Abstract

Herein we report encapsulation approaches for Cadmium Sulfide (CdS) encapsulated zeolitic imidazolate framework (ZIF)-8 (CdS@ZIF-8), such as “bottle-around-the-ship” and “ship-in-the-bottle.” In this study, these composites were evaluated for antibacterial and DNA-binding properties. To the best of our knowledge, this is the first report on the synthesis of CdS nanoparticles using ZIF-8 as a capping agent. The as-synthesized nanocomposites were characterized using Fourier transform infrared spectroscopy, X-ray diffraction, thermogravimetric analysis (TGA), Brunauer–Emmett–Teller surface area analysis, field emission-scanning electron microscopy, and high-resolution transmission electron microscopy. Characterization studies revealed that both encapsulation approaches provided different morphologies to the encapsulated framework. The antibacterial activity of the as-fabricated nanocomposite, in which ZIF-8 acts as a capping agent, was more effective against Escherichia coli (E. coli) than Staphylococcus aureus (S. aureus) and Bacillus subtilis (B. subtilis). Furthermore, DNA-binding studies of nanocomposites performed by UV absorption spectroscopic titration method in E. coli genomic DNA indicated that DNA binding occurs along with cleavage. Therefore, the designed nanocomposites demonstrate great promise for future anticancer research.

1 Introduction

Metal-organic frameworks (MOFs) are a class of porous, crystalline coordination polymers derived from metals or metallic clusters (known as “secondary building units,” SBUs) and organic linkers via strong coordinate bonds [1,2]. Recently, MOF nanocomposites have gained attention because of their intriguing physicochemical properties and broader practical applications than those of traditional MOFs. Interestingly, MOFs possess high specific surface areas [3], well-defined pore size distributions [4], and tailored internal surface characteristics [5]. MOFs are classified into several classes and subclasses [6]. One of the emerging subclasses of MOFs is the zeolitic imidazolate framework (ZIF), which has structural features similar to that of aluminosilicate zeolites, wherein the bridging and tetrahedral Si(Al) bonds in aluminosilicate zeolites are replaced with organic linkers and transition metal ions, respectively [7]. ZIF-based hybrid materials such as CelloZIFs [8] find applications in the field of reduction of 4-nitrophenol [9], multifunctional environmental remediation [10], heavy metal removal, and electrochemical sensing [11].

Cadmium sulfide (CdS) is a semiconductor quantum dot with remarkable features such as high stability, ease of preparation and handling, excellent physical, chemical, and structural properties, and a wide range of applications including catalysis, water splitting, and hydrogen evolution [12,13,14,15]. CdS nanoparticles play a significant role in developing anticancer drugs because they damage DNA in cancer cells via DNA oligomer binding [16,17]. In 2007, Li and his coworkers reported enhancement of drug uptake by cancer cells through the combination of anticancer drug doxorubicin with CdS nanoparticles [18]. It is observed that CdS nanoparticles cause death of affected cells in the form of Cd2+. Further, the exposure of Cd2+ in an oxidative environment causes their release as Cd atoms [19]. The particle size and stability of nanoparticles are crucial factors that regulate their potential applications. Therefore, the size and stability of nanoparticles are generally regulated by matrices, including zeolites, silica, polymers, glasses, reverse micelles, vesicles, capping agents, and stabilizers [20,21,22,23,24,25,26,27]. Agglomeration of CdS nanoparticles can be effectively prevented using capping agents such as long-chain alkylammonium salts (for example, cetyl trimethyl ammonium bromide [CTAB]). Recently, nanoparticle encapsulated MOFs have attracted attention because they exhibit the characteristic properties of both MOF and nanoparticles. They can be synthesized using two different methods: “bottle-around-the-ship” [28] and “ship-in-the-bottle” [29]. In the former method, pre-synthesized nanoparticles stabilized by capping agents are encapsulated in the cavities of growing MOFs, [7,30] whereas in the latter method, precursors of nanoparticles are allowed to grow inside the cavities of the MOF, which act as a template or capping agent [31]. Zeng et al. [32] and Malik et al. [33] have demonstrated the synthesis of CdS@ZIF-8 using the “bottle-around-the-ship” encapsulation strategy. It is reported that Fe3O4@ZIF-8 nanocomposite can be used as a contrast agent in bioimaging [34]. In vivo experiments on this composite material showed that the composite material displayed contrast enhancement, distinguishing the normal and tumor tissues under MRI. In the case of Ceftazidime @ZIF-8 composite, where ceftazidime is an antibacterial agent showed bacterial activity against Escherichia coli (E. coli) [35]. Similar to this study, physcion (PHY) drug encapsulated ZIF-8 exhibited enhanced antibacterial activity in comparison to the pure PHY drug [36]. Table 1 summarizes the encapsulation strategy, Brunauer–Emmett–Teller (BET) surface area, pore volume values, and applications of certain nanocomposites in previously published results.

Encapsulation strategy, BET surface area, pore volume, and applications of certain composites

| Composite | Encapsulation strategy | BET surface area (m2 g−1) | Pore volume (cm3 g−1) | Application | Ref. |

|---|---|---|---|---|---|

| CdS@ZIF-8 | Bottle-around-the-ship | No data available | No data available | Showed increased photocatalytic selectivity for H2 generation from formic acid | [32] |

| CdS@ZIF-8 | Bottle-around-the-ship | 1294.15 | 0.753 | Showed potential to be used as an antibacterial agent against E. coli and Staphylococcus aureus (S. aureus) | [33] |

| Fe3O4@ZIF-8 | Bottle-around-the-ship | No data available | No data available | Used as a contrast agent in bioimaging. In vivo studies showed that the composite material displayed contrast enhancement enabling distinguishing the normal and tumor tissues under MRI | [34] |

| Ceftazidime@ZIF-8 | Bottle-around-the-ship | 1,509 | No data available | Showed bactericidal activity against E. coli upon sustained release of the antibacterial cargo | [35] |

| PHY@ZIF-8 | Bottle-around-the-ship | No data available | No data available | Exhibited enhanced antibacterial activity in comparison to the pure PHY drug | [36] |

| CdS@ZIF-8 | Bottle-around-the-ship | 74.0 | No data available | Showed higher efficiency and better selectivity in photocatalytic reduction of CO2 to CO | [37] |

In this study, we synthesized CdS@ZIF-8 nanocomposites via the “bottle-around-the-ship” and “ship-in-the-bottle” methods to compare the properties of composites obtained using both approaches. As the CdS nanoparticles act as anticancer agents [19], the composites CdS@ZIF-8 were further tested for their antibacterial and DNA-binding properties. The morphological, physical, chemical, and textural properties of the fabricated nanocomposites were compared using Fourier transform infrared spectroscopy (FTIR), powder X-ray diffraction (PXRD), thermogravimetric analysis (TGA), nitrogen sorption isotherms, BET surface area analysis, the Barrett–Joyner–Halenda (BJH) method for pore size distribution, field emission scanning electron microscopy (FE-SEM), and high-resolution transmission electron microscopy (HR-TEM). Finally, the fabricated nanocomposites were evaluated by assessing their antibacterial activities against E. coli, S. aureus, and Bacillus subtilis (B. subtilis). In addition, DNA-binding analysis was performed with E. coli genomic DNA using the UV absorption spectroscopy.

2 Experimental

2.1 Materials

Zn(NO3)2·6H2O, CTAB, and methanol of analytical grade were purchased from RANKEM. In addition, 2-methylimidazole (Hmim) was purchased from TCI, and Cd(NO3)2·4H2O (Spectrum), Na2S·9H2O (HIMEDIA), HCl (NICE), and double-distilled water were used without further purification.

2.2 Synthesis of CdS and CTAB-capped CdS

Cd(NO3)2·4H2O (1.5423 g) was dissolved in 50 mL of methanol and a 1:1 mixture of HCl and water. Na2S·9H2O (0.3902 g) dissolved in methanol (50 mL) was added dropwise to the metal salt solution and stirred for 3 h. The greenish-yellow precipitate of CdS was obtained by sequential washing with the ethanol-water solution, then centrifuged and dried at 80°C for 48 h. CTAB-capped CdS was prepared according to the above procedure, except a methanolic solution of CTAB (0.2904 g in 10 mL of methanol) was added to the acidified metal salt solution.

2.3 Synthesis of ZIF-8

Zn(NO3)2·6H2O (2.888 g in 25 mL of methanol) was mixed with a methanolic solution of 2-methylimidazole (6.5196 g in 25 mL of methanol) and stirred for 4 h. Next the contents were transferred into a Teflon-lined autoclave and heated at 65°C for 24 h. After cooling, the obtained material was centrifuged, washed with an ethanol-water mixture, and dried in an oven at 80°C for 48 h. The white solid powder was stored in a vial for further analysis.

2.4 Synthesis of CdS@ZIF-8 (ship-in-the-bottle)

In the “ship-in-the-bottle” approach, pre-synthesized ZIF-8 was redispersed in 50 mL of methanol. The precursors of CdS (cadmium nitrate and sodium sulfide) were added to the redispersed solution of ZIF-8, and the procedure previously described for the synthesis of CdS was followed. A pale greenish-yellow CdS-encapsulated ZIF-8 solid was obtained, which was dried and stored for further analysis.

2.5 Synthesis of CTAB-capped CdS@ZIF-8 (bottle-around-the-ship)

In the “‘bottle-around-the-ship’” approach, pre-synthesized CTAB-capped CdS was redispersed in 5 mL of methanol. To this solution, the precursors of the ZIF-8 framework (zinc nitrate and 2-methylimidazole) were added, and a similar procedure to that of the synthesis of ZIF-8 was continued. A greenish-yellow CTAB-capped CdS@ZIF-8 solid was obtained and stored for further analysis.

2.6 Well-diffusion assay (antibacterial assay)

The agar well diffusion method is generally used to assess the antimicrobial activity of the prepared materials. In this method, autoclaved 15–20 mL of Mueller Hinton agar was poured onto glass Petri plates and allowed to solidify. The standardized inoculum of the test organism was uniformly spread on the surface of the plates using a sterile cotton swab. Four wells with a diameter of 8 mm (20 mm apart from one another) were punched aseptically in each plate using a sterile cork borer. Out of the 4 wells, 3 wells contained a compound solution (40 and 80 µL) and one contained gentamycin (80 μg per well) as a positive control and compound solvent as a negative control. The agar plates were incubated at 37°C for 24 h. After the incubation, a clear zone was observed. The inhibition of bacterial growth was measured in millimeters.

2.7 DNA-binding studies (UV-visible experiment)

For DNA-binding studies, a similar concentration of DNA (E. coli genome) was incubated (37°C for 2 h) using different prepared compounds (50 μg CdS, CdS@ZIF-8, CTAB-capped CdS, and CTAB-capped CdS@ZIF-8) in a phosphate buffer (pH 7.0).

2.8 Characterization

All prepared samples (ZIF-8, CdS nanoparticles, CTAB-capped CdS, CdS@ZIF-8, and CTAB-capped CdS@ZIF-8) were characterized using different instrumental techniques. The surface functionalities of the dried samples were determined using FTIR with an FTIR Shimadzu IRPrestige21 spectrophotometer with KBr pellets in the range of 4,000–400 cm−1. The crystallographic nature was obtained from the PXRD patterns of the dried samples recorded by a Bruker AXS D8 advance diffractometer using Cu Kα (λ = 1.5406 Å) radiation in the range of 3–80° in 2θ scale at high temperatures. The thermal stability and thermal decomposition nature of as-fabricated samples were determined using TGA with Perkin Elmer, STA 6000 instrument at a heating rate of 20°C min−1 under a nitrogen atmosphere over a temperature range of 40–860℃. The microstructure and morphologies of the prepared materials were observed using FE-SEM with a LEO SUPRA 55, GENESIS 2000 (Carl Zeiss, EDAX) and HR-TEM using a JEM-2100F (JEOL). Textural properties were obtained from N2 adsorption–desorption isotherms at 77 K. The BET and BJH methods were carried out with the aid of BELSORP max (MP). Antibacterial and DNA-binding studies were performed using an AquaMate 8000 UV-VIS spectrophotometer (Thermo Scientific).

3 Results and discussion

3.1 Bonding characteristics and functional group identification

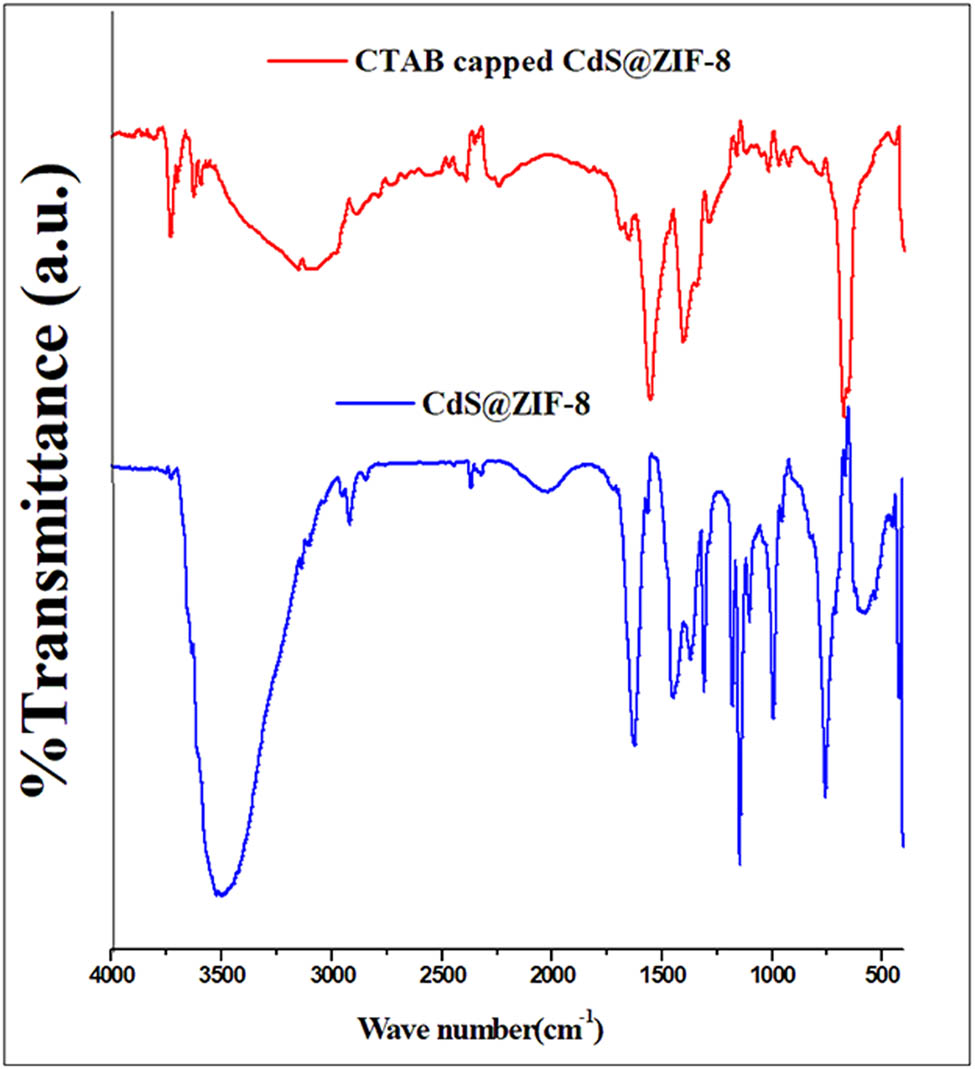

The bonding characteristics and functional groups of the as-prepared samples were determined using FTIR. A prominent shift was observed in the characteristic ZIF-8 at 651 cm−1 (Figure S1), indicating out-of-plane bending of the methyl group in 2-methylimidazole. In the “ship-in-the-bottle” approach, the peak corresponding to the out-of-plane bending of the methyl group in 2-methylimidazole shifted to 751 cm−1, as evident in the FTIR spectrum of CdS@ZIF-8 (Figure 1). This can be attributed to the presence of CdS nanoparticles in the pores of ZIF-8, which increased the energy for the out-of-plane bending of the methyl group in 2-methylimidazole. Furthermore, the characteristic absorption of the Zn–N peak at 445 cm−1 in ZIF-8 shifted to 430 cm−1 in CdS@ZIF-8. This is caused by the elongation of the Zn–N bond in the interaction of the ZIF-8 framework with the encapsulated CdS during composite formation [38,39]. The peak at 734 cm−1, corresponding to the Cd–S stretching frequency (Figure S1), was downshifted to 711 cm−1 in the CdS@ZIF-8 composite [40,41]. This is attributed to the interaction of sulfur in the CdS nanoparticles with zinc in the ZIF-8 framework. Peaks in the region of 3,100–3,600 cm−1 and at 1,628 cm−1 of CdS@ZIF-8 revealed the presence of hydroxyl (–OH) groups of H2O and adsorbed CO2 on the CdS surface, respectively [42]. The presence of these characteristic peaks confirmed the formation of the CdS@ZIF-8 composite. The FTIR spectrum of CTAB-capped CdS@ZIF-8 (synthesized by the ”bottle-around-the-ship” method) is shown in Figure 1. The vibrational frequency of the Zn–N peak at 445 cm−1 is retained exactly at the same position as that of ZIF-8 (Figure S1) [43], indicating the absence of the interaction of sulfur in CdS with zinc. This indicates that the morphology of ZIF-8 was retained during the synthesis of the CTAB-capped CdS@ZIF-8 composite. In addition, other characteristic peaks corresponding to ZIF-8- and CTAB-capped CdS (Figure S1) were retained in the CTAB-capped CdS@ZIF-8 nanocomposites, confirming its formation.

FTIR spectra of CdS@ZIF-8 and CTAB-capped CdS@ZIF8.

3.2 Crystallographic nature

The X-ray diffraction (XRD) patterns of CdS@ZIF-8 and CTAB-capped CdS@ZIF-8 nanocomposites are shown in Figure 2. The diffraction pattern of the as-synthesized nanocomposites showed a peak at 7.4°, which is characteristic of ZIF-8 (Figure S2) [44,45,46,47]. In the CdS@ZIF-8 nanocomposite, 3 prominent peaks of CdS were observed at 26.6, 43.7, and 52.1°, which is similar to the XRD pattern of CdS (Figure S2) [32,37,48,49]. The decrease in the intensities of the peaks corresponding to CdS nanoparticles in CdS@ZIF-8 indicates the encapsulation of nanoparticles in the MOF [50]. The diffraction pattern of the CTAB-capped CdS@ZIF-8 nanocomposite (Figure 2) shows 2θ values at 7.4, 10.5, 12.8, 18.1, 22.6, 26.6, 43.7, and 52.1°, where the first 5 peaks are attributed to ZIF-8 and the remaining peaks correspond to CTAB-capped CdS (Figure S2). The signal-to-noise (S/N) ratio of CdS particles was found to be lower in the encapsulated frameworks than in ZIF-8. This is attributed to the decrease in the particle size below 10 nm, which in turn broadens the peaks and results in a low S/N ratio [51]. Comparative analysis of the XRD patterns of ZIF-8, CdS, CdS@ZIF-8, and CTAB-capped CdS@ZIF-8 further confirmed the successful formation of CdS-encapsulated MOF nanocomposites via two different strategies, “bottle-around-the-ship” and “ship-in-the-bottle.”

XRD patterns of CdS@ZIF-8 and CTAB-capped CdS@ZIF8.

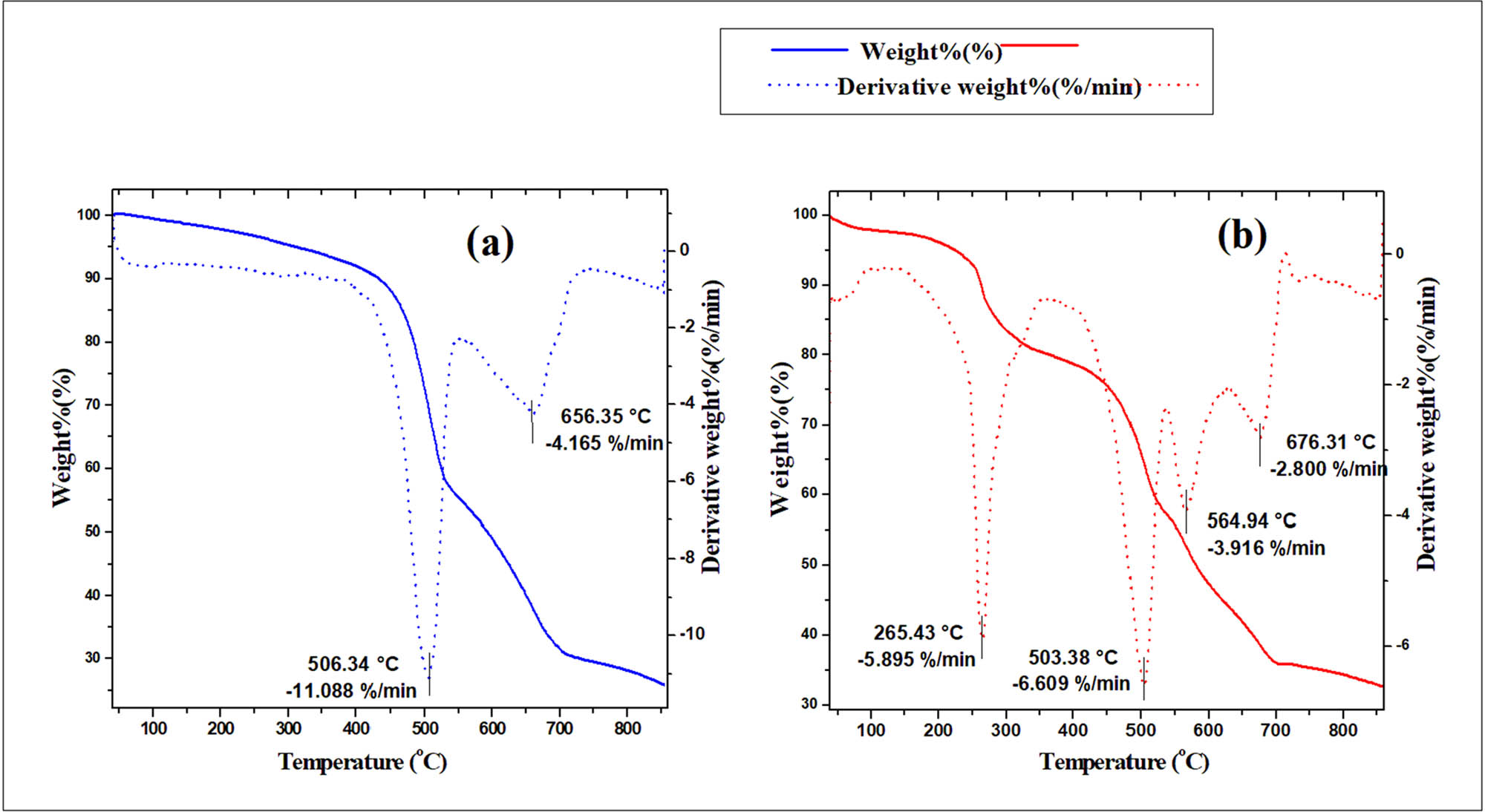

3.3 TGA

The thermogravimetric analyses of CdS@ZIF-8- and CTAB-capped CdS@ZIF-8 nanocomposites are shown in Figure 3(a) and (b), respectively. Both nanocomposites showed approximately 10% weight loss between 40 and 150°C, which could be attributed to the removal of the adsorbed water molecules [52,53,54,55]. This observation is consistent with the FTIR peaks in the region 3,100–3,600 cm−1. The TG/DTA curves of CdS@ZIF-8 (Figure 2(a)) revealed the multi-step decomposition and high thermal stability of the nanocomposite up to 430°C. The thermal decomposition seems to occur in two stages. The first decomposition in the region of 430–530°C corresponds to ZIF-8 decomposition (Figure S3(a)) [56]. The second decomposition step starts at 535°C, which corresponds to the decomposition of CdS (Figure S3(b)). This two-step thermal decomposition is an indication of the encapsulation of CdS nanoparticles into the pores of the ZIF-8 framework. In contrast, the CTAB-capped CdS@ZIF-8 composite (Figure 2(b)) was stable up to 240°C. The decomposition between 240 and 320°C corresponds to the degradation of the capping agent CTAB, which prevents the agglomeration of the CdS nanoparticles [57] (Figure S3(c and d)). Further degradation in the range 450–530°C was ascribed to the decomposition of the ZIF-8 framework. The region above 530°C corresponds to the decomposition of the CdS nanoparticles encapsulated in the ZIF-8 framework. Therefore, strategies such as “bottle-around-the-ship” and “ship-in-the-bottle” have proven to be equally effective in encapsulating CdS nanoparticles.

TG/DTA curves of (a) CdS@ZIF-8 and (b) CTAB-capped CdS@ZIF-8.

3.4 Textural analysis

Textural features of the nanocomposites (CdS@ZIF-8 and CTAB-capped CdS@ZIF-8) were obtained from nitrogen adsorption isotherms and BJH plots (Figure 4(a–d)). The adsorption isotherms of both nanocomposites show a combination of type I and IV isotherms [58,59,60]. The type I isotherm arises because of the presence of the ZIF-8 framework (Figure S4), whereas type IV was owing to CdS (Figure S4). The specific surface areas obtained by the BET method for CdS@ZIF-8 and CTAB-capped CdS@ZIF-8 nanocomposites were 221.96 and 977.73 m2 g−1, respectively. Furthermore, the pore volumes of the CdS@ZIF-8 and CTAB-capped CdS@ZIF-8 nanocomposites were 0.1182 and 0.5385 cm3 g−1, respectively. The decrease in the surface area and pore volume of the composites compared to pristine ZIF-8 (specific surface area 2,026 m2 g−1 and pore volume 0.6698 cm3 g−1) further confirms the encapsulation of CdS into the cavities of the MOFs.

Nitrogen adsorption/desorption isotherms of (a) CdS@ZIF-8 and (b) CTAB-capped CdS@ZIF-8; BJH plots of (c) CdS@ZIF-8 and (d) CTAB-capped CdS@ZIF-8.

The BJH plots of the nanocomposites are depicted in Figure 4(c) and (d). Both CdS@ZIF-8 and CTAB-capped CdS@ZIF-8 possessed pore diameters of 2.5 nm. This pore diameter was slightly larger than that of ZIF-8 (2 nm). The BJH plots of ZIF-8, CdS, and CTAB-capped CdS are shown in Figure S5. The larger pore diameter (2.5 nm) in both nanocomposites suggests the presence of a small percentage of mesopores, which is further confirmed by the shape of the nitrogen adsorption/desorption isotherms.

3.5 Structural and morphological analysis

FE-SEM images of ZIF-8 (Figure S6(a and b)) display both hexagonal and cubic morphologies. The average particle size was found to be 340 nm. However, the FE-SEM images of the CdS@ZIF-8 nanocomposite (Figure 5(a and b)) show a small elongation in the morphology. This elongation is attributed to the “ship-in-the-bottle” approach, wherein the formation of CdS nanoparticles inside the cavities of ZIF-8 causes an expansion of the framework. SEM images also show the encapsulated CdS nanoparticles, which are observed as dark spots inside the ZIF-8 framework. This indicates the encapsulation of the CdS nanoparticles into the ZIF-8 pores. The average particle size of the CdS@ZIF-8 nanocomposite was found to be 320 nm. Furthermore, as the growth of the CdS nanoparticles occurred inside the pores of the framework, the particle size of CdS did not grow beyond the pore diameter, and the ZIF-8 framework indirectly acted as a capping agent. In contrast, the FESEM images of the CTAB-capped CdS@ZIF-8 composite (Figure 5(c and d)) prepared using the “bottle-around-the-ship” method showed perfect cubic and hexagonal morphologies. This strategy of preparation retained the morphology because the development of the framework occurred along with encapsulation of CTAB-capped CdS nanoparticles. The images clearly indicate that CTAB-capped CdS nanoparticles were found inside as well as on the surfaces of the framework. The composite had an average particle size of 400 nm. This increase in the particle size of ZIF-8 was caused by the encapsulation of CTAB-capped CdS (average size of 3 nm) (Figure S6(e and f)) in the pores of the ZIF-8 framework. Detailed information regarding the morphology and size of the as-synthesized samples was obtained from the TEM images. The TEM images of ZIF-8, CdS, and CTAB-capped CdS are shown in Figure S7. The TEM images of CdS@ZIF-8 (Figure 6(a–c)) show an elongated hexagonal morphology, as indicated in FE-SEM. The dark region inside the framework (Figure 6c) indicates the encapsulation of CdS nanoparticles less than 5 nm in the core cavities of the framework composite, CdS@ZIF-8. This observation confirms the role of ZIF-8 as a capping agent for CdS nanoparticles, which helps prevent its agglomeration. The TEM images of the CTAB-capped CdS@ZIF-8 nanocomposites (Figure 6(d–f)) show cubic and hexagonal geometries. The average particle size in the TEM images was found to be the same as that in the FE-SEM images [61]. In Figure 6(d) and (e), CdS nanoparticles are observed on the surface cavities as well as in the core cavities of the cubic framework of the CTAB-capped CdS@ZIF-8 as dark regions. The TEM images show that both strategies, “bottle-around-the-ship” and “ship-in-the-bottle,” are equally effective in the successful encapsulation of CdS nanoparticles in the framework composites. These results are in agreement with the data obtained from BET analysis and BJH pore size distributions.

FE-SEM images of (a and b) CdS@ZIF-8 and (c and d) CTAB-capped CdS@ZIF-8.

HR-TEM images of (a–c) CdS@ZIF-8 and (d–f) CTAB-capped CdS@ZIF-8.

4 Applications

4.1 Antimicrobial activity and DNA binding

The results of the antibacterial activity of all the prepared samples (CdS@ZIF-8, CTAB-capped CdS@ZIF-8, ZIF-8, CdS, and CTAB-capped CdS) were determined by a well-diffusion assay against E. coli, S. aureus, and B. subtilis and listed in Table 2 and Table S1. The results revealed that the antibacterial activity of the same compound against different bacteria is different and depends on the structural components of the bacteria [62,63]. Similarly, the same bacteria against different compounds show different antibacterial activities, likely because of differences in the structural components of the compounds [64,65]. The antibacterial activity of ZIF-8, even at higher concentrations, was very low, which might be because E. coli is not sufficiently sensitive to ZIF-8 [66,67]. However, the composite CdS@ZIF-8 showed higher antibacterial activity against E. coli compared with the CTAB-capped CdS@ZIF-8 composite. This is because in the CdS@ZIF-8 composite, the Zn2+ ions were more easily available than in the ZIF-8- and CTAB-capped CdS@ZIF-8 nanocomposites. The antibacterial activities of CTAB-capped CdS@ZIF-8 against S. aureus and B. subtilis were higher than those against E. coli. This is because the liposomes of gram-positive bacteria (S. aureus and B. subtilis, which are fatty acid-enriched) were destroyed by the CTAB-capped CdS@ZIF-8 nanocomposite [64]. Thus, it can be concluded that the composite CdS@ZIF-8 synthesized via “ship-in-the-bottle” is more effective against E. coli than CTAB-capped CdS@ZIF-8.

Antibacterial activities of CdS@ZIF-8 and CTAB-capped CdS@ZIF-8

| Sample | Organism | Diameter of zone (mean value ± SD) (in mm) | ||

|---|---|---|---|---|

| +(80 μg) (control) | T1 (400 µg) | T2 (800 µg) | ||

| CdS@ZIF-8 | E. coli | 33.1 ± 0.16 | 12.2 ± 0.29 | 22.0 ± 0.24 |

| S. aureus | 30.0 ± 0.20 | 13.1 ± 0.16 | 14.9 ± 0.12 | |

| Bacillus subtilis | 35.1 ± 0.20 | 16.1 ± 0.12 | 19.8 ± 0.62 | |

| CTAB capped CdS@ZIF-8 | E. coli | 30.6 ± 0.54 | 15.0 ± 0.12 | 17.9 ± 0.08 |

| S. aureus | 30.0 ± 0.05 | 17.9 ± 0.08 | 26.0 ± 0.08 | |

| Bacillus subtilis | 35.2 ± 0.46 | 17.1 ± 0.05 | 21.2 ± 0.17 | |

Numerous scientific studies have shown that DNA is a major intracellular target of anticancer drugs. Interactions between tiny molecules and DNA can induce damage in cancer cells, preventing cell division and ultimately leading to cell death [68,69]. The DNA-binding studies of CdS@ZIF-8 and CTAB-capped CdS@ZIF-8 are summarized in Table 3 and those of ZIF-8, CdS, and CTAB-capped CdS are presented in Table S2. With respect to the control, both CdS@ZIF-8 and CTAB-capped CdS@ZIF-8 nanocomposites and CdS nanoparticles showed a redshift and hyperchromic effects, whereas ZIF-8 showed a blueshift. The hyperchromic effects and variation in wavelength (either redshift or blueshift) illustrate that intercalation occurs through electrostatic interactions or groove binding [41] between the composite material and E. coli genomic DNA.

DNA-binding studies of CdS@ZIF-8 and CTAB-capped CdS@ZIF-8

| Absorbance | Inference | Wavelength (nm) | Inference | |

|---|---|---|---|---|

| CdS@ZIF-8 (50 µg) + E. coli genomic DNA | 0.259 | Hyperchromic | 270 | Red shift |

| CTAB capped CdS@ZIF-8 (50 µg) + E. coli genomic DNA | 0.333 | Hyperchromic | 270 | Red shift |

5 Conclusion

In this study, we successfully developed CdS-encapsulated ZIF-8 nanocomposites via two strategic approaches: “ship-in-the-bottle” and “bottle-around-the-ship.” Nanocomposites derived from the “ship-in-the-bottle approach” showed good thermal stability; however, their morphology was distorted owing to the growth of CdS nanoparticles inside the cavities, which expanded the framework to a certain extent and prevented agglomeration. The framework indirectly acted as a capping agent. On the other hand, the “bottle-around-the-ship” approach retained the morphology as the framework developed along with the encapsulation of CTAB-capped CdS. CTAB-capped CdS was also present on the surface of the framework. FTIR, XRD, and BET analyses confirmed the formation of composites through both strategies. The surface morphology was confirmed by FE-SEM and HR-TEM. Future anticancer studies could benefit from leveraging the antibacterial and DNA-binding properties of these composites.

Acknowledgments

The authors are thankful to UGC, Government of India for providing research grant (No. 2348-MRP/15-16/KLKE029/UGC-SWRO) and are also thankful to Kyung Hee University, Republic of Korea and SAIF-Cochin, for characterisation. The authors extend their thanks to Athmic Biotech Solutions Pvt Ltd, Kerala for application studies.

-

Funding information: The authors are thankful to UGC, Government of India for providing research grant (No. 2348-MRP/15-16/KLKE029/UGC-SWRO).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Xiao X, Zou L, Pang H, Xu Q. Synthesis of micro/nanoscaled metal-organic frameworks and their direct electrochemical applications. Chem Soc Rev. 2020;49:301–31.10.1039/C7CS00614DSearch in Google Scholar

[2] Chen M, Long Z, Dong R, Wang L, Zhang J, Li S, et al. Titanium incorporation into Zr‐porphyrinic metal-organic frameworks with enhanced antibacterial activity against multidrug‐resistant pathogens. Small. 2020;16:1906240.10.1002/smll.201906240Search in Google Scholar PubMed

[3] Bagade R, Sonkusare V, Potbhare AK, Gomaji Chaudhary R, Husain R, Juneja HD. Microwave-mediated fabrication of mesoporous Bi-doped CuAl2O4 nanocomposites for antioxidant and antibacterial performances. Mater Today Proc. 2019;15:566–74.10.1016/j.matpr.2019.04.122Search in Google Scholar

[4] Silvio D, Lev S, Alexander NV. Deciphering the relations between pore structure and adsorption behavior in metal-organic frameworks: unexpected lessons from argon adsorption on copper-benzene-1,3,5-tricarboxylate. J Am Chem Soc. 2019;141:8397–401.10.1021/jacs.9b00906Search in Google Scholar PubMed

[5] Baumann AE, Burns DA, Liu B. Metal-organic framework functionalization and design strategies for advanced electrochemical energy storage devices. Commun Chem. 2019;2(1):1–4.10.1038/s42004-019-0184-6Search in Google Scholar

[6] Kim H, Hong CS. MOF-74-type frameworks: tunable pore environment and functionality through metal and ligand modification. Cryst Eng Comm. 2021;23:1377–87.10.1039/D0CE01870HSearch in Google Scholar

[7] Archana K, Pillai NG, Rhee KY, Asif A. Superparamagnetic ZIF-67 metal-organic framework nanocomposite. Compos B Eng. 2019;158:384–9.10.1016/j.compositesb.2018.10.005Search in Google Scholar

[8] Abdelhamid HN, Mathew AP. Cellulose-metal organic frameworks (CelloMOFs) hybrid materials and their multifaceted applications: A review. Coord Chem Rev. 2022;451:214623.10.1016/j.ccr.2021.214263Search in Google Scholar

[9] Abdelhamid HN, Mathew AP. In-situ growth of zeolitic imidazolate frameworks into a cellulosic filter paper for the reduction of 4-nitrophenol. Carbohydr Polym. 2021;274:118657.10.1016/j.carbpol.2021.118657Search in Google Scholar PubMed

[10] Abdelhamid HN, Mathew AP. Cellulose-zeolitic imidazolate frameworks (CelloZIFs) for multifunctional environmental remediation: Adsorption and catalytic degradation. Chem Eng J. 2021;426:131733.10.1016/j.cej.2021.131733Search in Google Scholar

[11] Abdelhamid HN, Georgouvelas D, Edlund U, Mathew AP. CelloZIFPaper: Cellulose-ZIF hybrid paper for heavy metal removal and electrochemical sensing. Chem Eng J. 2022;446:136614.10.1016/j.cej.2022.136614Search in Google Scholar

[12] Qiao S, Feng C, Guo Y, Chen T, Akram N, Zhang Y, et al. CdS nanoparticles modified Ni@NiO spheres as photocatalyst for oxygen production in water oxidation system and hydrogen production in water reduction system. Chem Eng J. 2020;395:125068.10.1016/j.cej.2020.125068Search in Google Scholar

[13] Li Y, Chen S, Zhang K, Gu S, Cao J, Xia Y, et al. Highly efficient and stable photocatalytic properties of CdS/FeS nanocomposites. N J Chem. 2020;44:14695–702.10.1039/D0NJ01424ASearch in Google Scholar

[14] Ai Z, Zhao G, Zhong Y, Shao Y, Huang B, Wu Y, et al. Phase junction CdS: high efficient and stable photocatalyst for hydrogen generation. Appl Catal B. 2018;221:179–86.10.1016/j.apcatb.2017.09.002Search in Google Scholar

[15] Fang Y, Li Z, Jiang Y, Wang X, Chen HY, Tao N, et al. Intermittent photocatalytic activity of single CdS nanoparticles. Proc Natl Acad Sci. 2017;114:10566–71.10.1073/pnas.1708617114Search in Google Scholar PubMed PubMed Central

[16] Saritha A, Venkata RR, Sireesha B. Synthesis, characterization, DNA binding, DNA cleavage and antibacterial studies of Ni(II) and Cu(II) complexes of pyridoxal semicarbazone. Der Pharma Chem. 2017;9:90–8.Search in Google Scholar

[17] Avery EB, David AB, Bingqian L, Sara TV. Metal-organic framework functionalization and design strategies for advanced electrochemical energy storage devices. Commun Chem. 2019;2(86):1–14.10.1038/s42004-019-0184-6Search in Google Scholar

[18] Li J, Wu C, Dai Y, Zhang R, Wang X, Fu D, et al. Doxorubicin-CdS nanoparticles: A potential anticancer agent for enhancing the drug uptake of cancer cells. J Nanosci Nanotechnol. 2007;7:435–9.10.1166/jnn.2007.18040Search in Google Scholar

[19] Alsaggaf MS, Elbaz AF, Badawy SE, Moussa SH. Anticancer and antibacterial activity of cadmium sulfide nanoparticles by aspergillus niger. Adv Polym Technol. 2020;2020:13–3.10.1155/2020/4909054Search in Google Scholar

[20] Dai J, Yang X, Hamon M, Kong L. Particle size-controlled synthesis of CdS nanoparticles on a microfluidic chip. Chem Eng J. 2015;280:385–90.10.1016/j.cej.2015.06.005Search in Google Scholar

[21] Wang D, Li X, Zheng LL, Qin LM, Li S, Ye P, et al. Size-controlled synthesis of CdS nanoparticles confined on covalent triazine-based frameworks for durable photocatalytic hydrogen evolution under visible light. Nanoscale. 2018;10:19509–16.10.1039/C8NR06691DSearch in Google Scholar

[22] Minowa Y, Kuramoto S, Kameyama T, Torimoto T, Ashida M. Synthesis of submicron-sized CdS particles using reverse micelles. J Nanophotonics. 2020;14:026013.10.1117/1.JNP.14.026013Search in Google Scholar

[23] Nagamine M, Osial M, Widera-Kalinowska J, Jackowska K, Krysiński P. Photosensitive thin films based on drop cast and langmuir-blodgett hydrophilic and hydrophobic CdS nanoparticles. Nanomaterials. 2020;10:2437.10.3390/nano10122437Search in Google Scholar PubMed PubMed Central

[24] Tudu SC, Zubko M, Kusz J, Bhattacharjee A. CdS nanoparticles (<5 nm): green synthesized using Termitomyces heimii mushroom–structural, optical and morphological studies. Appl Phys A. 2021;127:1–9.10.1007/s00339-020-04245-3Search in Google Scholar

[25] Madkour M, Bumajdad A, Al-Sagheer F. To what extent do polymeric stabilizers affect nanoparticles characteristics? Adv Colloid Interface Sci. 2019;270:38–53.10.1016/j.cis.2019.05.004Search in Google Scholar PubMed

[26] Nazir G, Khan MF, Akhtar I, Akbar K, Gautam P, Noh H, et al. Enhanced photoresponse of ZnO quantum dot-decorated MoS2 thin films. RSC Adv. 2017;7:16890–16900.10.1039/C7RA01222ESearch in Google Scholar

[27] Umekar MS, Bhusari GS, Potbhare AK, Mondal A, Kapgate BP, Desimone MF, Chaudhary RG. Bioinspired reduced graphene oxide based nanohybrids for photocatalysis and antibacterial applications. Curr Pharm Biotechnol. 2021;22:1759–17891.10.2174/1389201022666201231115826Search in Google Scholar PubMed

[28] Liyu C, Qiang X. Metal-organic framework for catalysis. Matter. 2019;1:57–89.10.1016/j.matt.2019.05.018Search in Google Scholar

[29] Abtin AE, Hamidreza S, Mohammadreza O, Ali K. “Ship-in-the-bottle”, a new synthesis strategy for preparing novel hybrid host-guest nano-composites for highly selective membrane gas separation. J Mater Chem A. 2018;6:1751–71.10.1039/C7TA08081FSearch in Google Scholar

[30] Zhang W, Lu G, Cui C, Liu Y, Li S, Yan W, et al. A family of metal‐organic frameworks exhibiting size‐selective catalysis with encapsulated noble‐metal nanoparticles. Adv Mater. 2014;26:4056–60.10.1002/adma.201400620Search in Google Scholar PubMed

[31] Aguilera-Sigalet J, Bradshaw D. Synthesis and applications of the metal-organic framework-quantum dot (QD@MOF) composites. Coord Chem Rev. 2016;307:267–91.10.1016/j.ccr.2015.08.004Search in Google Scholar

[32] Zeng M, Chai Z, Deng X, Li Q, Feng S, Wang J, et al. Core-shell CdS@ZIF-8 structures for improved selectivity in photocatalytic H2 generation from formic acid. Nano Res. 2016;9:2729–34.10.1007/s12274-016-1161-3Search in Google Scholar

[33] Malik A, Nath M, Mohiyuddin S, Packirisamy G. Multifunctional CdSNPs@ZIF-8: potential antibacterial agent against GFP-expressing Escherichia coli and Staphylococcus aureus and efficient photocatalyst for degradation of methylene blue. ACS Omega. 2018;3:8288–308.10.1021/acsomega.8b00664Search in Google Scholar PubMed PubMed Central

[34] Lin J, Xin P, An L, Xu Y, Tao C, Tian Q, et al. Fe3O4-ZIF-8 assemblies as pH and glutathione responsive T2-T1 switching magnetic resonance imaging contrast agent for sensitive tumor imaging in vivo. Chem Commun. 2019;55:478–81.10.1039/C8CC08943DSearch in Google Scholar PubMed

[35] Sava Gallis DF, Butler KS, Agola JO, Pearce CJ, McBride AA. Antibacterial countermeasures via MOF-supported sustained therapeutic release. Appl Mater Interfaces. 2019;11:7782–91.10.1021/acsami.8b21698Search in Google Scholar PubMed

[36] Soomro NA, Wu Q, Amur SA, Liang H, Ur Rahman A, Yuan Q, et al. Natural drug physcion encapsulated zeolitic imidazolate framework, and their application as antimicrobial agent. Colloids Surf B: Biointerfaces. 2019;182:110364.10.1016/j.colsurfb.2019.110364Search in Google Scholar PubMed

[37] Liu Y, Deng L, Sheng J, Tang F, Zeng K, Wang L, et al. Photostable core-shell CdS/ZIF-8 composite for enhanced photocatalytic reduction of CO2. Appl Surf Sci. 2019;498:143899.10.1016/j.apsusc.2019.143899Search in Google Scholar

[38] Li N, Zhou L, Jin X, Owens G, Chen Z. Simultaneous removal of tetracycline and oxytetracycline antibiotics from wastewater using a ZIF-8 metal organic framework. J Hazard Mater. 2019;366:563–72.10.1016/j.jhazmat.2018.12.047Search in Google Scholar PubMed

[39] He M, Yao J, Liu Q, Wang K, Chen F, Wang H. Facile synthesis of zeolitic imidazolate framework-8 from a concentrated aqueous solution. Micropor Mesopor Mat. 2014;184:55–60.10.1016/j.micromeso.2013.10.003Search in Google Scholar

[40] Kumar N, Purohit LP, Goswami YC. Spin coating of highly luminescent Cu doped CdS nanorods and their optical structural characterizations. Chalcogenide Lett. 2015;12:333–8.10.1007/978-81-322-2367-2_44Search in Google Scholar

[41] Weng R, Tian F, Yu Z, Ma J, Lv Y, Xi B. Visible-light-driven CO2 reduction to ethylene on CdS: Enabled by structural relaxation-induced intermediate dimerization and enhanced by ZIF-8 coating. Appl Catal B. 2021;285:119834.10.1016/j.apcatb.2020.119834Search in Google Scholar

[42] Wang F, Zheng T, Xiong R, Wang P, Ma J. CDs@ZIF-8 modified thin-film polyamide nanocomposite membrane for simultaneous enhancement of chlorine-resistance and disinfection byproducts removal in drinking water. ACS Appl Mater Interfaces. 2019;11:33033–42.10.1021/acsami.9b11006Search in Google Scholar PubMed

[43] Kumar P, Bansal V, Paul AK, Bharadwaj LM, Deep A, Kim KH. Biological applications of zinc imidazole framework through protein encapsulation. Appl Nanosci. 2016;6:951–7.10.1007/s13204-015-0511-xSearch in Google Scholar

[44] Qiu J, Zhang XF, Zhang X, Feng Y, Li Y, Yang L, et al. Constructing Cd0.5Zn0. 5S@ZIF-8 nanocomposites through self-assembly strategy to enhance Cr(VI) photocatalytic reduction. J Hazard Mater. 2018;349:234–41.10.1016/j.jhazmat.2018.02.009Search in Google Scholar PubMed

[45] Zheng G, de Marchi S, López-Puente V, Sentosun K, Polavarapu L, Pérez-Juste I, et al. Encapsulation of single plasmonic nanoparticles within ZIF‐8 and SERS analysis of the MOF flexibility. Small. 2016;12:3935–43.10.1002/smll.201600947Search in Google Scholar PubMed

[46] Pillai NG, Archana K, Rhee KY, Park SJ, Asif A. In vitro antiproliferative study of curcumin loaded nano zeolitic imidazolate framework hybrid biomaterials on HeLa cells. J Ind Eng Chem. 2019;79:288–94.10.1016/j.jiec.2019.07.003Search in Google Scholar

[47] Venna SR, Jasinski JB, Carreon MA. Structural evolution of zeolitic imidazolate framework-8. J Am Chem Soc. 2010;132:18030–3.10.1021/ja109268mSearch in Google Scholar PubMed

[48] Zhang C, Zhang J, Ou K, Liu Y, Guo Z, Chen X, et al. ZIF-8-coated CdS popcorn-like photocatalyst with enhanced visible-light-driven photocatalytic activity for degradation of toluene. Colloids Surf A Physicochem Eng Asp. 2021;615:126257.10.1016/j.colsurfa.2021.126257Search in Google Scholar

[49] Pathania D, Saritha S, Rathore BS. Synthesis, characterization and photocatalytic application of bovine serum albumin capped cadmium sulphide nanoparticles. Chalcogenide Lett. 2011;8:396–404.Search in Google Scholar

[50] Schejn A, Mazet T, Falk V, Balan L, Aranda L, Medjahdi G, et al. Fe3O4@ZIF-8: Magnetically recoverable catalysts by loading Fe3O4 nanoparticles inside a zinc imidazolate framework. Dalton Trans. 2015;44(22):10136–40.10.1039/C5DT01191DSearch in Google Scholar

[51] Holder CF, Schaak RE. Tutorial on powder X-ray diffraction for characterizing nanoscale materials. ACS Nano. 2019;13:7359–65.10.1021/acsnano.9b05157Search in Google Scholar PubMed

[52] Ratiram CG, Harjeet JD, Nilesh GV. Evaluation of kinetic parameters from TG/DTG data of chelate polymer compounds of isophthaoyl bis (paramethoxyphenylcarbamide). J Chin Adv Mater Soc. 2013;1:305–16.10.1080/22243682.2013.871210Search in Google Scholar

[53] Haque MA, Chaudhary RG. Synthesis, structural, morphological, and thermal decomposition kinetics of Iron(II) coordination polymer of sebacoyl bis (isonicotinoylhydrazone). Inorganica Chim Acta. 2017;462:298–307.10.1016/j.ica.2017.03.042Search in Google Scholar

[54] Chaudhary RG, Juneja HD, Gharpure MP. Thermal degradation behaviour of some metal chelate polymer compounds with bis(bidentate) ligand by TG/DTG/DTA. J Therm Anal Calorim. 2013;112:637–47.10.1007/s10973-012-2616-8Search in Google Scholar

[55] Chaudhary RG, Ali P, Gandhare NV, Tanna JA, Juneja HD. Thermal decomposition kinetics of some transition metal coordination polymers of fumaroyl bis(paramethoxyphenylcarbamide) using DTG/DTA techniques. Arab J Chem. 2019;12(7):1070–82.10.1016/j.arabjc.2016.03.008Search in Google Scholar

[56] Wan Q, Liu M, Xu D, Huang H, Mao L, Zeng G, et al. One-pot synthesis of nanoscale carbon dots-embedded metal-organic frameworks at room temperature for enhanced chemical sensing. J Mater Chem A. 2016;4:15880–7.10.1039/C6TA06403ESearch in Google Scholar

[57] Hashemi MSH, Eslami F, Karimzadeh R. Organic contaminants removal from industrial wastewater by CTAB treated synthetic zeolite Y. J Env Manage. 2019;233:785–92.10.1016/j.jenvman.2018.10.003Search in Google Scholar PubMed

[58] Rehman A, Park SJ. Comparative study of activation methods to design nitrogen-doped ultra-microporous carbons as efficient contenders for CO2 capture. Chem Eng J. 2018;352:539–48.10.1016/j.cej.2018.07.046Search in Google Scholar

[59] Rehman A, Heo YJ, Nazir G, Park SJ. Solvent-free, one-pot synthesis of nitrogen-tailored alkali-activated microporous carbons with an efficient CO2 adsorption. Carbon. 2021;172:71–82.10.1016/j.carbon.2020.09.088Search in Google Scholar

[60] Nazir G, Rehman A, Park SJ. Sustainable N-doped hierarchical porous carbons as efficient CO2 adsorbents and high-performance supercapacitor electrodes. J CO2 Util. 2020;42:101326.10.1016/j.jcou.2020.101326Search in Google Scholar

[61] Saliba D, Ammar M, Rammal M, Al-Ghoul M, Hmadeh M. Crystal growth of ZIF-8, ZIF-67, and their mixed-metal derivatives. J Am Chem Soc. 2018;140:1812–23.10.1021/jacs.7b11589Search in Google Scholar PubMed

[62] Ran J, Chen H, Bi S, Guo Q, Deng Z, Cai G, et al. One-step in-situ growth of zeolitic imidazole frameworks-8 on cotton fabrics for photocatalysis and antimicrobial activity. Cellulose. 2020;27:10447–59.10.1007/s10570-020-03483-1Search in Google Scholar

[63] Bagade R, Chaudhary RG, Potbhare A, Mondal A, Desimone M, Dadure K, et al. Microspheres/custard-apples copper (II) chelate polymer: characterization, docking, antioxidant and antibacterial assay. Chem Sel. 2019;4:6233–44.10.1002/slct.201901115Search in Google Scholar

[64] Abdel-Wahab BF, Awad GE, Badria FA. Synthesis, antimicrobial, antioxidant, anti-hemolytic and cytotoxic evaluation of new imidazole-based heterocycles. Eur J Med Chem. 2011;46:1505–11.10.1016/j.ejmech.2011.01.062Search in Google Scholar PubMed

[65] Potbhare AK, Chaudhary RG, Chouke PB, Yerpude S, Mondal A, Sonkusare VN, et al. Photosynthesis of nearly monodisperse CuO nanospheres using Phyllanthus reticulatus/Conyza bonariensis and its antioxidant/antibacterial assays. Mater Sci Engineering:C. 2019;99:783–93.10.1016/j.msec.2019.02.010Search in Google Scholar PubMed

[66] Guo YF, Fang WJ, Fu JR, Wu Y, Zheng J, Gao GQ, et al. Facile synthesis of Ag@ ZIF-8 core-shell heterostructure nanowires for improved antibacterial activities. Appl Surf Sci. 2018;435:149–55.10.1016/j.apsusc.2017.11.096Search in Google Scholar

[67] Miao W, Wang J, Liu J, Zhang Y. Self‐cleaning and antibacterial zeolitic imidazolate framework coatings. Adv Mater Interfaces. 2018;5:1800167.10.1002/admi.201800167Search in Google Scholar

[68] Wu H, Sun T, Li K, Liu B, Kou F, Jia F, et al. Synthesis, crystal structure, and DNA-binding studies of nickel(II) complex with the bis (2-benzimidazolymethyl) amine ligand. Bioinorganic Chem Appl. 2012;1–7:2012.10.1155/2012/609796Search in Google Scholar PubMed PubMed Central

[69] Chouke PB, Potbhare AK, Meshram NP, Rai MM, Dadure KM, Chaudhary K, et al. Bioinspired NiO nanospheres: Exploring in vitro toxicity using Bm-17 and L. rohita liver cells, DNA degradation, docking, and proposed vacuolization mechanism. ACS Omega. 2022;7:6869–84.10.1021/acsomega.1c06544Search in Google Scholar PubMed PubMed Central

© 2022 Archana Kumary et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods

- Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

- Green synthesis of spinel copper ferrite (CuFe2O4) nanoparticles and their toxicity

- The effect of TaC and NbC hybrid and mono-nanoparticles on AA2024 nanocomposites: Microstructure, strengthening, and artificial aging

- Excited-state geometry relaxation of pyrene-modified cellulose nanocrystals under UV-light excitation for detecting Fe3+

- Effect of CNTs and MEA on the creep of face-slab concrete at an early age

- Effect of deformation conditions on compression phase transformation of AZ31

- Application of MXene as a new generation of highly conductive coating materials for electromembrane-surrounded solid-phase microextraction

- A comparative study of the elasto-plastic properties for ceramic nanocomposites filled by graphene or graphene oxide nanoplates

- Encapsulation strategies for improving the biological behavior of CdS@ZIF-8 nanocomposites

- Biosynthesis of ZnO NPs from pumpkin seeds’ extract and elucidation of its anticancer potential against breast cancer

- Preliminary trials of the gold nanoparticles conjugated chrysin: An assessment of anti-oxidant, anti-microbial, and in vitro cytotoxic activities of a nanoformulated flavonoid

- Effect of micron-scale pores increased by nano-SiO2 sol modification on the strength of cement mortar

- Fractional simulations for thermal flow of hybrid nanofluid with aluminum oxide and titanium oxide nanoparticles with water and blood base fluids

- The effect of graphene nano-powder on the viscosity of water: An experimental study and artificial neural network modeling

- Development of a novel heat- and shear-resistant nano-silica gelling agent

- Characterization, biocompatibility and in vivo of nominal MnO2-containing wollastonite glass-ceramic

- Entropy production simulation of second-grade magnetic nanomaterials flowing across an expanding surface with viscidness dissipative flux

- Enhancement in structural, morphological, and optical properties of copper oxide for optoelectronic device applications

- Aptamer-functionalized chitosan-coated gold nanoparticle complex as a suitable targeted drug carrier for improved breast cancer treatment

- Performance and overall evaluation of nano-alumina-modified asphalt mixture

- Analysis of pure nanofluid (GO/engine oil) and hybrid nanofluid (GO–Fe3O4/engine oil): Novel thermal and magnetic features

- Synthesis of Ag@AgCl modified anatase/rutile/brookite mixed phase TiO2 and their photocatalytic property

- Mechanisms and influential variables on the abrasion resistance hydraulic concrete

- Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites

- Achieving excellent oxidation resistance and mechanical properties of TiB2–B4C/carbon aerogel composites by quick-gelation and mechanical mixing

- Microwave-assisted sol–gel template-free synthesis and characterization of silica nanoparticles obtained from South African coal fly ash

- Pulsed laser-assisted synthesis of nano nickel(ii) oxide-anchored graphitic carbon nitride: Characterizations and their potential antibacterial/anti-biofilm applications

- Effects of nano-ZrSi2 on thermal stability of phenolic resin and thermal reusability of quartz–phenolic composites

- Benzaldehyde derivatives on tin electroplating as corrosion resistance for fabricating copper circuit

- Mechanical and heat transfer properties of 4D-printed shape memory graphene oxide/epoxy acrylate composites

- Coupling the vanadium-induced amorphous/crystalline NiFe2O4 with phosphide heterojunction toward active oxygen evolution reaction catalysts

- Graphene-oxide-reinforced cement composites mechanical and microstructural characteristics at elevated temperatures

- Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar

- Preparation of layered gradient Cu–Cr–Ti alloy with excellent mechanical properties, thermal stability, and electrical conductivity

- Recovery of Cr from chrome-containing leather wastes to develop aluminum-based composite material along with Al2O3 ceramic particles: An ingenious approach

- Mechanisms of the improved stiffness of flexible polymers under impact loading

- Anticancer potential of gold nanoparticles (AuNPs) using a battery of in vitro tests

- Review Articles

- Proposed approaches for coronaviruses elimination from wastewater: Membrane techniques and nanotechnology solutions

- Application of Pickering emulsion in oil drilling and production

- The contribution of microfluidics to the fight against tuberculosis

- Graphene-based biosensors for disease theranostics: Development, applications, and recent advancements

- Synthesis and encapsulation of iron oxide nanorods for application in magnetic hyperthermia and photothermal therapy

- Contemporary nano-architectured drugs and leads for ανβ3 integrin-based chemotherapy: Rationale and retrospect

- State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials

- Insights on magnetic spinel ferrites for targeted drug delivery and hyperthermia applications

- A review on heterogeneous oxidation of acetaminophen based on micro and nanoparticles catalyzed by different activators

- Early diagnosis of lung cancer using magnetic nanoparticles-integrated systems

- Advances in ZnO: Manipulation of defects for enhancing their technological potentials

- Efficacious nanomedicine track toward combating COVID-19

- A review of the design, processes, and properties of Mg-based composites

- Green synthesis of nanoparticles for varied applications: Green renewable resources and energy-efficient synthetic routes

- Two-dimensional nanomaterial-based polymer composites: Fundamentals and applications

- Recent progress and challenges in plasmonic nanomaterials

- Apoptotic cell-derived micro/nanosized extracellular vesicles in tissue regeneration

- Electronic noses based on metal oxide nanowires: A review

- Framework materials for supercapacitors

- An overview on the reproductive toxicity of graphene derivatives: Highlighting the importance

- Antibacterial nanomaterials: Upcoming hope to overcome antibiotic resistance crisis

- Research progress of carbon materials in the field of three-dimensional printing polymer nanocomposites

- A review of atomic layer deposition modelling and simulation methodologies: Density functional theory and molecular dynamics

- Recent advances in the preparation of PVDF-based piezoelectric materials

- Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review

- Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2

- Perspectives in biopolymer/graphene-based composite application: Advances, challenges, and recommendations

- Graphene-based nanocomposite using new modeling molecular dynamic simulations for proposed neutralizing mechanism and real-time sensing of COVID-19

- Nanotechnology application on bamboo materials: A review

- Recent developments and future perspectives of biorenewable nanocomposites for advanced applications

- Nanostructured lipid carrier system: A compendium of their formulation development approaches, optimization strategies by quality by design, and recent applications in drug delivery

- 3D printing customized design of human bone tissue implant and its application

- Design, preparation, and functionalization of nanobiomaterials for enhanced efficacy in current and future biomedical applications

- A brief review of nanoparticles-doped PEDOT:PSS nanocomposite for OLED and OPV

- Nanotechnology interventions as a putative tool for the treatment of dental afflictions

- Recent advancements in metal–organic frameworks integrating quantum dots (QDs@MOF) and their potential applications

- A focused review of short electrospun nanofiber preparation techniques for composite reinforcement

- Microstructural characteristics and nano-modification of interfacial transition zone in concrete: A review

- Latest developments in the upconversion nanotechnology for the rapid detection of food safety: A review

- Strategic applications of nano-fertilizers for sustainable agriculture: Benefits and bottlenecks

- Molecular dynamics application of cocrystal energetic materials: A review

- Synthesis and application of nanometer hydroxyapatite in biomedicine

- Cutting-edge development in waste-recycled nanomaterials for energy storage and conversion applications

- Biological applications of ternary quantum dots: A review

- Nanotherapeutics for hydrogen sulfide-involved treatment: An emerging approach for cancer therapy

- Application of antibacterial nanoparticles in orthodontic materials

- Effect of natural-based biological hydrogels combined with growth factors on skin wound healing

- Nanozymes – A route to overcome microbial resistance: A viewpoint

- Recent developments and applications of smart nanoparticles in biomedicine

- Contemporary review on carbon nanotube (CNT) composites and their impact on multifarious applications

- Interfacial interactions and reinforcing mechanisms of cellulose and chitin nanomaterials and starch derivatives for cement and concrete strength and durability enhancement: A review

- Diamond-like carbon films for tribological modification of rubber

- Layered double hydroxides (LDHs) modified cement-based materials: A systematic review

- Recent research progress and advanced applications of silica/polymer nanocomposites

- Modeling of supramolecular biopolymers: Leading the in silico revolution of tissue engineering and nanomedicine

- Recent advances in perovskites-based optoelectronics

- Biogenic synthesis of palladium nanoparticles: New production methods and applications

- A comprehensive review of nanofluids with fractional derivatives: Modeling and application

- Electrospinning of marine polysaccharides: Processing and chemical aspects, challenges, and future prospects

- Electrohydrodynamic printing for demanding devices: A review of processing and applications

- Rapid Communications

- Structural material with designed thermal twist for a simple actuation

- Recent advances in photothermal materials for solar-driven crude oil adsorption

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods