Abstract

Developing a cost-effective industrially scalable manufacturing method that can improve the mechanical properties of nanocomposite foams with higher flexibility, compressibility, and, at the same time, mechanically robustness is of significant interest. In this study, porous thermoplastic polyurethane (TPU)/multiwalled carbon nanotube (MWCNT) was fabricated with the chemical blowing agent (CBA) by a combination of compounding-compression molding methods. The effects of CBA and MWCNT contents on the foam morphology, porosity, foam cell size, Young’s modulus, and compressibility of fabricated samples were investigated. Through conducting cyclic compressive tests, it was observed that nanocomposite foams exhibited consistent mechanical responses across multiple compressive cycles and demonstrated notable characteristics, including high compressibility (up to 76.4% compressive strain) and high elastic modulus (up to 8.8 ± 2.6 MPa). Moreover, theoretical approaches were employed to predict the elastic modulus of solid and foam TPU/MWCNT. For solid MWCNT/TPU, a specific micromechanical model based on different modifications of the Halpin-Tsai (HT) approach was used, which showed a good agreement with experimental data at different MWCNT contents. Furthermore, the constant parameters of Gibson and Ashby’s method were found to successfully predict the elastic modulus of foam TPU/MWCNT at different MWCNT and CBA percentages.

1 Introduction and background

In recent years, flexible strain sensors with their potential prospects have attracted great attention [1,2,3,4,5] in many fields. These fields include wearable electronics such as stretchable materials for electronic devices [6,7], wearable sensors [8], energy harvesters [9,10], and micropumps with active diaphragms [11]; field of human movement monitoring [12,13], soft robotics for elastomer actuators [14] or self-healing actuators [15], sensitive electronic skin [16], and prosthetics [17,18]. Piezoresistive nanocomposite foams consisting of conductive nanoparticles and a flexible polymeric matrix are one of the significant types of flexible strain sensors [19,20,21]. This type of sensor provides tremendous advantages, such as high electrical conductivity, high flexibility, compressibility, and lightweight [22]. The sensing mechanism of piezoresistive foam nanocomposites is based on the electrical resistance variation in response to applied external stress [23,24].

Foaming the nanocomposites can enhance their electrical properties [25] and tailor their mechanical properties, including flexibility [26,27], compressibility [28], and mechanical strength [29,30]. The mechanical properties of nanocomposite foam sensors are crucial for their design and development, in addition to the electrical properties. Pressure-detecting sensors must be both flexible and compressible when subjected to high-pressure loads, without compromising their morphology, durability, and mechanical strength. While the addition of conductive reinforcements can aid in the formation of conductive paths in the insulating polymer matrix, excessive filler content can harm the mechanical properties of the nanocomposite foam, reducing its processability and limiting its potential applications [31]. Despite successful demonstrations of nanocomposite foam sensors reported in the literature, they still have some limitations [32]. These sensors have low Young’s modulus, limited recoverability, weak compressive strength, and a restricted pressure detection range of up to 900 kPa [1,33,34,35,36,37]. Yao et al. [38] showed that the detection range of polyurethane–graphene sponges was as low as 10 kPa, indicating its poor mechanical strength. Some nanocomposite foams are insensitive to large strain levels (more than 30%) due to conductive network saturation [39]. Additionally, fabricating a piezoresistive nanocomposite foam with a controlled elastic modulus that can operate within a broad loading range at a limited thickness is challenging [40,41].

Moreover, developing a cost-effective and scalable fabrication technique to create nanocomposite foams with uniformly distributed conductive fillers and controlled porosity, cell wall thickness, and foam morphology for achieving superior mechanical properties in the foam structure is a critical objective. Many foaming fabrication methods such as the particulate leaching method [42,43] are not cost-effective and scalable to the industrial manufacturing process. Supercritical gas foaming is an environmentally friendly industrial-scale technique that creates porous structures in thermoplastic polymeric (TPU) matrixes. However, in the nanocomposites with high loadings of nanoparticles, the gas diffusion is decreased, which adversely affects the physical foaming process and reduces the expansion ratio of the foamed product [26,44]. Also, the physical blowing agent (PBA) requires high pressure to be dissolved in the polymeric phase, which limits some types of foaming processes that are not practical at high pressures [45]. Hence, to broaden the nanocomposite foam applications, a new strategy that is able to enhance its mechanical properties with high controllability via an industrially scalable method is of great interest. One possible alternative foaming technique is implementing chemical blowing agent (CBA) particles, which promise highly controllable foaming with a uniform close-cell structure [1,46]. When subjected to heat, CBA thermally decomposes and produces gas, which can be trapped inside the polymeric matrix and create a foam structure [47]. CBA content and decomposition rate have a significant role in the foaming process of polymeric mixtures [48]. Unlike PBA, CBA particles operate at the pressure-free operating condition and undergo the chemical reaction at the decomposition temperature, which makes them a proper candidate to be utilized in pressure-free foaming processes such as rotational foam molding [45]. Therefore, compared to PBAs, CBAs are easier to handle and have more engineering and economic efficiency [47].

The design parameters including the polymer matrix, porous structure, characteristics of conductive filler, and manufacturing technique significantly impact the electrical and mechanical properties of nanocomposite foams. Despite existing literature on the topic, currently, a comprehensive study investigating the impact of foam porosity and morphology, filler contents, and sample fabrication methods on piezoresistivity, repeatability, and mechanical properties of nanocomposite foam sensors is missing [35,49]. Therefore, more research in this field is necessary to consider all these factors. In the current study, TPU was used as the polymeric phase due to its beneficial properties, which expand its application in a variety of fields. TPU is a flexible material that suits our target for compressibility in this study [41,50]. Moreover, it has abrasion resistance, chemical resistance, and ease of processing due to being melt-processable and recyclable [26,51]. Having high mechanical and electrical properties including high conductivity, large aspect ratio, and high elastic modulus, multiwalled carbon nanotube (MWCNT) was chosen as the nanofiller in this study [52,53,54,55].

In this work, TPU/MWCNT foam nanocomposites with varying contents of MWCNT and CBA were fabricated, and their flexibility, compressibility, and mechanical properties were analyzed. Moreover, the effects of nanofiller and blowing agent contents on the foam porosity, morphology, and mechanical properties of TPU/MWCNT nanocomposites were investigated. The potential application of fabricated TPU/MWCNT nanocomposite foams is in pressure-detecting systems to help the rehabilitation of people with artificial joints and suffering from osteoarthritis [56,57]. Unbalanced pressure distribution applied to the artificial knee over time can cause the wear of the tibial insert and result in further problems [58]. Pressure-detecting sensors embedded in artificial knees can detect plantar pressure map which shows the pressure distribution applied to the knee. The recorded results from the pressure sensors will be used to detect the accuracy and further adjustment of the designed biomechanical system.

Due to the limitations and costs associated with experimental tests, theoretical models are also used in our research to predict Young’s modulus of solid and foam nanocomposites. This approach offers a better understanding of material properties and helps identify the ideal conductive reinforcement content, which can meet the desired mechanical property requirements [59]. Therefore, in this study, Young’s modulus of solid TPU/MWCNT nanocomposites was predicted by micromechanical models based on several modified HS approaches. Also, based on experimental results, the constant parameters of Gibson and Ashby’s method for evaluating Young’s modulus of foams made of pure TPU or MWCNT/TPU nanocomposites were proposed.

2 Experimental section

2.1 Experimental materials

TPU (Estane 58202, an 85A polyether-type thermoplastic polyurethane) was purchased from the Lubrizol Corporation. The CBA, azodicarbonamide (AC or ADCA) (CELLCOM-AC3000FD, decomposition temperature of 201–205°C), was ordered from Kum Yang Company Limited. The MWCNT (NC7000TM series, average length of 1.5 mm, average diameter of 9.5 nm) was purchased from Nanocyl Company. All materials were used in the sample fabrication as received without further modifications.

2.2 Manufacturing process of TPU nanocomposites and their foams

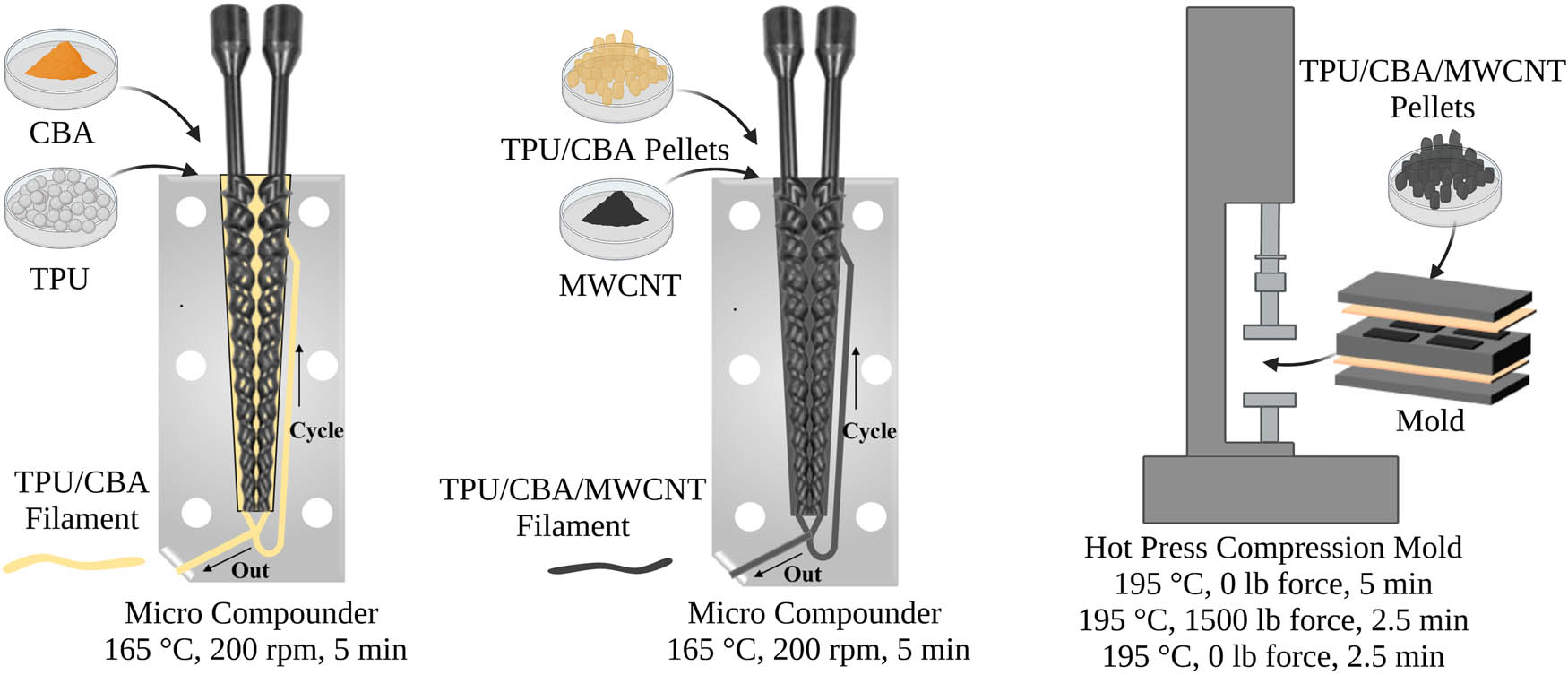

Fabrication of TPU/MWCNT foams involved two different stages. One stage was blending the materials with the micro-compounder (DSM Xplore, MICRO 15, The Netherlands) to create homogeneous filaments. The second stage involved using the hot press compression molding (Carver Model 4386, USA) to reshape the filaments and create the samples with the desired shape, which was suitable for characterization. Since the CBAs are temperature sensitive, these particles should not be activated during the blending process. Otherwise, during the compression molding process, due to the extra heat and high pressure, their structure will be damaged, and porous morphology will not be achieved. Therefore, during the blending stage, the operating temperature was selected far from the CBA decomposition temperature (higher than TPU’s melting point [155°C]) to just create solid TPU/CBA/MWCNT filaments. Later, in the compression molding stage, by increasing the working temperature, CBAs could decompose and create a porous structure.

Figure 1 shows the manufacturing process of TPU/MWCNT foams. At the beginning of this process, the specified weight ratios of TPU pellets and CBAs were fed to the micro-compounder through the conical forced feeding part. At this stage (the first step of compounding), materials were blended for 2.5 min with a speed of 200 rpm and a working temperature of 160°C. Then, the obtained filament was cut into small pieces for step 2 of compounding, and at this time, different weight ratios of MWCNTs were added to TPU/CBA pieces. It is worth mentioning that blending the MWCNTs at the same time with the TPU pellets and CBAs hindered the CBAs from being activated completely by heat in the compression molding stage. The reason for this phenomenon could be the entanglement of MWCNTs with TPU, which caused improper mixing of CBAs with TPU. Therefore, two-step compounding was conducted to create TPU/CBA/MWCNT solid filaments. In compounding step 2 similar operating condition as the first step was used. In the next stage, obtained TPU/CBA/MWCNT solid filaments were cut into small pieces and were filled into an aluminum mold with rectangular cuboid cavities (25.0 mm [L] × 12.5 mm [W] × 2.0 mm [T]). Then, the mold was transferred into the hot press compression molding with a preset temperature of 195°C. Once the mold was in contact with both heating platens of the device, it was heated up for 5 min without external pressure. After 5 min, the mold was pressurized to 1,000 psi for 2.5 min. Then, in order to provide space for the expansion of CBAs, the external pressure was released to zero while the mold was in contact with two heating plates for an additional 2.5 min. Afterward, the mold was removed from the hot press compression molding and instantly cooled with cold water. Once the samples were removed from the mold cavities, they were placed in an oven to dry at 70°C for 24 h. TPU foam samples were fabricated with the manufacturing process shown in Figure 1 with the only difference of excluding step 2 of compounding since MWCNTs were not used for this type of sample. Also, the fabrication process of solid TPU/MWCNT nanocomposite followed the same procedure as TPU/MWCNT foams, excluding the first step of compounding. The final products with various MWCNT and CBA contents are named as summarized in Table 1. In this table, Nn-Fm indicates a sample that has n wt% MWCNT content and m wt% CBA content.

Schematic of foam TPU/MWCNT manufacturing process.

Composition of fabricated samples

| Sample identification | MWCNT content (wt%) | CBA content (wt%) |

|---|---|---|

| N0-F0, N0-F3, N0-F5 | 0 | 0, 3, 5 |

| N1-F0, N1-F3, N1-F5 | 1 | 0, 3, 5 |

| N3-F0, N3-F3, N3-F5 | 3 | 0, 3, 5 |

| N5-F0, N5-F3, N5-F5 | 5 | 0, 3, 5 |

2.3 Characterization methods

Cyclic compression tests were carried out on an Instron 5944 machine (Instron, Norwood, USA-2kN load cell) with a displacement rate of 1 mm/min and a maximum allowable force of 1.9 kN in ten continuous loading–unloading cycles [41,60,61,62]. The average sample geometry was 25.0 mm (L) × 12.5 mm (W) × 2.0 mm (T). Young’s modulus of the samples was determined through a linear regression analysis of the compressive stress versus compressive strain curves, focusing on the initial 5% of the compressive strain in the first loading cycle. The slope of the resulting trendline was used as the calculated value for Young’s modulus.

A scanning electron microscope (SEM, JSM-IT100, InTouch Scope™, JOEL Inc, Tokyo, Japan) at 10 kV was used to observe the morphologies of the fabricated foams. For SEM sample preparation, foams were submerged in liquid nitrogen to be cryo-fractured. Then, the fractured cross-sectional surface was subjected to the sputter-coating device (DII-29010SCTR Smart Coater, JOEL Inc, Tokyo, Japan) for 4 min.

The average cell diameter of nanocomposite foams was assessed through the analysis of SEM micrographs using ImageJ software [63,64,65].

3 Theoretical approaches

To estimate the elastic modulus of the fabricated TPU/MWCNT foams at any MWCNT or porosity percentages, a theoretical approach has been developed. In this approach, in the first step, the elastic modulus of solid TPU/MWCNT nanocomposites is calculated at various MWCNT contents using micromechanical models based on the Halpin-Tsai (HT) approach. Then, using the results of the previous step, the elastic modulus of foams made of pure TPU or TPU/MWCNT nanocomposites is evaluated. In the second step, a method introduced by Gibson and Ashby [66] is used to calculate the elastic modulus ratio of foams to their solid material at any porosity percentage.

3.1 Solid TPU/MWCNT

To utilize this heavily employed approach for nanocomposite materials, various modifications to the original HT have been performed. In MWCNT-reinforced nanocomposites, there are a few parameters that affect the mechanical properties of the resulting nanocomposites such as the aspect ratio, agglomeration, orientation, and waviness of CNTs [67,68,69]. To capture the effect of MWCNT aspect ratio (AR) when they are dispersed with random orientations, the elastic modulus of such nanocomposites

where the definition of

where

where

Considering the geometrical shape of the reinforcement components, the coefficients of

To further involve the effect of reinforcement waviness and distribution states, another modified HT approach has been introduced, as mentioned in the following equation [73,74]:

where

The orientation factor is applied to consider the effect of random orientations of MWCNTs, as

Due to MWCNT’s high aspect ratio, they are usually bent when they are added to their matrix material. Therefore, a waviness factor, which is defined based on an assumed wave shape of long MWCNTs, has also been considered to capture the effect of MWCNT’s bending in the HT approach. As suggested in previous studies [73,76,77],

Moreover, to better modify the evaluation of the elastic modulus of the nanocomposite, an agglomeration factor is suggested to modify the utilized HT approach in equation (7) as follows [73,74]:

where

Finally, to bridge MWCNT content from weight fraction

where

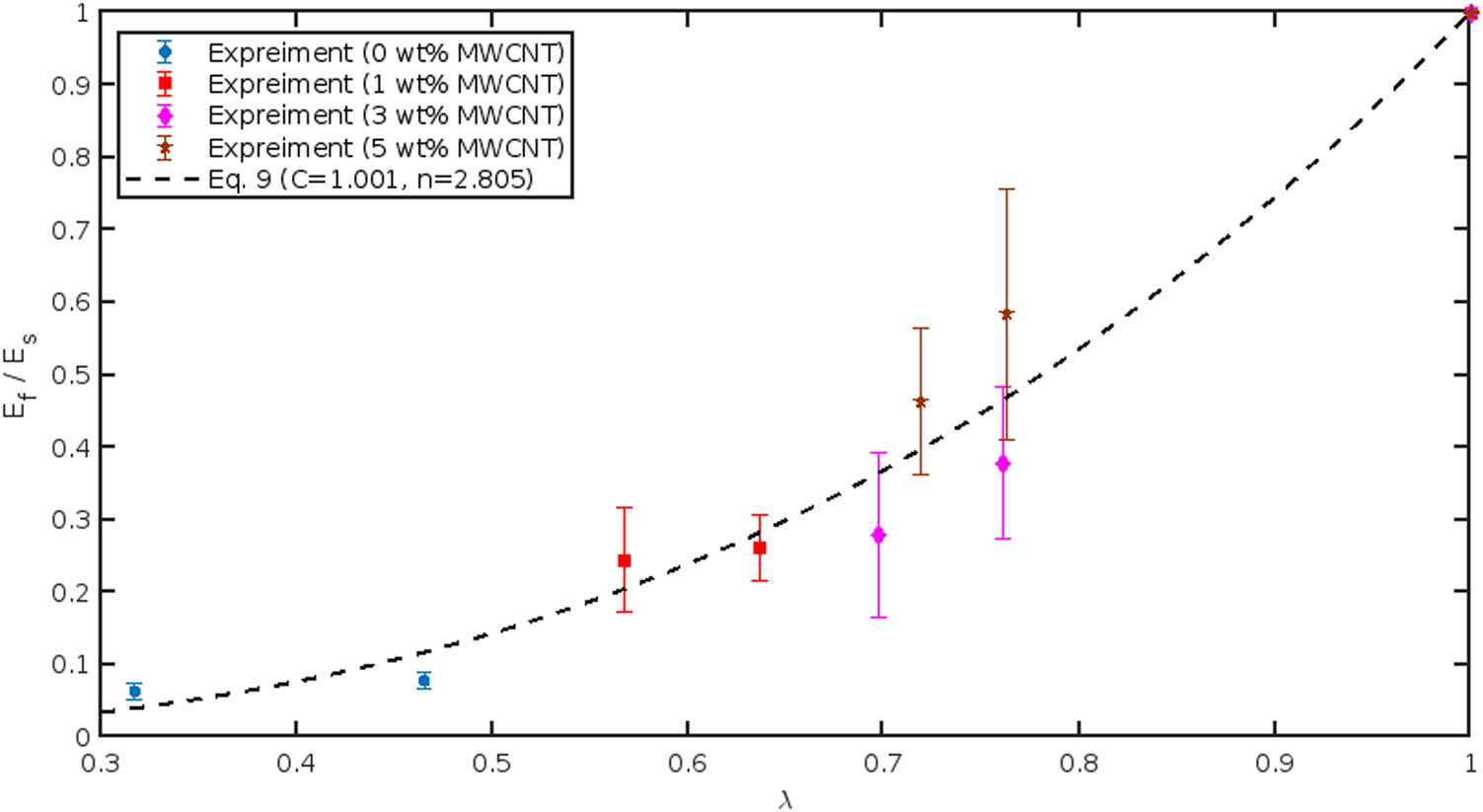

3.2 TPU and TPU/MWCNT foams

According to Gibson and Ashby’s method [66], the elastic modulus of foam is a function of density ratio

where C and n are two constants that can be defined by performing regression analysis on the experimental data. These constants are changed by void geometry, foam material, cell type, etc.

It is worth mentioning that the following equation shows the relation between density ratio and porosity percentage

Accordingly, for example,

4 Results and discussion

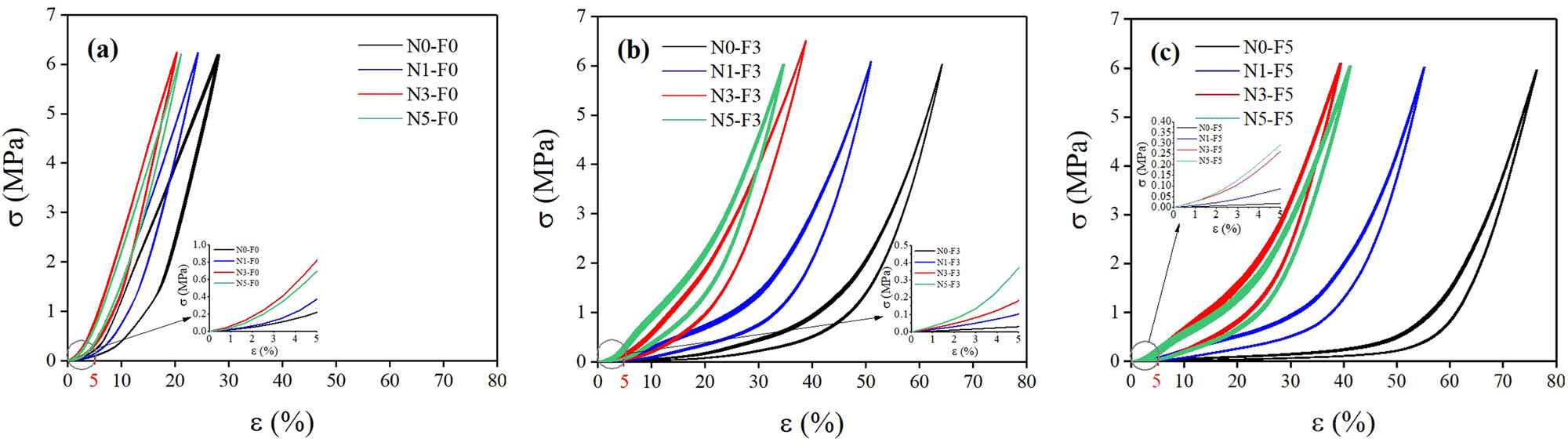

Figure 2 presents the cyclic compression test curves (ten cycles) for the fabricated samples with different contents of MWCNTs and CBAs. Furthermore, this figure presents a focused area of an initial 5% of the compressive strain in the first loading cycle for each sample. Young’s modulus of the samples is calculated based on linear regression analysis of the compressive stress versus compressive strain curves of this section. The curves in Figure 2 indicate that all the samples follow a repeatable mechanical behavior in different compression cycles. Moreover, this figure shows that the inclusion of CBAs in the polymer matrix increased the sample's flexibility and elevated their strain range under compression test. Based on the data plotted in Figure 2, it is evident that the inclusion of MWCNTs in the foam structures has a significant impact on their compressibility and maximum strain capacity. Table 2 presents a concise overview of the maximum strain capacity exhibited by different categories of nanocomposite foams when subjected to a uniform force range. As per Table 2, in comparison with the pristine foams (N0-F3 and N0-F5), the inclusion of 1 wt% MWCNT in N1-F3 and N1-F5 samples reduced their maximum strain by 13.3 and 21.1%, respectively. Also, increasing the MWCNT content to 3 wt% in N3-F3 and N3-F5 had a similar impact on their compressibility and the maximum strain that they could undergo. The maximum strain in N3-F3 and N3-F5 was further reduced by 25.4 and 36.8% compared to their pristine foams.

10 cyclic compression test curves. (a) solid TPU and TPU/MWCNT, (b) foam TPU and TPU/MWCNT with 3 wt.% CBA, and (c) foam TPU and TPU/MWCNT with 5 wt.% CBA.

Maximum strain levels under force of 1,900 N

| MWCNT (wt%) | 0 wt% CBA | 3 wt% CBA | 5 wt% CBA |

|---|---|---|---|

| 0 | 27.8 | 64.3 | 76.4 |

| 1 | 24.2 | 51.0 | 55.3 |

| 3 | 20.4 | 38.9 | 39.6 |

| 5 | 21.2 | 34.9 | 41.4 |

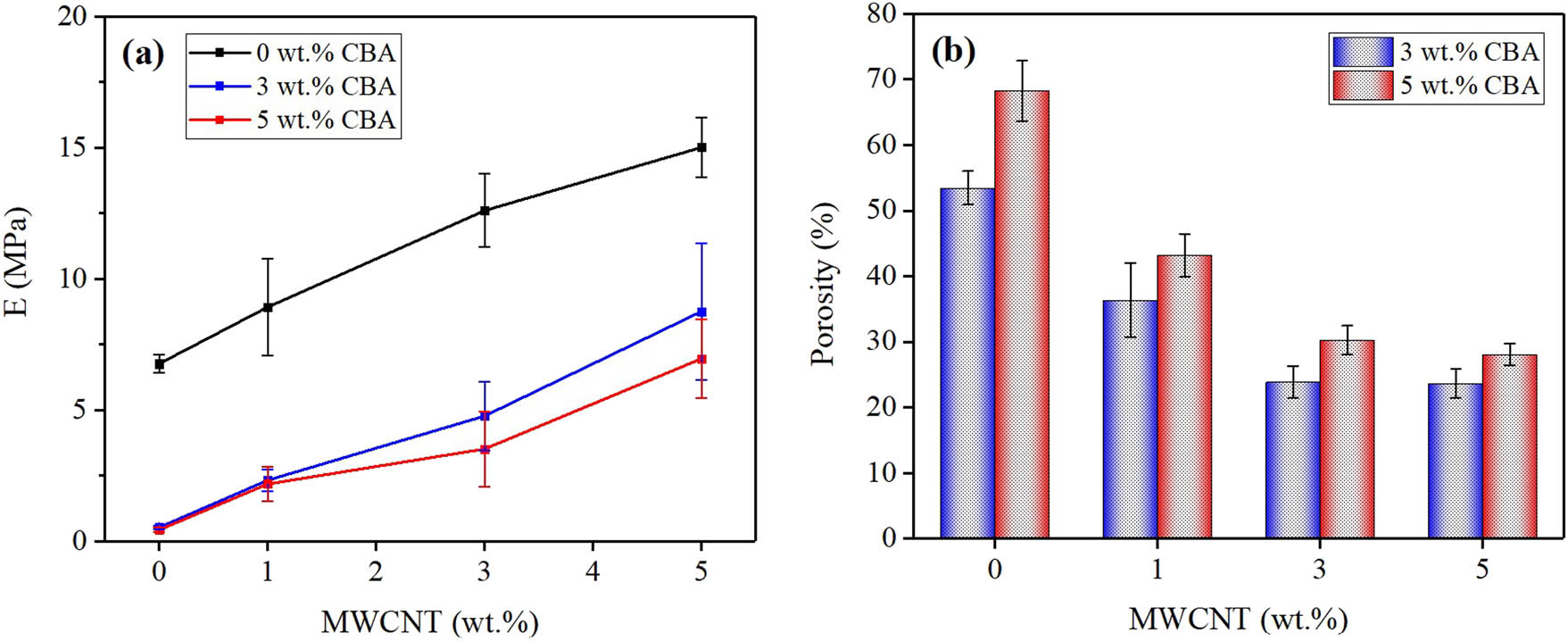

Figure 3(a) presents Young’s modulus of solid TPU, solid TPU/MWCNT with different MWCNT weight ratios, TPU foams with different CBA contents, and TPU/MWCNT foams with different MWCNT and CBA contents. This figure demonstrates that the foam TPU and TPU/MWCNT have considerably lower Young’s modulus compared to the solid TPU and TPU/MWCNT. This reduction in Young’s modulus is attributed to the inclusion of CBAs in the polymer matrix, which introduces a porous structure to the morphology of the samples, resulting in increased flexibility but decreased mechanical strength [61]. However, it is noteworthy that the foams fabricated in this study exhibit significantly enhanced mechanical strength compared to similar foams reported in the literature [39]. Moreover, Figure 3(a) shows that increasing the MWCNT content, increased Young’s modulus of both foam and solid samples in a similar trend. The high elastic modulus of MWCNTs contributes to the enhancement of mechanical strength observed in nanocomposite structures [42,43]. Moreover, the results revealed that N0-F3 demonstrated a higher Young’s modulus of 527 ± 80 kPa in comparison to N0-F5 with a Young’s modulus of 430 ± 78 kPa. Figure 3(b) illustrates the porosity characteristics of both foamed TPU and TPU/MWCNT samples. As depicted in this figure, an increase in the content of CBAs in nanocomposite foams with 5 wt% CBA resulted in higher porosity compared to the ones containing 3 wt% CBA. This increase in porosity resulted in enhanced flexibility and softness, consequently leading to reduced mechanical strength and Young’s modulus [63,64].

(a) Young’s modulus of TPU, TPU/MWCNT solid, and foamed nanocomposites, (b) porosity of foamed TPU and TPU/MWCNT at different CBA and MWCNT contents.

As depicted in Figure 3(b), the introduction of MWCNTs into the polymer matrix resulted in a reduction in the foam porosity of the nanocomposite foams containing both 3 and 5 wt% CBAs, as the MWCNT content was increased up to 3 wt%. This phenomenon could be attributed to the entanglement of MWCNTs with CBAs, which hindered the proper dispersion of CBAs within the polymer matrix and limited cell formation.

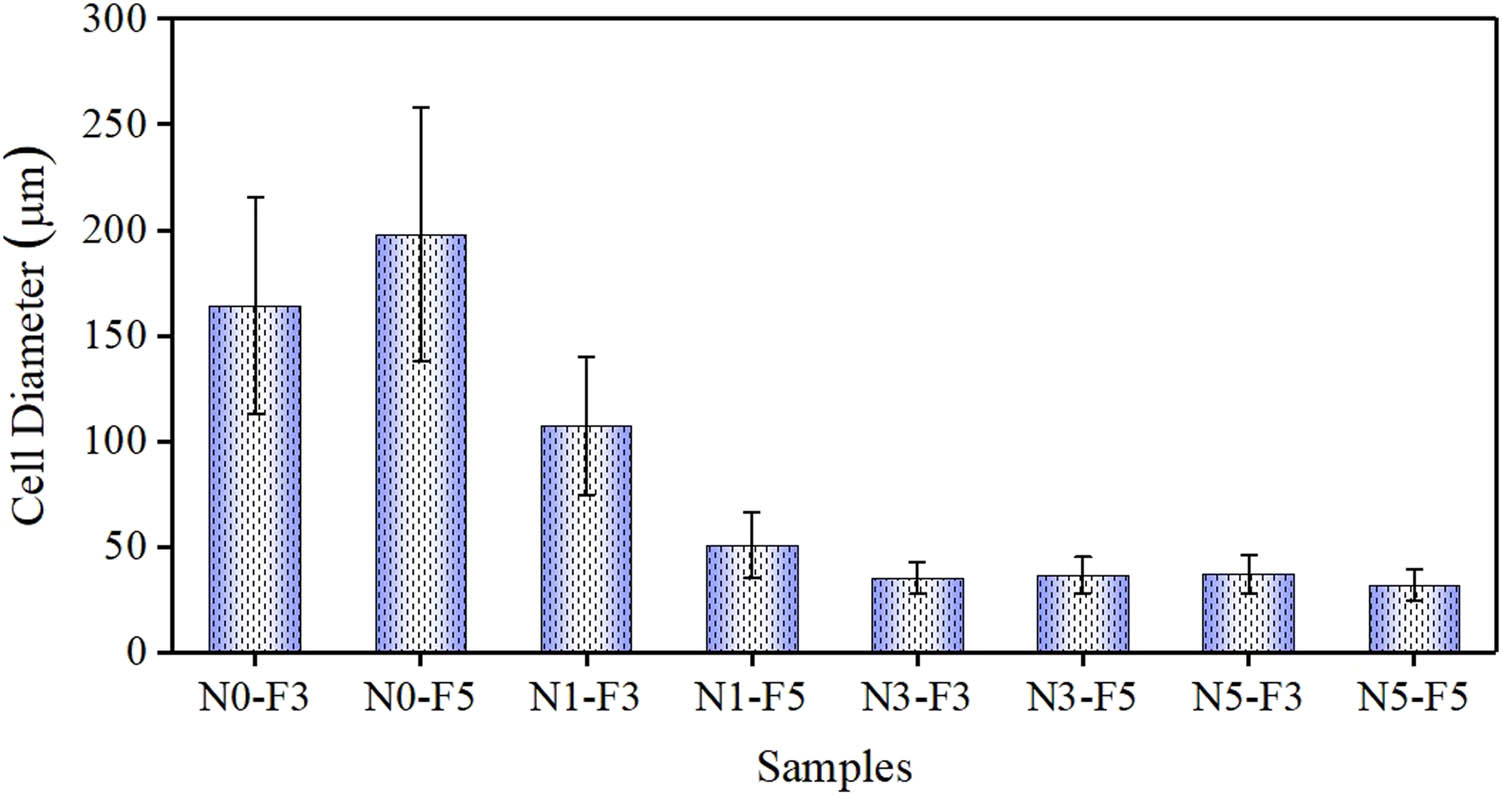

However, the porosity change was found to be negligible when the MWCNT content was further increased from 3 to 5 wt%, as per the obtained results. SEM micrographs with uniformly porous structures in Figure 4 confirm the results of porosity measurements. According to these micrographs, N0-F3 and N0-F5 samples had a larger number of voids with larger cell sizes in their structure. This revealed that increasing the CBAs weight ratio resulted in the growth of porosity in the N0-F5 sample due to the higher gas production during blowing agent decomposition. Moreover, the SEM micrographs show that as MWCNT content increased in the foam structures, smaller cells appeared in their morphology. Figure 5 summarizes the average cell size of different types of foams. The presence of MWCNTs with their fine dimensions and large surface area in the nanocomposite structure created more challenges for bubble growth within the polymer matrix, which led to reduced cell sizes. However, at large MWCNT contents, the average cell sizes in TPU/MWCNT foams with 3 and 5 wt% MWCNT were statistically equal [79]. Considering the results of Figures 3 and 5, it can be comprehended that, alongside the higher MWCNT content and reduced porosity, smaller foam cell sizes could contribute to the sample's stiffness, thereby resulting in an elevated value of Young’s modulus.

Cellular morphology of foamed TPU and TPU/MWCNT at different CBA and MWCNT contents.

Foams average cell size.

4.1 Theoretical characterization

As already mentioned in Section 3, the developed theoretical method starts with the characterization of solid TPU/MWCNT nanocomposites. The comparison between the average experimental results performed in this article and HT approaches presented in equations (1), (4), and (5) indicates which HT approach has the best level of accuracy in the elastic modulus estimation of such solid nanocomposites. As shown in Figure 6, equation (1) offers better estimations in comparison with equation (4). However, at a higher amount of MWCNT contents, they both fail in the estimation of the elastic modulus of solid TPU/MWCNT nanocomposites as they consider a steady increase of elastic modulus with the increase of CNT volume fraction, which cannot practically happen.

Comparison of the elastic modulus of solid TPU/MWCNT nanocomposites obtained from theoretical approaches with the results obtained from experimental tests with their standard deviations at various MWCNT weight percentages.

Due to the involvement of more MWCNT parameters in the estimation of elastic modulus, it can be seen that equation (5) offers the best estimations when the coefficients of the agglomeration factor (i.e.,

According to equation (9), first, the nondimensional form of elastic modulus ratio

Comparison of the elastic modulus ratio of porous TPU/MWCNT nanocomposites obtained from the theoretical approach with the results obtained from experimental tests at various density ratios.

5 Conclusion

This study aimed to fabricate foam TPU/MWCNT nanocomposites with varying MWCNT and CBA contents, using an industrially scalable foaming method, to enhance their mechanical properties. In conclusion, the results indicated that:

Increasing the MWCNT content improved the elastic moduli of both the foams and solid TPU/MWCNT.

The pristine foams and nanocomposite foams demonstrated higher void fraction values in samples with higher CBA content.

Introduction of MWCNTs into the polymer matrix resulted in a reduction in foam porosity and cell sizes of the nanocomposite foams containing both 3 and 5 wt% chemical CBAs, up to a MWCNT content of 3 wt%.

The modified HT model successfully estimated Young’s modulus of solid nanocomposites by including more MWCNT parameters such as aspect ratio, agglomeration state, waviness, and orientation.

Gibson and Ashby’s method was utilized to determine the best equation for estimating the elastic modulus of pure and nanocomposite TPU foams at a wide range of MWCNT and CBA contents.

Acknowledgments

The work described in this article was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC under grant no. RGPIN-217525). The authors are grateful for their support.

-

Funding information: This work was supported and funded by the Natural Sciences and Engineering Research Council of Canada (NSERC under grant no. RGPIN-217525).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

[1] Cai JH, Li J, Chen XD, Wang M. Multifunctional polydimethylsiloxane foam with multi-walled carbon nanotube and thermo-expandable microsphere for temperature sensing, microwave shielding and piezoresistive sensor. Chem Eng J. 2020;393(December 2019):124805.10.1016/j.cej.2020.124805Search in Google Scholar

[2] Chen Z, Sun YC, Wang J, Qi HJ, Wang T, Naguib HE. Flexible, reconfigurable, and self-healing TPU/vitrimer polymer blend with copolymerization triggered by bond exchange reaction. ACS Appl Mater Interfaces. 2020;12(7):8740–50.10.1021/acsami.9b21411Search in Google Scholar PubMed

[3] Behdinan K, Moradi-Dastjerdi R. Thermal buckling resistance of a lightweight lead-free piezoelectric nanocomposite sandwich plate. Adv Nano Res. 2022;12(6):593–603.Search in Google Scholar

[4] Moradi-Dastjerdi R, Behdinan K. Biaxial buckling analysis of an innovative active sandwich plate. Mech Based Des Struct Mach. 2024;52(1):275–88. 10.1080/15397734.2022.2107539.Search in Google Scholar

[5] Moradi-Dastjerdi R, Behdinan K. Electromechanical natural frequency analysis of an eco-friendly active sandwich plate. Actuators. 2022;11:261. 10.3390/act11090261.Search in Google Scholar

[6] Oh JY, Rondeau-Gagné S, Chiu YC, Chortos A, Lissel F, Wang GJN, et al. Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nature. 2016;539(7629):411–5.10.1038/nature20102Search in Google Scholar PubMed

[7] Rogers JA, Someya T, Huang Y. Materials and mechanics for stretchable electronics. Science (80-). 2010;327(5973):1603–7.10.1126/science.1182383Search in Google Scholar PubMed

[8] Zhou X, Zhu L, Fan L, Deng H, Fu Q. Fabrication of highly stretchable, washable, wearable, water-repellent strain sensors with multi-stimuli sensing ability. ACS Appl Mater Interfaces. 2018;10(37):31655–63.10.1021/acsami.8b11766Search in Google Scholar PubMed

[9] Hu C, Behdinan K, Moradi-Dastjerdi R. PVDF energy harvester for prolonging the battery life of cardiac pacemakers. Actuators. 2022;11(7):187. 10.3390/act11070187.Search in Google Scholar

[10] Meschino M, Wang L, Xu H, Moradi-Dastjerdi R, Behdinan K. Low-frequency nanocomposite piezoelectric energy harvester with embedded zinc oxide nanowires. Polym Compos. 2021;42:4573–85. 10.1002/pc.26169.Search in Google Scholar

[11] Angelou A, Norman C, Miran N, Albers S, Moradi-Dastjerdi R, Behdinan K. An eco-friendly, biocompatible and reliable piezoelectric nanocomposite actuator for the new generation of microelectronic devices. Eur Phys J Plus. 2021;136:678. 10.1140/epjp/s13360-021-01653-z.Search in Google Scholar

[12] Wang Y, Wang L, Yang T, Li X, Zang X, Zhu M, et al. Wearable and highly sensitive graphene strain sensors for human motion monitoring. Adv Funct Mater. 2014;24(29):4666–70.10.1002/adfm.201400379Search in Google Scholar

[13] Choi DY, Kim MH, Oh YS, Jung SH, Jung JH, Sung HJ, et al. Highly stretchable, hysteresis-free ionic liquid-based strain sensor for precise human motion monitoring. ACS Appl Mater Interfaces. 2017;9(2):1770–80.10.1021/acsami.6b12415Search in Google Scholar PubMed

[14] Christianson C, Goldberg NN, Deheyn DD, Cai S, Tolley MT. Translucent soft robots driven by frameless fluid electrode dielectric elastomer actuators. Sci Robot. 2018;3(17):1–9.10.1126/scirobotics.aat1893Search in Google Scholar PubMed

[15] Acome E, Mitchell SK, Morrissey TG, Emmett MB, Benjamin C, King M, et al. Hydraulically amplified self-healing electrostatic actuators with muscle-like performance. Science (80-). 2018 Jan 5;359(6371):61–5. https://www.science.org/doi/10.1126/science.aao6139.10.1126/science.aao6139Search in Google Scholar PubMed

[16] Wang Q, Jian M, Wang C, Zhang Y. Carbonized silk nanofiber membrane for transparent and sensitive electronic skin. Adv Funct Mater. 2017;27(9):1605657.10.1002/adfm.201605657Search in Google Scholar

[17] Gerratt AP, Michaud HO, Lacour SP. Elastomeric electronic skin for prosthetic tactile sensation. Adv Funct Mater. 2015;25(15):2287–95.10.1002/adfm.201404365Search in Google Scholar

[18] Mahdinejad Gorji J, Payganeh G, Moradi-Dastjerdi R. Mechanical and energy absorption behavior of an innovative high-performance auxetic structure. Mech Based Des Struct Mach. 2024;52(4):2316–35. 10.1080/15397734.2023.2177863.Search in Google Scholar

[19] Ghahramani P, Behdinan K, Naguib HE. Development of piezoresistive PDMS/MWCNT foam nanocomposite sensor with ultrahigh flexibility and compressibility. J Intell Mater Syst Struct. 20211045389X2110643 .Search in Google Scholar

[20] Wan F, Tran MP, Leblanc C, Béchet E, Plougonven E, Léonard A, et al. Experimental and computational micro-mechanical investigations of compressive properties of polypropylene/multi-walled carbon nanotubes nanocomposite foams. Mech Mater. 2015;91(P1):95–118.10.1016/j.mechmat.2015.07.004Search in Google Scholar

[21] Sheikh T, Sampath S, Bhattacharya B. Bimorph sensor based in-line inspection method for corrosion defect detection in natural gas pipelines. Sens Actuators A Phys. 2022;347:113940.10.1016/j.sna.2022.113940Search in Google Scholar

[22] Ding Y, Xu T, Onyilagha O, Fong H, Zhu Z. Recent advances in flexible and wearable pressure sensors based on piezoresistive 3D monolithic conductive sponges. ACS Appl Mater Interfaces. 2019;11(7):6685–704.10.1021/acsami.8b20929Search in Google Scholar PubMed

[23] Zhao H, Zhang Y, Bradford PD, Zhou Q, Jia Q, Yuan FG, et al. Carbon nanotube yarn strain sensors. Nanotechnology. 2010;21:305502.10.1088/0957-4484/21/30/305502Search in Google Scholar PubMed

[24] Tung TT, Robert C, Castro M, Feller JF, Kim TY, Suh KS. Enhancing the sensitivity of graphene/polyurethane nanocomposite flexible piezo-resistive pressure sensors with magnetite nano-spacers. Carbon N Y. 2016;108:450–60.10.1016/j.carbon.2016.07.018Search in Google Scholar

[25] Zang Y, Zhang F, Di CA, Zhu D. Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater Horiz. 2015;2(2):140–56.10.1039/C4MH00147HSearch in Google Scholar

[26] Petrossian G, Hohimer CJ, Ameli A. Highly-loaded thermoplastic polyurethane/lead zirconate titanate composite foams with low permittivity fabricated using expandable microspheres. Polymers (Basel). 2019;11(2):280.10.3390/polym11020280Search in Google Scholar PubMed PubMed Central

[27] Moradi-Dastjerdi R, Behdinan K. Damped harmonic vibrations of axisymmetric graphene-enhanced cylinders in thermal environment. Polym Compos. 2021;42(11):5763–73. 10.1002/pc.26258.Search in Google Scholar

[28] Sheikh T, Behdinan K. Insight of discrete scale and multiscale methods for characterization of composite and nanocomposite materials. Arch Comput Methods Eng. 2023 [cited 2022 Nov 2];30:1231–65. 10.1007/s11831-022-09840-6.Search in Google Scholar

[29] Moradi-Dastjerdi R, Behdinan K. Thermo-electro-mechanical behavior of an advanced smart lightweight sandwich plate. Aerosp Sci Technol. 2020;106:106142. 10.1016/j.ast.2020.106142.Search in Google Scholar

[30] Sheikh T, Behdinan K. The effect of process parameters on the mechanical properties of additively manufactured parts using a hierarchical multiscale model. Rapid Prototyp J. 2023;29(5):1029–43. 10.1108/RPJ-08-2022-0248.Search in Google Scholar

[31] Thompson MR, Motlagh GH, Oxby KJ, Hrymak AN. Multiple percolation in a carbon-filled polymer composites via foaming. J Appl Polym Sci. 2010;115(2):646–54.10.1002/app.30177Search in Google Scholar

[32] Huang W, Dai K, Zhai Y, Liu H, Zhan P, Gao J, et al. Flexible and lightweight pressure sensor based on carbon nanotube/thermoplastic polyurethane-aligned conductive foam with superior compressibility and stability. ACS Appl Mater Interfaces. 2017;9(48):42266–77.10.1021/acsami.7b16975Search in Google Scholar PubMed

[33] Tang Y, Guo Q, Chen Z, Zhang X, Lu C. In-situ reduction of graphene oxide-wrapped porous polyurethane scaffolds: Synergistic enhancement of mechanical properties and piezoresistivity. Compos Part A Appl Sci Manuf. 2019;116(October 2018):106–13.10.1016/j.compositesa.2018.10.025Search in Google Scholar

[34] Kim JS, Kim GW. Hysteresis compensation of piezoresistive carbon nanotube/polydimethylsiloxane composite-based force sensors. Sensors (Switzerland). 2017;17(2):229.10.3390/s17020229Search in Google Scholar PubMed PubMed Central

[35] Iglio R, Mariani S, Robbiano V, Strambini L, Barillaro G. Flexible polydimethylsiloxane foams decorated with multiwalled carbon nanotubes enable unprecedented detection of ultralow strain and pressure coupled with a large working range. ACS Appl Mater Interfaces. 2018;10(16):13877–85.10.1021/acsami.8b02322Search in Google Scholar PubMed

[36] Cao CF, Zhang GD, Zhao L, Gong LX, Gao JF, Jiang JX, et al. Design of mechanically stable, electrically conductive and highly hydrophobic three-dimensional graphene nanoribbon composites by modulating the interconnected network on polymer foam skeleton. Compos Sci Technol. 2019;171(August 2018):162–70.10.1016/j.compscitech.2018.12.014Search in Google Scholar

[37] Chen Q, Cao PF, Advincula RC. Mechanically robust, ultraelastic hierarchical foam with tunable properties via 3D printing. Adv Funct Mater. 2018;28(21):1–9.10.1002/adfm.201800631Search in Google Scholar

[38] Yao HB, Ge J, Wang CF, Wang X, Hu W, Zheng ZJ, et al. A flexible and highly pressure-sensitive graphene-polyurethane sponge based on fractured microstructure design. Adv Mater. 2013;25(46):6692–8.10.1002/adma.201303041Search in Google Scholar PubMed

[39] Patole SP, Reddy SK, Schiffer A, Askar K, Prusty BG, Kumar S. Piezoresistive and mechanical characteristics of graphene foam nanocomposites. ACS Appl Nano Mater. 2019;2(3):1402–11.10.1021/acsanm.8b02306Search in Google Scholar

[40] Boland CS, Khan U, Binions M, Barwich S. Graphene-coated polymer foams as tuneable impact sensors. Nanoscale. 2018;10:5366–75.10.1039/C7NR09247DSearch in Google Scholar

[41] Liu H, Dong M, Huang W, Gao J, Dai K, Guo J, et al. Lightweight conductive graphene/thermoplastic polyurethane foams with ultrahigh compressibility for piezoresistive sensing. J Mater Chem C. 2017;5(1):73–83.10.1039/C6TC03713ESearch in Google Scholar

[42] Ghahramani P, Eldyasti A, Leung SN. Open-cell polyvinylidene fluoride foams as carriers to promote biofilm growth for biological wastewater treatment. Polym Eng Sci. 2021 Aug 1 [cited 2021 Aug 13];61(8)2161–71. https://onlinelibrary.wiley.com/doi/full/10.1002/pen.25741.10.1002/pen.25741Search in Google Scholar

[43] Ghahramani P. Design and fabrication of open-cell foams for biological organic removal from wastewater. MSc Thesis. Toronto, Canada: York University; 2018.Search in Google Scholar

[44] Matuana LM, Faruk O. Effect of gas saturation conditions on the expansion ratio of microcellular poly(lactic acid)/wood-flour composites. Express Polym Lett. 2010;4(10):621–31. http://www.expresspolymlett.com/letolt.php?file=EPL-0001615&mi=c.10.3144/expresspolymlett.2010.77Search in Google Scholar

[45] Xu D, Pop-Iliev R, Park CB, Fenton RG. Fundamental study of CBA-blown bubble growth and collapse under atmospheric pressure. J Cell Plast. 2005;41(6):519–38.10.1177/0021955X05059031Search in Google Scholar

[46] Damanpack AR, Sousa A, Bodaghi M. Porous plas with controllable density by fdm 3d printing and chemical foaming agent. Micromachines. 2021;12(8):1–8.10.3390/mi12080866Search in Google Scholar PubMed PubMed Central

[47] Chung CY, Hwang SS, Chen SC, Lai MC. Effects of injection molding process parameters on the chemical foaming behavior of polypropylene and polystyrene. Polymers (Basel). 2021;13(14):2331.10.3390/polym13142331Search in Google Scholar PubMed PubMed Central

[48] Yamsaengsung W, Sombatsompop N. Effect of chemical blowing agent on cell structure and mechanical properties of EPDM foam, and peel strength and thermal conductivity of wood/NR composite-EPDM foam laminates. Compos Part B Eng. 2009;40(7):594–600.10.1016/j.compositesb.2009.04.003Search in Google Scholar

[49] Ameli A, Nofar M, Park CB, Pötschke P, Rizvi G. Polypropylene/carbon nanotube nano/microcellular structures with high dielectric permittivity, low dielectric loss, and low percolation threshold. Carbon N Y. 2014;71:206–17.10.1016/j.carbon.2014.01.031Search in Google Scholar

[50] Boubakri A, Guermazi N, Elleuch K, Ayedi HF. Study of UV-aging of thermoplastic polyurethane material. Mater Sci Eng A. 2010;527(7–8):1649–54.10.1016/j.msea.2010.01.014Search in Google Scholar

[51] Kim JH, Kim GH. Effect of rubber content on abrasion resistance and tensile properties of thermoplastic polyurethane (TPU)/rubber blends. Macromol Res. 2014;22(5):523–7.10.1007/s13233-014-2077-ySearch in Google Scholar

[52] Singh NP, Gupta VK, Singh AP. Graphene and carbon nanotube reinforced epoxy nanocomposites: A review. Polymer (Guildf). 2019 Oct [cited 2019 Oct 4];180:121724. https://www.sciencedirect.com/science/article/pii/S003238611930730X.10.1016/j.polymer.2019.121724Search in Google Scholar

[53] Moradi-Dastjerdi R, Behdinan K. Dynamic performance of piezoelectric energy harvesters with a multifunctional nanocomposite substrate. Appl Energy. 2021;293:116947. 10.1016/j.apenergy.2021.116947.Search in Google Scholar

[54] Ghahramani P, Behdinan K, Moradi-Dastjerdi R, Naguib HE. Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites. Nanotechnol Rev. 2022;11:55–64. 10.1515/ntrev-2022-0006.Search in Google Scholar

[55] Pan S, Feng J, Safaei B, Qin Z, Chu F, Hui D. A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets. Nanotechnol Rev. 2022 Jan [cited 2022 Aug 12];11(1):1658–69, https://www.degruyter.com/document/doi/10.1515/ntrev-2022-0107/html.10.1515/ntrev-2022-0107Search in Google Scholar

[56] Ghahramani P, Moradi-Dastjerdi R, Behdinan K, Naguib HE. Mechanical characterization of multifunctional highly porous carbon nanotube-reinforced foams. Polym Compos. 2023;44(4):2093–101. 10.1002/pc.27226.Search in Google Scholar

[57] Chang E, Ameli A, Alian AR, Mark LH, Yu K, Wang S, et al. Percolation mechanism and effective conductivity of mechanically deformed 3-dimensional composite networks: Computational modeling and experimental verification. Compos Part B Eng. 2021;207(December 2020):108552. 10.1016/j.compositesb.2020.108552.Search in Google Scholar

[58] Tanabe F, Yoshimoto S, Noda Y, Araki T, Uemura T, Takeuchi Y, et al. Flexible sensor sheet for real-time pressure monitoring in artificial knee joint during total knee arthroplasty. 39th Annu Int Conf IEEE Eng Med Biol Soc EMBS; 2017. p. 1591–4.10.1109/EMBC.2017.8037142Search in Google Scholar PubMed

[59] Fei Y, Jiang R, Fang W, Liu T, Saeb MR, Hejna A, et al. Highly sensitive large strain cellulose/multiwalled carbon nanotubes (MWCNTs)/thermoplastic polyurethane (TPU) nanocomposite foams: From design to performance evaluation. J Supercrit Fluids. 2022;188(June):105653.10.1016/j.supflu.2022.105653Search in Google Scholar

[60] Moore B, Jaglinski T, Stone DS, Lakes RS. On the bulk modulus of open cell foams. Cell Polym. 2007;26(1):1–10.10.1177/026248930702600101Search in Google Scholar

[61] Gui X, Cao A, Wei J, Li H, Jia Y, Li Z, et al. Soft, highly conductive nanotube sponges and composites with controlled compressibility. ACS Nano. 2010;4(4):2320–6.10.1021/nn100114dSearch in Google Scholar PubMed

[62] Rinaldi A, Tamburrano A, Fortunato M, Sarto MS. A flexible and highly sensitive pressure sensor based on a PDMS foam coated with graphene nanoplatelets. Sensors (Switzerland). 2016;16(12):2148.10.3390/s16122148Search in Google Scholar PubMed PubMed Central

[63] Hou Q, Grijpma DW, Feijen J. Porous polymeric structures for tissue engineering prepared by a coagulation, compression moulding and salt leaching technique. Biomaterials. 2003;24(11):1937–47.10.1016/S0142-9612(02)00562-8Search in Google Scholar

[64] Thilagashanthi T, Gunasekaran K, Satyanarayanan KS. Microstructural pore analysis using SEM and ImageJ on the absorption of treated coconut shell aggregate. J Clean Prod. 2021;324:129217. 10.1016/j.jclepro.2021.129217.Search in Google Scholar

[65] Yunus S, Sefa-Ntiri B, Anderson B, Kumi F, Mensah-Amoah P, Sackey SS. Quantitative pore characterization of polyurethane foam with cost-effective imaging tools and image analysis: A proof-of-principle study. Polymers (Basel). 2019;11(11):1879.10.3390/polym11111879Search in Google Scholar PubMed PubMed Central

[66] Gibson LJ, Ashby MF. The mechanics of foams: basic results. In: Cellular solids: Structure and properties. 2nd edn. Cambridge: Cambridge University Press; 1997. p. 175–234.10.1017/CBO9781139878326.007Search in Google Scholar

[67] Moradi-Dastjerdi R, Behdinan K. Stress waves in a lightweight substrate plate actuated with piezoelectric layers under sinusoidal time-dependent pressures. Aerosp Sci Technol. 2023;132:108057. 10.1016/j.ast.2022.108057.Search in Google Scholar

[68] Behdinan K, Moradi-Dastjerdi R. Advanced multifunctional lightweight aerostructures: Design, development, and implementation. In: Behdinan K, Moradi-Dastjerdi R, editors. 1st edn. Hoboken: John Wiley & Sons Ltd; 2021. p. 256. https://onlinelibrary.wiley.com/doi/book/10.1002/9781119756743.10.1002/9781119756743.ch1Search in Google Scholar

[69] Moradi-Dastjerdi R, Sheikhi MM, Shamsolhoseinian HR. Stress distribution in functionally graded nanocomposite cylinders reinforced by wavy carbon nanotube. Int J Adv Des Manuf Technol. 2014;7(4):43–54.Search in Google Scholar

[70] Kundalwal SI. Review on micromechanics of nano‐ and micro‐fiber reinforced composites. Polym Compos. 2018;39(12):4243–74. 10.1002/pc.24569.Search in Google Scholar

[71] Shokrieh MM, Rafiee R. Investigation of nanotube length effect on the reinforcement efficiency in carbon nanotube based composites. Compos Struct. 2010;92:2415–20.10.1016/j.compstruct.2010.02.018Search in Google Scholar

[72] Georgantzinos SK, Markolefas SI, Mavrommatis SA, Stamoulis KP. Finite element modelling of carbon fiber-carbon nanostructure-polymer hybrid composite structures. In MATEC Web of Conference. 2020 [cited 2022 Sep 23]. p. 314. 10.1051/matecconf/202031402004.Search in Google Scholar

[73] Kazem Hassanzadeh-Aghdam M, Jamali J. A new form of a Halpin-Tsai micromechanical model for characterizing the mechanical properties of carbon nanotube-reinforced polymer nanocomposites. Bull Mater Sci. 2019;42:117. 10.1007/s12034-019-1784-6.Search in Google Scholar

[74] Georgantzinos SK, Antoniou P, Markolefas S, Giannopoulos G. Finite element predictions on vibrations of laminated composite plates incorporating the random orientation, agglomeration, and waviness of carbon nanotubes Agglomeration factor of CNTs f mn Natural frequency (Hz) G Shear modulus h Total plate thickness. Acta Mech. 2022 [cited 2022 Sep 21];233:2031–59. 10.1007/s00707-022-03179-6.Search in Google Scholar

[75] Cox HL. The elasticity and strength of paper and other fibrous materials. Br J Appl Phys. 1952 Mar [cited 2022 Sep 23];3(3):72. https://iopscience.iop.org/article/10.1088/0508-3443/3/3/302.10.1088/0508-3443/3/3/302Search in Google Scholar

[76] Omidi M, Hossein Rokni DT, Milani AS, Seethaler RJ, Arasteh R. Prediction of the mechanical characteristics of multi-walled carbon nanotube/epoxy composites using a new form of the rule of mixtures. Carbon N Y. 2010;48(11):3218–28.10.1016/j.carbon.2010.05.007Search in Google Scholar

[77] Fisher FT, Bradshaw RD, Brinson LC. Fiber waviness in nanotube-reinforced polymer composites — I: Modulus predictions using effective nanotube properties. Compos Sci Technol. 2003;63:1–15.10.1016/S0266-3538(03)00069-1Search in Google Scholar

[78] Roberts AP, Garboczi EJ. Elastic moduli of model random three-dimensional closed-cell cellular solids. Acta Mater. 2001 Jan 22;49(2):189–97.10.1016/S1359-6454(00)00314-1Search in Google Scholar

[79] Farsheh AT, Talaeipour M, Hemmasi AH, Khademieslam H, Ghasemi I. Investigation on the mechanical and morphological properties of foamed nanocomposites based on wood flour/PVC/multi-walled carbon nanotube. BioResources. 2011;6(1):841–52.10.15376/biores.6.1.841-852Search in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface

- Potential pharmaceutical applications and molecular docking study for green fabricated ZnO nanoparticles mediated Raphanus sativus: In vitro and in vivo study

- Effect of temperature and nanoparticle size on the interfacial layer thickness of TiO2–water nanofluids using molecular dynamics

- Characteristics of induced magnetic field on the time-dependent MHD nanofluid flow through parallel plates

- Flexural and vibration behaviours of novel covered CFRP composite joints with an MWCNT-modified adhesive

- Experimental research on mechanically and thermally activation of nano-kaolin to improve the properties of ultra-high-performance fiber-reinforced concrete

- Analysis of variable fluid properties for three-dimensional flow of ternary hybrid nanofluid on a stretching sheet with MHD effects

- Biodegradability of corn starch films containing nanocellulose fiber and thymol

- Toxicity assessment of copper oxide nanoparticles: In vivo study

- Some measures to enhance the energy output performances of triboelectric nanogenerators

- Reinforcement of graphene nanoplatelets on water uptake and thermomechanical behaviour of epoxy adhesive subjected to water ageing conditions

- Optimization of preparation parameters and testing verification of carbon nanotube suspensions used in concrete

- Max-phase Ti3SiC2 and diverse nanoparticle reinforcements for enhancement of the mechanical, dynamic, and microstructural properties of AA5083 aluminum alloy via FSP

- Advancing drug delivery: Neural network perspectives on nanoparticle-mediated treatments for cancerous tissues

- PEG-PLGA core–shell nanoparticles for the controlled delivery of picoplatin–hydroxypropyl β-cyclodextrin inclusion complex in triple-negative breast cancer: In vitro and in vivo study

- Conduction transportation from graphene to an insulative polymer medium: A novel approach for the conductivity of nanocomposites

- Review Articles

- Developments of terahertz metasurface biosensors: A literature review

- Overview of amorphous carbon memristor device, modeling, and applications for neuromorphic computing

- Advances in the synthesis of gold nanoclusters (AuNCs) of proteins extracted from nature

- A review of ternary polymer nanocomposites containing clay and calcium carbonate and their biomedical applications

- Recent advancements in polyoxometalate-functionalized fiber materials: A review

- Special contribution of atomic force microscopy in cell death research

- A comprehensive review of oral chitosan drug delivery systems: Applications for oral insulin delivery

- Cellular senescence and nanoparticle-based therapies: Current developments and perspectives

- Cyclodextrins-block copolymer drug delivery systems: From design and development to preclinical studies

- Micelle-based nanoparticles with stimuli-responsive properties for drug delivery

- Critical assessment of the thermal stability and degradation of chemically functionalized nanocellulose-based polymer nanocomposites

- Research progress in preparation technology of micro and nano titanium alloy powder

- Nanoformulations for lysozyme-based additives in animal feed: An alternative to fight antibiotic resistance spread

- Incorporation of organic photochromic molecules in mesoporous silica materials: Synthesis and applications

- A review on modeling of graphene and associated nanostructures reinforced concrete

- A review on strengthening mechanisms of carbon quantum dots-reinforced Cu-matrix nanocomposites

- Review on nanocellulose composites and CNFs assembled microfiber toward automotive applications

- Nanomaterial coating for layered lithium rich transition metal oxide cathode for lithium-ion battery

- Application of AgNPs in biomedicine: An overview and current trends

- Nanobiotechnology and microbial influence on cold adaptation in plants

- Hepatotoxicity of nanomaterials: From mechanism to therapeutic strategy

- Applications of micro-nanobubble and its influence on concrete properties: An in-depth review

- A comprehensive systematic literature review of ML in nanotechnology for sustainable development

- Exploiting the nanotechnological approaches for traditional Chinese medicine in childhood rhinitis: A review of future perspectives

- Twisto-photonics in two-dimensional materials: A comprehensive review

- Current advances of anticancer drugs based on solubilization technology

- Recent process of using nanoparticles in the T cell-based immunometabolic therapy

- Future prospects of gold nanoclusters in hydrogen storage systems and sustainable environmental treatment applications

- Preparation, types, and applications of one- and two-dimensional nanochannels and their transport properties for water and ions

- Microstructural, mechanical, and corrosion characteristics of Mg–Gd–x systems: A review of recent advancements

- Functionalized nanostructures and targeted delivery systems with a focus on plant-derived natural agents for COVID-19 therapy: A review and outlook

- Mapping evolution and trends of cell membrane-coated nanoparticles: A bibliometric analysis and scoping review

- Nanoparticles and their application in the diagnosis of hepatocellular carcinoma

- In situ growth of carbon nanotubes on fly ash substrates

- Structural performance of boards through nanoparticle reinforcement: An advance review

- Reinforcing mechanisms review of the graphene oxide on cement composites

- Seed regeneration aided by nanomaterials in a climate change scenario: A comprehensive review

- Surface-engineered quantum dot nanocomposites for neurodegenerative disorder remediation and avenue for neuroimaging

- Graphitic carbon nitride hybrid thin films for energy conversion: A mini-review on defect activation with different materials

- Nanoparticles and the treatment of hepatocellular carcinoma

- Special Issue on Advanced Nanomaterials and Composites for Energy Conversion and Storage - Part II

- Highly safe lithium vanadium oxide anode for fast-charging dendrite-free lithium-ion batteries

- Recent progress in nanomaterials of battery energy storage: A patent landscape analysis, technology updates, and future prospects

- Special Issue on Advanced Nanomaterials for Carbon Capture, Environment and Utilization for Energy Sustainability - Part II

- Calcium-, magnesium-, and yttrium-doped lithium nickel phosphate nanomaterials as high-performance catalysts for electrochemical water oxidation reaction

- Low alkaline vegetation concrete with silica fume and nano-fly ash composites to improve the planting properties and soil ecology

- Mesoporous silica-grafted deep eutectic solvent-based mixed matrix membranes for wastewater treatment: Synthesis and emerging pollutant removal performance

- Electrochemically prepared ultrathin two-dimensional graphitic nanosheets as cathodes for advanced Zn-based energy storage devices

- Enhanced catalytic degradation of amoxicillin by phyto-mediated synthesised ZnO NPs and ZnO-rGO hybrid nanocomposite: Assessment of antioxidant activity, adsorption, and thermodynamic analysis

- Incorporating GO in PI matrix to advance nanocomposite coating: An enhancing strategy to prevent corrosion

- Synthesis, characterization, thermal stability, and application of microporous hyper cross-linked polyphosphazenes with naphthylamine group for CO2 uptake

- Engineering in ceramic albite morphology by the addition of additives: Carbon nanotubes and graphene oxide for energy applications

- Nanoscale synergy: Optimizing energy storage with SnO2 quantum dots on ZnO hexagonal prisms for advanced supercapacitors

- Aging assessment of silicone rubber materials under corona discharge accompanied by humidity and UV radiation

- Tuning structural and electrical properties of Co-precipitated and Cu-incorporated nickel ferrite for energy applications

- Sodium alginate-supported AgSr nanoparticles for catalytic degradation of malachite green and methyl orange in aqueous medium

- An environmentally greener and reusability approach for bioenergy production using Mallotus philippensis (Kamala) seed oil feedstock via phytonanotechnology

- Micro-/nano-alumina trihydrate and -magnesium hydroxide fillers in RTV-SR composites under electrical and environmental stresses

- Mechanism exploration of ion-implanted epoxy on surface trap distribution: An approach to augment the vacuum flashover voltages

- Nanoscale engineering of semiconductor photocatalysts boosting charge separation for solar-driven H2 production: Recent advances and future perspective

- Excellent catalytic performance over reduced graphene-boosted novel nanoparticles for oxidative desulfurization of fuel oil

- Special Issue on Advances in Nanotechnology for Agriculture

- Deciphering the synergistic potential of mycogenic zinc oxide nanoparticles and bio-slurry formulation on phenology and physiology of Vigna radiata

- Nanomaterials: Cross-disciplinary applications in ornamental plants

- Special Issue on Catechol Based Nano and Microstructures

- Polydopamine films: Versatile but interface-dependent coatings

- In vitro anticancer activity of melanin-like nanoparticles for multimodal therapy of glioblastoma

- Poly-3,4-dihydroxybenzylidenhydrazine, a different analogue of polydopamine

- Chirality and self-assembly of structures derived from optically active 1,2-diaminocyclohexane and catecholamines

- Advancing resource sustainability with green photothermal materials: Insights from organic waste-derived and bioderived sources

- Bioinspired neuromelanin-like Pt(iv) polymeric nanoparticles for cancer treatment

- Special Issue on Implementing Nanotechnology for Smart Healthcare System

- Intelligent explainable optical sensing on Internet of nanorobots for disease detection

- Special Issue on Green Mono, Bi and Tri Metallic Nanoparticles for Biological and Environmental Applications

- Tracking success of interaction of green-synthesized Carbopol nanoemulgel (neomycin-decorated Ag/ZnO nanocomposite) with wound-based MDR bacteria

- Green synthesis of copper oxide nanoparticles using genus Inula and evaluation of biological therapeutics and environmental applications

- Biogenic fabrication and multifunctional therapeutic applications of silver nanoparticles synthesized from rose petal extract

- Metal oxides on the frontlines: Antimicrobial activity in plant-derived biometallic nanoparticles

- Controlling pore size during the synthesis of hydroxyapatite nanoparticles using CTAB by the sol–gel hydrothermal method and their biological activities

- Special Issue on State-of-Art Advanced Nanotechnology for Healthcare

- Applications of nanomedicine-integrated phototherapeutic agents in cancer theranostics: A comprehensive review of the current state of research

- Smart bionanomaterials for treatment and diagnosis of inflammatory bowel disease

- Beyond conventional therapy: Synthesis of multifunctional nanoparticles for rheumatoid arthritis therapy

Articles in the same Issue

- Research Articles

- Tension buckling and postbuckling of nanocomposite laminated plates with in-plane negative Poisson’s ratio

- Polyvinylpyrrolidone-stabilised gold nanoparticle coatings inhibit blood protein adsorption

- Energy and mass transmission through hybrid nanofluid flow passing over a spinning sphere with magnetic effect and heat source/sink

- Surface treatment with nano-silica and magnesium potassium phosphate cement co-action for enhancing recycled aggregate concrete

- Numerical investigation of thermal radiation with entropy generation effects in hybrid nanofluid flow over a shrinking/stretching sheet

- Enhancing the performance of thermal energy storage by adding nano-particles with paraffin phase change materials

- Using nano-CaCO3 and ceramic tile waste to design low-carbon ultra high performance concrete

- Numerical analysis of thermophoretic particle deposition in a magneto-Marangoni convective dusty tangent hyperbolic nanofluid flow – Thermal and magnetic features

- Dual numerical solutions of Casson SA–hybrid nanofluid toward a stagnation point flow over stretching/shrinking cylinder

- Single flake homo p–n diode of MoTe2 enabled by oxygen plasma doping

- Electrostatic self-assembly effect of Fe3O4 nanoparticles on performance of carbon nanotubes in cement-based materials

- Multi-scale alignment to buried atom-scale devices using Kelvin probe force microscopy

- Antibacterial, mechanical, and dielectric properties of hydroxyapatite cordierite/zirconia porous nanocomposites for use in bone tissue engineering applications

- Time-dependent Darcy–Forchheimer flow of Casson hybrid nanofluid comprising the CNTs through a Riga plate with nonlinear thermal radiation and viscous dissipation

- Durability prediction of geopolymer mortar reinforced with nanoparticles and PVA fiber using particle swarm optimized BP neural network

- Utilization of zein nano-based system for promoting antibiofilm and anti-virulence activities of curcumin against Pseudomonas aeruginosa

- Antibacterial effect of novel dental resin composites containing rod-like zinc oxide

- An extended model to assess Jeffery–Hamel blood flow through arteries with iron-oxide (Fe2O3) nanoparticles and melting effects: Entropy optimization analysis

- Comparative study of copper nanoparticles over radially stretching sheet with water and silicone oil

- Cementitious composites modified by nanocarbon fillers with cooperation effect possessing excellent self-sensing properties

- Confinement size effect on dielectric properties, antimicrobial activity, and recycling of TiO2 quantum dots via photodegradation processes of Congo red dye and real industrial textile wastewater

- Biogenic silver nanoparticles of Moringa oleifera leaf extract: Characterization and photocatalytic application

- Novel integrated structure and function of Mg–Gd neutron shielding materials

- Impact of multiple slips on thermally radiative peristaltic transport of Sisko nanofluid with double diffusion convection, viscous dissipation, and induced magnetic field

- Magnetized water-based hybrid nanofluid flow over an exponentially stretching sheet with thermal convective and mass flux conditions: HAM solution

- A numerical investigation of the two-dimensional magnetohydrodynamic water-based hybrid nanofluid flow composed of Fe3O4 and Au nanoparticles over a heated surface

- Development and modeling of an ultra-robust TPU-MWCNT foam with high flexibility and compressibility

- Effects of nanofillers on the physical, mechanical, and tribological behavior of carbon/kenaf fiber–reinforced phenolic composites

- Polymer nanocomposite for protecting photovoltaic cells from solar ultraviolet in space

- Study on the mechanical properties and microstructure of recycled concrete reinforced with basalt fibers and nano-silica in early low-temperature environments

- Synergistic effect of carbon nanotubes and polyvinyl alcohol on the mechanical performance and microstructure of cement mortar

- CFD analysis of paraffin-based hybrid (Co–Au) and trihybrid (Co–Au–ZrO2) nanofluid flow through a porous medium

- Forced convective tangent hyperbolic nanofluid flow subject to heat source/sink and Lorentz force over a permeable wedge: Numerical exploration

- Physiochemical and electrical activities of nano copper oxides synthesised via hydrothermal method utilising natural reduction agents for solar cell application

- A homotopic analysis of the blood-based bioconvection Carreau–Yasuda hybrid nanofluid flow over a stretching sheet with convective conditions

- In situ synthesis of reduced graphene oxide/SnIn4S8 nanocomposites with enhanced photocatalytic performance for pollutant degradation

- A coarse-grained Poisson–Nernst–Planck model for polyelectrolyte-modified nanofluidic diodes

- A numerical investigation of the magnetized water-based hybrid nanofluid flow over an extending sheet with a convective condition: Active and passive controls of nanoparticles

- The LyP-1 cyclic peptide modified mesoporous polydopamine nanospheres for targeted delivery of triptolide regulate the macrophage repolarization in atherosclerosis

- Synergistic effect of hydroxyapatite-magnetite nanocomposites in magnetic hyperthermia for bone cancer treatment

- The significance of quadratic thermal radiative scrutinization of a nanofluid flow across a microchannel with thermophoretic particle deposition effects

- Ferromagnetic effect on Casson nanofluid flow and transport phenomena across a bi-directional Riga sensor device: Darcy–Forchheimer model

- Performance of carbon nanomaterials incorporated with concrete exposed to high temperature

- Multicriteria-based optimization of roller compacted concrete pavement containing crumb rubber and nano-silica

- Revisiting hydrotalcite synthesis: Efficient combined mechanochemical/coprecipitation synthesis to design advanced tunable basic catalysts

- Exploration of irreversibility process and thermal energy of a tetra hybrid radiative binary nanofluid focusing on solar implementations

- Effect of graphene oxide on the properties of ternary limestone clay cement paste

- Improved mechanical properties of graphene-modified basalt fibre–epoxy composites

- Sodium titanate nanostructured modified by green synthesis of iron oxide for highly efficient photodegradation of dye contaminants

- Green synthesis of Vitis vinifera extract-appended magnesium oxide NPs for biomedical applications

- Differential study on the thermal–physical properties of metal and its oxide nanoparticle-formed nanofluids: Molecular dynamics simulation investigation of argon-based nanofluids

- Heat convection and irreversibility of magneto-micropolar hybrid nanofluids within a porous hexagonal-shaped enclosure having heated obstacle

- Numerical simulation and optimization of biological nanocomposite system for enhanced oil recovery

- Laser ablation and chemical vapor deposition to prepare a nanostructured PPy layer on the Ti surface

- Cilostazol niosomes-loaded transdermal gels: An in vitro and in vivo anti-aggregant and skin permeation activity investigations towards preparing an efficient nanoscale formulation

- Linear and nonlinear optical studies on successfully mixed vanadium oxide and zinc oxide nanoparticles synthesized by sol–gel technique

- Analytical investigation of convective phenomena with nonlinearity characteristics in nanostratified liquid film above an inclined extended sheet

- Optimization method for low-velocity impact identification in nanocomposite using genetic algorithm

- Analyzing the 3D-MHD flow of a sodium alginate-based nanofluid flow containing alumina nanoparticles over a bi-directional extending sheet using variable porous medium and slip conditions

- A comprehensive study of laser irradiated hydrothermally synthesized 2D layered heterostructure V2O5(1−x)MoS2(x) (X = 1–5%) nanocomposites for photocatalytic application

- Computational analysis of water-based silver, copper, and alumina hybrid nanoparticles over a stretchable sheet embedded in a porous medium with thermophoretic particle deposition effects

- A deep dive into AI integration and advanced nanobiosensor technologies for enhanced bacterial infection monitoring

- Effects of normal strain on pyramidal I and II 〈c + a〉 screw dislocation mobility and structure in single-crystal magnesium

- Computational study of cross-flow in entropy-optimized nanofluids

- Significance of nanoparticle aggregation for thermal transport over magnetized sensor surface

- A green and facile synthesis route of nanosize cupric oxide at room temperature

- Effect of annealing time on bending performance and microstructure of C19400 alloy strip

- Chitosan-based Mupirocin and Alkanna tinctoria extract nanoparticles for the management of burn wound: In vitro and in vivo characterization

- Electrospinning of MNZ/PLGA/SF nanofibers for periodontitis

- Photocatalytic degradation of methylene blue by Nd-doped titanium dioxide thin films

- Shell-core-structured electrospinning film with sequential anti-inflammatory and pro-neurogenic effects for peripheral nerve repairment

- Flow and heat transfer insights into a chemically reactive micropolar Williamson ternary hybrid nanofluid with cross-diffusion theory

- One-pot fabrication of open-spherical shapes based on the decoration of copper sulfide/poly-O-amino benzenethiol on copper oxide as a promising photocathode for hydrogen generation from the natural source of Red Sea water

- A penta-hybrid approach for modeling the nanofluid flow in a spatially dependent magnetic field

- Advancing sustainable agriculture: Metal-doped urea–hydroxyapatite hybrid nanofertilizer for agro-industry

- Utilizing Ziziphus spina-christi for eco-friendly synthesis of silver nanoparticles: Antimicrobial activity and promising application in wound healing

- Plant-mediated synthesis, characterization, and evaluation of a copper oxide/silicon dioxide nanocomposite by an antimicrobial study

- Effects of PVA fibers and nano-SiO2 on rheological properties of geopolymer mortar

- Investigating silver and alumina nanoparticles’ impact on fluid behavior over porous stretching surface