Cutting-edge development in waste-recycled nanomaterials for energy storage and conversion applications

-

Mohamad Abd Elkodous

, Gomaa A. M. Ali

, Mouna El Abboubi

, Marina R. Abdelnour

Abstract

Agriculture and industrial wastes (AIWs) have attracted much attention because of their huge environmental, economic, and social impacts. AIWs have been considered a crucial link of a closed-loop for the fabrication of nanomaterials and composites wherein they replace traditional resources with sustainable waste in waste management. In this context, the proper disposal of AIWs is required. This review aims to investigate the technical feasibility of using innovative AIW resources and various strategies for the fabrication of nanomaterials for improving energy applications. First, the utilization of AIWs is classified comprehensively. Second, key technologies to produce nanomaterials are summarized. In addition, this review discusses the potential applications of the fabricated nanomaterials in energy storage and energy conversion.

Graphical abstract

Abbreviations

- 3D

-

three-dimensional

- ABS

-

acrylonitrile butadiene styrene

- AC

-

activated carbon

- ACPKS

-

activated carbon palm kernel shell

- AFC

-

alkaline fuel cell

- AIWs

-

agriculture and industrial wastes

- AuNPs

-

gold nanoparticles

- BA

-

bottom ash

- BEW

-

boron enrichment waste

- BFW

-

banana fruit waste

- BNC

-

bacterial nanocellulose

- CNTs

-

carbon nanotubes

- CE

-

counter electrode

- CR

-

congo red

- CFA

-

coal fly ash

- CLR

-

coal liquefaction residue

- CNC

-

cellulose nanocrystal

- CNFs

-

carbon nanofibers

- CNMs

-

carbon nanomaterials

- CQDs

-

carbon quantum dots

- CTP

-

coal tar pitch

- Cu2O

-

copper(i) oxide or cuprous oxide

- CuO

-

cupric oxide

- CVD

-

chemical vapor deposition

- DMFCs

-

direct methanol fuel cells

- DPW

-

date pulp waste

- DSSCs

-

dye-sensitized solar cells

- EY

-

eosin yellow

- E-CQDs

-

carbon quantum dots prepared by electrochemical oxidation

- EOL

-

end-of-life

- EPCB

-

end-of-life flexible printed circuit board

- E-Recycling

-

electronic recycling

- ESM

-

eggshell membrane

- FeNG

-

Fe–N-doped graphene

- FF

-

fill factor

- FA

-

fly ash

- FAO

-

Food and Agriculture Organization

- FCCVD

-

floating catalyst chemical vapor deposition

- F-CQDs

-

carbon quantum dots from fenugreek leaves

- G

-

graphene

- GA

-

gum Arabic

- GO

-

graphene oxide

- GQDs

-

graphene quantum dots

- GR-sludge

-

gold refining sludge

- GC

-

glass carbon

- GCD

-

galvanostatic charge-discharge

- HPC

-

honeycomb-like activated porous carbon

- HSs

-

hierarchical superstructures

- IPCE

-

incident photon-to-current efficiency

- KL

-

kraft lignin

- HDPE

-

high-density polyethylene

- LCAs

-

life cycle assessments

- LiBs

-

lithium-ion batteries

- LTFCs

-

low-temperature fuel cells

- LDPE

-

low-density polyethylene

- LED

-

light-emitting diode

- LLDPE

-

linear low-density polyethylene

- LSV

-

linear sweep voltammetry

- LSW

-

leather solid waste

- MAP

-

microwave-assisted pyrolysis

- MFCQDs

-

magneto fluorescent carbon quantum dots

- M-CQDs

-

carbon quantum dots from Miscanthus

- MP

-

mixed plastic

- MSW

-

municipal solid waste

- MWCNTs

-

multiwalled carbon nanotubes

- MF

-

magnetic field

- MFCs

-

microbial fuel cells

- MO

-

methyl orange

- MSI

-

metal-support interaction

- NDC

-

nitrogen-doped carbon

- NDPG

-

N-doped porous graphene

- NPs

-

nanoparticles

- NRs

-

nanorods

- N-ACs

-

nitrogen-doped activated carbons

- NBC

-

nitrogen-doped carbon

- N-CNFO

-

nitrogen-doped carbon nanofibers with open channels

- N-CQDs

-

nitrogen-doped carbon quantum dots

- NM-CQDs

-

nitrogen-doped microspore carbon quantum dots

- NMs

-

nanomaterials

- N-MWCNTs

-

nitrogen-doped multiwalled carbon nanotubes

- N-ACs

-

nitrogen-doped activated carbons

- NTs

-

nanotubes

- ORR

-

oxygen reduction reaction

- OER

-

oxygen evolution reaction

- OTC

-

oxytetracycline

- PAN

-

polyacrylonitrile

- PCNs

-

porous carbon nanoparticles

- PAC

-

porous activated carbon

- POME

-

palm oil mill effluent

- PA

-

polyamide

- PAC

-

porous activated carbon

- PCBs

-

printed circuit boards

- PE

-

polyethylene

- PP

-

polypropylene

- PS

-

polystyrene

- PET

-

polyethylene terephthalate

- PMMA

-

polymethylmethacrylate

- PVA

-

polyvinyl alcohol

- PVC

-

polyvinyl chloride

- PVP

-

polyvinylpyrrolidone

- PW

-

plastic waste

- PCE

-

power conversion efficiency

- PSCs

-

perovskite solar cells

- QDs

-

quantum dots

- QY

-

quantum yield

- r-PET

-

recycled polyethylene terephthalate

- rGO

-

reduced graphene oxide

- RHE

-

reversible hydrogen electrode

- RhB

-

rhodamine B

- C s

-

specific capacitance

- SG

-

S-doped graphene

- sGQDs

-

self-assembled graphene quantum dots

- SMNPs

-

spherical magnetic nanoparticles

- SWCNTs

-

single-walled carbon nanotubes

- SS

-

spider silk

- SCE

-

saturated calomel electrode

- J SC

-

short circuit current density

- TiRR

-

triiodide reduction reaction

- TAW

-

tricomposite agro waste

- TCs

-

tetracycline

- TEMPO

-

2,2,6,6-tetramethylpiperidine-1-oxyl radical

- TPO

-

tire pyrolysis oil

- TTDDA

-

4,7,10-trioxa-1,13-tridecanediamine

- WEEE

-

waste electrical and electronic equipment

- WEO

-

waste engine oil

- WMPs

-

waste mobile phones

- WPC

-

wood–plastic waste

- WPCBs

-

waste printed circuit boards

- WPT

-

waste palm trunk

- WPVB

-

waste poly vinyl butyral

- WWTPs

-

wastewater treatment plants

- Zn–C

-

zinc–carbon

- Zn–MnO2

-

zinc–manganese oxide

- ZnO NPs

-

zinc oxide nanoparticles

1 Introduction

Because of human population growth, accelerated industrialization, and urbanization, there is a steady rise in generated wastes. According to the World Bank project, by 2050, wastes will significantly exceed population growth by more than double [1,2]. Meanwhile, approximately 2.01 billion tons of municipal solid wastes (MSWs) are being collected globally annually and are anticipated to grow to 3.40 billion tons by 2025 [3]. Furthermore, solid waste management alone produced 1.6 billion tons of CO2 equivalent greenhouse gas emissions in 2016, accounting for approximately 5% of global emissions. Low-income countries spend 20% of their budgets on waste treatment on average, with an upward of 90% of wastes either openly dumped or burned, a key cause of environmental pollution and harmful health impacts [2,4]. This condition has encouraged the creation, adoption, and strengthening of various policy strategies and novel processes to minimize the waste impact on humans and the environment. Thus far, wastes have been used as a utility source to create value-added products.

Recycling waste materials into high-value products is a distinct possibility. However, the global economy remains far from achieving a closed-loop materials cycle because of inefficient or nonexistent recycling practices. For example, only approximately 10% of the 280 million tons of plastics produced each year are recycled [5]. It is worth noting that broadcast recycling is being implemented in different areas for general products (e.g., newspapers, glass bottles, plastic, and cans). However, this situation is less assured with long-lived products, including laptops, fridges, and vehicles, collectively known as e-waste. At the global level, approximately 30–50 million tons of waste from electrical and electronic equipment (WEEE), with an estimated annual growth rate of 5%, accumulates annually [6]. When manufactured in an environmentally sustainable manner, life cycle assessments have shown that nanomaterials’ (NMs) processing requires more energy and natural resources than traditional technologies. Waste materials as feedstock are appealing because they are readily available and inexpensive, whereas NMs synthesis is revolutionary waste management and recycling process [7]. Consequently, sustainable production of waste-derived NMs has become a hot topic of study in recent years. New and more stringent environmental regulations fuel the rising demand for waste recycling.

This has inspired researchers to synthesize new high-value and marketable NM-based products and serve as a strategy to boost industry interest in serious recycling efforts because of potentially attractive economic returns from state subsidies [6]. NMs have physicochemical properties that make them appealing for various applications in healthcare, textiles, food, and electronics. Interestingly, the distinct physicochemical properties of NMs play an important role in their energy applications [8,9].

One of the major problems in the 21st century is energy storage and energy conversion. With the accelerated decline of fossil fuels and worsening air pollution, there is an increased need for energy efficiency and the pursuit of sustainable and clean energy sources. Fuel cells, solar cells, supercapacitors, and lithium-ion batteries (LiBs) are examples of these technologies. All materials used in these devices are considered key to major energy conversion and storage advancements. Consequently, high-performance materials should have unique properties and be rationally engineered for critical energy conversion and storage applications. Various waste residues have been used as initial sources to produce NMs. Researchers have synthesized several NMs, such as metal oxide nanoparticles (NPs), carbon NPs, carbon nanotubes (CNTs), activated carbon (AC), graphene (G), and graphene quantum dots (GQDs), which have recently spurred attention because of their unique properties [10]. The utilization of waste materials is not only a way to find a plentiful and less expensive source for NM production but also a way to use waste materials that seem to be environmentally harmful in general. Future research in this field remains very open to obtaining high-value NMs from less expensive sources and more straightforward methods.

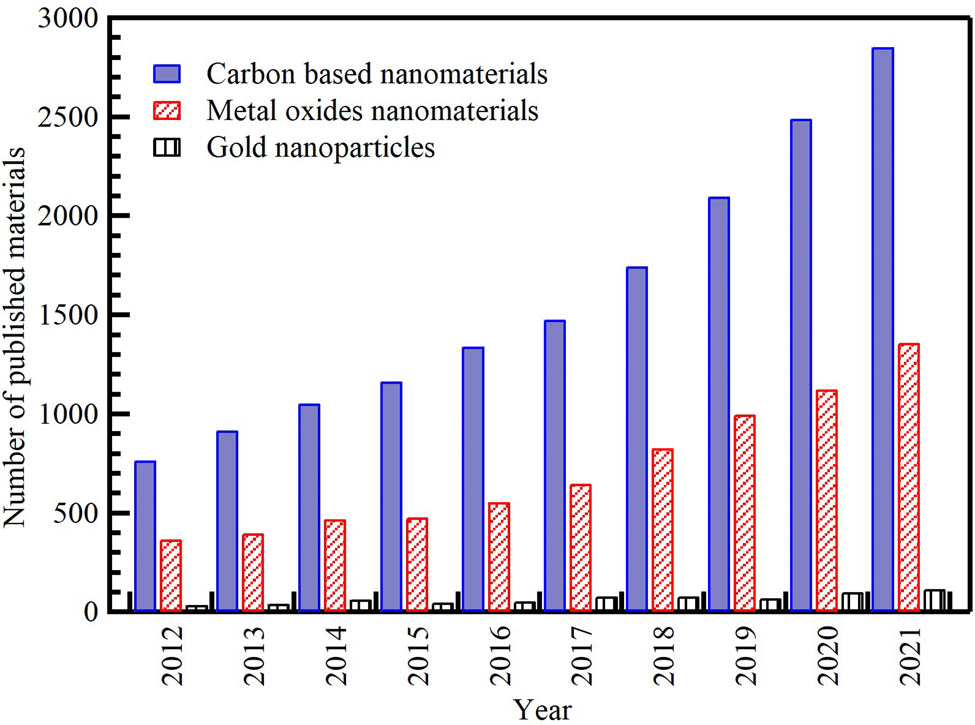

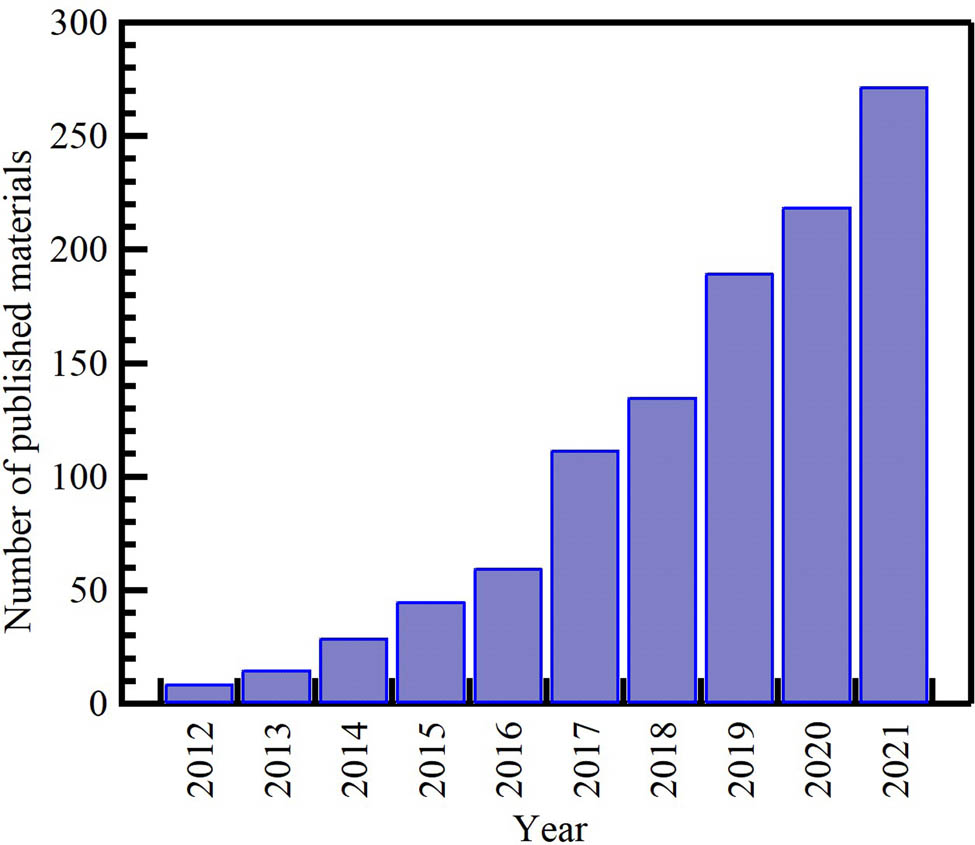

In recent years, waste-derived NMs have become a hot topic of study and research. As depicted in Figure 1, there has been growing evolution in the number of publications on waste-derived NMs from 2013 to early 2021. The academic interest in this field has steadily increased. The scientific output of waste-derived NM-related research has almost doubled over the last 8 years. Carbon nanomaterials (CNMs) and metal oxide NPs are the most investigated; most publications analyze these materials. Interest in CNMs’ research has been increasing steadily and at a speedy rate, from 764 publications in 2012 to 2,853 in 2021, with a 73% increase compared to 73% for metal oxide NPs and 70% for AuNPs. However, the number of studies for the last reported NMs remains low. This deficiency in research productivity could be attributed to several possible factors that are not mutually exclusive, such as the lack of interest in the subject matter among scientists, the small number of scientists in the field, and the lack of funding and governmental support.

Distribution of the cumulative number of publications on waste-derived NPs per year from the Scopus database (December 2021) according to keywords. Search strategy example: “waste” AND (“carbon nanomaterials” OR “carbon nanofibers” OR “graphene” OR “activated carbon” OR “carbon nanotubes”), metal oxide, gold nanoparticles in the title, abstract, or keywords field.

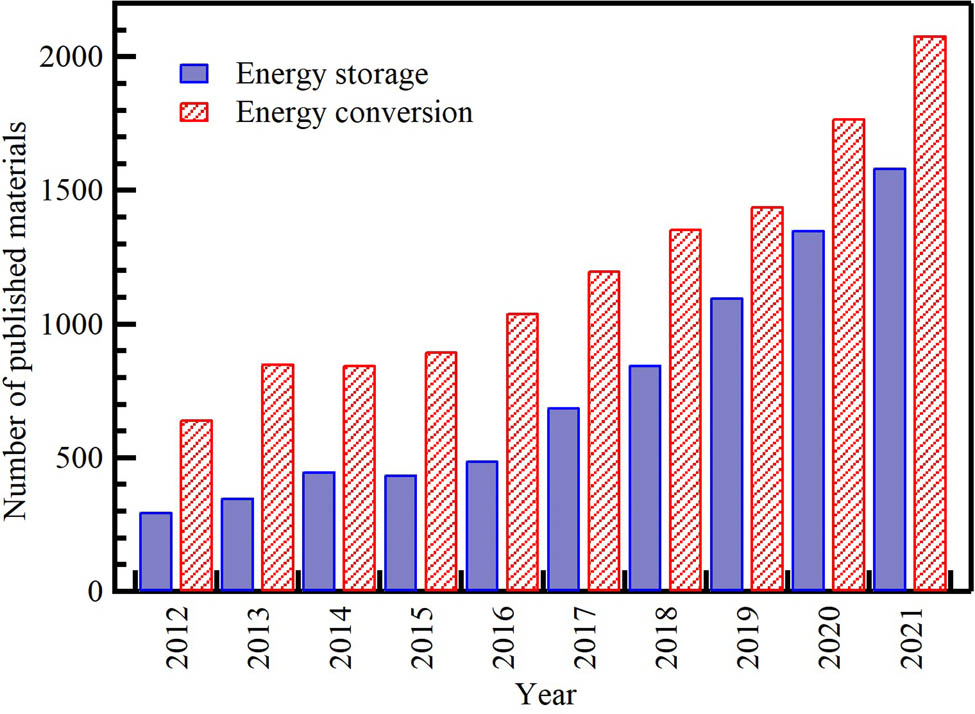

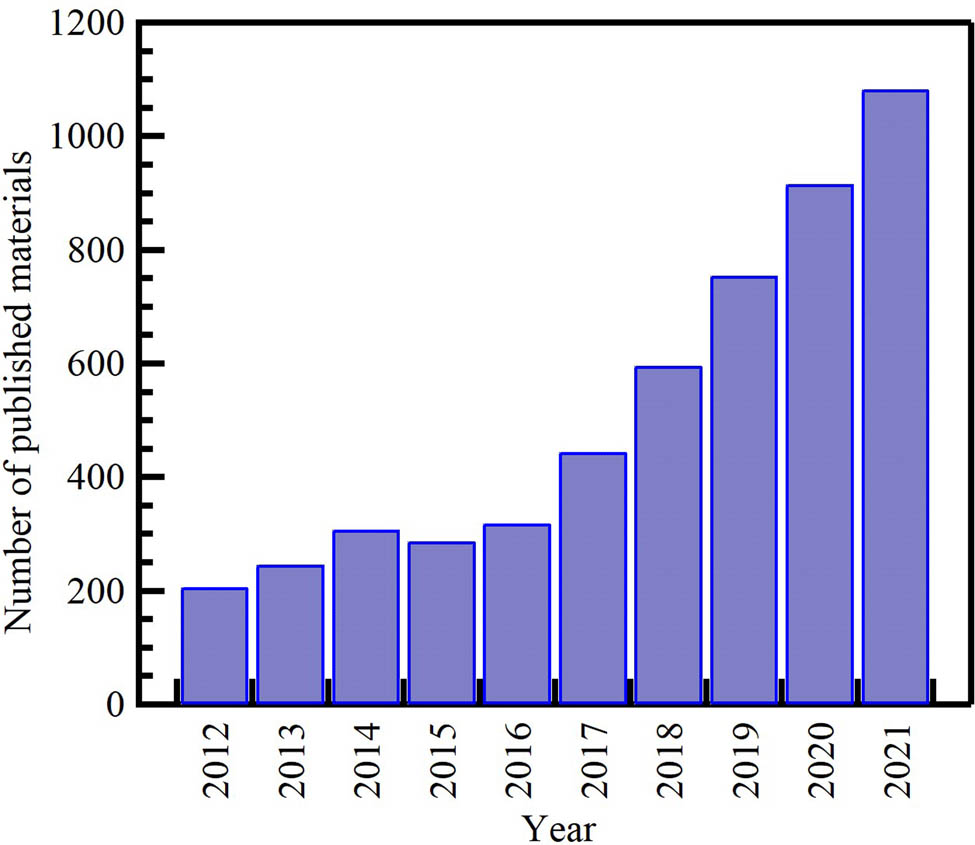

To meet the demands of modern society and address evolving environmental challenges, new, low-cost, and environmentally sustainable energy conversion and storage solutions must be established. Consequently, science in this area is rapidly progressing. Advanced materials are crucial for the high-efficiency conversion of clean and renewable energy to electrical energy and high energy density electrical storage that can be effectively recycled from waste. The characteristics of materials used in these applications significantly impact their performance. Figure 2 shows a bar chart of publications on waste-derived NMs in storage and conversion energy applications over the past 10 years. Between 2013 and 2021, there has been a large increase in publications for both applications. The number of publications for energy storage applications, such as batteries and supercapacitors, rose from 298 in 2012 to 1,584 in 2021. Whereas the number of publications for energy conversion applications, such as fuel cells, solar cells, green H2 production, and CO2 reduction, steadily rose from 643 in 2012 to 2,080 in 2021.

Distribution of the cumulative number of publications on waste-derived NP applications per year from the Scopus database (December 2021) according to keywords. Search strategy example: “waste” AND (“energy storage applications” OR “batteries” OR “supercapacitors”), (“energy conversion applications” OR “fuel cells” OR “solar cells” OR “green H2 production” OR “CO2 reduction”), in the title, abstract, or keywords field.

Generally, there has been an upward trend in waste-derived NMs for energy applications. The scientific community’s interest has focused on energy conversion applications from 2013 to 2016, with 327 publications in 2013 and 108 for energy storage. However, this situation later improved; since 2017, there has been a large spike in articles on energy storage. This substantial rise in the overall number of publications may be due to innovations in waste management, which have occurred in tandem with technological advancements and innovations, especially in electronics. Lithium and Ni–MeH battery systems follow a similar path for the transportation sector and the power grid.

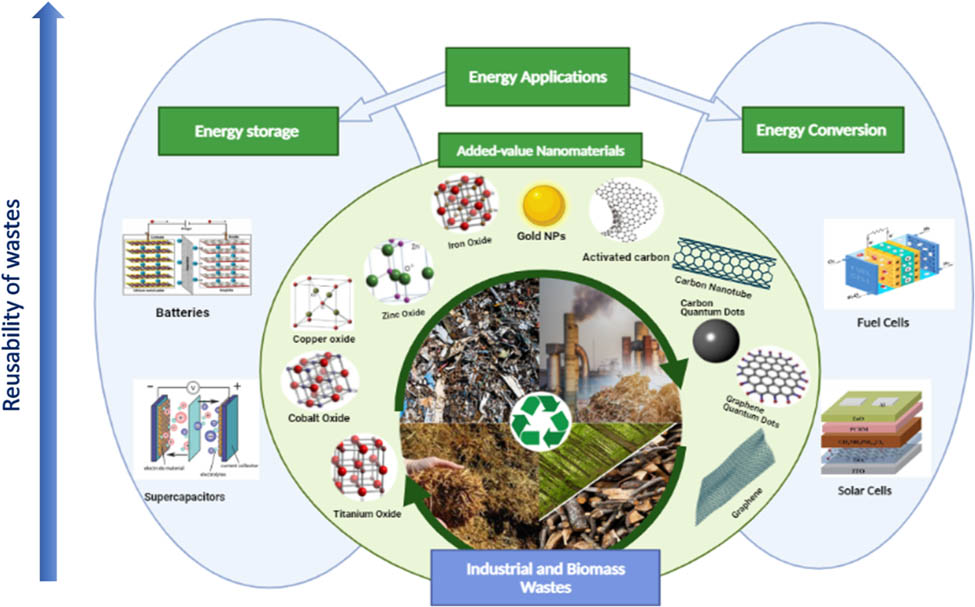

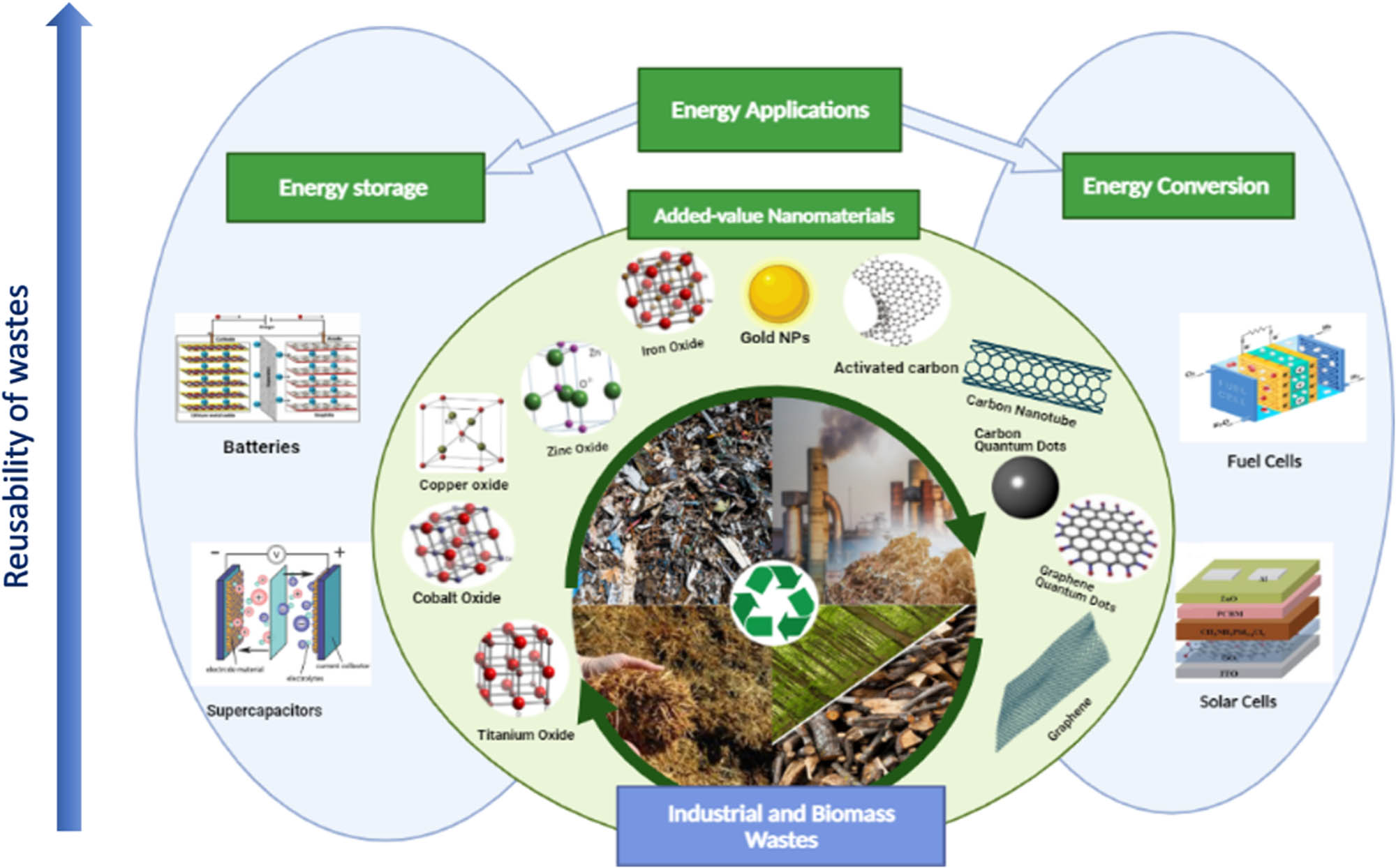

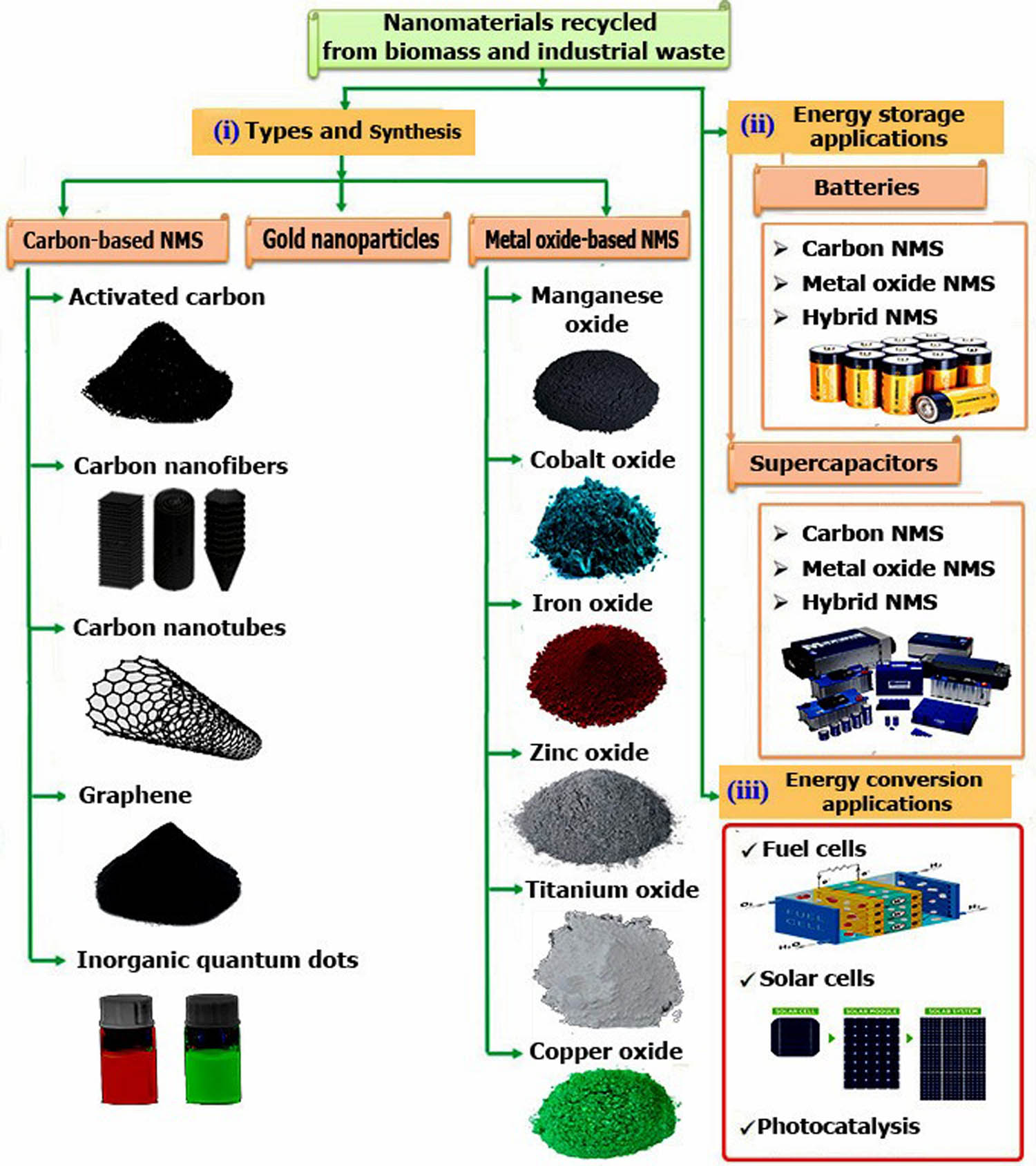

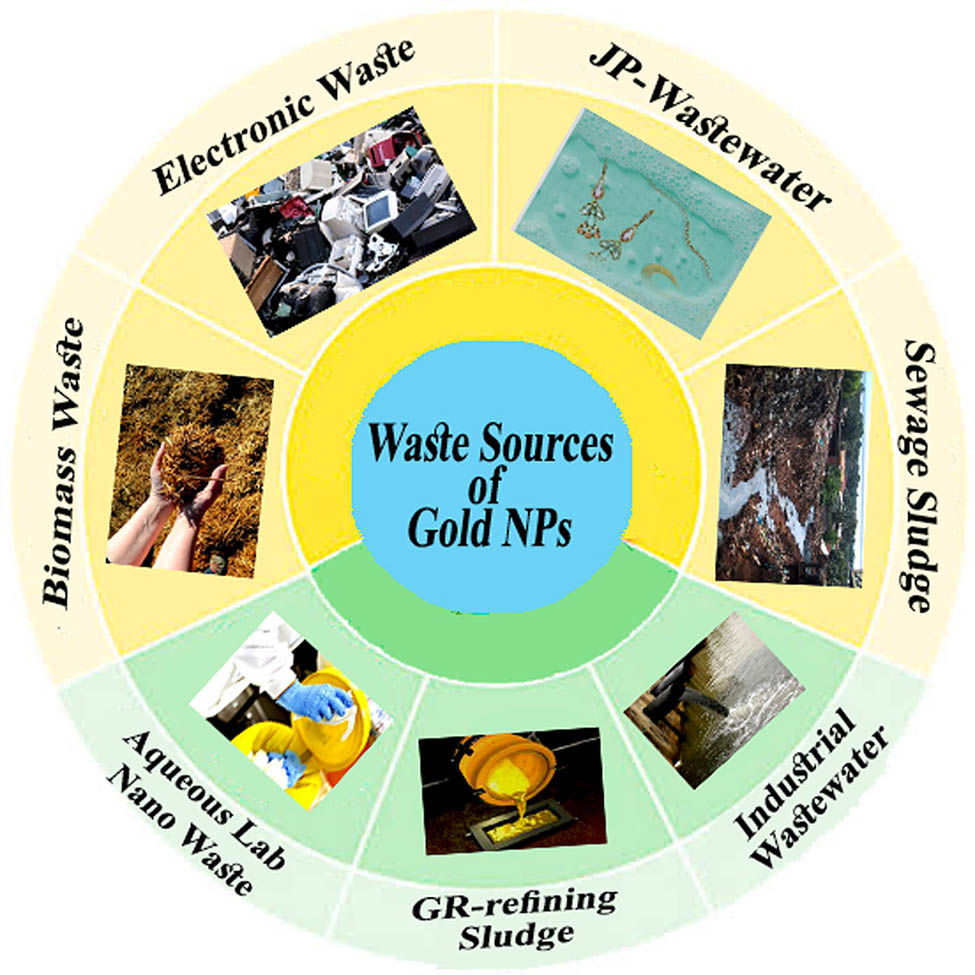

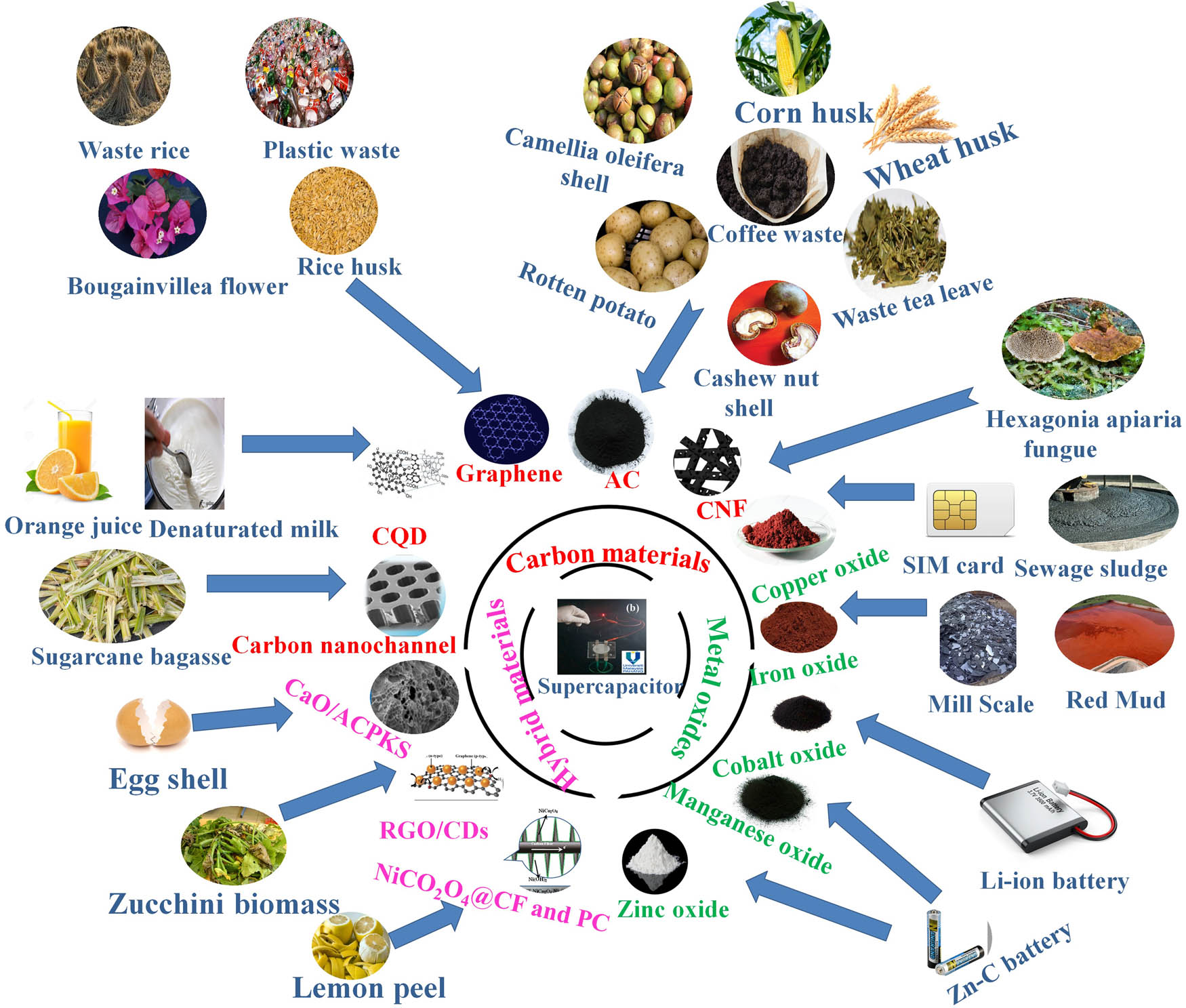

The current review aims to thoroughly evaluate the status, challenges, and future directions for domestic and industrial waste recycling as suitable input to produce NPs as added-value products. Herein the proprieties and the currently available synthesis techniques of NMs (e.g., metal oxide NPs, CNMs, AuNPs, and inorganic QDs) to critically analyze their efficiencies and drawbacks are explored. Various pretreatment methods for wastes are considered. Furthermore, the commercial viability of waste-derived NMs and several proof-of-concept implementations in advanced technologies, especially energy storage and energy conversion applications (e.g., batteries, supercapacitors, fuel cells, and solar cells), are emphasized. Literature classified the recycled NMs for energy storage and conversion into three categories: CNMs, AuNPs, and metal oxide NPs. The primary scheme of this review is summarized graphically in Figure 3. Finally, this study addresses knowledge deficiencies in literature by carefully evaluating this novel and forward-thinking research subject. Overall, results from this literature review indicate a need for continued research that focuses on the critical aspects required for scaling up production and application of waste-derived NMs. By thoroughly evaluating this emerging and forward-looking research issue, our review fills in the information gaps in the literature.

Schematic of recycled NMs from biomass and industrial wastes and their energy applications.

2 Synthesis and properties of nanomaterials recycled from biomass and industrial waste

Nanomaterials are a broad category that includes particulate compounds ranging from 1 to 100 nm with unique physical and chemical characteristics, large specific surface area, and nanoscale size. According to reports, their optical properties are influenced by their size. Their distinctive size, shape, and structure influence reactivity, robustness, and other features. Due to their properties, they are excellent candidates for residential and commercial applications, including catalysis, imaging, medical applications, energy-based research, and environmental applications. NMs might be classified into various groups depending on their physical and chemical properties.

Carbon-based nanomaterials, metal oxide-based nanomaterials, and gold nanoparticles are interesting and have applications in biology, medicine, industry, and energy. It is critical to conduct more research on the progress of recycled NMs derived from biomass and industrial wastes. Diverse sorts of NMs from various sources are summarized in the present review. Up to now, the excellent potential of recycling waste materials into value-added NMs is a hot topic. This section provides a complete, critical, and easily understandable overview of this original trending issue and a correlation between the synthetic procedure and the resulted properties of the fabricated nanomaterials. The first step in fabricating NMs from waste materials is selecting suitable waste detailed in this section. Additionally, several synthetic techniques have been employed to generate the final product of NMs, and the detailed methods for each type of NMs are discussed well in this section.

Waste management is requested to minimize the waste, reduce the environmental impacts, and create a source of added value NMs. Various waste materials have been recycled for the initial feedstock to produce NMs. In the past few years, researchers have synthesized NMs, such as metallic/carbon NPs, CNTs/nanosheets, AC, and nanofibers, from industrial or biomass waste residues. More recently, recycled NMs from cooking oil, biomass, and industrial waste and their subsequent applications have become highly attractive. There are many resources to produce NMs that can be simply categorized into biomass and industrial wastes. Indeed, the proportion of industrial and household wastes varies from country to country because of variations in economic activity [11].

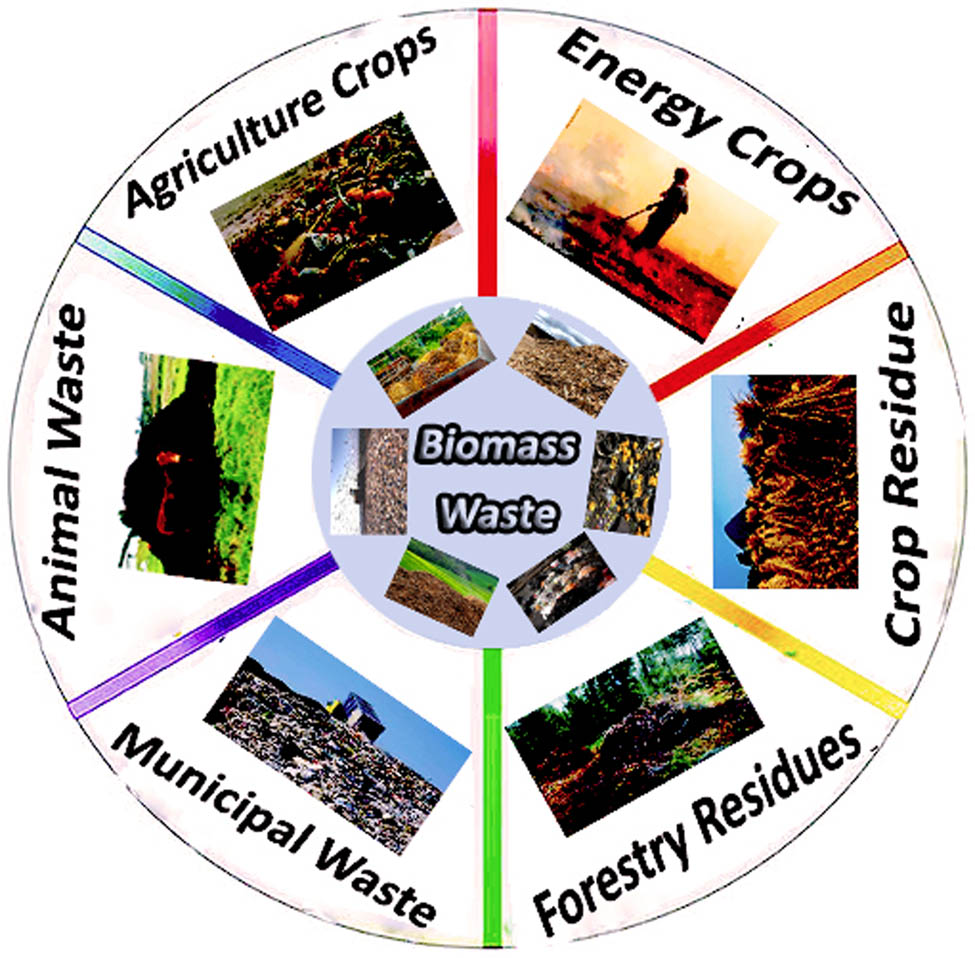

More than 220 billion tons of biomass residues, each year, from which a significant amount of lignin could be extracted. [12]. This includes all biologically generated materials used to characterize all living things on the planet. Energy crops, crops, residues, timber and wood wastes, municipal and animal wastes, aquatic plants, and algae are plentiful biomass resources (Figure 4).

Schematic of biomass resources in nature.

Biomass waste can be converted into NMs with several benefits. A simple pyrolysis process, for example, can turn tea waste into biochar for use as a fluoride adsorbent. Sugarcane and camphor were also used as precursors to produce graphene oxide (GO) and CNTs. Carbon-based structures are the most adaptable materials for current renewable energy and natural science technology [13]. The use of biomass as a raw material in the manufacture of NMs has been praised as a biobased economy and green solution to local and global pollution problems. Agricultural waste biomass, for example, has gained international recognition as a low-cost resource for NM synthesis [14]. Since carbon-based materials can be made from renewable biomass feedstocks, they are considered sustainable.

Nanoelectronics, biomedical research, renewable solar energy, drug-gene delivery, thermal insulation, and other fields have potential applications using metal oxides, nanoporous materials, and NPs. However, scientists must recognize that agricultural waste biomass-assisted synthesis is a less expensive, environmentally sustainable, and renewable technique. Because of their specific properties, the development of noble metal NPs, such as AuNPs, is of great interest. Manipulation of their size and form results in unique properties that could be useful in semiconductors [15].

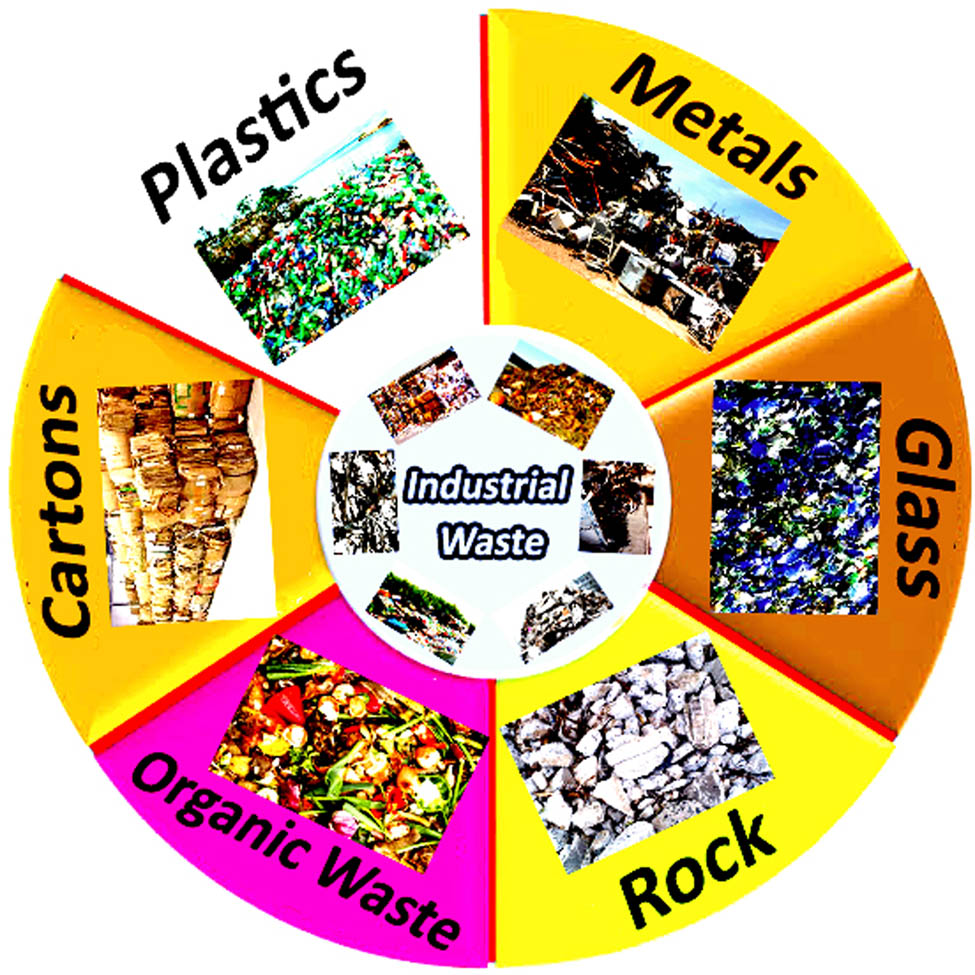

Generally, industrial waste is classified into two categories: nonhazardous and hazardous. Nonhazardous industrial waste, such as cartons, plastics, metals, and organic waste (Figure 5), is waste from industrial activity that does not threaten public health or the environment. Conversely, hazardous waste, of which only approximately 10% of the 280 million tons of plastic generated each year in the world is recycled, is a byproduct of industrial operation that poses a danger to public health or the environment, such as flammable, corrosive, active, and toxic materials. According to reports, just 3.8% of total industrial waste in Europe (EU-28) was listed as hazardous waste. Waste composition in industrial sectors in Europe (in 2014) and waste from households (MSW) accounted for just 8.3% of total waste, emphasizing the dominance of industrial waste.

Schematic of industrial waste in nature.

NMs can also use a range of industrial wastes as initial feedstocks, including batteries, polymers, and tires. Consequently, NM processing from various industrial wastes may be a long-term recycling process that protects the environment. China, for example, generates between 50 and 60 million units of waste lead batteries per year. Because of their insolubility, lead pastes primarily contain lead dioxide, lead sulfate, and lead oxide, which are difficult to recycle. Many spent lead batteries are currently being made, and recycling is one of the best ways to address this issue.

In China, Japan, Korea, and the United States, Zn–Mn batteries account for more than 90% of annual portable battery sales. China manufactures over 15 billion Zn–Mn batteries per year. Exposure to high levels of Zn will delay calcium absorption, resulting in lower Ca levels in the body. Consequently, recycling Zn from Zn–Mn battery waste encourages resource sustainability and avoids the introduction of these pollutants into the environment. Zn–Mn battery waste recycling has been extensively studied to produce various NMs, such as Zn NPs, nanofibers, and flaky NMs [16].

In summary, several sources of waste have been utilized as a precursor for the production of NMs, concerning two categories: biomass and industrial wastes. Figure 6 summarizes the classification of the fabricated NMs from sustainable waste.

Classification of nanomaterials from wastes.

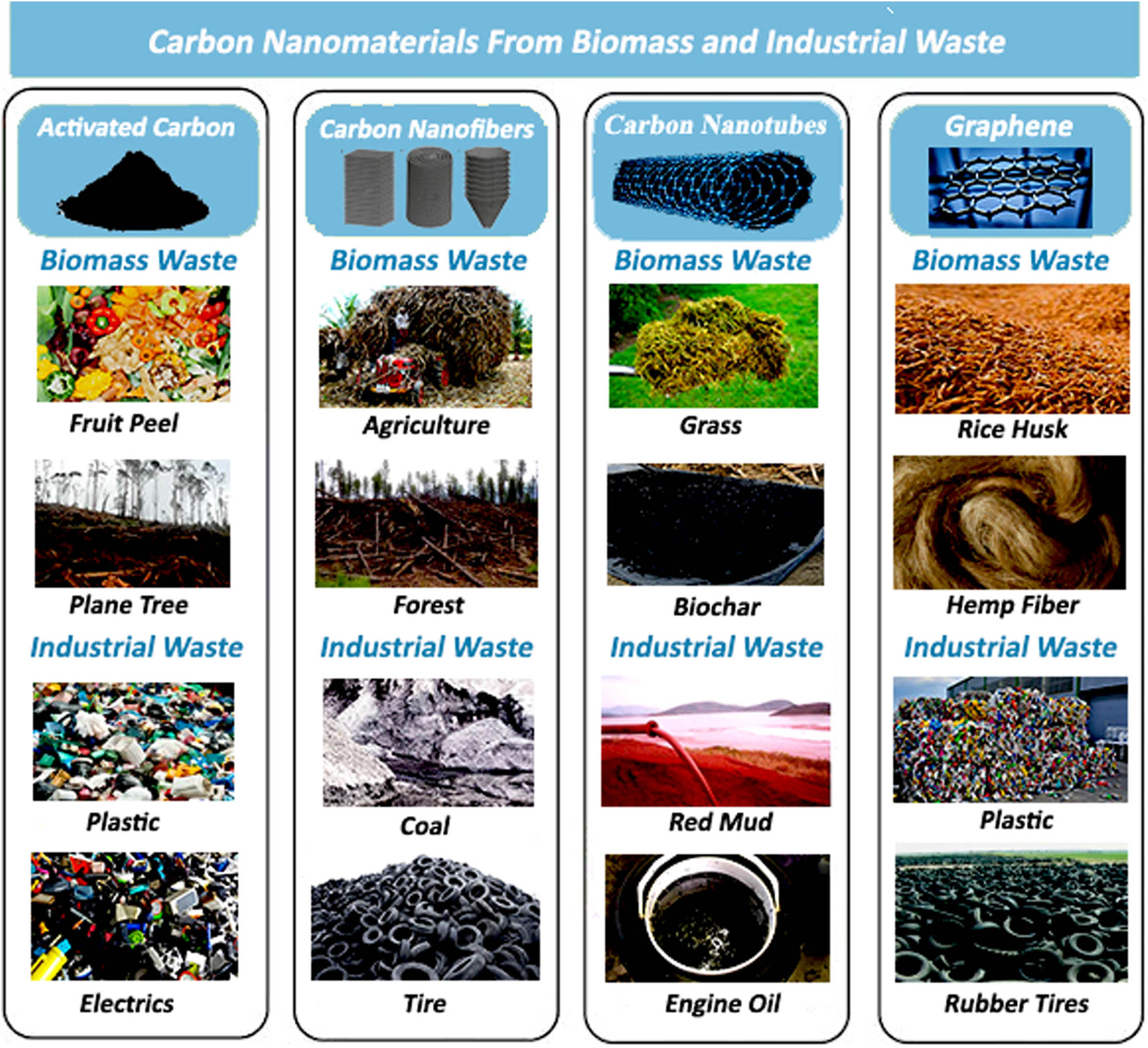

2.1 CNMs

CNMs fabrication still faces challenges in the exploration of new resources. These challenges are based on improving CNMs’ properties to obtain high-quality and high-purity materials, while meeting the current demands of energy applications [17,18,19,20]. In this respect, a search for new resources is required, increasing different morphology types while considering other factors. Various CNMs fabricated using different resources are discussed in detail with this motivation. The main sources for these CNMs are biomass and industrial waste (Figure 7). CNMs are classified into four categories: AC, carbon nanofibers (CNFs), CNTs, and G.

Types of carbon nanomaterial obtained from recycled waste.

2.1.1 AC

AC is a nongraphitic material and is one of the most famous carbonaceous materials because of its high specific surface area, distinctive pore size distribution, high degree of surface-active sites, and physicochemical stability [21,22,23]. Three recycled source materials that produce AC are biomass, industrial waste, and agro-industrial waste. Numerous biomass wastes have been explored for AC production. The greatest advantage of biomass waste is creating AC via various plant types, cellulose, hemicellulose, and lignin constituents. Hemicellulose in biomass partially hydrolyzes at low temperatures, resulting in the formation of AC out of polymerization [21].

Because of the ban on environmentally harmful palm waste disposal mechanisms, especially in the palm milling industry, challenges of palm waste should be managed by converting it into valuable materials, like AC [23,24,25]. Porous AC (PAC), associated with mesoporous and microporous properties, is also strongly dependent on the utilization of the biomass type and synthesis methodology [26,27,28]. The conversion of fruit peel wastes into PAC is interesting to activate alkalis like H3PO4 [29]. Interestingly, PAC nanosheets are derived from leaves, such as Syzygium oleana leaves, via pretreatment with KOH or NaOH before the pyrolysis process [30,31]. For the development of 3D biomass PAC, three standard biomass waste precursors have been chosen as carbon sources: bagasse, wheat straw, and wood shavings [32]. Mangrove and waste palm trunk (WPT) have been used as low-cost and sustainable precursor materials for the development of AC, which can be used in various applications under different carbonization and activation conditions. The surface area of AC derived from WPT was 1,402 m2 g−1, whereas that derived from mangrove was 2,131 m2 g−1 at the same activation conditions [33].

Coal as waste material has been used for the synthesis of AC. Recent research investigated the possibility of producing alternative and cheap triggering agents to improve the adsorption properties of AC using mine coal [34]. Rubber tire wastes are non-biodegradable and harm climate and land management. It was suggested that this material could be used in a management strategy for diverse applications, like energy and carbon production [35]. In one study, plastic waste (PW) was separated from the dry waste of an institute, which primarily consisted of packaging and laboratory waste. Polypropylene (PP), polyethylene terephthalate (PET), high-density polyethylene (HDPE), and low-density polyethylene (LDPE) are among the thermoplastic polymers used in PW [36]. End-of-life flexible printed circuit boards (PCBs) typically have a polyamide (PA)-based substrate with metal foils, such as copper, interconnecting the circuits.

Several resources are available for this process, including sawdust, wood–plastic, and leather solid wastes (LSWs). Sawdust is ideal for fabricating carbonaceous NMs because the carbon content from sawdust varies from 77.51 to 93.59%, with ash content as low as 0.08%. Agro-industrial wastes are also used as alternatives for the production of AC. Extrusion, hot pressing, and injection are used to create wood–plastic composite materials [37] from plastics like PP, PE, and polystyrene (PS), and biomass fibers like rice husk (RH), corn stalk, and peanut shell. By increasing the carbonization temperature, the surface area of biochar is increased, reaching a maximum value of 518.72 m2 g−1 [38].

Nagaraju et al. [39] successfully used naturally available pine cone flowers, which have abundant carbon contents, as biomass to prepare honeycomb-like porous AC powder with meso/macropore structure and porous 3D properties. Nagaraju used chemical activation with KOH and pyrolysis processes under Ar inert gas atmosphere. The synthesized sample was uniformly coated on fluorine-doped tin oxide (FTO) glass using a smooth brush. Compared with commercially available AC, the obtained results were improved (Figure 8).

![Figure 8

Schematic of (a–d) porous AC fabrication and (e–f) dye-sensitized solar cell preparation process with porous AC-coated FTO glass. Copied with permission from ref. [39]; Elsevier, 2017.](/document/doi/10.1515/ntrev-2022-0129/asset/graphic/j_ntrev-2022-0129_fig_008.jpg)

Schematic of (a–d) porous AC fabrication and (e–f) dye-sensitized solar cell preparation process with porous AC-coated FTO glass. Copied with permission from ref. [39]; Elsevier, 2017.

2.1.2 CNFs

CNFs resemble CNTs in structure but have more advantageous properties, such as decreased cost and ease of synthesis. The properties of CNFs make them the principal substituting blocks for the synthesis of CNFs at the nanoscale [40,41]. CNFs structures appear hollow, porous, smooth, helical, stacked with a high specific area, with good electrical and thermal conductivity with low weight, and are primarily used in energy and environmental sciences [42].

CNFs biomass waste is considered one of the most valuable CNM sources. It can be extracted from biomass waste sources, like bamboo, palm kernel shell, and pine nut shell-derived char. The process for determining extracted species is pyrolysis, wherein the process temperature is important to release different constituents of the CNMs [43,44].

CNFs are generated from pyrolytic bio-oil and biogas, depending on the heat extraction method [45,46]. The bio-oil microwave method’s production of phenols, methoxy phenols, substituted methoxyphenols, naphthalene, benzene, and alkenes leads to the fabrication of CNFs. Additionally, the biogas microwave-assisted pyrolysis (MAP) process, i.e., CO and CO2, leads to hollow CNFs, like those extracted from pine nut shells and palm kernel shells, at low temperatures via isothermal oxidation [46].

The extraction of cellulose nanofibrils is usually applied for various biomass, such as soft and hard woods, corn husk, and banana peel [47,48]. Waste-tire pyrolysis oil (TPO) and coal fly ash (CFA) are used to synthesize CNFs/CNTs [49]. TPO acts as a carbon precursor and is one of the most important byproducts of waste-tire thermal degradation in an oxygen-free environment [49]. The presence of iron (in the form of oxide) in the CFA is a catalyst that aids in growth [50].

Nitrogen-doped CNFs with open channels can be prepared using a simple electrospinning method with subsequent two-step carbonization using polyacrylonitrile, waste poly(vinyl butyral), and urea [51]. Also, using waste HDPE, self-prepared micron-sized silicon/CNFs/carbon (Si/CNFs/C) composite has been fabricated with pyrolyzed carbon and CNFs [52].

Coal liquefaction residue waste has been used to prepare CNFs films via electrospinning [53]. Also, coal-derived CNFs can be obtained from powder River Basin coal via electrospinning; the raw coal is depolymerized to form coal chars that are then combined with polymeric precursors (polyacrylonitrile [PAN]/polyvinylpyrrolidone [PVP]) to form a homogeneous solution for fabrication [54,55,56].

Zhang et al. [57] synthesized CNFs decorated with a carbonized loofah from loofah sheets using in situ chemical vapor deposition (CVD). The CNFs were used for water purification via solar energy due to the high lighttrapping capability of the CNFs. The loofah sheets were first carbonized at 500°C, washed with alcohol, dried, and then soaked in a dopamine-based solution. The polydopamine-coated carbonized loofah was further carbonized at 800°C and then impregnated with Ni(NO3)2 as a catalyst. Lastly, the sample was placed in a CVD furnace with a gas flow of N2 and ethanol. The CNFs showed a degree of crystallization with a lattice spacing of 0.34 nm and a diameter of 20 nm. X-ray diffraction (XRD) analysis confirmed the crystal structure of the carbonized loofah CNFs.

Cao et al. [58] used alkali lignin as a renewable carbon source, mixing it with PAN in a solution as a carbon precursor for CNFs preparation. It was blended with Sn-based PVP solution and then electro-spun at 23 kV at fixed temperature and humidity. Afterward, the spun nanofibers were preheated before being carbonized at 800°C. The result was porous CNFs with SnO x nanonodules distributed homogenously throughout the composite. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) were used to characterize the composite morphology (Figure 9), whereas XRD and Brunauer–Emmett–Teller (BET) surface area analyses were utilized to study the crystal and pore structure of the composite, respectively. Additionally, two- and three-symmetric electrode systems were built to test the electrochemical performance of the composite for supercapacitor applications.

![Figure 9

(a) SEM and (b) TEM images of CNFs. Copied with permission from ref. [58]; Elsevier, 2021.](/document/doi/10.1515/ntrev-2022-0129/asset/graphic/j_ntrev-2022-0129_fig_009.jpg)

(a) SEM and (b) TEM images of CNFs. Copied with permission from ref. [58]; Elsevier, 2021.

2.1.3 CNTs

CNTs have attracted attention because of their superior electrical, thermal, mechanical, and optical properties. Synthesis of CNTs from renewable resources will reduce costs and make the world more sustainable [59]. CNT feedstocks include biopolymers or bioderived chemical compounds, such as essential oils. CVD has completed the fabrication of CNTs from essential oils in the presence of ferrocene as a catalyst. Many precursors act as bio-feedstocks to produce CNTs. Palm oil is not a good carbon precursor for the production of CNTs [60]. However, poor quality CNTs are obtained from sunflower, palm, and sesame oils (I D/I G ratio of 1.00), which indicates that these precursors are not ideal for CNT synthesis.

There are other essential oils available to produce high-quality CNTs. The production of multiwalled carbon nanotubes (MWCNTs) by turpentine oil was discovered by Afre et al. [61]. High-quality MWCNTs were fabricated on quartz rather than silicon via CVD [62]. MWCNTs can easily be created using camphor oil in the presence of ferrocene [63]. According to Awasthi and coworkers, MWCNTs with 20 and 60 nm diameters were fabricated with castor oil [64]. Also, bamboo-shaped N-doped MWCNTs were produced by castor oil in the presence of ammonia [65].

Cobalt catalyzed carbonization of biomass chitosan results in the formation of cobalt/nitrogen-doped CNTs. The presence of cobalt causes a transition from graphene-like carbon nanosheets to tubular graphitic carbon [66]. Biochar is a carbon-rich porous material made from thermochemically treated biomass. Microwave-assisted heating makes CNTs from a mixture of biochar and ferrocene [67]. The coconut shell is an example of a mineral-rich biomass natural resource. By using the mineral content in the source material as catalysts for CNT growth, MWCNTs have been synthesized over coconut shell-derived charcoal pyrolyzed at 900°C [68].

Plastic wastes are considered as a main source of CNMs because of their high amounts of carbon. The most common waste plastics are PE and PP. Plastics are first decomposed in a pyrolysis reactor, and then CNTs are synthesized in a separate reactor using a catalyst. Catalyst growth is a major challenge for increasing CNT amount and quality [69].

High quality and quantity of CNTs can be obtained using 5 wt% of Mn in Fe-based catalyst via catalytic pyrolysis of PP rather than a Fe-based catalyst [69]. Therefore, selecting catalysts, especially bimetallic catalysts, is important for the fabrication of high-quality CNTs. MWCNTs have been produced by single-stage chemical vapor decomposition using PP in the presence of bimetallic Fe–Mn/Al2O3 catalyst [70].

CNTs can be manufactured from PE wastes using heavy metal-support interaction, e.g., La0.8Ni x Fe1−x O3−δ , at high temperatures [71]. Also, CNTs can be manufactured from PE waste at 800°C using a spherical alumina-supported catalyst, the diameter and yield increasing significantly as the Ni content increases [72].

A mixture of PP and LDPE was also used as the main source of CNTs using a two-stage fluidized catalytic bed reactor system with a fraction of 48 wt%. In one study, temperatures of the first- and second-stage reactors were regulated at 600 and 800°C, respectively [73]. MWCNTs can be obtained by using a pure mixture of LDPE, PP, and mixed plastics (MPs) over a Ni-based catalyst at two different temperatures, 500 and 800°C [74].

Coproduction of H2 with high yield and CNTs with high quality can be prepared from the pyrolytic product of waste tires using Ni supported on AC as a catalyst [75]. Single-walled carbon nanotubes (SWCNTs) with very efficient yield have been synthesized using vulcanized scrap rubber via thermal CVD at 850°C on suitable catalytic systems, such as bimetallic oxides of Fe and Ni supported on zeolites [76]. Also, well-defined CNTs can be obtained from scrap rubber by thermal aging the rubber at 90°C for 14 days before CVD using Fe–Ni–Cu/MgO as a catalyst and a growth temperature of 750°C applied for 60 min [77]. The stress buffer layer shell that occurs on the surface of micron-sized silicon waste is a CNT. A high-performance Si/nano-Cu/CNT/C porous structure was obtained from photovoltaic silicon waste by integrating nanocopper-assisted chemical etching with graphite and CNT coating technology [78]. CNTs with a high degree of graphitization can be obtained using a red mud sample by alkali treatment followed by fabrication of bio-composite films of PVA and, finally, the pyrolysis of the composite film at 500°C [79]. The floating catalyst CVD approach offers a continuous single-step process to synthesize aerogel CNTs using waste engine oil as a carbon source in a ferrocene catalyst at a temperature of 1,150°C [80].

Wu et al. [81] have shown that the same process from which hydrogen is produced from the plastic can be utilized to create cost-effective CNTs as a byproduct in NiMnAl-based catalysts. The examination of the resulting mixture showed that the carbon yield depends on the molar ratios of the NiMnAl catalyst used. NiMnAl with a molar ratio of 4:4:4 (Ni:Mn:Al) had a higher carbon yield (57.7 wt%) and a slightly higher CNT yield (91.2 wt%). However, CNTs formed using NiMnAl with a molar ratio of 4:2:4 had better uniformity and higher crystallinity overall. CNTs produced this way were shown to improve the mechanical strength of LPDE significantly. The CNT–LPDE composite had more stiffness than virgin LPDE and improved dynamic load handling abilities. The overall process is also cost-effective, which opens the door to potentially wide industrial applications.

Biomass-based methods for CNT formation have also undergone considerable developments over the last few years. Hidalgo et al. used biochar as a precursor for synthesizing CNTs by microwave irradiation [82]. Their method involves heating a mixture of biochar and ferrocene in a microwave reactor operating at 2.45 GHz, 80°C, 200 W, and 17 psi. Different kinds of biomass from different agricultural wastes were pyrolyzed to form different biochar samples, then used as carbon precursors in the synthesis process (Figure 10). The different biochar samples had diverse surface areas, pore volumes, aromaticity, etc., depending on the agricultural waste used and the pyrolysis conditions, which affected the characteristics of the CNTs produced. Biochar samples obtained from hazelnut hull and wheat straw pyrolyzed at 600°C yielded CNTs with overall higher quality. Biomass gasification also generates a carbon-rich mixture of gases, such as CO, CO2, and CH4 [83].

![Figure 10

SEM images of carbon products from various sources. Copied with permission from ref. [84]; Elsevier, 2018. (a) CNTs from CH4 decomposition process (P

CH4

= 0.2 atm), (b) CNTs from CO decomposition process (P

CO = 0.2 atm), (c) CNTs from CO/CH4 decomposition process (P

CO/P

CH4

= 0.5), and (d) CNTs from CO/CH4 decomposition process (P

CO/P

CH4

= 2).](/document/doi/10.1515/ntrev-2022-0129/asset/graphic/j_ntrev-2022-0129_fig_010.jpg)

SEM images of carbon products from various sources. Copied with permission from ref. [84]; Elsevier, 2018. (a) CNTs from CH4 decomposition process (P CH4 = 0.2 atm), (b) CNTs from CO decomposition process (P CO = 0.2 atm), (c) CNTs from CO/CH4 decomposition process (P CO/P CH4 = 0.5), and (d) CNTs from CO/CH4 decomposition process (P CO/P CH4 = 2).

2.1.4 Graphene

Graphene and its derivatives can be synthesized from unused waste material to produce novel materials. There are four main categories of recycled waste material sources to synthesize graphene and its derivatives: biomass, plastic, industrial, and other domestic wastes. In the following sections, each source will be discussed individually.

Graphene and its derivatives can be synthesized using different biomass wastes, such as RH, hemp fiber, sugarcane bagasse, glucose, and chitosan. The merits of using recycled agriculture wastes are their simplicity, environmental friendliness, high crystallinity, and the lack of toxic gas emissions during synthesis. RH contains more than 70% of carbonaceous components besides its silica (15–20%), lignin (25–30%), and cellulose (50%) constituents [85]. For high-purity graphene materials, a pretreatment process with a strong alkali, like KOH or NaOH, is required to eliminate SiO2 impurities [86].

Farmers burn hemp fibers every year; therefore, it is important to decrease this biowaste by benefiting from the availability and eco-friendliness of hemp fibers to produce distinctive materials, like graphene and its derivatives [87]. Hemp has been hydrothermally treated and accompanied by KOH activation to create extremely porous graphene materials [87].

Glucose is considered the only renewable monosaccharide plant-based source of carbon in nature produced simultaneously in plants’ photosynthesis process. Researchers used glucose as a raw material for the processing of graphene and its derivatives because of its uniqueness in nature [13,88].

Sugarcane bagasse is one of the main sources of glucose for the production of graphene and its derivatives [89]. The most common fabrication technique for graphene and its derivatives from sugarcane bagasse is the direct oxidation under a muffled atmosphere with ferrocene as a catalyst. Using a pyrolysis technique combined with a simple treatment, different forms of graphene, such as N-doped graphene, have been manufactured from chitosan [90].

Plastic bags and plastic water bottles (PET) are massively used today. All packaging materials formed of different polymeric composites are collected together as layers to form plastic materials with an inner layer of aluminum [91]. PE has been recycled to prepare promising graphene/mesoporous carbon composites for energy storage devices through the monitoring of graphene oxide (GO) during a lower temperature carbonization process [92]. High-quality graphene flakes have been prepared using PP waste while organically catalyzed with montmorillonite [93]. High-quality single-layered graphene can be made from PS and other carbon-containing wastes. Additionally, multilayer graphene sheets were prepared from waste expanded PS using FeCl3 as a catalyst [94].

High-quality monolayer and multilayer graphene was successfully fabricated using synthetic polymers, such as polymethylmethacrylate (PMMA), polyimide, and waste plastics, as the carbon precursor, whereas hydrogen gas acts as a reducing agent [94]. PMMA film was also used as a starting medium for CVD-grown graphene sheets on sapphire substrates with Cu catalysts [95].

High-quality graphene from PET waste was developed without any catalyst [96]. The treatment of PET wastes involves two main steps before forming carbon-based materials: grinding and crushing. Pyrolysis-generated mixed PWs are a major source of bulk graphene nanosheets [97]. In one study, PE, PP, and PS combined PWs were obtained from a local city council and second-hand markets, cleaned, and dried. The properties of the produced GO sheets varied from the starting raw materials such that the characteristic properties of the GO sheets were nearly identical to those of highly pure graphene [98,99].

Graphene films were developed from pure coal through a graphitization process that has been identified as simple and cost-effective. Since coal is a carbon-rich material for developing CNTs, fullerenes, and amorphous carbon thin films, it is also used to construct graphene, graphene derivatives, and anthracite coal [100,101]. Graphene materials have been recycled from lead and zinc–manganese batteries, besides some types of transportable batteries. This recycling method was carried out in a heating system where NPs of various morphologies were formed, such as hexagonal prisms, fibers, and sheets [16,102].

A significant number of tires, approximately one billion, are produced globally per year. Studies investigating the control of rubber tire disposal as an economically friendly sustainable source for carbonaceous materials composed of 81.2 wt% carbon [103] are in great demand. The high-value carbon graphene NPs resulting from these studies were derived from waste-tire rubber and exhibited good thermal stability and conductivity [104].

Electronic gadgets (phones, laptops, iPads, etc.) have become essential to everyday life. These electronic equipment comprise diverse mixtures of metals, plastics, glass, and even nanomaterials [105]. PCBs are considered the main constituents of such electronics, and they have been considered a good source for graphene synthesis. The recycling process of valuable and high-quality graphene NMs from high pollutant wastes offers a more energy-saving manufacturing process than extraction from ores [106].

Graphene has been prepared using different low-cost carbon-containing materials from daily use, such as cookies, chocolate, leftover bread, salads, grass, cockroaches, and even animal feces [107]. Although different elements, such as O, N, Fe, S, and P, were present in the primary material sources, the graphene was free of those elements. Thus, the synthesis of graphene from such sources is preferred [108].

Several natural waste materials for the synthesis of graphene and GO, such as tea leaves; coconut shells; peanut shells; fruit peels, i.e., orange, banana, and mango peels [109,110,111]; wood; bagasse; leaves; vegetation waste; fruit waste; and powder soot collected from the exhaust of diesel engine and waste newspapers have been used in graphene sheet synthesis [98]. Tea waste contains various components, such as polyphenol, caffeine, amino acids, and tannins, whereas tea leaf constituents include cellulose, hemicelluloses, lignin, tannins, and proteins [112]. Graphitic carbon can be produced because of the presence of these cellulosic materials by treatment at high pyrolysis temperatures [109].

Nut shell waste is globally used in animal feed or construction materials because of its novelty, low cost, and existence as a useful biological resource. Nut shells are of high carbon content and first produce biochar that can be easily converted into graphene [113]. Plenty of application fields encourage recycling such a low-cost graphene resource as it is used as a bio-adsorber or in metal ion removal and wastewater treatment [114].

Fungus can be treated hydrothermally to produce porous graphene materials; for example, the use of a fungus (Auricularia) with a KOH pretreatment and then a carbonization process. The resultant porous graphene material net structure is used in supercapacitor electrode production [115]. The pulping industry is a rich source of alkaline lignin, which has been used to successfully prepare graphene sheets thousands of nanometers in size [116].

Ding et al. [116] prepare 3D graphene from the precursor of black liquor (Figure 11). The black liquor was collected and filtrated to remove impurities. A 15% weight percentage of black liquor was dissolved in deionized water and heated at 180°C in an autoclave. Then, it was cooled at room temperature and washed with deionized water. Finally, graphene was obtained by centrifugation of suspension.

![Figure 11

Three-dimensional graphene schematic. Copied with permission from ref. [116]; Elsevier, 2020.](/document/doi/10.1515/ntrev-2022-0129/asset/graphic/j_ntrev-2022-0129_fig_011.jpg)

Three-dimensional graphene schematic. Copied with permission from ref. [116]; Elsevier, 2020.

Three-dimensional graphene comprises tightly combined micron-sized graphene sheets, and the graphene sheets have dihedral angles. Both sp2 and sp3 carbon atoms, with a ratio of 8:1, are present. Three-dimensional graphene with porous carbon, which consists of multilayers of graphene, is of considerable interest in many applications because of its distinctive properties, such as self-supporting, high surface area, high mechanical properties, high electrical conductivity, and a high degree of crystallization [117].

Researchers have also used agricultural waste as biowaste precursors to synthesize graphene to reduce toxic chemicals. Agriculture produces millions of tons of RH per year. Therefore, it is of great interest for the large-scale production of graphene. Kumar et al. [118] have synthesized graphene using RH as the precursor via the microwave method with ferrocene as a catalyst. The RH was washed and dried and, after drying, was mechanically ground to powder and mixed with ethanol using ferrocene as a catalyst [119]. Yeleuov et al. [120] synthesized graphene with RH as a precursor using a two-step chemical method. The graphene was then modified with nickel hydroxide through a simple chemical precipitation method. The properties of graphene provided it with high performance in energy storage applications.

2.1.5 Inorganic quantum dots

2.1.5.1 CQDs

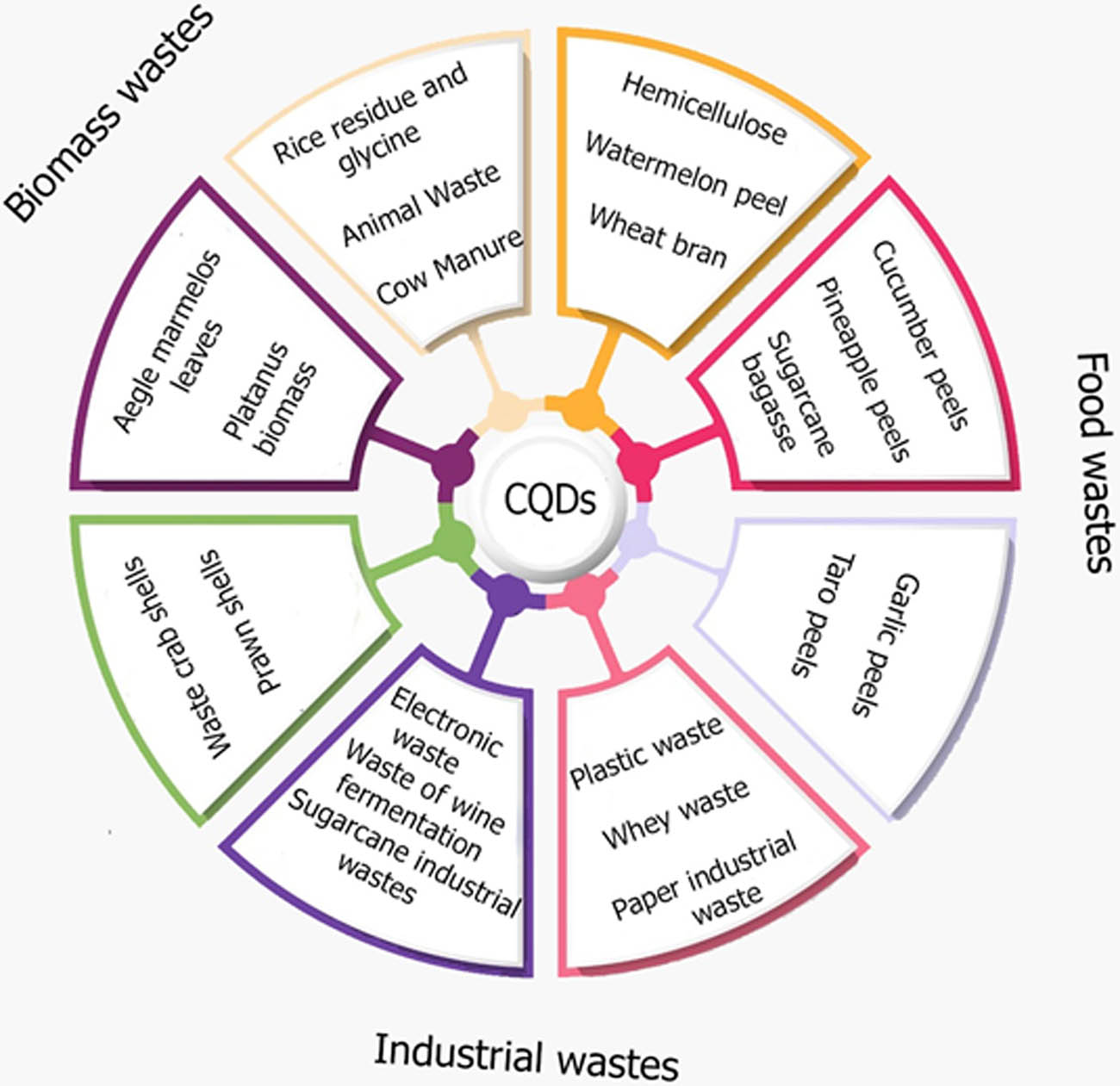

CQDs are a fascinating type of carbon NPs with diameters of approximately 10 nm. From a synthesis point of view, CQDs have been produced from several natural carbon sources or waste organic products; the benefits of using green carbon sources are their cost-effectiveness, eco-friendliness, and wide availability in nature [121,122]. Figure 12 shows the types of waste used to produce CQDs, which will be discussed in detail.

Wastes used as precursors for synthesizing CQDs.

The raw materials needed to produce CQDs from food waste are abundant, such as cucumber peel, pineapple peel, sugarcane bagasse, garlic peel, and taro peel. The type of food waste utilized in the synthesis of CQDs can affect its quality. For example, there were significant variations in essential properties of CQDs obtained from cucumber and pineapple peels using the same synthesis approach [123]. The CQDs obtained from pineapple peel were fully degraded after a few weeks of storage, whereas those from cucumber peel remained stable. Additionally, it was found that CQDs prepared from sugarcane bagasse, garlic peel, and taro peel using the same synthesis process (the ultrasonic-assisted wet-chemical oxidation method) had very different quantum yields (QYs) (4.5, 13.8, and 26.2%, respectively) [124].

From the waste management perspective, researchers have synthesized CQDs from industrial waste to dispose of the waste. There has been a significant advancement in plastic technology in several fields, including electronics, packaging, etc. Because of the negative health and environmental impacts of the inadequate management of PW and the large amounts of waste from plastic industries, it is urgent to convert this waste into CQDs [125,126]. These conversions are obtained from the pyrolysis of wastes of polyolefins. Plastic bottles, cups, and PE bags have been used for CQDs by simple hydrothermal carbonization and have notable QY values of 64, 65, and 62%, respectively, with sizes ranging from 5 to 30 nm [126].

Whey is the liquid remaining after curds have been removed during the cheese-making process [127]. The discharge of watery portions after separating fat and caseins from whole milk creates serious environmental problems. Scientists utilized whey waste, a major dairy, and cheese industry waste product, to resolve these problems into CQDs. Using a facile and environmentally friendly synthetic method and underoptimized synthesis parameters, the CQDs prepared from whey waste exhibited a notable QY (11.4%) and excitation-dependent emission behavior [128].

The paper industrial sector creates large quantities of pulp residual fiber waste that needs further treatment before discharge. In this context, the transformation of such waste into CQD materials has piqued interest in several applications [129]. The formation of tiny CQDs with excellent physicochemical characteristics, such as a QY of 2.7%, particle size of 17.5 nm, and steady-state and lifetime fluorescence, has been achieved by facile microwave-assisted protocol [129].

Additionally, printed office paper has been successfully converted into fluorescent CQDs associated with small particle size, good photostability, high photoluminescence QY (10.8%), and low toxicity [130]. Also, N-doped CQDs from office paper have demonstrated perfect optoelectronic properties, faster response, and better sensitivity in the visible range than undoped CQDs [131]. Interestingly, CQDs fabricated from paper waste from a supermarket showed a significantly higher photoluminescence QY (5.1%) than CQDs prepared from the lignocellulosic residue, with a particle size of approximately 4.8 nm and a high response rate for trinitrotoluene [132].

In recent decades, dumped sugarcane bagasse is soil and earth waste that poses major environmental and health problems, especially in developing countries [133]. Therefore, researchers have utilized industrial sugarcane waste as a carbon precursor to produce highly fluorescent CQDs with an effective QY of 17.98% [134,135].

Discharged batteries, the main component of electronic waste, were used as a precursor for synthesizing uniform spherical CQDs with a particle size of 5 nm and QY of ∼15.3% [136]. White wine lees have also been used as raw material for producing CQDs, exhibiting a QY of 2.53% and a particle size of 10 nm [137].

Biomass is a biodegradable, bio-organic, and abundant element derived from various sources, including agricultural, fishery, animal, and forestry wastes. High-quality and green CQDs have been successfully synthesized using potential valuable byproducts of plant refineries, like hemicellulose and ammonium hydroxide, as solvents. The highest QY of N-doped CQDs produced with these byproducts was up to 16%, higher than undoped CQDs (only 2%) [138]. Watermelon peel is another precursor used to fabricate CQDs and has a particle size of 2.0 nm, strong blue luminescence, satisfactory fluorescence lifetime, and high stability across a wide pH range and at high salt concentrations [139]. Wheat bran has also been used as a precursor for preparing CQDs via hydrothermal treatment. According to fluorescence emission studies, wheat bran CQDs showed the highest fluorescence emission at a wavelength of 500 nm, and the QY of these prepared CQDs was 33.23% [140]. Rice residue and glycine have been used as carbon and nitrogen sources to synthesize N-CQDs using a one-step hydrothermal approach. These N-CQDs showed excellent results as a probe to detect Fe3+ and tetracycline (TC) antibiotics, with a maximum emission at a wavelength of 440 nm and a high QY percentage (23.48%) [141,142]. A single-step hydrothermal carbonization method has been used for the green synthesis of water-soluble monodisperse CQDs with coconut husks as the carbon precursor. Hydroxyl and carboxyl functionals, which play crucial roles in surface passivation and result in more stable NP dispersion, were confirmed by Fourier transform infrared (FTIR) spectroscopy on the surface of the CQDs [143]. Waste tea leaves and peanut shells were also carbon sources used to synthesize CQDs by the one-step hydrothermal method. These CQDs showed high stability and high QY. There was no discernible morphological distinction between tea CQDs and peanut shell CQDs; both had diameters of 7–9 nm, uniform dispersion, and spherical shape, indicating that they were more stable in water [144].

Recently, numerous attempts have been made to upcycle polymeric waste to reduce polymer waste buildup. Chaudhary et al. [145] have reported a sustainable process to convert PW from bottles, cups, and PE bags through facile heating to create FL-CQDs (Figure 13). The XRD of the CQDs showed crystalline characteristics. Also, the CQDs possessed crystallite sizes ranging from 7.5 to 28.3 nm.

![Figure 13

Schematic displaying the production of FL-CQDs from various types of plastic waste. Copied with permission from ref. [145]; Elsevier, 2020.](/document/doi/10.1515/ntrev-2022-0129/asset/graphic/j_ntrev-2022-0129_fig_013.jpg)

Schematic displaying the production of FL-CQDs from various types of plastic waste. Copied with permission from ref. [145]; Elsevier, 2020.

Biowaste Aegle marmelos leaf powder synthesized CQDs via a hydrothermal carbonization process. The obtained CQDs exhibited a high photoluminescence QY of 22% and, in the presence of a wide range of ionic (KCl) concentrations, revealed their suitability for in vivo and in vitro biosensing applications [146]. Using a pulsed laser ablation method, n-doped microspore CQDs (NM-CQDs) were produced from waste Platanus biomass. The prepared NM-CQDs exhibited a high QY and fluorescence lifetime (32.4% and 6.56 ns, respectively). Furthermore, stable emission behaviors have been obtained for NM-CQDs under various conditions, including varying ionic salt concentrations, temperatures, irradiation times, pH values, and different excitation wavelengths. NM-CQDs are ideal for cellular staining images because of their strong and stable PL emission [147,148]. Additionally, the green synthesis of carbon NPs using a hydrothermal process from cow manure is becoming more prevalent. These CQDs have an approximately spherical morphology and a narrow distribution, with most particle sizes varying between 10 and 15 nm. Photocatalytic activity of the CQDs was observed by the degradation of methylene blue under visible light, which decreased up to 40% after 12 h [149].

Waste crab shells and three different transition metal ions, Gd3+, Mn2+, and Eu3+ were used in a one-pot MAP procedure to fabricate magnetofluorescent CQDs (MFCQDs). Waste crab shells served as carbon sources and ligands to form complexes with transition metal ions. Consequently, MFCQDs exhibit good stability at different ionic strengths and pH values, making them useful for biomedical applications in vivo. Additionally, intense fluorescence, perfect aqueous dispersibility, excellent magnetic resonance response using various transition metal ions, and a fluorescent QY of 19.84, 12.86, and 14.97% were observed for Gd-, Mn-, and Eu-CQDs, respectively [150,151]. Also, prawn shells have been used to synthesize fluorescent carbon dots. Results revealed that these CQDs (with an average diameter of 4 nm) have several desirable characteristics, including high monodispersity, good stability, the ability to remove blue fluorescence under UV light (365 nm), high QY (9%), and excellent water solubility [152].

With a green synthesis route, several synthesis methods have been developed to produce CQDs, including hydrothermal or solvothermal synthesis, microwave-assisted synthesis, laser ablation methods, and chemical oxidation methods. However, toxic chemical reagents or organic solvents are widely used as precursors in these traditional synthesis processes. Hydrothermal or solvothermal methods were used to prepare CQDs with citric acid and l-histidine as precursors; these synthesis techniques require large heat energy of 200°C for 5 h. The fluorescence QY of the obtained CQDs was approximately 22%, with a maximum emission wavelength of 414 nm [153]. Using these methods, CQDs obtained from rice residue and glycine has shown a high QY percentage (23.48%) [141]. Furthermore, highly fluorescent amphiphilic CQDs have been prepared via MAP using citric acid and 4,7,10-trioxa-1,13-tridecanediamine (TTDDA), which served as an A3 and B2 polyamidation-form monomer collection. TTDDA-based CQDs have exhibited a fluorescence QY of 29%, which is higher than CQDs prepared via waste crab shells [154]. Thus, the MAP technique is affected by uncontrollable reaction conditions and high energy demand.

Chemical oxidation, which is one of the most common synthesis methods, typically necessitates using a strong oxidizing agent (strong acid or alkali) during the synthesis process. This poses environmental concerns because it is difficult to eliminate excess oxidizing agents fully. Also, a serious drawback of this approach is the absence of homogeneity in the size distribution of the resulting particles [155].

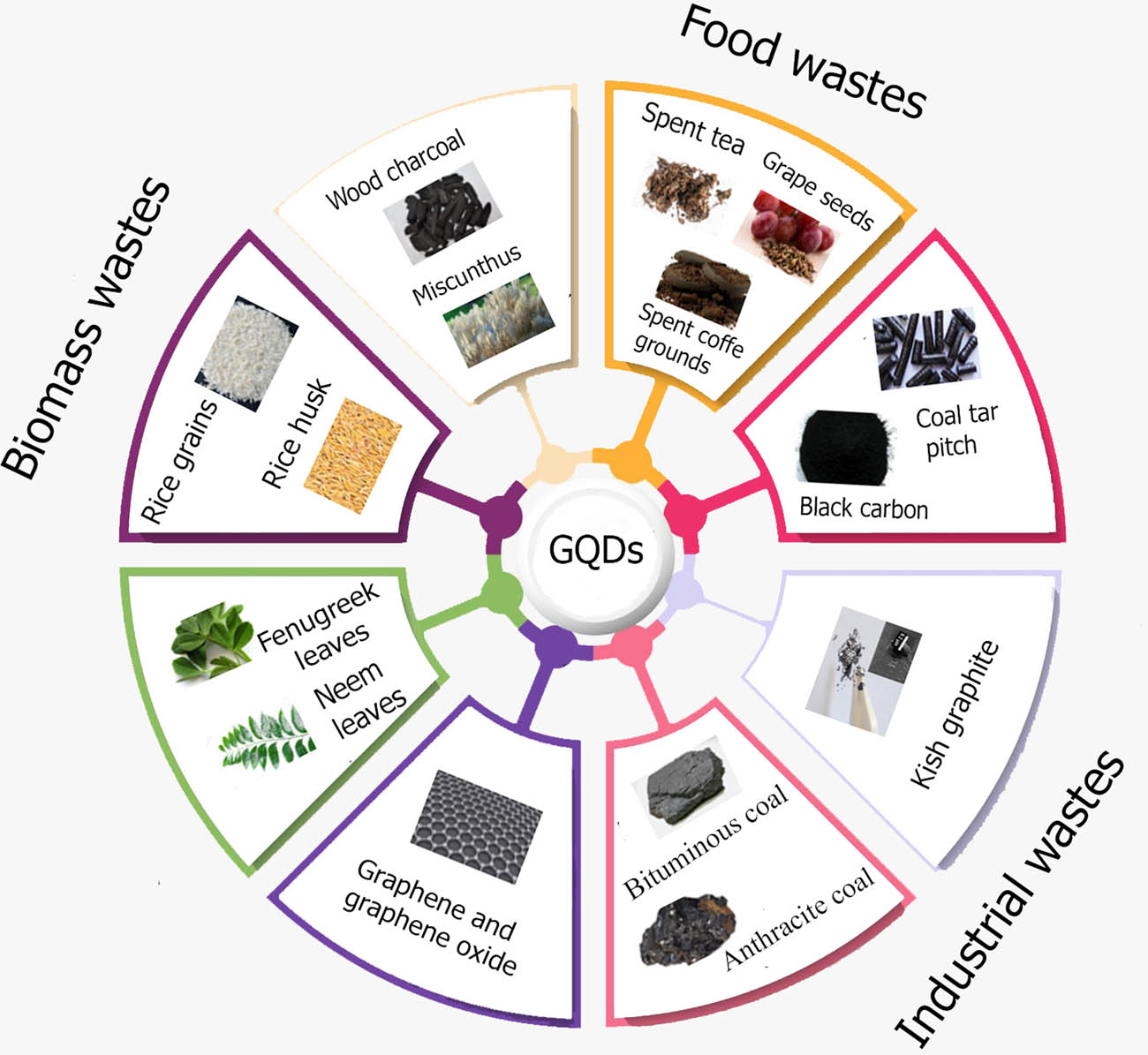

2.1.5.2 GQDs

GQDs are zero-dimensional (0D) derivatives of graphene [156,157]. They have unique physical and biological properties that are interesting for energy applications. The renewable, available, and inexpensive routes toward GQDs from biomass and industrial wastes are discussed. Figure 14 shows some types of waste used as precursors for producing GQDs. Natural biomass represents cost-effective and renewable resources for the fabrication of GQDs. High-quality GQDs with an average size of 3.9 nm have been obtained using the byproducts of rice milling [158]. RHs undergo pyrolysis to produce RH carbon. Strong acids were used to activate the RH carbon under a hydrothermal treatment at 200°C for 10 h to produce GQDs. The product achieved a yield of 15% and showed intense photoluminescence and high biocompatibility, exhibiting high functionality for biomedical fields [159]. Spent tea represents an inexpensive, renewable, and green biomass waste for GQDs. As a carbon precursor, spent tea has been used to synthesize GQDs with high yields of over 84% via simple microwave treatment [157].

Wastes used as precursors for synthesizing GQDs.

The green synthesis of GQDs by microwave treatment has been confirmed using grape seeds as the carbon source. The GQDs are easily collected and organized in an aqueous medium without any external direction; therefore, they are called “self-assembled” GQDs or (sGQDs). These sGQDs exhibited a QY of 31.79% and a production yield of 53.6%, with sizes in the range of 50–60 nm, which is large compared with other GQDs, i.e., sizes typically 1–8 nm [160].

Plant leaves have been used for the green production of GQDs without oxidation, reduction, passivation agents, or organic solvents [159]. It has been confirmed that biomass pyrolysis treatments can produce a disordered, highly porous form of carbon on the nanometer scale. The thermal treatment of this disordered carbon at 90°C can lead to GQDs at a large scale, which is favorable for inexpensive mercantile production [161]. Neem leaves (Azadirachta indica) have been treated for the fabrication of GO sheets at 300°C for 2 h. After 8 h of treatment, these GO sheets were subsequently broken down into GQDs. The process used green and facile one-pot hydrothermal synthesis method with water as a solvent [162]. The as-produced GQDs were highly photostable and suitable for white light-emitting diodes (LEDs); they had an average size of 5 nm and a high QY of 41.2% [163]. Fenugreek leaves (Trigonella foenum-graecum), a type of green plant, can also be used to produce GQDs. Fenugreek extracts are highly carbonaceous with many hydrocarbons, making them an ideal precursor for GQDs synthesis [163].

Ugly food (any food considered imperfect to sell) is one type of food waste; rice grains are included in this group. According to the FAO of the United Nations, these waste grains contain a significant carbon footprint [164]. Rice grains have been used as a carbon source in a facile and green approach to synthesize monodispersed GQDs with sizes of 2–6.5 nm. The QY of the as-produced GQDs in water depends on their size; it increases from 16% to 24% with a decrease in GQDs’ size (from 6.5 to 2.0 nm) [165].

GQDs have been synthesized by the electrochemical scissoring of wood charcoal, a type of biomass. Electrochemical oxidation has been used to cut charcoal graphene sheets into very small particles called E-GQDs [159]. The size of the product was uniform and ∼5 nm, with optical and structural properties. Wood charcoal is a cheap and widely available source for synthesizing E-GQDs [166].

Miscanthus or silver grass is a genus of African, Eurasian, and Pacific Island plants in the grass family. It is a biorefinery waste comprising sugars and depolymerized lignin. A straightforward, effective, and general strategy has been developed for fabricating GQDs from Miscanthus (M-GQDs). As-produced M-GQDs show many advantages, such as few-layer graphene-like single crystalline structure, sulfur and nitrogen codoping, bright fluorescence, excitation-dependent photoluminescence, and long fluorescence lifetime (11.95 ns). Moreover, M-GQDs exhibit notable fluorescence reduction with good linearity (≤0.995) toward a trace amount of Fe3+. M-GQDs are built from well-dispersed NPs with a uniform size of 4.05 ± 0.61 nm [167].

Green production of highly fluorescent GQDs with a high yield of more than 80 wt% was obtained using coal tar pitch, a thick liquid byproduct from coke and coal gas production. The as-produced GQDs exhibit a tight size distribution of 1.7 ± 0.4 nm and high solubility in aqueous solutions [168]. Additionally, gram-scale GQDs with a yield of 75 wt% and high purity (99.96 wt%) were obtained using Vulcan XC-72 carbon black from battery and fuel cell manufacturing [169]. These GQDs have exhibited multicolor photoluminescence, from green to light red. Bituminous coal is one of the largest types of industrial waste, especially in power plants, and has been used to synthesize GQDs with a uniform size of 2.96 ± 0.96 nm [170]. Anthracite coal is another coal type used to synthesize GQDs, similar to bituminous coal. The average diameter of the GQDs produced from anthracite coal was 29 ± 11 nm [171,172]. GO is a typical starting material for nanosized GQDs when in the presence of other facilitating functional groups [173]. A new path of transforming industrial waste, particularly car bumper waste, into CNMs has also been developed. Reduced GO (rGO) was obtained as a catalyst for the upcycling of waste bumper via an economical thermal decomposition method [174]. GQDs have been synthesized using GO as a precursor through acidic oxidation. The as-produced GQDs exhibited photoluminescence features and the same properties as peroxide catalytic functionality, which can be used to detect H2O2 with a detection limit of 87 nm [175]. GQDs have been obtained from GO by hydrothermal reaction. GQDs with 40 nm uniform lateral dimensions, a yield of 32%, and a QY of 3.6% have been obtained by the hydrothermal cutting method. This simple method shows the notable advantages of a one-step reaction and short time consumption [176]. This method was also used to synthesize GQDs from RH, neem leaf, and fenugreek leaf waste. GQDs were produced with QYs of 41.2, 38.9, and 15% from neem leaves, fenugreek leaves, and RH, respectively. A facile synthesis method of high-quality GQDs from 3D graphene grown by chemical vapor decomposition has been used via a new, highly efficient, and green electrochemical strategy. The as-produced GQDs possess a uniform distribution in diameter (3 nm) and thickness and are mostly single-layered [177]. Also, GQDs have been synthesized using wood charcoal in the same technique. This product is called E-GQDs and is uniform in size (∼5 nm) but is not a big different from this precursor and 3D graphene.

Wang and his team [178] reported a green fractionation bottom-up (two-step) approach to convert lignin into glowing carbon nanocrystal GQDs, as shown in Figure 15. Alkali lignin is fractionated using an acid hydrotrope, which can be readily recovered for sustainability. The GQDs had a nanoscale few-layer structure, were water-soluble, and exhibited long-term photostability, bright fluorescence (ultrahigh UV transmission ≥ 305 nm), outstanding biocompatibility, and ultralow cytotoxicity. With these features, lignin-based GQDs were utilized as probes for detecting hydrogen peroxide in biological systems. The researchers succeeded in detecting low concentrations of hydrogen peroxide (reaching 0.13 nM). Further theoretical validation for GQDs’ ultrasensitivity was confirmed using density functional theory. Synthesis methods of different carbon-based nanomaterials derived from different biomass/waste sources are listed in Table 1.

![Figure 15

Schematic for the green bottom-up synthesis of lignin-based GQDs via a two-step method. Copied with permission from ref. [178]; Royal Society of Chemistry, 2019.](/document/doi/10.1515/ntrev-2022-0129/asset/graphic/j_ntrev-2022-0129_fig_015.jpg)

Schematic for the green bottom-up synthesis of lignin-based GQDs via a two-step method. Copied with permission from ref. [178]; Royal Society of Chemistry, 2019.

Synthesis of different carbon-based nanomaterials derived from different biomass/waste sources

| Carbon nanomaterials | Biomass source | Synthesis method/technique | Reagent | Conditions | Result/yield morphology and structure | Ref. |

|---|---|---|---|---|---|---|

| Activated carbon | Tamarind fruit shell | Pyrolysis process/CVD technique | KOH/Ar gas | Muffle (800°C for 140 min) and Ar (5°C/min and 100 SCCM) | Activated carbon nanosheets | [179] |

| Coconut shells | Concurrent activation and magnetization processes on the biochars of coconut shells | FeCl3.6H2O/N2 gas | Mixing (2 h), oven (120°C), muffle (700°C), and pH (∼6.5–7.0) | Magnetic activated carbon | [180] | |

| RHs and straw | Pulping processes (pyrolysis)/biological process | Sodium hydroxide/sodium sulfite/sodium sulfite–sodium carbonate blend/NaOH/ammonia thermodesorption/cellulose and peroxidase enzymes | Pulping processes: Na2O (140°C for 2 h), NaOH (60°C for 1 h)Biological process: activation (27°C for 14 days) | Microporous activated carbons | [181] | |

| Carbon nanotubes | Palm kernel shell biomass | Fast microwave pyrolysis | N2 gas | Microwave (200°C), N2 (30 min), and microwave (1,200, 1,300, and 1,400°C for 30 min) | CNTs | [182] |

| Waste polypropylene | Pyrolysis | Waste polypropylene/nickel nitrate | Thermal treatment (H2 at 10 SCCM and Ar at 90 SCCM; ramp temperature [30°C/min], and reaction temperature [600°C, 700°C, and 800°C]), and cooling (RT) | MWCNTs | [183] | |

| Plastic wastes (low-density polyethylene, high-density polyethylene, polypropylene, polyethylene terephthalate, and polystyrene) | Pyrolysis | Ni–Mo/Al2O3 catalyst/H2/N2 gases | Catalytic conditions (600°C for 1 h of H2 [50 SCCM] and N2 [30 SCCM], and then 650°C/N2) | MWCNTs | [184] | |

| CNTs (650°C then RT, N2 at 100 SCCM) | ||||||

| Pomelo peel biomass | Microwave-assisted pyrolysis | Tantalum pentoxide, melamine, trithiocyanuric acid, potassium hydroxide, sulfuric acid, n-Hexane, and surfactant | Pyrolysis (N2 at 400 ml/min and 600°C for 30 min) | Ta-decorated and N, S-doped, CNT enriched mesoporous electrocatalyst | [185] | |

| Liquefied larch sawdust | In situ polymerization, foaming, and carbonization | Formaldehyde solution/sodium carbonate/sulfuric acid/tween 80/n-hexane | Carbonization (N2 at 800°C for 2 h) | MWCNTs/carbon foam nanocomposites | [186] | |

| Carbon nanofiber | Loofah biomass | Calcination/CVD | Dopamine hydrochloride/Tris-Cl solution/N2/Ni (NO3)2 solution/ethanol | Carbonization (N2 at 500°C for 2 h), drying (80°C), soaking (1 day), and further treatment (N2 at 800°C for 2 h) | CNFs | [57] |

| Rubber fruit shell | Hydrothermal process | H2SO4/H3PO4/NaOH | Rinsing (4 h), drying (60°C for 24 h), centrifugation (10,000 rpm for 30 min), stirring (300 rpm and 60°C for 30 h), and drying (90°C) | CNFs | [187] | |

| Sapindus trifoliatus nut shells | High-temperature carbonization followed by physical activation method | N2/Alumina boat/CO2 | Carbonization (N2 at 700°C for 3 h), furnace under N2 flow (80 cm3 min−1) at a heating rate of 5°C min−1 up to 700°C, and then CO2 for 2 h | CNFs | [188] | |

| Pithecellobium Jiringa shell waste | Pyrolysis | KOH/ZnCl2/N2 gas/CO2 gas | Precarbonization (250°C), carbonization (N2 at 600°C), and activation (CO2 for 850°C) | Carbon nanofiber/nanosheet | [189] | |

| Bamboo waste materials | Pyrolysis | KOH/N2 gas/CO2 gas | Carbonization (N2 for 1 h at 600–900°C) and activation (CO2 at 900°C for 2.5 h). | Highly porous activated carbon nanofibers | [190] | |

| Graphene | Pomelo peels | Ultralight microwave absorption | Hydrogen peroxide (H2O2) and acetic acid (HAc) | Autoclave (120°C for 3 h) and pyrolysis (Ar at 800°C for 3 h) | Graphene-like porous carbon nanosheets | [191] |

| Sawdust (from Betula platyphylla) | Shear exfoliation and carbothermal redox process | FeCl3·6H2O and hydrochloric acid | Precarbonization (N2 at 450°C for 2 h), annealing (N2 for 1,000°C for 3 h at 10°C min−1), and centrifugation (3,000 rpm for 20 min) | Graphene sheets | [192] | |

| Orange peel wastes | Ball-milled/the carbonization/activation process | KOH/N2/HCl | Precarbonization (N2 at 400°C for 2 h), stirring (RT for 12 h), and drying (90°C overnight) | Honeycomb-like architecture with a 3D hierarchically ordered pore size distribution | [193] | |

| Biomass film (kraft lignin [KL] and cellulose nanofibers) | Ultrafast laser writing technique | CNFs/KL/NaOH | — | Three-dimensional interconnected porous graphene network with defect-rich boundaries | [194] | |

| Quantum Dots | Spent black tea | Hydrothermal treatment | Sodium hydroxide (NaOH), nitric acid (HNO3 > 67%) and sulfuric acid (H2SO4 > 97%) were purchased from Fisher Scientific, UK. The metal salts include CoCl2, CaCl2, AlCl3, AgNO3, CrCl3, FeCl2, CuCl2, ZnCl2, SrCl2, FeCl3, PbCl2, NiCl2, MoCl2, LiCl, NaCl, MnCl2, and MgCl2 | Autoclave (200°C for 12 h) and dialysis (0.1 µm PVDF for 1 day) | NPs/Nanospheres (NSs)/GQDs | [195] |

| Corn stalk shell | Hydrothermal approach in near-critical water pyrolysis | — | Reaction (270°C and 5 MPa for 10 min), cooling (RT), and dialysis bag (1,000 Da for 24 h) | CQDs | [196] | |

| Lemon peel waste | Hydrothermal process | Waste lemon peels, titanium isopropoxide, methyl, 6-aminohexanoic acid, and sodium hypo chloride | Oven (100°C for 10 h), drying (100°C for 4 h), pH = ∼7, autoclave (200°C for 12 h), centrifugation (10,000 rpm for 30 min), and drying (100°C) | CQDs | [197] |

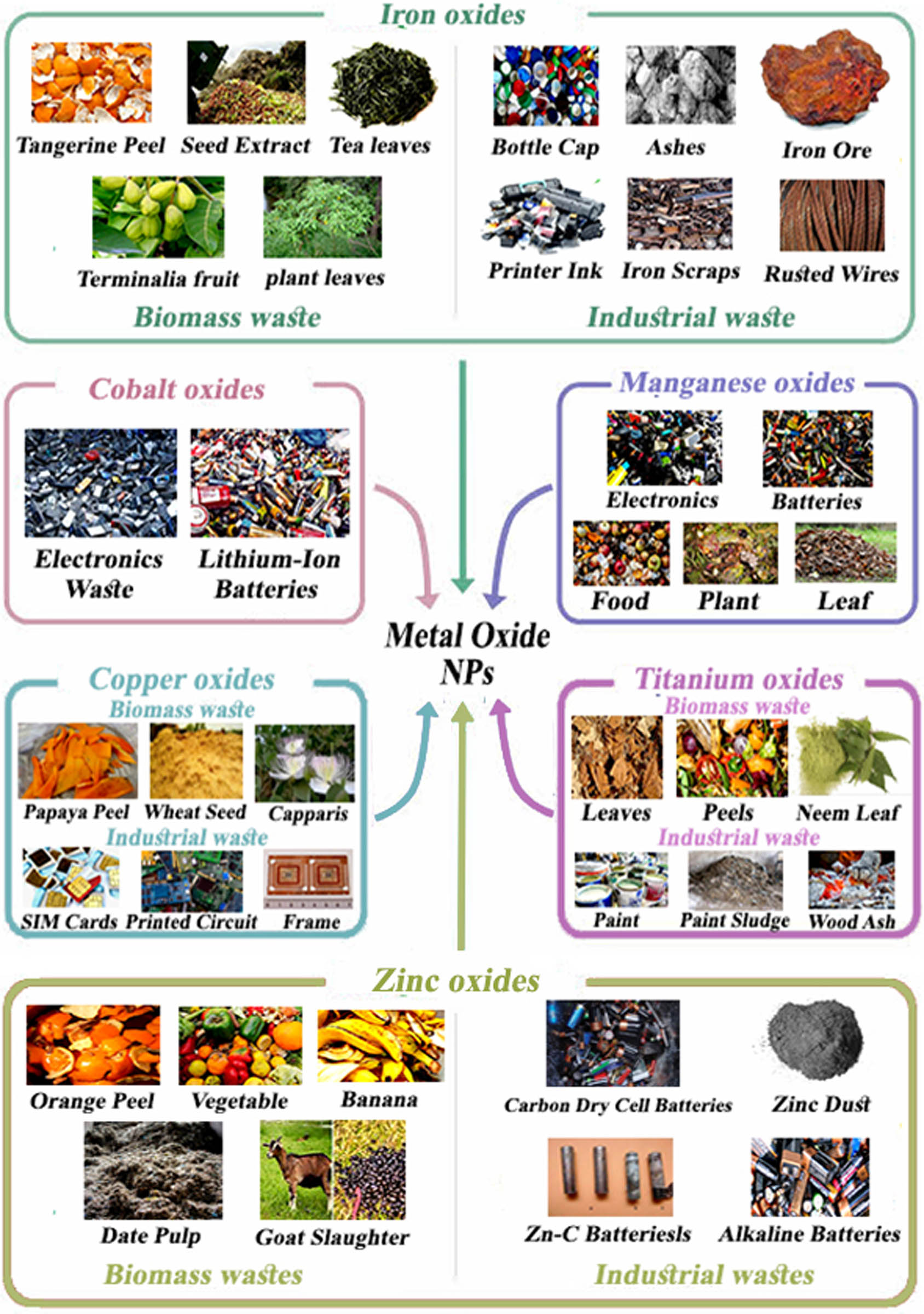

2.2 Metal oxide-based nanomaterials

Metal oxides have been used in energy storage, energy conversion, and catalysis based on need. This usage only increases based on improvements in metal oxides’ physical and chemical properties and the observation of new sources [198–200]. Figure 16 shows the wastes used to produce the different metal oxide NPs.

Wastes used as precursors for synthesizing different types of metal oxide nanoparticles.

The chemical treatment of metals, such as Mn and Co, and their oxides for NP fabrication has several advantages, such as high purity, size controllability, and high yield. However, many disadvantages also exist, such as the high cost of precursors and their poor availability. Conversely, extracting these materials from different waste sources has received much attention due to high production, low cost, increased availability, ease of handling, safety, speed, and high production yield. For recycling waste residues, various physical, chemical, and biological techniques have been reported to produce metal oxide NPs [201,202]. However, LiBs sources still produce a large amount of metal oxide. Current issues facing the production of metal oxides are based on green and biosynthesis techniques.

2.2.1 Manganese oxide

More than 60 billion alkaline manganese-based batteries are manufactured annually. The development of technology to recover or isolate Mn from Co, Ni, and Li is critical as Mn concentration of 3 g L−1 greatly reduces the selective separation of Co and Ni [203]. Since industrial LiB wastes typically contain both active materials and impurities, such as Al, Fe, and Cu, few major recycling technologies are available for recovering Mn [204]. Mn can be extracted in different forms, such as powder, metal, metal oxide, and NM, from electronic waste, battery waste, etc., [5,16,204,205]. Additionally, nanoscale MnO2 can be extracted from the waste of portable batteries [206–211], whereas porous flower-like MnO2-NiO has been recovered from spent Zn–Mn batteries [212], and MnCo2O4 and Li x MnO x+1 have been recovered from spent LiBs [213].

Interconnected spheroidal MnO x NPs, in nanorods (NRs) and nanoflowers have been recovered using Urginea sanguinea [214]. A green synthesis method for MnO2 NPs, with sizes of approximately 32 nm, has been achieved using Yucca gloriosa leaf extract and was stabilized using turmeric extract [215]. As a reducing and stabilizing agent, clove (i.e., Syzygium aromaticum extract) was used to prepare MnO NPs [216]. The successful biosynthesis of MnO2 NPs from rhizophytic bacteria Paenibacillus polymyxa strain is achieved. Utilization of KMnO4 as a precursor with an aqueous leaf extract of Kalopanax pictus for the production of MnO2 NPs, with an average particle size of 19.2 nm and a particle diameter ranging from 1 to 60 nm, was also achieved [217]. MnO2 NRs with an average size of 40–50 nm were successfully fabricated using a leaf extract of Phyllanthus amarus [218]. Mn3O4 NPs with an average crystallite size of 44 nm were recovered using manganese sulfate monohydrate as the precursor salt and leaf extract of Malabar nut (Adhatoda vasica Nees/Justicia adhatoda) as the reductant [218]. Moreover, Ananas comosus (L.) peel extract was used to fabricate Mn3O4 nanospheres with an average size of 10–34 nm [219]. Chen et al. also showed recovery in MnO2/Fe(0) composites from Li-ion batteries via ferrous sulfate, lithium manganite, and the hydrothermal technique. XRD peaks confirmed the presence of the β-MnO2 phase (Figure 17) [220]. Min et al. [221] have also reported the recovery of MnO2 from spent LiBs, which can fundamentally be formed from three steps: (1) pretreatment, (2) leaching, and (3) catalyst preparation (Figure 18).

![Figure 17

(a) TEM, (b) SEM, and (c–e) mapping images of MnO2/Fe(0) composites. Copied with permission from ref. [220]; Elsevier, 2021.](/document/doi/10.1515/ntrev-2022-0129/asset/graphic/j_ntrev-2022-0129_fig_017.jpg)