Abstract

Engineered cementitious composites (ECC) exhibit behaviors of multiple cracking and strain-hardening compared to ordinary concrete. However, the use of ultrafine silica sand (S) to produce ECC results in increased cost and environmental overload. This study was to develop an eco-friendly and cheaper ECC by incorporating different replacement ratios of industrial byproduct molybdenum tailings (MT). The mechanical properties of ECC with MT were evaluated. Based on industrial computer technology, nuclear magnetic resonance, and scanning electron microscope techniques, the three-dimensional spatial distribution and fluid distribution of pores and the microstructure of the ECC were investigated, respectively. The mechanical properties of stirrup-confined ECC stub columns were also investigated. Results indicated that the ECC incorporating 25% MT exhibited the best mechanical properties, in which the tensile strength (f t) increased by 32.16% and exhibited well strain-hardening behaviors. Under a 25% MT replacement ratio, ECC had the lowest porosity and good interfacial transition zone, and bonding interface between polyvinyl alcohol (PVA) fiber (PF) and matrix. Moreover, the stirrup-confined ECC stub column with 25% MT can ensure better both the peak stress (f cc) and peak strain (ε cc). The assessment of environmental impact and cost further indicated that the incorporation of MT to prepare ECC is a promising method.

1 Introduction

Engineered cementitious composites (ECC), a kind of fiber-reinforced cementitious composites, have ultra-high tensile ductility and saturated multiple cracking behaviors [1,2,3]. Generally, the deformability (tensile strain) of ECC could reach 1–8%, which makes the application prospect of ECC better than that of ordinary concrete. Moreover, the raw material silica sand (S) used for ECC is more expensive than that of river sand, which increases the production cost of ECC [4]. Meanwhile, with the concept of green building strongly promoted, clean development of high-performance and eco-friendly ECC is a new direction for the development of the construction industry.

To reduce the cost and achieve sustainable development of ECC, some industrial wastes have been tried as raw materials for the preparation of ECC [5,6]. For example, Xu et al. [7,8] incorporated artificial geopolymer as aggregate (GPA) to produce ECC and found that exhibit the cost-efficiency and sustainability of GPA-ECC, which provided a sustainable approach for enhancing the long-term tensile performance of high-strength ECC based on artificial aggregates. Zhang et al. [9] reported that when S was replaced by crumb rubber, the ductility of ECC increased, but the strength was reduced by about 35%. Li and Yang [10] found that the ductility of ECC was improved by replacing S with recycled fine aggregates of different particle sizes for the preparation of ECC. Similarly, Huang et al. [11] prepared ECC by incorporating iron ore tailings with different particle sizes as aggregate and reported that when the particle size of iron ore tailings used was within a reasonable range, ECC could obtain the same mechanical properties as conventional ECC. Turk and Demirhan [12] incorporated 100% limestone powder as aggregate to produce ECC and found that the mechanical properties of ECC were enhanced. Adesina and Das [4] incorporated glass with different replacement levels as aggregate to produce ECC and found that when S was replaced by glass aggregate, the mechanical properties of ECC did not deteriorate, and the embodied carbon and cost were reduced by 5.9 and 16.6%, respectively. It was found that using industrial byproducts to produce ECC can not only improve performance but also solve the problem of waste disposal, reduce production costs, and achieve cleaner production of ECC.

Molybdenum tailings (MT) are inevitable industrial byproducts of raw ore refining [13] and are considered to be one of the main pollution sources causing environmental degradation [14,15]. It was reported that approximately 36 million tons of MT are discharged per year in China [16], and the emissions from mine tailings in other countries are increasing year by year [17,18,19]. A large number of MT are treated by open-air stacking and landfilling, which not only take up a lot of land but also result in soil erosion, and air and water pollution [20,21,22]. Moreover, there is a risk of mudslides caused by the failure of tailings dams. Hence, the reuse of MT is very key to reducing environmental pollution and the healthy development of the mining industry [23,24].

Various methods of reuse of MT have been proposed to prevent further environmental degradation, such as processing glass ceramics [25], extraction of useful substances again [26,27], growing plants through improvement [28], and processing building materials [29,30]. It is worth noting that with the rapid development of the construction industry, the application of concrete and mortar can consume the largest amount of MT compared to other technologies of MT reuse. Jung and Jeong [29] developed an admixture for high-fluidity concrete by using MT powder and found that MT powder as an admixture can effectively control the flow, viscosity, and strength of high-fluidity concrete when the amount of cement replaced by MT powder was 20%. Siddique and Jang [13] investigated mortar mechanics and durability by incorporating MT as filler material and found that the properties of mortar were improved by mixing with MT, which further confirmed that using MT to prepare building material was a feasible solution for the reuse of MT. Quan et al. [16] used MT as fine aggregate to prepare concrete and found that incorporating 60% MT in concrete was the best reuse option for developing green concrete. Similarly, Gao and Guo [31] applied MT to concrete members and made a comprehensive evaluation of stub columns of concrete-filled steel tubes mixed with tailings. The study found that the resource utilization of MT in stub columns of concrete-filled steel tubes had good environmental and cost benefits.

Previous studies found that using MT to prepare cementitious composites is a good cleaner production method. However, to date, there are still few studies about using MT as a fine aggregate to prepare building materials. It is noteworthy that studies on the preparation of ECC using MT have not been found. Thus, to decrease the cost and carbon emission of ECC, and further expand the application of MT in building materials, research on the reuse of MT in ECC is a hot topic and has important environmental and cost benefits.

A comprehensive experimental study on the preparation of ECC using MT as an eco-friendly aggregate was carried out from both mesoscopic and microscopic points of view in this study. First, the crystal composition, microscopic morphology, particle size, and radioactivity of MT were characterized. The uniaxial tension performance, flexural performance, and axial compressive performance of ECC were measured. Additionally, nuclear magnetic resonance (NMR) and industrial computer technology (CT) were used to analyze the pore distribution of ECC to further reveal the influence of MT on the pore structure, after which the microstructure was analyzed using scanning electron microscopy (SEM). Additionally, the stirrup-confined ECC stub column under compression was also investigated.

2 Experimental details

2.1 Materials

The Ordinary Portland Cement (OPC) PO42.5R, silica fume (SF), and first-grade FA as cementitious materials were used. Table 1 provides the chemical composition of the cementitious materials and fine aggregates.

Chemical compositions of cementitious materials and fine aggregate (wt%)

| Cementitious materials | Fine aggregates | ||||

|---|---|---|---|---|---|

| OPC | FA | SF | S | MT | |

| CaO | 60.73 | 3.66 | 0.44 | 0.49 | 4.2 |

| SiO2 | 20.85 | 52.97 | 97.24 | 98.63 | 74.26 |

| Al2O3 | 4.92 | 29.96 | 0.19 | 0.47 | 5.22 |

| Fe2O3 | 3.59 | 7.98 | 0.05 | 0.49 | 11.89 |

| MgO | 2.87 | 1.52 | 0.17 | 0.14 | 2.88 |

| SO3 | 2.33 | 0.65 | 0.78 | 0.08 | 0.24 |

| Na2O | 0.25 | 0.55 | — | — | 0.22 |

| K2O | 0.46 | 1.18 | 0.93 | 0.08 | 1.01 |

| TiO2 | 0.27 | 0.49 | — | — | — |

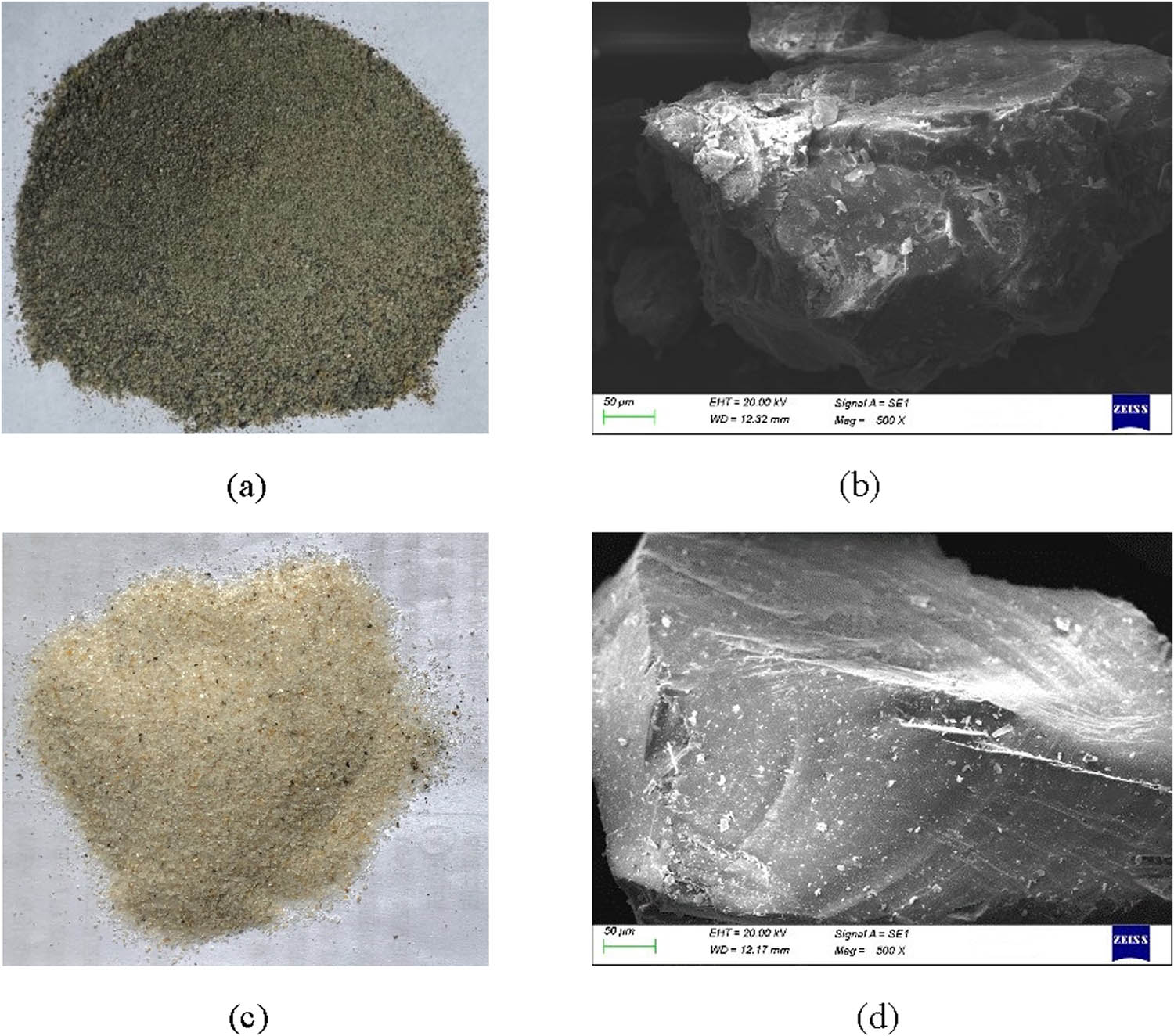

In this study, the MT from Shaanxi Province, China, and S were used as an aggregate. The main crystal composition and micromorphology of MT and S were determined by X-ray diffraction (XRD) and SEM, as shown in Figures 1 and 2, respectively. It was found from Figures 1 and 2 that the main crystal composition of MT is similar to that of S, which is mainly quartz, and the chemical activity was steady, but MT had more angular surfaces than that of S. In addition, according to the Chinese national standard GB14684-2011, the physical properties of MT and S including apparent density, loose bulk density, crushing index, and water absorption were tested and summarized as listed in Table 2. It can be observed from Table 2 that the crushing index of MT was 9.66% lower than that of S, in which the main reason for this phenomenon is that the particle size of MT is small (Figure 3).

XRD patterns of (a) MT and (b) S.

Microscopic structure of MT and S: (a) MT, (b) SEM of MT (enlarged 500 times), (c) S and (d) SEM of S (enlarged 500 times).

Physical properties of MT and S

| Apparent density (kg·m−3) | Loose bulk density (kg·m−3) | Crushing index (%) | Water absorption (%) | |

|---|---|---|---|---|

| MT | 2,734 | 1,897 | 14.86 | 0.88 |

| S | 2,756 | 1,844 | 16.45 | — |

Particle size curve of MT and S.

The fiber used was polyvinyl alcohol (PVA) fiber (PF), with its characteristic parameters, are shown in Table 3.

Characteristic parameters of fiber

| Length (mm) | Diameter (μm) | Density (g·cm−3) | Fracture elongation (%) | Tensile strength (MPa) | Modulus of elasticity (GPa) | |

|---|---|---|---|---|---|---|

| PF | 12 | 40 | 1.3 | 7 | 1,600 | 42 |

The HRB400 and HPB300 rebar is used for longitudinal and stirrup, respectively. Based on the test standards, some mechanical parameters were obtained by direct tensile testing of the pre-rebar specimens, as shown in Table 4.

Characteristic parameters of rebar

| Diameter (mm) | f y (MPa) | f u (MPa) | Elongation (%) | |

|---|---|---|---|---|

| HRB400 | 12 | 489 | 651 | 21 |

| HPB300 | 6 | 453 | 536 | 24 |

Note: the f y and f u present yield strength and tensile strength of rebar, respectively.

2.2 Mix proportions and specimen preparation

2.2.1 Mix proportions

Limited literature had reported the use of MT in concrete and mortar [32,33], and the maximum replacement ratio was set to 100% [16]. However, there are few reports about the utilization of MT in ECC. Thus, to investigate the influence of MT as an eco-friendly aggregate incorporated into ECC and the optimal replacement ratio of MT, only the replacement level of MT was changed. The MT replacement ratio (replace by weight) was 0% (pure S), 25, 50, 75, and 100% (pure MT), respectively. The water/cementitious materials were 0.3, and the aggregate/cementitious materials were 0.5. The volume content of PF was designed to be 2% [11,34]. Five groups’ mixed proportions are listed in Table 5.

Mix proportions (kg·m−3)

| No. | Fine aggregates | Cementitious materials | W | SP | PF | Flow diameter (mm) | 28 days f cu (MPa) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| S | MT | C | FA | SF | ||||||

| MT0 | 629 | 0 | 754.8 | 377.4 | 125.8 | 377 | 6.3 | 26 | 175 | 38.22 |

| MT25 | 471.7 | 157.3 | 754.8 | 377.4 | 125.8 | 377 | 6.3 | 26 | 165 | 45.68 |

| MT50 | 314.5 | 314.5 | 754.8 | 377.4 | 125.8 | 377 | 6.3 | 26 | 160 | 42.81 |

| MT75 | 157.3 | 471.7 | 754.8 | 377.4 | 125.8 | 377 | 6.3 | 26 | 150 | 41.1 |

| MT100 | 0 | 629 | 754.8 | 377.4 | 125.8 | 377 | 6.3 | 26 | 145 | 36.5 |

Nomenclature: using “MT25” as an example, MT denotes molybdenum tailing. The 25 denotes an MT replacement ratio of 25%.

2.2.2 Specimen preparation

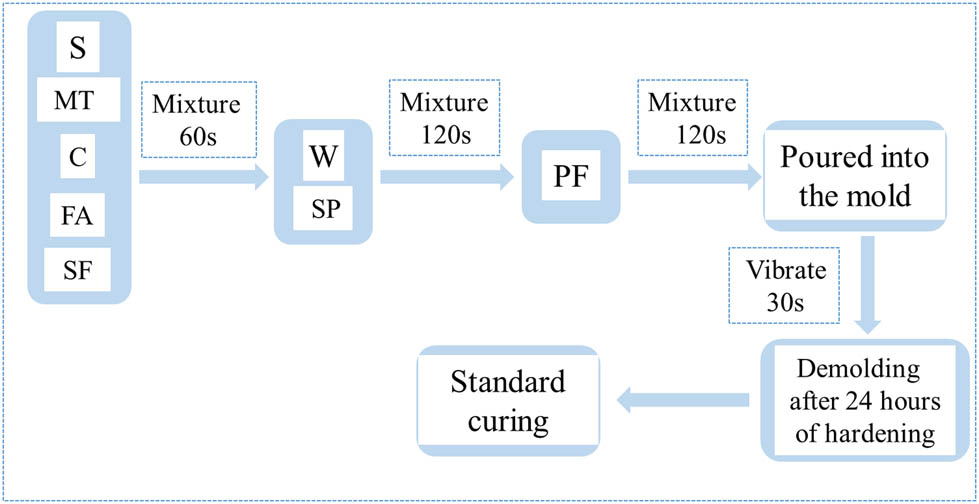

For the preparation of each ECC specimen, in step 1, all the weighed solids were poured into the mixer for mixing, and the mixing was 60 s. In step 2, the water and superplasticizer (SP) were added and stirred for 120 s. In step 3, the PF was slowly added and stirred for 120 s. In step 4, the mixture was put into a mold and vibrated in the 30 s. After consolidation, the molds were removed, and the specimens were placed in the curing box for curing. Figure 4 presents the specimen mixing process.

Specimen mixing process.

In this experiment, three parallel specimens for each group were prepared for tests. The cubes specimens (100 mm × 100 mm × 100 mm) were prepared to test the cube compressive strength (f cu). The Ф100 mm (diameter) × 200 mm (high) cylinders were prepared to test the axial compressive strength (f c) and elastic modulus (E c). The dog-bone-shaped specimens and 300 mm (length) × 76 mm (width) × 13 mm (thickness) thin slabs were prepared to test the tensile strength (f t) and flexural strength (f f), respectively.

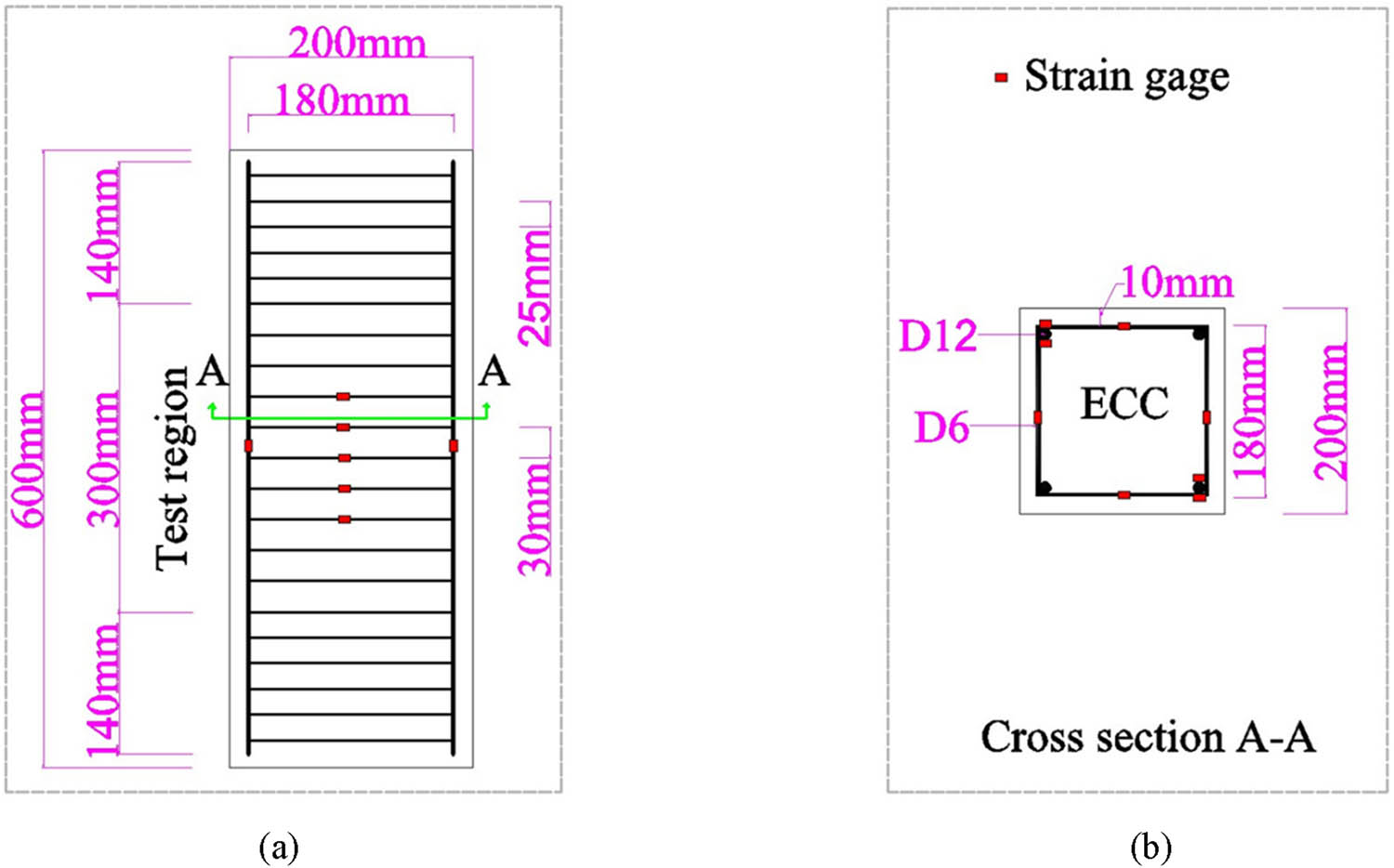

The stirrup-confined ECC stub column with different MT was prepared for testing the bearing capacity under axial compression. The dimensions of the stub column are shown in Figure 5. The designation and parameters including dimensions, stirrup ratio of volume, stirrup spacing, and MT replacement ratio of the stub column are listed in Table 6.

Dimensions of stub column: (a) elevation dimension and (b) cross-section dimension and strain gauge locations.

Parameters of the column

| No. | Length × width × thickness (mm) | Stirrup ratio of volume (%) | Stirrup spacing (mm) | MT replacement ratio (%) |

|---|---|---|---|---|

| CE-MT0 | 600 × 200 × 200 | 2.1 | 30 | 0 |

| CE-MT25 | 600 × 200 × 200 | 2.1 | 30 | 25 |

| CE-MT50 | 600 × 200 × 200 | 2.1 | 30 | 50 |

| CE-MT75 | 600 × 200 × 200 | 2.1 | 30 | 75 |

| CE-MT100 | 600 × 200 × 200 | 2.1 | 30 | 100 |

2.3 Test methods

2.3.1 ECC mechanical properties testing

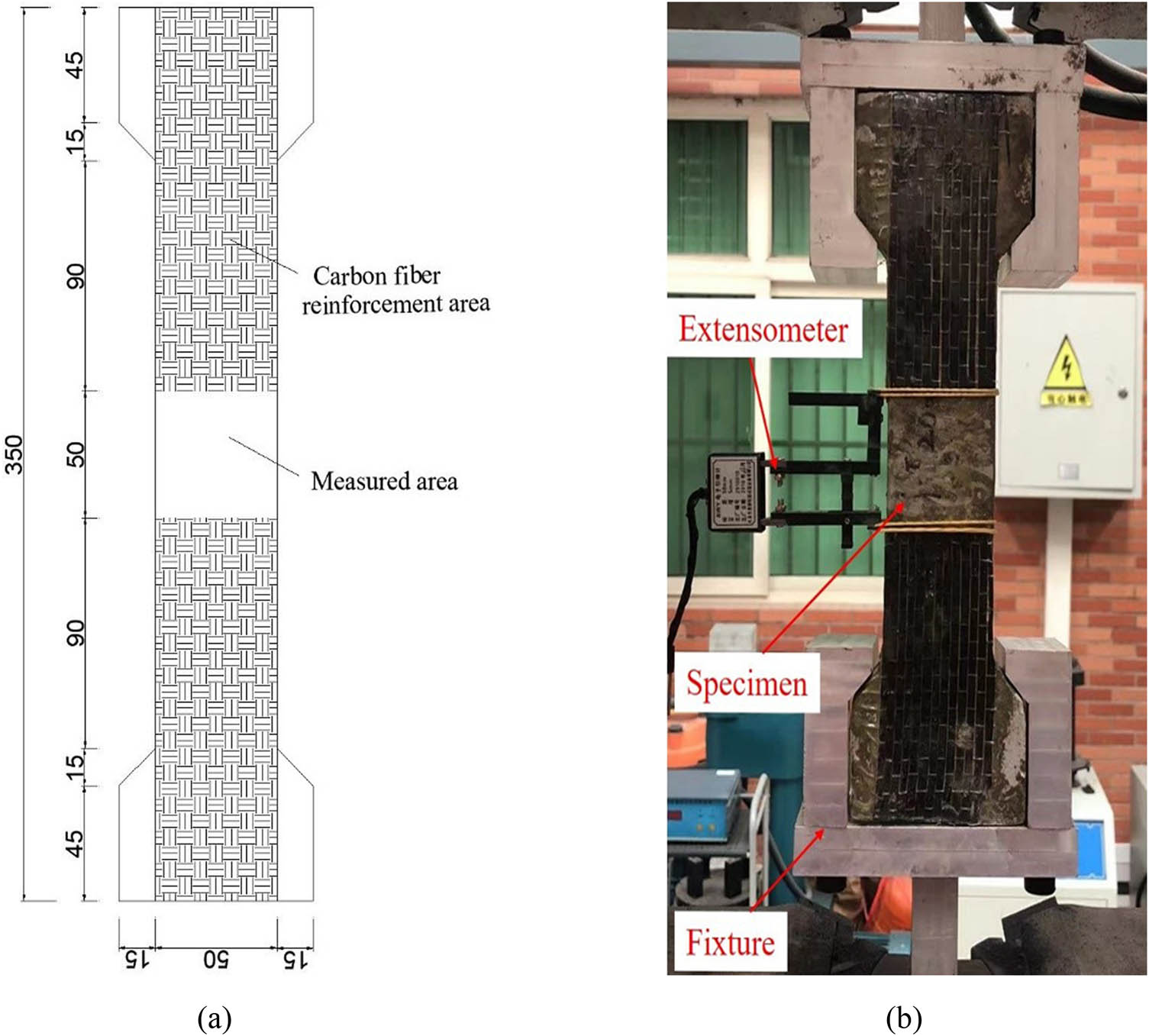

Based on the guidance of ASTM E8 and JSCE 2008 universal standards, the dog-bone-shaped specimen was reinforced with carbon fiber sheets outside the measuring area to avoid stress concentration before the tensile test, as shown in Figure 6. Then, the f t was investigated. The deformation data were obtained by the extensometer, and the quasi-static loading rate was set to 0.1 mm·min−1.

Uniaxial tension test: (a) specimen size and (b) test setup.

The thin slabs were used for testing the f f in a 20 kN compression machine by changing the chuck based on the ASTM C 1609 M. The midspan deflection data were collected by linear variable displacement transducer (LVDT).

According to the Chinese code GB/T 50081-2019, the f cu, f c, and E c of ECC were tested by a 1000 kN compression machine. The deformation data under the axial compression were collected using two LVDTs.

2.3.2 ECC pore structure testing

Industrial CT (MS-Voxe1450, Tianjin, China) was used to quantitatively evaluate the three-dimensional spatial pores distribution of ECC. In the scanning CT experiment, the operating voltage, current, and exposure time were 380 kV, 1.3 mA, and 0.5 s, respectively. The cube specimen was scanned continuously along the cross section to a depth of 0.5 mm, and every 20 mm along the height of the specimen. Finally, the 200 2D tomography CT images with 1,200 × 1,200 pixels resolution were acquired. The AVIZO 3D image processing software was used to perform the 3D reconstruction of pores by threshold segmentation.

The MacroMR12-150H-I NMR instrument was used to test the T2 spectrum and pore fluid distribution of ECC. The magnetic field and frequency were selected at 0.5T and 50–60 Hz, respectively.

2.3.3 ECC micro-morphology testing

The specimen size was approximately 0.5 cm × 0.5 cm × 0.2 cm. Before gold spraying and vacuuming the sample, the prepared samples were pretreated by being placed in ethanol for 24 h and dried at 40°C for 24 h. Then, the micromorphology test was conducted using the EVO-10 SEM.

2.3.4 Stirrup-confined ECC stub column mechanical properties testing

The ECC square section stub column was loaded on a 5000 kN compression machine, as shown in Figure 7. A mixed loading method of force and displacement was used. At the initial stage, the loading rate of 100 kN·min−1 was selected to control loading. After the specimens reached the maximum compressive load, the loading rate of 0.3 mm·min−1 was selected to control loading. The axial deformation of the column was measured using two LVDTs laid on the side. The peak stress of the column (f cc) was calculated by Eq. (1).

where the A

cov, A

s, and A present the area of concrete cover, the cross-sectional area of longitudinal rebar, and the cross-sectional area of the specimen, respectively; the

Compressive test setup.

2.3.5 Environmental impact (EI) assessment

Based on the reliability and applicability of the life cycle assessment (LCA), this method is recommended to quantitatively assess the EI of a product [35,36]. According to ISO 14040 and ISO 14044 standards, to complete an assessment of the EI through the LCA, it is necessary to define the goal and functional units, create a life cycle inventory, and calculate the EI categories.

Thus, this study was devoted to investigating the EI (cradle-to-gate) of prepared ECC with different MT replacement ratios at first. The defined functional unit is 1 m3 of ECC of a certain quality [37]. Then, the data relevant to the production of ECC from the life cycle inventory process and the LCA handbook were collected and calculated for the different EI categories.

The EI of the ECC was evaluated by five internationally recognized impact categories namely the photochemical ozone creation potential (POCP), acidification potential (AP), global warming potential (GWP), ozone depletion potential (ODP), and nitrification potential (NP) [38,39]. It should be noted that the EIs of MT and S during collection and transportation were not included in the life cycle analysis because both the MT plants and the sand plants are similar in distance to the city.

2.3.6 Cost assessment

The economic benefits of ECC with different MT replacement ratios were assessed by material costs.

3 Results and discussion

3.1 Uniaxial tension performance of ECC

3.1.1 Tensile stress–strain curves

The stress–strain curves of ECC under uniaxial tension are presented in Figure 8. Compared with MT0, the MT incorporation did not change the shape of the stress–strain curve of the ECC, which still contains three stages. The elastic stage presents linear-elastic performance, and the tension stress is mainly resisted by the matrix. The strain-hardening stage presents that deformation increases significantly, but only a small increase in tensile stress. The strain-softening stage is mainly that the bonding stress between the matrix and fiber resists the tensile stress, and no new cracks are generated. The cracks generated in the second stage widen with the decrease of the bonding force and finally break with the main crack. By observing the strain-hardening stage, it can be found that the strain-hardening behaviors of MT25, MT50, and MT75 are more significant than that of MT0, and the ε tr is more than 2%. Similarly, Huang et al. [40] reported ECC preparation using iron ore tailings also exhibits desirable strain-hardening behavior.

Stress–strain curve of ECC under uniaxial tension: (a) MT0, (b) MT25, (c) MT50, (d) MT75, (e) MT100 and (f) three-stages simplified model.

3.1.2 Tensile tests results

Table 7 lists the average values of test results including first cracking f t, f t, and tensile strain (ε tr). It found that the incorporation of MT up to 75% is beneficial to enhancing the tensile properties of ECC, and incorporating 25% MT is the most significant improvement. The test results of three characteristic points of MT25 including first cracking f t, f t, and ε tr increased by 22.69, 32.16, and 26.7%, respectively, compared with MT0. The improvement of tensile properties is mainly because the fine MT particles than that of S can effectively fill and refine the pores inside the matrix [41] and at the interface of PF and matrix so that the matrix density and bonding between the PF and the matrix will be increased, which can effectively consume energy during loading. Meanwhile, due to MT with more angular surfaces, this fact also facilitates the bonding between the PF and the matrix, increasing the tensile properties. A similar result is consistent with the previous study [42]. Unfortunately, when S is completely replaced by MT, the tensile properties of MT100 is deteriorated, especially at first cracking f t, which decreased by 21.42%. The decrease in tensile properties is mainly due to poor gradation increases in the porosity, resulting in deterioration of the bonding between the matrix and PF. In addition, the amount of cement slurry attached to the MT per unit area is reduced, which weakens the bonding including between matrix and aggregate (matrix and PF). This is also confirmed in Sections 3.4 and 3.5. It can be observed from the above research results incorporating 25% MT could ensure high tensile properties, which further solidifies that incorporation of MT to prepare ECC is a promising clean production method.

Tensile test results of ECC

| No. | First cracking f t (MPa) | f t (MPa) | ε tr (%) |

|---|---|---|---|

| MT0 | 2.52 (0.19) | 3.46 (0.06) | 1.89 (0.02) |

| MT25 | 3.26 (0.22) | 5.10 (0.54) | 2.58 (0.23) |

| MT50 | 3.15 (0.36) | 4.55 (0.38) | 2.34 (0.17) |

| MT75 | 2.77 (0.09) | 4.01 (0.24) | 2.09 (0.36) |

| MT100 | 1.98 (0.15) | 2.81 (0.04) | 1.62 (0.24) |

Note: the values in parentheses represent the standard error.

3.2 Flexural performance of ECC

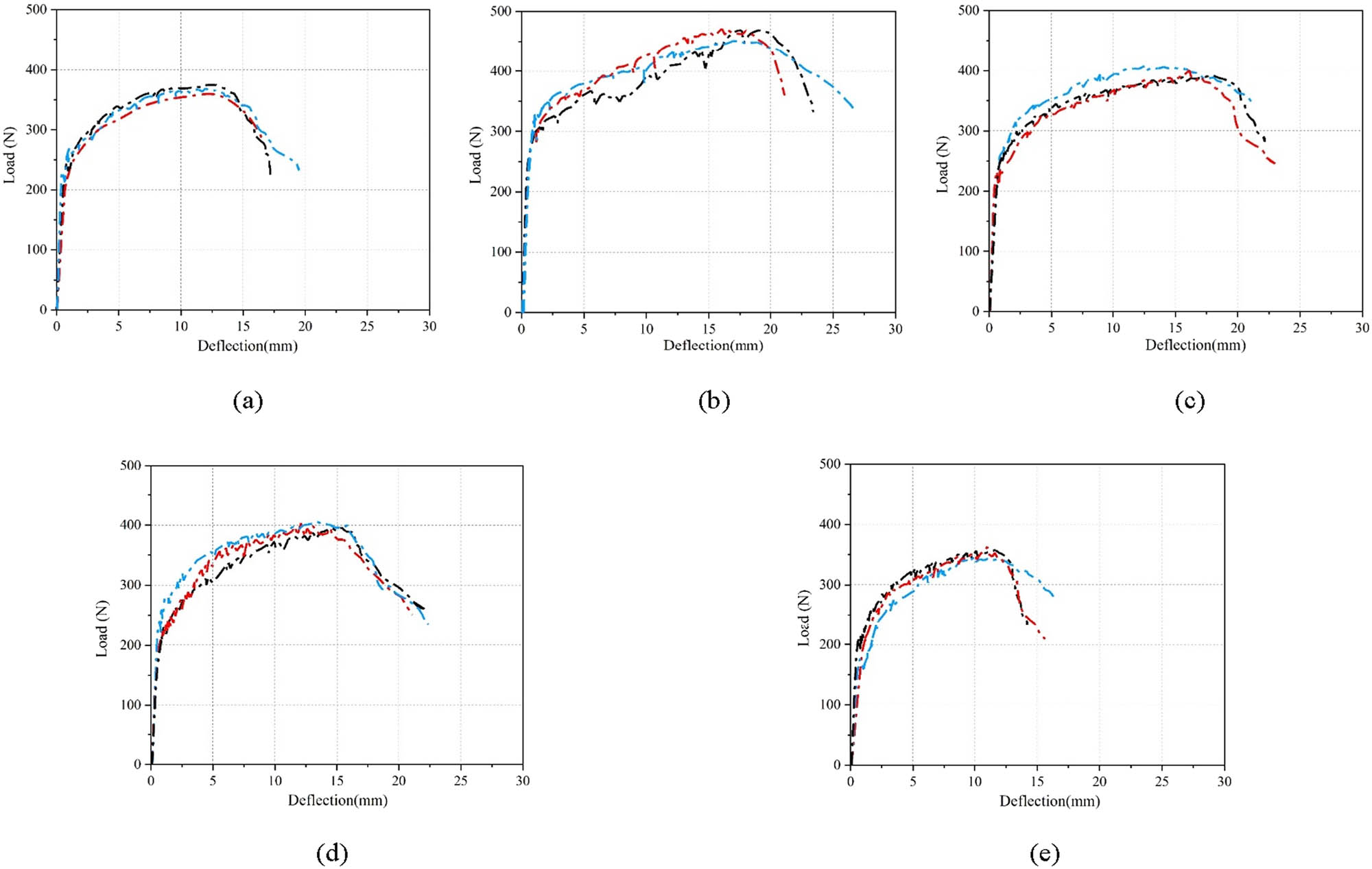

3.2.1 Load–deflection curves

Figure 9 presents the load–deflection curves of ECC under flexural load. Similar to the tensile stress–strain curve, the load–deflection curve also contains three parts (elastic part, deflection-hardening part, and descending softening part). The area covered by the load–deflection curve of ECC addition 25% MT is the largest, and the characteristic of deflection-hardening is obvious. But, as the MT replacement ratio increases, the area covered by the load–deflection curve and characteristic of deflection-hardening gradually deteriorated, especially at 100%, which is less than MT0.

Load–deflection curve of ECC under flexural load: (a) MT0, (b) MT25, (c) MT50, (d) MT75, and (e) MT100.

3.2.2 Flexural tests results

Table 8 lists the test results of flexural properties. It was found that the first cracking deflection of ECC fluctuates without an obvious change in the law. The first cracking deflection of ECC incorporating 100% MT is the largest. This is because, when S is completely replaced by MT, the overall stiffness of the ECC decreases. The ultimate deflection of the ECC initially increased and then decreased as increasing MT replacement ratio, which is similar to the changing trend of the tensile test results. The ultimate deflection of ECC incorporating 25% MT has the most significant, which increased by 43.28%, compared with MT0. Similarly, MT25 has also the highest first cracking load and f f, which increased by 19.43 and 19.79%, compared with MT0, respectively. This is mainly related to the high compactness and the good interaction between the PF and the matrix of MT25. However, when the MT replacement ratio is 100%, the first cracking load, ultimate deflection, and f f of ECC are deteriorated and smaller than that of MT0. Thus, ECC with 25–75% MT also has a favorable effect on the improvement of flexural properties.

Flexural test results of ECC

| No. | First cracking deflection (mm) | First cracking load (.) | Ultimate deflection (mm) | Ultimate load (N) | f f (MPa) |

|---|---|---|---|---|---|

| MT0 | 0.61 (0.06) | 210.36 (17.65) | 12.66 (0.89) | 376.94 (4.22) | 7.09 (0.08) |

| MT25 | 0.59 (0.02) | 251.24 (11.22) | 18.14 (1.78) | 473.09 (11.25) | 8.84 (0.29) |

| MT50 | 0.63 (0.03) | 215.18 (9.49) | 16.13 (2.63) | 395.48 (7.78) | 7.39 (0.18) |

| MT75 | 0.56 (0.03) | 206.23 (23.54) | 13.08 (2.04) | 401.12 (5.33) | 7.57 (0.11) |

| MT100 | 0.73 (0.09) | 186.59 (27.18) | 11.11 (1.56) | 343.06 (6.56) | 6.41 (0.15) |

Note: the values in parentheses represent the standard error.

3.2.3 Flexural toughness evaluation

Toughness under flexural stress is also an important indicator of material performance. At present, the evaluation methods of flexural toughness of composite materials mainly include JSCE-SF4, ASTM C1018, ASTM C 1609, RILEMT C162-TDF, and CECS 13-2009, which define and evaluate flexural toughness from different angles. However, of the many evaluation methods, the ASTM C1018 standard is an energy ratio method, which has relatively clear physical significance and is widely used. Based on the ASTM C1018 standard, this article uses toughness indexes to evaluate the toughness of ECC.

According to the load–deflection curve, the toughness index (I) can be calculated by the first crack deflection (δ c) in a specimen and its corresponding energy (the area under the load–deflection curve), as shown in Eq. (2).

where m presents the subscript of the I of different grades; the δ c presents the first cracking deflection; the A 0 presents the area surrounded by the δ c and the coordinate axis.

According to the literature [43], the ratios of the area under the corresponding curve of deformation under 5.5δ c, 15.5δ c, 25.5δ c, and deformation under peak load δ u divided by A 0 are taken as the toughness indexes, which were denoted I 10, I 30, I 50, and I u, respectively. The calculated flexural toughness index of ECC is summarized in Table 9.

Toughness indexes

| No. | I 10 | I 30 | I 50 | I u |

|---|---|---|---|---|

| MT0 | 11.12 (0.56) | 33.28 (2.19) | 45.94 (3.16) | |

| MT25 | 13.15 (1.62) | 42.36 (3.06) | 61.5 (4.78) | 79.25 (5.26) |

| MT50 | 11.85 (1.1) | 37.78 (2.77) | 55.8 (2.93) | 57.65 (3.03) |

| MT75 | 12.13 (1.56) | 34.56 (2.5) | 50.12 (2.89) | |

| MT100 | 10.55 (0.88) | 32.19 (1.98) | 40.69 (3.12) |

Note: the values in parentheses represent the standard error; I u presents the toughness index under ultimate deflection.

It can be observed that toughness indexes of ECC with different replacement ratios including I 10, I 30, I 50, and I u were close to m, indicating that the toughness indexes of ECC under the flexural load satisfied the requirements. The toughness indexes of ECC incorporating 25–75% MT is higher than that of MT0, especially at 25%. In addition, It is worth noting that toughness indexes MT25 and MT50 have longer sequences. This is because of notably increasing bonding between the PF and the matrix due to the MT good “fill effect,” and with more angular surfaces, the bond failure of the specimen will not occur prematurely during loading, showing a relatively obvious deflection hardening behavior, resulting in MT25 and MT50 have a remarkable flexural toughness. But up to 100% replacement ratio harms its toughness indexes.

3.3 Axial compressive performance of ECC

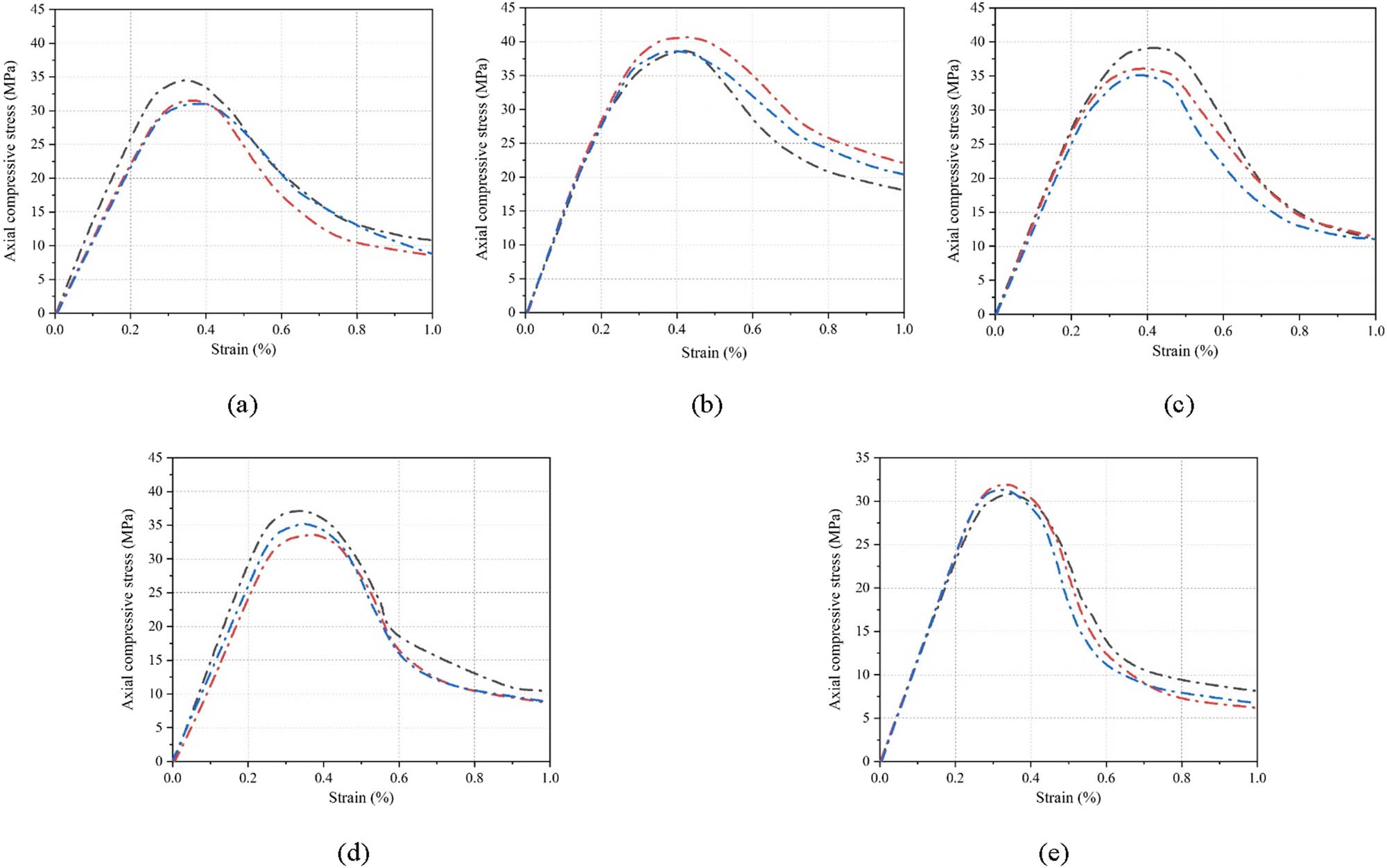

3.3.1 Compressive stress–strain curves

Figure 10 presents the stress–strain curves of ECC under axial compressive. Incorporating 25–75% MT could delay the decrease of post-peak f c, especially at 25%. In addition, the W 0.85f c of MT25, MT50, and MT75 is higher than that of MT0, which indicates that the specimens could consume energy well. After the failure of all the specimens, there is still a significant residual f c. Unfortunately, compared with MT0, the post-peak f c of MT100 drops faster, and the residual f c is smaller.

Stress–strain curve of ECC under axial compression: (a) MT0, (b) MT25, (c) MT50, (d) MT75, and (e) MT100.

3.3.2 Axial compressive test results

Table 10 summarizes average values of f c, axial compressive strain (ε cr), E c, W 0.85f c , and residual f c. It can be observed that when the replacement ratio of MT is less than 25%, the f c of the ECC shows a change of increasing, while after exceeding 25%, the f c of the ECC shows a gradually decreasing trend. For example, compared with MT0, the f c of MT25, MT50, and MT75 increased by 17.7, 12.22, and 8.54%, respectively. Similarly, this is mainly attributed to the fine particle of MT being helpful to decrease the porosity, resulting in an increased f c. Second, the “fill effect” of MT will result in the interfacial transition zone (ITZ) between matrix and aggregate being more dense and homogeneous and having no evident boundaries. Third, notably increasing bonding between the PF and the matrix due to MT with more angular surfaces, and “fill effect” restricts the lateral deformation of the test blocks and makes the whole test blocks be in a three-dimensional compression state, to improve the f c. Similarly, the ε cr of MT25, MT50, and MT75 increased by 11.06, 8.58, and 8.81%, respectively. However, the f c and ε cr of the MT100 decreased by 2.96 and 8.06%. This is mainly related to the fact that when the MT replacement ratio is 100%, the proportion of large-volume pores and the total porosity within the matrix increase. The bond strength between aggregates (matrix and PF) has also deteriorated.

Axial compressive test results of ECC

| No. | f c (MPa) | ε cr (%) | E c (GPa) | W 0.85f c | Residual f c (MPa) |

|---|---|---|---|---|---|

| MT0 | 32.32 (0.28) | 0.362 (0.17) | 21.8 (0.19) | 121.6 (0.21) | 9.45 (0.33) |

| MT25 | 39.28 (0.09) | 0.407 (0.20) | 22.9 (0.02) | 146.6 (0.34) | 20.19 (0.46) |

| MT50 | 36.82 (0.11) | 0.396 (0.08) | 22.7 (0.07) | 135.9 (0.28) | 11.23 (0.19) |

| MT75 | 35.34 (0.33) | 0.397 (0.53) | 22.3 (0.31) | 133.2 (0.17) | 11.67 (0.58) |

| MT100 | 31.39 (0.04) | 0.335 (0.28) | 22.2 (0.09) | 93.8 (0.12) | 6.96 (0.29) |

Note: the values in parentheses represent the standard error; W 0.85f c is the area enclosed by stress–strain curves under axial compressive from the origin to the f c dropping to 85%.

It is worth noting that the E c of ECC incorporating MT is higher than that of MT0. For example, the E c of MT25, MT50, MT75, and MT100 increased by 4.8, 3.96, 2.24, and 1.8%, compared with MT0, respectively. A similar finding has been reported in past studies. Shettima et al. [44] also reported the fact that with the increase of iron ore tailings replacement level, the E c was increased.

3.4 Pore characteristics of ECC

3.4.1 Three-dimensional spatial pore distribution from CT

Figure 11 shows the three-dimensional spatial pore distribution of ECC. When replacing S with 25–75% MT, the number of pores in MT25, MT50, and MT75 are lower than that of MT0. The best uniformity of pores space distribution inside MT25.

Three-dimensional spatial pores distribution: (a) MT0, (b) MT25, (c) MT50, (d) MT75, and (e) MT100.

According to the different volumes of the pores, the pores can be divided into five ranges [45]. Figure 12 shows the percentage of the different pores volumes in ECC. It can be observed that the pores with volumes of 0–0.1 mm3 are the most widely distributed. When S is completely replaced by MT, the pore volumes of MT100 gradually increase. The proportion of the pores with volumes 0.01–0.05, 0.05–0.1, 0.1–0.5, and >0.5 mm3 are higher than that of others, especially volumes >0.5 mm3.

Percentage of different volume pores.

3.4.2 T2 spectrum and pore fluid distribution from NMR

Figure 13(a) shows the pore structure of ECC and that each T2 spectrum curve includes the three peaks. Compared with the second and third peaks, the intensity of the first peak of the T2 spectrum curve is significant, indicating that the internal pores of the ECC are mainly micro-pores. Figure 13(b) found that when replacing S with 25–75% MT, the total porosity of MT25, MT50, and MT75 are reduced by 33.1, 21.15, and 6.18%, respectively, indicating that incorporating MT could effectively reduce the internal pores, especially at 25%, which confirms the “filling effect” of MT when incorporating a less than 75% MT. In addition, this finding explains one of the reasons from a mesoscopic point of view why the mechanical properties of MT25 are better than that of other groups. Unfortunately, the total porosity of MT100 with a 100% MT replacement ratio increases more than that of MT0. This indicates that the complete replacement of S by MT deteriorates the matrix pore structure.

Pore structure of ECC with different MT replacement ratios. (a) T2 spectrum curve and (b) pore percentage.

It is well known that pore structure has a direct effect on f cu development. The concrete f cu – porosity (P) model has been established by some scholars. Figure 14 shows the fitted results of the three models proposed in the literature [46] including models Hasselman proposed, Schiller proposed and Ryshkewitch proposed for f cu – P, respectively. It can be observed that the increase of porosity results in the degradation of f cu.

Relationship between f cu and porosity.

Table 11 lists the errors between the calculation results of each model and the test results. The calculation results of the model proposed by Hasselman are lower, compared to the test results. However, the errors between the calculation results obtained by the model Schiller proposed and the test results are the smallest, which shows a good application.

The errors between the calculation results of each model and test results

| Model | Hasselman model | Schiller model | Ryshkewitch model |

|---|---|---|---|

| Error range (%) | −0.6 to −11.36 | −3.55 to 1.48 | −4.5 to 2.49 |

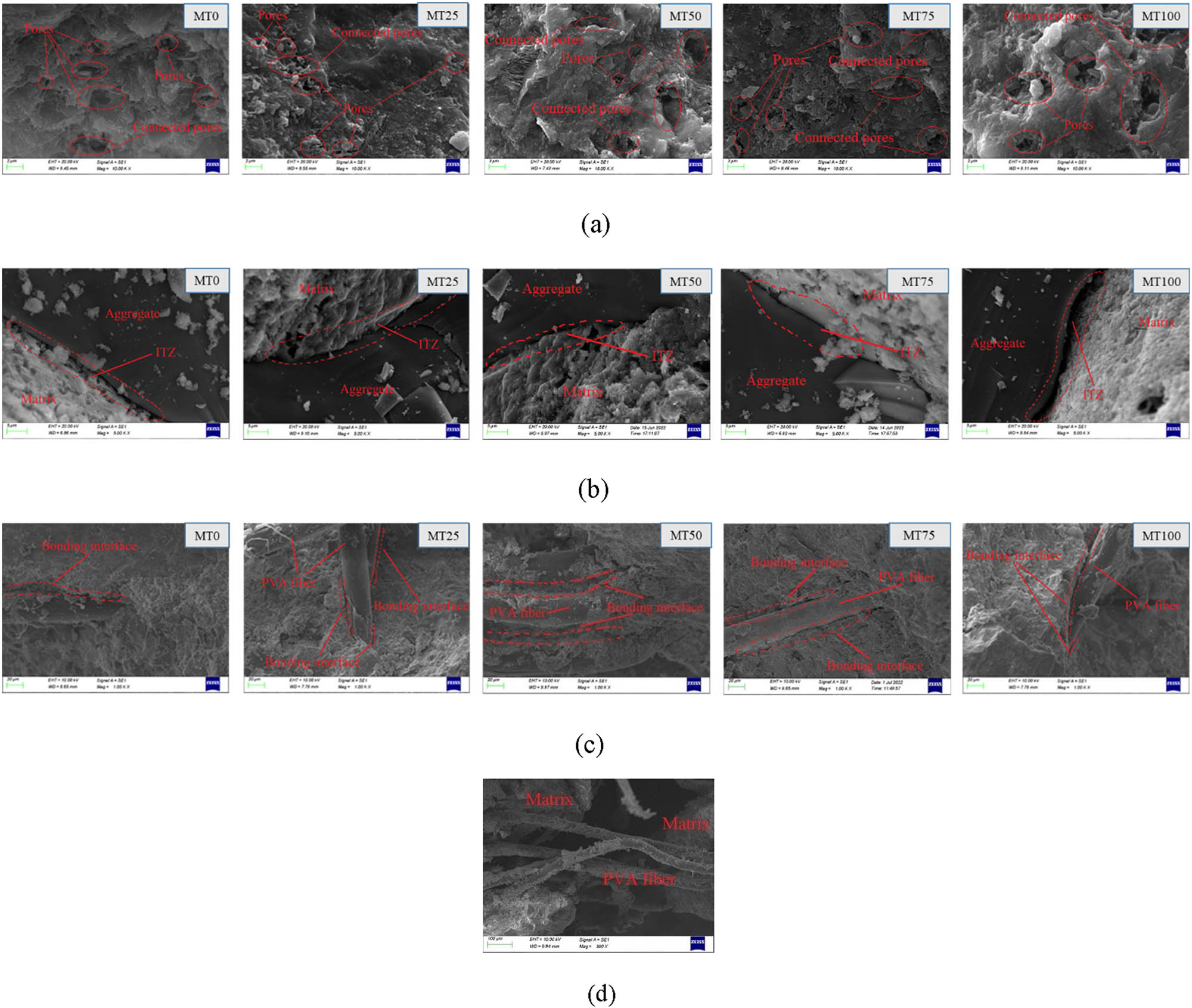

3.5 Microstructure of ECC from SEM

Figure 15 shows the microstructure of ECC. Figure 15(a) shows that compared with MT0, the number of pores and connected pores inside the MT25, MT50, and MT75 is reduced, and the compactness of the microstructure of three is in the following order from high to low: MT25 > MT50 > MT75. However, when S is completely replaced by MT, the number of connected pores and pores inside the MT100 significantly increases, and the density of the matrix is relatively loose, compared with MT0.

Microstructure of ECC: (a) effect of MT replacement ratio on matrix, (b) effect of MT replacement ratio on ITZ, (c) effect of MT replacement ratio on the bonding interface, and (d) debonding between PF and matrix.

The ITZ between the matrix and aggregate is shown in Figure 15(b). It is worth noting that as the MT replacement ratio increases, the ITZ gaps increase gradually. Compared with MT0, the ITZ gaps of the MT25, MT50, and MT75 are relatively small, especially MT25, which ITZ is well developed, and there are no obvious boundaries. Unfortunately, the ITZ gaps of MT100 are larger than that of MT0. Figure 15(c) shows the bonding interface between PF and the matrix. Similarly, it can be observed that incorporating up to 75% MT has a positive effect on the bonding interface between PF and the matrix. Under the 25% MT replacement ratio, PF is the best embedded in the matrix. However, under the 100% MT replacement ratio, the bonding interface MT100 is smaller than that of MT0. The SEM analysis results explain the high strength of MT25 from the microscopic points of view. It can be observed from Figure 15(d) found that the ultimate bonding failure occurs between fiber and matrix under load.

3.6 Axial compressive performance of stirrup-confined ECC stub column

3.6.1 Failure phenomenon

Figure 16 presents the failure patterns of columns. Due to the inhibition of PF, all the columns’ surfaces, except for many intricate cracks, did not fall off. With the MT replacement ratio increasing, the destruction of the columns seems to be more serious. For example, the width of cracks in the CE-MT25, CE-MT50, and CE-M T75 gradually increases, but the width of the crack is still smaller than that of CE-MT0. However, the width and number of cracks in the CE-MT100 increased significantly, compared with CE-MT0.

Failure patterns of columns: (a) CE-MT0, (b) CE-MT25, (c) CE-MT50, (d) CE-MT75, and (e) CE-MT100.

3.6.2 Axial force–strain relationship curve

Figure 17 presents the axial force–axial strain curve of the column. The column cracking, the rising segment of the curve, is not different by increasing the MT replacement ratio. Meanwhile, the initial stiffness of the column incorporating up to 75% MT exhibited insignificant differences. However, the initial stiffness of the column with 100% MT is reduced, which is consistent with the reduction in the f c of ECC. After reaching the peak stress, the curve enters the descending section. It can be observed that the influence of the MT replacement ratio on the descending segment of the curve is significantly greater than that of the rising segment. The descending section of the curve of the column with the higher ultimate bearing capacity is steeper because the stirrups play the role of passive restraint later. However, the descending section of the column with the lower ultimate bearing capacity is flat. This indicates that for ECC columns with low strength, the stirrup can give full play to its restraint effect.

Representative axial force–strain curve.

3.6.3 Axial compressive test results

Table 12 summarizes the main test results including N u, f cc, and ε cc of the column under axial compression. When the MT replacement ratio increases to 75%, both the f cc and ε cc of the column increase. For example, compared with CE-MT0, when the MT replacement ratio is 25, 50, and 75%, respectively, the f cc of the column increased by 9.75, 6.39, and 1.33%, and its ε cc increased by 14.94, 9.76, and 3.89%. Furthermore, it is noteworthy that the residual bearing capacity of CE-MT25, CE-MT50, and CE-MT75 is relatively high after the column failure. This is mainly attributed to the combined effect of the lateral restraint of the stirrup and the bridging restraint of the fibers.

Axial compressive test results of the columns

| No. | N u (kN) | f cc (MPa) | ε cc (%) |

|---|---|---|---|

| CE-MT0 | 2116.48 | 54.33 | 0.74 |

| CE-MT25 | 2377.34 | 60.2 | 0.87 |

| CE-MT50 | 2274.34 | 58.04 | 0.82 |

| CE-MT75 | 2125.78 | 55.06 | 0.77 |

| CE-MT100 | 1964.43 | 50.25 | 0.73 |

where N u is the ultimate bearing capacity of the column under compression.

3.7 EI of ECC

According to the literature and the material’s environmental statements [47,48,49,50,51], the life cycle inventory analysis of producing each ECC’s raw materials is summarized in Table 13. Based on the fact that MT is an industrial by-product and the discharge meets the relevant standards, the emissions associated with MT production are not considered. Moreover, the PF is also not considered due to the uniform amount of fiber in all mixtures in the calculation.

LCA data of ECC raw materials

| C | FA | SF | S | SP | MT | |

|---|---|---|---|---|---|---|

| GWP (kg CO2·kg−1) | 0.691 | 0.35 | 1.2 | 1.02 × 10−2 | 0.944 | 0 |

| POCP (kg R11·kg−1) | 1.0 × 10−4 | 9.34 × 10−5 | 1.09 × 10−4 | 2.58 × 10−6 | 5.58 × 10−4 | 0 |

| ODP (kg C2H4·kg−1) | 1.50 × 10−8 | 6.67 × 10−9 | 4.59 × 10−6 | 2.10 × 10−9 | 3.29 × 10−8 | 0 |

| NP (kg PO4·kg−1) | 1.2 × 10−5 | 1.52 × 10−4 | 5.48 × 10−4 | 3.00 × 10−6 | 5.97 × 10−3 | 0 |

| AP (kg SO2·kg−1) | 8.30 × 10−4 | 2.67 × 10−3 | 7.07 × 10−3 | 7.54 × 10−5 | 1.19 × 10−2 | 0 |

To quantitatively evaluate the EI of the ECC with different replacement ratios, the EI of producing 1 m3 of ECC is calculated, and obtained results are normalized based on MT0, as shown in Figure 18. It is clear that the environmental overload gradually decreases and the multi-deformation line of IOTCC is closest to the origin with increasing the replacement ratio of MT. For example, the GWP, POCP, ODP, NP, and AP of the MT25 decreased by 12.7, 7.54, 21.54, 0.7, and 12.39%, respectively, compared to the MT0. Therefore, the above results concluded that using MT as aggregate to prepare ECC is an ideal clean production method.

EI of ECC with different MT replacement ratios.

3.8 Cost assessment

The total cost of 1 m3 of ECC is listed in Table 14. The cost of each material comes from the price of local suppliers in Xi’an, China. MT is provided free of charge as waste [52,53]. It can be seen from Table 14 that the total cost of ECC decreases gradually with the increase of the MT replacement ratio. The incorporation of MT is helpful to reduce ECC costs and further promotes the sustainable application of MT as eco-friendly material in construction products.

Material cost (1 m3)

| No. | Material cost ($ per kg) | Total cost per m3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | FA | SF | S | PF | MT | W | SP | ||

| 0.070 | 0.020 | 0.310 | 0.041 | 40.15 | 0.000 | 0.001 | 0.896 | ||

| MT0 | 48.440 | 7.548 | 58.497 | 22.624 | 1043.9 | 0.000 | 0.377 | 5.071 | 1186.458 |

| MT25 | 48.440 | 7.548 | 58.497 | 16.968 | 1043.9 | 0.000 | 0.377 | 5.098 | 1180.929 |

| MT50 | 48.440 | 7.548 | 58.497 | 11.312 | 1043.9 | 0.000 | 0.377 | 5.080 | 1175.155 |

| MT75 | 48.440 | 7.548 | 58.497 | 5.656 | 1043.9 | 0.000 | 0.377 | 5.116 | 1169.535 |

| MT100 | 48.440 | 7.548 | 58.497 | 0.000 | 1043.9 | 0.000 | 0.377 | 5.161 | 1163.23 |

4 Conclusions

A comprehensive evaluation of the ECC with MT as aggregate was conducted, which mainly included the mechanical properties, pore distribution, and microstructure. Conclusions were obtained as follows:

The chemical composition, physical properties, and radioactivity of MT confirmed the feasibility to prepare ECC. As the MT replacement ratio increases, the compressive, tensile, and flexural properties of ECC initially increased and then decreased. The ECC with 25% MT exhibited the best mechanical properties. The f t of MT25 increased 32.16%, compared with only S as aggregate.

The CT and NMR results found that when the MT replacement ratio was less than 75%, the total porosity of ECC was reduced and the number and volume of spatially distributed pores were also reduced, compared with MT0. The ECC with 25% MT exhibits a better pore structure.

SEM micro morphology results indicated that ECC with 25% MT exhibited good ITZ and bonding interface between PF and matrix. The microstructure of ECC is relatively dense.

The axial compression results of the stirrup-confined ECC stub column indicated that the f cc, ε cc, and residual N u of the column were improved by incorporating up to 75% MT. The stirrup-confined ECC stub column with 25% MT can ensure better mechanical properties.

Based on the assessment results of EI and cost, the replacement of S by MT for ECC application reduced the production EI and cost of ECC, especially with a higher replacement ratio, which further solidifies the argument that the incorporation of MT to prepare ECC is a promising method.

It should be pointed out that the MT used in this article is from a specific location (Shaanxi Province, China). There are differences in the MT produced in different locations (crystal composition, micromorphology, crushing index, particle size, etc.). Therefore, some of the conclusions obtained in this study may be different for ECC prepared using MT from other locations. In future research, the ECC prepared by MT from different locations should be systematically studied to gain a more in-depth understanding of this environment-friendly material. In addition, further studies on structural members (beams, joints, and walls) are conducted. The successful application of industrial byproduct MT as eco-friendly materials will further promote the sustainable development of the construction industry.

Acknowledgments

The authors would like to acknowledge the financial support.

-

Funding information: This work was supported by the Project on Key Research and Development of Shaanxi, China (No. 2021SF-521, No. 2022SF-375), Natural Science Foundation of Shaanxi, China (No. 2021JQ-844), Natural Science Basic Research Program of Shaanxi (Program No. 2022JQ-497), and The Natural Science Foundation of Shaanxi Province (2021JM-165,2021JM-170).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Xu, L. Y., B. T. Huang, V. C. Li, and J. G. Dai. High-strength high-ductility engineered/strain-hardening cementitious composites (ECC/SHCC) incorporating geopolymer fine aggregates. Cement and Concrete Composites, Vol. 125, 2022, id. 125.10.1016/j.cemconcomp.2021.104296Suche in Google Scholar

[2] Xu, L. Y., B. T. Huang, J. C. Lao, J. Yao, V. C. Li, and J. G. Dai. Tensile over-saturated cracking of ultra-high-strength engineered cementitious composites (UHS-ECC) with artificial geopolymer aggregates. Cement and Concrete Composites, Vol. 136, 2023, id. 136.10.1016/j.cemconcomp.2022.104896Suche in Google Scholar

[3] Huang, B. T., J. X. Zhu, K. F. Weng, V. C. Li, and J. G. Dai. Ultra-high-strength engineered/strain-hardening cementitious composites (ECC/SHCC): Material design and effect of fiber hybridization. Cement and Concrete Composites, Vol. 129, 2022, id. 129.10.1016/j.cemconcomp.2022.104464Suche in Google Scholar

[4] Adesina, A. and S. Das. Mechanical performance of engineered cementitious composite incorporating glass as aggregates - ScienceDirect. Journal of Cleaner Production, Vol. 260, 2020, id. 121113.10.1016/j.jclepro.2020.121113Suche in Google Scholar

[5] Guan, X., Y. Li, T. Liu, C. Zhang, H. Li, and J. Ou. An economical ultra-high ductile engineered cementitious composite with large amount of coarse river sand. Construction and Building Materials, Vol. 201, 2019, pp. 461–472.10.1016/j.conbuildmat.2018.12.207Suche in Google Scholar

[6] Zhang, Z. and Q. Zhang. Matrix Tailoring of engineered cementitious composites (ECC) with non-oil-coated, low tensile strength PVA fiber. Construction and Building Materials, Vol. 161, No. FEB.10, 2018, pp. 420–431.10.1016/j.conbuildmat.2017.11.072Suche in Google Scholar

[7] Xu, L. Y., B. T. Huang, Q. Lan-Ping, and J. G. Dai. Enhancing long-term tensile performance of engineered cementitious composites (ECC) using sustainable artificial geopolymer aggregates. Cement and Concrete Composites, Vol. 133, 2022, id. 104676.10.1016/j.cemconcomp.2022.104676Suche in Google Scholar

[8] Xu, L. Y., B. T. Huang, J. C. Lao, and J. G. Dai. Tailoring strain-hardening behavior of high-strength engineered cementitious composites (ECC) using hybrid silica sand and artificial geopolymer aggregates. Materialsand Design, Vol. 220, 2022, id. 110876.10.1016/j.matdes.2022.110876Suche in Google Scholar

[9] Zhang, Z. G., H. Ma, and S. Z. Qian. Investigation on properties of ECC incorporating crumb rubber of different sizes. Journal of Cleaner Production, Vol. 13, No. 5, 2015, pp. 241–251.10.3151/jact.13.241Suche in Google Scholar

[10] Li, J. and E. H. Yang. Macroscopic and microstructural properties of engineered cementitious composites incorporating recycled concrete fines. Cement and Concrete Composites, Vol. 78, 2017, pp. 33–42.10.1016/j.cemconcomp.2016.12.013Suche in Google Scholar

[11] Huang, X., R. Ranade, W. Ni, and V. C. Li. Development of green engineered cementitious composites using iron ore tailings as aggregates. Construction and Building Materials, Vol. 44, 2013, pp. 757–764.10.1016/j.conbuildmat.2013.03.088Suche in Google Scholar

[12] Turk, K. and S. Demirhan. The mechanical properties of engineered cementitious composites containing limestone powder replaced by microsilica sand. Canadian Journal of Civil Engineering, Vol. 40, No. 2, 2013, pp. 151–157.10.1139/cjce-2012-0281Suche in Google Scholar

[13] Siddique, S. and J. G. Jang. Assessment of molybdenum mine tailings as filler in cement mortar. Journal of Building Engineering, Vol. 31, 2020, id. 101322.Suche in Google Scholar

[14] Kinnunen, P., A. Ismailov, S. Solismaa, H. Sreenivasan, M. L. Räisänen, E. Levänen, et al. Recycling mine tailings in chemically bonded ceramics – A review. Journal of Cleaner Production, Vol. 174, 2018, pp. 634–649.10.1016/j.jclepro.2017.10.280Suche in Google Scholar

[15] Dong, K., F. Xie, W. Wang, Y. Chang, D. Lu, X. Gu, et al. The detoxification and utilization of cyanide tailings: A critical review - ScienceDirect. Journal of Cleaner Production, Vol. 302, 2021, id. 126946.10.1016/j.jclepro.2021.126946Suche in Google Scholar

[16] Quan, X. Y., S. L. Wang, K. N. Liu, J. Xu, N. Zhao, and B. Liu Influence of molybdenum tailings by-products as fine aggregates on mechanical properties and microstructure of concrete. Journal of Building Engineering, Vol. 54, 2022, id. 104677.10.1016/j.jobe.2022.104677Suche in Google Scholar

[17] Fontes, W. C., J. C. Mendes, S. N. Da Silva, and R. A. Peixoto. Mortars for laying and coating produced with iron ore tailings from tailing dams. Construction & Building Materials, Vol. 112, 2016, pp. 995–988.10.1016/j.conbuildmat.2016.03.027Suche in Google Scholar

[18] Osinubi, K. J., P. Yohanna, and A. O. Eberemu. Cement modification of tropical black clay using iron ore tailings as admixture. Transportation Geotechnics, Vol. 5, 2015, pp. 35–49.10.1016/j.trgeo.2015.10.001Suche in Google Scholar

[19] Bian, Z., X. Miao, S. Lei, S. E. Chen, W. Wang, and S. Struthers. The Challenges of Reusing Mining and Mineral-Processing Wastes. Science, Vol. 337, No. 6095, 2012, pp. 702–703.10.1126/science.1224757Suche in Google Scholar PubMed

[20] Davila, R. B., M. Fontes, A. A. Pacheco, and M. Ferreira. Heavy metals in iron ore tailings and floodplain soils affected by the Samarco dam collapse in Brazil. Science of the Total Environment, Vol. 709, 2019, id. 136151.10.1016/j.scitotenv.2019.136151Suche in Google Scholar PubMed

[21] Han, F., L. Li, S. Song, and J. Liu. Early-age hydration characteristics of composite binder containing iron tailing powder. Powder Technology, Vol. 315, 2017, pp. 315–331.10.1016/j.powtec.2017.04.022Suche in Google Scholar

[22] Kim, M. J. and Y. Jung. Vertical distribution and mobility of arsenic and heavy metals in and around mine tailings of an abandoned mine. Environmental Letters, Vol. 39, No. 1, 2004, pp. 203–222.10.1081/ESE-120027379Suche in Google Scholar PubMed

[23] Sun, Y., R. Yu, S. Wang, Y. Zhou, M. Zeng, F. Hu, et al. Development of a novel eco-efficient LC2 conceptual cement based ultra-high performance concrete (UHPC) incorporating limestone powder and calcined clay tailings: Design and performances - ScienceDirect. Journal of Cleaner Production, Vol. 315, 2021, id. 128236.10.1016/j.jclepro.2021.128236Suche in Google Scholar

[24] Zhang, C. and S. Li. Utilization of iron ore tailing for the synthesis of zeolite A by hydrothermal method. Journal of Material Cycles and Waste Management, Vol. 20, 2018, pp. 1605–1614.10.1007/s10163-018-0724-7Suche in Google Scholar

[25] Shi, J., F. He, C. Ye, L. Hu, J. Xie, H. Yang, et al. Preparation and characterization of CaO–Al2O3–SiO2 glass-ceramics from molybdenum tailings. Materials Chemistry and Physics, Vol. 57–64, No. 197, 2017, pp. 57–64.10.1016/j.matchemphys.2017.05.028Suche in Google Scholar

[26] Wang, X. L., J. M. Wang, and Z. J. Ma. Experimental research on recovery of phlogopite from molybdenum tailings. Bulletin of the Chinese Ceramic Society, Vol. 1010, 2014, pp. 1609–1612.10.4028/www.scientific.net/AMR.1010-1012.1609Suche in Google Scholar

[27] Jiangang, F., C. Kaida, W. Hui, G. Chao, and L. Wei. Recovering molybdenite from ultrafine waste tailings by oil agglomerate flotation - ScienceDirect. Minerals Engineering, Vol. 39, No. 1, 2012, pp. 133–139.10.1016/j.mineng.2012.07.006Suche in Google Scholar

[28] Antonelli, P. M., L. H. Fraser, W. C. Gardner, K. J. Broersma, and M. E. Phillips. Long term carbon sequestration potential of biosolids-amended copper and molybdenum mine tailings following mine site reclamation. Ecological Engineering the Journal of Ecotechnology, Vol. 117, 2018, pp. 38–49.10.1016/j.ecoleng.2018.04.001Suche in Google Scholar

[29] Jung, M. Y. and C. J. G. Jeong. Recycling of tailings from Korea Molybdenum Corporation as admixture for high-fluidity concrete. Environmental Geochemistry & Health, Vol. 33, Suppl 1, 2011, pp. 113–119.10.1007/s10653-010-9355-1Suche in Google Scholar PubMed

[30] Gao, S. and S. B. Kang. Sustainable applications for utilizing molybdenum tailings in concrete. Journal of Cleaner Production, Vol. 266, 2020, id. 122020.Suche in Google Scholar

[31] Gao, S. and L. Guo. Mechanical properties of circular thin-tubed molybdenum tailing concrete stubs. Construction and Building Materials, Vol. 268, 2020, id. 121215.10.1016/j.conbuildmat.2020.121215Suche in Google Scholar

[32] Siddique, S. and J. G. Jang. Assessment of molybdenum mine tailings as filler in cement mortar. Journal of Building Engineering, Vol. 31, 2020, id. 101322.10.1016/j.jobe.2020.101322Suche in Google Scholar

[33] Yu, R., E. Dong, Z. Shui, D. Qian, D. Fan, J. Wang, et al. Advanced utilization of molybdenum tailings in producing ultra high-performance composites based on a green activation strategy. Construction and Building Materials, Vol. 330, 2022, id. 127272.10.1016/j.conbuildmat.2022.127272Suche in Google Scholar

[34] Li, V. C. and C. K. Y. Leung. Steady-state and multiple cracking of short random fiber composites. Journal of Engineering Mechanics, Vol. 118, No. 11, 1992, pp. 2246–2264.10.1061/(ASCE)0733-9399(1992)118:11(2246)Suche in Google Scholar

[35] Kurda, R., J. D. Brito, and J. D. Silvestre. A comparative study of the mechanical and life cycle assessment of high-content fly ash and recycled aggregates concrete. Journal of Building Engineering, Vol. 29, 2020, id. 101173.10.1016/j.jobe.2020.101173Suche in Google Scholar

[36] Chen, X., H. Wang, H. Najm, G. Venkiteela, and J. Hencken. Evaluating engineering properties and environmental impact of pervious concrete with fly ash and slag. Journal of Cleaner Production, Vol. 237, 2019, id. 117714.10.1016/j.jclepro.2019.117714Suche in Google Scholar

[37] Han, Y., Z. Yang, T. Ding, Xiao J. Environmental and economic assessment on 3D printed buildings with recycled concrete. Journal of Cleaner Production, Vol. 278, No. 2, 2020, id. 123884.10.1016/j.jclepro.2020.123884Suche in Google Scholar

[38] Wang, X., R. Yu, Z. Shui, Z. Zhao, Q. Song, B. Yang, et al. Development of a novel cleaner construction product: Ultra-high performance concrete incorporating lead-zinc tailings. Journal of Cleaner Production, Vol. 196, No. pt.1-862, 2018, pp. 172–182.10.1016/j.jclepro.2018.06.058Suche in Google Scholar

[39] Russell, A. J. Handbook on life cycle assessment: Operational guide to the ISO standards. Journal of Cleaner Production, B. Guinée Jeroen, Ed., Kluwer Academic Publishers, Dordrecht, 2005, Vol. 13, No. 13–14, pp. 1359.Suche in Google Scholar

[40] Huang, X., R. Ranade, Q. Zhang, W. Ni, and V. C. Li. Mechanical and thermal properties of green lightweight engineered cementitious composites. Construction and Building Materials, Vol. 48, No. nov., 2013, pp. 954–960.10.1016/j.conbuildmat.2013.07.104Suche in Google Scholar

[41] Na, Z. A., B. Bt, and B. Xl. Cementitious activity of iron ore tailing and its utilization in cementitious materials, bricks and concrete. Construction and Building Materials, Vol. 288, 2021, id. 123022.10.1016/j.conbuildmat.2021.123022Suche in Google Scholar

[42] Zhou, A., H. Wei, T. Liu, D. Zou, Y. Li, and R. Qin. Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale. Nanotechnology Reviews, Vol. 10, No. 1, 2021, pp. 636–652.10.1515/ntrev-2021-0037Suche in Google Scholar

[43] Lin, C., S. Wang, M. Chen, and Y. Lu. Experimental study on the mechanical properties of different fiber-reinforced seawater sea-sand engineered cementitious composites. Construction and Building Materials, Vol. 304, 2021, id. 124562.10.1016/j.conbuildmat.2021.124562Suche in Google Scholar

[44] Shettima, A. U., M. W. Hussin, Y. Ahmad, and J. Mirza. Evaluation of iron ore tailings as replacement for fine aggregate in concrete. Construction & Building Materials, Vol. 120, No. sep. 1, 2016, pp. 72–79.10.1016/j.conbuildmat.2016.05.095Suche in Google Scholar

[45] Liu, F., T. Zhang, T. Luo, M. Zhou, K. Zhang, and W. Ma. Study on the deterioration of concrete under dry-wet cycle and sulfate attack. Materials, Vol. 13, No. 18, 2020, id. 4095.10.3390/ma13184095Suche in Google Scholar PubMed PubMed Central

[46] Liu, L., Z. He, X. Cai, and S. Fu. Application oflow-field NMR to the pore structure of concrete. Applied Magnetic Resonance, Vol. 2020, No. 2, 2020, pp. 1–17.10.1007/s00723-020-01229-7Suche in Google Scholar

[47] Marinkovi, S. B. Life cycle assessment (LCA) aspects of concrete. Eco-Efficient Concrete, 2013, pp. 45–80.10.1533/9780857098993.1.45Suche in Google Scholar

[48] Habert, G., J. Lacaillerie, and N. Roussel. An environmental evaluation of geopolymer based concrete production: reviewing current research trends. Journal of Cleaner Production, Vol. 19, No. 11, 2011, pp. 1229–1238.10.1016/j.jclepro.2011.03.012Suche in Google Scholar

[49] Caldas, L. R., M. H. Da Gloria, F. Pittau, V. M. Andreola, G. Habert, and R. D. Toledo Filho. Environmental impact assessment of wood bio-concretes: Evaluation of the influence of different supplementary cementitious materials - ScienceDirect. Construction and Building Materials, Vol. 268, 2021, id. 121146.10.1016/j.conbuildmat.2020.121146Suche in Google Scholar

[50] Vargas, F., M. Lopez, and L. Rigamonti. Environmental impacts evaluation of treated copper tailings as supplementary cementitious materials. Resources Conservation and Recycling, Vol. 160, 2020, id. 104890.10.1016/j.resconrec.2020.104890Suche in Google Scholar

[51] Muller, H. S., M. Haist, and M. Vogel. Assessment of the sustainability potential of concrete and concrete structures considering their environmental impact, performance and lifetime. Construction and Building Materials, Vol. 67, 2014, pp. 321–337.10.1016/j.conbuildmat.2014.01.039Suche in Google Scholar

[52] Gao, S. and S. B. Kang. Sustainable applications for utilizing molybdenum tailings in concrete. Journal of Cleaner Production, Vol. 266, 2020, id. 122020.10.1016/j.jclepro.2020.122020Suche in Google Scholar

[53] Quan, X., S. Wang, J. Li, J. Luo, K. Liu, J. Xu, et al. Utilization of molybdenum tailings as fine aggregate in recycled aggregate concrete. Journal of Cleaner Production, Vol. 372, 2022, id. 133649.10.1016/j.jclepro.2022.133649Suche in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Artikel in diesem Heft

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology