Abstract

As rubber is a hyperelastic material, its nonlinear deformation behavior during aging is significantly influenced by various factors, including the material characteristics, demonstrating a significant uncertainty. Most of the existing uncertain prediction methods of rubber nonlinear property degradation are based on the probability density function, which requires a large number of samples to obtain the probability distribution and requires a lot of work. Therefore, the interval model is used in this study to characterize the uncertainty. However, the traditional interval constitutive models ignore the correlation between interval variables, and the prediction results have large errors. In order to minimize prediction errors and improve prediction accuracy, an interval Mooney–Rivlin (M–R) correlation model that considers the correlation between parameters was established. To address the influence of uncertainties, an interval Arrhenius model was constructed. The M–R model requires multiple fittings of stress–strain curves to obtain the model parameters, and the prediction process is relatively complex. Therefore, combing the two proposed models, the relationship equations of rubber tensile stress with aging temperature and aging time were first established by interval Arrhenius, and then the interval M–R model was used to obtain the variation ranges of parameters

1 Introduction

Rubber materials are widely used in major fields, such as vibration isolation, damping, and energy absorption, owing to their high wear resistance, tear resistance, deformation recoverability, and compression elongation [1]. During long-term use, rubber is affected by temperature, oxidation, stress, as well as the degradation of its mechanical properties, which is known as the aging phenomenon. This aging process affects not only the material performance but also its service life. Therefore, there is a high theoretical relevance and practical engineering benefit in studying the prediction of mechanical quality degradation [2,3].

Long-term thermo-oxidative degradation of any polymer is a problem under normal environmental conditions unless a sealed system is used or inert conditions are deliberately introduced. Therefore, thermally driven degradation is a focal point in the field of “polymer degradation and stability” [4]. In thermo-oxidative aging studies of rubber materials, the accelerated aging test is widely used as an effective method to obtain performance index data [5,6]. The Arrhenius model is favored by researchers in accelerated lifetime tests [7,8,9,10,11] and is widely used for life prediction of polymers in different environments (especially temperature) [12,13]. The reason for this common application is that the method is easy to implement and is relevant in some cases [14]. However, as research has progressed, more results have shown the limitations of the Arrhenius model [15,16,17]. To cope with different aging conditions, some scholars conducted a series of studies using the traditional Arrhenius model, and various improved Arrhenius-modified models were successively proposed [18,19,20,21,22,23,24].

Moreover, because rubber is a hyperelastic material, its deformation in actual engineering exhibits strong nonlinear features, and a suitable nonlinear model must be chosen to characterize the material stress–strain properties [25,26]. In the field of hyperelastic modeling, Khaniki et al. [27] discussed the traditional hyperelastic strain energy density models such as neo-Hookean, Mooney–Rivlin (M–R), Ogden, Polynomial, Arruda–Boyce, Yeoh, and Gent. These intrinsic models are now present in many studies and used to understand the nonlinear mechanical behavior of different structures (hyperelastic shells, hyperelastic plates, hyperelastic beams, etc.) [28,29,30]. For rubber-like materials, Destrade et al. [31] pointed out that the core of the modeling problem is not related to the functional form of the strain energy, but depends on the method of fitting and the way of reading the data. Whereas before, Marckmann and Verron [32] had already pointed out in their study the applicability of the M–R model for describing the nonlinear mechanical properties of rubber-like materials at small and medium strains (less than 200%). And the study by Puglisi and Saccomandi [33] points out that while Mooney’s theory does not provide a satisfactory and self-consistent basis for the properties of rubber in the most general strain states, a comparison of its predictions with experimental data suggests that the model is more predictive than the neo-Hookean model. As research progresses, more and more hyperelastic constitutive models have been proposed that begin to take into account environmental aging factors such as temperature, time, and humidity [34,35].

However, in an actual service process, the degradation of the mechanical properties of rubber products presents many uncertainties, and this affects the deformation behavior of the mechanical components, such as rubber sealing components [36]. If the aforementioned deterministic model is used for prediction, the results contain large errors. To address these problems, Liu et al. [37] combined Monte Carlo and Bayesian averaging methods to establish new aging prediction models. Varga et al. [38] proposed a model based on a two-dimensional normal probability density function (PDF) algorithm to generate the transformed Arrhenius parameter

All the above methods have certain shortcomings: the method that introduces Bayes can only guarantee accuracy at the p-quantile, the algorithm of László Varga et al. requires solving probability distributions, the method of Woo and Shao considers only the random distribution of one parameter, and the WFB principal structure model requires a long experimental testing time. In summary, the existing literature analyzes the uncertainty from the stochastic, statistical top and requires obtaining the probability distribution function before predicting the performance degradation of a rubber material. The prerequisite for the use of these methods is sufficient statistical information; otherwise, it is difficult to determine the probability density function of the parameter. For small sample data, the interval model method with nonprobability statistics is more appropriate [42,43]. However, the traditional interval method typically directly introduces multiple interval variables, and the influence of aging conditions on interval model parameters and the constraint relationship between variables are often ignored. This can lead to inaccuracies between the predicted range of interval variables and the actual, generating large prediction errors and increasing the complexity of uncertainty estimation.

To further reduce the workload of existing uncertainty prediction methods and simplify the prediction process while improving the prediction accuracy, this study proposes an interval acceleration prediction method based on the Arrhenius and M–R models, which includes the interval Arrhenius and interval M–R correlation models. The interval Arrhenius model converts the interval uncertainty problem into a deterministic problem, and the latter is used to accurately describe the nonlinear characteristics of rubber materials during deformation. Based on the performance degradation data of rubber, the interval Arrhenius model was constructed by considering the tensile stress of rubber at different strain rates as the performance degradation index, and the interval correlation model, which can accurately characterize material stress–strain properties, was established by considering the parameter correlation. To confirm the accuracy of the proposed model, thermally accelerated aging tests were conducted on rubber at predetermined temperatures. The results showed that the prediction intervals obtained using this method accurately correlate with the actual values. Therefore, the method proposed in this work can effectively avoid the influence of interval expansion on the accuracy of prediction results and achieve accurate prediction of service rubber performance degradation, which is of great benefit for the improvement of material performance and quality as well as the lifetime evaluation of rubber sealing material products made from the production process, and this is also of great significance for the stable development of China’s industrial field.

2 Materials and tests

2.1 Materials

In this study, rectangular chloroprene rubber plates were used as the test material. All the rubber samples were 150 × 130 × 2 mm in size, which were produced especially for this experiment. Figure 1 shows the rubber sheets used in the test. The main mechanical properties and composition of the material are shown in Tables 1 and 2, respectively.

Specific dimensions of the tested rubber sheets.

Main mechanical properties of unaged rubber

| Mechanical properties | Values |

|---|---|

| Shore hardness (ha) | 52 |

| Density (g·cm‒3) | 1.25 |

| Tensile strength (MPa) | 16.2 |

| Ductility (%) | 657 |

Material recipes

| Ingredient | Proportion |

|---|---|

| Chloroprene rubber | 100 |

| Carbon black | 30 |

| Magnesium oxide | 4 |

| Zinc oxide | 5 |

| Stearic acid | 1.5 |

| Accelerator | 2.5 |

| P-phenylenediamine antioxidant | 2 |

| Diphenylamine antioxidant | 2 |

2.2 Accelerated aging test for rubber

The rubber thermal oxidation aging test was conducted based on the ISO188 standard. The number of samples was adjusted to ten to account for the possible dispersion of mechanical behavior among the various rubber specimens. To ensure the efficiency of the accelerated test and avoid the influence of excessive accelerated aging temperature on the aging mechanism of rubber, the temperatures were set to 70, 80, 90, and 100°C. The specimens were placed in an air-circulating oven during the experiments, as shown in Figure 2. Since the degradation of rubber properties with aging often follows an exponential function, the time points for testing the mechanical properties of materials are usually set dense initially and then sparse. For every 10°C increase in temperature, the aging rate increases by a factor of roughly 0.5–1, so the total aging time setting becomes progressively less as the aging temperature increases. Table 3 lists the time-points set for the mechanical properties of the rubber tested in this study.

High-temperature test oven for rubber aging.

High-temperature airbag rubber performance aging test time-points

| Test temperature (℃) | ||||

|---|---|---|---|---|

| 70 | 80 | 90 | 100 | |

| Test time node (days) | 0 | 0 | 0 | 0 |

| 2 | 1 | 1 | 0.5 | |

| 4 | 2 | 2 | 1 | |

| 8 | 4 | 4 | 2 | |

| 16 | 8 | 7 | 4 | |

| 24 | 16 | 14 | 8 | |

When the set aging time was reached, the rubber samples were removed from the oven and then cooled at room temperature for more than 24 h.

2.3 Tensile test

To obtain uniaxial tensile specimens of the rubber materials, we cut the aged rubber pieces into dumbbell-shaped specimens using a cutter, as shown in Figure 3. The dumbbell-shaped specimens used in this study were 45 mm long, 6 mm wide, and 2 mm thick. At the laboratory temperature (23 ± 2°C), the uniaxial tensile test was conducted on the aged rubber plates according to ASTM D412 to obtain the change rule of the mechanical performance of aging rubber.

Tensile specimen.

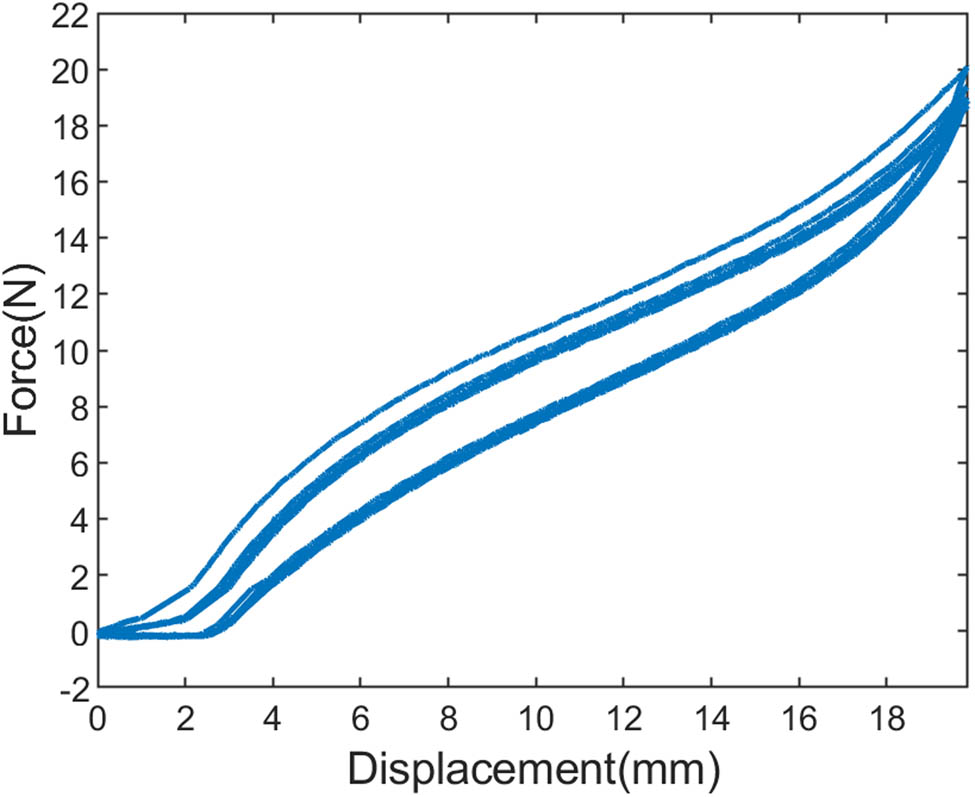

The tensile tests were performed on a universal testing machine, equipped with a 5 kN load cell. During the experiment, the dumbbell-shaped specimens were vertically clamped between two fixtures with 10 ± 0.5 mm at the top and bottom, so that the tensile force was evenly loaded onto the cross-section. The tensile fixture controls the elongation of the rubber samples through a fixed limiter, and in this study, the maximum displacement is set to 20 mm, which enables the maximum strain of the rubber specimens to reach 80% in all cases. Five cyclic tensile testing (rate: 50 mm·min‒1) were conducted on the cut specimens at each test node. Figure 4 shows the cyclic tensile results of a rubber specimen after the test. As shown in the figure, the rubber exhibits a stress-softening phenomenon. After each stretch, the deformation force required for the same strain in the rubber decreases. The force–displacement curve remains the same after five cycles. This phenomenon is known as the Mullins effect, also referred to as stress softening. To eliminate this effect and obtain more accurate data, we conducted five cyclic tensile tests on each sample and then took the result of the sixth tensile test after the cycle as the final test data. For each aging condition, ten samples were tested and the results were averaged. Figure 5 shows the average stress–strain curves for 4 days of aging at different temperatures.

Cyclic tensile results of a rubber specimen.

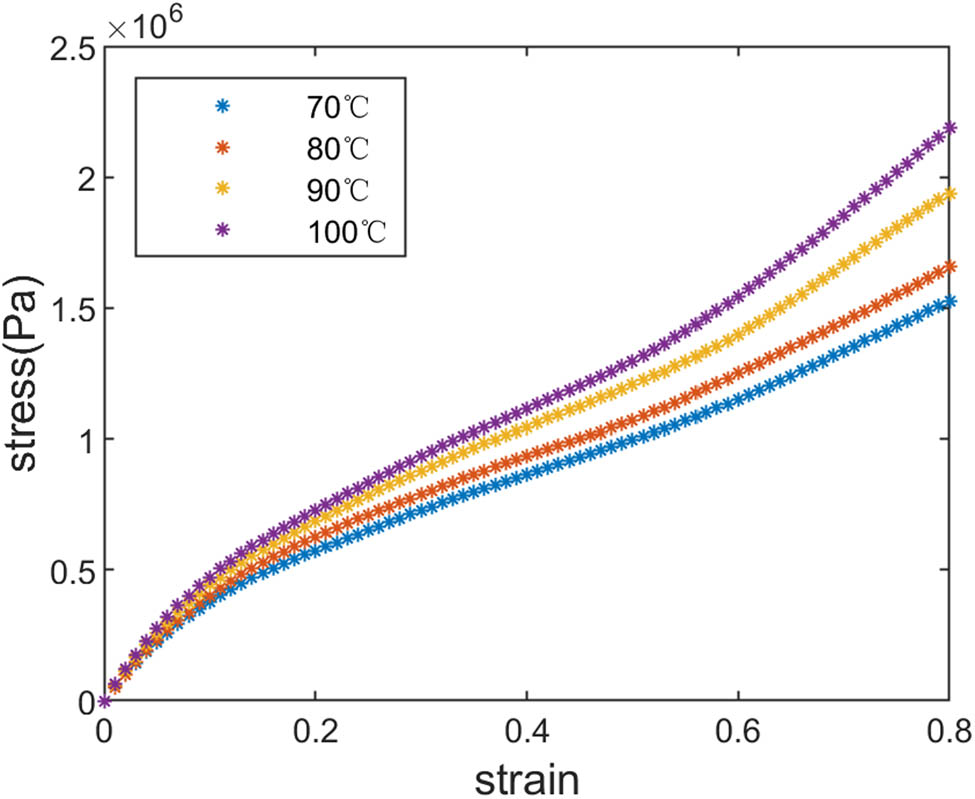

The average stress–strain curves for 4 days of aging at different temperatures.

It is evident from the preliminary examination of the data in Figure 5 that the rubber experiences an increase in tensile stress with temperature over the course of the same aging process. Rubber aging is accelerated by temperature, and high temperatures cause it to proceed quickly. The stress–strain curves of different rubber samples at the same aging time at a fixed temperature are obviously different, showing a large dispersion. The dispersion of the properties of the rubber samples increase as the strain rate increases, indicating that the uncertainty of the rubber material is variable.

The range of rubber tensile stresses with respect to time at the set temperature was obtained based on the stress–strain curves obtained at each test node. Figure 6 shows the average stress–strain curves of the specimens at 100°C with aging time. Figure 6 shows that the stress at the same strain rate varies with aging time; therefore, the tensile stress at each strain rate can be used as the performance degradation index parameter of the rubber material. The stress–strain curves from the test were processed, and the ratio of maximum stress to minimum stress at each strain rate was obtained by selecting 30, 60 and 90% strain rates. Table 4 shows the ratio of maximum stress to minimum stress for several samples at three strain rates at 100°C. Table 4 also shows that the stress fluctuations of the rubber at the same strain rate increase with aging time, indicating that the uncertainty of the material is variable.

Average stress–strain curves for ten specimens at 100°C.

Ratio of the maximum stress to the minimum stress for a specimen under three strain rates at 100°C

| Aging time (days) | Strain | ||

|---|---|---|---|

| 0.3 | 0.6 | 0.9 | |

| 0.5 | 1.0896 | 1.1147 | 1.1165 |

| 1 | 1.1005 | 1.1200 | 1.1276 |

| 2 | 1.1123 | 1.1306 | 1.1389 |

| 4 | 1.1167 | 1.1542 | 1.1887 |

| 8 | 1.1360 | 1.1832 | 1.3216 |

3 Date processing in the accelerated test

3.1 Interval acceleration prediction model

During the service of air springs, external forces on the rubber material are uncertain, and their deformation exhibits strong nonlinear characteristics. To effectively simulate the mechanical behavior of rubber materials, a suitable nonlinear model must be used to describe their stress–strain characteristics. When temperature is utilized as the accelerating stress, the Arrhenius model is typically employed as an acceleration model. In this study, the interval Arrhenius and M–R models were introduced to establish an interval acceleration prediction model that considers the influence of the uncertainty and correlation between parameters. To simplify the prediction process, an interval model of rubber tensile stress at different strain rates was directly established and converted into interval expressions of

3.1.1 Interval M–R correlation model

At present, many types of intrinsic hyperelastic models exist for rubber materials, and for the stress–strain characteristics of rubber materials, the M–R model parameters are usually used to describe them. The M–R model, which is widely used in engineering, is expressed as follows:

where

Assuming that the material is incompressible, the stress–strain relationship for the M–R constitutive model can be derived for the special case of uniaxial tension as follows:

where

The interval M–R model proposed in this study introduces interval variables

where

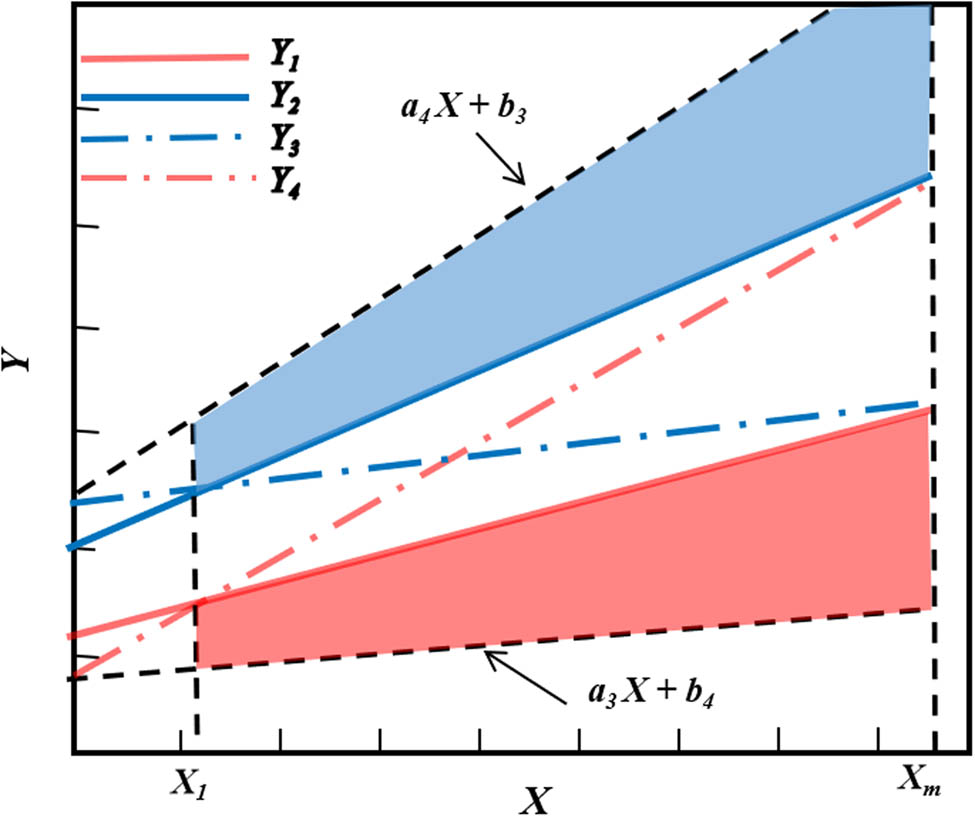

Schematic of the interval correlation model.

The blue and pink areas in Figure 7 are the interval expansions, which are caused by ignoring the correlation between the two parameters

Therefore, when the slope parameter

Here

The three cases in Eq. (6) are analyzed. During

Eq. (10) represents the rewritten Eq. (5). Given

Therefore, the corresponding parameters of four curves

3.1.2 Interval Arrhenius model

The notion of time–temperature equivalent superposition serves as the theoretical basis for high-temperature accelerated testing of rubber, and the conventional Arrhenius model is typically used to describe the nonlinear equivalence between temperature and reaction time scales. In this model, the aging time

where

where

Taking the logarithm of both sides of Eq. (12) and performing mathematical conversions, we obtain

We let

Similarly, taking the logarithms of both sides of Eq. (13) and performing a mathematical conversion yield

We let

Eq. (13) can be obtained by analyzing the rubber property degradation curve. If the curve correlation is linear, then

where

The interval Arrhenius model proposed in this study introduces the interval radius function

Here

In interval analysis theory, an interval model problem can be decomposed into two deterministic parameter problem processes. Therefore, the aging property index of rubber can be characterized by the median and interval radii, as shown in Eq. (23).

A consistency check of the failure mechanism is required to verify the availability of the test data. Arrhenius considered the prefactor and activation energy of the reaction to be constants that do not vary with temperature for a given reaction. According to Equation (14), the activation energy obtained by deriving is given by Eq. (24).

The reaction activation energy in each temperature interval was calculated using Eq. (24) to confirm the consistency of the failure mechanism of the median and interval radii. Then,

3.2 Modeling process

Based on the stress–strain curves obtained from the tensile tests, the curves for the stress fluctuation of the rubber material over time at each strain were fitted. The data on rubber property degradation acquired under various temperatures and strain rates were then used to perform nonlinear fitting of Eq. (12). The interval Arrhenius model and interval M–R model were then used to develop interval acceleration equations for rubber to predict the degradation of aging properties and the rubber lifetime at room temperature. Figure 8 shows the process flow for the rubber-accelerated aging modeling approach considering the effect of uncertainties.

Flow chart of the modeling method for accelerated aging intervals of rubber.

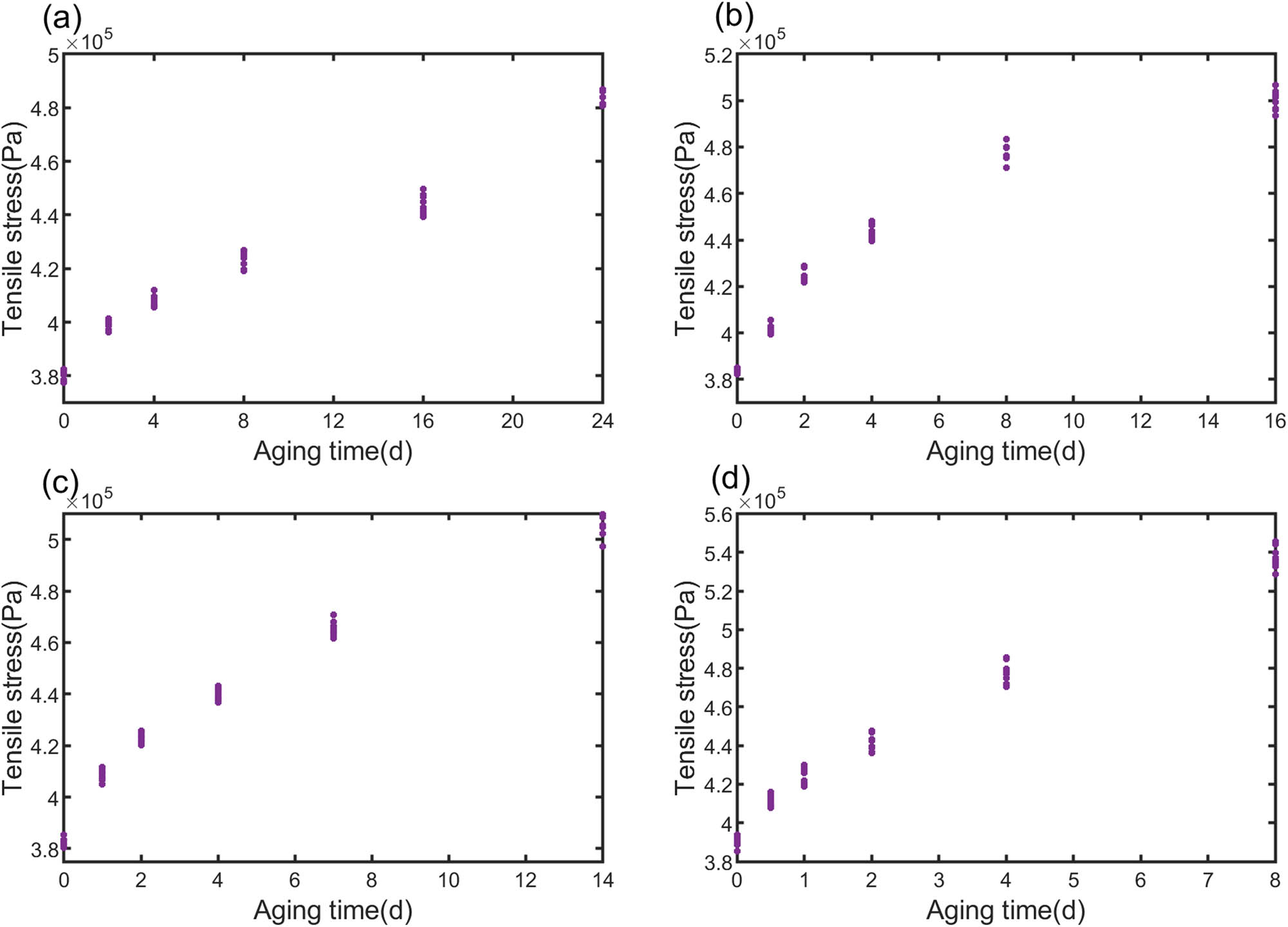

Taking a 10% strain rate as an example, degradation data of rubber tensile stress with aging time at multiple temperatures were obtained, as shown in Figure 9. Eqs (21) and (22) were used to calculate the median and interval radii, respectively, for different aging times at multiple temperatures. Based on the obtained degradation data of the rubber properties, nonlinear fitting of Eqs (19) and (20) was performed. Fitting parameters

Degradation data of rubber tensile stress with aging time at multiple temperatures: (a) 70, (b) 80, (c) 90, and (d) 100°C.

According to the established interval model, the trends of the tensile stress of the rubber material with aging time and aging temperature at different strain rates were obtained. Assuming that the aging time is

4 Results and discussion

4.1 Parameter identification for the interval Arrhenius model

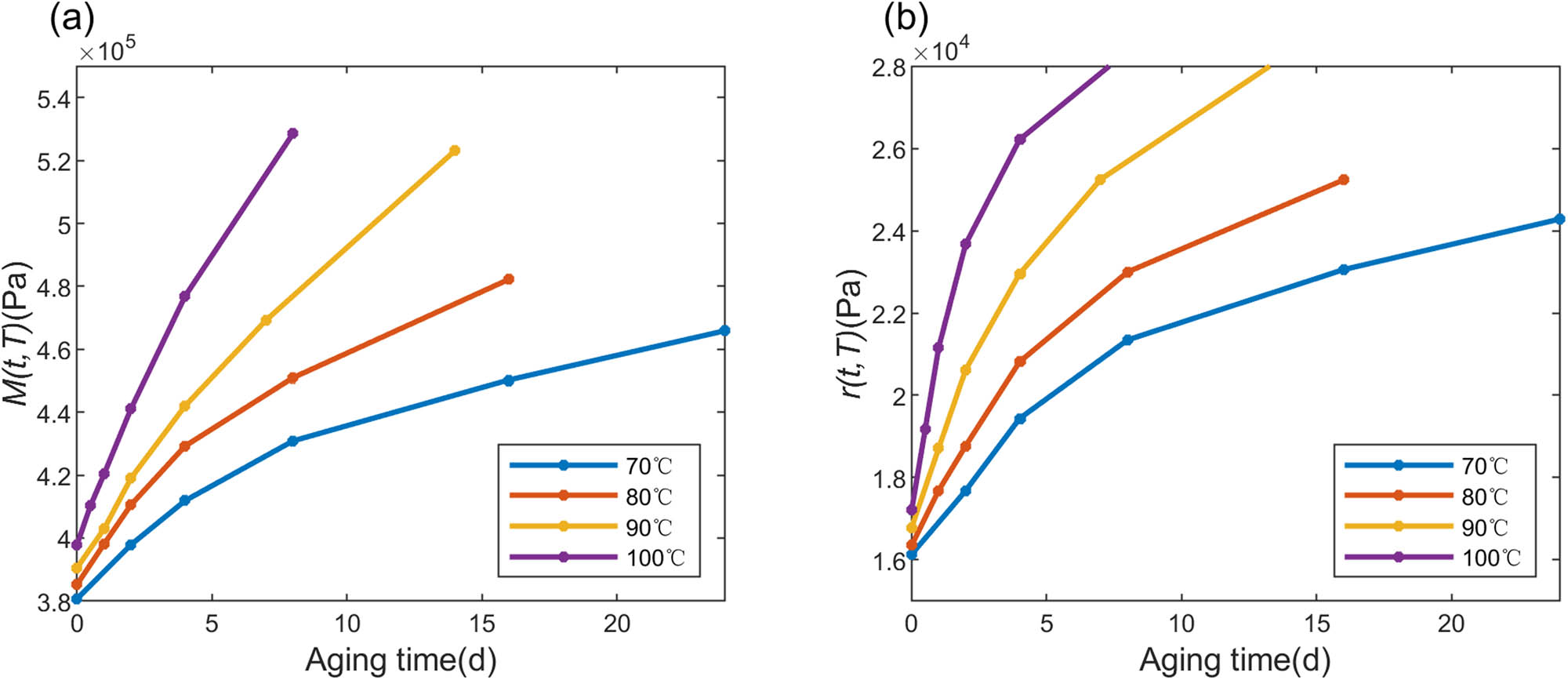

Figure 10 shows the variation curve of the rubber aging model parameters with aging time at a 10% strain rate.

Curves of the rubber performance degradation index at a 10% strain rate: (a) median M(t, T) and (b) interval radius r(t, T).

Table 5 lists the computational results for the rubber interval aging model parameters. Table 6 presents the results of the acceleration model coefficient calculations for each aging index. The computed activation energies are listed in Table 7 for each temperature range.

Interval model parameters of rubber sample used in this study

| Rubber model parameters | All temperatures | 70°C | 80°C | 90°C | 100°C | All temperatures |

|---|---|---|---|---|---|---|

|

|

|

|

||||

|

|

12.8674 | 0.0258 | 0.0379 | 0.0543 | 0.0762 | 0.65 |

|

|

9.7013 | 0.1070 | 0.1372 | 0.1732 | 0.2148 | 0.44 |

Acceleration coefficient of each aging index at different temperatures

| Rubber model aging parameters |

|

|

|---|---|---|

|

|

9.8102 | 4618.8867 |

|

|

6.4402 | 2975.0902 |

Activation energy values as a function of temperature range

| 90–100 (°C) | 80–90 (°C) | 70–80 (°C) | |

|---|---|---|---|

|

|

559.3448 | 555.6568 | 551.0110 |

|

|

361.7803 | 359.7995 | 350.4580 |

The activation energy calculations shown in Table 7 confirm the consistency of the rubber failure mechanism in the accelerated aging test, enabling the interval model to be used to forecast the actual aging of the rubber. As described in Section 3.1.2, the interval model can be divided into two parts. Eq. (20) can be used to represent the relationship between the rubber tensile stress and aging time and temperature, while Eqs (25) and (26) show the relationship between the median and interval radii and aging time and temperature, respectively.

Using the above method, the expressions for stress as a function of aging time and temperature at each strain rate were established, as listed in Table 8.

Interval prediction model for tensile stress of rubber at different strains

| Strain (%) | Stress (Pa) |

|---|---|

| 10 |

|

| 20 |

|

| 30 |

|

| 40 |

|

| 50 |

|

| 60 |

|

| 70 |

|

| 80 |

|

4.2 Parameter identification for the interval M–R model

Based on the obtained interval Arrhenius equation, the expressions for the parameters on the left side of Eq. (10) were obtained. The specific parameter values for both sides of Eq. (10) at each strain rate are shown in Table 9 as an example of aging at 60°C for 20 days.

Parameter identification by the M–R model for aged rubber

|

|

1/

|

Mid of

|

Radius of

|

|---|---|---|---|

| 10 | 10 | 2.4292 | 0.1236 |

| 20 | 5 | 1.9892 | 0.1001 |

| 30 | 3.3333 | 1.9429 | 0.1039 |

| 40 | 2.5 | 2.012 | 0.1115 |

| 50 | 2 | 2.3566 | 0.1301 |

| 60 | 1.6667 | 2.9080 | 0.1679 |

| 70 | 1.4286 | 4.0154 | 0.2475 |

| 80 | 1.25 | 5.9727 | 0.3886 |

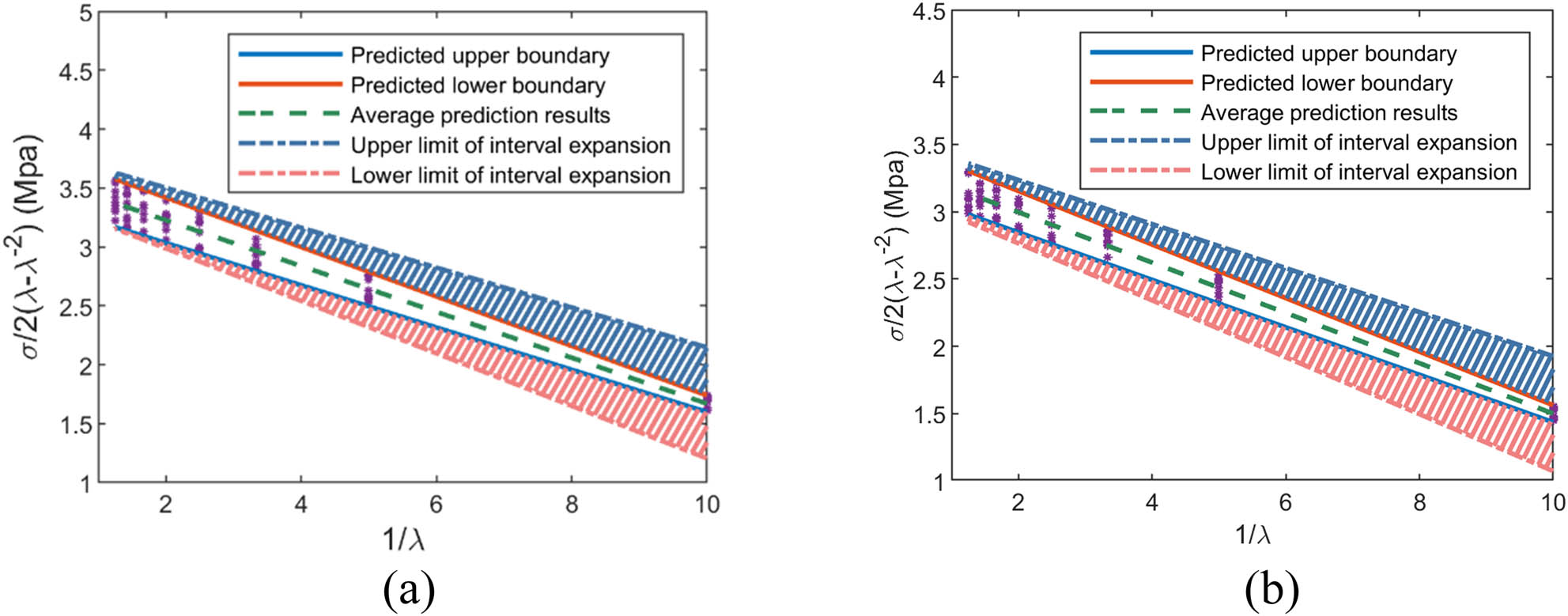

Figure 11 shows the reacquired stress–strain curves with the horizontal coordinates

Reacquired interval stress–strain curve of the rubber used in this study.

The expressions for the four schematic lines of

4.3 Test verification

Ten samples were obtained for accelerated aging tests at 60 and 25°C to confirm the effectiveness of the proposed interval model. The rubber specimens were held at room temperature (23

Values of parameter

| Specimens |

|

|||||||

|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | |

| 1 | 1.6147 | 2.5169 | 3.1079 | 3.0225 | 3.4024 | 3.1525 | 3.4966 | 3.2739 |

| 2 | 1.6793 | 2.7592 | 3.1216 | 2.9717 | 3.307 | 3.2528 | 3.4076 | 3.3998 |

| 3 | 1.6438 | 2.7433 | 2.9125 | 3.2885 | 3.0966 | 3.2158 | 3.469 | 3.3138 |

| 4 | 1.6352 | 2.6106 | 2.8933 | 3.1661 | 3.2032 | 3.367 | 3.1791 | 3.1777 |

| 5 | 1.6751 | 2.5439 | 3.0992 | 3.0825 | 3.2766 | 3.445 | 3.2474 | 3.3714 |

| 6 | 1.6229 | 2.6208 | 2.8656 | 3.1891 | 3.3913 | 3.2864 | 3.4445 | 3.505 |

| 7 | 1.6932 | 2.6166 | 2.8382 | 3.2363 | 3.2366 | 3.4113 | 3.2219 | 3.2726 |

| 8 | 1.6052 | 2.7086 | 2.9728 | 3.0662 | 3.2741 | 3.2213 | 3.1484 | 3.1855 |

| 9 | 1.6022 | 2.6137 | 3.1057 | 3.1994 | 3.2951 | 3.3099 | 3.3109 | 3.2675 |

| 10 | 1.6378 | 2.7742 | 2.932 | 3.0181 | 3.3886 | 3.2461 | 3.5128 | 3.437 |

Values of parameter

| Specimens |

|

|||||||

|---|---|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | |

| 1 | 1.5483 | 2.4667 | 2.829 | 2.7952 | 3.0226 | 3.0107 | 3.1654 | 3.1241 |

| 2 | 1.469 | 2.4892 | 2.7993 | 2.9814 | 3.0904 | 2.9771 | 3.2417 | 3.1903 |

| 3 | 1.4653 | 2.3846 | 2.6526 | 3.0036 | 2.9755 | 3.1647 | 3.0293 | 3.0335 |

| 4 | 1.5421 | 2.4162 | 2.8048 | 2.99 | 3.0103 | 3.0149 | 3.2315 | 3.1513 |

| 5 | 1.4984 | 2.4042 | 2.6469 | 2.8147 | 3.1316 | 2.9571 | 3.2425 | 3.1846 |

| 6 | 1.4549 | 2.5049 | 2.8741 | 2.8853 | 3.1234 | 2.9137 | 3.0433 | 2.9829 |

| 7 | 1.4648 | 2.3497 | 2.8576 | 2.7622 | 3.0141 | 3.2068 | 2.9704 | 3.1314 |

| 8 | 1.519 | 2.5339 | 2.7542 | 2.8545 | 3.124 | 3.1198 | 3.1935 | 3.2668 |

| 9 | 1.507 | 2.3867 | 2.7999 | 2.7979 | 2.862 | 3.1768 | 2.9741 | 3.0154 |

| 10 | 1.4726 | 2.4372 | 2.8827 | 2.8918 | 3.0955 | 3.2016 | 3.1811 | 3.1223 |

The test results of the parameters of the intrinsic model for different samples after aging at 60°C for 20 days

| Intrinsic model parameters | Specimens | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

|

|

3.5831 | 3.5738 | 3.5472 | 3.6234 | 3.6152 | 3.7229 | 3.6882 | 3.5825 | 3.5138 | 3.5592 |

|

|

−0.1880 | −0.1864 | −0.1882 | −0.1910 | −0.1977 | −0.2127 | −0.2081 | −0.1849 | −0.1748 | −0.1823 |

The test results of the parameters of the intrinsic model for different samples after aging at 25°C for 10 days

| Intrinsic model parameters | Specimens | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

|

|

3.3575 | 3.4473 | 3.3593 | 3.4091 | 3.391 | 3.339 | 3.3696 | 3.4545 | 3.2941 | 3.4596 |

|

|

−0.1802 | −0.1965 | −0.1901 | −0.1881 | −0.1931 | −0.1814 | −0.1913 | −0.1939 | −0.1778 | −0.1984 |

Interval model for the prediction of degradation of rubber mechanical properties: (a) after aging at 60°C for 20 days and (b) after aging at 25°C for 10 days.

As shown in the above figure, the test values of mechanical properties of the tested samples at the set temperature can be accurately covered by the interval prediction model. This indicates that the proposed method for constructing an interval model by introducing interval variables is feasible and effective for predicting the degeneration of mechanical properties of rubber during service. In Figure 12(a), the maximum error between the upper boundary and the measured results is 15%, and the maximum error between the lower boundary and the measured results is 17%. Similarly in Figure 12(b), the maximum error of both boundaries and measurements does not exceed 20%. However, the maximum errors between the predicted and experimental results of rubber mechanical property parameters based on the average values are 72 and 69%, respectively. The prediction area of the model proposed in this study is reduced by nearly 60% compared to the previous model, and the proposed method can provide a more conservative and accurate life range for the prediction of the life of the rubber material in service, which can avoid the safety problems caused by over-life operation of the rubber products to a certain extent. It can also be seen from Figure 12 that the prediction area of the method is significantly smaller than that of the traditional interval analysis method, which indicates that the correlation between interval parameters affects the prediction accuracy. The interval model used in this study can effectively avoid the influence of errors caused by interval expansion and improve the prediction accuracy.

The research presented above demonstrates the suitability of the recently developed rubber interval model for characterizing the nonlinear stress–strain behavior of rubber-like elastomers at various strain rates. In practice, according to the service temperature and length of service of rubber products, combined with the proposed interval model can calculate the variation range of parameters

5 Conclusion

Based on the measured data of accelerated rubber aging, a kinetic equation for the trajectory of accelerated rubber aging was established considering the influence of parameter uncertainty and correlation. Based on the conventional Arrhenius model, an interval variable was introduced to represent the uncertainty, and an interval Arrhenius model describing the relationship between tensile stress and temperature under uncertainty was proposed. The interval expansion problem in the linear regression equation was analyzed, the correlation between the parameters of the intrinsic model was verified, and the interval M–R correlation model was used to describe the nonlinear properties of rubber. Experimental evidence was used to confirm the validity of the model. The main findings of this study are as follows:

Differences in the mechanical properties of samples of different rubber materials and the effect of uncertainty on the lifetime prediction model must be considered.

The prediction results of the proposed model accurately correlate with the measured results with a maximum error of no more than 20%, while the maximum error of the prediction results of the average-based prediction method with the measured data is close to 80%.

By considering the correlation between the two interval parameters in the M–R two-parameter model, the constructed prediction model can more accurately characterize the nonlinear mechanical behavior of rubber materials and solves the problem that the range of variation of the interval parameters in the traditional interval M–R model is not consistent with the reality.

The prediction model in this study is based on the tensile test data at room temperature (23°C), and only the effect of temperature on rubber aging is considered. Therefore, the application of the model is premised on meeting the requirement that changes in ambient temperature do not directly affect the properties of rubber materials. It is worth noting that our study only demonstrated the effectiveness of the proposed predictive model in predicting the parameters of the M–R model interval for air spring rubber aging. However, the model developed in this study can be applied to the prediction of other types of rubber products under uncertainty and air aging through feasible extensions, which can provide a new idea for the life prediction of rubber products. Since the interval Arrhenius model developed in this study only includes the prediction of tensile stresses at strains from 10 to 80% (at 10% strain increments), the

Further research can consider narrowing the interval envelope based on the interval model to increase the estimation precision, such as adjusting the strain increment. In addition, the influence of additional factors needs to be considered, as rubber products are affected by more than just temperature during service. It is necessary to continue investigating the prediction of rubber performance under combined factors to establish a rubber aging prediction model that is more in line with actual engineering.

Acknowledgments

The authors wish to acknowledge the National Key R&D Program of China for financial support (grant number 2022YFB4300300).

-

Funding information: This research was funded by National Key R&D Program of China, Grant number 2022YFB4300300.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Gent, A. N. Engineering with rubber: how to design rubber components, 3rd edn, Carl Hanser Verlag, Munich, 2012.10.3139/9783446428713.fmSearch in Google Scholar

[2] Gillen, K. T., M. Celina, R. L. Clough, and J. Wise. Extrapolation of accelerated aging data-Arrhenius or erroneous? Trends in Polymer Science, Vol. 8, No. 5, 1997, pp. 250–257.Search in Google Scholar

[3] Liu, Q., W. Shi, K. Li, Z. Chen, and H. Liu. Performance degradation prediction and reliability evaluation of rubber aging in natural environment under alternating cyclic thermal load. IEEE Access, Vol. 7, 2019, pp. 63027–63035.10.1109/ACCESS.2019.2917008Search in Google Scholar

[4] Celina, M. C. Review of polymer oxidation and its relationship with materials performance and lifetime prediction. Polymer Degradation and Stability, Vol. 98, No. 12, 2013, pp. 2419–2429.10.1016/j.polymdegradstab.2013.06.024Search in Google Scholar

[5] Moghadam, M. K., J. Morshedian, M. Ehsani, M. Bahrami, and H. Saddadi. Lifetime prediction of HV silicone rubber insulators based on mechanical tests after thermal ageing. IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 20, No. 3, 2013, pp. 711–716.10.1109/TDEI.2013.6518939Search in Google Scholar

[6] Woo, C. S., S. S. Choi, S. B. Lee, and H. S. Kim. Useful lifetime prediction of rubber components using accelerated testing. IEEE Transactions on Reliability, Vol. 59, No. 1, 2010, pp. 11–17.10.1109/TR.2010.2042103Search in Google Scholar

[7] Hartler, G. Parameter estimation for the Arrhenius model. IEEE Transactions on Reliability, Vol. 35, No. 4, 1986, pp. 414–418.10.1109/TR.1986.4335489Search in Google Scholar

[8] Nelson, W. B. Accelerated testing: statistical models, test plans, and data analysis, John Wiley & Sons, New York, 2009.Search in Google Scholar

[9] Nelson, W. Analysis of accelerated life test data-Part I: The Arrhenius model and graphical methods. IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 4, 1971, pp. 165–181.10.1109/TEI.1971.299172Search in Google Scholar

[10] Šimon, P., Z. Cibulková, and P. Thomas. Accelerated thermooxidative ageing tests and their extrapolation to lower temperatures. Journal of Thermal Analysis and Calorimetry, Vol. 80, No. 2, 2005, pp. 381–385.10.1007/s10973-005-0664-zSearch in Google Scholar

[11] Bystritskaya, E. V., A. L. Pomerantsev, and O. Y. Rodionova. Evolutionary design of experiment for accelerated aging tests. Polymer Testing, Vol. 19, No. 2, 2000, pp. 221–229.10.1016/S0142-9418(98)00077-4Search in Google Scholar

[12] Le Huy, M. and G. Evrard. Methodologies for lifetime predictions of rubber using Arrhenius and WLF models. Die Angewandte Makromolekulare Chemie, Vol. 261, No. 1, 1998, pp. 135–142.10.1002/(SICI)1522-9505(19981201)261-262:1<135::AID-APMC135>3.0.CO;2-WSearch in Google Scholar

[13] Davies, P. and G. Evrard. Accelerated ageing of polyurethanes for marine applications. Polymer Degradation and Stability, Vol. 92, No. 8, 2007, pp. 1455–1464.10.1016/j.polymdegradstab.2007.05.016Search in Google Scholar

[14] Le Saux, V., P. Y. Le Gac, Y. Marco, and S. Calloch. Limits in the validity of Arrhenius predictions for field ageing of a silica filled polychloroprene in a marine environment. Polymer Degradation and Stability, Vol. 99, 2014, pp. 254–261.10.1016/j.polymdegradstab.2013.10.027Search in Google Scholar

[15] Gillen, K. T., M. Celina, and R. Bernstein. Review of the ultrasensitive oxygen consumption method for making more reliable extrapolated predictions of polymer lifetimes. Society of Plastics Engineers. ANTEC,2004: 62nd Annual Technical Conference; 2004 May 16–20; Chicago, IL, Society of Plastics Engineers, Connecticut, 2004, pp. 2289–2293.Search in Google Scholar

[16] Gillen, K. T., R. Bernstein, and M. Celina. Non-Arrhenius behavior for oxidative degradation of chlorosulfonated polyethylene materials. Polymer Degradation and Stability, Vol. 87, No. 2, 2005, pp. 335–346.10.1016/j.polymdegradstab.2004.09.004Search in Google Scholar

[17] Celina, M., K. T. Gillen, and R. A. Assink. Accelerated aging and lifetime prediction: Review of non-Arrhenius behaviour due to two competing processes. Polymer Degradation and Stability, Vol. 90, 2005, pp. 395–404.10.1016/j.polymdegradstab.2005.05.004Search in Google Scholar

[18] Wang, Y. S., W. Wang, Q. Liu, Z. B. Cui, and J. Wang. Analysis on the Non-Arrhennius life prediction method of Rubber. Advanced Materials Research, Vol. 683, 2013, pp. 366–371.10.4028/www.scientific.net/AMR.683.366Search in Google Scholar

[19] Liu, Q., W. Shi, Z. Chen, K. Li, H. Liu, and S. Li. Rubber accelerated ageing life prediction by Peck model considering initial hardness influence. Polymer Testing, Vol. 80, 2019, id. 106132.10.1016/j.polymertesting.2019.106132Search in Google Scholar

[20] Naveršnik, K. Humidity-corrected Arrhenius equation: The reference condition approach. International Journal of Phamaceutics, Vol. 500, No. 1–2, 2016, pp. 360–365.10.1016/j.ijpharm.2016.01.047Search in Google Scholar PubMed

[21] Mao, S. S. Statistical analysis of accelerated life testing-step-stress models under the exponential distribution case. Acta Mathematicae Applicatae Sinica, Vol. 8, No. 3, 1985, pp. 311–316.Search in Google Scholar

[22] Changyong, D., D. Shaojiang, and T. Wei. Modelling for the flow behavior of a new metastable beta titanium alloy by GA-based Arrhenius equation. Materials Research Express, Vol. 6, No. 2, 2018, id. 026544.10.1088/2053-1591/aaedf7Search in Google Scholar

[23] Zhou, J., J. Yao, H. H. Hu, and Y. Song. Accelerated aging life evaluation method of silicone rubber based on segmented nonlinear Arrhenius model. Materials Research Innovations, Vol. 19, No. Sup 5, 2015, pp. 855–860.10.1179/1432891714Z.0000000001207Search in Google Scholar

[24] Du, R. L., K. Wu, D. A. Xu, C. Y. Chao, L. Zhang, and X. D. Du. A modified Arrhenius equation to predict the reaction rate constant of Anyuan pulverized-coal pyrolysis at different heating rates. Fuel Processing Technology, Vol. 148, 2016, pp. 295–301.10.1016/j.fuproc.2016.03.011Search in Google Scholar

[25] Raheem, H. M. and A. M. Al-Mukhtar. Experimental and analytical study of the hyperelastic behavior of the hydrogel under unconfined compression. Procedia Structural Integrity, Vol. 25, 2020, pp. 3–7.10.1016/j.prostr.2020.04.002Search in Google Scholar

[26] Raheem, H. M. and A. M. Al-Mukhtar. Experimental investigation of the effects of infusing a foam into hydrogels on the hyperelastic coefficients. Material design & processing. Communications, Vol. 3, No. 4, 2021, id. e180.10.1002/mdp2.180Search in Google Scholar

[27] Khaniki, H. B., M. H. Ghayesh, R. Chin, and M. Amabili. Hyperelastic structures: A review on the mechanics and biomechanics. International Journal of Non-Linear Mechanics, Vol. 148, 2022, id. 104275.10.1016/j.ijnonlinmec.2022.104275Search in Google Scholar

[28] Khaniki, H. B., M. H. Ghayesh, and R. Chin. Theory and experiment for dynamics of hyperelastic plates with modal interactions. International Journal of Engineering Science, Vol. 182, 2023, id. 103769.10.1016/j.ijengsci.2022.103769Search in Google Scholar

[29] Khaniki, H. B., M. H. Ghayesh, R. Chin, and L. Q. Chen. Experimental characteristics and coupled nonlinear forced vibrations of axially travelling hyperelastic beams. Thin-Walled Structures, Vol. 170, 2022, id. 108526.10.1016/j.tws.2021.108526Search in Google Scholar

[30] Khaniki, H. B., M. H. Ghayesh, R. Chin, and S. Hussain. Nonlinear continuum mechanics of thick hyperelastic sandwich beams using various shear deformable beam theories. Contin Mech Thermodyn, Vol. 34, No. 3, 2022, pp. 781–827.10.1007/s00161-022-01090-ySearch in Google Scholar

[31] Destrade, M., G. Saccomandi, and I. Sgura. Methodical fitting for mathematical models of rubber-like materials. Proceedings. Mathematical, Physical, and Engineering Sciences, Vol. 473, No. 2198, 2017, id. 20160811.10.1098/rspa.2016.0811Search in Google Scholar

[32] Marckmann, G. and E. Verron. Comparison of hyperelastic models for rubber-like materials. Rubber Chemistry and Technology, Vol. 79, No. 5, 2006, pp. 835–858.10.5254/1.3547969Search in Google Scholar

[33] Puglisi, G. and G. Saccomandi. Multi-scale modelling of rubber-like materials and soft tissues: an appraisal. Proceedings. Mathematical, Physical, and Engineering Sciences, Vol. 472, No. 2187, 2016, id. 20160060.10.1098/rspa.2016.0060Search in Google Scholar PubMed PubMed Central

[34] Bystritskaya, E. V., A. L. Pomerantsev, and O. Y. Rodionova. Prediction of the aging of polymer materials. Chemometrics and Intelligent Laboratory Systems. Vol. 47, No. 2, 1999, pp. 175–178.10.1016/S0169-7439(98)00205-6Search in Google Scholar

[35] Rodionova, O. Y. and A. L. Pomerantsev. Prediction of rubber stability by accelerated aging test modeling. Journal of Applied Polymer Science, Vol. 95, No. 5, 2005, pp. 1275–1284.10.1002/app.21347Search in Google Scholar

[36] Lee, S. P. and K. W. Kang. Deformation analysis of rubber seal assembly considering uncertainties in mechanical properties. Journal of Mechanical Science and Technology, Vol. 33, No. 7, 2019, pp. 3345–3353.10.1007/s12206-019-0629-ySearch in Google Scholar

[37] Liu, L., X. Y. Li, E. Zio, R. Kang, and T. M. Jiang. Model uncertainty in accelerated degradation testing analysis. IEEE Transactions on Reliability, Vol. 66, No. 3, 2017, pp. 603–615.10.1109/TR.2017.2696341Search in Google Scholar

[38] Varga, L., B. Szabó, I. G. Zsély, Zempléni A., and Turányi T. Numerical investigation of the uncertainty of Arrhenius parameters. Journal of Mathematical Chemistry, Vol. 49, No. 8, 2011, id. 1798.10.1007/s10910-011-9859-7Search in Google Scholar

[39] Woo, C. S., W. D. Kim, and J. D. Kwon. A study on the material properties and fatigue life prediction of natural rubber component. Materials Science and Engineering: A Structure Materials, Vol. 483, 2008, pp. 376–381.10.1016/j.msea.2006.09.189Search in Google Scholar

[40] Shao, Y., and R. Kang. A life prediction method for O-ring static seal structure based on physics of failure. 2014 Prognostics and System Health Management Conference (PHM-2014 Hunan), 2014 Aug 24–27, Zhangjiajie, China, IEEE, 2014, pp. 16–21.10.1109/PHM.2014.6988124Search in Google Scholar

[41] Korba, A. G., A. Kumar, and M. Barkey. A hyper-elastic thermal aging constitutive model for rubber-like materials. Journal of Elastomers and Plastics, Vol. 52, No. 8, 2020, pp. 677–700.10.1177/0095244319883405Search in Google Scholar

[42] Nagy, T. and T. Turanyi. Uncertainty of Arrhenius parameters. International Journal of Chemical Kinetics, Vol. 43, No. 7, 2011, pp. 359–378.10.1002/kin.20551Search in Google Scholar

[43] Héberger, K., S. Kemény, and T. Vidóczy. On the errors of Arrhenius parameters and estimated rate constant values. International Journal of Chemical Kinetics, Vol. 19, No. 3, 1987, pp. 171–181.10.1002/kin.550190302Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants