Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

-

Jiarong Tian

, Yingbo Xia

Abstract

Poly(lactic acid) (PLA) biocomposites are usually plasticized to overcome the problem of poor ductility, which decreases the valuable tensile strength. In this study, novel nanofibrillated cellulose (NFC) was extracted to enhance the acetyl tributyl citrate (ATBC) plasticized PLA biocomposites. Interestingly, NFC not only exhibited an excellent strengthening effect but also showed a further toughening effect in the biocomposites. When 4 wt% NFC was added, the tensile strength, elongation at break, and impact strength of the biocomposites with 15 wt% ATBC and 20 wt% ATBC reached 52.6 MPa, 28.4%, 34.9 J/m and 35.8 MPa, 300.1%, 40 J/m, respectively. This is at least 1.1 folds higher in strength and 2.3 folds higher in impact toughness than the biocomposites without NFC. Glass transition and melting temperature slightly increased with NFC addition. More importantly, the mechanism of the strengthening and toughening effect was definitely elucidated, and the comprehensive performance of the application was evaluated. The findings of the study provide significant guidance for PLA application, such as in food packaging, medical engineering materials, and household products.

1 Introduction

Poly(lactic acid) (PLA) is a biodegradable linear aliphatic thermoplastic polymer derived from natural polysaccharides such as cassava, corn starch, and so on [1]. Due to the excellent tensile strength, good transparency, excellent biocompatibility, and easy processability, PLA is expected to be the most promising alternative to traditional petroleum-based plastics [2]. PLA is not only a bio-based plastic, which is made from bioresources through biochemical methods, but also a biodegradable plastic, which can be completely degraded into CO2 and H2O by composting [3,4]. It has broad potential applications such as in medical materials (stents, artificial bones, surgical sutures, etc.) [5], packaging materials (packaging bags, disposable lunch boxes, packaging films, etc.) [6], and engineering materials (car interiors, decoration profiles, electronic product shells, etc.) [7]. With the global “plastic ban” becoming stricter, PLA has been showing unprecedented prospects [8]. As reported, the global production capacity of biodegradable plastics increased from 2.33 million tons in 2013 to 3.45 million tons in 2020, and the main production is PLA bio-based composites [8]. However, PLA is brittle with very low toughness and elongation. The high brittleness has limited its application in flexible packaging and other fields with excellent toughness requirements.

Employing plasticizer to increase the toughness and ductility of PLA is a widely reported method. Different plasticizers, such as acetyl tributyl citrate (ATBC) and polyethylene glycol (PEG), can reduce the inherent brittleness and increase the ductility of PLA [9]. ATBC is considered to be one of the most effective plasticizers for PLA because it is biobased, biodegradable, biocompatible, and safe for food contact [10]. In the case of the PLA/ATBC plasticized system, the non-polar part of the ATBC molecule isolates the PLA molecules, which reduces the binding effect between the PLA molecules and makes it easy to slip between the molecular chains. Shi et al. [11] compared PEG with ATBC to toughen PLA and found that PEG had poor compatibility with PLA. When PEG addition exceeded 5 wt%, a phase separation appeared. Moreover, ATBC exhibited better compatibility with PLA than PEG. When 17 wt% of ATBC was added, the elongation at break of PLA reached more than 300%, but the strength decreased remarkably. From many previous research studies [12,13,14], the loss of the valuable strength and modulus of PLA in the plasticized system is inevitable, which seems to be contradictory. Fortunately, reinforcements such as nanocellulose could be expected to provide effective solutions to overcome the conflict.

Cellulose can be used as a low-cost filler for reinforcing and/or toughening polymer matrix composites [15]. The biocomposites with natural cellulose provide positive advantages, including biocompatibility, mechanical properties, abrasion resistance, and biodegradability [16,17,18]. Herrera et al. [19] fabricated a PLA matrix nanocomposite with 1 wt% of cellulose nanocrytals (CNC) and 20 wt% glycerol triacetate as plasticizer and found a 31% increase in the elongation at break. Cellulose nanowhiskers (CNW) were employed to toughen PLA in our previous work [20], and the elongation at break reached 250% [21]. Nevertheless, the preparations of nanocelluloses (CNC, CNW, etc.) with a single form (rod-like) are cumbersome, and the reaction condition is severe. Further, the new nanocellulose called nanofibrillated cellulose (NFC) was reported as well. It exhibited an overall networked structure of rod shape with numerous nanofibrils on the edges. Thus, the possibility of forming physical entanglements and interlocks between the NFC and the PLA molecular chains increased [22]. The reinforcing effect could be achieved, which shows more advantages than previously reported nanocellulose materials such as CNC and CNW [23]. Notably, NFC has a unique reinforcing potential for PLA, which is expected to protect the strength and modulus of PLA in the ATBC plasticizing system. Although this has been confirmed at lower ATBC content (≤10 wt%), the ductility and impact toughness are not satisfactory enough [22]. Thus, the strengthening effect and/or toughening effect generated by the NFC in the full plasticized PLA composites (e.g., ATBC content ≥15 wt%) still need to be further investigated.

Based on the above, the plasticization of PLA always reduces the inherent strength. NFC with numerous nanofibrils showed the potential to protect the strength and modulus of PLA in the ATBC plasticizing system. In this work, the new type of nanocellulose was incorporated into a vigorous ATBC plasticized PLA system, aiming to break down the conflict between strength and ductility. Micro-morphology, mechanical properties and thermal properties of PLA/NFC biocomposites with various NFC additions (0–8 wt%) along with different ATBC additions (15 –20 wt%) were characterized and analyzed. The effects of NFC content on the properties of PLA/ATBC plasticized composites were investigated. The surface and interface characteristics of PLA/NFC composites were studied, and the strengthening/toughening mechanism was illustrated. Finally, the optimal addition amounts of NFC and ATBC were obtained. These results will provide data and method references for the application of high tenacious PLA composites in the fields such as food packaging.

2 Materials and methods

2.1 Materials

PLA (IngeoTM, 3001D), produced by NatureWorks LLC (Minnetonka, USA), was used as the polymer matrix. According to the supplier, the D-isomer content of PLA is 4%, the melting flowrate measured at 210°C and 2.16 kg is 22 g/10 min, and the density is 1.24 g/cm3. Microcrystalline cellulose (MCC) and acetyl tributyl citrate (ATBC), ACS grade, were produced from Sinochem (Shanghai, China). The particle size of MCC is 20–100 μm. NaOH and urea, ACS grade, were purchased from Aladdin Chemical (Shanghai, China). All other reagents and solvents were received from commercial sources without further purification.

2.2 Preparation of NFC

The fabrication approaches of NFC were detailed and illustrated in our previous study [22]. Briefly, MCC particles were first swelled by a NaOH/urea aqueous solution at room temperature for 2 h. Then, the insoluble was rinsed and neutralized with deionized water. Afterward, the resultant particles were reconstituted into deionized water with a solids content of 20 wt%, homogenized in an ultrasonic cell pulverizer (SientzBiotech, Ningbo, China) for 60 min. Lastly, the cellulose suspension was centrifuged (PK120 centrifuge, ALC, Winchester, UK) and freeze-dried (5,810R, Eppendorf, Hamburg, Germany) to obtain the white NFC particle.

2.3 Fabrication of PLA/NFC composites

Different composition of PLA/NFC blend was prepared with a micro-extruder (MiniLab HAAKE RheomexCTW5, ThermoScience, Karlsruhe, Germany) with a double conical screw, the capacity of which was 7 cm3. Approximately 5 g of PLA and NFC were fed into the extruder chamber compounding for 5 min with a screw speed of 60 rpm and temperature of 180°C. Different amounts of NFC (0–8 wt%) and ATBC (15–20 wt%) were used as reinforcement and green plasticizer, respectively. The compositions of all the prepared PLA composites are summarized in Table 1. After melt blending, the blends were directly squeezed into a hopper at 180°C, and mold-injected to tensile and notched Izod impact test specimens at 40°C (HAKKE Minijet II, Thermo Scientific, Karlsruhe, Germany). The size of the tensile specimen was 115 mm3 × 6 mm3 × 2 mm3 with a dumbell shape according to ASTM D638, and the notched Izod impact specimen was 64 mm3 × 12.7 mm3 × 3.2 mm3 according to the ASTM D256.

Composites formulations

| Formulation | PLA (wt%) | NFC (wt%) | ATBC (wt%) |

|---|---|---|---|

| Control | 100 | 0 | 0 |

| P-A15 | 100 | 0 | 15 |

| P-N2-A15 | 100 | 2 | 15 |

| P-N4-A15 | 100 | 4 | 15 |

| P-N6-A15 | 100 | 6 | 15 |

| P-N8-A15 | 100 | 8 | 15 |

| P-A20 | 100 | 0 | 20 |

| P-N2-A20 | 100 | 2 | 20 |

| P-N4-A20 | 100 | 4 | 20 |

| P-N6-A20 | 100 | 6 | 20 |

| P-N8-A20 | 100 | 8 | 20 |

Note: P refers to PLA, N refers to NFC, and A refers to ATBC. The amounts of NFC and ATBC are based on the additional amount of PLA weight.

2.4 Scanning electron microscope and transmission electron microscope analysis

The morphology of NFC and the tensile fractural morphology of PLA/NFC composites were observed by a scanning electron microscope (SEM) (S-8010, Hitachi, Japan). All samples were coated with gold before observation. The emission voltage of the electron microscope was 4.0 kV. TEM was used to characterize the distribution and morphology of NFC in the PLA matrix. The PLA/NFC biocomposites were cut with MTXL ultra-micro spinner (RMC, US) and observed with a JEM 1230 transmission electron microscope (JEOL, Tokyo, Japan) at 200 kV.

2.5 Mechanical tests

The mechanical properties of the PLA/NFC composites were evaluated through the tensile tests using a universal testing machine (CMT4503, MTS Inc.) at room temperature. The tensile test specimens were inject-molded according to ASTM D638 type IV. The sizes of specimens for tensile tests were 115 mm3 × 6 mm3 × 2 mm3 with a dumbbell shape. The gauge length and the crosshead speed for tensile test were set to 25 mm and 5 mm/min, respectively. The specimens for notched Izod impact were inject-molded and tested on an impact testing machine (GT-7045-HM, Gotech, China) according to ASTM D256. The size was 64 mm3 × 12.7 mm3 × 3.2 mm3 with an impact notch on the long side. The data provided for analysis were an average value of five specimens.

2.6 Differential scanning calorimetry (DSC) analysis

Thermal properties of PLA/NFC composites with different NFC and ATBC contents were studied by DSC (200F3, Netzsch, Germany). Approximately 10.0 mg of sample was weighed and sealed in an aluminum crucible. The sample was heated from 30 to 180°C, held for 3 min at 180°C, then cooled down to 0°C, and afterward heated to 180°C again. The cooling and heating rate was constant at 10°C/min. The second heating thermogram was recorded for further evaluation. Nitrogen was used (1) as the purge gas at a rate of 50 m L/min. An empty sealed aluminum crucible was used as a reference. The cold crystallinity X cc was calculated according to equation (1):

where ΔH cc refers to the cold crystallization enthalpy of the composites; ΔH 0 refers to the enthalpy value of PLA 100% crystallized, which is 93.6 J/g [24]; X PLA refers to the weight ratio of PLA in the composites.

2.7 Thermogravimetric analysis (TGA)

Thermal stability of PLA/NFC composites was measured with a thermogravimetric analyzer (STA 2500, Netzsch, Germany). Approximately 10.0 mg sample was put into a standard alumina crucible, and then heated from 30 to 600°C at a heating rate of 10°C/min under a nitrogen flow rate of 50 mL/min. An empty crucible was taken as a reference. All thermal degradation parameters were calculated in the analysis software.

3 Results and discussion

3.1 NFC morphology analysis

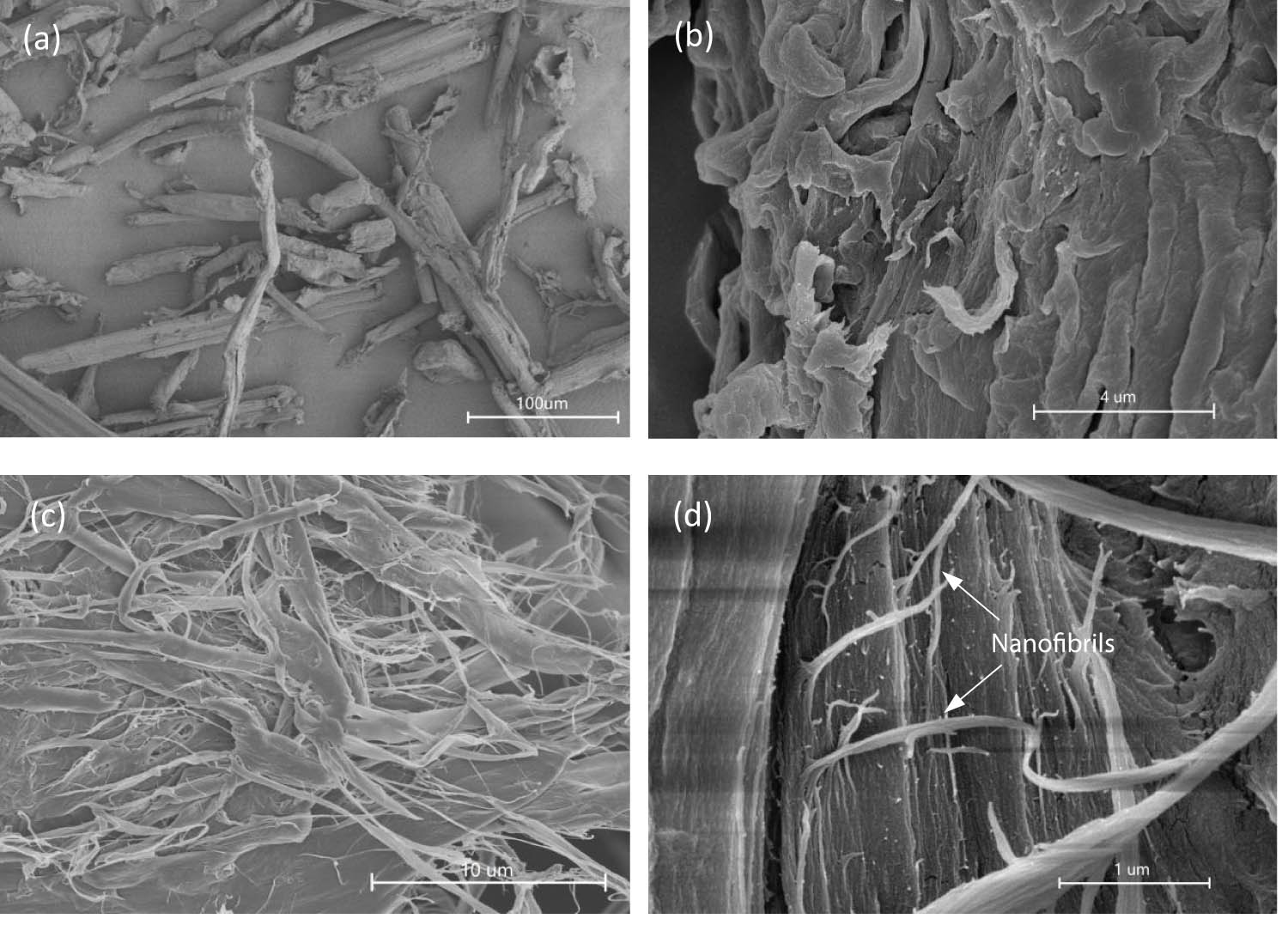

The micro-morphology of MCC and mechanical treated MCC are shown in Figure 1. Short, rod-like and irregular shape of MCC with rough surface and rugged grains can be seen in Figure 1(a). The particle size (20–100 μm) of MCC according to the supplier was observed. A layer of impurities on MCC surface can be noticed, which can be attributed to the existence of hemicellulose and amorphous area according to Chen et al. [25]. Figure 1(b) shows the morphology of the swelled MCC. The tightly arranged microfibrils begin to swell and separate, resulting from the removal of hemicellulose as well as impurities by NaOH and the amide polar group of urea, the hydrogen bonds between the microfibrils debond. Zhu et al. [26] noted the same feature, where a decrease in the hemicelluloses content was shown to partially promote the irreversible microfibril generation. This fact resulted in more compact fibrillar structures with large fibril aggregation size. It is conducive to separate nano-microfibrils further through mechanical treatment [26]. As shown in Figure 1(c), the margins of MCC particles are fuzzed, staggered nanofibrils and microfibrils are clearly visible. Network-like structures between fibrils can also be noticed. Interestingly, only fibrillation occurs, and NFC remains the overall shape and the size of MCC particles. Figure 1(d) shows the nanofibrils visible on the surface, where cellulose fibers dissociate into individual nanofibrils by mechanical shearing.

SEM images of (a) raw MCC; (b) swelled MCC; (c) NFC; (d) nanofibrils on NFC.

Compared with the traditional acid hydrolysis for preparing cellulose nanocrystals or nanowhiskers [21], the present strategy for fabricating the NFC is no need for any acid treatment that is toxic, complex and high-cost. More importantly, uniformly dispersion of nanocellulose particles into polymer matrix is difficult to be achieved [27]. NFC possesses a hierarchical structure, showing micron-scale particles in appearance and nano-scale fibrils in detail, which seems easier to disperse than CNC and CNW [22,27]. Particularly, the nanofibrillated network structure could form physical entanglements and/or mechanical locks with polymer chains, thereby greatly enhancing the mechanical properties of the resultant composites. In addition, polymer molecular chain in a plasticized system shows enhanced mobility and tends to interact with NFC filler. Thus, compared with CNW and CNC as fillers, NFC apparently possesses more potential to strengthen PLA composites.

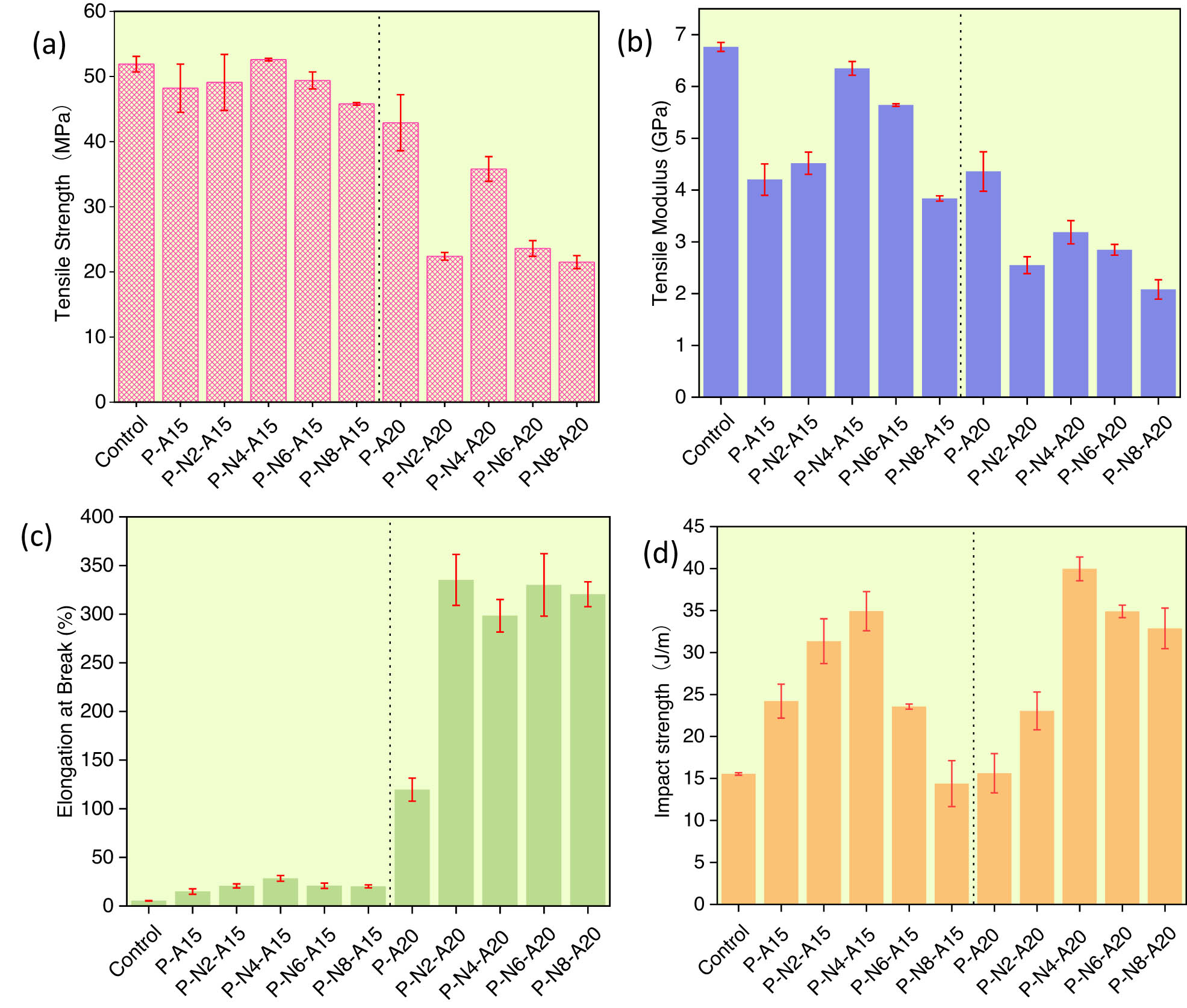

3.2 Tensile properties of the PLA/NFC composites

Tensile strength, tensile modulus and elongation at break of the PLA/NFC composites with different contents of NFC (0–8 wt%) and ATBC (15 and 20 wt%) are shown in Figure 2. The three tensile values containing both 15 and 20 wt% ATBC present a same trend that increases firstly, and then declines with the increase of NFC content. NFC content of 4 wt% is found to be the optimal additive amount for 15 and 20 wt% ATBC composites mutually. In the 15 wt% ATBC case, the maximum values of the tensile properties are 52.6 MPa, 6.3 GPa and 28.4%, respectively. The tensile strength and tensile modulus can be comparable to that of pure PLA or even higher and, while, the elongation at break increases approximately by 425%. It demonstrates that not only strong interfacial adhesion between NFC and PLA matrix occurs, but also efficient plasticization of ATBC for PLA generates. Differing from the plasticization system (10 wt% ATBC) of Galvez et al. [28], in which the tensile modulus and the tensile strength decreased by 44 and 50% in comparison to neat PLA. In addition, the tensile properties of 15 wt% ATBC plasticized composites are sequentially improved comparing to our previous work with 10 wt% ATBC plasticization [22].

Tensile properties of PLA/NFC composites and notched Izod impact property of PLA/NFC composites: (a) tensile strength, (b) tensile modulus, (c) elongation at break, (d) impact strength.

In the case of 20 wt% ATBC plasticized composites, the tensile strength and tensile modulus reduce observably when compared with the 15 wt% ATBC case, but the elongation at break increases tremendously. This is consistent with the feature in the plasticization system, which can be attributed to the reduction of intermolecular force [28]. The ATBC with abundant polar groups easily enters the gap between PLA chains during melt blending, which weakens the binding and entanglement force between PLA chains and increases the mobility of PLA chains and, therefore, increases the elongations of PLA composites. The elongation at break reaches 300.1% when 4 wt% NFC and 20 wt% ATBC is added, corresponding to that of 28.4% in the 4 wt% NFC and 15 wt% ATBC case. In fact, the acetyl and citric acid groups on the ATBC molecule interact strongly with the PLA chain, which helps to decrease the tensile strength and increase the elongation at break. This case exhibits a tremendous increase in elongation at break, while reduction or even halved in tensile strength and modulus. This phenomenon is much common in plasticized systems and usually requires reinforcements to compensate for the loss of strength and modulus [29].

More importantly, 4 wt% NFC shows a neutral effect of tensile strength and ductility, although the elongation reaches 300.1%, the tensile strength remains acceptable. In fact, NFC is found to own the ability to strengthen and ductility at the same time. It is shown in Figure 2a–c that with the increase of NFC content, the tensile strength, modulus and elongation all improve in the plasticized composites. This special function of NFC will also be confirmed in the impact test. This can be attributed to the reinforcement of NFC rigid particles in macroscopically, and the directional adjustment of PLA molecular chains in microscopically due to the driving of nanofibrils.

3.3 Notched Izod impact performance of the PLA/NFC composites

Figure 2d shows the notched Izod impact toughness of the PLA/NFC composites. With the addition of 15 wt% ATBC, the impact strength increases from 15.5 to 24.2 J/m, indicating an efficient toughening effect of the ATBC. With the increase of NFC content, the impact strength shows an upward trend at first, reaches a maximum value of 34.92 J/m at 4 wt% NFC, and then slightly decreases. As the ATBC increases to 20 wt%, the impact strength further improves. The maximum value reaches 39.96 J/m at 4 wt% NFC identically, and then slightly declines with the increase of NFC. These facts illustrate the further toughening effect of NFC in the PLA/ATBC system [21]. When ATBC content is 20 wt%, the impact strength of the composite without NFC is comparable to that of pure PLA, but with the NFC addition, the impact strength increases rapidly.

Combined with the following DSC analysis, it can be speculated that there may be two reasons for the toughening effect. The one may be the heterogeneous nucleation effect of NFC, and the other may be the mechanical interlocks between NFC and PLA. DSC shows that NFC enhances the crystallization ability and crystallinity of the PLA composites significantly. Under the ATBC effect, the interaction between PLA chains weakens and mobility strengthens. Molecular chains could self-arrange in a regular manner near NFC particles to form small crystals, which prevents the formation of cracks under impact. In addition, NFC and PLA form numerous structurally stable mechanical interlocks and entanglements within the entire composites due to the special structure of branching NFC. These structures and effects may hinder the generation of initial cracks and resist the propagation of cracks. However, when the NFC content exceeds 4 wt%, phase separation or stress concentration will happen due to insufficient dispersibility, resulting in decrease of the impact strength.

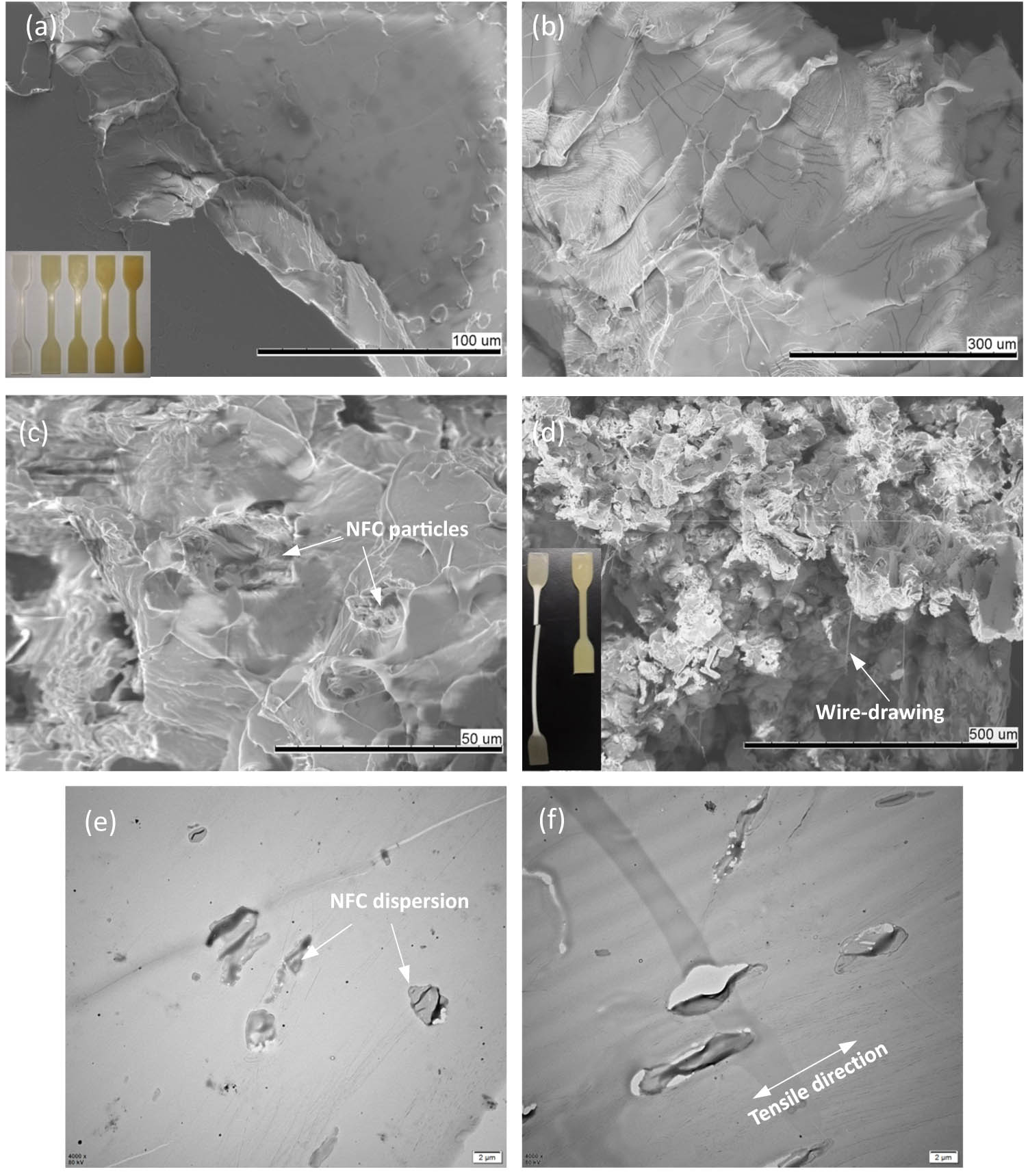

3.4 Fractural interface morphology

Figure 3a–d show the SEM images of the fractural surfaces from tensile test of the neat PLA, plasticized PLA and PLA/NFC composites. Figure 3e and f present the TEM images of the PLA/NFC composites. The fractural surfaces are analyzed in order to visualize the effect of the ATBC and the NFC on the fractural behavior. As expected, Figure 3a shows a brittle instinct of PLA, the fractural surface is smooth and flat, and no evidence of plastic deformation can be seen. Figure 3b reveals a homogeneous surface that is representative of good compatibility between PLA and ATBC plasticizer. Additionally, some plasticization features can be observed in the form of fibrils and lamellas resulting from plastic deformation during tension. This phenomenon can be fully supported by the previous mechanical properties, where elongation at break and impact strength nearly doubled with 15 and 20 wt% addition of ATBC plasticizer. But the result is different from the previously reported plasticizers such as cottonseed oil [30], which reported that microvoids and debonding appeared when over 10 wt% of the plasticizer was used. This fact could be related to strong interactions between PLA molecular chains and the ATBC. These strong interactions avoid occurring phase separation as observed in Figure 3b. With the addition of NFC (Figure 3c and d), the fractural surfaces become coarse and rugged. A large number of crazes and wire-drawings can be observed, exhibiting a ductile fracture.

SEM images of tensile fractural surface of (a) pure PLA, (b) PLA with 15 wt% ATBC, (c) PLA composites with 15 wt% ATBC and 4 wt% NFC, (d) PLA composites with 20 wt% ATBC and 4 wt% NFC, (e) cross-sectional TEM image of PLA composites with 20 wt% ATBC and 4 wt% NFC, (f) vertical-sectional TEM image of PLA composites with 20 wt% ATBC and 4 wt% NFC after tension.

NFC is well dispersed throughout the polymer matrix, which is in total accordance with TEM results. In the case of the composites containing 15 wt% ATBC and 4 wt% NFC (Figure 3c), the NFC appears to be more tightly bound to the PLA matrix in comparison to that with 20 wt% ATBC (Figure 3d). In the Figure 3d, as the content of ATBC increases to 20 wt%, some spherical cavities/voids can be observed. These are produced by a cavitation process caused by debonding. This result is consistent with what Carbonell-Verdu et al. have reported [30]. They attributed the fact that the amount of plasticizer began to saturate. The presence of protruding NFC fibers at the fractural surface suggests that ATBC rich phase dispersed in the PLA matrix facilitates the slippage of fibers out of the matrix during tension. In general, SEM images reveal good miscibility between PLA and ATBC plasticizer even for high plasticizer content as observed by Qin et al. [31]. NFC can play a comprehensive strengthening and toughening role in the mixed PLA plasticizing system. Figure 3e shows the uniform dispersion of NFC in PLA matrix under the efficient plasticization. This contributes to improved mechanical properties and avoids stress concentrations. Figure 3f shows the appearance of NFC embedded in the PLA matrix after stretching. The rod-shaped NFC is evenly arranged along the stretching direction, and the length direction of the NFC is consistent with the PLA stretching.

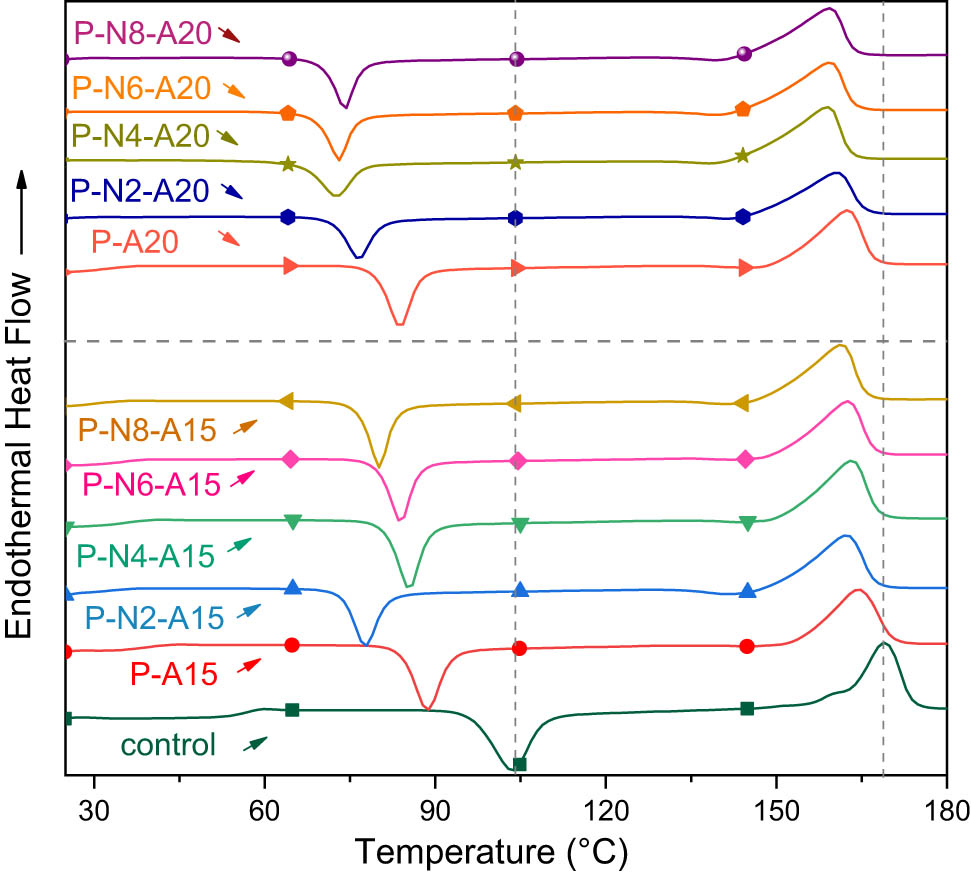

3.5 Thermal property of PLA/NFC composites

DSC thermograms of the pure PLA and plasticized PLA/NFC composites are shown in Figure 4. Thermal parameters with respect to glass transition temperature (T g), cold crystallization temperature (T cc), melting temperature (T m), crystallization enthalpy (ΔH cc) and degree of crystallinity (X cc) are tabulated in Table 2. The thermal peaks of all curves tend to move towards the low temperature. The melting peaks are wider than the pure PLA due to the effect of the plasticizer that makes the small crystals easier to melt. Effective plasticization plays an important part in thermal transition. As the amount of ATBC increases, The T g, T cc, and T m of the PLA/NFC composites gradually decrease. Comparing the PLA/NFC composites of 15 wt% ATBC with 20 wt% ATBC, the T g decreases from 39.1 to 32.1°C. This result is consistent with the mechanical analysis, and it is possible that 20 wt% of ATBC has reached saturation. ATBC exhibits a sufficient plasticizing effect, and it weakens the mutual binding effect between PLA molecules, reduces the activation energy required for segment movement, and greatly improves the mobility of PLA chains. This has a positive effect on lowering the cold crystallization temperature and improving cold crystallinity. As previously reported [32,33], the cold crystallization represents the realignment of PLA chains to form a more packed structure. It is evident that the plasticizer enables this rearrangement as it increases polymer chain mobility. The cold crystallization temperature changes from 103.6°C for neat PLA to values of 88.6 and 83.8°C for 15 and 20 wt% plasticized PLA formulations, respectively.

DSC thermograms of pure PLA and PLA/NFC composites.

DSC parameters of the PLA/NFC composites

| Samples | T g (°C) | T cc (°C) | ΔH cc (J/g) | X cc (%) | T m (°C) | ΔH m (J/g) |

|---|---|---|---|---|---|---|

| Control | 56.9 | 103.6 | 6.4 | 6.8 | 169.0 | 14.9 |

| P-A15 | 39.1 | 88.6 | 24.4 | 30.7 | 164.5 | 35.3 |

| P-N2-A15 | 33.8 | 77.7 | 19.7 | 25.3 | 162.4 | 33.1 |

| P-N4-A15 | 35.9 | 85.4 | 23.7 | 31.2 | 162.5 | 33.5 |

| P-N6-A15 | 35.2 | 83.9 | 20.4 | 27.6 | 163.3 | 35.9 |

| P-N8-A15 | 31.0 | 80.2 | 19.5 | 27.0 | 161.5 | 35.3 |

| P-A20 | 32.1 | 83.8 | 21.1 | 28.1 | 162.6 | 32.0 |

| P-N2-A20 | 21.4 | 72.6 | 15.3 | 21.0 | 160.6 | 28.3 |

| P-N4-A20 | 24.1 | 76.5 | 18.2 | 25.6 | 159.0 | 35.4 |

| P-N6-A20 | 22.5 | 73.1 | 14.9 | 21.5 | 159.4 | 31.2 |

| P-N8-A20 | 22.6 | 74.1 | 15.9 | 23.7 | 159.3 | 31.2 |

Furthermore, after adding NFC, T g decreases, which is different from the increase of T g in other reports [34,35]. This may be the plasticization effect of the NFC nanofibrils. Meanwhile, thanks to the heterogeneous nucleation of NFC promotes the crystallization of PLA molecular chains, resulting in a decrease in T c [36]. And the crystallinity reaches the maximum values of 31.2 and 25.6% at 4 wt% NFC content for 15 wt% ATBC and 20 wt% ATBC, respectively. When compared with pure PLA, the crystallinity is increased by approximately 3–5 times after adding NFC and ATBC. This is the result of synthesizing heterogeneous nucleation and plasticization, which improves the strength and toughness of the final composites simultaneously. The results of thermal analysis can be mutually confirmed with the results of mechanical analysis.

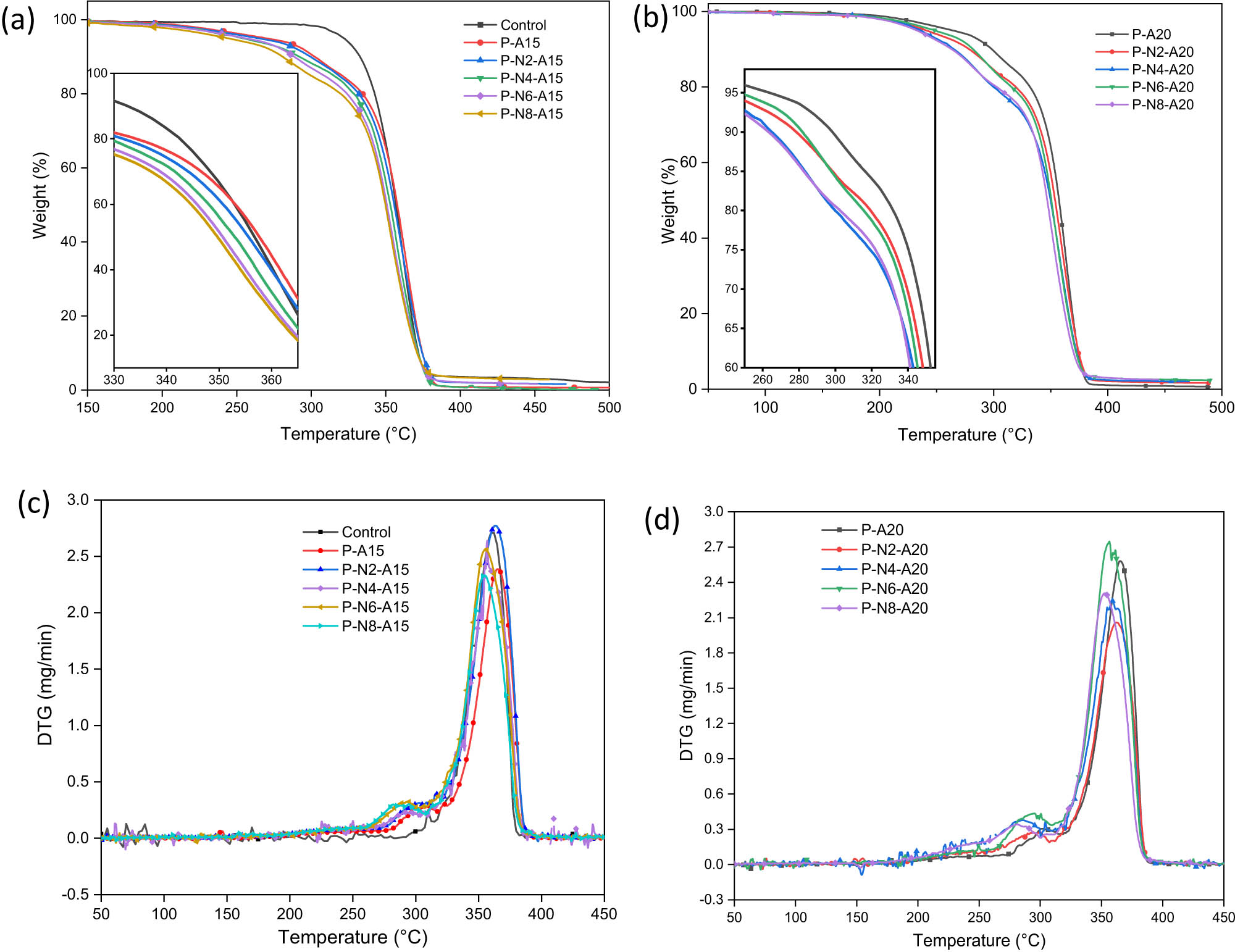

3.6 TGA

The thermal degradation gravimetric curves of the PLA/NFC composites with 15 and 20 wt% ATBC are shown in Figure 5a and b, and their derivative curves are shown in Figure 5c and d, respectively. The thermal degradation parameters are summarized in Table 3. The thermal degradation process of the composites basically presents a single peak (ca. 330–380°C), which indicates the good compatibility between the components. Nonetheless, a small but noticeable shoulder (ca. 280–310°C) in the first stage of the degradation can be attributed to the presence of NFC. This shoulder is more evident in the PLA/NFC composites containing 20 wt% ATBC (Figure 5d) than in the neat PLA. This may be due to the fact that ATBC increases the mobility of PLA, making it easier for heat to be transferred to NFC, resulting in a decrease in the degradation temperature. This result can be confirmed by the decreased T onset, degradation temperature range, and T max in this study, and it can also be corroborated by the results of other plasticized investigations [37]. Additionally, there is an increment in T onset after adding ATBC corresponding to the PLA formulations, whereas NFC shifts it to lower temperatures, leading to a decrease in T onset. Similar findings were reported by Carbonell-Verdu et al. [30], who investigated the thermal stability of cottonseed oil composites that the T onset increased from 335.5°C (no plasticizer) to 339.2°C (plasticizer 10 wt%). They concluded that the presence of plasticizer enabled chain mobility and this facilitated crystallization as polymer chains could move to a packed structure [30]. Besides, Radakisnin et al. [38] reported a similar decease on the degradation temperature by adding nanocellulose. They found some portions of the PLA matrix were replaced with the less thermally stable cellulose fibers that reduced the thermal stability of the polymer matrix as a whole. Moreover, a similar finding was reported by Xu et al. [22], when NFC was added, the highly mobile PLA molecular chain formed a network structure with NFC.

Thermal degradation of the PLA/NFC composites: (a) TGA of 15 wt% ATBC plasticized composites, (b) TGA of 20 wt% ATBC plasticized composites, (c) DTG of 15 wt% ATBC plasticized composites, and (d) DTG of 20 wt% ATBC plasticized composites.

TGA data of the PLA/NFC composites

| Samples | T onset (°C) | Temperature range (°C) | T max1 (°C) | T max2 (°C) | Mass loss at 450°C (%) |

|---|---|---|---|---|---|

| Control | 339.9 | 339.9–372.8 | — | 362.0 | 99.5 |

| P-A15 | 341.8 | 341.8–376.8 | 296.8 | 365.8 | 99.9 |

| P-N2-A15 | 338.4 | 338.4–376.1 | 308.5 | 363.1 | 98.3 |

| P-N4-A15 | 336.6 | 336.6–373.1 | 302.0 | 356.8 | 98.2 |

| P-N6-A15 | 331.2 | 331.2–371.5 | 293.4 | 355.4 | 98.3 |

| P-N8-A15 | 330.8 | 330.8–370.3 | 294.6 | 354.3 | 97.5 |

| P-A20 | 342.0 | 342.0–376.3 | 301.4 | 365.4 | 99.3 |

| P-N2-A20 | 335.4 | 335.4–376.4 | 294.0 | 362.1 | 98.3 |

| P-N4-A20 | 330.1 | 330.1–374.4 | 283.2 | 358.8 | 97.7 |

| P-N6-A20 | 331.0 | 331.0–372.5 | 295.3 | 356.7 | 97.5 |

| P-N8-A20 | 326.8 | 326.8–369.6 | 280.9 | 352.8 | 97.2 |

PLA epigenetically crystallized near nanofibrils (less regular than PLA spherulites), and thus, the thermal stability slightly declined. Orue et al. [39] also reported the diminution of PLA crystal size when cellulose and plasticizer were employed. By taking into account the DSC and TGA analysis, it is possible to assume that PLA molecular chain and NFC not only form mechanical interlocks, but also form a large number of fine spherulites near the nanofibrils. However, phase separation may generate for those formulations containing 8 wt% NFC. And thus, the T max decreases ca. 10°C when compared to neat PLA. Furthermore, the char residue at 450°C of the composites increases with the increase in NFC content which may improve the fire retardancy of the material.

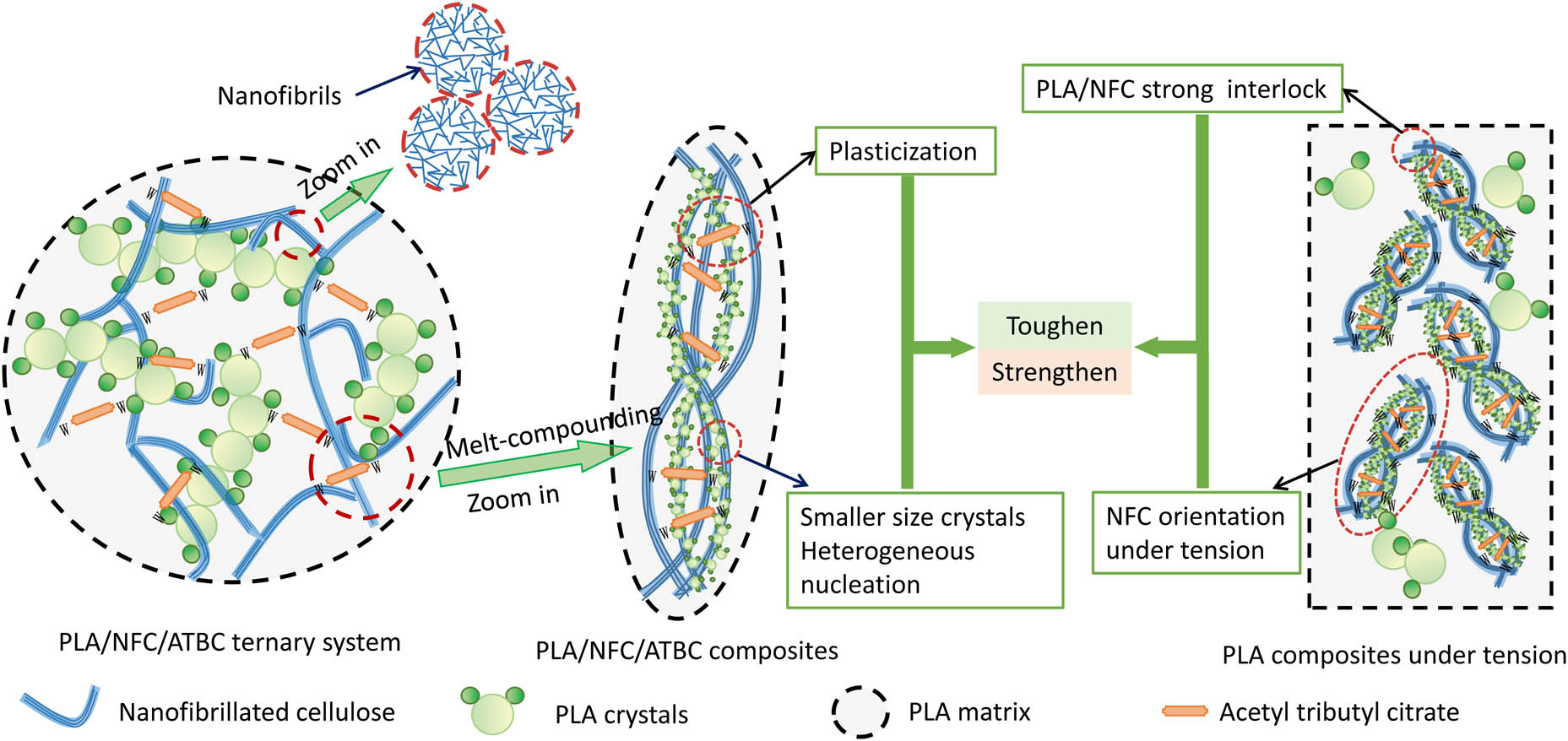

3.7 Toughening and strengthening mechanism of PLA/NFC composites

Integrated with the above results and discussion, it can be assumed that owing to the exceptional morphology of NFC, the PLA/NFC interaction and the PLA crystallization express exquisite synergistic promotion on mechanical properties of the plasticized biocomposites. The toughening and strengthening mechanism of PLA/NFC composites is illustrated in Figure 6. Undoubtedly, this conspicuous reinforcement and toughness can be attributed to the unique hierarchical structure of NFC that possesses network-like nanofibrils encircled by small-sized crystals with dense arrangement, providing further prodigious ability for damage tolerance [40]. As for its strengthening effect, on the one hand, NFC itself was known as rigid particles with a larger quantity of nanofibrils (higher strength). This means lots of reinforcing elements that could contribute to dispersion of external force. On the other hand, small-size epitaxial crystals assembling next to the NFC nanofibrils could aggregate a larger amount of force bearing points serving as load for dissipative stress. This phenomenon is consistent with the findings of Zhou et al. [12], who reported that the addition of flexible nanofibrils to PLA composites had a good reinforcement effect.

Schematic illustration of the toughening and strengthening mechanism of the composites.

Concerning to toughening mechanism, as we previously reported [21,22], it likely originates from the enhancement of NFC mobility facilitated by ATBC plasticization. Mechanical and structural interface interaction between plasticized PLA molecular chains and NFC nanofibrils could synergistically facilitate the stretch deformation. Further, NFC adjusts into the direction of stretching, in good agreement with the findings of TEM, endowing the composites with superior toughness. Overall, this hierarchical system shows a great superiority to synchronously improve the strength and toughness of PLA, which exhibits potential as a new strategy for overcoming the conflict between strength and toughness.

3.8 Comprehensive performance analysis

When it comes to material choice, particularly for package and structure applications, strength, toughness, ductility, thermal stability, and resistance should be taken into consideration. Figure 7a compares the key mechanical properties (tensile strength, tensile modulus, impact strength, and elongation), thermal properties of PLA composites with those of different formulations. It is well known that there are contradictions in the improvement of strength, toughness, and heat resistance of polymer materials, and it is difficult to achieve simultaneous enhancement. PLA is the commonly used biodegradable polymer with high strength and good transparency, but the poor ductility limits its practical application since high toughness is vital for package purposes. Plasticizer ATBC seems to be a feasible alternative to toughen PLA (Figure 7a), but the strength and thermal properties cannot be guaranteed. Further, employment of NFC as reinforcement exhibits high tensile and impact strength, good thermal stability and resistance (Figure 7b and c). Therefore, it is necessary to explore the balance point between strength, toughness and thermal properties, which satisfies the requirements of high-performance package and structure materials.

![Figure 7

(a) A radar plot showing a comparison among the neat PLA, PLA/ATBC composites, and PLA/NFC/ATBC composites (P: poly(lactic acid); N: nanofibrillated cellulose; A: acetyl tributyl citrate; and the numbers indicate the weight%) [22]. The results are normalized to the range of 0–7. (b) Typical strain-stress of the neat PLA and PLA/NFC/ATBC composites. (c) Comparison of the impact strength of the PLA composites [22].](/document/doi/10.1515/ntrev-2022-0142/asset/graphic/j_ntrev-2022-0142_fig_007.jpg)

(a) A radar plot showing a comparison among the neat PLA, PLA/ATBC composites, and PLA/NFC/ATBC composites (P: poly(lactic acid); N: nanofibrillated cellulose; A: acetyl tributyl citrate; and the numbers indicate the weight%) [22]. The results are normalized to the range of 0–7. (b) Typical strain-stress of the neat PLA and PLA/NFC/ATBC composites. (c) Comparison of the impact strength of the PLA composites [22].

Interestingly, the optimal amount of NFC addition is found to be 4 wt% for the both ATBC plasticized composites. The tensile strains at 15 and 20 wt% ATBC content are 4 times and 61 times higher than that of pure PLA, respectively (Figure 7b). The impact strengths are 2.3 folds and 2.7 folds higher than that of pure PLA as well (Figure 7c). Besides, NFC can be used as low-cost filler to reinforce and/or toughen polymer matrix to compensate for the loss of strength and modulus. When compared the P-N4-A15 case with P-A15 case, the tensile modulus increases by 51.1%, the tensile strength increases by 9.1%, and impact strength enhances by 45.8%. This indicates that NFC has a strengthening and toughening effect in the composites. The rigid porous ultrafine bamboo char was also employed to improve the strength and toughness of PLA/CNW composites similarly [13].

Taking the crystallinity, glass transition temperature, and thermal degradation temperature into consideration, the annealing treatment in the later stage of the product is expected to improve the heat resistance, thereby improving the comprehensive performance of the product. NFC could be an effective heterogeneous nucleation agent in the PLA composites. The annealing treatment of the composites should be further studied. Generally, the PLA composite formulation of 4 wt% NFC and 15 wt% ATBC could fulfill the need of load-bearing and ductile functionality of packaging applications, such as plastic lunch boxes. While for high-toughness plastic films purpose, such as disposable plastic bags, the formulation of 4 wt% NFC and 20 wt% ATBC is recommended.

4 Conclusion

Nanofabrillated cellulose with abundant nanofibrils is fabricated and characterized. The tensile strengthening and impact toughening effects of the NFC for PLA/ATBC plasticized biocomposites are confirmed. The NFC addition mounts of 4 wt% is proved to be optimal for the biocomposites with both 15 and 20 wt% ATBC. The tensile elongation at break and impact strength of the former increase by 107 and 46% and these of the latter improve by 97 and 167%, comparing to the biocomposites without NFC. Notably, tensile strength remains and is comparable to commercially available film products. Further, T g, X cc, and T m of the biocomposites reduce to 35.9°C, 31.2%, 162.5°C and 24.1°C, 25.6%, 159.0°C, respectively. The formulations with NFC and ATBC could fulfill various requirements of load-bearing and high ductile functionality of packaging applications. Ultimately, the findings will provide an effective strategy for acquiring PLA materials with both tensile strength and impact toughness.

Acknowledgments

The authors thank Mr. Cesar A. Fontanillo Lopez, affiliated with KU-Leuven Center for IT and IP Lawc, for the language review.

-

Funding information: This work was financially supported by the Fund for Scientific Research in the Public Interest of Ningbo (No. 2021S067 and 2022S150), the Foundation of the Department of Education of Zhejiang Province (Y202148281), and the Student Research and Innovation Program of Ningbo University (2021SRIP1125).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Armentano I, Bitinis N, Fortunati E, Mattioli S, Rescignano N, Verdejo R, et al. Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog Polym Sci. 2013;38(10–11):1720–47.10.1016/j.progpolymsci.2013.05.010Search in Google Scholar

[2] Zhang S, Liang Y, Qian X, Hui D, Sheng K. Pyrolysis kinetics and mechanical properties of poly(lactic acid)/bamboo particle biocomposites: Effect of particle size distribution. Nanotechnol Rev. 2020;9:524–33.10.1515/ntrev-2020-0037Search in Google Scholar

[3] Farah S, Anderson DG, Langer R. Physical and mechanical properties of PLA, and their functions in widespread applications-A comprehensive review. Adv Drug Deliv Rev. 2016;107:367–92.10.1016/j.addr.2016.06.012Search in Google Scholar PubMed

[4] Tian XY, Liu TF, Wang QR, Dilmurat A, Li DC, Ziegmann G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J Clean Prod. 2017;142:1609–18.10.1016/j.jclepro.2016.11.139Search in Google Scholar

[5] Parthasarathy J, Hatoum H, Flemister DC, Krull CM, Walter BA, Zhang W, et al. 3D printed bone tissue regenerative PLA/HA scaffolds with comprehensive performance optimizations. Mater Des. 2021;201:109490.10.1016/j.matdes.2021.109490Search in Google Scholar

[6] Nazrin A, Sapuan SM, Zuhri MYM, Tawakkal ISMA, Ilyas RA. Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites. Nanotechnol Rev. 2021;11:86–95.10.1515/ntrev-2022-0007Search in Google Scholar

[7] Dong K, Panahi-Sarmad M, Cui ZY, Huang XY, Xiao XL. Electro-induced shape memory effect of 4D printed auxetic composite using PLA/TPU/CNT filament embedded synergistically with continuous carbon fiber: A theoretical and experimental analysis. Compos Part B-Eng. 2021;220:108994.10.1016/j.compositesb.2021.108994Search in Google Scholar

[8] Yang Y, Zhang L, Xiong Z, Tang Z, Zhang R, Zhu J. Research progress in the heat resistance, toughening and filling modification of PLA. Sci China Chem. 2016;59:1355–68.10.1007/s11426-016-0222-7Search in Google Scholar

[9] Ruiz MB, Pérez-Camargo RA, López JV, Penott-Chang E, Múgica A, Coulembier O, et al. Accelerating the crystallization kinetics of linear polylactides by adding cyclic poly(L-lactide): Nucleation, plasticization and topological effects. Int J Biol Macromol. 2021;186:255–67.10.1016/j.ijbiomac.2021.07.028Search in Google Scholar PubMed

[10] Zhang Y, Li J, Su G. Comprehensively screening of citric acid ester (CAE) plasticizers in Chinese foodstuffs, and the food-based assessment of human exposure risk of CAEs. Sci Total Env. 2022;817:152933.10.1016/j.scitotenv.2022.152933Search in Google Scholar PubMed

[11] Shi Y, Li M, Wang N, Xing M, Wu Q. Para-amino benzoic acid doped micro-grooved carbon fibers to improve strength and biocompatibility of PLA-PEG. Sci China Mater. 2016;59:911–20.10.1007/s40843-016-5065-0Search in Google Scholar

[12] Zhou SY, Niu B, Xie XL, Ji X, Zhong GJ, Hsiao BS, et al. Interfacial shish-kebabs lengthened by coupling effect of in situ flexible nanofibrils and intense shear flow: Achieving hierarchy to conquer the conflicts between strength and toughness of polylactide. ACS Appl Mater Interf. 2017;9(11):10148–59.10.1021/acsami.7b00479Search in Google Scholar PubMed

[13] Sheng K, Zhang S, Qian S, Lopez CAF. High-toughness PLA/bamboo cellulose nanowhiskers bionanocomposite, strengthened with silylated ultrafine bamboo-char. Compos Part B-Eng. 2019;165:174–82.10.1016/j.compositesb.2018.11.139Search in Google Scholar

[14] Qian S, Tao Y, Ruan Y, Lopez CAF, Xu L. Ultrafine bamboo-char as a new reinforcement in poly(lactic acid)/bamboo particle biocomposites: The effects on mechanical, thermal, and morphological properties. J Mater Res. 2018;33(22):3870–9.10.1557/jmr.2018.290Search in Google Scholar

[15] Li A, Xu D, Luo L, Zhou Y, Yan W, Leng X, et al. Overview of nanocellulose as additives in paper processing and paper products. Nanotechnol Rev. 2021;10:264–81.10.1515/ntrev-2021-0023Search in Google Scholar

[16] Bhasney SM, Bhagabati P, Kumar A, Katiyar V. Morphology and crystalline characteristics of polylactic acid PLA/linear low density polyethylene LLDPE/microcrystalline cellulose MCC fiber composite. Compos Sci Technol. 2019;171:54–61.10.1016/j.compscitech.2018.11.028Search in Google Scholar

[17] Rana AK, Frollini E, Thakur VK. Cellulose nanocrystals: Pretreatments, preparation strategies, and surface functionalization. Int J Biol Macromol. 2021;182:1554–81.10.1016/j.ijbiomac.2021.05.119Search in Google Scholar PubMed

[18] Nechyporchuk O, Belgacem MN, Bras J. Production of cellulose nanofibrils: A review of recent advances. Ind Crop Prod. 2016;93:2–25.10.1016/j.indcrop.2016.02.016Search in Google Scholar

[19] Herrera N, Mathew AP, Oksman K. Plasticized polylactic acid/cellulose nanocomposites prepared using melt-extrusion and liquid feeding: Mechanical, thermal and optical properties. Compos Sci Technol. 2015;106:149–55.10.1016/j.compscitech.2014.11.012Search in Google Scholar

[20] Qian S, Sheng K, Yu K, Xu L, Lopez CAF. Improved properties of PLA biocomposites toughened with bamboo cellulose nanowhiskers through silane modification. J Mater Sci. 2018;53(15):10920–32.10.1007/s10853-018-2377-2Search in Google Scholar

[21] Qian S, Sheng K. PLA toughened by bamboo cellulose nanowhiskers: Role of silane compatibilization on the PLA bionanocomposite properties. Compos Sci Technol. 2017;148:59–69.10.1016/j.compscitech.2017.05.020Search in Google Scholar

[22] Xu L, Zhao J, Qian S, Zhu X, Takahashi J. Green-plasticized poly(lactic acid)/nanofibrillated cellulose biocomposites with high strength, good toughness and excellent heat resistance. Compos Sci Technol. 2021;203:108613.10.1016/j.compscitech.2020.108613Search in Google Scholar

[23] Qian S, Zhang H, Yao W, Sheng K. Effects of bamboo cellulose nanowhisker content on the morphology, crystallization, mechanical, and thermal properties of PLA matrix biocomposites. Compos Part B-Eng. 2018;133:203–9.10.1016/j.compositesb.2017.09.040Search in Google Scholar

[24] Ma Y, Qian S, Hu L, Qian J, Lopez CAF, Xu L. Mechanical, thermal, and morphological properties of PLA biocomposites toughened with silylated bamboo cellulose nanowhiskers. Polym Compos. 2019;40(8):3012–9.10.1002/pc.25144Search in Google Scholar

[25] Chen QF, Shi YH, Chen GX, Cai M. Enhanced mechanical and hydrophobic properties of composite cassava starch films with stearic acid modified MCC (microcrystalline cellulose)/NCC (nanocellulose) as strength agent. Int J Biol Macromol. 2020;142:846–54.10.1016/j.ijbiomac.2019.10.024Search in Google Scholar PubMed

[26] Zhu M, Wang Y, Zhu S, Xu L, Jia C, Dai J, et al. Anisotropic, transparent films with aligned cellulose nanofibers. Adv Mater. 2017;29:29.10.1002/adma.201606284Search in Google Scholar PubMed

[27] Girard M, Bertrand F, Tavares JR, Heuzey MC. Rheological insights on the evolution of sonicated cellulose nanocrystal dispersions. Ultrason Sonochem. 2021;78:105747.10.1016/j.ultsonch.2021.105747Search in Google Scholar PubMed PubMed Central

[28] Galvez J, Aguirre JPC, Salazar MAH, Mondragon BV, Wagner E, Caicedo C. Effect of extrusion screw speed and plasticizer proportions on the rheological, thermal, mechanical, morphological and superficial properties of PLA. Polymers. 2020;12(9):2111.10.3390/polym12092111Search in Google Scholar PubMed PubMed Central

[29] He HL, Yang PY, Duan ZW, Wang ZQ, Liu YF. Reinforcing effect of hybrid nano-coating on mechanical properties of basalt fiber/poly(lactic acid) environmental composites. Compos Sci Technol. 2020;199:108372.10.1016/j.compscitech.2020.108372Search in Google Scholar

[30] Carbonell-Verdu A, Samper MD, Garcia-Garcia D, Sanchez-Nacher L, Balart R. Plasticization effect of epoxidized cottonseed oil (ECSO) on poly(lactic acid). Ind Crop Prod. 2017;104:278–86.10.1016/j.indcrop.2017.04.050Search in Google Scholar

[31] Qin Y, Kang G, Cao Y. Finely tuned polyamide structure with green plasticizers to construct ultrafast water channels for effective desalination. Sci Total Env. 2021;784:147089.10.1016/j.scitotenv.2021.147089Search in Google Scholar PubMed

[32] Mazzanti V, Pariante R, Bonanno A, de Ballesteros R, Mollica O, Filippone F, et al. Reinforcing mechanisms of natural fibers in green composites: Role of fibers morphology in a PLA/hemp model system. Compos Sci Technol. 2019;180:51–9.10.1016/j.compscitech.2019.05.015Search in Google Scholar

[33] Scaffaro R, Maio A, Gulino EF. Hydrolytic degradation of PLA/posidonia oceanica green composites: A simple model based on starting morpho-chemical properties. Compos Sci Technol. 2021;213:108930.10.1016/j.compscitech.2021.108930Search in Google Scholar

[34] Zhu B, Wang YM, Liu H, Ying J, Liu CT, Shen CY. Effects of interface interaction and microphase dispersion on the mechanical properties of PCL/PLA/MMT nanocomposites visualized by nanomechanical mapping. Compos Sci Technol. 2020;190:108048.10.1016/j.compscitech.2020.108048Search in Google Scholar

[35] Greco A, Ferrari F. Thermal behavior of PLA plasticized by commercial and cardanol-derived plasticizers and the effect on the mechanical properties. J Therm Anal Calorim. 2020;146:131–41.10.1007/s10973-020-10403-9Search in Google Scholar

[36] Gazzotti S, Rampazzo R, Hakkarainen M, Bussini D, Ortenzi MA, Farina H, et al. Cellulose nanofibrils as reinforcing agents for PLA-based nanocomposites: An in situ approach. Compos Sci Technol. 2019;171:94–102.10.1016/j.compscitech.2018.12.015Search in Google Scholar

[37] Liu WD, Qiu JH, Chen TT, Fei MG, Qiu RH, Sakai E. Regulating tannic acid-crosslinked epoxidized soybean oil oligomers for strengthening and toughening bamboo fibers-reinforced poly(lactic acid) biocomposites. Compos Sci Technol. 2019;181:107709.10.1016/j.compscitech.2019.107709Search in Google Scholar

[38] Radakisnin R, Abdul Majid MS, Mohd Jamir MR, Mat Tahir MF, Meng CE, Al Alshahrani H. Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique. Nanotechnol Rev. 2021;10(1):1469–83.10.1515/ntrev-2021-0098Search in Google Scholar

[39] Orue A, Eceiza A, Arbelaiz A. The effect of sisal fiber surface treatments, plasticizer addition and annealing process on the crystallization and the thermo-mechanical properties of poly(lactic acid) composites. Ind Crop Prod. 2018;118:321–33.10.1016/j.indcrop.2018.03.068Search in Google Scholar

[40] Pantaloni D, Rudolph AL, Shah DU, Baley C, Bourmaud A. Interfacial and mechanical characterisation of biodegradable polymer-flax fibre composites. Compos Sci Technol. 2021;201:108529.10.1016/j.compscitech.2020.108529Search in Google Scholar

© 2022 Jiarong Tian et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer

- Homotopic simulation for heat transport phenomenon of the Burgers nanofluids flow over a stretching cylinder with thermal convective and zero mass flux conditions

- Incorporation of copper and strontium ions in TiO2 nanotubes via dopamine to enhance hemocompatibility and cytocompatibility

- Mechanical, thermal, and barrier properties of starch films incorporated with chitosan nanoparticles

- Mechanical properties and microstructure of nano-strengthened recycled aggregate concrete

- Glucose-responsive nanogels efficiently maintain the stability and activity of therapeutic enzymes

- Tunning matrix rheology and mechanical performance of ultra-high performance concrete using cellulose nanofibers

- Flexible MXene/copper/cellulose nanofiber heat spreader films with enhanced thermal conductivity

- Promoted charge separation and specific surface area via interlacing of N-doped titanium dioxide nanotubes on carbon nitride nanosheets for photocatalytic degradation of Rhodamine B

- Elucidating the role of silicon dioxide and titanium dioxide nanoparticles in mitigating the disease of the eggplant caused by Phomopsis vexans, Ralstonia solanacearum, and root-knot nematode Meloidogyne incognita

- An implication of magnetic dipole in Carreau Yasuda liquid influenced by engine oil using ternary hybrid nanomaterial

- Robust synthesis of a composite phase of copper vanadium oxide with enhanced performance for durable aqueous Zn-ion batteries

- Tunning self-assembled phases of bovine serum albumin via hydrothermal process to synthesize novel functional hydrogel for skin protection against UVB

- A comparative experimental study on damping properties of epoxy nanocomposite beams reinforced with carbon nanotubes and graphene nanoplatelets

- Lightweight and hydrophobic Ni/GO/PVA composite aerogels for ultrahigh performance electromagnetic interference shielding

- Research on the auxetic behavior and mechanical properties of periodically rotating graphene nanostructures

- Repairing performances of novel cement mortar modified with graphene oxide and polyacrylate polymer

- Closed-loop recycling and fabrication of hydrophilic CNT films with high performance

- Design of thin-film configuration of SnO2–Ag2O composites for NO2 gas-sensing applications

- Study on stress distribution of SiC/Al composites based on microstructure models with microns and nanoparticles

- PVDF green nanofibers as potential carriers for improving self-healing and mechanical properties of carbon fiber/epoxy prepregs

- Osteogenesis capability of three-dimensionally printed poly(lactic acid)-halloysite nanotube scaffolds containing strontium ranelate

- Silver nanoparticles induce mitochondria-dependent apoptosis and late non-canonical autophagy in HT-29 colon cancer cells

- Preparation and bonding mechanisms of polymer/metal hybrid composite by nano molding technology

- Damage self-sensing and strain monitoring of glass-reinforced epoxy composite impregnated with graphene nanoplatelet and multiwalled carbon nanotubes

- Thermal analysis characterisation of solar-powered ship using Oldroyd hybrid nanofluids in parabolic trough solar collector: An optimal thermal application

- Pyrene-functionalized halloysite nanotubes for simultaneously detecting and separating Hg(ii) in aqueous media: A comprehensive comparison on interparticle and intraparticle excimers

- Fabrication of self-assembly CNT flexible film and its piezoresistive sensing behaviors

- Thermal valuation and entropy inspection of second-grade nanoscale fluid flow over a stretching surface by applying Koo–Kleinstreuer–Li relation

- Mechanical properties and microstructure of nano-SiO2 and basalt-fiber-reinforced recycled aggregate concrete

- Characterization and tribology performance of polyaniline-coated nanodiamond lubricant additives

- Combined impact of Marangoni convection and thermophoretic particle deposition on chemically reactive transport of nanofluid flow over a stretching surface

- Spark plasma extrusion of binder free hydroxyapatite powder

- An investigation on thermo-mechanical performance of graphene-oxide-reinforced shape memory polymer

- Effect of nanoadditives on the novel leather fiber/recycled poly(ethylene-vinyl-acetate) polymer composites for multifunctional applications: Fabrication, characterizations, and multiobjective optimization using central composite design

- Design selection for a hemispherical dimple core sandwich panel using hybrid multi-criteria decision-making methods

- Improving tensile strength and impact toughness of plasticized poly(lactic acid) biocomposites by incorporating nanofibrillated cellulose

- Green synthesis of spinel copper ferrite (CuFe2O4) nanoparticles and their toxicity

- The effect of TaC and NbC hybrid and mono-nanoparticles on AA2024 nanocomposites: Microstructure, strengthening, and artificial aging

- Excited-state geometry relaxation of pyrene-modified cellulose nanocrystals under UV-light excitation for detecting Fe3+

- Effect of CNTs and MEA on the creep of face-slab concrete at an early age

- Effect of deformation conditions on compression phase transformation of AZ31

- Application of MXene as a new generation of highly conductive coating materials for electromembrane-surrounded solid-phase microextraction

- A comparative study of the elasto-plastic properties for ceramic nanocomposites filled by graphene or graphene oxide nanoplates

- Encapsulation strategies for improving the biological behavior of CdS@ZIF-8 nanocomposites

- Biosynthesis of ZnO NPs from pumpkin seeds’ extract and elucidation of its anticancer potential against breast cancer

- Preliminary trials of the gold nanoparticles conjugated chrysin: An assessment of anti-oxidant, anti-microbial, and in vitro cytotoxic activities of a nanoformulated flavonoid

- Effect of micron-scale pores increased by nano-SiO2 sol modification on the strength of cement mortar

- Fractional simulations for thermal flow of hybrid nanofluid with aluminum oxide and titanium oxide nanoparticles with water and blood base fluids

- The effect of graphene nano-powder on the viscosity of water: An experimental study and artificial neural network modeling

- Development of a novel heat- and shear-resistant nano-silica gelling agent

- Characterization, biocompatibility and in vivo of nominal MnO2-containing wollastonite glass-ceramic

- Entropy production simulation of second-grade magnetic nanomaterials flowing across an expanding surface with viscidness dissipative flux

- Enhancement in structural, morphological, and optical properties of copper oxide for optoelectronic device applications

- Aptamer-functionalized chitosan-coated gold nanoparticle complex as a suitable targeted drug carrier for improved breast cancer treatment

- Performance and overall evaluation of nano-alumina-modified asphalt mixture

- Analysis of pure nanofluid (GO/engine oil) and hybrid nanofluid (GO–Fe3O4/engine oil): Novel thermal and magnetic features

- Synthesis of Ag@AgCl modified anatase/rutile/brookite mixed phase TiO2 and their photocatalytic property

- Mechanisms and influential variables on the abrasion resistance hydraulic concrete

- Synergistic reinforcement mechanism of basalt fiber/cellulose nanocrystals/polypropylene composites

- Achieving excellent oxidation resistance and mechanical properties of TiB2–B4C/carbon aerogel composites by quick-gelation and mechanical mixing

- Microwave-assisted sol–gel template-free synthesis and characterization of silica nanoparticles obtained from South African coal fly ash

- Pulsed laser-assisted synthesis of nano nickel(ii) oxide-anchored graphitic carbon nitride: Characterizations and their potential antibacterial/anti-biofilm applications

- Effects of nano-ZrSi2 on thermal stability of phenolic resin and thermal reusability of quartz–phenolic composites

- Benzaldehyde derivatives on tin electroplating as corrosion resistance for fabricating copper circuit

- Mechanical and heat transfer properties of 4D-printed shape memory graphene oxide/epoxy acrylate composites

- Coupling the vanadium-induced amorphous/crystalline NiFe2O4 with phosphide heterojunction toward active oxygen evolution reaction catalysts

- Graphene-oxide-reinforced cement composites mechanical and microstructural characteristics at elevated temperatures

- Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar

- Preparation of layered gradient Cu–Cr–Ti alloy with excellent mechanical properties, thermal stability, and electrical conductivity

- Recovery of Cr from chrome-containing leather wastes to develop aluminum-based composite material along with Al2O3 ceramic particles: An ingenious approach

- Mechanisms of the improved stiffness of flexible polymers under impact loading

- Anticancer potential of gold nanoparticles (AuNPs) using a battery of in vitro tests

- Review Articles

- Proposed approaches for coronaviruses elimination from wastewater: Membrane techniques and nanotechnology solutions

- Application of Pickering emulsion in oil drilling and production

- The contribution of microfluidics to the fight against tuberculosis

- Graphene-based biosensors for disease theranostics: Development, applications, and recent advancements

- Synthesis and encapsulation of iron oxide nanorods for application in magnetic hyperthermia and photothermal therapy

- Contemporary nano-architectured drugs and leads for ανβ3 integrin-based chemotherapy: Rationale and retrospect

- State-of-the-art review of fabrication, application, and mechanical properties of functionally graded porous nanocomposite materials

- Insights on magnetic spinel ferrites for targeted drug delivery and hyperthermia applications

- A review on heterogeneous oxidation of acetaminophen based on micro and nanoparticles catalyzed by different activators

- Early diagnosis of lung cancer using magnetic nanoparticles-integrated systems

- Advances in ZnO: Manipulation of defects for enhancing their technological potentials

- Efficacious nanomedicine track toward combating COVID-19

- A review of the design, processes, and properties of Mg-based composites

- Green synthesis of nanoparticles for varied applications: Green renewable resources and energy-efficient synthetic routes

- Two-dimensional nanomaterial-based polymer composites: Fundamentals and applications

- Recent progress and challenges in plasmonic nanomaterials

- Apoptotic cell-derived micro/nanosized extracellular vesicles in tissue regeneration

- Electronic noses based on metal oxide nanowires: A review

- Framework materials for supercapacitors

- An overview on the reproductive toxicity of graphene derivatives: Highlighting the importance

- Antibacterial nanomaterials: Upcoming hope to overcome antibiotic resistance crisis

- Research progress of carbon materials in the field of three-dimensional printing polymer nanocomposites

- A review of atomic layer deposition modelling and simulation methodologies: Density functional theory and molecular dynamics

- Recent advances in the preparation of PVDF-based piezoelectric materials

- Recent developments in tensile properties of friction welding of carbon fiber-reinforced composite: A review

- Comprehensive review of the properties of fly ash-based geopolymer with additive of nano-SiO2

- Perspectives in biopolymer/graphene-based composite application: Advances, challenges, and recommendations

- Graphene-based nanocomposite using new modeling molecular dynamic simulations for proposed neutralizing mechanism and real-time sensing of COVID-19

- Nanotechnology application on bamboo materials: A review

- Recent developments and future perspectives of biorenewable nanocomposites for advanced applications

- Nanostructured lipid carrier system: A compendium of their formulation development approaches, optimization strategies by quality by design, and recent applications in drug delivery

- 3D printing customized design of human bone tissue implant and its application

- Design, preparation, and functionalization of nanobiomaterials for enhanced efficacy in current and future biomedical applications

- A brief review of nanoparticles-doped PEDOT:PSS nanocomposite for OLED and OPV

- Nanotechnology interventions as a putative tool for the treatment of dental afflictions

- Recent advancements in metal–organic frameworks integrating quantum dots (QDs@MOF) and their potential applications

- A focused review of short electrospun nanofiber preparation techniques for composite reinforcement

- Microstructural characteristics and nano-modification of interfacial transition zone in concrete: A review

- Latest developments in the upconversion nanotechnology for the rapid detection of food safety: A review

- Strategic applications of nano-fertilizers for sustainable agriculture: Benefits and bottlenecks

- Molecular dynamics application of cocrystal energetic materials: A review

- Synthesis and application of nanometer hydroxyapatite in biomedicine

- Cutting-edge development in waste-recycled nanomaterials for energy storage and conversion applications

- Biological applications of ternary quantum dots: A review

- Nanotherapeutics for hydrogen sulfide-involved treatment: An emerging approach for cancer therapy

- Application of antibacterial nanoparticles in orthodontic materials

- Effect of natural-based biological hydrogels combined with growth factors on skin wound healing

- Nanozymes – A route to overcome microbial resistance: A viewpoint

- Recent developments and applications of smart nanoparticles in biomedicine

- Contemporary review on carbon nanotube (CNT) composites and their impact on multifarious applications

- Interfacial interactions and reinforcing mechanisms of cellulose and chitin nanomaterials and starch derivatives for cement and concrete strength and durability enhancement: A review

- Diamond-like carbon films for tribological modification of rubber

- Layered double hydroxides (LDHs) modified cement-based materials: A systematic review

- Recent research progress and advanced applications of silica/polymer nanocomposites

- Modeling of supramolecular biopolymers: Leading the in silico revolution of tissue engineering and nanomedicine

- Recent advances in perovskites-based optoelectronics

- Biogenic synthesis of palladium nanoparticles: New production methods and applications

- A comprehensive review of nanofluids with fractional derivatives: Modeling and application

- Electrospinning of marine polysaccharides: Processing and chemical aspects, challenges, and future prospects

- Electrohydrodynamic printing for demanding devices: A review of processing and applications

- Rapid Communications

- Structural material with designed thermal twist for a simple actuation

- Recent advances in photothermal materials for solar-driven crude oil adsorption

Articles in the same Issue

- Research Articles

- Theoretical and experimental investigation of MWCNT dispersion effect on the elastic modulus of flexible PDMS/MWCNT nanocomposites

- Mechanical, morphological, and fracture-deformation behavior of MWCNTs-reinforced (Al–Cu–Mg–T351) alloy cast nanocomposites fabricated by optimized mechanical milling and powder metallurgy techniques

- Flammability and physical stability of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch/poly(lactic acid) blend bionanocomposites

- Glutathione-loaded non-ionic surfactant niosomes: A new approach to improve oral bioavailability and hepatoprotective efficacy of glutathione

- Relationship between mechano-bactericidal activity and nanoblades density on chemically strengthened glass

- In situ regulation of microstructure and microwave-absorbing properties of FeSiAl through HNO3 oxidation

- Research on a mechanical model of magnetorheological fluid different diameter particles

- Nanomechanical and dynamic mechanical properties of rubber–wood–plastic composites

- Investigative properties of CeO2 doped with niobium: A combined characterization and DFT studies

- Miniaturized peptidomimetics and nano-vesiculation in endothelin types through probable nano-disk formation and structure property relationships of endothelins’ fragments

- N/S co-doped CoSe/C nanocubes as anode materials for Li-ion batteries

- Synergistic effects of halloysite nanotubes with metal and phosphorus additives on the optimal design of eco-friendly sandwich panels with maximum flame resistance and minimum weight

- Octreotide-conjugated silver nanoparticles for active targeting of somatostatin receptors and their application in a nebulized rat model

- Controllable morphology of Bi2S3 nanostructures formed via hydrothermal vulcanization of Bi2O3 thin-film layer and their photoelectrocatalytic performances

- Development of (−)-epigallocatechin-3-gallate-loaded folate receptor-targeted nanoparticles for prostate cancer treatment

- Enhancement of the mechanical properties of HDPE mineral nanocomposites by filler particles modulation of the matrix plastic/elastic behavior

- Effect of plasticizers on the properties of sugar palm nanocellulose/cinnamon essential oil reinforced starch bionanocomposite films

- Optimization of nano coating to reduce the thermal deformation of ball screws

- Preparation of efficient piezoelectric PVDF–HFP/Ni composite films by high electric field poling

- MHD dissipative Casson nanofluid liquid film flow due to an unsteady stretching sheet with radiation influence and slip velocity phenomenon

- Effects of nano-SiO2 modification on rubberised mortar and concrete with recycled coarse aggregates

- Mechanical and microscopic properties of fiber-reinforced coal gangue-based geopolymer concrete

- Effect of morphology and size on the thermodynamic stability of cerium oxide nanoparticles: Experiment and molecular dynamics calculation

- Mechanical performance of a CFRP composite reinforced via gelatin-CNTs: A study on fiber interfacial enhancement and matrix enhancement

- A practical review over surface modification, nanopatterns, emerging materials, drug delivery systems, and their biophysiochemical properties for dental implants: Recent progresses and advances

- HTR: An ultra-high speed algorithm for cage recognition of clathrate hydrates

- Effects of microalloying elements added by in situ synthesis on the microstructure of WCu composites

- A highly sensitive nanobiosensor based on aptamer-conjugated graphene-decorated rhodium nanoparticles for detection of HER2-positive circulating tumor cells

- Progressive collapse performance of shear strengthened RC frames by nano CFRP

- Core–shell heterostructured composites of carbon nanotubes and imine-linked hyperbranched polymers as metal-free Li-ion anodes

- A Galerkin strategy for tri-hybridized mixture in ethylene glycol comprising variable diffusion and thermal conductivity using non-Fourier’s theory

- Simple models for tensile modulus of shape memory polymer nanocomposites at ambient temperature

- Preparation and morphological studies of tin sulfide nanoparticles and use as efficient photocatalysts for the degradation of rhodamine B and phenol

- Polyethyleneimine-impregnated activated carbon nanofiber composited graphene-derived rice husk char for efficient post-combustion CO2 capture

- Electrospun nanofibers of Co3O4 nanocrystals encapsulated in cyclized-polyacrylonitrile for lithium storage

- Pitting corrosion induced on high-strength high carbon steel wire in high alkaline deaerated chloride electrolyte

- Formulation of polymeric nanoparticles loaded sorafenib; evaluation of cytotoxicity, molecular evaluation, and gene expression studies in lung and breast cancer cell lines

- Engineered nanocomposites in asphalt binders

- Influence of loading voltage, domain ratio, and additional load on the actuation of dielectric elastomer

- Thermally induced hex-graphene transitions in 2D carbon crystals

- The surface modification effect on the interfacial properties of glass fiber-reinforced epoxy: A molecular dynamics study

- Molecular dynamics study of deformation mechanism of interfacial microzone of Cu/Al2Cu/Al composites under tension

- Nanocolloid simulators of luminescent solar concentrator photovoltaic windows

- Compressive strength and anti-chloride ion penetration assessment of geopolymer mortar merging PVA fiber and nano-SiO2 using RBF–BP composite neural network

- Effect of 3-mercapto-1-propane sulfonate sulfonic acid and polyvinylpyrrolidone on the growth of cobalt pillar by electrodeposition

- Dynamics of convective slippery constraints on hybrid radiative Sutterby nanofluid flow by Galerkin finite element simulation

- Preparation of vanadium by the magnesiothermic self-propagating reduction and process control

- Microstructure-dependent photoelectrocatalytic activity of heterogeneous ZnO–ZnS nanosheets

- Cytotoxic and pro-inflammatory effects of molybdenum and tungsten disulphide on human bronchial cells

- Improving recycled aggregate concrete by compression casting and nano-silica

- Chemically reactive Maxwell nanoliquid flow by a stretching surface in the frames of Newtonian heating, nonlinear convection and radiative flux: Nanopolymer flow processing simulation

- Nonlinear dynamic and crack behaviors of carbon nanotubes-reinforced composites with various geometries

- Biosynthesis of copper oxide nanoparticles and its therapeutic efficacy against colon cancer

- Synthesis and characterization of smart stimuli-responsive herbal drug-encapsulated nanoniosome particles for efficient treatment of breast cancer