Abstract

The nano-silver-coated tin (Sn@Ag) paste was modeled using the method of the Anand unified viscoplastic constitutive model and elastic model. After thermal cyclic loading, the plastic strain of the solder joints increased cumulatively, while the maximum equivalent stress remained basically stable. The simulation results show that the maximum displacement occurs at the solder joint at the farthest end from the center of the chip, which is a dangerous solder joint. Using the finite element method and EPRI (the American Electric Power Research Institute) estimation method, the fatigue life of the nano-silver-coated tin solder joint is predicted to be 616 weeks, which is significantly higher than that of the nano-silver solder joint. It is indicated that adding a certain amount of nano-tin to the nano-silver paste to form a core–shell structure can improve the shear strength of the solder joint and reduce the plastic strain, thereby significantly improving the reliability of the solder joint. It is proved by experiments that the nano-silver paste is feasible for flip–chip interconnection. The research on this topic provides experimental reference and theoretical basis for the application of a new generation of interconnection materials in power devices and promotes the development and application of microelectronic packaging technology.

1 Introduction

Nanoscale silver paste is widely used in chip connection but its application is limited by high sintering temperatures and low bonding strengths. The addition of low melting point alloying elements is a good way to reduce the sintering temperature and increase the sintering strength of the nano-silver slurry [1]. Among doped metals, tin, indium, and gallium all have low melting points but the cost of indium and gallium is relatively high; therefore, we choose nano tin as a dopant [2]. Considering that tin is easy to be oxidized, and the core–shell material can prevent tin oxidation and ensure the uniform distribution of tin in the matrix, this study adopts the scheme of preparing the core–shell material Sn@Ag.

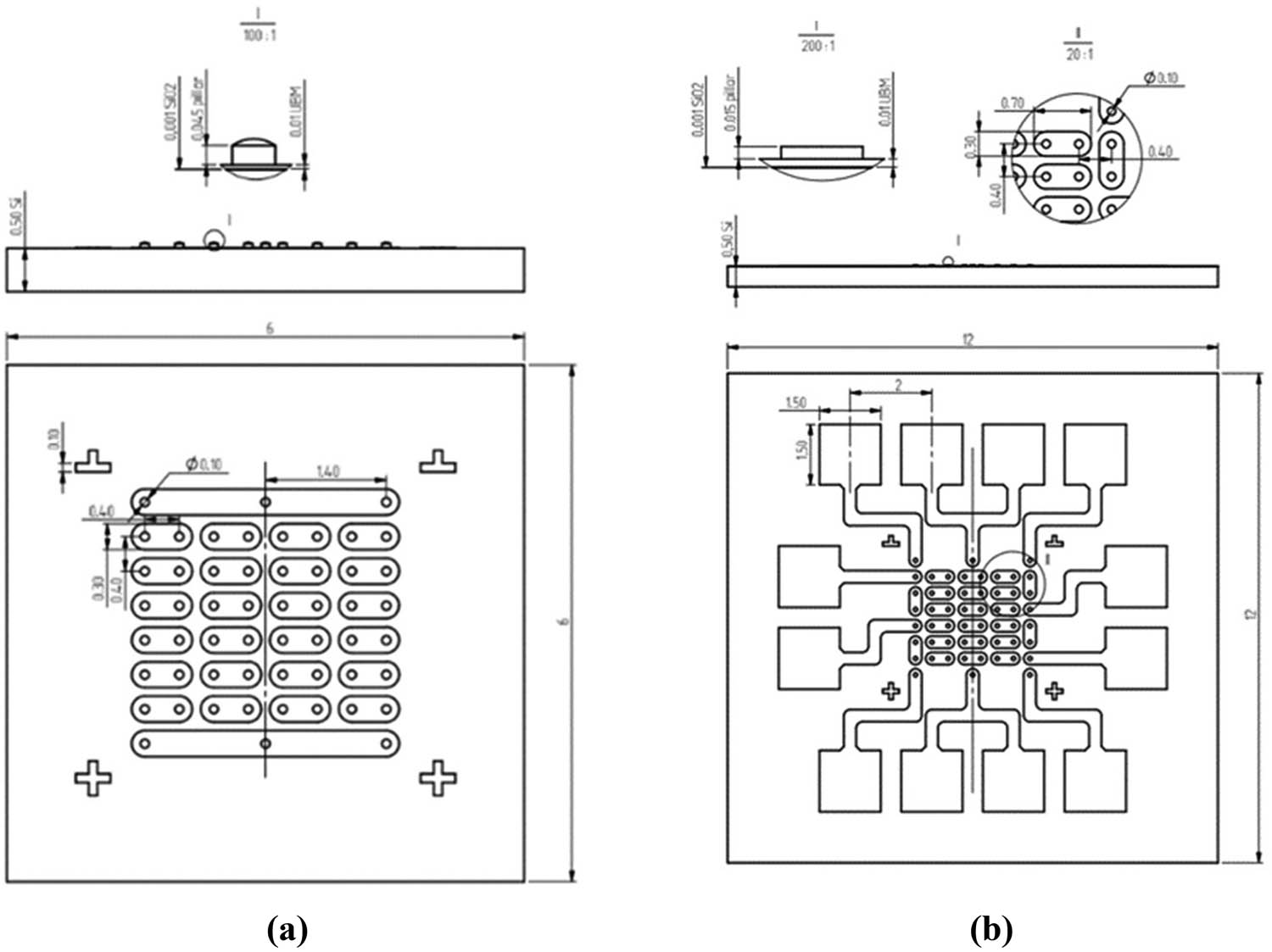

The sn-silver solid solution and the intermetallic compound Ag3Sn (strengthened phase) were formed by sintering the nano-Sn@Ag slurry. When the content of tin is 5%, the sintering strength of the nanometer Sn@Ag slurry is the highest [3], and the ratio of Ag3Sn particles to Ag matrix is 1:5 after sintering. The hardness of the intermetallic compound Ag3Sn is very high, so the plastic strain generated by the solder joint is mainly formed by the silver matrix. Therefore, in this article, Ag3Sn is regarded as an elastic material in finite element modeling and expressed by the elastic equation [4]. The matrix Ag is regarded as a viscoplastic material and is expressed by the Anand constitutive equation [5]. This study considers inverted solder joints as an example. The diameter of nano-silver-coated tin solder joints is 100 μm, and the bottom plate is a PCB board, as shown in Figure 1.

Flip chip and the bottom plate: (a) flip chip (silicon) and (b) baseboard (PCB).

2 Finite element analysis of the nano Sn@Ag solder joint

2.1 Anand constitutive equation and parameter determination

The relation between the saturation stress and strain rate of the viscoplastic Anand model is as follows:

The relationship between stress and strain at different temperatures and different strain rates can be expressed as follows:

The above equation contains the nine parameters of the Anand constitutive equation:

Anand model parameters of the nano-silver matrix

|

A (

|

Q/R (1/k) | m | n |

|

|

|

|

α |

|---|---|---|---|---|---|---|---|---|

| 9.81 | 5,709 | 0.6572 | 0.00326 | 11 | 67.389 | 15,800 | 2.768 | 1 |

2.2 Finite element model of the solder joint

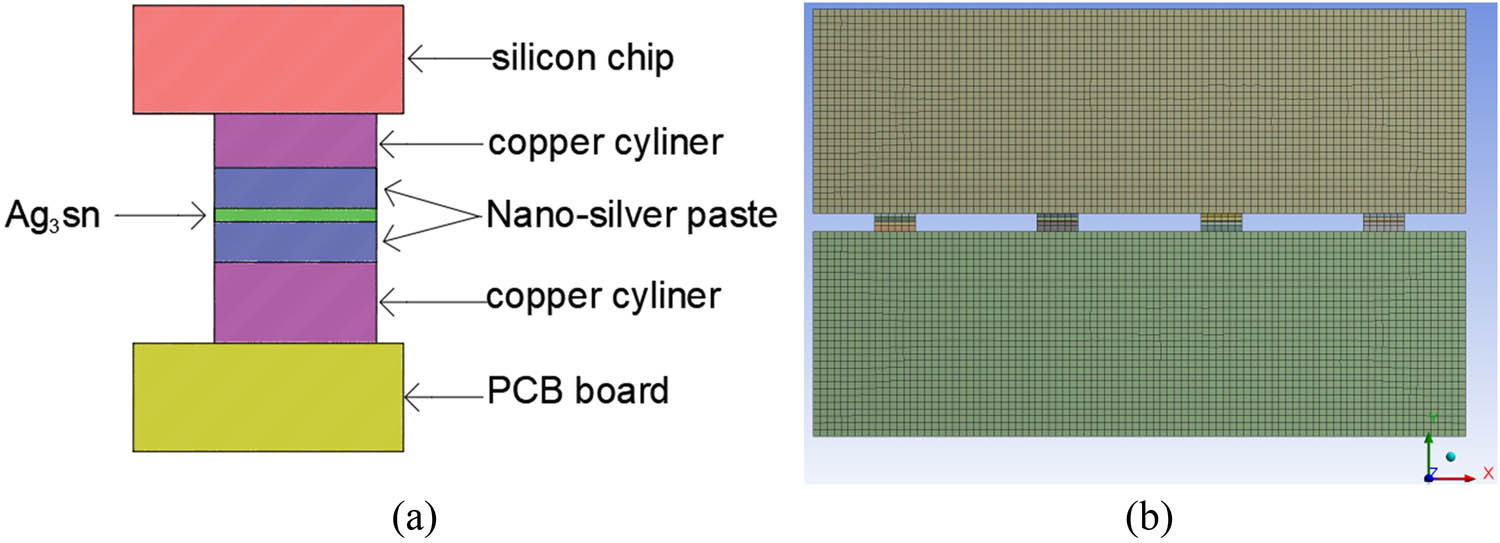

This chip module model is composed of three parts: the upper part is made of a Si chip, the lower part is made of a printed circuit board (PCB), and the middle part is made of a Cu column and nano Sn@Ag solder joint. For the convenience of operation, it is assumed that a solder joint contains a cylindrical Ag3Sn with a thickness of 0.004 mm, which is distributed in the middle of the Ag matrix, as shown in Figure 2a. Ag3Sn particles are replaced by this structure. In the finite element analysis software WorkBench, because of symmetry, the 1/4 structure is selected to build a model and analyze it. The model of 3D and 2D model modeling can also be used at this time, but the 3D mesh model is more complex, as the system calculation takes longer; however, model using 2D modeling can simplify the mesh, reduce the calculation time, and achieve similar results, as shown in Figure 2b.

(a) Finite element modeling and (b) meshing.

The material properties of each component are shown in Table 2 [7]. The elastic modulus, Poisson’s ratio, and thermal expansion coefficient of the Si chip, PCB board, Cu column, Ag3Sn, and nano-Ag are listed in Table 2.

Material properties of chip components

| Component | Modulus of elasticity (GPa) | Poisson’s ratio | Coefficient of thermal expansion (10−6 per °C) |

|---|---|---|---|

| Chip(Si) | 131 | 0.3 | 2.8 |

| Copper pillar | 110 | 0.34 | 16.4 |

| Ag3Sn | 80 | 0.35 | 18 |

| Nano-silver | 6.28 | 0.37(25℃) | 19.6 |

| FR-4 | 17.2 | 0.28 | 16 |

2.3 Stress–strain analysis of solder joints

The thermal cycling load is determined according to various conditions that may be encountered during service. The temperature range is −50°C to 150°C and the temperature rise and fall rate are 25°C·min−1; The cycling load is maintained for 10 min when it rises to the highest temperature and 10 min when it is lowered to the lowest temperature. The cycle period is 36 min, and this model calculates 5 cycles.

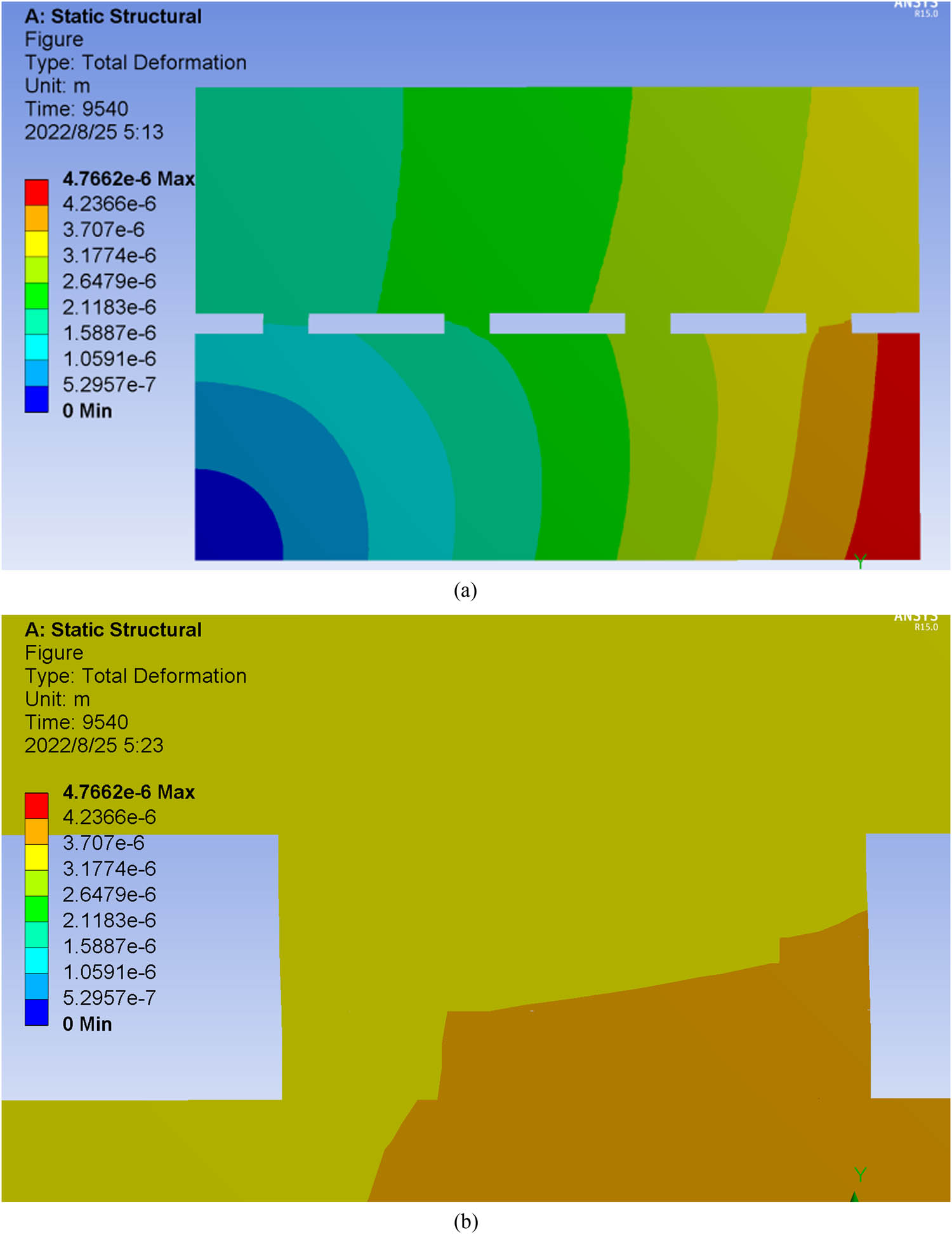

When the chip is subjected to a thermal load, it first produces a certain degree of displacement, that is, deformation. Figure 3 shows the displacement diagram of chip components and single solder joint under multiple cycle temperature loads. As shown in Figure 3a, the solder joint farthest from the chip center has the largest displacement and is a dangerous solder joint. This is mainly because the central part of the chip is fixed and constrained, while the other parts of the chip are free. According to the principle of thermodynamics, the farther the solder joint is from the center of the chip, the larger its deformation will be. As shown in Figure 3b, under multiple periodic temperature loads, the contact area between the dangerous solder joint and the copper column shows obvious displacement, while the displacement in the internal area of the solder joint is small. This is mainly because the thermal expansion coefficient of the nano-silver–tin solder and copper column is different from each other, and as the deformation degree of the two is different, there is obvious displacement at the contact interface of the two. As the solder joint internal material is the same and the deformation difference is not big, the solder joint internal displacement is small.

Solder joint displacement diagram of the flip chip: (a) interconnect chip and (b) dangerous solder joints.

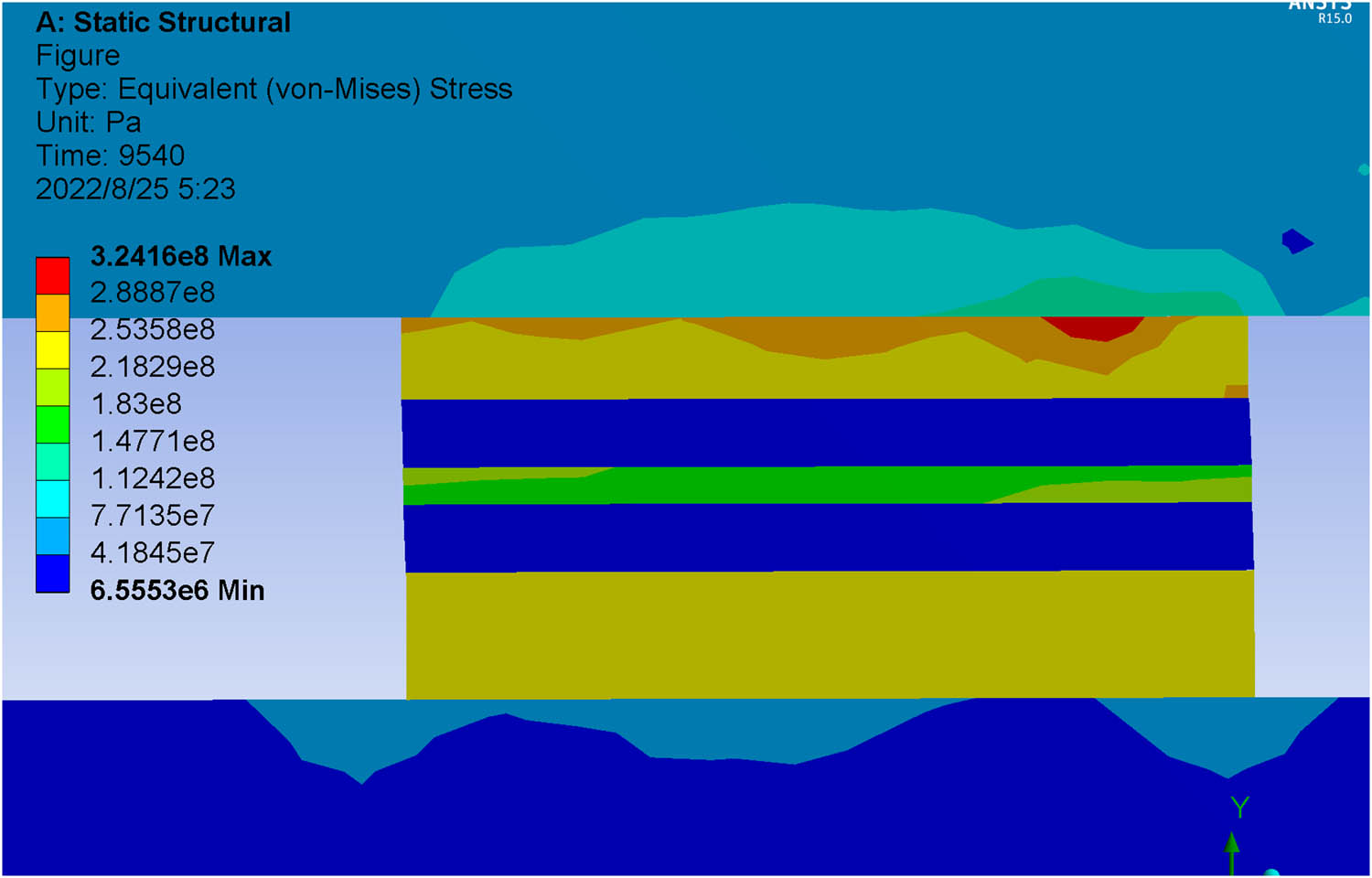

Figure 4 shows the stress diagram of the hazardous solder joint. It can be seen that the area where the solder joint is connected to the Cu column generates significant stress, while the stress distributed inside the solder joint is small. Figure 5 is the stress curve of the dangerous solder joint, from which it can be seen that the maximum equivalent stress basically remains unchanged with the increase of the number of periodic temperature loads. However, it can be observed from the stress–strain curve of the solder joint in Figure 6 that the plastic strain of the solder joint has a cumulative process over time. This is mainly because when the thermal load reaches 150℃, the deformation of the solder joint has exceeded the elastic range, and the plastic strain begins to occur. The plastic strain is an unrecoverable deformation so although the maximum stress remains basically unchanged, the plastic strain will gradually increase through a cumulative process. It can be predicted that the plastic strain of the dangerous solder joint will gradually increase with the continuous loading of the periodic temperature load, which will eventually cause chip failure.

Equal stress diagram of the dangerous solder joint.

Relation between the equivalent stress of the dangerous solder joint and time.

Stress–strain curve of the solder joint.

In order to analyze the plastic deformation of inverted solder joints under periodic temperature loading in more detail, the plastic strain loading history of dangerous solder joints was studied. Figure 7 shows the relation curve between the plastic strain and time of dangerous solder joints of the nano-silver-coated tin solder.

Equivalent plastic strain curve of the dangerous solder joint.

3 Reliability analysis of the nano-Sn@Ag solder joint

Under the action of a periodic temperature load, the distribution of stress and strain of the solder joint is variable, and not only time and pressure parameters can affect the reliability of welding, but also the sintering temperature and solder composition and other factors affect the performance of the solder joint. According to experience, plastic strain can cause cracking of solder joints and lead to failure of solder joints, and the Coffin–Manson (C-M)-modified model is a fatigue equation related to plastic strain. Therefore, this project adopts this model in the finite element to predict the life of nano-Sn@Ag solder joints.

Since the 1960s, according to the COD theory and J-integral elastic–plastic fracture mechanics theory, some teams have derived the failure criterion of crack development under large yield deformation, that is, δ ≤ δ c, J ≤ J IC, so that the fatigue life of the crack can be calculated by calculating the J-integral. Meanwhile, in engineering practice, this article uses the American Electric Power Research Institute (EPRI) engineering method to estimate the J integral and calculate the solder joint life. This method can predict fatigue life without using the finite element method, which is an estimation method other than the finite element method.

3.1 Prediction of the fatigue life of solder joints by the finite element method

The modified equation of C–M proposed by Engel–Maier has become a more reasonable one among the many derivative equations, and the calculation conclusion with this equation will be more accurate, which is widely used in the derivation of fatigue cycle number of solder joints and other fields:

By using finite element software to calculate the strain range of the inner nodes of the nano-silver–tin slurry, the solder joints in the most dangerous areas can be found.

The fatigue cycles of pure nano-silver solder joints and nano-Sn@Ag solder joints were calculated by the derivation study, and are listed in Table 3. The results show that the cycle failure times of the nano-Sn@Ag solder joint are significantly higher than that of the pure nano-Ag solder joint. According to the previous experiment, it can be predicted that after doping with alloying element Sn, the nano-Ag3Sn phase is formed during the sintering process of the nano-Ag-Sn slurry, which plays the role of second phase strengthening.

Comparison of fatigue cycles of two solder joints

| Solder joints | Δε | Δγ | N f |

|---|---|---|---|

| Nano-silver | 0.0173 | 0.02966 | 432 |

| Nano-silver + Ag3Sn | 0.01472 | 0.0255 | 616 |

3.2 Prediction of the fatigue life of solder joints by the EPRI engineering estimation method

The J-integral engineering estimation method was introduced by the EPRI for the first time [8,9]. This method has the advantages of fewer parameters, a simple calculation process, etc., and has been widely used in fatigue life estimation [10,11]. The estimation method is to decompose the J-integral into linear and nonlinear components [12,13].

From the initial crack size to the critical size integral, we have [14]

where a is the crack size, x and r are material constants, J is the J-integration, and

3.3 Calculation of the influence of solder joint topography on fatigue life using two different methods

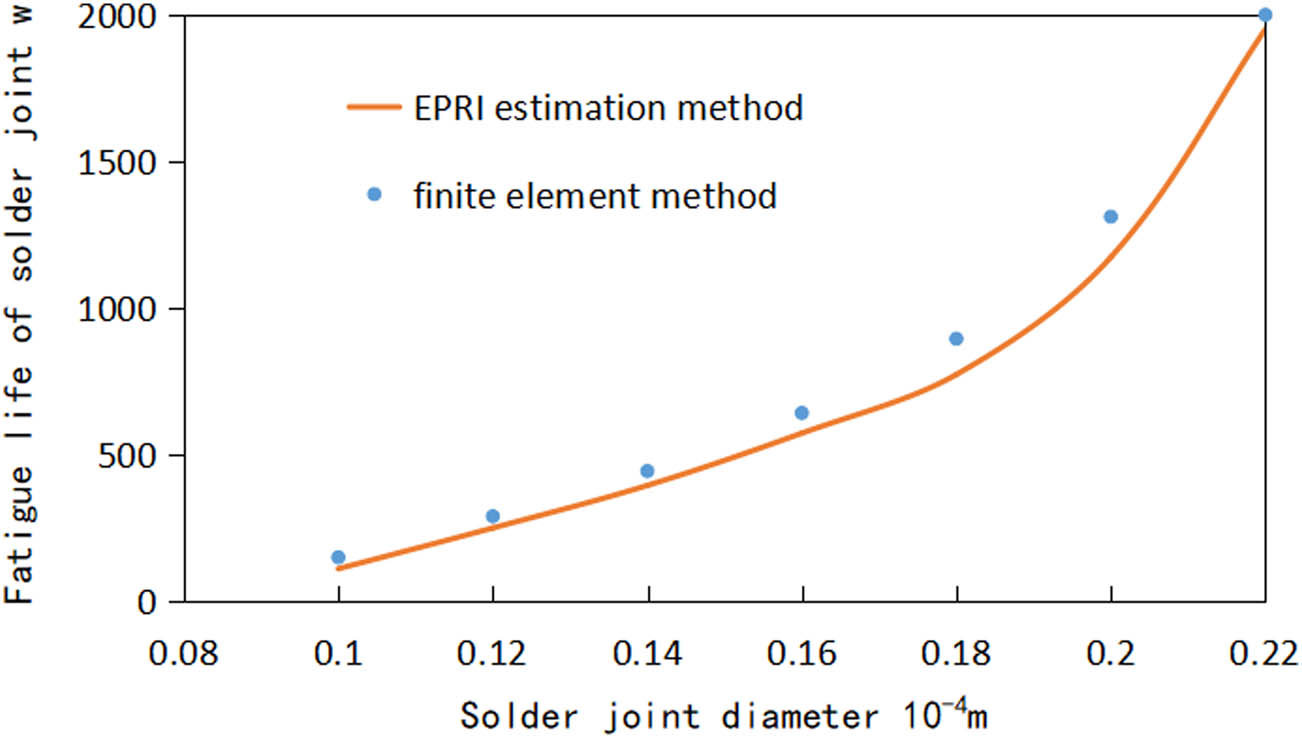

The EPRI estimation method and the finite element method were used to calculate the influence of the solder joint diameter change on the fatigue life. The single-factor experiment method was used to select seven different diameters as research targets while keeping the solder joint height unchanged. The diameters selected successively were 0.10, 0.12, 0.14, 0.16, 0.18, 0.20, and 0.22 (unit: ×10−4 m).

As shown in Figure 8, the horizontal coordinate refers to the diameter of the solder joint, and the vertical coordinate refers to the number of fatigue cycles of the solder joint. According to the figure, as the diameter of the solder joint continues to increase, the plastic strain range of the internal joints decreases, and the derived thermal fatigue life gradually increases. From the comparison of the calculation results of the two methods, it can be seen that they are in good agreement, which proves that the C–M modified model has higher calculation accuracy.

Influence of the solder joint diameter on fatigue life calculated using the two methods.

The EPRI estimation method and the finite element method were used to calculate the influence of the solder joint height variation on fatigue life, and the single-factor experiment method was used to select seven different heights as research targets under the condition that the solder joint diameter remained unchanged. The height values selected in turn were 0.02, 0.025, 0.03, 0.035, 0.04, 0.045, and 0.05 (unit: ×10−4 m).

As shown in Figure 9, the horizontal coordinate refers to the height of the solder joint, and the vertical coordinate refers to the fatigue life of the solder joint. According to the figure, as the height of the solder joint increases, the plastic strain range of the joint decreases, and the derived thermal fatigue life increases gradually. According to the slope degree of the curve, the change in height has a stronger correlation with the thermal fatigue life of the solder joint. A comparison between the EPRI estimation method and finite element method shows that they are in good agreement, which proves that FEM has high calculation accuracy and wide application range.

Influence of the solder joint height variation on fatigue life calculated using the two methods.

4 Summary

The nano-Sn@Ag solder was modeled using the Anand constitutive model and the elastic model, and the simulation results provide a certain reference for the finite element analysis of the particle-enhanced nano-solder to promote the development of research on the interconnect reliability of the nano-silver slurry.

Using finite element simulation, it was determined that the maximum displacement of chip components occurs at the junction of the solder joint and copper column, which is a dangerous area. Although the equivalent stress of the solder joint remains stable after thermal cycling, its plastic strain will accumulate and increase, which will lead to the ultimate failure of the interconnect chip.

After five cycles of thermal cycle load, the equivalent plastic strain range of the chip dangerous solder joint was found to be 0.01472, and the plastic shear strain range of the solder joint was 0.0255. Using the C–M correction equation, the thermal fatigue cycle number of the nano-silver-coated tin solder joint was derived to be 616 weeks.

The finite element method and the EPRI estimation method were used to calculate the results, and it was found that the fatigue cycle number of nano-Sn@Ag solder joints was significantly higher than that of nano-Ag solder joints, indicating that the addition of a certain amount of Sn element to the nano-silver paste could improve the shear strength of solder joints and thus increase the number of thermal fatigue cycles of solder joints.

-

Funding information: The authors state that no funding was involved.

-

Author contributions: Hui Yang: writing – review & editing, methodology, and formal analysis. Wenhui Chen: writing – original draft, visualization, and project administration.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Tsai CH, Huang WC, Chew LM, Schmitt W, Li J, Nishikawa H, et al. Low-pressure micro-silver sintering with the addition of indium for high-temperature power chips attachment. J Mater Res Technol-JMR&T. 2021;15:4541–53.10.1016/j.jmrt.2021.10.079Suche in Google Scholar

[2] Qiwang C. Preparation and Properties of Nano-tin modified nano-silver paste for Power chip Interconnect. Master’s Thesis. South China University of Technology; 2018.Suche in Google Scholar

[3] Yang CX, Li X, Lu GQ, Mei YH. Enhanced pressureless bonding by Tin Doped Silver Paste at low sintering temperature. Mater Sci Eng A. 2016;660:71–6.10.1016/j.msea.2016.02.082Suche in Google Scholar

[4] Lu XZ, Lv Z, Sun Q, Murugesan M, Zhou C, Zhang X, et al. Enhanced mechanical and thermal properties of Ag Joints Sintered by Spark Plasma Sintering. J Electron Mater. 2022;51(11):6310–9.10.1007/s11664-022-09849-4Suche in Google Scholar

[5] Su YT, Fu GC, Liu CQ, Zhang K, Zhao L, Liu C, et al. Thermo-elasto-plastic phase-field modelling of mechanical behaviours of sintered nano-silver with randomly distributed micro-pores. Comput Methods Appl Mech Eng. 2021;378:113729.10.1016/j.cma.2021.113729Suche in Google Scholar

[6] Yu DJ, Chen X, Chen G, Lu GQ, Wang ZQ. Applying Anand model to low-temperature sintered nanoscale silver paste chip attachment. Mater Des. 2009;30(10):4574–9.10.1016/j.matdes.2009.04.006Suche in Google Scholar

[7] Guo SJ. Meso-cyclic constitutive model for ratcheting behavior of particle-reinforced metal matrix composites. Doctoral Dissertation. Southwest Jiaotong University; 2012.Suche in Google Scholar

[8] Kumar V, German MD, Wilkening WW. Translated by Institute of Engineering Mechanics, Tsinghua University. The progress of EPRI NP-3607 plastic fracture analysis. Beijing: Tsinghua University Press; 1984. p. 48–64.Suche in Google Scholar

[9] Zikry M. Ductile fracture. Handb Mater Modeling. 2005;(25):1171–81.10.1007/978-1-4020-3286-8_59Suche in Google Scholar

[10] Sun L, Li PN, Liu CJ. Equivalent remote stress method of J-integral evaluation for any stress-strain relationship materials. J Mech Strength. 2003;25(4):450–5.Suche in Google Scholar

[11] Zahoor A. Evaluation of J-integral estimation scheme for flawed through-wall pipes. Nucl Eng Des. 1987;100(1):1–9.10.1016/0029-5493(87)90067-7Suche in Google Scholar

[12] Guoqiang D. Fracture parameters of miter bend inner crack. Master Dissertation. Dalian University of Technology; 2009.Suche in Google Scholar

[13] Qi X, Lv YB, Xu ZX. The determining of Ramberg-Osgood-shaped power hardening material’s hardening factor and hardening exponent. J Wuhan Transp Univ. 1996;20(3):319–22.Suche in Google Scholar

[14] Sun P, Andersson C, Wei XC, Cheng ZN, Shangguan DK, Liu J Coffin-Manson constant determination for a Sn-8Zn-3Bi lead-free solder joint Solder. Surf Mt Technol. 2006;18(2):4–11.10.1108/09540910610665071Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Value-added utilization of coal fly ash and recycled polyvinyl chloride in door or window sub-frame composites

- High removal efficiency of volatile phenol from coking wastewater using coal gasification slag via optimized adsorption and multi-grade batch process

- Evolution of surface morphology and properties of diamond films by hydrogen plasma etching

- Removal efficiency of dibenzofuran using CuZn-zeolitic imidazole frameworks as a catalyst and adsorbent

- Rapid and efficient microwave-assisted extraction of Caesalpinia sappan Linn. heartwood and subsequent synthesis of gold nanoparticles

- The catalytic characteristics of 2-methylnaphthalene acylation with AlCl3 immobilized on Hβ as Lewis acid catalyst

- Biodegradation of synthetic PVP biofilms using natural materials and nanoparticles

- Rutin-loaded selenium nanoparticles modulated the redox status, inflammatory, and apoptotic pathways associated with pentylenetetrazole-induced epilepsy in mice

- Optimization of apigenin nanoparticles prepared by planetary ball milling: In vitro and in vivo studies

- Synthesis and characterization of silver nanoparticles using Origanum onites leaves: Cytotoxic, apoptotic, and necrotic effects on Capan-1, L929, and Caco-2 cell lines

- Exergy analysis of a conceptual CO2 capture process with an amine-based DES

- Construction of fluorescence system of felodipine–tetracyanovinyl–2,2′-bipyridine complex

- Excellent photocatalytic degradation of rhodamine B over Bi2O3 supported on Zn-MOF nanocomposites under visible light

- Optimization-based control strategy for a large-scale polyhydroxyalkanoates production in a fed-batch bioreactor using a coupled PDE–ODE system

- Effectiveness of pH and amount of Artemia urumiana extract on physical, chemical, and biological attributes of UV-fabricated biogold nanoparticles

- Geranium leaf-mediated synthesis of silver nanoparticles and their transcriptomic effects on Candida albicans

- Synthesis, characterization, anticancer, anti-inflammatory activities, and docking studies of 3,5-disubstituted thiadiazine-2-thiones

- Synthesis and stability of phospholipid-encapsulated nano-selenium

- Putative anti-proliferative effect of Indian mustard (Brassica juncea) seed and its nano-formulation

- Enrichment of low-grade phosphorites by the selective leaching method

- Electrochemical analysis of the dissolution of gold in a copper–ethylenediamine–thiosulfate system

- Characterisation of carbonate lake sediments as a potential filler for polymer composites

- Evaluation of nano-selenium biofortification characteristics of alfalfa (Medicago sativa L.)

- Quality of oil extracted by cold press from Nigella sativa seeds incorporated with rosemary extracts and pretreated by microwaves

- Heteropolyacid-loaded MOF-derived mesoporous zirconia catalyst for chemical degradation of rhodamine B

- Recovery of critical metals from carbonatite-type mineral wastes: Geochemical modeling investigation of (bio)hydrometallurgical leaching of REEs

- Photocatalytic properties of ZnFe-mixed oxides synthesized via a simple route for water remediation

- Attenuation of di(2-ethylhexyl)phthalate-induced hepatic and renal toxicity by naringin nanoparticles in a rat model

- Novel in situ synthesis of quaternary core–shell metallic sulfide nanocomposites for degradation of organic dyes and hydrogen production

- Microfluidic steam-based synthesis of luminescent carbon quantum dots as sensing probes for nitrite detection

- Transformation of eggshell waste to egg white protein solution, calcium chloride dihydrate, and eggshell membrane powder

- Preparation of Zr-MOFs for the adsorption of doxycycline hydrochloride from wastewater

- Green nanoarchitectonics of the silver nanocrystal potential for treating malaria and their cytotoxic effects on the kidney Vero cell line

- Carbon emissions analysis of producing modified asphalt with natural asphalt

- An efficient and green synthesis of 2-phenylquinazolin-4(3H)-ones via t-BuONa-mediated oxidative condensation of 2-aminobenzamides and benzyl alcohols under solvent- and transition metal-free conditions

- Chitosan nanoparticles loaded with mesosulfuron methyl and mesosulfuron methyl + florasulam + MCPA isooctyl to manage weeds of wheat (Triticum aestivum L.)

- Synergism between lignite and high-sulfur petroleum coke in CO2 gasification

- Facile aqueous synthesis of ZnCuInS/ZnS–ZnS QDs with enhanced photoluminescence lifetime for selective detection of Cu(ii) ions

- Rapid synthesis of copper nanoparticles using Nepeta cataria leaves: An eco-friendly management of disease-causing vectors and bacterial pathogens

- Study on the photoelectrocatalytic activity of reduced TiO2 nanotube films for removal of methyl orange

- Development of a fuzzy logic model for the prediction of spark-ignition engine performance and emission for gasoline–ethanol blends

- Micro-impact-induced mechano-chemical synthesis of organic precursors from FeC/FeN and carbonates/nitrates in water and its extension to nucleobases

- Green synthesis of strontium-doped tin dioxide (SrSnO2) nanoparticles using the Mahonia bealei leaf extract and evaluation of their anticancer and antimicrobial activities

- A study on the larvicidal and adulticidal potential of Cladostepus spongiosus macroalgae and green-fabricated silver nanoparticles against mosquito vectors

- Catalysts based on nickel salt heteropolytungstates for selective oxidation of diphenyl sulfide

- Powerful antibacterial nanocomposites from Corallina officinalis-mediated nanometals and chitosan nanoparticles against fish-borne pathogens

- Removal behavior of Zn and alkalis from blast furnace dust in pre-reduction sinter process

- Environmentally friendly synthesis and computational studies of novel class of acridinedione integrated spirothiopyrrolizidines/indolizidines

- The mechanisms of inhibition and lubrication of clean fracturing flowback fluids in water-based drilling fluids

- Adsorption/desorption performance of cellulose membrane for Pb(ii)

- A one-pot, multicomponent tandem synthesis of fused polycyclic pyrrolo[3,2-c]quinolinone/pyrrolizino[2,3-c]quinolinone hybrid heterocycles via environmentally benign solid state melt reaction

- Green synthesis of silver nanoparticles using durian rind extract and optical characteristics of surface plasmon resonance-based optical sensor for the detection of hydrogen peroxide

- Electrochemical analysis of copper-EDTA-ammonia-gold thiosulfate dissolution system

- Characterization of bio-oil production by microwave pyrolysis from cashew nut shells and Cassia fistula pods

- Green synthesis methods and characterization of bacterial cellulose/silver nanoparticle composites

- Photocatalytic research performance of zinc oxide/graphite phase carbon nitride catalyst and its application in environment

- Effect of phytogenic iron nanoparticles on the bio-fortification of wheat varieties

- In vitro anti-cancer and antimicrobial effects of manganese oxide nanoparticles synthesized using the Glycyrrhiza uralensis leaf extract on breast cancer cell lines

- Preparation of Pd/Ce(F)-MCM-48 catalysts and their catalytic performance of n-heptane isomerization

- Green “one-pot” fluorescent bis-indolizine synthesis with whole-cell plant biocatalysis

- Silica-titania mesoporous silicas of MCM-41 type as effective catalysts and photocatalysts for selective oxidation of diphenyl sulfide by H2O2

- Biosynthesis of zinc oxide nanoparticles from molted feathers of Pavo cristatus and their antibiofilm and anticancer activities

- Clean preparation of rutile from Ti-containing mixed molten slag by CO2 oxidation

- Synthesis and characterization of Pluronic F-127-coated titanium dioxide nanoparticles synthesized from extracts of Atractylodes macrocephala leaf for antioxidant, antimicrobial, and anticancer properties

- Effect of pretreatment with alkali on the anaerobic digestion characteristics of kitchen waste and analysis of microbial diversity

- Ameliorated antimicrobial, antioxidant, and anticancer properties by Plectranthus vettiveroides root extract-mediated green synthesis of chitosan nanoparticles

- Microwave-accelerated pretreatment technique in green extraction of oil and bioactive compounds from camelina seeds: Effectiveness and characterization

- Studies on the extraction performance of phorate by aptamer-functionalized magnetic nanoparticles in plasma samples

- Investigation of structural properties and antibacterial activity of AgO nanoparticle extract from Solanum nigrum/Mentha leaf extracts by green synthesis method

- Green fabrication of chitosan from marine crustaceans and mushroom waste: Toward sustainable resource utilization

- Synthesis, characterization, and evaluation of nanoparticles of clodinofop propargyl and fenoxaprop-P-ethyl on weed control, growth, and yield of wheat (Triticum aestivum L.)

- The enhanced adsorption properties of phosphorus from aqueous solutions using lanthanum modified synthetic zeolites

- Separation of graphene oxides of different sizes by multi-layer dialysis and anti-friction and lubrication performance

- Visible-light-assisted base-catalyzed, one-pot synthesis of highly functionalized cinnolines

- The experimental study on the air oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid with Co–Mn–Br system

- Highly efficient removal of tetracycline and methyl violet 2B from aqueous solution using the bimetallic FeZn-ZIFs catalyst

- A thermo-tolerant cellulase enzyme produced by Bacillus amyloliquefaciens M7, an insight into synthesis, optimization, characterization, and bio-polishing activity

- Exploration of ketone derivatives of succinimide for their antidiabetic potential: In vitro and in vivo approaches

- Ultrasound-assisted green synthesis and in silico study of 6-(4-(butylamino)-6-(diethylamino)-1,3,5-triazin-2-yl)oxypyridazine derivatives

- A study of the anticancer potential of Pluronic F-127 encapsulated Fe2O3 nanoparticles derived from Berberis vulgaris extract

- Biogenic synthesis of silver nanoparticles using Consolida orientalis flowers: Identification, catalytic degradation, and biological effect

- Initial assessment of the presence of plastic waste in some coastal mangrove forests in Vietnam

- Adsorption synergy electrocatalytic degradation of phenol by active oxygen-containing species generated in Co-coal based cathode and graphite anode

- Antibacterial, antifungal, antioxidant, and cytotoxicity activities of the aqueous extract of Syzygium aromaticum-mediated synthesized novel silver nanoparticles

- Synthesis of a silica matrix with ZnO nanoparticles for the fabrication of a recyclable photodegradation system to eliminate methylene blue dye

- Natural polymer fillers instead of dye and pigments: Pumice and scoria in PDMS fluid and elastomer composites

- Study on the preparation of glycerylphosphorylcholine by transesterification under supported sodium methoxide

- Wireless network handheld terminal-based green ecological sustainable design evaluation system: Improved data communication and reduced packet loss rate

- The optimization of hydrogel strength from cassava starch using oxidized sucrose as a crosslinking agent

- Green synthesis of silver nanoparticles using Saccharum officinarum leaf extract for antiviral paint

- Study on the reliability of nano-silver-coated tin solder joints for flip chips

- Environmentally sustainable analytical quality by design aided RP-HPLC method for the estimation of brilliant blue in commercial food samples employing a green-ultrasound-assisted extraction technique

- Anticancer and antimicrobial potential of zinc/sodium alginate/polyethylene glycol/d-pinitol nanocomposites against osteosarcoma MG-63 cells

- Nanoporous carbon@CoFe2O4 nanocomposite as a green absorbent for the adsorptive removal of Hg(ii) from aqueous solutions

- Characterization of silver sulfide nanoparticles from actinobacterial strain (M10A62) and its toxicity against lepidopteran and dipterans insect species

- Phyto-fabrication and characterization of silver nanoparticles using Withania somnifera: Investigating antioxidant potential

- Effect of e-waste nanofillers on the mechanical, thermal, and wear properties of epoxy-blend sisal woven fiber-reinforced composites

- Magnesium nanohydroxide (2D brucite) as a host matrix for thymol and carvacrol: Synthesis, characterization, and inhibition of foodborne pathogens

- Synergistic inhibitive effect of a hybrid zinc oxide-benzalkonium chloride composite on the corrosion of carbon steel in a sulfuric acidic solution

- Review Articles

- Role and the importance of green approach in biosynthesis of nanopropolis and effectiveness of propolis in the treatment of COVID-19 pandemic

- Gum tragacanth-mediated synthesis of metal nanoparticles, characterization, and their applications as a bactericide, catalyst, antioxidant, and peroxidase mimic

- Green-processed nano-biocomposite (ZnO–TiO2): Potential candidates for biomedical applications

- Reaction mechanisms in microwave-assisted lignin depolymerisation in hydrogen-donating solvents

- Recent progress on non-noble metal catalysts for the deoxydehydration of biomass-derived oxygenates

- Rapid Communication

- Phosphorus removal by iron–carbon microelectrolysis: A new way to achieve phosphorus recovery

- Special Issue: Biomolecules-derived synthesis of nanomaterials for environmental and biological applications (Guest Editors: Arpita Roy and Fernanda Maria Policarpo Tonelli)

- Biomolecules-derived synthesis of nanomaterials for environmental and biological applications

- Nano-encapsulated tanshinone IIA in PLGA-PEG-COOH inhibits apoptosis and inflammation in cerebral ischemia/reperfusion injury

- Green fabrication of silver nanoparticles using Melia azedarach ripened fruit extract, their characterization, and biological properties

- Green-synthesized nanoparticles and their therapeutic applications: A review

- Antioxidant, antibacterial, and cytotoxicity potential of synthesized silver nanoparticles from the Cassia alata leaf aqueous extract

- Green synthesis of silver nanoparticles using Callisia fragrans leaf extract and its anticancer activity against MCF-7, HepG2, KB, LU-1, and MKN-7 cell lines

- Algae-based green AgNPs, AuNPs, and FeNPs as potential nanoremediators

- Green synthesis of Kickxia elatine-induced silver nanoparticles and their role as anti-acetylcholinesterase in the treatment of Alzheimer’s disease

- Phytocrystallization of silver nanoparticles using Cassia alata flower extract for effective control of fungal skin pathogens

- Antibacterial wound dressing with hydrogel from chitosan and polyvinyl alcohol from the red cabbage extract loaded with silver nanoparticles

- Leveraging of mycogenic copper oxide nanostructures for disease management of Alternaria blight of Brassica juncea

- Nanoscale molecular reactions in microbiological medicines in modern medical applications

- Synthesis and characterization of ZnO/β-cyclodextrin/nicotinic acid nanocomposite and its biological and environmental application

- Green synthesis of silver nanoparticles via Taxus wallichiana Zucc. plant-derived Taxol: Novel utilization as anticancer, antioxidation, anti-inflammation, and antiurolithic potential

- Recyclability and catalytic characteristics of copper oxide nanoparticles derived from bougainvillea plant flower extract for biomedical application

- Phytofabrication, characterization, and evaluation of novel bioinspired selenium–iron (Se–Fe) nanocomposites using Allium sativum extract for bio-potential applications

- Erratum

- Erratum to “Synthesis, characterization, and evaluation of nanoparticles of clodinofop propargyl and fenoxaprop-P-ethyl on weed control, growth, and yield of wheat (Triticum aestivum L.)”

Artikel in diesem Heft

- Research Articles

- Value-added utilization of coal fly ash and recycled polyvinyl chloride in door or window sub-frame composites

- High removal efficiency of volatile phenol from coking wastewater using coal gasification slag via optimized adsorption and multi-grade batch process

- Evolution of surface morphology and properties of diamond films by hydrogen plasma etching

- Removal efficiency of dibenzofuran using CuZn-zeolitic imidazole frameworks as a catalyst and adsorbent

- Rapid and efficient microwave-assisted extraction of Caesalpinia sappan Linn. heartwood and subsequent synthesis of gold nanoparticles

- The catalytic characteristics of 2-methylnaphthalene acylation with AlCl3 immobilized on Hβ as Lewis acid catalyst

- Biodegradation of synthetic PVP biofilms using natural materials and nanoparticles

- Rutin-loaded selenium nanoparticles modulated the redox status, inflammatory, and apoptotic pathways associated with pentylenetetrazole-induced epilepsy in mice

- Optimization of apigenin nanoparticles prepared by planetary ball milling: In vitro and in vivo studies

- Synthesis and characterization of silver nanoparticles using Origanum onites leaves: Cytotoxic, apoptotic, and necrotic effects on Capan-1, L929, and Caco-2 cell lines

- Exergy analysis of a conceptual CO2 capture process with an amine-based DES

- Construction of fluorescence system of felodipine–tetracyanovinyl–2,2′-bipyridine complex

- Excellent photocatalytic degradation of rhodamine B over Bi2O3 supported on Zn-MOF nanocomposites under visible light

- Optimization-based control strategy for a large-scale polyhydroxyalkanoates production in a fed-batch bioreactor using a coupled PDE–ODE system

- Effectiveness of pH and amount of Artemia urumiana extract on physical, chemical, and biological attributes of UV-fabricated biogold nanoparticles

- Geranium leaf-mediated synthesis of silver nanoparticles and their transcriptomic effects on Candida albicans

- Synthesis, characterization, anticancer, anti-inflammatory activities, and docking studies of 3,5-disubstituted thiadiazine-2-thiones

- Synthesis and stability of phospholipid-encapsulated nano-selenium

- Putative anti-proliferative effect of Indian mustard (Brassica juncea) seed and its nano-formulation

- Enrichment of low-grade phosphorites by the selective leaching method

- Electrochemical analysis of the dissolution of gold in a copper–ethylenediamine–thiosulfate system

- Characterisation of carbonate lake sediments as a potential filler for polymer composites

- Evaluation of nano-selenium biofortification characteristics of alfalfa (Medicago sativa L.)

- Quality of oil extracted by cold press from Nigella sativa seeds incorporated with rosemary extracts and pretreated by microwaves

- Heteropolyacid-loaded MOF-derived mesoporous zirconia catalyst for chemical degradation of rhodamine B

- Recovery of critical metals from carbonatite-type mineral wastes: Geochemical modeling investigation of (bio)hydrometallurgical leaching of REEs

- Photocatalytic properties of ZnFe-mixed oxides synthesized via a simple route for water remediation

- Attenuation of di(2-ethylhexyl)phthalate-induced hepatic and renal toxicity by naringin nanoparticles in a rat model

- Novel in situ synthesis of quaternary core–shell metallic sulfide nanocomposites for degradation of organic dyes and hydrogen production

- Microfluidic steam-based synthesis of luminescent carbon quantum dots as sensing probes for nitrite detection

- Transformation of eggshell waste to egg white protein solution, calcium chloride dihydrate, and eggshell membrane powder

- Preparation of Zr-MOFs for the adsorption of doxycycline hydrochloride from wastewater

- Green nanoarchitectonics of the silver nanocrystal potential for treating malaria and their cytotoxic effects on the kidney Vero cell line

- Carbon emissions analysis of producing modified asphalt with natural asphalt

- An efficient and green synthesis of 2-phenylquinazolin-4(3H)-ones via t-BuONa-mediated oxidative condensation of 2-aminobenzamides and benzyl alcohols under solvent- and transition metal-free conditions

- Chitosan nanoparticles loaded with mesosulfuron methyl and mesosulfuron methyl + florasulam + MCPA isooctyl to manage weeds of wheat (Triticum aestivum L.)

- Synergism between lignite and high-sulfur petroleum coke in CO2 gasification

- Facile aqueous synthesis of ZnCuInS/ZnS–ZnS QDs with enhanced photoluminescence lifetime for selective detection of Cu(ii) ions

- Rapid synthesis of copper nanoparticles using Nepeta cataria leaves: An eco-friendly management of disease-causing vectors and bacterial pathogens

- Study on the photoelectrocatalytic activity of reduced TiO2 nanotube films for removal of methyl orange

- Development of a fuzzy logic model for the prediction of spark-ignition engine performance and emission for gasoline–ethanol blends

- Micro-impact-induced mechano-chemical synthesis of organic precursors from FeC/FeN and carbonates/nitrates in water and its extension to nucleobases

- Green synthesis of strontium-doped tin dioxide (SrSnO2) nanoparticles using the Mahonia bealei leaf extract and evaluation of their anticancer and antimicrobial activities

- A study on the larvicidal and adulticidal potential of Cladostepus spongiosus macroalgae and green-fabricated silver nanoparticles against mosquito vectors

- Catalysts based on nickel salt heteropolytungstates for selective oxidation of diphenyl sulfide

- Powerful antibacterial nanocomposites from Corallina officinalis-mediated nanometals and chitosan nanoparticles against fish-borne pathogens

- Removal behavior of Zn and alkalis from blast furnace dust in pre-reduction sinter process

- Environmentally friendly synthesis and computational studies of novel class of acridinedione integrated spirothiopyrrolizidines/indolizidines

- The mechanisms of inhibition and lubrication of clean fracturing flowback fluids in water-based drilling fluids

- Adsorption/desorption performance of cellulose membrane for Pb(ii)

- A one-pot, multicomponent tandem synthesis of fused polycyclic pyrrolo[3,2-c]quinolinone/pyrrolizino[2,3-c]quinolinone hybrid heterocycles via environmentally benign solid state melt reaction

- Green synthesis of silver nanoparticles using durian rind extract and optical characteristics of surface plasmon resonance-based optical sensor for the detection of hydrogen peroxide

- Electrochemical analysis of copper-EDTA-ammonia-gold thiosulfate dissolution system

- Characterization of bio-oil production by microwave pyrolysis from cashew nut shells and Cassia fistula pods

- Green synthesis methods and characterization of bacterial cellulose/silver nanoparticle composites

- Photocatalytic research performance of zinc oxide/graphite phase carbon nitride catalyst and its application in environment

- Effect of phytogenic iron nanoparticles on the bio-fortification of wheat varieties

- In vitro anti-cancer and antimicrobial effects of manganese oxide nanoparticles synthesized using the Glycyrrhiza uralensis leaf extract on breast cancer cell lines

- Preparation of Pd/Ce(F)-MCM-48 catalysts and their catalytic performance of n-heptane isomerization

- Green “one-pot” fluorescent bis-indolizine synthesis with whole-cell plant biocatalysis

- Silica-titania mesoporous silicas of MCM-41 type as effective catalysts and photocatalysts for selective oxidation of diphenyl sulfide by H2O2

- Biosynthesis of zinc oxide nanoparticles from molted feathers of Pavo cristatus and their antibiofilm and anticancer activities

- Clean preparation of rutile from Ti-containing mixed molten slag by CO2 oxidation

- Synthesis and characterization of Pluronic F-127-coated titanium dioxide nanoparticles synthesized from extracts of Atractylodes macrocephala leaf for antioxidant, antimicrobial, and anticancer properties

- Effect of pretreatment with alkali on the anaerobic digestion characteristics of kitchen waste and analysis of microbial diversity

- Ameliorated antimicrobial, antioxidant, and anticancer properties by Plectranthus vettiveroides root extract-mediated green synthesis of chitosan nanoparticles

- Microwave-accelerated pretreatment technique in green extraction of oil and bioactive compounds from camelina seeds: Effectiveness and characterization

- Studies on the extraction performance of phorate by aptamer-functionalized magnetic nanoparticles in plasma samples

- Investigation of structural properties and antibacterial activity of AgO nanoparticle extract from Solanum nigrum/Mentha leaf extracts by green synthesis method

- Green fabrication of chitosan from marine crustaceans and mushroom waste: Toward sustainable resource utilization

- Synthesis, characterization, and evaluation of nanoparticles of clodinofop propargyl and fenoxaprop-P-ethyl on weed control, growth, and yield of wheat (Triticum aestivum L.)

- The enhanced adsorption properties of phosphorus from aqueous solutions using lanthanum modified synthetic zeolites

- Separation of graphene oxides of different sizes by multi-layer dialysis and anti-friction and lubrication performance

- Visible-light-assisted base-catalyzed, one-pot synthesis of highly functionalized cinnolines

- The experimental study on the air oxidation of 5-hydroxymethylfurfural to 2,5-furandicarboxylic acid with Co–Mn–Br system

- Highly efficient removal of tetracycline and methyl violet 2B from aqueous solution using the bimetallic FeZn-ZIFs catalyst

- A thermo-tolerant cellulase enzyme produced by Bacillus amyloliquefaciens M7, an insight into synthesis, optimization, characterization, and bio-polishing activity

- Exploration of ketone derivatives of succinimide for their antidiabetic potential: In vitro and in vivo approaches

- Ultrasound-assisted green synthesis and in silico study of 6-(4-(butylamino)-6-(diethylamino)-1,3,5-triazin-2-yl)oxypyridazine derivatives

- A study of the anticancer potential of Pluronic F-127 encapsulated Fe2O3 nanoparticles derived from Berberis vulgaris extract

- Biogenic synthesis of silver nanoparticles using Consolida orientalis flowers: Identification, catalytic degradation, and biological effect

- Initial assessment of the presence of plastic waste in some coastal mangrove forests in Vietnam

- Adsorption synergy electrocatalytic degradation of phenol by active oxygen-containing species generated in Co-coal based cathode and graphite anode

- Antibacterial, antifungal, antioxidant, and cytotoxicity activities of the aqueous extract of Syzygium aromaticum-mediated synthesized novel silver nanoparticles

- Synthesis of a silica matrix with ZnO nanoparticles for the fabrication of a recyclable photodegradation system to eliminate methylene blue dye

- Natural polymer fillers instead of dye and pigments: Pumice and scoria in PDMS fluid and elastomer composites

- Study on the preparation of glycerylphosphorylcholine by transesterification under supported sodium methoxide

- Wireless network handheld terminal-based green ecological sustainable design evaluation system: Improved data communication and reduced packet loss rate

- The optimization of hydrogel strength from cassava starch using oxidized sucrose as a crosslinking agent

- Green synthesis of silver nanoparticles using Saccharum officinarum leaf extract for antiviral paint

- Study on the reliability of nano-silver-coated tin solder joints for flip chips

- Environmentally sustainable analytical quality by design aided RP-HPLC method for the estimation of brilliant blue in commercial food samples employing a green-ultrasound-assisted extraction technique

- Anticancer and antimicrobial potential of zinc/sodium alginate/polyethylene glycol/d-pinitol nanocomposites against osteosarcoma MG-63 cells

- Nanoporous carbon@CoFe2O4 nanocomposite as a green absorbent for the adsorptive removal of Hg(ii) from aqueous solutions

- Characterization of silver sulfide nanoparticles from actinobacterial strain (M10A62) and its toxicity against lepidopteran and dipterans insect species

- Phyto-fabrication and characterization of silver nanoparticles using Withania somnifera: Investigating antioxidant potential

- Effect of e-waste nanofillers on the mechanical, thermal, and wear properties of epoxy-blend sisal woven fiber-reinforced composites

- Magnesium nanohydroxide (2D brucite) as a host matrix for thymol and carvacrol: Synthesis, characterization, and inhibition of foodborne pathogens

- Synergistic inhibitive effect of a hybrid zinc oxide-benzalkonium chloride composite on the corrosion of carbon steel in a sulfuric acidic solution

- Review Articles

- Role and the importance of green approach in biosynthesis of nanopropolis and effectiveness of propolis in the treatment of COVID-19 pandemic

- Gum tragacanth-mediated synthesis of metal nanoparticles, characterization, and their applications as a bactericide, catalyst, antioxidant, and peroxidase mimic

- Green-processed nano-biocomposite (ZnO–TiO2): Potential candidates for biomedical applications

- Reaction mechanisms in microwave-assisted lignin depolymerisation in hydrogen-donating solvents

- Recent progress on non-noble metal catalysts for the deoxydehydration of biomass-derived oxygenates

- Rapid Communication

- Phosphorus removal by iron–carbon microelectrolysis: A new way to achieve phosphorus recovery

- Special Issue: Biomolecules-derived synthesis of nanomaterials for environmental and biological applications (Guest Editors: Arpita Roy and Fernanda Maria Policarpo Tonelli)

- Biomolecules-derived synthesis of nanomaterials for environmental and biological applications

- Nano-encapsulated tanshinone IIA in PLGA-PEG-COOH inhibits apoptosis and inflammation in cerebral ischemia/reperfusion injury

- Green fabrication of silver nanoparticles using Melia azedarach ripened fruit extract, their characterization, and biological properties

- Green-synthesized nanoparticles and their therapeutic applications: A review

- Antioxidant, antibacterial, and cytotoxicity potential of synthesized silver nanoparticles from the Cassia alata leaf aqueous extract

- Green synthesis of silver nanoparticles using Callisia fragrans leaf extract and its anticancer activity against MCF-7, HepG2, KB, LU-1, and MKN-7 cell lines

- Algae-based green AgNPs, AuNPs, and FeNPs as potential nanoremediators

- Green synthesis of Kickxia elatine-induced silver nanoparticles and their role as anti-acetylcholinesterase in the treatment of Alzheimer’s disease

- Phytocrystallization of silver nanoparticles using Cassia alata flower extract for effective control of fungal skin pathogens

- Antibacterial wound dressing with hydrogel from chitosan and polyvinyl alcohol from the red cabbage extract loaded with silver nanoparticles

- Leveraging of mycogenic copper oxide nanostructures for disease management of Alternaria blight of Brassica juncea

- Nanoscale molecular reactions in microbiological medicines in modern medical applications

- Synthesis and characterization of ZnO/β-cyclodextrin/nicotinic acid nanocomposite and its biological and environmental application

- Green synthesis of silver nanoparticles via Taxus wallichiana Zucc. plant-derived Taxol: Novel utilization as anticancer, antioxidation, anti-inflammation, and antiurolithic potential

- Recyclability and catalytic characteristics of copper oxide nanoparticles derived from bougainvillea plant flower extract for biomedical application

- Phytofabrication, characterization, and evaluation of novel bioinspired selenium–iron (Se–Fe) nanocomposites using Allium sativum extract for bio-potential applications

- Erratum

- Erratum to “Synthesis, characterization, and evaluation of nanoparticles of clodinofop propargyl and fenoxaprop-P-ethyl on weed control, growth, and yield of wheat (Triticum aestivum L.)”