Abstract

Carbon nanotubes (CNTs) and graphene nanoplatelets (GNPs) are extremely ideal nanofillers for applications in damping polymer. This work explores the damping behavior of polymer nanocomposite beams made of epoxy resin reinforced with CNTs and GNPs experimentally. Beam specimens for the vibration tests together with dynamic mechanical analysis (DMA) are fabricated with different weight ratios of CNTs and GNPs, upon which DMA and free vibration tests are conducted. Scanning electron microscope images are also obtained to check the dispersion of nanofillers in microscale. It is found that the first-order loss factor of composite beam specimens shows a rise of 41.1% at 0.4 wt% CNT content compared with that of pure epoxy, while the first-order loss factor of composite beam specimens with 0.025 wt% GNP content increases up by 128.9%. The maximum value of the first-order loss factor of nanocomposite beams with GNP reinforcement is 62.2% higher than that with CNTs.

1 Introduction

Carbon nanotubes (CNTs) and graphene nanoplatelets (GNPs) have gained a lot of interest as high-performance composites in industries and academies. Ever since the discovery of CNTs in 1991, their exceedingly high aspect ratio, stiffness, elastic modulus, impressive strength, and low density make them greatly favorable reinforced materials for polymer matrices [1,2,3]. However, potential application of these one-dimensional nanoparticles is severely limited by the weak interfaces of CNTs and the polymer matrices. Additionally, their high aspect ratio results in aggregation of CNTs. To minimize the aggregation effect, high dispersive energies are required to properly disperse CNT into polymer matrices. This results in low thresholds of nanofiller concentration and failure of high aspect ratio, and finally limits the mechanical properties of composites. On account of the huge specific surface area and ultrahigh mechanical strength, GNPs exhibit desired application characteristics in the polymers [4,5,6]. Furthermore, surface modifications can enhance the dispersion of GNPs and realize the strong interface between GNPs and matrix, which improve the mechanical strength and Young’s modulus of nanocomposites [7,8]. As for the matrix, epoxy resin is a promising candidate considering its chemical resistance, specific strength, high stiffness, and dimensional stability [9,10,11]. By the addition of CNTs/GNPs, the mechanical properties of epoxy resin-based nanocomposites can be further improved. Hence, CNT/GNP-reinforced polymer nanocomposites have been widely used for the noise reduction and vibration control in various engineering sectors [12,13,14,15,16].

In the last decade, the damping properties of polymer nanocomposites reinforced by CNTs have been extensively studied both theoretically and experimentally [17,18,19,20,21,22,23,24,25,26,27,28,29,30]. Zhou et al. [23] investigated the damping ratio and loss factor of CNT-reinforced polymer nanocomposites considering interfacial friction between CNTs and the resin. Experiments were carried out to verify the theoretical results. Khan et al. [24] explored the vibration damping properties of polymer composites reinforced by multiwall CNTs and carbon fiber (CF) through dynamic mechanical analysis (DMA), and free and forced vibration tests. DeValve and Pitchumani [25] experimentally studied the damping effects of CF and CNT- reinforced composites via vibration tests of cantilever beams in both the fixed frame and rotating frame. The experimental results revealed that 2 wt% of CNTs can increase the damping by more than 130% in a stationary composite beam. For the composite beam rotating at 500 rpm, it could increase more than 150%. Bandarian et al. [26] studied the acoustic damping behavior of open-cell flexible polyurethane foams reinforced with multiwall CNTs, and found that the acoustic damping behavior improved significantly by a small content of nanotubes.

Recently, researchers also carried out experimental studies to explore the damping performances of nanocomposites reinforced by GNPs [31,32,33,34]. Chen et al. [31] investigated the surface energy and damping behaviors of GNP-reinforced polymer composites experimentally, and reported that GNP reinforcement could enhance the damping properties of petroleum resin and ethylene propylene rubber composites. The damping capability of recycled mortar reinforced with GNPs was evaluated by DMA in ref. [32], where the recycled mortar with GNP exhibited a higher damping capability than the recycled mortar without GNPs. Lu et al. [33] investigated GNP-reinforced sandwich polyurethane composites via DMA. It was found that in comparison with the baseline polyurethane beam, the dynamic and quasi-static damping properties of the composites with exceedingly low content of GNPs markedly increased by 94 and 71%, respectively. The damping effects in multiscale GNPs/fiberglass/epoxy composites were investigated via vibration tests by Rafiee et al. [34], where it was observed that the damping ratio increased at higher contents of GNP nanoparticles.

It is found from literature review that some experimental studies have been working on the damping characteristics of polymer nanocomposites reinforced by CNTs and GNPs separately; little research has been conducted to compare the damping behaviors of polymer nanocomposites reinforced by CNTs/GNPs. In this work, the damping performances of epoxy nanocomposite beams reinforced by CNT/GNP are experimentally investigated. Specimens of vibration tests and DMA beams initially are fabricated by epoxy reinforced by CNTs/GNPs. Then, DMA is carried out on CNT/GNP-reinforced epoxy nanocomposite beam specimens to determine the frequency/thermal-dependent damping behavior. Following DMA, vibration tests are conducted to investigate the damping behavior of nanocomposite beams associated with the first three modes. Microstructure imaging of scanning electron microscope (SEM) is also employed to reveal the CNT/GNP dispersion and explain the damping behaviors observed in vibration tests. Finally, based on those measured data, comparison investigations are performed to assess the damping effects of GNP and CNT reinforcements on epoxy resin.

2 Fabrication

2.1 Materials

E51 epoxy resin YT-CC301HhPqc is used as the matrix for this work, while multiwall CNTs JCGMT-999-25-20-COOH prepared via the process of chemical vapor deposition under 2,800°C temperature and GNPs JCG-1-150n-COOH produced by chemical reduction are used as the filling materials. According to its manufacturers, the mixing weight rate between curing agent and epoxy resin is 1:3. Tables 1–3, respectively, exhibit the material properties of CNTs/GNPs together with mechanical performances of the epoxy resin.

Material characteristics of CNTs

| Material | Outer diameter (nm) | Length (μm) | Purity (%) |

|---|---|---|---|

| CNTs | 20–30 | 5–30 | 99.8 |

Material characteristics of GNPs

| Material | Thickness (nm) | Purity (%) |

|---|---|---|

| GNPs | 0.8–1.2 | 99.8 |

Mechanical characteristics of epoxy resin

| Material | Density (kg/m3) | Elastic modulus (GPa) | Poisson ratio |

|---|---|---|---|

| Epoxy | 980 | 1.00 | 0.38 |

2.2 Specimens’ fabrication

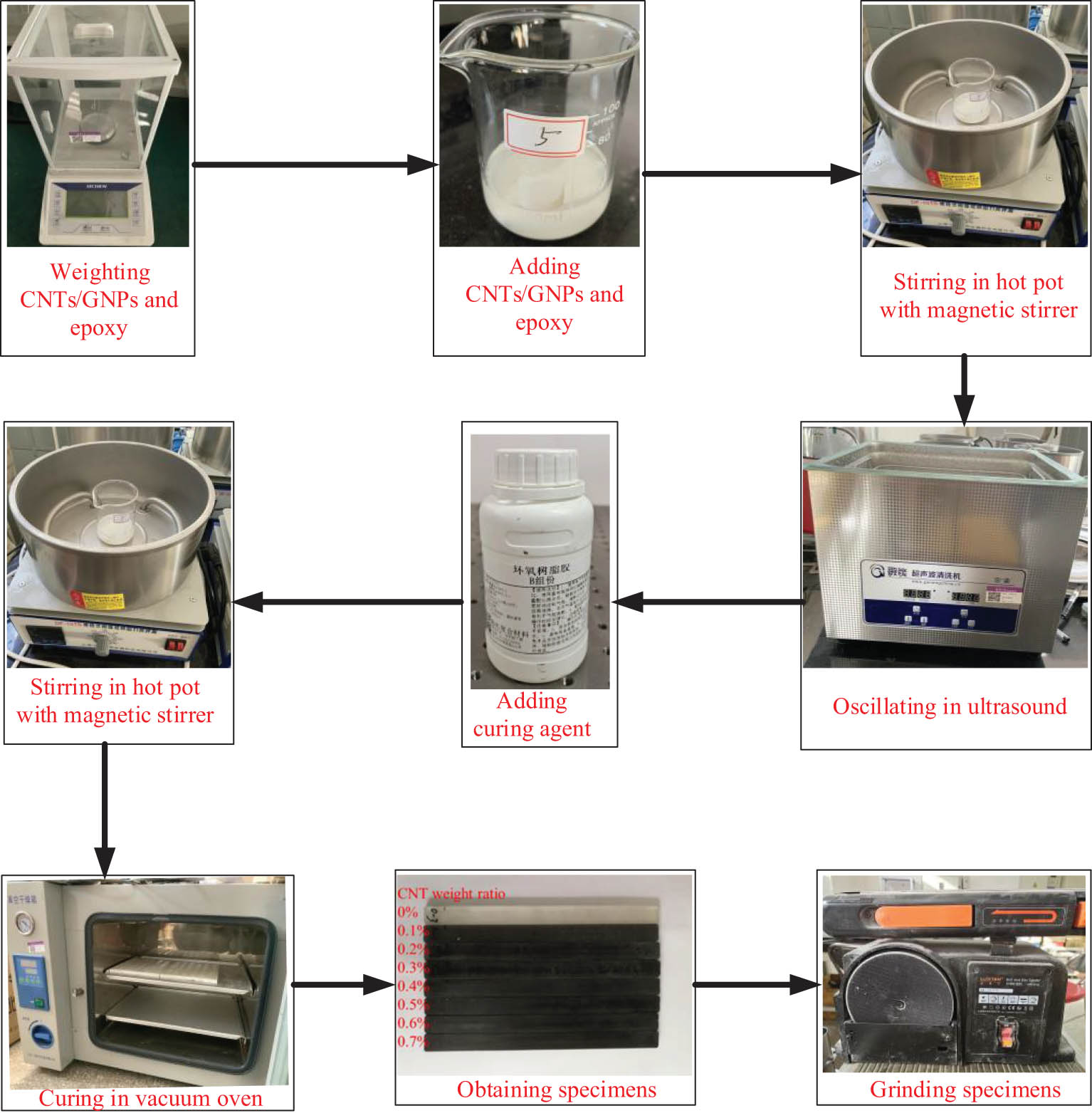

The generation of polymer nanocomposite beam specimens reinforced by CNTs/GNPs is exhibited in Figure 1. The epoxy matrix is added with GNPs and multiwall CNTs at certain amounts of weight ratio. A magnetic stirrer with a power of 20 W is utilized to stir the mixture for 30 min, which is then sonicated for half an hour by using ultrasonic disperser with a power of 600 W. Afterward, an epoxy resin curing agent is added at a weight ratio of 3/1 of the resin to curing agent. The mixture is stirred for 10 min through applying a magnetic stirrer and subsequently poured into the polytetrafluoroethylene (PTFE) molds with a size of 30 mm × 10 mm × 2 mm to prepare the specimens for vibration test. Before pouring the mixture of CNTs/GNPs and epoxy, the beam-shaped cavities of PTFE molds are carefully cleaned by absolute ethanol via the ultrasonic disperser, and a mold release agent is applied for 30 min. Ultimately, the molds are stored in a vacuum oven at an ambient temperature of 25°C for 6 h. Repeat the above steps to acquire epoxy composite beams having different weight ratios of CNT/GNP for three-point bending DMA tests. In those specimens, the CNT weight ratios can be adjusted at 0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, and 0.7%, while the weight ratios of GNPs are 0.0125, 0.0375, 0.0625, 0.0875, 0.1, 0.2, 0.3, and 0.4%. Following the same procedure, the vibration test specimens are also produced in a PTFE mold with the size of 200 mm

Preparation of epoxy nanocomposites reinforced by CNTs/GNPs.

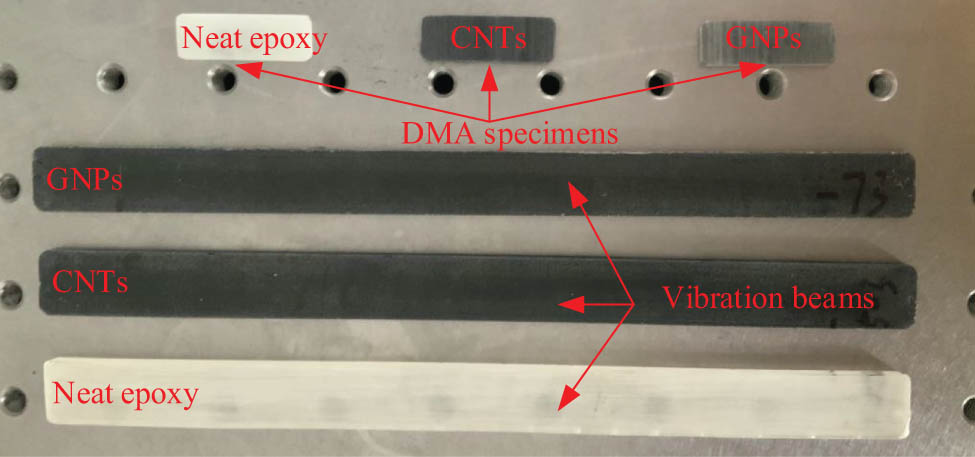

Specimens of epoxy composites reinforced by CNTs/GNPs.

3 Experiments

To evaluate the damping effects of CNTs and GNPs on epoxy resin, DMA, vibration tests, and SEM are conducted. Comparison studies are carried out on the test results of epoxy specimens reinforced by CNTs and GNPs.

3.1 DMA

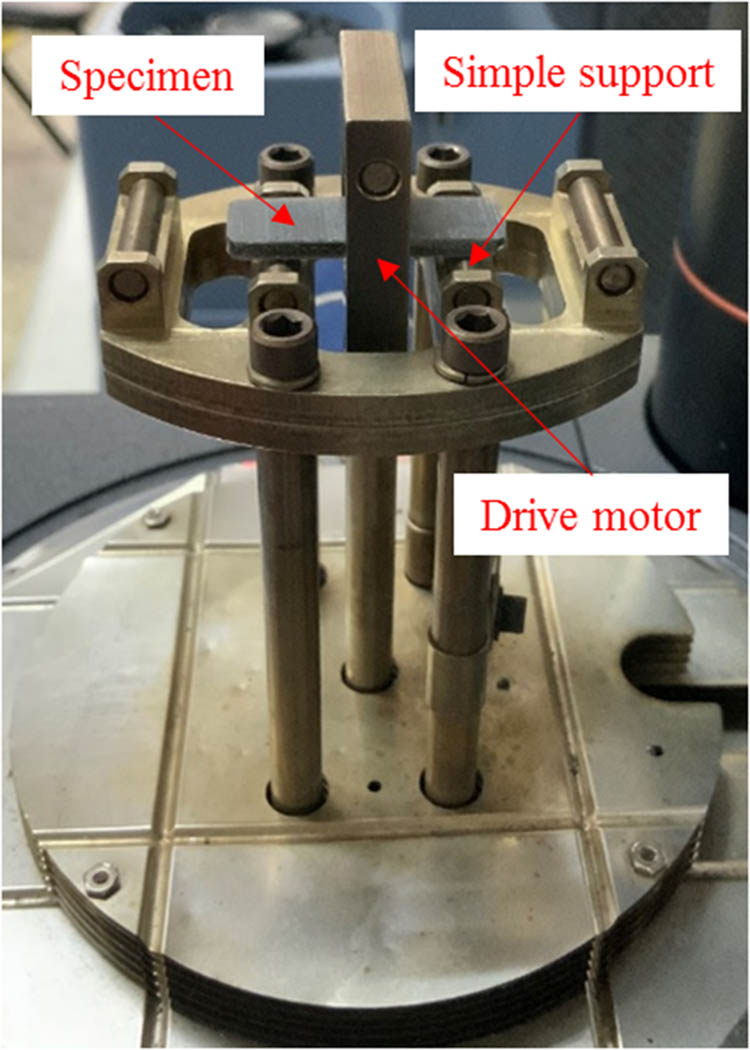

DMA can separate the elastic and viscous responses of materials when simple harmonic strain, for instance sinusoidal strain, is applied. The operating mechanism includes employing sinusoidal deformation and detecting its force, or utilizing sinusoidal force to the sample and testing its deformation, or even employing the constant deformation or force and detecting its relaxation or creep modulus. The tests of three-point bending DMA are performed for the characterization of the frequency-dependent damping behavior of epoxy resin reinforced by CNTs, as revealed in Figure 3. The specimens can be excited under 25°C temperature utilizing the constant displacement amplitude-isothermal-frequency scanning program between 4 and 200 Hz and a constant displacement amplitude-isofrequency-thermal scanning program between 30 and 180°C with a frequency of 20 Hz.

DMA setup picture.

In this work, the Kelvin–Voigt model is adopted to extract the parameters of viscoelasticity, in which the loss and storage moduli

where

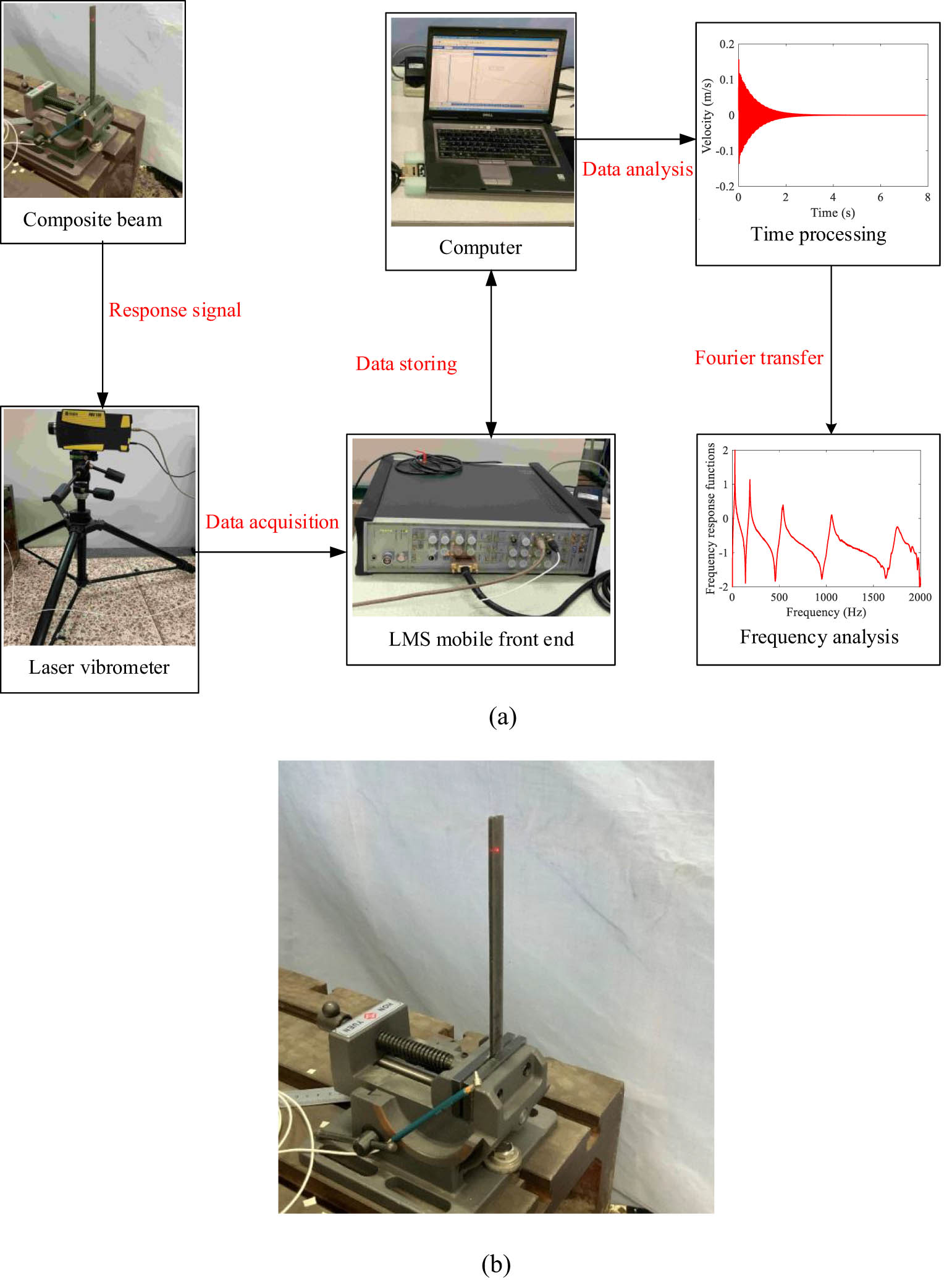

3.2 Vibration tests

As exhibited in Figure 4, the vibration tests are implemented at 25°C to determine the vibration response for the composite beam specimens being fixed at one end with 180 mm free length. The specimens for cantilever beam are excited via the impact hammer, and at the free end, the beam response is tracked through the portable digital vibration meter. The signals of laser vibration meter and impact hammer are acquired by LMS system. The resolution is 0.125 Hz and the frequency range is between 0 and 2,048 Hz.

Vibration test setup: (a) schematic diagram of measuring system; (b) enlarged picture of cantilever beam sample.

Three specimens are prepared and tested for different weight ratios of CNTs/GNPs, and each test with certain specimen and loading conditions is repeated three times to ensure the accuracy of measurement. LMS Test Lab is employed to analyze the determined frequency response functions (FRFs) to obtain the damping ratio and natural frequency related to different modes. The damping ratio is obtained from FRFs via half-power bandwidth approach, as exhibited below:

where

3.3 SEM

For SEM imaging, the samples with a length of 15 mm, a width of 3 mm, and a thickness of 3 mm are cut from the beam specimens for vibration tests. Then, the specimens are cleaned via oscillation in ethyl alcohol using an ultrasonic disperser and plated gold powder for 300 s to increase conductivity before imaging. The standard metal stubs are mounted with fractured specimen for imaging. Thermionic source emission microscope is applied to acquire SEM images. With the aim of achieving imaging with high resolution, the acceleration voltage is maintained below 2 keV in order to minimize the electron beam interaction volume in sample.

4 Results and discussion

4.1 DMA results

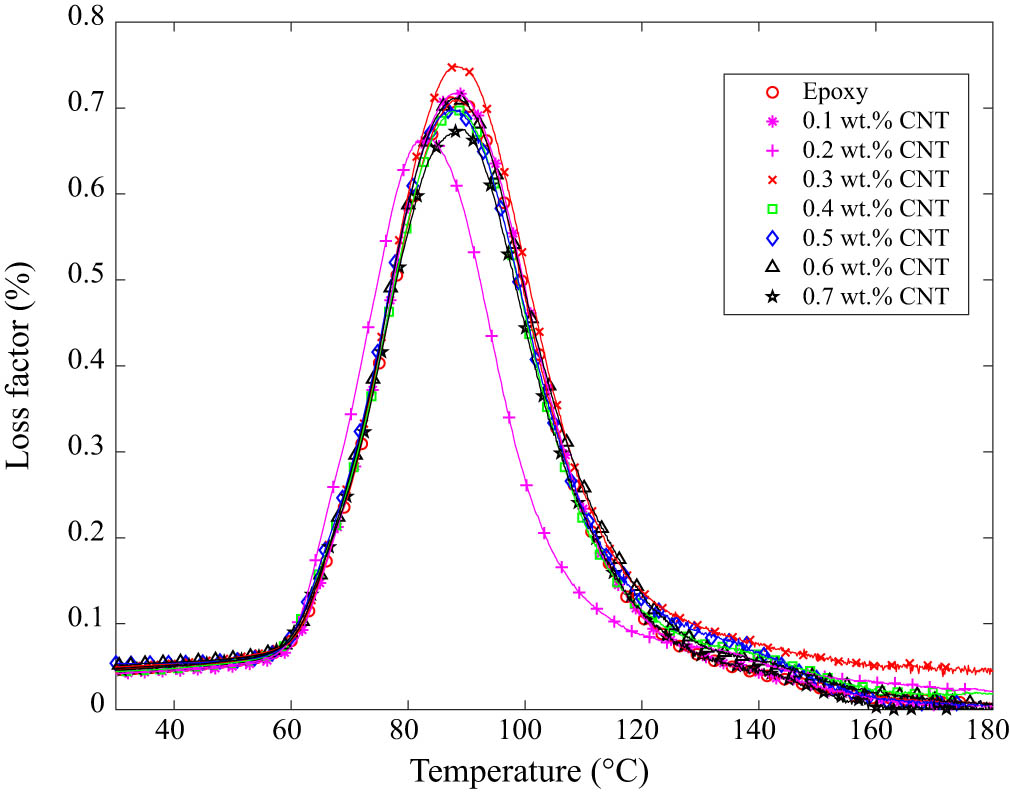

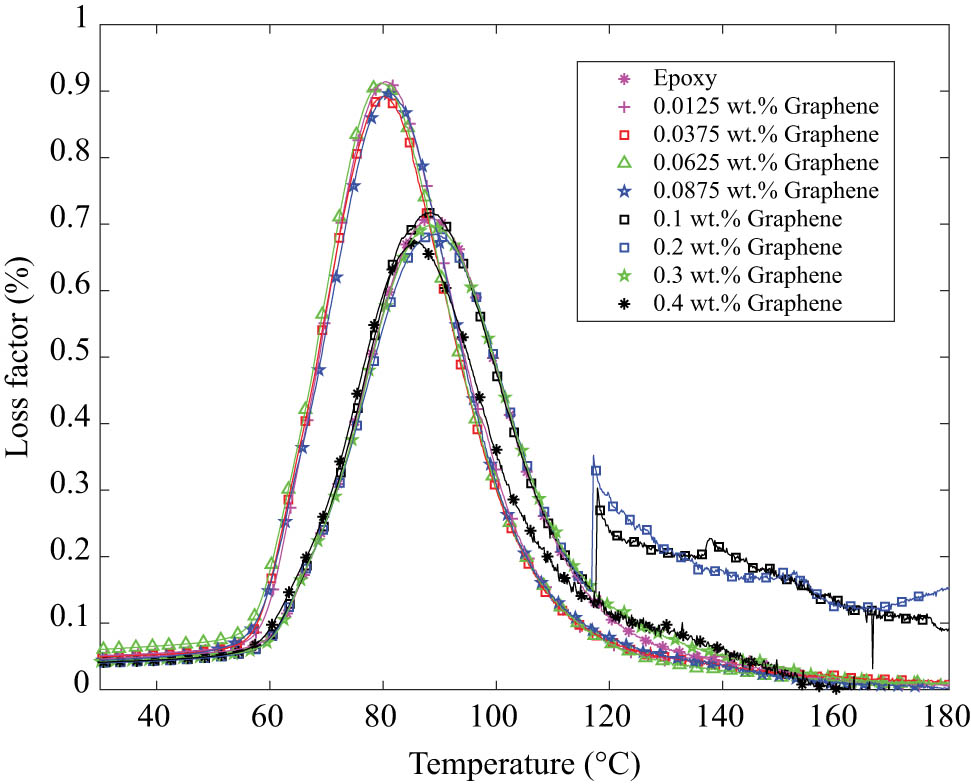

The variations of loss factors for the epoxy nanocomposite beam specimens reinforced by CNTs/GNPs along with excitation temperature and frequency are acquired via DMA as reflected in Figures 5–8, respectively. Table 4 lists the glass transition temperature for both pure epoxy and CNT/GNP-reinforced epoxy materials. The DMA outcomes in Figure 5 and Table 4 suggest that the glass transition temperature of neat epoxy specimens is almost 90°C. For specimens with 0.1, 0.3, 0.4, 0.5, 0.6, and 0.7 wt% CNT content, the glass transition temperature changes little; whereas, the glass transition temperature of specimens reinforced by 0.2 wt% CNT content decreases to 82°C with the decrement of loss factor at glass transition temperature. It can be seen in Figure 6 and Table 4 that as for GNP-reinforced epoxy nanocomposites, the glass transition temperature decreases with little GNP content. To be specific, the glass transition temperatures of specimens with 0.0125, 0.0375, 0.0625, and 0.0875 wt% GNP content are close to 80°C. However, as the weight ratio of GNPs continues to increase and becomes higher than 0.1 wt%, the glass transition temperatures return back to 88°C. Compared with pure epoxy, the loss factor of specimens at glass transition temperature with little GNP content is increased, while the increment of loss factor at glass transition temperature with high weight fractions of GNPs is insignificant. Based on Figures 5 and 6, when the temperature becomes higher than 120°C, the loss factors with a large amount of GNP content show a sudden increase, which indicates that the epoxy is getting to melt. However, for composites incorporating with little GNP content or CNT content, the loss factor decreases smoothly when the temperature increases higher than the glass transition temperature.

Temperature-dependent loss factor of CNT-reinforced composites by DMA tests.

Temperature-dependent loss factor of GNP-reinforced composites by DMA tests.

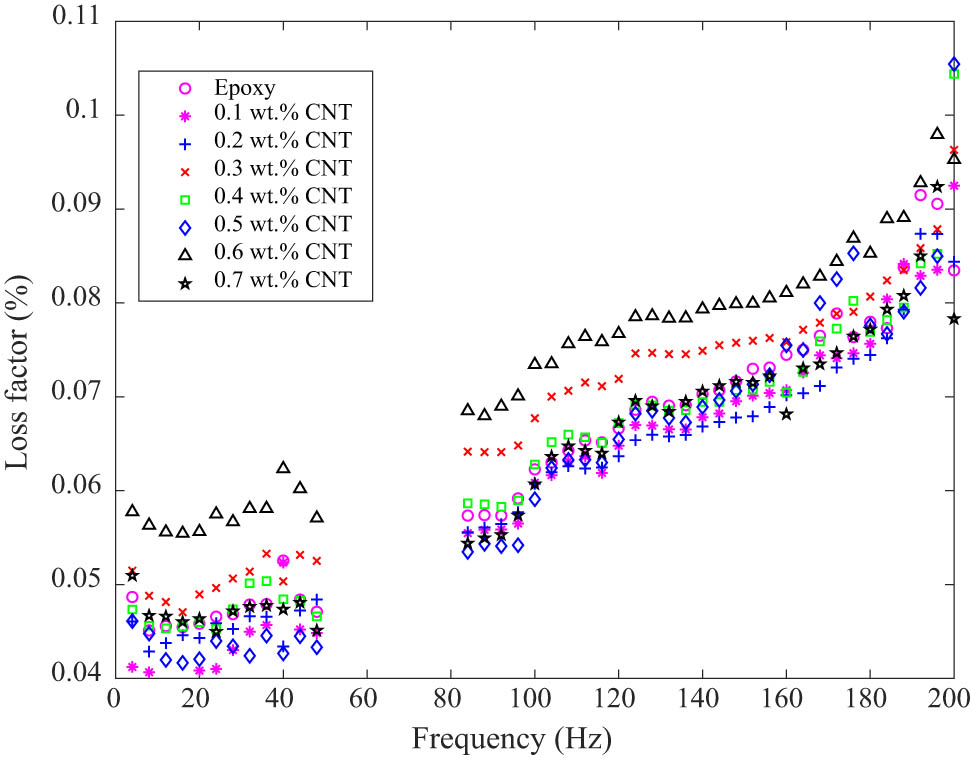

Frequency-dependent loss factor of CNT-reinforced composites by DMA tests.

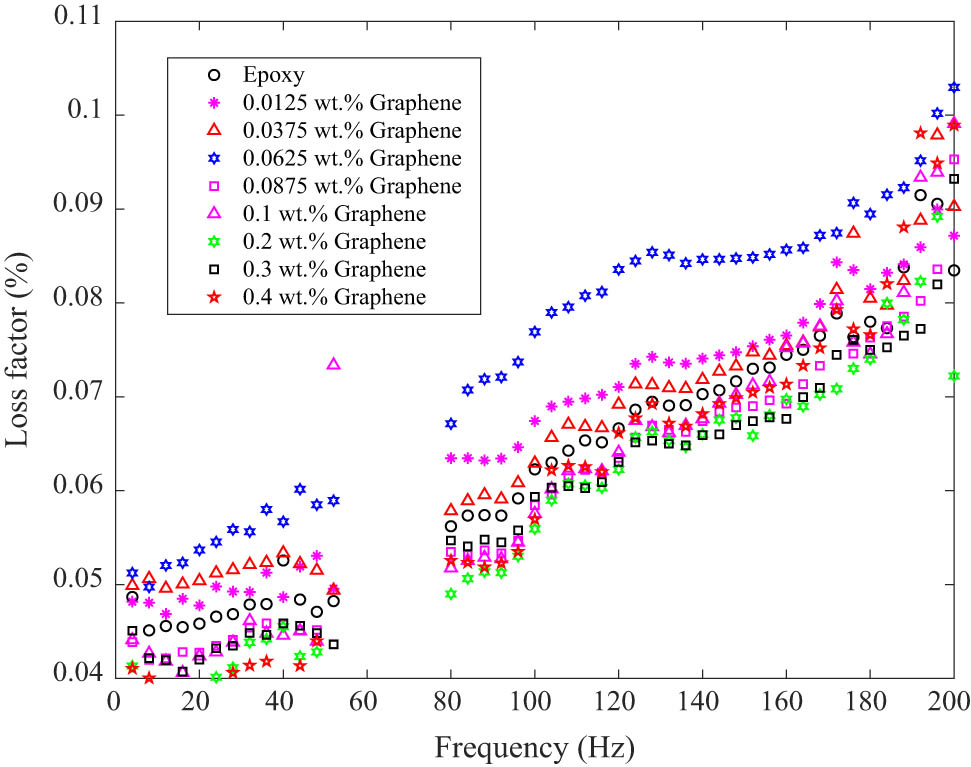

Frequency-dependent loss factor of GNP-reinforced composites by DMA tests.

Glass transition temperature for different materials

| CNT wt% | Glass transition temperature (°C) | GNP (wt%) | Glass transition temperature (°C) |

|---|---|---|---|

| 0 | 88.57 | 0.0125 | 80.52 |

| 0.1 | 88.38 | 0.0375 | 80.05 |

| 0.2 | 81.67 | 0.0625 | 79.56 |

| 0.3 | 88.08 | 0.0875 | 81.11 |

| 0.4 | 87.84 | 0.1 | 87.45 |

| 0.5 | 87.29 | 0.2 | 89.26 |

| 0.6 | 88.06 | 0.3 | 88.63 |

| 0.7 | 89.59 | 0.4 | 85.81 |

The frequency-dependent loss factors of CNT/GNP-reinforced epoxy nanocomposites are illustrated in Figures 7 and 8, where no loss factor values are observed in the frequency region from 50 to 80 Hz due to the fact that the beam samples are in the resonant state, and the loss factors cannot be measured exactly by DMA tests in this frequency region. According to Figure 7, the highest loss factors are achieved at 0.1 wt% CNTs. When the weight ratio continues to increase, the loss factor starts to reduce and even lower than the loss factor of epoxy resin without reinforcement of CNTs. It is considered that this behavior principally results from CNT aggregation for high weight ratio. Figure 8 shows that the maximum loss factors are achieved at 0.0625 wt% GNPs in the frequency range 4–160 Hz, and 0.05 wt% GNPs in the frequency range 160–200 Hz. With the increasing weight ratio, the variation trends of loss factors for GNP-reinforced epoxy specimens are consistent with those of specimens with CNT reinforcements, that is, the value of loss factors continue to reduce and is lower than the loss factors of pure epoxy resin. However, the reason for the decrease of loss factors with GNP reinforcement is the lubricative effect of GNPs with high weight ratio, which is different from that of CNT reinforcement. In Figures 7 and 8, with the increasing frequency of excitation, the loss factor values also increase, suggesting that the damping effect of epoxy resin composites reinforced by CNTs/GNPs is enhanced.

4.2 Vibration test results

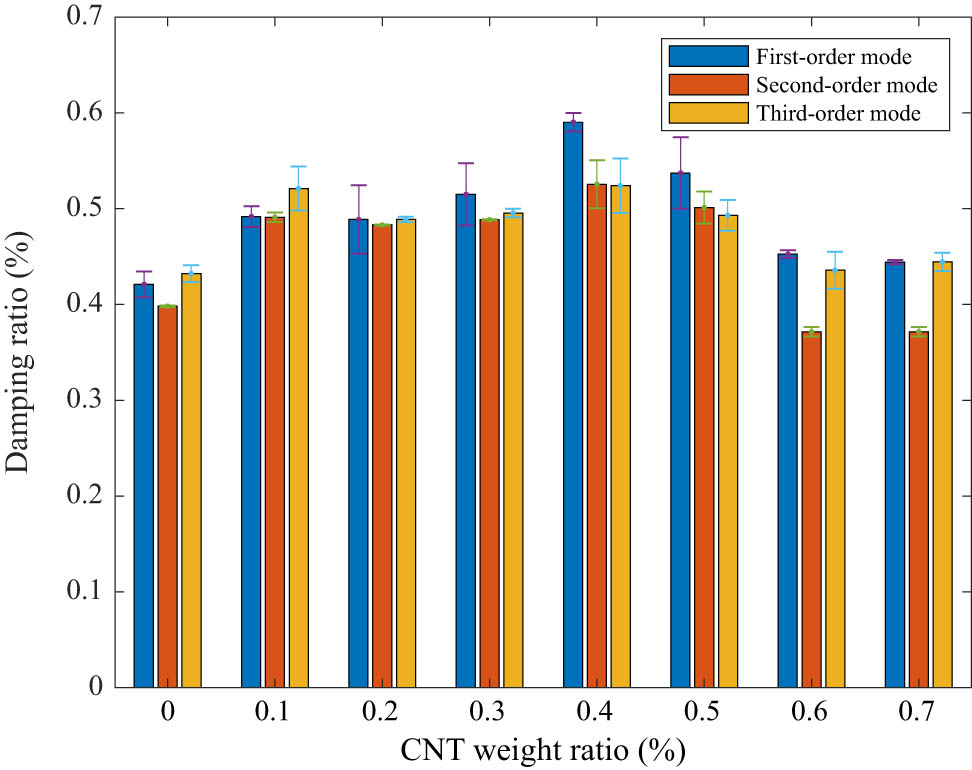

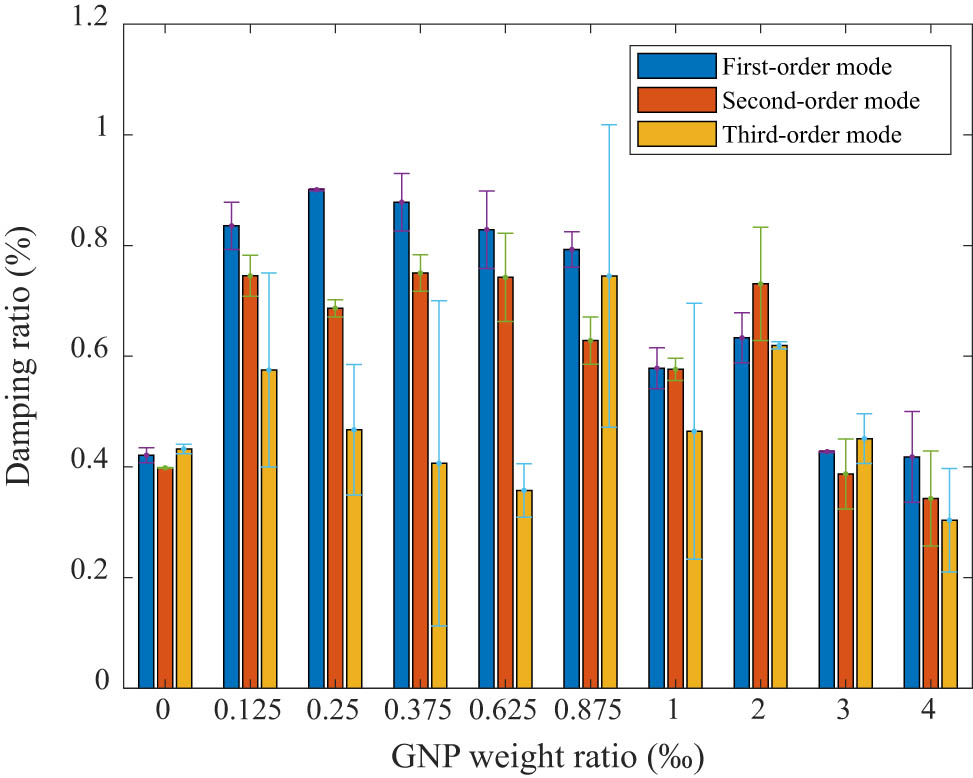

Through vibration tests, the damping ratios together with standard deviations of the first three modes of polymer nanocomposites reinforced by CNTs/GNPs with different weight ratios of CNTs/GNPs are acquired as shown in Figures 9 and 10. It can be observed from Figure 9 that the damping ratios related to the second mode are always less than those in the first mode for CNT-reinforced composites. In the third mode, the damping ratio is higher than that in the first mode when the content of CNT is less than 0.2 wt%; when it increases to 0.2 wt%, the damping ratio is almost the same with that in the first mode; then, as the CNT content continues to increase, the damping ratio is always lower than that in the first mode. For the first three modes, the maximum damping ratios always occur with 0.4 wt% CNT content. As shown in Figure 10, the damping ratios of the first mode are higher than those of the second and third modes for GNP-reinforced composites with the exception of 0.2 wt% GNP content in the second mode and 0.3 wt% GNP content in the third mode. In conclusion, the damping ratios related to the first mode are higher than those in second and third modes in most cases for both CNT- and GNP-reinforced nanocomposites. The standard deviations of damping ratios for GNP-reinforced composites are higher than that for CNT-reinforced composites. Because of the flocculent structure and low density of GNPs, it would be difficult to control the added mass of GNPs in the nanocomposites. Besides, the damping ratios are more sensitive for GNPs as nanofillers than CNTs. To be specific, 0.025 wt% GNP content can increase 128.9% of damping ratio for nanocomposites.

Damping ratios of the composite beams reinforced by CNT via vibration tests.

Damping ratios of the composite beams reinforced by GNP via vibration tests.

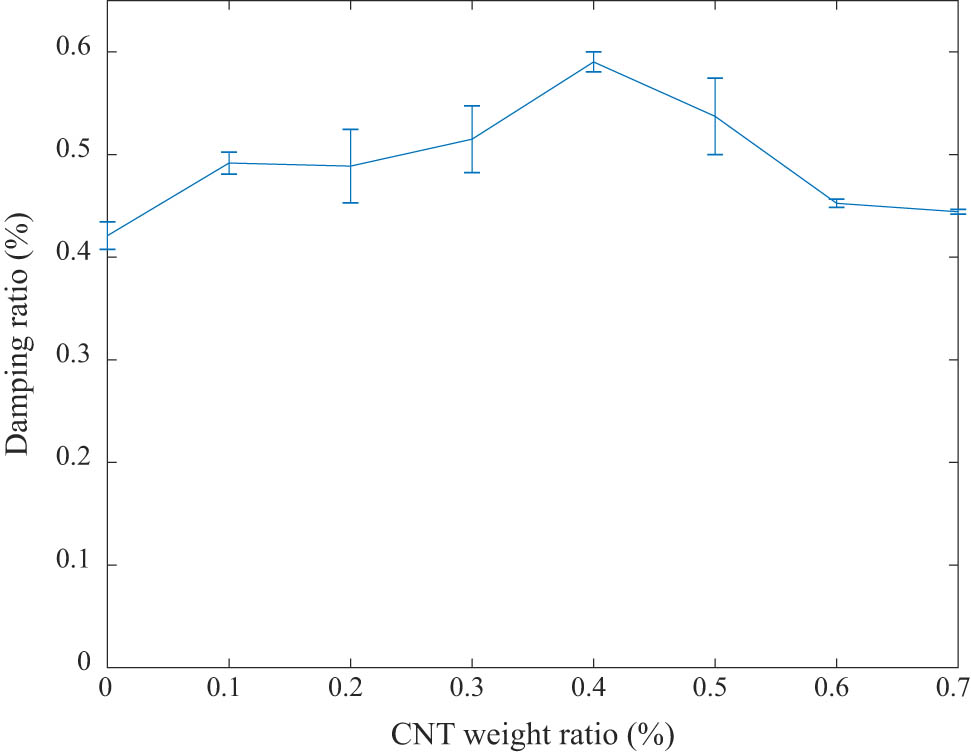

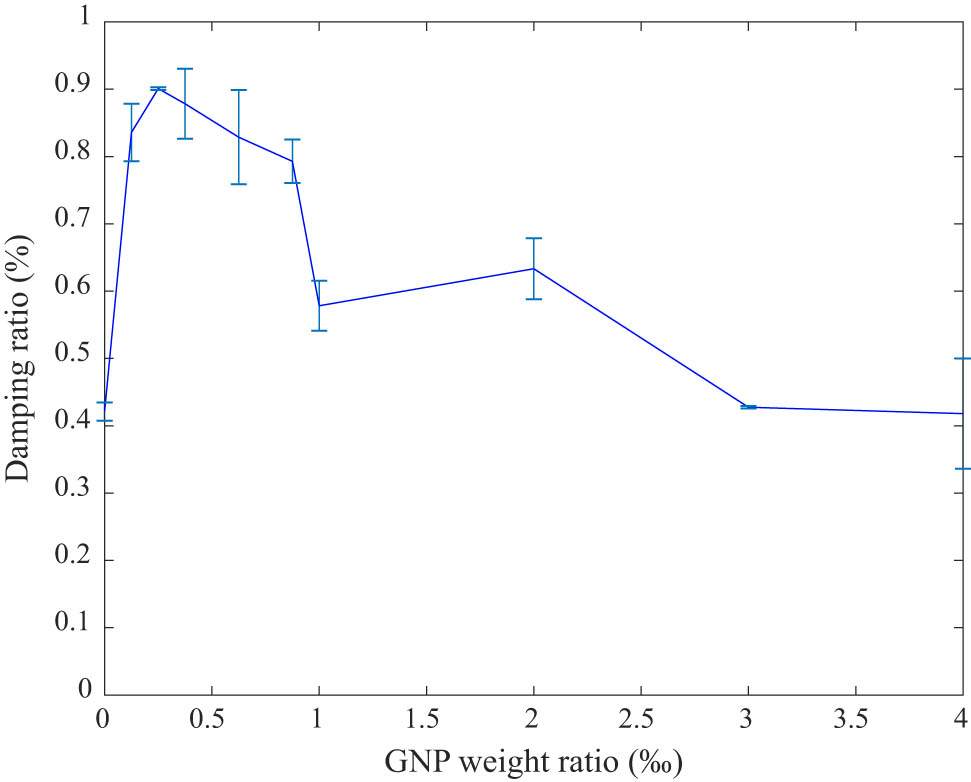

To further demonstrate the damping effects of CNT/GNP reinforcement, for nanocomposites filled with different CNT/GNP contents, the histogram and error bar of the damping ratios related to the first mode are shown in Figures 11 and 12. With the increase of the weight ratio of CNTs, the damping ratio of the first mode increases first and subsequently reduces, which has been approved by the polynomial regression model in ref. [35]. Overall, the damping ratio for the first mode with CNT reinforcement is always higher than that in the pure epoxy resin. Moreover, the damping ratio of 0.4 wt% CNTs to the first mode is 0.591%, which is 41.1% higher than the damping ratio in pure epoxy resin. The aggregation of CNTs in the epoxy resin matrix is obtained at a high weight ratio of CNTs, which can explain the reason why the damping ratio reduces when the weight ratio of CNTs further increases to more than 0.4%. These test outcomes support the view [36] that CNTs dispersed most uniformly with a weight ratio of 0.4%. It is shown in Figure 12 that the damping ratio for the first mode of GNP-reinforced composites has the similar variant trend with that of CNT-reinforced composites, and the damping ratio is always greater than that in the pure epoxy for the first mode. Furthermore, the maximum damping ratio in the first mode is 0.901% at 0.025 wt% GNPs, which shows a significant increase of 128.9% compared with pure epoxy. On the whole, the damping ratio first increases and then decreases with the increase of GNP/CNT content for composites, and there is a specific weight ratio of GNP/CNT content that reaches the maximum damping ratio.

First-order damping ratios of the composite beams reinforced by CNT through vibration tests.

First-order damping ratios of the composite beams reinforced by GNP through vibration tests.

4.3 Microstructure analysis

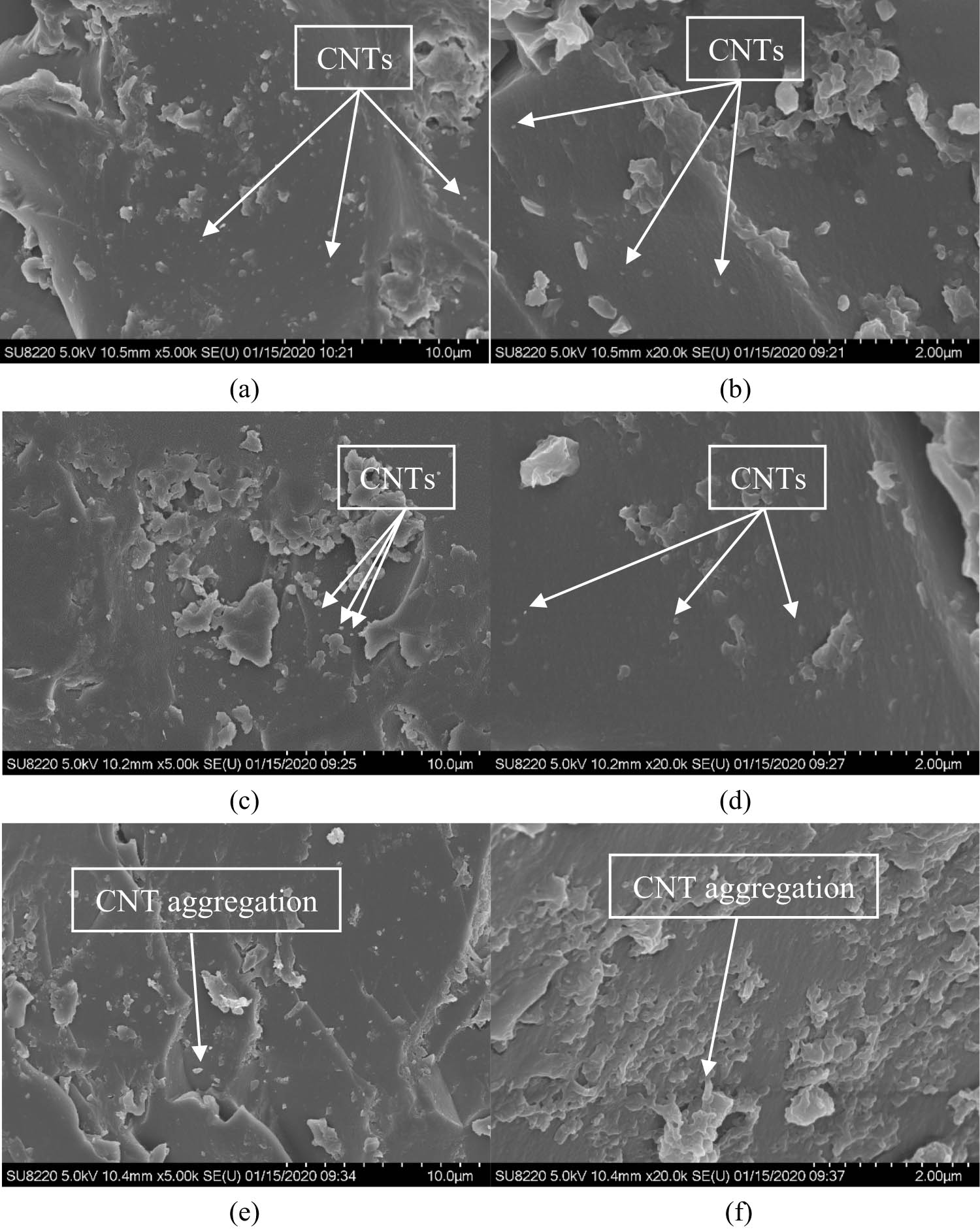

Figures 13 and 14 show the SEM micrographs of composites with 0.1, 0.4, and 0.6 wt% CNTs and 0.025 and 0.4 wt% GNPs, respectively. As can be seen from the micrographs in Figure 13, some of the CNTs are attached on the surface of epoxy, whose longitudinal axis parallels to the fracture surface, and some are embedded CNTs, whose tips are sticking out of the cross section. In short, it can be seen that CNTs are evenly distributed on the fracture surface in Figure 13(c) and (d). Additionally, there are almost no agglomerates of CNTs at 0.4 wt% CNT content. CNT aggregation in the fracture surface for composites with 0.6 wt% CNTs can be observed in Figure 13(e) and (f), in which CNTs have greater waviness than the composites containing 0.1 and 0.4 wt% CNTs. The high level of homogeneous dispersion and distribution is the reason for the strong damping effect during vibration, which explains why the damping ratio at a CNT content of 0.4 wt% is the highest in vibration tests.

Microstructure imaging of CNT-reinforced epoxy at 0.1 wt% CNTs at (a) 5,000× and (b) 20,000×; 0.4 wt% CNTs at (c) 5,000× and (d) 20,000×; 0.6 wt% CNTs at (e) 5,000× and (f) 20,000×.

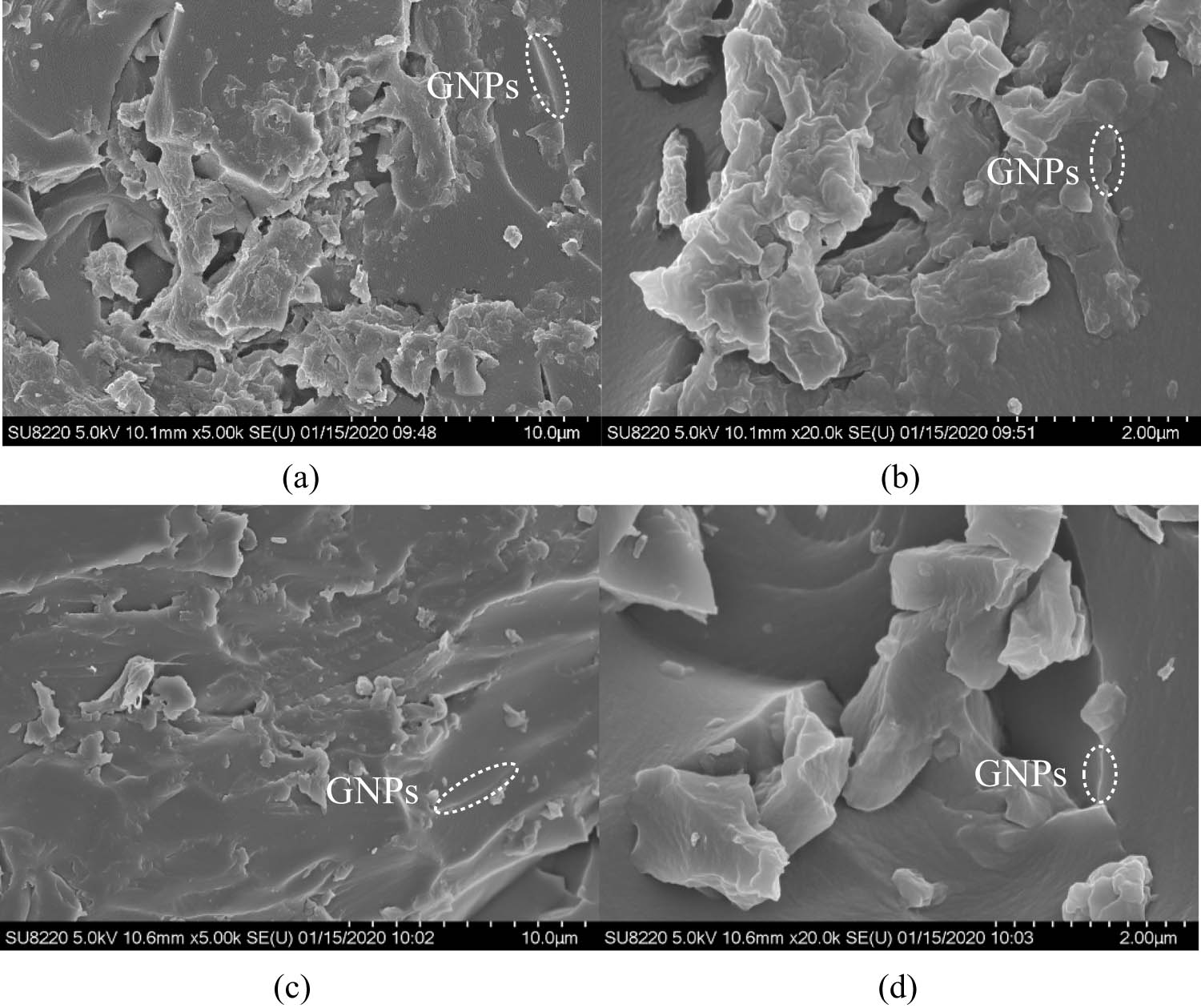

Microstructure imaging of GNP-reinforced epoxy at 0.025 wt% GNPs at (a) 5,000× and (b) 20,000×; 0.4 wt% GNPs at (c) 5,000× and (d) 20,000×.

It can be seen from the micrographs in Figure 14 that composites with 0.025 wt% GNPs show a rougher and patchier fracture surface than that with 0.4 wt% GNPs. This indicates stronger interactions between GNPs and epoxy surface. GNPs are homogeneously distributed on the fracture surface and form a strong bond with epoxy matrix. In addition, epoxy matrix has good affinity to GNPs, so they tend to exfoliate into epoxy matrices under mechanical loading. Therefore, the strong band in GNP–epoxy interface and GNP exfoliation lead to high damping ratios. When GNP content is increased, the lubrication between GNP–epoxy interface and GNP–GNP interface tends to cause the decrease of damping ratios. This is the reason for the vibration test results, where the damping ratio at 0.025 wt% GNPs is maximum, and the damping ratio initially increases and then decreases.

5 Conclusion

This article focused on investigating the damping properties of polymer nanocomposite beams reinforced by CNTs/GNPs experimentally. CNT/GNP-reinforced composite beam specimens were fabricated, upon which the vibration tests and DMA were implemented for the exploration of damping mechanism, and the nanocomposite microstructure was confirmed by SEM tests. According to the comparisons of DMA, vibration tests results, and SEM images, the conclusions are listed as follows:

The loss factors of CNT/GNP-reinforced epoxy beams increase along with the increment of excitation frequency. The glass transition temperature is decreasing by the dispersion of CNTs, but insignificantly affected by GNPs.

With the increasing weight ratios of GNPs and CNTs, the damping ratios of the first mode increase first and subsequently reduce. The maximum first damping ratio of epoxy nanocomposite beams reinforced by CNTs of 0.4 wt% is 0.591%, which is 41.1% higher than that in pure epoxy. Correspondingly, the maximum value of 0.901% is reached for the first-order damping ratio of epoxy nanocomposite beams reinforced by GNPs when the GNP weight ratio is 0.025 wt%, in contrast to the epoxy resin with no GNPs, the damping ratio is increased by 128.9%.

The elastic–viscoelastic mechanism explains the increasing damping behavior of composites reinforced by CNTs. The strong bond between GNPs and epoxy explains the increasing damping behavior of GNP-reinforced composite.

Polymer nanocomposites reinforced by CNTs/GNPs have been extensively applied in different engineering sectors owing to their excellent mechanical properties. The work in this article focuses on the damping effects of CNT/GNP reinforcement, which benefits the design and application of polymer nanocomposites in harsh environment.

-

Funding information: This work was supported by National Natural Science Foundation of China (Grant No. 11972204).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: David Hui, who is the coauthor of this article, is a current Editorial Board member of Nanotechnology Reviews. This fact did not affect the peer-review process. The authors declare no other conflict of interest.

References

[1] Xie XL, Mai YW, Zhou XP. Dispersion and alignment of carbon nanotubes in polymer matrix: a review. Mater Sci Eng R Rep. 2005;49:89–112.10.1016/j.mser.2005.04.002Search in Google Scholar

[2] Winey KI, Vaia RA. Nanocomposites. MRS Bull. 2007;32:314.10.1557/mrs2007.229Search in Google Scholar

[3] Al-Saleh MH, Sundararaj U. A review of vapor grown carbon nanofiber/polymer conductive composites. Carbon. 2009;47:2–22.10.1016/j.carbon.2008.09.039Search in Google Scholar

[4] Wang C, Pan D, Chen S. Energy dissipative mechanism of GNP foam materials. Carbon. 2018;132:641–50.10.1016/j.carbon.2018.02.085Search in Google Scholar

[5] Lahiri D, Das S, Choi W, Agarwal A. Unfolding the damping behavior of multilayer GNP membrane in the low-frequency regime. ACS Nano. 2012;6(5):3992–4000.10.1021/nn3014257Search in Google Scholar PubMed

[6] Li H, Niu Y, Li Z, Xu Z, Han Q. Modeling of amplitude-dependent damping characteristics of fiber reinforced composite thin plate. Appl Math Model. 2020;80:394–407.10.1016/j.apm.2019.11.048Search in Google Scholar

[7] Li B, Olson E, Perugini A, Zhong WH. Simultaneous enhancements in damping and static dissipation capability of polyetherimide composites with organosilane surface modified graphene nanoplatelets. Polymer. 2011;52(24):5606–14.10.1016/j.polymer.2011.09.048Search in Google Scholar

[8] Dhawan A, Jindal P. Mechanical behavior of carboxylic functionalized graphene reinforced polyurethane nanocomposites under static and dynamic loading. Polym Composite. 2021;42(9):4911–22.10.1002/pc.26199Search in Google Scholar

[9] Safaei B. The effect of embedding a porous core on the free vibration behavior of laminated composite plates. Steel Compos Struct. 2020;35:659–70.Search in Google Scholar

[10] Safaei B. Frequency-dependent damped vibrations of multifunctional foam plates sandwiched and integrated by composite faces. Eur Phys J Plus. 2021;136(6):646.10.1140/epjp/s13360-021-01632-4Search in Google Scholar

[11] Liu YF, Qin ZY, Chu FL. Nonlinear forced vibrations of FGM sandwich cylindrical shells with porosities on an elastic substrate. Nonlinear Dyn. 2021;104(2):1007–21.10.1007/s11071-021-06358-7Search in Google Scholar

[12] Sun L, Gibson RF, Gordaninejad F, Suhr J. Energy absorption capability of nanocomposites: a review. Compos Sci Technol. 2009;69(14):2392–409.10.1016/j.compscitech.2009.06.020Search in Google Scholar

[13] Bandarian M, Shojaei A, Rashidi AM. Thermal, mechanical and acoustic damping properties of flexible open-cell polyurethane multi-walled carbon nanotube foams: effect of surface functionality of nanotubes. Polym Int. 2011;60(3):475–82.10.1002/pi.2971Search in Google Scholar

[14] Lee J, Kim GH, Ha CS. Sound absorption properties of polyurethane/nano-silica nanocomposite foams. J Appl Polym Sci. 2011;123(4):2384–90.10.1002/app.34755Search in Google Scholar

[15] Gao WL, Qin ZY, Chu FL. Wave propagation in functionally graded porous plates reinforced with graphene platelets. Aerosp Sci Technol. 2020;102:105860.10.1016/j.ast.2020.105860Search in Google Scholar

[16] Zhang LF, Zhang FB, Qin ZY, Han QK, Wang TY, Chu FL. Piezoelectric energy harvester for rolling bearings with capability of self-powered condition monitoring. Energy. 2022;238:121770.10.1016/j.energy.2021.121770Search in Google Scholar

[17] Rajoria H, Jalili N. Passive vibration damping enhancement using carbon nanotube-epoxy reinforced composites. Compos Sci Technol. 2005;65(14):2079–93.10.1016/j.compscitech.2005.05.015Search in Google Scholar

[18] Agrawal R, Nieto A, Chen H, Mora M, Agarwal A. Nanoscale damping characteristics of boron nitride nanotubes and carbon nanotubes reinforced polymer composites. ACS Appl Mater Interfaces. 2013;5(22):12052–7.10.1021/am4038678Search in Google Scholar PubMed

[19] Montazeri A, Montazeri N. Viscoelastic and mechanical properties of multi walled carbon nanotube/epoxy composites with different nanotube content. Mater Des. 2011;32(4):2301–7.10.1016/j.matdes.2010.11.003Search in Google Scholar

[20] Jia Y, Peng K, Gong XL, Zhang Z. Creep and recovery of polypropylene/carbon nanotube composites. Int J Plast. 2011;27(8):1239–51.10.1016/j.ijplas.2011.02.004Search in Google Scholar

[21] Pan Y, Weng GJ, Meguid SA, Bao WS, Zhu ZH, Hamouda AMS. Interface effects on the viscoelastic characteristics of carbon nanotube polymer matrix composites. Mech Mater. 2013;58:1–11.10.1016/j.mechmat.2012.10.015Search in Google Scholar

[22] Azrar L, El Ouafi J, Aljinaidi AA. Viscoelectroelastic closed form models for frequency and time dependent effective properties of reinforced viscoelectroelastic composites. Compos Struct. 2017;159:842–65.10.1016/j.compstruct.2016.09.080Search in Google Scholar

[23] Zhou XH, Shin E, Wang KW, Bakis CE. Interfacial damping characteristics of carbon nanotube-based composites. Compos Sci Technol. 2004;64(15):2425–37.10.1016/j.compscitech.2004.06.001Search in Google Scholar

[24] Khan SU, Li CY, Siddiqui NA, Kim JK. Vibration damping characteristics of carbon fiber-reinforced composites containing multi-walled carbon nanotubes. Compos Sci Technol. 2011;71(12):1486–94.10.1016/j.compscitech.2011.03.022Search in Google Scholar

[25] DeValve C, Pitchumani R. Experimental investigation of the damping enhancement in fiber-reinforced composites with carbon nanotubes. Carbon. 2013;63:71–83.10.1016/j.carbon.2013.06.041Search in Google Scholar

[26] Bandarian M, Shojaei A, Rashidi AM. Thermal, mechanical and acoustic damping properties of flexible open‐cell polyurethane/multi‐walled carbon nanotube foams: effect of surface functionality of nanotubes. Polym Int. 2011;60(3):475–82.10.1002/pi.2971Search in Google Scholar

[27] Kamarian S, Bodaghi M, Isfahani RB, Song JI. A comparison between the effects of shape memory alloys and carbon nanotubes on the thermal buckling of laminated composite beams. Mech Based Des Struc. 2020;1–24.10.1080/15397734.2020.1776131Search in Google Scholar

[28] Kamarian S, Bodaghi M, Isfahani RB, Shakeri M, Yas MH. Influence of carbon nanotubes on thermal expansion coefficient and thermal buckling of polymer composite plates: Experimental and numerical investigations. Mech Based Des Struc. 2021;49(2):217–32.10.1080/15397734.2019.1674664Search in Google Scholar

[29] Fattahi AM, Safaei B, Qin Z, Chu F. Experimental studies on elastic properties of high density polyethylene-multi walled carbon nanotube nanocomposites. Steel Compos Struct. 2021;38(2):177–87.Search in Google Scholar

[30] Pan SQ, Dai QY, Safaei B, Qin ZY, Chu FL. Damping characteristics of carbon nanotube reinforced epoxy nanocomposite beams. Thin Wall Struct. 2021;166:108127.10.1016/j.tws.2021.108127Search in Google Scholar

[31] Chen B, Ma N, Bai X, Zhang ZM, Zhang Y. Effects of graphene oxide on surface energy, mechanical, damping and thermal properties of ethylene-propylene-diene rubber/petroleum resin blends. RSC Advances. 2012;2(11):4683–9.10.1039/c2ra01212jSearch in Google Scholar

[32] Wei JJ, Long WJ, Fang CL, Li HD, Guo YG. Effect of graphene oxide on the damping capability of recycled mortar. IOP Conf Ser Mat Sci Eng. 2018;317(1):012001.10.1088/1757-899X/317/1/012001Search in Google Scholar

[33] Lu WJ, Qin FX, Wang YF, Luo Y, Wang H, Scarpa F, et al. Engineering graphene wrinkles for large enhancement of interlaminar friction enabled damping capability. ACS Appl Mater Inter. 2019;11(33):30278–89.10.1021/acsami.9b09393Search in Google Scholar PubMed

[34] Rafiee M, Nitzsche F, Labrosse MR. Fabrication and experimental evaluation of vibration and damping in multiscale graphene/fiberglass/epoxy composites. J Compos Mater. 2019;53(15):2105–18.10.1177/0021998318822708Search in Google Scholar

[35] Wang X, Akobi M, Nikaeen P, Khattab A, He T, Li J, et al. Modeling and statistical understanding: the effect of carbon nanotube on mechanical properties of recycled polycaprolactone/epoxy composites. J Appl Polym Sci. 2021;138(8):49886.10.1002/app.49886Search in Google Scholar

[36] Mahmoodi MJ, Vakilifard M. CNT-volume-fraction-dependent aggregation and waviness considerations in viscoelasticity-induced damping characterization of percolated-CNT reinforced nanocomposites. Compos Part B Eng. 2019;172:416–35.10.1016/j.compositesb.2019.05.071Search in Google Scholar

© 2022 Shengqi Pan et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods

- Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

- Green synthesis of spinel copper ferrite (CuFe2O4) nanoparticles and their toxicity

- The effect of TaC and NbC hybrid and mono-nanoparticles on AA2024 nanocomposites: Microstructure, strengthening, and artificial aging

- Excited-state geometry relaxation of pyrene-modified cellulose nanocrystals under UV-light excitation for detecting Fe3+

- Effect of CNTs and MEA on the creep of face-slab concrete at an early age

- Effect of deformation conditions on compression phase transformation of AZ31

- Application of MXene as a new generation of highly conductive coating materials for electromembrane-surrounded solid-phase microextraction

- A comparative study of the elasto-plastic properties for ceramic nanocomposites filled by graphene or graphene oxide nanoplates

- Encapsulation strategies for improving the biological behavior of CdS@ZIF-8 nanocomposites

- Biosynthesis of ZnO NPs from pumpkin seeds’ extract and elucidation of its anticancer potential against breast cancer

- Preliminary trials of the gold nanoparticles conjugated chrysin: An assessment of anti-oxidant, anti-microbial, and in vitro cytotoxic activities of a nanoformulated flavonoid

- Effect of micron-scale pores increased by nano-SiO2 sol modification on the strength of cement mortar

- Fractional simulations for thermal flow of hybrid nanofluid with aluminum oxide and titanium oxide nanoparticles with water and blood base fluids

- The effect of graphene nano-powder on the viscosity of water: An experimental study and artificial neural network modeling

- Development of a novel heat- and shear-resistant nano-silica gelling agent

- Characterization, biocompatibility and in vivo of nominal MnO2-containing wollastonite glass-ceramic

- Entropy production simulation of second-grade magnetic nanomaterials flowing across an expanding surface with viscidness dissipative flux

- Enhancement in structural, morphological, and optical properties of copper oxide for optoelectronic device applications

- Aptamer-functionalized chitosan-coated gold nanoparticle complex as a suitable targeted drug carrier for improved breast cancer treatment

- Performance and overall evaluation of nano-alumina-modified asphalt mixture

- Analysis of pure nanofluid (GO/engine oil) and hybrid nanofluid (GO–Fe3O4/engine oil): Novel thermal and magnetic features

- Synthesis of Ag@AgCl modified anatase/rutile/brookite mixed phase TiO2 and their photocatalytic property

- Mechanisms and influential variables on the abrasion resistance hydraulic concrete

- Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites

- Achieving excellent oxidation resistance and mechanical properties of TiB2–B4C/carbon aerogel composites by quick-gelation and mechanical mixing

- Microwave-assisted sol–gel template-free synthesis and characterization of silica nanoparticles obtained from South African coal fly ash

- Pulsed laser-assisted synthesis of nano nickel(ii) oxide-anchored graphitic carbon nitride: Characterizations and their potential antibacterial/anti-biofilm applications

- Effects of nano-ZrSi2 on thermal stability of phenolic resin and thermal reusability of quartz–phenolic composites

- Benzaldehyde derivatives on tin electroplating as corrosion resistance for fabricating copper circuit

- Mechanical and heat transfer properties of 4D-printed shape memory graphene oxide/epoxy acrylate composites

- Coupling the vanadium-induced amorphous/crystalline NiFe2O4 with phosphide heterojunction toward active oxygen evolution reaction catalysts

- Graphene-oxide-reinforced cement composites mechanical and microstructural characteristics at elevated temperatures

- Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar

- Preparation of layered gradient Cu–Cr–Ti alloy with excellent mechanical properties, thermal stability, and electrical conductivity

- Recovery of Cr from chrome-containing leather wastes to develop aluminum-based composite material along with Al2O3 ceramic particles: An ingenious approach

- Mechanisms of the improved stiffness of flexible polymers under impact loading

- Anticancer potential of gold nanoparticles (AuNPs) using a battery of in vitro tests

- Review Articles

- Proposed approaches for coronaviruses elimination from wastewater: Membrane techniques and nanotechnology solutions

- Application of Pickering emulsion in oil drilling and production

- The contribution of microfluidics to the fight against tuberculosis

- Graphene-based biosensors for disease theranostics: Development, applications, and recent advancements

- Synthesis and encapsulation of iron oxide nanorods for application in magnetic hyperthermia and photothermal therapy

- Contemporary nano-architectured drugs and leads for ανβ3 integrin-based chemotherapy: Rationale and retrospect

- State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials

- Insights on magnetic spinel ferrites for targeted drug delivery and hyperthermia applications

- A review on heterogeneous oxidation of acetaminophen based on micro and nanoparticles catalyzed by different activators

- Early diagnosis of lung cancer using magnetic nanoparticles-integrated systems

- Advances in ZnO: Manipulation of defects for enhancing their technological potentials

- Efficacious nanomedicine track toward combating COVID-19

- A review of the design, processes, and properties of Mg-based composites

- Green synthesis of nanoparticles for varied applications: Green renewable resources and energy-efficient synthetic routes

- Two-dimensional nanomaterial-based polymer composites: Fundamentals and applications

- Recent progress and challenges in plasmonic nanomaterials

- Apoptotic cell-derived micro/nanosized extracellular vesicles in tissue regeneration

- Electronic noses based on metal oxide nanowires: A review

- Framework materials for supercapacitors

- An overview on the reproductive toxicity of graphene derivatives: Highlighting the importance

- Antibacterial nanomaterials: Upcoming hope to overcome antibiotic resistance crisis

- Research progress of carbon materials in the field of three-dimensional printing polymer nanocomposites

- A review of atomic layer deposition modelling and simulation methodologies: Density functional theory and molecular dynamics

- Recent advances in the preparation of PVDF-based piezoelectric materials

- Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review

- Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2

- Perspectives in biopolymer/graphene-based composite application: Advances, challenges, and recommendations

- Graphene-based nanocomposite using new modeling molecular dynamic simulations for proposed neutralizing mechanism and real-time sensing of COVID-19

- Nanotechnology application on bamboo materials: A review

- Recent developments and future perspectives of biorenewable nanocomposites for advanced applications

- Nanostructured lipid carrier system: A compendium of their formulation development approaches, optimization strategies by quality by design, and recent applications in drug delivery

- 3D printing customized design of human bone tissue implant and its application

- Design, preparation, and functionalization of nanobiomaterials for enhanced efficacy in current and future biomedical applications

- A brief review of nanoparticles-doped PEDOT:PSS nanocomposite for OLED and OPV

- Nanotechnology interventions as a putative tool for the treatment of dental afflictions

- Recent advancements in metal–organic frameworks integrating quantum dots (QDs@MOF) and their potential applications

- A focused review of short electrospun nanofiber preparation techniques for composite reinforcement

- Microstructural characteristics and nano-modification of interfacial transition zone in concrete: A review

- Latest developments in the upconversion nanotechnology for the rapid detection of food safety: A review

- Strategic applications of nano-fertilizers for sustainable agriculture: Benefits and bottlenecks

- Molecular dynamics application of cocrystal energetic materials: A review

- Synthesis and application of nanometer hydroxyapatite in biomedicine

- Cutting-edge development in waste-recycled nanomaterials for energy storage and conversion applications

- Biological applications of ternary quantum dots: A review

- Nanotherapeutics for hydrogen sulfide-involved treatment: An emerging approach for cancer therapy

- Application of antibacterial nanoparticles in orthodontic materials

- Effect of natural-based biological hydrogels combined with growth factors on skin wound healing

- Nanozymes – A route to overcome microbial resistance: A viewpoint

- Recent developments and applications of smart nanoparticles in biomedicine

- Contemporary review on carbon nanotube (CNT) composites and their impact on multifarious applications

- Interfacial interactions and reinforcing mechanisms of cellulose and chitin nanomaterials and starch derivatives for cement and concrete strength and durability enhancement: A review

- Diamond-like carbon films for tribological modification of rubber

- Layered double hydroxides (LDHs) modified cement-based materials: A systematic review

- Recent research progress and advanced applications of silica/polymer nanocomposites

- Modeling of supramolecular biopolymers: Leading the in silico revolution of tissue engineering and nanomedicine

- Recent advances in perovskites-based optoelectronics

- Biogenic synthesis of palladium nanoparticles: New production methods and applications

- A comprehensive review of nanofluids with fractional derivatives: Modeling and application

- Electrospinning of marine polysaccharides: Processing and chemical aspects, challenges, and future prospects

- Electrohydrodynamic printing for demanding devices: A review of processing and applications

- Rapid Communications

- Structural material with designed thermal twist for a simple actuation

- Recent advances in photothermal materials for solar-driven crude oil adsorption

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods

- Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

- Green synthesis of spinel copper ferrite (CuFe2O4) nanoparticles and their toxicity

- The effect of TaC and NbC hybrid and mono-nanoparticles on AA2024 nanocomposites: Microstructure, strengthening, and artificial aging

- Excited-state geometry relaxation of pyrene-modified cellulose nanocrystals under UV-light excitation for detecting Fe3+

- Effect of CNTs and MEA on the creep of face-slab concrete at an early age

- Effect of deformation conditions on compression phase transformation of AZ31

- Application of MXene as a new generation of highly conductive coating materials for electromembrane-surrounded solid-phase microextraction

- A comparative study of the elasto-plastic properties for ceramic nanocomposites filled by graphene or graphene oxide nanoplates

- Encapsulation strategies for improving the biological behavior of CdS@ZIF-8 nanocomposites

- Biosynthesis of ZnO NPs from pumpkin seeds’ extract and elucidation of its anticancer potential against breast cancer

- Preliminary trials of the gold nanoparticles conjugated chrysin: An assessment of anti-oxidant, anti-microbial, and in vitro cytotoxic activities of a nanoformulated flavonoid

- Effect of micron-scale pores increased by nano-SiO2 sol modification on the strength of cement mortar

- Fractional simulations for thermal flow of hybrid nanofluid with aluminum oxide and titanium oxide nanoparticles with water and blood base fluids

- The effect of graphene nano-powder on the viscosity of water: An experimental study and artificial neural network modeling

- Development of a novel heat- and shear-resistant nano-silica gelling agent

- Characterization, biocompatibility and in vivo of nominal MnO2-containing wollastonite glass-ceramic

- Entropy production simulation of second-grade magnetic nanomaterials flowing across an expanding surface with viscidness dissipative flux

- Enhancement in structural, morphological, and optical properties of copper oxide for optoelectronic device applications

- Aptamer-functionalized chitosan-coated gold nanoparticle complex as a suitable targeted drug carrier for improved breast cancer treatment

- Performance and overall evaluation of nano-alumina-modified asphalt mixture

- Analysis of pure nanofluid (GO/engine oil) and hybrid nanofluid (GO–Fe3O4/engine oil): Novel thermal and magnetic features

- Synthesis of Ag@AgCl modified anatase/rutile/brookite mixed phase TiO2 and their photocatalytic property

- Mechanisms and influential variables on the abrasion resistance hydraulic concrete

- Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites

- Achieving excellent oxidation resistance and mechanical properties of TiB2–B4C/carbon aerogel composites by quick-gelation and mechanical mixing

- Microwave-assisted sol–gel template-free synthesis and characterization of silica nanoparticles obtained from South African coal fly ash

- Pulsed laser-assisted synthesis of nano nickel(ii) oxide-anchored graphitic carbon nitride: Characterizations and their potential antibacterial/anti-biofilm applications

- Effects of nano-ZrSi2 on thermal stability of phenolic resin and thermal reusability of quartz–phenolic composites

- Benzaldehyde derivatives on tin electroplating as corrosion resistance for fabricating copper circuit

- Mechanical and heat transfer properties of 4D-printed shape memory graphene oxide/epoxy acrylate composites

- Coupling the vanadium-induced amorphous/crystalline NiFe2O4 with phosphide heterojunction toward active oxygen evolution reaction catalysts

- Graphene-oxide-reinforced cement composites mechanical and microstructural characteristics at elevated temperatures

- Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar

- Preparation of layered gradient Cu–Cr–Ti alloy with excellent mechanical properties, thermal stability, and electrical conductivity

- Recovery of Cr from chrome-containing leather wastes to develop aluminum-based composite material along with Al2O3 ceramic particles: An ingenious approach

- Mechanisms of the improved stiffness of flexible polymers under impact loading

- Anticancer potential of gold nanoparticles (AuNPs) using a battery of in vitro tests

- Review Articles

- Proposed approaches for coronaviruses elimination from wastewater: Membrane techniques and nanotechnology solutions

- Application of Pickering emulsion in oil drilling and production

- The contribution of microfluidics to the fight against tuberculosis

- Graphene-based biosensors for disease theranostics: Development, applications, and recent advancements

- Synthesis and encapsulation of iron oxide nanorods for application in magnetic hyperthermia and photothermal therapy

- Contemporary nano-architectured drugs and leads for ανβ3 integrin-based chemotherapy: Rationale and retrospect

- State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials

- Insights on magnetic spinel ferrites for targeted drug delivery and hyperthermia applications

- A review on heterogeneous oxidation of acetaminophen based on micro and nanoparticles catalyzed by different activators

- Early diagnosis of lung cancer using magnetic nanoparticles-integrated systems

- Advances in ZnO: Manipulation of defects for enhancing their technological potentials

- Efficacious nanomedicine track toward combating COVID-19

- A review of the design, processes, and properties of Mg-based composites

- Green synthesis of nanoparticles for varied applications: Green renewable resources and energy-efficient synthetic routes

- Two-dimensional nanomaterial-based polymer composites: Fundamentals and applications

- Recent progress and challenges in plasmonic nanomaterials

- Apoptotic cell-derived micro/nanosized extracellular vesicles in tissue regeneration

- Electronic noses based on metal oxide nanowires: A review

- Framework materials for supercapacitors

- An overview on the reproductive toxicity of graphene derivatives: Highlighting the importance

- Antibacterial nanomaterials: Upcoming hope to overcome antibiotic resistance crisis

- Research progress of carbon materials in the field of three-dimensional printing polymer nanocomposites

- A review of atomic layer deposition modelling and simulation methodologies: Density functional theory and molecular dynamics

- Recent advances in the preparation of PVDF-based piezoelectric materials

- Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review

- Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2

- Perspectives in biopolymer/graphene-based composite application: Advances, challenges, and recommendations

- Graphene-based nanocomposite using new modeling molecular dynamic simulations for proposed neutralizing mechanism and real-time sensing of COVID-19

- Nanotechnology application on bamboo materials: A review

- Recent developments and future perspectives of biorenewable nanocomposites for advanced applications

- Nanostructured lipid carrier system: A compendium of their formulation development approaches, optimization strategies by quality by design, and recent applications in drug delivery

- 3D printing customized design of human bone tissue implant and its application

- Design, preparation, and functionalization of nanobiomaterials for enhanced efficacy in current and future biomedical applications

- A brief review of nanoparticles-doped PEDOT:PSS nanocomposite for OLED and OPV

- Nanotechnology interventions as a putative tool for the treatment of dental afflictions

- Recent advancements in metal–organic frameworks integrating quantum dots (QDs@MOF) and their potential applications

- A focused review of short electrospun nanofiber preparation techniques for composite reinforcement

- Microstructural characteristics and nano-modification of interfacial transition zone in concrete: A review

- Latest developments in the upconversion nanotechnology for the rapid detection of food safety: A review

- Strategic applications of nano-fertilizers for sustainable agriculture: Benefits and bottlenecks

- Molecular dynamics application of cocrystal energetic materials: A review

- Synthesis and application of nanometer hydroxyapatite in biomedicine

- Cutting-edge development in waste-recycled nanomaterials for energy storage and conversion applications

- Biological applications of ternary quantum dots: A review

- Nanotherapeutics for hydrogen sulfide-involved treatment: An emerging approach for cancer therapy

- Application of antibacterial nanoparticles in orthodontic materials

- Effect of natural-based biological hydrogels combined with growth factors on skin wound healing

- Nanozymes – A route to overcome microbial resistance: A viewpoint

- Recent developments and applications of smart nanoparticles in biomedicine

- Contemporary review on carbon nanotube (CNT) composites and their impact on multifarious applications

- Interfacial interactions and reinforcing mechanisms of cellulose and chitin nanomaterials and starch derivatives for cement and concrete strength and durability enhancement: A review

- Diamond-like carbon films for tribological modification of rubber

- Layered double hydroxides (LDHs) modified cement-based materials: A systematic review

- Recent research progress and advanced applications of silica/polymer nanocomposites

- Modeling of supramolecular biopolymers: Leading the in silico revolution of tissue engineering and nanomedicine

- Recent advances in perovskites-based optoelectronics

- Biogenic synthesis of palladium nanoparticles: New production methods and applications

- A comprehensive review of nanofluids with fractional derivatives: Modeling and application

- Electrospinning of marine polysaccharides: Processing and chemical aspects, challenges, and future prospects

- Electrohydrodynamic printing for demanding devices: A review of processing and applications

- Rapid Communications

- Structural material with designed thermal twist for a simple actuation

- Recent advances in photothermal materials for solar-driven crude oil adsorption