Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

Abstract

The carbon nanotube (CNT) is becoming more popular due to their low-density, high-strength etc. Among CNTs, multi-walled carbon nanotubes (MWCNTs) are gaining more importance due to their enhanced thermal and electrical conductivity. The present research is exploring the applicability of MWCNTs reinforced with AA2024-T351 alloys for electromechanical applications. This study is currently undertaken for using MWCNTs as a reinforcing particulate for the purpose to enhance the characteristics including low density, high strength, and hardness together with excellent thermal and electrical conductivity of the aluminum alloy matrices. Therefore, this article provides a state-of-the-art experimental approach to fabricate and furthermore, to evaluate the mechanical characteristics, microstructural analysis, and fatigue behavior of Al–Cu–Mg–T351/MWCNT composites under both the mechanical and thermal loading by utilizing powder technology processing route. The uniform dispersion of CNTs has been exposed using ball milling process. Results revealed that the MWCNTs provide extraordinary synergistic strength, enhances fatigue resistance, creep resistance, ductility, and other mechanical characteristics of the aluminum-based composites. The mechanical loading of the composite exhibited increased properties as compared to thermal-loaded aluminum-MWCNT composites. Findings conclude that the maximum hardness of 35Hv obtained for sintered AA2024-T351 and 45Hv for 0.5% MWCNT heat-treated samples indicate that the addition of MWCNT enhances the hardness which may be because CNT is evenly dispersed at the interfacial space. Maximum UTS of 105.21 MPa was obtained with 0.5% MWCNT for sintered composites. Microstructural analysis of the Al–Cu–Mg–T351/MWCNTs composite exhibits reasonably uniform distribution, void formation, and good interfacial bonding. X-ray Diffraction method patterns of fabricated composite shows that the CNT is present at 2β = 23.6 and 44.6°, whereas high peaks of aluminum are present at uniform dispersed positions. Transmission electron magnifying instrument study further substantiates the above research. Fracture micrographs of the Al–Cu–Mg–T351/MWCNTs composite portray the resistant nature of the nanotubes due to the presence of CNTs, Al–Cu, and aluminum carbide elements in the alloy and the reactions that happened during heat treatment. This significant improvement was attributed to the shear interactions among the constituents and high load carrying capacity of the CNT, uniform dispersion, and interface bond strength among the matrix and constituents. The findings in the study will undoubtedly be beneficial for the development of high-strength, MWCNTs/Al–Cu–Mg–T351, matrix composites in future for multifunctional applications on broader spectrum.

1 Introduction

In metal matrix nanoparticle composites (MNCs), the nanoscaled reinforcement is mixed with the matrix material to attain excellent mechanical, corrosion, and dynamic properties at room temperature. It also has various advantageous properties like excellent wear resistance, fatigue, and creep resistance [1,2]. There are various methods to fabricate MNCs such as solid-state, liquid-state, in situ processes, and deposition methods which are the most promising techniques to fabricate MNCs for structural applications. MNCs have the most efficient properties, which vary from bulk materials. The nanoscaled reinforcement-based composite material has attracted much interest in industries, while very minimum interest for domestic purposes. Generally, inorganic nanoparticles are dispersed in polymer or metal or ceramic. In comparison with the macro and micro- reinforced particulate sizes, nanoparticle have an influence on the material characteristics like, chemical, mechanical, and physicochemical properties [3]. Due to its surface to volume ratio characteristics, a minimum amount of reinforcement will improve the MNCs property significantly. Recently, carbon nanotubes (CNTs) have been considered as ideal reinforcements because of their higher aspect ratio, strength, and thermomechanical property. To overcome the limitations of micro/macro-reinforced composites, nanoparticle-reinforced composite is a good alternative solution [4,5,6]. Though it provides a solution, the dispersion of nanoparticle into the matrix material is the major challenge faced by the researchers [7,8].

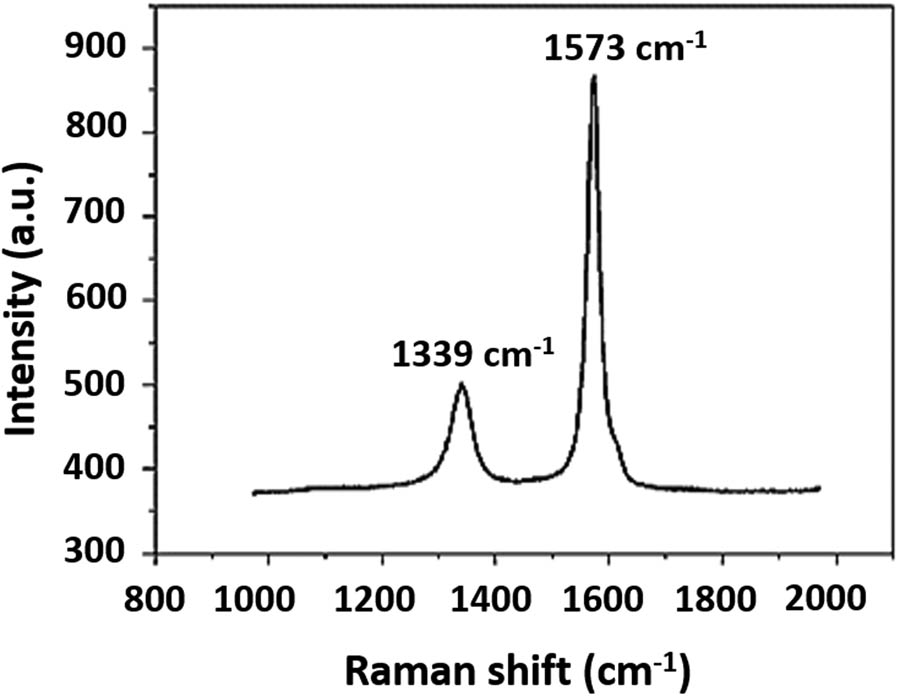

Aluminum matrix composites (AMCs) show better mechanical and corrosion resistance properties than pure aluminum (Al) and Al alloys. AMCs have an extensive variety of applications like sporting goods, electronic packaging, armors, nuclear, bio-technology, aerospace, marine, automotive, and transportation industries due to its high Young’s modulus, specific strength, wear resistance, and lightweight. Besides, Al and its alloys have more advantages than other composite matrixes, such as good damping capacities, high stiffness and specific strength, good machinability, and dimensional stability. Compared to all other Al alloys, AA2024-T351 is used in various applications because of its mechanical and corrosion resistance property, and only limited researchers have selected AA2024-T351 as matrix material [9,10]. Moreover, Al is also a low density with good stiffness metal that can be processed either by a liquid/powder metallurgy technique to make a composite. Extensive work has been carried out by several researchers using SiC, Al2O3, TiB2, etc., as reinforcing material in processing Al composite. To strengthen the matrix material nano-sized ceramic particles are the latest interest of the researchers as it has good ductility, better fatigue, and better resistance to creep at high temperature. In the past few years, metal MNCs have attracted various applications because of their mechanical properties compared to microparticle reinforcement. The purity of the CNT also serves a crucial purpose in the property [11]. The purity of the multi-walled CNT (MWCNT) can be evaluated for defects based on Raman spectroscopy [11,12], as shown in Figure 1.

The ratio of the G-band to the D-band clearly shows that the intensity will be 1,300–1,680/cm, and the G-band intensity represents the amount of amorphous content present in the CNT. The diminution in the intensity of G-band represents the high purity of the CNT [11,12].

Different kinds of matrix/particulate reinforcing constituent materials used and the conclusions drawn from past research studies are given in Table 1.

Investigations on AMCs by researchers

| Investigators | Matrix | Reinforcement | Remarks | References |

|---|---|---|---|---|

| Liao and Tan. (2011) | Al | CNT of 0.5 wt% | Increase in tensile strength by 66% with minor decrease in ductility | [13] |

| Choi et al. (2010) | Al | MWCNT of 0, 1.5, 3, 4.5, and 6 vol% | CNT increases strength and wear resistance. Grain size also plays a significant role | [14] |

| Stein et al. (2012) | AA5083 | MWCNT of 1.5 wt% | Tensile, Young’s modulus, and yield strength increased by 18%, 3%, and 27%, respectively. The load transfer mechanism plays a dominant role in CNT/matrix | [15] |

| Stein et al. (2014) | AA5083 | MWCNT of 0, 0.5, 1, 1.5, and 2 wt% | With the concentration of CNTs, mechanical properties significantly increase persistently up to 1.5 wt%. The mechanical property is decreased by increasing the concentration of CNT | [11] |

| MWCNT of 0, 0.74, 1.47, 2.20, and 2.93 vol% | ||||

| Kim et al. (2013) | A356 | Al2O3 of 10, 15, and 20 vol% | Al2O3 helps to disperse the CNT into the matrix material. Excess amount of Al2O3 or CNT influenced the material because of cluster formation and, indeed, very low wettability | [12] |

| CNTs of 1, 2, and 3 vol% | ||||

| Fukuda et al. (2010) | AZ31B (Mg alloy) | CNT of 0.89 and 2.66 vol% | Mg alloy composite material’s corrosion resistance is increased due to the addition of CNT | [16] |

| Tak et al. (2011) | Al | Al2O3 of 5 vol% and CNT of 1–10 vol% | The electrical conductivity of the material is increased by adding CNT. Machining accuracy was achieved using EDM | [17] |

| Kim and Kim (2014) | Al | Al2O3 of 10, 15, and 20 vol% | Al2O3 helps to disperse the CNT into the matrix material. The hardness value is increased significantly. At the surface, the reinforcement was aligned in a longitudinal direction | [18] |

| CNTs of 1, 2, and 3 vol% | ||||

| Wu et al. (2011) | AA6061 | CNT of 1 wt% | Increased hardness value was obtained at 620°C. Relatively weaker bonding and lower density was obtained at 600°C (lower temperature). To achieve an optimal microstructure, carbide formation at the interfaces of the reinforcement and matrix material must be controlled | [19] |

| Bakshi et al. (2011) | Al | CNT of 1–10 vol% | The interface between matrix and CNT is important; improper bonding could lead to failure in load transfer to the CNT | [20] |

| Li et al. (2010) | Mg | CNT of 0.1, 0.5, and 1 wt% | On addition of a minimum amount of CNT, the mechanical property was improved. No carbide formation was observed through X-ray diffraction method (XRD) results. CNT was well dispersed into the Mg matrix | [21] |

| Kondoh et al. (2014) | AA6063 | CNT of 0.56 and 1.22 vol% | Yield strength value decreases gradually on addition of CNT due to the inadequate effect of hardening of by Mg2Si precipitates | [22] |

| Kang et al. (2012) | Al | CNT of 1 wt% | Aluminum carbide (Al4C3) was created at the MWCNT surface. The mechanical property of the composite material was enhanced | [23] |

| Gupta et al. (2012) | UHMWPE | Al2O3 of 2–5 wt% | UHMWPE-reinforced CNT shows enhanced protein density. The wettability of the material is also increased, and a significant role was played by surface energy | [24] |

| CNT of 2–4 wt% | ||||

| Thakur et al. (2007) | Mg | CNT of 0.3, 0.5, 0.7, and 1 wt% and vol% | The coefficient of thermal expansion value of Mg is reduced because of nanosized SiC-CNT addition. By adding SiC and nanosized CNT, the micro-hardness value of the developed composite material was increased. When nanosized CNT, as well as SiC, were incorporated into the matrix material, 0.2% enhancement in tensile and yield strength, and reduced failure strain were obtained | [25] |

| SiC of 0.7, 0.5, and 0.3 wt% and 0.4, 0.3, and 0.2 vol% | ||||

| Goh et al. (2008) | Mg | CNT of 0.3, 1.3, 1.6, and 2 wt% | During tensile deformation of Mg alloy and Mg-1.3 wt% CNT nanocomposites, there are some instigations of both basal slidings as well as a nonbasal slip. The ductility of the material is improved in Mg-CNT nanocomposites due to prismatic slip. Compared to Mg alloy, the developed composite shows increased hardness value | [26] |

| Esawi AMK (2010) | Al | MWCNT of 0.5, 1, 2, and 5 wt% | Mechanical property values were enhanced as a result of the addition of MWCNT, and the predicted values also close to the tested values. The predicted value varied at 5 wt% of CNT addition | [27] |

| The cluster formation of CNT affected the mechanical property at 5 wt% CNT | ||||

| Kwon et al. (2014) | AA6061 | CNT of 6 wt% and SiC of 1 vol% | The Vickers hardness value was enhanced by adding SiC and CNT because of the increase in the milling time. The hardness value is five times higher than that of AA6061 | [28] |

Bradbury et al. [6] studied the microstructure of Al and MWCNT using transmission electron magnifying instrument (TEM) images. The MWCNT was on the Al particle superficial substrate, and during the mechanical alloying process, the length of the MWCNT was broken; however, no crack was found in the interface with the matrix. The microstructure characterization of the tensile specimen and scanning electron microscope (SEM) images revealed the occurrence of the fracture surface on the tensile specimens and some CNT particles were observed in the cracks [6]. Nam (2012) observed from the SEM image that the CNT is attached along with the Cu particle. The CNT was uniformly dispersed in the Al–Cu alloy matrix material. From the XRD, it is clearly shown that there is no sign of Al4C3 between Al–Cu and CNT [29]. Akbarpour et al. [30] observed that along with the uniformly distributed CNT nanoparticles in the matrices of the composite some cluster formation was also visible in the SEM image because of the inclusion of CNT. The grain size of the matrix material showed some deviation from the standard size [30]. Q. Li (2009) investigated the microstructure using the SEM image of Mg alloy-MWCNT composite and found a big bundle of cluster formation. The presence of MWCNT without any damage is confirmed using Raman spectroscopy [21]. Kwon et al. (2010) observed the microstructure of the Al-CNT composite using the FE-SEM image. There is no change in the diameter of the CNT particle, but the length was reduced during the de-binding process. The CNT was uniformly and omnidirectionally distributed on the surface of each Al particle [31]. Kuzumaki et al. used the powder metallurgy process for the first time to fabricate CNT/Al composite. They used carbon powder containing approximately 60 vol% of CNT. They mixed 5–10% of carbon powder with Al powder with a size of 40 μm and having a purity of 99.99%. The mix was then agitated in the ethanol solution at 300 rpm for 30 mins. Then, the composite powder was removed from the solution and prepared by the vacuum drying method. Due to the impurity of the CNT, non-uniform dispersion is observed in the Al powder [32]. Xu et al. mixed the pure CNT produced by catalytic decomposition of propylene, with 99.5% purity, with powdered Al having an average particle size of 70 μm. Different wt% of CNTs were mixed with 35 g Al powder by hand grinding for 30 min. They observed some agglomeration of CNT at the grain boundary of Al; this agglomeration was probably due to the hand grinding process [33]. However, unlike Kuzumaki, Xu et al. could see some interfacial reactions in the form of carbide between Al and CNT. Esawi et al. reported that the strength was enhanced as the CNT content increased within a specific range. The best result was obtained when the content of CNT was 2 wt%, while further addition of CNT caused a deterioration in strength [34]. Zhang et al. investigated the CNT/SiC/Al 6061 hybrid composite processed by squeeze casting and found that the heat treatment improved the bond strength among CNT, SiC, and Al, which enhanced the strength of the composite [35]. However, Zhao et al. investigated the CNT/Al 6061 composite made by FSP and found that the T6 heat treatment strengthening effect was insignificant [36].

Hence, in the recent few years, CNTs are gaining importance in processing Al composite. MWCNT is a material having low density, high strength, and hardness together with excellent thermal and electrical conductivity. This research work uses the MWCNT as a reinforcing constituent to improve the characteristics of the Al alloy matrix. The popularity of MWCNT is due to its specific characteristics such as mechanical strength (15–20 times more than steel), density (5 times lighter than steel), thermal conductivity nearly equal to that of diamond and almost 5 times that of copper, and electrical conductivity same as that of copper [37]. These new type of composites promise application in the lightweight components, nonlinear optics, batteries, nanowires, sensors, and high strength devices. A study on the thermal and mechanical properties of CNT has revealed that it has Young’s modulus of 800 GPa with a yield strength of 20 GPa [38]. Work on the mechanical behavior of CNT composite has been conducted using TEM to investigate the interfacial structure and mechanical properties [39]. The hardness of Al + 5% SWCNT was 78% higher than that of Al. An addition of 1% MWCNT to Al shows enormous enhancement in yield strength (almost 500%), which promises this material for several industrial applications [40]. Further, nano-mechanics of CNT composite indicates that SWCNTs have elastic modulus around 1TPa and can withstand 5–10% axial strength corresponding to the stress of about 50 GPa [41].

Thermo-mechanical characteristics of CNT bring them to cover a larger sector of industrial applications [42]. Due to its enhanced thermal and electrical conductivity, CNTs excel in wide industrial applications where the conventional material fails [43]. The work on the hot pressing technique of Al-CNT composites reveals a moderate increase in electrical conductivity at room temperature when compared with an increased volume fraction of the CNTs [33]. The controlled mechanical milling process of Al-CNT exhibited a strong surface interface bonding among matrix and reinforcement [44]. Al-CNT composite of 4.5 vol% MWCNT reveals elastic yield/proof strength of 620 MPa and fractural toughness of 61 MPa mm1/2, which is almost 15 and 7 times higher, respectively, as compared to the matrix [45]. The dispersion quality of CNT governs the homogeneity and hence ultimate mechanical property of the composite. Studies have shown that CNT affects the mechanical properties of the base Al, and the composite can be produced by the powder metallurgy technique, as observed in other studies [46,47].

Since Al–Cu–Mg–T351 is utterly a novel matrix material with high physicomechanical characteristics and as far as the existing studies/sources are concerned, the outcomes have inferred that, in the current decade, Al–Cu–Mg–T351-based metallic composites with MWCNTs as a reinforcing particulate have been characterized by limited researchers to investigate their suitable potential in high-strength structural applications. The processing fabrication method has been optimized by using combined effect of ball-milling and powder-metallurgy. Such novel composites provide significant characteristics and offers promising application in the industrial automotive, aircraft, electromechanical, lightweight component, nonlinear optics, batteries, nanowires, sensors, and high-strength devices. Additionally, MWCNT is a material having low density, high strength, and hardness together with excellent thermal and electrical conductivity. This research work uses the MWCNT as a reinforcing constituent to improve the characteristics of the Al alloy matrix by using optimized mechanical milling and powder metallurgy techniques. As the load transfer mechanism plays a dominant role in MWCNTs/Al–Cu–Mg–T351 matrix, the primary objective of this novel study is to escalate the physciomechanical, wear resistance, corrosion resistant, and thermal conductivity characteristics of the fabricated composites by ameliorating the surface interface bonding adherence among matrix and reinforcement and refining the grain size. The current work is focused on the study of MWCNT reinforced with AA2024-T351 alloy and its suitability for electromechanical applications as exhibited in Figure 2.

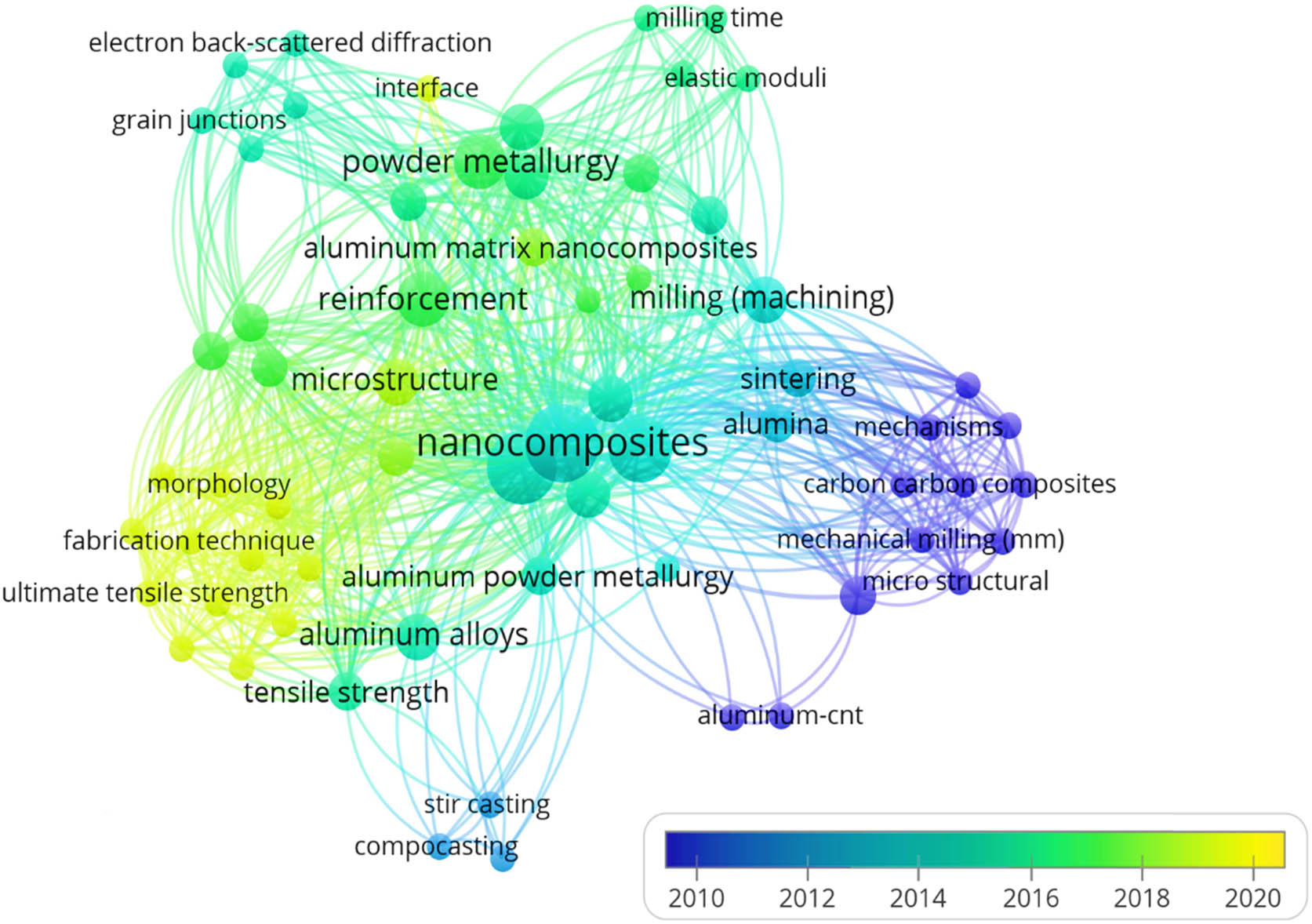

Systematic mapping summary of scientific advancements regarding an implication of MWCNTs on a physicomechanical, interface adhesion strength, and morphological characteristics of MWCNTs/Al–Cu–Mg–T351 alloy cast nanocomposites.

2 Experimental details

2.1 Materials

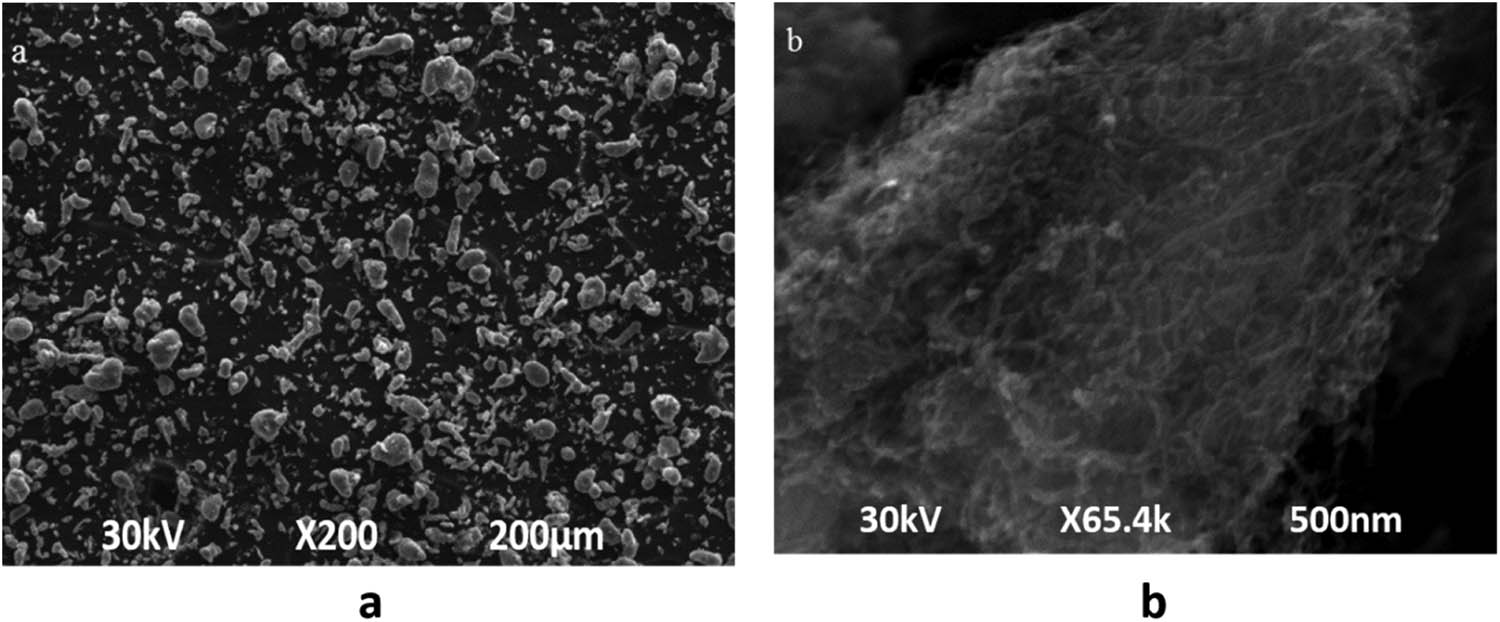

Al (AA2024-T351) powder with mechanical properties and chemical composition are presented in Tables 2 and 3, respectively. AA2024-T351 with physical/mechanical properties of density of 2.78 g/cm3, melting point of 660°C, hardness of 120 BHN, ultimate tensile strength of 469 MPa, and ductility/elongation of 19% has been used for matrix material. The SEM image of AA2024-T351 is shown in Figure 3(a). The properties of the AA2024-T351 alloy are presented in Table 3.

Chemical composition of AA2024-T351 alloy

| Elements | Mg | Si | Fe | Cu | Zn | Ti | Mn | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|

| Amount of wt% | 1.5 | 0.5 | 0.5 | 4.5 | 0.25 | 0.15 | 0.5 | 0.1 | Balance |

Properties of AA2024-T351 alloy

| Parameters | Average particle size (µm) | Melting point (°C) | Density (g/cm3) | Brinell hardness (BHN) | Ultimate tensile strength (MPa) | Ductility/elongation (%) |

|---|---|---|---|---|---|---|

| Values | 75 | 660 | 2.78 | 120 | 469 | 19 |

(a) SEM of Al–Cu–Mg–T351 Al powder and (b) SEM image of CNT powder (MWCNT).

Pristine MWCNT powder of 98% purity (Figure 3b) having 80–98 vol%, as assessed through SEM analysis, with no residual catalyst impurities was procured from Nanoshel USA. The MWCNT of 10–20 nm × 2–6 nm × 10–20 µm size, melting point of 3,652–3,697°C, and having a density of 1–2 g/cm3 has been used in the present work.

The Raman spectroscopy (LabRAM HR-HORIBA, France-SAS, micro-spectrometer), as revealed in Figure 4, indicates the prevalence of defect in MWCNT samples around two sharp curves 1,339 and 1,573/cm. The Raman-order peak at 1,573/cm was attributed by the molecular vibrational frequency mode of the graphite plane in the carbon–carbon atoms termed as first-order spectra G-band, and the frequency at 1,339/cm was named as the D-band mode because of the vibrational movement of non-bridging carbon–carbon dangling bonds in the structural disorder/defect in the plane-mode.

Raman spectra pattern of MWCNTs.

The previous outcomes reported by Papageorgiou et al. [48] presented a review article on the literature related to graphene and CNT-reinforced PMCs. The article focused on parameters affecting the mechanical behavior of such composites. The article described the use of Raman spectroscopy to evaluate the stress transfer efficiency among the constituents. This article also described the challenges and future scope of these composites.

2.2 Methods

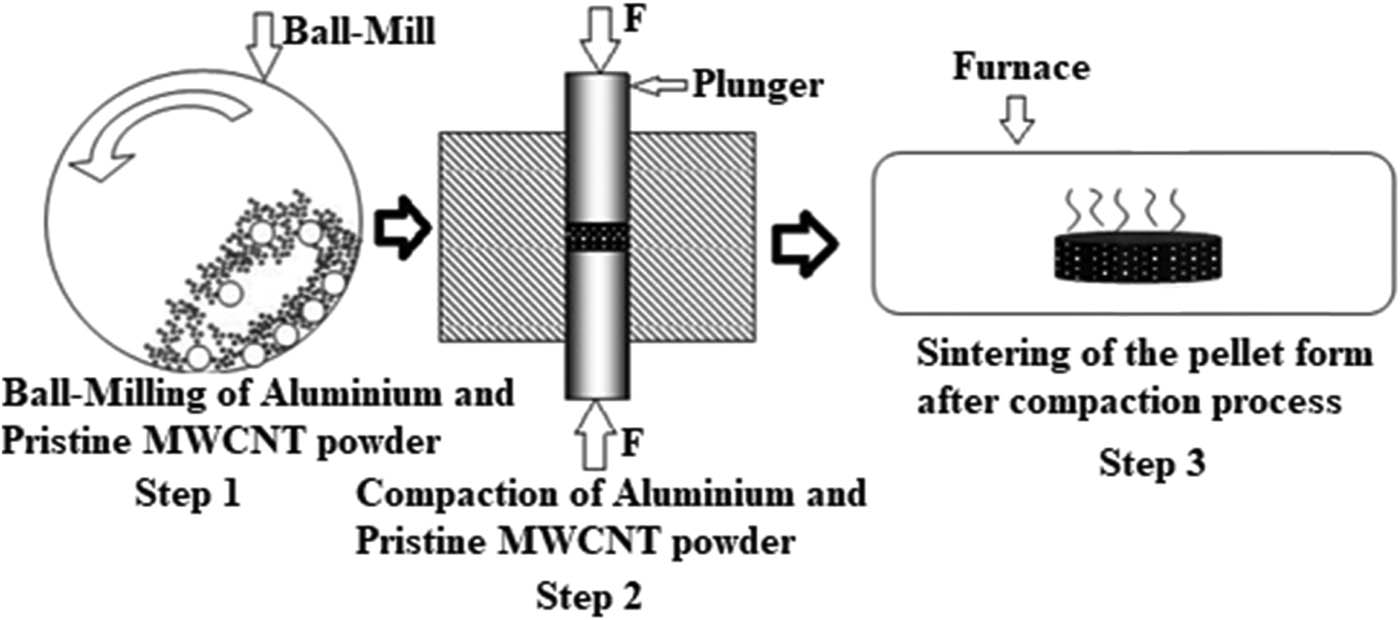

2.2.1 Fabrication of MWCNTs/AA2024-T351 alloy nanocomposite

MWCNT powder was treated subsequently by blending it with concentrated nitric acid (HNO3), filtered and washed with deionized water, and dried at 120°C. The process was carried out to eradicate the impurities like amorphous carbon, graphitic particles, or any other contaminants observed in MWCNTs. The Al (AA2024-T351) powder was mixed with MWCNTs powder in the weight percentage of 0.1, 0.2, 0.3, 0.4, and 0.5% using ball mill continuously for the duration of 10 h at 200 rpm to get homogeneous mixing as shown in Figure 5 [49,50]. Further, the mixture of each proportion is compacted in a hydraulic press of 1,000 kN capacity [51]. The mixed powder is pressed by a load of 180 kN to get billets of size 20 mm diameter and 55 mm length. Compacted specimens were sintered in a vacuum tube furnace at 580°C for 2 h in a nitrogen atmosphere followed by air cooling [52]. The related findings reported by Ali and Rubel [53] presented a comparative review article on the CNT-reinforced Mg and Al-based metal matrix composites. Authors reported that more attention on the fabrication is required to obtain uniform distribution of the CNTs in the base matrices. Also, the need of reduction in CNT fibers breakage during processing is necessary during fabrication. Further, the relationship among the processing factors, macro and micro structure, modeling, and simulation of such composite is still required to increase their scope in many industrial applications.

Fabrication of MWCNTs/Al nanocomposite using powder metallurgy processing route.

A recently reported comparable outcomes were shown by Hussain et al. [54] who developed MWCNT fiber-reinforced nano-Al matrix composites using powder metallurgy process and evaluated the effect of reinforcement contents on the hardness value of the base matrix. Authors reported that mass density varied proportionally with respect to the reinforcement contents, structure of composites, and milling time. Also, by increasing milling time, a fine structure was obtained.

2.3 Mechanical loading

The split die was indigenously designed and fabricated using the P20 tool steel of grade 40CrMnNiMo8-6-4, German (1.2738): EN 4957:2000 tool steel, having a die-angle of 60° and extrusion ratio of 2. In order to evade the disruption or failure liable to happen during extrusion, the billets were tapered at the entry for smooth extrusion. Sintered billets of size 20 mm diameter and 50 mm length were cold extruded in a hydraulic press at an average load of 300 kN and an average speed of 0.5 mm/min.

2.4 Thermal loading

Sintered samples of both matrix and its composites were heat treated in a muffle furnace (Thermolyne-scientific, PID-controller) at a temperature range from 20 to 1,000°C. Samples were initially solutionized by heating them to 560°C and maintained at this temperature for 8 h, followed by water quenching and artificial aging by heating for 4 h at 180°C.

2.5 Preparation of samples for density, hardness, and tensile tests

The density test was carried out according to Archimedes’ principle. Theoretical densities of all the sintered, sintered-heat treated, and sintered-extruded samples of both the matrix and composites were determined using the rule of mixtures. Hardness tests were performed according to the ASTM E92 standard [55], and the tensile test was done according to the ASTM E8 standard for all the samples [56].

2.6 Morphological study using XRD, SEM, and TEM

The morphological study of the AA2024-T351 + MWCNT composites was done using a SEM (Tescan vega-3 LMU, Czech Republic). Crystal structures of the composite were analyzed by an X-ray diffractometer (Panalytical, Netherlands) with Cu-Ka radiation. Nanoshel USA supplied TEM images of MWCNT, and TEM images of AA2024-T351 + MWCNT were taken from JEOL JEM-2100 LaB6, (JEOL, Akishima-Japan), TEM operates at an accelerating voltage of 200 kV and a lattice resolution of 0.14 nm and magnification of 2,000×–1,500,000×.

3 Results and discussions

3.1 Measurement of density and porosity

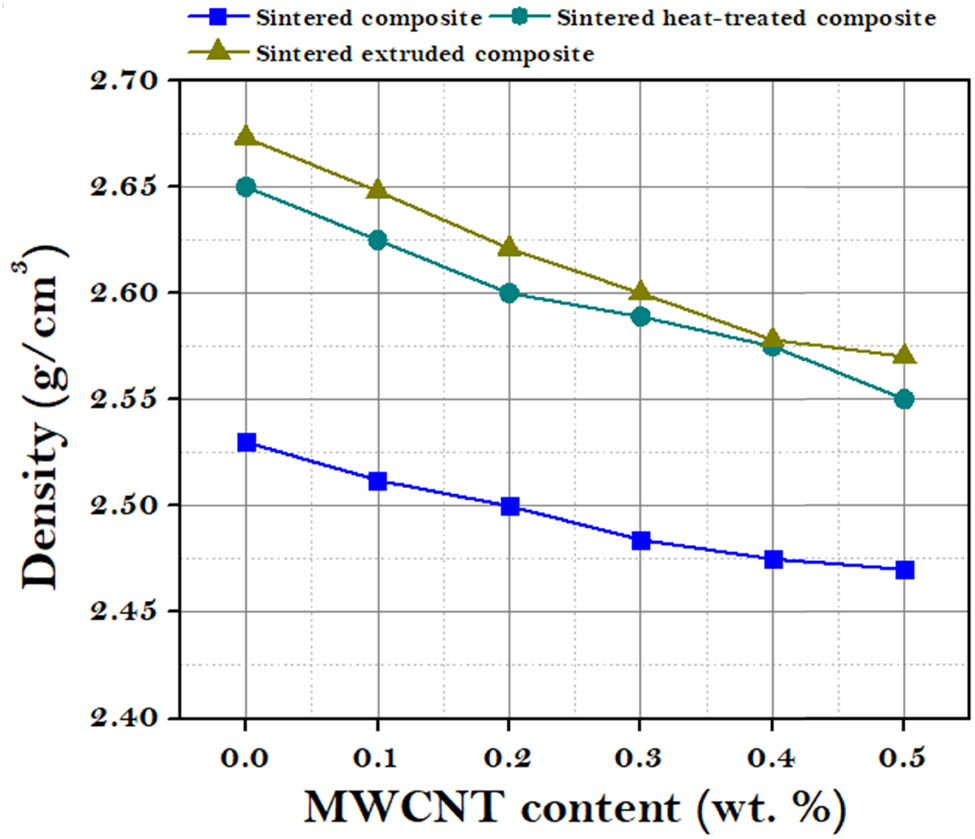

Theoretical and experimental density measurements were studied using the rule of the mixture and using the Archimedes principle [57]. Figure 6 shows that the density of the composites with varying weight percentage of reinforcements of 0, 0.1, 0.2, 0.3, 0.4, and 0.5 wt% MWCNTs decreases with an increase in MWCNTs addition. This fact may be due to the displacement of atoms by the lightweight carbon atom, which usually occupies the interstitial position of the Al crystal structure [58].

Density of the composites with varying weight percentages of MWCNTs.

Further, the decrease in the density was attributed to increasing pores observed in sintered nanocomposite because MWCNT was processed in an HNO3 environment in which carboxyl (−COOH) or hydroxyl (−OH) functional group exist. At sintering temperatures and heat-treated composites of different percentages of reinforcing MWCNT, the impurities in the composite material were pushed out completely [56]. This leads to the shrinking of the particles and reduction in the volume, thereby enhancing the density of a given volume of Al2024-T351 + MWCNT.

Second, porosity which predominantly occurs in most of the sintered metallic compositions decreases the density even though dislocations take place, as shown in Figure 6. Initially, the density of the sintered-heat treated samples increases by 4.48% and sintered-extruded samples increases by 5.23% compared to sintered composites.

As the percentage addition of MWCNT increases, the density individually decreases by 2.3, 3.8, and 4.04% in sintered, sintered-heat treated, and sintered-extruded AA2024-T351 + 0.5% MWCNT composites, respectively. Similarly, porosity usually exists in sintered AA2024-T351 + MWCNT composites. It increases with an increasing percentage of MWCNT from 0 to 0.5% [59]. This can be reduced by heat treating and extruding the composite.

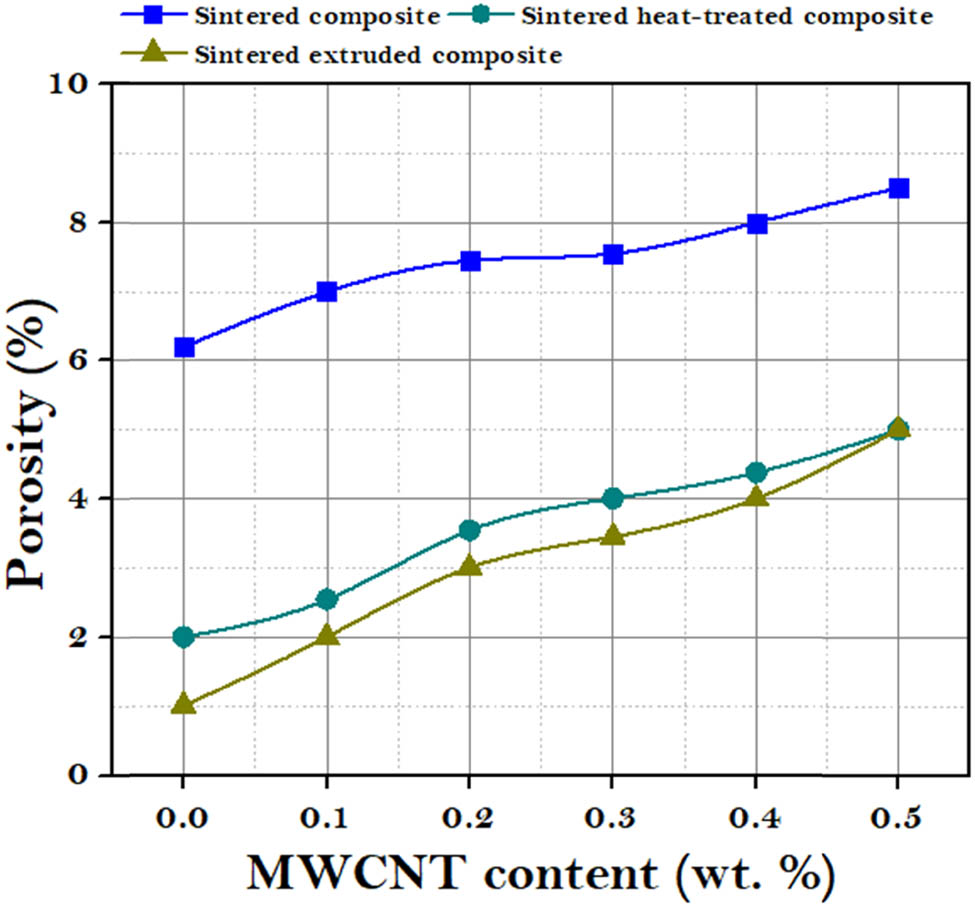

It is observed from Figure 7 that the percentage of porosity in a sintered composite ranges from 6.88–8.24% for various percentages of MWCNT. Porosity is 2.47–5.31% in case of sintered-heat treated composites after the addition of MWCNT. This reduction in porosity is due to the intergranular motion of matrix and dislocations due to higher temperature during heat treatment [60,61]. The decrease in porosity, as observed in the sintered-heat treated composite, maybe due to the dislocation movement of atoms and extension of grain boundaries by the addition of CNT at high temperatures during heat treatment [60].

Porosity of the composites with varying weight percentages of MWCNTs.

The related findings have been unveiled by Sharma et al. [62] who developed MWCNTs-reinforced alumina matrix composites using powder metallurgy processing route. Conventional and field-assisted sintering processes were followed during the fabrication of composites. Mechanical, tribological, and microstructural behaviors were analyzed. The effect of sintering time and temperature were evaluated. Authors observed reduction in hardness and density of base matrix with the addition of CNT up to 0.2 wt% and then increased continuously with further increase in CNT contents. Composites, which were sintered conventionally, possessed better wear resistance with respect to sintering time. However, the spark plasma sintered composites exhibited better density and mechanical and wear properties than other ones.

Further reinforcement of MWCNT decreases the porosity marginally because its interfacial bonding hinders the movement during heat treatment of the nanocomposite. The addition of MWCNT increases the porosity, which may be because its hardness will not allow the pores to slide across each other during the application of pressure during either sintering or heat treatment. Further reduction in porosity of sintered-extruded by 12% compared to sintered-heat treated is because of the refining of grains.

Comparable outcomes have been described by Suk [63] who prepared lightweight CNT-reinforced AMCs with significant reduction in the weight of Al and the mechanical behavior was analyzed using simulation. Authors also observed an enhancement of about 106% in tensile strength, 247% in toughness, and 244% in modulus of elasticity with an addition of CNT in the base Al matrix. This improvement was attributed to the shear interactions among the constituents and high load carrying capacity of the CNT.

3.2 Mechanical properties

3.2.1 Hardness

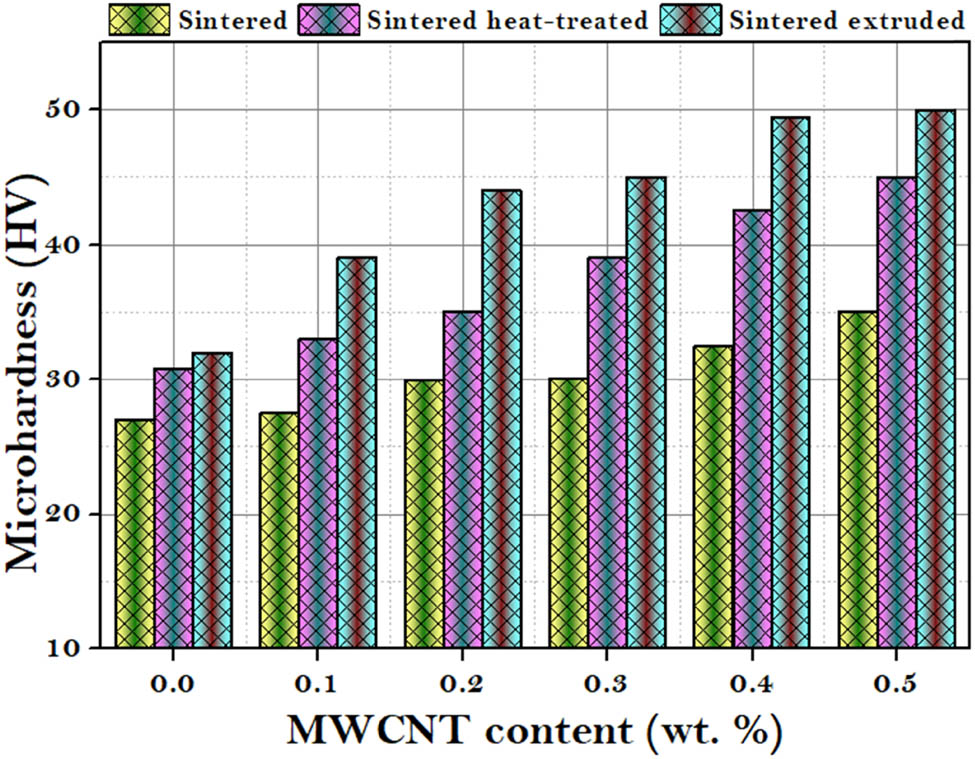

Hardness tests have been conducted using a Vickers micro-hardness tester (HXD:1000-TM). Test results of the study are shown in Figure 8(a–d), for sintered, sintered-heat treated, and sintered-extruded samples of the AA2024-T351 + MWCNT composites. Maximum hardness of 35Hv was obtained for sintered AA2024-T351, and 45Hv for 0.5% MWCNT heat-treated samples was obtained indicating that the addition of MWCNT enhances the hardness which may be because CNTs are evenly dispersed at the interfacial space [64].

Microhardness of sintered, sintered-heat treated, and sintered-extruded samples plotted against wt% of AA2024-T351 + MWCNT composites.

Further, sintered and sintered-extruded composites exhibited hardness of 50Hv which is an overall increase of 42.8%. The enhancement in the hardness incurred as a result of the formation of Al4C3 during heat treatment [65–67]. The proper surface interface bonding among matrix and reinforcing constituents may be considered as the other prime factor for the increase in the hardness [60,68,69].

Similar empirical evidences are reported by Soni et al. [70] who evaluated titanium dioxide and MWCNT-reinforced Al (Al6061) metal matrix composites. Authors followed ultrasonic-based squeeze casting to fabricate AMCs. The reinforcement contents were pre-processed using different methods before mixing to achieve regular dispersion within the base matrix. Advanced techniques such as SEM, TEM, XRD, optical microscopy (OM), and X-ray microscopy (XRM) were used to evaluate the morphology of newly developed AMCs. Hardness test and tensile test were also conducted to evaluate mechanical behavior of the composites. Authors observed significant improvement in the strength and hardness values with the addition of MWCNTs together with TiO2. Also 20 min of sonication was best to attain uniform microstructure. The fabrication using ultrasonic-assisted stir casting and pre-processing of reinforcements before mixing produced AMCs with best composite properties. Moreover, squeeze casting composites possessed better properties than stir casting ones.

3.2.2 Tensile strength

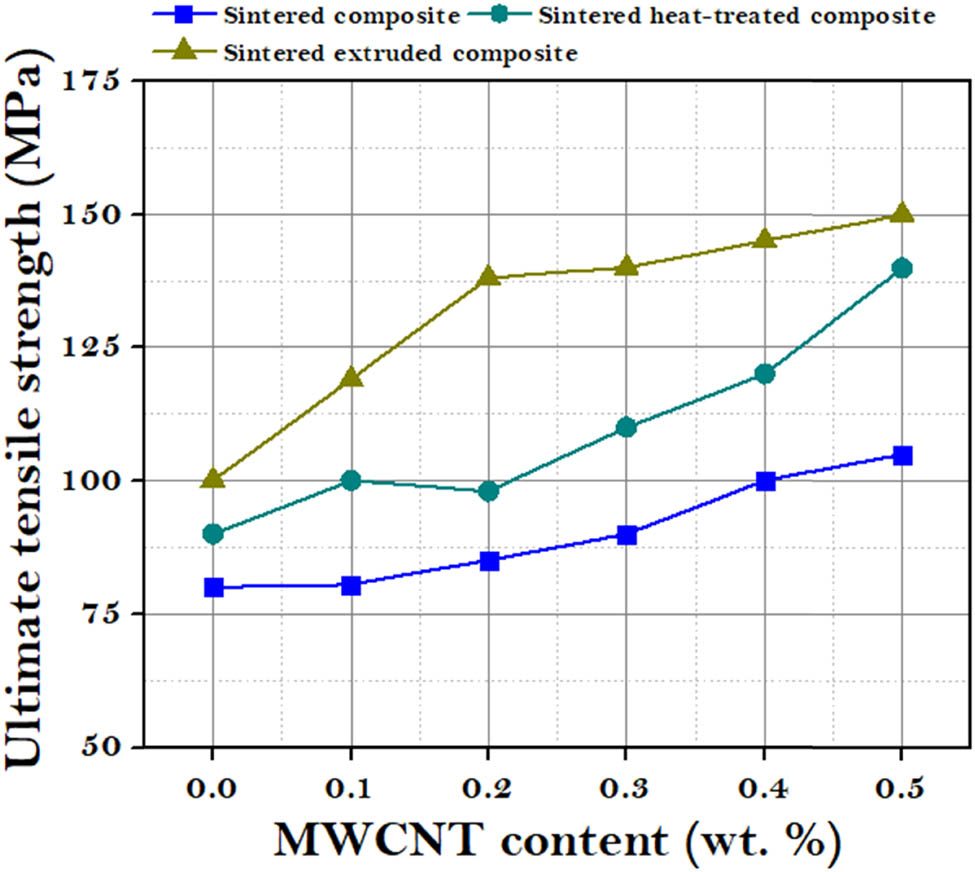

Further, the tensile test has been conducted on the universal testing machine (ZwickRoell Z100:Z250) (IS: 1608-2005). Ultimate tensile strength (UTS) of the composites exhibited a substantial improvement, as shown in Figure 9, for sintered-heat treated composites when compared to sintered-extruded composites [57]. Maximum UTS of 105.21 MPa was obtained with 0.5% MWCNT for sintered composites. Further increase in UTS to 140.02 MPa was observed in sintered-heat treated composites, while sintered-extruded composites exhibited 150.93 MPa, indicating an increase of 33.1 and 43.46% increase in strength, respectively.

Ultimate tensile strength of sintered, heat-treated, and extruded samples plotted against wt% of CNT.

Sintered-extruded specimens showed better capability, which may be due to the intergranular refinement [60,71]. This is evident from the various research studies that report effective uniform dispersion and better interfacial bonding between the matrix and bent MWCNTs leading to enhanced properties [60].

Heat treating of sintered nanocomposite enhances the UTS due to the mobility of large mass of atoms resulting in smaller grain sizes [60,71] due to applied tensile force. An increase in temperature during heat treatment fills the pores and reduces the imperfection, which was observed during the sintering process. This is evident from the earlier research studies; the tensile load exerted on the composite transferred to the CNT, thereby pulling the CNT which leads to bending of the nanotubes and break in the form of telescopic sheath [60,71]. Thermal treatment is also a factor for enhancing the strength of AA2024-T351 + MWCNT composites [72,73].

Comparable outcomes have been revealed by Yuan et al. [74] who developed CNTs-reinforced AMCs using milling- and rolling-based powder metallurgy process to evaluate the influence of reinforcement’s contents on the microstructure and mechanical behavior of the base matrix. Authors reported that tensile strength of 382 MPa and fracture ductility of 9.8% were obtained with the addition of 1.5% CNT contents in the base matrix. Authors also reported that the used process is the best route to produce CNTs-reinforced AMCs with better mechanical properties.

3.3 Morphological analysis

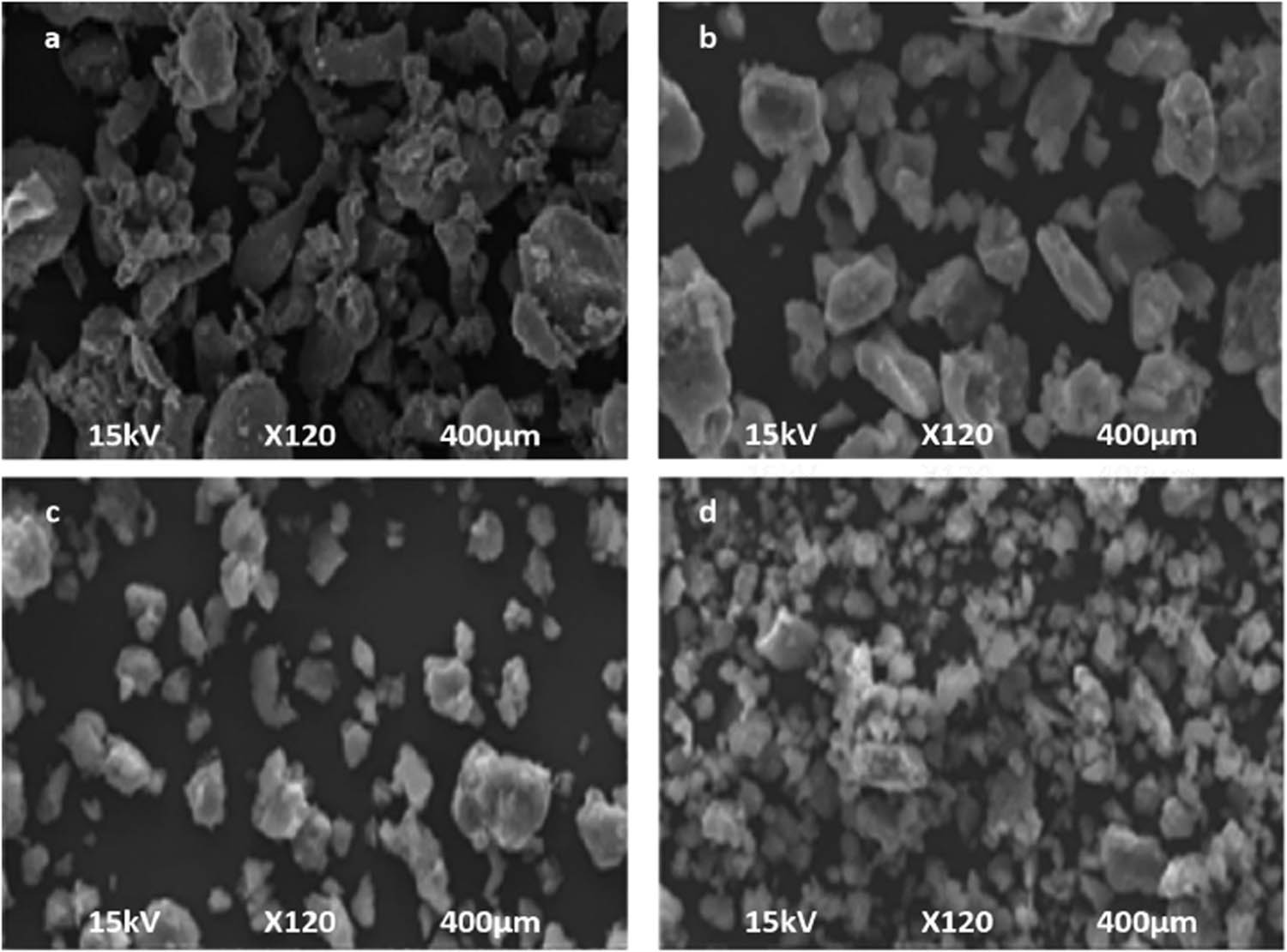

Figure 10 illustrates the SEM micrographs of Al alloy powder obtained at a frequent time intervals from 0 to 30 h during ball milling operation. During the preliminary initial stage, the Al particulates were equiaxial or unrecrystallized grain structure with uneven or distorted morphology. Because of the ductility characteristic of Al, the pellets distorted and transformed into a flake-like segment after 5 h of the mechanical alloying process.

SEM micrographs of Al powder at, (a) 5 h; (b) 15 h, (c) 25 h, and (d) 30 h, ballmilling time-periods.

The pulverized Al powder with uneven, erratic, and non-spherical grain size had a diverse wide-range dispersion. After 5 h of attrition, the alloying elements provided a stratified uniform homogenous mixture. After 10 h of the ball milling process, the grain particulates first formed a smooth, flattened plate-like surface. Furthermore, after 15 h of milling-processing continuance, the particulate segments with plate-like texture experience strain-hardening, culminating in the continued persistence of solid-phase re-welding and brittle micro-cracks based fractured-mechanics morphological shape/structure.

The flakes-like fragments with lamellar morphology continuously persist with significantly reduced particulate grain size, even after 15 h of the ball milling process. A lower size distribution-defined aspect ratio of the powdery particulates was observed for 20 h, and afterward, there was a restricted narrow distribution that appears in the particulate matter. Continuous attrition processing up to 30 h reveals a significant shift in the size of the uniformly dispersed particulate.

Similar empirical evidences are reported by Billah and Chen [75] who prepared Ni-coated CNT-reinforced AMCs using powder metallurgy route. Prior to mixing, CNT contents were coated with Ni using electroless deposition technique. Authors observed increasing trends of tensile strength and hardness. An improvement in tensile strength around 129% and yield strength of about 157% were obtained with the addition of 7% Ni-coated CNTs in the base matrix. Also, the coating of Ni on CNT improved the interfacial bonding significantly among the constituents with even dispersion of the reinforcements.

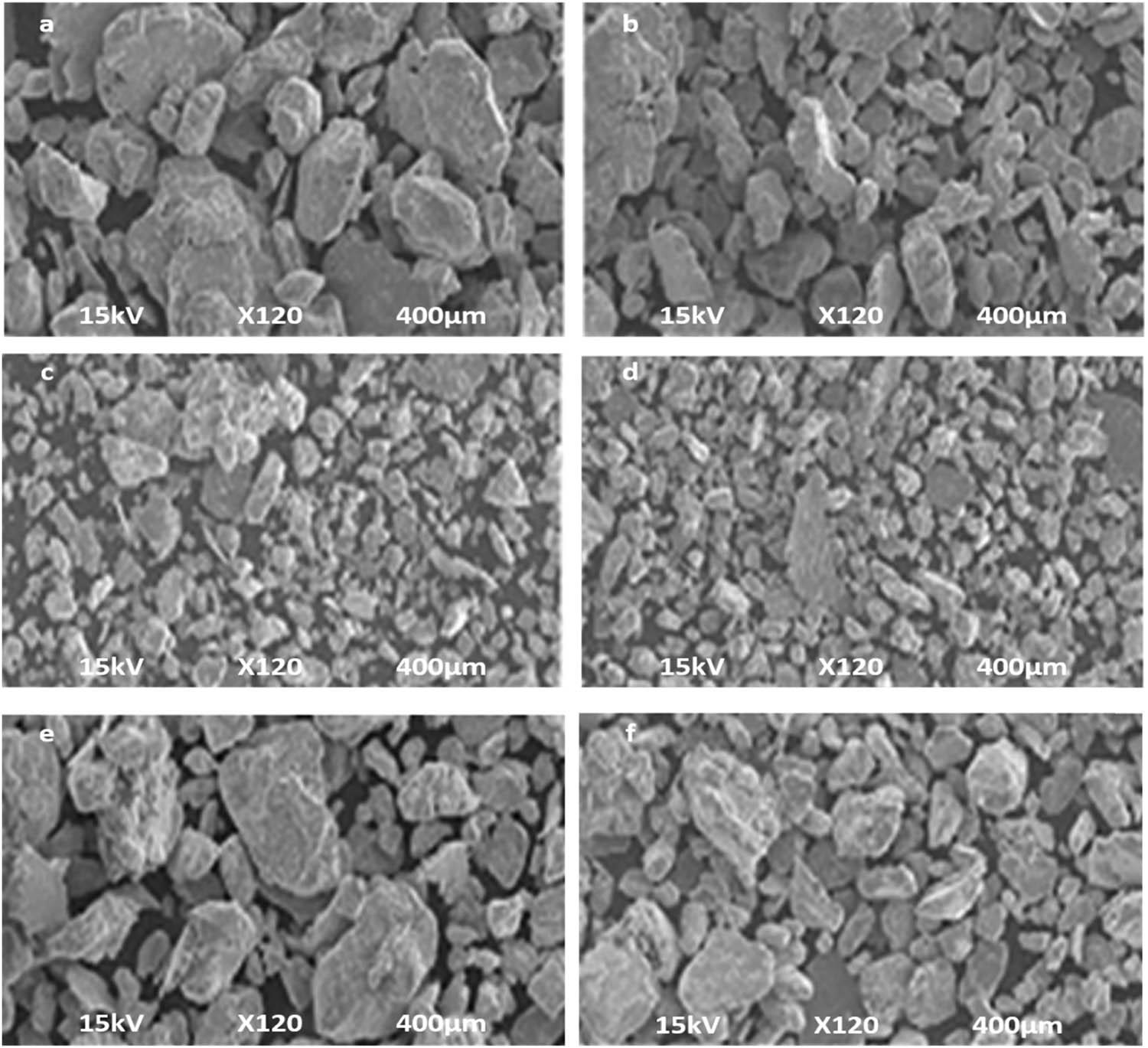

SEM analysis was used to describe the morphology of the extruded Al/MWCNT nanocomposites and also to examine the influence of concentrations of MWCNTs reinforcement on the distribution of Al matrix thereof.

Figure 11 indicates that while all samples were mechanical alloyed/milled at different time intervals, the particle size reduced as the percentage content of MWCNTs increased. This consequence can be ascribed to the way that the MWCNTs serve as a processing control organic surfactant, mitigating the influence of cold-pressure contact welding and facilitating the process of fracturing mechanics of the particulate grains. This diminution in particulate grain matter was owing to the raised propinquity of CNTs, which serve as a refiner by generating a tougher particle surface after each influence from planetary ball milling medium, thereby raising their brittleness.

SEM micrographs of Al–Cu–Mg–T351/MWCNT nanocomposite pulverized powder mechanical alloyed for specific time period according to the percentage weight content of MWCNT.

Therefore, during the attrition process, where each particulate endures continual, persistent fatigue fracture welding cycles, external secondary stages regarding CNTs intervene with this phased process at the same time that they have been integrated into the Al pellets by making them tougher at each time period. This influence was substantially increased with increasing CNTs’ content, thus acquiring a preponderance of the fracturing process and hard/tough as well as tiny minute fragments.

A related research finding was observed by Kundalwal and Rathi [76] who prepared nano MWCNT particulates-reinforced epoxy polymer matrix composites using ultrasonically processed dual mixing method to evaluate various characteristics of the newly developed PMCs. Authors reported that there was an improvement of 21% in tensile strength, 46% in toughness, 22% in shear strength, and 26% in storage modulus with the addition of 0.5% MWCNTs in the epoxy resins. Results of TEM analysis revealed uniform distribution of reinforcements without clustering at any location.

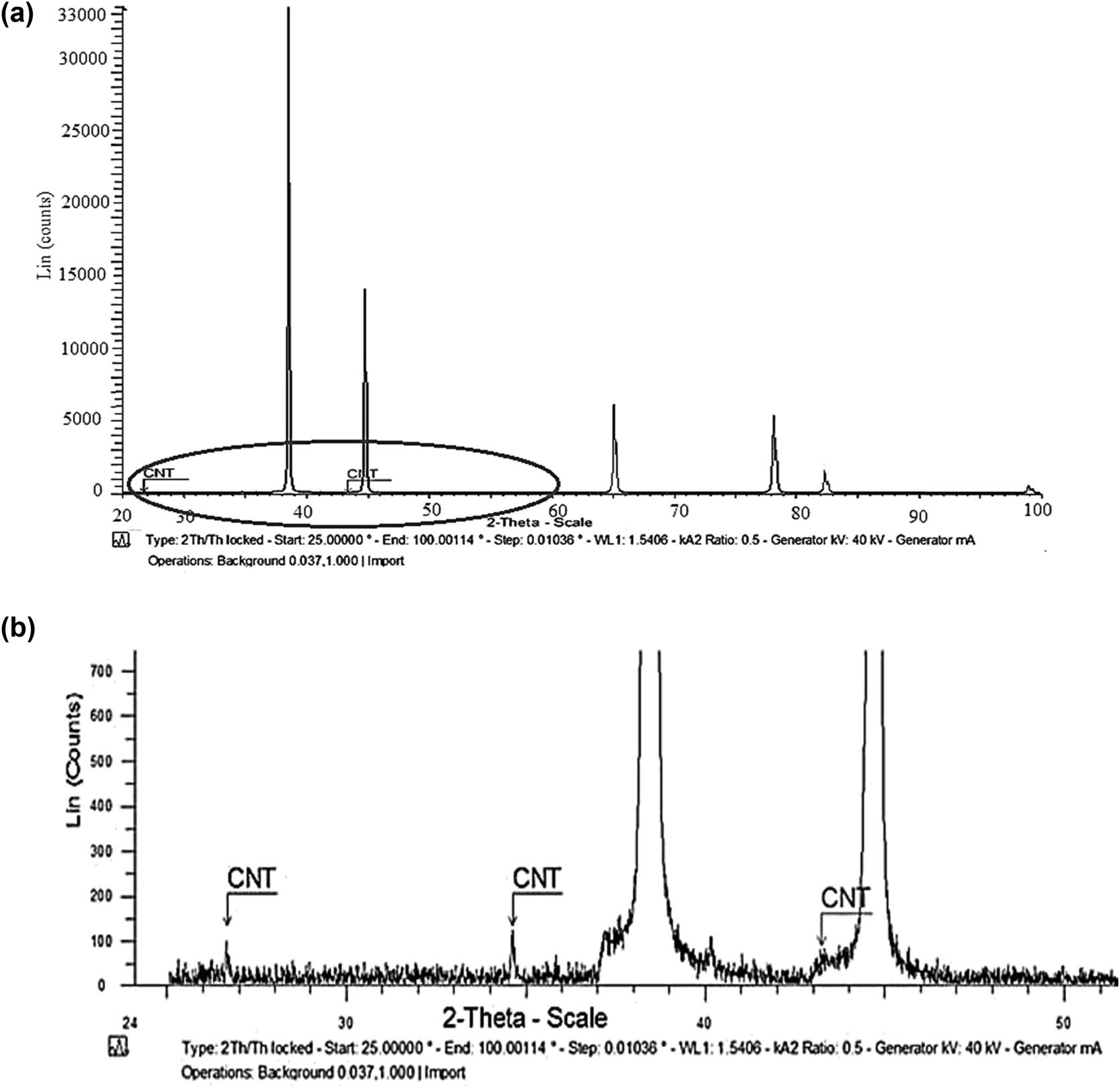

The surface characteristic of AA2024-T351 + MWCNT was studied by XRD analysis as shown in Figure 12(a). Figure 12(b) is the enlarged image (circled portion) of Figure 12(a) of AA2024-T351 + 0.5% MWCNT and reveals that the bulk material comprises of AA2024-T351 and CNTs which indicate that the remaining phases were minor constituents of the composites. XRD scans of Al2024-T351 + MWCNT shows that the CNT is present at 2β = 23.6 and 44.6°, whereas high peaks of aluminum are present at uniform dispersed positions.

(a) XRD image of Al–Cu–Mg–T351 + 0.5% MWCNT composite. (b) Enlarged XRD image of Al–Cu–Mg–T351 + 0.5% MWCNT composite.

Similar outcomes have been observed by Fathi [77] who presented a review article on mechanical behavior of nano composites that describes the difficulties arising during fabrication and enhancement of mechanical properties of the nano composites like MMCs, PMCs etc. Authors presented that these properties of the nanocomposites were highly dependent on their composition, particle size, level of distribution etc.

SEM micrograph images of AA2024-T351 + MWCNT composites of varying percentages processed through ball milling, as shown in Figure 13(a–f), reveals the uniform distribution of CNT. Al particles of 200 mesh size were chosen for better compactness during sintering. Sintered-heat treated and sintered-extruded composites have a favorable effect on tensile strength and hardness.

SEM of heat-treated (a) 0%, (b) 0.1%, (c) 0.2%, (d) 0.3%, (e) 0.4%, and (f) 0.5% MWCNT-reinforced Al–Cu–Mg–T351 alloy.

SEM of sintered-heat treated composites showed the formation of Al4C3 as a result of high temperature after heat treatment. The considerable effect of MWCNT along with carbide formed due to heat treatment resulted in enhanced properties of the tensile strength of the composite. The presence of CNTs, Al–Cu, and Al4C3 are observed after aging heat treatment.

The related research has been reported by Shivaramu et al. [78] who presented an experimental study on MMC’s of Al-Si alloy, which was strengthened with MWCNTs utilizing powder metallurgy processing technique. During production, the concentration of MWCNTs was varied as 0, 0.25, 0.5, 0.75, and 1.0 wt%. The composites were analyzed employing TEM, XRD, and energy-dispersive spectra techniques. Tensile test was conducted according to ASTM G99-95a standard. Wear test was conducted under variable loads and sliding distances (disk/wheel rotational speed ranging from 250 to 750 rpm), and load suddenly dropped with the increment in sliding distance. For certain nanocomposites, though, the ratio of volume loss per unit distance escalated on linear basis with sliding distance. The reinforcing constituents for varied concentrations of MWCNTs exhibited reduced wear resistance, the incorporation of aforesaid caused moderately superior wear rate. Due to the obvious superior characteristics of the reinforcing particulates, the abrasion resistance had strengthened to fervent extent. The type of mechanism operation with volumetric-wear-loss was discovered employing an SEM. The accompanying research revealed by Carneiro and Simoes [79] evaluated the influence of morphology and structure of MWCNTs on the properties of metal matrix composites. The simulation was performed and the results were validated experimentally. Authors reported that morphology and microstructure were the most predominant factors affecting the particle distribution. The related findings have been described by Feijoo et al. [80] who fabricated Al alloy (AA7075)-based composites, which were reinforced with 0.5 and 1 wt% MWCNTs. Composites were fabricated using powder metallurgical process using ball mills for better reinforcement distribution within the matrix. The powders of Al and MWCNT were analyzed using XRD and SEM techniques. The Scherrer formula was adopted to analyze the change in crystal size and micro level deformations of crystal lattice. Authors observed regular dispersion of reinforcements within the matrix without porosity. Also, Al-0.5%MWCNTs composite possessed better hardness and tensile strength together with improved ductility than others.

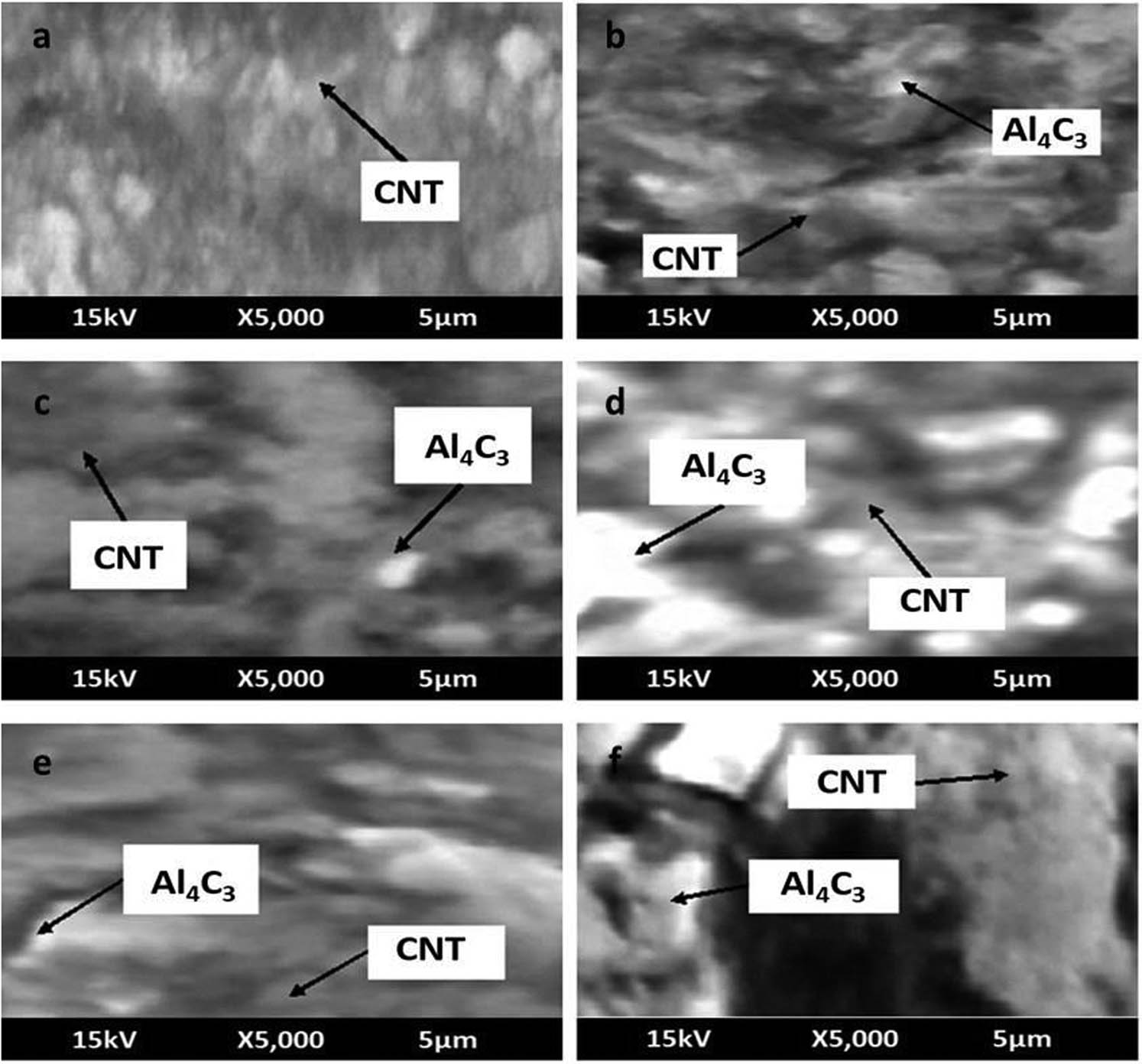

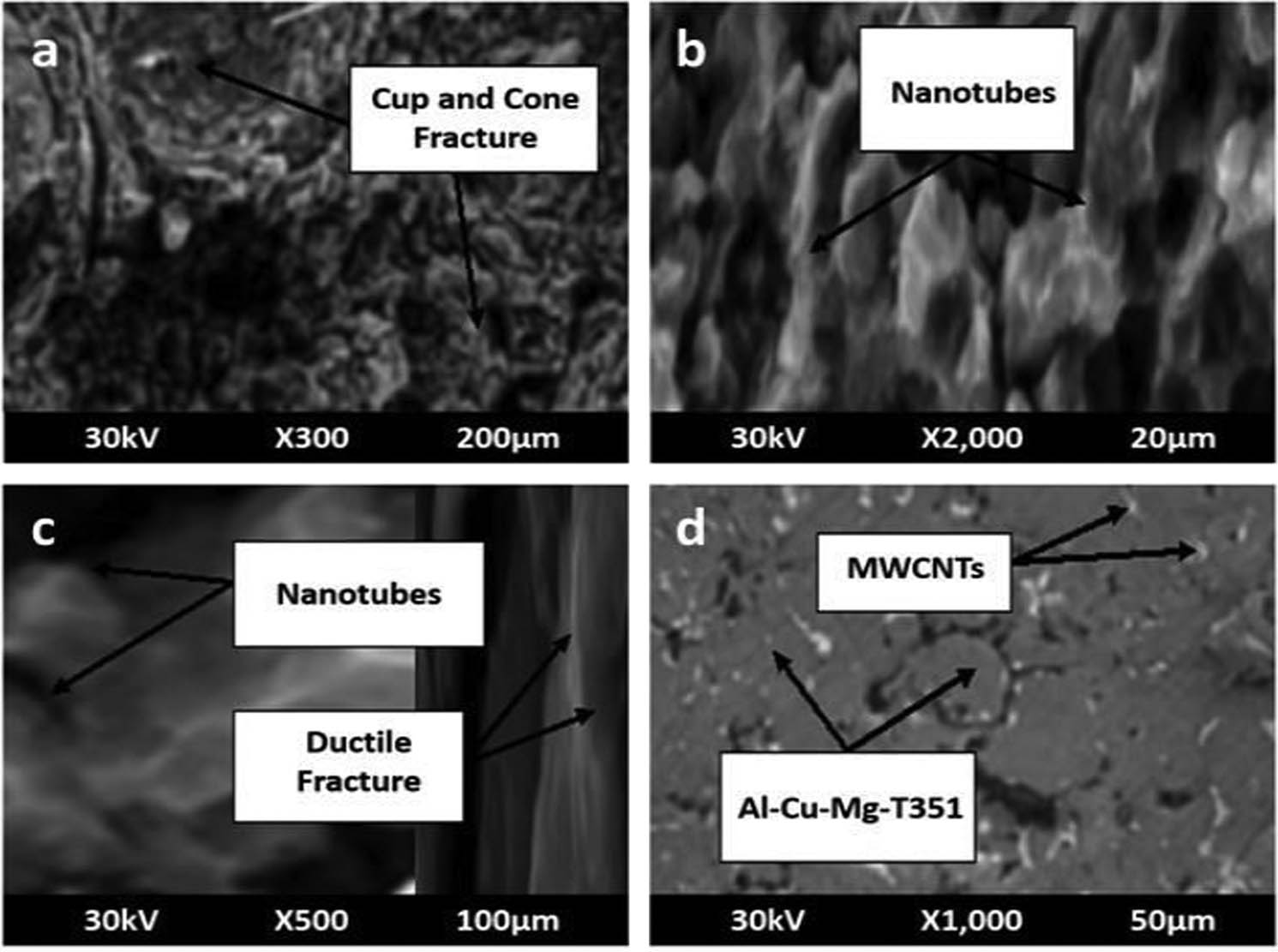

SEM profile of sintered-heat treated and sintered-extruded composites exhibits the Al2024-T351 + MWCNT fractured nature of nanocomposites, which is similar to the base Al fracture as shown in Figure 14(a–d). The presence of CNTs, Al–Cu, and Al4C3 are observed after aging [71] may be due to the presence of elements present in the alloy, and the reactions that happened during the heat treatment. Fracture micrographs of the Al2024-T351 + MWCNT composite displayed the resistance nature of nanotubes, as illustrated in Figure 14(c) by way of deformation. The breaking of the material for the applied force due to which matrix pulls out and nanotubes breaks in telescopic sheath form are reported by few investigators [71–83]. Bent nanotubes increase Young’s modulus during applied tensile load and are rigid in nature [71].

SEM image of Al–Cu–Mg–T351 + MWCNT, (a) tensile fracture with cup-cone failure, (b) sintered-heat treated surface with MWCNT fracture, (c) enlarged image of the X, and (d) sintered-heat treated surface with the distribution of nanotubes at the grain boundary.

The related research has been exhibited by Uriza-Vega et al. [84] who prepared MWCNT-reinforced AMCs. Al alloy (Al-7075) was used as base matrix and MWCNTs were synthesized prior to blending in the base matrix and then mixed in the base matrix. The reinforcements were dispersed evenly within the matrix using ultrasonic process, which was followed by milling. The influence of CNTs on the microstructure and mechanical behavior was then analyzed using advance testing techniques. Authors observed uniform distribution of the reinforcements without much clustering as seen in the SEM images. The mechanical behavior was significantly improved with the addition of CNT up to 2 wt% in the base matrix.

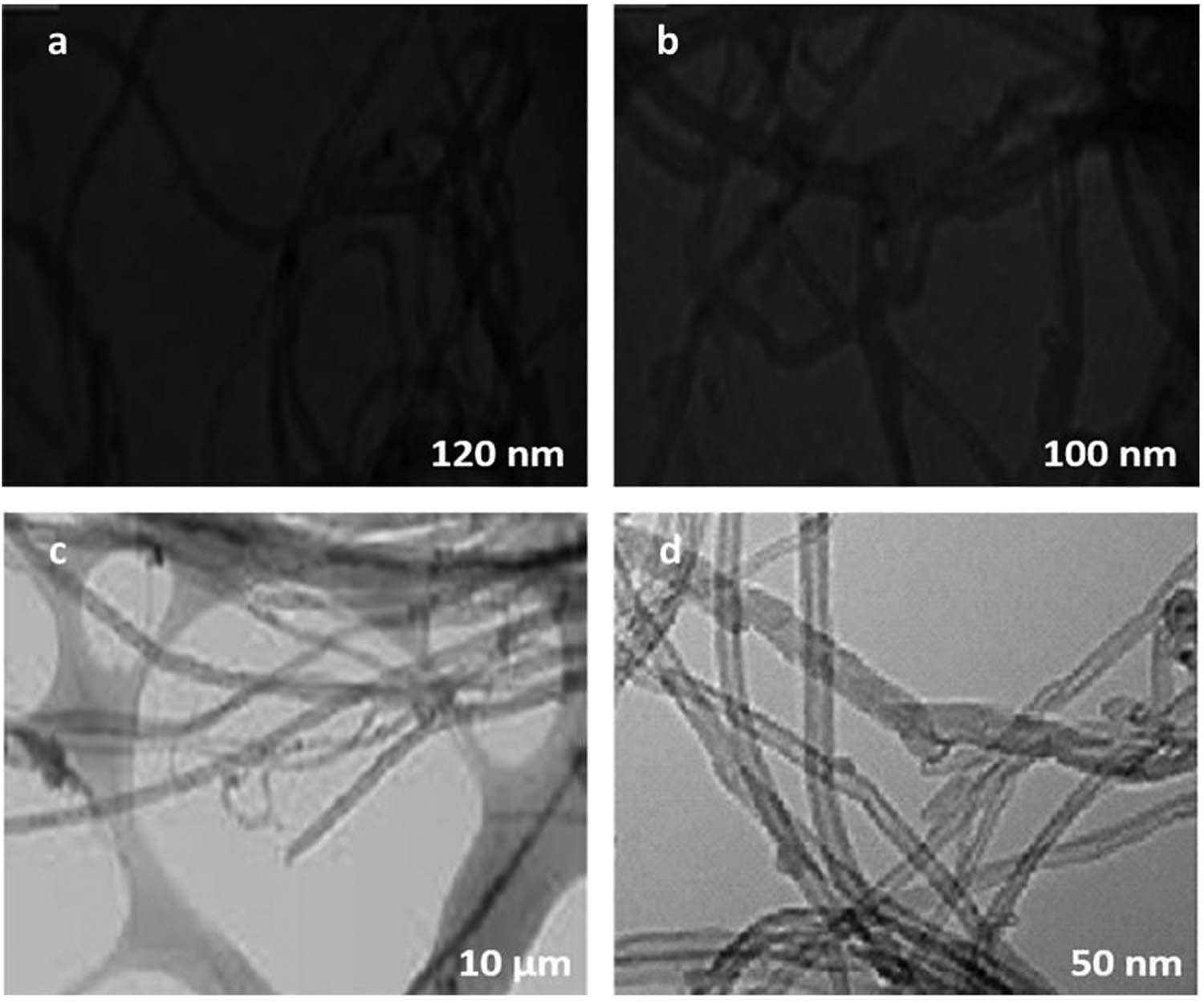

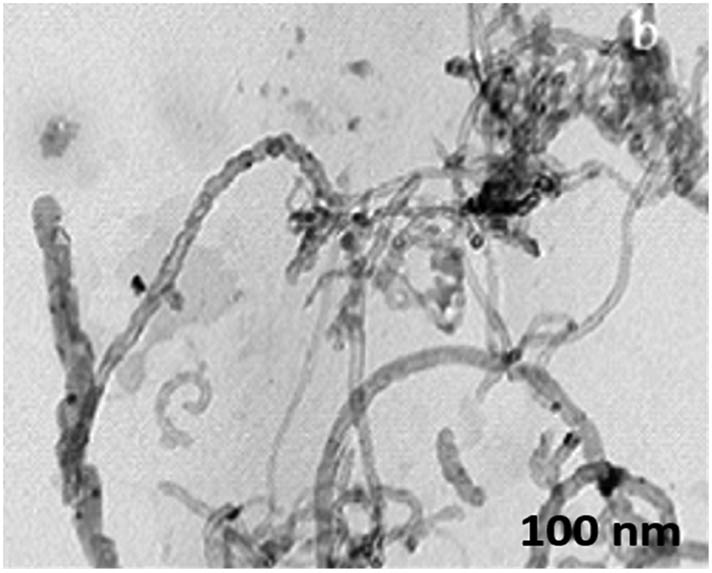

Figure 15(a–d) shows the TEM image of MWCNT and Figure 16 illustrates the TEM image of AA2024-T351 + 0.5% MWCNT powder showing the distribution of MWCNT in the composite. MWCNTs are dispersed uniformly and agglomerated evenly at various places in all the reinforced fractions in the composite after a higher rate of the ball milling process. This agglomerated MWCNT has been reduced by controlled ball milling time, not crossing 20 h [82].

(a–d) TEM images of MWCNT powder (courtesy: Nanoshel, USA).

TEM image of Al–Cu–Mg–T351 + 0.5% MWCNT nanocomposites.

TEM image reveals the presence of entangled networks of CNT, and the formation of nanoscale particles of Al4C3 due to heat treatment can be observed [83].

The results of a study of relevant studies have now been unveiled by Tserpes et al. [85] who performed testing of tension and nano-indentation of nanocomposite to find mechanical and nano-mechanical properties of the MWCNT-reinforced polypropylene PMCs. The SEM and scanning probe microscopy analysis for structural properties and topography were also performed. The outcomes of this research work indicated an enhancement in the modulus of elasticity and yield stress. A good dispersion of MWCNTs was observed by the authors and material was divided in three regions namely polymer, interface, and CNTs cluster/conglomeration region. Resistance varied substantially across numerous different regions, ranging from minimal to 130 MPa. The incorporation of CNTs to polypropylene contributed to increased modulus, flexibility, resilience, and elasticity; however, the surface portion seemed to be relatively plastic, according to the ([hardness]3/[modulus-of-elasticity2]) proportion relationship.

The assertions of an existing literature have indeed been disclosed by Devadiga and Fernandes [86] who studied the wear behavior of the CNT and fly ash (FA)-reinforced nano AMCs. During fabrication, the composition of CNT was varied from 0.25 to 0.75 wt % in steps of 0.25 and FA was varied from 4 to 16 wt% in steps of 4 and composites were prepared using powder metallurgy route. The wear behavior was analyzed according to L9 OA. Authors observed that the composition of reinforcements was the most influencing parameter affecting the wear behavior. Authors reported that composition of MWCNTs as 0.25%, FA as 8%, milling time of 2 h, sintering time of 6 h, normal load of 10 N, speed of 200 rpm, and track-distance of 500 m employed better wear resistance among others.

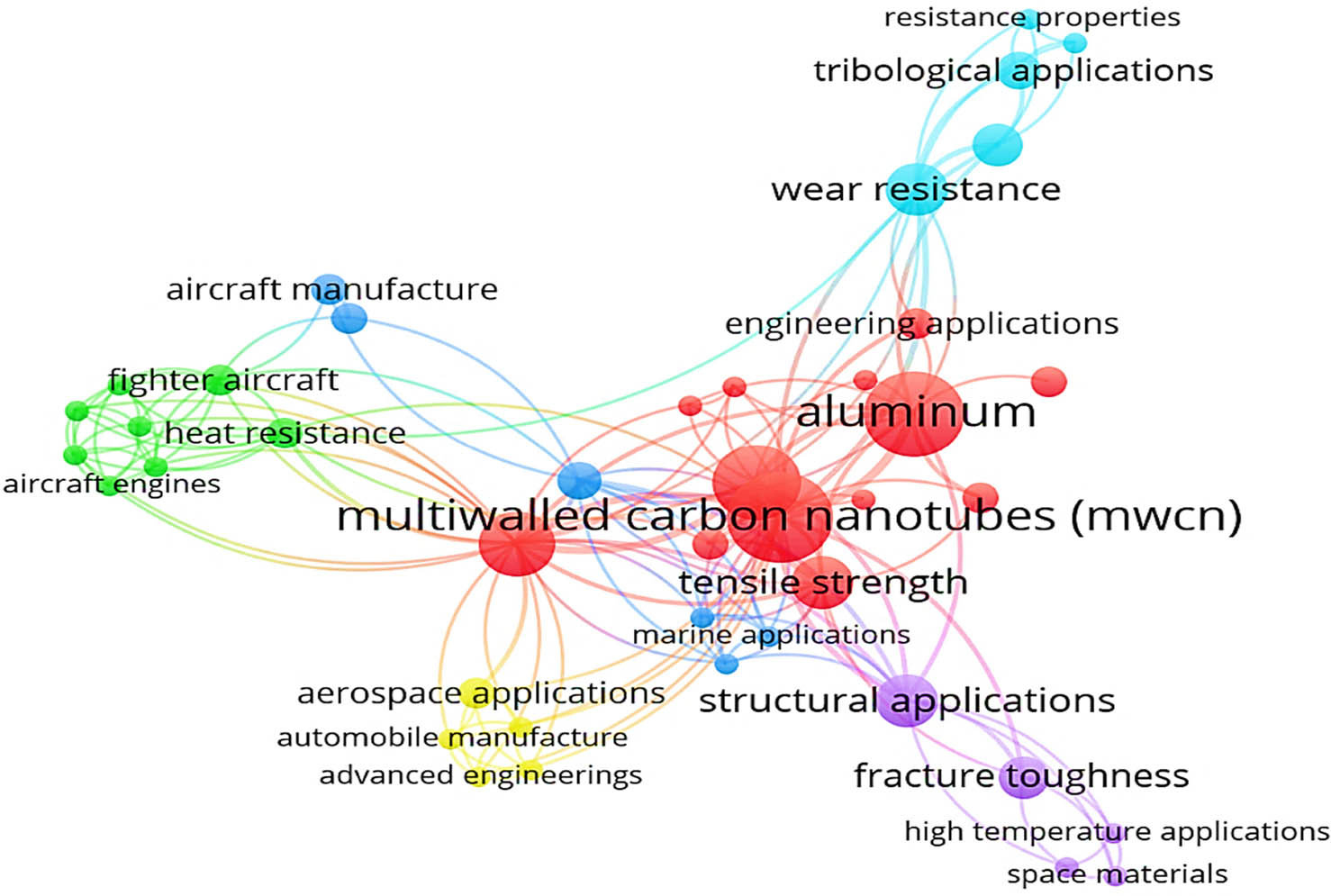

The scientometric analysis has been performed to chalk out potential applications based upon current research trends in the area of MWCNTs-reinforced Al–Cu–Mg–T351 metallic composites. Figure 17 shows the key work overlay chart of last 10 years in the domain of prospective applications of Al–Cu–Mg–T351/MWCNT nanocomposites [87–115]. It has been inferred that, in the current decade, metallic composites with MWCNTs as a reinforcing particulates have been characterized by limited researchers to investigate their suitable potential in structural applications [103–108]. Such novel composites provide significant characteristics and offer promising application in the industrial automotive, aircraft, electromechanical, lightweight component, nonlinear optics, batteries, nanowires, sensors, and high-strength devices.

Bibliometric analysis on the applications of MWCNTs/Al–Cu–Mg–T351 nanocomposites for structural loadbearing applications.

Based upon the aforementioned outcomes from the current novel study, it is concluded that the MWCNTs/Al-Cu-Mg-T351-based nanocomposites have considerable promising applications in automobiles, aviation, and other advanced cutting edge industries, due to its ability to obtain maximum physicomechanical and thermal conductivity characteristics of the composites even at lower reinforcing phase composition owing to the reinforcement’s elongated specific surface area, and the consequences that come with nano-structuring. The advancement of progressive scientific works and innovations in the domain of MWCNTs/Al–Cu–Mg–T351-based nanocomposites have been significantly aided by rise in global industrialized synthesis of MWCNTs as well as advance breakthroughs in the perspective of its commercialized, real-world applications in myriads of sectors.

4 Conclusion and future outlook

Reinforcement of MWCNT with the AA2024-T351 matrix has shown this composite as a potential lightweight material suitable for industrial applications. The development of AA2024-T351 + MWCNT composite by the powder technology route has shown the uniform dispersion of CNT using the ball milling process. Sintered and sintered-heat treated composites have shown the formation of Al4C3 with traces of “Cu” with good interfacial bonding between matrix and reinforcement. The microstructure of SEM and TEM reveals a uniform distribution of CNT and direction of the nanotube in the matrix for both extruded and heat-treated samples. SEM and TEM images revealed that CNT decomposes at a relatively low temperature of 450°C and forms fine Al4C3 precipitates. The inter-granular refinement due to reaction and internal stress relieved during increased heat at the time of sintering and heat treatment enhances the properties. The dispersion strengthening effect by unbundled or bent CNT particles enabled the improvement in the tensile property. Extruded and heat-treated specimens showed enhanced hardness and tensile strength. Tensile-fractured surface exhibited the ductile fracture with a telescopic sheath like pulling of the nanotubes in the composite. It is apparent that milling-time does indeed have a substantial influence on the improvement of physicomechanical characteristics, specifically, elastic modulus. The influence of MWCNT’s concentration, process regulating/governing reagents, CNT dimension, and inert gas environmental conditions on MWCNTs/Al composite is indeed explored. Considering findings from present experimental tests performed with the combined effect of ball milling and powder metallurgy techniques, it is concluded that MWCNT distribution is significantly vital in producing novel composites of high-strength. As a result, the ball milling parameters must be optimized in order to produce the optimal combination of MWCNTs distribution, superior MWCNTs/metallic matrix interfacial contact, relatively low cold working of the metal matrix, and minimal MWCNT damages. Numerous futuristic challenges include accomplishing relatively homogenous distribution of MWCNT's at higher-concentrations, diffusion of MWCNTs at a microlevel if bulk-processing and production processes are used. Furthermore, the adverse-affect of MWCNT orientation/configuration, efforts to bridge the gap between nanoscale and bulk-characteristics, and thus continuing to develop advanced creative modernistic approaches with all of these factors or considerations are keeping in mind.

Acknowledgement

The author Shubham Sharma wishes to acknowledge the Department of RIC, IKGPTU, Kapurthala, Punjab, India for providing the opportunity to conduct this research task.

-

Funding information: The result was obtained through the financial support of the Ministry of Education, Youth and Sports of the Czech Republic and the European Union (European Structural and Investment Funds – Operational Programme Research, Development and Education) in the frames of the project “Modular platform for autonomous chassis of specialized electric vehicles for freight and equipment transportation,” Reg. No. CZ.02.1.01/0.0/0.0/16_025/0007293. Author Shubham Sharma wishes to acknowledge the Department of RIC, IKGPTU, Kapurthala, Punjab, India for providing opportunity to conduct this research task. Author P. Sudhakara gratefully acknowledges the support from Science and Engineering Research Board (SERB-YSS/2015/001294)), New Delhi, India.

-

Author contributions: S.S.: conceptualization, methodology, supervision, and writing – original draft preparation; S.S. and V.P.: formal analysis and investigation; S.S., V.P., P.S., J.S., M.P., and R.A.I.: resources; S.S., V.P., P.S., and J.S.: writing – review and editing; S.S., V.P., M.P., and R.A.I.: project administration; S.S. and M.P.: funding acquisition. All authors have read and agreed to the published version of the manuscript.

-

Conflict of interest: The authors declare no conflict of interest.

References

[1] Dong SR, Tu JP, Zhang XB. An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes. Mater Sci Eng A. 2001;313(1–2):963–70.10.1016/S0921-5093(01)00963-7Search in Google Scholar

[2] Jintakosol T, Kumfu S, Singjai P, Busabok C, Mai C. Effect of wear tests on silicon carbide nanowires/aluminium metal powder composites. Chiang Mai J Sci. 2012;39:41–8.Search in Google Scholar

[3] Bartolucci Stephen F, Paras J, Rafiee MA, Rafiee J, Lee S, Kapoor D, et al. Graphene-aluminum nanocomposites. Mater Sci Eng A. 2011;528(27):7933–7.10.1016/j.msea.2011.07.043Search in Google Scholar

[4] Choi H, Kwon G, Lee G, Bae D. Reinforcement with carbon nanotubes in aluminum matrix composites. Scr Materialia. 2008;59(3):360–3.10.1016/j.scriptamat.2008.04.006Search in Google Scholar

[5] Kwangmin C, Jiyeon S, Donghyun B, Choi H. Mechanical properties of aluminum-based nanocomposite reinforced with fullerenes. Trans Nonferrous Met Soc China. 2014;24:47–52.10.1016/S1003-6326(14)63287-8Search in Google Scholar

[6] Bradbury CR, Gomon JK, Kollo L, Kwon H, Leparoux M. Hardness of Multi Wall Carbon Nanotubes reinforced aluminium matrix composites. J Alloy Compd. 2014;585:362–7.10.1016/j.jallcom.2013.09.142Search in Google Scholar

[7] Bakshi Srinivasa R, Singh V, Seal S, Agarwal A. Aluminum composite reinforced with multiwalled carbon nanotubes from plasma spraying of spray dried powders. Surf Coat Technol. 2009;203:1544–54.10.1016/j.surfcoat.2008.12.004Search in Google Scholar

[8] Elshalakany AB, Osman TA, Khattab A, Azzam B, Zaki M. Microstructure and mechanical properties of MWCNTs reinforced A356 aluminum alloys cast nanocomposites fabricated by using a combination of rheocasting and squeeze casting techniques. J Nanomaterials. 2014;2014:1–4.10.1155/2014/386370Search in Google Scholar

[9] Kurita H, Kwon H, Estili M, Kawasaki A. Multi-walled carbon nanotube-aluminum matrix composites prepared by combination of hetero-agglomeration method, spark plasma sintering and hot extrusion. Mater Trans. 2011;52(10):1960–5.10.2320/matertrans.M2011146Search in Google Scholar

[10] Abbass M, Fouad M. A study of wear behavior of aluminum alloy matrix nanocomposites fabricated by powder technology. Eng Tech J. 2014;32:1720–32.10.30684/etj.32.7A9Search in Google Scholar

[11] Stein J, Lenczowski B, Anglaret E, Fréty N. Influence of the concentration and nature of carbon nanotubes on the mechanical properties of AA5083 aluminium alloy matrix composites. Carbon. 2014;77:44–52.10.1016/j.carbon.2014.05.001Search in Google Scholar

[12] Kim HH, Babu JSS, Kang CG. Fabrication of A356 aluminum alloy matrix composite with CNTs/Al2O3 hybrid reinforcements. Mater Sci Eng: A. 2013;573:92–9.10.1016/j.msea.2013.02.041Search in Google Scholar

[13] Liao J, Tan MJ. A simple approach to prepare Al/CNT composite: spread-dispersion (SD) method. Mater Lett. 2011;65:2742–4.10.1016/j.matlet.2011.05.067Search in Google Scholar

[14] Choi HJ, Lee SM, Bae DH. Wear characteristic of aluminum-based composites containing multi-walled carbon nanotubes. Wear. 2010;270:12.10.1016/j.wear.2010.08.024Search in Google Scholar

[15] Stein J, Lenczowski B, Fr´ety N, Anglaret E. Mechanical reinforcement of a high-performance aluminium alloy AA5083 with homogeneously dispersed multi-walled carbon nanotubes. Carbon. 2012;50(6):2264–72.10.1016/j.carbon.2012.01.044Search in Google Scholar

[16] Fukuda H, Szpunar JA, Kondoh K, Chromik R. The influence of carbon nanotubes on the corrosion behaviour of AZ31B magnesium alloy. Corros Sci. 2010;52(12):3917–23.10.1016/j.corsci.2010.08.009Search in Google Scholar

[17] Tak HS, Ha CS, Lee HJ, Lee HW, Jeong YK, Kang MC. Characteristic evaluation of Al2O3/CNTs hybrid materials for micro-electrical discharge machining. Trans Nonferrous Met Soc China. 2011;21(11):s28–32.10.1016/S1003-6326(11)61055-8Search in Google Scholar

[18] Kim HH, Babu JSS, Kang CG. Hot extrusion of A356 aluminum metal matrix composite with carbon nanotube/Al2O3 hybrid reinforcement. Metall Mater Trans A. 2014;45(5):2636–45.10.1007/s11661-014-2185-5Search in Google Scholar

[19] Wu Y, Kim GY. Carbon nanotube reinforced aluminum composite fabricated by semi-solid powder processing. J Mater Process Technol. 2011;211:1341–1.10.1016/j.jmatprotec.2011.03.007Search in Google Scholar

[20] Bakshi Srinivasa R, Agarwal A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites. Carbon. 2011;49(2):533–44.10.1016/j.carbon.2010.09.054Search in Google Scholar

[21] Li Q, Rottmair CA, Singer RF. CNT reinforced light metal composites produced by melt stirring and by high pressure die casting. Compos Sci Technol. 2010;70(16):2242–7.10.1016/j.compscitech.2010.05.024Search in Google Scholar

[22] Kondoh K, Fukuda H, Umeda J, Imai H, Fugetsu B. Microstructural and mechanical behavior of multi-walled carbon nanotubes reinforced Al-Mg-Si alloy composites in aging treatment. Carbon. 2014;72:15–21.10.1016/j.carbon.2014.01.013Search in Google Scholar

[23] Kang K, Bae G, Kim B, Lee C. Thermally activated reactions of multi-walled carbon nanotubes reinforced aluminum matrix composite during the thermal spray consolidation. Mater Chem Phys. 2012;133(1):495–9.10.1016/j.matchemphys.2012.01.071Search in Google Scholar

[24] Gupta A, Tripathi G, Basu B, Balani K. Dependence of protein adsorption on wetting behavior of UHMWPE-HA-Al2O3-CNT hybrid biocomposites. JOM. 2012;64(4):506–13.10.1007/s11837-012-0295-3Search in Google Scholar

[25] Thakur SK, Kwee GT, Gupta M. Development and characterization of magnesium composites containing nano-sized silicon carbide and carbon nanotubes as hybrid reinforcements. J Mater Sci. 2007;42(24):10040–6.10.1007/s10853-007-2004-0Search in Google Scholar

[26] Goh CS, Wei J, Lee LC, Gupta M. Ductility improvement and fatigue studies in Mg-CNT nanocomposites. Compos Sci Technol. 2008;68(6):1432–9.10.1016/j.compscitech.2007.10.057Search in Google Scholar

[27] Esawi AMK, Morsi K, Sayed A, Taher M, Lanka S. Effect of carbon nanotube (CNT) content on the mechanical properties of CNT-reinforced aluminium composites. Compos Sci Technol. 2010;70(16):2237–41.10.1016/j.compscitech.2010.05.004Search in Google Scholar

[28] Kwon H, Saarna M, Yoon S, Weidenkaff A, Leparoux M. Effect of milling time on dual-nanoparticulate-reinforced aluminum alloy matrix composite materials. Mater Sci Engineering: A. 2014;590:338–45.10.1016/j.msea.2013.10.046Search in Google Scholar

[29] Nam DH, Kim YK, Cha SI, Hong SH. Effect of CNTs on precipitation hardening behavior of CNT/Al–Cu composites. Carbon. 2012;50(13):4809–14.10.1016/j.carbon.2012.06.005Search in Google Scholar

[30] Akbarpour MR, Salahi E, Hesari F, Simchi A, Kim HS. Fabrication, characterization and mechanical properties of hybrid composites of copper using the nanoparticulates of SiC and carbon nanotubes. Mater Sci Eng A. 2013;572:83–90.10.1016/j.msea.2013.02.039Search in Google Scholar

[31] Kwon H, Park DH, Silvain JF, Kawasaki A. Investigation of carbon nanotube reinforced aluminum matrix composite materials. Compos Sci Technol. 2010;70(3):546–50.10.1016/j.compscitech.2009.11.025Search in Google Scholar

[32] Kuzumaki T, Miyazawa K, Ichinose H, Ito K. Processing of carbon nanotube reinforced aluminum composite. J Mater Res. 1998;13(9):2445–9.10.1557/JMR.1998.0340Search in Google Scholar

[33] Xu CL, Wei BQ, Ma RZ, Liang J, Ma XK, Wu DH. Fabrication of aluminum-carbon nanotube composites and their electrical properties. Carbon NY. 1999;37:855–8.10.1016/S0008-6223(98)00285-1Search in Google Scholar

[34] Esawi AMK, Morsi K, Sayed A, Taher M, Lanka S. Effect of carbon nanotube (CNT) content on the mechanical properties of CNT-reinforced aluminium composites. Compos Sci Technol. 2010;70(16):2237–41.10.1016/j.compscitech.2010.05.004Search in Google Scholar

[35] Zhang XX, Wei HM, Li AB, Fu YD, Geng L. Effect of hot extrusion and heat treatment on CNTs-Al interfacial bond strength in hybrid aluminium composites. Compos Interfaces. 2013;20:231.10.1080/15685543.2013.793093Search in Google Scholar

[36] Zhao K, Liu ZY, Xiao BL, Ni DR, Ma ZY. Origin of insignificant strengthening effect of CNTs in T6-treated CNT/6061Al composites. Acta Metall Sin (Engl Lett). 2018;31:134–42.10.1007/s40195-017-0626-zSearch in Google Scholar

[37] Choudhary V, Singh BP, Mathur RB. In: Satoru Suzuki, editor, Syntheses and applications of carbon nanotubes and their composites. chapter: carbon nanotubes and their composites. Satoru Suzuki Synth. Appl. Carbon Nanotubes. their Compos. London, UK: Intech Open Science; 2013. p. 193–222.10.5772/52897Search in Google Scholar

[38] Ruoff RS, Lorents DC. Mechanical and thermal properties of carbon nanotubes. Carbon. 1995;33(7):925–30.10.1016/B978-0-08-042682-2.50021-7Search in Google Scholar

[39] Jackman H. Available from: https://doi.org/urn:nbn:se:kauSearch in Google Scholar

[40] Majid M, Majzoobi GH, Noozad GA, Reihani A, Mortazavi SZ, Gorji MS. Fabrication and mechanical properties of MWCNTs-reinforced aluminum composites by hot extrusion. Rare Met. 2012;31(4):372–8.10.1007/s12598-012-0523-6Search in Google Scholar

[41] Srivastava D, Wei C, Cho K. Nanomechanics of carbon nanotubes and composites. Appl Mech Rev. 2003;56(2):215–30.10.1115/1.1538625Search in Google Scholar

[42] Abdalla S, Al-Marzouki F, Al-Ghamdi AA, Abdel-Daiem A. Different technical applications of carbon nanotubes. Nanoscale Res Lett. 2015;10(1):358–8.10.1186/s11671-015-1056-3Search in Google Scholar PubMed PubMed Central

[43] Yumura M. Carbon nanotube industrial applications. Japan: AIST Today International Edition; 2003. p. 10.Search in Google Scholar

[44] Liao J, Tan MJ. Mixing of carbon nanotubes (CNTs) and aluminum powder for powder metallurgy use. Powder Technol. 2011;208(1):42–8.10.1016/j.powtec.2010.12.001Search in Google Scholar

[45] Choi H, Shin J, Min B, Park J, Bae D. Reinforcing effects of carbon nanotubes in structural aluminum matrix nanocomposites. J Mater Res. 2009;24(8):2610–6.10.1557/jmr.2009.0318Search in Google Scholar

[46] Kurita H, Kwon H, Estili M, Kawasaki A. Multi-walled car-bon nanotube-aluminum matrix composites prepared by combination of hetero-agglomeration method, spark plasma sintering and hot extrusion. Mater Trans. 2011;52(10):1960–5.10.2320/matertrans.M2011146Search in Google Scholar

[47] Moghadam AD, Omrani E, Menezes PL, Rohatgi PK. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene–a review. Compos B Eng. 2015;77:402–20.10.1016/j.compositesb.2015.03.014Search in Google Scholar

[48] Papageorgiou DG, Li Z, Liu M, Kinloch IA, Young RJ. Mechanisms of mechanical reinforcement by graphene and carbon nanotubes in polymer nanocomposites. Nanoscale. 2020;12(4):2228–67.10.1039/C9NR06952FSearch in Google Scholar PubMed

[49] Liu ZY, Xiao BL, Wang WG, Ma ZY. Tensile strength and electrical conductivity of carbon nanotube reinforced aluminum matrix composites fabricated by powder metallurgy combined with friction stir processing. J Mater Sci Technol. 2014;30:649–55.10.1016/j.jmst.2014.04.016Search in Google Scholar

[50] Esawi A, Morsi K. Dispersion of carbon nanotubes (CNTs) in aluminum powder. Compos A Appl Sci Manuf. 2007;38(2):646–50.10.1016/j.compositesa.2006.04.006Search in Google Scholar

[51] Jafari M, Abbasi MH, Enayati MH, Karimzadeh F. Mechanical properties of nanostructured Al2024-MWCNT composite prepared by optimized mechanical milling and hot-pressing methods. Adv Powder Technol. 2012;23(2):205–10.10.1016/j.apt.2011.02.008Search in Google Scholar

[52] Agarwal A, Bakshi SR, Lahiri D. Carbon nanotubes reinforced metal matrix composites. First edn. Boca Raton, FL, USA: CRC Press; 2011.Search in Google Scholar

[53] Ali MH, Rubel RI. A comparative review of Mg/CNTs and Al/CNTs composite to explore the prospect of bimetallic Mg-Al/CNTs composites. AIMS Mater Sci. 2020;7(3):217–43.10.3934/matersci.2020.3.217Search in Google Scholar

[54] Hussain MD, Khan U, Chanda A, Jangid R. Fabrication and hardness analysis of F-MWCNTs reinforced aluminium nanocomposite. Proc Eng. 2016;173:1611–8.10.1016/j.proeng.2016.12.262Search in Google Scholar

[55] ASTM, E92 Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials, ASTM B. Stand, 2017. Available from: 10.1520/E0092-16.Copyright.Search in Google Scholar

[56] S E8/E8m. Tension Testing of Metallic Materials, ASTM Int, 2016.Search in Google Scholar

[57] Kurita H, Estili M, Kwon H, Miyazaki T, Zhou W, Silvain JF, et al. Load-bearing contribution of multi-walled carbon nanotubes on tensile response of aluminum. Compos A Appl Sci Manuf. 2015;68:133–9.10.1016/j.compositesa.2014.09.014Search in Google Scholar

[58] Housaer F, Legris A, B´eclin F, Touzin M, Tingaud D, Ji G, et al. Characterization of Al/MWCNTs composites prepared by powder metallurgy routes. MATEC Web Conf. 2013;7:1–3.10.1051/matecconf/20130701002Search in Google Scholar

[59] Goh CS, Wei J, Lee LC, Gupta M. Development of novel carbon nanotube reinforced magnesium nanocomposites using the powder metallurgy technique. Nanotechnology. 2006;17(1):7–12.10.1088/0957-4484/17/1/002Search in Google Scholar

[60] Sridhar I, Narayanan KR. Processing and characterization of MWCNT reinforced aluminum matrix composites. J Mater Sci. 2009;44(7):1750–6.10.1007/s10853-009-3290-5Search in Google Scholar

[61] Laha T, Agarwal A. Effect of sintering on thermally sprayed carbon nanotube reinforced aluminum nanocomposite. Mater Sci Eng A. 2008;480(1–2):323–32.10.1016/j.msea.2007.07.047Search in Google Scholar

[62] Sharma N, Syed AN, Ray BC, Yadav S, Biswas K. Alumina-MWCNT composites: microstructural characterization and mechanical properties. J Asian Ceram Societies. 2019;7(1):1–19.10.1080/21870764.2018.1552235Search in Google Scholar

[63] Suk ME. Enhanced tensile properties of weight-reduced nanoporous carbon nanotube-aluminum composites. Mater Express. 2019;9(7):801–7.10.1166/mex.2019.1561Search in Google Scholar

[64] Bunakov NA, Kozlov DV, Golovanov VN, Klimov ES, Grebchuk EE, Efimov MS, et al. Fabrication of multi-walled carbon nanotubes-aluminum matrix composite by powder metallurgy technique. Results Phys. 2016;6:231–2.10.1016/j.rinp.2016.04.013Search in Google Scholar

[65] Esawi AMK, Morsi K, Sayed A, Taher M, Lanka S. The influence of carbon nanotube (CNT) morphology and diameter on the processing and properties of CNT-reinforced aluminium composites. Compos A Appl Sci Manuf. 2011;42(3):234–43.10.1016/j.compositesa.2010.11.008Search in Google Scholar

[66] Choi H, Wang L, Cheon D, Lee W. Preparation by mechanical alloying of Al powders with single-, double-, and multi-walled carbon nanotubes for carbon/metal nanocomposites. Compos Sci Technol. 2013;74:91–8.10.1016/j.compscitech.2012.10.011Search in Google Scholar

[67] Ci L, Ryu Z, Jin-Phillipp NY, Ru¨hle M. Investigation of the interfacial reaction between multi-walled carbon nanotubes and aluminum. Acta Mater. 2006;54(20):5367–75.10.1016/j.actamat.2006.06.031Search in Google Scholar

[68] Patil RG, Chatpalli V, Kannan KR. Study on Young’s modulus and microhardness of carbon nanotubes reinforced copper nanocomposite. Mater Sci Technol. 2010;26(4):478–81.10.1179/026708309X12468927349497Search in Google Scholar

[69] Kwon H, Cho S, Leparoux M, Kawasaki A. Dual-nanoparticulate-reinforced aluminum matrix composite materials. Nanotechnology. 2012;23(22):225704.10.1088/0957-4484/23/22/225704Search in Google Scholar PubMed

[70] Soni SK, Thomas B. Influence of TiO2 and MWCNT nanoparticles dispersion on microstructure and mechanical properties of Al6061 matrix hybrid nanocomposites. Mater Res Express. 2020;6(12):1265–8.10.1088/2053-1591/ab5dfeSearch in Google Scholar

[71] George R, Kashyap KT, Rahul R, Yamdagni S. Strengthening in carbon nanotube/aluminium (CNT/Al) composites. Scr Materialia. 2005;53(10):1159–63.10.1016/j.scriptamat.2005.07.022Search in Google Scholar

[72] Kim KT, Eckert J, Menzel SB, Gemming T, Hong SH. Grain refinement assisted strengthening of carbon nanotube reinforced copper matrix nanocomposites. Appl Phys Lett. 2008;92(12):121901.10.1063/1.2899939Search in Google Scholar

[73] Li H, Misra A, Horita Z, Koch CC, Mara NA, Dicker-son PO, et al. Strong and ductile nanostructured Cu-carbon nanotube composite. Appl Phys Lett. 2009;95(7):71907.10.1063/1.3211921Search in Google Scholar

[74] Yuan C, Tan Z, Fan G, Chen M, Zheng Q, Li Z. Fabrication and mechanical properties of CNT/Al composites via shift-speed ball milling and hot-rolling. J Mater Res. 2019;34(15):2609–19.10.1557/jmr.2019.219Search in Google Scholar

[75] Billah MM, Chen Q. Al-CNT-Ni composite with significantly increased strength and hardness. SN Appl Sci. 2019;1:1–6.10.1007/s42452-019-0530-4Search in Google Scholar

[76] Kundalwal SI, Rathi A. Improved mechanical and viscoelastic proper ties of CNT-composites fabricated using an innovative ultrasonic dual mixing technique. J Mech Behav Mater. 2020;29(1):77–85.10.1515/jmbm-2020-0008Search in Google Scholar

[77] Fathi MSA. Mechanical properties of nanocomposite materials: A. Rev J Southwest Jiaotong Univ. 2020;1:55.10.35741/issn.0258-2724.55.1.10Search in Google Scholar

[78] Shivaramu HT, Nayak V, Umashankar KS. Dry sliding wear characteristics of multi-walled carbon nanotubes reinforced Al-Si (LM6) alloy nanocomposites produced by powder metallurgy technique. Mater Res Express. 2020;7(4):45001.10.1088/2053-1591/ab825cSearch in Google Scholar

[79] Carneiro I, Simões S. Effect of morphology and structure of MWCNTs on metal matrix nanocomposites. Materials. 2020;13(23):5557.10.3390/ma13235557Search in Google Scholar PubMed PubMed Central

[80] Feijoo I, Pena G, Cabeza M, Cristóbal MJ, Rey P. MWCNT-reinforced AA7075 composites: effect of reinforcement percentage on mechanical properties. Metals. 2021;11(6):969.10.3390/met11060969Search in Google Scholar

[81] Pérez-Bustamante R, González-Ibarra MJ, González-Cantú J, Estrada-Guel I, Herrera-Ramírez JM, Miki-Yoshida M, et al. AA2024-CNTs composites by milling process after T6-temper condition. J Alloy Compd. 2012;536:17–20.10.1016/j.jallcom.2011.12.001Search in Google Scholar

[82] Pérez-Bustamante R, Pérez-Bustamante F, Estrada-Guel I, Santillán-Rodríguez CR, Matutes-Aquino JA, Herrera-Ramírez JM, et al. Characterization of Al2024-CNTs composites produced by mechanical alloying. Powder Technol. 2011;212(3):390–6.10.1016/j.powtec.2011.06.007Search in Google Scholar

[83] Lipecka J, Andrzejczuk M, Lewandowska M, Janczak-Rusch J, Kurzydlowski KJ. Evaluation of thermal stability of ultrafine grained aluminium matrix composites reinforced with carbon nanotubes. Compos Sci Technol. 2011;71(16):1881–5.10.1016/j.compscitech.2011.09.001Search in Google Scholar

[84] Uriza-Vega E, Carrenõ-Gallardo C, López-Meléndez C, Cuadros-Lugo E, Pérez-Bustamante R, Ledezma-Sillas E, et al. Mechanical behavior of multiwalled carbon nanotube reinforced 7075 aluminum alloy composites prepared by mechanical milling and hot extrusion. Mater Res. 2019;22–2.10.1590/1980-5373-mr-2018-0652Search in Google Scholar

[85] Tserpes K, Chanteli A, Pantelakis S, Koumoulos EP, Charitidis CA. Mechanical and nanomechanical properties of MWCNT/PP nanocomposite. Frattura ed Integrit’a Strutturale. 2018;12(46):73–83.10.3221/IGF-ESIS.46.08Search in Google Scholar

[86] Devadiga U, Fernandes P. Taguchi analysis for sliding wear characteristics of carbon nanotube-fly ash reinforced aluminium nanocomposites. Heliyon. 2021;7(2):6170.10.1016/j.heliyon.2021.e06170Search in Google Scholar

[87] Chohan JS, Mittal N, Kumar R, Singh S, Sharma S, Dwivedi SP, et al. Optimization of FFF process parameters by naked mole-rat algorithms with enhanced exploration and exploitation capabilities. Polymers. 2021;13(11):1702–2.10.3390/polym13111702Search in Google Scholar PubMed PubMed Central

[88] Kumar J, Singh D, Kalsi NS, Sharma S, Pruncu CI, Pimenov DY, et al. Comparative study on the mechanical, tribological, morphological and structural properties of vortex casting processed, Al-SiC-Cr hybrid metal matrix composites for high strength wear-resistant applications: Fabrication and characterizations. J Mater Res Technol. 2020;9(6):13607–15.10.1016/j.jmrt.2020.10.001Search in Google Scholar

[89] Dwivedi SP, Saxena A, Sharma S. Influence of nano-CuO on synthesis and mechanical behavior of spent alumina catalyst and grinding sludge reinforced aluminum based composite. Int J Metalcasting. 2021;13:1–18. 10.1007/s40962-021-00597-5.Search in Google Scholar

[90] Sivalingam P, Krishnaraj V, Sharma S, Mouleeswaran SK, Kumar RJ, Zitoune R. Experimental study on thermal and morphological analysis of green composite sandwich made of flax and agglomerated cork. J Therm Anal Calorim. 2020;139:3003–12.10.1007/s10973-019-08691-xSearch in Google Scholar

[91] Muni RN, Singh J, Kumar V, Sharma S. Parametric optimization of rice husk ash, copper, magnesium reinforced aluminium matrix hybrid composite processed by EDM. ARPN J Eng Appl Sci. 2019;14(22):1828–34.Search in Google Scholar

[92] Muni RN, Singh J, Kumar V, Sharma S. Influence of rice husk ash, Cu, Mg on the mechanical behaviour of Aluminium Matrix hybrid composites. Int J Appl Eng Res. 2019;14(8):1828–34.Search in Google Scholar

[93] Dwivedi SP, Saxena A, Sharma S, Srivastava AK, Maurya NK. Influence of SAC and eggshell addition in the physical, mechanical and thermal behaviour of Cr reinforced aluminium based composite. Int J Cast Met Res 2021;34(1):43–55.10.1080/13640461.2021.1877943Search in Google Scholar

[94] Saxena A, Dwivedi SP, Dixit A, Sharma S, Srivastava AK, Maurya NK. Computational and experimental investigation on mechanical behavior of zirconia toughened alumina and nickel powder reinforced EN31 based composite material. Materialwissenschaft und Werkstofftechnik. 2021;52(5):548–60.10.1002/mawe.202000152Search in Google Scholar

[95] Sharma S, Singh J, Gupta MK, Mia M, Dwivedi SP, Saxena A, et al. Investigation on mechanical, tribological and microstructural properties of Al-Mg-Si-T6/SiC/muscovite-hybrid metal-matrix composites for high strength applications. J Mater Res Technol. 2021;12(21):1564–81.10.1016/j.jmrt.2021.03.095Search in Google Scholar

[96] Dwivedi SP, Agrawal R, Sharma S. Effect of friction stir process parameters on mechanical properties of chrome containing leather waste reinforced aluminium based composite. Int J Precis Eng Manufacturing-Green Technol. 2021;8(3):935–43.10.1007/s40684-021-00312-zSearch in Google Scholar

[97] Kumar J, Singh D, Kalsi NS, Sharma S, Mia J, Singh M, et al. Investigation on the mechanical, tribological, morphological and machinability behavior of stir-casted Al/SiC/Mo reinforced MMCs. J Mater Res Technol. 2021;12:930–46.10.1016/j.jmrt.2021.03.034Search in Google Scholar

[98] Aggarwal V, Singh J, Sharma S, Sharma A, Singh G, Parshad J. Empirical modeling of machining parameters during WEDM of Inconel 690 using response surface methodology. AIP Conference Proceedings. Vol. 2281; 2020. p. 020032. 10.1063/5.0027284.Search in Google Scholar

[99] Aggarwal V, Singh J, Sharma S, Harish K, Garg A, Sharma G, et al. An experimental study of wire breakage frequency on different electrodes during WEDM of Inconel-722. IOP Conf Series: Mater Sci Eng. 2020;954:12013.10.1088/1757-899X/954/1/012013Search in Google Scholar

[100] Aggarwal V, Pruncu CI, Singh J, Sharma S, Pimenov DY. Empirical investigations during WEDM of Ni-27Cu-3.15Al- 2Fe-1.5Mn based superalloy for high temperature corrosion resistance applications. Materials. 2020;13(16):3470.10.3390/ma13163470Search in Google Scholar PubMed PubMed Central

[101] Qureshi MN, Sharma S, Singh J, Khadar SDA, Baig RU. Evaluation of surface roughness in the turning of mild steel under different cutting conditions using back propagation neural network. Proc Estonian Acad Sci. 2020;69:109–15.10.3176/proc.2020.2.02Search in Google Scholar

[102] Islam S, Dwivedi SP, Dwivedi VK, Sharma S, Kozak D. Development of marble dust/waste PET based polymer composite material for environmental sustainability: fabrication and characterizations. J Mater Perform Charact. 2021;10(1):538–52.10.1520/MPC20210034Search in Google Scholar

[103] Sharma S, Sudhakara P, Singh J, Ilyas RA, Asyraf MRM, Razman MR. Critical review of biodegradable and bioactive polymer composites for bone tissue engineering and drug delivery applications. Polymers. 2021;13(6):2623.10.3390/polym13162623Search in Google Scholar PubMed PubMed Central

[104] Ilyas RA, Sapuan SM, Asyraf MRM, Dayana DAZN, Amelia JJN, Rani MSA, et al. Polymer composites filled with metal derivatives: a review of flame retardants. Polymers. 2021;13:1701.10.3390/polym13111701Search in Google Scholar PubMed PubMed Central

[105] Sharma S, Sudhakara P, Borhana A, Singh J, Ilyas RA. Recent trends and developments in conducting polymer nanocomposites for multifunctional applications. Polymers. 2021;13(17):2898.10.3390/polym13172898Search in Google Scholar PubMed PubMed Central

[106] Sharma S, Sudhakara P. Fabrication and optimization of hybrid AA-6082-T6 alloy/8%Al2O3(Alumina)/2%Grp metal matrix composites using novel Box-Behnken methodology processed by wire-sinking electric discharge machining. Mater Res Express. 2019;6:116594. 10.1088/2053-1591/ab4b97.Search in Google Scholar