Abstract

Vanadium dioxide (VO2) has attracted extensive attention due to the specific metal-insulator phase transition as well as the wide device applications. The practical performance of VO2-based device strongly depends on the quality of VO2, since the higher quality of VO2 film always shows much more pronounced phase transition behavior. Thus, the preparation of high quality VO2 film is essential and highly desirable. In this work, we have prepared high-quality VO2 film on SiC substrate by water vapor oxidation with graphene (G) buffer layer, which showed excellent phase transformation properties. Compared with the VO2/SiC sample without G buffer layer, the VO2/G/SiC films show the resistance changes up to four-orders of magnitude across the phase transition boundary and superior optoelectronic properties, which indicates the significant role of G layer in the film growth process. The current study not only provides an economical and feasible method for VO2/G/SiC thin film preparation with high quality, but also supply some clues for the application of G-based VO2 devices in the future.

1 Introduction

As a typical correlated oxide material, Vanadium dioxide (VO2) has attracted great interest because of the metal-insulator phase transition (MIT) near 68°C [1,2,3]. This specific MIT behavior of VO2 always showed sharp resistivity change with the 4–5 orders of magnitude and pronounced optical switching effects, which made it promising for a wide range of applications in optical switching devices [4,5], smart windows [6,7], memory devices [8,9], infrared laser protection [10], supercapacitor [11] and lithium storage device [12].

It was known that the practical performance of VO2 based device strongly depends on the quality of VO2, since the excellent single crystal VO2 film always showed pronounced phase transition behavior. Thus, the preparation of high quality VO2 film is essential and highly desirable. Currently, various VO2 film preparation techniques have been developed, including the pulsed laser deposition [13,14], molecular beam epitaxy (MBE) [15,16], magnetron sputtering and other physical deposition technologies. However, these methods often required complex parameter control processes and expensive equipment, which seriously limited their practical applications. Direct thermal oxidation of V film in oxygen atmosphere was a much simpler method. However, due to the polyvalent properties of V atoms, the oxidation of V film was not easy to be controlled for pure VO2 film preparation [17,18]. Thus, during the traditional oxidation process of V film, the film was sensitive to the gas pressure and annealing parameters, which greatly affected the pure VO2 film preparation with high quality. Different from the usual thermal oxidation, the wet oxidation technology was considered as a relatively mild oxidation method, which was able to avoid the peroxidation of the VO2 film [19,20,21]. The water oxidation device was simple and easy to operate, which was suitable for the preparation of high-quality films on large substrates, which lay a foundation for the practical application of the device. More importantly, it was easy to prepare high-quality VO2 film with large size, which was beneficial for the practical applications.

The growth of high-quality VO2 thin film also needed to consider the lattice match between the film and substrate. In fact, the substrate with lattice matching and photoelectric characteristics played an active role in the preparation of high quality VO2 films as well as the practical application of the devices. It was known that graphene (G) layer had attracted a lot of attention because of unique properties. Normally, the G single layer was a semi-metal with Dirac fermions (zero effective mass) as charge carriers, which could produce extraordinary effects, such as mobility up to 200,000 cm2·V−1·S−1 [22], ballistic distances up to one micron at room temperature. If a phase transition VO2 film is combined with G layer, some interesting optical and electrical properties would be integrated for some functional device applications. In fact, the fast adaptive thermal camouflage based on flexible VO2/G/CNT films had been successfully fabricated [23]. The enhanced optical response of VO2 doped into G films was also observed [24]. In addition, VO2 film deposited on G/Ge substrate or SiC substrate was studied to examine the phase transition behavior [25]. However, using G as the buffer layer to prepare high-quality VO2 film on SiC crystal substrate had not been reported.

In this work, homogeneous and pure monoclinic VO2/G/SiC film with excellent MIT performance were prepared by wet oxidation method. The effects of annealing time and Ar flux rate on the properties of VO2 films were systematically investigated. The results showed that the continuous VO2/G/SiC film exhibited resistance changes of nearly four-orders of magnitude. As a mild oxidation method, the current wet oxidation technique inhibited the peroxidation process of V, thus pure VO2 film was obtained. In addition, by using the G as a buffer layer, the quality of the VO2 film was further improved, which showed more pronounced phase transformation properties.

2 Experiment

Single crystal silicon carbide (0001) (6H–SiC) was cleaned by RCA process [26]. The vacuum of the MBE device was kept at 1 × 10−7 Pa. The SiC substrate was first heated to 300°C to eliminate impurities such as water vapor. At the substrate temperature of 300°C, Cu atoms were deposited on SiC substrate in the MBE chamber and the deposition time was 10 min. Then, the samples were annealed at 1,380°C for different times. With the assistance of Cu atoms, the G layers were successfully prepared on SiC substrate.

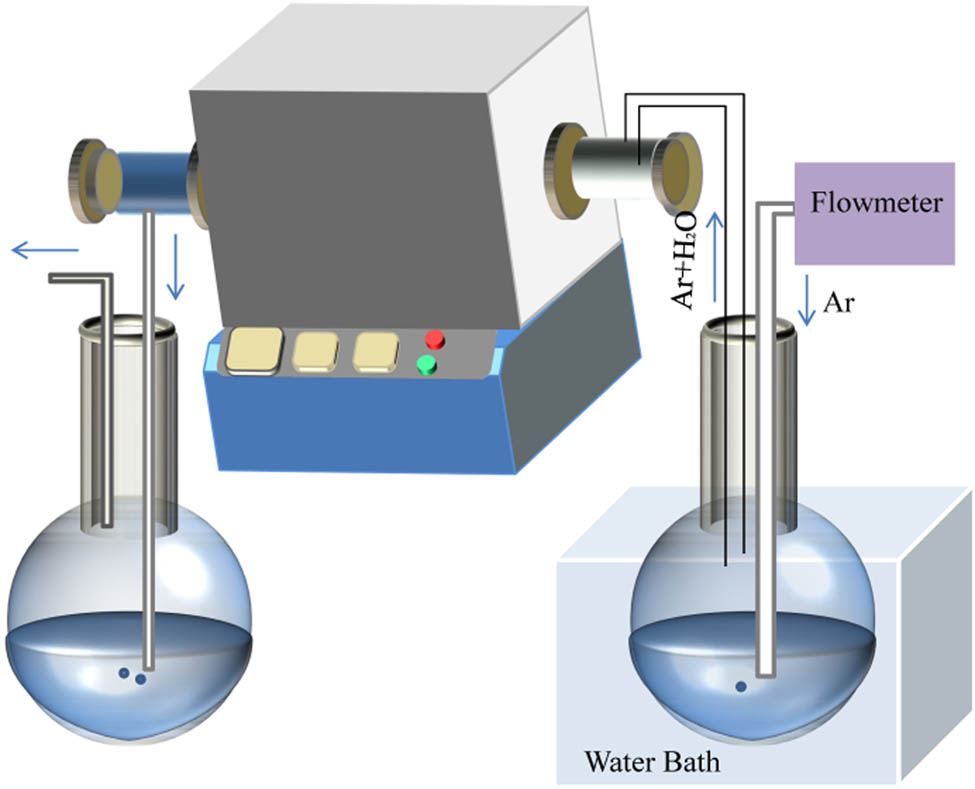

The V element was deposited on G surface at room temperature by sputtering for 30 min in the magnetron sputtering equipment and the deposition rate was about 7 nms·min−1. The V/G/SiC samples were put into the water oxidation system, and the appropriate amount of argon (Ar) gas was introduced to oxidize the prepared metal film at 550°C. Ar as carrier gas was controlled by a mass flow controller and bubbles were generated after piped into the water bath bottle. The flask was placed in a water bath, which was heated to produce steam. The water bath temperature and Ar flow controlled the water vapor content in the furnace. In the water oxidation system, a certain amount of argon was introduced to oxidize the prepared metal films. During the wet oxidation, the water flask half-filled with deionized water was kept in the water bath at a temperature of 79°C. The detailed schematics are described in Figure 1 [27].

Schematic diagram of water vapor assisted oxidation. The tube furnace and flow meter recorded the temperature and flow of Ar gas, Ar and water vapor entered the tube furnace and oxidized V metal film.

The samples were tested by Raman spectrometer (λ = 532 nm), and the surface morphologies were examined by field emission electron microscopy (SU8220, Hitachi, Japan). X-ray photoelectron spectroscopy (XPS, AXIS SUPRA+, Al Kα) was used to analyze the chemical state of the samples. High-resolution X-ray Diffractometer (XRD, Panalytical, the Netherlands) was used to test the crystal structure. Step size and time per step of the XRD measurements were 0.005° and 0.3 s, accordingly. The working voltage of the XRD equipment is 40 kV and the working current is 40 mA. In addition, the phase transition performance of the samples was characterized by using a home-made four-probe test system with a variable temperature sample stage.

3 Results

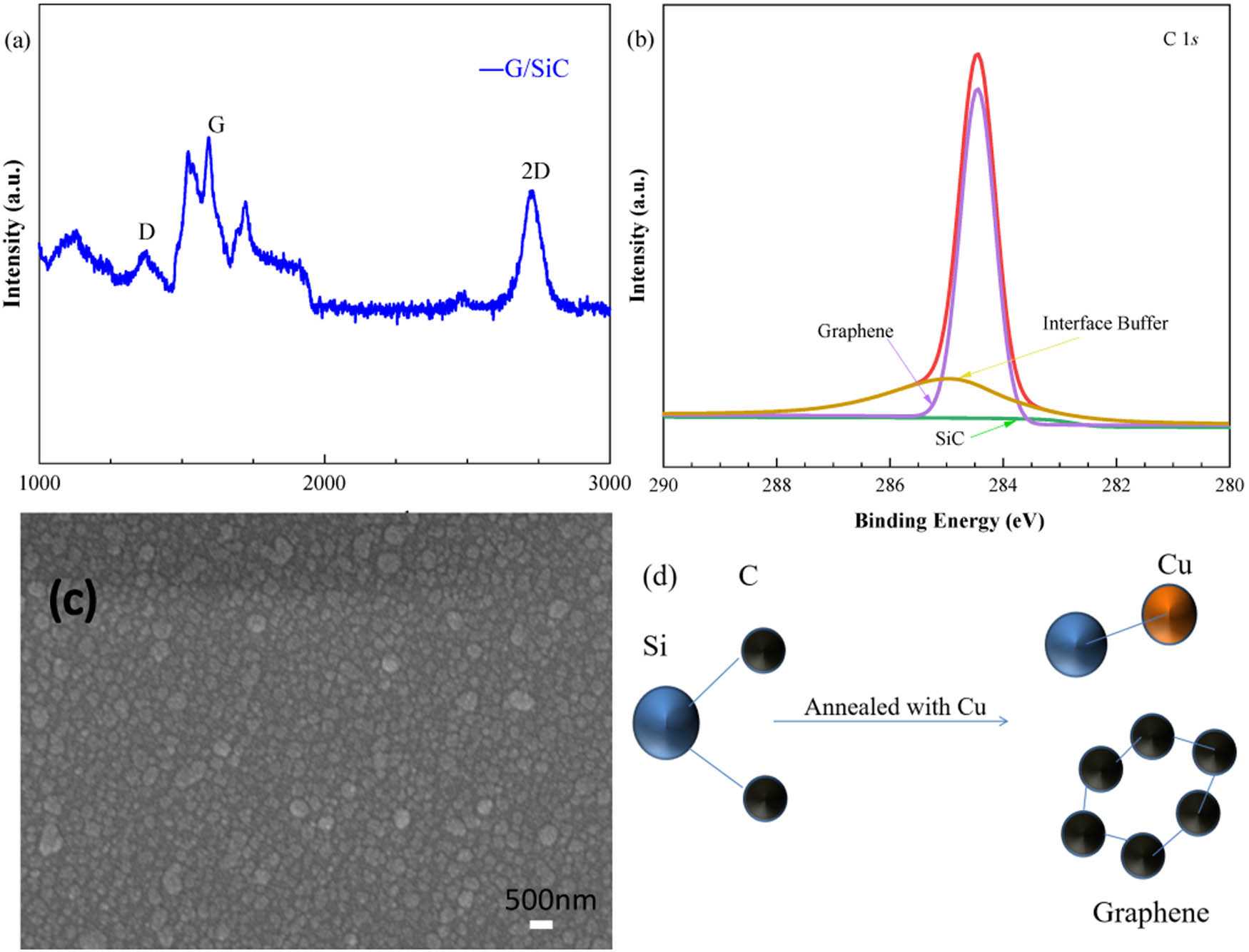

The quality of G greatly affected the crystallinity of VO2. Under the assistance of Cu atoms pre-deposition, the G layers were obtained on the top surface of SiC single crystal substrate. The characterized spectra and schematic illustration diagram of the G sample are shown in Figure 2. From Figures 2(a), D, G and 2D peaks at 1,360, 1,590 [28] and 2,730 cm−1 [29,30] can be observed, respectively. The strong G and 2D peaks proved the existence of high-quality G. The weak D peaks indicated that the G on the SiC surface had fewer defects and better crystal quality. Moreover, the absence of other peaks also implied that only G existed on the surface of SiC. The grain size (La) of G was calculated using the following formula [31]:

(a) Raman spectra of the samples prepared by annealing of SiC after introduction of Cu atoms, (b) the XPS spectra C 1s of the G/SiC samples, (c) surface morphology of the G/SiC as examined by SEM, and (d) schematic illustration of the reaction happened during the deposition. The black, blue and brown spheres represented C, Si and Cu atoms, respectively. Reaction equation: SiC + Cu → copper silicide + C (G).

Thus, the grain size of G was estimated to be about 73 nm.

Figure 2(b) showed the XPS spectrum of the G/SiC sample. The characteristic peak of the samples were divided into G with binding energy of 284.4 eV, surface buffer layer of 284.9 eV and SiC substrate of 283.3 eV, respectively [32,33]. The peak centered at 284.4 eV was related to sp2 hybridization in the G layer. The asymmetry of the C 1s peak in the direction of higher binding energies was a sign of defects in sp3 hybridized orbital carbon atoms, with a broad peak at 284.9 eV [34,35]. The dominant G content suggested that the samples underwent an adequate annealing process, and high-quality G was prepared on the surface of silicon carbide, which was consistent with Raman measurements.

In order to investigate the surface morphology of G, the G/SiC sample was characterized by SEM. It was observed that the G film was continuous and uniformly distributed over large areas with very few surface defects in Figure 2(c). The binding process of copper and silicon atoms promoted the reconstruction of carbon atoms on the surface of SiC, which improved the crystallinity of G. The schematic diagram of G/SiC sample preparation is shown in Figure 2(d). Compared with traditional annealing treatment for SiC single crystal for G preparation, the introduced Cu atoms on SiC surface would lead to higher quality G layer formation. This is contrary to the fact that the SiC and Cu were combined to form copper silicide, and carbon atoms were reconstructed on the surface of SiC [36].

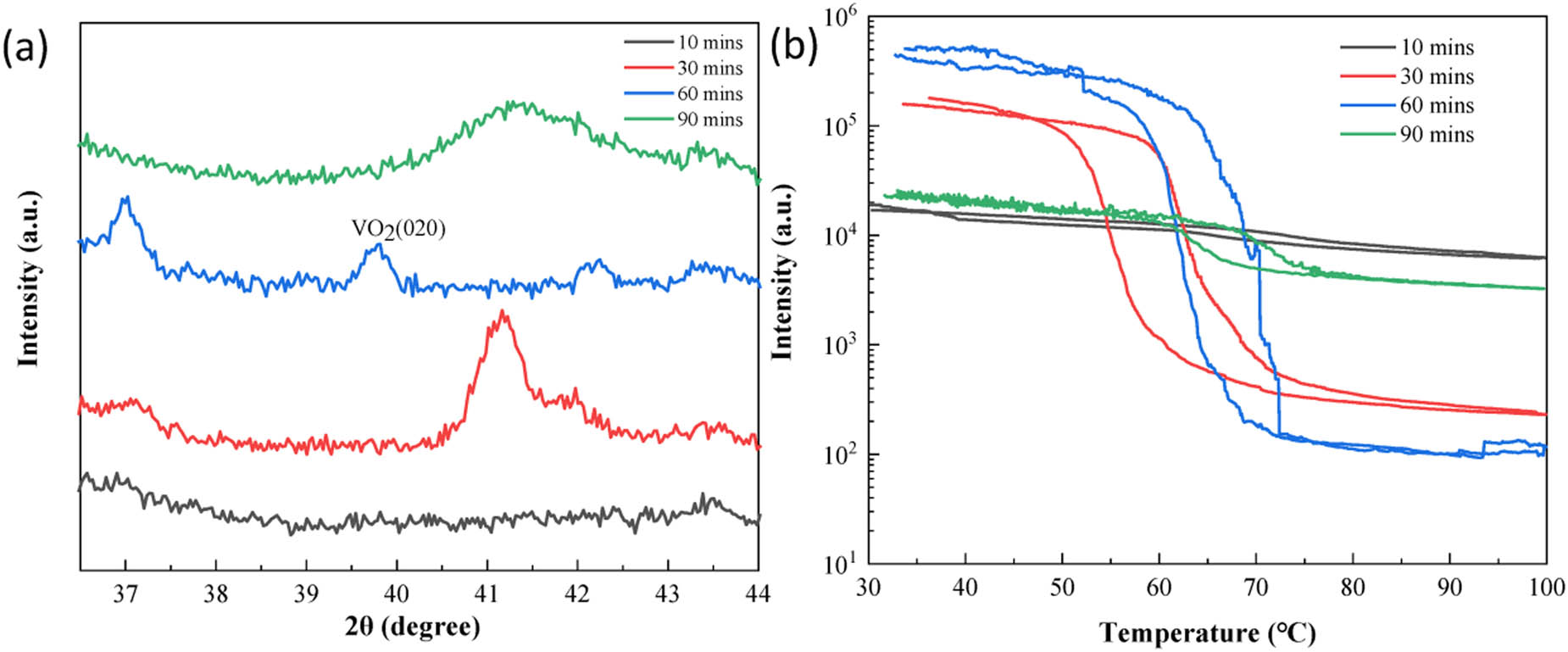

It was suggested that after the Cu atoms were deposited on SiC surface, the annealing time was a key factor for G layer formation by the annealing treatment at 1,380°C. In addition, the quality of the formed G layer further affected the VO2 film growth. Thus, by controlling the annealing time of Cu/SiC, a series of G/SiC were obtained. And then, metallic V layer was deposited onto these G/SiC substrate. By using the wet oxidation method, VO2/G/SiC films were finally prepared and analyzed by XRD tests. Figure 3(a) shows the XRD pattern of VO2/G/SiC samples with different annealing times. When the annealing time was 10 min, there was no characteristic peak. However, when the annealing time reached 60 min, the sample had a strong characteristic peak at 2θ = 39.89°, indicating that the preferred orientation of the sample was (020) plane (JCPDS card #82-0661) [5,37,38]. The resistance measurements as the function of temperature (R–T curve) for the VO2/G/SiC samples are shown in Figure 3(b). It was clear that the phase transition curve of the samples with annealing time of 10 and 90 min were relatively smooth, which showed the resistance change of only one. However, the sample with the annealing time of 60 min showed the resistance change of 3–4 orders of magnitude during the phase transition process. These results were in good agreement with the XRD measurement, which indicated that the annealing treatment with 60 min was more suitable for the VO2/G/SiC sample preparation. In this case, the G layer played a great role in promoting the property of VO2 film. Meanwhile, the results showed that the water oxidation technology could be used to prepare VO2 film with excellent electrical properties on the G/SiC substrate.

(a) The XRD pattern of the different annealing times of Cu/SiC substrate, (b) R–T curve measurements for the prepared VO2/G/SiC film by water vapor assisted oxidation at different annealing times.

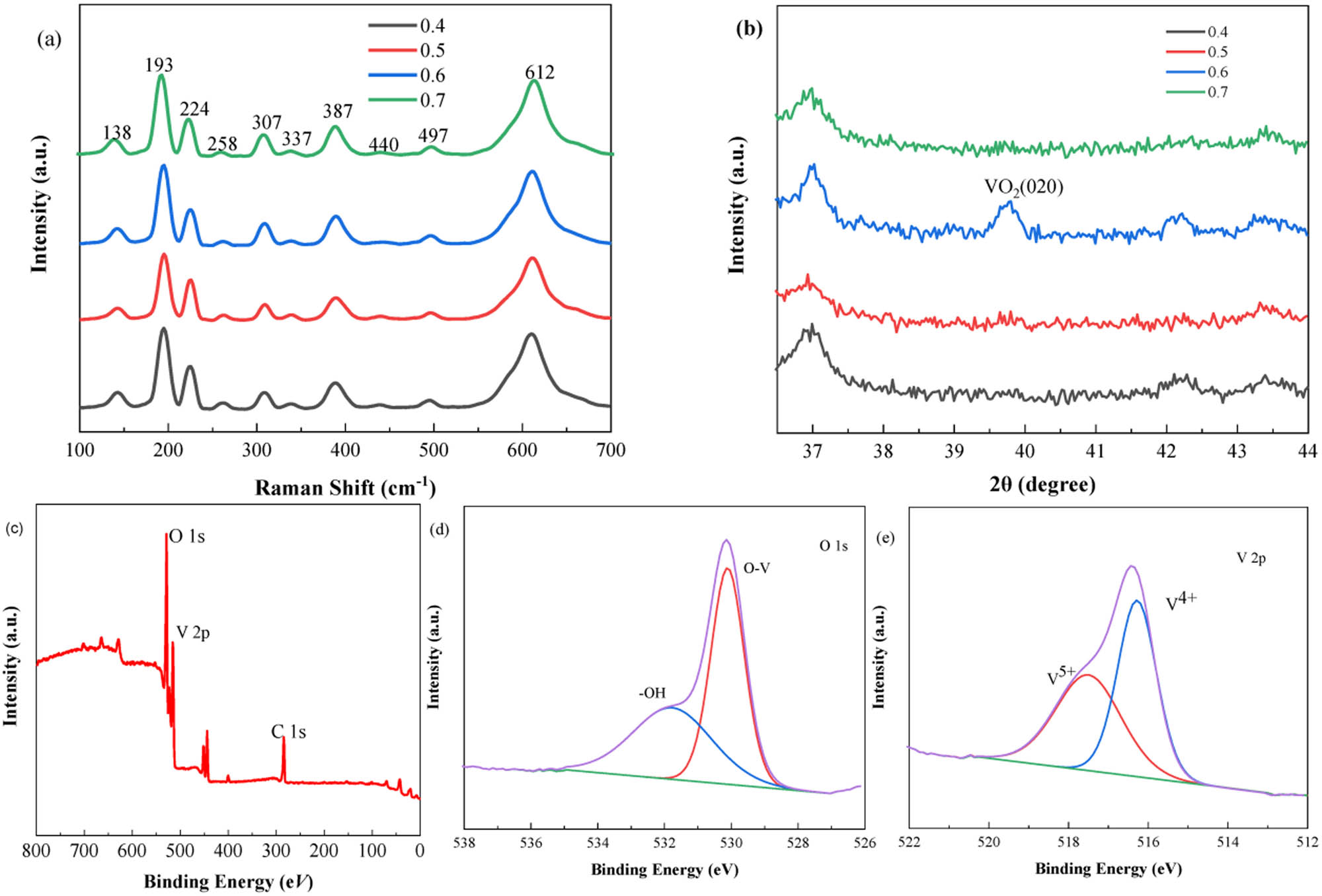

The Ar flux also affected the water vapor oxidation effect and regulated the quality of VO2. Figure 4(a) shows the Raman spectra of the VO2/G/SiC samples at different Ar flux rates. All samples showed peaks of different intensities at 138, 193, 224, 258, 307, 337, 387, 440, 497 and 612 cm−1, which were quite consistent with the characteristic peaks of monoclinic VO2(M-VO2) [39,40,41]. The crystal structures were characterized by XRD with the θ–2θ scan mode and the results were demonstrated in Figure 4(b). It was observed that the unique peak around 2θ = 39.9° was assigned to the diffraction from monoclinic VO2 (020) (JCPDS card #82-0661). This indicated that 0.6 L·min−1 was the best Ar flow condition for the preparation of VO2/G/SiC sample. It was worth noting that all samples had strong characteristic peaks at 2θ = 37°, which was speculated to generate other vanadium oxides.

(a) Raman spectrum, (b) XRD pattern of the prepared VO2/G/SiC samples at different Ar flow (unit: L·min−1), (c) XPS spectrum, (d) and (e) show the curve-fittings of O 1s and V 2p peaks for the VO2/G/SiC films at Ar flow rate of 0.6 L·min−1 by water vapor assisted oxidation.

The chemical state of the obtained VO2/G/SiC film with the Ar flow rate of 0.6 L·min−1 were examined by XPS in Figure 4(c). The detailed XPS curve-fittings are shown in Figure 4(d) and (e). The O 1s peak at 530 eV mainly originated from the O–V bond and the O 1s peak at 531.5 eV should be attributed to the –OH adsorbed on the surface. Similarly, V 2p3/2 had a peak binding energy of 516.1 eV and 517.3 eV [42]. The appearance of V4+ peak at 516 eV indicated the formation of VO2 on the substrate surface [43], while the presence of a higher binding energy of 517.3 eV indicated that the sample contained a small amount of V5+ This may be due to a slight surface oxidation of the sample when exposed to air. From the above characterizations, it was clear that the obtained VO2/G/SiC film produced by water vapor oxidation at the Ar flow rate of 0.6 L·min−1 showed the pure monoclinic phase structure and excellent stoichiometry.

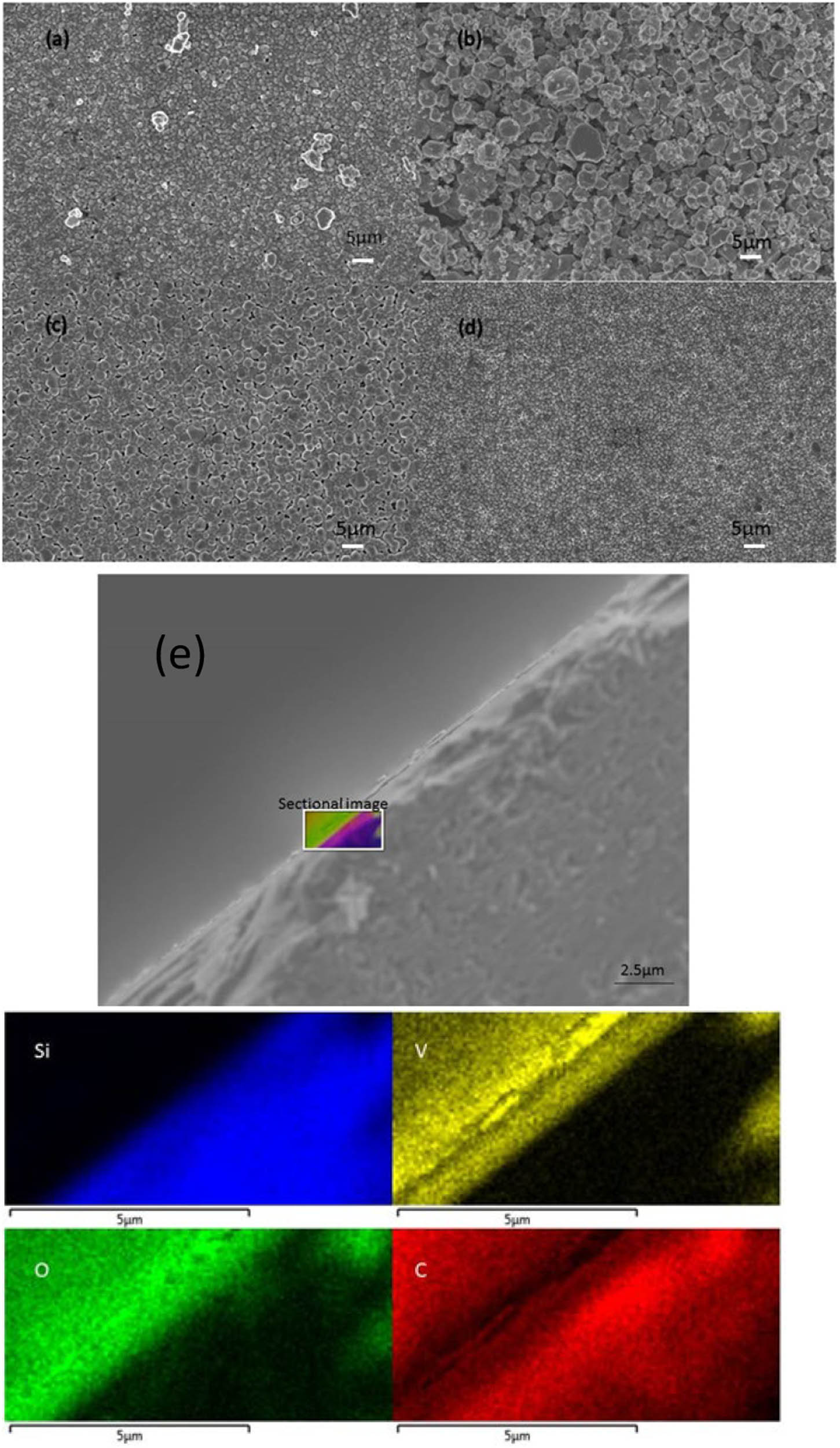

The surface morphology of the samples was characterized by SEM and is shown in Figure 5(a–d). When the Ar flow rate was 0.4 L·min−1, the grain size of the sample surface was small and the particle size was varied. When the Ar flow rate increased to 0.5 L·min−1, the surface particles were randomly distributed in island shape and the film continuity was discontinuous and a few holes appeared. When the Ar flow rate increased to 0.6 L·min−1, the continuity of the sample was improved and no holes existed. For the sample fabrication at the Ar flow rate of 0.7 L·min−1, the grain size started to decrease again. The experimental results demonstrated that the optimal argon oxide flow of the VO2/G/6H–SiC film was 0.6 L·min−1, which was consistent with the results obtained by XPS and Raman tests. Figure 5(e) shows a cross-section image of the sample and the distribution of each element. The cross-section image mainly contains three colors corresponding to the three-layer structure of the sample. This diagram served as proof of the existence of the VO2/G/6H–SiC film.

(a)–(d) SEM images of the VO2/G/SiC film prepared by wet oxidation at a flow rate of 0.4, 0.5, 0.6 and 0.7 L·min−1, respectively. (e) The sectional image of the VO2/G/SiC film fabricated by water vapor assisted method at a flow rate of 0.6 L·min−1.

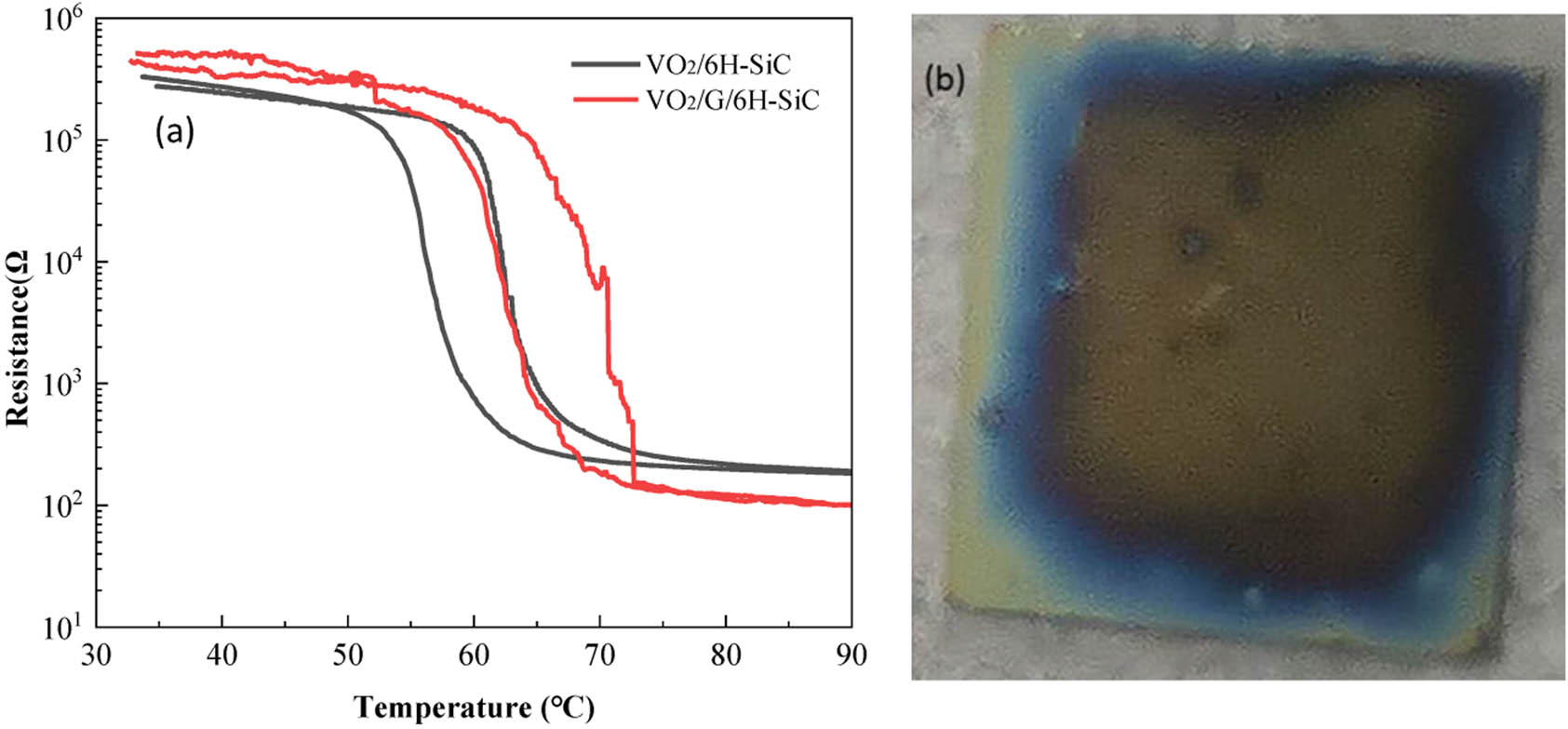

In order to further study the electrical properties of the samples, a four-probe variable temperature resistance tester was used to measure the resistance–temperature curves (R–T) of the films. Figure 6(a) shows the R–T curves of the VO2/G/SiC films at different Ar flow rates. When the Ar flow rate was 0.4, 0.5 and 0.7 L·min−1, the resistivity changes were only two- or three-orders of magnitude. For the sample fabricated at the argon flow rate of 0.6 L·min−1, the resistivity changes were nearly four-orders of magnitude. When the argon flow rate increased from 0.4 to 0.6 L·min−1, the R–T curve became sharper and the resistance ratio between the insulating metal phases increased during the MIT process. Accordingly, the change in R–T curve further determined that 0.6 L·min−1 should be the optimal argon flow for wet oxidation. The results showed that VO2 film prepared by wet oxidation had good electrical properties, and the resistance variation reached nearly four-orders of magnitude after optimization. As a buffer layer, high-quality G had excellent optical and electrical properties, which further improved the electrical properties of VO2 and also extended the application range of devices. The related differential curve for the optimized VO2/G/SiC film at the flow rate of 0.6 L·min−1 is shown in Figure 5(b). Critical transition temperatures (T heat and T cool) are defined as the corresponding peak positions of the Gaussian fitted d(log(R))/dT curve during heating and cooling, respectively. Phase transition temperature is defined as T MIT = (T heat + T cool)/2. The critical temperatures were determined as 62.0°C for the cooling process and 70.8°C for the heating process, which were quite consistent with the previous reports by other deposition techniques [19,44,45]. The thermally induced width (T heat − T cool) of the sample was 8.8°C and the phase transition temperature was 66.4°C.

(a) The R–T curve for the VO2/G/SiC film prepared by wet oxidation at different Ar flow rates (unit: L·min−1) and (b) related differential curves for the optimized VO2/G/SiC film at a flow rate of 0.6 L·min−1.

To investigate the effect of G on the preparation of VO2, the R–T curves of VO2/6H–SiC and VO2/G/6H–SiC films are shown in Figure 7. It can be seen that under the same experimental conditions, the resistivity change of VO2/G/SiC film was close to four-orders of magnitude and the phase transition temperature was closer to that of VO2 [46,47,48,49,50], while the resistivity change of VO2/SiC film was only close to three-orders of magnitude. This indicated that doped G increased the resistivity of VO2/SiC film and improved the quality of VO2 after optimization. The optical photo of the sample obtained under optimal synthesis conditions (60 min, 0.6 L·min−1) is shown in Figure 7(b). Although the film has not been prepared on large-size substrate in this study, some research groups have prepared high-quality VO2 on large-size Si wafers by wet oxidation method, indicating that the film can be prepared on large-size substrate by this method. Based on this fact, our group attempted to prepare VO2 films on G/SiC substrate, which paved the way for large size SiC substrate related applications.

(a) After optimization, R–T results of VO2/G/SiC and VO2/SiC thin films under the same experimental conditions and (b) the optical photo of the sample obtained under optimal synthesis conditions (the annealing time of SiC was 60 min and the Ar gas flow rate was 0.6 L·min−1).

4 Conclusion

In conclusion, high quality VO2/G/SiC films were successfully prepared by moderate water oxidation technique. The experimental results showed that the G-based VO2 films with resistance variation of nearly four-orders of magnitude exhibited excellent electrical properties and crystallinity. In the water oxidation method, water vapor as a moderate oxidant was used to effectively oxidize the metal V precursor film into a pure M–VO2 film. Graphene, as a buffer layer, had excellent photoelectric properties, which further improved the electrical properties of VO2 and broadened the application range of related devices. This work provided a facile and modest method for the preparation of VO2 films, which was of practical significance for the further application of G-based VO2 devices in the future.

-

Funding information: This work was partially supported by Natural Science Foundation of China (51402120 and 11974127), Natural Science Foundation of Anhui Higher Education Institutions of China (KJ2019ZD40) and Anhui Natural Science Foundation (2108085QA30).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Fan, L. L., S. Chen, G. M. Liao, Y. L. Chen, H. Ren, and C. W. Zou. Comprehensive studies of interfacial strain and oxygen vacancy on metal-insulator transition of VO2 film. Journal of Physics: Condensed Matter, Vol. 28, 2016, id. 255002.10.1088/0953-8984/28/25/255002Search in Google Scholar PubMed

[2] Théry, V., A. Boulle, A. Crunteanu, J. C. Orlianges, A. Beaumont, R. Mayet, et al. Structural and electrical properties of large area epitaxial VO2 films grown by electron beam evaporation. Journal of Applied Physics Letters, Vol. 121, 2017, id. 055303.10.1063/1.4975117Search in Google Scholar

[3] Zhang, H. T., L. Zhang, D. Mukherjee, Y. X. Zheng, R. C. Haislmaier, N. Alem, et al. Wafer-scale growth of VO2 thin films using a combinatorial approach. Nat Comm, Vol. 6, 2015, id. 8475.10.1038/ncomms9475Search in Google Scholar PubMed PubMed Central

[4] Liu, K., D. Y. Fu, J. B. Cao, J. Suh, K. X. Wang, C. Cheng, et al. Dense electron system from gate-controlled surface metal-insulator transition. Nano Letters, Vol. 12, 2012, pp. 6272–6277.10.1021/nl303379tSearch in Google Scholar PubMed

[5] Chen, F. H., L. L. Fan, S. Chen, G. M. Liao, Y. L. Chen, P. Wu, et al. Control of the metal-insulator transition in VO2 epitaxial film by modifying carrier density. ACS Applied Materials & Interfaces, Vol. 7, 2015, pp. 6875–6881.10.1021/acsami.5b00540Search in Google Scholar PubMed

[6] Hao, Q., W. Li, H. Y. Xu, J. W. Wang, Y. Yin, H. Y. Wang, et al. VO2/TiN Plasmonic thermochromic smart coatings for room-temperature applications. Advanced Materials, Vol. 30, 2018, id. 1705421.10.1002/adma.201705421Search in Google Scholar PubMed

[7] Chang, T. C., X. Cao, N. Li, S. W. Long, X. Gao, L. R. Dedon, et al. Facile and low-temperature fabrication of thermochromic Cr2O3/VO2 smart coatings: enhanced solar modulation ability, high luminous transmittance and UV-shielding function. ACS Applied Materials & Interfaces, Vol. 9, 2017, pp. 26029–26037.10.1021/acsami.7b07137Search in Google Scholar PubMed

[8] Xue, W. H., G. Liu, Z. C. Zhong, Y. H. Dai, J. Shang, Y. W. Liu, et al. A 1D vanadium dioxide nanochannel constructed via electric-field-induced ion transport and its superior metal-insulator transition. Advanced Materials, Vol. 29, 2017, id. 1702162.10.1002/adma.201702162Search in Google Scholar PubMed

[9] Javier, D. V., S. Pavel, T. Federico, N. M. Vargas, Y. Kalcheim, P. Wang, et al. Subthreshold firing in Mott nanodevices. Nature, Vol. 569, 2019, pp. 388–392.10.1038/s41586-019-1159-6Search in Google Scholar PubMed

[10] Fan, L. L., Y. L. Chen, Q. H. Liu, S. Chen, L. Zhu, Q. Q. Meng, et al. Infrared response and optoelectronic memory device fabrication based on epitaxial VO2 film. ACS Applied Materials & Interfaces, Vol. 8, 2016, pp. 32971–32977.10.1021/acsami.6b12831Search in Google Scholar PubMed

[11] Lv, W. F., C. Yang, G. Meng, R. F. Zhao, A. J. Han, R. Wang, et al. VO2(B) nanobelts/reduced graphene oxide composites for high-performance flexible all-solid-state supercapacitors. Scientific Reports, Vol. 9, 2019, id. 10831.10.1038/s41598-019-47266-6Search in Google Scholar PubMed PubMed Central

[12] Li, S., Y. Cen, Q. Xiang, K. A. Muhammad, B. B. Hu, W. Li, et al. Vanadium dioxide-reduced graphene oxide binary host as an efficient polysulfide plague for high-performance lithium–sulfur batteries. Journal of Materials Chemistry A, Vol. 7, 2019, pp. 1658–1668.10.1039/C8TA10422KSearch in Google Scholar

[13] Fan, L. L., Y. F. Wu, C. Si, C. W. Zou, Z. M. Qi, L. B. Li, et al. Oxygen pressure dependent VO2 crystal film preparation and the interfacial epitaxial growth study. Thin Solid Films, Vol. 520, 2012, pp. 6124–6129.10.1016/j.tsf.2012.05.086Search in Google Scholar

[14] Alok, G., N. Jagdish, and D. Titas. Near bulk semiconductor to metal transition in epitaxial VO2 thin films. Applied Physics Letters, Vol. 97, 2010, id. 151912.10.1063/1.3503632Search in Google Scholar

[15] Fan, L. L., S. Chen, Y. F. Wu, F. H. Chen, W. S. Chu, X. Chen, et al. Growth and phase transition characteristics of pure M-phase VO2 epitaxial film prepared by oxide molecular beam epitaxy. Applied Physics Letters, Vol. 103, 2013, id. 131914.10.1063/1.4823511Search in Google Scholar

[16] Lee, S., T. L. Meyer, P. Sungkyun, E. Takeshi, and H. N. Lee. Growth control of the oxidation state in vanadium oxide thin films. Applied Physics Letters, Vol. 105, 2014, id. 223515.10.1063/1.4903348Search in Google Scholar

[17] Ferran, U. B., C. Aurelian, and J. P. Raskin. Raman and XPS characterization of vanadium oxide thin films with temperature. Applied Surface Science, Vol. 403, 2017, pp. 717–727.10.1016/j.apsusc.2017.01.160Search in Google Scholar

[18] Geert, R., B. D. Schutter, D. Wouter, M. Koen, R. Iuliana, and D. Christophe. In situ X-ray diffraction study of the controlled oxidation and reduction in the V–O system for the synthesis of VO2 and V2O3 thin films. Journal of Material Chemistry C, Vol. 3, 2015, pp. 11357–11365.10.1039/C5TC02553BSearch in Google Scholar

[19] Liang, W. Z., M. Gao, C. Lu, Z. Zhang, C. H. Chan, L. J. Zhuge, et al. Enhanced metal-insulator transition performance in scalable vanadium dioxide thin films prepared using a moisture-assisted chemical solution approach. ACS Applied Materials & Interfaces., Vol. 10, 2018, pp. 8341–8348.10.1021/acsami.7b18533Search in Google Scholar PubMed

[20] Luo, L. L., M. Su, P. F. Yan, L. F. Zou, D. K. Schreiber, D. R. Baer, et al. Atomic origins of water-vapour-promoted alloy oxidation. Nature Mater, Vol. 17, 2018, pp. 514–518.10.1038/s41563-018-0078-5Search in Google Scholar PubMed

[21] Chen, R. Q., C. W. Zou, X. D. Yan, A. Ahmed, and W. Gao. Growth mechanism of ZnO nanostructures in wet-oxidation process. Thin Solid Films, Vol. 519, 2011, pp. 1837–1844.10.1016/j.tsf.2010.10.012Search in Google Scholar

[22] Chen, J. H., C. Jang, S. Xiao, M. Ishigami, and M. S. Fuhrer. Intrinsic and extrinsic performance limits of graphene devices on SiO2. National Nanotechnology, Vol. 3, 2008, pp. 206–209.10.1038/nnano.2008.58Search in Google Scholar PubMed

[23] Xiao, L., H. Ma, J. K. Liu, W. Zhao, Y. Jia, Q. Zhao, et al. Fast adaptive thermal camouflage based on flexible VO2/graphene/CNT thin films. Nano Letters, Vol. 15, 2015, pp. 8365–8370.10.1021/acs.nanolett.5b04090Search in Google Scholar PubMed

[24] Kim, H., Y. Kim, T. Y. Kim, A. R. Jang, Y. J. Hu, H. H. Seung, et al. Enhanced optical response of hybridized VO2/graphene films. Nanoscale, Vol. 5, 2013, pp. 2632–2636.10.1039/c3nr34054fSearch in Google Scholar PubMed

[25] Zhou, H. J., J. H. Li, Y. C. Xin, X. Cao, S. H. Bao, and P. Jin. Electron transfer induced thermochromism in a VO2–graphene–Ge heterostructure. Journal of Material Chemistry C, Vol. 3, 2015, pp. 5089–5097.10.1039/C5TC00448ASearch in Google Scholar

[26] Kang, C. Y., J. Tang, L. M. Li, H. B. Pan, P. S. Xu, S. Q. Wei, et al. In situ study on the electronic structure of graphene grown on 6H–SiC (0 0 0 ¯1) with synchrotron radiation photoelectron spectroscopy. Applied Surface Science, Vol. 258, 2012, pp. 2187–2191.10.1016/j.apsusc.2011.02.068Search in Google Scholar

[27] Ren, H., B. W. Li, X. Y. Zhou, S. Chen, Y. M. Li, C. L. Hu, et al. Wafer-size VO2 film prepared by water-vapor oxidant. Applied Surface Science, Vol. 525, 2020, id. 146642.10.1016/j.apsusc.2020.146642Search in Google Scholar

[28] Sunmin, R., L. Liu, B. Stephane, Y. J. Yu, H. T. Liu, P. Kim, et al. Atmospheric oxygen binding and hole doping in deformed graphene on a SiO2 substrate. Nano Letters, Vol. 10, 2010, pp. 4944–4951.10.1021/nl1029607Search in Google Scholar PubMed

[29] Briggs, N., B. Bersch, Y. X. Wang, J. Jiang, R. J. Koch, N. Nayir, et al. Atomically thin half-van der Waals metals enabled by confinement heteroepitaxy. Nature Materials, Vol. 19, 2020, pp. 637–643.10.1038/s41563-020-0631-xSearch in Google Scholar PubMed

[30] Faugeras, C., A. Nerrière, M. Potemski, A. Mahmood, E. Dujardin, C. Berger, et al. Few-layer graphene on SiC, pyrolitic graphite, and graphene: A Raman scattering study. Applied Physics Letters, Vol. 92, 2008, id. 011914.10.1063/1.2828975Search in Google Scholar

[31] Kang, C. Y., L. L. Fan, S. Chen, Z. L. Liu, P. S. Xu, and C. W. Zou. Few-layer graphene growth on 6H-SiC (0001) surface at low temperature via Ni-silicidation reactions. Applied Physics Letters, Vol. 100, 2012, id. 251604.10.1063/1.4729876Search in Google Scholar

[32] Kazuma, Y., T. Takayuki, K. Atsushi, and T. Kazutoshi. Fabrication of a single layer graphene by copper intercalation on a SiC (0001) surface. Applied Physics Letters, Vol. 104, 2014, id. 053115.10.1063/1.4864155Search in Google Scholar

[33] Wang, Z. J., A. Y. Dong, M. M. Wei, Q. Fu, and X. H. Bao. Graphene as a surfactant for metal growth on solid surfaces: Fe on graphene/SiC (0001). Applied Physics Letters, Vol. 104, 2014, id. 181604.10.1063/1.4875799Search in Google Scholar

[34] Lee, D. and J. Seo. Graphene growth on sapphire via palladium silicidation. Applied Surface Science, Vol. 492, 2019, pp. 23–26.10.1016/j.apsusc.2019.06.216Search in Google Scholar

[35] Weatherup, R. S., B. C. Bayer, and B. Raoul. In situ characterization of alloy catalysts for low-temperature graphene growth. Nano Letters, Vol. 11, 2011, pp. 4154–4160.10.1021/nl202036ySearch in Google Scholar PubMed

[36] Kim, H. W., I. Song, and T. H. Kim. Millimeter-scale growth of single-oriented graphene on a palladium silicide amorphous film. ACS Nano, Vol. 13, 2019, pp. 1127–1135.10.1021/acsnano.8b05299Search in Google Scholar PubMed

[37] Jiang, M., X. Cao, S. H. Bao, H. J. Zhou, and P. Jin. Regulation of the phase transition temperature of VO2 thin films deposited by reactive magnetron sputtering without doping. Thin Solid Films, Vol. 562, 2014, pp. 314–318.10.1016/j.tsf.2014.04.090Search in Google Scholar

[38] Cheng, X. K., Q. Gao, K. F. Li, Z. L. Liu, Y. X. Zhang, B. Li, et al. Enhanced phase transition properties of VO2 thin films on 6H-SiC (0001) substrate prepared by pulsed laser deposition. Nanomaterials, Vol. 9, 2019, id. 1061.10.3390/nano9081061Search in Google Scholar PubMed PubMed Central

[39] Ren, G. F., R. B. Zhang, and Z. Y. Fan. VO2 nanoparticles on edge oriented graphene foam for high rate lithium ion batteries and supercapacitors. Applied Surface Science, Vol. 441, 2018, pp. 466–473.10.1016/j.apsusc.2018.02.059Search in Google Scholar

[40] Zhang, S. X., J. Y. Chou, and L. J. Lauhon. Direct correlation of structural domain formation with the metal insulator transition in a VO2 nanobeam. Nano Letters, Vol. 9, 2009, pp. 4527–4532.10.1021/nl9028973Search in Google Scholar PubMed

[41] Kang, C. Y., C. Zhang, L. W. Zhang, S. S. Liang, C. C. Geng, G. H. Cao, et al. Transformation of crystalline structure and photoelectric properties in VO2/glass thin films by inserting TiO2 buffer layers. Applied Surface Science, Vol. 463, 2019, pp. 704–712.10.1016/j.apsusc.2018.08.193Search in Google Scholar

[42] Liang, J. R., X. Yu, Y. R. Zhao, X. W. Fan, W. H. Wu, and S. L. Wang. Enhancement of metal-insulator transition performance of VO2 thin films by conventional furnace annealing. Thin Solid Films, Vol. 730, 2021, id. 138709.10.1016/j.tsf.2021.138709Search in Google Scholar

[43] Chen, S., Z. W. Wang, L. L. Fan, Y. L. Chen, H. Ren, H. Ji, et al. Sequential insulator-metal-insulator phase transitions of VO2 triggered by hydrogen doping. Physical Review B, Vol. 96, 2017, id. 125130.10.1103/PhysRevB.96.125130Search in Google Scholar

[44] Aetukuri, N. B., A. X. Gray, and D. Marc. Control of the metal–insulator transition in vanadium dioxide by modifying orbital occupancy. Nature Physics, Vol. 9, 2013, pp. 661–666.10.1038/nphys2733Search in Google Scholar

[45] Fan, L. L., S. Chen, Z. L. Luo, Q. H. Liu, Y. F. Wu, L. Song, et al. Strain dynamics of ultrathin VO2 film grown on TiO2 (001) and the associated phase transition modulation. Nano Letters, Vol. 14, 2014, pp. 4036–4043.10.1021/nl501480fSearch in Google Scholar PubMed

[46] Bharathi, R. and A. M. Umarji. Phase evolution and infrared transmittance in monophasic VO2 synthesized by a rapid non-equilibrium process. Materials Chemistry and Physics, Vol. 190, 2017, pp. 219–229.10.1016/j.matchemphys.2016.12.070Search in Google Scholar

[47] Bharathi, R., N. Rameshwari, and A. M. Umarji. Metal–insulator transition characteristics of vanadium dioxide thin films synthesized by ultrasonic nebulized spray pyrolysis of an aqueous combustion mixture. Journal of Physics D: Applied Physics, Vol. 48, 2015, id. 305103.10.1088/0022-3727/48/30/305103Search in Google Scholar

[48] Yu, W. L., S. Li, and C. Huang. Phase evolution and crystal growth of VO2 nanostructures under hydrothermal reactions. RSC Advances, Vol. 6, 2016, pp. 7113–7120.10.1039/C5RA23898FSearch in Google Scholar

[49] Lin, H. R., X. H. Guo, K. X. Song, J. Feng, S. L. Li, and X. F. Zhang. Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers. Nanotechnology Reviews, Vol. 10, 2021, pp. 62–72.10.1515/ntrev-2021-0006Search in Google Scholar

[50] Dong, X. D., A. Q. Wang, J. P. Xie, and Z. Wang. Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites. Nanotechnology Reviews, Vol. 10, 2021, id. 1.10.1515/ntrev-2021-0088Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants