Abstract

Modified multimodal (MMP) Cr3C2–NiCr coatings were fabricated by high-velocity oxy-fuel (HVOF) spraying deposited on a CuCrZr alloy substrate. However, due to the lack of its inevitable porosity, an additional laser re-melting (LRM) approach is highly required to improve the coating performance. Therefore, the LRM technique is employed in this study to improve the microstructure properties of an MMP Cr3C2–NiCr coating by HVOF. Solid-state phase transformation from Cr3C2 to Cr7C3 occurred during the LRM process. After the LRM process, the coating exhibits the presence of Cr3C2 nanoparticles that serve as reinforcement. These nanoparticles demonstrate minimal lattice misfit and exhibit high stability throughout the LRM process. The surface of the coating undergoes modification, resulting in the formation of homogeneous nano (20–130 nm), micron (150 nm to 0.3 μm), and submicron (2–3 μm) Cr3C2 structures, along with high-density microstructures, after the LRM process. Nano-Cr3C2 particle reinforced with high total work function and incredibly increased corrosion rate significantly improves coating corrosion resistance. Overall, porosity decreased from 3.9% of the HVOF coating to 0.3% of the LRM. As a result, the current density of anticorrosion decreased from 33.7 to 4.35 µA·cm−2, and the Vickers microhardness average values ranged from 1,050 to 1,300 HV0.3, indicating improved microstructure development and related properties.

Graphical abstract

1 Introduction

Modern surface engineering development has continually attracted scientists’ interest due to its unique advantages, such as improvement in the appearance of the substrate surface, enhancement in the microstructural properties, environmental protection damage, and mechanical properties. Several thermally sprayed metal coating techniques such as high-velocity oxy-fuel (HVOF), oxy-fuel wire, high-velocity air-fuel, oxy-fuel powder, electric arc wire, and plasma arc powder indicate major industrial solutions to protect surfaces from environmental damages [1,2,3,4].

The present study uses CuCrZr alloy as a substrate because of its widespread use in the optical, marine, automotive, and electrical equipment sectors. However, poor wear resistance and low hardness continue to limit industrial applications of copper [5,6]. Thus, there is a growing interest in improving copper alloy surface properties by employing surface coatings [7]. Using a thermal spraying method, surface-coated materials’ most common industrial choices are compositions based on chromium carbides (Cr3C2) and/or tungsten carbides (WC). Compared to Cr3C2, the application of WC-based coating is limited to work below 500°C temperature due to its low thermal expansion coefficient and oxidation resistance [8]. However, in contrast to WC-based composites, Cr3C2-based compositions (i.e., Cr3C2–NiCr) can be operated at 800–900°C due to the high oxidation resistance [9]. Furthermore, the Cr3C2-based coating shows excellent resistance against corrosion in alkaline, chloride, and acidic (sulfuric and nitric) environments [10,11,12]. Therefore, Cr3C2-based composition is the first choice for applications such as high-temperature surface protection services, pump housing, valve stem, or spindle services compared to WC-based composition coating. In addition, another important reason to replace WC-based hard metal coatings with Cr3C2-based coatings is its low cost.

Among Cr3C2-based compositions, Cr3C2–NiCr is the widely used chromium-based nanocomposite due to their valuable applications of wear protection, which can be found in various fields such as chemical plant, petroleum, aerospace, and automotive services [13,14,15]. As mentioned above, the microhardness and corrosion resistance properties of the Cr3C2–NiCr composition system are suitable for surface coatings that can protect them from environmental damage and can improve the lifetime of the surface-coated materials, where WC-based compositions (WC-Co or WC-Ni) cannot be used. Many researchers even projected using Cr3C2–NiCr compositions as metal cutting tools due to their high hardness and low sintering temperatures [16,17].

Various thermal spraying methods are commonly used to coat chromium carbide composites. Among them, HVOF is the widely used method to enhance the surface properties of the base materials. The HVOF process is continuous and convenient for applying coatings to industrial installations at the site. HVOF-sprayed coatings, including cermet and anticorrosion alloys, have been subject to seawater corrosion testing. However, because of the spraying process, the HVOF deposits present a poorly melted state of chromium-based compositions (not all particles melted; un-melted hard particles were also found in the coating), indicating numerous porosities and cracks. This decreases the efficiency of their surface contact with the substrate’s material, which leads to corrosion. Due to these disadvantages, HVOF is limited to some applications, particularly those that require more excellent resistance to wear, corrosion, and impact [18,19]. Therefore, an additional technique such as laser re-melting (LRM) is necessary to improve the surface engineering microstructure and corrosion resistance properties.

Laser treatment is a successful process used in industrial production due to its advantages in high energy density and stability [20,21,22]. This technique has proven to be a practical process for creating carbides-reinforced coatings. Furthermore, it can improve the quality of thermal spray coatings. Their objective is to fuse, totally or partially, the ceramic layer so that the material becomes more homogeneous in the posterior solidification and the pores disappear [23,24,25]. In the literature, various studies have highlighted that the microhardness, microstructural densification, and wear-resistant properties of the thermally sprayed WC-based or Cr3C2-based cermet coatings processed by the LRM have been improved [23–29]. According to Janka et al. [30], the low-power operating laser avoids re-melting the coating, and it could cause another chromium-carbide layer, precipitating the supersaturated Ni-based composite. Therefore, as a whole, the microstructure retained the morphologies and distribution of the as-sprayed carbide coating with an additional layer of chromium carbide. Furthermore, Mateos et al. [26] stated that the tungsten-based carbide coating enhanced with random and unbalanced shape distribution, while a prominent dendrite shape was also observed after LRM completion. Qin et al. [25] also observed that the compact microstructure of the columnar dendrites, equiaxed dendrites, and fine grain of the HVOF Cr3C2–NiCr coatings had been enhanced, which improved the corrosion and wear resistance, as well as the carbide morphologies, its distribution became it more random and irregular after LRM. Therefore, to develop the microstructure, corrosion resistance, and hardness of the Cr3C2–NiCr surface coating on a copper alloy substrate, here in this study, we have used LRM due to its sophisticated properties after the HVOF process.

Thus, the present work deals with LRM treatments after the HVOF technique, which is beneficial to tailor the surface coating of modified multimodal (MMP) Cr3C2–NiCr toward developing microstructure, corrosion resistance properties and enhancing surface microhardness. We hope that this versatile LRM technique after HVOF could solve the significant problems of surface engineering technology.

2 Materials and experimental methods

2.1 Materials

All the materials are bought from commercial resources and used without further purification. The substrate used in this study is CuCrZr alloy (Cu ∼ 99.09, Cr ∼ 0.81, Zr ∼ 0.08, and other 0.02 wt%), with a corresponding production of RS2020045519, the standard of JB/T7598-2008, and a melting furnace number of C1000965. MMP Cr3C2–NiCr powder size exhibited dimensions, and 15–45 μm distributions were obtained from Fujian Dilong Innovation Development Co., Ltd., China.

2.2 Experimental methods

The X-ray fluorescence technique was used to find the chemical composition of MMP Cr3C2–NiCr powders, as listed in Table 1. Furthermore, focused ion beam analysis was performed to cut a single powder particle, and the phase composition was measured by a D8 advanced X-ray diffractometer (XRD) Cu Kα radiation of λ = 0.154056 nm analysis. SEM/EDS (Modal ZEISS sigma 300) was used for morphological studies and the proportion of the elements. Samples for SEM observation were prepared using standard mechanical polishing procedures associated with etching in aqua regia at room temperature. The microstructure of the MMP Cr3C2–NiCr coating interfacial layer was also investigated by cross-sectional TEM (FEI TECHNI G2 F30 operated at 200 keV with a point-to-point resolution of 0.23 nm). TEM analysis specimens were prepared by mechanical grinding, polishing, and dimpling. Electron diffraction patterns and high-resolution TEM images were taken. For the porosity analysis, SEM images of the coating were placed into a common computer folder, and particles were counted and sized automatically within ImageJ (Image-Pro®Plus v 6.0). This macro converted raw images to a binary image (black indicating a particle and white being the background) using autothresholding and a “fill holes” command to blacken any internal white pixels in the interior of a particle. The macro outputted a list of the projected area, image coordinates, and circularity for each particle detected in the images. Measurement of the microhardness of the coating was performed using an HRD-1000TMC Vickers microhardness tester at 3 N for a loading time of 15 s. For each hardness profile along the depth direction of the coating, three repeat tests were performed (the spacing of each press mark was larger than 50 mm), and their averaged results were used. Electrochemical corrosion resistance measurements were made at room temperature, exposing 1 cm2 in a three-electrode cell containing 3.5% NaCl solution using Versa STAT 3: Modal-400 version 2.60.6.

Chemical composition of MMP Cr3C2–NiCr powder

| Powder composite | Cr | C | Ni | Ce | Zr | La | O |

|---|---|---|---|---|---|---|---|

| Sample (wt%) | 62.2 | 17.51 | 15.88 | 1.64 | 0.0012 | 0.0046 | 2.76 |

2.3 Coating preparation

The CuCrZr substrates were ultrasonically cleaned with acetone and sandblasted with Al2O3, sandblasting with pressure P manually by the pressure regulator ±0.2 MPa with a distance of 1.0 cm to the sample surface. In all, 110 µm alumina (Al2O3) (Sandblasting Machine Ningbo Yinzhou Wuxiang Xinzhe Machinery Factory) particles were used for the sandblasting process, and the forward blasting speed was set at 3.5 mm·s−1. The surface roughness values after and before sandblasting Ra are 0.99 and 5.011 μm. An HVOF spraying system (HV-80-JP, China) was used to prepare MMP Cr3C2–NiCr coatings of average 150 μm thickness on the surface of the copper substrate. Kerosene and oxygen were used as fuel and powder carrier gases, respectively. Kerosene flow and spray distance changed during the following orthogonal experiment design. The pressures of kerosene and oxygen were fixed at 19–23 (L·min−1) and 40–53 (L·min−1) during the spraying process, respectively.

LRM experiments were conducted on a JHM-1GX/Y-600 China laser processor under the inert gas (nitrogen gas flow 5–10 L·min−1) to re-melt the whole surface area of the sprayed coating. A fully re-melted coating surface was achieved with 50–60% overlap between the neighboring tracks, laser power ranging from 200 to 500 W, a spotlight diameter of 3 mm, and a scanning rate of 10–12 mm·s−1. The coating thickness was kept constant with an average value of 100 μm. The specimen was irradiated at an irradiation angle of 90°. Experiments under the same conditions were carried out with optimum process parameters. Coating samples were mounted on a moving numerically controlled X–Y table below the fixed laser processing head.

3 Results and discussion

3.1 Microstructure analysis

3.1.1 MMP powders

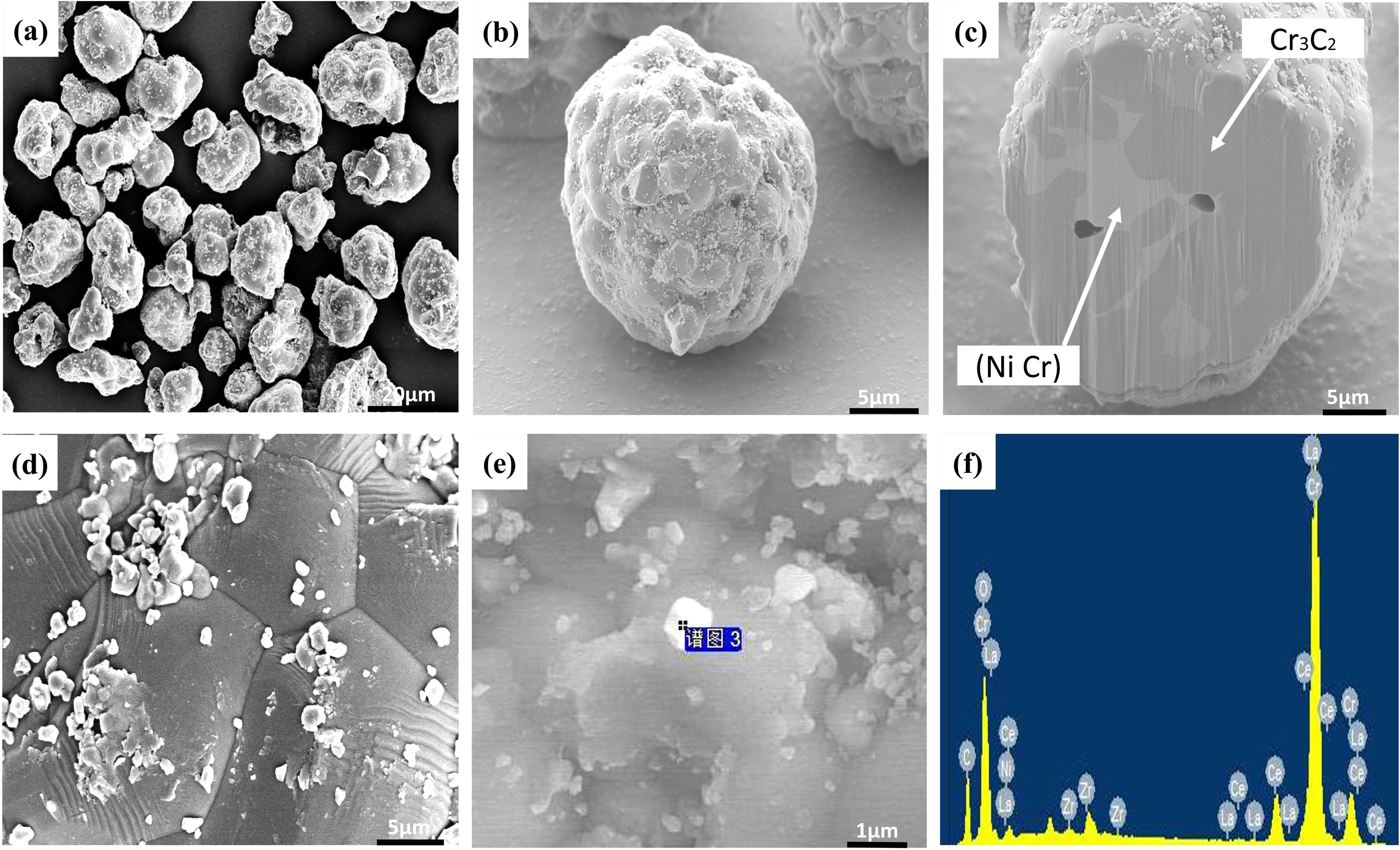

Figure 1 displays the SEM analysis results, which revealed that the MMP Cr3C2–NiCr powders consisted of nano-sized grains (30–150 nm), submicron-sized grains (200 nm–0.3 μm), micron-sized grains (3–5.3 μm) of Cr3C2, as well as NiCr grains. The agglomerated structure was a multiscale chromium carbide and nickel carbide cermet core with a metal binder shell covered by submicron and nano-chromium carbide particles. The multimodal structure maintained three kinds of states. The first state is submicron Cr3C2 grains embedded in the voids constructed by micron Cr3C2 grains. The second state included NiCr binder phases and nano-Cr3C2 grains embedded in the voids formed by submicron and micron Cr3C2 grains, and the third state, nano-Cr3C2 grains dispersed in NiCr metal binder phases. Furthermore, Cr3C2 has a density of 6.68 g·cm−2, a melting point of 1,890°C, and a boiling point of 3,800°C, making it an excellent wear-resistant coating due to its exceptional resistance to erosion and corrosion.

SEM/EDS of MMP Cr3C2–NiCr powder: (a) with low magnification, (b) single particle of the powder, (c) cross-sectional view of the single particle, and (d)–(f) with high magnification surface of the single particle.

In addition, Figure 1(c)–(e) shows the aggregation of Cr2C3 particles of different sizes used as feeding powders. The cross-sectional analysis reveals that the cross-section of the single particles is more compact and denser. In Figure 1(e), at high magnification, the surface of the single particle appears to be composed of a tiny nano-Cr2C3 modifier. In addition, Figure 1(f) shows that EDS analysis confirms that these feeding powders will retain part of the oxygen and deposit it on the surface of the substrate during the spraying process. During the deposition process, an amount of the gas can be squeezed out, while a small part of the gas cannot be removed and remains in the coating, causing porosity on the surface. A few gaps or cracks form if this part of the oxygen is retained in the combined amount of the Cr2C3 particles and the NiCr binder phase. Due to rapid heating and cooling stages during HVOF coating, the melted NiCr phase is hard to flow and fill the voids among the feed particles.

3.1.2 Phase analysis for MMP powders and coatings

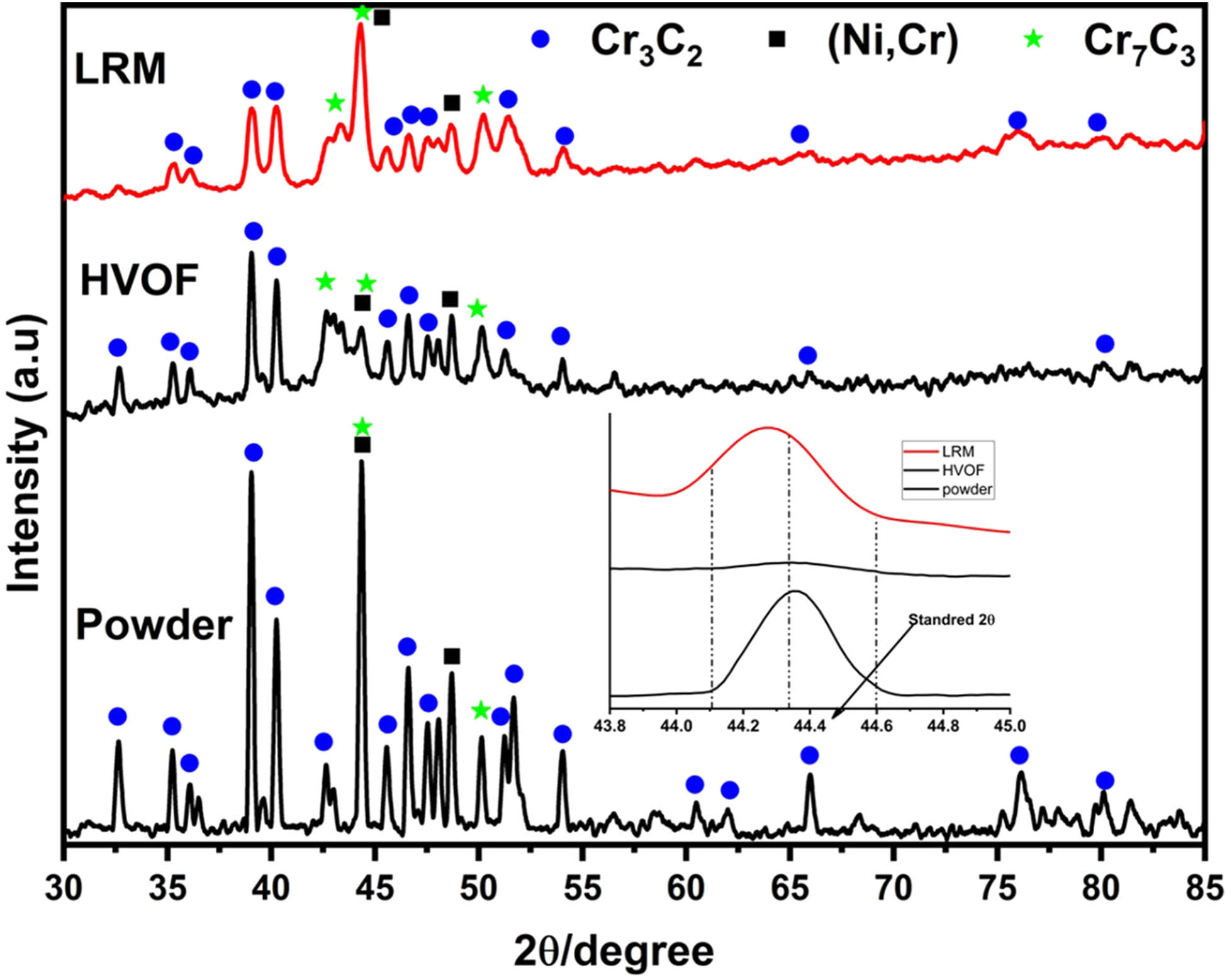

Figure 2 shows the XRD spectra of the MMP Cr3C2–NiCr powder and its corresponding HVOF and LRM coatings. Each XRD spectrum mainly consists of the hard particles of Cr3C2 with orthorhombic (Pnma, 62) structured phase (reference PDF#71-2287) and a small amount of NiCr and tiny Cr7C3 phases. The broadening of the 2θ around 46° and 51.5° diffraction peaks in the XRD spectrum of Cr3C2–NiCr powder indicates the presence of nano and submicron Cr3C2. After HVOF, the newly emerged Cr3C2–NiCr coating broadening of the (2θ = 41.1–44.6°) diffraction peak in the XRD spectral line indicates the presence of nanocrystallite NiCr; it is clear that the peak shifted with minor angle (2θ = 0.1 → 0.6°). Furthermore, the XRD peaks show that the content of Cr7C3 increases after HVOF and LRM coatings, which suggests that the decomposition of a small amount of Cr3C2 particles occurred during HOVF and LRM coatings. At high laser beam input energy and an oxidizing atmosphere, a solid-state reaction occurs, which leads to the decomposition of the initial phases, and the intensity of the other phases increases [31,32]

X-ray diffraction patterns of coating before and after LRM and powder.

The diffraction peak broadening and 50–52° corresponding to 2θ, in the XRD spectra of Cr3C2–NiCr coating after LRM indicate the presence of nano and submicron Cr3C2 and fine dendrite. Additionally, Figure 2 suggests a 1–2° broadening in the peak at 42°, corresponding to the 2θ angle. This broadening indicates that an excessive degree of supercooling occurred for the NiCr/Cr7C3 phases, resulting in the development of a nanocrystalline phase due to rapid solidification [33].

3.1.3 Microstructure analysis for MMP coatings

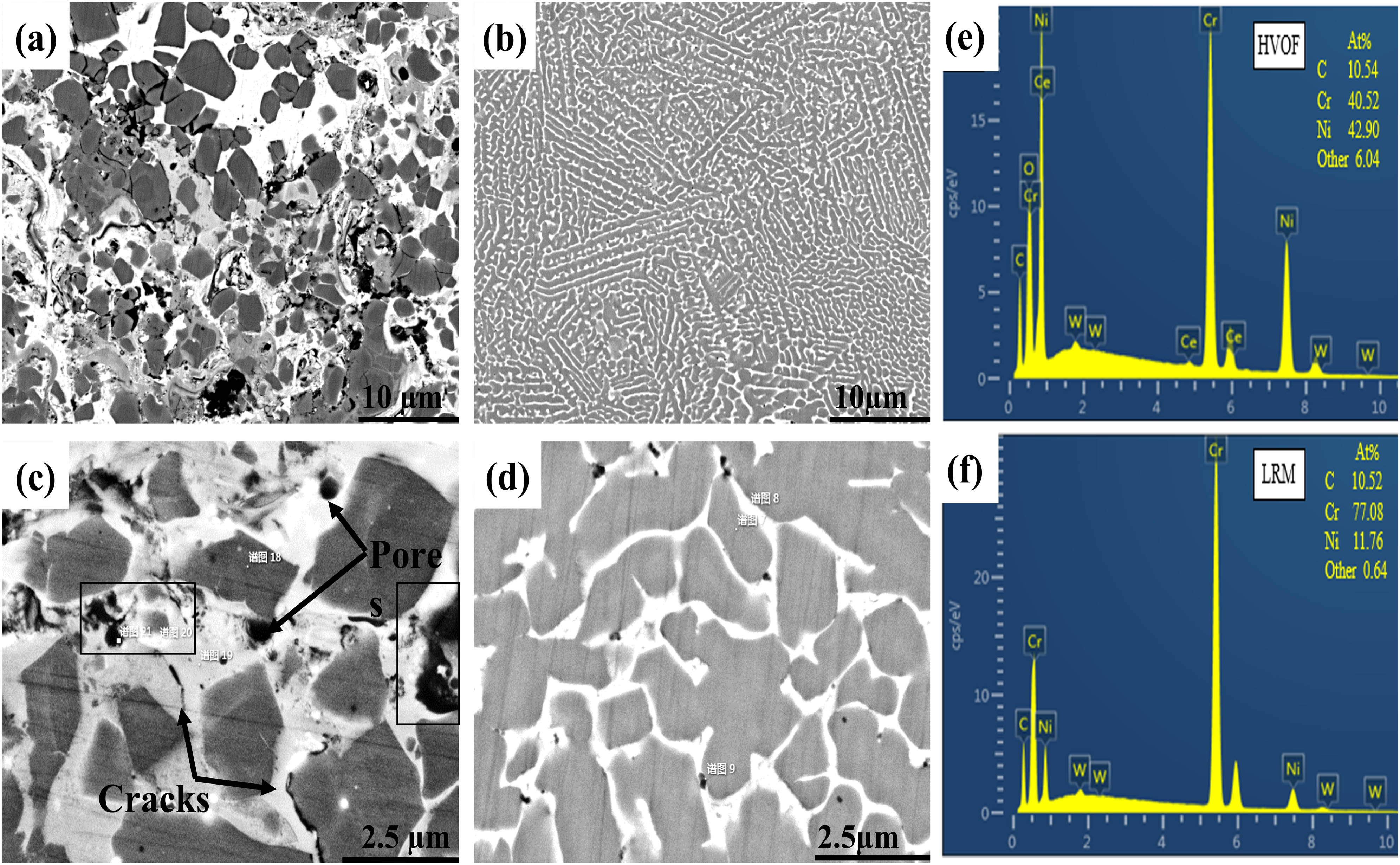

Figure 3 shows the SEM images of the MMP Cr3C2–NiCr coating before and after the LRM process at different magnifications. Figure 3(a) and (c) shows that numerous dark irregular particles of Cr3C2 and its aggregates are unevenly distributed within the light gray NiCr binder phase. Additionally, several pores and cracks are present in the complete and NiCr phases, indicating a relatively low coating quality due to the selection of an inappropriate combination of spray process parameters.

SEM images of the surface of HVOF coating (a) and (c) and after LRM coatings (b) and (d), and EDS results (e) HVOF and (f) LRM.

Figure 3(b) and (d) shows that homogeneous and densified dendritic microstructures are formed during the LRM process. Some of the first dendrite grains have lengths ranging from 15 to 20 μm and are aligned along a specific direction. At higher magnification, the original irregular Cr3C2 particles change into irregular square and long strips, clearly showing that some particles connect to form larger ones, and the edges and corners of the individual particles become smooth. The average length of the squares is 2–3 μm. Small irregular block structures combine in Figure 3(b) and (d). Figure 3(e)–(f) (EDS elemental analysis before and after LRM) shows that a small amount of rare earth exists in the coating besides C, Cr, and Ni elements. The LRM coating process exhibited a uniformly distributed carbide phase on the coating’s surface. Depending on the amount of carbon in the carbide phase, different levels of dark gray are observed, as shown in Figure 3(d).

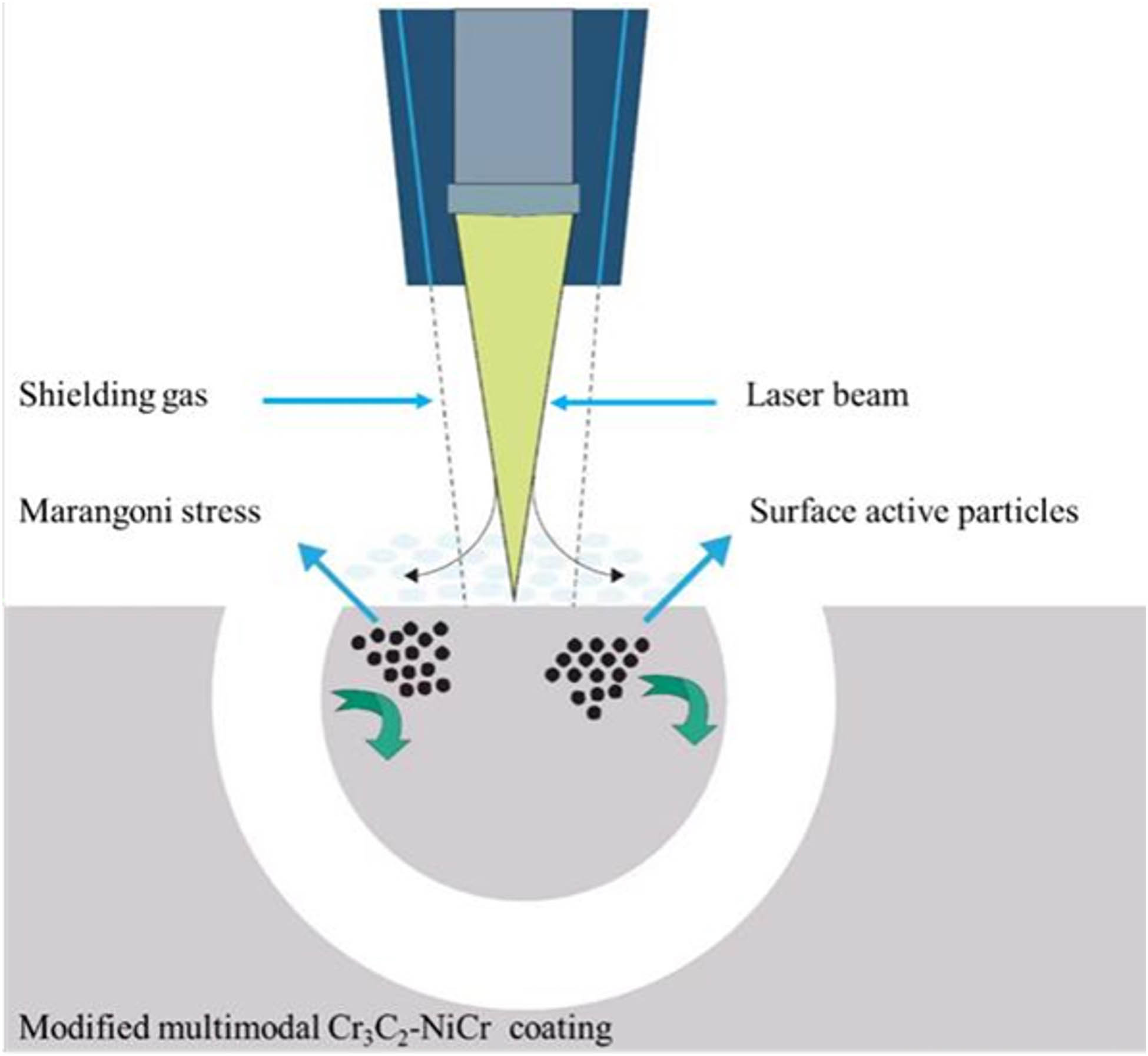

In addition, the LRM process generates Marangoni stress on the coating’s surface due to the high energy flow through the laser beam. This stress arises from the surface tension gradient, gravity, and flexibility inside the molten pool caused by the high-frequency laser beam; Figure 4 illustrates this phenomenon [14,34,35]. In this phenomenal situation during the LRM process, the un-melted particles of Cr3C2 and Cr7C3 start circulation and re-distribution in coating [36]. Moreover, during the LRM process, rare earth is added to the structure to refine it, reduce the surface tension of the liquid phase, decrease the interface energy between the metal and the coating, and increase the wettability and bonding strength. The adhesion strength of the coating after LRM (76.31 ± 1.21 MPa) significantly improved compared to the HVOF coating (48.54 ± 1.03 MPa). As a result, the LRM process effectively controls the distribution and size of carbides during their re-solidification and melting-growth period. This leads to improved microstructure properties, enhanced coating consistency, and increased resistance to corrosion.

Sketch of the melt pool during the LRM process.

MMP Cr3C2–NiCr coating refers to the microstructural states formed by the particle aggregates of micron, submicron, and nano carbides, as well as nanoparticles distributed in the molten binder phase after modification of nano-rare earth oxides. From Figure 5, the MMP Cr3C2–NiCr coating features remain after LRM, which provides the microstructural guarantee for good comprehensive coating performance. Figure 5 represents the elemental interdiffusion across the interface between the coating and substrate and was characterized through EDS analysis; the composition of the elements is listed in Table 2.

SEM/EDS analysis of cross-section interface/substrate after LRM (a)–(h).

Elemental composition of the MMP Cr3C2–NiCr coating

| Elements | Cu | Cr | C | Ni | Ce | Zr | La |

|---|---|---|---|---|---|---|---|

| Sample, wt% | 11.21 | 62.41 | 16.21 | 3.94 | 2.45 | 2.20 | 1.58 |

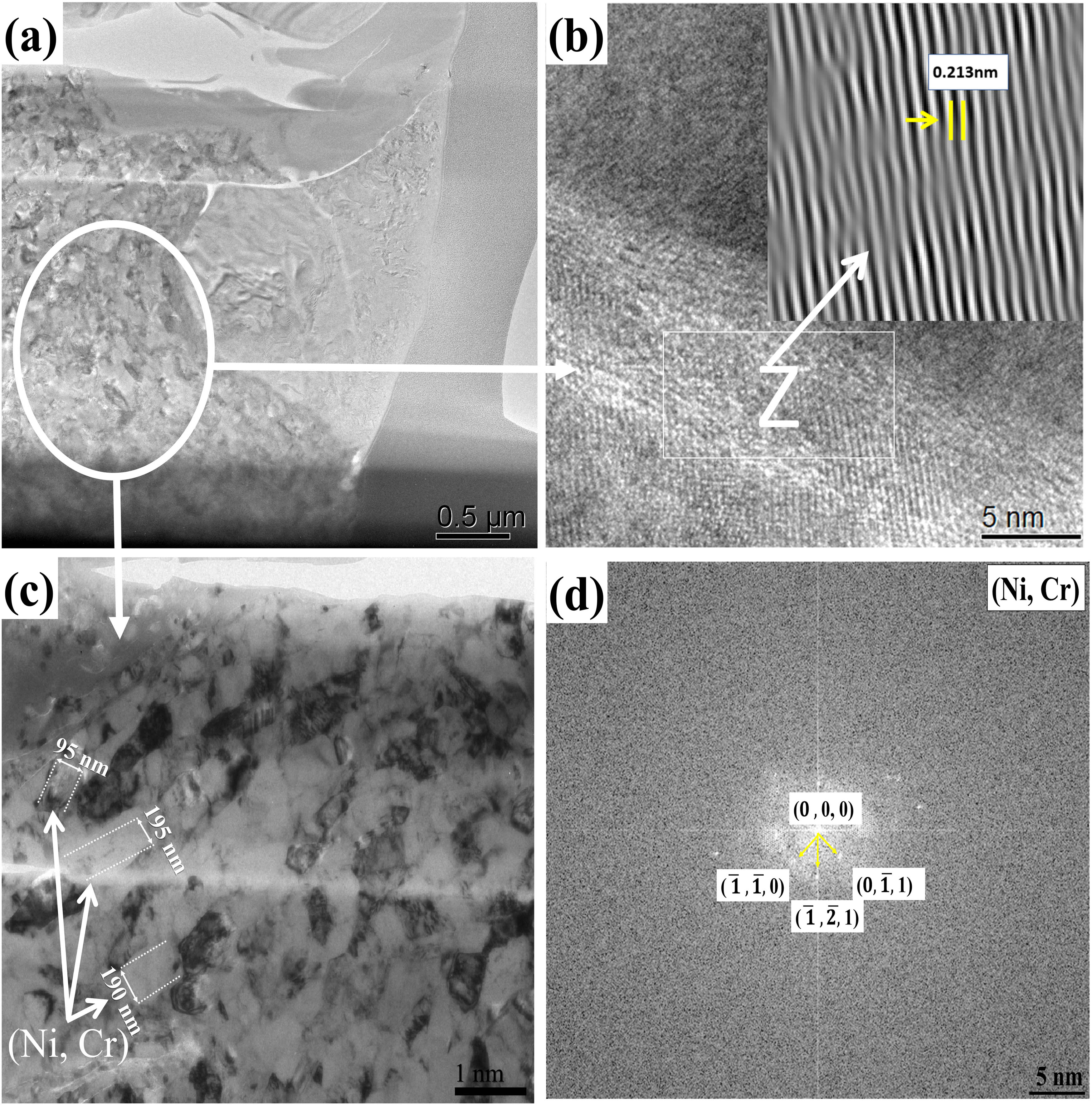

For a further detailed analysis of the microstructural information, the bright-field images obtained through TEM and their corresponding selected area electron diffraction patterns are presented in Figure 6. Based on XRD and SEM analysis results and TEM diffraction patterns, it can be confirmed that both the lamella structure is Cr3C2. TEM images of the coating after the LRM process: the area mentioned in Figure 6 shows a cubic “Y” and with high magnification in Figure 6(b)–(d) is a Cr3C2 crystallite with a size of 1.113 μm and a corresponding indexed diffraction pattern. The Cr3C2 hard phase (PDF card#35-0804 orthorhombic (Pnam, 62)) precipitated in the coating during the LRM process. TEM and XRD have established that the coatings nano–micron and submicron grain structures retain, and their content remains unchanged. Furthermore, Figure 6 provides a detailed view of the interface/coating area, highlighted by a rectangle marked with an “X” in Figure 6(e) and (f). This area reveals the presence of strengthening Cr7C3 phases (ranging from 0.3 to 1.38 μm) within the coating due to the LRM process. As mentioned earlier, the XRD spectra indicated an increase in the Cr7C3 phases during the LRM process. TEM analysis further confirms this observation, which reveals that the coating primarily comprises nano-Cr3C2 and Cr7C3 phases.

(a) Cross-sectional TEM images of MMP Cr3C2-NiCr coating after LRM and (b)-(c) Cr3C2 with high magnification (d) Cr3C2 with the indexed diffraction pattern, (e) Cr7C3 with high magnification and (f) Cr7C3 with the indexed diffraction pattern.

In Figure 6(a), marked with the rectangle labelled as “Z” and at high magnification in Figure 7(a), the inverse fast Fourier transform result in the insets of Figure 7(d) shows that the crystal phase was identified as NiCr, exhibiting a cubic structure (PDF#26-0429, Pm−3n (233)). It grows preferentially along the [1̅,2̅,0] direction with a d-spacing of 0.213 nm (as shown in Figure 7(b)). In Figure 7(c), several irregular elongated nano-crystallite phases with varying dimensions and shapes are visibly indicated. These long nanocrystalline phases are randomly dispersed throughout the MMP coating after the LRM process. Multiple crystalline phases, including Cr3C2, Cr7C3, and NiCr, are confirmed and marked within a rectangle in Figures 6(a) and 7(c). Those crystalline phases constituted multiple crystal forms with different dimensions, shapes, and orientations, thus producing various diffraction spots. This observation reinforces the presence of nanocrystalline carbide particles in the MMP Cr3C2–NiCr coating after the LRM process. These particles exhibit a size range from nano to micron to submicron dimensions. The sizes vary as follows: Cr3C2 (70–190 nm), NiCr (190–195 nm), and Cr7C3 (151 nm to 1.38 μm). The presence of nanoparticles in the coating formulation improved the mechanical and anticorrosion properties of the coating.

Cross-sectional TEM images of MMP Cr3C2-NiCr coating after LRM: (a) With high magnification, (b) With d-spacing, (c) NiCr, and (d) (IFFT) inverse fast Fourier transform.

3.2 Microhardness

The porosity results of the MMP Cr3C2–NiCr coating before and after the LRM process are depicted in Figure 8(a). The porosity investigation aims to determine the pore volume, considering the average pore size and its circularity [31]. Recent research on laser-molten nanocomposite carbides has revealed that evaporation can influence the elements’ portion due to local solid laser power inputs [34]. As the laser power increases from 300 to 400 W and 500 W, the material polymerizes, increasing total porosity due to structural changes and gasified decomposition of the Cr3C2–NiCr collecting O2 within the pores of the coating. After the LRM process, the porosity ratio reduces with various laser parameters due to each material system component’s variable boiling and melting temperatures. High porosity values were discovered with a high laser power of 500 W with a scanning speed of 12 mm·s−1; however, the porosity ratio reduced with a decrease in laser power to 300 W with a scanning speed of 10 mm·s−1. The porosity decreased from 3.9% of the HVOF coating to 0.3% of the LRM process. The increase in porosity adversely affects the ductility and tensile strength of the coating. This negative impact can be attributed to reduced porosity hardness, resulting in a decline in coating density [37]. Archimedes water displacement method obtained the density coating before and after the LRM process with average values of 3.552and 6.552 g·cm−3, respectively.

(a) The average porosity of the coatings (%) before and after LRM. (b) Vickers hardness HV0.3 before and after LRM.

The microhardness of the coating surface before and after LRM was measured by an HXD-1000TMC digital microhardness tester with a load of 3 N and a dwelling time of 15 s. In Figure 8(b), it is observed that after LRM, the values of the Vickers hardness increased respectively. However, the average Vickers hardness of the HVOF coating is approximately 1,050 HV0.3, while after LRM, the values of the hardness increase gradually with the average values of 1,050–1,300 HV0.3. LRM, the solidified coating layer, is easier to re-melt and primarily affected by heat. If there are any tiny pores or cracks, they will disappear due to sufficient energy. In addition, high laser energy makes the bonding phase melt into liquid, filling the pores in the coating and improving the density of the coating.

3.3 Corrosion-resistant analysis

3.3.1 Corrosion-resistant phenomena

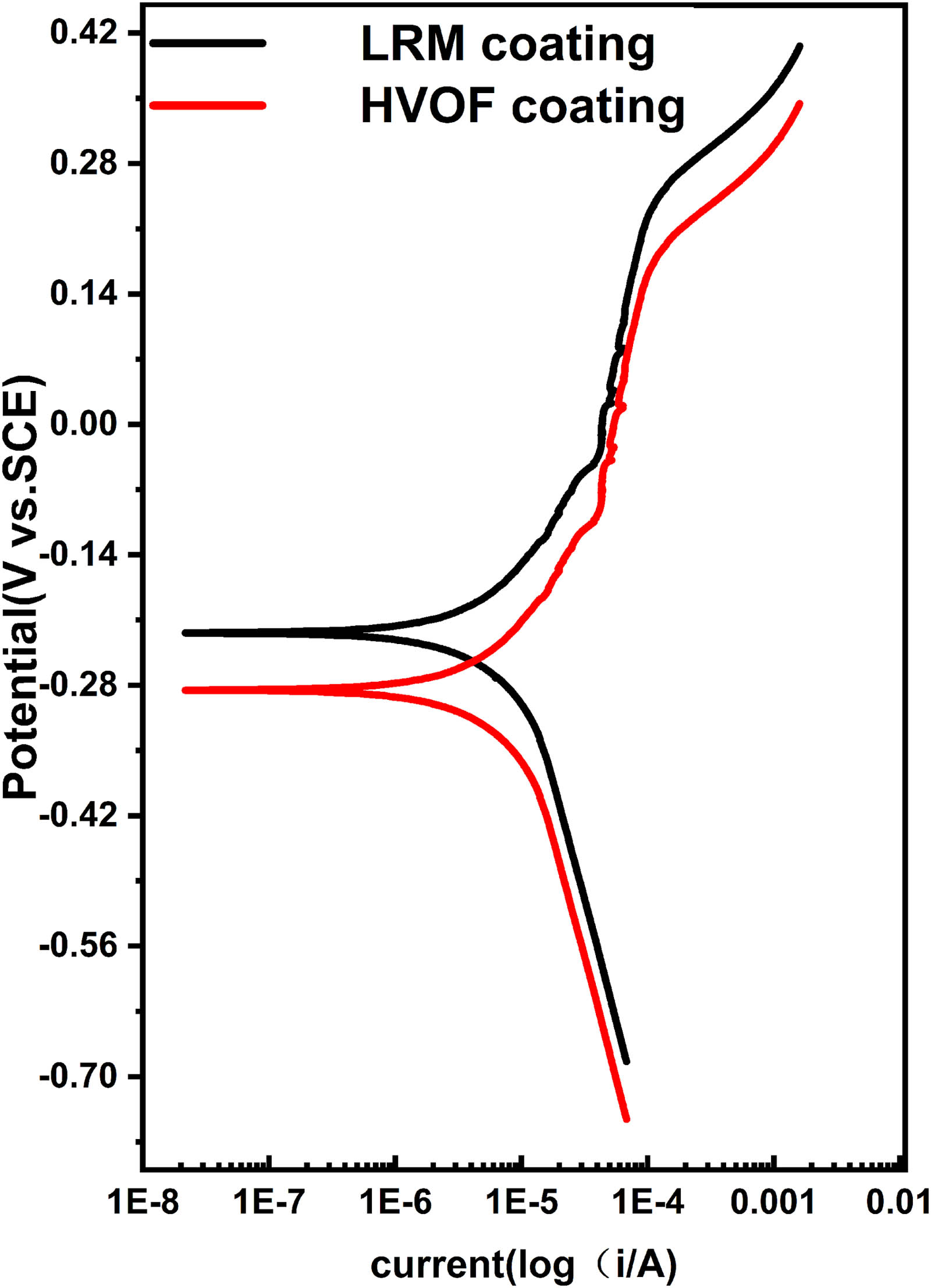

Figure 9 illustrates a comprehensive analysis of the potentiodynamic polarization resistance for HVOF and LRM coatings. The information includes Tafel plots and corresponding data presented in Table 3. Additionally, Eq. (3) (Stern-Geary) was utilized to evaluate the results and further understand the corrosion behavior of the coatings

Potentiodynamic polarization plots of the HVOF sprayed and LRM.

Comparison of the corrosion HVOF and LRM

| S/No | E corr (V) | βa (V) | βc (V) | I corr (µA·cm−2) |

|---|---|---|---|---|

| HVOF coating | 0.171 | 0.594 | 0.686 | 33.794 |

| After LRM | 0.064 | 1.458 | 4.854 | 4.35 |

In the Stern-Geary equation, βa represents the slope of the anodic branch, βc shows the cathodic slope, “E corr” is the corrosion potential, and “I corr” is the corrosion current density. The corrosion rate of the coating after LRM is eight times less than before LRM.

By solving Eq. (3) for the experimental data results, the value of the corrosion current density “I corr” of the Cr3C2–NiCr coating after LRM measured at about 4.35–4.733 µA·cm−2, which is less than before 33.7 µA·cm−2 measured for HVOF. LRM increases the density of the coating, leading to the blockage of the immersion path of the corrosion solution, improving the corrosion resistance. Furthermore, the decrease of corrosion current density after LRM is related to the homogenization of microstructure, and the obtained result proves that using the LRM process after HVOF is highly significant to deposit better quality of MMP Cr3C2–NiCr-based coating on a substrate, which can operate in corrosive industrial application.

The occurrence of pitting corrosion should be because the electrode potential of a specific phase is relatively low, and the LRM changes or increases the electrode potential of the phase, as mentioned earlier in Table 3. The formation of oxide film improves the uniform corrosion ability of the coating [38]. Furthermore, some nickel ions diffuse into the formed oxide layer, accelerating the protective coating layer’s formation and improving pitting corrosion resistance. Metals may have active, passive, or active-passive electrochemical behavior depending on the metal and environment. Active–passive metal NiCr shows active–passive and trans-passive regimes on the anodic polarization [39]. Research studies suggest that in Cr and Ni in Cr3C2–NiCr coatings, NiCr could form a corresponding passive layer of chromium to control corrosion [3,40].

Compared to the HVOF coating, the LRM process resulted in a positive shift in the corrosion potential. Additionally, it was observed that the passive current density decreased after the LRM process. In comparison, MMP Cr3C2–NiCr coating after the LRM process is composed of nano, submicron, micron Cr3C2 grains, NiCr grains, and a tiny number of modifiers. The agglomerated structure consisted of a multiscale chromium and nickel carbide cermet core, with a surrounding shell of a metal binder, further covered with submicron and nano-chromium carbide particles. The nanoparticles turn into inert physical barriers to the initiation and development of corrosion, improving the corrosion resistance of the coating. According to the electrochemical corrosion principle, the larger the corrosion potential is, the smaller the current density is, the corrosion tendency of the materials is, and the better the corrosion resistance [39,41]. Some of the research investigations confirmed that the corrosion resistance of Cr3C2–NiCr coatings is the result of oxide formation, such as Cr2O3 and Ni2O3, protecting the substrate from the corrosion resistance and enhancing the lifetime of the substrates [42].

3.3.2 Corrosion mechanism

Electrochemical resistance mechanisms include anodic (which is oxidation) as well as cathodic (reduction) NaCl [Na+, Cl−] [43]. The decomposition of a metal M is an anodic reaction:

For corrosion to occur, the anodic reaction’s electron must be consumed by a cathodic reaction. The two most prevalent cathodic reactions in aqueous corrosion are oxidation and reduction [44]. An electron generated by the anodic reaction is consumed at the cathode (Eq. 5 shows that the reaction occurs),

The presence of the nano, micron, and submicron particles after modification of the coating with the LRM process regulates materials on the nanoscale. It more effectively develops the potential of the materials’ properties. This can be strongly reflected in the above microstructure analysis of the coating, which shows the decrease of the interface between the substrate and MMP Cr3C2–NiCr coating after the LRM process. In addition, by improving the nanostructure of the coating through nano-modification by the LRM process, anticorrosion properties increase.

4 Conclusions

In conclusion, modified multimodal Cr3C2–NiCr coatings were deposited on the CuCrZr alloy substrate. Laser beam properties of LRM and their effect on surface modification of MMP Cr3C2–NiCr coatings prepared by HVOF spraying are investigated. The main conclusions are presented as follows:

After the LRM process, observed changes in the coating reveal a distinct transformation of the original irregular Cr3C2 particles into irregular square and long strips. Moreover, certain particles tend to merge, resulting in the formation of larger particle aggregates. Furthermore, the edges and corners of the individual particles become noticeably smoother during the LRM process. The average length of the squares is 2–3 μm. In addition, the laser beam accelerated the Marangoni flow, promoting carbide nucleation and their homogeneous distribution.

The HVOF MMP Cr3C2–NiCr coatings consist of nano-sized, submicron-sized, and micron-sized hard grains and metallic binder phases. During the LRM process, submicron grains of Cr3C2 become embedded in the voids created by larger Cr3C2 grains, while the nano-sized Cr3C2 grains disappear within the NiCr metal binder phases.

The coating density was measured before and after the LRM process, with average values of 3.552 and 6.552 g·cm−3, respectively. Compared to the HVOF coating, the MMP Cr3C2–NiCr coating after the LRM process exhibits a uniform and dense structure free from apparent lamellar formations. Additionally, the porosity is reduced by approximately 0.31–0.9%.

The Vickers hardness test with a load of 3 N, LRM Vickers hardness (HV0.3) values approximately 1,300 HV0.3, while HVOF coating values approximately 1,050 HV0.3.

The corrosion resistance of the coating increased after LRM and the corrosion current density after LRM was found to be 4.35 µA·cm−2, whereas the current density of the HVOF coating was 33.794 µA·cm−2. The corrosion rate after the LRM of the coating decreases. The protective, homogeneous oxide layer was formed on the Cr3C2–NiCr surface, protecting the tested materials against corrosion.

Acknowledgments

The authors are grateful for the valuable help from the support of the National Natural Science Fund (No. 51671096) project of China and Professor Wang You from the Harbin Institute of Technology.

-

Funding information: This research was supported by National Natural Science Fund (No. 51671096) project of China and Professor Wang You from the Harbin Institute of Technology.

-

Author contributions: Ming Hu: contributed significantly to designing the conception of the study and conducted final approval of the manuscript. Irfan: performed the research, analyzed, and interpreted the collected data, and wrote the manuscript. Lingyu Meng: helped to perform the experiment. Chenxi Shi: contributed to carrying out additional analyses with constructive discussions. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and analyzed during the current study are available from the corresponding author upon reasonable request.

References

[1] Chong, K., Y. Zou, D. Wu, Y. Tang, and Y. Zhang. Pulsed laser re-melting supersonic plasma sprayed Cr3C2-NiCr coatings for regulating microstructure, hardness, and corrosion properties. Surface and Coatings Technology, Vol. 418, 2021 Jul, id. 127258.10.1016/j.surfcoat.2021.127258Search in Google Scholar

[2] Ping, X. L., H. G. Fu, S. T. Sun, J. Lin, X. Y. Guo, and Y. P. Lei. Microstructure and performance of Nb-bearing Ni60A-Cr3C2 coatings manufactured by laser cladding. Surface Engineering, Vol. 36, No. 12, 2020 Dec, pp. 1294–1306.10.1080/02670844.2019.1631510Search in Google Scholar

[3] Sadeghimeresht, E., N. Markocsan, and P. Nylen. Microstructural characteristics and corrosion behavior of HVAF-and HVOF-sprayed Fe-based coatings. Surface and Coatings Technology, Vol. 318, 2017 May, pp. 365–373.10.1016/j.surfcoat.2016.11.088Search in Google Scholar

[4] Zhu, L., S. Wang, H. Pan, C. Yuan, and X. Chen. Research on remanufacturing strategy for 45 steel gear using H13 steel powder based on laser cladding technology. Journal of Manufacturing Processes, Vol. 49, 2020 Jan, pp. 344–354.10.1016/j.jmapro.2019.12.009Search in Google Scholar

[5] Ni, J., J. Li, W. Luo, Q. Han, Y. Yin, Z. Jia, et al. Microstructure and properties of in-situ TiC reinforced copper nano-composites fabricated via long-term ball milling and hot pressing. Journal of Alloys and Compounds, Vol. 755, 2018 Jul, pp. 24–28.10.1016/j.jallcom.2018.04.327Search in Google Scholar

[6] Yang, F., Q. Qin, T. Shi, X. Lu, C. Chen, Z. Guo, et al. In-situ synthesis of TiC-Al2O3 coating on copper surface. Surface and Coatings Technology, Vol. 373, 2019 Sep, pp. 65–74.10.1016/j.surfcoat.2019.05.064Search in Google Scholar

[7] Bateni, M. R., F. Ashrafizadeh, J. A. Szpunar, and R. A. Drew. Improving the tribological behavior of copper through novel Ti–Cu intermetallic coatings. Wear, Vol. 253, No. 5–6, 2002 Sep, pp. 626–639.10.1016/S0043-1648(02)00143-6Search in Google Scholar

[8] Janka, L., L. M. Berger, J. Norpoth, R. Trache, S. Thiele, C. Tomastik, et al. Improving the high temperature abrasion resistance of thermally sprayed Cr3C2-NiCr coatings by WC addition. Surface and Coatings Technology, Vol. 337, 2018 Mar, pp. 296–305.10.1016/j.surfcoat.2018.01.035Search in Google Scholar

[9] Wang, H., X. Yan, H. Zhang, M. Gee, C. Zhao, X. Liu, et al. Oxidation-dominated wear behaviors of carbide-based cermets: A comparison between WC-WB-Co and Cr3C2-NiCr coatings. Ceramics International, Vol. 45, No. 17, 2019 Dec, pp. 21293–21307.10.1016/j.ceramint.2019.07.113Search in Google Scholar

[10] Dzhurinskiy, D., A. Babu, P. Pathak, A. Elkin, S. Dautov, and P. Shornikov. Microstructure and wear properties of atmospheric plasma-sprayed Cr3C2-NiCr composite coatings. Surface and Coatings Technology, Vol. 428, 2021 Dec, id. 127904.10.1016/j.surfcoat.2021.127904Search in Google Scholar

[11] Wu, H. and D. Kong. Effects of laser power on friction–wear performances of laser thermal sprayed Cr3C2–NiCr composite coatings at elevated temperatures. Optics & Laser Technology, Vol. 117, 2019 Sep, pp. 227–238.10.1016/j.optlastec.2019.04.022Search in Google Scholar

[12] Yuan, J. M., T. S. Dong, B. G. Fu, G. L. Li, L. Liu, and R. Wang. Effect of Tungsten Inert Gas Arc Re-melting on Microstructure and Wear Properties of Plasma-Sprayed NiCr-Cr3C2 Coating. Journal of Materials Engineering and Performance, Vol. 28, 2019 Oct, pp. 6320–6329.10.1007/s11665-019-04350-2Search in Google Scholar

[13] Kumar, R., K. Goyal, and D. Bhandari. Slurry erosion behavior of thermally sprayed ceramic nano-composite coatings on turbine steel. International Journal of Applied Ceramic Technology, Vol. 19, No. 6, 2022 Nov, pp. 3049–3061.10.1111/ijac.14117Search in Google Scholar

[14] Schwanekamp, T., G. Marginean, and M. Reuber. Laser beam melting of Cr3C2-NiCr. International Journal of Refractory Metals and Hard Materials, Vol. 85, 2019 Dec, id. 105069.10.1016/j.ijrmhm.2019.105069Search in Google Scholar

[15] Sharma, A., A. Vijay, and F. Sadeghi. Finite element modeling of fretting wear in anisotropic composite coatings: Application to HVOF Cr3C2–NiCr coating. Tribology International, Vol. 155, 2021 Mar, id. 106765.10.1016/j.triboint.2020.106765Search in Google Scholar

[16] Singh, S., K. Goyal, and R. Bhatia. Mechanical and microstructural properties of yttria-stabilized zirconia reinforced Cr3C2-25NiCr thermal spray coatings on steel alloy. Journal of Electrochemical Science and Engineering, Vol. 12, No. 5, 2022 Oct, pp. 819–828.10.5599/jese.1278Search in Google Scholar

[17] Özer, A. and Y. K. Tür. Sintering behaviour and mechanical properties of Cr3C2–NiCr cermets. Bulletin of Materials Science, Vol. 36, 2013 Oct, pp. 907–911.10.1007/s12034-013-0541-5Search in Google Scholar

[18] Qiao, Y., J. Huang, D. Huang, J. Chen, W. Liu, Z. Wang, and Z. Zhibin. Effects of laser scanning speed on microstructure, microhardness, and corrosion behavior of laser cladding Ni45 coatings. Journal of Chemistry, Vol. 2020, 2020 Aug, id. 1438473.10.1155/2020/1438473Search in Google Scholar

[19] Zhang, J., J. Lei, Z. Gu, F. Tantai, H. Tian, J. Han, et al. Effect of WC-12Co content on wear and electrochemical corrosion properties of Ni-Cu/WC-12Co composite coatings deposited by laser cladding. Surface and Coatings Technology, Vol. 393, 2020 Jul, id. 125807.10.1016/j.surfcoat.2020.125807Search in Google Scholar

[20] Zhang, P., X. Zou, S. Zhang, C. Xia, C. Liang, N. Liu, et al. Improve the binding force of PEEK coating with Mg surface by femtosecond lasers induced micro/nanostructures. Journal of Materials Science, Vol. 56, No. 23, 2021 Aug, pp. 13313–13322.10.1007/s10853-021-06140-5Search in Google Scholar

[21] Zhang, Y., X. Gao, X. Liang, K. Chong, D. Wu, and Y. Zou. Effect of laser re-melting on the microstructure and corrosion property of the arc-sprayed AlFeNbNi coatings. Surface and Coatings Technology, Vol. 398, 2020 Sep, id. 126099.10.1016/j.surfcoat.2020.126099Search in Google Scholar

[22] Chen, H. and D. Kong. Effects of laser re-melting speeds on microstructure, immersion corrosion, and electrochemical corrosion of arc–sprayed amorphous Al–Ti–Ni coatings. Journal of Alloys and Compounds, Vol. 771, 2019 Jan, pp. 584–594.10.1016/j.jallcom.2018.08.252Search in Google Scholar

[23] Mazaheri, Y., R. Malmir, M. M. Jalilvand, M. Sheikhi, and A. Heidarpour. Mechanical properties and tribological performance of A356/Cr3C2-NiCr surface composite developed by high-velocity oxy-fuel and post friction stir processing treatment. Surfaces and Interfaces, Vol. 28, 2022 Feb, id. 101627.10.1016/j.surfin.2021.101627Search in Google Scholar

[24] Panziera, R. C., A. C. de Oliveira, M. Pereira, and F. Ratszunei. Study of the effects of the laser re-melting process on the microstructure and properties of the WC–10Co–4Cr coating sprayed by HVOF. Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 42, 2020 Mar, pp. 1–8.10.1007/s40430-020-2201-1Search in Google Scholar

[25] Qin, E., B. Wang, W. Li, W. Ma, H. Lu, and S. Wu. Optimized microstructure and properties of Cr3C2-NiCr cermet coating by HVOF/laser hybrid processing. Journal of Thermal Spray Technology, Vol. 28, 2019 Jun, pp. 1072–1080.10.1007/s11666-019-00877-xSearch in Google Scholar

[26] Mateos, J. J., J. M. Cuetos, E. Fernandez, and R. Vijande. Tribological behaviour of plasma-sprayed WC coatings with and without laser re-melting. Wear, Vol. 239, No. 2, 2000 Apr, pp. 274–281.10.1016/S0043-1648(00)00325-2Search in Google Scholar

[27] Chen, H., C. Xu, Q. Zhou, I. M. Hutchings, P. H. Shipway, and J. Liu. Micro-scale abrasive wear behaviour of HVOF sprayed and laser-remelted conventional and nanostructured WC–Co coatings. Wear, Vol. 258, No. 1-4, 2005 Jan, pp. 333–338.10.1016/j.wear.2004.09.044Search in Google Scholar

[28] Bolelli, G., L. M. Berger, T. Börner, H. Koivuluoto, V. Matikainen, L. Lusvarghi, et al. Sliding and abrasive wear behaviour of HVOF-and HVAF-sprayed Cr3C2–NiCr hardmetal coatings. Wear, Vol. 358, 2016 Jul, pp. 32–50.10.1016/j.wear.2016.03.034Search in Google Scholar

[29] Zhang, H., K. Chong, W. Zhao, and Z. Sun. Effects of pulse parameters on in-situ Ti-V carbides size and properties of Fe-based laser cladding layers. Surface and Coatings Technology, Vol. 344, 2018 Jun, pp. 163–169.10.1016/j.surfcoat.2018.03.021Search in Google Scholar

[30] Janka, L., J. Norpoth, S. Eicher, M. R. Ripoll, and P. Vuoristo. Improving the toughness of thermally sprayed Cr3C2-NiCr hardmetal coatings by laser post-treatment. Materials & Design, Vol. 98, 2016 May, pp. 135–142.10.1016/j.matdes.2016.03.007Search in Google Scholar

[31] Du, J. Y., F. Y. Li, L. M. Wang, H. Y. Lu, X. J. Ran, and X. Y. Zhang. Influences of plasma arc re-melting on microstructure and service performance of Cr3C2-NiCr/NiCrAl composite coating. Surface and Coatings Technology, Vol. 369, 2019 Jul, pp. 16–30.10.1016/j.surfcoat.2019.04.037Search in Google Scholar

[32] Magnani, M., P. H. Suegama, N. Espallargas, C. S. Fugivara, S. Dosta, J. M. Guilemany, et al. Corrosion and wear studies of Cr3C2-NiCr-HVOF coatings sprayed on AA7050 T7 under cooling. Journal of Thermal Spray Technology, Vol. 18, 2009 Sep, pp. 353–363.10.1007/s11666-009-9305-6Search in Google Scholar

[33] Matthews, S., B. James, and M. Hyland. The role of microstructure in the high temperature oxidation mechanism of Cr3C2–NiCr composite coatings. Corrosion Science, Vol. 51, No. 5, 2009 May, pp. 1172–1180.10.1016/j.corsci.2009.02.027Search in Google Scholar

[34] Schwanekamp, T., G. Marginean, M. Reuber, and A. Ostendorf. Impact of cobalt content and grain growth inhibitors in laser-based powder bed fusion of WC-Co. International Journal of Refractory Metals and Hard Materials, Vol. 105, 2022 Jun, id. 105814.10.1016/j.ijrmhm.2022.105814Search in Google Scholar

[35] Arrizubieta, J. I., A. Lamikiz, F. Klocke, S. Martínez, K. Arntz, and E. Ukar. Evaluation of the relevance of melt pool dynamics in Laser Material Deposition process modeling. International Journal of Heat and Mass Transfer, Vol. 115, 2017 Dec, pp. 80–91.10.1016/j.ijheatmasstransfer.2017.07.011Search in Google Scholar

[36] Ott, D. K., W. Cyrs, and T. M. Peters. Passive measurement of coarse particulate matter, PM10–2.5. Journal of Aerosol Science, Vol. 39, No. 2, 2008 Feb, pp. 156–167.10.1016/j.jaerosci.2007.11.002Search in Google Scholar

[37] Lemaitre, J. and R. Desmorat. Engineering damage mechanics: ductile, creep, fatigue and brittle failures. Springer Science & Business Media, 2006.Search in Google Scholar

[38] Guilemany, J. M., J. Fernandez, J. Delgado, A. V. Benedetti, and F. Climent. Effects of thickness coating on the electrochemical behaviour of thermal spray Cr3C2–NiCr coatings. Surface and Coatings Technology, Vol. 153, No. 2–3, 2002 Apr, pp. 107–113.10.1016/S0257-8972(01)01679-6Search in Google Scholar

[39] Li, X. and K. Ogle. The passivation of Ni-Cr-Mo alloys: time resolved enrichment and dissolution of Cr and Mo during passive-active cycles. Journal of The Electrochemical Society, Vol. 166, No. 11, 2019 May, id. C3179.10.1149/2.0201911jesSearch in Google Scholar

[40] Dehgahi, S., R. Amini, and M. Alizadeh. Microstructure and corrosion resistance of Ni-Al2O3-SiC nano-composite coatings produced by electrodeposition technique. Journal of Alloys and Compounds, Vol. 692, 2017 Jan, pp. 622–628.10.1016/j.jallcom.2016.08.244Search in Google Scholar

[41] Yang, X., W. Fan, and Z. Li. A continuum damage model for prediction of crack initiation life of pitting corrosion and fatigue. International Journal of Damage Mechanics, Vol. 31, No. 6, 2022 Jun, pp. 797–814.10.1177/10567895221089666Search in Google Scholar

[42] Feng, Q., T. Li, H. Teng, X. Zhang, Y. Zhang, C. Liu, et al. Investigation on the corrosion and oxidation resistance of Ni–Al2O3 nano-composite coatings prepared by sediment co-deposition. Surface and Coatings Technology, Vol. 202, No. 17, 2008 May, pp. 4137–4144.10.1016/j.surfcoat.2008.03.001Search in Google Scholar

[43] Li, S., Z. Guo, J. Xiong, Y. Lei, Y. Li, J. Tang, et al. Corrosion behavior of HVOF sprayed hard face coatings in alkaline-sulfide solution. Applied Surface Science, Vol. 416, 2017 Sep, pp. 69–77.10.1016/j.apsusc.2017.04.149Search in Google Scholar

[44] Sherif, E. M. and S. M. Park. Effects of 1, 4-naphthoquinone on aluminum corrosion in 0.50 M sodium chloride solutions. Electrochimica Acta, Vol. 51, No. 7, 2006 Jan, pp. 1313–1321.10.1016/j.electacta.2005.06.018Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants