Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

Abstract

The aim of this study is to investigate the effect of alkaline treatment and addition of microcrystalline cellulose (MCC) on the density, tensile strength, elastic modulus, impact strength, and Poisson’s ratio of unsaturated polyester resin composites reinforced by cantala fibers (UPR-CFs). The fibers were immersed in alkaline solution of 6% NaOH for 0, 3, 6, 9, and 12 h. The composite had cantala fibers (CFs) and MCC volume fraction (v f) of 30 and 5%, respectively. The results showed that the alkaline treatment for 6 h resulted in the highest density, tensile strength, and elastic modulus of the composites, while the highest Poisson’s ratio was achieved in UPR-untreated CF composites. The addition of MCC filler also increased the density, tensile strength, and elastic modulus of the composite significantly. Both alkaline treatment and MCC addition did not significantly affect the impact strength. With the increase in the strength and modulus of elasticity, composites can be applied more widely to structures that bear higher loads.

1 Introduction

The rapid development of science and technology has also increased the need for new materials, one of which is composite material. Composite is a material that consists of at least two components, namely, matrix and reinforcement, which has advantages such as light weight, good mechanical properties, durability, heat resistance, corrosion resistance, easy fabrication, and relatively low production costs [1]. Now composites are widely used in the industrial world, for example in the car, aircraft, and construction industries [2]. Increasing problems of environmental pollution, waste and the greenhouse effect have encouraged the industry to use environmentally friendly and renewable composite materials in producing products [3], namely, biocomposite. It is a composite material in which at least one component comes from nature, usually consisting of a polymer matrix with natural fibers as reinforcement and/or filler, such as flax, hemp, agave, kenaf, jute, and sisal [4]. There was also utilization of coconut fibers in ceramic matrixed composite, such as concrete roads due to their higher toughness compared to other natural fibers and cheaper cost. The application of natural fibers reduced the thickness of concrete roads and lowered the use of more expensive materials [5]. The previous study also indicated that the addition of 2% coconut fibers enhanced the overall properties of concrete having silica-fume and super plasticizer content of 15 and 1%, respectively [6]. The addition of 50 mm length coconut fibers of 2% into the concrete containing 10% fly ash and 15% silica-fume showed higher overall properties than those without coconut fibers [7].

Natural fibers are fibers produced from plants, animals, or minerals [8], which have advantages over synthetic fibers, such as being abundant in nature, lightweight, non-corrosive, low density, good thermal properties, inexpensive, environmentally friendly, and renewable [9]. The most abundant natural fibers on earth are plant or vegetable fibers [10]. One of the plant fibers that can be implemented in biocomposites is agave fiber [11], where the agave plant species that is easily found in Indonesia is an Agave cantala. An Agave cantala plant has some characteristics. The color of its leaves is bluish-gray and their edges are slightly thorny, which through the extraction process will produce cantala fibers (CFs) that are strong and hard. Based on research results from the Industrial Research and Development Agency of the Yogyakarta Department of Industry, a CF has a cellulose content of around 64.23%, making it a potential reinforcing component in composite materials.

Some polymer matrices often used in natural fiber reinforced composites can be classified as thermoplastic and thermoset polymers [12]. Most thermoplastic polymers have non-polar properties, such as PE, PP, and PVC, while thermosets have polar properties, such as unsaturated polyester resins (UPR), epoxy, and phenol [13]. UPR is a synthetic resin with straight chains resulting from the reaction of glycol with difunctional acids, such as maleic acid and adipic acid. This resin has high mechanical properties, heat and chemical resistance, low price, and easy fabrication, and has been widely applied in the automotive and construction fields [14].

In natural fibers, the compound that most affects the mechanical properties of the composite is cellulose [15]. Cellulose is a sustainable, abundant, and naturally occurring polymer derived from biomass [16]. One of the problems in composite fabrication is the uneven distribution of natural fiber cellulose. Therefore, the cellulose particles of natural fiber must be reduced in the form of microcrystalline cellulose (MCC) [17]. MCC is pure cellulose isolated from alpha cellulose using mineral acids with the advantages of being renewable, inexpensive, non-toxic, good in mechanical properties, and biocompatible [18]. The addition of MCC increased the tensile and flexural strength and elastic modulus of UPR matrixed composites [19]. The most optimum addition of MCC was obtained by 5%. Therefore, MCC is often added to UPR as matrix for plant fiber composites.

The mechanical properties of a fiber-reinforced polymer composite are greatly influenced by the adhesion bond between their fibers and matrix. Natural fibers have hydrophilic properties that prevent adhesion bonds with hydrophobic polymer matrices. These properties can be improved by chemical treatment of the fiber surface [20], one of which is alkali [21,22]. Alkaline treatment uses a solution of distilled water and NaOH, with a variable concentration and immersion time, which serves to remove hemicellulose and lignin on the surface of natural fibers [22]. Agave americana fibers treated by alkali indicated significant reduction in hemicellulose, lignin, and other impurities [23].

One of the important variables in the alkaline treatment (NaOH) is immersion time because it affects the fiber surface in order to obtain the maximum mechanical properties of the fiber [24]. Asim et al. [25] have investigated the effect of alkaline immersion time on the mechanical properties of pineapple fiber with two variables, namely, 3 and 6% NaOH concentrations and immersion times of 3, 6, 9, and 12 h. The results showed that the highest mechanical properties of pineapple fiber were obtained within 6 h because it can remove hemicellulose and lignin effectively. In addition, the alkaline treatment also increases the surface area and roughness of the pineapple fiber so that it can create a strong adhesive bond with the thermoset or thermoplastic matrix.

The characteristics of the composite are also greatly influenced by the method of composite manufacture. In the last decade, the conventional method often used in industry is the hand lay-up and spray-up due to its easiness and simplicity, but there is one drawback, namely, that there is still a lot of trapped air [26]. One new method that eliminates air ingress is compression molding, using pressure on the top and bottom of the die. The advantages of this method are the small amount of residual material, high precision, environmental friendliness, and reduced air bubbles [27].

CF has the potential to be used as a reinforcement for UPR + MCC matrix composites. However, the effect of alkali treatment time on CF and MCC addition on physical and mechanical properties of unsaturated polyester resin composites reinforced by cantala fibers (UPR-CFs) composite fabricated using a compression molding process has not been investigated yet. This study investigates the properties of materials, including density, tensile strength, elastic modulus, impact strength, and the value of the composite Poisson’s ratio. The fracture morphology of the specimen will be observed using scanning electron microscopy (SEM). By understanding the effect of the duration of the alkali treatment and the addition of MCC to the UPR-CFs composite, the utilization of these composites can be expanded to applications capable of withstanding greater loads, such as furniture, partition panels, building components, and vehicle body parts.

2 Materials and methods

2.1 Materials

CFs were obtained from Agave cantala plants, as shown in Figure 1(a), in Pengasih District, Kulon Progo Regency, Special Province of Yogyakarta, Indonesia. Unsaturated polyester YUKALAC 157-BQTN EX of Ortho-Phthalic type was purchased from PT. Justus Kimiaraya, Semarang, Indonesia, which was used as the matrix. The MEKPO brand catalyst, being a mixture of methyl ethyl ketone peroxide diplasticizer of the phthalate type and having function to speed up the curing process was also obtained from PT. Justus Kimiaraya, Semarang. Aldrich-branded MCC in the form of white powder with a size of 20 μm, and a density of 1.56 g·cm−3, playing a role as an additional reinforcement in polymer composites, was purchased from Sigma-Aldrich PTE. Ltd, Singapore.

(a) Agave cantala plant and (b) CFs.

Distilled water functioned as a solvent for NaOH crystals in the alkaline fiber treatment. NaOH crystals with a content of 99% were purchased from MERCK, Jakarta, Indonesia. Acetic acid, also purchased from MERCK, served to remove alkaline properties and neutralize the pH of CF after alkaline immersion. Wax mirror glaze, purchased from PT. Indus Chemika Suplindo, Tangerang, Indonesia, was used as release agent.

2.2 Method

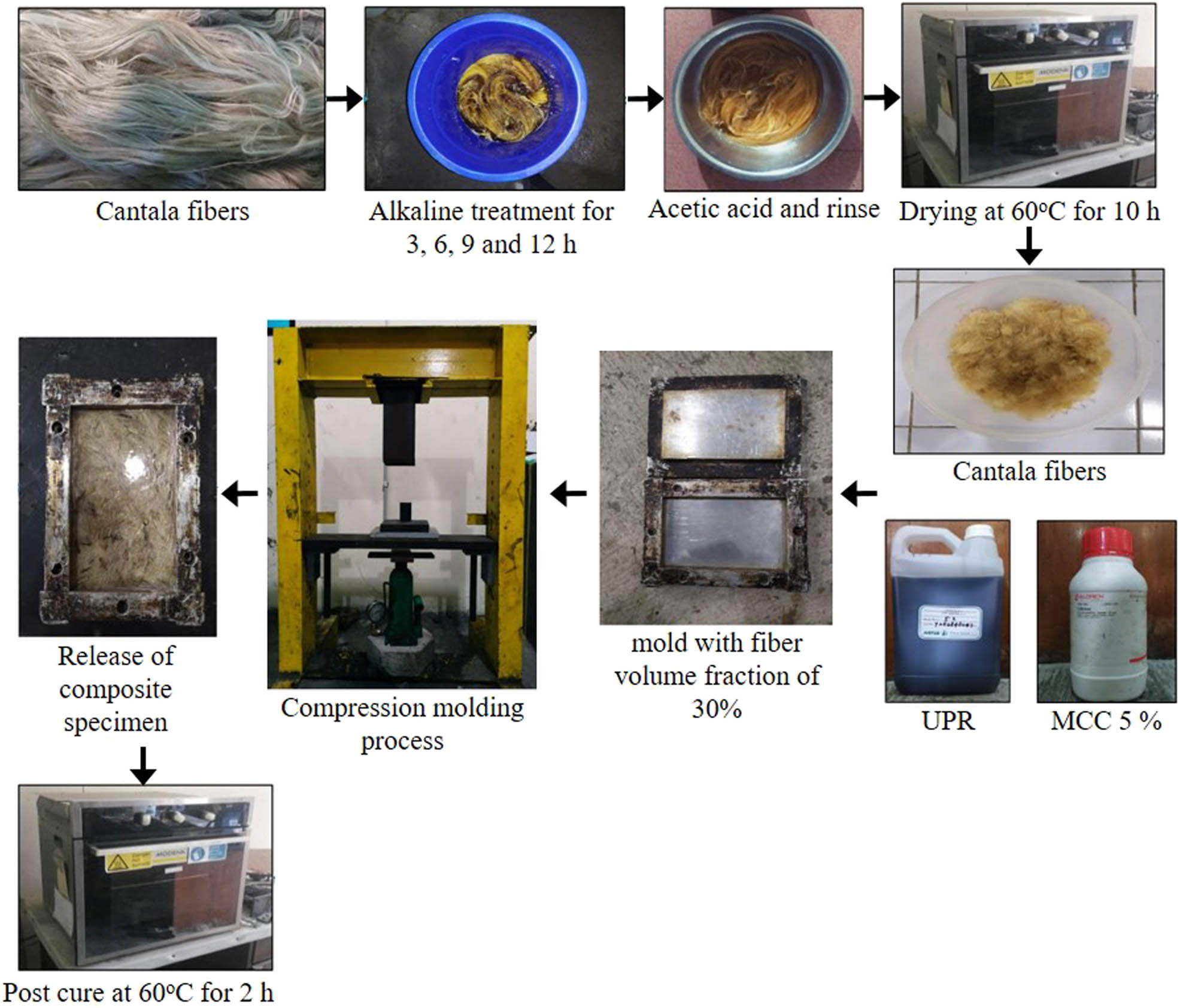

2.2.1 Fiber preparation

The cantala plant was cut by choosing good quality leaves, then the cantala leaf extraction process was carried out to get the fiber, then a drying process is carried out for 1–2 days until the CF dried, as indicated in Figure 1(b). The process of alkaline treatment used NaOH crystals mixed in distilled water, then the fibers were soaked for various times of 3, 6, 9 and 12 h with the composition of CF, distilled water, and NaOH crystals being 500 g, 2.35 L, and 150 g, respectively.

The CF was taken, rinsed, and then soaked in acetic acid with a concentration of 1%, then rinsed with water repeatedly until the pH of the water became neutral. The fibers were allowed to stand at room temperature for 24 h, then heated in an oven at 60oC for 10 h. If it was dry, the next process was to cut the fiber to a size of ±10 mm and put it in a container.

2.2.2 Composite manufacturing process

CFs with 30% volume fraction were put into a mold with a size of 170 mm × 110 mm × 10 mm, which had previously been coated with wax mirror glaze. Then, the matrix consisting of UPR resin, catalyst, and MCC with a volume fraction of 1 and 5%, respectively, was put into the mold until the mixture was evenly distributed. After that pressure was applied at 10 N/mm2 for 12 h at room temperature. The composite was then put into the oven for curing for 2 h at 60oC. Scheme of the fiber preparation and composite manufacturing process are shown in Figure 2. The composites produced, as indicated in Figure 3, were then named as shown in Table 1.

Fiber preparation and composite manufacturing process.

Variation in composite specimens.

Nomenclature of composites

| Symbol of composites | Annotation |

|---|---|

| UPR | UPR matrixed composites without CF |

| UPR + MCC | UPR and MCC (v f = 5%) composites without CFs |

| AL0.MCC | UPR and MCC (v f = 5%) composites with untreated CFs |

| AL3.MCC | UPR and MCC (v f = 5%) composites with alkaline-treated CFs for 3 h |

| AL6.MCC | UPR and MCC (v f = 5%) composites with alkaline-treated CFs for 6 h |

| AL9.MCC | UPR and MCC (v f = 5%) composites with alkaline-treated CFs for 9 h |

| AL12.MCC | UPR and MCC (v f = 5%) composites with alkaline-treated CFs for 12 h |

2.2.3 Density test

Calculation of the actual density of composite materials with ASTM D792 standard is given in Eq. (1) [28].

where ρ, ρ w, m a, and m w represent the density of the composite (kg·m−3), the density of water at room temperature (kg·m−3), the mass of the composite in air (kg), and the mass of the composite in water (kg), respectively. Based on the rule of mixture, the theoretical value of the density of polymer composites can be calculated by Eq. (2) [29].

where ρ c, ρ f, and ρ m represent the density of the composite, fiber, and matrix (kg·m−3), respectively, and v f represents the volume fraction of the fiber.

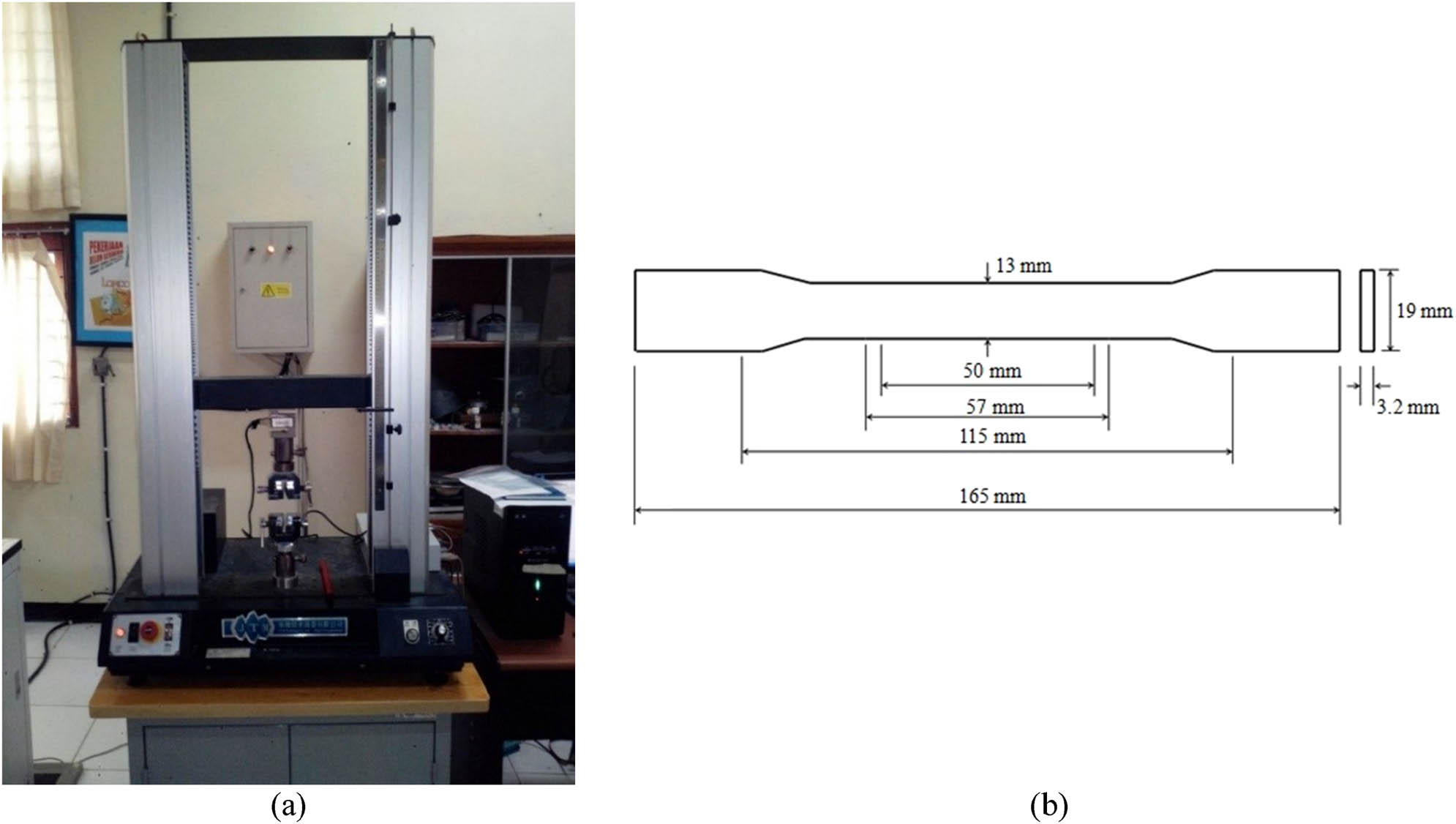

2.2.4 Tensile test

This test was carried out to determine the tensile strength and elastic modulus of the composite, carried out based on ASTM D638 standard using the JTM-UTS510 universal testing machine, made in People’s Republic of China (Figure 4(a)), with an accuracy of 0.5%, crosshead speed of 50 mm·min−1, and load-cell capacity of 500 kg [30]. The specimen dimension is shown in Figure 4(b). As a comparison, micromechanical modeling was carried out using the Hirsch and Manera models to predict the value of tensile strength and elastic modulus, respectively [31], as shown in Eqs. (3) and (4).

where σ c, σ m, and σ f represent the strength of the composite, matrix, and fiber (MPa), respectively. ν m and x represent the volume fraction of the matrix and parameter of short fiber orientation, respectively. E c, E m, and E f represent the elastic modulus of the composite, matrix, and fiber, respectively.

Tensile test of composites: (a) universal testing machine; and (b) specimen of tensile test based on ASTM D638.

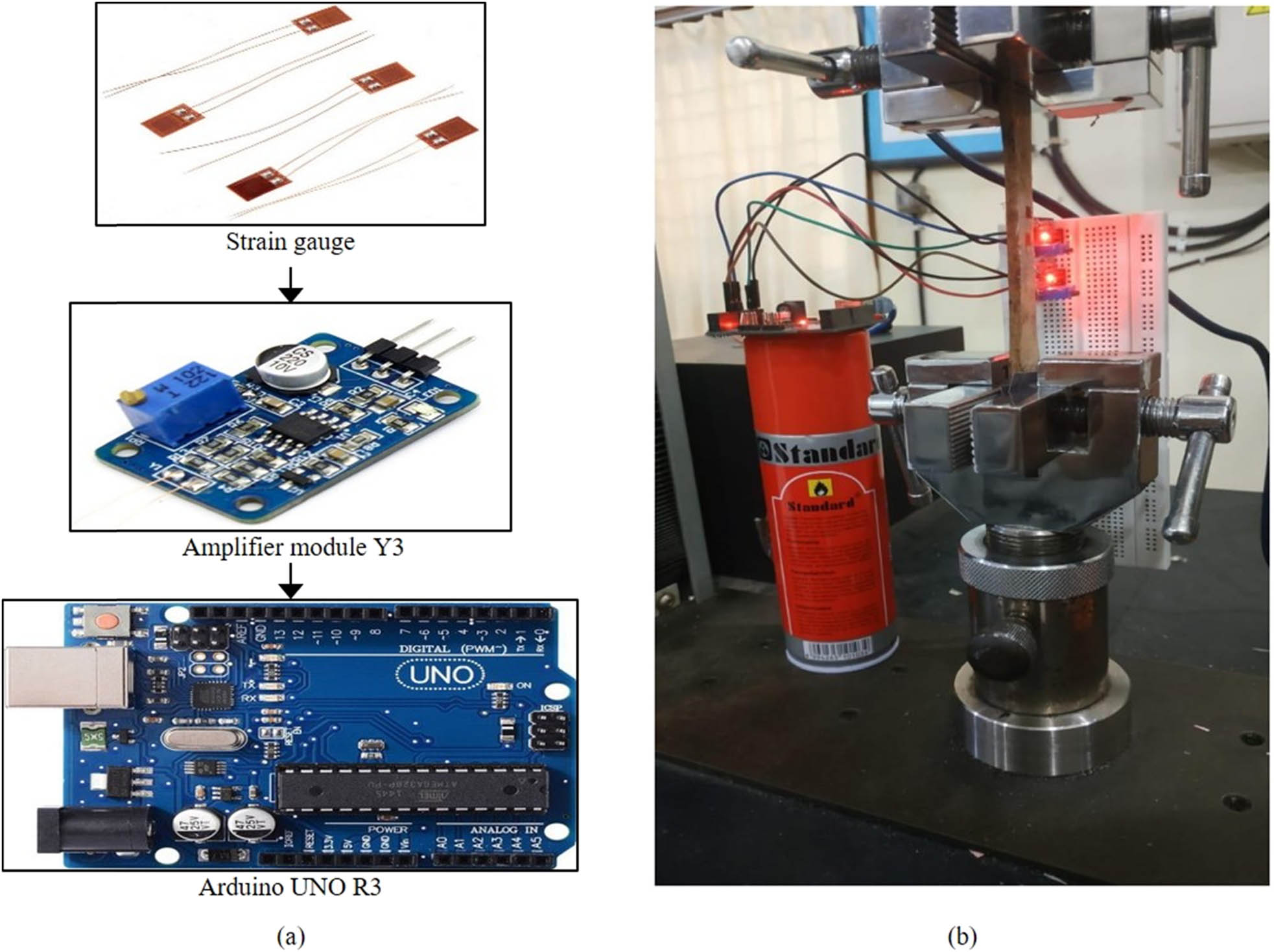

2.2.5 Poisson’s ratio test

The Poisson’s ratio test is carried out to determine the ratio of the lateral and axial deformation strain values which can be determined using Eq. (5) [32], based on ASTM D638 standard.

where ν, ε l, and ε 2 represent the Poisson’s ratio, lateral strain (%), and axial strain (%), respectively. Poisson’s ratio measurement used three devices to obtain data, namely, strain gauge, amplifier, and microcontroller, often referred to as data acquisition, as shown in Figure 5(a) and (b). Microcontroller is a tool used for data acquisition from analog to digital. The Poisson’ ratio results in data acquisition are still in the form of a voltage difference. The conversion from difference in electric stress to strain can be determined as follows:

where ∆E a, ∆E out, and G represent the difference in the output voltage (V), the difference in the input voltage (V), and the amplifier gain, respectively. Meanwhile, the amount of strain can be determined based on Eq. (7).

where GF is the gauge factor.

(a) Scheme of data acquisition for measuring Poisson’ ratio; and (b) measurement of Poisson’ ratio.

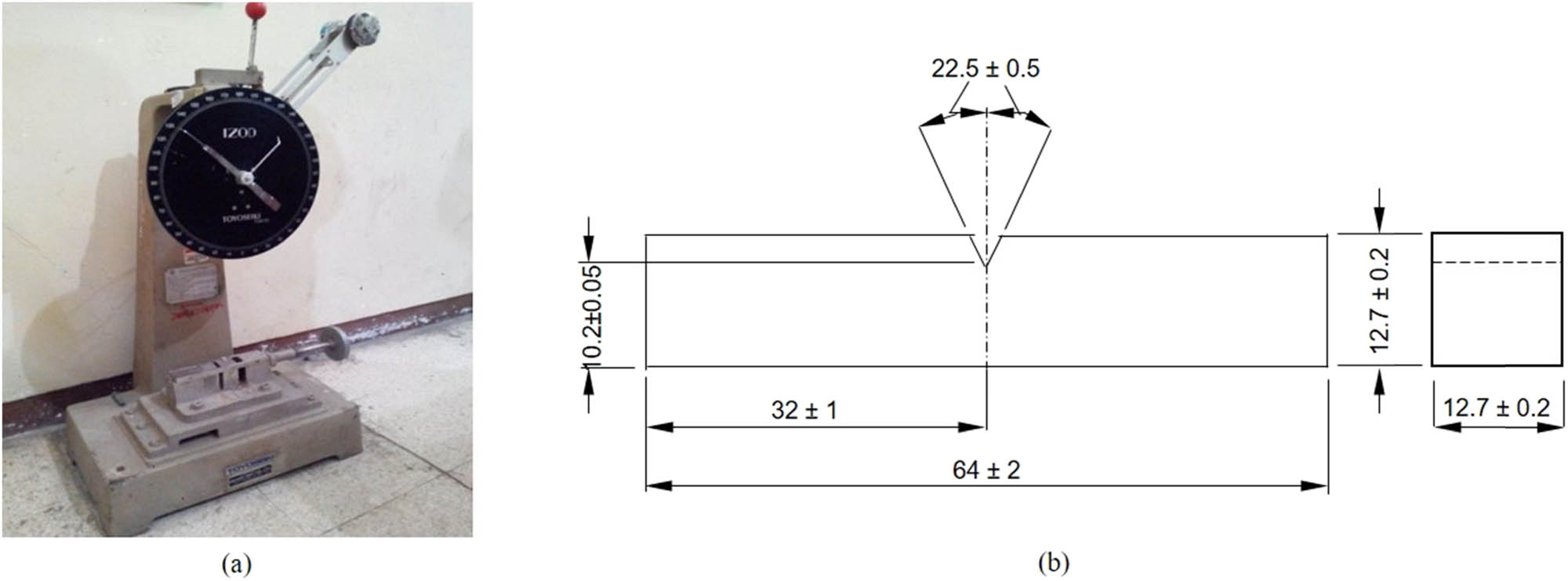

2.2.6 Impact test

The amount of energy absorbed by the material when it receives an impact load was measured by Toyo Seiki impact testing machine, as shown in Figure 6(a), made in Japan, where in the izod method, the specimen was placed standing [33]. In this case, the specimen refers to ASTM D5941, Figure 6(b). The impact strength is calculated from the potential energy of the pendulum before it is released minus the potential energy of the pendulum after it strikes the specimen, as shown in Eq. (8).

where W, w, R, β, and α′ represent the total energy absorbed (J), the weight of the pendulum (N), the distance from the center of mass to the center of rotation of the pendulum (m), the angle of reflection of the swing arm (deg.), and the initial angle of the arm swing (deg.), respectively. The value of the impact strength of the specimen according to the thickness and width of the specimen is shown in Eq. (9).

where α, h, and b represent the value of the impact strength (J·m−2), the thickness of the specimen (m), and the width of the specimen (m), respectively.

Izod impact: (a) testing machine; and (b) specimen dimension based on ASTM D5941.

2.3 Microscopic examination of UPR-CFs composite using SEM

The fracture morphology of UPR-CFs composites after tensile testing were examined using SEM to determine their fracture mechanism. The SEM equipment was FEI type Inspect-F50 (Figure 7), made in USA, with 10 kV voltage. Before examination, the specimens were gold-coated using sputtering machine and then laid on a silver-painted holder. This SEM used low vacuum mode for non-conductive samples.

SEM equipment.

3 Results and discussion

3.1 Density of UPR-CF composites

Figure 8 indicates that the addition of MCC increases the density of UPR + MCC composites by 3.00% than the neat UPR. This is due to the higher density of MCC than that of UPR. The addition of MCC also reduces voids significantly. This case is in accordance with the study on the improvement of mechanical properties due to the addition of MCC to nylon 6 matrixed composites [34].

Theoretical and experimental density of UPR + MCC-CFs as a function of alkaline treatment time.

The effect of time variation in alkali treatment on CF on the theoretical and experimental density value of the UPR-CFs composite is also shown in Figure 8. The maximum density of UPR-CFs with alkaline-treated fibers is higher, 4.88 and 7.19% for both theoretical and experimental results, respectively, than the untreated one. The alkaline treatment partially eliminated the amorphous components of fibers, such as hemicellulose and lignin, so that the percentage of crystalline one, cellulose, was increased. The higher density of the crystalline component of the fibers than the amorphous ones causes an increase in the composite density [35]. The higher increase in experimental results than the theoretical ones is caused by the lower experimental density of the composite with untreated fibers than the theoretical one.

The average theoretical density values of the composites are higher than the experimental ones. This is caused by the assumption of the rule of mixture that there is no porosity in polymer composites [36]. The research results of the influence of time of alkaline treatment on the density value of CFs by Sakuri et al. [37] are used as a reference for the theoretical density value of UPR-CFs composite. Analysis of variance (ANOVA) done on experimental results indicates that the duration of alkaline treatment significantly influences the density of UPR-CFs composite. The highest density of composites due to alkaline treatment is achieved for 6 h alkaline treatment of CFs, for both theoretical and experimental results. Longer treatment leads to a decrease in composite density. It is due to the degradation of crystalline component of a fiber after the amorphous ones. The fiber also undergoes a polymorphic transformation from cellulose I to cellulose II which lead to the decrease in crystalline area of the fiber that in turn causes the decrease in composite density [38].

Cisneros-López et al. [39] investigated the effect of alkali treatment on the density value of CF reinforced linear low-density polyethylene composites. The result is 16.02% smaller than the UPR.MCC-CFs composite, because the addition of MCC increases the spread of cellulose with a wider micron size so that the density of the material will increase and the empty space will decrease. MCC also adds a filler component to the composite so that the density value will increase [35,40].

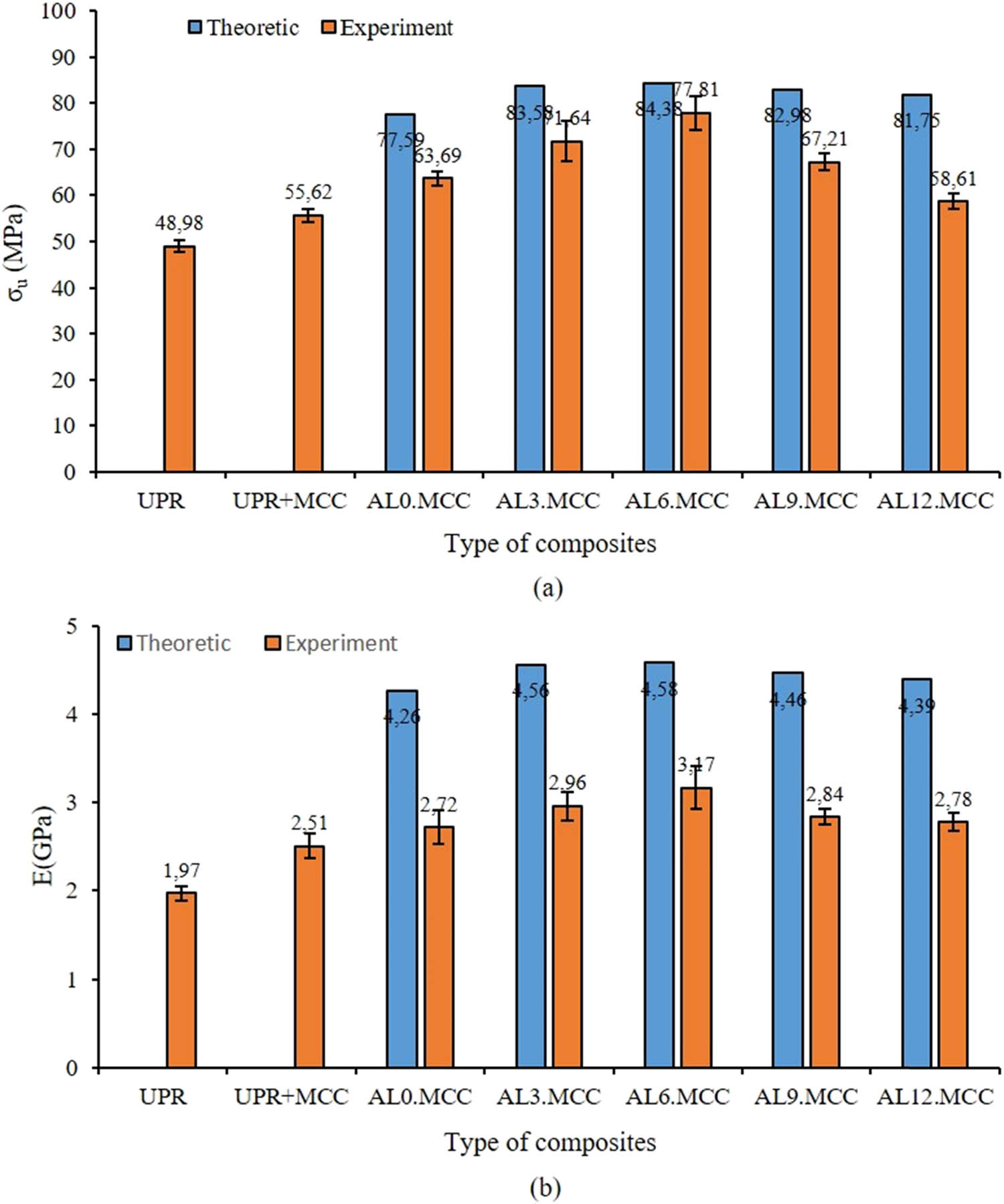

3.2 Tensile strength and elastic modulus of UPR-CF composites

The tensile strength value of the UPR-CFs composite can be seen in Figure 9(a). The theoretical tensile strength of the composite is higher than the experimental one. This is due to the theoretical assumption that the fiber and matrix bond is perfect [36]. The theoretical calculation uses Hirsch’s model because it can accurately predict the tensile strength of composites [31]. Sakuri et al. [17] studied the effect of alkali treatment time on the tensile strength of CFs, which used the micromechanical reference on the tensile strength of UPR-CFs. ANOVA done on experimental results reveals that the duration of alkaline treatment significantly influences the tensile strength of composites.

(a) Tensile strength; and (b) elastic modulus of UPR.MCC-CFs as a function of alkaline treatment time.

Figure 9(a) shows that the tensile strength of the UPR-CFs composite increased with the alkali treatment time. This is due to that the alkaline treatment of fiber can reduce the amorphous compounds, namely, hemicellulose, lignin, pectin, and other dirty substances. Reducing the amorphous area of the fiber increases the surface roughness of the fiber so that the interfacial bond between the fiber and the matrix becomes better [35]. Alkaline treatment of natural fibers also reduces hydrophilic properties in order to provide better interfacial bonds with hydrophobic matrices [41].

The most optimal tensile strength value of the UPR-CFs composite was obtained in the alkaline treatment for 6 h because it isolated cellulose effectively and removed elements such as lignin, hemicellulose, and impurities so that the tensile strength of the composite became better [37]. The maximum increase in the tensile strength due to the alkaline treatment was 8.75 and 22.17% for theoretical and experimental results, respectively. This was due to lower experimental tensile strength of composites with untreated fibers. The decrease in the tensile strength of the composites during the alkaline treatment for 9 and 12 h was caused by the excessive degradation of lignin, hemicellulose, and cellulose elements [42].

The value of the composite tensile strength is also affected by the addition of MCC. In Figure 9(a), it can be seen that the tensile strength of the UPR + MCC composite is 13.57% higher than the neat UPR polymer because MCC is a micron-sized crystalline cellulose material. In addition, the tensile strength of the UPR-CFs composite with alkaline treatment for 6 h was 58.86% higher than the neat UPR caused by micron-sized MCCs which expanded the bond surface, thus increasing the compatibility between UPR and CFs. MCC size also increased the density between materials so that voids in the composite were reduced causing load transfer from matrix to fiber to be better. This was in accordance with the study of Sakuri et al. [37] related to mechanical properties of CFs reinforced UPR subjected to MCC.

Nesimnasi et al. [43] compared the effect of alkali treatment time with a concentration of 5% on the tensile strength of the UPR-CF composite fabricated using the compression molding method but not using MCC, the highest tensile strength of the composite was 36.86 MPa. These results show that the UPR-CFs composite with the addition of MCC has a 52.6% higher tensile strength than without MCC. This is due to the addition of MCC increasing the spread of micron-sized crystalline cellulose, where cellulose is the component that has the highest strength in natural fibers. In addition, the addition of MCC also increases hydrogen bonding so as to improve the tensile strength of the composite [18,34].

The elastic modulus value of the UPR-CF composite with variations in alkali treatment time is shown in Figure 9(b). The theoretical value of the elastic modulus is higher than the experiment because the Manera rule of mixture model uses the assumption of perfect matrix and fiber bonds. The Manera method is a method for predicting the elastic modulus of composites with the condition that the matrix elastic modulus (E m) is between 2 and 4 GPa [31,37].

The experimental elastic modulus obtained was analyzed statistically using ANOVA. It indicated that the time of alkaline treatment significantly influenced the values of elastic modulus. They increased due to the alkaline treatment, but after 6 h, there was a decrease. This was caused by an increase in the tensile strength curve compared to a decrease in the strain curve before 6 h treatment. The alkaline treatment removed hemicellulose, lignin, and other impurities thereby improving the adhesion bond between the fiber and matrix [42].

Alkaline treatment of CF for 9 and 12 h caused a decrease in the value of the elastic modulus. This was due to the prolonged alkaline treatment causing damage to the structure of hemicellulose, lignin, and cellulose in the CFs, thereby reducing the tensile strength of the composite. In addition, the long alkaline treatment increased the strain because the bond between the fiber and the matrix was very strong so that the CFs stretched longer together with the matrix. However, these fibers became brittle so that the load received by the UPR matrix was more dominant. As a result, the composite strain was more dominated by the matrix [44].

The elastic modulus of the UPR composite with the addition of MCC was 27.41% higher than that of neat UPR. This was due the addition of MCC filler increasing the stiffness so that the elastic modulus increased. These results were in accordance with the research of Kiziltas et al. [34], namely, the addition of MCC to the nylon 6 matrix resulted in an increase in the elastic modulus value of the composite. In addition, Mathew et al. [45] conducted the same study using polylactic acid (PLA), with the MCC addition, the elastic modulus was higher than that of neat PLA because the addition of MCC made the composite strain value decrease [46].

The value of the modulus of elasticity in the UPR + MCC-CFs composite was higher than that of UPR-sugarcane waste composite [47]. This happened because the micron-sized MCC increased the wider distribution of reinforcing filler which made the tenacity value of the composite to decrease so that the value of the elastic modulus of the composite increased [34]. The components of cantala and bagasse fiber have almost the same components, i.e., CF contains cellulose, hemicellulose, and lignin, respectively, by 65, 12, and 9.9%, while bagasse fiber contains 55.2, 16. 8, and 25.3%, respectively [48].

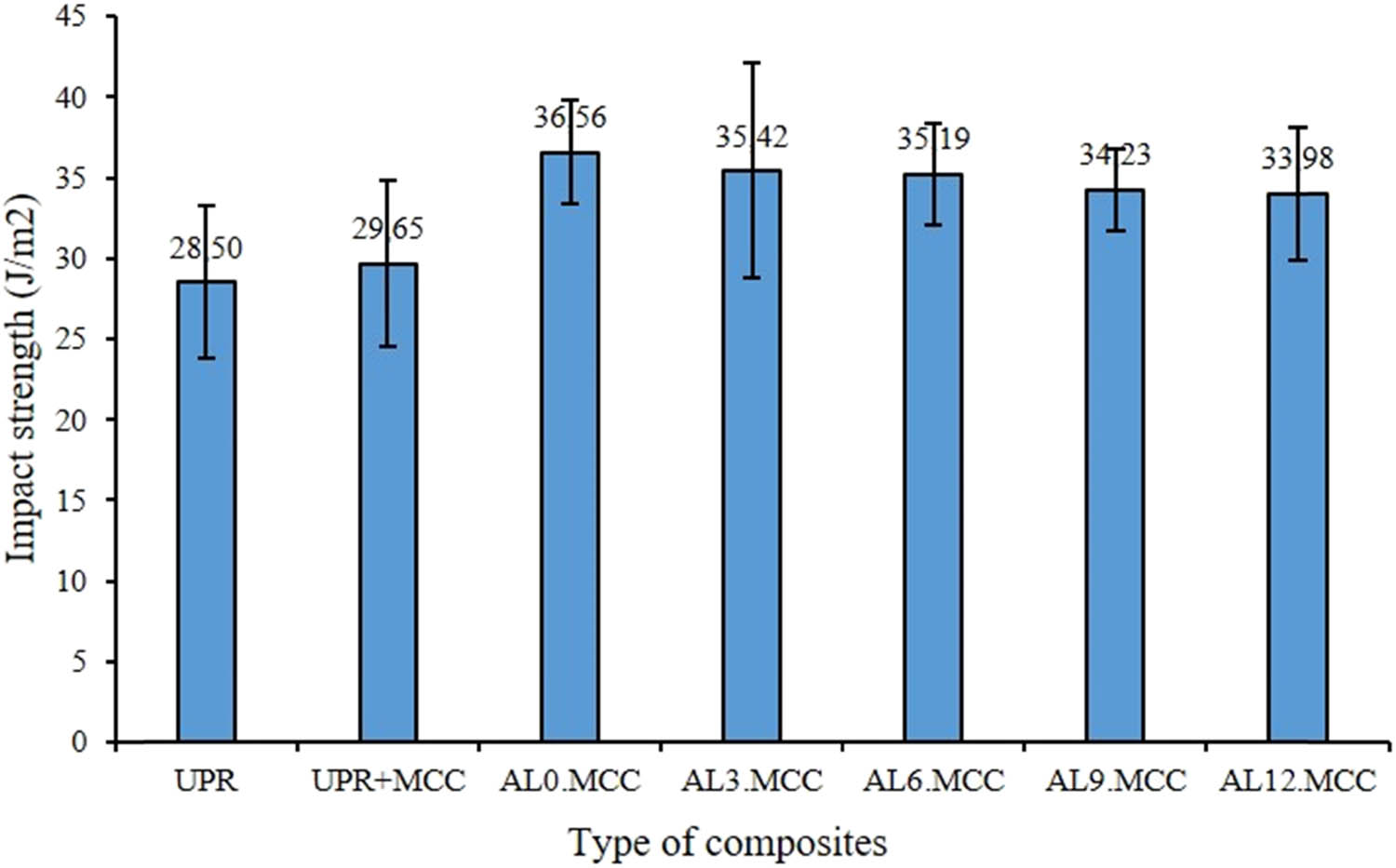

3.3 Impact strength of UPR-CFs composite

The impact strength of the UPR.MCC-CFs composite can be seen in Figure 10. Analysis of variance revealed that the duration of alkaline treatment did not significantly influence the strength of composites. However, the average impact strength achieved its maximum value, 36.56 kJ·m−2, in the composite without alkaline treatment (AL0.MCC). This was due to a poor fiber and matrix interface bonding in the impact fracture which forms an irregular fracture direction which made the composite able to withstand shock loads and absorb more energy. In contrast, UPR-CF composites with alkaline treatment having good fiber–matrix interface bonding produced straight and fast impact fractures because the fiber and matrix withstood loads together resulting in lower impact strength [49]. The highest decrease in impact strength was 7.05% for 12 h of alkaline treatment. These results were in accordance with the existing research, namely, longer alkaline treatment tended to decrease the impact strength of the composites [50].

Impact strength of UPR + MCC-CFs composite as a function of alkaline treatment time.

Previous studies also had proven that the impact strength of the UPR-arena fiber composites decreased with increasing duration of alkaline treatment. This was caused by the loss of the arena fiber structure, namely, lignin, hemicellulose, and cellulose so that the energy absorbed by the composite was reduced which resulted in a decrease in impact strength [50].

The addition of MCC to the UPR-CFs composite increased the impact strength up to 4.02%. This was due to the addition of MCC filler with the right concentration to make MCC dispersion in the UPR perfect without agglomeration so that the load transfer was held together between the matrix and MCC. Neat UPR had an impact strength of 28.50 kJ·m−2, while the impact strength of the UPR + MCC-CFs composite was 29.65 kJ·m−2. However, the addition of MCC with an excess concentration reduced the impact strength because the mobility of the polymer matrix decreased so that it could not disperse MCC completely which resulted in the not-optimal bonds between filler and matrix [34].

The most optimal UPR-CFs composite with the addition of MCC was in a correlation with the study by Rahman et al. [46] who obtained an impact strength of the UPR-arena fiber composite without the addition of MCC of 32.1 kJ·m−2. The increase in impact strength was due to MCC increasing the structure in the form of micron-sized crystalline cellulose so that it can absorb more energy [17].

3.4 Poisson’s ratio value of UPR-CFs composite

The Poisson’s ratio value of the UPR-CFs composite with variations in the alkaline treatment time can be seen in Table 2. It shows that the longer treatment time caused the Poisson’s ratio value of the composites to decrease. This was due to the longer alkaline treatment of the fibers which caused the amorphous areas to disappear so that the composite strain value decreased and the Poisson’s ratio value also declined. The amorphous region is the first region to bear loads before the crystalline region of natural fibers. The UPR-CFs composite with the highest Poisson’s ratio was the fiber composite without alkaline treatment (AL0.MCC) because the fiber still had a lot of amorphous regions so that it could withstand more loads resulting in increased strain values [51,52]. The alkaline treatment for 6 h decreased the Poisson’s ratio of composites by around 2.38% compared to the untreated ones. This minimum Poisson’s ratio was achieved due to the elimination of amorphous components of the fibers, such as hemicellulose and lignin. The dominance of cellulose led to the higher stiffness of the composite causing lower Poisson’s ratio obtained.

Poisson’ ratio of UPR.MCC-CF composite as a function of alkaline treatment time

| Composite specimens |

|

|

Vxy |

|---|---|---|---|

| UPR | 0.0054 | 0.0128 | 0.421 |

| UPR.MCC | 0.0051 | 0.0127 | 0.401 |

| AL0.MCC | 0.0045 | 0.0119 | 0.378 |

| AL3.MCC | 0.0047 | 0.0126 | 0.373 |

| AL6.MCC | 0.0048 | 0.0130 | 0.369 |

| AL9.MCC | 0.0042 | 0.0113 | 0.371 |

| AL12.MCC | 0.0041 | 0.0110 | 0.372 |

The Poisson’s ratio of neat UPR was 4.99% higher than the UPR + MCC composite. This was due to the nature of the MCC material which had high stiffness, making the composites have low strain values in both the lateral (x) and axial (y) directions [34]. In addition, thermoset polymers have strong crosslinks and covalent bonds so that the Poisson’s ratio tends to be high. UPR-natural fiber polymer composites have a lower poison’s ratio than the neat UPR composites due to the addition of fiber filler and many crosslink molecules so that the stiffness properties increase [53,54].

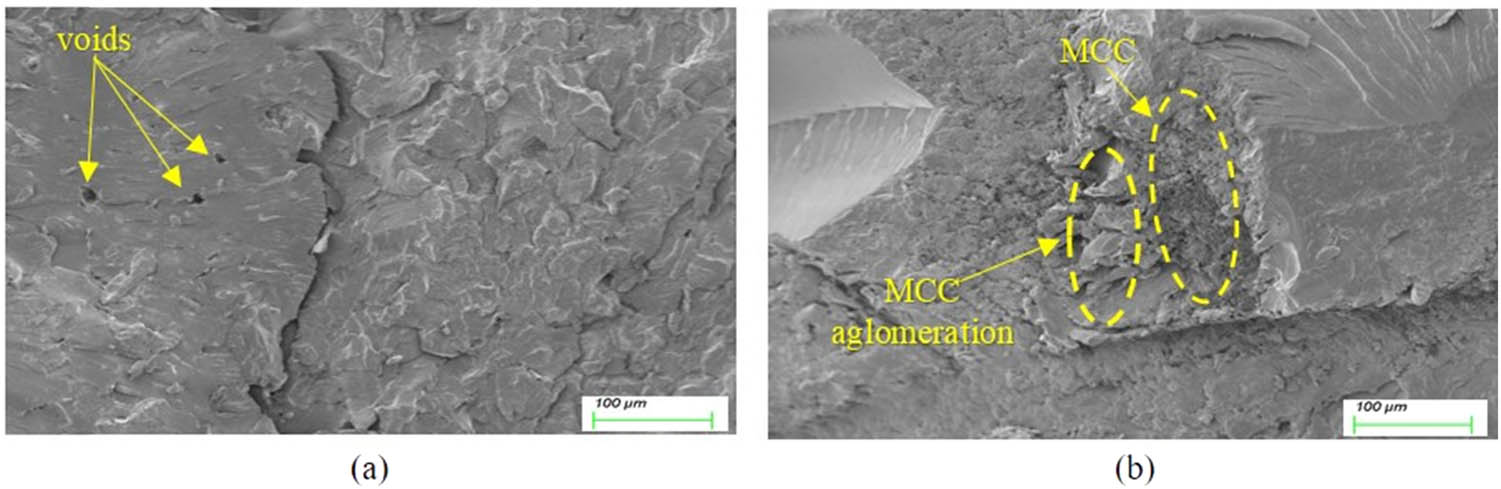

3.5 Microscopic observation of UPR-CFs composite

Microscopic observation of the UPR + MCC-CFs composite was carried out on fractures of the composite tensile test specimen observed using SEM, as shown in Figure 11(a). The cross section shows the quality of the fiber-matrix bond, porosity, fiber breakage, and fiber pullout [52].

SEM image of: (a) neat UPR composite fracture; and (b) UPR + MCC composite fracture.

The fracture of the tensile test specimen on the neat UPR composite, which is shown in Figure 11(a), still has many voids and the shape of the fracture is flat and smooth caused by the absence of fibers so that it cannot withstand excessive loads and indicates high brittle properties. For comparison, Figure 11(b) shows that some of the MCC grains bond well with the UPR matrix so that the tensile strength of the composite increases. The fracture of the UPR + MCC composite occurs because there are still many interfaces between the UPR and MCC matrices so that the bond is not optimal. In addition, the composite fracture also has a little agglomeration caused by the inhomogeneous MCC distribution [34,35,55].

Figure 12(a) shows that in the UPR + MCC-CFs composite without alkaline treatment (AL0.MCC), the fiber surface is still smooth and then there is an interfacial gap and it is dominated by pull-out fiber. The interface was caused by the fiber still containing lignin, hemicellulose, and other impurities, as well as differences in the hydrophilic and hydrophobic properties of the matrix which made the mechanical interlocking between the fiber and the matrix poor so that the composite experienced fiber pull-out [56,57]. Fracture with fiber pull-out on the composite indicates that its strength is lower than the one with fiber breakage [44].

SEM image of UPR + MCC-CFs fracture: (a) without alkali treatment; and (b) with alkaline treatment for 6 h.

Figure 12(b) indicates that in the UPR + MCC-CFs composite with alkaline treatment for 6 h, there are some fiber breakage and little fiber pull-outs. The tight bonds between fibers and matrix in the composite are due to the elimination of hemicellulose and lignin. In addition, alkaline treatment increases the roughness of the fiber so that the bond between natural fibers and the thermoset matrix becomes more optimal when the matrix transfers the load to the fiber so that the tensile strength of the composite becomes higher [56,58].

The results of these microscopic observations were confirmed by Sakuri et al.’s observations regarding the morphology of CFs with variations in the time of alkaline treatment [17]. The result is that fiber without alkaline treatment still has a smooth surface and contains a lot of lignin, hemicellulose, and impurities, while CF with alkaline treatment for 6 h can remove lignin, hemicellulose, and other impurities effectively which makes the surface area of the fiber. The CF gets wider and coarser so it forms a better bond with the matrix.

MCC on the UPR-CFs composite makes the composite surface smoother because of its micron-sized particles. A smooth surface indicates that the material has intermolecular crosslinks. In addition, MCC also reduces voids or porosity so that the strength of the polymer matrix composite increases. The addition of MCC to the composite increases the strength of the composite because the bond between MCC and the matrix is getting better. This is because in MCC there are only crystalline regions, namely, pure cellulose compounds [59,60].

4 Conclusion

From the results and discussion of the research, following conclusions can be drawn:

Theoretically, alkaline treatment of the CFs significantly increased the values of density, tensile strength, and elastic modulus of the CF-reinforced unsaturated polyester composites of 4.88, 8.75, and 7.51%, respectively, but experimentally, it significantly raised them 7.19, 22.17, and 16.50%, respectively. The alkaline treatment decreased the value of Poisson’s ratio by 2.38% and did not change the impact strength of UPR-CFs composite significantly. However, longer treatment reduced the tensile strength and modulus due to the excessive elimination of hemicellulose and lignin, and the degradation of cellulose.

The addition of MCC to the UPR-CF composites significantly increased the values of density, tensile strength, and elastic modulus of 3.00, 13.57, and 27.41%, respectively. It decreased the value of Poisson’s ratio by 4.75% and did not change the impact strength value significantly.

Fracture of composites reinforced with CF without alkali treatment was dominated by fiber pull-out, while composites with alkali treatment indicated a lot of fiber breakage. This indicated that the alkaline treatment enhanced the interfacial strength between unsaturated polyester matrix and CF surface.

The increase in strength and modulus of elasticity due to the alkali treatment and the addition of MCC allows for the widespread use of these composites for structures with higher load bearing.

Acknowledgments

The author expresses his gratitude to the Universitas Sebelas Maret, Surakarta, Indonesia for the financial support of this research.

-

Funding information: This research was funded by the Universitas Sebelas Maret, Surakarta, Indonesia.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request. All data generated or analysed during this study are included in this published article.

References

[1] Rajak, D. K., D. D. Pagar, R. Kumar, and C. I. Pruncu. Recent progress of reinforcement materials: a comprehensive overview of composite materials. Journal of Materials Research Technology, Vol. 8, No. 6, 2019, pp. 6354–6374.10.1016/j.jmrt.2019.09.068Search in Google Scholar

[2] Ku, H., H. Wang, N. Pattarachaiyakoop, and M. Trada. A review on the tensile properties of natural fiber reinforced polymer composites. Composites: Part B, Vol. 42, 2011, pp. 856–873.10.1016/j.compositesb.2011.01.010Search in Google Scholar

[3] Reddy, B. R. and S. H. Dhoria. Effect of alkaline treatment on mechanical properties of kenaf fiber reinforced polyester composites. AIP Conference Proceedings, Vol. 1943, 2018, pp. 1–7.10.1063/1.5029673Search in Google Scholar

[4] Zuccarello, B. and G. Marannano. Random short sisal fiber biocomposites: Optimal manufacturing process and reliable theoretical models. Materials & Design, Vol. 149, 2018, pp. 87–100.10.1016/j.matdes.2018.03.070Search in Google Scholar

[5] Khan, M., A. Rehman, and M. Ali. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Construction and Building Materials, Vol. 244, 2020, pp. 1–12.10.1016/j.conbuildmat.2020.118382Search in Google Scholar

[6] Khan, M. and M. Ali. Effect of super plasticizer on the properties of medium strength concrete prepared with coconut fiber. Construction and Building Materials, Vol. 182, 2018, pp. 703–715.10.1016/j.conbuildmat.2018.06.150Search in Google Scholar

[7] Khan, M. and M. Ali. Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Construction and Building Materials, Vol. 203, 2019, pp. 174–187.10.1016/j.conbuildmat.2019.01.103Search in Google Scholar

[8] Mussig, J. and T. Slootmaker. Types of fibre. In Industrial Applications of Natural Fibres. Structure, Properties and Applications, 1st ed., J. Mussig, Stevens, C., Eds., John Willey & Sons, Ltd., Bremen, Germany, 2010, pp. 41–48.Search in Google Scholar

[9] Geethika, V. N. and V. D. P. Rao. Study of tensile strength of agave americana fibre reinforced hybrid composites. Materials Today: Proceedings, Vol. 4, No. 8, 2017, pp. 7760–7769.10.1016/j.matpr.2017.07.111Search in Google Scholar

[10] Sanjay, M. R., P. Madhu, M. Jawaid, P. Senthamaraikannan, S. Senthil, and S. Pradeep. Characterization and properties of natural fiber polymer composites: A comprehensive review. Journal of Cleaner Production, Vol. 172, 2018, pp. 566–581.10.1016/j.jclepro.2017.10.101Search in Google Scholar

[11] Zuccarello, B., G. Marananno, and A. Mancino. Optimal manufacturing and mechanical characterization of high performance biocomposites reinforced by sisal fibers. Composite Structures, Vol. 194, 2018, pp. 575–583.10.1016/j.compstruct.2018.04.007Search in Google Scholar

[12] Callister, W. D. and D. G. Rethwisch. Materials Science and Engineering: An Introduction, 10th ed., John Wiley & Sons, Inc, New Jersey, 2018.Search in Google Scholar

[13] Mwaikambo, L. Y. and M. P. Ansell. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. Journal of Applied Polymer Science. Vol. 84, No. 12, 2002, pp. 2222–2234.10.1002/app.10460Search in Google Scholar

[14] Gharbi, A., R. B. Hassen, and S. Boufi. Composite materials from unsaturated polyester resin and olive nuts residue: The effect of silane treatment. Industrial Crops and Products, Vol. 62, 2014, pp. 491–498.10.1016/j.indcrop.2014.09.012Search in Google Scholar

[15] Rangappa, S. M., S. Siengchin, J. Parameswaranpillai, M. Jawaid, and T. Ozbakkaloglu. Lignocellulosic fiber reinforced composites: Progress, performance, properties, applications, and future perspectives. Polymer Composites, Vol. 43, No. 2, 2022, pp. 645–691.10.1002/pc.26413Search in Google Scholar

[16] Kian, L. K., M. Jawaid, H. Ariffin, and O. Y. Alothman. Isolation and characterization of microcrystalline cellulose from roselle fibers. International Journal of Biological Macromolecules, Vol. 103, 2017, pp. 931–940.10.1016/j.ijbiomac.2017.05.135Search in Google Scholar PubMed

[17] Sakuri, S., E. Surojo, and D. Ariawan. Thermogravimetry and interfacial characterization of alkaline treated cantala fiber/microcrystalline cellulose-composite. Procedia Structural Integrity, Vol. 27, 2020, pp. 85–92.10.1016/j.prostr.2020.07.012Search in Google Scholar

[18] Trache, D., M. H. Hussin, C. T. Hui Chuin, S. Sabar, M. R. N. Fazita, O. F. A. Taiwo, et al. Microcrystalline cellulose: Isolation, characterization and bio-composites application — A review. International Journal of Biological Macromolecules, Vol. 93, 2016, pp. 789–804.10.1016/j.ijbiomac.2016.09.056Search in Google Scholar PubMed

[19] Sakuri, S., D. Ariawan, and E. Surojo. Mechanical properties of microcrystalline cellulose filled unsaturated polyester blend composite with various treatment. In: AIP Conference Proceedings 2097, 2019, pp. 1–6.10.1063/1.5098240Search in Google Scholar

[20] Shangtong, S., T. Pongprayoon, and N. Yanumet. Mechanical property improvement of unsaturated polyester composite reinforced with admicellar-treated sisal fibers. Composites Part A Applied Science Manufacturing, Vol. 40, No. 6–7, 2009, pp. 687–694.10.1016/j.compositesa.2008.12.004Search in Google Scholar

[21] Goud, G. and R. N. Rao. Effect of fibre content and alkali treatment on mechanical properties of Roystonea regia-reinforced epoxy partially biodegradable composites. Bulletin of Materials Science, Vol. 34, No. 7, 2011, pp. 1575–1581.10.1007/s12034-011-0361-4Search in Google Scholar

[22] Ferreira, D. P., J. Cruz, and R. Faungeiro. Surface modification of natural fibers in polymer composites. In: Green Composites for Automotive Applications, 1st ed., G. Koronis and Silva, A., Eds., Elsevier Ltd, Singapore, 2019, pp. 3–41.10.1016/B978-0-08-102177-4.00001-XSearch in Google Scholar

[23] Madhu, P., M. R. Sanjay, M. Jawaid, S. Siengchin, A. Khan, and C. I. Pruncu. A new study on effect of various chemical treatments on agave americana fiber for composite reinforcement: Physico-chemical, thermal, mechanical and morphological properties. Polymer Testing, Vol. 85, 2020, pp. 1–7.10.1016/j.polymertesting.2020.106437Search in Google Scholar

[24] Raharjo, W. W., H. Sukanto, and M. Anwar. Effect of soaking time in alkali solution on the interfacial shear strength of cantala fiber/recycled HDPE composites. Materials Science Forum, Vol. 827, 2015, pp. 375–380.10.4028/www.scientific.net/MSF.827.375Search in Google Scholar

[25] Asim, M., M. Jawaid, K. Abdan, and M. Nasir. Effect of alkali treatments on physical and mechanical strength of pineapple leaf fibres. In: IOP Conference Series: Materials Science and Engineering, 2018, pp. 1–6.10.1088/1757-899X/290/1/012030Search in Google Scholar

[26] Saputra, A. H. and G. Setyarso. Vacuum infusion equipment design and the influence of reinforcement layers addition to the resin infusion time. In: IOP Conference Series: Materials Science and Engineering, 2016, pp. 1–6.10.1088/1757-899X/162/1/012015Search in Google Scholar

[27] Park, C. H. and W. I. Lee. Compression molding in polymer matrix composites. In Manufacturing Techniques for Polymer Matrix. Composites (PMCs), 1st ed., S.G. Advani and Hsiao, K.T., Eds., Woodhead Publishing Ltd, Singapore, 2012, pp. 47–94.10.1533/9780857096258.1.47Search in Google Scholar

[28] Anonim. ASTM D-792 Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement, ASTM International, West Conshohocken, PA 19428-2959, United States, 1998, pp. 1–5.Search in Google Scholar

[29] Madan, R., S. Bhowmick, and K. N. Saha. Stress and deformation of functionally graded rotating disk based on modified rule of mixture. Materials Today: Proceedings, Vol. 5, No. 9, 2018, pp. 17778–17785.10.1016/j.matpr.2018.06.102Search in Google Scholar

[30] Anonim, A. S. T. M. D 638 Standard Test Method for Tensile Properties of Plastics, ASTM International, West Conshohocken, PA 194282959, United States, 2002, pp. 1–13.Search in Google Scholar

[31] Andre, N. G., D. Ariawan, and Z. A. M. Ishak. Elastic anisotropy of kenaf fibre and micromechanical modeling of nonwoven kenaf fibre/epoxy composites. Journal of Reinforced Plastics and Composites, Vol. 35, No. 19, 2016, pp. 1424–1433.10.1177/0731684416652740Search in Google Scholar

[32] Aili, A., M. Vandamme, J. M. Torrenti, and B. Masson. Theoretical and practical differences between creep and relaxation Poisson’s ratios in linear viscoelasticity. Mechanics of Time-Dependent Materials., Vol. 19, 2015, pp. 537–555.10.1007/s11043-015-9277-5Search in Google Scholar

[33] Anonim, A. S. T. M. D 256 Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics, ASTM International, West Conshohocken, PA 19428-2959, United States, 1998, pp. 1–21.Search in Google Scholar

[34] Kiziltas, A., D. J. Gardner, Y. Han, and H. S. Yang. Mechanical properties of microcrystalline cellulose (MCC) filled engineering thermoplastic composites. Journal of Polymers and the Environment, Vol. 22, 2014, pp. 365–372.10.1007/s10924-014-0676-5Search in Google Scholar

[35] Raharjo, W. W., R. Soenoko, Y. S. Irawan, and A. Suprapto. The influence of chemical treatments on cantala fiber properties and interfacial bonding of cantala fiber/recycled high density polyethylene (rHDPE). Journal of Natural Fibers, Vol. 15, No. 1, 2017, pp. 98–111.10.1080/15440478.2017.1321512Search in Google Scholar

[36] Tham, M. W., M. R. N. Fazita, H. P. S. Abdul Khalil, N. Z. Mahmud Zuhudi, M. Jaafar, S. Rizal, et al. Tensile properties prediction of natural fibre composites using rule of mixtures: A review. Journal of Reinforced Plastics and Composites, Vol. 38, No. 5, 2018, pp. 211–248.10.1177/0731684418813650Search in Google Scholar

[37] Sakuri, S., E. Surojo, D. Ariawan, and A. R. Prabowo. Investigation of agave cantala-based composite fibers as prosthetic socket materials accounting for a variety of alkali and microcrystalline cellulose treatments. Theoretical and Applied Mechanics Letters, Vol. 10, No. 6, 2020, pp. 405–411.10.1016/j.taml.2020.01.052Search in Google Scholar

[38] Wang, X., L. Chang, X. Shi, and L. Wang. Effect of hot-alkali treatment on the structure composition of jute fabrics and mechanical properties of laminated composites. Materials (Basel), Vol. 12, No. 9, 2019, pp. 1–13.10.3390/ma12091386Search in Google Scholar PubMed PubMed Central

[39] Cisneros-López, E. O., J. Anzaldo, F. J. Fuentes-Talavera, R. González-Núñez, J. R. Robledo-Ortíz, and D. Rodrigue. Effect of agave fiber surface treatment on the properties of polyethylene composites produced by dry-blending and compression molding. Polymer Composites, Vol. 38, No. 1, 2017, pp. 96–104.10.1002/pc.23564Search in Google Scholar

[40] Gopanna, A., K. P. Rajan, S. P. Thomas, and M. Chavali. Polyethylene and polypropylene matrix composites for biomedical applications. In: Materials for Biomedical Engineering, Thermoset and Thermoplastic Polymers, 1st ed., V. Grumezescu, and Grumezescu, A.M., Eds., Elsevier Inc, New York, 2019, pp. 175–216.10.1016/B978-0-12-816874-5.00006-2Search in Google Scholar

[41] Li, X., L. G. Tabil, and S. Panigrahi. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. Journal of Polymers and the Environment, Vol. 15, 2007, pp. 25–33.10.1007/s10924-006-0042-3Search in Google Scholar

[42] Diharjo, K. pengaruh perlakuan alkali terhadap sifat tarik bahan komposit serat rami-polyester. Journal Teknik Mesin, Vol. 8, No. 1, 2006, pp. 8–13.Search in Google Scholar

[43] Nesimnasi, J. J. S., K. Boimau, and Y. M. Pell. Pengaruh perlakuan alkali (NaOh) pada serat agave cantala terhadap kekuatan tarik komposit polyester. Lontar Jurnal Teknik Mesin Undana, Vol. 2, No. 1, 2015, pp. 29–38.Search in Google Scholar

[44] Aydın, M., H. Tozlu, S. Kemaloglu, A. Aytac, and G. Ozkoc. Effects of alkali treatment on the properties of short flax fiber–poly(lactic acid) eco-composites. Journal of Polymers and the Environment, Vol. 19, 2011, pp. 11–17.10.1007/s10924-010-0233-9Search in Google Scholar

[45] Mathew, A. P., K. Oksman, and M. Sain. Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). Journal of Applied Polymer Science, Vol. 97, No. 5, 2005, pp. 2014–2025.10.1002/app.21779Search in Google Scholar

[46] Rahman, M. B. N., B. Riyanta, and K. Diharjo. Pengaruh fraksi volume serat dan lama perendaman alkali terhadap kekuatan impak komposit serat aren-polyester. Semesta Teknika, Vol. 14, No. 1, 2011, pp. 26–32.10.18196/st.v14i1.567Search in Google Scholar

[47] Abu-Jdayil, B. Unsaturated polyester microcomposites. In Unsaturated Polyester Resins Fundamentals, Design, Fabrication, and Application, 1st ed., S. Thomas, Chirayil, C.J., and Hosur, M., Eds., Elsevier Inc, Amsterdam, 2019, pp. 67–100.10.1016/B978-0-12-816129-6.00003-XSearch in Google Scholar

[48] Faruk, O., A. K. Bledzki, H. Fink, and M. Sain. Progress in Polymer Science Biocomposites reinforced with natural fibers: 2000–2010. Progress in Polymer Science, Vol. 37, No. 11, 2012, pp. 1552–1596.10.1016/j.progpolymsci.2012.04.003Search in Google Scholar

[49] Ariawan, D., M. S. Salim, R. M. Taib, M. Z. A. Thirmizir, and Z. A. M. Ishak. Durability of alkali and heat-treated kenaf fiber/unsaturated polyester composite fabricated by resin transfer molding under natural weathering exposure. Advanced Polymer Technology, Vol. 37, No. 5, 2018, pp. 1420–1434.10.1002/adv.21801Search in Google Scholar

[50] Bachtiar, D., S. M. Sapuan, and M. M. Hamdan. The influence of alkaline surface fibre treatment on the impact properties of sugar palm fibre-reinforced epoxy composites. Polymer-Plastics Technology and Engineering, Vol. 48, No. 4, 2009, pp. 379–383.10.1080/03602550902725373Search in Google Scholar

[51] Zin, M. H., K. Abdan, N. Mazlan, E. S. Zainudin, and K. E. Liew. The effects of alkali treatment on the mechanical and chemical properties of pineapple leaf fibres (PALF) and adhesion to epoxy resin. IOP Conference Series Materials Science Engineering, Vol. 368, 2018, pp. 1–10.10.1088/1757-899X/368/1/012035Search in Google Scholar

[52] Arpitha, G. R. and B. Yogesha. An overview on mechanical property evaluation of natural fiber reinforced polymers. Materials Today: Proceedings, Vol. 4, No. 2, 2017, pp. 2755–2760.10.1016/j.matpr.2017.02.153Search in Google Scholar

[53] Okoli, O. I. and G. F. Smith. The effect of strain rate and fibre content on the Poisson’s ratio of glass/epoxy composites. Composite Structures, Vol. 48, No. 1–3, 2000, pp. 157–161.10.1016/S0263-8223(99)00089-6Search in Google Scholar

[54] Mahato, K., S. Goswami, and A. Ambarkar. Morphology and mechanical properties of sisal fibre/vinyl ester composites. Fibers and Polymers, Vol. 15, 2014, pp. 1310–1320.10.1007/s12221-014-1310-9Search in Google Scholar

[55] Wong, K. J., S. Zahi, K. O. Low, and C. C. Lim. Fracture characterisation of short bamboo fibre reinforced polyester composites. Materials & Design, Vol. 31, No. 9, 2010, pp. 4147–4154.10.1016/j.matdes.2010.04.029Search in Google Scholar

[56] Ariawan, D., T. S. Rivai, E. Surojo, S. Hidayatulloh, H. I. Akbar, and A. R. Prabowo. Effect of alkali treatment of Salacca Zalacca fiber (SZF) on mechanical properties of HDPE composite reinforced with SZF. Alexandria Engineering Journal, Vol. 59, No. 5, 2020, pp. 3981–3989.10.1016/j.aej.2020.07.005Search in Google Scholar

[57] Cai, M., H. Takagi, A. N. Nakagaito, Y. Li, and G. I. N. Waterhouse. Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Composites Part A: Applied Science and Manufacturing, Vol. 90, 2016, pp. 589–597.10.1016/j.compositesa.2016.08.025Search in Google Scholar

[58] Aziz, S. H. and M. P. Ansell. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: Part 1 - polyester resin matrix. Composites Science and Technology, Vol. 64, No. 9, 2004, pp. 1219–1230.10.1016/j.compscitech.2003.10.001Search in Google Scholar

[59] Alashwal, B. Y., M. S. Bala, A. Gupta, S. Sharma, and P. Mishra. Improved properties of keratin-based bioplastic film blended with microcrystalline cellulose: A comparative analysis. Journal of King Saud Univversity - Science, Vol. 32, No. 1, 2020, pp. 853–857.10.1016/j.jksus.2019.03.006Search in Google Scholar

[60] Rowe R. C., P. Sheskey, and M. Quinn. Handbook of Pharmaceutical Excipients, 6th ed., Pharmaceutical Press, London, UK, 2009.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings