Abstract

Based on the conventional triaxial compression test of marble, the microscopic parameters corresponding to the macroscopic mechanical properties of marble were obtained by PFC2D, and on this basis, discrete element method models were established to conduct numerical tests of triaxial compression of marble under different confining pressures and loading rates to study the effect of loading rates on the rock specimens. Under the same confining pressure, brittle damage occurs in marble when the loading rate is low, and the damage type transforms from brittle to ductile as the loading rate increases. The peak strength, cracking stress, damage stress, cohesion, and internal friction angle of marble appear to increase with the increase in the loading rate under the same confining pressure. The characteristic stresses and strength parameters are linearly related to the loading rate. The influence of the loading rate on the peak strength is the most significant. With the increase in the confining pressure, the fitting coefficient of the linear relationship between initiation stress and loading rate decreases from 18.9 to 15.4 for different confining pressures, indicating that the growth rate of initiation stress decreases with the increase in the confining pressure when the loading rate is increased, and the increase in confining pressure suppresses the growth rate of initiation stress with loading rate.

1 Introduction

In recent years, with the degree of exploitation of underground space and the increasing demand for renewable energy in China, more complex rock mechanics problems have arisen in constructing large hydropower stations and their main structures. For example, during the construction of the underground engineering of hydropower, the in situ stress will change and cause the deformation of the surrounding rock [1,2,3]. The surrounding rock gradually accumulates damage during the loading process. When the exterior load exceeds a certain level, the rock is damaged, its strength is reduced, and in severe cases, the surrounding rock is destroyed and destabilized [4,5]. After the excavation of underground projects, a high-ground stress environment is often formed, and the mechanical parameters of the deep rock body deteriorate [6,7,8].

When changing the loading rate, the mechanical properties of the rock change, which is called the loading rate effect. The rock loading rate effect is one of the crucial causes of various dynamic hazards in the development of underground space and resources [9,10,11]. Changing the loading rate will affect the stress distribution, displacement distribution, deformation damage characteristics, and energy storage and dissipation of the engineering rock under the excavation load, affecting the stability of the surrounding rock. The loading rate effect has even more significant impact on hard brittle rocks [12,13]. Therefore, the loading rate effect of deep rock masses under different confining pressures is of important research significance.

The study of loading rate effect was carried out by conducting laboratory tests under different stress paths, with construction environment and rock type as variables. Jiang et al. [14] changed the loading rate of shale in uniaxial compression tests, detected the acoustic emission energy of rock specimens during the loading process, and calculated the critical index by the maximum likelihood estimation method to analyze the critical failure actions of rock specimens. Qin et al. [15] carried out lateral compression tests on crushed vein rocks at different loading rates and combined the energy characteristics of rocks in acoustic emission and the crushing process of particles in numerical tests to obtain the deformation mechanism of coal gangue under compression. Zhao et al. [16] discussed the elastic energy, dissipation energy, and damage variables of rocks during the change in stress–strain curve by conducting uniaxial compression tests on brittle granite at different loading rates. Moreover, damage variables obtained from the stress–strain curve and the damage characteristics of the rock from the perspective of energy evolution were studied and compared. Li et al. [17] conducted uniaxial compression tests under different loading rates on original rock samples and rock samples containing initial damage to investigate the effects of loading rate and initial damage on the energy evolution characteristics.

Loading rate effect is mostly studied by uniaxial compression tests, and the effect of rate on the mechanical properties of rocks under different confining pressures is less studied.

Due to the limitation of test equipment and testing means, monitoring the continuous phenomenon during the stressing process of rock specimens in laboratory tests is difficult. It is difficult to obtain the crack initiation, extension, and penetration inside the sample, which cannot reveal the loading rate effect of the rock from the microscopic level during the loading process [18,19]. There are also limitations in the simulation of complex mechanical environments. Therefore, the loading rate effects of rock samples in different stress paths need to be studied based on laboratory tests combined with numerical simulation techniques.

Discrete element method (DEM) has special advantages in obtaining crack propagation, damage accumulation, stress adjustment, and dynamic procedure of test and microscopic destruction in rock specimen, which has been widely used to study the micro behaviors of granular materials. Therefore, DEM is a powerful complement to conventional laboratory tests and numerical simulations based on the finite element method [20,21,22,23,24]. Kim et al. [25] conducted numerical tests of uniaxial compression and Brazilian splitting under different loading rates on granite by DEM model to quantitatively analyze the effects of loading rate on stress-strain, fracture morphology, and energy conversion during damage. Zhou et al. [26] established a numerical model by PFC3D and carried out compression tests under 10 MPa confining pressure to obtain the evolution of axial stress and the number of cracks in simulated rock specimens under different axial loading rates. The laboratory tests with loading rate effect as research object is difficult to carry out. Numerical tests make up for the limitations of laboratory tests and reflect the scientific principles easily and comprehensively.

DEM is used as the primary research tool to obtain the effect of loading rate on the strength parameters and characteristic stresses such as initiation stress, damage stress, and peak strength of hard and brittle marble under different confining pressures to provide a reference for the construction safety during underground rock mining and represents the other trend to research micro failure mechanism of rock besides the experiment carried out in the laboratory.

2 Triaxial numerical tests on marble

2.1 Establishment of numerical model

Based on the particle flow method, the numerical model was developed using PFC2D simulation software. Since the contact bond model can only transfer force, while the parallel bond model can transfer force and bending moment, it is more reasonable to use the parallel bond model to simulate the mechanical test of rock material [27,28,29].

In the parallel bond model, it is necessary to assign micromechanical parameters corresponding to the macroscopic parameters of the rock, so laboratory triaxial compression tests were conducted. The rock specimen was taken from the Jinping Grade II hydropower station and processed into a cylindrical model of 50 mm in diameter and 100 mm in height. The loading of the processed rock samples was controlled by displacement, and the confining pressure was set to 5, 10, and 15 MPa, and three tests were conducted under the same confining pressure.

The numerical tests were carried out based on laboratory triaxial compression tests of marble. The particle size of marble in nature generally ranged from 0.4 to 1.7 mm. The size of the numerical model is consistent with the size of the marble specimen, and the particle size ratio is 1.66 [30]. After several trial calculations, L/R min was chosen to be 125, the minimum particle radius is 0.4 mm, and the number of particles was 4,943, which was a good fit. Based on the elastic modulus, peak strength, and peak strain of the marble rock sample, the mesoscopic parameters of the numerical model are repeatedly adjusted, and the final parameters are shown in Table 1.

Micro-mechanical parameters of numerical model

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Density (kg·m−3) | 2,700 | Radius multiplier | 1.0 |

| Particle size ratio | 1.66 | Parallel bond modulus (GPa) | 25.0 |

| Minimum particle size (mm) | 0.4 | Parallel bond stiffness ratio | 3.5 |

| Particle contact modulus (GPa) | 23.0 | Parallel bond normal strength (MPa) | 75.0 |

| Particle contact stiffness ratio | 3.5 | Parallel bond shear strength (MPa) | 63.0 |

| Friction coefficient | 0.4 | — | — |

2.2 Microscopic parameter verification

Numerical triaxial compression tests were carried out on the numerical models using DEM under three confining pressures (5, 10, and 15 MPa) to investigate the reasonableness of the mesoscopic parameters.

Figure 1 shows the stress–strain curves of conventional triaxial compression laboratory tests under different confining pressures (5, 10, and 15 MPa).

Stress–strain curves in conventional triaxial compression tests.

Figure 2 shows the comparison of stress–strain curves in the laboratory test and numerical test. As seen in Figure 2, the trends of stress–strain curves are similar for the two tests under different confining pressures.

Stress strain curves. (a) Stress and axial strain curves and (b) stress and volume strain curves.

The macro mechanical parameters obtained from the laboratory tests and numerical tests under different confining pressures (5, 10, and 15 MPa) are shown in Table 2. From Table 2, it can be seen that the mechanical parameters obtained from both tests are similar.

Mechanical parameters of marble and numerical model

| Confining pressure (MPa) | Peak stress (MPa) | Peak strain (%) | Elastic modulus (GPa) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Laboratory test | Numerical test | Relative error (%) | Laboratory test | Numerical test | Relative error (%) | Laboratory test | Numerical test | Relative error (%) | |

| 5 | 163.06 | 160.08 | 1.83 | 0.491 | 0.441 | 10.18 | 41.28 | 36.63 | 11.26 |

| 10 | 170.54 | 166.28 | 2.50 | 0.536 | 0.468 | 12.69 | 42.33 | 37.33 | 11.81 |

| 15 | 178.73 | 175.40 | 1.86 | 0.573 | 0.505 | 11.87 | 44.31 | 38.09 | 14.04 |

Figure 3 shows the crack distribution of the marble under different confining pressures (5, 10, and 15 MPa) when the failure occurred in the laboratory and numerical simulation tests. It can be seen from Figure 3 that the final fracture surface morphology of both is a single fracture surface with diagonal, and the failure shape of marble is of shear failure. The width of the fracture zone increases with the confining pressure without obvious other fractures. Comparing stress–strain curves, macro-mechanical parameters, and damage forms of specimens in two tests shows that the mesoscopic parameters well reflect the macro-mechanical properties of marble.

Failure characteristics. (a) 5 MPa, (b) 10 MPa, and (c) 15 MPa.

2.3 Triaxial compression numerical test under different loading rates

The loading rate is set to a low and stable value during the loading process to ensure that the specimen remains in quasi-static equilibrium throughout the test. The DEM model is in a dynamic mode controlled by Newton’s second law, and the time step in each calculation cycle is a minimal value [31]. Loading is achieved by controlling the wall to move at a constant rate in opposite directions. Since the loading rate recommended in the PFC2D manual for the triaxial compression test is 0.02 m·s−1, the loading rate selected for the parameter calibration is 0.02 m·s−1. Apply lateral pressure and axial pressure to predetermined confining pressure at a loading speed of 0.02 m·s−1. The confining pressure remains constant during the test. Converting the time step to the loading plate movement speed, it takes more than 100,000 steps to move the plate by 1 mm at 0.2 m·s−1 loading rate, which satisfies the static loading requirement [32]. Based on the completion of the calibration, the loading rate interval of the indoor test was used as a reference and the numerical simulations with loading rates of 0.005, 0.01, 0.05, 0.1, 0.3, and 0.5 m·s−1 were designed to analyze the effect of loading rate on rock deformation and damage [33,34].

3 Numerical simulation tests under different loading rates

3.1 Effect of loading rate on the stress–strain curve

The stress–strain curves for the six loading rates under triaxial compression conditions under confining pressures of 5, 10, and 15 MPa are shown in Figure 4.

Stress–strain curves for different loading rates. (a) 5 MPa, (b) 10 MPa, and (c) 15 MPa.

As shown in Figure 4, the numerical model under different loading rates has no compaction stage, and the stress–strain curve is divided into the elastic phase, plastic stage, and failure stage. The loading rate still affects the stress–strain curve. When the loading rate is lower than 0.1 m·s−1, the stress–strain curve reaches its peak and then falls off rapidly, and the brittle characteristics of the rock sample occur. As the loading rate increases, the stress-strain decreases slowly in the post-peak phase, indicating that the ductile damage characteristics of the specimen become more pronounced at higher loading rates, which is consistent with the findings of Liu et al. [35].

The peak strength and strain of marble increased with the increase in loading rate under the same confining pressure. When the confining pressure varies from 5 to 15 MPa, the effect of loading rate on the peak strength of marble increases with the increase in confining pressure. When the loading rate increased from 0.005 to 0.5 m·s−1 under 5 MPa confining pressure, the peak strength increased from 159.6 to 171.2 MPa accordingly, and the increase was 7.30%. The peak strength of marble increased from 174.5 to 191.1 MPa when the rate was increased from 0.005 to 0.5 m·s−1 at 15 MPa, and the increase in peak strength was 9.52%.

3.2 Effect of loading rate on strength parameters

In geotechnical engineering, the Mohr–Coulomb strength criterion can characterize the “ultimate equilibrium condition” between the stresses at the time of imminent damage and determine whether the rock will be damaged under the current stress state. According to the Mohr–Coulomb strength criterion, the cohesion and the angle of internal friction are obtained. The relationship between the values of the strength parameters and the loading rate is shown in Figure 5. From Figure 5, it can be seen that the cohesion and internal friction angle are linearly related to the loading rate when the loading rate ranges from 0.005 to 0.5 m·s−1. The cohesion and internal friction rise of the marble increase with the increase in the loading rate. The correlation coefficients of cohesion and internal friction angle with the loading rate were 0.996 and 0.971, respectively, indicating that the two strength parameters were highly correlated with the loading rate. The strength parameters change significantly under high loading rate, which indicates that the rock samples are highly fragmented under high loading rate and the frictional effect between the particles is obvious.

Relationship between strength parameters and loading rates.

3.3 Effect of loading rate on characteristic stress

The compressive damage process of the rock is divided into stages. The three steps of the stress–strain curve correspond to the characteristic stresses of initiation stress, damage stress, and peak stress. According to the research results of Zhu et al. [36,37,38], the stress value corresponding to the first appearance of microcrack in PFC was selected as the initiation stress. The inflection point of the volume strain curve and the peak point of the stress–strain curve was taken as the damage stress and peak stress. Take the loading rate of 0.005 m·s−1 under 10 MPa confining pressure as an example, as shown in Figure 6. Among them, the volumetric strain is calculated as follows:

where ε 1 is the circumferential strain and ε 2 is the axial strain.

Stress–strain curve of the specimen at a loading rate of 0.005 m·s−1.

Figure 7 shows the analysis of the characteristic stress of marble under different confining pressures (5, 10, and 15 MPa) about the loading rate. From Figure 7, it can be seen that the characteristic stress of marble gradually increases with the increase in loading rate, and there is an apparent positive correlation between the characteristic stress and the loading rate. Under the same confining pressure, the growth rate of the peak strength increases faster with the speed increase when the rate range is 0.005–0.5 m·s−1. The loading rate has the most significant effect on peak strength compared to initiation stress and damage stress. The correlation between the loading rate and the peak strength was higher than 0.99 for different confining pressures, consistent with the findings of Zheng et al. [39]. When the confining pressure increases, the expansion of marble at the same loading rate requires higher stress. The overall initiation and damage stress level is increased accordingly, and the growth is more significant at lower rates. When the loading rate was 0.005 m·s−1, the rise of initiation and damage stress was 4.76 and 23.48%, and the increase was reduced to 2.94 and 11.14%, respectively, when the loading rate was 0.5 m·s−1. Confining pressure has a suppression effect on the specimen’s deformation. The effect of confining pressure on the peak stress is more significant at a high-speed rate. The peak stress increase is 6.66% when the loading rate is at the interval minimum (0.005 m·s−1) and 11.60% at the interval maximum loading rate (0.5 m·s−1) by increasing the confining pressure.

Relationship between characteristic stress and loading rates. (a) 5 MPa, (b) 10 MPa, and (c) 15 MPa.

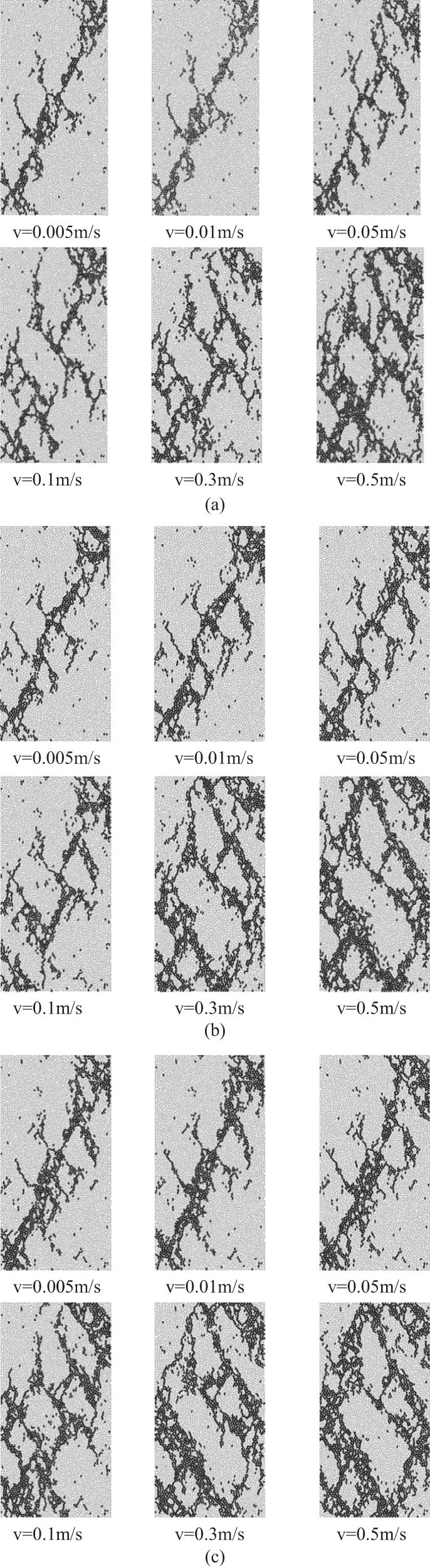

3.4 Effect of loading rate on crack development

The final damage pattern of the specimens under different confining pressures and loading rates in the numerical simulation test is shown in Figure 8. As seen from Figure 8, when the loading rate takes the value interval from 0.005 to 0.05 m·s−1, the diagonal oblique cracks are produced on the surface of the marble when it is damaged, and the damage form is a shear failure. With the increase in the loading rate of 0.1–0.5 m·s−1, the internal microcracks of marble changed from being concentrated on both sides of the diagonal cracks to uniformly distributed inside the rock sample, and more cracks appeared at the top and bottom of the specimen as well. The fragmentation degree of rock samples at high loading rates was significantly higher than that at other low loading rates [40]. Shear failure along the diagonal no longer occurred in rock samples [41]. The form of destruction appeared significantly different from that at low rates, which is consistent with the conclusion of the relevant study by Li et al. [27,42].

Failure characteristics. (a) 5 MPa, (b) 10 MPa, and (c) 15 MPa.

The number of cracks throughout the loading was recorded by compiling the FISH code to obtain the variation in the number of cracks with axial strain in the numerical test of triaxial compression of marble. The curves of the number of cracks vs strain inside the marble under different loading rates are shown in Figure 9. From Figure 9, it can be seen that the total number of cracks increases exponentially with the increase in loading rate, and the axial deformation when cracks appear in the rock samples at different rates is approximately the same. In the numerical experiments, monitoring stops when the rock sample breaks. As the loading rate increases, the strength of the rock increases, requiring greater deformation to cause the overall destruction of the rock sample, and therefore the strain at the crack monitoring cutoff is greater. The total number of cracks generated by loading under different confining pressures increases with the increase in the loading rate. This is because at higher loading rates, both compressive strength and axial strain rise. The number of microcracks gradually increases with the increase in the loading rates. At the same time, the surrounding pressure limits the lateral deformation of the rock sample and slows down the accumulation rate of rock damage, so the increase is slowed down accordingly. When the rate was increased from 0.005 to 0.5 m·s−1, the total number of cracks generated by the loading process increased by 122% at a confining pressure of 5 MPa and 30.2% at a confining pressure of 15 MPa.

Micro-crack number evolution curves. (a) 5 MPa, (b) 10 MPa, and (c) 15 MPa.

Figure 10 shows the variation curves of the number of tensile cracks and shear cracks with loading rate under different confining pressures. Considering that the total number of cracks in each numerical test is different, the total number of cracks at the peak point and the total number of cracks at the time of failure are normalized. It can be seen from Figure 10 that with the increase in the confining pressure, the proportion of shear cracks in the specimen increases at different rates. When the confining pressure is high, the microcrack closing pressure increases and the crack propagation is limited. The number of tensile cracks gradually decreases, and the number of shear cracks gradually increases. It can be seen from Figure 10(b) that under the same confining pressure, with the increase in loading rate, the curve fluctuates up and down within a certain range, but it is not obvious, which indicates that the number of normalized tensile cracks and shear cracks on the final failure surface of the specimen under same confining pressure are basically the same.

Normalized change curve of crack number under different confining pressures. (a) At peak stress and (b) at failure.

4 Conclusion

Numerical triaxial compression tests were conducted on marble under different confining pressures based on laboratory tests combined with DEM models. The loading rate effect of hard brittle marble under conventional confining pressure was investigated by monitoring and recording rock specimens’ stress–strain curves, crack numbers, and characteristic stress changes throughout the loading process. The experimental results were compared and verified with the results of existing related studies to obtain the effect of different loading rates on the deformation and damage of hard brittle rocks in triaxial compression tests. By adjusting the excavation rate and supporting reinforcement measures, the threat of engineering hazards caused by excavation can be effectively controlled. The following conclusions are drawn:

1) The transformation from brittle failure to ductile failure occurs in hard brittle marble at different loading rate within the range of 0.005–0.5 m·s−1, and this transformation gradually becomes less evident with increasing confining pressure.

2) A significant linear relationship exists between characteristic stress and loading rate, all positively correlated. The peak strength has the highest positive correlation with the loading rate, and there is a significant enhancement effect of high-speed loading on the rock strength. When the rate level increases from the minimum value (0.005 m·s−1) to the maximum value (0.5 m·s−1) in the interval, with the increase in confining pressure, the increase ratio of peak stress correspondingly increases from 6.66 to 11.60% accordingly. The increase in the confining pressure will weaken the dependence of each characteristic stress on the loading rate.

3) Under the same confining pressure, the faster the loading rate, the later the crack generation, the higher the crack initiation stress, and finally, the damage appears. The increase in the number of cracks was reduced from 122 to 30.2% by increasing the loading rate when the confining pressure was increased from 5 to 15 MPa.

Acknowledgments

The authors thank the National Natural Science Foundation of China (Nos 51609080 and 51708188) and the Hubei Key Research and Development projects (No. 021BAA050). The authors also express sincere gratitude to the editor and reviewers for their valuable comments, which have greatly improved this article.

-

Funding information: This research was granted by the National Natural Science Foundation of China (Nos 51609080 and 51708188) and the Hubei Key Research and Development projects (No. 021BAA050).

-

Author contributions: Yang: conceptualization and methodology; Yin, Cheng, and Hou: validation and investigation; and Zhang: supervision.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data supporting this study’s findings are available from the corresponding author upon reasonable request.

References

[1] Dong, L. L., L. Peng, Y. H. Li, T. S. Zhao, Y. P. Sun, P. W. Xiao, et al. Mechanical response and stability analysis of surrounding rock mass during roof arch excavation of high stress underground powerhouse. Chinese Journal of Rock Mechanics and Engineering, Vol. 42, 2023, pp. 1–14.Search in Google Scholar

[2] Fan, Q. X., Z. L. Wang, H. Wei, L. Peng, H. B. Wang, J. R. Xu, et al. Technological innovations in construction of underground caverns in basaltic rocks at Baihetan Hydropower Station on Jinsha River. Scientia Sinica (Technological), Vol. 51, No. 9, 2021, pp. 1088–1106.10.1360/SST-2021-0053Search in Google Scholar

[3] Li, B., Q. F. Ding, N. W. Xu, Y. F. Lei, Z. P. Zhu, and J. F. Liu. Mechanical response and stability analysis of rock mass in high geostress underground powerhouse caverns subjected to excavation. Journal of Central South University, Vol. 2710, 2020, pp. 2971–2984.10.1007/s11771-020-4522-8Search in Google Scholar

[4] Zhao, J., G. T.Guo, D. P. Xu, X. Huang, C. Hu, Y. L. Xia, et al. Experimental study of deformation and failure characteristics of deeply-buried hard rock under triaxial and cyclic loading and unloading stress paths, Rock and Soil Mechanics, Vol. 41, No. 5, 2020, pp. 1521–1530.Search in Google Scholar

[5] Feng, Z. Z. and Y. X. Shen. Study on precursor identification of rock instability based on surface displacement. Chinese Journal of Rock Mechanics and Engineering, Vol. 40, No. S2, 2021, pp. 3024–3032.Search in Google Scholar

[6] Li, H. Y., X. H. Liu, Y. Zheng, and W. G. Xiao. Analysis of characteristic energy during the progressive failure of deep-buried marble in Jinping. Chinese Journal of Rock Mechanics and Engineering, Vol. 40, No. S2, 2022, pp. 3229–3239.Search in Google Scholar

[7] Ding, X. L., Y. T. Zhang, S. L. Huang, J. J. Chi, C. J. Zhang, and D. X. Deng. Large deformation mechanism of surrounding rock masses of tunnels, prediction method of squeezing large deformation and its application. Chinese Journal of Rock Mechanics and Engineering, Vol. 42, No. 3, 2023, pp. 521–544.Search in Google Scholar

[8] Yang, Y. S., H. Zhou, S. H. Mei, Z. R. Zhang, and J. L. Li. A case study of the excavation damage zone expansion time effect in hard brittle country rock under high geostress: characteristics and mechanism. Rock and Soil Mechanics, Vol. 41, No. 4, 2020, pp. 1357–1365.Search in Google Scholar

[9] Jiang, D. Y., Z. Y. Yang, J. Y. Fan, Z. Z. Li, J. J. Suo, and J. Chen. Experimental study of load rate effect of salt rock during loading and unloading. Rock and Soil Mechanics, Vol. 44, No. 2, 44, 2023, pp. 403–414.Search in Google Scholar

[10] Yang, Y. S., M. Y. Ying, S. P. Cheng, and J. W. Hou. The effect of loading rate of granite under confining pressure based on particle flow simulation. Water Resources and Power, Vol. 40, No. 10, 2022, pp. 170–172.Search in Google Scholar

[11] Liang, Z. Z., X. K. Qian, Y. F. Zhang, and Z. Y. Liao. Numerical simulation of dynamic fracture properties of rocks under different static stress conditions. Journal of Central South University, Vol. 29, No. 2, 2022, pp. 624–644.10.1007/s11771-022-4903-2Search in Google Scholar

[12] Zhou, H., Y. S. Yang, H. B. Xiao, C. Q. Zhang, and Y. P. Fu. Research on loading rate effect of tensile strength property of hard brittle marble-test characteristics and mechanism. Chinese Journal of Rock Mechanics and Engineering, Vol. 32, No. 9, 2013, pp. 1868–1875.Search in Google Scholar

[13] Meng, Q. B., L. J. Han, H. Pu, S. Y. Wen, and H. Li. Experimental on the effect of strain rate and size on the energy accumulation and dissipation of rock. Journal of China Coal Society, Vol. 40, No. 10, 2015, pp. 2386–2398.Search in Google Scholar

[14] Jiang, D. Y., K. N. Xie, X. Jiang, J. Chen, and X. Yuan. Statistical analysis of acoustic emission energy distribution during uniaxial compression of shale. Chinese Journal of Rock Mechanics and Engineering, Vol. 35, No. S2, 2016, pp. 3822–3828.Search in Google Scholar

[15] Qin, T., X. Guo, Y. L. Huang, Z. X. Wu, W. Y. Qi, and H. Wang. Study on macro-meso deformation law and acoustic emission characteristics of granular gangue under different loading rates. Minerals, Vol. 2, No. 11, 2022, pp. 1422–1435.10.3390/min12111422Search in Google Scholar

[16] Zhao, K., X. Yu, Y. Zhou, Q. Wang, J. X. Wang, and J. L. Hao. Energy evolution of brittle granite under different loading rates. International Journal of Rock Mechanics and Mining Sciences, Vol. 132, 2020, id. 104392.10.1016/j.ijrmms.2020.104392Search in Google Scholar

[17] Li, S. G., G. F. Chen, H. Q. Shuang, H. F. Lin, and P. X. Zhao. Experimental study on effect of loading rate and initial damage on energy evolution of sandstone. Journal of Mining & Safety Engineering, Vol. 36, No. 2, 2019, pp. 373–380.Search in Google Scholar

[18] Tian, W. Q., S. Q. Yang, and G. Fang. Particle flow simulation on mechanical behavior of coal specimen under triaxial cyclic loading and unloading. Journal of China Coal Society, Vol. 41, No. 3, 2016, pp. 603–610.Search in Google Scholar

[19] Zhang, Y., Z. Q. Ding, C. Fang, and B. T. Cong. Three-dimensional particle flow simulation on macro-micro mechanical properties of granite under triaxial cyclic loading and unloading. Mining Research and Development, Vol. 39, No. 4, 2019, pp. 52–58.Search in Google Scholar

[20] Shi, C., Q. Zhang, and S. N. Wang. Numerical Simulation Technology and Application with Particle Flow Code (PFC5.0). China Architecture and Building Press, Beijing, 2018.Search in Google Scholar

[21] Cundall, P. A. and O. D. L. Strack. A discrete numerical model for granular assemblies. Géotechnique, Vol. 29, No. 1, 1979, pp. 47–65.10.1680/geot.1979.29.1.47Search in Google Scholar

[22] Francois., N., L. Sibille, F. Donze, and F. Darve. From microscopic to macroscopic second-order work in granular assemblies. Mechanics of Materials, Vol. 39, No. 7, 2007, pp. 664–684.10.1016/j.mechmat.2006.10.003Search in Google Scholar

[23] Guo, J. J. and X. Y. Cheng. Test of Crack Evolution of Coal Samples Under Cyclic Loading and Numerical Simulation. Safety in Coal Mines, Vol. 50, No. 9, 2019, pp. 71–74.Search in Google Scholar

[24] Hong, J. T. and M. Xu. DEM study on the undrained mechanical behavior of gassy sand. Acta Geotechnica, Vol. 15, No. 8, 2020, pp. 2179–2193.10.1007/s11440-019-00910-xSearch in Google Scholar

[25] Kim, E., M. A. Stine, and D. B. M. D. Oliveira. Effects of water content and loading rate on the mechanical properties of Berea sandstone. Journal of the Southern African Institute of Mining and Metallurgy, Vol. 119, No. 12, 2019, pp. 1077–1082.Search in Google Scholar

[26] Zhou, E. K., Z. C. Wang, H. Chen, W. Q. Zhang, and X. B. Wu. Effects of loading rate on macroscopic and mesoscopic mechanical properties of sandstone. Chinese Journal of Underground Space and Engineering, Vol. 16, No. S2, 2020, pp. 647–655.Search in Google Scholar

[27] Zhang, Y. and J. T. Li. Study on fracture characteristics of marble under monotone and cyclic loading. Chinese Journal of Rock Mechanics and Engineering, Vol. 38, No. S2, 2019, pp. 3313–3320.Search in Google Scholar

[28] Sun, C., Y. H. Ao, J. M. Zhang, and S. Wang. Particle flow of meso-fracture characteristics and macro-scale effect of granites. Chinese Journal of Geotechnical Engineering, Vol. 42, No. 9, 2020, pp. 1687–1695.Search in Google Scholar

[29] Liu, J. and J. T. Li. Analysis on meso-damage characteristics of marble under triaxial cyclic loading and unloading based on particle flow simulation. Journal of Central South University (Science and Technology), Vol. 9, No. 11, 2018, pp. 2797–2803.Search in Google Scholar

[30] Hao, B. Q., C. S. Zhang, C. L. Wang, and C. Ren. Study on determination of micro-parameters of rock PFC2D model. Coal Science and Technology, Vol. 50, No. 4, 2022, pp. 132–141.Search in Google Scholar

[31] Cheng, P. Y. Loading rate effect analysis on rock particle flow model under uniaxial compression. Chinese Journal of Underground Space and Engineering, Vol. 14, No. 3, 2018, pp. 635–642.Search in Google Scholar

[32] Cho, N., C. D. Martin, and D. C. Sego. A clumped particle model for rock. International Journal of Rock Mechanics and Mining Sciences, Vol. 44, No. 7, 2007, pp. 997–1010.10.1016/j.ijrmms.2007.02.002Search in Google Scholar

[33] Wang, X. D. and K. Wang. Effect of loading rate on mechanical properties and energy conversion mechanism of granite fracture. Safety in Coal Mines, Vol. 51, No. 4, 2020, pp. 31–35.Search in Google Scholar

[34] Ma, L. J., B. Xue, D. R. Wang, C. Zhou, and S. Y. Luo. Loading rate effect on shear strength and deformation properties of salt rock. Journal of Basic Science and Engineering, Vol. 30, No. 4, 2022, pp. 1039–1047.Search in Google Scholar

[35] Liu, X. H., Y. Zheng, Q. J. Hao, X. Gui, and Y. Xue. Brittleness characteristics of quasi-static triaxial coal rock based on characteristic stress. Chinese Journal of Rock Mechanics and Engineering, Vol. 40, No. 12, 2021, pp. 2454–2465.Search in Google Scholar

[36] Zhu, J., J. H. Deng, Y. M. Huang, T. Liu, and Y. J. Ma. Study of loading rate effect on characteristic stresses of marble. Journal of Harbin Institute of Technology, Vol. 52, No. 2, 2020, pp. 75–81.Search in Google Scholar

[37] Liu, X. H., X. Gui, J. Yu, Q. J. Hao, and X. P. Zhao. Dilatancy characteristics and crack evolution of deep-buried marble under unloading confining pressure. Chinese Journal of Underground Space and Engineering, Vol. 18, No. 6, 2022, pp. 1922–1932.Search in Google Scholar

[38] Hou, Z. Q., Y. Wang, D. Q. Liu, and C. H. Li. Investigation of the anisotropic mechanical behaviors and energy evolution of interbedded marble. Journal of Mining & Safety Engineering, Vol. 36, No. 4, 2019, pp. 794–804.Search in Google Scholar

[39] Zheng, H. H., Z. Q. Ma, L. Zou, D. Y. Zhang, and X. C. Liu. Effect of loading rate and confining pressure on strength and energy characteristics of mudstone under pre-cracking damage. Energies, Vol. 15, No. 10, 2022, pp. 1–15.10.3390/en15103545Search in Google Scholar

[40] Yin, X. T., X. R. Ge, C. G. Li, and S. L. Wang. influences of loading rates on mechanical behaviors of rock materials. Chinese Journal of Rock Mechanics and Engineering, Vol. 29, No. S1, 2010, pp. 2610–2615.Search in Google Scholar

[41] Yu, L. Q., Q. L. Yao, Q. Xu, W. N. Wang, Z. J. Niu, and W. D. Liu. Experimental and numerical simulation study on crack propagation of fractured fine sandstone under the influence of loading rate. Journal of China Coal Society, Vol. 4611, 2021, pp. 3488–3501.Search in Google Scholar

[42] Li L. F., H. L. Deng, X. H., Zhang, and L. P. Han. Experimental study on the effect of loading rate on triaxial mechanical properties of real-time high temperature granite. Science Technology and Engineering. Vol. 20, No. 16, 2020, pp. 6397–6403.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants