Abstract

State-of-the-art treatment of such orthopedic diseases as fracture and femoral head necrosis implies the installation of prosthesis or fixed equipment into patients’ injured parts using bone drilling. This study proposes an ultrasonic longitudinal torsion-assisted drilling (ULTAD) technique for biotic bone drilling. A comparative experiment was carried out between conventional drilling and ULTAD drilling in biotic bone, namely porcine femur. These tests proved that under the same drilling parameters, the ultrasonic component in bone drilling could reduce the drilling temperature and forces, improve the material removal by chip breaking, shorten the length of bone debris, and facilitate their discharge. Moreover, the proposed ULTAD technique reduced the number, length, and width of microcracks in the borehole wall, thus protecting the drilled biotic bone from internal damage.

1 Introduction

To treat fractures and related orthopedic diseases, microholes are drilled in the patient’s injured bones to implant plates, nails, and other fixation devices by doctors. However, relatively high drilling forces and temperatures in conventional bone-drilling operations may cause serious damage to bone tissue [1,2]. Therefore, factors influencing the bone-drilling process have been thoroughly investigated [3,4,5,6].

Therefore, it is necessary to investigate the forces and temperatures during the bone-drilling process. The mechanism of bone chips’ removal during bone drilling is the continuous relative motion between the drill bit and the bone tissue surface that allows the removal of bone chips. The friction between the drill bit and the bone tissue surface and the variation of shear force during the drill feed lead to the variation of drilling temperature. Due to the poor thermal conductivity of the bone tissue, the drill bit has a high temperature in contact with the bone tissue [7]. Studies have shown that when bone tissue is continuously exposed to 47°C for 60 s or 50°C for 30 s, the cells become permanently necrotic [8].

A large number of scholars have conducted research on how to reduce drilling temperatures, drilling forces, and the number of microcracks. The study shows that the controlled machining parameters have a significant effect on the drilling force and the temperature in the drilling bone zone [9]. Therefore, some studies related to the processing parameters of bone drilling were carried out. Song’s team built a 3D model of a new drill bit that assembles the inner core (bit) and the drill sleeve together, conducted a drilling simulation study using a 3D cylinder instead of the skull, and found that the tip angle of the bit has a greater effect on temperature than on drilling force [10]. MacAvelia et al. found through conventional drilling (CD) experiments that the tool speed has a direct effect on the cutting force at a constant feed rate and drill diameter [11]. Fernandes et al. [12] used thermocouples to monitor the temperature rise during bone drilling and found that bones of different densities had different drilling temperatures during the drilling process. Sugita et al. [13] designed a drilling tool for drilling cattle bones, which can reduce temperature rise and cutting force, and found that multi-groove cutting tool design can reduce the temperature during drilling. Soriano [14] found that the drilling force increases with increasing tool feed rate and decreases with increasing tool speed by studying the variation of drilling force and temperature during bovine bone drilling. Sarparast et al. [15] found that increasing the tool speed could reduce the drilling force and temperature when drilling bovine femur. Yahui et al. found that the drilling force fluctuated to some extent due to the mechanical properties of the bone, and the relationship between the drilling force and the experimental parameters was close to an exponential relationship according to the regression model established [16–18].

In addition to traditional bone drilling, a great deal of research has focused on developing new bits and new bone-drilling techniques to optimize drilling forces and temperatures and improve drilling quality [19–24]. Ultrasonic vibration-assisted machining has the advantages of reducing the drilling heat and drilling force generated during machining, improving the surface quality of the workpiece, reducing the exit burr height, and improving the drilling condition [25,26]. Wang et al. found that the temperature in the borehole area was inversely related to the frequency and amplitude of ultrasonic vibration [27]. Chen et al. [28] found that low-frequency ultrasonic vibration can effectively reduce thermal damage during drilling; compared with conventional bone drilling, the maximum drilling temperature of this drilling method can be reduced by 27% and the thermal damage coefficient can be reduced by 18.3%. To reduce the drilling force and drilling temperature and improve drilling temperature, related scholars put forward the method of rotary ultrasonic bone drill. Gupta and Pandey [29] performed rotational ultrasound and CD tests on pig bone and found that drilling force and drilling temperature decreased with increasing ultrasound amplitude and tool speed. Singh et al. [30] applied rotary ultrasonic drilling to human cadaveric bone samples and found that rotary ultrasonic drilling bone drilling temperatures could be reduced to 50–60% and drilling forces could be reduced by 30–40% compared to conventional bone drilling. However, during rotational ultrasonic bone drilling, friction between the soft tissue of the bone and the sharp edge of the drill bit can lead to increased drilling temperatures and increased drilling forces at the bone–bit interface. The increased drilling force and temperature may lead to increased microcracking and risk of bone thermal necrosis in bone repair procedures, and the drilling force may affect bone chip morphology and microcrack generation at the bone–bit interface site.

Studies have shown that ultrasonic longitudinal torsion-assisted drilling (ULTAD) can improve the drilling forces and excessive drilling temperatures during machining. However, ULTAD technology has not been applied to bone-drilling tests [31].

Herein, we propose a novel technique for biotic bone drilling: ULTAD. The proposed technique is compared with CD of biotic bone to clarify trends of drilling force and temperature during drilling and compare the surface quality of biotic bones after drilling.

2 Kinematics analysis in ULTAD

2.1 Basic principles of the ULTAD

Figure 1 describes the ULTAD motion model of drill bone. The axial displacement equation of the blade in ULTAD is:

where A is the ultrasonic amplitude (unit: μm);

Simplified model of ULTAD. (a) Schematic representation of ULTAD process. (b) Cutting edge trajectory for ULTAD.

The tool path at a specific moment during the ULTAD can be expressed as:

At zero amplitude A = 0, the cutting edge path during the CD can be determined as follows:

According to equations (2) and (3), the cutting tool paths during ULTAD and CD bone-drilling processes at

Cutting edge path during the CD.

Cutting edge path during the ULTAD.

As can be seen in Figures 2 and 3, there is a clear difference between the two cutting edge paths: in CD, the cutting edge path is a regular spiral curve; in ULTAD, the cutting edge path is wavy and can be approximated by a sine curve. This can be attributed to the change in tool motion (regular feed) due to the presence of ultrasonic longitudinal torsional vibrations. This also indicates that ULTAD has a larger repetitive cutting area for the same drilling conditions, which facilitates the change of chip thickness, achieving bone chip breakage and improving the surface finish of the drilling.

2.2 Chip thickness analysis

During the drilling process, the crushing and discharge of bone chips have a direct impact on the drilling temperature. The longer the chip is, the more difficult it is to remove and the higher the drilling temperature. Therefore, it is necessary to analyze the bone chip fracture effect.

According to the twist drill design, at the same time, two main cutting edges (a cutting edge, b cutting edge) on the point of symmetry about the central axis, their angle difference is π. Therefore, the axial displacement equations of a and b are:

Therefore, the variable cutting thickness under ULTAD can be obtained:

The motion track diagram and chip thickness curve diagram of ultrasonic vibration drill bone cutting edge are drawn in MATLAB, as shown in Figure 4.

Motion trajectory and chip thickness of bone cutting edge by ULTAD. f = 35 kHz, A = 4 μm, n = 2,000 rpm, fr = 0.001 mm·r−1.

As can be seen in Figure 4, the distance between two adjacent main cutting edges in the ULTAD drill bone varies regularly and periodically. With the twist drill rotating at high speed and constantly feeding, there will be a regular intersection between the two insert trajectories, i.e. the chip thickness between the two cutting edges changes periodically during the ULTAD bone-drilling process, and when the chip thickness of the two cutting edge trajectories intersecting is zero, thus achieving bone chip crushing. According to this property, the desired chip effect (thickness and length) can be obtained theoretically by changing the ULTAD parameters and machining parameters.

3 Materials and methods

3.1 Materials

It was found that the bone density and fracture stress of pigs and dogs were closest to those of human bones [32]. Therefore, fresh pig bones were selected as the test material to ensure the accuracy of the test results. First, the two large ends of the femur of pigs slaughtered and purchased on the same day were sawed off, leaving the spine. Then, to facilitate clamping and to facilitate the observation of drilling quality and repeated cleaning of the inner wall of the hole after the experiment, the pig femur before and after treatment is shown in Figure 5.

Test materials. (a) Untreated pig bone and (b) treated pig bone.

3.2 Equipment

The test tool is a 4 mm diameter stainless steel twist drill with a tip angle and spiral angle of 118 and 28°, respectively, as shown in Figure 6.

Experimental tool.

Fresh pork bone-drilling tests were conducted on a VMC850E machine on a vertical machining center. The test platform is shown in Figure 7. A crystal piezoelectric triaxial dynamometer model 9257B was used to collect drilling forces during drilling, in conjunction with a 5070A multi-channel charge amplifier. A FLIR T640 infrared thermometer was used to capture the temperature changes during drilling. SEM was used to observe microcracks on the surface of the biologic bone.

The test platform.

3.3 Tool ultrasonic amplitude test

Measurement of drill end amplitude output is performed using a KEYENCE-LK laser displacement sensor. The device has a sampling period of 128–2048 μs and a repeatability accuracy of 0.01 μm. When measuring the tool tip amplitude, the beam needs to be focused at the tool to be tested, and by adjusting the distance between the laser displacement transducer and the tool, the vibration data can be collected stably, and the value of the measured amplitude is known by the auxiliary software. Since the tip of the drill is not a flat surface, it is very difficult to gather the beam at the tip. On the premise of ensuring the accuracy of the measurement data, a small part of the tip of the drill to be measured is ground off with a grinding wheel to form a microplane. The maximum axial amplitude measured was 8 μm, as shown in Figure 8.

Amplitude test data.

Since this experiment uses a longitudinal twist type composite variable amplitude rod, in addition to calibrating the axial vibration of the drill, this experiment also deflects the laser displacement sensor by a certain angle to calibrate the cutting edge amplitude and to improve the accuracy, multiple points of amplitude calibration were performed on both the left and right sides of the drill.

3.4 Approach

The selection of machining parameters is determined according to the previous research, as shown in Table 1 [33]. The cutting edge path at any time was derived via Eq. (2). Each drilling test was conducted three times with the same parameter, and the mean value was adopted as the test result. Under the same processing parameters, the ULTAD and CD were conducted on the same pig femur by alternating processing. First, zero ultrasonic component was used for CD. Then, a non-zero one was added to provide the ULTAD to ensure the test reliability.

Selected test parameters and their values

| Processing parameters | Value |

|---|---|

| Bit diameter (mm) | 4.0 |

| Frequency (Hz) | 35,000 |

| Amplitude (μm) | 0, 2, 4, 6, and 8 |

| Spindle speed (rpm) | 800, 1,400, 2,000, 2,600, and 3,200 |

| Feed rate (m·min−1) | 10, 20, 30, 40, and 50 |

4 Results

The following discussion is related to the results of the test group with a spindle speed of 2,000 rpm, a feed rate of 20 mm·min−1, an ultrasonic-assisted frequency of 35 kHz, and an ultrasonic amplitude of 4 μm.

4.1 Drilling temperature during ULTAD

Drilling zone temperatures measured via the FLIR T640 infrared thermometer during the ULTAD and CD as shown in Figure 9. Herein, the blue part was the processed pig femur. As observed, ULTAD bone drilling could effectively reduce the maximal temperature in the drilling zone by 4℃. The discharge of hot chips released part of the heat.

Infrared thermograph. (a) ULTAD and (b) CD.

4.2 Axial force in ULTAD

A piezoelectric crystal three-way dynamometer was used to collect the axial force data under the two bone-drilling conditions, as shown in Figure 10.

Diagram of axial force with time. (a) ULTAD and (b) CD.

The axial force started to rise slowly when the drill bit touched the porcine femur and started drilling; when the drill bit was completely in the porcine femur, the axial drilling force showed a steady state with slight fluctuations at this stage; and when it was in the drilling-out stage, the axial force started to decrease slowly. The maximum axial force was 41.98 and 32.05 N for CD and ULTAD, respectively, with a difference of 23.65%. This strongly indicates that ULTAD effectively reduces the axial drilling force.

This improvement was mainly due to the change in contact modes between the tool and bone from continuous contact to intermittent contact, which reduced the effective contact area, thus reducing the friction between tool and bone and then reducing the maximum axial force. As observed, the ULTAD had a slightly larger fluctuation range than CD because there was acceleration between the bit and biotic bone under the ULTAD bone-drilling conditions. The acceleration changed periodically, which induced the larger fluctuation range under ultrasonic-assisted conditions.

4.3 Chip-breaking effect of ULTAD

Bone debris obtained via these two processing methods (see Figure 11) was selected for the comparative analysis.

Bone debris obtained by the two processing methods. (a) ULTAD and (b) CD.

As shown in Figure 11, the bone debris under the CD conditions included chips with a relatively long length. This increased the possibility of bone debris wrapping around the tool, inhibiting their removal, and scratching the inner wall of the hole in their removal process. The bone debris lengths under the ULTAD conditions were much shorter than under CD conditions. This was mainly because the paths between the two cutting edges in CD were parallel. The chip thickness was stable, and there was only a mechanical chip-breaking mode. In the ULTAD bone drilling, due to ultrasonic vibration, the two paths of cutting edges changed periodically, thus changing the thickness of bone debris and forming the geometrical chip-breaking effect to a certain extent.

4.4 Borehole cracking under ULTAD bone-drilling conditions

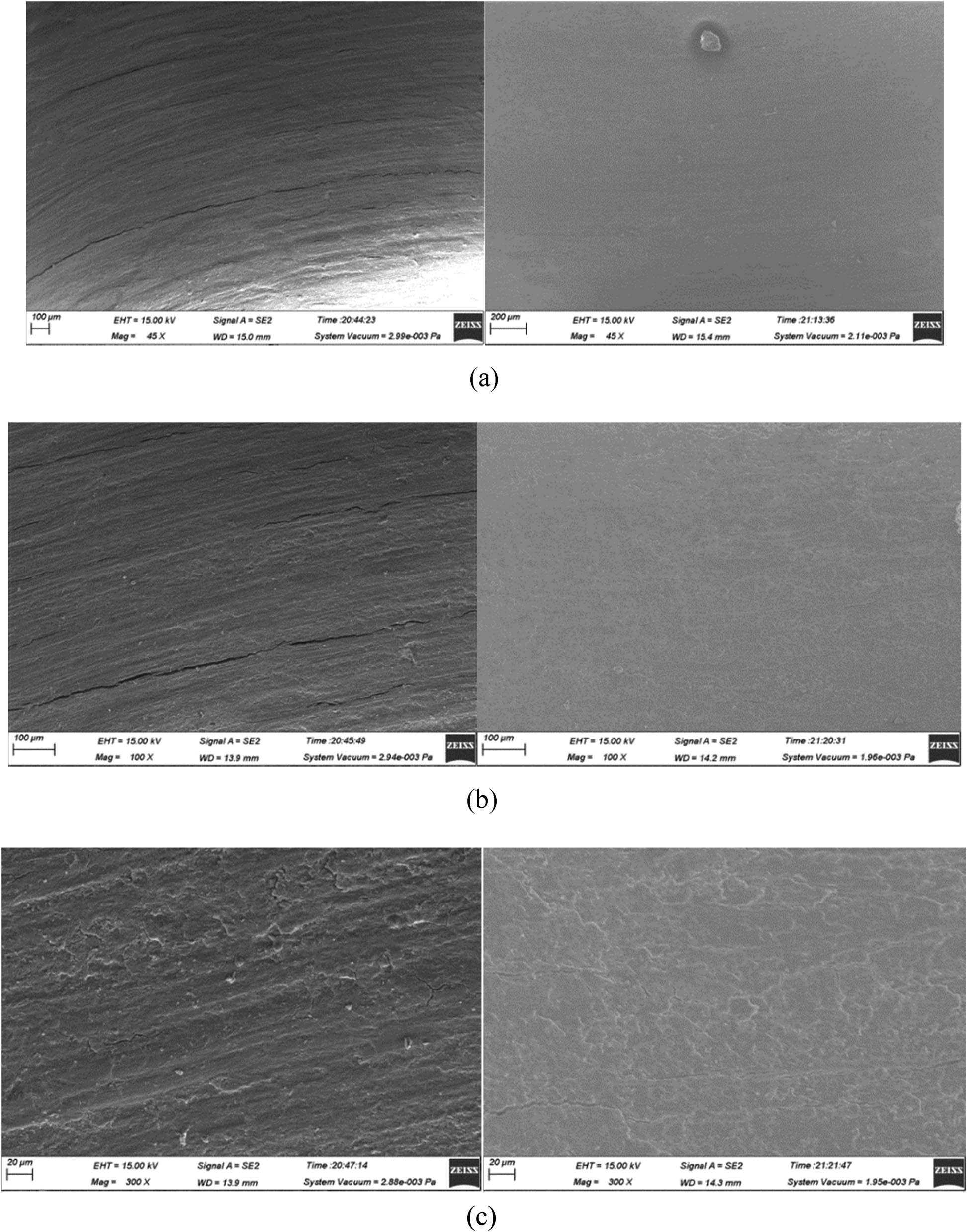

Drilling can easily cause tissue damage or even cracking of the biotic bone. It was necessary to study the microcracks of the inner wall of boreholes obtained via the CD and ULTAD bone drilling under the same processing parameters.

For bone drilling and microcrack on the inner wall of the hole, the images were selected for comparative analysis. The comparison of the microcracks on the inner wall of the boreholes drilled via the ULTAD and CD under the same processing parameters is presented in Figure 12 with magnifications of 45×, 100×, and 300×.

The comparison of the microcracks on the inner wall of the boreholes drilled. Left: CD; right: ULTAD. (a) 45×; (b) 100× and (c) 300×.

In Figure 12, at 45× and 100×, magnifications, the number, length, and width of cracks induced by CD were larger than that of ULTAD. Besides, in the former case, the inner wall of the borehole was rougher, and the knife mark was more obvious. At a 300× magnification, flake bone debris on the inner wall surface of the workpiece could be observed under both different processing methods, but the bone debris of the ULTAD was more compact. According to Agarwal et al., the strength of microcracks increases with increasing cutting force [34]. Compared to CD, ultrasonic torsional drilling has lower drilling forces and therefore better surface quality. In addition, the ultrasonic impact reduced the fracture stress of the workpiece, making the material removal easier and reducing the number, length, and width of microcracks.

5 Discussion

Due to the experimental conditions, this article does not study the effect of ultrasonic frequency on the maximum axial force and maximum temperature law. The tool used in this article is relatively single, and the next twist drill with different parameters can be selected for more detailed study.

Since the workpiece in this article is a fresh pig femur, there will be some differences between each individual workpiece. To eliminate the influence of experimental materials, fresh pig femurs of the same batch and the same growth cycle can be used in the next study.

6 Conclusions

In this article, we demonstrate that ULTAD is a method to improve the quality of bone drilling and reduce the risk of the procedure through the development of ULTAD model and drilling characteristics.

Compared with CD, ULTAD can effectively reduce the axial force in the borehole. The stress distribution in the ULTAD bone borehole is more uniform, and the maximum stress distribution area is smaller. Under the same processing parameters, the area temperature is lower in ULTAD compared to CD. the CD chip is in a continuous state, while the shape of the UVAD chip becomes intermittent, indicating that ULTAD bone drilling facilitates chip fracture. Also, ULTAD bone drilling can reduce the number, length, and width of microcracks on the hole wall.

Acknowledgments

The authors are thankful for the financial support from the National Natural Science Funds of China (U1904170).

-

Funding information: This work was financially supported by the National Natural Science Funds of China (U1904170).

-

Author contributions: All authors have accepted responsibility for the entire content of this article and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The data used to support the findings of this study are available from the corresponding author upon request.

References

[1] Jamil, M., A. M. Khan, H. Hegab, M. Mia, and M. K. Gupta. Modeling, multi-objective optimization and cost estimation of bone drilling under micro-cooling spray technique: An integrated analysis. International Journal on Interactive Design and Manufacturing (IJIDeM), Vol. 14, 2020, pp. 435–450.10.1007/s12008-019-00635-xSearch in Google Scholar

[2] Jamil, M., A. M. Khan, M. Mia, A. Iqbal, M. K. Gupta, and B. Sen. Evaluating the effect of micro-lubrication in orthopedic drilling. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, Vol. 233, 2019, pp. 1024–1041.10.1177/0954411919865389Search in Google Scholar PubMed

[3] Jamil, M., S. Rafique, A. M. Khan, H. Hegab, M. Mia, M. K. Gupta, et al. Comprehensive analysis on orthopedic drilling: A state-of-the-art review. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, Vol. 234, 2020, pp. 537–561.10.1177/0954411920911283Search in Google Scholar PubMed

[4] Mediouni, M., T. Kucklick, S. Poncet, R. Madiouni, A. Abouaomar, H. Madry, et al. An overview of thermal necrosis: Present and future. Current Medical Research and Opinion, Vol. 35, 2019, pp. 1555–1562.10.1080/03007995.2019.1603671Search in Google Scholar PubMed

[5] Panda, A., A. K. Sahoo, and A. K. Rout. Investigations on surface quality characteristics with multi-response parametric optimization and correlations. Alexandria Engineering Journal, Vol. 55, 2016, pp. 1625–1633.10.1016/j.aej.2016.02.008Search in Google Scholar

[6] Pandey, R. K. and S. S. Panda. Drilling of bone: A comprehensive review. Journal of Clinical Orthopaedics and Trauma, Vol. 4, 2013, pp. 15–30.10.1016/j.jcot.2013.01.002Search in Google Scholar PubMed PubMed Central

[7] Gok, K., M. Erdem, Y. Kisioglu, A. Gok, and M. Tumsek. Development of bone chip-vacuum system in orthopedic drilling process. Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 43, No. 4, 2021.10.1007/s40430-021-02959-wSearch in Google Scholar

[8] Gok, K., L. Buluc, U. S. Muezzinoglu, and Y. Kisioglu. Development of a new driller system to prevent the osteonecrosis in orthopedic surgery applications. Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 37, 2015, pp. 549–558. 10.1007/s40430-014-0186-3Search in Google Scholar

[9] Jin-bang, S., C. Ming, Z. Zi-han, and W. Liang. An investigation on cutting force and temperature during high speed micro-drilling on bone. Machinery Design & Manufacture, Vol. 137–139, 2015, id. 143.Search in Google Scholar

[10] Shaokang, S., C. Xiang, Z. Guangming, D. Shengfu, H. Bin, and L. Yang. Simulation and optimization of key parameters for medical bone drilling. Modern Manufacturing Engineering, Vol. 11, 2020, pp. 73–78.Search in Google Scholar

[11] MacAvelia, T., A. Ghasempoor, and F. Janabi-Sharifi. Force and torque modelling of drilling simulation for orthopaedic surgery. Computer methods in biomechanics and biomedical engineering, Vol. 17, 2014, pp. 1285–1294.10.1080/10255842.2012.739163Search in Google Scholar PubMed

[12] Fernandes, M. G. A., E. M. M. Fonseca, and R. J. Natal. Thermal analysis during bone drilling using rigid polyurethane foams: Numerical and experimental methodologies. Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 38, 2016, pp. 1855–1863.10.1007/s40430-016-0560-4Search in Google Scholar

[13] Sugita, N., K. Ishii, J. Sui, and M. Terashima. Multi-grooved cutting tool to reduce cutting force and temperature during bone machining. CIRP Annals, Vol. 63, 2014, pp. 101–104.10.1016/j.cirp.2014.03.069Search in Google Scholar

[14] Soriano, G. A. A. P. Medical engineering and physics. Machining Science and Technology, Vol. 17, 2013, pp. 611–636.10.1080/10910344.2013.837353Search in Google Scholar

[15] Sarparast, M., M. Ghoreishi, T. Jahangirpoor, and V. Tahmasbi. Experimental and finite element investigation of high-speed bone drilling: Evaluation of force and temperature. Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 42, No. 6, 2020, id. 349.10.1007/s40430-020-02436-wSearch in Google Scholar

[16] Chuncheng, C., H. Yahui, Z. Qingchun, and Z. Shanqing. Secondary Development of Abaqus in the Simulation of Bone Drilling Based On Python, Modern. Manufacturing Engineering, Vol. 54–57, 2018, id. 113.Search in Google Scholar

[17] Ling, H., H. Yahui, S. Jianbo, and Y. Cuilei. Study of drilling force on cortical bone based on finite element analysis. Tool Engineering, Vol. 11, 2015, pp. 25–28. Search in Google Scholar

[18] Qingyun, Z., H. U. Yahui, H. E. Zhixiang, and Y. Chengjun. Experimental study on drilling forces of cortical based on orthogonal regression. Machine Tool & Hydraulics, Vol. 5, 2014, pp. 8–10.Search in Google Scholar

[19] Agarwal, R., V. Gupta, and J. Singh. A novel drill bit design for reducing bone-chip morphology in orthopaedic bone drilling. Materials Today: Proceedings, Vol. 63, 2022, pp. 131–135. 10.1016/j.matpr.2022.02.408Search in Google Scholar

[20] Agarwal, R., V. Jain, V. Gupta, S. Saxena, and V. Dwibedi. Effect of surface topography on pull-out strength of cortical screw after ultrasonic bone drilling: An in vitro study. Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 42, No. 7, 2020, id. 363.10.1007/s40430-020-02449-5Search in Google Scholar

[21] Akhbar, M. F. A. and A. W. Sulong. Surgical drill bit design and thermomechanical damage in bone drilling: A review. Annals of Biomedical Engineering, Vol. 49, 2021, pp. 29–56.10.1007/s10439-020-02600-2Search in Google Scholar PubMed

[22] Alam, K. and V. V. Silberschmidt. Analysis of temperature in conventional and ultrasonically-assisted drilling of cortical bone with infrared thermography. Technology and Health Care, Vol. 22, 2014, pp. 243–252.10.3233/THC-140813Search in Google Scholar PubMed

[23] Gupta, V., R. P. Singh, P. M. Pandey, and R. Gupta. In vitro comparison of conventional surgical and rotary ultrasonic bone drilling techniques. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, Vol. 234, 2020, pp. 398–411. 10.1177/0954411919898301Search in Google Scholar PubMed

[24] Shakouri, E., M. H. Sadeghi, M. R. Karafi, M. Maerefat, and M. Farzin. An in vitro study of thermal necrosis in ultrasonic-assisted drilling of bone. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, Vol. 229, 2015, pp. 137–149.10.1177/0954411915573064Search in Google Scholar PubMed

[25] Hu, Y., Z. Fan, H. Zhang, C. Zhang, and W. Fu. Surface quality and pullout strength of ultrasonically-assisted drilling cortical bone. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, Vol. 235, 2021, pp. 378–388.10.1177/0954411920983662Search in Google Scholar PubMed

[26] Li, C. Testing and research of drilling feed force on fresh corpse femoral. China Digital Medicine, Vol. 6, 2015, pp. 57–61.Search in Google Scholar

[27] Wang, Y., M. Cao, X. Zhao, G. Zhu, C. McClean, Y. Zhao, et al. Experimental investigations and finite element simulation of cutting heat in vibrational and conventional drilling of cortical bone. Medical Engineering & Physics, Vol. 36, 2014, pp. 1408–1415.10.1016/j.medengphy.2014.04.007Search in Google Scholar PubMed

[28] Chen, Y., Y. Tu, J. Zhuang, Y. Tsai, C. Yen, and C. Hsiao. Evaluation of the parameters affecting bone temperature during drilling using a three-dimensional dynamic elastoplastic finite element model. Medical & Biological Engineering & Computing, Vol. 55, 2017, pp. 1949–1957.10.1007/s11517-017-1644-8Search in Google Scholar PubMed

[29] Gupta, V. and P. M. Pandey. An in-vitro study of cutting force and torque during rotary ultrasonic bone drilling. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, Vol. 232, 2018, pp. 1549–1560.10.1177/0954405416673115Search in Google Scholar

[30] Singh, R. P., P. M. Pandey, C. Behera, and A. R. Mridha. Effects of rotary ultrasonic bone drilling on cutting force and temperature in the human bones. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, Vol. 234, 2020, pp. 829–842.10.1177/0954411920925254Search in Google Scholar PubMed

[31] Wang, X., F. Jiao, D. Wang, Y. Niu, D. Huo, and K. Cheng. Development of a longitudinal–torsional ultrasonic vibration-aided drilling system for drilling carbon fiber-reinforced polymer materials. Proceedings of the Institution of Mechanical Engineers. Part C, Journal of Mechanical Engineering Science, Vol. 233, 2019, pp. 4176–4186. 10.1177/0954406219833084Search in Google Scholar

[32] Gupta, V., P. M. Pandey, and V. V. Silberschmidt. Rotary ultrasonic bone drilling: Improved pullout strength and reduced damage. Medical Engineering & Physics, Vol. 41, 2017, pp. 1–8.10.1016/j.medengphy.2016.11.004Search in Google Scholar PubMed

[33] Dongyu, H. E., Y. Zhibo, S. Wang, and H. Daocheng. Research on drilling force of ultrasonic vibration assisted drilling of biological bone. Journal of Henan Polytechnic University(Natural Science), Vol. 40, 2021, pp. 122–125.Search in Google Scholar

[34] Agarwal, R., R. P. Singh, V. Gupta, and J. Singh. Influence of cutting force on temperature, microcracks and chip morphology during rotary ultrasonic bone drilling: An in-vitro study. Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 44, 2022, id. 301. 10.1007/s40430-022-03608-6Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants