Abstract

The author in order to solve the problem of optimizing the accuracy of mechanical equipment failure detection proposes a vibration signal collection and computer simulation detection for mechanical equipment failure. Using wavelet domain Wiener filtering-based mechanical equipment fault detection method, the author first combined Wiener filtering and wavelet threshold filtering, established a vibration signal collection model for mechanical equipment, obtained the true signal and the filtered signal error and fusion of the principle of wavelet threshold filtering to perform orthogonal wavelet transform on noisy signals, and through the principle of fast independent component analysis to separate the vibration signals of mechanical equipment, build the initial separation matrix of the signal with unit variance, and found the estimated value of the source signal; the collection of vibration signals of mechanical equipment is completed according to the estimated value, realizing the optimization of the detection of mechanical faults and equipment failures. The simulation results prove that the signal-to-noise ratio of the vibration signal of mechanical equipment collected by this method is higher than 15.7% of the signal-to-noise ratio based on the FastICA method; this is mainly because when this method is used for anti-interference collection of vibration signals of mechanical equipment, combining the principle of fast independent component analysis to separate the vibration signals of mechanical equipment, construct the initial separation matrix of the signal with unit variance. Using the proposed method for signal acquisition can greatly reduce the error, and it can provide effective support for fault detection of mechanical equipment.

1 Introduction

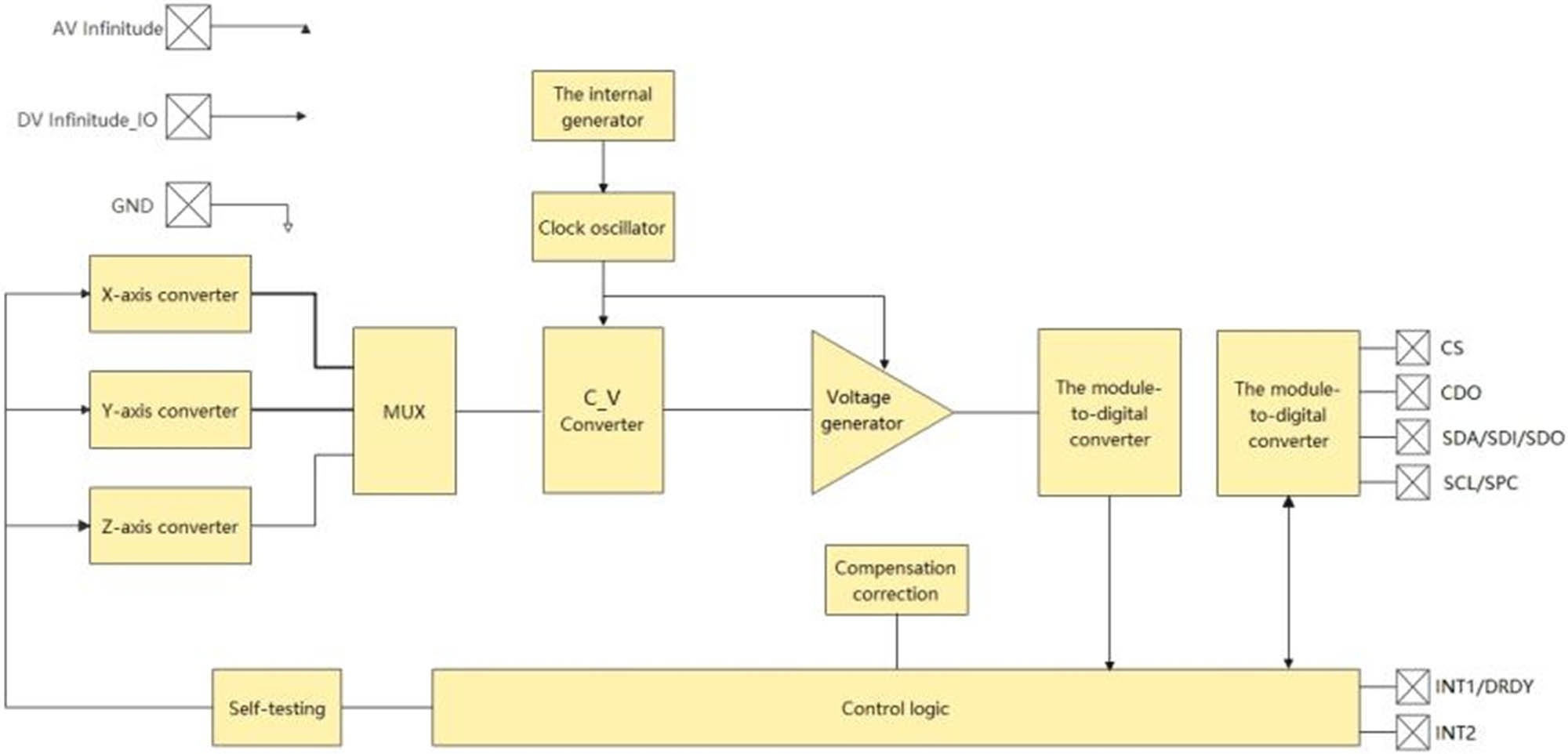

To effectively detect the operating status of power equipment and then perform fault diagnosis of mechanical equipment, find, and solve the problem in the early stage of the failure, a vibration signal collection and computer simulation detection for mechanical equipment failure are proposed. The coal conveying system equipment of thermal power plants is diverse and discrete, the environment is harsh, has high dust, and high electromagnetic interference, for coal handling system equipment testing, and most of the equipment is judged according to its mechanical vibration conditions [1]. Vibration is important status information in the process of mechanical equipment status detection and fault diagnosis, in order to reduce the loss caused by vibration; it is necessary to detect the vibration state of mechanical equipment, accurately measure the specific parameters of vibration, then provide early warning of equipment failure, and carry out equipment maintenance and maintenance in time [2]. Due to the complexity of mechanical equipment vibration, various factors need to be considered comprehensively in the vibration signal processing, including the accuracy in the data acquisition process and the influence of various noise interference in the data processing; it is a very complicated data processing process [3,4]. The traditional vibration detection method mainly realizes a single collection of vibration signals; in the process of signal and noise processing, the conventional spectrum analysis method is used to process, leading to a large error rate of the test results; it is difficult to guarantee the accuracy of the detection data, and this has attracted the attention of many scholars and researchers. The design compilation of the vibration signal detection system for mechanical equipment failure is shown in Figure 1.

Design compilation of vibration signal detection system for mechanical equipment failure.

Regarding the issue above, the author proposes a mechanical equipment fault vibration signal acquisition based on wavelet domain, Wiener filtering and computer simulation testing. A low-power, high-reliability vibration signal acquisition and processing system is introduced, using a built-in IC piezoelectric acceleration sensor, equipment vibration signals are collected; after collecting the signal processing, on the one hand, the data is transmitted to the PC through wireless transmission; on the other hand, the current vibration acceleration value of the detection device is displayed on the LCD screen of the display terminal. The simulation results prove that using the proposed method for signal acquisition can improve the efficiency of mechanical equipment fault detection and reduce the detection error. It has strong robustness.

2 Literature review

In the case of lateral vibration of mechanical equipment, the fault signal is disturbed by the lateral vibration generated by the equipment and presents the characteristics of low-frequency signal, as shown in Figure 2 [5]. When the traditional mean clustering method detects complex and large-scale equipment failures, due to the low frequency of the signal, failure convergence clustering must be performed first. In the process of convergent clustering, the K-means algorithm does not take into account the convergence characteristics of the phase neighbors of the low-frequency signal, causing the algorithm to converge too slowly; the detection time is too long and the accuracy is not high [6]. It focuses on the anti-interference acquisition method of mechanical equipment vibration signal based on pattern matching. This method first obtains the cycle start and end points of the signal, and gets the fundamental frequency period of the vibration signal; on this basis, the anti-interference collection of vibration signals of mechanical equipment is completed. The signal acquisition complexity of this method is low; however, when the current method is used for anti-interference collection of mechanical equipment vibration signals, it is difficult to resist the interference of external factors, and there is the problem of poor signal acquisition robustness [7]. It proposes an anti-jamming acquisition method based on improved particle swarms of mechanical equipment vibration signals. This method gives the criterion of the independence of the signal, defines the fourth-order cumulative of the signal random variable, fusion in the particle swarm theory takes kurtosis as the objective function, and optimizes the collection of vibration signals of mechanical equipment. This method has strong signal acquisition robustness; however, the signal acquisition process is cumbersome and time-consuming [8]. It introduces a micro-electro-mechanical system (MEMS) capacitive acceleration sensor bit detection system, and the acceleration of the detected object motion is converted into motion displacement by integration calculation, realizing real-time detection of the movement of objects. The method has good stability, but the hardware design only considers the collection of a single data and did not consider the impact of the surrounding environment; the applicability in a noisy environment is limited [9]. It introduces a displacement measurement method of a three-axis acceleration sensor, and it mainly uses the spectrum analysis method to calculate the displacement. This method uses the frequency domain method to remove the trend term and signal noise to obtain the vibration amplitude, but it did not consider the influence of the law of data changing with time [10]. It analyzes the motion trajectory of a single-axis acceleration sensor, aiming at noise and measurement errors; the Kalman filter is used to improve the accuracy of the measurement. This method only analyzes the vibration in a single direction, and no further optimization is considered in the later integration operation, and the accuracy is insufficient [11]. It proposes a fault detection method based on Drosophila optimization Regarding the signal-to-noise ratio output by the bistable stochastic resonance system as the taste concentration of the Drosophila optimization method, sub-sampling technology is used to select stochastic resonance system structure parameters and for complete periodic signal feature enhancement [12]. It uses data simulation and related data of bearing inner ring failure to conduct experiments, and experimental results show that the method is relatively simple; however, the convergence speed of fault detection is relatively slow, which cannot meet the requirements of modern technological development [13]. It proposes a fault signal detection method based on power function bistable stochastic resonance. Taking the gain of the average signal-to-noise ratio as a measurement index, a way to find the optimal system parameter combination is proposed. The weak signal and noise and the system can produce the best resonance effect. Based on the power function bistable stochastic resonance the simulation signal under Levy noise conditions is detected [14]. It uses wavelet transform combined with power function bistable stochastic resonance to detect bearing fault signals. Experiments show that this method has a certain stability, but this method also has the problem of a slow convergence rate [15]. It proposes an equipment fault detection method based on probability and wavelet analysis. Divide each layered wavelet coefficient by quantile data, according to the decomposition value of each layer, and the probability of failure at each position of the signal is calculated. Combine the wavelet threshold to analyze the calculation results. Experimental results show that the detection speed of this method is fast, but the detection accuracy is not ideal; that is, the detection accuracy coefficient is low [16].

Computer Failure Automatic Detection System.

3 Research methods

3.1 Principles of sampling, location, and detection of vibration information for mechanical equipment failure

The method of sampling and positioning detection of mechanical equipment vibration information first uses the microcontroller unit (MCU) main controller and completes the data collection of vibration information through the vibration sensor. The collected information is transmitted to the data analysis center through Ethernet for comprehensive analysis and optimization processing; finally, the vibration displacement is calculated [17]. The whole detection process is shown in Figure 3, and the specific steps of the method for sampling and positioning the vibration information of mechanical equipment are described in detail as follows.

Vibration information detection process of mechanical equipment.

Assuming that the data sampling is implemented in an analog way, analog/digital (A/D) conversion is then used to sample the vibration signal of mechanical equipment, and the sampled data are converted by the reference voltage and output the analog voltage value v proportional to the acceleration, as shown in the formula (1); the voltage value is converted to the acceleration value as shown in the formula (1):

Assuming that data sampling is implemented in digital mode, the serial peripheral interface (SPI) bus is then used to directly read the corresponding register, according to the numerical conversion manual of acceleration sensor; it is further converted into acceleration value [18]. After the sampled data are converted into acceleration value, using Kalman filtering method, process model and measurement model are used for state estimation to complete data filtering, and the two models are expressed by formula (2) and formula (3):

In the formula, x(k) is the variable to be estimated, w(k) is process noise, A(k) is the process matrix, z(k) is the data collected by the vibration sensor, c(k) is the measurement matrix, and v(k) is the measurement noise. According to the law that the value to be estimated changes over time, and according to A(k), the next state x(k + 1) is estimated from x(k), different noise variance models are established for different application fields, and all the collected data are iteratively calculated to complete the filtering of all the data.

The filtered acceleration data a i is calculated by quadratic integration, as expressed in Eq. (4), to obtain the displacement of vibration as shown in formula (4):

In the formula, n represents the number of collected data and Δt is the sampling time interval, which is determined by the sampling frequency.

In summary, the available vibration information sampling and positioning principle are discussed; this principle method is used to complete the sampling and positioning detection of vibration information of mechanical equipment.

3.2 Improving the realization of fault detection methods for mechanical equipment

Data sampling of vibration displacement detection system

The embedded data acquisition system consists of MCU main controller with UART, SPI, PIT, DMA, A/D, MEMS vibration sensor, and RS485 bus interface unit. It is composed of Ethernet physical interface unit to realize the sampling of analog quantity and digital quantity. The analog acceleration sensor uses A/D conversion to complete 8-bit to 24-bit precision data sampling. The hardware design circuit is shown in Figure 4.

Analog signal acquisition hardware design diagram.

Data collection of a digital acceleration sensor mainly uses the SPI bus to set and read the corresponding register of the acceleration sensor, and the setting procedure of the digital acceleration sensor is shown as in Figure 5.

Orthogonal wavelet transform of noisy signal

Data acquisition settings of the digital acceleration sensor.

When optimizing the detection and optimization of mechanical equipment failures, need to collect vibration signals, combine Wiener filtering and wavelet threshold filtering, get the ideal vibration signal, define the stationary random process of the signal, give the observation signal model, and get the unit sample response of the filter; the error between the real signal and the filtered signal is calculated, and the noisy signal is subjected to orthogonal wavelet transform through wavelet threshold filtering [19,20]. The specific steps are detailed as follows:

Assuming that y″ represents the ideal vibration signal, A represents the maximum value of the AC component of the vibration signal, w represents the angular frequency of the rotation of the mechanical shaft, ϕ represents the initial phase of the vibration signal, and t represents the duration of the vibration signal, then formula (7) is used to calculate the ideal vibration signal represented by A as shown in formula (5):

If E(y) represents the mathematical expectation of the signal stationary random process, R y (·) stands for autocorrelation function, t 1 and t 2 represent the signal duration at different moments, then formula (6) is to calculate E(y) as shown in formula (6):

In the above formula, I

drtp

represents the offset of the initial phase, and

Assuming that s(n) represents the real vibration signal of mechanical equipment, w(n) represents additive white Gaussian noise, and the observation signal model is given by Eq. (9) as shown in Eq. (7):

In the above formula, y′″(n) represents the FIR filter criterion, h(k) represents the unit sampling response of the FIR filter, and N′″ represents the filter order.

Suppose that e(n) represents the error between the real signal and the filtered signal, ϕ xx (m) represents the autocorrelation function of the observed signal x(n), ϕ xx (m) represents the real signal, then use formula (8) to calculate e(n) as shown in formula (8):

In the above formula, m jkp represents the influence of non-stationary noise on the signal, and I represents the ergodic coefficient.

Suppose that o jkp represents the wavelet decomposition coefficient, T sd represents the low-frequency coefficient of the signal, H ip represents the high-frequency coefficient of the signal, then use Eq. (11) to perform orthogonal wavelet transformation on the noisy signal through wavelet threshold filtering, as shown in Eq. (9):

In the above formula, γ swp represents the minimum-maximum variance threshold.

In summary, it can be explained that, in the anti-interference optimization collection process of vibration signals of mechanical equipment, first Wiener filtering and wavelet threshold filtering are combined, and the vibration signal acquisition model of mechanical equipment is set up to obtain the error between the real signal and the filtered signal; combining the principle of wavelet threshold filtering to perform orthogonal wavelet transform on noisy signals has laid the foundation for the realization of anti-jamming optimal collection of vibration signals of mechanical equipment [21].

4 Results discussion

In order to prove the effectiveness of the mechanical equipment fault detection method based on the wavelet domain Wiener filter, the author conducted an experiment. The author built a simulation platform for anti-interference acquisition of vibration signals of mechanical equipment in the MATLAB environment [22]. The experimental data come from the vibration source signal records of two different motors and add different degrees of Gaussian white noise interference to the source signal.

4.1 Signal acquisition effects of different methods

The proposed Wiener filtering method is adopted based on wavelet domain and based on FastICA method to carry out anti-interference acquisition experiment of mechanical equipment vibration signal; the effects of two different methods are compared for anti-interference collection of vibration signals of mechanical equipment. The comparison results are shown in Figures 6–8.

Source signal.

Signals collected by FastICA method.

Signals collected by the method.

It can be analyzed and explained in Figures 6–8, under certain interference conditions, the vibration signal effect of mechanical equipment is collected using this method; it is better than the vibration signal effect of mechanical equipment collected by FastICA method. This is mainly because when this method is used for anti-interference collection of vibration signals of mechanical equipment, first combine Wiener filtering and wavelet threshold filtering, establish a vibration signal collection model for mechanical equipment, and get the error between the real signal and the filtered signal; fusion of the principle of wavelet threshold filtering to perform orthogonal wavelet transform on noisy signals improved the effectiveness of the proposed wavelet domain Wiener filtering method for mechanical equipment vibration signal acquisition [23,24].

4.2 Comparison of signal-to-noise ratio of signals collected by different methods

The author uses the Wiener filtering method proposed in this article based on the wavelet domain, and based on FastICA method carried out anti-interference acquisition experiment of mechanical equipment vibration signal; the signal-to-noise ratio of the signals collected by the two different methods is compared, and the comparison result is shown in Figure 9.

Signal-to-noise ratio of signals collected by different methods.

It can be illustrated from Figure 9 the signal-to-noise ratio of the vibration signal of mechanical equipment collected by this method; it is higher than 15.7% of the signal-to-noise ratio based on the FastICA method. This is mainly because when this method is used for anti-interference collection of vibration signals of mechanical equipment, combining the principle of fast independent component analysis to separate the vibration signals of mechanical equipment, the initial separation matrix of the signal with unit variance is built; on this basis, an estimate of the source signal is obtained, completing the anti-interference collection of vibration signals of mechanical equipment; according to the estimated results, it guarantees the signal-to-noise ratio of this method to collect vibration signals of mechanical equipment [25].

5 Conclusion

In view of the large error rate and low accuracy of current methods in mechanical vibration detection, the author compared other literature methods and mechanical equipment fault detection method based on wavelet domain Wiener filtering; the hardware can realize the three-dimensional data collection of digital sensors and analog sensors, and the software analyzes the error factors of the acceleration data in the displacement calculation process. After experimental verification, the author compares with other literature methods; as a result, the method proposed by the author can effectively remove the influence of noise, reduce the error in the integration process, and significantly improve the accuracy of the vibration signal detection of mechanical equipment. Future research methods: The sample selection criteria of the active learning method are mainly aimed at the samples with high uncertainty of classification results, representative sample, and high probability of false positive, which improves the utilization rate of data by the model to a certain extent, but this is still established, on the basis that there is little difference in the number of fault samples of various categories. In practical engineering applications, in addition to the lack of labeled samples, the unbalanced number of faulty samples is also a big problem. In the future, it can be considered to take sampling and generation measures for a few samples based on the AL-DNN in this article to alleviate the problem of an unbalanced number of samples, leading to model bias.

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Barman J, Hazarika D. Linear and quadratic time-frequency analysis of vibration for fault detection and identification of nfr trains. IEEE Trans Instrum Meas. 2020;69(11):8902–9.10.1109/TIM.2020.2998888Suche in Google Scholar

[2] Chen HK, Wang TF, Wu SS, Li YY. Research on separation and enhancement of speech micro-vibration from macro motion. Optoelectron Lett. 2020;16(6):462–6.10.1007/s11801-020-9169-zSuche in Google Scholar

[3] Wang S, Jing B, Jiao X, Pan J. Degradation pattern identification and remaining useful life prediction for mechanical equipment using SKF-EN. IEEE Access. 2020;8:147662–72.10.1109/ACCESS.2020.3015783Suche in Google Scholar

[4] Borges F, Pinto A, Ribeiro D, Barbosa T, Ferreira D. An unsupervised method based on support vector machines and higher-order statistics for mechanical faults detection. IEEE Lat Am Trans. 2020;18(6):1093–101.10.1109/TLA.2020.9099687Suche in Google Scholar

[5] Kim Y, Park J, Na K, Yuan H, Youn BD, Kang CS. Phase-based time domain averaging (PTDA) for fault detection of a gearbox in an industrial robot using vibration signals. Mech Syst Signal Process. 2020;138:106544.10.1016/j.ymssp.2019.106544Suche in Google Scholar

[6] Shi H, Zhang H, Ma L, Sun Y, Zhang Y. Inductive-capacitive coulter counting: detection and differentiation of multi-contaminants in hydraulic oil using a microfluidic sensor. IEEE Sens J. 2020;21(2):2067–76.10.1109/JSEN.2020.3016000Suche in Google Scholar

[7] Charlier P, Cabon M, Herman C, Benouna F, Logier R, Houfflin-Debarge V, et al. Comparison of multiple cardiac signal acquisition technologies for heart rate variability analysis. J Clin Monit Comput. 2020;34(4):743–52.10.1007/s10877-019-00382-0Suche in Google Scholar PubMed

[8] Zhou W, Wei ZY, Wang GF, Han KN, Liu R, Ma LH. Transverse tensile deformation and failure of three-dimensional five-directional braided carbon fiber composites. Fibers Polym. 2021;22(4):1099–110.10.1007/s12221-021-9199-6Suche in Google Scholar

[9] Allen R, Wanersdorfer K, Zebley J, Emt-P GS, Rnmsn TC, Sarani B. Interhospital transfer of critically ill patients because of coronavirus disease 19–related respiratory failure. Air Med J. 2020;39(6):498–501.10.1016/j.amj.2020.07.007Suche in Google Scholar PubMed PubMed Central

[10] Dai W, Sun J, Huang T, Lu Z, Zhu L. Precision retaining time prediction of machining equipment based on operating vibration information. IEEE Access. 2020;8:144156–66.10.1109/ACCESS.2020.3014334Suche in Google Scholar

[11] Meddour I, Messekher SE, Younes R, Yallese MA. Selection of bearing health indicator by gra for anfis-based forecasting of remaining useful life. J Braz Soc Mech Sci Eng. 2021;43(3):1–14.10.1007/s40430-021-02878-wSuche in Google Scholar

[12] Yan H, Zhao Y, Yang R, Li T. Monitoring operational status of electromechanical systems using audiovisual information fusion. J Braz Soc Mech Sci Eng. 2020;42(8):1–13.10.1007/s40430-020-02522-zSuche in Google Scholar

[13] Yang H, Qin Y, Ren J, Gu J. Analysis of casting hook load on ladle crane. J Fail Anal Prev. 2020;21(1):1–7.10.1007/s11668-020-01075-6Suche in Google Scholar

[14] Tian M, Han L, Meng Q. Experimental study on the mechanical performance of grouted specimen with composite ultrafine cement grouts. KSCE J Civ Eng. 2020;24(1):38–48.10.1007/s12205-020-0040-3Suche in Google Scholar

[15] Doan DC, Tansel Y. Reliability centered maintenance analysis using analytic hierarchy process for electro-mechanical actuators. Aerotecnica Missili Spazio. 2021;100(4):321–35.10.1007/s42496-021-00089-zSuche in Google Scholar

[16] Rahmani S, Heidari A, Saed B, Mahpour A, Navidbakhsh M, Alizadeh M. Biomechanical, structural and performance analysis of a specific type of cardiac assist device used in left ventricular failures. Iran J Sci Technol Trans Mech Eng. 2020;44(4):1053–64.10.1007/s40997-019-00304-0Suche in Google Scholar

[17] Li Y, Li H, Wei G. Failure correlation reliability analysis of solid rocket motor grain based on polynomial chaos expansion. J Mech Sci Technol. 2020;34(5):1–7.10.1007/s12206-020-0710-6Suche in Google Scholar

[18] Du Y, Feng G, Kang H, Zhang Y, Zhang X. Effects of steel fiber grout on the mechanical performance and failure characteristics of fully grouted bolts. Structures. 2021;33(1):1096–1106.10.1016/j.istruc.2021.05.013Suche in Google Scholar

[19] Guo X, Liu W, Li X, Shi H, Song Z. Fatigue resistance and failure behavior of penetration and non-penetration laser welded lap joints. Chin J Mech Eng. 2021;34(1):1–10.10.1186/s10033-021-00557-4Suche in Google Scholar

[20] Rao P, Katz D, Hieda M, Sabe M. How to manage temporary mechanical circulatory support devices in the critical care setting. Heart Fail Clin. 2020;16(3):283–93.10.1016/j.hfc.2020.03.001Suche in Google Scholar PubMed

[21] Nie G, Wang X, Shen L, Cai Y. A fast method for the acquisition of weak long-code signal. GPS Solut. 2020;24(4):1–13.10.1007/s10291-020-01018-6Suche in Google Scholar

[22] Thomas D. Failure analysis of forestry equipment for product improvement in extreme environments. J Fail Anal Prev. 2020;20(6):1811–3.10.1007/s11668-020-01044-zSuche in Google Scholar

[23] Bashir MS, Alouini MS. Signal acquisition with photon-counting detector arrays in free-space optical communications. IEEE Trans Wirel Commun. 2020;19(4):2181–95.10.1109/TWC.2019.2962670Suche in Google Scholar

[24] Konduru AK, Iqbal J. Multidimensional feature diversity based speech signal acquisition. Int J Speech Technol. 2020;23(3):527–35.10.1007/s10772-020-09736-5Suche in Google Scholar

[25] Kavuri A, Das M. Relative contributions of anatomical and quantum noise in signal detection and perception of tomographic digital breast images. IEEE Trans Med Imaging. 2020;39(11):3321–30.10.1109/TMI.2020.2991295Suche in Google Scholar PubMed

© 2022 Yonggang Wang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Fractal approach to the fluidity of a cement mortar

- Novel results on conformable Bessel functions

- The role of relaxation and retardation phenomenon of Oldroyd-B fluid flow through Stehfest’s and Tzou’s algorithms

- Damage identification of wind turbine blades based on dynamic characteristics

- Improving nonlinear behavior and tensile and compressive strengths of sustainable lightweight concrete using waste glass powder, nanosilica, and recycled polypropylene fiber

- Two-point nonlocal nonlinear fractional boundary value problem with Caputo derivative: Analysis and numerical solution

- Construction of optical solitons of Radhakrishnan–Kundu–Lakshmanan equation in birefringent fibers

- Dynamics and simulations of discretized Caputo-conformable fractional-order Lotka–Volterra models

- Research on facial expression recognition based on an improved fusion algorithm

- N-dimensional quintic B-spline functions for solving n-dimensional partial differential equations

- Solution of two-dimensional fractional diffusion equation by a novel hybrid D(TQ) method

- Investigation of three-dimensional hybrid nanofluid flow affected by nonuniform MHD over exponential stretching/shrinking plate

- Solution for a rotational pendulum system by the Rach–Adomian–Meyers decomposition method

- Study on the technical parameters model of the functional components of cone crushers

- Using Krasnoselskii's theorem to investigate the Cauchy and neutral fractional q-integro-differential equation via numerical technique

- Smear character recognition method of side-end power meter based on PCA image enhancement

- Significance of adding titanium dioxide nanoparticles to an existing distilled water conveying aluminum oxide and zinc oxide nanoparticles: Scrutinization of chemical reactive ternary-hybrid nanofluid due to bioconvection on a convectively heated surface

- An analytical approach for Shehu transform on fractional coupled 1D, 2D and 3D Burgers’ equations

- Exploration of the dynamics of hyperbolic tangent fluid through a tapered asymmetric porous channel

- Bond behavior of recycled coarse aggregate concrete with rebar after freeze–thaw cycles: Finite element nonlinear analysis

- Edge detection using nonlinear structure tensor

- Synchronizing a synchronverter to an unbalanced power grid using sequence component decomposition

- Distinguishability criteria of conformable hybrid linear systems

- A new computational investigation to the new exact solutions of (3 + 1)-dimensional WKdV equations via two novel procedures arising in shallow water magnetohydrodynamics

- A passive verses active exposure of mathematical smoking model: A role for optimal and dynamical control

- A new analytical method to simulate the mutual impact of space-time memory indices embedded in (1 + 2)-physical models

- Exploration of peristaltic pumping of Casson fluid flow through a porous peripheral layer in a channel

- Investigation of optimized ELM using Invasive Weed-optimization and Cuckoo-Search optimization

- Analytical analysis for non-homogeneous two-layer functionally graded material

- Investigation of critical load of structures using modified energy method in nonlinear-geometry solid mechanics problems

- Thermal and multi-boiling analysis of a rectangular porous fin: A spectral approach

- The path planning of collision avoidance for an unmanned ship navigating in waterways based on an artificial neural network

- Shear bond and compressive strength of clay stabilised with lime/cement jet grouting and deep mixing: A case of Norvik, Nynäshamn

- Communication

- Results for the heat transfer of a fin with exponential-law temperature-dependent thermal conductivity and power-law temperature-dependent heat transfer coefficients

- Special Issue: Recent trends and emergence of technology in nonlinear engineering and its applications - Part I

- Research on fault detection and identification methods of nonlinear dynamic process based on ICA

- Multi-objective optimization design of steel structure building energy consumption simulation based on genetic algorithm

- Study on modal parameter identification of engineering structures based on nonlinear characteristics

- On-line monitoring of steel ball stamping by mechatronics cold heading equipment based on PVDF polymer sensing material

- Vibration signal acquisition and computer simulation detection of mechanical equipment failure

- Development of a CPU-GPU heterogeneous platform based on a nonlinear parallel algorithm

- A GA-BP neural network for nonlinear time-series forecasting and its application in cigarette sales forecast

- Analysis of radiation effects of semiconductor devices based on numerical simulation Fermi–Dirac

- Design of motion-assisted training control system based on nonlinear mechanics

- Nonlinear discrete system model of tobacco supply chain information

- Performance degradation detection method of aeroengine fuel metering device

- Research on contour feature extraction method of multiple sports images based on nonlinear mechanics

- Design and implementation of Internet-of-Things software monitoring and early warning system based on nonlinear technology

- Application of nonlinear adaptive technology in GPS positioning trajectory of ship navigation

- Real-time control of laboratory information system based on nonlinear programming

- Software engineering defect detection and classification system based on artificial intelligence

- Vibration signal collection and analysis of mechanical equipment failure based on computer simulation detection

- Fractal analysis of retinal vasculature in relation with retinal diseases – an machine learning approach

- Application of programmable logic control in the nonlinear machine automation control using numerical control technology

- Application of nonlinear recursion equation in network security risk detection

- Study on mechanical maintenance method of ballasted track of high-speed railway based on nonlinear discrete element theory

- Optimal control and nonlinear numerical simulation analysis of tunnel rock deformation parameters

- Nonlinear reliability of urban rail transit network connectivity based on computer aided design and topology

- Optimization of target acquisition and sorting for object-finding multi-manipulator based on open MV vision

- Nonlinear numerical simulation of dynamic response of pile site and pile foundation under earthquake

- Research on stability of hydraulic system based on nonlinear PID control

- Design and simulation of vehicle vibration test based on virtual reality technology

- Nonlinear parameter optimization method for high-resolution monitoring of marine environment

- Mobile app for COVID-19 patient education – Development process using the analysis, design, development, implementation, and evaluation models

- Internet of Things-based smart vehicles design of bio-inspired algorithms using artificial intelligence charging system

- Construction vibration risk assessment of engineering projects based on nonlinear feature algorithm

- Application of third-order nonlinear optical materials in complex crystalline chemical reactions of borates

- Evaluation of LoRa nodes for long-range communication

- Secret information security system in computer network based on Bayesian classification and nonlinear algorithm

- Experimental and simulation research on the difference in motion technology levels based on nonlinear characteristics

- Research on computer 3D image encryption processing based on the nonlinear algorithm

- Outage probability for a multiuser NOMA-based network using energy harvesting relays

Artikel in diesem Heft

- Research Articles

- Fractal approach to the fluidity of a cement mortar

- Novel results on conformable Bessel functions

- The role of relaxation and retardation phenomenon of Oldroyd-B fluid flow through Stehfest’s and Tzou’s algorithms

- Damage identification of wind turbine blades based on dynamic characteristics

- Improving nonlinear behavior and tensile and compressive strengths of sustainable lightweight concrete using waste glass powder, nanosilica, and recycled polypropylene fiber

- Two-point nonlocal nonlinear fractional boundary value problem with Caputo derivative: Analysis and numerical solution

- Construction of optical solitons of Radhakrishnan–Kundu–Lakshmanan equation in birefringent fibers

- Dynamics and simulations of discretized Caputo-conformable fractional-order Lotka–Volterra models

- Research on facial expression recognition based on an improved fusion algorithm

- N-dimensional quintic B-spline functions for solving n-dimensional partial differential equations

- Solution of two-dimensional fractional diffusion equation by a novel hybrid D(TQ) method

- Investigation of three-dimensional hybrid nanofluid flow affected by nonuniform MHD over exponential stretching/shrinking plate

- Solution for a rotational pendulum system by the Rach–Adomian–Meyers decomposition method

- Study on the technical parameters model of the functional components of cone crushers

- Using Krasnoselskii's theorem to investigate the Cauchy and neutral fractional q-integro-differential equation via numerical technique

- Smear character recognition method of side-end power meter based on PCA image enhancement

- Significance of adding titanium dioxide nanoparticles to an existing distilled water conveying aluminum oxide and zinc oxide nanoparticles: Scrutinization of chemical reactive ternary-hybrid nanofluid due to bioconvection on a convectively heated surface

- An analytical approach for Shehu transform on fractional coupled 1D, 2D and 3D Burgers’ equations

- Exploration of the dynamics of hyperbolic tangent fluid through a tapered asymmetric porous channel

- Bond behavior of recycled coarse aggregate concrete with rebar after freeze–thaw cycles: Finite element nonlinear analysis

- Edge detection using nonlinear structure tensor

- Synchronizing a synchronverter to an unbalanced power grid using sequence component decomposition

- Distinguishability criteria of conformable hybrid linear systems

- A new computational investigation to the new exact solutions of (3 + 1)-dimensional WKdV equations via two novel procedures arising in shallow water magnetohydrodynamics

- A passive verses active exposure of mathematical smoking model: A role for optimal and dynamical control

- A new analytical method to simulate the mutual impact of space-time memory indices embedded in (1 + 2)-physical models

- Exploration of peristaltic pumping of Casson fluid flow through a porous peripheral layer in a channel

- Investigation of optimized ELM using Invasive Weed-optimization and Cuckoo-Search optimization

- Analytical analysis for non-homogeneous two-layer functionally graded material

- Investigation of critical load of structures using modified energy method in nonlinear-geometry solid mechanics problems

- Thermal and multi-boiling analysis of a rectangular porous fin: A spectral approach

- The path planning of collision avoidance for an unmanned ship navigating in waterways based on an artificial neural network

- Shear bond and compressive strength of clay stabilised with lime/cement jet grouting and deep mixing: A case of Norvik, Nynäshamn

- Communication

- Results for the heat transfer of a fin with exponential-law temperature-dependent thermal conductivity and power-law temperature-dependent heat transfer coefficients

- Special Issue: Recent trends and emergence of technology in nonlinear engineering and its applications - Part I

- Research on fault detection and identification methods of nonlinear dynamic process based on ICA

- Multi-objective optimization design of steel structure building energy consumption simulation based on genetic algorithm

- Study on modal parameter identification of engineering structures based on nonlinear characteristics

- On-line monitoring of steel ball stamping by mechatronics cold heading equipment based on PVDF polymer sensing material

- Vibration signal acquisition and computer simulation detection of mechanical equipment failure

- Development of a CPU-GPU heterogeneous platform based on a nonlinear parallel algorithm

- A GA-BP neural network for nonlinear time-series forecasting and its application in cigarette sales forecast

- Analysis of radiation effects of semiconductor devices based on numerical simulation Fermi–Dirac

- Design of motion-assisted training control system based on nonlinear mechanics

- Nonlinear discrete system model of tobacco supply chain information

- Performance degradation detection method of aeroengine fuel metering device

- Research on contour feature extraction method of multiple sports images based on nonlinear mechanics

- Design and implementation of Internet-of-Things software monitoring and early warning system based on nonlinear technology

- Application of nonlinear adaptive technology in GPS positioning trajectory of ship navigation

- Real-time control of laboratory information system based on nonlinear programming

- Software engineering defect detection and classification system based on artificial intelligence

- Vibration signal collection and analysis of mechanical equipment failure based on computer simulation detection

- Fractal analysis of retinal vasculature in relation with retinal diseases – an machine learning approach

- Application of programmable logic control in the nonlinear machine automation control using numerical control technology

- Application of nonlinear recursion equation in network security risk detection

- Study on mechanical maintenance method of ballasted track of high-speed railway based on nonlinear discrete element theory

- Optimal control and nonlinear numerical simulation analysis of tunnel rock deformation parameters

- Nonlinear reliability of urban rail transit network connectivity based on computer aided design and topology

- Optimization of target acquisition and sorting for object-finding multi-manipulator based on open MV vision

- Nonlinear numerical simulation of dynamic response of pile site and pile foundation under earthquake

- Research on stability of hydraulic system based on nonlinear PID control

- Design and simulation of vehicle vibration test based on virtual reality technology

- Nonlinear parameter optimization method for high-resolution monitoring of marine environment

- Mobile app for COVID-19 patient education – Development process using the analysis, design, development, implementation, and evaluation models

- Internet of Things-based smart vehicles design of bio-inspired algorithms using artificial intelligence charging system

- Construction vibration risk assessment of engineering projects based on nonlinear feature algorithm

- Application of third-order nonlinear optical materials in complex crystalline chemical reactions of borates

- Evaluation of LoRa nodes for long-range communication

- Secret information security system in computer network based on Bayesian classification and nonlinear algorithm

- Experimental and simulation research on the difference in motion technology levels based on nonlinear characteristics

- Research on computer 3D image encryption processing based on the nonlinear algorithm

- Outage probability for a multiuser NOMA-based network using energy harvesting relays