Abstract

The creep of face-slab concrete in a rockfill dam is critical for determining the restrained stress and cracking resistance of the concrete at an early age. In this article, the mix proportion of the face-slab concrete for a rockfill dam under construction without any cracking resistance additive was taken as the reference concrete (called JC) mix proportion. The carbon nanotubes (CNTs) and magnesium oxide expansion agent (MEA) were incorporated into JC to prepare face-slab concretes called NC and PC, respectively. The temperature–stress tests under temperature matching curing (TMC) and constant temperature curing (CTC) modes were conducted on these three kinds of concretes to investigate the effects of CNTs and MEA on the early-age creep properties of the face-slab concrete under variable stress conditions. The results showed that the creep performance of NC concrete under CTC mode was lower than that under TMC mode. Combined with mercury intrusion porosimetry test results, the mechanism of the effect of CNTs and MEA on creep was analyzed. The results showed that the temperature change may lead to the CNTs debonding from the cementitious matrix or matrix cracking for the NC concrete. The incorporation of CNTs can increase the early-age creep and improve the cracking resistance of concrete.

1 Introduction

The internal stresses caused by the constrained concrete deformation at early age exceeding the concrete tensile strength is a leading cause of concrete cracking at early ages [1]. When constrained, the concrete develops stresses at an early age depending on the temperature variations, autogenous shrinkage, and viscoelastic-creep property, leading to stress relaxation [2]. The tensile creep of concrete is a key factor in accurately evaluating internal stress.

For the constrained early-age concrete, creep can relax more than 60% tensile stress caused by the volume changes [3,4]. Therefore, it is imperative to consider creep when assessing the concrete cracking resistance. At present, the expansive properties of cement with high MgO content or concrete mixed with magnesium oxide expansion agent (MEA) have been widely studied. Hawreen [5] showed by scanning electron microscopy that carbon nanotubes (CNTs) can play a bridging role in concrete and affect micro-cracks extension within the interfacial transition zone. In addition, CNTs had a significant inhibiting effect on the early-age concrete shrinkage and thus affected concrete creep. Nochaiya [6] demonstrated using mercury intrusion porosimetry (MIP) that CNTs incorporation could effectively reduce the porosity of cementitious materials, making the microstructure denser and more compact. The possible reasons are the bridging effects, fiber pull-out, micro-filling, and accelerated hydration by the CNTs. It can also improve the microstructure of cementitious materials [7]. Chen et al. [8] confirmed that the lower the reactivity of MEA, the stronger the effect of its particle size on the expansion. Ma [9] suggested that for the same dosage incorporation of MEA, the concrete under higher curing temperature exhibited faster expansion and reached greater ultimate expansion during a shorter period. In addition to the study of MEA to improve the concrete cracking resistance [10], Zhang and Deng [11] further conducted an in-depth study on the expansion mechanism of the cement paste incorporating MEA. It was found that the expansion was caused by the generation and growth of Mg(OH)2 crystals. Most creep tests and models presented earlier mainly focused on compressive creep of mature concrete, while there are a few studies on tensile creep of concrete at early ages [12,13]. In recent years, researchers have begun to pay attention to early-age creep with the application of high-performance concrete. However, they still focused on compressive creep and even took the long age compressive creep as early-age tensile creep, so the assessment accuracy of early-age tensile creep decreased and can only be used for the qualitative analysis [14].

The viscoelastic behavior of concrete may be different under tension and compression. So, the tensile creep study is necessary for analyzing the internal stress of concrete. Although some progress has been made by using the CNTs and MEA to improve the mechanical properties and durability of cementitious materials, the effects and mechanisms of the two anti-cracking admixtures on the creep of concrete at an early age are still unclear [15,16]. It is direly needed to investigate the effect of the CNTs and MEA on the early-age creep of the face-slab concrete by multi-scale tests, to elucidate the mechanism of improved cracking resistance. Till now, the research on creep mechanism mainly includes viscoelastic theory, seepage theory, viscous flow theory, plastic flow theory, and micro-crack theory [17,18]. The solidification theory for concrete creep [19,20] combines elastic, viscoelastic, and rheological theories.

It is very difficult to measure early-age tensile creep. Most of the current research uses the following two testing methods. One is to apply a constant load on a concrete specimen using a device [21]. In this method, first, a constant load determined by the early-age tensile strength of concrete is applied to the concrete specimen. However, because of the low tensile strength of early-age concrete, this testing method is more suitable for measuring the tensile creep after 3-day age. The other testing method employs a uniaxial constraint testing device, which can measure creep deformation and restrained stress under different conditions by controlling the restrained degree and temperature variation [22]. The temperature–stress testing machine (TSTM) can be employed to conduct three simulations to study and analyze the cracking resistance of the face-slab concrete at an early age by linking the concrete material to its performance in structures, namely, the simulation for fresh concrete behaviors at an early age starts with mixing, the simulation for the concrete structure being restrained, and the curing temperature simulation for the concrete inside the actual structure. It is a scientific method for testing the physical and mechanical properties and cracking resistance of concrete at an early age from a holistic perspective. In this study, the early-age creeps of the three face-slab concretes – JC for the reference face-slab concrete, NC for the JC incorporation of CNTs, and PC for the JC incorporation of MEA – were experimentally investigated using TSTM and MIP tests.

2 Experimental work

In this study, 0.1 wt% CNT or 5.0 wt% MgO-type expansive agent (MEA) was added to a reference face-slab concrete to prepare three face-slab concrete mixes, and these were termed JC, NC, and PC, respectively. The TST were conducted for both restrained and free three kinds of concrete specimens under temperature matching curing (TMC) mode and constant temperature curing (CTC) mode. In order to investigate the mechanism of CNTs and MEA affecting the early-age creep of face-slab concrete, a MIP experiment was performed to study the effects of the two anti-cracking agents on the pore structure of the face-slab concrete.

2.1 Materials

In this study, Ordinary Portland cement P.O 42.5 and Class F fly ash were used. The chemical composition of the cement is shown in Table 1. The coarse and fine aggregates were all artificial crushed gravel. Crushed sand with a fineness modulus of 2.97 was selected. The apparent density and absorption were determined as 2630 kg/m3 and 1.7%, respectively. The mixture design used two coarse aggregate gradations. The small gravel with a 5–20 mm particle size accounted for 45% of the total coarse aggregate by mass. The medium gravel with a 20–40 mm particle size accounted for another 55%. The apparent density of both the small gravel and medium gravel was found as 2,620 kg/m3, whereas the corresponding water absorption was 0.61 and 0.88%, respectively. Polycarboxylate superplasticizer and air-entraining agent were also used. The properties of the CNTs are given in Table 2. The properties of the MEA and mortar with MEA are shown in Table 3. The other material properties can be found in the reference [23].

The chemical compositions of cement

| Oxide | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | LOI |

|---|---|---|---|---|---|---|---|

| Content/% | 23.21 | 5.23 | 3.70 | 58.62 | 2.05 | 2.78 | 2.44 |

Physical properties of multi-walled CNTs

| Inner diameter (nm) | Outer diameter (nm) | Length (μm) | Purity (%) | Specific surface area (m2/g) | True density (g/cm3) | Electric conductivity (S/cm) |

|---|---|---|---|---|---|---|

| 5–15 | >50 | <10 | >95 | >40 | ∼2.1 | >100 |

Properties of MEA and mortar with MEA

| Items | MgO Content (%) | LOI (%) | Reaction time (s) | Setting time (min) | Fineness | Restrained expansion rate | ||

|---|---|---|---|---|---|---|---|---|

| Initial | Final | 1.18-mm-square Hole Sieve Residual (%) | 80-μm-square hole sieve residual (%) | 7 days in 20°C Water | ||||

| MEA | 86.54 | 1.20 | 112 | 160 | 200 | 0 | 1.6 | 0.015 |

Chen and Chen [24] showed that the expansion of concrete increased with the increased dosage of MgO. The concentration of the used MEA was 5% of the binder by mass according to the Chinese industry-standard GB23439-2009 [25]. The optimized concentration of the CNTs is 0.1% [5,26,27]. The same raw materials were employed in all three face-slab concrete mixes. The mix proportions of the three face-slab concrete are shown in Table 4.

Mix proportions of the three kinds of concretes (kg/m3)

| Concrete mix | Unit content (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| W/B | Water | Cement | Fly ash | Sand | Gravel | Water-reducer (W.R.) | Air-entraining agent (A.E.) | ||

| (5–20) mm | (20–40) mm | ||||||||

| JC | 0.48 | 120 | 188 | 63 | 768 | 541 | 661 | 1.506 | 0.0100 |

| PC | 0.48 | 120 | 188 | 63 | 768 | 537 | 657 | 1.750 | 0.0125 |

| NC | 0.48 | 120 | 188 | 63 | 768 | 541 | 661 | 1.875 | 0.0088 |

2.2 TST

2.2.1 Curing regime for TSTM test

2.2.1.1 TMC mode test

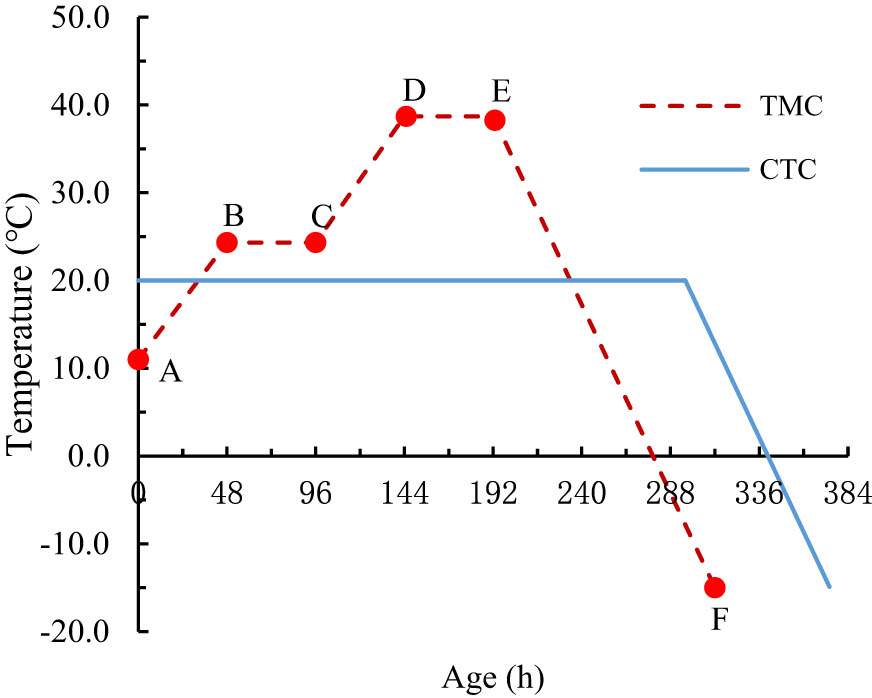

Based on the ambient temperature and the heat release capacity of the binder of an actual concrete face-slab rockfill dam (CFRD) during its construction period, the TMC history curve was designed to guide the curing of the TSTM specimen, as shown in Figure 1. The casting temperature of the three concretes was set as 11°C to be consistent with the actual pouring conditions of the CFRD project. The face-slab structure is often cured by water on the concrete surface within 90 days with fast heat dissipation. Thus, the semi-adiabatic temperature rise was suggested as the first temperature plateau of the TMC curve [23]. Combined with the pouring temperature, the first temperature plateau values of JC, PC, and NC were 24.0, 24.5, and 24.1°C, respectively. Based on the local maximum ambient temperature over the years at the construction site, a temperature of 38.7°C was adopted as the second temperature plateau value. The lowest setting temperature of the TSTM is –15.0°C. Each experiment took 48 h to raise and maintain the temperature to the designed temperature peak value, and the cooling duration was set to 120 h. The TSTM test lasted for about 312 h.

Schematic diagram of the designed TMC and CTC for guiding TSTM tests of the three face-slab concretes.

2.2.1.2 CTC mode test

As shown in Figure 1, the constant temperature stage and the cooling stage are the two parts of the CTC mode. At the constant temperature stage, the circulating medium temperature of the template in the TSTM was controlled at 20°C, while the center of the TSTM specimen was kept at the same temperature. The temperature difference between them was kept within ±0.15°C. The cooling start time under CTC mode was determined according to the cooling start time under TMC mode, which kept the face-slab concrete having the same maturity based on the equivalent curing age. Figure 1 shows the temperature history curve input in the computer to guide TST under CTC mode. It took 12.3, 12.4, and 12.3 days, respectively, to keep the JC, PC, and NC at the 20°C CTC stage. The cooling rate under CTC mode was kept the same as that under the TMC mode at the cooling stage. The TSTM specimen was cooled at a rate of 0.45°C/h until the TSTM minimum temperature limit of –15.0°C was reached. It took 3.3 days at the cooling stage.

2.2.2 TSTM test procedure

The HYPY-TSTM-I was employed. The testing principle and method have already been provided in detail [22,28] and are not repeated here to avoid duplication of redundant information. As shown in Figure 2, the TSTM used two dog-bone-shape specimens for a single test, one for the restrained specimen and the other for the free specimen. The sizes of the TSTM specimen are as follows: a center section of 150 mm × 150 mm and an effective length of 1,500 mm. The two specimens were cured under the same temperature history since casting in the TSTM. The two specimens for each test were wrapped with a plastic sheet and sealed in the molds to avoid drying shrinkage. The ambient temperature of the lab was controlled by (20 ± 2)°C. The TSTM was equipped with two molds, a load cell, a temperature-controlled system, temperature sensors, and displacement sensors. This device is the same as the previous work [23]. The concrete temperature, applied load, specimen deformations, and displacement of moving cross-head were automatically recorded by a computer. The testing began immediately after casting, and the test data were recorded every 1 min.

![Figure 2

Schematic diagram of the TSTM system [22].](/document/doi/10.1515/ntrev-2022-0145/asset/graphic/j_ntrev-2022-0145_fig_002.jpg)

Schematic diagram of the TSTM system [22].

2.3 Pore structure by MIP

A mercury porosimeter-AutoPore IV 9510 was used for the MIP test. Mortar specimens from the corresponding face-slab concrete were used for the tests. The 28 days cured mortar specimen was broken, and the obtained 3–5 mm fragments were stored in ethanol to inhibit the hydration reaction. The three specimens for each face-slab concrete mix were removed after 24 h and dried in a 60°C oven for another 24 h. Subsequently, the pore structure and pore size distribution were characterized by the MIP test.

3 TSTM test results and analysis

3.1 TMC mode test

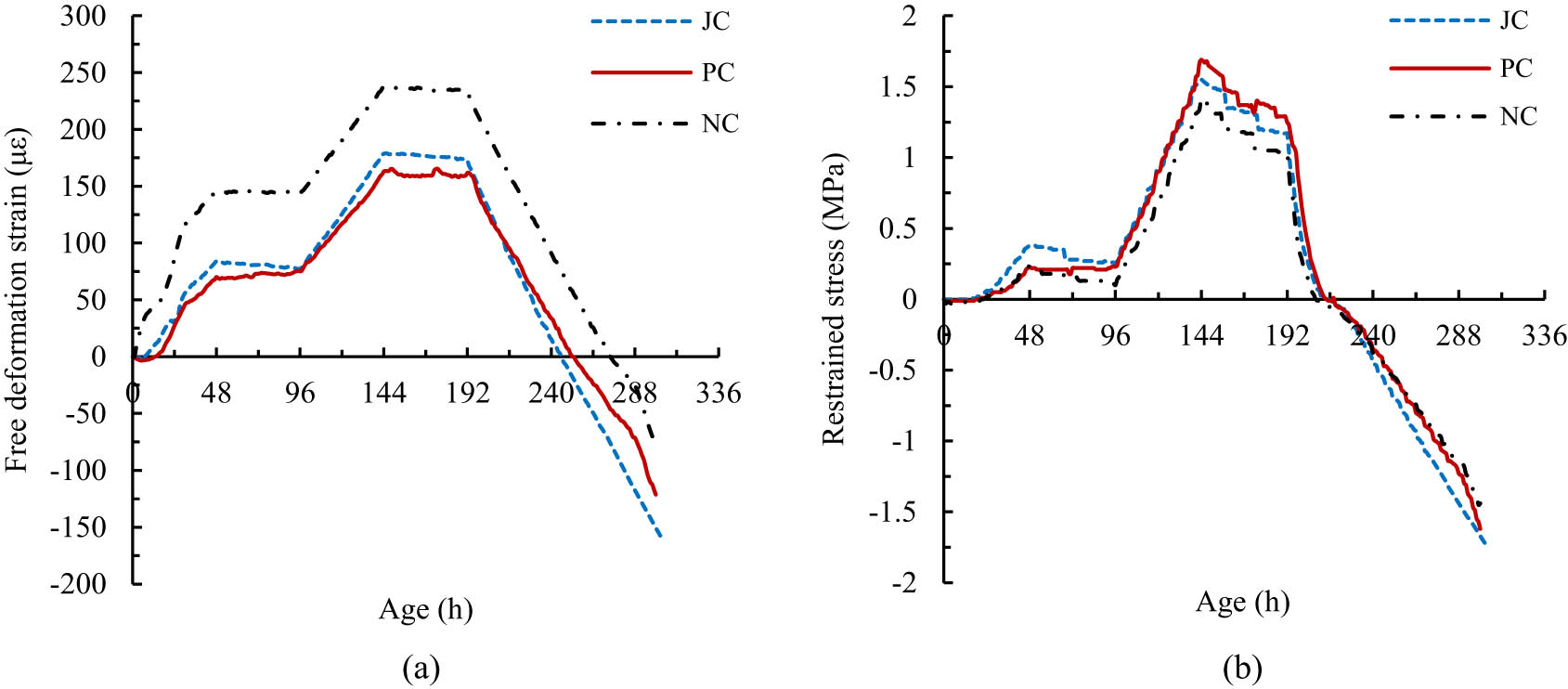

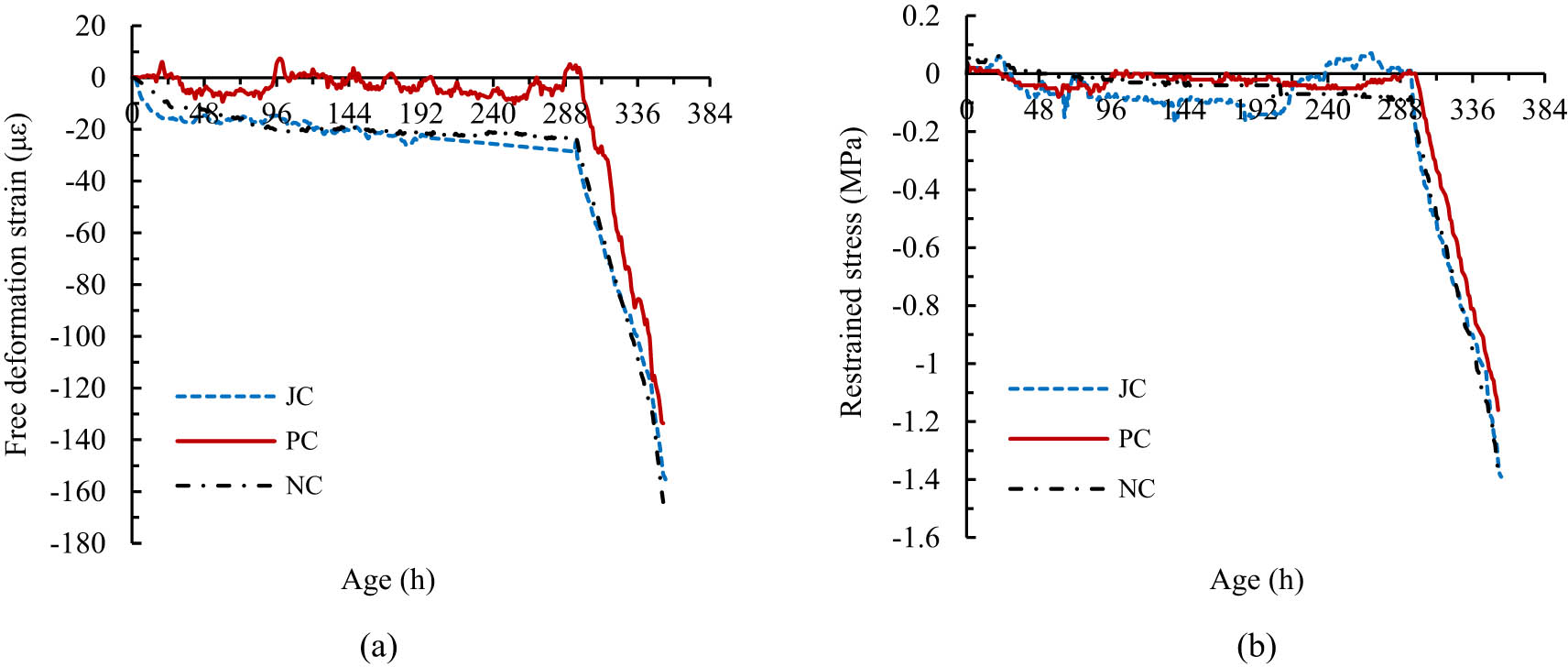

The measured temperature development curves for the three face-slab concretes under TMC mode are shown in Figure 3, and the free deformation strain and restrained stress development curves are shown in Figure 4.

Measured temperature curves of the three concretes under TMC mode.

Measured free strain and restrained stress curves of the three concretes under TMC mode: (a) free deformation strain and (b) restrained stress.

Figure 4(a) shows that the free strain of JC, PC, and NC increased with the increase in temperature, and the expansion deformation reached 84.2, 75.1, and 145.7 με, respectively, at the first temperature peak and 179.0, 165.7, and 239.0 με at the second temperature peak. At the cooling stage, the contraction rate of JC is slightly faster than that of NC, and PC is the slowest. The maximum shrinkage deformation of JC, PC, and NC is –164.0, –124.3, and –74.5 με, respectively. The thermal expansion deformation of NC was the largest, which may be because the micro-filling effect of CNTs decreased the concrete porosity, making the microstructure denser, refined, and more compact. The expansion due to volume elimination by the pore water and solid materials entering the pores was less, making the early thermal expansion coefficient of concrete higher [29].

The development of restrained stress of three concretes under TMC mode is shown in Figure 4(b). The positive value is for compressive stress, whereas the negative value represents tensile stress. It is shown that all three concretes exhibited compression during the heating and temperature peak stage. The compressive stress increased with the increase in temperature. At the second temperature peak stage, the maximum compressive stresses of 1.55, 1.69, and 1.42 MPa were reached. During the period of temperature peak maintenance, the compressive stress of JC, PC, and NC decreased with age due to the concrete creep. At the cooling stage, the specimen shrank rapidly, and the tensile stress of the concretes developed rapidly after 214 h. The tensile stress of JC reached –1.80 MPa at 303 h, PC reached –1.64 MPa at 301 h, and NC reached –1.44 MPa at 300 h. The cracking stresses of JC, PC, and NC were –2.00, –2.29, and –1.98 MPa, respectively. It can be seen from Figure 3(b) that at the heating stage, the compressive stress development of NC was lower than that of JC and PC, while at the cooling stage, the tensile stress development of NC was also lower than those of JC and PC. The possible reason may be as follows:

The bridging and filling effects of the CNTs improved the stress distribution in concrete and reduced the restrained stress.

The stress relaxation of NC was large, and the compressive creep and tensile creep can relax part of the constrained stress.

3.2 CTC mode test

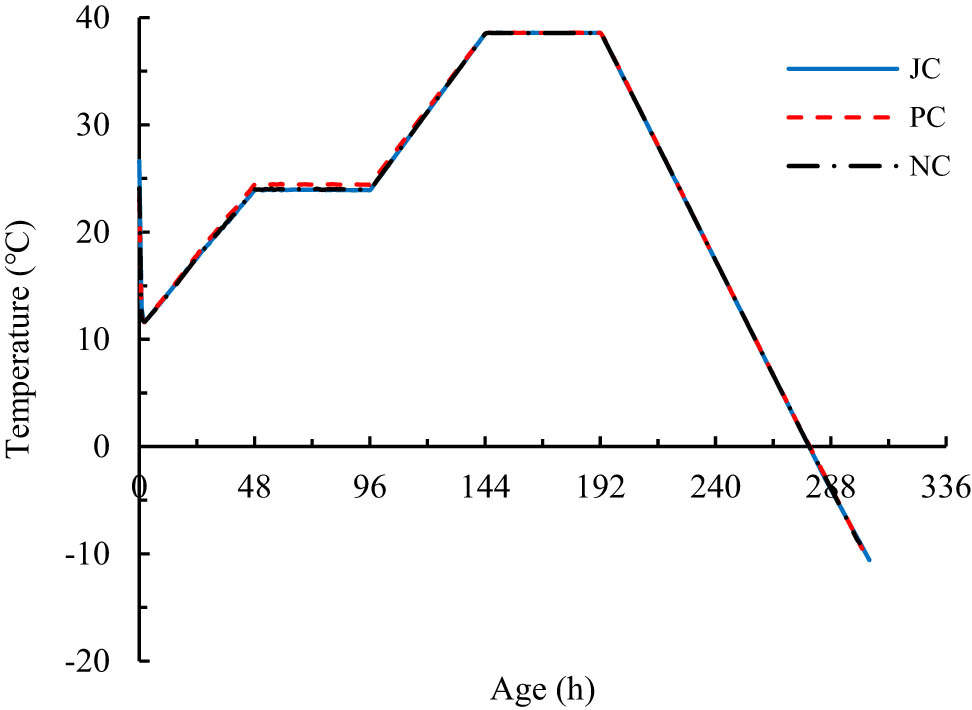

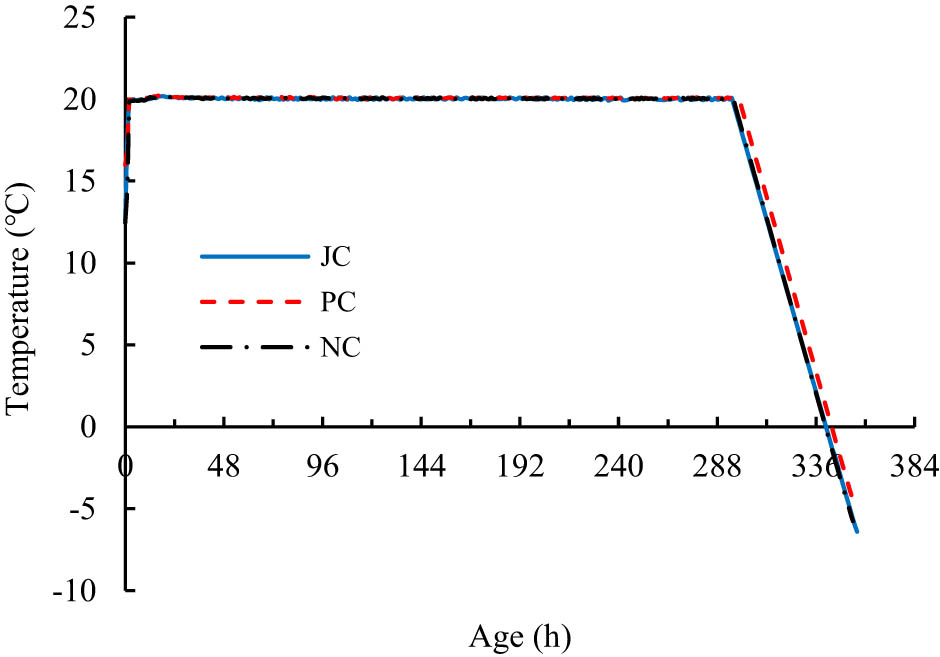

The measured temperature development curves for the three face-slab concretes under CTC mode are shown in Figure 5, and the free deformation strain and restrained stress development curves are shown in Figure 6.

Measured temperature curves of the three concretes under CTC mode.

(a) Free deformation strain and (b) restrained stress curves of the three concretes under CTC mode.

The free strain curves of the three concretes under CTC mode are shown in Figure 6(a). At the stage of the constant curing temperature of 20°C, JC and NC exhibited a slowly increasing shrinkage deformation due to the autogenous shrinkage of concrete. However, the expansion and shrinkage of the PC concrete were superimposed due to MEA addition, while the free strain of PC oscillated around zero at the constant temperature stage. It shows that the MEA could effectively compensate for the concrete shrinkage and delay the occurrence of tensile stress. Before cooling, the free strain of JC and NC specimens reached –29.8 and –24.8 με, respectively. At the constant temperature maintenance stage, the free strain of NC was reduced by 16.8% compared to JC. It may be due to the CNTs bridging micro-cracks and filling pores, which effectively reduced the autogenous shrinkage of concrete [26]. At the cooling stage, the JC, PC, and NC shrunk rapidly, and the maximum shrinkage deformation values were –158.0, –138.0, and –170.3 με, respectively.

The development curves of restrained stress of the three concretes under CTC mode are shown in Figure 6(b). The initial restrained stresses in JC, PC, and NC were compressive. At the constant temperature stage, the central temperature of the NC specimen fluctuated around 20°C, and the tensile stress increased due to the continuous shrinkage of NC. At the constant temperature stage, the restrained stresses of the JC and NC were very small, within 0.08 MPa to –0.16 MPa. The constrained stress of PC fluctuated around 0 MPa. The three concretes reached the maximum tensile stresses at the cooling stage, including –1.41 MPa at 356.0 h for JC, –1.21 MPa at 354.5 h for PC, and –1.42 MPa at 354.5 h for NC. The cracking stresses in JC, PC, and NC were –1.71, –1.99, and –1.97 MPa, respectively. According to the temperature–stress relationship curves of the three concretes at the cooling stage, the cracking temperatures of JC, PC, and NC were –14.8, –22.3, and –19.4°C, respectively.

Combined with Figures 4 and 6, it can be seen that there were obvious differences between the developments of early-age restrained stress of the three concretes. Under the TMC mode, each concrete group was compressed at the heating and temperature peak maintenance stages (before 192 h). At the cooling stage, the concrete shrank, and the tensile stress began to develop after 214 h. Under the CTC mode, the stresses of the three concretes were almost tensile at the constant temperature stage, and the tensile stress developed rapidly at the cooling stage. The results demonstrated that the cracking stresses of the three concretes under TMC mode were higher than those under CTC mode. The curing temperature significantly affected the development of early-age restrained stress in the concretes.

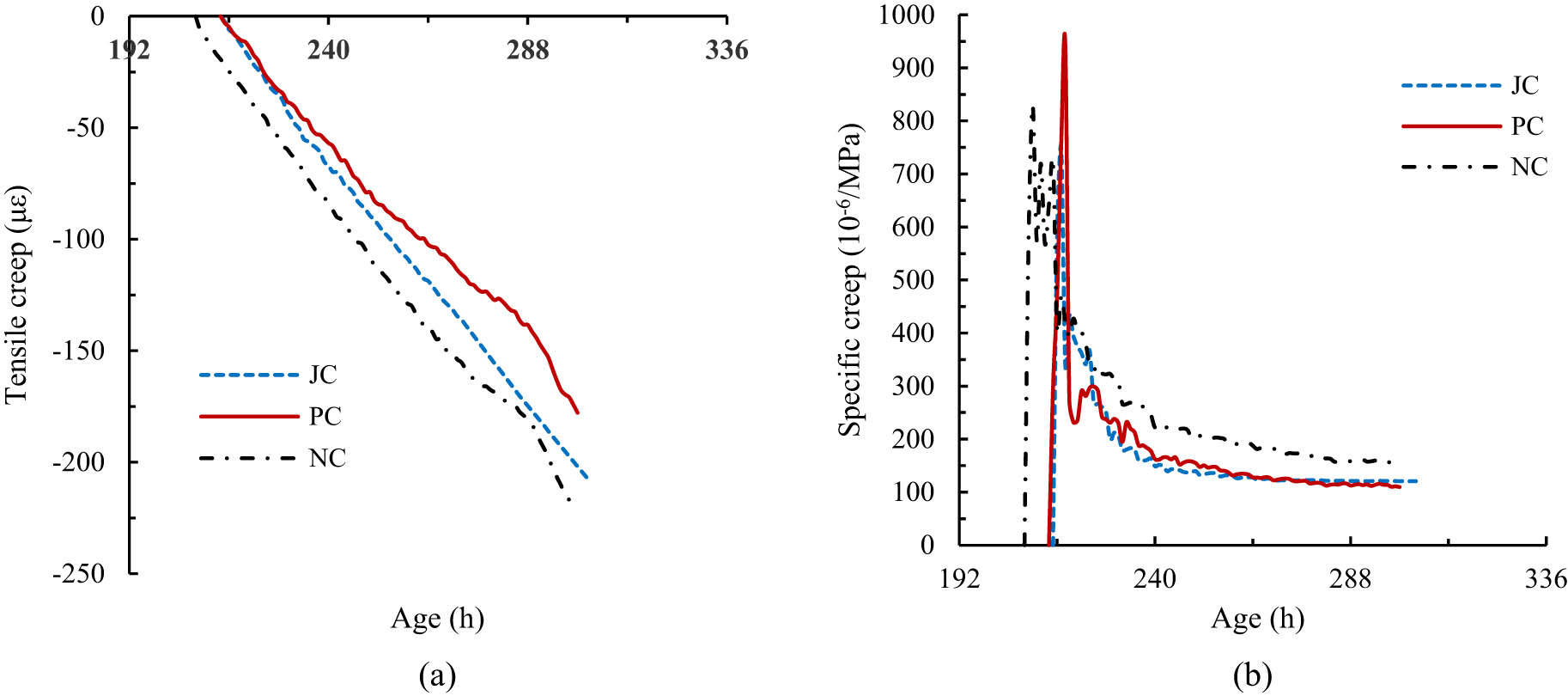

3.3 Creep and specific creep of the concrete under TMC mode

In this article, the creep is calculated by subtracting the cumulative curve from the free shrinkage using the strain assessment method proposed by Kovler [30]. The tensile creeps of JC, PC, and NC under TMC mode were determined, as shown in Figure 7(a). In order to better evaluate the creep of concrete under variable stress, the specific creep was introduced, namely, the corresponding creep under unit load. The creeps are shown in Figure 7(b).

(a) Tensile creep and (b) specific creep, for three concretes under TMC mode.

From Figure 7(a), it can be found that the tensile creeps of JC, PC, and NC developed at the ages of 215, 215, and 209 h, respectively. When the curing temperature of TSTM dropped to –15°C, the tensile creeps of the three concretes were 208.6, 177.8, and 217.0 με, respectively. The tensile creep trend was found as NC > JC > PC. From Figure 7(b), when the specific creeps of the three concretes tended to stabilize, the specific creep of NC was greater than those of JC and PC. The specific creep of JC was close to that of PC. It may be because the tensile stress of PC was smaller than those of the other two concretes due to MEA addition.

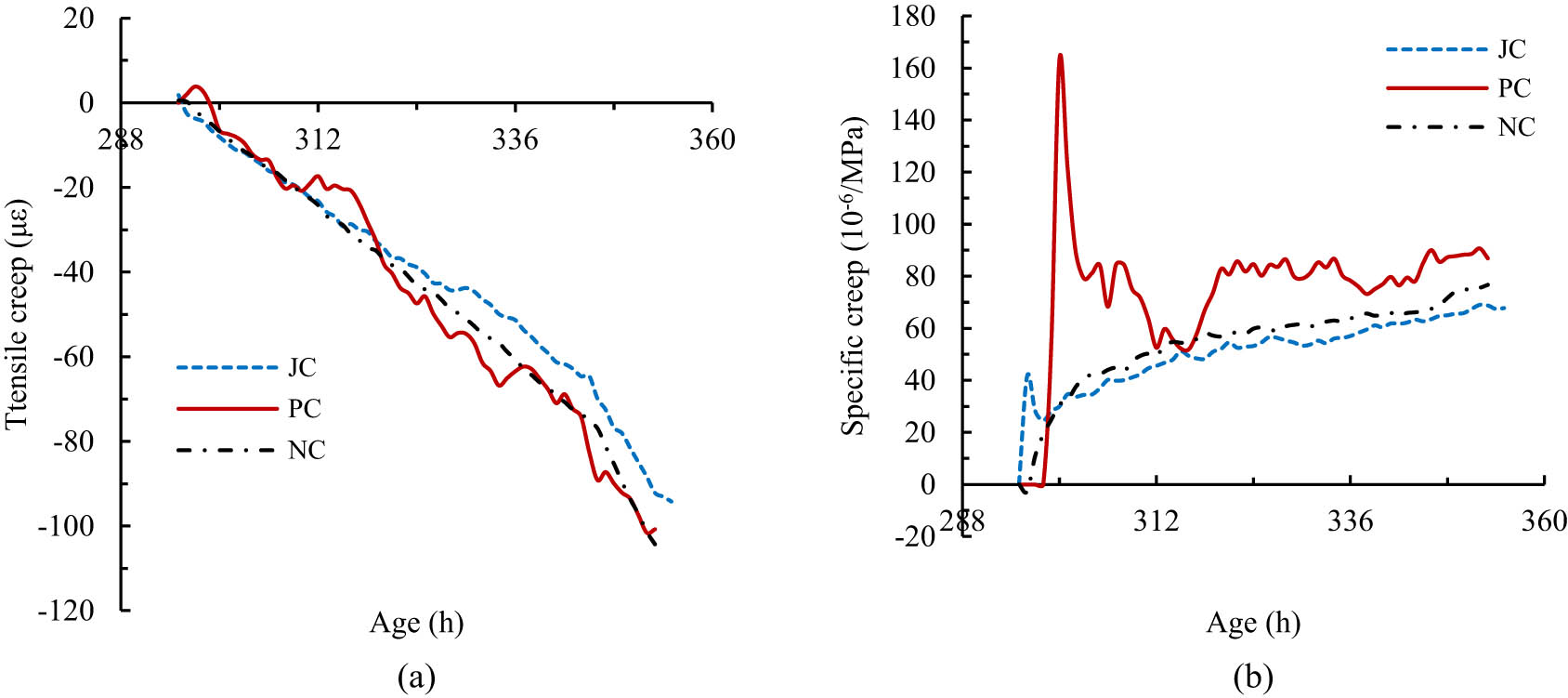

3.4 Creep and specific creep of the concrete under CTC mode

The tensile creeps and specific creeps of JC, PC, and NC under CTC mode are shown in Figure 8. From Figure 8(a), it can be found that the tensile creeps and development rates of the three concretes under CTC mode were lower than those under TMC mode. This is attributed to the larger thermal expansion deformations and shrinkage deformations of the specimens under TMC mode. It promoted the development of restrained stress. Compared to the properties under TMC mode, the creeps of the three concretes were closer to each other under the CTC mode. From Figure 7(b), when the specific creeps of the three concretes tended to be stable, the order of the specific creep was PC > NC > JC.

(a) Tensile creep and (b) specific creep of three concretes under CTC mode.

The temperature played a dual role in affecting concrete creep [31]. The higher curing temperature accelerated the hydration rate of concrete, promoted the maturity of concrete, and led to the rapid increase of elastic modulus and strength of concrete at an early age [32]. The negative correlation between concrete strength and creep made the creep decrease (negative effect). On the other hand, the increased temperature can decrease the viscosity of water and C–S–H gel, and accelerate the bond breakages and restorations of the C–S–H gel layer [33], thus increasing the creep rate (positive effect). The positive effect usually dominates it, that is, the concrete creep increases with increasing temperature [31]. Comparing Figure 7 with Figure 8, it can be found that the curing temperature has a significant effect on the creep of the concrete.

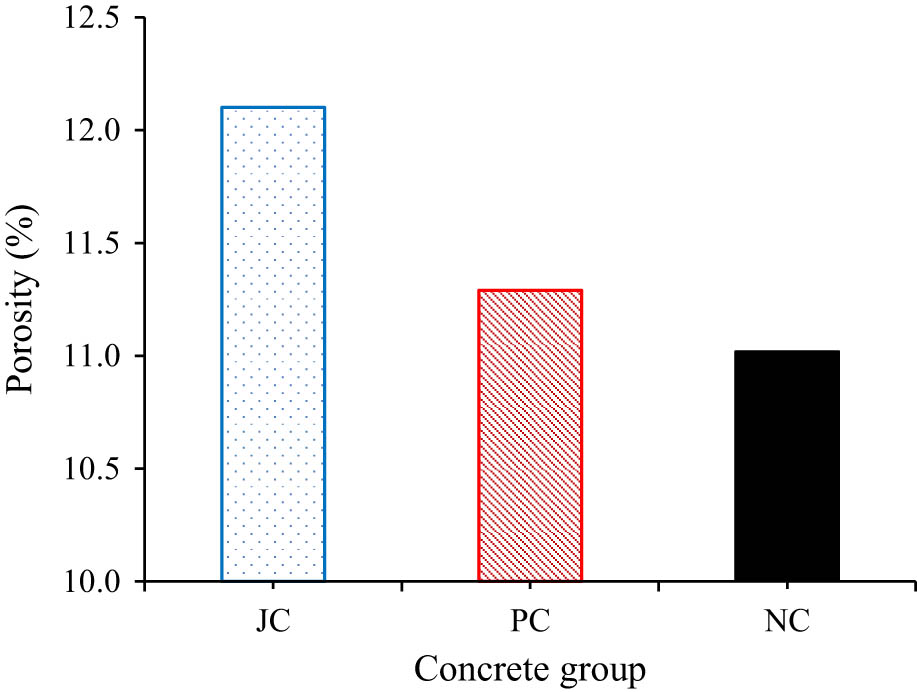

4 MIP test results and analysis

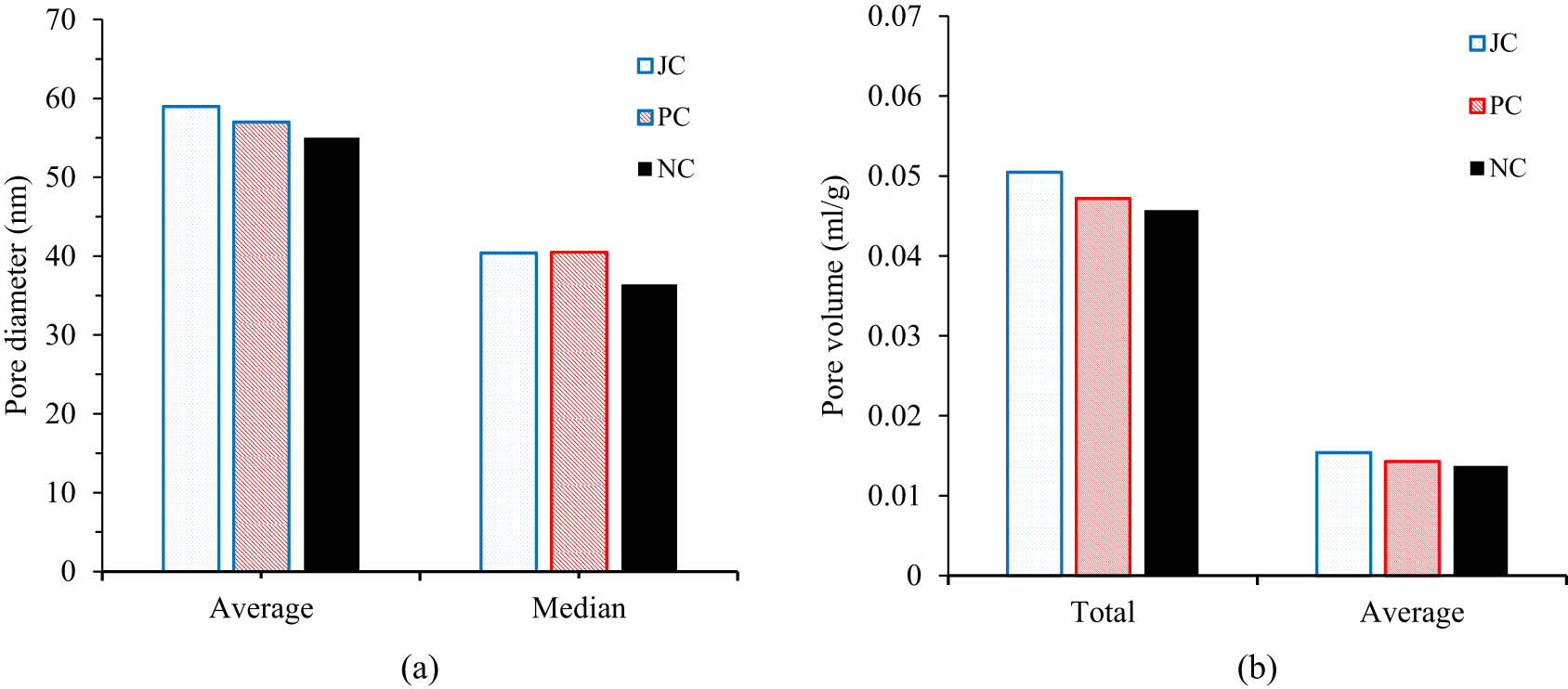

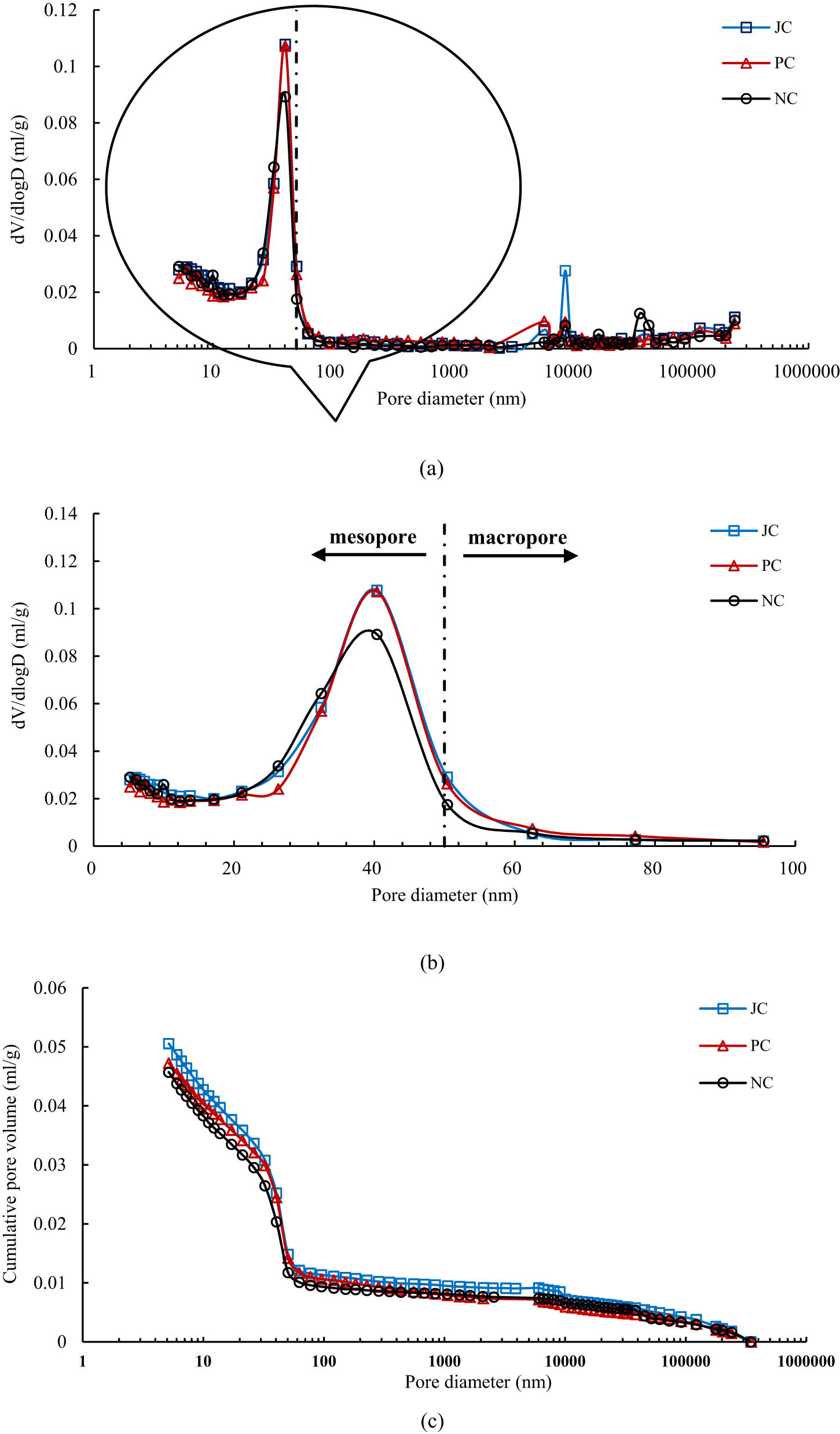

The MIP tests of the three face-slab concretes were conducted at 28 days of age. The porosity, pore-volume, and pore size distribution curves of the corresponding mortars were obtained, as shown in Figure 9 through Figures 10 and 11. From Figure 9, the total porosity of PC decreased by 6.6%, and that of PC decreased by 9.1% compared to JC, respectively. As shown in Figure 10, the pore volume, average pore diameter, and median pore diameter of JC, PC, and NC decreased. As shown in Figure 11, the pore size distribution curves of JC, PC, and NC had the same trend, and the most probable pore sizes were all 40 nm. As shown in Figure 11(b) and (c), the pores were divided into two categories: the pore size is larger than 50 nm (macropores) and smaller than 50 nm (mesopores). The dV/d(log D) of JC had the peak value and that of NC had the lowest value, which was about 0.11 and 0.09 mL/g, respectively.

Porosity of the three concretes at 28 days.

Comparison of (a) pore diameter and (b) pore volume of the three concretes.

Pore size distribution and cumulative pore volume of JC, PC, and NC at 28 days: (a) pore size distribution, (b) enlarged pore size distribution, and (c) cumulative pore volume.

Compared to JC, the porosity, average pore size, pore volume, and dV/d(log D) of PC decreased owing to the denser microstructure. This was because the MgO hydration led to the volume expansion of Mg(OH)2. Compared to JC, the porosity, average pore size, and dV/d(log D) of NC decreased. It may be because the smaller diameter (50 nm) and larger specific surface area of the CNTs can effectively fill the pores between the hydration products and provide larger nucleation sites, namely, the micro-filler and nucleation effects provided by CNTs [34,35,36]. It improved the microstructure of the face-slab concrete and reduced the porosity.

5 Analysis of creep mechanism

5.1 The effect of MEA on the creep

The TSTM test results showed that both MEA and CNTs could improve the early-age creep performance of the face-slab concretes. The MEA used in this study was the light burning type. The light-burning MEA can produce volume expansion and effective expansion energy by the hydration reaction [37]. The expansion of cement paste mixed with MEA was originally due to the formation and growth of Mg(OH)2 crystals [38]. The magnesium hydroxide crystals (brucite) were formed by the hydration of magnesium oxide, and the volume can be increased by 94.0–123.8%. The expansion mainly depended on the location and size of Mg(OH)2 crystals. The direct driving force of the expansion comes from the swelling force and crystallization pressure of Mg(OH)2 crystals. However, as the hydration rate of the MgO was unsteady, so it led to the unstable released expansion energy. The microscopic result of the MEA expansion was to fill and squeeze the original pores of the concrete. So, the porosity, pore diameter, and pore volume for PC were significantly lower than those for JC. At the macro-level, the original cracks of early-age concrete may be filled and squeezed by the MEA hydration products, enhancing the concrete tensile creep and improving the cracking resistance.

5.2 Effect of CNTs on the creep

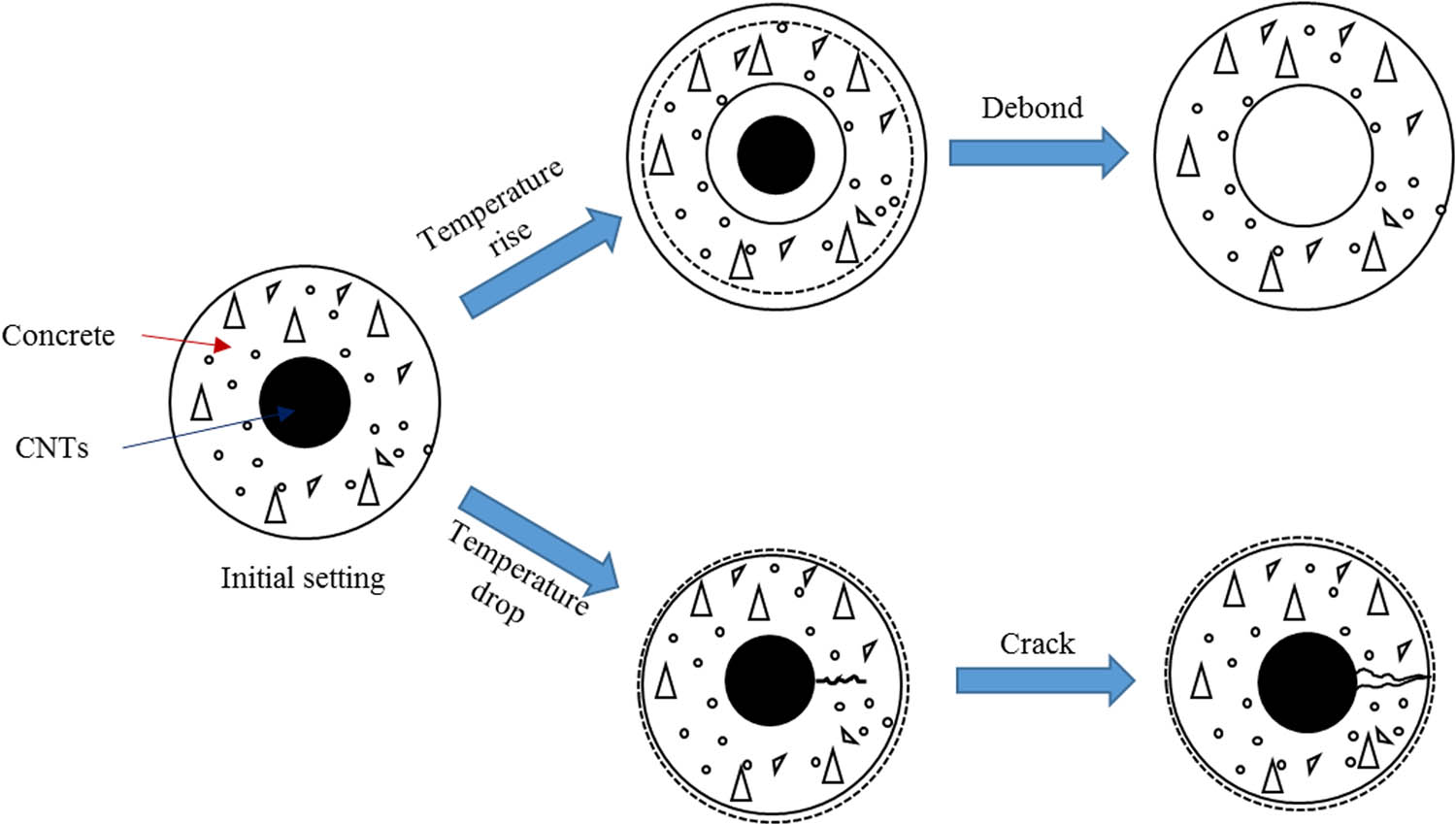

The TSTM test results showed that the creep of NC under TMC mode was significantly larger than that under CTC mode. Under both curing modes, the creep of NC was larger than that of JC. According to the Chinese testing code [39], the tested thermal expansion coefficient of JC at 180 days was 8.04 × 10−6/°C. It is known that the thermal expansion coefficient of CNTs was about –12.00 × 10−6/°C [40]. Figure 12 is the schematic diagram of the effect of temperature change on the NC. Under TMC mode, CNTs contract with the increasing temperature and expand with the decreasing temperature, whereas the cementitious matrix exhibits the opposite behavior. As shown in Figure 12, the CNTs are tightly wrapped by the matrix since the initial setting moment, and the holes with the same radius as CNTs are formed. When the temperature does not change, the CNTs are embedded and adhere to the holes. As the temperature increases, the holes grow larger with concrete expansion, and CNTs shrink and radially debond with the matrix. When the temperature decreases, the holes tend to shrink. At this time, CNTs expand and squeeze with the matrix, resulting in the concrete cracking by the circumferential tension. When concrete is mixed with a proper amount of CNTs, the porosity and pore structure of the concrete can be improved. Also, it is possible to increase the tensile strength and ultimate tensile strain of concrete with CNT incorporation. On the other hand, the difference in thermal expansion coefficient between the CNTs and concrete will lead to the CNTs debonding or the matrix cracking in concrete when the temperature changes. The multiple factors affected the creep performance of the concrete.

Effect of temperature change on the NC (the dashed line shows the initial position of the matrix before deformation).

Besides the material factors affecting concrete creep, for example, cement quality, water/cement ratio, aggregate properties, gradation, and admixtures, there are other factors, such as curing conditions, load level, and specimen size. The theories mentioned earlier failed to explain the concrete creep mechanism due to these multiple factors. By comparing and studying the creep and pore structure of the three concretes under TMC mode, the creep mechanism of the face-slab concrete was explained. Because the hardened cement paste has an extremely high inner surface area, the state of the adsorbed water on the pore surface and the condensed water in the pores will significantly impact the volume stability, mechanical properties, and durability of concrete.

6 Conclusions

Combined with the TSTM test and microscopic test, the effects of the CNTs and MEA on the creep characteristics of the face-slab concrete were investigated in this study. The following conclusions have been drawn from the obtained results.

Under TMC mode, the restrained stress of NC was higher than that of JC and PC. The tensile creep of NC concrete was also higher than that of JC and PC. It indicated that NC concrete had a stronger creep and stress relaxation ability at an early age, and its cracking resistance was better than JC concrete. It was attributed to the difference in thermal and mechanical properties between the CNTs and concrete. When the temperature rises, the concrete expands and the CNTs contract, resulting in radial debonding between the CNTs and concrete. When the temperature decreases, the concrete tends to shrink, and the expansion of CNTs squeezes the concrete, resulting in the concrete cracking by the circumferential tension. The addition of CNTs increased the creep of concrete.

Under CTC mode, the cracking temperature of NC concrete decreased by 4°C and the cracking stress increased by 15.2% compared to JC. The restrained stress development in JC and NC was similar. The tensile creep of NC concrete was 10.7% higher than that of JC. The results showed that NC concrete still had stronger creep, stress relaxation, and early-age cracking resistance under CTC mode. The creep performance of NC concrete under CTC mode was lower than that under TMC mode.

The results showed that the MEA had a slight advantage as an anti-cracking agent, but its stability was not as good as the CNTs. Although the activity and fineness of the MEA can be controlled within the standard range, the consistency of surface morphology and particle size distribution of the MgO particles was not as good as the nanoscale CNTs, and its reaction time and expansion effect were not controllable. Compared to the MEA, CNTs can play the micro-filling and bridging roles due to their excellent physical and mechanical properties, which are beneficial to the cracking resistance of the face-slab concrete.

-

Funding information: This work was financially supported by the National Natural Science Foundation of China (Grant Nos. 51879235, 51479178, No. 52078460, and No. 52009123).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Bažant ZP, Jirásek M. Basic properties of concrete creep, shrinkage, and drying. Berlin: Springer; 2018.10.1007/978-94-024-1138-6_3Search in Google Scholar

[2] Zhao Z, Zhong Y, Li X, Sun Y. Tensile creep of dam concrete at early age under variable temperature history. J Hydroelectric Eng. 2020;39(8):46–54.Search in Google Scholar

[3] Liang S, Wei Y. Effects of water-to-cement ratio and curing age on microscopic creep and creep recovery of hardened cement pastes by microindentation. Cem Concr Compos. 2020;113:103619.10.1016/j.cemconcomp.2020.103619Search in Google Scholar

[4] Ye S, Luo S, Zheng J. Influence of mineral admixture on tensile creep of recycled concrete at early ages. J Fuzhou University(Natural Sci Ed). 2018;46(5):700–4.Search in Google Scholar

[5] Hawreen A, Bogas JA. Creep, shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr Build Mater. 2019;198:70–81.10.1016/j.conbuildmat.2018.11.253Search in Google Scholar

[6] Nochaiya T, Chaipanich A. Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl Surf Sci. 2011;257(6):1941–5.10.1016/j.apsusc.2010.09.030Search in Google Scholar

[7] Wang B, Liu S. Exploration into micromechanism of carbon nanotubes improved cement-based materials. Low Temp Architect Technol. 2013;35(12):1–3.Search in Google Scholar

[8] Chen X, Gao P, Geng F, Zhao J, Huang X. Research on deformation of cement paste with MgO-expansive. Bull Chin Ceram Soc. 2012;31(3):617–21.Search in Google Scholar

[9] Ma Y. Study of concrete temperature and stress based on hydration degree. Nan Jing, China: Hohai University; 2006.Search in Google Scholar

[10] Mo L, Deng M, Wang A. Effects of MgO-based expansive additive on compensating the shrinkage of cement paste under non-wet curing conditions. Cem Concr Compos. 2012;34:34–383.10.1016/j.cemconcomp.2011.11.018Search in Google Scholar

[11] Zhang Q, Deng M. Review on the expansion mechanism of cement paste mixed with Mgotype expansion agent. Coll Mater Sci Eng Nanjing Uni Tech. 2009;111–5.Search in Google Scholar

[12] Huang Y, Xiao L, Gao J, Liu Y. Tensile creep and unloading creep recovery testing of dam concrete with fly ash. J Mater Civ Eng. 2019;31(5):05019001.10.1061/(ASCE)MT.1943-5533.0002682Search in Google Scholar

[13] Wei Y, Wu Z, Huang J, Liang S. Comparison of compressive, tensile, and flexural creep of early-age concretes under sealed and drying conditions. J Mater Civ Eng. 2018;30(11):04018289.10.1061/(ASCE)MT.1943-5533.0002495Search in Google Scholar

[14] Yang Y, Xu S, Ye D, Wang Z. Tensile creep behavior of high strength concrete at early ages. J Chin Ceram Soc. 2009;37(7):1124–9.Search in Google Scholar

[15] Chen W, Gong Z, Yang J. Application of magnesium oxide expansive agent in crack control of mass concrete. Architect Technol. 2019;50(1):98–101.Search in Google Scholar

[16] Cao F, Yan P. Effects of reactivity and dosage of magnesium oxide expansive agents on long-term volume variation of concrete. J Chin Ceram Soc. 2018;45(8):1126–32.Search in Google Scholar

[17] Guo W, Wei Y. Microprestress Solidification theory-based experimental and modeling of early-age concrete tensile creep at elevated temperatures. Eng Mech. 2017;34(3):197–203.Search in Google Scholar

[18] Jin Y. Application of rheological model in concrete creep research. Value Eng. 2021;40(17):170–2.Search in Google Scholar

[19] Bazant ZP, Prasannan S. Solidification theory for concrete creep. I: Formulation. J Eng Mech. 1989;115(8):1691–703.10.1061/(ASCE)0733-9399(1989)115:8(1691)Search in Google Scholar

[20] Bažant ZP, Hauggaard AB, Baweja S, Ulm FJ. Microprestress-solidification theory for concrete creep. I: Aging and drying effects. J Eng Mech. 1997;123(11):1188–94.10.1061/(ASCE)0733-9399(1997)123:11(1188)Search in Google Scholar

[21] Pane I, Hansen W. Early age creep and stress relaxation concrete containing blended cements. Mater & Struct. 2002;35(2):92–6.10.1007/BF02482107Search in Google Scholar

[22] Zhao Z, Wang K, Lange DA, Zhou H, Wang W, Zhu D. Creep and thermal cracking of ultra-high volume fly ash mass concrete at early age. Cem Concr Compos. 2019;99:191–202.10.1016/j.cemconcomp.2019.02.018Search in Google Scholar

[23] Zhao Z, Zhou H, Wang K, Wu Xu, Shah SP. Effects of CNT and MgO-type expansive agent on the cracking resistance of face slab concrete of CFRD. J Mater Civ Eng, ASCE. 2022. Accepted for publication. 10.1061/(ASCE)MT.1943-5533.0004497.Search in Google Scholar

[24] Chen R, Chen C. Study on the limit content of MEA in hydraulic concrete. Water Resources Planning and Design. 2018;94–96(3):158.Search in Google Scholar

[25] GB23439-2009. Expansive agents for concrete, Standards Press of China; 2009.Search in Google Scholar

[26] Carriço A, Bogas JA, Hawreen A, Guedes M. Durability of multi-walled carbon nanotube reinforced concrete. Constr Build Mater. 2018;164:121–33.10.1016/j.conbuildmat.2017.12.221Search in Google Scholar

[27] Shi T, Li Z, Li S. Autogenous shrinkage and crack resistance of carbon nanotubes reinforced cement based composites. Acta Mater Compositae Sin. 2019;36(6):28–35.Search in Google Scholar

[28] Nguyen DH, Nguyen VT, Lura P, Dao VTN. Temperature-stress testing machine–A state-of-the-art design and its unique applications in concrete research. Cem Concr Compos. 2019;102:28–38.10.1016/j.cemconcomp.2019.04.019Search in Google Scholar

[29] Gao G, Qian C, Zhu C, Wang H. Effect of fly ash on thermal expansion coefficient of concrete. J Southeast Univ (Nat Sci Ed). 2006;36:185–90.Search in Google Scholar

[30] Kolver K. Testing system for determining the mechanical behaviour of early age concrete under restrained and free uniaxial shrinkage. Mater Struct. 1994;27:324–30.10.1007/BF02473424Search in Google Scholar

[31] Bažant ZP, Cusatis G, Cedolin L. Temperature effect on concrete creep modeled by microprestress-solidification theory. J Eng Mech. 2004;130(6):691–9.10.1061/(ASCE)0733-9399(2004)130:6(691)Search in Google Scholar

[32] Kim JK, Han SH, Song YC. Effect of temperature and aging on the mechanical properties of concrete: Part I. Experimental results. Cem Concr Res. 2002;32(7):1087–94.10.1016/S0008-8846(02)00744-5Search in Google Scholar

[33] Ye H. Creep Mechanisms of Calcium–Silicate–Hydrate: An overview of recent advances and Challenges. Int J Concr Struct Mater. 2015;9(4):453–62.10.1007/s40069-015-0114-7Search in Google Scholar

[34] Zhao Z, Qi T, Zhou W, Hui D, Xiao C, Qi J, et al. A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials. Nanotechnol Rev. 2020;9(1):303–22.10.1515/ntrev-2020-0023Search in Google Scholar

[35] Feng C, Zhang Y, Qian Y, Liu J, Zhang J, Shi F, et al. Research progress on CNTs/CNFs-modified cement-based composites–a review. Constr Build Mater. 2019;202:290–307.10.1016/j.conbuildmat.2019.01.024Search in Google Scholar

[36] Hawreen A, Bogas JA, Dias APS. On the mechanical and shrinkage behavior of cement mortars reinforced with carbon nanotubes. Constr Build Mater. 2018;168:459–70.10.1016/j.conbuildmat.2018.02.146Search in Google Scholar

[37] Nobre J, Ahmed H, Bravo M, Evangelista L, de Brito J. Magnesia (MEA) production and characterization, and its influence on the performance of cementitious materials: A Review. Materials. 2020;13:4752.10.3390/ma13214752Search in Google Scholar PubMed PubMed Central

[38] Bai H, Deng M, Tang M. Expansion of concrete with light-burned magnesia cured at 80℃ in water and autoclaver at 216℃. Sci & Technol Rev. 2008;10:61–4.Search in Google Scholar

[39] DL/T 5150-2017. Test code for hydraulic concrete. Beijing: China Electric Power Press; 2017.Search in Google Scholar

[40] Kwon YK, Berber S, Tomanek D. Thermal contraction of carbon fullerenes and nanotubes. Phys Rev Lett. 2004;92(1):015901.10.1103/PhysRevLett.92.015901Search in Google Scholar PubMed

© 2022 Zhifang Zhao et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods

- Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

- Green synthesis of spinel copper ferrite (CuFe2O4) nanoparticles and their toxicity

- The effect of TaC and NbC hybrid and mono-nanoparticles on AA2024 nanocomposites: Microstructure, strengthening, and artificial aging

- Excited-state geometry relaxation of pyrene-modified cellulose nanocrystals under UV-light excitation for detecting Fe3+

- Effect of CNTs and MEA on the creep of face-slab concrete at an early age

- Effect of deformation conditions on compression phase transformation of AZ31

- Application of MXene as a new generation of highly conductive coating materials for electromembrane-surrounded solid-phase microextraction

- A comparative study of the elasto-plastic properties for ceramic nanocomposites filled by graphene or graphene oxide nanoplates

- Encapsulation strategies for improving the biological behavior of CdS@ZIF-8 nanocomposites

- Biosynthesis of ZnO NPs from pumpkin seeds’ extract and elucidation of its anticancer potential against breast cancer

- Preliminary trials of the gold nanoparticles conjugated chrysin: An assessment of anti-oxidant, anti-microbial, and in vitro cytotoxic activities of a nanoformulated flavonoid

- Effect of micron-scale pores increased by nano-SiO2 sol modification on the strength of cement mortar

- Fractional simulations for thermal flow of hybrid nanofluid with aluminum oxide and titanium oxide nanoparticles with water and blood base fluids

- The effect of graphene nano-powder on the viscosity of water: An experimental study and artificial neural network modeling

- Development of a novel heat- and shear-resistant nano-silica gelling agent

- Characterization, biocompatibility and in vivo of nominal MnO2-containing wollastonite glass-ceramic

- Entropy production simulation of second-grade magnetic nanomaterials flowing across an expanding surface with viscidness dissipative flux

- Enhancement in structural, morphological, and optical properties of copper oxide for optoelectronic device applications

- Aptamer-functionalized chitosan-coated gold nanoparticle complex as a suitable targeted drug carrier for improved breast cancer treatment

- Performance and overall evaluation of nano-alumina-modified asphalt mixture

- Analysis of pure nanofluid (GO/engine oil) and hybrid nanofluid (GO–Fe3O4/engine oil): Novel thermal and magnetic features

- Synthesis of Ag@AgCl modified anatase/rutile/brookite mixed phase TiO2 and their photocatalytic property

- Mechanisms and influential variables on the abrasion resistance hydraulic concrete

- Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites

- Achieving excellent oxidation resistance and mechanical properties of TiB2–B4C/carbon aerogel composites by quick-gelation and mechanical mixing

- Microwave-assisted sol–gel template-free synthesis and characterization of silica nanoparticles obtained from South African coal fly ash

- Pulsed laser-assisted synthesis of nano nickel(ii) oxide-anchored graphitic carbon nitride: Characterizations and their potential antibacterial/anti-biofilm applications

- Effects of nano-ZrSi2 on thermal stability of phenolic resin and thermal reusability of quartz–phenolic composites

- Benzaldehyde derivatives on tin electroplating as corrosion resistance for fabricating copper circuit

- Mechanical and heat transfer properties of 4D-printed shape memory graphene oxide/epoxy acrylate composites

- Coupling the vanadium-induced amorphous/crystalline NiFe2O4 with phosphide heterojunction toward active oxygen evolution reaction catalysts

- Graphene-oxide-reinforced cement composites mechanical and microstructural characteristics at elevated temperatures

- Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar

- Preparation of layered gradient Cu–Cr–Ti alloy with excellent mechanical properties, thermal stability, and electrical conductivity

- Recovery of Cr from chrome-containing leather wastes to develop aluminum-based composite material along with Al2O3 ceramic particles: An ingenious approach

- Mechanisms of the improved stiffness of flexible polymers under impact loading

- Anticancer potential of gold nanoparticles (AuNPs) using a battery of in vitro tests

- Review Articles

- Proposed approaches for coronaviruses elimination from wastewater: Membrane techniques and nanotechnology solutions

- Application of Pickering emulsion in oil drilling and production

- The contribution of microfluidics to the fight against tuberculosis

- Graphene-based biosensors for disease theranostics: Development, applications, and recent advancements

- Synthesis and encapsulation of iron oxide nanorods for application in magnetic hyperthermia and photothermal therapy

- Contemporary nano-architectured drugs and leads for ανβ3 integrin-based chemotherapy: Rationale and retrospect

- State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials

- Insights on magnetic spinel ferrites for targeted drug delivery and hyperthermia applications

- A review on heterogeneous oxidation of acetaminophen based on micro and nanoparticles catalyzed by different activators

- Early diagnosis of lung cancer using magnetic nanoparticles-integrated systems

- Advances in ZnO: Manipulation of defects for enhancing their technological potentials

- Efficacious nanomedicine track toward combating COVID-19

- A review of the design, processes, and properties of Mg-based composites

- Green synthesis of nanoparticles for varied applications: Green renewable resources and energy-efficient synthetic routes

- Two-dimensional nanomaterial-based polymer composites: Fundamentals and applications

- Recent progress and challenges in plasmonic nanomaterials

- Apoptotic cell-derived micro/nanosized extracellular vesicles in tissue regeneration

- Electronic noses based on metal oxide nanowires: A review

- Framework materials for supercapacitors

- An overview on the reproductive toxicity of graphene derivatives: Highlighting the importance

- Antibacterial nanomaterials: Upcoming hope to overcome antibiotic resistance crisis

- Research progress of carbon materials in the field of three-dimensional printing polymer nanocomposites

- A review of atomic layer deposition modelling and simulation methodologies: Density functional theory and molecular dynamics

- Recent advances in the preparation of PVDF-based piezoelectric materials

- Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review

- Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2

- Perspectives in biopolymer/graphene-based composite application: Advances, challenges, and recommendations

- Graphene-based nanocomposite using new modeling molecular dynamic simulations for proposed neutralizing mechanism and real-time sensing of COVID-19

- Nanotechnology application on bamboo materials: A review

- Recent developments and future perspectives of biorenewable nanocomposites for advanced applications

- Nanostructured lipid carrier system: A compendium of their formulation development approaches, optimization strategies by quality by design, and recent applications in drug delivery

- 3D printing customized design of human bone tissue implant and its application

- Design, preparation, and functionalization of nanobiomaterials for enhanced efficacy in current and future biomedical applications

- A brief review of nanoparticles-doped PEDOT:PSS nanocomposite for OLED and OPV

- Nanotechnology interventions as a putative tool for the treatment of dental afflictions

- Recent advancements in metal–organic frameworks integrating quantum dots (QDs@MOF) and their potential applications

- A focused review of short electrospun nanofiber preparation techniques for composite reinforcement

- Microstructural characteristics and nano-modification of interfacial transition zone in concrete: A review

- Latest developments in the upconversion nanotechnology for the rapid detection of food safety: A review

- Strategic applications of nano-fertilizers for sustainable agriculture: Benefits and bottlenecks

- Molecular dynamics application of cocrystal energetic materials: A review

- Synthesis and application of nanometer hydroxyapatite in biomedicine

- Cutting-edge development in waste-recycled nanomaterials for energy storage and conversion applications

- Biological applications of ternary quantum dots: A review

- Nanotherapeutics for hydrogen sulfide-involved treatment: An emerging approach for cancer therapy

- Application of antibacterial nanoparticles in orthodontic materials

- Effect of natural-based biological hydrogels combined with growth factors on skin wound healing

- Nanozymes – A route to overcome microbial resistance: A viewpoint

- Recent developments and applications of smart nanoparticles in biomedicine

- Contemporary review on carbon nanotube (CNT) composites and their impact on multifarious applications

- Interfacial interactions and reinforcing mechanisms of cellulose and chitin nanomaterials and starch derivatives for cement and concrete strength and durability enhancement: A review

- Diamond-like carbon films for tribological modification of rubber

- Layered double hydroxides (LDHs) modified cement-based materials: A systematic review

- Recent research progress and advanced applications of silica/polymer nanocomposites

- Modeling of supramolecular biopolymers: Leading the in silico revolution of tissue engineering and nanomedicine

- Recent advances in perovskites-based optoelectronics

- Biogenic synthesis of palladium nanoparticles: New production methods and applications

- A comprehensive review of nanofluids with fractional derivatives: Modeling and application

- Electrospinning of marine polysaccharides: Processing and chemical aspects, challenges, and future prospects

- Electrohydrodynamic printing for demanding devices: A review of processing and applications

- Rapid Communications

- Structural material with designed thermal twist for a simple actuation

- Recent advances in photothermal materials for solar-driven crude oil adsorption

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods

- Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

- Green synthesis of spinel copper ferrite (CuFe2O4) nanoparticles and their toxicity

- The effect of TaC and NbC hybrid and mono-nanoparticles on AA2024 nanocomposites: Microstructure, strengthening, and artificial aging

- Excited-state geometry relaxation of pyrene-modified cellulose nanocrystals under UV-light excitation for detecting Fe3+

- Effect of CNTs and MEA on the creep of face-slab concrete at an early age

- Effect of deformation conditions on compression phase transformation of AZ31

- Application of MXene as a new generation of highly conductive coating materials for electromembrane-surrounded solid-phase microextraction

- A comparative study of the elasto-plastic properties for ceramic nanocomposites filled by graphene or graphene oxide nanoplates

- Encapsulation strategies for improving the biological behavior of CdS@ZIF-8 nanocomposites

- Biosynthesis of ZnO NPs from pumpkin seeds’ extract and elucidation of its anticancer potential against breast cancer

- Preliminary trials of the gold nanoparticles conjugated chrysin: An assessment of anti-oxidant, anti-microbial, and in vitro cytotoxic activities of a nanoformulated flavonoid

- Effect of micron-scale pores increased by nano-SiO2 sol modification on the strength of cement mortar

- Fractional simulations for thermal flow of hybrid nanofluid with aluminum oxide and titanium oxide nanoparticles with water and blood base fluids

- The effect of graphene nano-powder on the viscosity of water: An experimental study and artificial neural network modeling

- Development of a novel heat- and shear-resistant nano-silica gelling agent

- Characterization, biocompatibility and in vivo of nominal MnO2-containing wollastonite glass-ceramic

- Entropy production simulation of second-grade magnetic nanomaterials flowing across an expanding surface with viscidness dissipative flux

- Enhancement in structural, morphological, and optical properties of copper oxide for optoelectronic device applications

- Aptamer-functionalized chitosan-coated gold nanoparticle complex as a suitable targeted drug carrier for improved breast cancer treatment

- Performance and overall evaluation of nano-alumina-modified asphalt mixture

- Analysis of pure nanofluid (GO/engine oil) and hybrid nanofluid (GO–Fe3O4/engine oil): Novel thermal and magnetic features

- Synthesis of Ag@AgCl modified anatase/rutile/brookite mixed phase TiO2 and their photocatalytic property

- Mechanisms and influential variables on the abrasion resistance hydraulic concrete

- Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites

- Achieving excellent oxidation resistance and mechanical properties of TiB2–B4C/carbon aerogel composites by quick-gelation and mechanical mixing

- Microwave-assisted sol–gel template-free synthesis and characterization of silica nanoparticles obtained from South African coal fly ash

- Pulsed laser-assisted synthesis of nano nickel(ii) oxide-anchored graphitic carbon nitride: Characterizations and their potential antibacterial/anti-biofilm applications

- Effects of nano-ZrSi2 on thermal stability of phenolic resin and thermal reusability of quartz–phenolic composites

- Benzaldehyde derivatives on tin electroplating as corrosion resistance for fabricating copper circuit

- Mechanical and heat transfer properties of 4D-printed shape memory graphene oxide/epoxy acrylate composites

- Coupling the vanadium-induced amorphous/crystalline NiFe2O4 with phosphide heterojunction toward active oxygen evolution reaction catalysts

- Graphene-oxide-reinforced cement composites mechanical and microstructural characteristics at elevated temperatures

- Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar

- Preparation of layered gradient Cu–Cr–Ti alloy with excellent mechanical properties, thermal stability, and electrical conductivity

- Recovery of Cr from chrome-containing leather wastes to develop aluminum-based composite material along with Al2O3 ceramic particles: An ingenious approach

- Mechanisms of the improved stiffness of flexible polymers under impact loading

- Anticancer potential of gold nanoparticles (AuNPs) using a battery of in vitro tests

- Review Articles

- Proposed approaches for coronaviruses elimination from wastewater: Membrane techniques and nanotechnology solutions

- Application of Pickering emulsion in oil drilling and production

- The contribution of microfluidics to the fight against tuberculosis

- Graphene-based biosensors for disease theranostics: Development, applications, and recent advancements

- Synthesis and encapsulation of iron oxide nanorods for application in magnetic hyperthermia and photothermal therapy

- Contemporary nano-architectured drugs and leads for ανβ3 integrin-based chemotherapy: Rationale and retrospect