifically associated with the C–S–H gel phase, the primary hydration product of all Portland cement-based cementitious materials [112].

![Figure 10

Schematic of particles of C–S–H, referred to as globules or bricks, reprinted with permission from ref. [112]; Copyright 2018, Japan Concrete Institute. They are about 4 nm across and have a layered structure with interlayer space and small pores imperfectly aligned. Their packing arrangement is such that the pores tend to have specific sizes and overall packing efficiency.](/document/doi/10.1515/ntrev-2022-0149/asset/graphic/j_ntrev-2022-0149_fig_010.jpg)

Schematic of particles of C–S–H, referred to as globules or bricks, reprinted with permission from ref. [112]; Copyright 2018, Japan Concrete Institute. They are about 4 nm across and have a layered structure with interlayer space and small pores imperfectly aligned. Their packing arrangement is such that the pores tend to have specific sizes and overall packing efficiency.

The nanostructure of cement paste, particularly its nanometer-scale pore system, primarily controls important bulk properties, including strength, shrinkage, creep, permeability, and durability [116]. Particularly, the mechanical properties of the cementitious matrices are influenced by the volume, size, and morphology of pores. High-performance cement requires the capillary porosity to be low [112] because connected pores will allow water to enter the matrix to dissolve hydration products, mainly Ca(OH)2, thus leading to poor durability [117].

In general, there are two distinct C–S–H hydration regions depending on the volume fraction of gel pores and different modulus in the matrix: (1) low-density (LD) C–S–H and (2) high-density (HD) C–S–H [117]. The first one has a low packing fraction, and the latter has a high packing fraction of nanoscale solid C–S–H particles, as shown in Figure 11, which can be distinguished by a nanoindentation tool [119]. The densities of different C–S–H phases can be determined by nitrogen penetration tests. HD C–S–H is made up of densely packed particles into which nitrogen cannot penetrate. On the other hand, particles of LD C–S–H are not packed tightly, and nitrogen can penetrate partially into this structure, as shown in Figure 11 [118].

![Figure 11

(a) 2D schematic of LD C–S–H formed by the late-stage and/or by drying and (b) 2D schematic of HD C–S–H, the predominant type of C–S–H that forms during the late-stage at water/cement ratio = 0.4, reprinted with permission from ref. [118]; Copyright 2000, Elsevier Ltd.](/document/doi/10.1515/ntrev-2022-0149/asset/graphic/j_ntrev-2022-0149_fig_011.jpg)

(a) 2D schematic of LD C–S–H formed by the late-stage and/or by drying and (b) 2D schematic of HD C–S–H, the predominant type of C–S–H that forms during the late-stage at water/cement ratio = 0.4, reprinted with permission from ref. [118]; Copyright 2000, Elsevier Ltd.

Four main factors might govern the structural changes in C–S–H hydration products:

dissolution and growth of mineral phases,

diffusion of mobile species in solution,

complexation reactions among species in solution or at solid surfaces, and

nucleation of new phases [112].

5 Surface interactions of PNMs with cement

Tricalcium silicate dissolves rapidly in water to release calcium ions (Ca2+), silicon ions

As discussed previously, the C/S ratio plays a crucial role in the chemical structure of C–S–H, and its phase composition and densification may also be affected by the diffusion of calcium ions. Calcium ions have coordination capacity with oxygen atoms of oxygen-containing functional groups and can be attached to negatively charged polymers via electrostatic interaction, as shown in Figure 12 [120,121]. The chemical reactivity and the electrophilic attack of those functional groups decrease in the following order as phosphate > carboxylate > sulfate > hydroxyl [121]. The binding strength of Ca2+ with different functional groups decreases in the order of phosphate > carboxylate > sulfate (sulfonate) > hydroxyl because the Ca–O distance (bond length) of the complex of the phosphate is the shortest which ranges from 2.28 to 2.31 Å. The second shortest is the complex of the carboxylate, around 2.38 Å, which is shorter than that of the complex of sulfate, about 2.42 Å [121,122].

![Figure 12

The complexes of three monomers (carboxylate, sulfonate, and phosphate) with Ca2+, reprinted with permission from ref. [121]; Copyright 2019, Elsevier Ltd.](/document/doi/10.1515/ntrev-2022-0149/asset/graphic/j_ntrev-2022-0149_fig_012.jpg)

The complexes of three monomers (carboxylate, sulfonate, and phosphate) with Ca2+, reprinted with permission from ref. [121]; Copyright 2019, Elsevier Ltd.

Due to the lack of experimental data and analysis in the literature, it is not well understood about interfacial interaction between PNMs and cement and their influences on the performances of hardened cement composites. The discussion below is mainly based on studies on the interaction between the cement and superplasticizer polymers because superplasticizers contain similar ionic functional groups, particularly sulfate (sulfonate) groups and carboxylate groups similar to those on the surface of polysaccharide nanofibers. It is envisioned that the potential interaction between PNMs and cement may be largely linked to the interfacial interaction of ionic functional groups (anionic sulfate, sulfonate, and carboxylate groups) on the surface of PNMs with the metal cations in the pore solution and cationic compounds.

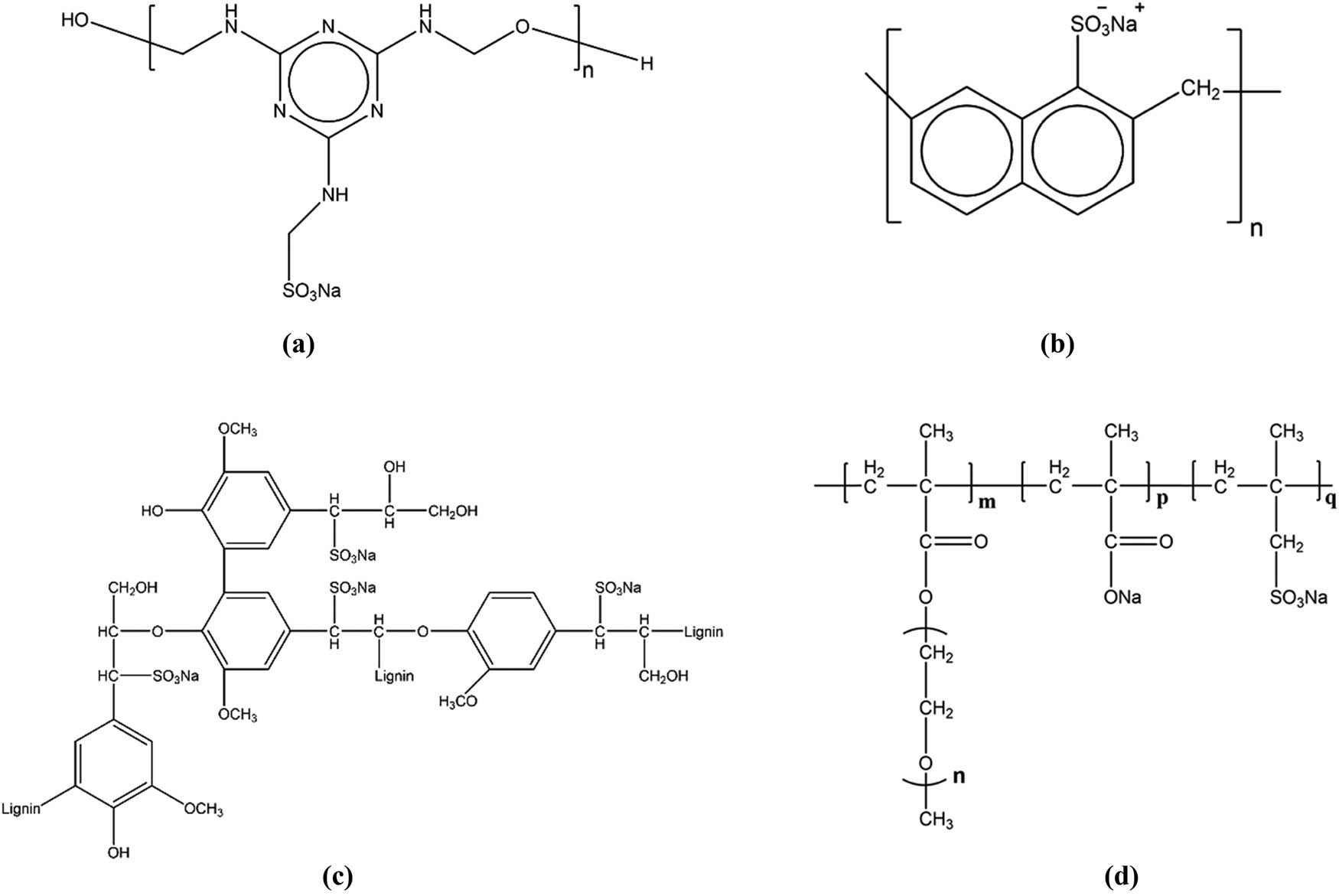

One of the main functions of superplasticizers is to disperse cement particles. Traditional superplasticizers usually have anionic functional groups, particularly carboxylate and sulfate (sulfonate) groups which can induce the negative charge [123]. Commonly used superplasticizers include sulfonated melamine-formaldehyde condensates, sulfonated naphthalene-formaldehyde condensates, modified lignosulfonates, and PCE derivatives [124,125,126,127], as illustrated in Figure 13.

General structure of (a) sulfonated melamine formaldehyde polycondensates; (b) chemical structure of sulfonated naphthalene-formaldehyde condensates; (c) schematic drawing of the main building blocks of the lignosulfonate molecule; and (d) chemical structure of the polycarboxylate copolymer.

It is widely accepted that superplasticizers change the dispersion properties of cement through steric hindrance effect and electrostatic repulsion effect [91,123,128,129]. Figure 14 shows a typical structure of a sulfated chitosan superplasticizer. Lv et al. [130] proposed the adsorption mechanism of sulfated chitosan superplasticizer (SCS) on cement particles. SCS macromolecules adsorb on cement particle surface by the interaction between various functional groups (

![Figure 14

Schematic diagram of the absorption mechanism of SCS on cement particles surface, reprinted with permission from ref. [130]; Copyright 2013, The American Ceramic Society.](/document/doi/10.1515/ntrev-2022-0149/asset/graphic/j_ntrev-2022-0149_fig_014.jpg)

Schematic diagram of the absorption mechanism of SCS on cement particles surface, reprinted with permission from ref. [130]; Copyright 2013, The American Ceramic Society.

As discussed earlier, the TEMPO-mediated oxidation method is one of the most widely used and also simplest methods to produce carboxylated chitin and cellulose nanomaterials with high yield and crystallinity [64]. While there is no information on the chemical interactions between carboxylated chitin and cellulose nanomaterials and cement, we will refer to research on carboxylate-modified CNTs [131].

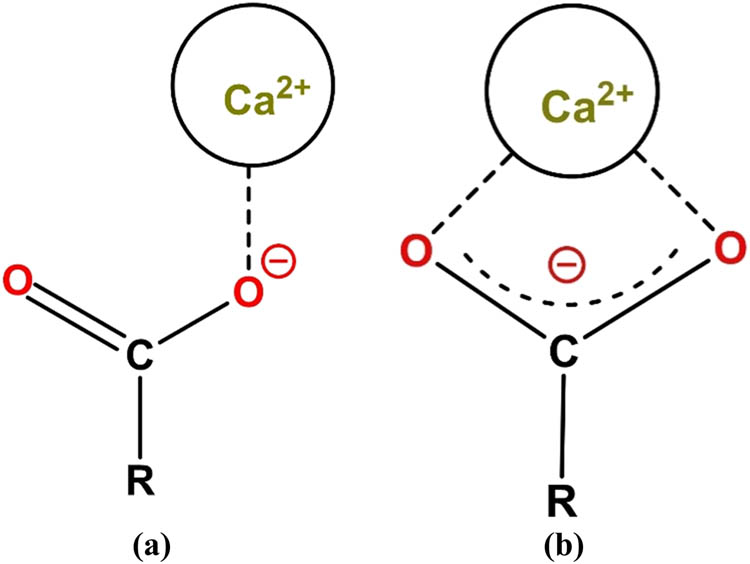

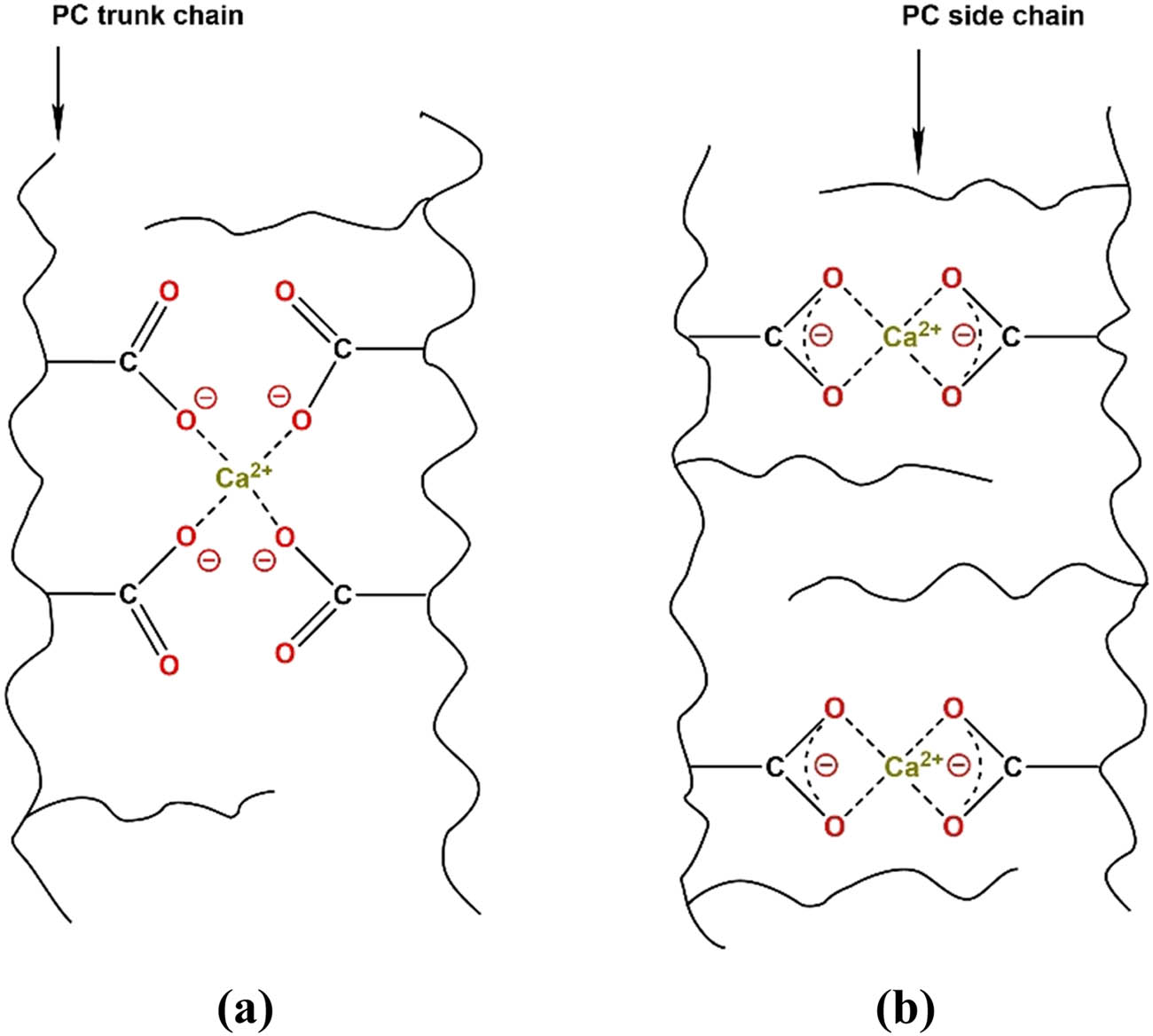

Within an acidic solution with a pH of ∼2, carboxylate groups are in carboxylic acid form (–COOH). In contrast, within a highly alkaline cement pore solution, carboxylate groups can be fully deprotonated and become negatively charged [125]. In general, the density of negative charges for PCE polymers varies depending on the pH in the pore solution and the molecular structure. The density of negative charges can vary from 20 to 110% when the pH change from 7 to 12.6 [125]. In general, as schematically depicted in Figure 15, there are two forms of coordination bonding between carboxylate groups with Ca2+ [125]. As for a monodentate form, Ca2+ coordinates with only one oxygen atom of the –COO− groups in an end-on configuration. In this way, –COO− is a monodentate ligand for Ca2+. As for a bidentate form, Ca2+ is bound to both oxygen atoms of a –COO− functionality in a side-on configuration. So –COO− is a bidentate ligand for Ca2+.

Schematic illustration of two types of coordination between Ca2+ and –COO − groups: –COO − as a (a) monodentate; or (b) bidentate ligand.

The type of coordination between –COO− groups and Ca2+ depend on the steric accessibility of the carboxylate groups. As shown in Figure 16, for PCE molecules with high side chain density, the carboxylate groups will be shielded by the side chains and the bidentate ligand for Ca2+ will be the major coordination type. By contrast, in the PCE molecules containing a high amount of (–COO−), Ca2+ will be coordinated as monodentate [125]. When compared with carboxylate (–COO−) functionality, the individual metal-oxygen interactions with the sulfonate group are weaker when employed with metal cations. Organosulfonates

Schematic illustration of (a) monodentate complexation of Ca2+ by two polycarboxylate (PC) trunk chains with low side chain density; and (b) bidentate complexation of Ca2+ by two PC trunk chains with high side chain density.

Chitosan, a major chitin derivative obtained on an industrial scale by strong alkaline deacetylation, has been used as a chelating agent to remove metal ions in solution because metal cations can be chelated with amino groups (–NH2) in near-neutral solutions [134]. The amino groups are strongly reactive with metal ions, which is mainly due to the nitrogen atoms of the amino groups (–NH2) holding free-electron doublets that can react with metal cations [134]. It was reported that amino groups on chitosan have a good affinity for transition metal ions (Zn2+, Cu2+, and Ag+) by chelation mechanisms through the “bridge model” (a transition metal ion is coordinated with four nitrogen atoms of intra- and inter-chitosan chains) or “pendant model” (a transition metal ion is attached to an amino group of the chitosan chain like a pendant). However, the amino groups (–NH2) have a very limited affinity for alkali metals (Na+ and K+) and alkaline-earth metals (Ca2+and Mg2+) [135,136,137,138]. In cement applications, it was known that Ca2+ is one of the major ions in the pore solution. It can be inferred that the binding strength of Ca2+ with the carboxylate groups on TEMPO-oxidized chitin nanofibers (TOChNFs) will be much stronger than that of Ca2+ with the amino groups on partially deacetylated chitin nanofibers or mechanically fibrillated chitin nanofibers. Protonated amino groups

Based on the above discussions, the possible interactions and states of PNMs with cement might exist as follows:

intercalation or the formation of an organo-mineral phase (OMP); the formation of OMP often occurs in the presence of nonionic, anionic, and cationic polymers, which can be formed by coprecipitation, intercalation, or micellization [139];

adsorbed PNMs on the surface of cement particles which help disperse cement agglomerates;

excess PNMs in the suspensions without chemical or mechanical interaction with cement [139].

5.1 Interactions of sulfated

(

–

OSO

3

−

)

CNCs with cement

CNCs obtained from sulfuric acid hydrolysis contain anionic sulfate groups

![Figure 17

The schematic diagram of two different types of CNCs in the fresh cement paste, reprinted with permission from ref. [43]; Copyright 2016, Elsevier.](/document/doi/10.1515/ntrev-2022-0149/asset/graphic/j_ntrev-2022-0149_fig_017.jpg)

The schematic diagram of two different types of CNCs in the fresh cement paste, reprinted with permission from ref. [43]; Copyright 2016, Elsevier.

Aluminate-containing hydrates constitute an essential part (about 25 vol% in pastes) of the hydrate assemblage, which contribute to space-filling (strength development) in the same way as C–S–H and Portlandite. It was reported (as shown in Figure 18) that sulfonated melamine formaldehyde (SMF) polymers are positioned between the (Ca2Al(OH)6)+ main sheets via electrostatic interaction [127]. SMF can be intercalated into a hydrocalcumite host structure yielding stable (layered double hydroxide) LDH compound and the so-called inorganic–organic hybrid materials that were confirmed by XRD analysis, revealing that SMF indeed is located within the host structure [127]. There are no reports in the literature that states negatively charged sulfated cellulose nanocrystals can intercalate into (Ca2Al(OH)6)+ main sheets via electrostatic interaction. However, negatively charged sulfated cellulose nanocrystals may have good interfacial bonding with cationic cement hydrates due to electrostatic interactions.

![Figure 18

Schematic representation of sulfonated melamine formaldehyde intercalation compound, reprinted with permission from ref. [127]; Copyright: 2015, Elsevier.](/document/doi/10.1515/ntrev-2022-0149/asset/graphic/j_ntrev-2022-0149_fig_018.jpg)

Schematic representation of sulfonated melamine formaldehyde intercalation compound, reprinted with permission from ref. [127]; Copyright: 2015, Elsevier.

5.2 Interactions of carboxylated (–COO−) CNFs with cement

Carboxylated CNFs (carboxylate content: 0.5 mmol/g-CNF) obtained by the TEMPO oxidation method have been used in cement applications. The addition of 0.3 wt% carboxylated CNFs improved the compressive strength by 50% [41]. As evidenced in Figure 19, sulfated CNCs were found to retard the hydration process [42], while the carboxylated CNF was found to accelerate the hydration process [41]. The acceleration of cement hydration at an early stage (first 24 h curing) was ascribed to the carboxylated NFC acting as nuclei to promote the formation of the hydration products. X-ray diffraction results revealed an increased volume of C–S–H products and other hydration products such as Portlandite and ettringite. However, Jiao et al. [40] found that the addition of carboxylated CNFs has no clear effect on the cement hydration at an early stage, but it retarded the hydration at a later stage. As a result, the initial and final setting times were extended by about 100 and 90 mins, respectively, with the addition of 0.4 wt% of carboxylated CNFs.

![Figure 19

(a) Heat flow curves of the sulfated CNC-reinforced cement pastes for the first 40 h, reprinted with permission from ref. [42]; Copyright: Elsevier, 2015; (b) setting time of carboxylated NFC-reinforced cement pastes, reprinted with permission from ref. [41]; Copyright 2017, SAGE Publications.](/document/doi/10.1515/ntrev-2022-0149/asset/graphic/j_ntrev-2022-0149_fig_019.jpg)

Opposite cement hydration kinetics after adding carboxylated CNFs were reported in the literature by different researchers; for example, Jiao et al. [40] reported that carboxylated CNFs prolonged the setting time while Mejdoub et al. [41] observed the setting time shortened in the presence of carboxylated CNFs. Furthermore, the overall DOH was increased, and the porosity and pore size was reduced with the addition of carboxylate CNFs [40,41].

As in the previous discussion, the binding capability of carboxylate groups with metal cations, particularly Ca2+, was much stronger than that of sulfate groups. High surface areas and strong binding strength of Ca2+ with carboxylate groups make carboxylated CNFs effective nucleating agents. More hydration products are formed in the open pores which are originally filled with water, resulting in the formation of more homogeneous, dense, and compact microstructure in the presence of carboxylated NFC [40,41,120]. As a result, the interfacial bonding between carboxylated CNFs and cement hydrates can be significantly enhanced to improve the microstructure (reduced pore size and porosity) and mechanical strength of the hardened cement.

The enhanced interfacial bonding combined with high-specific surface areas of carboxylated CNFs can ensure efficient stress transfer and thus prevent the propagation of nano cracks. However, it was reported by Goncalves et al. [39] that the negatively charged ionic groups of CNFs could scavenge some calcium cations in the aqueous phase (as evident from the thermogravimetric analysis), which affect the formation of other hydration products, e.g., ettringite and Ca(OH)2.

As discussed, the presence of carboxylate groups will induce a series of chemical reactions around the interfaces and therefore enhance the reinforcement efficiency. Thus, CNTs have been treated by a mixture solution of sulfuric acid (H2SO4) and nitric acid (HNO3) to introduce carboxylate groups on their surface. The addition of carboxylated CNTs in the cement composites exhibited improved microstructure (finer pore size distribution and reduced porosity) and enhanced mechanical properties [20], as shown in Figure 20. On the other hand, untreated carbon fibers did not improve compressive strength (Figure 20) because the bonding force between the fibers and cement matrix may be insufficient.

![Figure 20

Typical load-displacement curves of cement-CNT composites. PCC: control Portland cement composite; PCCF: Portland cement-untreated carbon fibers composite; PCCT: Portland cement-carboxylated CNT composite, reprinted with permission from ref. [20]; Copyright 2005, Elsevier.](/document/doi/10.1515/ntrev-2022-0149/asset/graphic/j_ntrev-2022-0149_fig_020.jpg)

Typical load-displacement curves of cement-CNT composites. PCC: control Portland cement composite; PCCF: Portland cement-untreated carbon fibers composite; PCCT: Portland cement-carboxylated CNT composite, reprinted with permission from ref. [20]; Copyright 2005, Elsevier.

Based on the discussion above, we can envision the general scheme of the interfacial interaction between the carboxylate groups in CNFs and the C–S–H hydrate or Ca(OH)2, as illustrated in Figure 21. The interaction can lead to a strong covalent bonding in the interface between the nanofibers and matrix in the composites, and therefore increases the load-transfer efficiency from cement matrix to nanofibers, and eventually results in improved mechanical strength [20,140].

There is no direct comparison of the effect of sulfate groups and carboxylate groups of PNMs on the stabilization and growth of C–S–H. However, Wang et al. [141] reported the stabilization effect of SPs with carboxylate groups or sulfate groups on the structure and properties of nano-C–S–H products. The results indicated that PCE superplasticizer is more effective for stabilization of the nano-C–S–H particles than polysulfonate (PSE) superplasticizer results in finer particle forming. This is explained by the stronger bonding between the carboxylate functional groups and C–S–H gels [141]. Moreover, XRD result indicated that PCE or PSE as stabilizers might distort the structure of C–S–H and decrease the crystallinity of C–S–H because the PCE or PSE polymers were inserted into the layer structure of C–S–H by complexation between functional groups and Ca2+, resulting in the interval expansion between the layers [141]. This result is consistent with that reported by Sun et al. [142], who reported that the carboxylate-metal ion groups are arranged vertically in the C–S–H layer, leading to an increase in the interlayer spacing. Sun et al. [142] also pointed out that PCE superplasticizer existed in two different locations in the C–S–H structure: grafted on the surface or partially intercalated in the interlayer regions.

5.3 Interactions and states of mechanically fibrillated CNFs with cement

The surface chemistry on mechanically fibrillated cellulose is much simpler than those obtained by sulfuric acid hydroxide or the TEMPO-mediated oxidation method. The hydroxyl group (–OH) is the major reactive functional group on the surface of mechanical fibrillated CNFs. Carboxylate groups may exist if CNFs are mechanically fibrillated from wood pulp with a small amount of hemicellulose. Thus, some mechanically fibrillated CNFs are negatively charged [53]. Our measurements of zeta potential of mechanically fibrillated CNFs in a simulated pore solution to represent the cement pore solution about 1 h into the hydration gave a value of −51.84 ± 18.74 mV, which is a much higher absolute value than the –9.1 mV value reported for cement particles in pore solution at pH = 12.7, reported by Cao et al. [42]. Mechanically fibrillated CNFs tend to adhere to cement particles rather than agglomeration themselves. Therefore, the affinity strength between the particles have the following order: f (cement–CNF) > f (cement–cement) > f (CNF–CNF). The zeta potential results show that the affinity strength between cement and CNF is stronger than that between cement particles. Thus, mechanically fibrillated CNFs may also have an electrostatic stabilization effect on cement, thus helping improve the dispersion of cement particles. Our results show that CNCs can delay the set time of cement more efficiently than CNFs. Furthermore, the CNCs can delay the final setting time by over an hour compared to unmodified cement. In addition, the longest delay in setting time is reached when the CNC concentration in cement is 0.05 wt% [76].

5.4 Interactions of carboxylated (–COO−) chitin nanofibers and nanocrystals with cement

Chitin has a similar chemical structure to cellulose, as shown in Figures 1 and 3. It can be expected that the surface chemistry of carboxylated chitin is similar to that of carboxylated cellulose. We can envision similar interfacial interactions between carboxylated chitin nanomaterials and cement. As mentioned earlier, controlling the amount of the oxidant NaClO in the TEMPO-mediated oxidation process will result in two distinct forms of carboxylated chitin nanomaterials with different amounts of carboxylate content. A low amount of oxidant NaClO can yield long and more entangled chitin nanofibers with low carboxylate content on the surface, while a high amount of oxidant NaClO can produce short rod-like chitin nanocrystals, as shown in Figure 5.

5.5 Interactions of partially deacetylated chitin nanofibers with cement

The main reactive groups on the surface of partially deacetylated chitin nanofibers are amino groups (–NH2) and hydroxyl groups (–OH). The partially deacetylated chitin nanofibers were stable in the acidic water medium due to the electrostatic repulsion forces induced by the protonation of amino groups. The zeta potential will dramatically drop under neutral or alkaline conditions. In our previous zeta potential measurements, the zeta potential of partially deacetylated chitin nanofibers obtained by 4 h hydrolysis by 33 wt% NaOH decreased from 44 to 16 mV when the pH was increased from 3 to 7. The absolute value of 20 mV is typically assumed to be the minimum value for moderate colloidal stability. Therefore, the partially deacetylated chitin nanofibers will tend to aggregate when increasing the pH to 7, as shown in Figure 22.

Partially deacetylated chitin nanofibers in acidic or neutral media.

In the earlier discussions regarding the electrostatic stabilization effects of CNFs on the cement particles, the main mechanism might be that the CNFs were preferably attached to the surface of cement particles via electrostatic attraction. Negatively charged CNFs or nanocrystals were absorbed to the cationic surface of cement particles, thus preventing cement aggregations and improving the DOH. Our current research shows that partially deacetylated chitin nanofibers have a positive surface charge under acidic and alkaline conditions.

Hall [98] reported that chitin nanocrystal with amino functional groups (–NH2) or amide groups (–NHR) was ideal to be used as a corrosion inhibitor in the cement because they can form strong films on the surface of metals through non-covalent binding with the metal surfaces. Whether the partially deacetylated chitin nanofibers or mechanically fibrillated chitin nanofibers have a similar corrosion-inhibiting behavior is yet to be proven in future work.

5.6 Interactions of mechanically fibrillated chitin nanofibers with cement

The reactive hydroxyl group (–OH) is the primary functional group on the surface of mechanically fibrillated chitin nanofibers. There are a small number of amino groups on the surface of chitin nanofibers due to a small fraction of deacetylation during the extraction process, as mentioned previously. Suspensions of mechanically fibrillated chitin nanofiber were unstable in the neutral or alkaline condition but did not show any issues dispersing in the alkaline cement pore solution. With their surface charges, we found that chitin nanofibers at a concentration of 0.035 wt% delay the initial and final setting times of cement paste by 35 and 78 min, respectively. Lower or higher concentrations attain shorter setting times. Higher electrostatic repulsion of chitin nanofibers due to high zeta potential values (–28.04 ± 2.6 mV in simulated pore solution) and high density of functional groups might be the contributing factor for the nanochitin function as a set retarder.

Typically, the addition of nanoparticles accelerates cement hydration because small particles might provide more heterogeneous nucleation sites and/or space where hydration products can grow [107,143]. Nucleation sites of nanoparticles will promote a more homogeneous, denser cement microstructure. This is attributed to the filling effect, which can enhance hydration product growth in the pore space and filling voids between the cement (clicker) particles, and hence a reduction in porosity, as shown in Figure 23. PNMs can act as heterogeneous nucleation sites and thereby accelerate the formation of C–S–H nuclei. Peschard et al. also reported that polysaccharides could restrict the C3A hydration rather than promote nucleation [69]. More work is still needed to elucidate the combined effect of the nano-size effect and ionic absorption capability of PNMs on the phase composition chemical and crystalline growth of hydration products.

Effect of concentration of chitin nanofibers on the setting time of cement paste.

6 Strength-enhancing mechanisms of PNMs in cement composites

Polysaccharide-based materials could have a significant effect on the mechanical performance of cement composites. Previous studies regarding the effect of PNM type, source material, production method, size, and surface functional groups on the mechanical properties of cement composites, as well as the mechanical properties, were summarized in Tables 1 and 2. Table 3 includes a summary of studies of cement using PNMs and also other derivatives of chitin and chitosan. The effect of PNMs on properties other than strength, such as setting time and rheology, is also listed in these tables wherever available.

A consensus from Tables 1 and 2 is that CNFs and CNCs can increase the compressive and/or flexural strength at different dosages, though contradicting findings were reported in some cases. For example, several studies [34,37,40,144] reported a flexural strength increase from 15 to 72% using CNFs and Jiao et al. and Mejdoub et al. [40,41] reported a 20–43% increase in compressive strength using CNFs. In contrast, Hisseine et al. and Rosato et al. [36,145] reported a reduction in the compressive strength of cement in the presence of CNFs. However, the reason was not explained. For CNCs, Cao, Dousti, and Mazlan et al. [42,45,46] reported increased flexural strength.