Abstract

Concrete is one of the most extensively utilized building materials that can be produced, and has the potential to release a significant quantity of CO2 into the environment. In this research, through studying lightweight (LW) concrete, attempts are made to produce environmentally friendly LW concrete with high strength using nanosilica rather than part of the cement and waste glass powder instead of aggregates. Recycled polypropylene fibers are used to increase the concrete’s compressive strength and nonlinear behavior. The use of glass powder was 20, 25, and 30% of the weight of aggregates, the consumption of nanosilica was 1, 2, and 3% of the weight of cement, and the consumption of recycled fibers (FORTA Ferro-Green) was 0.5, 1, and 1.5% of the weight of cement. Leca is also utilized as a LW aggregate. According to 7- and 28-day experimentation results and field emission scanning electron microscope analysis, the best sample had 1.5% fiber, 3% nanosilica, and 25% waste glass powder, and had a compressive and tensile strengths of roughly 1.7 and 1.6 times, respectively, those of the control specimen after 28 days. Also, using 3% nanosilica instead of cement can reduce greenhouse gas emissions by about 3%.

1 Introduction

The amount of CO2 produced during manufacturing of the ordinary Portland cement (OPC) is 7% of total wastes generated in the atmosphere. This amount of CO2, which also affects produced concrete quality, could be reduced by manufacturing green concrete,. The other solution is the application of supplementary materials of cementitious type [1].

Among the cementitious products, one could refer to nanomaterials that possess a very small size, often smaller than 100 nm [2], and due to this feature, they exhibit different mechanical and physical characteristics that make them distinct from other materials. Because of these characteristics, these materials have been under the focus of attention by many researchers and have found applications in various industries in recent decades [3,4]. Also, nanomaterials exhibit increased compressive strength and enhanced permeability when used in cement due to their very large surface area. The increase in compressive strength has been studied by a researcher [3,5], where it has been shown that the addition of nanoparticles as a partial replacement for cement decreases the amount of corrosion; therefore, it has been found that using nanoparticles in ordinary concrete has many advantages. Many researchers have realized that nanoparticles in the concrete make it more compact with a higher homogeneity [6]. Examples of nanosilica in the form of cementitious material are silica [7,8], nanoclay [5,9–12], carbon nanotubes [13,14], nano titania [15–17], nano alumina, carbon nanofiber [18–21], nano zinc [22], nanographene oxide [23], nano metakaolin [24], nano-ZrO2C, modified montmorillonite clay nanoparticles [25], and nano iron oxide [26,27]. This study reviews the research on the effects of nanosilica material on the splitting tensile strength, compressive strength, and flexural strength of lightweight (LW) concrete [28].

Researchers [29] studied the impact of nanosilica on the compressive strength of LW concrete in cellular form. For this purpose, a number of cellular LW concrete specimens that contained nanosilica at 5 wt% of cement were tested. To make a comparison, a number of specimens were also prepared that lacked nanosilica material. The specimens were tested at 3, 7, and 28-days of age. The results of their study revealed that even a slight amount of nanosilica improved the compressive strength in comparison to specimens that lacked this material (Figure 1). Also, it was known that adding nanosilica increases the compressive strength even at early ages, which is due to the pozzolanic activity. Researchers prepared various concrete mixes, including those that lacked any amount of nanosilica (as control specimens) and specimens containing just cement and specimens that contained (1 and 2%) nanosilica and specimens that contained cement and slag at 60% (as an alternative to cement) in addition to the same percentages of nanosilica used in the specimens [31]. Then, they conducted compressive strength tests on the abovementioned LW concrete specimens. Their research results revealed that the compressive strength of both specimens was enhanced by an increase in the percentage of used nanosilica. Furthermore, it was observed that this effect is more obvious in the early ages than later ones. Figure 2 shows the compressive strength test results for various percentages of nanosilica used in the specimens. In another study, Atmaca et al. examined the impact of adding nanosilica on the mechanical characteristics of high-strength LW concrete [32]. The specimens were prepared in two groups; the first comprised of 5 specimens with different replacement percentages of 0, 10, 20, 30, and 40% of LW aggregates instead of normal aggregates. The second group of specimens comprised the abovementioned materials and percentages but with added nanosilica at 3% to all the specimens. The results of compressive strength tests performed on the specimens showed that the specimens containing nanosilica (at 3%) exhibited a higher compressive strength than those which lacked nanosilica (with the same replaced nanosilica percentages instead of LW material) at different ages (3, 7, 28, and 90 days). Furthermore, the splitting tensile strength was also investigated for the 2 abovementioned groups at 28- and 90-days of age. As observed in Figure 3, it was found that the presence of nanosilica in the LW concrete, regardless of the used percentage of LA aggregates, had caused an increase in the tensile strength.

![Figure 1

Compressive strength of all specimens [30].](/document/doi/10.1515/nleng-2022-0008/asset/graphic/j_nleng-2022-0008_fig_001.jpg)

Compressive strength of all specimens [30].

![Figure 2

Compressive strength of LW concrete; (a): cement + nanosilica and (b) cement + slag + nanosilica [31].](/document/doi/10.1515/nleng-2022-0008/asset/graphic/j_nleng-2022-0008_fig_002.jpg)

Compressive strength of LW concrete; (a): cement + nanosilica and (b) cement + slag + nanosilica [31].

![Figure 3

Splitting tensile strength of LW concrete [32].](/document/doi/10.1515/nleng-2022-0008/asset/graphic/j_nleng-2022-0008_fig_003.jpg)

Splitting tensile strength of LW concrete [32].

In another research, researchers used two dosages of nanosilica to achieve high-performance LW concrete [33]. The majority of research works have used dosages in the range of 3–10% of nanosilica in the concrete to examine the behavior of LW concrete with this type of nanomaterial. Due to the high cost of this material, the nanosilica percentages applied in the mixes were 0, 0.05, 0.10, 0.20, and 1 wt% of cement in the compressive and flexural strengths tests. The results revealed a nonlinear relation between dosages of used nanosilica and the tensile and compressive strengths, and even a small percentage of nanosilica could improve the compressive strength and flexural strength. Furthermore, it was found that concrete strength is enhanced by up to 0.10 wt% of cement (the critical point), and further increase in nanosilica results in reduced concrete strength properties.

In another study, it was found that adding nanosilica at different dosages enhanced the compressive strength of LW concrete [34]. The authors applied 4 nanosilica percentages of 0, 1, 2, and 3% to examine its effect on the shrinkage, compressive strength, and sensitivity to the formation of initial cracks in the LW concrete specimens prepared with two aggregate types. They found that the compressive strength increases with the age of specimens, and this increase in strength has a higher rate at an early age, but then it decreases with time. The other finding was that the maximum compressive strength was obtained at 3% use of nanosilica, which was true for all the specimen ages, i.e., 3, 7, and 28 days. Concerning the shrinkage test, it was observed that adding nanosilica at all the studied percentages did not have a noticeable effect on the long-term shrinkage strain of the LW concrete specimens, but increasing the nanosilica dosages in LW concrete specimens caused an increase in the shrinkage strain percentage. It has been illustrated by Kamasamudram et al. that nanosilica has a positive effect on cement paste rheology, microscopic phase formation, hydration, and compressive strength [35].

Furthermore, it was observed that using nanosilica caused a reduction in the area where early cracks were formed in LW concrete. Other researchers also applied different ratios of nanosilica in LW concrete to study the characteristics of LW concrete specimens made with LW aggregates [36]. The concrete used for testing by the researchers mentioned above had a density in the range of 1,400–1,500 kg/m3. Assessing the role of nanosilica in the behavior of specimens made of LW concrete was based on the results obtained from conducting tests of tensile and compressive strengths having nanosilica ratios of 0, 0.75, 1.5, and 2.5%. The obtained results showed that adding nanosilica clearly increases both the tensile and compressive strengths, and the obtained results were much higher than those obtained from specimens that lacked nanosilica. The authors reported that the mixtures containing 0.75 and 2% nanosilica exhibited higher strength than the specimens containing 1.5% nanosilica, but the maximum tensile strength corresponded to 2% use of nanosilica in the specimens. Researchers, in another research, examined the effect of adding nanosilica on the compressive and flexural strengths of mixtures having densities ranging from 900 to 1,000 kg/m3. They used nanosilica at 0, 1, 2, and 4 wt% of cement in the mixtures [37]. Their research also revealed an obvious increase in the compressive strength of concrete specimens by adding nanosilica. The same results were obtained for the flexural strength, especially at 2 and 4 wt% of cement ratios. In another research, Suleiman et al. investigated the compressive strength of LW concrete wherein burnt bricks were used as coarse aggregates, and nanosilica was added to the specimens at 0, 1, 2, and 3%. They concluded that increasing the ratio of used nanosilica increases the compressive strength, and the maximum strength corresponds to 3% use of nanosilica [30]. Orouji et al. found that adding 1.5% fiber in concrete improves flexural strength significantly [38]. In another research, Mortezagholi et al. deduced that using microsilica gel can improve compressive and flexural strengths of concrete [39]. McSwain et al. found that using fibers in concrete can make ultra-high-performance concrete [40]. Also, Landis et al. proved that fibers in concrete could improve the energy dissipation mechanism [41].

According to previous research, it was found that using nanosilica can increase the compressive strength of LW concrete. In this study, waste glass powder and recycled polypropylene (PP) fibers are used to make LW and environmentally friendly concrete from nanosilica. Percentage of used nanosilica is 1, 2, and 3% instead of cement weight, percentage of used waste glass powder is 20, 25, and 30% instead of fine aggregates, and percentage of recycled PP fibers is 0.5, 1, and 1.5% by weight of cement. After making compressive and tensile specimens and performing slump tests, the specimens are tested according to the standard after 7 days and 28 days, and their results are evaluated.

2 Experimental program

2.1 Specifications of used materials

2.1.1 Water

The water quality and conditions in fiber-reinforced concrete are similar to those in regular concrete. Water should be devoid of dangerous chemicals such as iron oxides, acids, alkalis, salts, organic debris, chloride ions, and other contaminants. Impurities in water may disrupt cement setting, diminish concrete strength and durability, create discoloration, stain the concrete surface, and even corrode the reinforcing. In this investigation, drinking water was utilized. Table 1 shows the chemical properties of water.

Chemical analysis of water

| Water resource | TDS | Sulfate | CaCO3 | pH |

|---|---|---|---|---|

| Drinking water | 339 | 56 | 135 | 7.3 |

2.1.2 Superplasticizer

Due to the usage of fibers and the difficulties in combining fibers with concrete, and to improve the workability of the concrete, Abadgaran Company’s POWER PLAST-ES superplasticizer with polycarboxylate chemical base was included following ASTM C1017 and ASTM C494 standards. This minimizes water usage while increasing concrete strength and workability. The material utilized is 0.3–0.6% of the cement’s weight. Table 2 shows the superplasticizer specs.

Chemical properties of superplasticizer

| Properties | |

|---|---|

| Appearance | Liquid-light brown |

| Chloride ion | Less than 0.1% |

| pH | 6.5–7.5 |

| Freezing point | 2°C |

2.1.3 Nanosilica

According to the previous studies, by the addition of nanosilica, the concrete strength increases, but on the other hand, too much nanosilica, due to the fineness of grains, increases water absorption amount concerning cement. This consequently increases the amount of concrete water and reduces the strength. Therefore, to investigate the role of nanosilica on concrete strength, 3 nanosilica dosages of 1, 2, and 3% were used for cement replacements. In Tables 3 and 4, chemical and physical properties of nanosilica are shown, respectively.

Chemical properties of nanosilica

| By weight% | Compounds |

|---|---|

| 75–98 | SiO2 |

| 0.03–5.78 | Al2O3 |

| 0.06–4.54 | Fe2O3 |

| 0.01 ± 0.83 | CaO |

| 0.36 ± 0.52 | MgO |

| 1.15 ± 2.02 | K2O |

| 0.17 ± 0.23 | Na2O |

Physical properties of nanosilica

| Physical properties of nanosilica | Limits |

|---|---|

| Type | Liquid |

| Color | Milky white |

| Specific weight (g/cm3) | 1,400 |

2.1.4 Aggregate

2.1.4.1 Sand, gravel, and Leca

In this research, the used rock materials included the river bed sand and LW Leca produced by Leca Co. of Saveh City. The sand grading was performed according to ASTM C33 standard, and LW Leca grading was according to ASTM C330.

Leca, due to its unique characteristics such as low weight, low electrical conductivity, appropriate sound insulation, resistance against fire, durability, and chemical stability, is one of the most utilized LW aggregates made from expanded clay soil.

The water absorption percentages of sand and LW Leca aggregates were 1.4 and 6%, respectively, according to ASTM C128 standard. According to the performed test, the sand surface moisture used in this research was 5.4% and based on ASTM D2216-90 standard.

2.1.4.2 Waste glass powder

Table 5 shows the varied sizes of waste glass utilized in the specimens that included glass powder. Table 6 shows the chemical composition and physical qualities of waste glass, which was made up of a mix of window glass waste and canned glass in this investigation. The waste glass powder is used as a partial substitute for fine aggregates in 3 dosages: 20, 25, and 30%. The used waste glass powder is illustrated in Figure 4.

Gradation and dosage of waste glass powder

| Size (µm) | % (by weight) |

|---|---|

| 1–125 | 0.33 |

| 300–500 | 0.33 |

| 500–700 | 0.33 |

Chemical composition and physical properties of waste glass powder

| Chemical composition | % | Physical properties | |

|---|---|---|---|

| Al2O3 | 0.48 | Pozzolanic index (%) | 77 |

| MgO | 3.90 | Density | 1,752 |

| CaO | 8.82 | Fineness modulus | 2.82 |

| Fe2O3 | 0.08 | Water absorption | 0.44 |

| TiO2 | — | Color | White – light gray |

| SiO2 | 69.42 | ||

| Na2O | 12.28 | ||

| K2O | 0.12 | ||

Samples per gradation of waste glass powder.

2.1.5 Fibers

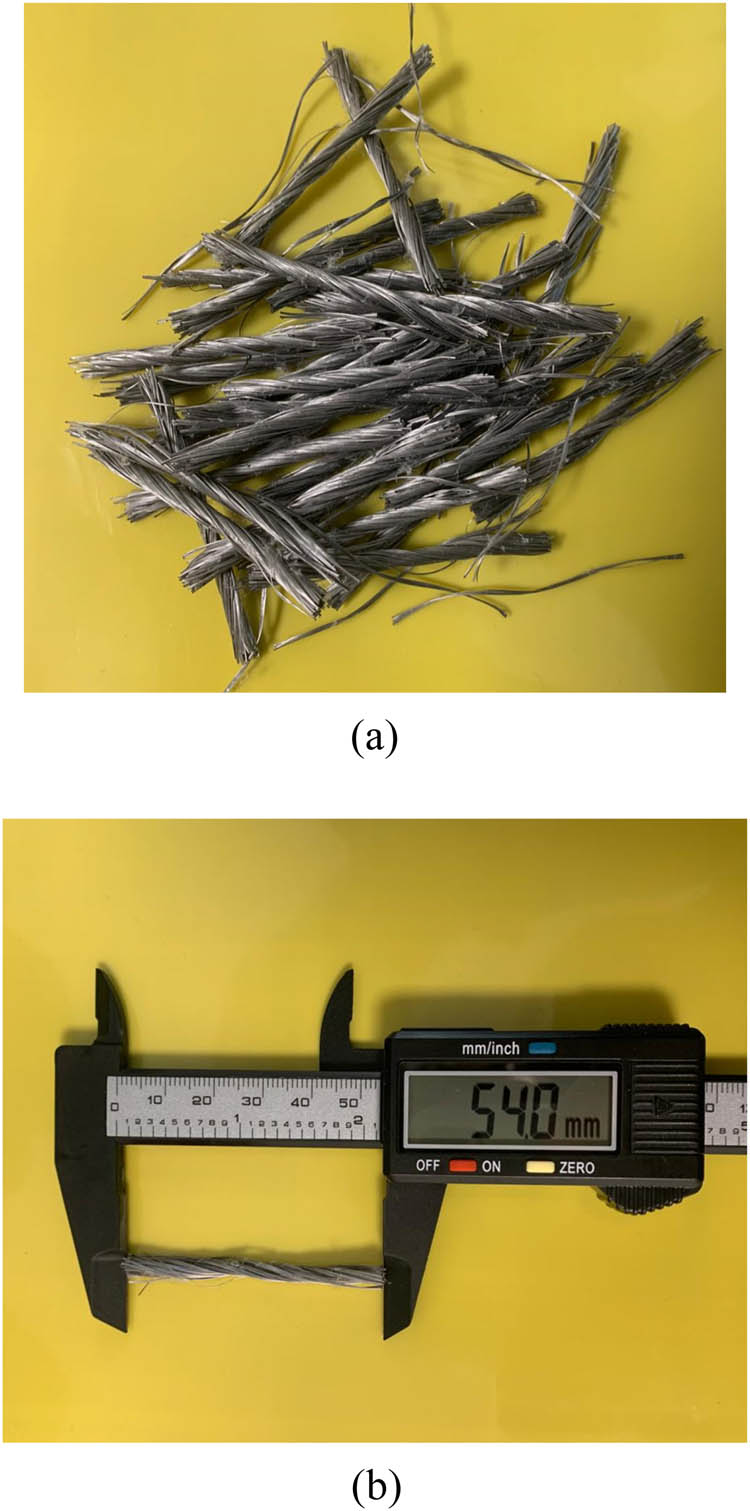

Fibers are one of the most critical materials used in the present research. In this study, macro-synthetic fibers were used (FORTA Ferro-Green). The Forta-Green blend consists of 100% recycled PP fibrillated (network) fibers and a high-performance twisted-bundle macro-monofilament fiber. The fibers used in this study are with different dosages and combinations, which are specified in Table 8. The fibers are used following ASTM C1116 standard. The fiber’s properties are given in Table 7. Moreover, in Figure 5, FORTA Ferro-Green is shown.

The specifications of the fiber

| Properties | Barchip 48 |

|---|---|

| Name | Forta Ferro-Green |

| Length (mm) | 54 |

| Specific gravity | 0.91 |

| Tensile strength (MPa) | 570–660 |

| Melting point (°C) | 160 |

| Material | Recycled PP |

| Form | Monofilament/fibrillated |

| Color | Gray/dark gray |

| Acid/alkali resistance | Excellent |

| Absorption | Nil |

(a) Shape of fibers and (b) fiber length.

2.2 Concrete mix design

The materials described above were combined using the weight ratio given in Table 8 in accordance with ACI 213-R30. The dry materials were combined first in the mixer, then the water and superplasticizer were progressively added. The water–cement ratio (W/C) was attempted to be kept at 0.4 in this mix design. All specimens have a specific weight of 1,600–1,650 kg/m3.

Concrete mix design

| No. | Name | Fiber (%) | Glass powder (%) | Nanosilica (%) | W/C | Cement (kg/m3) | Aggregate (kg/m3) | Filler (kg/m3) | Leca (kg/m3) | Superplasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | F0g0n0 | 0 | 0 | 0 | 0.4 | 488.88 | 533.33 | 177.7 | 266.6 | 2.66 |

| 2 | F0g0n1 | 0 | 0 | 1 | 0.4 | 484 | 533.333 | 177.7 | 166.6 | 2.66 |

| 3 | F0g0n2 | 0 | 0 | 2 | 0.4 | 479.1 | 533.33 | 177.7 | 266.6 | 2.66 |

| 4 | F0g0n3 | 0 | 0 | 3 | 0.4 | 474.2 | 533.33 | 177.7 | 266.6 | 2.66 |

| 5 | F0.5g0n0 | 0.5 | 0 | 0 | 0.4 | 488.88 | 533.33 | 177.7 | 266.6 | 2.66 |

| 6 | F1g0n0 | 1 | 0 | 0 | 0.4 | 488.88 | 533.33 | 177.7 | 266.6 | 2.66 |

| 7 | F1.5g0n0 | 1.5 | 0 | 0 | 0.4 | 488.88 | 533.33 | 177.7 | 266.6 | 2.66 |

| 8 | F0g20n0 | 0 | 20 | 0 | 0.4 | 488.88 | 533.33 | 177.7 | 266.6 | 2.66 |

| 9 | F0g25n0 | 0 | 25 | 0 | 0.4 | 488.88 | 533.33 | 177.7 | 266.6 | 2.66 |

| 10 | F0g30n0 | 0 | 30 | 0 | 0.4 | 488.88 | 533.33 | 177.7 | 266.6 | 2.66 |

| 11 | F1.5g25n3 | 1.5 | 25 | 3 | 0.4 | 474.2 | 533.33 | 177.7 | 266.6 | 2.66 |

| 12 | F1.5g25n0 | 1.5 | 25 | 0 | 0.4 | 488.88 | 533.33 | 177.7 | 266.6 | 2.66 |

| 13 | F1.5g25n3 | 1.5 | 0 | 3 | 0.4 | 474.2 | 533.33 | 177.7 | 266.6 | 2.66 |

| 14 | F0g25n3 | 0 | 25 | 3 | 0.4 | 474.2 | 533.33 | 177.7 | 266.6 | 2.66 |

The symbol “n” represents the quantity of nanosilica, the letter “F” represents the percentage of used fiber, and the letter “g” represents the percentage of used glass in the concrete.

2.3 Characteristics of the specimens

In this section, the number of specimens made and their characteristics are given in Table 9.

Specification of compressive specimens

| No. | Name | Fiber (%) | Waste glass (%) | Microsilica (%) |

|---|---|---|---|---|

| 1 | F0g0n0 | 0 | 0 | 0 |

| 2 | F0g0n1 | 0 | 20 | 0 |

| 3 | F0g0n2 | 0 | 25 | 0 |

| 4 | F0g0n3 | 0 | 30 | 0 |

| 5 | F0.5g0n0 | 0 | 0 | 8 |

| 6 | F1g0n0 | 0 | 0 | 10 |

| 7 | F1.5g0n0 | 0 | 0 | 12 |

| 8 | F0g20n0 | 0 | 20 | 8 |

| 9 | F0g25n0 | 0 | 20 | 10 |

| 10 | F0g30n0 | 0 | 20 | 12 |

| 11 | F1.5g25n3 | 0 | 25 | 8 |

| 12 | F1.5g25n0 | 0 | 25 | 10 |

| 13 | F1.5g25n3 | 0 | 25 | 12 |

| 14 | F0g25n3 | 0 | 30 | 8 |

2.3.1 Compressive and tensile specimens

Considering the amount of fiber, nanosilica, and waste glass powder used, 14 types of compressive and tensile specimens with dimensions of 15 cm × 15 cm × 15 cm and 10 cm × 20 cm were prepared. For each combination, 3 specimens with ages of 7 and 28 days were made and tested.

3 Test results

3.1 Compressive strength test

After averaging the findings of the compressive specimens, they are shown here.

According to the ASTMC143 standard, the slump test has been carried out. The compressive strength and slump test results for cube specimens are shown in Table 10. The average weight of the dried specimens was between 5.2 and 5.5 kg.

Compressive strength test results

| No. | Name | 7 days (MPa) | 28 days (MPa) | Slump (mm) |

|---|---|---|---|---|

| 1 | F0g0n0 | 30.1 | 38 | 68 |

| 2 | F0g0n1 | 34.2 | 43 | 59 |

| 3 | F0g0n2 | 39.1 | 49 | 57 |

| 4 | F0g0n3 | 44.3 | 56 | 54 |

| 5 | F0.5g0n0 | 30 | 38.7 | 51 |

| 6 | F1g0n0 | 31.6 | 39.4 | 42 |

| 7 | F1.5g0n0 | 32.5 | 40.7 | 66 |

| 8 | F0g20n0 | 32.7 | 41 | 58 |

| 9 | F0g25n0 | 37.5 | 47 | 55 |

| 10 | F0g30n0 | 36.2 | 45 | 52 |

| 11 | F1.5g25n3 | 51 | 64 | 49 |

| 12 | F1.5g25n0 | 38.7 | 48.2 | 44 |

| 13 | F1.5g25n3 | 45.6 | 57.3 | 67 |

| 14 | F0g25n3 | 49.9 | 62.3 | 60 |

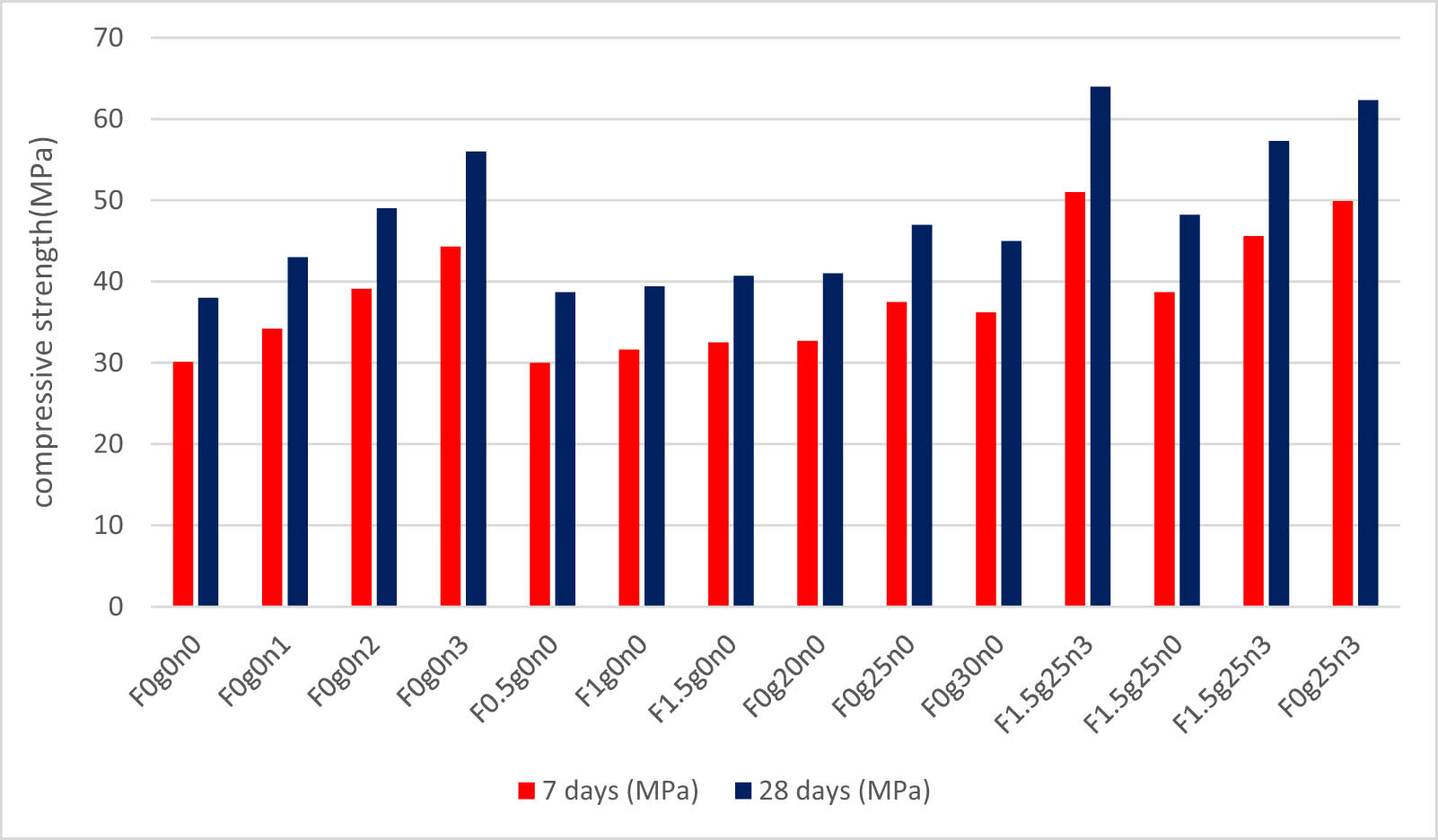

As can be observed from Figure 6, with increase in the consumption of nanosilica, the 28-day compressive strength of the specimens increased, so that by replacing 3% nanosilica instead of cement, the compressive strength of the concrete specimen increased by 47% compared to that of control. By adding glass powder instead of fine particles, the compressive strength of the specimen increases.

Comparisons of compressive strengths.

Glass powder should be used at an optimum of 25%. Compressive strength increases by 23% when 25% glass powder is used. For the most part, recycled fibers did not influence the samples’ compressive strength, but they did have an impact on their ductility. Compressive strength is increased by 7% when fiber cement weight is included in the mix at a rate of 1.5%. The highest compressive strength is related to the F1.5g25n3 specimen. The combination of fibers, glass powder, and nanosilica has increased the compressive strength by 68%. Nanosilica and glass powder have been able to increase the specimen compressive strength by filling the empty space of the concrete mixture and affecting the hydration process.

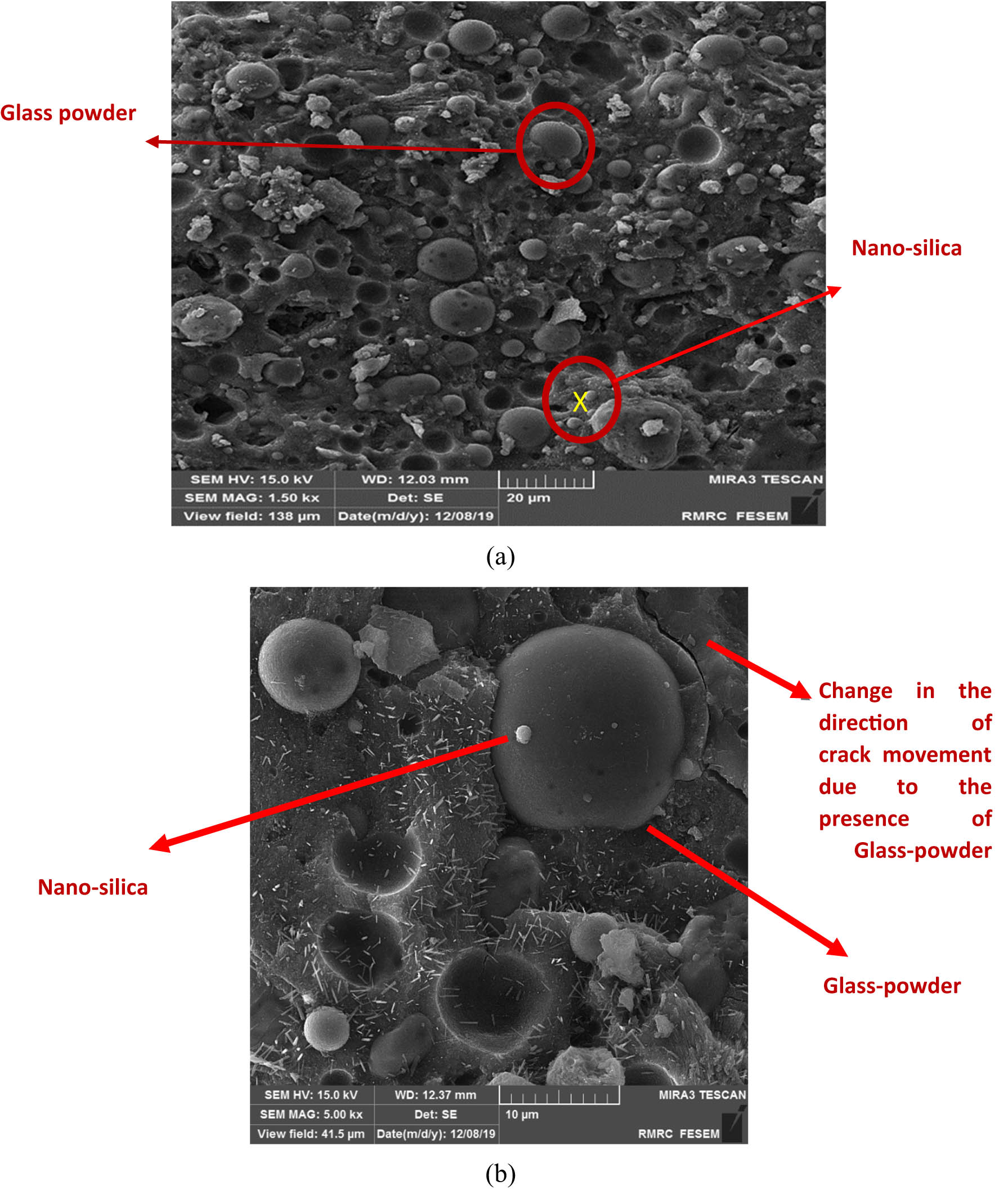

3.2 Scanning electron microscopy (SEM) analysis

The findings of a SEM test were used to examine the concrete’s microscopic structure and the impact of adding glass powder and nanosilica on the mix. Figure 7 shows the SEM analysis.

SEM test: (a) concrete specimens containing 25% glass powder and 3% nanosilica and (b) change in the direction of crack movement due to the presence of glass powder.

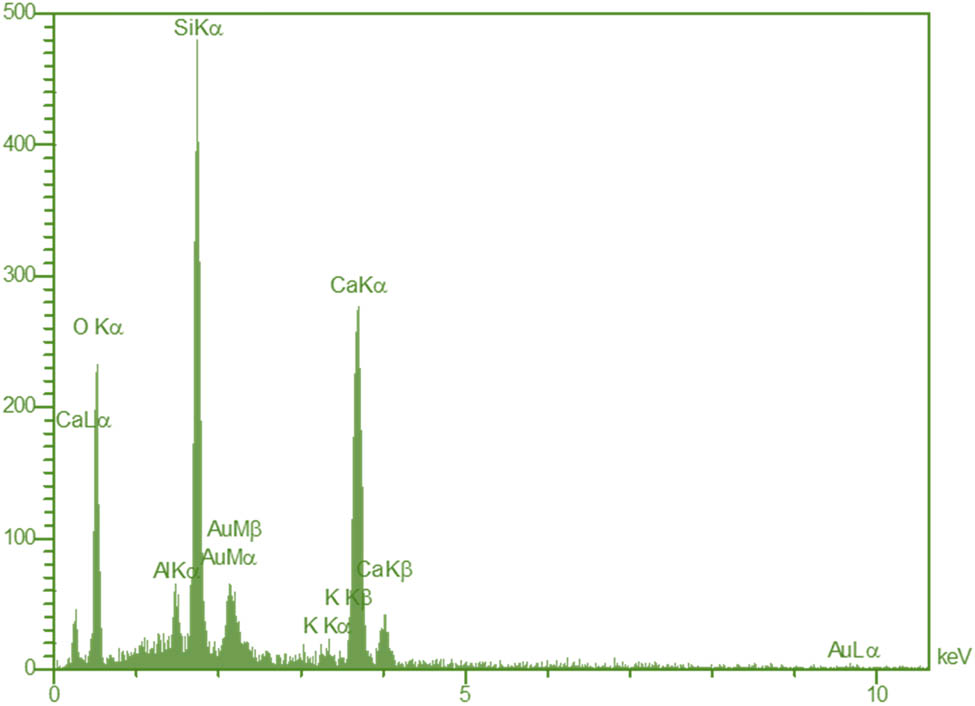

In Figure 8, X refers to the structure of nanosilica as determined by the IDFiX report test.

IDFiX report test diagram related to nanosilica.

It can be observed that nanosilica particles and glass powder are well dispersed in the concrete matrix and have increased the strength of concrete due to their adhesion properties.

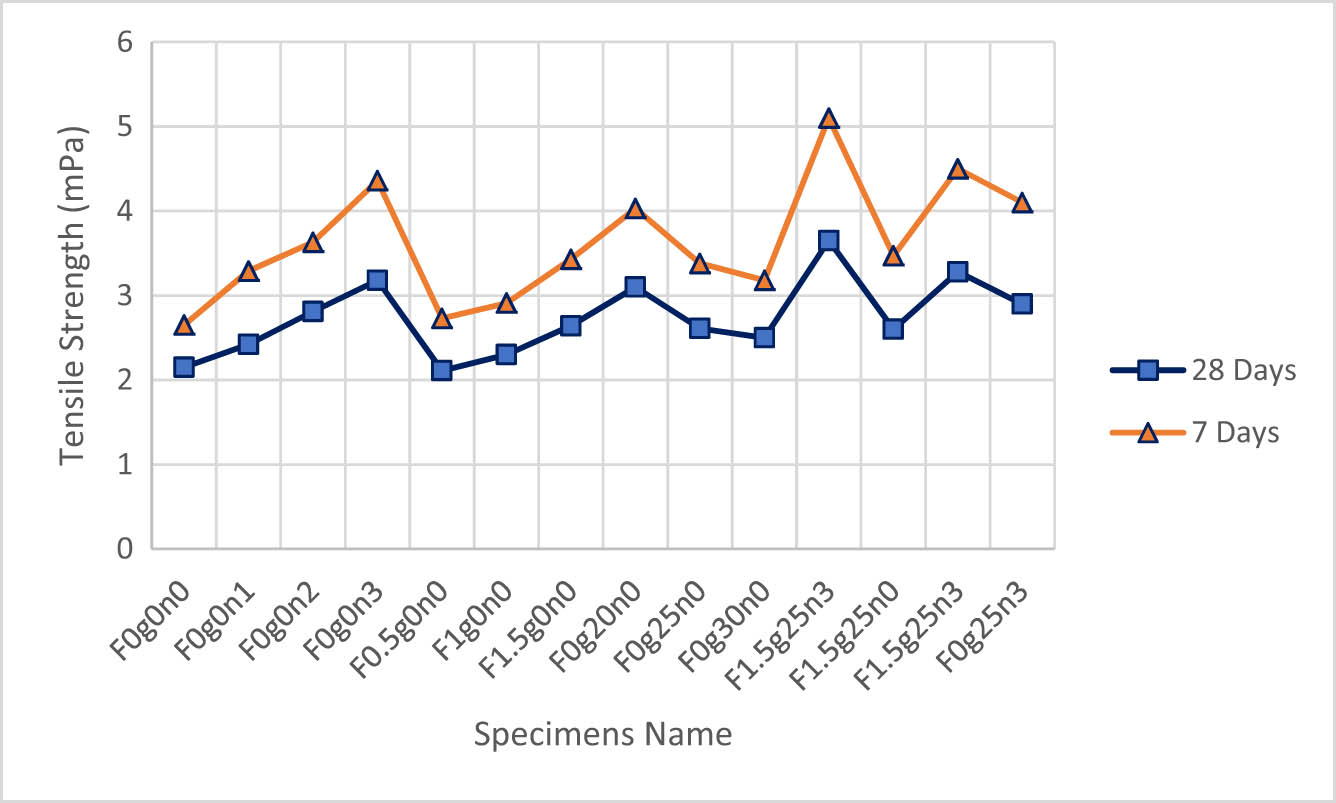

3.3 Tensile strength test

The results of the tensile strength test are shown in Table 11. This test was performed for all 14 specimens at the ages of 7 and 28 days. In Figure 9, tensile strength specimen is shown.

Tensile strength

| No. | Name | 7 days (MPa) | 28 days (MPa) |

|---|---|---|---|

| 1 | F0g0n0 | 2.15 | 2.65 |

| 2 | F0g0n1 | 2.42 | 3.29 |

| 3 | F0g0n2 | 2.81 | 3.63 |

| 4 | F0g0n3 | 3.18 | 4.36 |

| 5 | F0.5g0n0 | 2.11 | 2.73 |

| 6 | F1g0n0 | 2.3 | 2.91 |

| 7 | F1.5g0n0 | 2.64 | 3.43 |

| 8 | F0g20n0 | 3.1 | 4.03 |

| 9 | F0g25n0 | 2.61 | 3.38 |

| 10 | F0g30n0 | 2.5 | 3.18 |

| 11 | F1.5g25n3 | 3.65 | 5.1 |

| 12 | F1.5g25n0 | 2.6 | 3.47 |

| 13 | F1.5g25n3 | 3.28 | 4.4 |

| 14 | F0g25n3 | 2.9 | 4.1 |

Tensile strength test machine.

As can be observed in Figure 10, with the addition of fibers, the tensile strength of the specimens increased significantly. Also, with the addition of nanosilica and glass powder, the tensile strength of the samples increased. The best tensile strength of the specimen contains 1.5% of fibers, 3% of nanosilica, and 25% of glass powder, so its 28-day tensile strength is 1.6 times that of the control specimen.

Comparison of tensile strength.

4 Life cycle assessment (LCA)

Due to the rapid development of the building industry and the exponential growth of the construction sector, the consequences of boundless human interventions in the environment gradually became apparent, and subsequently, efforts were made to preserve living conditions. One of the best ways to improve the properties of concrete from an environmental point of view is to find suitable alternatives to the cement used in concrete. Meanwhile, pozzolans, which have long been used as a substitute and complement to cement in construction, can solve the problems related to production limitation to a large extent. Pozzolans have increased their compressive strength and durability by replacing a part of cement while saving energy consumption required in cement production and reducing pollutant emissions.

With the advent of nanotechnology, nanosilica has become one of the most critical nanoparticles with high pozzolanic properties in concrete that require high resistance to corrosion and abrasion or in cases where the use of pavement concrete has been used. In this article, mix design number 11 has been selected as the best mixing design. Using this mix design, cement consumption has been reduced by 3%, and nanosilica has been used instead.

The LCA consists of four main stages: (1) Goal and scope definition. (2) Inventory analysis. (3) Impact assessment. (4) Interpretation. According to the ISO 14040 standard, the first step in LCA is reviewing the goal and scope definition. In this article, two scenarios are defined by determining the construction of one cubic meter of concrete for application in a residential structure with a useful life of 50 years. The first scenario is concrete with mixing design number 1 and the second scenario is concrete with mixing design number 11. AkzoNobel company [42] published a report on environmental performance in 2020. According to this report, Table 12 examines energy use and emissions for both the scenarios.

As shown in Table 12, replacing cement with 3% nanosilica can reduce energy usage, greenhouse gas emissions, freshwater usage, and producing hazardous waste non-reusable by 3%, which helps to make sustainable concrete.

Energy use and emissions for both scenarios

| First scenario (mix design 1) | Second scenario (mix design 11) | |

|---|---|---|

| Energy use (GJ/ton) | 0.89 | 0.86 |

| Greenhouse gas emissions and direct CO2 emissions (kg/ton) | 8.99 | 8.73 |

| Freshwater use (m3/ton) | 1.43 | 1.39 |

| Hazardous waste non-reusable (kg/ton) | 2.29 | 2.22 |

Also, using discarded glass powder and PP fibers simultaneously may reduce CO2 emissions. Cutright et al. investigated the impact of utilizing PP fibers instead of steel rebar to decrease CO2 emissions [43]. Four steel rebars @12 are used to construct a roof with a thickness of approximately 20 cm; the quantity of CO2 emission is 3.35 kg for 1 m2 concrete. When PP fibers are used, this quantity decreases to 1.47 kg. Table 13 shows the quantity of CO2 released during construction of a 5-story, 300 m2 structure [38].

The amount of emitted CO2 during the construction

| Concrete type | CO2 emissions (kg) |

|---|---|

| Reinforced concrete with rebar | 5,025 |

| PP fiber reinforced concrete | 2,205 |

5 Conclusion

The following results were obtained after performing experiments on cubic specimens and examining microscopic images.

According to the findings in the literature, the compressive strength increases as the amount of nanosilica increases. The specimen with the best compressive strength contains 3% nanosilica and has a 28-day compressive strength that is 47% higher than that of the control specimen.

The highest amount of waste glass powder is 25%, and the compressive strength of concrete reduces with increased use due to its brittleness. The specimen containing 25% waste glass powder has a compressive strength that is 24% higher than that of the control specimen.

The compressive strength increases as the amount of recycled PP fibers used increases. The specimen with 1.5% fibers had the highest use rate, increasing the strength by 7% when compared to the control specimen. The fibers have no influence on the compressive strength of concrete, but they do contribute significantly to its ductility.

The best tensile strength is achieved by 1.5% of fibers, 3% of nanosilica, and 25% of waste glass powder, so its 28-day tensile strength is 1.6 times that of the control sample.

Simultaneous use of nanosilica, waste glass powder, and recycled fibers in LW concrete can increase its compressive strength. As a result, the compressive strength of the specimen, including 1.5% fibers, 3% nanosilica, and 25% glass powder, is 68% higher than that of the control specimen. Recycled glass powder collects this type of waste from the environment while also contributing to the sustainability of aggregates’ natural resources. Nanosilica is a sustainable material that helps to reduce the quantity of cement used. Recycled fibers are also entirely eco-friendly because they are manufactured from recycled resources. The use of this green material minimizes the amount of CO2 released into the atmosphere.

Acknowledgments

The authors appreciate the Structure and Construction Materials Laboratory of Tarbiat Modares School of Engineering, Tarbiat Modares University (TMU), and Shahid Beheshti University (SBU) for their assistance in the experimental work.

-

Funding information: The authors state no funding is involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Nivethitha D, Srividhya S, Dharmar S. Review on mechanical properties of cement mortar enhanced with nanoparticles. Int J Sci Res (IJSR). 2016;5(1):913–6.10.21275/v5i1.NOV152794Suche in Google Scholar

[2] Alshammari SM. The effect of nanosilica on porosity and strength. [dissertation]. Dayton (OH): University of Dayton; 2018.Suche in Google Scholar

[3] Abd-elmagied MF. Influence of different nano materials on mechanical properties of plain concrete. Eur J Eng Res Sci. 2019;4(6):129–34.10.24018/ejers.2019.4.6.1389Suche in Google Scholar

[4] Li H, Xiao HG, Yuan J, Ou J. Microstructure of cement mortar with nano-particles. Compos part B: Eng. 2004;35(2):185–9.10.1016/S1359-8368(03)00052-0Suche in Google Scholar

[5] Patel K. The use of nanoclay as a constructional material. Department of civil engineering, LD college of engineering Ahmedabad, Gujarat, India. Int J Eng Res Appl. 2012;2(4):1382–6.Suche in Google Scholar

[6] Srinivas K. Nanomaterials for concrete technology. Int J Civil Struct Environ Infrastruct Eng Res Dev (IJCSEIERD). 2014;1(4):79–90.Suche in Google Scholar

[7] Al Ghabban A, Al Zubaidi AB, Pozzolanic FZ. Activity and durability of nanosilica, micro silica and silica gel contained concrete. AIP Conf Proc. 1968;1968(1):030019. AIP Publishing LLC.10.1063/1.5039206Suche in Google Scholar

[8] Kadhim MJ, Abbas LK, Rasin FA. Study the characterizations of cement mortar by nano pozzolanic materials additions. Al-Khwarizmi Eng J. 2017;13(4):152–63.10.22153/kej.2017.06.004Suche in Google Scholar

[9] Morsy MS, Alsayed SH, Aqel M. Hybrid effect of carbon nanotube and nano-clay on physico-mechanical properties of cement mortar. Constr Build Mater. 2011;25(1):145–9.10.1016/j.conbuildmat.2010.06.046Suche in Google Scholar

[10] Wang WC, Wang SY, Lin CH. Effect of hot environment on strength and heat transfer coefficient of nano-clay concrete paper title. J Mater Sci Chem Eng. 2016;4(7):45–52.10.4236/msce.2016.47007Suche in Google Scholar

[11] Aly M, Hashmi MS, Olabi AG, Messeiry M, Hussain AI, Abadir EF. Effect of nano-clay and waste glass powder on the properties of flax fibre reinforced mortar. ARPN J Eng Appl Sci. 2011;6(10):19–28.Suche in Google Scholar

[12] Morsy MS, Alsayed SH, Aqel M. Effect of nano-clay on mechanical properties and microstructure of ordinary portland cement mortar. Int J Civ Environ Eng IJCEE-IJENS. 2010;10(1):23–7.Suche in Google Scholar

[13] Luo J, Hou D, Li Q, Wu C, Zhang C. Comprehensive performances of carbon nanotube reinforced foam concrete with tetraethyl orthosilicate impregnation. Constr Build Mater. 2017;30(131):512–6.10.1016/j.conbuildmat.2016.11.105Suche in Google Scholar

[14] Zhang J, Liu X. Dispersion performance of carbon nanotubes on ultra-light foamed concrete. Processes. 2018;6(10):194.10.3390/pr6100194Suche in Google Scholar

[15] Feng D, Xie N, Gong C, Leng Z, Xiao H, Li H, et al. Portland cement paste modified by TiO2 nanoparticles: a microstructure perspective. Ind Eng Chem Res. 2013;52(33):11575–82.10.1021/ie4011595Suche in Google Scholar

[16] Pimenta Teixeira K, Perdigão Rocha I, De Sá Carneiro L, Flores J, Dauer EA, Ghahremaninezhad A. The effect of curing temperature on the properties of cement pastes modified with TiO2 nanoparticles. Materials. 2016;9(11):952.10.3390/ma9110952Suche in Google Scholar PubMed PubMed Central

[17] Kurihara R, Maruyamao I. Impact of TiO2 nanoparticles on drying shrinkage of hardened cement paste. J Adv Concr Technol. 2018;6:272–81.10.3151/jact.16.272Suche in Google Scholar

[18] Jahromi SG. Effect of carbon nanofiber on mechanical behavior of asphalt concrete. Int J Sustain Constr Eng Technol. 2015;6(2):57–66.Suche in Google Scholar

[19] Metaxa ZS, Konsta-Gdoutos MS, Shah SP. Mechanical properties and nanostructure of cement-based materials reinforced with carbon nanofibers and polyvinyl alcohol (PVA). Microfibers (Spec Publ). 2010;1(270):115–24.Suche in Google Scholar

[20] Palmquist SM, Kintzel E, Andrew K. Scanning electron microscopy to examine concrete with carbon nanofibers. Proceedings of the 5th Pan American Conference for NDT; Oct 2–6, 2011; Cancun, Mexico; 2011.Suche in Google Scholar

[21] Muhammad MSA, Parviz S, Arshad A, Muhammad YSA. Carbon nano fibre reinforcements in concrete. Indonesian J Sci Technol. 2019;4(1):1–16.10.17509/ijost.v4i1.4140Suche in Google Scholar

[22] Nivethitha D, Dharma S. Effect of zinc oxide nanoparticle on strength of cement mortar. IJSTE – Int J Sci Technol Eng. 2016;3(5):123–7.Suche in Google Scholar

[23] Pan Z, He L, Qiu L, Korayem AH, Li G, Zhu JW, et al. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem Concr Compos. 2015;1(58):140–7.10.1016/j.cemconcomp.2015.02.001Suche in Google Scholar

[24] Taher AT, Zaki WK, Khaled AM, Serag F. Hybrid effect of nano silica and metakaolin on mechanical properties of cement mortar. Int J Eng Res Technol (IJERT). 2019;8(3):211–5.10.17577/IJERTV8IS030145Suche in Google Scholar

[25] Papatzani S. Effect of nanosilica and montmorillonite nanoclay particles on cement hydration and microstructure. Mater Sci Technol. 2016;32(2):138–53.10.1179/1743284715Y.0000000067Suche in Google Scholar

[26] Nazari A, Riahi S, Riahi S, Shamekhi SF, Khademno A. Benefits of Fe2O3 nanoparticles in concrete mixing matrix. J Am Sci. 2010;6(4):2–6.Suche in Google Scholar

[27] Heikal M. Characteristics, textural properties and fire resistance of cement pastes containing Fe2O3 nano-particles. J Therm Anal Calorimetry. 2016;126(3):1077–87.10.1007/s10973-016-5715-0Suche in Google Scholar

[28] Amudhavalli NK, Ravi C. A review on nanotechnology in concrete. Int J Civ Eng Technol (IJCIET). 2019;10(3):1953–60.Suche in Google Scholar

[29] Nakul S, Jayeshkumar P. Nanotechnology in cellular lightweight concrete. Periapex-Indian J Res. 2012;1:5.Suche in Google Scholar

[30] Al-Luhybi AS, Altalabani D. The influence of nano-silica on the properties and microstructure of lightweight concrete: a review. Mater Sci Eng. 2021;1094(1):012075.10.1088/1757-899X/1094/1/012075Suche in Google Scholar

[31] Du H, Du S, Liu X. Effect of nano-silica on the mechanical and transport properties of lightweight concrete. Constr Build Mater. 2015;1(82):114–22.10.1016/j.conbuildmat.2015.02.026Suche in Google Scholar

[32] Atmaca N, Abbas ML, Atmaca A. Effects of nano-silica on the gas permeability. Constr Build Mater. 2017;30(147):17–26.10.1016/j.conbuildmat.2017.04.156Suche in Google Scholar

[33] Zhang P, Xie N, Cheng X, Feng L, Hou P, Wu Y. Low dosage nano-silica modification on lightweight aggregate concrete. Nanomat Nanotechnol. 2018;8:18479804–61283.10.1177/1847980418761283Suche in Google Scholar

[34] Wang XF, Huang YJ, Wu GY, Fang C, Li DW, Han NX, et al. Effect of nano-SiO2 on strength, shrinkage and cracking sensitivity of lightweight aggregate concrete. Constr Build Mater. 2018;30(175):115–25.10.1016/j.conbuildmat.2018.04.113Suche in Google Scholar

[35] Kamasamudram K, Ashraf W, Landis E. Cellulose nanofibrils with and without nanosilica for the performance enhancement of Portland cement systems. Constr Build Mater. 2021;285:121547.10.1016/j.conbuildmat.2020.121547Suche in Google Scholar

[36] Ismail OS, El-Nawawy OA, Ragab KS, Kohail M. Performance of the lightweight concrete with available nano-silica in case fully replacement of coarse aggregate. Int J Sci Eng Res. 2018;9(1):223.Suche in Google Scholar

[37] Abd Elrahman M, Chung SY, Sikora P, Rucinska T, Stephan D. Influence of nanosilica on mechanical properties, sorptivity, and microstructure of lightweight concrete. Materials. 2019;12(19):3078.10.3390/ma12193078Suche in Google Scholar PubMed PubMed Central

[38] Orouji M, Zahrai M, Najaf E. Effect of glass powder & polypropylene fibers on compressive and flexural strengths, toughness and ductility of concrete: An environmental approach. Structures. 2021;33:4616–28.10.1016/j.istruc.2021.07.048Suche in Google Scholar

[39] Mortezagholi M, Zahrai SM, Najaf E. Using AP2RC & P1RB micro-silica gels to improve concrete strength and study of resulting contamination. Adv Concr Constr. 2016;43:195–206.10.12989/acc.2016.4.3.195Suche in Google Scholar

[40] McSwain AC, Berube KA, Cusatis G, Landis EN. Confinement effects on fiber pullout forces for ultra-high-performance concrete. Cem Concr Compos. 2018;91:53–8.10.1016/j.cemconcomp.2018.04.011Suche in Google Scholar

[41] Landis EN, Kravchuk R, Loshkov D. Experimental investigations of internal energy dissipation during fracture of fiber-reinforced ultra-high-performance concrete. Front Struct Civ Eng. 2019;13:190–200.10.1007/s11709-018-0487-1Suche in Google Scholar

[42] AkzoNobel Report-Environmental; 2020. https://report.akzonobel.com/2020/ar/sustainability/sustainability-performance summary/environmental.htmlSuche in Google Scholar

[43] Cutright T, Mahoney M, Franey K, Patnaik A. Carbon footprint assessment of polypropylene fiber reinforced concrete floors. Int J Construct Environ. 2013;3(1):73–84.10.18848/2154-8587/CGP/v03i01/37372Suche in Google Scholar

© 2022 Erfan Najaf et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Fractal approach to the fluidity of a cement mortar

- Novel results on conformable Bessel functions

- The role of relaxation and retardation phenomenon of Oldroyd-B fluid flow through Stehfest’s and Tzou’s algorithms

- Damage identification of wind turbine blades based on dynamic characteristics

- Improving nonlinear behavior and tensile and compressive strengths of sustainable lightweight concrete using waste glass powder, nanosilica, and recycled polypropylene fiber

- Two-point nonlocal nonlinear fractional boundary value problem with Caputo derivative: Analysis and numerical solution

- Construction of optical solitons of Radhakrishnan–Kundu–Lakshmanan equation in birefringent fibers

- Dynamics and simulations of discretized Caputo-conformable fractional-order Lotka–Volterra models

- Research on facial expression recognition based on an improved fusion algorithm

- N-dimensional quintic B-spline functions for solving n-dimensional partial differential equations

- Solution of two-dimensional fractional diffusion equation by a novel hybrid D(TQ) method

- Investigation of three-dimensional hybrid nanofluid flow affected by nonuniform MHD over exponential stretching/shrinking plate

- Solution for a rotational pendulum system by the Rach–Adomian–Meyers decomposition method

- Study on the technical parameters model of the functional components of cone crushers

- Using Krasnoselskii's theorem to investigate the Cauchy and neutral fractional q-integro-differential equation via numerical technique

- Smear character recognition method of side-end power meter based on PCA image enhancement

- Significance of adding titanium dioxide nanoparticles to an existing distilled water conveying aluminum oxide and zinc oxide nanoparticles: Scrutinization of chemical reactive ternary-hybrid nanofluid due to bioconvection on a convectively heated surface

- An analytical approach for Shehu transform on fractional coupled 1D, 2D and 3D Burgers’ equations

- Exploration of the dynamics of hyperbolic tangent fluid through a tapered asymmetric porous channel

- Bond behavior of recycled coarse aggregate concrete with rebar after freeze–thaw cycles: Finite element nonlinear analysis

- Edge detection using nonlinear structure tensor

- Synchronizing a synchronverter to an unbalanced power grid using sequence component decomposition

- Distinguishability criteria of conformable hybrid linear systems

- A new computational investigation to the new exact solutions of (3 + 1)-dimensional WKdV equations via two novel procedures arising in shallow water magnetohydrodynamics

- A passive verses active exposure of mathematical smoking model: A role for optimal and dynamical control

- A new analytical method to simulate the mutual impact of space-time memory indices embedded in (1 + 2)-physical models

- Exploration of peristaltic pumping of Casson fluid flow through a porous peripheral layer in a channel

- Investigation of optimized ELM using Invasive Weed-optimization and Cuckoo-Search optimization

- Analytical analysis for non-homogeneous two-layer functionally graded material

- Investigation of critical load of structures using modified energy method in nonlinear-geometry solid mechanics problems

- Thermal and multi-boiling analysis of a rectangular porous fin: A spectral approach

- The path planning of collision avoidance for an unmanned ship navigating in waterways based on an artificial neural network

- Shear bond and compressive strength of clay stabilised with lime/cement jet grouting and deep mixing: A case of Norvik, Nynäshamn

- Communication

- Results for the heat transfer of a fin with exponential-law temperature-dependent thermal conductivity and power-law temperature-dependent heat transfer coefficients

- Special Issue: Recent trends and emergence of technology in nonlinear engineering and its applications - Part I

- Research on fault detection and identification methods of nonlinear dynamic process based on ICA

- Multi-objective optimization design of steel structure building energy consumption simulation based on genetic algorithm

- Study on modal parameter identification of engineering structures based on nonlinear characteristics

- On-line monitoring of steel ball stamping by mechatronics cold heading equipment based on PVDF polymer sensing material

- Vibration signal acquisition and computer simulation detection of mechanical equipment failure

- Development of a CPU-GPU heterogeneous platform based on a nonlinear parallel algorithm

- A GA-BP neural network for nonlinear time-series forecasting and its application in cigarette sales forecast

- Analysis of radiation effects of semiconductor devices based on numerical simulation Fermi–Dirac

- Design of motion-assisted training control system based on nonlinear mechanics

- Nonlinear discrete system model of tobacco supply chain information

- Performance degradation detection method of aeroengine fuel metering device

- Research on contour feature extraction method of multiple sports images based on nonlinear mechanics

- Design and implementation of Internet-of-Things software monitoring and early warning system based on nonlinear technology

- Application of nonlinear adaptive technology in GPS positioning trajectory of ship navigation

- Real-time control of laboratory information system based on nonlinear programming

- Software engineering defect detection and classification system based on artificial intelligence

- Vibration signal collection and analysis of mechanical equipment failure based on computer simulation detection

- Fractal analysis of retinal vasculature in relation with retinal diseases – an machine learning approach

- Application of programmable logic control in the nonlinear machine automation control using numerical control technology

- Application of nonlinear recursion equation in network security risk detection

- Study on mechanical maintenance method of ballasted track of high-speed railway based on nonlinear discrete element theory

- Optimal control and nonlinear numerical simulation analysis of tunnel rock deformation parameters

- Nonlinear reliability of urban rail transit network connectivity based on computer aided design and topology

- Optimization of target acquisition and sorting for object-finding multi-manipulator based on open MV vision

- Nonlinear numerical simulation of dynamic response of pile site and pile foundation under earthquake

- Research on stability of hydraulic system based on nonlinear PID control

- Design and simulation of vehicle vibration test based on virtual reality technology

- Nonlinear parameter optimization method for high-resolution monitoring of marine environment

- Mobile app for COVID-19 patient education – Development process using the analysis, design, development, implementation, and evaluation models

- Internet of Things-based smart vehicles design of bio-inspired algorithms using artificial intelligence charging system

- Construction vibration risk assessment of engineering projects based on nonlinear feature algorithm

- Application of third-order nonlinear optical materials in complex crystalline chemical reactions of borates

- Evaluation of LoRa nodes for long-range communication

- Secret information security system in computer network based on Bayesian classification and nonlinear algorithm

- Experimental and simulation research on the difference in motion technology levels based on nonlinear characteristics

- Research on computer 3D image encryption processing based on the nonlinear algorithm

- Outage probability for a multiuser NOMA-based network using energy harvesting relays

Artikel in diesem Heft

- Research Articles

- Fractal approach to the fluidity of a cement mortar

- Novel results on conformable Bessel functions

- The role of relaxation and retardation phenomenon of Oldroyd-B fluid flow through Stehfest’s and Tzou’s algorithms

- Damage identification of wind turbine blades based on dynamic characteristics

- Improving nonlinear behavior and tensile and compressive strengths of sustainable lightweight concrete using waste glass powder, nanosilica, and recycled polypropylene fiber

- Two-point nonlocal nonlinear fractional boundary value problem with Caputo derivative: Analysis and numerical solution

- Construction of optical solitons of Radhakrishnan–Kundu–Lakshmanan equation in birefringent fibers

- Dynamics and simulations of discretized Caputo-conformable fractional-order Lotka–Volterra models

- Research on facial expression recognition based on an improved fusion algorithm

- N-dimensional quintic B-spline functions for solving n-dimensional partial differential equations

- Solution of two-dimensional fractional diffusion equation by a novel hybrid D(TQ) method

- Investigation of three-dimensional hybrid nanofluid flow affected by nonuniform MHD over exponential stretching/shrinking plate

- Solution for a rotational pendulum system by the Rach–Adomian–Meyers decomposition method

- Study on the technical parameters model of the functional components of cone crushers

- Using Krasnoselskii's theorem to investigate the Cauchy and neutral fractional q-integro-differential equation via numerical technique

- Smear character recognition method of side-end power meter based on PCA image enhancement

- Significance of adding titanium dioxide nanoparticles to an existing distilled water conveying aluminum oxide and zinc oxide nanoparticles: Scrutinization of chemical reactive ternary-hybrid nanofluid due to bioconvection on a convectively heated surface

- An analytical approach for Shehu transform on fractional coupled 1D, 2D and 3D Burgers’ equations

- Exploration of the dynamics of hyperbolic tangent fluid through a tapered asymmetric porous channel

- Bond behavior of recycled coarse aggregate concrete with rebar after freeze–thaw cycles: Finite element nonlinear analysis

- Edge detection using nonlinear structure tensor

- Synchronizing a synchronverter to an unbalanced power grid using sequence component decomposition

- Distinguishability criteria of conformable hybrid linear systems

- A new computational investigation to the new exact solutions of (3 + 1)-dimensional WKdV equations via two novel procedures arising in shallow water magnetohydrodynamics

- A passive verses active exposure of mathematical smoking model: A role for optimal and dynamical control

- A new analytical method to simulate the mutual impact of space-time memory indices embedded in (1 + 2)-physical models

- Exploration of peristaltic pumping of Casson fluid flow through a porous peripheral layer in a channel

- Investigation of optimized ELM using Invasive Weed-optimization and Cuckoo-Search optimization

- Analytical analysis for non-homogeneous two-layer functionally graded material

- Investigation of critical load of structures using modified energy method in nonlinear-geometry solid mechanics problems

- Thermal and multi-boiling analysis of a rectangular porous fin: A spectral approach

- The path planning of collision avoidance for an unmanned ship navigating in waterways based on an artificial neural network

- Shear bond and compressive strength of clay stabilised with lime/cement jet grouting and deep mixing: A case of Norvik, Nynäshamn

- Communication

- Results for the heat transfer of a fin with exponential-law temperature-dependent thermal conductivity and power-law temperature-dependent heat transfer coefficients

- Special Issue: Recent trends and emergence of technology in nonlinear engineering and its applications - Part I

- Research on fault detection and identification methods of nonlinear dynamic process based on ICA

- Multi-objective optimization design of steel structure building energy consumption simulation based on genetic algorithm

- Study on modal parameter identification of engineering structures based on nonlinear characteristics

- On-line monitoring of steel ball stamping by mechatronics cold heading equipment based on PVDF polymer sensing material

- Vibration signal acquisition and computer simulation detection of mechanical equipment failure

- Development of a CPU-GPU heterogeneous platform based on a nonlinear parallel algorithm

- A GA-BP neural network for nonlinear time-series forecasting and its application in cigarette sales forecast

- Analysis of radiation effects of semiconductor devices based on numerical simulation Fermi–Dirac

- Design of motion-assisted training control system based on nonlinear mechanics

- Nonlinear discrete system model of tobacco supply chain information

- Performance degradation detection method of aeroengine fuel metering device

- Research on contour feature extraction method of multiple sports images based on nonlinear mechanics

- Design and implementation of Internet-of-Things software monitoring and early warning system based on nonlinear technology

- Application of nonlinear adaptive technology in GPS positioning trajectory of ship navigation

- Real-time control of laboratory information system based on nonlinear programming

- Software engineering defect detection and classification system based on artificial intelligence

- Vibration signal collection and analysis of mechanical equipment failure based on computer simulation detection

- Fractal analysis of retinal vasculature in relation with retinal diseases – an machine learning approach

- Application of programmable logic control in the nonlinear machine automation control using numerical control technology

- Application of nonlinear recursion equation in network security risk detection

- Study on mechanical maintenance method of ballasted track of high-speed railway based on nonlinear discrete element theory

- Optimal control and nonlinear numerical simulation analysis of tunnel rock deformation parameters

- Nonlinear reliability of urban rail transit network connectivity based on computer aided design and topology

- Optimization of target acquisition and sorting for object-finding multi-manipulator based on open MV vision

- Nonlinear numerical simulation of dynamic response of pile site and pile foundation under earthquake

- Research on stability of hydraulic system based on nonlinear PID control

- Design and simulation of vehicle vibration test based on virtual reality technology

- Nonlinear parameter optimization method for high-resolution monitoring of marine environment

- Mobile app for COVID-19 patient education – Development process using the analysis, design, development, implementation, and evaluation models

- Internet of Things-based smart vehicles design of bio-inspired algorithms using artificial intelligence charging system

- Construction vibration risk assessment of engineering projects based on nonlinear feature algorithm

- Application of third-order nonlinear optical materials in complex crystalline chemical reactions of borates

- Evaluation of LoRa nodes for long-range communication

- Secret information security system in computer network based on Bayesian classification and nonlinear algorithm

- Experimental and simulation research on the difference in motion technology levels based on nonlinear characteristics

- Research on computer 3D image encryption processing based on the nonlinear algorithm

- Outage probability for a multiuser NOMA-based network using energy harvesting relays