Abstract

To study the effects of macro- and micro-fiber on the concrete beams, bending resistance tests were conducted on the polypropylene fiber-reinforced concrete beams. Stepwise loaded tests were carried out to obtain the load–deflection curves for different test pieces, cracking load values of the first inclined crack, recording and depicting crack development, changes in mid-span deflection of the test pieces, load–strain relationships of concrete, etc. The crack patterns and failure modes were observed. The research findings have shown that the ultimate load of the concrete beams doped with multi-size polypropylene fiber is 58.31 and 34.08% higher than that of ordinary concrete beams and concrete beams with single macro-fiber, respectively. Notably, the ultimate anti-bending bearing capacity of the beams significantly improves following the addition of macro-fiber. Polypropylene fiber can offset the defects caused by macro-fiber, remarkably suppress the development of cracks, and control the deformation of beams due to the effects of micro-fiber of different dimensions.

1 Introduction

With the constant development of scientific technologies, synthetic fiber has been drawing people’s attention, becoming popular rapidly, and playing vital roles in many industries. Notably, polypropylene fiber has a wide application range, outstanding performance, and stable chemical properties, is highly dispersible and hydrophobic relative to steel fiber, and ha sufficient strength and corrosion resistance, displaying significant advantages. In recent years, many scholars have studied the action mechanism of polypropylene fiber-reinforced concrete (PFRC) and attained enormous research achievements. Karahan, Fallah, Zhang et al., studied the endurance of PFRC containing coal ash [1] and nano-silicon dioxide and silicon powder [2], as well as the effects of the powder-doped coal ash and silica fume concrete [3]. Nili and Afroughsabet studied the impact properties and strength of the concrete mixture of polypropylene and silica fume as per water–cement ratios of 0.36 and 0.46 [4], discovering that the addition of polypropylene fiber improves the mechanical properties of the material, the addition of silicon powder contributes to fiber dispersion, and the effects of the steel–polypropylene fiber on the impact properties of concrete through experiments and numerical simulation [5]. Noumowe [6] studied the mechanical properties and microstructure of the PFRC at a high temperature of 200°C. The research has found that fiber can be easily melted and highly volatile at high temperatures, but its mechanical properties vary a little. Kakooei et al. [7] discussed the effects of polypropylene fiber on the compressive strength, permeability, and resistivity of the concrete. Pachideh and Gholhaki [8] studied the effects of different temperatures on the mechanical properties of concrete containing steel and polypropylene fibers with different amounts of cement added. The research has shown that the fire disaster has more significant effects on concrete containing steel. Arslan et al. [9] studied the effects of polypropylene fiber on the shear resistance capability of stirrup-free reinforced concrete. The research has shown that the addition of polypropylene fiber improves the shear strength and ductility of beams. Cao et al. [10] computed the stress strength factors of instability and crack development in PFRC beams using the improved double-K model. Bicer, Sahoo, Zhmagul, Kozar, Jurkiewiez, et al. studied the bending properties according to a test [11], effects of adding steel and polypropylene fibers in the concrete on the overall bending response [12], the stress intensity factor of reinforced concrete beams in bending [13], crack growth in concrete beams in bending [14], and hybrid steel–timber beams in bending [15].

In the present experimental work, many achievements have been acquired in the research of fiber-reinforced concrete [16,17,18,19,20,21,22]. To study the bending resistance of polypropylene fiber in strengthening the concrete beams, a total of nine test beams were designed and fabricated and divided into three groups of beams of three each, A0, A1, and A2. Of the three groups, A0 comprises ordinary concrete beams and serves as the control group; A1 comprises concrete beams doped with polypropylene macro-fiber alone; A2 comprises multi-size PFRC beams doped with two types of micro-polypropylene fibers and one type of macro-polypropylene fiber. It is theoretically and practically significant to reveal the mechanism of action of macro- and micro-polypropylene fibers using the normal section anti-bending test.

2 Design of test

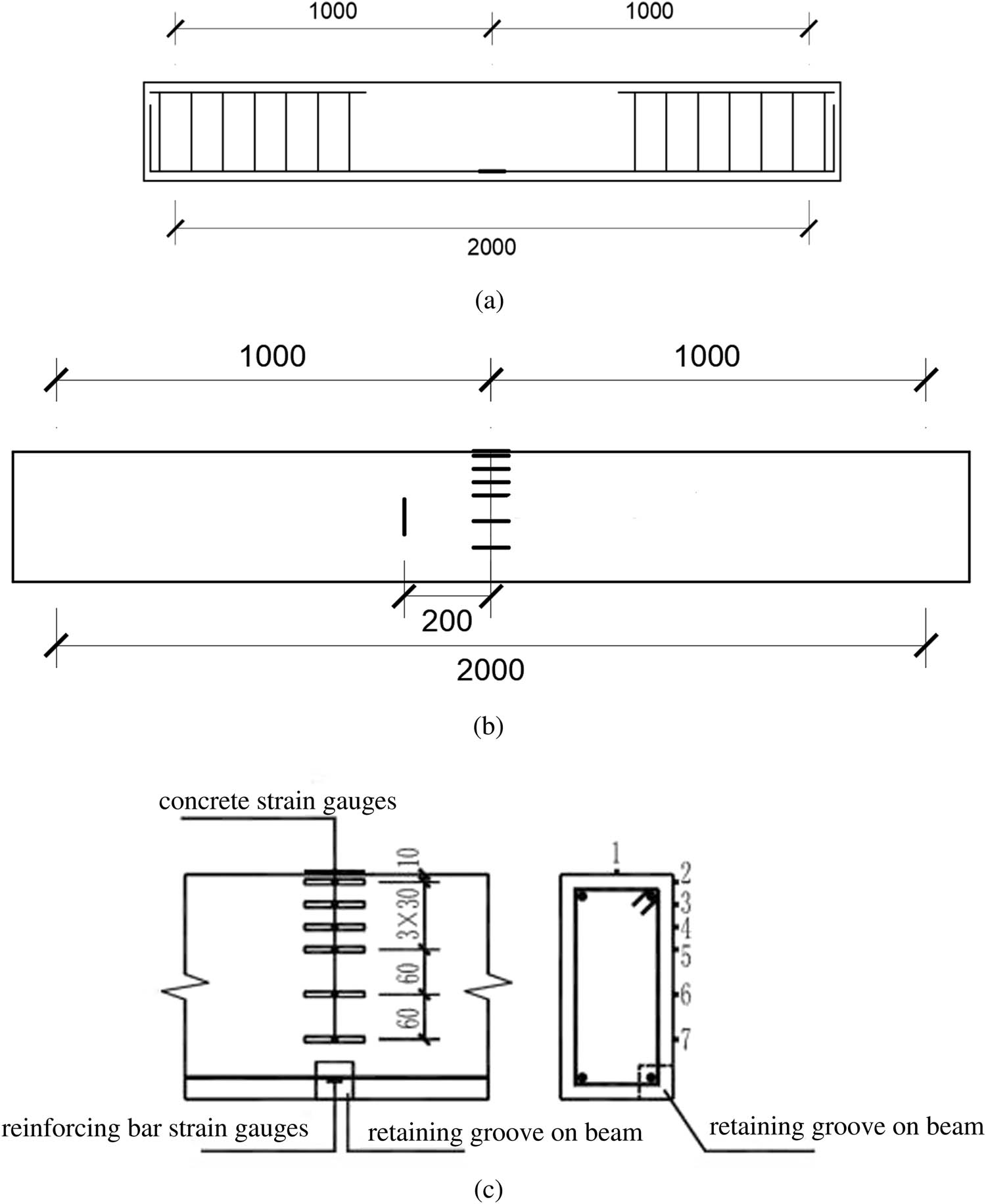

The geometric dimensions, steel ratios of longitudinal bars, steel ratios of stirrups, and concrete mixture ratios of the nine rectangular beams are the same. The sectional dimension of all rectangular beams is b × h × l = 150 mm × 300 mm × 2,200 mm. Figure 1 shows the geometric dimensions and reinforcement drawing of beams.

2.1 Design of test materials and mixture ratios

The raw materials used in the test are as follows:

Polypropylene fiber-reinforced concrete is a composite building material formed by cement, water, sand, gravel, water reducer, and polypropylene fiber. They were mixed as per a particular ratio and stirred. The specific parameters are as follows:

Cement: The test used ordinary 42.5R silicate cement. Concrete should not be poured until the cement was inspected ahead and no dampness was found.

Sand: Artificial sand, microness modulus 3.1, bulk accumulation density 1,530 kg·m−3; super-microsand, microness modulus 0.8, bulk accumulation density 1,294 kg·m−3.

Stones: Gravel (5–10 mm), place of origin is Chongqing Mount Gele, clay content 0.5%, apparent density 2,680 kg·m−3, bulk accumulation density 1,385 kg·m−3; gravel (10–20 mm), place of origin is Chongqing Mount Gele, clay content 0.7%, apparent density 2,690 kg·m−3, bulk accumulation density 1,405 kg·m−3;

Water reducer: Polycarboxylic acid high-efficiency reducer, yellowish-brown, liquid.

Polypropylene fiber: The polypropylene macro-fiber used the fiber CF1. The micro-fiber used the fibers FF1 and FF2. Table 1 shows specific physical performance parameters.

Physical and mechanical indexes of polypropylene fiber

| Fiber number | Average diameter (μm) | Length (mm) | Tensile strength (MPa) | Elasticity modulus (GPa) | Elongation at break (%) | Density (g·cm−3) | Recommended amount of doping (kg·m−3) |

|---|---|---|---|---|---|---|---|

| FF1 | 26.1 | 19 | 641 | 4.5 | 40 | 0.91 | 0.9 |

| FF2 | 100 | 19 | 322 | 4.9 | 15 | 0.91 | 0.9 |

| CF1 | 800 | 50 | 706 | 7.4 | 10 | 0.95 | 6.0 |

In the test, the mixture ratio of concrete (cement:water:sand:stone:water reducer) was 380:175:701:1144:3.80. The experiment used the concrete with a strength grade of C30. The water–cement ratio was 0.46. The amount of fiber doped was determined by the test design and the amount of fiber doped recommended by the factory: the recommended amount of micro-fiber doped is 0.9 kg·m−3 and the recommended amount of macro-fiber doped is 6.0 kg·m−3. Table 2 shows the mixture ratios of the materials. The sand used during concrete placement mainly comprises two parts: one is super-microsand, accounting for 1/5, and the other is manufactured sand, accounting for 4/5. The gravel used during concrete placement also comprises two parts: one is gravel with a diameter of 5–10 mm, accounting for 2/5, and the other is gravel with a diameter of 10–20 mm, accounting for 3/5. The test piece A0 was fabricated by the placement of ordinary concrete and used as a benchmark reference test piece. A1 is the test piece CF1 doped with polypropylene macro-fiber alone, and the amount of fiber doped is 6.0 kg·m−3. A2 is the test piece doped with three types of macro- and micro-polypropylene fiber. The amounts of the three types of polypropylene fibers are 0.6, 0.6, and 4.8 kg·m−3, respectively.

Mixture ratio of the C30 concrete (kg·m−3)

| Test piece number | Fiber type | Cement | Sand | Gravel | Water | Sand ratio (%) | Amount of fiber doped | Water reducer (%) |

|---|---|---|---|---|---|---|---|---|

| A0 | No fiber | 380 | 701 | 1,144 | 175 | 38 | 0 | 1 |

| A1 | CF1 | 380 | 701 | 1,144 | 175 | 38 | 6.0 | 1 |

| A2 | FF1 + FF2 + CF1 | 380 | 701 | 1,144 | 175 | 38 | 0.6 + 0.6 + 4.8 | 1 |

2.2 Fabrication and curing of concrete beams

If the fiber in the concrete can be well dispersed, the initial defects of the concrete will improve considerably, and it will better display its performance, thus guaranteeing and improving the concrete’s performance. The concrete may experience performance degradation and adverse effects and may not meet the engineering demand if the polypropylene fiber is distributed in clusters rather than uniformly due to its low elasticity modulus. Thus, higher requirements for fiber dispersity are usually imposed to ensure uniform distribution during concrete placement, thus exerting its functions and avoiding fiber clustering.

By reference to Structural and Technical Specifications for Fiber-reinforced Concrete (CECS38:2004) [23], the processes of design, stirring, and curing are detailed as follows:

The concrete mixture ratio was determined in advance. The amount of material was calculated before each batch of test pieces was fabricated by concrete placement. Raw materials were weighed with an electronic size.

The sand and gravel weighed were poured into a mixing drum with its surface wetted and stirred for about 1 min. Then, polypropylene fiber was uniformly scattered in the mixing drum during stirring.

The materials were stirred for about extra 2 min after the fiber was scattered. The agitator was paused to check whether fiber clusters were present. The fiber clusters, if any, were broken and uniformly scattered in the agitator. Stirring continued.

The weighed cement was gently poured into the mixing drum, and the materials were stirred for 2 min. A water reducer was added to the water in advance, and it was poured into the agitator while stirring was continuing. At the moment, it was observed that the fiber in the concrete had been uniformly dispersed. The concrete was observed for changes in properties. The agitating extent would be considered to meet the demand if the moisture was proper.

A slump test was conducted after the concrete was properly mixed. Any residual concrete and rust on the mold should be removed before the metal mold is used. A layer of oil should be applied to the interior surface of the mold for easy demolding after molding test pieces. The amount of oil should be appropriate, and no excess oil should be seen flowing on the surface. The properly fabricated concrete was added to the treated metal mold. After an appropriate amount was reached, the concrete was uniformly vibrated with a vibrator. Meanwhile, the concrete surface was smoothed with a trowel. The surface was observed and considered to meet the requirements after it was confirmed that no bubbles came out. The concrete should be covered with a piece of preservative film to avoid the evaporation of water.

To cure the concrete, the ground should be flat, and the concrete mold should be placed on it. During the process, the mold should be kept horizontal and should not be inclined. Otherwise, the test pieces would become irregular. The mold was removed after the test piece was allowed to stand still for generally 24 h. Test pieces were numbered and cured. This process needed to be completed in a standard curing chamber. The temperature of the curing chamber was 20 ± 2°C. The humidity was over 90%. The duration lasted for 28 days.

2.3 Data collection and arrangement of measuring points

Arrangement of measuring points for each beam:

A 50-ton load sensor was used to acquire the concentrated load applied to the beam.

Dial gauges were used to acquire displacement deformation at the beam mid-span and the supporting seat.

80 mm strain gauges were used to measure the strain of concrete at different heights of the mid-span cross-section and the transverse strain of concrete of the cross-section at 200 mm away from the mid-span.

2-mm-long strain gauges were used to measure the strain of the longitudinal bars. The arrangement of various measuring points is shown in Figure 2. The 50-ton load sensor was connected to the static strain gages to obtain the loading data. The dial gages were connected to the sensor for measuring the displacement of the midspan and both ends of the beam.

Drawing for arrangement of measuring points for test beams. (a) Measuring point for the strain gauges for longitudinal bars, (b) measuring point for the strain gauges for concrete beams, and (c) detailed drawing for the strain gauges for the mid-span cross-section concrete.

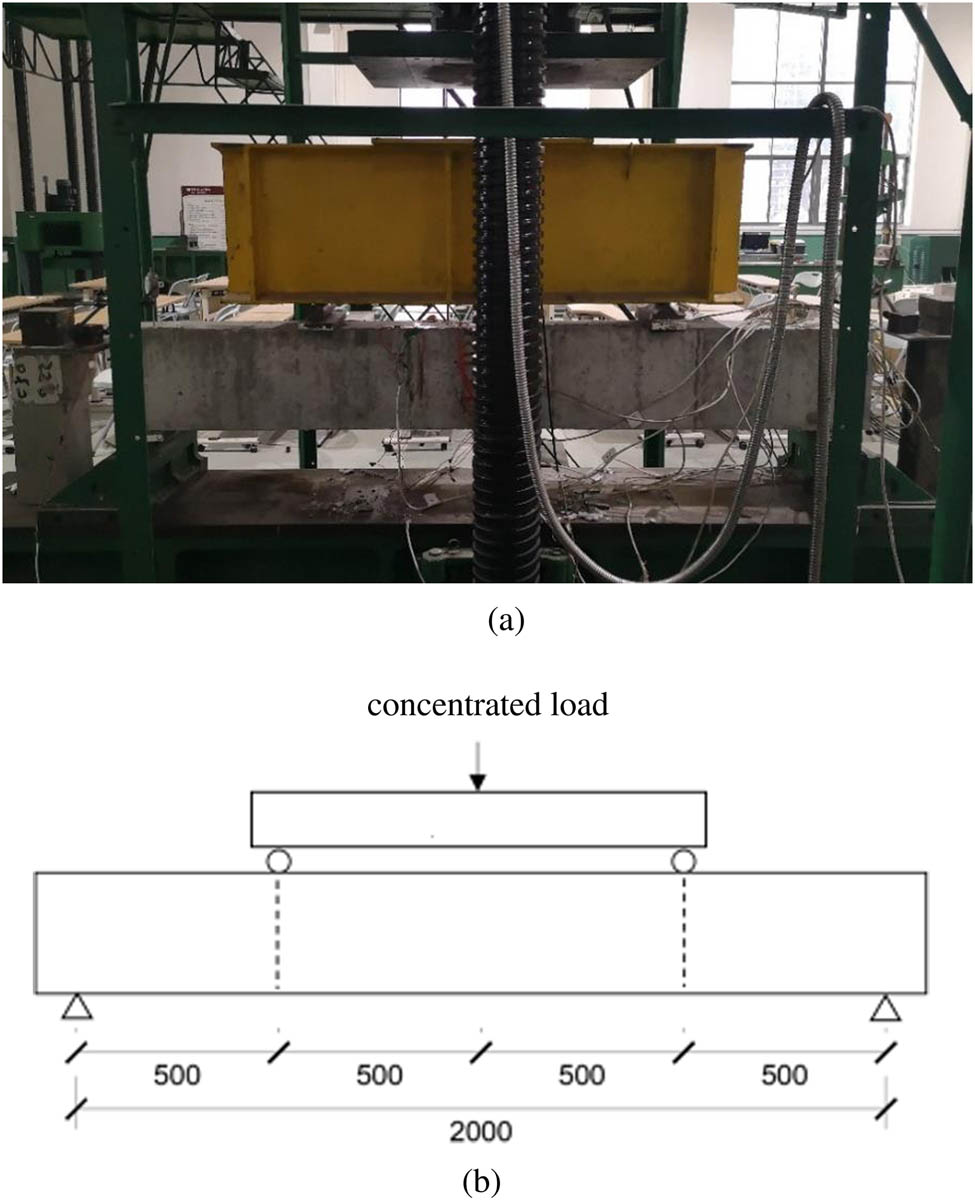

2.4 Loading equipment and loading plans

A pre-loading test was conducted before a formal loading. A 5,000 kN electro-hydraulic servo pressure testing machine was used to symmetrically apply force to the distribution beam in three stages. The force of each stage was 5% of the estimated value of the ultimate load of the test beam. The pressure was unloaded to 0 MPa provided that the machine could normally operate. Then, loading was formally performed. Loading was performed in stages. Each stage was 10 kN. It reduced by half when the load value approximated the cracking load. After the load exceeded the peak load, loading was performed at a constant speed until the bearing capacity of the test beam decreased to 85% of the peak load. Unloading was performed following completion. Observations were made at all times during the whole process. The conditions, development, strike, and load of cracks were recorded. Figure 3 depicts the schematic diagram for experimental setup for the test beam.

Schematic diagram for experimental setup. (a) Experimental setup and (b) diagram of experimental set-up.

3 Test results and analyses

3.1 Load–midspan deflection curve

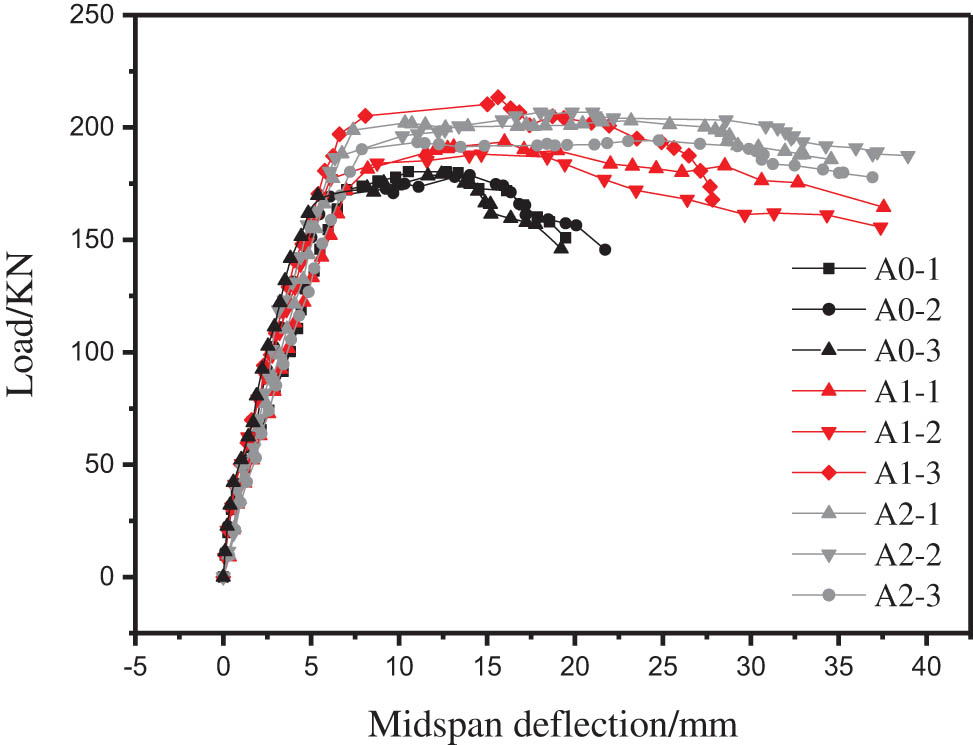

The load–midspan deflection was used to describe the macroscopic properties of the concrete beams. The load–midspan deflection curve can visually display the changes in beam deflection with changes in loading force.

The rectangular beam load–midspan deflection curve is shown in Figure 4. Table 3 shows the ultimate load and corresponding midspan displacement of the test beams.

Load–midspan deflection curve of the test beam.

Ultimate load and corresponding midspan deflection of the test beam

| Number of test beam | Ultimate load (kN) | Midspan deflection corresponding to the ultimate load (mm) |

|---|---|---|

| A0-1 | 180.36 | 10.53 |

| A0-2 | 178.77 | 14.02 |

| A0-3 | 179.29 | 12.32 |

| A1-1 | 193.60 | 16.00 |

| A1-2 | 188.13 | 14.67 |

| A1-3 | 213.40 | 15.63 |

| A2-1 | 202.95 | 23.19 |

| A2-2 | 206.80 | 21.01 |

| A2-3 | 194.25 | 24.77 |

For ease of analysis, Figure 5 shows the average load–midspan deflection curve in A0, A1, and A2 groups, and Table 4 presents the ultimate load of beams and corresponding midspan deflection of the test beams in A0, A1, and A2 groups.

Average load–midspan deflection curve of the test beam.

Ultimate load and corresponding midspan deflection of the test beams

| Number of test beam | Ultimate load (kN) | Midspan deflection corresponding to the ultimate load (mm) | Initial stiffness (MPa) |

|---|---|---|---|

| A0 | 178.99 | 13.17 | 30.82 |

| A1 | 198.03 | 15.55 | 29.22 |

| A2 | 200.38 | 20.85 | 28.04 |

Based on an analysis of Figure 5 and Table 4, we can draw the following conclusions:

The addition of polypropylene fiber significantly improves the ultimate bearing capacity of the rectangular beams. The ultimate anti-bending bearing capacity of beam A1 of concrete doped with macro-polypropylene fiber alone and beam A2 of concrete doped with three types of multi-size polypropylene fibers increases by 10.64 and 11.95%, respectively, compared with that of beam A0 of ordinary concrete.

Based on a comparison between beam A1 of concrete doped with macro-polypropylene fiber alone and beam A0 of ordinary concrete, the ultimate anti-bending bearing capacity of the beam improves significantly after the addition of macro-fiber. Based on a comparison between beams A2 and A1 of concrete doped with multi-size polypropylene fiber, it can be found that the addition of several types of multi-size polypropylene fibers and a single type of macro-fiber play similar roles in improving the ultimate anti-bending bearing capacity of the concrete beams. But the midspan deflection corresponding to the ultimate load of the beam of multi-size PFRC is the greatest. The midspan deflection corresponding to the ultimate load of A1 and A2 increases by 18.07% and 58.31%, respectively, compared with that of A0. The multi-size polypropylene fiber can significantly toughen concrete beams.

Based on an analysis of the curve, after the ordinary concrete beam A0 reaches its ultimate bearing capacity, the curve enters the descending section instantly. The bearing capacity rapidly decreases to less than 85% of the ultimate bearing capacity in the case of a small decrease in deflection. As indicated in Figure 5, the curve is steep and the descending slope is small. The curve does not descend suddenly, and its bearing capacity is decreasing along a relatively stable curve after the macro-PFRC beams and the multi-size PFRC beams reach the extreme values of load. In particular, the load–deflection curve of beam A2 of multi-size PFRC is most saturated, indicating that although the ultimate anti-bending bearing capacity of the multi-size PFRC and the ultimate anti-bending bearing capacity of the macro-fiber are similar, the multi-size polypropylene fiber substantially strengthens the beam’s ductility and plays significant roles in resisting cracks and increasing toughness.

3.2 Load–longitudinal bar strain curve

The load–longitudinal bar strain curve was used to analyze the force condition of the longitudinal bars in the concrete beams following the addition of polypropylene fiber. Based on a tensile test on the bars, the yield strain of the longitudinal bars was 2,278 με.

For ease of analysis, the average values of the nine beams were used to plot the load–longitudinal bar strain curves for the three sets of tests, as shown in Figure 6 and Table 5.

Load–longitudinal bar strain curves for beams in each group.

Ultimate load and corresponding longitudinal bar strain of test beams

| Type of beam | Ultimate load (kN) | Longitudinal bar strain corresponding to the ultimate load

|

|---|---|---|

| A0 | 178.99 | 11,190 |

| A1 | 198.03 | 16,844 |

| A2 | 200.38 | 17,225 |

Figure 6 compares the longitudinal bar strain of the ordinary concrete beam A0, beam A1 of concrete doped with polypropylene macro-fiber alone, and beam A2 of concrete doped with multi-size polypropylene fibers. As can be seen in the figure, the longitudinal bars of A0, A1, and A2 exceed the yield strain of longitudinal bars and reach the yield when they reach the ultimate anti-bending bearing capacity of beams. Based on a comparison of beams A1 and A2 of concrete doped with polypropylene fiber and beam A0 of ordinary concrete, the load on the beams of concrete doped with fiber is larger than the load on the beams of ordinary concrete in the case of the same longitudinal bar strain before the component reaches the ultimate bearing capacity. This indicates that the fiber in the concrete and the longitudinal bars jointly bear the load, exert good synergistic effects, and improve the anti-bending bearing capacity of the concrete beams. The longitudinal bar strains of beam A1 of concrete doped with macro-fiber alone and beam A2 of concrete doped with multi-size polypropylene fibers reach 16,844 με and 17,255 με, respectively, which are 50.5 and 54.2% higher than that of ordinary concrete beams. Nevertheless, based on the comparison of the latter half section of the two curves, the descending section of the load–longitudinal strain curve for the beams of concrete doped with multi-size polypropylene fiber is more stable and saturated, with better concrete beam integrity and ductility. Adding the multi-size polypropylene fiber to the concrete can make its internal structural stress uniform. Polypropylene fibers of different dimensions can produce synergistic effects together with reinforcement bars, improve the concrete’s toughness, and improve the ultimate anti-bending bearing capacity of concrete beams.

3.3 Comparison of cracking loads

During the process of loading, the test beams were observed for cracks. The load data were acquired immediately after any cracks were observed. Meanwhile, the ZBL-F130 crack width observer visualizer was used to measure the crack width. The cracking loads of the normal section anti-bending test beams in the three groups and the corresponding crack width are shown in Table 6.

Cracking load and crack width of test beams

| Number of test beam | A0-1 | A0-2 | A0-3 | A1-1 | A1-2 | A1-3 | A2-1 | A2-2 | A2-3 |

|---|---|---|---|---|---|---|---|---|---|

| Cracking load (kN) | 66.89 | 63.28 | 63.60 | 62.12 | 64.18 | 69.69 | 79.78 | 76.23 | 80.06 |

| Crack width (mm) | 0.078 | 0.078 | 0.076 | 0.043 | 0.052 | 0.054 | 0.041 | 0.036 | 0.031 |

By analyzing the cracking load and crack width of the test beams, we can draw the following conclusions:

The cracking loads of concrete in various groups with different amounts of addition are averaged. The cracking load of ordinary concrete beams is 64.59 kN. The cracking load of the beams of concrete doped with polypropylene macro-fiber alone is 65.33 kN. The cracking load of the beams of concrete doped with three types of multi-size polypropylene fiber is 78.69 kN. The cracking load of concrete beams doped with polypropylene macro-fiber alone increases by 1.15%, and the cracking load of concrete beams doped with multi-size polypropylene fiber increases by 21.83% when compared to that of ordinary concrete beams.

Based on a comparison between A0 and A1, the addition of the polypropylene macro-fiber does not significantly elevate the cracking load of the concrete beams, but the crack width at crack initiation decreases. This is because the bond stress of the polypropylene macro-fiber strengthens the concrete’s integrity and shrinks the width of the initial cracks accordingly.

The cracking load of beams of concrete doped with multi-size polypropylene fiber increases significantly, and the crack width shrinks significantly compared with that of ordinary concrete beams. This is because polypropylene fibers of different dimensions support and complement each other, thus forming a spatial reticular structure, strengthening the beam’s toughness, and inhibiting the development of cracks. Based on a comparison between beam A2 and beam A1, the initial cracks of concrete beams were significantly suppressed after the concrete was doped with polypropylene micro-fibers of different dimensions in addition to polypropylene macro-fiber, indicating that the polypropylene micro-fiber dominates in the initial stage of concrete cracks development.

3.4 Crack pattern and failure mode

Generally, vertical curved cracks occurred first in the purely bending section of the beam when the load on the beam was being increased until failure. Vertical curved cracks were observed during loading. It was found that the number of cracks significantly increased with time. The height and width were constantly developing. Small cracks occurred in the shear span area. Finally, a large vertical crack occurred in the vicinity of the midspan. The compressive zone of the midspan concrete was crushed, and the test piece failed.

As can be seen in Figure 7, all three test pieces, A0, A1, and A2, suffer normal section bending failure under the action of load. A major crack with a large width extending upward occurs in the midspan.

(Continued)

Based on a comparison between the ordinary concrete beam A0 and beam A1 of concrete doped with macro-polypropylene fiber alone, the normal cracks produced by the A0 test piece are more than those produced by A1, and the cracks are more densely distributed in A0 than in A1. In the middle and later periods of compression of the test piece, it was apparently observed that the propagation of cracks in the test piece A1 was inhibited and impeded by the polypropylene macro-fiber. Finally, the concrete in the compressive zone of the test piece A0 is completely crushed and falls off in a large size. The concrete in the compressive zone of the test piece A1 is crushed, but the process of falling off is significantly inhibited. This indicates that adding the polypropylene macro alone can effectively limit the crushing of concrete.

Beam A2 of concrete doped with macro and micro multi-size polypropylene fibers of three dimensions, beam A1 of concrete doped with macro-polypropylene fiber alone, and beam A0 of ordinary concrete were compared and analyzed. The addition of polypropylene fiber inhibits the development of cracks, increases the number of cracks during compression of the concrete beams, and inhibits the width of cracks. The production and development of microcracks of beam A2 in the initial bending stage are more suppressed than those of A1 due to the fact that the concrete of beam A2 is doped with polypropylene micro-fiber in addition to the polypropylene macro-fiber. The three-dimensional disordered supporting system formed by the macro- and micro-fiber distributed in the beams of concrete doped with multi-size polypropylene fiber can also exert synergistic effects and bear the force together with the matrix, thus making the force applied on the internal structure of the concrete more uniform and improving the integrity and ductility of the concrete. Thus, the crack propagation in the beams of concrete doped with multi-size polypropylene fiber and the crushing of concrete in the compressive zone are significantly inhibited.

The addition of multi-size polypropylene fiber strengthens the deformation capacity of beams, reduces crack intervals, shrinks the crack width, and decreases the number of cracks. The three-dimensional disordered supporting system formed by the excellent gradation of macro- and micro-polypropylene fibers of different dimensions improves the beam integrity, strengthens the beam plasticity, and improves the beam stability.

3.5 Concrete deformation

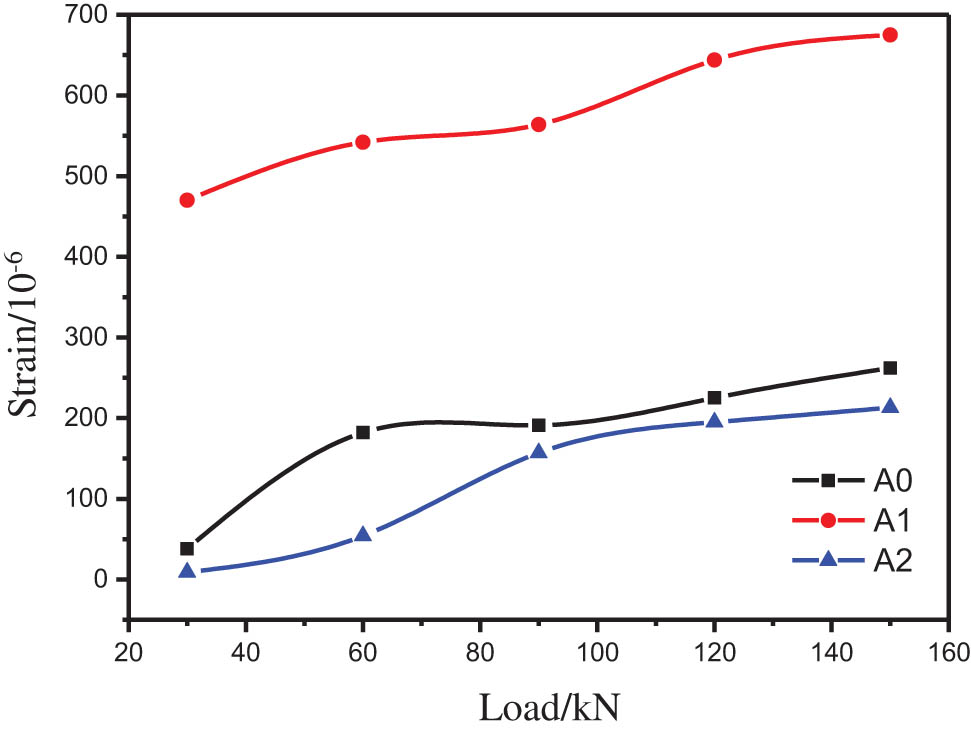

To study the effects of polypropylene fiber on the deformation of test beam concrete, the strain of beam A0 of ordinary concrete, the strain of beam A1 of concrete doped with macro-polypropylene fiber alone, and the strain of beam A2 of concrete doped with multi-size polypropylene fibers were analyzed and studied. Two methods were used to study the concrete strain. One was to acquire the longitudinal strain of the concrete of the same cross-section as the test beam midspan at different heights. The other was to acquire the transverse strain of the concrete of the cross-section at 200 mm from the concrete beam midspan.

80-mm-long concrete strain gauges were arranged along a certain height from the top of the concrete beam midspan to its bottom to measure concrete deformation at different cross-section heights of the purely bending section. For ease of analysis and comparison, the mean strain values in the case of beam loads of 30, 60, 90, 120, and 150 kN were used to plot as shown in Figure 8.

Distribution of strain of the beam midspan concrete along the cross-section height. (a) Ordinary concrete beam A0. (b) Beam A1 of concrete doped with polypropylene macro-fiber alone. (c) Beam A2 of beams of concrete doped with multi-size polypropylene fiber.

Figure 8 shows the concrete strain at different cross-section heights of the midspan of three groups of concrete beams under different loads. Based on a comparative analysis of beam A0 of ordinary concrete and beam A1 of concrete doped with macro-fiber alone, the strain in the compressive zone of A1 is significantly larger than that of A0. This is because the addition of macro-fiber increases the initial defects of the concrete beams. These initial defects cause the bearing capacity of concrete to decrease in the initial stage of compression and thus increase the strain in the compressive zone of the concrete. The strain of concrete in the tensile zone of the beams of concrete doped with multi-size polypropylene fiber is the largest. This is because the network of multi-size polypropylene fibers improves the ductility of the concrete beams.

Moreover, with the increase in load, the data from the concrete strain gauges may be somewhat missing and deviate. This is because cracks penetrate the strain gauges and cause them to fail. These error factors are excluded, and the results of three sets of tests are comprehensively analyzed. In terms of the ordinary concrete beam A0 and beams A1 and A2 of concrete doped with polypropylene fiber, the strain of each point of the midspan cross-section concrete is approximately in direct proportion to its distance to the neutral axis, and the cross-section is basically kept planar from the beginning of loading to failure. It can be inferred that the beams of PFRC basically meet the plane assumption during the process of bending.

To have a more comprehensive understanding of the variation rules of concrete strain, a strain gauge was located at 200 mm from the beam midspan to measure the transverse deformation of concrete at the cross-section. The measurement results are shown in Figure 9.

Comparison of transverse strains of concrete.

As can be seen in Figure 9, the three groups of beams can be arranged in descending order by the transverse strain of concrete: beam A1 of concrete doped with macro-fiber alone is greater than beam A0 of ordinary concrete, which is greater than beam A2 of concrete doped with multi-size polypropylene fiber. After the addition of polypropylene macro-fiber, the transverse strain of concrete increases somewhat. This is because the addition of polypropylene macro-fiber changes the microstructure of the concrete and increases the initial defects of the concrete. In addition, the larger diameter of the polypropylene macro-fiber increases the number and size of microcracks. Thus, the transverse strain of concrete increases after the addition of the macro-fiber. In the beams of concrete doped with multi-size polypropylene fiber, the macro-fiber along with two other types of micro-polypropylene fibers of different dimensions are added. The gradation of the fiber dimension is better, allowing for the formation of a staggered spatial network and improving the integrity of the concrete matrix. Moreover, the diameter of the polypropylene micro-fiber and the diameter of the concrete microcracks are similar in size. The polypropylene micro-fiber can significantly inhibit the occurrence and development of microcracks in concrete and reduce initial defects in the concrete matrix. Thus, the PFRC has the minimum transverse strain and displays the best integrity. As a result, beam A2 of beams of concrete doped with multi-size polypropylene fiber can bear the greatest load under the same concrete strain. As can be seen in the curve for concrete strain of the test beams in the three groups, the ascending section of the concrete strain curve for the beam doped with polypropylene fiber is smoother and without any obvious inflection point than that of ordinary concrete. This indicates that the addition of polypropylene fiber improves the internal structure of the concrete beams. In particular, the staggered and disordered three-dimensional system formed by the beams of concrete doped with multi-size polypropylene fiber significantly inhibits the development of cracks, controls the deformation of beams, and enables the beams of concrete doped with multi-size polypropylene fiber to bear greater force under the identical minimal deformation.

3.6 Calculation of bending resistance for multi-size PFRC beams

According to the code for the design of concrete structures (GB50010-2010) [24], bending resistance for multi-size PFRC beams is calculated as follows:

where

According to Eq. (1), calculate the bending bearing capacity of the normal section of three groups of test beams and compare the test results and theoretical calculation results, as shown in Table 7.

Comparison of the test results and theoretical calculation results

| Number of test beam | Test results of bending bearing capacity (kN·m) | Theoretical calculation results of bending bearing capacity (kN·m) | Test results divided by theoretically calculated results |

|---|---|---|---|

| A0-1 | 45.09 | 43.17 | 1.04 |

| A0-2 | 44.69 | 43.17 | 1.04 |

| A0-3 | 44.82 | 43.17 | 1.04 |

| A1-1 | 48.40 | 47.43 | 1.02 |

| A1-2 | 47.03 | 47.43 | 0.99 |

| A1-3 | 53.35 | 47.43 | 1.12 |

| A2-1 | 50.74 | 53.11 | 0.96 |

| A2-2 | 51.70 | 53.11 | 0.97 |

| A2-3 | 48.56 | 53.11 | 0.91 |

4 Conclusions

By conducting normal section anti-bending tests on ordinary concrete beams, beams of concrete doped with polypropylene macro-fiber alone, and beams of concrete doped with multi-size polypropylene fiber, we intensively studied the effects of multi-size polypropylene fiber on the load–midspan deflection curve, longitudinal bar strain curve, concrete strain, crack pattern, and failure mode of rectangular concrete beams and draw the following conclusions:

The addition of polypropylene fiber can significantly improve the ultimate anti-bending bearing capacity of rectangular beams. The ultimate anti-bending strength of beam A1 of concrete doped with polypropylene macro-fiber and beam A2 of concrete doped with multi-size polypropylene fibers improves by 10.64% and 11.95%, respectively, compared with that of ordinary concrete beams. However, the midspan deflection corresponding to the ultimate load of the beams of concrete doped with multi-size polypropylene fiber is 58.31 and 34.08% higher than that of A0 and A1, respectively.

Unlike beams of ordinary concrete, beams of concrete doped with polypropylene fiber do not have a sudden descending section on the load–deflection curve after they reach the ultimate load. This indicates that the multi-size polypropylene fiber substantially strengthens the beam’s ductility and elevates the anti-bending bearing capacity of beams.

The polypropylene fiber can improve the internal structure of the concrete matrix, but the addition of macro-fiber will increase the number of initial defects of the concrete matrix. By contrast, the multi-size polypropylene fiber can offset the defects caused by macro-fiber by utilizing the functions of micro-fiber of different dimensions. Notably, the disordered three-dimensional system formed by the multi-size polypropylene fiber can significantly inhibit the propagation of cracks and control the beam deformation, enabling the beams of concrete doped with multi-size polypropylene fiber to bear greater bearing capacity in the case of identical minor deformations of concrete.

-

Funding information: This study is supported by the Training Plan for Outstanding Young Scientific Research Talents in Colleges and Universities of Fujian Province (Grant No. GY-Z18160), and we gratefully acknowledge this support.

-

Author contributions: Ninghui Liang designed the experiments, Yang Hu conducted the experiments, and Xin Yang analyzed the experimental data. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state that there is no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

[1] Karahan, O. and C. D. Atls. The durability properties of polypropylene fiber reinforced fly ash concrete. Materials & Design, Vol. 32, No. 2, 2011, pp. 1044–1049.10.1016/j.matdes.2010.07.011Search in Google Scholar

[2] Fallah, S. and M. Nematzadeh. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Construction and Building Materials, Vol. 132, 2017, pp. 170–187.10.1016/j.conbuildmat.2016.11.100Search in Google Scholar

[3] Zhang, P. and Q. F. Li. Effect of polypropylene fiber on durability of concrete composite containing fly ash and silica fume. Composites Part B - Engineering, Vol. 45, No. 1, 2013, pp. 1587–1594.10.1016/j.compositesb.2012.10.006Search in Google Scholar

[4] Nili, M. and V. Afroughsabet. The effects of silica fume and polypropylene fibers on the impact resistance and mechanical properties of concrete. Construction and Building Materials, Vol. 24, No. 6, 2010, pp. 927–933.10.1016/j.conbuildmat.2009.11.025Search in Google Scholar

[5] Nia, A. A., M. Hedayatian, M. Nili, and V. A. Sabet. An experimental and numerical study on how steel and polypropylene fibers affect the impact resistance in fiber-reinforced concrete. International Journal of Impact Engineering, Vol. 46, 2012, pp. 62–73.10.1016/j.ijimpeng.2012.01.009Search in Google Scholar

[6] Noumowe, A. Mechanical properties and microstructure of high strength concrete containing polypropylene fibres exposed to temperatures up to 200 degrees C. Cement and Concrete Research, Vol. 35, No. 11, 2005, pp. 2192–2198.10.1016/j.cemconres.2005.03.007Search in Google Scholar

[7] Kakooei, S., H. M. Akil, M. Jamshidl, and J. Rouhl. The effects of polypropylene fibers on the properties of reinforced concrete structures. Construction and Building Materials, Vol. 27, No. 1, 2012, pp. 73–77.10.1016/j.conbuildmat.2011.08.015Search in Google Scholar

[8] Pachideh, G. and M. Gholhaki. An experimental study on the effects of adding steel and polypropylene fibers to concrete on its resistance after different temperatures. Journal of Testing and Evaluation, Vol. 47, No. 2, 2019, pp. 1606–1620.10.1520/JTE20170145Search in Google Scholar

[9] Arslan, G., R. S. O. Keskin, and M. Ozturk. Shear behaviour of polypropylene fibre-reinforced-concrete beams without stirrups. Proceedings of the Institution of Civil Engineers-Structures and Buildings, Vol. 170, No. 3, 2017, pp. 190–198.10.1680/jstbu.16.00202Search in Google Scholar

[10] Cao, P., D. C. Feng, C. J. Zhou, and W. X. Zuo. Study on fracture behavior of polypropylene fiber reinforced concrete with bending beam test and digital speckle method. Computers and Concrete, Vol. 14, No. 5, 2014, pp. 527–546.10.12989/cac.2014.14.5.527Search in Google Scholar

[11] Bicer, K., H. Yalciner, A. P. Balks, and A. Kumbasaroglu. Effect of corrosion on flexural strength of reinforced concrete beams with polypropylene fibers. Construction and Building Materials, Vol. 185, 2018, pp. 574–588.10.1016/j.conbuildmat.2018.07.021Search in Google Scholar

[12] Sahoo, D. R., A. Solanki, and A. Kumar. Influence of steel and polypropylene fibers on flexural behavior of RC beams. Journal of Materials in Civil Engineering, Vol. 27, No. 8, 2015, id. 04014232.10.1061/(ASCE)MT.1943-5533.0001193Search in Google Scholar

[13] Zhmagul, N., Z. B. Bakirov, N. Vatin, M. Bakirov, I. A. Kurokhtina, D. Tokanov, et al. Stress intensity factor of reinforced concrete beams in bending. Buildings, Vol. 11, No. 7, 2021, id. 287. 0.3390/buildings11070287.Search in Google Scholar

[14] Kozar, I., N. B. Odorcic, S. Mrakovcic, and Z. Bozic. Layered model of crack growth in concrete beams in bending. Procedia Structural Integrity, Vol. 31, No. 16, 2021, pp. 134–139.10.1016/j.prostr.2021.03.022Search in Google Scholar

[15] Jurkiewiez, B., S. Durif, A. Bouchair, and C. Grazide. Experimental and analytical study of hybrid steel-timber beams in bending. Structures, Vol. 39, 2022, pp. 1231–1248.10.1016/j.istruc.2022.03.055Search in Google Scholar

[16] Hussien, M. A., M. Moawad, M. H. Seleem, H. E. M. Sallam, and H. M. El-Emam. Mixed-mode fracture toughness of high strength FRC: A realistic experimental approach. Archives of Civil and Mechanical Engineering, Vol. 22, 2022, id. 168.10.1007/s43452-022-00492-8Search in Google Scholar

[17] Merwad, A. M., A. A. EI-Sisi, S. A. A. Mustafa, and H. E. M. Sallam. Lateral impact response of rubberized-fibrous concrete-filled steel tubular columns: Experiment and numerical study. Buildings, Vol. 12, No. 10, 2022, id. 1566.10.3390/buildings12101566Search in Google Scholar

[18] Ali, A. Y. F., H. M. El-Emam, M. H. Seleem, H. E. M. Sallam, and M. Moawad. Effect of crack and fiber length on mode I fracture toughness of matrix-cracked FRC beams. Construction and Building Materials, Vol. 341, 2022, id. 127924.10.1016/j.conbuildmat.2022.127924Search in Google Scholar

[19] Elakhras, A. A., M. H. Seleem, and H. E. M. Sallam. Intrinsic fracture toughness of fiber reinforced and functionally graded concretes: An innovative approach. Engineering Fracture Mechanics, Vol. 258, 2021, id. 108098.10.1016/j.engfracmech.2021.108098Search in Google Scholar

[20] Othman, M. A., H. M. El-Emam, M. H. Seleem, H. E. M. Sallam, and M. Moawad. Flexural behavior of functionally graded concrete beams with different patterns. Archives of Civil and Mechanical Engineering, Vol. 21, 2021, id. 169.10.1007/s43452-021-00317-0Search in Google Scholar

[21] De Domenico, D. and G. Ricciardi. Shear strength of RC beams with stirrups using an improved Eurocode 2 truss model with two variable-inclination compression struts. Engineering Structures, Vol. 198, 2019, id. 109359.10.1016/j.engstruct.2019.109359Search in Google Scholar

[22] Cladera, A., A. Marí, J. M. Bairán, C. Ribas, E. Oller, and N. Duarte. The compression chord capacity model for the shear design and assessment of reinforced and prestressed concrete beams. Structural Concrete, Vol. 17, No. 6, 2016, pp. 1017–1032.10.1002/suco.201500214Search in Google Scholar

[23] Structural and technical specifications for fiber-reinforced concrete (CECS38:2004), China Planniang Press, Beijing, 2004.Search in Google Scholar

[24] Code for design of concrete structures (GB50010-2010), China Architecture & Building Press, Beijing, 2015.Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants