Abstract

The present work aims to carry out a feasible study of wire electro-discharge machining (WEDM) during the machining of Inconel 690 superalloy gears. Processing conditions of power-on time, power-off time, current, and spark-gap voltage are varied to evaluate the process performance in terms of material removal rate (MRR), surface roughness (SR), and wire consumption. Parametric optimization has been carried out using combined approach of response surface methodology (RSM) and artificial neural network (ANN). Results revealed that ANN predicted values are 99% in agreement with the experimental results which validates its effectiveness as compared to RSM predicted values. A viability study of noise characteristics of the processed gear is also done using a noise testing setup. Additionally, FE-SEM has been used to analyze the machined surface’s topography. Greater discharge energy brought by a longer pulse length raises the values of MRR, SR, and recast layer thickness (RLT). This study explores the capability of WEDM to produce a more precise and smooth gear profile as compared to other conventional machining methods. Additionally, RLT and microhardness of the machined surface have been critically studied to comprehend the better understanding of the process mechanism.

1 Introduction

With the advance in micro-electromechanical systems and micro systems, the need for micro-components and micro-devices also increases. For the transmission of motion and power in these micro-systems, there is a need of miniature gears. Miniature gears used in micro-systems have a vast area of application which include miniature motors and pumps, actuators, miniature gearbox, robots, timing mechanism, scientific instruments, aerospace industry, military applications, medical equipment, electronic devices and instruments, etc. [1,2]. Depending on the design and the required quality level, a variety of manufacturing procedures are utilized for the machining of small gears. When machining gears, some of the traditional procedures utilized are hobbing, stamping, extrusion, forging, powder metallurgy, etc. However, in the case of these standard procedures, a secondary finishing operation is necessary to achieve the requisite surface quality of the micro gear, which is a significant disadvantage for them [3]. Electro-spark erosion-based non-conventional machining techniques are now available to help manufacturers produce high-quality small gears with improved surface quality and dimensional precision.

When it comes to machining electrically conductive materials, regardless of their toughness and hardness, wire electro-discharge machining (WEDM) has become a unique form of electro-spark erosion. It creates surfaces with little grit and has the potential to cut any intricate shape or geometry with great precision. Literature can enlighten readers about important traits, influencing variables, process capacity, etc. [4,5,6,7]. The WEDM’s material removal method is depicted in Figure 1. For the production of miniature parts for the aerospace sector, dentistry and medical equipment, gear pumps, and motors, among other things, WEDM is frequently utilized. Every machining process has a number of elements that influence how successfully it accomplishes one or more objectives. To improve the process performance, a variety of optimization approaches for single-objective, multi-objective, or both forms of process characteristic optimizations are available.

Process mechanism for removing material: (a) schematic and (b) pictorial view.

In the past, Hori and Murtaza used micro- WEDM for the processing of micro spur gear. It was concluded that the micro spur gear has a uniform profile and there was no undercutting error at root area of the gear profile [8]. Benavides et al. used micro-WEDM for the machining of 304 SS. Results show that machined surface has micro-level surface finish with good profile characteristics. The thickness of recast layer formed during the machining was also less [9]. Uhlmann et al. [10] concluded that micro-WEDM is highly capable of manufacturing miniaturized components with high surface finish and low profile error. Ali et al. [11] discussed the comparative study of conventional and WEDM for the fabrication of meso spur gear of copper. It is concluded that gears formed by WEDM process have an average surface roughness (SR) of 1 µm along with the dimensional variation of less than 2%. Talon et al. [12] used EDM to manufacture the Ti-6AL-4V spur gear. It was concluded that use of process parameters in a controlled way gives highly precise results. To forecast the value of CS during the WEDM of SiCp/6061 Al metal matrix composite, Shandilya et al. employed a combined method of response surface methodology (RSM) and artificial neural network (ANN) [13]. During the WEDM, the wire tool breaking process was investigated by Liao et al. During the processing, a computer-aided pulse-discrimination system was cast-off to acquire a large amount of sparking frequency data. The main causes of wire tool breakage were determined to be an excessive spark arc and a sudden increase in the sparking frequency [14]. Paul et al. [15] conducted an experimental study on manufacturing of miniature gear of Inconel 718 using WEDM process. Results show that at high discharge energy levels there is a high presence of coral reef on the machined surface, while in case of low discharge energy levels there are random micro-cracks present on the machined surface. Chaubey and Jain [16] studied the microstructure of meso gears machined by WEDM process on a rectangular plate of stainless steel. It was concluded that the gears have uniform tooth profile and are free from the presence of sharp edges at both the end faces. Chaudhary et al. [17] conducted a multi-response optimization for miniature gear of Nimonic alloy fabricated by WEDM process using different dielectric fluids. Results reveals that ethylene glycol mixed de-mineralized water used as a dielectric fluid is the most significant parameter among all the input process parameters. Singh and Misra [18] used a combined RSM and ANN technique to examine the surface finish of WEDM-machined combustor material. The predicted and experimental values were found to be in good agreement, proving the validity of the experimental study. Abhilash and Chakradhar have employed the Naive Bayes classifier technique to analyze and categorize the wire rupture during Superalloy 718 machining utilizing WEDM. Short-circuit sparks were found to be the most important factor in wire tool failure [19]. Depending upon the characteristics and its application, various materials like tool-steel, carbon-steel, copper and its alloys, aluminum and its alloys, titanium and its alloys, nickel and its alloys, plastics, nylon, Teflon etc., are used for the manufacturing of miniature gears. Miniature gear made of superalloys has been widely used in aerospace industry, medical implants, electronic industry, gas turbine industry, automobile sector, etc. [20].

Published articles lack any work on formation of miniature gears from nickel-based superalloys and studying the effects of operating conditions on noise characteristics of the gears. Very few authors discuss about the effects of process variables on the tribological behavior of the processed component. So, the present investigation aimed at:

Formation of miniature gears from nickel-based superalloy Inconel 690 using WEDM and studying the surface integrity of the tooth profile.

Studying the postprocess changes in the surface topography of the processed component by employing scanning electron microscopy (SEM).

Analysis of recast layer formation on the gear tooth surface and variation in recast layer thickness (RLT) along the machined surface using FE-SEM.

RSM and ANN-based multi-objective process variable optimization

Studying the effects of operating conditions on the gear noise characteristics.

2 Materials and methodology

2.1 Materials

In the present study a nickel-based superalloy Inconel 690 is used as the workpiece material. Inconel 690 has high chromium content in it which offers high strength and high corrosion resistance property in aqueous medium and high temperature. It has immense demand in industrial area and is very much needed in aerospace and gas turbine industry. A rectangular plate with dimensions 150 mm × 150 mm × 15 mm is used for the manufacturing of miniature gears. Miniature spur gears with outer diameter of 10 mm are cut from the rectangular plate. EDS analysis of the workpiece material and wire tool is demonstrated in Figure 2, respectively.

EDS analysis of (a) Inconel 690 and (b) fresh wire.

2.2 Methodology

In the present study, WEDM machine (Model: Sprint cut- ELECTRONICA) is used for the cutting of miniature gears from the workpiece surface. Superalloy 690 is a very hard material to cut because of its high strength and hardness. A pictorial view of the process followed during the present study is shown in Figure 3. Initially, grinding and buffing of workpiece plate is done to remove the layer of impurities present on its surface in order to avoid the wire breakage and proper spark generation during WEDM. In the present analysis, power-on time (T on), power-off time (T off), peak current (I p), and spark gap voltage (S v) are used as input process variables. Process performance is evaluated in respect of material removal rate (MRR), SR, and wire consumption (WC). Ranges and level of input process variables are tabulated in Table 1.

Pictorial view of process flow chart: (a) WEDM machine setup, (b) processing of superalloy 690 by WEDM, (c and d) miniature spur gears and their cavity in the plate after WEDM, (e) SR measurement, and (f) microhardness analysis.

Ranges and levels of input variables

| Variables | Input process parameters | |||||

|---|---|---|---|---|---|---|

| Source | Range | Unit | Level | |||

| 1 | 2 | 3 | ||||

| Power-on time (T on) | A | 105–131 | µs | 105 | 118 | 131 |

| Power-off time (T off) | B | 30–60 | µs | 30 | 45 | 60 |

| Peak current (I p) | C | 40–220 | A | 40 | 130 | 220 |

| Spark gap voltage (S v) | D | 20–80 | V | 20 | 50 | 80 |

In the next step, an experimental plan is set for accomplishment of the experiments using WEDM with the help of Box–Behnken design (BBD) of RSM [21,22,23,24]. Although the central composite design (CCD) has been chosen in various past research [25,26,27,28,29], BBD was chosen over CCD as it provides lesser number of experiments for same number of parameters. As per Box behnken design, a total of 29 runs are done with 5 replications of center shown in Table 2. The manufacturing of miniature gears from the super alloy 690 square plate using WEDM is shown in Figure 3(c). Following WEDM processing, the SR of the miniature gears is measured using a Telesurf surfcom (Make: Accretech) roughness tester. The treated surface’s roughness is measured according to ISO 1997 standards. The calculations used a cut-off value of 2.5 m and a sampling length of 4 mm. Five tests were run on each machined surface, and the average result was used to determine the roughness value. FE-SEM (Make: Joel, JSM-6390LV, 20.0 keV) was used for microstructural investigation, and Vickers’ hardness tester was used for microhardness measurement [30,31,32].

Experimental runs

| No. of runs | Input process variables | Experimental results | RSM predicted | ANN predicted | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T on | T off | I p | S v | MRR | SR | WC | MRR | SR | WC | MRR | SR | WC | |

| 1 | A1 | B1 | C2 | D2 | 3.83 | 1.64 | 42.98 | 9.17 | 1.67 | 51.46 | 3.83 | 1.67 | 42.97 |

| 2 | A3 | B1 | C2 | D2 | 6.67 | 3.82 | 19.56 | 14.6 | 3.69 | 30.00 | 9.03 | 3.55 | 17.90 |

| 3 | A1 | B3 | C2 | D2 | 1.27 | 0.73 | 144.92 | 4.85 | 0.81 | 137.26 | 1.28 | 0.81 | 144.66 |

| 4 | A3 | B3 | C2 | D2 | 5.55 | 3.18 | 31 | 11.7 | 3.10 | 25.30 | 5.54 | 3.12 | 31.08 |

| 5 | A2 | B2 | C1 | D1 | 4.2 | 2.46 | 40.09 | 6.34 | 2.25 | 47.91 | 9.09 | 1.48 | 18.50 |

| 6 | A2 | B2 | C3 | D1 | 6.11 | 3.11 | 27.17 | 15.7 | 3.06 | 25.91 | 6.10 | 3.06 | 27.32 |

| 7 | A2 | B2 | C1 | D3 | 2.34 | 1.54 | 71.75 | 4.23 | 1.54 | 75.79 | 2.31 | 1.59 | 71.47 |

| 8 | A2 | B2 | C3 | D3 | 6.42 | 2.85 | 25.79 | 15.8 | 3.01 | 20.75 | 9.04 | 2.84 | 18.06 |

| 9 | A1 | B2 | C2 | D1 | 2.23 | 1.63 | 78.11 | 8.30 | 1.43 | 77.47 | 3.34 | 0.94 | 73.32 |

| 10 | A3 | B2 | C2 | D1 | 6.67 | 3.02 | 28.22 | 13.8 | 3.09 | 22.13 | 6.71 | 3.25 | 28.22 |

| 11 | A1 | B2 | C2 | D3 | 1.68 | 0.72 | 94.8 | 6.60 | 0.55 | 100.2 | 1.49 | 0.86 | 94.56 |

| 12 | A3 | B2 | C2 | D3 | 7.47 | 3.11 | 22.15 | 13.4 | 3.21 | 22.11 | 7.47 | 3.18 | 22.02 |

| 13 | A2 | B1 | C1 | D2 | 4.64 | 2.39 | 36.42 | 6.65 | 2.36 | 33.31 | 7.96 | 2.39 | 20.64 |

| 14 | A2 | B3 | C1 | D2 | 1.6 | 1.82 | 105.14 | 3.04 | 1.92 | 101.44 | 1.76 | 1.69 | 104.01 |

| 15 | A2 | B1 | C3 | D2 | 4.84 | 3.98 | 19.34 | 17.1 | 3.79 | 22.37 | 4.82 | 3.84 | 19.39 |

| 16 | A2 | B3 | C3 | D2 | 5.18 | 2.83 | 32.91 | 13.55 | 2.77 | 35.34 | 5.18 | 2.78 | 32.93 |

| 17 | A1 | B2 | C2 | D2 | 1.36 | 0.47 | 130.65 | 2.49 | 0.58 | 126.39 | 1.33 | 0.81 | 116.33 |

| 18 | A3 | B2 | C1 | D2 | 3.98 | 2.51 | 43.1 | 6.30 | 2.51 | 42.33 | 4.07 | 2.44 | 42.63 |

| 19 | A1 | B2 | C3 | D2 | 2.41 | 1.39 | 71.85 | 10.62 | 1.50 | 70.53 | 2.44 | 1.38 | 71.87 |

| 20 | A3 | B2 | C3 | D2 | 6.86 | 3.88 | 18.98 | 19.19 | 3.88 | 21.15 | 6.83 | 3.81 | 18.97 |

| 21 | A2 | B1 | C2 | D1 | 5.14 | 2.81 | 32.5 | 12.09 | 3.07 | 24.22 | 5.16 | 2.74 | 32.65 |

| 22 | A2 | B3 | C2 | D1 | 7.28 | 2.54 | 32.95 | 10.92 | 2.63 | 41.40 | 7.27 | 2.55 | 33.13 |

| 23 | A2 | B1 | C2 | D3 | 5.14 | 2.96 | 22.75 | 13.50 | 2.98 | 12.21 | 5.15 | 2.84 | 22.76 |

| 24 | A2 | B3 | C2 | D3 | 2.42 | 2.11 | 69.94 | 7.47 | 1.96 | 76.13 | 2.42 | 2.15 | 70.11 |

| 25 | A2 | B2 | C2 | D2 | 9.38 | 2.83 | 17.96 | 14.48 | 2.31 | 18.13 | 8.65 | 2.39 | 18.22 |

| 26 | A2 | B2 | C2 | D2 | 8.34 | 2.08 | 18.46 | 14.48 | 2.31 | 18.13 | 8.65 | 2.39 | 18.22 |

| 27 | A2 | B2 | C2 | D2 | 8.26 | 2.17 | 17.63 | 14.48 | 2.31 | 18.13 | 8.65 | 2.39 | 18.22 |

| 28 | A2 | B2 | C2 | D2 | 8.37 | 2.29 | 18.35 | 14.48 | 2.31 | 18.13 | 8.65 | 2.39 | 18.22 |

| 29 | A2 | B2 | C2 | D2 | 8.38 | 2.22 | 18.22 | 14.48 | 2.31 | 18.13 | 8.65 | 2.39 | 18.22 |

3 Results and discussion

T on, T off, I p, and S v are selected as input factors for the current study, while MRR, SR, and WC are regarded as response variables. The effects of various input factors on process performance are depicted in Figure 4. Among all the input factors, T on is discovered to have the greatest influencing power. The output data demonstrate that as T on increases, MRR and SR also rise and vice versa. The number of electrons striking the work surface in a single discharge increases as T on and I p grow. More materials are removed from the work surface for each discharge. As a result, MRR rises as T on and I p rises. The metal is removed from the work surface in the form of craters, which is a well-known phenomenon of WEDM. Increased material removal results in a poor surface finish and a higher SR value. On the other hand, WC has a different response as compared to MRR and SR for T on [33,34,35]. High discharge energy is associated with higher T on and I p values. As a result, the wire tool length required to eradicate the material from the work piece is reduced. As the wire feed remains constant throughout the process, T off increases the pulse duration, requiring more wire tool length to eradicate the material from the work piece. A larger S v widens the space between the work piece and the wire tool, resulting in reduced spark concentration. As a result, the amount of wire used increases. It is obvious from the results that I p also has similar possessions like T on on MRR, SR, and WC. T off and S v also have some severe effects on MRR, SR, and WC [36,37,38]. As the T off and S v value drops, some rise in the value of MRR and SR is noticed.

Various input factors’ effect on: (a) MRR, (b) SR, and (c) WC.

The time period of sparks creation in the WEDM process increases with the increase in T on value, which inexorably influences the MRR. The spark gap narrows as the S v decreases, increasing the number of sparks produced per unit of time. The machining rate is indirectly accelerated, increasing the MRR [39,40,41]. The findings show that higher T on and I p values result in increased MRR and SR. According to interaction plots, the increase in T on and I p values is predominantly associated with an increase in MRR; however, after reaching a certain point, MRR begins to decline. Though, as seen in Figure 4a, MRR for T off and S v declines as their values increase. According to the findings for SR, which are depicted in Figure 4b, SR rises as T on and I p values increase.

3.1 Multi-objective optimization

ANN is a MATLAB toolkit. Backpropagation neural network (BPNN) models are commonly created with it. WEDM has a large sum of input process factors which have a substantial impact on the process output. Because of the intricacy and stochastic nature of the data, statistical analysis is possible, but precise guess of values using a scientific equation is not valid. As a training vector, four input process variables are included in the current study.

Various limitations, such as the number of iterations, hidden layer nodes, network type, and so on, affect the performance of a BPNN model. As a result, during BPNN training, selecting the most optimal values for input process variables is crucial [30].

The ideal configuration of the ANN model is determined for current study by altering the sum of neurons in the hidden layer. For the current ANN model, the dataset is split into three parts: 60% for training, 20% for validation, and 20% for testing. The current model is an FF-BPNN with a Levenberg–Marquardt training procedure. In the existing model, 1 buried layer contains 20 neurons. The linear regression graphs of actual vs predicted values for ANN are shown in Figure 5. The R-values achieved for the training and validation datasets in this model are 0.99148 and 0.99459, respectively, which are extremely near to 1. The current model’s results reveal that actual and anticipated values are in good agreement. In addition, Figure 6 shows a comparison graph between the actual values and the expected outcomes. In comparison to the quadratic RSM model, the constructed ANN model provides more exact and generalized predicted values, as seen in the comparison graph.

Comparative graph of actual and ANN projected values, using linear regression analysis.

Relative graph of actual vs predicted values for (a) MRR, (b) SR, and (c) WC.

4 Surface topography and noise characteristics analysis

4.1 Surface integrity

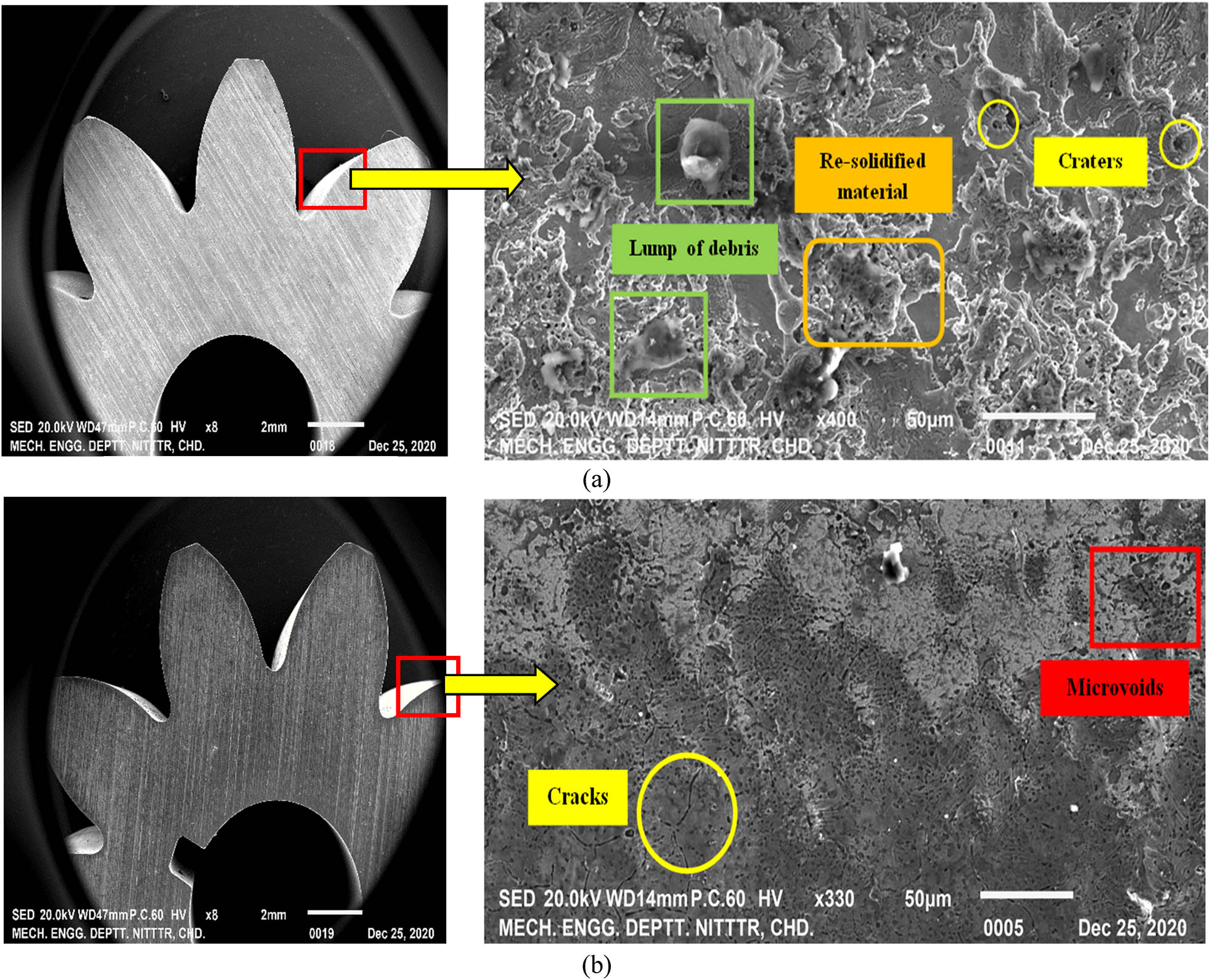

Investigation of profile characteristics on the WEDM small gear profile reveals the existence of micro-cracks and bowl-shaped cavities called craters on the gear tooth surface, as well as some spherical droplets [42,43,44]. Some molten metal and re-solidified material can also be seen on the gear tooth surface in the form of a lump of debris. Figure 7 shows a burr-free uniform tooth profile of WEDMed gears machined under various operating circumstances, as well as their microstructures. Small craters, spherical modules with a lump of debris, and re-solidified material are portrayed on the surface of the machined work piece, according to Figure 7a and b.

SEM micrographs of gear profile and gear tooth surface machined at (a) T on, 118; T off, 30; I p, 220; S v, 50 and (b) T on, 105; T off, 45; I p, 130; S v, 50.

4.2 Microhardness analysis

The hardness of the work piece is affected by the formation of recast layers on its top surface. Testing for microhardness is an easy technique to confirm this. In this work, a microhardness testing machine is used to examine the variation in the microhardness values of the core material and the machined region [45,46]. The variance in microhardness along the subsurface of the recast layer is seen in Figure 8. In comparison to the core materials, microhardness rises close to the subsurface of the recast layer, as depicted in the graphs. The formation of recast layers on the face of the processed work surface enhances the hardness of the work piece. Because the recast layer is formed exclusively on the machined area of the work piece, the hardness of the core material is not affected. A total of six indentations have been made on each work surface, starting from one end to the other end, as shown in Figure 8. From the results, it can be seen that the value of hardness decreases as the testing point moves from machine area to the core area of the processed work piece.

Microhardness analysis.

4.3 Noise characteristics

These types of problems significantly reduce the gear’s service life. The setup used for noise measurement, as shown in Figure 9, comprises of a pair of spur gear in which one is the master gear and the other one is the testing gear. The noise generated during the meshing of the gears was measured at different time intervals. A DC motor, which is used to supply power, is connected to the master gear. Master gear can rotate from 1,500 to 2,800 RPM. The speed of the master gear can be varied with the help of the RPM controller. Two Perspex boxes are used, one is to cover the power supply chamber, i.e., motor and the other one for the gear meshing chamber to avoid the sound of the surroundings.

Noise testing setup: (a) schematic view and (b) photographic view.

A non-contact RPM meter, i.e., testo-465 with a measuring range of +1 to +99,999 RPM and accuracy of ±0.02% of the measured value is used for monitoring the speed of rotation. For noise measurement, a sound level meter, i.e., testo 816-1 with a measuring range of 30–130 dB is used. A comparative study between gears manufactured by two different conventional processes, i.e., milling and shaping is done to analyze the effects of machining process on the noise characteristics of the gear. Both the gears are meshed with the master gear individually for different run time, and during the meshing period, their noise levels are recorded using sound level meter [47,48]. Noise level of gear manufactured through milling process is higher as compared to that of gear manufactured through shaping process. Initially, the sound level for both the processes was approximately 99 dB for a run time of 60 s. As the run time increases, the difference between the noise levels of both the processes also increases. In case of WEDM machined gears, noise was measured at three different levels of time, i.e., 60, 120 and 180 s respectively. In case of 60 s, maximum level of noise generated by the meshing gears is 98 dB, while in case of 120 s meshing time, the maximum noise level is 99.7 dB. For 180 s meshing time, the noise level reaches up to 102 dB.

From the experimental results, it was concluded that with the increase in the meshing time, the noise and vibration also increases, but when compared to the conventional machining processes, the gear manufactured by WEDM process generates less noise [49,50]. A comparative graph of both the conventional methods with WEDM process is shown in Figure 10. Average noise levels for milling, shaping, and WEDM processed gears at different run time are shown in Table 3.

Comparative graph of noise level for milling, shaping, and WEDM processed gears.

Noise level results at different intervals of time

| S. No | Gears | Average noise levels | ||

|---|---|---|---|---|

| 60 s | 120 s | 180 s | ||

| 1 | Milling gear | 99.40 dB | 108.12 dB | 109.38 dB |

| 2 | Shaper gear | 99.42 dB | 102.37 dB | 107.60 dB |

| 3 | WEDM gear | 98.13 dB | 99.75 dB | 101.91 dB |

5 Conclusion

The present study accomplishes that the gear tooth profile, which was machined at different parametrical settings (maximum MRR and SR conditions), has small craters and spherical modules with a lump of debris and re-solidified materials on its surface, according to surface integrity analysis. As there are fewer craters and less amount of debris on the surface of the machined surface under minimum MRR and SR parametrical settings, this surface is found to be smoother. From experimental runs, it was concluded that, among all the input process variables, pulse-on time (T on) is the most significant variable which affects the process performance mostly. When BPNN models are compared to quadratic RSM models, it is found that the generated BPNN models have more precision and accuracy. Noise characteristic analysis shows that with the increase in the meshing time, the gear noise level also increases. From the comparative analysis, it is clear that the gears machined by WEDM process have good micro-geometry and high surface quality as compared to that manufactured by conventional gear manufacturing processes.

Acknowledgments

The researchers would like to thank Research Facility Cell, National Institute of Technology Kurukshetra for their support and guidance.

-

Funding information: The authors state no funding involved.

-

Author contributions: Conceptualization: Atul Raj, Joy Prakash Misra, Ravinder Pal Singh, Gurminder Singh, and Shubham Sharma; formal analysis: Atul Raj, Joy Prakash Misra, Ravinder Pal Singh, Gurminder Singh, and Shubham Sharma; investigation: Atul Raj, Joy Prakash Misra, Ravinder Pal Singh, Gurminder Singh, and Shubham Sharma; writing – original draft preparation: Atul Raj, Joy Prakash Misra, Ravinder Pal Singh, Gurminder Singh, and Shubham Sharma; writing – review and editing: Shubham Sharma and Sayed M. Eldin; supervision: Shubham Sharma and Sayed M. Eldin; project administration: Shubham Sharma and Sayed M. Eldin; and funding acquisition: Shubham Sharma and Sayed M. Eldin. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Jain, N. K. and S. K. Chaubey. Review of miniature gear manufacturing, Comprehensive Materials Finishing. Elsevier Inc., Oxford, UK, Vol. 1–3, 2017. ISBN 9780128032503.10.1016/B978-0-12-803581-8.09159-1Search in Google Scholar

[2] Singh, S., G. Singh, C. Prakash, S. Ramakrishna, L. Lamberti, and C. I. Pruncu. 3D printed biodegradable composites: An insight into mechanical properties of PLA/chitosan scaffold. Polymer Testing, Vol. 89, 2020, id. 106722.10.1016/j.polymertesting.2020.106722Search in Google Scholar

[3] Raj, A. and J. P. Misra. Challenges and opportunities in ECH of gears. Materials Science Forum, Vol. 969 MSF, 2019, pp. 595–600.10.4028/www.scientific.net/MSF.969.595Search in Google Scholar

[4] Bobbili, R., V. Madhu, and A. K. Gogia. Effect of wire-EDM machining parameters on surface roughness and material removal rate of high strength armor steel. Materials and Manufacturing Processes, Vol. 28, 2013, pp. 364–368.10.1080/10426914.2012.736661Search in Google Scholar

[5] Mouralova, K., J. Kovar, L. Klakurkova, J. Bednar, L. Benes, and R. Zahradnicek. Analysis of surface morphology and topography of pure aluminium machined using WEDM. Measurement, Vol. 114, 2018, pp. 169–176. 10.1016/j.measurement.2017.09.040Search in Google Scholar

[6] Mussada, E. K., C. C. Hua, and A. K. P. Rao. Surface hardenability studies of the die steel machined by WEDM. Materials and Manufacturing Processes, Vol. 33, 2018, pp. 1745–1750.10.1080/10426914.2018.1476695Search in Google Scholar

[7] Sharma, N., R. Khanna, and R. Gupta. Multi quality characteristics of WEDM process parameters with RSM. Procedia Engineering, Vol. 64, 2013, pp. 710–719.10.1016/j.proeng.2013.09.146Search in Google Scholar

[8] Hori, K. and Y. Murtaza. Wire electrical discharge machining of micro-involute gears. Transactions of the Japan Society of mechanical engineers, Vol. 57, 1977, pp. 364–370.Search in Google Scholar

[9] Benavides, G. L., L. F. Bieg, M. P. Saavedra, and E. A. Bryce. High aspect ratio meso-scale parts enabled by wire micro-EDM. Microsystem Technologies, Vol. 8, 2002, pp. 395–401.10.1007/s00542-002-0190-xSearch in Google Scholar

[10] Uhlmann, E., S. Piltz, and U. Doll. Machining of micro/miniature dies and moulds by electrical discharge machining - recent development. Journal of Materials Processing Technology, Vol. 167, 2005, pp. 488–493.10.1016/j.jmatprotec.2005.06.013Search in Google Scholar

[11] Ali, M. Y., A. N. Mustafizul Karim, E. Y. T. Adsesta, A. F. Ismail, A. A. Abdullah and M. N. Idris. Comparative study of conventional and micro WEDM based on machining of meso/micro sized spur gear. International Journal of Precision Engineering and Manufacturing, Vol. 11, 2010, pp. 779–784.10.1007/s12541-010-0092-2Search in Google Scholar

[12] Huertas Talón, J. L., J. C. Cisneros Ortega, C. López Gómez, E. Ros Sancho, and E. Faci Olmos. Manufacture of a spur tooth gear in Ti-6Al-4V alloy by electrical discharge. Computer-Aided Design, Vol. 42, 2010, pp. 221–230.10.1016/j.cad.2009.11.001Search in Google Scholar

[13] Shandilya, P., P. K. Jain, and N. K. Jain. RSM and ANN modeling approaches for predicting average cutting speed during WEDM of SiCp/6061 Al MMC. Procedia Engineering, Vol. 64, 2013, pp. 767–774.10.1016/j.proeng.2013.09.152Search in Google Scholar

[14] Liao, Y. S., Y. Y. Chu, and M. T. Yan. Study of wire breaking process and monitoring of WEDM. International Journal of Machine Tools and Manufacture, Vol. 37, 1997, pp. 555–567.10.1016/S0890-6955(95)00049-6Search in Google Scholar

[15] Paul, T., S. Chakraborty, N. K. Mandal, and D. Bose. An experimental investigation on development of miniature spur gear by WEDM of inconel 718. Proceedings of. 6th International & 27th All India Manufacturing Technology, Design and Research Conference (AIMTDR-2016), 2016, pp. 1523–1527.Search in Google Scholar

[16] Chaubey, S. K. and N. K. Jain. Investigations on microgeometry of meso bevel and meso helical gears manufactured by WEDM process. The International Journal of Advanced Manufacturing Technology, Vol. 93, 2017, pp. 4217–4231.10.1007/s00170-017-0884-ySearch in Google Scholar

[17] Chaudhary, T., A. N. Siddiquee, A. K. Chanda, M. H. Abidi, and A. Al-Ahmari. Multi-response optimization for nimonic alloy miniature gear fabrication using wire electrical discharge machining. Advances in Mechanical Engineering, Vol. 12, 2020, pp. 1–13.10.1177/1687814020967580Search in Google Scholar

[18] Singh, B. and J. P. Misra. Surface finish analysis of wire electric discharge machined specimens by RSM and ANN Modeling. Measurement, Vol. 137, 2019, pp. 225–237. 10.1016/j.measurement.2019.01.044Search in Google Scholar

[19] Abhilash, P. M. and D. Chakradhar. Sustainability improvement of WEDM process by analysing and classifying wire rupture using kernel-based naive bayes classifier. Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 43, 2021, pp. 1–9.10.1007/s40430-021-02805-zSearch in Google Scholar

[20] Singh, B. and J. P. Misra. Process regulations and mechanism of WEDM of combustor material. SAE International Journal of Aerospace, Vol. 12, 2019, pp. 77–96. 10.4271/01-12-01-0004Search in Google Scholar

[21] Myers, R. H. and D. C. Montgomery. Response surface methodology: Process and product optimization using designed experiments. Journal of Statistical Planning and Inference, 59, 1997, pp. 185–186.10.1016/S0378-3758(97)81631-XSearch in Google Scholar

[22] Batra, N. K., R. P. Singh, and S. Dayal. Experimental investigation and statistical modelling of cutting speed in AL6063-W composite by wire EDM process. Materials Today: Proceedings, Vol. 62, 2022, pp. 1408–1412.10.1016/j.matpr.2021.12.418Search in Google Scholar

[23] Pal Singh, R., N. K. Batra, and S. Dayal. Influence of machining parameters on surface roughness in AL6063-W composite by wire EDM Process: Experimental investigations and process optimization. Materials Today: Proceedings, Vol. 63, 2022, pp. 192–196.10.1016/j.matpr.2022.02.462Search in Google Scholar

[24] Singh, G., S. Singh, J. Singh, and P. M. Pandey. Parameters effect on electrical conductivity of copper fabricated by rapid manufacturing. Materials and Manufacturing Processes, 2020, pp. 1–12.10.1080/10426914.2020.1784937Search in Google Scholar

[25] Singh, G. and P. M. Pandey. Rapid manufacturing of copper components using 3D Printing and ultrasonic assisted pressureless sintering: Experimental investigations and process optimization. Journal of Manufacturing Processes, Vol. 43, 2019, pp. 253–269.10.1016/j.jmapro.2019.05.010Search in Google Scholar

[26] Singh, S., G. Singh, K. Sandhu, C. Prakash, and R. Singh. Investigating the optimum parametric setting for MRR of expandable polystyrene machined with 3D printed end mill tool. Materials Today: Proceedings, Vol. 33, 2020, pp. 1513–1517.10.1016/j.matpr.2020.03.465Search in Google Scholar

[27] Dikshit, I., G. Bhushan, R. P. Singh, and N. K. Batra. Statistical modeling and optimization of density in a novel carbon/jute fiber reinforced hybrid composite. Materials Today: Proceedings, Vol. 63, 2022, pp. 259–263.10.1016/j.matpr.2022.03.052Search in Google Scholar

[28] Singh, R. P., P. Mohan, and A. Ranjan. An in-vitro study of temperature rise during rotary ultrasonic bone drilling of human bone. Medical Engineering & Physics, Vol. 79, 2020, pp. 33–43.10.1016/j.medengphy.2020.03.002Search in Google Scholar PubMed

[29] Singh, R. P., P. M. Pandey, A. R. Mridha, and T. Joshi. Experimental investigations and statistical modeling of cutting force and torque in rotary ultrasonic bone drilling of human cadaver bone. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, Vol. 234, 2020, pp. 148–162.10.1177/0954411919889913Search in Google Scholar PubMed

[30] Desai, K. M., B. K. Vaidya, R. S. Singhal, and S. S. Bhagwat. Use of an artificial neural network in modeling yeast biomass and yield of β-Glucan. Process Biochemistry, Vol. 40, 2005, pp. 1617–1626. 10.1016/j.procbio.2004.06.015.Search in Google Scholar

[31] Sheng, C., G. He, Z. Hu, C. Chou, J. Shi, J. Li, et al. Yarn on yarn abrasion failure mechanism of ultrahigh molecular weight polyethylene fiber. Journal of Engineered Fibers and Fabrics, Vol. 16, 2021, id. 1925832385.10.1177/15589250211052766Search in Google Scholar

[32] Ning, F., G. He, C. Sheng, H. He, J. Wang, R. Zhou, et al. Yarn on yarn abrasion performance of high modulus polyethylene fiber improved by graphene/polyurethane composites coating. Journal of Engineered Fibers and Fabrics, 2021, Vol. 16, pp. 1–10. 10.1177/1558925020983563Search in Google Scholar

[33] Lv, B., S. Wang, T. Xu, and F. Guo. Effects of minor Nd and Er additions on the precipitation evolution and dynamic recrystallization behavior of Mg–6.0Zn–0.5Mn alloy. Journal of Magnesium and Alloys, Vol. 9, No. 3, 2021, pp. 840–852. 10.1016/j.jma.2020.06.018Search in Google Scholar

[34] Zhang, B., Z. Wang, H. Yu, and Y. Ning. Microstructural origin and control mechanism of the mixed grain structure in Ni-based superalloys. Journal of Alloys and Compounds, Vol. 900, 2022, id. 163515. 10.1016/j.jallcom.2021.163515Search in Google Scholar

[35] Liang, L., M. Xu, Y. Chen, T. Zhang, W. Tong, H. Liu, et al. Effect of welding thermal treatment on the microstructure and mechanical properties of nickel-based superalloy fabricated by selective laser melting. Materials science & engineering A, Structural Materials: Properties, Microstructure and Processing, Vol. 819, 2021, id. 141507. 10.1016/j.msea.2021.141507Search in Google Scholar

[36] Xie, J., Y. Chen, L. Yin, T. Zhang, S. Wang, and L. Wang. Microstructure and mechanical properties of ultrasonic spot welding TiNi/Ti6Al4V dissimilar materials using pure Al coating. Journal of Manufacturing Processes, Vol. 64, 2021, pp. 473–480.10.1016/j.jmapro.2021.02.009Search in Google Scholar

[37] Deng, H., Y. Chen, Y. Jia, Y. Pang, T. Zhang, S. Wang, et al. Microstructure and mechanical properties of dissimilar NiTi/Ti6Al4V joints via back-heating assisted friction stir welding. Journal of Manufacturing Processes, Vol. 64, 2021, pp. 379–391.10.1016/j.jmapro.2021.01.024Search in Google Scholar

[38] Yuhua, C., M. Yuqing, L. Weiwei, and H. Peng. Investigation of welding crack in micro laser welded NiTiNb shape memory alloy and Ti6Al4V alloy dissimilar metals joints. Optics & Laser Technology, Vol. 91, 2017, pp. 197–202. 10.1016/j.optlastec.2016.12.028Search in Google Scholar

[39] Zhao, Y. Co-precipitated Ni/Mn shell coated nano Cu-rich core structure: A phase-field study. Journal of Materials Research Technology, Vol. 21, 2022, pp. 546–560.10.1016/j.jmrt.2022.09.032Search in Google Scholar

[40] Zhang, P., Z. Liu, X. Yue, P. Wang, and Y. Zhai. Water jet impact damage mechanism and dynamic penetration energy absorption of 2A12 aluminum alloy. Vacuum, Vol. 206, 2022, id. 111532. 10.1016/j.vacuum.2022.111532Search in Google Scholar

[41] Zhang, P., Z. Liu, J. Liu, J. Yu, Q. Mai, and X. Yue. Effect of aging plus cryogenic treatment on the machinability of 7075 aluminum alloy. Vacuum, Vol. 208, 2023, id. 111692. 10.1016/j.vacuum.2022.111692Search in Google Scholar

[42] Zhang, P., J. Liu, Y. Gao, Z. Liu, and Q. Mai. Effect of heat treatment process on the micro machinability of 7075 aluminum alloy. Vacuum, Vol. 207, 2023, id. 111574.10.1016/j.vacuum.2022.111574Search in Google Scholar

[43] Zhu, Z. Y., Y. L. Liu, G. Q. Gou, W. Gao, and J. Chen. Effect of heat input on interfacial characterization of the butter joint of hot-rolling CP-Ti/Q235 bimetallic sheets by Laser + CMT. Scientific Reports, Vol. 11, No. 1, 2021, id. 10020.10.1038/s41598-021-89343-9Search in Google Scholar PubMed PubMed Central

[44] Yang, J., S. Bai, J. Sun, H. Wu, S. Sun, S. Wang, et al. Microstructural understanding of the oxidation and inter-diffusion behavior of Cr-coated Alloy 800H in supercritical water. Corrosion Science, Vol. 211, 2023, id. 110910.10.1016/j.corsci.2022.110910Search in Google Scholar

[45] Zhu, Q., J. Chen, G. Gou, H. Chen, and P. Li. Ameliorated longitudinal critically refracted—Attenuation velocity method for welding residual stress measurement. Journal of Materials Processing Technology, Vol. 246, 2017, pp. 267–275.10.1016/j.jmatprotec.2017.03.022Search in Google Scholar

[46] Xu, H., T. He, N. Zhong, B. Zhao, and Z. Liu. Transient thermomechanical analysis of micro cylindrical asperity sliding contact of SnSbCu alloy. Tribology International, Vol. 167, 2022, id. 107362.10.1016/j.triboint.2021.107362Search in Google Scholar

[47] Liu, C., Y. Zhao, Y. Wang, T. Zhang, and H. Jia. Hybrid dynamic modeling and analysis of high-speed thin-rimmed gearsASME. Journal of Mechanical Design, Vol. 143, No. 12, 2021, id. 123401.10.1115/1.4051137Search in Google Scholar

[48] Niu, X., S. Zhu, J. He, D. Liao, J. A. F. O. Correia, F. Berto, et al. Defect tolerant fatigue assessment of AM materials: Size effect and probabilistic prospects. International Journal of Fatigue, Vol. 160, 2022, id. 106884.10.1016/j.ijfatigue.2022.106884Search in Google Scholar

[49] He, J., S. Zhu, C. Luo, X. Niu, and Q. Wang. Size effect in fatigue modelling of defective materials: Application of the calibrated weakest-link theory. International Journal of Fatigue, Vol. 165, 2022, id. 107213.10.1016/j.ijfatigue.2022.107213Search in Google Scholar

[50] Li, X., S. Zhu, D. Liao, J. A. F. O. Correia, F. Berto, Q. Wang. Probabilistic fatigue modelling of metallic materials under notch and size effect using the weakest link theory. International Journal of Fatigue, Vol. 159, 2022, id. 106788.10.1016/j.ijfatigue.2022.106788Search in Google Scholar

© 2023 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants

Articles in the same Issue

- Review Articles

- Progress in preparation and ablation resistance of ultra-high-temperature ceramics modified C/C composites for extreme environment

- Solar lighting systems applied in photocatalysis to treat pollutants – A review

- Technological advances in three-dimensional skin tissue engineering

- Hybrid magnesium matrix composites: A review of reinforcement philosophies, mechanical and tribological characteristics

- Application prospect of calcium peroxide nanoparticles in biomedical field

- Research progress on basalt fiber-based functionalized composites

- Evaluation of the properties and applications of FRP bars and anchors: A review

- A critical review on mechanical, durability, and microstructural properties of industrial by-product-based geopolymer composites

- Multifunctional engineered cementitious composites modified with nanomaterials and their applications: An overview

- Role of bioglass derivatives in tissue regeneration and repair: A review

- Research progress on properties of cement-based composites incorporating graphene oxide

- Properties of ultra-high performance concrete and conventional concrete with coal bottom ash as aggregate replacement and nanoadditives: A review

- A scientometric review of the literature on the incorporation of steel fibers in ultra-high-performance concrete with research mapping knowledge

- Weldability of high nitrogen steels: A review

- Application of waste recycle tire steel fibers as a construction material in concrete

- Wear properties of graphene-reinforced aluminium metal matrix composite: A review

- Experimental investigations of electrodeposited Zn–Ni, Zn–Co, and Ni–Cr–Co–based novel coatings on AA7075 substrate to ameliorate the mechanical, abrasion, morphological, and corrosion properties for automotive applications

- Research evolution on self-healing asphalt: A scientometric review for knowledge mapping

- Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review

- A review of microscopic characterization and related properties of fiber-incorporated cement-based materials

- Comparison and review of classical and machine learning-based constitutive models for polymers used in aeronautical thermoplastic composites

- Gold nanoparticle-based strategies against SARS-CoV-2: A review

- Poly-ferric sulphate as superior coagulant: A review on preparation methods and properties

- A review on ceramic waste-based concrete: A step toward sustainable concrete

- Modification of the structure and properties of oxide layers on aluminium alloys: A review

- A review of magnetically driven swimming microrobots: Material selection, structure design, control method, and applications

- Polyimide–nickel nanocomposites fabrication, properties, and applications: A review

- Design and analysis of timber-concrete-based civil structures and its applications: A brief review

- Effect of fiber treatment on physical and mechanical properties of natural fiber-reinforced composites: A review

- Blending and functionalisation modification of 3D printed polylactic acid for fused deposition modeling

- A critical review on functionally graded ceramic materials for cutting tools: Current trends and future prospects

- Heme iron as potential iron fortifier for food application – characterization by material techniques

- An overview of the research trends on fiber-reinforced shotcrete for construction applications

- High-entropy alloys: A review of their performance as promising materials for hydrogen and molten salt storage

- Effect of the axial compression ratio on the seismic behavior of resilient concrete walls with concealed column stirrups

- Research Articles

- Effect of fiber orientation and elevated temperature on the mechanical properties of unidirectional continuous kenaf reinforced PLA composites

- Optimizing the ECAP processing parameters of pure Cu through experimental, finite element, and response surface approaches

- Study on the solidification property and mechanism of soft soil based on the industrial waste residue

- Preparation and photocatalytic degradation of Sulfamethoxazole by g-C3N4 nano composite samples

- Impact of thermal modification on color and chemical changes of African padauk, merbau, mahogany, and iroko wood species

- The evaluation of the mechanical properties of glass, kenaf, and honeycomb fiber-reinforced composite

- Evaluation of a novel steel box-soft body combination for bridge protection against ship collision

- Study on the uniaxial compression constitutive relationship of modified yellow mud from minority dwelling in western Sichuan, China

- Ultrasonic longitudinal torsion-assisted biotic bone drilling: An experimental study

- Green synthesis, characterizations, and antibacterial activity of silver nanoparticles from Themeda quadrivalvis, in conjugation with macrolide antibiotics against respiratory pathogens

- Performance analysis of WEDM during the machining of Inconel 690 miniature gear using RSM and ANN modeling approaches

- Biosynthesis of Ag/bentonite, ZnO/bentonite, and Ag/ZnO/bentonite nanocomposites by aqueous leaf extract of Hagenia abyssinica for antibacterial activities

- Eco-friendly MoS2/waste coconut oil nanofluid for machining of magnesium implants

- Silica and kaolin reinforced aluminum matrix composite for heat storage

- Optimal design of glazed hollow bead thermal insulation mortar containing fly ash and slag based on response surface methodology

- Hemp seed oil nanoemulsion with Sapindus saponins as a potential carrier for iron supplement and vitamin D

- A numerical study on thin film flow and heat transfer enhancement for copper nanoparticles dispersed in ethylene glycol

- Research on complex multimodal vibration characteristics of offshore platform

- Applicability of fractal models for characterising pore structure of hybrid basalt–polypropylene fibre-reinforced concrete

- Influence of sodium silicate to precursor ratio on mechanical properties and durability of the metakaolin/fly ash alkali-activated sustainable mortar using manufactured sand

- An experimental study of bending resistance of multi-size PFRC beams

- Characterization, biocompatibility, and optimization of electrospun SF/PCL composite nanofiber films

- Morphological classification method and data-driven estimation of the joint roughness coefficient by consideration of two-order asperity

- Prediction and simulation of mechanical properties of borophene-reinforced epoxy nanocomposites using molecular dynamics and FEA

- Nanoemulsions of essential oils stabilized with saponins exhibiting antibacterial and antioxidative properties

- Fabrication and performance analysis of sustainable municipal solid waste incineration fly ash alkali-activated acoustic barriers

- Electrostatic-spinning construction of HCNTs@Ti3C2T x MXenes hybrid aerogel microspheres for tunable microwave absorption

- Investigation of the mechanical properties, surface quality, and energy efficiency of a fused filament fabrication for PA6

- Experimental study on mechanical properties of coal gangue base geopolymer recycled aggregate concrete reinforced by steel fiber and nano-Al2O3

- Hybrid bio-fiber/bio-ceramic composite materials: Mechanical performance, thermal stability, and morphological analysis

- Experimental study on recycled steel fiber-reinforced concrete under repeated impact

- Effect of rare earth Nd on the microstructural transformation and mechanical properties of 7xxx series aluminum alloys

- Color match evaluation using instrumental method for three single-shade resin composites before and after in-office bleaching

- Exploring temperature-resilient recycled aggregate concrete with waste rubber: An experimental and multi-objective optimization analysis

- Study on aging mechanism of SBS/SBR compound-modified asphalt based on molecular dynamics

- Evolution of the pore structure of pumice aggregate concrete and the effect on compressive strength

- Effect of alkaline treatment time of fibers and microcrystalline cellulose addition on mechanical properties of unsaturated polyester composites reinforced by cantala fibers

- Optimization of eggshell particles to produce eco-friendly green fillers with bamboo reinforcement in organic friction materials

- An effective approach to improve microstructure and tribological properties of cold sprayed Al alloys

- Luminescence and temperature-sensing properties of Li+, Na+, or K+, Tm3+, and Yb3+ co-doped Bi2WO6 phosphors

- Effect of molybdenum tailings aggregate on mechanical properties of engineered cementitious composites and stirrup-confined ECC stub columns

- Experimental study on the seismic performance of short shear walls comprising cold-formed steel and high-strength reinforced concrete with concealed bracing

- Failure criteria and microstructure evolution mechanism of the alkali–silica reaction of concrete

- Mechanical, fracture-deformation, and tribology behavior of fillers-reinforced sisal fiber composites for lightweight automotive applications

- UV aging behavior evolution characterization of HALS-modified asphalt based on micro-morphological features

- Preparation of VO2/graphene/SiC film by water vapor oxidation

- A semi-empirical model for predicting carbonation depth of RAC under two-dimensional conditions

- Comparison of the physical properties of different polyimide nanocomposite films containing organoclays varying in alkyl chain lengths

- Effects of freeze–thaw cycles on micro and meso-structural characteristics and mechanical properties of porous asphalt mixtures

- Flexural performance of a new type of slightly curved arc HRB400 steel bars reinforced one-way concrete slabs

- Alkali-activated binder based on red mud with class F fly ash and ground granulated blast-furnace slag under ambient temperature

- Facile synthesis of g-C3N4 nanosheets for effective degradation of organic pollutants via ball milling

- DEM study on the loading rate effect of marble under different confining pressures

- Conductive and self-cleaning composite membranes from corn husk nanofiber embedded with inorganic fillers (TiO2, CaO, and eggshell) by sol–gel and casting processes for smart membrane applications

- Laser re-melting of modified multimodal Cr3C2–NiCr coatings by HVOF: Effect on the microstructure and anticorrosion properties

- Damage constitutive model of jointed rock mass considering structural features and load effect

- Thermosetting polymer composites: Manufacturing and properties study

- CSG compressive strength prediction based on LSTM and interpretable machine learning

- Axial compression behavior and stress–strain relationship of slurry-wrapping treatment recycled aggregate concrete-filled steel tube short columns

- Space-time evolution characteristics of loaded gas-bearing coal fractures based on industrial μCT

- Dual-biprism-based single-camera high-speed 3D-digital image correlation for deformation measurement on sandwich structures under low velocity impact

- Effects of cold deformation modes on microstructure uniformity and mechanical properties of large 2219 Al–Cu alloy rings

- Basalt fiber as natural reinforcement to improve the performance of ecological grouting slurry for the conservation of earthen sites

- Interaction of micro-fluid structure in a pressure-driven duct flow with a nearby placed current-carrying wire: A numerical investigation

- A simulation modeling methodology considering random multiple shots for shot peening process

- Optimization and characterization of composite modified asphalt with pyrolytic carbon black and chicken feather fiber

- Synthesis, characterization, and application of the novel nanomagnet adsorbent for the removal of Cr(vi) ions

- Multi-perspective structural integrity-based computational investigations on airframe of Gyrodyne-configured multi-rotor UAV through coupled CFD and FEA approaches for various lightweight sandwich composites and alloys

- Influence of PVA fibers on the durability of cementitious composites under the wet–heat–salt coupling environment

- Compressive behavior of BFRP-confined ceramsite concrete: An experimental study and stress–strain model

- Interval models for uncertainty analysis and degradation prediction of the mechanical properties of rubber

- Preparation of PVDF-HFP/CB/Ni nanocomposite films for piezoelectric energy harvesting

- Frost resistance and life prediction of recycled brick aggregate concrete with waste polypropylene fiber

- Synthetic leathers as a possible source of chemicals and odorous substances in indoor environment

- Mechanical properties of seawater volcanic scoria aggregate concrete-filled circular GFRP and stainless steel tubes under axial compression

- Effect of curved anchor impellers on power consumption and hydrodynamic parameters of yield stress fluids (Bingham–Papanastasiou model) in stirred tanks

- All-dielectric tunable zero-refractive index metamaterials based on phase change materials

- Influence of ultrasonication time on the various properties of alkaline-treated mango seed waste filler reinforced PVA biocomposite

- Research on key casting process of high-grade CNC machine tool bed nodular cast iron

- Latest research progress of SiCp/Al composite for electronic packaging

- Special Issue on 3D and 4D Printing of Advanced Functional Materials - Part I

- Molecular dynamics simulation on electrohydrodynamic atomization: Stable dripping mode by pre-load voltage

- Research progress of metal-based additive manufacturing in medical implants